Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1532results about How to "Inhibit current" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

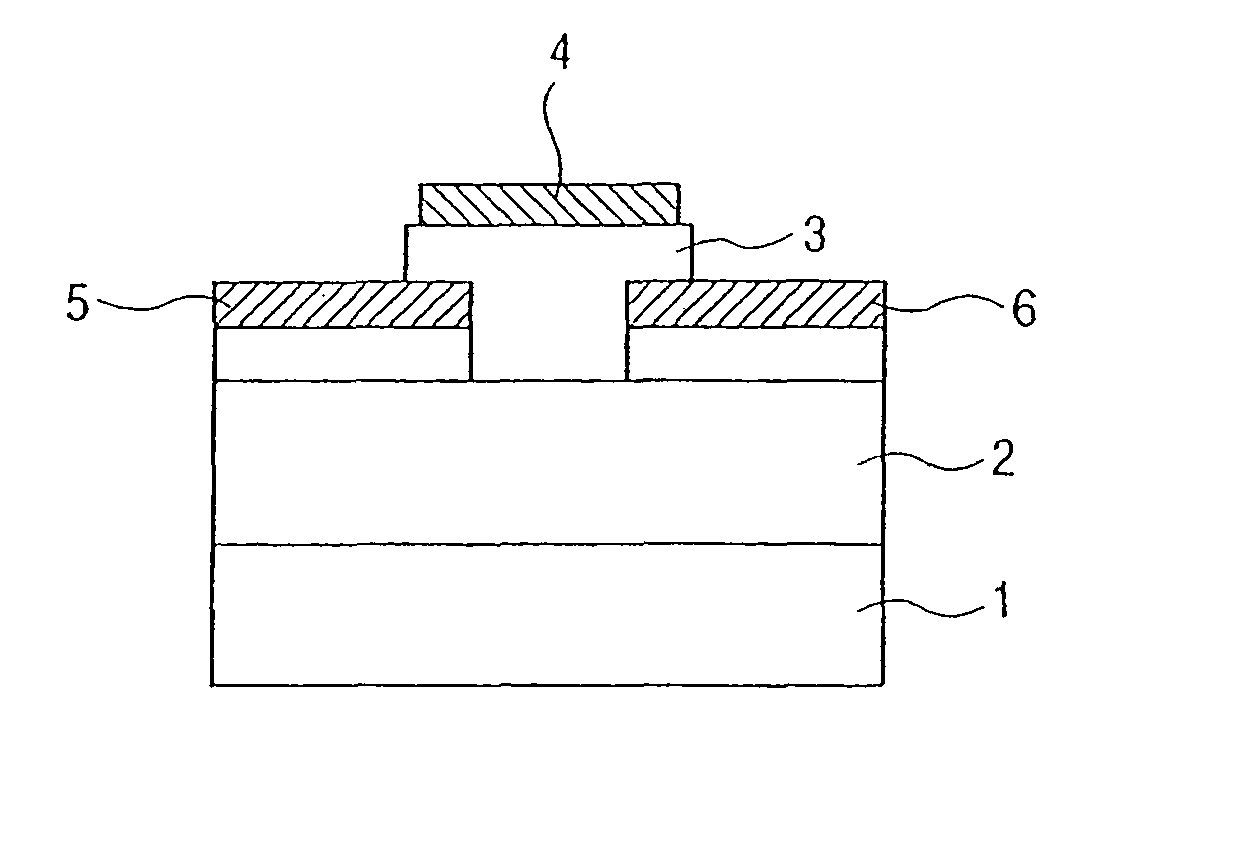

Field effect transistor

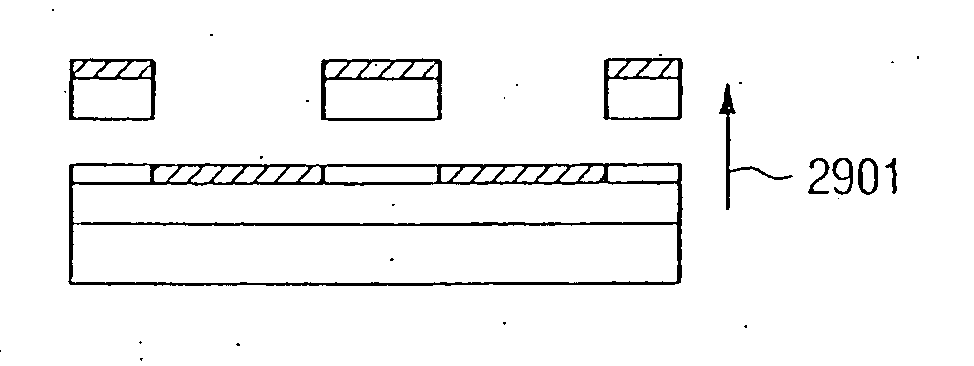

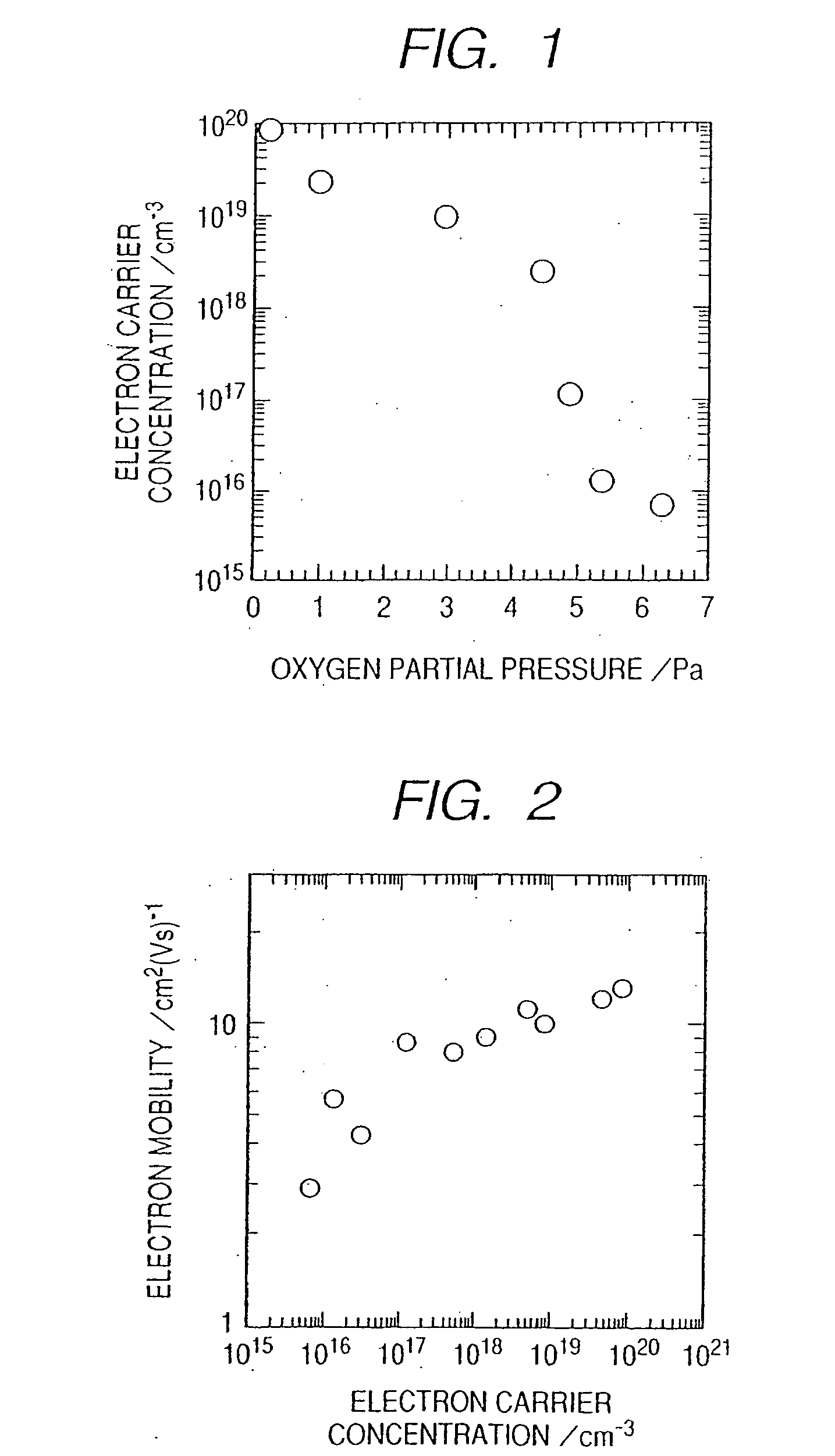

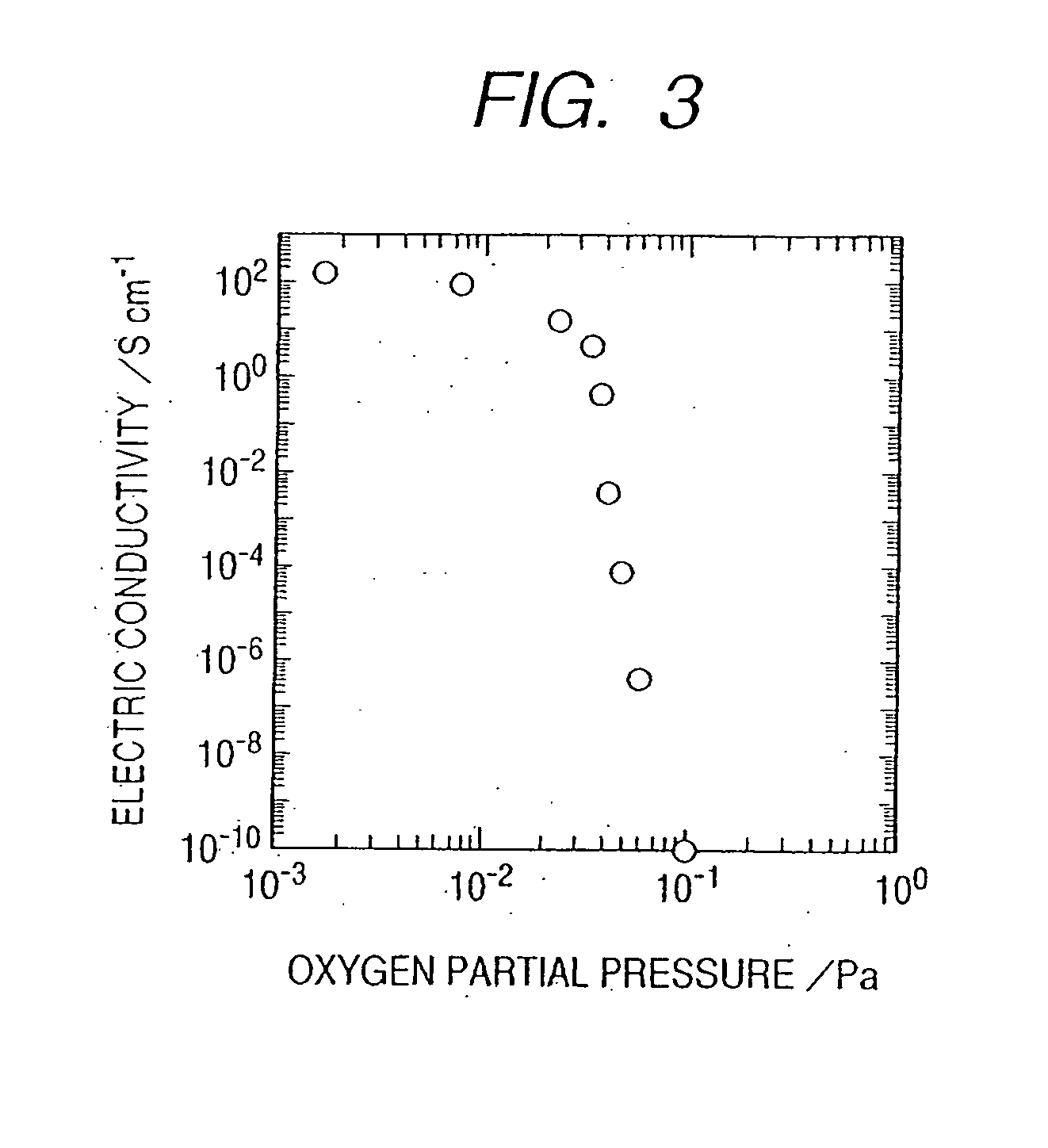

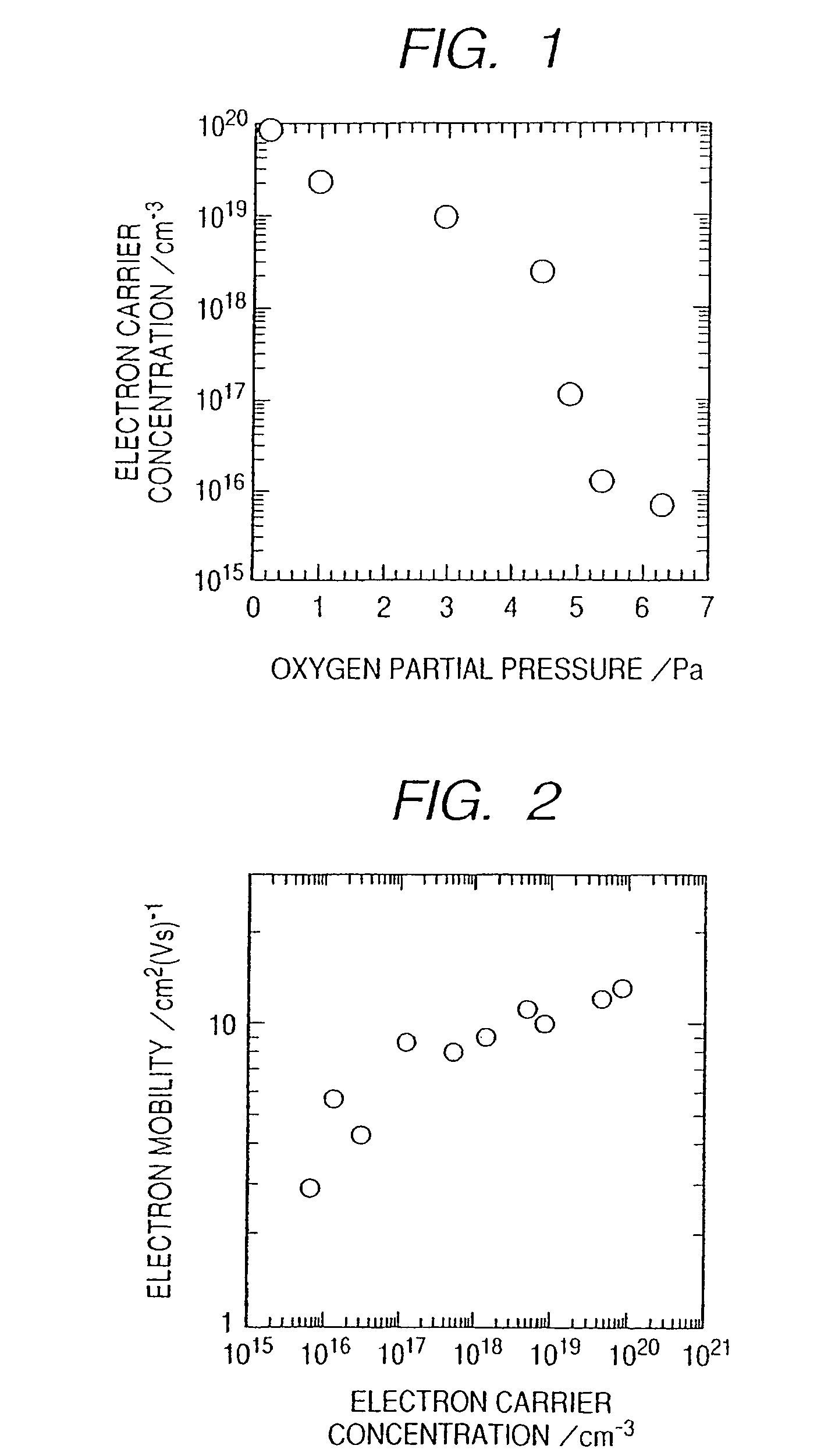

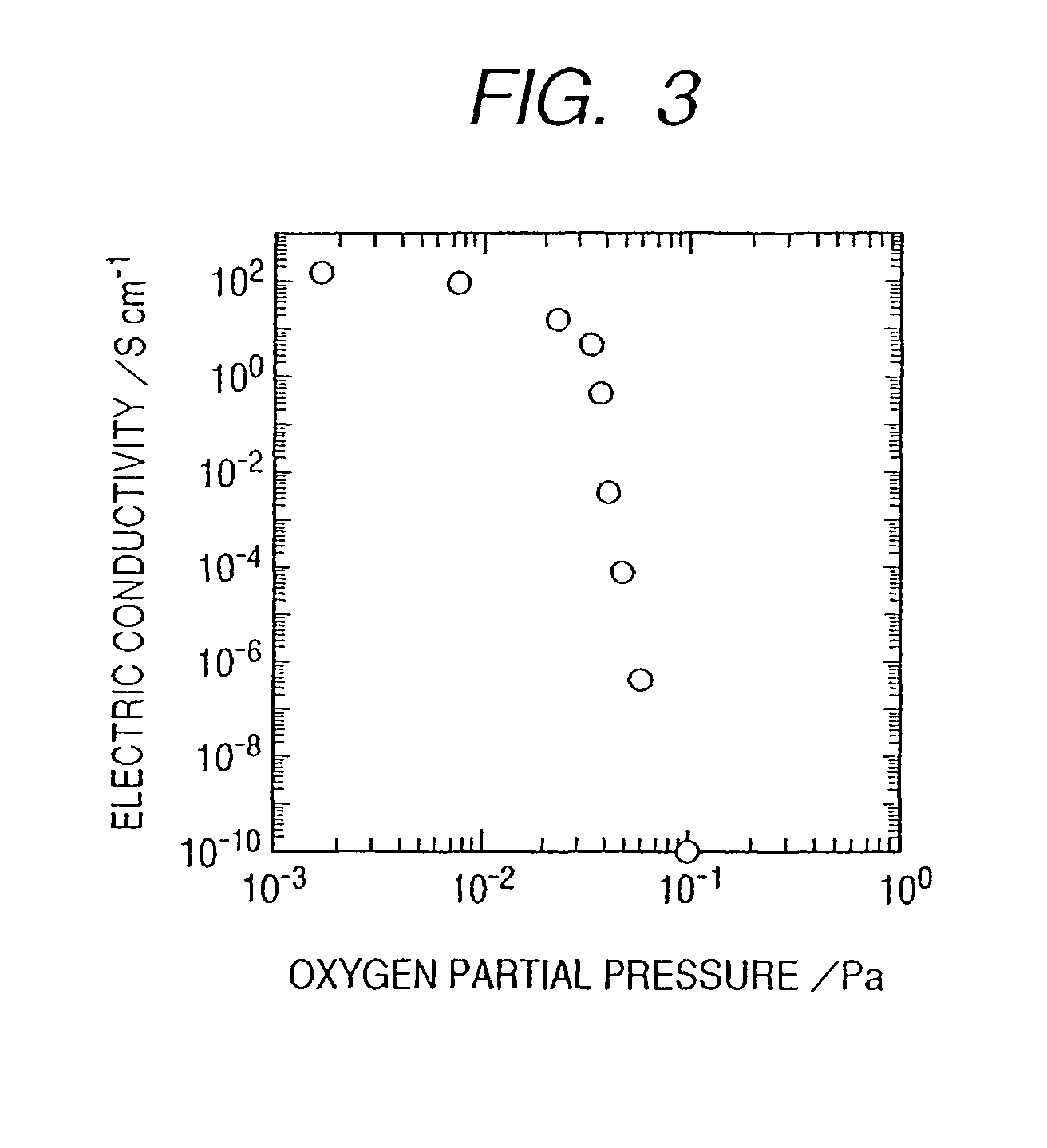

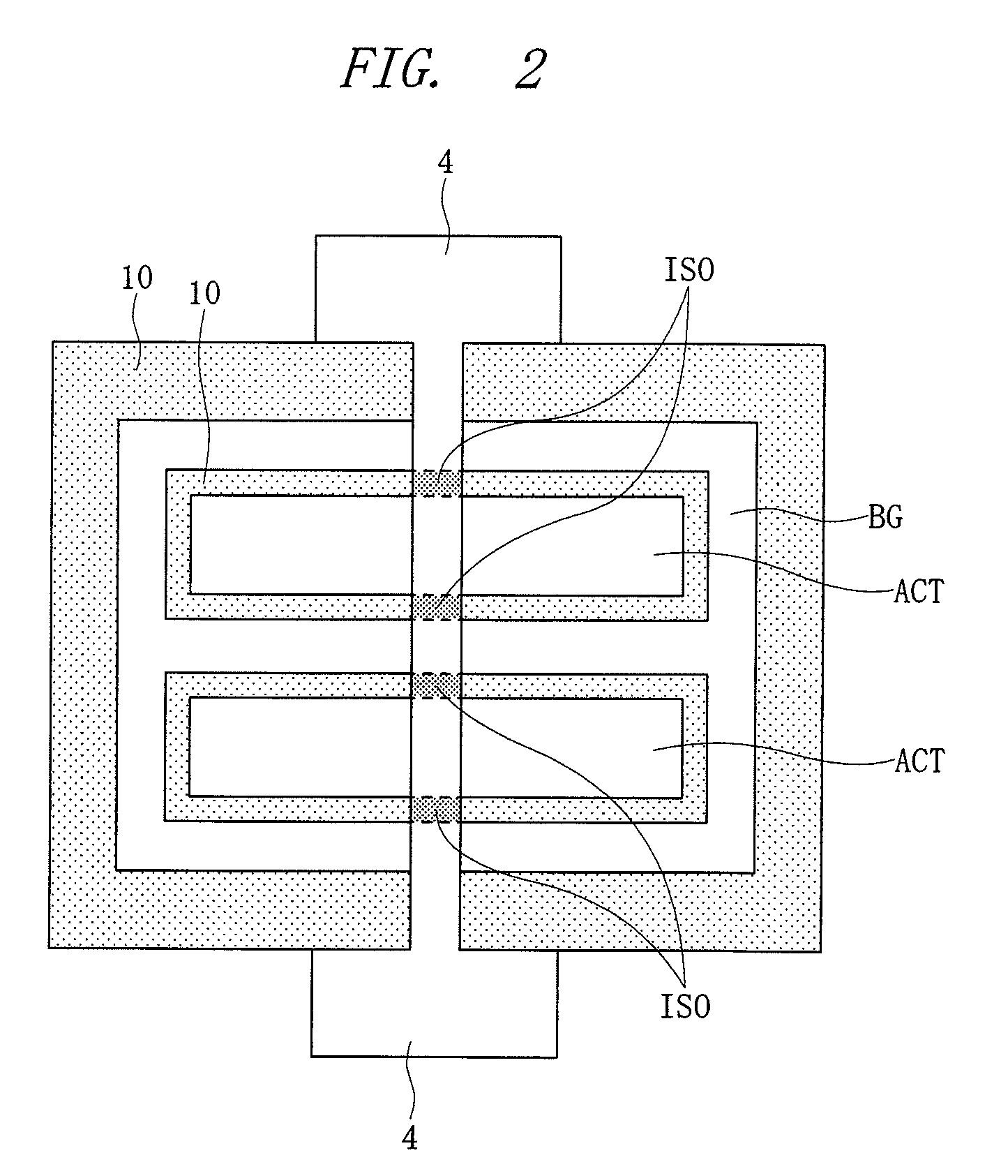

ActiveUS20060113539A1Inhibit currentMaintain good propertiesSolid-state devicesSemiconductor/solid-state device manufacturingField-effect transistorElectron

A novel field-effect transistor is provided which employs an amorphous oxide. In an embodiment of the present invention, the transistor comprises an amorphous oxide layer containing electron carrier at a concentration less than 1×10−18 / cm3, and the gate-insulating layer is comprised of a first layer being in contact with the amorphous oxide and a second layer different from the first layer.

Owner:CANON KK +2

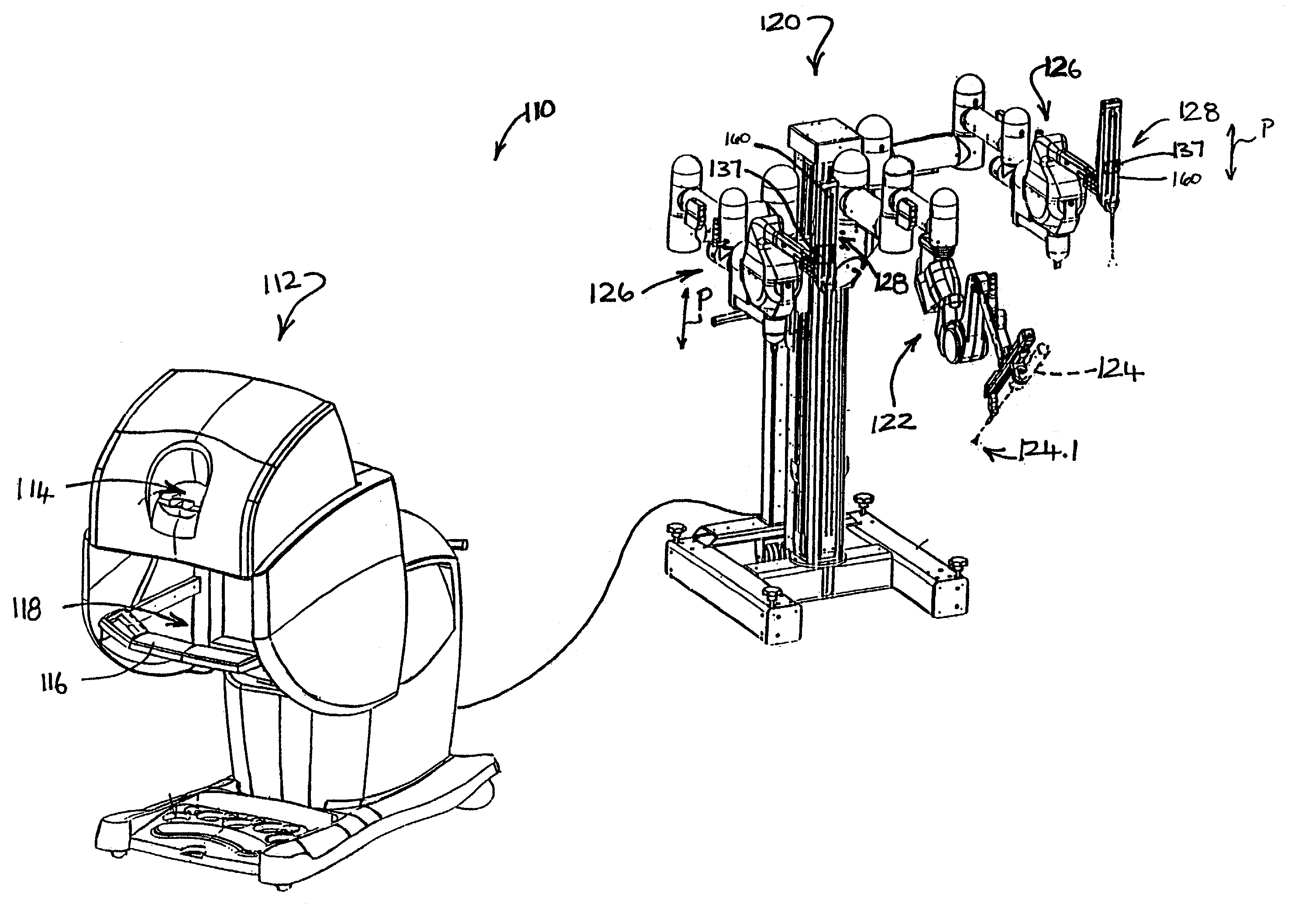

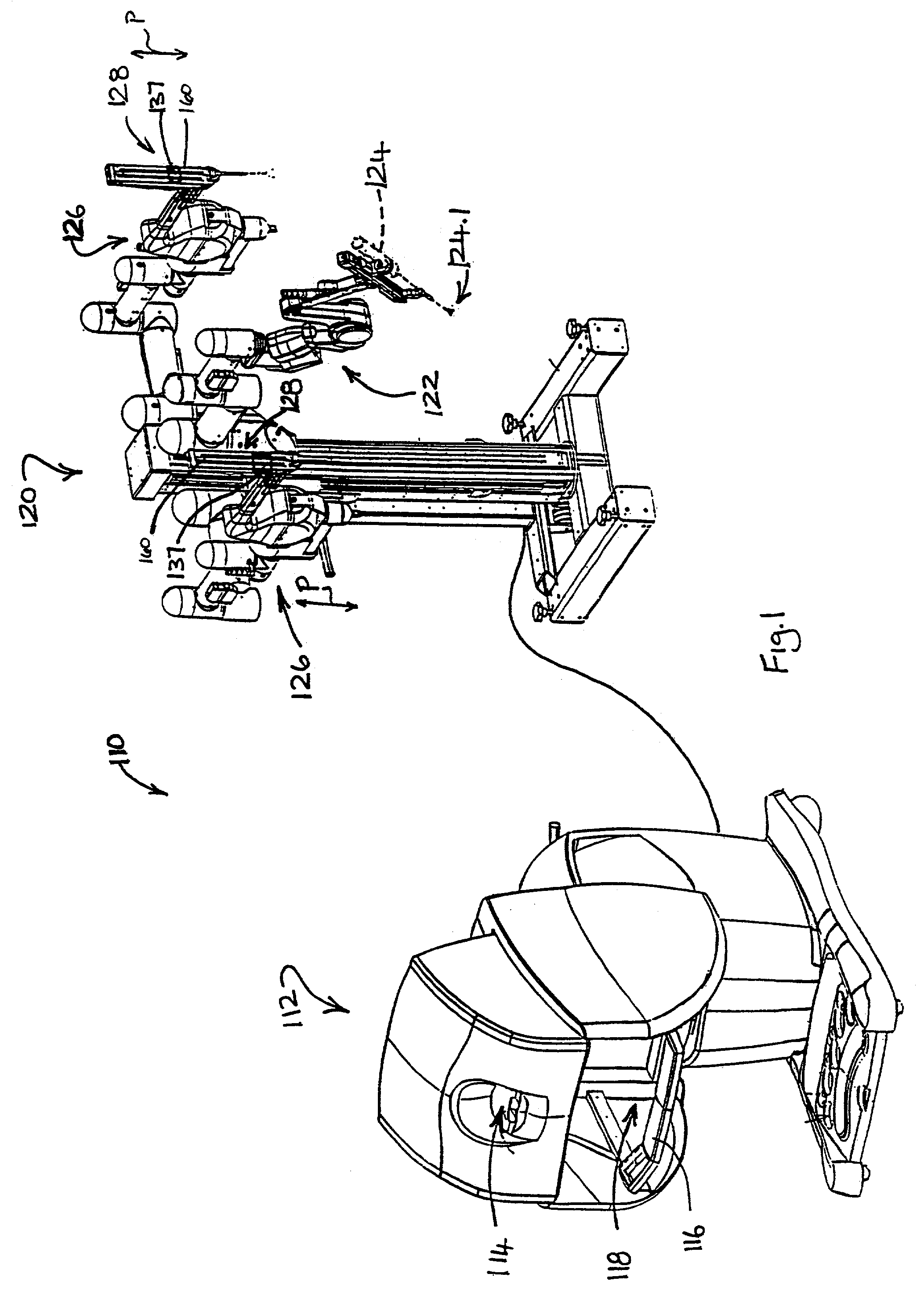

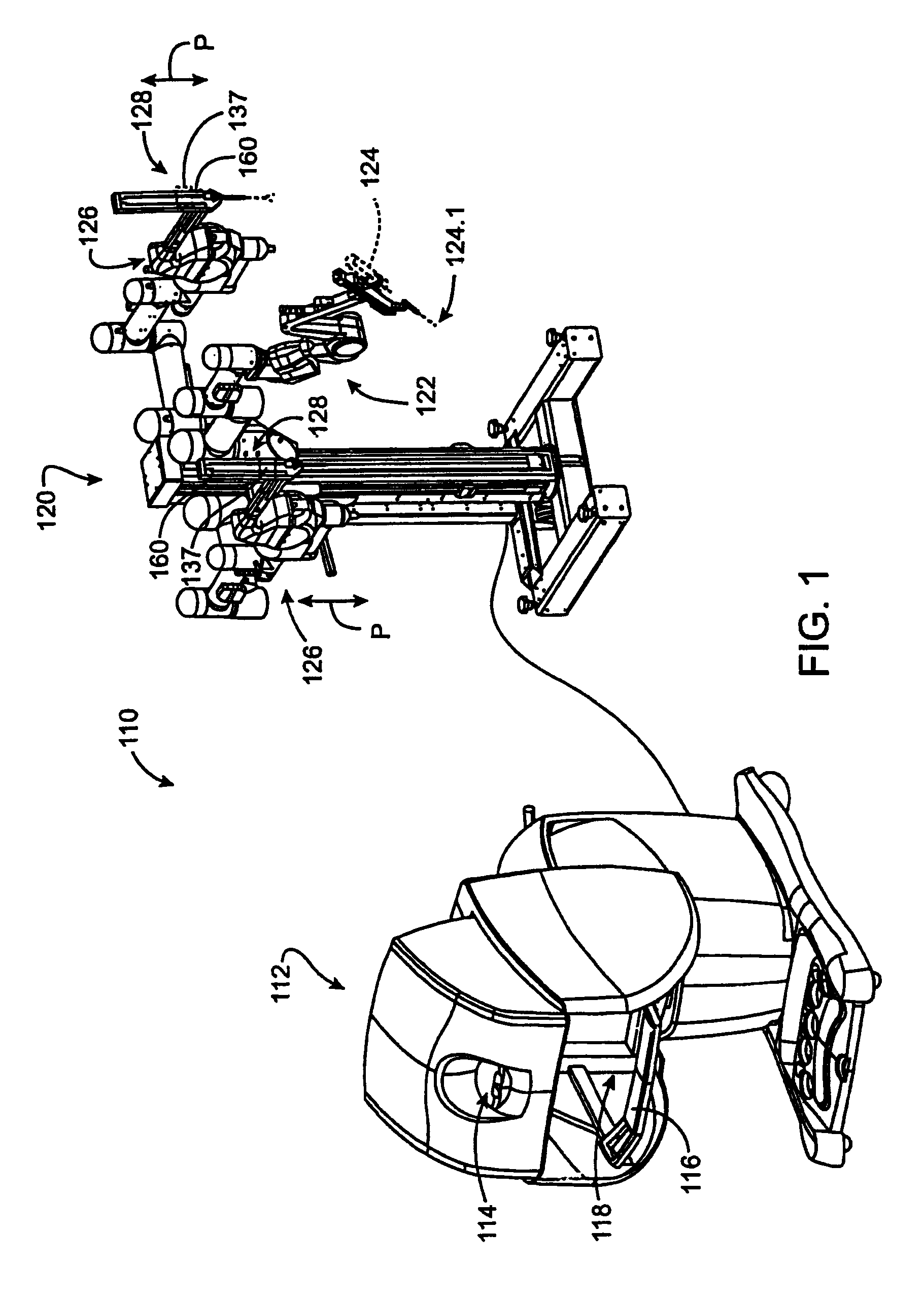

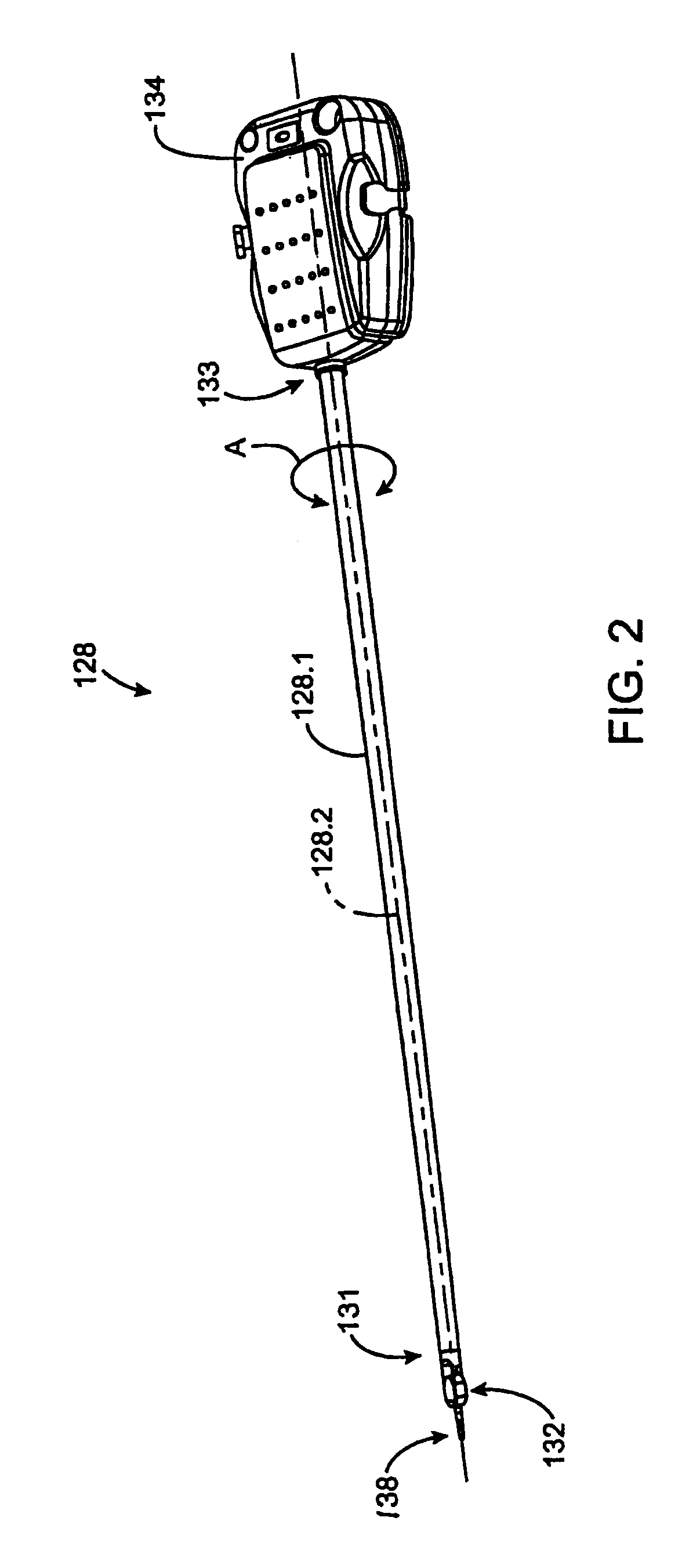

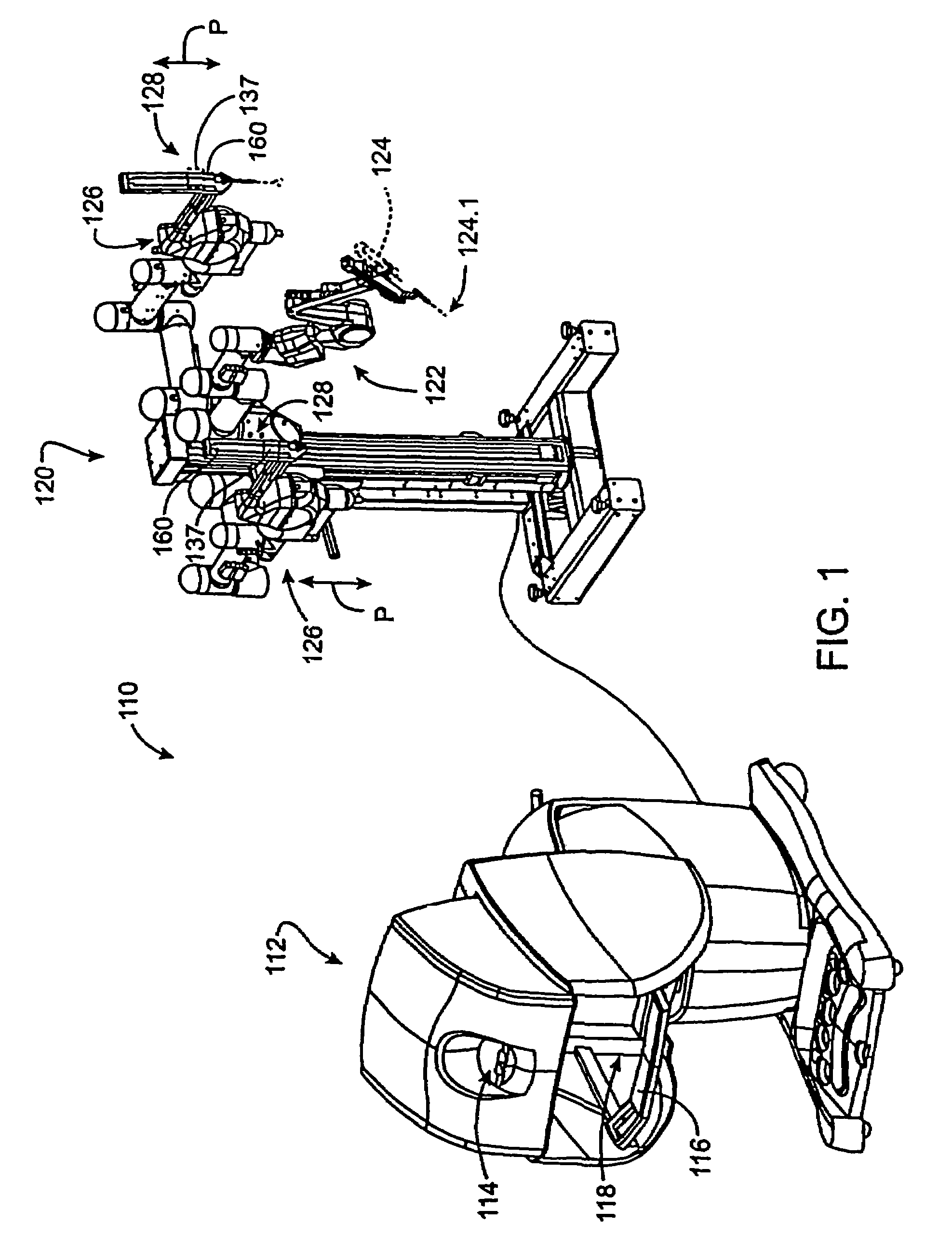

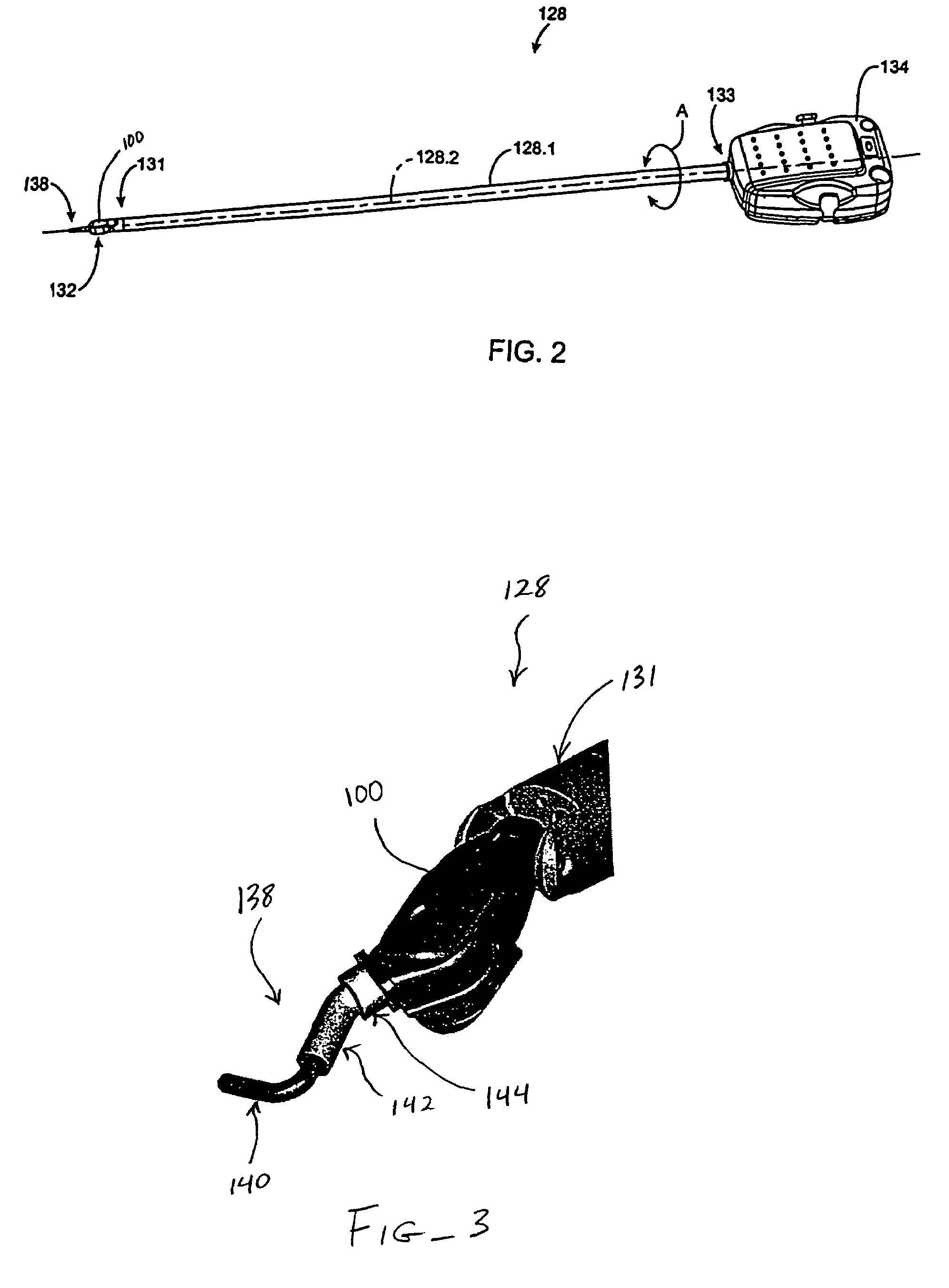

Robotic tool with monopolar electro-surgical scissors

InactiveUS6994708B2Reduce bleedingCoagulated bloodDiagnosticsSurgical scissorsSurgical operationElectrical conductor

The present invention provides robotic surgical instruments and systems that include electrosurgical cutting / shearing tools and methods of performing a robotic surgical procedure. The surgical instruments can advantageously be used in robotically controlled minimally invasive surgical operations. A surgical instrument generally comprises an elongate shaft having a proximal end and a distal end. An end effector, for performing a surgical operation such as cutting, shearing, grasping, engaging, or contacting tissue adjacent a surgical site, is coupleable to a distal end of the shaft. Preferably, the end effector comprises a pair of scissor-like blades for cooperatively shearing the tissue. A conductor electrically communicating with at least one blade delivers electrical energy to tissue engaged by the blades. An interface coupled to the proximal end of the shaft and removably connectable to the robotic surgical system is also included.

Owner:INTUITIVE SURGICAL OPERATIONS INC

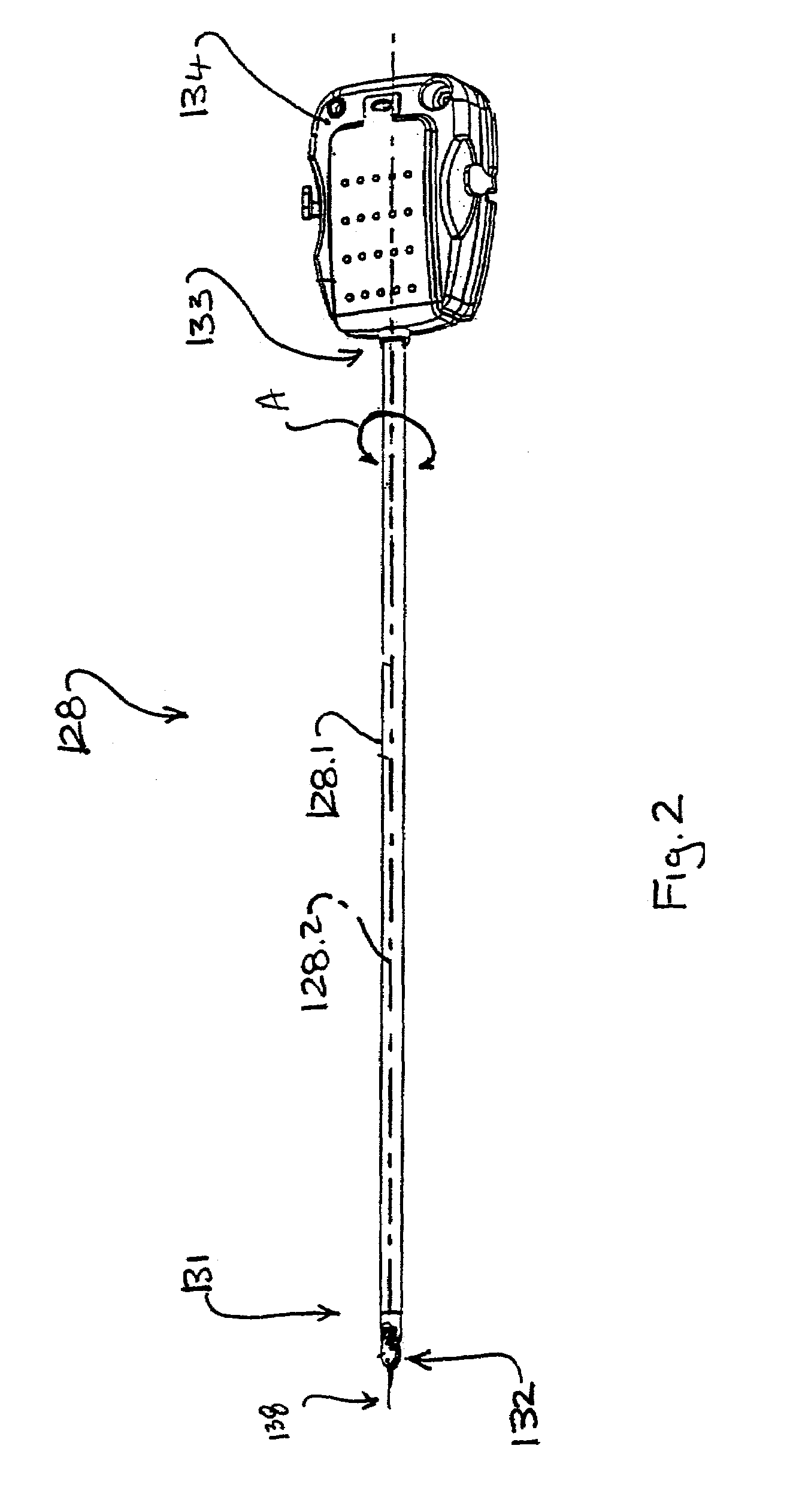

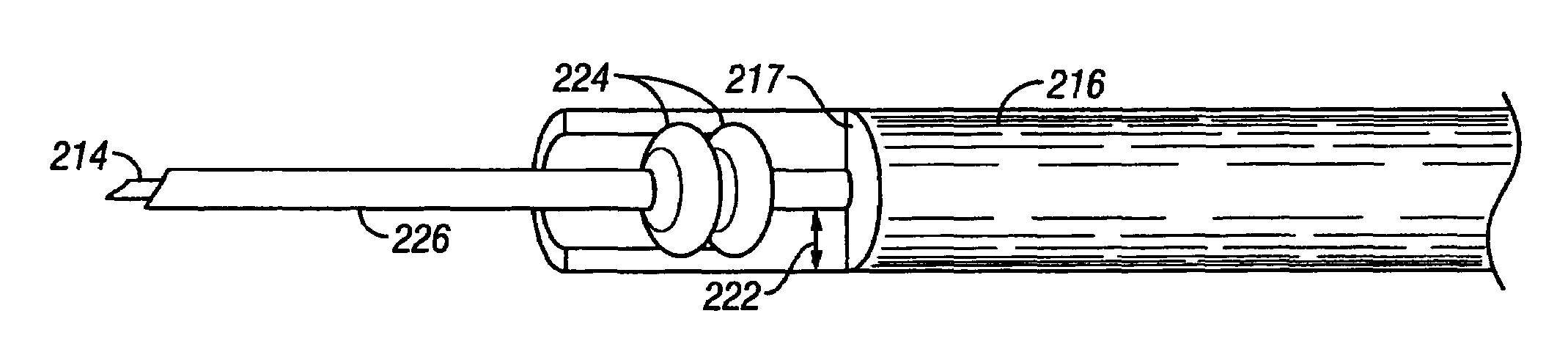

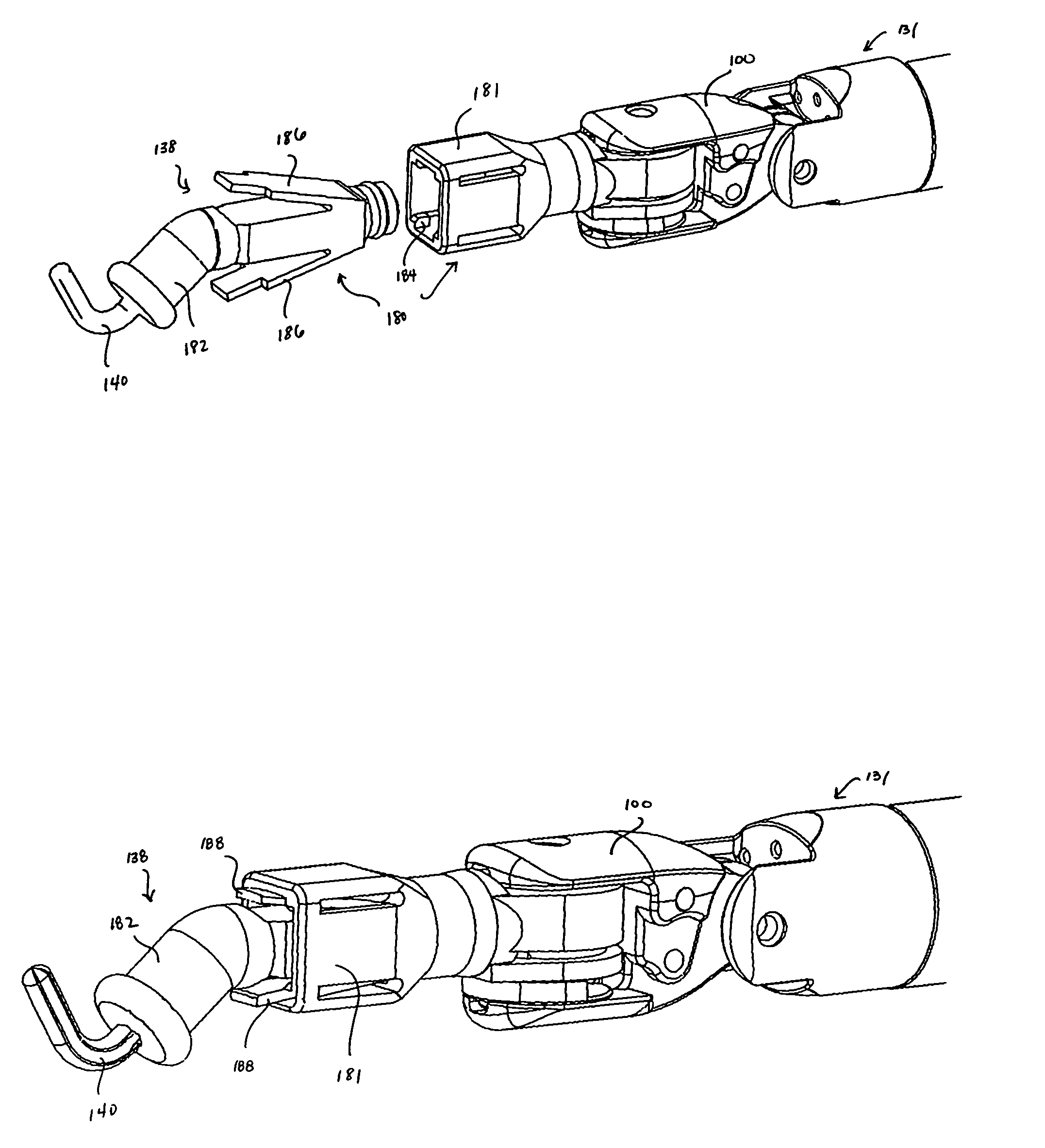

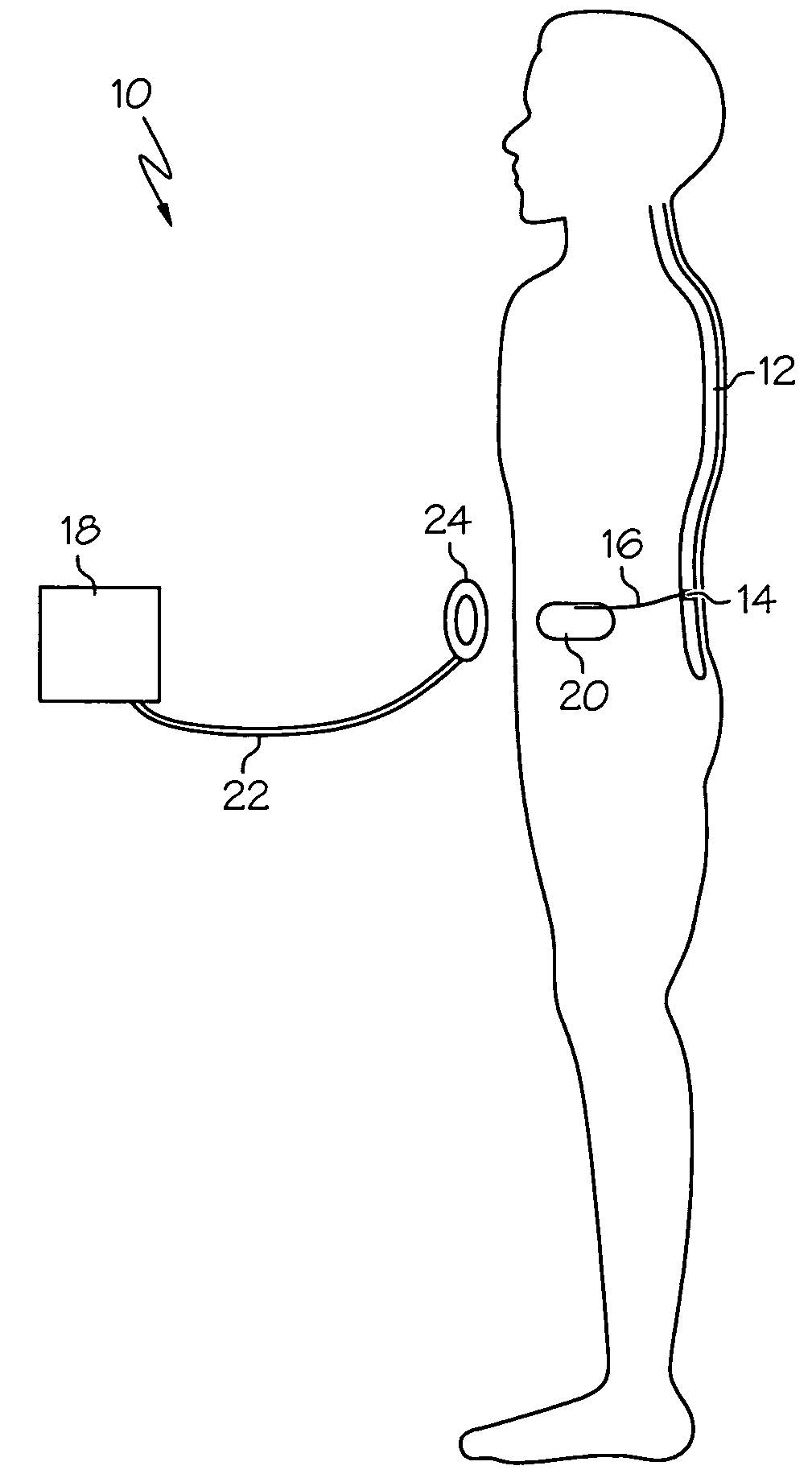

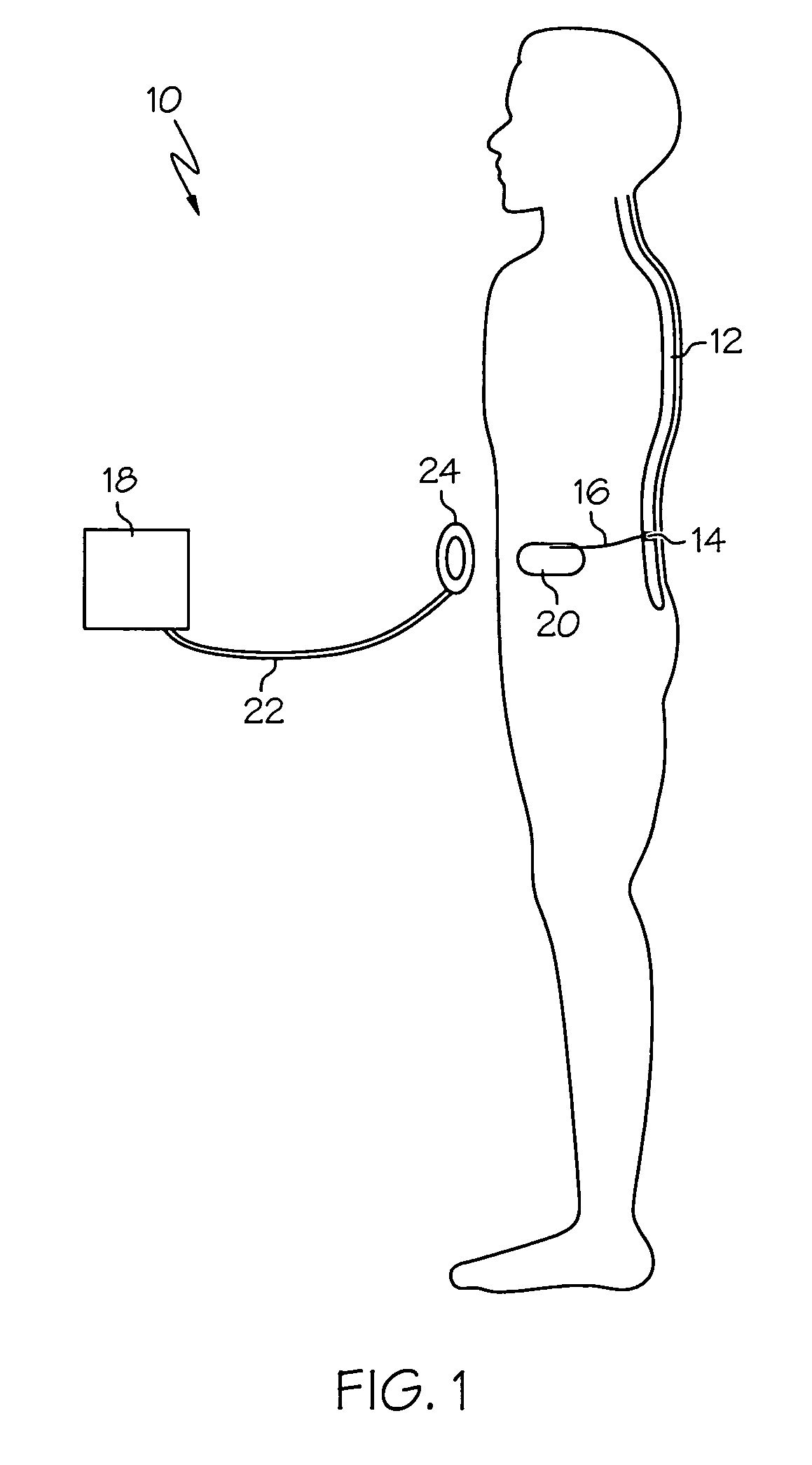

Surgical tool having electrocautery energy supply conductor with inhibited current leakage

InactiveUS7083615B2Low costEasy to manufactureDiagnosticsSurgical instruments for heatingCapacitanceElectrical conductor

The present invention provides improved electrosurgical instruments and systems having electrocautery energy supply conductors that provide inhibited current leakage and methods of performing a robotically controlled minimally invasive surgical procedure while preventing unintended capacitive coupling. A surgical instrument generally comprises an elongate shaft having a proximal end and a distal end and defining an internal longitudinally extending passage. An electrocautery end effector is coupled to or disposed at the distal end of the shaft. An interface or tool base is coupled to or disposed at the proximal end of the shaft and removably connectable to the robotic surgical system. Typically, an independent electrical conductor extends from the interface to the end effector to transmit electrical energy to tissue engaged by the end effector. A sealed insulation tube extends within the passage and over the conductor. A separation is maintained between the sealed insulation tube and the conductor.

Owner:INTUITIVE SURGICAL OPERATIONS INC

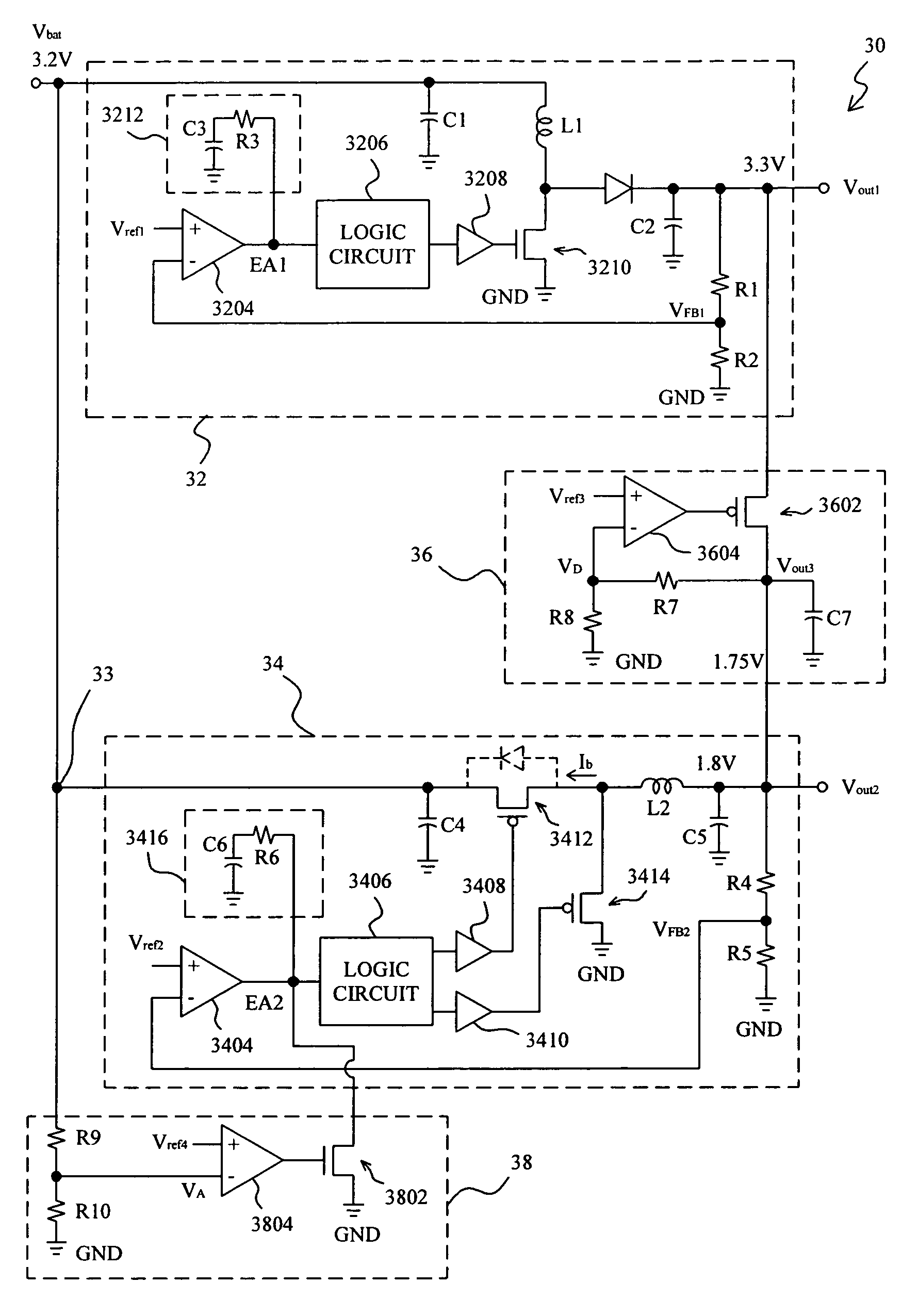

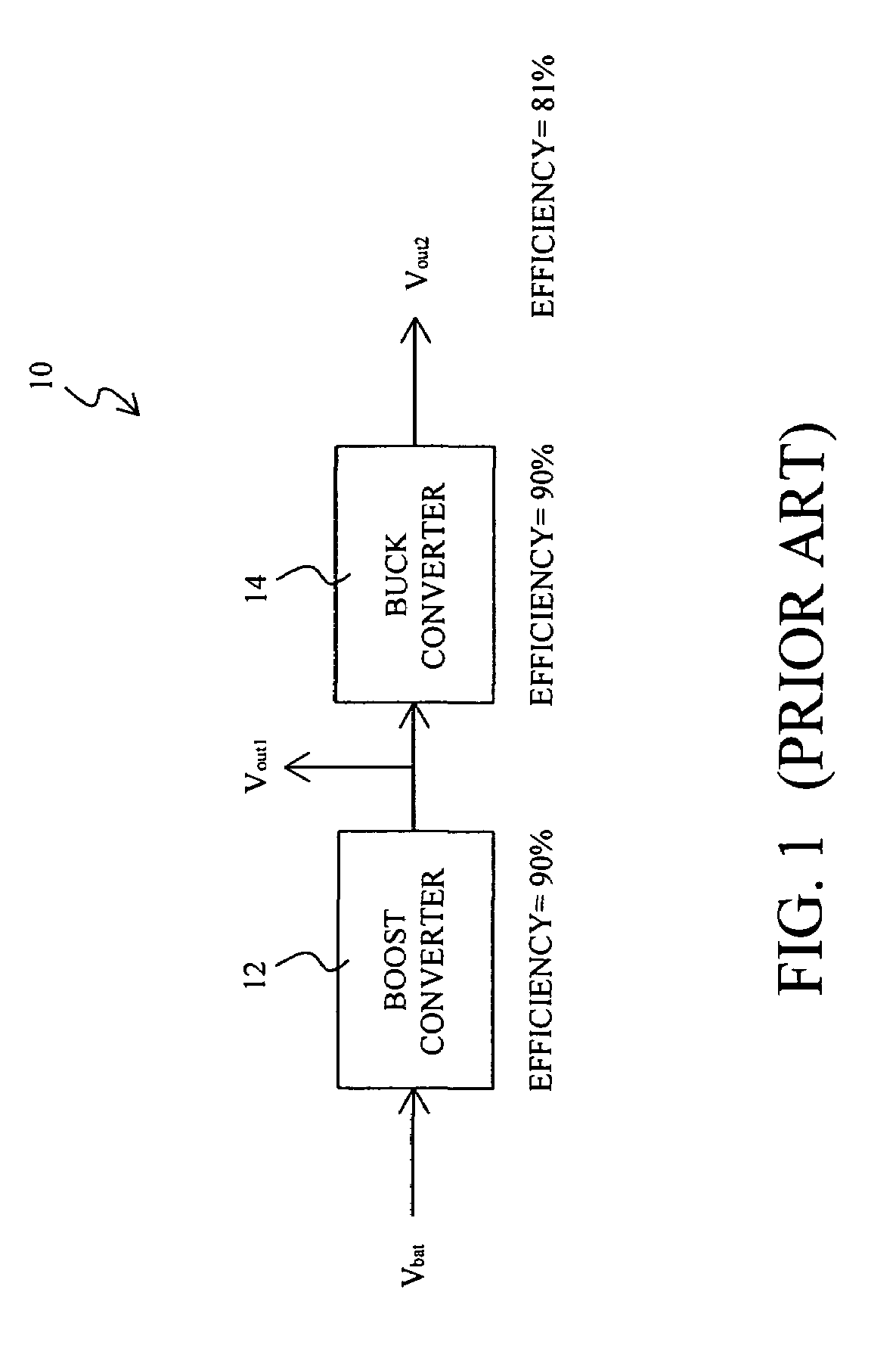

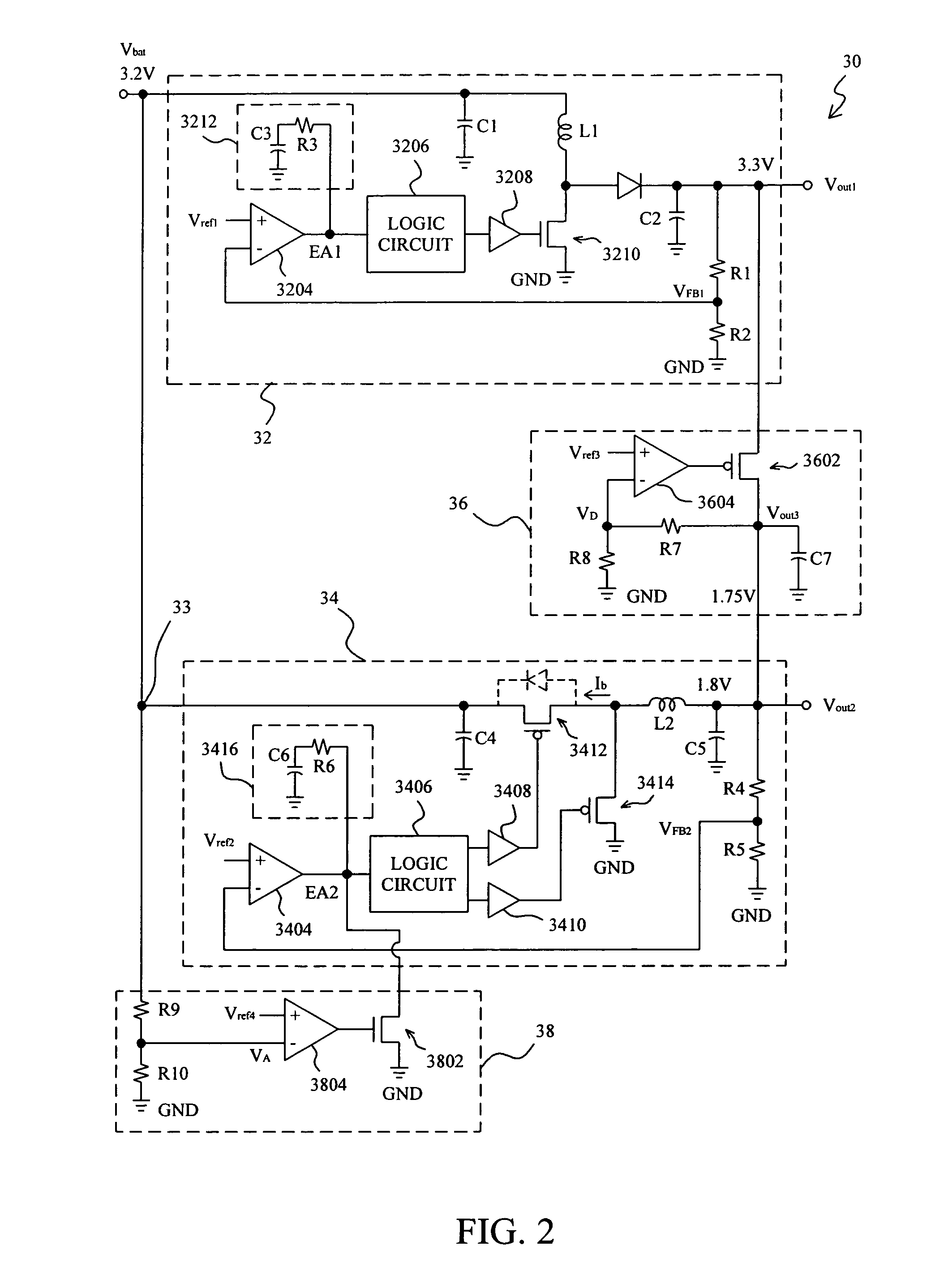

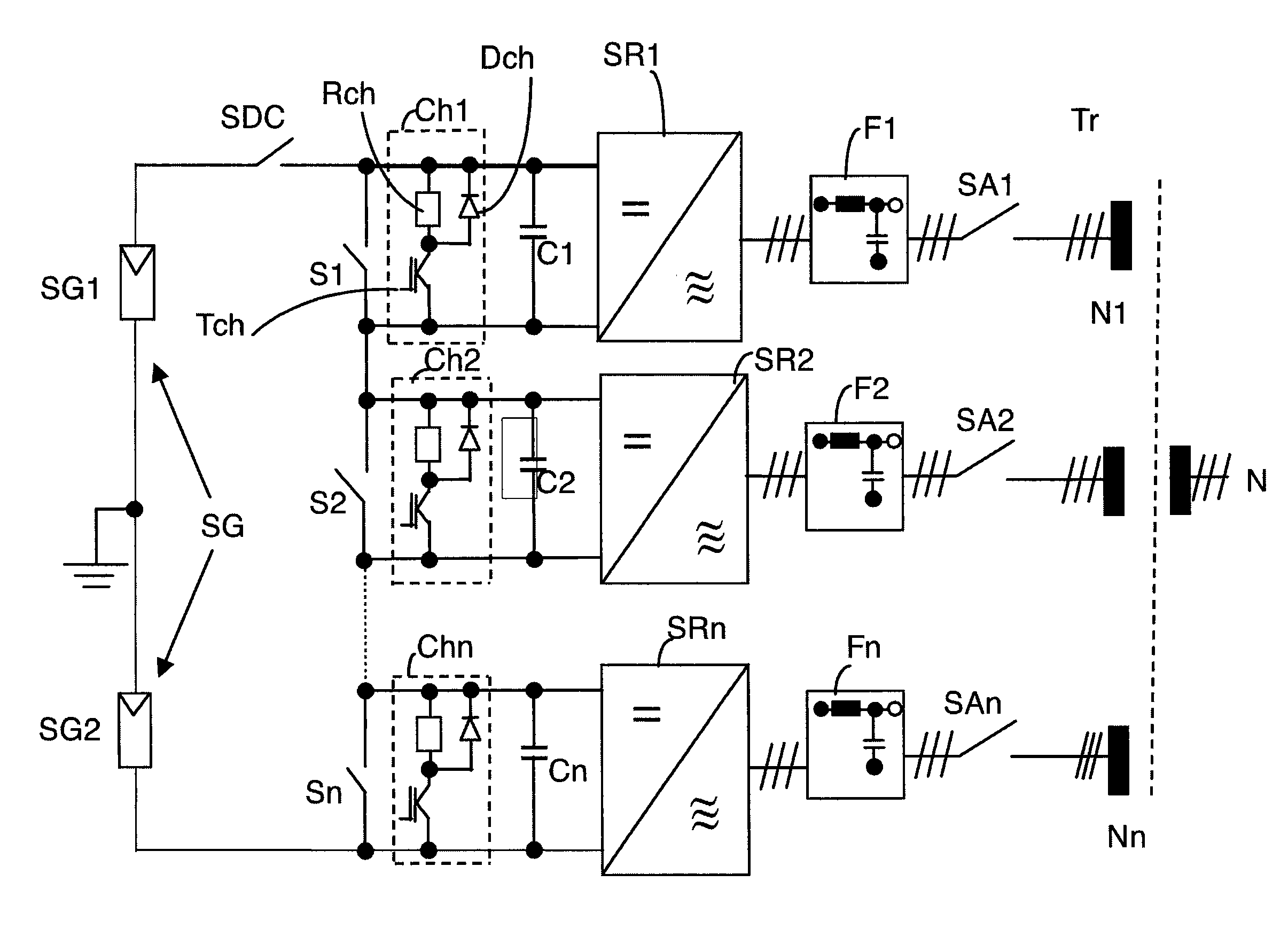

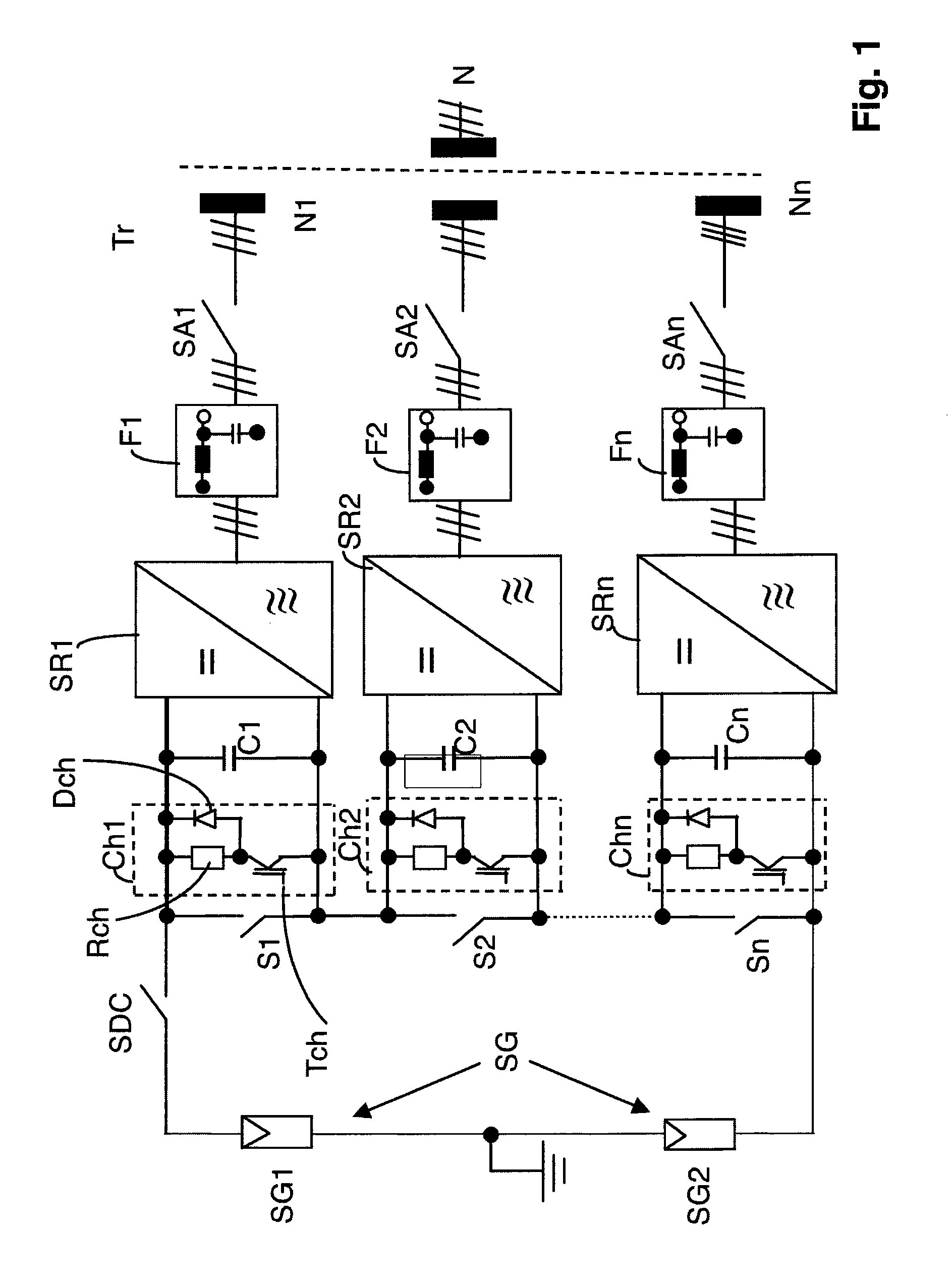

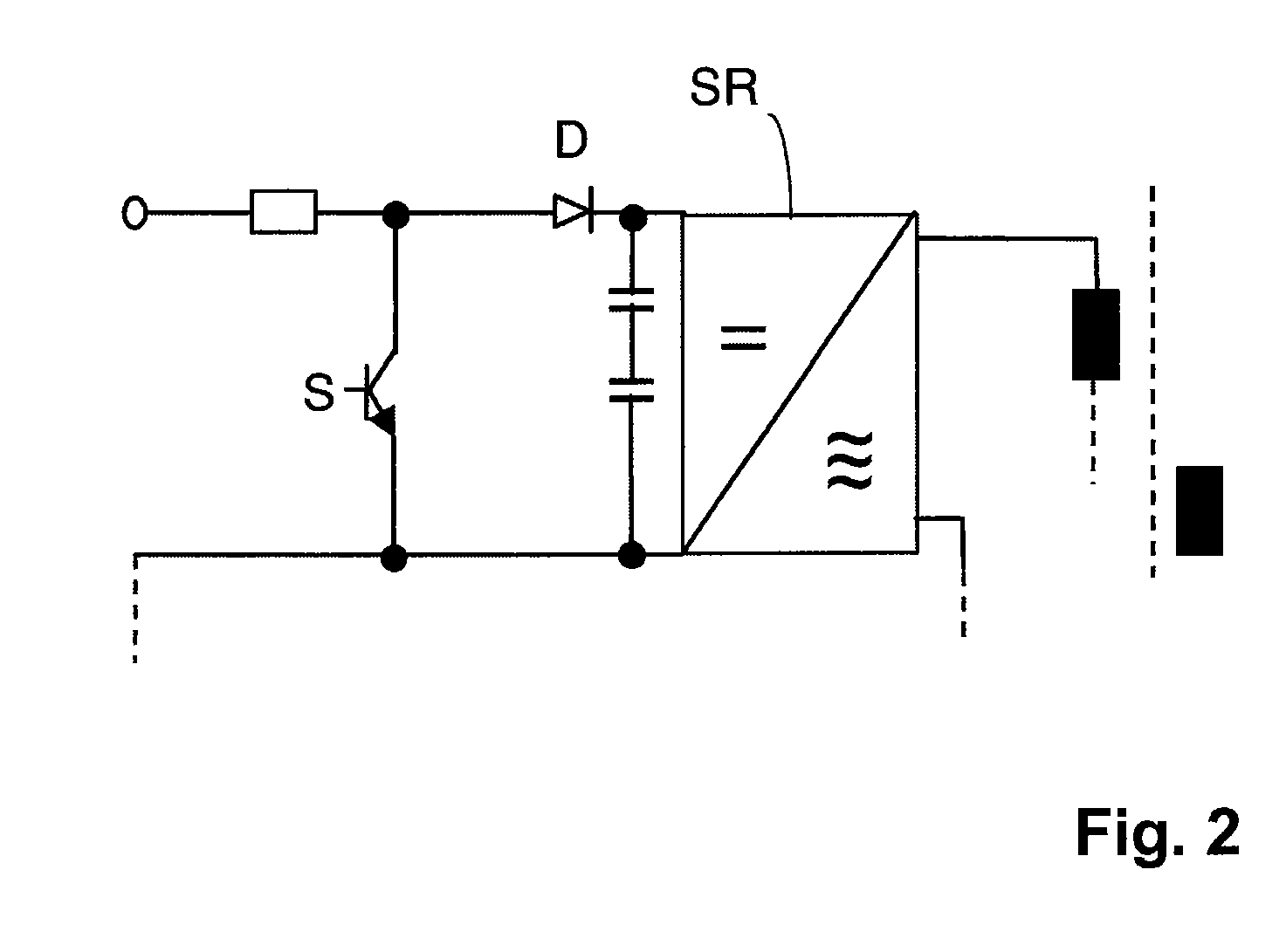

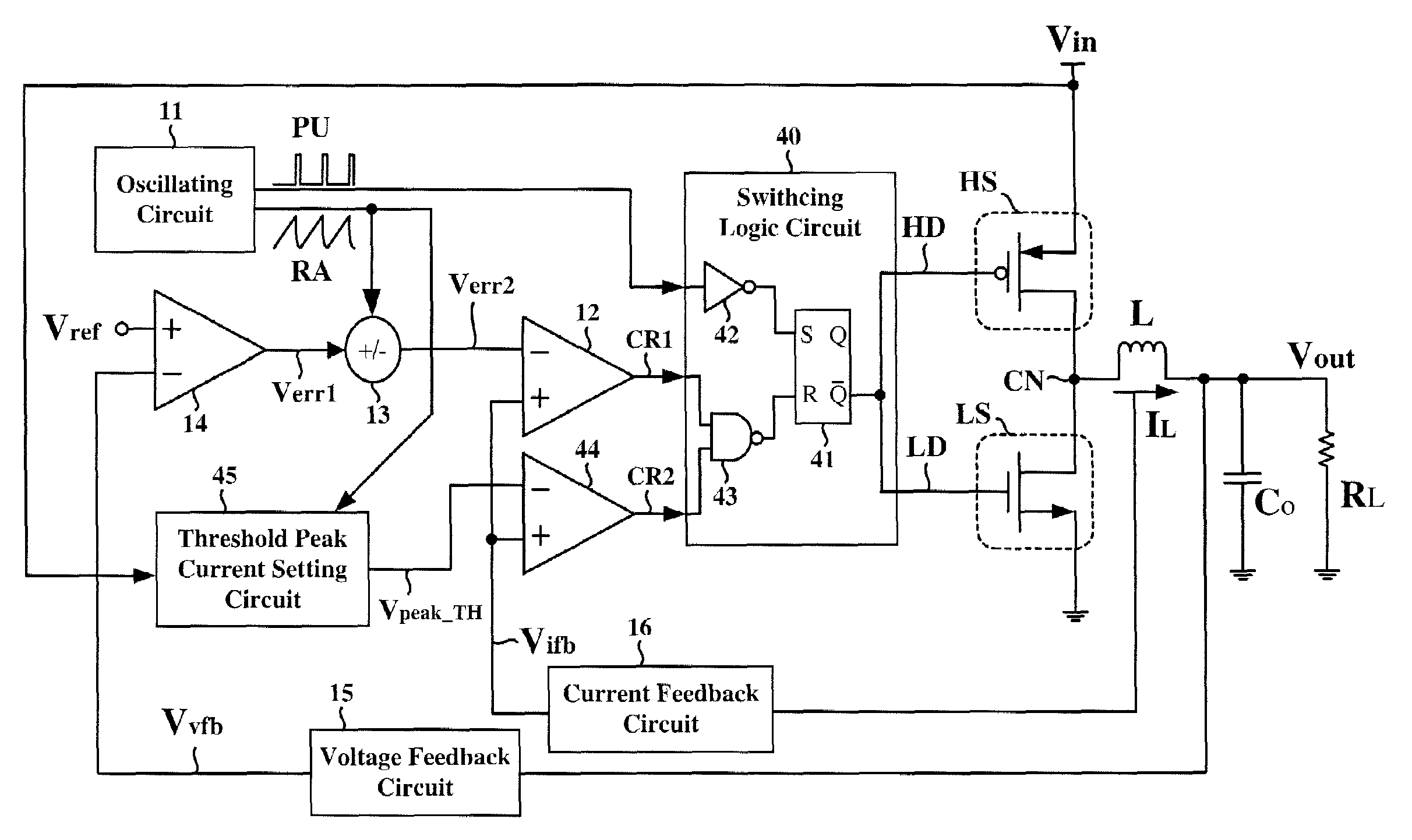

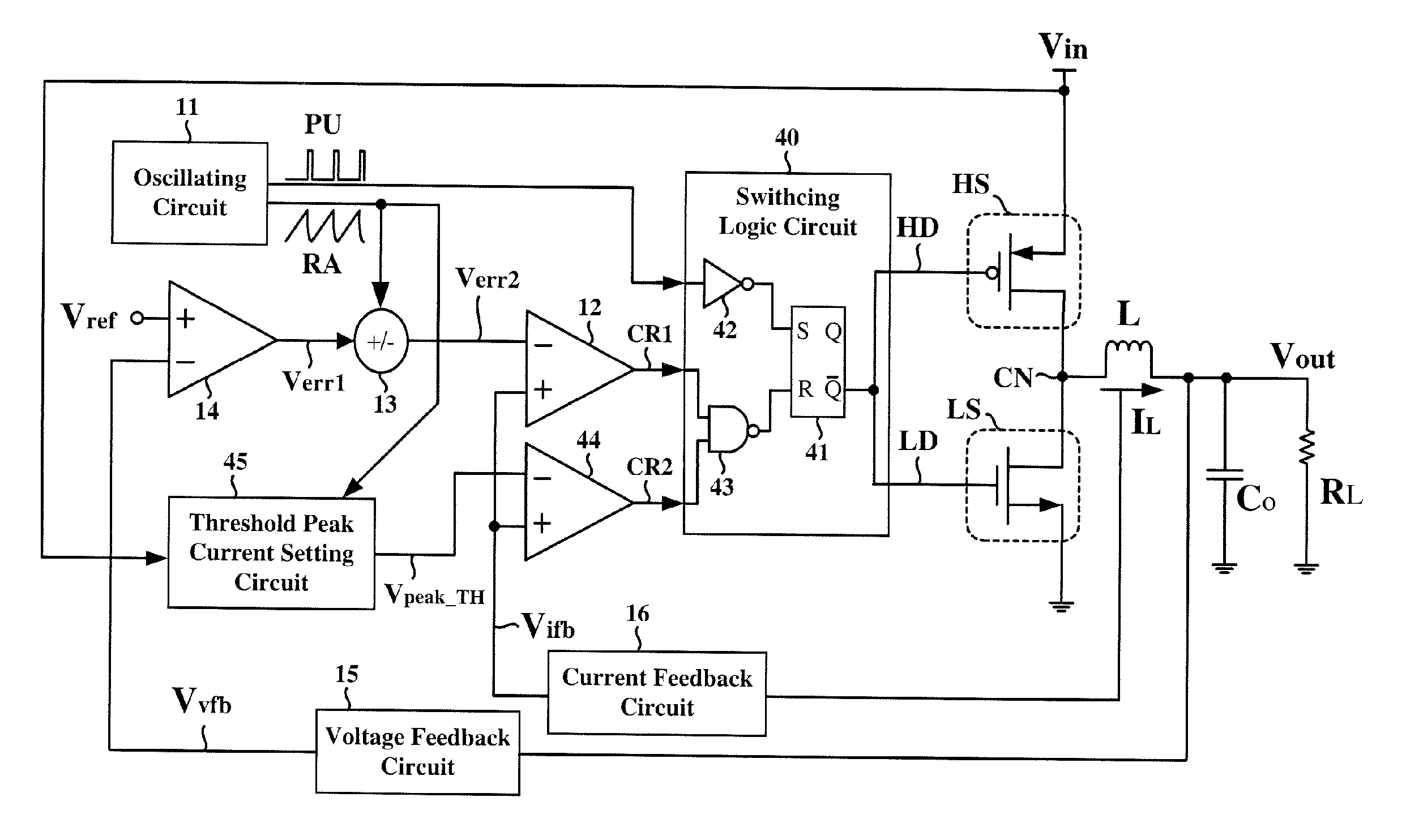

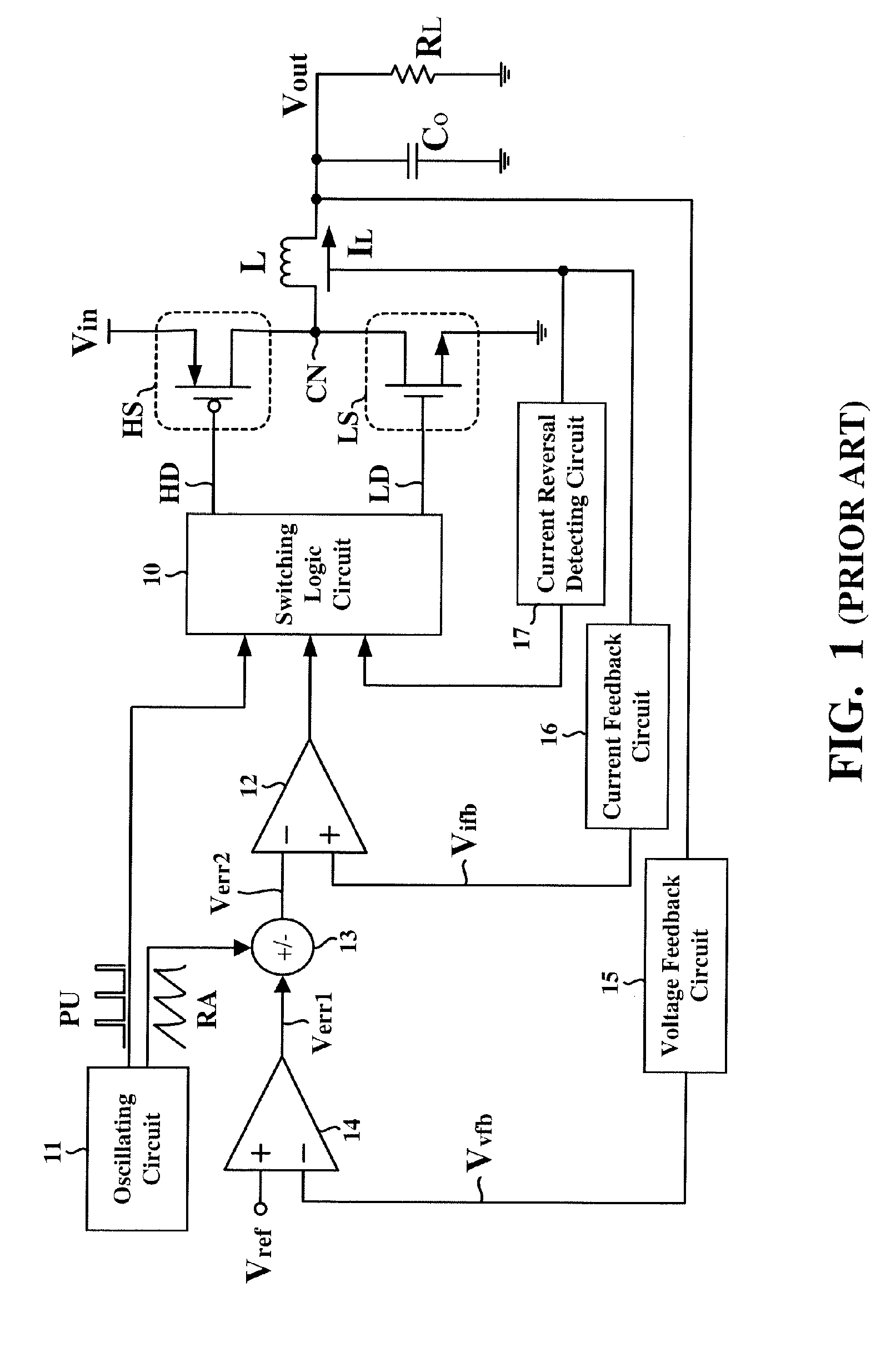

High efficiency power converter

InactiveUS7202653B2Improve efficiencyInhibit currentDc network circuit arrangementsDc-dc conversionLinear regulatorReverse current

Owner:RICHTEK TECH

Electro-surgical instrument with replaceable end-effectors and inhibited surface conduction

ActiveUS7367973B2Avoid conductionInhibit currentDiagnosticsSurgical instruments for heatingElectricityActive electrode

Improved robotic surgery end-effectors include at least one insulation material for inhibiting surface conduction of electrical current in a proximal direction, from a distal active electrode toward the proximal end of the end-effector and toward the rest of the surgical instrument itself. Some embodiments include two layers of insulation to further prevent proximally-directed current. By inhibiting proximal current flow, the end-effectors prevent unwanted patient burns as well as electricity-related wear and tear in and around the area where the end-effector is coupled with the rest of the surgical instrument. In various embodiments, such end-effectors are preferably removably coupleable with a robotic surgical instrument.

Owner:INTUITIVE SURGICAL OPERATIONS INC

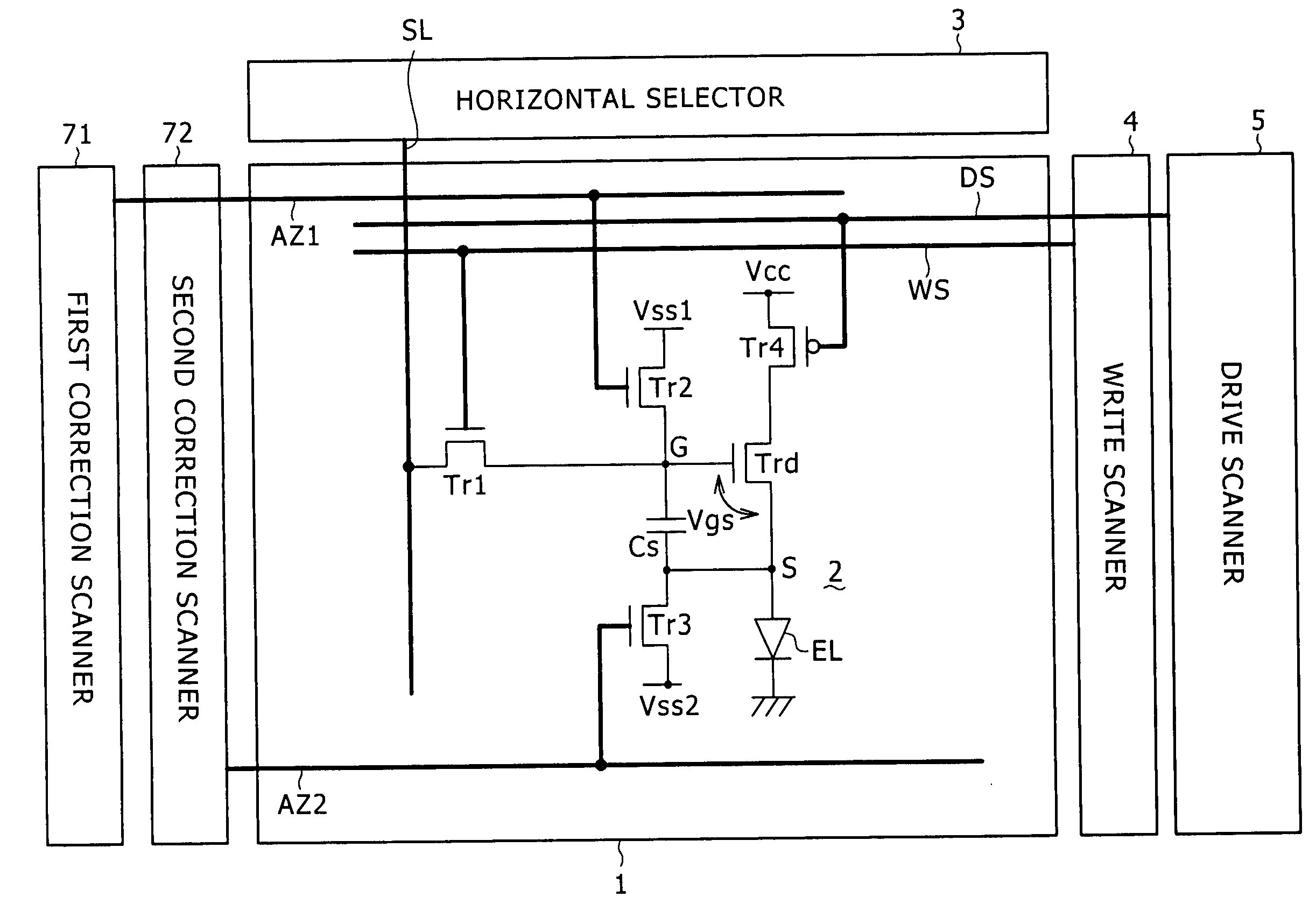

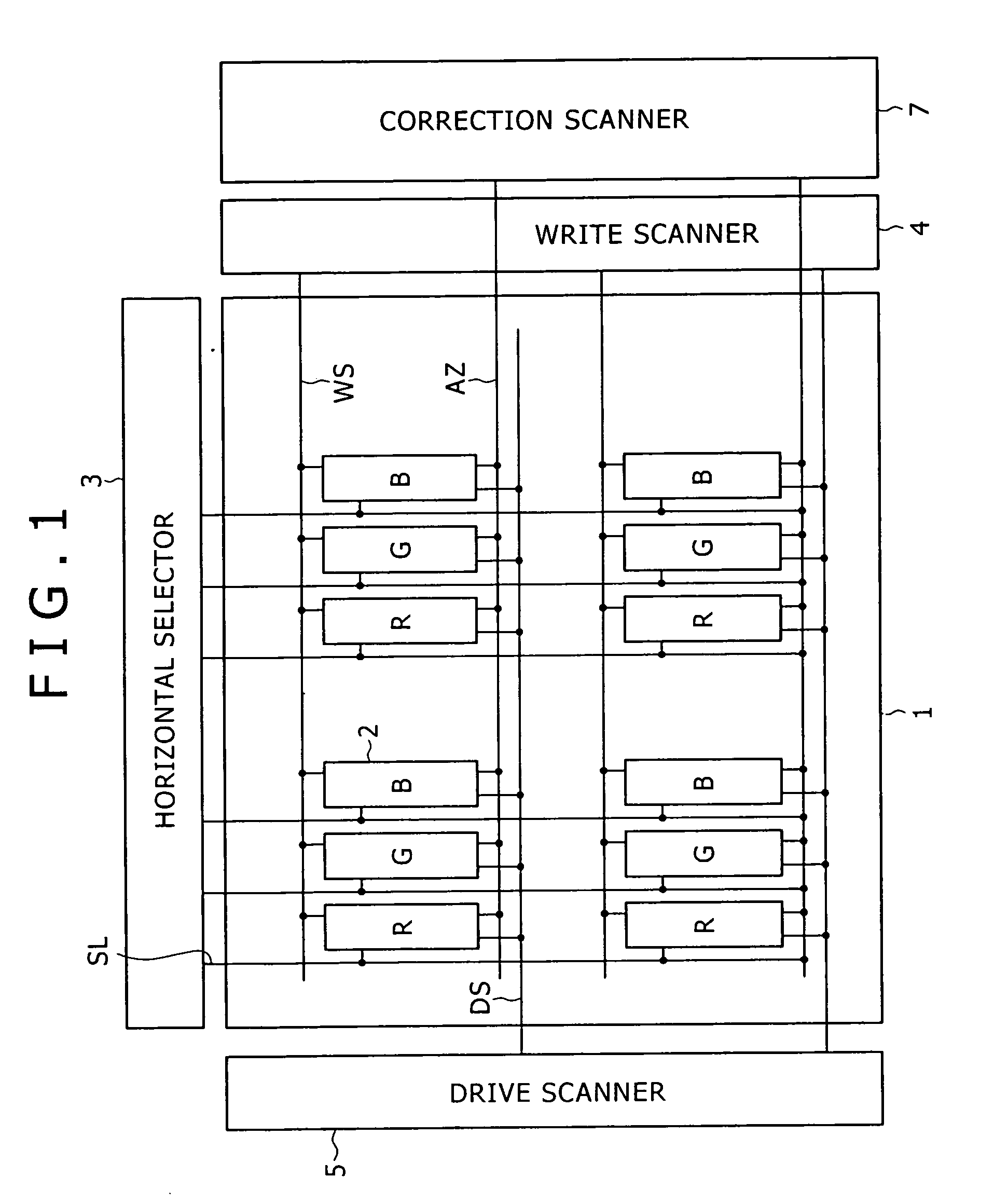

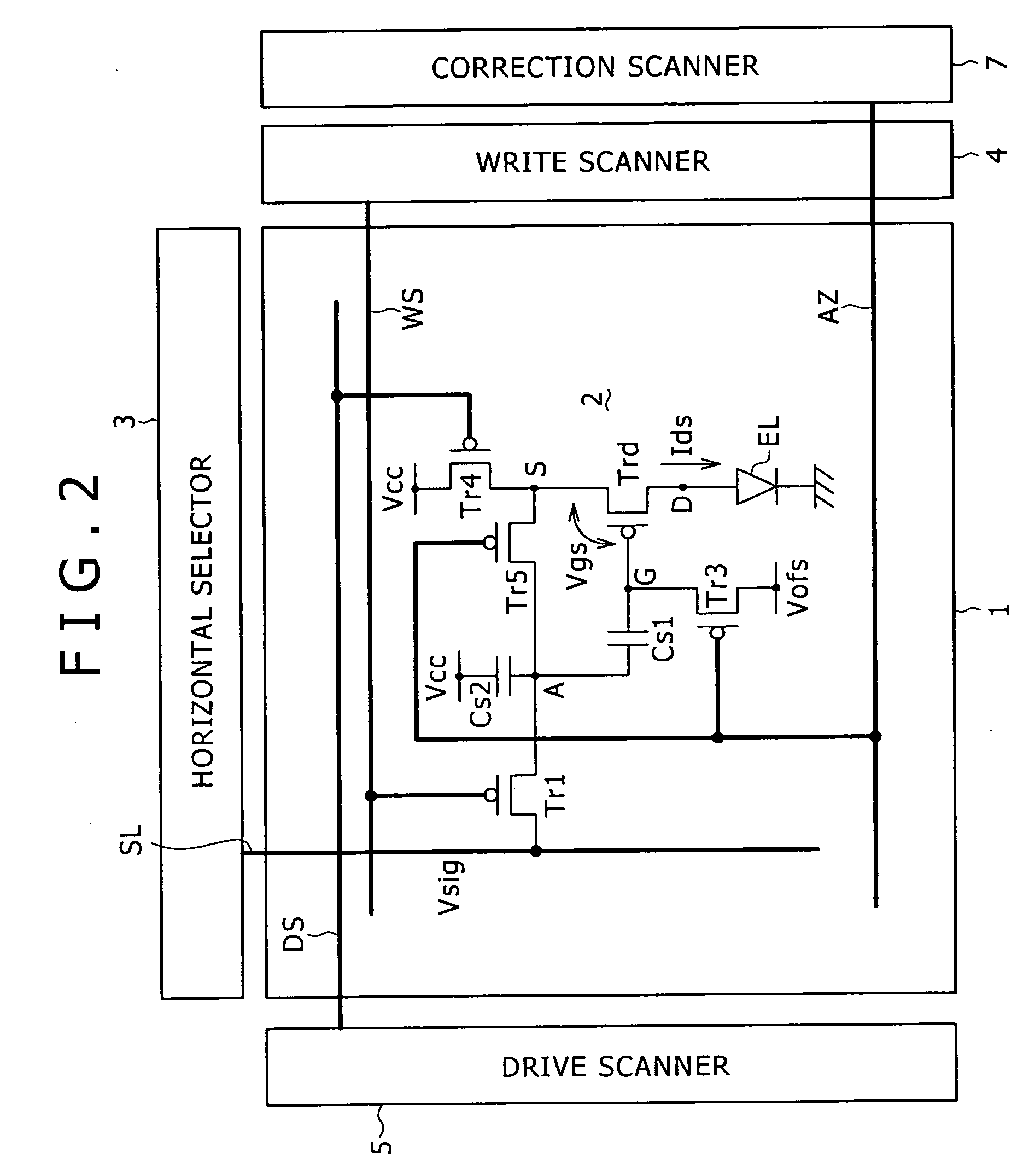

Pixel circuit, display and driving method thereof

InactiveUS20060170628A1Eliminate dependenciesImprove mobilityElectroluminescent light sourcesHeater elementsCapacitanceScan line

The invention provides a pixel circuit that can cancel the influence of the mobility of a drive transistor. A drive transistor supplies to a light-emitting element, an output current dependent upon an input voltage during a certain emission period. The light-emitting element emits light with a luminance dependent upon a video signal in response to the output current supplied from the drive transistor. The pixel circuit includes a correction unit that corrects the input voltage held by a capacitive part before the emission period or at the beginning of the emission period, in order to cancel the dependence of the output current on the carrier mobility. The correction unit operates during part of a sampling period in response to control signals supplied from scan lines. Specifically, the correction unit extracts the output current from the drive transistor while the video signal is sampled, and negatively feeds back the output current to the capacitive part to thereby correct the input voltage.

Owner:SONY CORP

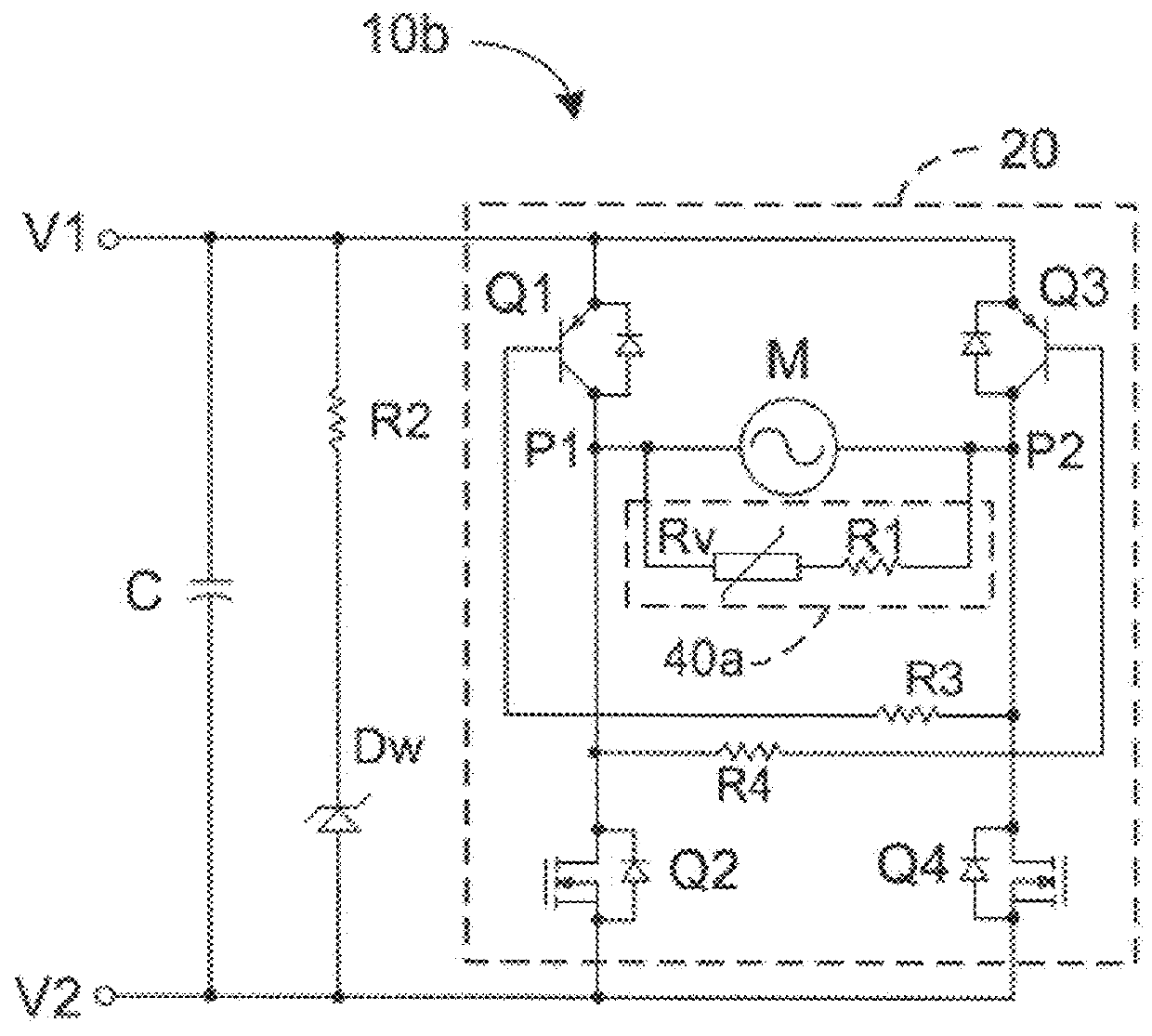

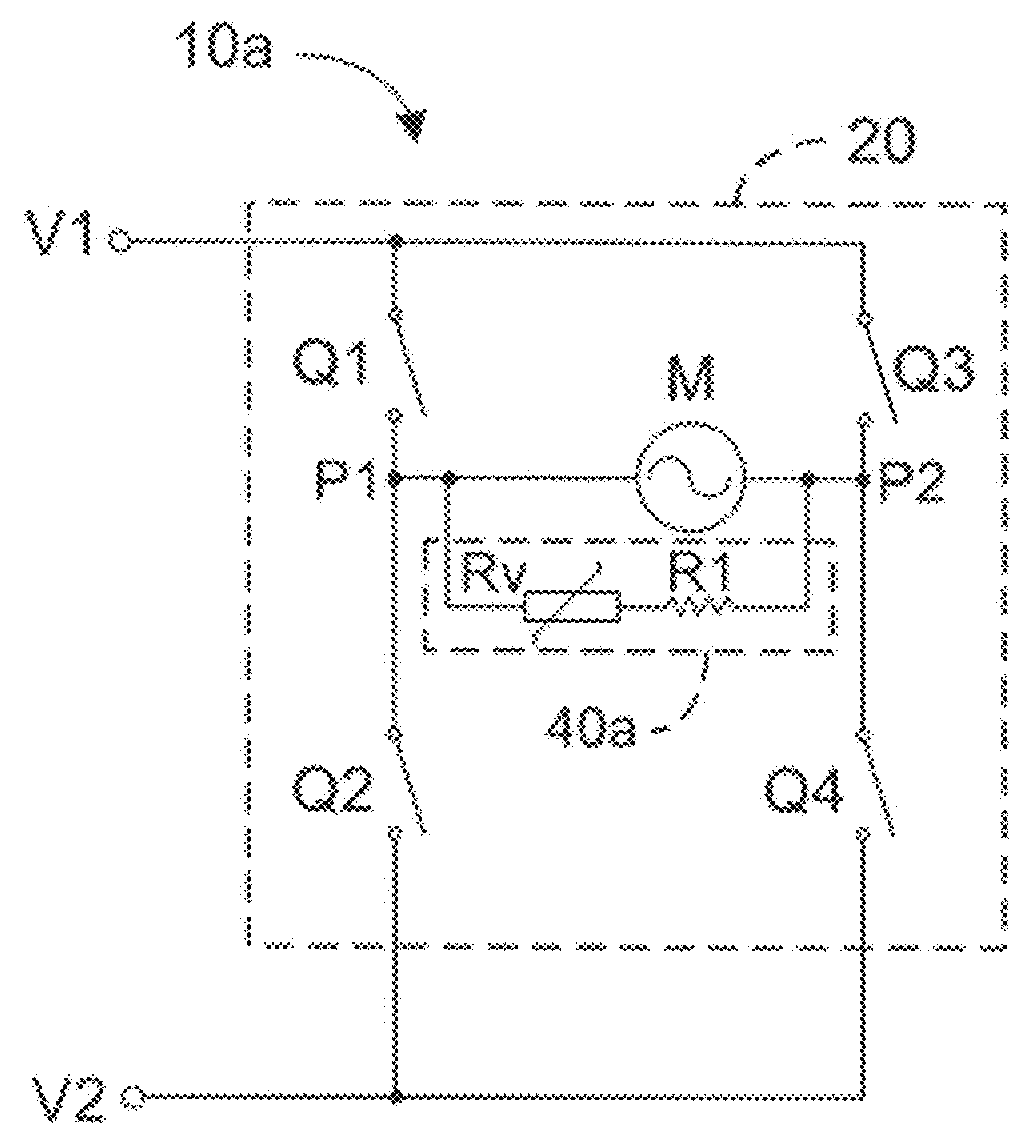

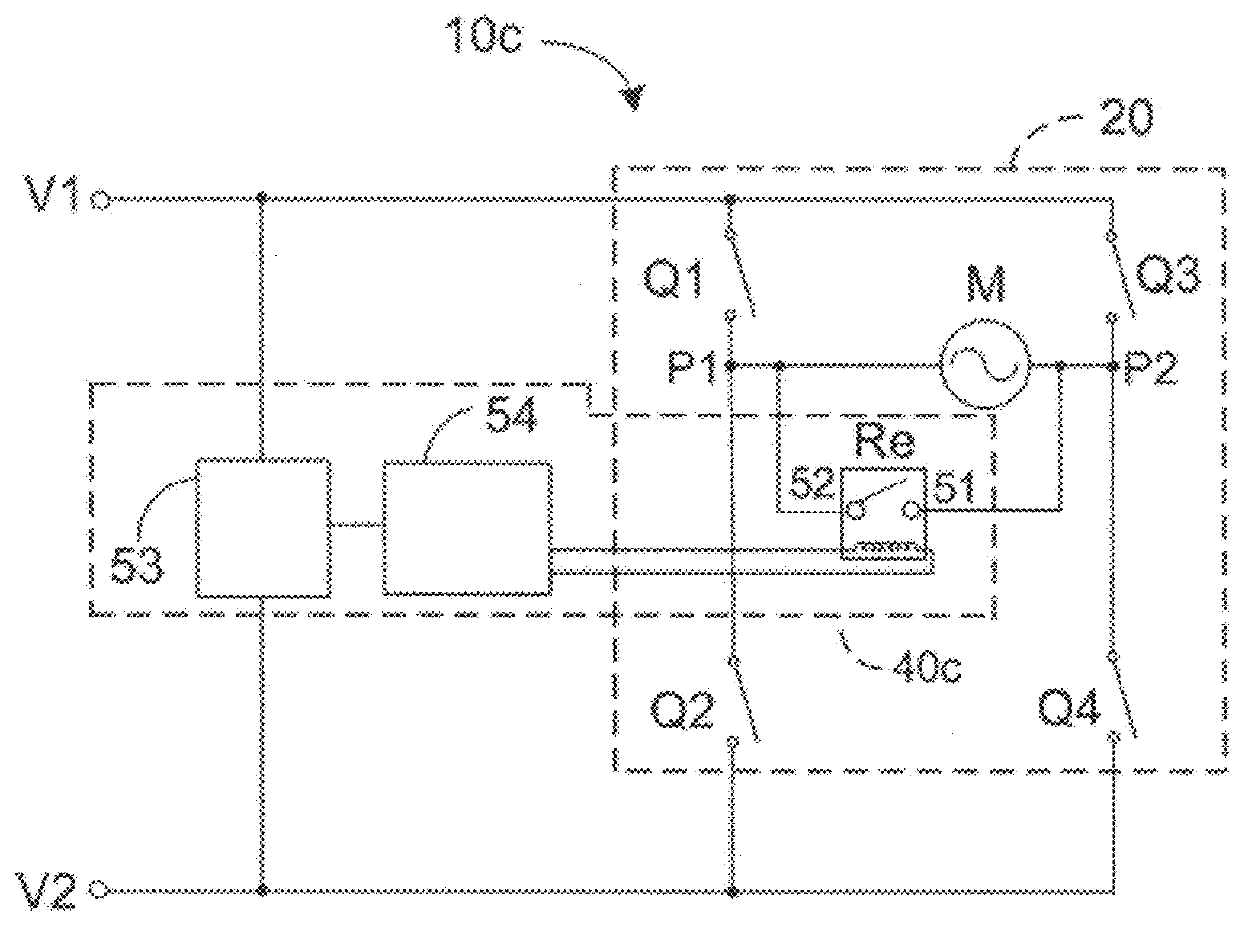

Control circuit for a DC motor

ActiveUS9385640B2Inhibit currentSingle motor speed/torque controlField or armature current controlControl circuitDC motor

A control circuit for a DC motor, has: a first and second input ports for connection to a DC source; a H-bridge driving circuit, having first and second switches connected in series between the input ports, and third and fourth switches connected in series between the input ports, a first output port between the first and second switches and a second output port between the third and fourth switches, and a shunt circuit and / or a blocking circuit. The motor is connected between the first and second output ports. The shunt circuit is connected between the first second output ports and has a resistance that will decrease in response to BEMF generated by the motor. The blocking circuit is connected in series with the motor between the output ports and has a resistance that increases in response to BEMF generated by the motor.

Owner:JOHNSON ELECTRIC SA

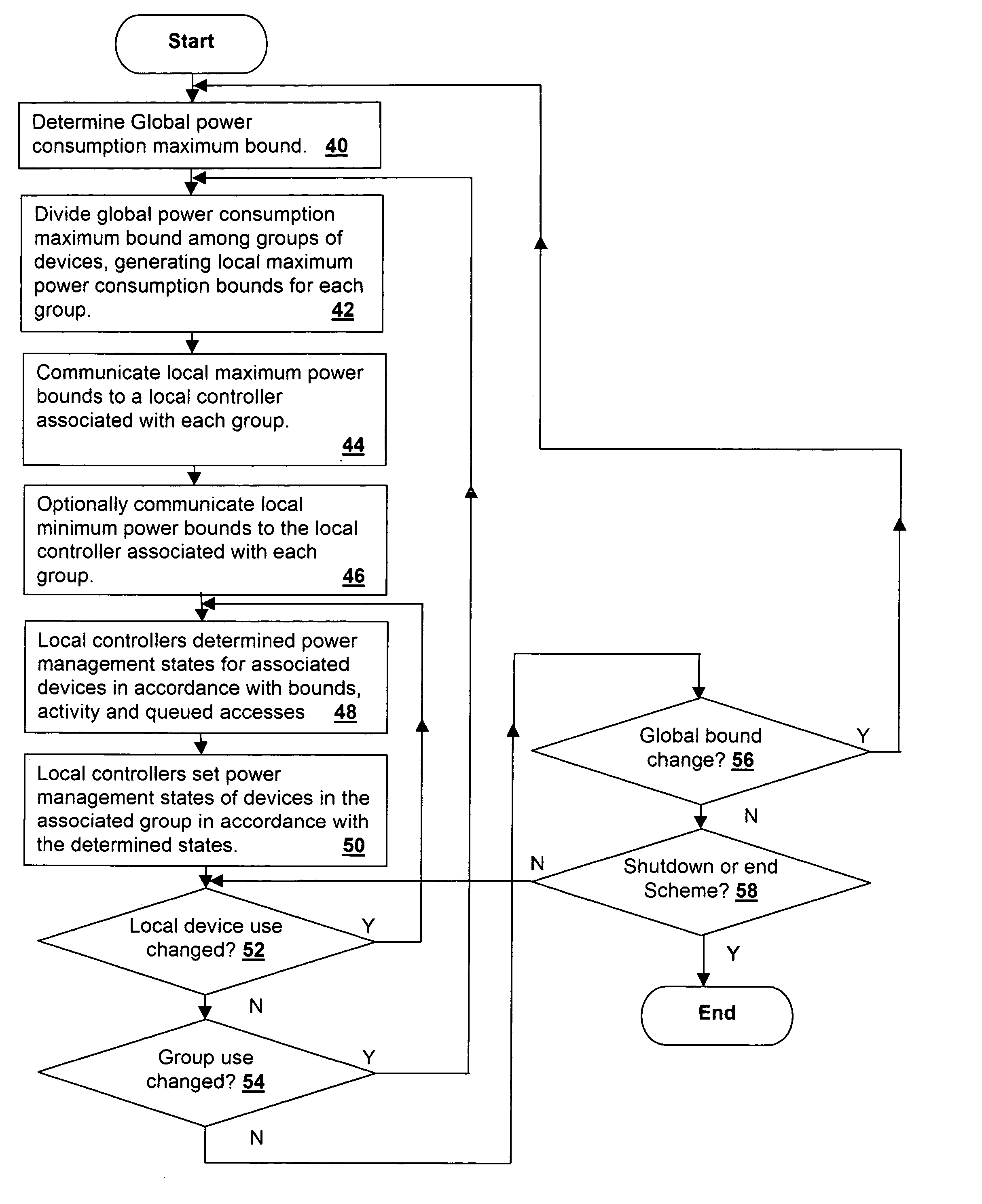

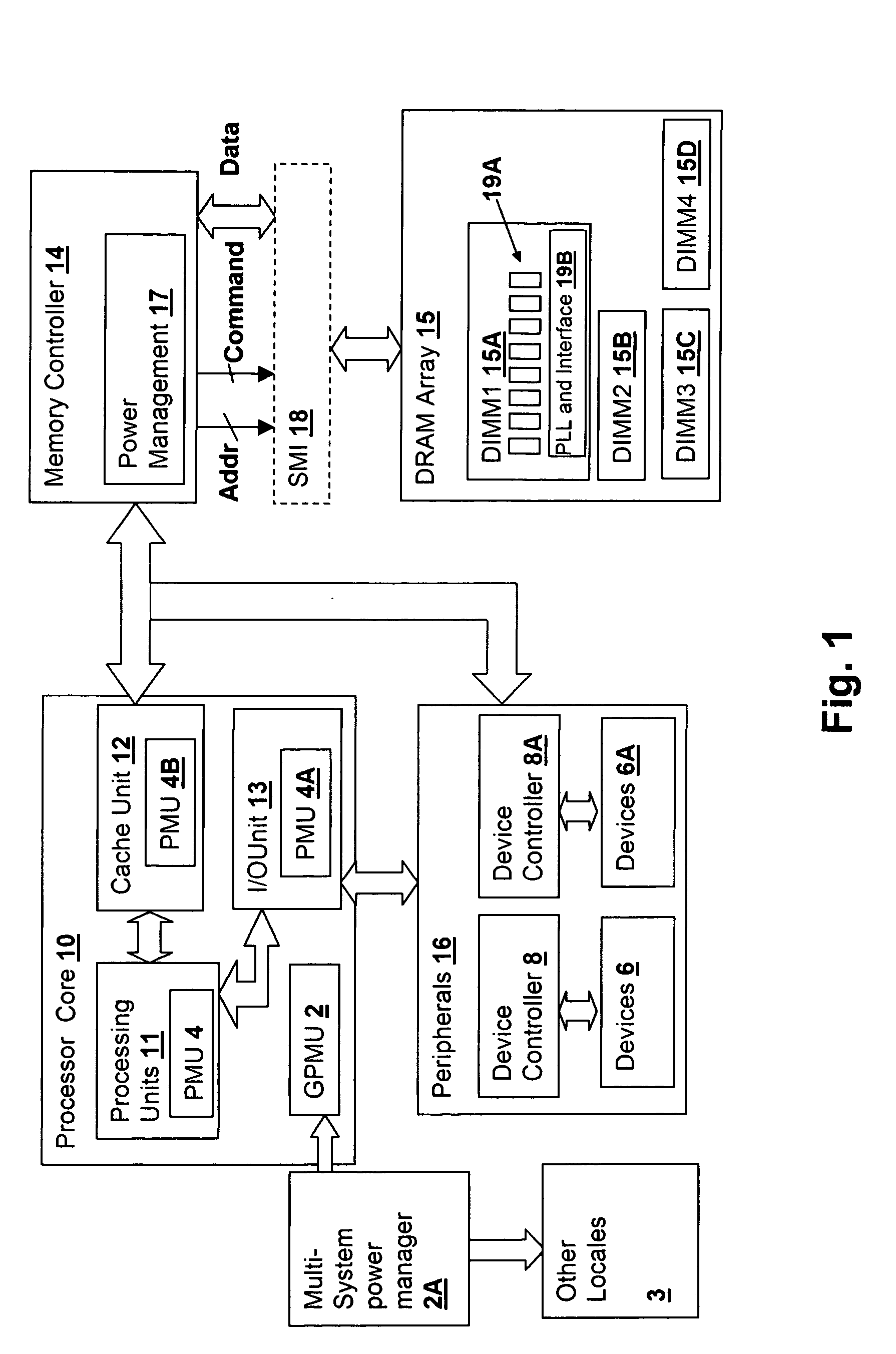

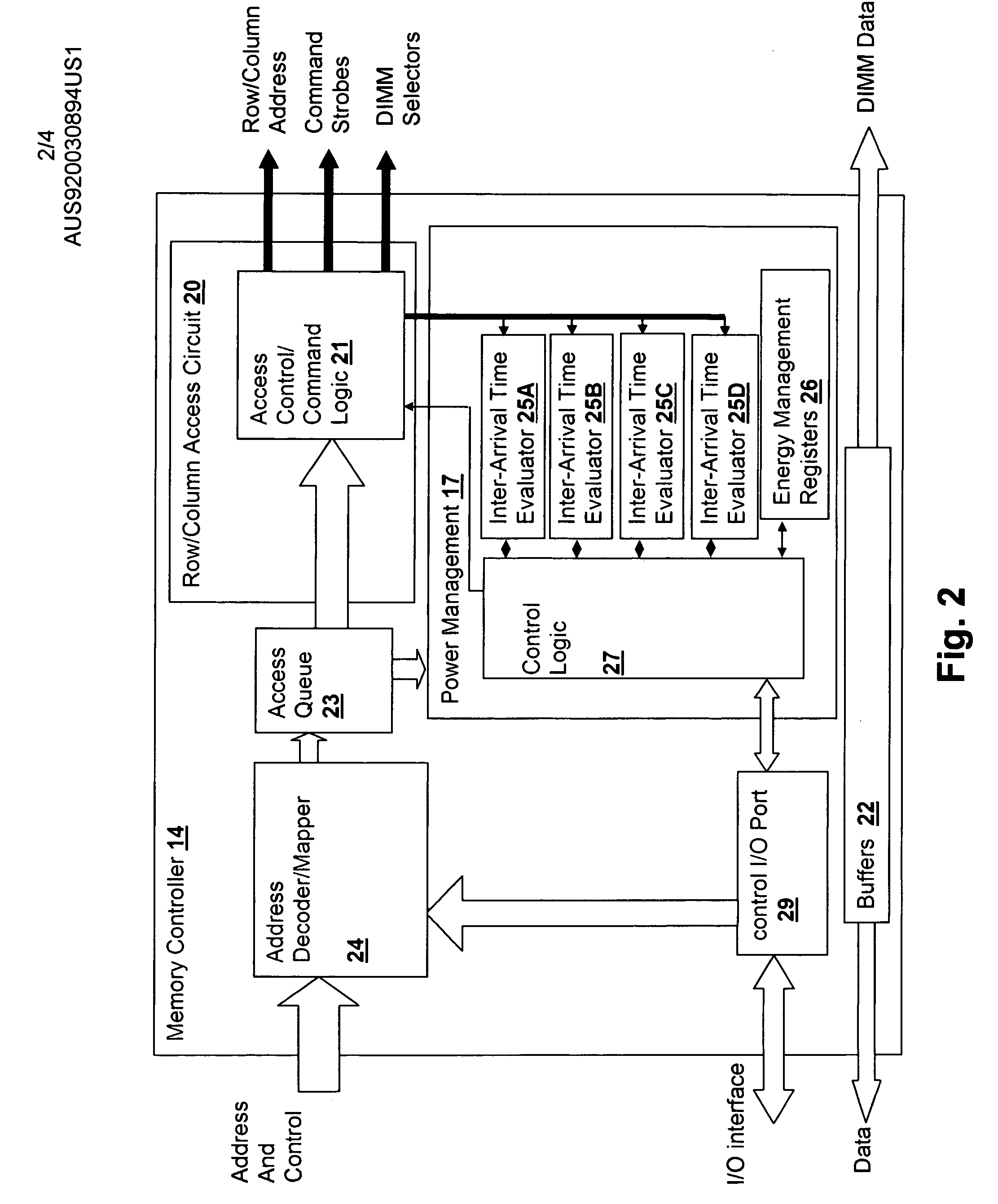

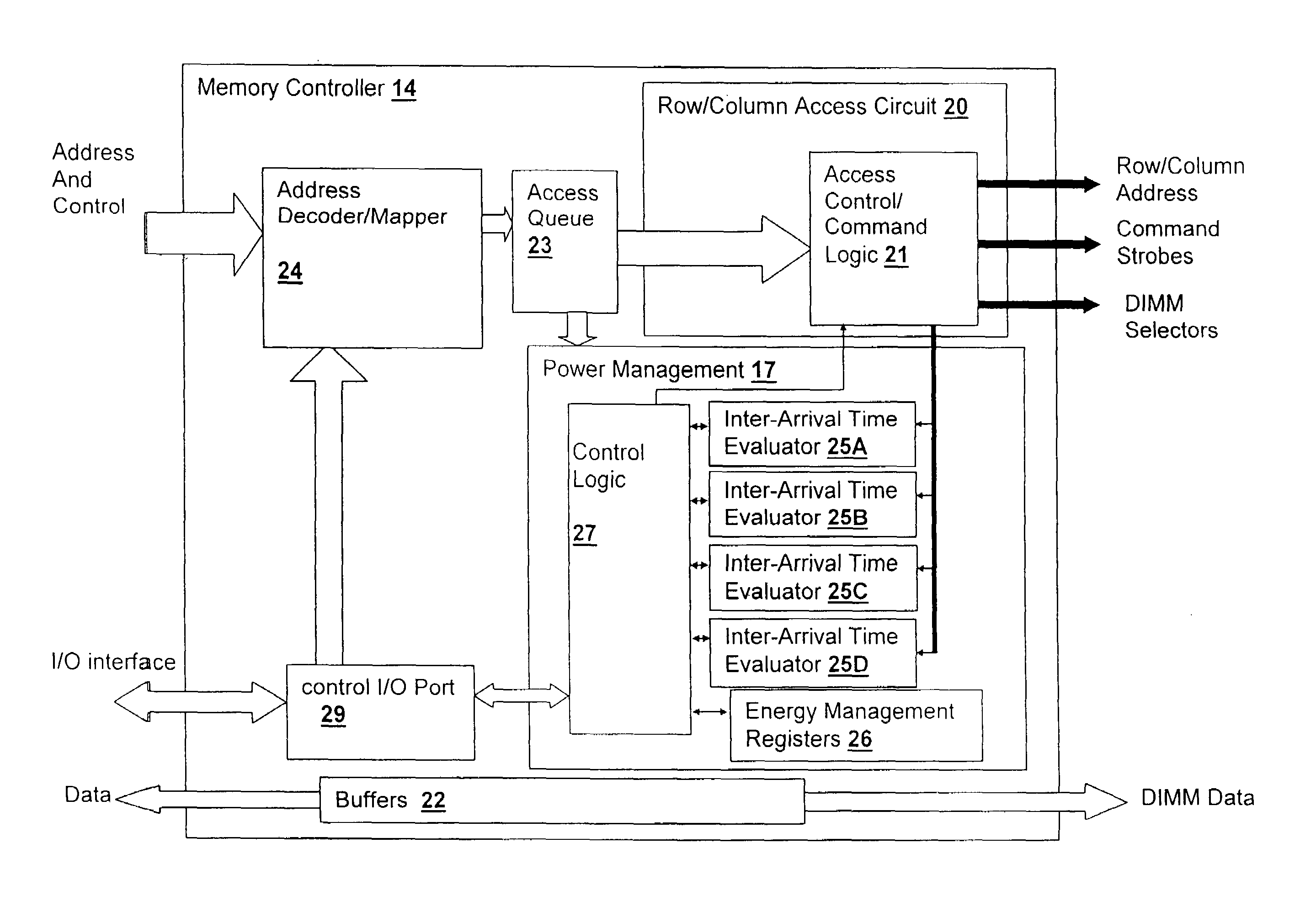

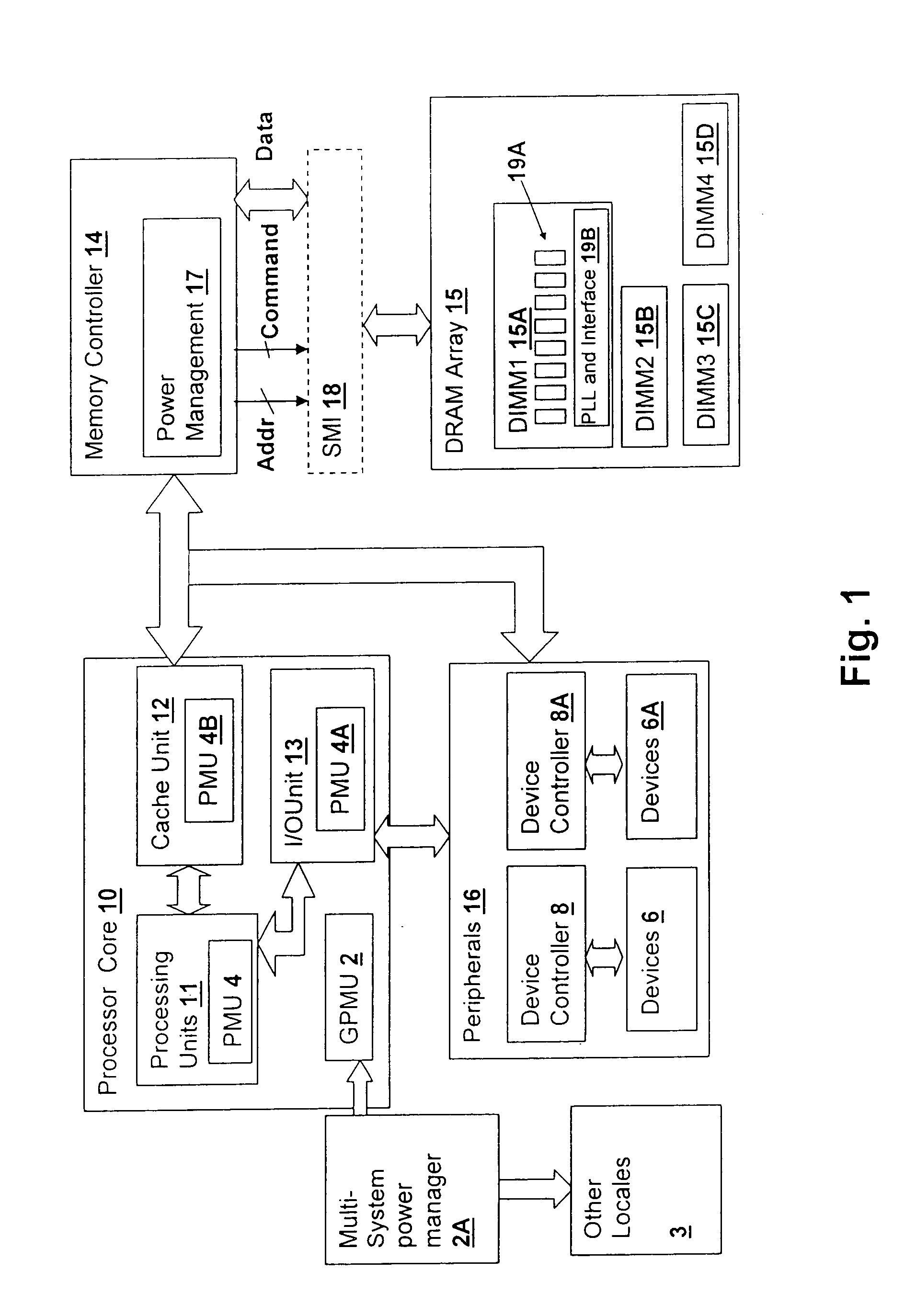

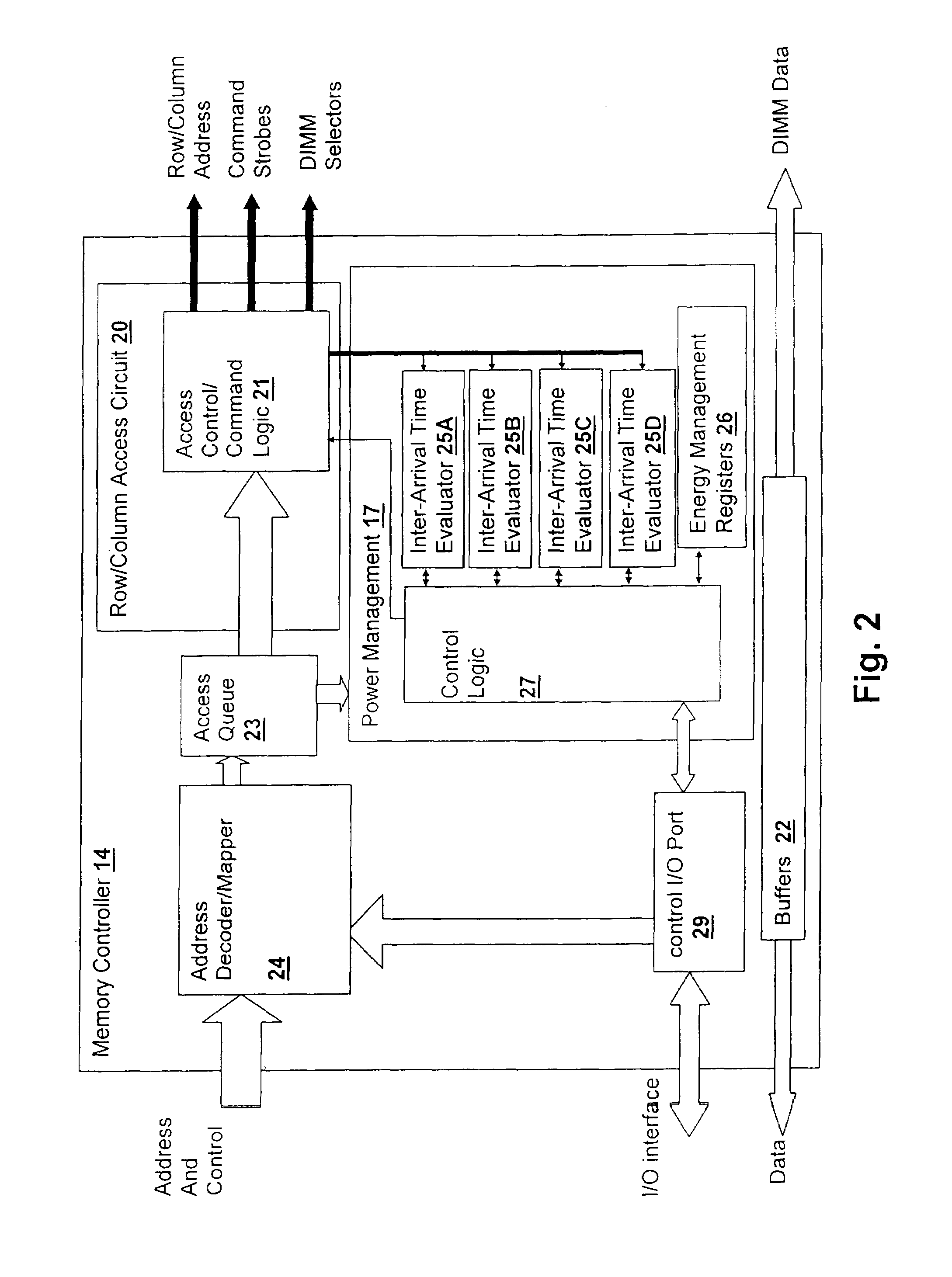

Method and system for power management including local bounding of device group power consumption

ActiveUS20050125703A1Inhibit currentSlow changeEnergy efficient ICTVolume/mass flow measurementMemory controllerGlobal system

A method and system for power management including local bounding of device group power consumption provides the responsiveness of local power control while meeting global system power consumption and power dissipation limits. At the system level, a global power bound is determined and divided among groups of devices in the system so that local bounds are determined that meet the global system bound. The local bounds are communicated to device controllers associated with each group of devices and the device controllers control the power management states of the associated devices in the group to meet the local bound. Thus, by action of all of the device controllers, the global bound is met. The controllers may be memory controllers and the devices memory modules, or the devices may be other devices within a processing system having associated local controllers. Alternatively or in concert, the devices may be entire processing systems and the associated controller a power management controller for associated processing systems, whereby multiple processing locales may be power-managed consistent with a global power consumption budget.

Owner:HUAWEI TECH CO LTD

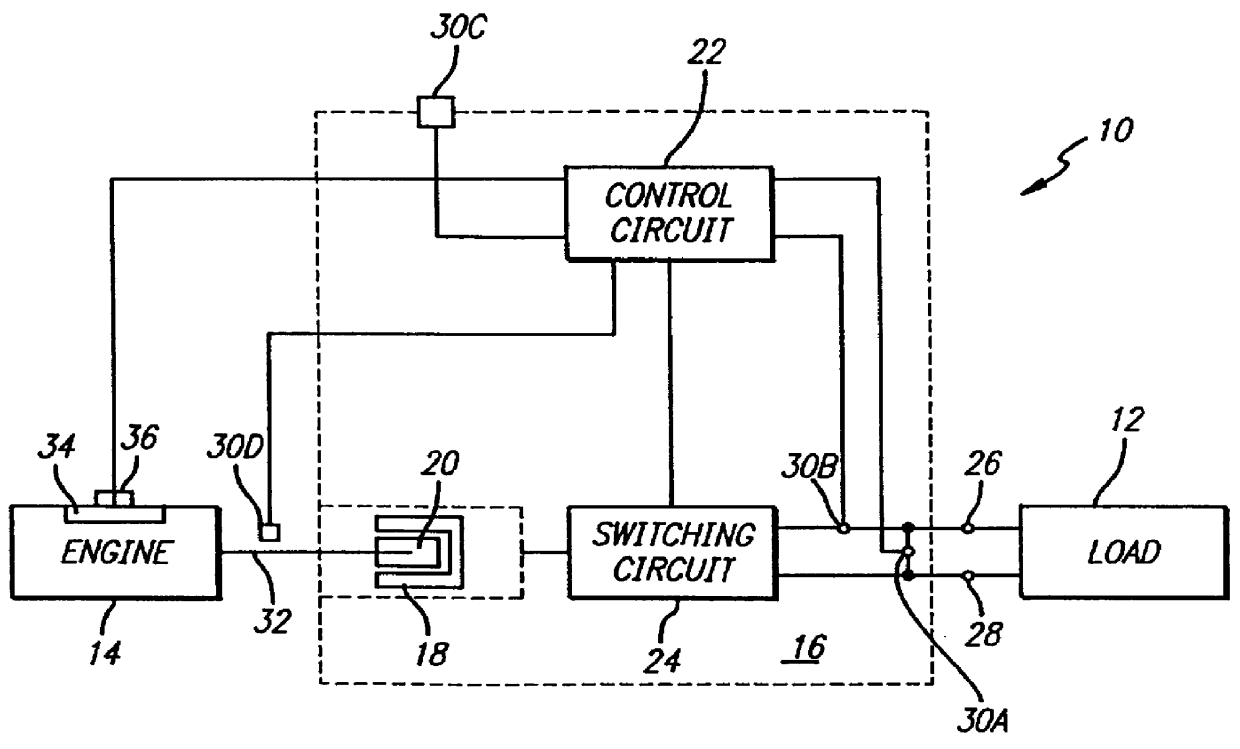

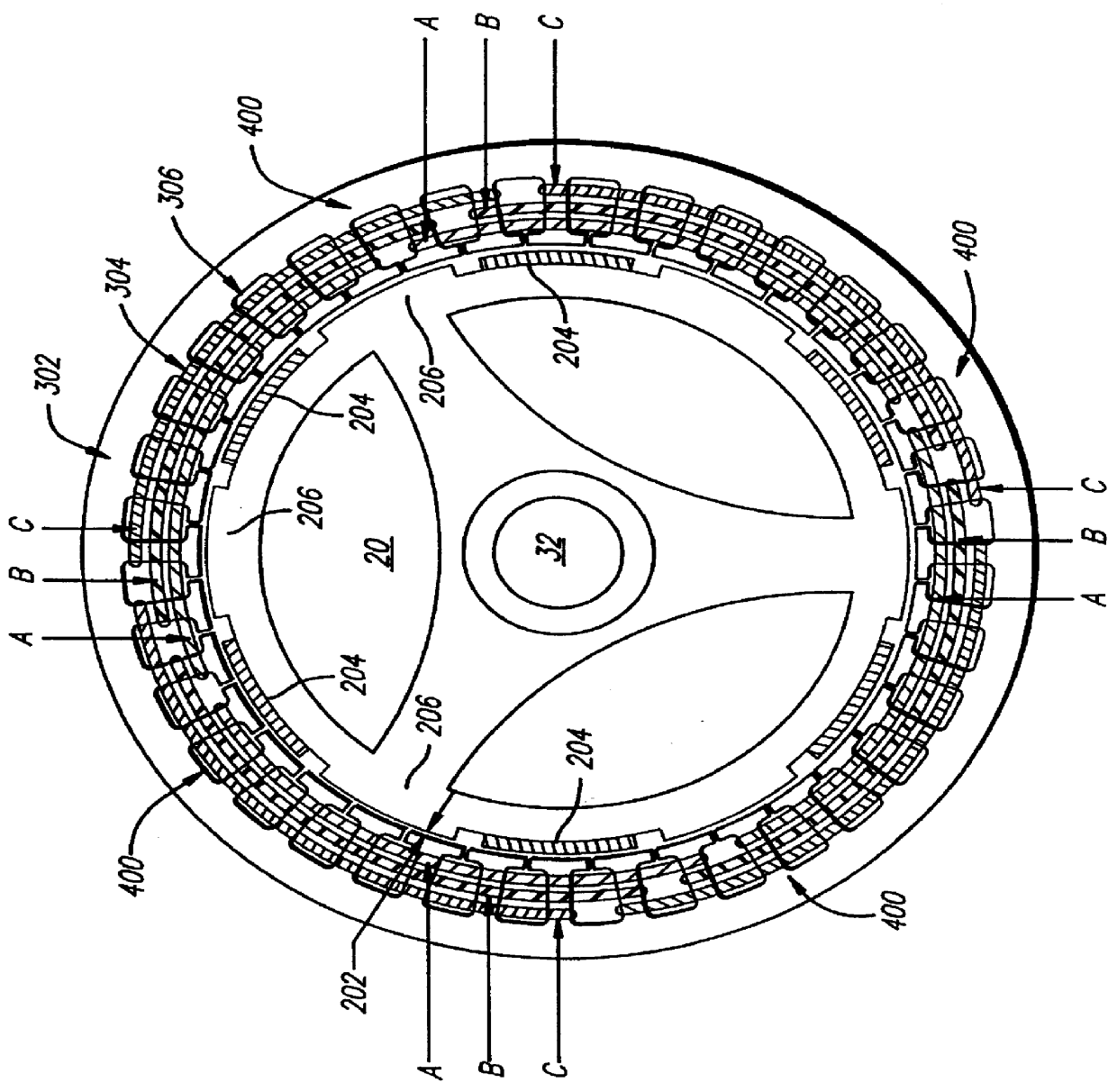

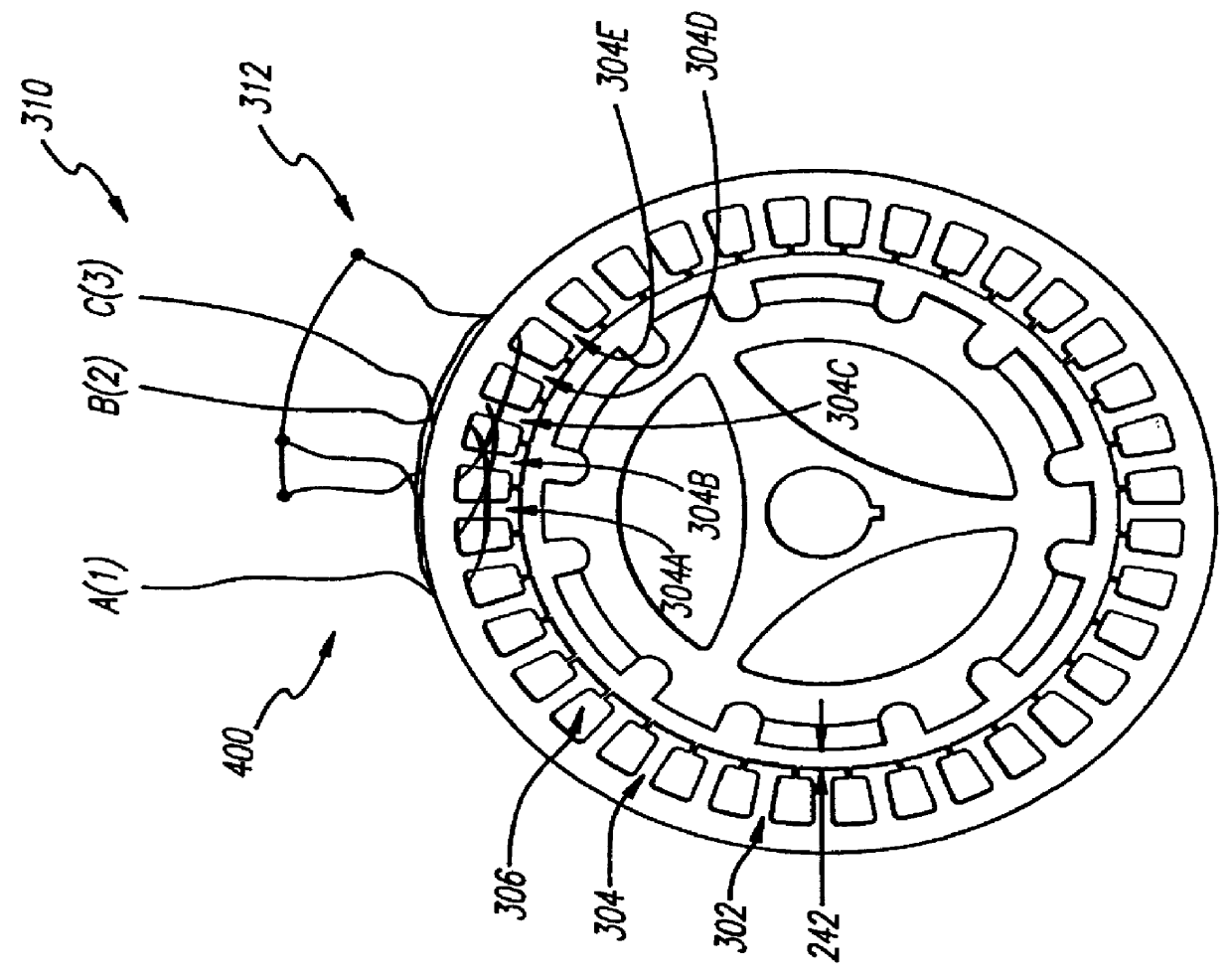

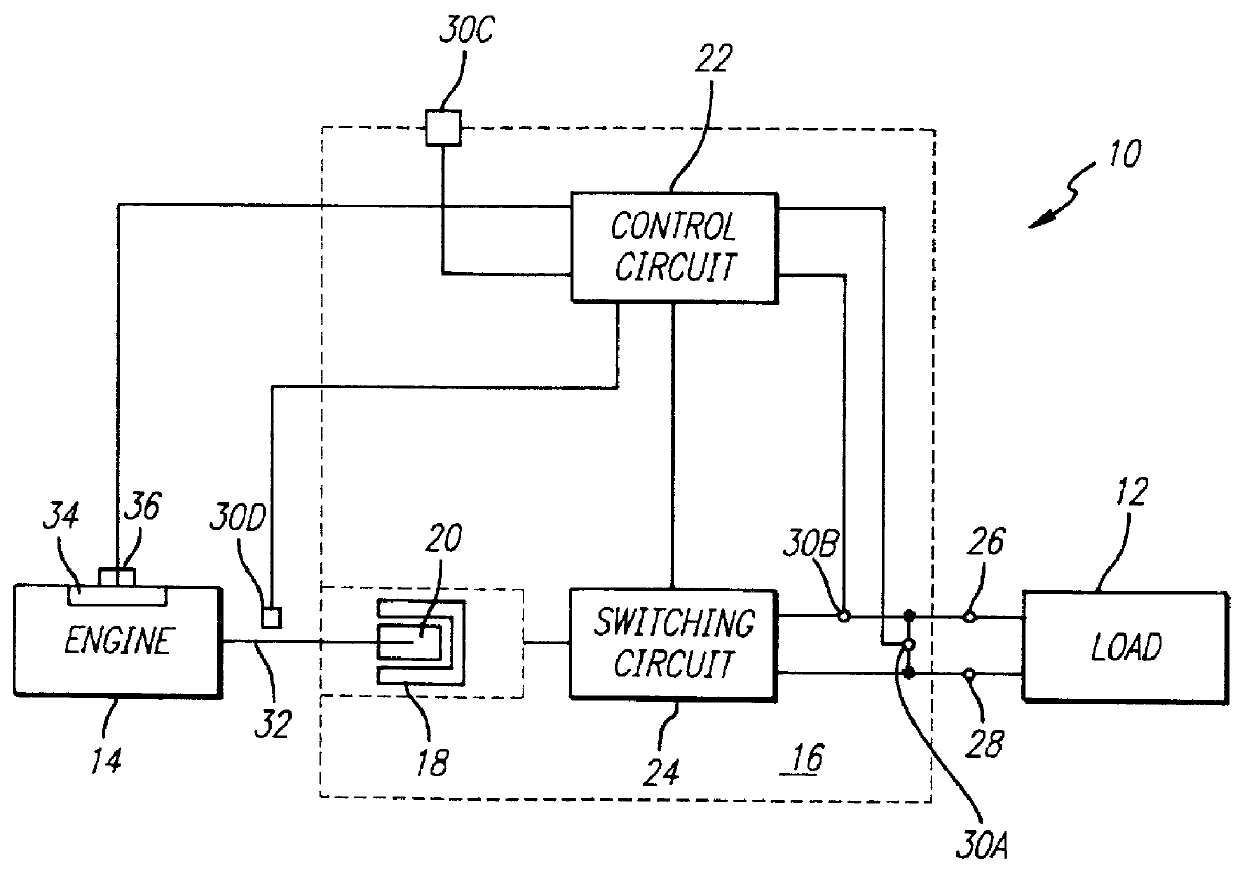

Throttle control for small engines and other applications

InactiveUS6118186AInhibit currentElectric motor startersEngine controllersThrottle controlSufficient time

The throttle of an engine in an engine driven generator system operating under an intermittently heavy load, as in supplying current to a welder, is controlled such that successive control signals sent to a throttle actuator for adjusting the engine throttle position are inhibited until at least a predetermined time has elapsed since the last preceding adjustment to the throttle. This procedure ensures that, as to each incremental adjustment to the throttle, the engine has sufficient time to respond, thereby preventing over-speeding or stalling the engine. The throttle actuator may be a stepper motor which is stepped by throttle position change signals from a processor which monitors engine speed and generator load to determine whether the throttle should be adjusted and, if so, in which direct. Alternatively, the throttle actuator may be a solenoid pulling against a spring in accordance with the average current through the solenoid coil. In this embodiment, the processor causes pulse width modulated signals to be applied across the solenoid coil with throttle position changes being reflected in changes to the width of the pulses, such changes in the pulse width being delayed for at least the predetermined time since the last preceding adjustment to the throttle.

Owner:PRAMAC AMERICA

Load demand throttle control for portable generator and other applications

The throttle of an engine in an engine driven generator system operating subject to a wide and rapidly variable load, as in supplying current to a welder, is operated such that control signals are sent to a throttle actuator for adjusting the engine throttle position in response to load changes. The throttle actuator may be a solenoid pulling against a spring in accordance with the average current through the solenoid coil. In this embodiment, the processor causes pulse width modulated signals to be applied across the solenoid coil with throttle position changes being reflected in changes to the width of the pulses, such changes in the pulse width being delayed for at least the predetermined time since the last preceding adjustment to the throttle. Alternatively, the throttle actuator may be a stepper motor which is stepped by throttle position change signals from a processor which monitors engine speed and generator load to determine whether the throttle should be adjusted and, if so, in which direction and to what extent for optimum response.

Owner:PRAMAC AMERICA

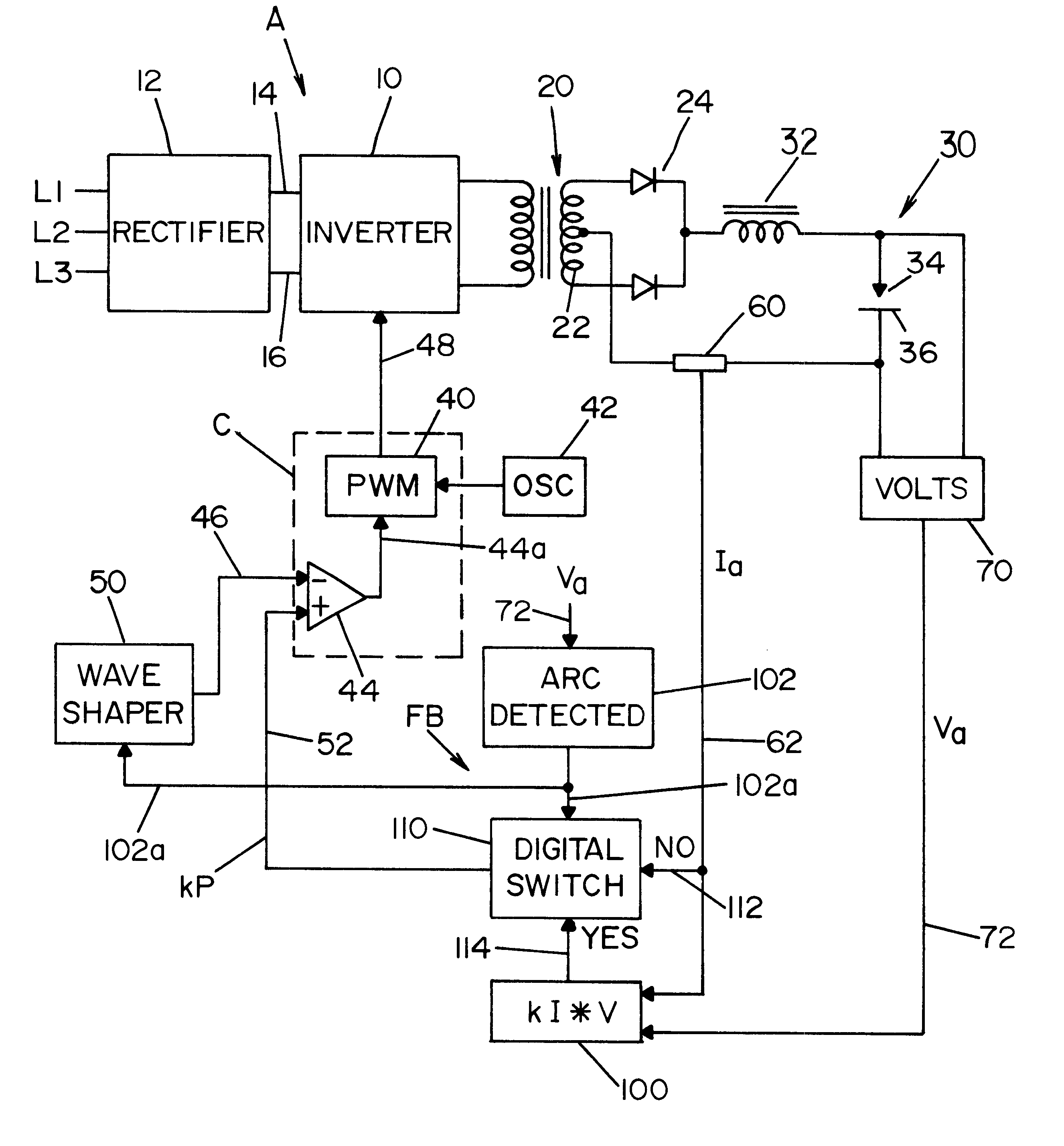

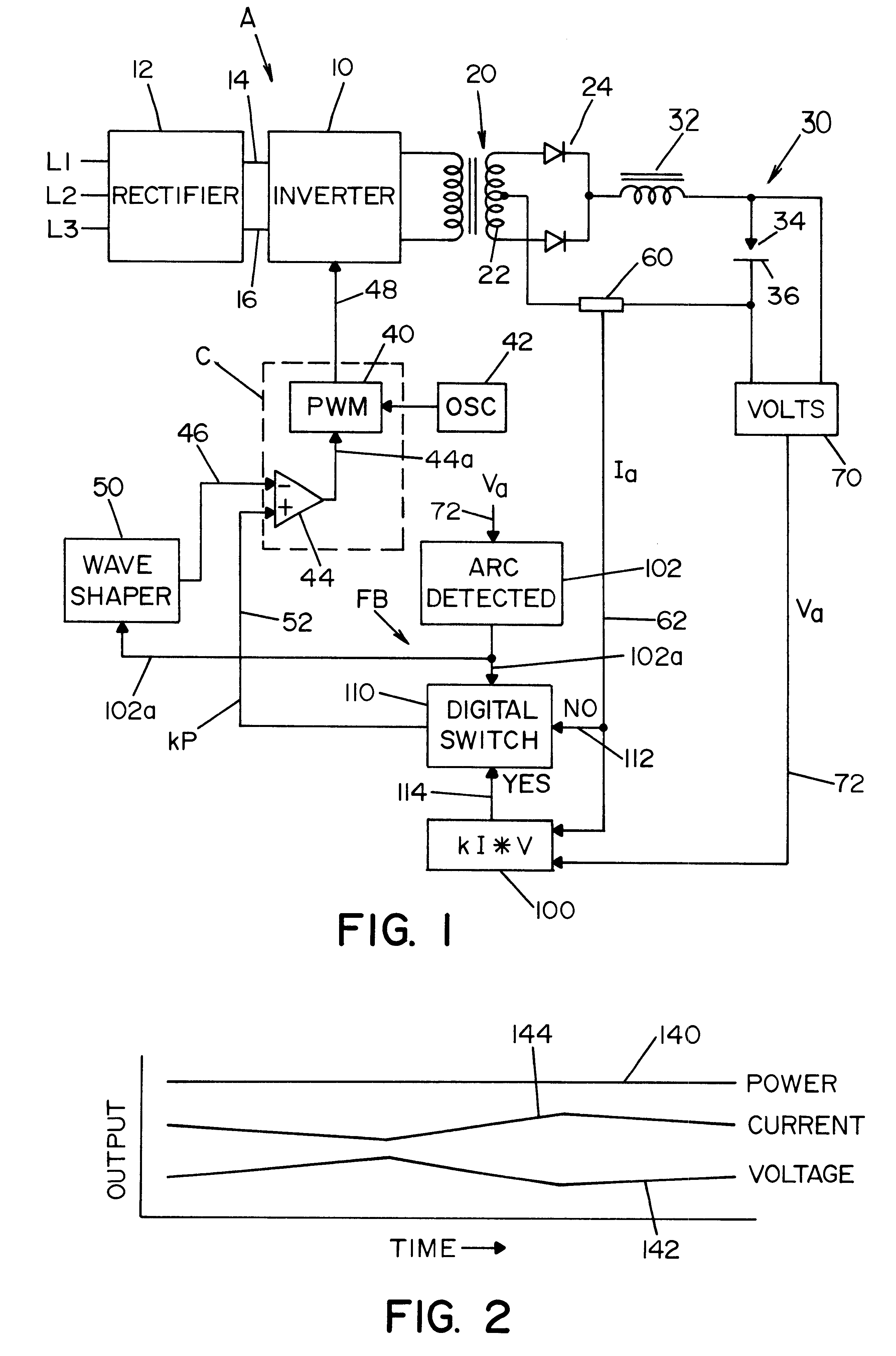

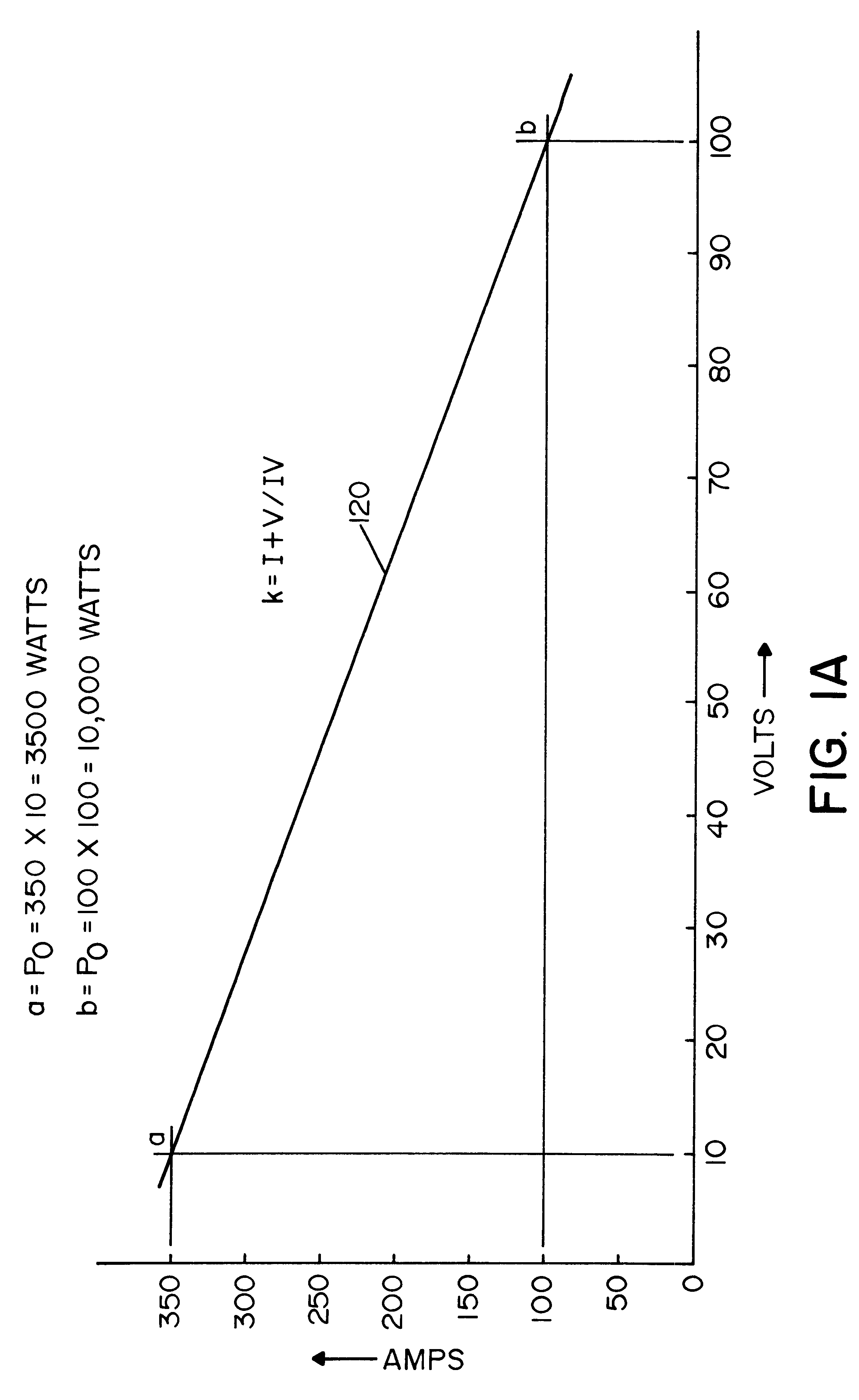

System and method for controlling an electric arc welder

InactiveUS6498321B1Inhibit currentRealize automatic adjustmentArc welding apparatusControl signalControl system

A control system for an electric arc welder performing a welding process between an electrode and a workpiece, which system comprises: a high speed switching type power supply with a controller operated at a switching frequency of at least about 10 kHz with an input current control signal to adjust the output current of the power supply; a first sensor sensing the actual arc voltage; a second sensor sensing the actual arc current; a first circuit for creating a power signal representing the desired real time power level at progressive times during the welding process; a second circuit for creating a function of the sensed actual voltage and the sensed actual current; and a third circuit for adjusting the current control signal in accordance with the difference between the power signal and the function of the actual voltage and current, preferably arc power.

Owner:LINCOLN GLOBAL INC

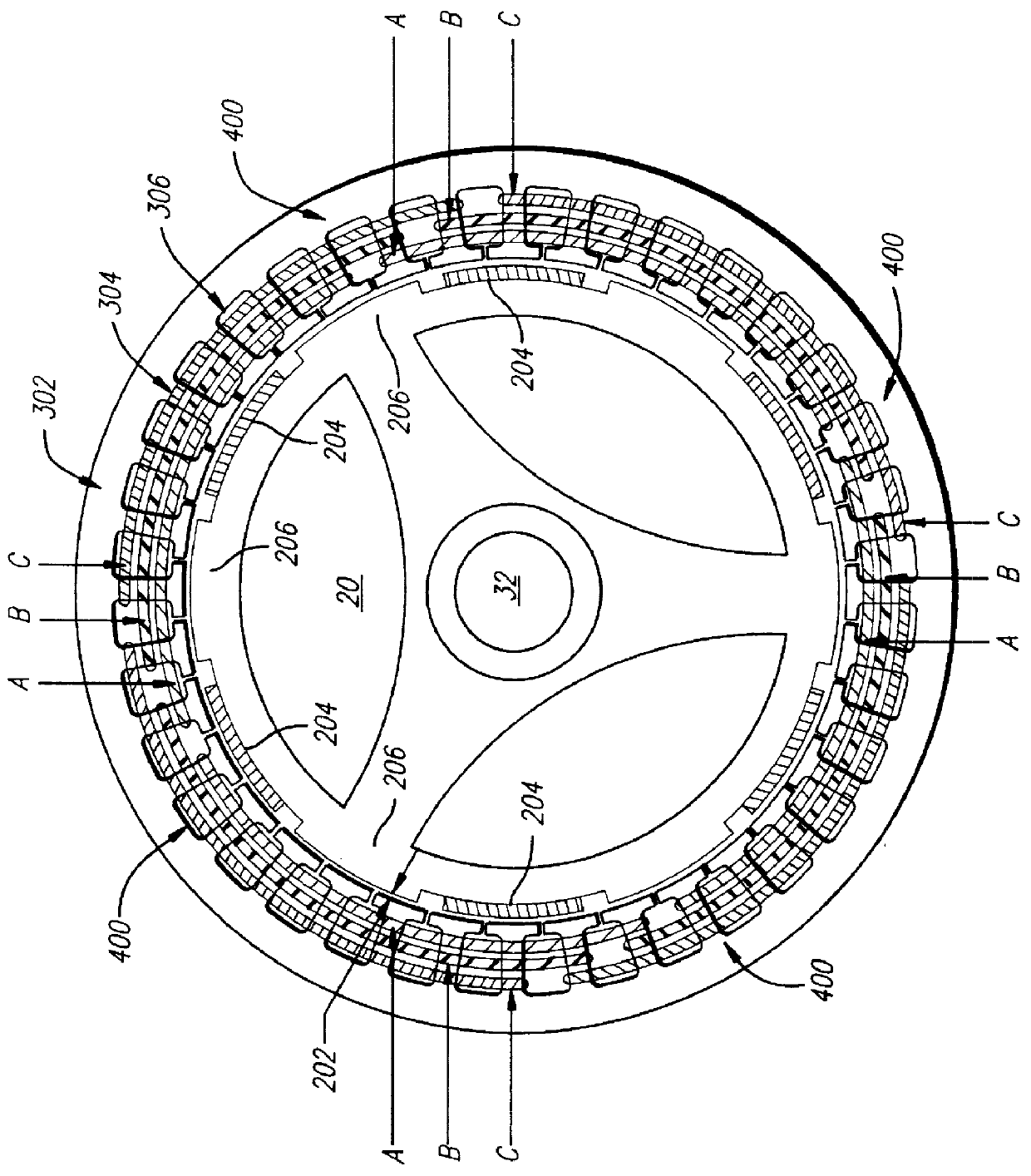

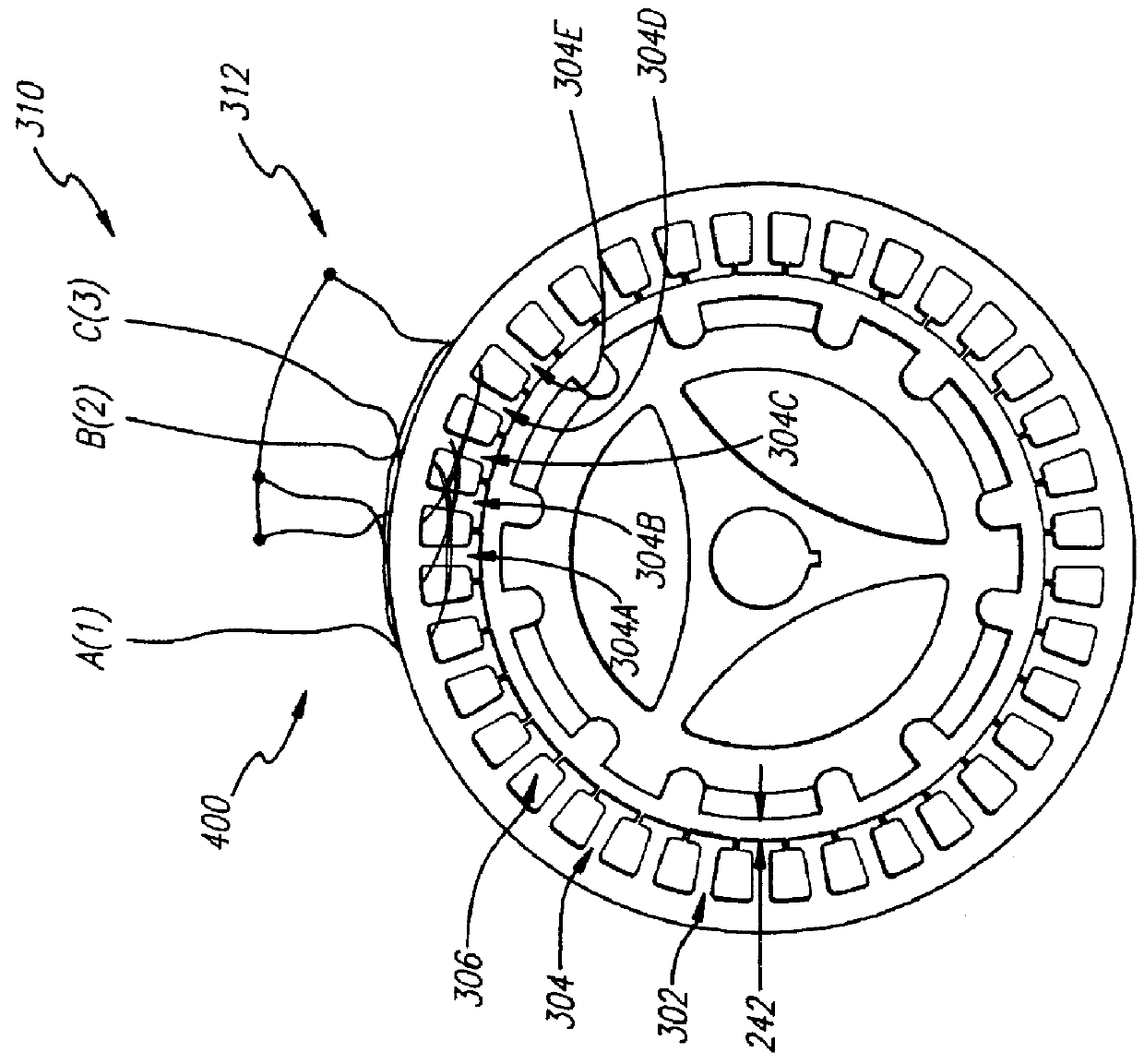

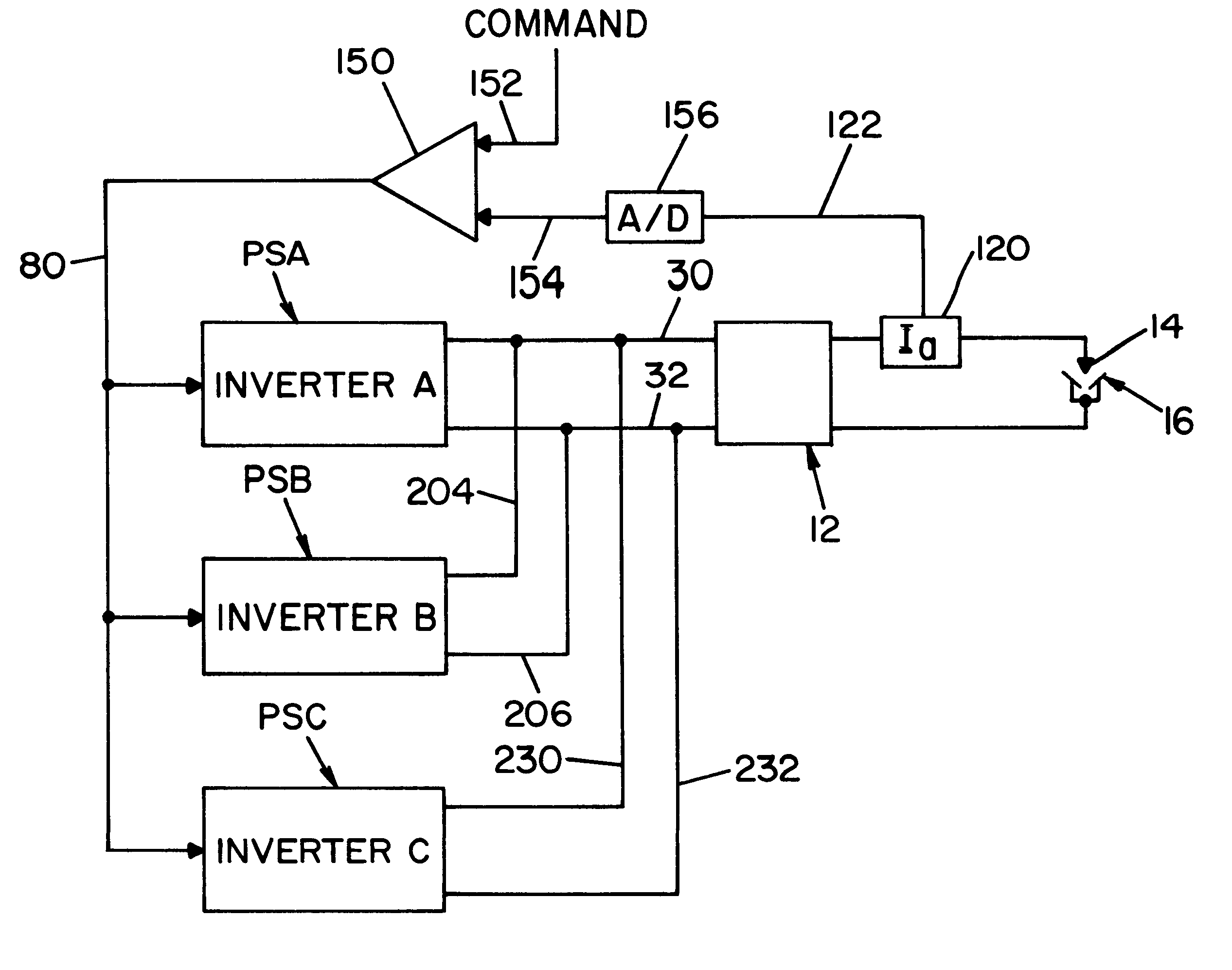

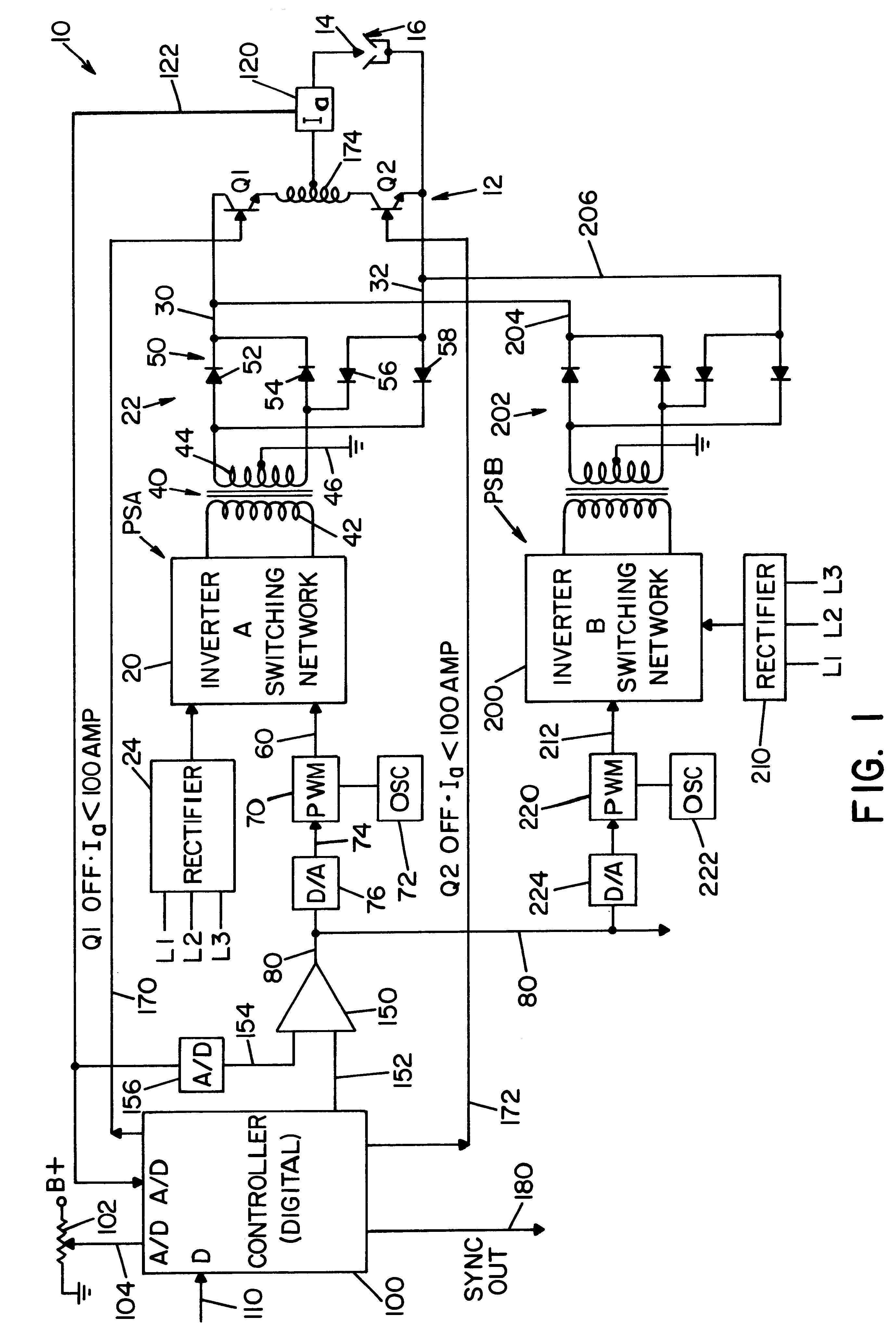

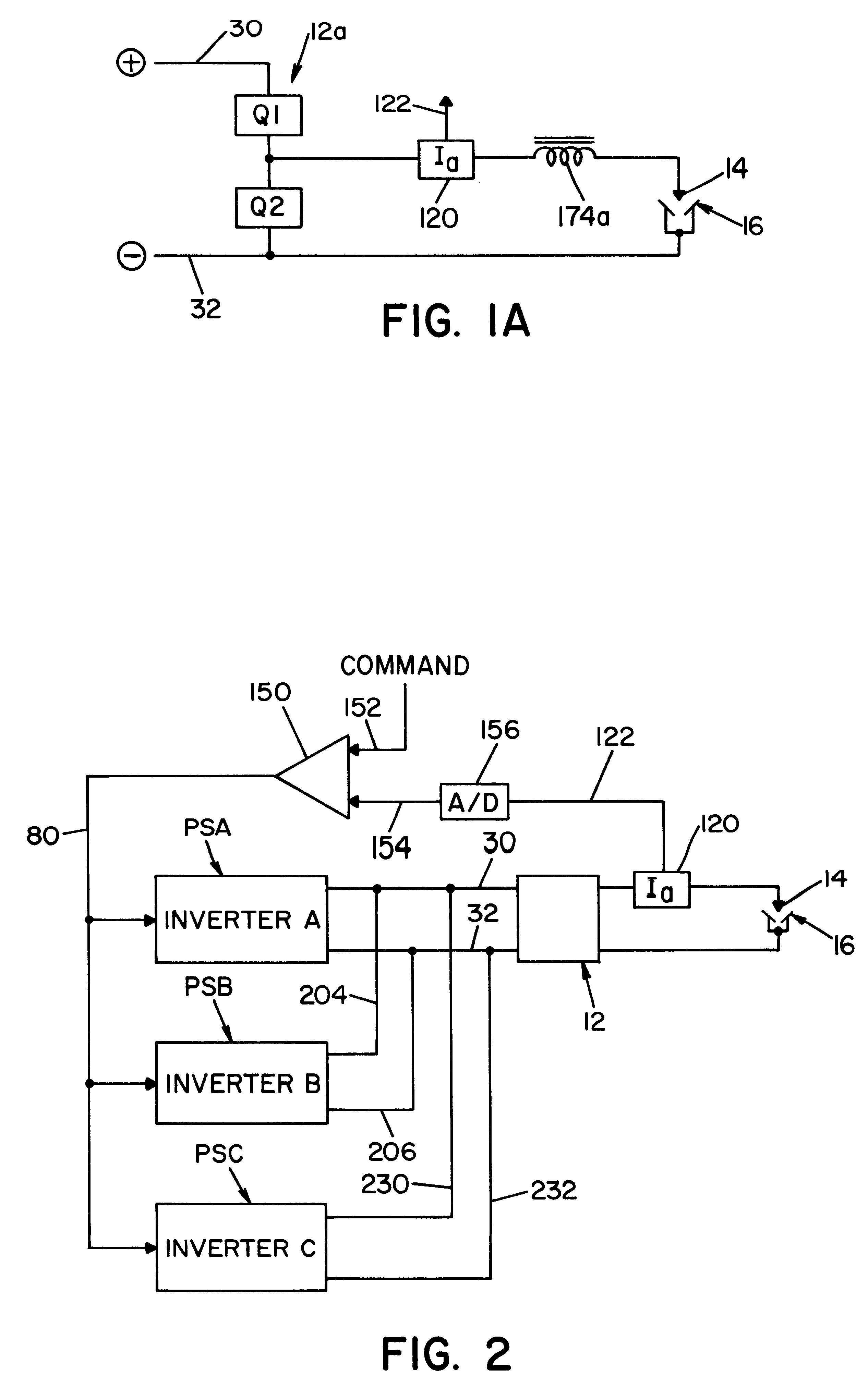

Electric ARC welder with a plurality of power supplies

An electric arc welder comprising a plurality of power supplies connected to a single welding station with a D.C. input for passing an arc welding current across an electrode and workpiece, each of the power supplies including a switching type inverter with an output D.C. current determined by a signal applied to the input of the power supply, a circuit connecting the output D.C. currents in parallel at the input of the welding station, a feedback circuit including a sensor for creating a current signal representing the arc current, a command signal source, and a circuit for creating a master current signal based upon the sensed current signal and the command signal, and a circuit for applying said master current signal to the input of the plurality of power supplies whereby the D.C. current to the D.C. input of the welding station is equally shared by the power supplies.

Owner:LINCOLN GLOBAL INC

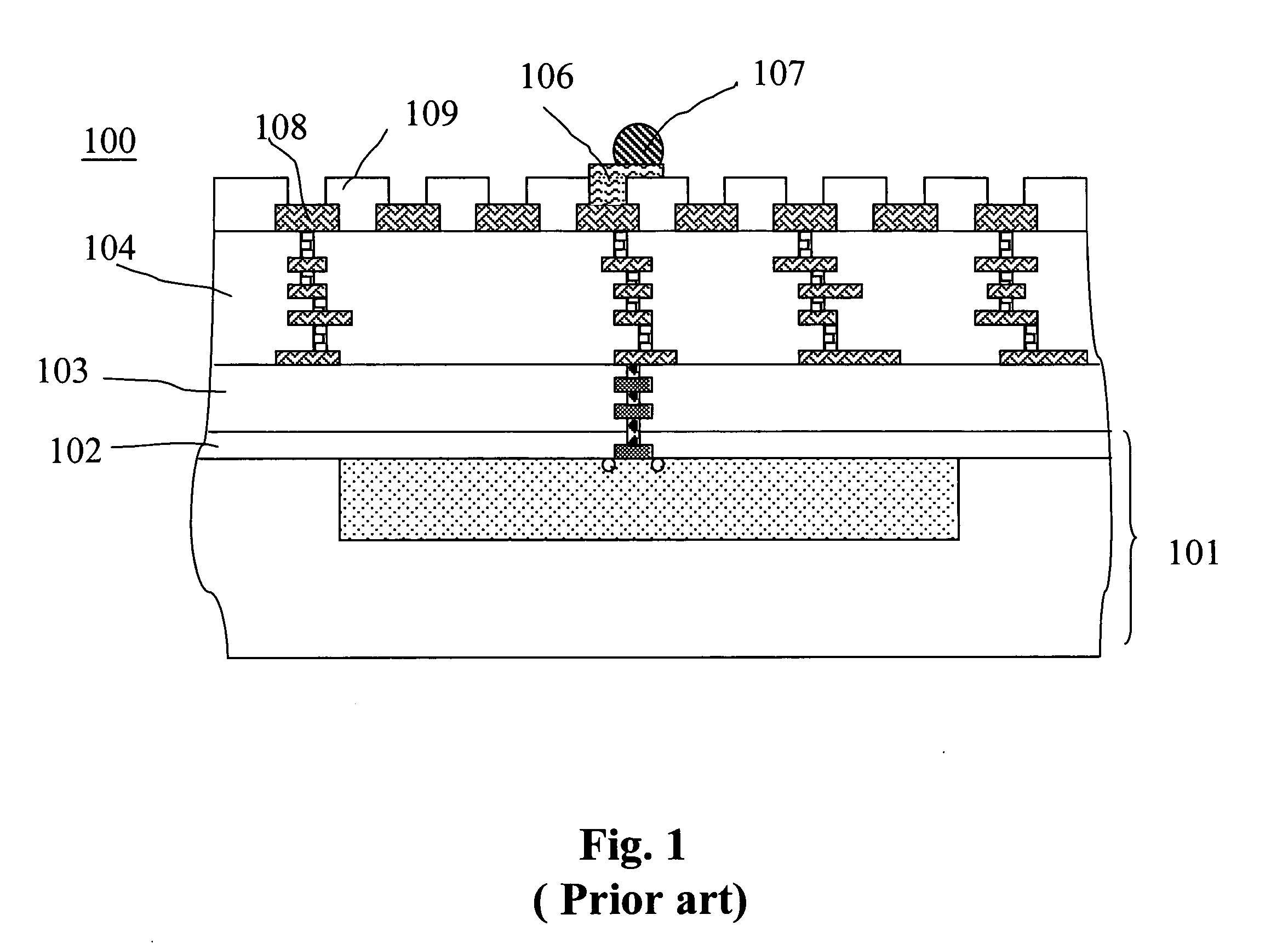

Method for manufacturing thin film transistor array panel for liquid crystal display

Simplified method of manufacturing liquid crystal displays. A gate wire including a gate line, a gate pad and a gate electrode is formed on the substrate by using the first mask. A gate insulating layer, a semiconductor layer, a ohmic contact layer and a metal layer are sequentially deposited to make a quadruple layers, and patterned by a dry etch of using the second mask. At this time, the quadruple layers is patterned to have a matrix of net shape layout and covering the gate wire. An opening exposing the substrate is formed in the display area and a contact hole exposing the gate pad is formed in the peripheral area. Next, ITO is deposited and a photoresist layer coated on the ITO. Then, the ITO layer is patterned by using the third mask and a dry etch, and the data conductor layer and the ohmic contact layer not covered by the ITO layer is dry etched. After depositing a passivation layer, a opening is formed by using the fourth mask and the exposed semiconductor layer through the opening is etched to separate the semiconductor layer under the adjacent data line.

Owner:SAMSUNG ELECTRONICS CO LTD

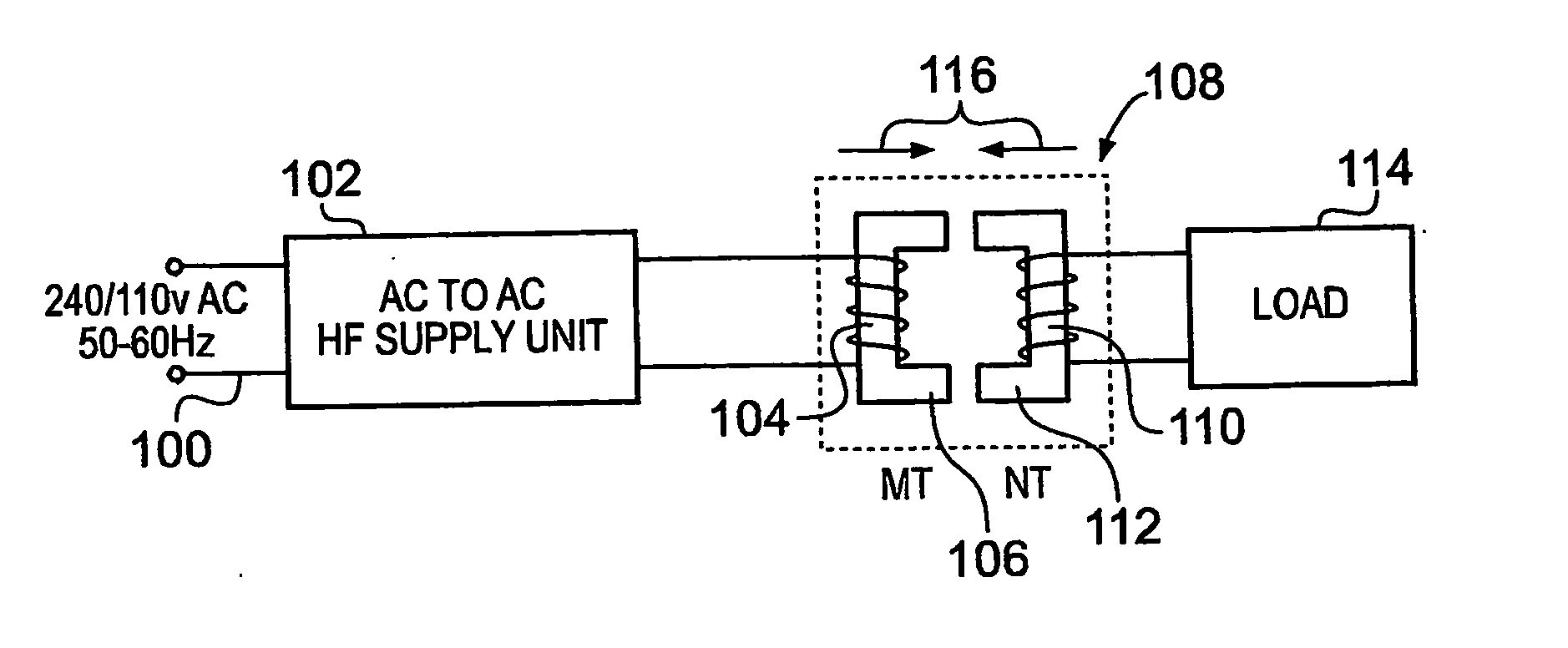

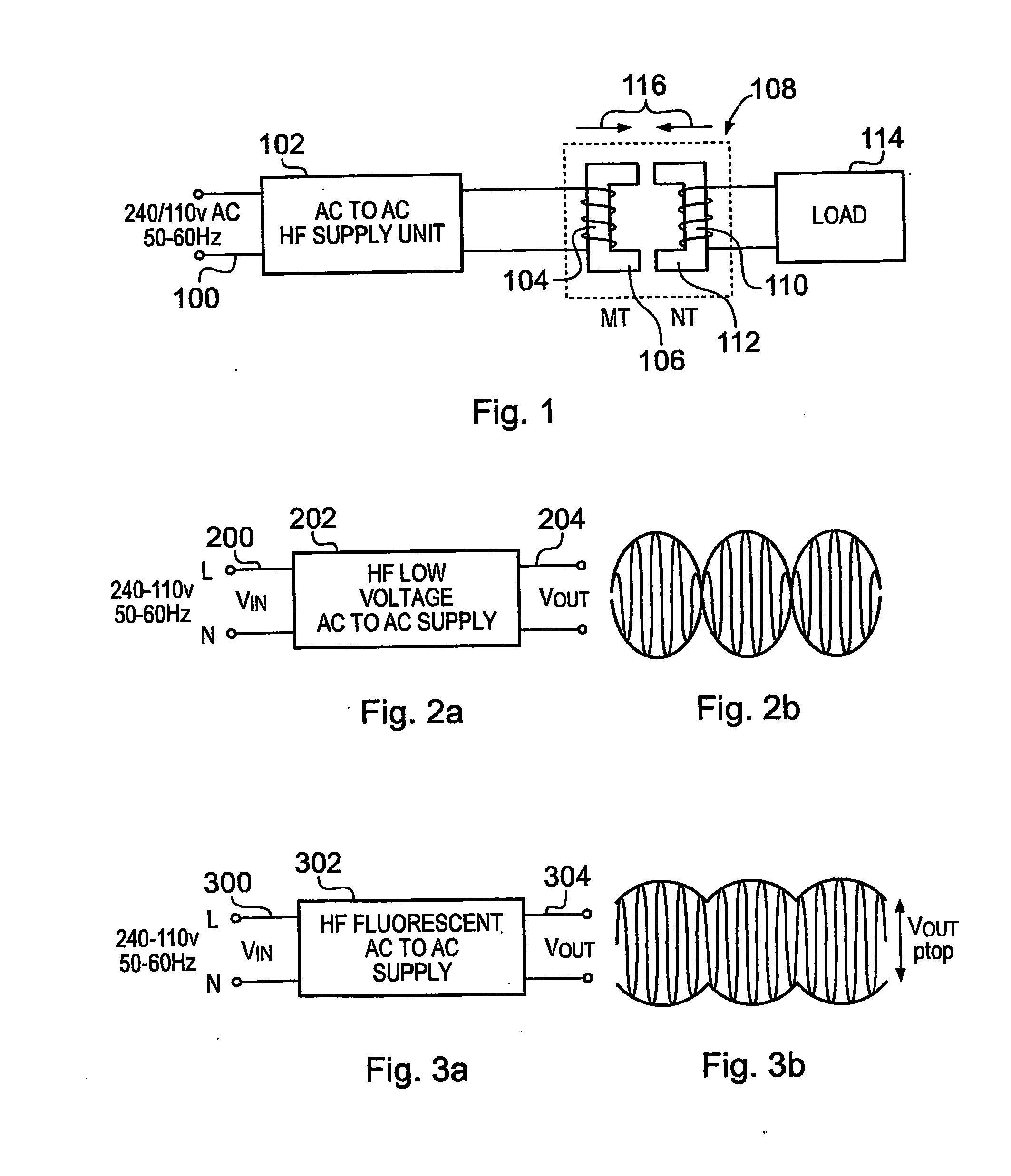

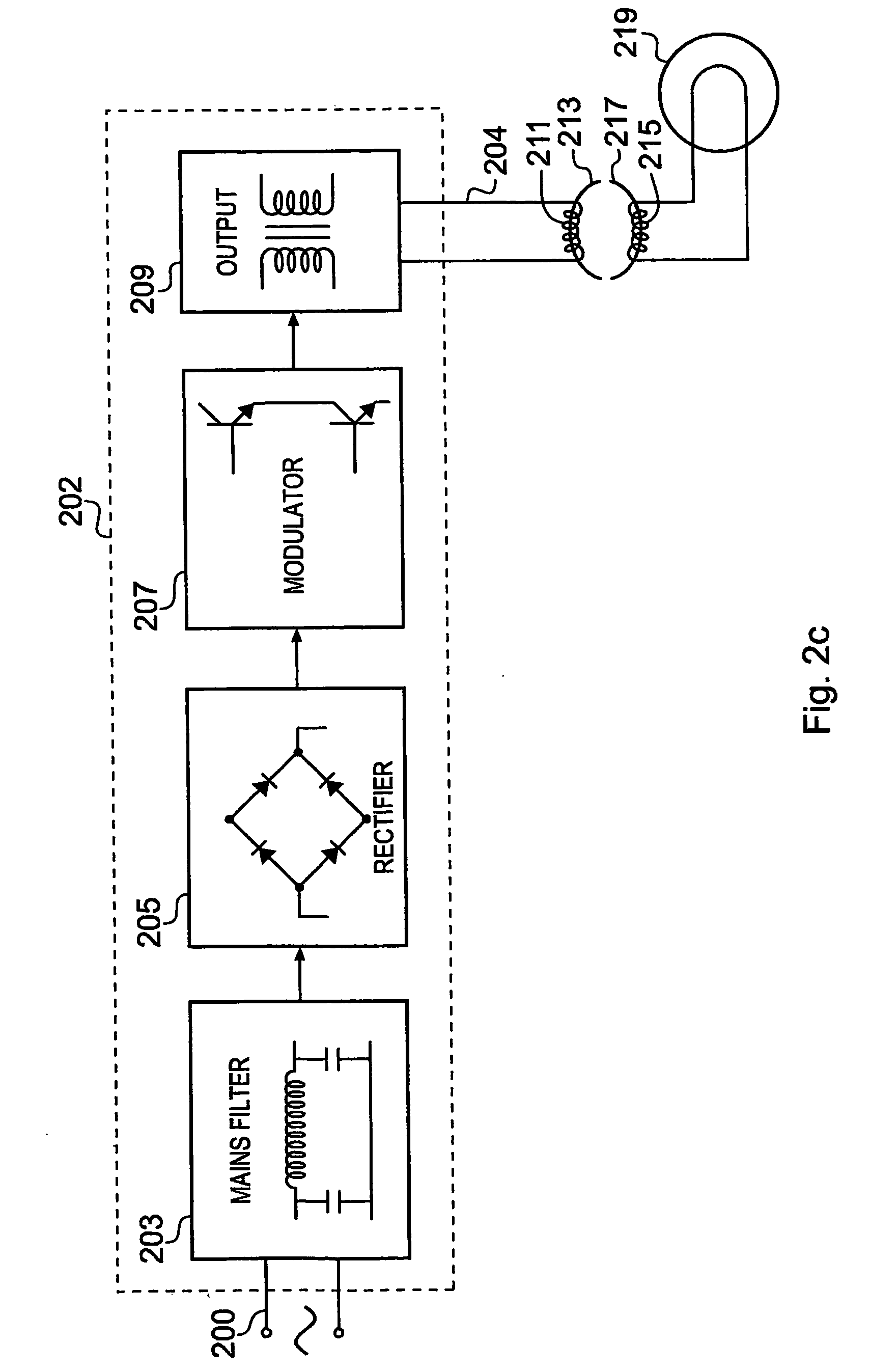

Apparatus for supplying energy to a load and a related system

InactiveUS20070076459A1Avoid eddy currentsImprove system efficiencyPoint-like light sourceConversion with intermediate conversion to dcLow voltageTransformer

Apparatus for supplying energy to a load, comprises a power supply unit (102) e.g. a switched mode electronic transformer or electronic ballast having an input for receiving current at mains frequency and a means for stepping-up said mains frequency to a higher frequency e.g. 30-50 kHz and an output for delivering energy at the higher frequency. A two part connector (108) has a first core portion (106) that has a primary winding (104) connected to the output of the power supply unit and a mating second core portion (112) that has a secondary winding (110) for delivery of energy to a load (114), the core portions being of a high resistivity material, e.g. a ferrite having a resistivity of at least 104 Ωcm. The apparatus may be used to power e.g. low voltage halogen or other incandescent lighting, fluorescent lighting, or an electric motor, a power supply for a computer, radio, television or like electronic device, a heater or the like.

Owner:LIMPKIN GEORGE A +1

Field effect transistor

ActiveUS7868326B2Inhibit currentMaintain good propertiesSolid-state devicesSemiconductor/solid-state device manufacturingField-effect transistorElectron

A novel field-effect transistor is provided which employs an amorphous oxide. In an embodiment of the present invention, the transistor comprises an amorphous oxide layer containing electron carrier at a concentration less than 1×10−18 / cm3, and the gate-insulating layer is comprised of a first layer being in contact with the amorphous oxide and a second layer different from the first layer.

Owner:CANON KK +2

Power Converter Circuitry

ActiveUS20100020576A1Avoid flowInhibit currentEmergency protective circuit arrangementsDc-dc conversionPower gridPhotovoltaic generator

A power converter circuitry for converting a DC voltage generated by a generator with varying output power in the mean voltage range into an alternating voltage for feeding into a grid, with several series-connected power converters, which are connected in parallel with said generator, as well as with a controllable bridging switch for each power converter, said bridging switch lying in a direct voltage intermediate circuit and bridging the respective power converter in the closed condition, is intended to be used for a photovoltaic generator. This is achieved in that a resistance chopper is connected between each power converter and the generator, no input diode being provided in the current path from the generator to the power converter, and that each bridging switch is connected in parallel with the resistance chopper in the direct voltage intermediate circuit.

Owner:SMA SOLAR TECH AG

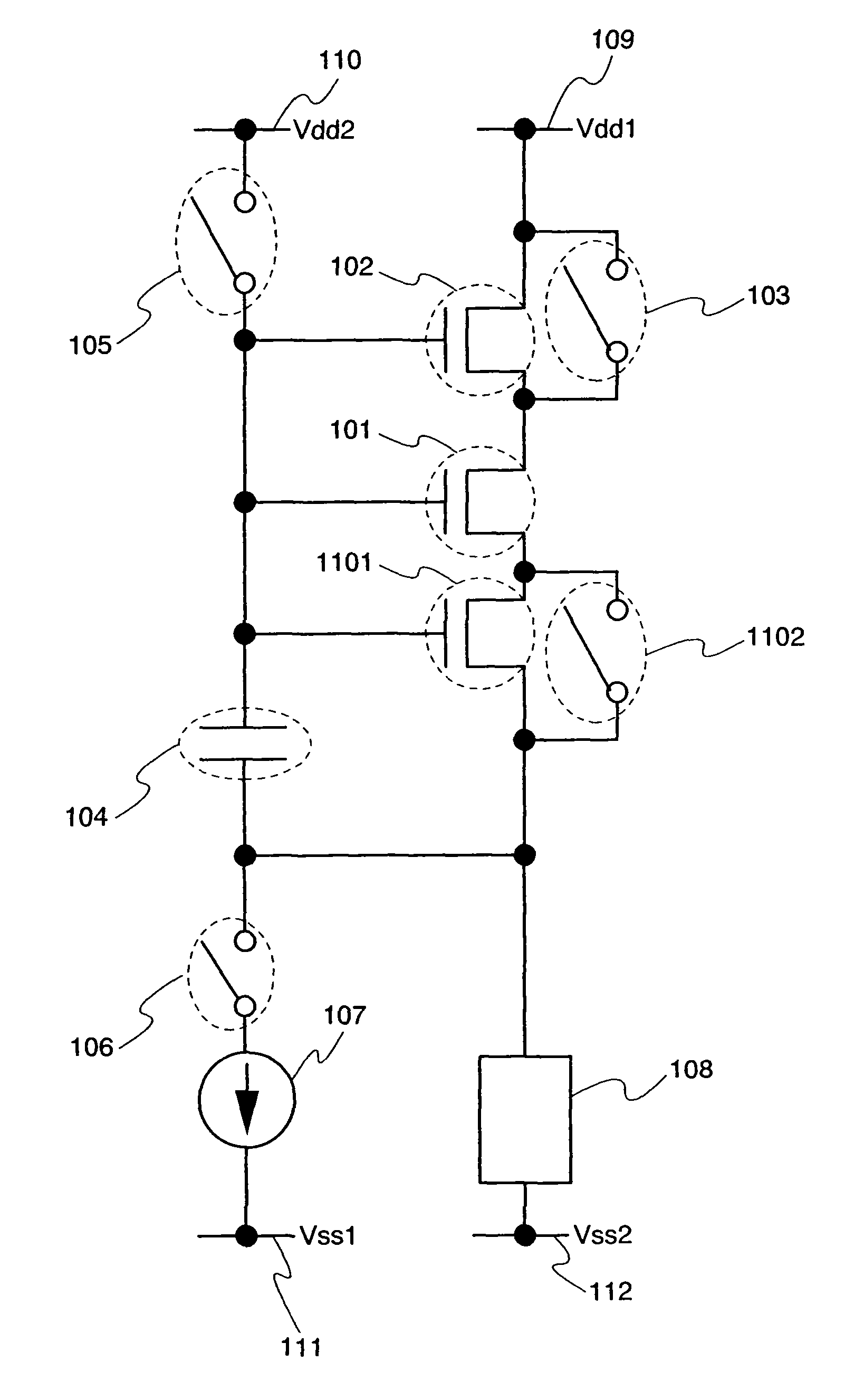

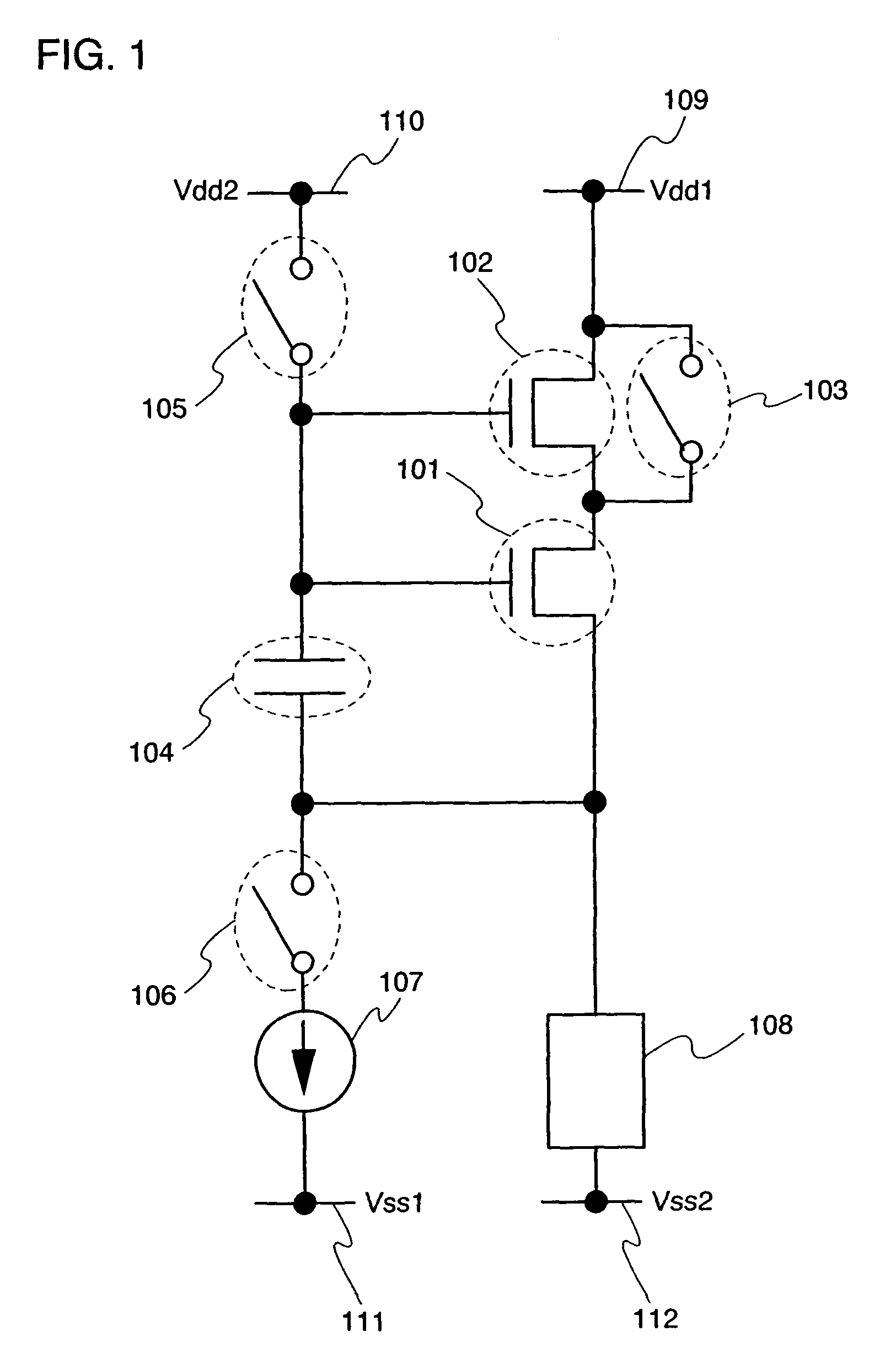

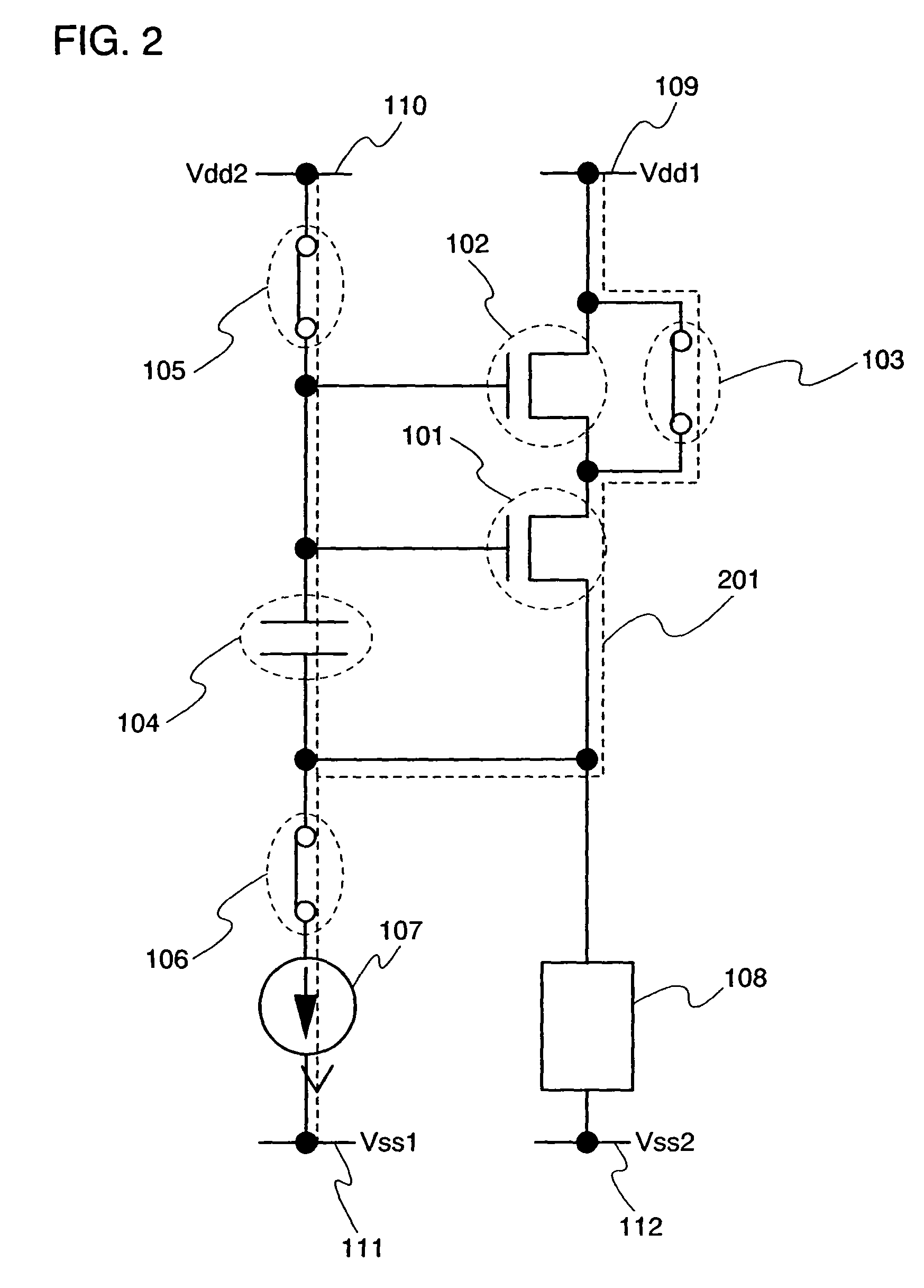

Semiconductor device, display device and electronic device equipped with the semiconductor device

InactiveUS20070035340A1Reduce power consumptionAvoid flowImpedence convertorsElectroluminescent light sourcesCapacitanceElectrical resistance and conductance

The present invention provides a semiconductor device which can prevent a current from flowing into a display element at a signal writing operation, without increasing power consumption and without changing a potential of a power supply for supplying a current to a load in each row. When a predetermined current is supplied to a transistor to set a gate-source voltage of the transistor, a potential of a gate terminal of the transistor is adjusted so as to prevent a current from flowing into a load which is connected to a source terminal of the transistor. Thus, a potential of a wire connected to the gate terminal of the transistor is made different from that of a wire connected to a drain terminal of the transistor. At that time, an operation of a transistor is shifted so as to allow a large amount of current to flow, and influences by intersection capacitance parasitic to a wire or the like or wire resistance are hardly caused, and a set operation is conducted quickly.

Owner:SEMICON ENERGY LAB CO LTD

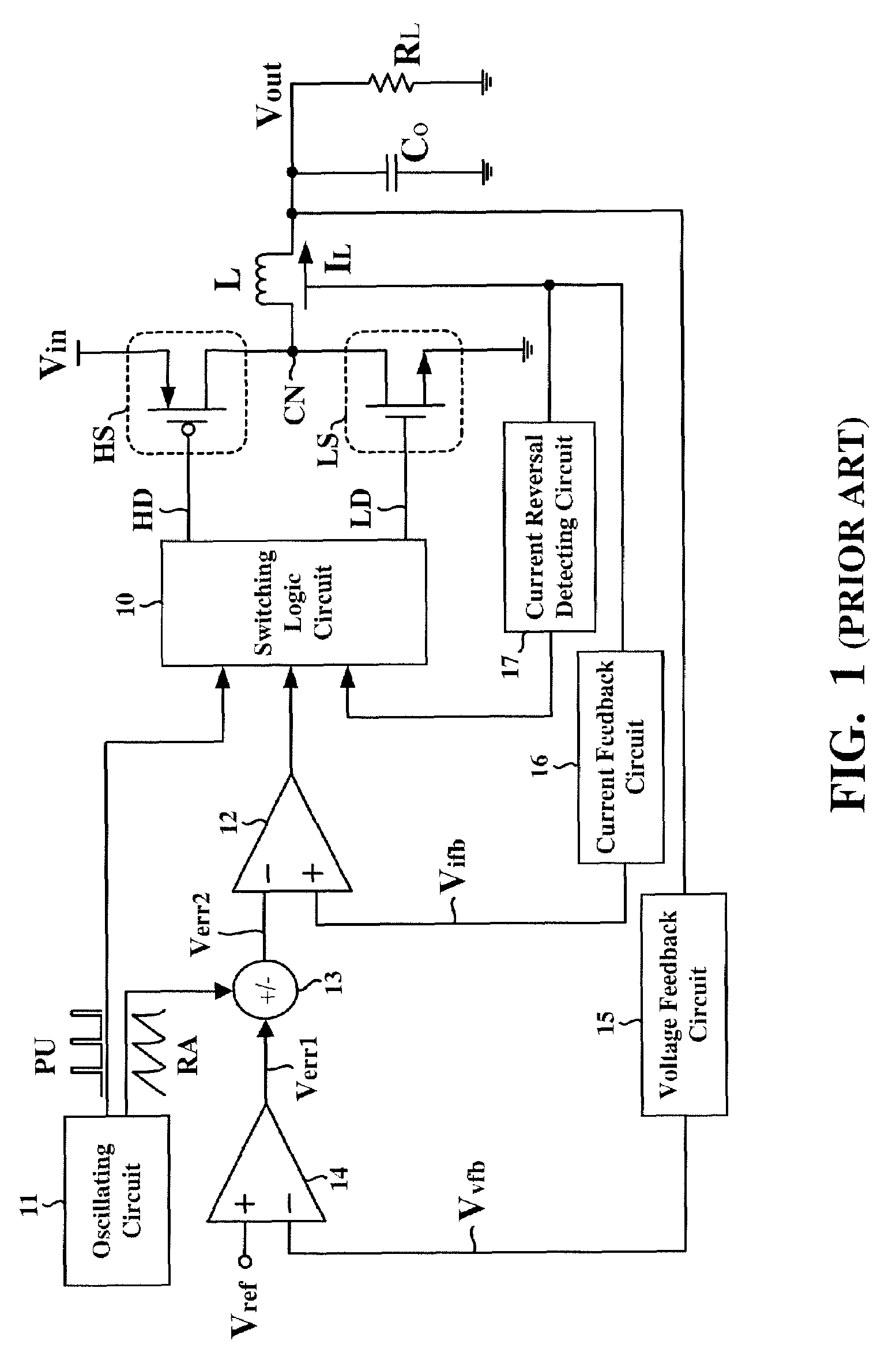

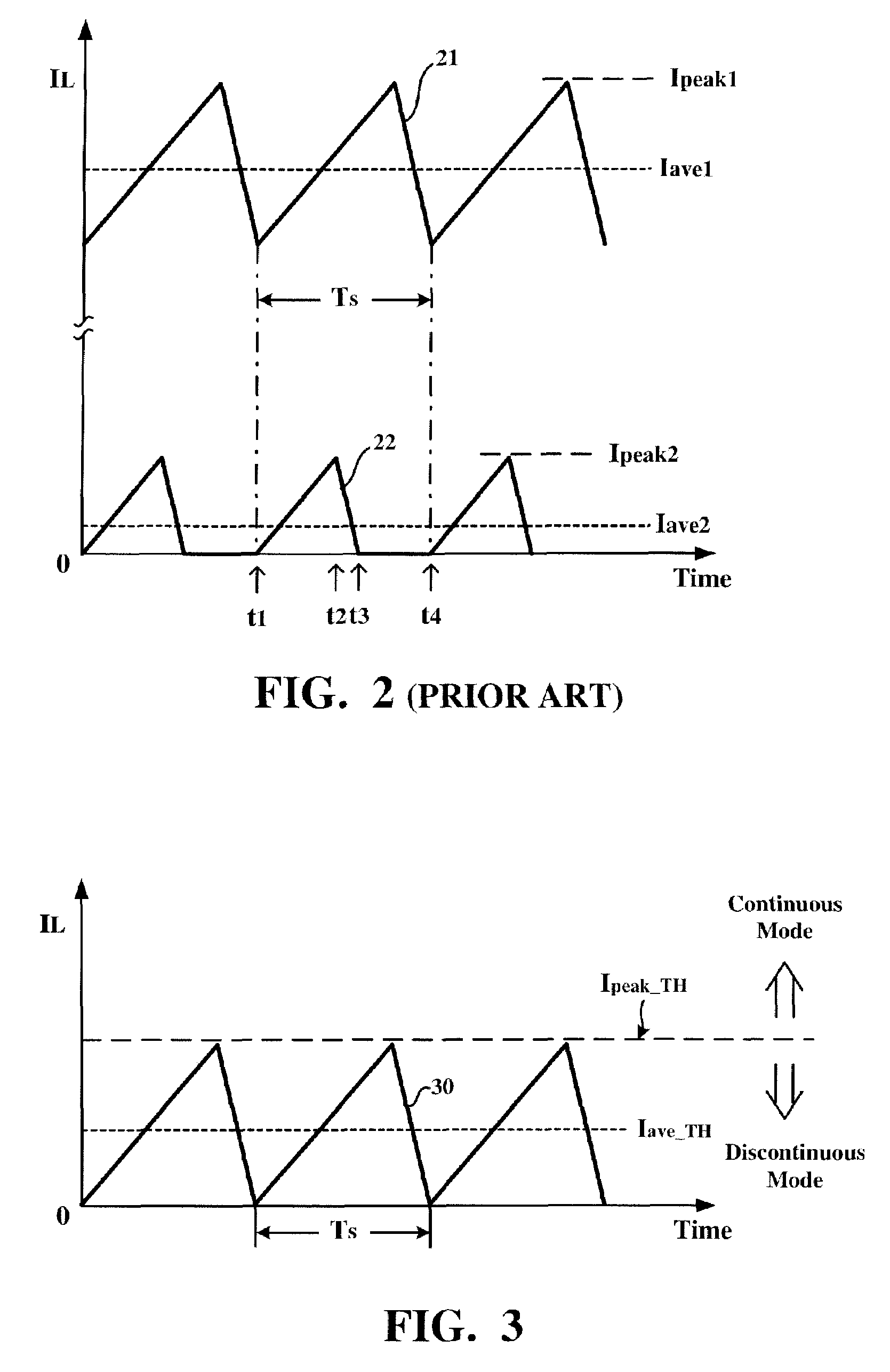

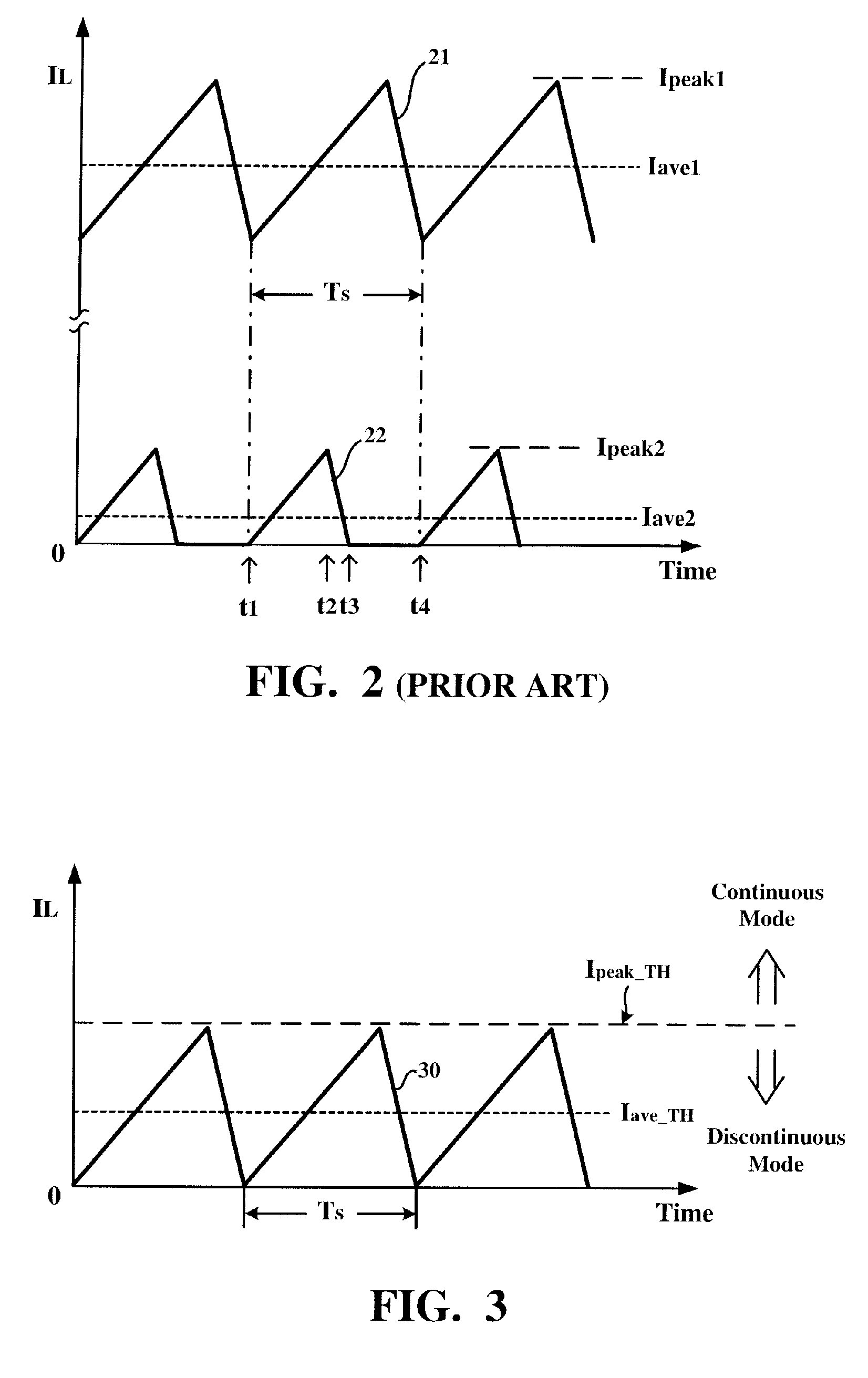

Switching voltage regulator operating without a discontinuous mode

InactiveUS7180274B2Avoid disadvantagesReduce switchingEfficient power electronics conversionDc-dc conversionValue setSwitched current

A switching circuit operates with a first operating state and a second operating state. During the first operating state, the switching circuit allows a switching current to linearly increase. During the second operating state, the switching circuit allows the switching current to linearly decrease. A control circuit is coupled to the switching circuit for controlling the switching circuit to operate with the first operating state or the second operating state. A setting circuit generates a threshold signal for the control circuit to ensure that during the first operating state the switching current linearly increases to become higher than or equal to a current value set by the threshold signal. Thereby, the switching current is prevented from linearly decreasing to reverse polarity during the second operating state.

Owner:GLOBAL MIXED MODE TECH

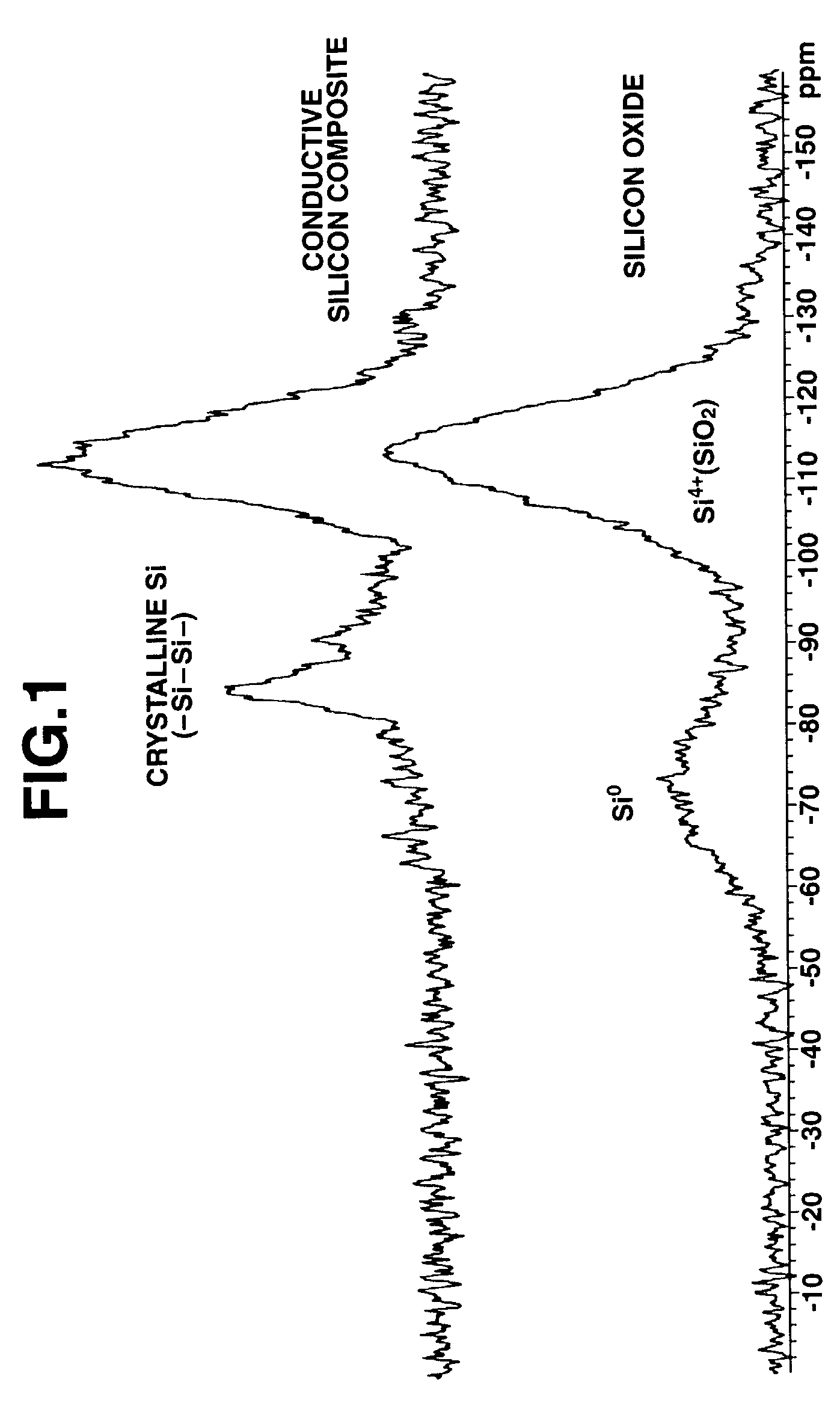

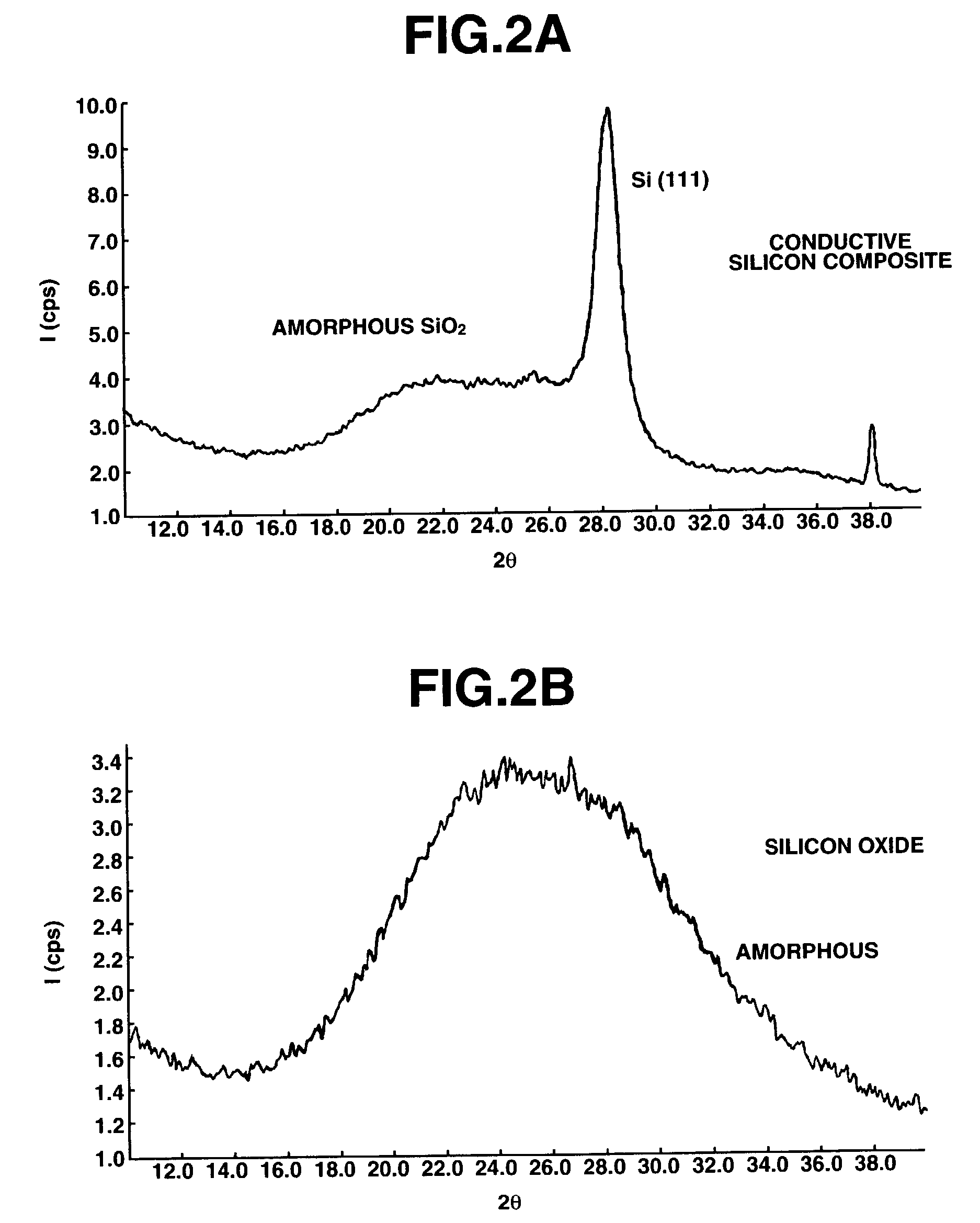

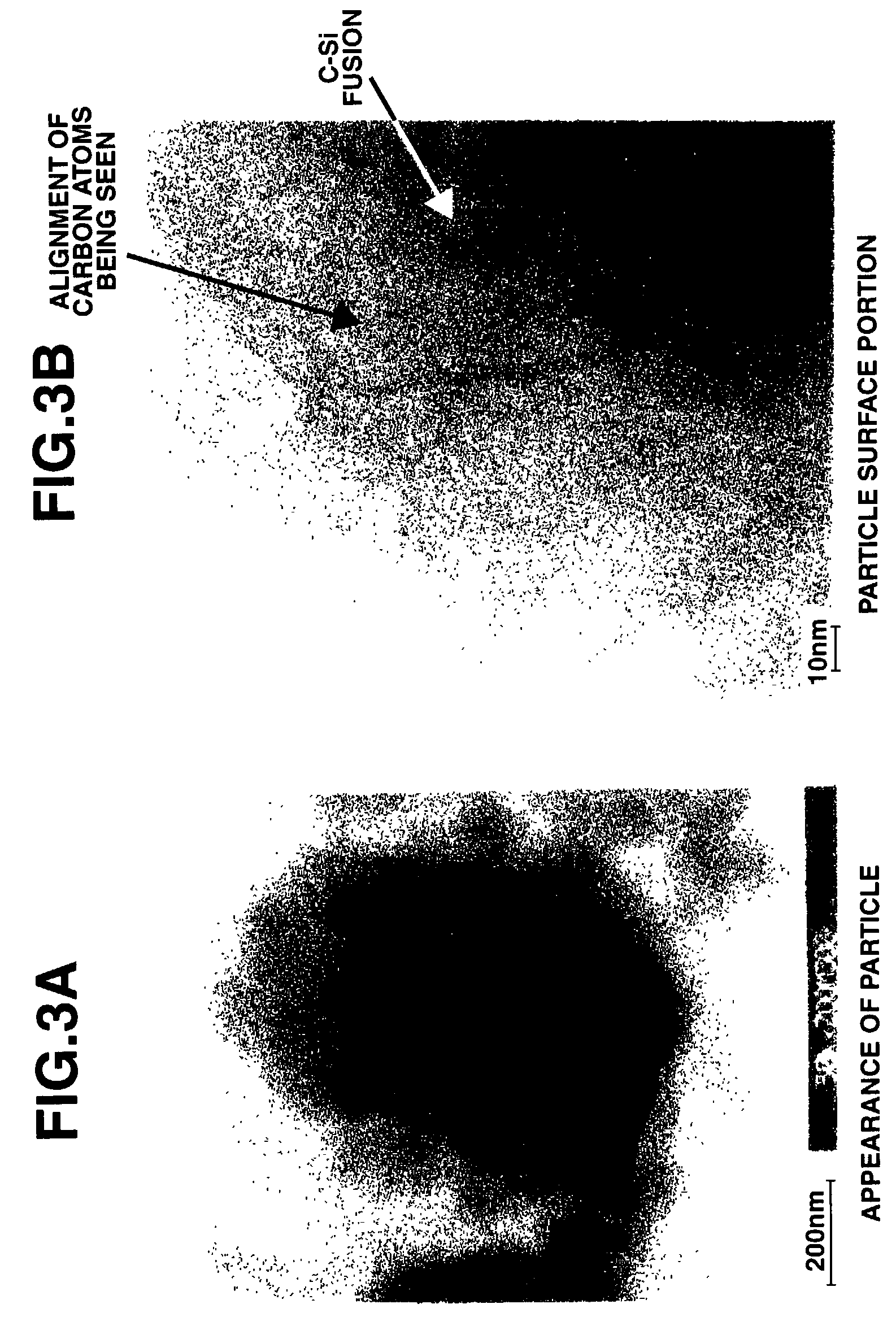

Conductive silicon composite, preparation thereof, and negative electrode material for non-aqueous electrolyte secondary cell

ActiveUS7037581B2Improve cycle performanceReduce conductivityMaterial nanotechnologyPigmenting treatmentSilicon dioxideSilicon

Owner:SHIN ETSU CHEM IND CO LTD

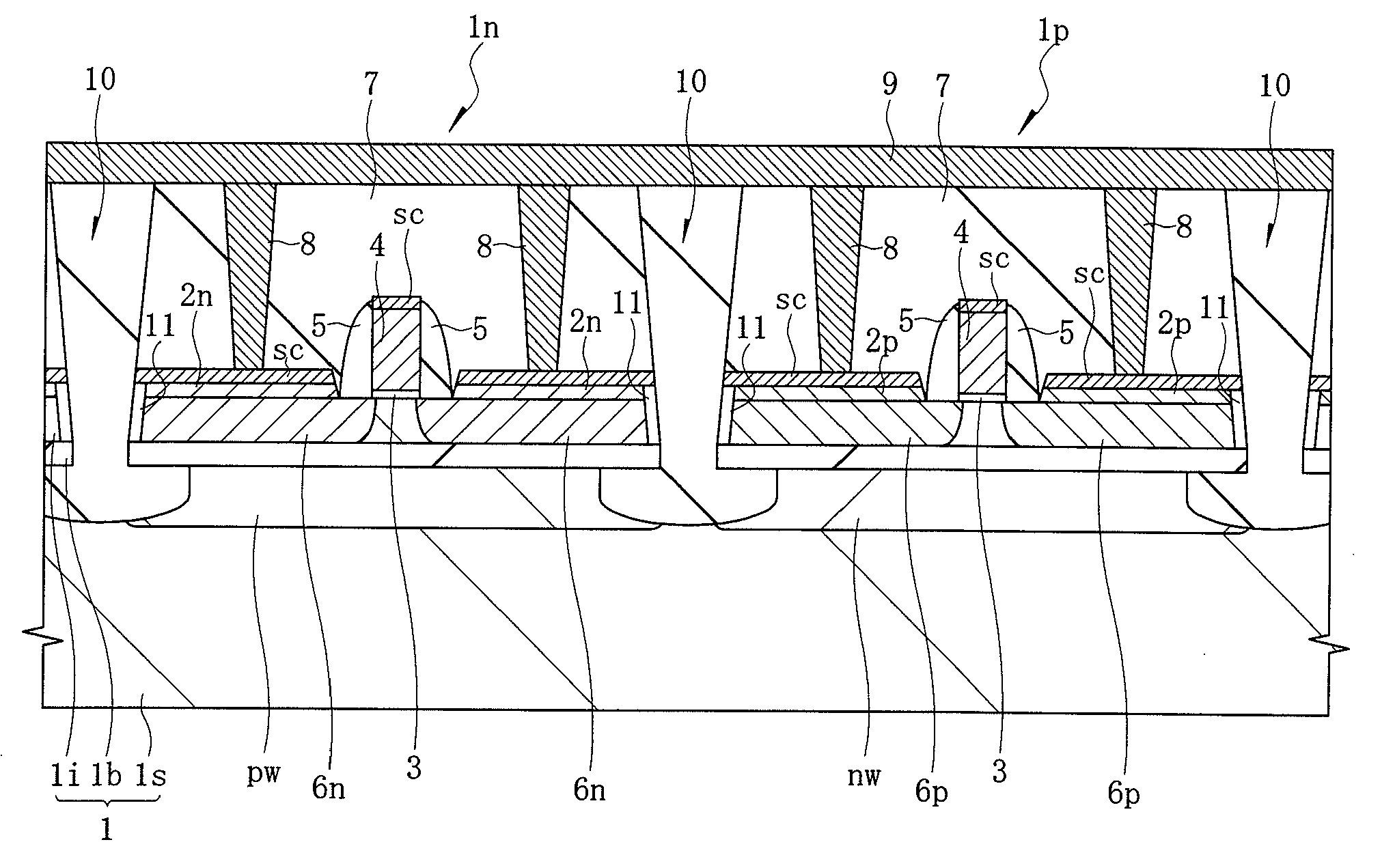

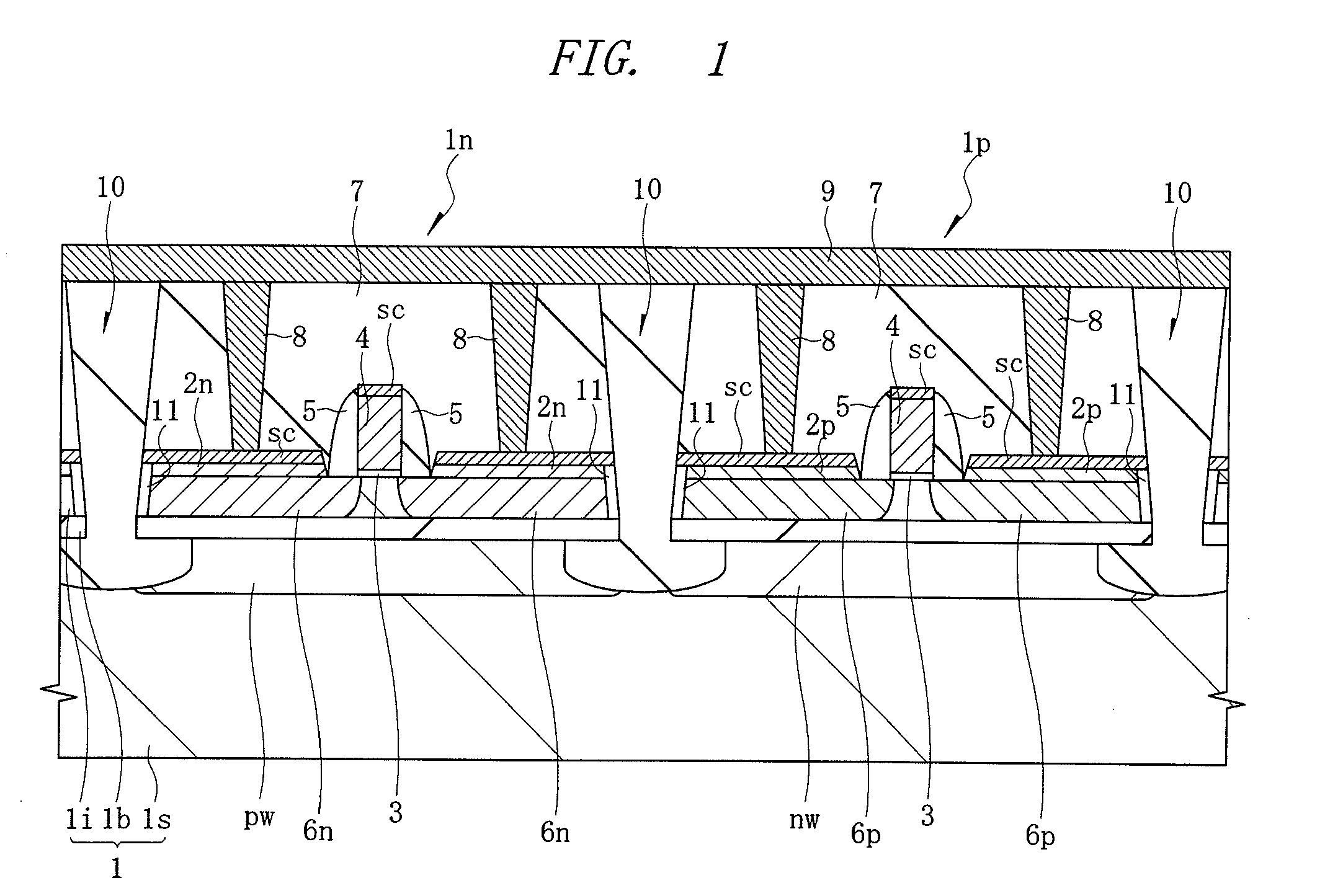

Semiconductor device and manufacturing method thereof

InactiveUS20100258869A1Inhibit currentLower junction capacitanceSolid-state devicesSemiconductor/solid-state device manufacturingSoi substrateSemiconductor

An n well and a p well disposed at a predetermined interval on a main surface of a SOI substrate with a thin BOX layer are formed, and an nMIS formed on the p well has a pair of n-type source / drain regions formed on semiconductor layers stacked on a main surface of the SOI layer at a predetermined distance, a gate insulating film, a gate electrode and sidewalls sandwiched between the pair of n-type source / drain regions. A device isolation is formed between the n well and the p well, and a side edge portion of the device isolation extends toward a gate electrode side more than a side edge portion of the n-type source / drain region (sidewall of the BOX layer).

Owner:HITACHI LTD

Method and system for power management including local bounding of device group power consumption

ActiveUS7155623B2Inhibit currentSlow changeEnergy efficient ICTVolume/mass flow measurementMemory controllerGlobal system

A method and system for power management including local bounding of device group power consumption provides the responsiveness of local power control while meeting global system power consumption and power dissipation limits. At the system level, a global power bound is determined and divided among groups of devices in the system so that local bounds are determined that meet the global system bound. The local bounds are communicated to device controllers associated with each group of devices and the device controllers control the power management states of the associated devices in the group to meet the local bound. Thus, by action of all of the device controllers, the global bound is met. The controllers may be memory controllers and the devices memory modules, or the devices may be other devices within a processing system having associated local controllers. Alternatively or in concert, the devices may be entire processing systems and the associated controller a power management controller for associated processing systems, whereby multiple processing locales may be power-managed consistent with a global power consumption budget.

Owner:HUAWEI TECH CO LTD

Electrical tissue stimulation apparatus and method

InactiveUS7546164B2Easy to disassembleInhibit currentTransvascular endocardial electrodesExternal electrodesElectricityElectrode array

An implantable lead for electrical stimulation of tissue has wire-like extendable members whose tips curl back upon themselves in open tissue spaces to form 2- or 3-dimensional electrodes. The electrodes may be positioned axially or in other directions from the lead body. Traction on the lead body or extendable members allows easy withdrawal as the member tip electrodes uncurl, allowing removal without major surgery. This apparatus and method is useful for minimally invasive insertion of electrodes or electrode arrays, especially through a narrow body lumen or Tuohy needle, providing therapeutic stimulation of nervous tissue, muscle or organs.

Owner:MEDTRONIC INC

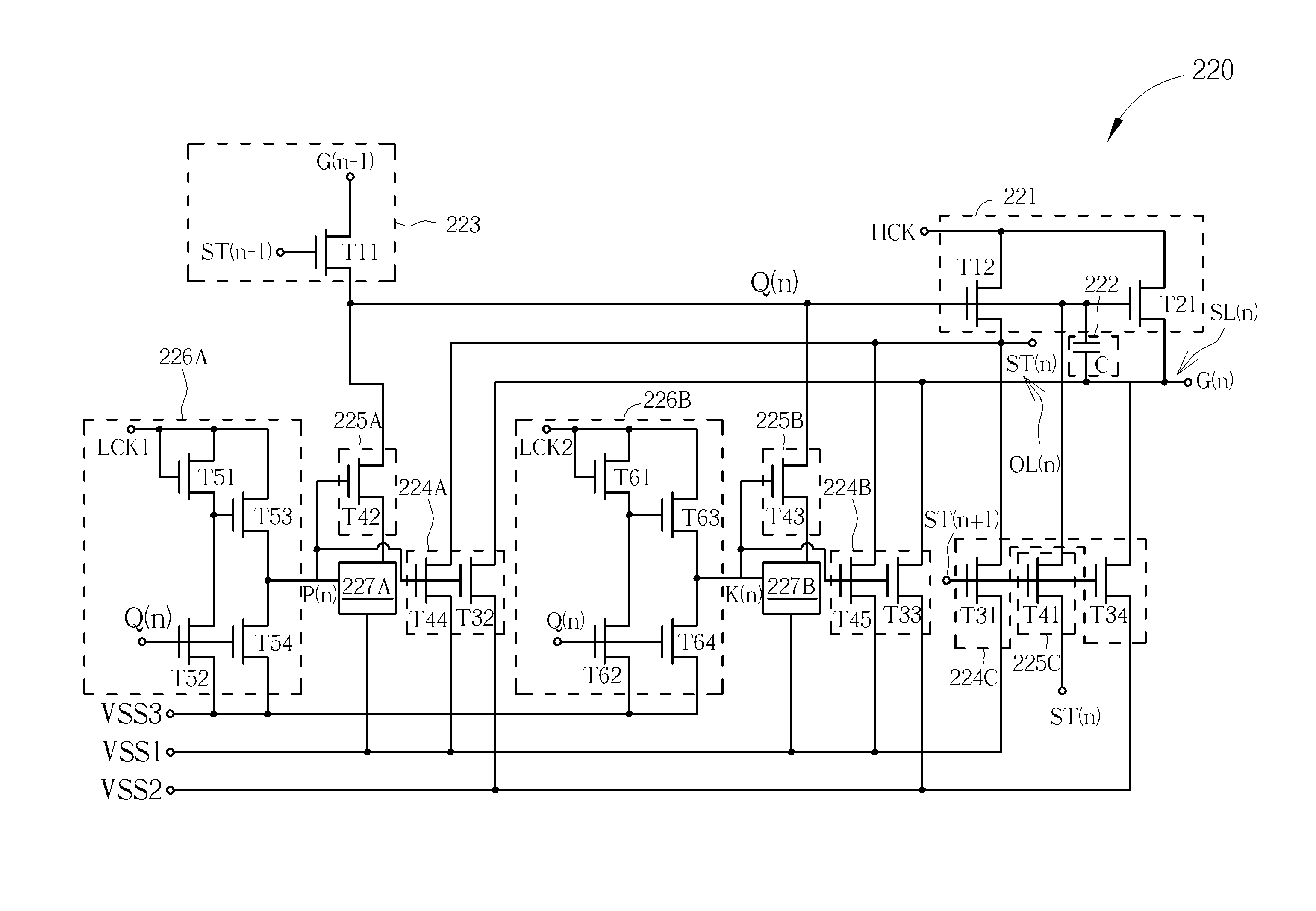

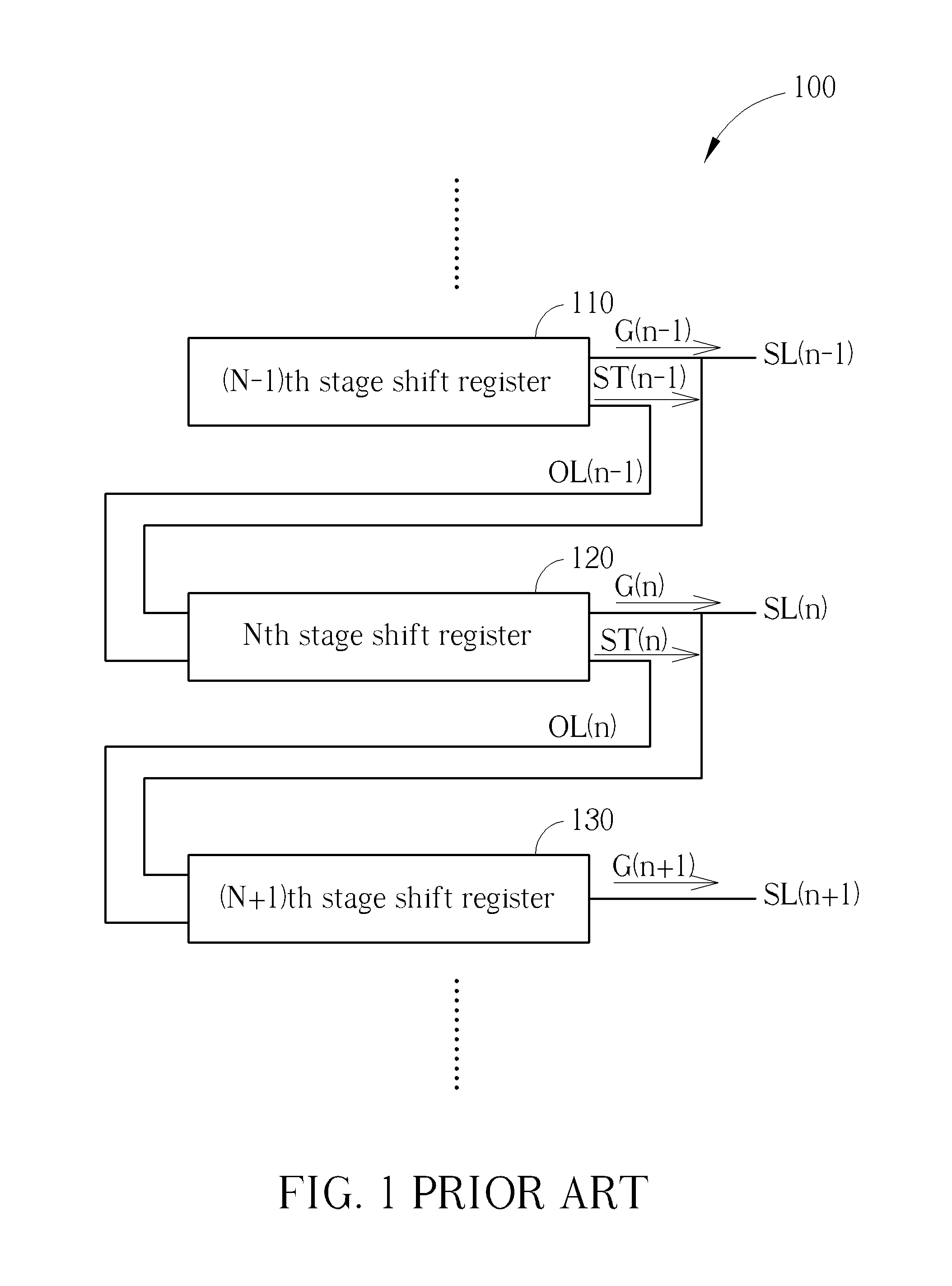

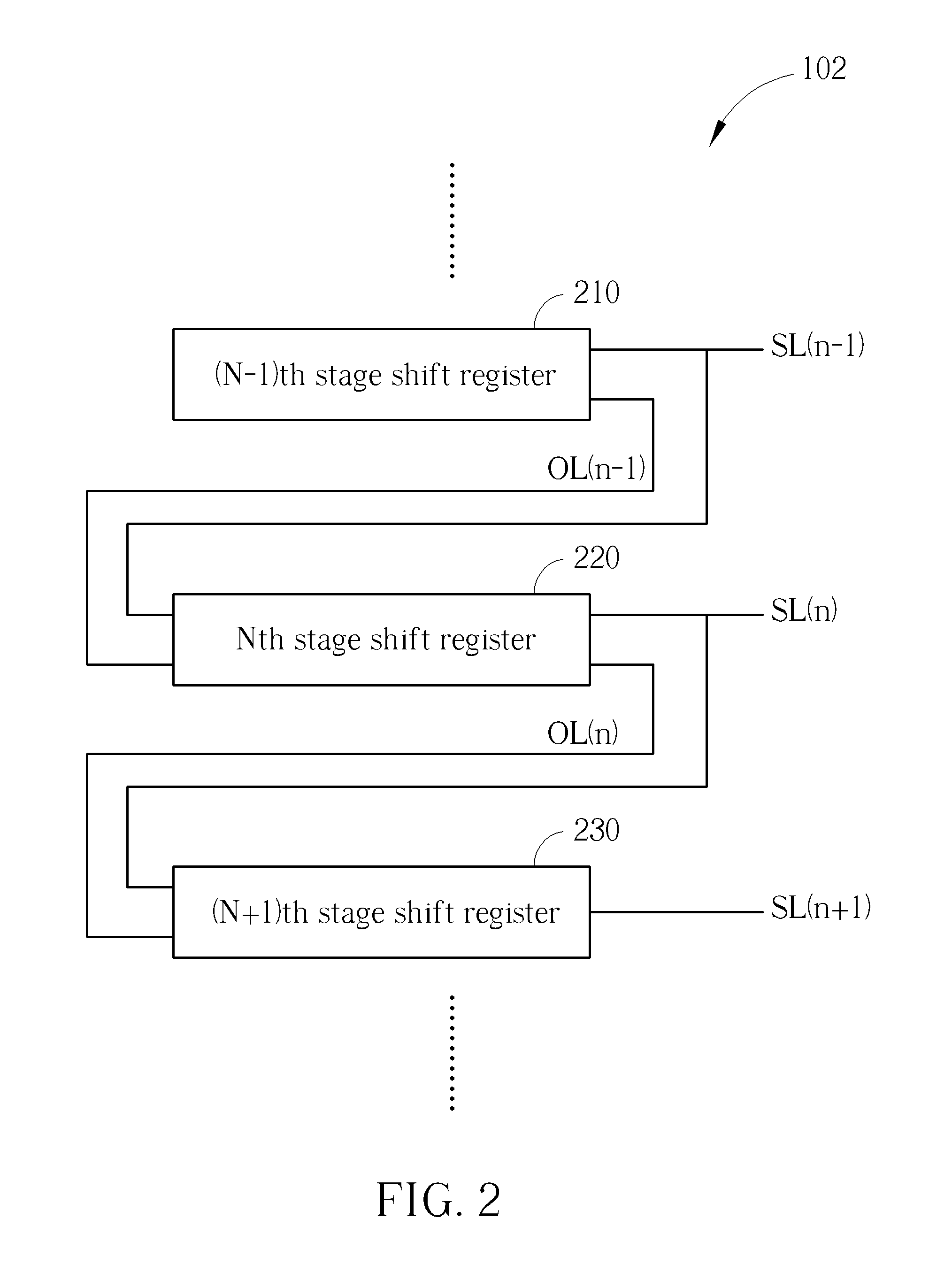

Gate driving circuit

ActiveUS20140103983A1Inhibit currentHigh voltage levelStatic indicating devicesDigital storageDriver circuitShift register

A shift register of a gate driving circuit includes a pull-up unit for pulling up a first output signal and a first gate signal to a high voltage level according to a driving voltage and a high-frequency clock signal, a start-up unit for transmitting a second gate signal, an energy-store unit for providing the driving voltage to the pull-up unit according to the second gate signal, a first discharging unit for pulling down the driving voltage to a first voltage level according to a first control signal, a first leakage-preventing unit for turning off the first discharging unit when the first gate signal reaches the high voltage level, a first pull-down unit for respectively pulling down the first output and first gate signals to the first and a second voltage levels according to the first control signal, and a first control unit for generating the first control signal.

Owner:AU OPTRONICS CORP

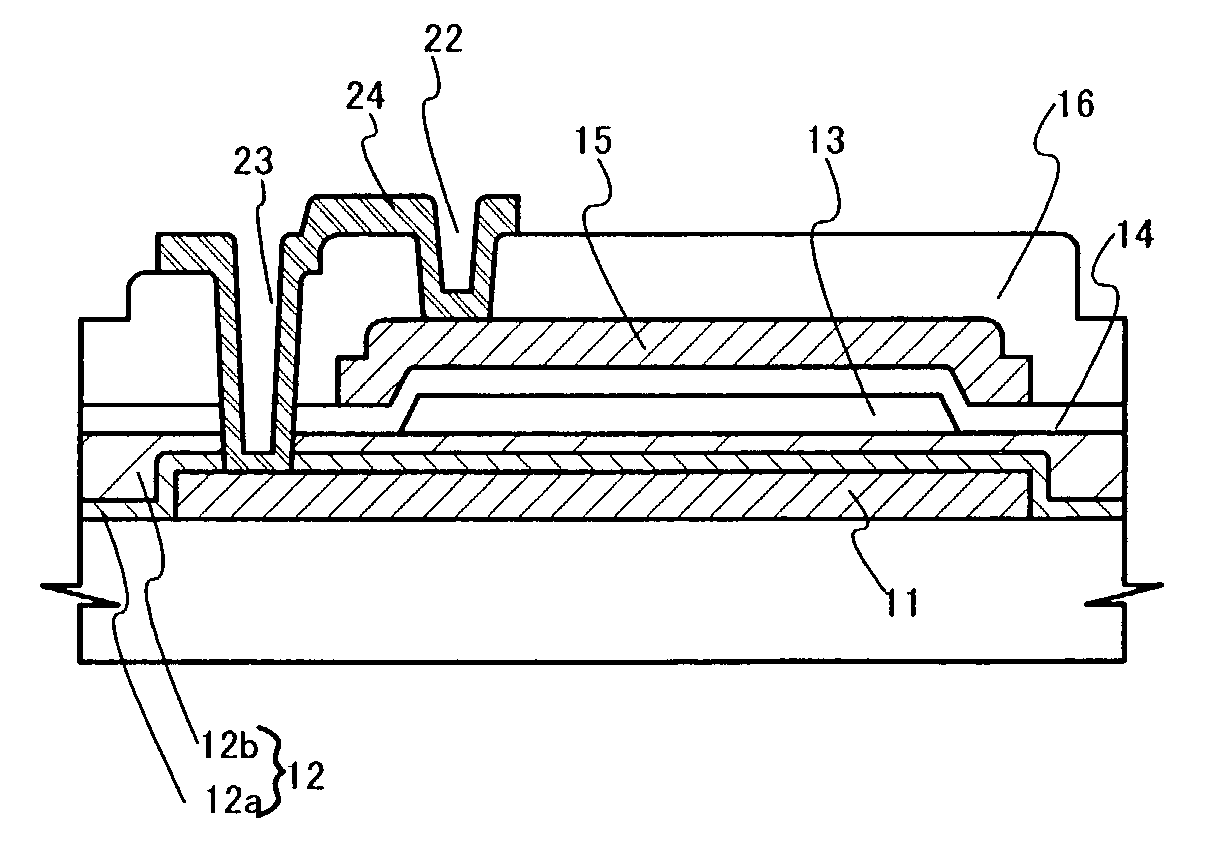

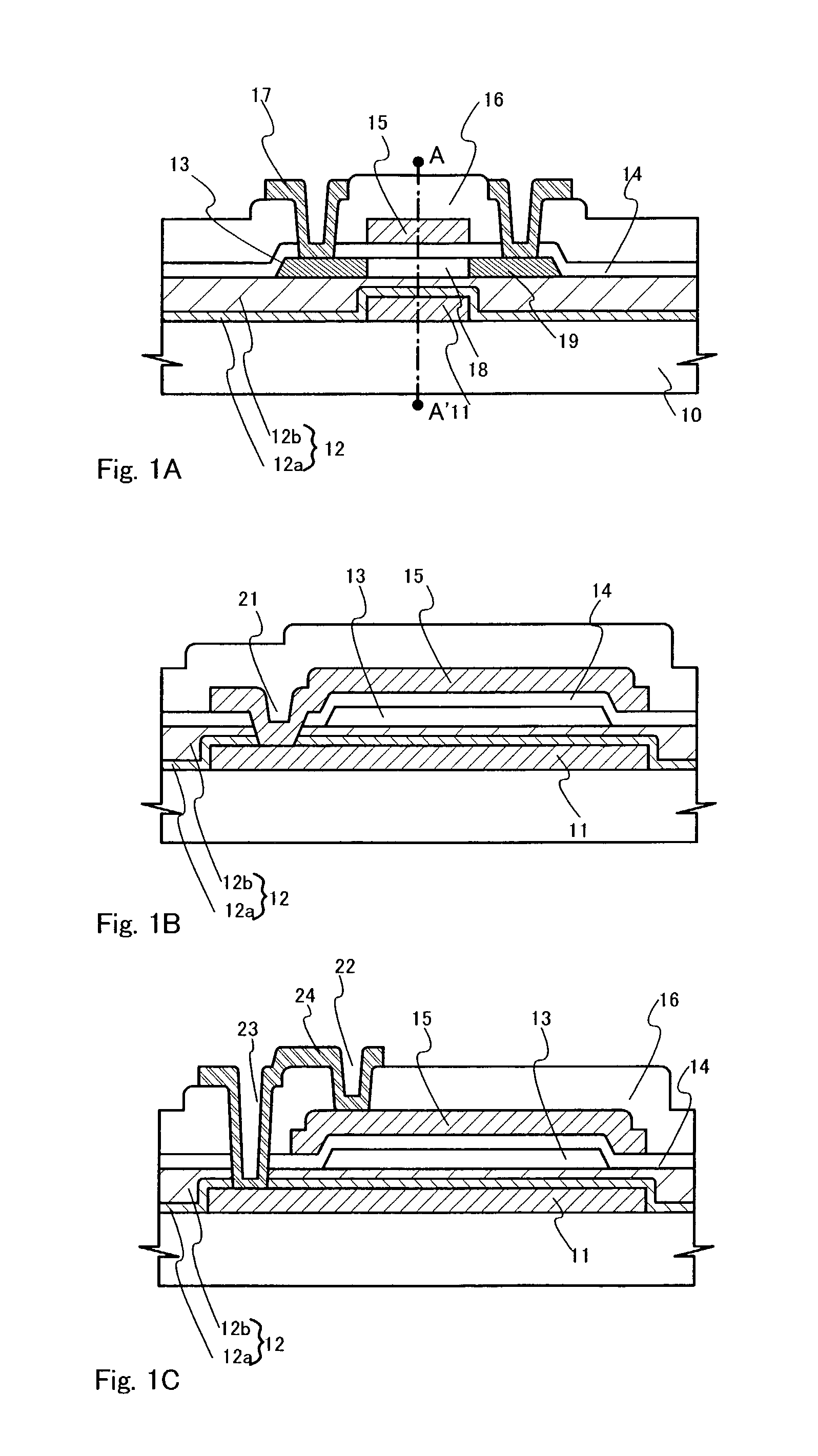

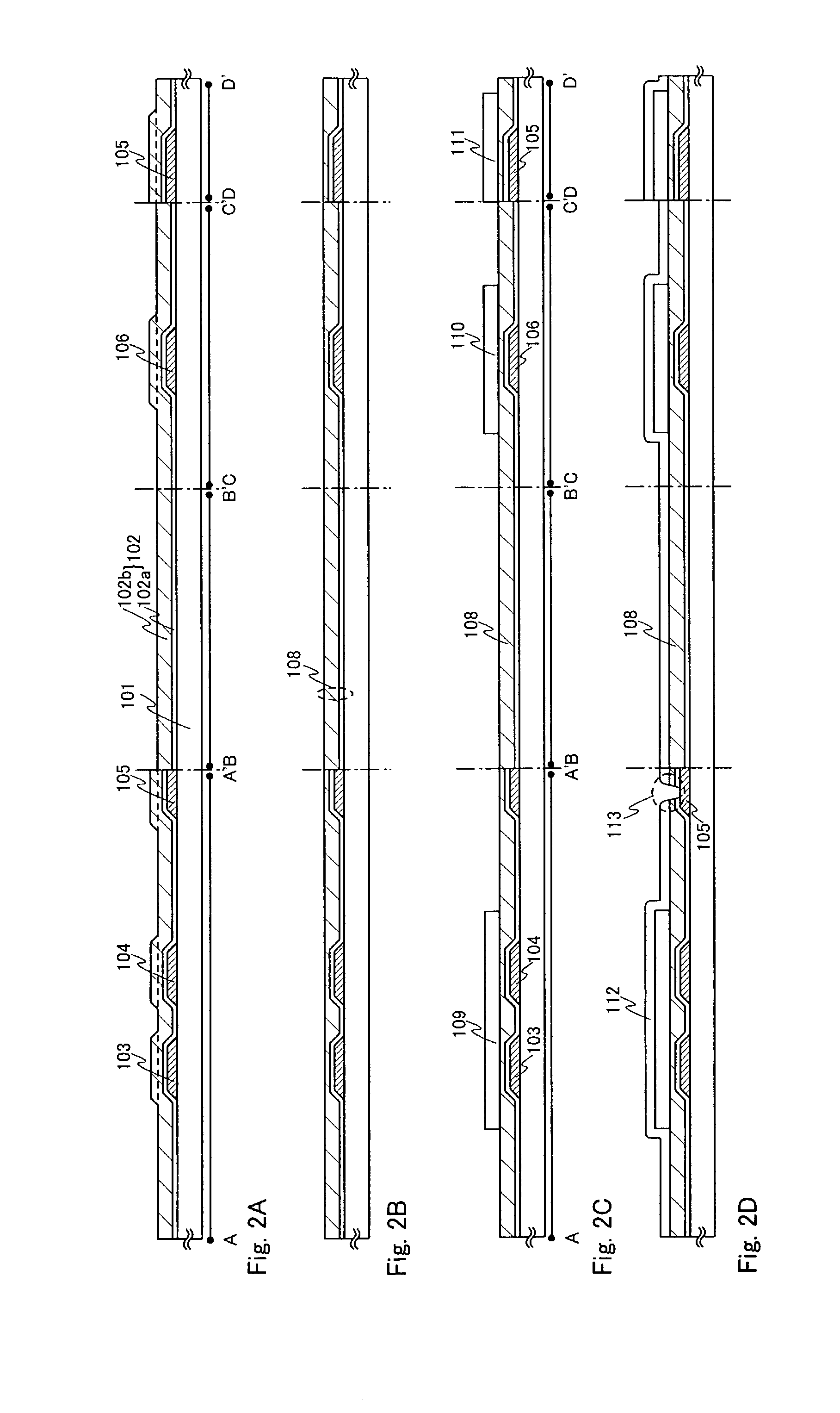

Light emitting device

InactiveUS20030025166A1Suppress irregularityInhibit currentTransistorSolid-state devicesDriver circuitLight emitting device

An object of the invention is to provide a technique for improving the characteristics of a TFT and realizing an optimum structure of the TFT for the driving conditions of a pixel section and a driving circuit by a small number of photo masks. Therefore, a light emitting device has a semiconductor film, a first electrode and a first insulating film nipped between the semiconductor film and the first electrode. Further, the light emitting device has a second electrode and a second insulating film nipped between the semiconductor film and the second electrode. The first and second electrodes are overlapped with each other through a channel forming area arranged in the semiconductor film. In the case of a TFT in which a reduction in off-electric current is considered important in comparison with an increase in on-electric current, a constant voltage (common voltage) is applied to the first electrode at any time. In the case of a TFT in which the increase in on-electric current is considered important in comparison with the reduction in off-electric current, the same voltage is applied to the first and second electrodes.

Owner:SEMICON ENERGY LAB CO LTD

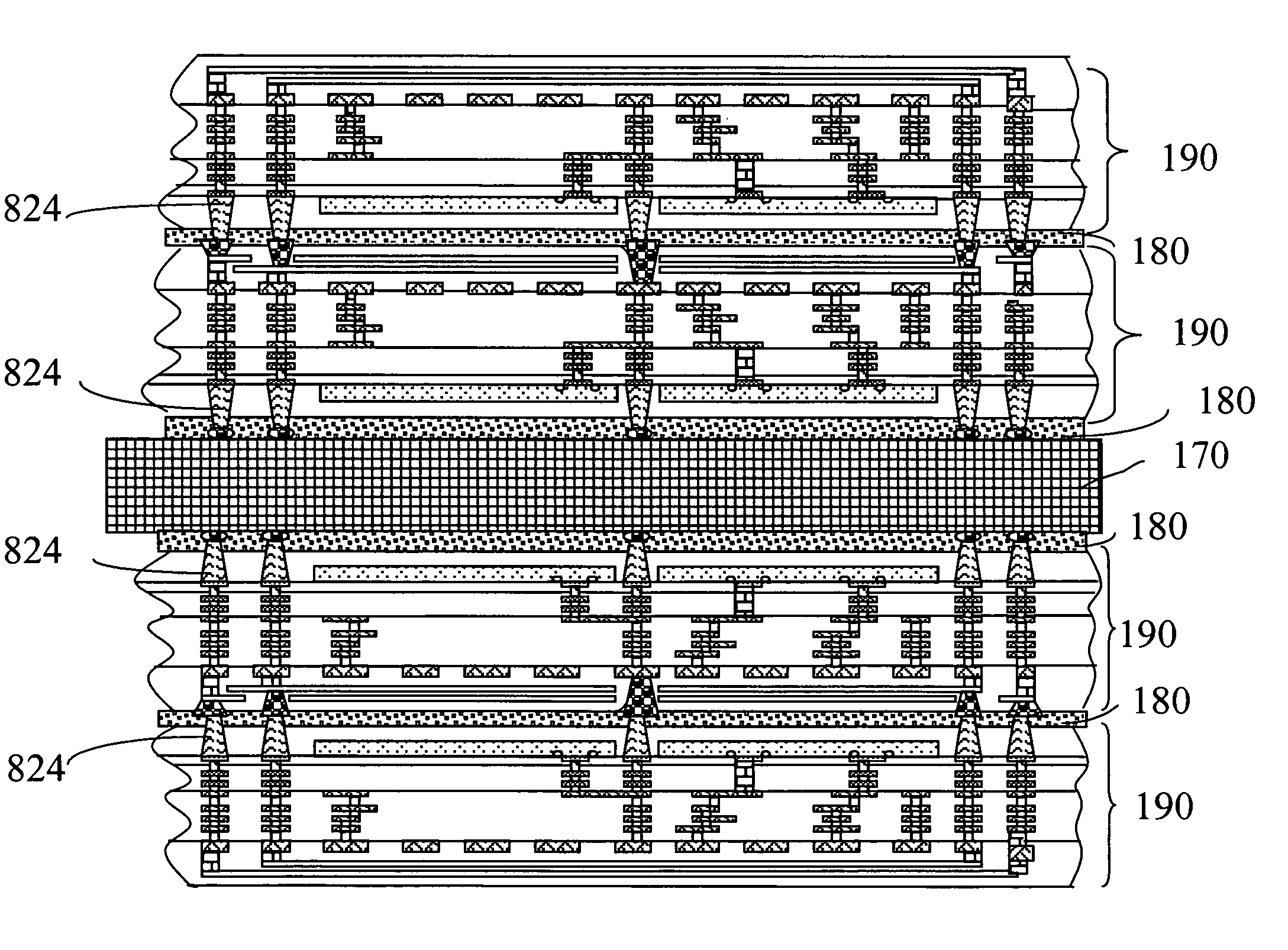

Integrated circuit device and the manufacturing method thereof

InactiveUS20050101116A1Prevents noise currentAvoid electromagnetic interferenceSemiconductor/solid-state device detailsSolid-state devicesIntegrated circuitActive devices

An integrated circuit device has a substrate, an interconnection level, a shielding level and a plurality of stitching studs. The substrate has a plurality of active devices, and the stitching studs pass through the substrate. The interconnection level is on the substrate, having a plurality of metal lines to provide interconnections between the active devices with a plurality of plugs. The shielding level is on the interconnection level, having an electromagnetic shielding pattern. The electromagnetic shielding pattern, the plugs, and the stitching studs are connected to form an electromagnetic shielding housing of the integrated circuit device.

Owner:TSENG SHIH HSIEN

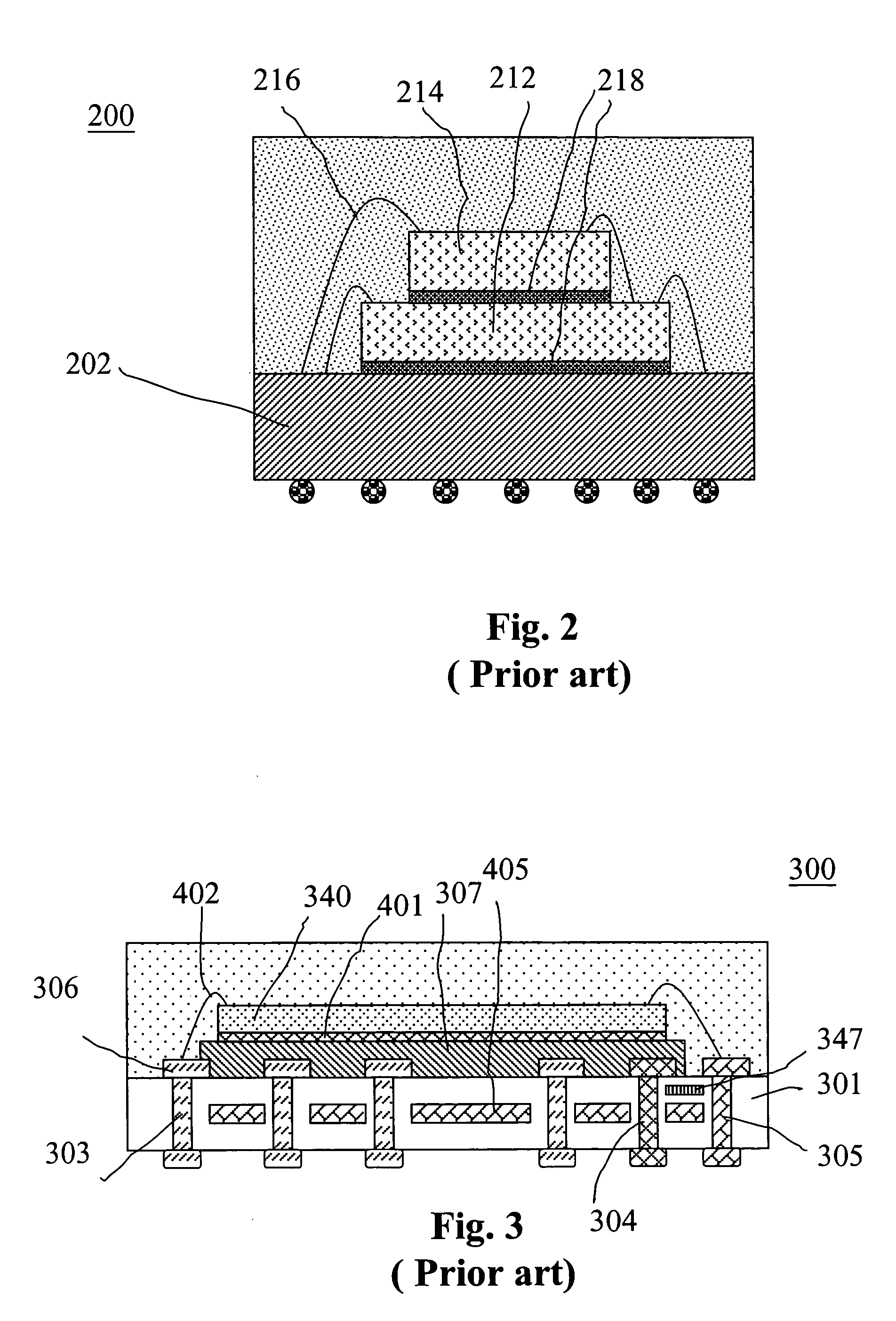

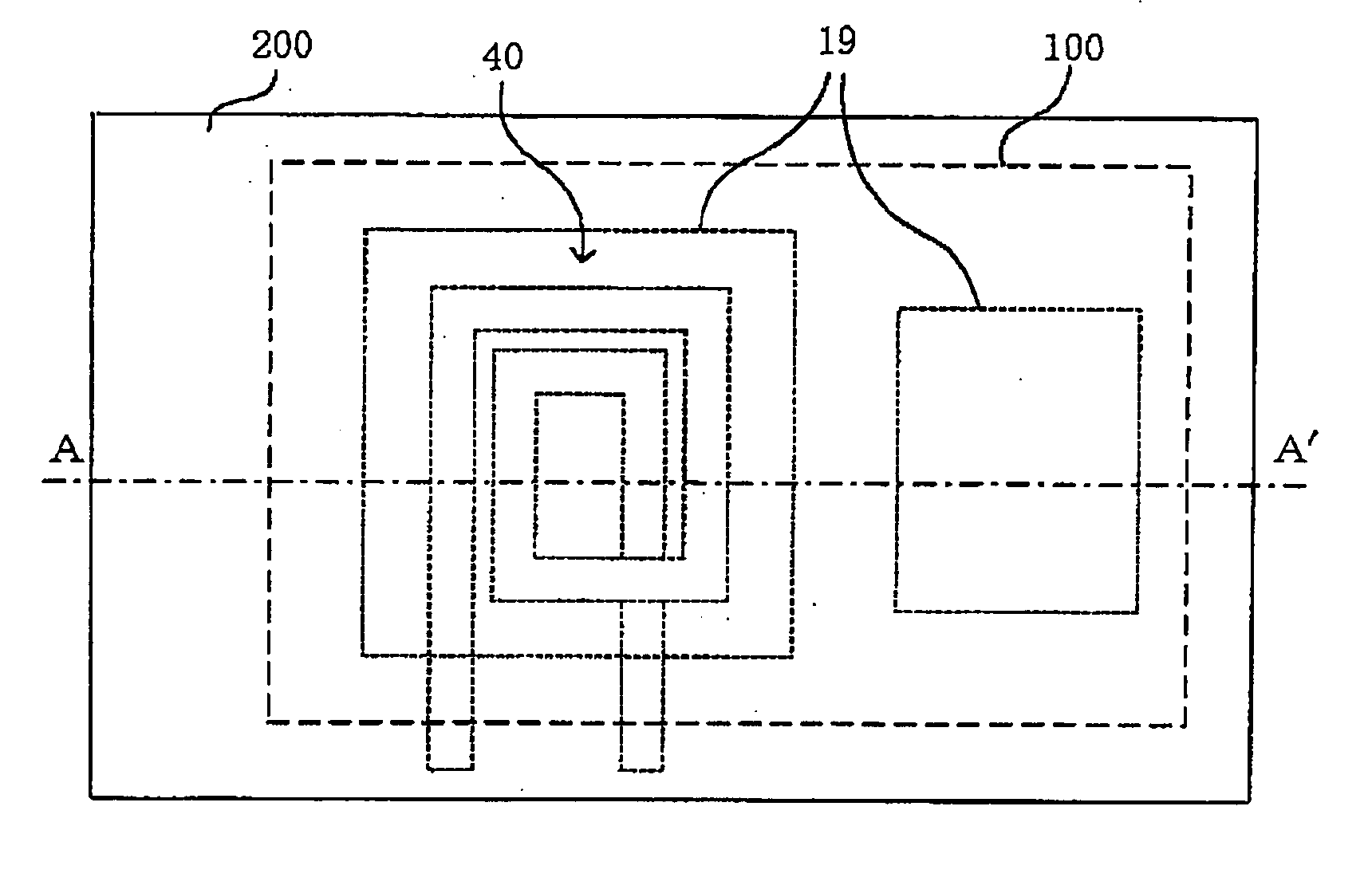

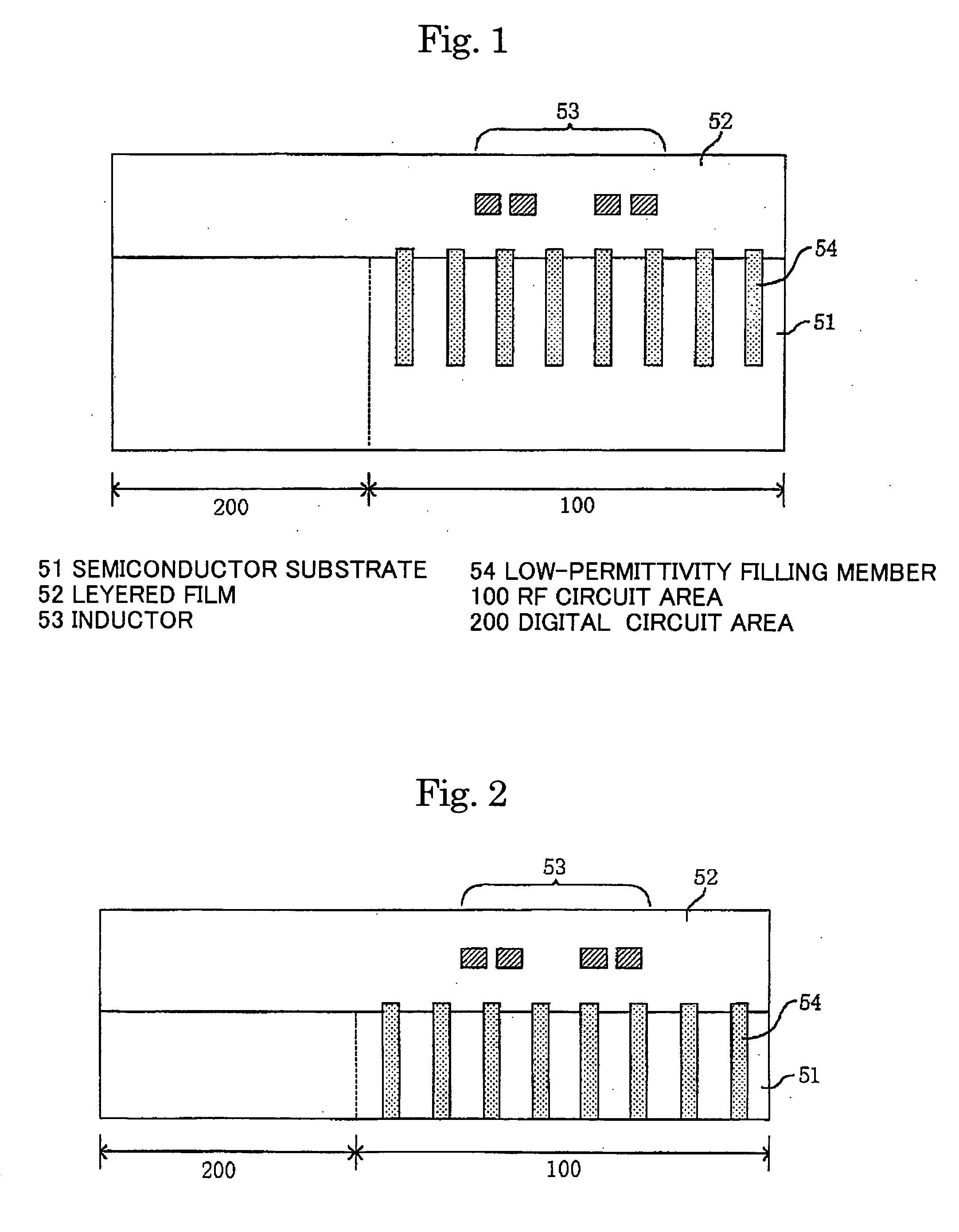

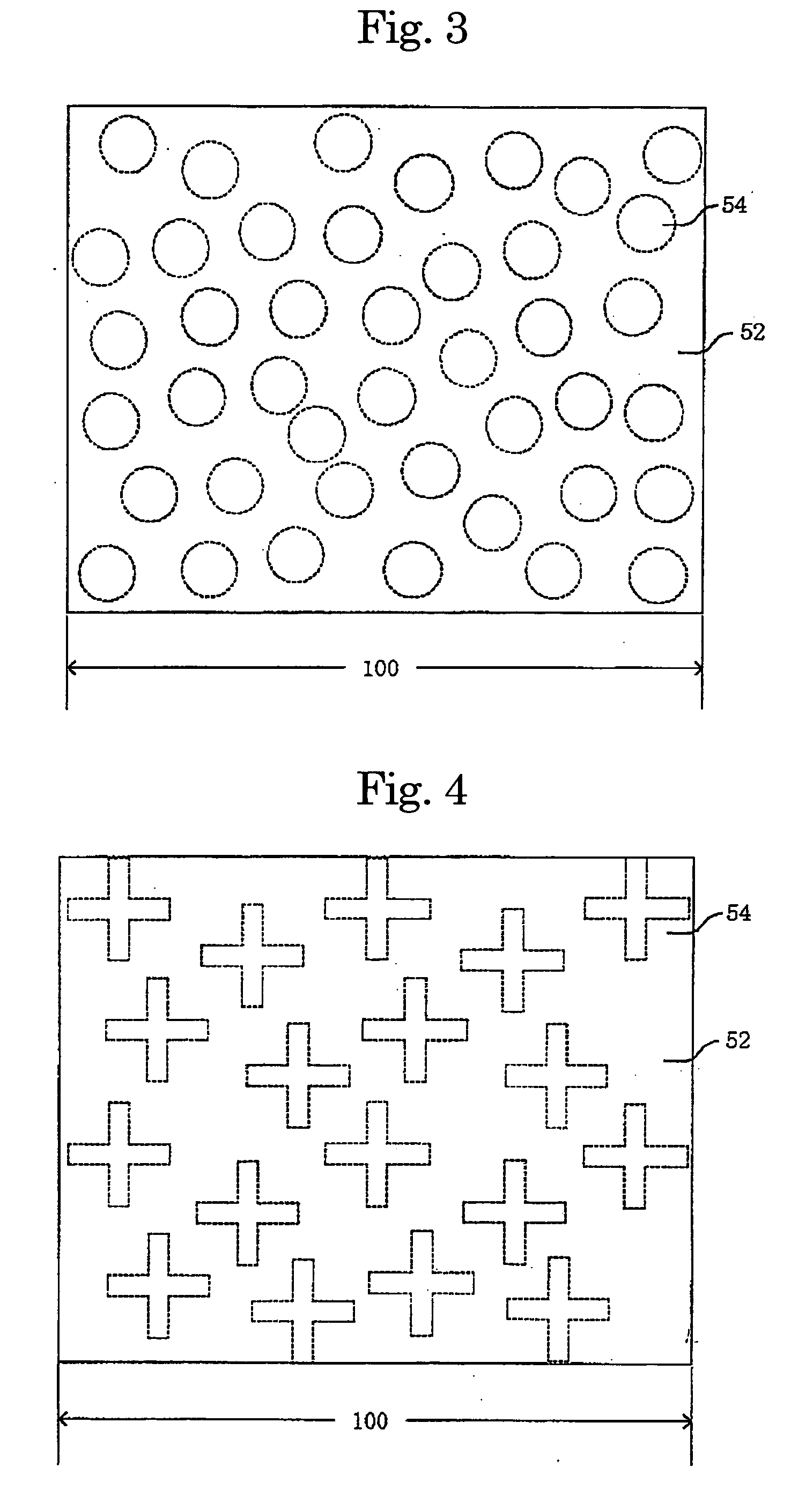

Semiconductor device and method for manufacturing same

InactiveUS20060157798A1Reduce the induction currentMade smallSemiconductor/solid-state device detailsSolid-state devicesMOSFETDevice material

[Object] An object of the present invention is to mount both a RF circuit including an inductor formed therein and a digital circuit on a single chip. [Means for Solving Problems] MOSFETs are formed on a semiconductor substrate 1 in regions isolated by an element isolation film 2. A plurality of low-permittivity insulator rods including a low-permittivity insulator embedded therein and penetrating a first interlevel dielectric film 4 to reach the internal of the silicon substrate are disposed in the RF circuit area 100. An inductor 40 is formed on the interlevel dielectric film in the RF circuit area by using multi-layered interconnects. A high-permeability isolation region in which a composite material including a mixture of high-permeability material and a low-permittivity material is formed in the region of the core of the inductor and periphery thereof.

Owner:NEC CORP

Switching voltage regulator operating without a discontinuous mode

InactiveUS20060125454A1Avoid disadvantagesReduce switchingEfficient power electronics conversionDc-dc conversionValue setSwitched current

A switching circuit operates with a first operating state and a second operating state. During the first operating state, the switching circuit allows a switching current to linearly increase. During the second operating state, the switching circuit allows the switching current to linearly decrease. A control circuit is coupled to the switching circuit for controlling the switching circuit to operate with the first operating state or the second operating state. A setting circuit generates a threshold signal for the control circuit to ensure that during the first operating state the switching current linearly increases to become higher than or equal to a current value set by the threshold signal. Thereby, the switching current is prevented from linearly decreasing to reverse polarity during the second operating state.

Owner:GLOBAL MIXED MODE TECH

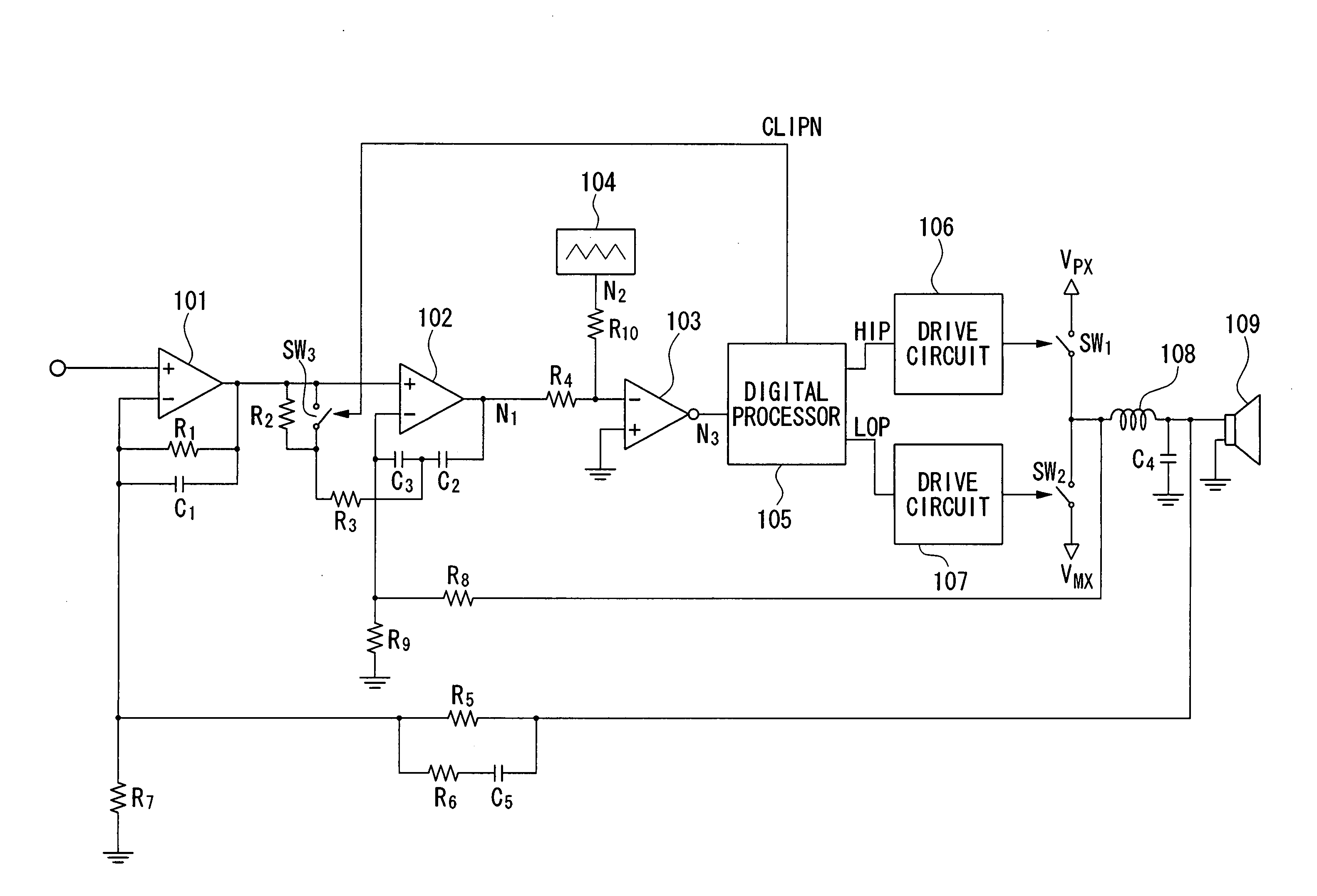

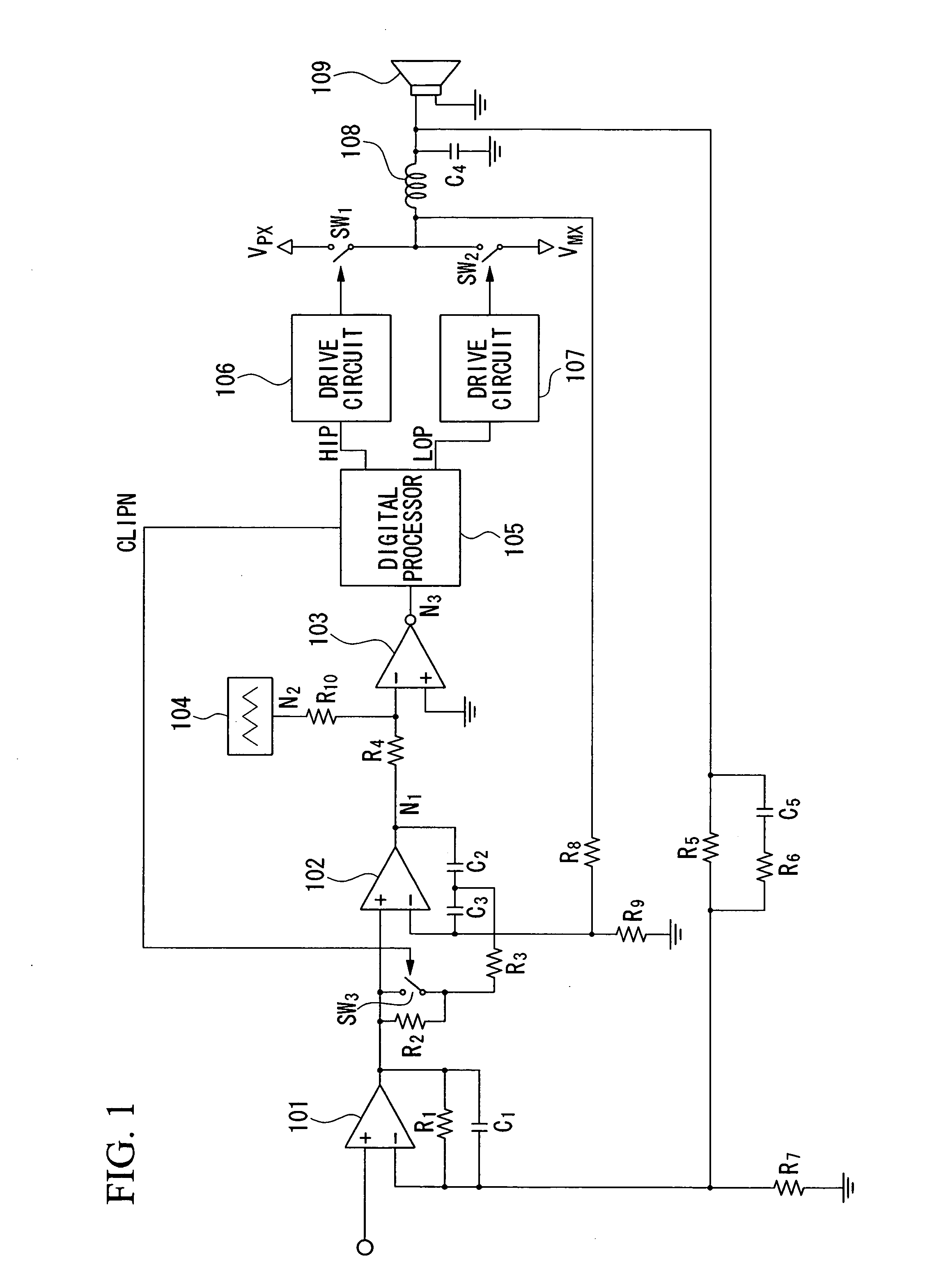

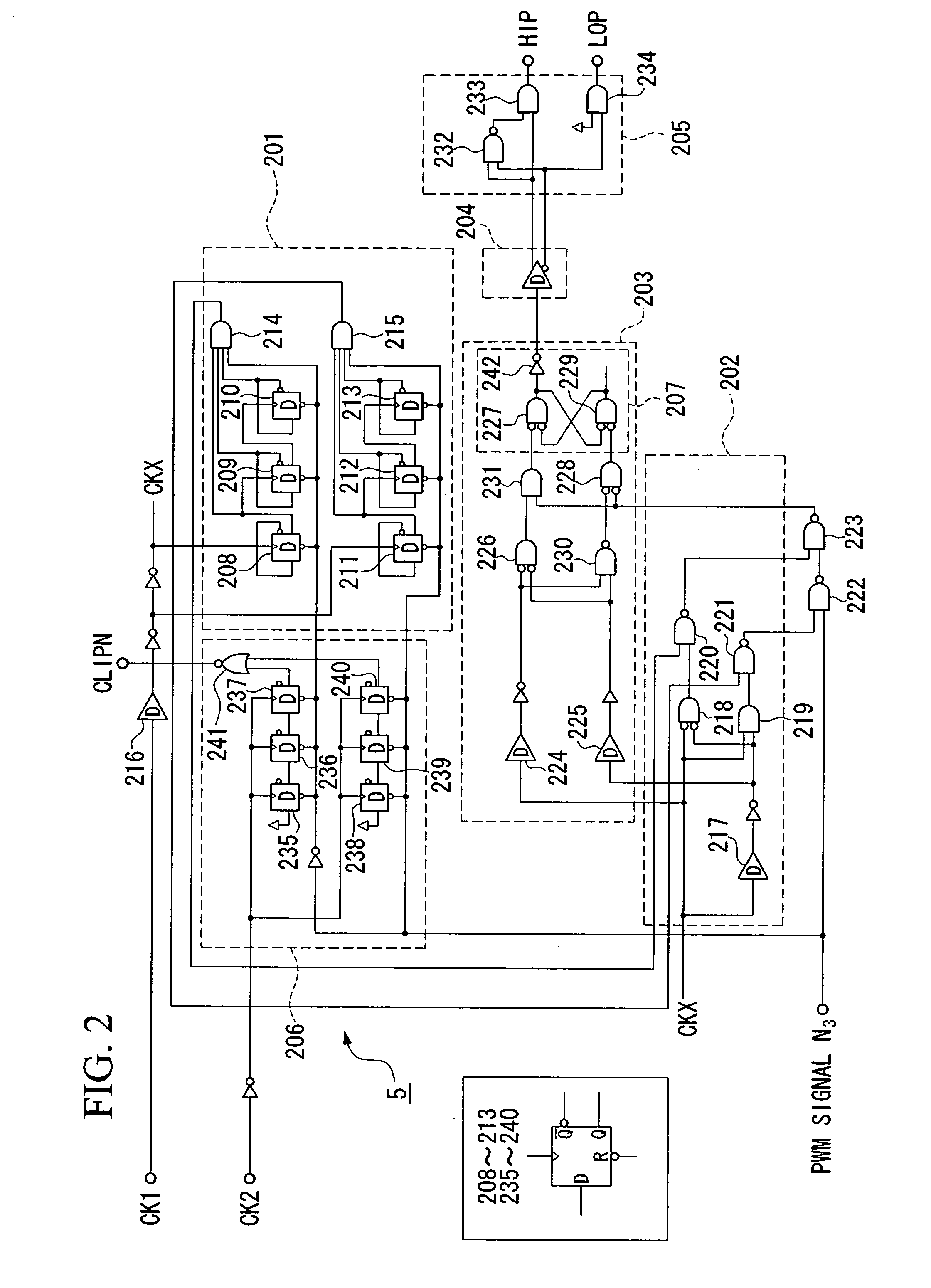

Pulse-width modulation amplifier and suppression of clipping therefor

ActiveUS20060008095A1Avoid excessive currentPower use efficiency decreaseAmplifier modifications to reduce noise influenceGain controlLeading edgeAudio power amplifier

A pulse-width modulation (PWM) amplifier is adapted to a class-D amplifier in which an analog input signal is subjected to integration, pulse-width modulation, and switched amplification, wherein a glitch elimination circuit eliminates noise from a pulse-width modulated signal, from which a high pulse signal and a low pulse signal are isolated such that each pulse is delayed by a dead time at the leading-edge timing thereof. When both of them are simultaneously set to a high level, one of them is reduced in level. In response to the occurrence of clipping, an integration constant applied to an operational amplifier is automatically changed from a primary integration constant to a secondary integration constant. When the clipped state is sustained for a prescribed time, an inversion pulse is compulsorily introduced into the pulse-width modulated signal.

Owner:YAMAHA CORP

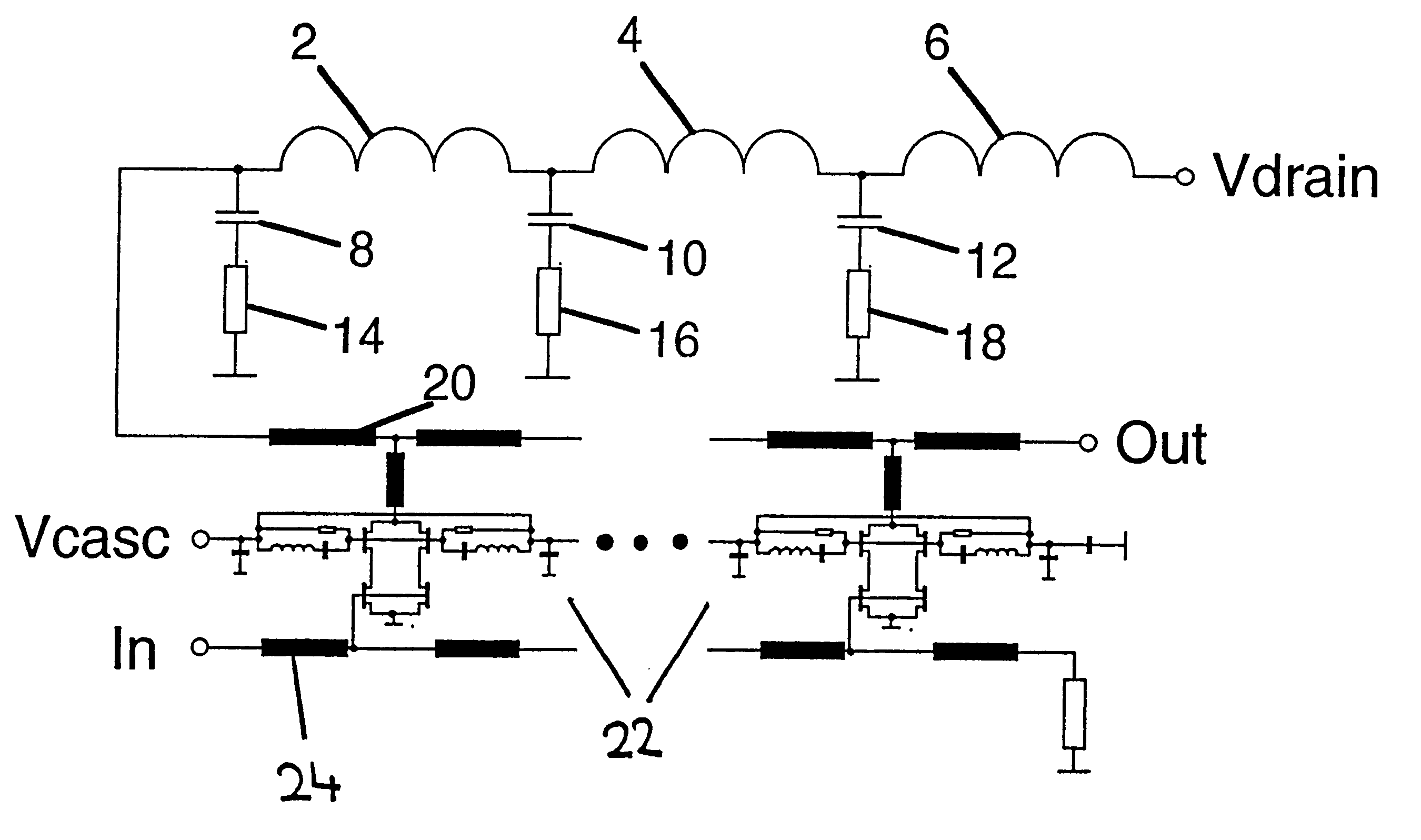

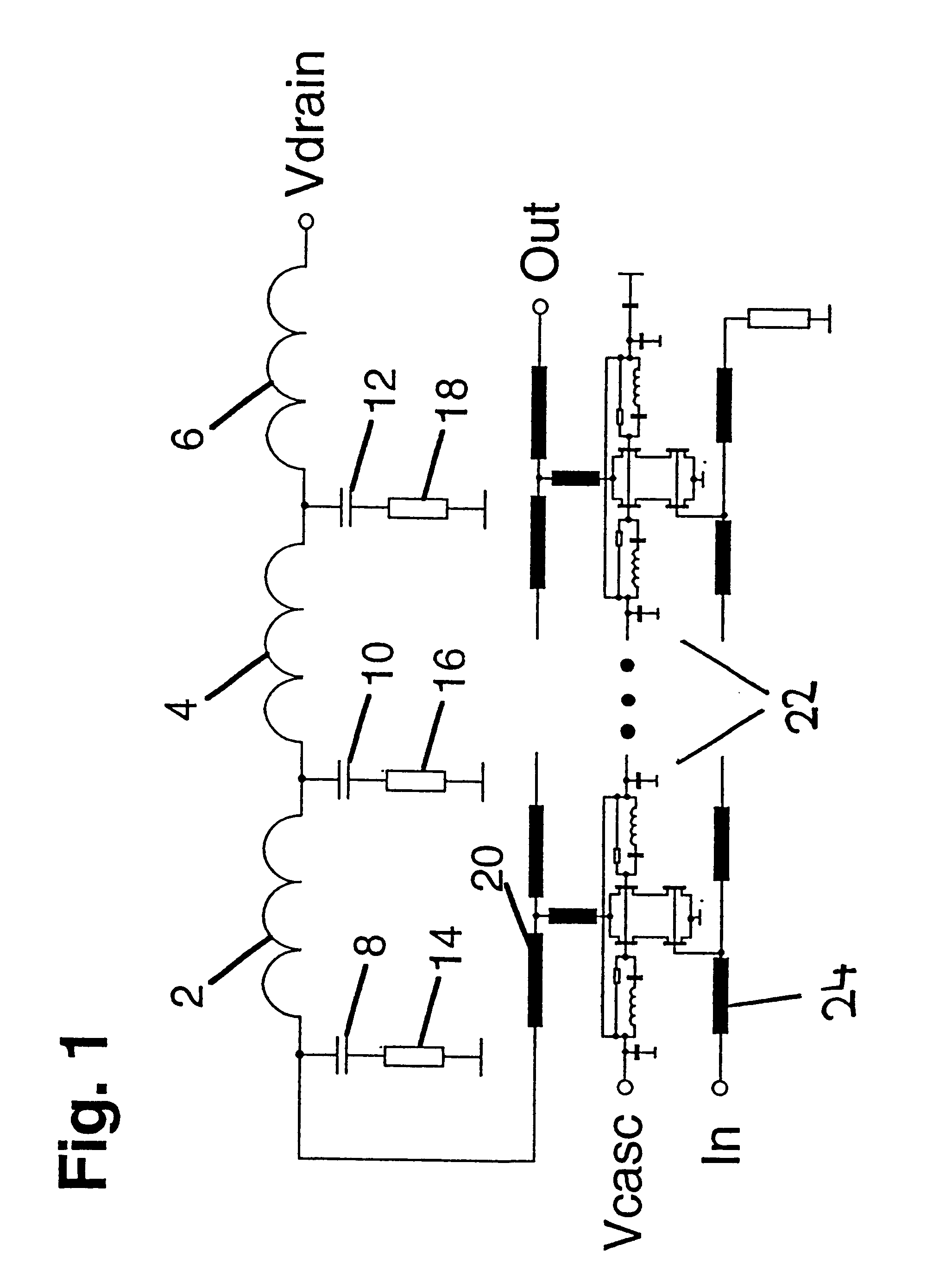

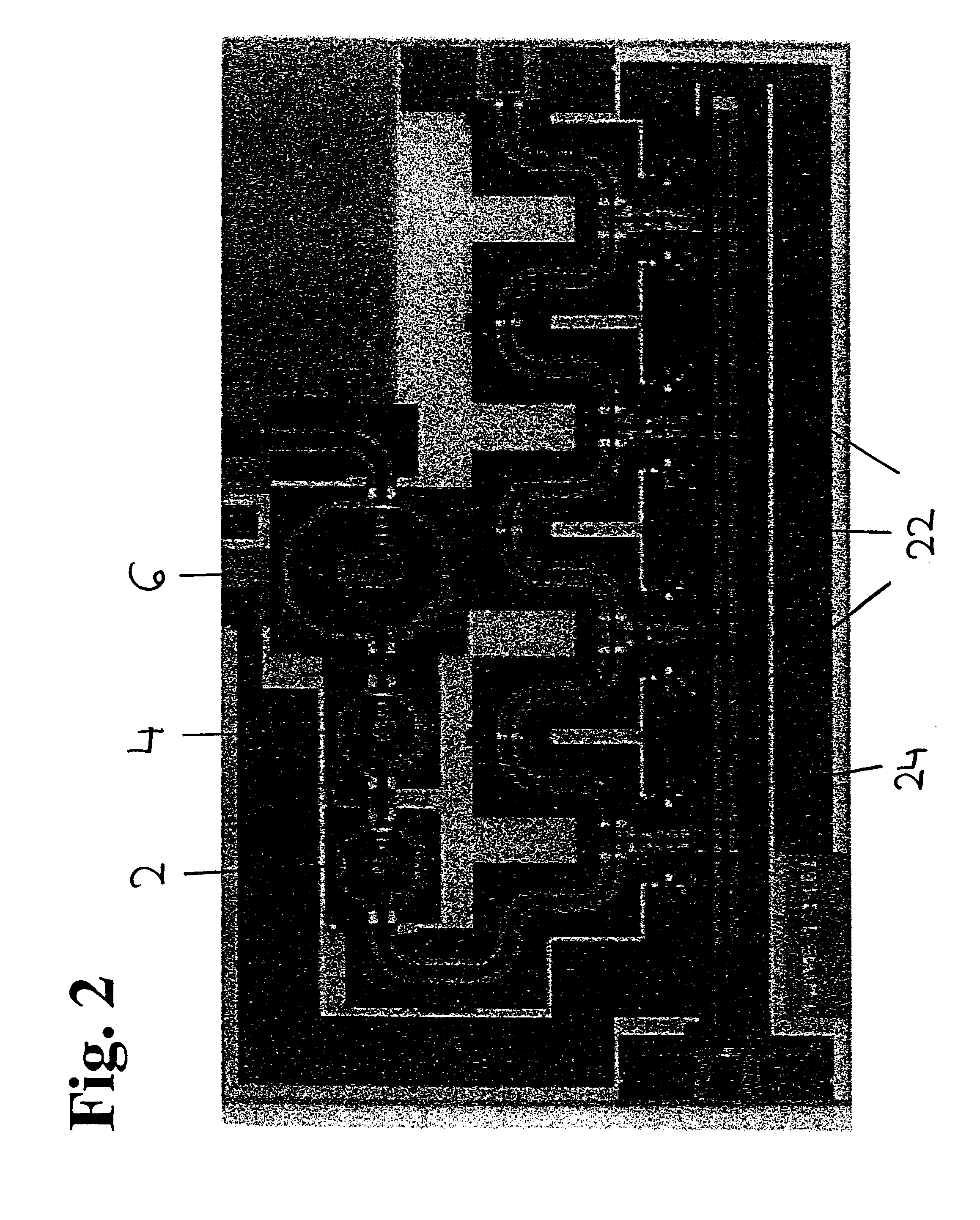

Supply voltage decoupling device for HF amplifier circuits

InactiveUS6653903B2Inhibit currentLittle power lossAmplifier modifications to reduce temperature/voltage variationAmplifiers wit coupling networksElectrical resistance and conductanceDistributed amplifier

A device for decoupling a supply voltage for HF amplifier circuits is described which includes an output line for coupling out an amplified signal, wherein one end of the output line, which is not used for coupling out signals, is connected to a circuit element designed as decoupling circuit. The circuit element has a low ohmic d.c. resistance and presents an HF-power absorption capacity that increases as the frequency increases, thus constituting a reflection-free termination for high frequencies. The circuit element is preferably constituted by several discrete subcircuits connected in succession. The device permits the operation of integrated distributed amplifiers of high performance at a low power loss caused by the decoupling circuit.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

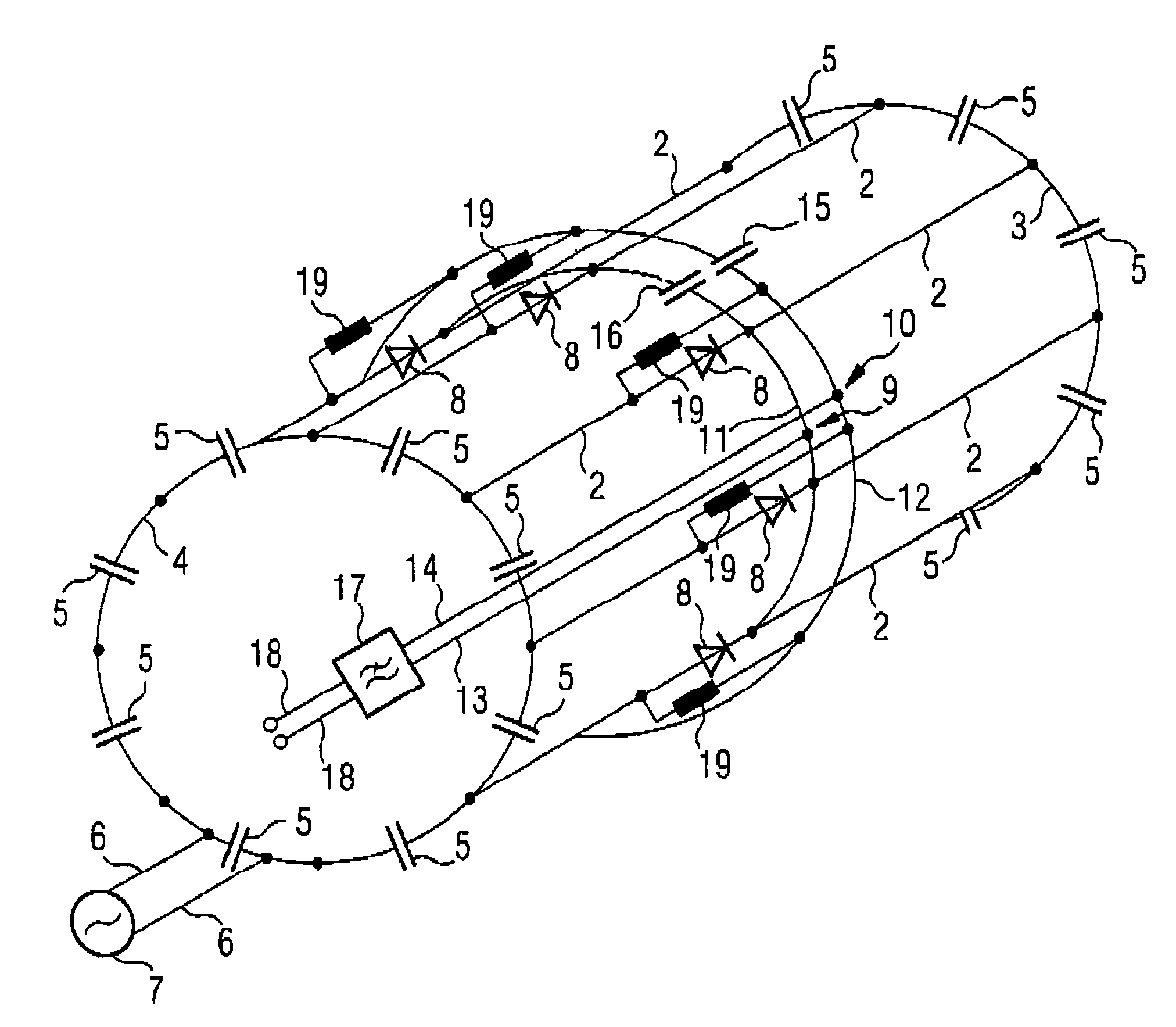

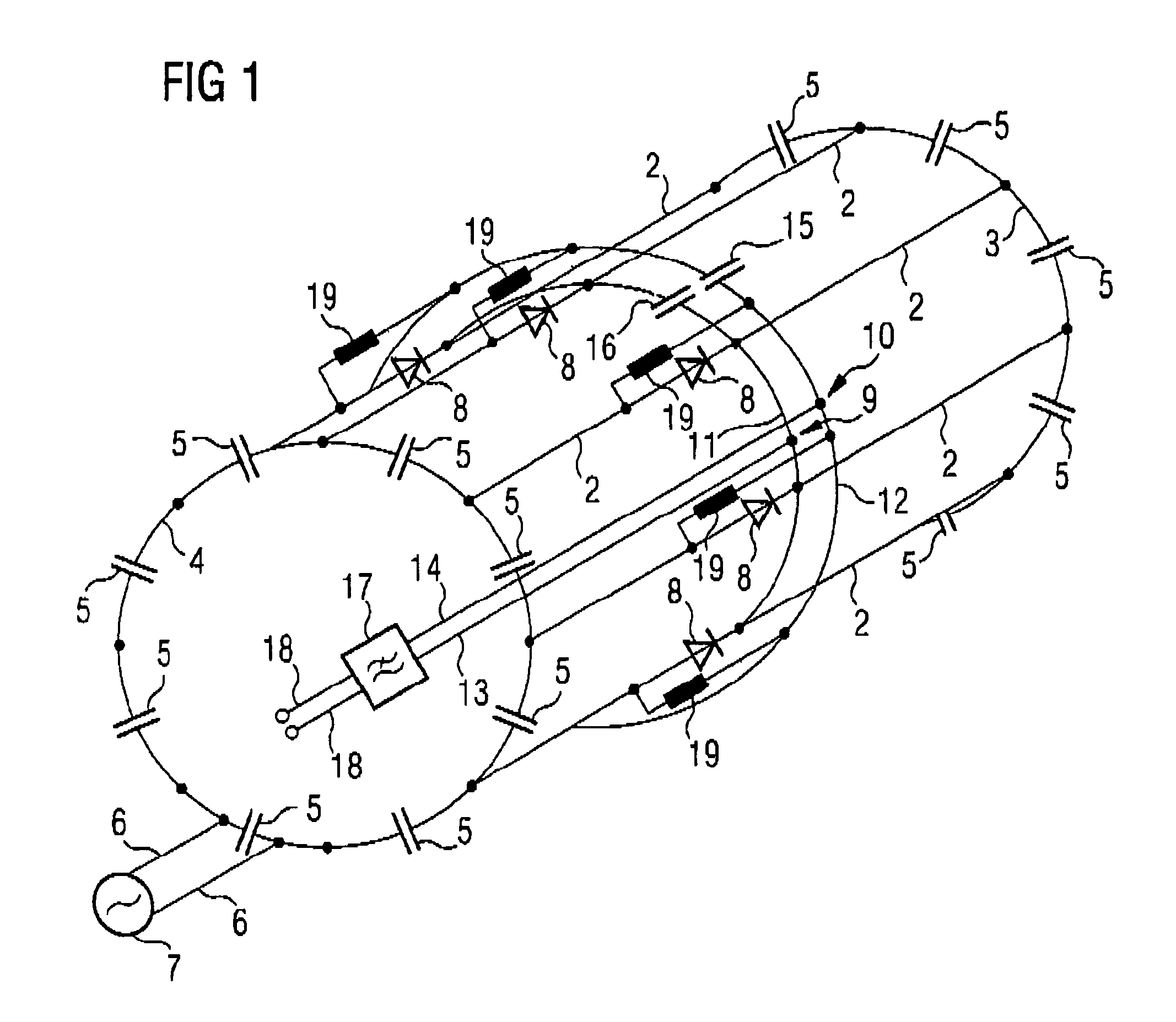

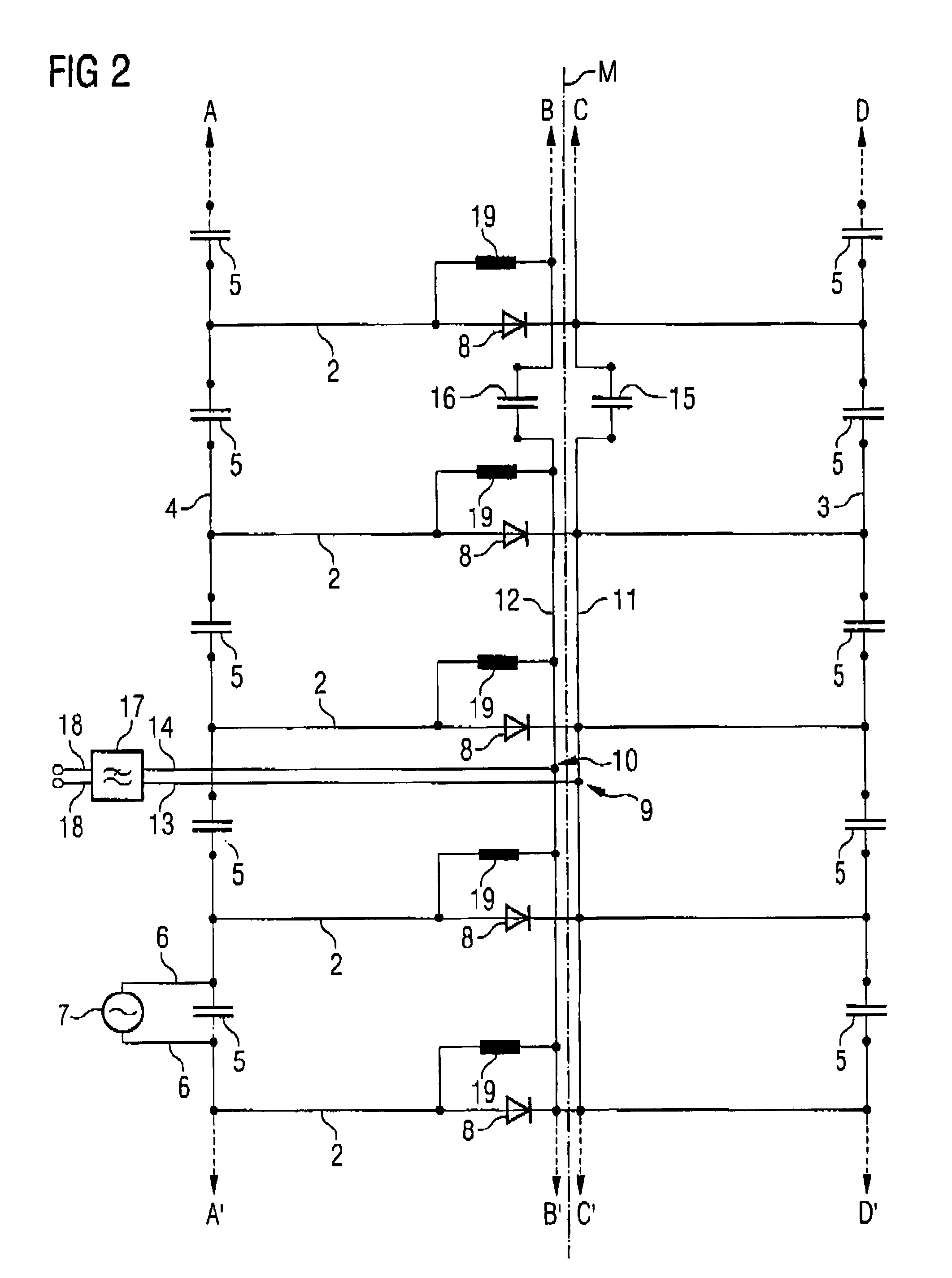

Magnetic resonance antenna

ActiveUS6943551B2Low switching voltageSimple and cost-effectiveElectric/magnetic detectionMeasurements using magnetic resonanceResonanceRadio frequency

A magnetic resonance antenna has longitudinal antenna rods in a birdcage structure, and antenna ferrules connecting the longitudinal antenna rods at their ends in terms of radio-frequency. The magnetic resonance antenna has a number of radio-frequency switching elements that interrupt, in terms of radio-frequency, at least one part of the longitudinal antenna rod to detune the eigen-resonance frequency of the antenna with respect to an operating magnetic resonance frequency. For this purpose, the magnetic resonance antenna is provided with two switching lines, directed to the radio-frequency switching elements from outside of the birdcage structure, the switching lines having a ring line connected thereto running annularly on or in the birdcage structure and transverse to the longitudinal antenna rods.

Owner:SIEMENS HEALTHCARE GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com