Leakage-proof structure and method for leakage maintenance of toilet floor

A technology for toilets and floors, applied in the direction of floors, building structures, insulation layers, etc., can solve the problems of poor adhesion between leakage plugging materials and ceramic tiles, aging of leakage plugging materials, and re-leakage, etc., to shorten the maintenance period, The effect of preventing leakage and improving the efficiency of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

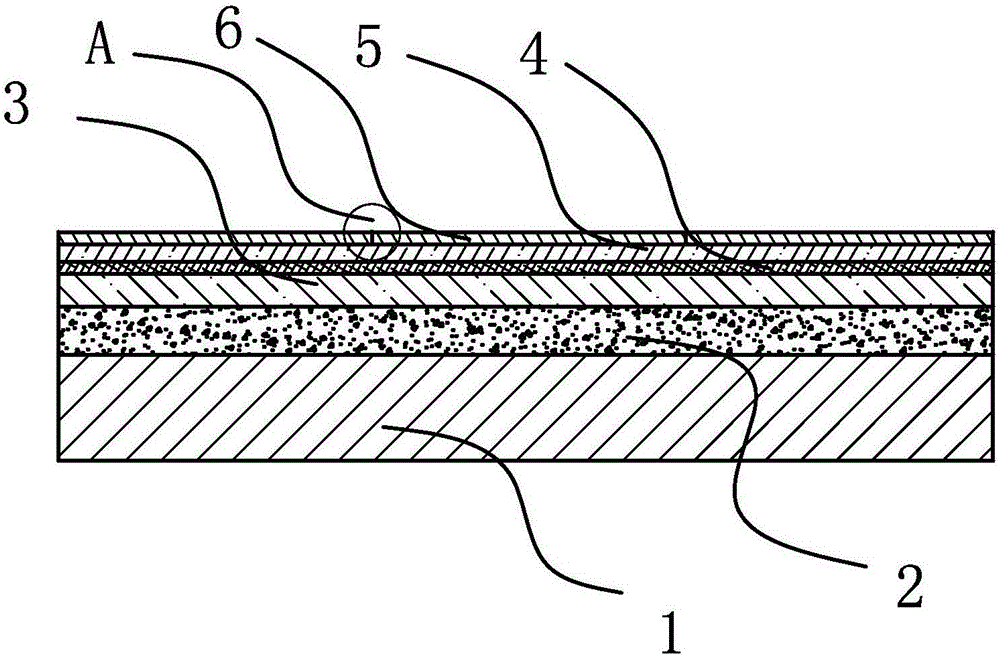

[0039] The leak-proof structure of the bathroom ground leakage maintenance includes a ground base 1, the surface of the ground base 1 is laid with a cement mortar bonding layer 2, and the surface of the cement mortar bonding layer 2 is laid with a ceramic tile layer 3, wherein the ceramic tile layer 3 can be used according to actual needs. The surface of the tile layer 3 is coated with a waterproof coating layer 4, and the surface of the waterproof coating layer 4 is laid with a self-leveling layer 5, and the surface of the self-leveling layer 5 is covered with some plastics. Floors 6, and make several plastic floorboards 6 therein be laid closely, and the edge of adjacent plastic floorboards 6 leans against.

[0040] After cleaning the bathroom floor, it includes removing obstacles such as the bathroom laundry table and partitions, and cleaning the gaps in the bathroom first. After cleaning, apply JS polymer cement waterproof coating on the surface of the tile layer 3 for furt...

Embodiment 2

[0042] The leakage-proof structure of the bathroom floor leakage maintenance is consistent with Embodiment 1, and will not be repeated here. The difference is that the leakage-proof structure of the bathroom floor leakage maintenance specific maintenance method is as follows:

[0043] After cleaning the bathroom floor, it includes removing obstacles such as the bathroom laundry table and partitions, and cleaning the gaps in the bathroom first. After cleaning, apply JS polymer cement waterproof coating on the surface of the tile layer 3 for further cleaning. The waterproof treatment makes the waterproof coating layer 4 be formed, and the three-layer construction method is adopted in the coating process, which is equivalent to coating three times, so that the total amount of the waterproof coating layer 4 after coating is 2.0kg / m 2 , make the thickness of the waterproof coating layer 4 be 2.0mm, then carry out the water storage test for 48 hours, after detecting that there is no ...

Embodiment 3

[0045] The leak-proof structure of the bathroom ground leakage maintenance includes a ground base 1, the surface of the ground base 1 is laid with a cement mortar bonding layer 2, and the surface of the cement mortar bonding layer 2 is laid with a ceramic tile layer 3, wherein the ceramic tile layer 3 can be used according to actual needs. The surface of the tile layer 3 is coated with a waterproof coating layer 4, and the surface of the waterproof coating layer 4 is laid with a self-leveling layer 5, and the surface of the self-leveling layer 5 is covered with some plastics. Floor 6, and make each plastic floor 6 therein close laying, and the edge of adjacent plastic floor 6 is against; Wherein, cement mortar bonding layer 2 also has step layer 8, and step layer 8 is positioned at the left side of cement mortar bonding layer 2 side, and the step layer 8 is against the wall 9; a number of squatting pits 10 are arranged on the step layer 8, and a water pipe 11 is correspondingly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com