Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

755results about How to "Stable tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

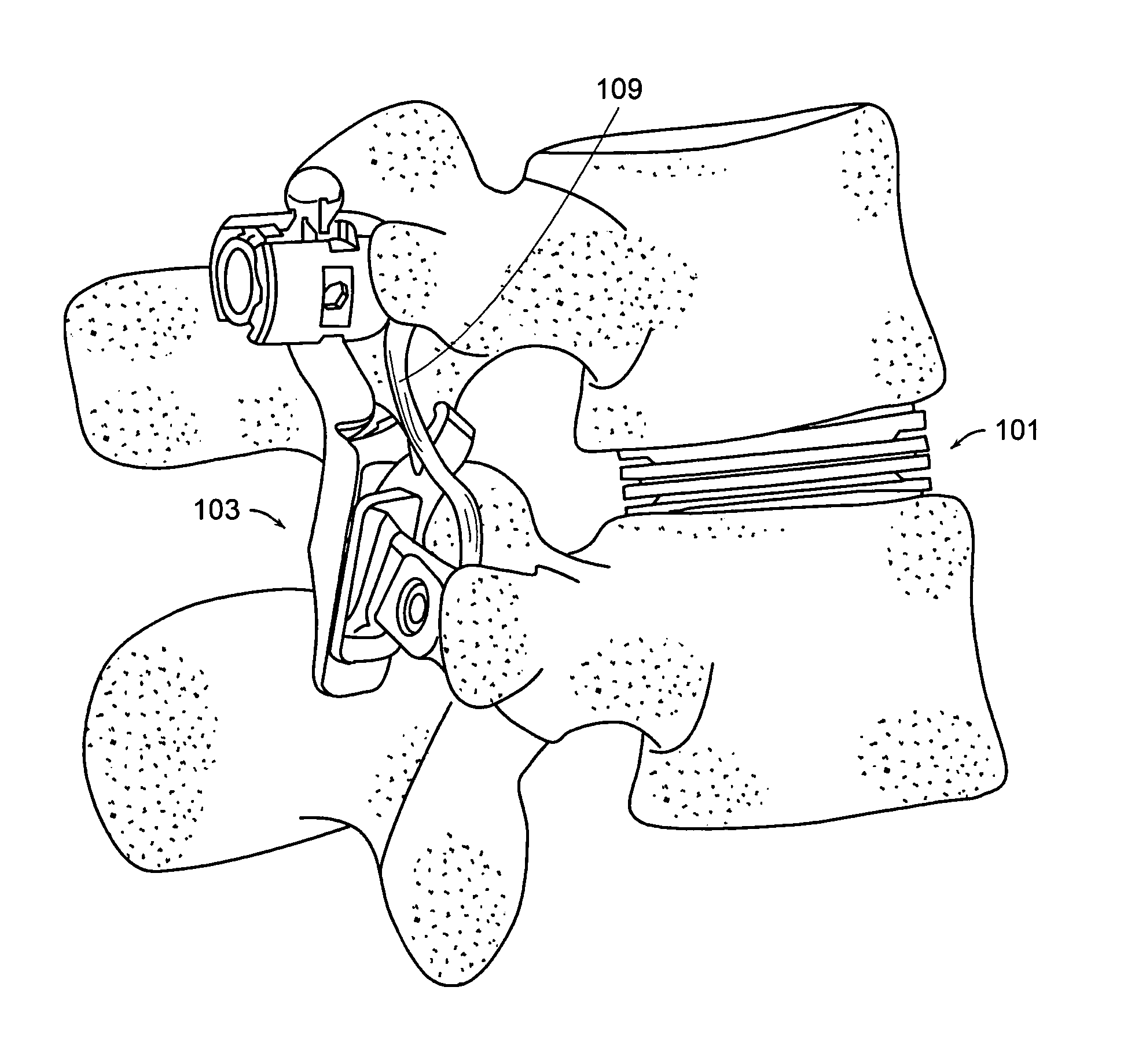

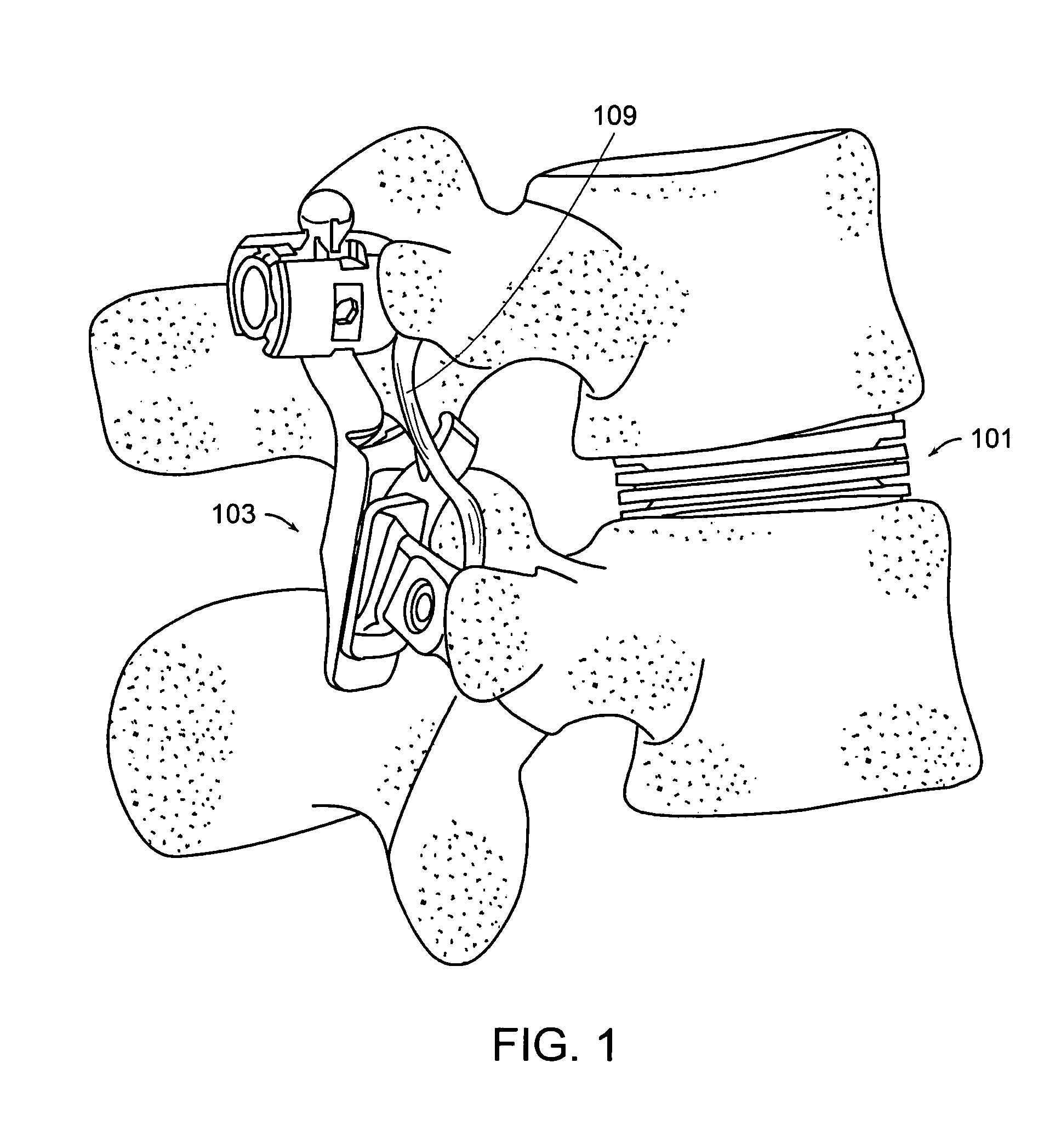

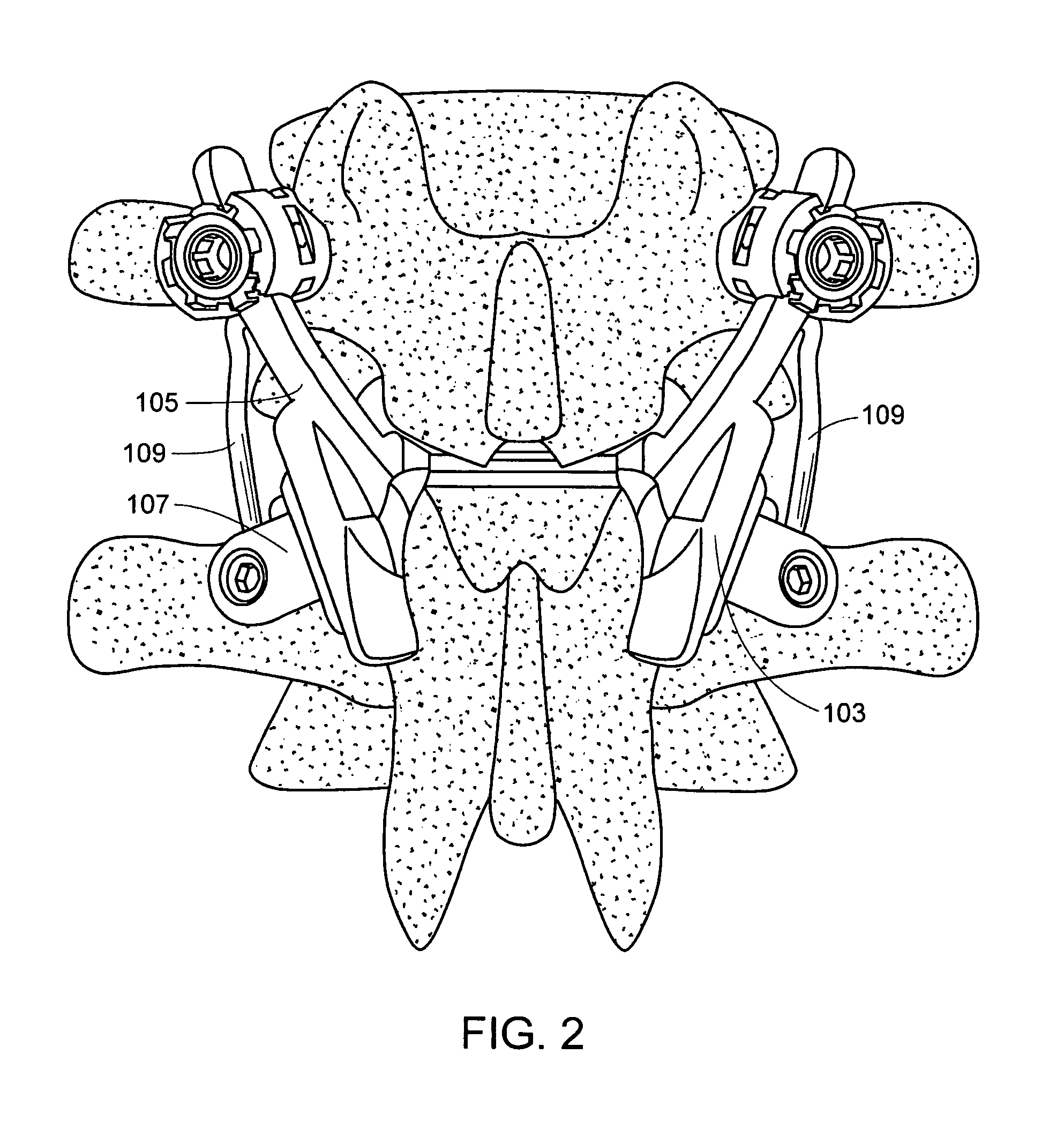

Functional spinal unit prosthetic

InactiveUS20050055096A1Improve joint stabilityStable tensionSuture equipmentsInternal osteosythesisSacroiliac jointFacet joint

A facet joint replacement system having an elongate rod and a polyaxial screw having a groove therein, wherein the rod is slidably received within the groove of the polyaxial screw.

Owner:DEPUY SPINE INC (US)

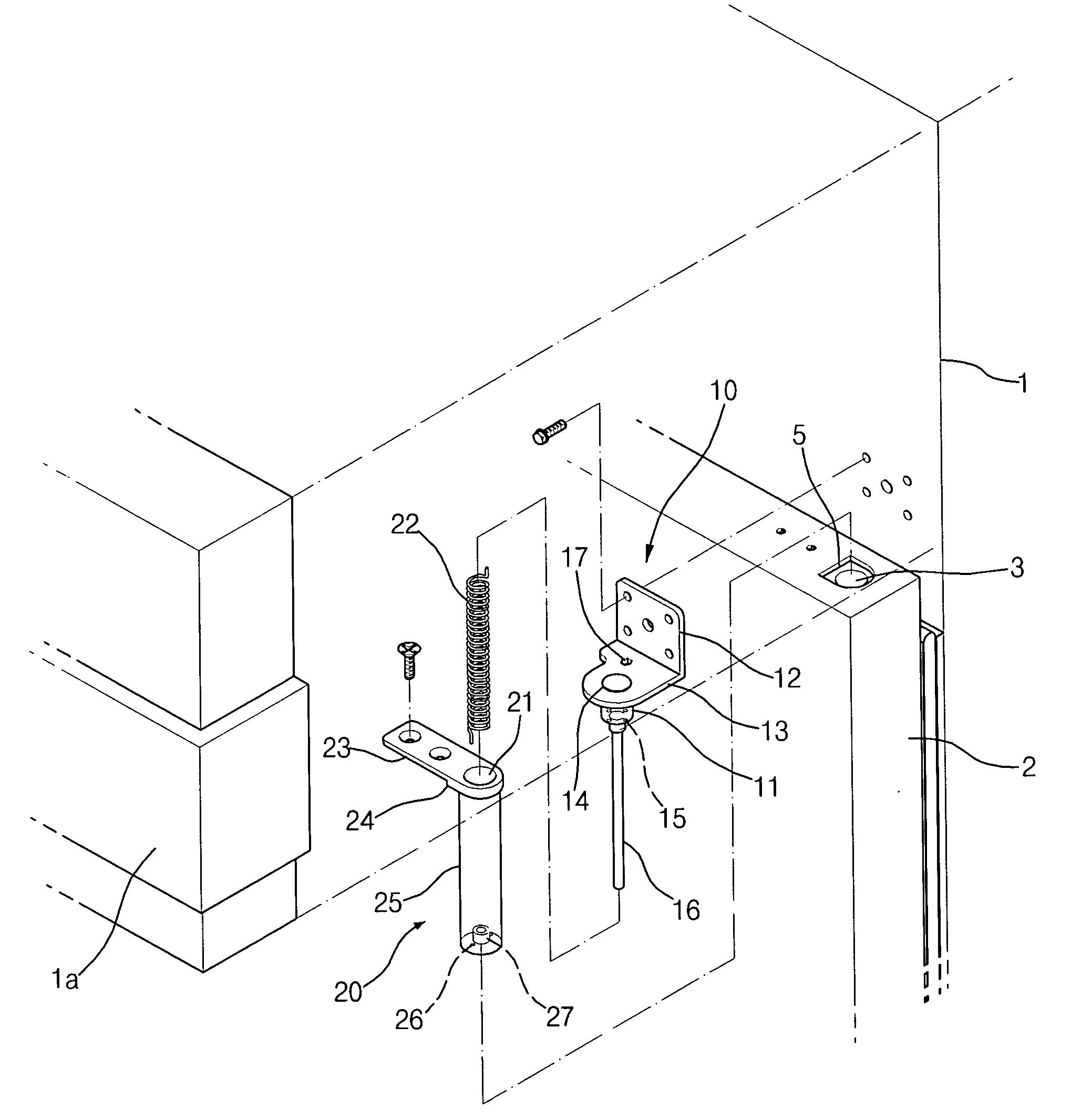

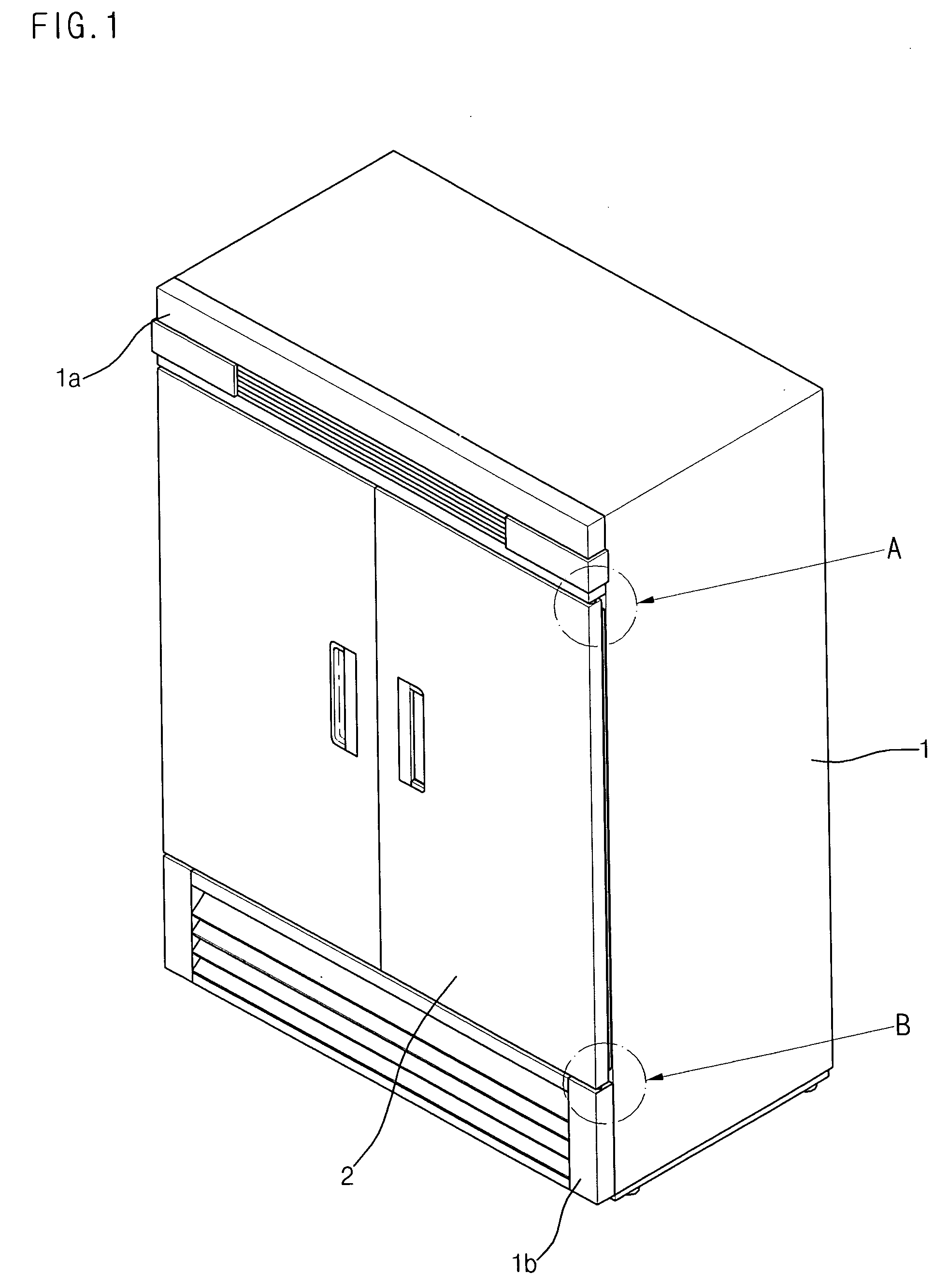

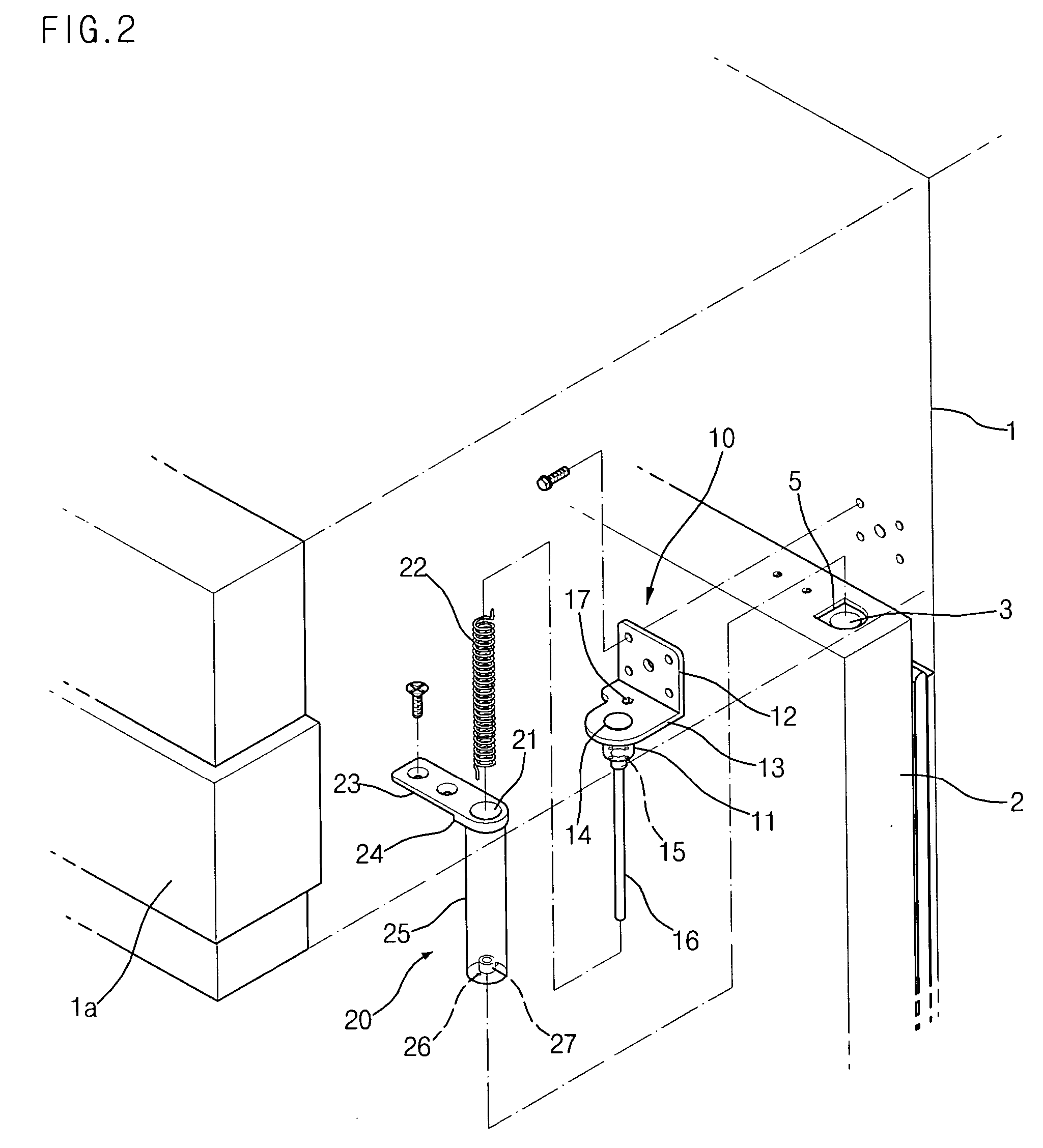

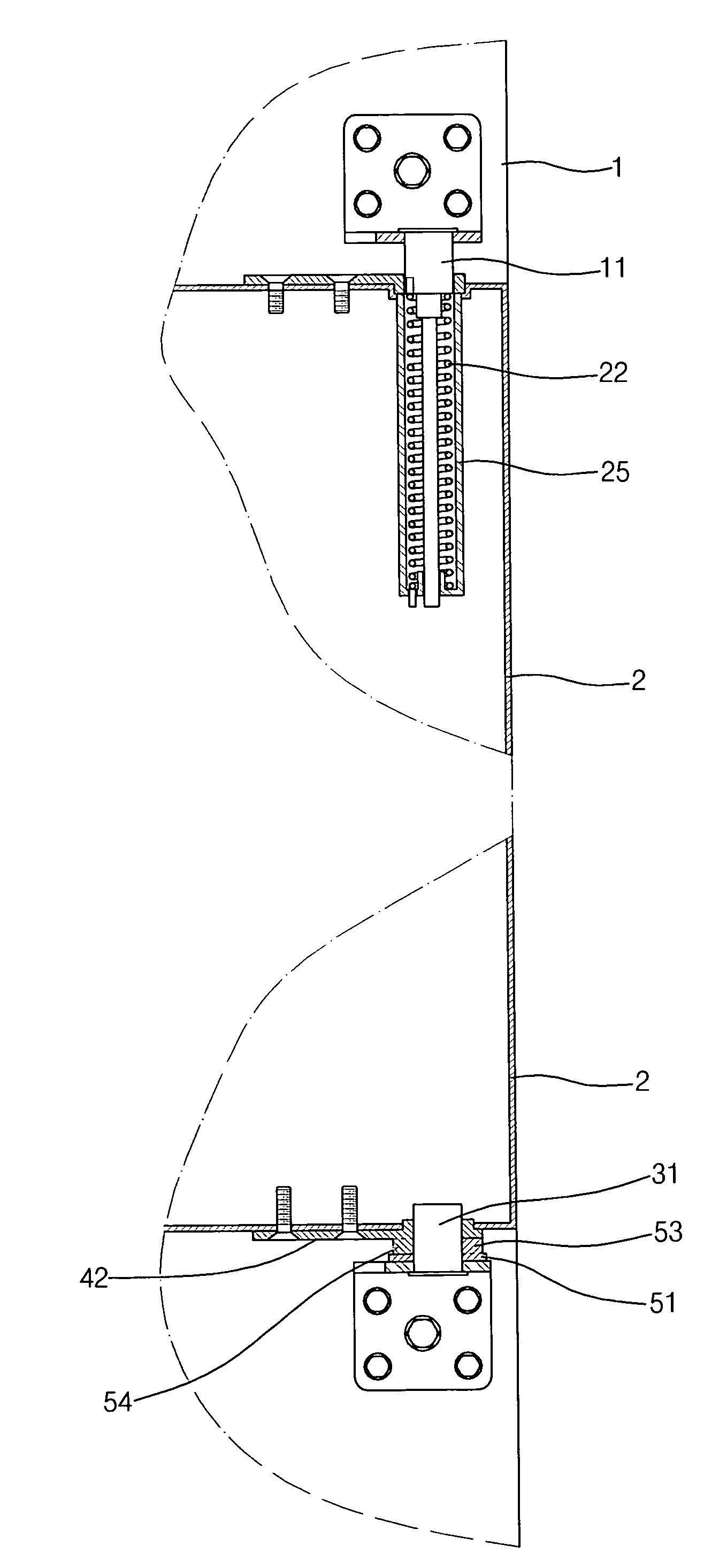

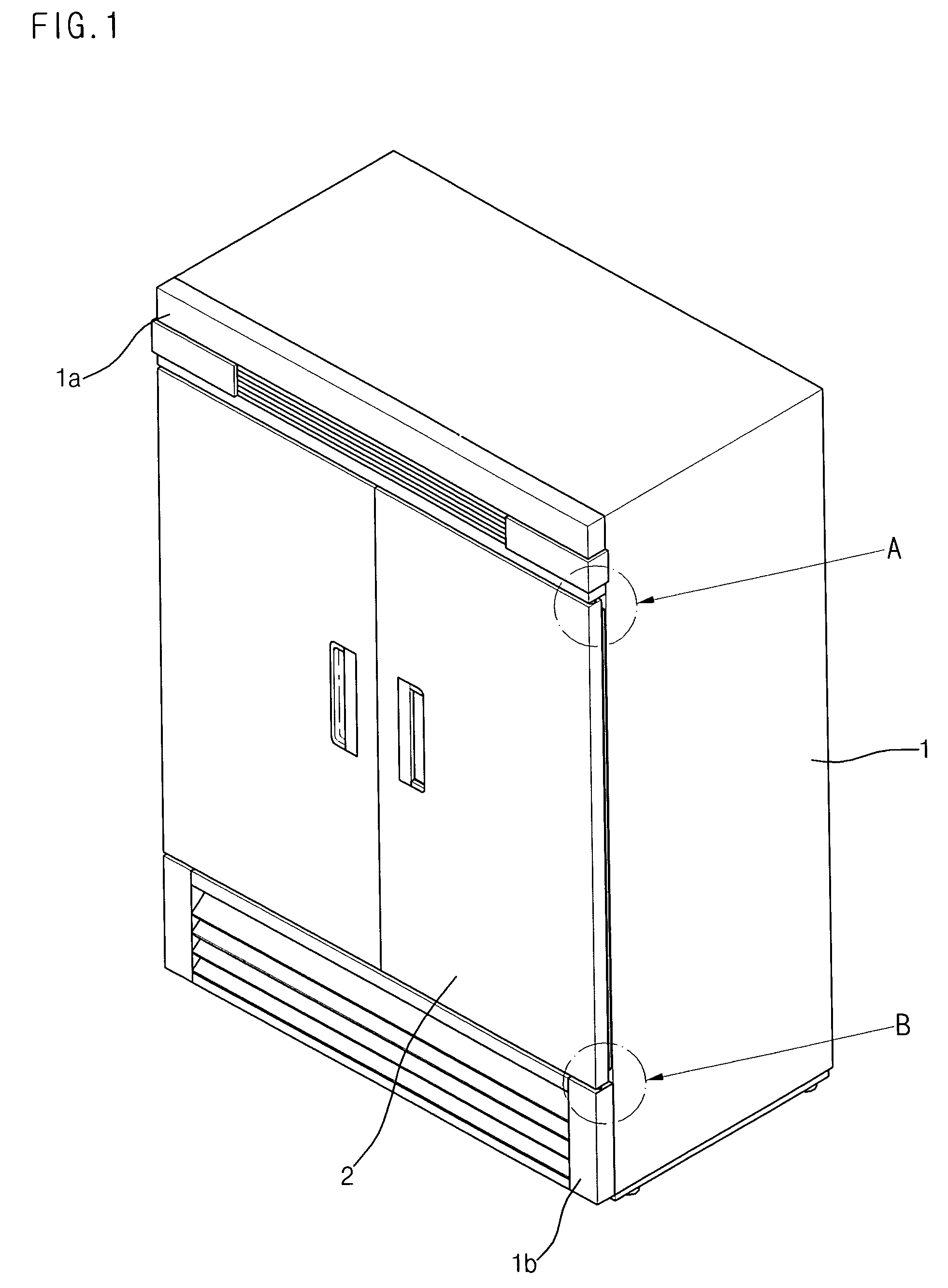

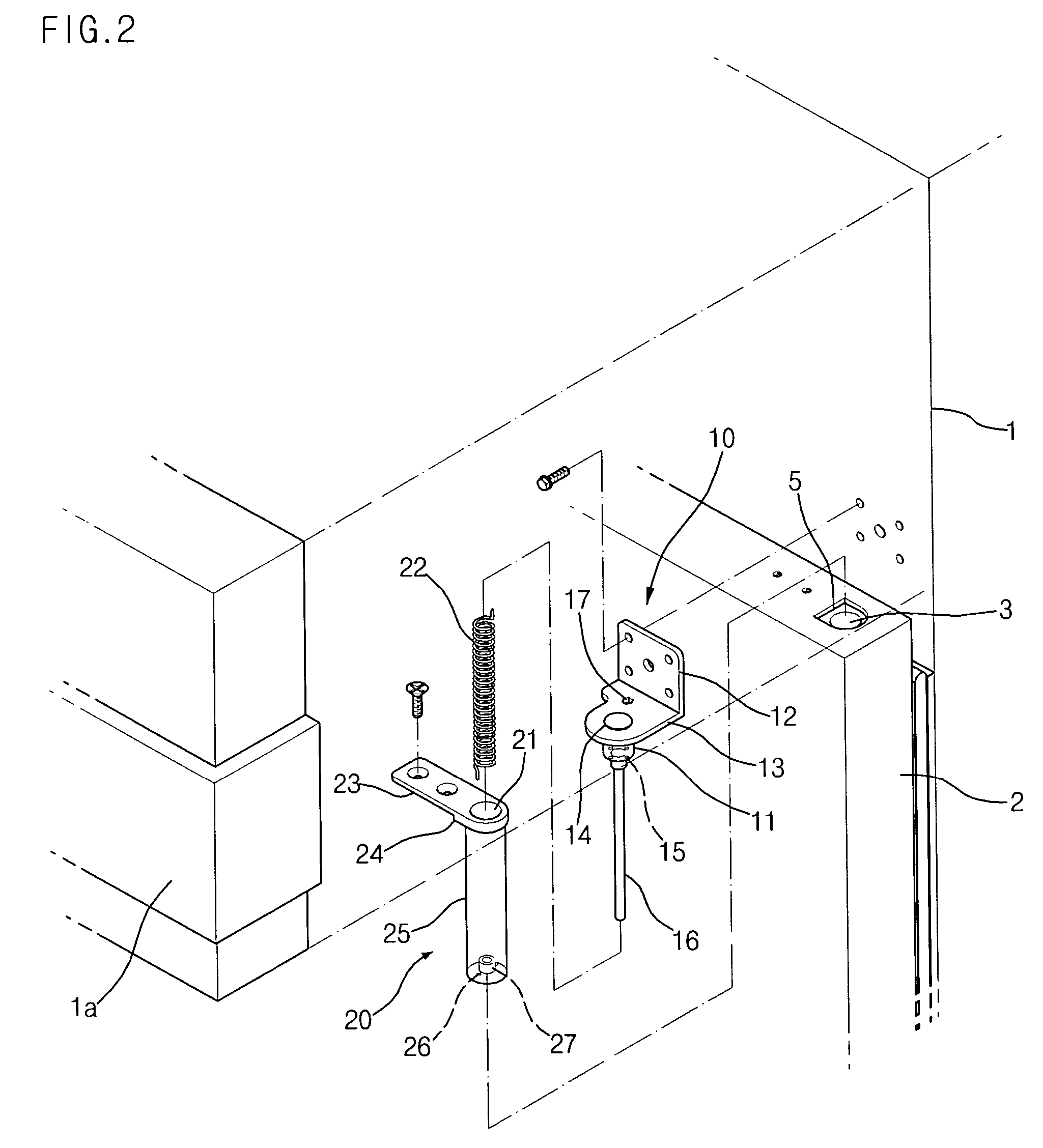

Door hinge structure for refrigerator

InactiveUS20050188506A1Simplified door hinge structureImprove convenienceLighting and heating apparatusHingesTorsion springRefrigerated temperature

Disclosed herein is a door hinge structure for a refrigerator. The door hinge structure comprises an upper fixture unit which is screwed to a predetermined front upper portion of a refrigerator body, and has an upper hinge pin to be inserted in a top aperture formed at an upper surface of a refrigerator door, an upper hinge unit which is mounted on the upper surface of the door, and has a through opening for allowing a distal end of the upper hinge pin to be slidably inserted therethrough, the upper hinge unit being coupled with the upper fixture unit by making use of a torsion spring so that it is vertically spaced therewith, a lower fixture unit which is screwed to a predetermined front lower portion of the body, and has a lower hinge pin to be inserted in a bottom aperture formed, at a lower surface of the door, a lower hinge unit which is mounted on the lower surface of the door, and has a through opening for the insertion of the lower hinge pin, and a stopper member which is interposed between the lower fixture unit and the lower hinge unit and is adapted to stop pivotal movement of the door at least one time.

Owner:LOTTE ALUMINUM

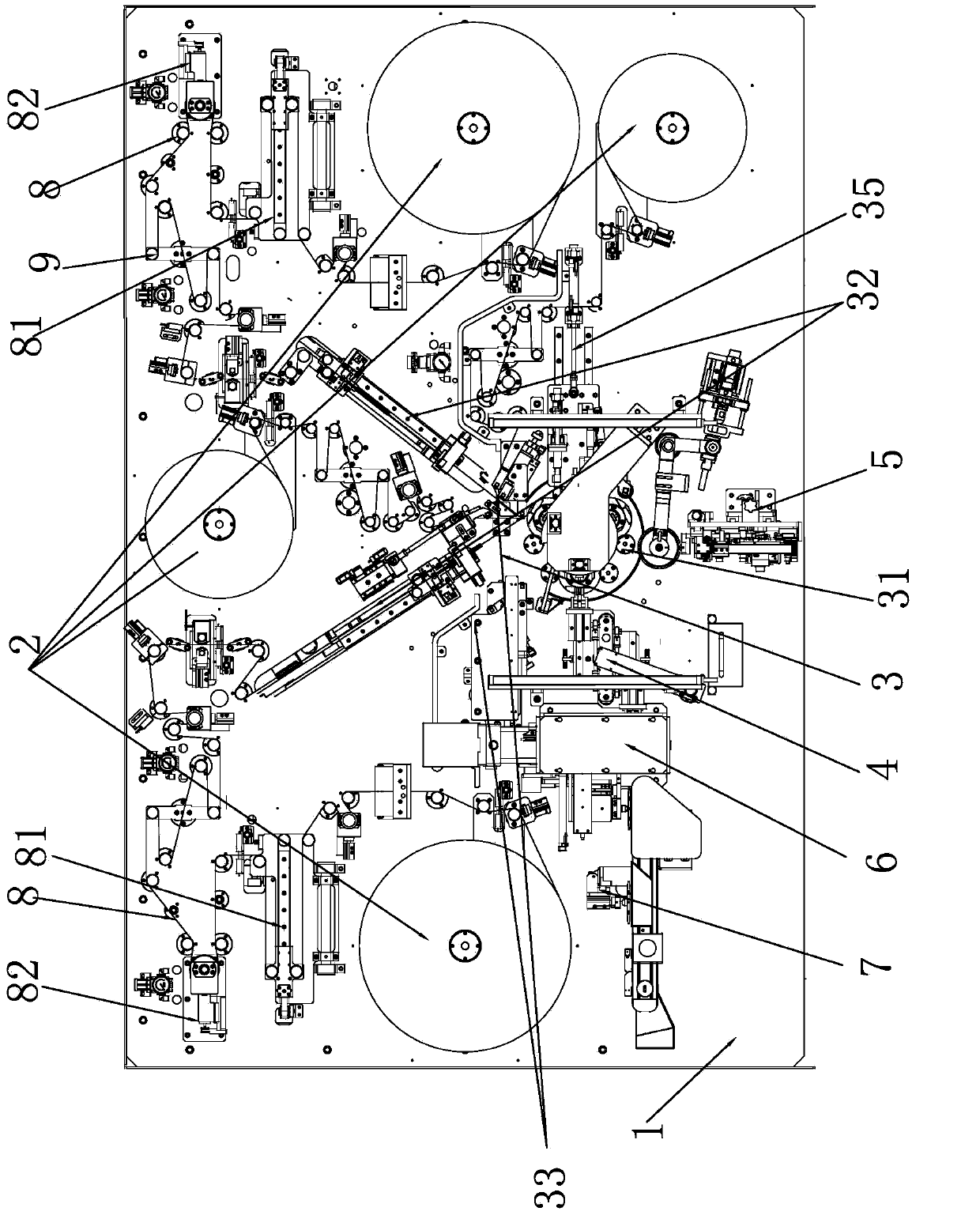

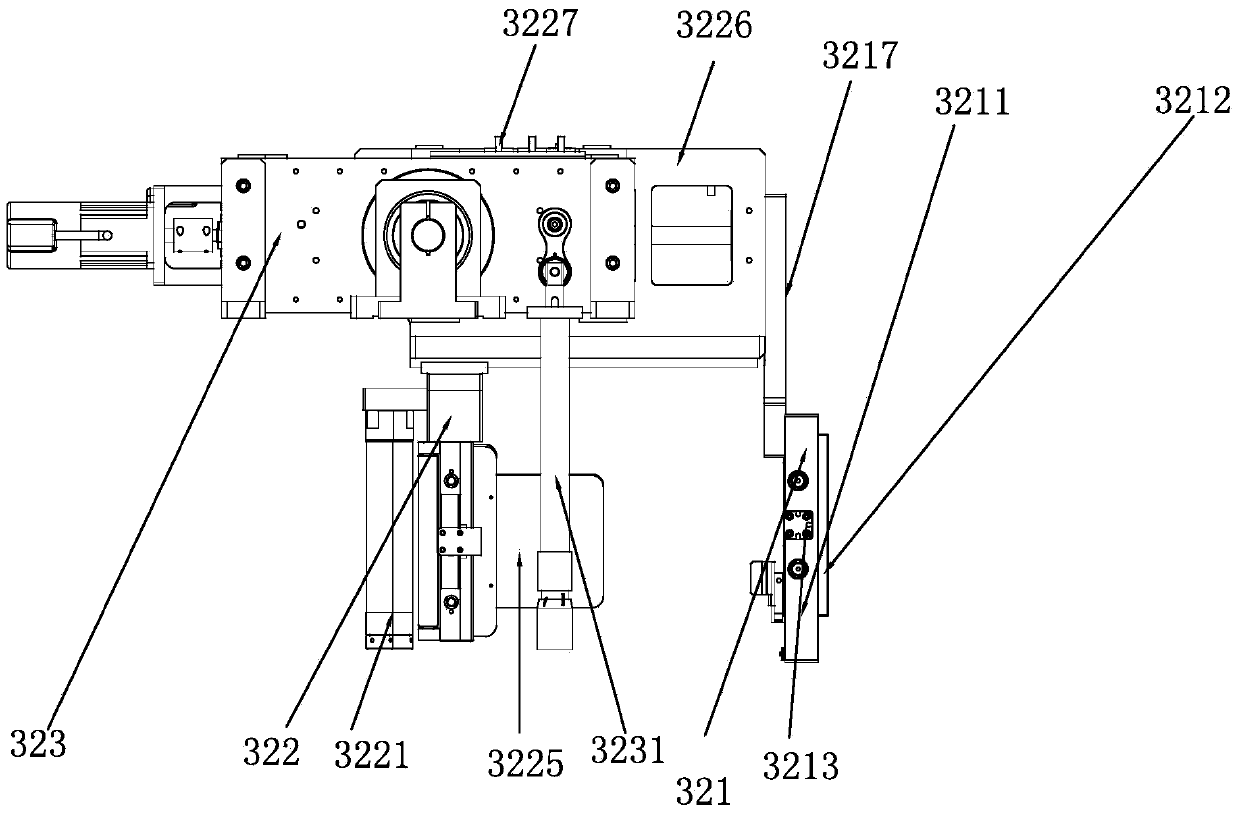

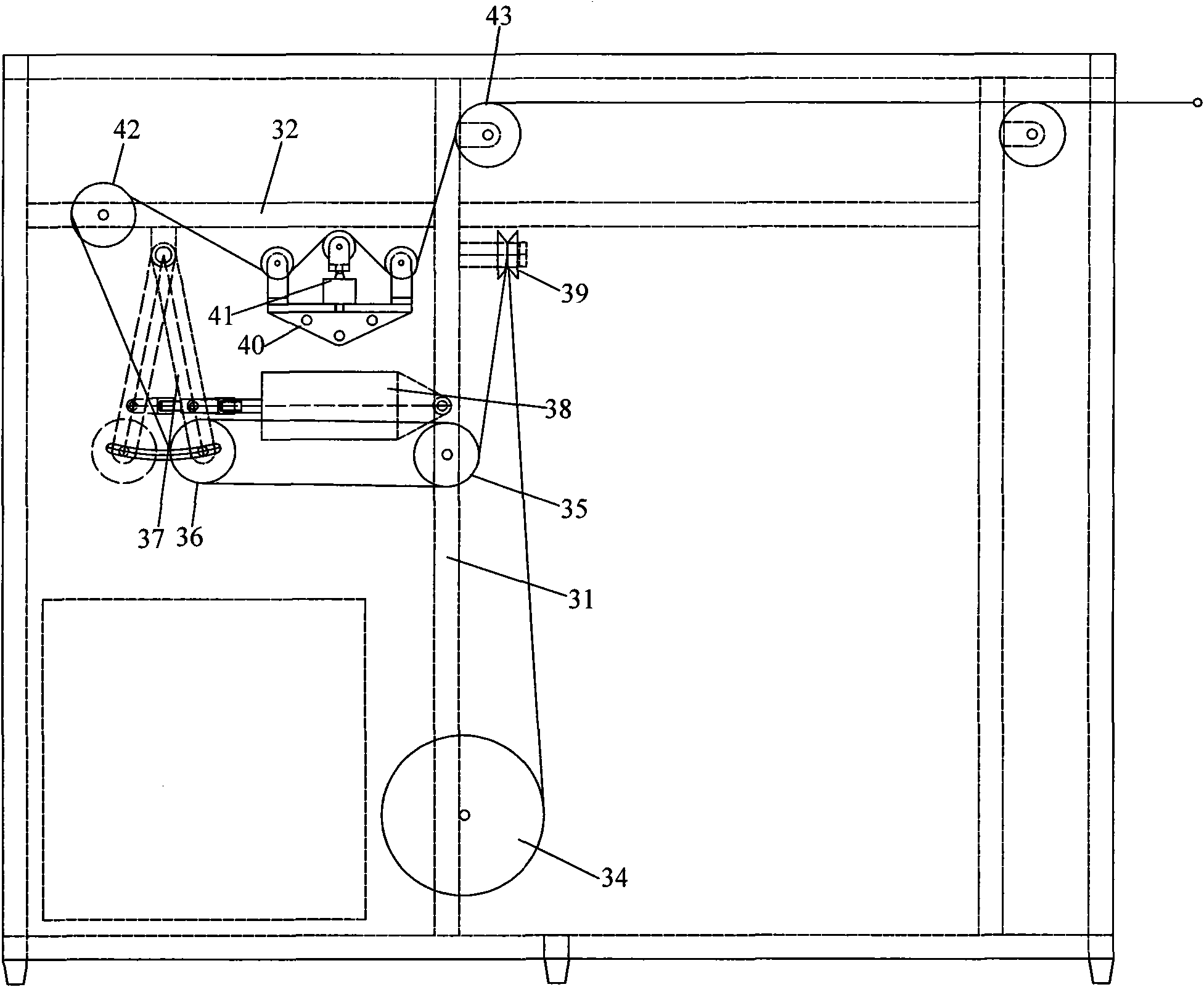

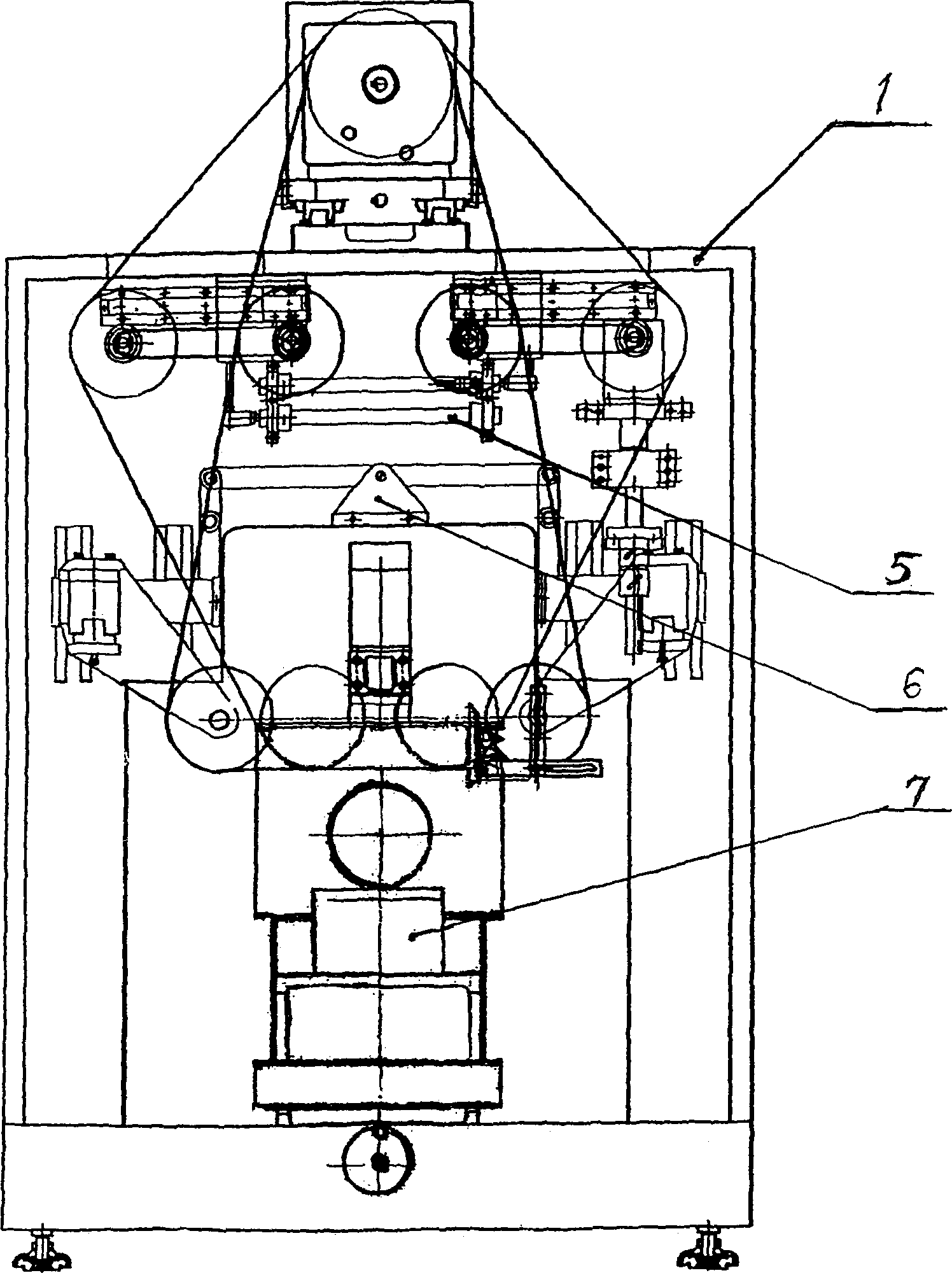

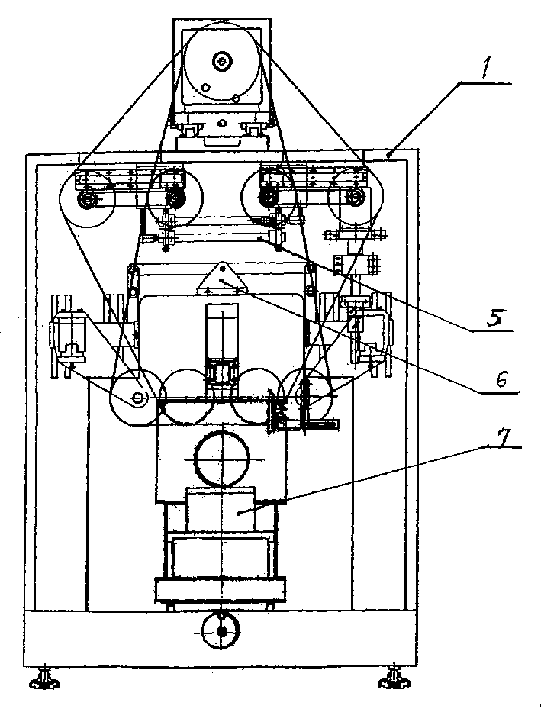

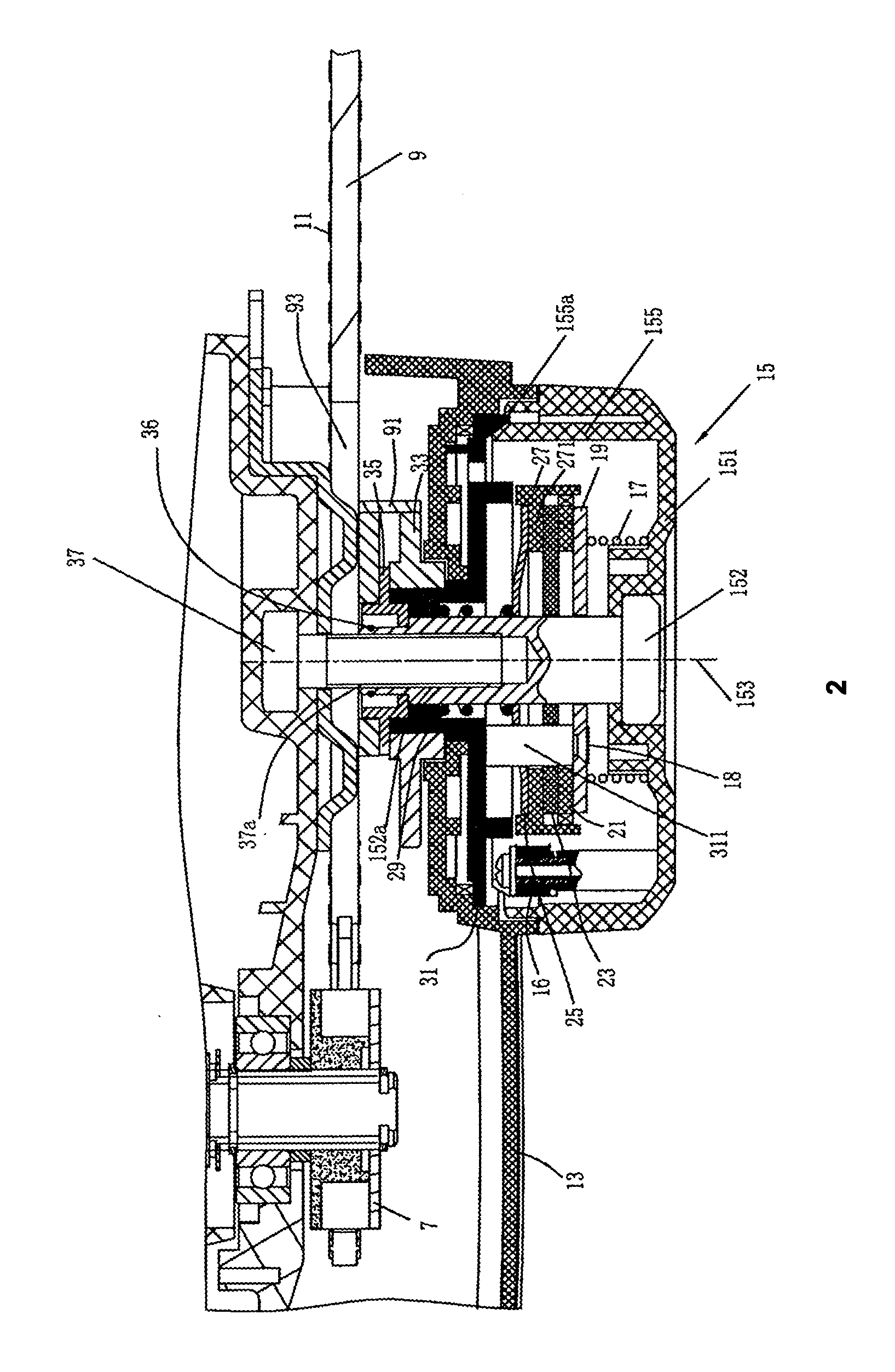

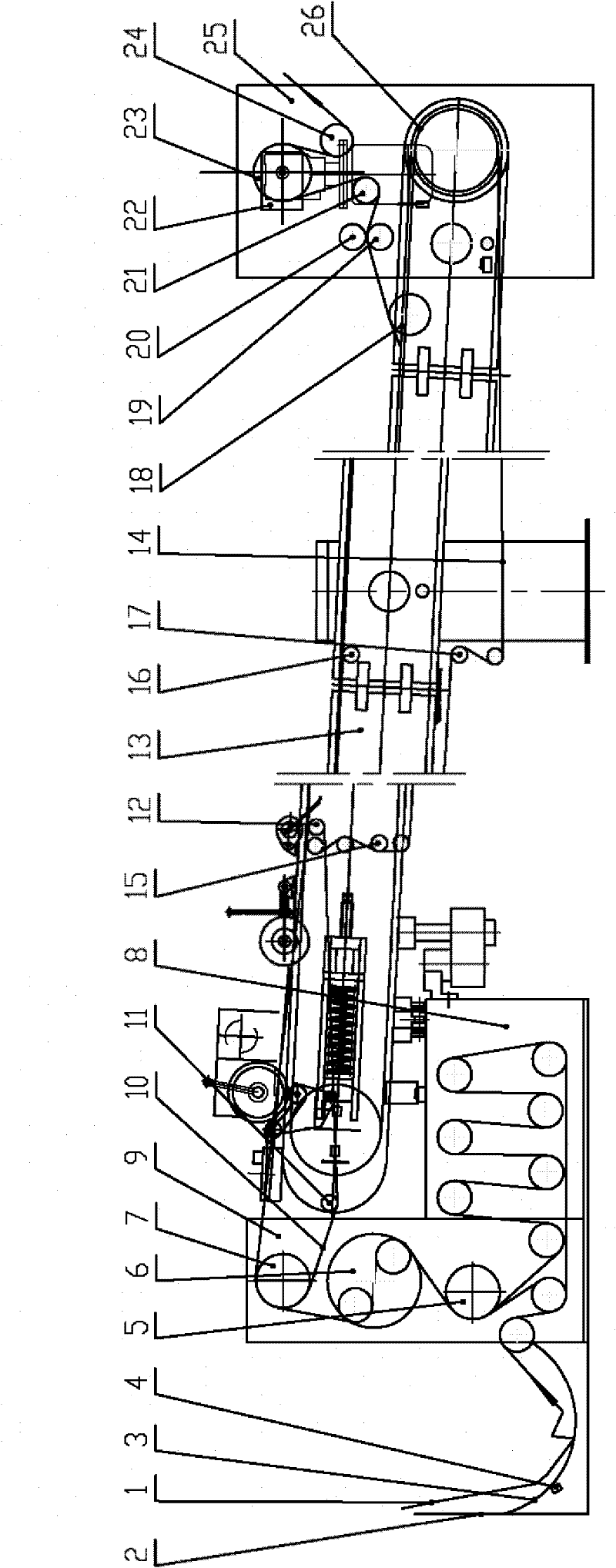

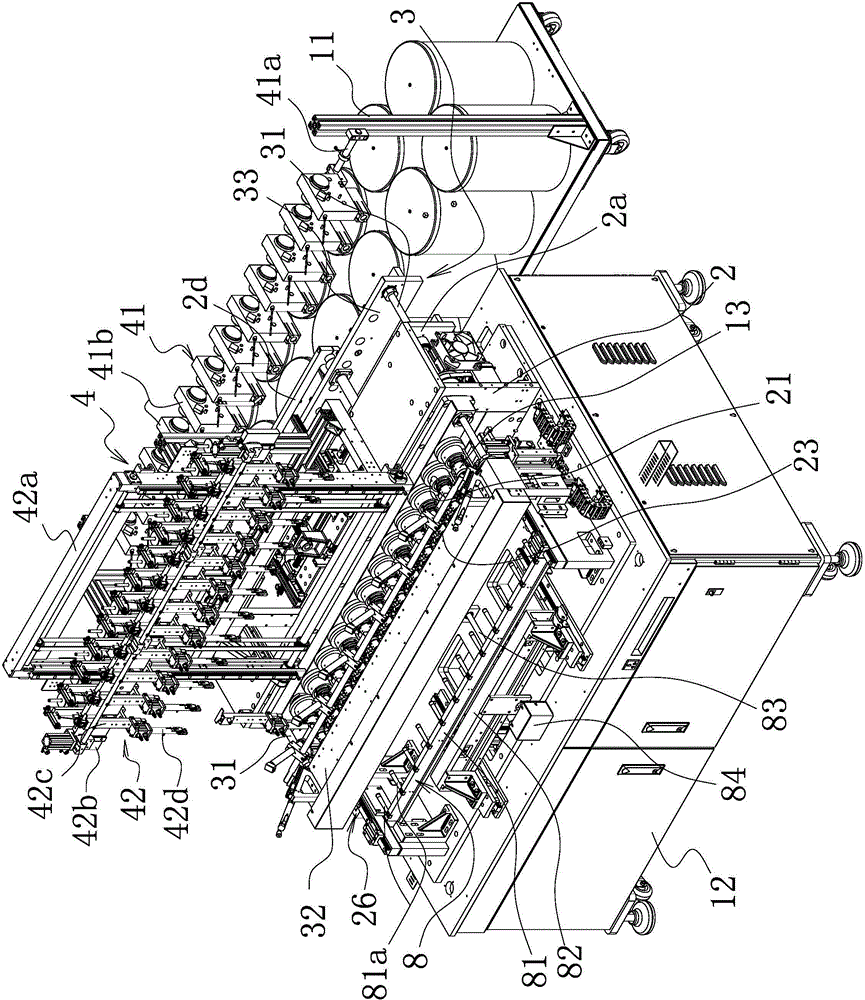

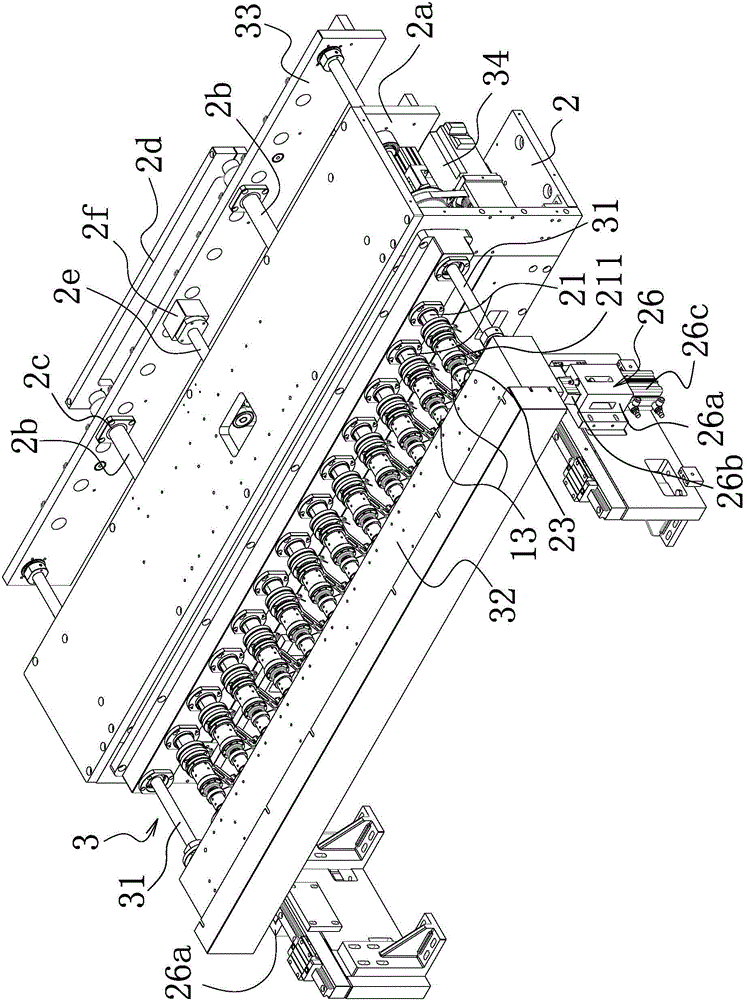

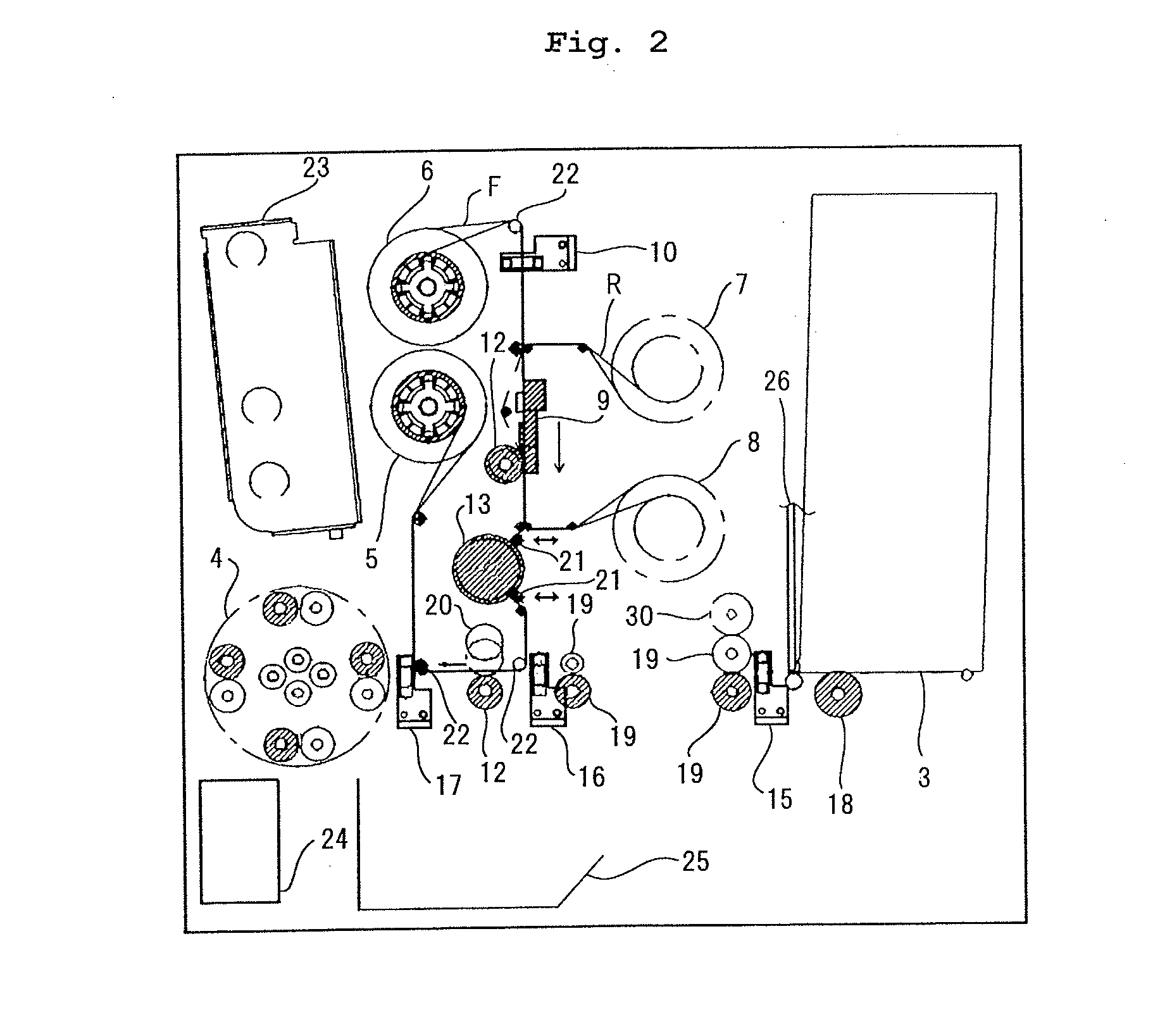

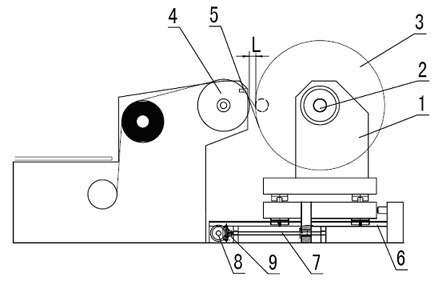

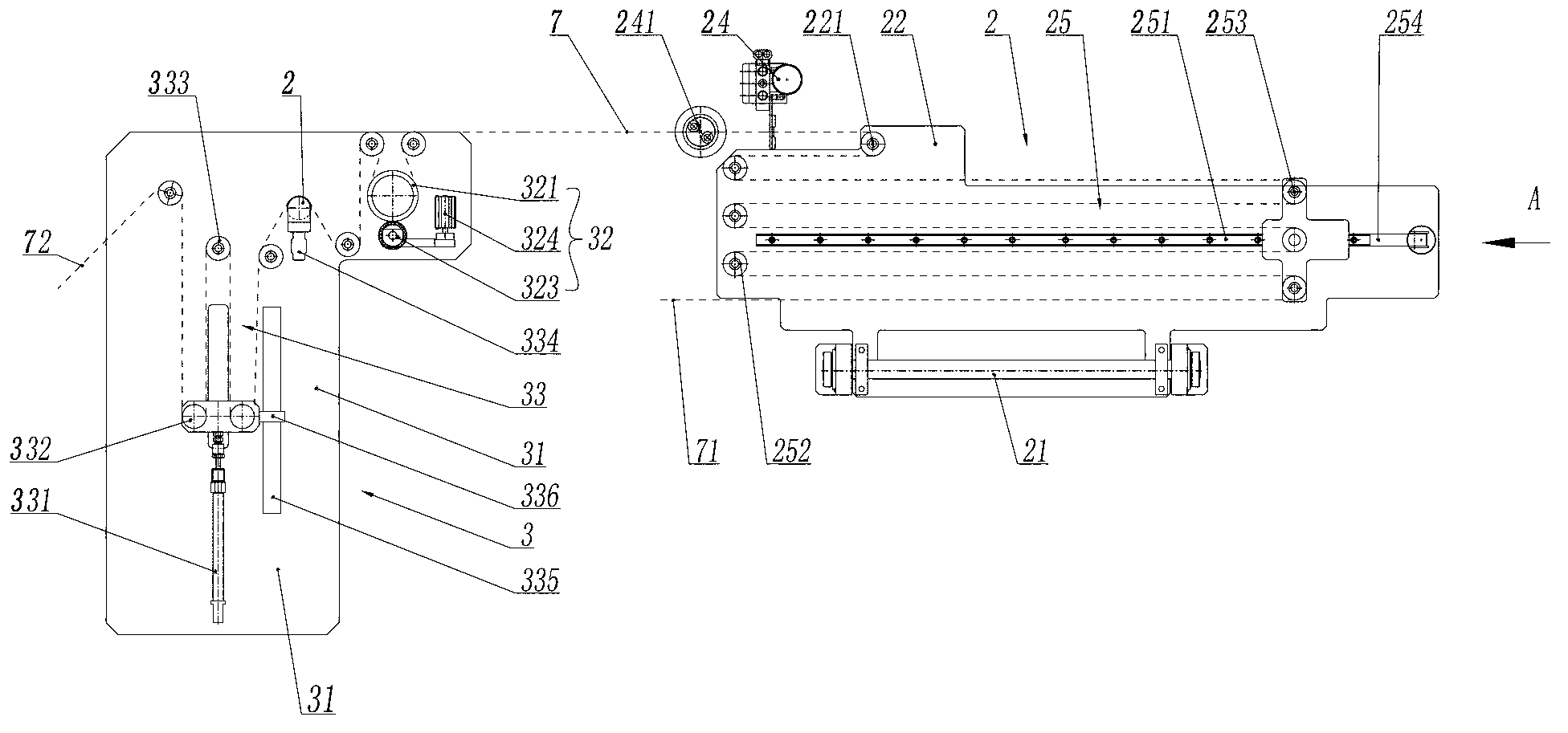

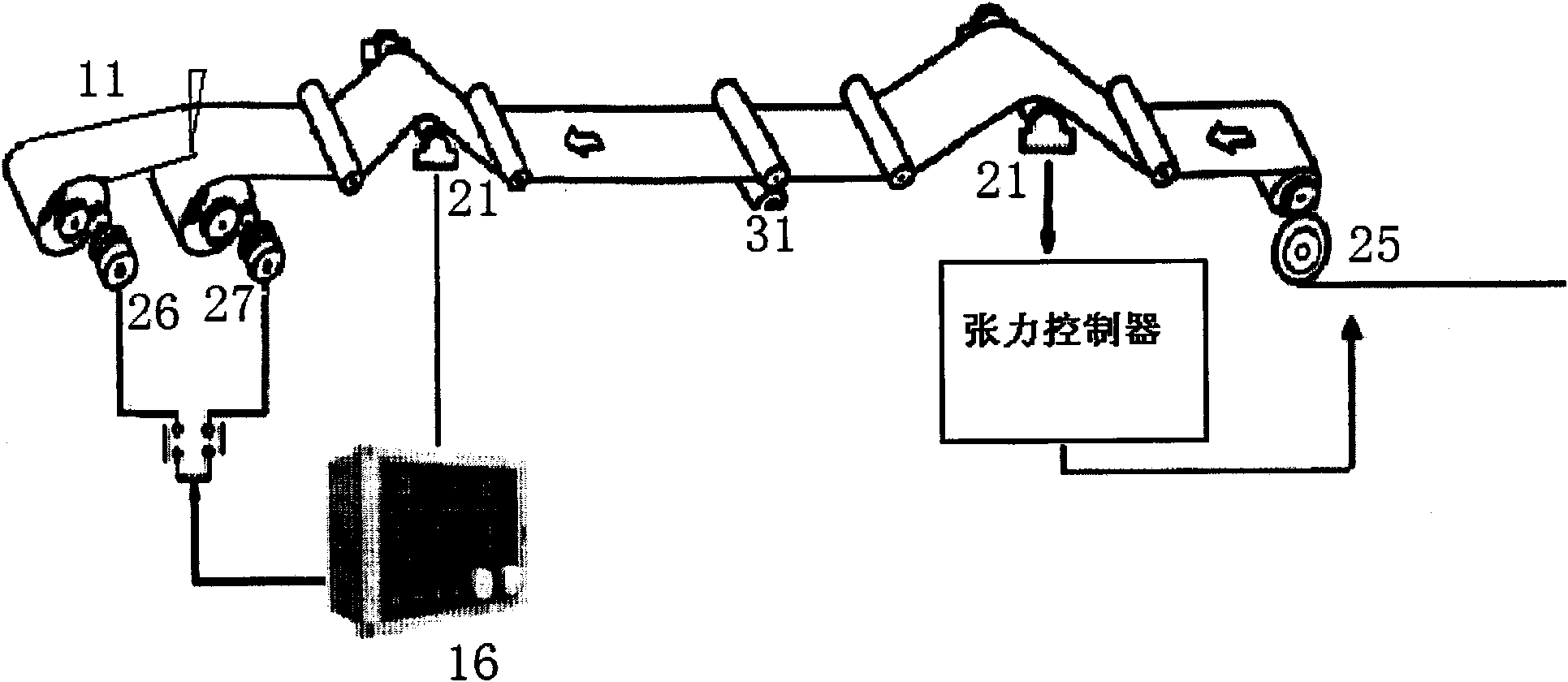

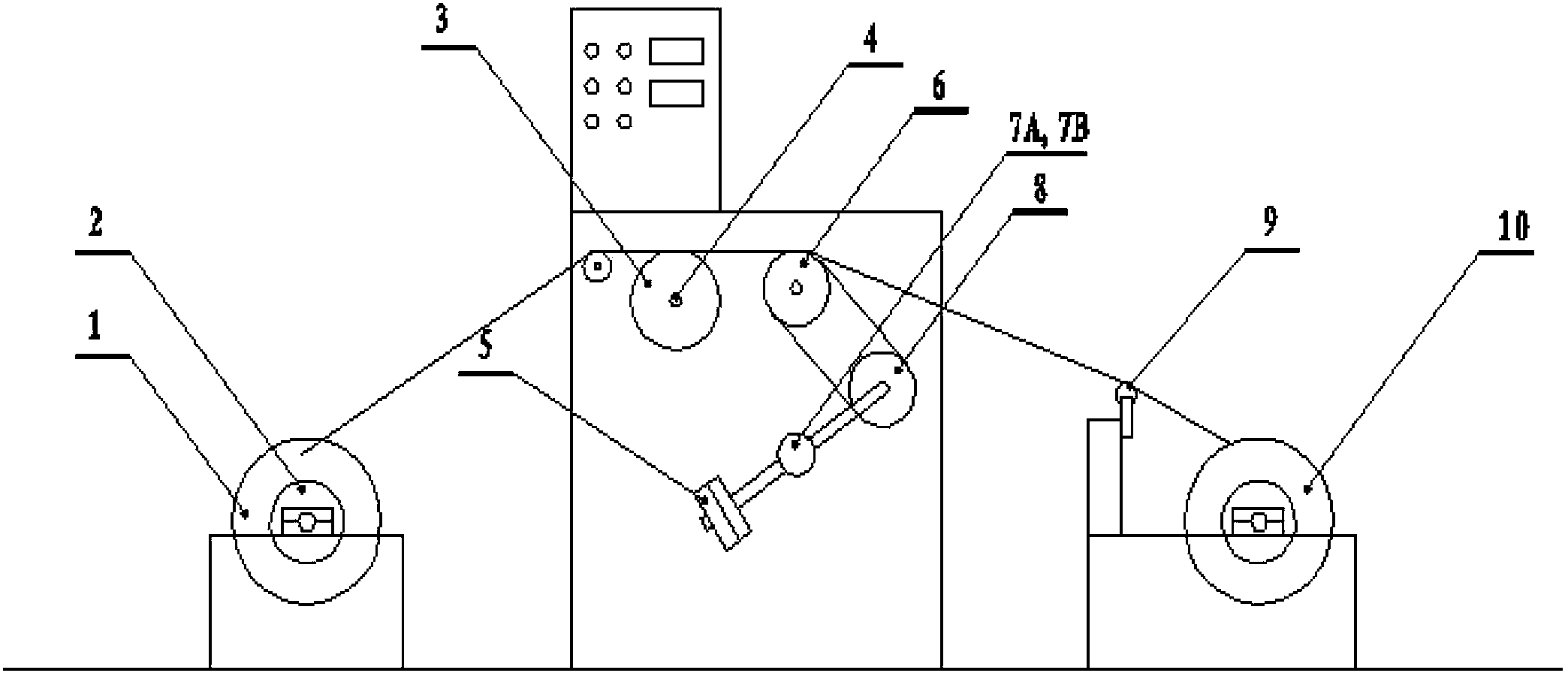

Reeling machine

ActiveCN104009249ATension balanceStable tensionPrimary cell manufactureAssembling battery machinesControl engineeringMachine

The invention discloses a reeling machine which comprises a rack assembly, an unreeling mechanism, a reeling mechanism, a feeding mechanism, a rubberizing device and a tension control mechanism, wherein the tension control mechanism comprises a pole piece deviation correcting device and a driving device which are arranged between the unreeling mechanism and the reeling mechanism; a reeling needle of the reeling mechanism performs a cam motion; the driving device is used for driving a pole piece to be synchronous with the traction of the reeling needle performing the cam motion to the pole piece and simultaneously preventing the unreeling of the pole piece and an deviation correcting operation from influencing the tension of the pole piece. According to the reeling machine, the stable tension control is effectively realized.

Owner:SHENZHEN YINGHE TECH

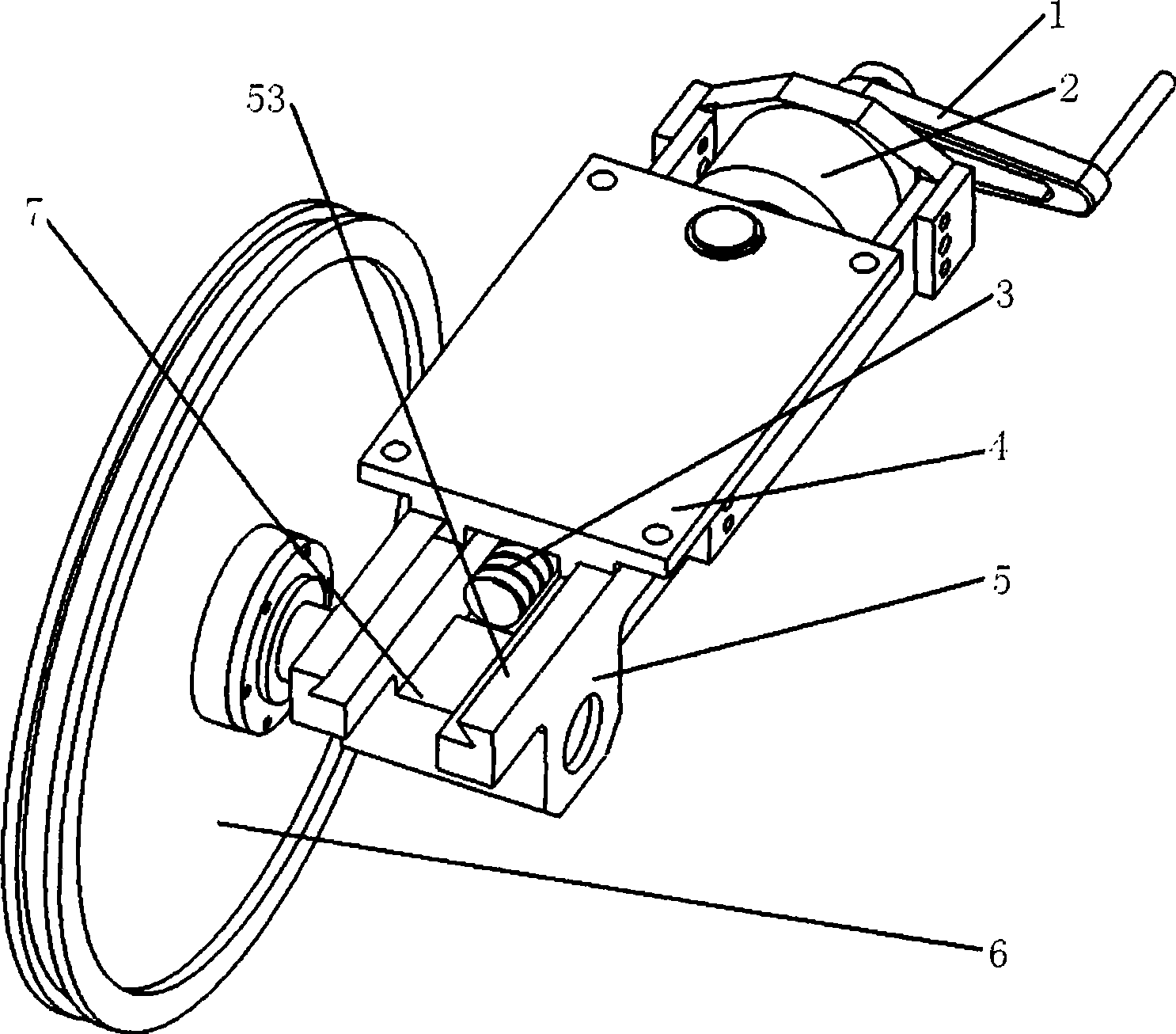

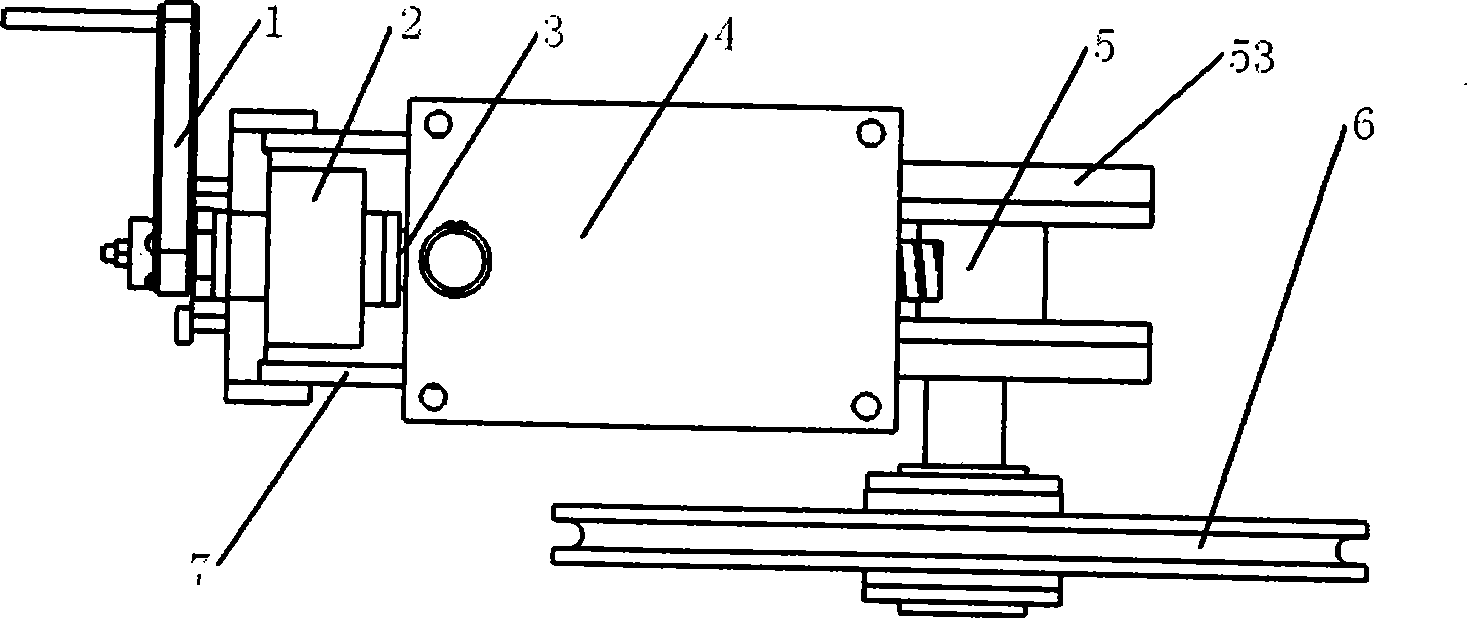

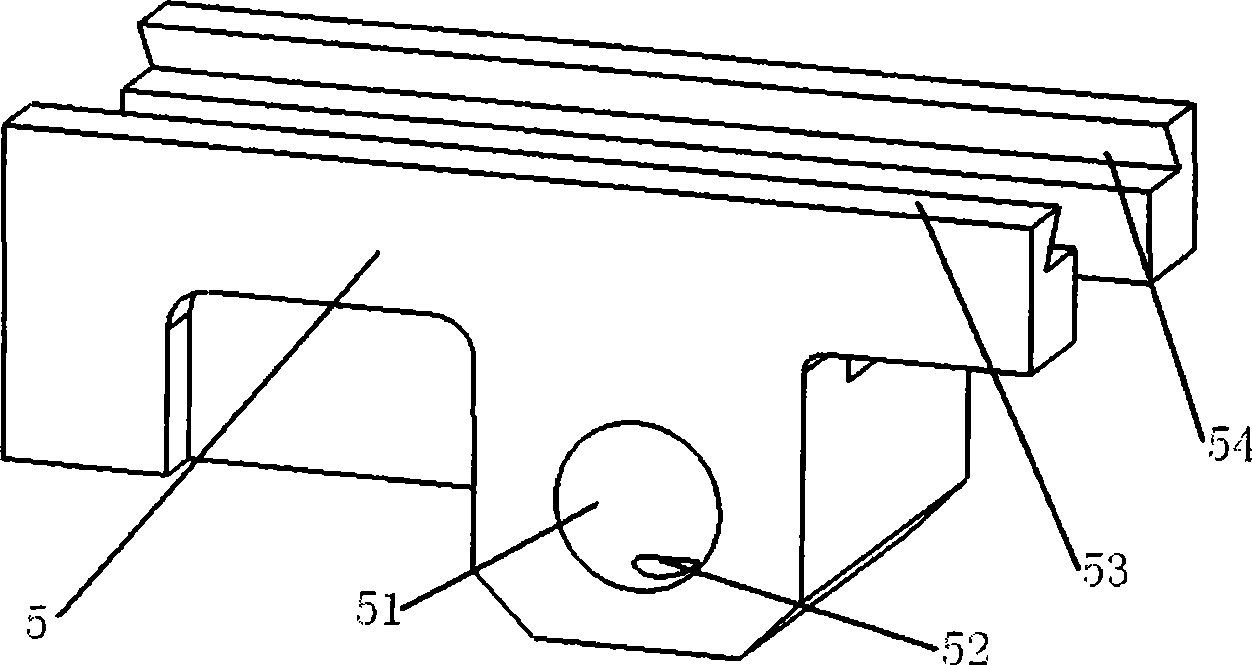

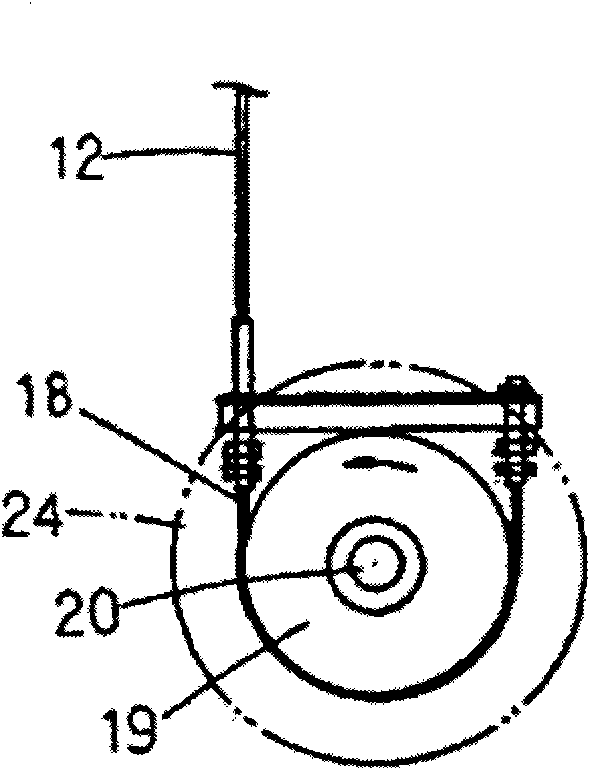

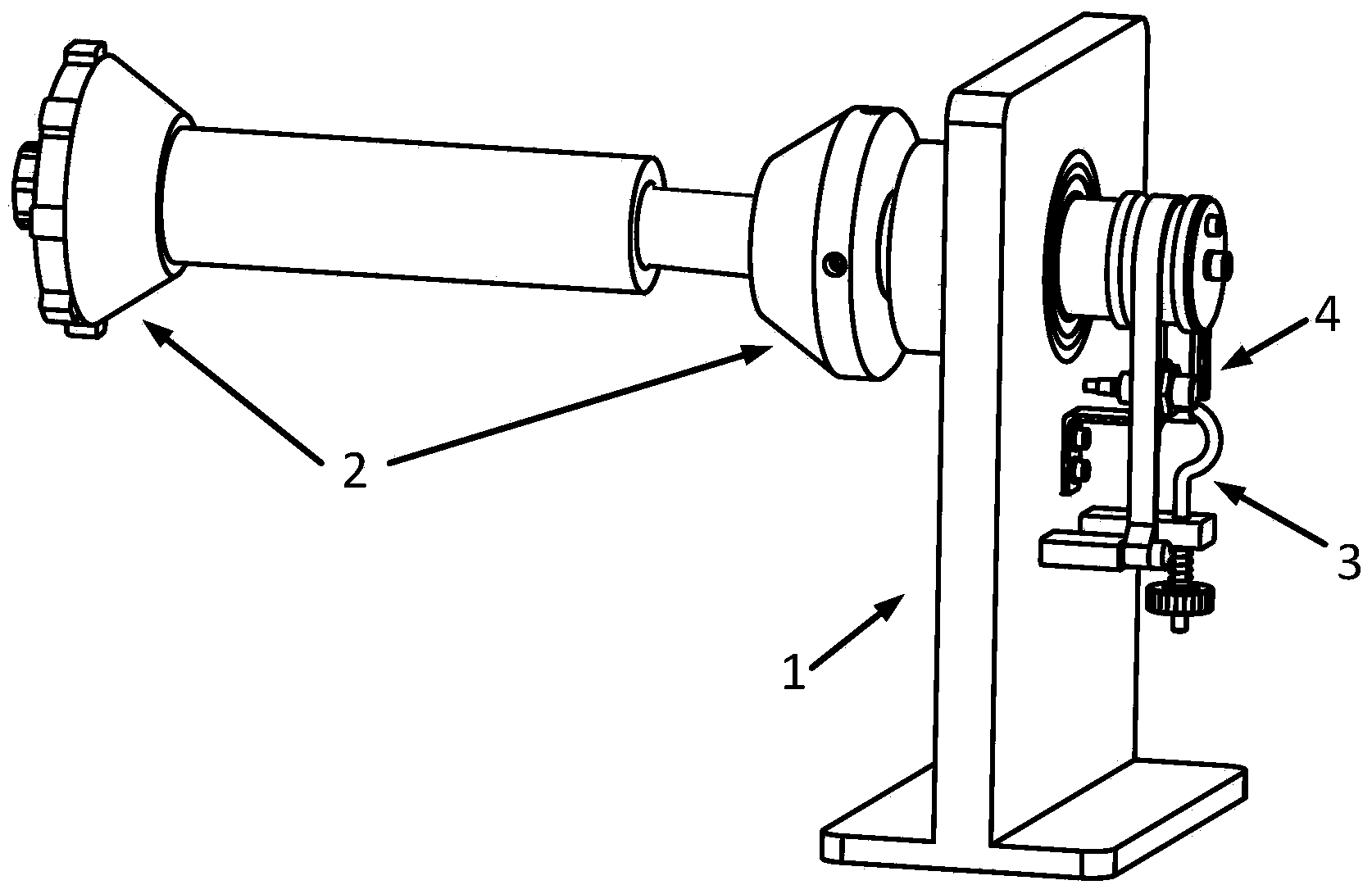

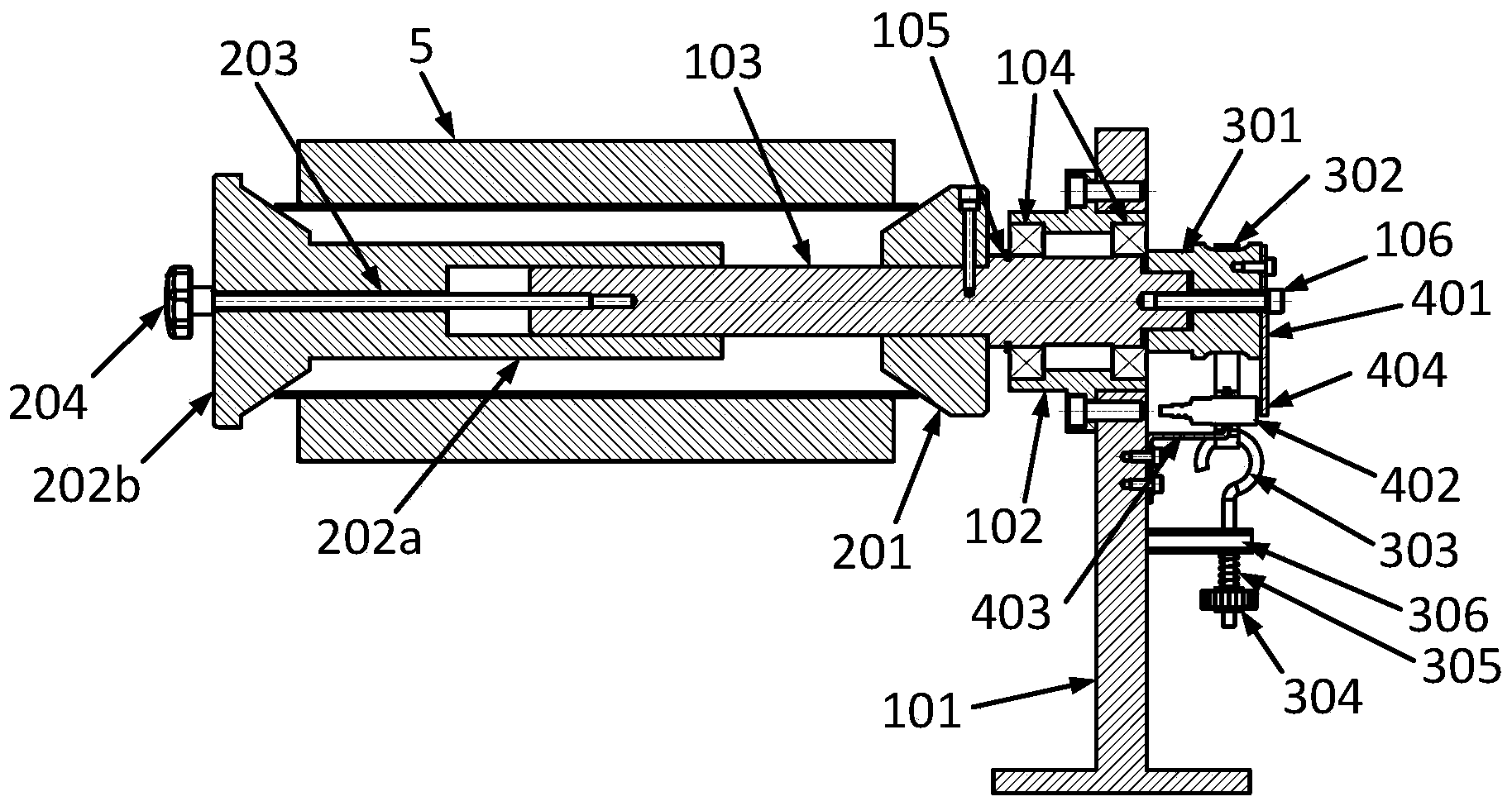

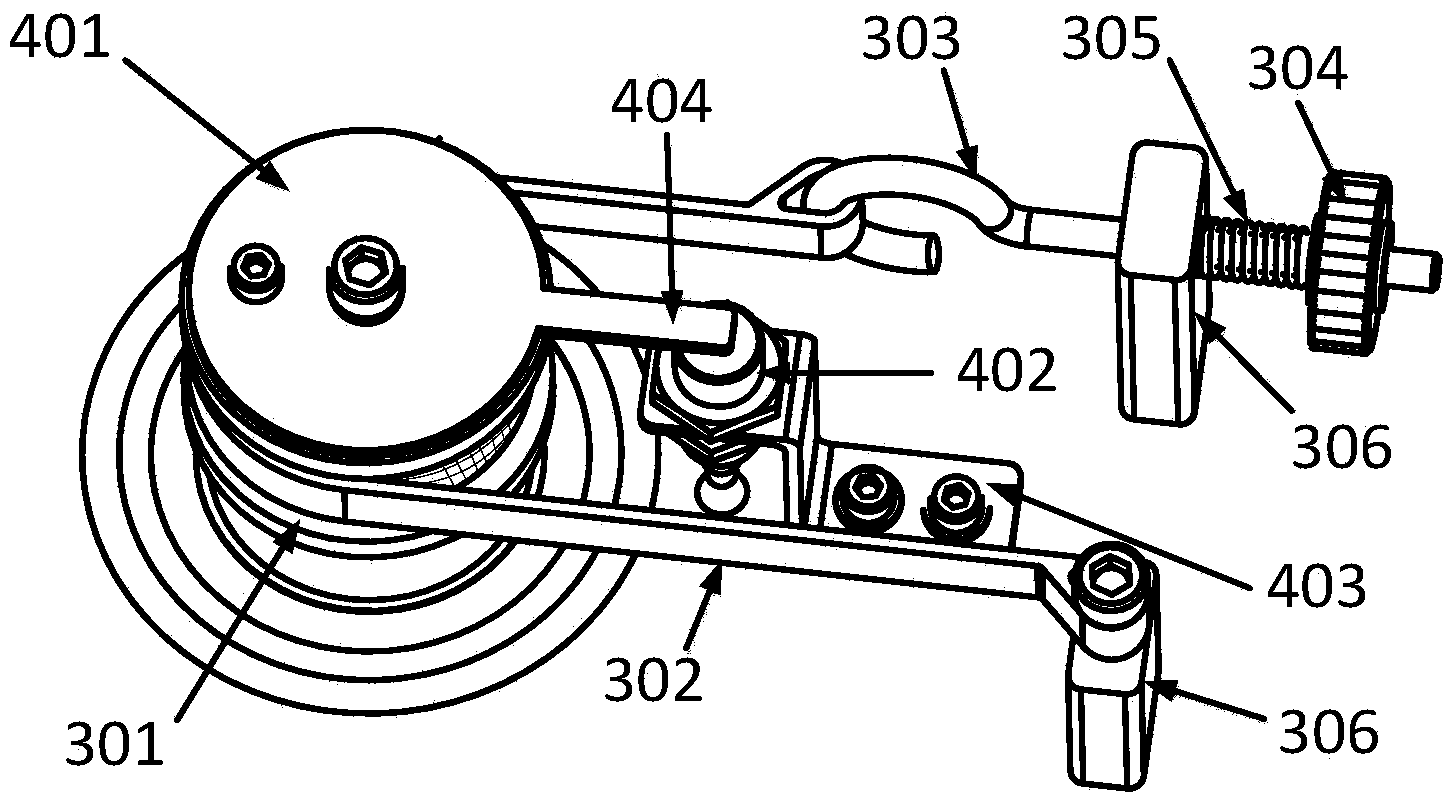

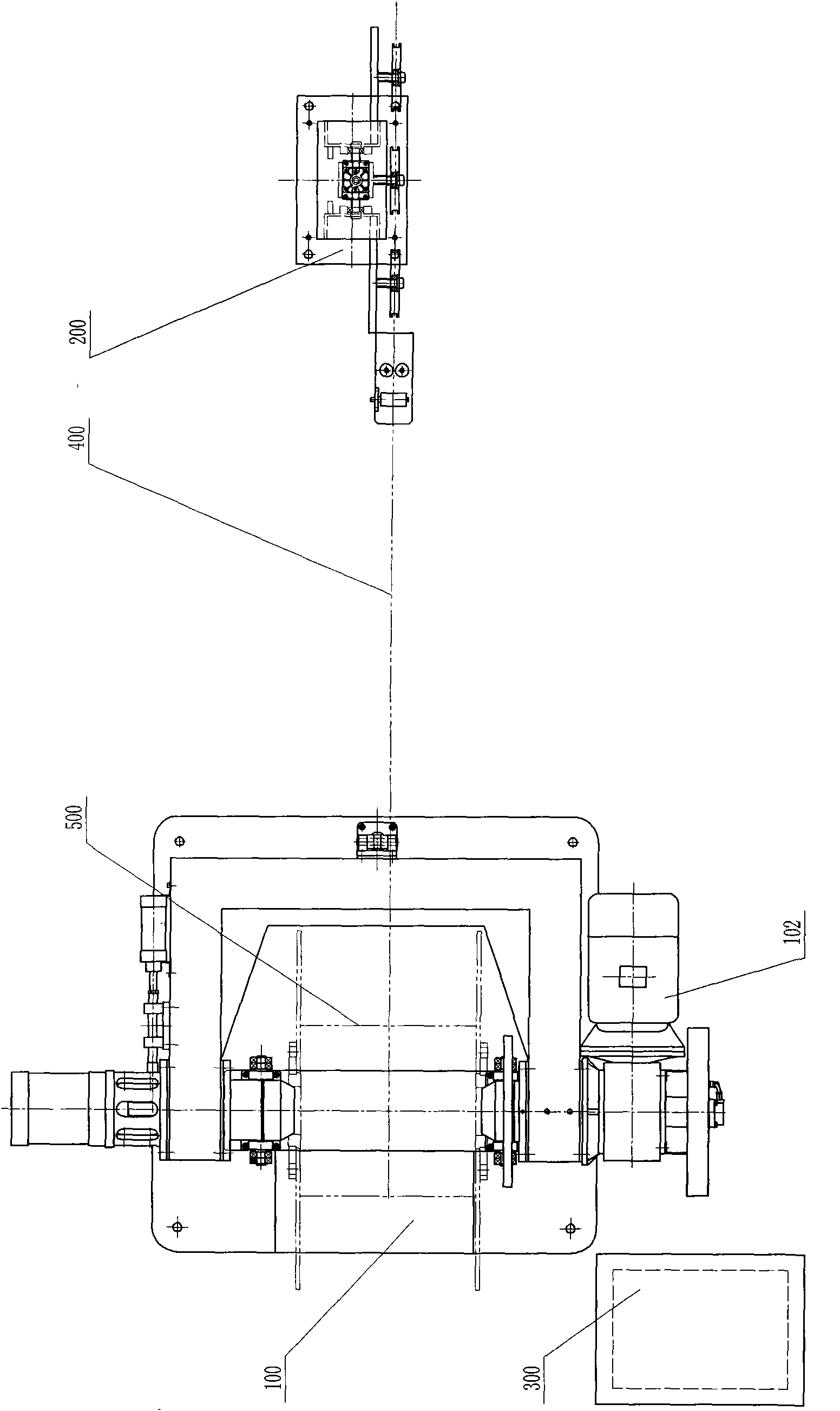

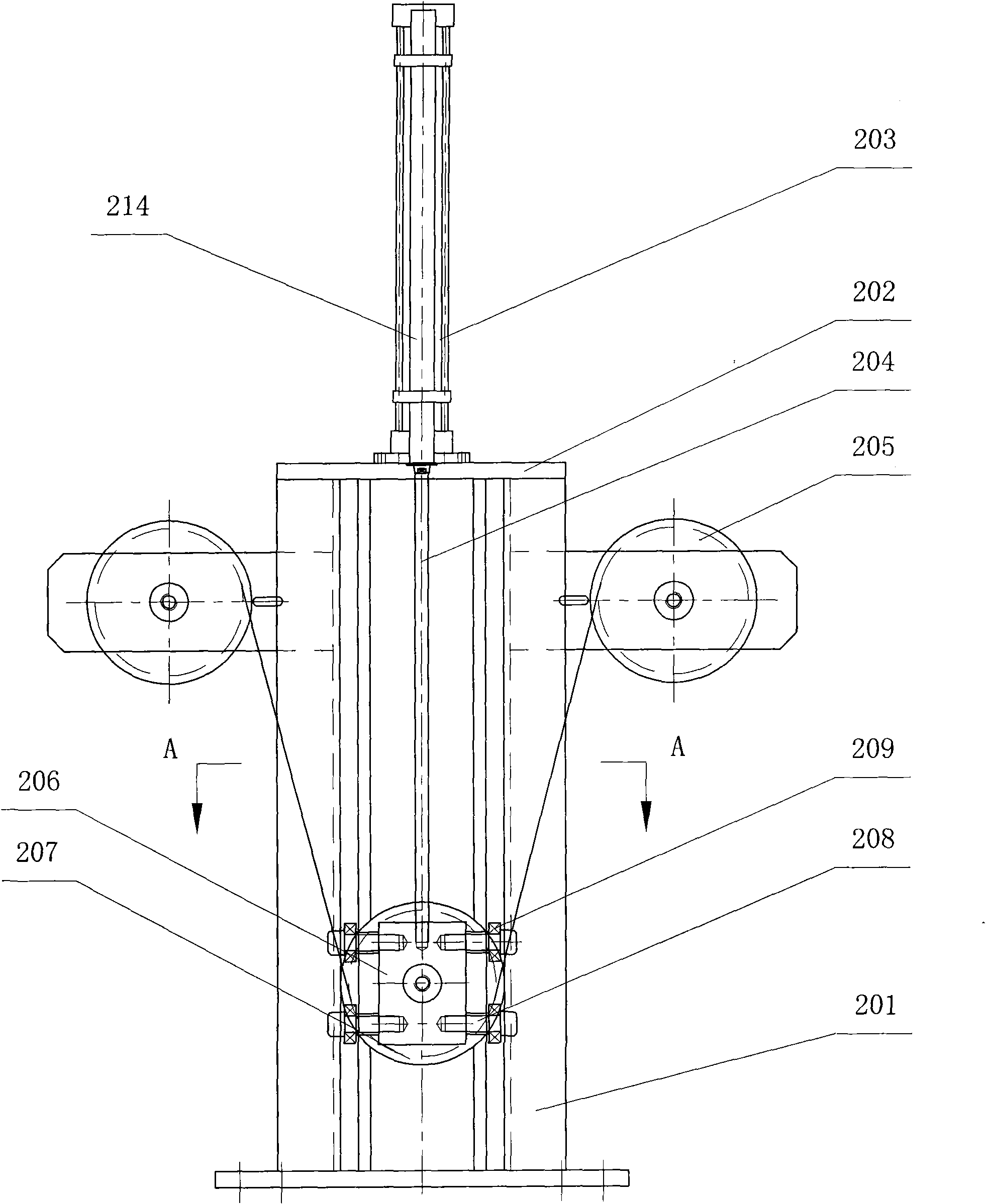

Tension device of underwater diamond rope saw

InactiveCN101468409AStable tensionEasy to assemble and disassembleMetal sawing devicesStone-like material working toolsMulti materialDiamond wire saw

The invention relates to a tensioning device of an underwater diamond wire saw, which comprises a tensioning wheel, a tensioning wheel axle seat, a tensioning force detection mechanism, an adjustment handle, a screw rod and a base, wherein the inner side surface of the base is in slide fit with the tensioning wheel axle seat, while the outer side surface is connected together with a frame of the diamond wire saw; the screw rod is positioned inside the tensioning wheel axle seat, and one end of the screw rod passes through the tensioning wheel axle seat to be connected and fixed with the adjustment handle; one end of the tensioning wheel axle seat is provided with an axle seat hole for the tensioning wheel axle seat to pass through so as to be positioned; and the tensioning force detection mechanism is sleeved on the screw rod and is positioned at one end of the tensioning wheel axle seat away from the axle seat hole. The tensioning device can ensure the initial tensioning force of a wire saw string bead wire, stable tensioning force during machining and convenient assembly and disassembly of the string bead wire; moreover, the tensioning device carries out realtime monitoring and controls the radial feeding speed of the string bead wire through a tension sensor, thereby ensuring safe, smooth, efficient and accurate cutting operation; therefore, the tensioning device can meet the requirements of large-diameter or multi-material filled pipes for carrying out cutting operation.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Door hinge structure for refrigerator

InactiveUS7111363B2Simplified door hinge structureSmoothly keep a refrigerator door openLighting and heating apparatusHingesEngineeringTorsion spring

Disclosed herein is a door hinge structure for a refrigerator. The door hinge structure comprises an upper fixture unit which is screwed to a predetermined front upper portion of a refrigerator body, and has an upper hinge pin to be inserted in a top aperture formed at an upper surface of a refrigerator door, an upper hinge unit which is mounted on the upper surface of the door, and has a through opening for allowing a distal end of the upper hinge pin to be slidably inserted therethrough, the upper hinge unit being coupled with the upper fixture unit by making use of a torsion spring so that it is vertically spaced therewith, a lower fixture unit which is screwed to a predetermined front lower portion of the body, and has a lower hinge pin to be inserted in a bottom aperture formed, at a lower surface of the door, a lower hinge unit which is mounted on the lower surface of the door, and has a through opening for the insertion of the lower hinge pin, and a stopper member which is interposed between the lower fixture unit and the lower hinge unit and is adapted to stop pivotal movement of the door at least one time.

Owner:LOTTE ALUMINUM

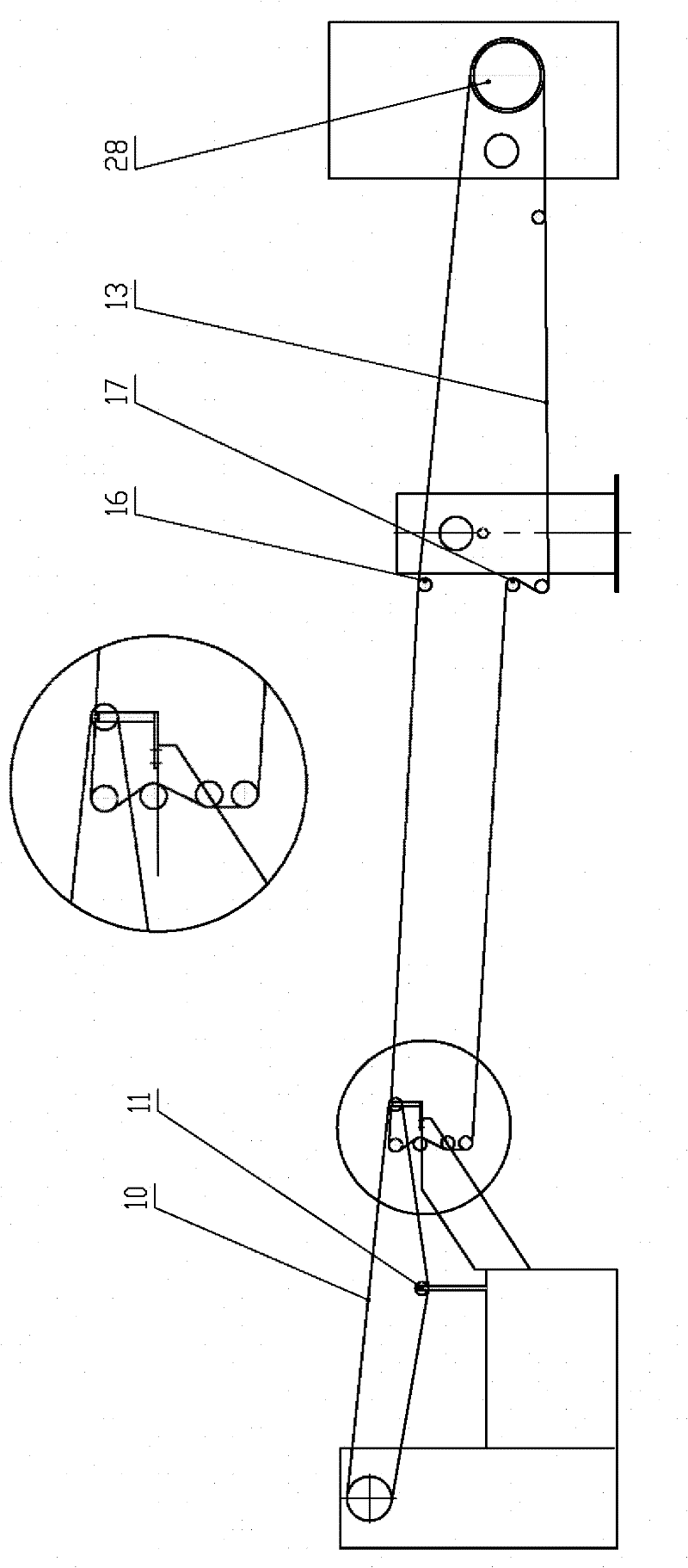

Design method of line unwinding constant tension control device in line winding system

The invention relates to a design method of a line unwinding constant tension control device in a line winding system. A servomotor and a line unwinding wheel are arranged on a frame, the line unwinding wheel is driven by the servomotor, a pulley block which comprises two fixed pulleys and a movable pulley is arranged on the frame behind the line unwinding wheel, the movable pulley is arranged between the two fixed pulleys and is arranged on a swing rod, the swing rod is articulated with the frame, an air cylinder is articulated on the frame, a piston rod of the air cylinder is connected with the swing rod in a driving mode, a tension sensor is arranged on the frame behind the pulley block, lines output by the line unwinding wheel are introduced into the tension sensor by the pulley block, and the lines which pass through the tension sensor are towed to a line winding host machine. The loading force of the air cylinder has a proportional relation with force and a force arm which act on the movable pulley of the swing rod, and the constant tension is ensured in a small angle. When the swing rod is lower than a balance position, inverse voltage is output to control the servomotor to wind the lines; when the swing rod is higher than the balance position, positive voltage is output to control the servomotor to unwinding the lines; and when used, the line unwinding content tension control device has higher stability.

Owner:苏州工业园区慧博自动化技术有限公司

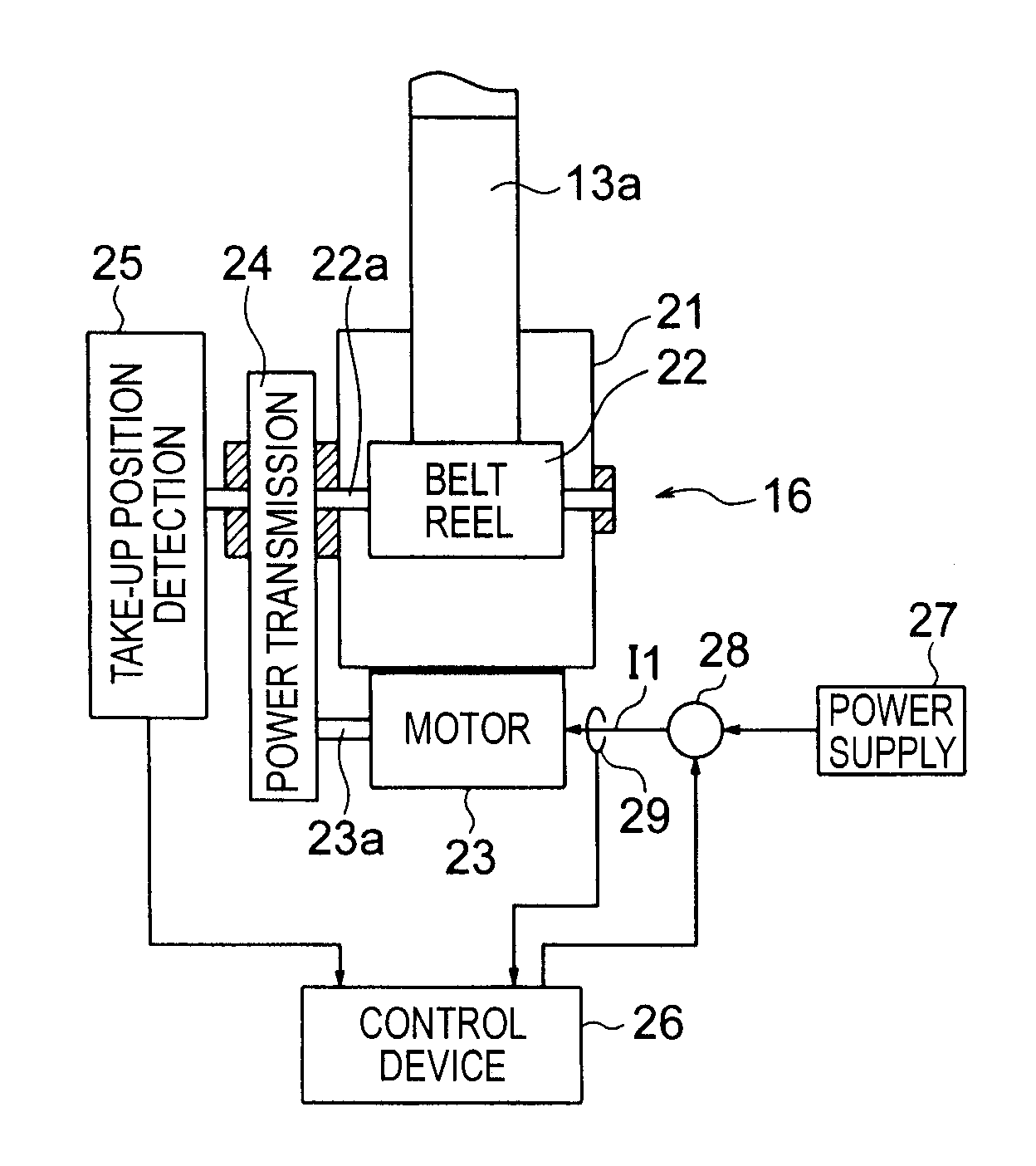

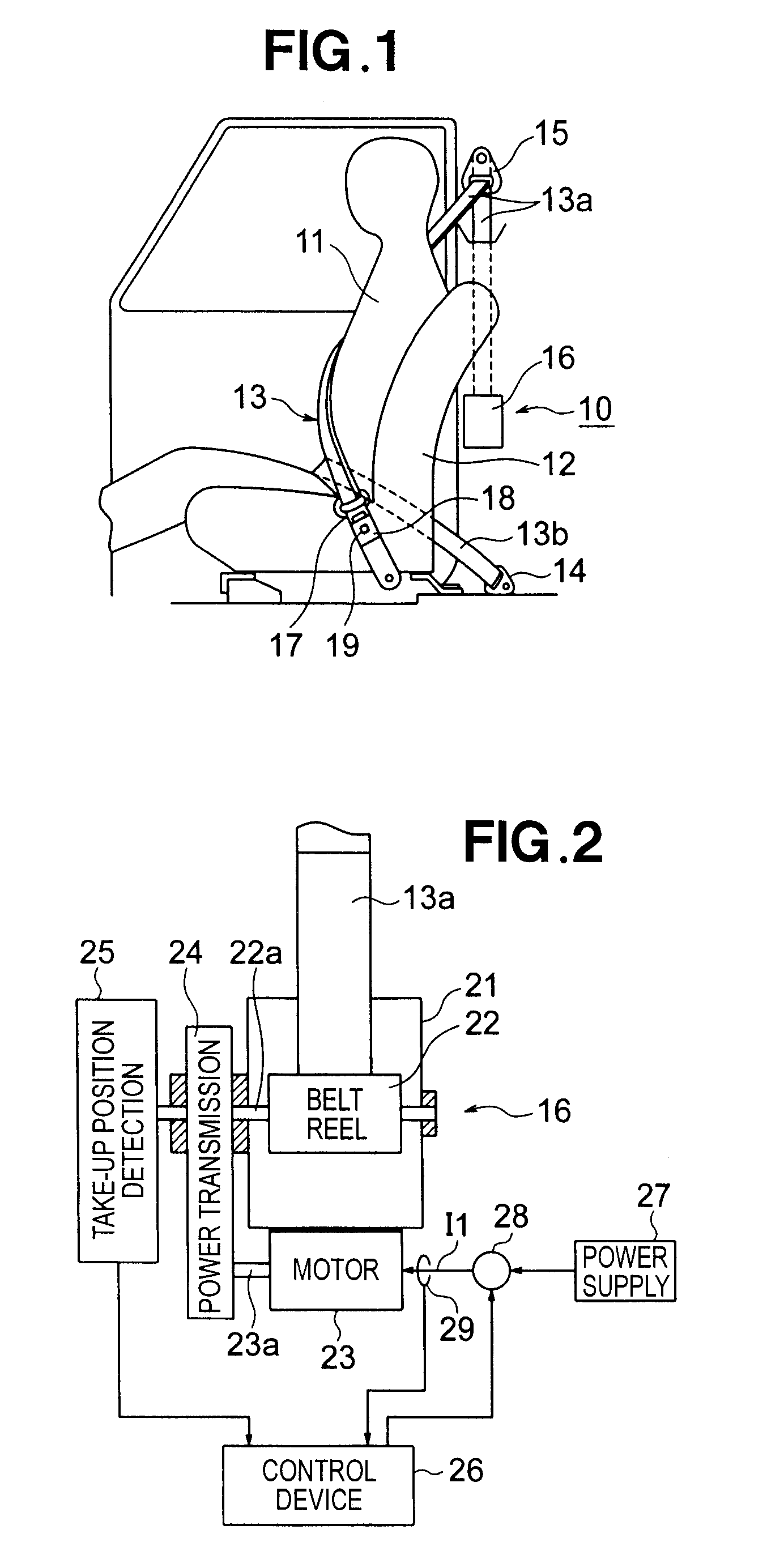

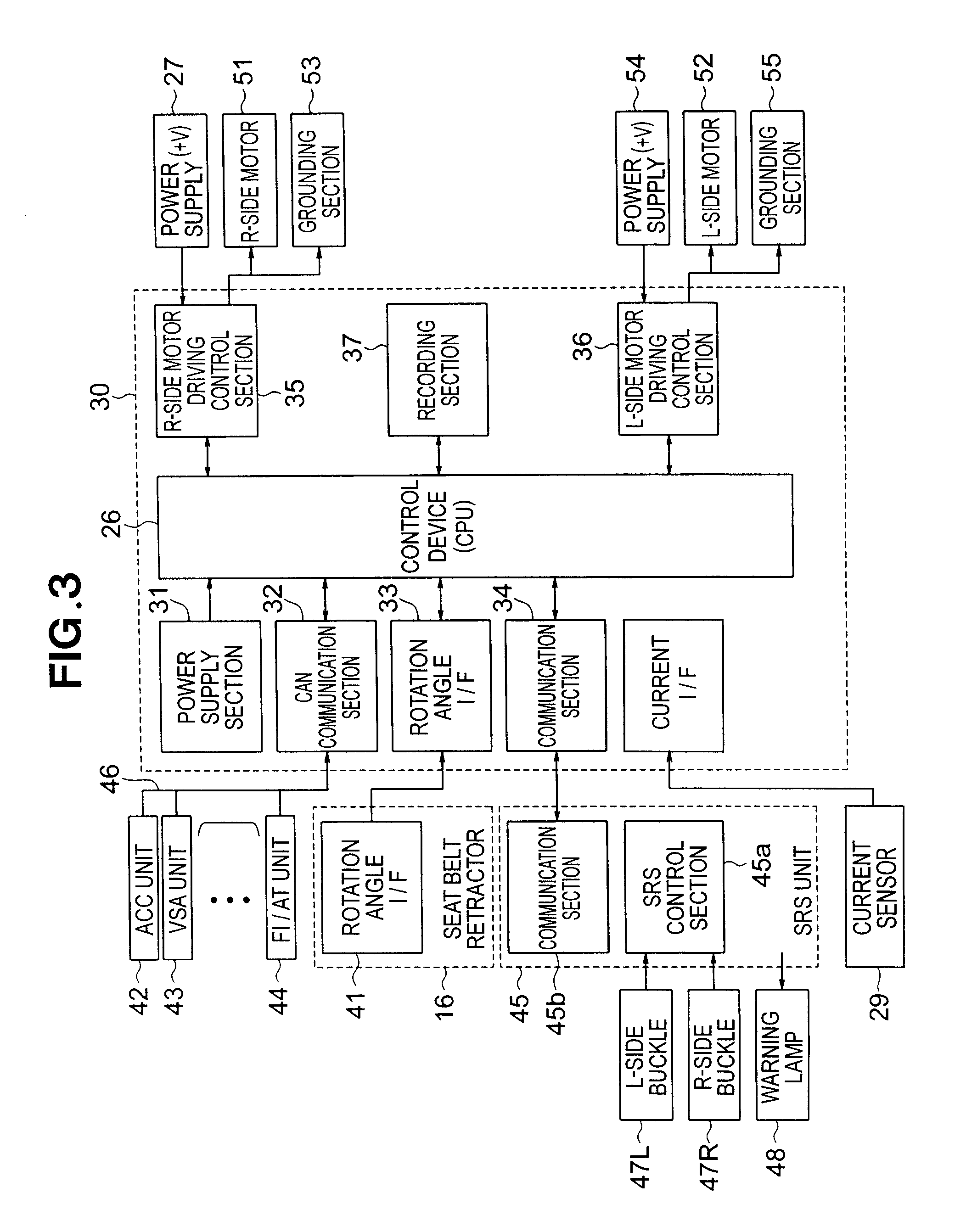

Vehicle seat belt apparatus

ActiveUS20080093833A1Process stabilityImprove comfortBelt retractorsDigital data processing detailsSeat beltBelt safety

A seat belt apparatus includes a belt reel having a belt wound thereon, a motor for driving the reel to take up the belt; a control section for adjusting an amount of electric current supply to the motor to thereby control a belt-taking-up driving force of the motor, a current detection section for detecting the current supplied to the motor, and a rotation detection section for detecting a rotational position of the reel. The control section includes a constant current control section for executing a constant current control mode so that the current supply to the motor takes a target value, and a target current supply value change section for changing the target value when a detection signal from the rotation detection section has satisfied a predetermined condition in the constant current control mode.

Owner:HONDA MOTOR CO LTD

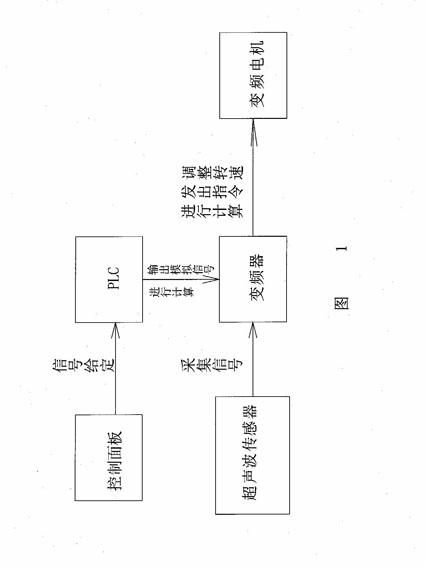

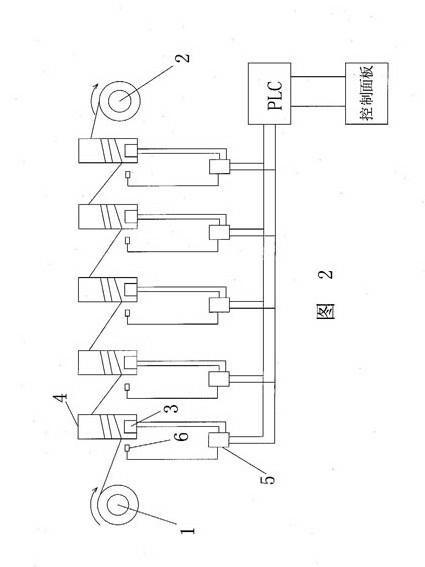

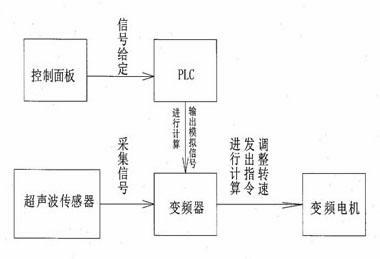

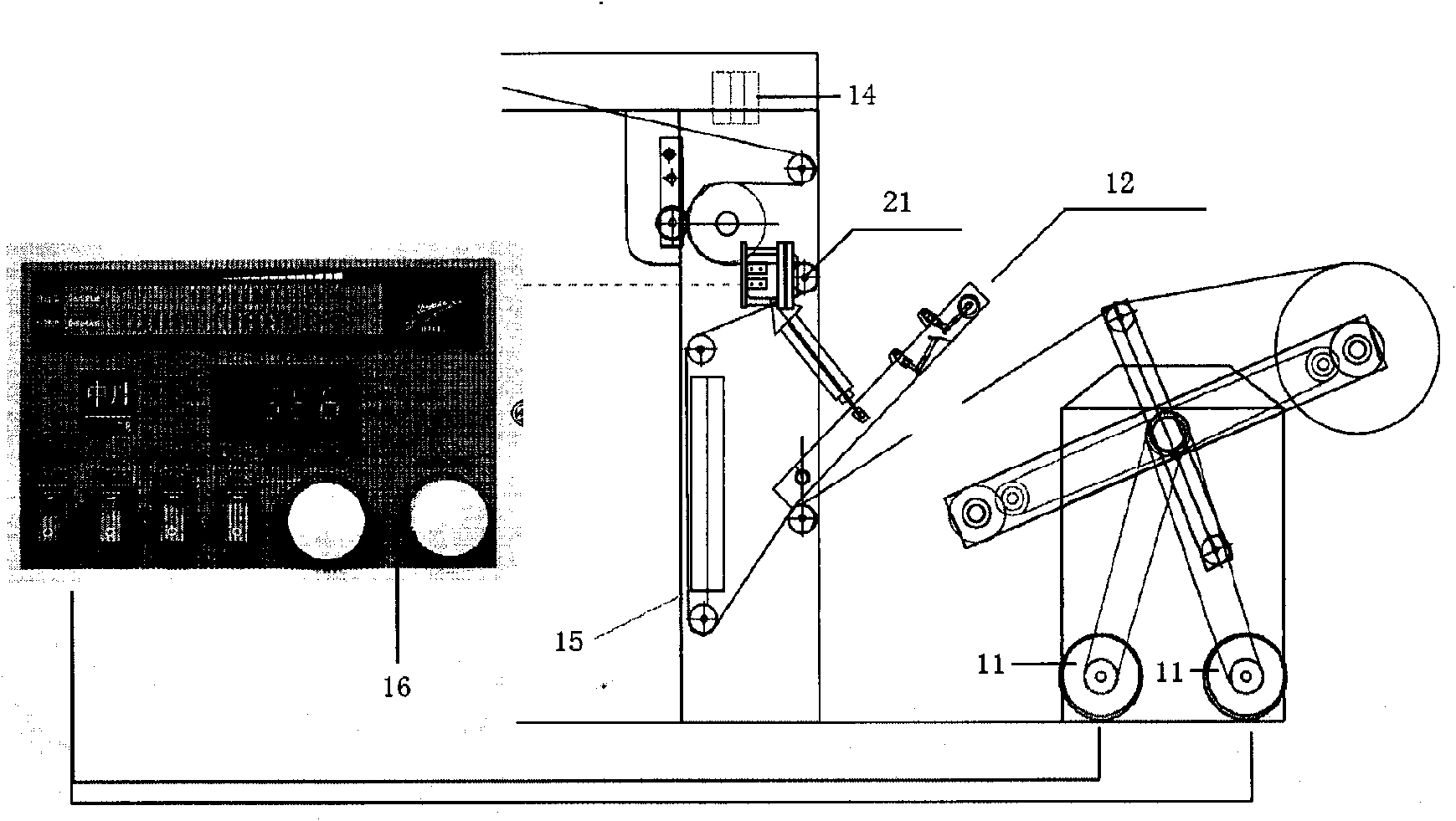

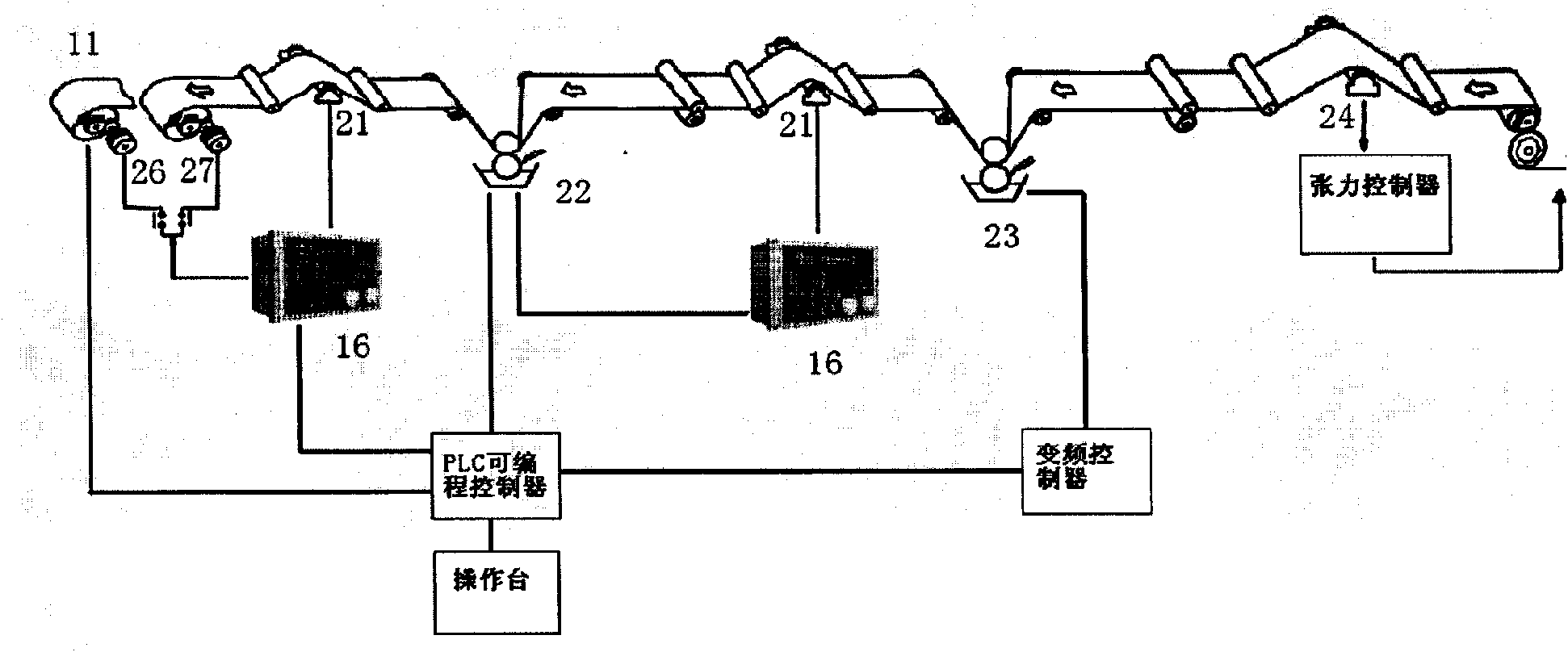

Metal wire tension detection and control device in straight line wire drawing machine

The invention provides a device for conveniently detecting and controlling tension of a metal wire in the wire drawing process, which is used for solving the problem of higher failure rate due to a severe working environment in the conventional tension detection and control device. The technical scheme is that: the front end of the wire drawing machine is provided with a wire unreeling wheel (1), and the tail end of the wire drawing machine is provided with a wire reeling wheel (2) using a variable frequency motor; variable frequency motors (3) are used by wire drawing units and wire reeling units; each wire drawing unit comprises a revolving drum (4), a frequency converter (5), a mechanical braking device and the like; an analog signal of a set speed is connected to a programmable logic controller (PLC) control unit and is output to the input end of the frequency converter (5) by the PLC control unit; meanwhile, an ultrasonic sensor (6) is arranged between every two wire drawing units; and the ultrasonic sensors (6) are used for transmitting corresponding data signals to serve as feedback signals for control according to variation in distances from transmitting ends and receiving ends of the ultrasonic sensors (6) to an object to be measured so as to adjust the rotation speeds of the variable frequency motors (3).

Owner:YUXI YUBEI METALWORK

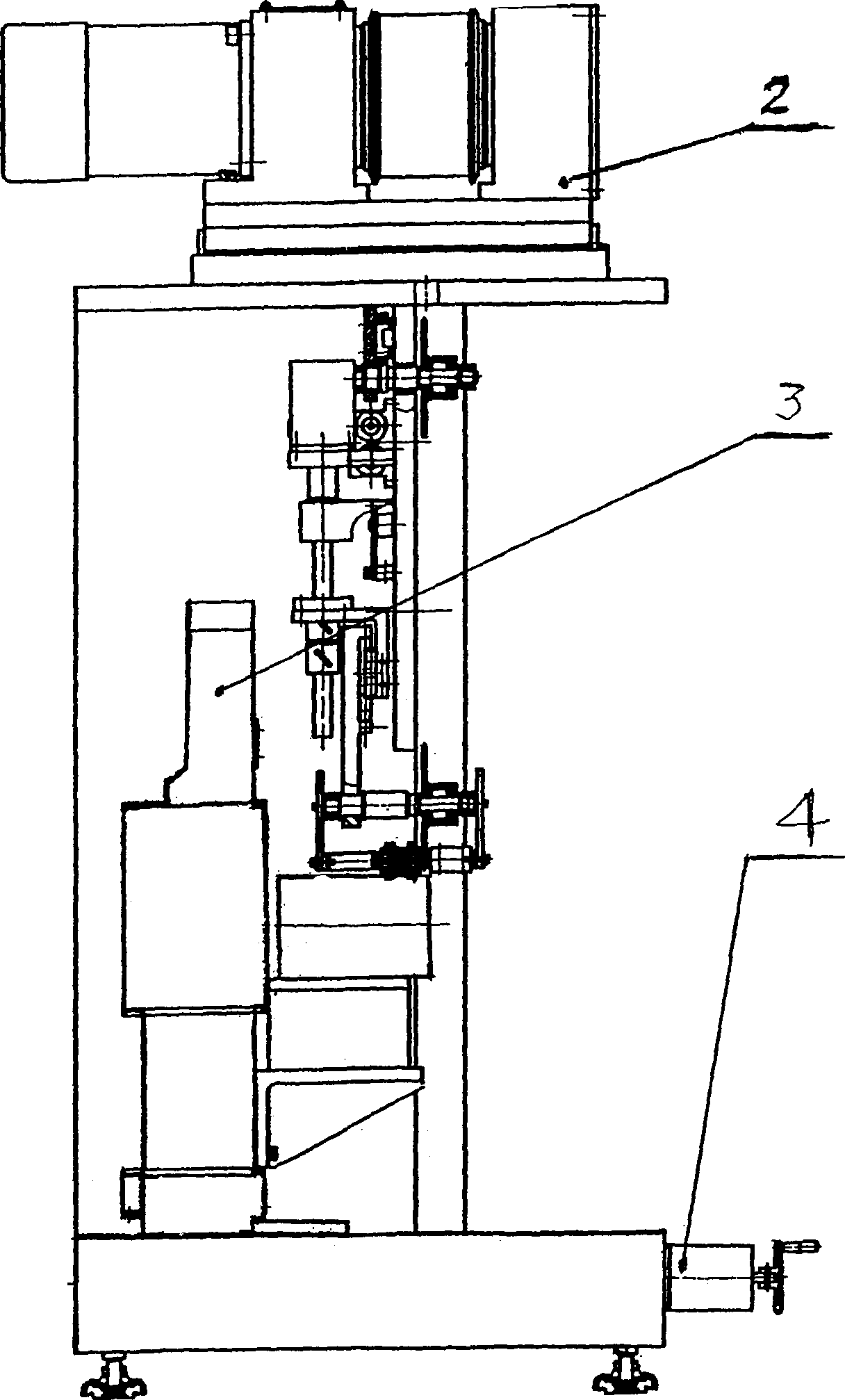

Automatically controlled high-precision crystal wire electrode cutting machine

InactiveCN1387979AImprove rigidityAvoid deformationFine working devicesMetal working apparatusEngineeringMechanical engineering

The present invention relates to cutting equipment and is especially one computerized efficient and high-precision wire electrode cutting machine. The cutting machine consists of frame, winding cylinder driven by one DC motor to rotate in either right direction or reverse direction, Z-axis bench, Y-axis bench, tension mechanism with one pair of tension wheels controlled by one pair of micro cylinders to support the cutting wire, oscillating mechanism with one pair of oscillating support wheels and fixture. The cutting machine is used mainly for cutting silicon wafer, quartz glass, ceramic, jewel, magnesia and other hard and fragile material.

Owner:沈阳科晶设备制造有限公司

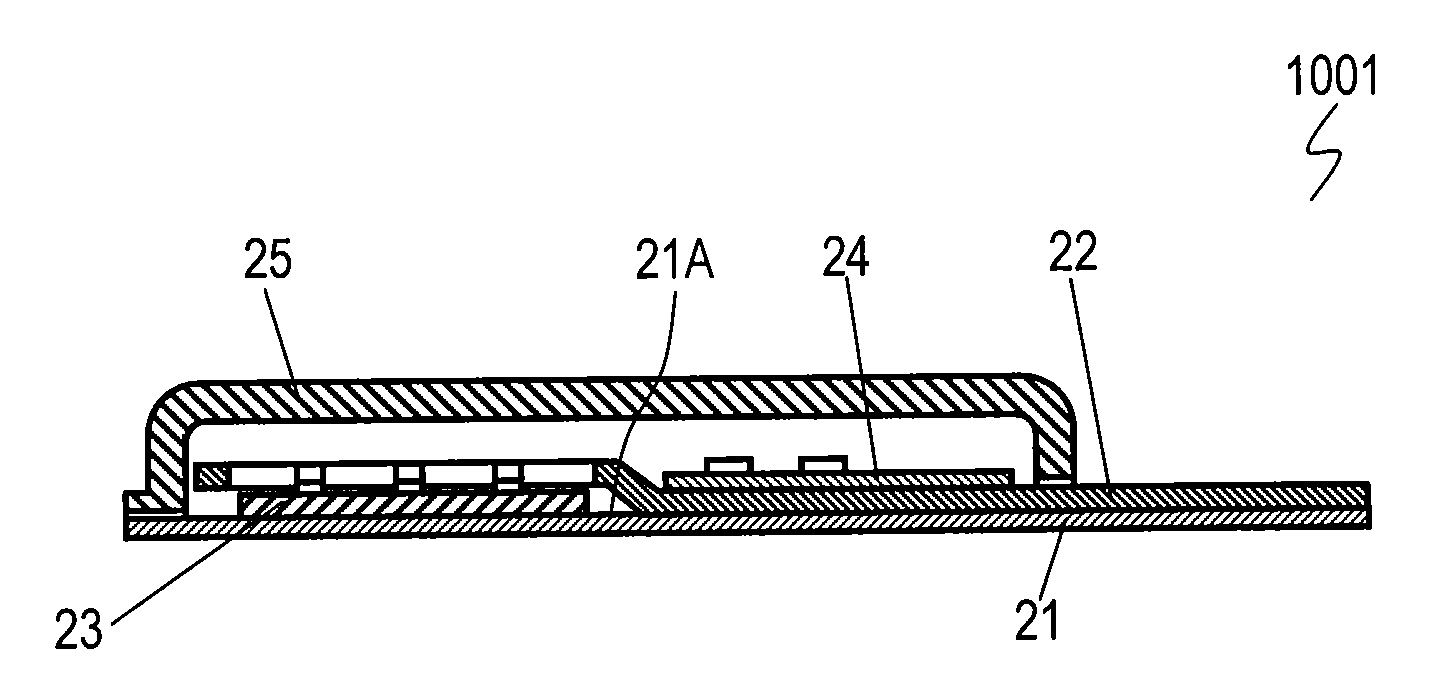

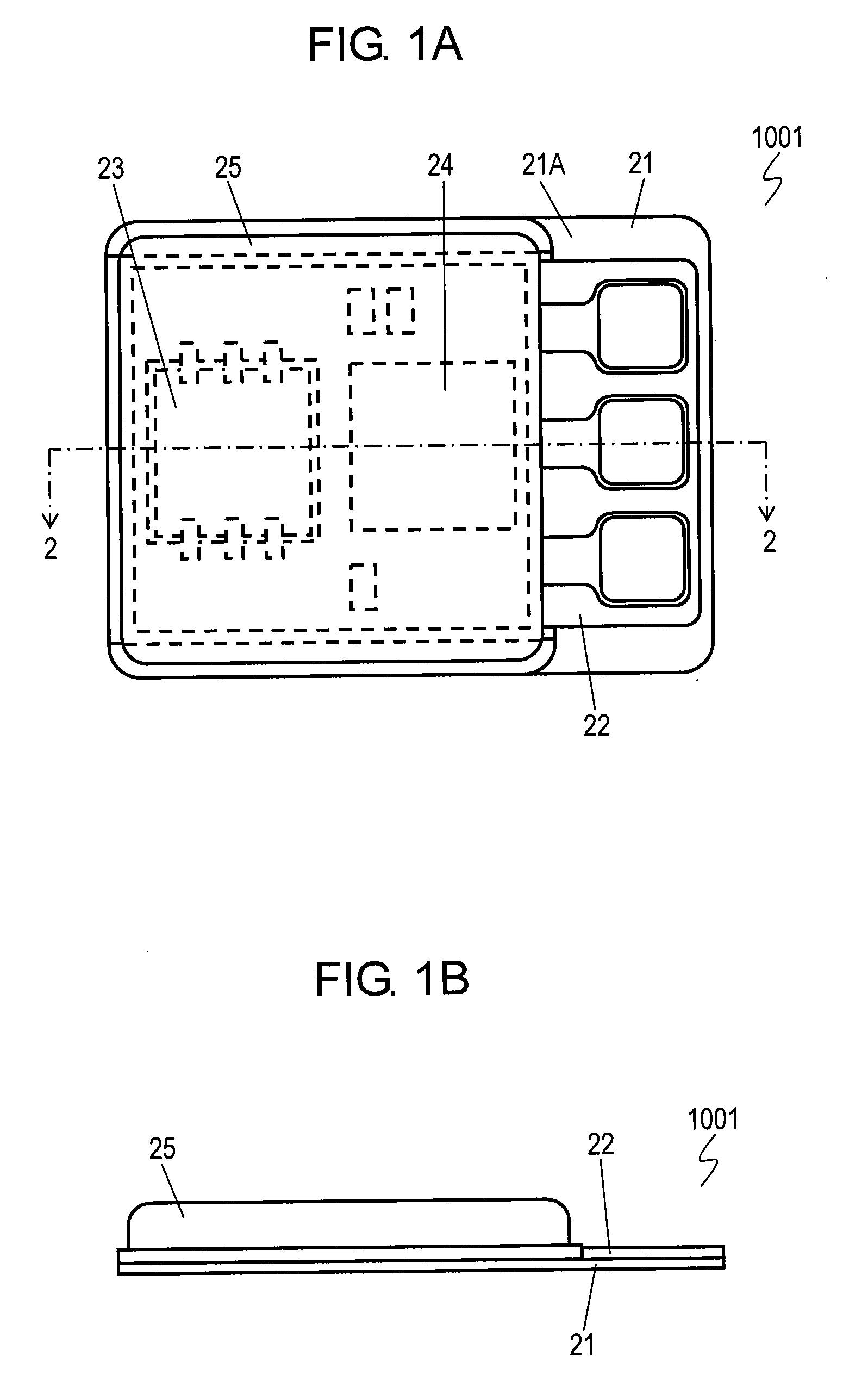

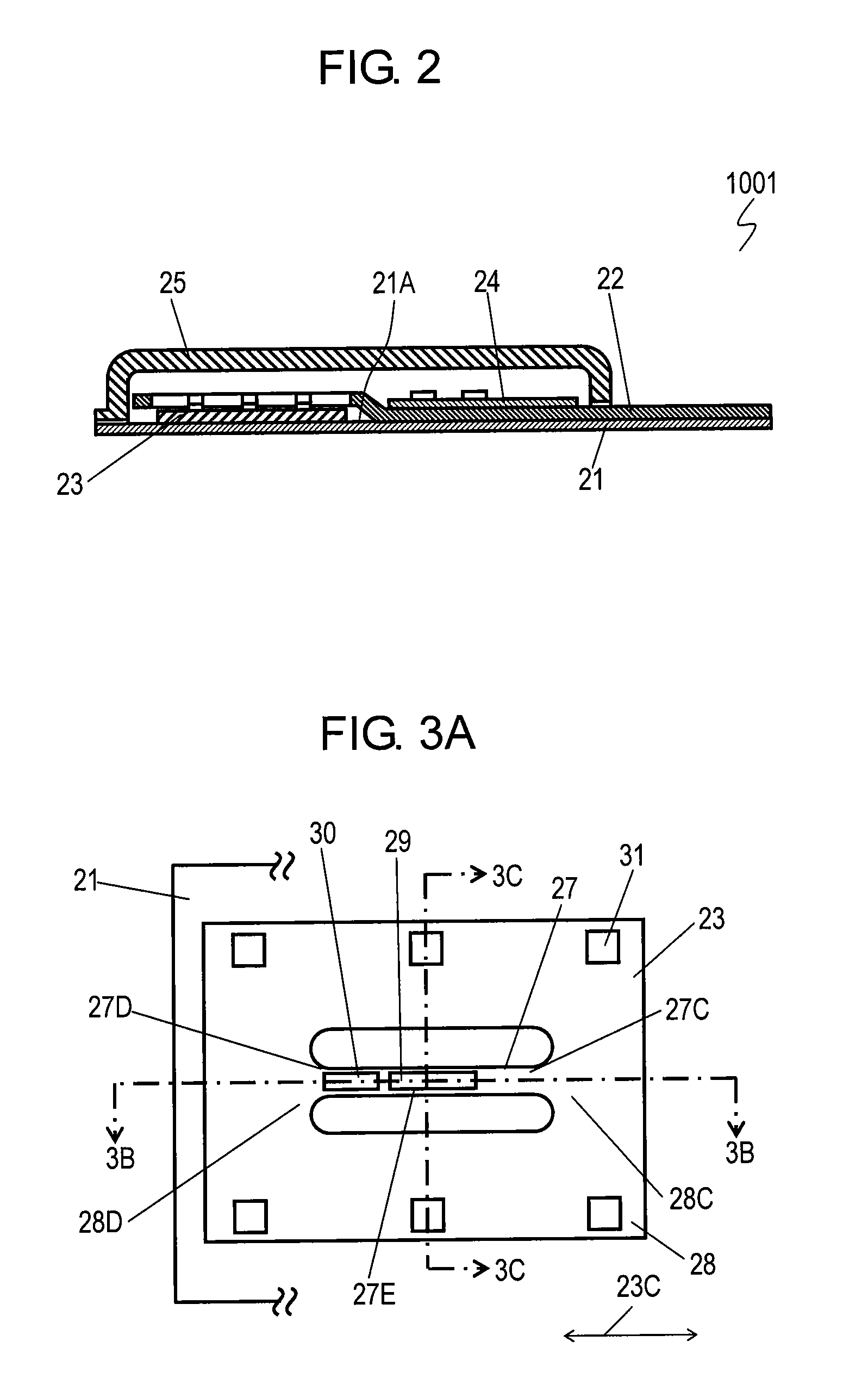

Physical quantity sensor

InactiveUS20120000288A1Strain stabilityStable tensionVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesAcousticsPhysical quantity

A physical quantity sensor includes a deformable body in which strain occurs in response to a stress applied thereto, a vibrator vibrating with a frequency according to the strain or with an amplitude according to the strain, and a processor processing a signal output from the vibrator. The vibrator is mounted to the deformable body such that the strain transmits to the vibrator. The processor is bonded to the deformable body such that the strain does not substantially transmit to the processor. This physical quantity sensor can stably detects strain and tension acting on an object.

Owner:PANASONIC CORP

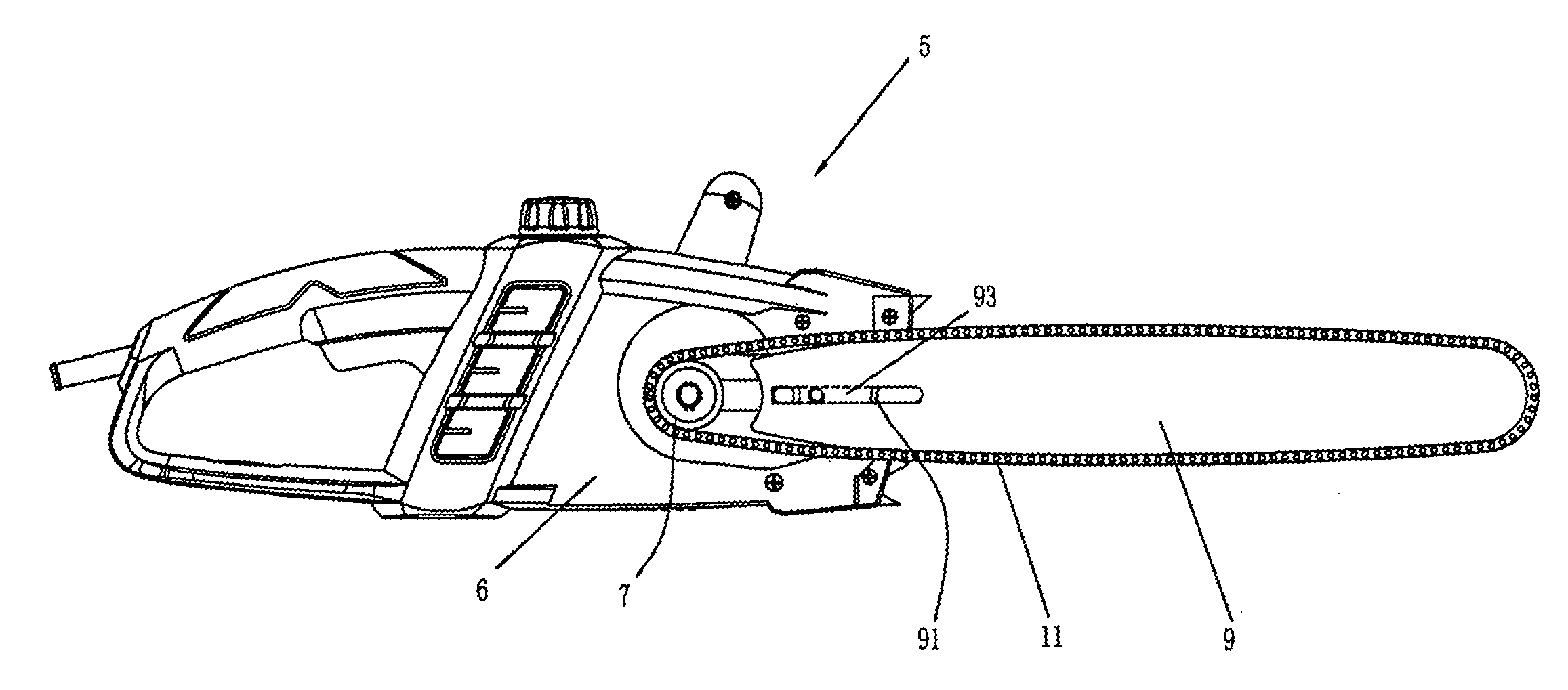

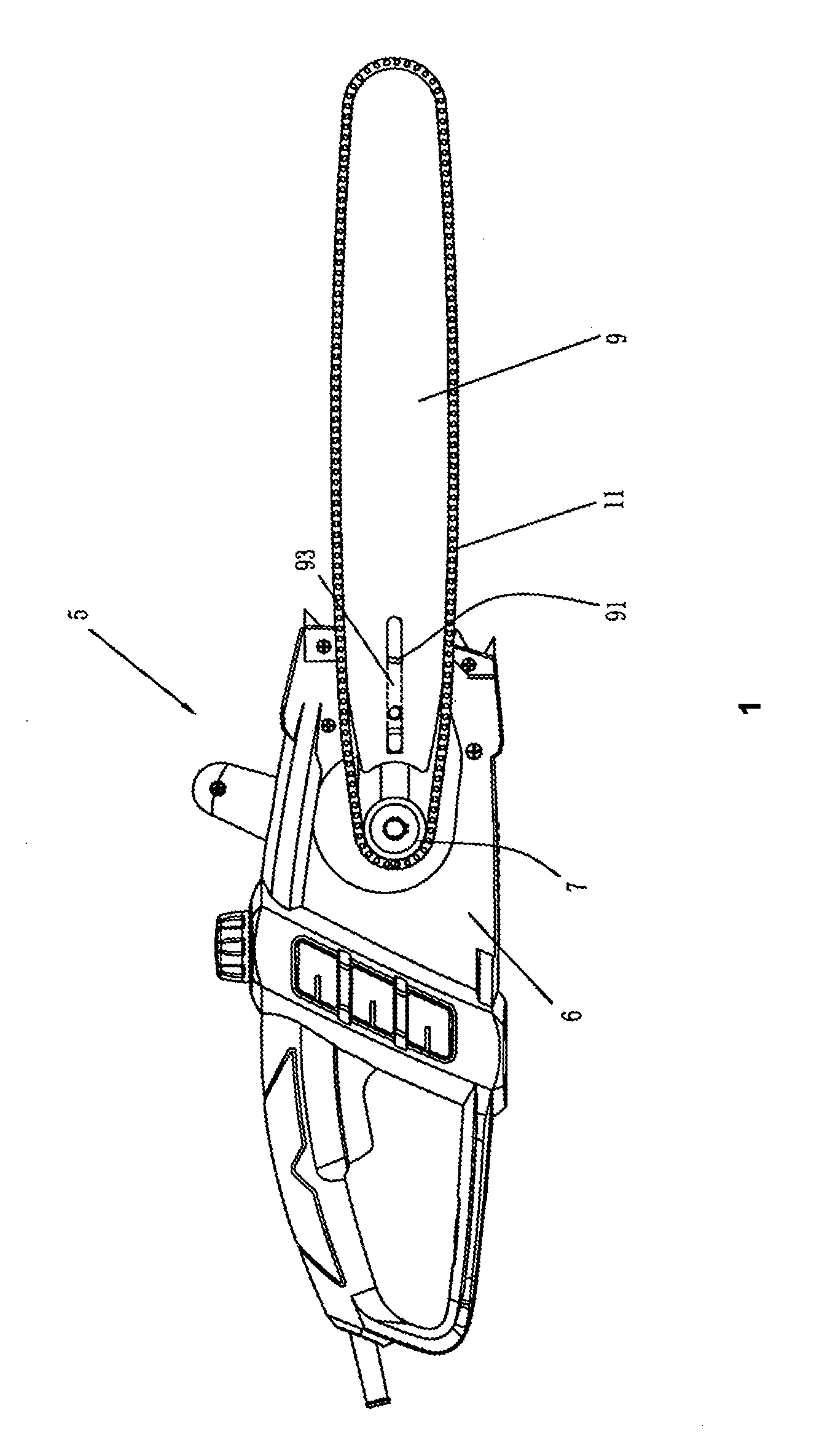

Chain saw

ActiveUS20110308096A1Stable, anti-abrasivePreventing the saw chain from loosing and jumping offMetal sawing devicesMetal sawing accessoriesSprocketEngineering

A chain saw includes a housing, a sprocket wheel which is provided in the housing for driving a saw chain, and a chain guide for guiding the movement of the saw chain. The chain guide extends out longitudinally from the housing and is movable longitudinally relative to the housing. The chain saw includes a chain tensioning device. The chain tensioning device comprises a driven member arranged on the chain guide and a driving member which drives the driven member to move the chain guide longitudinally and a rotating device rotating the driving member. A stepless clutch device is arranged between the rotating device and the driving member. The chain tensioning device presses the chain guide while it tensioning the saw chain. Thus it prevents effectively the chain guide from loosing after the saw chain is tensioned. The operation of the chain tensioning device is labour-saving. The chain tensioning device has a stable structure and it is hard to be worn.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

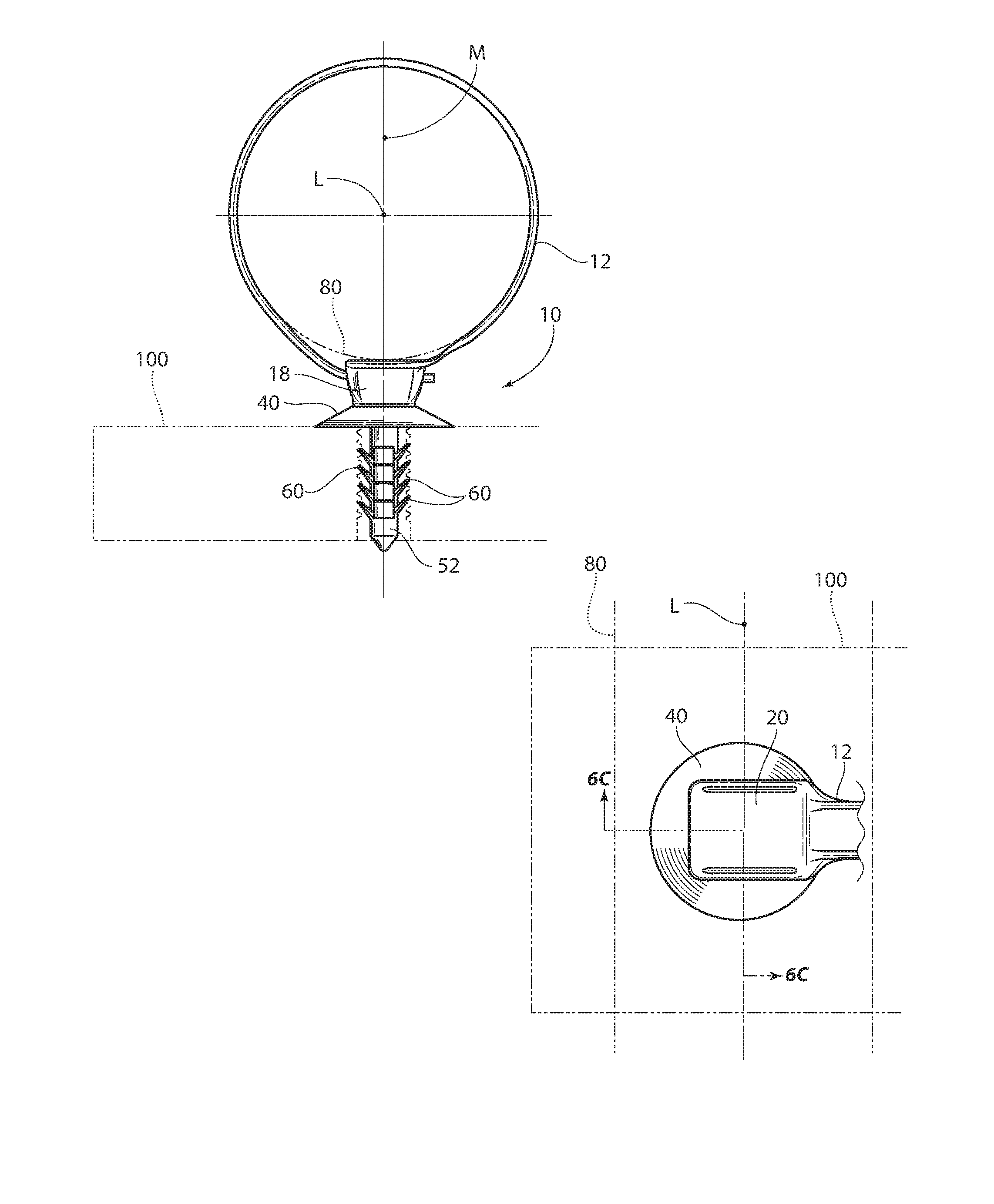

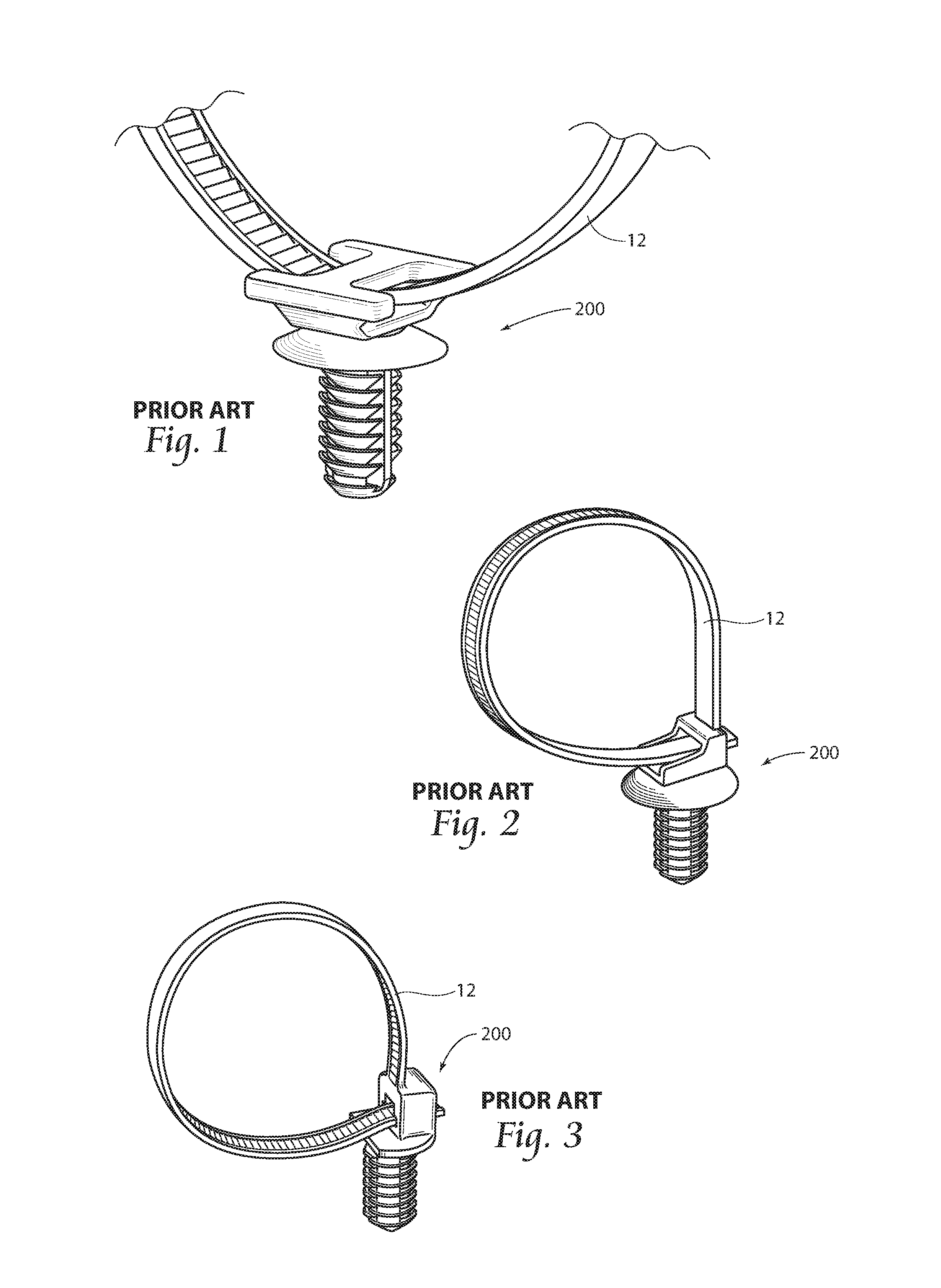

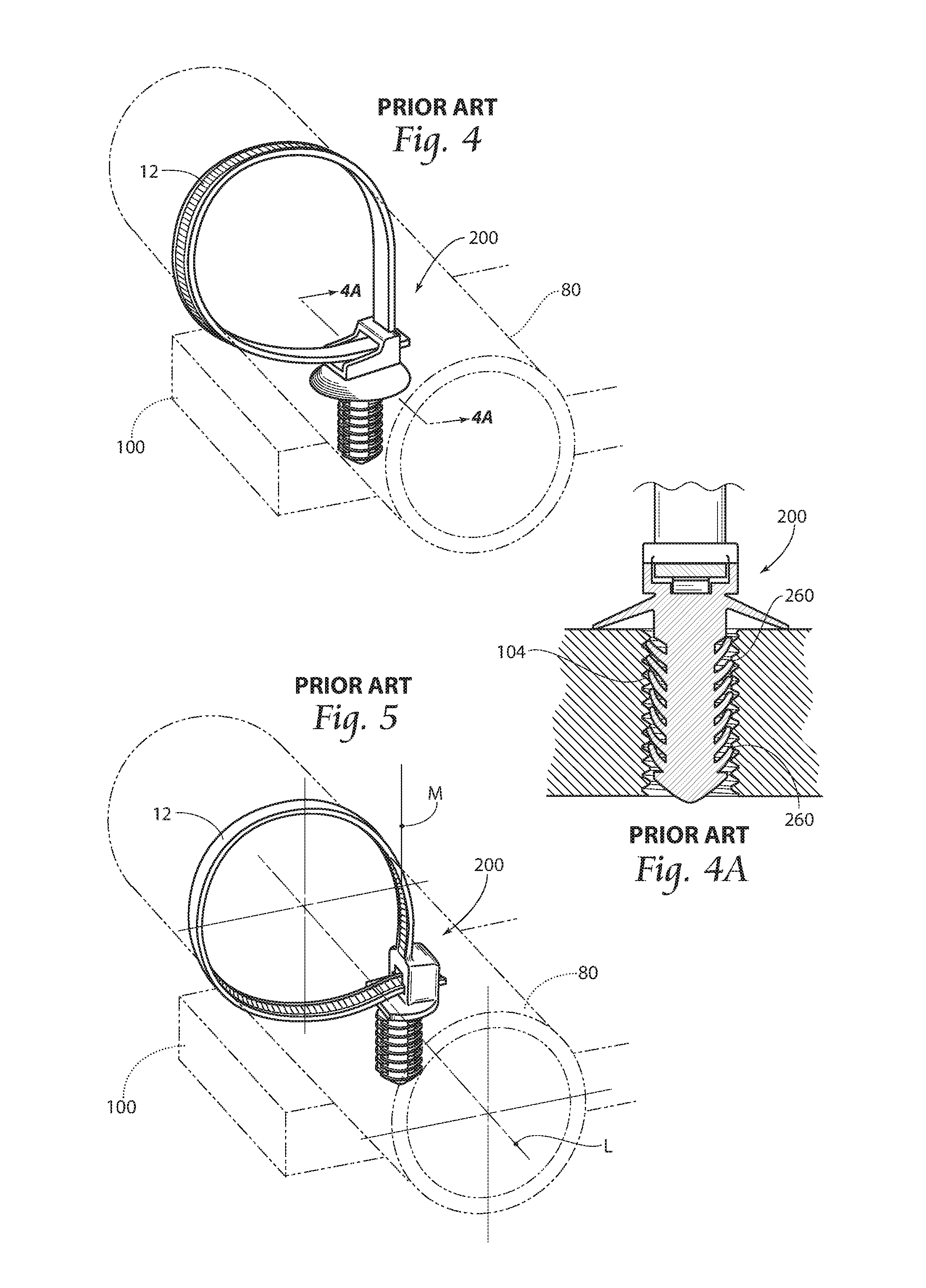

Fir tree mount

InactiveUS20160223100A1Improved retention and mountingPrevent exitPipe supportsElectrical apparatusEngineeringSupport surface

The disclosed device provides an improved mounting assembly for supporting elongated items or bundles against a support surface having a bore. The assembly provides a mount including an integrally formed flexible tie for retaining the items. The tie includes a hinge member to allow the tie to encircle the elongate items, to apply an even circumferential force against the items, and to align the items with the bore. The tie further includes an aperture having a pawl, which engages the flexible strap when it is inserted in the aperture to secure the elongate items. The device also includes a mounting stud having a plurality of branch rows, each row including a plurality of longitudinally spaced branches. The branches extend radially outwardly from a center section and each terminates in a distal end, with the distal ends of branches in adjacent branch rows defining an interrupted helical path.

Owner:HELLERMANNTYTON CORP

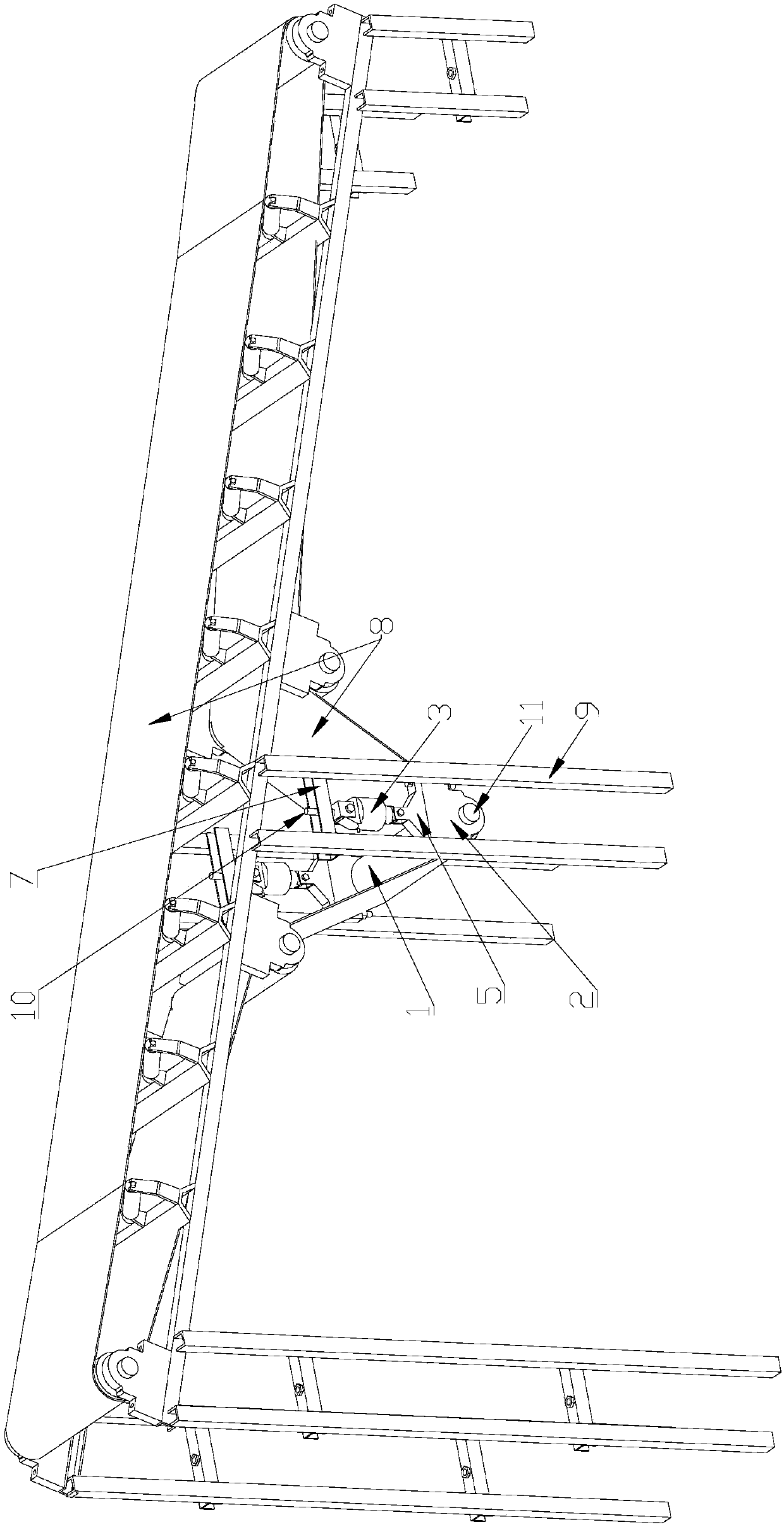

Vertical guide rail automatic cloth conveying device for transfer printing machine

ActiveCN102248758AWeft neatUniform distribution of squeeze liquidTransfer printingEngineeringDrive motor

The invention discloses a vertical guide rail automatic cloth conveying device for a transfer printing machine. The device comprises a cloth storage device, a headstock box, a cloth conveying device and a tailstock box, wherein a weft adjustment device and an overfeed device are arranged in the headstock box; the cloth conveying device consists of a vertical guide rail cloth flatly-conveying system and a fabric carrying device; an active pin miss device, an active cloth feeding device and two sets of tension detection devices are arranged in the tailstock box; the weft adjustment device is positioned on the rear lower side of the headstock box; the overfeed device is positioned in the middle of the headstock box and consists of an upper overfeed device, a lower overfeed device and a widthexpansion device; the vertical guide rail cloth flatly-conveying system comprises a vertical guide rail and a pin plate conveying chain and is used for supporting the two sides of a fabric; the fabric carrying device consists of a cloth carrying flat belt part and a rope-shaped cloth carrying belt part and is used for supporting the middle part of the fabric; the active pin miss device consists of an active pin miss wheel and an active pin miss roller and is used for stripping the fabric from the pin plate; the active cloth feeding device consists of an active cloth feeding roller, a drive motor and a speed reducer; and each set of tension detection device consists of a tension sensor and a tension roller.

Owner:NEWTECH TEXTILE TECH DEV SHANGHAI

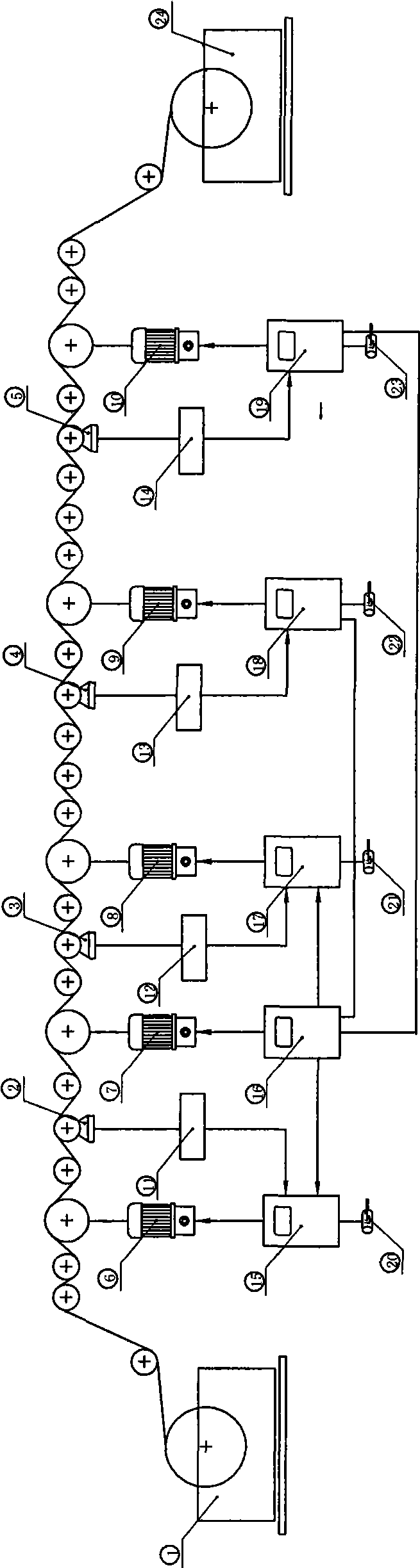

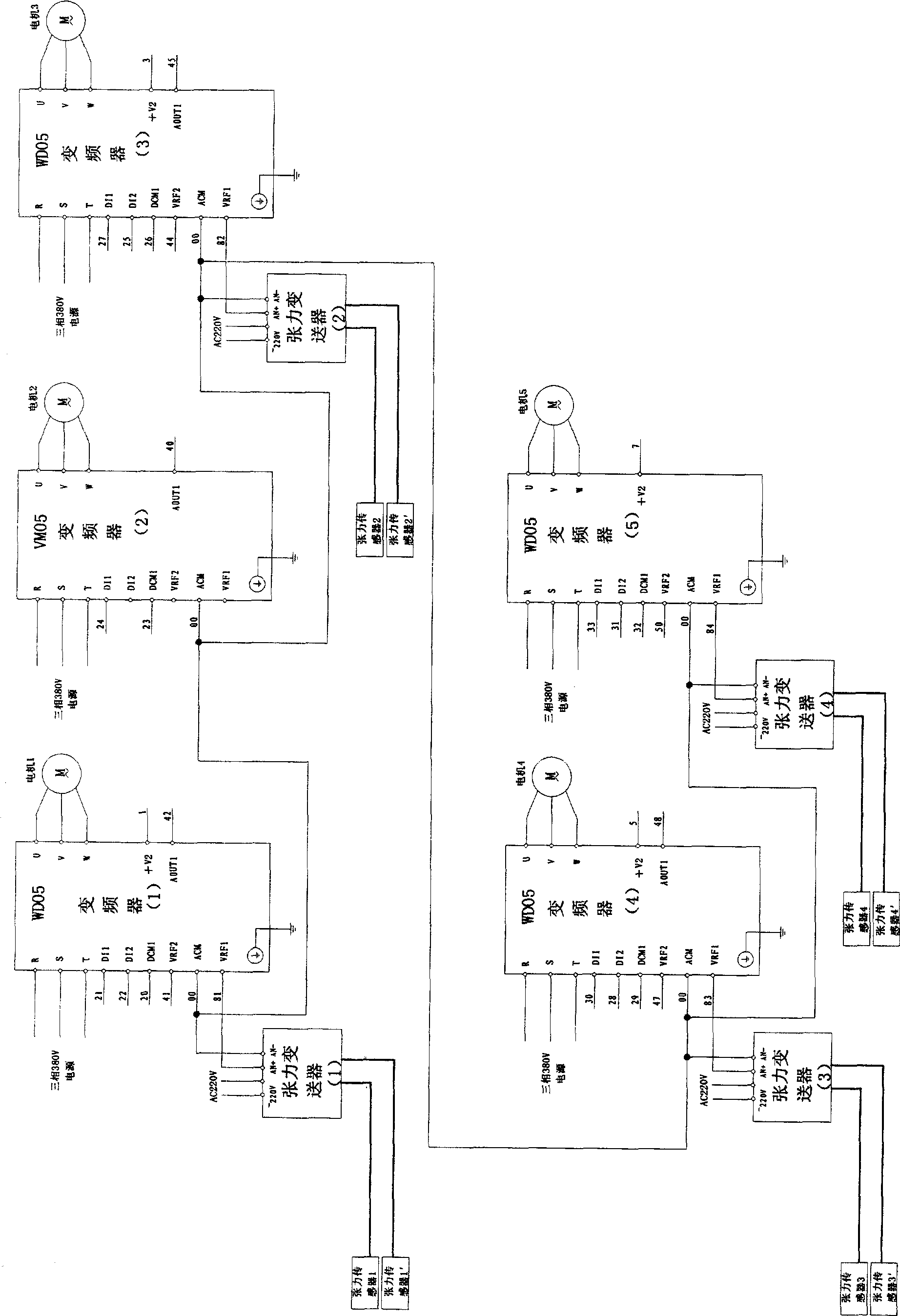

Tension control system

InactiveCN101508391AGuaranteed uptimeImprove performanceWebs handlingFrequency changerAutomatic control

The invention discloses a tension control system, which comprises a driving roller, a driven roller and a tension adjusting device, and is characterized in that in a closed-loop full automatic tension control system formed by a tension sensor on a position of a film, a tension converter, a special winding frequency converter, an electric motor, the driving roller, a group of driven rollers and the tension sensor on the position of the film; the tension sensor of the film, the tension converter and the special winding frequency converter are connected through signal wires in turn; the special winding frequency converter is connected with the electric motor through a cable; the electric motor is directly connected to the driving roller; and the driving roller and the driven rollers are connected by chain wheels. The tension control system adopts frequency conversion winding control technology to overcome the defects of the prior transmission mode, the tension on each position of a production line can be displayed intuitively, and the integral tension of the whole line can be adjusted. The tension control system can be widely applied to the transmission control of the production lines for processing aluminum foils, films, textiles, printing, plastics, and the like.

Owner:GUANGXI HEZHOU GUIDONG ELECTRONICS TECH

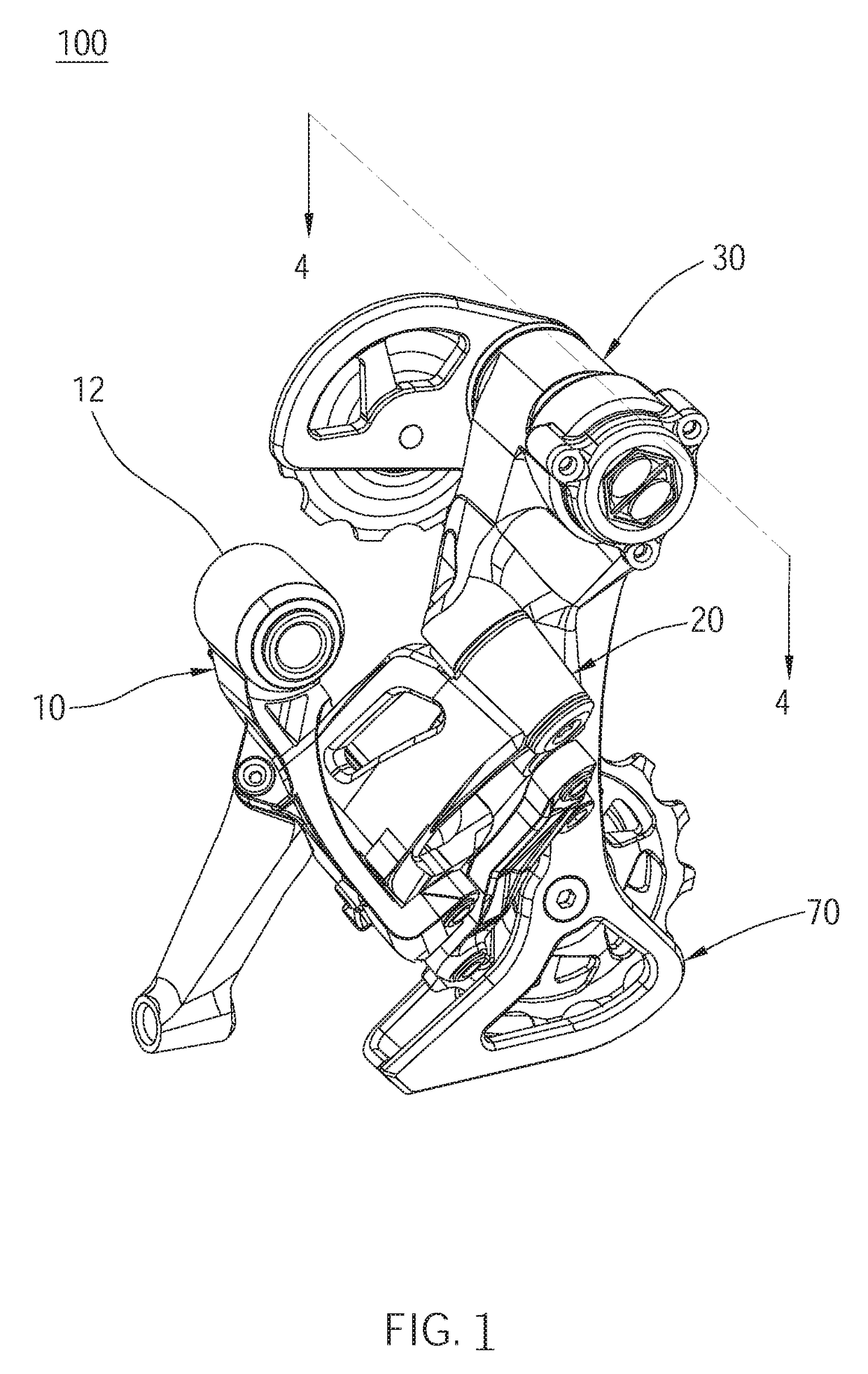

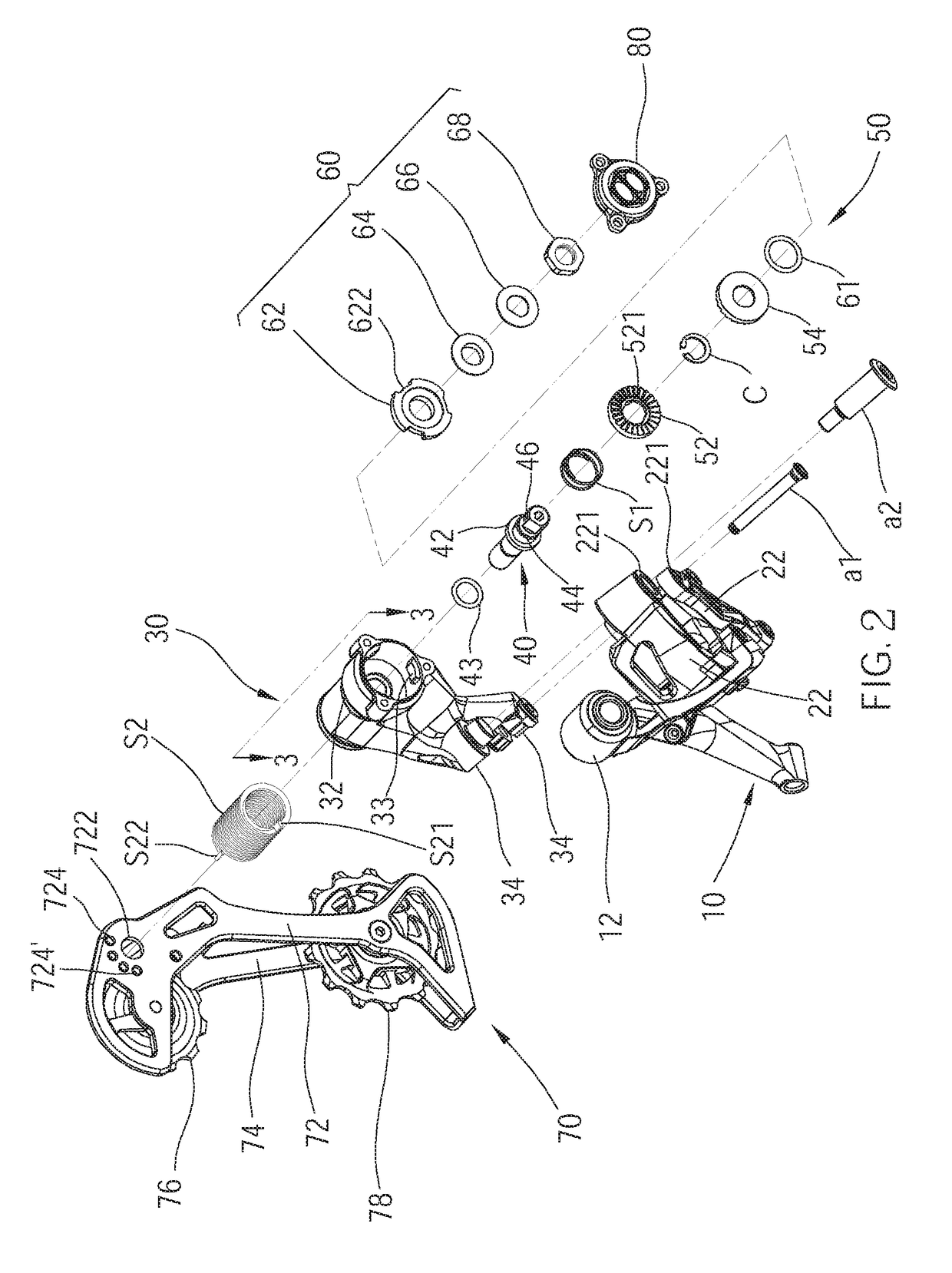

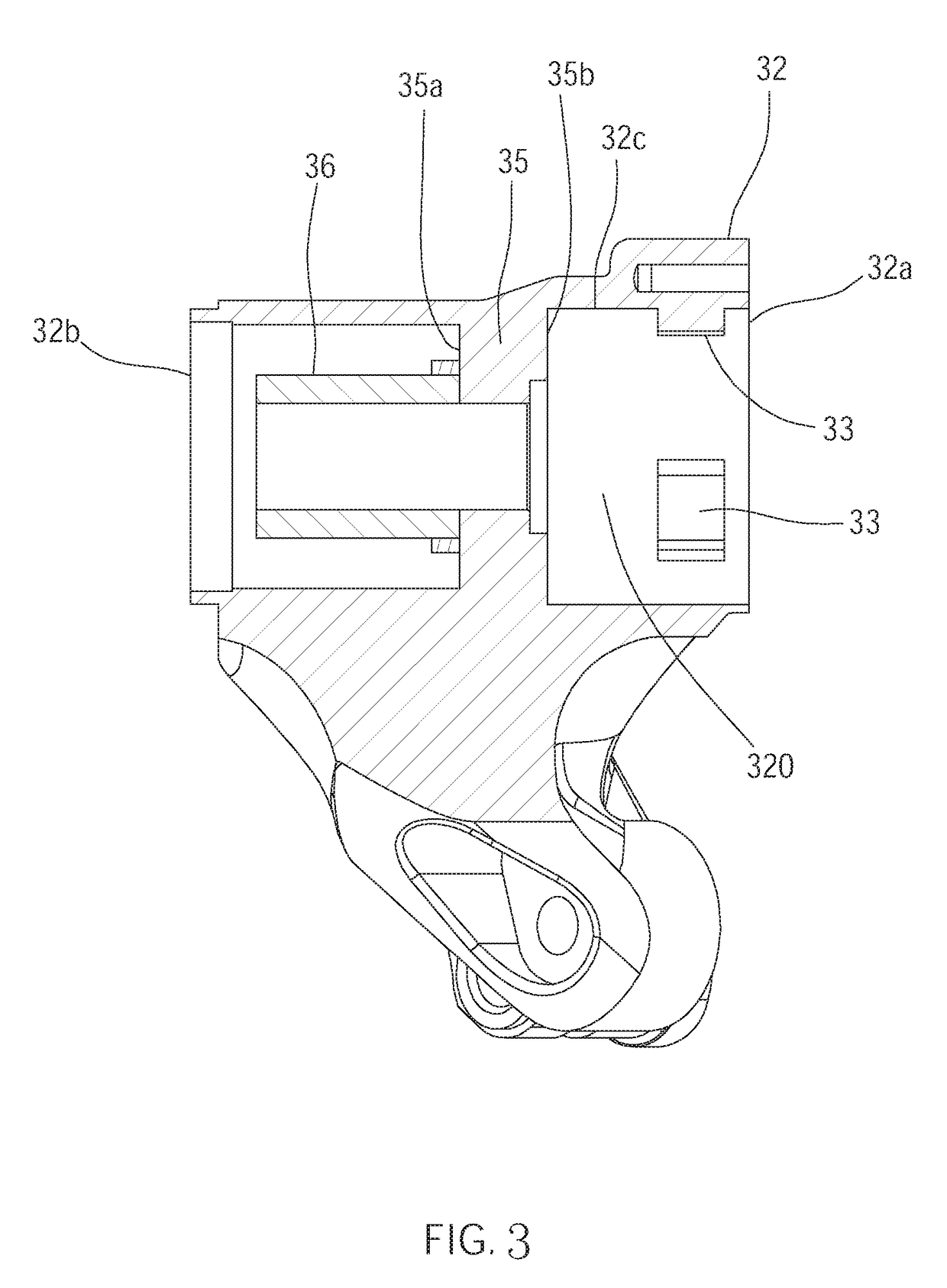

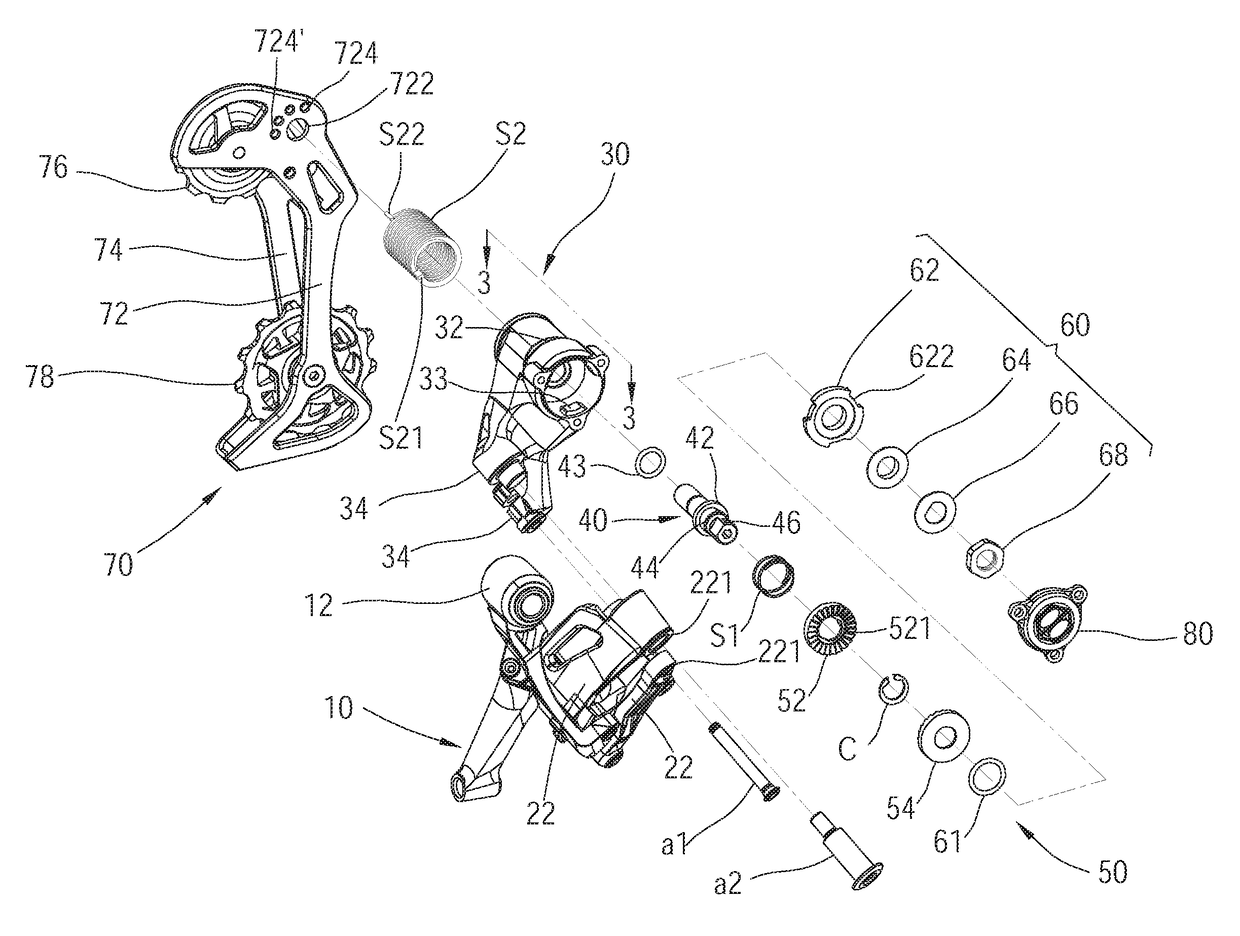

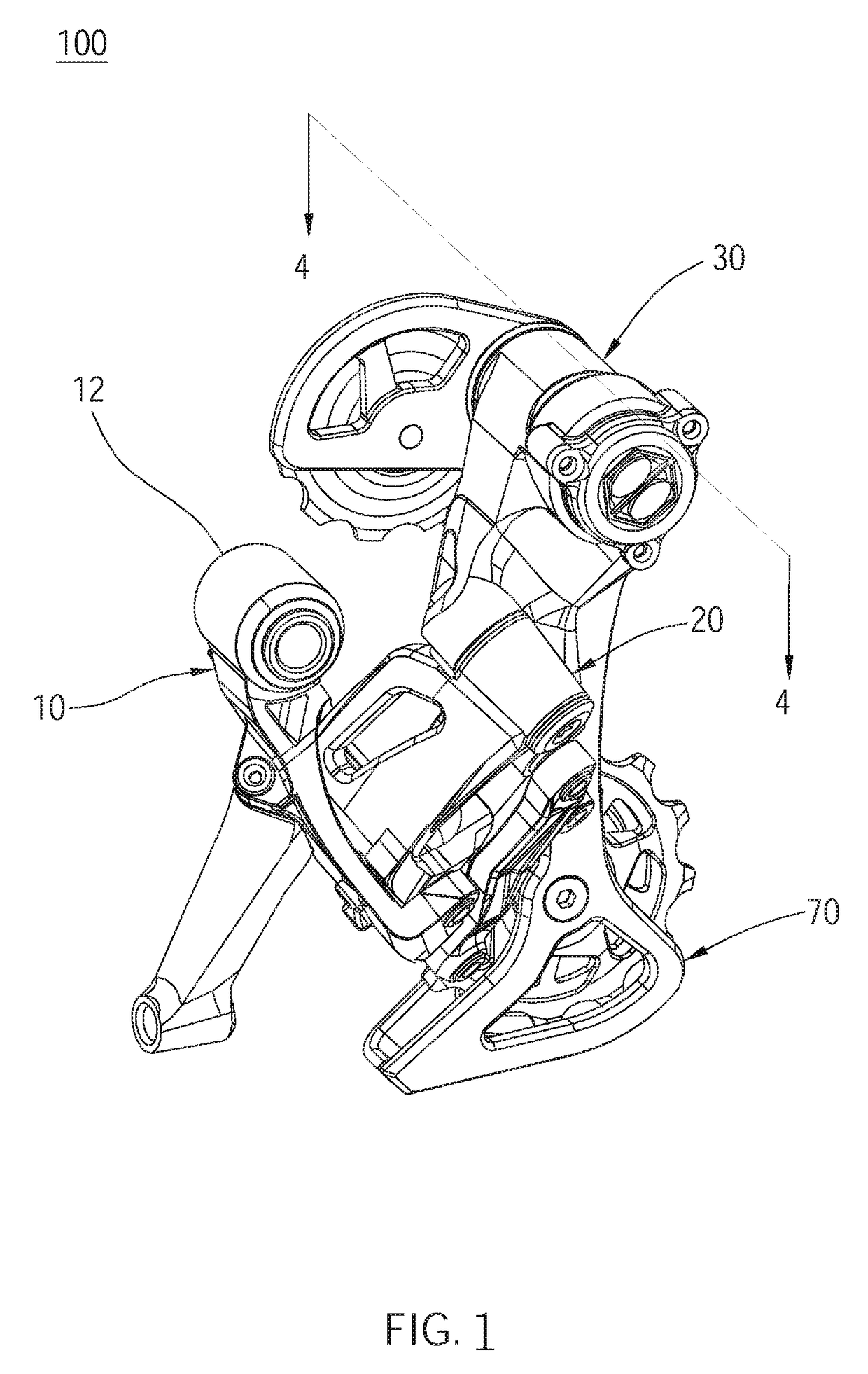

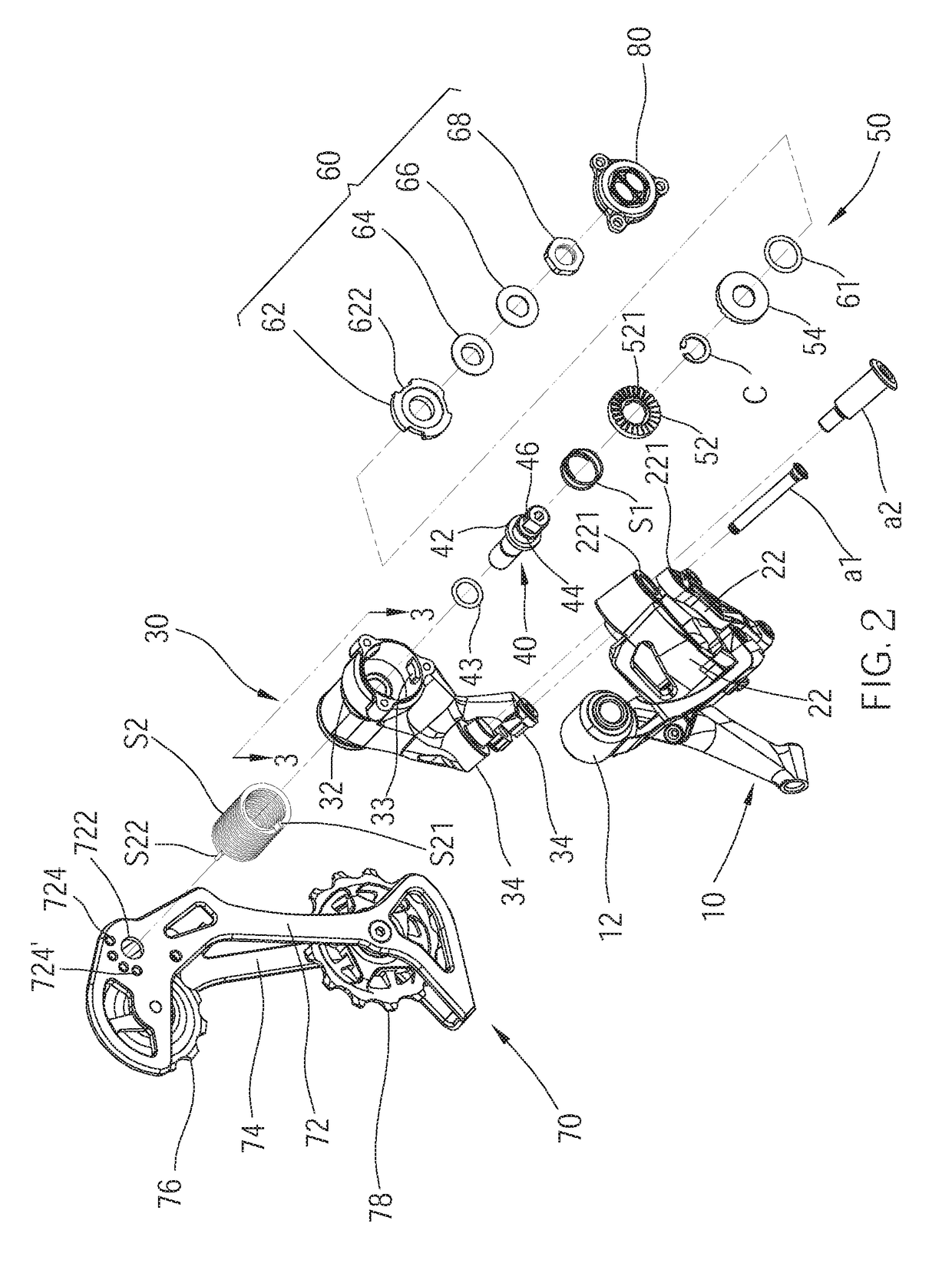

Bicycle rear derailleur

Owner:LEE CHI ENTERPRISES +1

Belt conveyor automatically detecting and adjusting tension

InactiveCN107555093AReal-time tension detectionStable tensionConveyorsControl devices for conveyorsControl systemForce curves

The invention relates to the technical field of belt tensioning wheels, in particular to a belt conveyor automatically detecting and adjusting tension. The belt conveyor comprises a rack, a belt, a tensioning wheel and shaft lugs connected to the rack. A shaft hole is formed in the position, close to one end, of each shaft lug. Shaft parts at the two ends of the tensioning wheel are rotationally connected into the shaft holes of the shaft lugs on the two sides correspondingly. The belt conveyor is characterized by further comprising a tension detecting and adjusting device, and the signal endsof hydraulic pressure sensors of the tension detecting and adjusting device are in both-way connection with the signal input end of a control system. Compared with the prior art, the structure characteristics of the belt conveyor are sufficiently combined; commonly, the conveyor only needs the two hydraulic pressure sensors, the design of the control system is relatively simple, a real-time tensioning force curve and abnormal alarms can be provided for production and management personnel in combination with a man-machine interaction system, the tension of the belt conveyor can be detected inreal time and finely adjusted, the tension of the belt conveyor is kept to be constantly stabilized near the set value, and stability of production technology parameters is ensured.

Owner:SHANGHAI YUNTONG INFORMATION SCI & TECH CO LTD

Composite material uncoiling centering adjustment device with damping function

The invention discloses a composite material uncoiling centering adjustment device with a damping function. A rotating central spindle is mounted on an uncoiling support through a pair of deep groove ball bearings in a double-bearing bearing seat. The rotating central spindle is provided with a centering shaft sleeve and a centering adjusting central shaft which are concentric, the centering shaft sleeve and the centering adjusting central shaft are provided with conical faces which are the same, and the distance of the centering shaft sleeve and the centering adjusting central shaft is adjustable, so that a coiling block and the rotating central spindle are concentrically fixed. The other end of the rotating central spindle is provided with a friction drum which is provided with a damping belt in a winding mode, one end of the damping belt is fixedly connected with the uncoiling support, and the other end of the damping belt is connected with a hook head of an adjusting hook. The cylinder end of the adjusting hook is connected to a damping support through an adjusting spring and an adjusting nut, and the tension of uncoiling can be changed by adjusting the adjusting nut. A rotating detecting piece is fixed on the end face of a friction wheel, the detecting end of a proximity sensor directly faces the extending end of the proximity sensor, and whether composite materials are broken is judged by detecting variation of received signals. The composite material uncoiling centering adjustment device has the advantages of being suitable for composite material coiling blocks of different specifications and adjustable in tension in the uncoiling process, and having the function of detecting breakage.

Owner:BEIHANG UNIV

Hollow coil winding equipment

ActiveCN104916427AShorten heating timeLow powerFilament handlingCoils manufactureHeating systemHeating time

The invention relates to hollow coil winding equipment, which solves the technical problem that the heating time is long and the cost is high in the prior art. The hollow coil winding equipment comprises a bobbin unit, a stand arranged at one side of the bobbin unit and a plurality of winding fixtures. A mounting base is arranged on the stand. A plurality of main shafts which correspond to the winding fixtures one to one and which are connected with the winding fixtures in a rotary manner are arranged on the mounting base. A plurality of counter shafts which correspond to the winding fixtures one to one and which can be used for driving the winding fixtures to rotate are arranged on the mounting base. The equipment further comprises a heating system which can be used for heating the two ends of wound coils and the wound coils wound on the winding fixtures. The equipment further comprises a tension control system for enabling the two ends of the wound coils to have constant tension while the wound coils are continuously wound on the winding fixtures. The invention has the advantages that the hollow coil winding equipment could greatly reduce the heating time, and is low in cost and stronger in practicability.

Owner:TANAC AUTOMATION

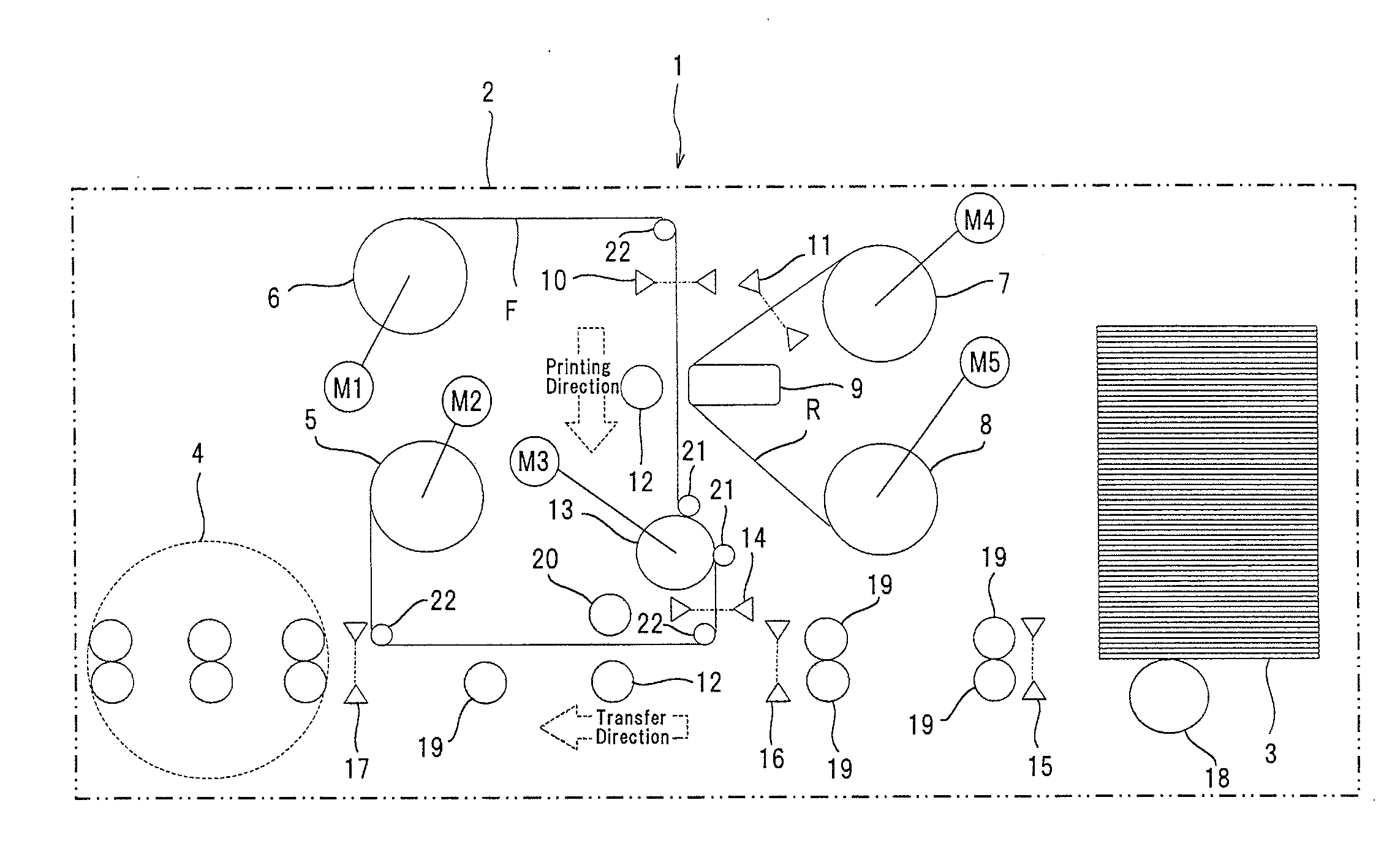

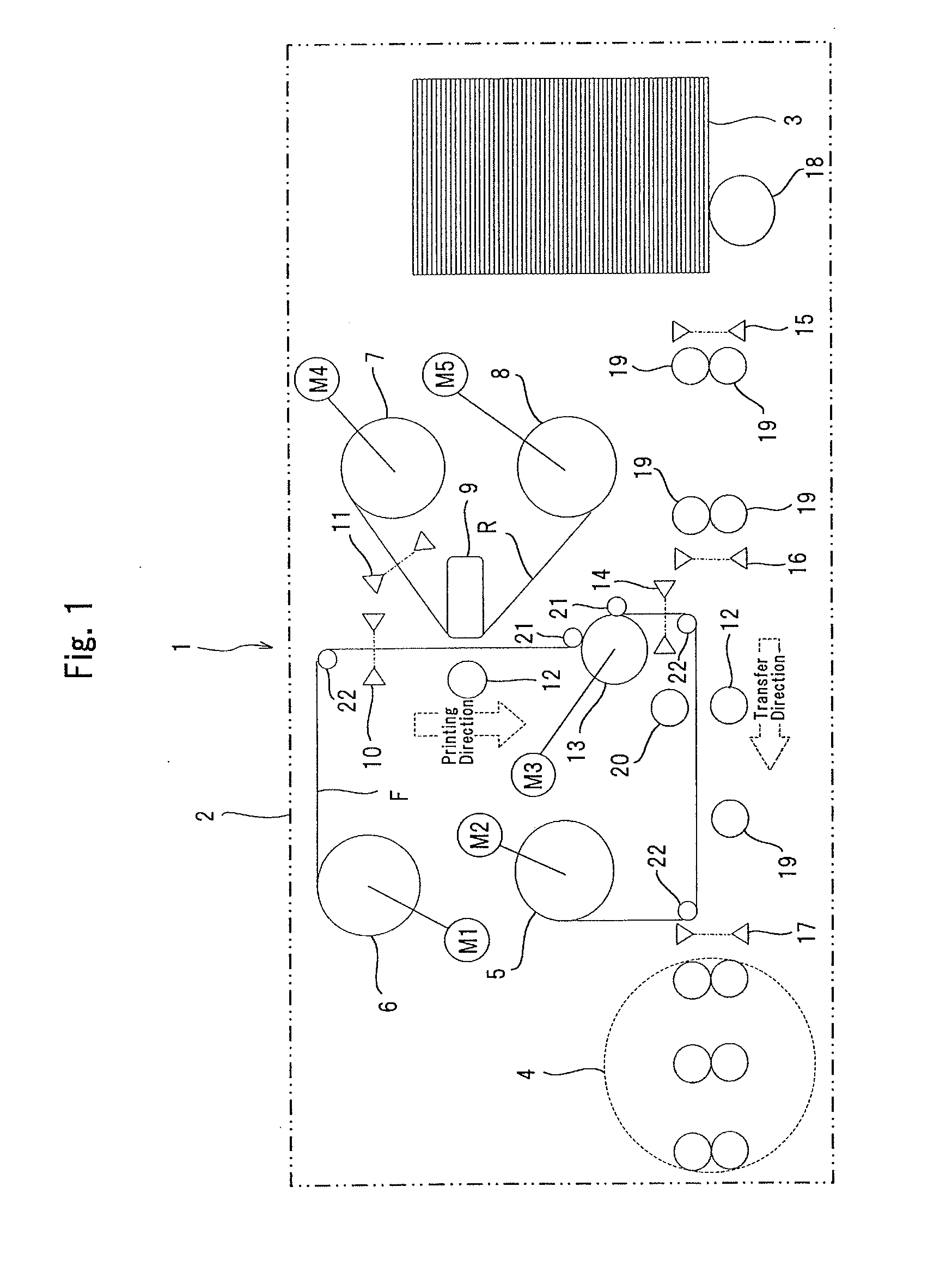

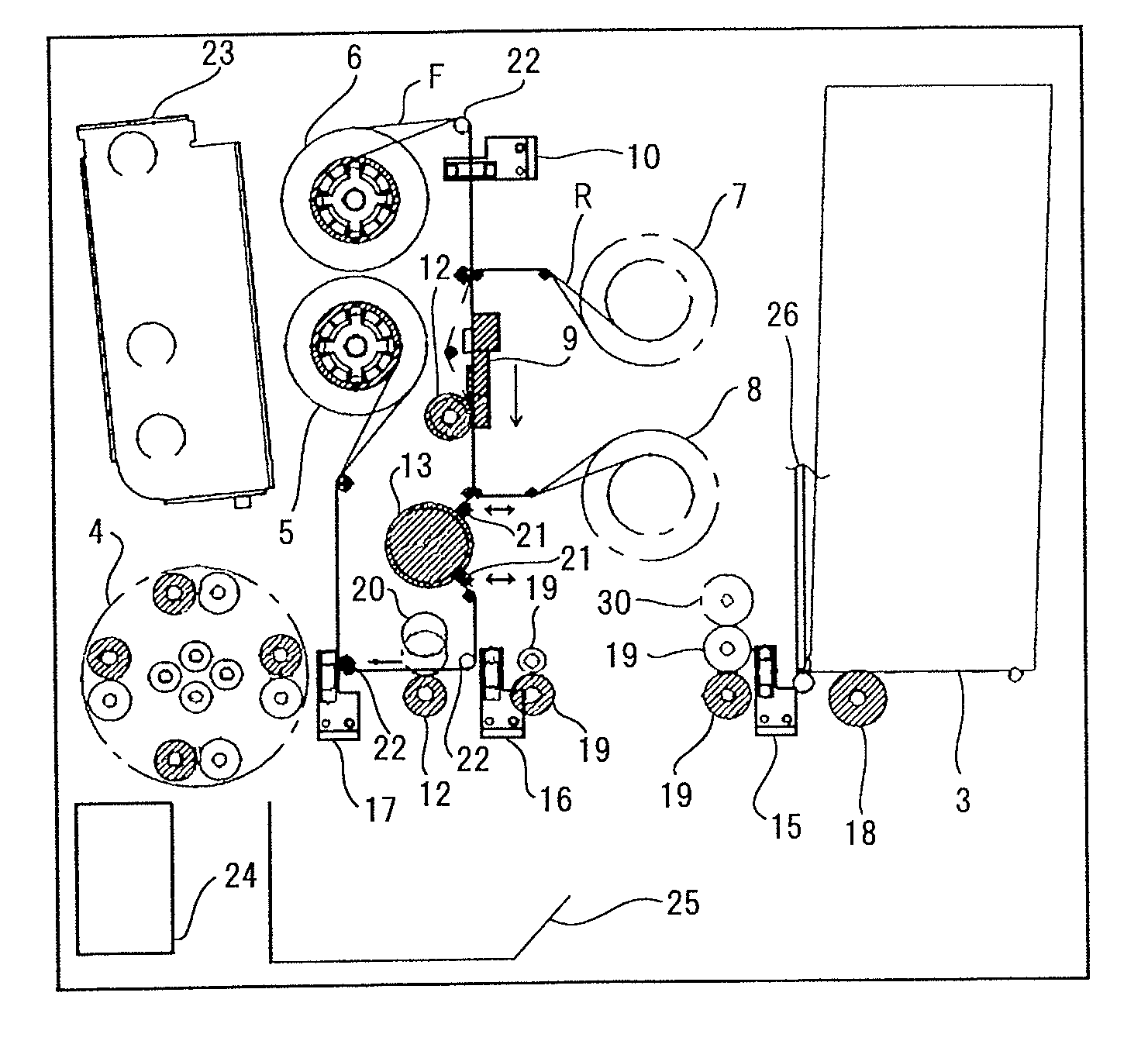

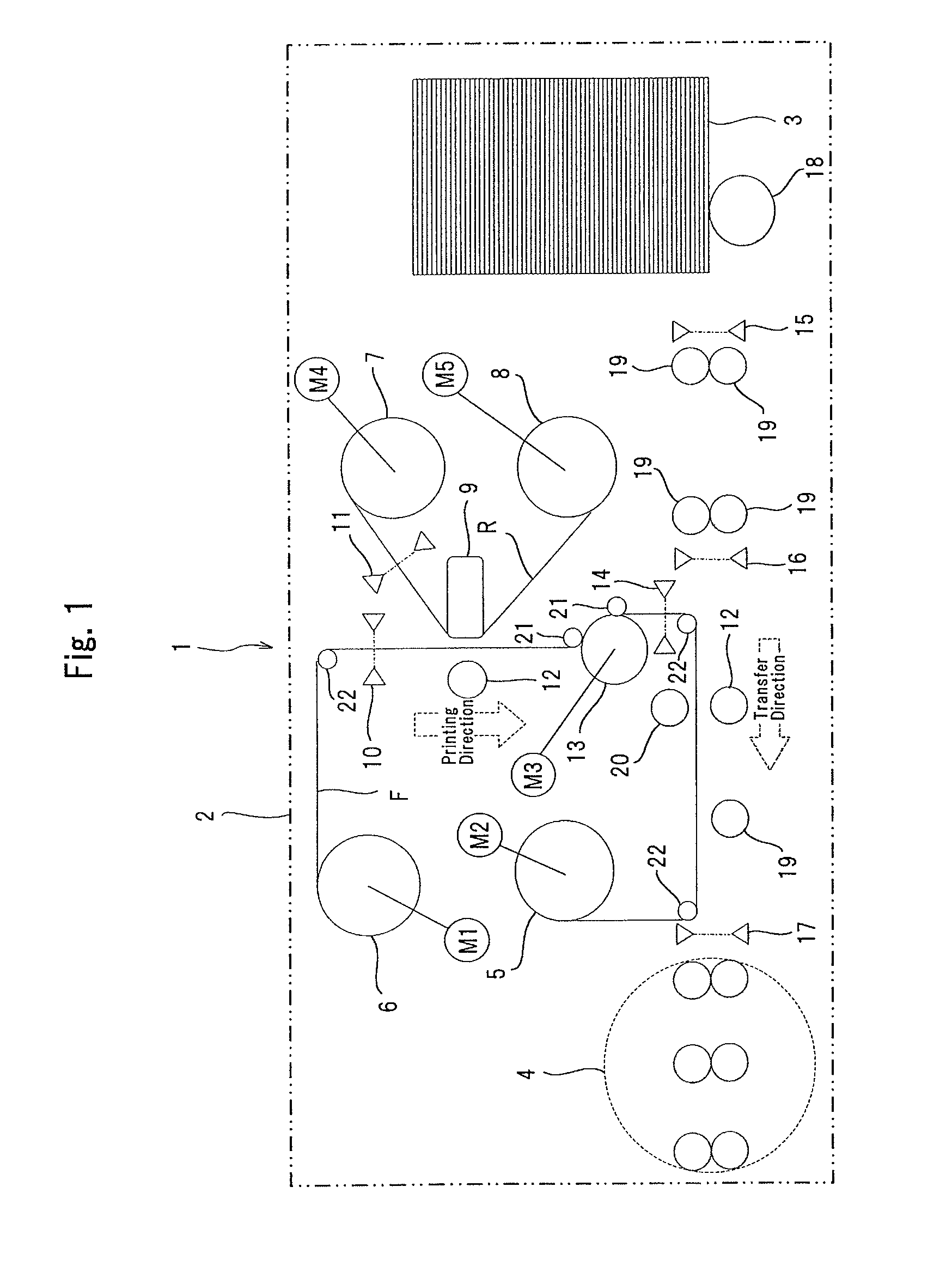

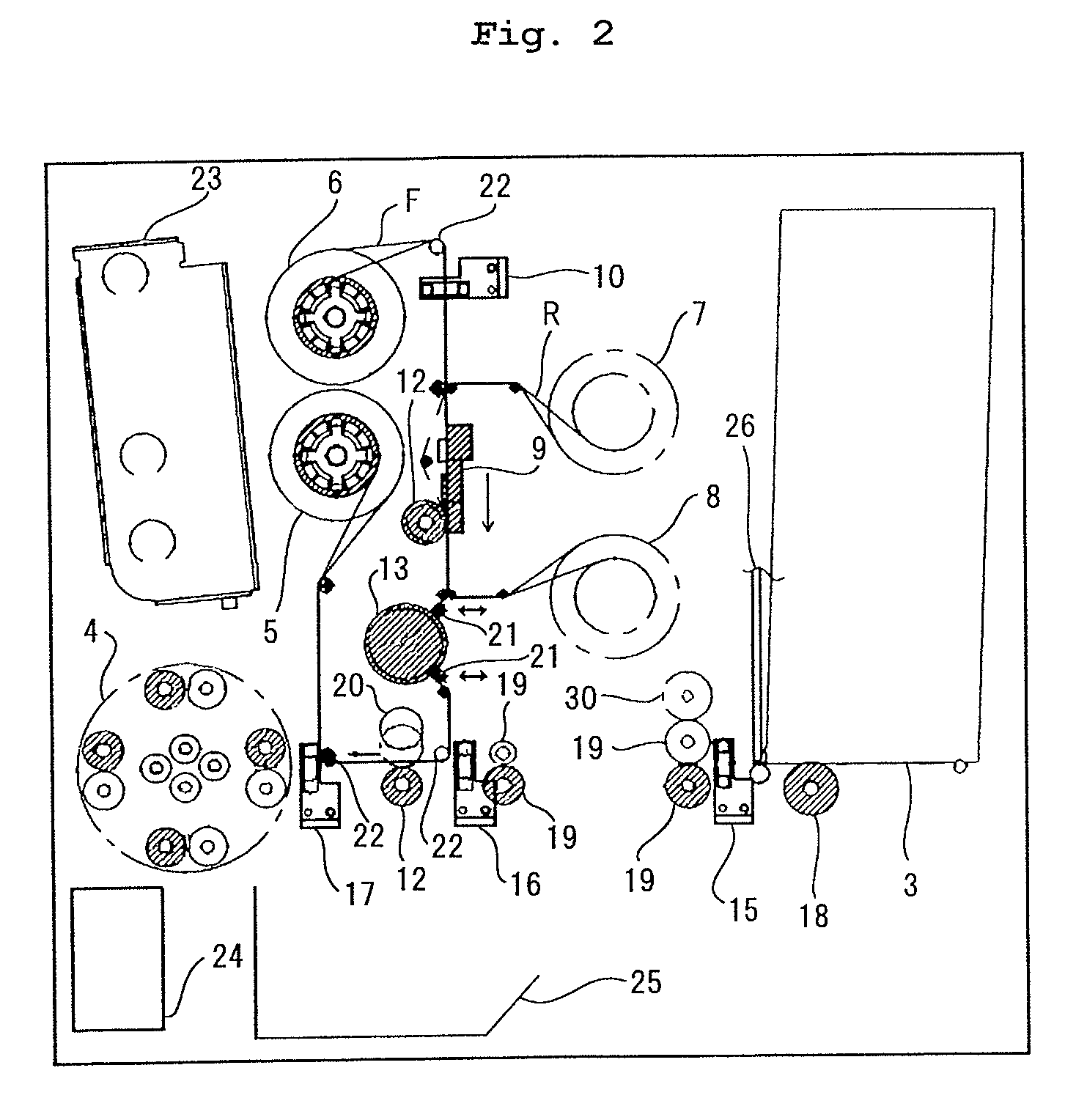

Printing device and printing method

ActiveUS20120176460A1High quality printingStable tensionRecording apparatusPrinting mechanismsEngineeringThermal Head

The present invention provides a printing device which provides high printing quality. The printing device includes: an image forming section which has a thermal head 9 and a platen roller 12; a media conveyance section for conveying an intermediate transfer film F; a ribbon conveyance section for conveying an ink ribbon R; a sensor 10 for detecting a first mark formed on the film F; and a control section for controlling the image forming section, the media conveyance section, and the ribbon conveyance section in accordance with output information from the sensor 10. The control section presses the head 9 into contact with the roller 12 when the first mark is not detected, which is when the first mark is further upstream than the position of the sensor 10, while the film F and the ribbon R are being conveyed, and selectively heats a heating element formed in the head 9 when the film F is positioned in the printing start position, which is a state in which the first mark is detected when the first mark is further downstream than the position of the sensor 10.

Owner:TOPPAN PRINTING CO LTD +1

Printing device and printing method

ActiveUS8654164B2High quality printingStable tensionPrinting mechanismsRecording apparatusEngineeringHeat sensitive

Owner:TOPPAN PRINTING CO LTD +1

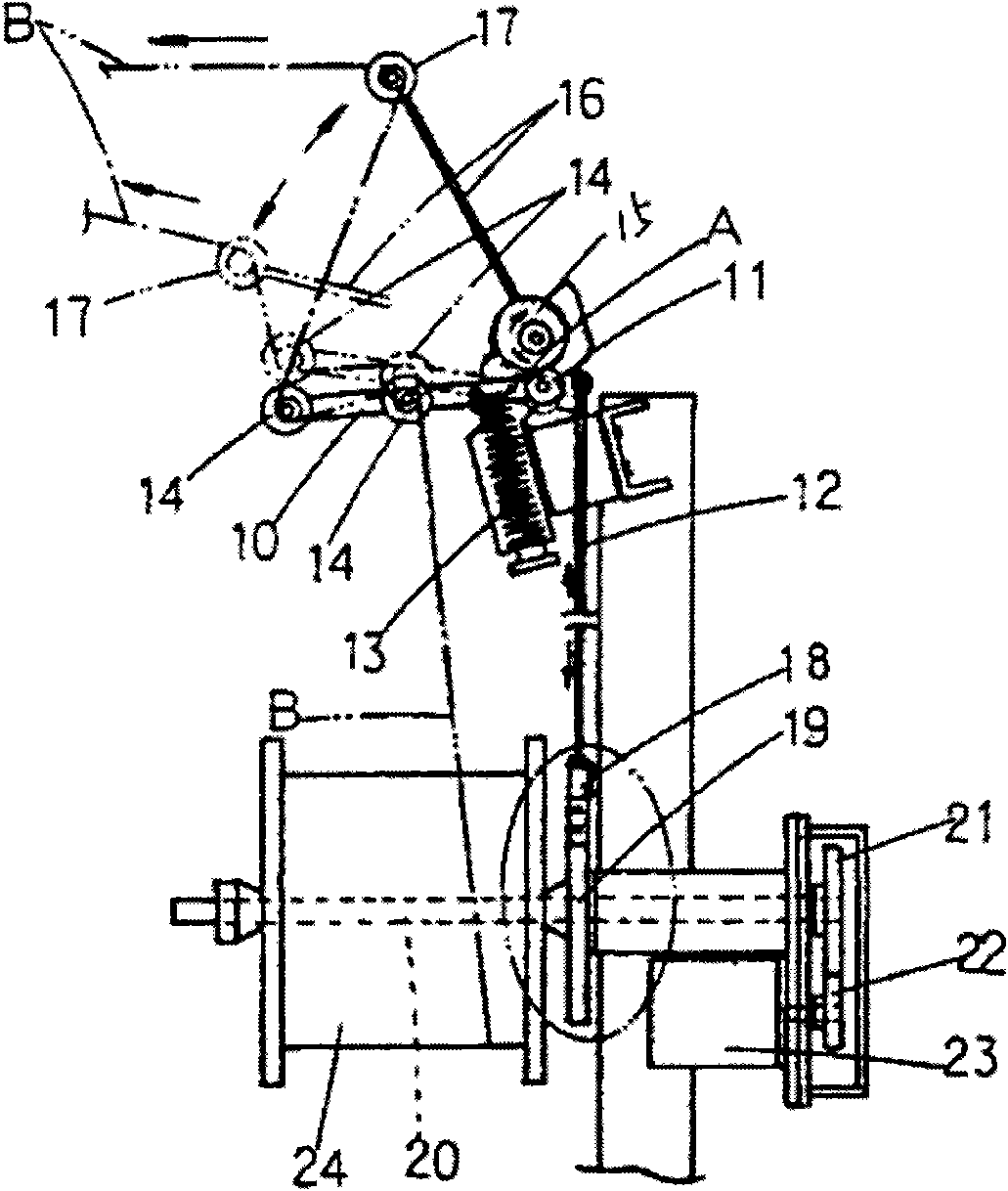

Bicycle rear derailleur

A bicycle rear derailleur is provided, which includes a base adapted to be mounted on a bicycle frame, a movable member, a linkage assembly pivotally connected to and between the base and the movable member, a pivot shaft provided within and pivotally rotatable relative to the movable member, a chain guide fixed to an end of the pivot shaft, a restriction assembly provided on the pivot shaft, and a friction assembly provided within the movable member to provide a rotational friction on the restriction assembly. Whereby, the chain guide is pivotally awing toward a first direction by a force; when the chain guide swings toward a second direction which is opposite to the first direction by another force, it is forced by a swing resistance.

Owner:LEE CHI ENTERPRISES +1

Design method of automatic moving feeding frame of base material longitudinal cutting device

ActiveCN102040115AConstant distanceStable tensionArticle deliveryWebs handlingEngineeringDesign methods

The invention relates to a base material longitudinal cutting device, particularly to a design method of an automatic moving feeding frame of a base material longitudinal cutting device, characterized by comprising a sensor, an automatic adjusting device, a power mechanism, a transmission mechanism and an adjusting mechanism; the sensor is electrically connected with the automatic adjusting device, the automatic adjusting device is electrically connected with the power mechanism, the power mechanism is in transmission connection with a moving mechanism through the transmission mechanism, and the moving mechanism is fixedly connected with the feeding frame. The automatic moving feeding frame of the base material longitudinal cutting device can ensure constant distance between an unwinding shaft base material surface and an unwinding guide rail, so that tension is steady, and cutting speed is improved.

Owner:XIAN XINDA MACHINERY

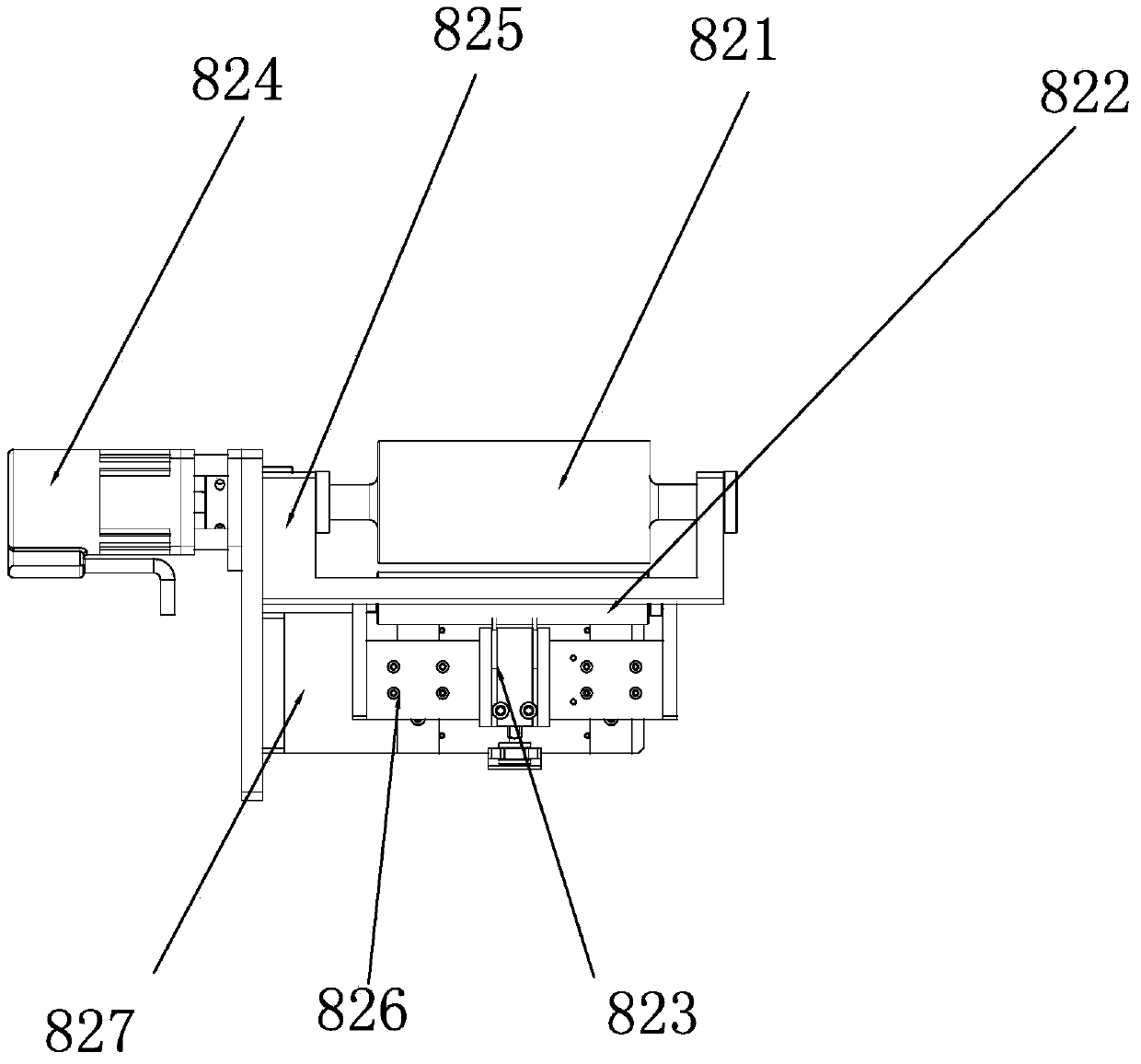

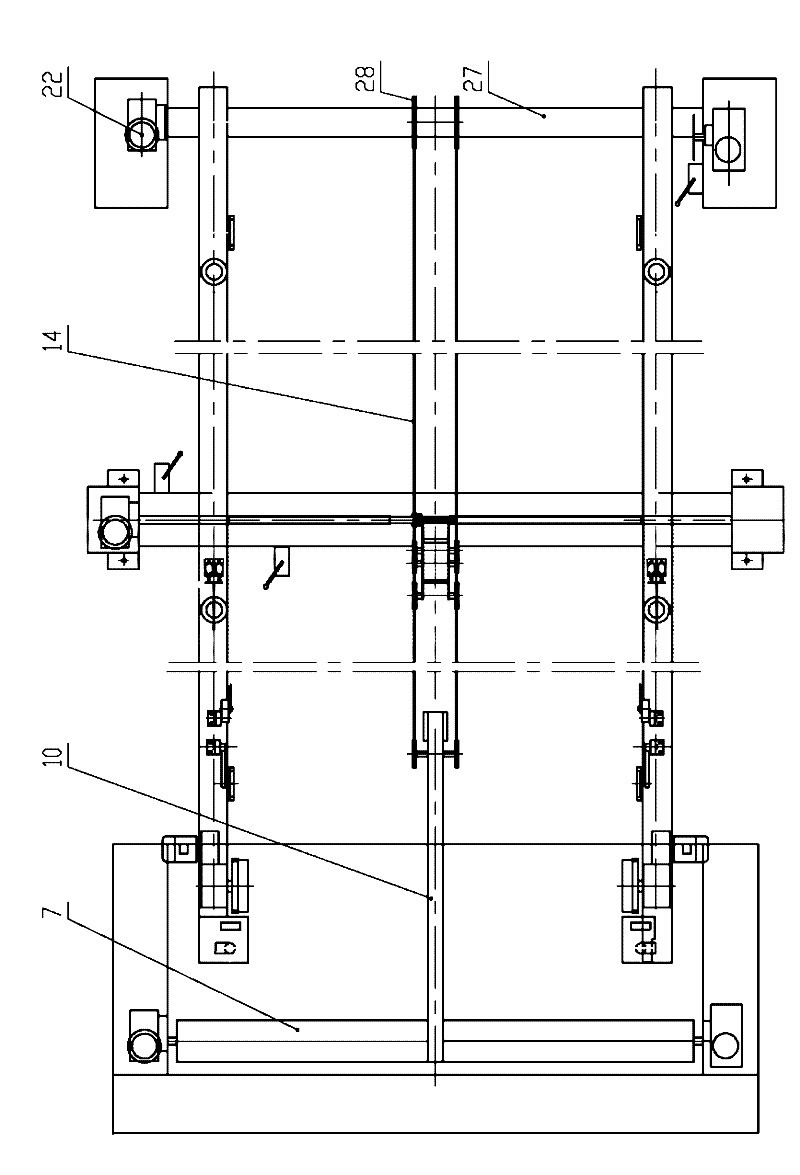

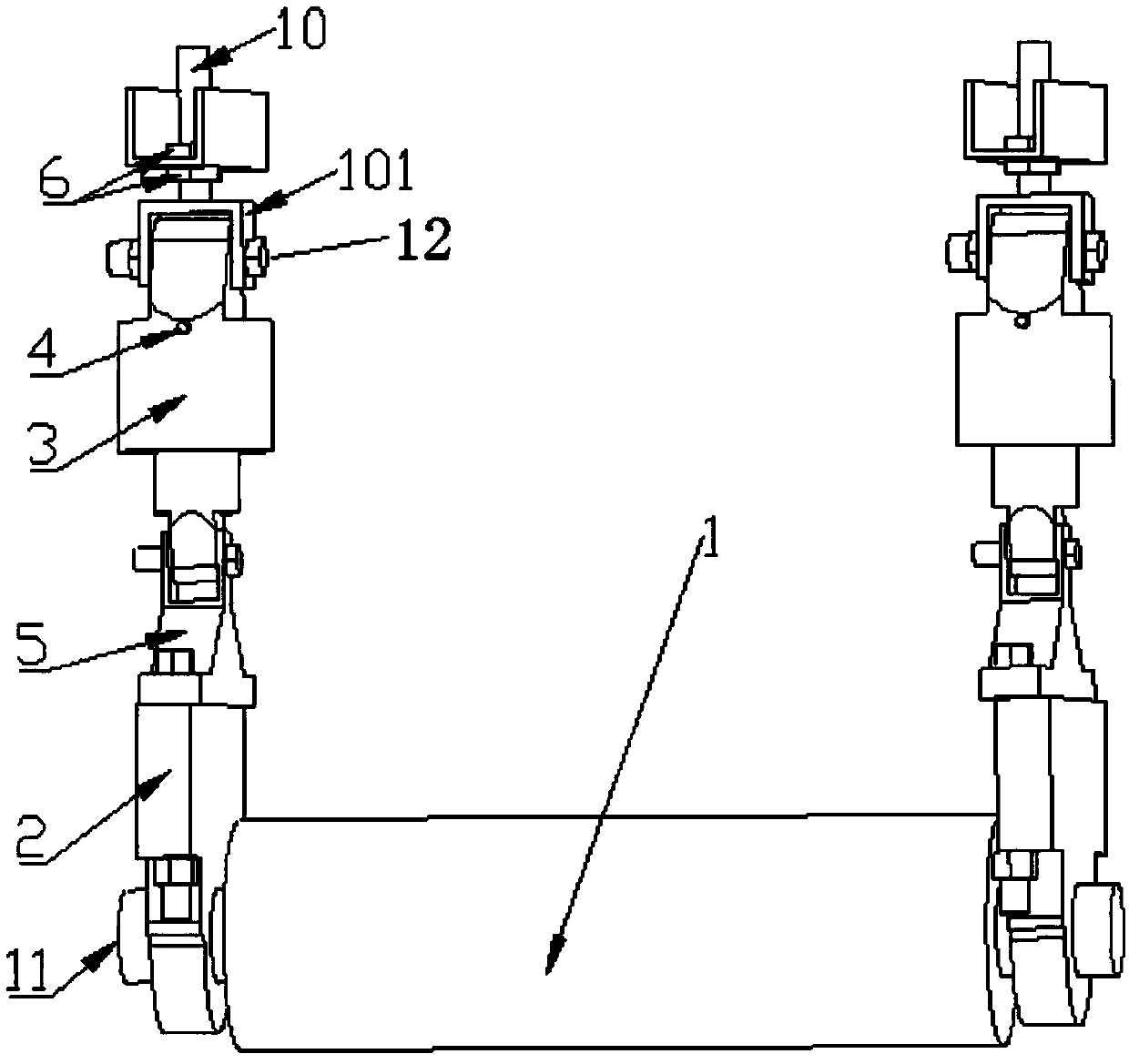

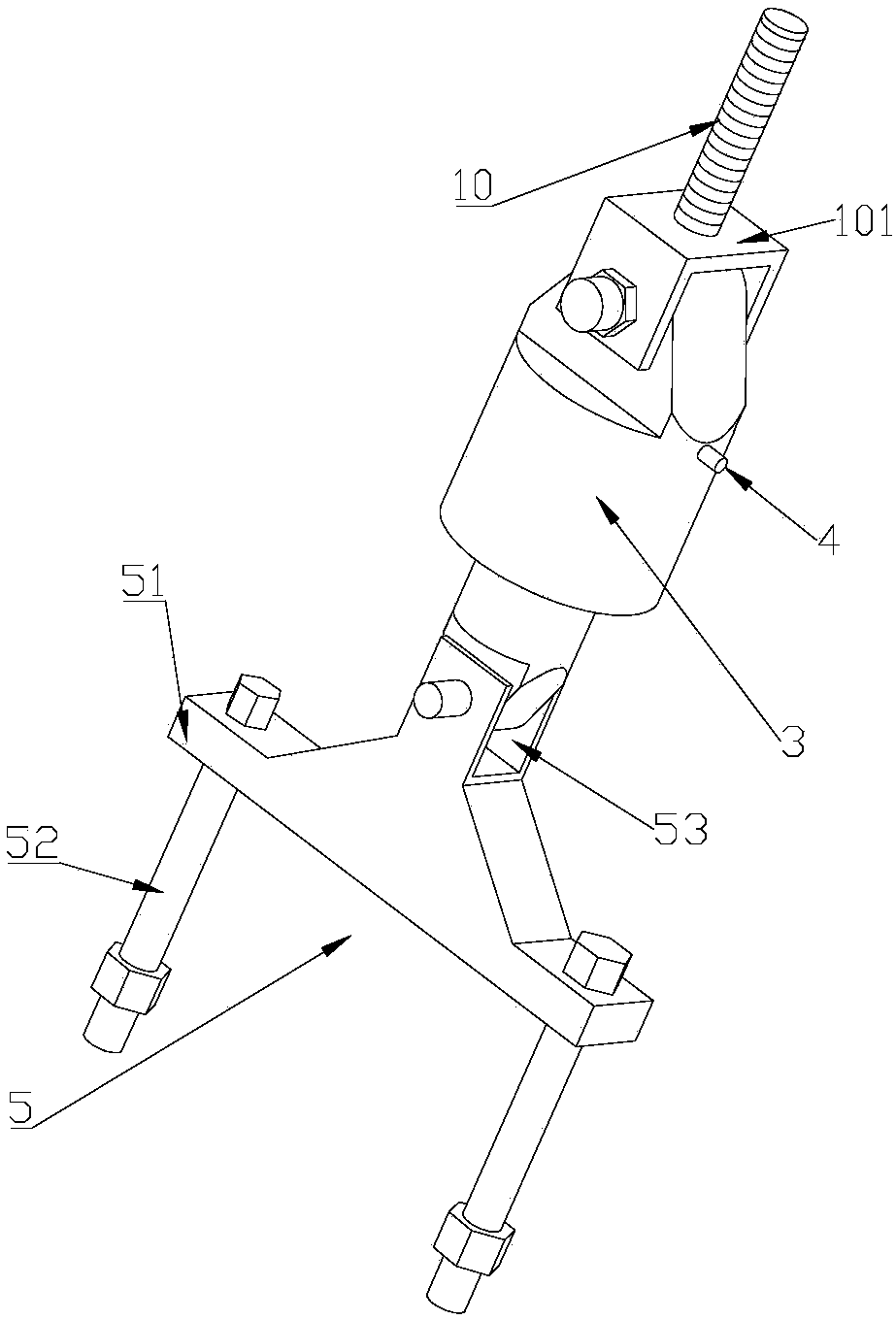

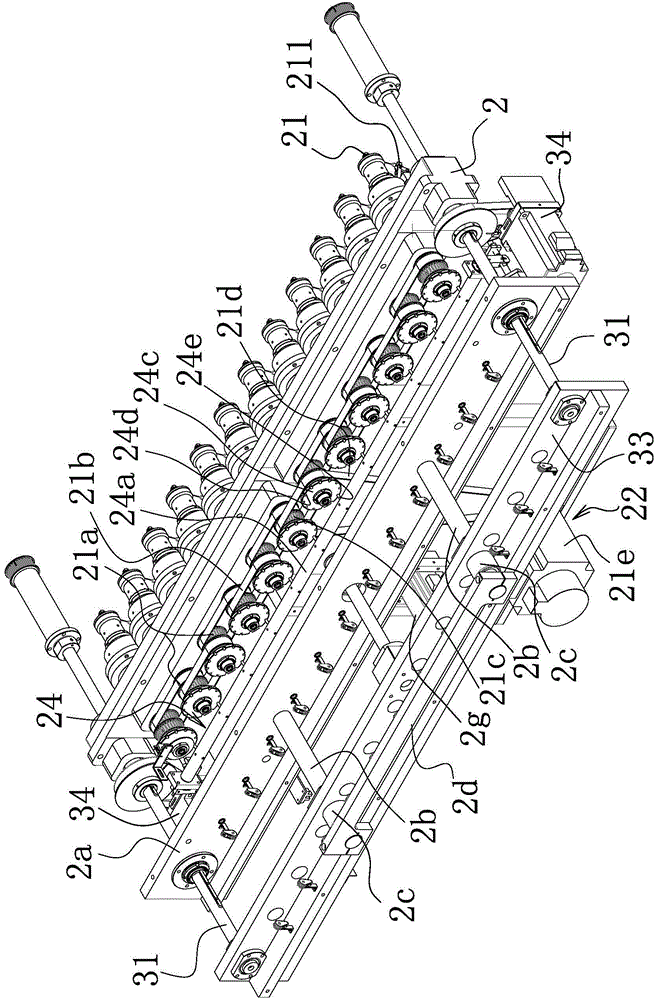

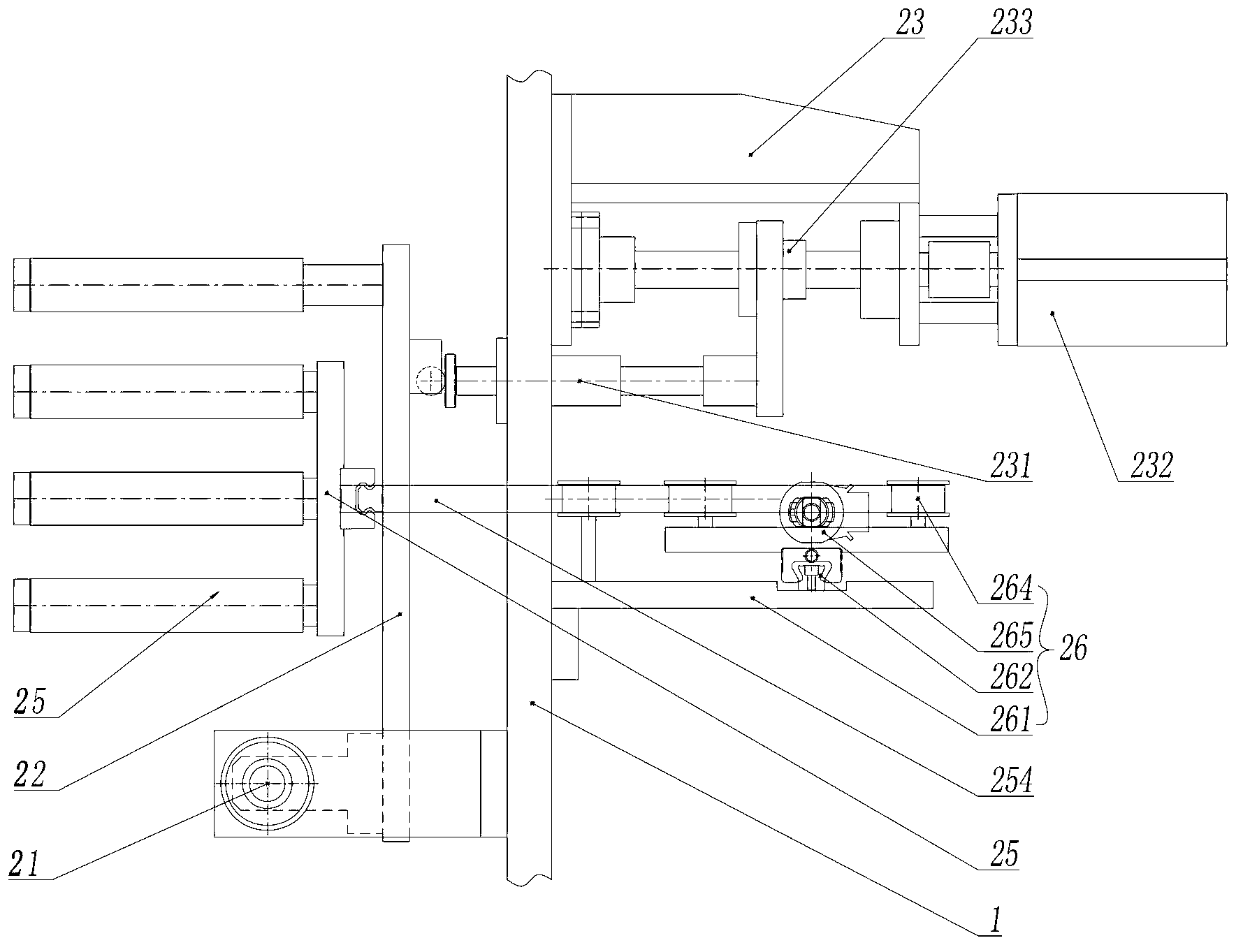

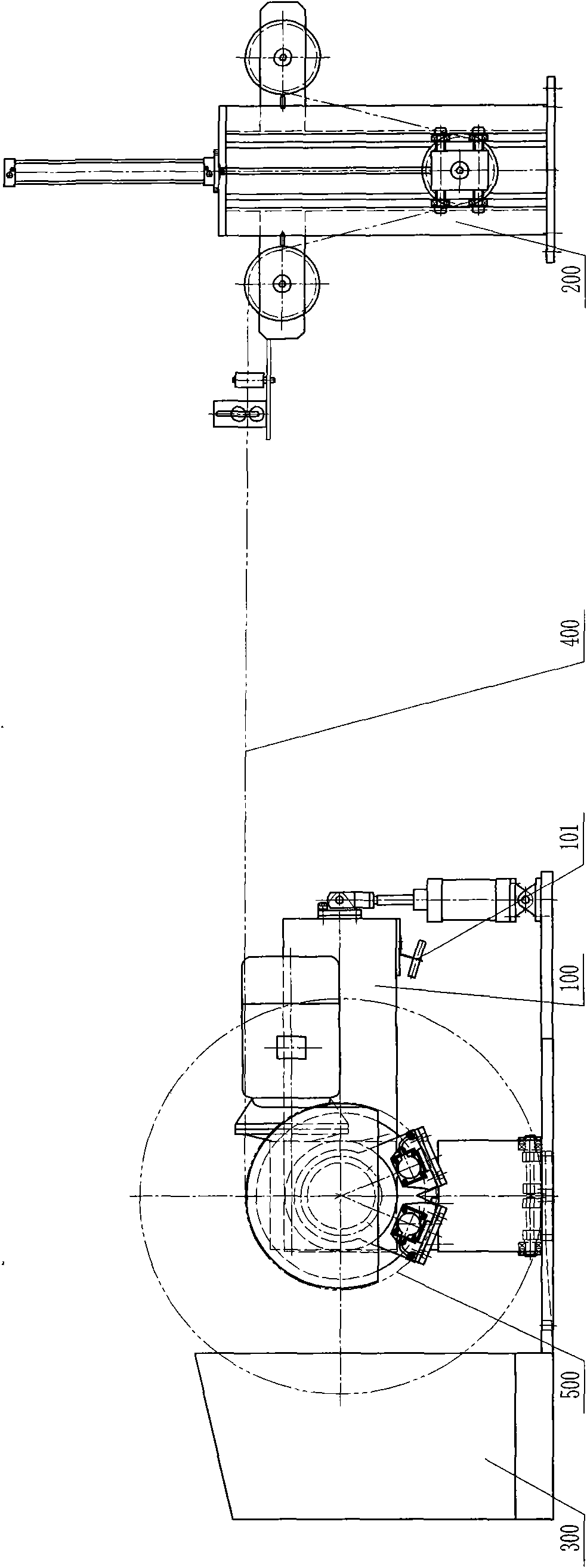

Piece-making and winding joining device

ActiveCN103231935AEliminate vertical deviationHigh positioning accuracyFinal product manufactureSecondary cells manufactureWinding machineWind system

The invention discloses a piece-making and winding joining device which is used for process control of a pole piece between a piece-making system and a winding system of an electric core fully automatic winding machine. The piece-making and winding joining device comprises a vertically arranged substrate of the fully automatic winding machine, a swing deviation correction part arranged on the substrate, a pole piece driving mechanism and a tension control mechanism, wherein the delivery direction of the pole piece is parallel with the substrate; the swing deviation correction part is connected after the piece-making procedure, is internally provided with a snakelike buffer region of the pole piece, and is used for performing swing deviation correction on the pole piece after subjected to the piece-making procedure; and the pole piece driving mechanism and the tension control mechanism are connected sequentially, and are used for drawing the pole piece in the snakelike buffer region and performing tension control on the pole piece which enters into the winding procedure. The piece-making and winding joining device has the advantages that: the swing deviation correction mechanism removes vertical deviation between the pole piece and the vertical substrate efficiently, enables the edge positioning precision of the pole piece to be high and enables the pole piece to enter into the winding part in parallel and precisely; and the tension control mechanism controls the tension of the pole piece, and adopts different tensions for pole pieces with different widths so as to prevent corrugation and breakage of the pole pieces.

Owner:DONGGUAN ARECONN PRECISION MACHINERY

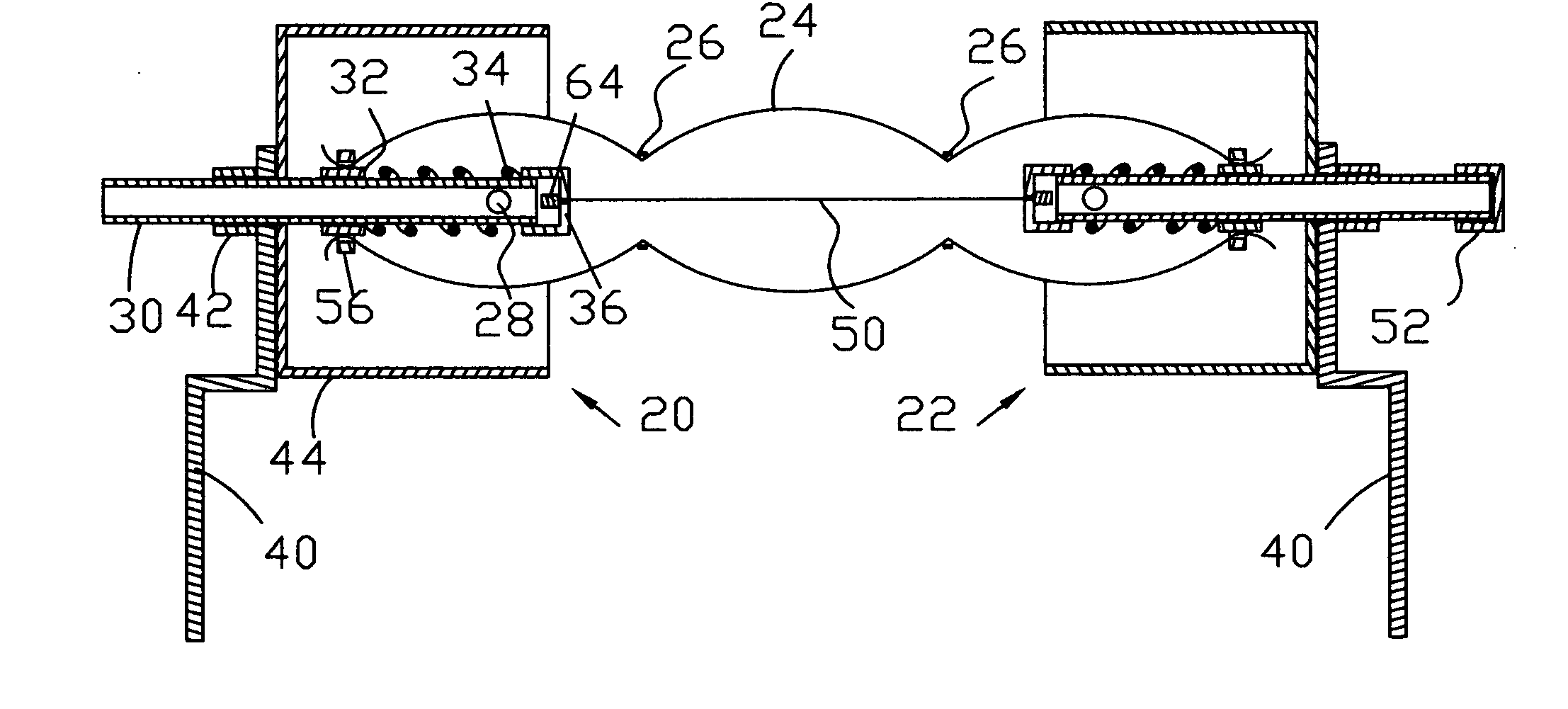

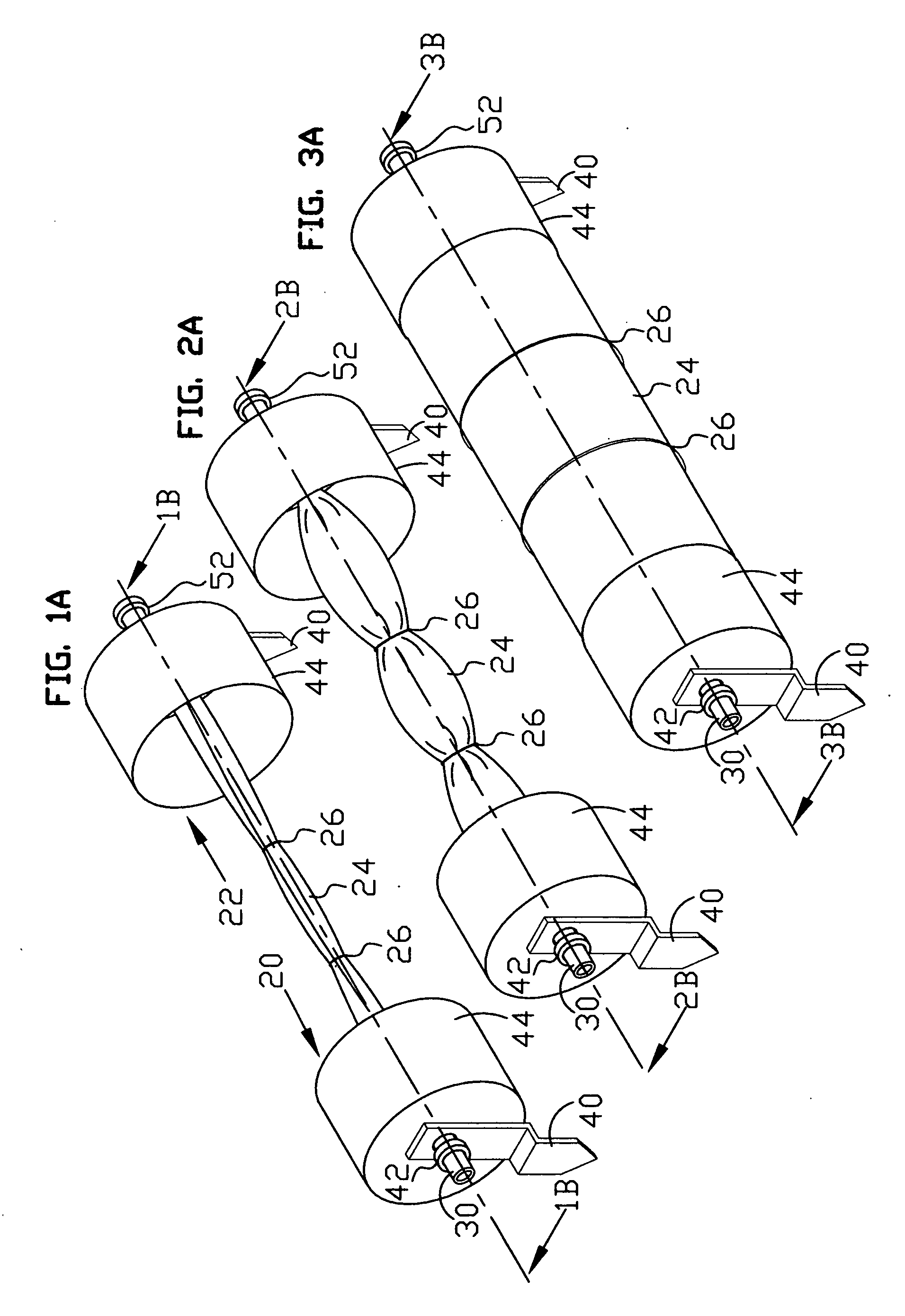

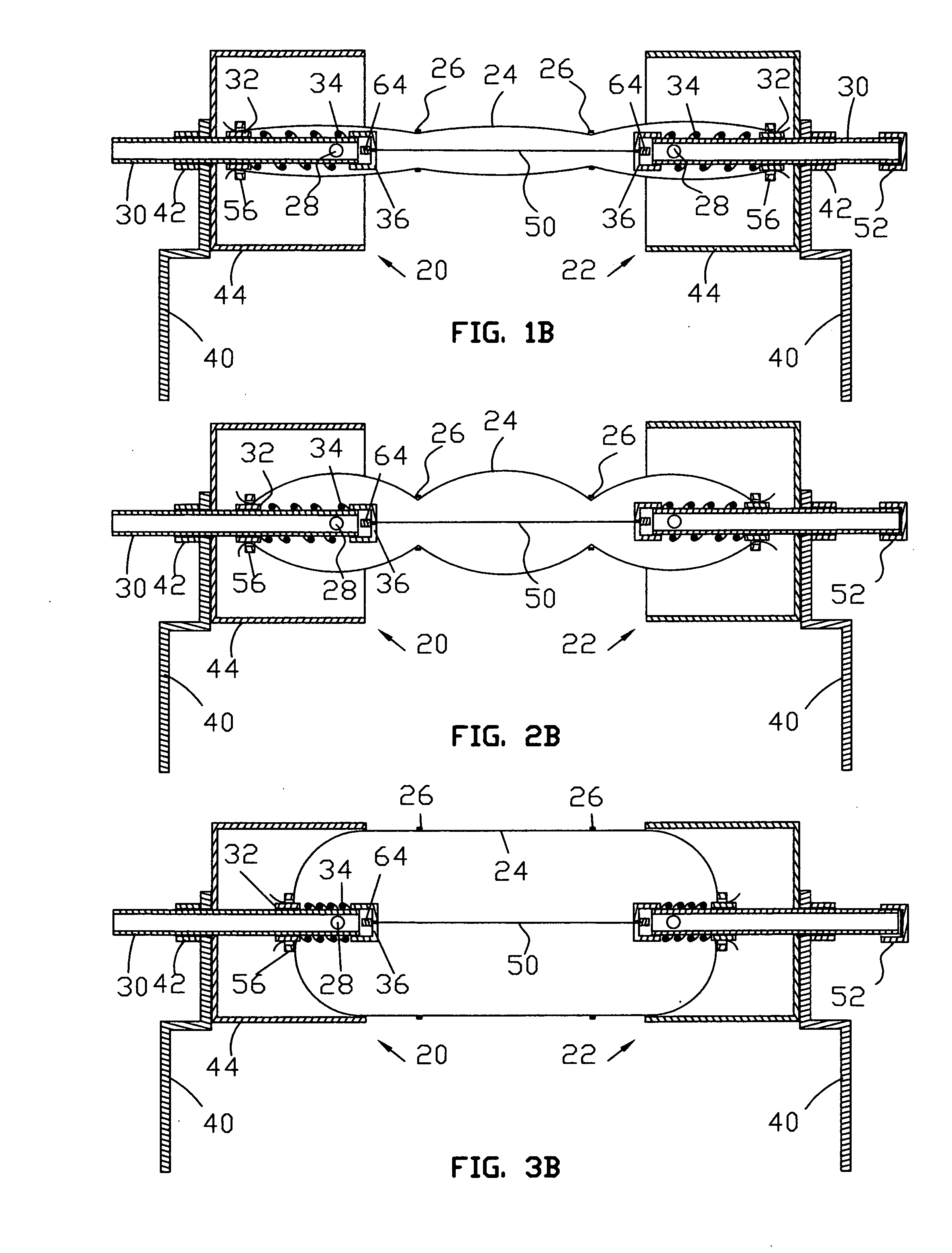

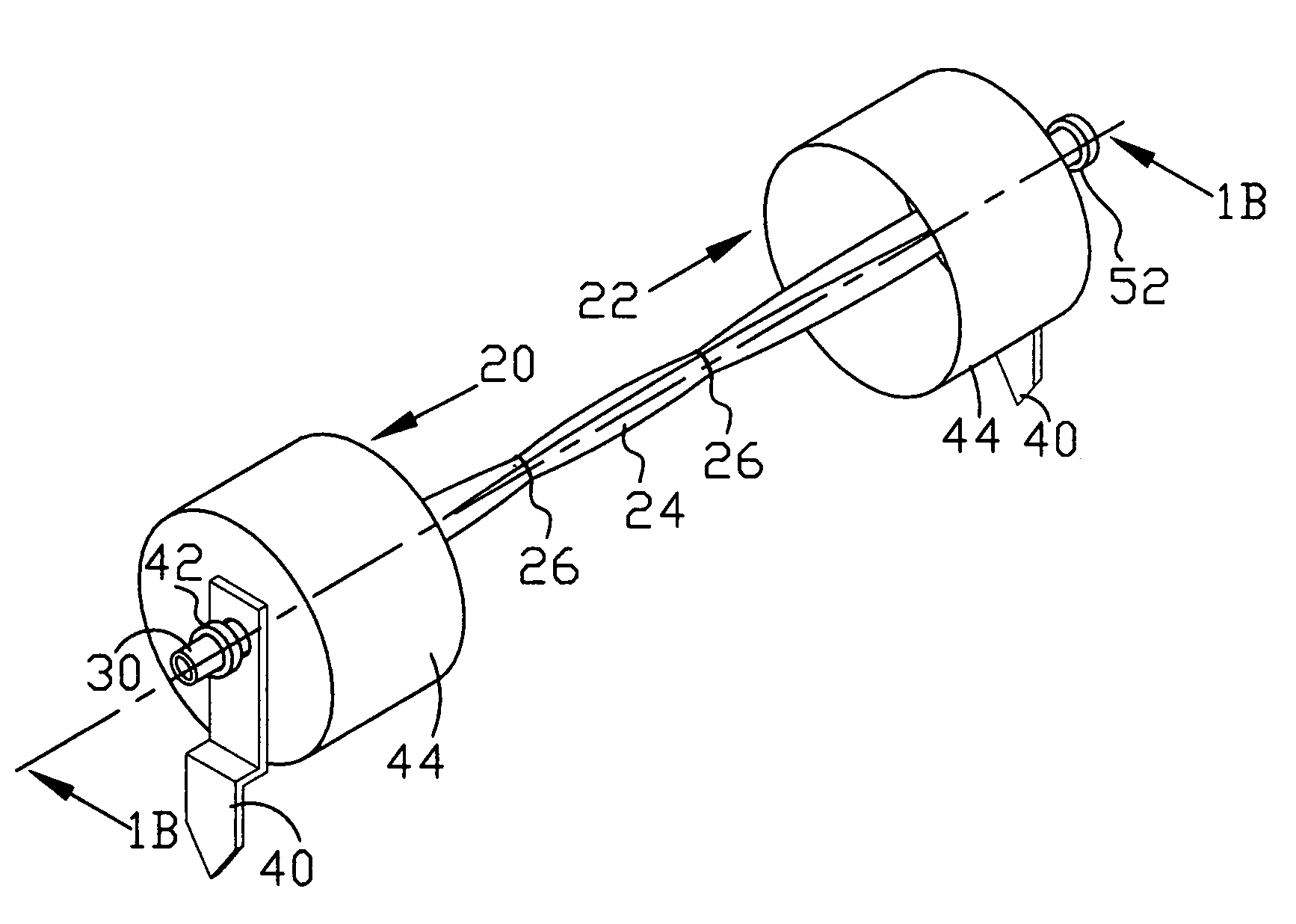

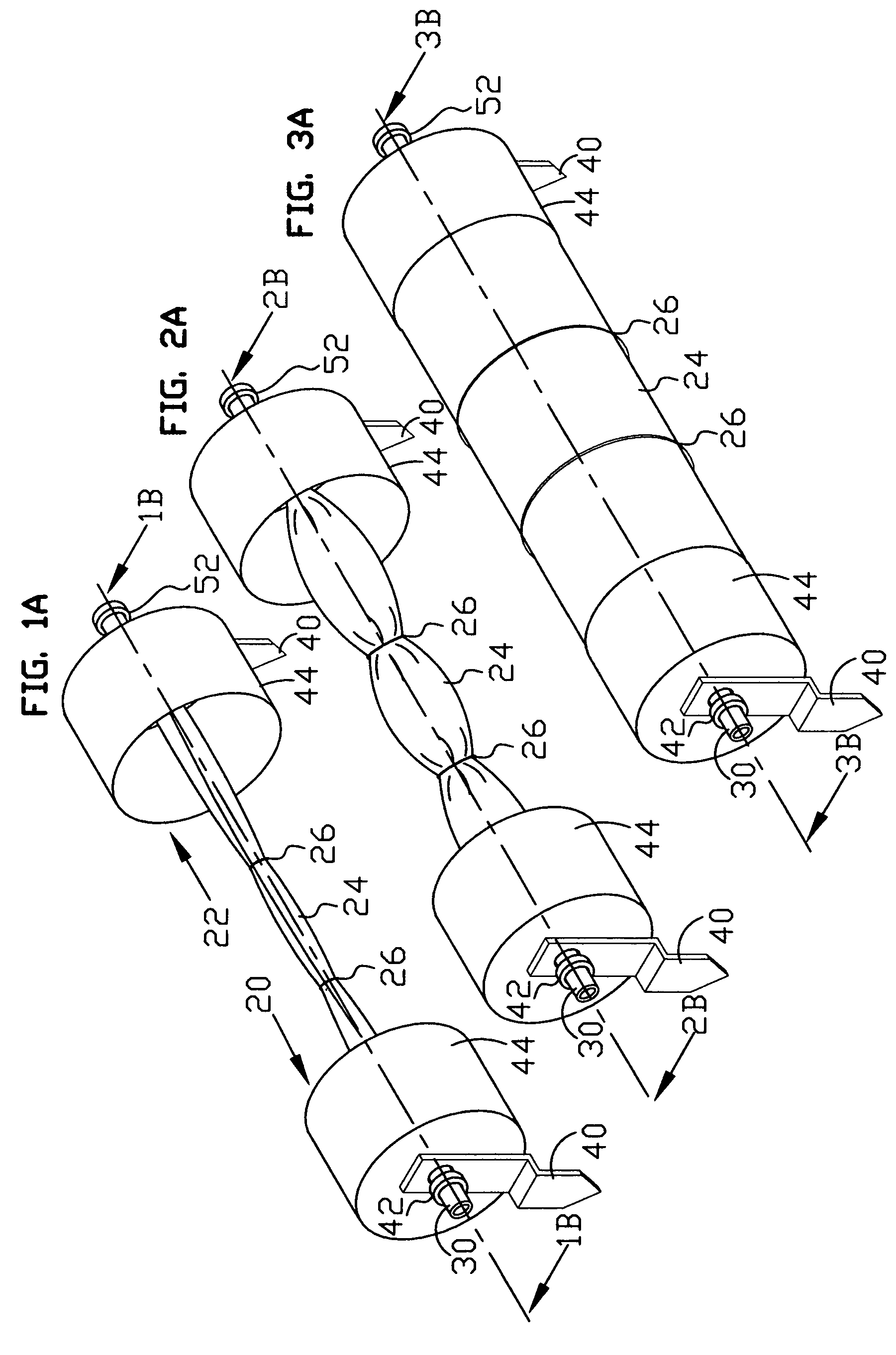

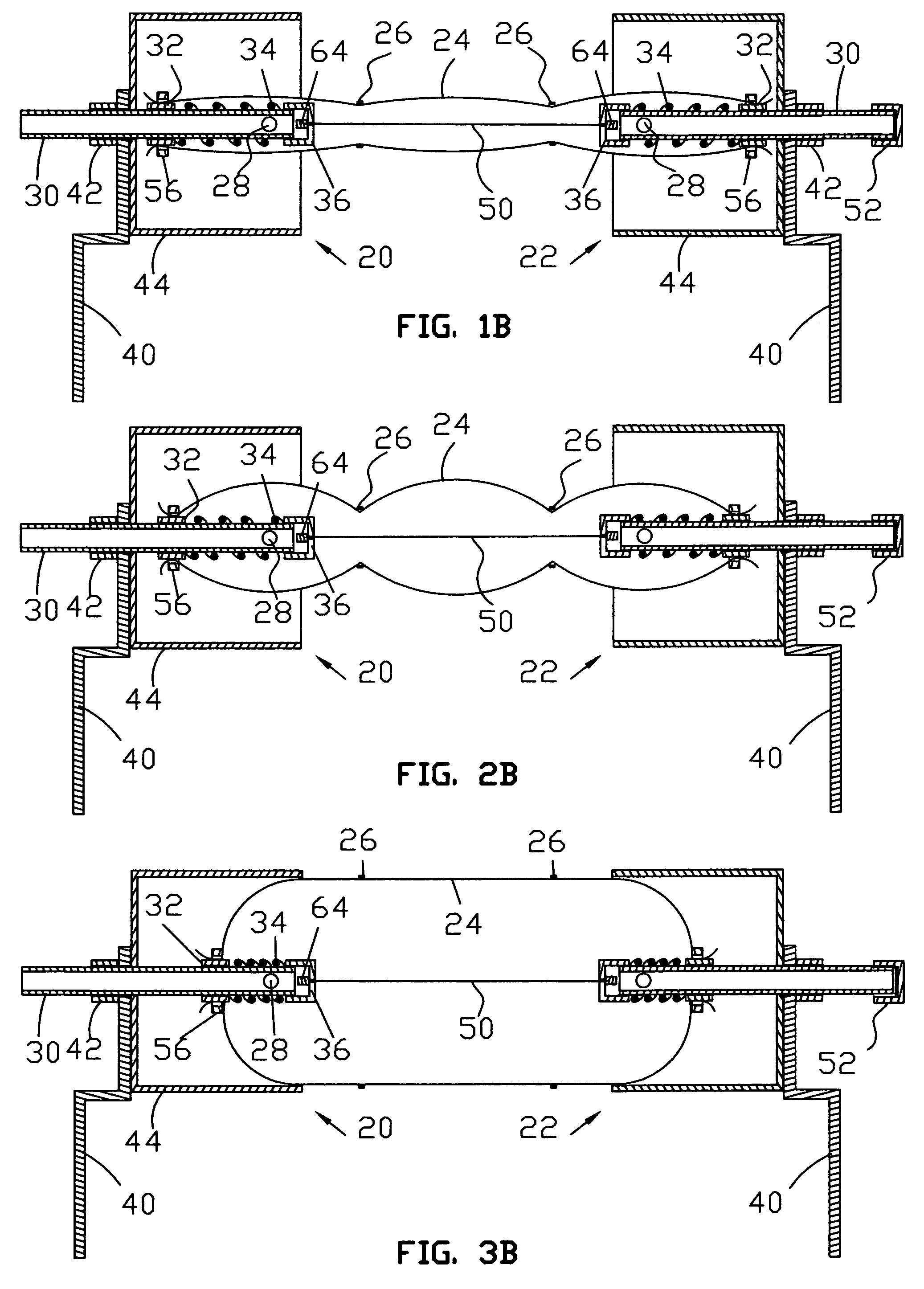

Tensioned inflatable cover module

InactiveUS20060059788A1Convenient lengthStable tensionRoof covering using tiles/slatesClimate change adaptationEngineeringLength contraction

Modular inflatable cover for buildings, comprising separate coaxial conduits (30) secured together by tensionable link (50) and fluid-connected by coaxial inflatable tube (24). Tube (24) securely embraces sliders (32) that in turn closely but freely embrace conduits (30). Sliders (32) are urged by springs (34) to keep tube (24) taught. Elastic cinctures (26) on tube (24) and springs (34) tensionably cooperate against inflation means to provide reliable control of openings between adjacent modules in an assembly. Conduits (30) are securely torqued to ground anchors (40) by coupling (42). End covers (44) and sliders (32) are provided to compensate for and facilitate length shrinkage of tube (24), upon inflation. The present invention provides a variable cover with integral support that is uniquely capable of exploiting canyons and other ground depressions for an unprecedented scale of environment control. Applications include greenhouses, shutters, insulation and shelters.

Owner:KASSIANOFF EDOUARD PICHKO

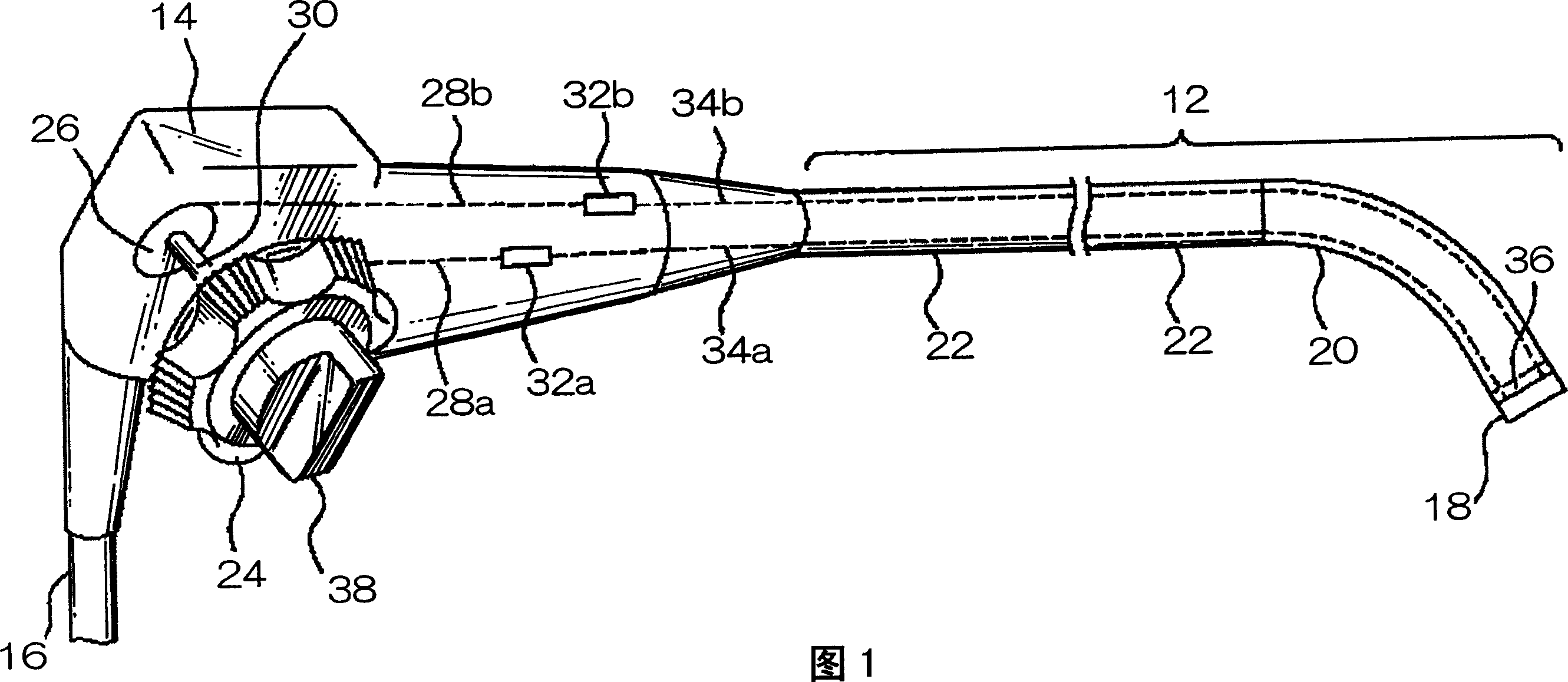

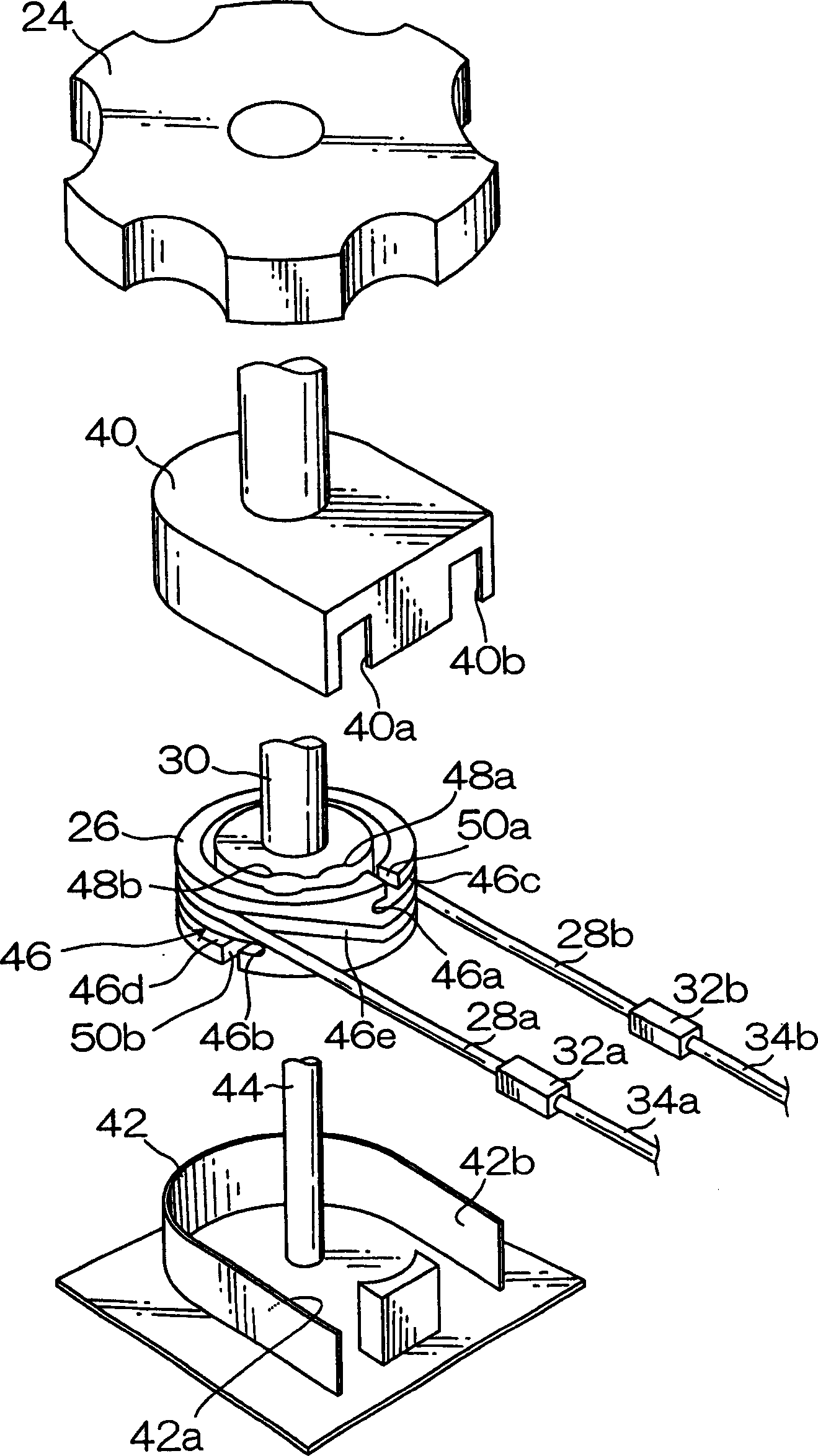

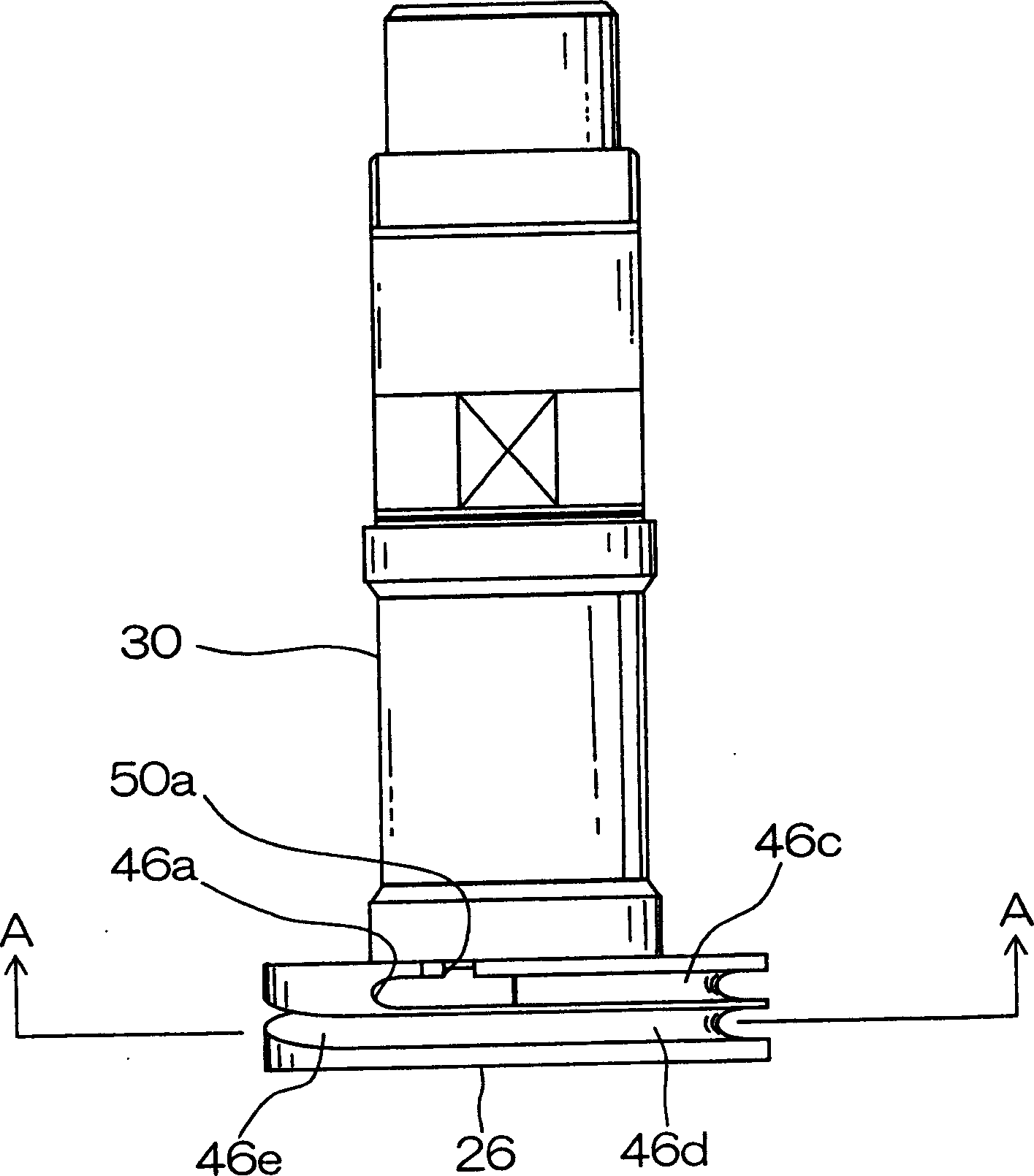

Bend operating apparatus for endoscope

The curving operation device of an endoscope is provided with the pulley 26 to be turned by an angle knob 24 and a groove 46 in a helical shape is formed on the outer peripheral surface of the pulley 26. The proximal end parts of a pair of traction wires 28a and 28b are wound from the end parts 46a and 46b of the groove 46 to the groove 46. The distal parts of the traction wires 28a and 28b are extended from the pulley 26 and connected via connecting members 32a and 32b to angle wires 34a and 34b. The traction wires 28a and 28b are constituted by twisting the plurality of wires 56 in the same direction as the winding direction of the groove 46.

Owner:FUJI PHOTO OPTICAL CO LTD

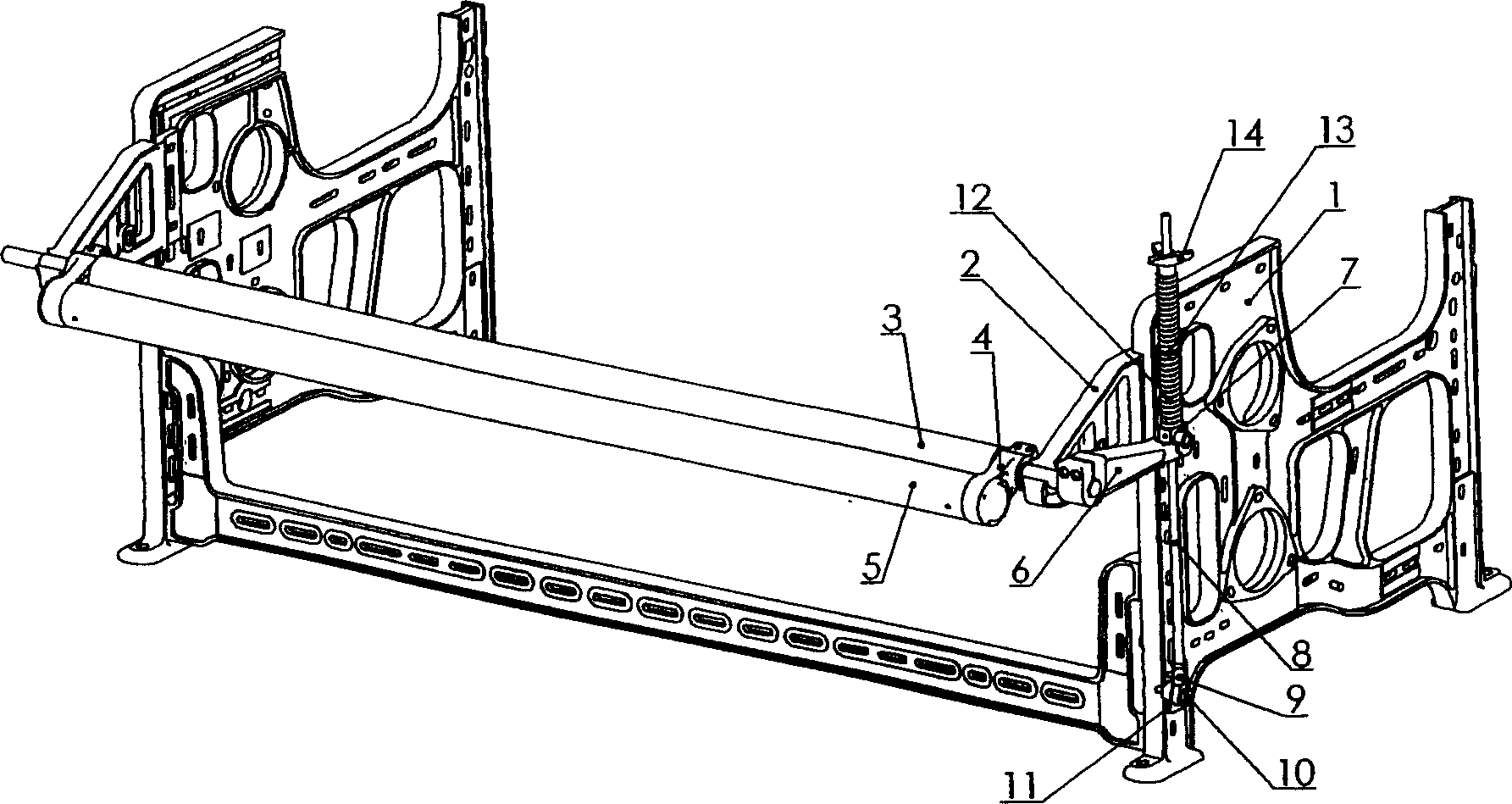

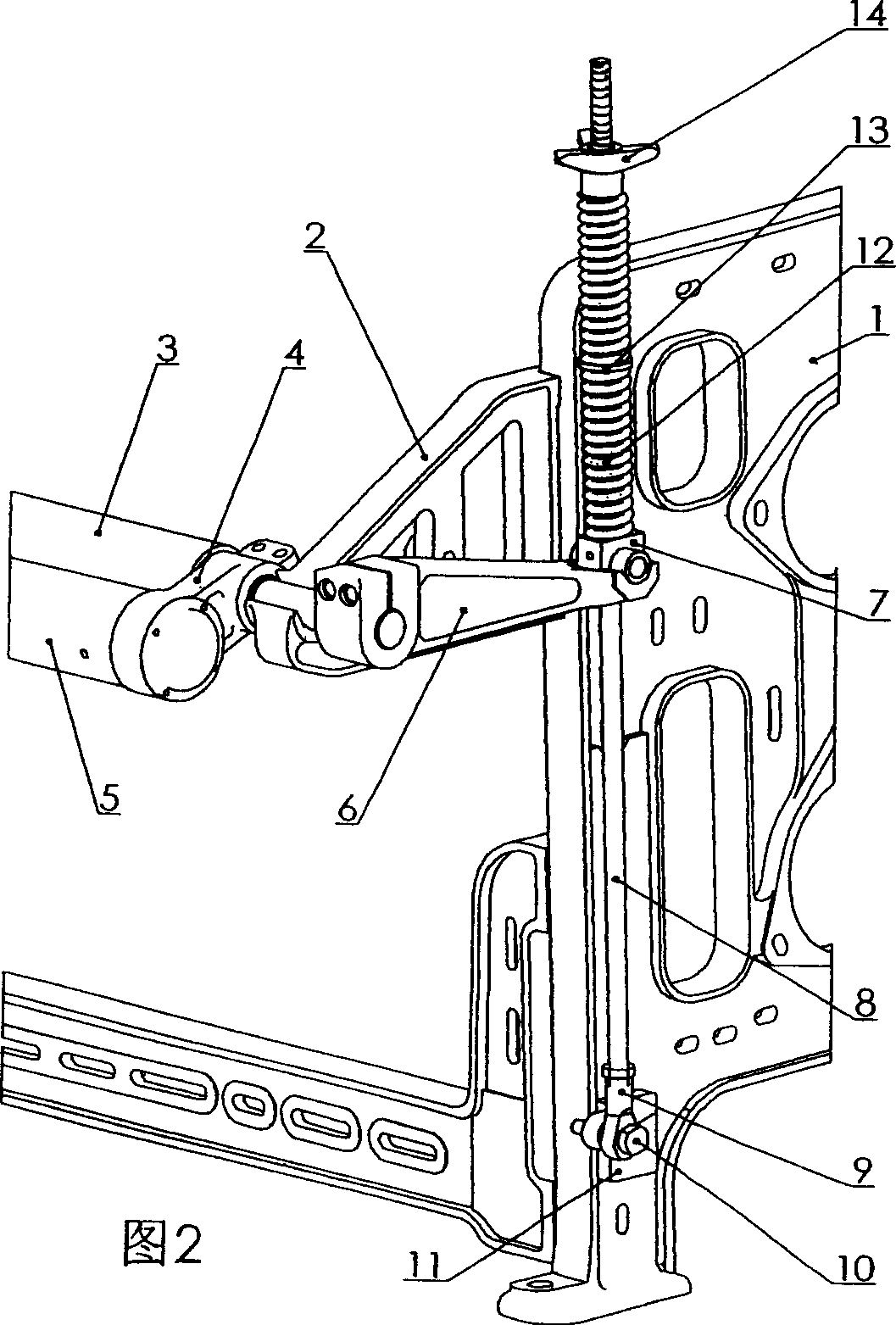

Bottom warp feeding tension balance regulating mechanism for towel rapier loom

The invention relates the towel gripper loom ground warp and run-in warp tension balance controlling mechanism, comprising back rail pin, back bar conjunction, ranging arm conjunction, stretch roll conjunction installed on ranging arm conjunction by axle bearing, balance bar fixed on back bar conjunction, counterbalancing mass on the back end of balance bar. The lower end of tension balance bar is fixed on wall plate, and the tension balance bar comprises adjustment hand-wheel, compression spring, spring positioning disk and counterbalancing mass, and the adjustment hand-wheel is connected with tension balance bar by thread. The mechanism has the following advantages: 1 reducing cutting end; 2 reducing friction and reducing broken ends; 3 making the tension on loom stable.

Owner:邹荣金

Slip motor automatic control device

InactiveCN101604952ASame torqueSynchronous control is directly effectiveDynamo-electric brake controlAutomatic controlClosed loop

The invention relates to a slip motor automatic control device. The device comprises a slip motor, a tension signal acquisition device and a slip motor controller, wherein the tension signal acquisition device is used for converting the tension expanded when materials are processed into a tension signal; and the slip motor controller is used for comparing the tension signal with the preset normal value and automatically controlling the slip motor according to the comparison result. The device adopts the closed loop tension automatic control mode, and sets the normal value according to the characteristics of the materials; and when a tension senor detects a tension error of the materials, the voltage and the current needed by the slip motor are automatically regulated and outputted after automatic comparison, so that the automatic circulation functions of target determining, automatic detection, automatic comparison and automatic regulation are achieved.

Owner:BEIJING JINPUTE PRINGTING MACHINE

Belt unreeling device

InactiveCN101850485ASpeed matchPrecisely control startup speedWelding/cutting media/materialsSoldering mediaPull forceEngineering

The invention discloses a belt unreeling device which comprises a belt unreeling machine, an electric control system and a speed difference buffer detector, wherein the belt unreeling machine is provided with a drive motor; the speed difference buffer detector feeds a speed difference signal between the belt unreeling machine and the next stage device back to the electric control system, and the electric control system adjusts the rotation speed of the drive motor according to the speed difference signal; the belt unreeling machine is provided with a distance sensor for measuring the diameter of the material reel; the range sensor feeds a reel diameter signal of the material reel back to the electric control system; and the electric control system controls the initial rotation speed of the drive motor according to the reel diameter signal and the preset speed of the next stage device of the belt unreeling machine. The invention can realize speed matching between the current device and the next device, ensures stable relative running speed and stable tensile force on the steel belt, reduces the frequency of the steel belt being fractured by tension, enhances the production efficiency and ensures the product quality.

Owner:TIANJIN SAINTEAGLE WELDING CO LTD

Low-carbon wire constant tension rewinding shaft device

The invention relates to a low-carbon wire rewinding shaft device, in particular to a low-carbon wire constant tension rewinding shaft device. The low-carbon wire constant tension rewinding shaft device structurally comprises a flexible damping payoff mechanism, a constant speed traction mechanism, a tension control mechanism and a plastic finished product bobbin, wherein the flexible damping payoff mechanism, the constant speed traction mechanism, the tension control mechanism and the plastic finished product bobbin are arranged in the running direction of a rewound wire. According to the low-carbon wire constant tension rewinding shaft device, the take-up speed can be regulated to stabilize tension according to a tension change represented by the specification and strength of the wire, so that the phenomena of circle swinging, wire clamping and tightness non-uniformity of the rewound wire are avoided, and the quality of a product is greatly improved.

Owner:TIANJIN HUAYUAN WIRE PROD

Tensioned inflatable cover module

InactiveUS7562493B2Convenient lengthStable tensionRoof covering using tiles/slatesClimate change adaptationGreenhouseEngineering

Owner:KASSIANOFF EDOUARD PICHKO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com