Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1539results about How to "Smooth cut" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

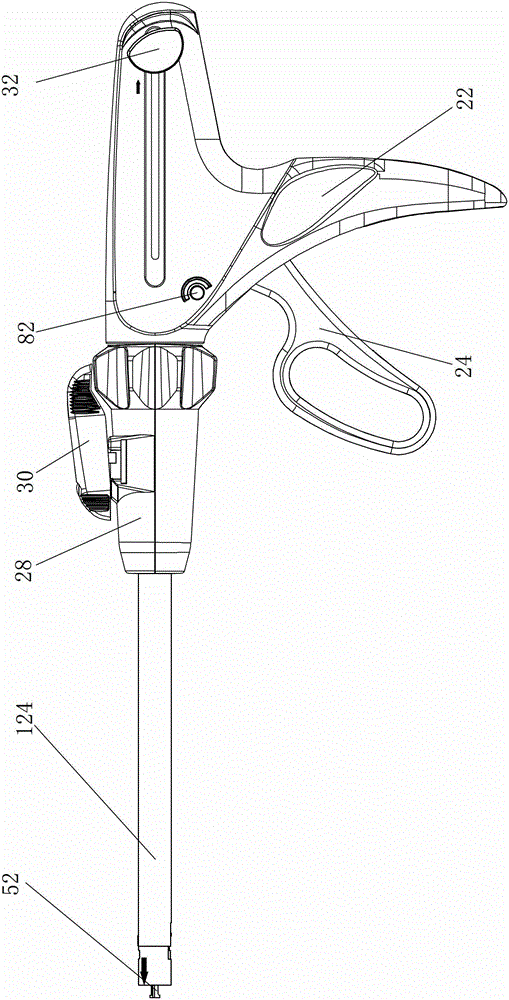

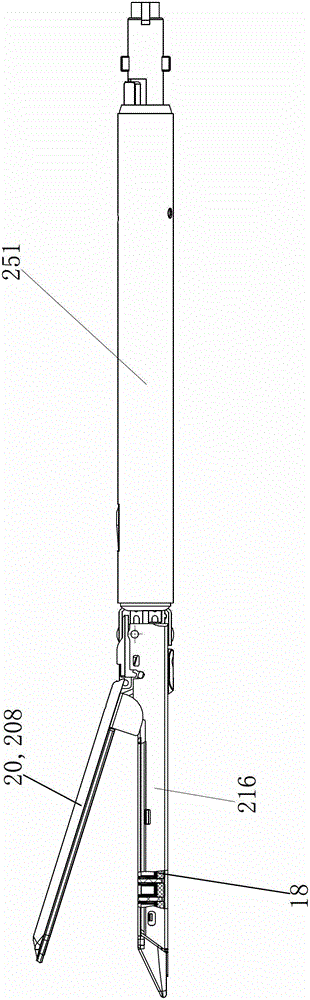

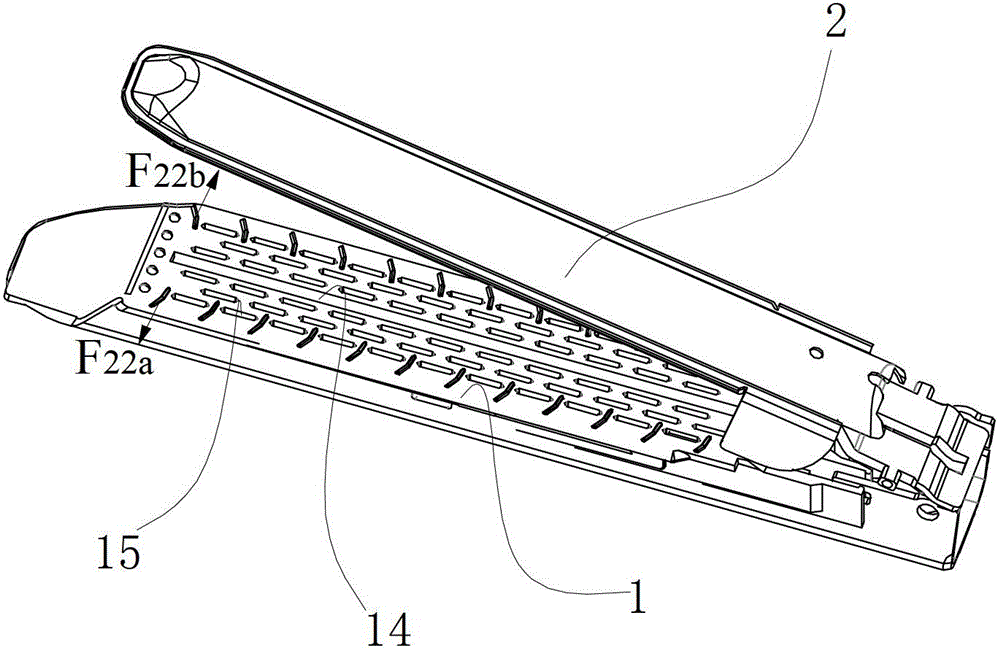

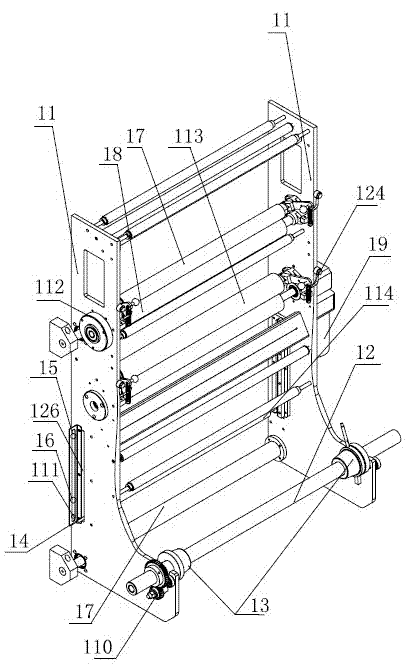

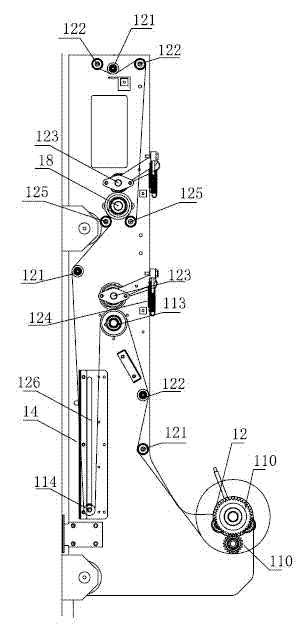

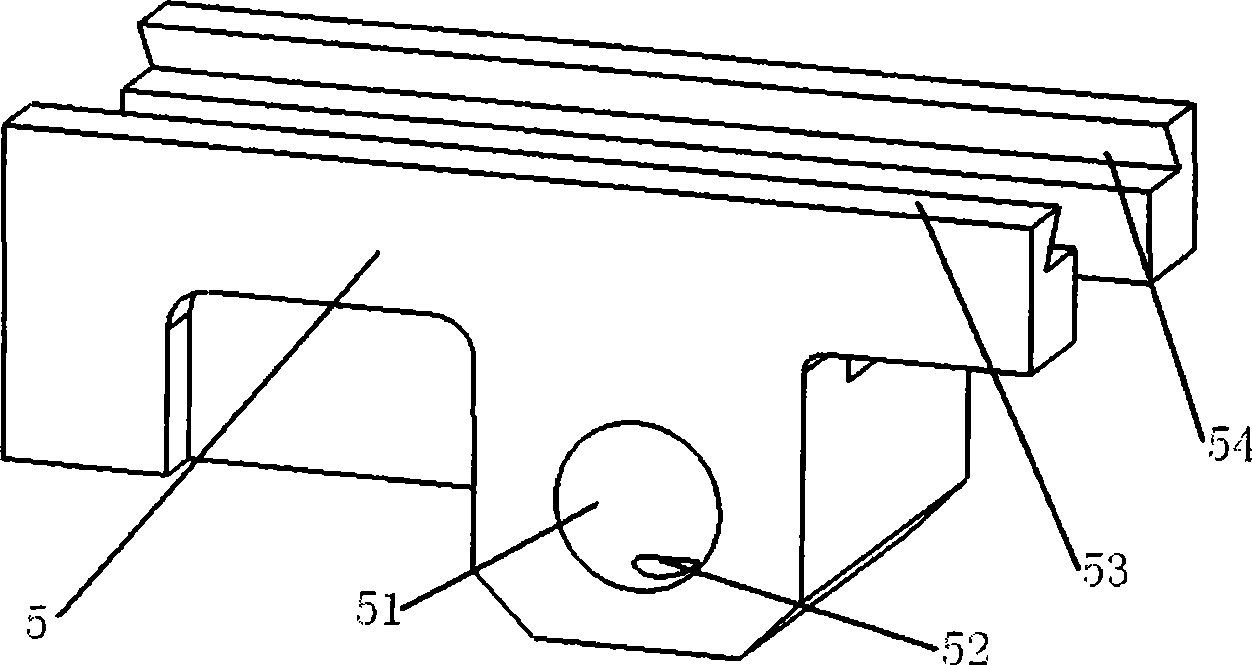

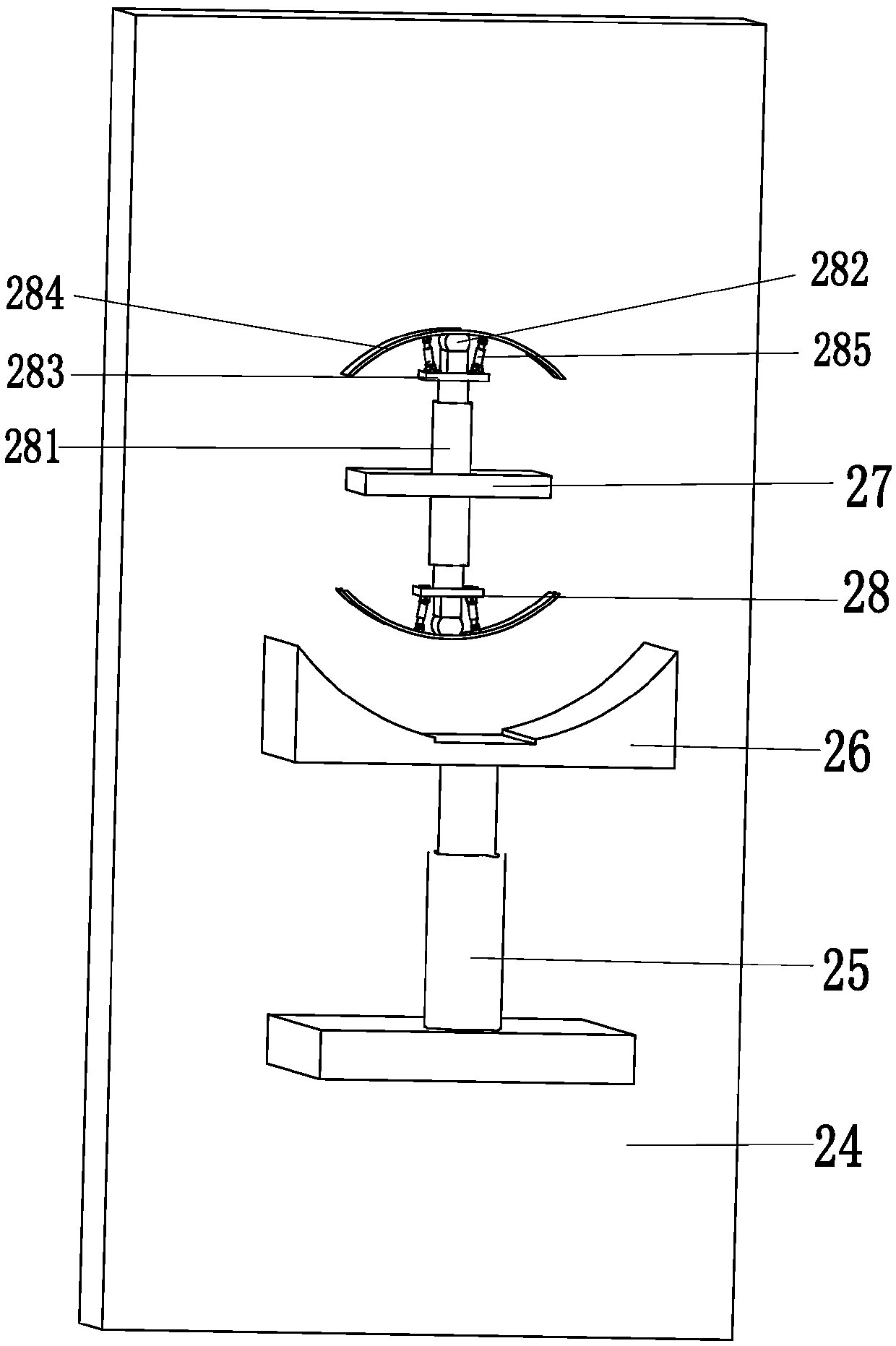

Tissue clamping part of linear cutting stapler and its staple cartridge seat

ActiveCN102973300BCause some damagesNot easy to slip offSurgical staplesEngineeringStructural engineering

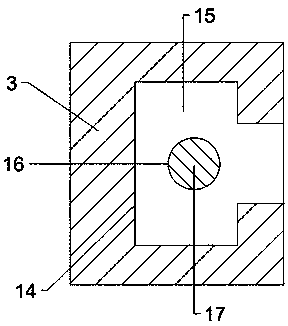

The invention discloses a tissue clamping member of a linear cutting anastomat and a nail granary of the tissue clamping member. The left side and the right side of a nail discharging surface of the nail granary are respectively provided with one column of barrier bars and barrier bulges, which are parallel to a knife pushing groove, and the front end part of a nail supporting surface of a nail supporting base of the tissue clamping member is provided with one row of semi-spherical concave holes along the left-right direction. During the use, the barrier bulges apply an acting force with the direction which is opposite to the advancing direction of a cutting knife to the clamped human body tissue, the two columns of barrier bars apply leftwards and rightwards acting forces which have the direction opposite to the advancing direction of the cutting knife and face outside to the clamped human body tissue, therefore the clamped tissue is stable and firm without slipping, wherein the left column of barrier bar applies to a leftwards acting force to the human body tissue and the right column of barrier bar applies to a rightwards acting force to the human body tissue, therefore, the clamped tissue is tightened, and the cutting knife carries out cutting more smoothly when advancing forwards.

Owner:CHANGZHOU XIN NENG YUAN MEDICAL STAPLER

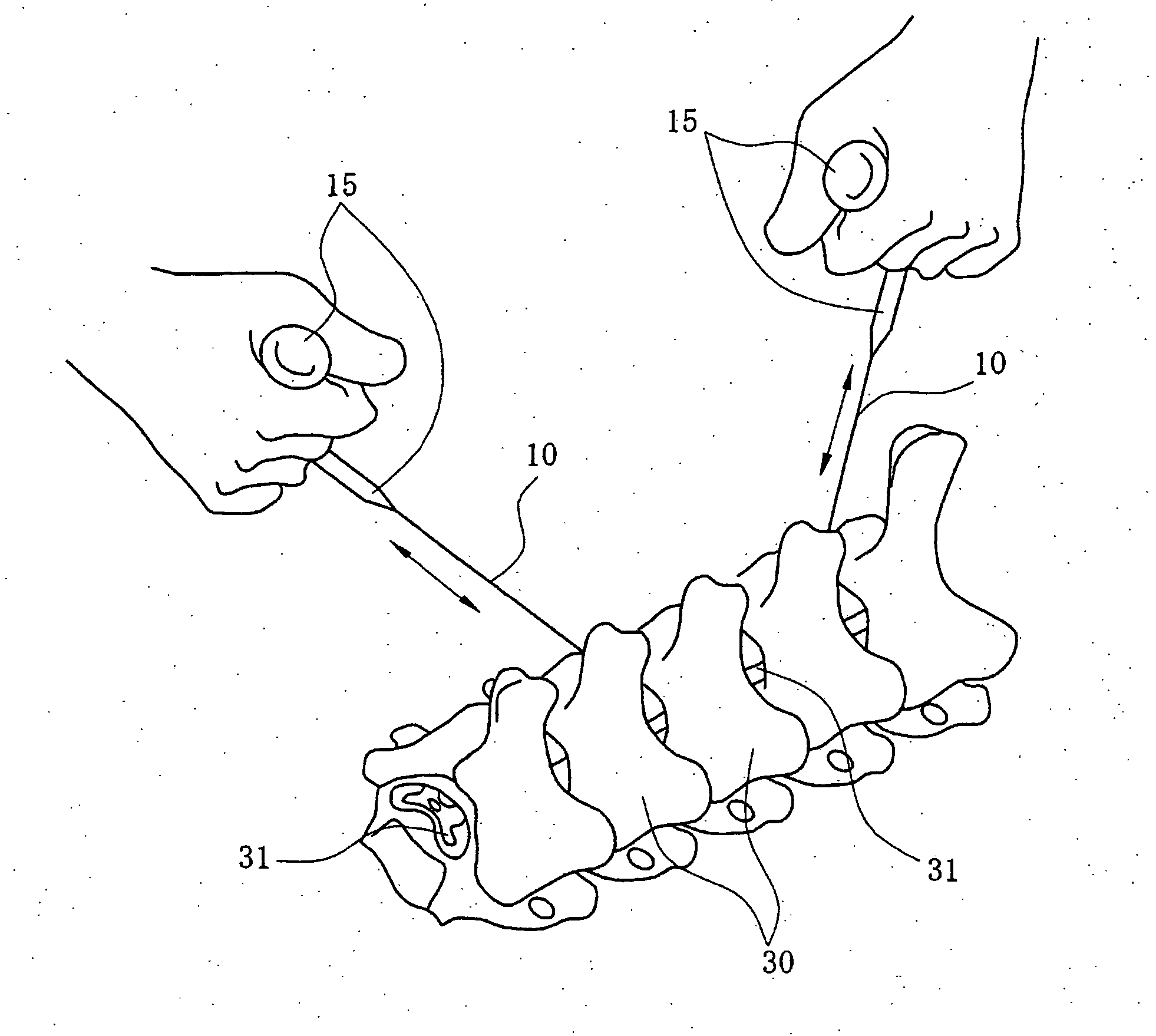

Surgical saw

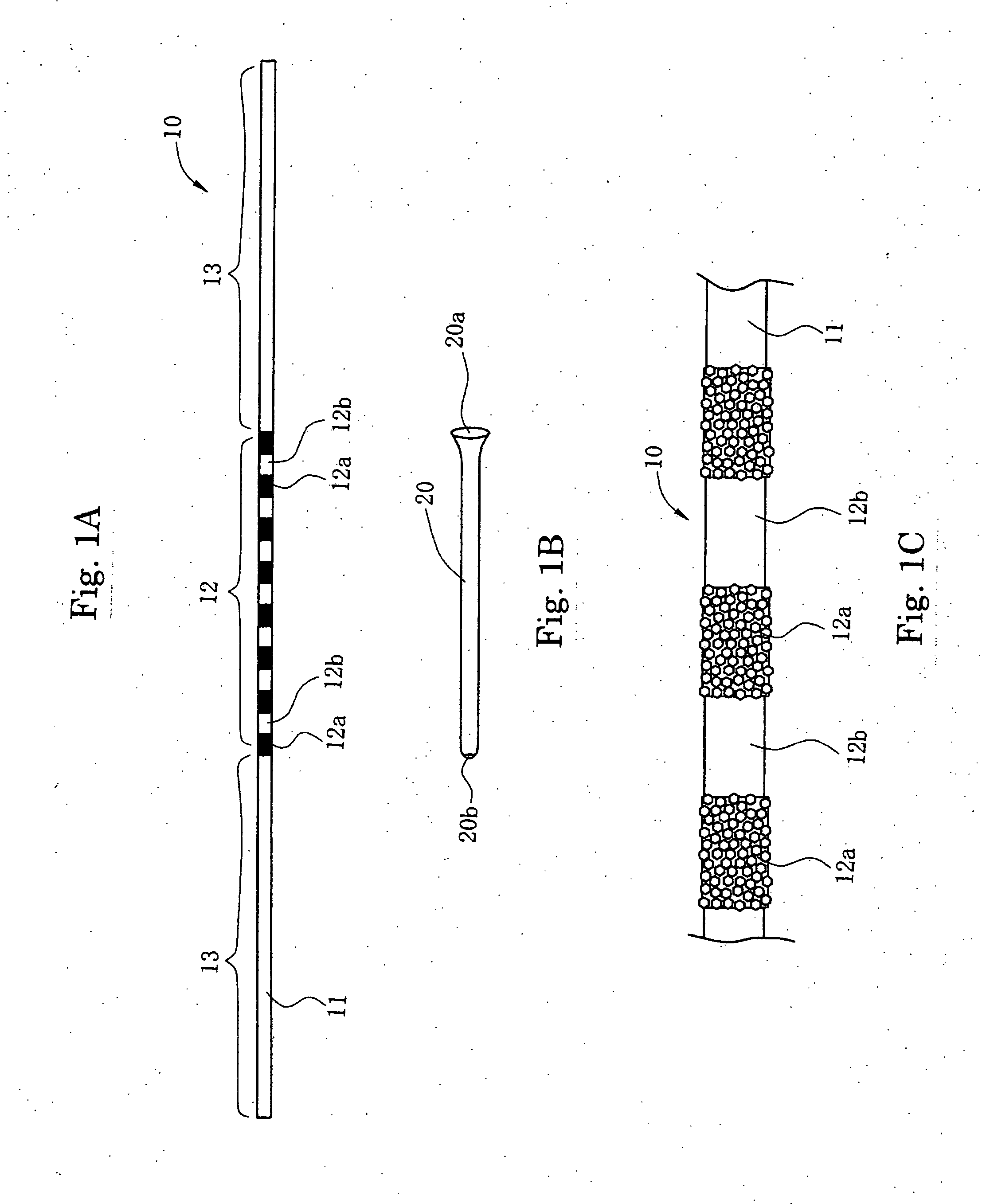

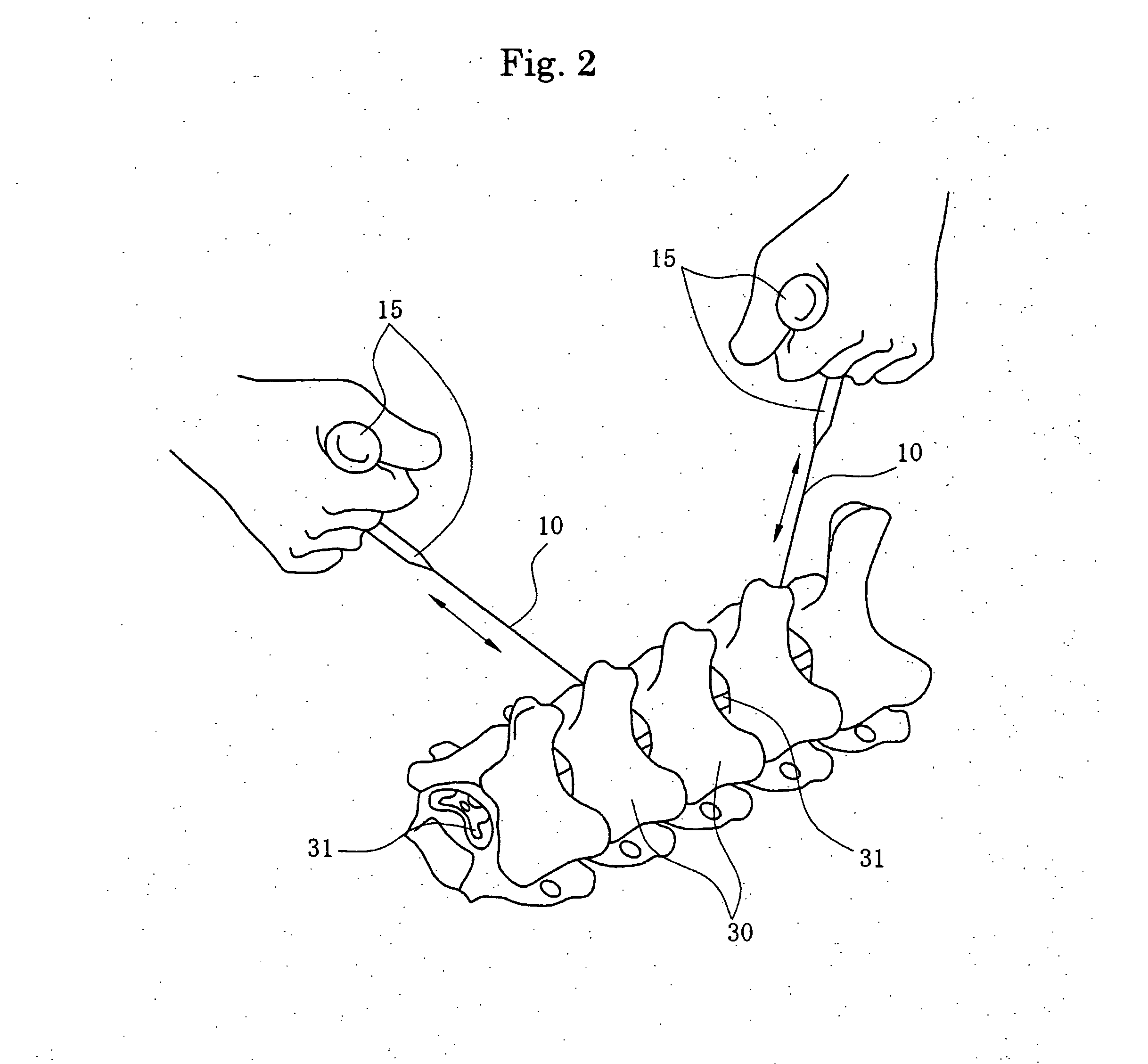

A surgical saw for cutting bone that can be used with ease in tight places yet maintain sufficient cutting power. The surgical saw 10 has a flexible linear body made of twisted stainless steel wire and cutting parts formed on the flexible linear body. The cutting parts are made of abrasive material affixed to the flexible linear body 12a alternating with portions of the flexible linear body with no abrasive particles 12b. Auxiliary cutting parts 13 of lesser cutting power may be provided along both lateral sides of each of the cutting parts 12.

Owner:MANI INC

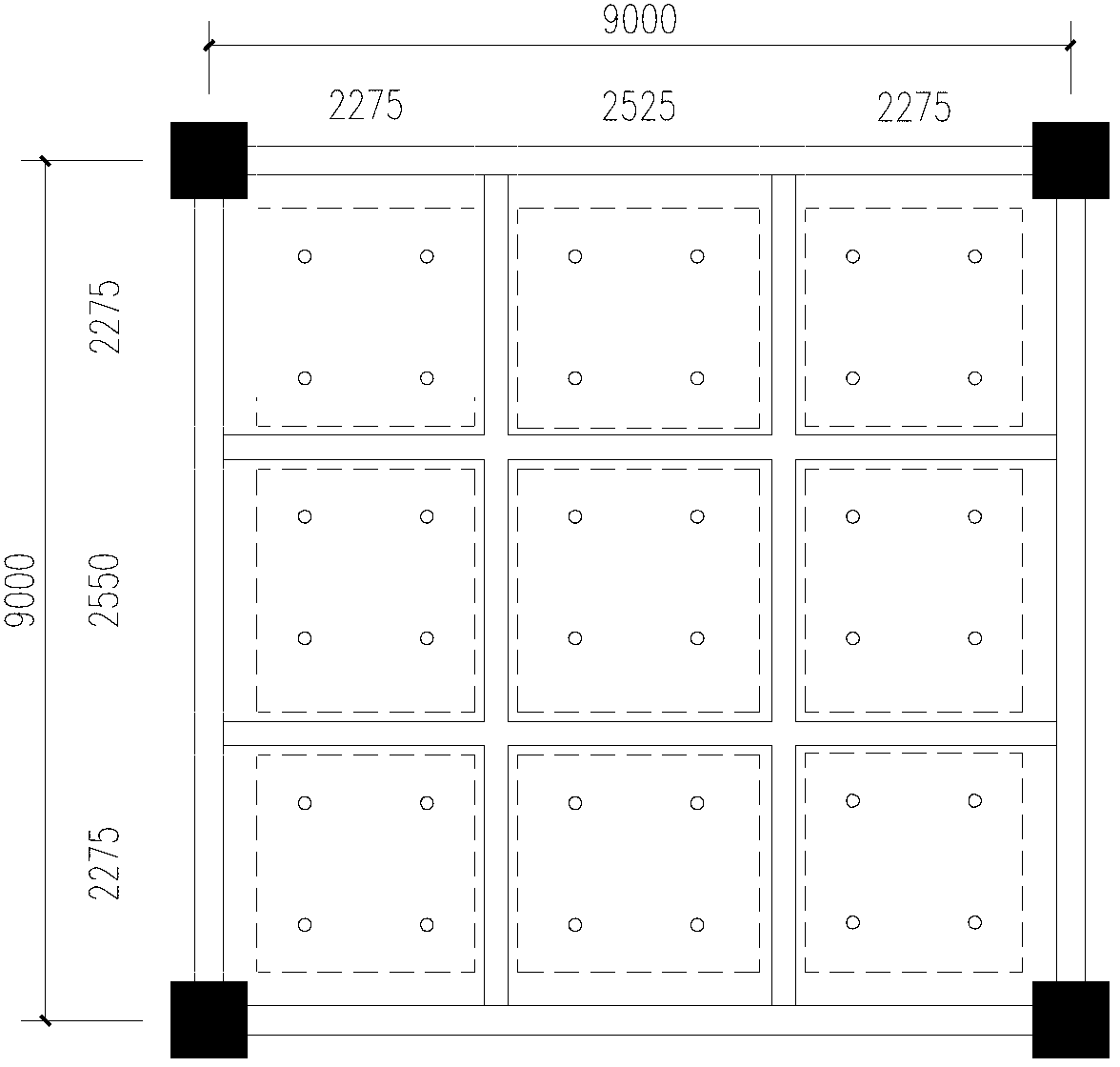

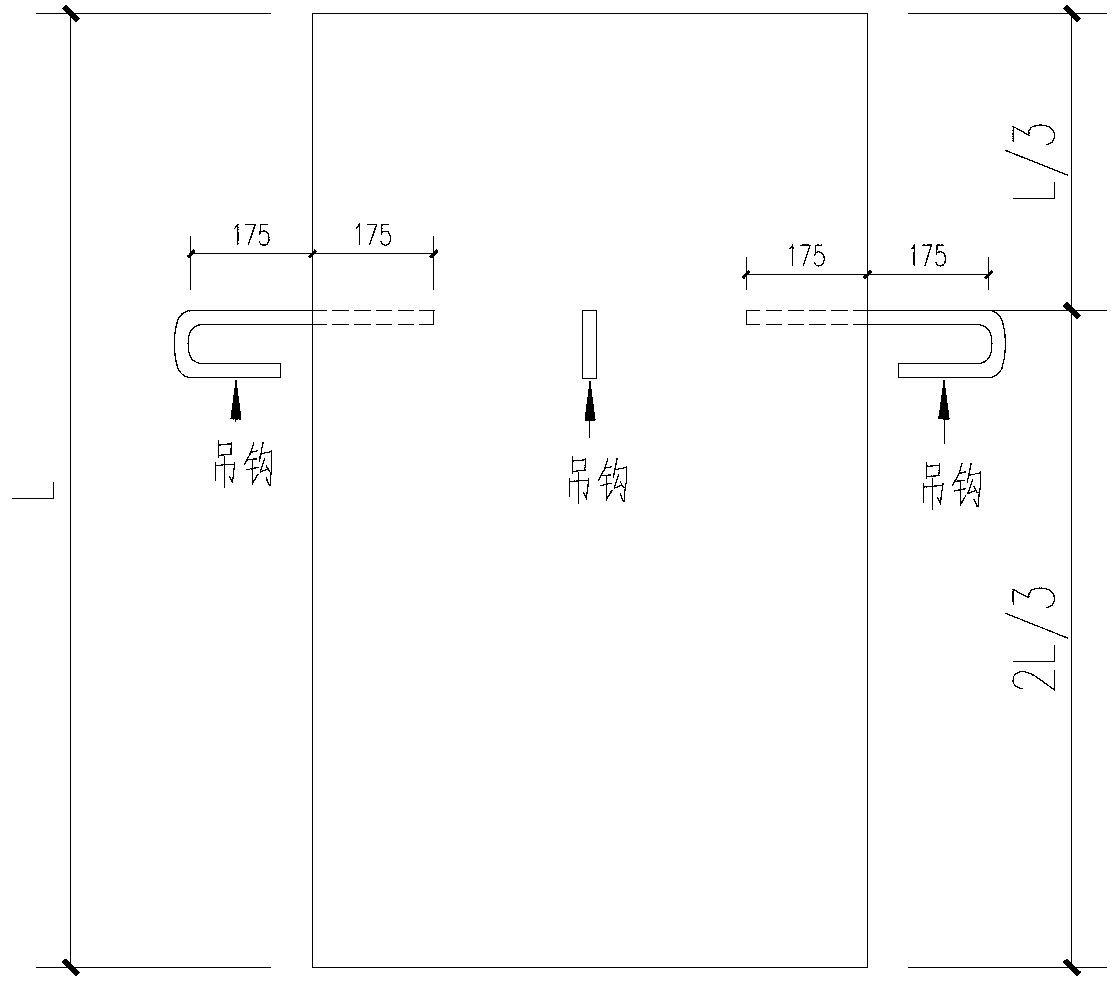

Concrete static force cutting dismantling construction method

InactiveCN103291085ANo vibration loadStructure has no effectBuilding repairsFalseworkReinforced concrete

The invention discloses a concrete static force cutting dismantling construction method which mainly comprises the steps of construction equipment selection, cutting unit division, supporting scaffold erection, hoisting auxiliary facility installation, cutting construction, component hoisting and site cleaning. The concrete static force cutting dismantling construction method has the obvious advantages that the effect on the surrounding structures is small in the process of constructing, the constructing speed, the constructing precision and the safety are high, and components which are cut through the static force are convenient to clean. The concrete static force cutting dismantling construction method is suitable for dismantling various reinforced concrete members, and especially for dismantling the part structures with the high demand for dismantling and with the small effect on an original structure. Time and production cost are greatly saved, and the construction period is effectively shortened.

Owner:恒中达建筑有限公司 +1

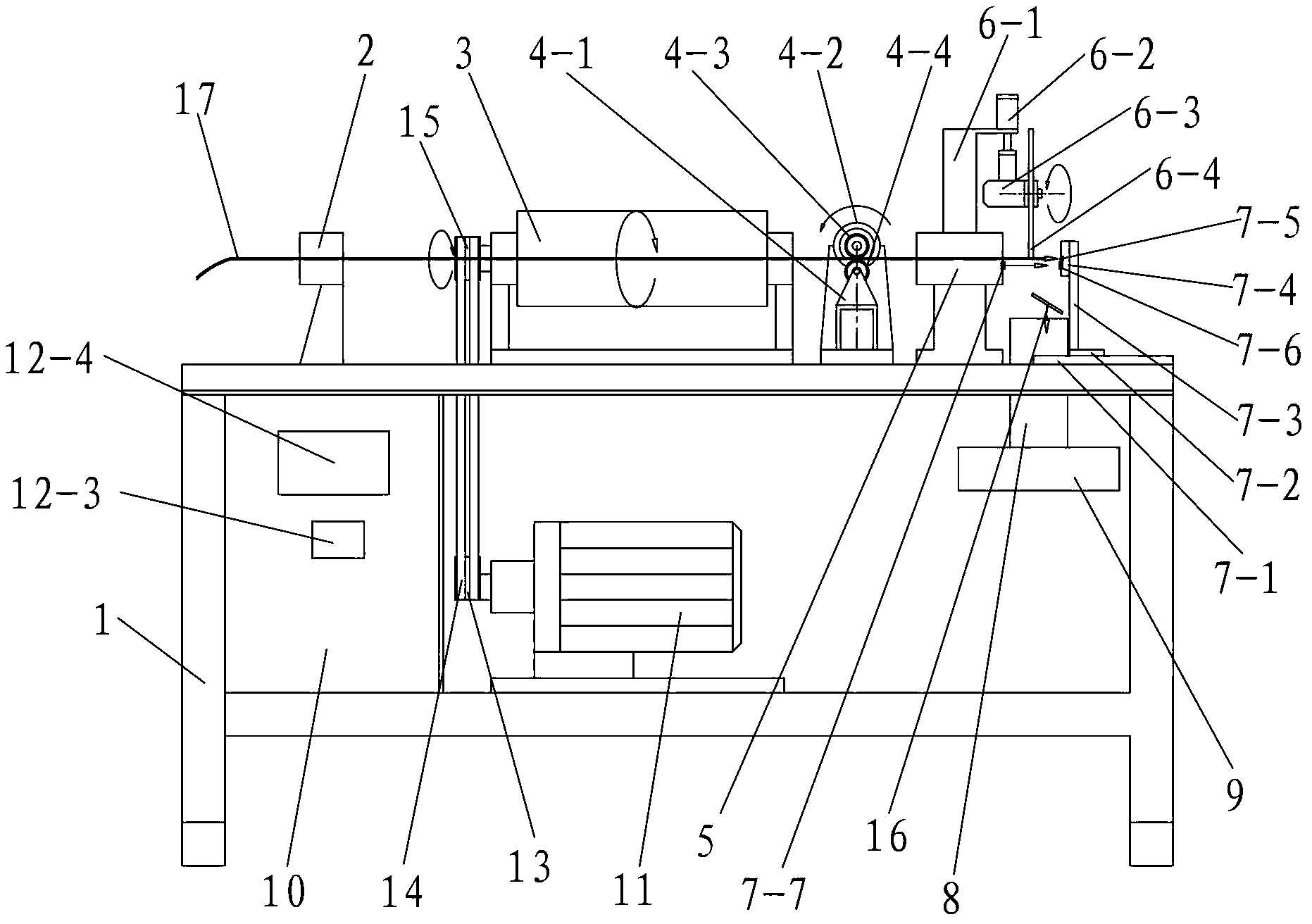

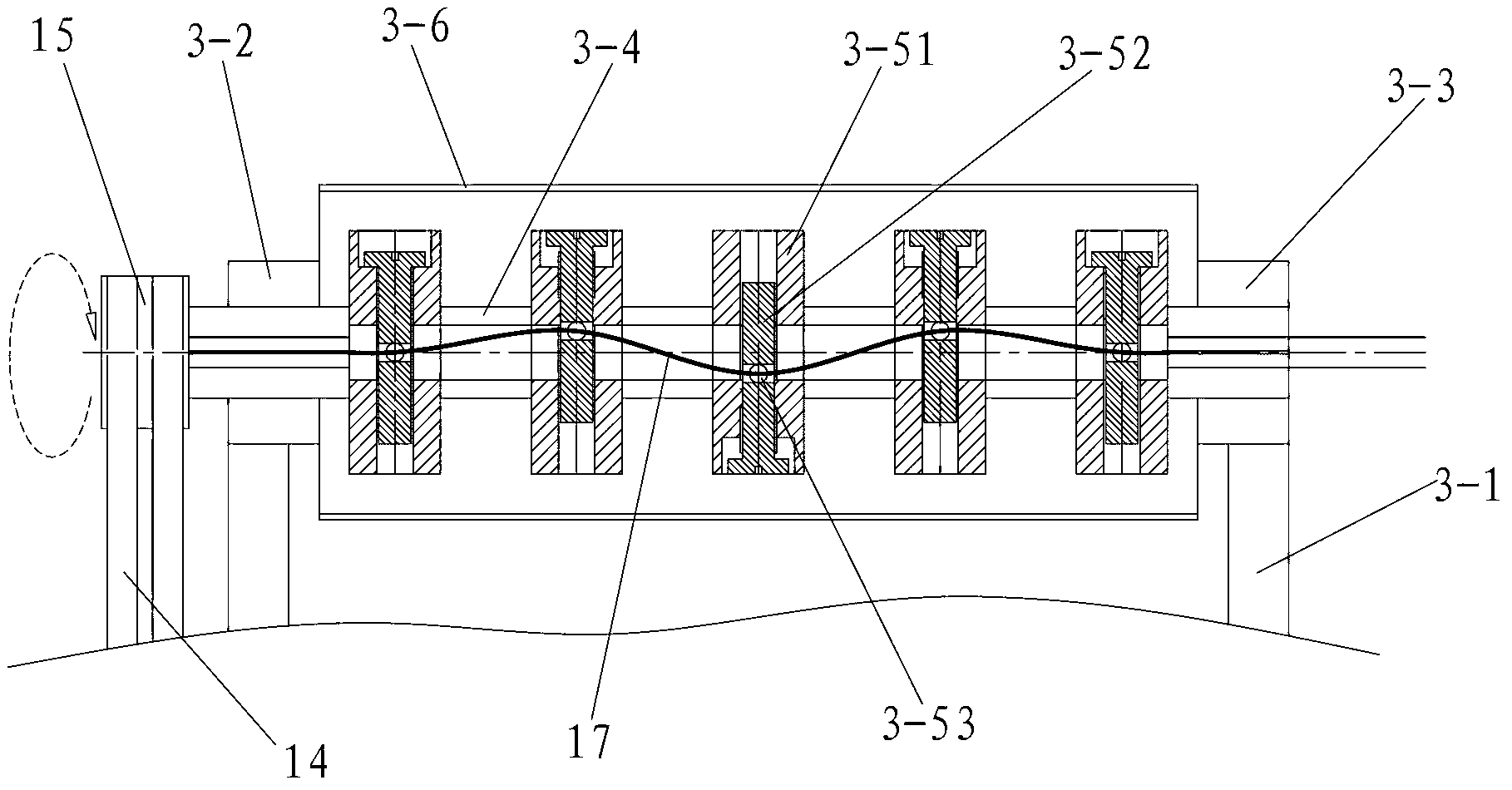

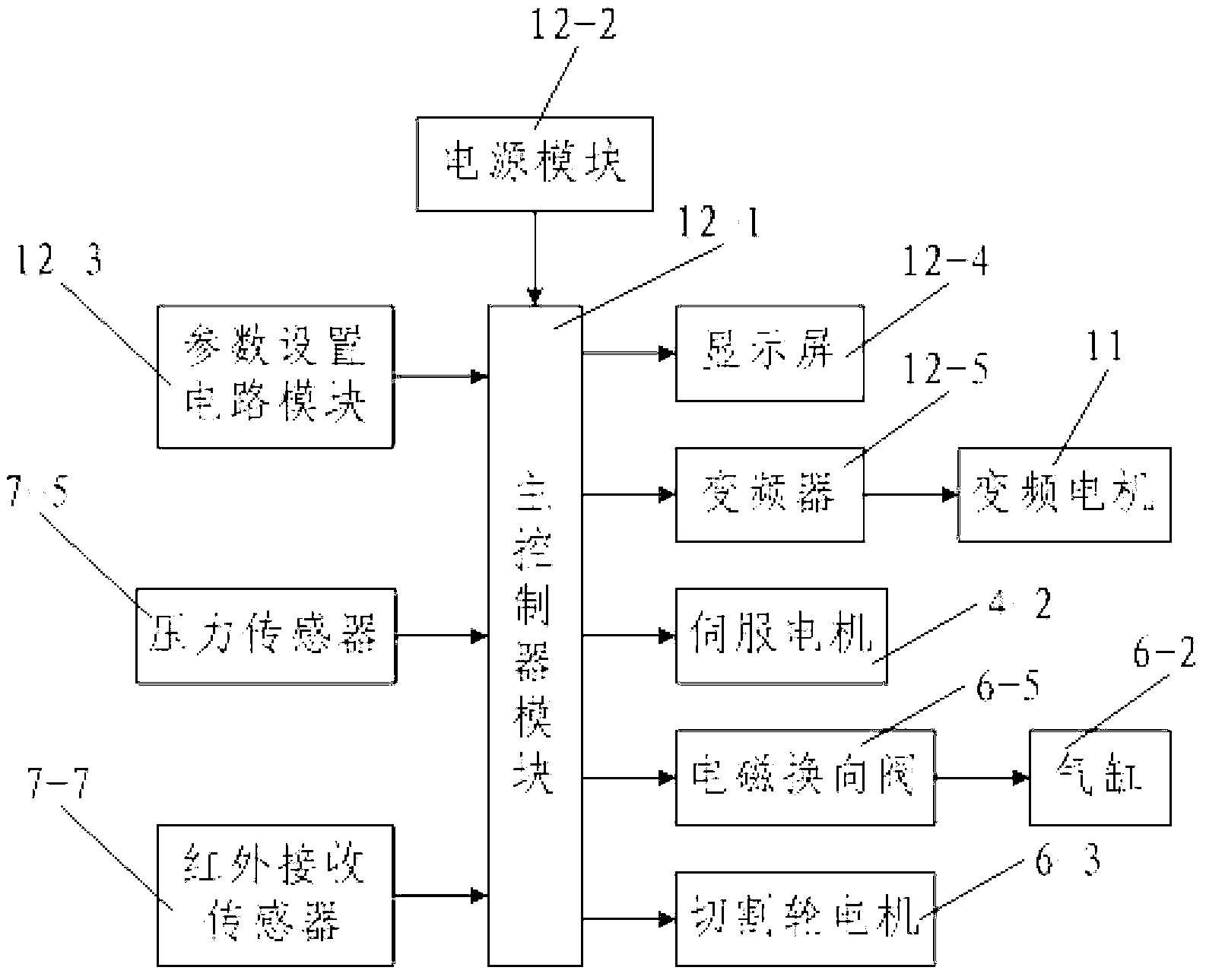

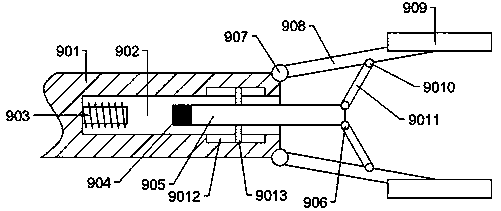

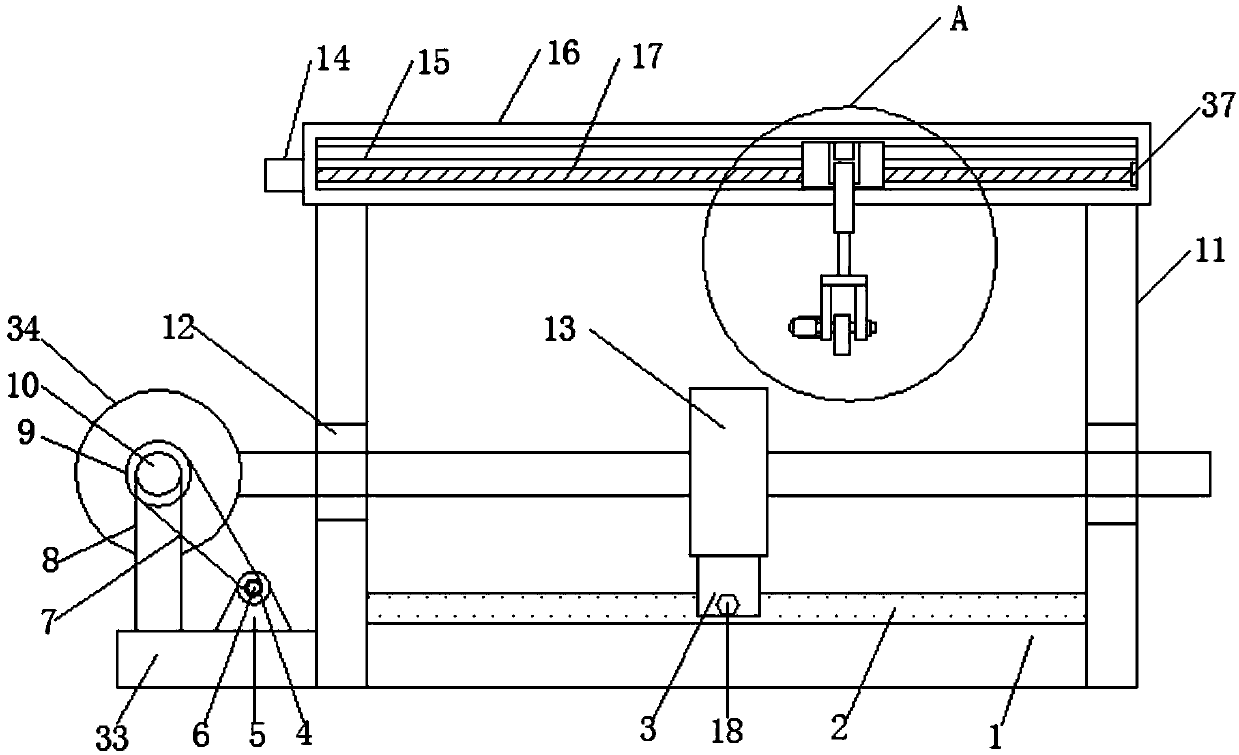

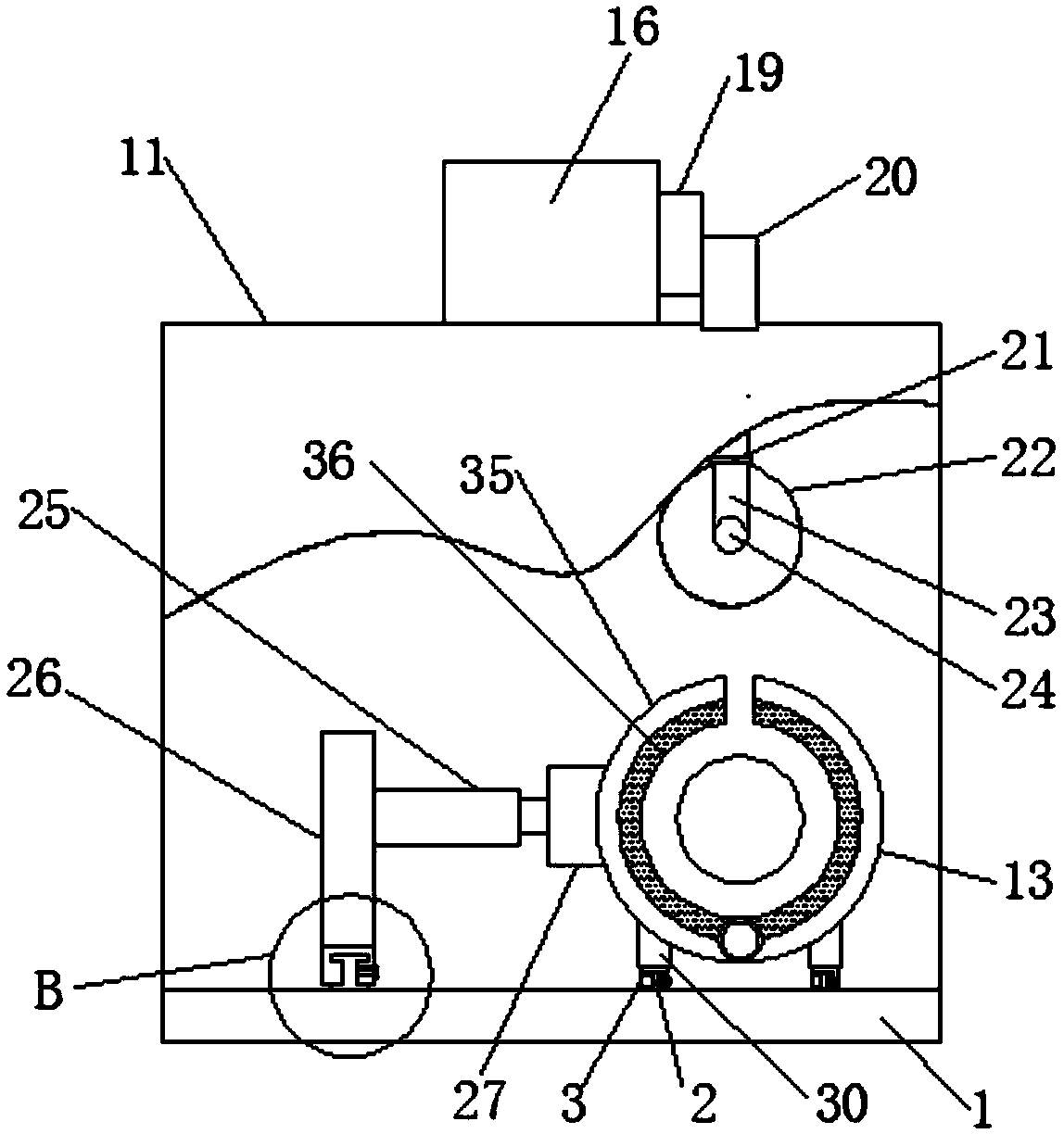

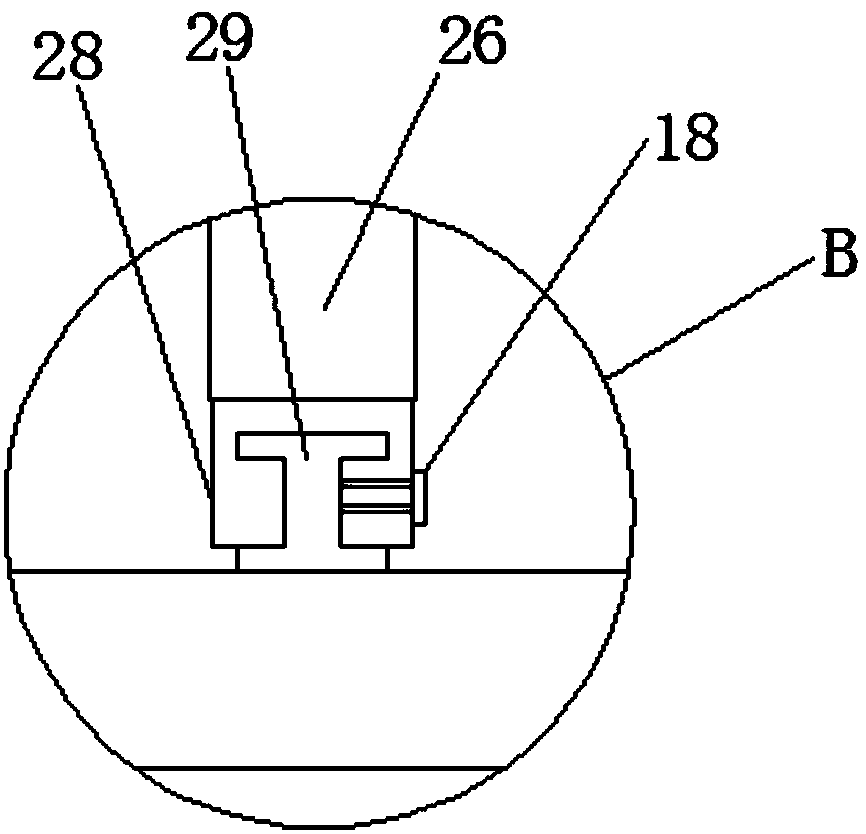

Metal wire rod precision alignment cutting device and method

The invention discloses a metal wire rod precision alignment cutting device and a method. The device comprises a double-layer machine frame. A front end guiding tank, a revolving alignment tank, a traction mechanism, a back end guiding tank, a cutting mechanism and a machinery sizing mechanism are arranged on the top portion of the double-layer machine frame. The revolving alignment tank comprises a revolving alignment straight tank support seat, an alignment guiding tank, a plurality of alignment modules and a protection cover. The traction mechanism comprises a traction mechanism support seat, a servo motor, a driving friction wheel and a driven friction wheel. The cutting mechanism comprises a cutting wheel support frame, an air cylinder, a cutting wheel motor and a slice-shaped cutting wheel. The machinery sizing mechanism comprises a horizontal scale plate, a pressure sensor, an infrared transmitting sensor and an infrared receiving sensor. The method includes the steps that the metal wire rod enters the revolving alignment tank through a front end guiding rank. The metal wire rod is alignmented, tracted, cut and prepared and enters the next working circulation. The metal wire rod precision alignment cutting device and the method is high in automatic degree. The shape of the cut metal line segment and the size precision are high. The cutting opening is smooth, free of deckle edge and free of splitting off. The metal wire rod precision alignment cutting device and the method are strong in practicality.

Owner:JINDUICHENG MOLYBDENUM CO LTD

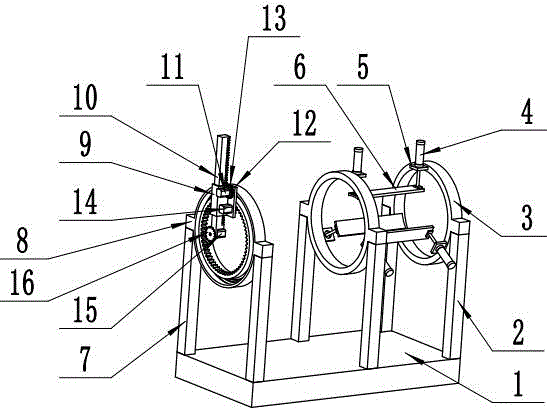

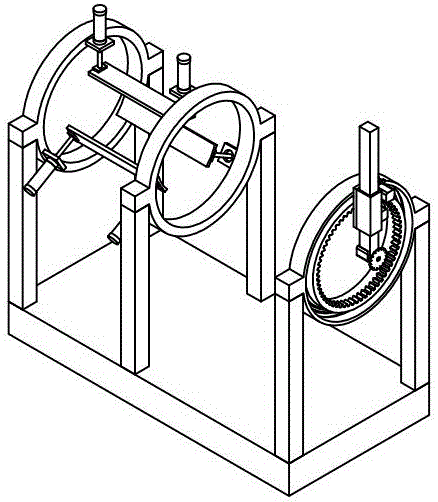

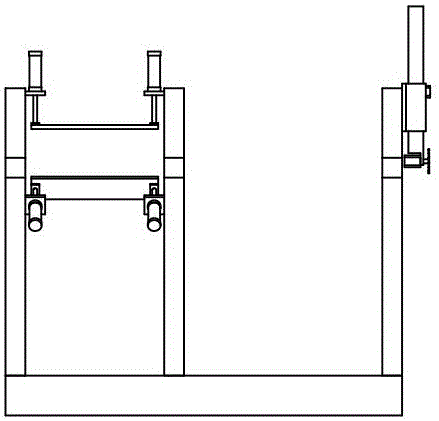

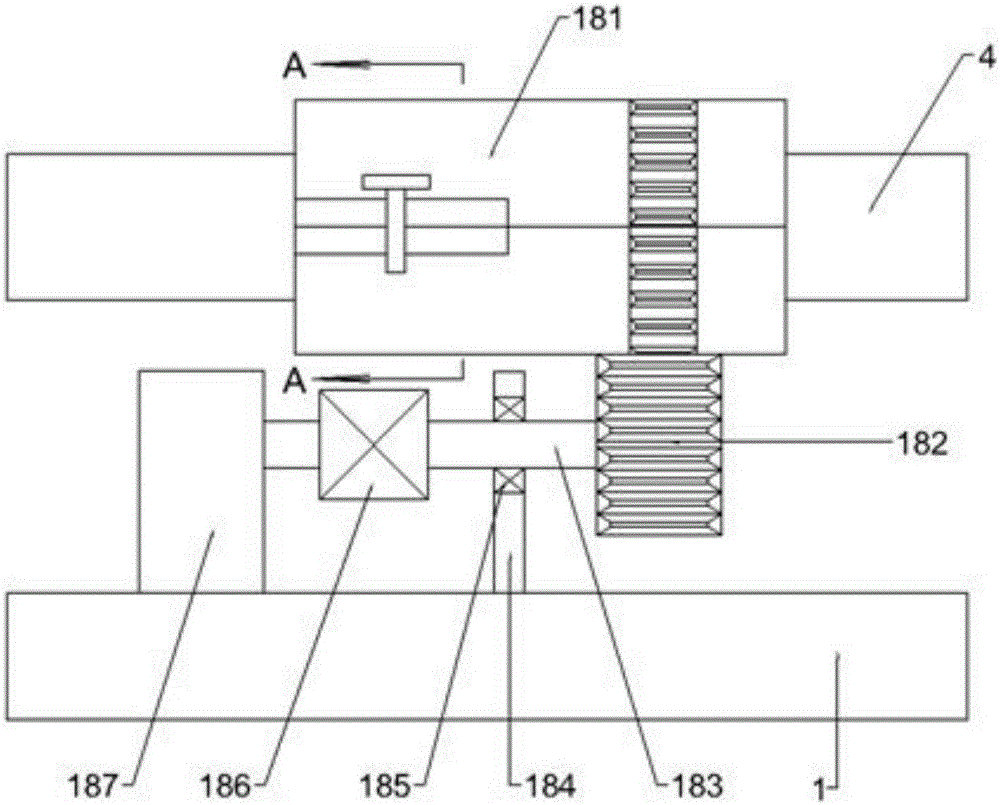

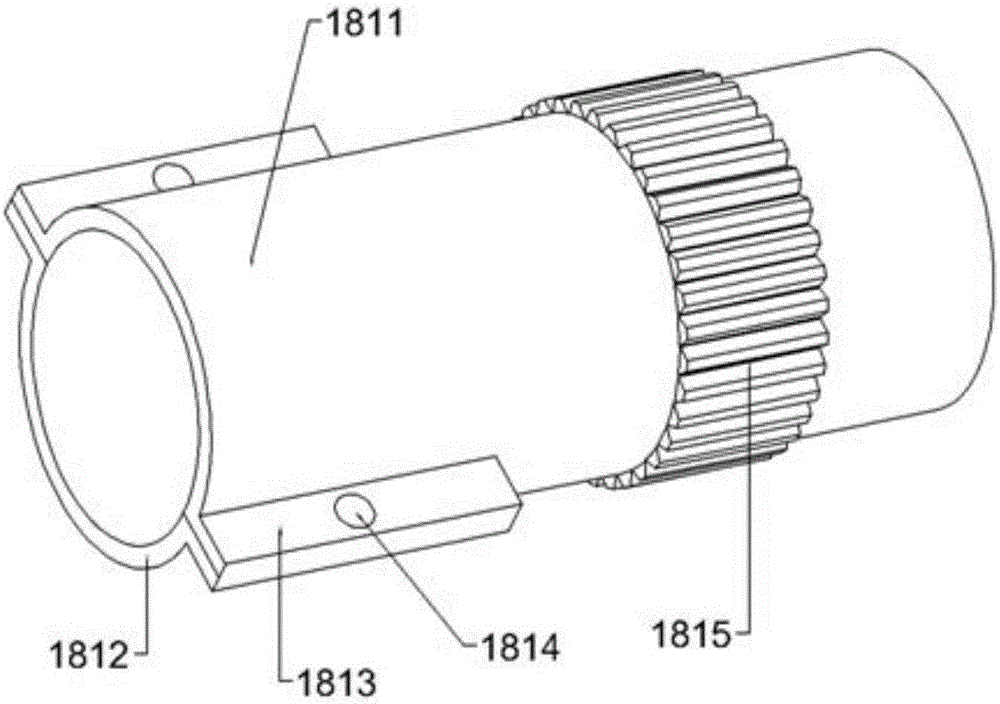

Outer-pipe circular cutting robot for steel pipe

ActiveCN106001735AImprove cutting efficiencyFast cutting speedTube shearing machinesShearing machine accessoriesGear wheelElectric machinery

The invention relates to an outer-pipe circular cutting robot for a steel pipe. The robot comprises a base, a steel pipe pressing plate, a circular cutting frame, an expansion link sleeve, an expansion link, an expansion link motor, a cutting mechanism fixing plate, a rotary motor, a cutting blade, an electric brush, an expansion link rack and an expansion link cutting motor fixing frame, wherein steel pipe frame stand columns of the expansion link motor fixing plate is fixedly arranged on the base, a steel pipe fixing sleeve is fixedly arranged on the steel pipe frame stand columns, the circular cutting frame is fixedly arranged on circular cutting frame stand columns, and the circular cutting frame stand columns are fixedly arranged on the base; the expansion link is arranged on the expansion link sleeve in a sliding way, the expansion link motor is fixedly arranged on the expansion link motor fixing plate, a stretching motor gear is fixedly arranged on an expansion link motor shaft, and the stretching motor gear is meshed with the expansion link rack; and the cutting motor is fixedly arranged on the expansion link cutting motor fixing frame, and the cutting blade is fixedly arranged on the cutting motor shaft. The robot can improve the steel pipe cutting efficiency, and is high in cutting speed, trim in notches and good in effect.

Owner:青岛昊坤机械制造有限公司

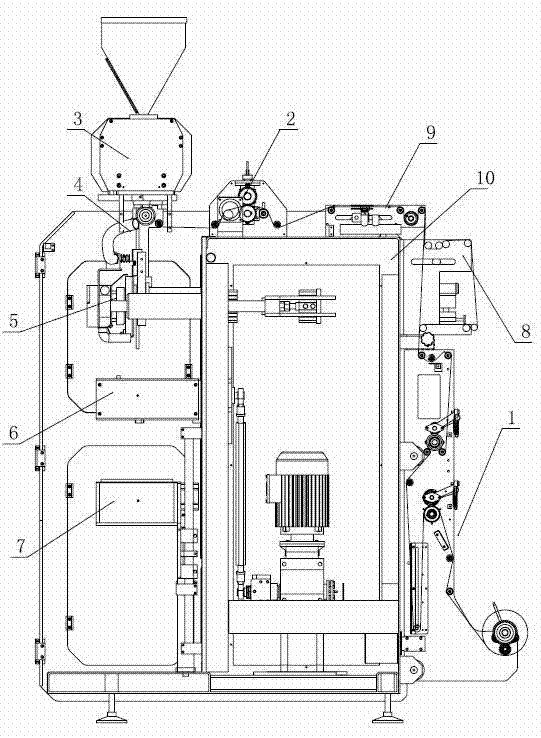

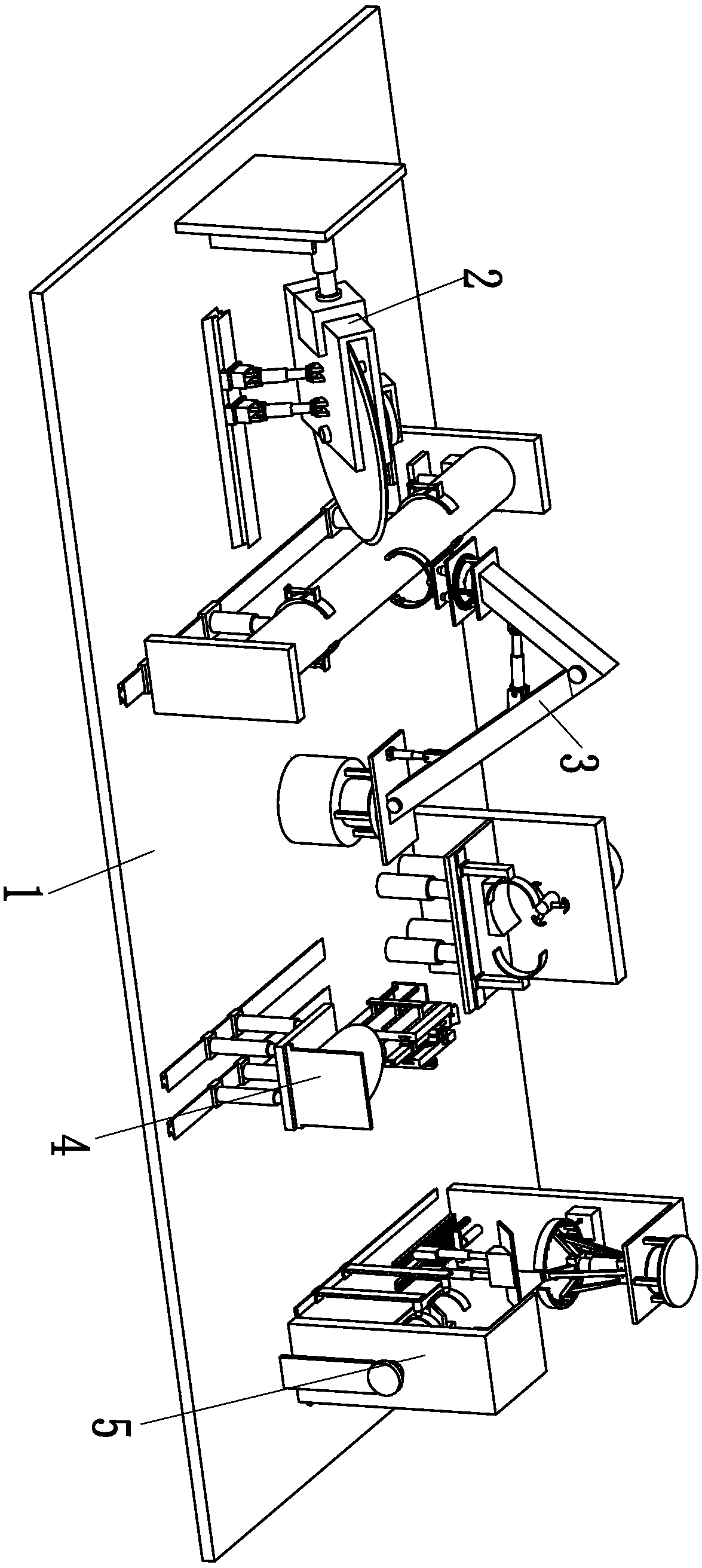

Multicolumn strip packing machine

ActiveCN102730214AIncrease productivitySimple structureWrapping material feeding apparatusWrapper twisting/gatheringReciprocating motionEngineering

The invention relates to a multicolumn strip packing machine, in particular to a multicolumn strip packing machine capable of carrying out continuous bag-making and packing through automatic operation, comprising a frame, and a film feeding mechanism, a slitting cutter mechanism, a feeding mechanism, a bag molding mechanism, a longitudinal sealing mechanism, a transverse sealing mechanism and a cut-off mechanism arranged on the frame respectively, wherein the transverse sealing mechanism comprises a transverse sealing device which comprises a transverse sealing floating device, two transverse sealing holders, and transverse sealing seats arranged on the two transverse sealing holders respectively; a plurality of transverse sealing guide shafts are together sleeved to transverse beam sliders on the same side; at least one transverse sealing seat is connected to a transverse sealing cylinder for driving the transverse sealing seat to do reciprocating motion; and the axial direction of the transverse sealing guide shaft is consistent with the motion direction of the transverse sealing seat. The transverse sealing mechanism of the multicolumn strip packing machine is capable of providing a buffering force for an object to be packed so that the impact on the object to be packed can be reduced and the object to be packed can be protected against damage; and a plurality of combined components are arranged in a multi-row parallel manner, so that the production of a plurality of packing bags can be completed at the same time; as a result, the production efficiency is greatly improved.

Owner:SHANGHAI SOONTRUE MACHINERY EQUIP

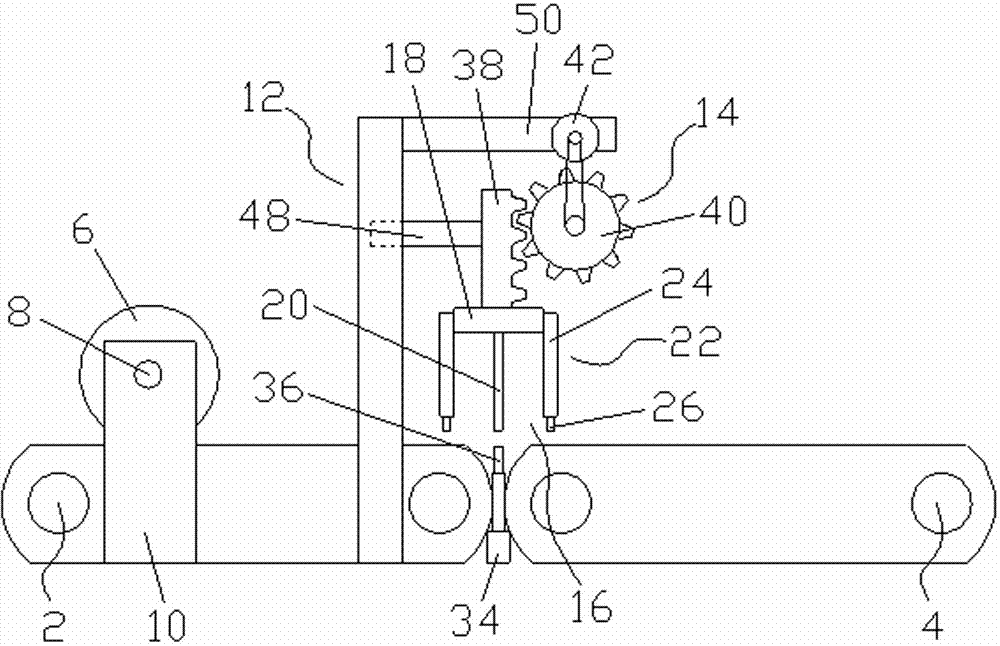

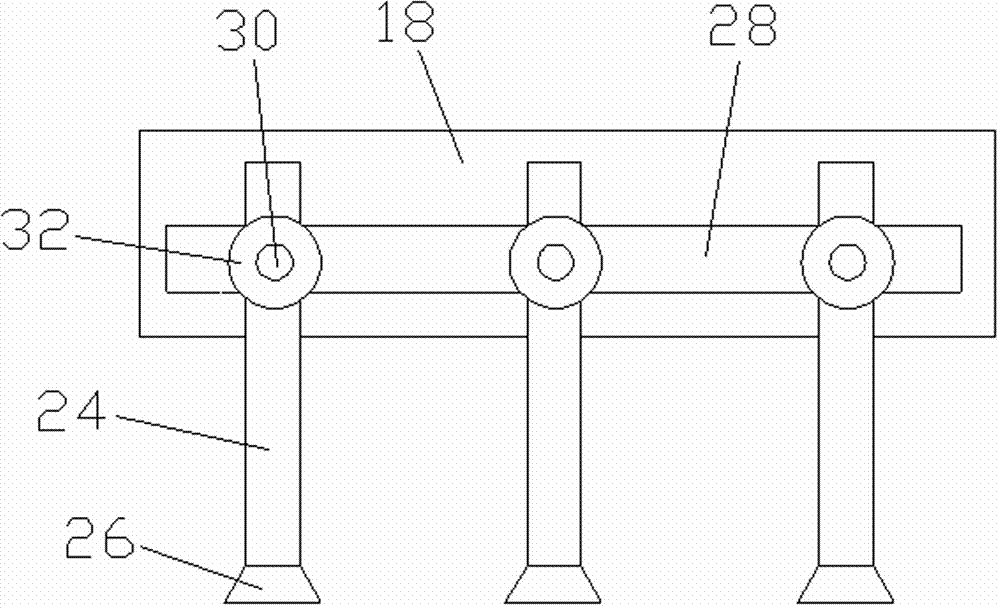

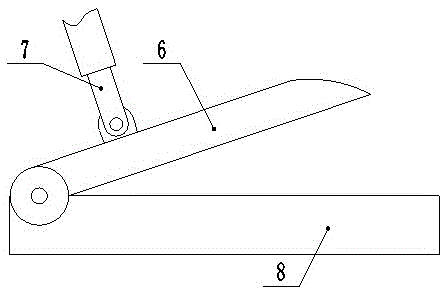

Cloth cutting device

The invention relates to a cloth cutting device. The cloth cutting device comprises a first delivery mechanism and a second delivery mechanism which are arranged in sequence. A gap is formed between the first delivery mechanism and the second delivery mechanism. A cloth feeding roller is arranged above the first delivery mechanism. The two ends of the cloth feeding roller are arranged on supports located on the two sides of the first delivery mechanism through supporting shafts respectively. A lifting mechanism is further arranged and comprises a sliding assembly, a driving assembly connected with the sliding assembly and a cutting assembly which is driven by the driving assembly to move vertically. The cutting assembly comprises a cutter holder, a cutter connected to the middle of the lower end of the cutter holder and pressing rods connected to the two sides of the cutter holder respectively. According to the cloth cutting device, a gear drives a rack to move vertically, and then the cutter is driven to cut cloth; in the cutting process, press rod heads press the cloth, so that the cloth does not shift; meanwhile, an air cylinder pushes a top plate to be matched with the cutter, so that cutting is conducted smoothly, and work efficiency is improved.

Owner:WUJIANG MINGJIA WEAVING

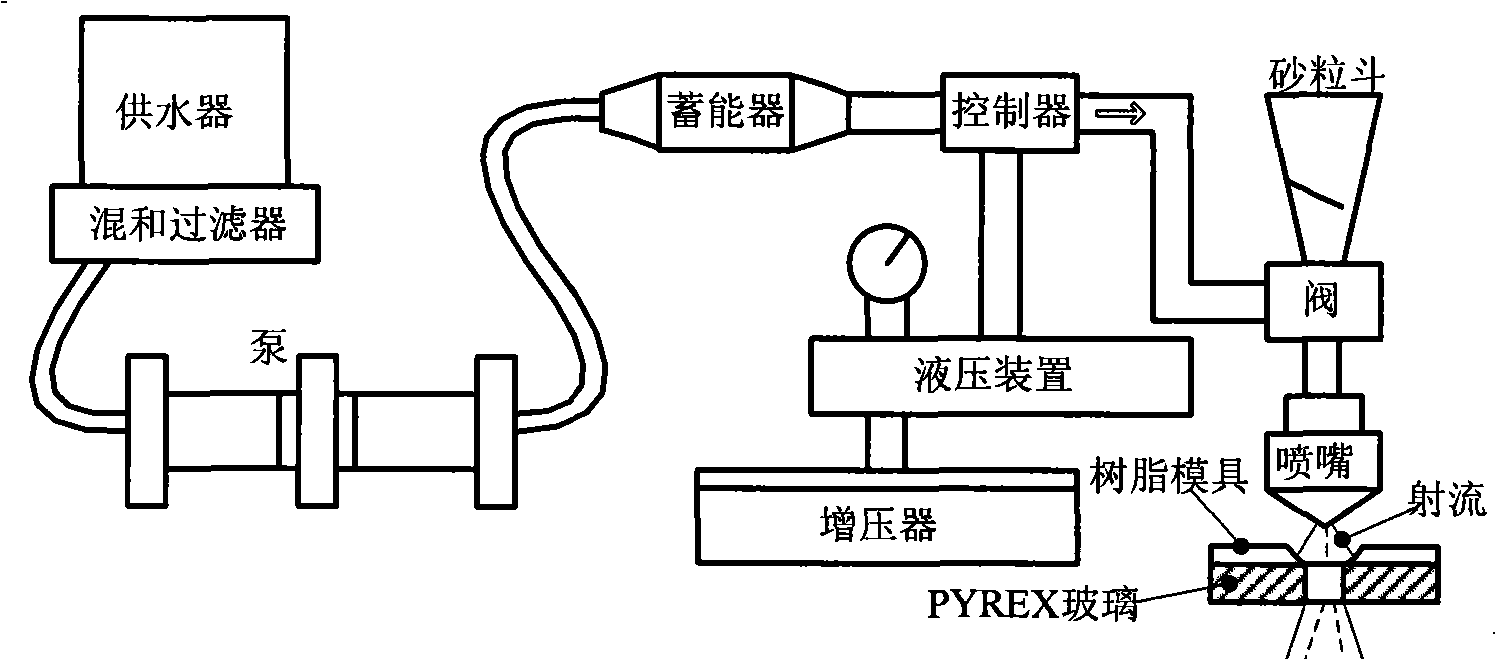

Manufacturing method for floating type micro-silicon electrostatic gyro/accelerometer sensitive structure

InactiveCN101279713AInhibit sheddingThickness loss is negligibleAcceleration measurement using interia forcesDecorative surface effectsLevitationAccelerometer

The invention relates to a method for preparing a levitation-type micro-silicon electrostatic gyro / accelerometer sensitive structure, which belongs to the technical field of silicon structure processing. The method comprises the steps: glass etching; glass gold splashing: a metal layer raising 400-600 tenthmeters higher than a glass surface; perforating the glass; a first and a second RIE etching for the silicon slice; film beam process: high-temperature dry oxidation and surface corrosion; a first electrostatic bonding for glass and silicon; thinning and polishing to the silicon slice; ICP etching for the silicon slice; a third RIE etching for the silicon slice; a fourth RIE etching for the silicon slice; a second electrostatic bonding for glass and silicon; ICP removal for film beam to prepare the levitation-type micro-silicon electrostatic gyro / accelerometer sensitive structure. The method adopts the proposal of sandblasting perforating for perforating the glass, introduces the silicon dioxide film beam as a sacrificial layer and adopts the ICP film beam removal process; the method can effectively solve the problem of adherence of a sandwich microstructure in the second electrostatic bonding and does not need post treatment so that the method has higher efficiency and better compatibility with the MEMS process.

Owner:TSINGHUA UNIV +1

Slotting and milling process for vane of integral vane wheel

InactiveCN1986127ASmall radial componentSmall amount of deformationMilling cuttersImpellerNumerical control

The slotting and milling cutter process for vane of integral vane wheel is completed in a numerically controlled machine tool with slotting and milling cutter advancing in the radial direction of the vane wheel and axial direction of the cutter. It has small radial force component caused by cutting, less vibration of the workpiece and the cutter, smooth cutting, small and controllable vane deformation, high machining quality and high machining efficiency. The present invention can meet the requirement of machining great diameter and high precision vane wheel product.

Owner:WUHAN MARINE MACHINERY PLANT

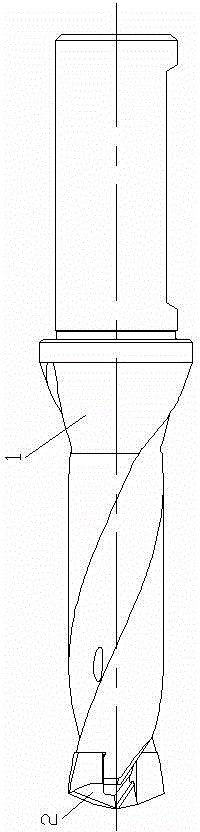

Drill bit of replaceable cutter head type structure

ActiveCN104907612AImprove installation accuracyGuaranteed stabilityTransportation and packagingCutting insertsEngineeringDrill bit

The invention discloses a drill bit of a replaceable cutter head type structure. Currently, a drill bit of a replaceable cutter head type structure high in machining accuracy, high in mounting accuracy and stable in rotating does not exist. The drill bit comprises a cutter rod, a cutter head and a fixing screw. The cutter rod comprises a cutter rod body. The drill bit is characterized in that a cutter head locating groove is formed in the front end of the cutter rod body, two supporting planes are arranged on the cutter head locating groove, after one supporting plane rotate around the axis of the cutter rod by 180 degrees, the supporting plane and the other supporting plane are overlapped, a locking groove is formed in a fixing column, the fixing column is arranged in a cutter head locating hole in a sleeved mode, a cutter head body is placed in the cutter head locating groove, the two supporting faces on the cutter head are tightly attached to the two supporting planes on the cutter rod respectively, the locating bottom face on the cutter head is tightly attached to the bottom of the cutter head locating groove, the fixing screw is in thread connection into a cutter head fixing hole, and the front end of the fixing screw abuts against the locking groove in the cutter head. The drill bit is high in machining accuracy, high in mounting accuracy, stable in rotating and stable in cutting, the cutter head can be abandoned, and service life is long.

Owner:ZHEJIANG XINXING TOOLS CO LTD

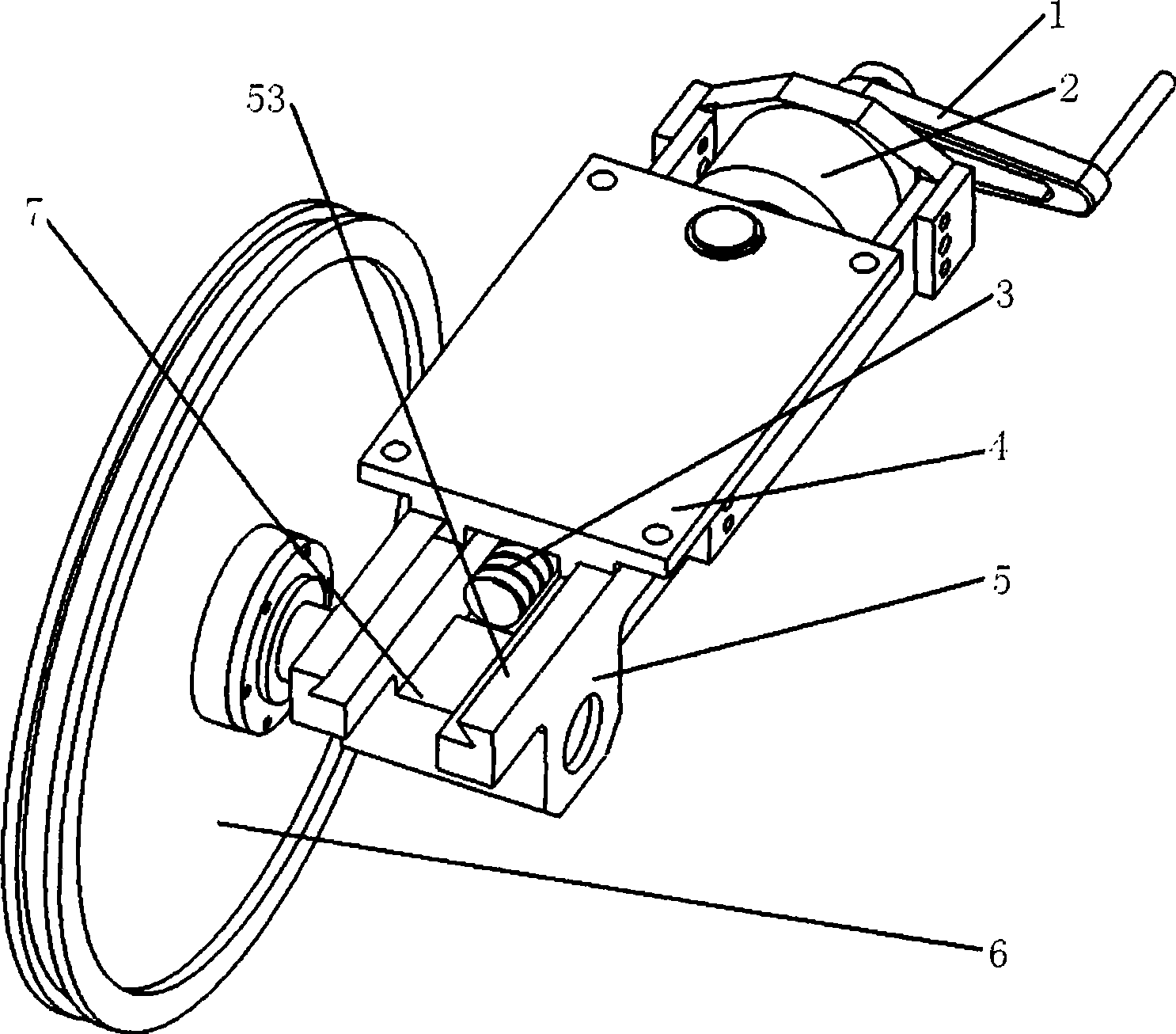

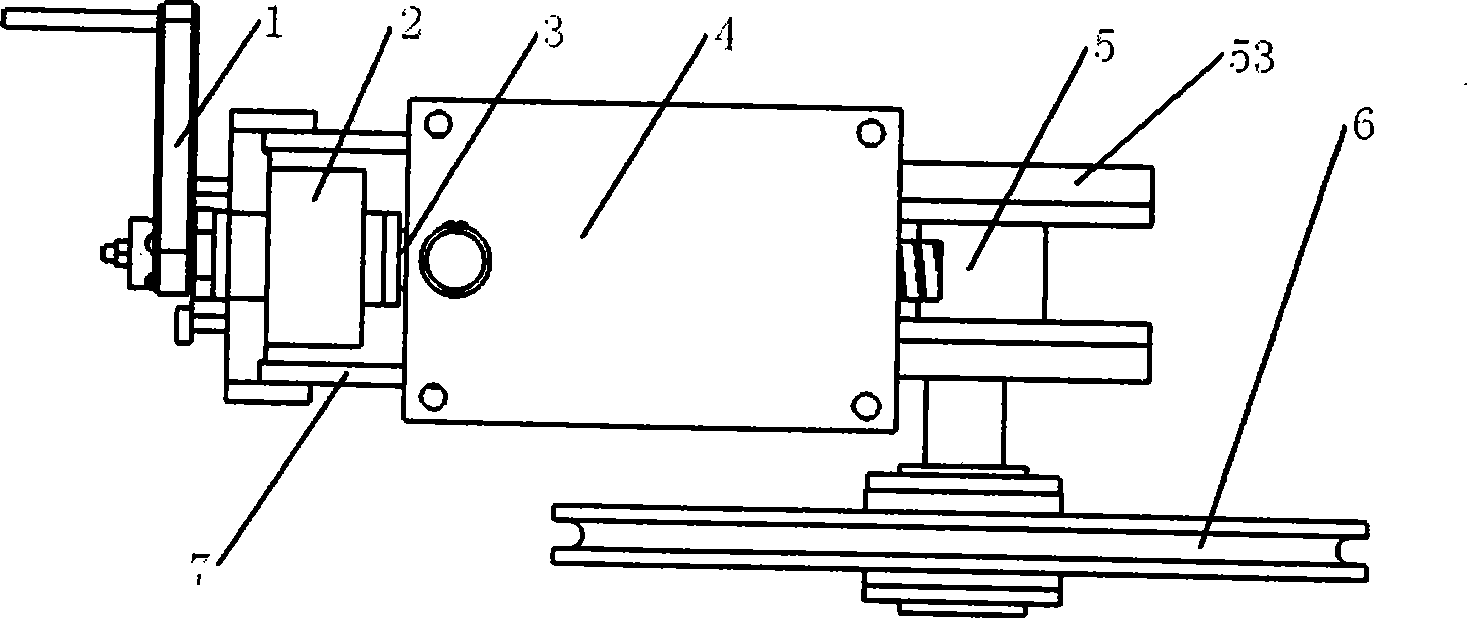

Tension device of underwater diamond rope saw

InactiveCN101468409AStable tensionEasy to assemble and disassembleMetal sawing devicesStone-like material working toolsMulti materialDiamond wire saw

The invention relates to a tensioning device of an underwater diamond wire saw, which comprises a tensioning wheel, a tensioning wheel axle seat, a tensioning force detection mechanism, an adjustment handle, a screw rod and a base, wherein the inner side surface of the base is in slide fit with the tensioning wheel axle seat, while the outer side surface is connected together with a frame of the diamond wire saw; the screw rod is positioned inside the tensioning wheel axle seat, and one end of the screw rod passes through the tensioning wheel axle seat to be connected and fixed with the adjustment handle; one end of the tensioning wheel axle seat is provided with an axle seat hole for the tensioning wheel axle seat to pass through so as to be positioned; and the tensioning force detection mechanism is sleeved on the screw rod and is positioned at one end of the tensioning wheel axle seat away from the axle seat hole. The tensioning device can ensure the initial tensioning force of a wire saw string bead wire, stable tensioning force during machining and convenient assembly and disassembly of the string bead wire; moreover, the tensioning device carries out realtime monitoring and controls the radial feeding speed of the string bead wire through a tension sensor, thereby ensuring safe, smooth, efficient and accurate cutting operation; therefore, the tensioning device can meet the requirements of large-diameter or multi-material filled pipes for carrying out cutting operation.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Multifunctional transposable diameter-adjustable multitool machine boring tool

The present invention relates to a multifunctional turnable position adjustable diameter multi-cutter machine-fastened hole-borning cutting-tool. It is characterized by that said invention mainly includes the following several portions: cutting-tool shaft, cutter and cutter support, cutter-regulating disk, turning disk, scale disk, cutter-mounting groove, spring and regulating bolt. Said invention also provides the concrete structure of every above-mentioned portion and the connection mode of all the above-mentioned portions, and also provides its working principle and concrete operation method.

Owner:王诚信

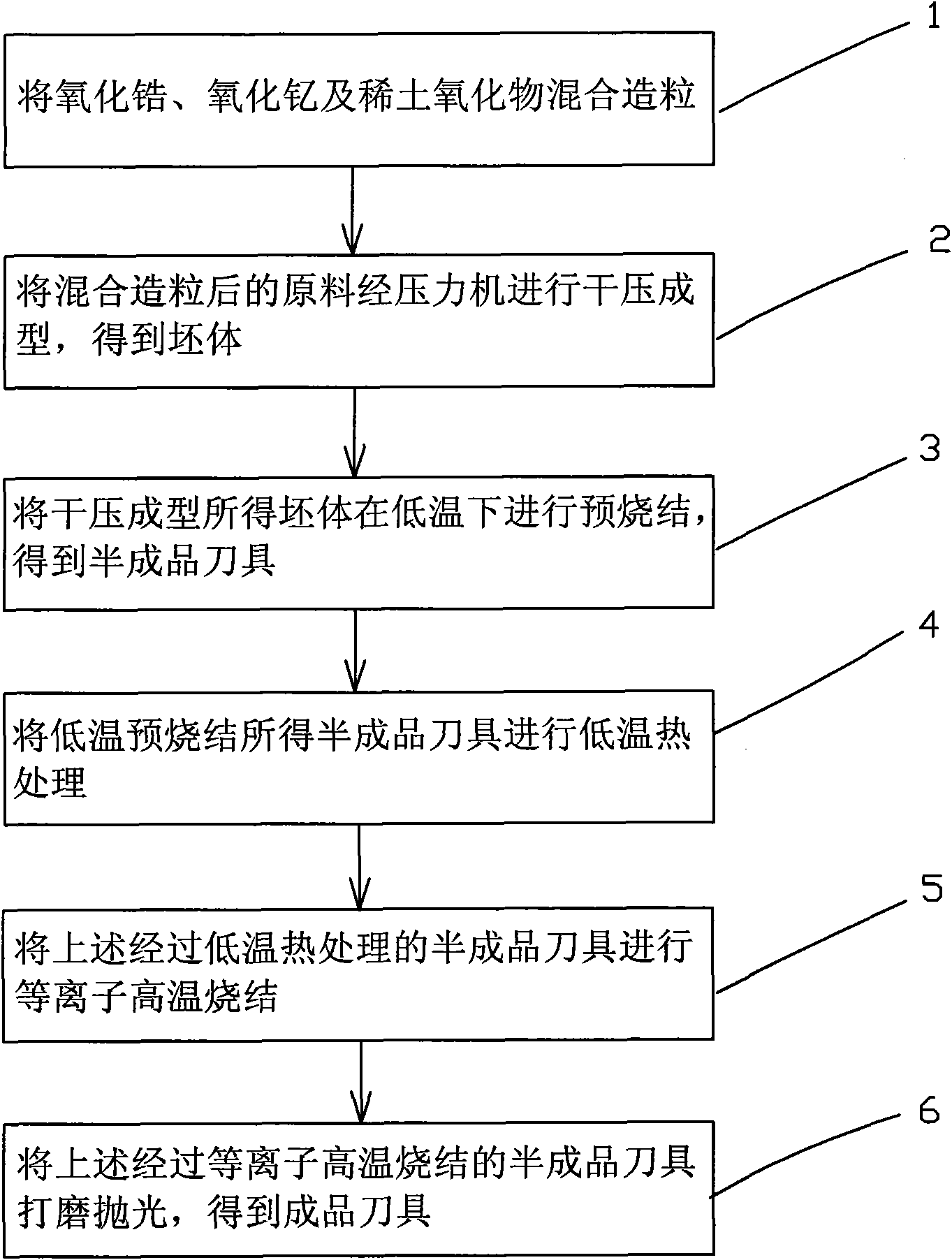

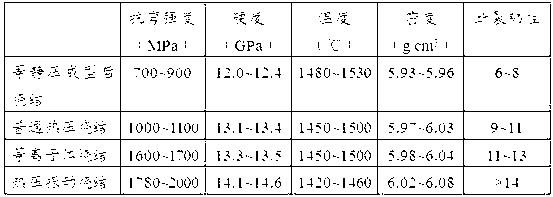

Super-strong and super-toughened ceramic cutter and manufacturing method thereof

ActiveCN101602111AImprove yield rateHigh hardnessCeramic shaping apparatusTurning toolsRare earthMaterials science

The invention relates to a super-strong and super-toughened ceramic cutter and a manufacturing method thereof. The ceramic cutter comprises the following components in portion by weight: 89 to 95 portions of zirconia, 2 to 8 portions of yttria, and 2 to 4 portions of rare earth oxide. The manufacturing method for the ceramic cutter comprises the following: step 1, mixing and granulating the zirconia, the yttria and the rare earth oxide; step 2, dry-pressing and molding the mixed and granulated raw materials by a press to obtain a blank; step 3, pre-sintering the blank obtained by the dry-pressing and molding at the low temperature to obtain a semi-finished cutter; step 4, thermally treating the semi-finished cutter obtained by the low-temperature pre-sintering at the low temperature; step 5, carrying out plasma high-temperature sintering for the semi-finished cutter which is thermally treated at the low temperature; and step 6, grinding and polishing the semi-finished cutter which is subjected to the plasma high-temperature sintering to obtain a finished cutter. The ceramic cutter has high hardness and good abrasion resistance, and has the remarkable advantages on thermal stability, heat conduction, corrosion resistance, oxidation resistance, high-temperature hardness, high-temperature strength, and the like. The method has the advantages of simple process and high production efficiency, and is favorable for mass mechanized production.

Owner:深圳市宏通新材料有限公司

Full-automatic tube-cutting chamfering machine

ActiveCN103231248AExtended service lifeReduce work intensityMetal-working feeding devicesOther manufacturing equipments/toolsEngineeringUltimate tensile strength

The invention discloses a full-automatic tube-cutting chamfering machine. The full-automatic tube-cutting chamfering machine comprises a feeding mechanism, a clamping mechanism, a stepping feeding mechanism, a chamfering mechanism and a cutting mechanism which are fixed on a base station and sequentially arranged along the material delivering direction. The full-automatic tube-cutting chamfering machine has the advantages that the machine is environmental-friendly; the machine is high in accuracy, performs internal and external chamfering to a cutter edge and then performs length positioning through a cutting surface with no burrs, a round tube rotates at high speed but a cutter does not rotate, and the cuts are absolutely in order; the labor intensity of workers is low, the workers only enable the round tube to penetrate into a spindle in a stand-alone state, and the machine automatically clamps and processes fed materials; the work efficiency is high, one person manages 4-5 machines; the service life of the cutter is long, the adopted cutter is straight and can be grinded, and the cutter can be used again only by being dismantled and repaired after used for a certain times; and the production cost is low, inner circles and excircles can be chamfered in one time, and chamfering processing is not required in the follow-up processes.

Owner:杭州杨氏实业有限公司

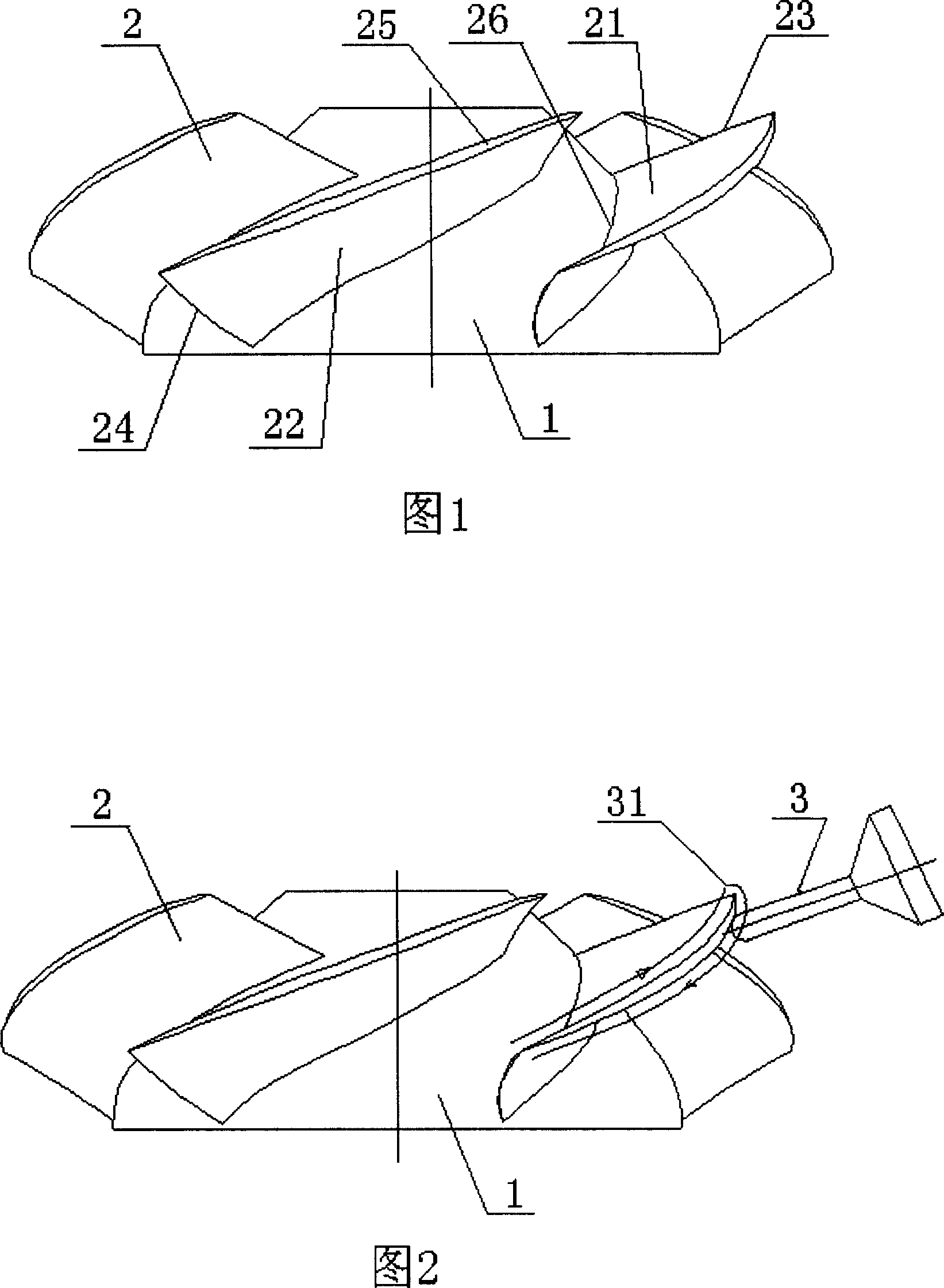

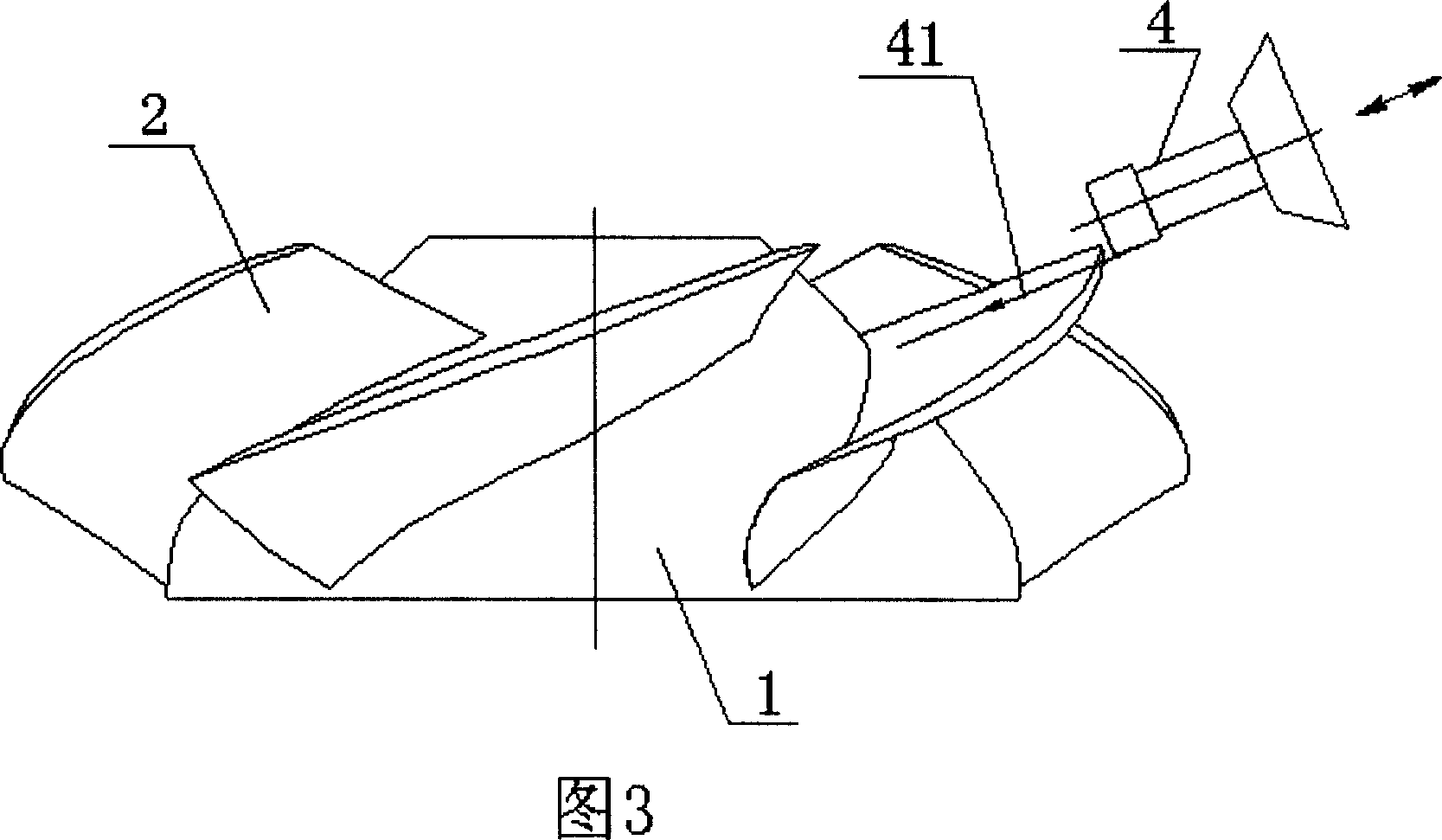

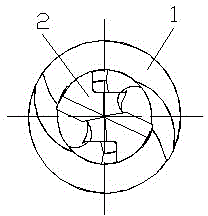

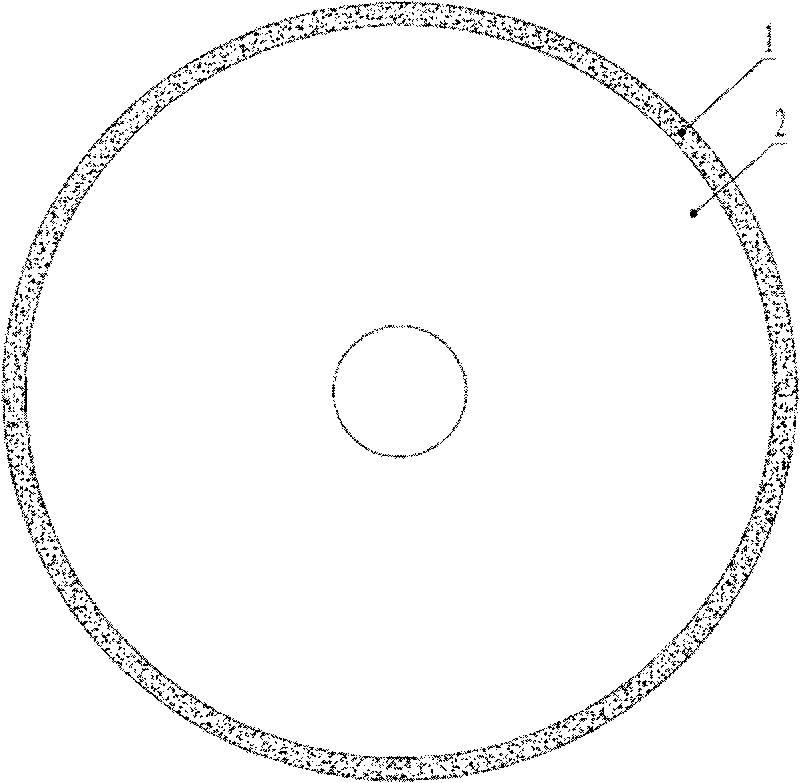

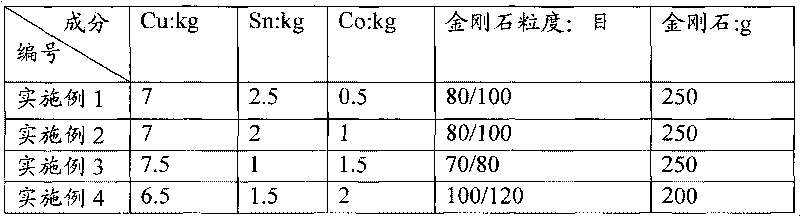

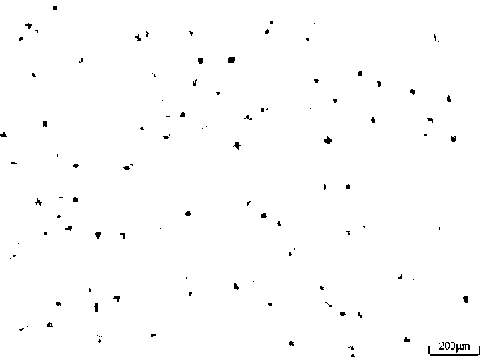

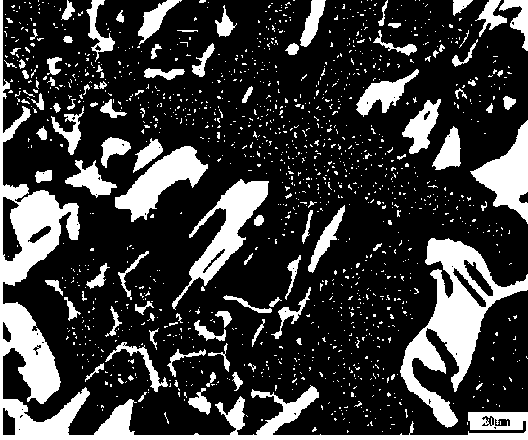

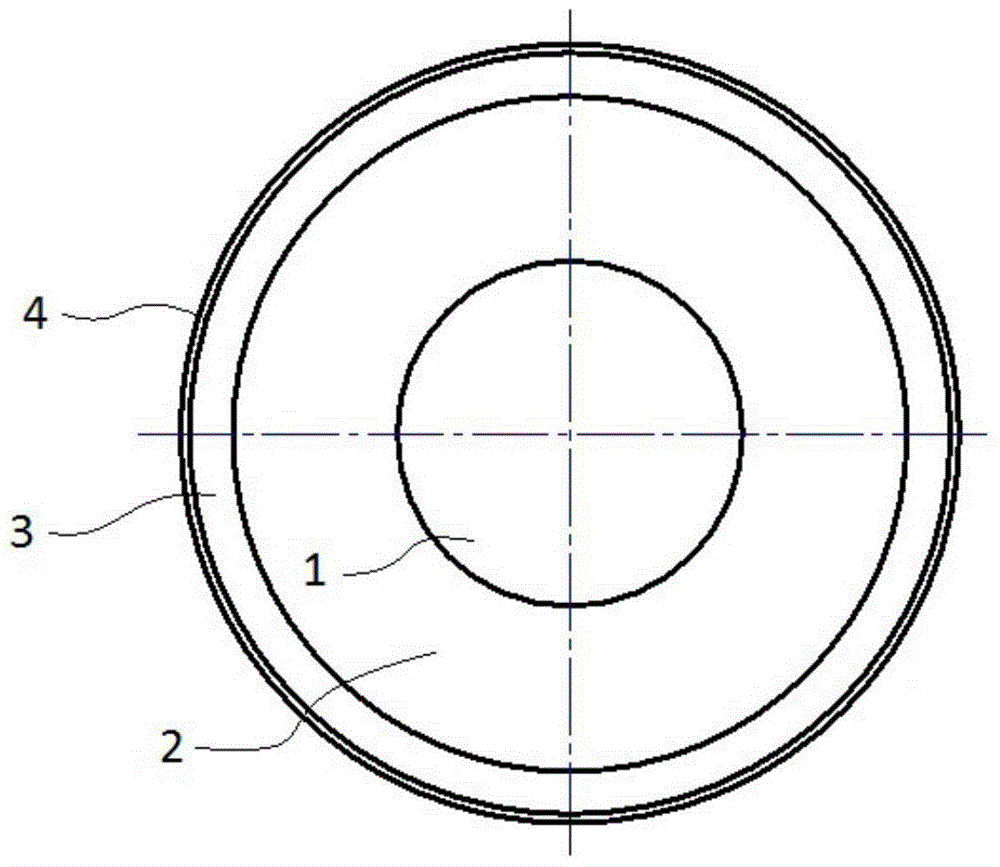

Marble cutting saw blade and preparation method thereof

ActiveCN101758560AFast cutting speedPromote infiltrationStone-like material working toolsAlloyPowder metallurgy

The invention relates to a super-hard tool and a preparation method thereof in the field of powder metallurgy, in particular to a marble cutting saw blade and a preparation method thereof. The saw blade comprises a matrix (1) and a tool bit (2), wherein the tool bit (2) is formed by mixing, thermally pressing and then sintering the matrix powder and the diamond particle; the component of the matrix powder includes 65 to 75 wt% of Cu, 10 to 20 wt% of Sn and 5 to 20 wt% of Co; and the weight of the diamond particle is 2 to 2.5 wt% of that of the matrix powder. The diamond saw blade is prepared after the steps of batching materials, mixing materials, cold press moulding, hot press moulding and subsequent treatment. Compared with the similar products, the Cu-base alloy diamond saw blade of the invention prolongs 1 to 3 times of the service life and reduces 30 to 50% of the cost on the premise of ensuring the constant sharpness and saw-cutting flatness.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

Manufacturing method for high-speed steel working roll at hot continuous rolling finish rolling rear section

The invention discloses a manufacturing method for a high-speed steel working roll at a hot continuous rolling finish rolling rear section. The working layer of a roll body comprises the following chemical components in percentages by weight: 2.00-3.50% of C, 0.40-2.00% of Si, 0.50-1.20% of Mn, 1.50-4.50% of Cr, 2.00-5.00% of Ni, 2.00-10.00% of Mo, V, W and Nb, 0-0.05% of S, 0-0.10% of P, and the balance of Fe and unavoidable impurities. The manufacturing method comprises the steps of smelting, inoculation and spheroidizing and pouring, and heat treatment. Through the alloy compositions with reasonable design and the production technology, a special graphite and metallographic structure is obtained. According to the high-carbon high-speed steel roll at the hot continuous rolling finish rolling rear section, the quality of rear surface of a machine under the roll can be effectively controlled, and meanwhile the abrasive resistance and heat cracking resistance of the roll are improved.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

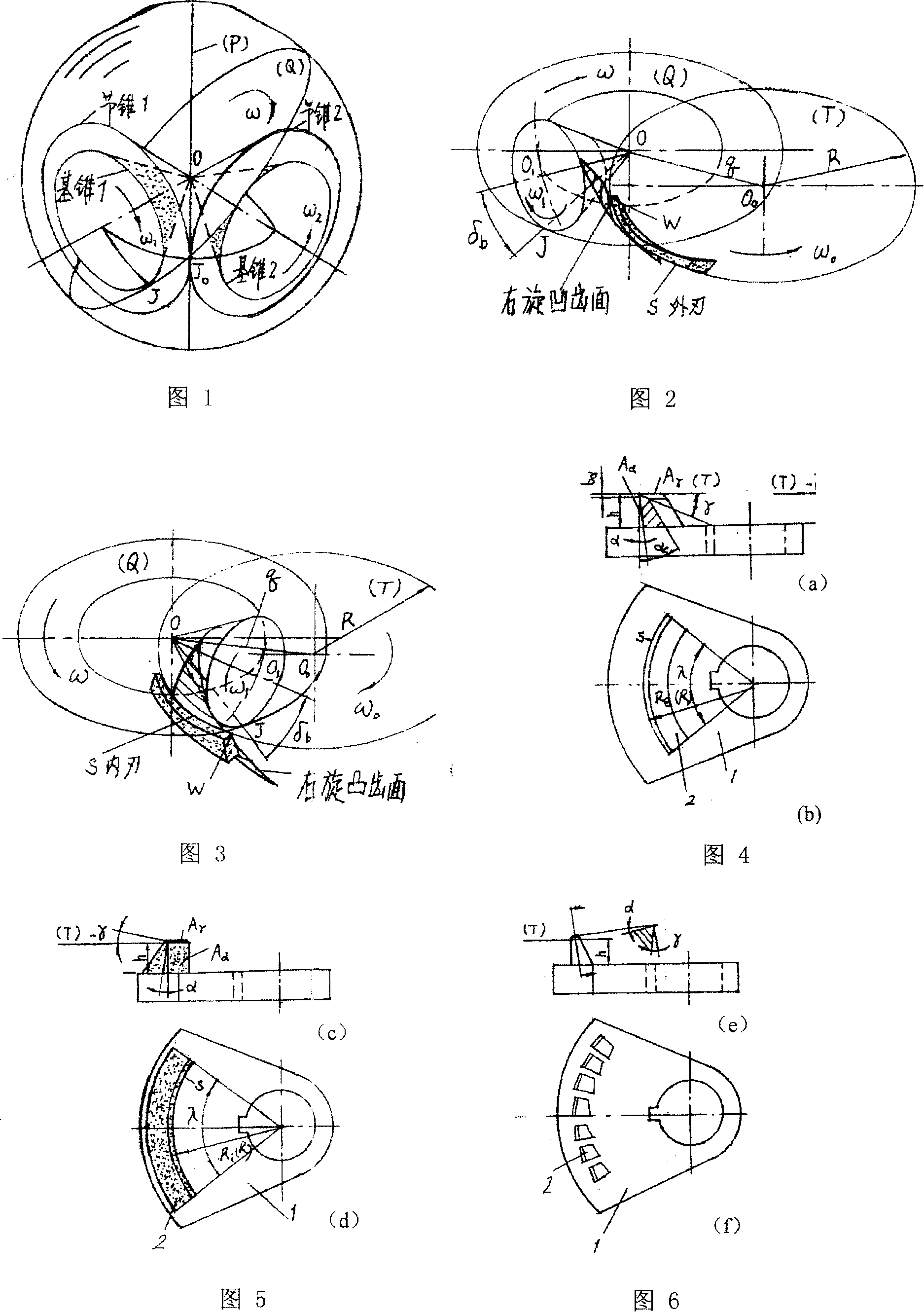

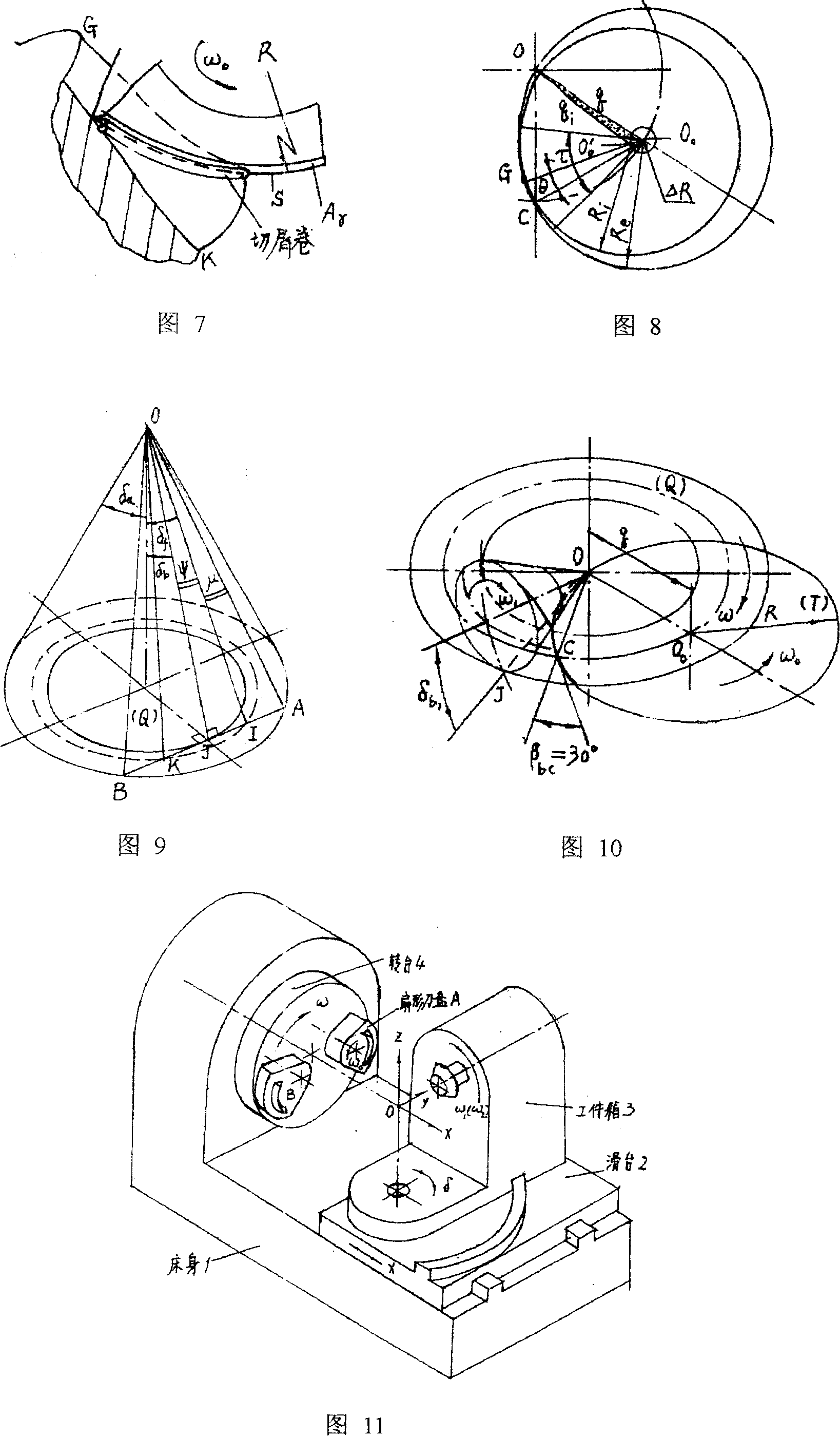

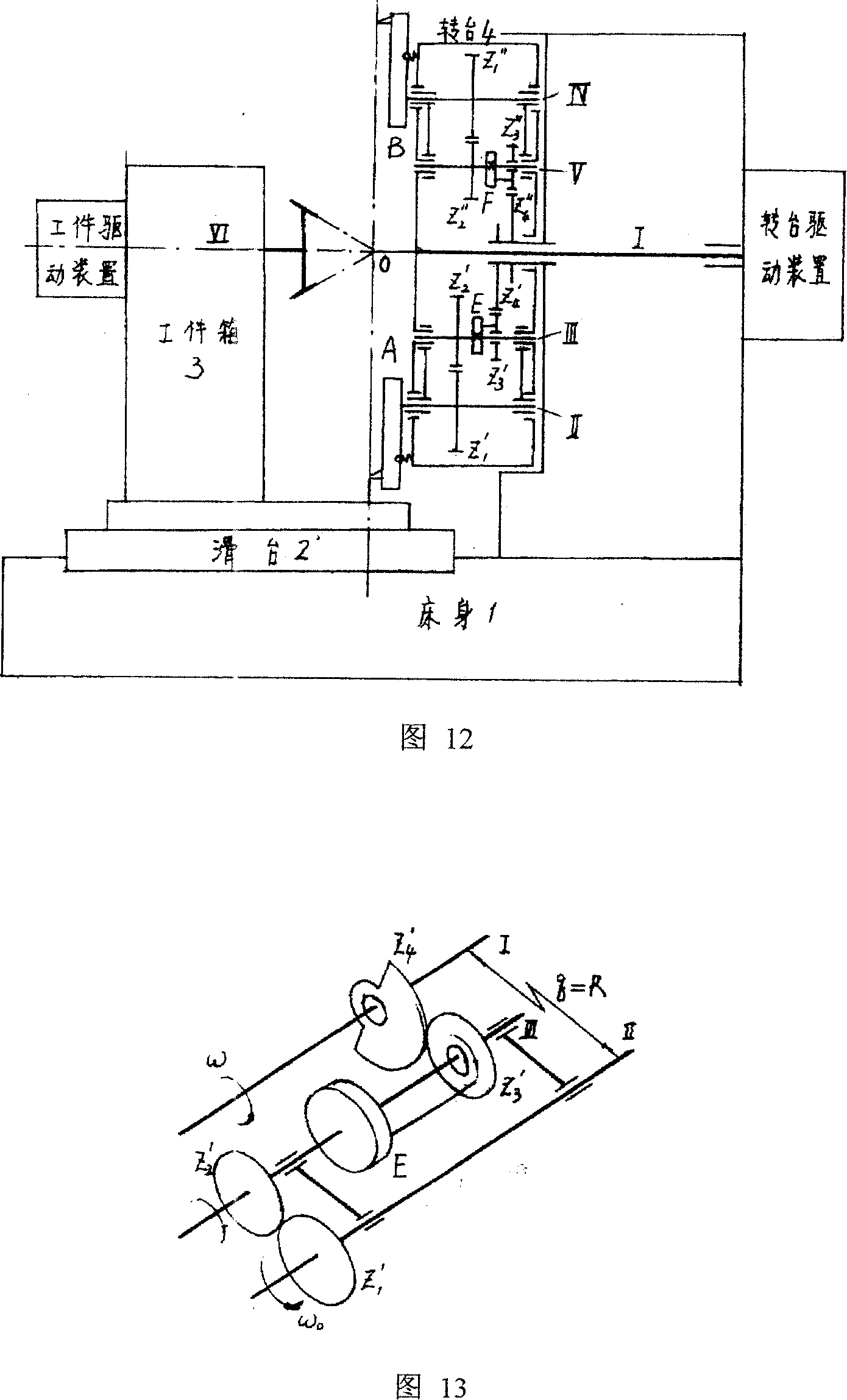

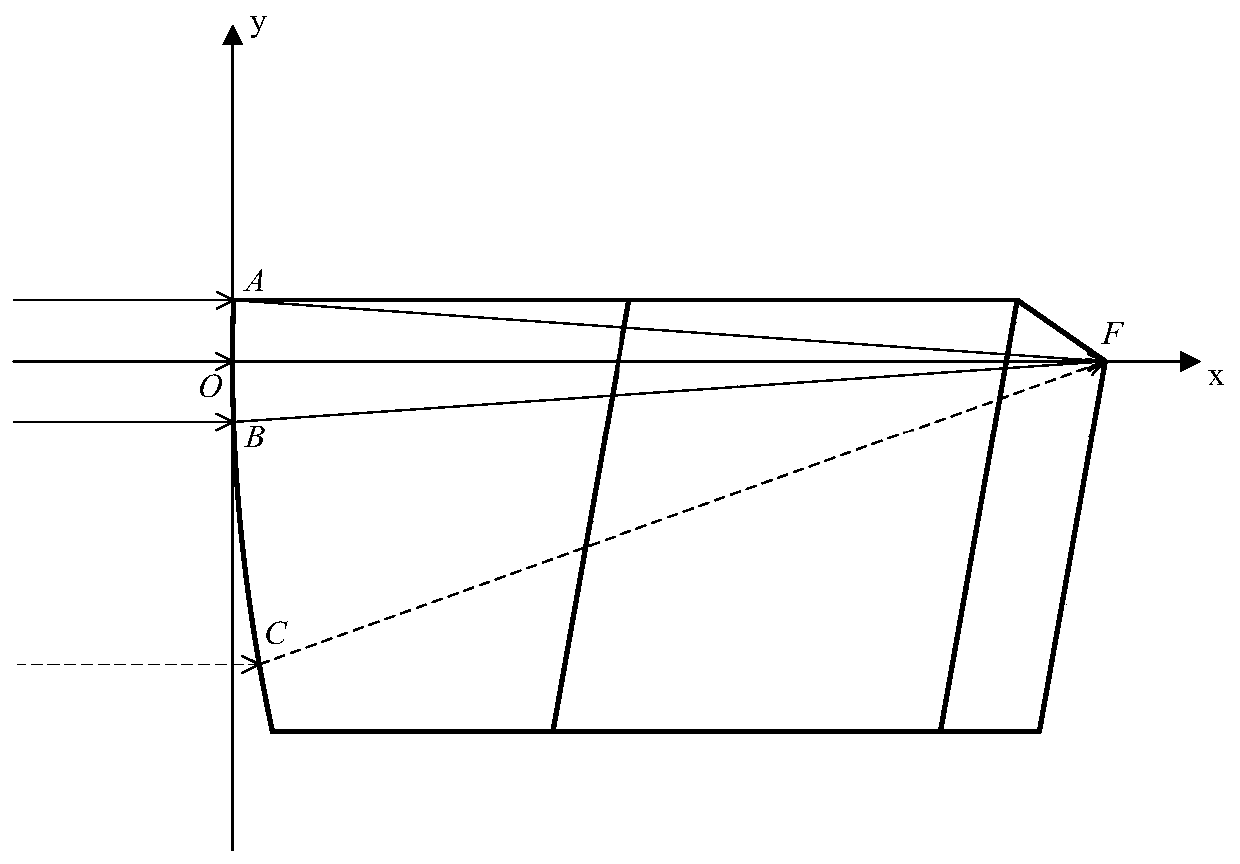

Method for producing cutter teeth of spiral bevel gear with spherical involute profile of tooth tapered tooth

InactiveCN101152677AImprove mesh qualitySimple configurationMilling equipment detailsGear teeth manufacturing toolsGear wheelEngineering

The invention relates to a gear cutting method for manufacture of spiral bevel gear with spherical involute tooth profile shrinkage tooth which is the gear cutting method that an arc-shaped cutting edge skiving cutterhead with turning radius of R on an end surface (T) is adopted for turning of spherical involute tooth profile and the shrinkage tooth is adopted to manufacture the tooth surface of the spiral bevel gear. When in cutting, a tooth casting is tangental to spherical large round plane (Q) represented by machine tool shaking station turning plane and maintains pure rolling according to base cone, rotating speed of every shaft of the machine tool is set up according to following speed ratio relations: when rotating speed of the shaking station is omega, rotating speed of the tooth casting is (1) type, wherein, ZQ is hypothetical tooth number of the shaking station, rotating speed of a cutterheadshaft is (2) type, and omega is opposite to the direction of omega 0; skiving cutterhead knife edge S is tangental to processed tooth surface and tooth surface fine turning process without generation of undercut is finished in the state of large bevel turning. Engaging quality of the cutting gear manufactured with the method is improved, with transient speed ratio constancy and insensitivity of influence of contacting area by transmission included angle alteration, moreover, the gear processed with the method can be exchanged and the invention simplifies the design of the gear and machine tool.

Owner:彭福华

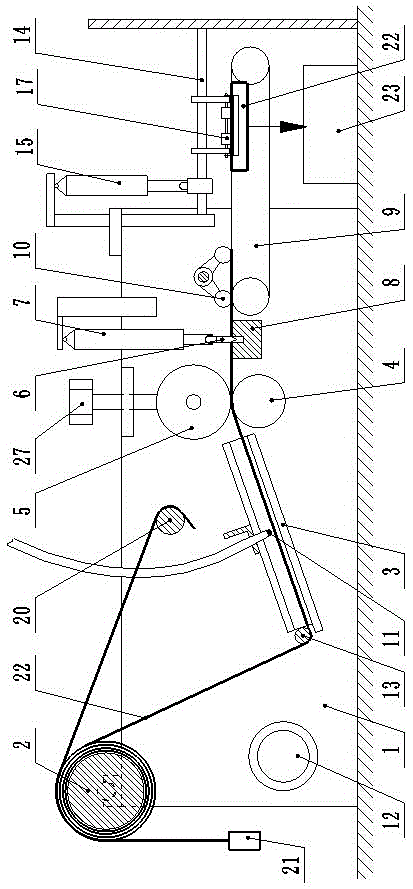

Automatic cutting and conveying device of trademark paper of woven bags or mesh bags

InactiveCN105538380ARealize automatic croppingRealize automatic one-shot moldingSevering textilesMetal working apparatusFixed frameTrademark

The invention discloses an automatic cutting and conveying device of trademark paper of woven bags or mesh bags and belongs to the technical field of automatic manufacture of the woven bags or the mesh bags. The technical problem to be solved is to provide an automatic cutting and conveying device of trademark paper of woven bags or mesh bags, achieve full automation of sewing of the trademark paper and save labor cost and time cost. The technical scheme adopted by the invention is as follows: a paper winding shaft is mounted at one end of a box body; a fixing frame is mounted inside the box body; a circular reversing rod is arranged on one side near the paper winding shaft; a driving conveying wheel, a cutting device, a conveying belt and an unloading device; the unloading device is mounted at the top of an outlet section of the conveying belt; a conveying device of a host for sewing the woven bags or the mesh bags is arranged at the lower part of the outlet section of the conveying belt; a plurality of mark points are uniformly arranged on trademark paper of the paper winding shaft; a trademark paper movable end passes through the fixing frame, the driving conveying wheel and the cutting device and is clamped between a second pressing wheel and the conveying belt; a probe is mounted on the fixing frame and corresponds to a mark point path of the trademark paper.

Owner:XINJIANG TIANLI PLASTIC CHEM CO LTD

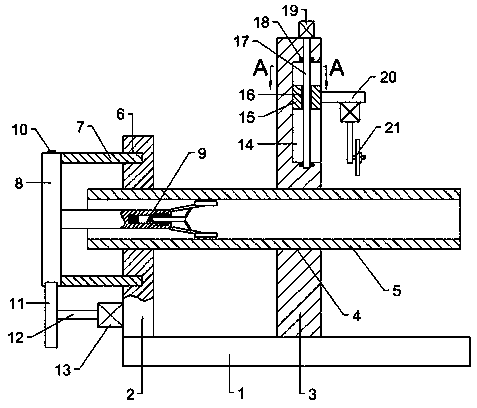

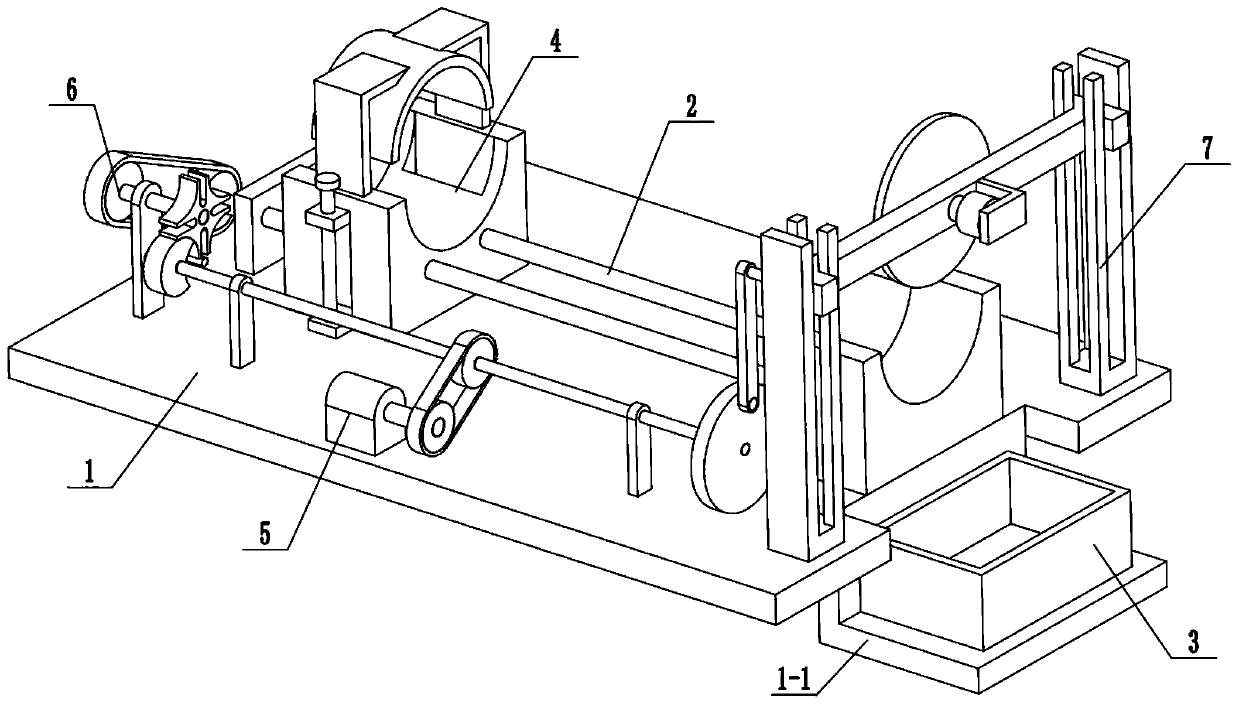

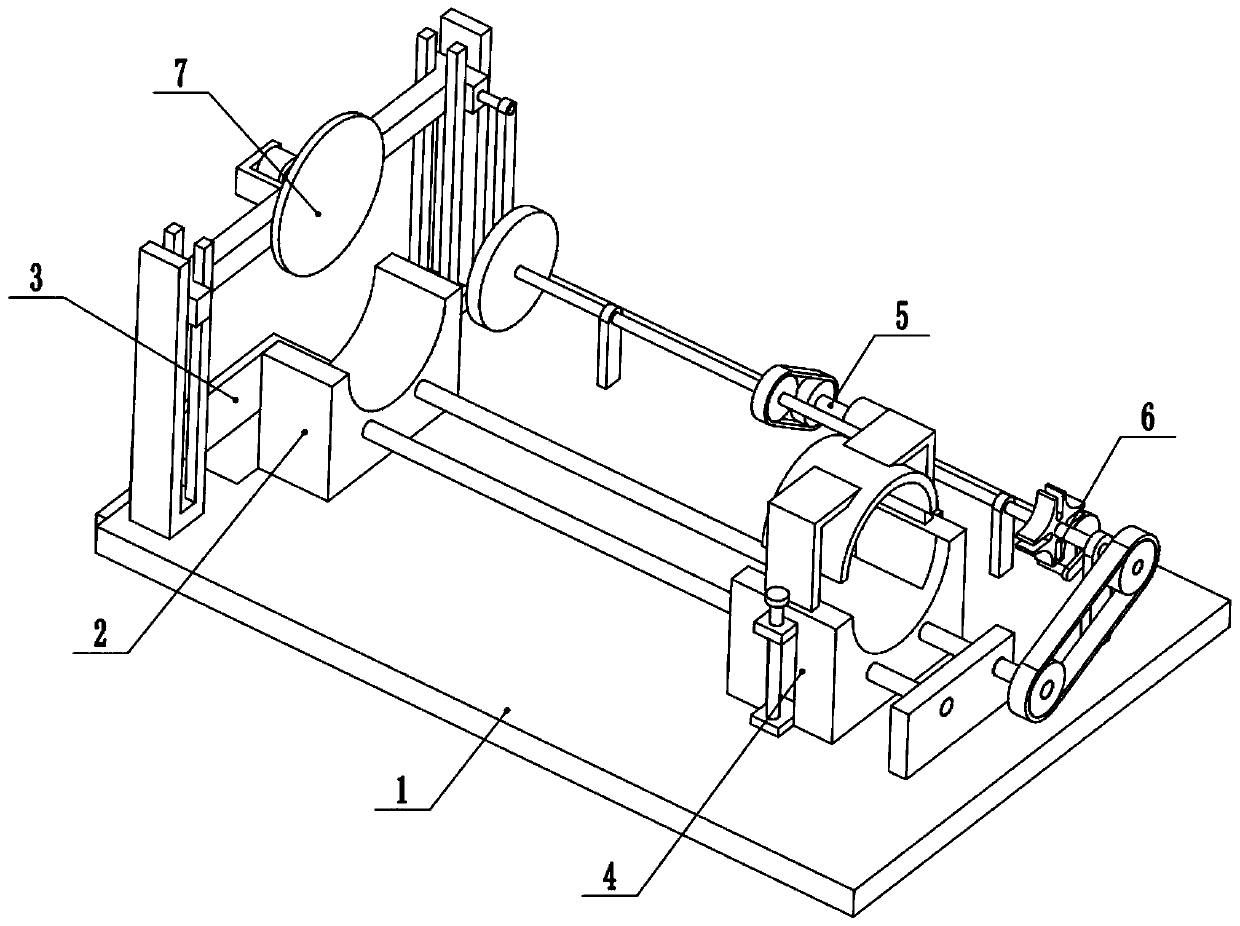

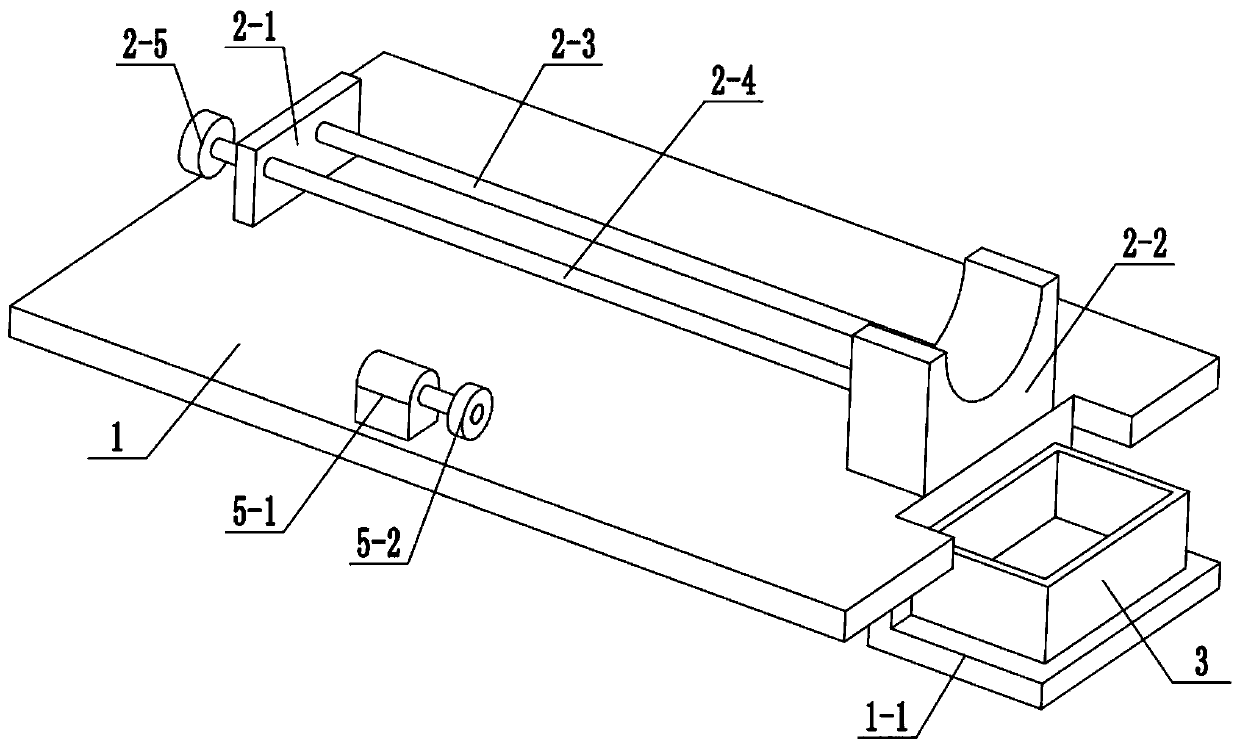

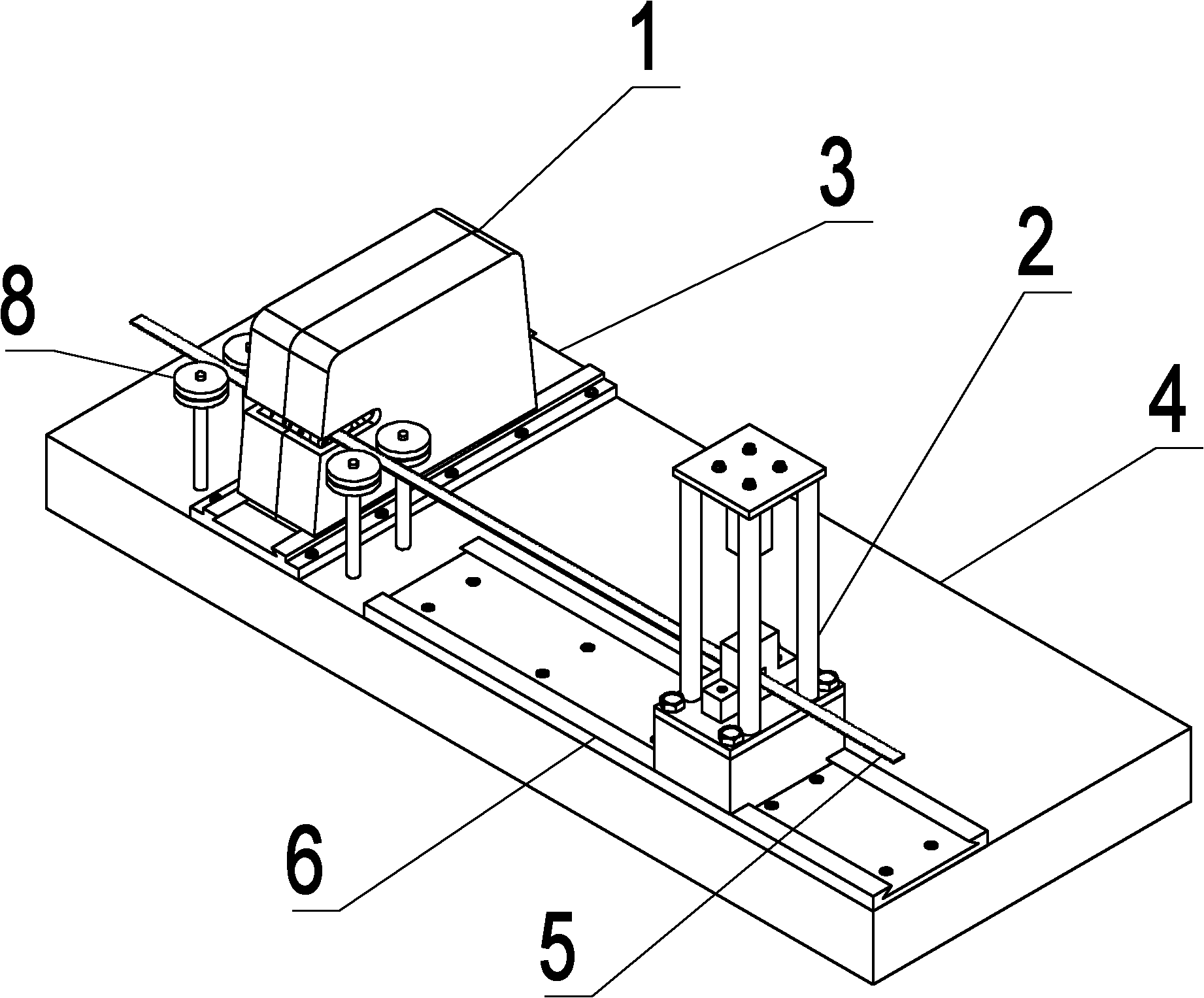

Automatic cutting and grinding equipment for low-carbon steel pipe for splicing of building structure grid frame

InactiveCN107838685AEasy to fixAccurate splicingOther manufacturing equipments/toolsArchitectural engineeringCarbon steel

The invention relates to an automatic cutting and grinding equipment for low-carbon steel pipes used for splicing building structure grids, which includes a supporting base plate, a cutting device, a clamping device, a grinding device and a fixing device, and a cutting device is installed on the top of the left end of the supporting base plate , the clamping device is installed on the top of the support base plate, the grinding device is connected with the middle part of the support base plate, and the fixing device is installed on the top right side of the support base plate. The present invention can solve the existing steel pipe welding problems that the steel pipe cannot be firmly fixed when the steel pipe is cut, the cut of the steel pipe after cutting is not neat, the cut of the steel pipe needs to be manually polished, the grinding effect of the cut of the steel pipe is poor, and the steel pipe needs to be manually polished before welding. The position of the steel pipe is corrected, and there will be errors in the position of the steel pipe after correction; it can realize the functions of cutting the steel pipe at a fixed angle, grinding the incision of the cut steel pipe, and accurately splicing the polished steel pipe together.

Owner:吴秋敏

Self-adaptive full-automatic pipe cutting machine

InactiveCN103962624AImprove adaptabilityEasy to useMetal sawing devicesTube shearing machinesEngineeringSelf adaptive

The invention discloses a self-adaptive full-automatic pipe cutting machine which comprises annular supports, an annular rail, an annular drive mechanism, clamping mechanisms, a feeding mechanism and cutters. The annular rail is arranged on the annular supports, the clamping mechanisms are arranged on one sides of the annular supports, the annular drive mechanism is arranged on the annular rail, the feeding mechanism is arranged on the annular drive mechanism, and the cutters are arranged at the front end of the feeding mechanism. Through the mode, the self-adaptive full-automatic pipe cutting machine has the advantages of being high in reliability performance, accurate in locating, compact in structure, high in cutting-off speed, high in efficiency, orderly in cutting opening, good in pipe adaptability, convenient to use and the like, and meanwhile has the wide market prospects in the pipe cutting field.

Owner:SUZHOU GENFU MACHINERY SCI & TECH

Building steel pipe cutting-off equipment with steel pipe synchronous rotation function

The invention discloses building steel pipe cutting-off equipment with a steel pipe synchronous rotation function. The equipment comprises a base, wherein the left part of the base is fixedly connected with a first supporting plate, and a movable through hole is formed in the first supporting plate; a second supporting plate is fixedly connected to the position, located on the right side of the first supporting plate, of the base, another movable through hole is formed in the second supporting plate, and a steel pipe is jointly erected in the two movable through holes; annular grooves are formed in the left side wall of the first supporting plate, and sleeves are arranged in the annular grooves; a disc is fixedly connected to the left ends of the sleeves, a steel pipe clamping device is fixedly connected to the right side wall of the disc, a gear ring is fixedly connected to the edge of the disc, and a gear is meshed with the lower side of the gear ring. The building steel pipe cutting-off equipment with the steel pipe synchronous rotation function has the beneficial effects that a rotating shaft drives the gear to rotate, the gear drives the gear ring to rotate, and the gear ringcan drive the steel pipe to rotate through the disc and the steel pipe clamping device, so that the large-diameter steel pipe is conveniently cut, furthermore, a notch is flat, subsequent trimming does not need to be carried out, and operation safety performance is higher.

Owner:KUNSHAN RUIHENGFENG TECH CONSULTING

Wood cutting device for forestry engineering

ActiveCN109732707ASmooth cutNot easy to shiftFeeding devicesGripping devicesEngineeringMaterials processing

The invention relates to the field of building material processing equipment, in particular to a wood cutting device for forestry engineering. A rectangular through slot is formed in the middle end ofthe right end of a base; an L-shaped seat plate is fixedly connected into the rectangular through slot; a wood collecting box is placed onto the L-shaped seat plate; a feeding slide base is fixedly connected onto the base; the wood collecting box is positioned below the right end of the feeding slide base; a wood fixed slide base is connected on the feeding slide base; a power device is fixedly connected to the front end of the base; the power device is in transmission connection to a cutting assembly through a belt; and the cutting assembly is fixedly connected to the right end of the base.The wood cutting device can fix wood, and the fixed wood is not liable to deviate, so that wood cutting is more smooth, wood scrap is avoided, and waste of wood resources is avoided; and an intermittent feeding mechanism can automatically feed the fixed wood to cut, so that a constructor is prevented from risk during operation.

Owner:陈芬芬

Power cable cutting device

PendingCN107775699AGood truncation effectConvenient truncationApparatus for cutting/splicing cablesMetal working apparatusPower cableSlide plate

The invention discloses a power cable cutting device. The power cable cutting device comprises a support base, wherein vertical plates are arranged on the left side wall and the right side wall of thesupport base; a convex plate is arranged above a second slider; a second cylinder is fixedly mounted on the front side wall of the convex plate and fixedly connected with the outer side wall of a second fixture block through a cushion block; a cutter is located above a first fixture block and the second fixture block. According to the power cable cutting device, a third motor is started to drivea cable feed roller to perform paying off, while a to-be-cut cable penetrates through the through holes in the left vertical plate and the right vertical plate, the second cylinder is started to drivethe second fixture block to move backwards, so that the to-be-cut cable is located between the first fixture block and the second fixture block, then the second cylinder drives the second fixture block to move forwards to clamp the to-be-clamped cable, left-right movement can be realized by a mobile table, accordingly, the cutter is enabled to move to the right sides of the first fixture block and the second fixture block, and a second motor is started to drive the cutter to rotate for cutting the cable.

Owner:丁家琪

Ceramic cutting tool with ultrahigh strength and ultrahigh toughness, and preparation method thereof

The invention discloses a ceramic cutting tool with ultrahigh strength and ultrahigh toughness. The ceramic cutting tool with ultrahigh strength and ultrahigh toughness is prepared by a hot-press vibratory sintering process by using zirconium oxide, yttrium oxide and a rare earth oxide as main raw materials. Accordingly, the invention also discloses a preparation method of the ceramic cutting tool with ultrahigh strength and ultrahigh toughness. The preparation method comprises the steps of prepressing molding preprocessed powder to obtain a semi-finished cutting tool; performing low temperature heat treatment on the semi-finished cutting tool; hot-press vibratory sintering the semi-finished cutting tool processed by the low temperature heat treatment; and polishing and burnishing the semi-finished cutting tool processed by the hot-press vibratory sintering process to obtain the ceramic cutting tool with ultrahigh strength and ultrahigh toughness. Due to the adoption of the preparation method, the cutting toll has high hardness, good wear resistance and excellent thermal shock resistance, high bending strength and high fracture toughness. The cutting tool has obvious advantages in thermal conductivity, corrosion resistance, antioxidant activity, high temperature hardness, high temperature strength, etc.

Owner:FOSHAN CERAMICS RES INST GRP CO LTD +1

Pipeline cutting equipment with pipeline rotary-cutting function

InactiveCN106735518APrevent pinch offEnsure safetyTube shearing machinesShearing machine accessoriesEngineeringMechanical engineering

The invention relates to pipeline cutting equipment with a pipeline rotary-cutting function. The pipeline cutting equipment comprises a base, a supporting pole is fixedly arranged at the right end of the base, and two installing frames are fixedly arranged on the base. A first through hole is formed in each installing frame, a pipeline penetrates through the first through holes, and a pipeline rotating device is arranged between the two installing frames. A second through hole is formed in the lower portion of the supporting pole, and the right end of the pipeline is located in the second through hole. A baffle is arranged on the portion, on the right side of the second through hole, of the supporting pole. The pipeline cutting equipment with the pipeline rotary-cutting function has the beneficial effects that when cutting of the pipeline is about to be completed, the second through hole can be used for supporting the cut-off portion of the pipeline, so that the phenomenon that a cutting blade is pinched off due to inclining of the pipeline is avoided, and it is guaranteed that cutting is smoothly conducted; the pipeline rotating device is used for driving the pipeline to rotate by one circle, but a cutting machine keeps still on the whole; and the size of the cutting blade of the cutting machine can be minimized, and safety of cutting operation is effectively guaranteed.

Owner:安徽谢佑圣电子科技有限公司

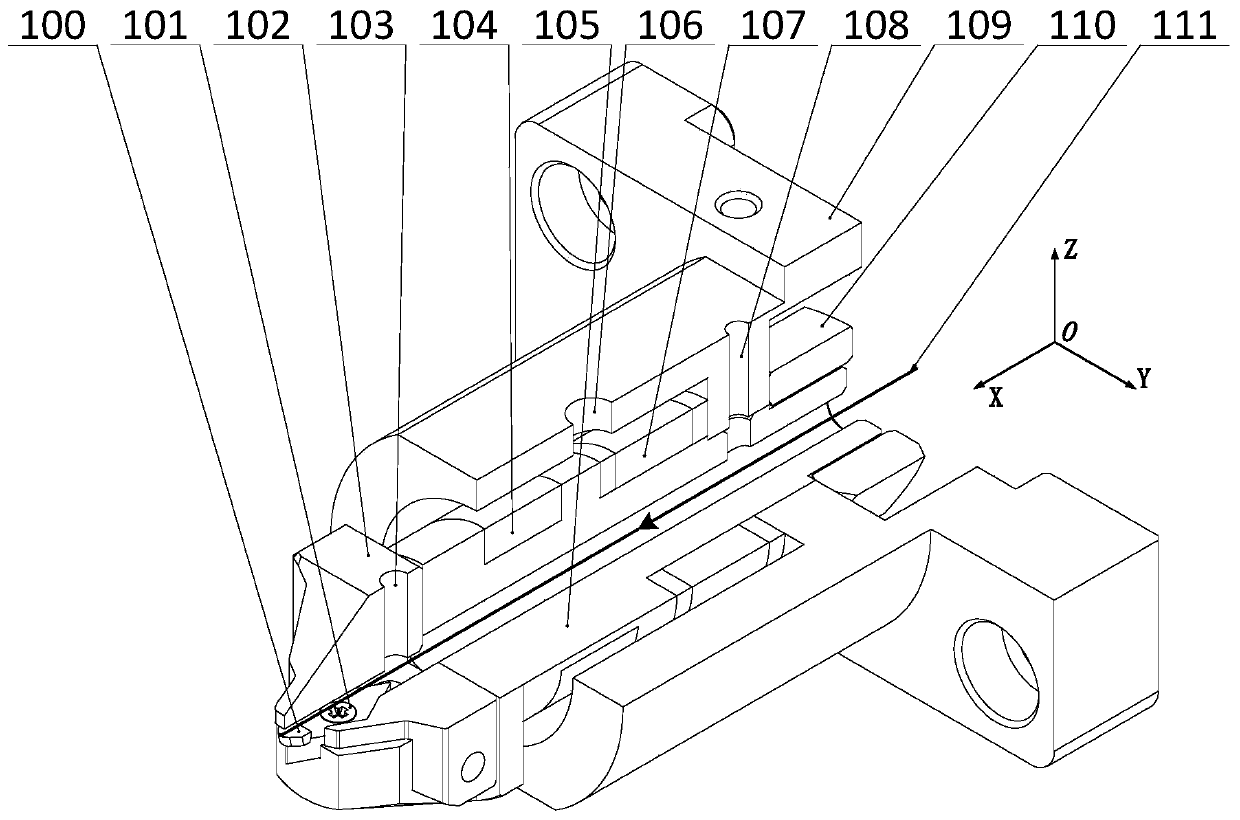

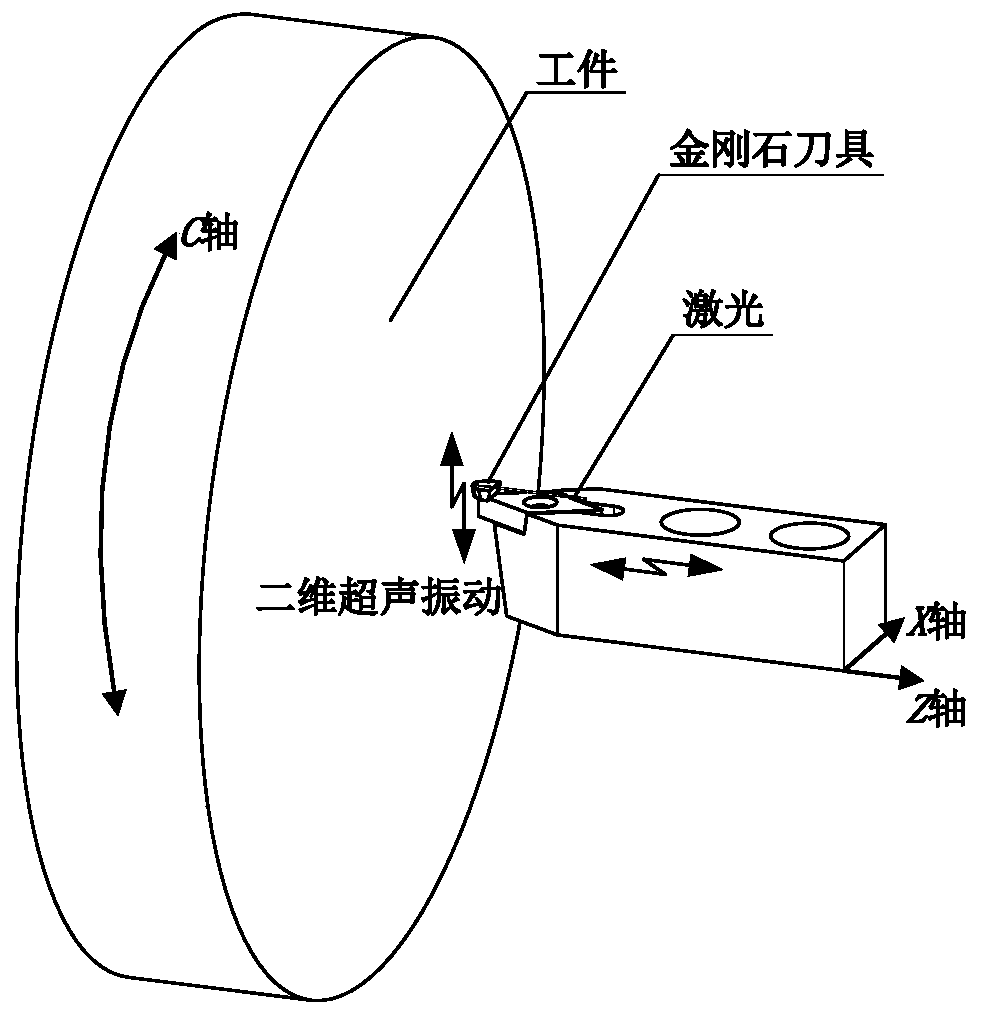

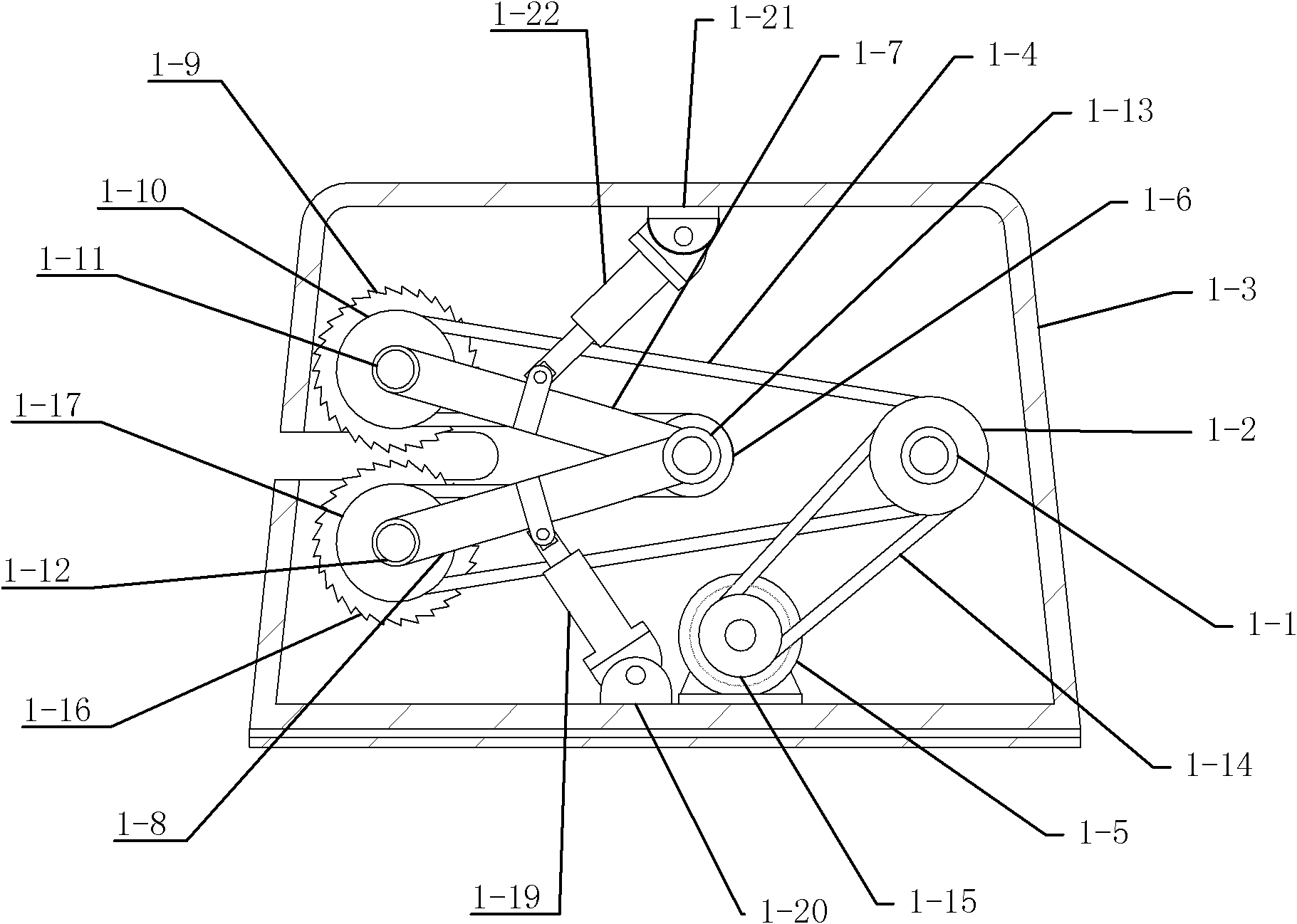

Ultrasonic vibration micro laser assisted composite single-point diamond cutting processing system

ActiveCN111069767AAvoid misalignmentGuaranteed accuracyLaser beam welding apparatusDiamond cuttingEngineering

The invention belongs to the field of ultra-precision processing, and discloses an ultrasonic vibration micro laser assisted composite single-point diamond cutting processing system. The system comprises a laser emitting module and a cutting module, wherein the laser emitting module is used to emit laser, the cutting module comprises a tool, an ultrasonic amplitude-change pole and a piezoelectricunit, a through hole is formed in the center of the ultrasonic amplitude-change pole, laser emitted by the laser emitting module is focused on the tip point of the tool through the through hole, the piezoelectric unit converts an electrical signal into a pressure signal to enable the ultrasonic amplitude-change pole to drive the tool to vibrate, thereby converting the cutting method from continuous cutting to intermittent cutting, the back end of the tool is an elliptical spherical surface, and when the tool vibrates, the laser is always focused on the tip point of the tool through the back end of the tool to avoid the misalignment of the laser and the tip point when the ultrasonic amplitude-change pole vibrates. Through the system, the organic integration of ultrasonic vibration, single point cutting technology and micro laser assisted processing technology is realized, and the processing efficiency and precision are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

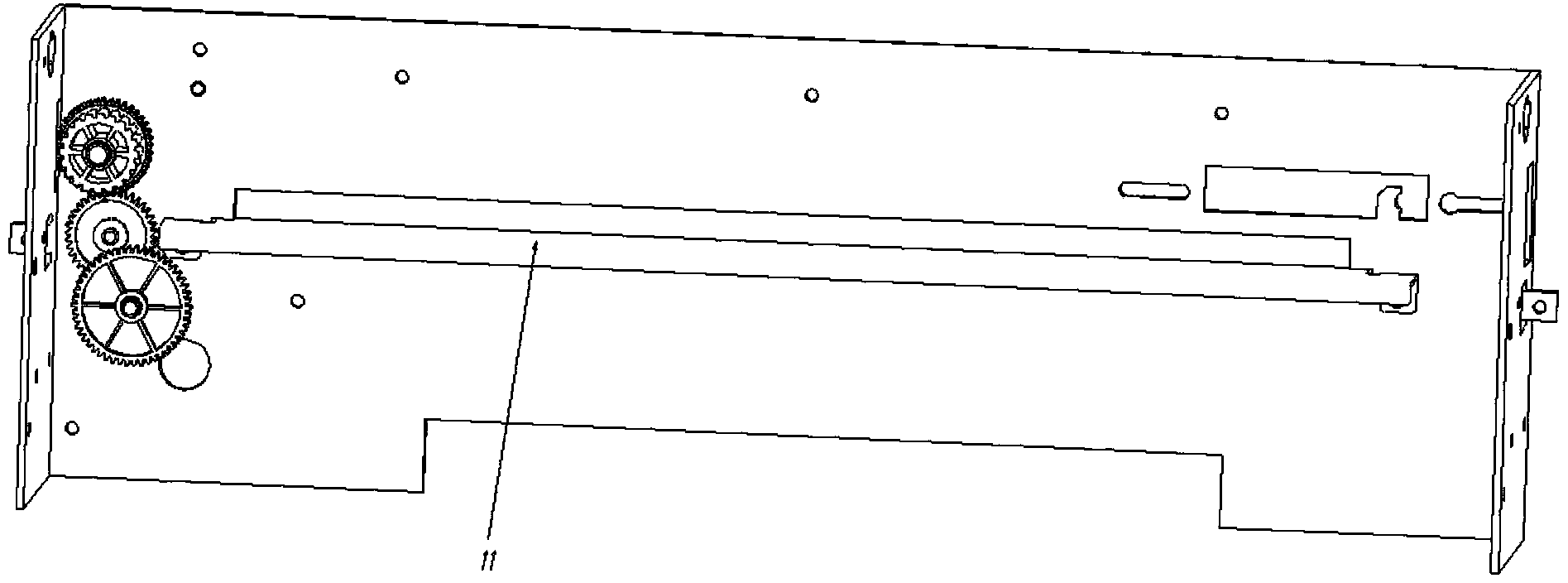

Hob type paper cutting device

ActiveCN104070841ASimple structureGood paper cutting reliabilityOther printing apparatusMetal working apparatusControl systemDrive motor

The invention discloses a paper cutting device, particularly relates to a hob type paper cutting device applied to a printer, and belongs to the field of computer communication technology. The hob type paper cutting device comprises a driving motor, a transmission mechanism, a rolling movable knife, a fixed knife, a holder, a paper pressing assembly, a guide support, a guide shaft, a guide plate, a position sensor, a tensioning support assembly, a control system and the like. The transmission mechanism transmits rotation movement of the driving motor to the rolling movable knife to perform automatic paper cutting. The hob type paper cutting device has the advantages that the hob type paper cutting device is modular in design manufacture, low in cost and convenient to maintain, assemble and disassemble; a pressure angle remains unchanged during paper cutting, so that paper is cut stably; a paper cutting assembly is simple in structure and good in paper cutting reliability.

Owner:NANJING FUJITSU ELECTRONICS INFORMATION TECH CO LTD

Device for cutting off flat tube of heat exchanger

ActiveCN102009349AReduce throttling lossIncrease productivityOther manufacturing equipments/toolsPlate heat exchangerMilling cutter

The invention provides a device for cutting off a flat tube of a heat exchanger, which comprises a machine base, a milling mechanism capable of transversely sliding along the machine base and a die-cutting mechanism capable of longitudinally sliding along the machine base, wherein the flat tube which is longitudinally conveyed along the machine base is arranged in the milling mechanism and the die-cutting mechanism by penetration, a milling cutter for milling the flat tube and forming a milling cut is arranged on the milling mechanism, and a die cutter which can detect the position of the milling cut and perform die-cutting is arranged on the die-cutting mechanism. The device has the advantages that the device for cutting off the flat tube of the heat exchanger can avoid the deformation and the shrinkage of the cut-off end surfaces of the flat tube, lead the flow of refrigerant to be smooth and improve the heat exchange efficiency of the heat exchanger.

Owner:浙江兰通空调设备有限公司

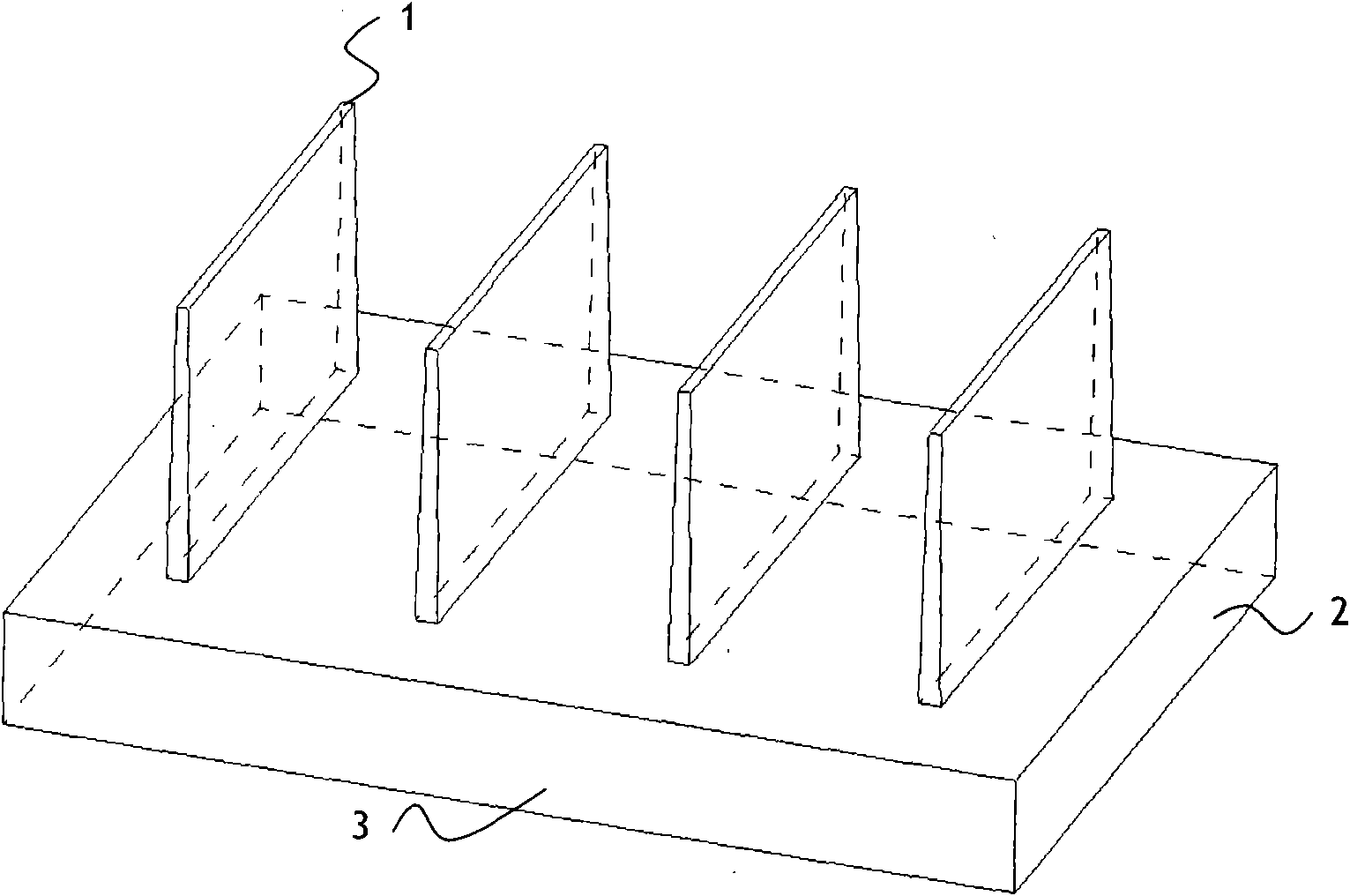

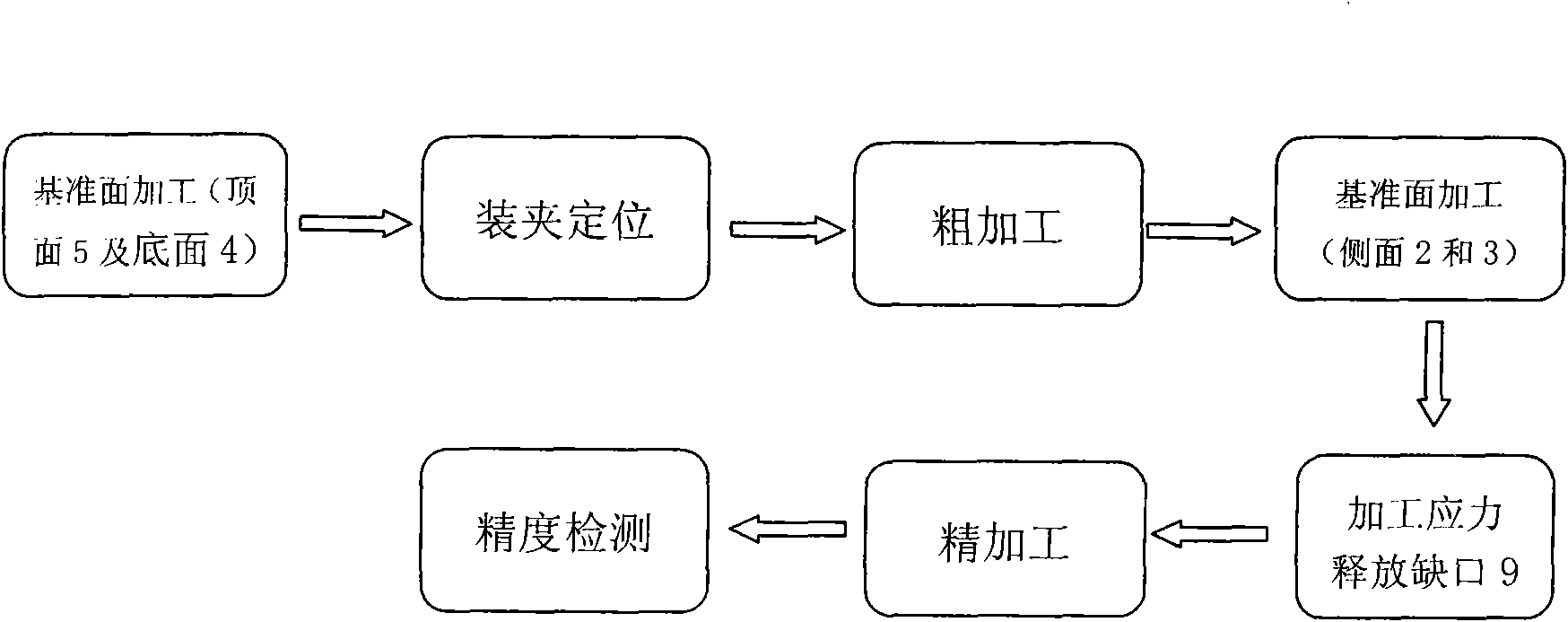

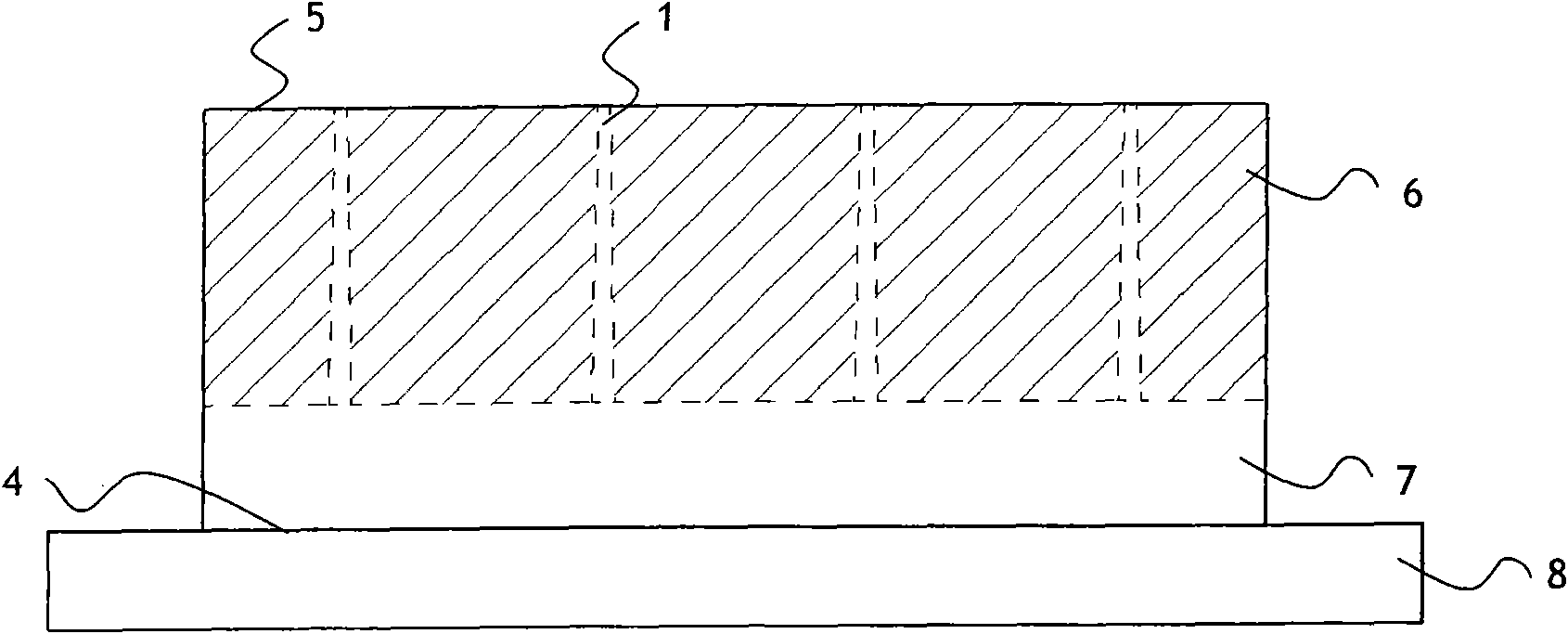

Numerical control machining method for thin-wall copper electrode

The invention relates to a numerical control machining method for a thin-wall copper electrode, which comprises the following steps of: reasonably selecting a clamp, a cutter and a cutting parameter for improving the working efficiency; reasonably distributing the step and a feed route; controlling the deformation of a workpiece; after rough machining is finished, mounting a residual stress release notch at the side surface of the workpiece; eliminating deformation caused by residual stress during rapid rough machining, wherein a rough machining cutter adopts a ball end milling cutter instead of a generally used flat end vertical milling cutter; and carrying out symmetrical machining on the design of the feed route. The method for machining the workpiece sequentially comprises the steps of machining a reference surface 5 and a reference surface 4, clamping for positioning, roughly machining, machining a reference surface 2 and a reference surface 3, machining a stress release notch 9, finely machining and detecting precision. By adopting a plurality of process measures for controlling deformation, the invention has the advantages of greatly reducing the deformation of machining parts and effectively improving the precision and the stability of the parts. By actually measuring the workpiece on a three-coordinate measuring machine, a surface roughness value can be reduced to minimum and can completely meet the requirement on products.

Owner:潘建新 +1

Slitting cutting disc and preparation method thereof

The invention discloses a slitting cutting disc and a preparation method thereof, which belong to the process field of cutters. The slitting cutting disc is of a circle blade, and comprises a center hole, a cutter disc and a blade, wherein the center hole is arranged in the center of the cutter disc, the blade is arranged on an outer ring of the cutter disc, a blade opening is arranged on an outer ring of the blade, and the opening angle delta ( ) of blade opening is 23-27 degrees. The opening thickness h of the blade opening is 0.24-0.26mm. The materials which are made into the slitting cutting disc comprise components with percentage by weight: carbon (C) 1.15-1.33%, nitrogen (N) 0.2-0.4%, manganese (Mn) 0.30-0.40%, silicon (Si) 0.52-1.20%, chromium (Cr) 8.50-10.50%, tungsten (W) 1.50-2.50%, vanadium (V) 0.35-0.50%, molybdenum (Mo) 0.25-0.4%, nickel (Ni) 0.30-0.40%, copper (Cu) <=0.30%, sulphur (S)<=0.020% and phosphorus (P)<=0.027%, and the allowance is ferrum (Fe). The slitting cutting disc has the advantages that the slitting cutting disc is excellent in abrasive resistance and is not easy to deform, and the blade opening resists abrasion, not easy to crack, long in service life and easy to make.

Owner:安徽华天机械股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com