Super-strong and super-toughened ceramic cutter and manufacturing method thereof

A technology of ceramic cutting tools and manufacturing methods, which are applied in ceramic forming machines, cutting tools for lathes, manufacturing tools, etc., can solve the problems of insufficient fracture toughness, easy cracking, poor bending strength and thermal shock resistance, etc. The production process is easy to achieve, the friction force is small, and the production efficiency is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

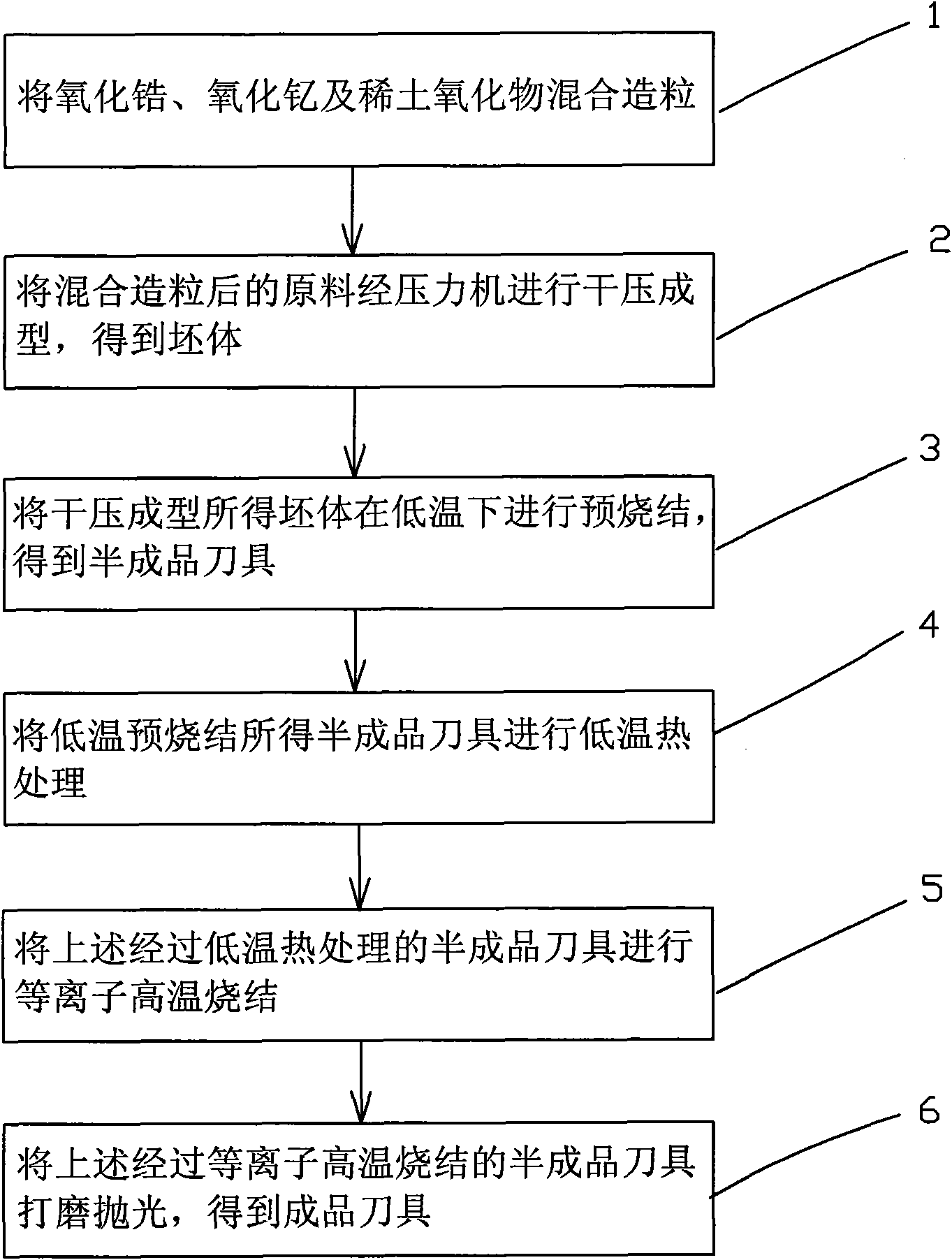

Image

Examples

Embodiment Construction

[0026] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

[0027] The invention provides a super-strength and super-tough ceramic cutting tool, which has the following components and contents: 89-92 parts of zirconia, 2-8 parts of yttrium oxide and 2-4 parts of rare earth oxide. The present invention breaks the routine that the traditional ceramic cutting tools generally use aluminum oxide base and silicon nitride as the base material, adopts zirconium oxide as the main base material, and is made with yttrium oxide and rare earth oxide in a certain proportion. As far as cutting tools are concerned, they have high hardness and good wear resistance, and have obvious advantages in thermal stability, thermal conductivity, corrosion resistance, oxidation resistance, high-temperature hardness, and high-tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com