Method for making Electric impedance type glass/glass type touch screen

A production method and touch screen technology, applied in the direction of glass/slag layered products, chemical instruments and methods, mechanical mode conversion, etc., can solve the problems of complex production process, and achieve the effect of simple process, simple method and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

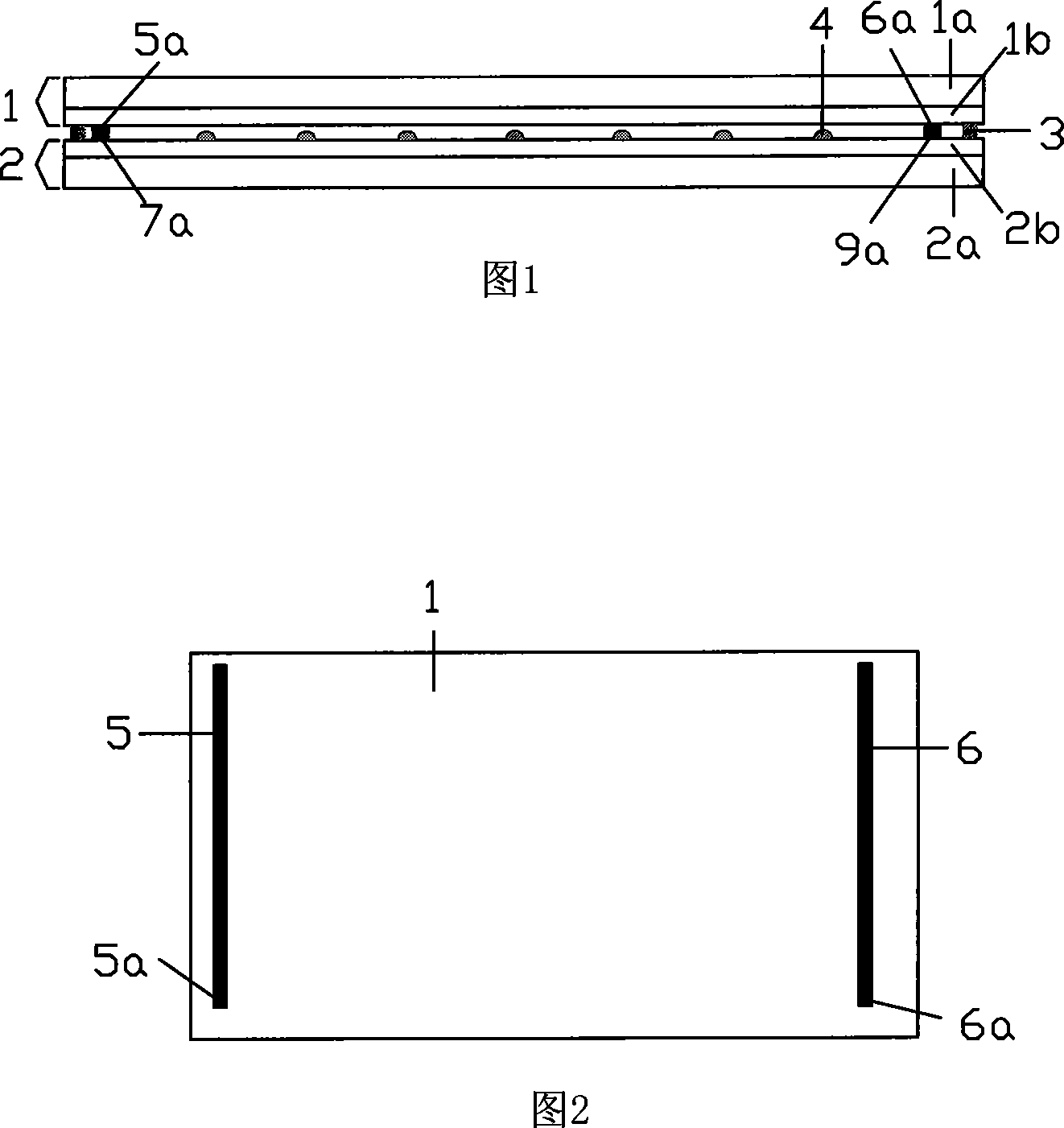

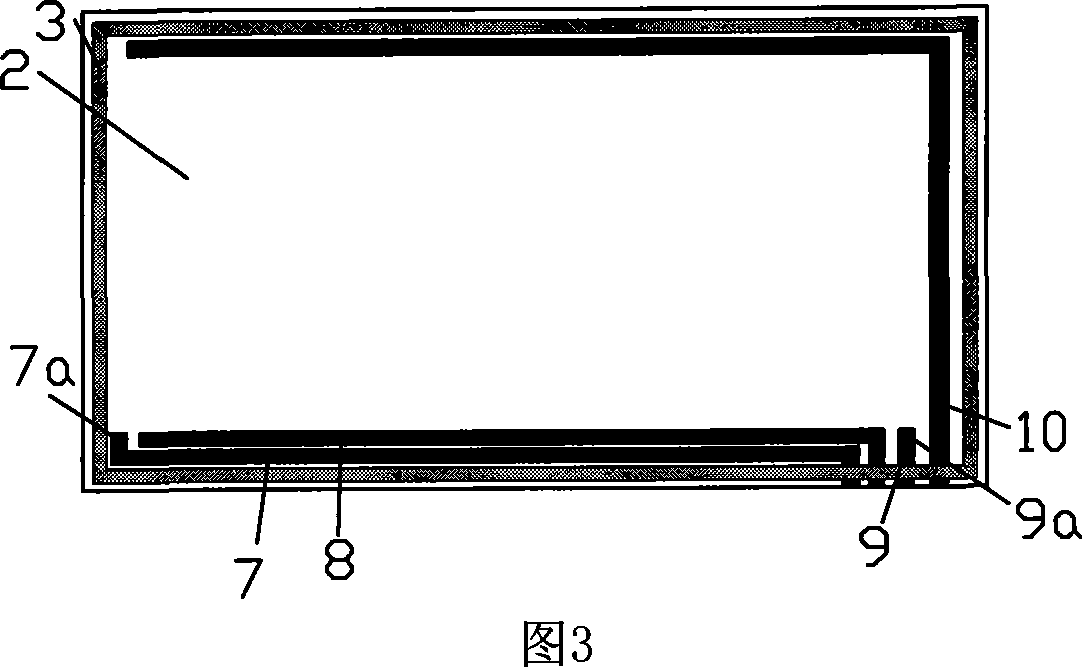

[0032] A resistive glass / glass touch screen as shown in Figure 1 to Figure 3, its manufacturing process is: after the upper and lower glass substrates of the touch screen are bonded and sealed, they are soaked in a groove filled with etching solution for etching, and the glass substrate A certain thickness is formed after etching. The specific production steps are as follows:

[0033] A. Etch a pattern on the transparent conductive layer 2b of the lower glass substrate 2 and make scattered isolation points 4, and then make electrodes 7, 8, 9, 10 on the top, and the thickness d2 of the electrodes is 8-25 microns.

[0034] B. Make an adhesive 3 on the lower glass substrate 2. The adhesive can be heat-cured epoxy resin, which is mixed with rod-shaped or spherical particles with a diameter between 5 microns and 20 microns. The main function of the mixed rod-shaped or spherical particles is Determine the distance d between the edges of the upper and lower glass substrates;

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com