Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2310results about How to "Quick cut" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

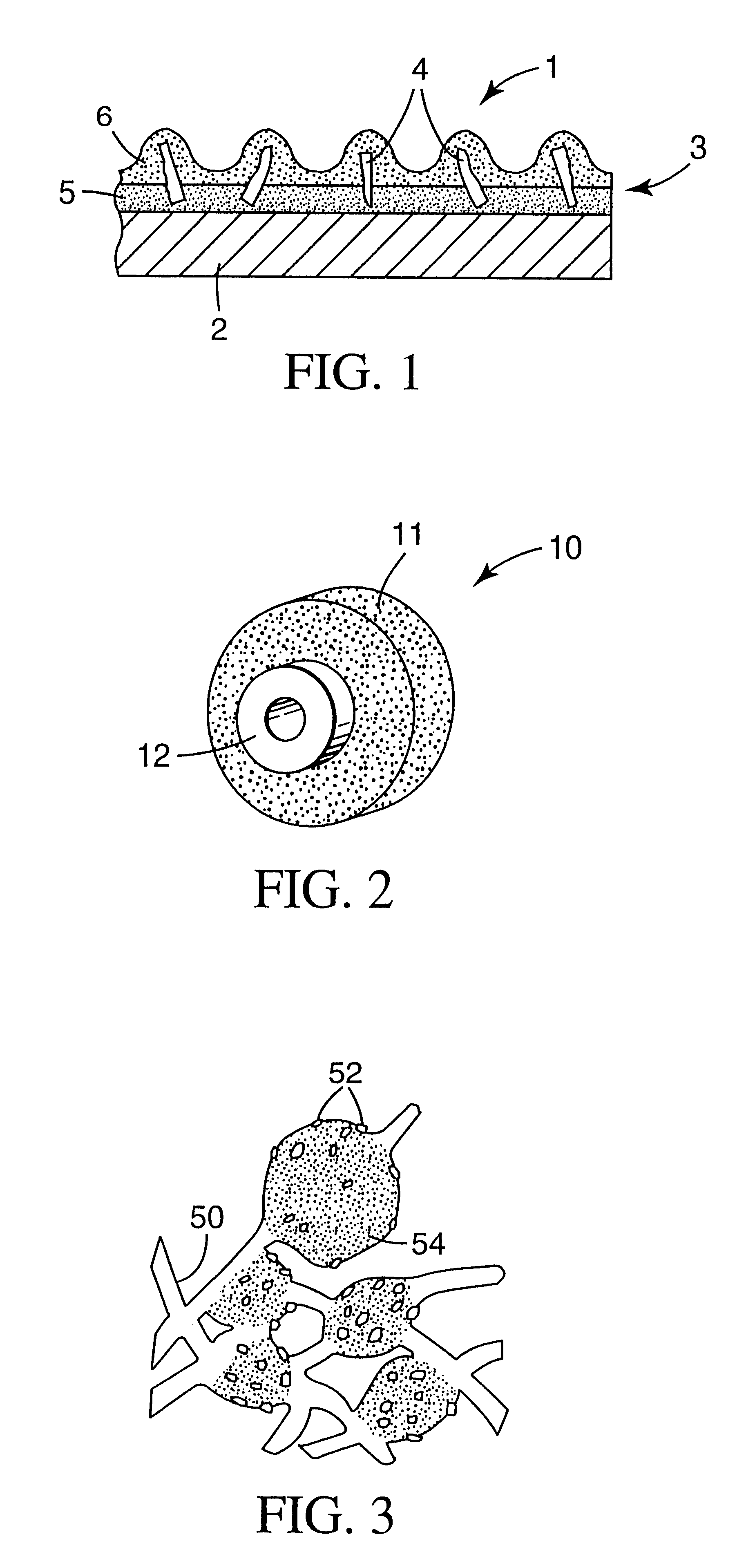

Abrasive grain, abrasive articles, and methods of making and using the same

Owner:3M INNOVATIVE PROPERTIES CO

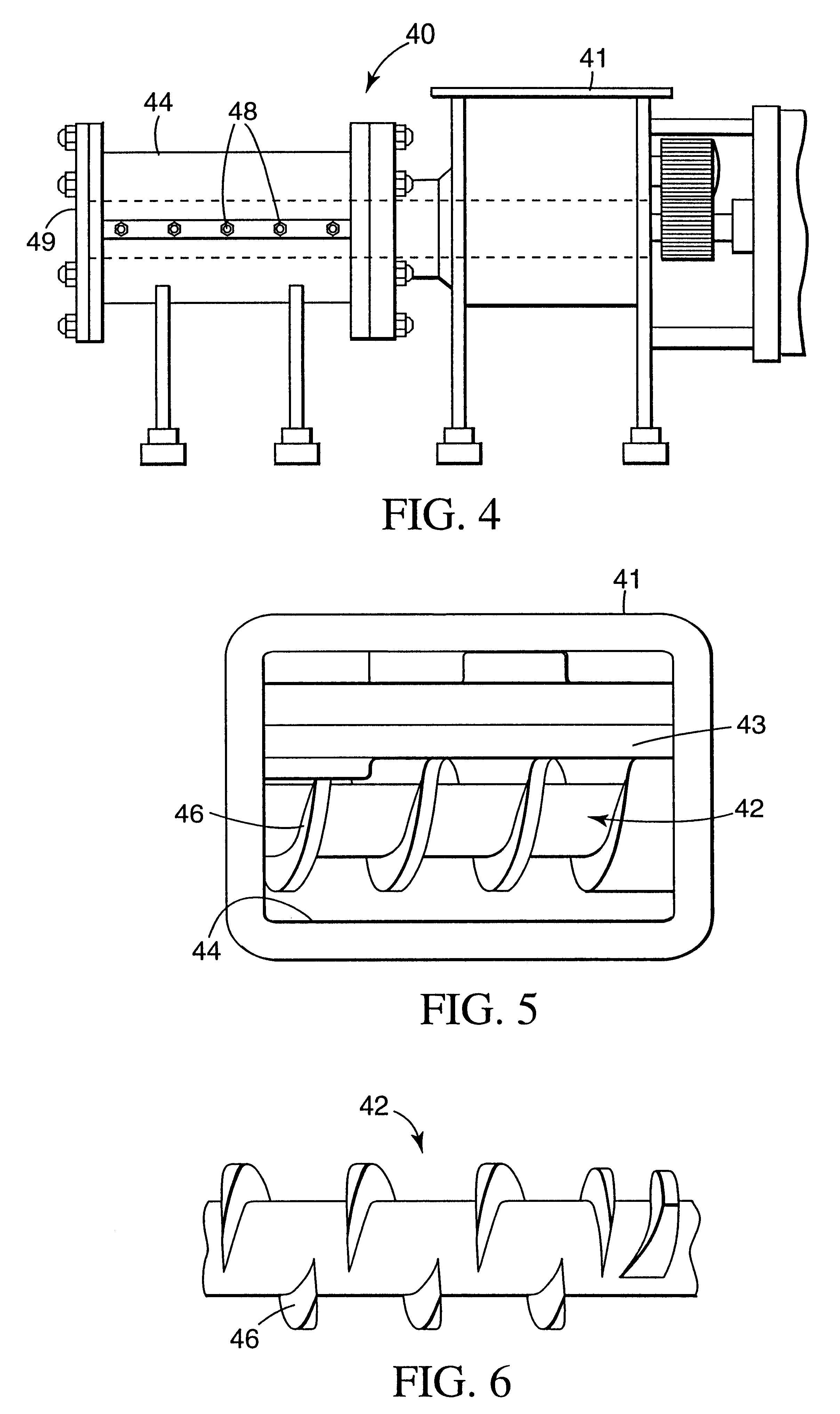

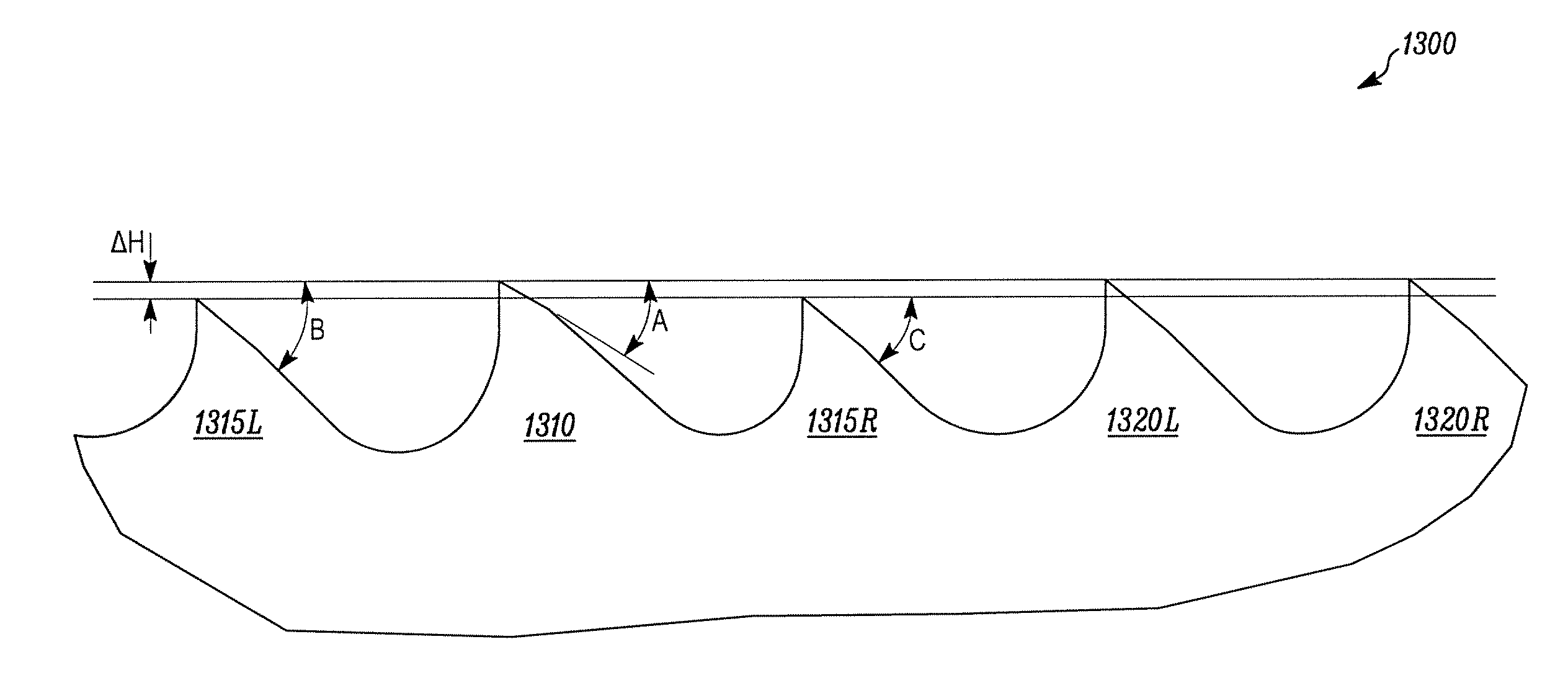

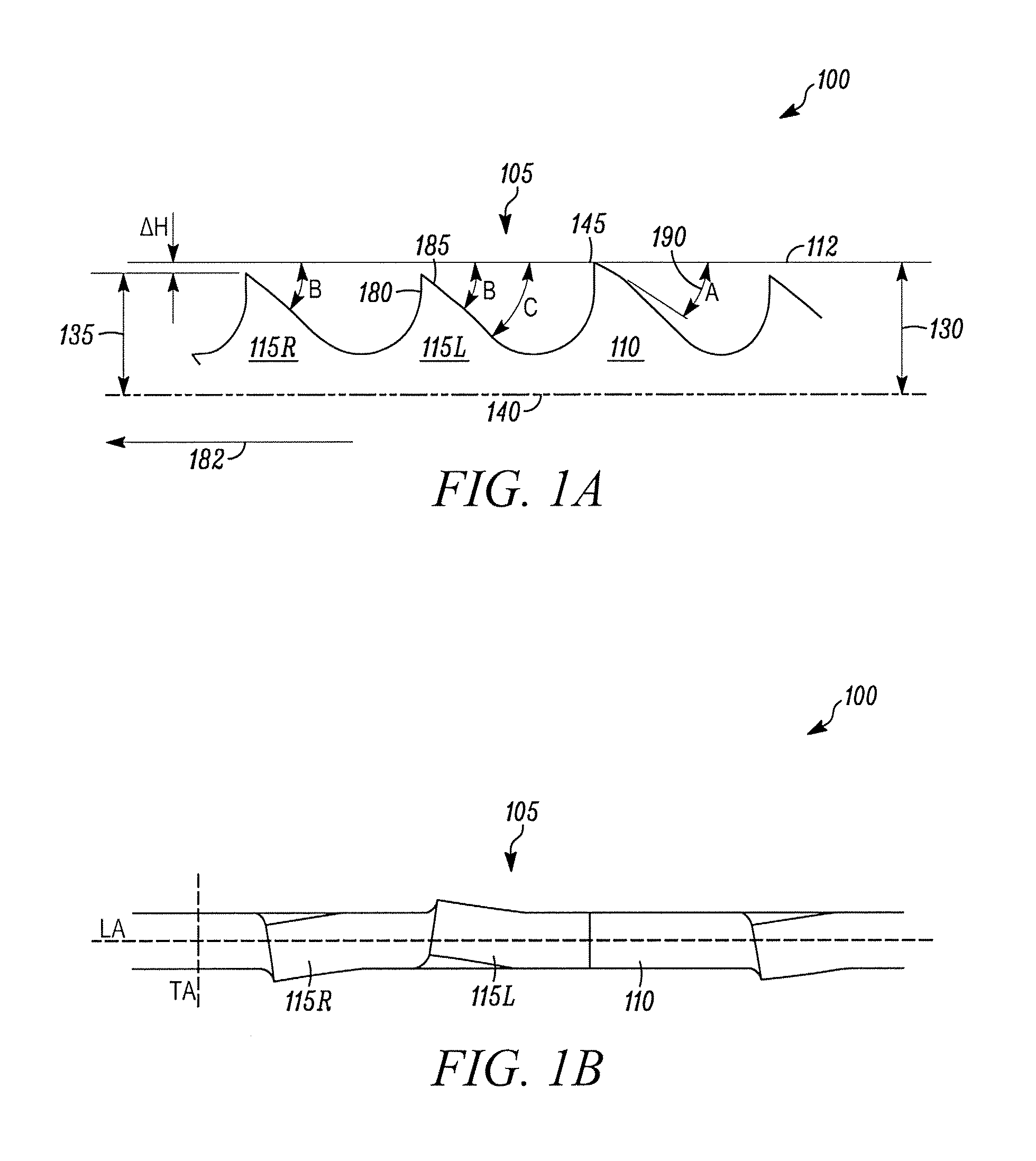

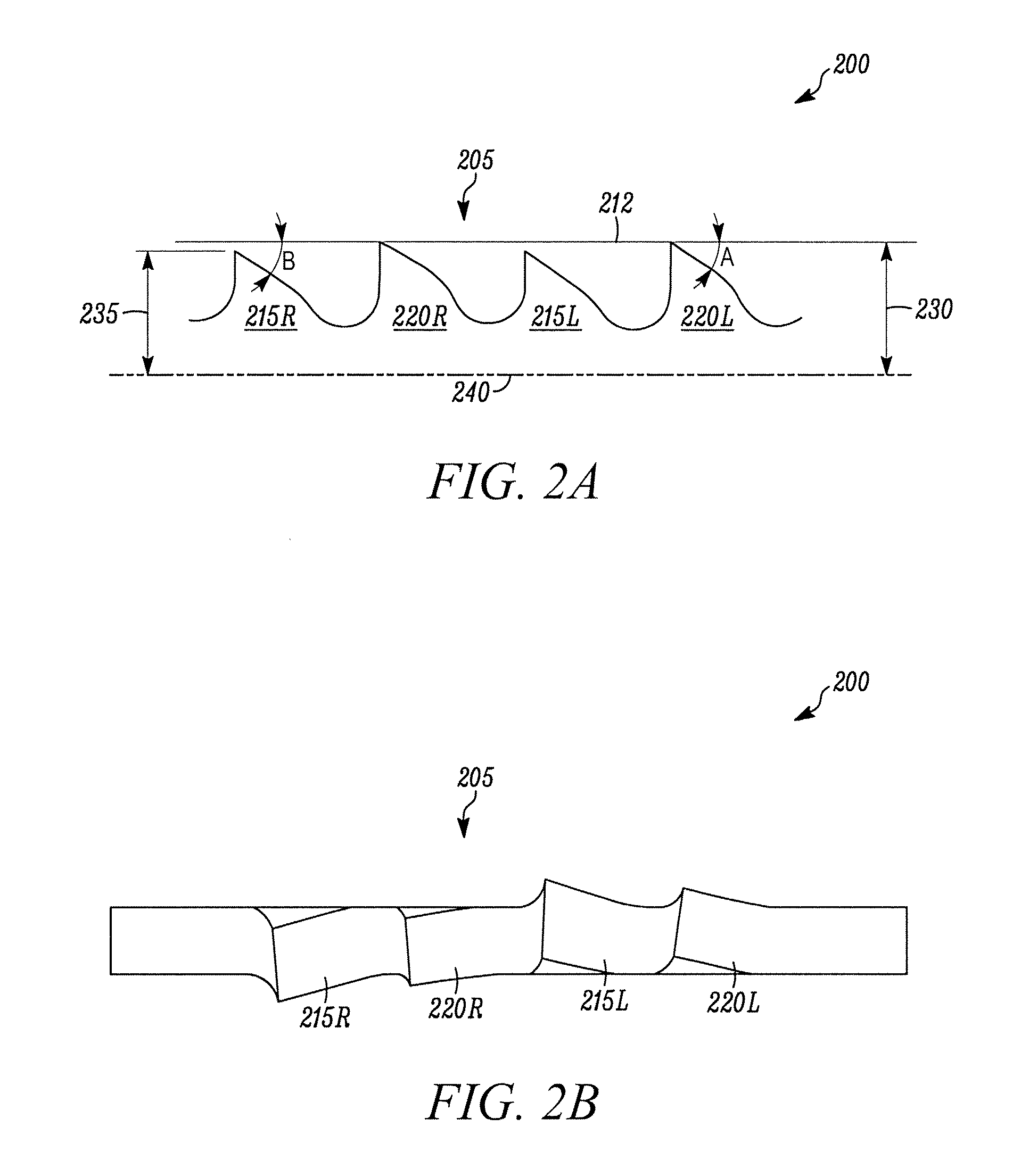

Reciprocating Saw Blade Having Variable-Height Teeth and Related Method

ActiveUS20080307936A1Improve performanceIncrease cutting forceMetal sawing devicesMetal sawing toolsPortable powerEngineering

A reciprocating saw blade, for use in a portable power reciprocating saw including a chuck for releasably engaging the saw blade, includes a tang having an elongated axis and being engageable with the chuck for attaching the saw blade to the reciprocating saw. The saw further includes a blade portion having a cutting edge that defines a plurality of cutting teeth. The cutting teeth define a repeating pattern of successive groups of teeth. Each group of teeth is less than about a half inch in length, and includes a plurality of laterally offset teeth, at least one relatively high first tooth and at least one relatively low second tooth. Prior to tooth set, the at least one relatively high first tooth is at least about 0.002 inch higher than the at least one relatively low second tooth.

Owner:BLACK & DECKER INC

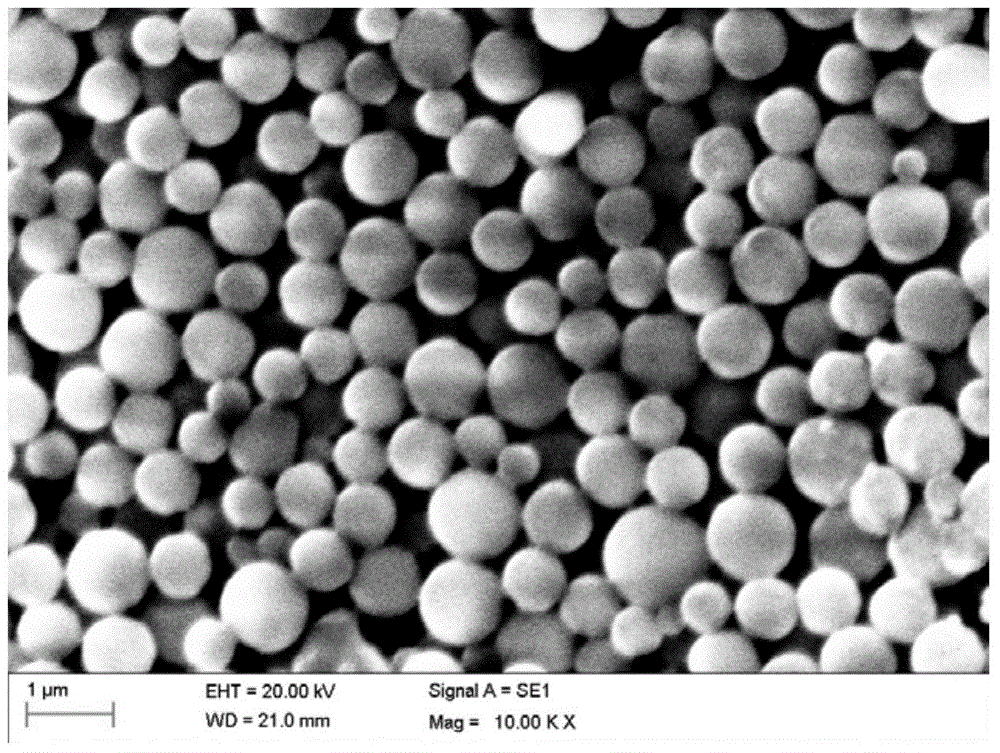

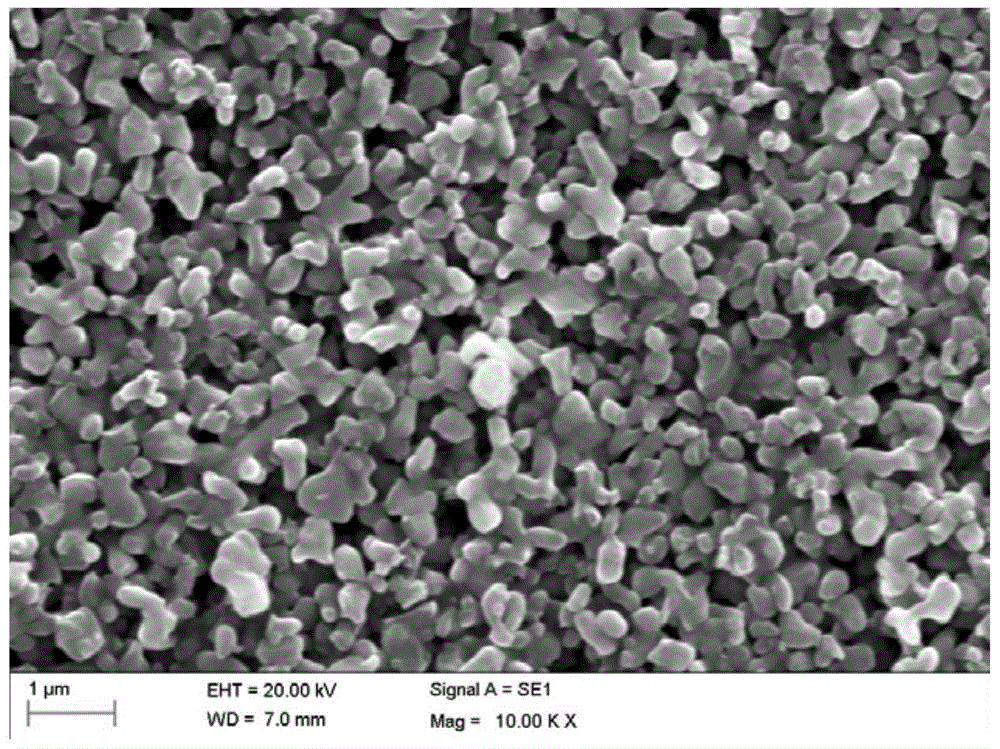

Lithium ion battery composite diaphragm and preparation method and application thereof

InactiveCN104157811AGood air permeabilityImprove securitySecondary cellsCell component detailsLithium electrodePolymer

The invention discloses a lithium ion battery composite diaphragm and a preparation method and an application thereof, belonging to the technical field of lithium ion batteries. The composite diaphragm comprises a polyolefin microporous membrane, a polymer microsphere based coating on one side surface of the polyolefin microporous membrane, and an inorganic ceramic-based coating on the other side surface of the polyolefin microporous membrane. The lithium ion battery composite diaphragm has good air permeability, liquid retaining capability and high-temperature resistance and can remarkably improve the security and the circulation property of the battery. The melting point or softening point of the polymer microsphere-based coating in the composite diaphragm is 90-140 DEG C, and when the temperature of the battery is increased, the polymer microsphere based coating is molten or swelled within a short time, then the apertures of the polyolefin microporous membrane are blocked rapidly, the thermal turn-off effect of the diaphragm is achieved, a lithium ion conveying channel is cut off, and short circuit inside the battery is prevented; meanwhile as ceramic grains inside the inorganic ceramic-based coating have the high-temperature resistance property, the polyolefin microporous membrane is effectively prevented from shrinkage, and the situation that positive and negative films directly come into contact to cause short circuit of the battery.

Owner:SHANGHAI FANNENG NEW MATERIAL TECH CO LTD

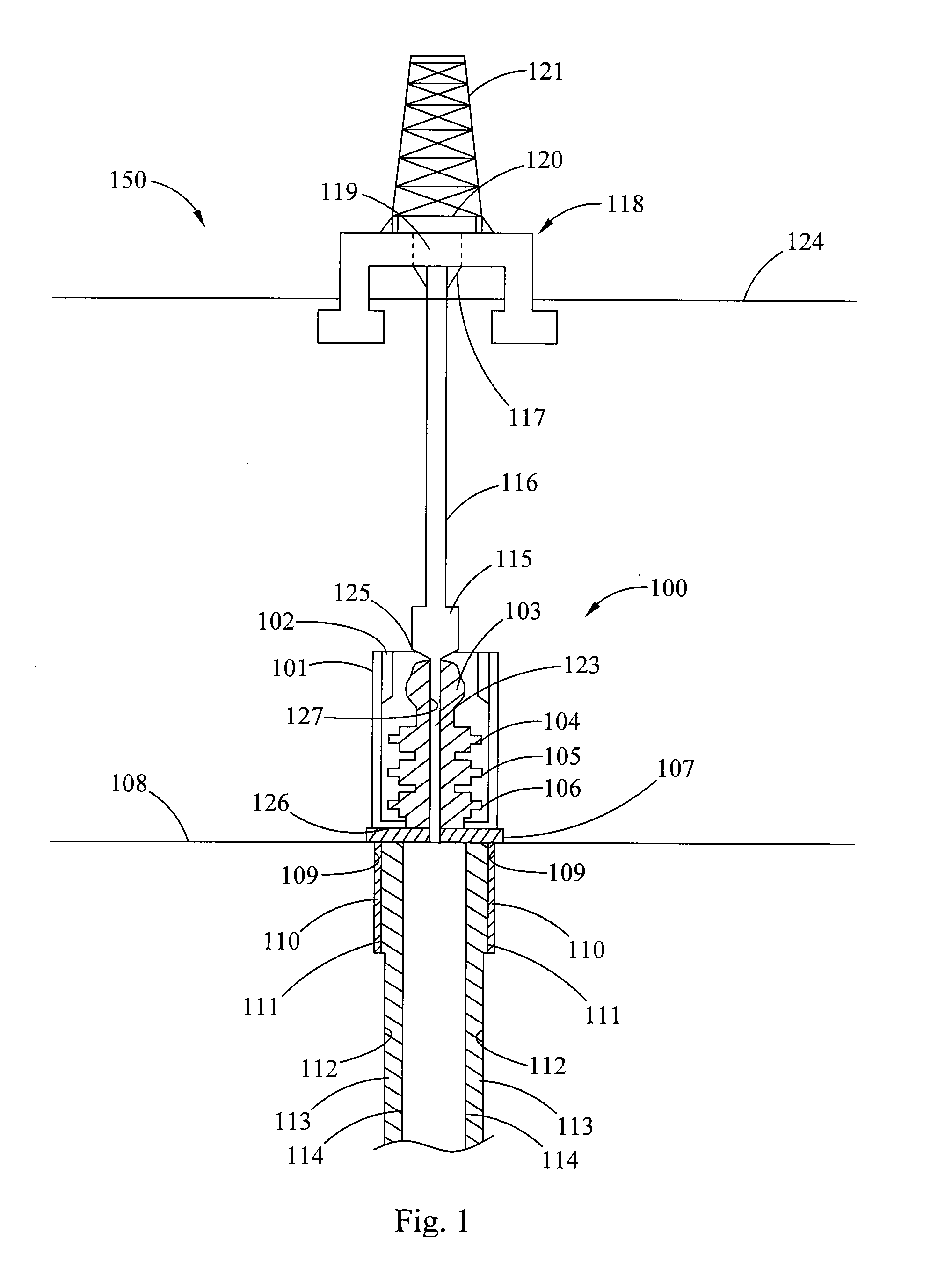

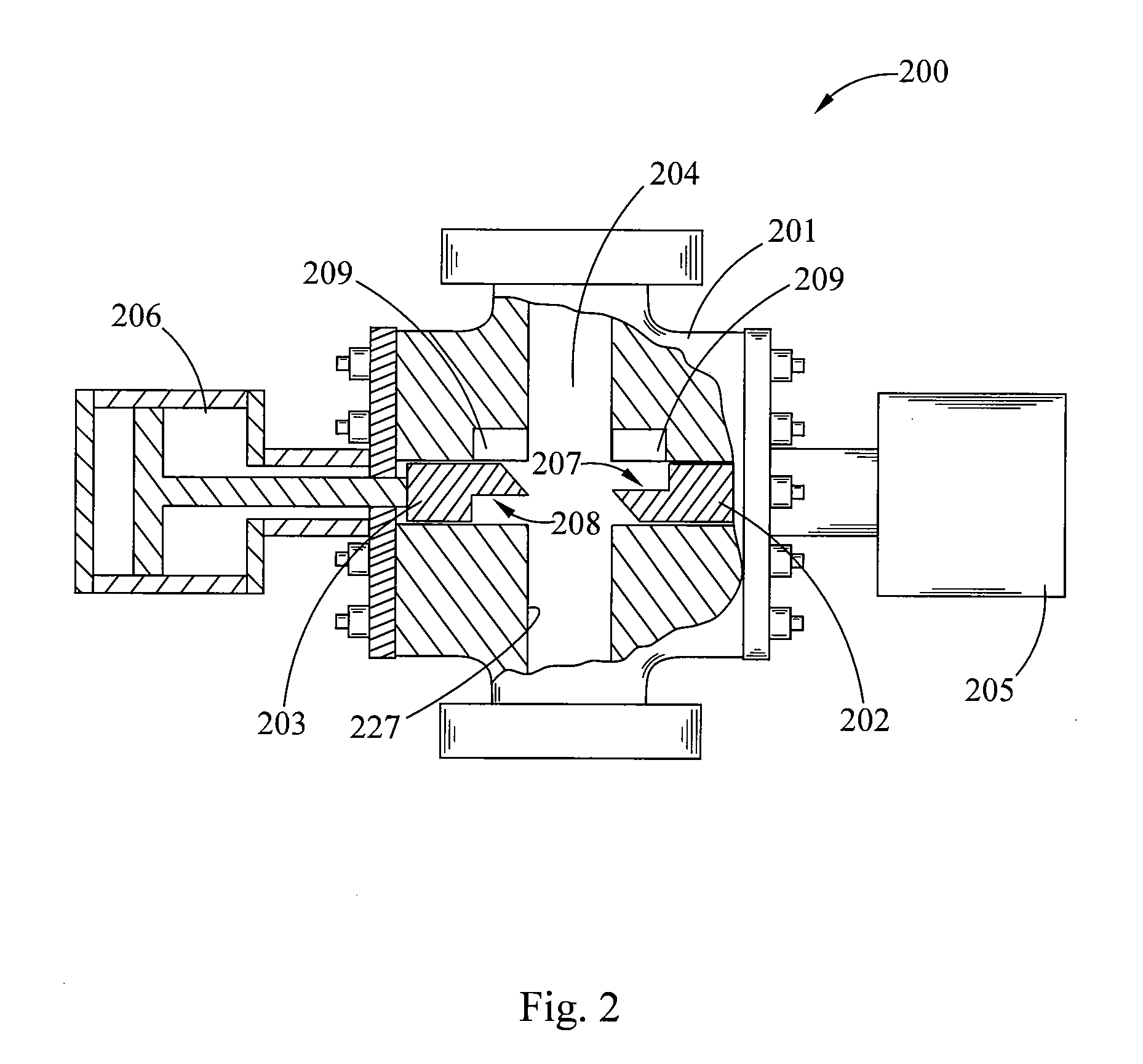

Laser assisted blowout preventer and methods of use

ActiveUS20120217018A1Quick cutProtection from damageDrilling rodsDerricks/mastsHigh power lasersLaser assisted

There is provided a high power laser assisted blowout preventer and methods of use. In particular, there are provided systems and assemblies for utilizing high power laser energy within a blowout preventer to cut tubulars that are present within the bore of the blowout prevent, reducing the risk that such tubulars will inhibit the ability of the blowout preventer to seal a well.

Owner:FORO ENERGY

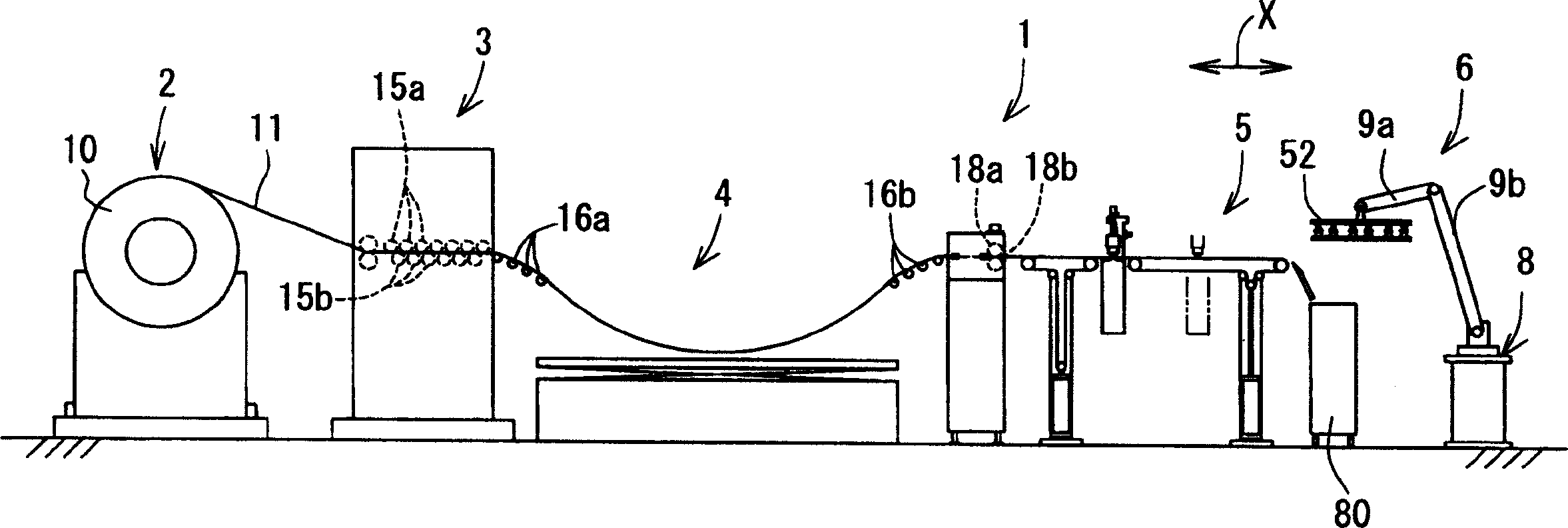

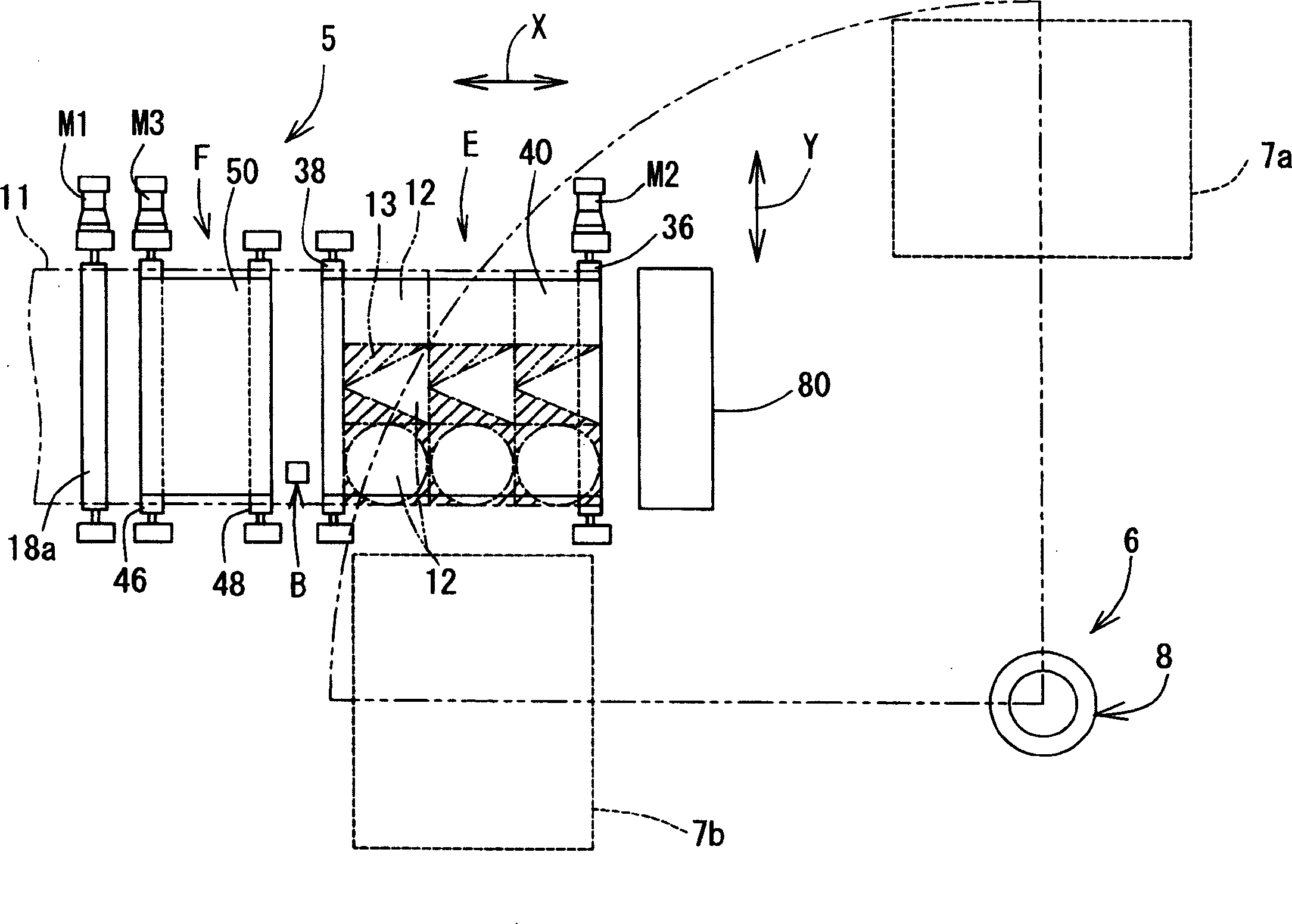

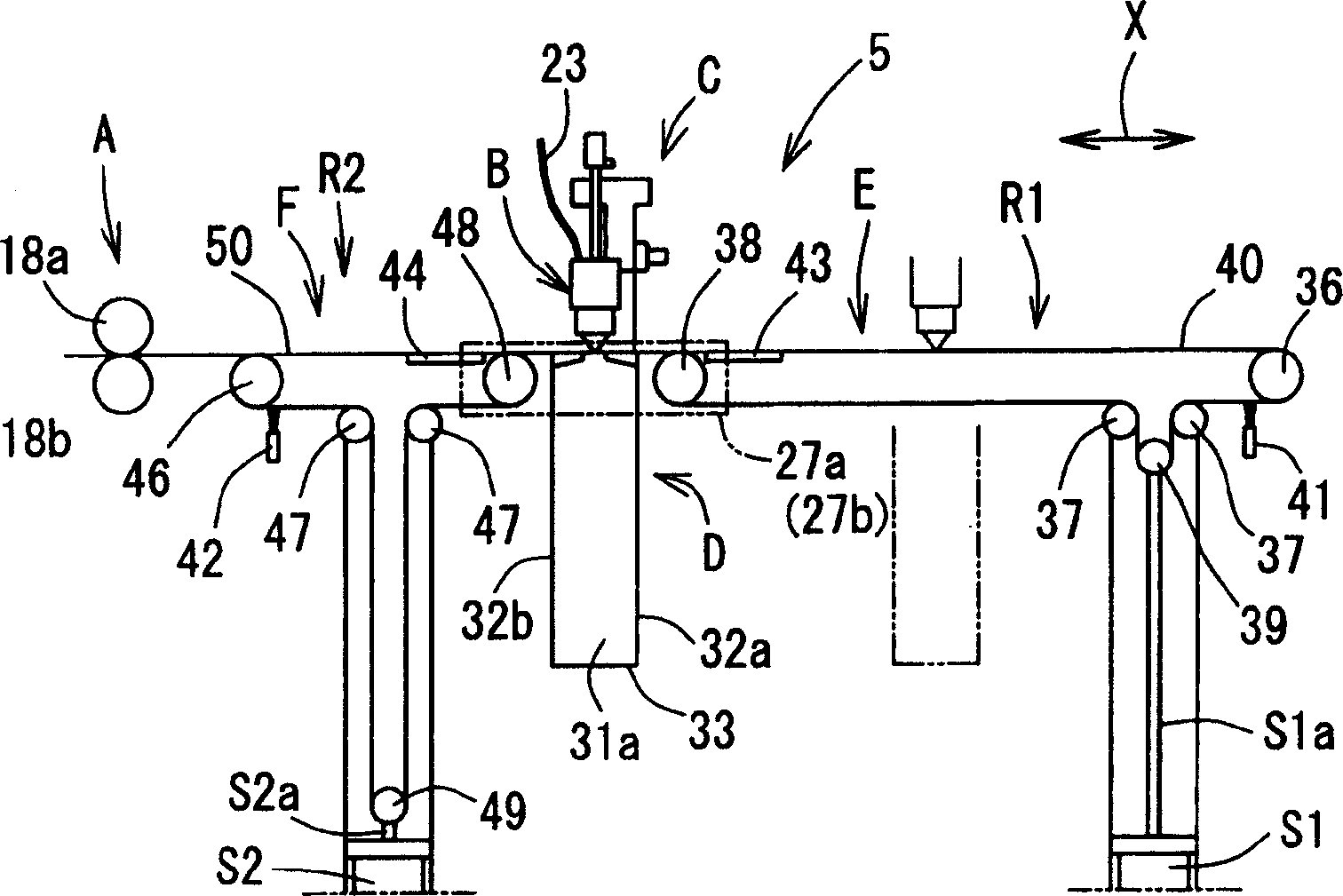

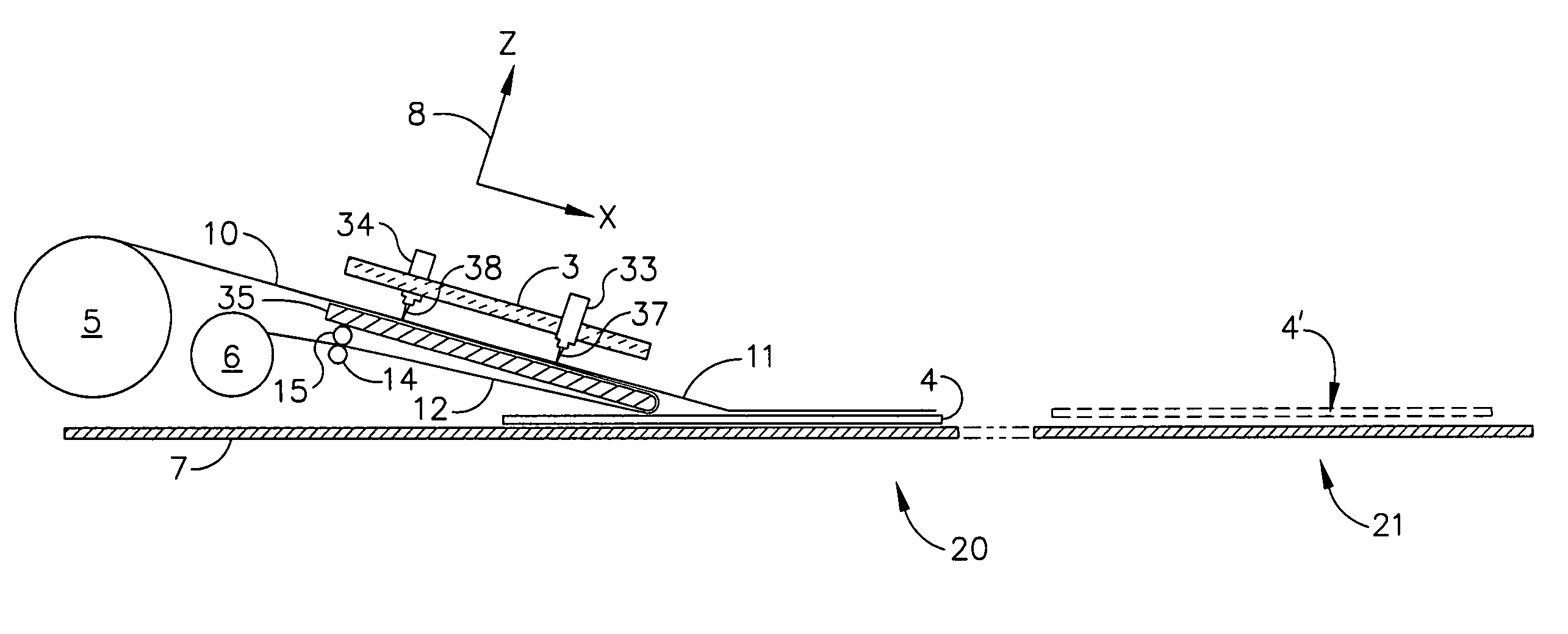

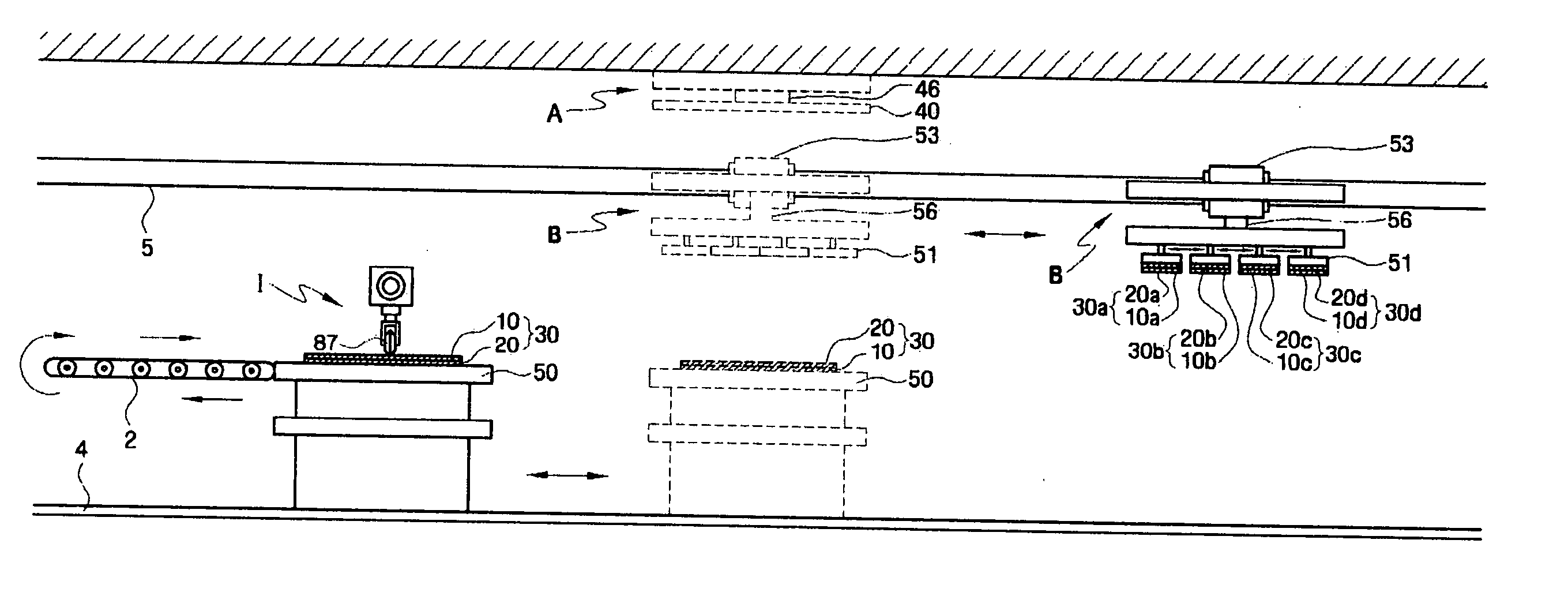

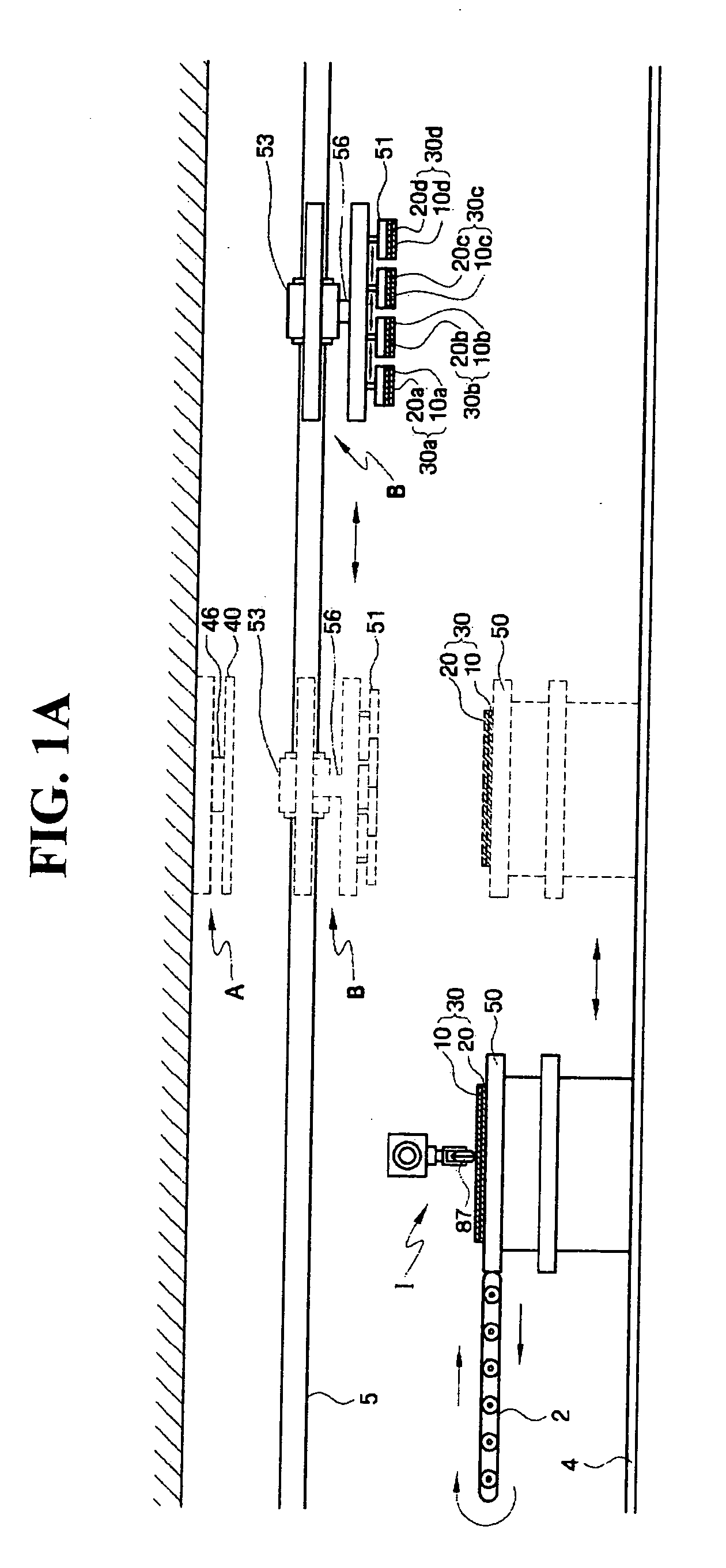

Laser cutting device, laser cutting method and laser cutting system

InactiveCN1652895APrevent adhesionReliable supportConveyorsWelding/soldering/cutting articlesEngineeringLaser cutting

A laser cutting device, comprising a material feeding means for feeding a sheet-like material in a feeding direction, a processing head capable of radiating laser beam toward the material, a head moving means for moving the processing head in a material feeding direction X and a material lateral direction Y, an upstream side support means (belt conveyor mechanism F) for supporting the material on the upstream side of the lower part of the processing head and increasing / decreasing the support area (R2) of the material in the feeding direction according to the movement of the processing head in the feeding direction, and a downstream side support means (belt conveyor mechanism E) for supporting a part cut on the processing side lower part of the processing head and increasing / decreasing the support area (R1) of the cut part in the feeding direction according to the movement of the processing head in the feeding direction.

Owner:TOYOTA STEEL CENT CO LTD

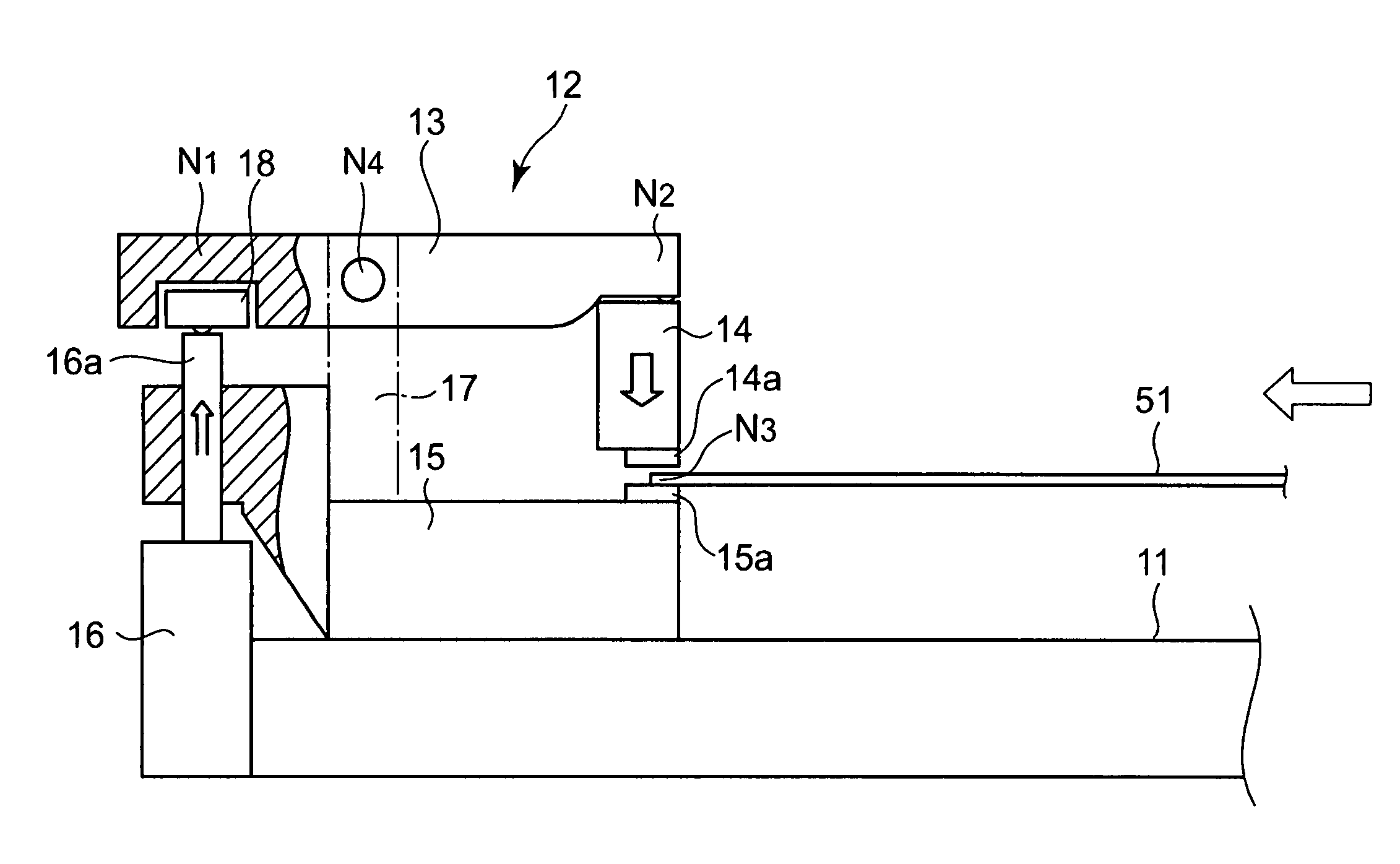

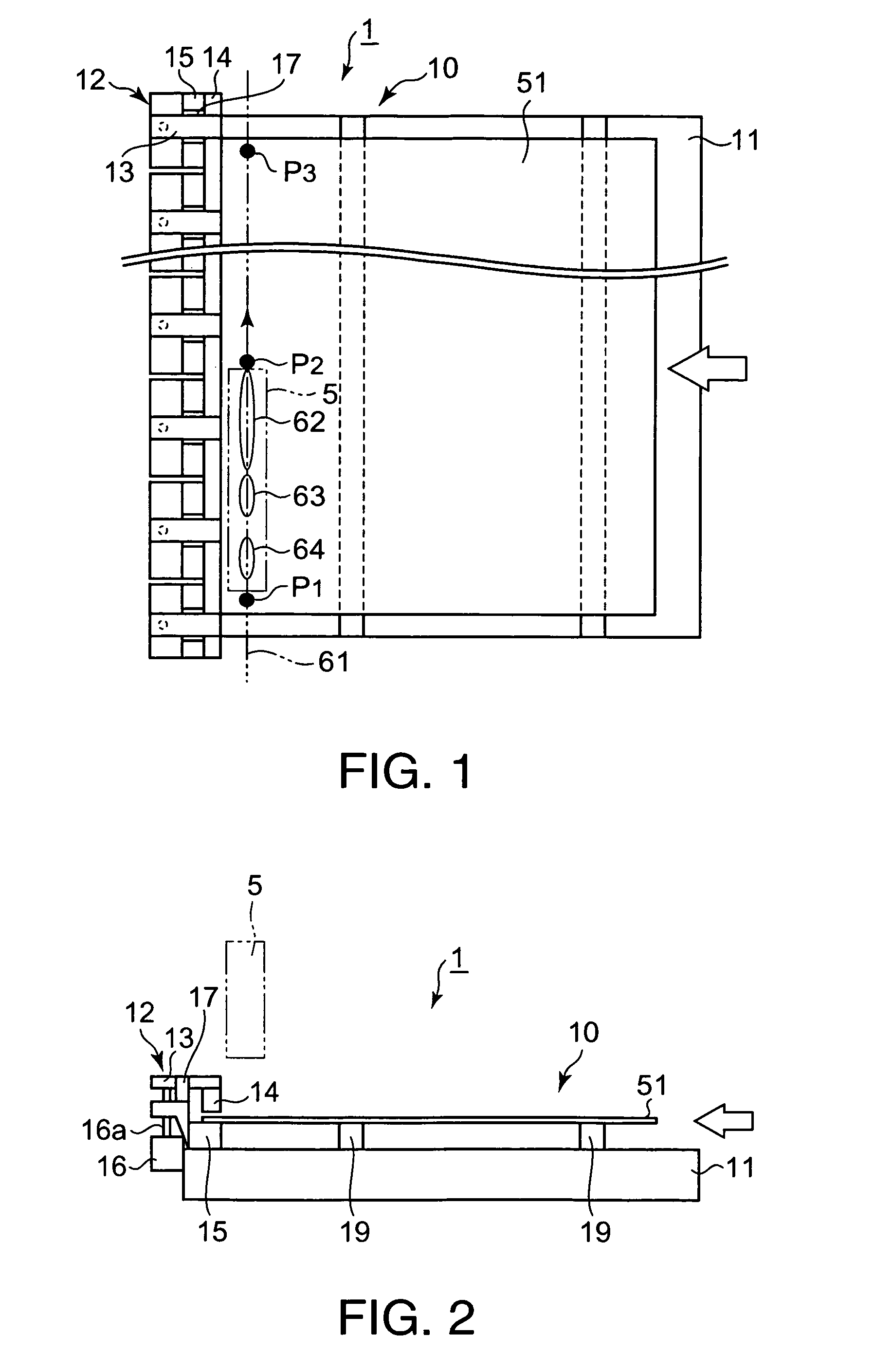

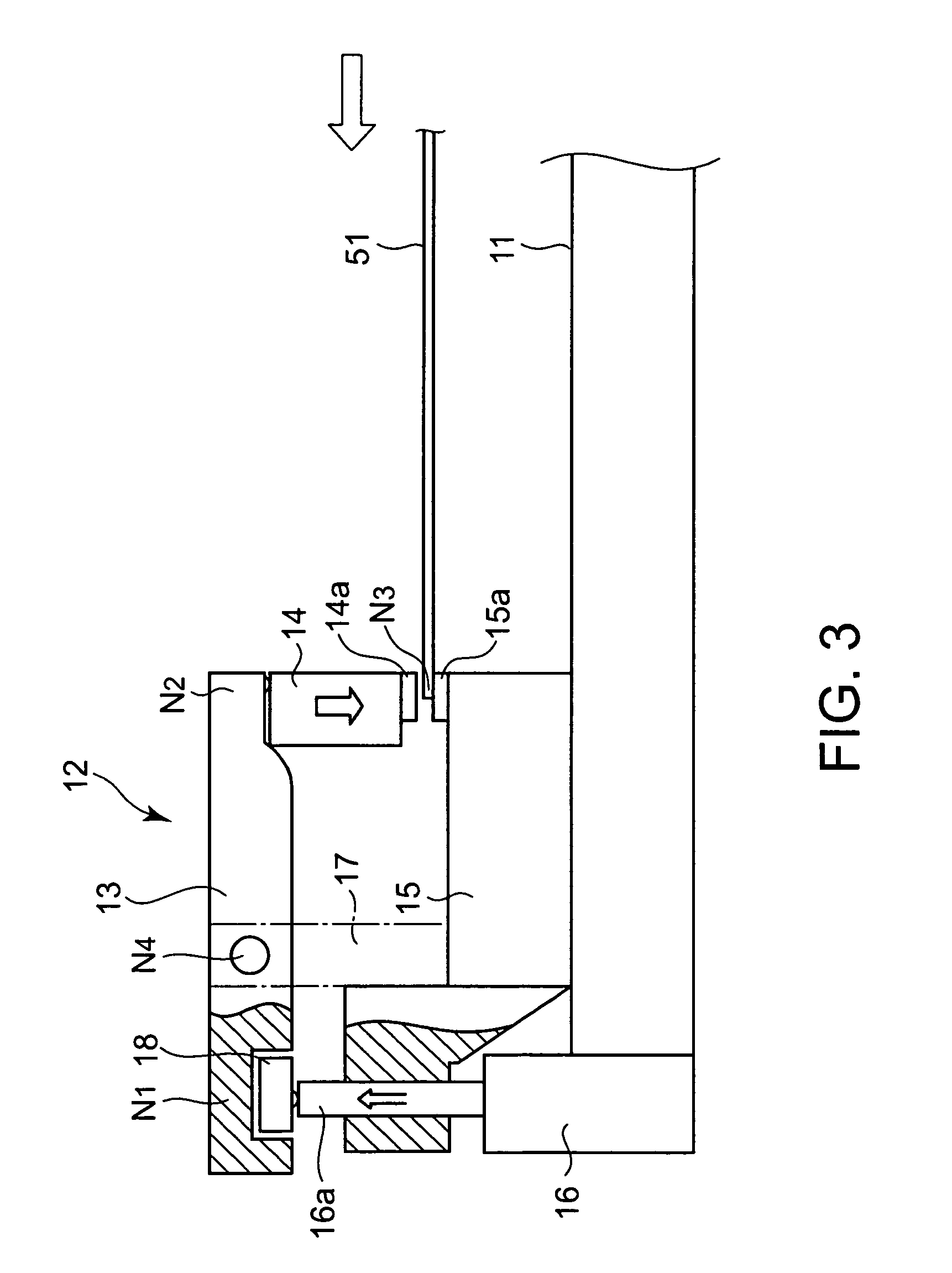

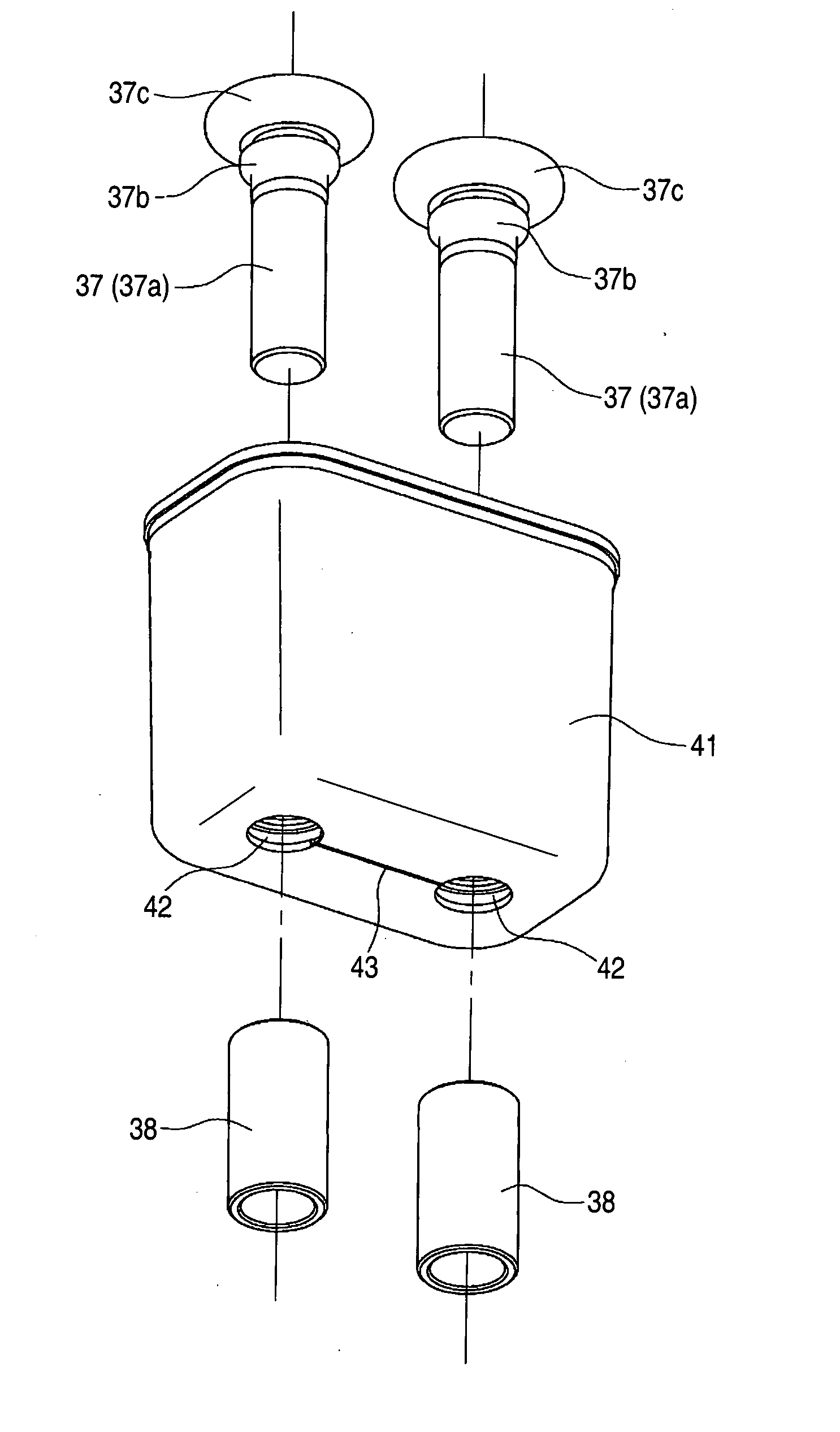

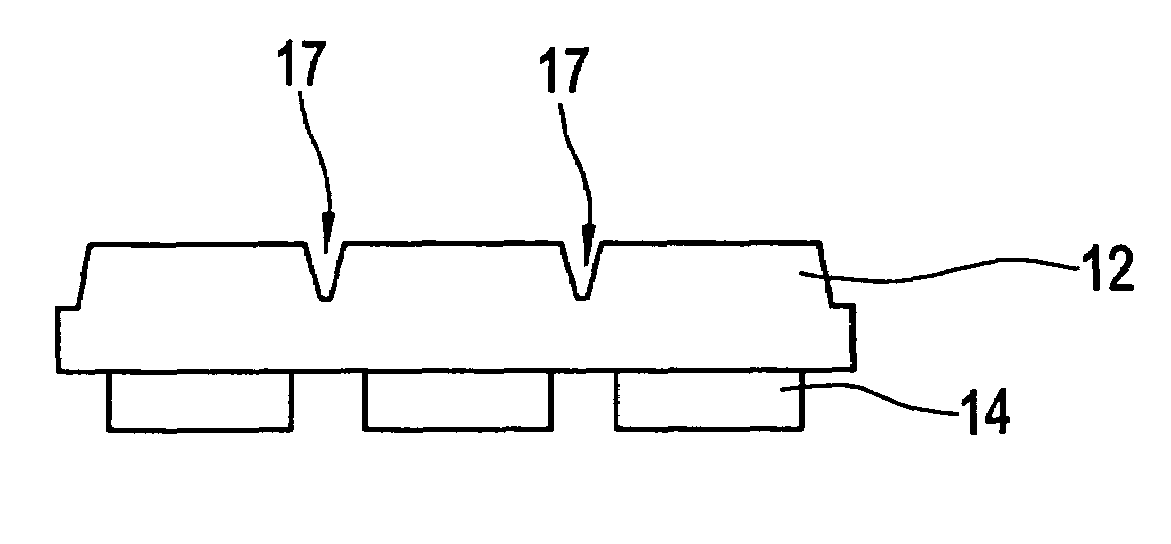

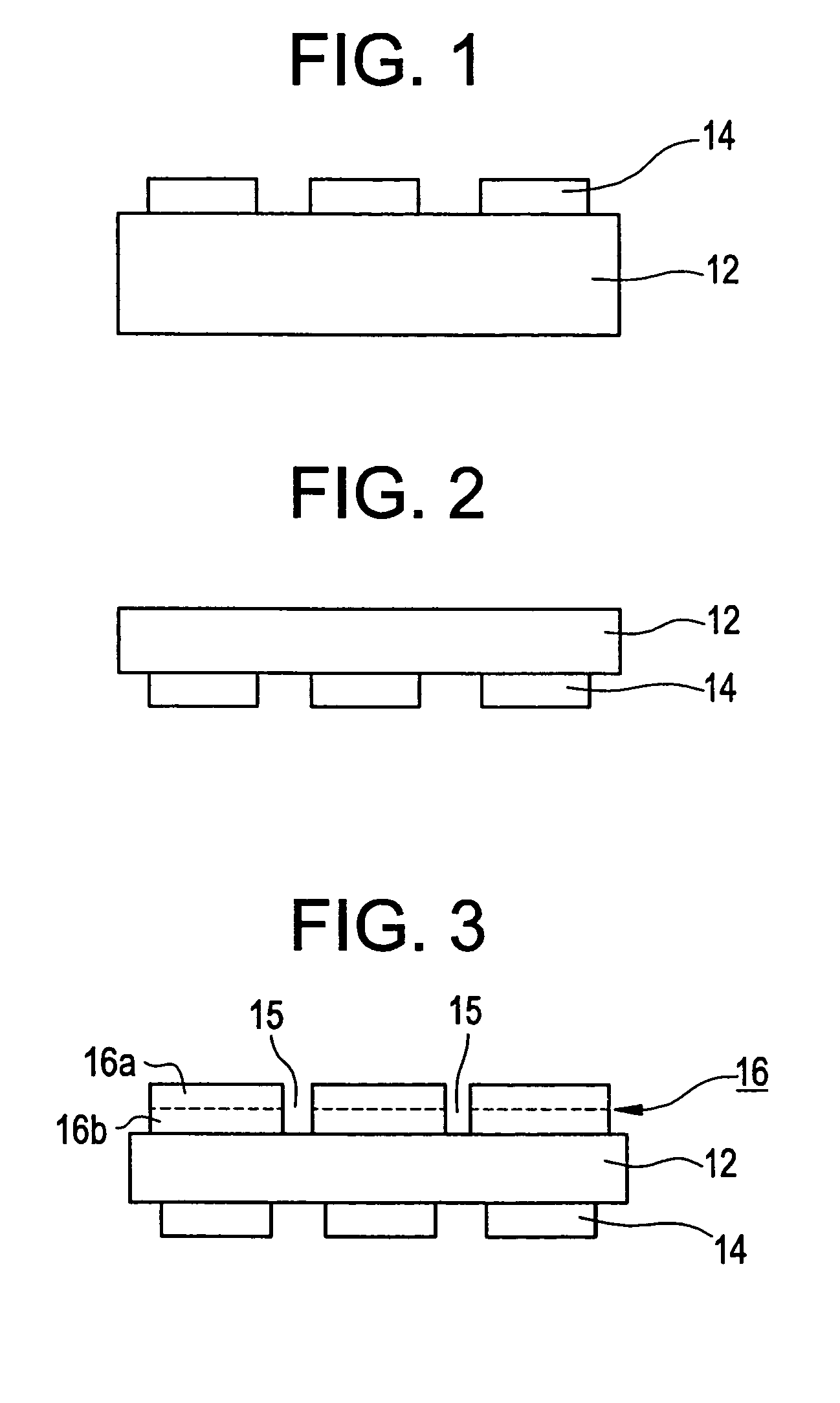

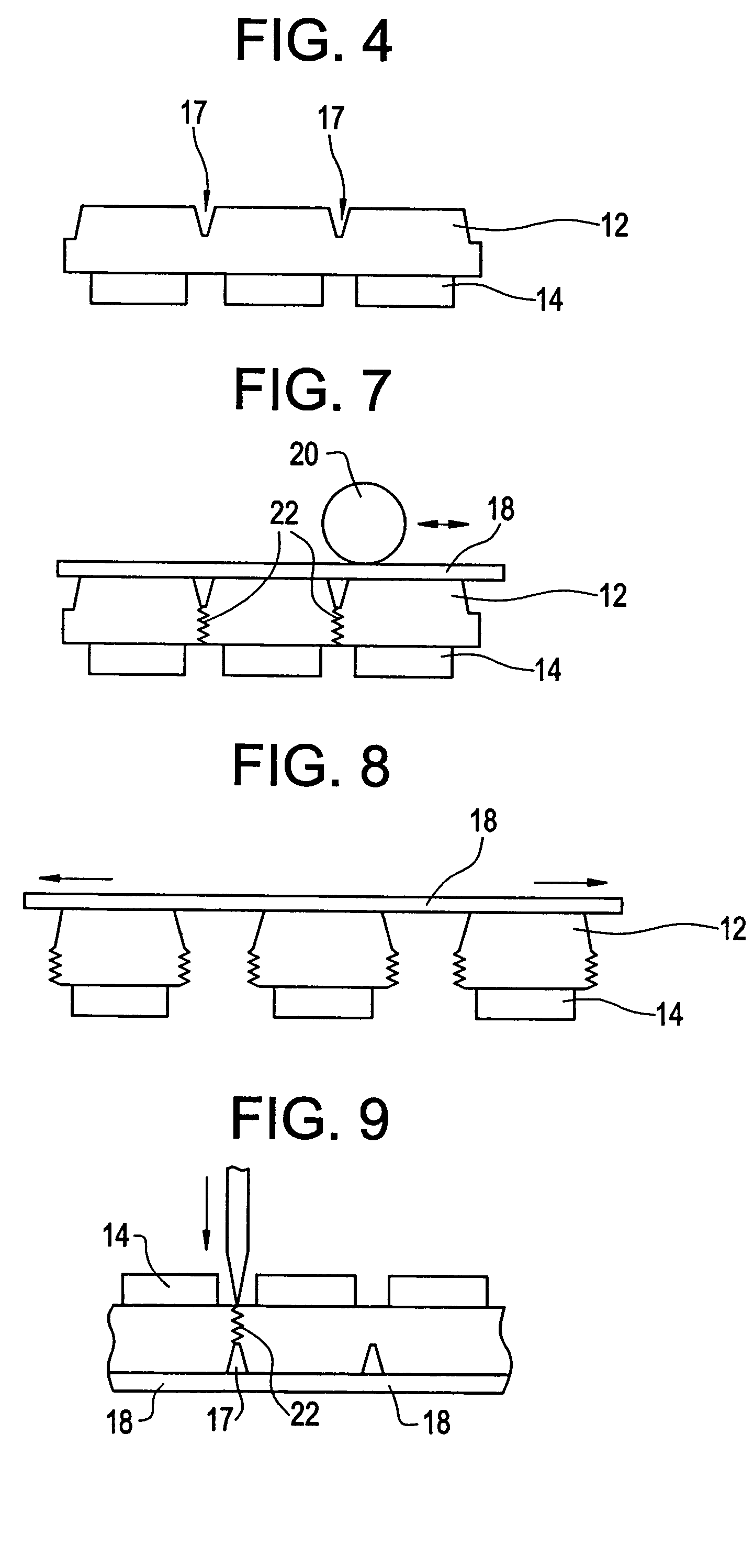

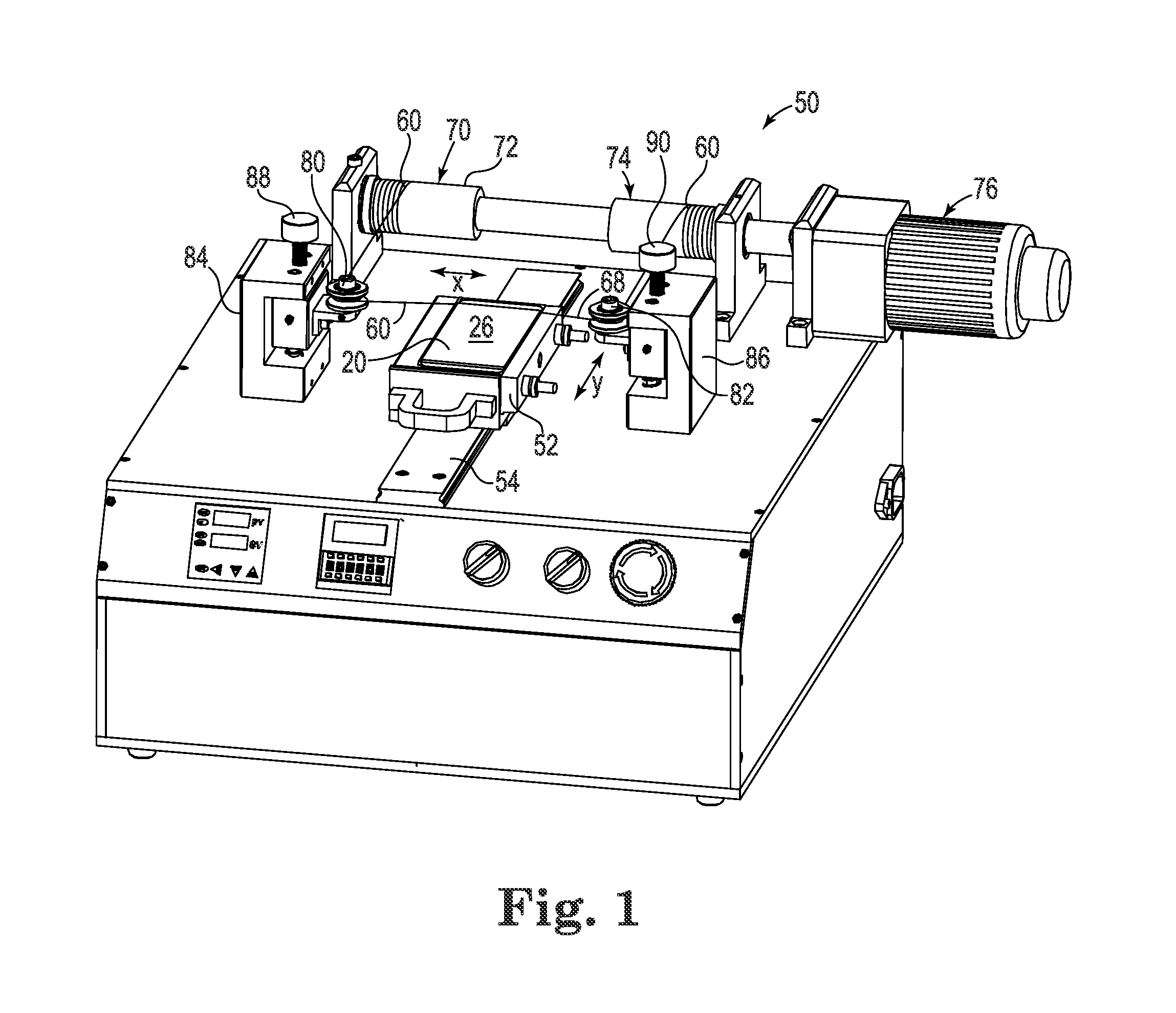

Brittle workpiece splitting system and brittle workpiece splitting method

InactiveUS8104385B2Improve processing qualityAchieving splitting processGlass blowing apparatusGlass reforming apparatusSplit linesMechanical engineering

The brittle workpiece splitting system 1 includes a substrate holding mechanism 10 for holding a substrate 51, and a processing unit 5 for splitting the substrate 51 held by the substrate holding mechanism 10 by a splitting process. The substrate holding mechanism 10 has an edge damper 12 adapted to clamp an edge part of the substrate 51 from the sides of the opposite surfaces of the edge part, and support members 19 for supporting the substrate 51 thereon at a predetermined height. The support members 19 are disposed on the side opposite the side of the edge damper 12 with respect to the intended split line 61 parallel to the edge part of the substrate 51. The edge damper 12 has an edge holder 15 on which the substrate 51 is seated, and a pressure bar 14 for pressing the substrate 51 against the edge holder 15 to hold the substrate 51 between the edge holder 15 and the pressure bar 14. Resin members 14a and 15a made of an elastic material having comparatively high rigidity are attached to parts, to be brought into contact with the substrate 51, of the pressure bar 14 and the edge holder 15, respectively. The support members 19 are made of a low-friction material to permit the horizontal movement of the substrate 51 during the splitting process.

Owner:SHIBAURA MECHATRONICS CORP +1

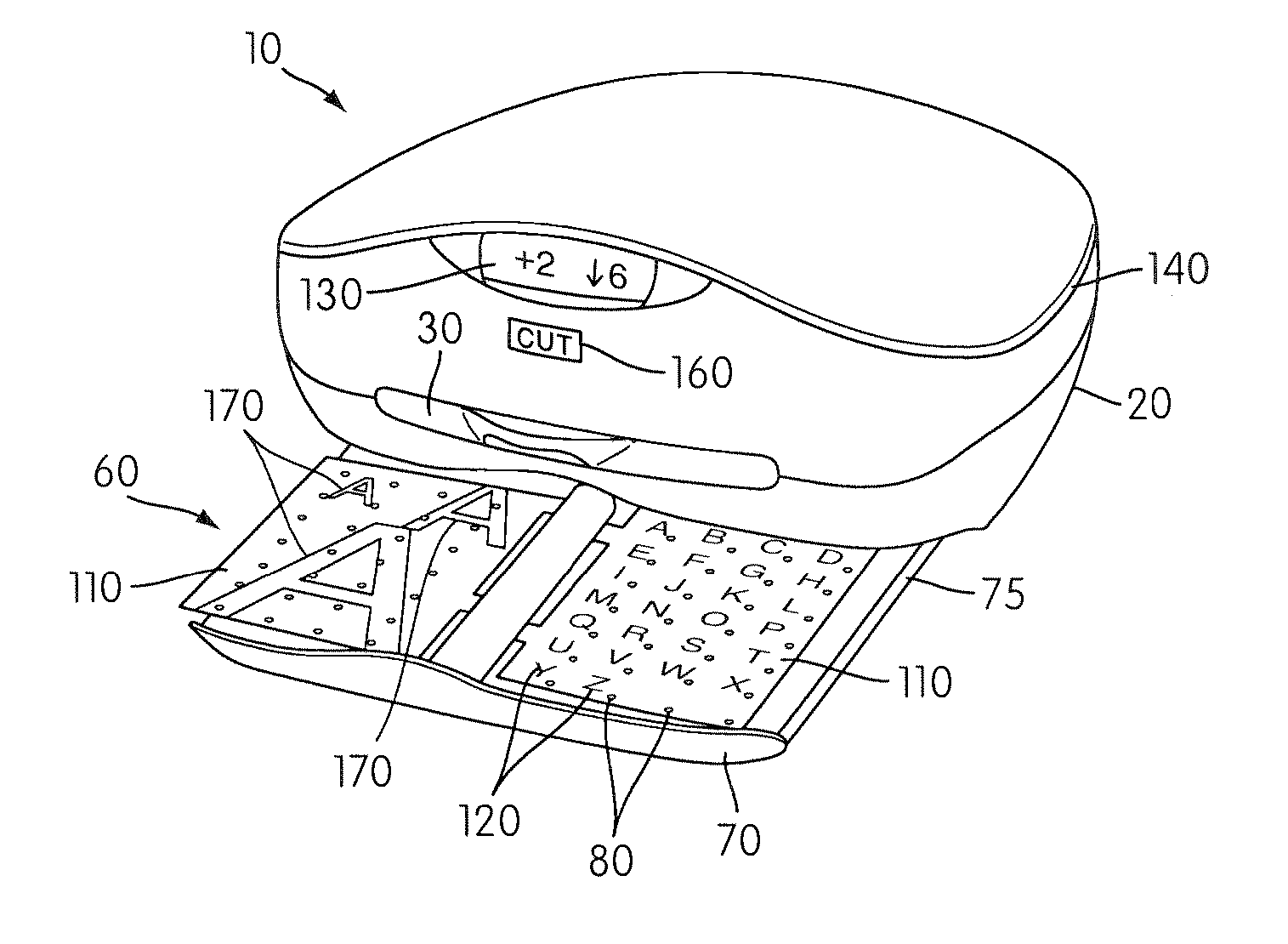

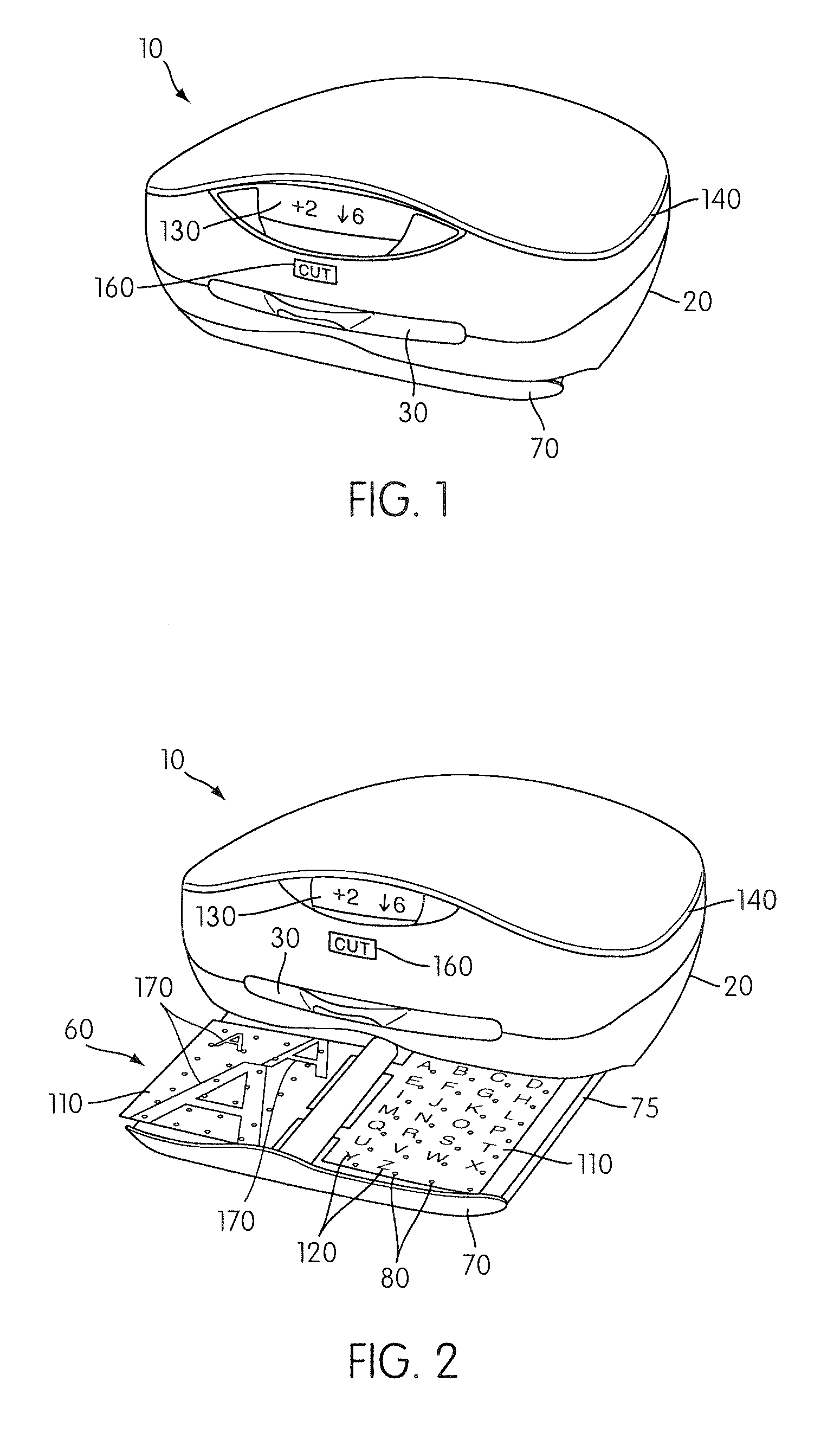

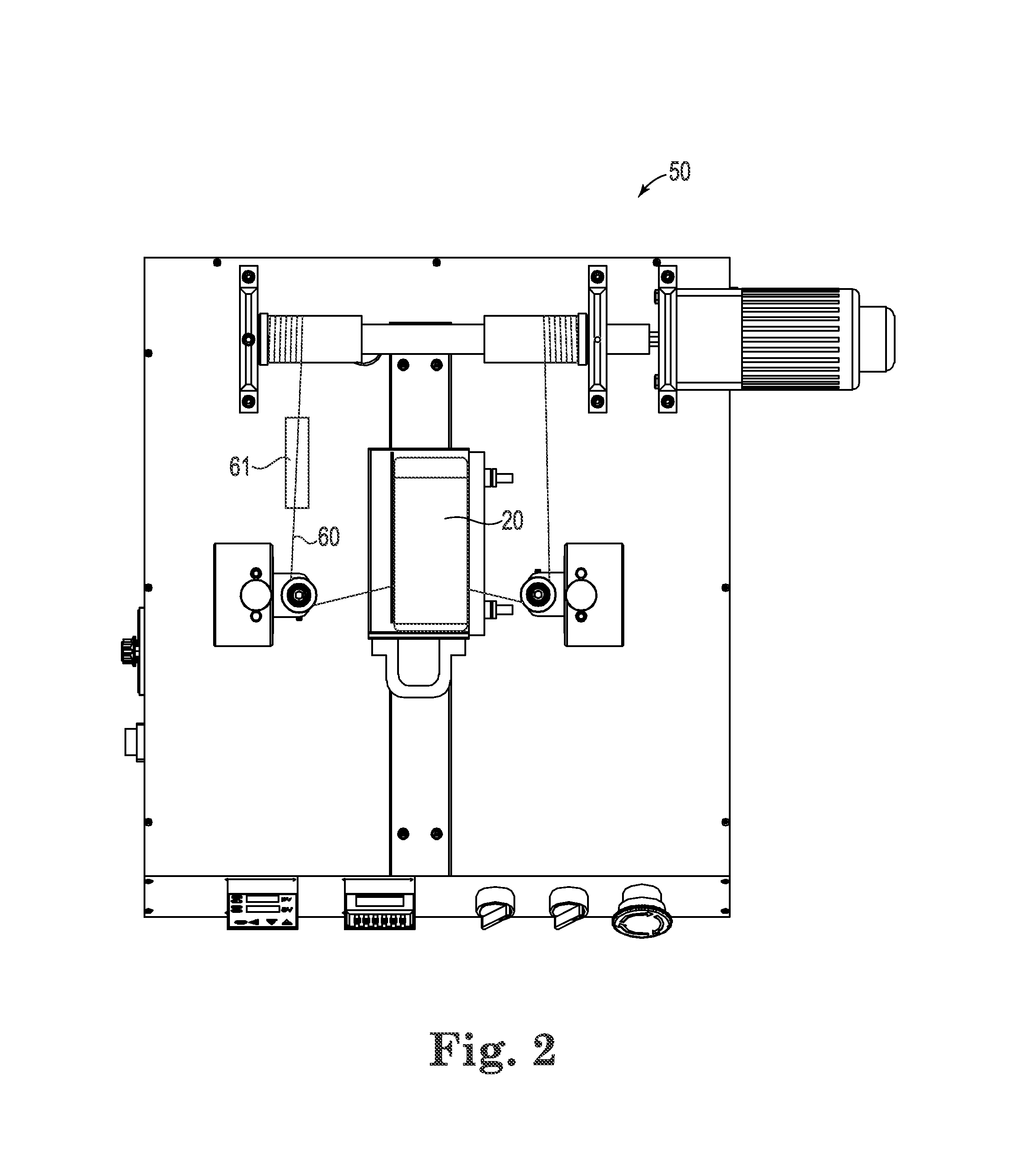

Automatic pattern making apparatus

InactiveUS20070227332A1Quickly and easily selectedQuick cutMetal working apparatusContainer making machineryEngineeringAdhesive

An automatic paper cutting apparatus includes an X-Y cutter, a cutter controller, and a pattern booklet. The pattern booklet includes a plurality of pattern identifiers and a memory device with cutting instructions for each of the identified patterns. The booklet removably mounts to the cutter controller so that an operator can select a pattern from the pattern booklet and have the memory device provide the corresponding set of cutting instructions to the cutter controller. The cutter controller uses the instructions to control the X-Y cutter and cut the desired pattern. A cutting platform of the X-Y cutter has a tacky adhesive that releaseably secures a work piece to the cutting platform during cutting operations. The cutting platform includes surface features that engage a spur gear. The cutter controller selectively rotates the spur gear to drive the cutting platform in the Y direction. The apparatus may use a journaling, embossing, perforating instrument instead of the cutter to make a pattern on the work piece.

Owner:ESSELTE LLC

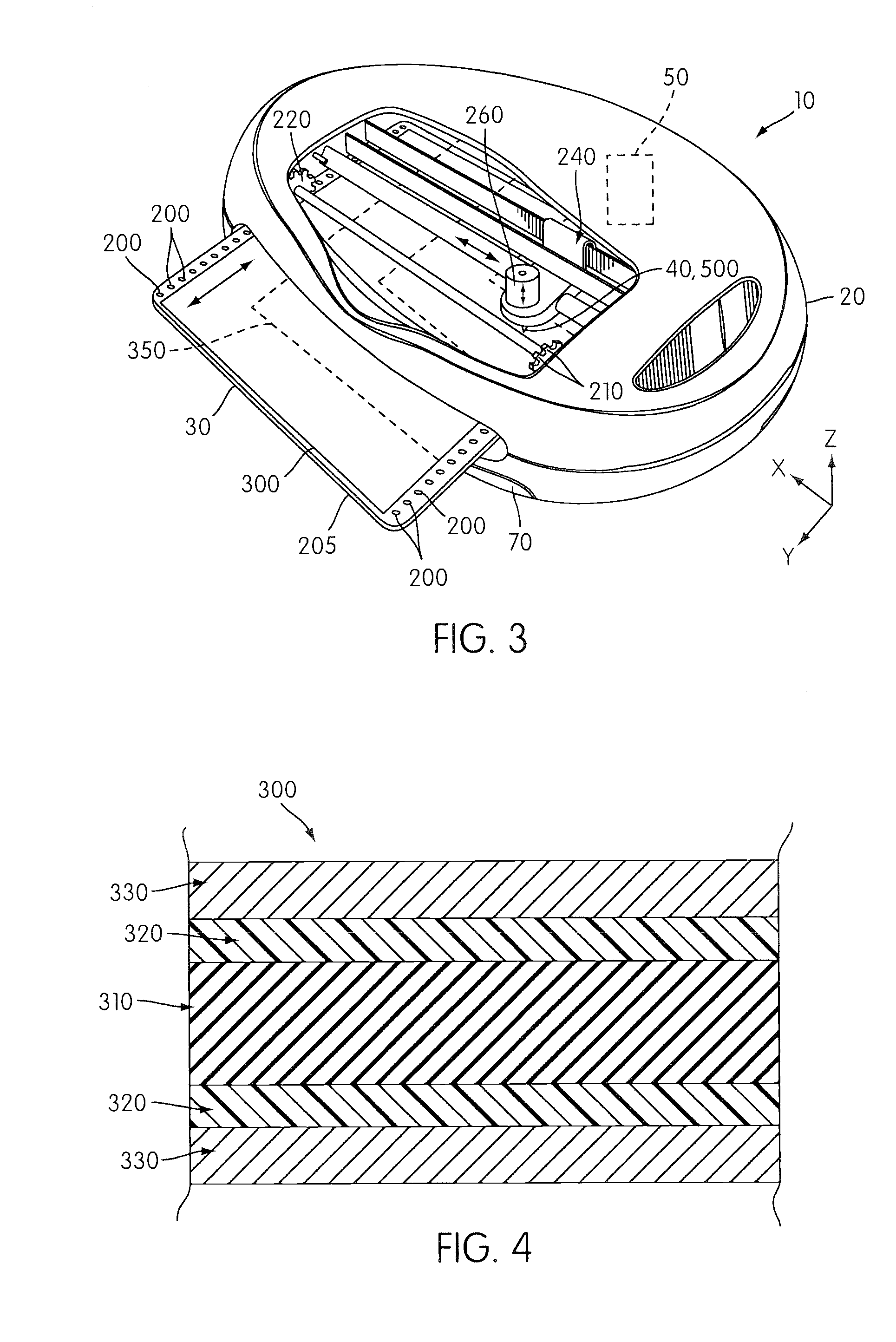

Apparatus and method for composite material trim-on-the-fly

InactiveUS7879177B2Quick cutImprove productivityLamination ancillary operationsControlling laminationMaterials scienceComposite structure

Owner:THE BOEING CO

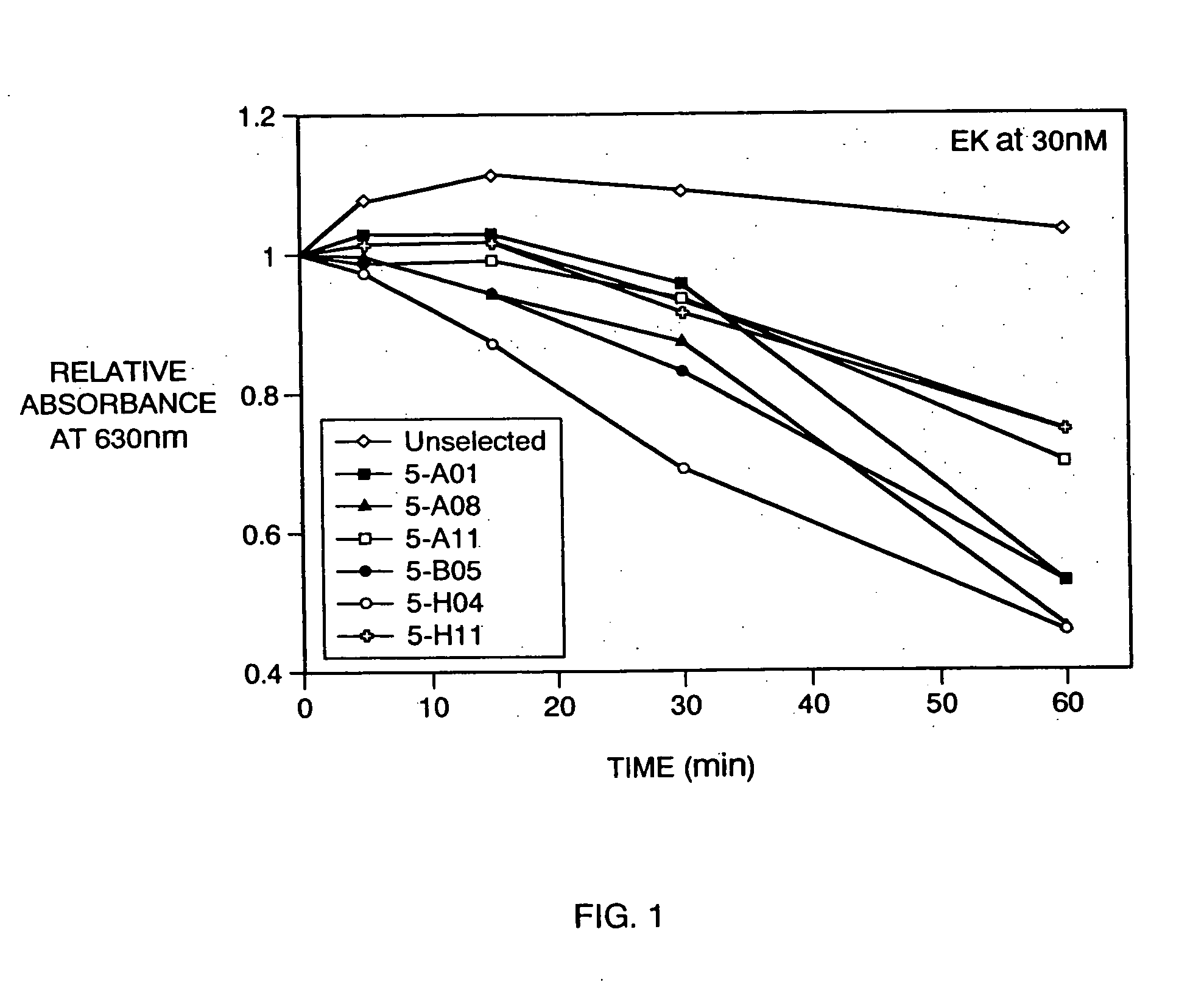

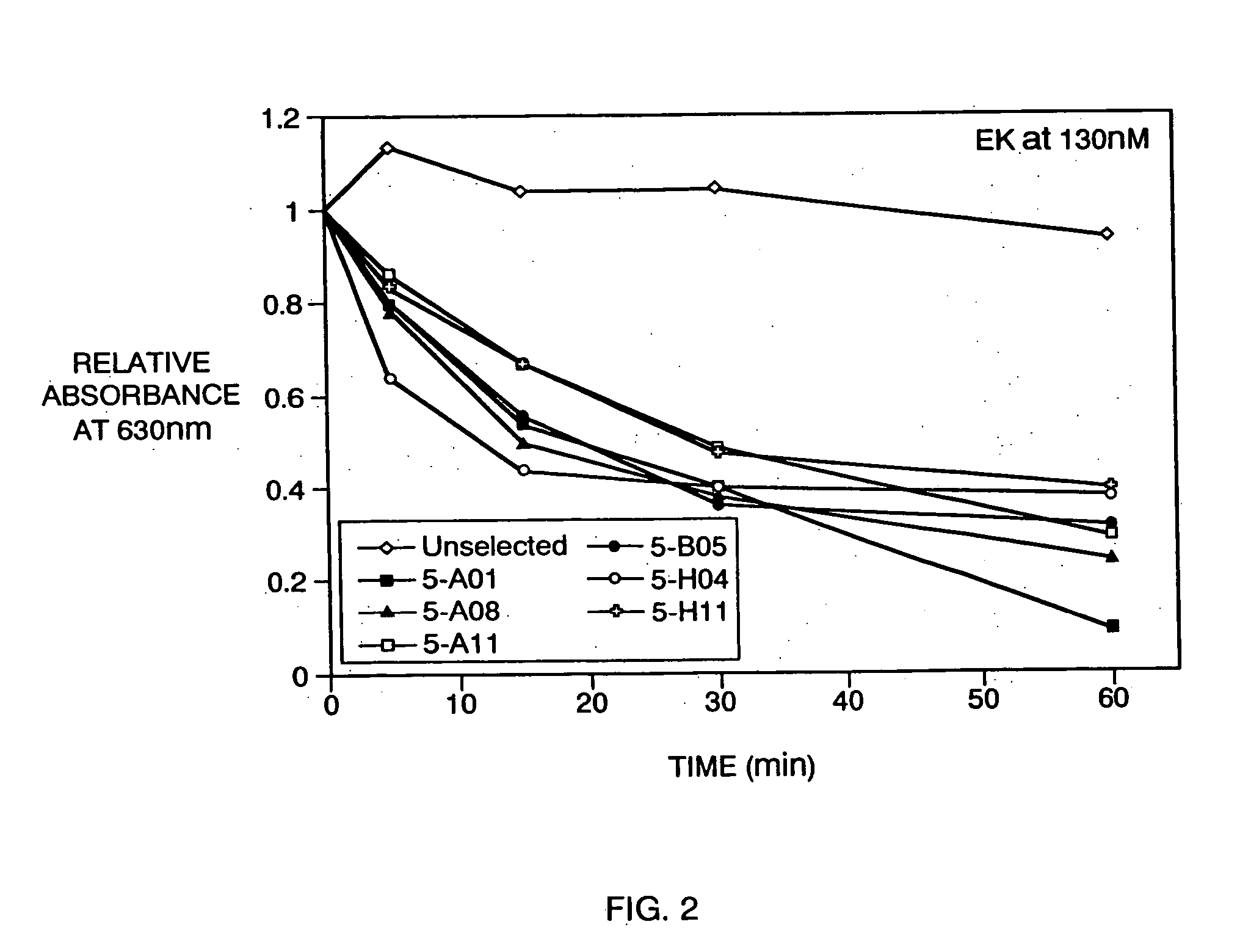

Novel enterokinase cleavage sequences

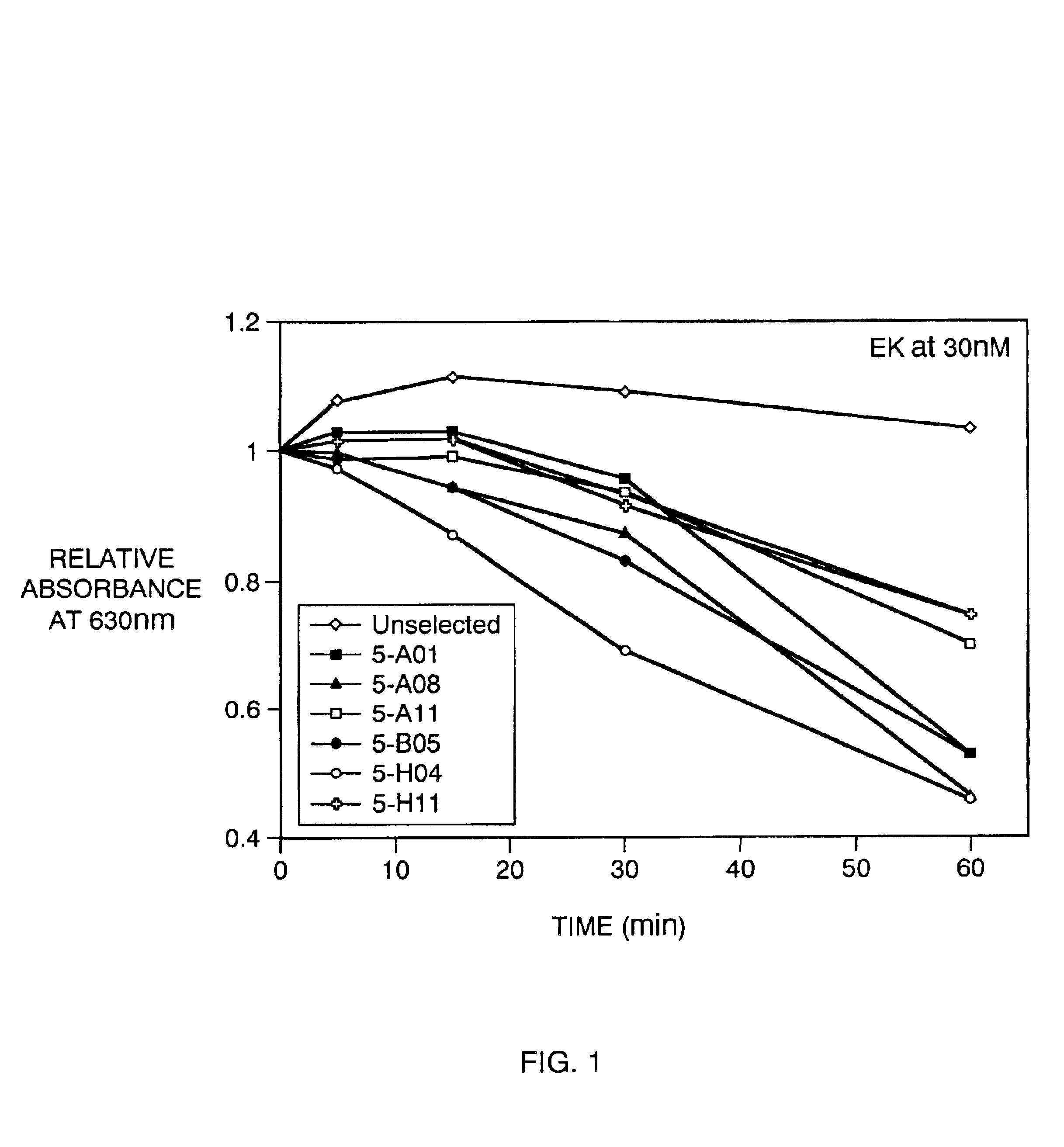

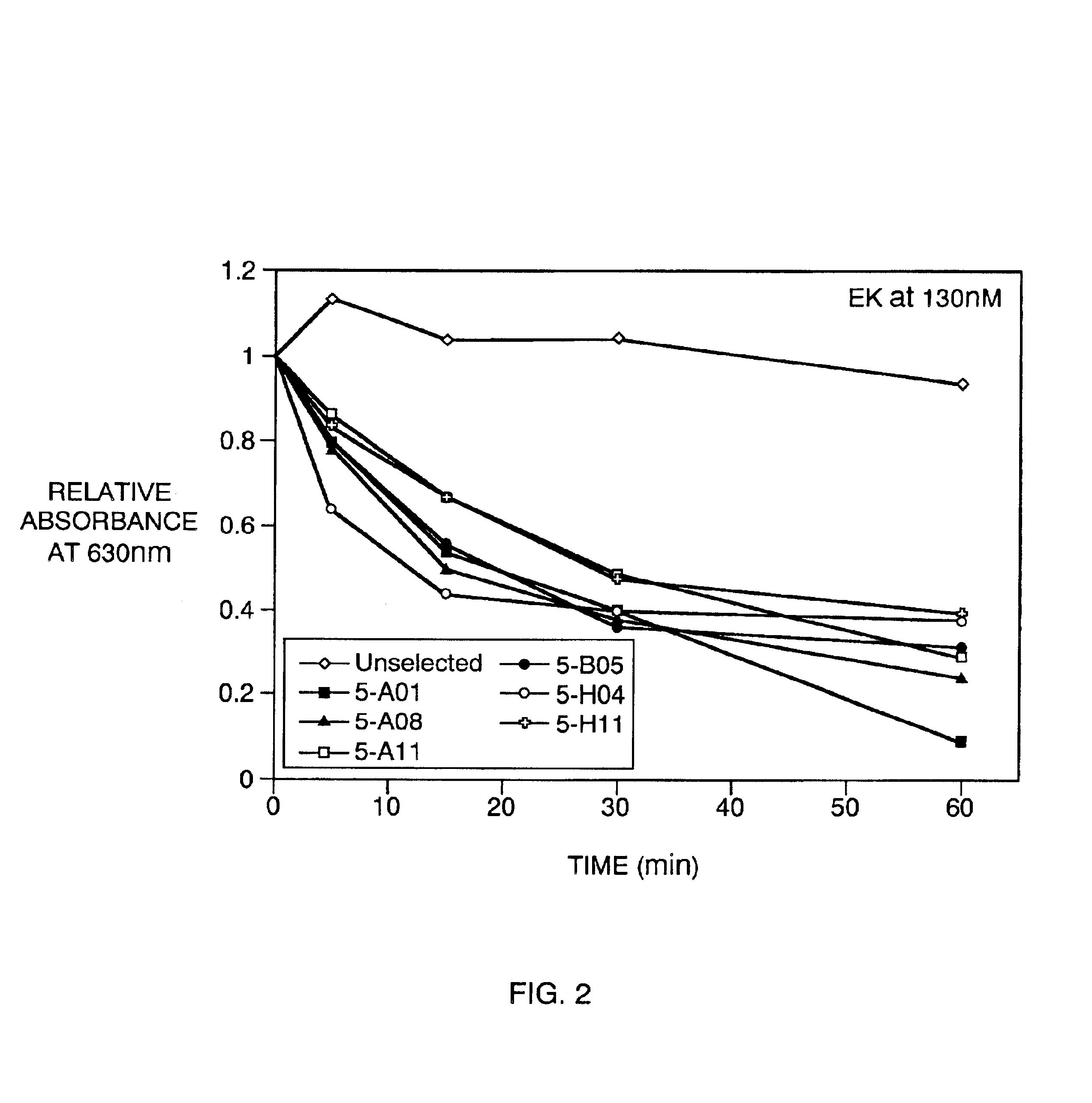

InactiveUS20070031879A1Strong specificityQuick cutPeptide librariesBacteriaRecognition sequenceSolid substrate

Novel enterokinase cleavage sequences are provided. Also disclosed are methods for the rapid isolation of a protein of interest present in a fusion protein construct including a novel enterokinase cleavage sequence of the present invention and a ligand recognition sequence for capturing the fusion construct on a solid substrate. Preferred embodiments of the present invention show rates of cleavage up to thirty times that of the known enterokinase cleavage substrate (Asp)4-Lys-Ile.

Owner:DYAX CORP

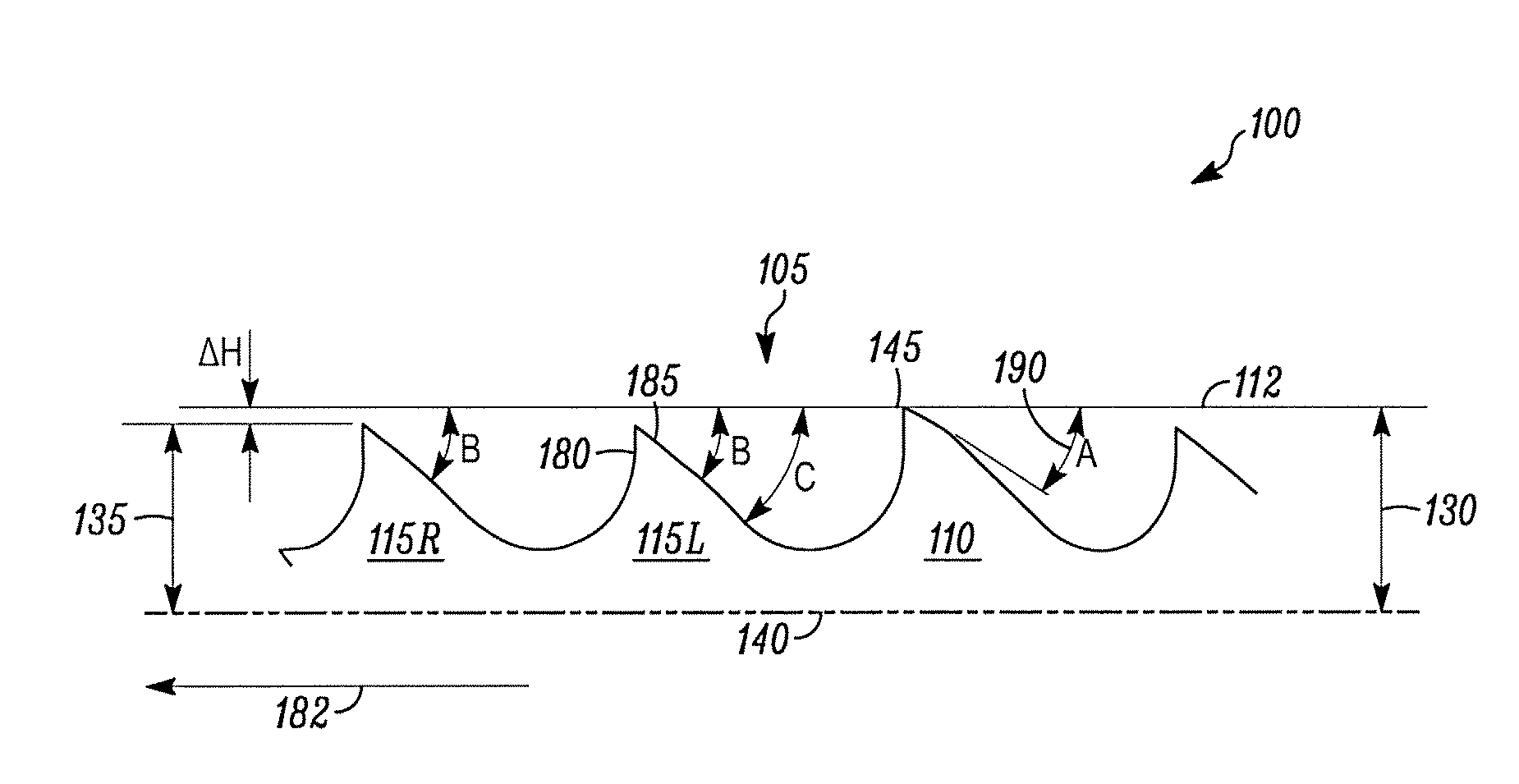

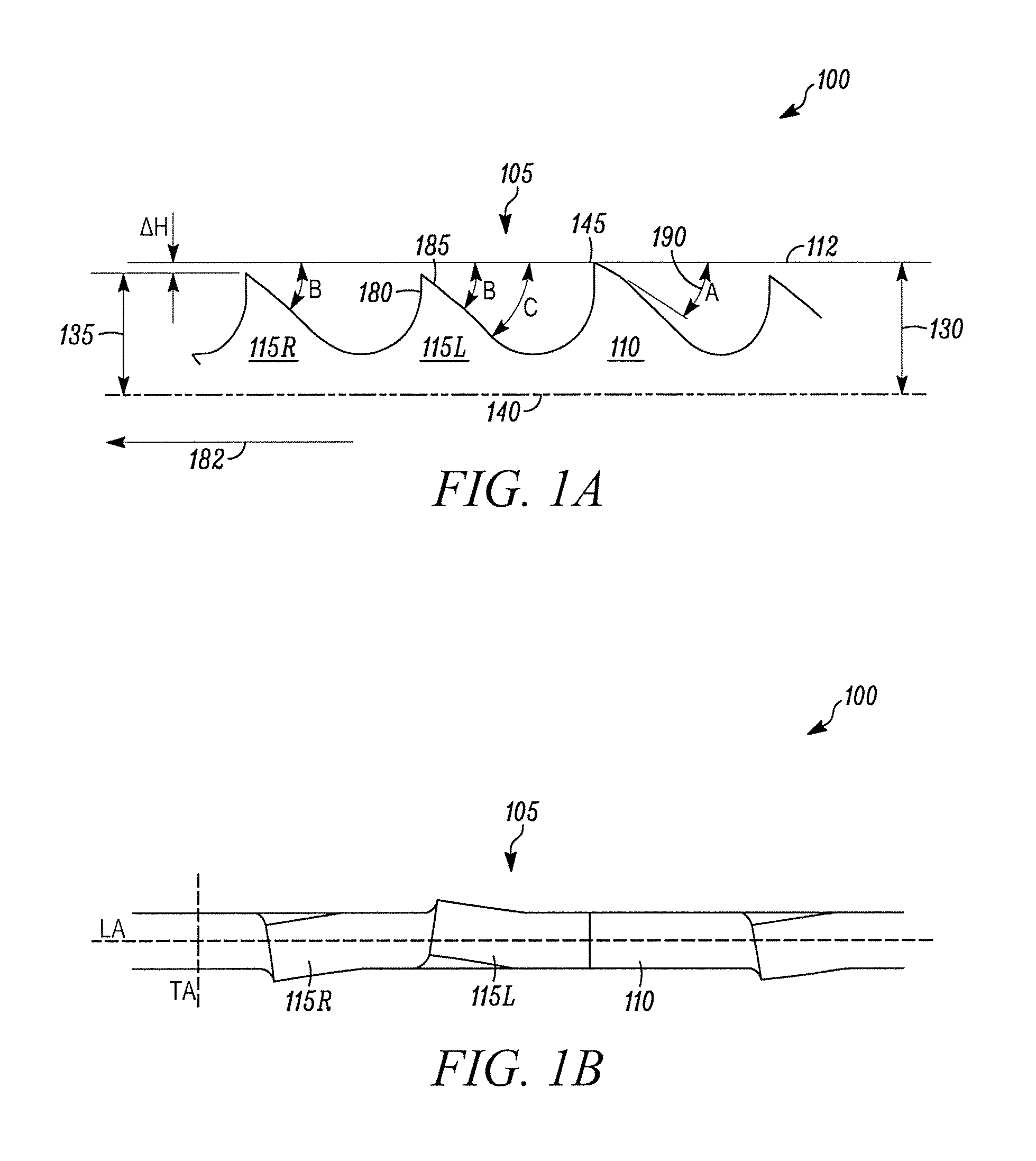

Reciprocating saw blade having variable-height teeth and related method

ActiveUS8210081B2Increase loadHigh teethMetal sawing devicesMetal sawing toolsPortable powerEngineering

A reciprocating saw blade, for use in a portable power reciprocating saw including a chuck for releasably engaging the saw blade, includes a tang having an elongated axis and being engageable with the chuck for attaching the saw blade to the reciprocating saw. The saw further includes a blade portion having a cutting edge that defines a plurality of cutting teeth. The cutting teeth define a repeating pattern of successive groups of teeth. Each group of teeth is less than about a half inch in length, and includes a plurality of laterally offset teeth, at least one relatively high first tooth and at least one relatively low second tooth. Prior to tooth set, the at least one relatively high first tooth is at least about 0.002 inch higher than the at least one relatively low second tooth.

Owner:BLACK & DECKER INC

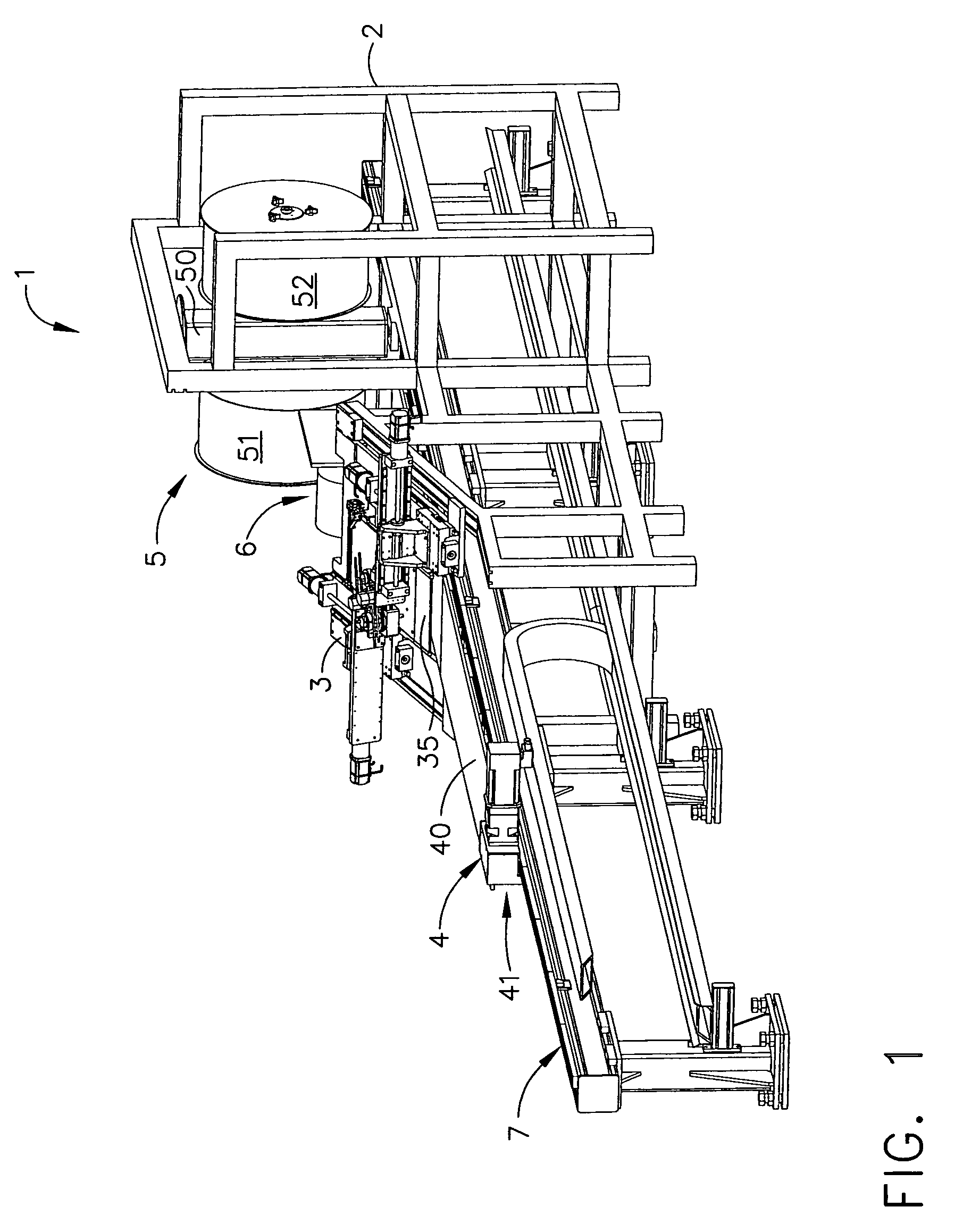

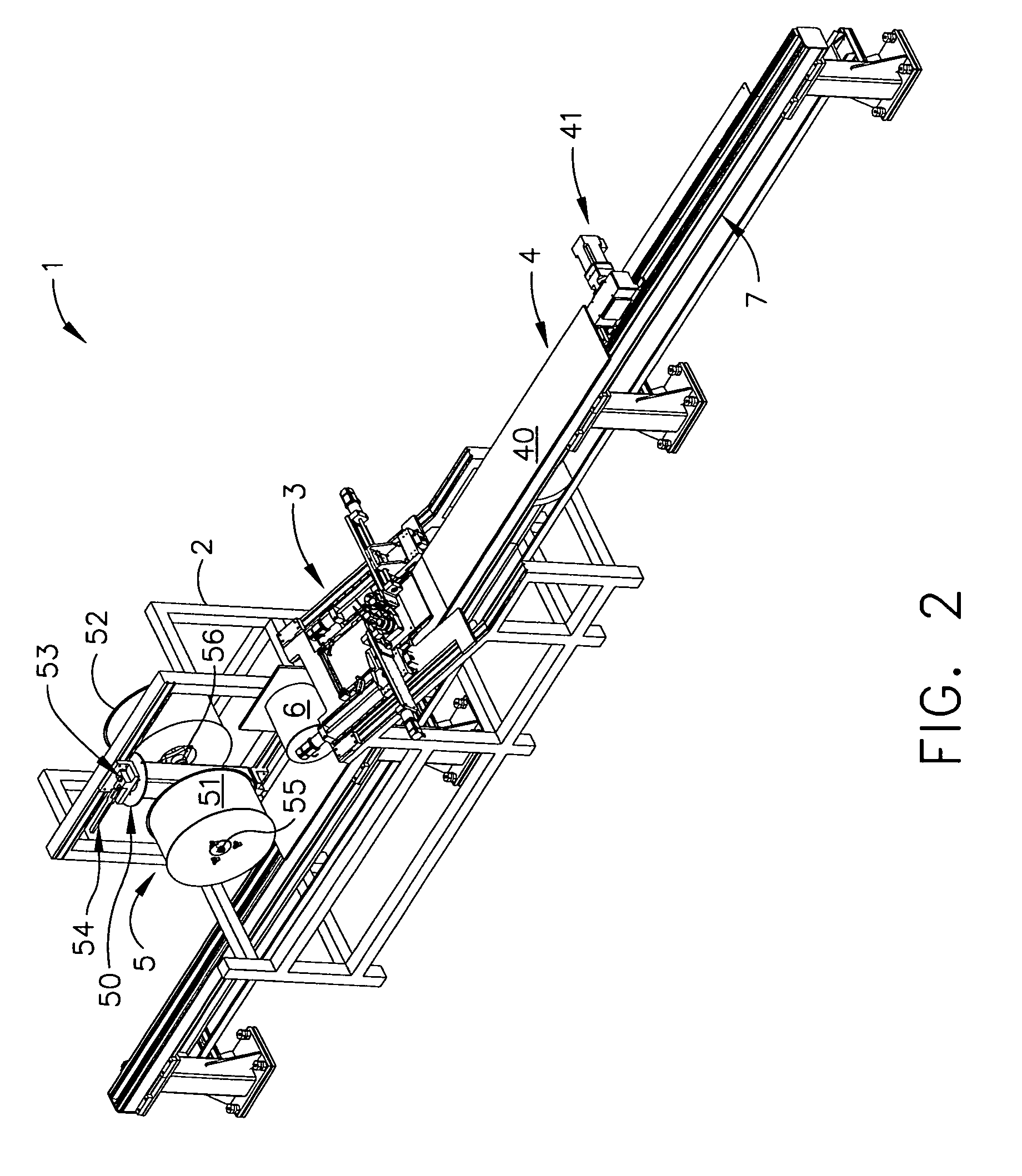

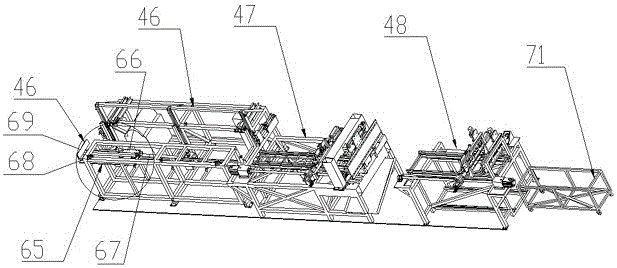

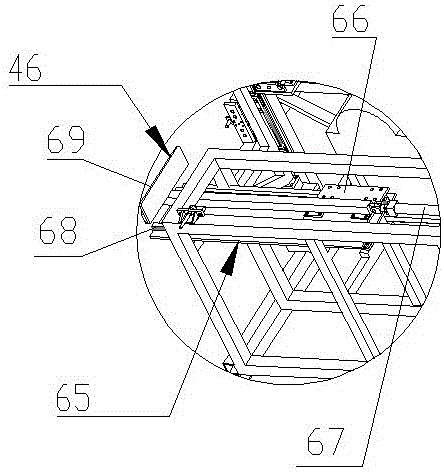

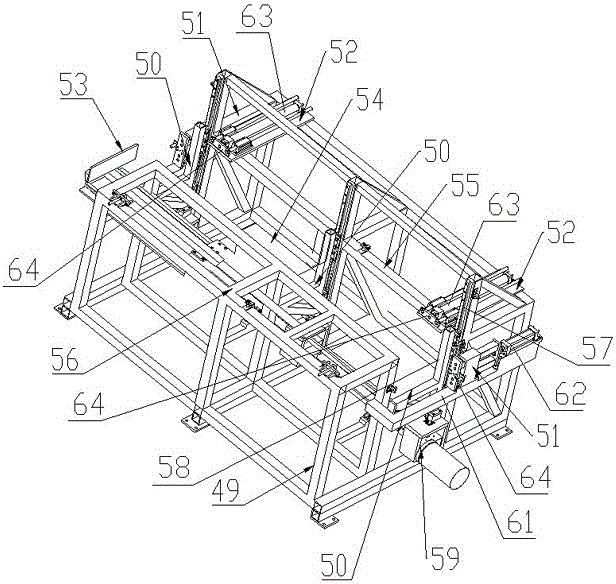

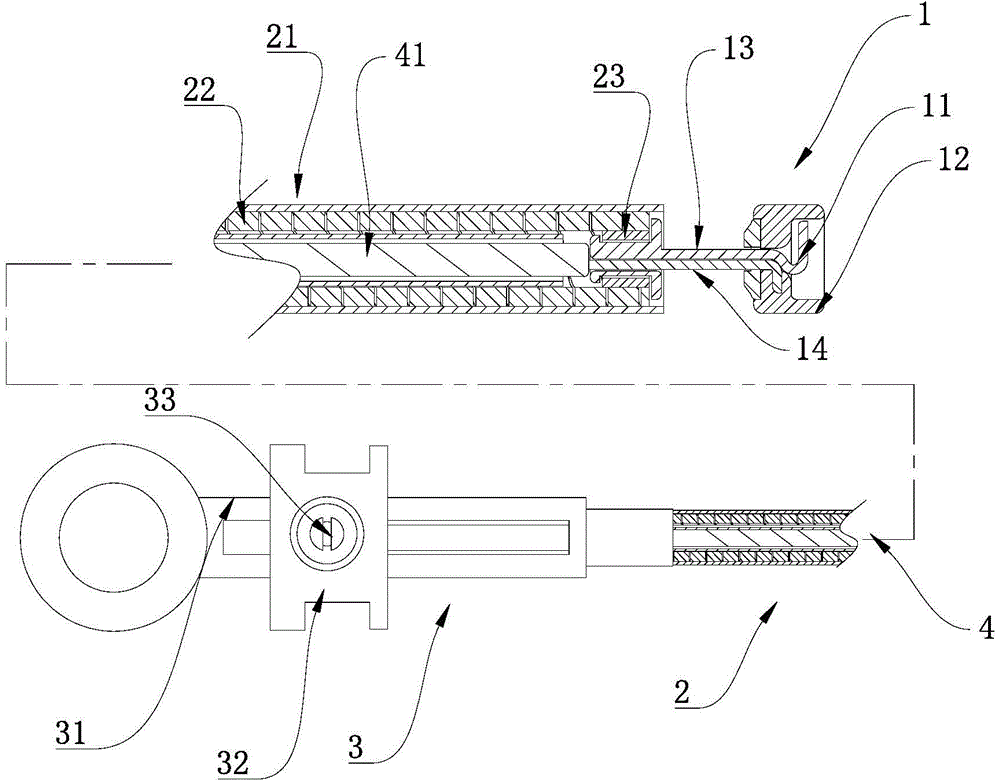

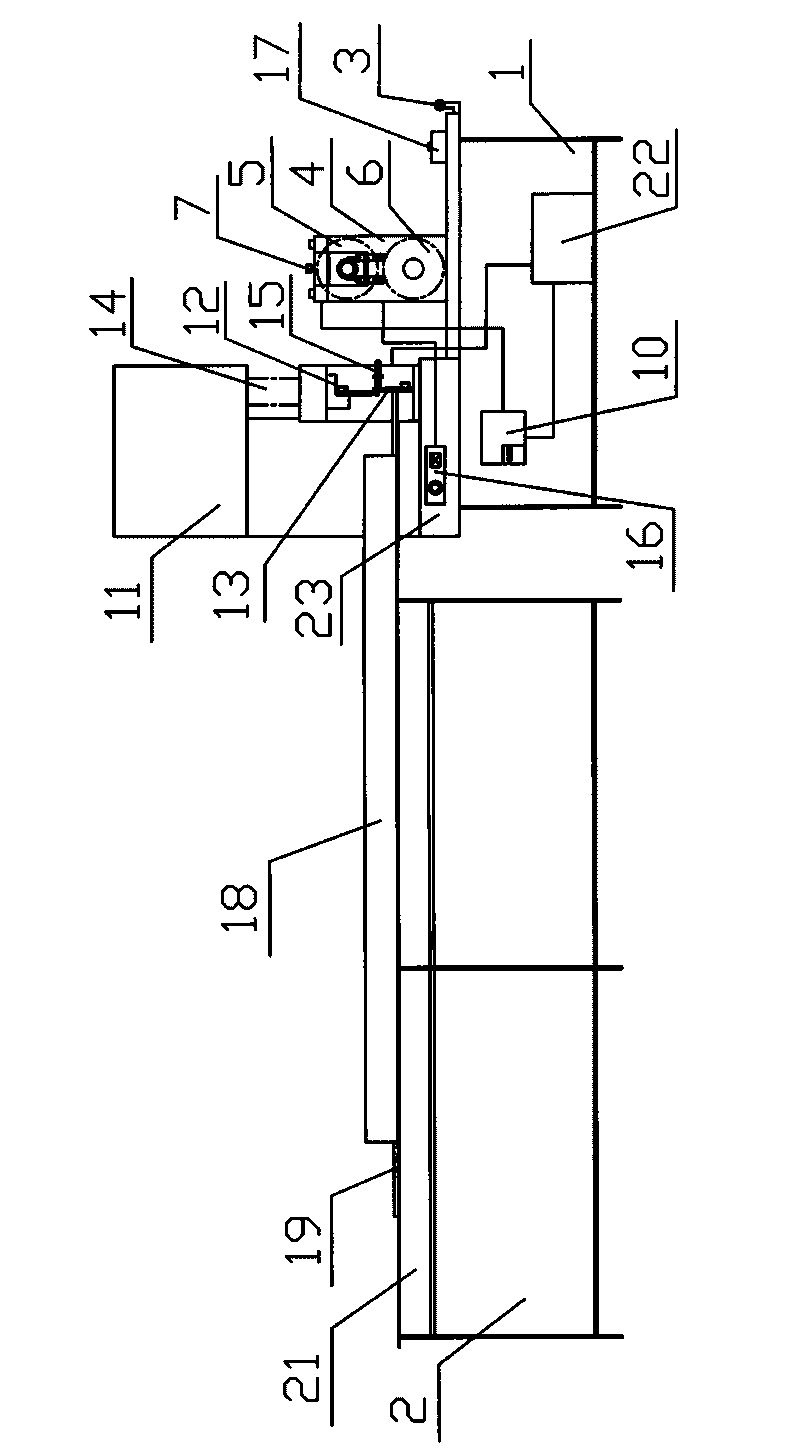

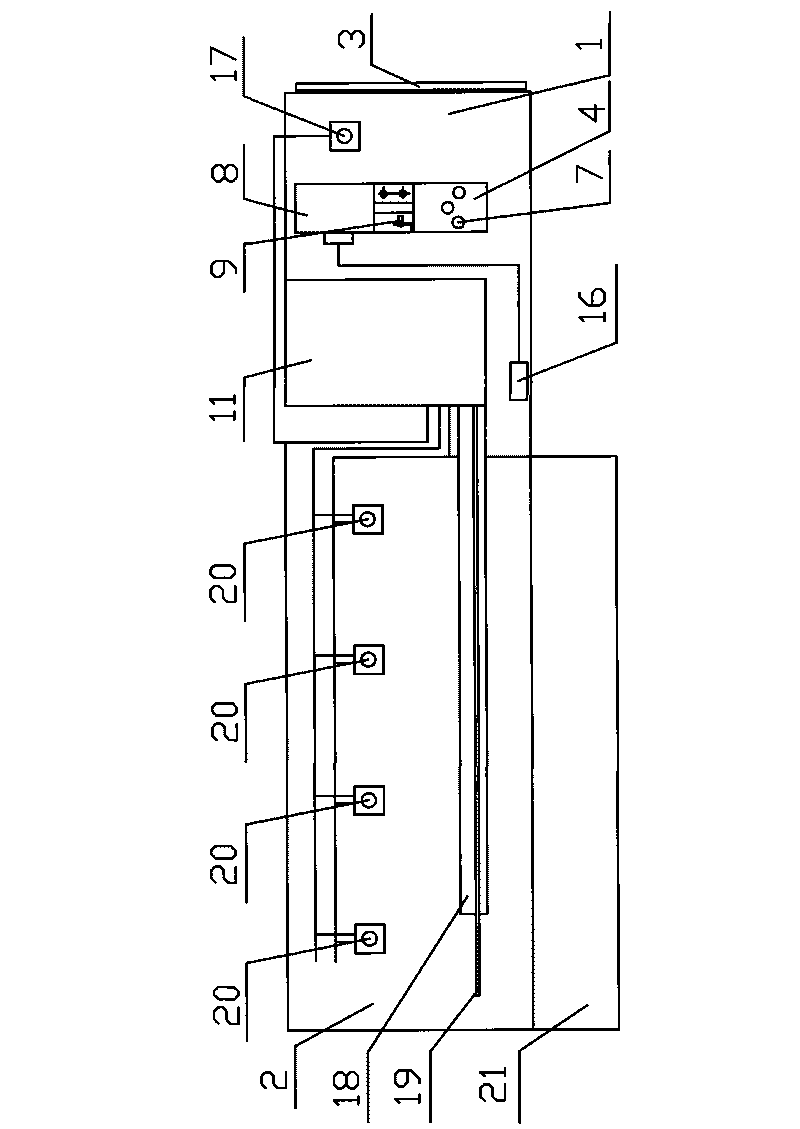

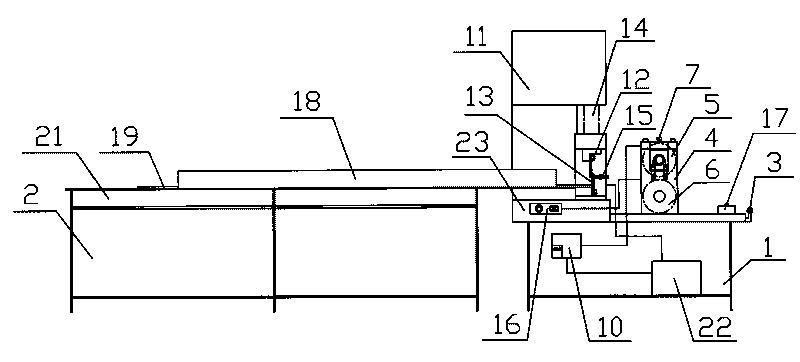

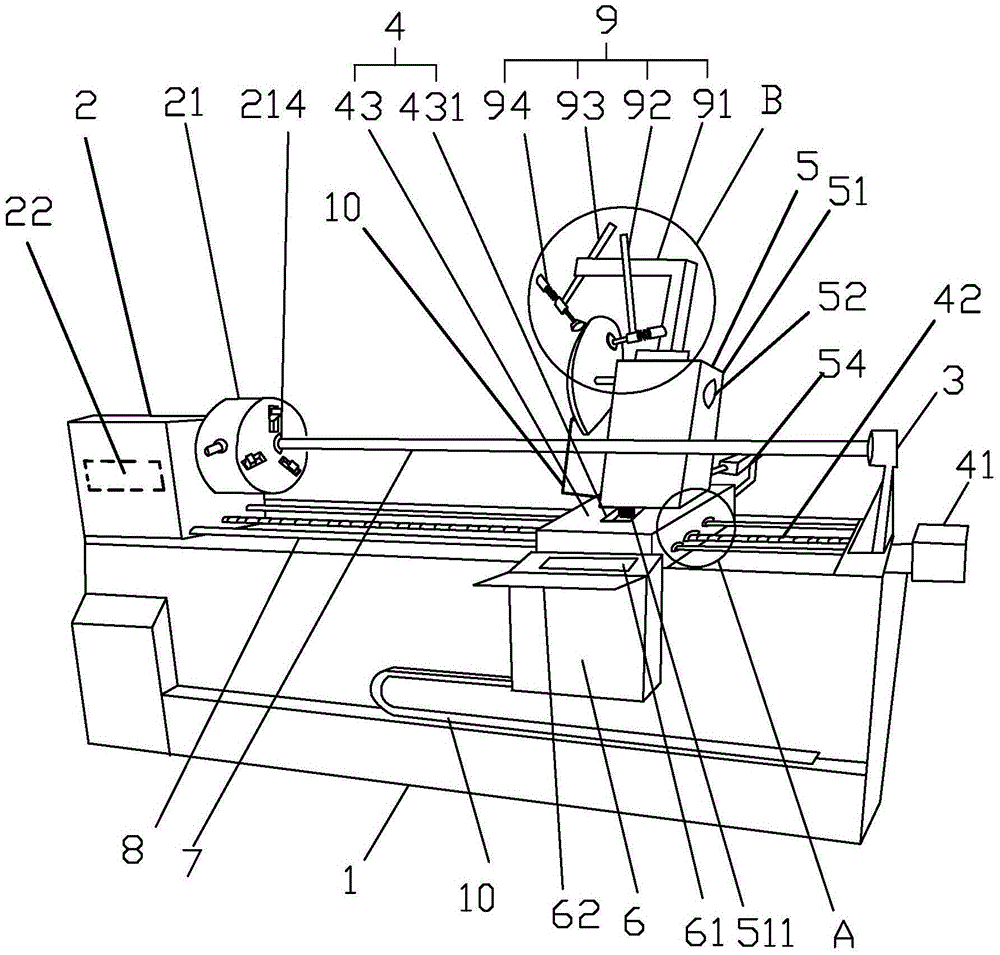

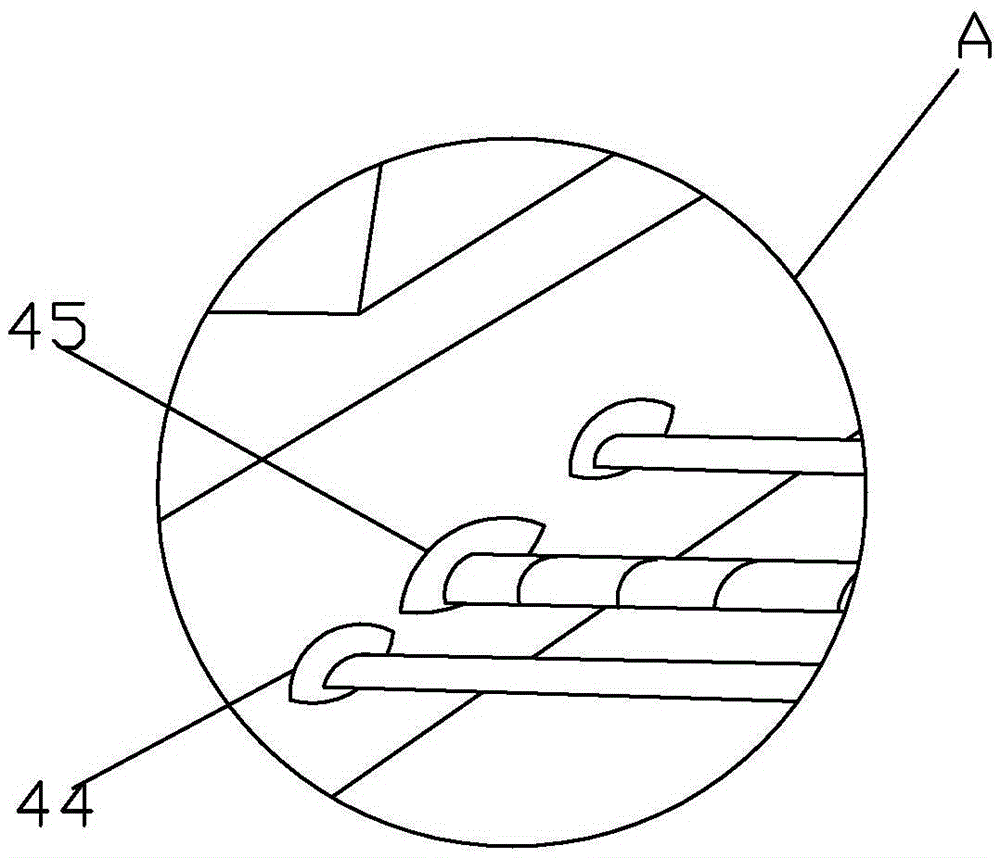

Automatic assembly line for feeding, cutting and punching pipe automatically

ActiveCN106271629AHigh degree of automationImprove cutting efficiencyMetal sawing devicesOther manufacturing equipments/toolsPunchingAssembly line

The invention discloses an automatic assembly line for feeding, cutting and punching a pipe automatically. The automatic assembly line comprises a front feeding mechanism, a middle feeding and cutting mechanism and an automatic punching and unloading mechanism which are arranged in sequence from left to right; the front feeding mechanism comprises a first supporting frame, a lifting mechanism, a pipe clamping mechanism, a transverse pushing mechanism and a longitudinal pushing mechanism; the middle feeding and cutting mechanism comprises a second supporting frame, a first clamping conveying mechanism, an automatic cutting mechanism and an automatic clamping mechanism; the automatic punching and unloading mechanism comprises a third supporting frame, a second clamping conveying mechanism, a drilling clamping mechanism and two sliding drilling mechanisms which are positioned on the right side of the second clamping conveying mechanism and are arranged at an interval. The automatic assembly line can realize automatic feeding, and is low in labour intensity and high in work efficiency; the pipe can be cut automatically; the cutting quality is good; high-efficiency cutting operation of one or more pipes can be realized synchronously; the punching operation can be performed on the two ends of the pipe simultaneously; the function of clamping a plurality of pipes at one time and punching the pipes in sequence can be realized.

Owner:JIANGSU JINPENG VEHICLE CO LTD

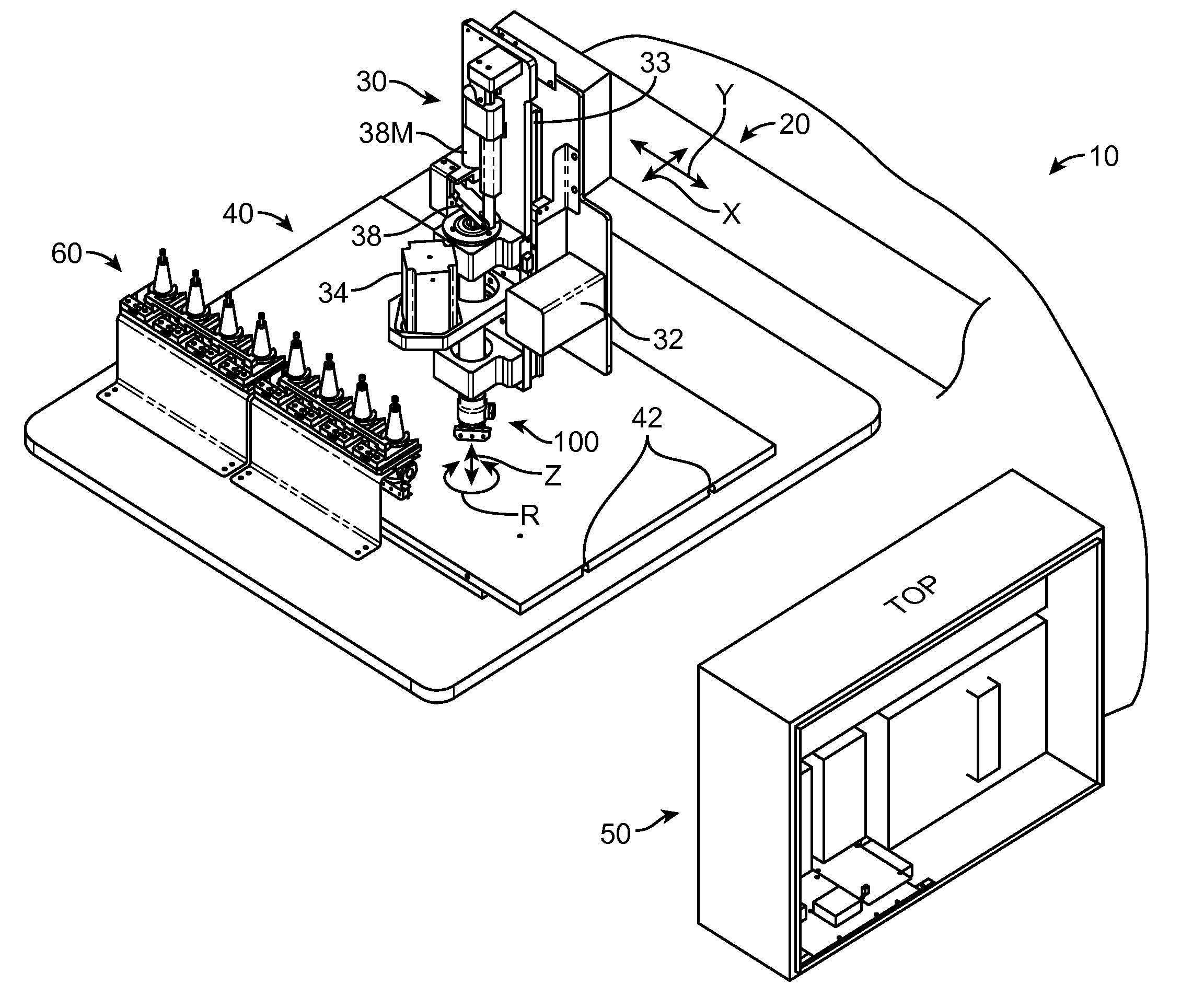

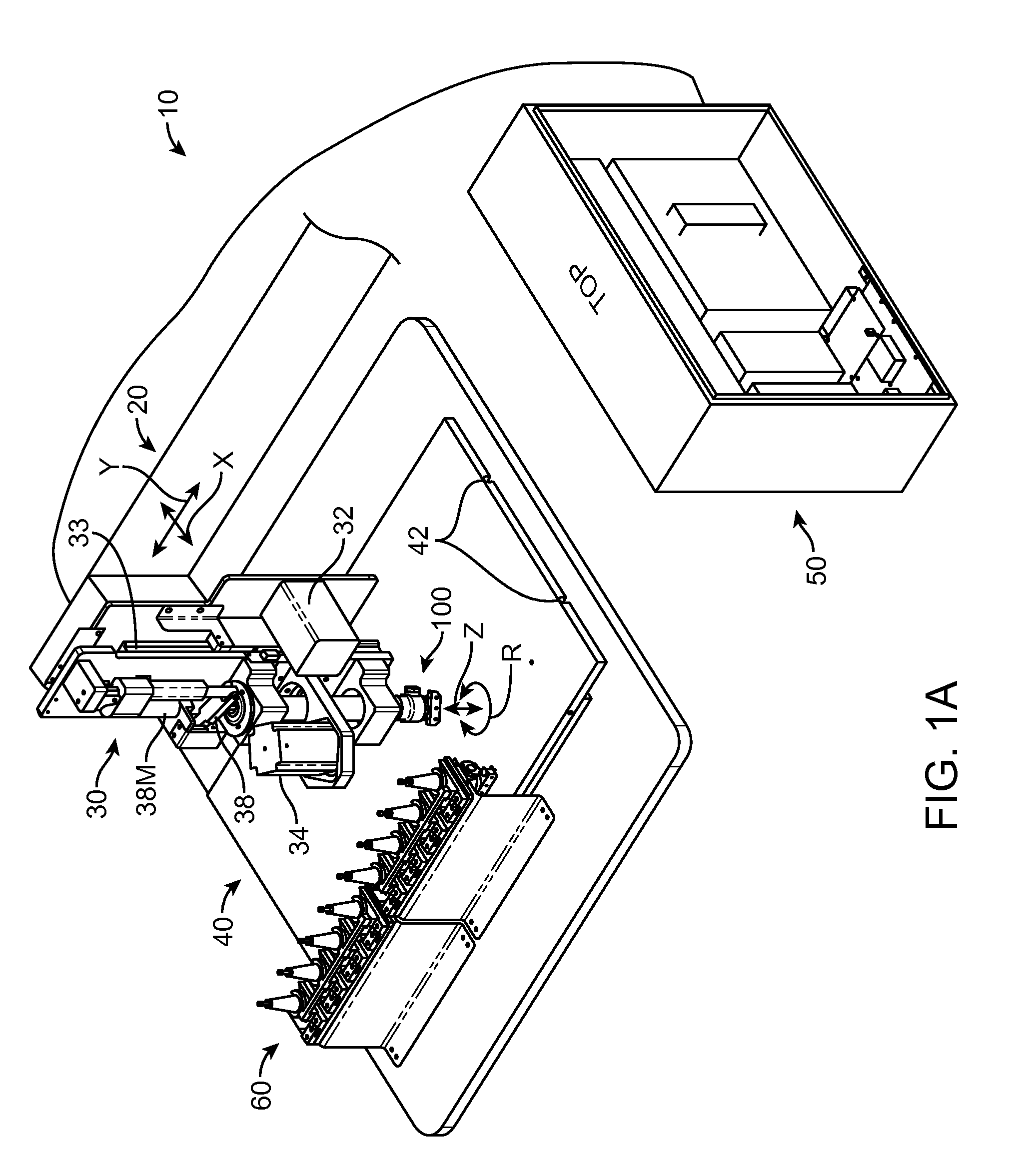

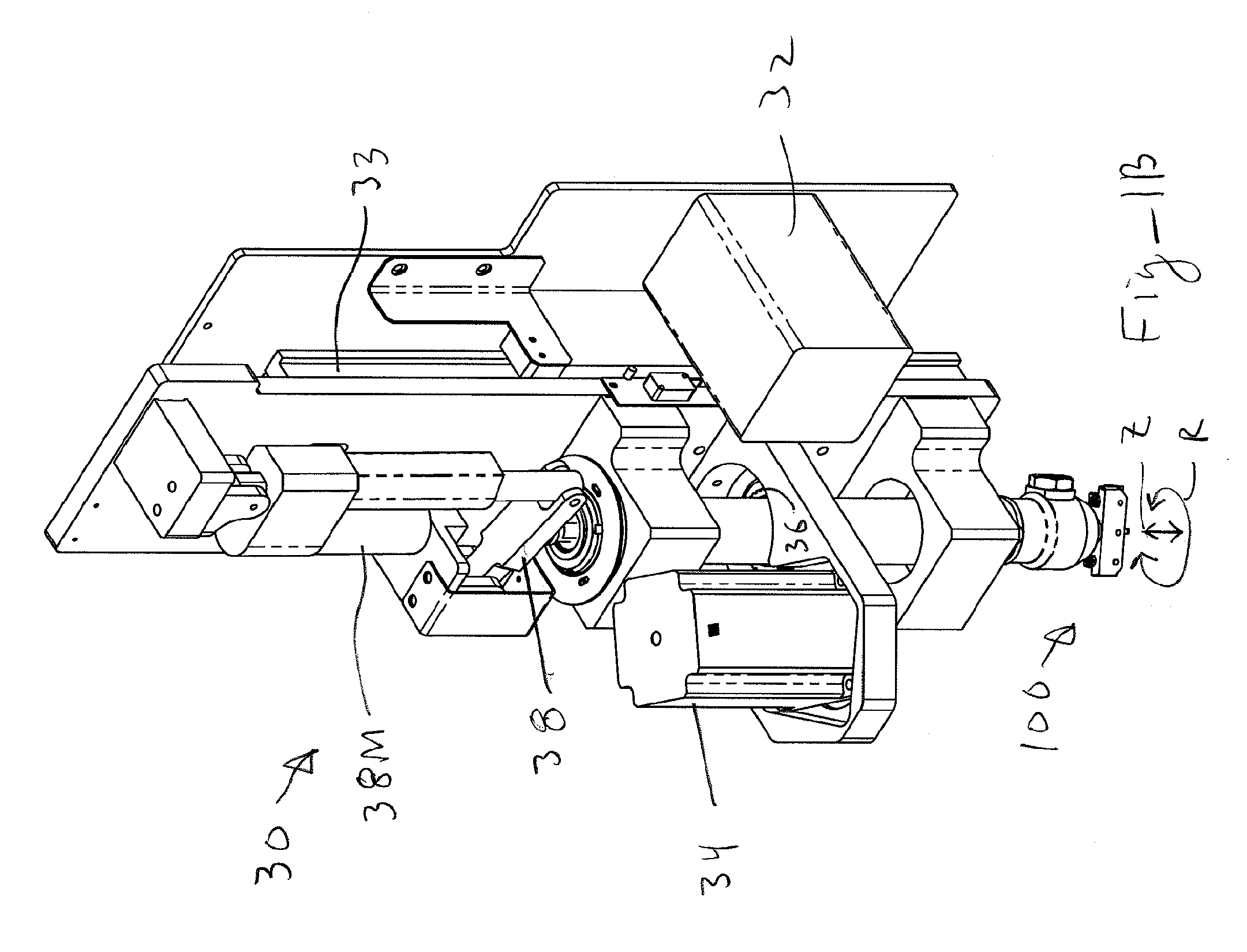

Rapid converting of sheet material methods and apparatus

InactiveUS20120330449A1Speed up the conversion processEasy to understandMetal working apparatusSpecial data processing applicationsEngineeringMachining process

Methods and apparatus provide an input for a user located remote from a cutting machine to cut a part. The user can instruct the cutting machine to cut the part to the user's specification in many ways, for example such that the user can instruct the cutting machine without having knowledge of the machine's cutting processes or construction. The methods and apparatus of the embodiments described herein can convert a machine processes into an image of the part to be cut such that the user can easily view and understand the image of the part to be cut remote from the cutting machine.

Owner:RAPID CONVERTING

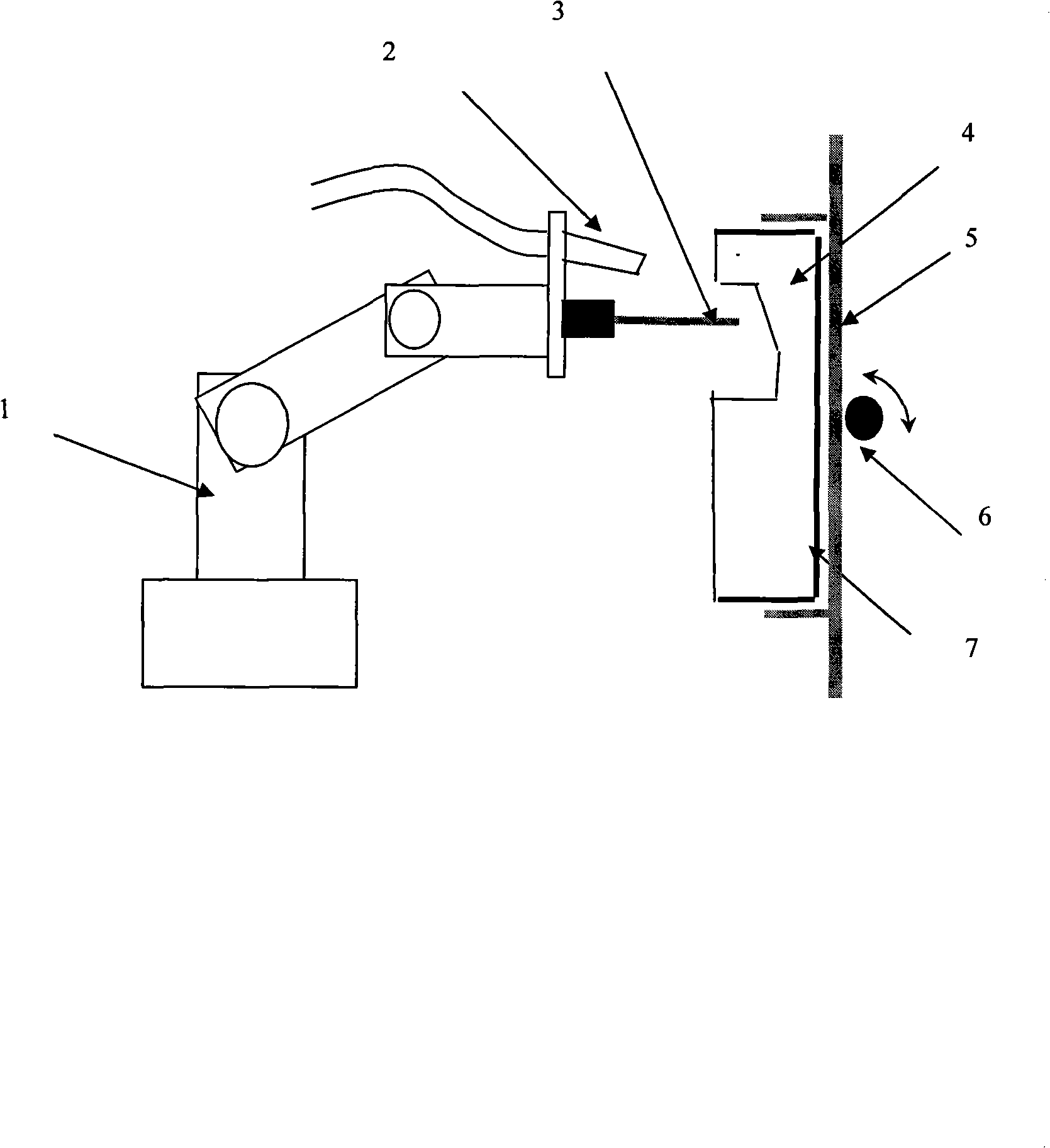

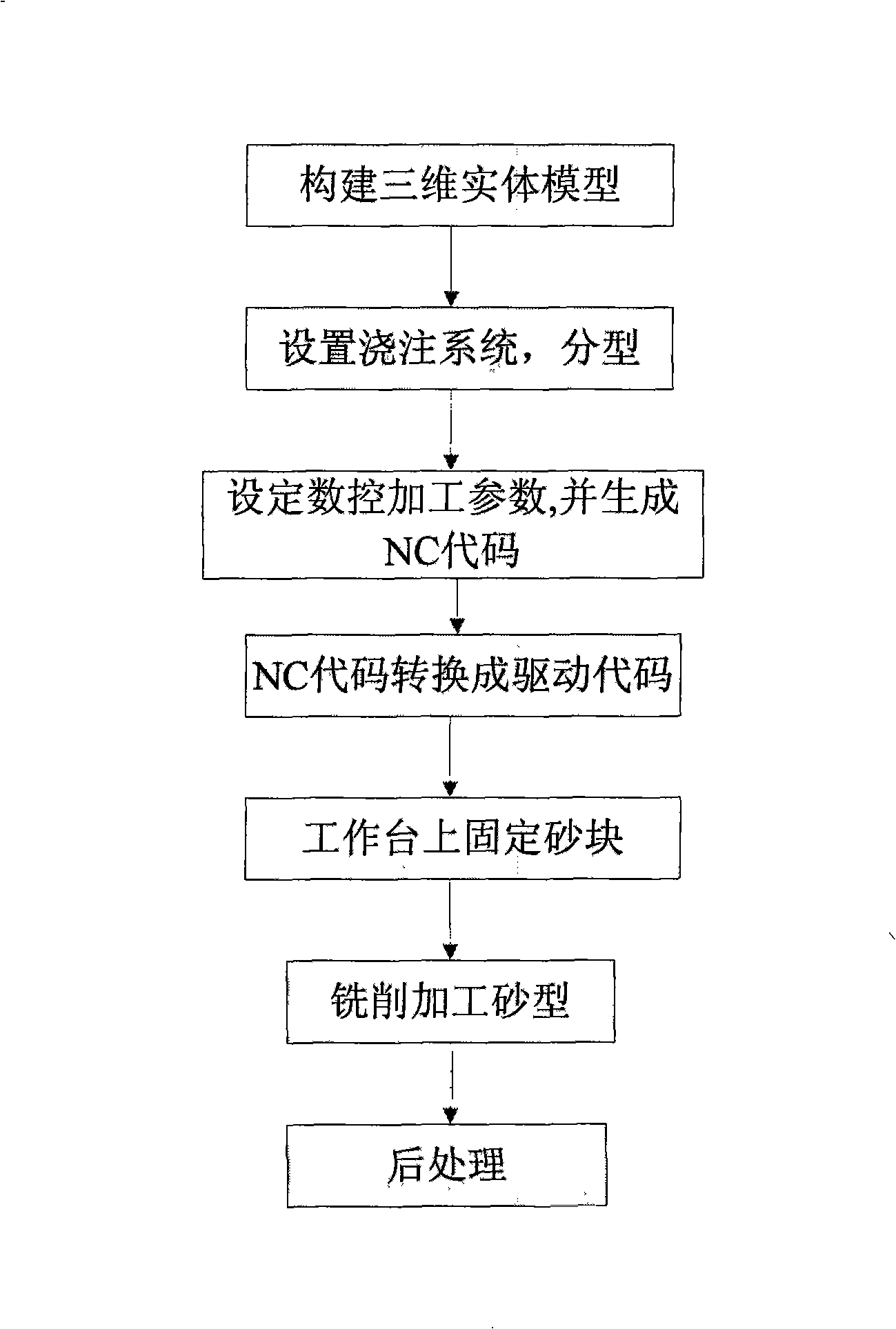

Sand mold milling method based on industrial robot

InactiveCN101279357AReduce preparationQuick cutFoundry mouldsFoundry coresBatch processingAttitude control

The invention relates to a method for adopting an industrial robot to carry out the ordinary sand mold milling processing, which pertains to the filed of the cross technology of casting, numeric control processing and the industrial robot. The steps of the method of the invention are that: a tool and a planned milling path are selected according to the shape of a sand mold to be processed, the generated NC code is translated into a control code of the robot according to a motion model of the industrial robot, thus realizing the gesture control of the robot during the processing process, carrying out the milling of a sand lump and finally carrying out the post-processing of the sand lump after the processing. Compared with the existing traditional casting mold processing method, the processing method of the invention can save the manufacturing link of the mold, reduce the processing procedure, shorten the production period and reduce the production cost; compared with the machine tool-based sand mold milling processing method, the processing method of the invention has larger processing range and higher processing flexibility, in particular to a motion guide track without the need of carrying out the strict sand control protection. The method of the invention is especially applicable to the single and small-batch processing and manufacturing of the large-scale sand mold.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

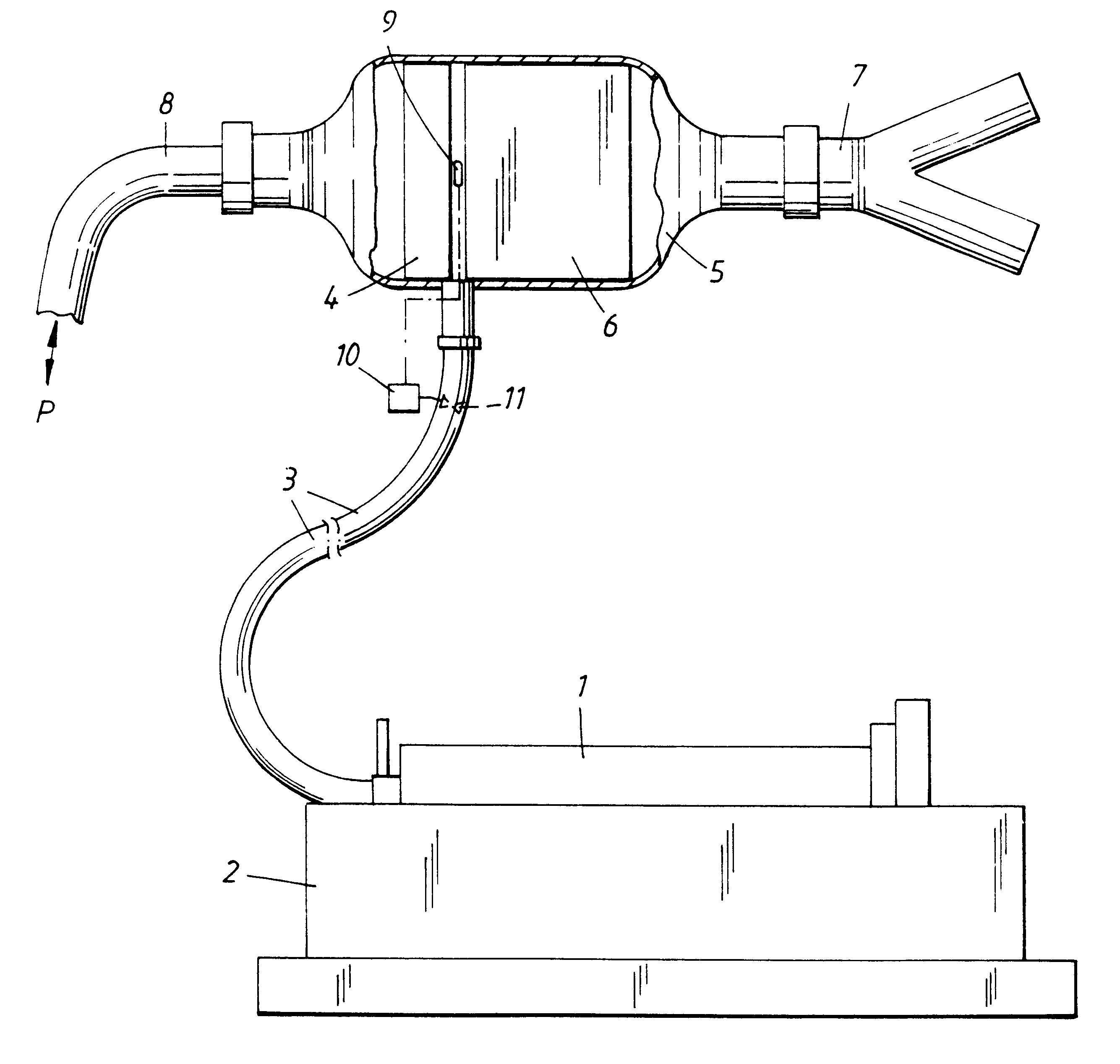

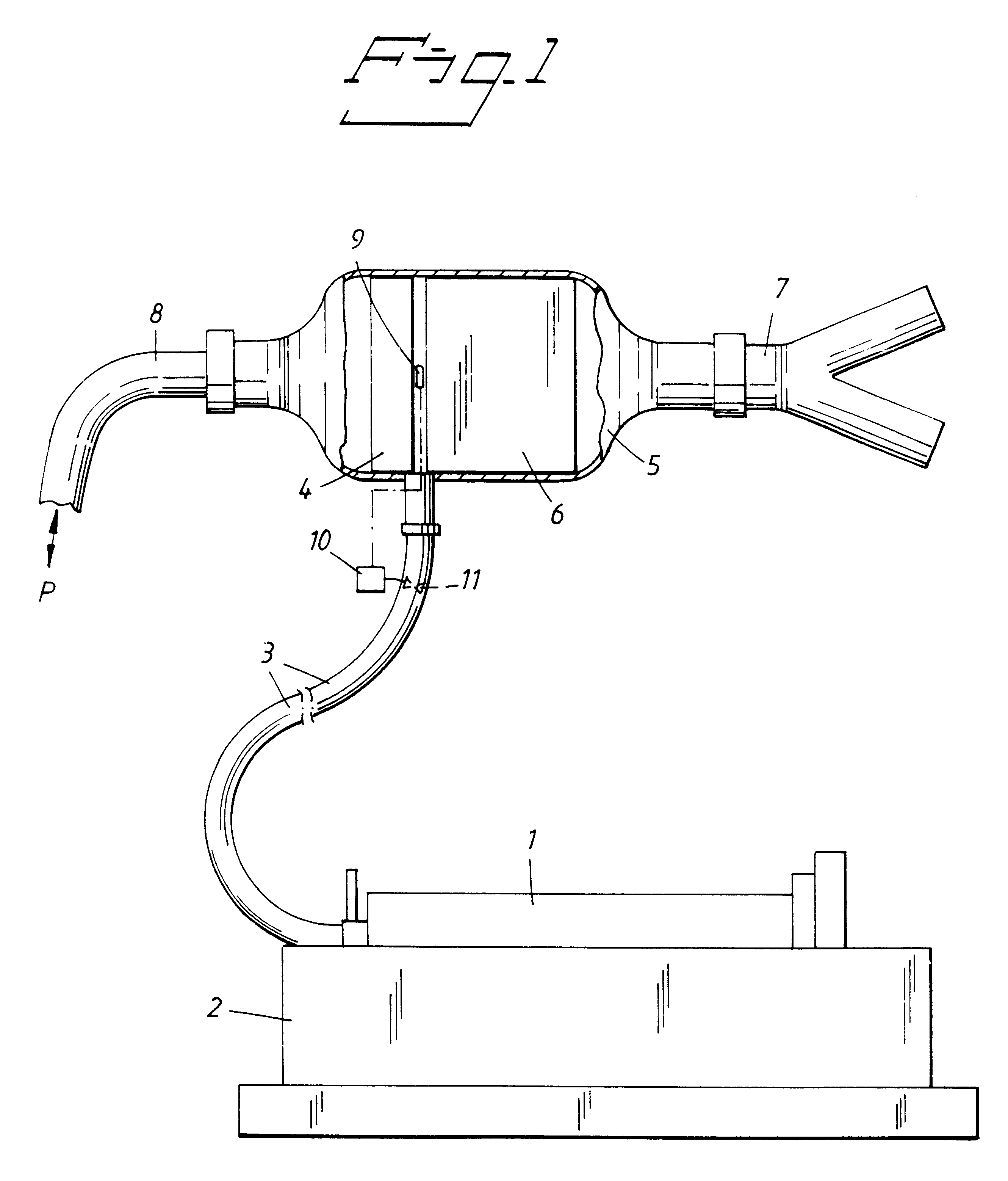

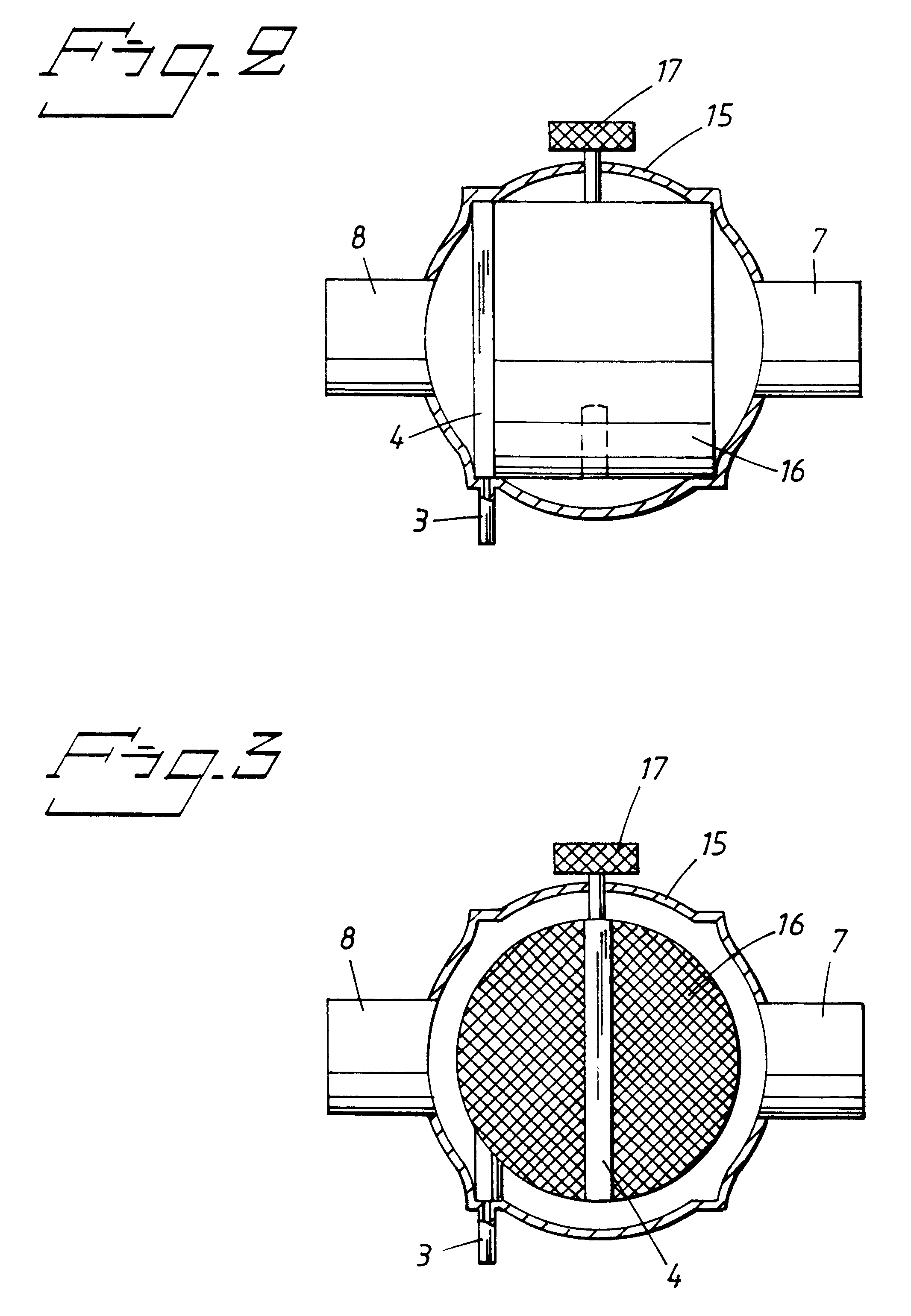

Device for recovering anaesthetic

InactiveUS6488028B1Easy to controlQuick cutRespiratorsBreathing filtersAnesthetic AgentAbsorption filter

A device for recovering anaesthetic. During the administration of inhaled anaesthetic, the device is connected to a patient. It includes an anaesthetic evaporator for supplying anaesthetic to the patient and an absorption filter for absorption and desorption of the medium. The device includes a body placed between the absorption filter and the patient with the gases breathed by the patient passing across the body and the anaesthetic evaporating on the surface thereof. The absorption filter is in the form of a flat element placed in the flow path of a gas breathed by the patient and contains fibers of active carbon. The absorption filter is movably arranged in a housing between a position in which substantially all the gases breathed pass through the filter and the position in which a small portion of the gases breathed passes therethrough.

Owner:HUDSON RCI +1

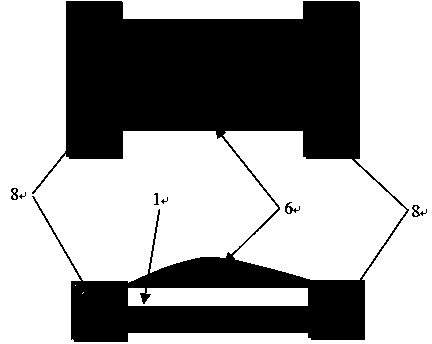

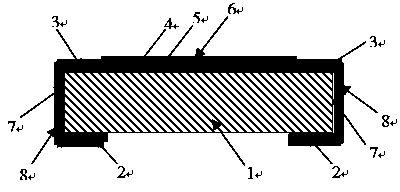

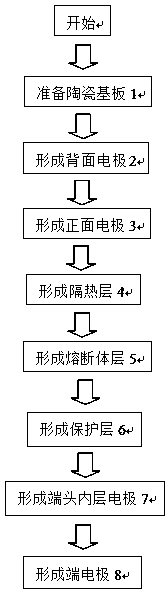

Conductive adhesive for over-temperature overcurrent protective element and production method thereof

ActiveCN103436197AReduce conductivityWith over-temperature and over-current dual protection functionPolyureas/polyurethane adhesivesAldehyde/ketone condensation polymer adhesivesEpoxyPolymer science

The invention provides conductive adhesive for an over-temperature overcurrent protective element with over-temperature and overcurrent dual functions and a production method thereof, in order to solve the problems that the existing over-temperature protective element needs to be provided with pins, occupied volume is large and the surface mounting requirement can not be met. The conductive adhesive for the over-temperature overcurrent protective element is composed of matrix resin and a conductive filler, wherein the matrix resin is at least one of systems of epoxy resin, organic silicon resin, polyimide resin, phenolic resin, polyurethane and acrylic resin; the conductive filler is at least one of gold, silver, copper, aluminium and nickel metal powders or a graphite conductive compound. A protective element prepared from the conductive adhesive has over-temperature and overcurrent dual functions, electrical conductivity of an inner-layer low-melting-point alloy is at least two orders of magnitude lower than that of a silver surface; in a circuit, current is only conducted by virtue of the silver surface, and the electrical conductivity of the conductive adhesive can not be obviously reduced due to shunting effect of a low-melting-point alloy.

Owner:NANJING SART SCI & TECH DEV

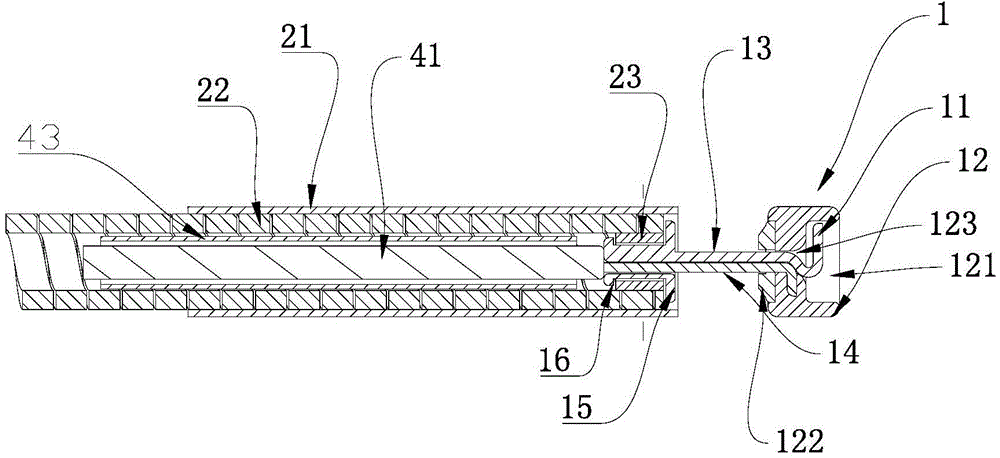

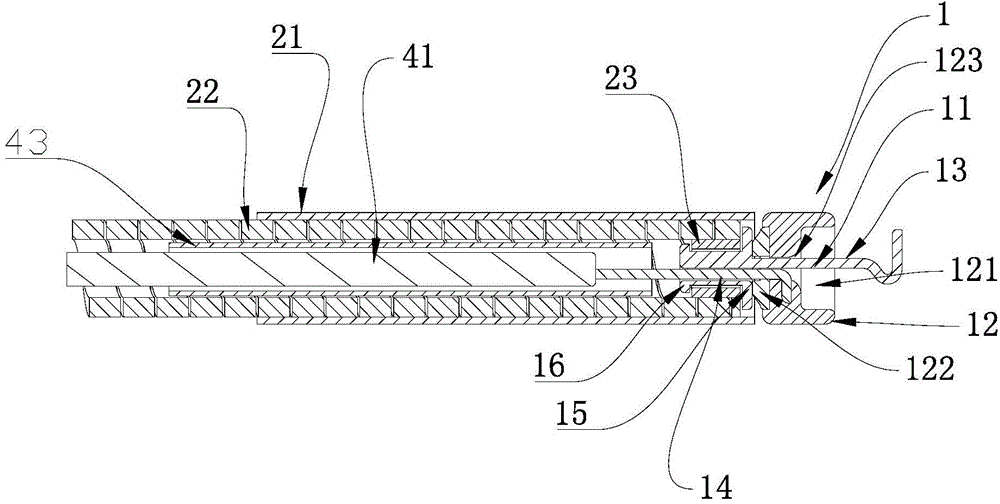

Combined electrotome

ActiveCN104055572ARelieve painEnsure surgical safetySurgical instruments for heatingElectrical conductorHigh frequency power

The invention relates to a combined electrotome which comprises a cutter head part, a hose part and a handle part, wherein the cutter head part comprises at least two or more than two cutter heads which can relatively move or rotate, and each cutter head is connected with a cutter rod; the hose part comprises an insulation outer tube, wherein at least one spindle made of a conductor material penetrates through the insulation outer tube, one end of the spindle is connected with the handle part which is used for controlling the spindle to move, and the other end of the spindle is connected with a cutter bar which is driven to move by the spindle; the handle part comprises a handle, wherein at least one sliding handle is arranged on the handle, the sliding handle is connected with the spindle which is driven by the sliding handle to control at least one cutter to move, so that at least one cutter or cutter bar is exposed or contained, and a cable connector which is connected with a high-frequency power source is further arranged on the sliding handle. The combined electrotome has the advantages that a doctor can select an appropriate electrotome type to safely and quickly complete an operation, so that the operation safety of a patient can be greatly guaranteed, and the pain of the patient is relieved.

Owner:HANGZHOU AGS MEDTECH CO LTD

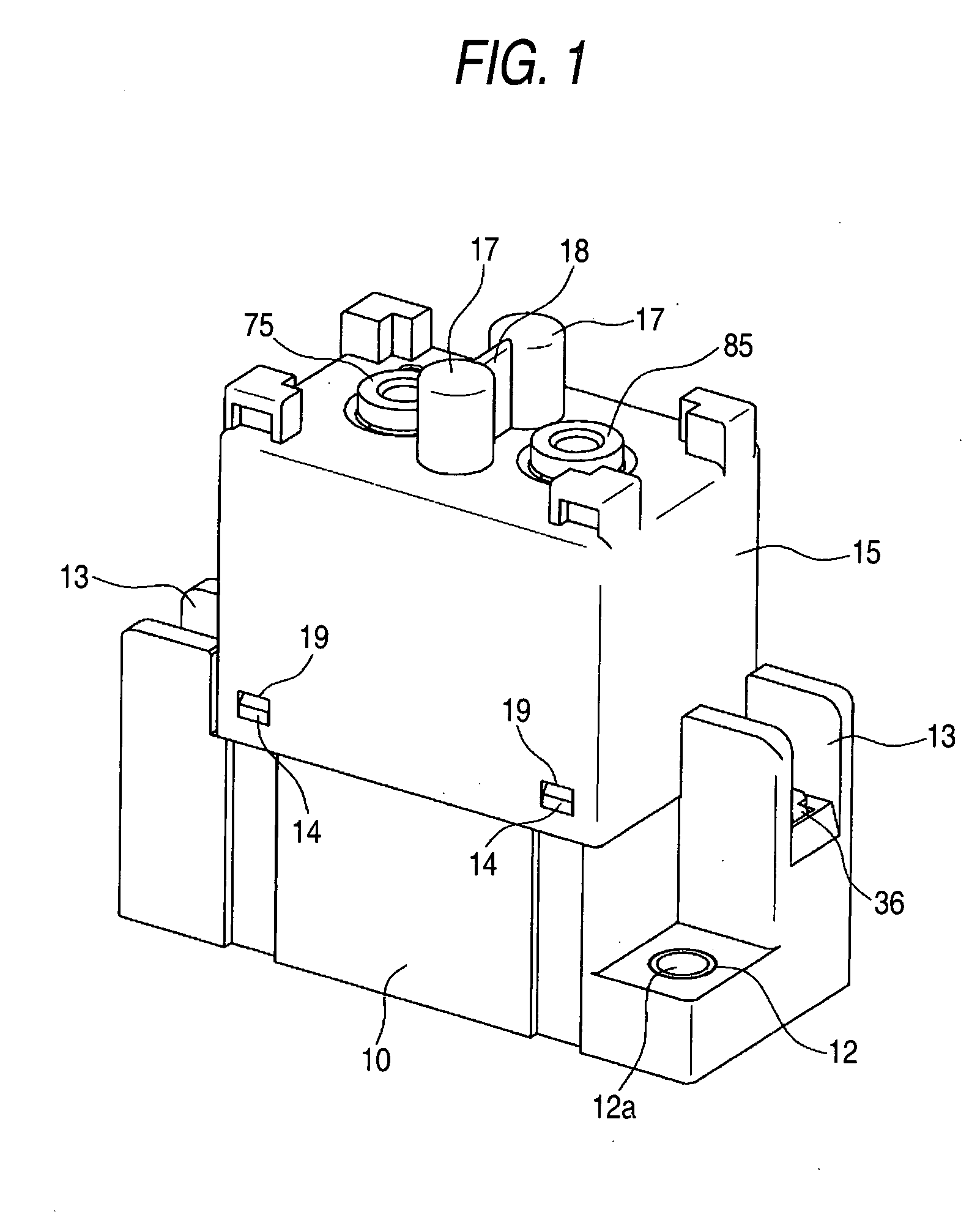

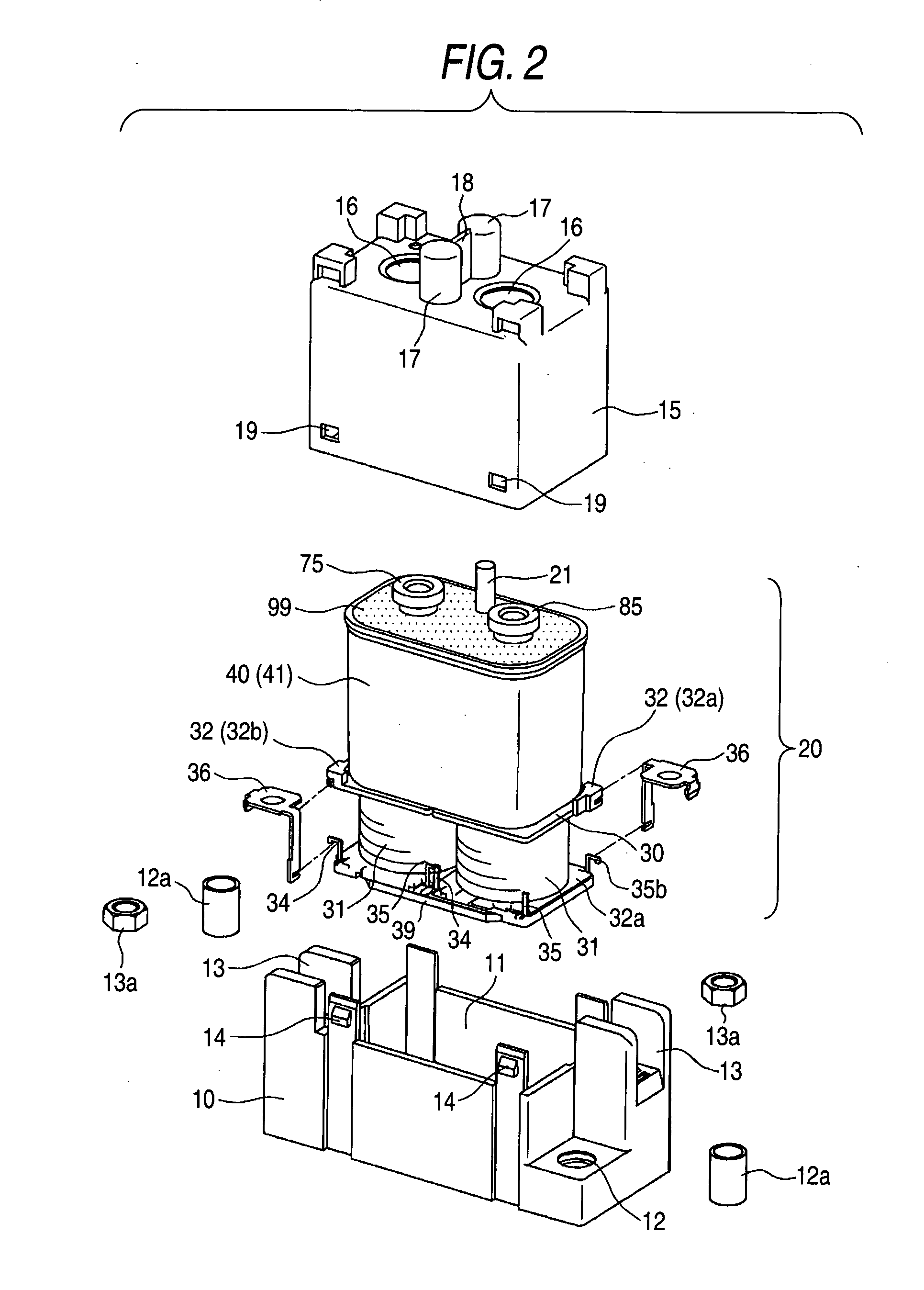

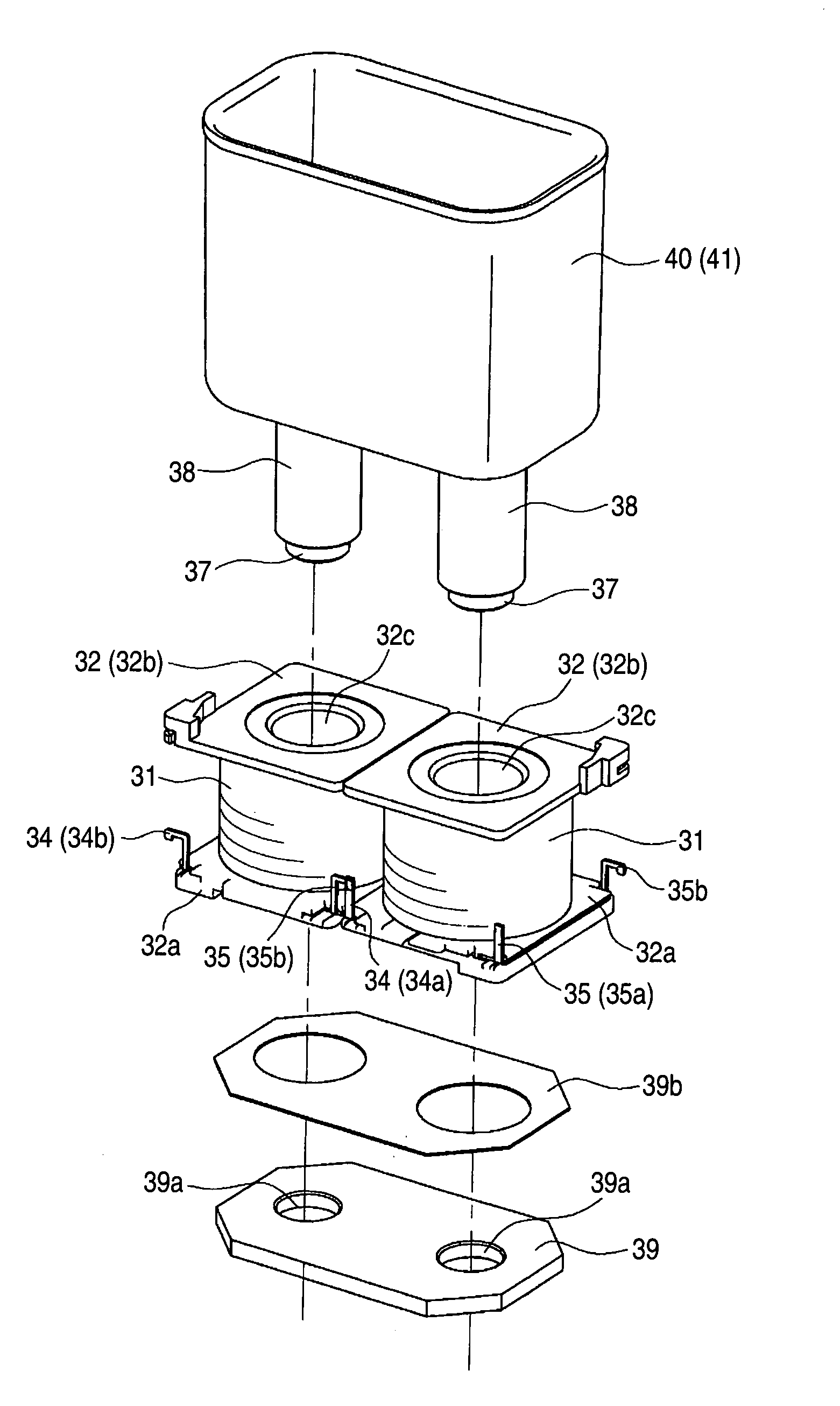

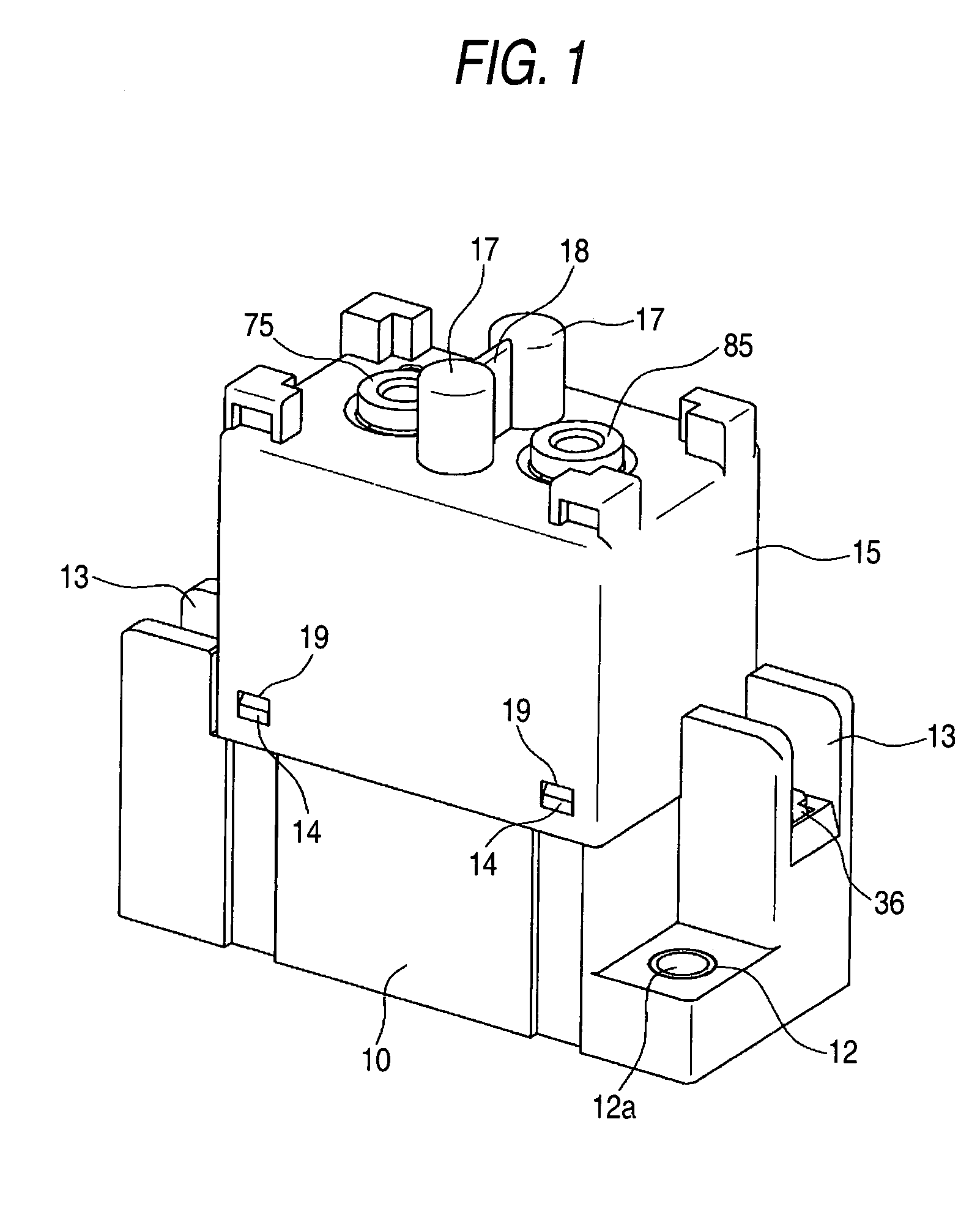

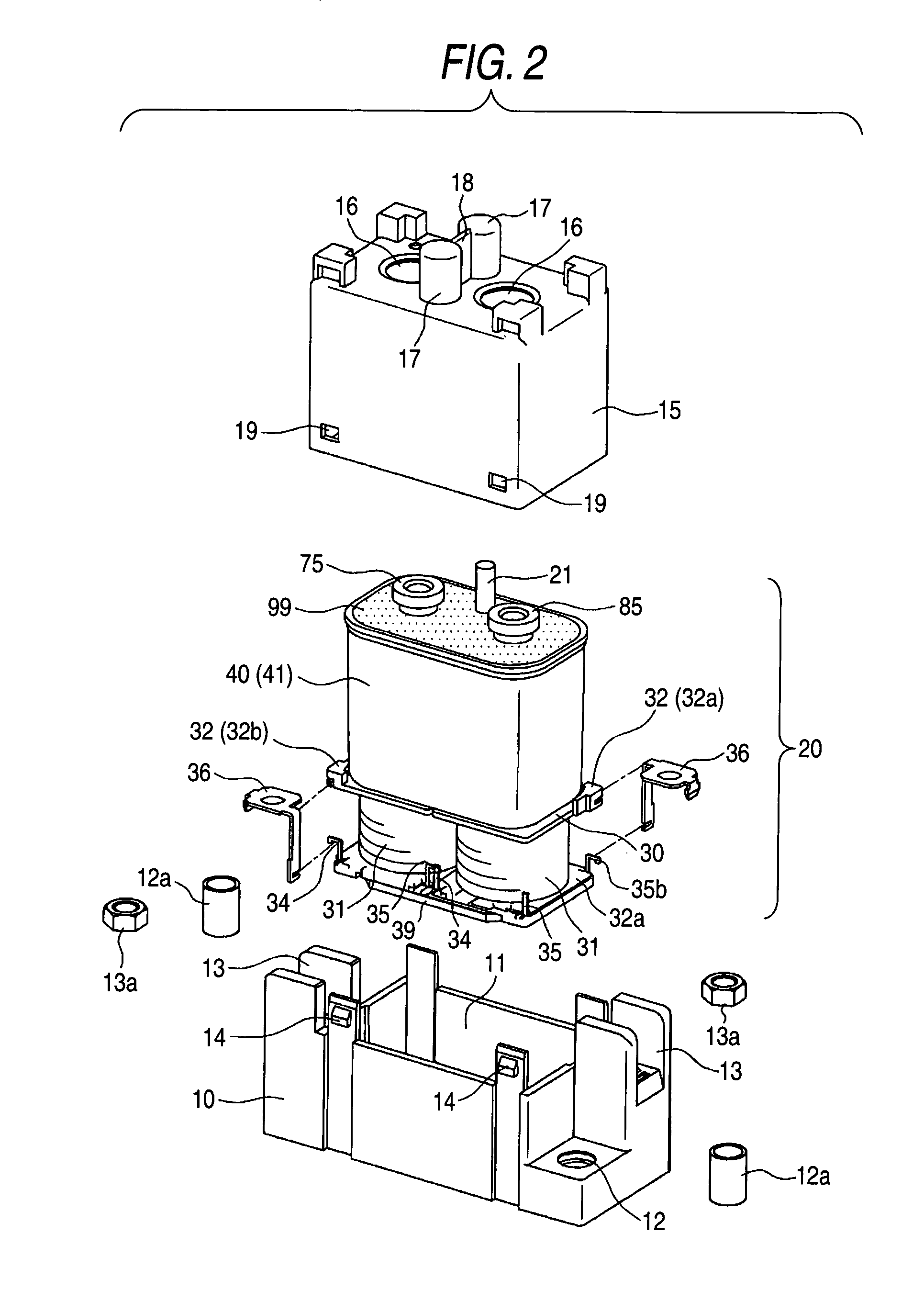

Switching device

ActiveUS20050146405A1Avoid damageQuick cutContacts enclosures/screensElectromagnetic relay detailsMagnetizationMagnetic poles

It is to provide an electromagnetic relay that can perform the return operation of a movable iron piece quickly, free from a fear of welding the contact. In the electromagnetic relay, an iron core is penetrated through a through hole formed on the bottom surface of the aluminum case and coil is wound around the shaft of the protruding iron core. Through applying a voltage to the coil for magnetization and stopping the voltage for demagnetization, a contact mechanism is driven with a movable iron piece that is going and returning, attracted by and separated from a magnetic pole portion of the iron core. In particular, a slit for preventing generation of eddy current is provided on the opening end of the through hole.

Owner:ORMON CORP

Switching device

ActiveUS7157995B2Avoid damageQuick cutContacts enclosures/screensElectromagnetic relay detailsReciprocating motionMagnetization

An electromagnetic relay has an iron core having a protruding shaft and a magnetic pole portion. The protruding shaft is penetrated through a through hole provided on a metal case, and coil is wound around the protruding shaft. A voltage is applied to the coil for magnetization and stopped for demagnetization, hence to drive a contact mechanism with a movable iron piece that is attracted by and separated from the magnetic pole portion, thereby causing a reciprocating motion of the movable iron piece. The relay can prevent generation of eddy current.

Owner:ORMON CORP

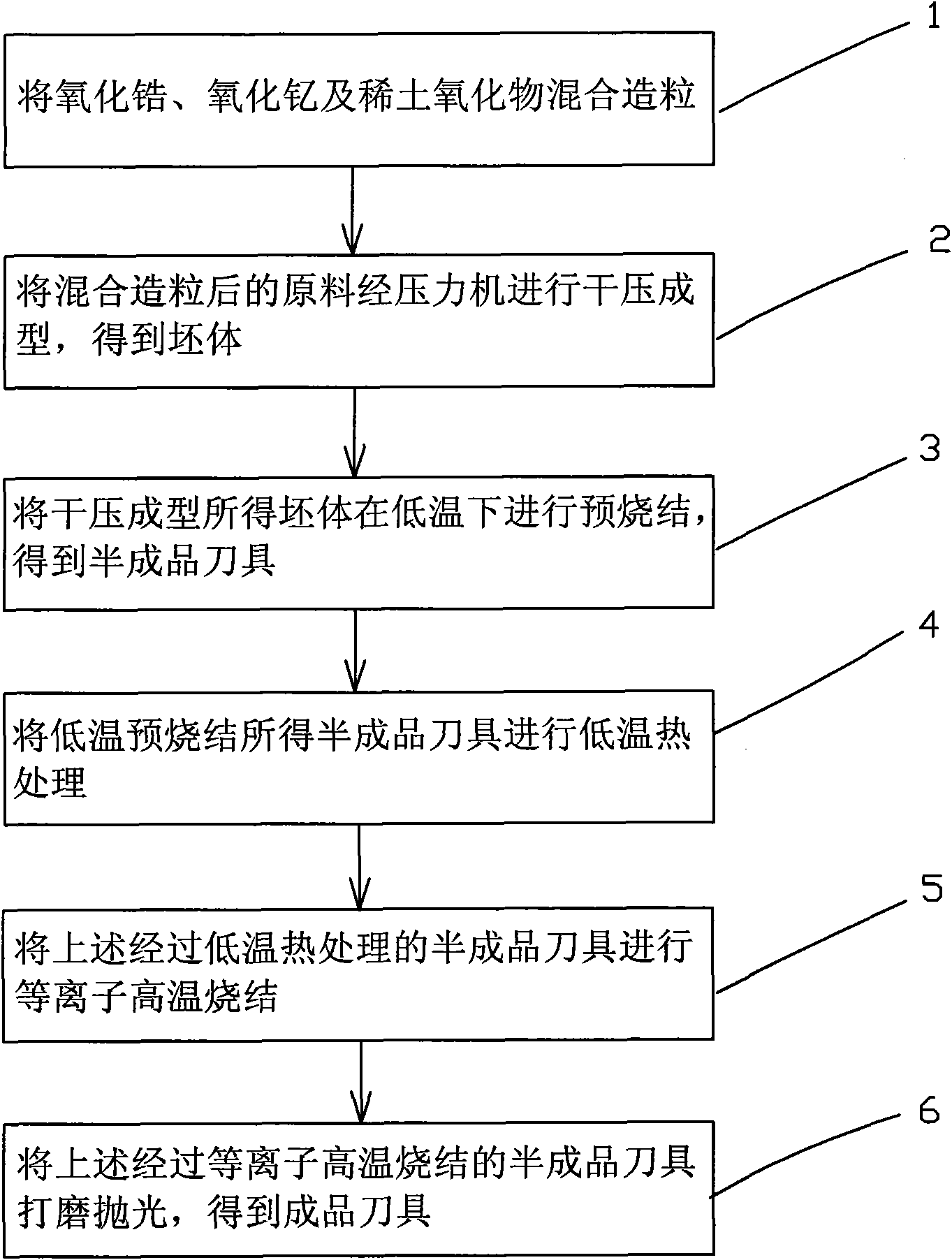

Super-strong and super-toughened ceramic cutter and manufacturing method thereof

ActiveCN101602111AImprove yield rateHigh hardnessCeramic shaping apparatusTurning toolsRare earthMaterials science

The invention relates to a super-strong and super-toughened ceramic cutter and a manufacturing method thereof. The ceramic cutter comprises the following components in portion by weight: 89 to 95 portions of zirconia, 2 to 8 portions of yttria, and 2 to 4 portions of rare earth oxide. The manufacturing method for the ceramic cutter comprises the following: step 1, mixing and granulating the zirconia, the yttria and the rare earth oxide; step 2, dry-pressing and molding the mixed and granulated raw materials by a press to obtain a blank; step 3, pre-sintering the blank obtained by the dry-pressing and molding at the low temperature to obtain a semi-finished cutter; step 4, thermally treating the semi-finished cutter obtained by the low-temperature pre-sintering at the low temperature; step 5, carrying out plasma high-temperature sintering for the semi-finished cutter which is thermally treated at the low temperature; and step 6, grinding and polishing the semi-finished cutter which is subjected to the plasma high-temperature sintering to obtain a finished cutter. The ceramic cutter has high hardness and good abrasion resistance, and has the remarkable advantages on thermal stability, heat conduction, corrosion resistance, oxidation resistance, high-temperature hardness, high-temperature strength, and the like. The method has the advantages of simple process and high production efficiency, and is favorable for mass mechanized production.

Owner:深圳市宏通新材料有限公司

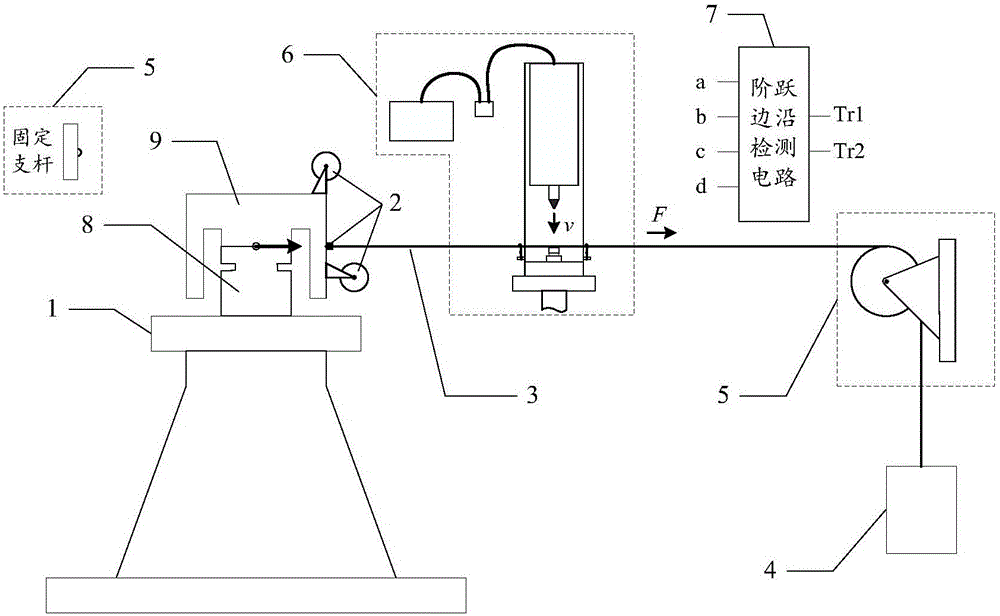

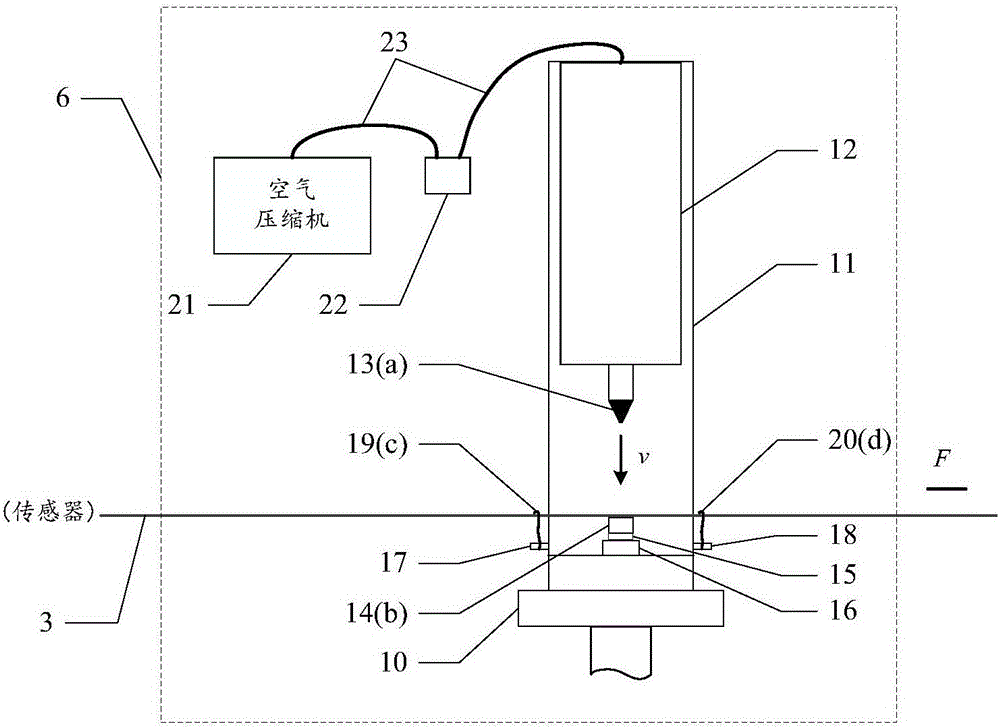

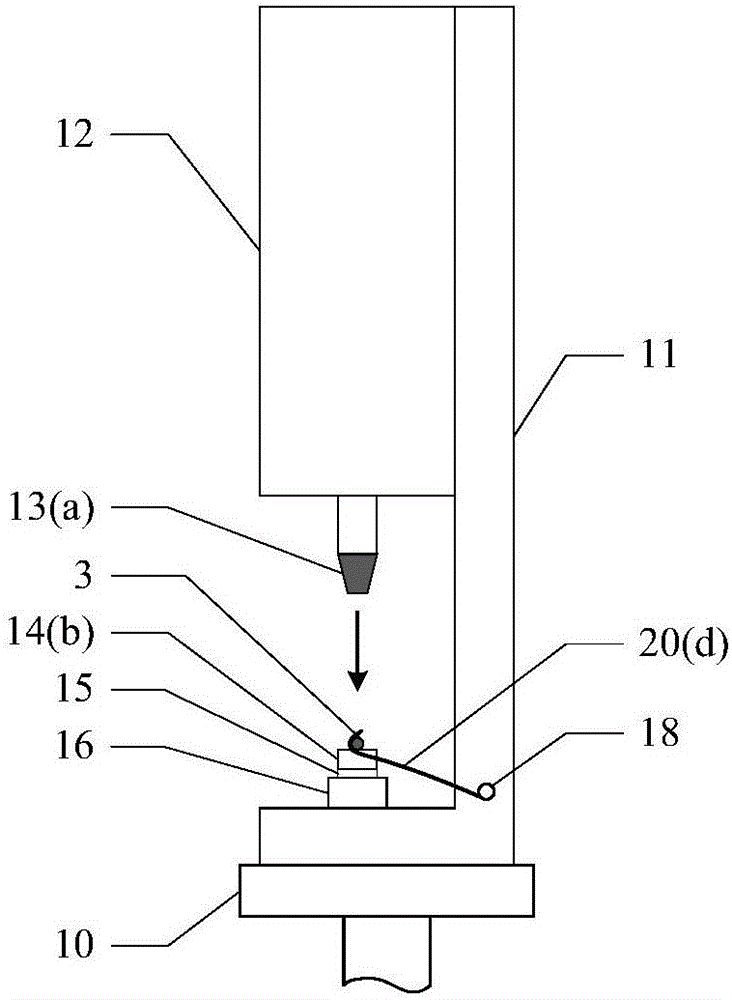

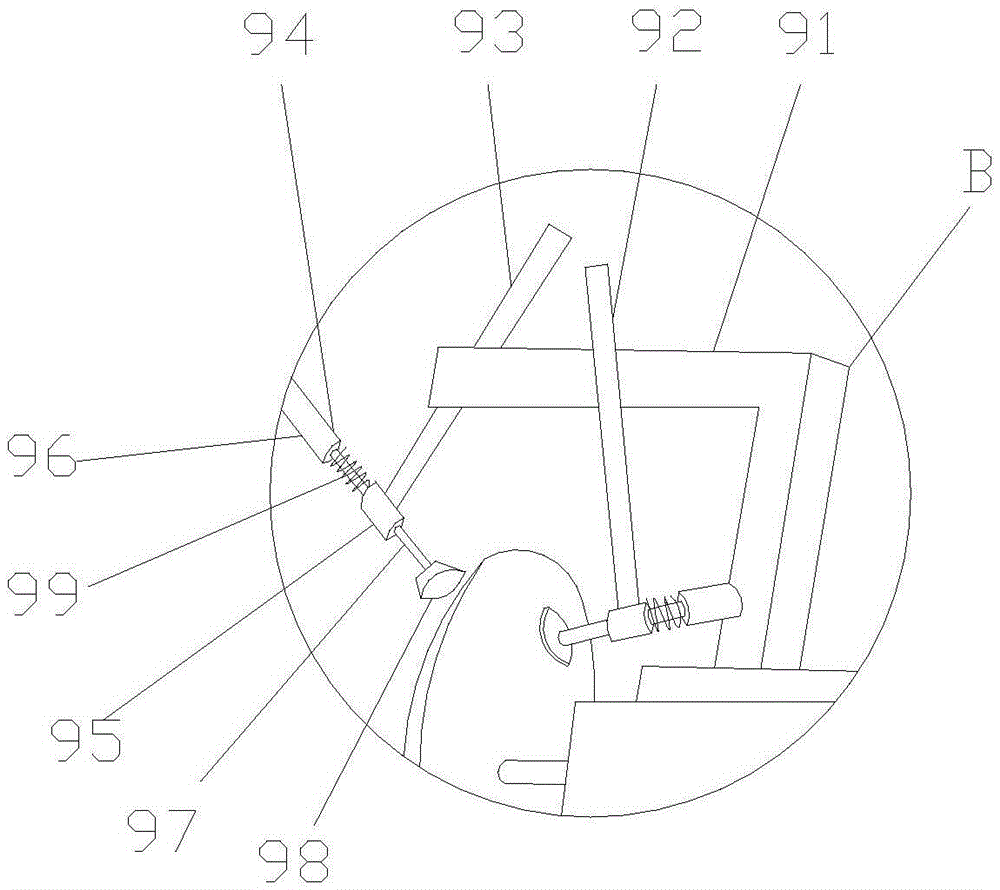

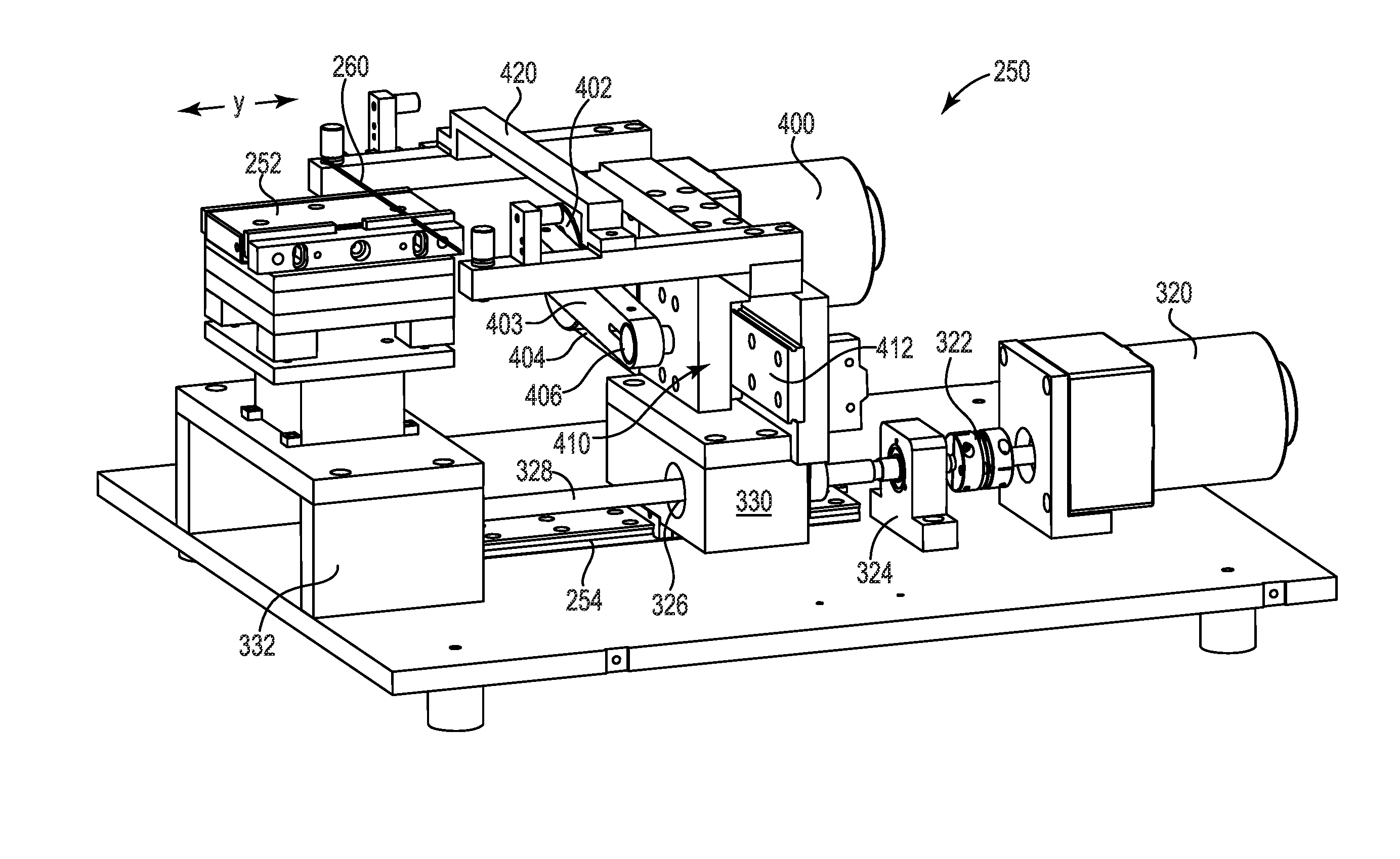

Step force generating device for dynamic calibration of force sensor

ActiveCN106706207AAchieving Negative Step ForceAchieving Negative Step TorqueApparatus for force/torque/work measurementForce/torque/work measurement apparatus calibration/testingContact timeEngineering

The invention provides a step force generating device for dynamic calibration of a force sensor, wherein the step force generating device is suitable for dynamic calibration experiment of a force sensor having an irregular tool structure of a load terminal or needing to carry out loading of a plurality of directive forces / torques. The step force generating device comprises a calibration table, a directional loading assembly, a steel force transmission wire, a force source, a pulley suspension system, an impact shearing device and a step edge detection circuit. A stable load is applied to a force sensor by using the directional loading assembly based on steel wire force transmission; and the steel force transmission wire is impacted and sheared suddenly to carry out step unloading on the force sensor to realize negative step excitation on the force sensor. The impact shearing device uses a high-speed and large-impact-force impact cylinder as an impact execution mechanism to extend a dynamic calibration frequency and a load range of the force sensor. With cooperation of an impact gasket block, the disturbance during the impact shearing process can be suppressed, so that the dynamic calibration precision can be improved. The step edge detection circuit obtains step edge time based on starting steel force transmission wire contact time by a detection impact head and a steel force transmission wire shearing time.

Owner:HEFEI UNIV OF TECH

Fixed-length line automatic feeding and cutting device

The invention discloses a fixed-length line automatic feeding and cutting device which comprises a first workbench and a second workbench, the top of one end of the first workbench is provided with an idler wheel, the first workbench is provided with a feeder, the feeder is connected with a motor and provided with an inductive switch, a counter is arranged below the first workbench and connected with the inductive switch, a crimping machine is arranged on one side of the first workbench, a cutting device is arranged in the crimping machine, a speed governing switch is arranged on the front part of the seat of the crimping machine, a guide chute is arranged in front of the upper surface of the second workbench, a length measuring scale is arranged on the bottom inside the guide chute, a plurality of linkage control switches are arranged at the back part of the upper surface of the second workbench, and the linkage control switches are all connected with the cutting device. The invention has the advantages of saved human resource, high accuracy and improved production efficiency, and is applicable for cutting special lines such as shielding line, twisted-pair line and the like.

Owner:南通大地电气股份有限公司

Method of etching substrates

InactiveUS7012012B2Improve productivityIncrease the number ofPolycrystalline material growthAfter-treatment detailsResistInductively coupled plasma

Thinning and dicing substrates using inductively coupled plasma reactive ion etching (ICP RIE). When dicing, a hard photo-resist pattern or metal mask pattern that defines scribe lines is formed on a sapphire substrate or on a semiconductor epitaxial layer, beneficially by lithographic techniques. Then, the substrate is etched along the scribe lines to form etched channels. An etching gas comprised of BCl3 and / or BCl3 / Cl2 gas is used (optionally, Ar can be added). Stress lines are then produced through the substrate along the etched channels. The substrate is then diced along the stress lines. When thinning, a surface of a substrate is subjected to inductively coupled plasma reactive ion etching (ICP RIE) using BCl3 and / or BCl3 / Cl2 gas, possibly with some Ar. ICP RIE is particularly useful when working sapphire and other hard substrates.

Owner:SUZHOU LEKIN SEMICON CO LTD

Cloth slitter

InactiveCN105619505APrevent affecting cutting accuracyGood cutting precisionSevering textilesMetal working apparatusEngineeringMechanical engineering

The invention mainly discloses a cloth slitter. According to the technical scheme, the cloth slitter comprises a machine frame, a machine head, a machine tail, a moving device, a cutting device, a knife sharpening device and a PLC control cabinet; a loop bar is arranged between the machine head and the machine tail; the cutting device is connected to the upper side of the moving device; the PLC control cabinet controls the moving device and the cutting device; the cutting device comprises a cutting frame, a first motor, a cutting knife and an air cylinder; the knife sharpening device comprises a supporting frame, a first polishing support, a second polishing support and a pair of polishing modules, wherein the first polishing support and the second polishing support are installed on the two sides of the supporting frame respectively in an inclined mode and are connected to the respective corresponding polishing modules, and the polishing modules are located on the two sides of the cutting knife respectively. The cloth slitter has the advantages of being simple in structure, convenient to operate, accurate in cutting and capable of polishing the cutting knife.

Owner:SHENGZHOU YIHAI MOTOR PARTS FACTORY

Method for cutting glass by laser

A method for cutting glass by laser comprises the following steps: (A) a laser focus is arranged on the lower surface of the glass; (B) laser beams form a cut surface in the glass; (C) with a machined surface ascending, the focus of the whole laser beams also ascends relative to the machined glass. In the invention, a bursting point is generated in the glass by the laser focus, the focus energy exceeds the damage threshold of the glass, the glass absorbs the laser energy to generate high temperature and points are burst on the glass and form the cut surface through a moving system, thus realizing fast and high-quality cutting of the glass.

Owner:HANS LASER TECH IND GRP CO LTD

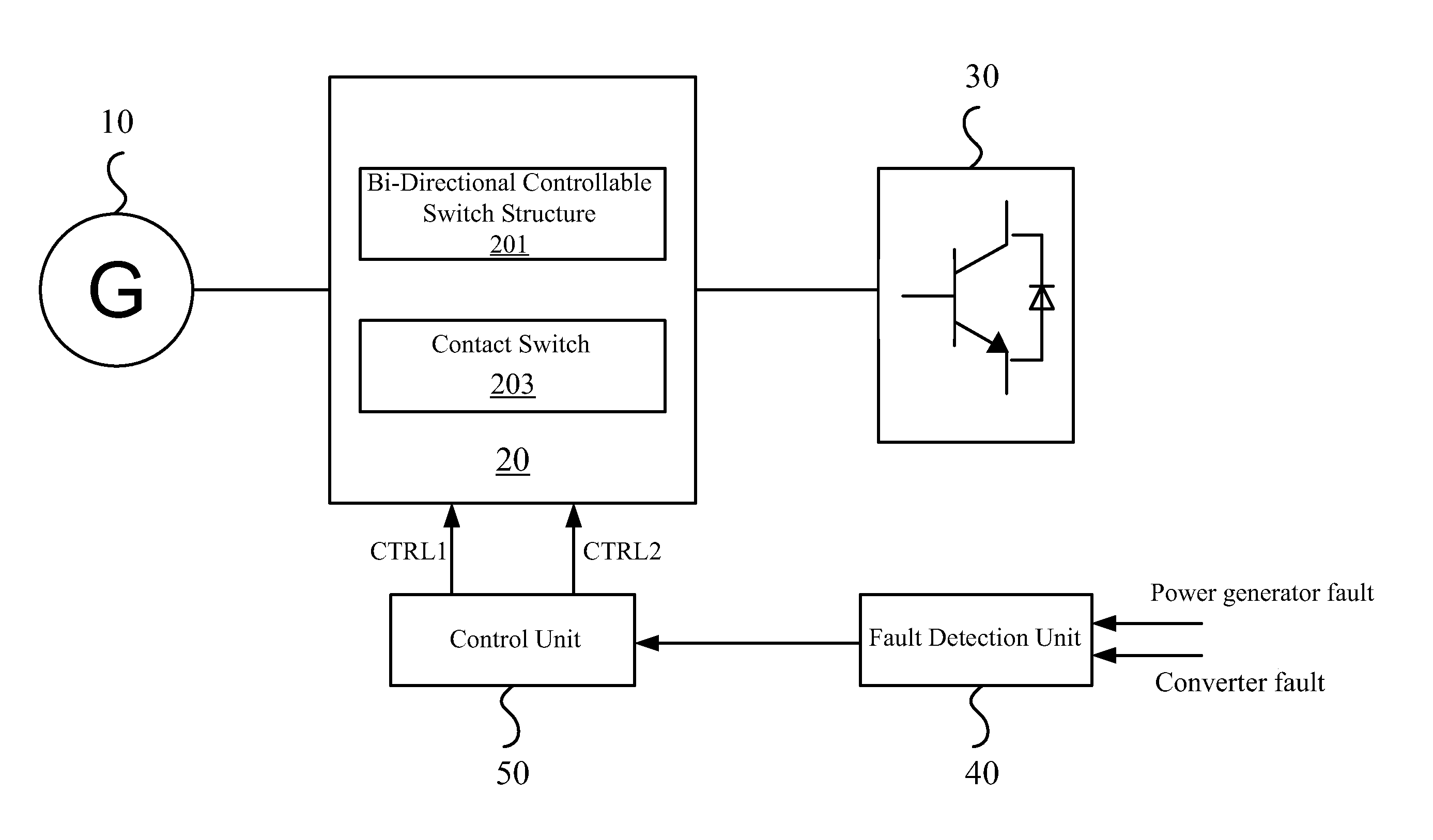

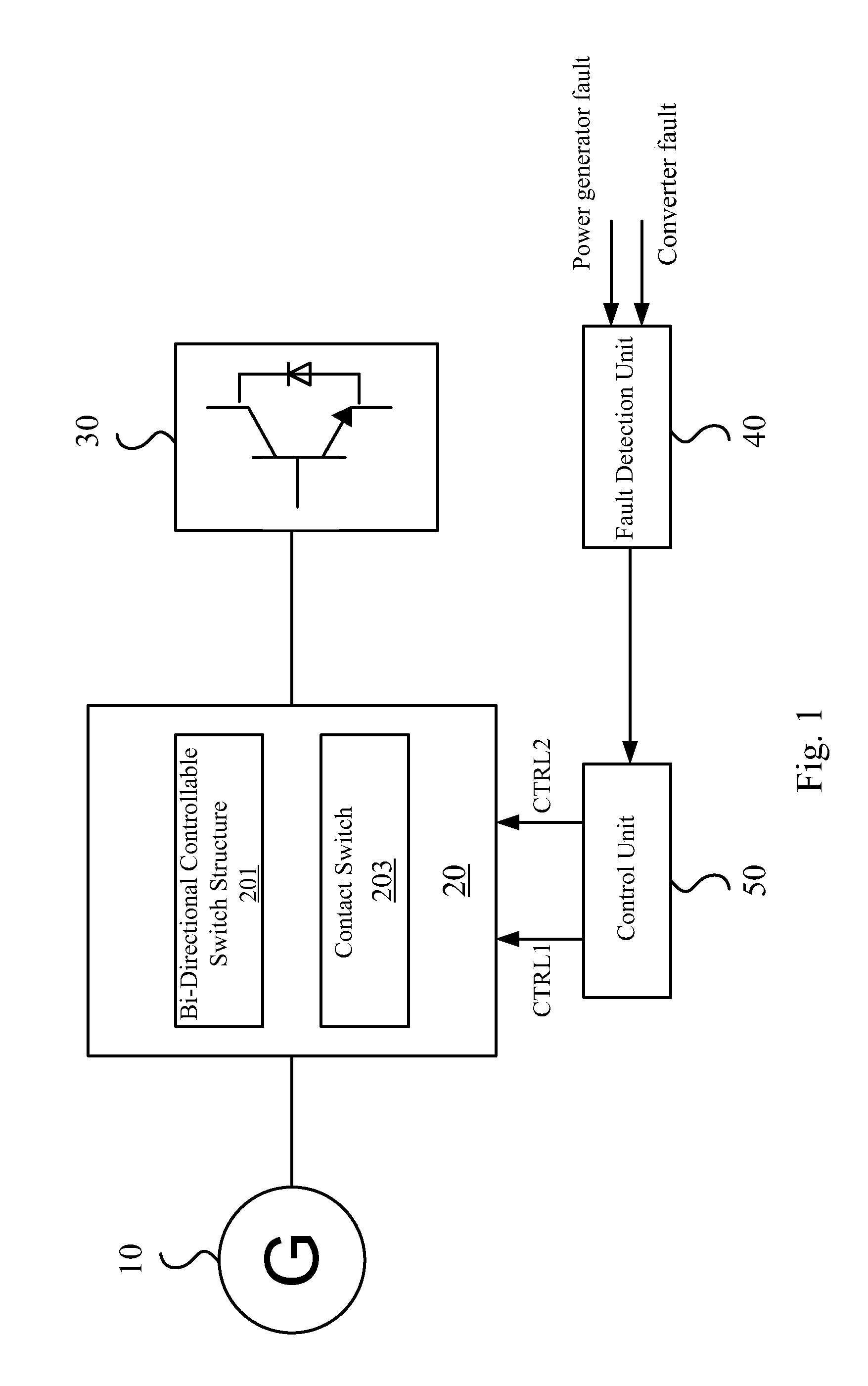

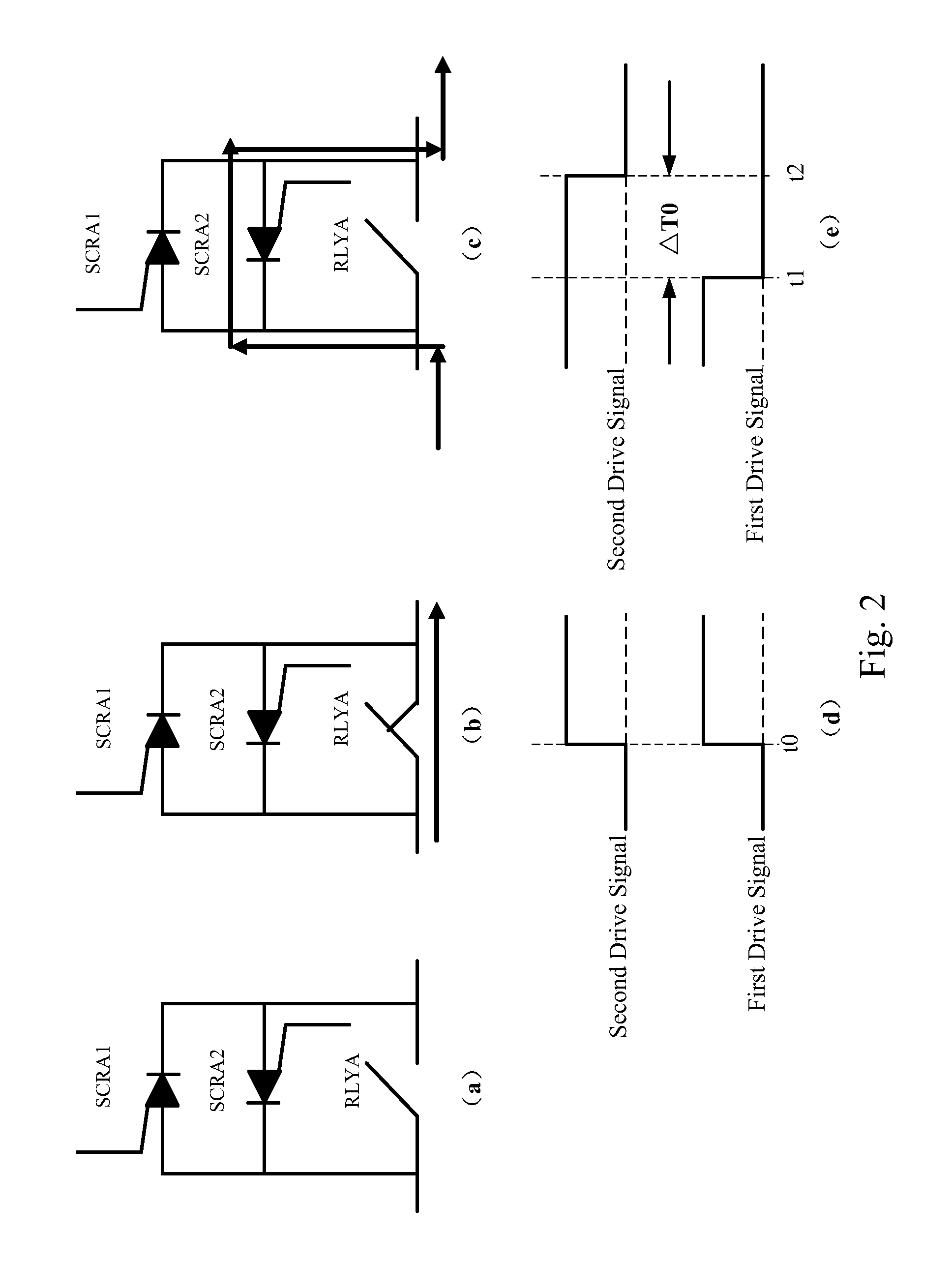

Switch unit and power generation system thereof

ActiveUS20130235492A1Operational stability be increaseHigh performanceElectric switchesEmergency protective arrangements for limiting excess voltage/currentElectrical and Electronics engineeringPower generation system

The present disclosure provides a switch unit and a power generation system thereof. The switch unit includes a contact switch having a main contact and a control terminal, where the control terminal receives a first drive signal to turn on the contact switch; and a bi-directional controllable switch structure, which is connected in parallel to two ends of the main contact of the contact switch and receives one or more second drive signals to turn on the switch structure. When the switch unit performs a turn-off operation, the bi-directional controllable switch structure provides a commutation bypass for the contact switch, so as to protect the contact switch.

Owner:DELTA ELECTRONICS INC

Enterokinase cleavage sequences

Novel enterokinase cleavage sequences are provided. Also disclosed are methods for the rapid isolation of a protein of interest present in a fusion protein construct including a novel enterokinase cleavage sequence of the present invention and a ligand recognition sequence for capturing the fusion construct on a solid substrate. Preferred embodiments of the present invention show rates of cleavage up to thirty times that of the known enterokinase cleavage substrate (Asp)4-Lys-Ile.

Owner:DYAX CORP

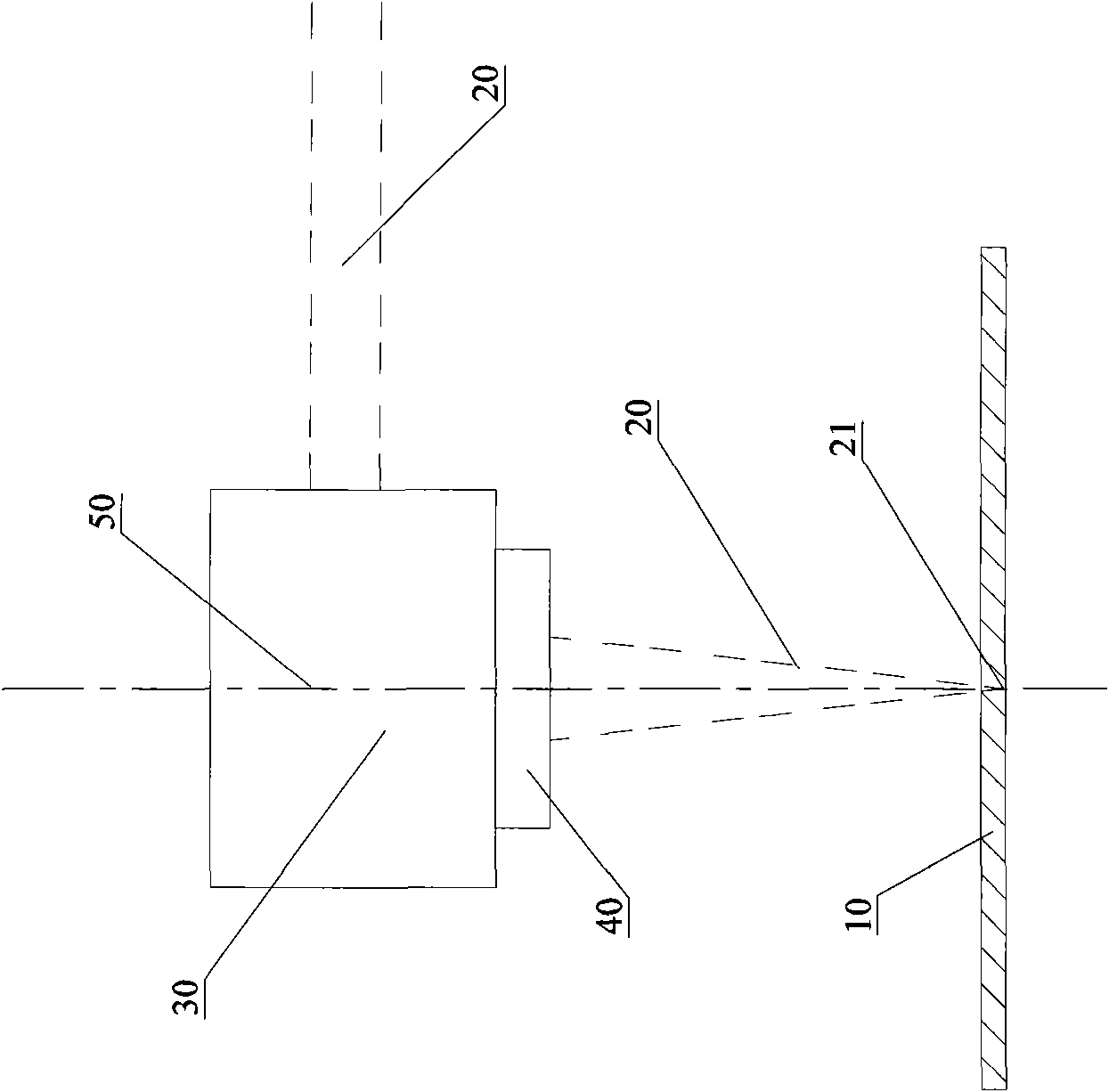

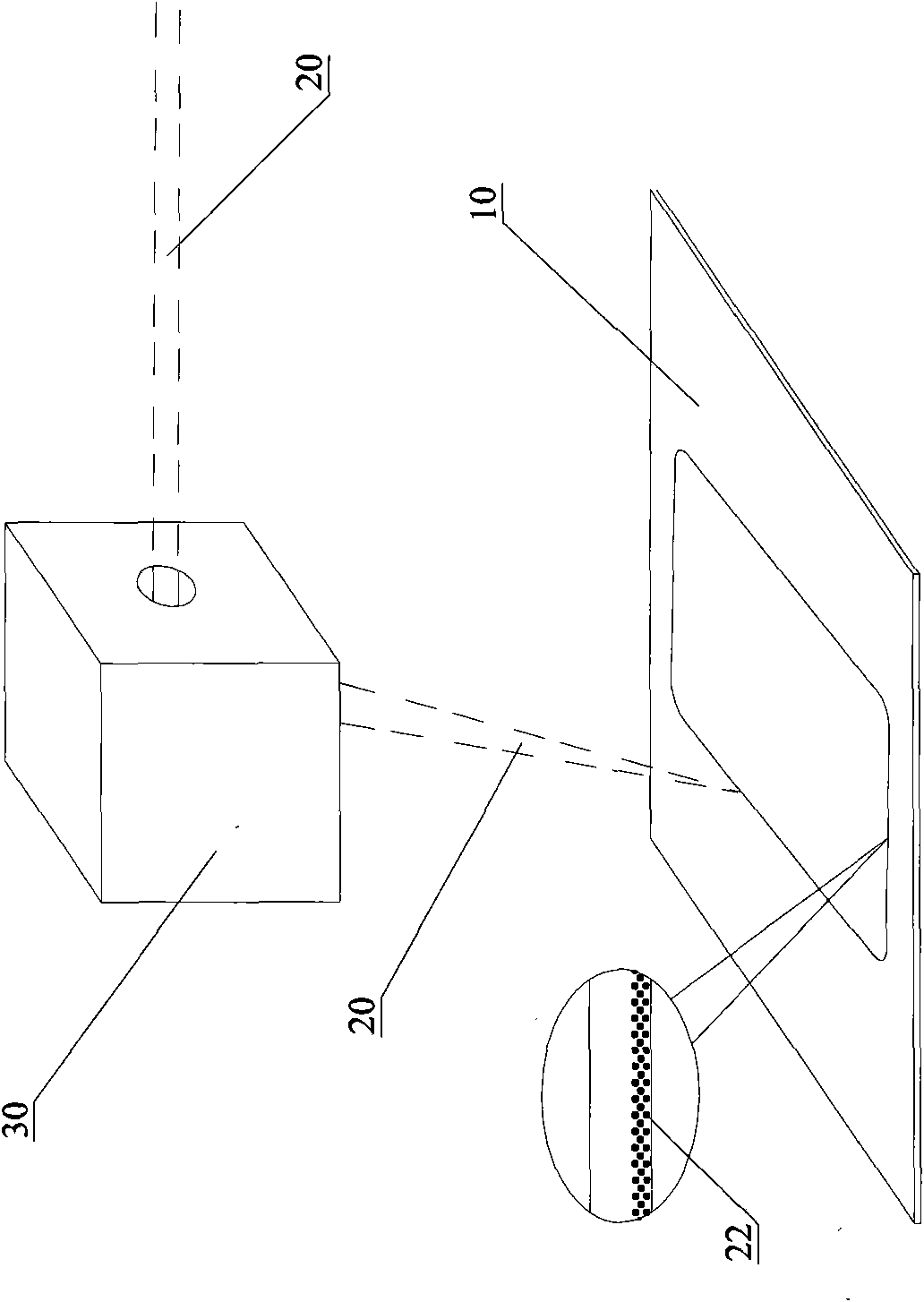

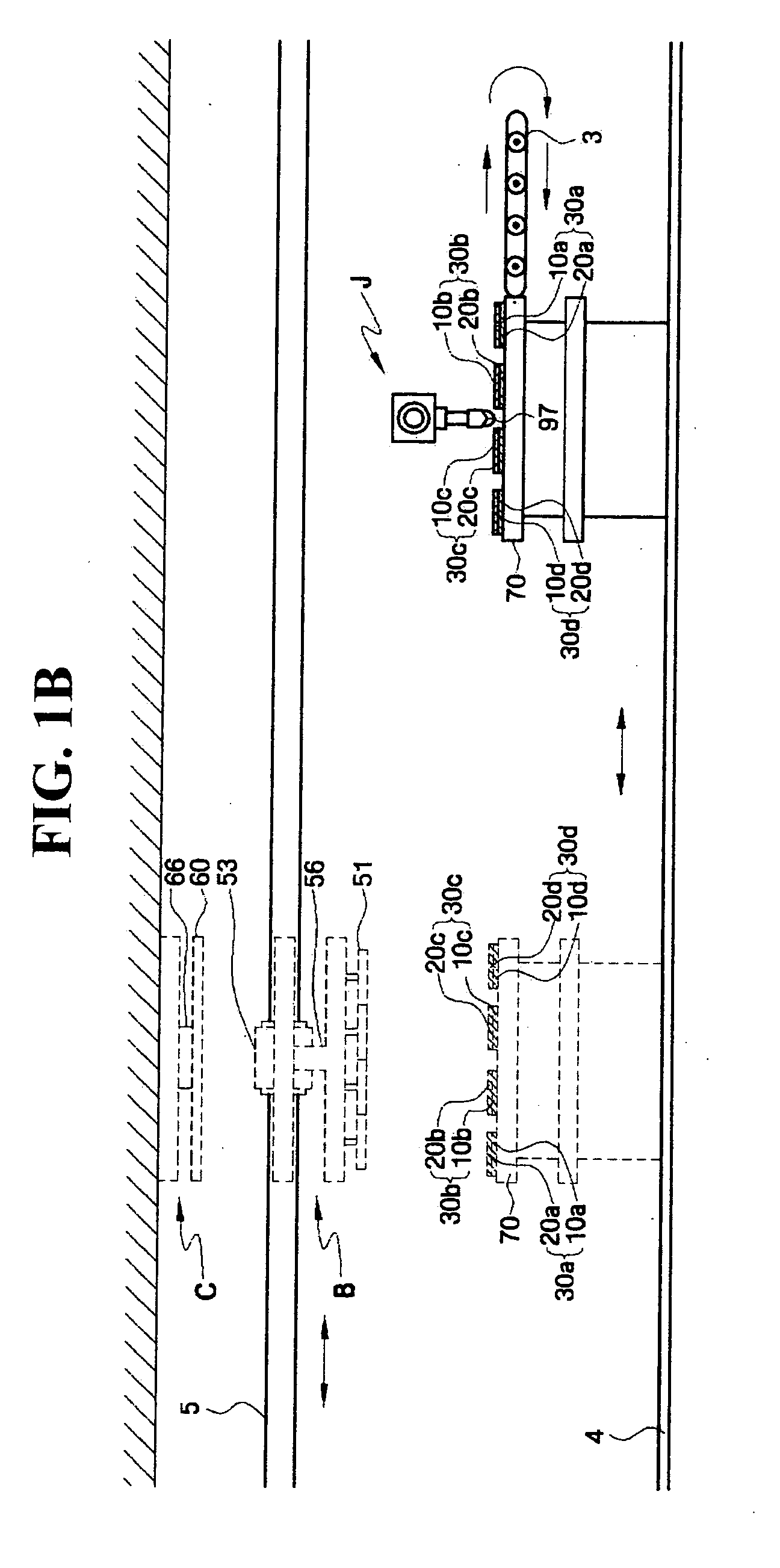

System and method for cutting liquid crystal display substrate

InactiveUS20070044606A1Faster cutting systemQuick cutConveyorsFine working devicesLiquid-crystal displayBiomedical engineering

A cutting system and method for a liquid crystal display (LCD) substrate in which a first cutting unit cuts the LCD substrate in one direction into a plurality of sub-substrates each including at least one panel, a carrier unit separates the sub-substrates from each other and simultaneously carries the separated sub-substrates to a second cutting unit that cuts the separated sub-substrates into individual LCDs.

Owner:SAMSUNG ELECTRONICS CO LTD

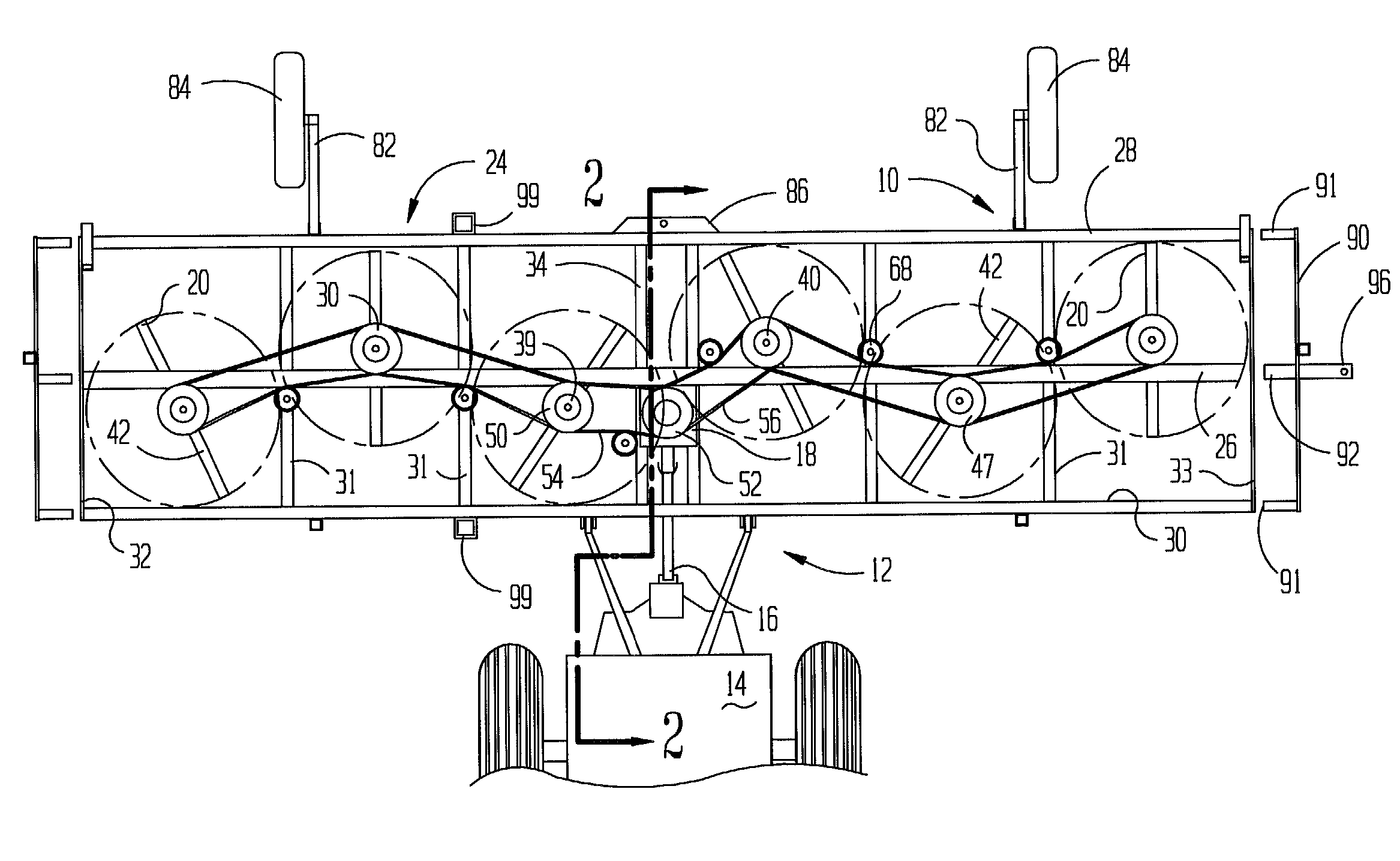

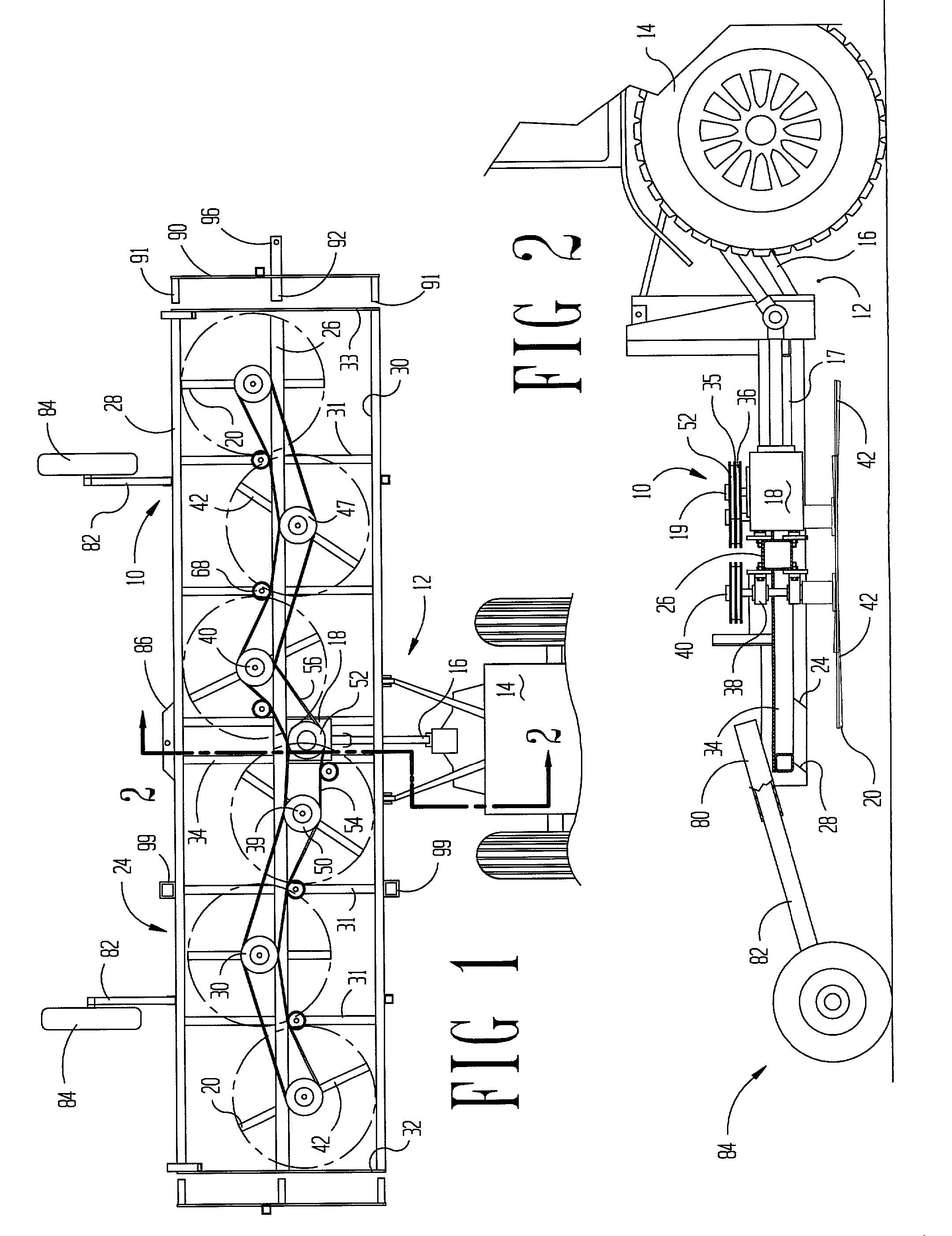

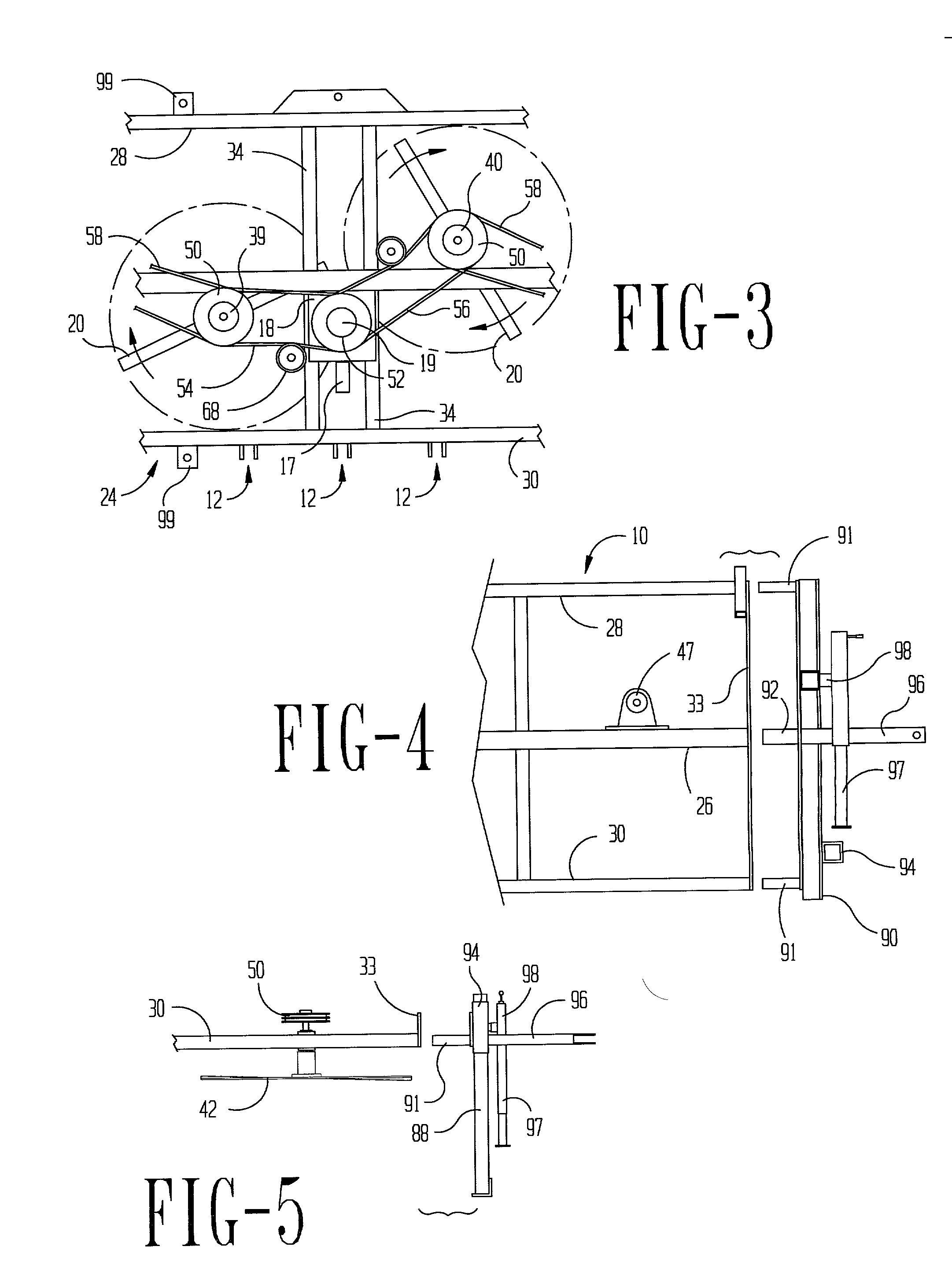

Topper and shredder

An agricultural implement attached to a farm tractor by a three point hitch is used to cut the top of mature cotton stalks, or shred harvested crops or mow turn rows. Knives are mounted on the bottom of vertical shafts which are rotated by belt driven pulleys. The pulleys are driven from a right angle gear box which is driven from the power take off of the tractor. The knives are staggered along either side of a beam traverse to the direction of travel, so that the knives cannot strike other knives as they mow over-lapping swaths.

Owner:HEARD MARTIN PERRY

Method and Apparatus for Display Screen Shield Replacement

A method and apparatus for replacement of damages display shield (typically glass) covering a display screen on a device, typically a mobile phone. Mobile phones have an electronic display protected by a glass shield. Between the glass and the display is often a plastic polarizing or other intermediary sheet. Removal of a damage glass can be accomplished by cutting thru the polarizer with a moving wire or blade. This separates the glass from the sensitive display and allows replacement of the glass without damaging the more expensive display.

Owner:VIKING TECH L C

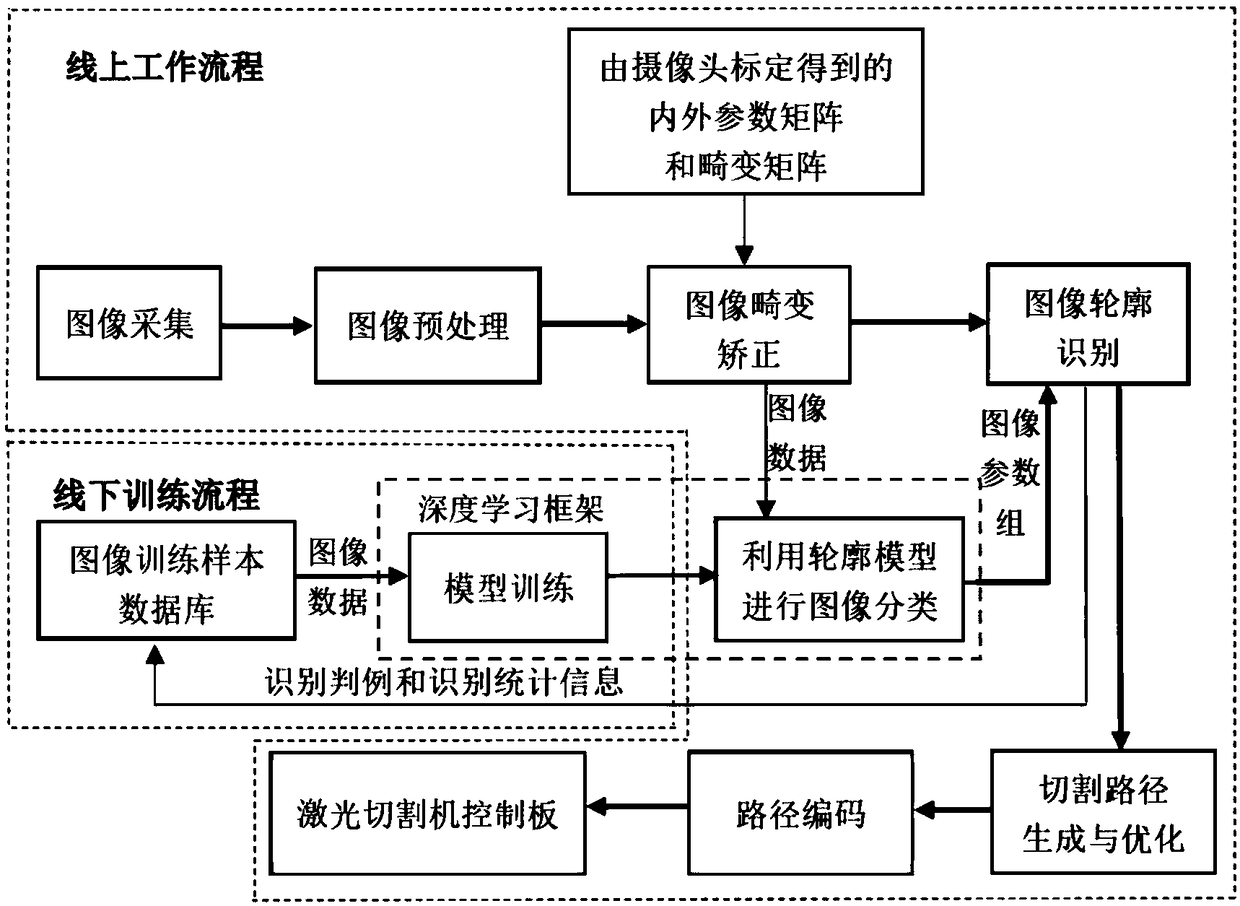

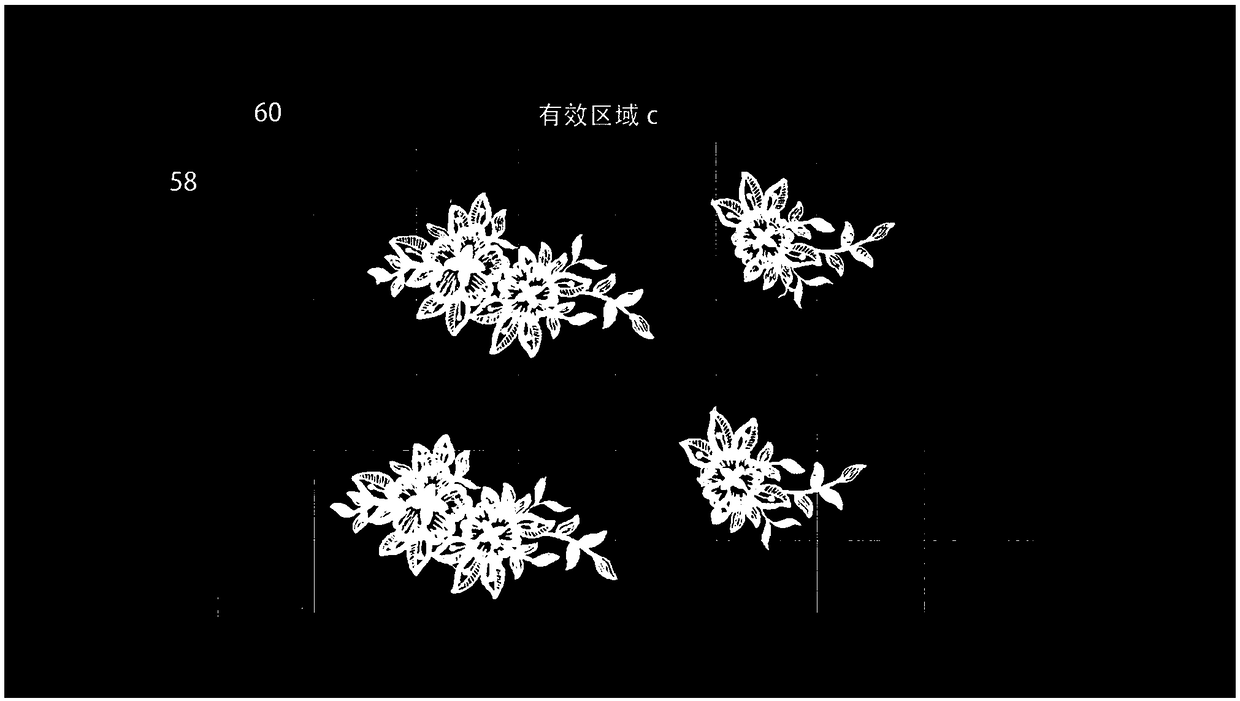

Machine vision cutting method applied to laser cutting machine

ActiveCN108875740AQuick cutAchieve automatic optimizationCharacter and pattern recognitionPattern recognitionMachine vision

The invention discloses a machine vision cutting method applied to a laser cutting machine. The machine vision cutting method comprises an image distortion correction module, an image contour recognition module, a parameter optimization module based on supervised machine learning and a cutting path generation module; the image distortion correction module processes an acquired image to obtain an original image; the image contour recognition module performs contour recognition on the original image; the cutting path generation module generates a cutting path of the laser cutting machine according to a contour recognition result; and the parameter optimization module based on the supervised machine learning optimizes the image contour recognition module, so that the recognition contour extraction of the image contour recognition module is more accurate. The method of the invention has the advantages of being easy to operate, high in recognition precision, high in recognition speed and the like, can be adapted to a complex production environment, and improves the generality of the laser cutting machine.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com