Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2082results about How to "Fast cutting speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

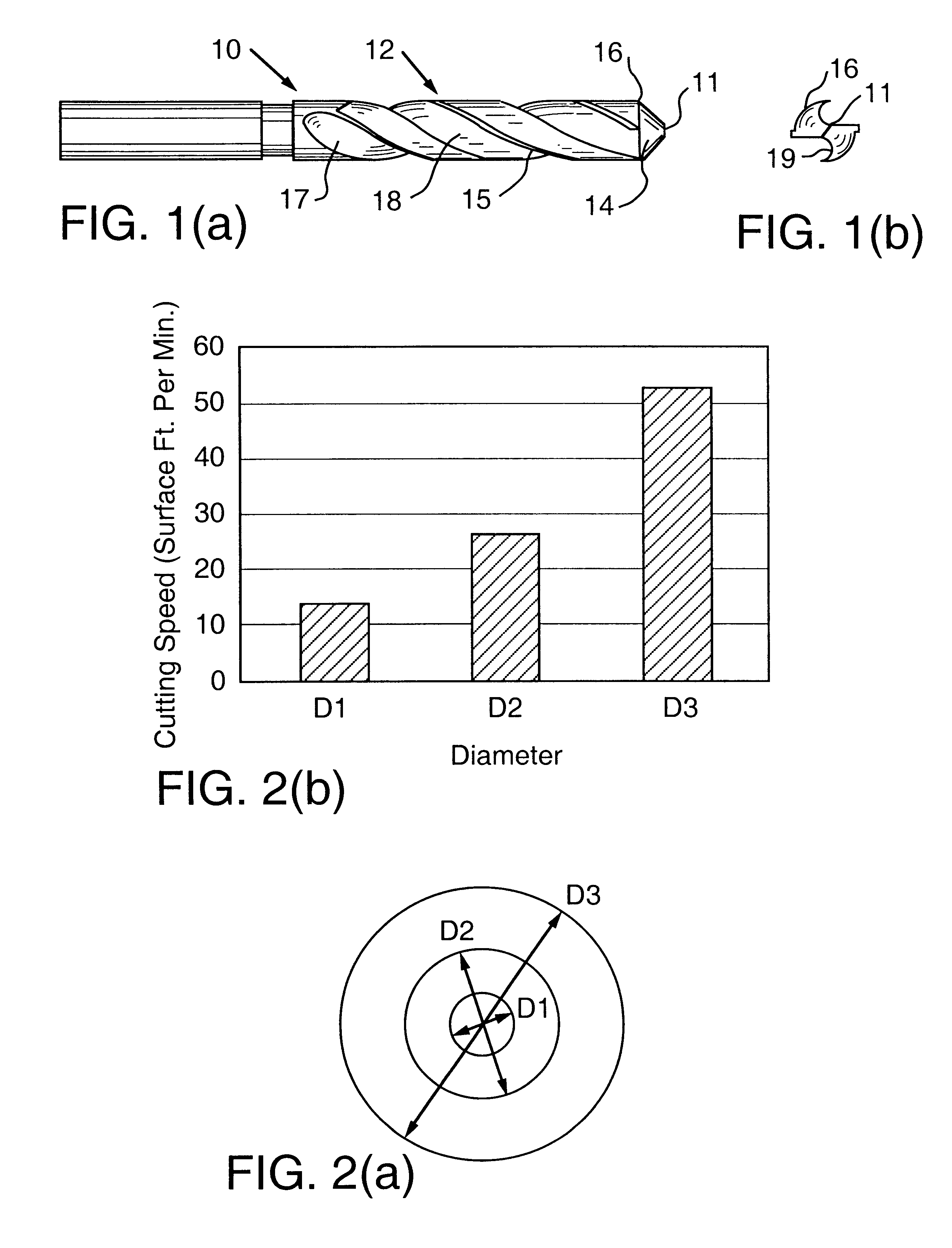

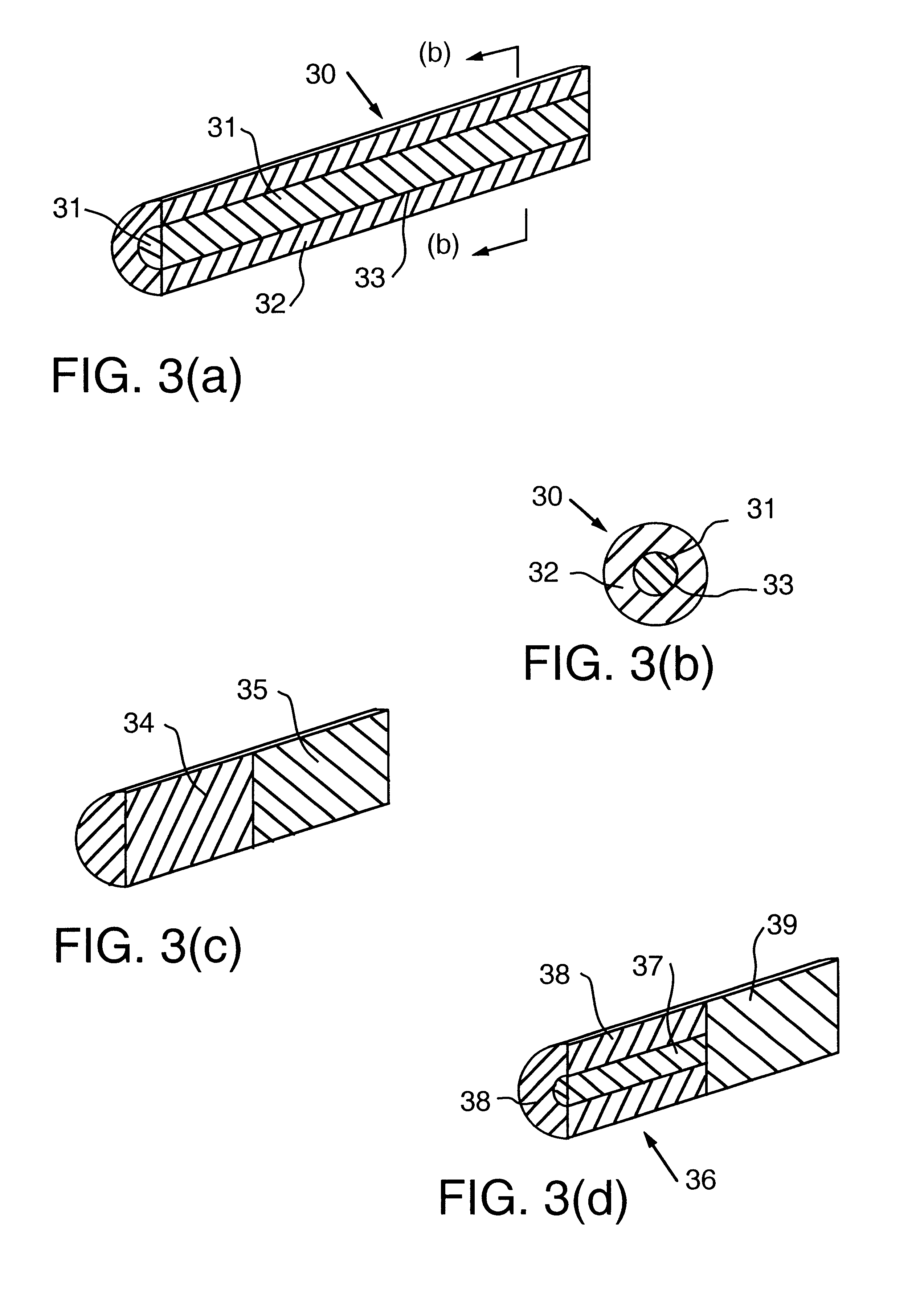

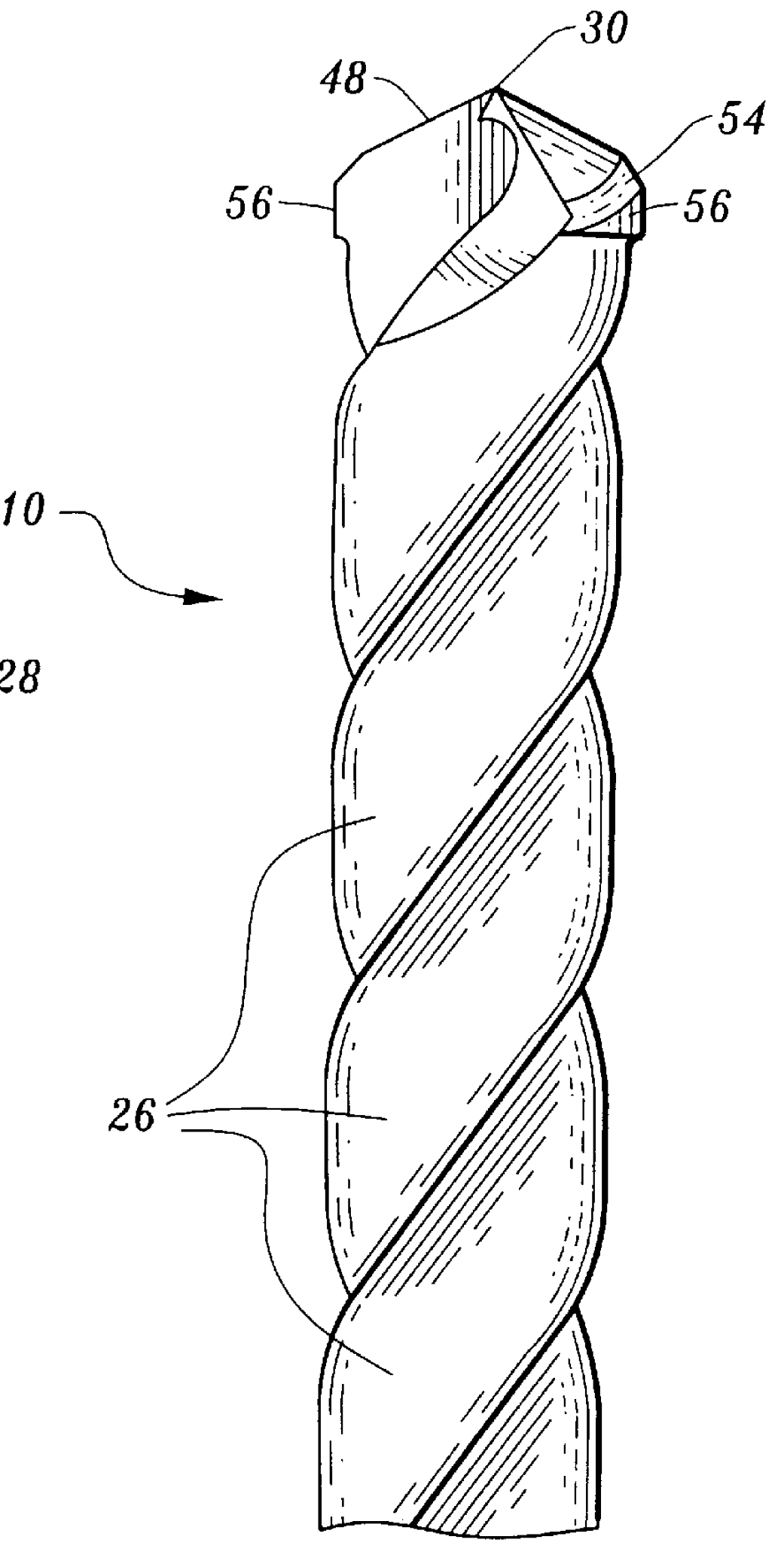

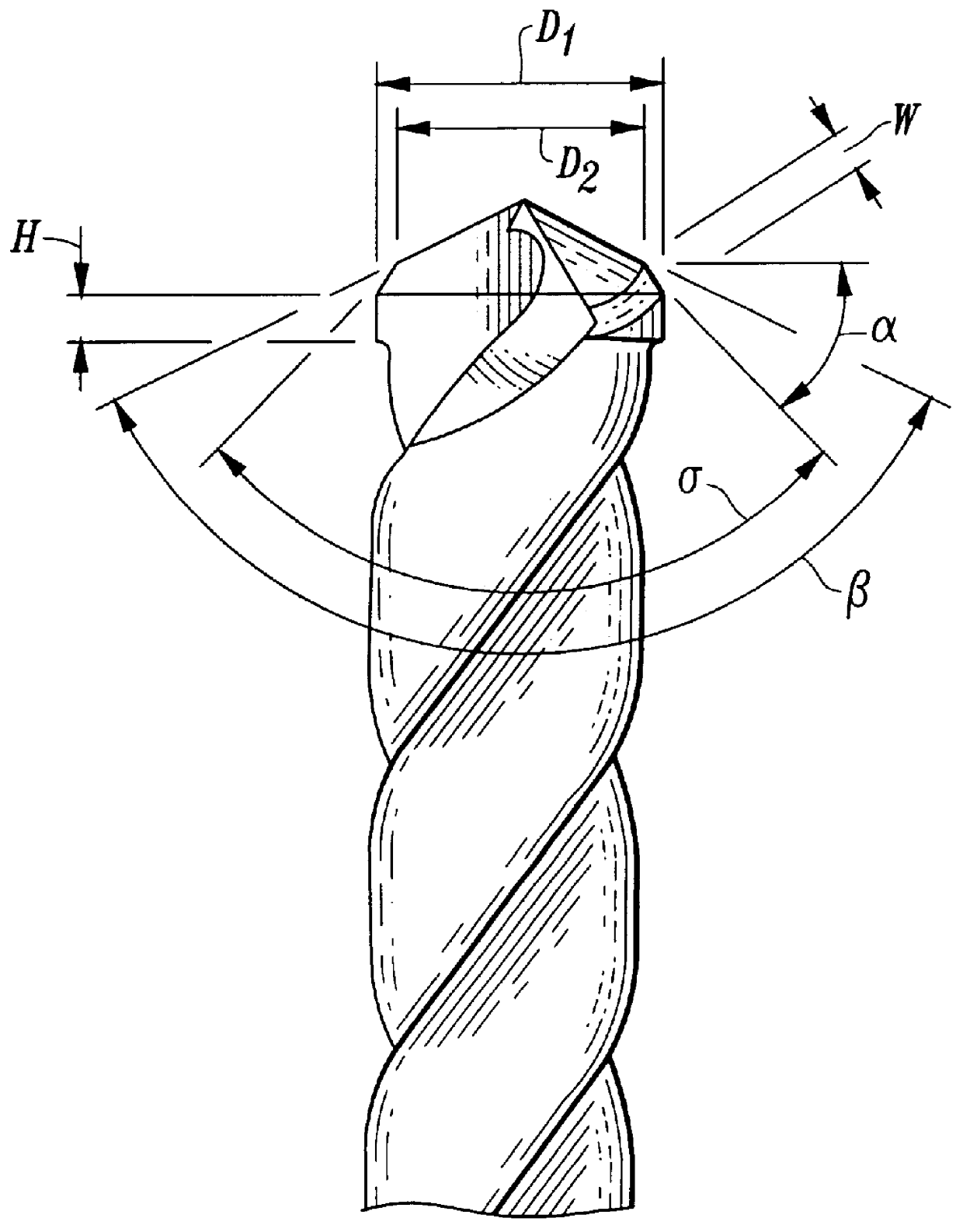

Composite rotary tool and tool fabrication method

InactiveUS6511265B1High cutting speedIncrease in costWood turning toolsTransportation and packagingThermal conductivityElastic modulus

A composite rotary tool includes at least first and second regions comprising first and second materials, respectively. The first and second regions are autogenously bonded and differ with respect to at least one characteristic such as, for example, modulus of elasticity, hardness, wear resistance, fracture toughness, tensile strength, corrosion resistance, coefficient of thermal expansion, or coefficient of thermal conductivity. A method for producing the composite rotary tool includes placing a first metallurgical powder into a first region of a void of a mold, and placing a second metallurgical powder into a second region of the void. The first metallurgical powder differs from the second metallurgical powder, and at least a portion of the first metallurgical is brought into contact with the second metallurgical powder. The mold is compressed to consolidate the first and second metallurgical powders to form a compact, and the compact subsequently is sintered.

Owner:KENNAMETAL INC

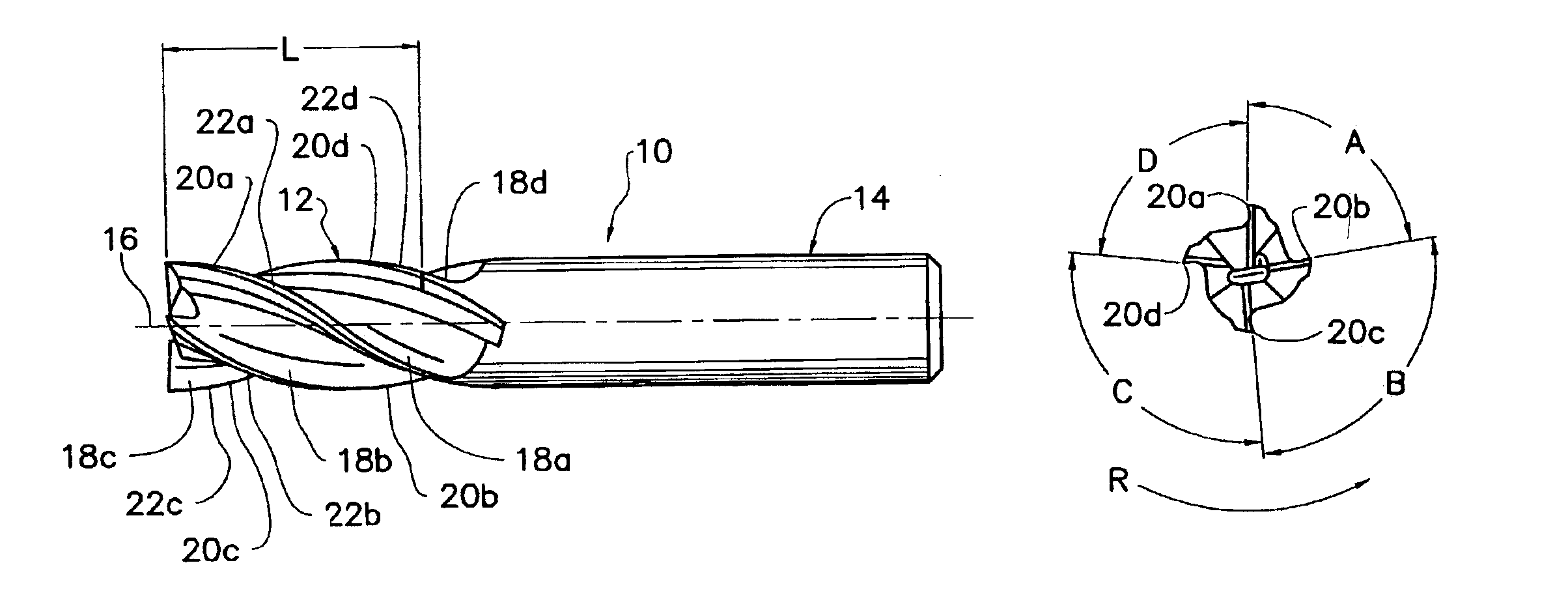

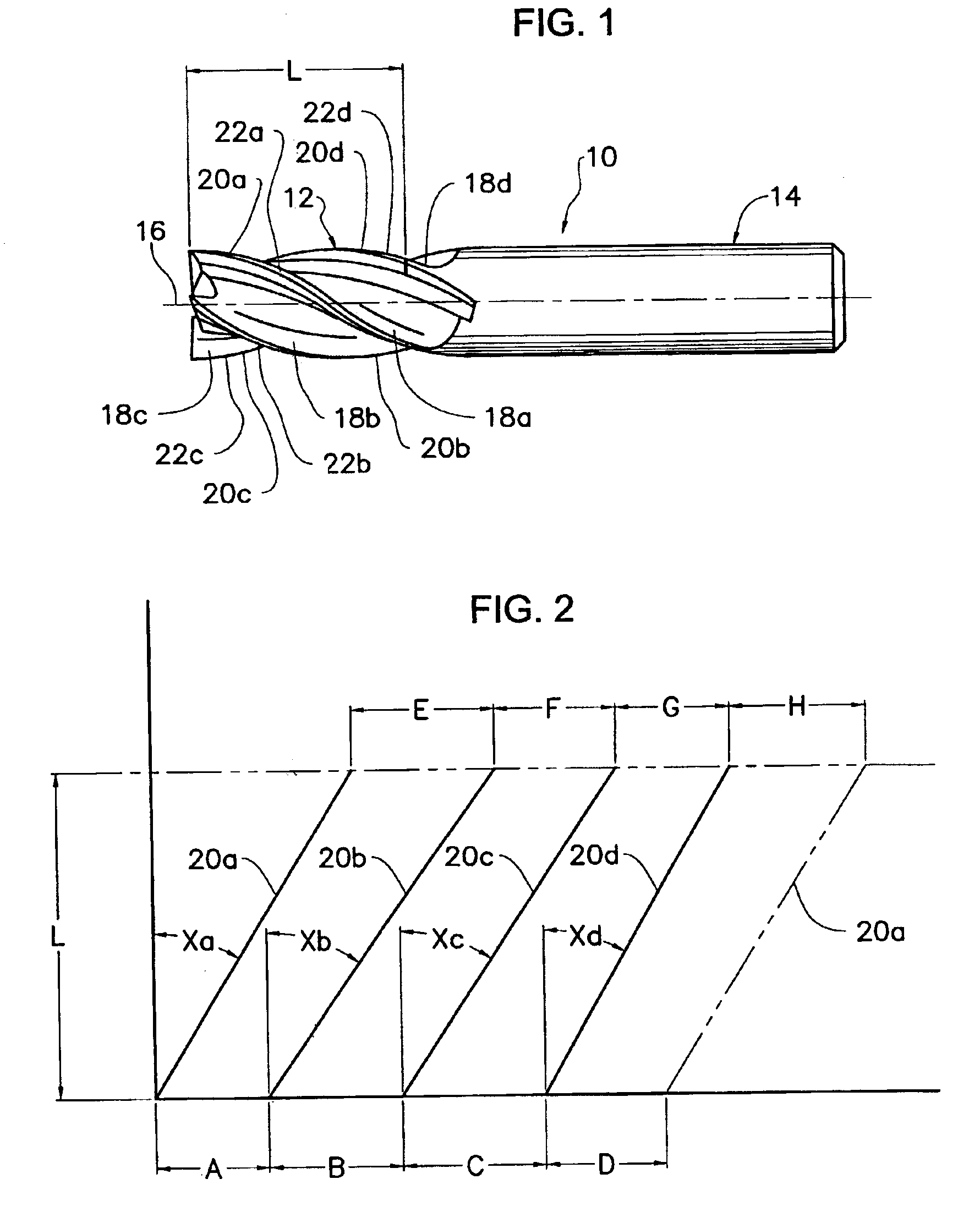

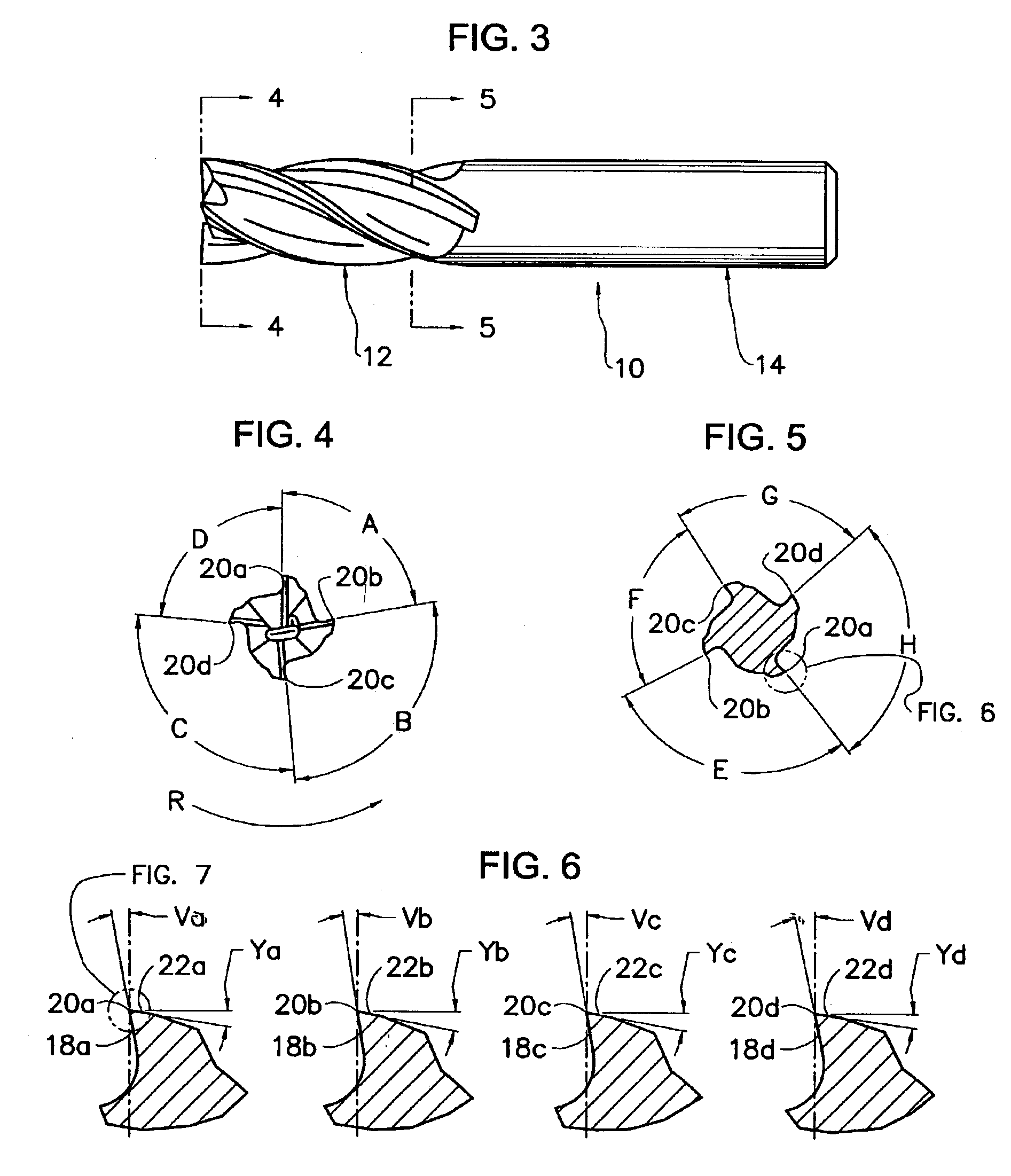

Rotary cutting tool

A rotary cutting tool that includes an elongated tool body, rotatable along a longitudinal axis of rotation is disclosed. It has a fluted cutting end on one end and a shank end on the opposite end of the tool body. The fluted cutting end includes a nose, a periphery and an end surface that extends from the nose to the periphery. A plurality of axial flutes extends from the end surface to the fluted cutting end and combines with a plurality of cutting edges. The cutting edges are unequally spaced along the circumference of the end surface lying in a plane perpendicular to the longitudinal axis of rotation. In addition, all cutting edges are of a different helix from one another and the cutting edge geometries vary from one another to create a different sound pattern. This reduces resonant harmonic vibrations.

Owner:NIAGARA CUTTER LLC

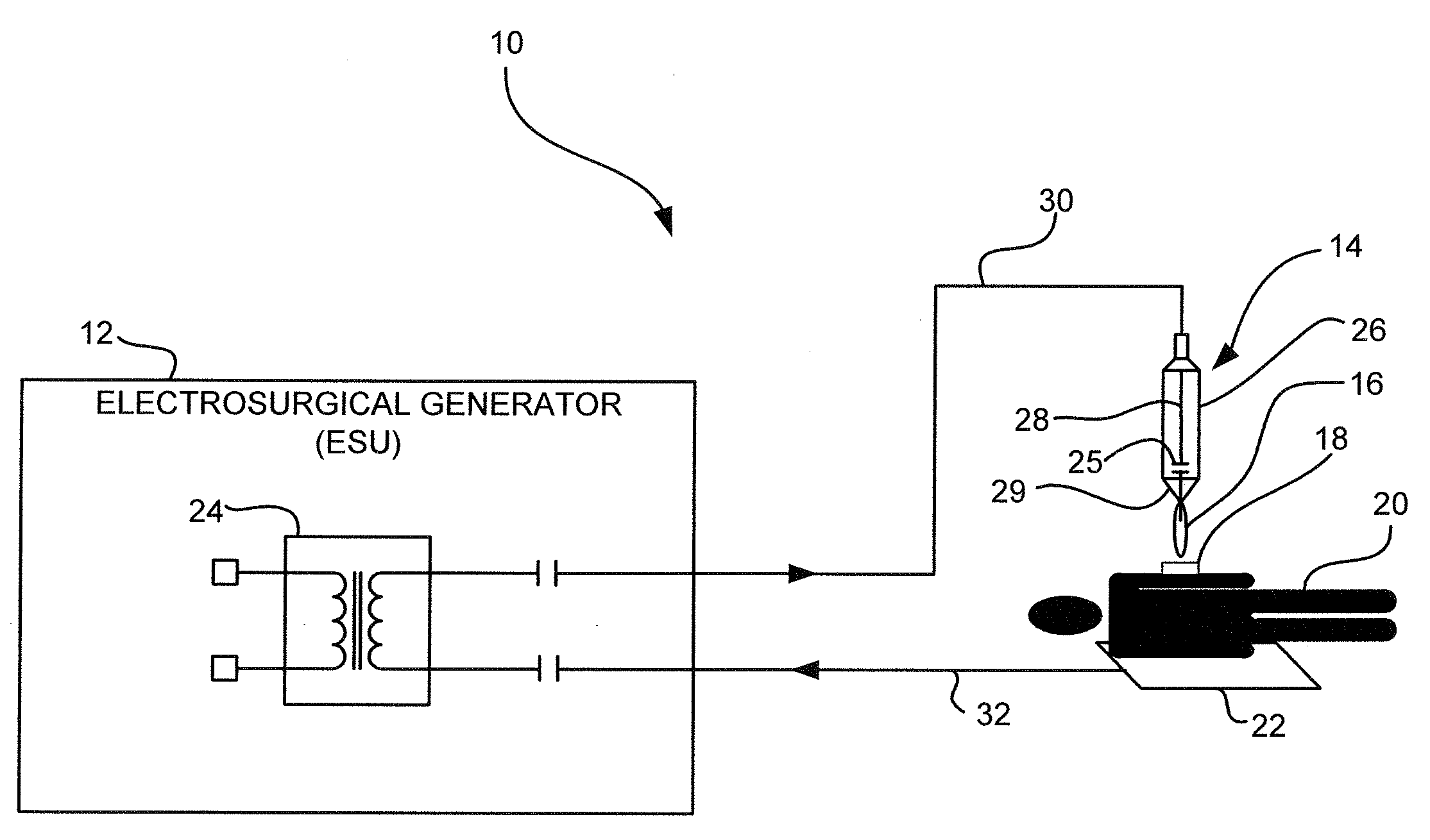

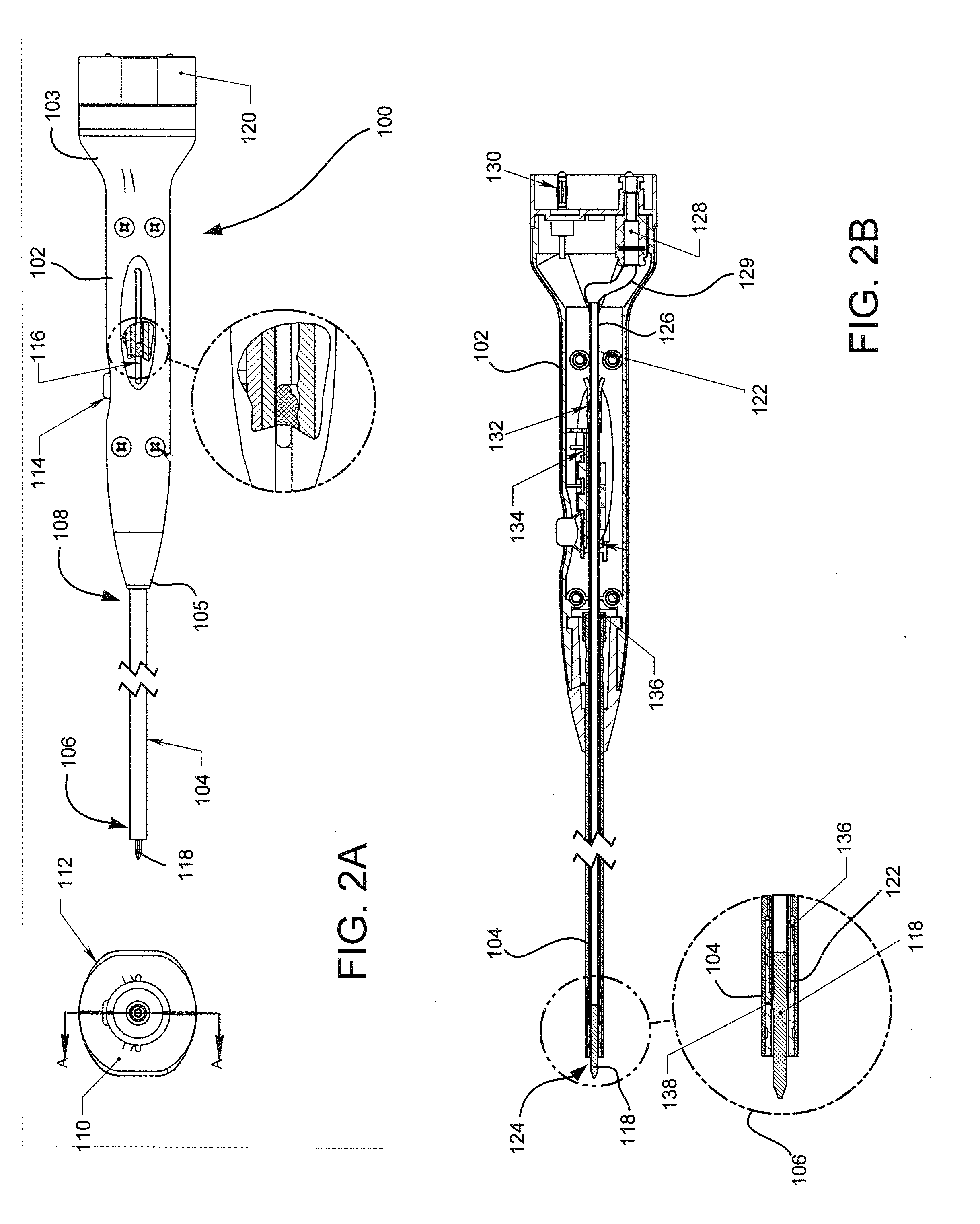

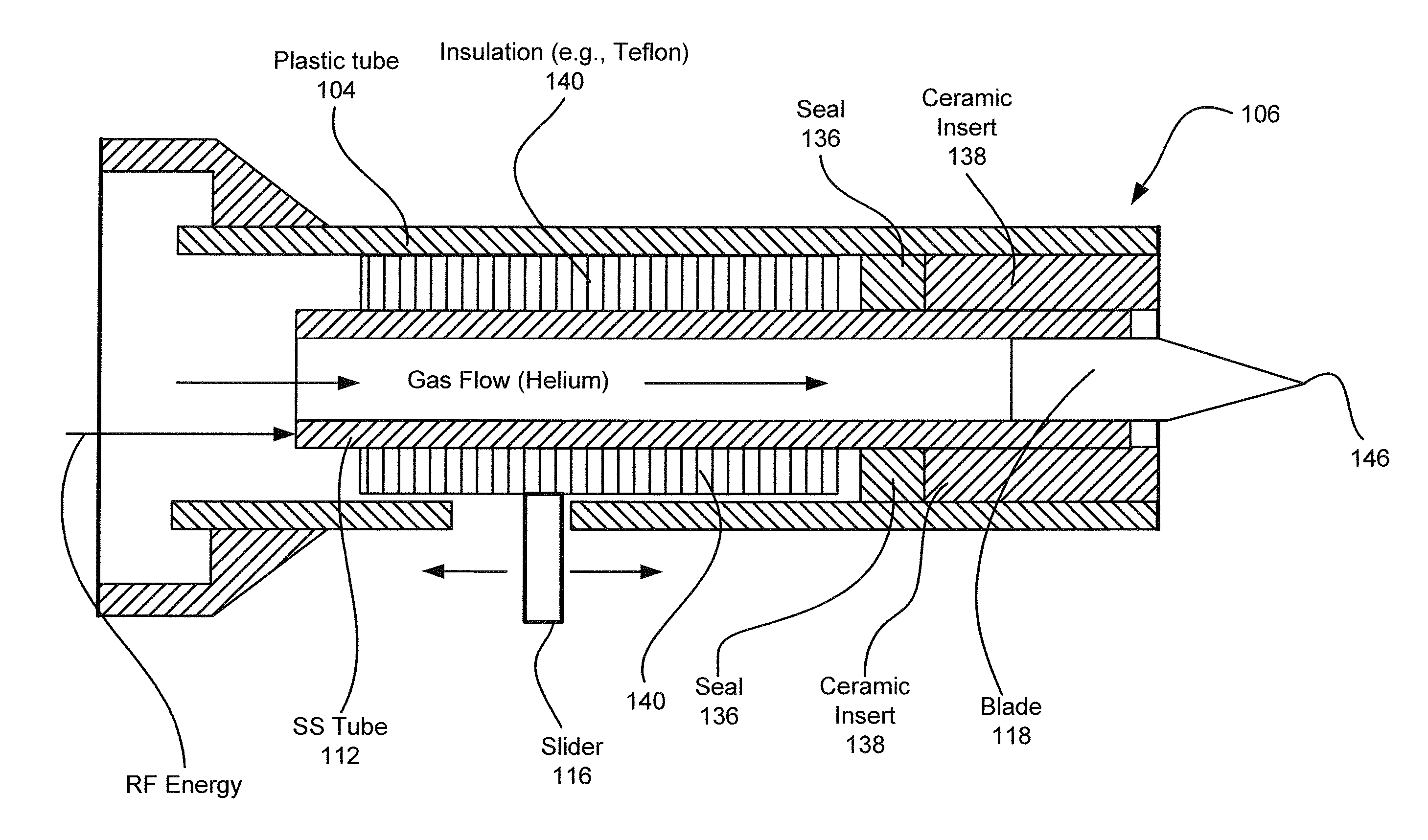

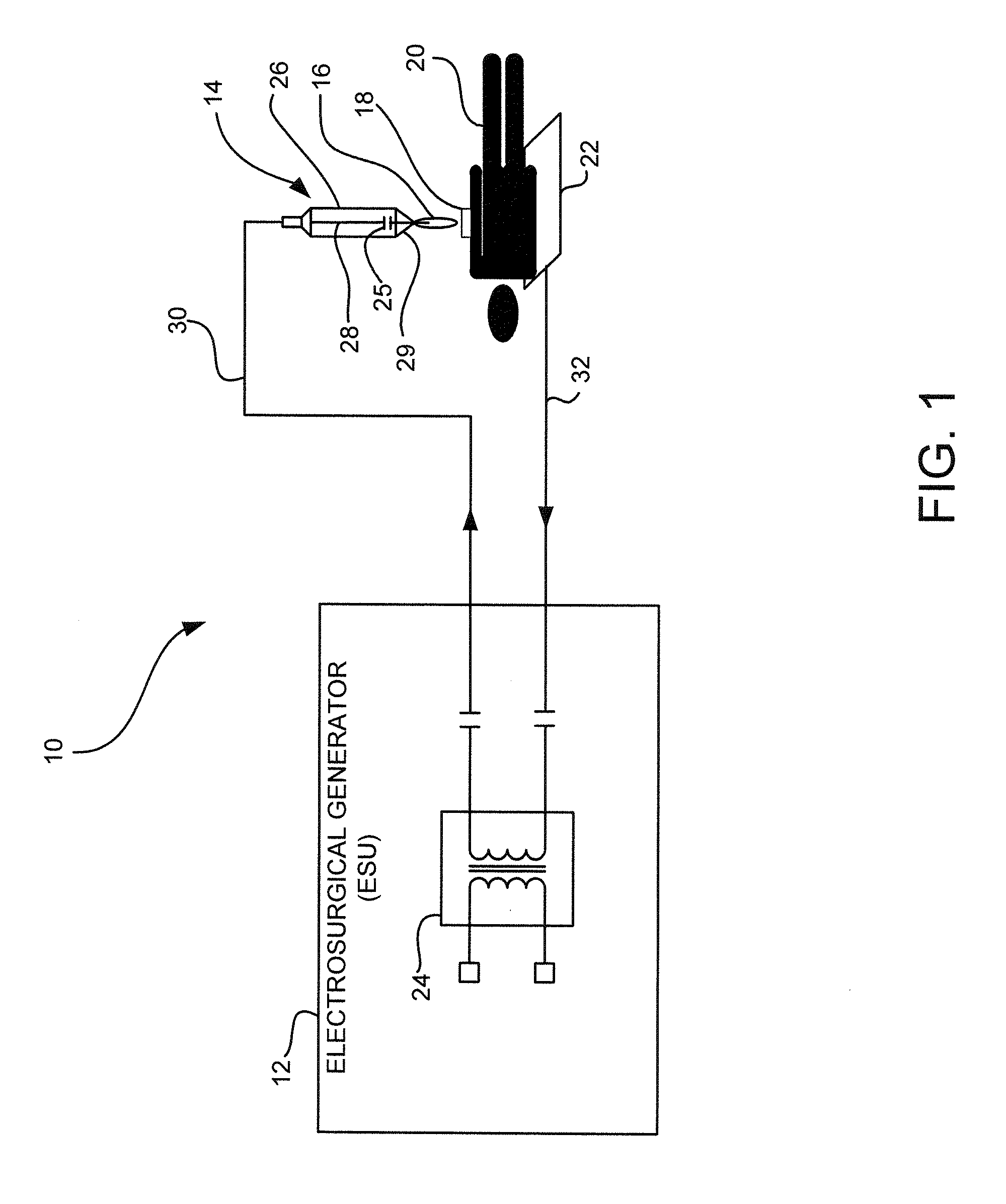

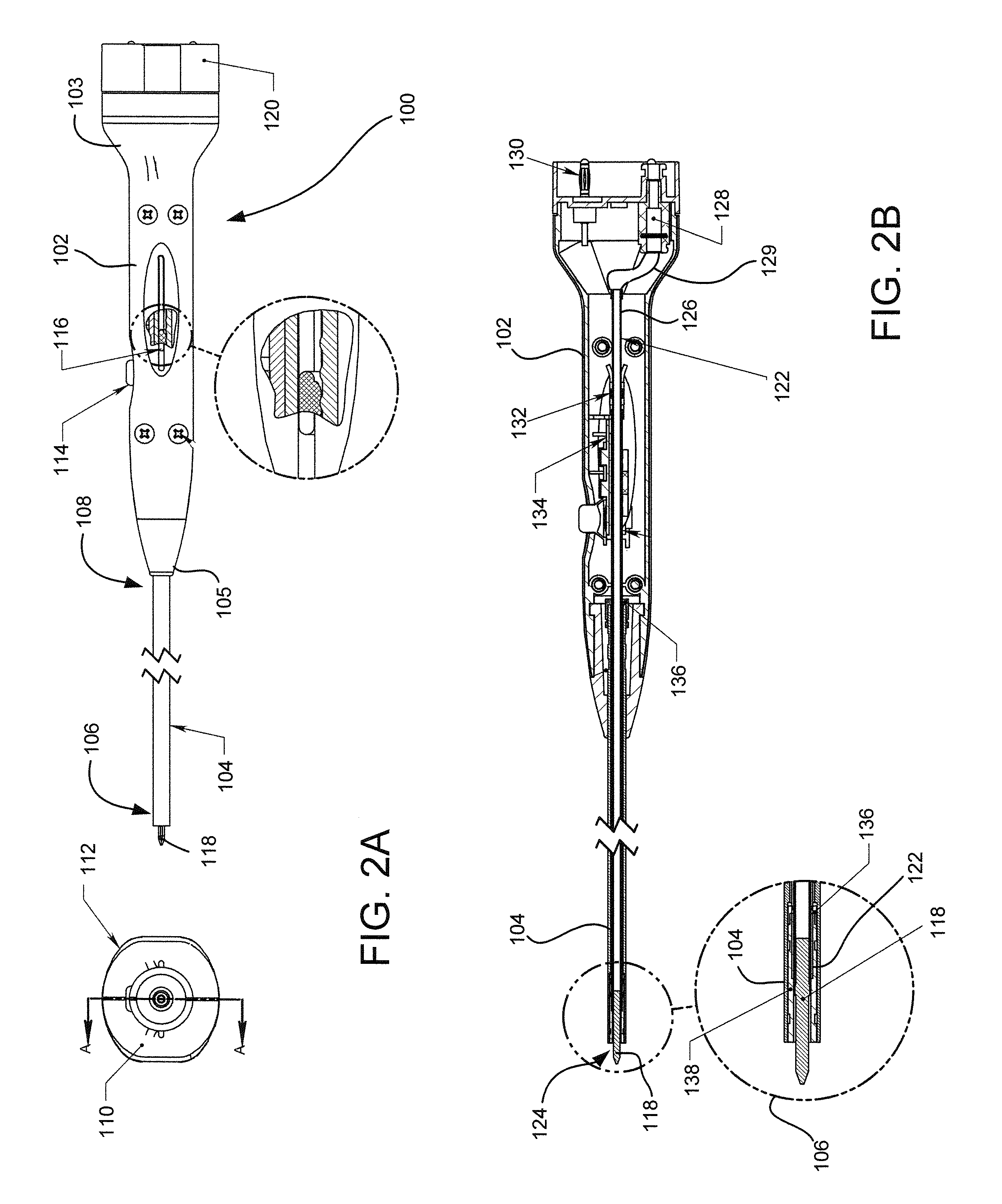

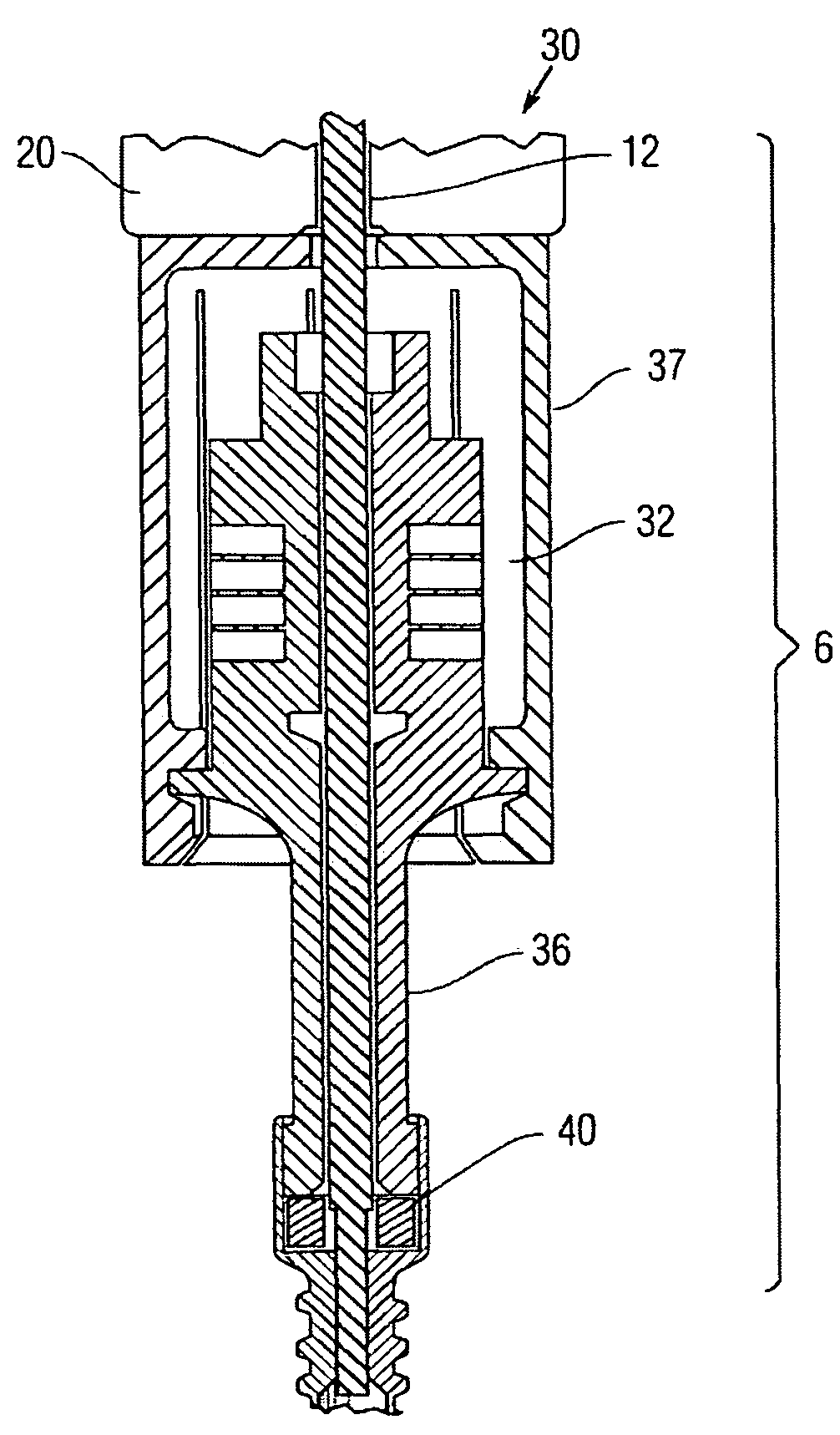

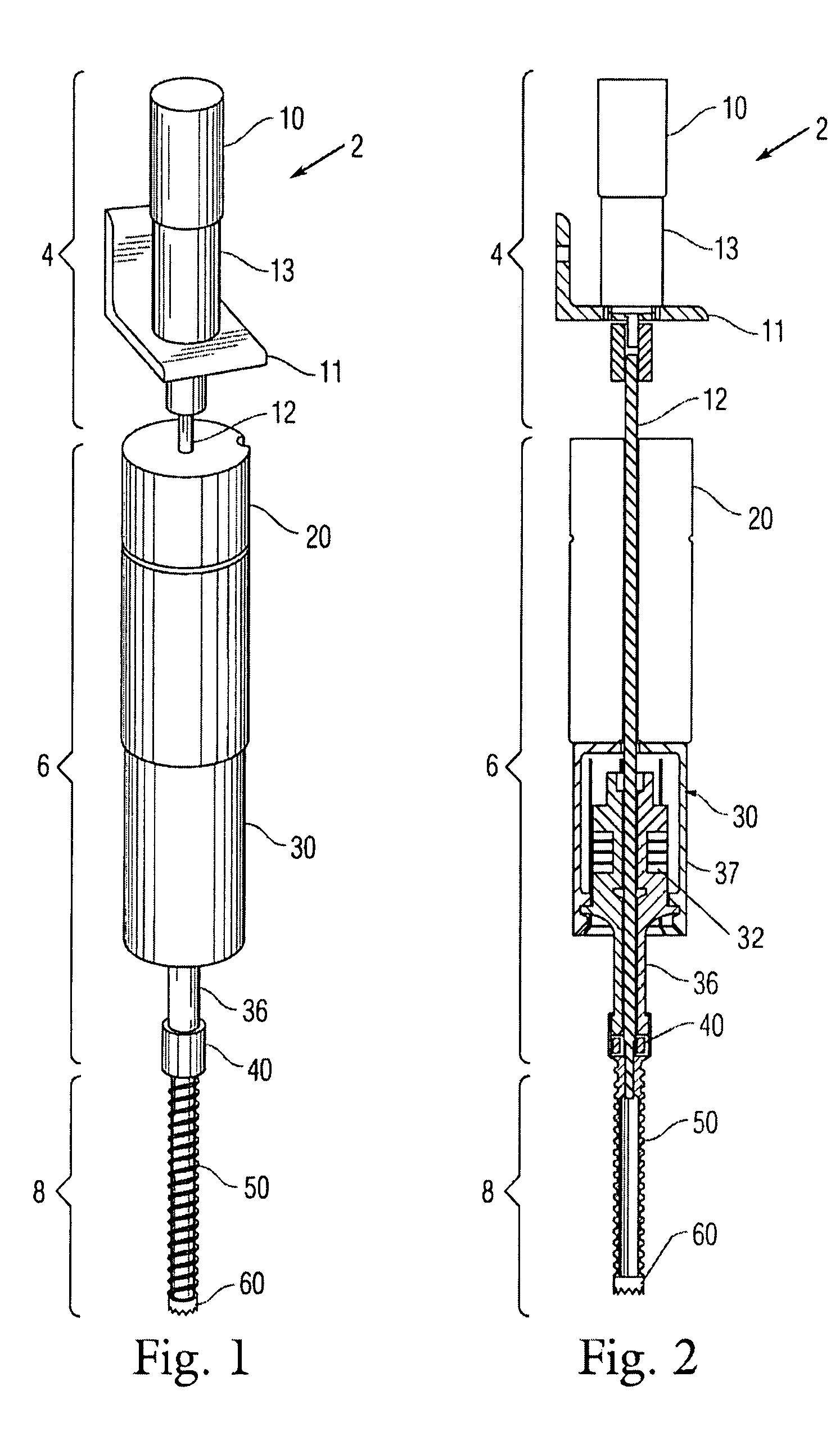

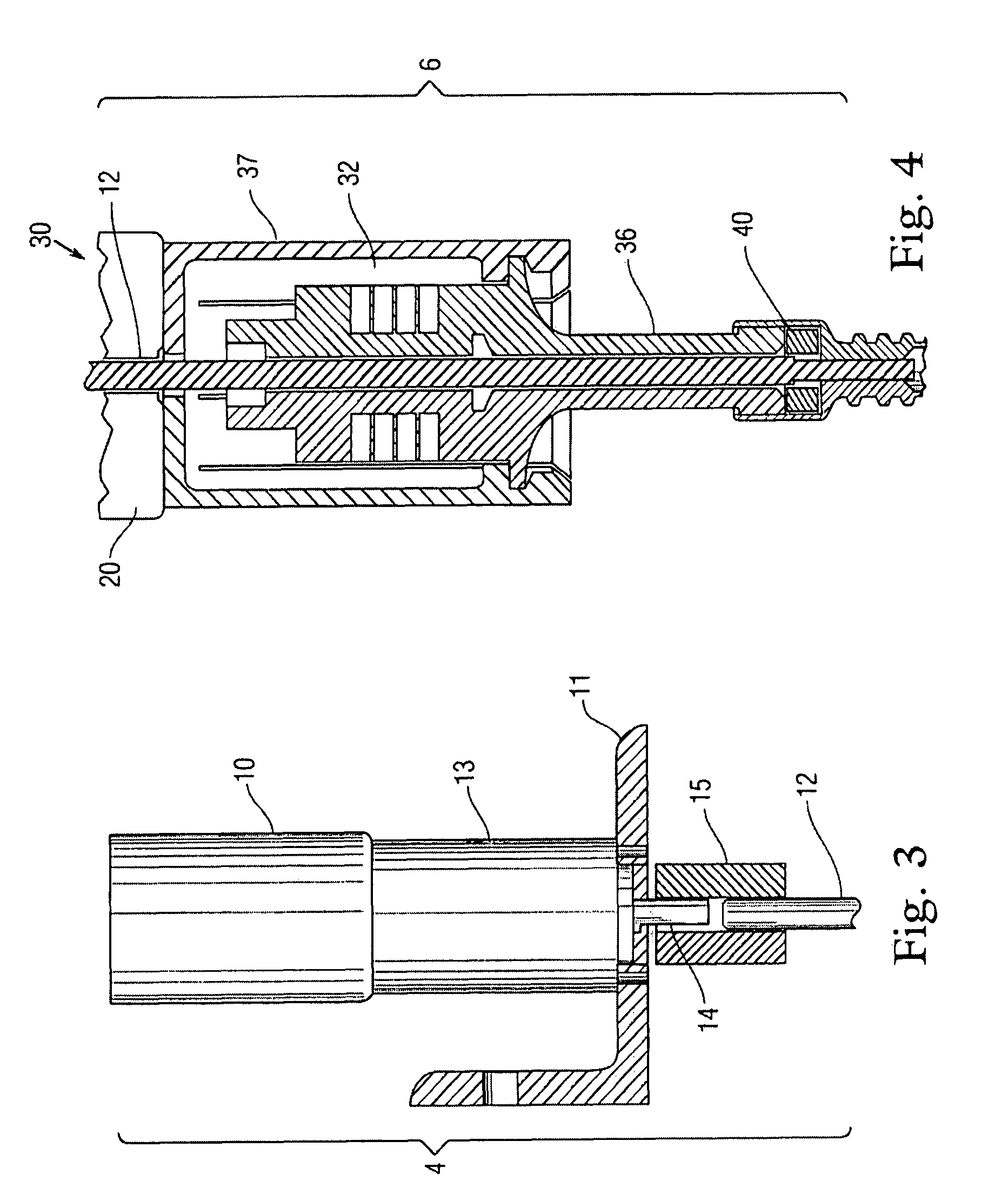

Electrosurgical apparatus with retractable blade

ActiveUS20120116397A1Little collateral damageLess resistanceSurgical instruments for heatingKnife bladesEngineering

An electrosurgical apparatus with a retractable blade for use in cold plasma applications, electrosurgical cutting and mechanical cutting is provided. The electrosurgical apparatus employs a tip of the retractable blade as a sharp conductive point to generate a plasma beam or discharge. When the blade is retracted within the electrosurgical apparatus, it is electrically energized while an inert gas flows over it, producing a cold plasma discharge. In the de-energized state, the blade is advanced and used as a traditional, mechanical surgical blade.

Owner:BOVIE MEDICAL CORPORATION

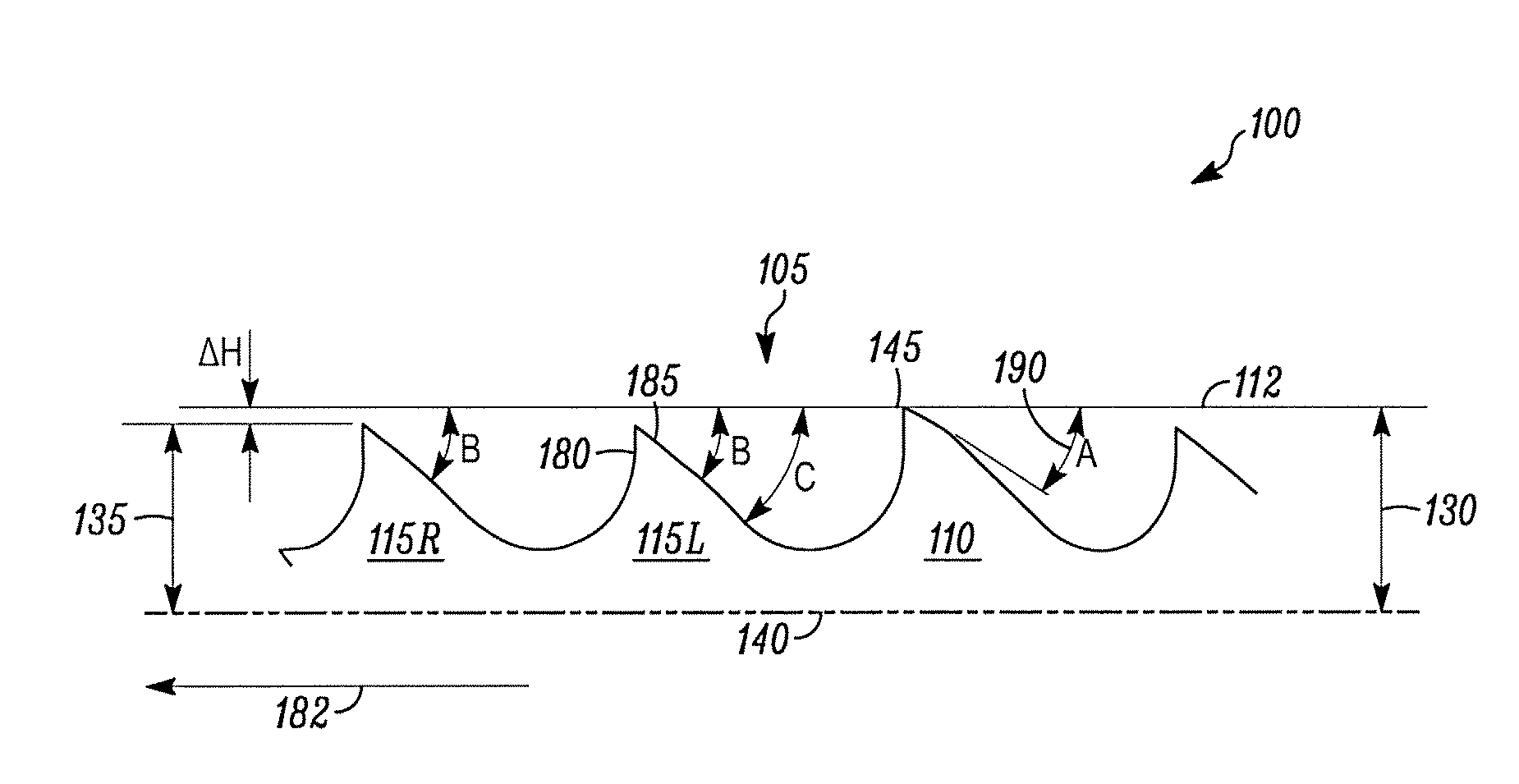

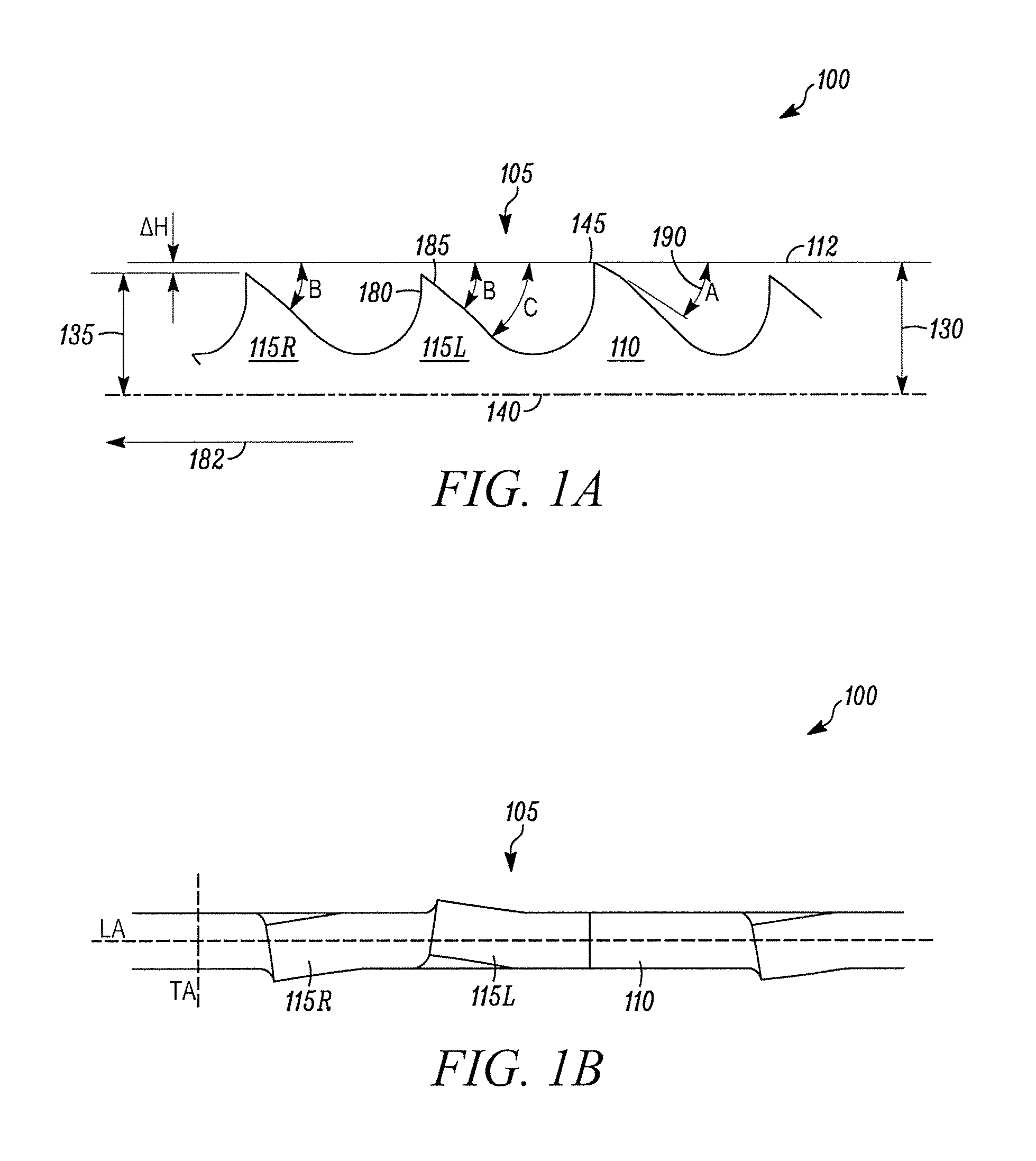

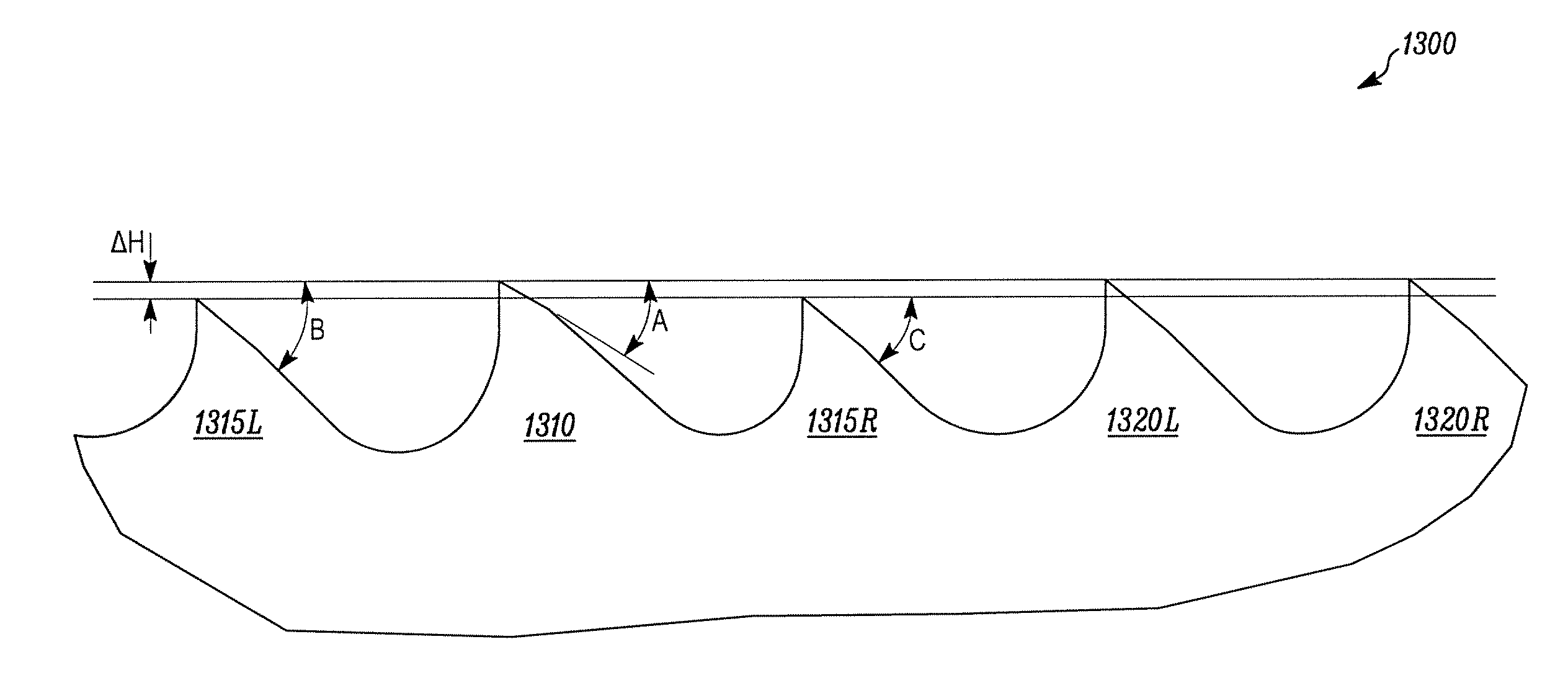

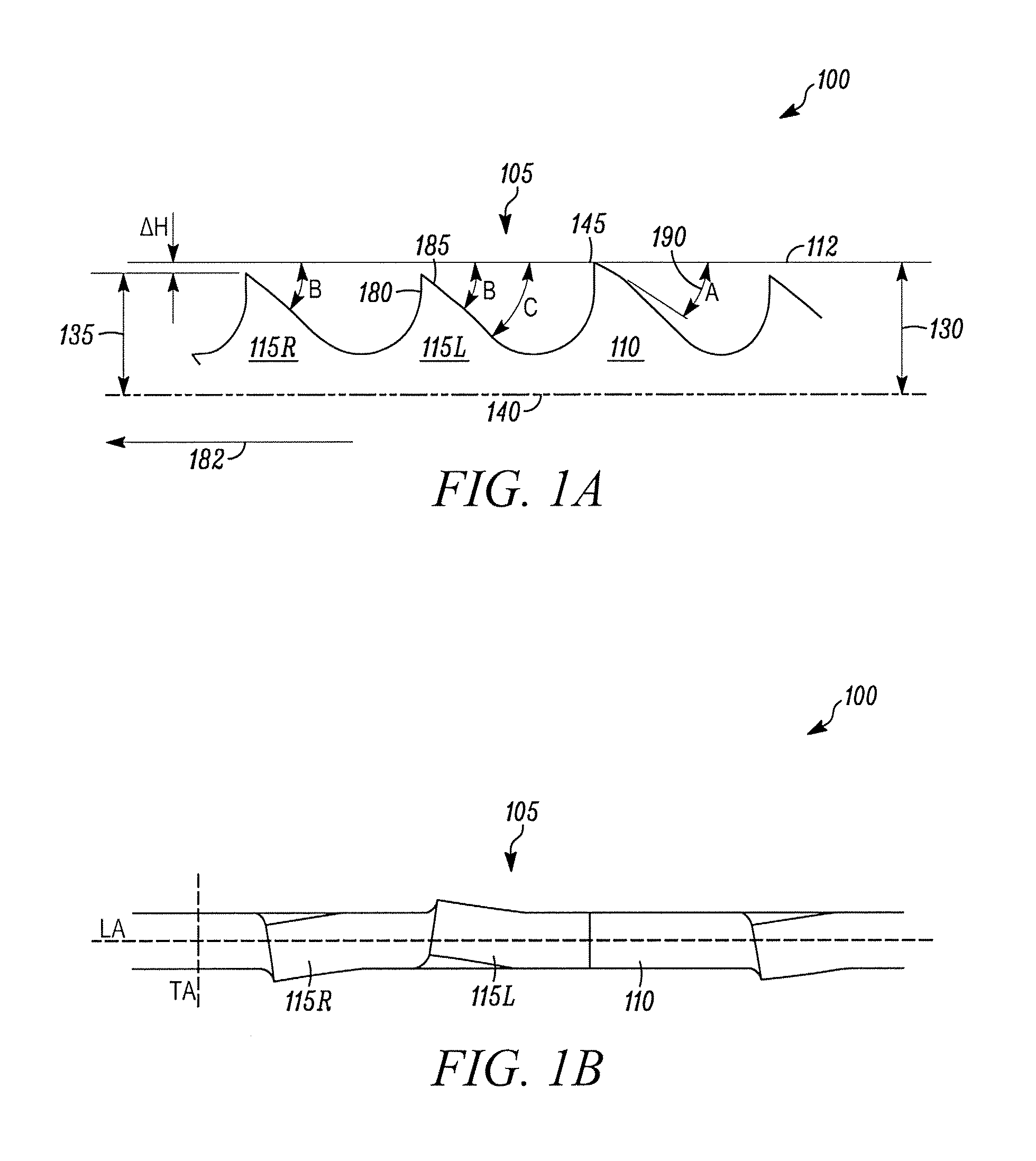

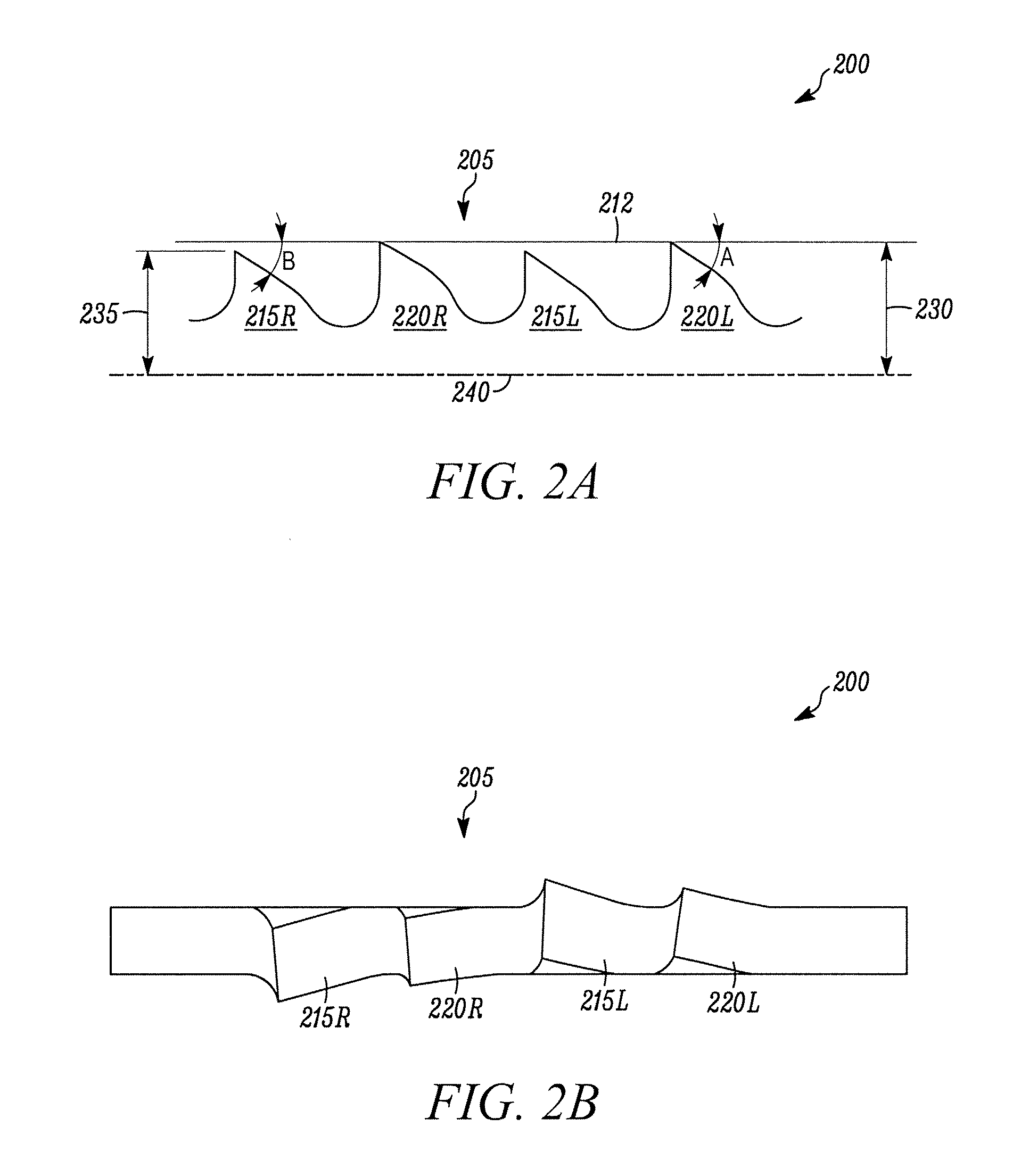

Reciprocating Saw Blade Having Variable-Height Teeth and Related Method

ActiveUS20080307936A1Improve performanceIncrease cutting forceMetal sawing devicesMetal sawing toolsPortable powerEngineering

A reciprocating saw blade, for use in a portable power reciprocating saw including a chuck for releasably engaging the saw blade, includes a tang having an elongated axis and being engageable with the chuck for attaching the saw blade to the reciprocating saw. The saw further includes a blade portion having a cutting edge that defines a plurality of cutting teeth. The cutting teeth define a repeating pattern of successive groups of teeth. Each group of teeth is less than about a half inch in length, and includes a plurality of laterally offset teeth, at least one relatively high first tooth and at least one relatively low second tooth. Prior to tooth set, the at least one relatively high first tooth is at least about 0.002 inch higher than the at least one relatively low second tooth.

Owner:BLACK & DECKER INC

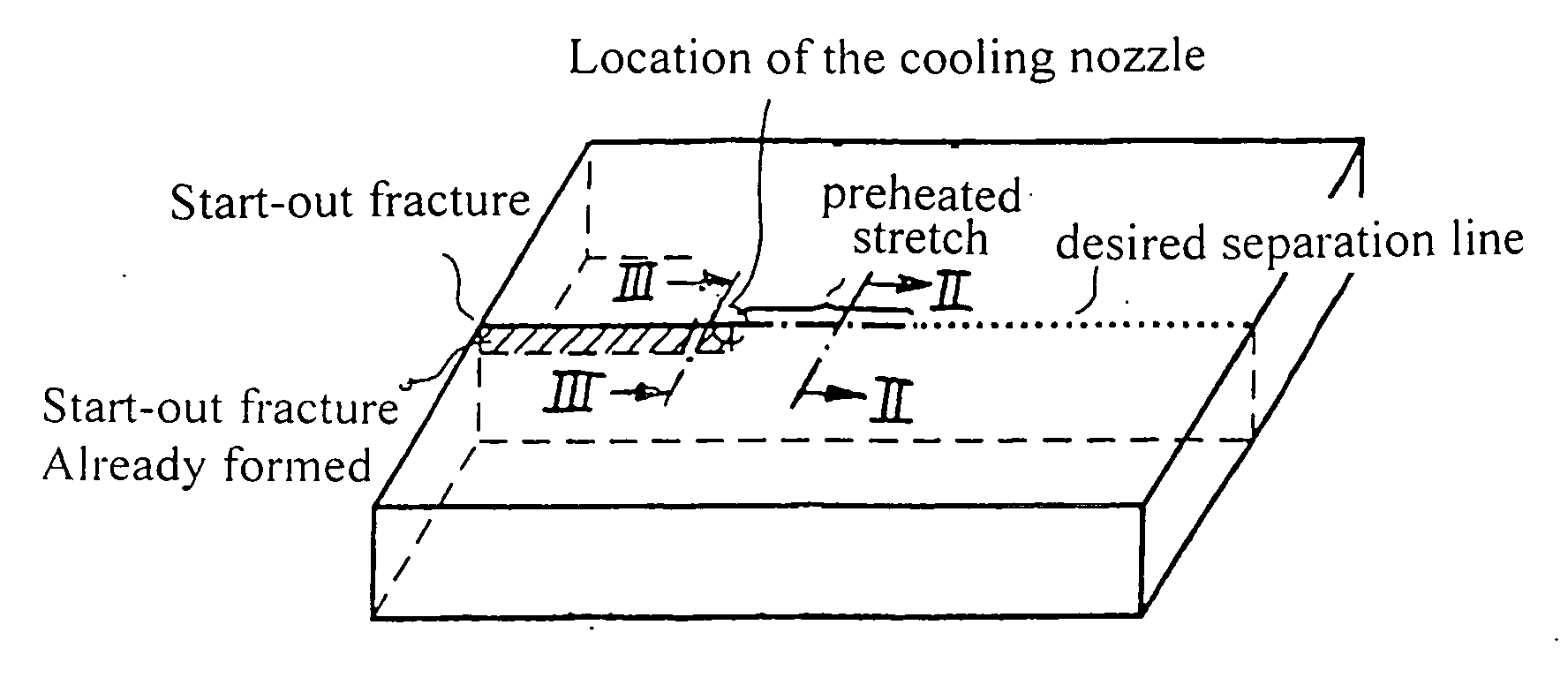

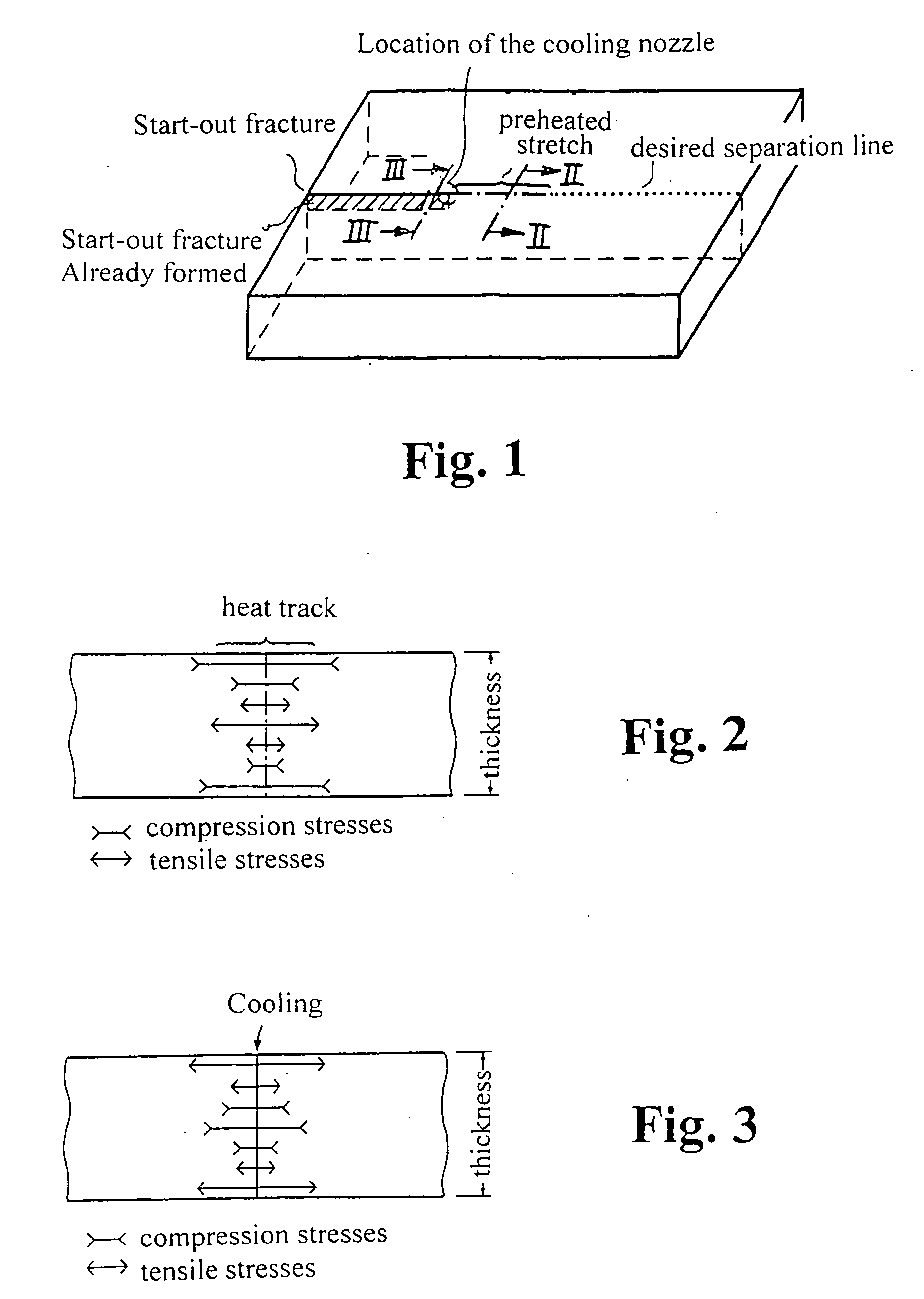

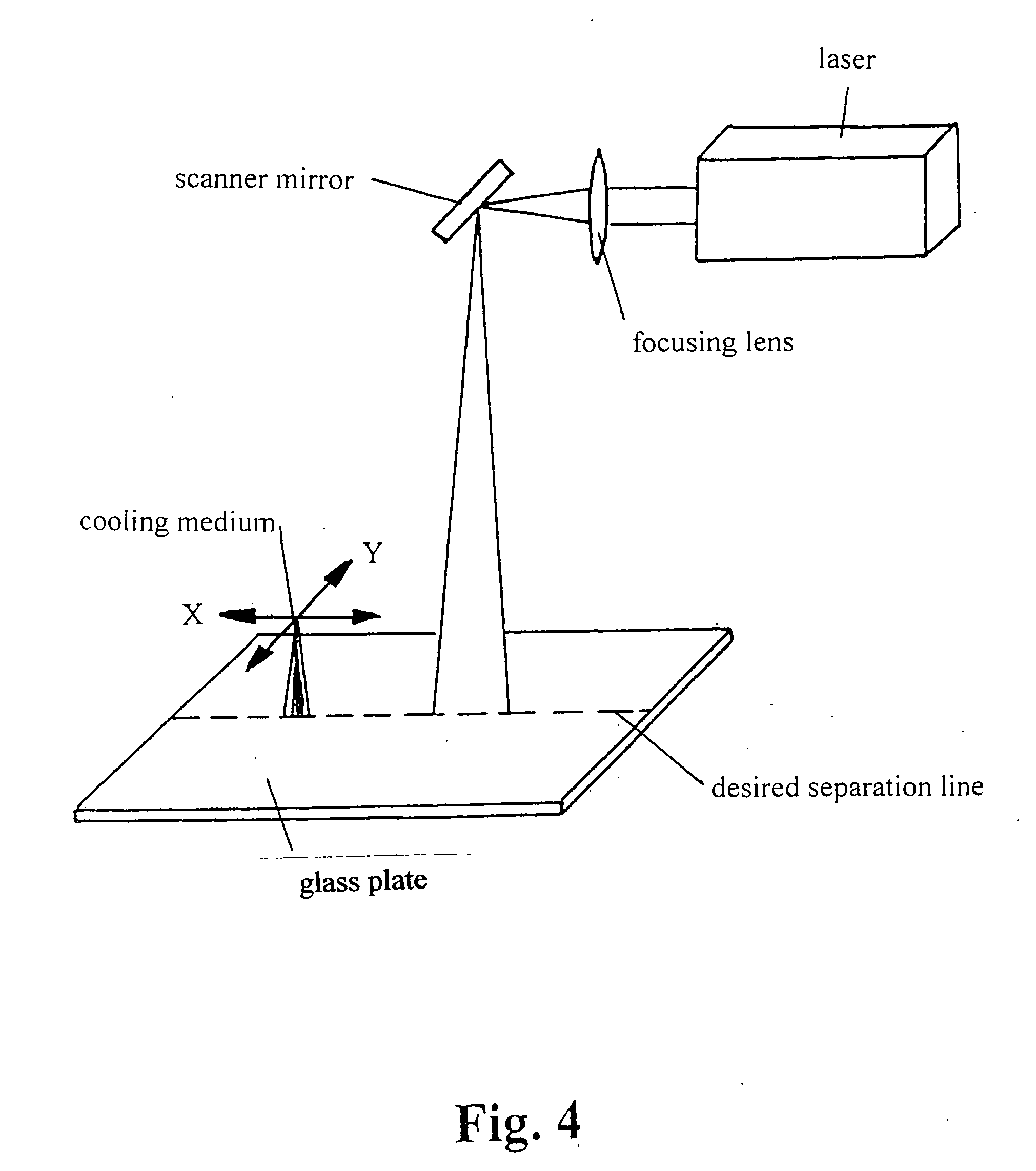

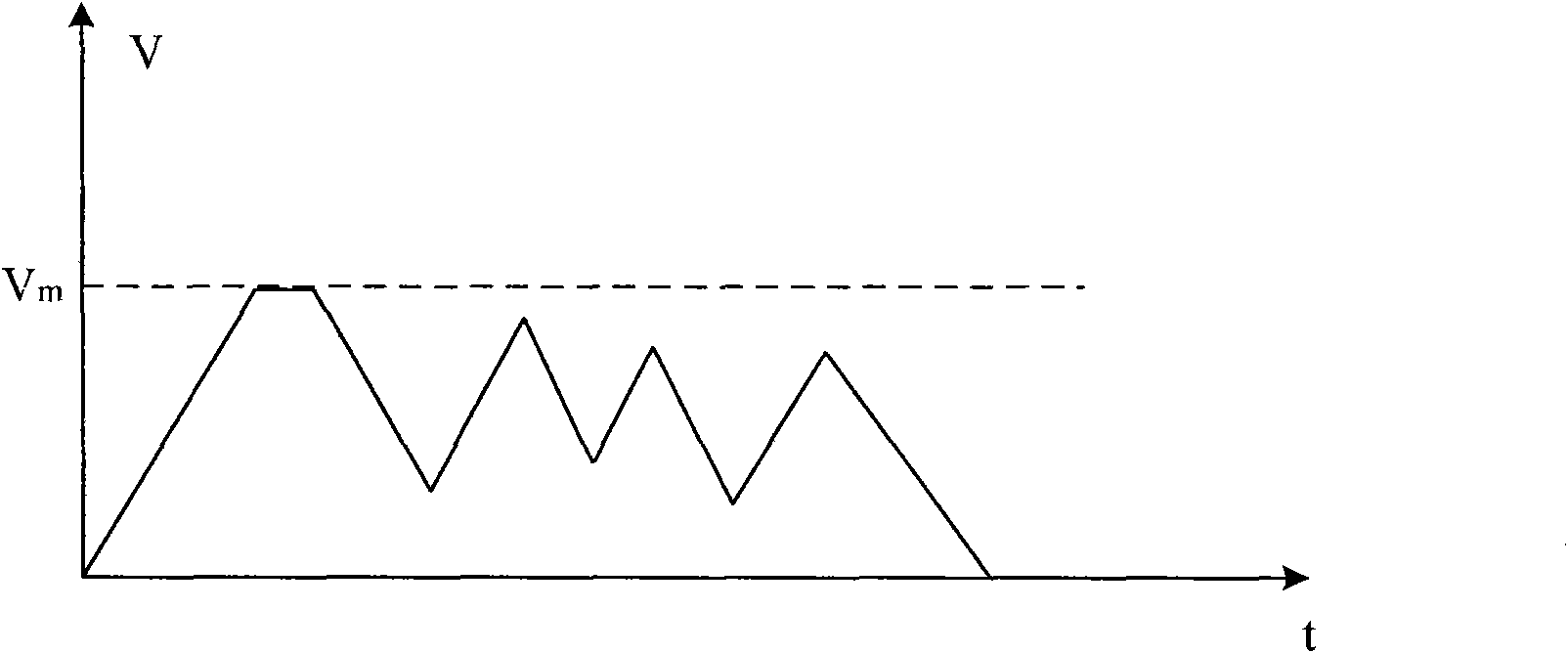

Method for laser-induced thermal separation of plate glass

InactiveUS20070151962A1Reduce surface temperatureFast cutting speedGlass severing apparatusWelding/soldering/cutting articlesFlat glassLaser heating

In a method for a laser-induced thermal separation of plate glass by thermal scoring using a laser beam heating the glass along a desired separation line with subsequent cooling of the laser-heated line, wherein the heat is applied by the laser beam in a number of repetitive passes at intensities based on glass thickness and desired cutting speeds.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV +1

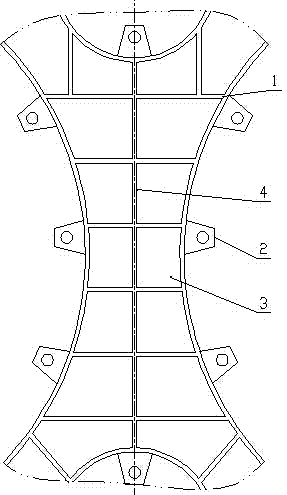

Plane wing titanium alloy thin-wall web efficient numerical control machining technology

A plane wing titanium alloy thin-wall web efficient numerical control machining technology comprises the following steps that (1) blanking is carried out; (2) web outer contour machining is carried out, and an ear piece for locating is machined; (3) a web is clamped, and a cavity on the front face of the web is machined; (4) a web side wall is machined; (5) web quick converting is carried out, and a cavity on the back face of the web is machined; (6) the locating ear piece is removed by milling; and (7) quality testing is carried out. The rigidity of a machining technology system is improved, unstressed machining is achieved, by optimized design of a feed track, the stability of a machining process is improved, machining speed is increased, titanium alloy shallow cutting large feeding milling technology parameters are used, heat deforming during machining is lowered, rectifying processes are omitted, the metal removing rate is improved by 30%-50%, finally, machining efficiency is obviously improved, the clamping time of workpieces is obviously shortened through a quick-reloading technology, the repeated locating accuracy of clamping is guaranteed, and accordingly numerically-controlled machine tool machining efficiency is greatly improved.

Owner:HUANGHE S & T COLLEGE

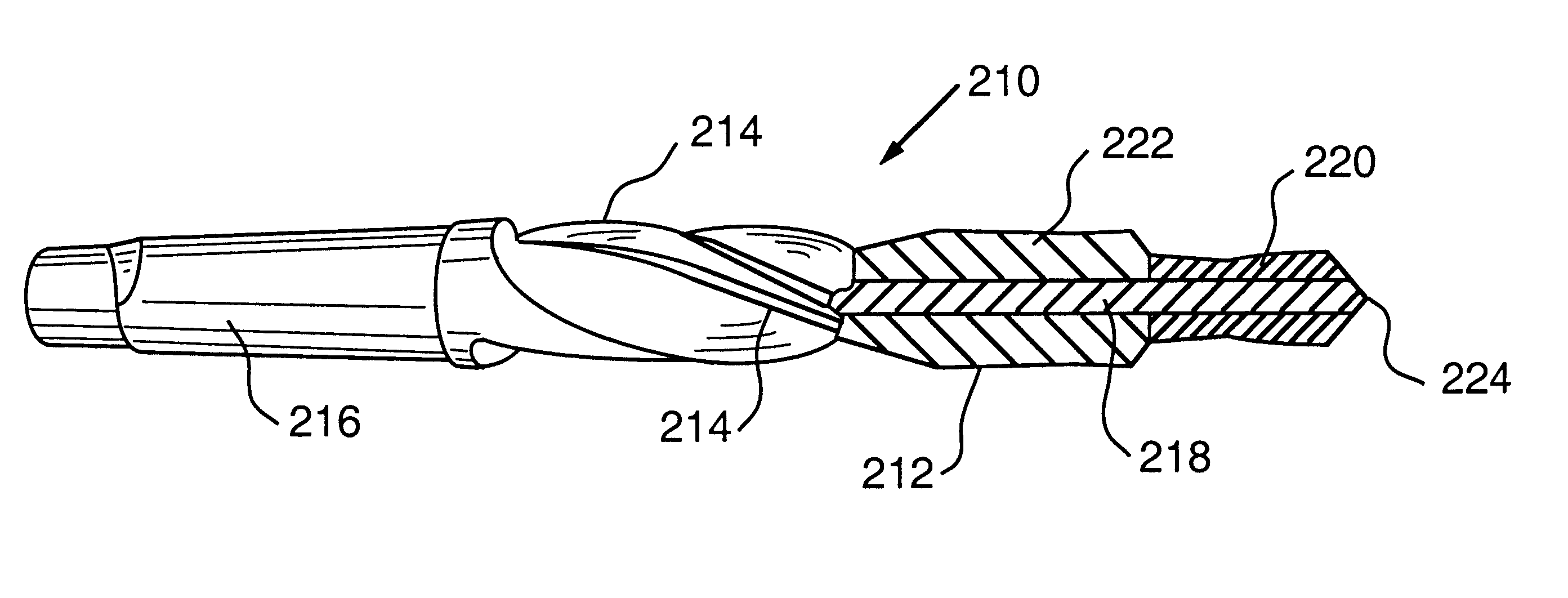

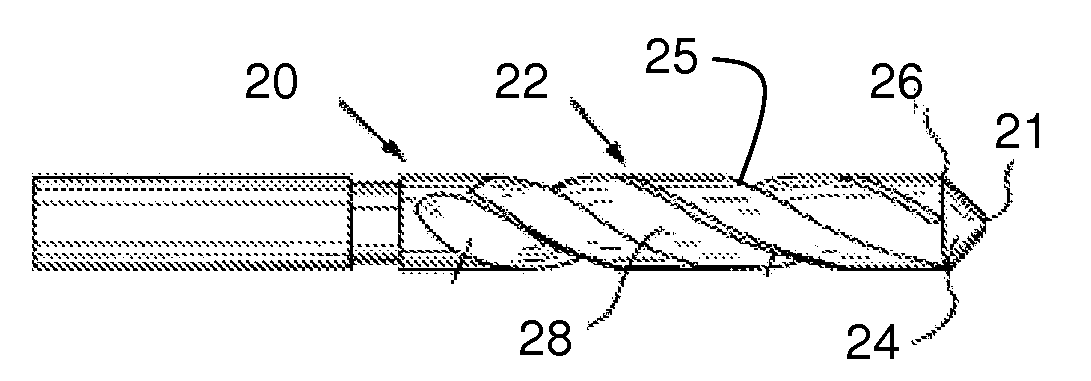

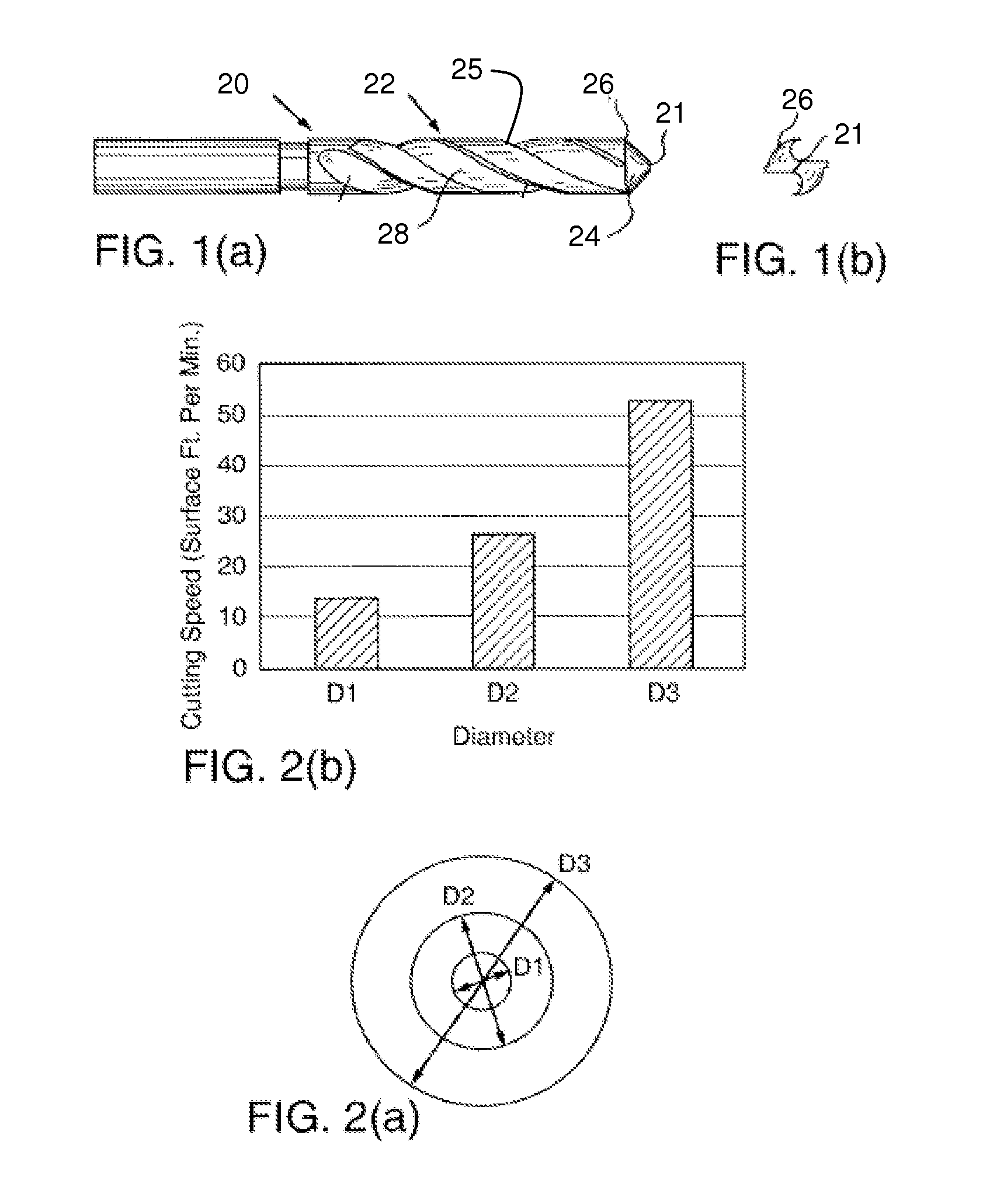

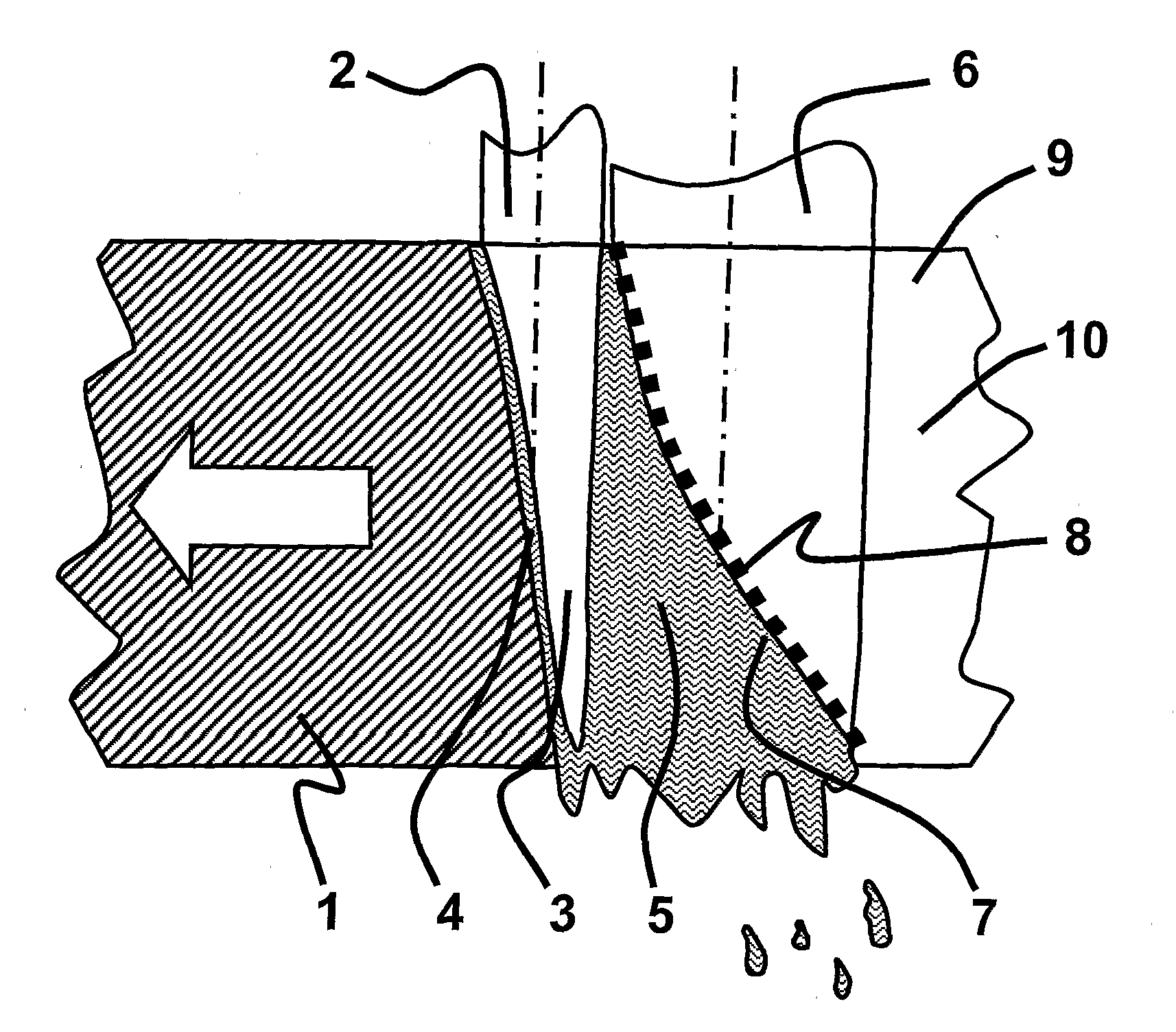

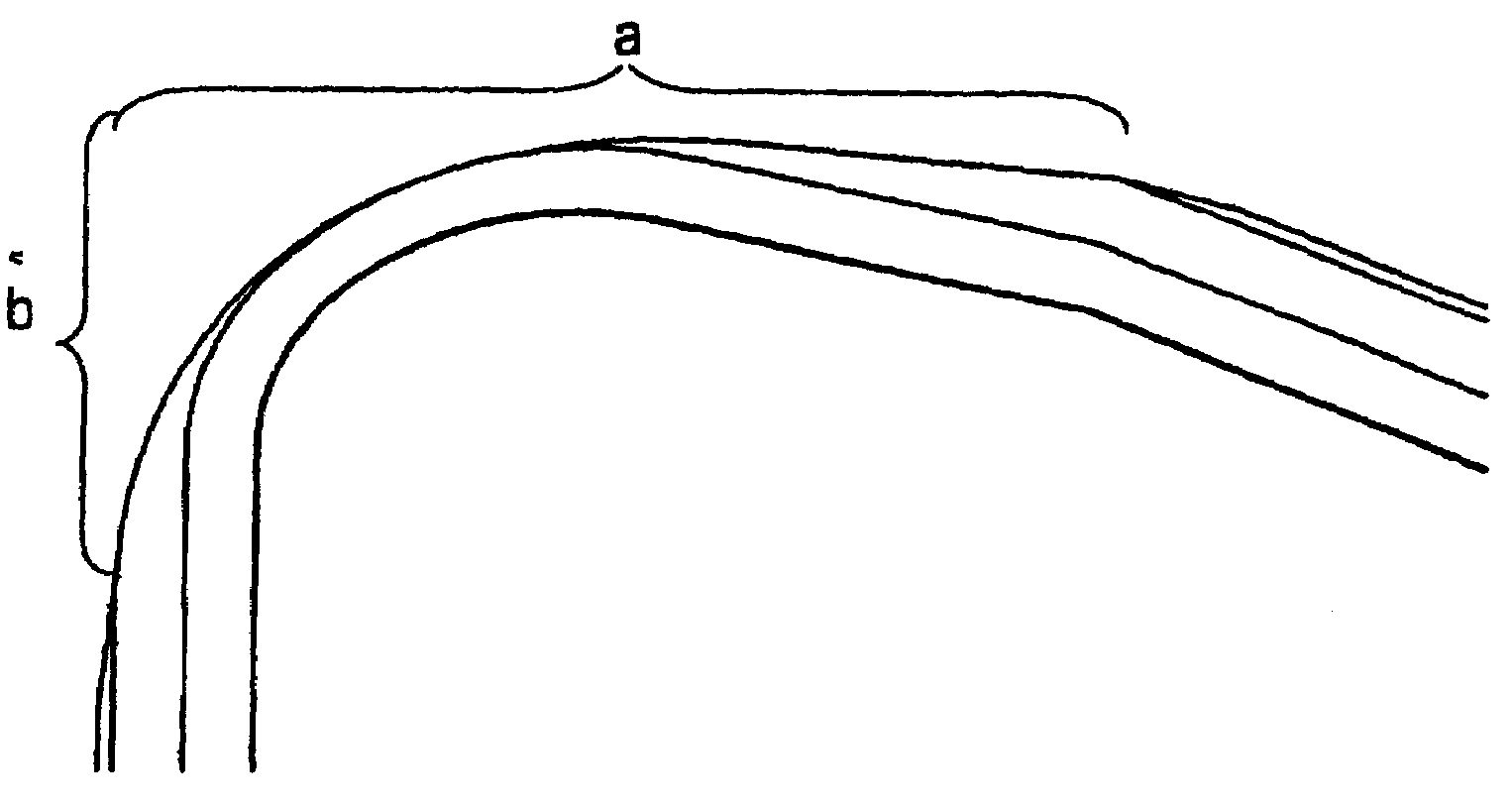

Composite cemented carbide rotary cutting tools and rotary cutting tool blanks

ActiveUS20100290849A1Reduce strength and mechanical wear resistanceReduce wearWood turning toolsMetal-working drilling toolsAlloyCemented carbide

Composite articles, including composite rotary cutting tools and composite rotary cutting tool blanks, and methods of making the articles are disclosed. The composite article includes an elongate portion. The elongate portion includes a first region composed of a first cemented carbide, and a second region autogenously bonded to the first region and composed of a second cemented carbide. At least one of the first cemented carbide and the second cemented carbide is a hybrid cemented carbide that includes a cemented carbide dispersed phase and a cemented carbide continuous phase. At least one of the cemented carbide dispersed phase and the cemented carbide continuous phase includes at least 0.5 percent by weight of cubic carbide based on the weight of the phase including the cubic carbide.

Owner:KENNAMETAL INC

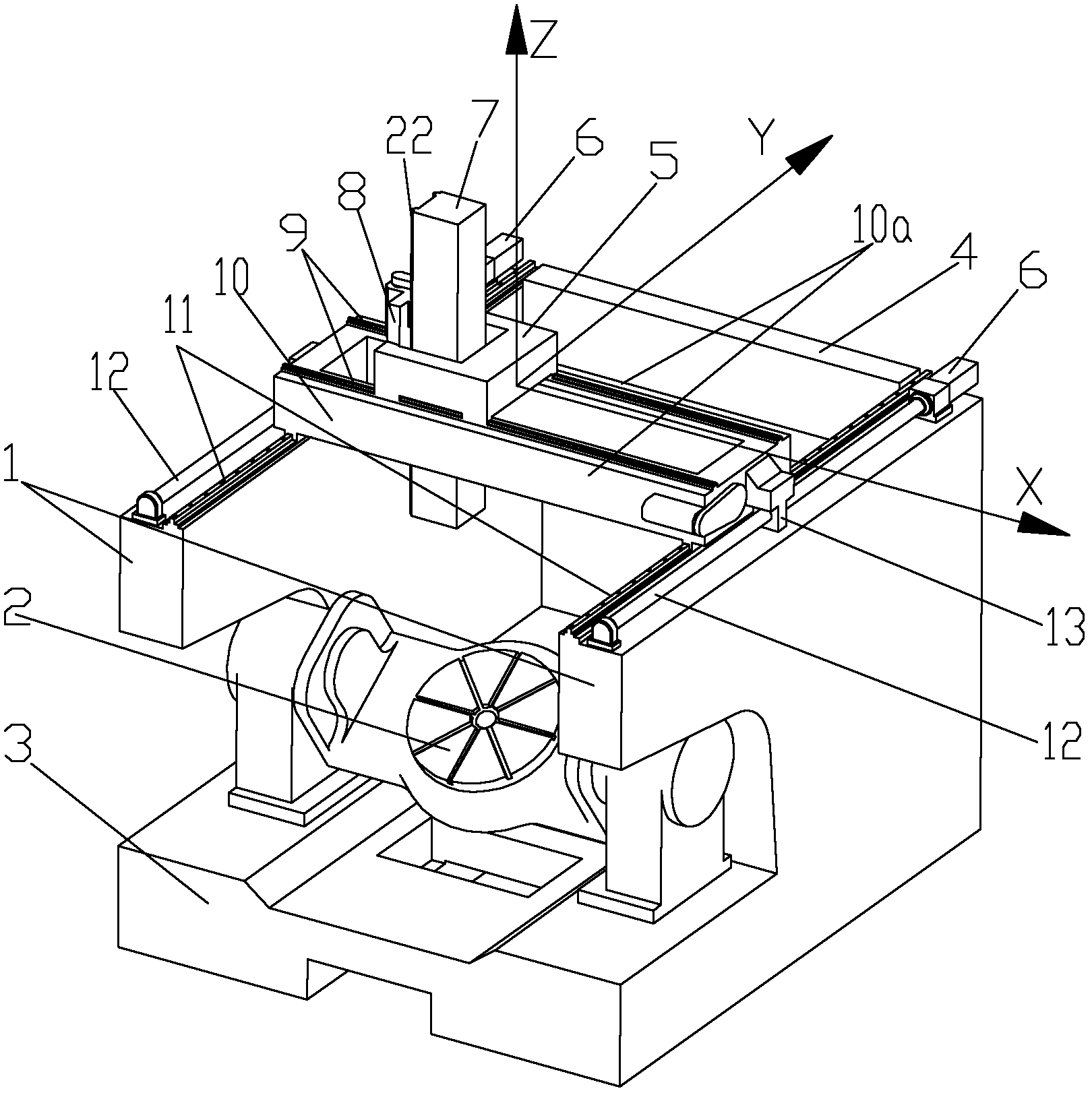

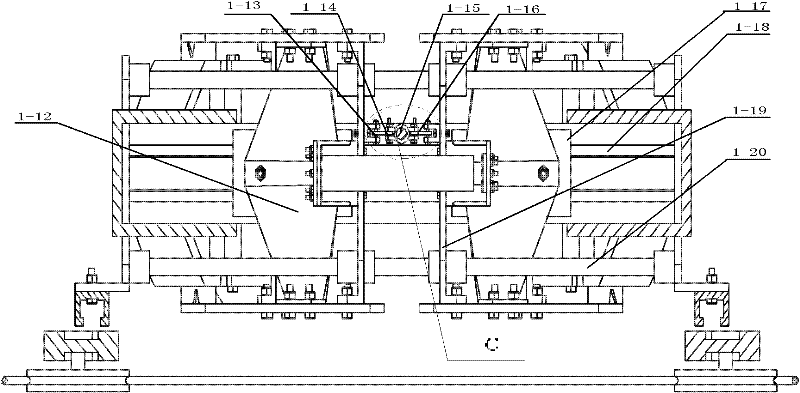

Small high-speed five-axis linkage machine tool

InactiveCN102632422AGuaranteed stabilitySmall sizeMachine tool componentsFeeding apparatusBridge typeEngineering

The invention discloses a small high-speed five-axis linkage machine tool, which comprises a foundation structure, a spindle box component and a cradle type worktable. The spindle box component is supported on the foundation structure, and a crossbeam with a frame-shaped structure is arranged on two upright columns to form a bridge-type portal structure. The torque bearing capacity of the crossbeam is improved, the small high-speed five-axis linkage machine tool has all advantages of a five-axis linkage machine tool in the prior art, and carries identical machining reacting force, the volume of a structural part is reduced, and the weight of the structural part is greatly lightened; a spindle box is positioned between two transverse rods of the frame-shaped crossbeam, overturning moment is eliminated, and the stability of the machine tool can be guaranteed; in addition, sizes of various components are greatly reduced on the premise of identical machining capacity, and the stroke of the machine tool can be large in the design; and by the aid of the structure, the machining precision is greatly improved, the machining range is greatly expanded, better dynamic characteristics and higher feeding speed and higher cutting speed can be realized, cutting and machining time is greatly shortened, better surface machining quality is obtained, and machining efficiency is enhanced.

Owner:CHONGQING UNIV

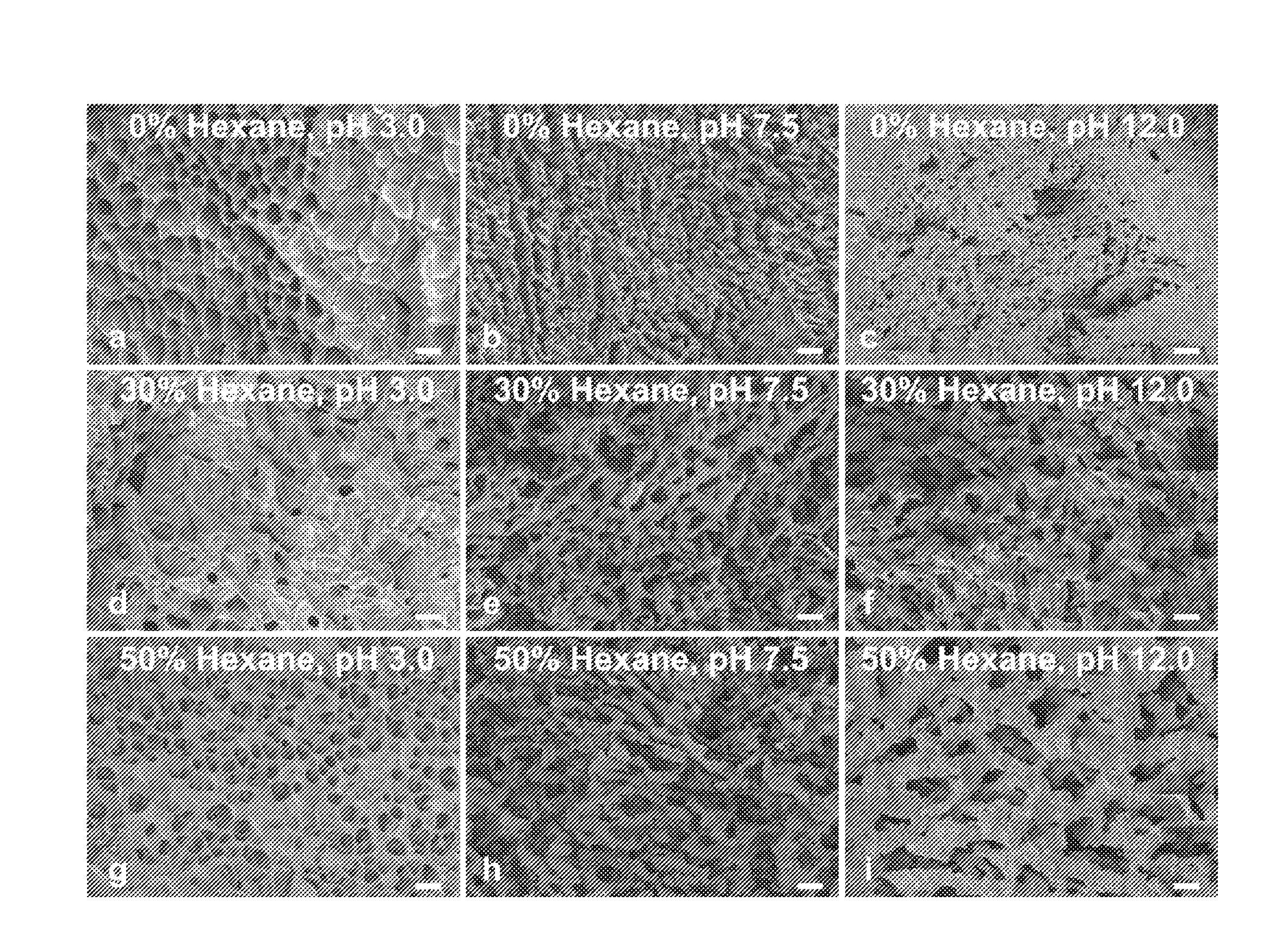

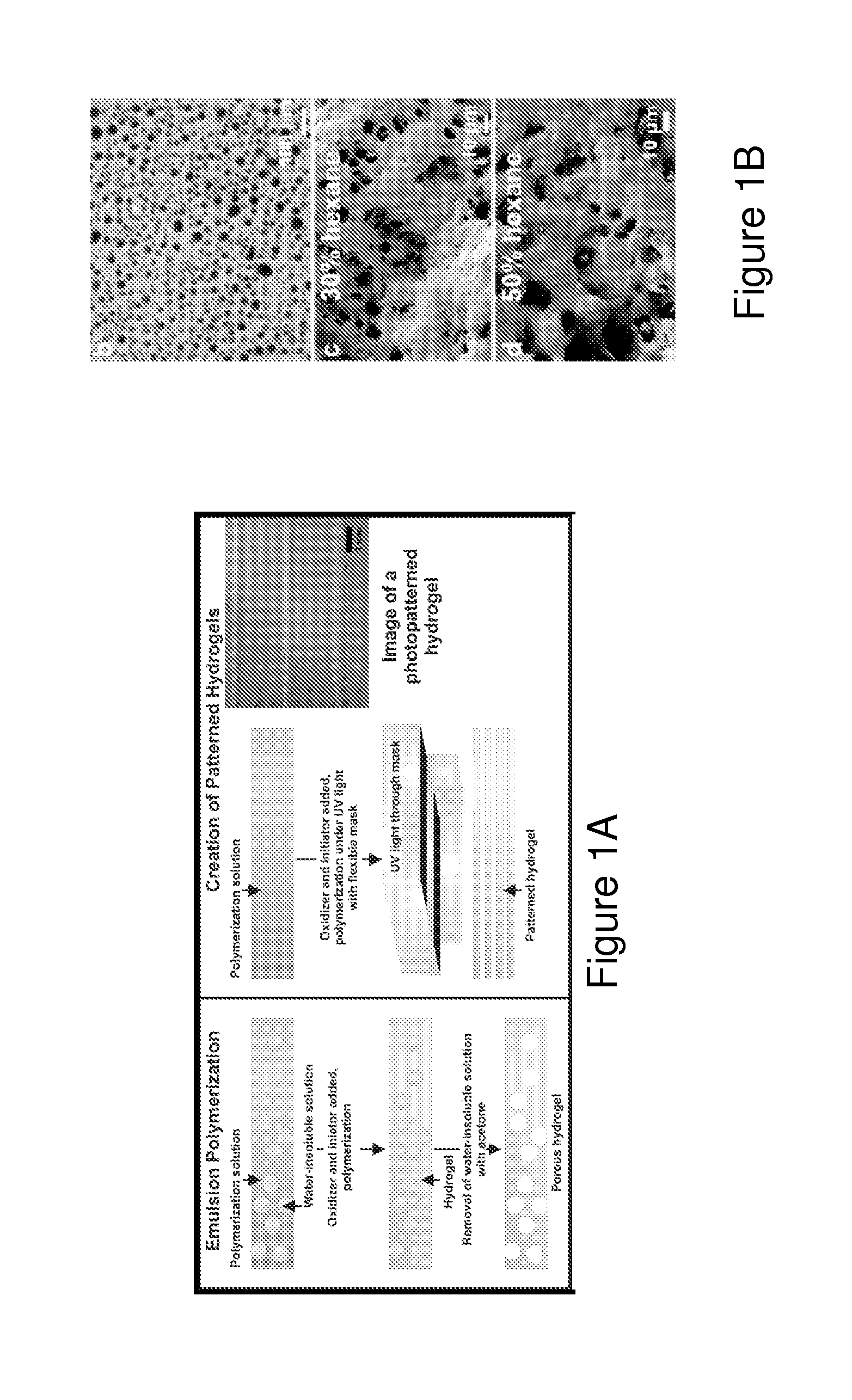

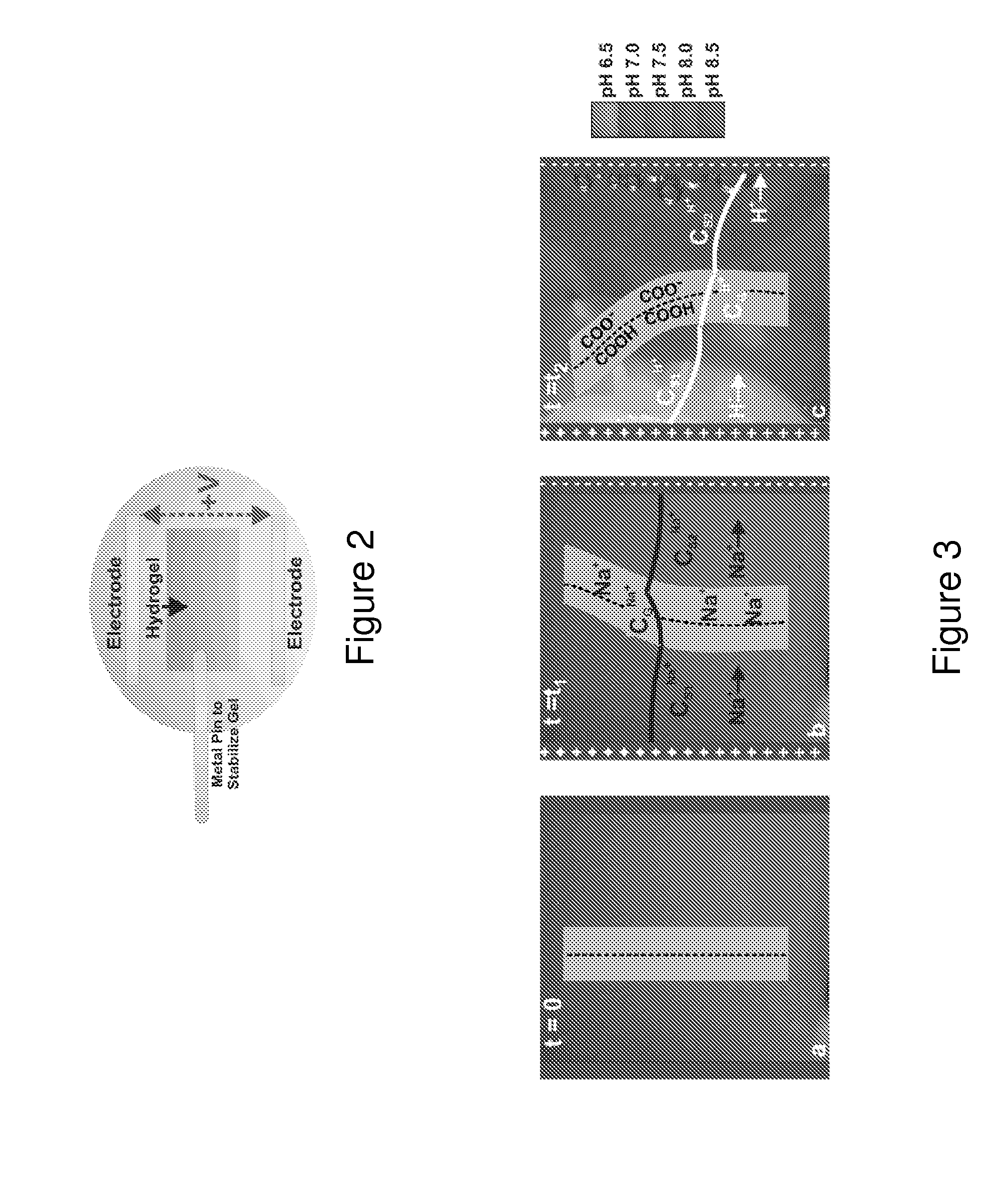

Porous electroactive hydrogels and uses thereof

ActiveUS20120029416A1Maximize electroactuationReduce the cross-sectional areaBiocideFinger bandagesMaterials sciencePolymer science

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

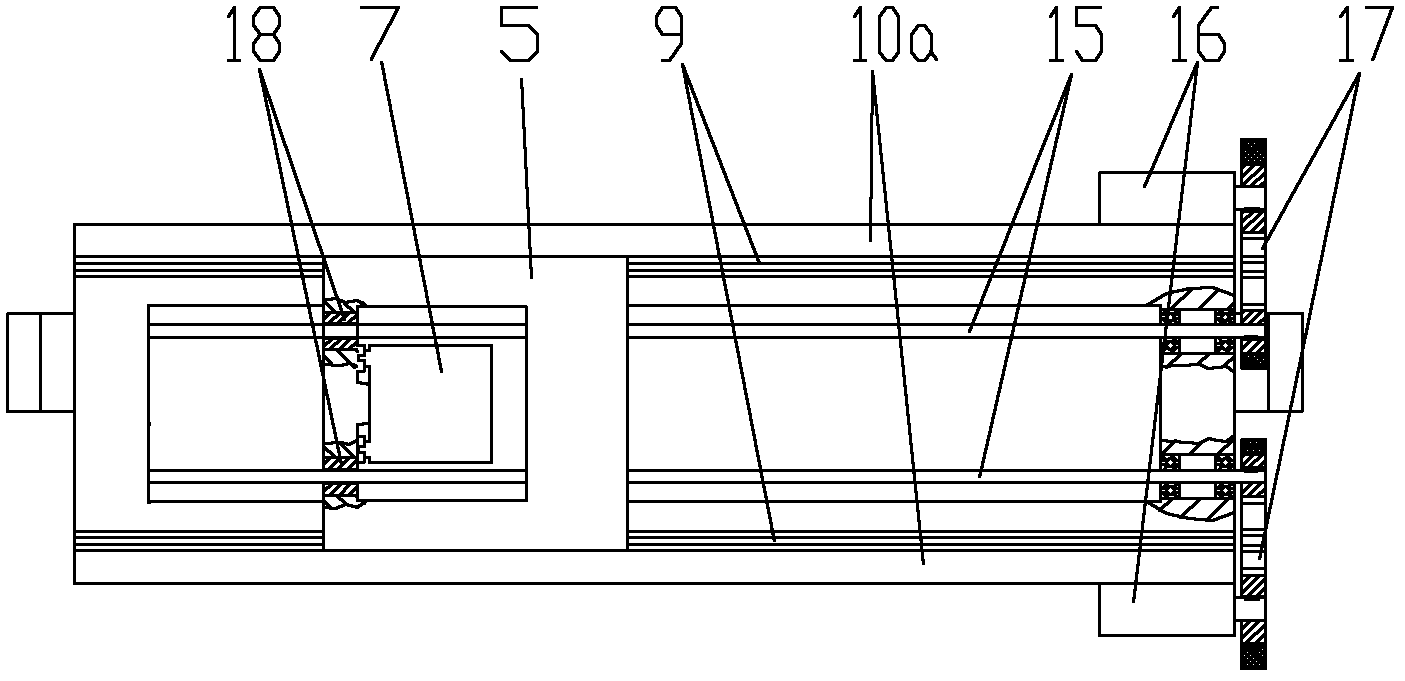

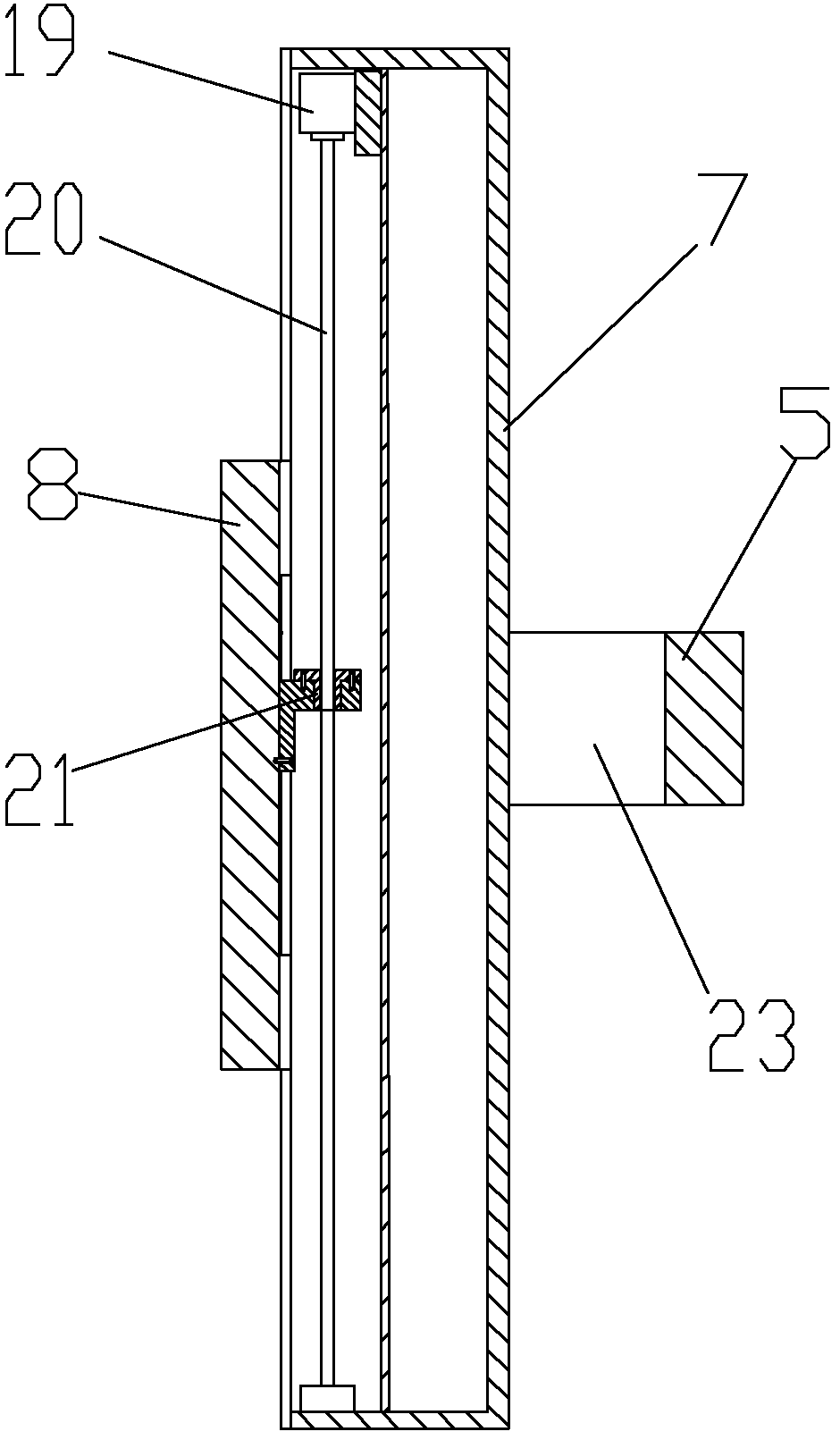

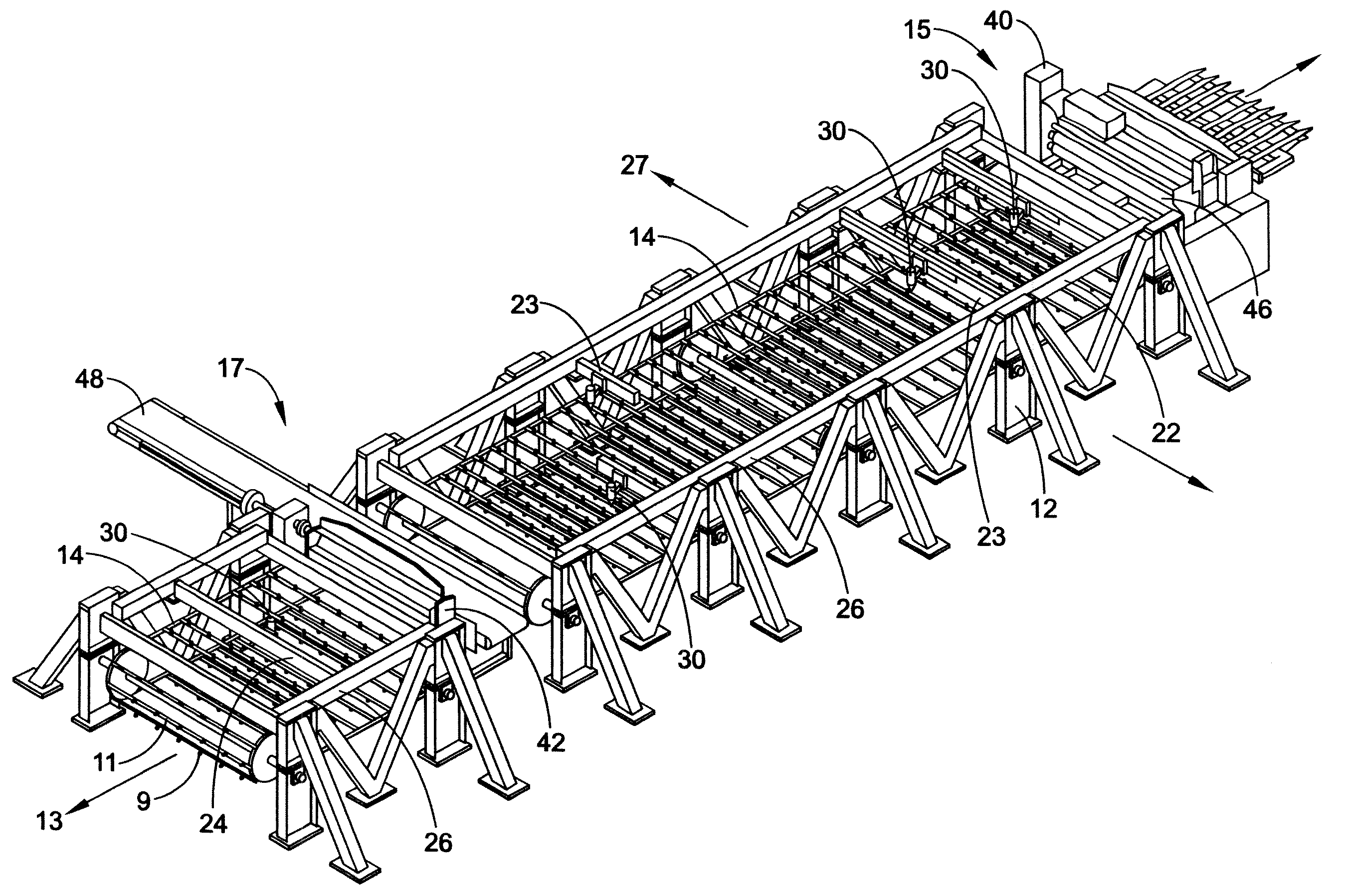

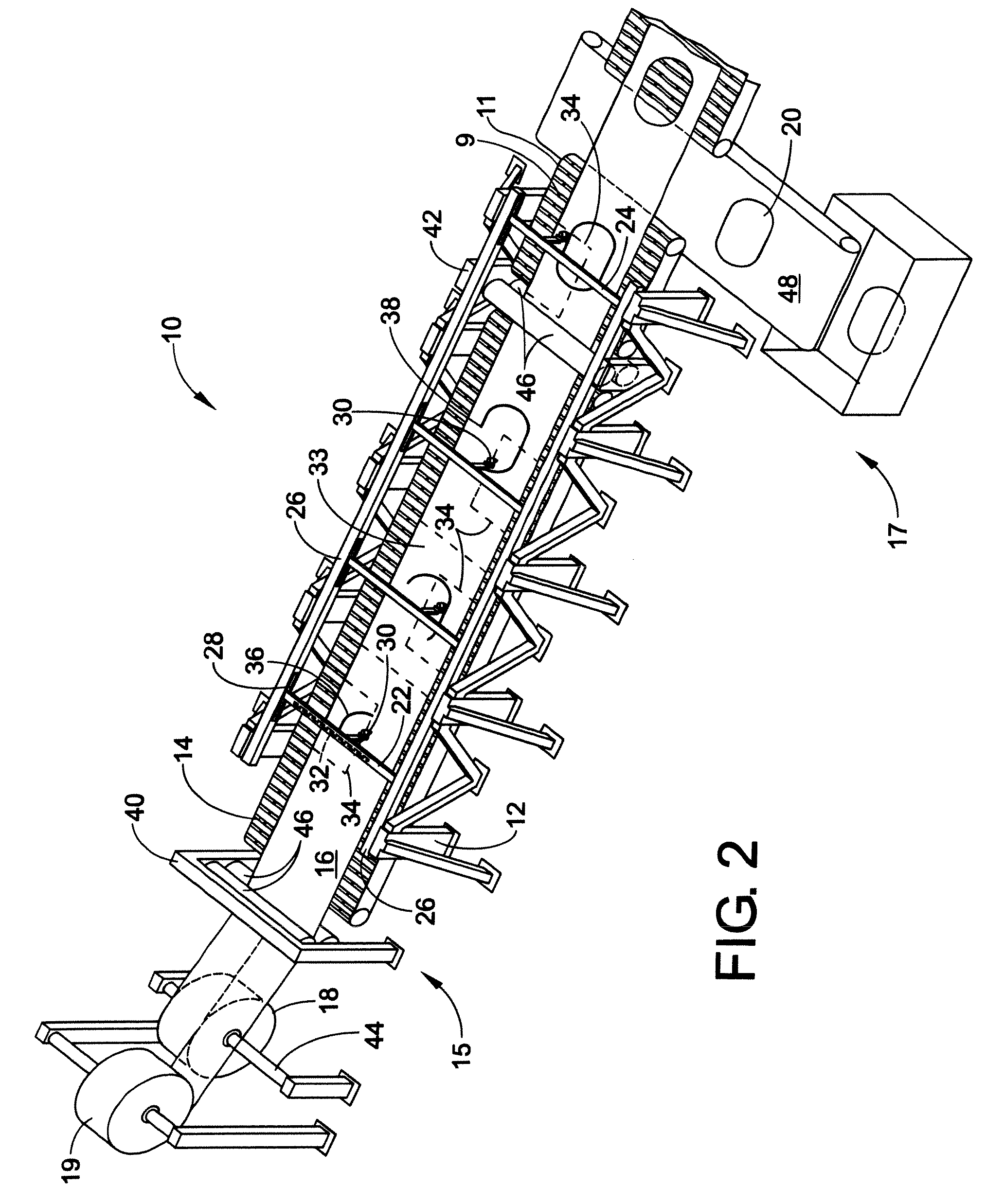

Progressive laser blanking device for high speed cutting

ActiveUS20090212033A1Prevent saggingPerformance maximizationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

A laser blanking device for high speed cutting of a rapidly fed strip of coil stock includes a pin conveyor traveling a recurring loop along a longitudinal axis. At least two moveable gantries are supported above the pin conveyor. Each gantry is capable of moving at least a limited length along the longitudinal axis. At least one moveable laser head is suspended on each gantry, and the laser heads are capable of moving along the corresponding gantry along multiple axes transverse to or parallel to the longitudinal axis of the device. The device further has an entry pinch roll assembly and a second pinch roll assembly positioned at opposed ends of the conveyor. A pair of pinch rollers cooperates with each pinch roll assembly to apply tension to the strip traveling therebetween. Each pinch roller continually feeds the moving strip along the conveyor while the laser heads situated between the pinch roll assemblies move and progressively cut a perimeter portion of a blank or cut-out from the moving strip.

Owner:LASERCOIL TECH

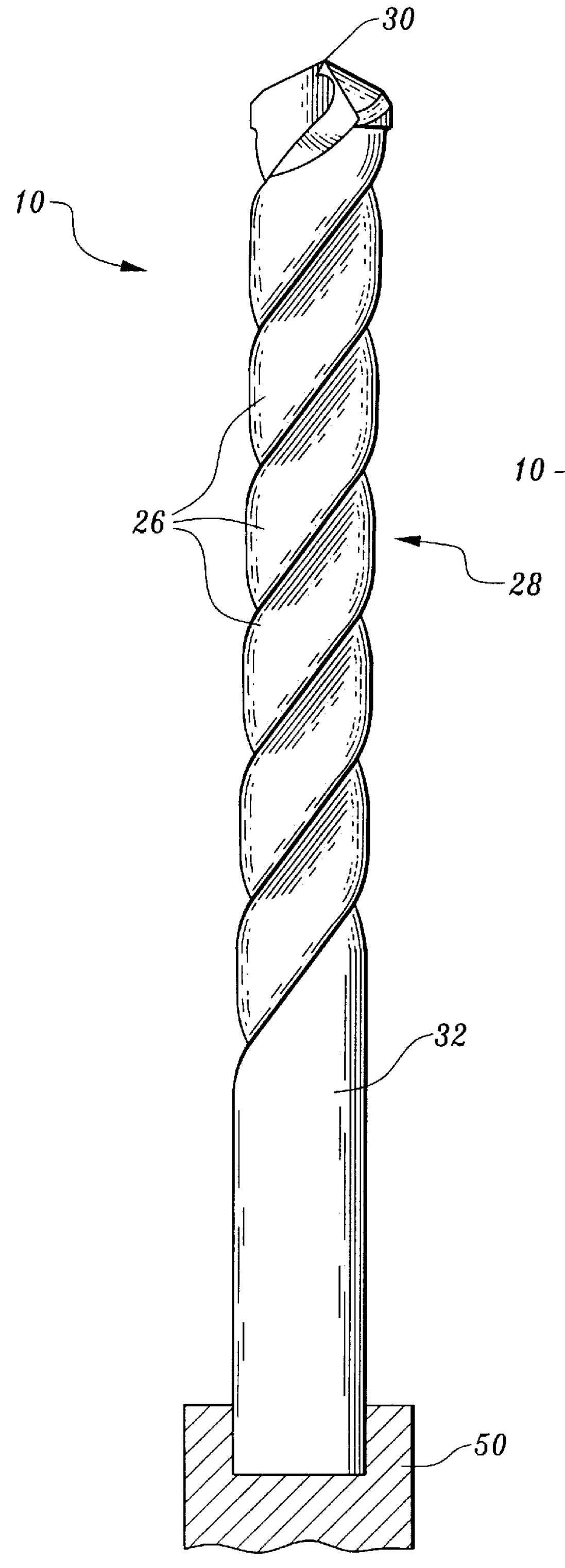

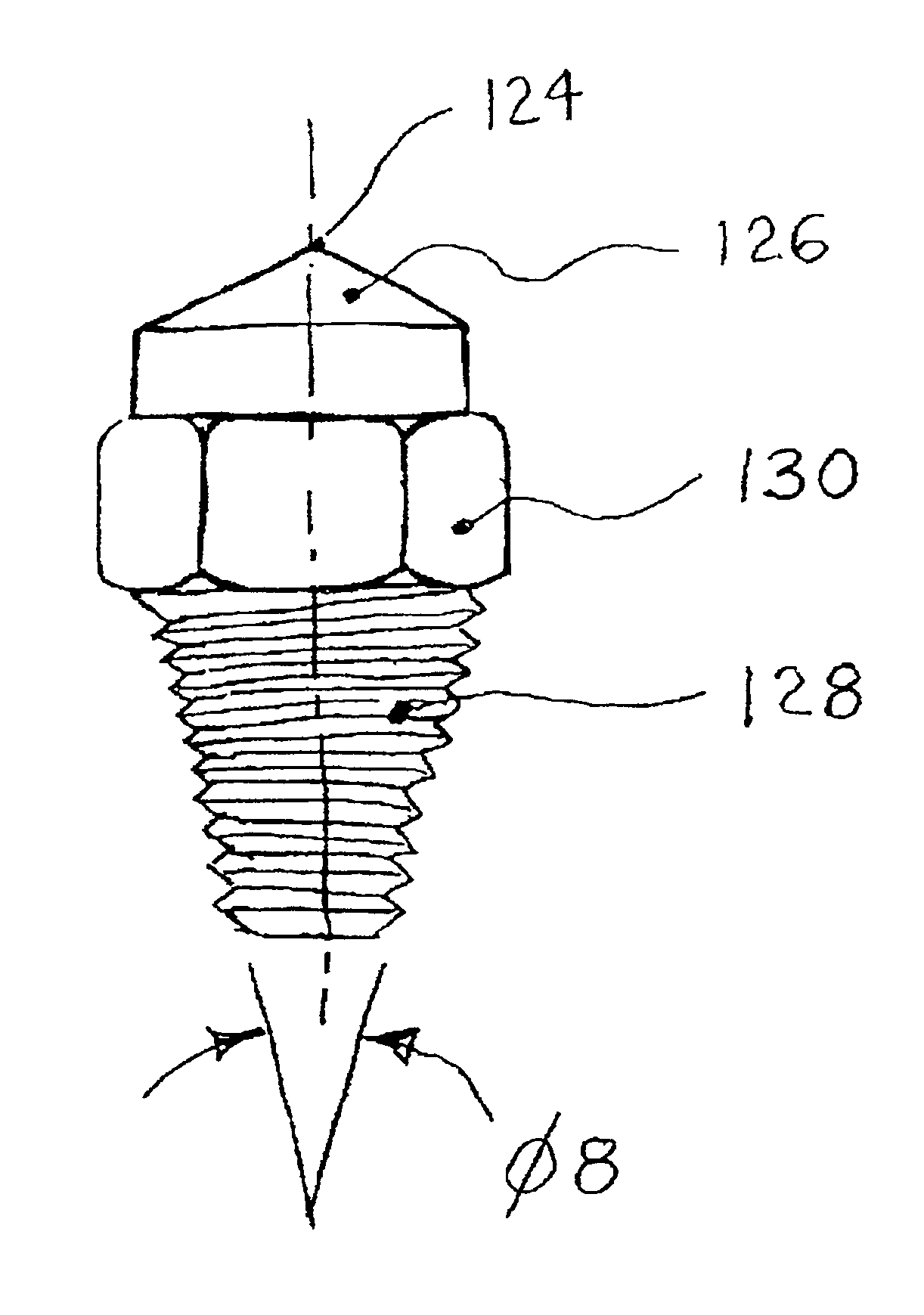

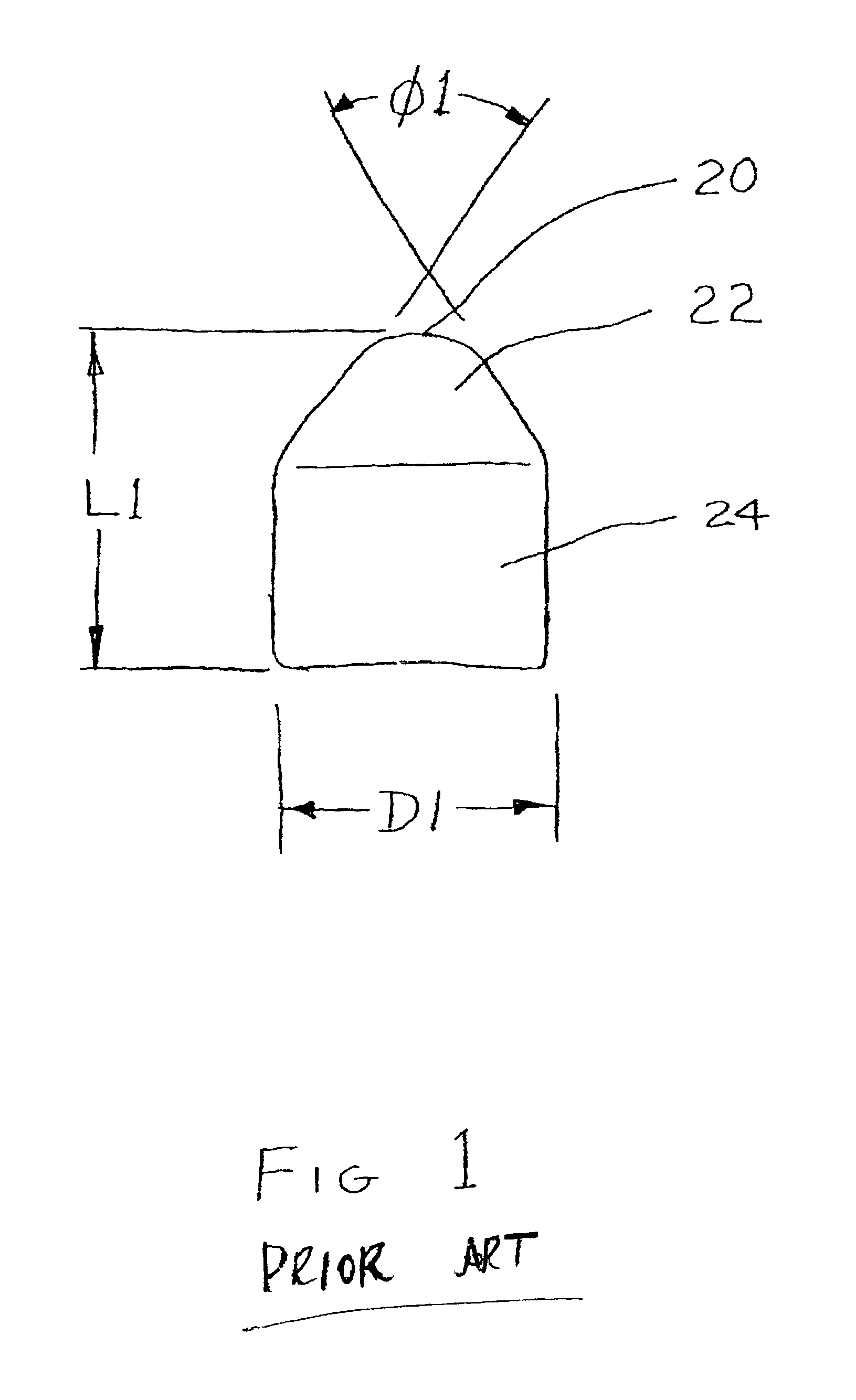

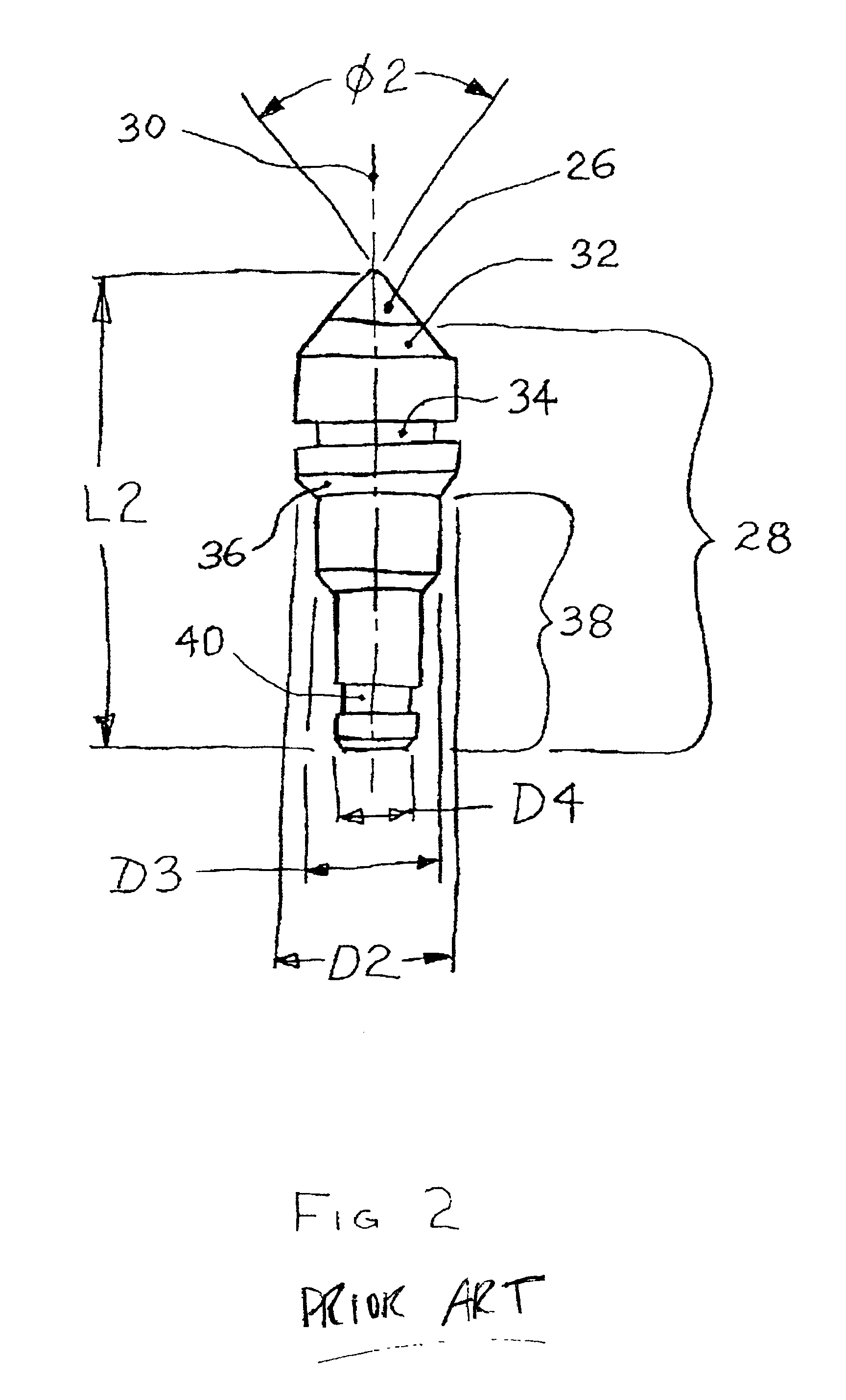

Precision drill bit

InactiveUS6126367AReduce frictionExtended bit lifeWood turning toolsTransportation and packagingHand heldDrill bit

Owner:LOCK N STITCH INC

Electrosurgical apparatus with retractable blade

An electrosurgical apparatus with a retractable blade for use in cold plasma applications, electrosurgical cutting and mechanical cutting is provided. The electrosurgical apparatus employs a tip of the retractable blade as a sharp conductive point to generate a plasma beam or discharge. When the blade is retracted within the electrosurgical apparatus, it is electrically energized while an inert gas flows over it, producing a cold plasma discharge. In the de-energized state, the blade is advanced and used as a traditional, mechanical surgical blade.

Owner:BOVIE MEDICAL CORP

Small straight-line section interpolation method of numerical control system on basis of multicycle optimal corner

InactiveCN101556472AFast processingFast cutting speedProgramme controlComputer controlLine segmentProcessing accuracy

The invention relates to a small straight-line section interpolation method of a numerical control system on the basis of multicycle optimal corner, comprising the following steps of: on the basis of processing precision and limitation of maximum processing speed, determining interpolation parameters of an optimal corner with multicycle trasition of each corner on a processing path according to geometric parameters at the corner on the processing path, the maximum acceleration of each driving shaft of a machine tool and an optimized target; adjusting the interpolation parameters of the optimal corner of each corner and leading the processing speed of two ends of each small straight-line section to meet reachability requirement; and then carrying out interpolation of straight line sections and corners to all the small straight-line sections on the processing path, connecting interpolate point sequences of the straight line sections with interpolate point sequences of corners, sequentially outputting the interpolate point sequences in real time, and driving a numerical control machine tool to conduct actual processing. The method can effectively improve the whole processing speed, has fast calculating speed, meets the requirement of real time processing, has stable and reliable working performance and strong practicability and can be applicable to various three-shaft numerical control machine tool with different types.

Owner:ACAD OF MATHEMATICS & SYSTEMS SCIENCE - CHINESE ACAD OF SCI

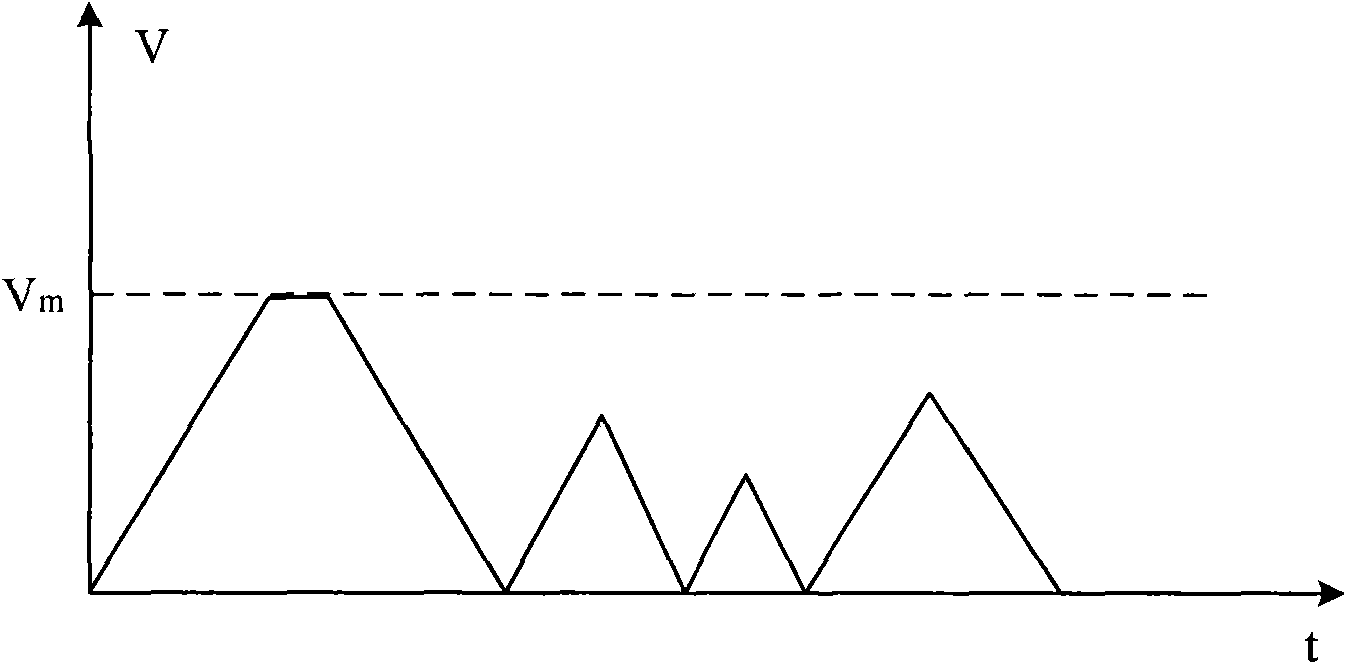

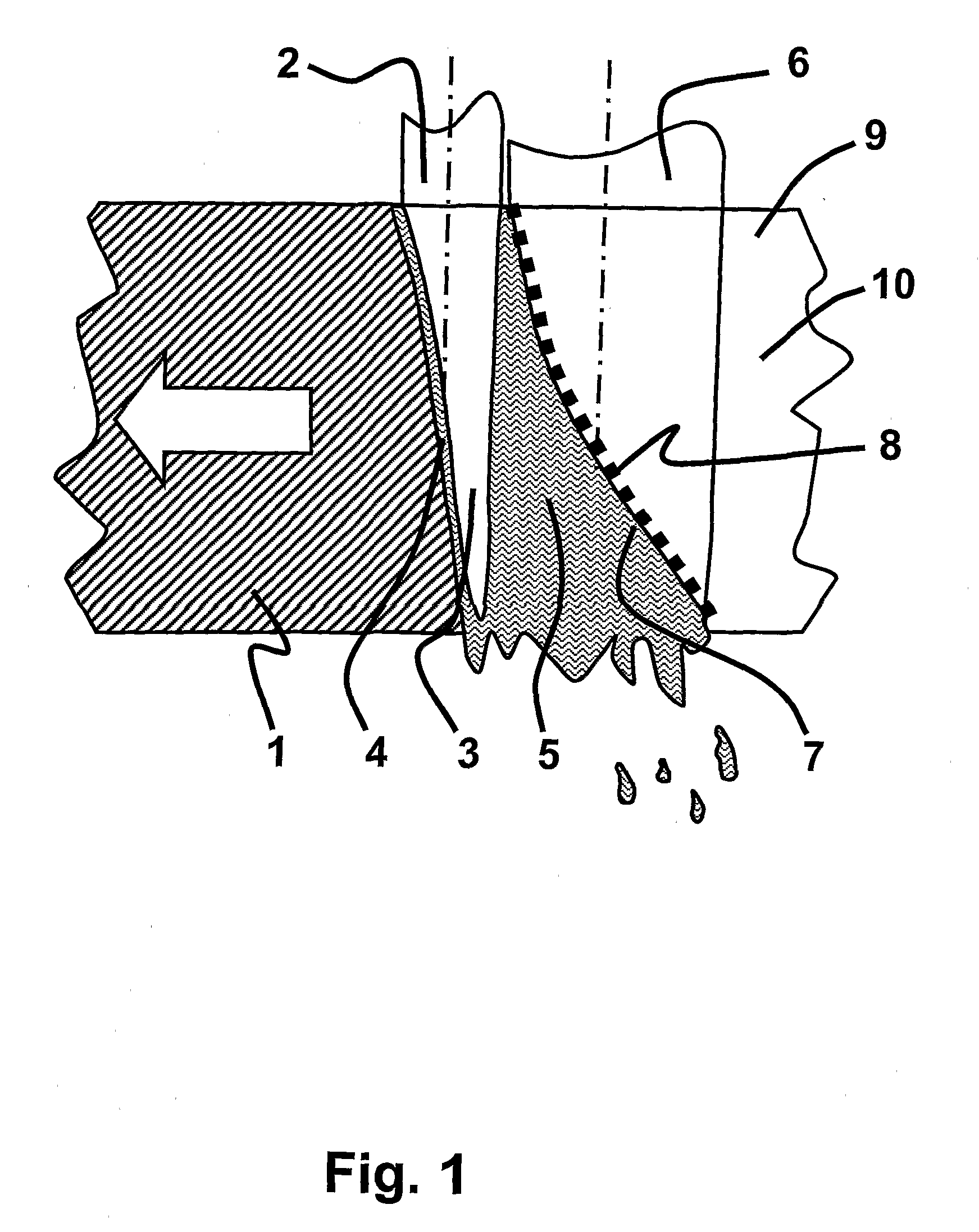

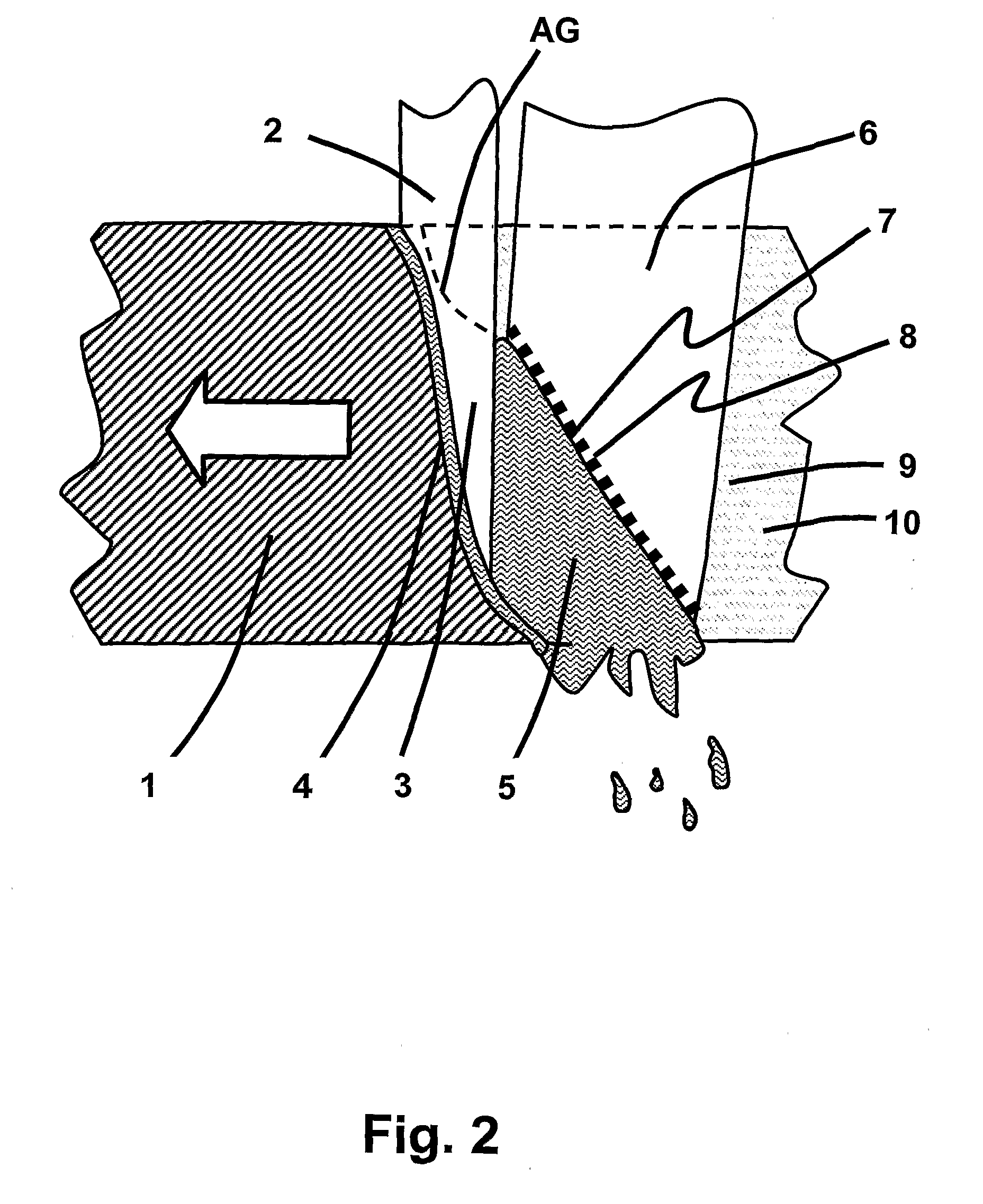

Method and system for laser processing

InactiveUS20100044353A1Increase pressureStable flowLaser beam welding apparatusLaser processingHigh power lasers

The invention relates to laser cutting, using multiple laser beams directed to a processing region. At least one first laser beam (2) is coupled into the work piece (1) material to generate a melt (5) and to form a keyhole (3). At least one second beam (6) is guided onto selected surface regions (7) of the melt (5). The laser energy is provided to the processing region as individual beams that may be conditioned independently. The invention has the advantage that arbitrary energy distributions can be arranged in the processing region as determined according to the requirements of the laser cutting process, rather than being limited by an inappropriate beam shape of a single high power laser beam.

Owner:OLSEN FLEMMING OVE

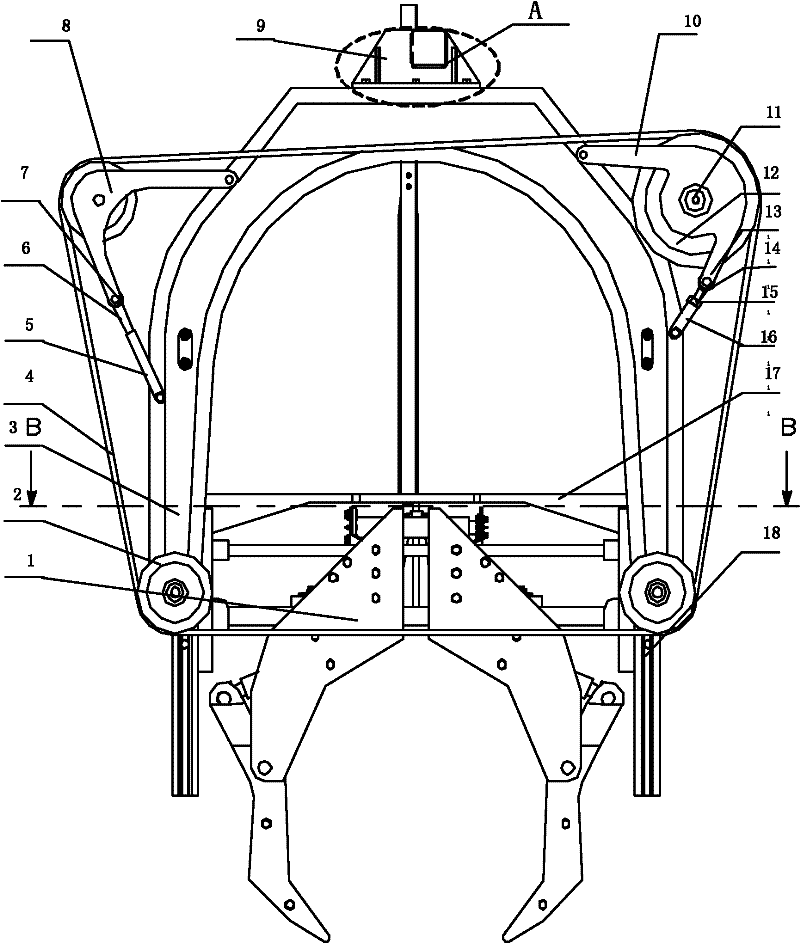

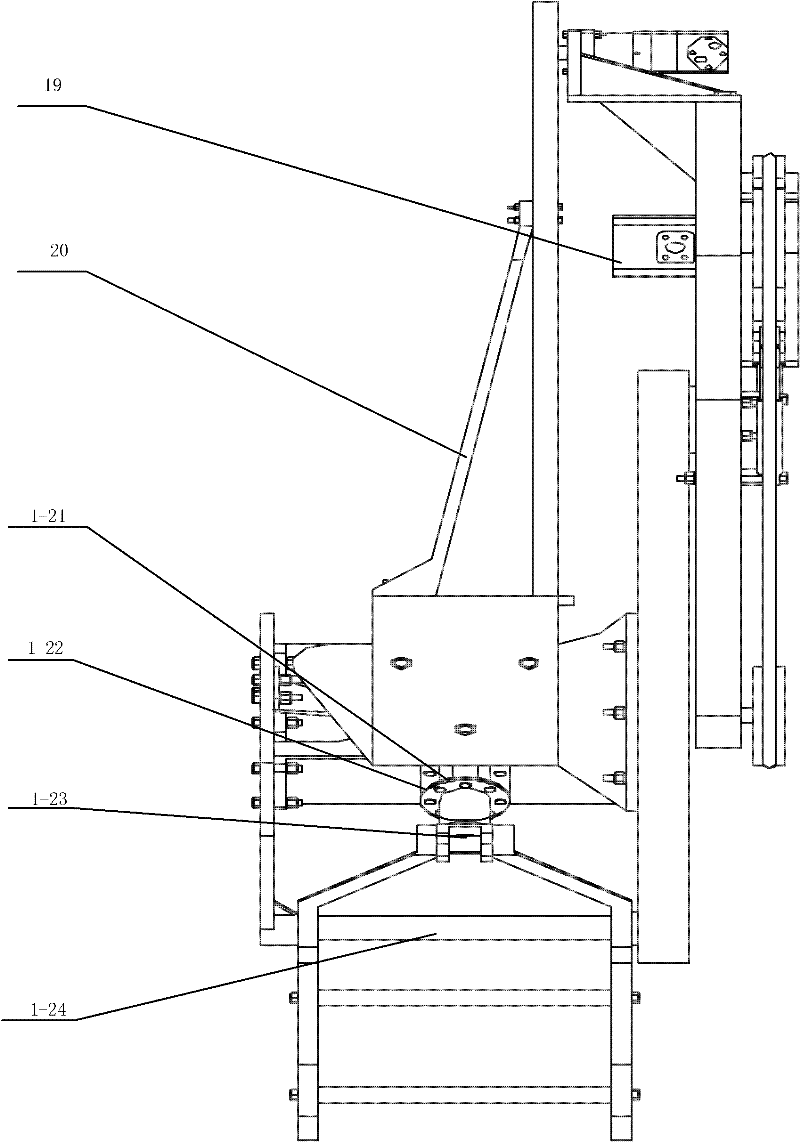

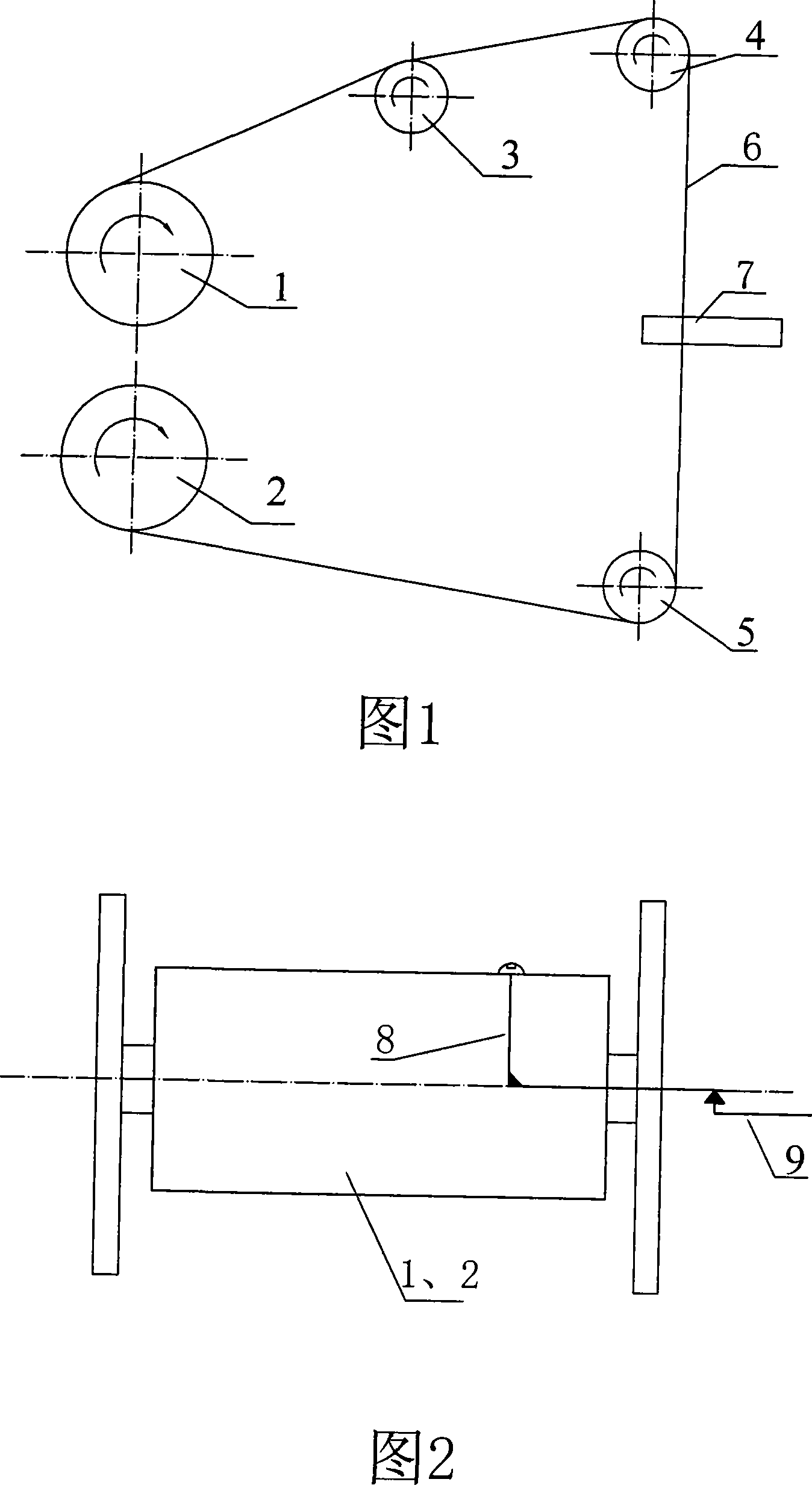

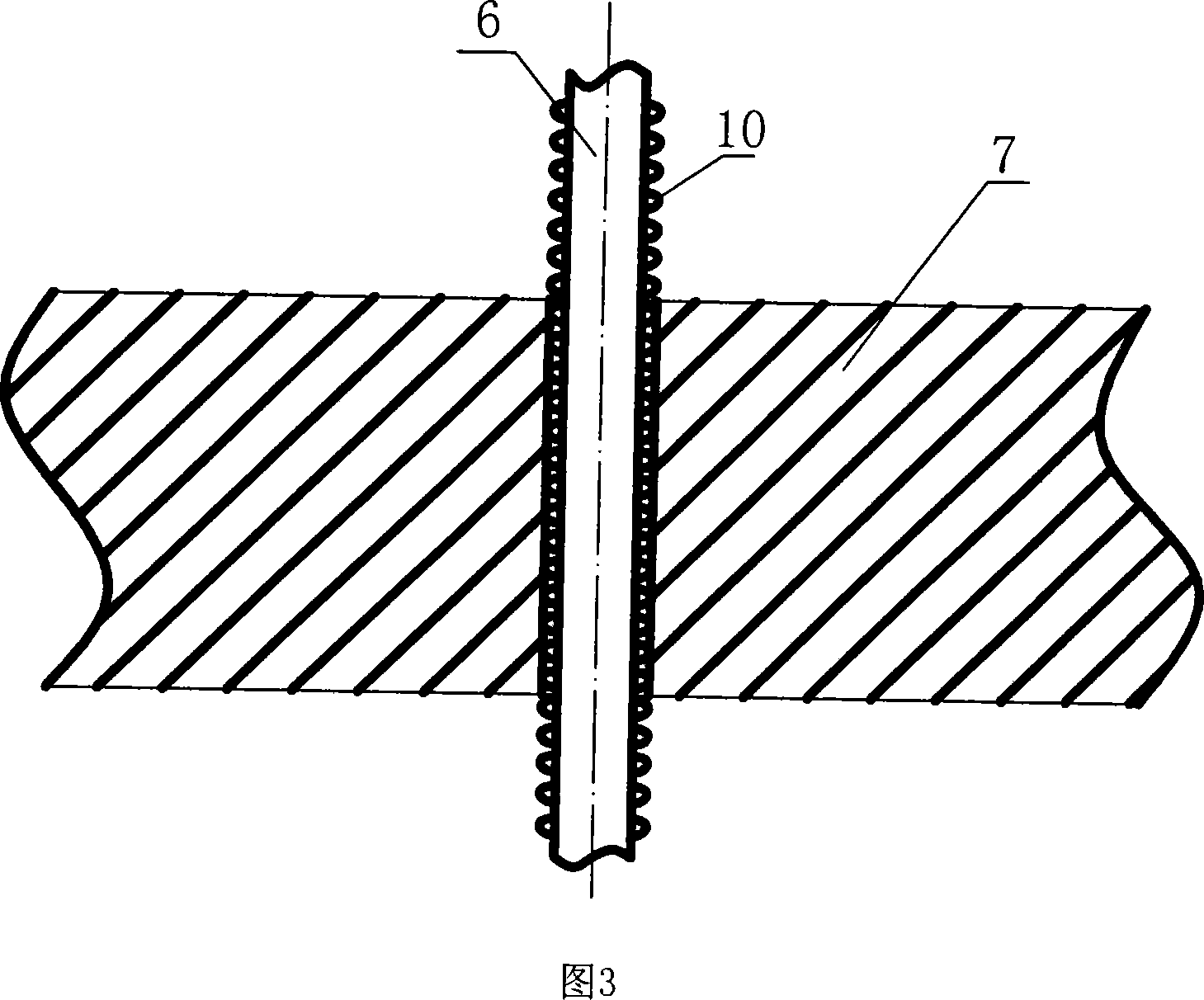

Variable structure adaptive feed type rope saw

InactiveCN102229009ALarge diameter rangeGuaranteed tensionMetal sawing devicesHydraulic cylinderControl system

The invention mainly aims to provide a variable structure adaptive feed type rope saw for cutting composite pipes with different diameters amphibiously. The rope saw consists of a clamping mechanism, a cutting mechanism, a feeding mechanism and a tensioning mechanism; the clamping mechanism comprises a V-shaped plate, the V-shaped plate is formed by folding two mutually independent half plates, each half plate is connected with respective sliding block, and the sliding block and a guide rail I form a sliding pair; the two half plates fixed on respective sliding blocks can move relatively in the radial direction along the guide rail I; the half plates are connected with a hydraulic cylinder respectively, and the hydraulic cylinder is connected with a control system; and the lower ends of the half plates are connected with clamping claws through fixing pins, and the rear ends of the clamping claws are connected with the hydraulic cylinder. The rope saw is suitable for the pipes with diameters of phi 300 to phi 1,500 millimeters, so the diameter range of the cut pipes is greatly expanded; and meanwhile, different cutting speeds can be automatically adjusted according to different cutting states to adapt the rope saw, and the cutting efficiency is improved.

Owner:HARBIN ENG UNIV

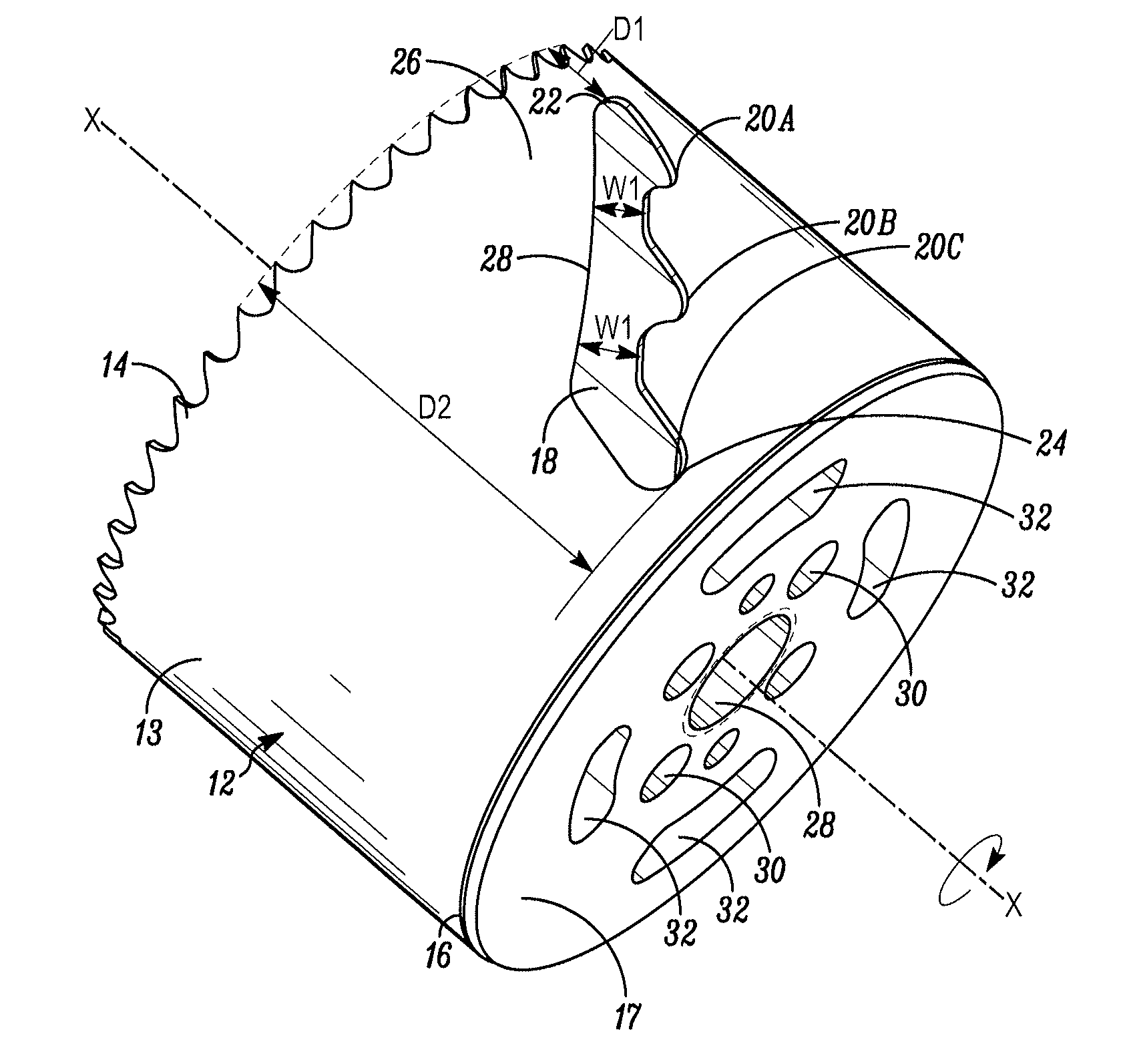

Hole Cutter with Chip Egress Aperture

ActiveUS20110170967A1Easy to moveAvoid collectingTransportation and packagingCircular sawsMechanical engineering

A hole cutter has a substantially cylindrical blade body defining a blade body circumference, a cutting edge formed on one end of the blade body, and an axially-elongated slot formed through the substantially cylindrical blade body. The axially-elongated slot is configured to receive chips flowing from the cutting edge within the interior of the blade body and (i) into the slot, and / or (ii) through the slot, to prevent the collection of such chips within the interior of the blade body and / or at an interface between the blade body and work piece. The axially-elongated slot defines a first end adjacent to the cutting edge, a second end axially spaced further from the cutting edge, and a slot area. The hole cutter further defines a total slot area to blade body circumference ratio within the range of about 0.1 to about 0.3 depending on the size of the hole cutter.

Owner:BLACK & DECKER INC

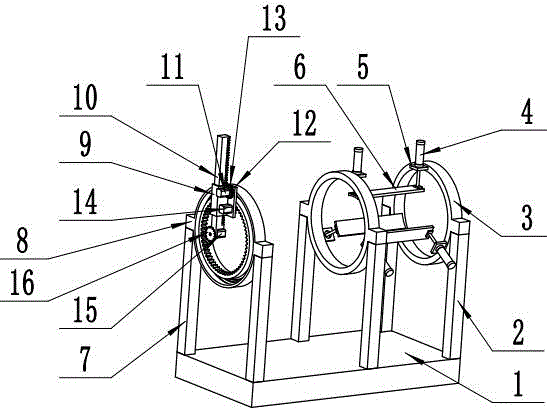

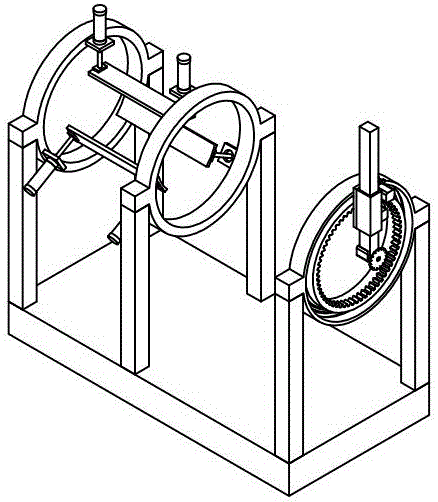

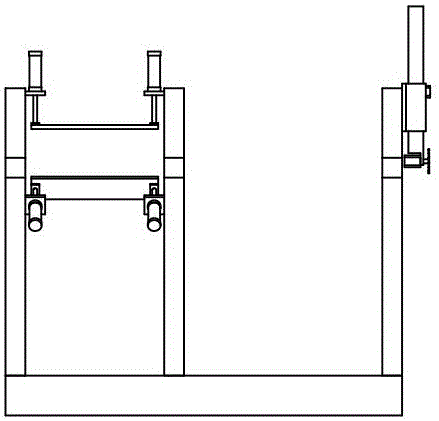

Outer-pipe circular cutting robot for steel pipe

ActiveCN106001735AImprove cutting efficiencyFast cutting speedTube shearing machinesShearing machine accessoriesGear wheelElectric machinery

The invention relates to an outer-pipe circular cutting robot for a steel pipe. The robot comprises a base, a steel pipe pressing plate, a circular cutting frame, an expansion link sleeve, an expansion link, an expansion link motor, a cutting mechanism fixing plate, a rotary motor, a cutting blade, an electric brush, an expansion link rack and an expansion link cutting motor fixing frame, wherein steel pipe frame stand columns of the expansion link motor fixing plate is fixedly arranged on the base, a steel pipe fixing sleeve is fixedly arranged on the steel pipe frame stand columns, the circular cutting frame is fixedly arranged on circular cutting frame stand columns, and the circular cutting frame stand columns are fixedly arranged on the base; the expansion link is arranged on the expansion link sleeve in a sliding way, the expansion link motor is fixedly arranged on the expansion link motor fixing plate, a stretching motor gear is fixedly arranged on an expansion link motor shaft, and the stretching motor gear is meshed with the expansion link rack; and the cutting motor is fixedly arranged on the expansion link cutting motor fixing frame, and the cutting blade is fixedly arranged on the cutting motor shaft. The robot can improve the steel pipe cutting efficiency, and is high in cutting speed, trim in notches and good in effect.

Owner:青岛昊坤机械制造有限公司

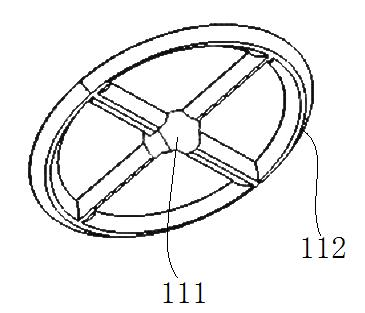

Wave saw blade

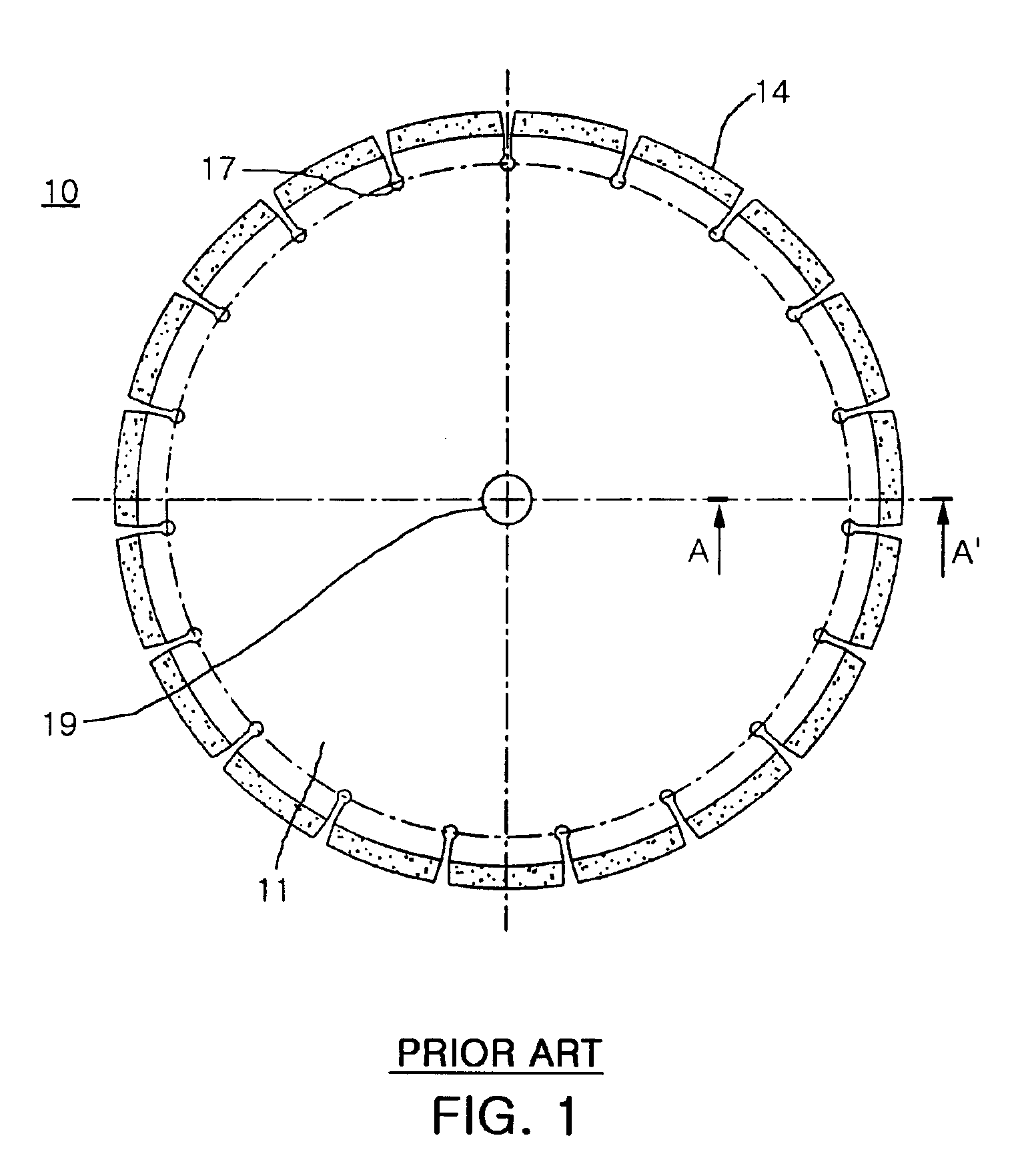

InactiveUS6872133B2Withstanding cutting forceReduce vibrationRevolution surface grinding machinesMetal sawing toolsWave shapeMechanical engineering

A saw blade for cutting hard workpieces, such as concrete or stone, characterized by improvement of the shape of a shank of the saw blade providing a plurality of cutting tips of the saw blade with a rotational force while the cutting tips are securely attached to the shank. The saw blade comprises a disc-shaped shank having an insertion hole formed at the center thereof, through which a rotating shaft of an electric-powered tool is inserted, and wave-shaped portions formed over a prescribed portion of the radius of the disc-shaped shank, and a plurality of cutting tips attached to the outer circumference of the shank for cutting a workpiece. The wave-shaped portions are spaced a prescribed distance from each other and alternately arranged on the front and rear surfaces of the disc-shaped shank. The prescribed portion of the radius of the disc-shaped shank is at a distance from the center of the insertion hole. The cutting tips contain particles of high hardness.

Owner:NIWA DAIYAMONDO INDS

Novel manufacturing method for back drilling of PCB (Printed Circuit Board)

InactiveCN101998768AImprove the problem of cloakingProtect from being etchedPrinted circuit manufactureBoring/drilling machinesEngineeringFlying probe

The invention discloses a novel manufacturing method for the back drilling of a PCB (Printed Circuit Board), which comprises the steps of: A) drilling the PCB substrate for the first time after the PCB substrate is subjected to cutting, bonding with a dry film, browning the inner layer and treating with a pressing board; B) carrying out the copper-deposition panel electroplating or added-panel electroplating; C) carrying out the back drilling on holes to be subjected to the back drilling; D) carrying out alkaline etching treatment on the board subjected to the back drilling; and E) carrying out solder stripping treatment on the PCB board, detecting the PCB board subjected to the solder stripping treatment through a flying probe tester and obtaining a finished product when the PCB is detected to be qualified. In the manufacturing method, the pattern tin electroplating is carried out after the external layer dry film on the PCB is made, then the back drilling is carried out on the hole to be subjected to the back drilling, and then etching is carried out so that the burr generated in the course of the drilling can be eliminated and the copper in a part of the hole with the copper can be protected from being etched at the same time.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

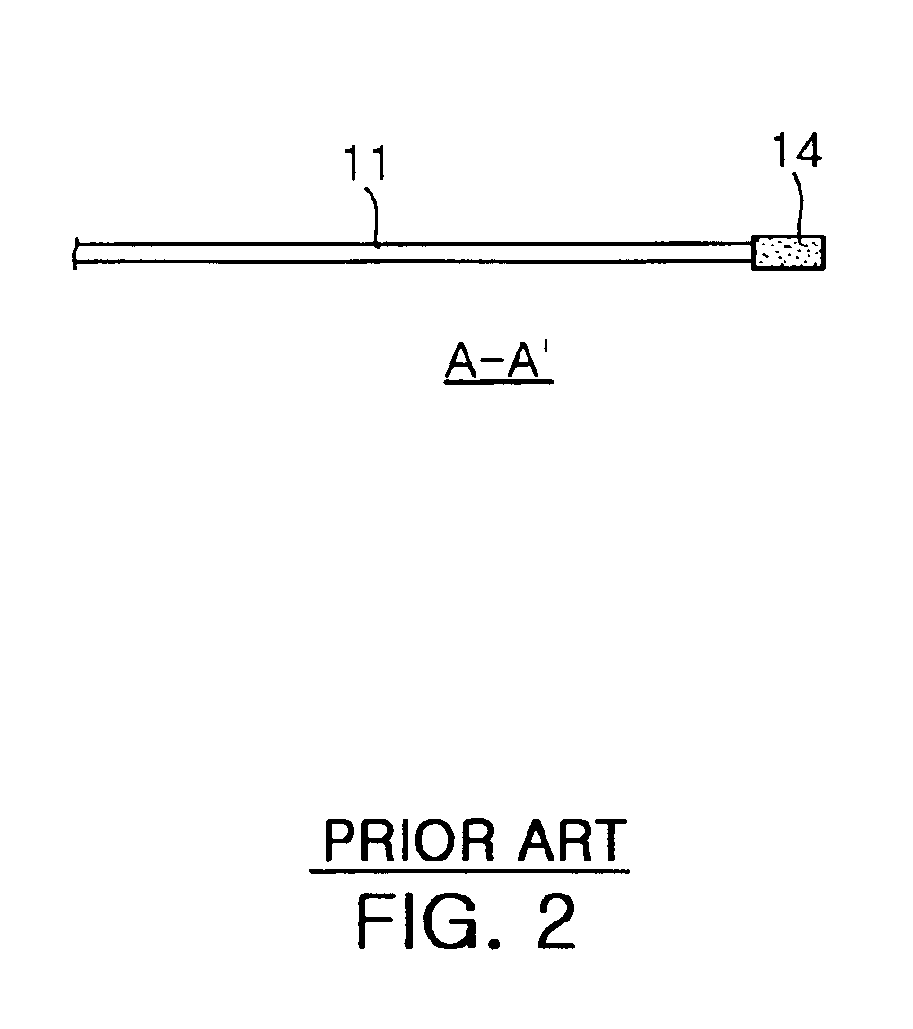

Thread cutting tap and a method of its manufacture

InactiveUS7553114B2Improved chip handling propertyFast cutting speedThread cutting toolsWood turning toolsFluteEngineering

A thread cutting tap having a threaded portion for cutting out a thread in a wall of a workpiece opening into which the threaded portion is to be introduced. The threaded portion is provided with at least two cutting edges extending in a circumferential direction of the body. Each cutting edge is an integral peripheral part of a flank portion extending substantially radially from the body. The flank portions define between one another a chip removal flute extending in the longitudinal extension of the body for removal of chips. At least one of the flank portions has a side wall divided into a pair of elongated concave surfaces separated by an elongated ridge constituting a chip-breaking member. The chip removal flutes are at least partly helically shaped.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Monocrystalline silicon high-efficient composite cutting method and cutting system thereof

InactiveCN101138869AImprove cutting effectSave the texture processFine working devicesMetalElectric spark

An efficiently composite cutting method of monocrystalline silicon is characterized in that a monocrystalline silicon rod for cutting is installed and nipped at an electric spark linear cutting machine; metallic thread which is concreted with diamond grinding material is used as cutting wire to make the electric spark linear cutting; the advantages that the processing speed of the electric spark linear cutting is high and the cutting effect of the diamond grinding material at the metallic thread of the concreted grinding material is good are completely exerted; the purpose to realize the quickly and efficiently cutting towards the monocrystalline silicon rod is achieved; at the same time the surface of the cut monocrystalline silicon naturally forms a fleece-faced texture which has the effect of anti-reflection. The present invention has a series of advantages of simple method, high efficiency of processing, good quality etc.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

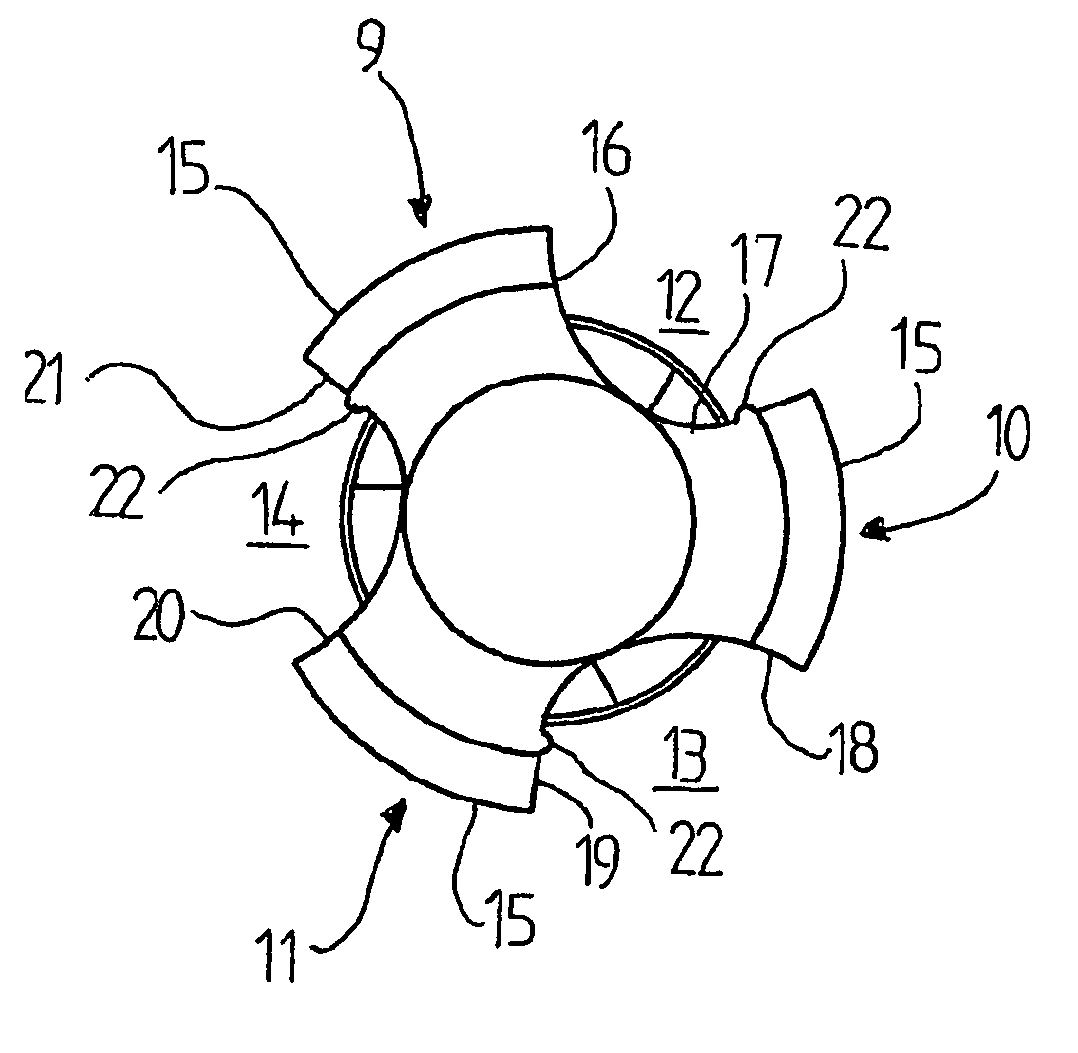

Ultrasonic rotary-hammer drill

InactiveUS7740088B1Light weightConsume low amountDrill bitsPiezoelectric/electrostriction/magnetostriction machinesDrive shaftAcoustic wave

A mechanism for drilling or coring by a combination of sonic hammering and rotation. The drill includes a hammering section with a set of preload weights mounted atop a hammering actuator and an axial passage through the hammering section. In addition, a rotary section includes a motor coupled to a drive shaft that traverses the axial passage through the hammering section. A drill bit is coupled to the drive shaft for drilling by a combination of sonic hammering and rotation. The drill bit includes a fluted shaft leading to a distal crown cutter with teeth. The bit penetrates sampled media by repeated hammering action. In addition, the bit is rotated. As it rotates the fluted bit carries powdered cuttings helically upward along the side of the bit to the surface.

Owner:NAT AERONAUTICS & SPACE ADMINISTATION U S GOVERNMENT AS REPRESENTED BY THE ADMINISTATOR OF THE

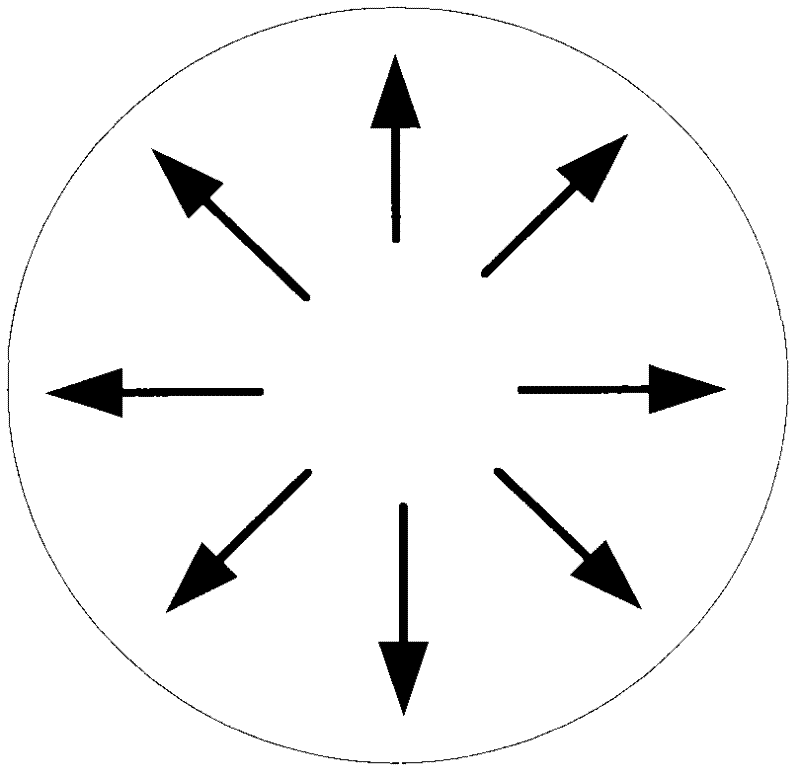

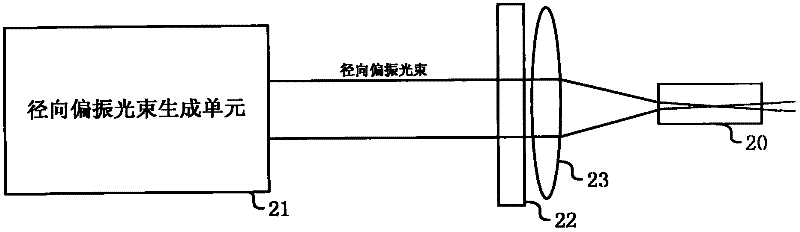

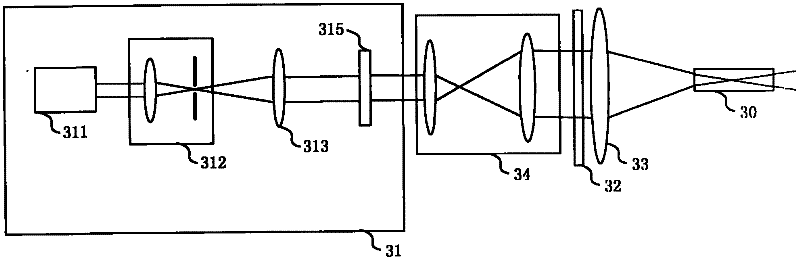

Laser beam based micropore machining device and method

InactiveCN102642092AFlexible control of cutting depthFlexible control of cutting widthLaser beam welding apparatusLight beamDiameter ratio

The invention relates to a laser beam based micropore machining device and method. The device comprises a radially polarized beam generation unit for converting a laser beam into a radially polarized beam, and emitting the radially polarized beam to a diffractive optical element, the diffractive optical element for modulating the amplitude and phase of the radially polarized beam, and emitting the modulated radially polarized beam to a focusing lens, and the focusing lens for focusing the modulated radially polarized beam, and obtaining a focusing field of the radially polarized beam in the vicinity of a focus of the focusing lens, wherein the intensity distribution of the focusing filed is determined by the structure of the diffractive optical element and the numerical aperture of the focusing lens, and the micropore machining of a material to be machined is carried out by controlling the intensity distribution of the focusing field. The laser beam based micropore machining device provided by the embodiment of the invention can be used for machining the micropores with large depth to diameter ratio and improving the cutting speed and efficiency of the micropores.

Owner:BEIJING INFORMATION SCI & TECH UNIV

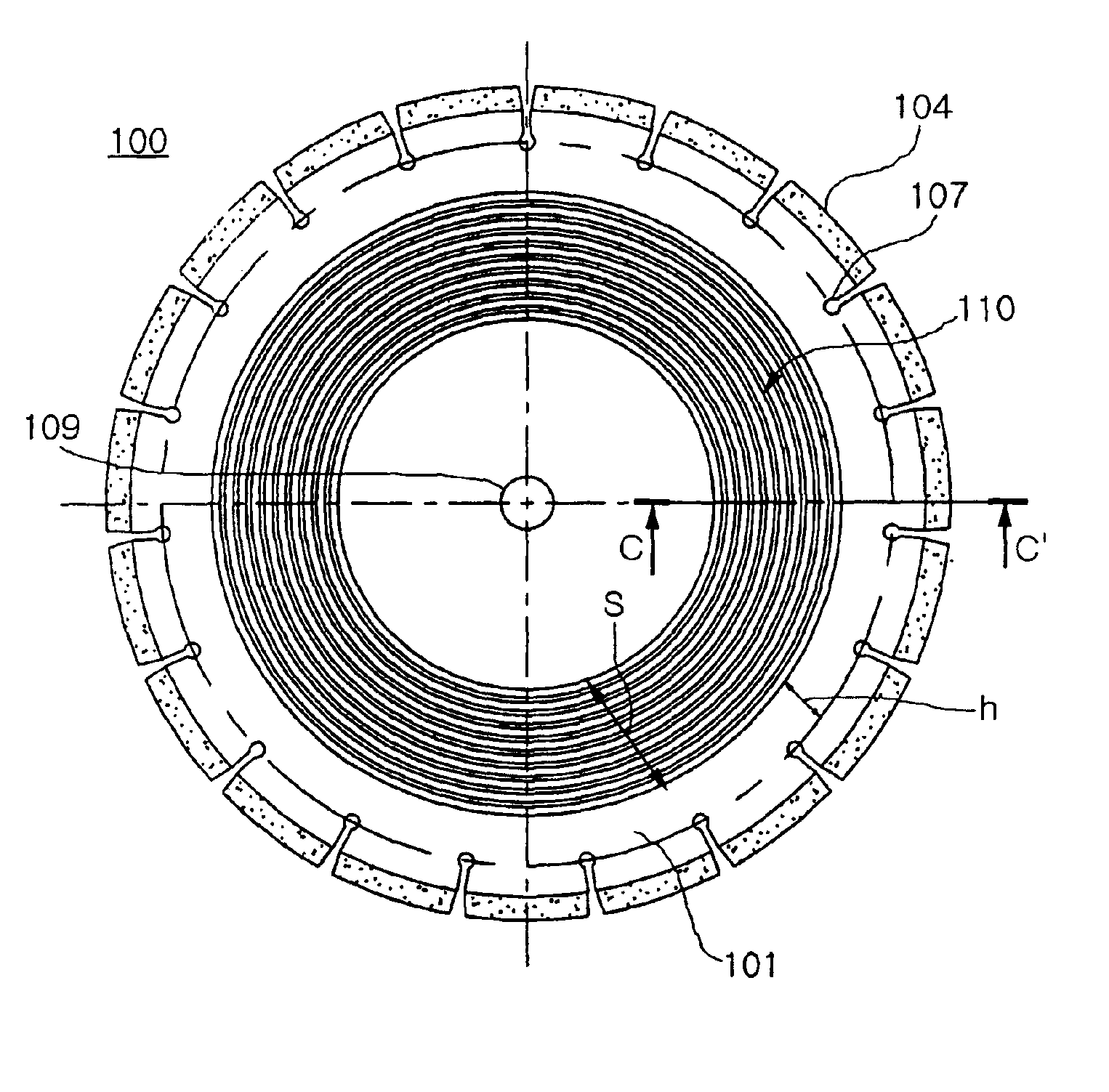

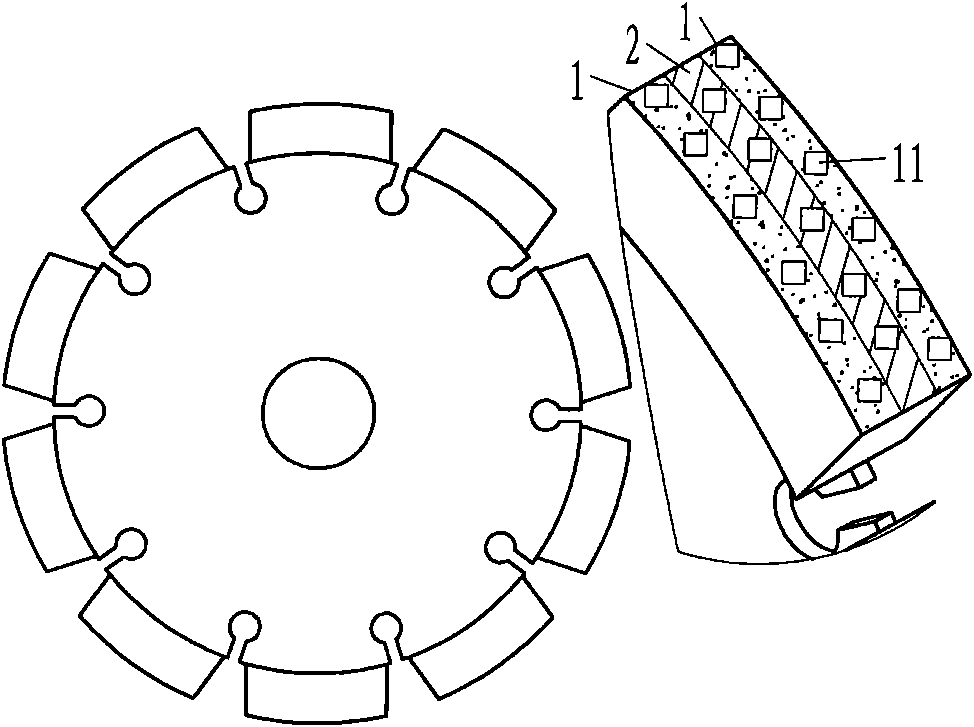

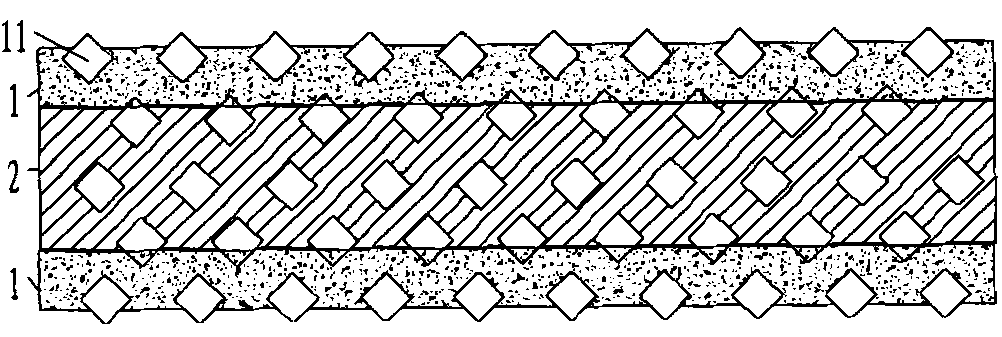

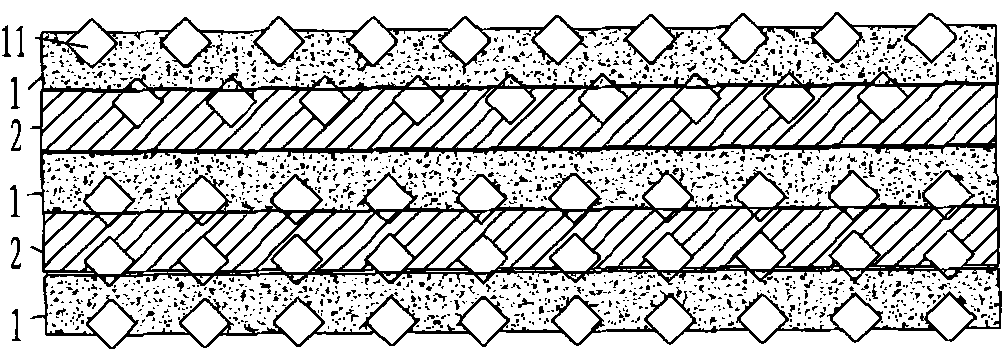

Brazing-hot pressing diamond tool and manufacturing method thereof

The invention relates to a grinding tool, in particular to a brazing-hot pressing diamond tool. The diamond tool consists of a steel matrix and a diamond tool bit, wherein the diamond tool bit consists of a plurality of alloy layers which are vertical to a working surface of the tool bit; the alloy layers are prepared from two alloy matrixes with different formulas by a vacuum hot pressing method; a prearranged diamond abrasive particle layer is arranged inside each alloy matrix layer; outer layers on two sides of the tool bit are brazing alloy matrix layers (1); a single-layer prearranged diamond abrasive particle layer is arranged inside each brazing alloy matrix layer (1); an intermediate layer of the tool bit is a pre-alloying matrix layer (2); and a single-layer or multi-layer prearranged diamond abrasive particle layer is arranged inside the pre-alloying matrix layer (2). The brazing-hot pressing diamond tool solves the problem that a multi-layer brazing tool is covered by a thick solder layer so as to cause low exposure effect and also solves the problem that a sintered diamond tool is insufficient in diamond holding force so as to make the diamond fall off too early. Therefore, the service life of the diamond tool is greatly prolonged and the processing efficiency thereof is greatly improved.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

Rotary contact structures and cutting elements

Owner:DVORACHEK HAROLD A

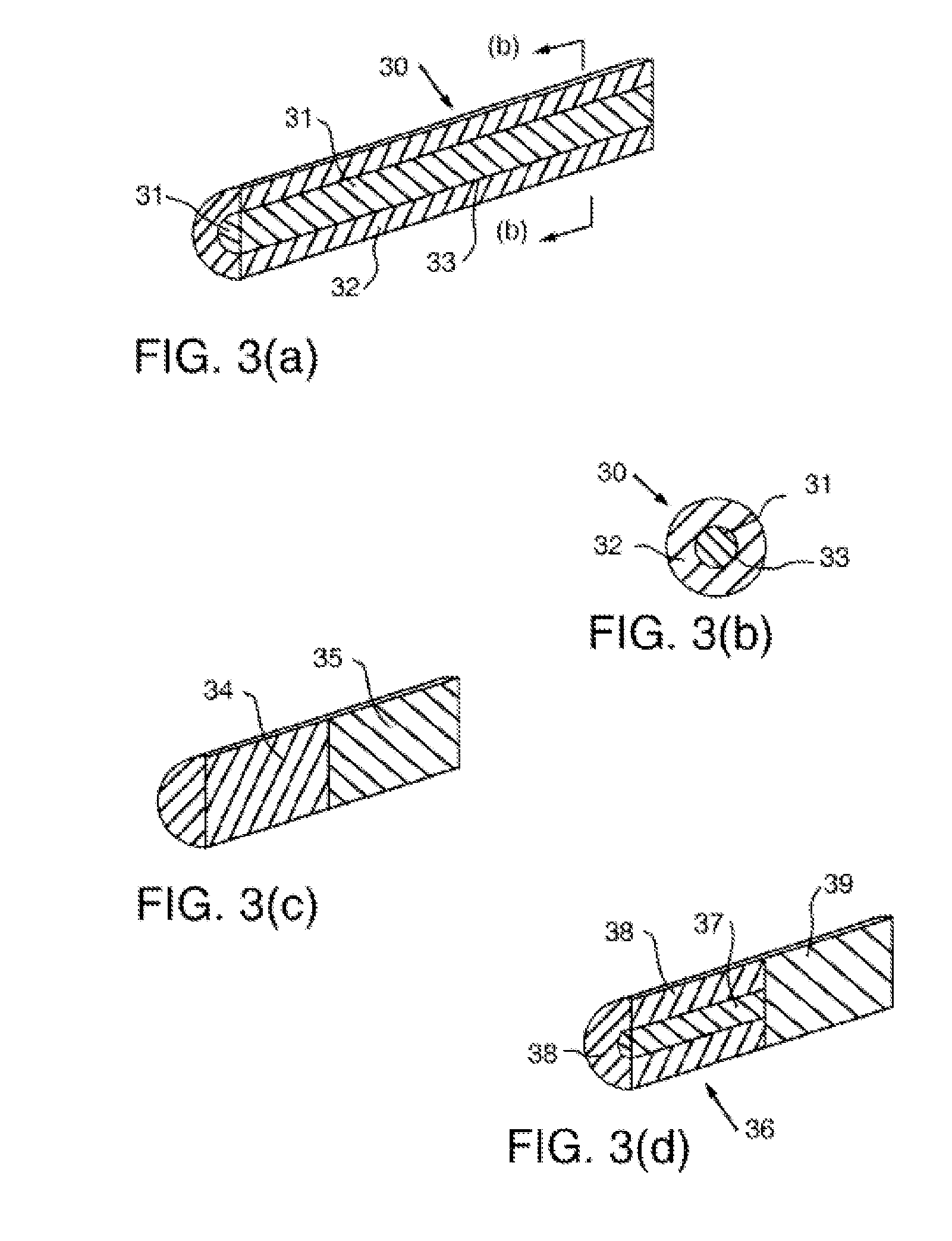

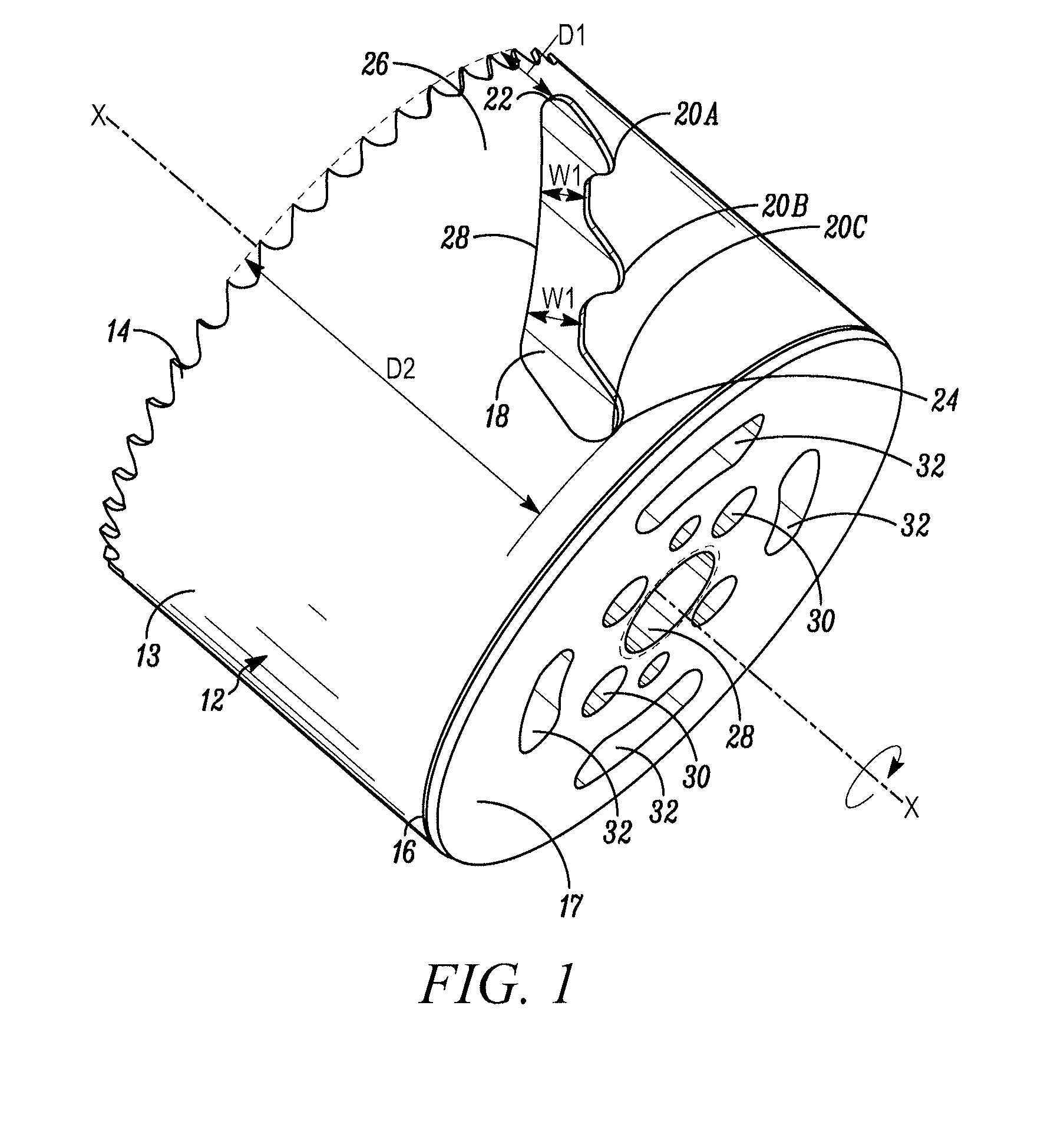

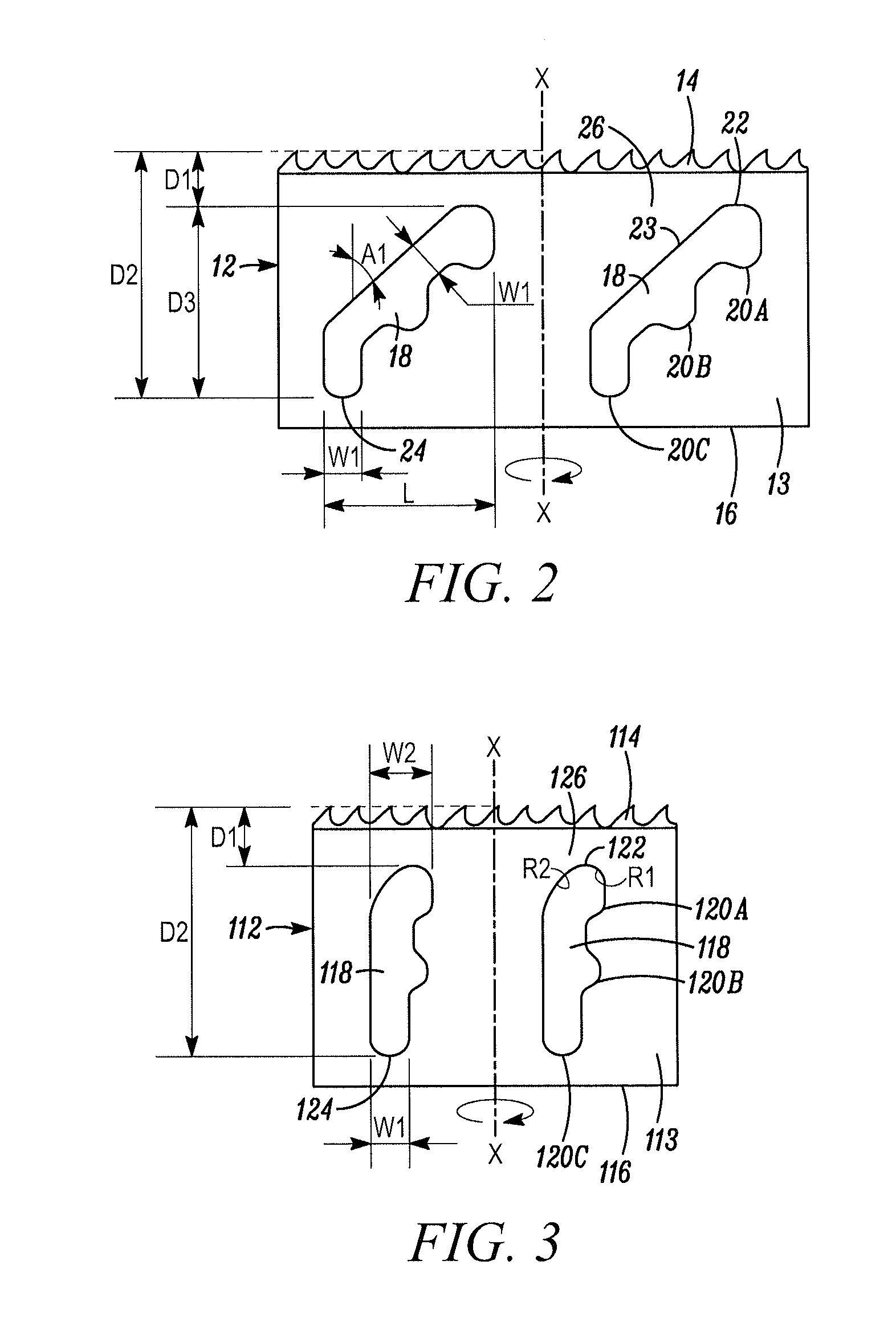

Reciprocating saw blade having variable-height teeth and related method

ActiveUS8210081B2Increase loadHigh teethMetal sawing devicesMetal sawing toolsPortable powerEngineering

A reciprocating saw blade, for use in a portable power reciprocating saw including a chuck for releasably engaging the saw blade, includes a tang having an elongated axis and being engageable with the chuck for attaching the saw blade to the reciprocating saw. The saw further includes a blade portion having a cutting edge that defines a plurality of cutting teeth. The cutting teeth define a repeating pattern of successive groups of teeth. Each group of teeth is less than about a half inch in length, and includes a plurality of laterally offset teeth, at least one relatively high first tooth and at least one relatively low second tooth. Prior to tooth set, the at least one relatively high first tooth is at least about 0.002 inch higher than the at least one relatively low second tooth.

Owner:BLACK & DECKER INC

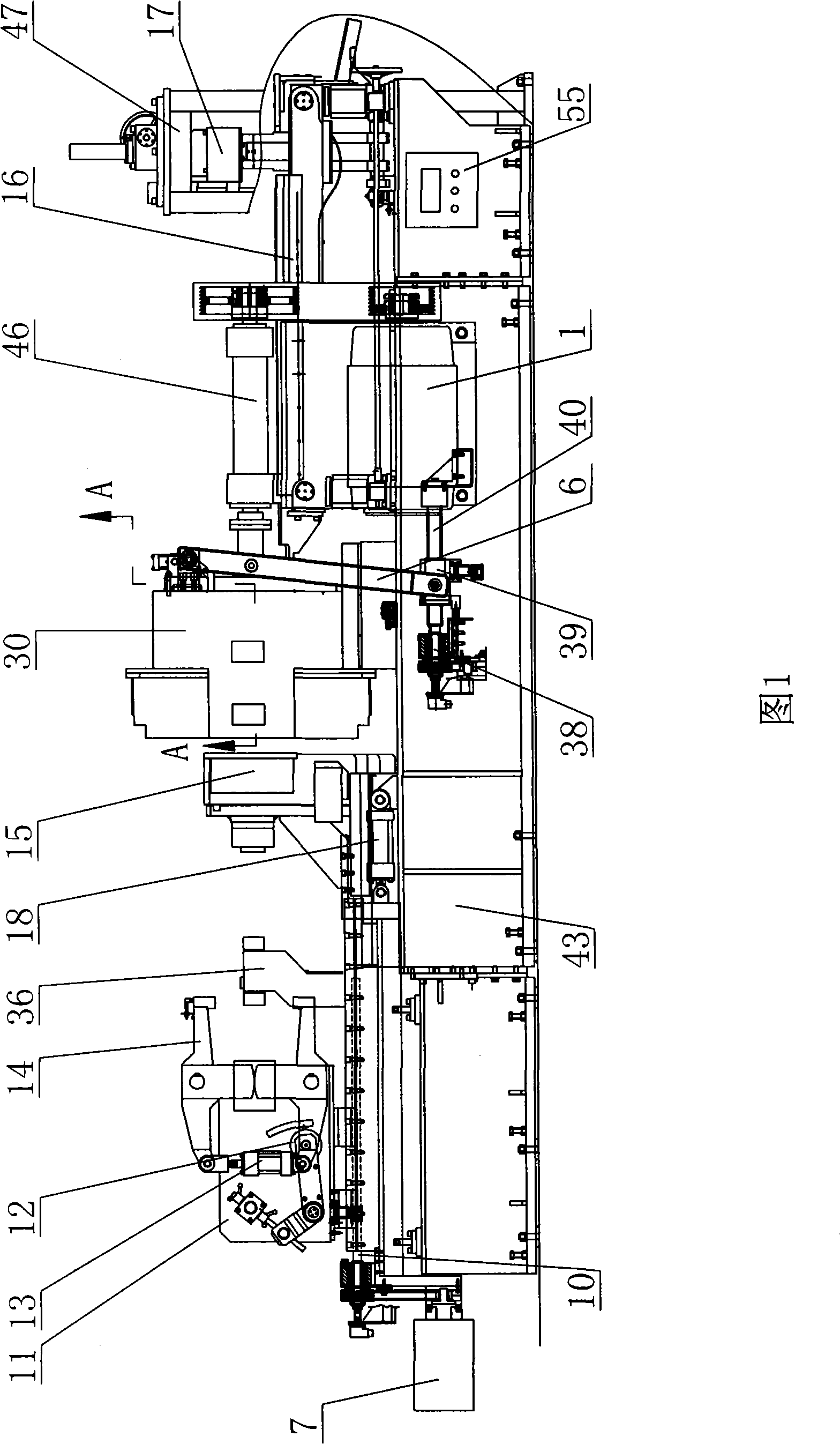

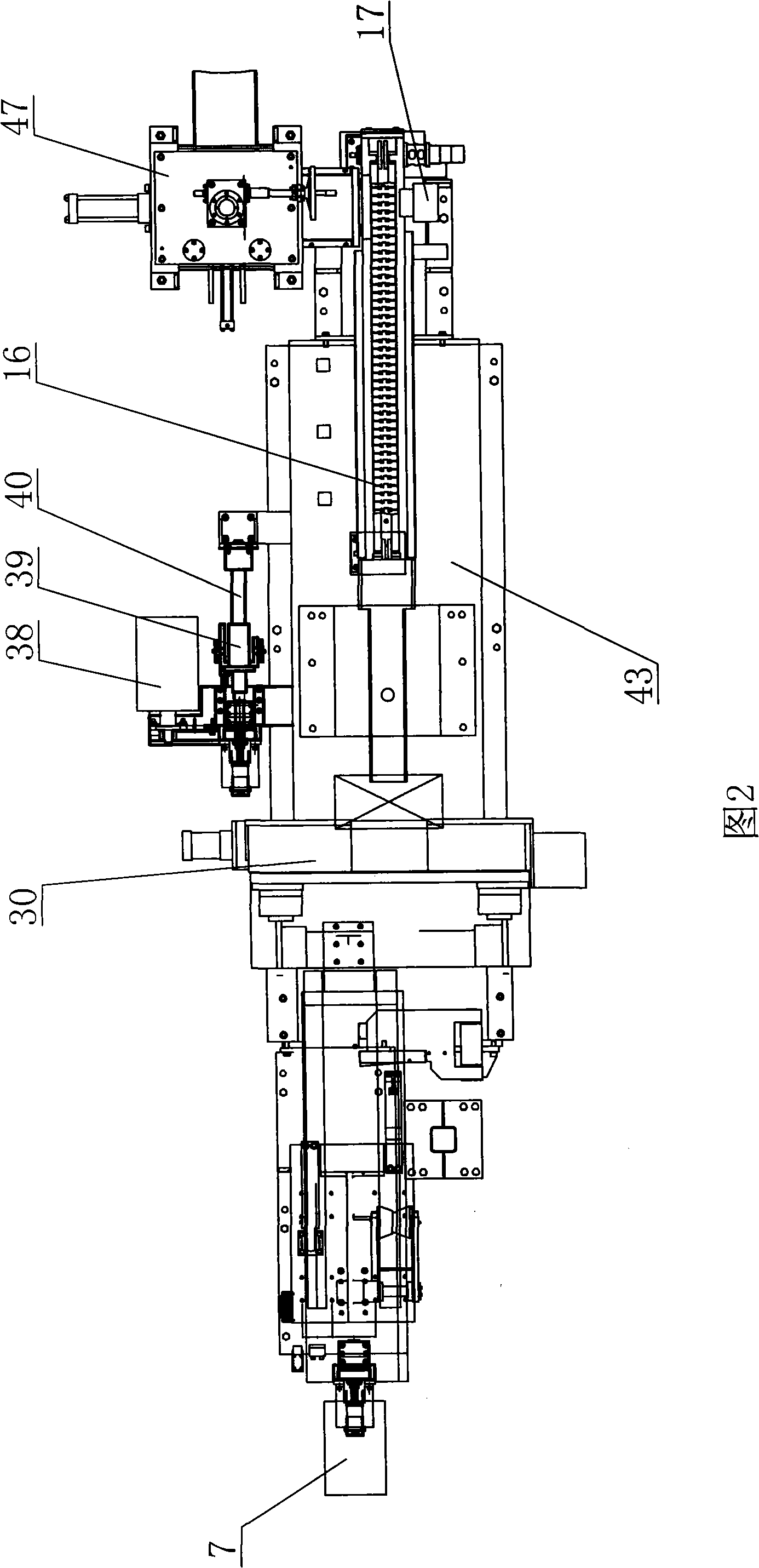

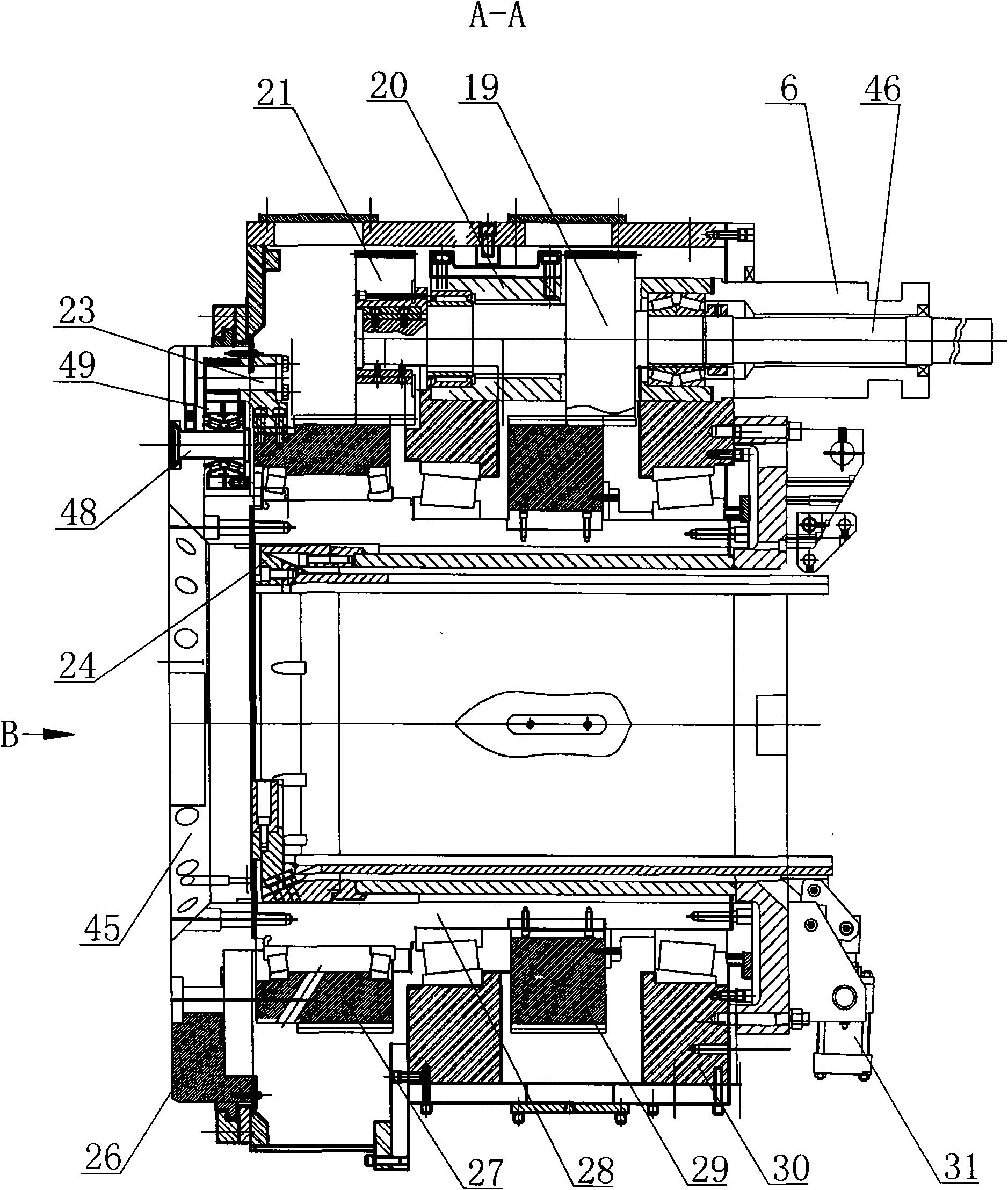

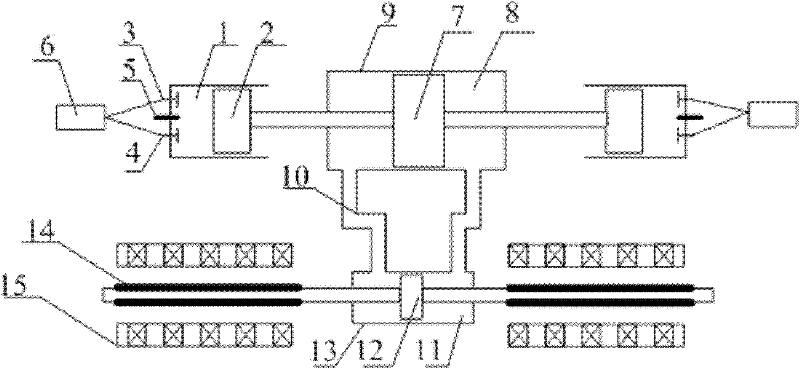

Machine tool for cutting pipe

ActiveCN101279384ASave powerEasy to controlFeeding apparatusTube shearing machinesGear wheelDrive shaft

The invention discloses a tube-cutting machine tool, comprising a machine tool body which is provided with a main shaft box, a main motor, a feeding device and a clamping device; the interior of the main shaft box is provided with a main shaft and a transmission shaft, the main motor is connected with the transmission shaft by a transmission device, a first main transmission bevel gear and a first feed bevel gear are arranged on the main shaft, one end of the main shaft is provided with a tool pan, a tool is arranged on the tool pan, a second main transmission bevel gear and a second feed bevel gear are arranged on a transmission shaft, a feed box is arranged on the transmission shaft, a feed power and transmission device is arranged on the machine tool body, the feed power and transmission device is connected with the feed box, a first feed transmission block is arranged on the first feed bevel gear, a second feed transmission block is arranged on the tool pan, and a transmission direction-changing device is arranged between the first feed transmission block and the second feed transmission block. The tube-cutting machine tool can realize the automatic feed, automatic size fixation and automatic clamping, the tool can carry out the automatic feed and withdrawal, and the clamping device can be released automatically after the processing, thus automatically transmitting the finished product and greatly improving the working efficiency.

Owner:山东德晟机器人股份有限公司

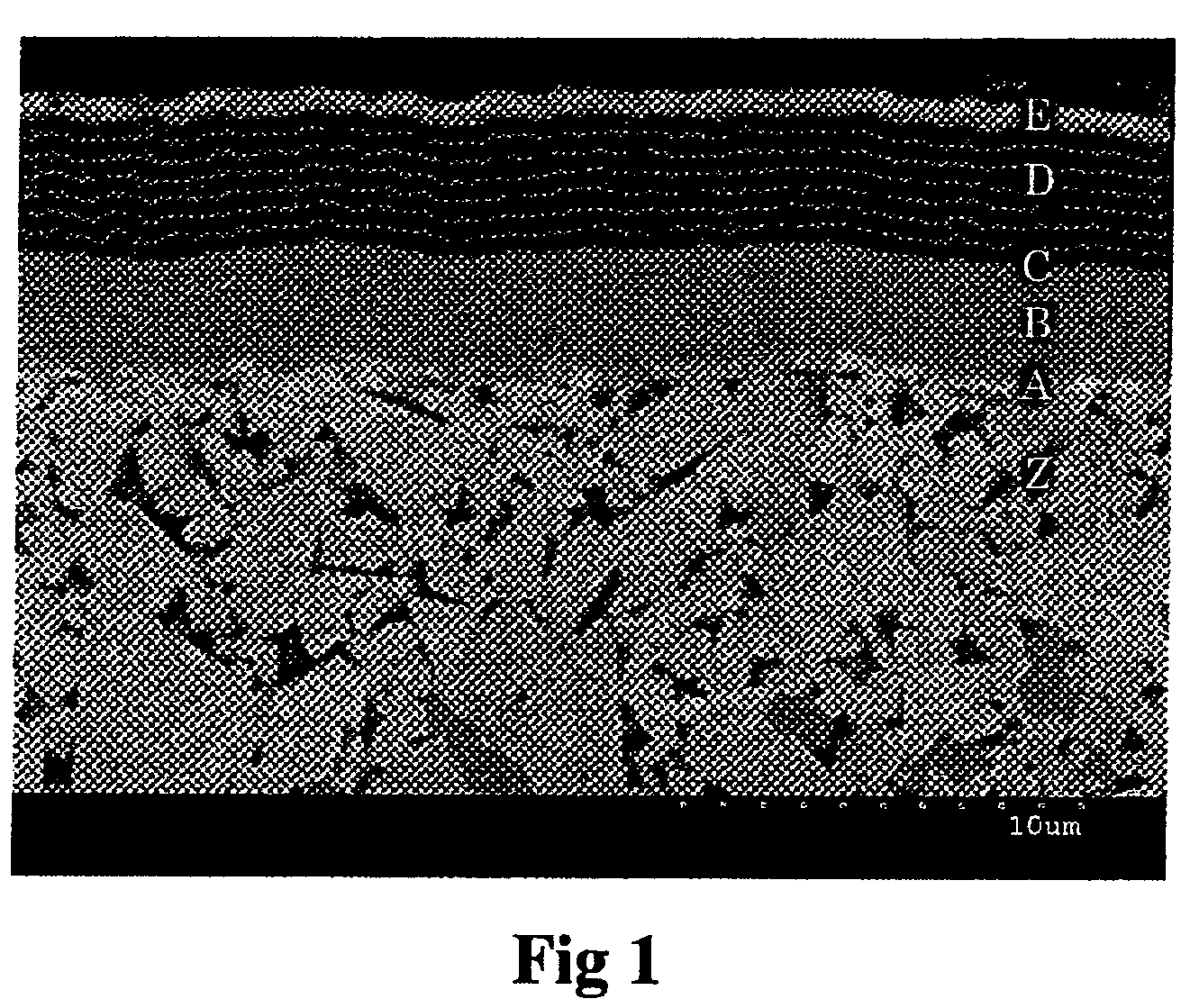

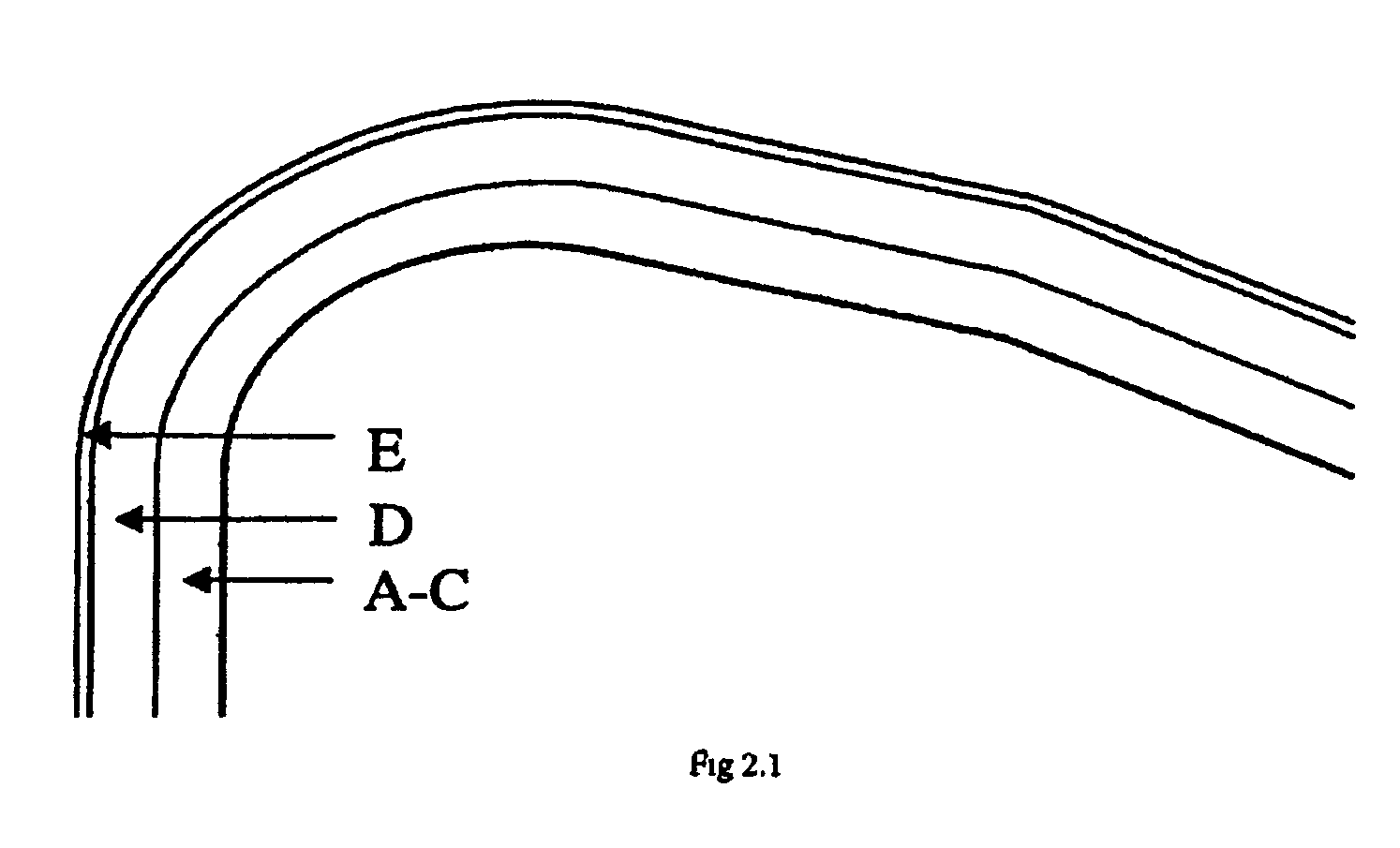

Coated insert

ActiveUS7396371B2Improve performanceFast cutting speedPigmenting treatmentOther chemical processesCemented carbideLayer thickness

The present invention relates to a cutting insert particularly for turning of stainless steel comprising a cemented carbide substrate and a post-treated coating witha substrate of cemented carbide having a composition of from about 5.0 to less than about 8.0 wt % Co, from about 3.0 to about 8.0 wt % cubic carbides of the metals Ti, Ta and Nb with a Ti / (Ti+Ta+Nb) ratio of from about 0.05 to about 0.3 and balance tungsten carbide (WC) having a grain size of from about 1.5 to about 3.5 μm in the as-sintered state. Further, the substrate has a surface zone of from about 5 to about 30 μm characterized by an enrichment of binder phase and a depletion of cubic carbides,and a coating having a first, innermost layer system of one or several layers of TiCxNyOz with x+y+z≦1 with a total thickness of from about 0.7 to about 5.5 μm and a second multilayer system consisting of from about 5 to about 31 alternating layers of Al2O3 and TiCxNyOz (x+y+z≦1), preferably κ-Al2O3 and TiN, the Al2O3-layers having an individual layer thickness of less than about 0.5 μm and the TiCxNyOz-layers less than about 0.2 μm with a total thickness of the multilayer of from about 1.0 to about 5.0 μm. The multilayer is exposed along the edge line and into the rake and flank face. In an alternative embodiment the multilayer is replaced by an Al2O3-layer.

Owner:SANDVIK INTELLECTUAL PROPERTY AB +1

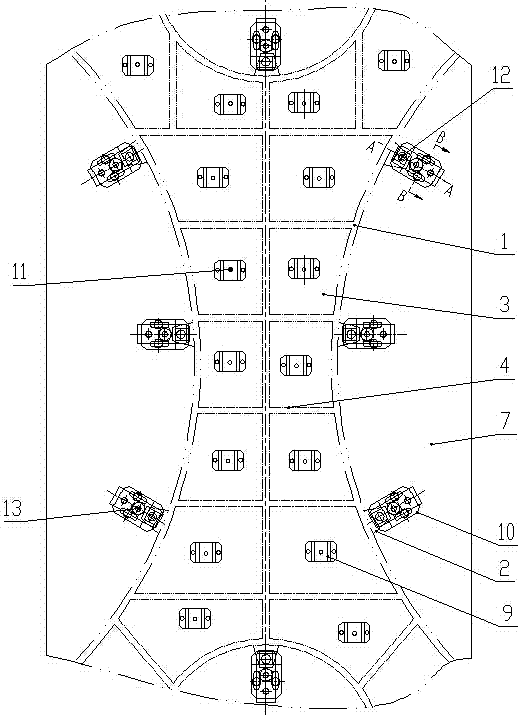

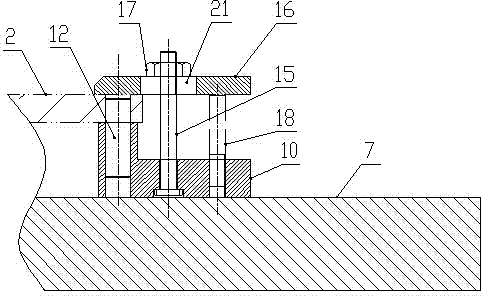

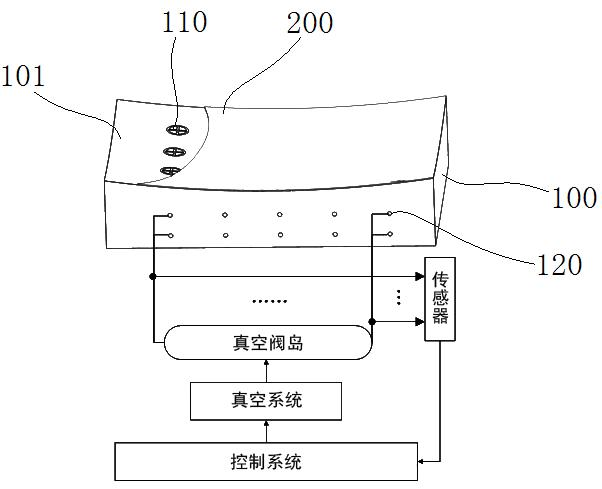

Multipoint profiling rigid clamp and method for processing thin-wall workpiece by using same

InactiveCN102179708ASolve rigid problemsSolve Vibration ProblemsPositioning apparatusMetal-working holdersControl systemSurface type

The invention discloses a multipoint profiling rigid clamp, comprising a clamp body. The clamp body is provided with a positioning surface for positioning a processed workpiece; the positioning surface is provided with a vacuum sucker; the clamp body is internally provided with a vacuum hole channel; one end of the vacuum hole channel is connected with the vacuum sucker, and the other end of the vacuum hole channel is connected with a vacuum valve island arranged at the outer part of the clamp body; the vacuum valve island is connected with a vacuum system connected with a control system; andthe vacuum hole channel is also connected with the control system by a vacuum sensor. A method for processing a thin-wall workpiece by using the multipoint profiling rigid clamp comprises the steps of: modeling, analyzing, determining and optimizing key positioning points, arranging the vacuum sucker, processing the positioning surface of the clamping body and finally carrying out processing on the thin-wall workpiece. The multipoint profiling rigid clamp is used for a high-speed milling finish processing stage of the complex profile of the thin-wall workpiece, the positioning surface of the clamp is consistent to the surface type of the processed workpiece, the uniform distribution of a clamping force is guaranteed and the clamping and the deformation of the thin-wall workpiece are avoided.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Hydraulic high-speed free piston linear generator

The invention relates to a hydraulic high-speed free piston linear generator and belongs to the field of energy power. The hydraulic high-speed free piston linear generator mainly comprises a free piston internal combustion engine, a hydraulic transmission mechanism and a linear generator, wherein the hydraulic transmission mechanism comprises a first hydraulic piston, a first hydraulic cavity, afirst hydraulic pump, a high-pressure oil pipe, a second hydraulic cavity, a second hydraulic piston and a second hydraulic pump; the connection relation in the hydraulic transmission mechanism is that: the first hydraulic piston is arranged in the first hydraulic pump, the second hydraulic piston is arranged in the second hydraulic pump, and the first hydraulic pump is communicated with the second hydraulic pump through the high-pressure oil pipe, so that the hydraulic transmission mechanism is formed; two free pistons of the internal combustion engine and the first hydraulic piston form a piston component through connecting rods; and an active cell of the linear generator is connected with the second hydraulic piston through another connecting rod. By adopting the hydraulic transmissionmechanism, the cutting speed of a motor active cell is increased and the working efficiency is improved; and the speed of the motor active cell is n times higher than the motion speed of the piston.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com