Variable structure adaptive feed type rope saw

An adaptive and variable structure technology, which is applied in the direction of sawing machine, metal sawing equipment, metal processing equipment, etc., can solve the problems of increasing equipment manufacturing cost, inability to use pipes with different diameters, and narrow use range, so as to improve work stability The effect of increasing the degree of difficulty, increasing the difficulty of the structure, and increasing the cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

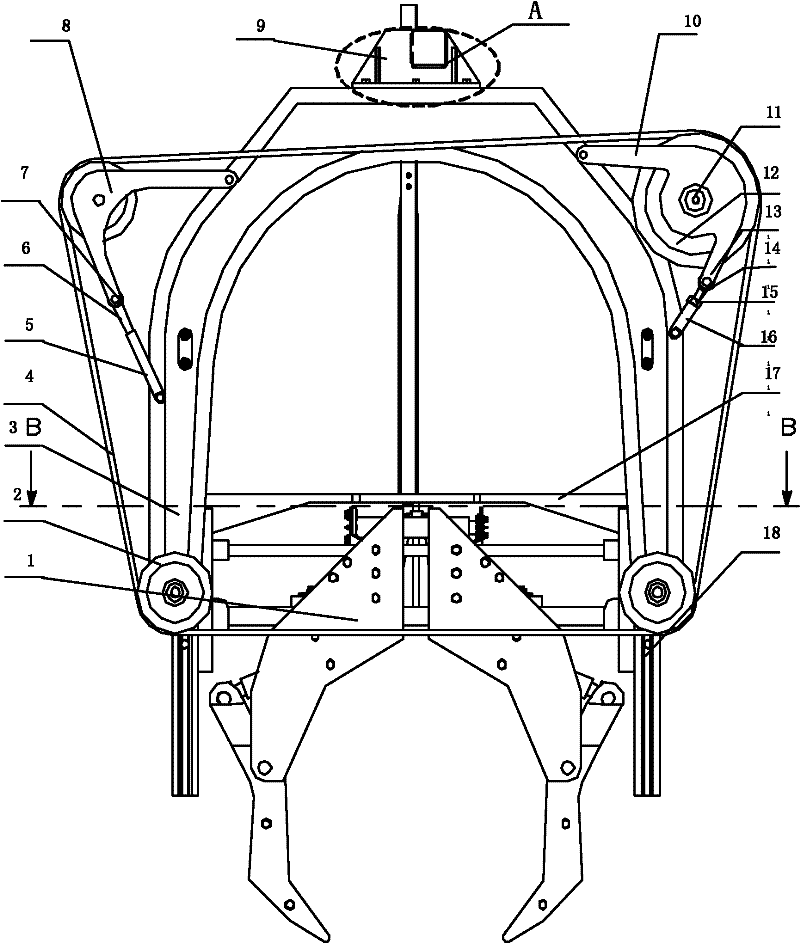

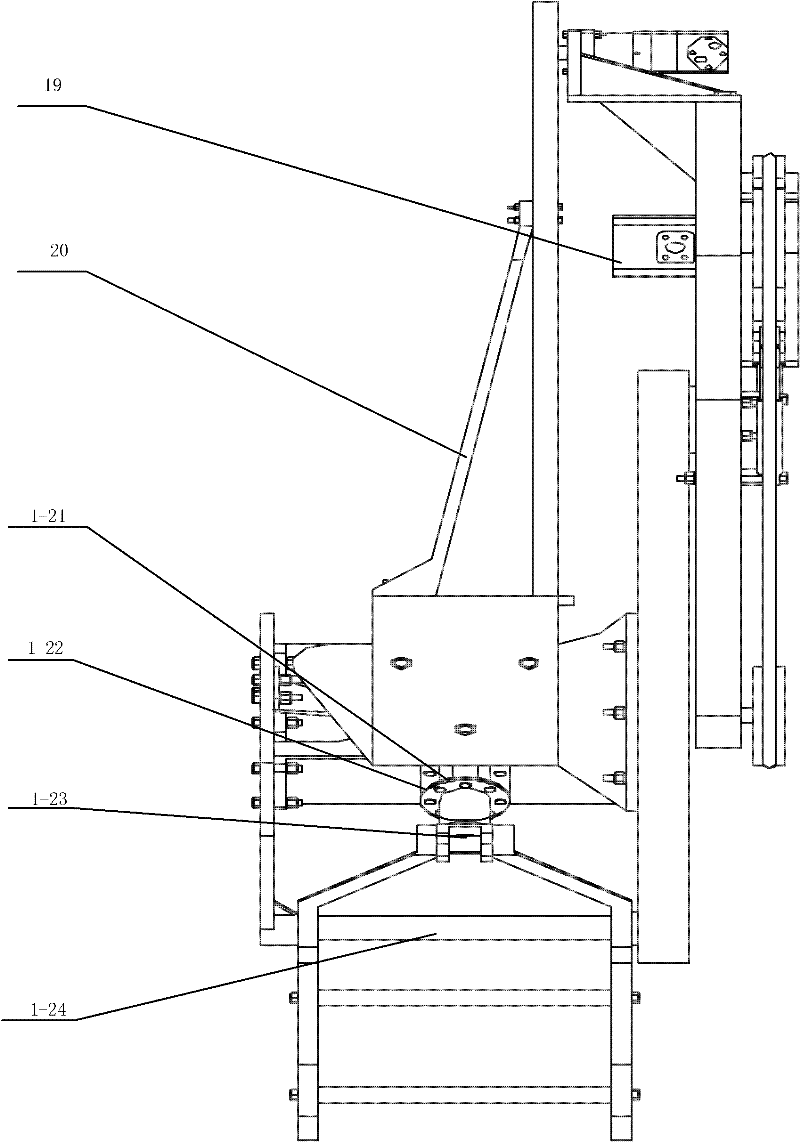

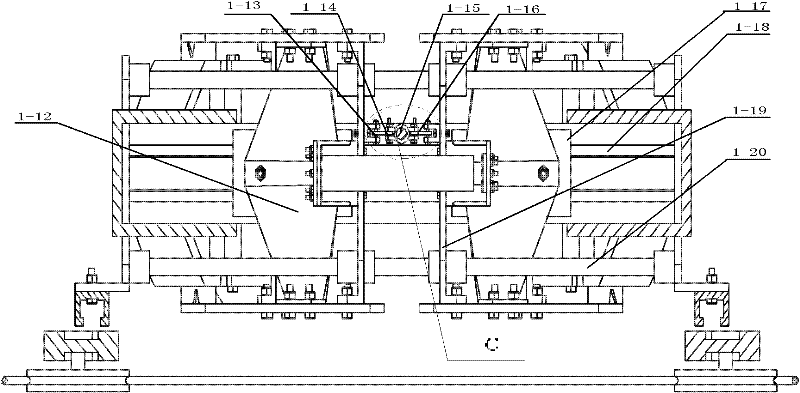

[0030] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0031]In the variable structure adaptive feed wire saw machine, the sliding pair is formed by the dovetail groove guide rail 1-18 and the sliding block 1-17, and the sliding pair connects the sliding block 1-17, the rib plate 1-12 and the V The templates 1-9 are connected, so that the main rail device for the movement of the manipulator is formed. Sleeve and polished rod guide rail 1-20 are arranged on connecting plate 1-19 to form auxiliary moving pair, and connect connecting plate 1-19 and V-shaped plate 1-9 by bolt pair to form the main guide device that manipulator moves. Drive the hydraulic cylinder 1-8 and the hydraulic rod 1-10 to push the connecting rod 1-7 connected with the sliding sleeve 1-14, thereby moving the clamping claw. Due to the use of the two-way hydraulic rod 1-10, an auxiliary synchronization mechanism is designed in o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com