Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

842 results about "Diamond tool" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A diamond tool is a cutting tool with diamond grains fixed on the functional parts of the tool via a bonding material or another method. As diamond is a superhard material, diamond tools have many advantages as compared with tools made with common abrasives such as corundum and silicon carbide.

Brazed diamond tools and methods for making the same

Owner:SUNG CHIEN MIN

Brazed diamond tools and methods for making the same

InactiveUS20040112359A1Avoid large movementsImprove cutting efficiencyDrill bitsConstructionsChemical LinkageBraze alloy

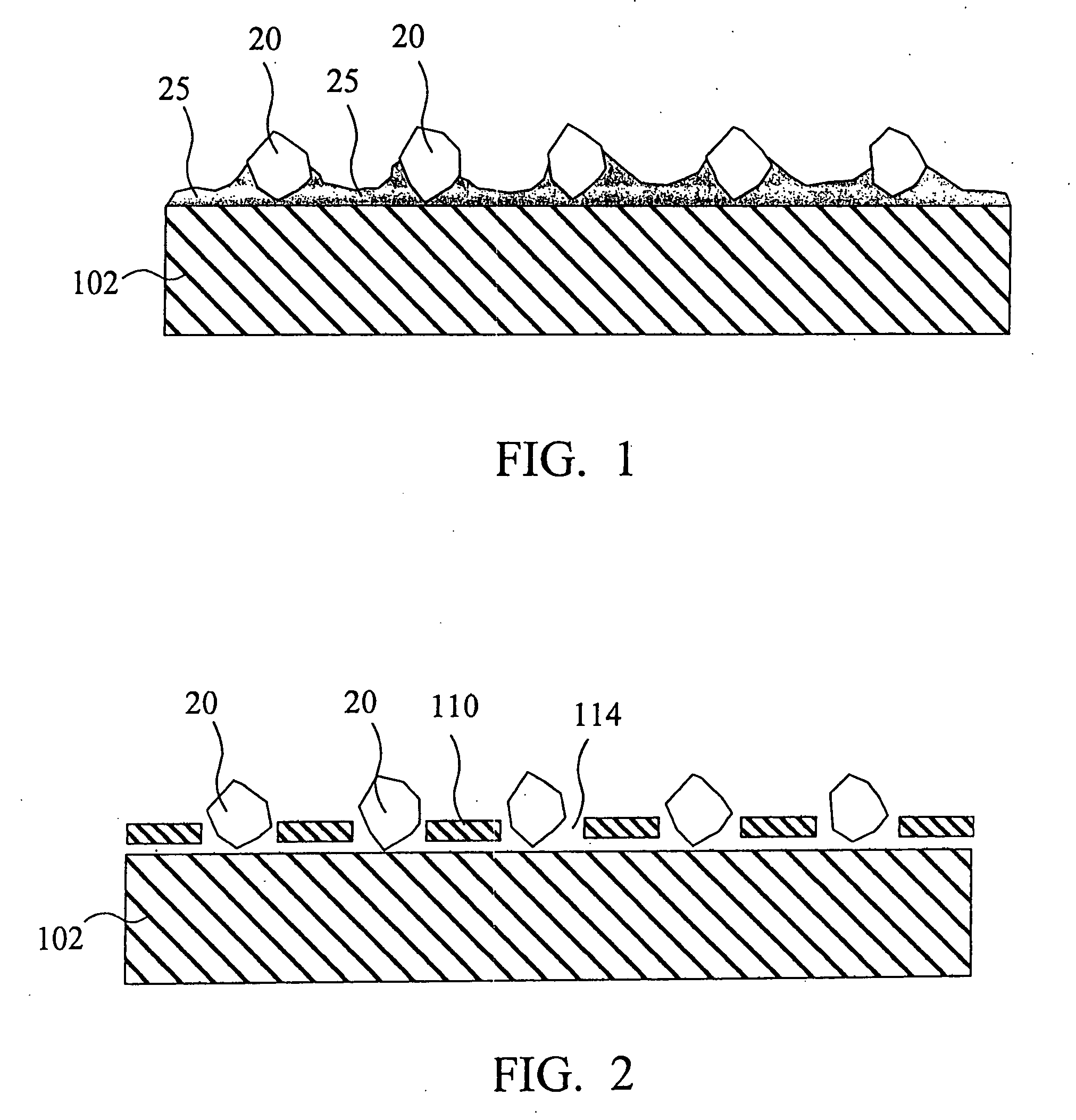

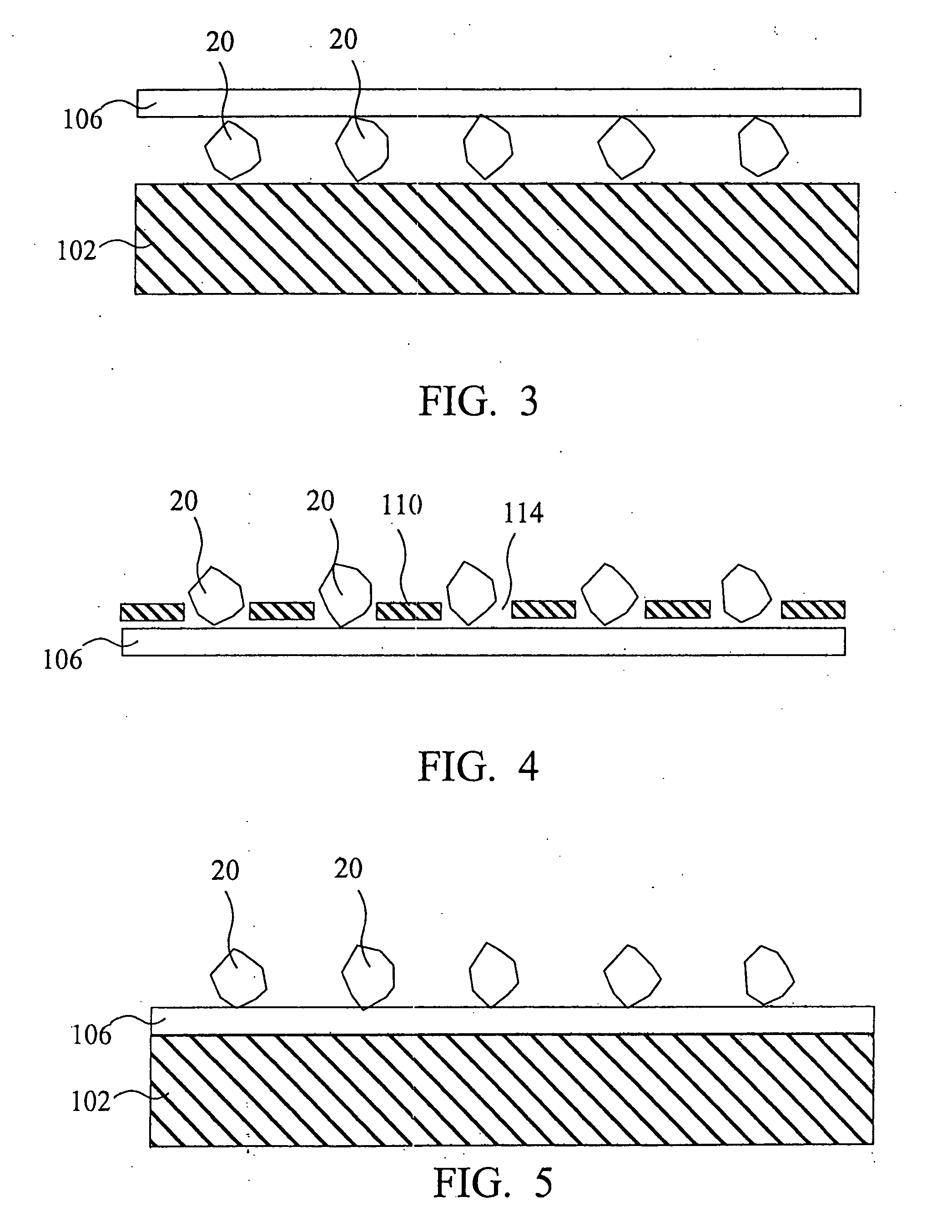

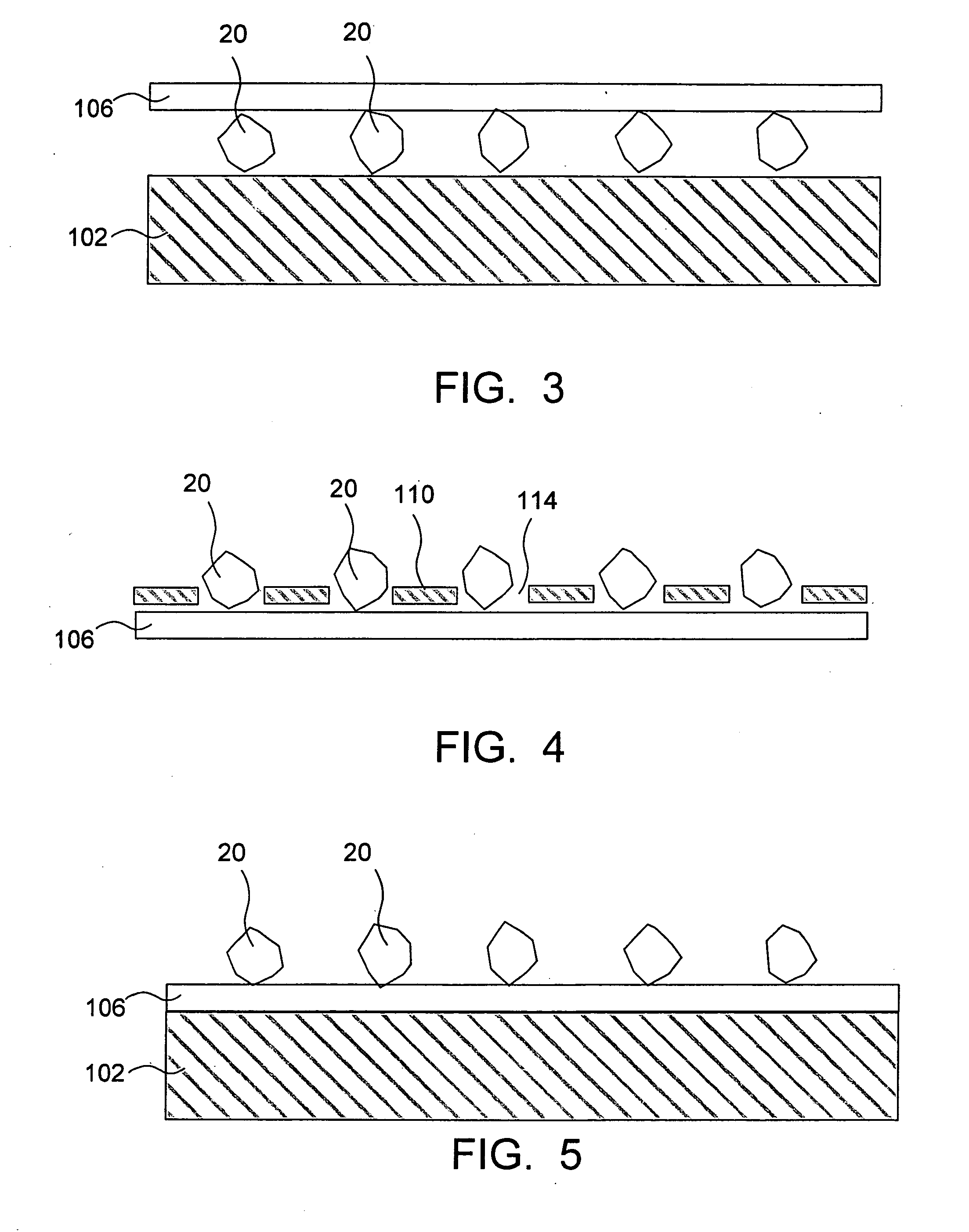

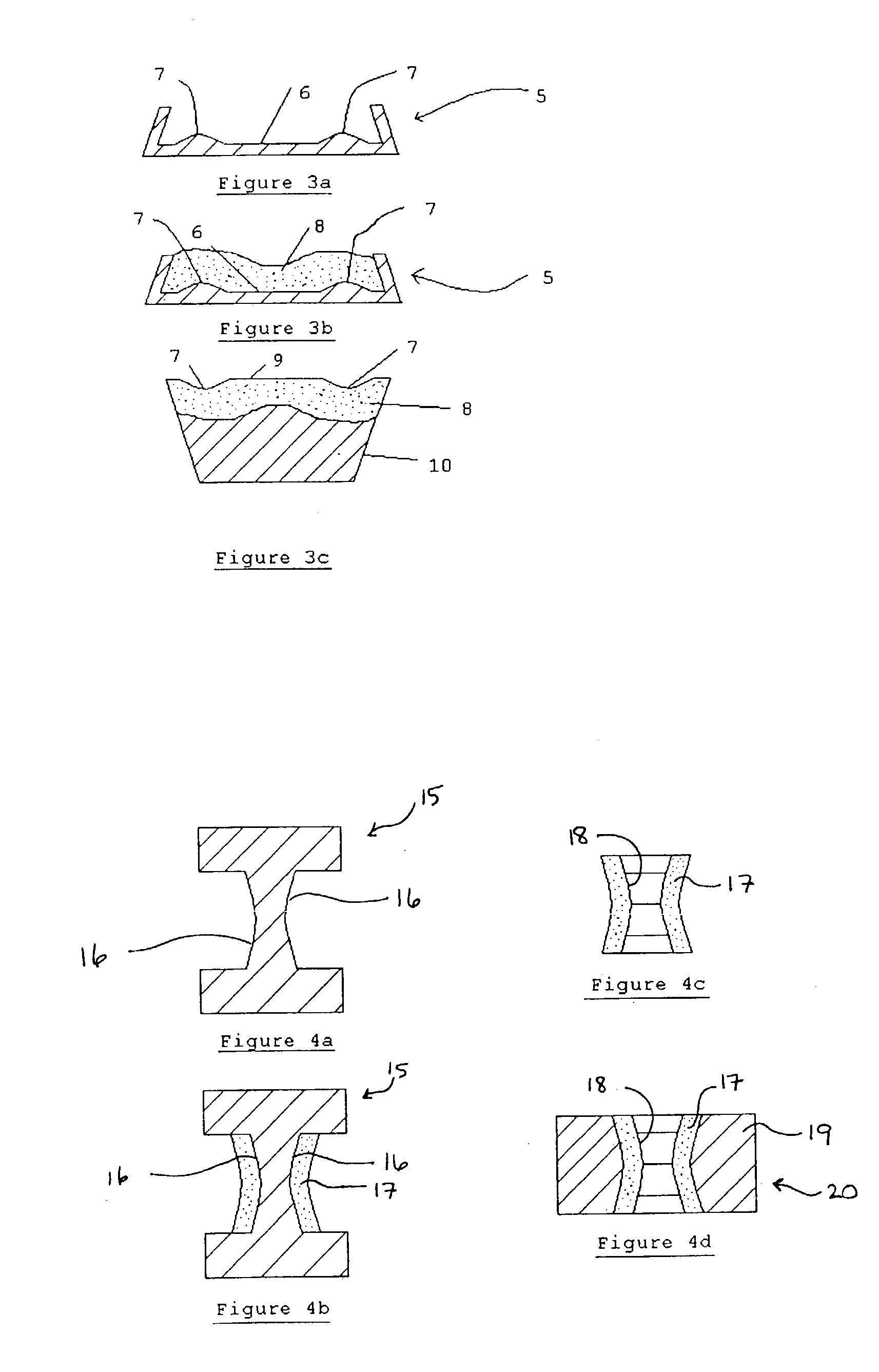

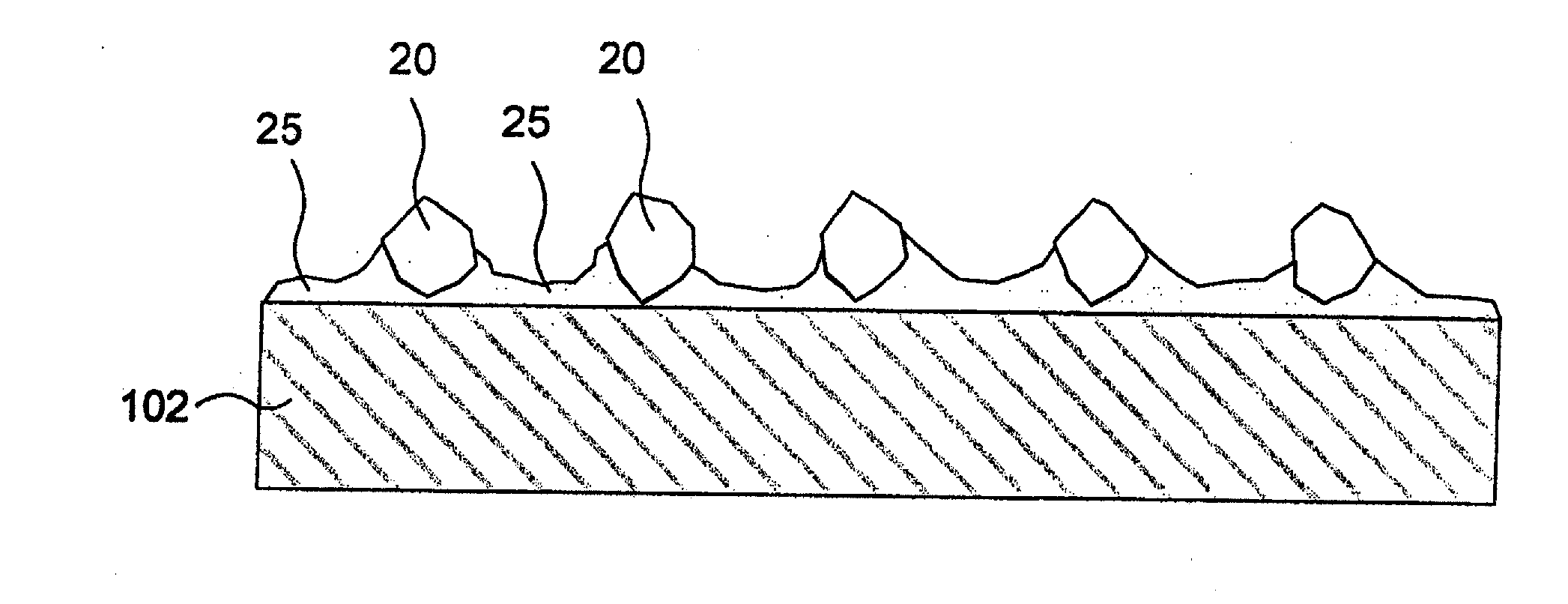

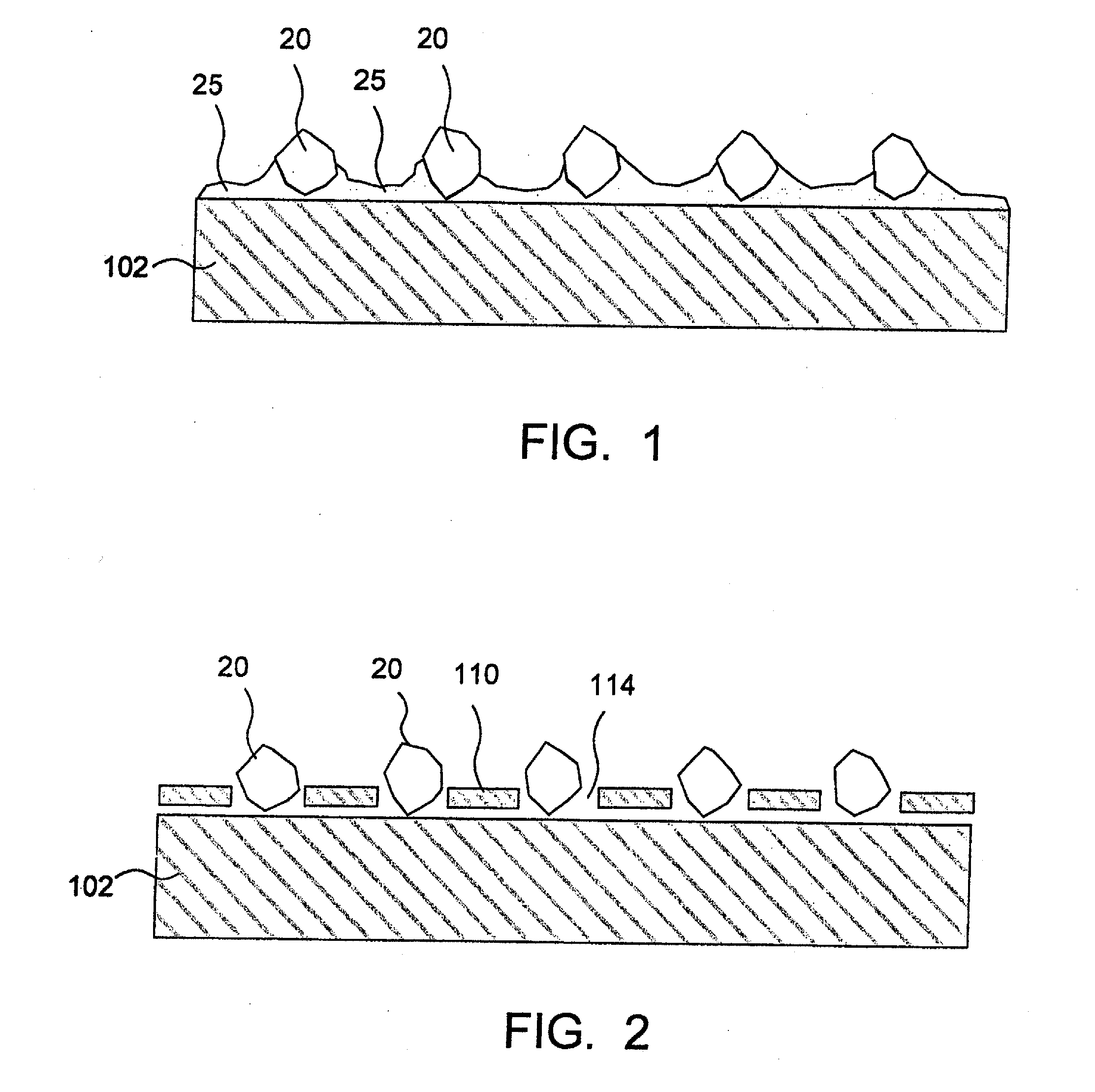

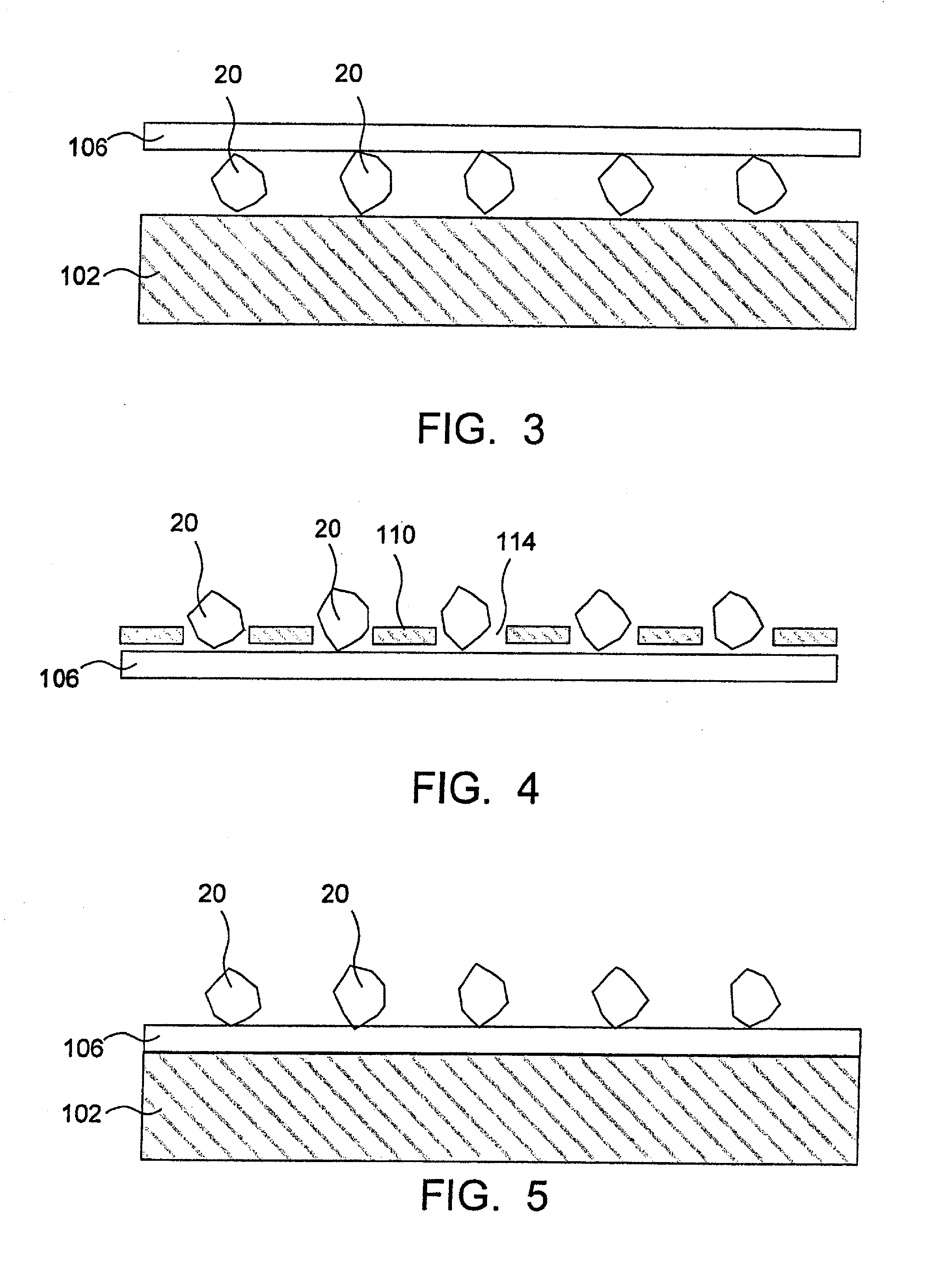

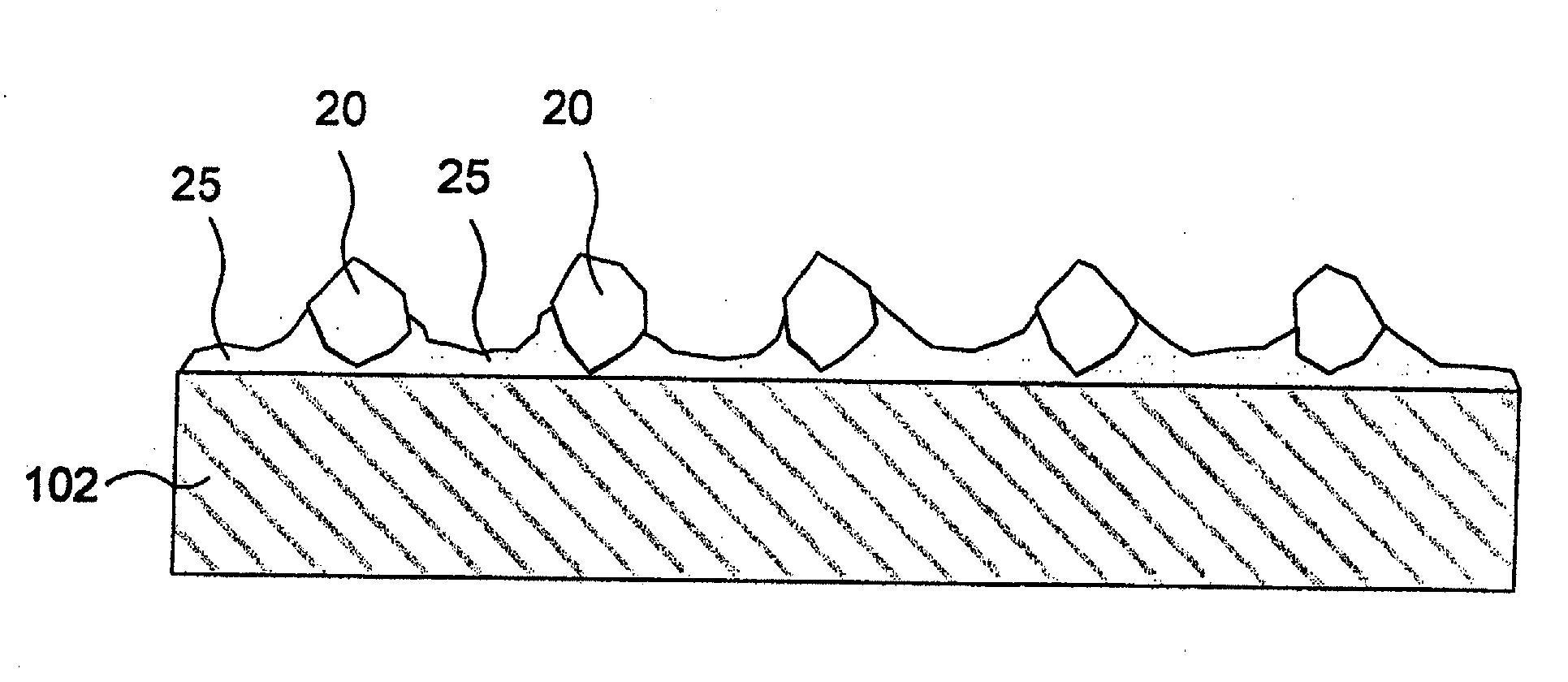

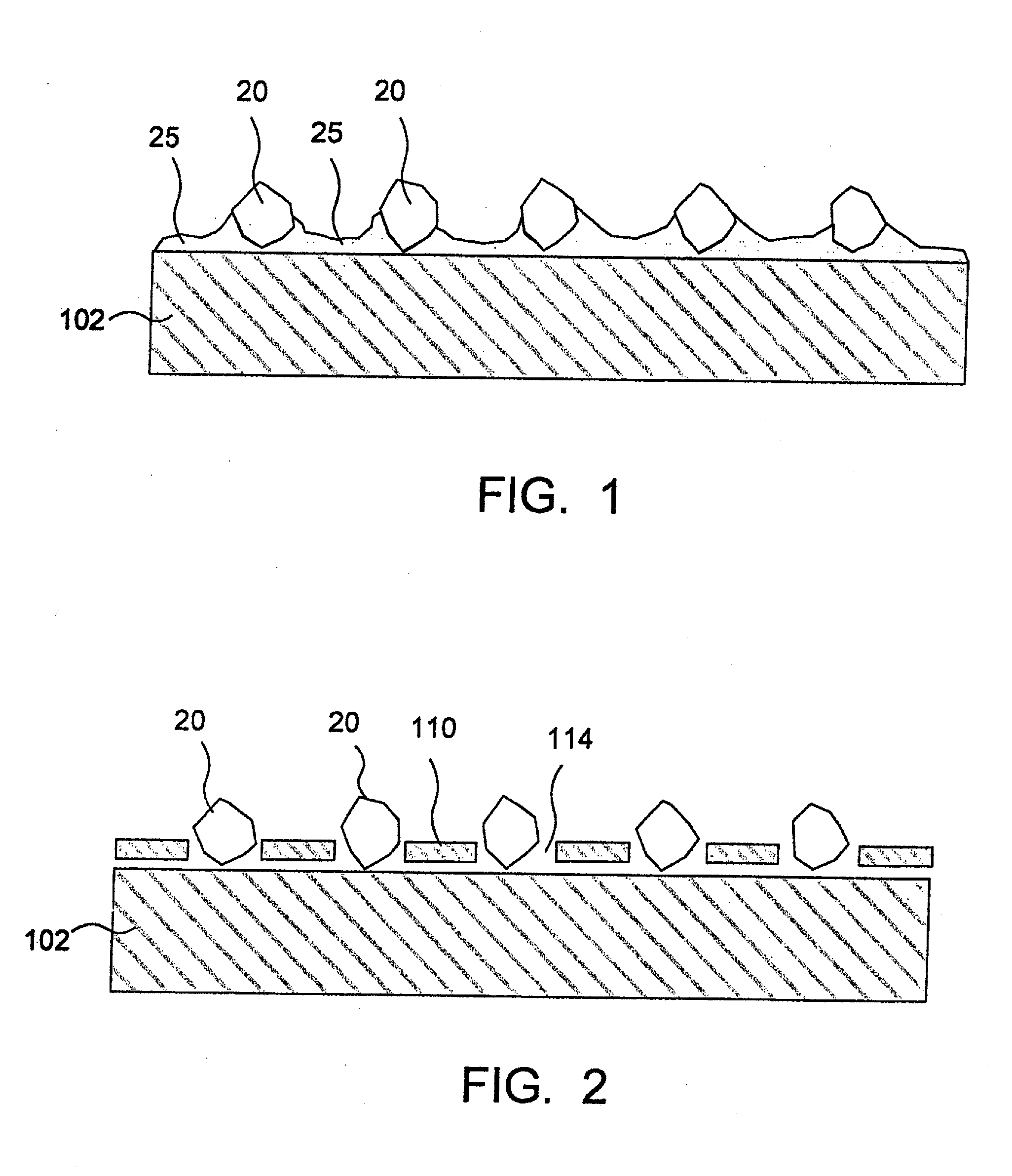

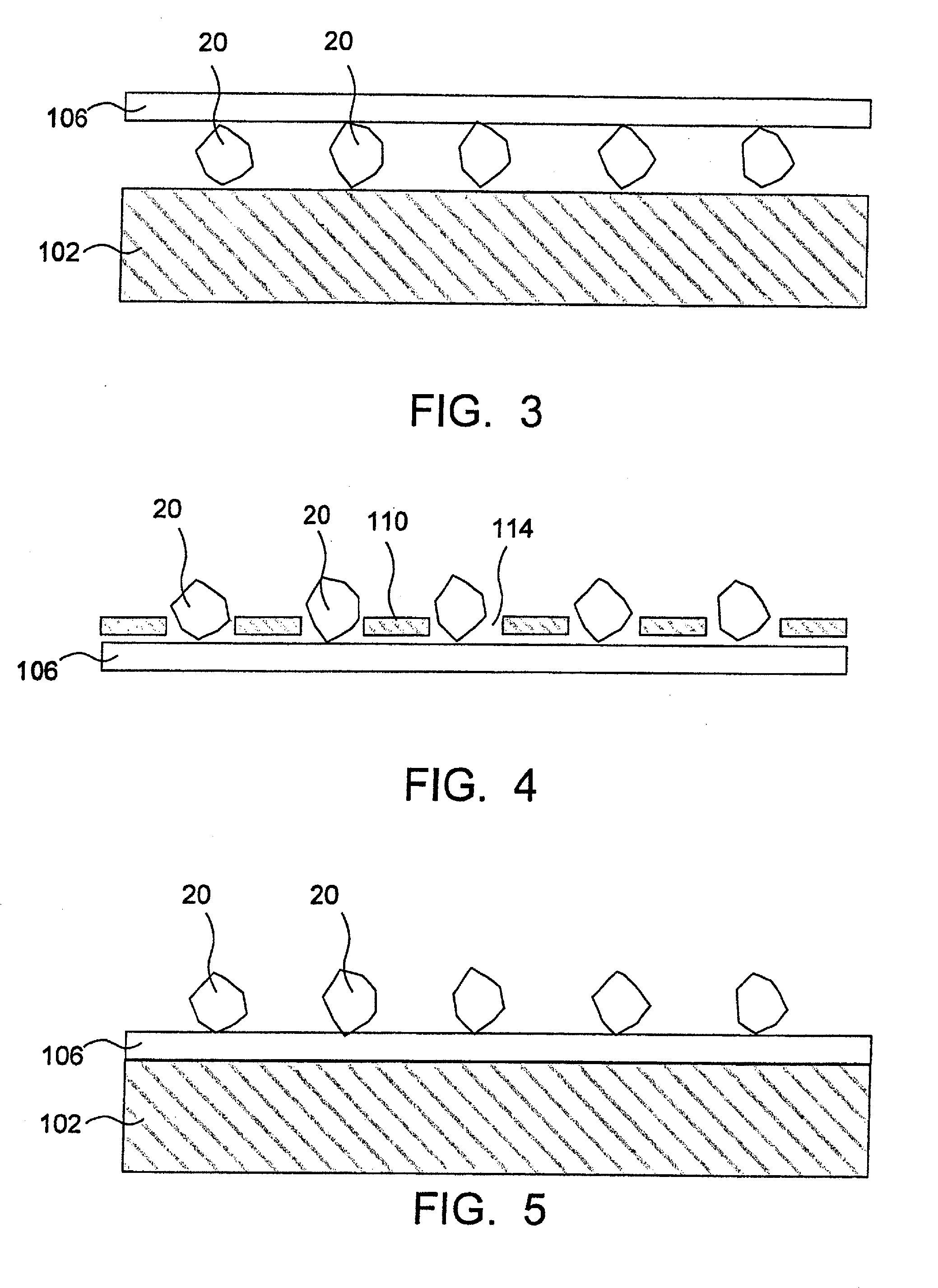

Superabrasive tools and methods for the making thereof are disclosed and described. In one aspect, superabrasive particles are chemically bonded to a matrix support material according to a predetermined pattern by a braze alloy. The brazing alloy may be provided as a powder, thin sheet, or sheet of amorphous alloy. A template having a plurality of apertures arranged in a predetermined pattern may be used to place the superabrasive particles on a given substrate or matrix support material.

Owner:SUNG CHIEN MIN

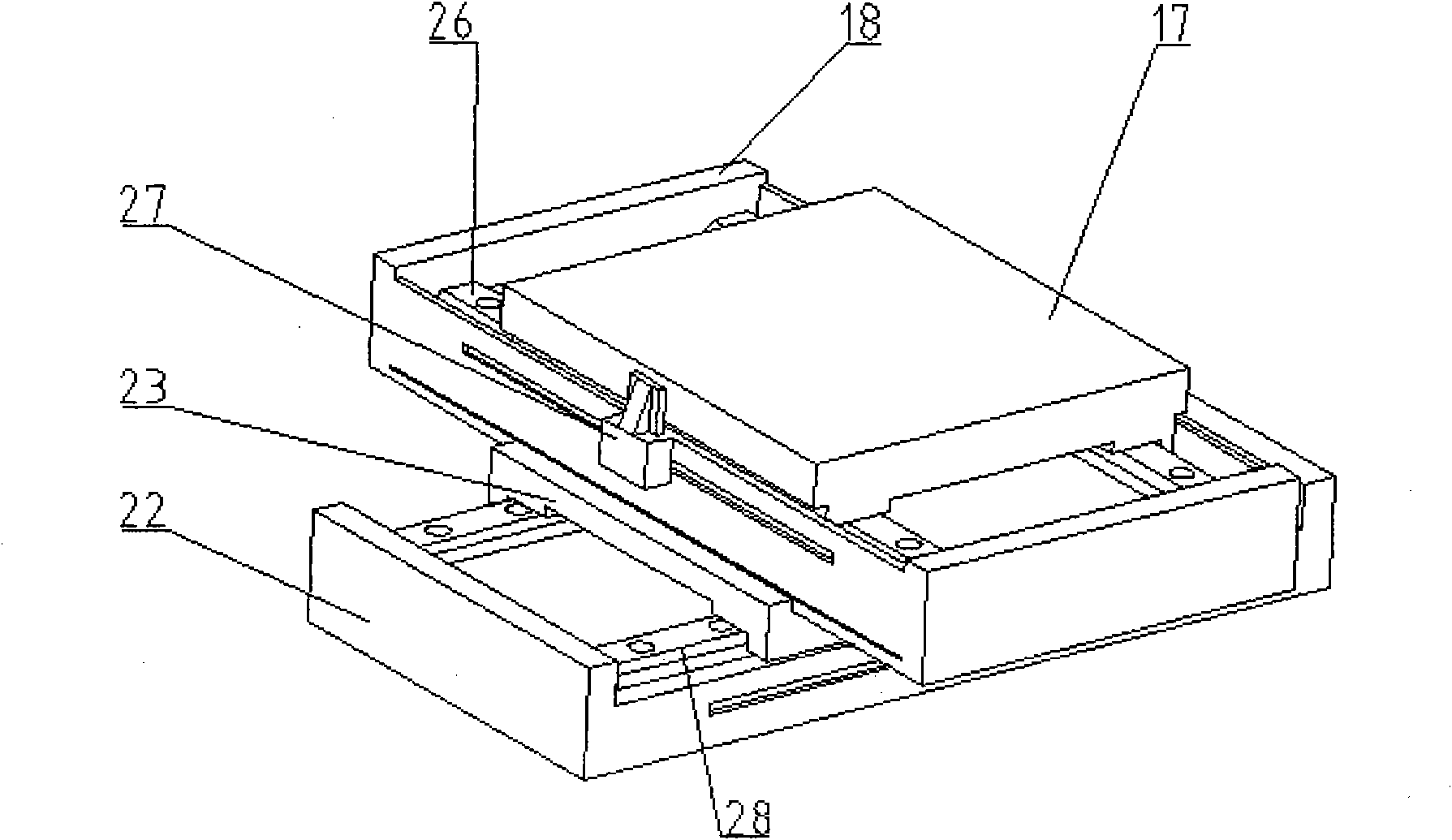

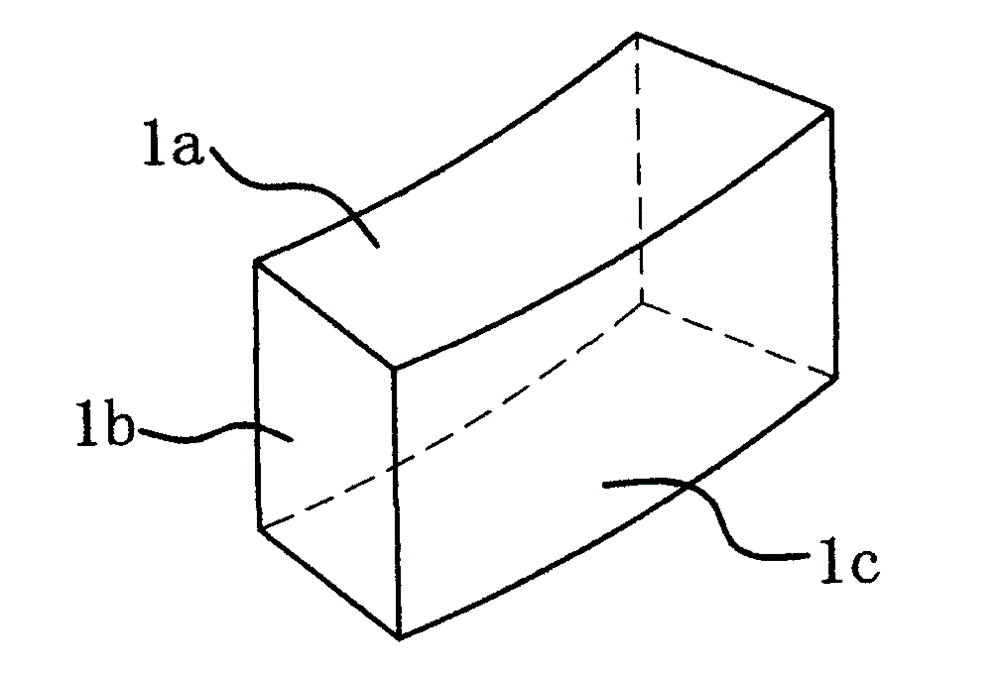

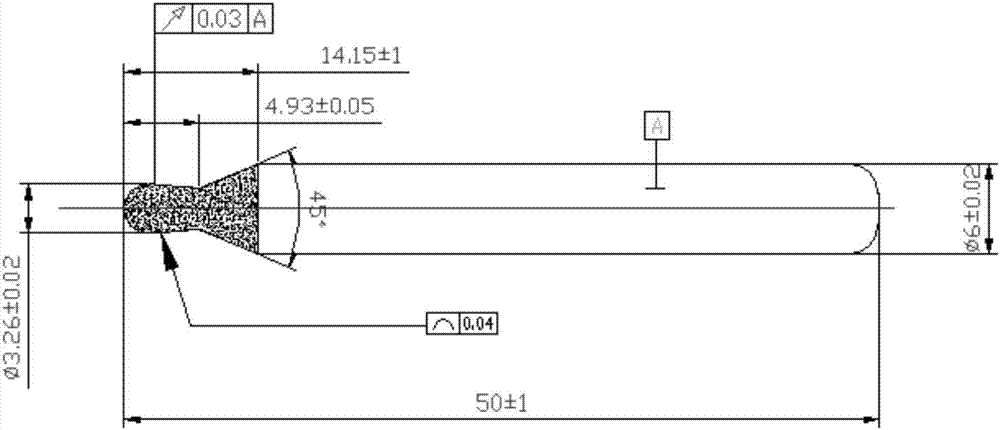

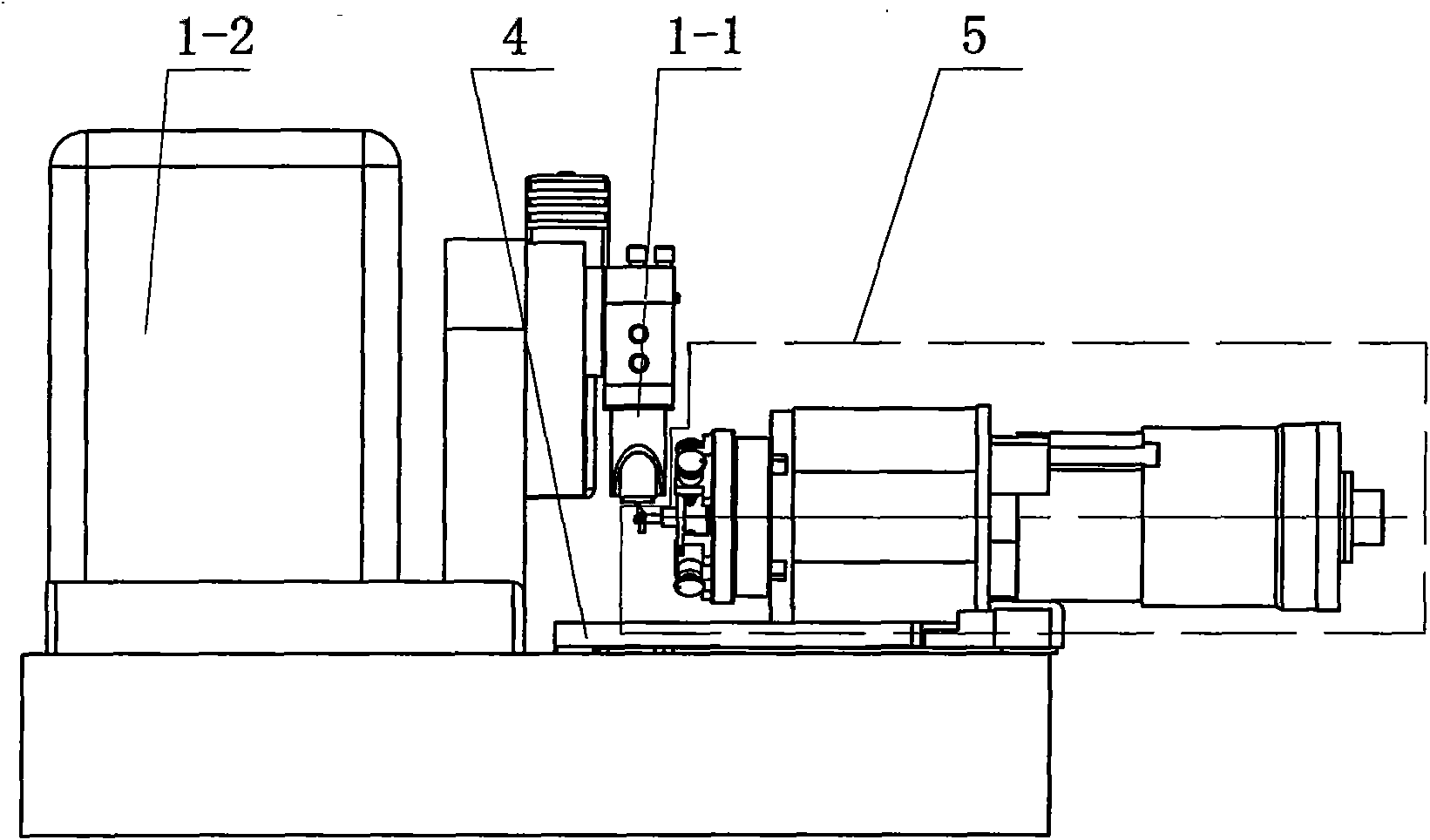

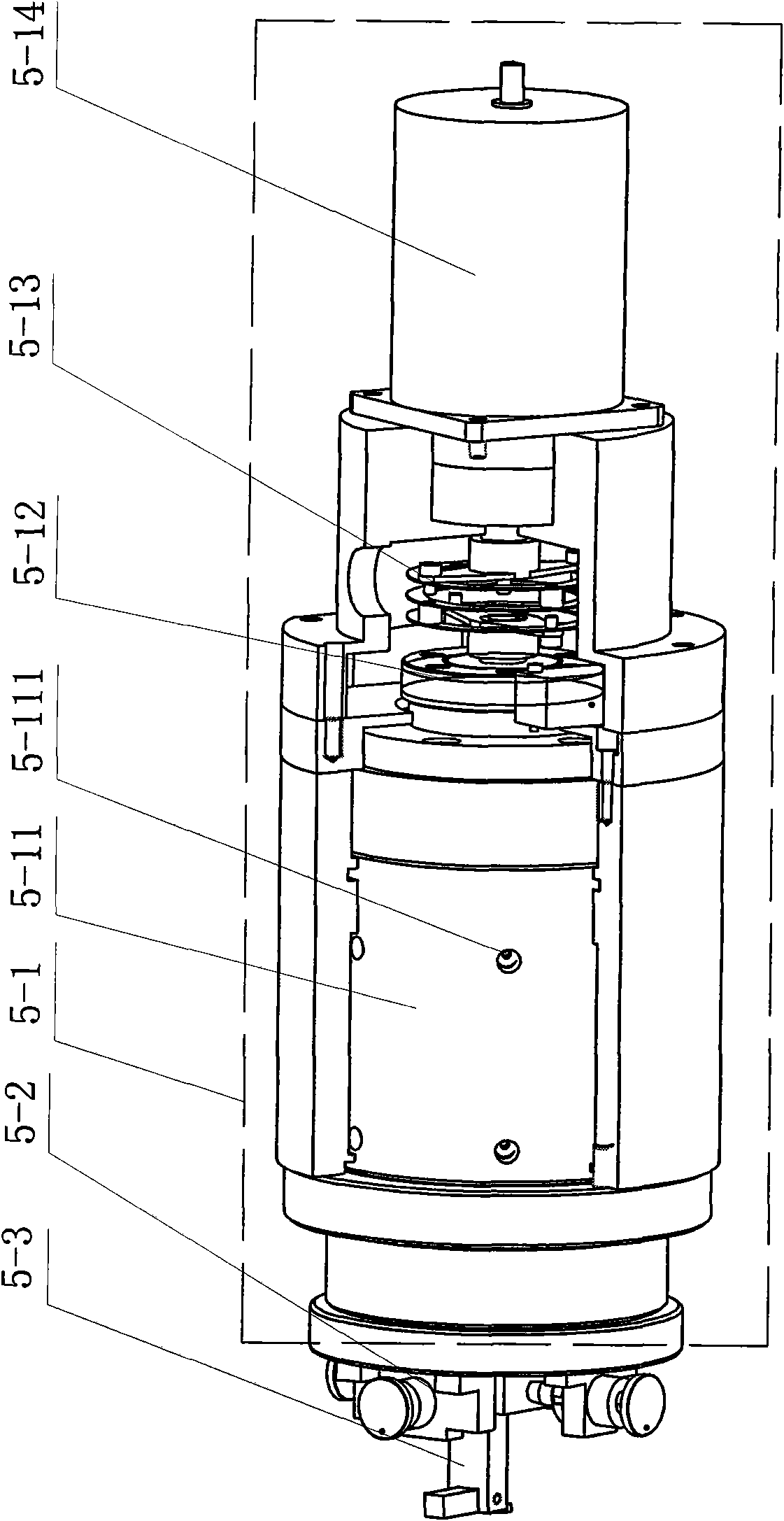

Super-precision trans-scale in-situ nanometer indentation marking test system

ActiveCN101520389AThe test method is accurateAccurate and effective research and testing methodsUsing optical meansInvestigating material hardnessHead pressingImage resolution

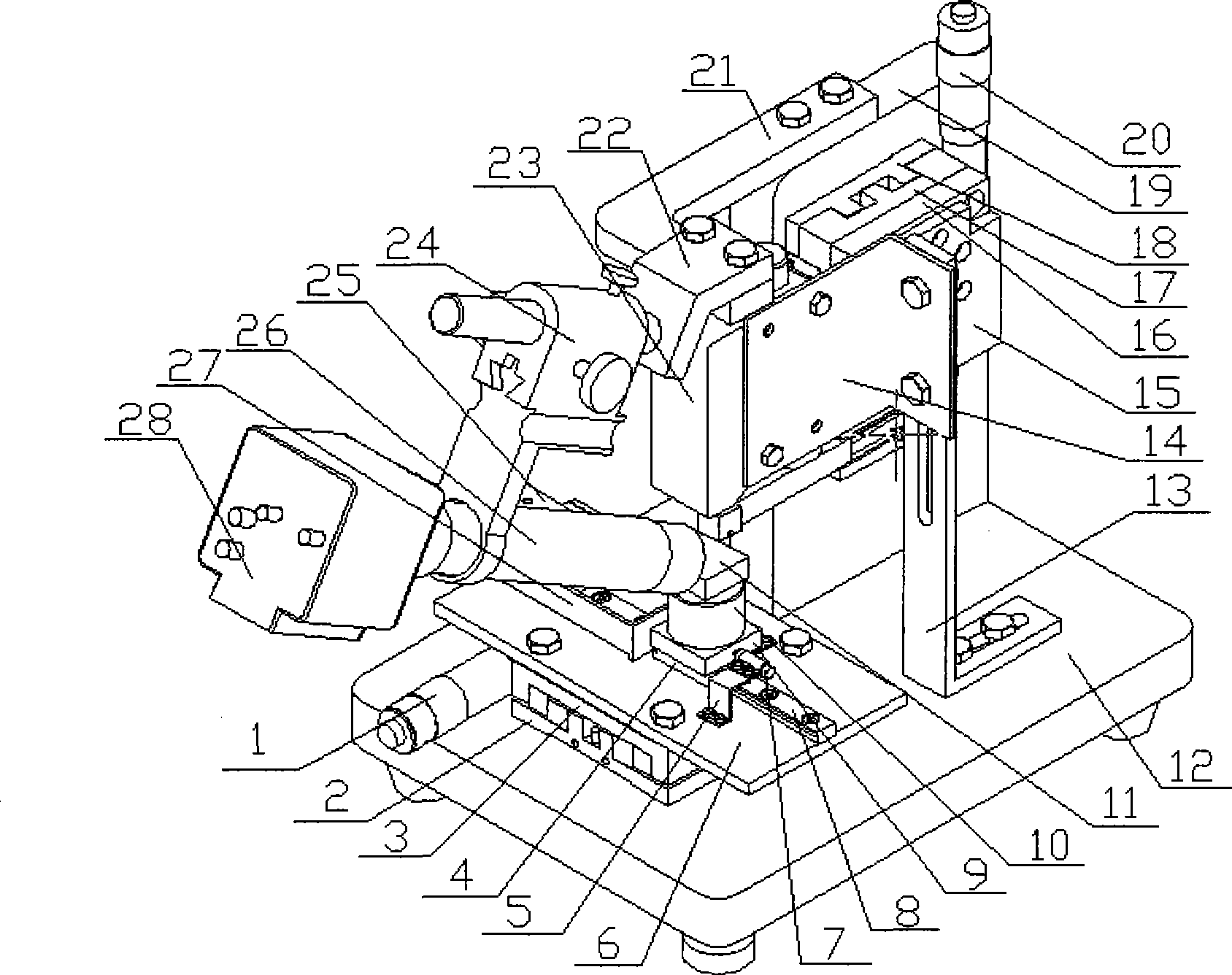

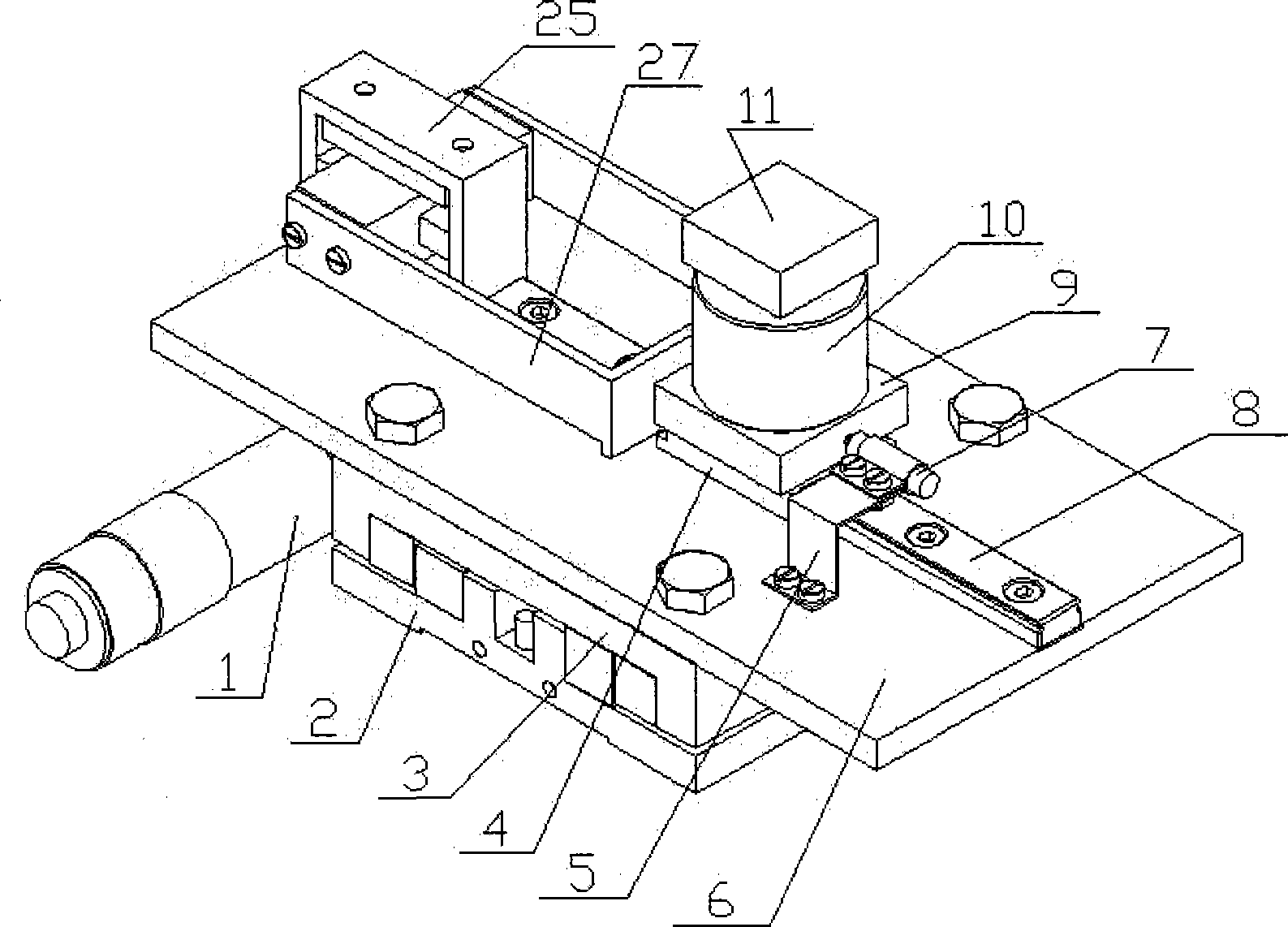

The invention relates to a super-precision trans-scale in-situ nanometer indentation marking test system which integrates driving, loading, detecting and micro-nanometer dynamic performance tests, super-precision marking processing and in-situ observation into a whole. The system mainly comprises an objective table, a regulation mechanism, a detection unit, a precise pressed-into driving unit, a detection unit of load signals and displacement signals and a high-resolution digital microscopic imaging system, wherein the objective table is precisely positioned along the directions of the X axis and the Y axis; the regulation mechanism and the precise pressed-into driving unit are in the direction of the Z axis and are assembled on a base; the high-resolution digital microscopic imaging system is used for observing the deforming and damaging conditions of the material in the storing and testing process; the objective table as well as the regulation mechanism and the precise pressed-into driving unit in the direction of the Z axis are assembled on a base; the high-resolution digital microscopic imaging system is arranged on the objective table; a precise dynamic sensor detecting the pressure of a diamond tool head pressed into a material and a sensor I detecting the precise displacement of the objective table in the directions of the X axis and the Y axis are arranged on the objective table; and a sensor II used for detecting the precise displacement of a diamond tool head in the direction of the Z axis of pressed-into depth is arranged on the base by a support I.

Owner:JILIN UNIV

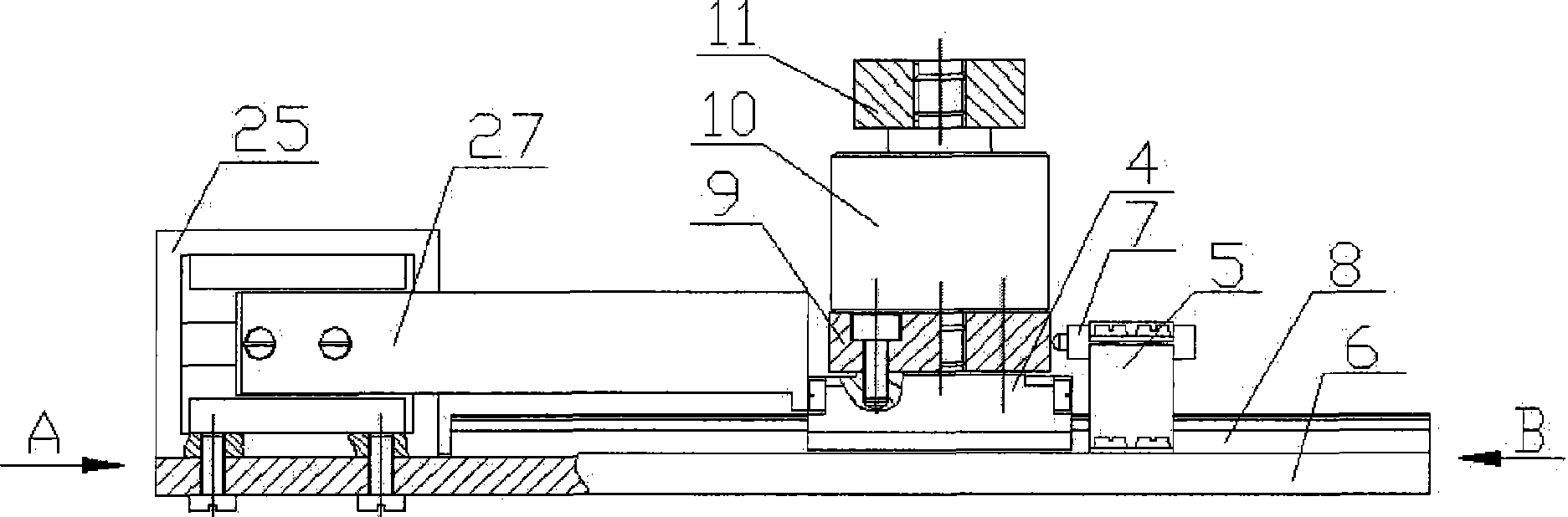

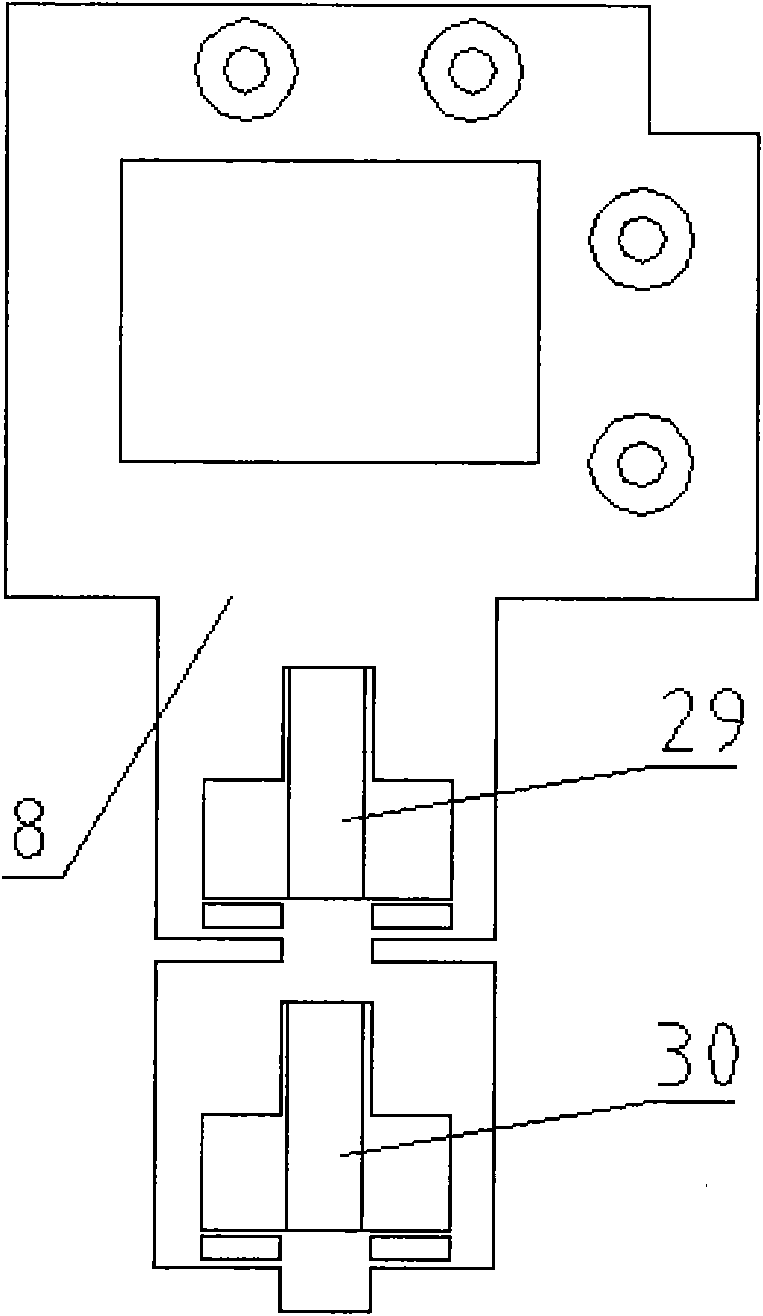

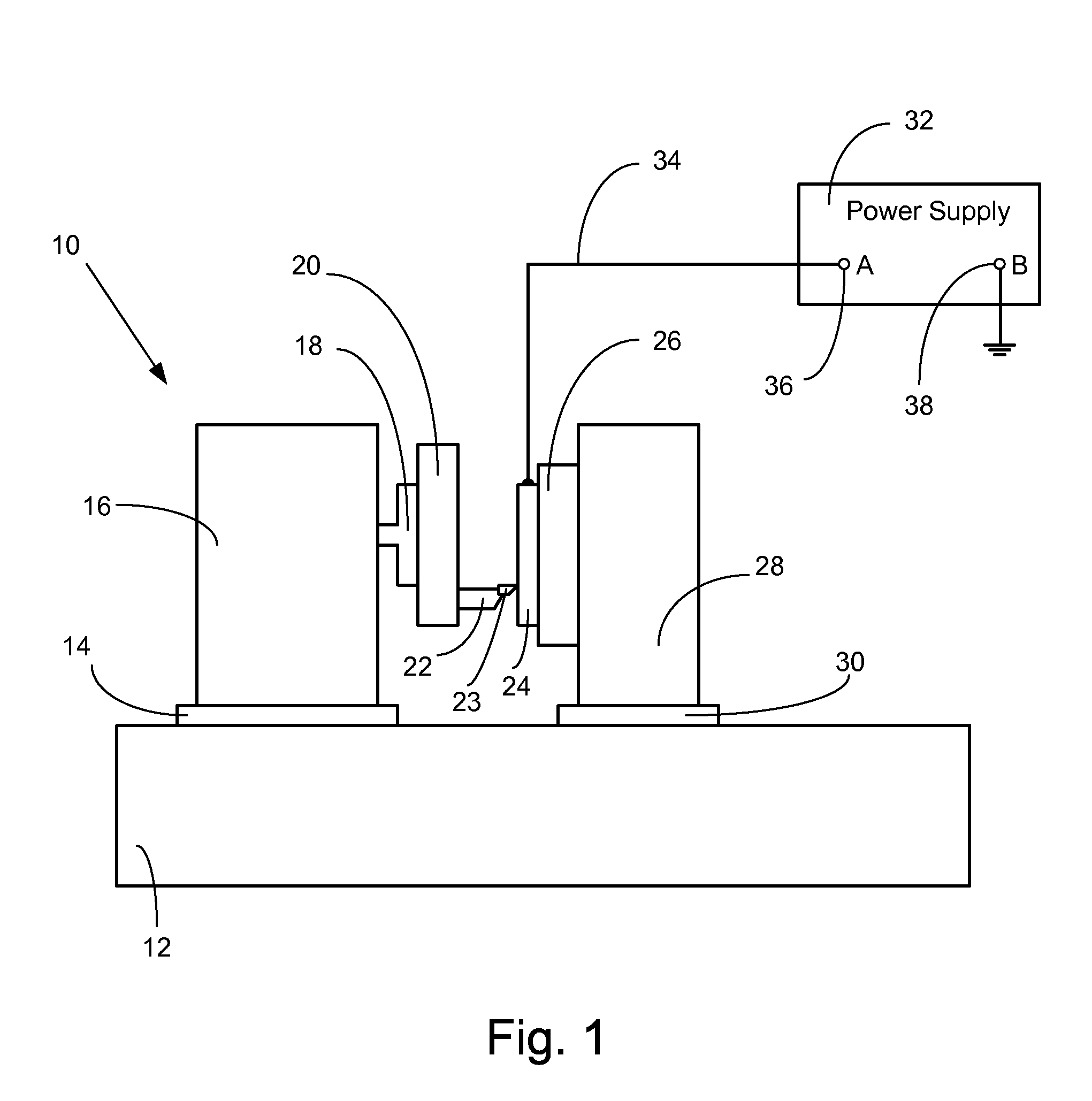

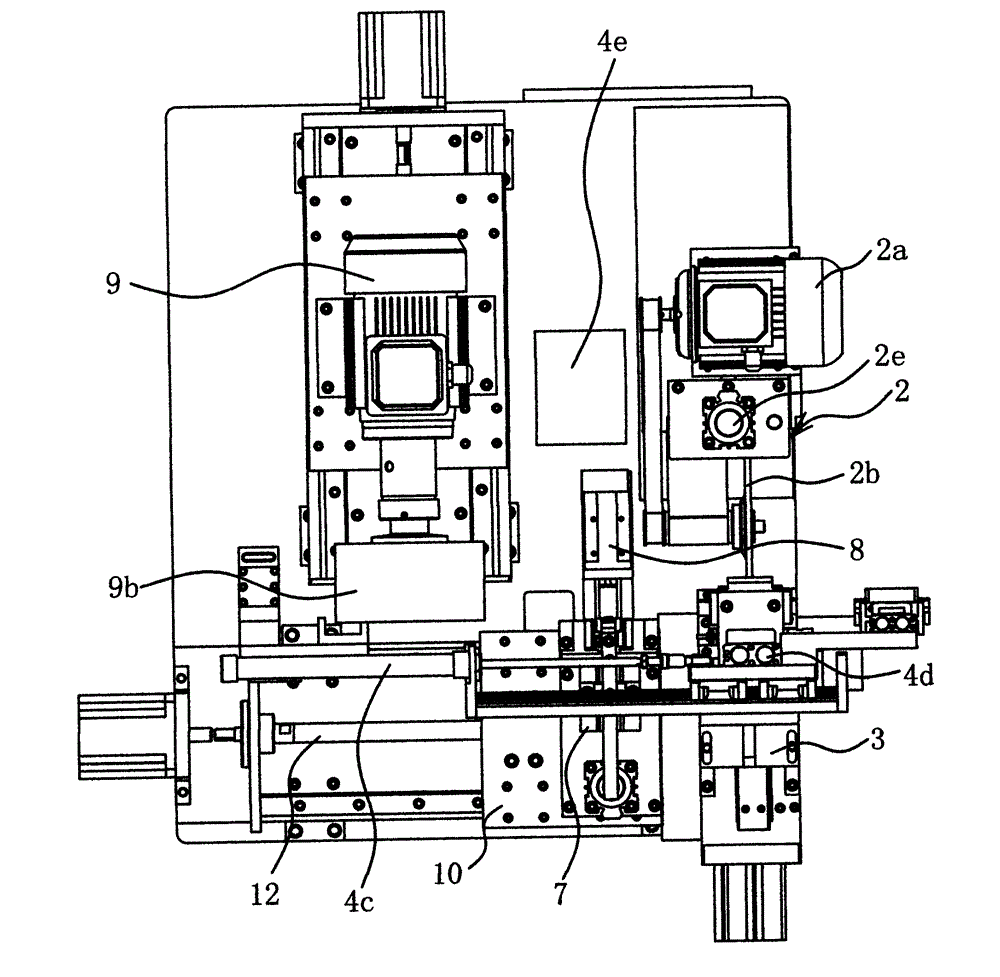

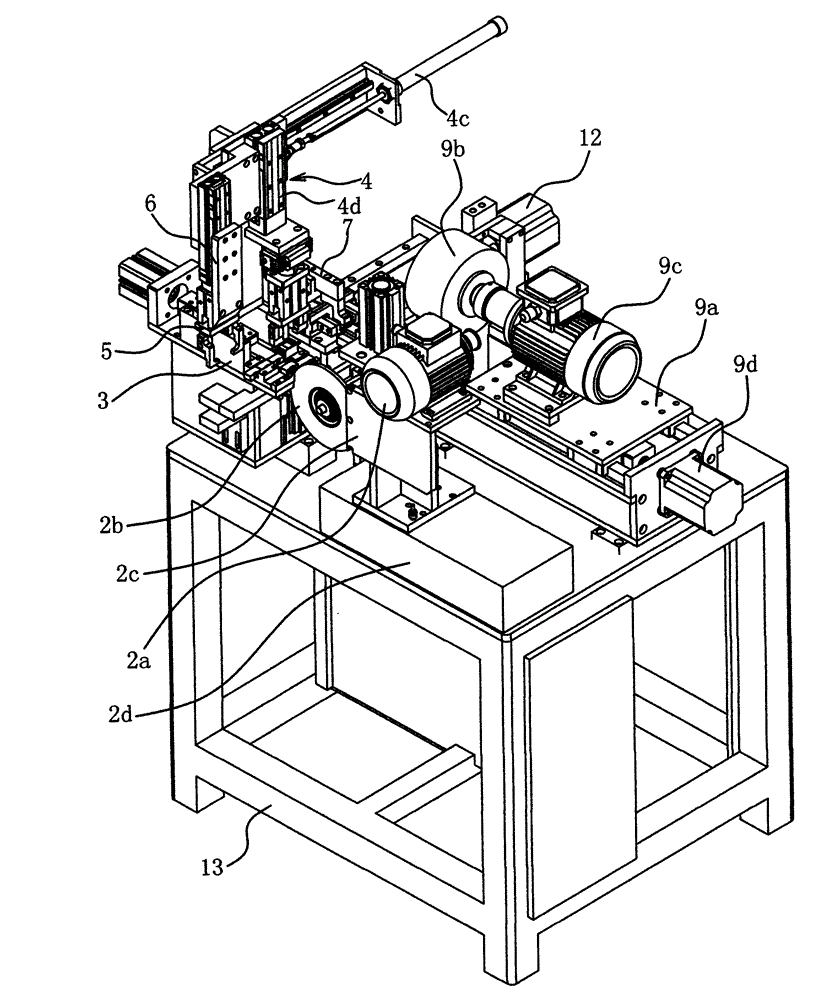

Diamond tool welding machine

ActiveCN103223538AReasonable arrangementSimple structureMetal working apparatusEngineeringMechanical engineering

The invention provides a diamond tool welding machine, and belongs to the technical field of operation. The welding machine solves the problem that the conventional brazing is low in automaticity. The welding machine comprises a machine frame and a positioning tooling fixed on the machine frame, wherein a tool bit clamping device is arranged above the positioning tooling, the tool bit clamping device is connected with the machine frame through linear guide components, and a driving part is arranged between the tool bit clamping device and the machine frame; a welding rod and a dipple glue station I are arranged on the motion trajectory of the tool bit clamping device corresponding to one side of the positioning tooling in sequence, and a dipple glue station two and a tool bit positioning base are arranged on the motion trajectory of the tool bit clamping device corresponding to the other side of the positioning tooling in sequence; a translational base is also arranged on the linear guide components, and a soldering lug sucking device corresponding to the welding rod and a dipple glue device corresponding to the dipple glue station I are arranged on the translational base; and the translational base is in rigid connection with the tool bit clamping device. The welding machine provided by the invention has the advantages that the welding machine is reasonable in arrangement, has a simple structure, and is convenient to operate and low in manufacturing cost.

Owner:项大清

Brazed diamond tools and methods for making the same

Superabrasive tools and methods for the making thereof are disclosed and described. In one aspect, superabrasive particles are chemically bonded to a matrix support material according to a predetermined pattern by a braze alloy. The brazing alloy may be provided as a powder, thin sheet, or sheet of amorphous alloy. A template having a plurality of apertures arranged in a predetermined pattern may be used to place the superabrasive particles on a given substrate or matrix support material.

Owner:SUNG CHIEN MIN

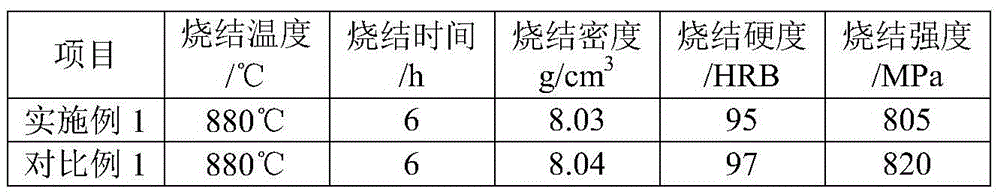

Pre-alloying powder for diamond tool and manufacturing method thereof

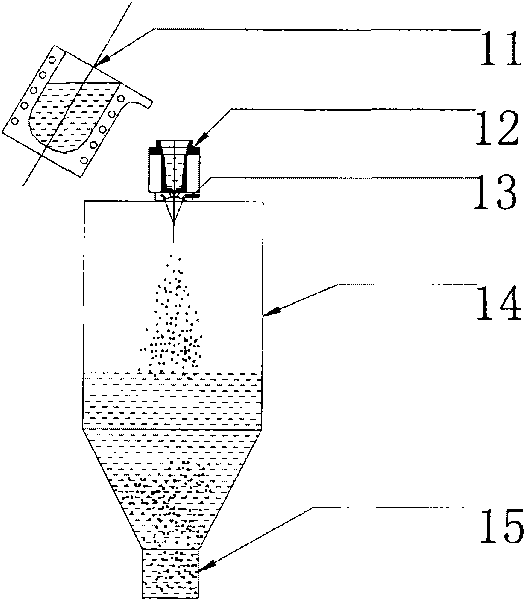

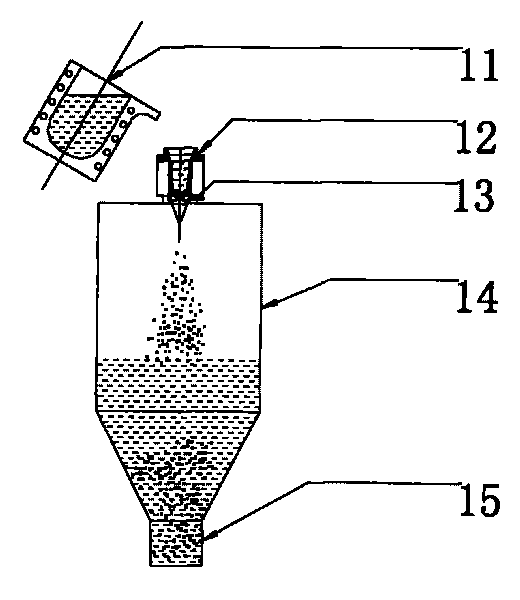

The invention relates to pre-alloying powder for a diamond tool and a manufacturing method thereof. The pre-alloying powder adopts Fe phase or Cu phase as the main phase. The pre-alloying powder is characterized in that: trace B strengthens crystal boundary and refines crystal particles; Ni, Co and Me (at least one of Mn, Cr, Si, Ti, V, W and Mo is selected) are adopted as strengthening elements; and Sn, P and C further adjusts an alloy structure. The pre-alloying powder is prepared by the high-pressure water atomization powdering technology. The manufacturing method is characterized in that: alloy liquid is smashed by high-pressure water which is preferential for many times, the meso-position diameter D50 of the powder measured by a laser particle-size meter is within 7 to 18mum, and the preference is within 7 to 13mum; the full oxygen content measured by a full oxygen analyzer is smaller than or equal to 0.35% (mass), and the preference is smaller than or equal to 0.25% (mass).

Owner:ADVANCED TECH BAZHOU SPECIAL POWDER CO LTD

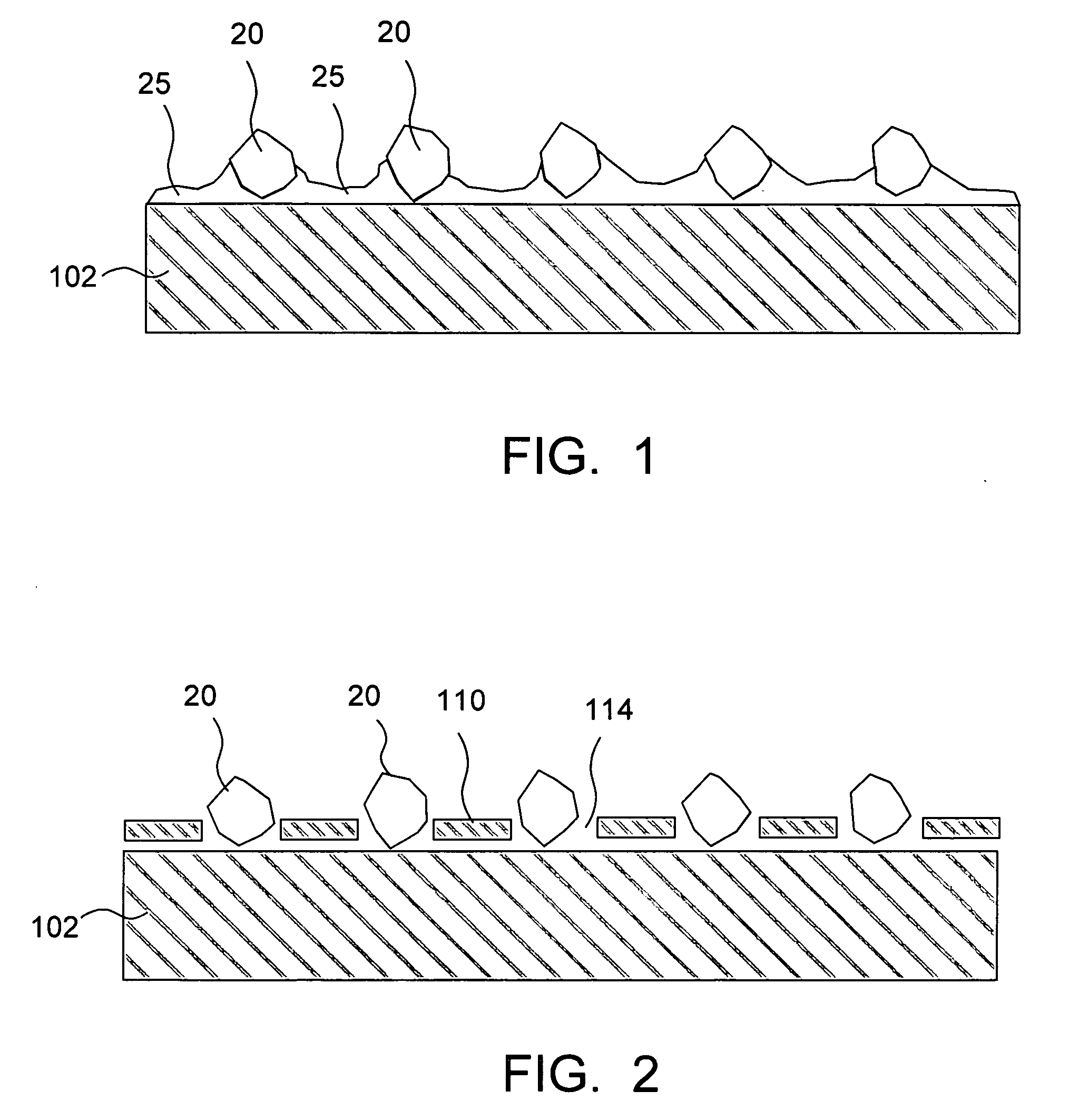

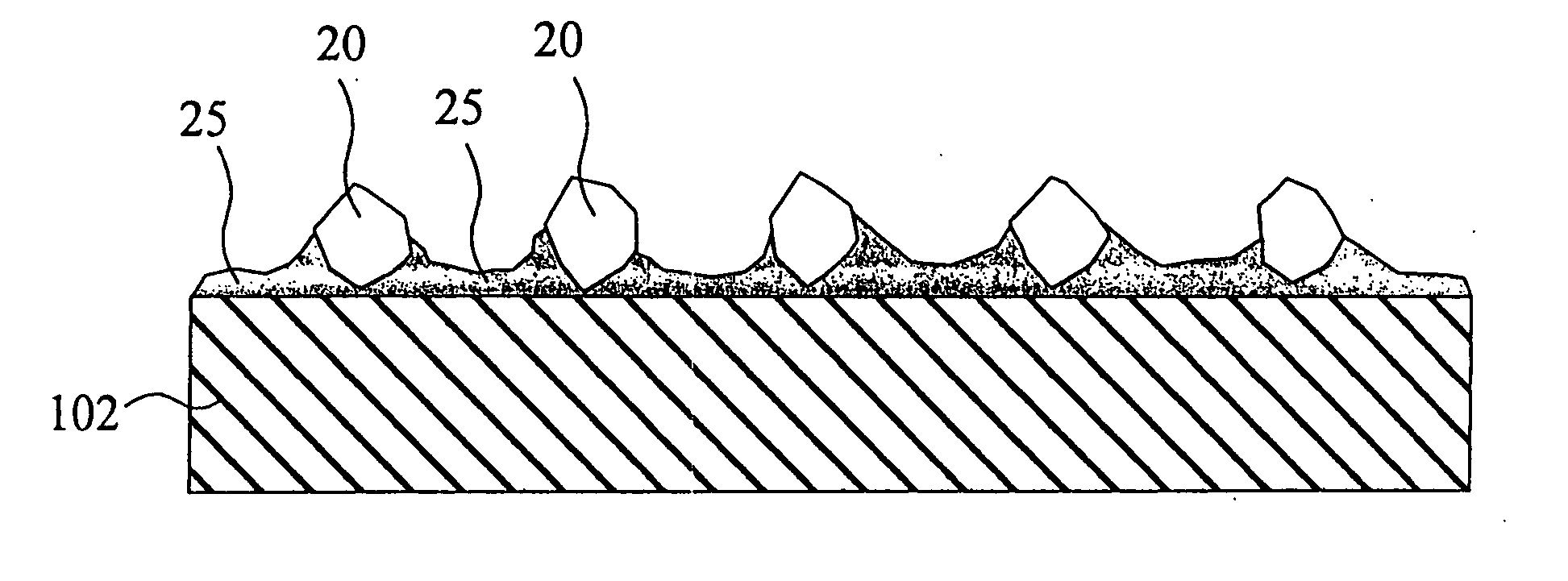

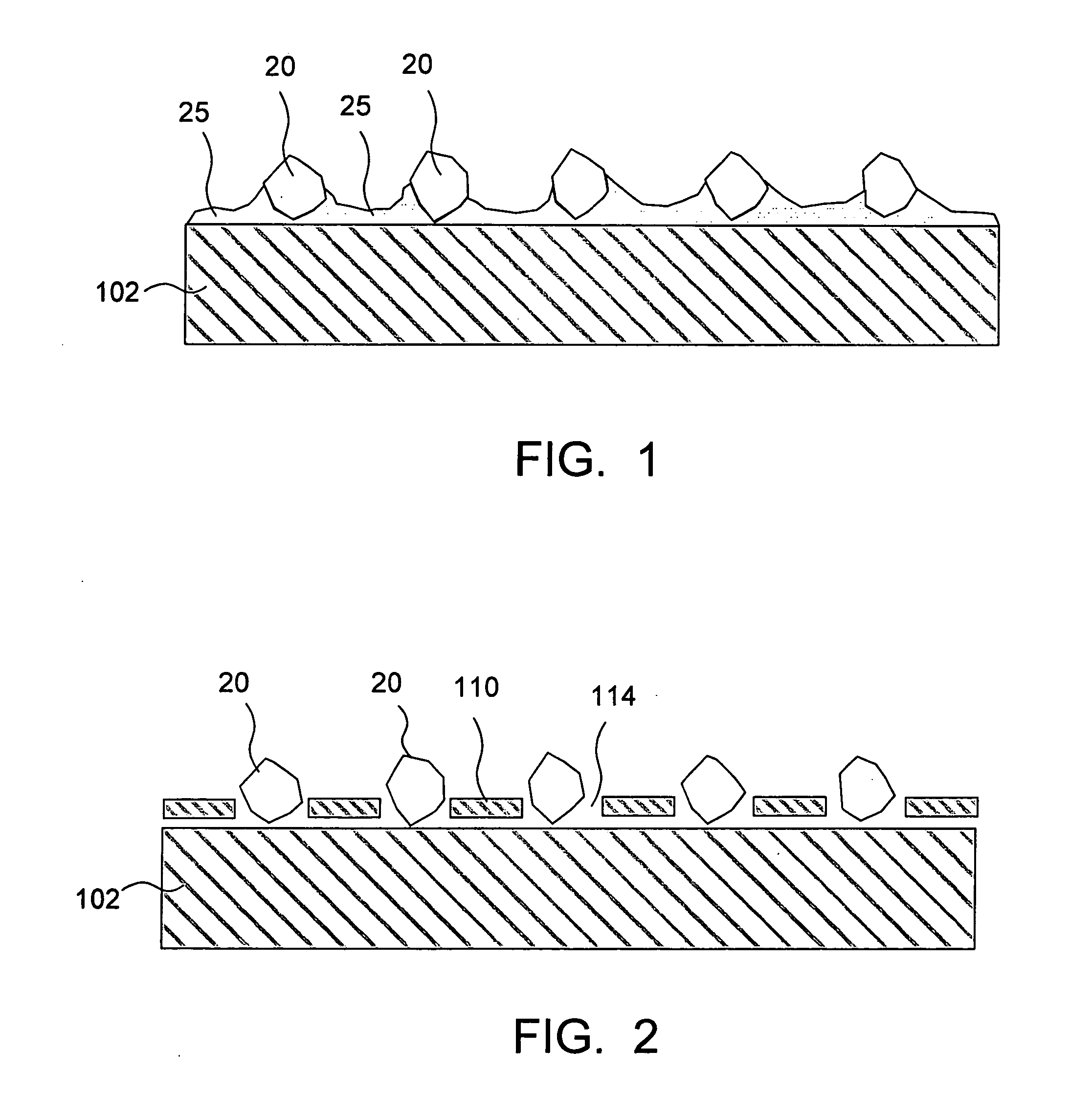

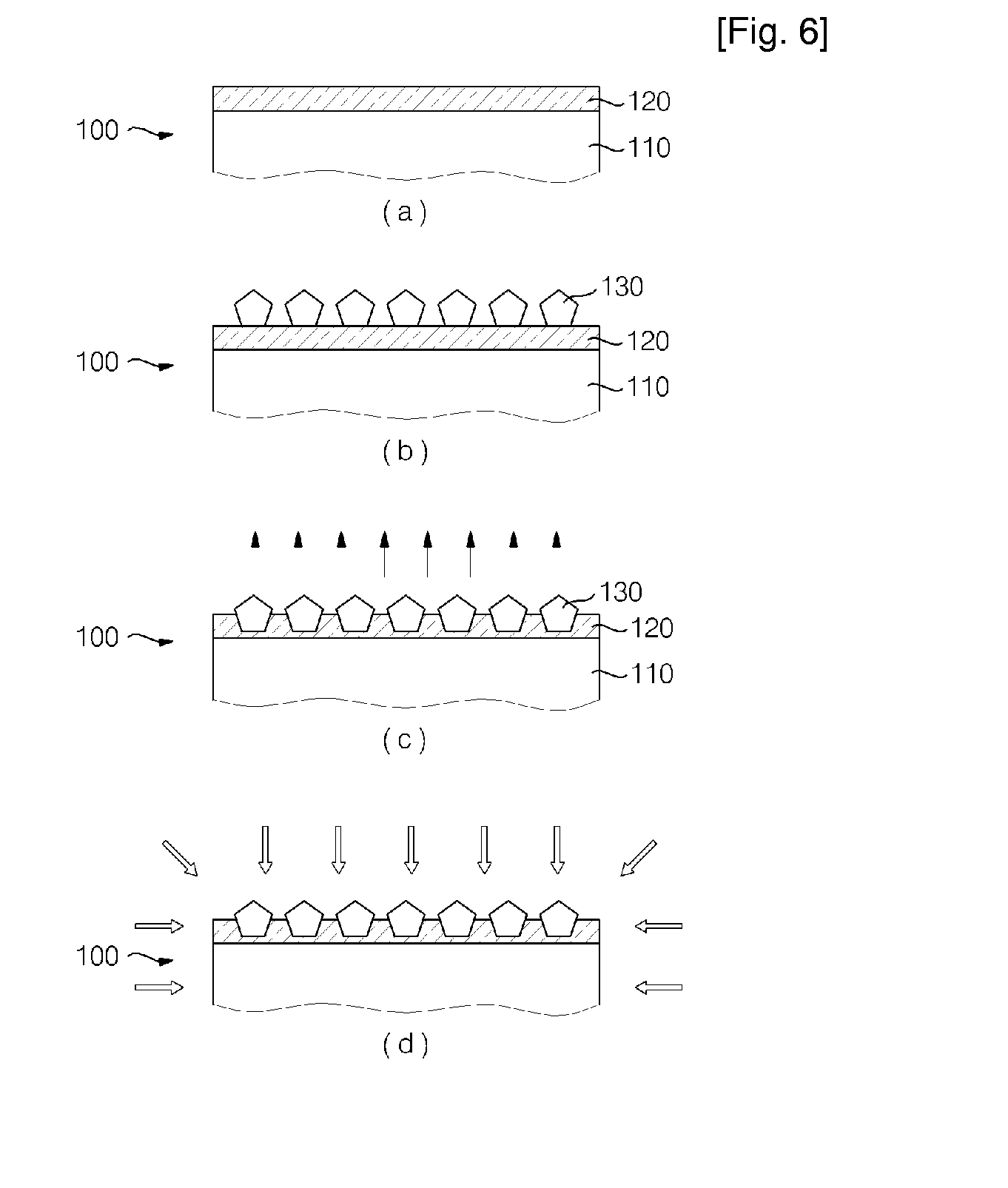

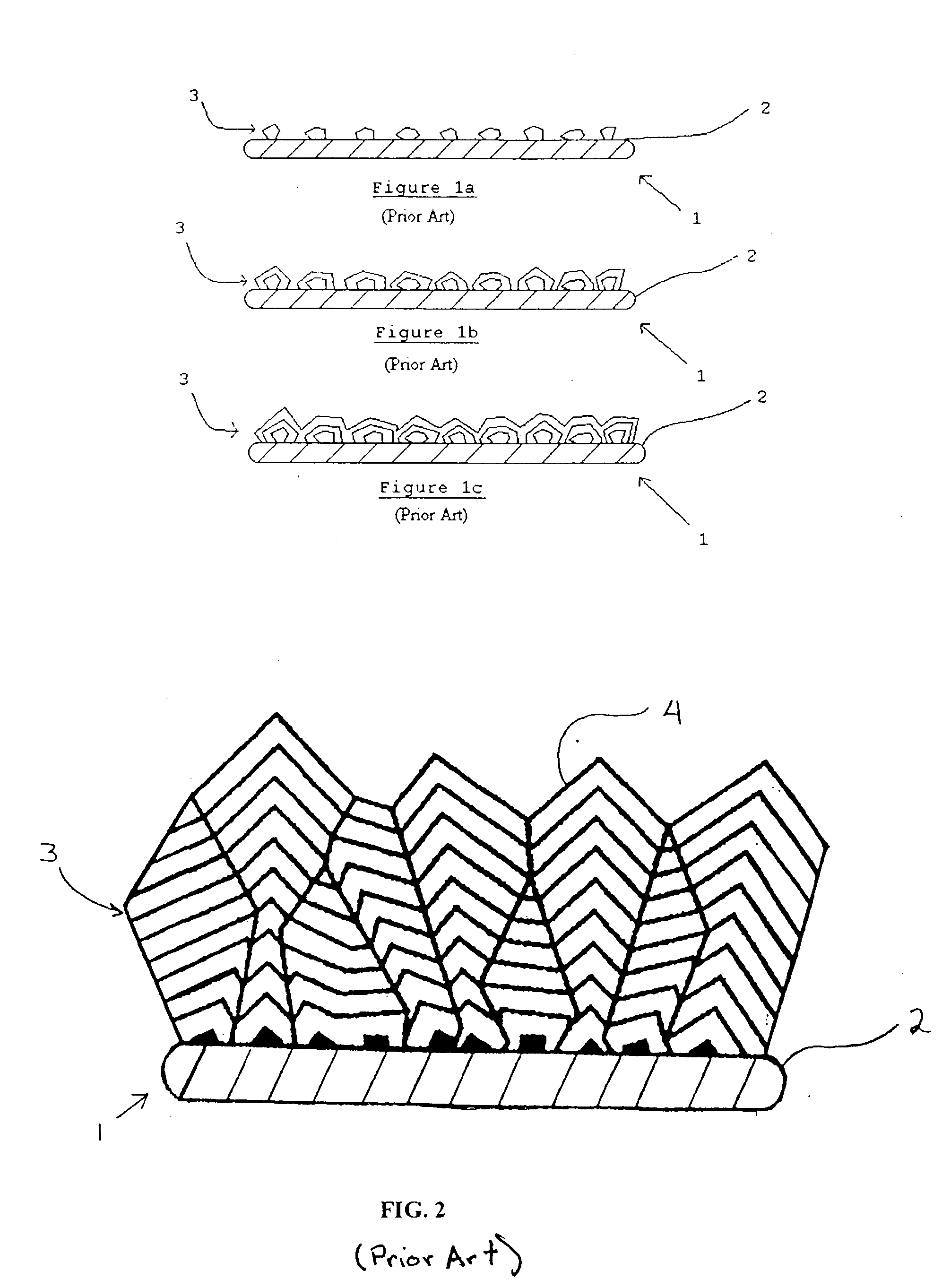

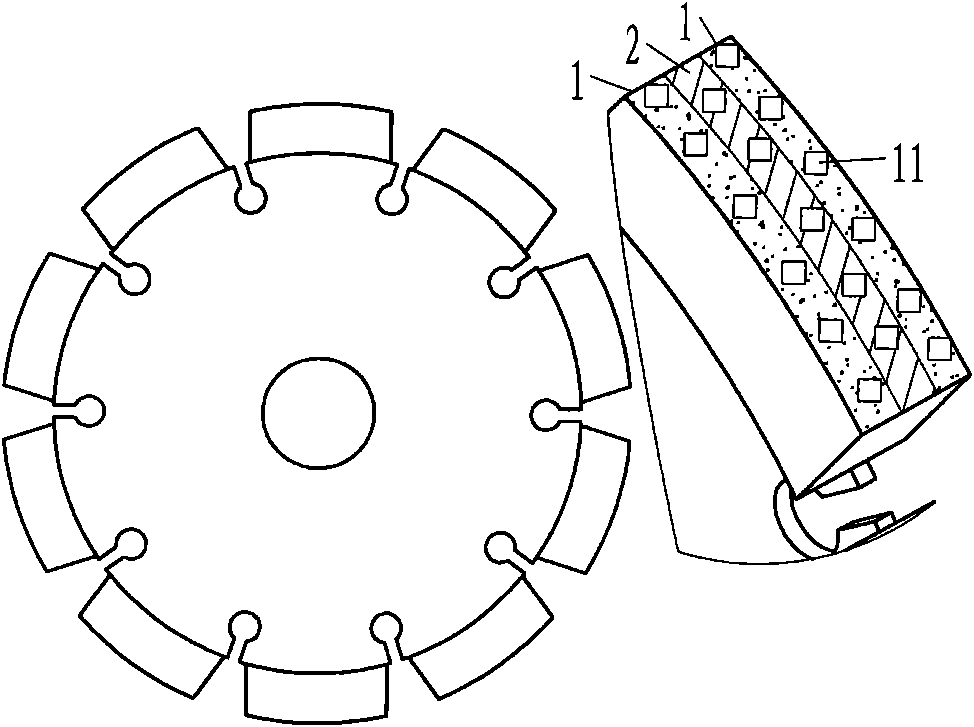

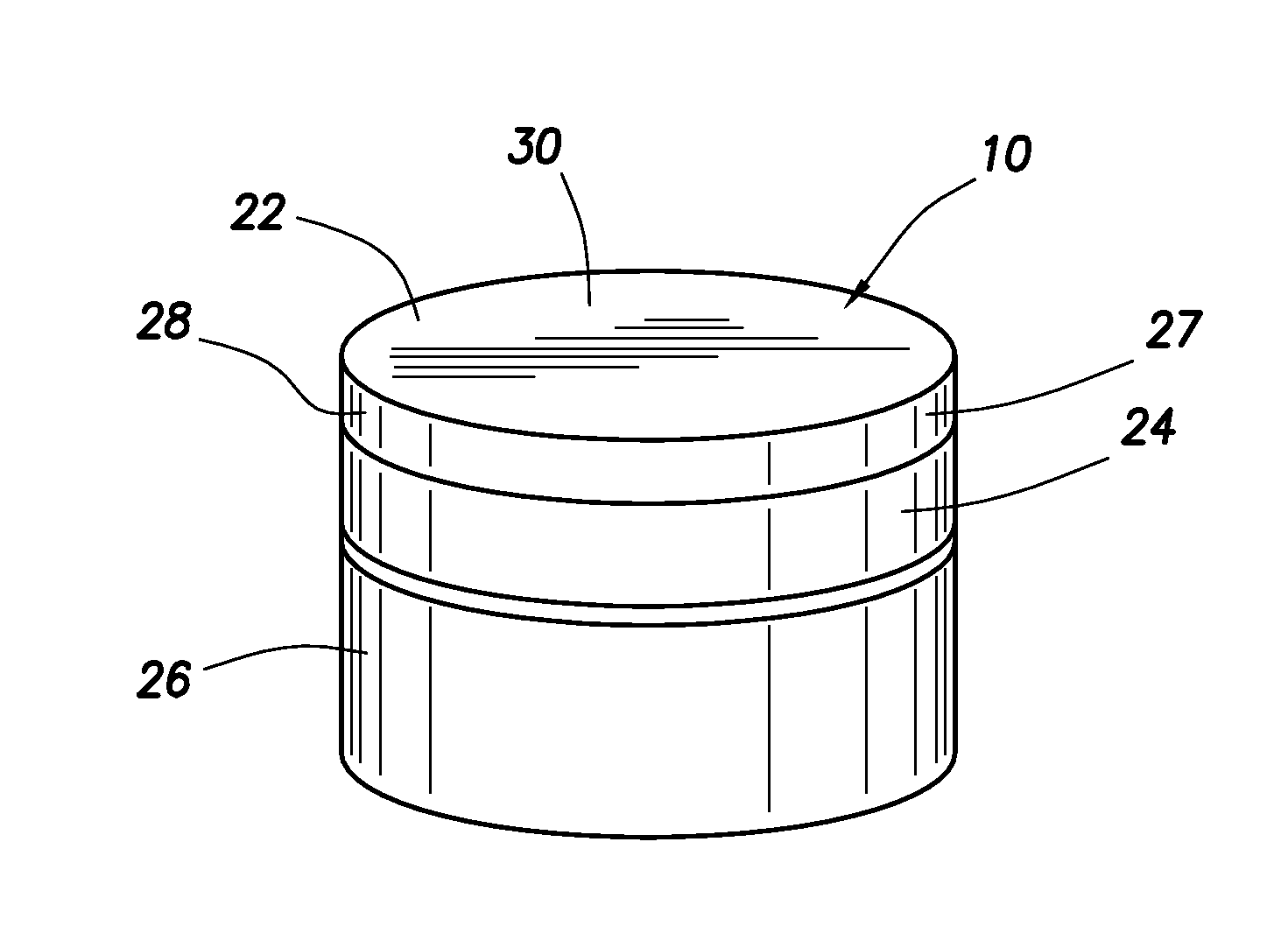

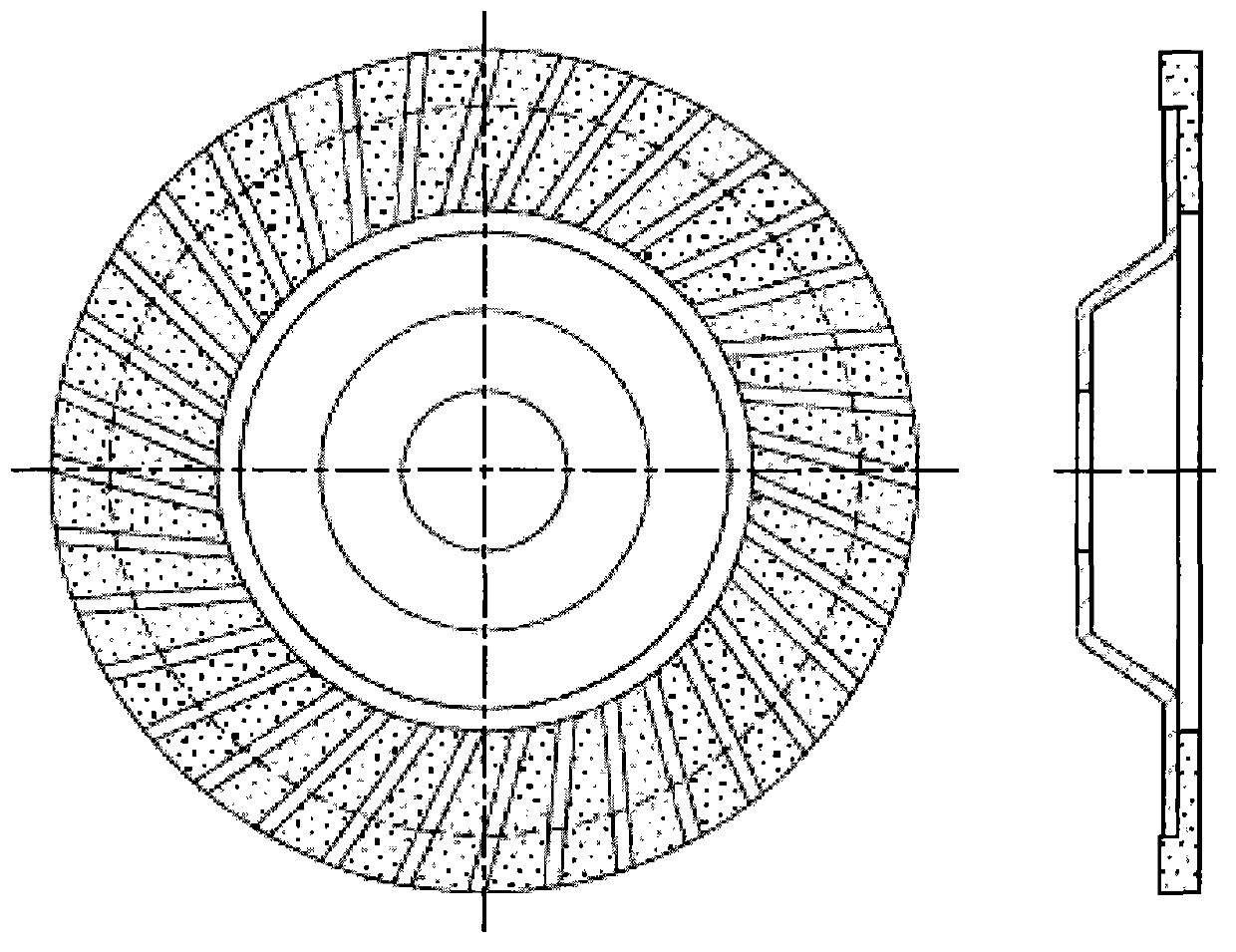

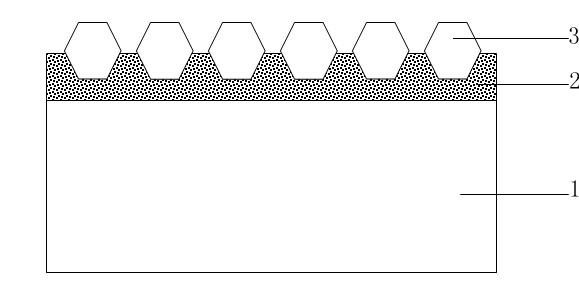

Diamond tools with multilayers of abrasive grain and method for manufacturing the same

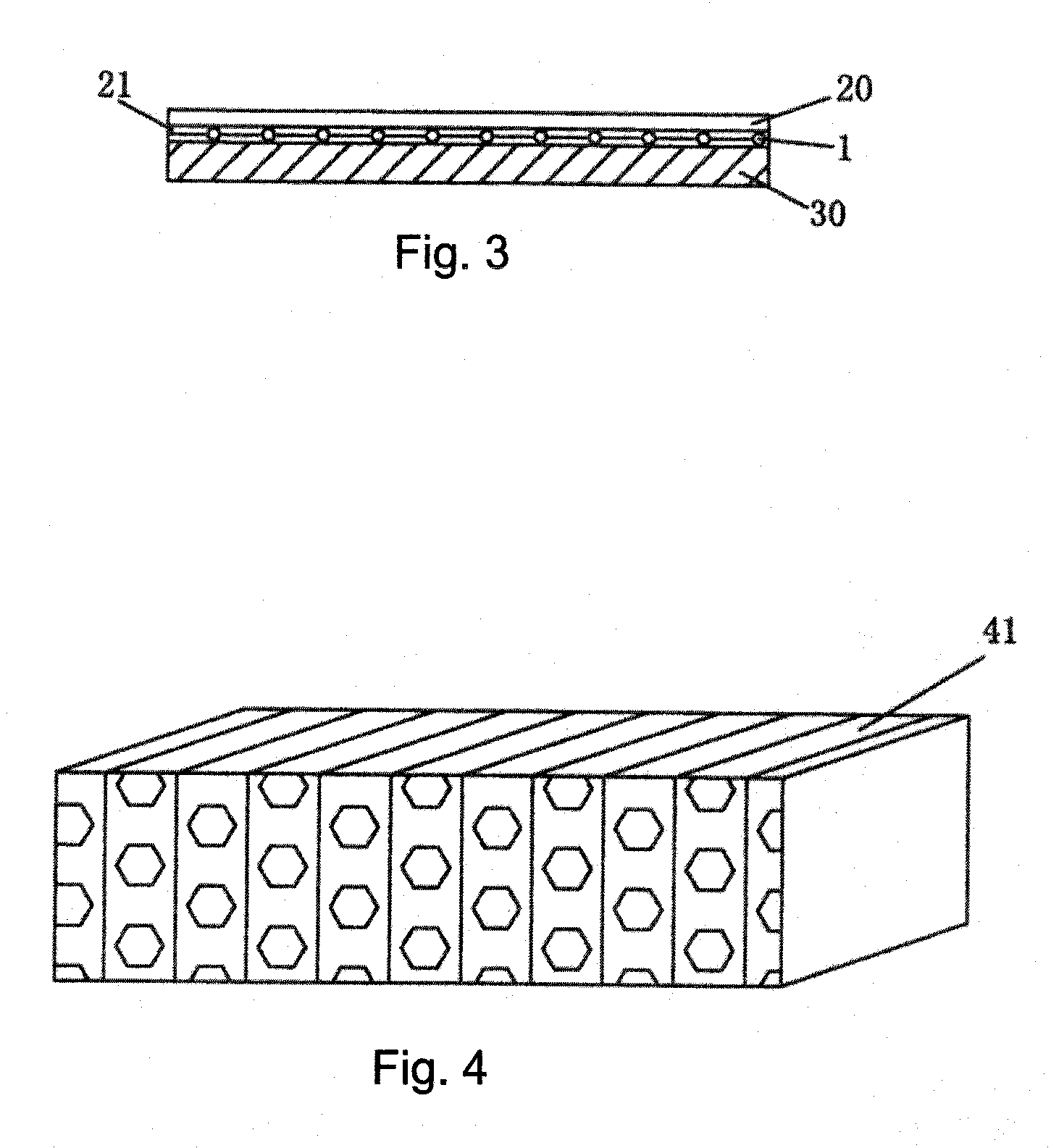

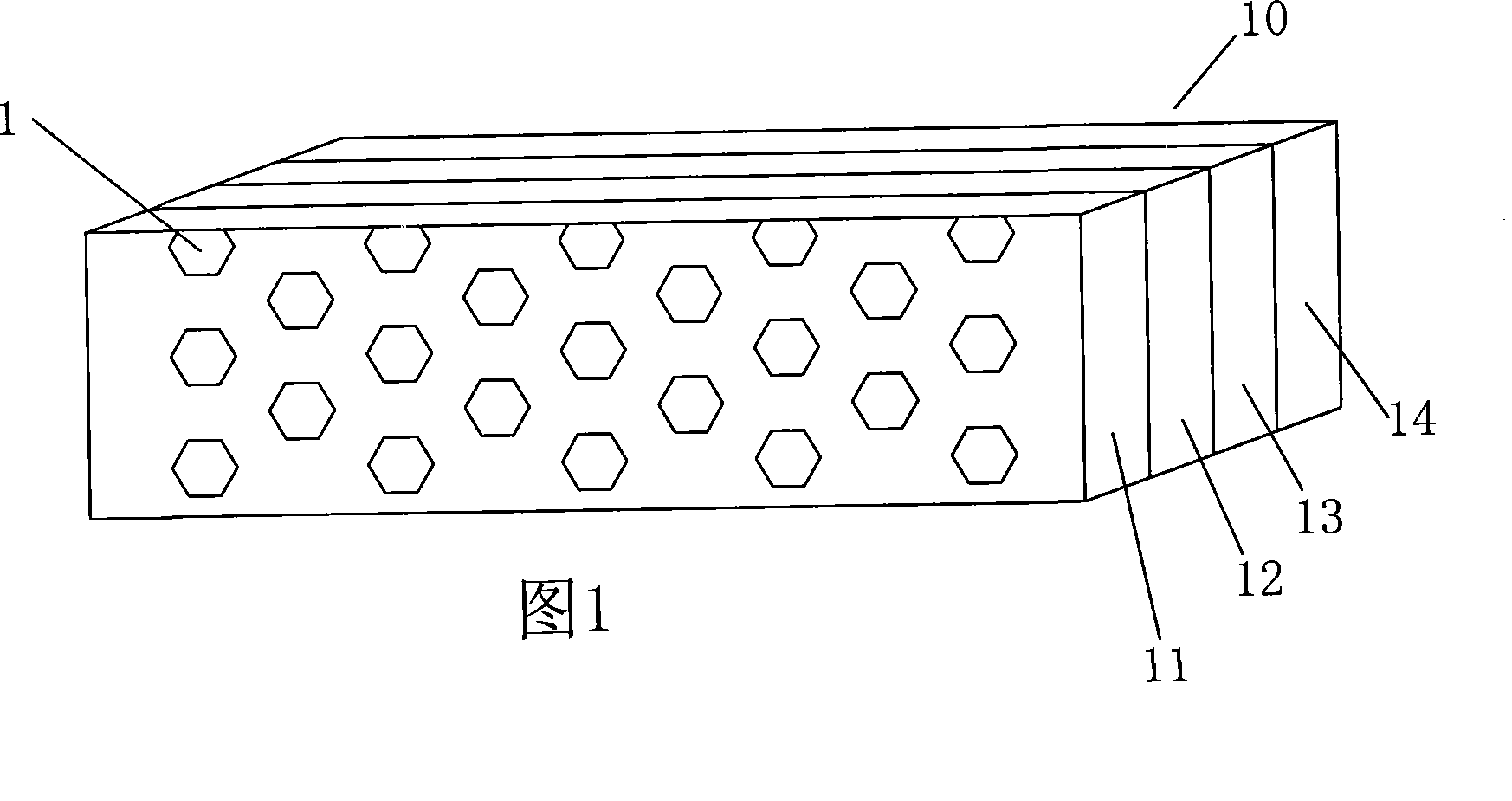

ActiveUS20070151554A1Evenly distributedUniform thicknessBonded abrasive wheelsGrinding devicesElectroplatingHeat treated

The present invention relates to a diamond tool and a method of manufacturing the same, wherein multiple abrasive layers are formed through a brazing or electroplating method, thereby improving the performance and service life of the tool. According to the method of the present invention, a plurality of concave portions are formed in a surface of the shank. A bonding paste is coated into the concave portions and abrasives are dispersed in the bonding paste to thereby form a lower abrasive layer. Again, a bonding material is coated on the lower abrasive layer and abrasives are dispersed in the bonding material to thereby form an upper abrasive layer. Then, a heat treatment is executed to fusion-bond the bonding material and abrasives onto the surface of the shank. Therefore, the diamond tools manufactured through a multiple brazing or electroplating method according to the invention can significantly extend the service life thereof, which has been a detrimental weakness of the conventional diamond tools having a single abrasive layer, in spite of various advantages of the brazing and electroplating methods. Furthermore, multiple abrasive layers can be formed inside the concave portions having a desired spacing, width and depth, thereby significantly improving the service life and the cutting performance of diamond tools.

Owner:SHINHAN DIAMOND IND

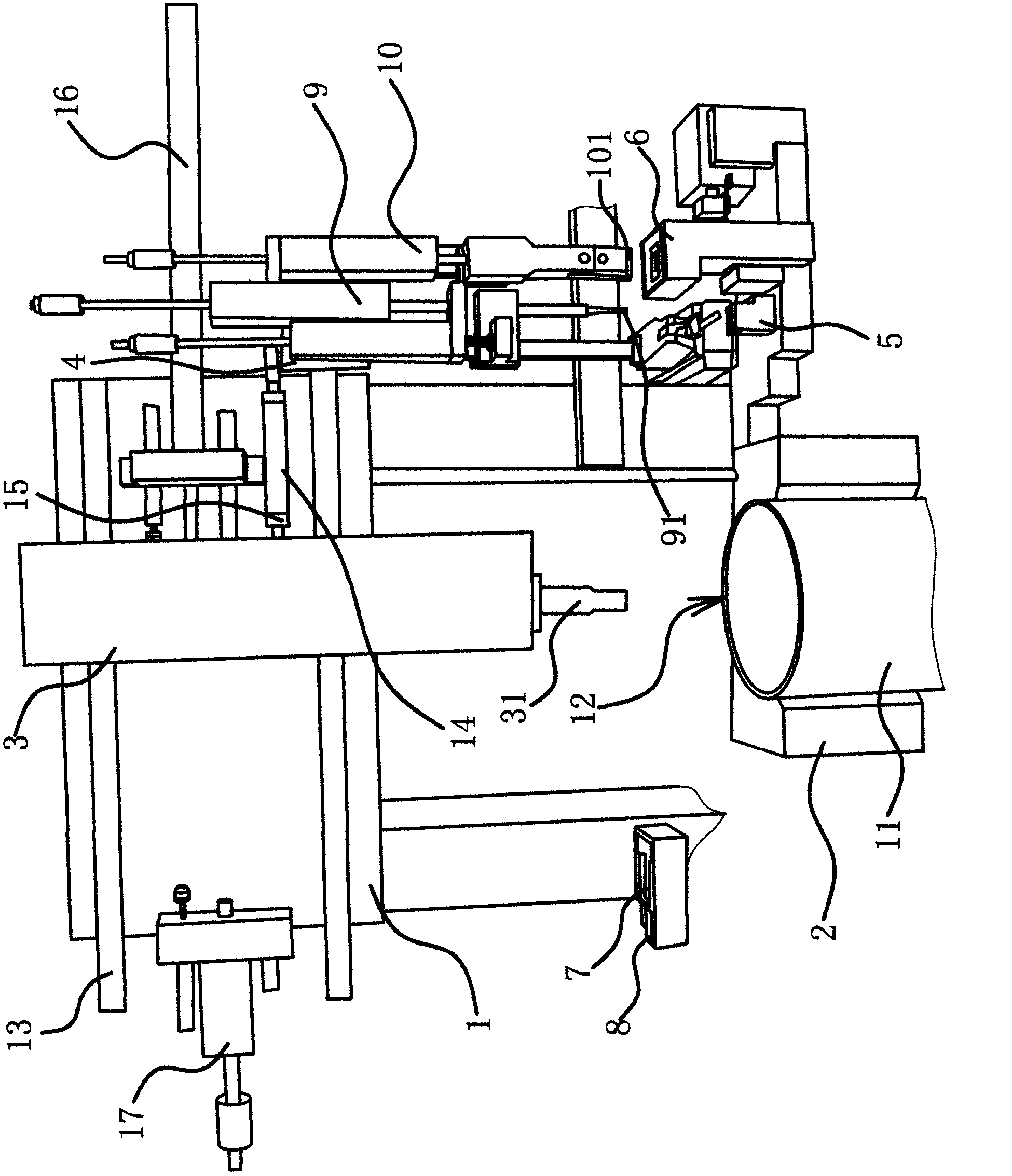

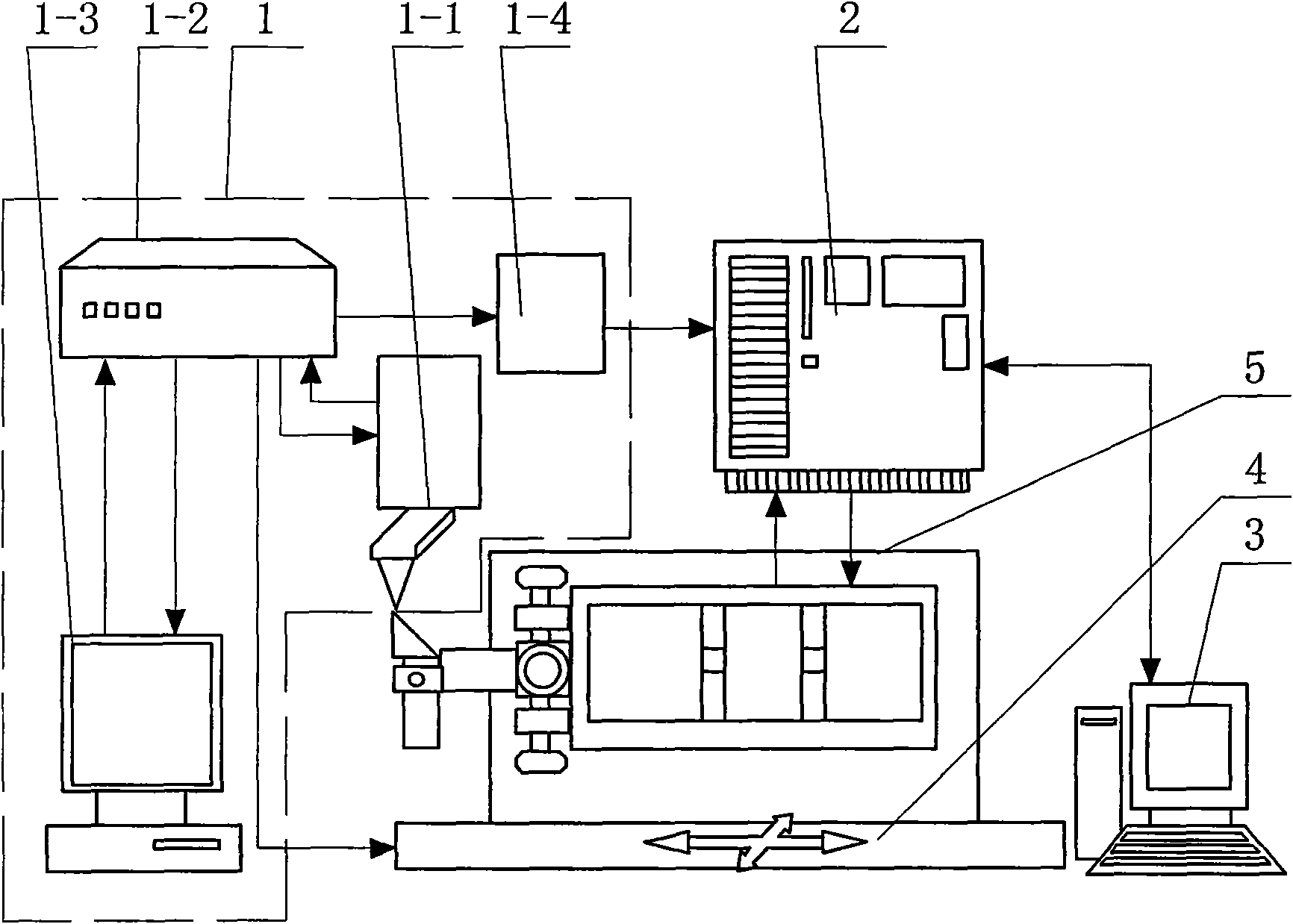

Micron-nano scale in-situ nano indentation and scratching test system

InactiveCN101876609AThe test method is accuratePrecision equipmentUsing optical meansInvestigating material hardnessImage resolutionEngineering

The invention relates to a micron-nano scale in-situ nano indentation and scratching test system which integrates driving, precise loading and signal detection, micron-nano scale mechanics performance testing, ultraprecise scratching processing and high resolution in-situ observing as one. The system is mainly composed of a precise positioning platform at X-axis and Y-axis directions, a precise linear positioning platform at Z-axis direction, a precise indentation driving unit, a load signal and displacement signal detection unit and a high resolution digital microscopic imaging system for observing and storing material deformation and damage conditions in the test process. The precise positioning platform at the X-axis and Y-axis directions is assembled on a base, the precise linear positioning platform at the Z-axis direction is assembled on a side plate, the precise indentation driving unit, a precise mechanical sensor for detecting the indentation material pressure of a diamond tool head and a precise displacement sensor for detecting the indentation depth of the diamond tool head to along the Z-axis direction are assembled on the precise linear positioning platform at the Z-axis direction, and the high resolution digital microscopic imaging system is assembled on a beam.

Owner:赵宏伟

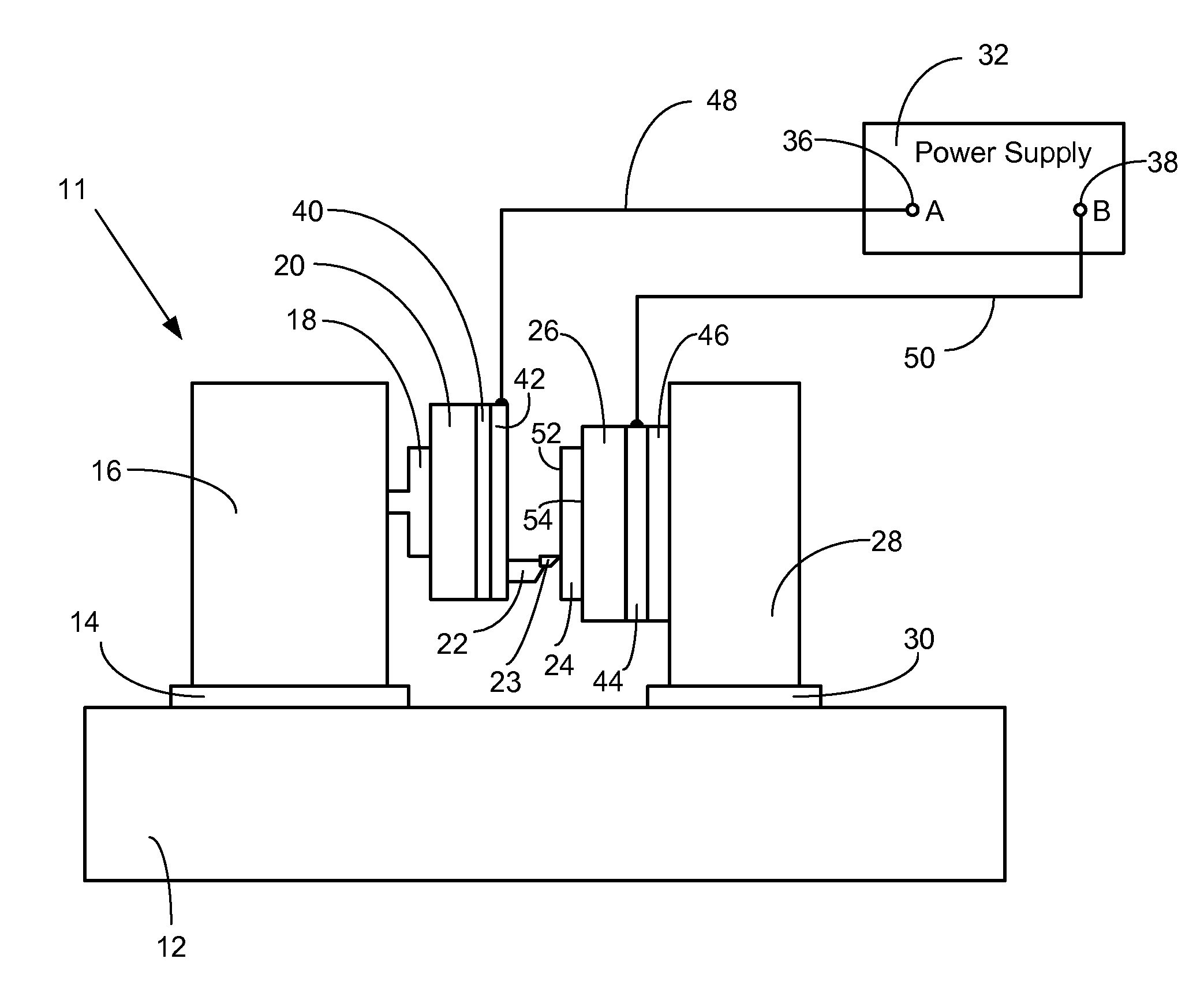

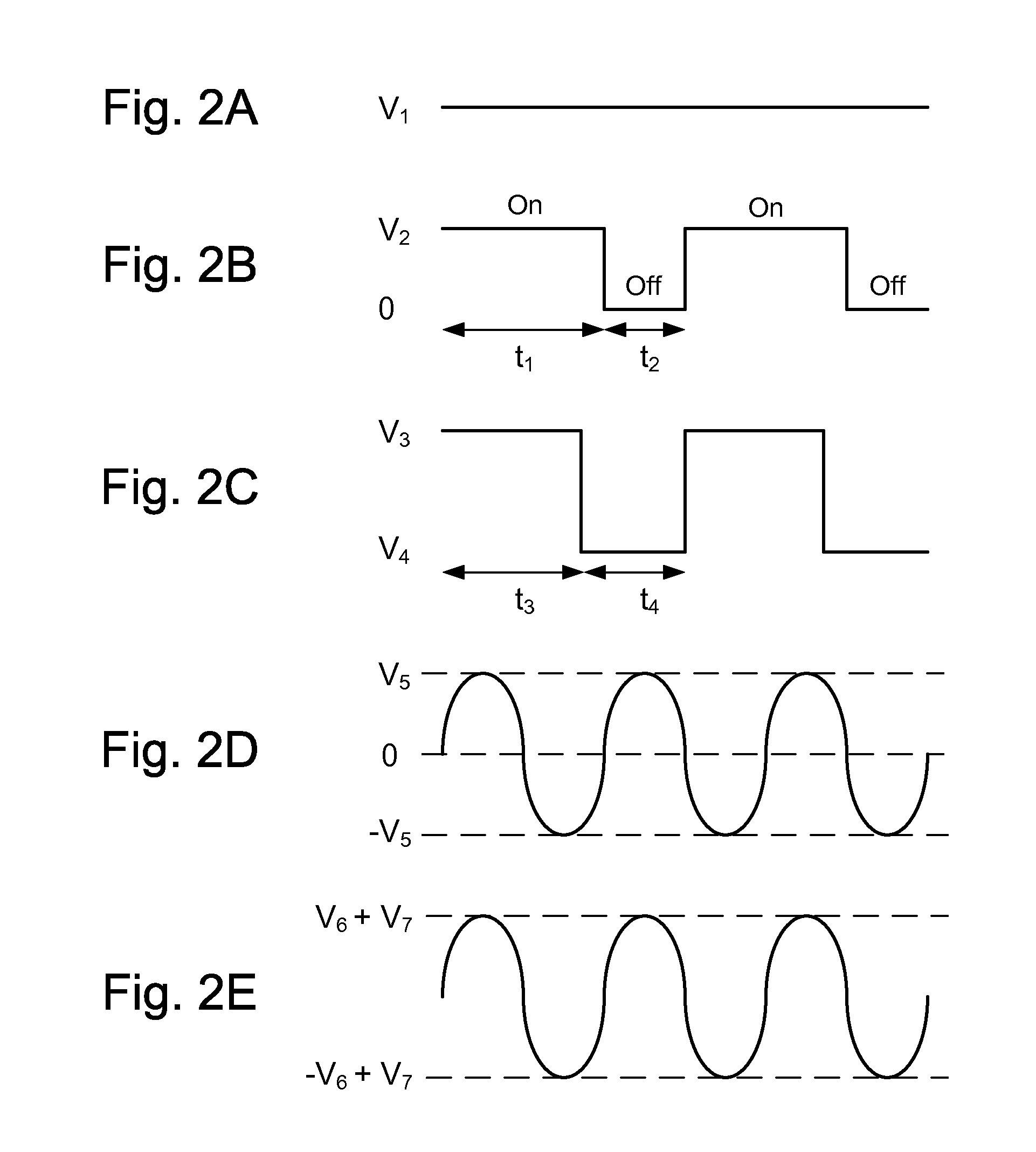

Method for extending diamond tool life in diamond machining of materials that chemically react with diamond

InactiveUS7198043B1Improve tool lifeAvoid chemical reactionsMilling cuttersArc welding apparatusChemical reactionMachining

The present invention provides a method for extending diamond tool life in diamond machining of materials that chemically react with the diamond tool in which the surface electric potential of the workpiece is adjusted or tuned to be adequate to inhibit the chemical reaction between the diamond tool and the workpiece during the diamond machining operation. As the chemical reaction is inhibited, the chemical wear rate of the diamond tool is reduced and diamond tool life is extended. The surface electric potential of the workpiece can be adjusted by electrically charging the workpiece. In one embodiment, conduction charging is used to adjust the surface electric potential of the workpiece to inhibit the chemical reaction between the diamond tool and the workpiece. In another embodiment, induction charging is used to adjust the surface electric potential of the workpiece to inhibit the chemical reaction between the diamond tool and the workpiece.

Owner:ZHANG GANG

Cast diamond products and formation thereof by chemical vapor deposition

InactiveUS20040031438A1From normal temperature solutionsCeramic shaping apparatusGas phaseChemical vapor deposition

The present invention provides diamond tools, and methods for the formation thereof, using CVD techniques. In one aspect, a mold is provided which has an interface surface configured to inversely match a configuration intended for the working surface of a diamond layer in a tool. An adynamic diamond mass or layer is then deposited upon the diamond interface surface of the mold, and a support layer is joined to the growth surface of the adynamic diamond layer. At least a portion of the mold is then removed to expose the working surface of the diamond which has received a shape which inversely corresponds to the configuration of the mold's diamond interface surface.

Owner:SUNG CHIEN MIN

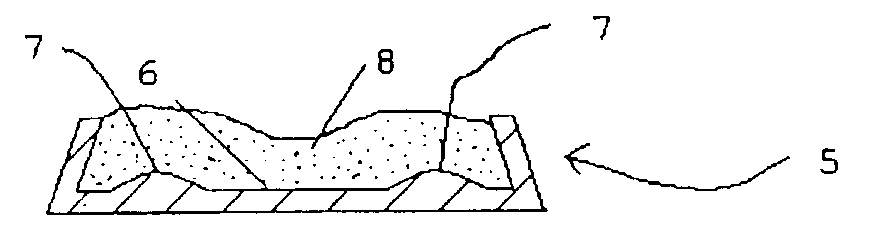

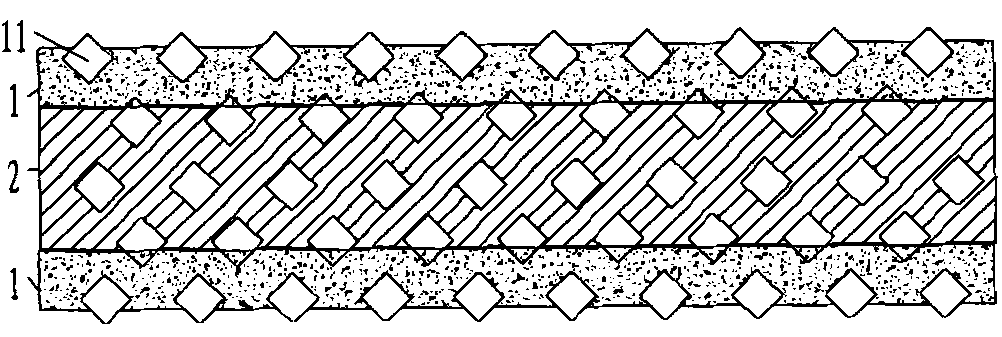

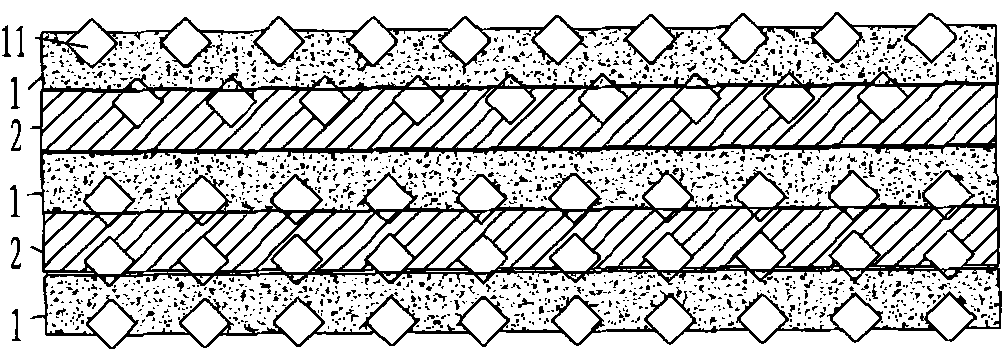

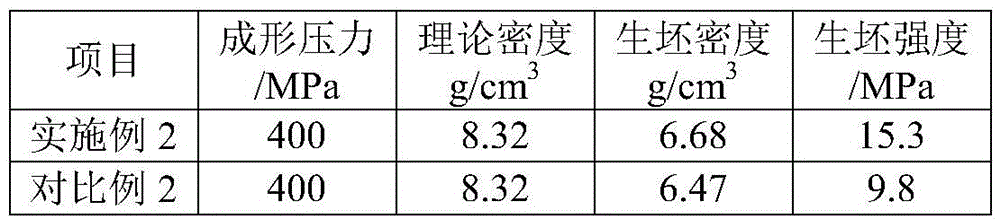

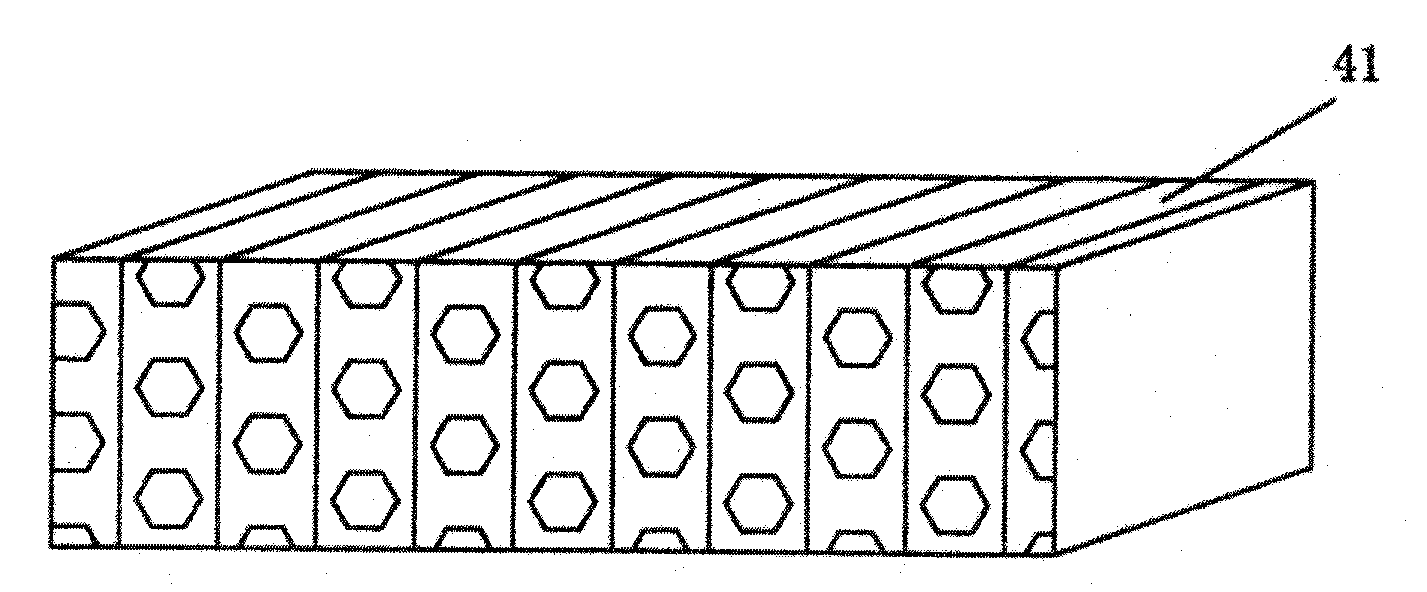

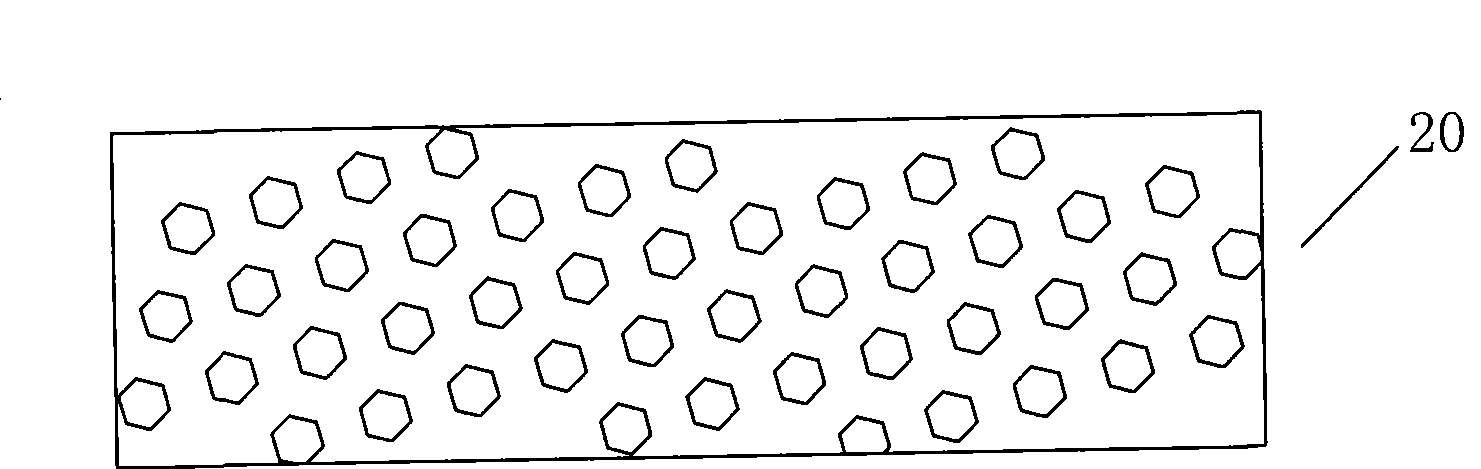

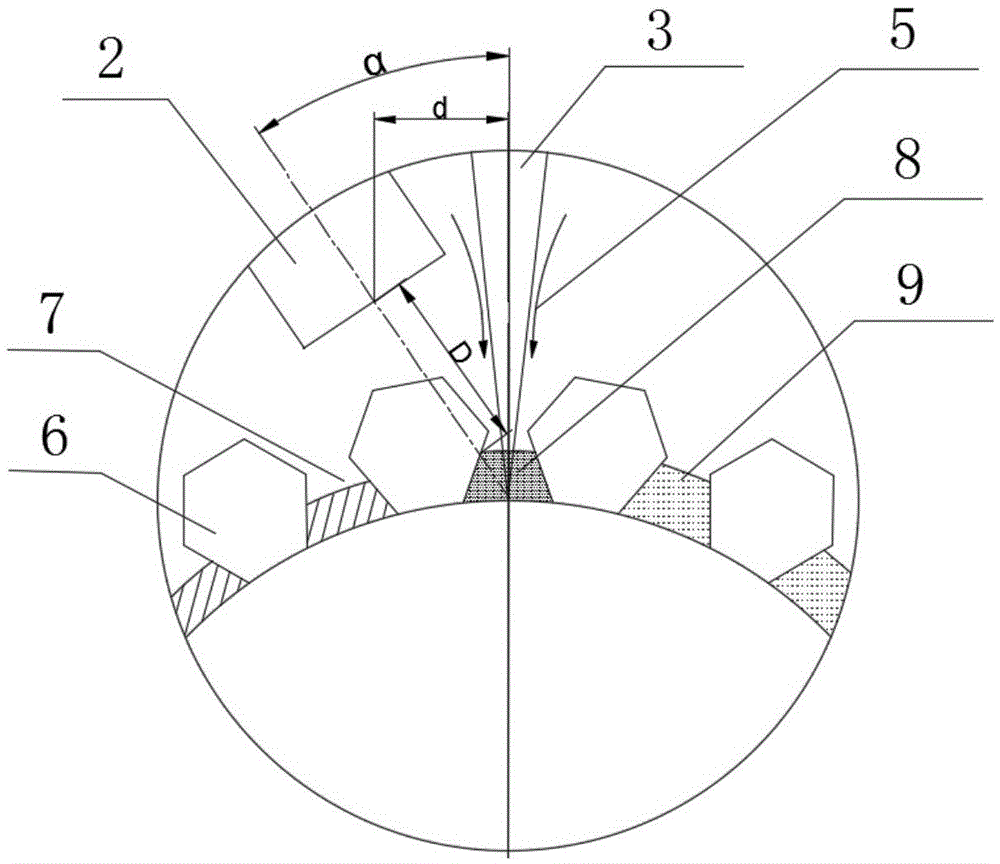

Brazing-hot pressing diamond tool and manufacturing method thereof

The invention relates to a grinding tool, in particular to a brazing-hot pressing diamond tool. The diamond tool consists of a steel matrix and a diamond tool bit, wherein the diamond tool bit consists of a plurality of alloy layers which are vertical to a working surface of the tool bit; the alloy layers are prepared from two alloy matrixes with different formulas by a vacuum hot pressing method; a prearranged diamond abrasive particle layer is arranged inside each alloy matrix layer; outer layers on two sides of the tool bit are brazing alloy matrix layers (1); a single-layer prearranged diamond abrasive particle layer is arranged inside each brazing alloy matrix layer (1); an intermediate layer of the tool bit is a pre-alloying matrix layer (2); and a single-layer or multi-layer prearranged diamond abrasive particle layer is arranged inside the pre-alloying matrix layer (2). The brazing-hot pressing diamond tool solves the problem that a multi-layer brazing tool is covered by a thick solder layer so as to cause low exposure effect and also solves the problem that a sintered diamond tool is insufficient in diamond holding force so as to make the diamond fall off too early. Therefore, the service life of the diamond tool is greatly prolonged and the processing efficiency thereof is greatly improved.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

Atomized alloyed powder substituting cobalt and nickel in diamond tools

The invention discloses an alloy powder manufactured by high pressure water atomization, and the compositions (weight percentage) of the alloy powder are: 0 to 60 percent of copper, 20 to 50 percent of iron, 5 to 20 percent of nickel, 0 to 15 percent of cobalt, 0 to 15 percent of tin, 0 to 5 percent of molybdenum, 0 to 5 percent of titanium, 0 to 5 percent of rare earth elements, 0 to 5 percent of aluminum, and 0 to 5 percent of silicon. Materials are high temperature molten and alloyed according to a certain proportion and are atomized by high-pressure water; the obtained alloy powder is dried, reduced by hydrogen, finally the atomized alloy powder is prepared. The alloy powder can be taken as a bonding agent for producing diamond tools and replace the originally used cobalt powder and nickel powder; the alloy powder can achieve performances no less than the original cobalt or nickel composition bonding agents, and greatly reduce the manufacturing cost of diamond tools.

Owner:上海芬迪超硬材料科技有限公司

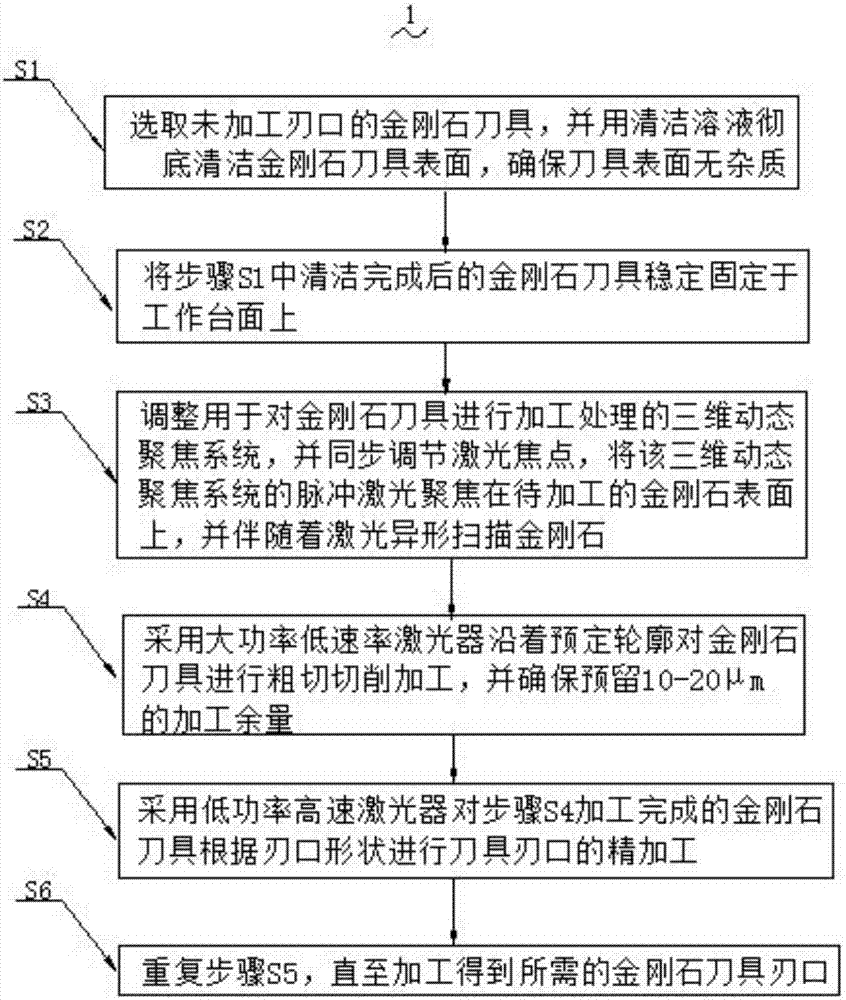

Precise laser processing method for diamond tool

ActiveCN107127459AImprove cleanlinessClear edgesOther manufacturing equipments/toolsMetal working apparatusLaser processingControllability

The invention provides a precise laser processing method for a diamond tool. The method comprises the following steps that a diamond tool of which the cutting edge is not processed is selected, and the surface of the diamond tool is thoroughly cleaned with a cleaning solution; S2, the cleaned diamond tool is fixed to the surface of a workbench; S3, a three-dimensional dynamic focusing system used for conducting processing treatment on the diamond tool is adjusted, and pulse laser of the three-dimensional dynamic focusing system is focused on the surface of to-be-processed diamond; S4, rough cutting processing is conducted on the diamond tool through a high-power low-speed laser device; and S5, finish processing is conducted on the diamond tool with a low-power high-speed laser device according to the shape of the cutting edge. According to the diamond tool prepared through the method, the cutting edge cleanliness is high, the edge is clear, pollution to the environment is small, and the processing efficiency, the product yield and the automation controllability degree are high. Compared with other methods, the precise laser processing method has obvious advantages on the aspects of efficiency, cost, shape control and the like.

Owner:深圳光韵达激光应用技术有限公司 +1

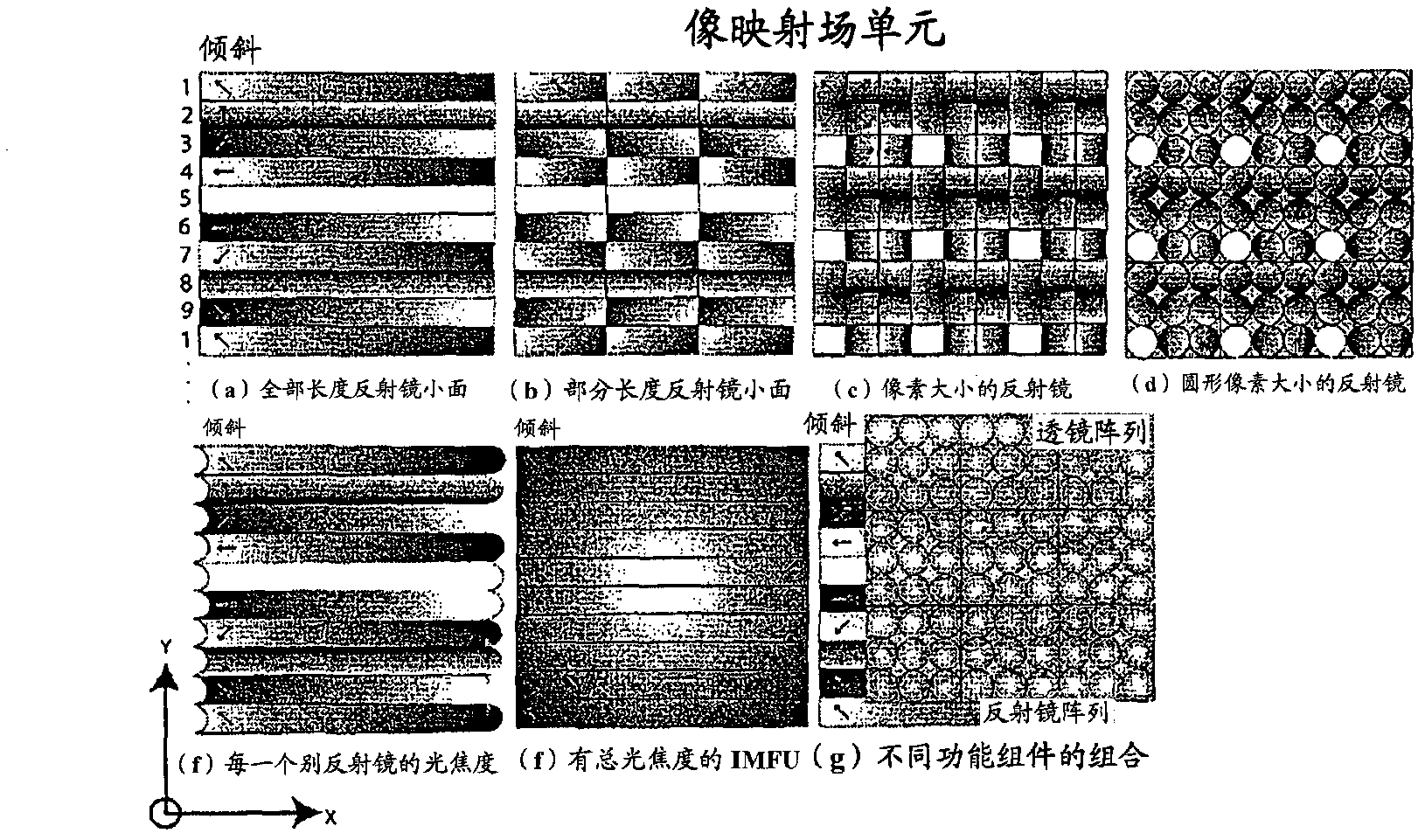

image mapping spectrometer

Devices and methods for hyperspectral and multispectral imaging are discussed. In particular, methods like mapping spectrometer systems, methods of use and fabrication are given. Generally speaking, an image mapping spectrometer includes an image mapping field unit, a spectral separation unit, and a selective imager. Image mapping spectrometers can be used for spectral imaging of optical samples. In some embodiments, the image-mapping field unit of the image-mapping spectrometer can be fabricated using surface-formed diamond tools.

Owner:威廉马什赖斯大学

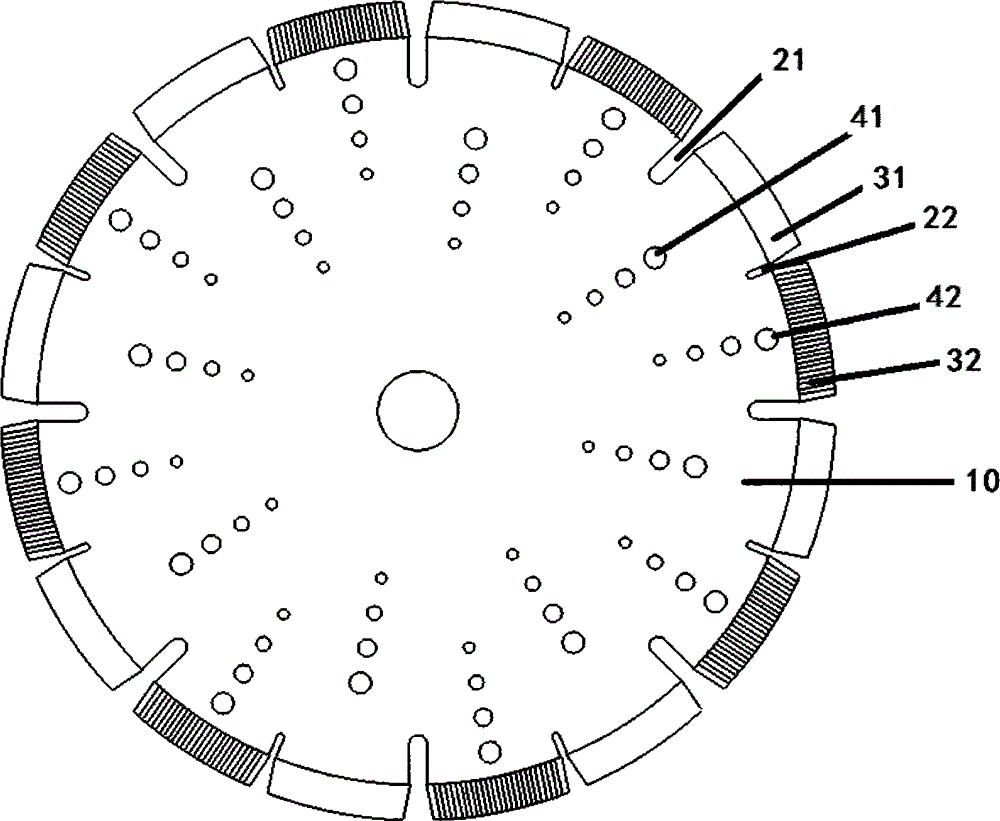

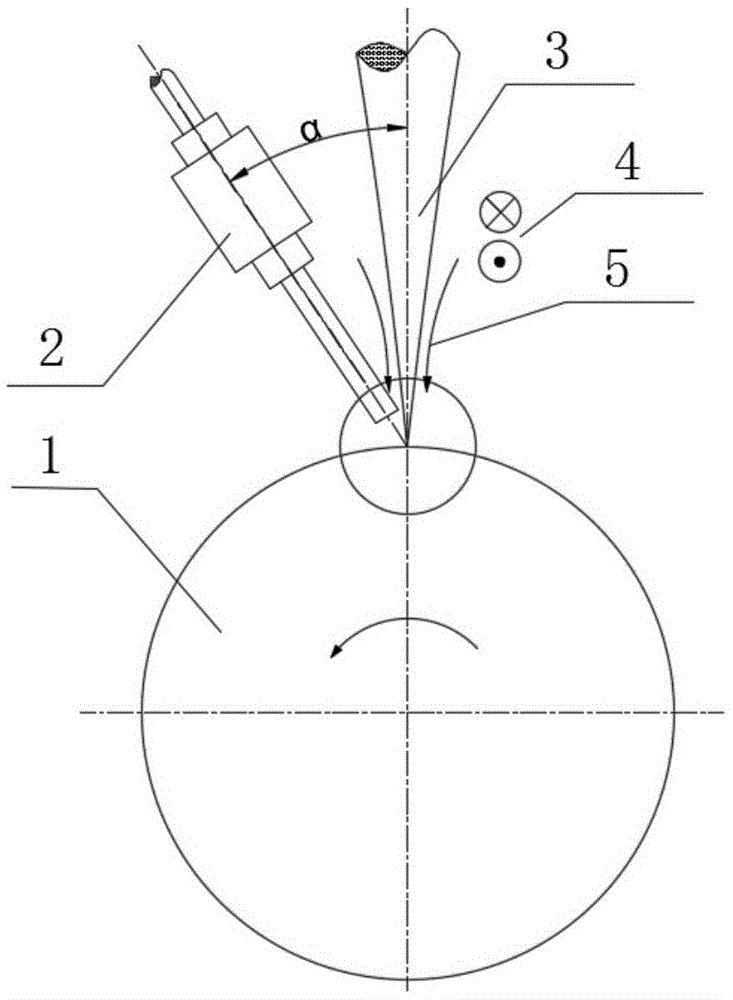

Dry and wet dual-purpose laser welding diamond saw blade

ActiveCN104875287AImprove cutting efficiencyImprove cutting effectStone-like material working toolsDual purposeMaterials science

The invention relates to a dry and wet dual-purpose laser welding diamond saw blade, and belongs to the technical field of diamond processing tools. The diamond saw blade comprises a circular base body which comprises a side circumferential surface located on the edge. A plurality of chip removal grooves extending in the circle center direction inwards are formed in the side circumferential surface at intervals. Diamond tool bits are formed between the chip removal grooves. The chip removal grooves include the first chip removal grooves and the second chip removal grooves, wherein the first chip removal grooves and the second chip removal grooves are formed at intervals. The diamond tool bits include the first diamond tool bits and the second diamond tool bits, wherein the first diamond tool bits and the second diamond tool bits are arranged at intervals. The cross sections of the first chip removal grooves are larger than those of the second chip removal grooves. The surfaces of the first diamond tool bits are planes. A plurality of protruding strips are arranged on the surfaces of the second diamond tool bits. Grooves are formed between the protruding strips. Chip removal and heat dissipation can be well conducted through the diamond saw blade in the cutting process, the good cutting performance can be kept under the condition of no cooling water grinding, and the purpose of conducting processing under extreme conditions is achieved for users.

Owner:JIANGSU FENGTAI TOOLS

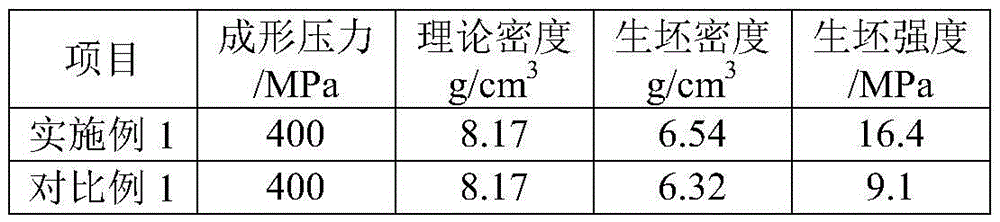

Fully-prealloyed powder and preparation method thereof

ActiveCN105463291AImprove control abilityImprove wear resistanceTransportation and packagingMetal-working apparatusUltimate tensile strengthImpurity

The invention discloses fully-prealloyed powder. The fully-prealloyed powder is prepared from, by weight percentage, 30%-65% of Fe, 15%-45% of Cu, 1%-15% of Sn, 0%-15% of Ni, 1%-30% of Co, 0%-5% of Qt and the balance inevitable impurities, wherein Qt is selected from one or more of Mn, Cr, Ti, P and W. The invention further discloses a preparation method of the fully-prealloyed powder. The formability and sintering strength of the fully-prealloyed powder are improved, and the sintering density of the fully-prealloyed power is increased; in the whole process, only the fully-prealloyed powder is used as a bonding agent in a diamond tool bit; and the advantages that the fully-prealloyed powder is low in sintering temperature, wide in process range and good in pullout strength on diamond are brought into full play.

Owner:BOSUN TOOLS CO LTD

RE-containing prealloy powder

ActiveCN1986116AGood composition uniformitySufficient sintering reactivityRare-earth elementScanning electron microscope

The present invention relates to a kind of pre-alloyed powder and its application in making diamond tool. The pre-alloyed powder consists of at least two selected from Fe, Co, Cu and Ni as basic components, one or several of Mn, Ti, Sn, Mo, W and WC, and one or two of RE, such as La and Ce. It contains at most 80 % of Fe, at most 40 % of Co, at most 80 % of Cu, at most 40 % of Ni, at most 8 % of M and 0-5 % of RE, where, M is one or several of Mn, Ti, Sn, Mo, W and WC and RE is La and / or Ce. The pre-alloyed powder has also inevitable impurity. Scanning electronic microscope measurement shows that the pre-alloyed powder has basic particle size smaller than 15 micron and oxygen content not more than 2 %. The pre-alloyed powder is used as adhesive in making diamond tool.

Owner:GRIPM ADVANCED MATERIALS CO LTD

Diamond tool bit bottom surface grinding device

ActiveCN103331488AEasy to produceLabor savingSawing tools dressing arrangementsDrilling toolsTool bitSurface grinding

The invention provides a diamond tool bit bottom surface grinding device, which belongs to the technical field of the operation. The problem that the traditional diamond tool bit bottom surface grinding has low production efficiency because of grinding by a common machine tool is solved. The diamond tool bit bottom surface grinding device comprises a rack, wherein the rack is provided with a first grinding mechanism, a transfer discrimination mechanism and a second grinding mechanism, wherein the first grinding mechanism can be used for grinding the certain end surface of a diamond tool bit into a bright surface; the transfer discrimination mechanism can be used for transferring out the diamond tool bit capable of grinding the certain end surface of the diamond tool bit into the bright surface, can be used for judging whether the bright surface is positioned on the bottom surface or a tool surface and enables the diamond tool bit to face to the same direction according to the judgment result; and the second grinding mechanism can be used for bearing the diamond tool bit with the same facing direction of the transfer discrimination mechanism and can be used for grinding the diamond tool bit bottom surface. The diamond tool bit bottom surface grinding device has the advantages of convenience in production, labor force saving, high automation degree and high efficiency. According to the test, the diamond tool bit bottom surface grinding device can be used for grinding ten diamond tool bit bottom surfaces in one minute.

Owner:ZHEJIANG BANNINGER FLUID CONTROL CO LTD

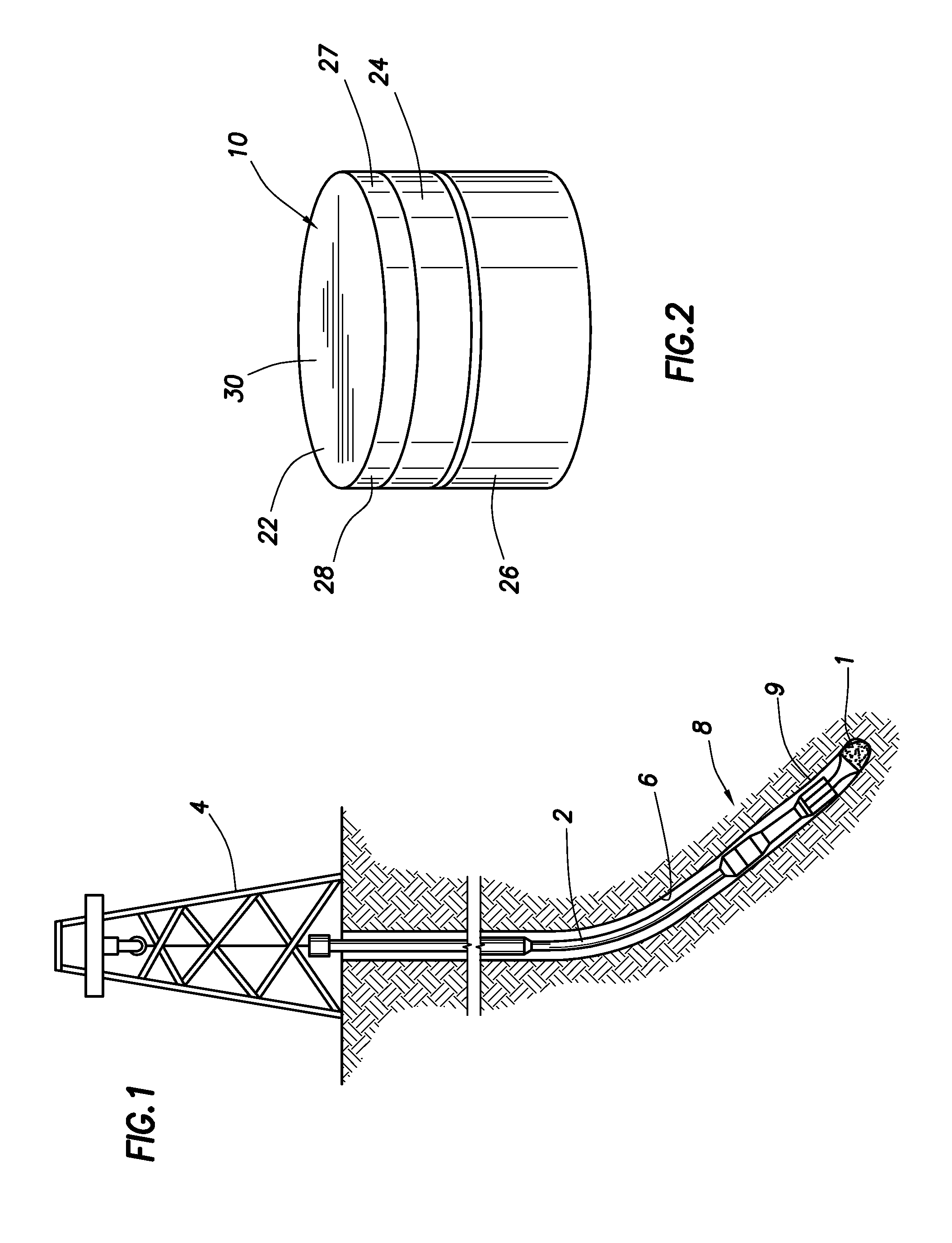

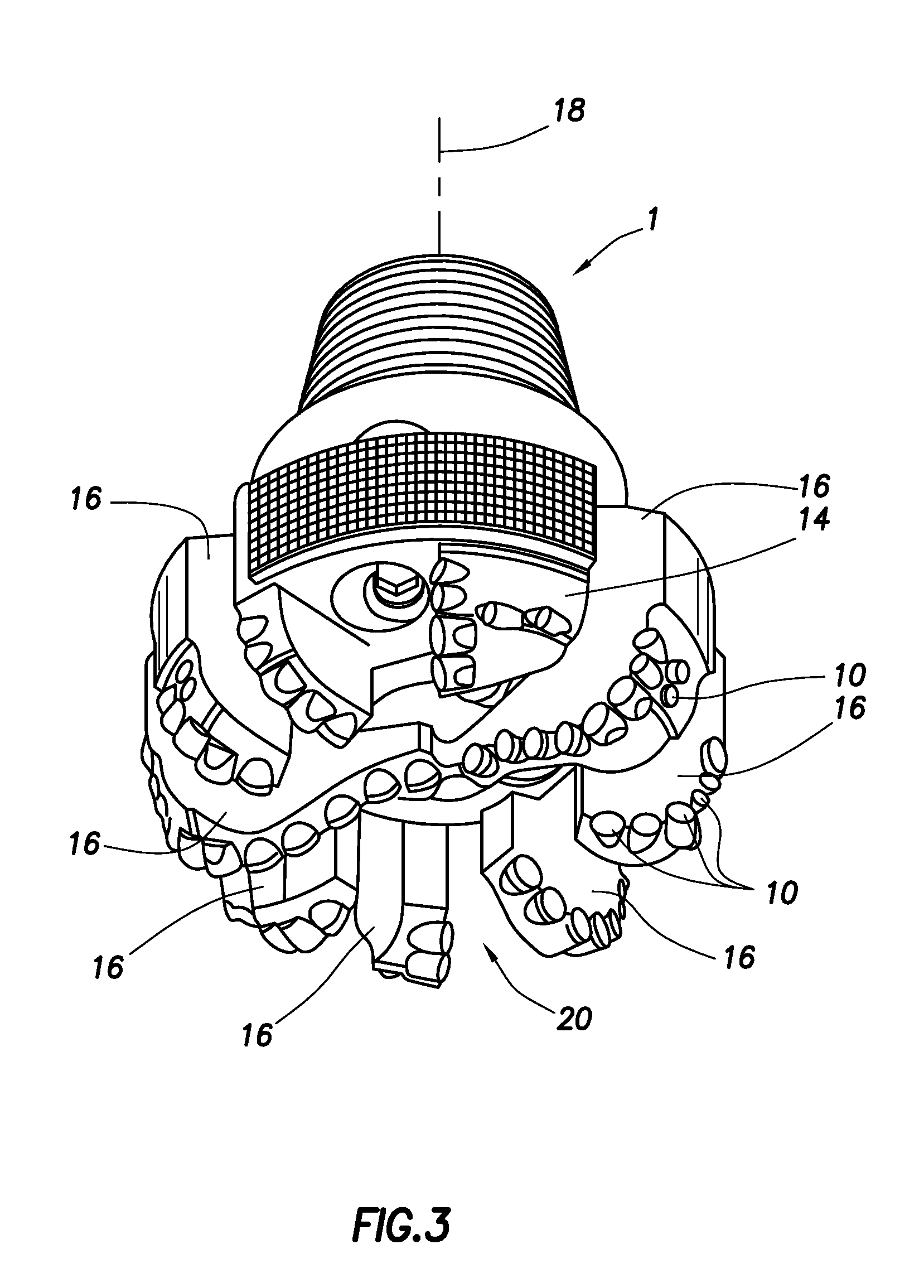

Polycrystalline diamond cutting element

ActiveUS20120097457A1Improve wear lifeImprove featuresDrill bitsConstructionsPolycrystalline diamondDrill bit

A polycrystalline-diamond cutting element for a drill bit of a downhole tool. The cutting element includes a substrate and a diamond table bonded to the substrate. The diamond table includes a diamond filler with at least one leached polycrystalline diamond segment packed therein along at least one working surface thereof. The cutting element may be formed by positioning the diamond table on the substrate and bonding the diamond table onto the substrate such that the polycrystalline diamond segment is positioned along at least one working surface of the diamond table. A spark plasma sintering or double press operation may be used to bond the diamond table onto the substrate.

Owner:NAT OILWELL DHT

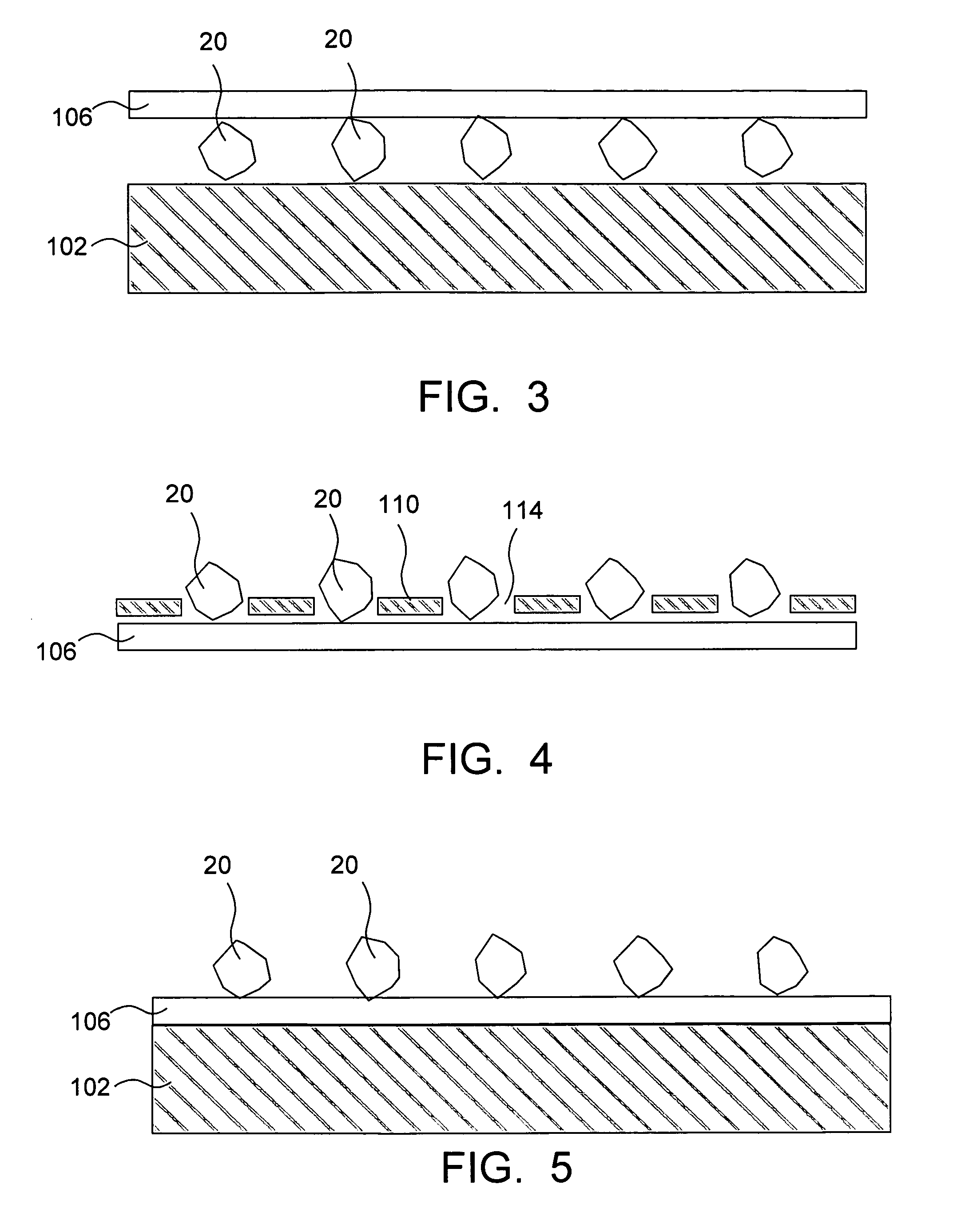

Brazed Diamond Tools and Methods for Making the Same

InactiveUS20120260582A1Low costEvenly spacedPigmenting treatmentPressurized chemical processBraze alloyThin sheet

Superabrasive tools and methods for the making thereof are disclosed and described. In one aspect, superabrasive particles are chemically bonded to a matrix support material according to a predetermined pattern by a braze alloy. The brazing alloy may be provided as a powder, thin sheet, or sheet of amorphous alloy. A template having a plurality of apertures arranged in a predetermined pattern may be used to place the superabrasive particles on a given substrate or matrix support material.

Owner:KINIK

Brazed diamond tools and methods for making the same

InactiveUS20110296766A1Low costEvenly spacedPigmenting treatmentPressurized chemical processBraze alloyThin sheet

Superabrasive tools and methods for the making thereof are disclosed and described. In one aspect, superabrasive particles are chemically bonded to a matrix support material according to a predetermined pattern by a braze alloy. The brazing alloy may be provided as a powder, thin sheet, or sheet of amorphous alloy. A template having a plurality of apertures arranged in a predetermined pattern may be used to place the superabrasive particles on a given substrate or matrix support material.

Owner:CHIEN MIN SUNG +1

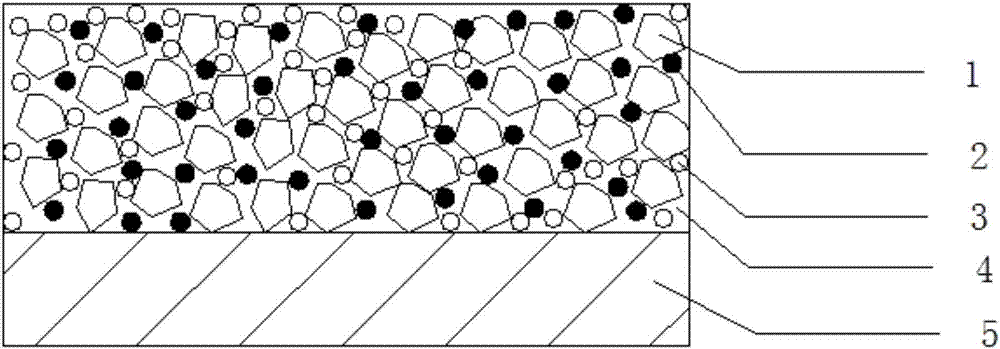

Multilayer brazed diamond tool and manufacturing method thereof

ActiveCN106881671AGood edgeShort lifeBonded abrasive wheelsGrinding devicesManufacturing technologyAlloy

The invention provides a multilayer brazed diamond tool. The multilayer brazed diamond tool comprises a matrix and a multiple diamond composite layers combined with the surface of the matrix. The multiple diamond composite layers contain diamond particles, framework particles and alloy brazing filler. The diamond particles are disorderly distributed in the multiple diamond composite layers. According to the multilayer brazed diamond tool, the diamond composite layers of the tool contain the multiple layers of diamond particles, so that the service life can be prolonged; furthermore, each diamond composite layer contains a large amount of air holes, the air holes can store cooling liquid, contain chips, discharge chips, prevent burning damage and facilitate diamond exposure, and therefore the diamond tool is continuously sharp; besides, combination between the alloy brazing filler and the diamond is firm, the brazing filler is completely alloyed, so that the uniformity is good, and the performance consistency is high; in addition, the manufacturing technology of the multilayer brazed diamond tool is simple and free of limitation of the dimension and shape of the diamond tool.

Owner:LENS TECH CHANGSHA

Nano core-shell type copper-nickel bimetal powder body and preparing method and application thereof

ActiveCN101209493AOvercome the disadvantage of easy oxidationMeet the requirement of transparent appearanceCoatingsThioureaConductive materials

The invention relates to a bimetal powder of copper and nickel and a preparation method thereof. The invention solves the defect of easy oxidation of the simple substance nanometer copper powder and improves the use effect of the ordinary copper nickel composite powder. Referring to the prior art, the invention firstly prepares a nanometer copper powder, the copper powder is stirred and dispersed homogeneously in the water, and suspension liquid of the copper powder is prepared; the suspension liquid of the copper powder is blended with the nickel sulfate solution comprising macromolecule protective agent and special copper coordination agent thiourea so as to cause a replacement reaction between nickel ion and the copper; surfaces of the ultrafine copper particles are partly or all coated with the nickel, thus forming the core-shell copper-nickel bimetal nanometer powder. The bimetal powder can be taken as lubricant, lubricating grease extreme pressure-antiwear additives, additives in powder metallurgy, or as porous materials, antibacterial materials, antifouling coatings, conductive materials, magnetic materials, self-lubricating materials, antifriction materials, diamond tools, and raw materials or additives of electrical carbon products.

Owner:HAILIAN INST OF LUBRICATING MATERIALS SHANGHAI

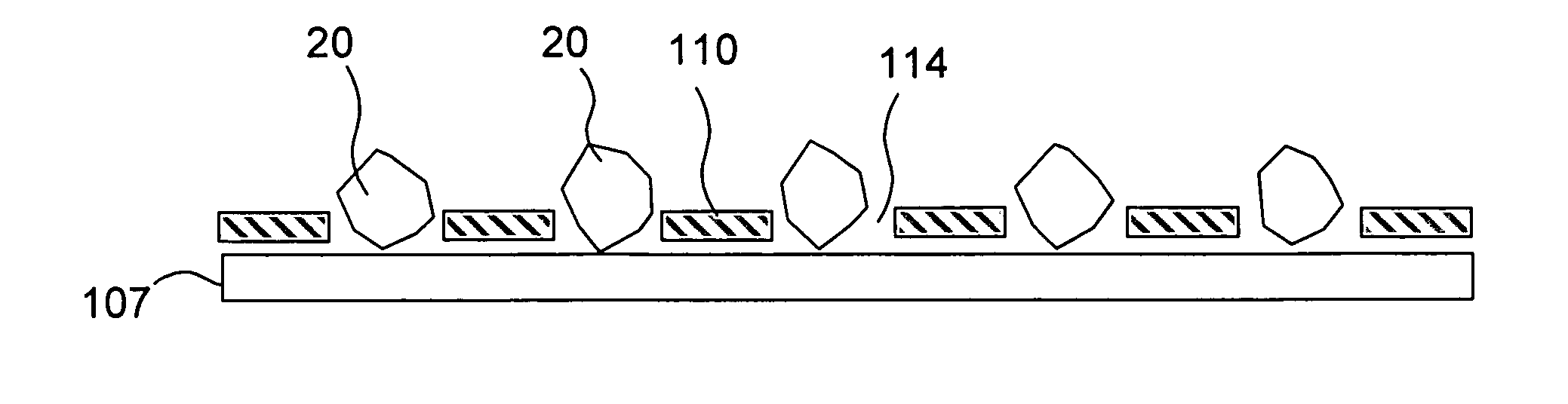

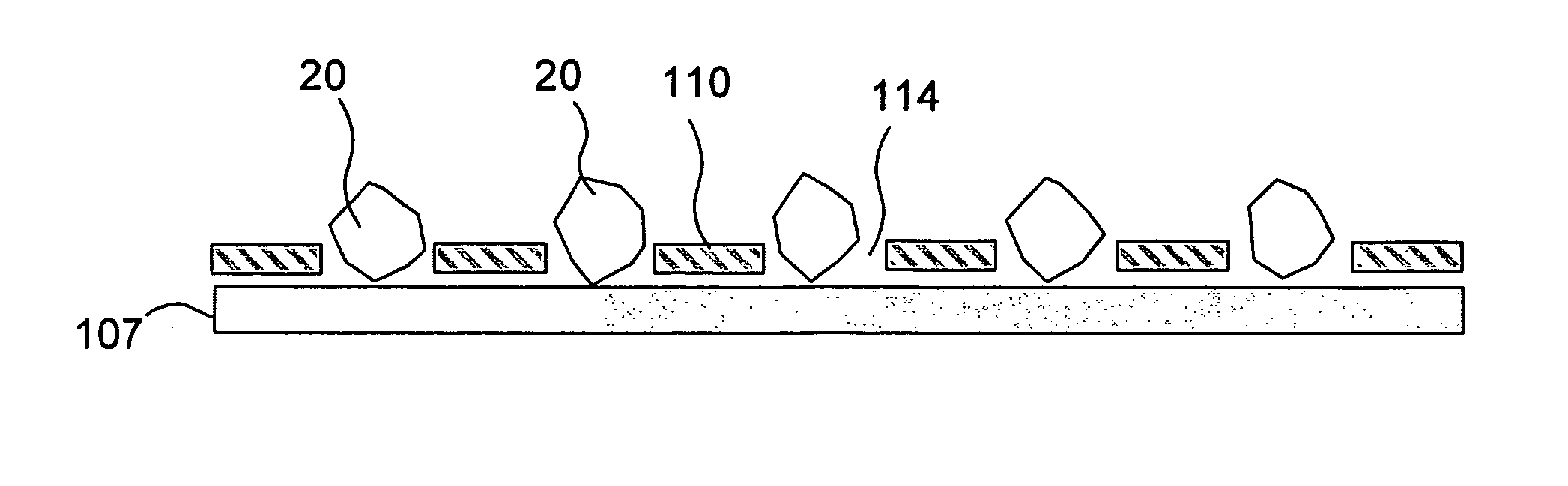

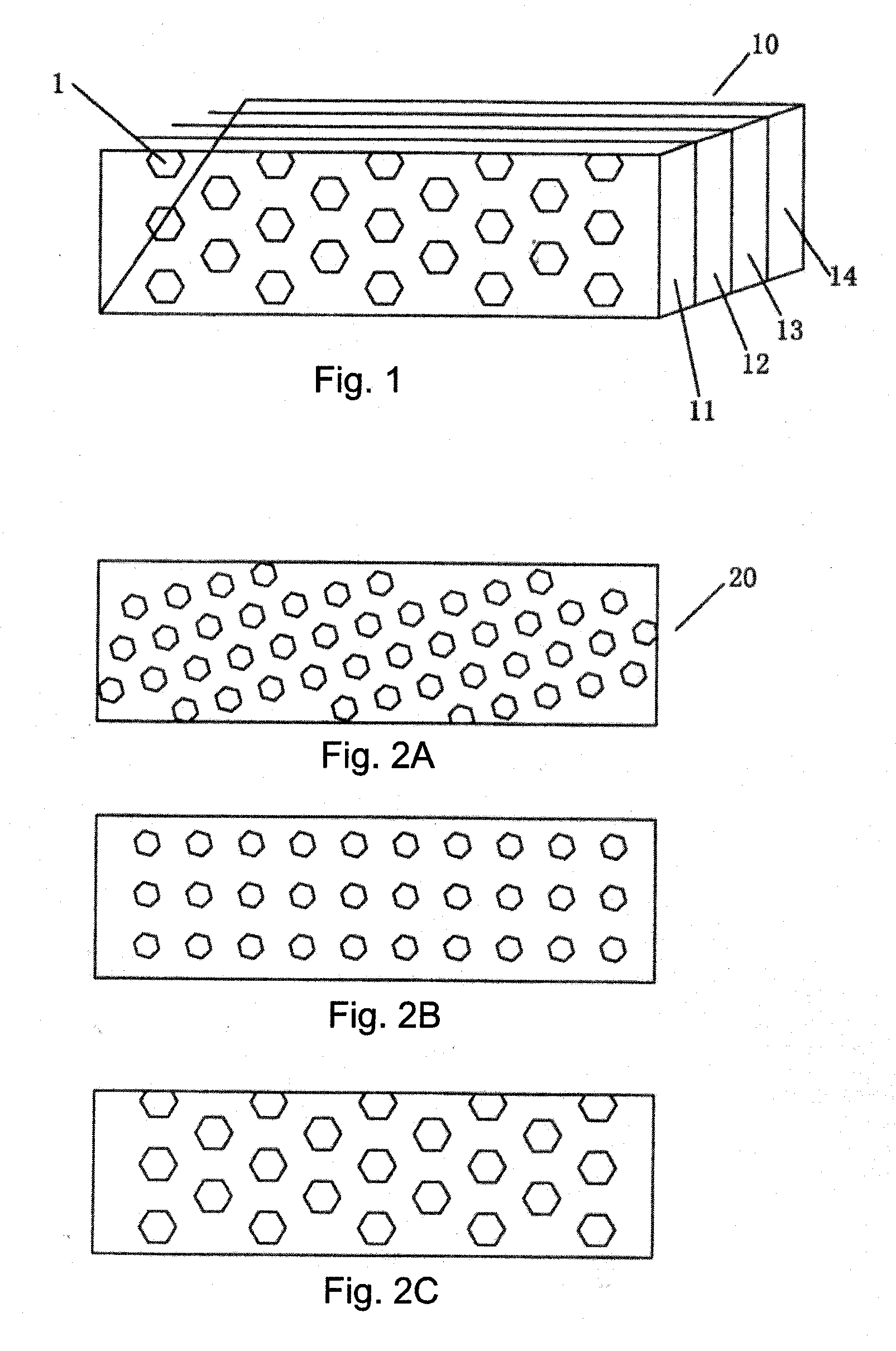

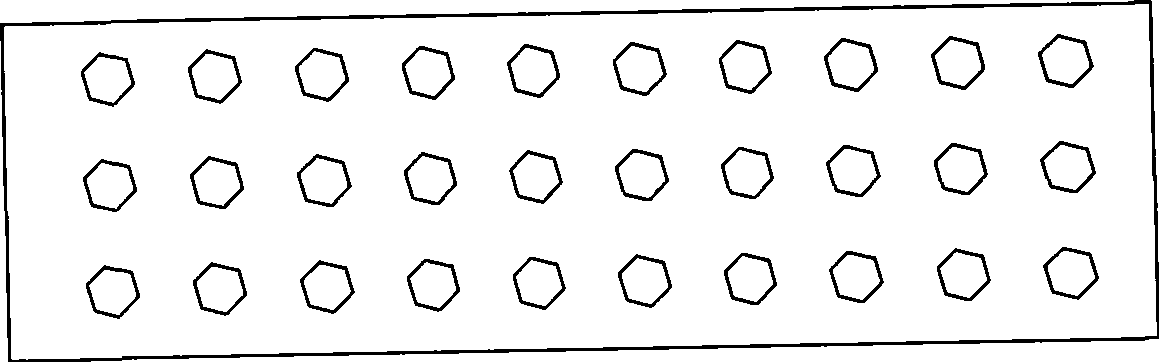

Grinding Tools that Contain Uniform Distribution of Abrasive Grits and Method of Manufacture Thereof

InactiveUS20090094902A1Evenly distributedIncrease concentrationPigmenting treatmentOther chemical processesTemplate designWear particle

The present invention relates to a method of uniformly distributing abrasive grits on grinding tools. It can be applied in the cutting, grinding segments of diamond tools, which are typically used in cutting and drilling various hard and fragile materials, such as granite, marble, concrete, asphalt, etc. The present invention provides a template, the template designed based on the arranging requirement of abrasive particles such as diamond grits. The template can adsorb only a single layer of abrasive particles and is then placed onto a sheet, where the diamond grits are pressed into the sheet, with the diamond grits distributed uniformly on the sheet.

Owner:HOU JIAXIANG

Ordered arrangement method for abrading agent granule on abrading tool and abrading tool

ActiveCN101376234AReduce concentrationReduce power consumptionBonded abrasive wheelsGrinding devicesMaterials scienceDiamond tool

Owner:侯家祥

Diamond cutting grinding piece

ActiveCN103273433AGuaranteed connection strengthSafe and reliable performanceFlexible-parts wheelsStone-like material working toolsDiamond cuttingBrick

The invention relates to a diamond cutting grinding piece. The diamond cutting grinding piece comprises a diamond cutting grinding piece body arranged on a substrate, wherein the diamond cutting grinding piece body is evenly distributed in the circumferential direction, and corrugated water channels which are beneficial to heat dissipation and chip removal in the process of grinding are formed in the surface of the diamond cutting grinding piece body. The diamond cutting grinding piece organically combines the cutting performance and grinding performance through the unique design, is simple and reliable in structure, convenient to operate, low in manufacturing cost and long in service life, solves the problem that the cutting performance and the grinding performance of a diamond tool are independent from each other in an existing market, and is particularly applicable to cutting and grinding of building materials such as stones, concrete, ceramics, bricks and tiles.

Owner:JIANGSU FENGTAI TOOLS

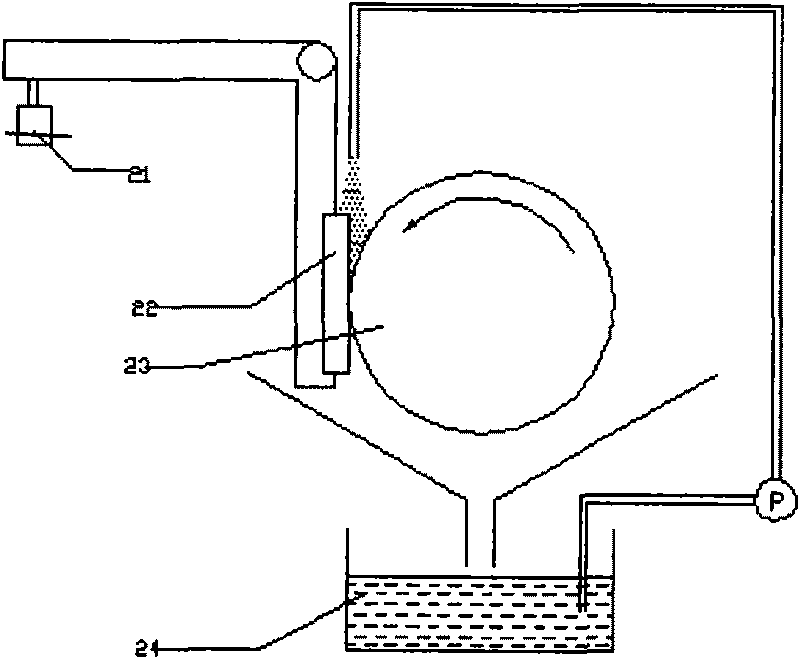

Preparation method for modified superfine low-oxygen water-atomized alloy powder used for diamond tool

The invention discloses a preparation method for modified superfine low-oxygen water-atomized alloy powder used for a diamond tool. The alloy matrix powder for a tool bit of the diamond tool can be manufactured through the method. The preparation method has the characteristics that the alloy powder is modified by adding multiple strengthening elements and the bending strength of a sintered matrix is improved at the same time; the superfine-grained alloy powder is manufactured through an ultrahigh-pressure water atomization technology, the alloy powder sintering compaction is lowered while the composition uniformity of single powder; the low-oxygen-content alloy powder is obtained through control over a smelting technique and a reduction technique, and the compactness of the sintered matrix is improved.

Owner:TIZ ADVANCED ALLOY TECH CO LTD

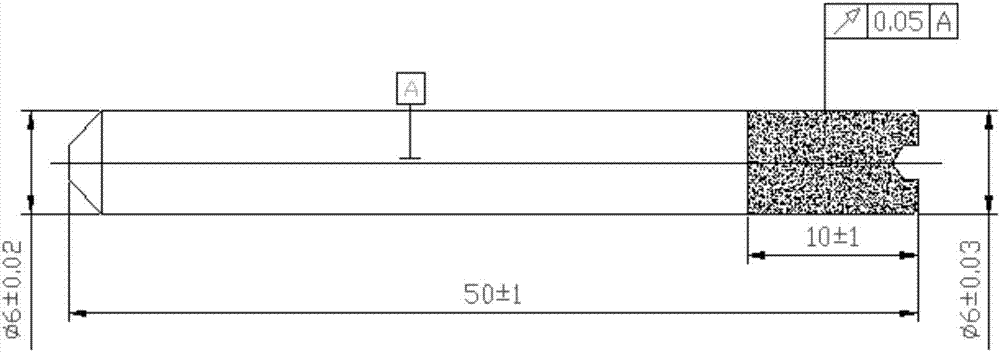

Device for detecting roundness of arc of tool tip of diamond tool with arc edge

InactiveCN101660905AQuick measurementAccurate measurementUsing optical meansAtomic force microscopyControl signal

The invention relates to a device for detecting the roundness of an arc of a tool tip of a diamond tool with an arc edge, which belongs to the technical field of the detection of the roundness of thearc of the tool tip of the diamond tool. The device can solve the problem that the existing device for detecting the roundness of the arc of the tool tip of the diamond tool with the arc edge has theshortcomings of low detection precision and inability of meeting the requirement for the high-precision measurement of the roundness of the arc of the tool tip. The device consists of an atomic forcemicroscopy system, a single-chip microcomputer controller, a measurement control computer, a two-dimensional precision displacement workbench and a rotary shaft system, wherein the rotary shaft systemis arranged on the two-dimensional precision displacement workbench, the measurement control computer is used for displaying detection data and outputting a control signal to the single-chip microcomputer controller for controlling the rotation of the rotary shaft system, the relative position of the rotary shaft system and a scanning probe of the atomic force microscopy system is regulated through the two-dimensional precision displacement workbench, and the signal detected by the scanning probe is transferred from the controller in the atomic force microscopy system to the control computerfor monitoring. The device is used for detecting the roundness of the arc of the tool tip of the diamond tool.

Owner:HARBIN INST OF TECH

Method for manufacturing diamond tool with self-lubrication function

InactiveCN102059423AEasy to useImprove the lubrication effectSoldering apparatusChemical reactionNi cr alloy

The invention provides a method for manufacturing a diamond tool with self-lubrication function. The method comprises the following steps: adding graphite particles with lubrication function into Ni-Cr alloy, wherein the graphite particles account for 2 to 20 percent of the total mass of the whole brazing filler metal; uniformly stirring mixture of the Ni-Cr alloy and the graphite particles to together form the brazing filler metal of a braze welding diamond tool; manufacturing a molded blank of the diamond tool according to a sequence of diamond tool metal substrate, the brazing filler metal and the diamond abrasive particles; putting the molded blank of the diamond tool into a heating furnace, adopting the brazing process, wherein the heating temperature is between 900 and 1,100 DEG C, the temperature is preserved for 1 to 20 minutes to ensure that the Ni-Cr alloy performs chemical reactions with the graphite particles and the diamond abrasive particles respectively to manufacture the diamond tool with the self lubrication function. The method can effectively improve the use performance, the lubrication effect and the scrap storage capability of the diamond tool to ensure that the diamond tool has higher grinding efficiency.

Owner:禹州市和汇超硬材料有限公司

Method for brazing diamond tool through lasers with assistance of ultrasonic waves

ActiveCN105479025AControl the amount of thermal deformationShort manufacturing cycleOther manufacturing equipments/toolsMetal working apparatusHeating furnaceLaser beams

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com