Multilayer brazed diamond tool and manufacturing method thereof

A diamond tool and diamond technology, used in metal processing equipment, manufacturing tools, grinding/polishing equipment, etc., can solve the problems of large diamond particle size and high service life, and achieve the effect of prolonging service life, simple production process and good processing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] The present invention also provides a kind of preparation method of multilayer brazing diamond tool, comprises the following steps:

[0072] 1) After mixing diamond particles, skeleton particles, alloy solder powder and adhesive, a paste is obtained;

[0073] 2) Compounding the paste obtained in the above steps on the surface of the preheated substrate, heating and curing after airing, to obtain a solidified green body;

[0074] 3) Vacuum brazing the solidified body obtained in the above steps to obtain a multilayer brazed diamond tool.

[0075] The selection and preferred range of materials in the preparation method of the present invention are consistent with the selection and preferred range of materials for the aforementioned multi-layer brazed diamond tools, and will not be repeated here.

[0076] In the invention, the paste is obtained by firstly mixing diamond particles, skeleton particles, alloy solder powder and adhesive.

[0077] In the present invention, th...

Embodiment 1

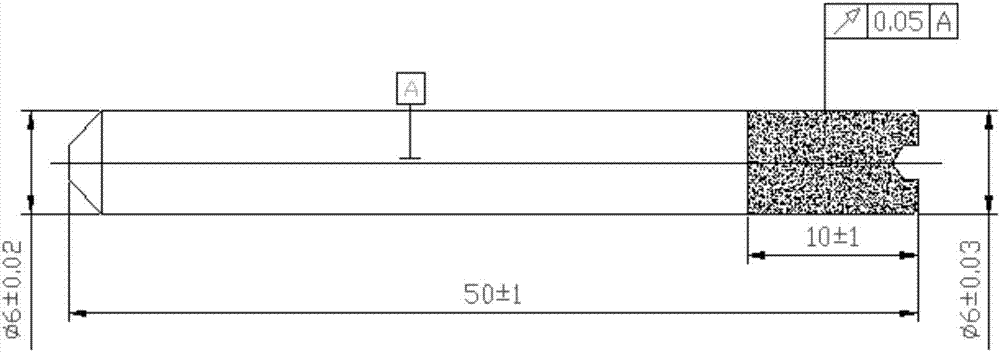

[0122] see figure 2 , figure 2 A schematic diagram of the shape and size of the diamond tool prepared in Example 2.

[0123] Such as figure 2 As shown, its production steps are as follows:

[0124] 1. Select 45# steel as the matrix material of the diamond tool, and process it into the required matrix structure by mechanical processing. The good substrate is cleaned with acetone, and then placed in a drying oven to preheat to 40-50°C.

[0125] 2. Use copper-based solder powder as the flux for diamond tools. The composition of copper-based solder is Gu-Sn-Ti, and its melting point is about 890°C.

[0126] 3. Select the diamond particle size 170 / 200, clean it with aqua regia and ultrasonic waves, and dry it.

[0127] 4. WC powder is selected as the skeleton structure, and its particle size is 300 mesh.

[0128] (5) First mix the solder, WC, and diamond evenly in a weight ratio of 3:1:1, then add 5-8% of the total weight of the solder and diamond as an organic adhesive, and...

Embodiment 2

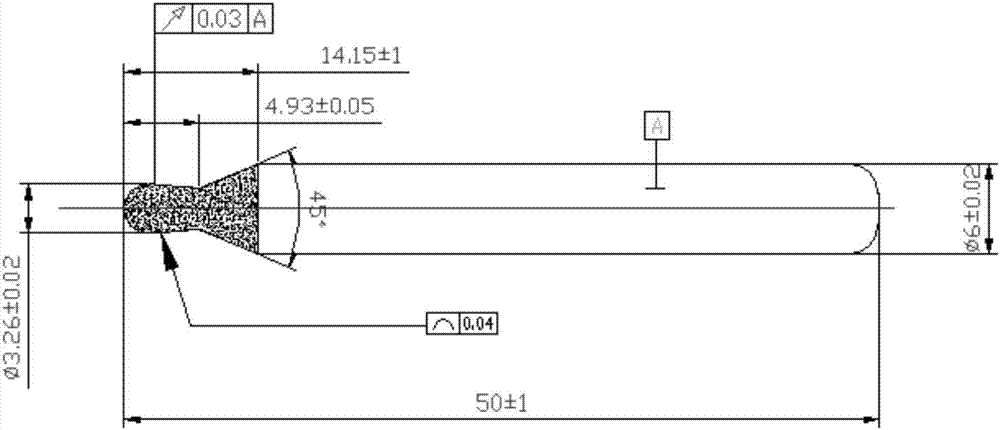

[0136] see image 3 , image 3 A schematic diagram of the shape and size of the diamond tool prepared in Example 2.

[0137] Such as image 3 As shown, its production steps are as follows:

[0138] (1) Choose free-cutting iron as the matrix material of the diamond tool, and process it into the required matrix structure by mechanical processing. Among them, the joint between the matrix and the working layer should be processed as rough as possible to increase the bonding strength, and to The processed substrate was cleaned with acetone.

[0139] (2) Nickel-based solder powder is selected as the flux for diamond tools. The composition of nickel-based solder is NiCrBSi, the melting point of the solder is about 960°C, and the particle size is not less than 300#.

[0140] (3) Select the diamond particle size of 170 / 200, clean it with aqua regia and ultrasonic waves, and dry it for later use.

[0141] (4) WC powder is selected as the skeleton structure, and its particle size is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com