Digital light processing 3D printing device and method based on nonlinear focusing multi-partition exposure

A technology of digital light processing and partition exposure, which is applied in the field of additive manufacturing, can solve the problems of affecting the forming accuracy of parts, inaccurate focus positioning, and edge warping, and achieve the effects of reducing edge warping, improving molding quality, and reducing shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

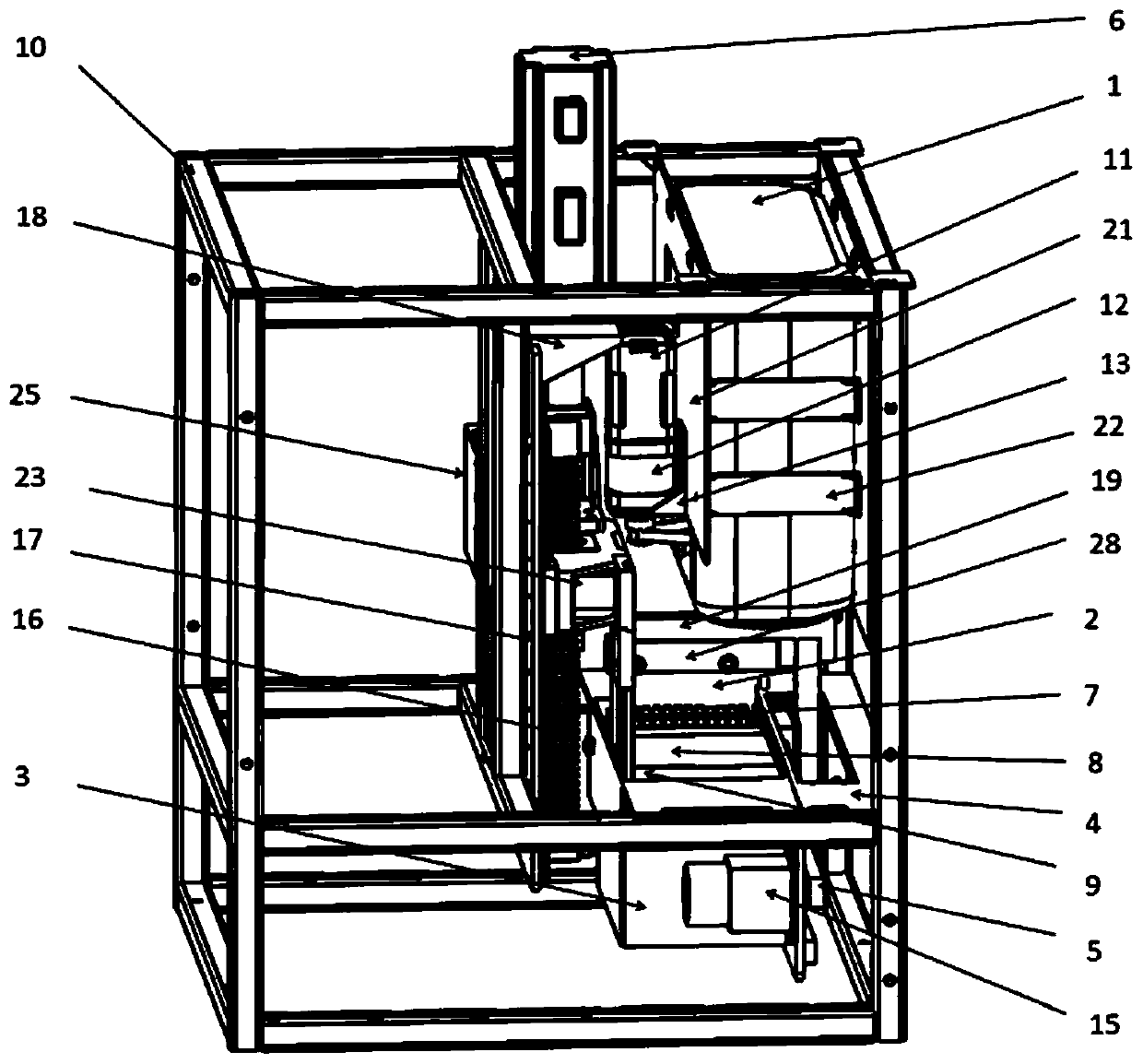

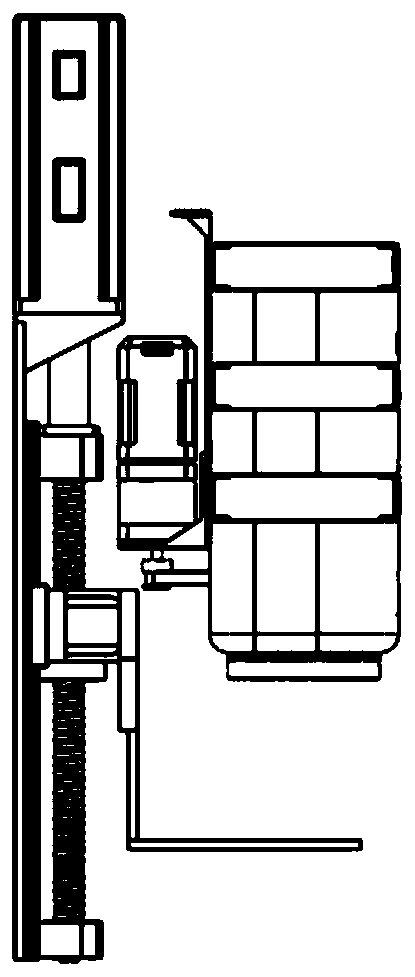

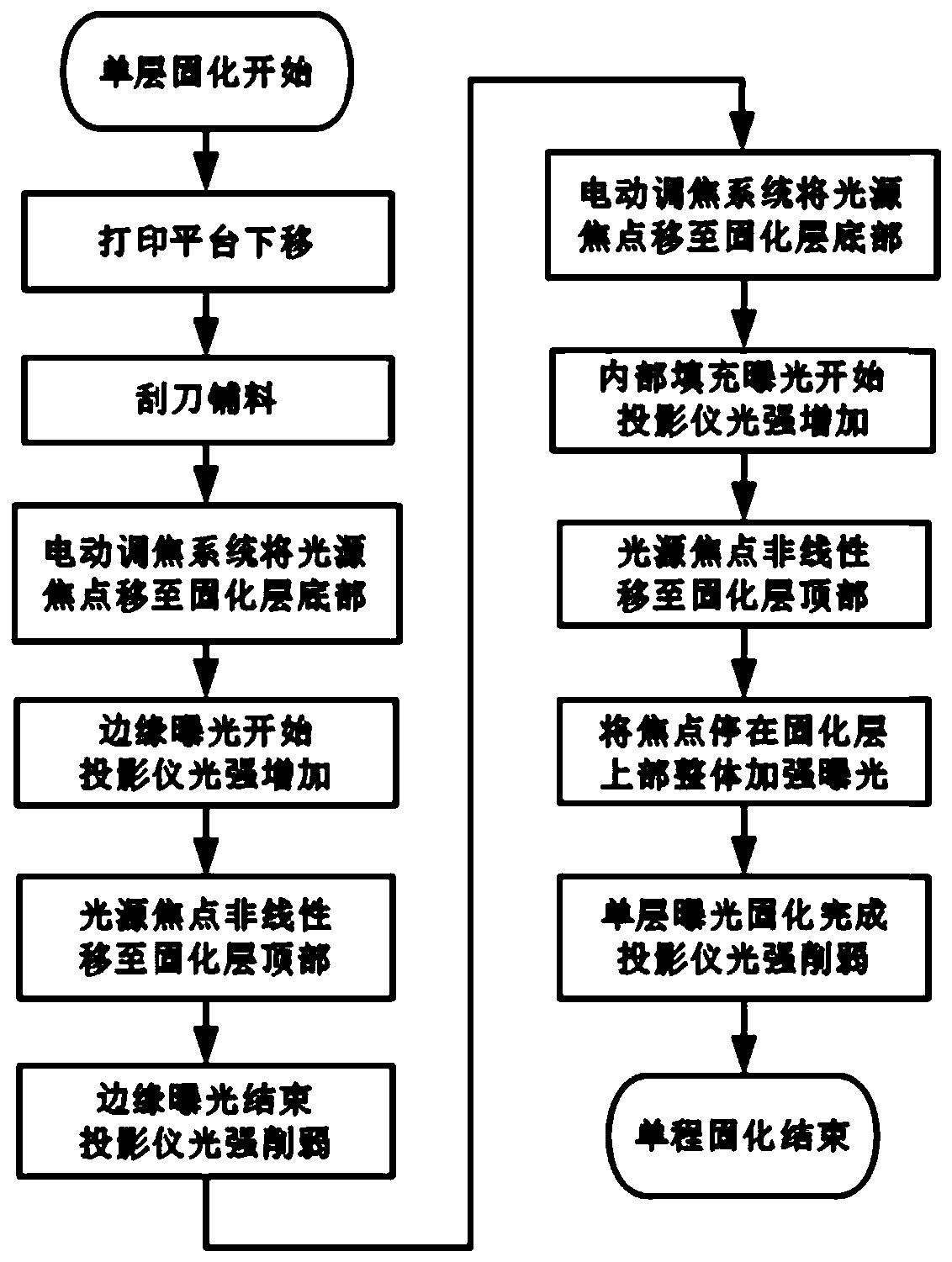

[0037] like figure 1 As shown in the figure, the present invention relates to a digital light processing 3D printing device based on sub-regional continuous multiple exposure, including a projector 1, a scraper 2, a material storage tank 3, a material spreading drive system fixing frame 4, an X-axis linear guide 5, a servo Motor 6, roller brush 7, printing platform 8, pressure plate 9, square frame 10, focusing motor 11, planetary reducer 12, motor holder 13, projector front bracket 14, X-axis stepper motor 15, ball wire Lever mechanism 16, Z-axis support plate 17, servo motor holder 18, L-shaped rod 19, grating scale connecting plate 20, projector rear bracket 21, projector bracket connector 22, single screw nut pair connecting frame 23, grating Ruler 21, grating ruler connecting block 25, grating ruler reading head 26, reading head fixing frame 27, grooved concave scraper connecting block 28 and Z-axis linear guide 29; the X-axis linear guide 5 is configured as a double X-ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com