Diamond drilling bit with a plurality of sets of serrated structures automatically formed by weakened matrix with order positioning and manufacture process

A diamond drill bit and manufacturing process technology, used in drill bits, metal processing equipment, earth-moving drilling, etc., can solve problems such as no footage, and achieve the effect of reducing energy consumption and improving rock crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

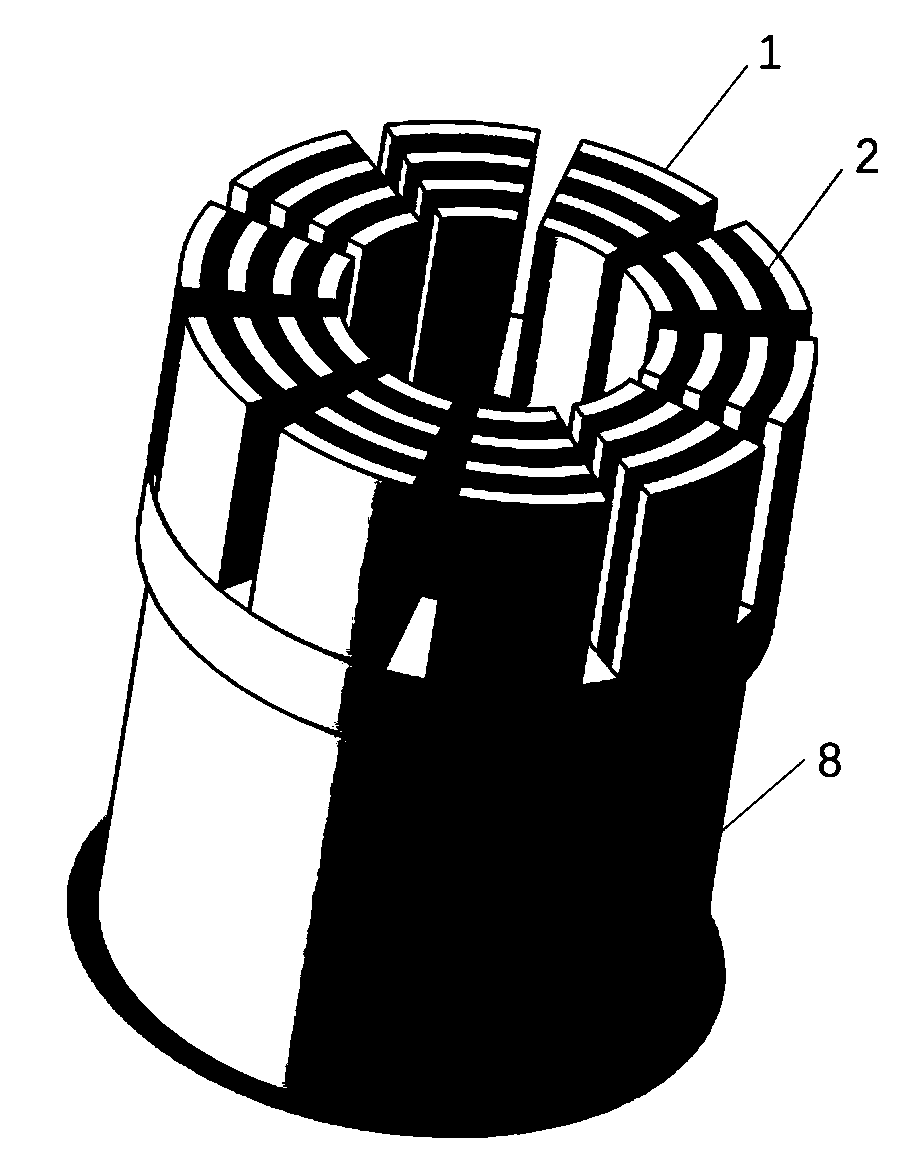

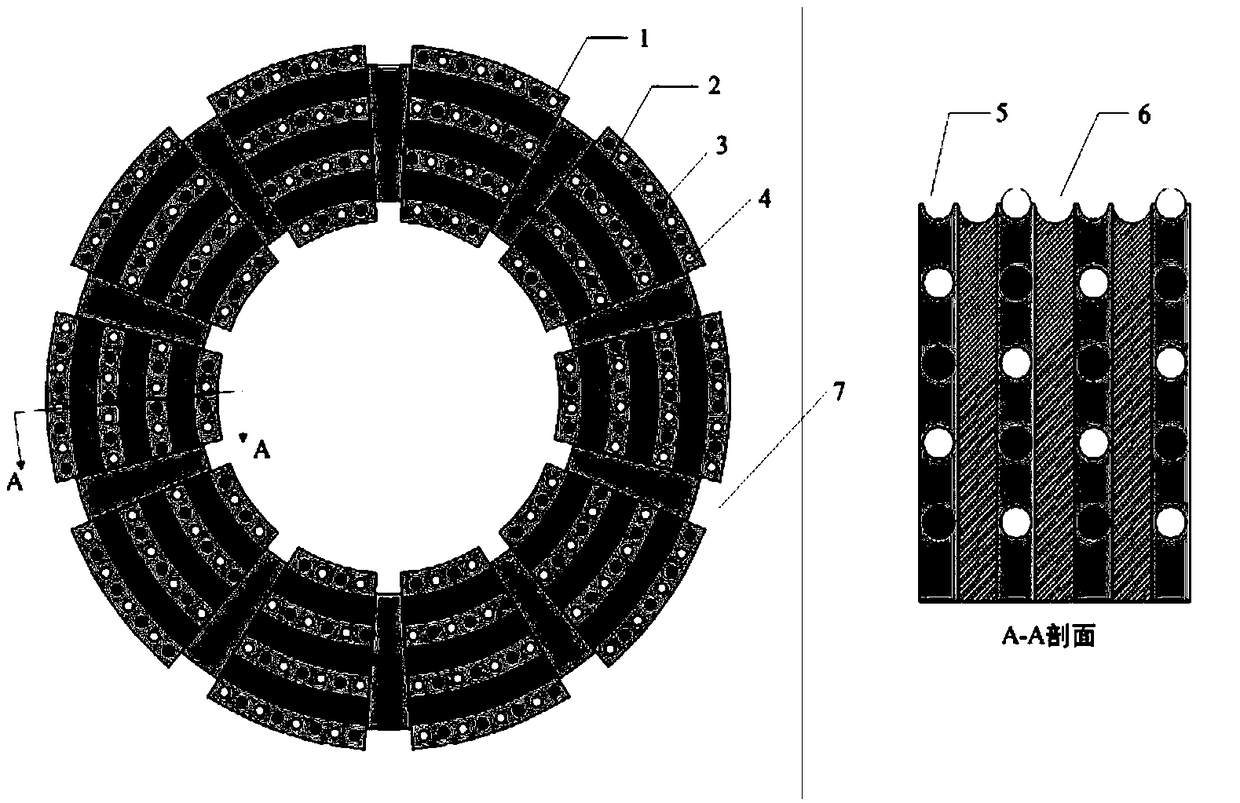

[0019] refer to figure 1 and figure 2 , orderly positioning and weakening the carcass to form multiple groups of serrated diamond drill bits are composed of drill teeth and steel body 8 and so on. The drill tooth is assembled and sintered by the working layer sheet 1 and the intermediate layer sheet 2 at intervals. The working layer sheet 1 is distributed with diamond particles 4 and weakened matrix particles 3 arranged in an orderly manner; the weakened matrix particles fall off when the drill bit is working Dimples 5 are formed, diamond particles protrude, and the intermediate layer is worn out in advance to form grooves 6, and multiple sets of serrated working lip surfaces 7 are automatically formed. The drill teeth and the steel body 8 are fused as a whole through heating.

[0020] The outer diameter / inner diameter of the drill bit is Φ76 / 49mm, the size of the working layer sheet of the drill bit matrix: length × height × thickness = (22~12) mm × 12mm × 0.3mm; the size ...

Embodiment 2

[0031] refer to figure 1 and figure 2 , orderly positioning and weakening the carcass to form multiple groups of serrated diamond drill bits are composed of drill teeth and steel body 8 and so on. The drill teeth are assembled and sintered by the working layer sheet 1 and the intermediate layer sheet 2 at intervals. The working layer sheet 1 is distributed with diamond particles 4 and weakened matrix particles 3 arranged in an orderly manner; the weakened matrix particles fall off when the drill bit is working Dimples 5 are formed, diamond particles protrude, and the intermediate layer is worn out in advance to form grooves 6, and multiple sets of serrated working lip surfaces 7 are automatically formed. The drill teeth and the steel body 8 are fused as a whole through heating.

[0032] The outer diameter / inner diameter of the drill bit is Φ101.6 / 84mm, the size of the working layer sheet of the drill body: length × height × thickness = (25~19.5) mm × 14mm × 0.4mm; the size ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com