Grinding Tools that Contain Uniform Distribution of Abrasive Grits and Method of Manufacture Thereof

a technology of grinding tools and abrasives, applied in the field of cutting and grinding tools, can solve the problems of reducing cutting efficiency, reducing cutting efficiency, and reducing the sum power consumption of abrasive tools, so as to reduce the noise of perigee and increase the cutting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

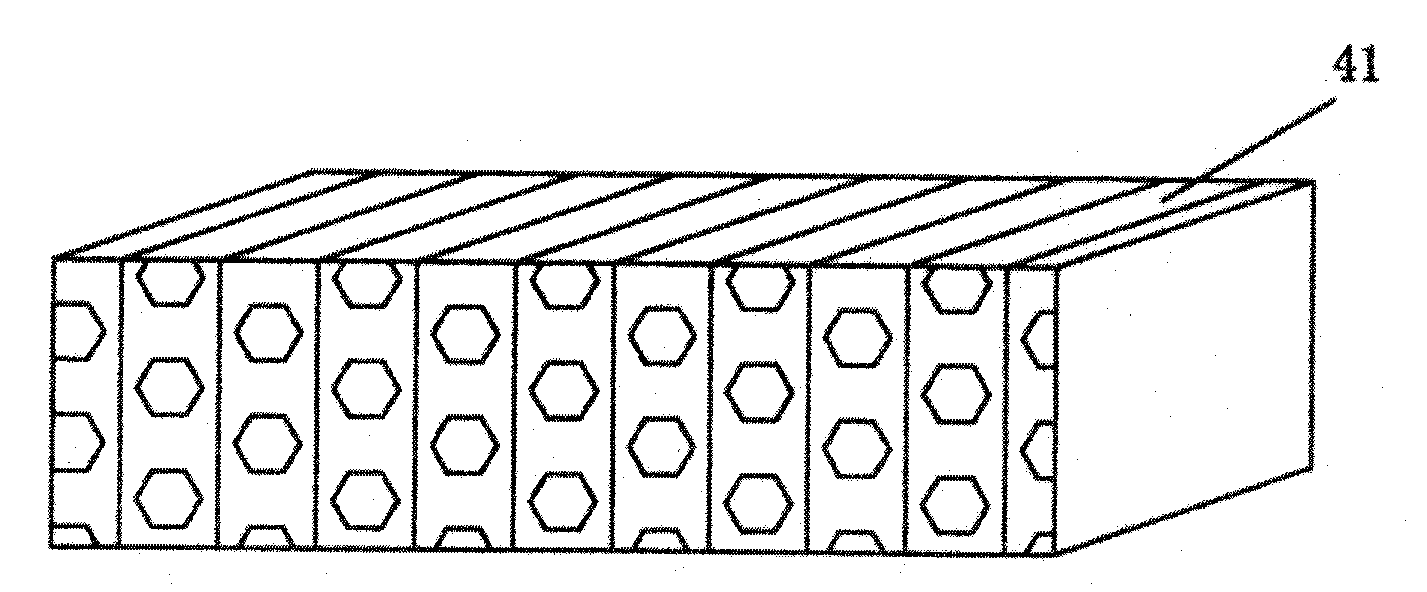

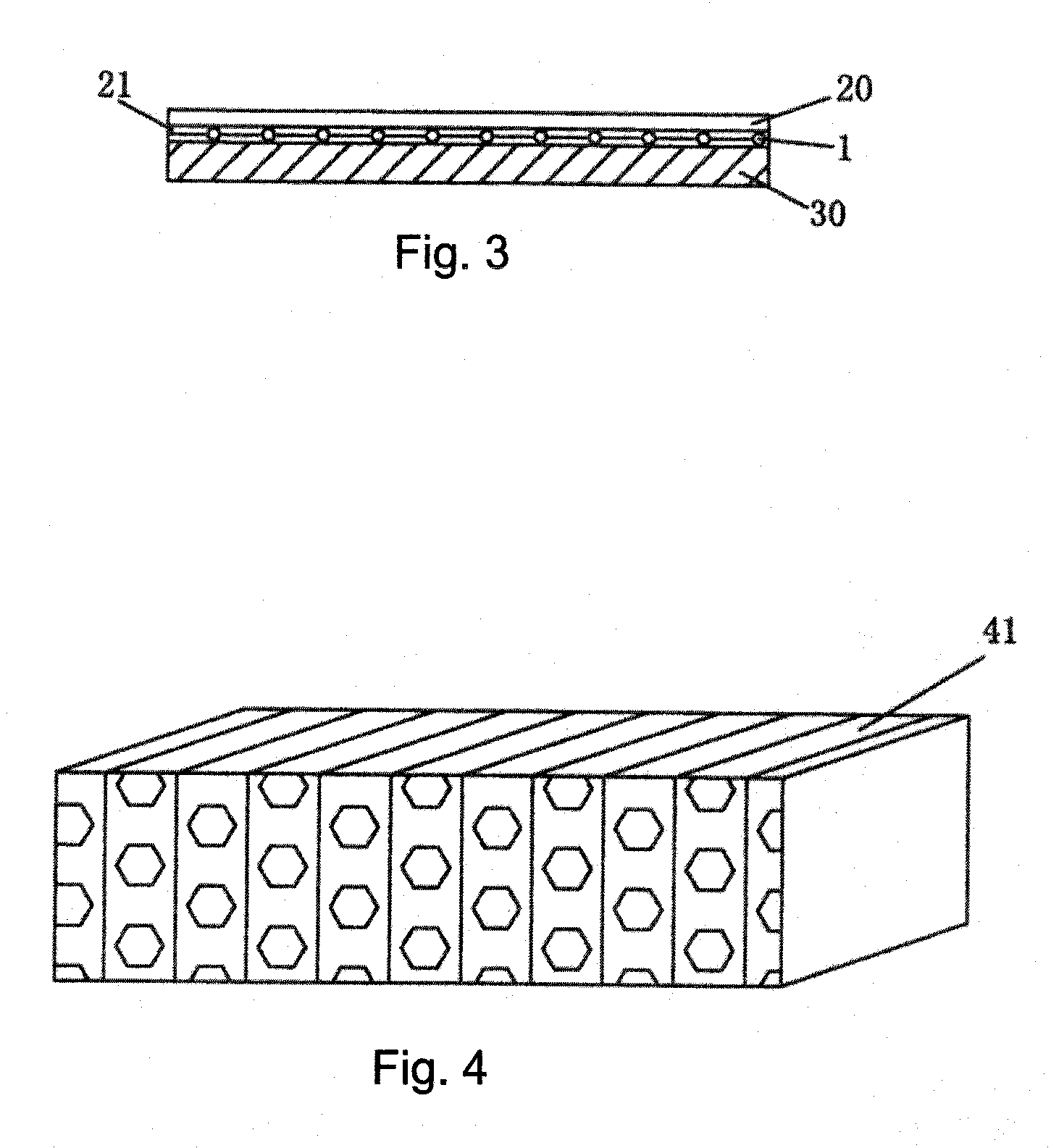

[0044]FIG. 1 shows a perspective view of a segment of diamond tool, indicated at 10. The segment 10 is formed by a plurality of layers, 11, 12, 13, and 14, which are impregnated with abrasive grits, indicated as hexagonal frame 1.

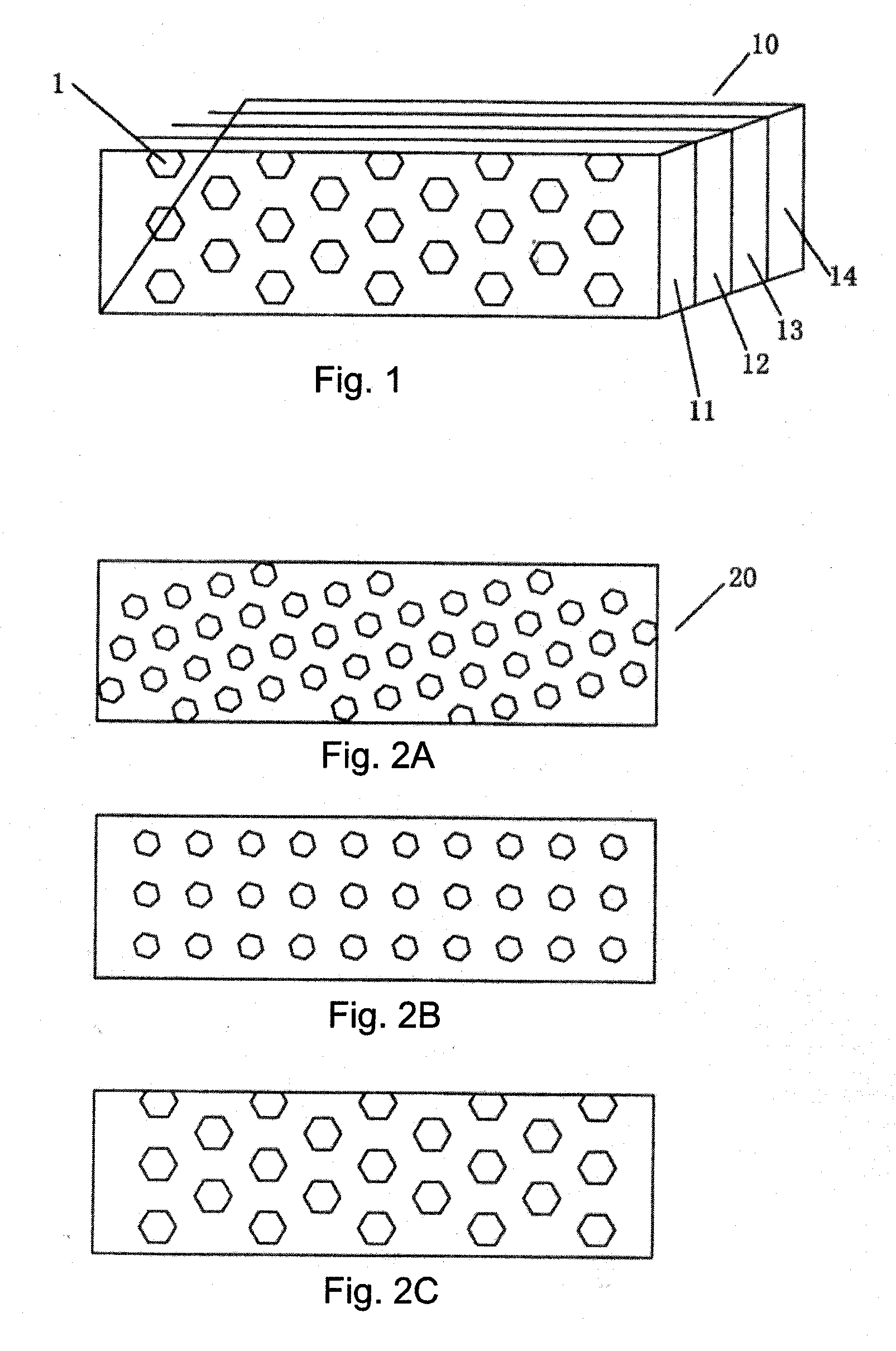

[0045]Referring to FIGS. 2A, 2B, and 2C, electromagnetic template 20 of the present invention is capable of adsorbing single layer of abrasive particles (for example, diamond grits) after the corona is discharged. When the adsorptive points are occupied by the adsorbed diamond grits, the other grits can not be adsorbed on the same place, so the adsorbed grits form a single layer, and the template can be designed on the requirement of the arrangement of diamond or other abrasive particles. Thus the diamond, cubic boron nitride grits are uniformly distributed on the template, and the distribution form can be designed freely on the desire of the designers.

[0046]FIGS. 2A, 2B, and 2C are views of the distribution of abrasive particles on the template, wherein FI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com