Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

622results about "Sawing tools dressing arrangements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

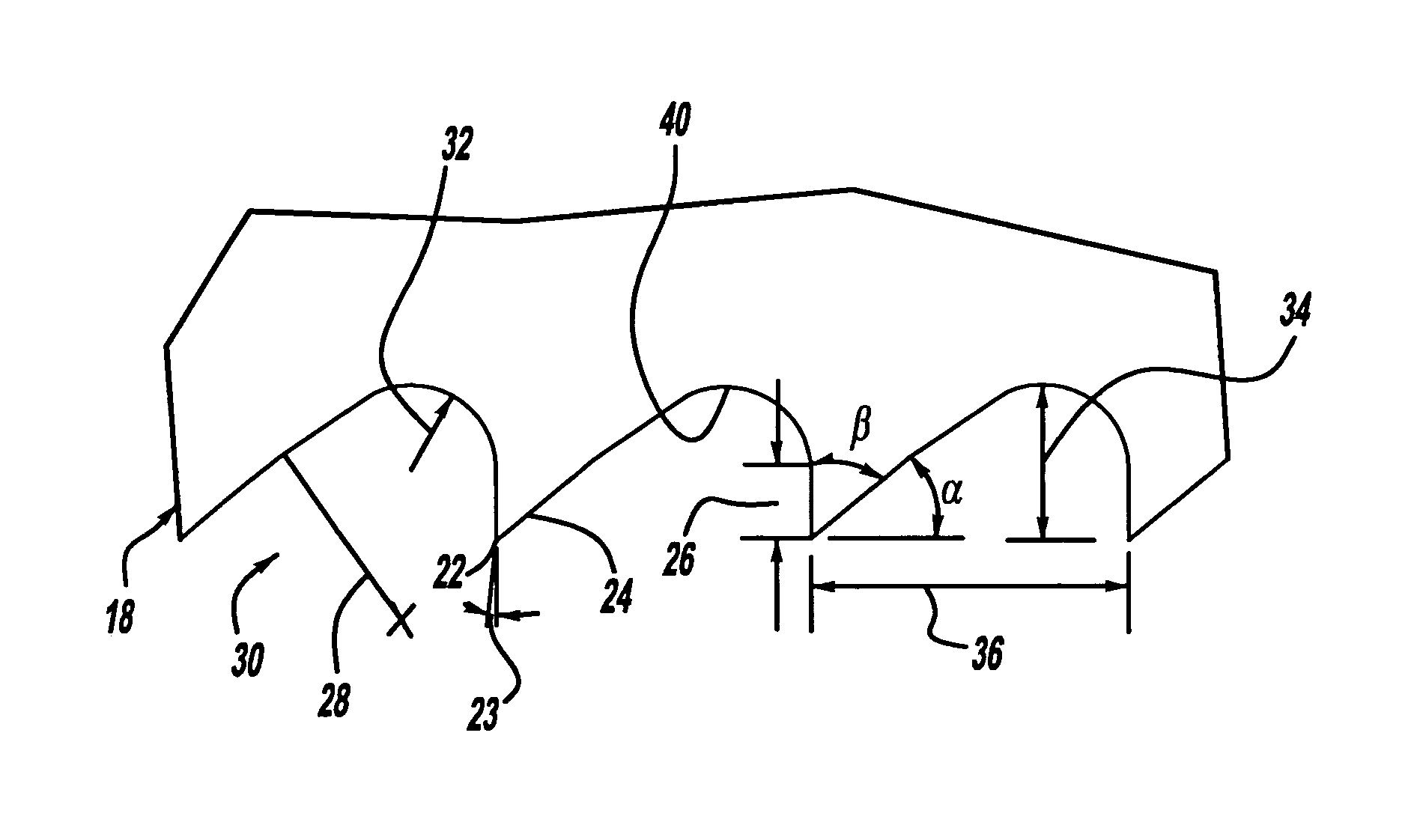

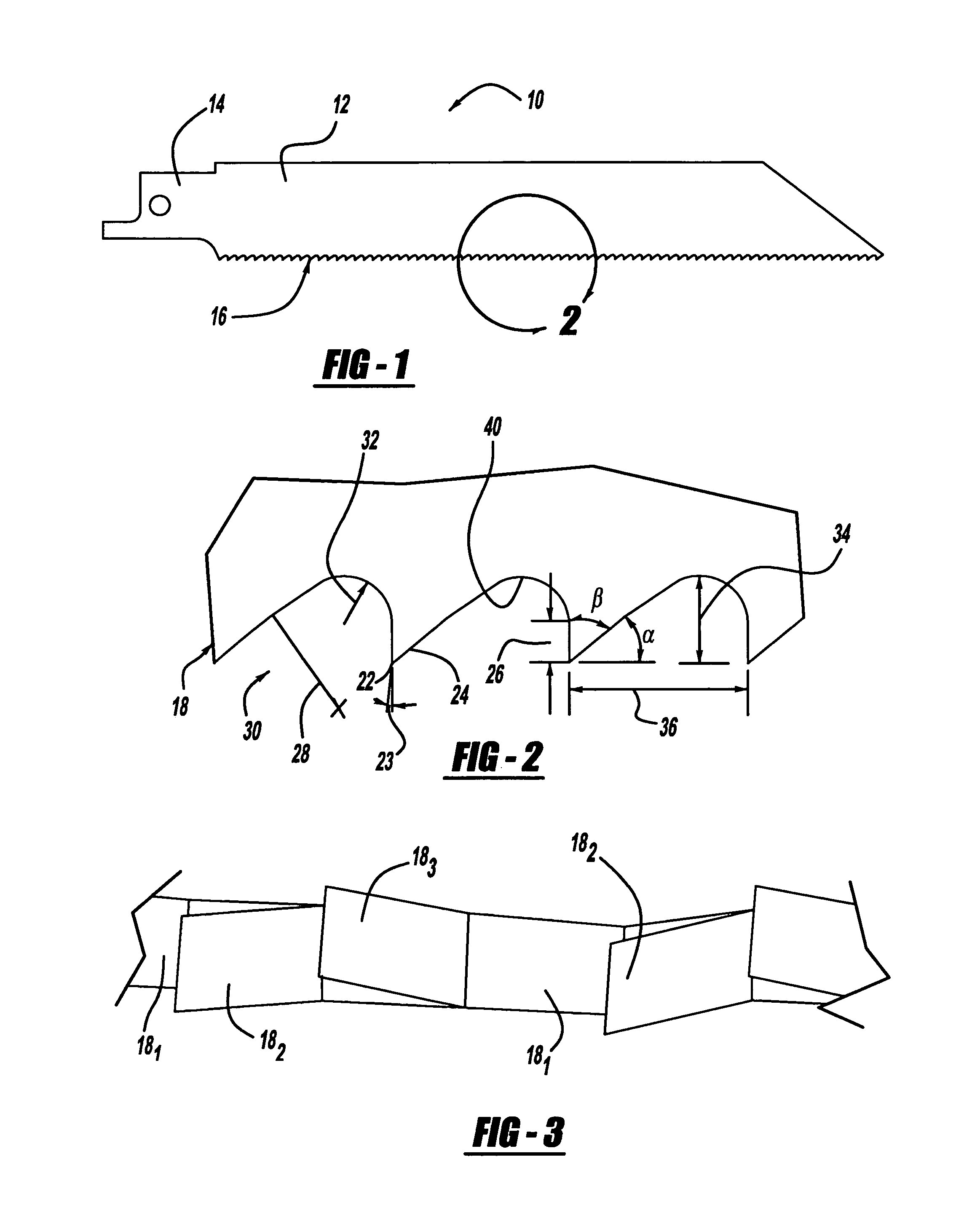

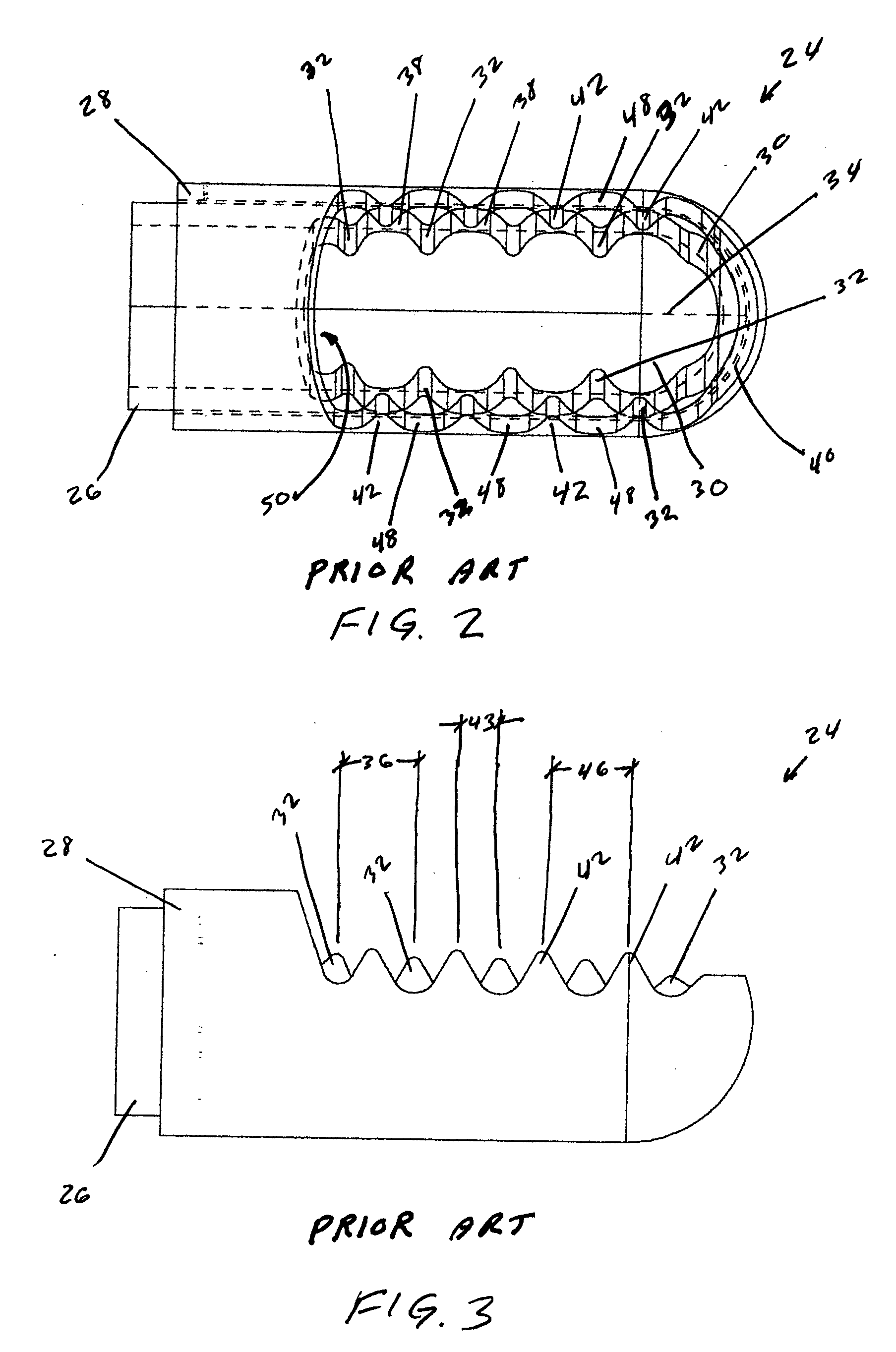

Tooth form design for reciprocating saw blade

A reciprocating saw has a tooth form that decreases the cutting time of the saw blade and extends the life of the saw blade. The tooth height is longer than conventional metal cutting reciprocating saws. Also, the tooth form has a larger gullet. The tooth rake angle remains substantially constant during the life of the saw blade.

Owner:BLACK & DECKER INC

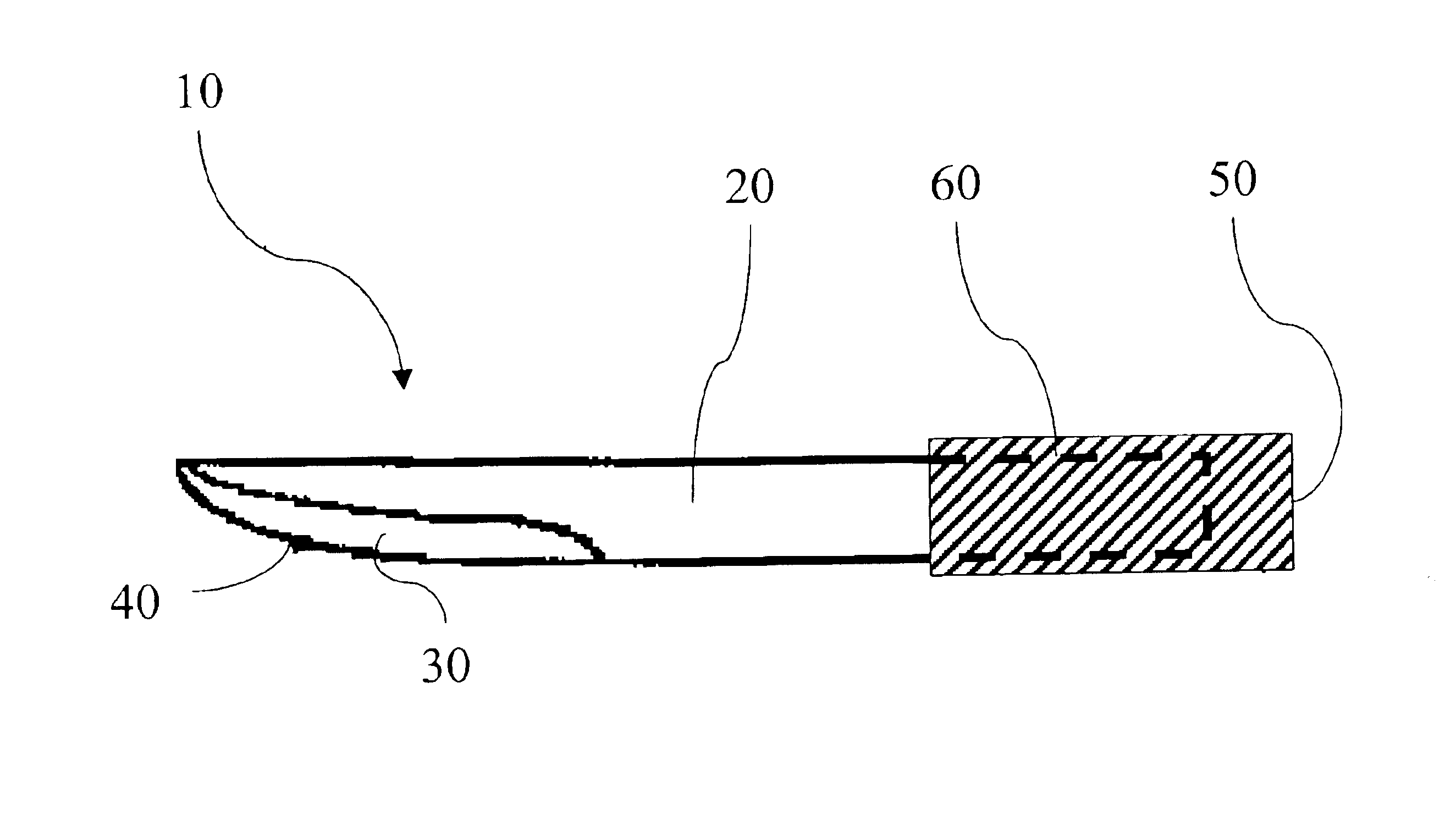

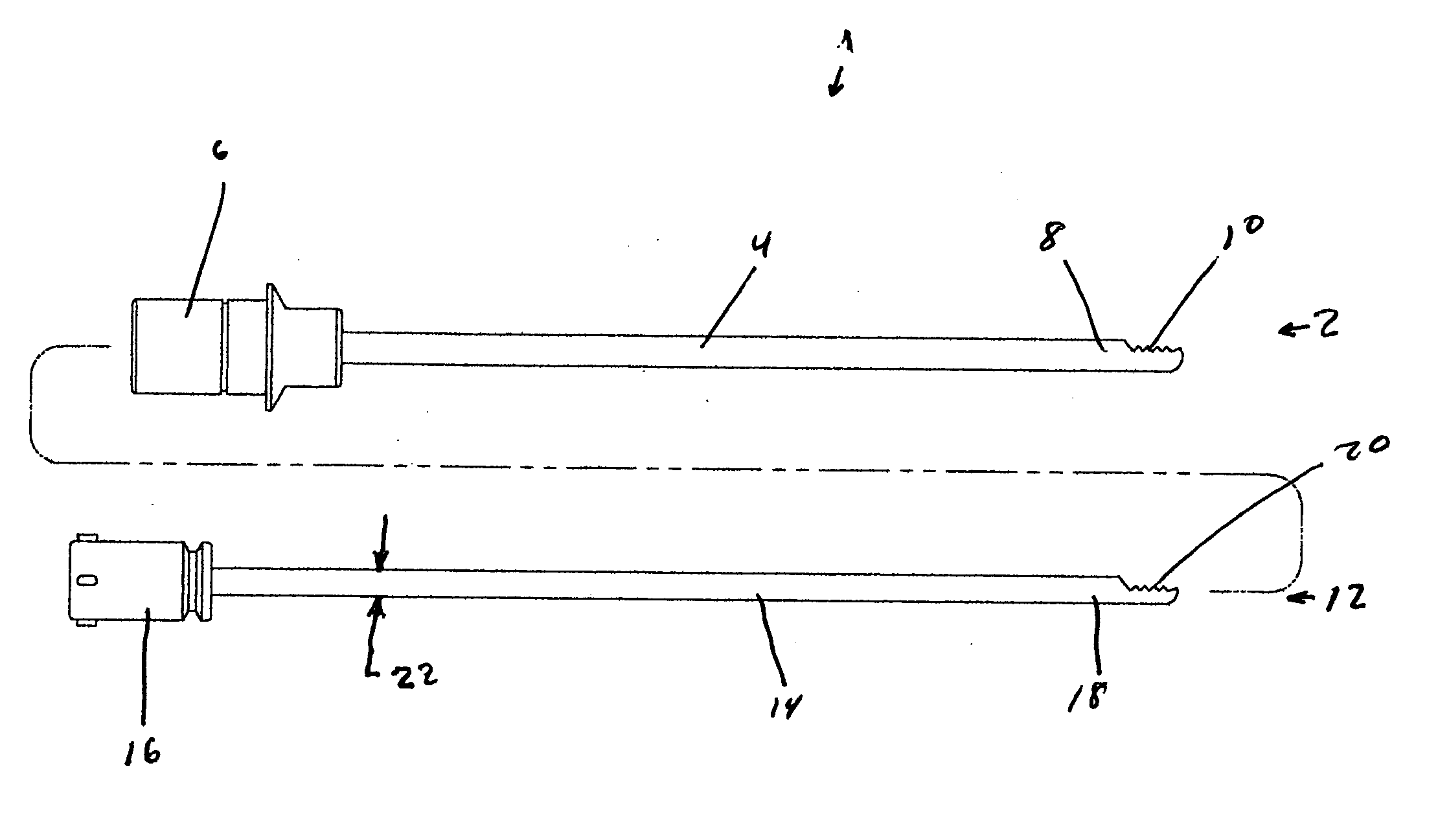

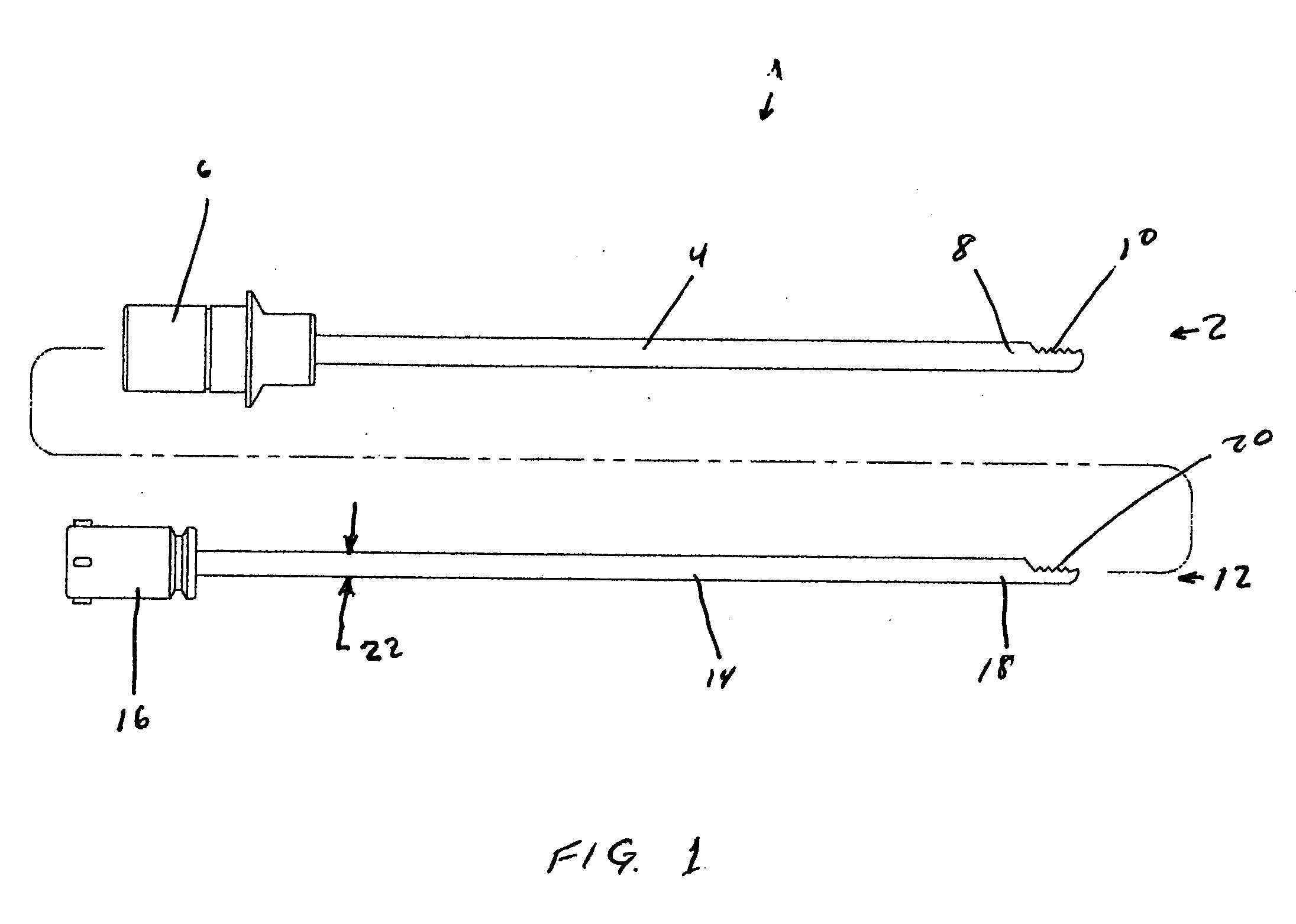

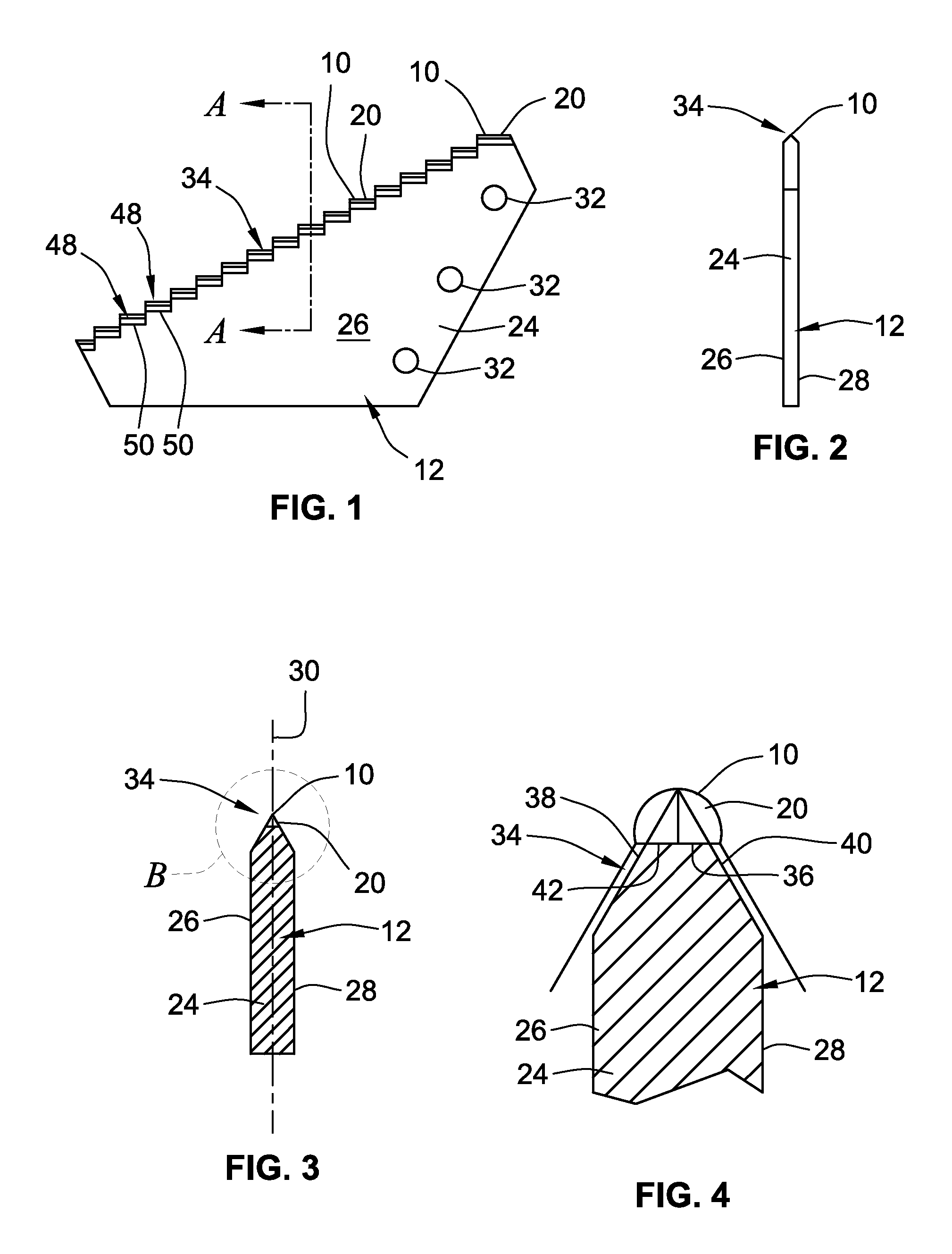

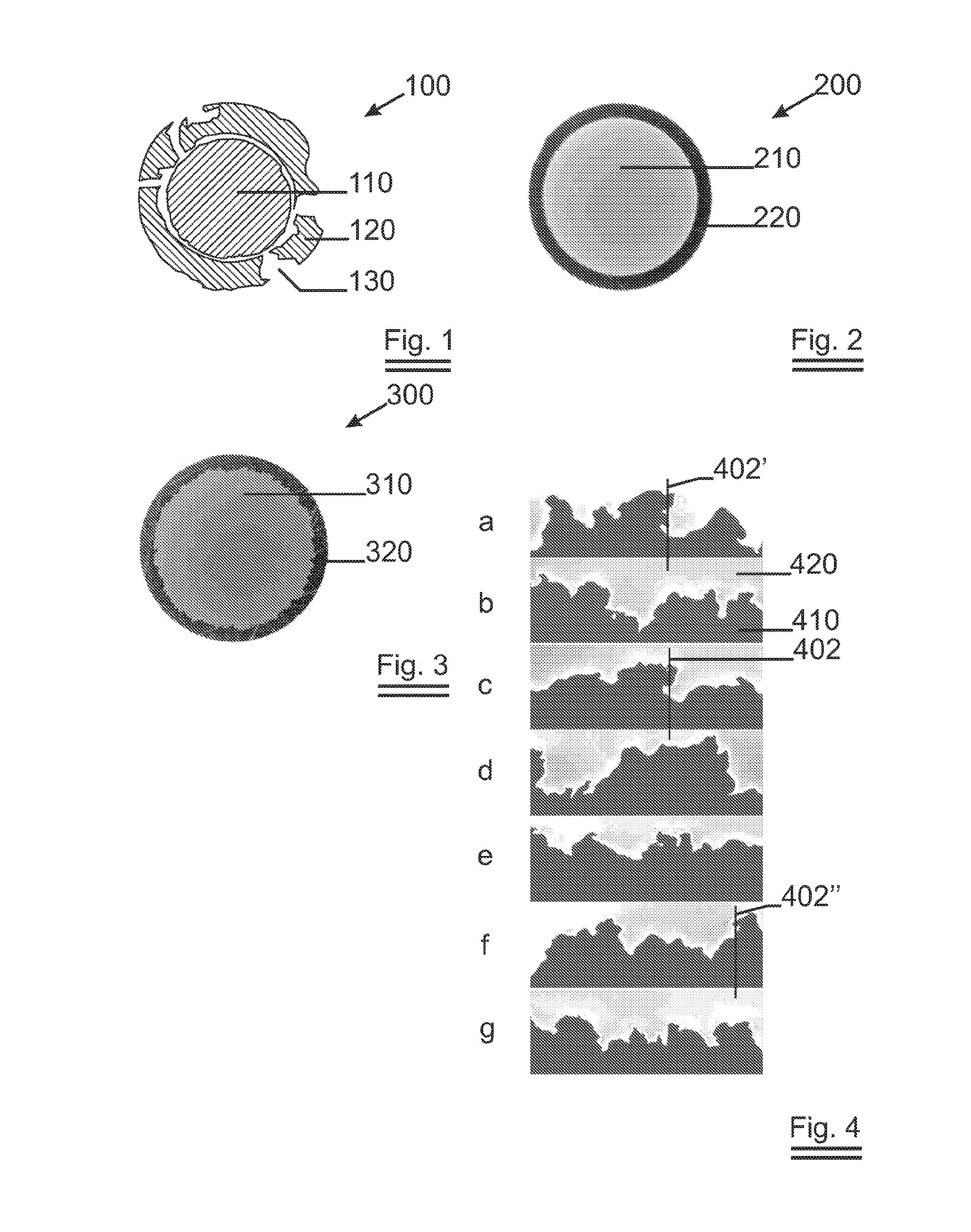

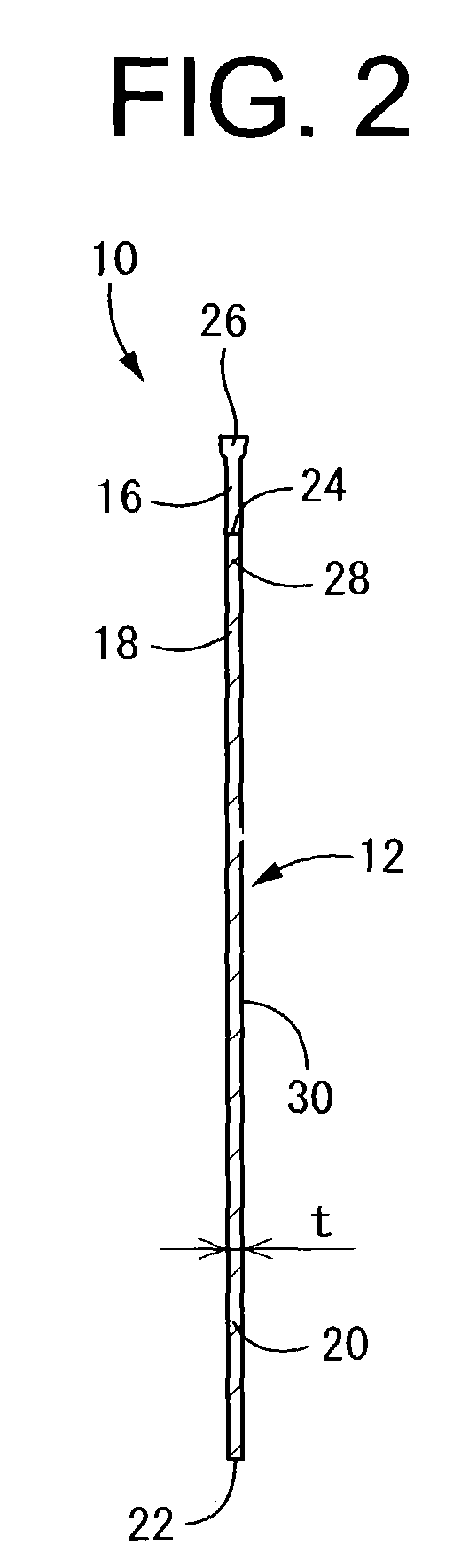

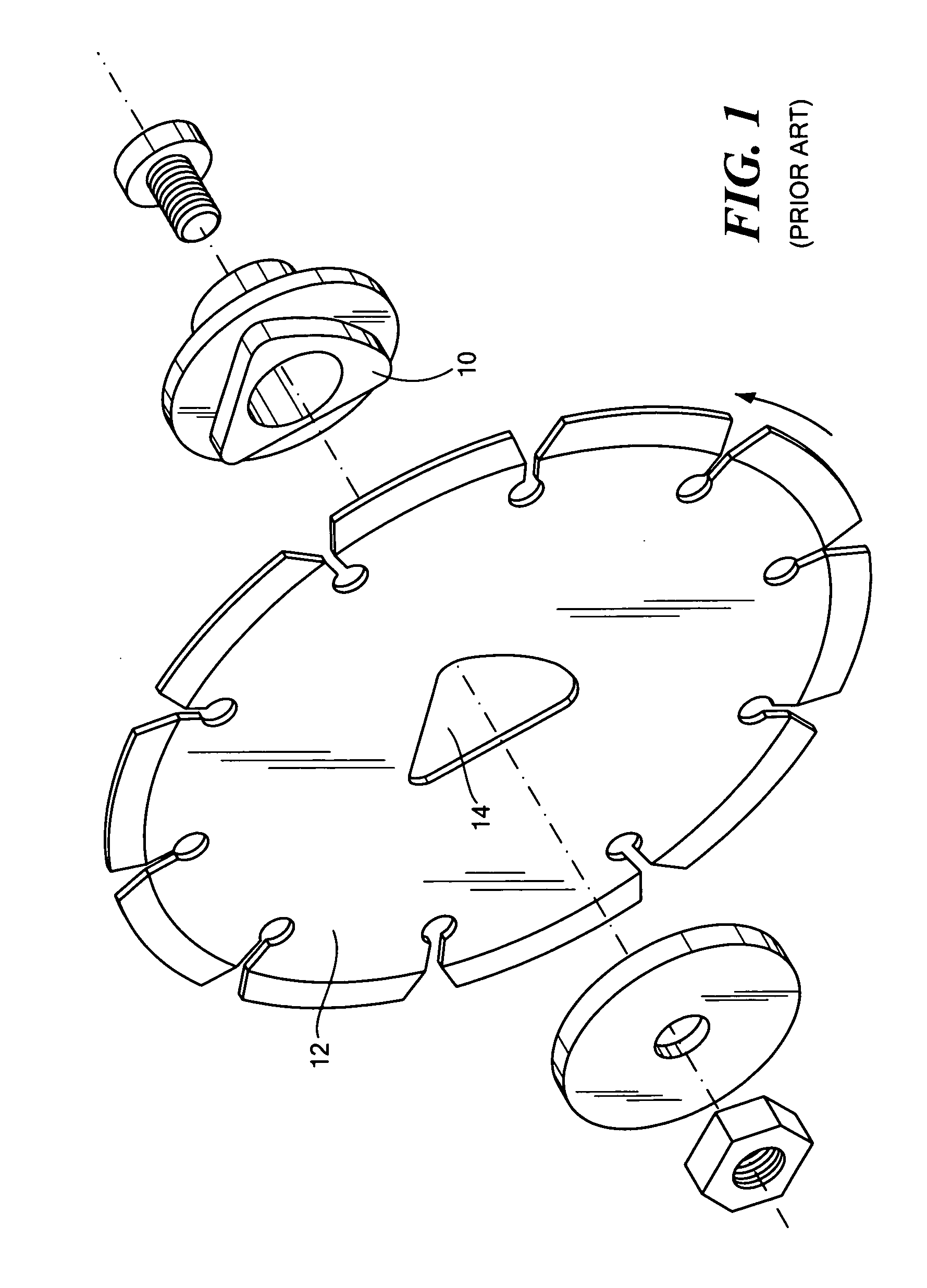

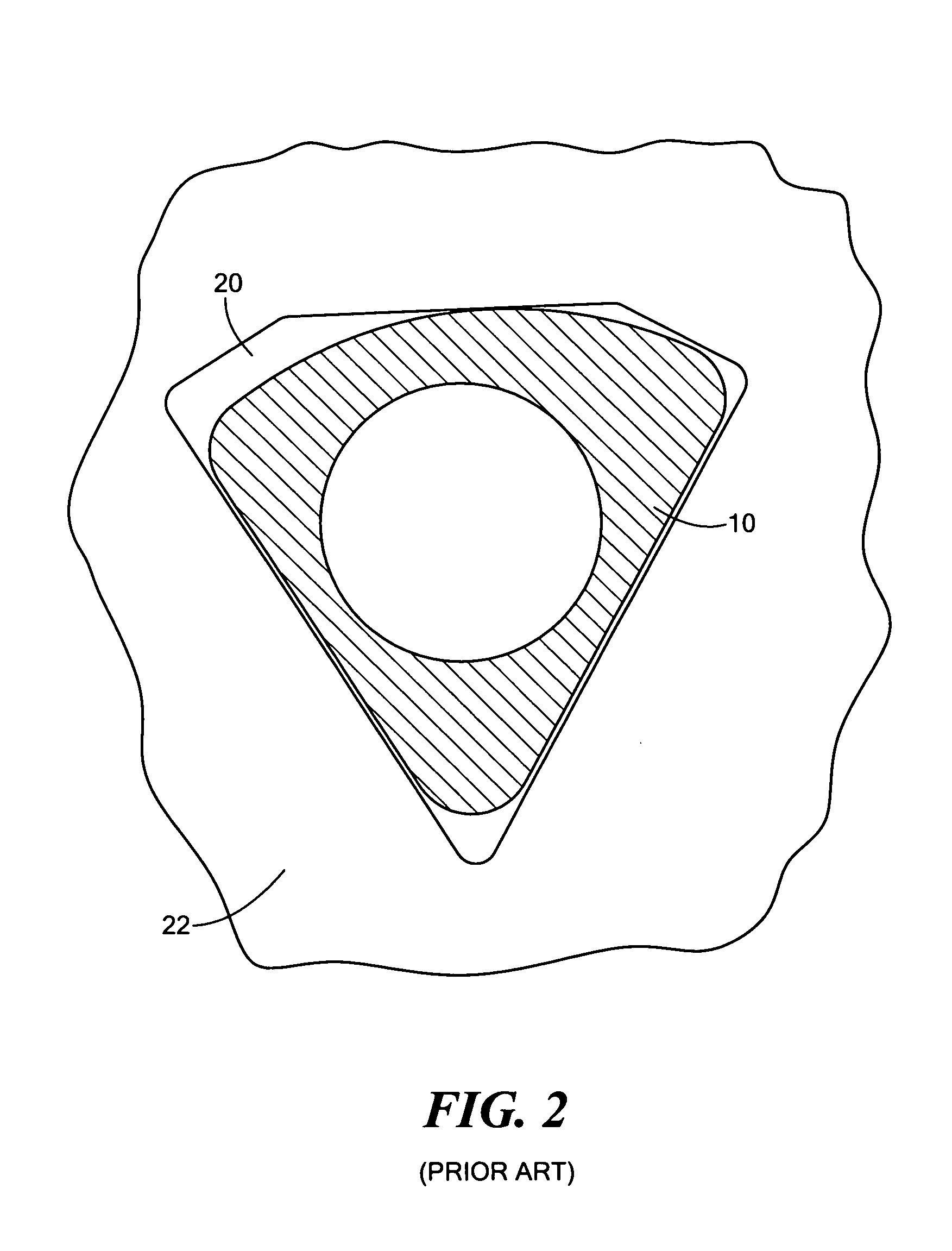

Asymmetric shaver and methods for making same

InactiveUS20050065538A1Improve resection efficiencyImprove efficiencyCannulasSawing tools dressing arrangementsCnc grindingEngineering

A surgical shaver blade is provided with a stationary elongated outer tube, having a cutting window at its distal tip and a rotatable elongated inner tube having a cutting window at its distal tip. Each cutting window is not symmetrical about any line in a sectional view through the window normal to the tube axis. In a preferred embodiment the cutting edges of each window have a plurality of teeth, the teeth of one lateral cutting edge being offset axially from the teeth of the other lateral edge so that the teeth of one edge align axially with the valleys between teeth on the opposite edge. When the shaver is used in oscillate mode, the teeth of one direction of rotation align with tissue that was between teeth during the previous opposite direction rotation thereby enhancing the ability of the teeth to penetrate the tissue and prevent its ejection from the cutting window as the cutting edges approach. In another embodiment the outer window is asymmetric without teeth and the inner window is asymmetric with teeth. In yet another embodiment only the inner cutting edges are asymmetric. The cutting edges are formed in a single grinding operation or multiple grinding operations using a multi-axis CNC grinding machine, or electrochemically.

Owner:ASYMMETRICS

Diamond/cubic boron nitride saw blade for cutting metal and fabricating method therefor

ActiveCN1669708ANo harmHuman and Environmental HazardsMetal sawing toolsSawing tools dressing arrangementsBoron carbideBoron nitride

This invention relates to a saw bit belonging to mechanical working field, which comprises metal base being alloy steel or carbon steel, with Phi8-Phi10mm radiating holes equispaced on its surface; Carcass including alumina, zircite, quartz, tungsten carbide, zirconium diboride, molybdenum disilicide; common abradant including brown fused alumina, carbofrax, green silicon carbide, cubic carbofrax, boron carbide; superhard abradant including diamond and cubic boron nitride. The produce process includes mixing carcass flour, working layered material batching-mixing process, welding layered material batching-mixing process, koldflo, thermal pressing-sintering formation, arc milling, welding, dressing and making edge. The invention has improved working efficiency, lowered product cost, and is suitable for cutting metal tube, plate such as this materials.

Owner:SF DIAMOND CO LTD

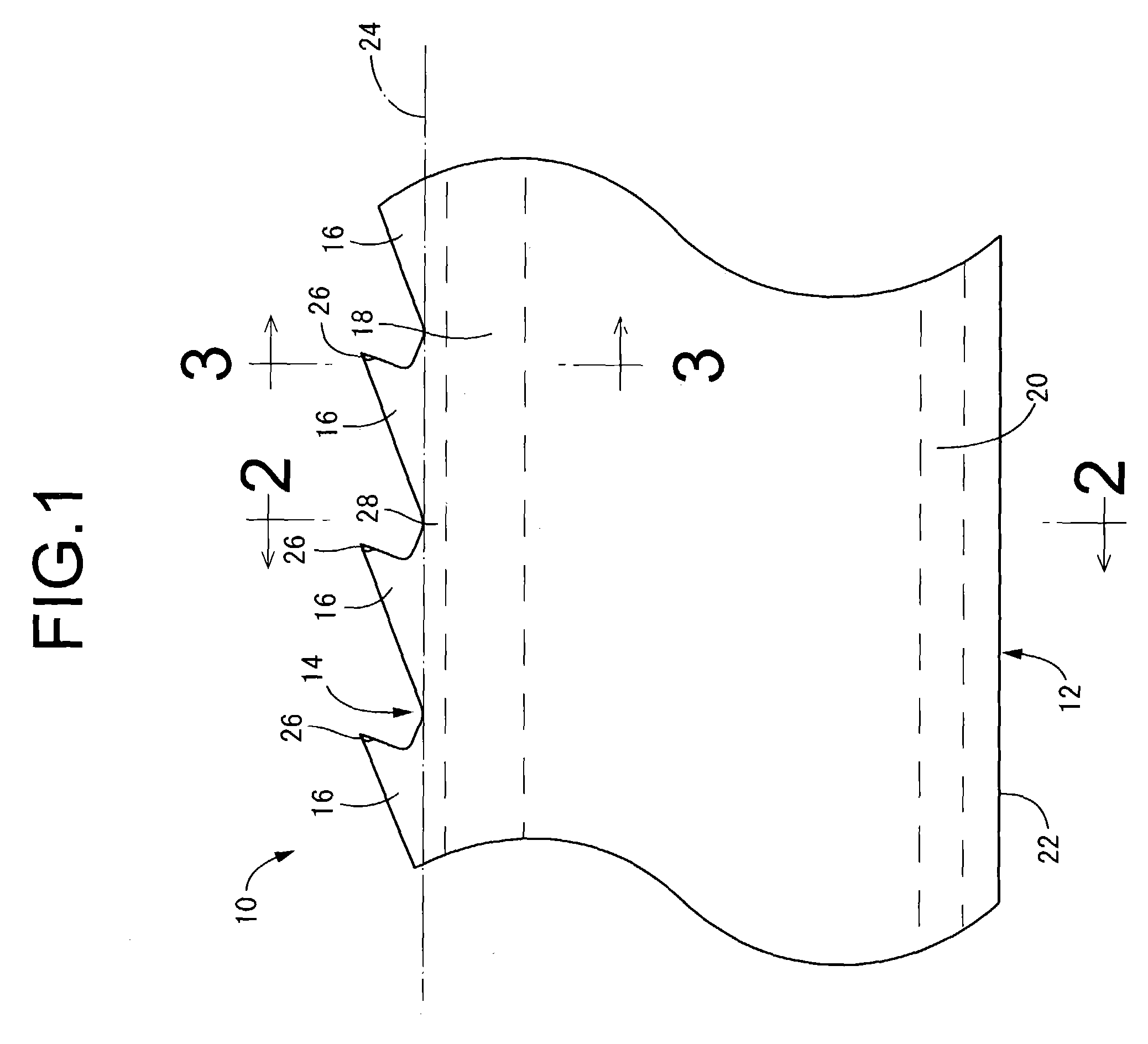

Band saw blade

The present disclosure relates to band saw blades often used for cutting wood at a sawmill. A band saw blade has teeth, and at least one tooth has a back angle that is greater than the back angle of conventional band saw blades. The greater back angle results in teeth having a smaller tooth angle so that the teeth make deeper penetration into wood or other materials that are cut by the blade.

Owner:COOKS SAW MFG

Laser Clad Cutting Edge for Agricultural Cutting Components

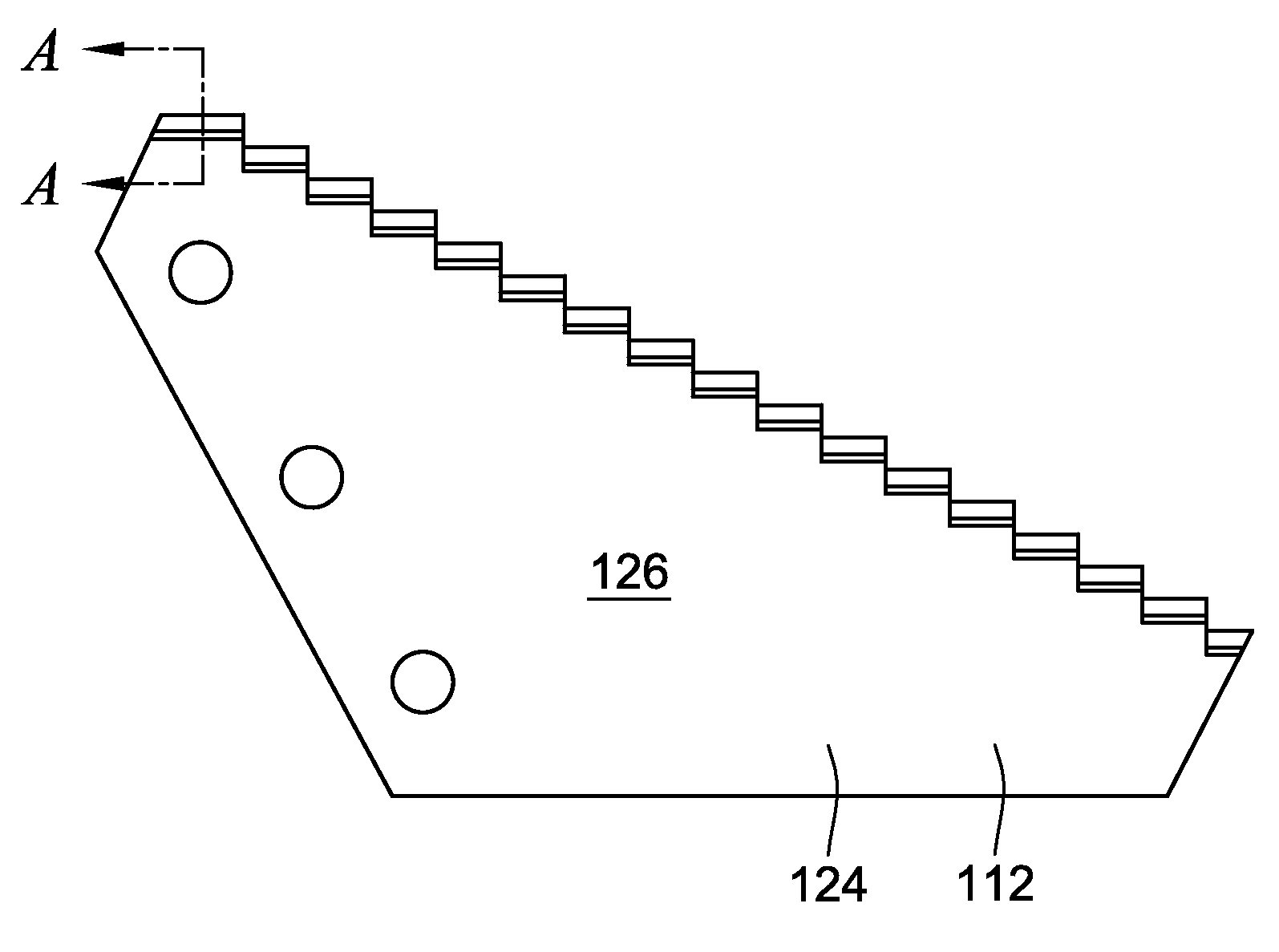

InactiveUS20130233145A1Reduce wearAvoid premature wearMetal sawing devicesMowersEngineeringKnife blades

An agricultural cutting blade has top and bottom surfaces and mounting apertures extending through top and bottom surfaces. A cutting edge support surface (e.g. that may be a flat, pointed or rounded) is formed on the cutting blade body with the cutting edge support extending along a side of the cutting blade body transversely between the top and bottom surfaces. A clad material deposited upon the cutting edge support such as by laser cladding process. The clad material can be built up, that is layered in partial or full overlapping relation to provide at least 2 and often more than 4 layers of clad material at one or more locations. A cutting edge provided by the clad material that may be a ground surface into a laser clad bead.

Owner:KONDEX CORP

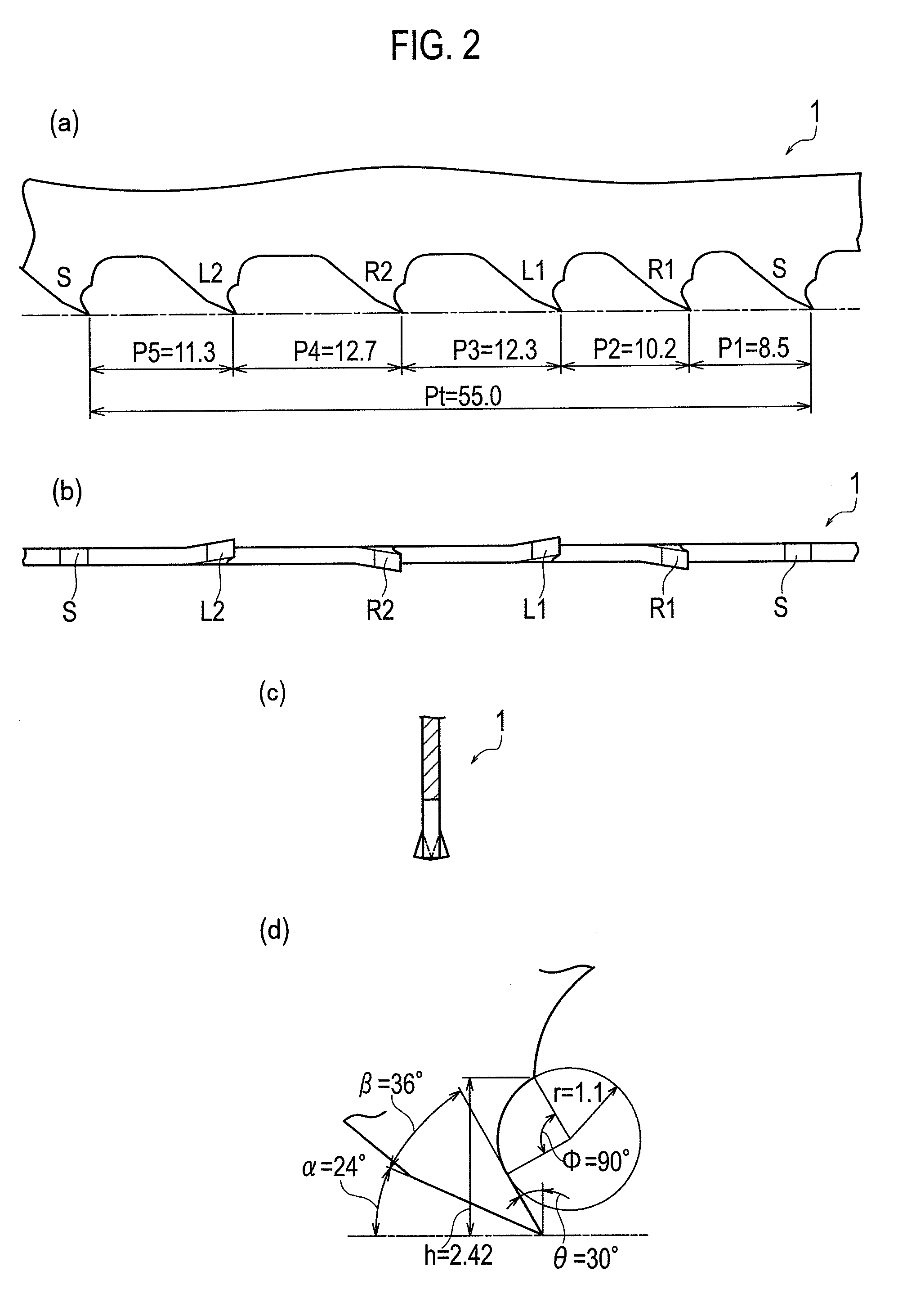

Saw blade and manufacturing method thereof

InactiveUS20110154970A1Reduce cutting resistanceImprove the immunityMetal sawing devicesMetal sawing toolsEngineeringRake angle

Provided is a saw blade including saw teeth, each of the saw teeth satisfying 17°≦θ≦40°, 35°≦β≦58°, 15°<α, where θ is a rake angle, β is a tooth angle, and α is a clearance angle; a sum of the rake angle θ, the tooth angle β, and the clearance angle α being 90′; a radius r of an arc-shaped chip curler portion 7 in contact with a rake surface 5 of each of the saw teeth being in a range within 10%±4% of any of a saw tooth pitch and an average saw tooth pitch of the saw blade; a fan angle φ of the chip curler portion 7 being in a range within 85°±20°; and a dimension h from an intersection portion 11 of the chip curler portion 7 and a gullet forming surface 3 extending from a tooth bottom side of each of the saw teeth, to a tooth point of each of the saw teeth being in a range within (2r×1.1)±0.2(2r×1.1).

Owner:AMADA CO LTD +1

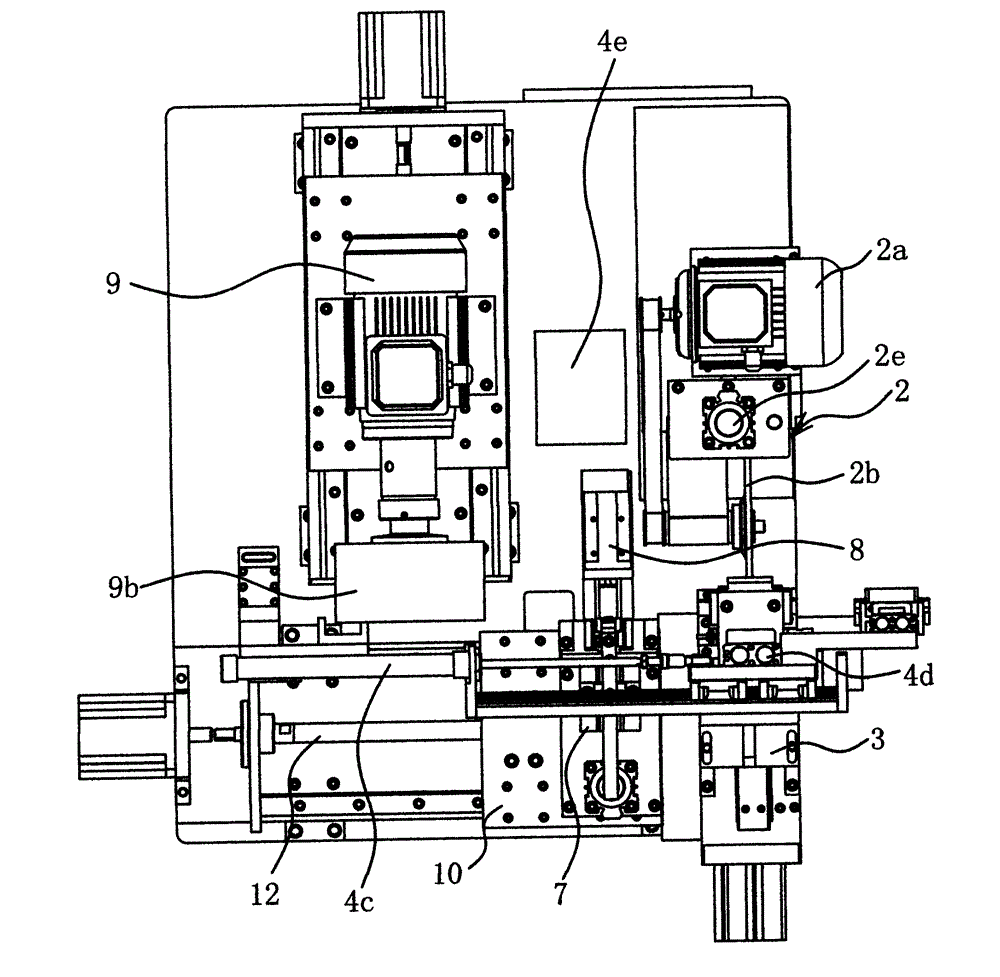

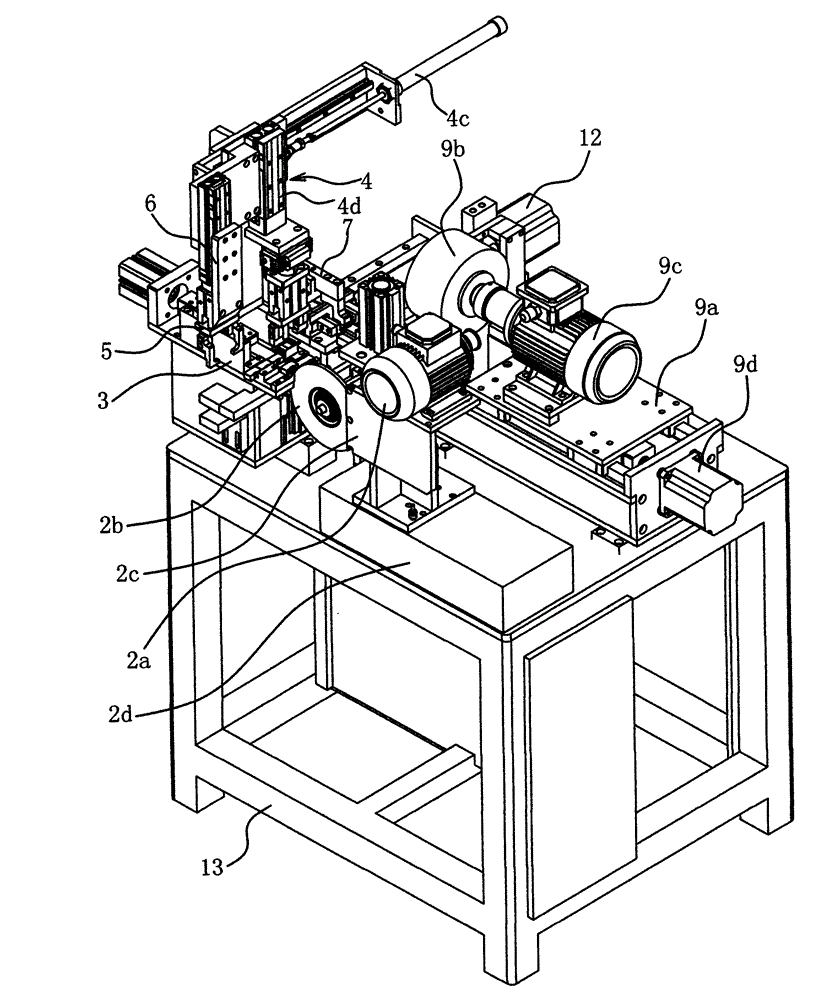

Diamond tool bit bottom surface grinding device

ActiveCN103331488AEasy to produceLabor savingSawing tools dressing arrangementsDrilling toolsTool bitSurface grinding

The invention provides a diamond tool bit bottom surface grinding device, which belongs to the technical field of the operation. The problem that the traditional diamond tool bit bottom surface grinding has low production efficiency because of grinding by a common machine tool is solved. The diamond tool bit bottom surface grinding device comprises a rack, wherein the rack is provided with a first grinding mechanism, a transfer discrimination mechanism and a second grinding mechanism, wherein the first grinding mechanism can be used for grinding the certain end surface of a diamond tool bit into a bright surface; the transfer discrimination mechanism can be used for transferring out the diamond tool bit capable of grinding the certain end surface of the diamond tool bit into the bright surface, can be used for judging whether the bright surface is positioned on the bottom surface or a tool surface and enables the diamond tool bit to face to the same direction according to the judgment result; and the second grinding mechanism can be used for bearing the diamond tool bit with the same facing direction of the transfer discrimination mechanism and can be used for grinding the diamond tool bit bottom surface. The diamond tool bit bottom surface grinding device has the advantages of convenience in production, labor force saving, high automation degree and high efficiency. According to the test, the diamond tool bit bottom surface grinding device can be used for grinding ten diamond tool bit bottom surfaces in one minute.

Owner:ZHEJIANG BANNINGER FLUID CONTROL CO LTD

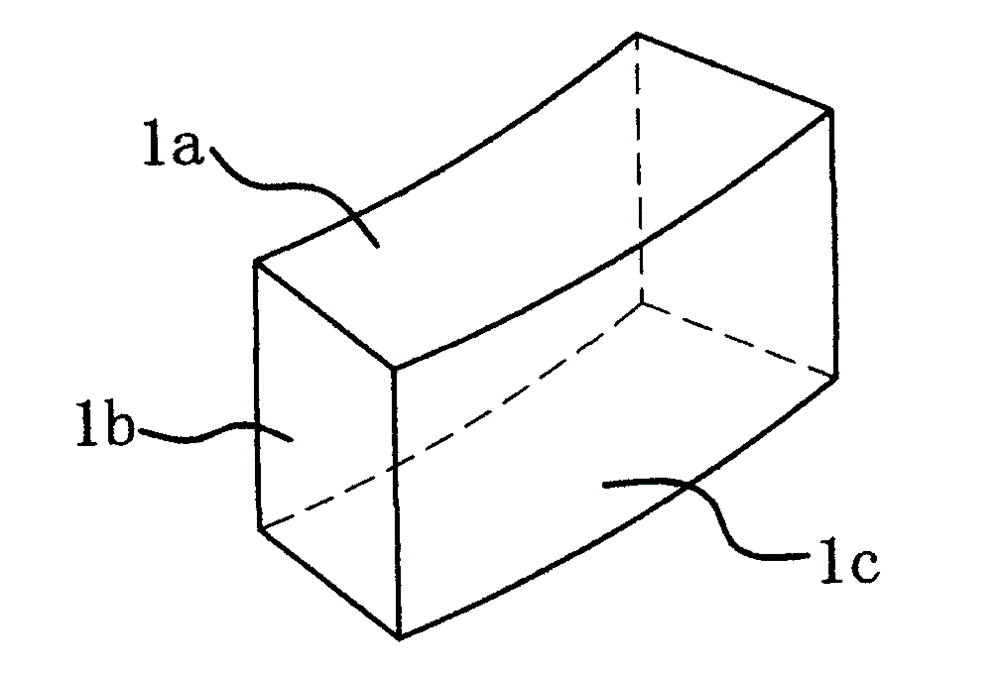

Curved and toothed cutting blade for a trimmer and a grinding wheel for manufacturing therefor

InactiveUS20090119932A1Efficient preparationReduce manufacturing costRevolution surface grinding machinesSawing tools dressing arrangementsEngineeringGrinding wheel

A curved and toothed cutting blade for a trimmer comprising a base body having at least a connecting member for mounting onto a trimmer and a longitudinal cutting edge on one side which is symmetrically concave downward and has teeth, wherein the curve of the cutting edge is in the form of a segment of the interior of a circular arc of a lens with the two interior angles of any teeth not having different degrees of angle and the dent in between any two teeth being not perpendicular to the base pitch of the tips of the two teeth and slanted towards the center point of the curve of the cutting edge; and a grinding wheel for manufacturing the cutting blade, wherein the cutting blade is manufactured by a grinding wheel which is in the form of a lens with the two endpoints truncated with diameter being the largest in the middle and gradually decreasing towards the two ends and the surface of which has grooves of sizes and shapes which correspond to the sizes and shapes of the teeth of the cutting blade. The manufacturing process is simple and of low cost.

Owner:SPECIALIFE INDS

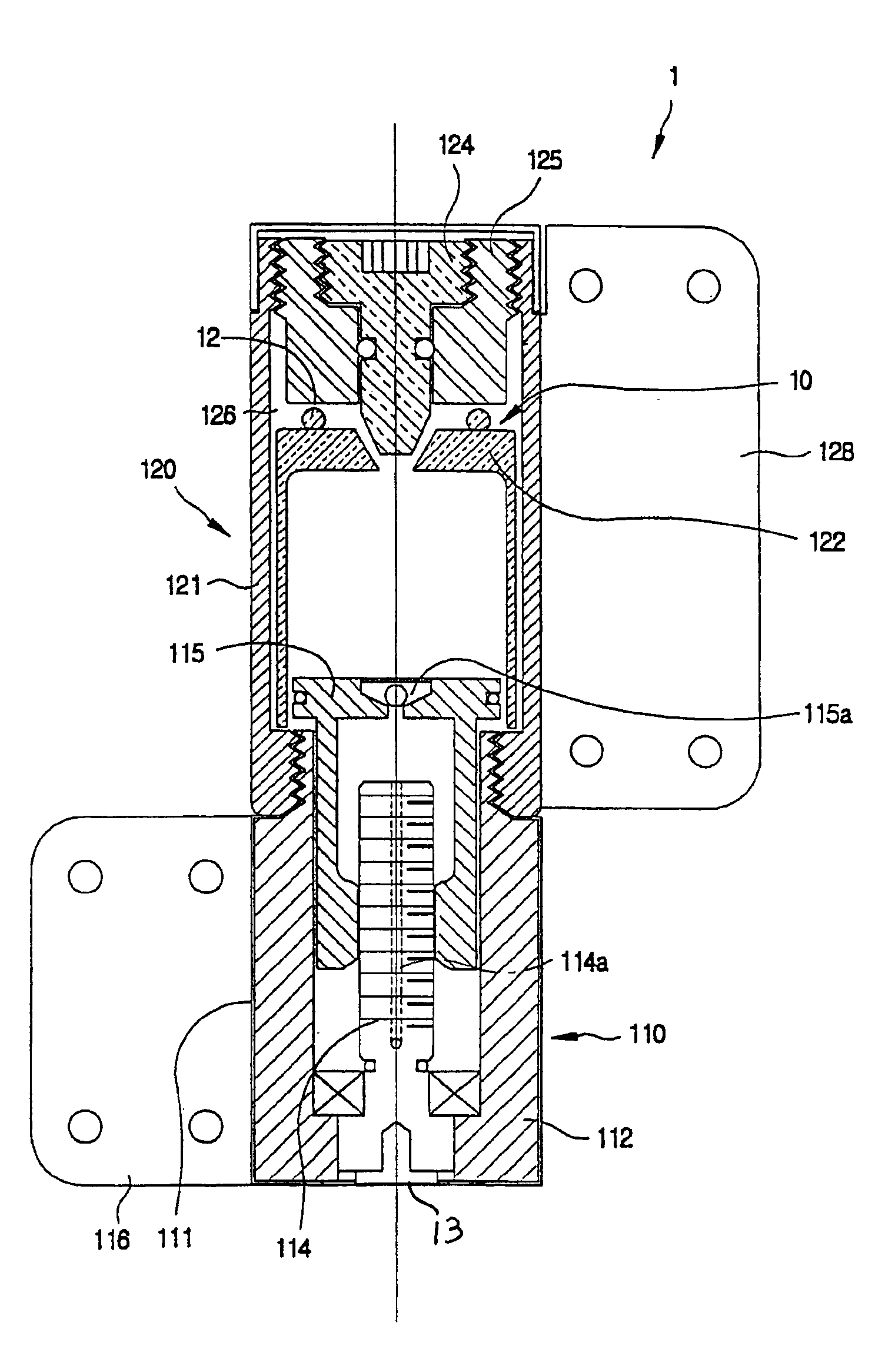

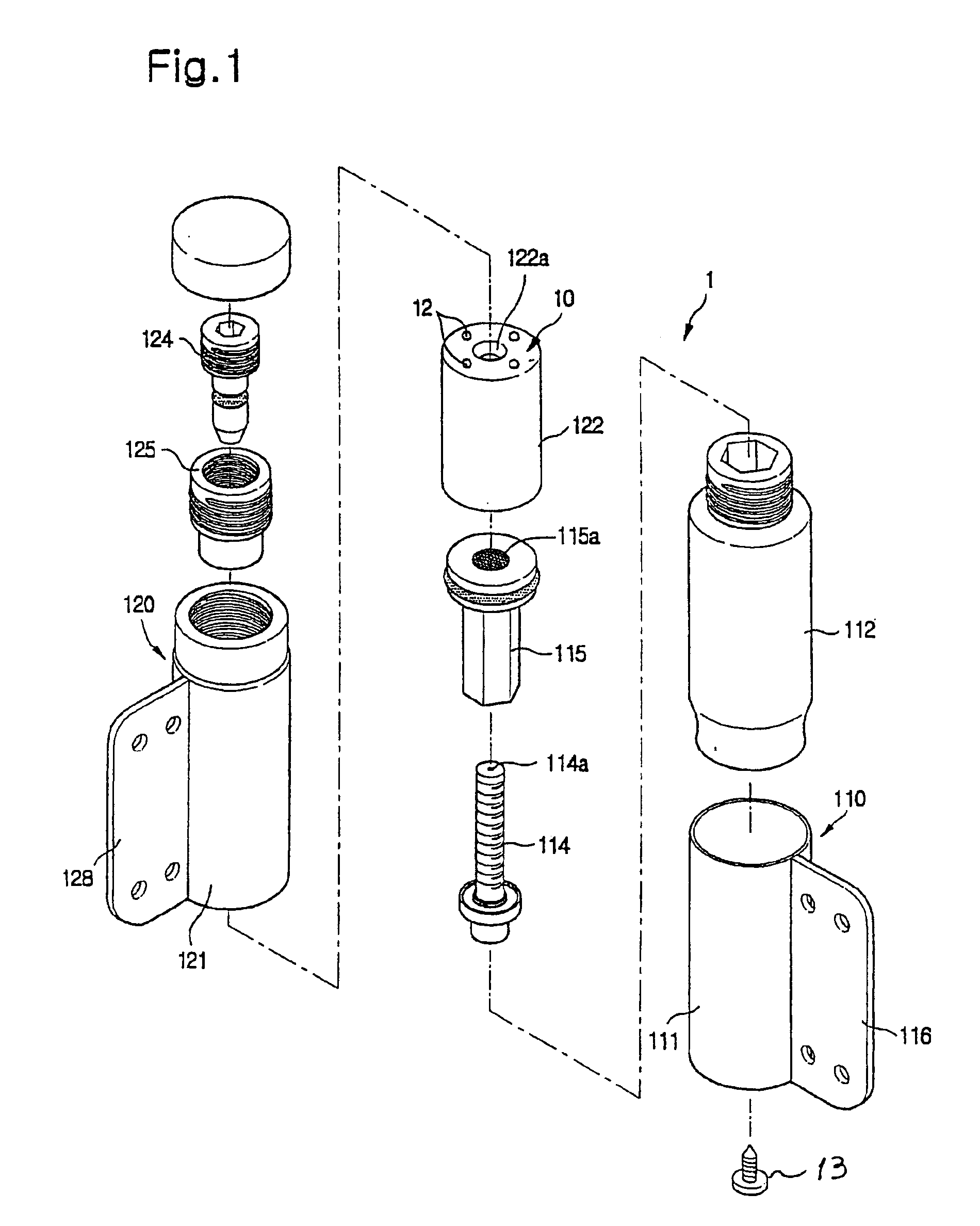

Apparatus for opening and closing door

InactiveUS6854161B2Convenient amountSimple structureBuilding braking devicesSawing tools dressing arrangementsPiston GuideEngineering

An improved apparatus for opening and closing a door including a hydraulic hinge and a spring-type hinge is provided. The hydraulic hinge includes a rotary member having a first housing, a piston guide placed inside the first housing, a rotary shaft disposed inside the piston guide and a piston screwed with the rotary shaft, and a fixed member having a second housing, a cylinder placed inside the second housing and having an oil outlet penetrating the cylinder for allowing oil to pass through the oil outlet, an outflow part formed on the top surface of the cylinder and having a plurality of support protrusions, a head mounted on the top surface of the cylinder and an adjusting bolt screwed with the head such an oil circulating passage is formed in the fixed member. The spring-type hinge includes a spring for closing an opened door by compressive tension and an elevation part rotatably elevated while being rotated, the elevation part having a spring fixing part formed on the top surface thereof for fixing the lower end of the spring.

Owner:JEONG CHAN IN

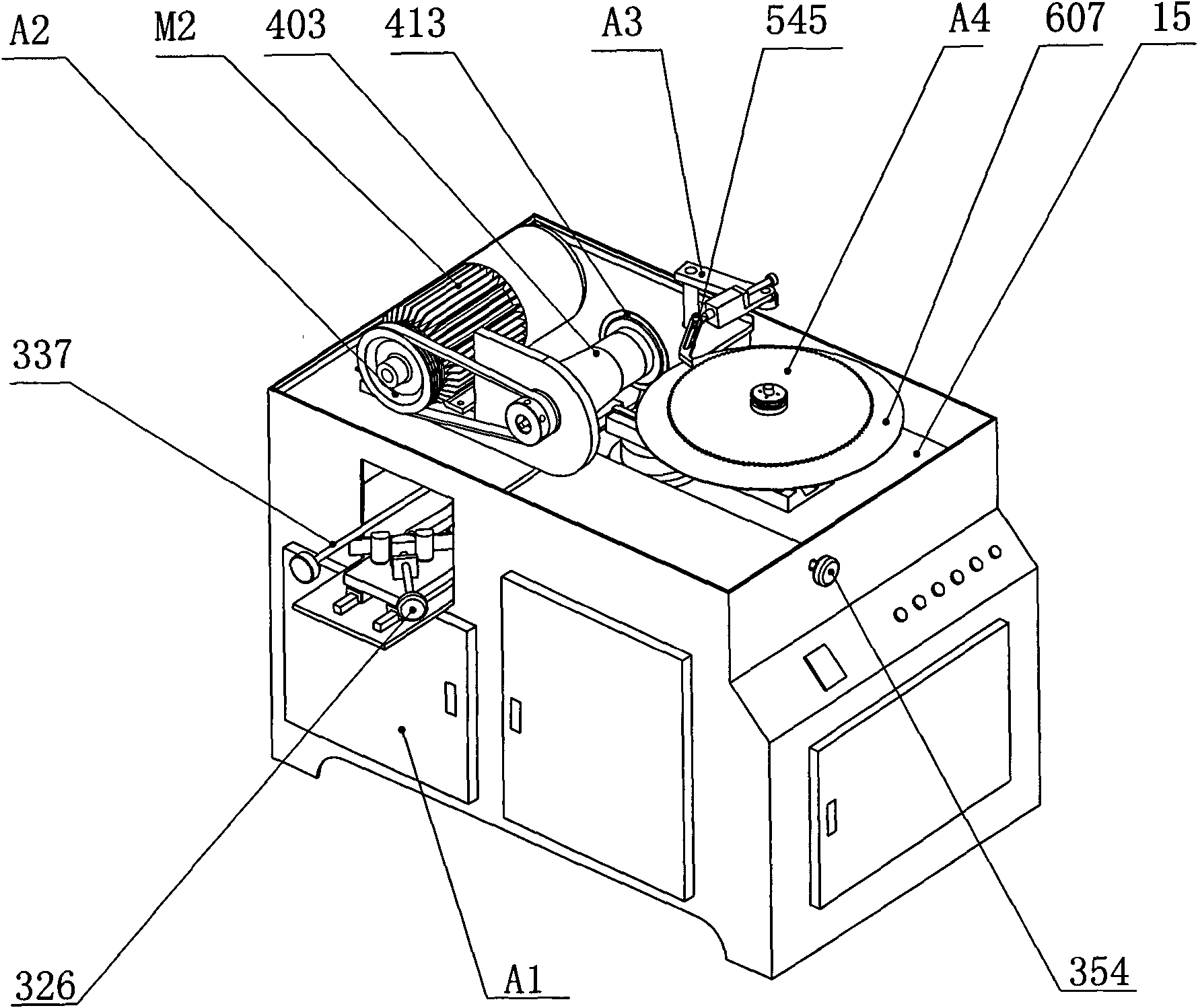

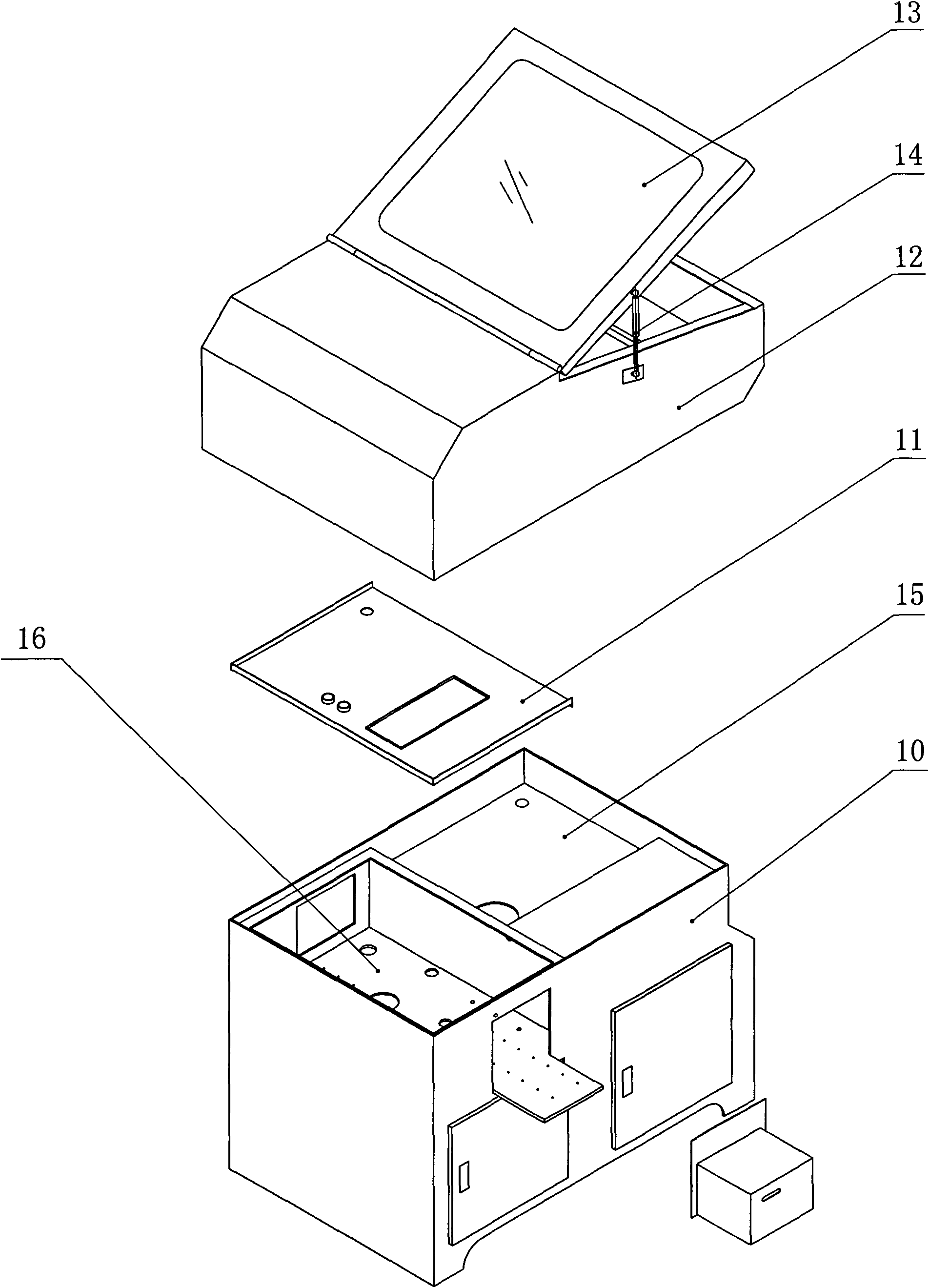

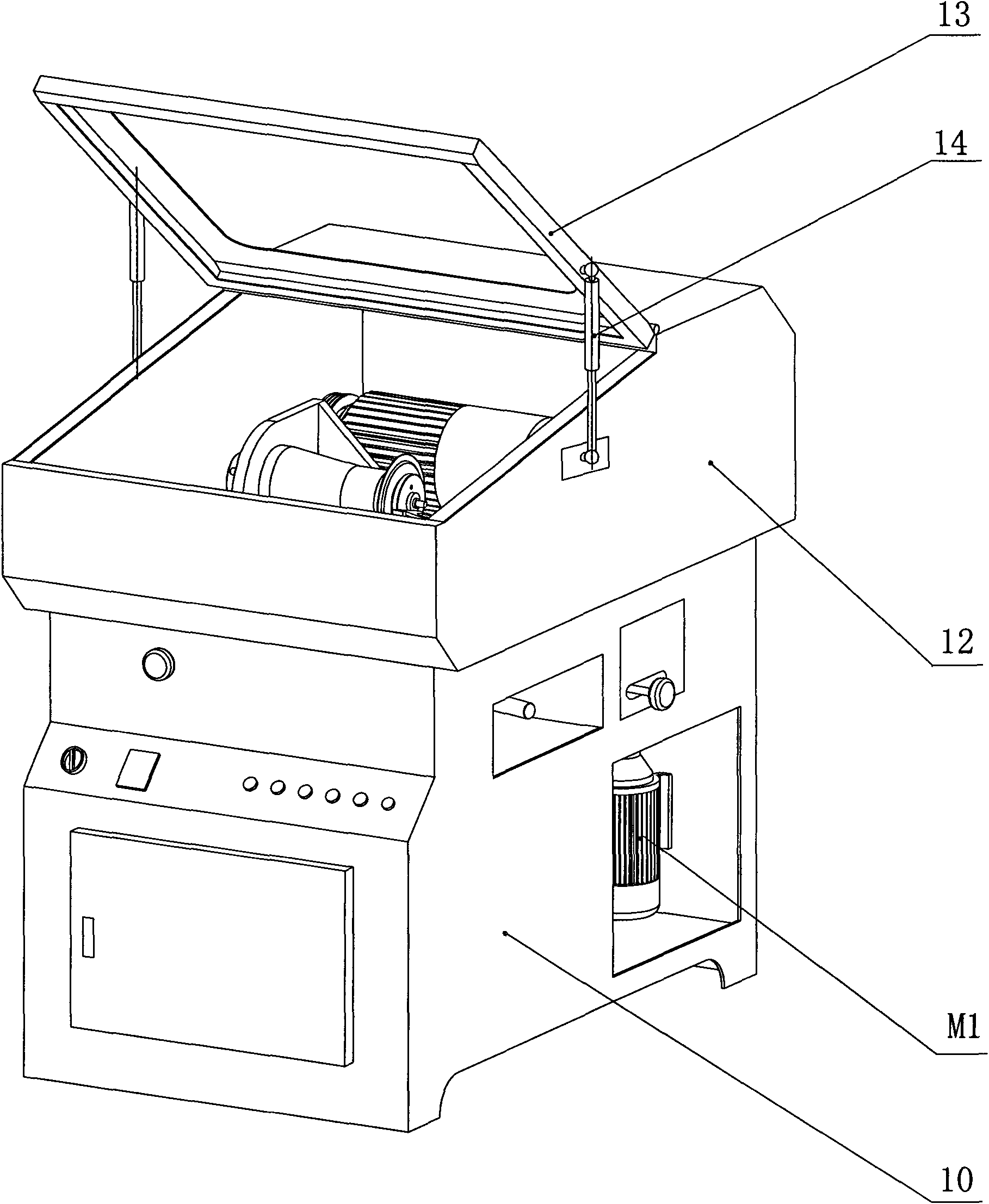

Saw blade grinding machine of metal circular saw blade

ActiveCN101658962AHeight adjustableSawing tools dressing arrangementsReciprocating motionCircular saw

The invention relates to a saw blade grinding machine of a metal circular saw blade, which comprises a machine frame, a grinding tooth and cutting knife driving device and a saw blade positioning device, wherein the grinding tooth and cutting knife driving device and the saw blade positioning device are arranged on the machine frame; the grinding tooth and cutting knife driving device comprises acutting knife drive motor which can drive a cutting knife to rotate, and the saw blade positioning device comprises a central shaft which can be fixedly connected with the metal circular saw blade; amain power driving system and a first eccentric wheel are also arranged on the machine frame; the saw blade grinding machine of the metal circular saw blade is characterized in that the main power driving system comprises a main drive motor which can drive the first eccentric wheel to rotate; and the first eccentric wheel can drag the grinding tooth and cutting knife driving device to carry out areciprocating motion by a first stroke conversion system. By the design and the connection of a flexible structure, the entire machine realizes the mechanical automation of the processing process, andthe processing accuracy of the saw blade is high. Because the invention has the characteristics, the invention can be used for a sawtooth grinding machine of the metal circular saw blade.

Owner:广东捷泰克智能装备有限公司

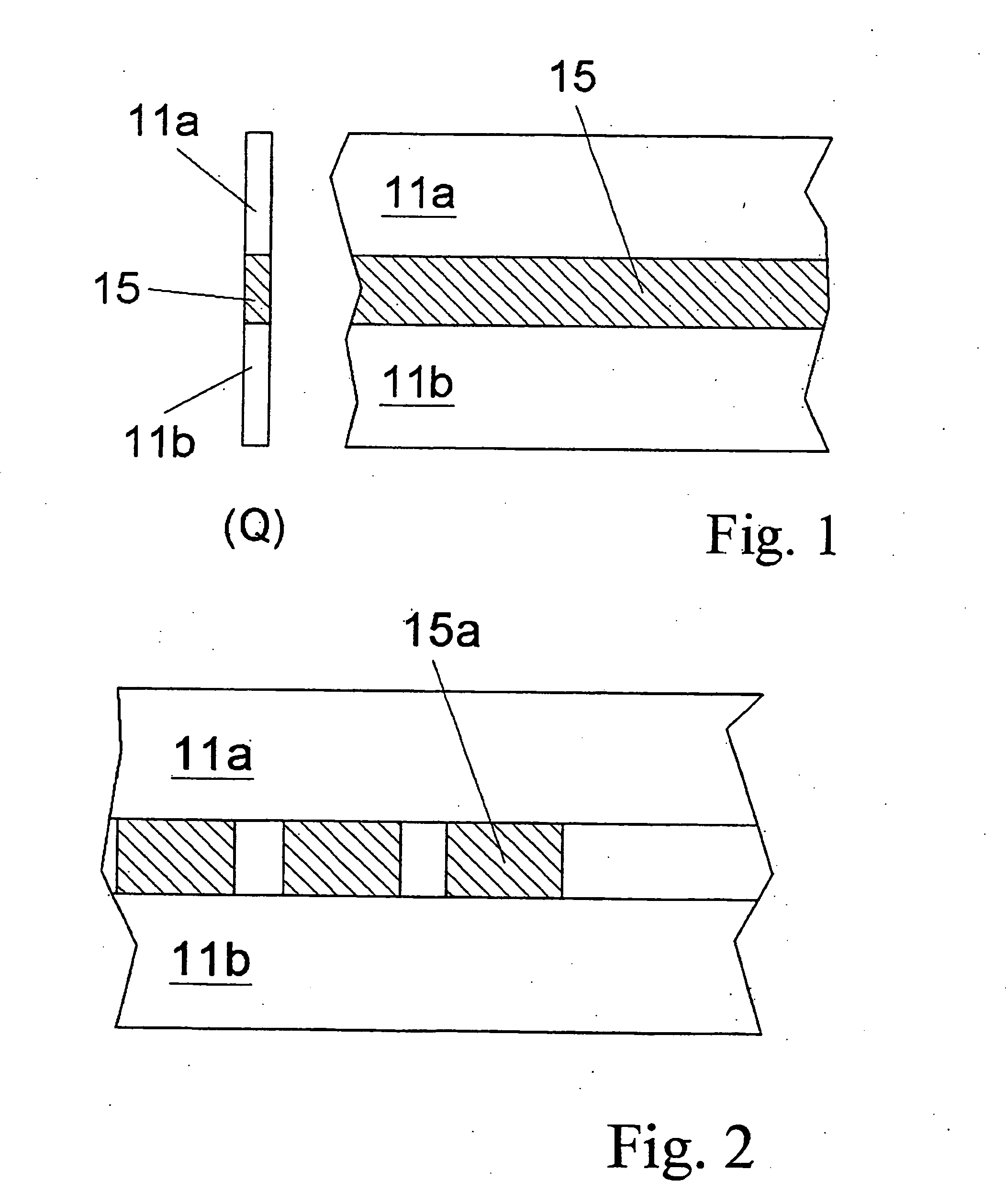

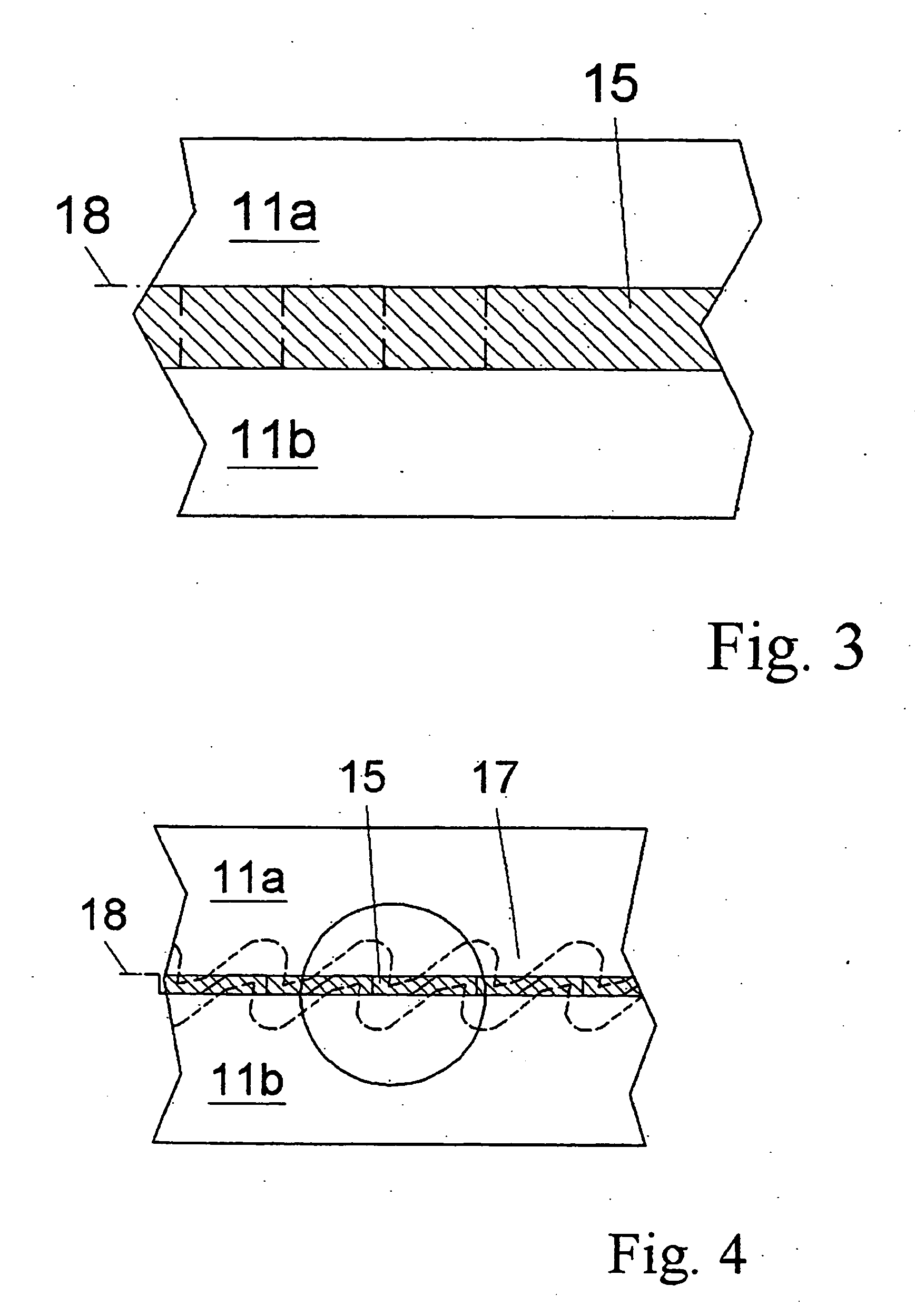

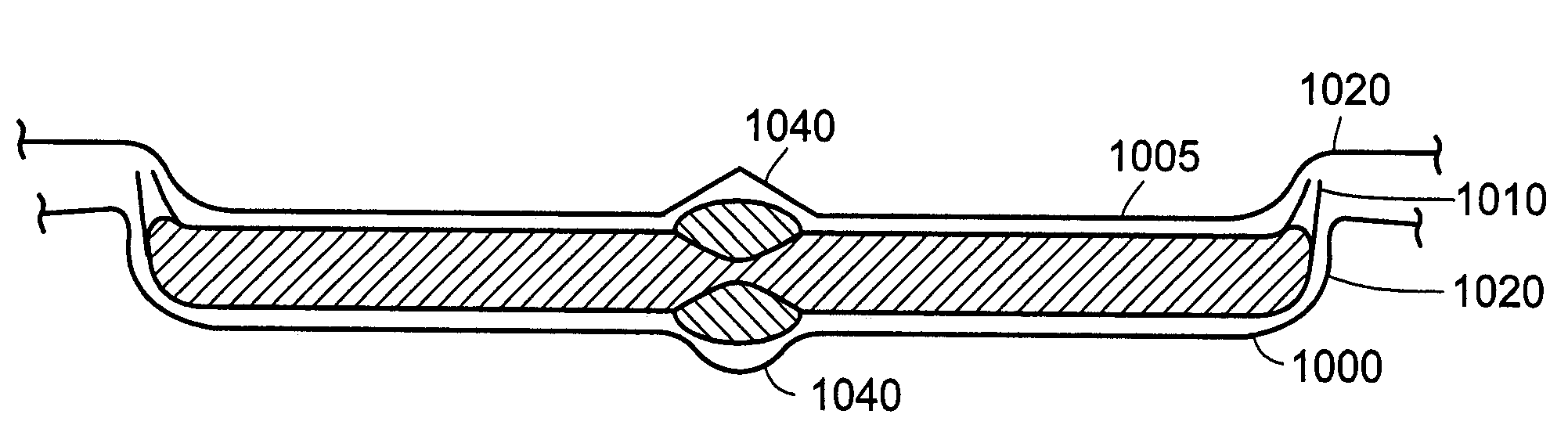

Starting Component For The Production Of Saw Blades Or Bands And Method For The Production Thereof

The present invention relates to a precursor component for the manufacturing of saw blades respectively saw bands, a method for the production of this precursor component, as well as a method for the production of saw blades, respectively saw bands. The above mentioned precursor component comprises at least a pre-manufactured carrier band respectively a pre-manufactured carrier disc, preferably a steel band respectively a steel disc and at least one pre-manufactured segment comprising of a precursor material for a cutting contour of saw blades respectively saw bands, wherein the carrier band respectively the carrier disc as well as the segment comprise a first and second face side, respectively and the first face side is more narrow than the second face side; and wherein the at least one carrier band respectively the at least one carrier disc is connected with the at least one segment via its respective narrow face side, such that by means of a separation of the final precursor component along a separation line which runs through the at least one segment two bi-metal bands respectively bi-metal discs can be generated which comprise one part of the at least one segment, respectively.

Owner:BOEHLER UDDEHOLM PRECISION STRIP GMBH

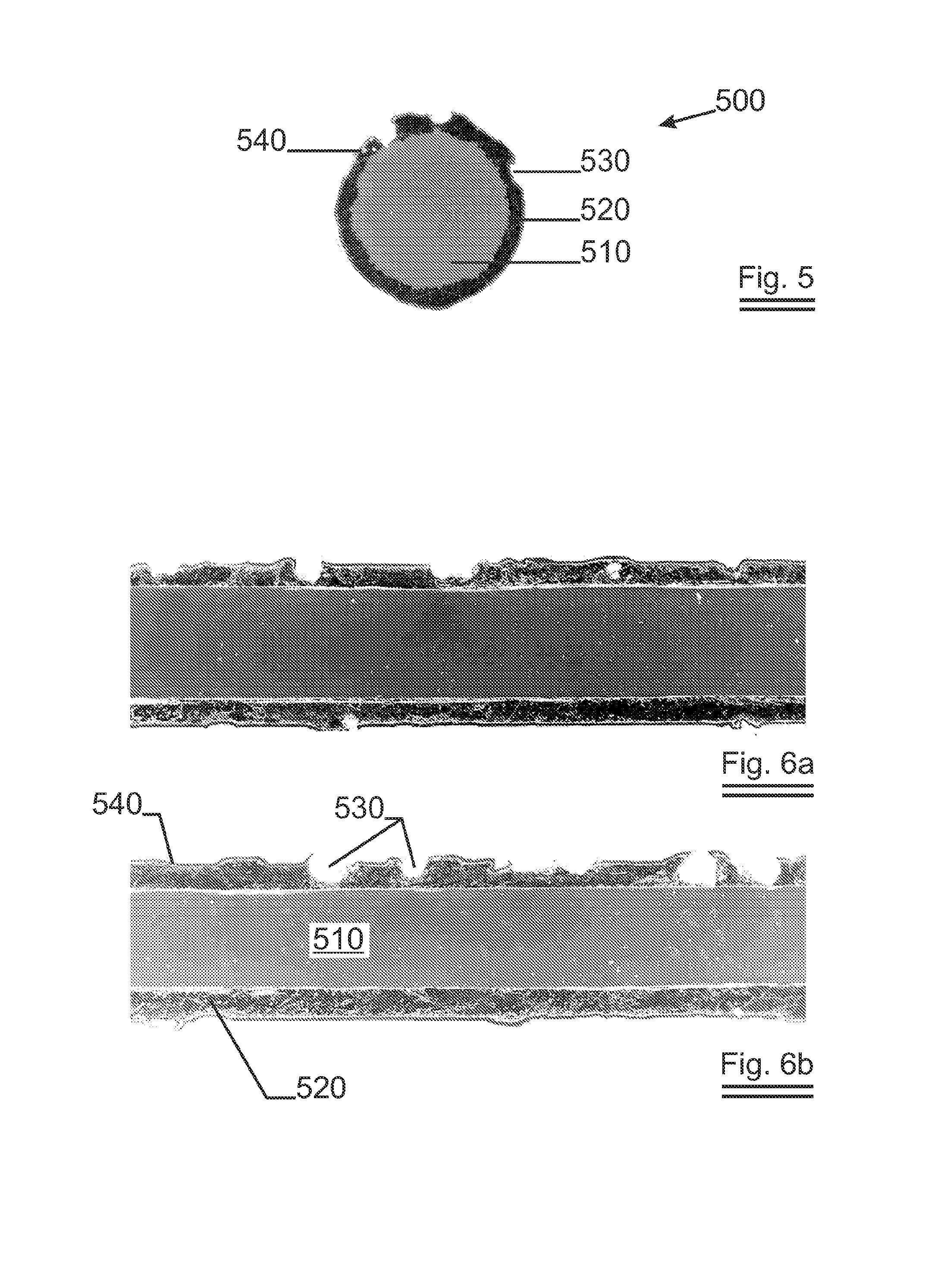

Fixed abrasive sawing wire with a rough interface between core and outer sheath

InactiveUS20120037140A1Extended service lifeMinimise kerf lossAbrasion apparatusMetal sawing toolsMetalMaterials science

A fixed abrasive sawing wire is presented that comprises a core (310) and an outer sheath layer (320) that is softer than the core. In the sheath abrasive particles are embedded that are held by a binding layer. The bond between core and sheath is enhanced by making it rough. The arithmetical mean deviating roughness must at least be higher than 0.50 micron. Particularly preferred is when interlocking between the core and the sheath is introduced. Such interface roughness can be obtained by subjecting the wire to sufficient cold forming by wire drawing. Interlocking will occur at even higher degrees of cold forming. The binding layer can be a metallic binding layer or an organic binding layer.

Owner:NV BEKAERT SA

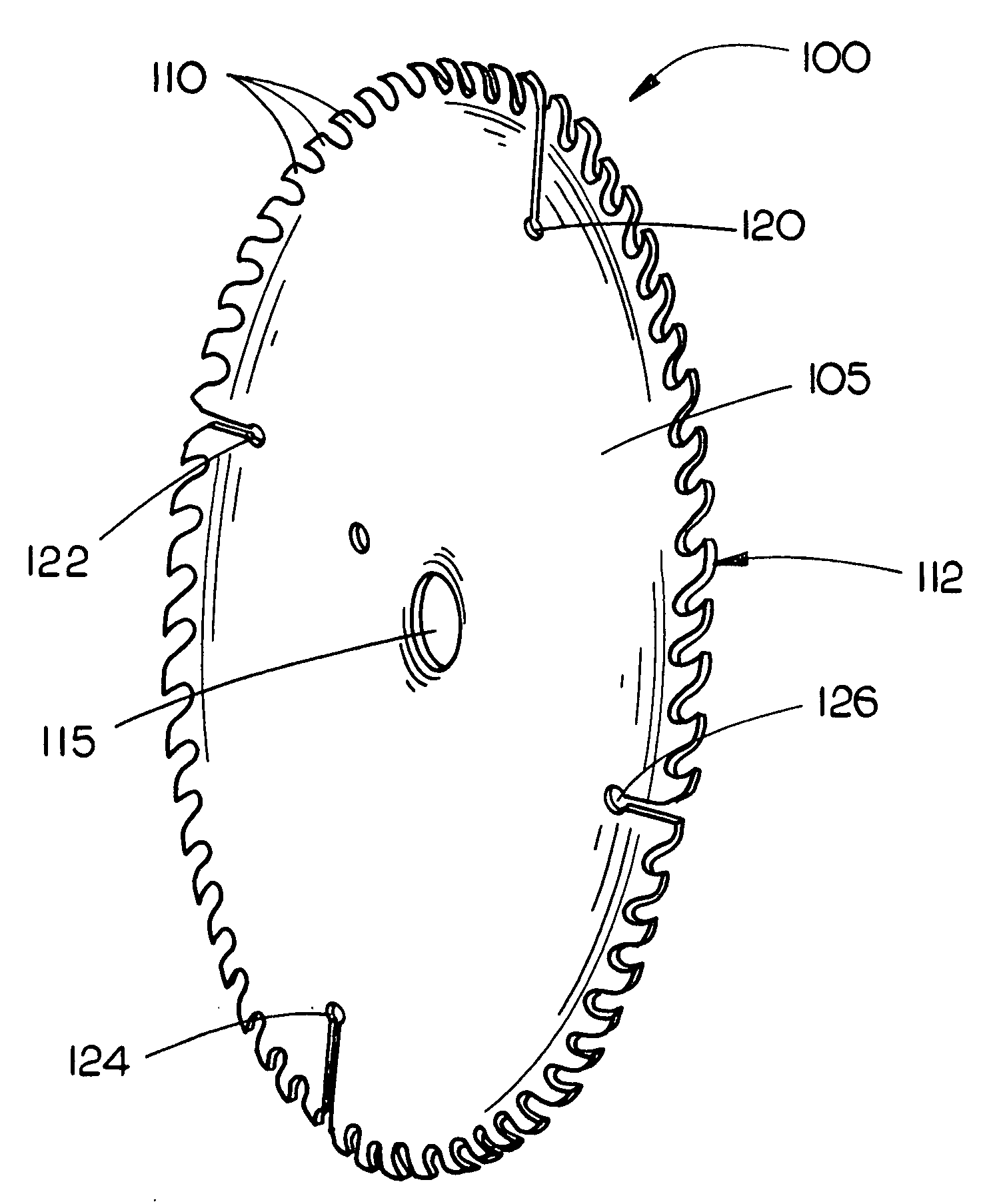

Composite circular saw blade

A composite circular saw blade. In an exemplary embodiment, a circular saw blade includes a body generally circular in shape including an aperture and an outer periphery. The aperture being generally defined in the center of the body and configured to be at least partially received by a circular saw arbor body. Further, a plurality of teeth are disposed around the outer periphery of the body for providing a cutting edge. The body is formed of a composite material, the composite material including two or more structurally complementary substances in which one of the two or more structurally complementary substances is a matrix material.

Owner:BLACK & DECKER INC

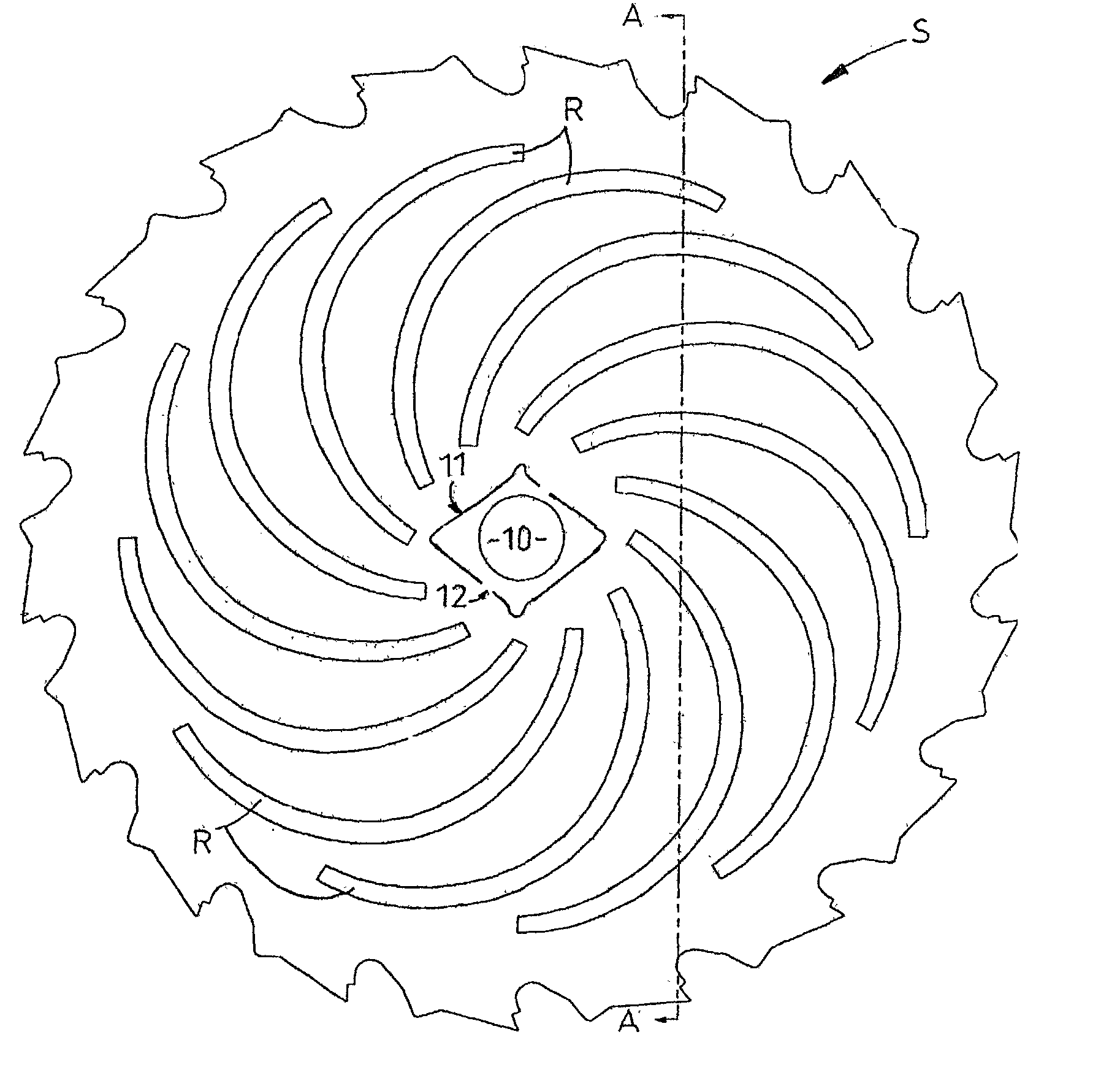

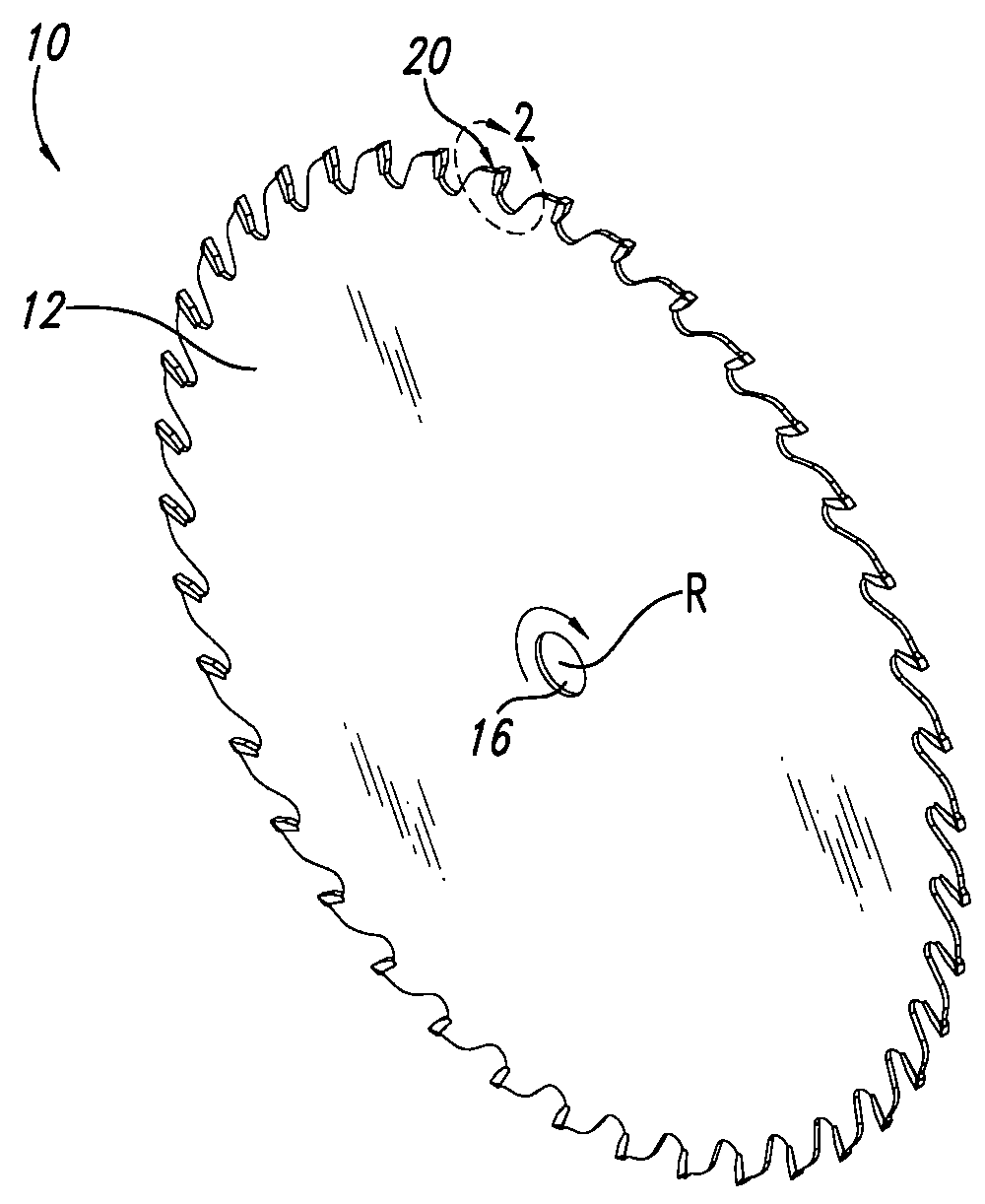

Laser cut saw blades

A method of manufacturing a tungsten carbide tipped circular saw blade (S) The method and blade are characterised by pressing a rib pattern (R) into the body of the blade (S). The rib pattern strengthens the blade body and avoids warping, particularly in thin blades, e.g. less than 1 mm thick.

Owner:IZARD INDS

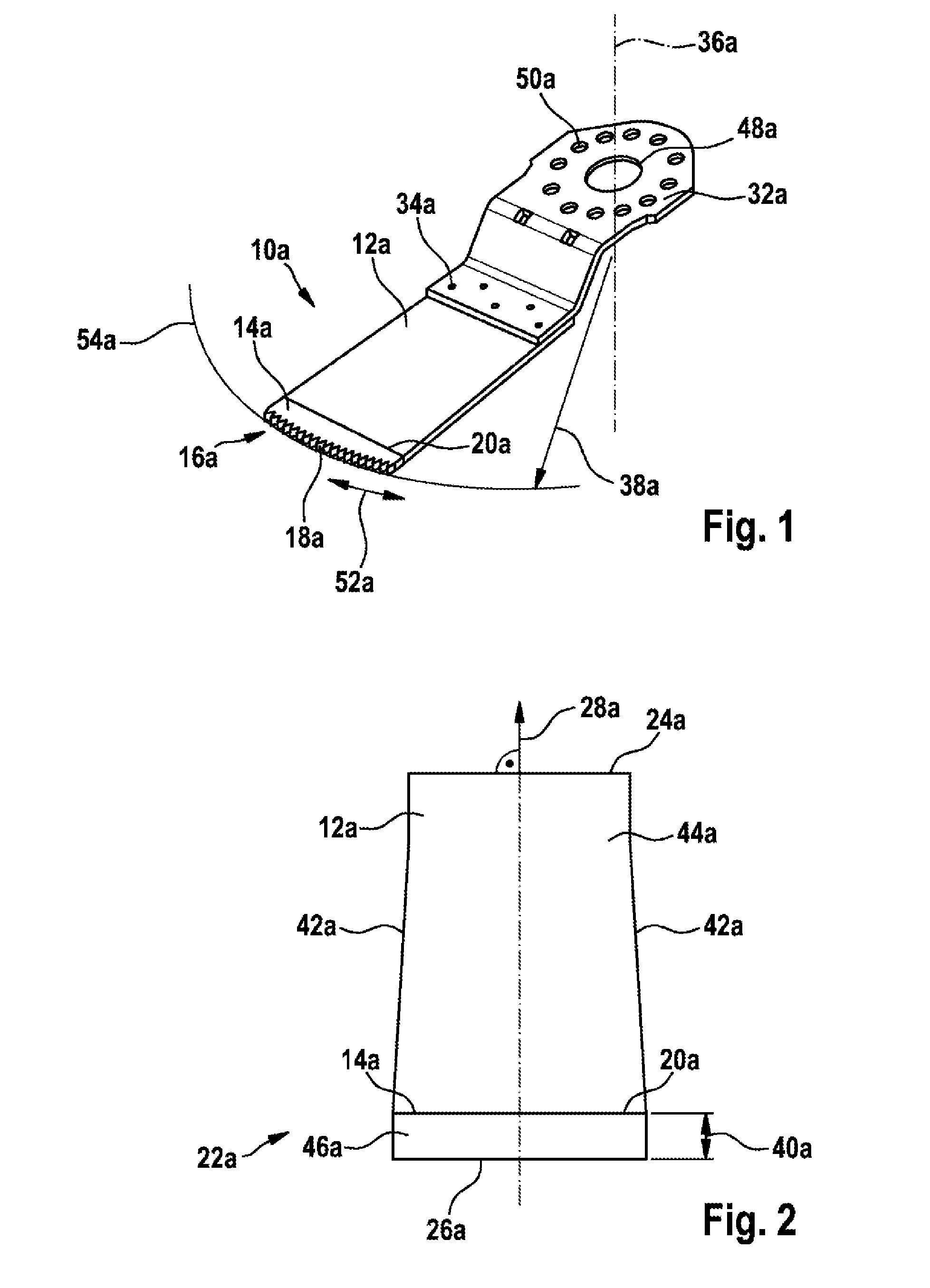

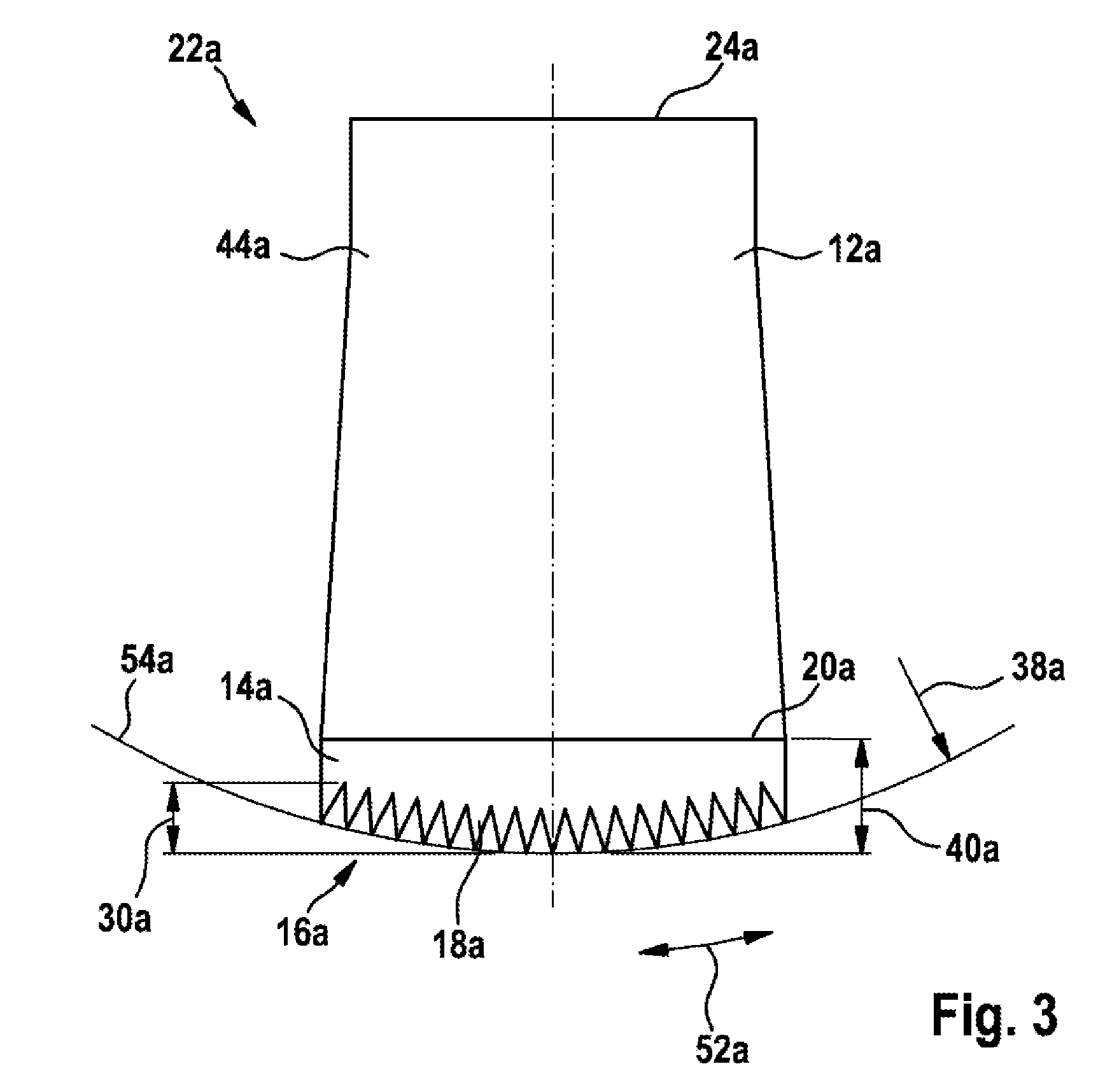

Tool

ActiveUS20140190328A1Improve wear resistanceConvenient heightMetal sawing devicesMetal sawing tool makingMechanical engineering

A tool, in particular a plunge-cut saw blade, includes a saw blade that has at least one main body and at least one working part. The working part has at least one working edge with saw teeth and is connected integrally to the main body along a straight connecting edge. The working edge includes a curved and / or polygon-like formation thereon.

Owner:ROBERT BOSCH GMBH

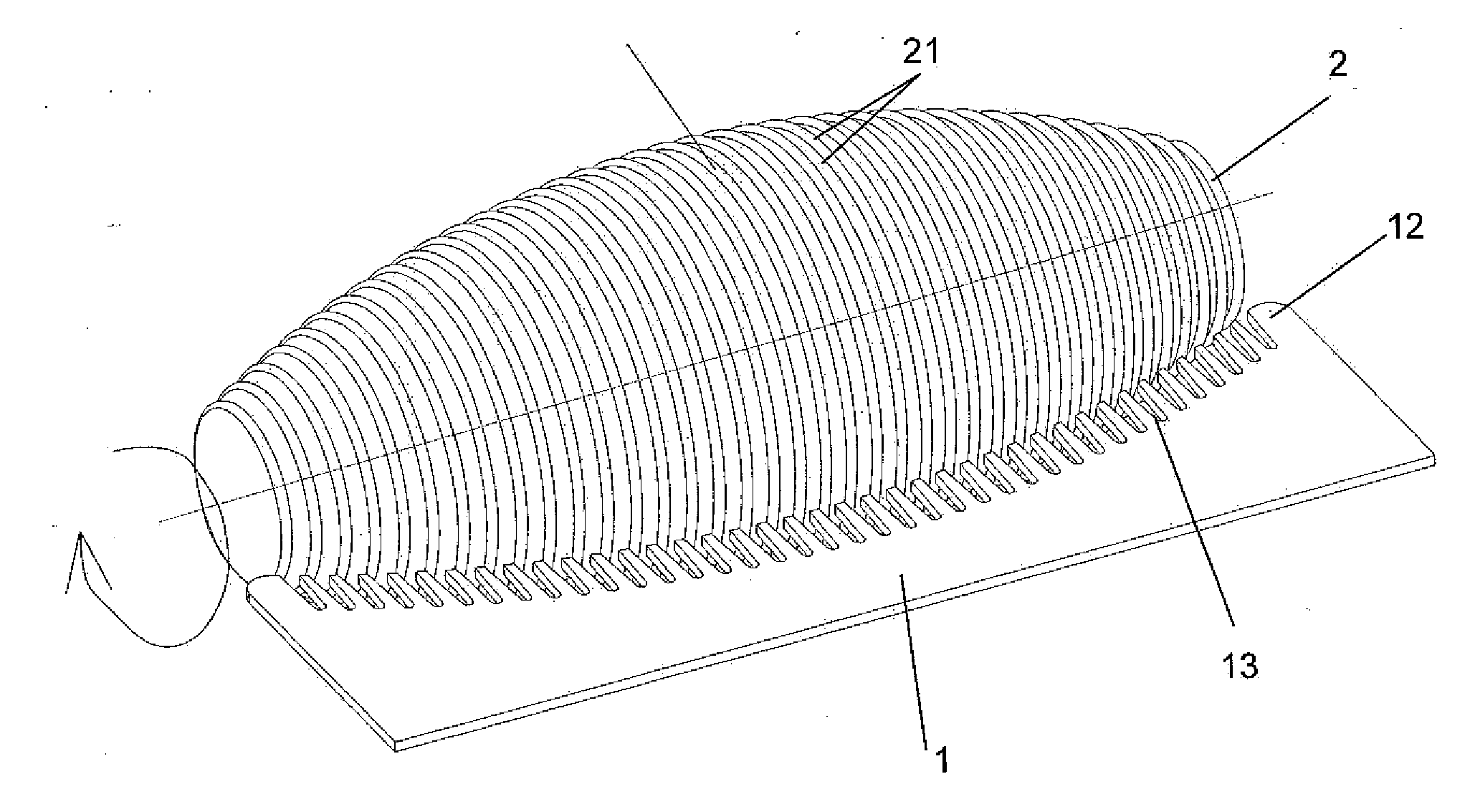

Band saw, band saw processing apparatus and band saw manufacturing method

InactiveUS7121180B2Improve rigidityHigh strengthMetal sawing devicesMetal sawing tool makingEngineeringBase line

A band saw includes a continuous saw body and multiple saw teeth provided on an edge portion of said saw body entirely. The edge portion of the saw body and the saw teeth are angled toward an inner side of the saw body by creating a bend near a tooth base line of the saw body. A band saw processing method and a method of manufacturing the band saw are also disclosed.

Owner:YG MARUSHIMO MACHINE SAW

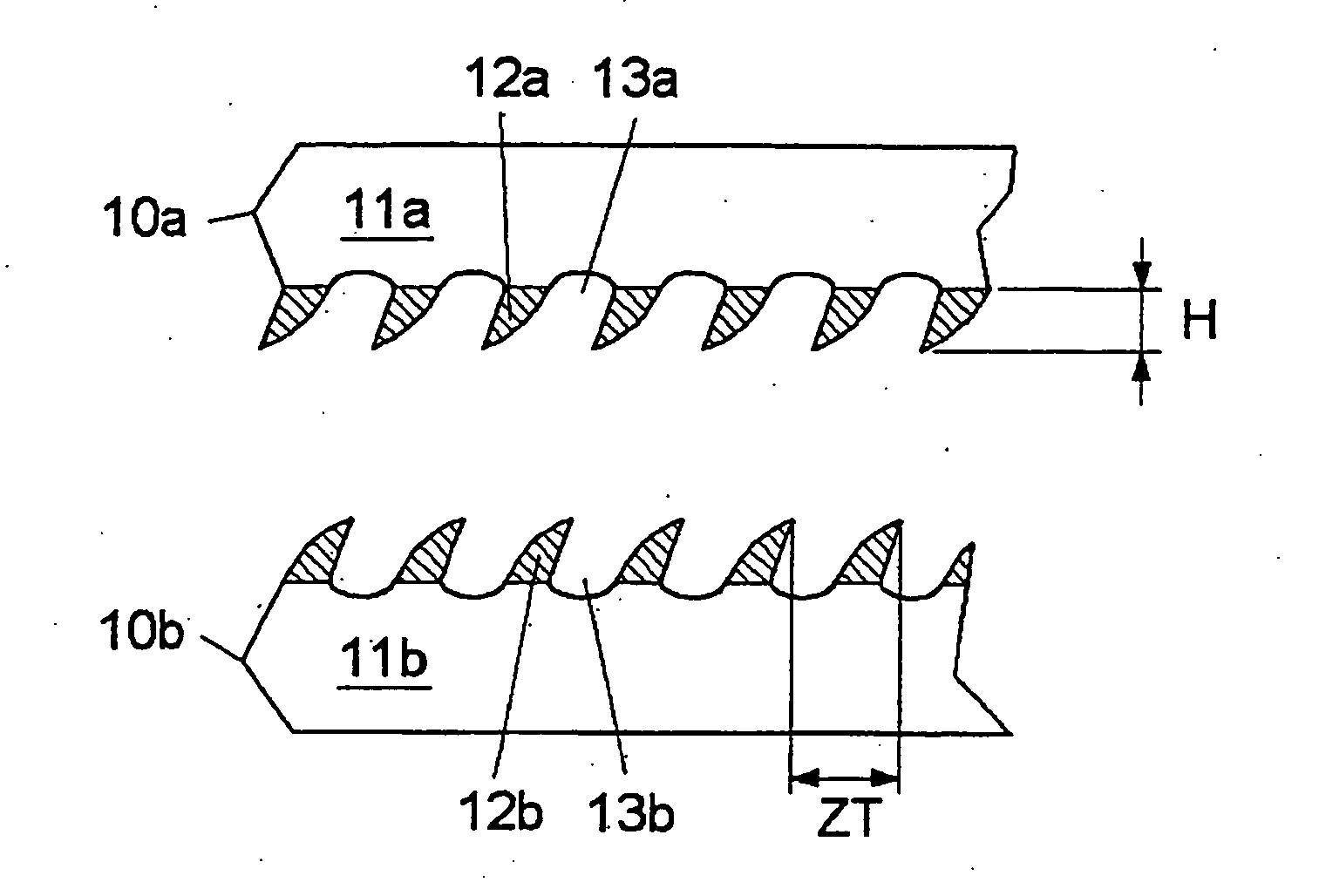

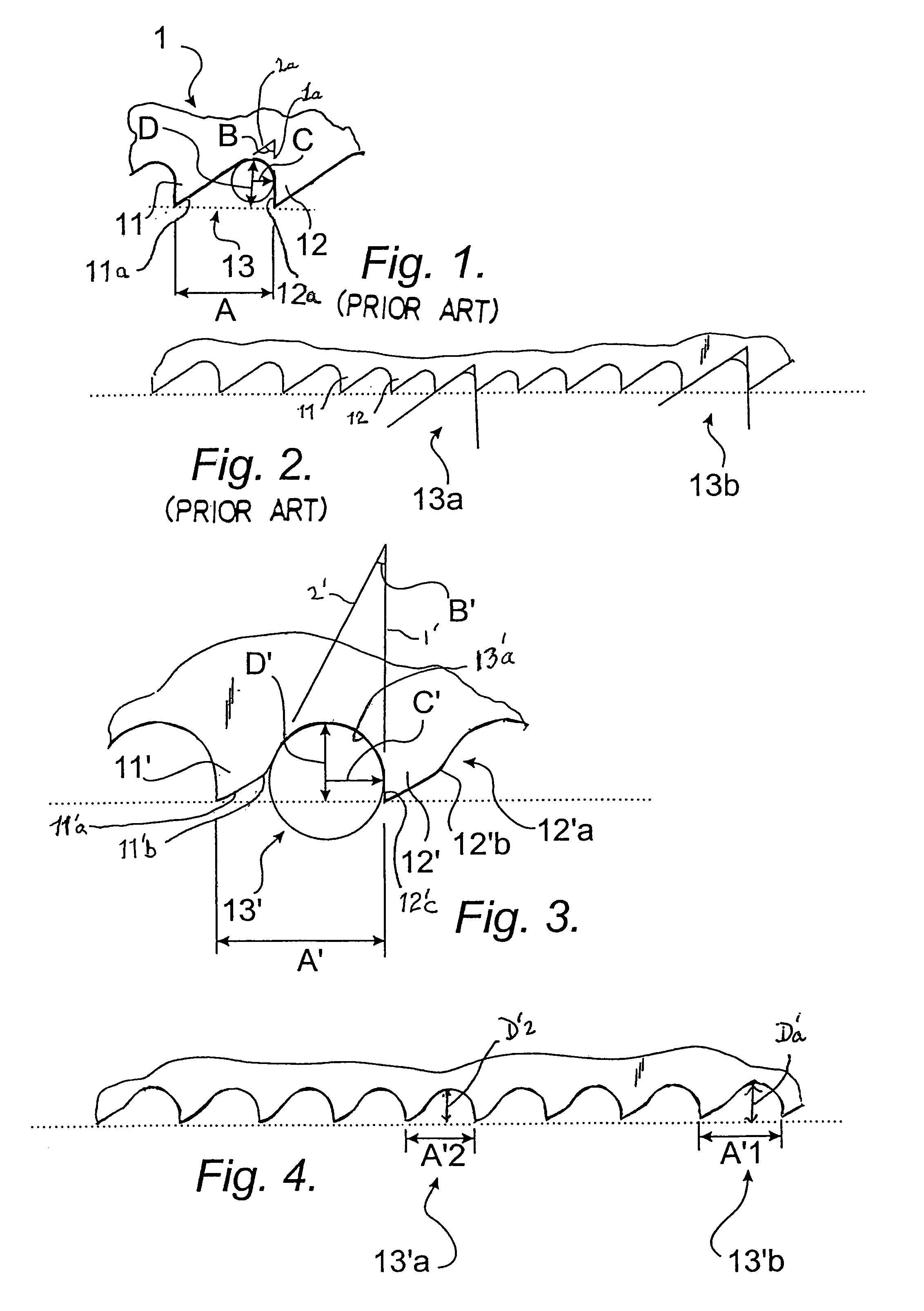

Versatile bandsaw blade

InactiveUS7178441B2Increase beam intensityImprove tooth strengthMetal sawing devicesMetal sawing toolsEngineeringKnife blades

Owner:KAPMAN

Saw blade and method of manufacturing the same

InactiveUS20100126326A1Constant widthGain is not constantMetal sawing devicesMetal sawing tool makingUpper toothCircular saw

A circular saw blade includes a substantially circular body having a plurality of protruding tip support regions spaced around the periphery thereof, each tip support region including at least a seat for supporting a cutting tip. The tip support region may further include a substantially planar upper tooth face, a grindable tip reinforcement portion and / or a lower tip angle less than 90 degrees. A cutting tip is secured to the seat of each tip support region preferably with a top face of each cutting tip substantially parallel to and offset from an upper tooth face of each tip support region. Each cutting tip of the circular saw blade is further configured to maintain a cutting edge at a substantially constant width when material is removed from the top face thereof. A method of manufacturing a saw blade is also provided.

Owner:CLOUTIER MICHAEL F

Saw chains having hardened cutting elements and methods for production thereof

InactiveUS20060243097A1Metal sawing devicesSawing tools dressing arrangementsCarbideMaterials science

Hardened cutter elements commonly called cutters used in saw chains to act as cutter links. The hardened cutters have hard insets applied and connected to the cutting face of the cutter. The insets are made of a hard, tough material, such as a suitable carbide. Also shown are saw chains having the hardened cutter links with the hard insets. The preferred insets include a rear portion having a semi-cylindrical attachment surface. The attachment surface is configured for attachment to a filed or ground cutting face of a conventional saw chain cutter. A front portion of the inset has a cutting face which is provided with beveled cutting face corners and preferably chamfered edges extending rearwardly from the inset cutting face. Methods of producing the cutters with insets and for producing saw chains with the hardened cutters are also described.

Owner:UNIFIRE POWER BLOWER

Composite metal article and method of making

InactiveUS7373857B2Improve relationshipSuperior cutting and wear-resistant propertyArc welding apparatusRollsMetallurgyMetal

A composite metal article from two dissimilar metals is prepared. A metal base is comprised of a first metal and having first and second opposing surfaces and a least one longitudinally-positioned depression in each of the first and second opposing surfaces for receiving a wire. An elongated metal element comprised of a second metal is introduced into each of the at least one first and second depressions of the metal base to form a composite assembly, and the composite assembly is heated under pressure to urge the adjacent surfaces of the second metal elements and the depressions together to form a bonded article.

Owner:WILLIAM ENG LLC

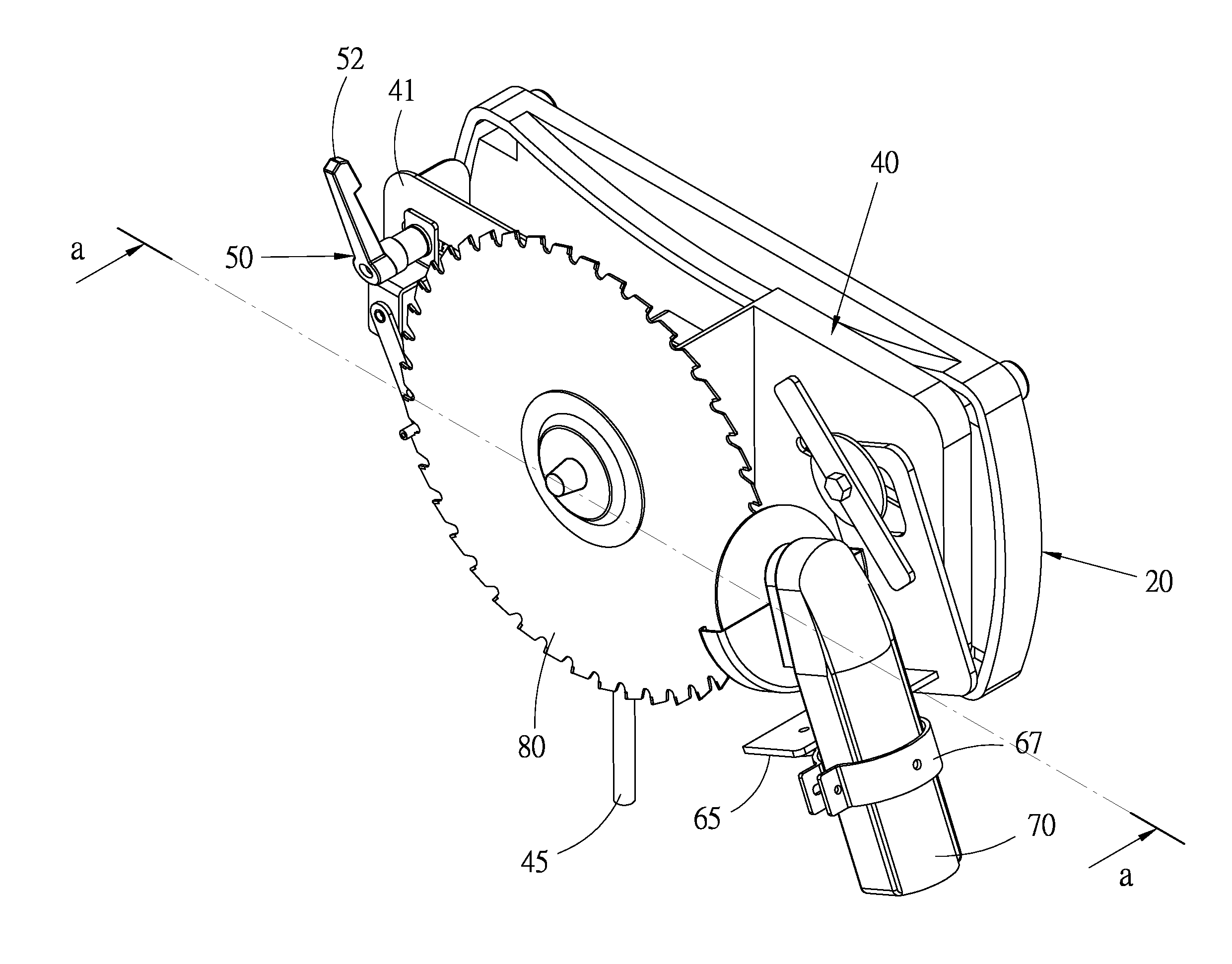

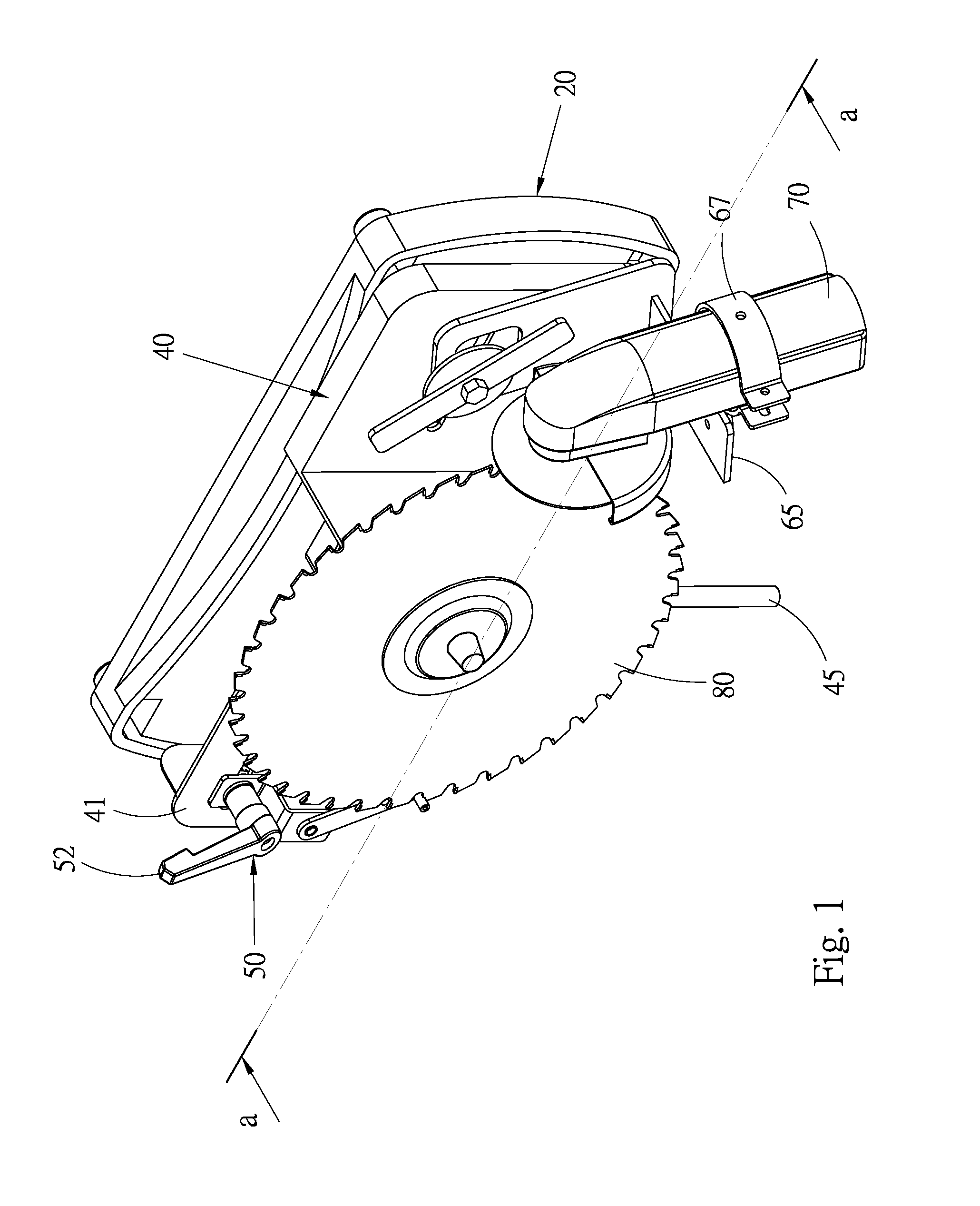

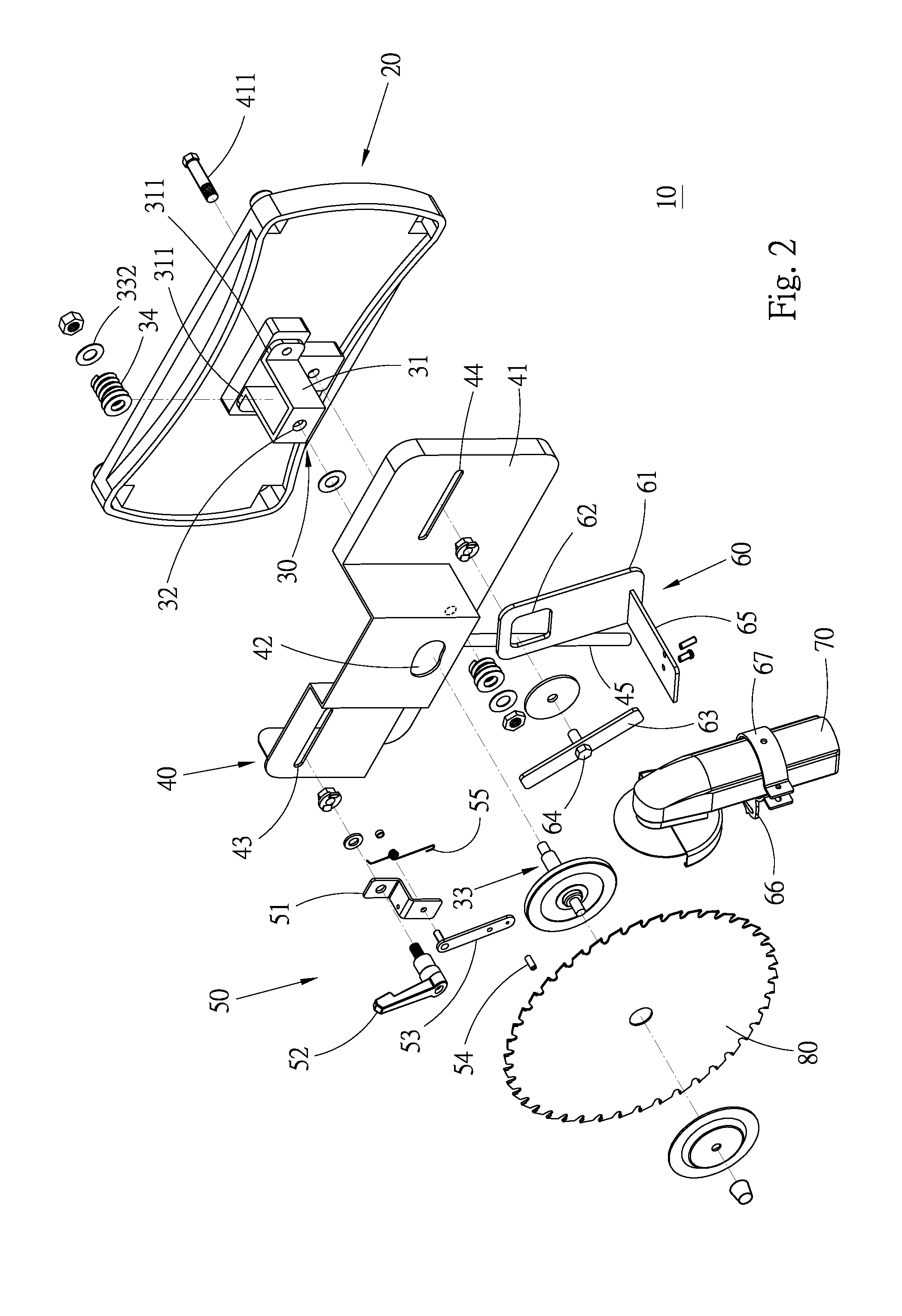

Bed-type circular saw blade grinder

InactiveUS20110237166A1Simple structureEasy to manufactureEdge grinding machinesSawing tools dressing arrangementsCircular sawEngineering

A bed-type circular saw blade grinder includes: a bed section; a support section fixedly connected with the bed section, a circular saw blade being rotatably connected with the support section; a rotary seat pivotally disposed on the bed section via a pivot shaft and reciprocally rotatable about the pivot shaft between a first position and a second position, the rotary seat having a first connection section and a second connection section positioned on two sides of the pivot shaft; a circular saw blade restriction section disposed at the first connection section for driving the circular saw blade to intermittently rotate; and a grinding unit disposed at the second connection section for grinding saw teeth. When the rotary seat is pivotally rotated between the first and second positions, the rotary seat drives the circular saw blade restriction section and the grinding unit to move with the rotary seat.

Owner:CHANG TUNG MIN

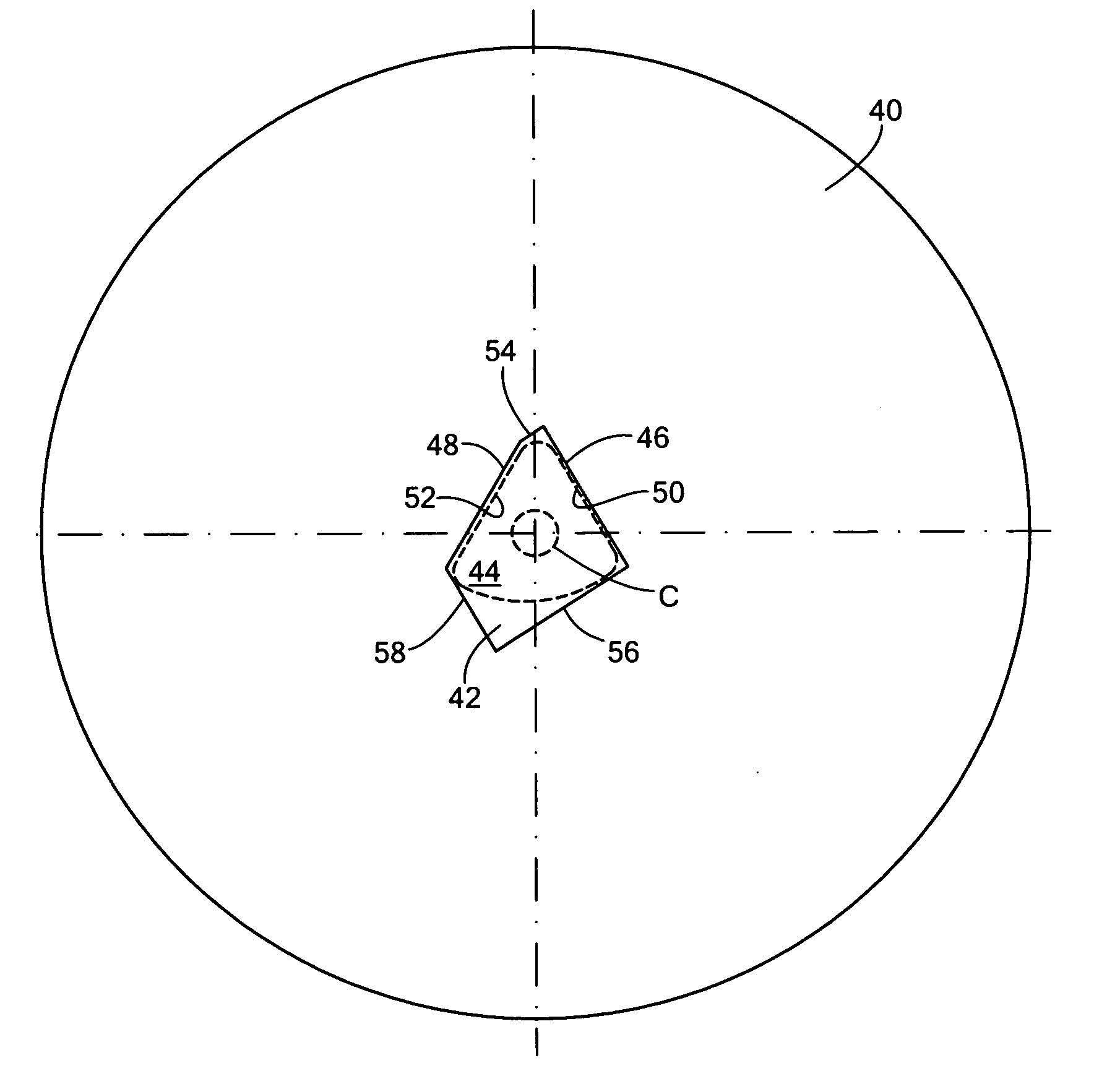

Rotating blade arbor hole

A rotating blade for a cutting machine. The blade defines an arbor hole for an arbor typically having at least three sides. The preferred arbor hole includes first and second sides each of which conform to adjacent sides of the arbor, a short side joining the first and second sides, a third side connected to the first side, and a fourth side connecting the third side to the second side.

Owner:BURKE MICHAEL PATRICK

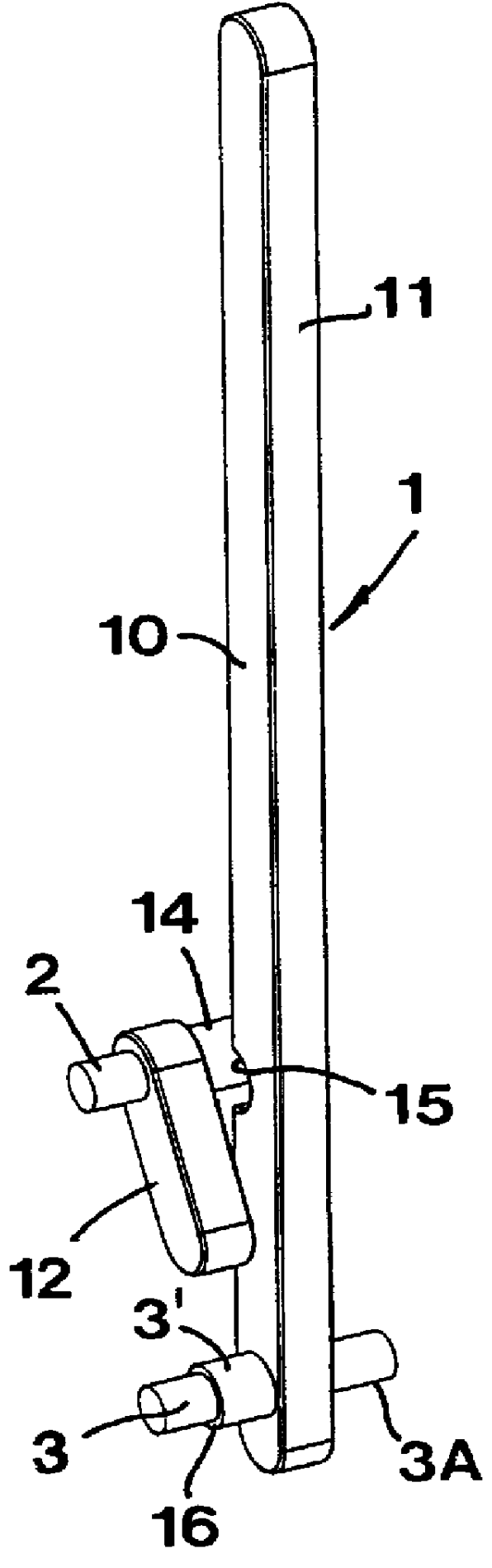

Key for insert holders of the blade type

Owner:SANDVIK INTELLECTUAL PROPERTY AB

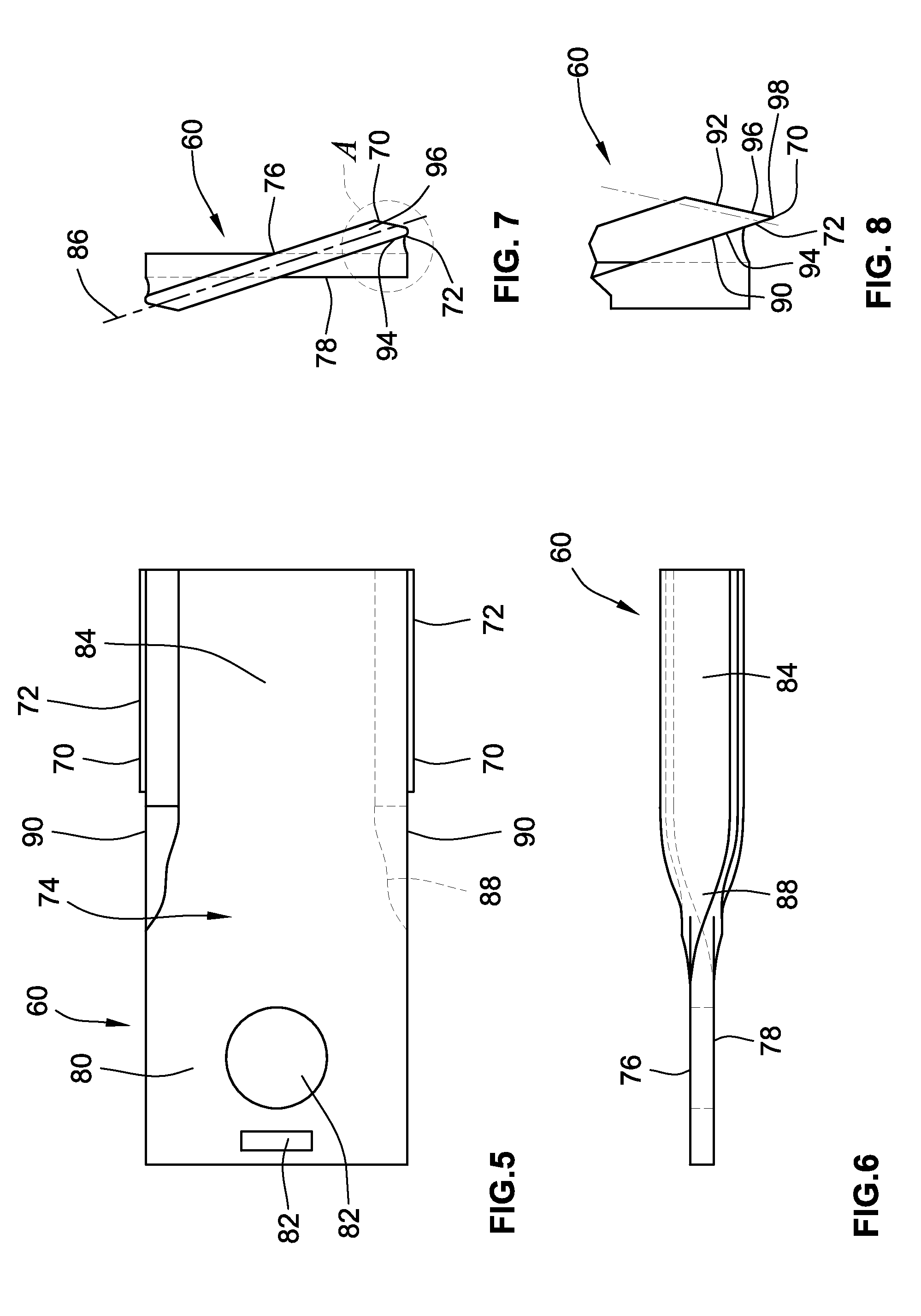

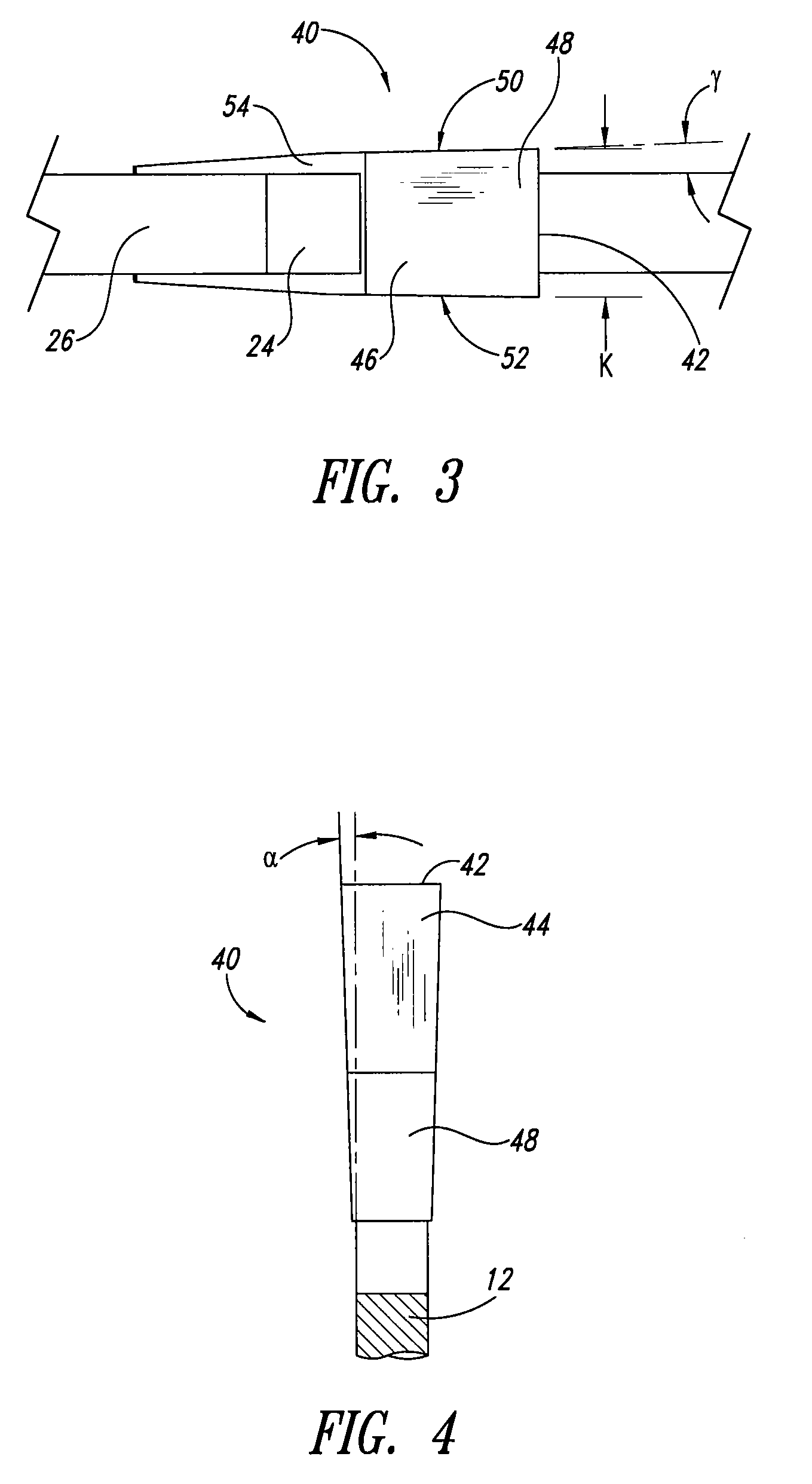

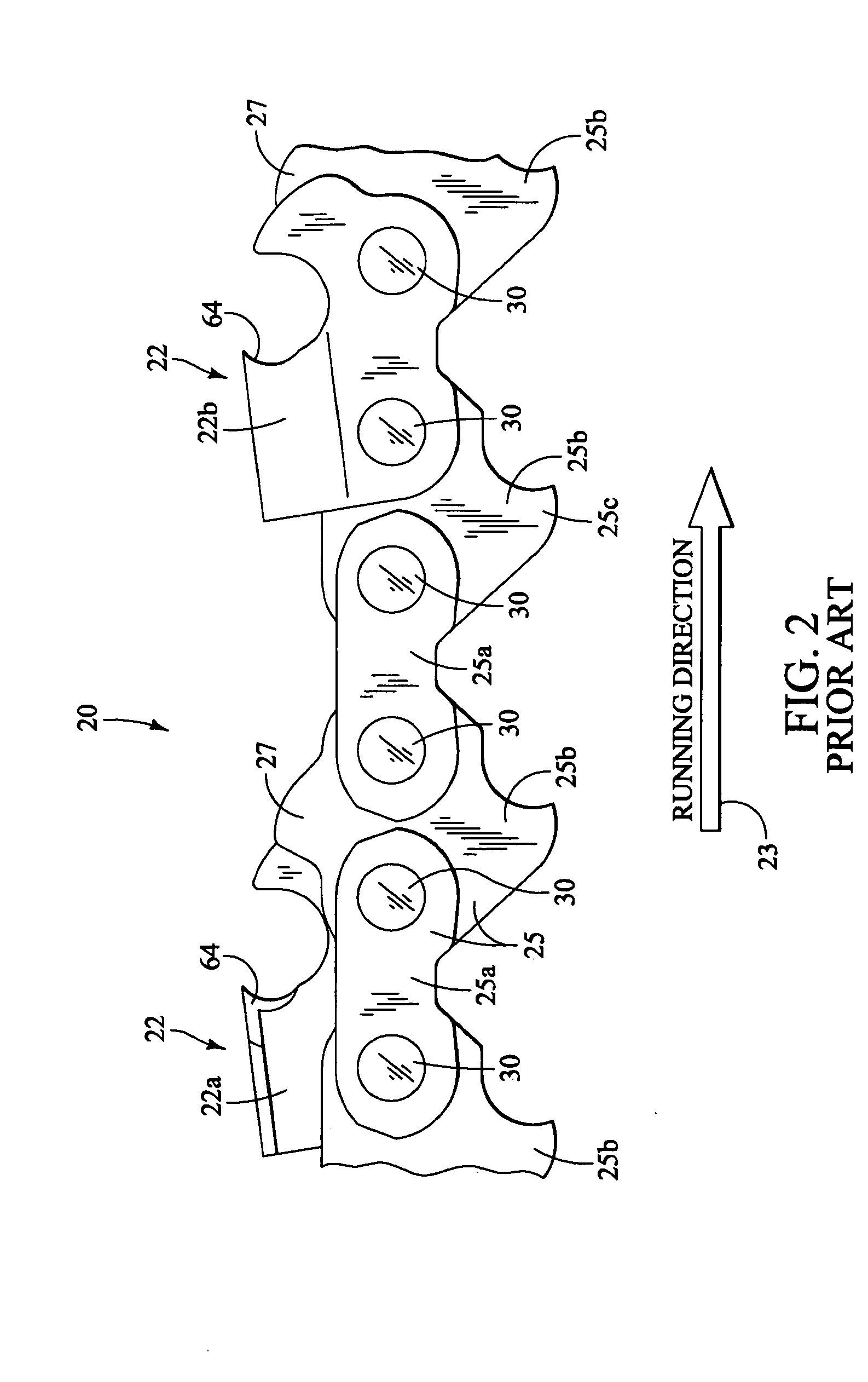

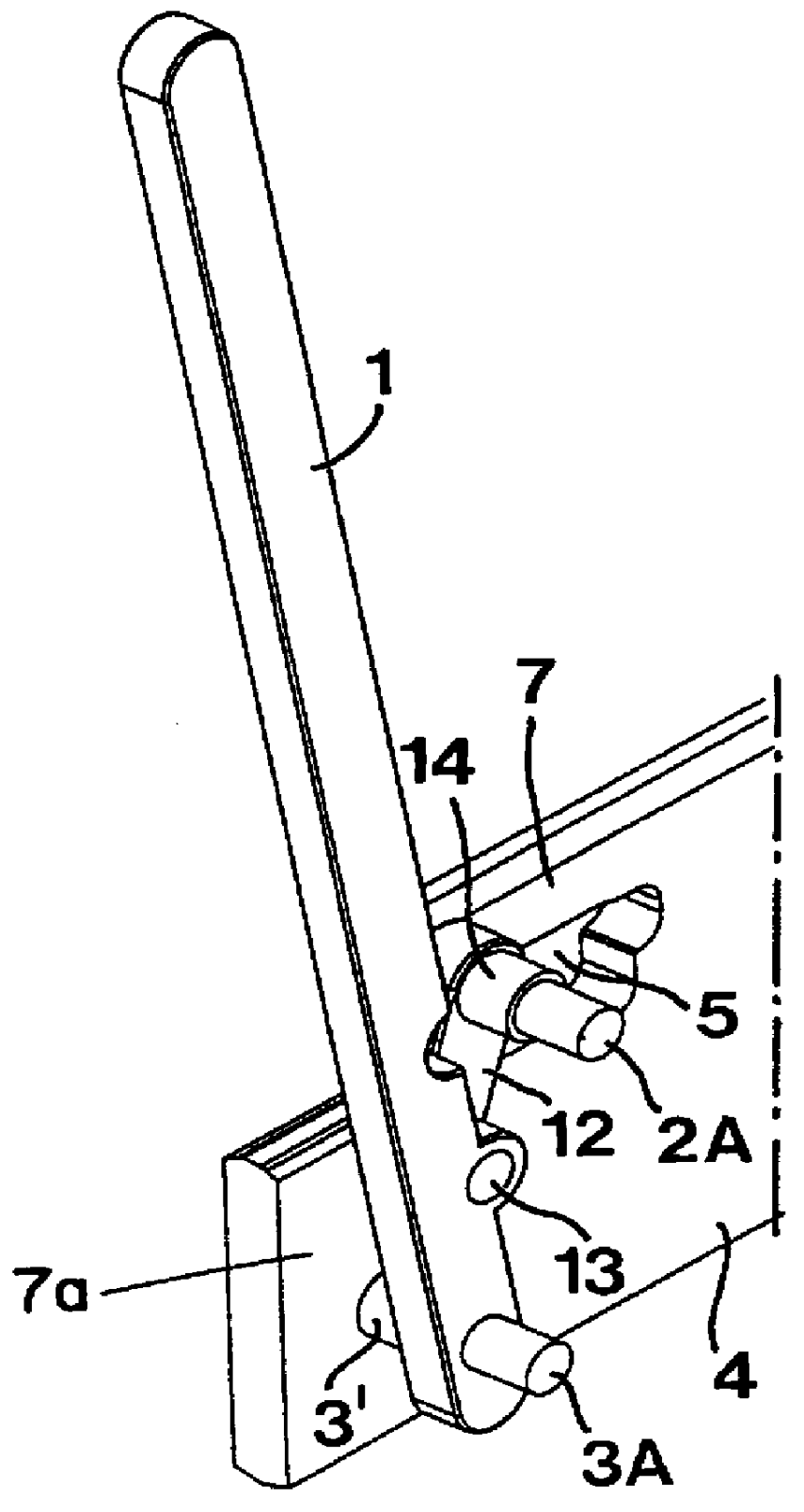

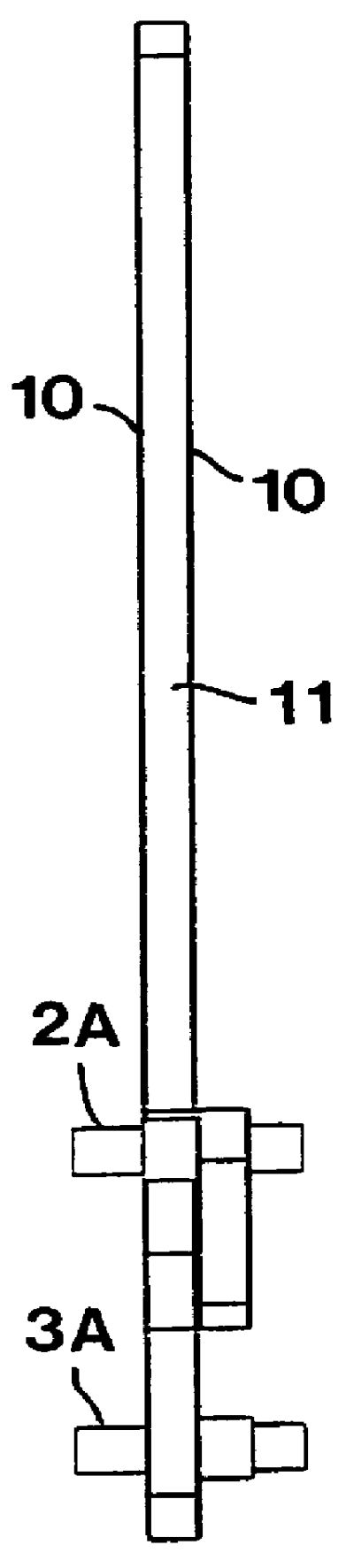

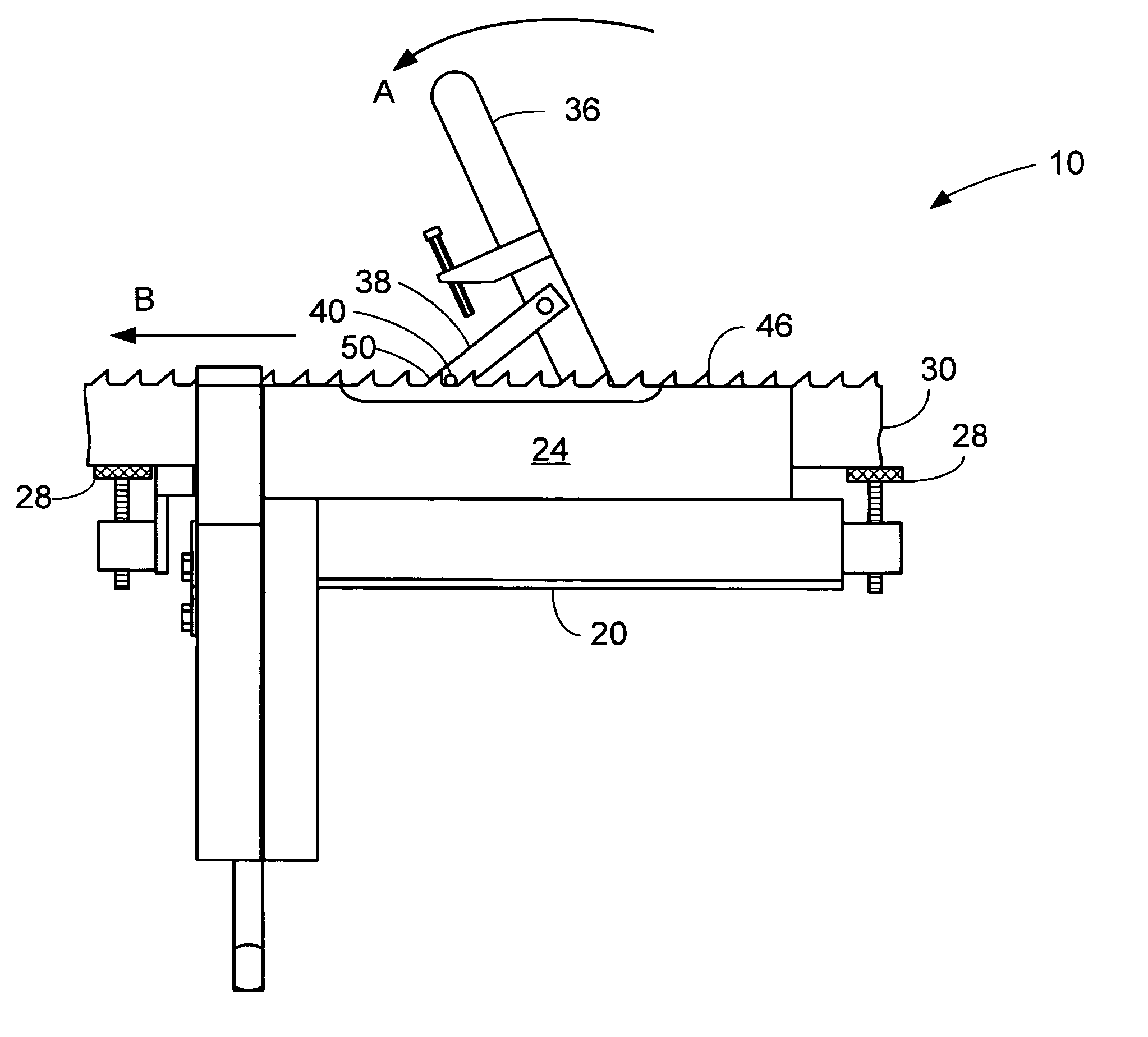

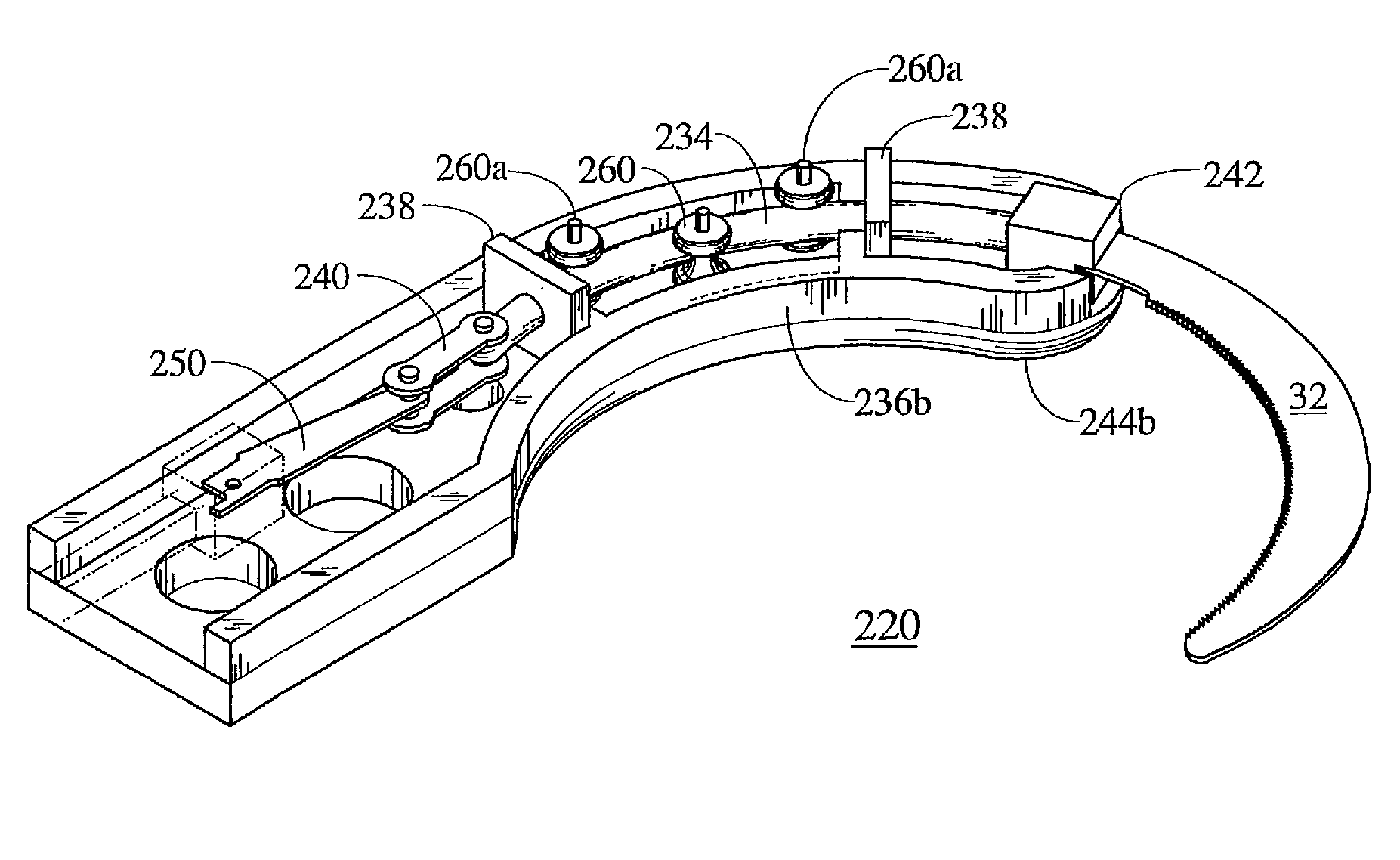

Band saw blade setter with up-set and down-set

InactiveUS20060086208A1Reduce settingsAdd settingsSawing tools dressing arrangementsTool bitEngineering

A setter for setting the teeth of a band saw blade. The setter has at least one up-set tool bit configured to increase the set of a blade tooth. The distance between the up-set tool bit and the blade tooth is adjustable by a first threaded member. The setter also has at least one down-set tool bit configured to decrease the set of the blade tooth. The distance between the down-set tool bit and the blade tooth is adjustable by a second threaded member. A mechanical linkage is configured to move the at least one up-set tool bit toward the blade tooth, and also configured to move the at least one down-set tool bit toward the blade tooth during a set operation. Wherein during the set operation, a clamping linkage clamps the blade within the setter, and the at least one up-set tool bit is driven toward the blade tooth of the clamped band saw blade by the mechanical linkage, and the at least one down-set tool bit is driven toward the opposing side of the blade tooth of the clamped band saw blade by the mechanical linkage. The distance between the at least one up-set tool bit and the blade tooth is adjusted via the first threaded member such that during the set operation, the up-set tool bit applies a first up-set displacement to the blade tooth. The distance between the at least one down-setting tool bit and the blade tooth is adjusted via the second threaded member such that during the set operation, the down-set tool bit applies a first down-set displacement to the blade tooth. The mechanical linkage of the setter comprising a follower arm and cam design.

Owner:GSCHWIND ART F SR +1

Composite tool

InactiveUS6861161B2Extended service lifeIncrease cutting outputNon-rotary toothed toolsSoldering apparatusMetallic materialsCobalt

A composite tool comprising a supporting part of a metallic material having a first composition and a working part of a metallic material having a second composition which is different from the first composition, a process for the manufacture thereof and a method of cutting an austentic alloy article with this composite tool. The supporting part of the composite tool is made of a tenacious iron-based material, and the working part is made of a precipitation harden iron-cobalt-tungsten alloy. The parts are joined by a metallic connection.

Owner:MACHNER & SAURER

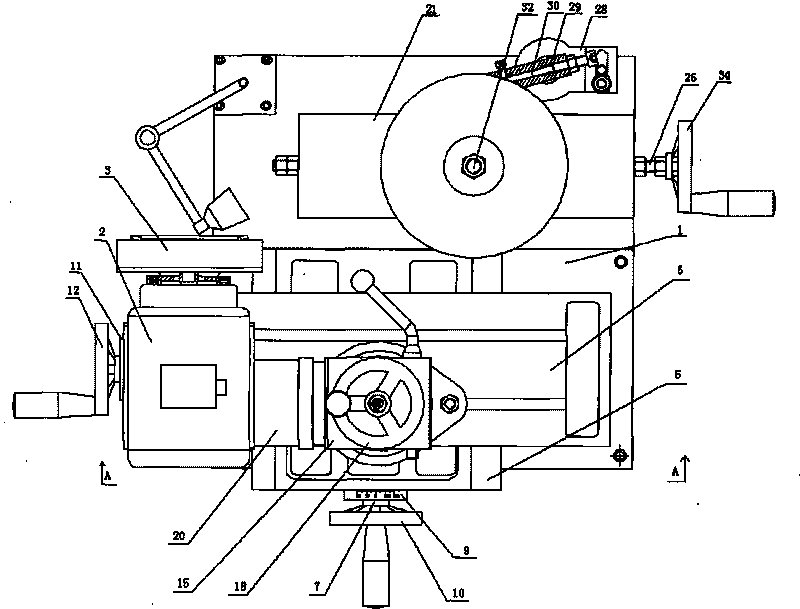

Automatic saw blade gear grinding machine

InactiveCN101704131ASimple structurePractical and convenientSawing tools dressing arrangementsGear grindingVertical plane

The invention discloses an automatic saw blade gear grinding machine, which comprises a base, an electric motor, a grinding wheel arranged on a main shaft of the electric motor, a saw blade gear shifting device, an electric motor displacement adjusting device for adjusting a lateral displacement and a longitudinal displacement of the electric motor on the base, an electric motor lifting adjusting device for adjusting a distance between the electric motor and the base, and an electric motor angle adjusting device for adjusting a rotation angle of the electric motor in a horizontal plane or in a vertical plane. The electric motor displacement adjusting device is arranged on the base. The electric motor lifting adjusting device is rotationally arranged on the electric motor displacement adjusting device and can be locked and positioned by a fastening piece; the electric motor angle adjusting device is rotationally arranged on the electric motor lifting adjusting device and can be locked and positioned by the fastening piece; the electric motor is arranged on the electric motor angle adjusting device; and the saw blade gear shifting device is arranged on the base, drives a saw blade to carry out reciprocating motion and pushes the saw blade to rotate. The automatic saw blade gear grinding machine can carry out multiaspect and multi-angle adjustment on the electric motor and realize automatic grinding of different saw blades.

Owner:南京唯高机械制造有限公司

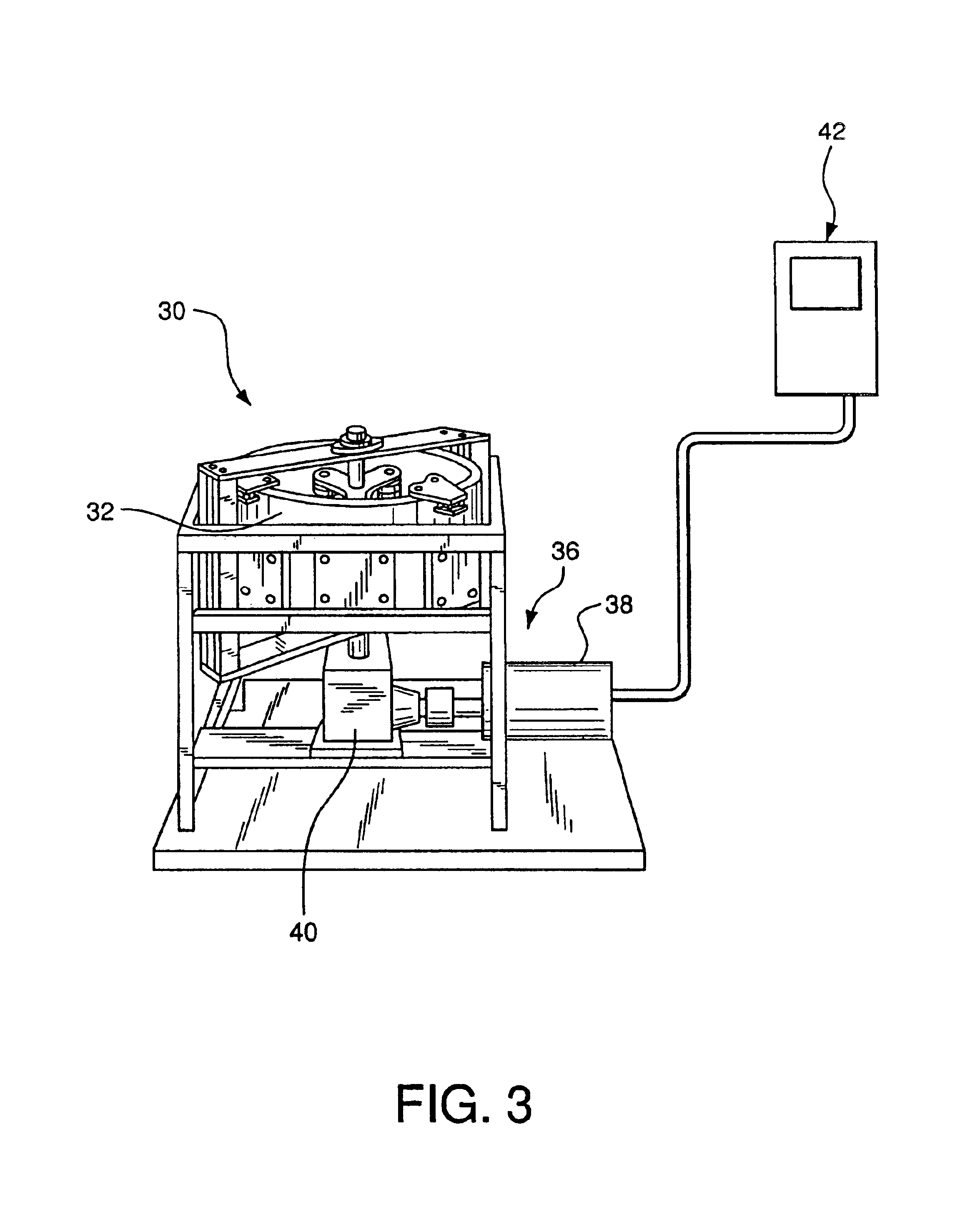

Reciprocating tool

InactiveUS8261455B2Easy to operateEasy accessMetal sawing devicesFiling/rasping devicesReciprocating motionEngineering

An arcuate action tool attachment is adapted to receive an input and to convert that input into reciprocating output motion along an arcuate path. The tool may be adapted to be combined with an existing linear reciprocating device or a rotary device, or the tool may comprise a single unit including a linear reciprocating device or a rotary device. The tool may be fitted with one or more curved or arc-shaped accessories, such as saw blades or the like, that reciprocate along the arcuate paths that may have substantially the same radius of curvature as the accessory.

Owner:HENRICKSON ERIK P

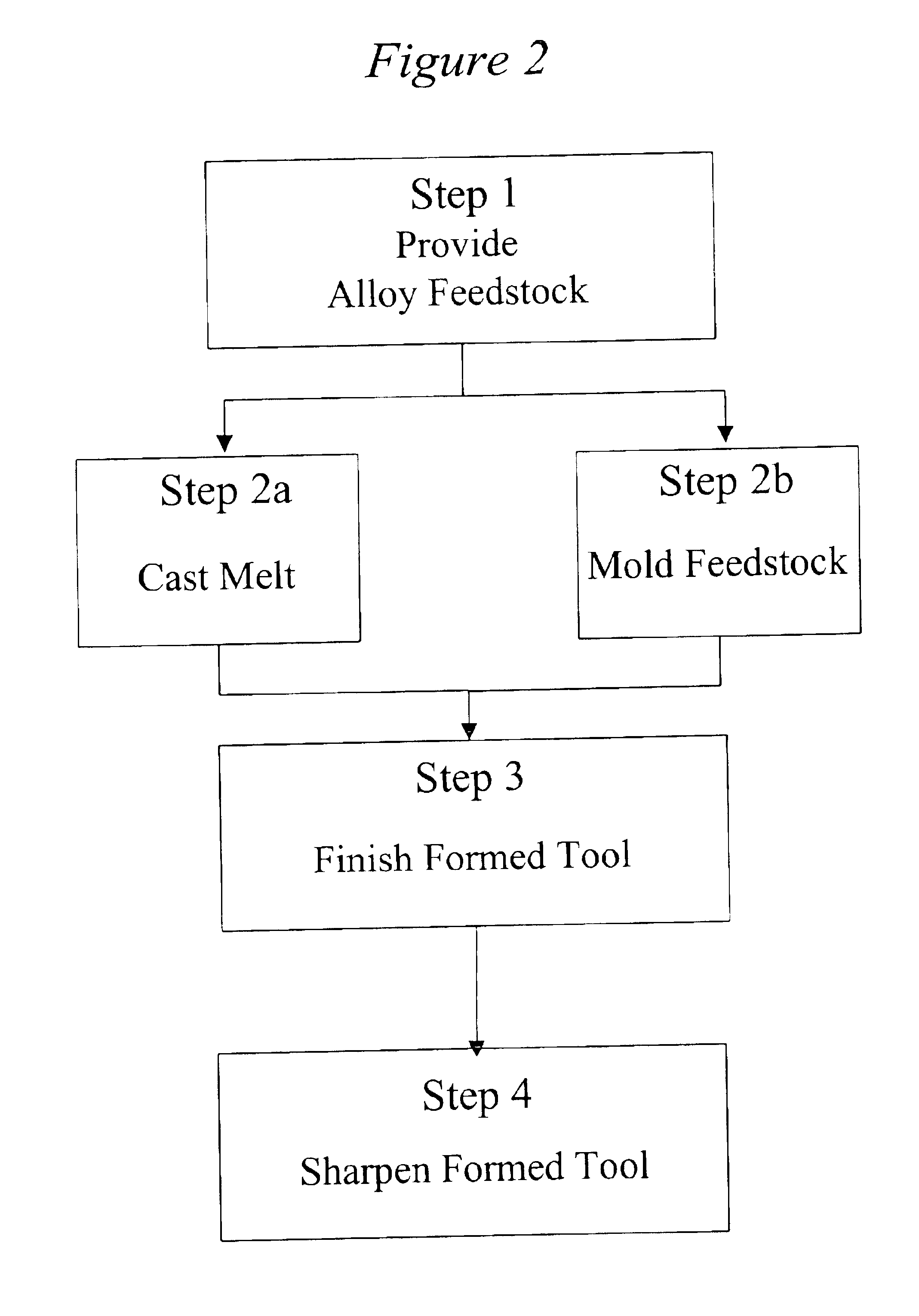

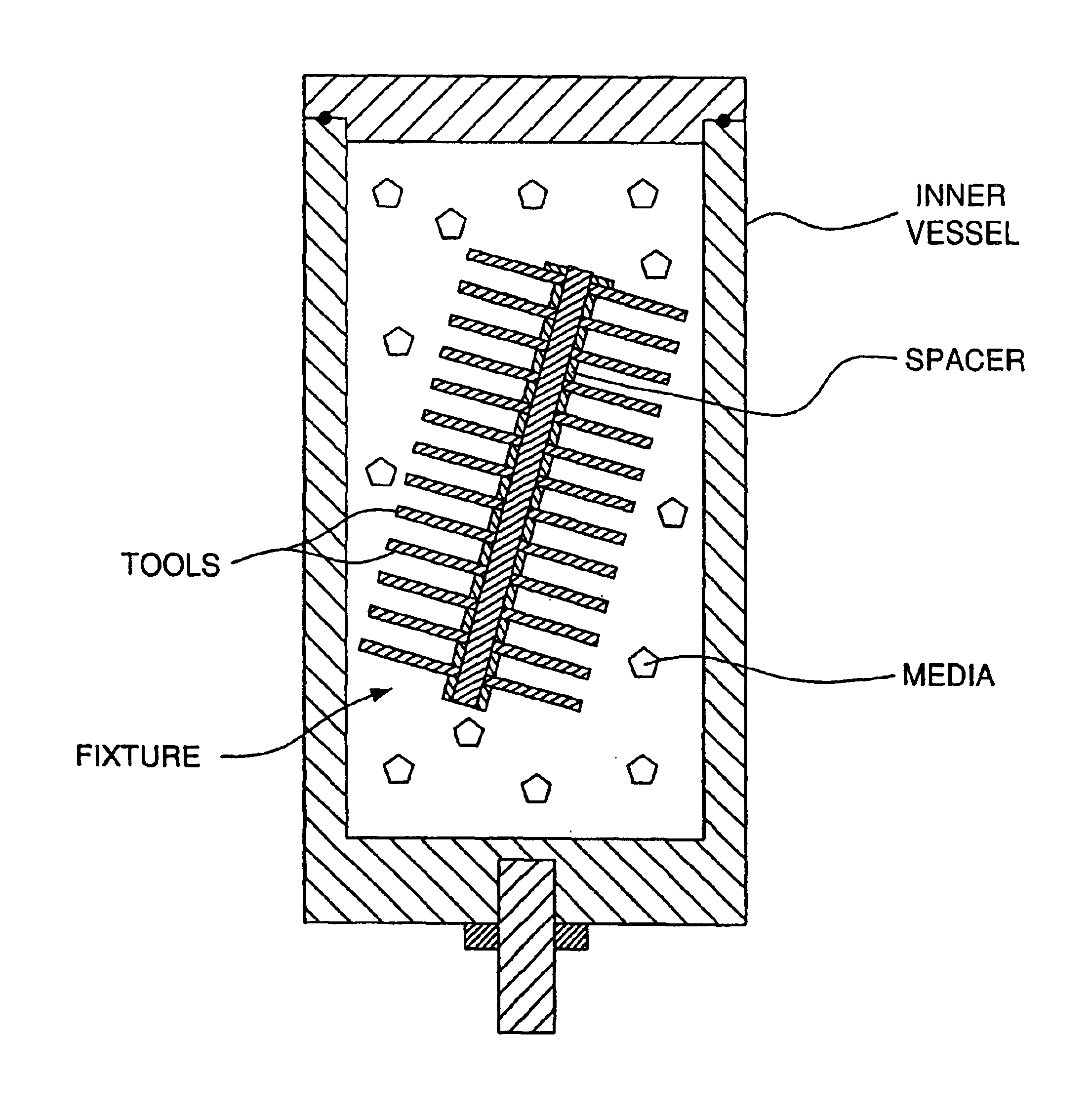

Method of manufacturing a tool using a rotational processing apparatus

InactiveUS6875081B2Smooth surface finishMetal sawing devicesEdge grinding machinesSurface finishEngineering

A method for forming a tool having a smooth surface finish is disclosed. The method involves the step of first rotating a plurality of tools within an inner vessel at high speed relative to the outer vessel with a first abrasive. The first abrasive is then removed and a second abrasive is added to the vessel. The inner vessel is then rotated, again at high speed, with the second abrasive. The resulting tools have reduced surface anomalies.

Owner:MIKRONITE TECH GROUP

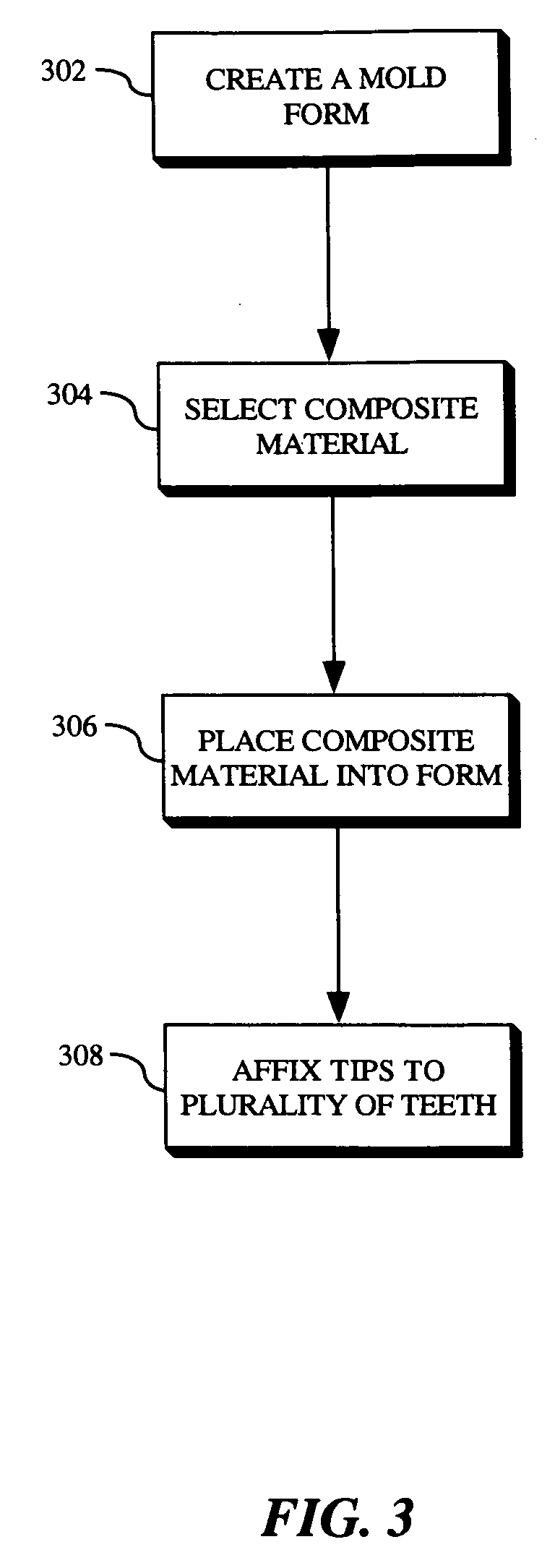

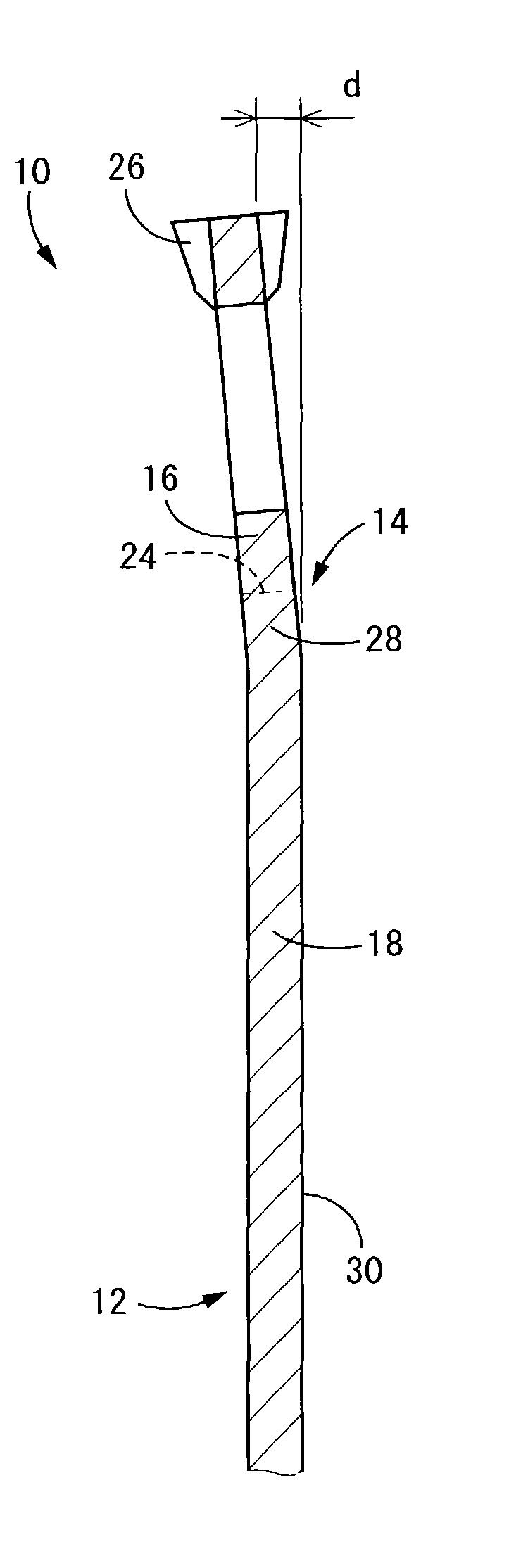

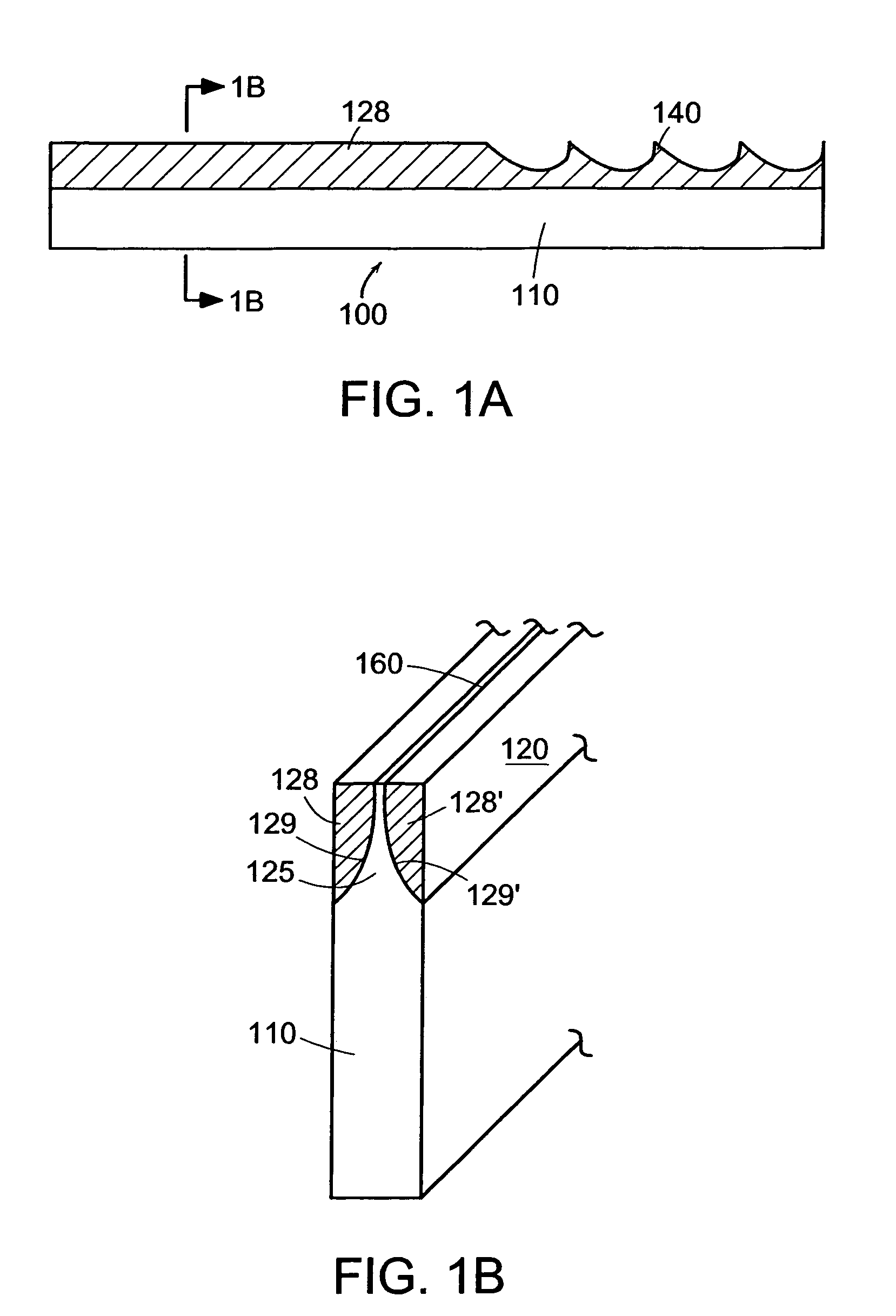

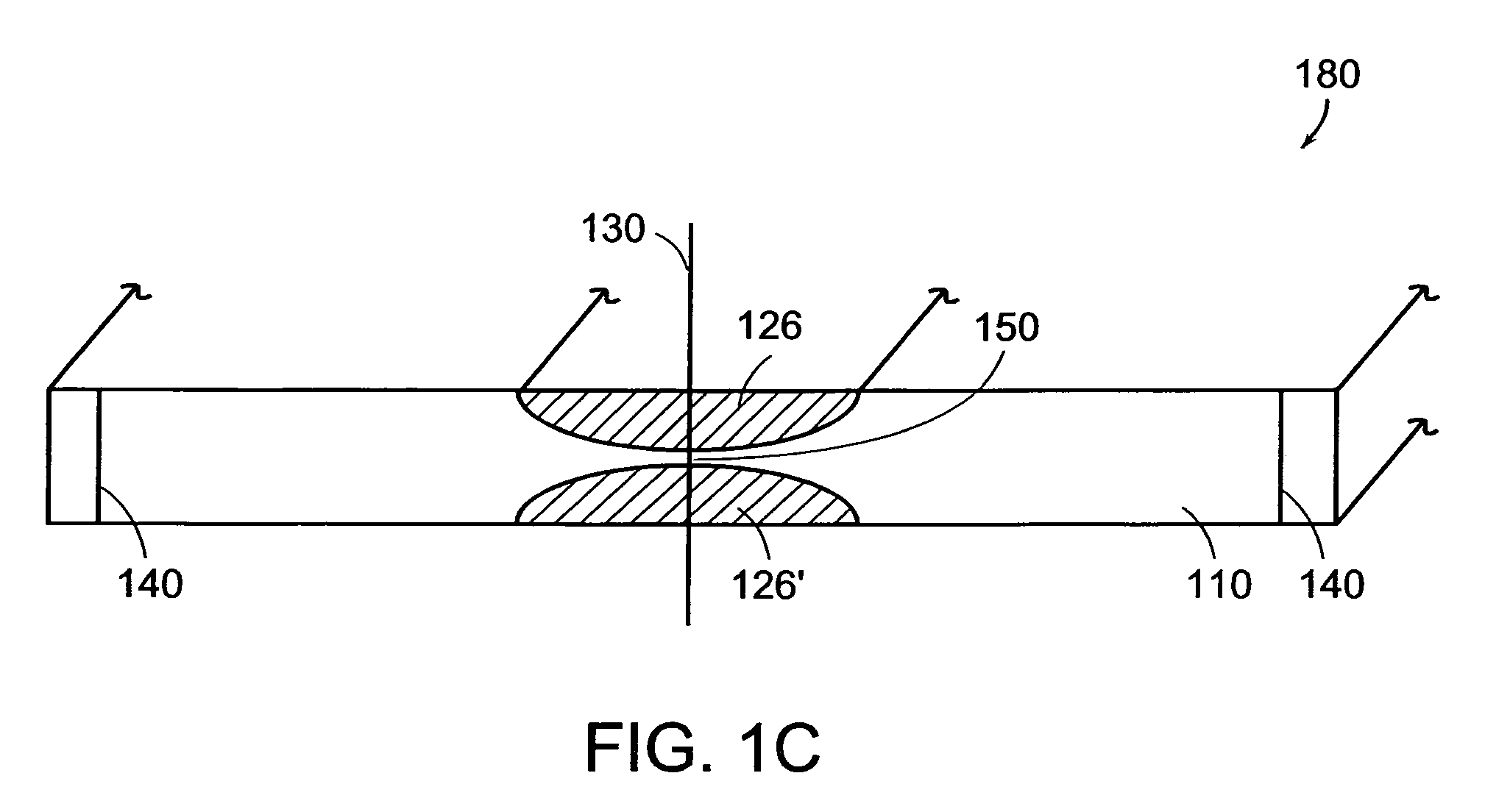

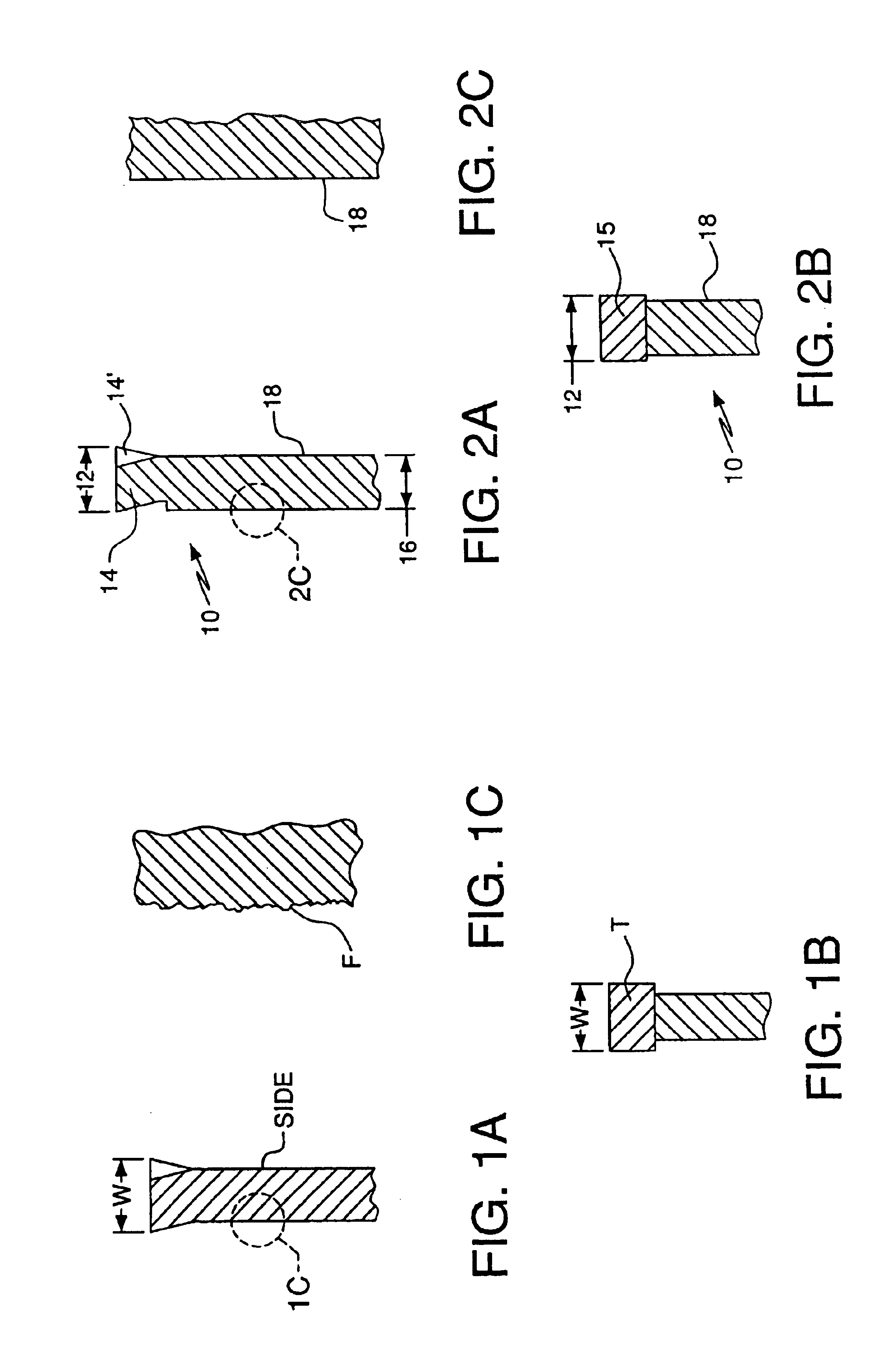

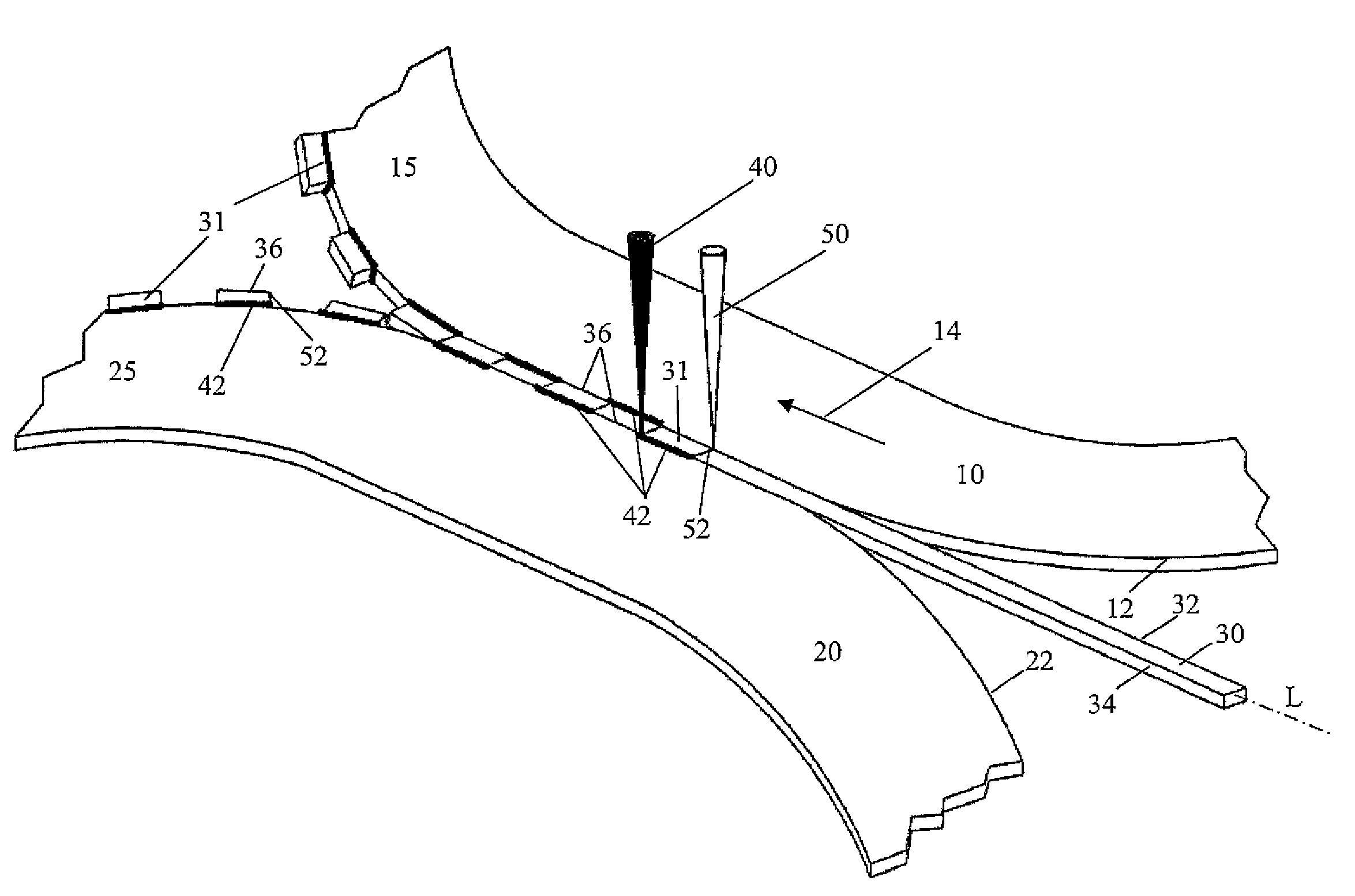

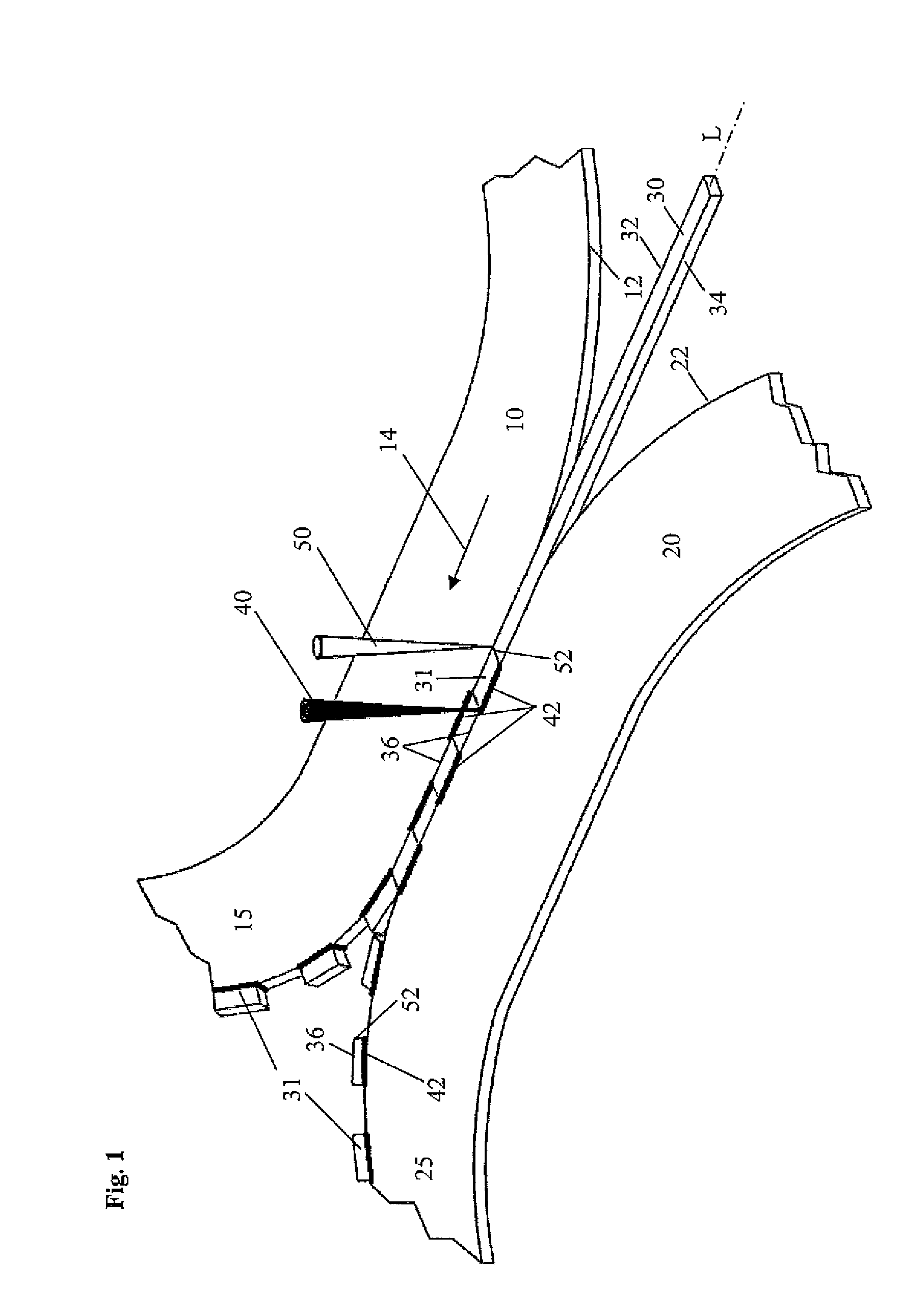

Method of producing initial components for saw blades or saw bands

InactiveUS20090114064A1Quality improvementWelding process can be automatedMetal sawing tool makingSawing tools dressing arrangementsEngineeringLaser

The present invention relates to a method for manufacturing of preforms (15, 25) for saw blades respectively saw bands, comprising the following steps (a) arranging a strip (30) of a cutting material for a cutting edge of saw blades respectively saw bands without any play between the edges (12, 22) of a first carrier band (10) and a second carrier band (20); (b) guiding of a laser or electron beam (40) along a first edge (32) of the strip (30) for welding part per part of the first carrier band (10) to the strip (30), wherein regions (36) along the first edge (32) of the strip (30) remain unwelded; (c) guiding of a laser or electron beam (40) along a second edge (34) of the strip (30) for welding part per part of the second carrier band (20) to the strip (30), wherein regions (36) along the second edge (34) of the strip (30) remain unwelded; and (d) guiding a laser, water or electron beam (50) between the first edge (32) and the second edge (34) of the strip (30) or the second edge (34) and the first edge (32) of the strip (30) for separating of the strip (30) into segments (31).

Owner:BOEHLER UDDEHOLM PRECISION STRIP GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com