Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

237results about How to "Constant width" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

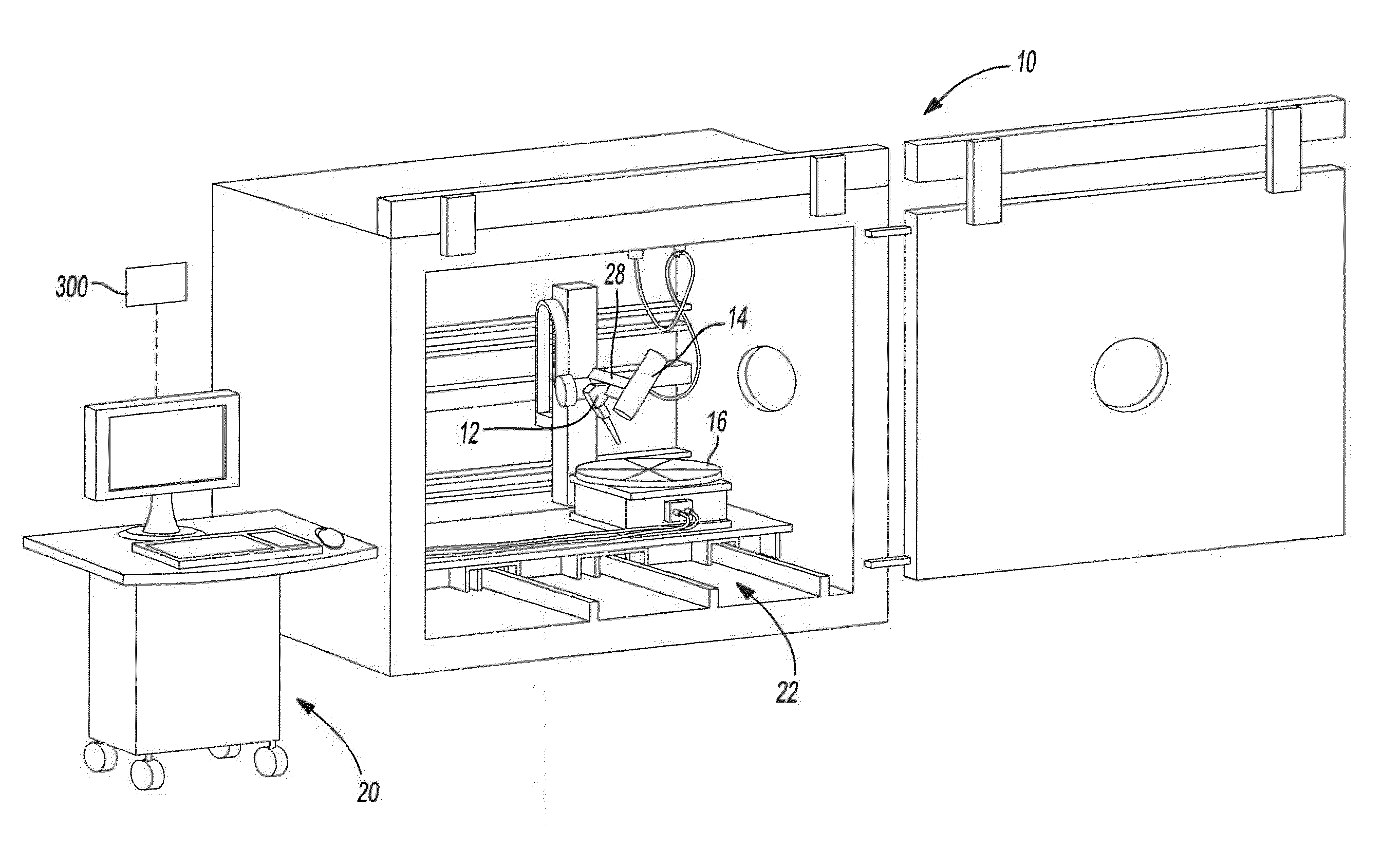

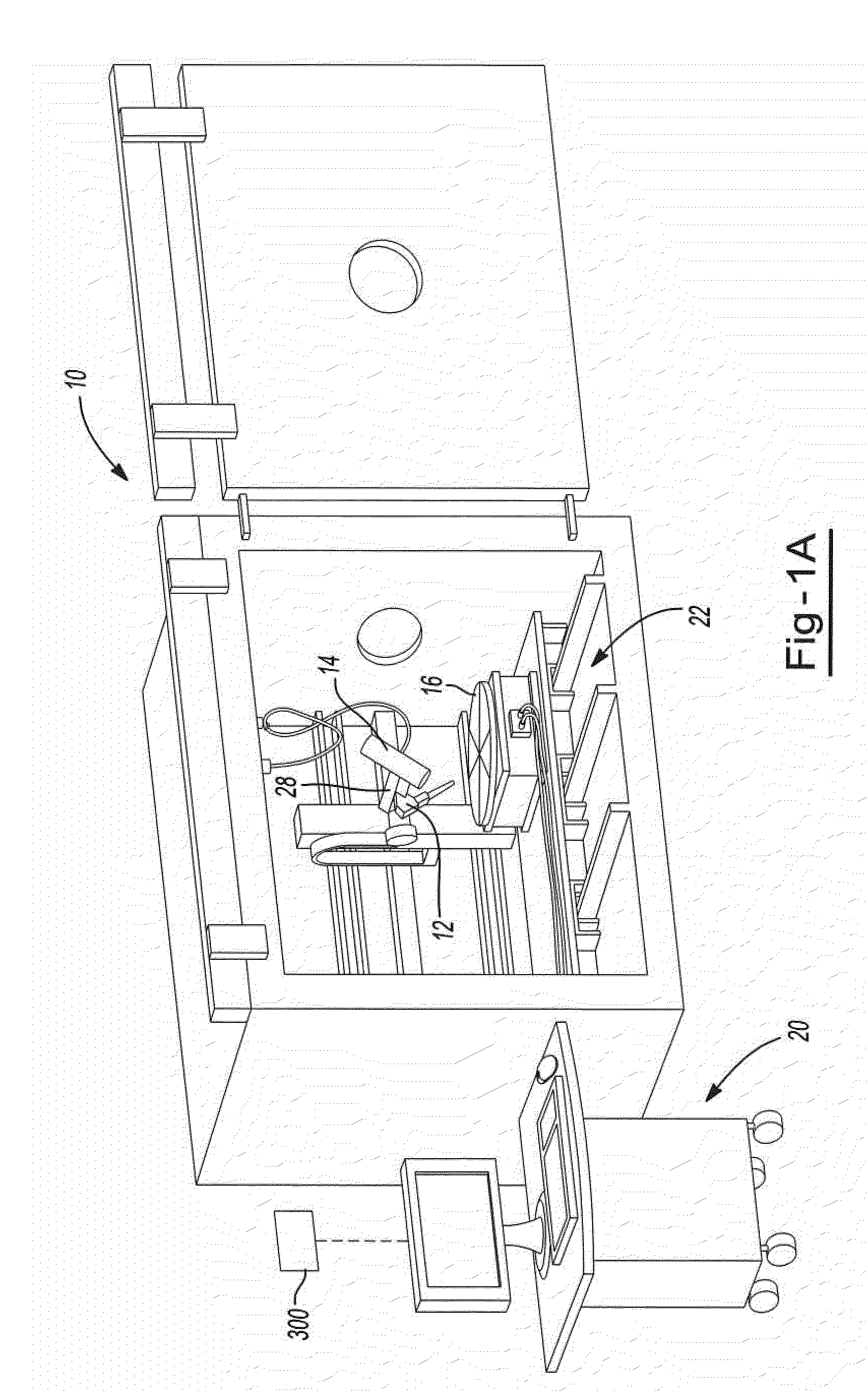

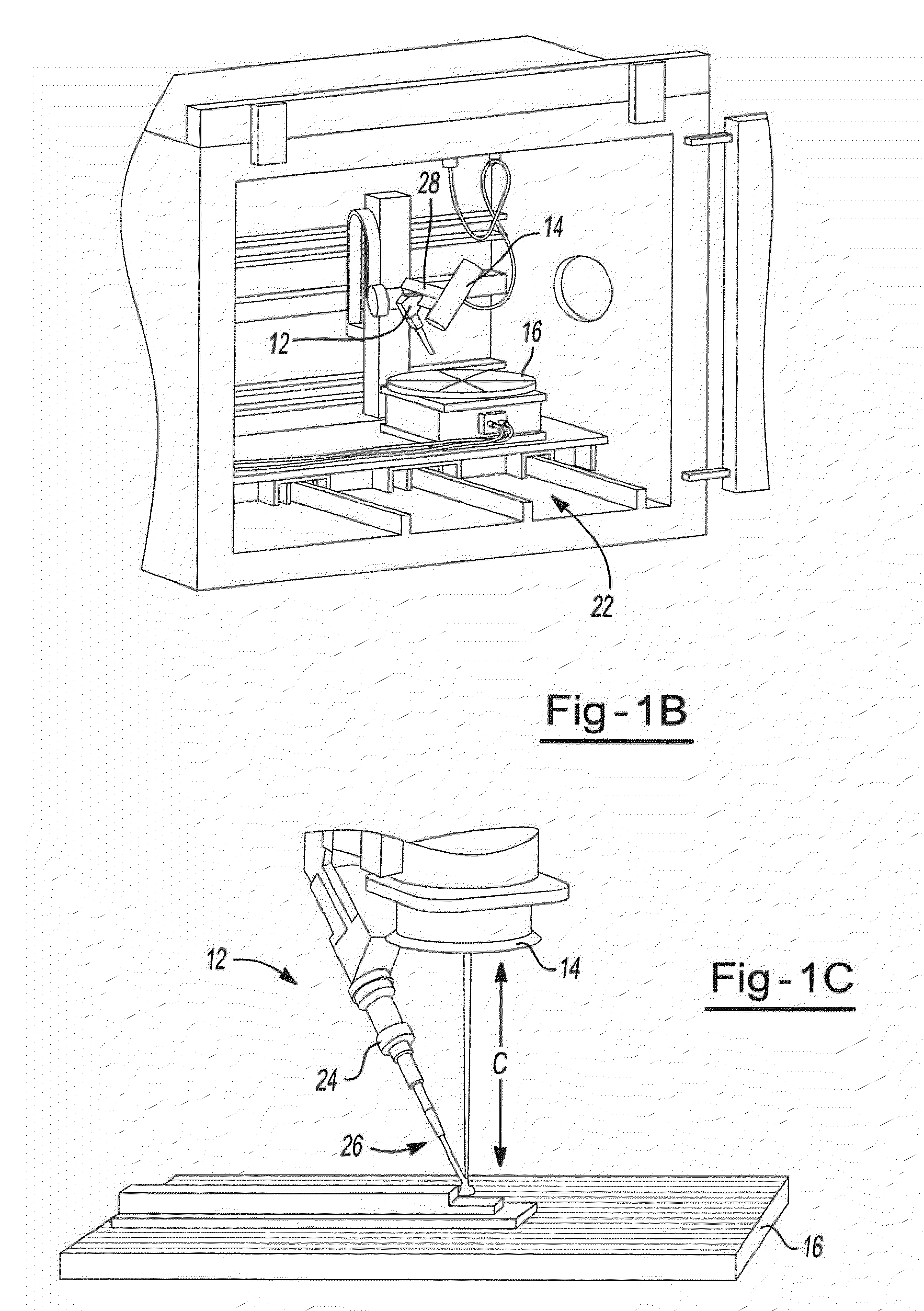

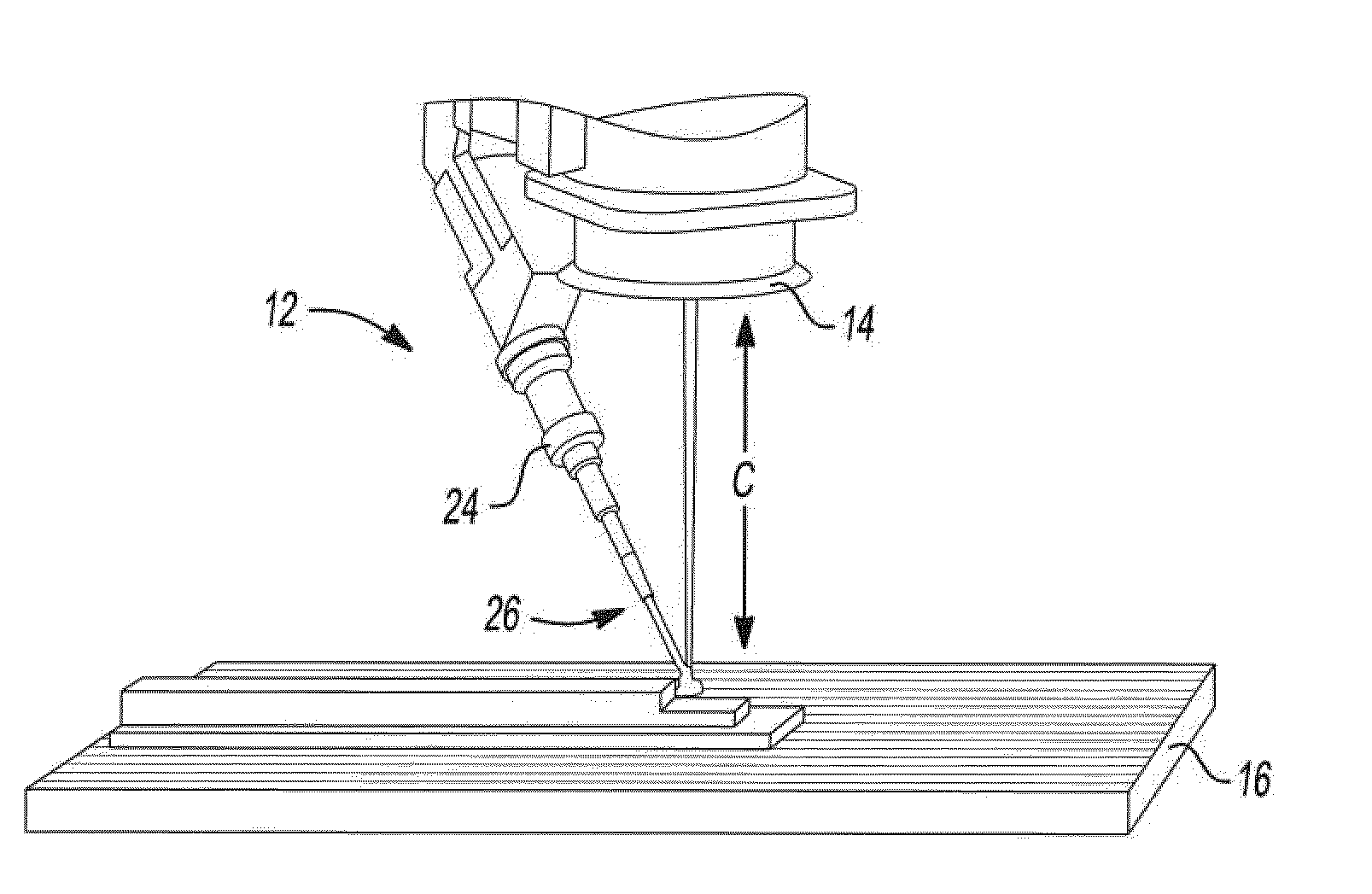

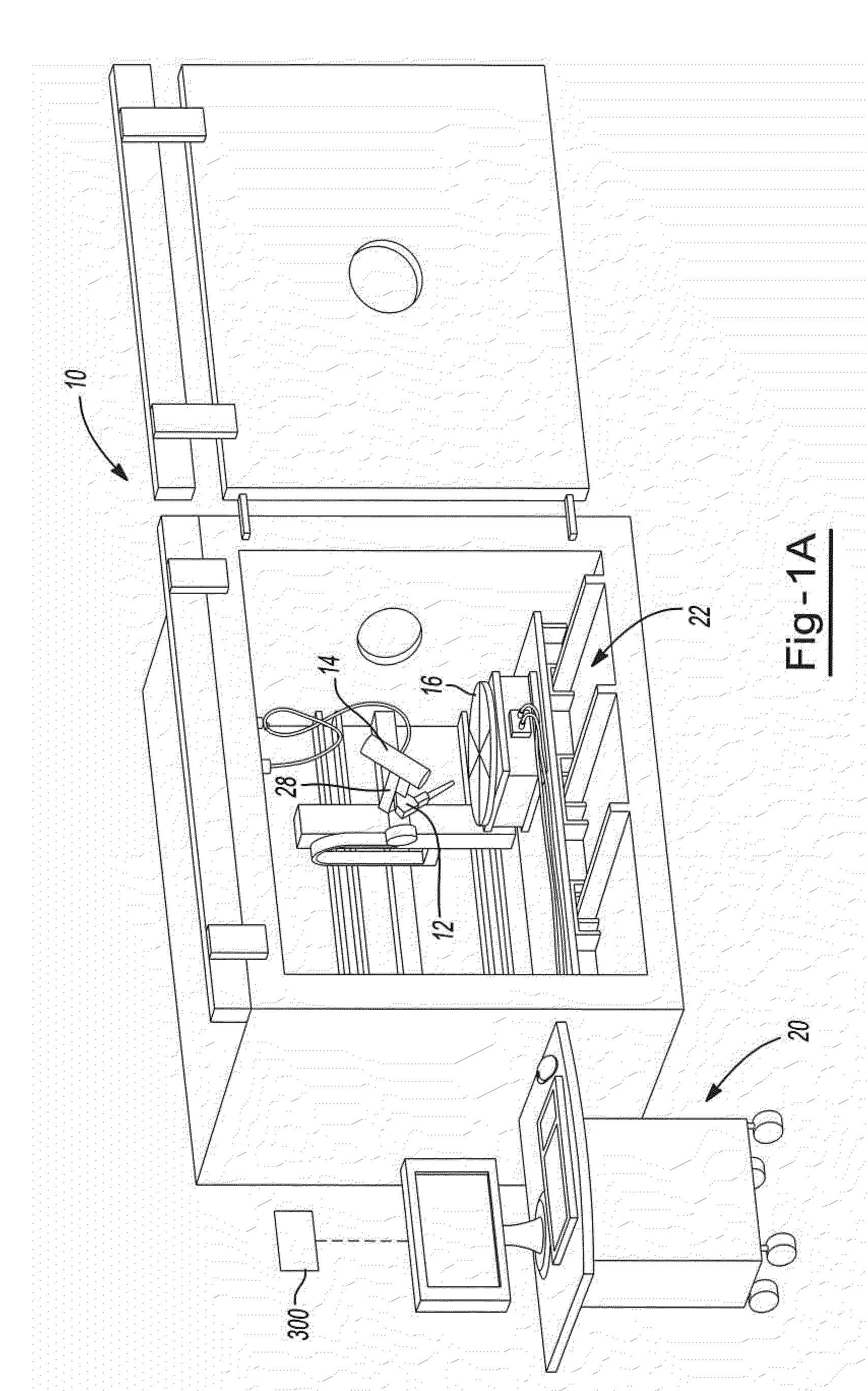

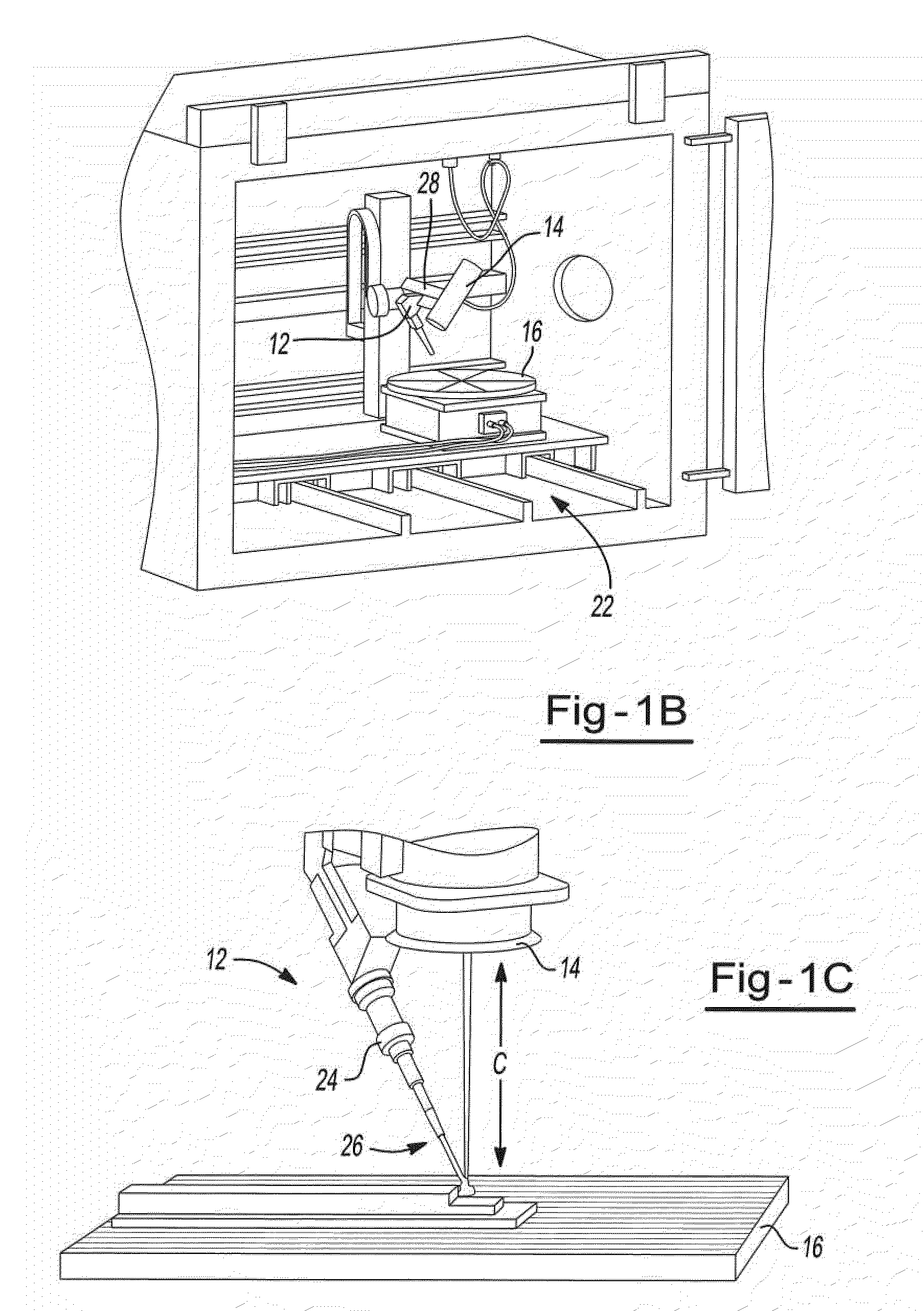

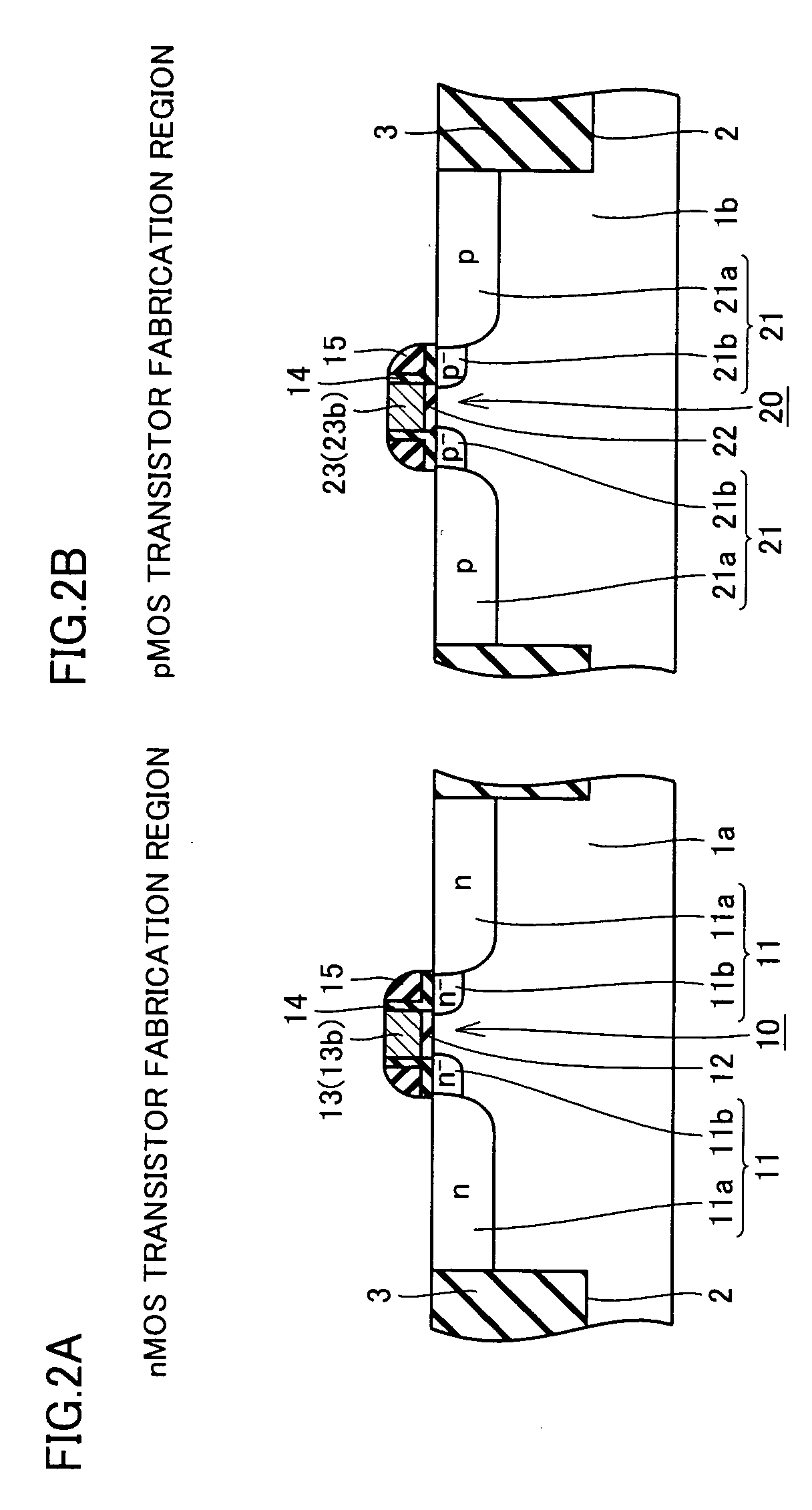

Electron beam layer manufacturing using scanning electron monitored closed loop control

ActiveUS20110114839A1Speed up the processQuick buildAdditive manufacturing apparatusMaterial analysis using wave/particle radiationClosed loopTrailing edge

A process (and apparatus for performing the process) for layer manufacturing a three-dimensional work piece comprising the steps of; feeding raw material in a solid state to a first predetermined location; exposing the raw material to an electron beam to liquefy the raw material; depositing the raw material onto a substrate as a molten pool deposit, the deposit having a forward edge region in an x-y plane with a forward edge region width and a trailing edge region in the x-y plane with a trailing edge region width, under at least one first processing condition; monitoring the molten pool deposit for at least one preselected condition using detecting of scatter from a scanning electron beam contemporaneously with the depositing step; solidifying the molten pool deposit; automatically altering the first processing condition to a different processing condition based upon information obtained from the comparing step; and repeating steps at one or more second locations for building up layer by layer, generally along a z-axis that is orthogonal to the x-y plane, a three-dimensional work piece.

Owner:SCIAKY SA

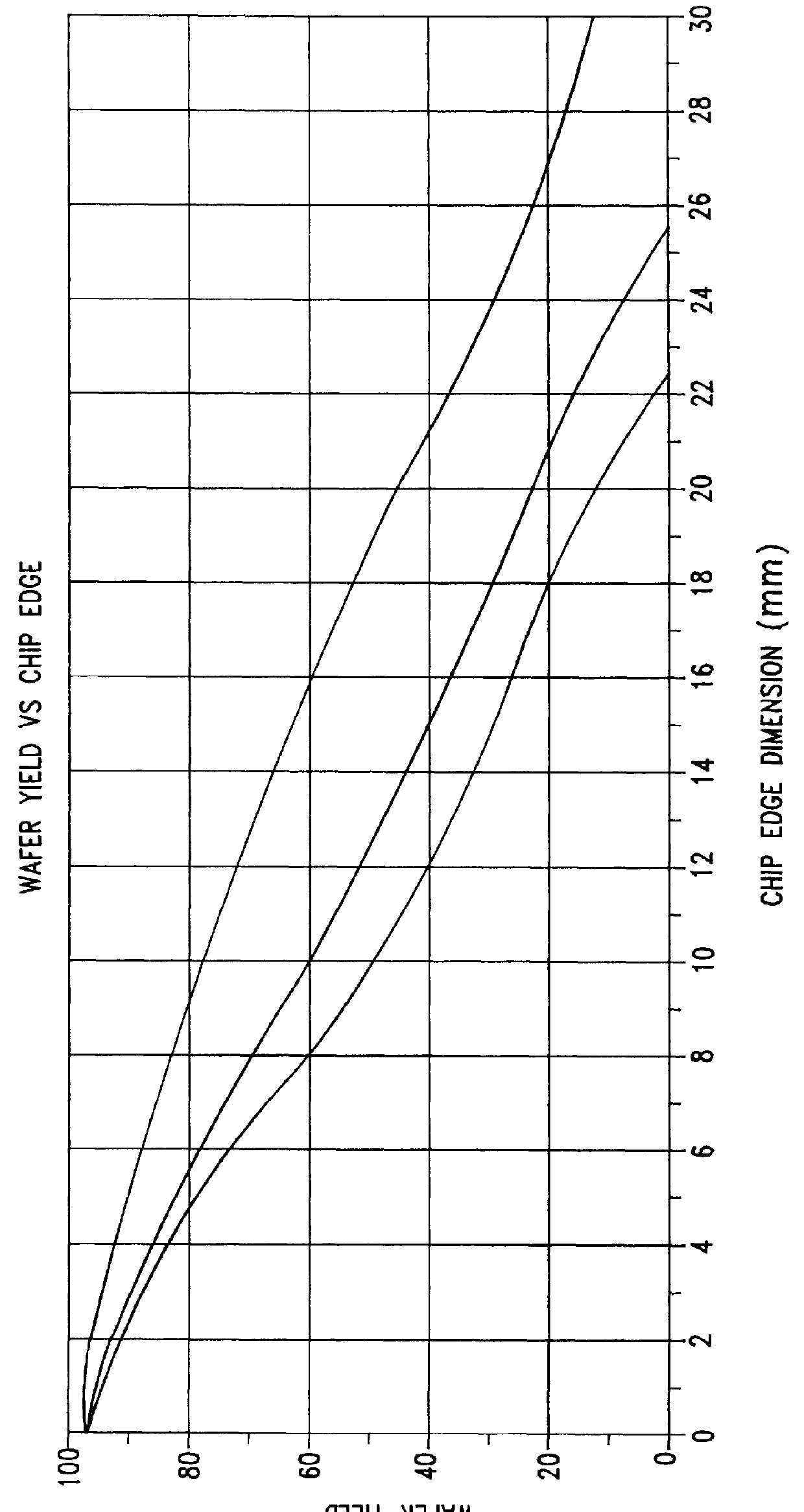

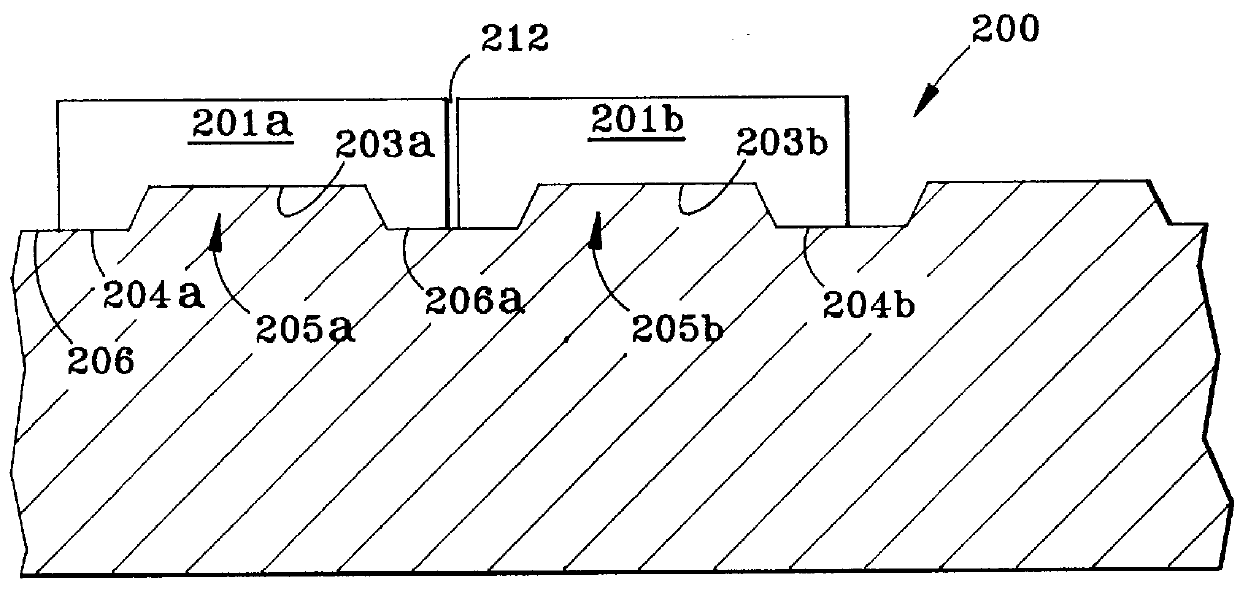

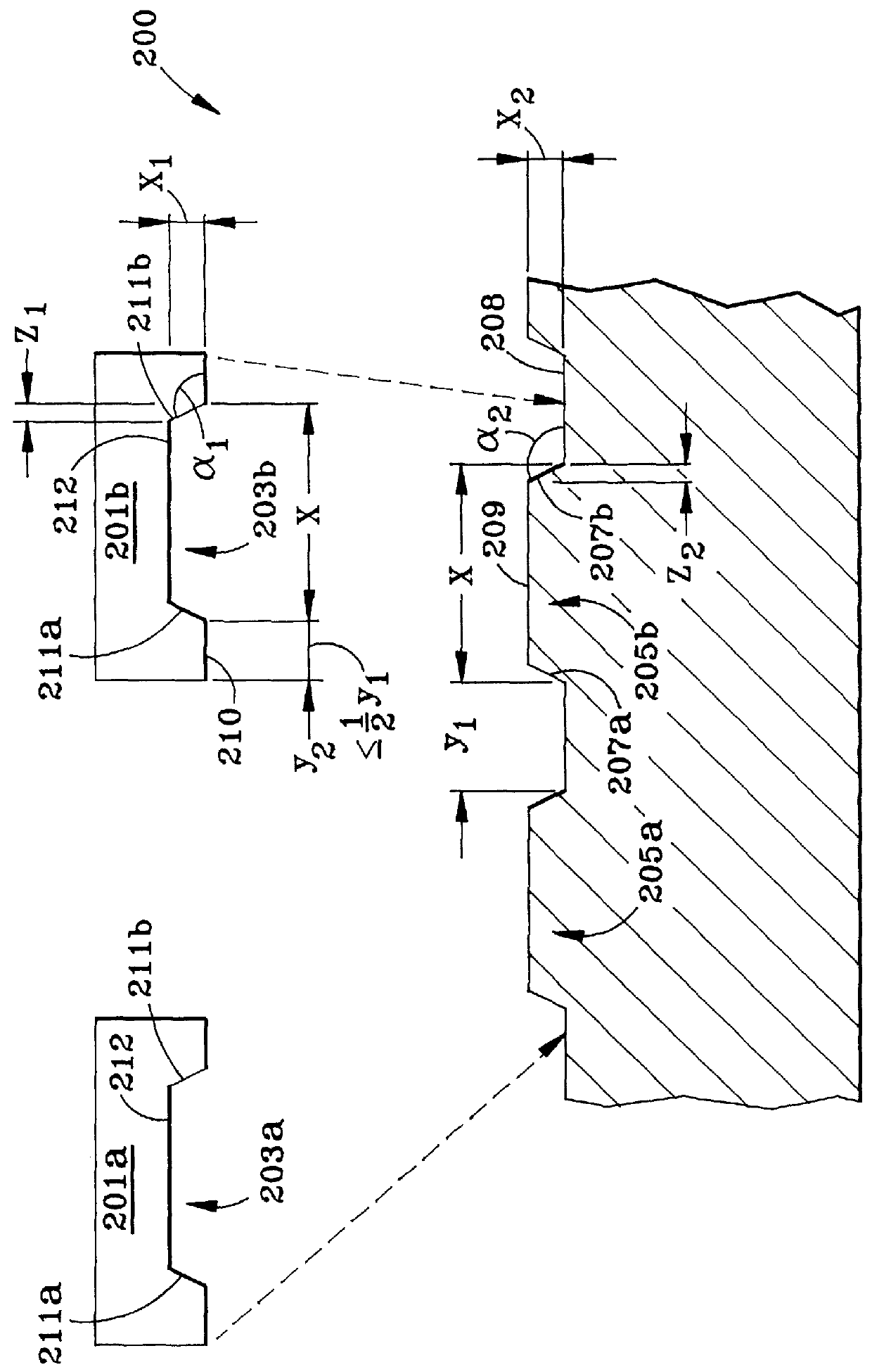

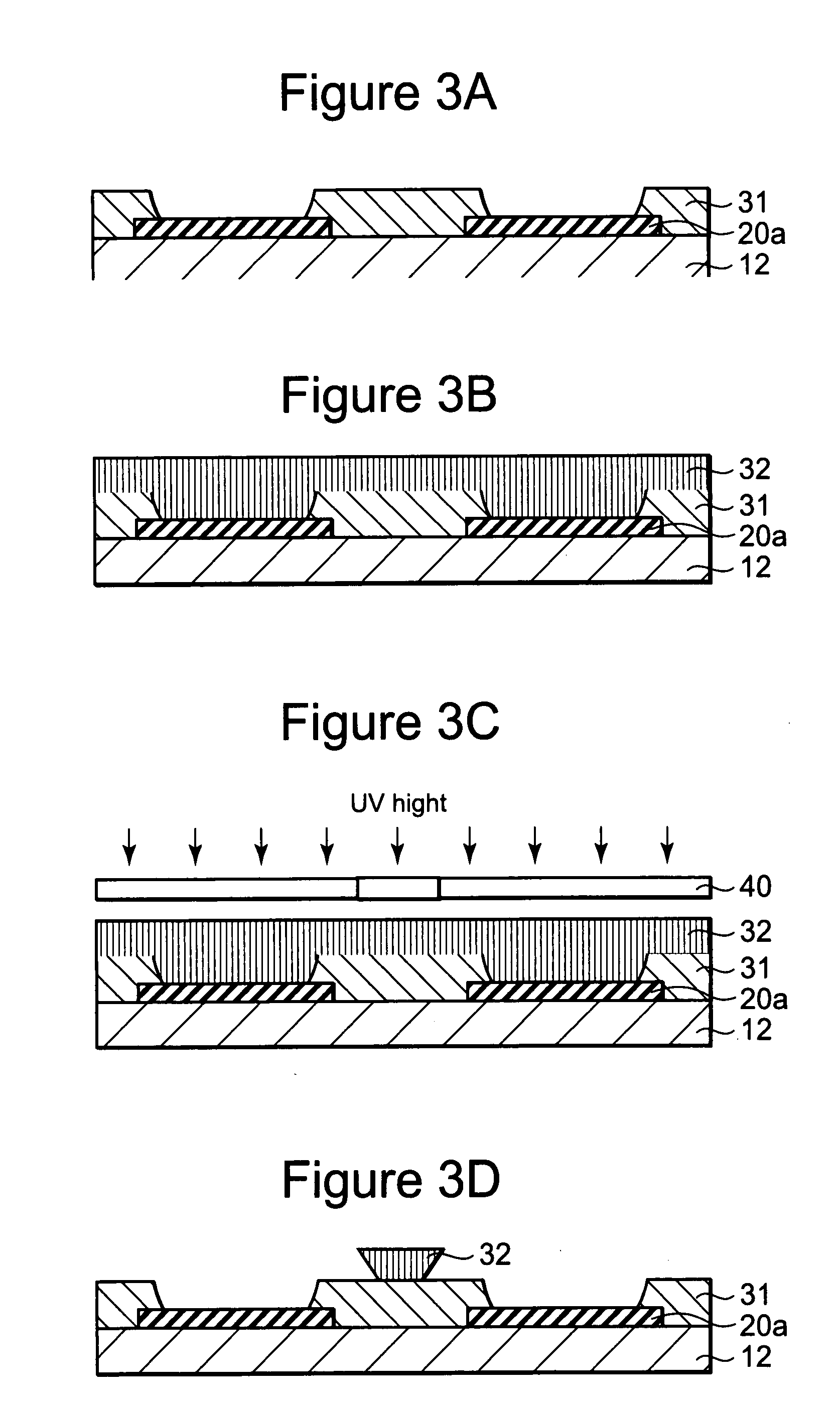

Method for fabricating a very dense chip package

InactiveUS6087199AConstant widthIncrease widthSemiconductor/solid-state device detailsSolid-state devicesIn planeTopography

A method for fabricating an integrated circuit package or arrangement includes providing a carrier having a surface topography of projections or recesses for supporting individual semiconductor circuit chips having conversely matching bottom surface topographies to permit self-aligned positioning of the chip on the carrier. Chips are provided such that top faces of neighboring chips lie substantially in planes separated by a distance of greater than 0.0 mu m. The carrier is arranged and dimensioned such that the neighboring chips are separated by a gap G or spacing in a range of 1 mu m<G< / =100 mu m. A metallic interconnect is provided over the top faces and the gap. Preferably, the interconnect has a gradual slope over the gap.

Owner:GOOGLE LLC

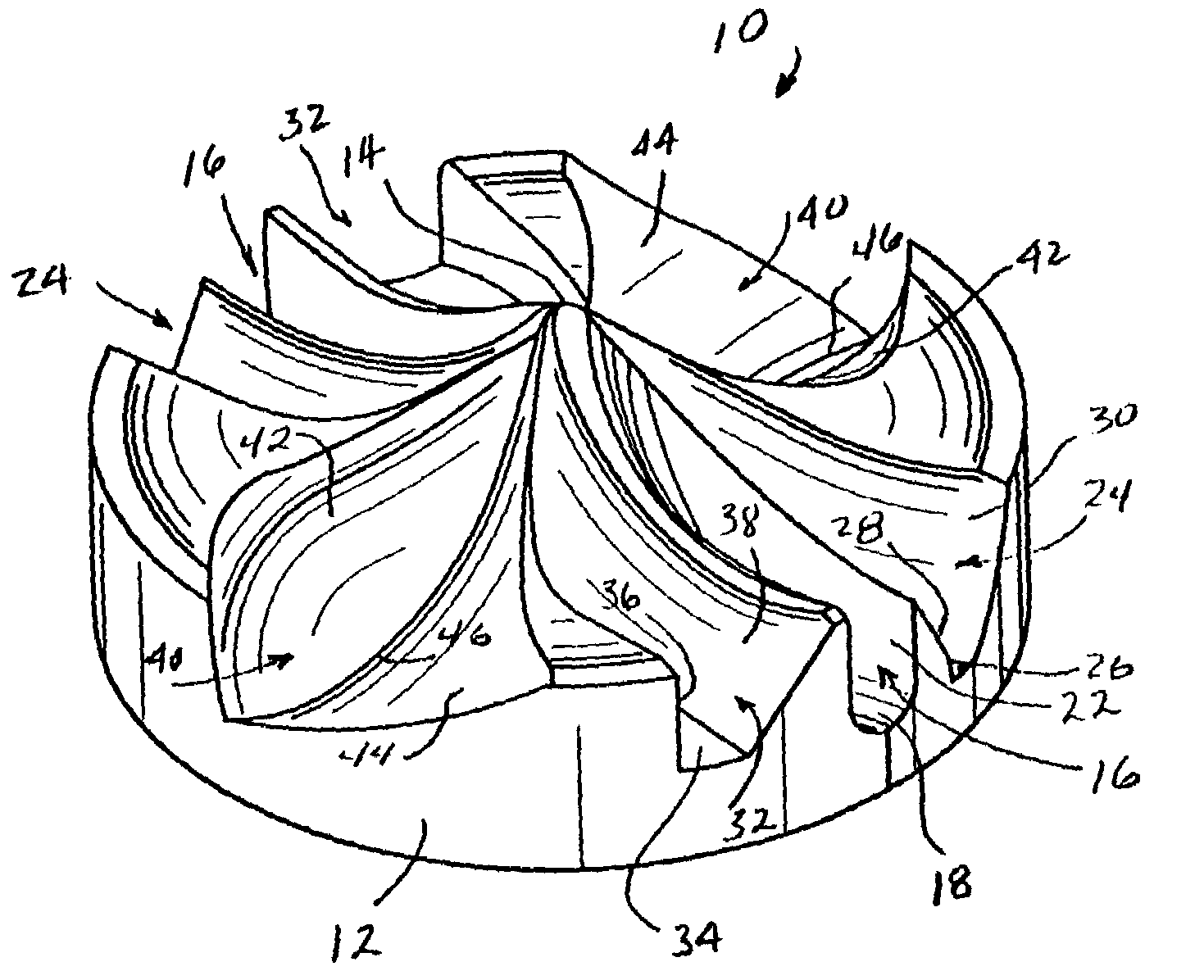

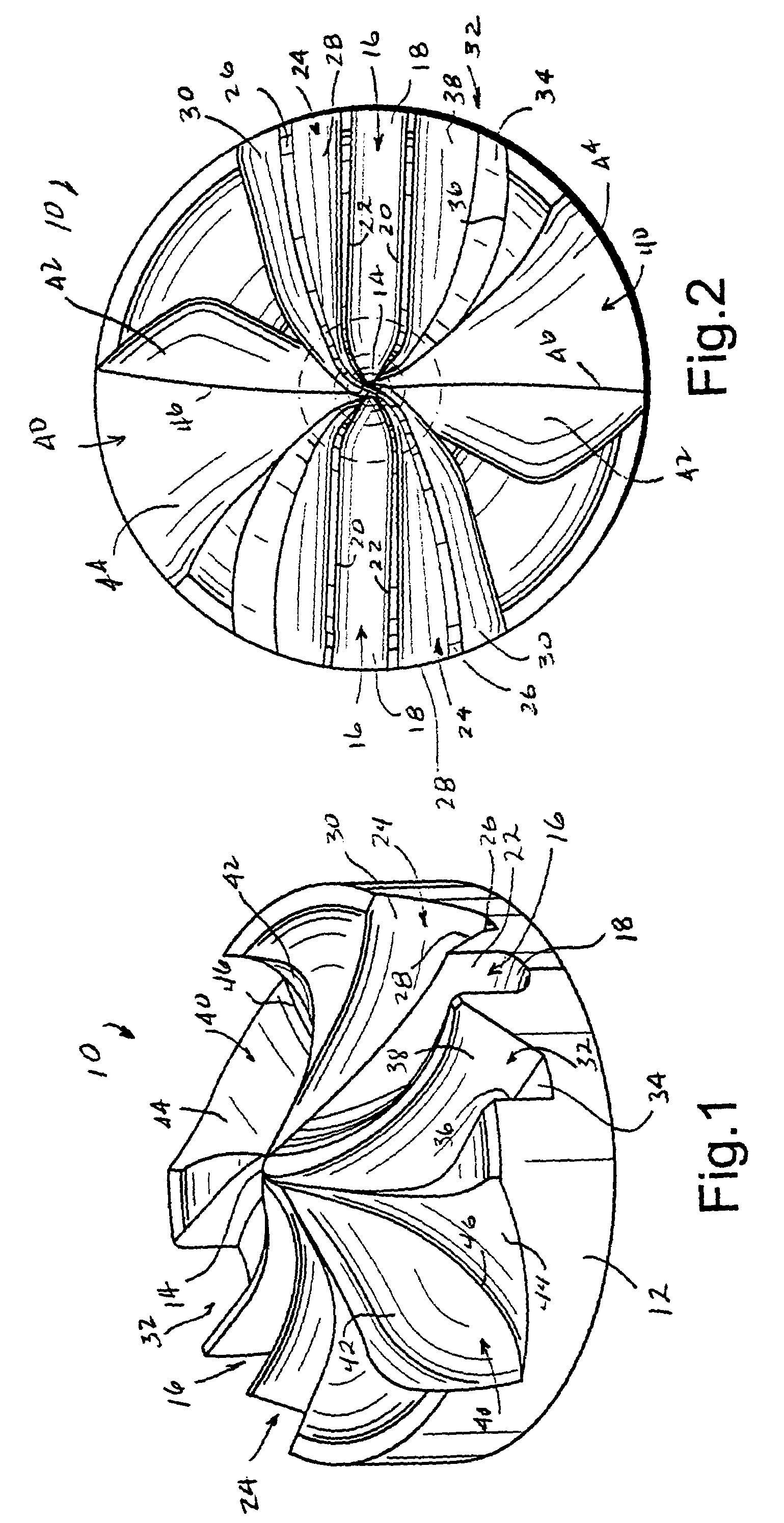

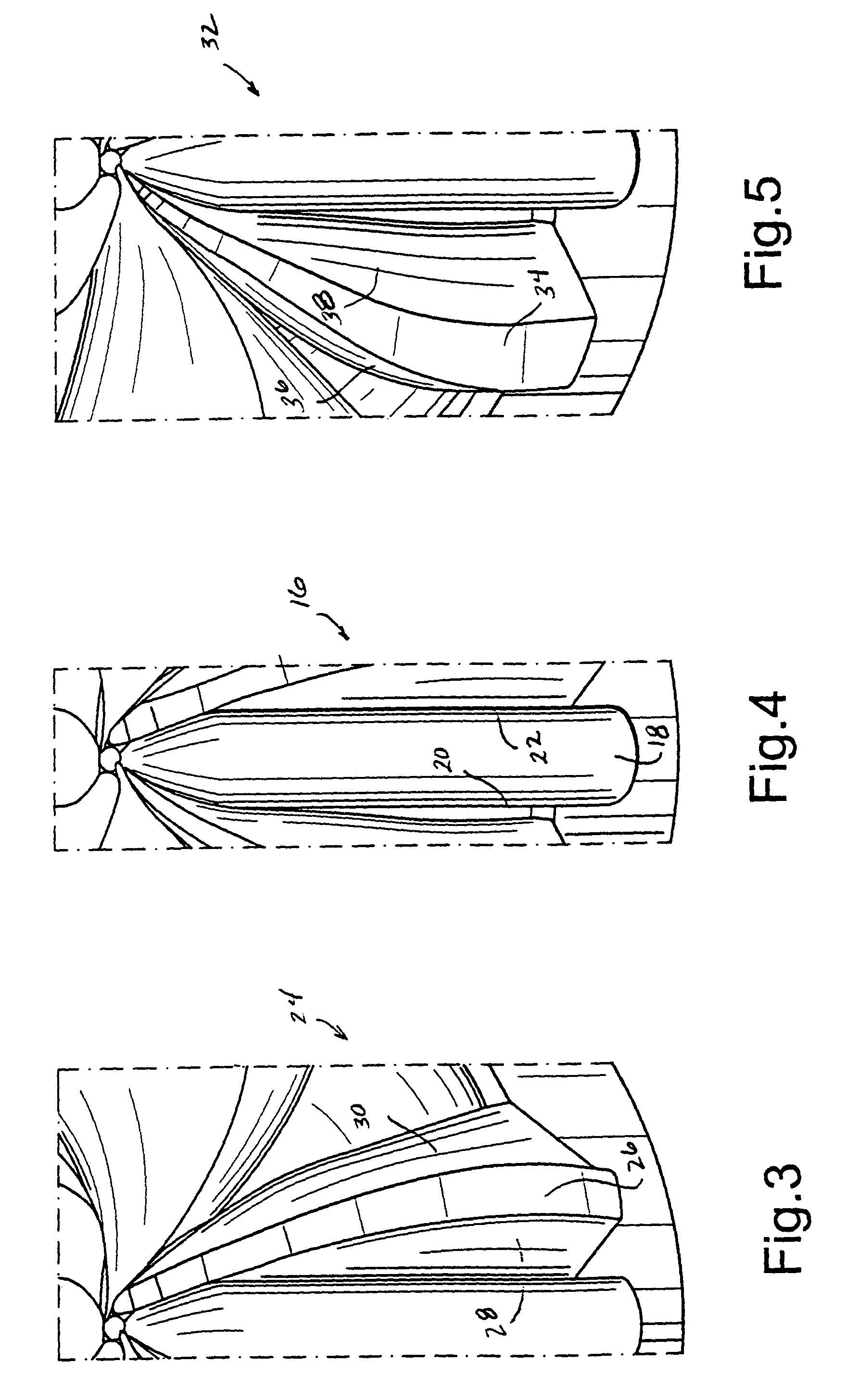

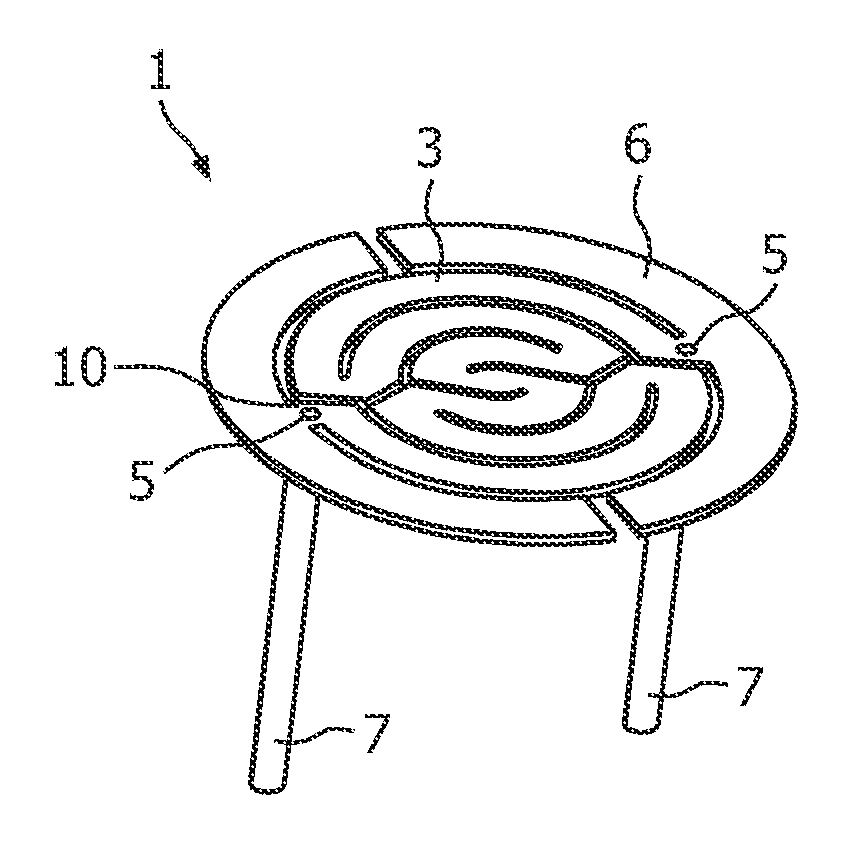

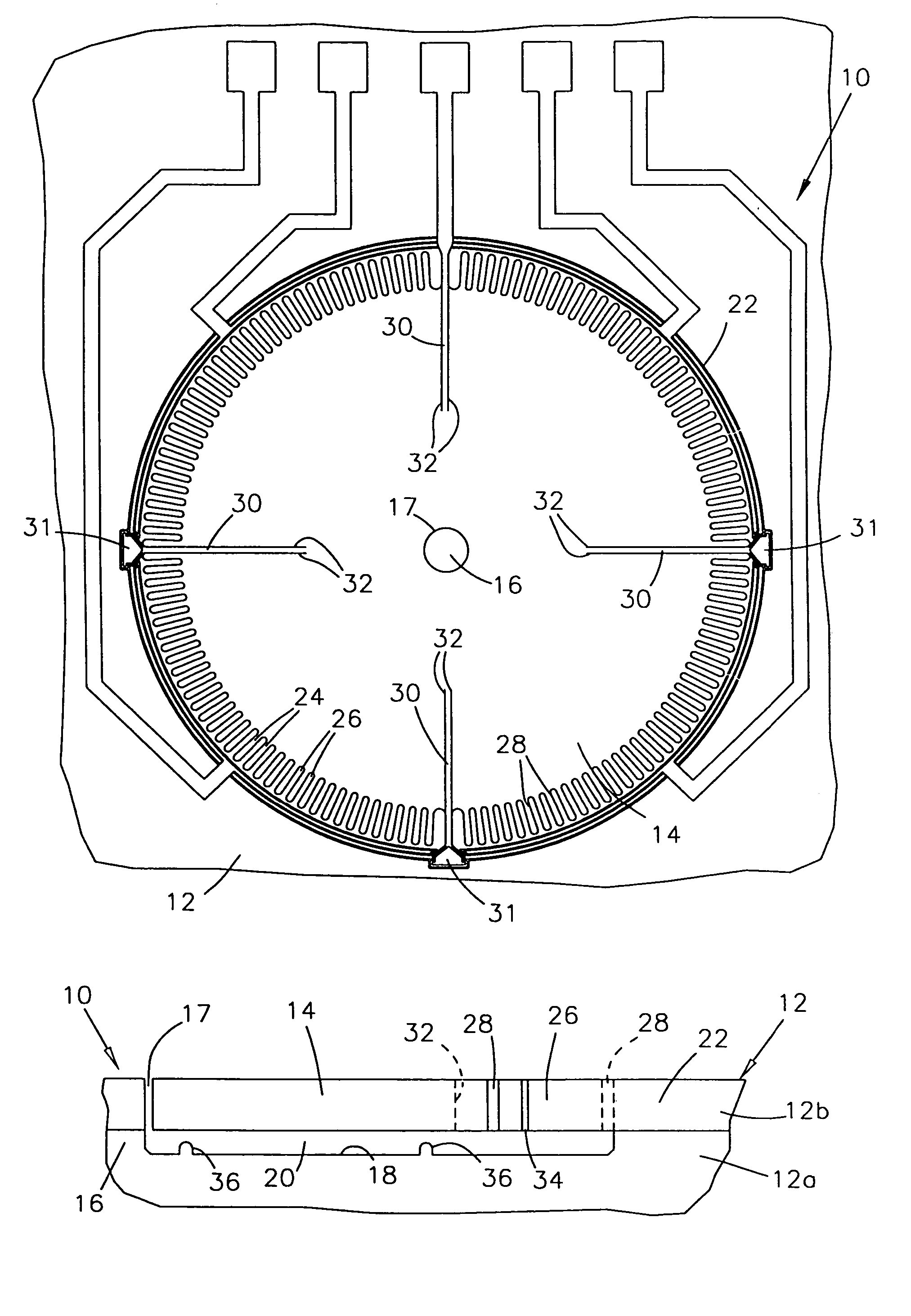

Water distribution plate for rotating sprinklers

ActiveUS7240860B2Increase rangeIncreases throw radiusBurnersMovable spraying apparatusEngineeringNozzle

A rotor plate for a sprinkler includes a water impingement surface bounded by an annular peripheral wall and having a radial center, and adapted to be impinged upon by a stream emitted from a nozzle. The water impingement surface is formed to include at least one radially extending drive channel having an entrance proximate the radial center and an exit in the peripheral wall, the drive channel curving from entrance to exit in a first direction so as to cause the plate to rotate when the stream exits at an offset from the center of rotation; at least one range channel extending substantially radially with little or no curving, from entrance to exit; and at least one brake channel curving from entrance to exit in a second direction opposite the first direction to thereby resist rotation of the plate caused by at least one drive channel.

Owner:HUNTER INDUSTRIES

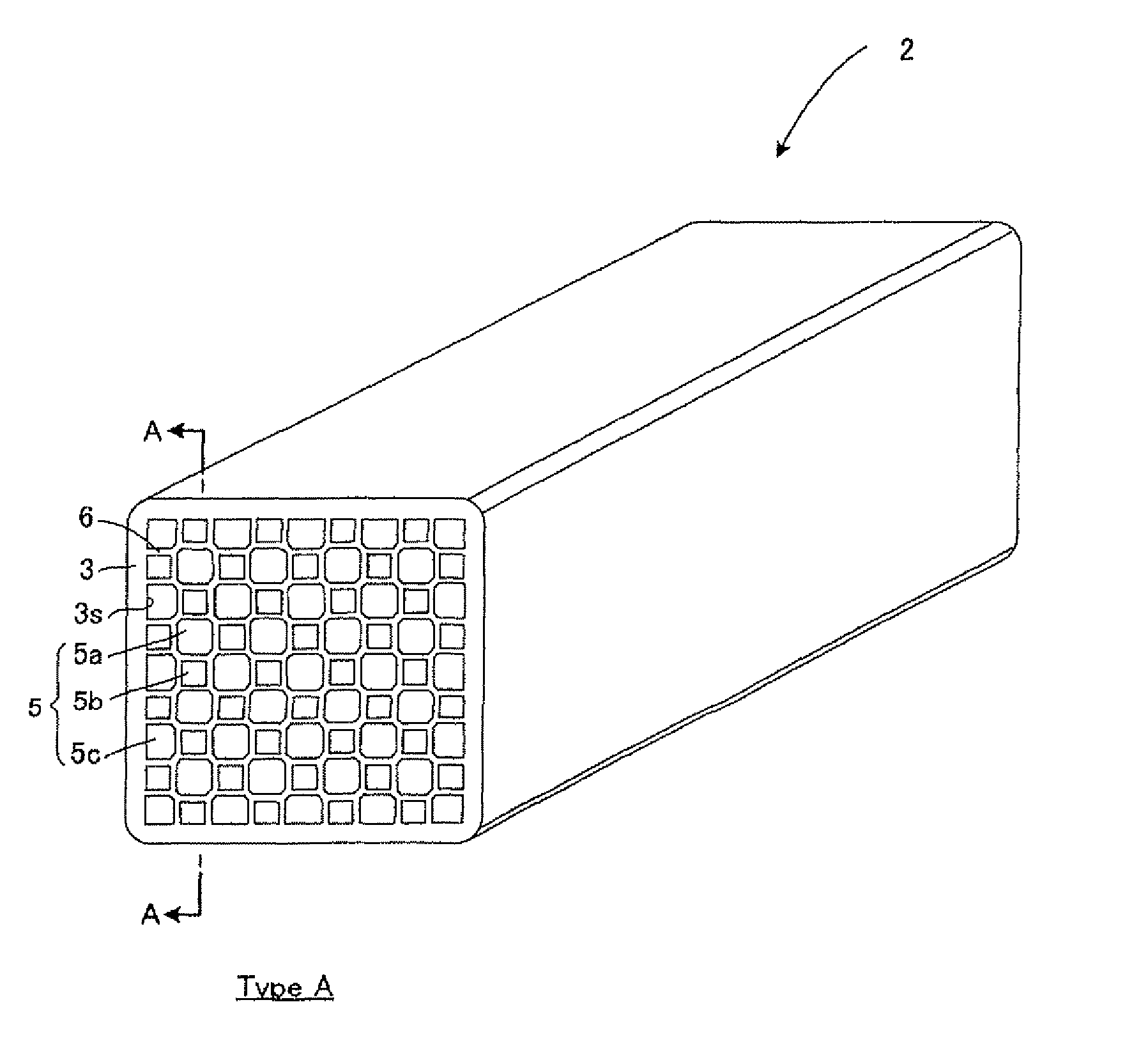

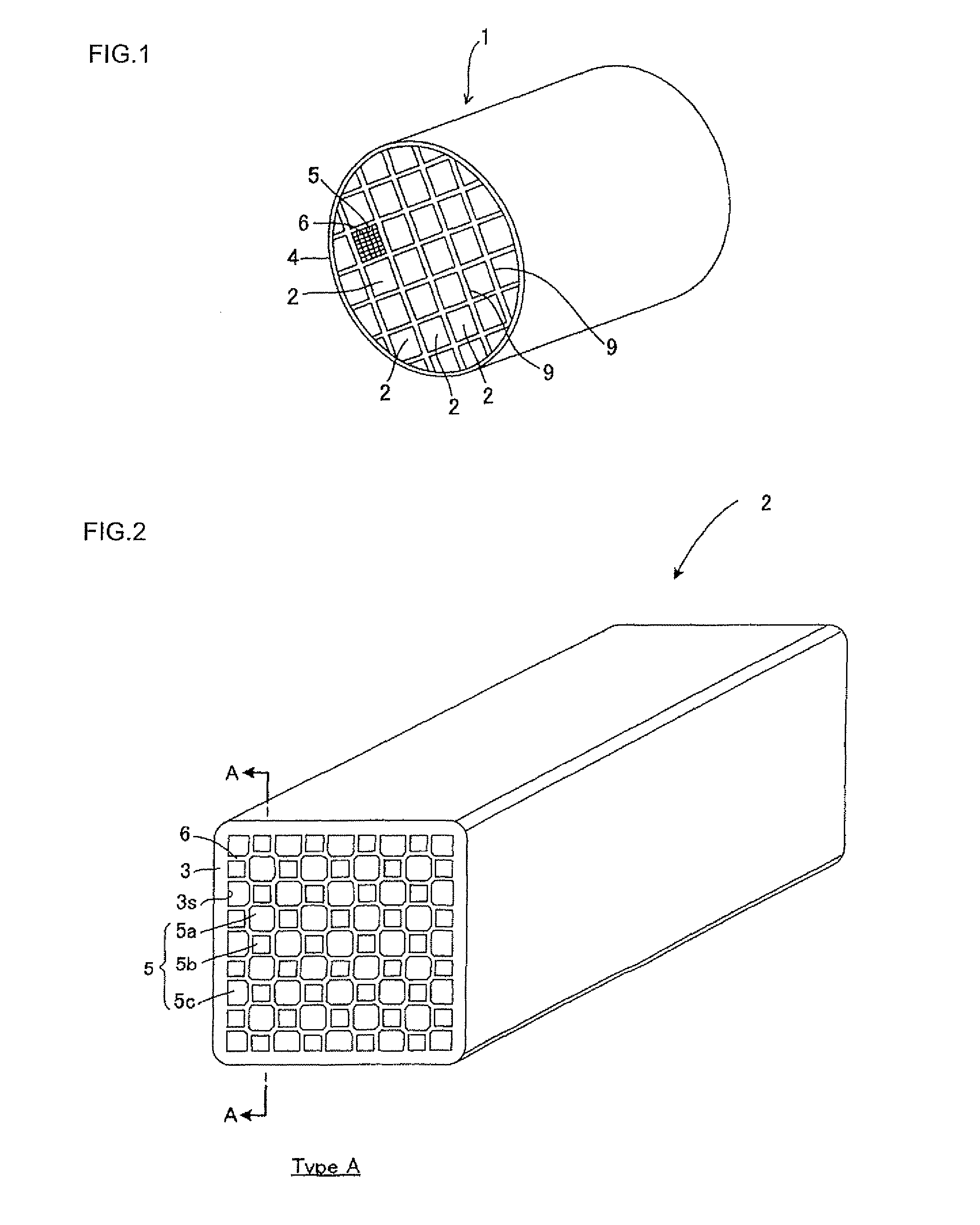

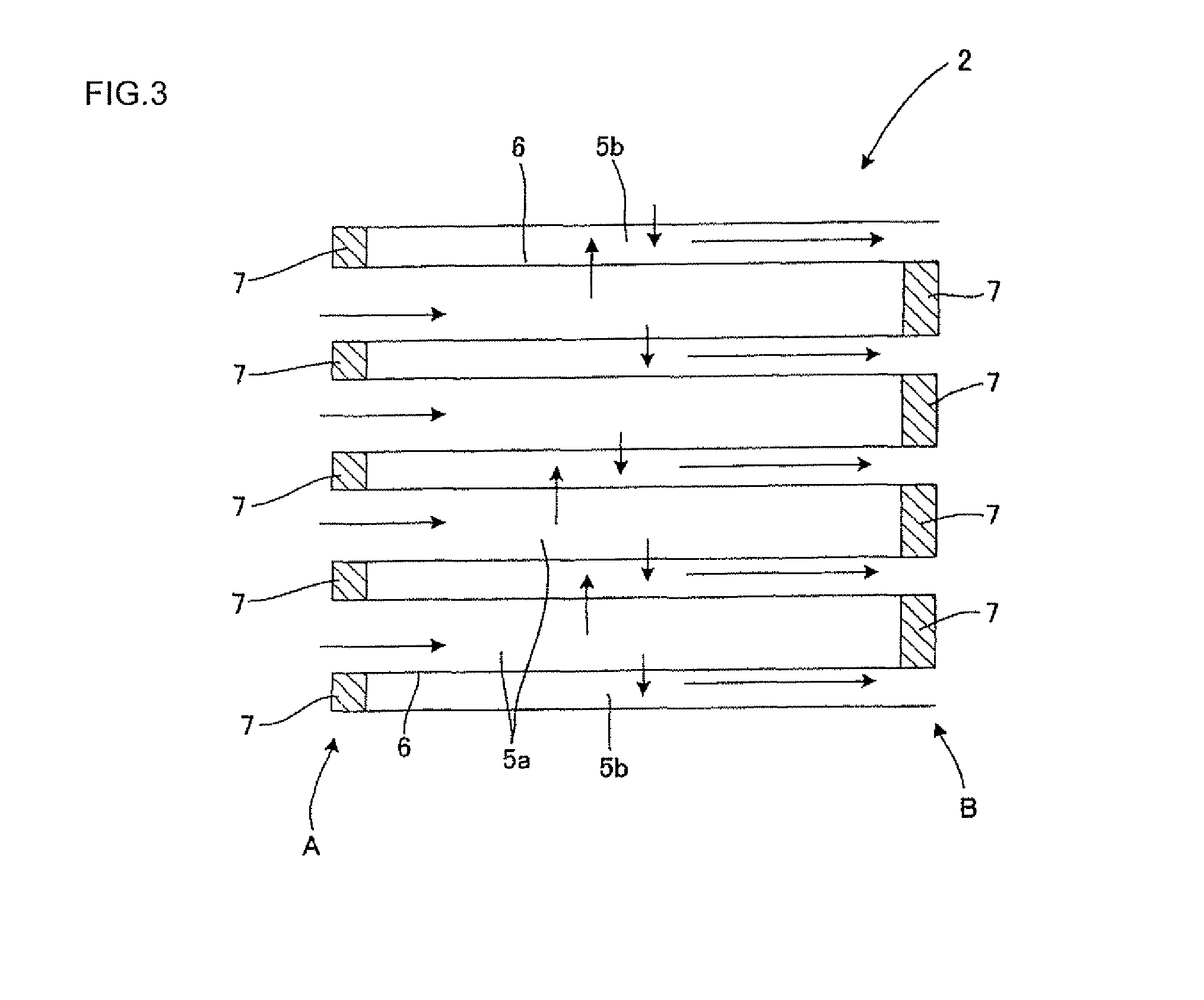

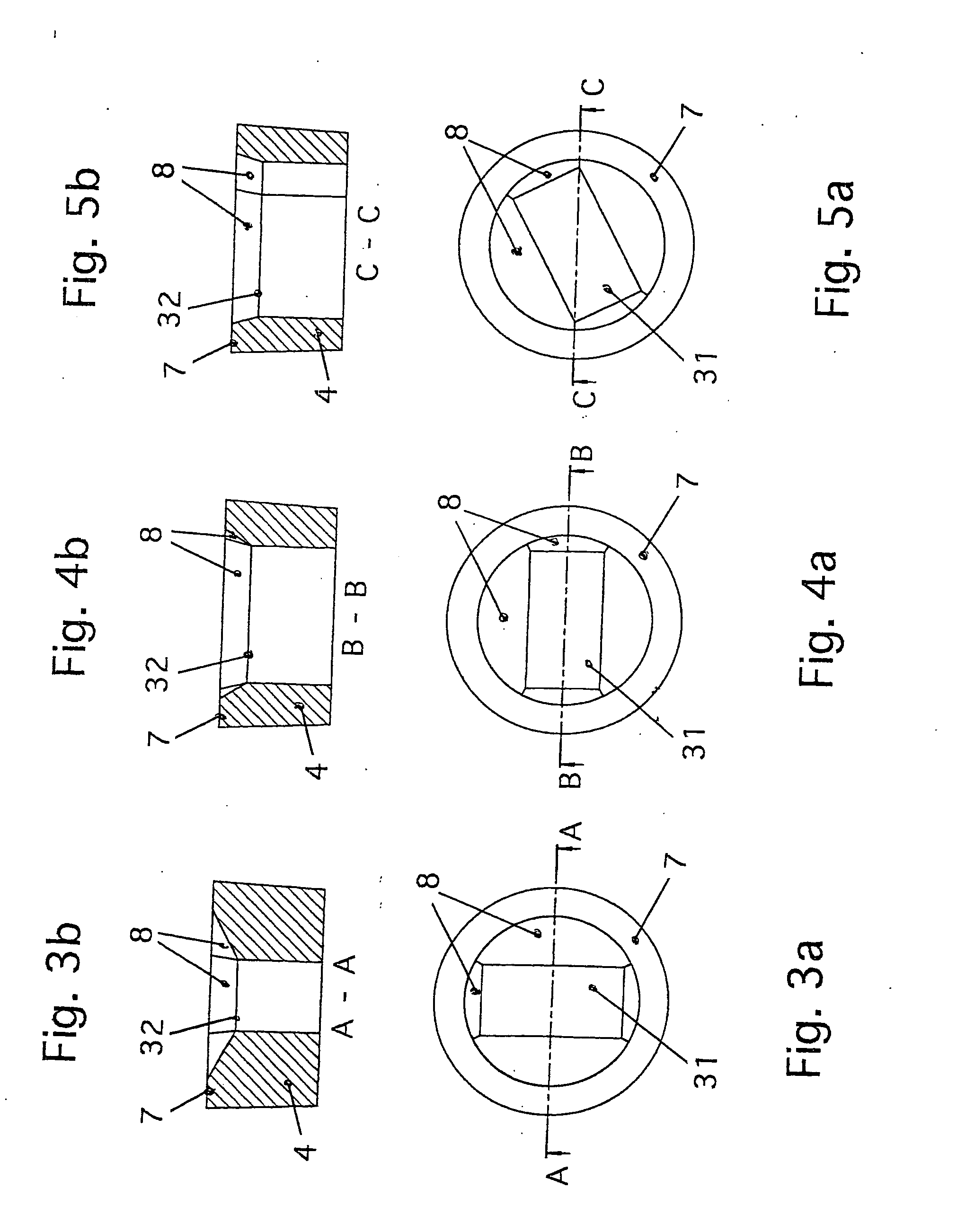

Honeycomb segment

ActiveUS7858169B2Avoid cloggingHigh bonding strengthPhysical/chemical process catalystsDispersed particle filtrationHoneycombMechanical engineering

A honeycomb segment containing outer walls and porous partition walls disposed inside the outer walls has a structure where first cells each open in one end portion on one side and plugged in the other end portion on the other side and second cells each plugged in one end portion on one side and open in the other end portion on the other side are alternately disposed, a cross-sectional area of the first cells in a cross section cut along a plane perpendicular to a longitudinal direction of the cells is larger than that of the second cells, and the first cells and the second cells are alternately disposed in a first direction and in a second direction perpendicular to the first direction in the cross section, and the outer walls are linearly formed so as to have a uniform thickness except for corner portions.

Owner:NGK INSULATORS LTD

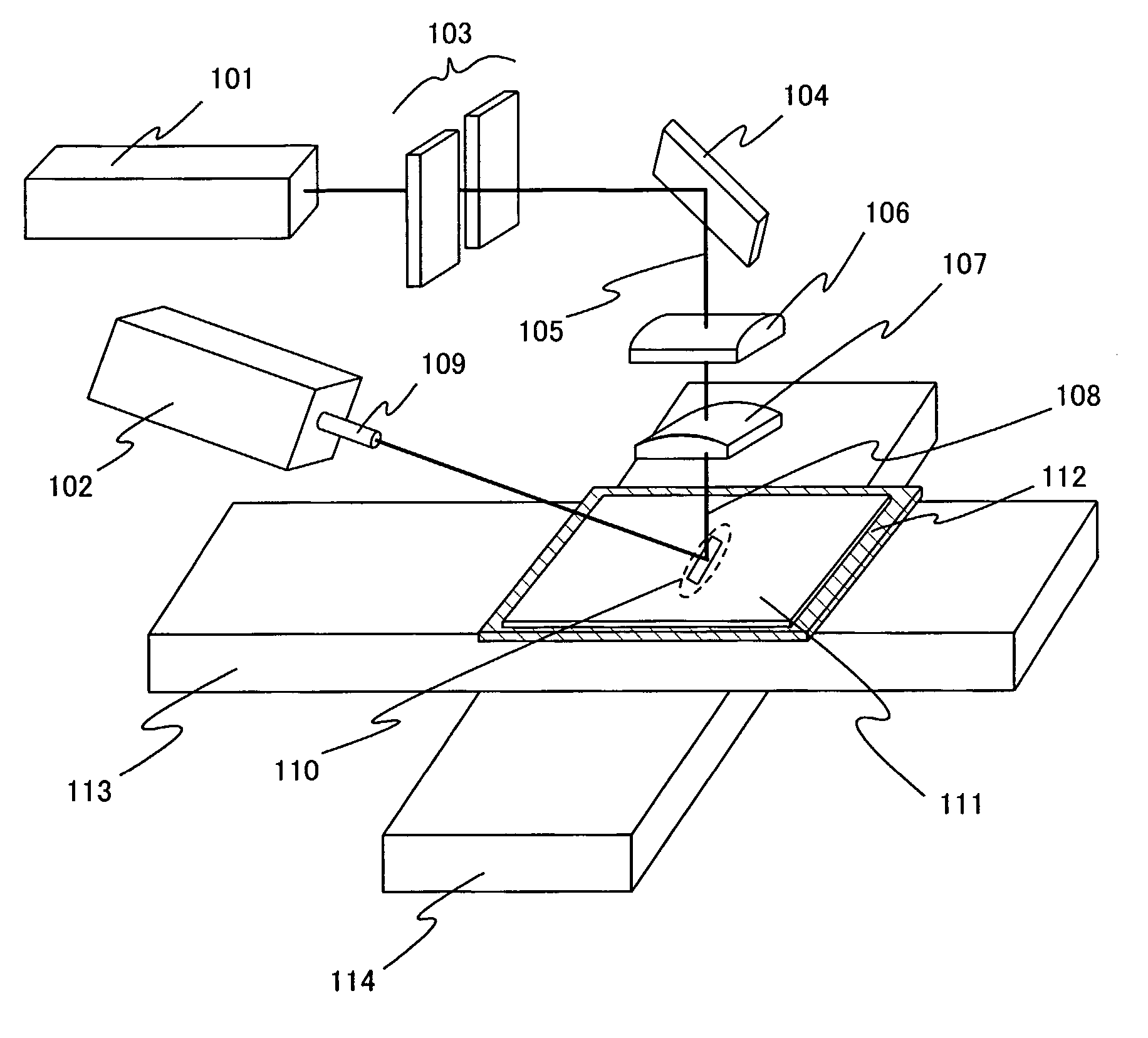

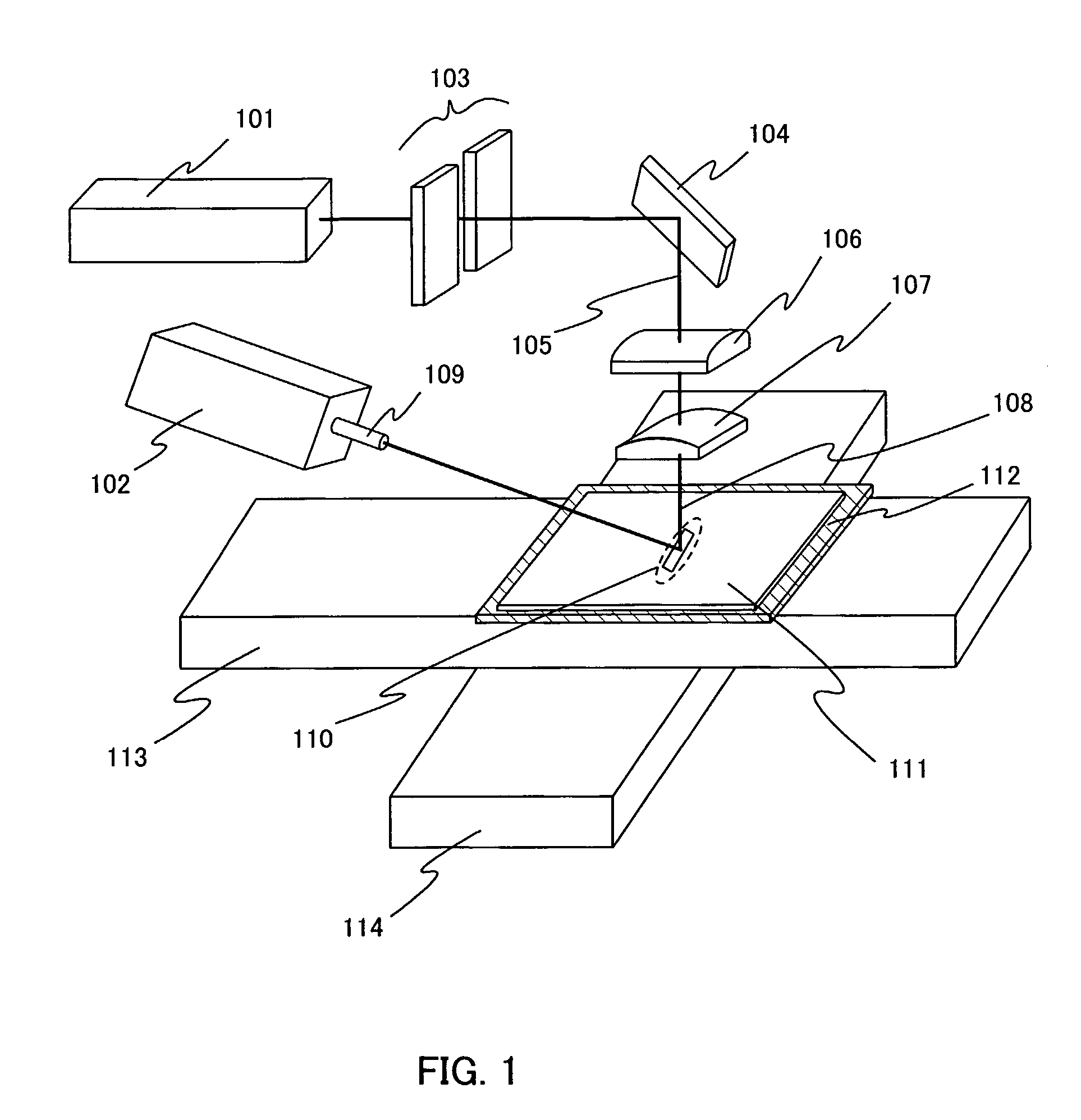

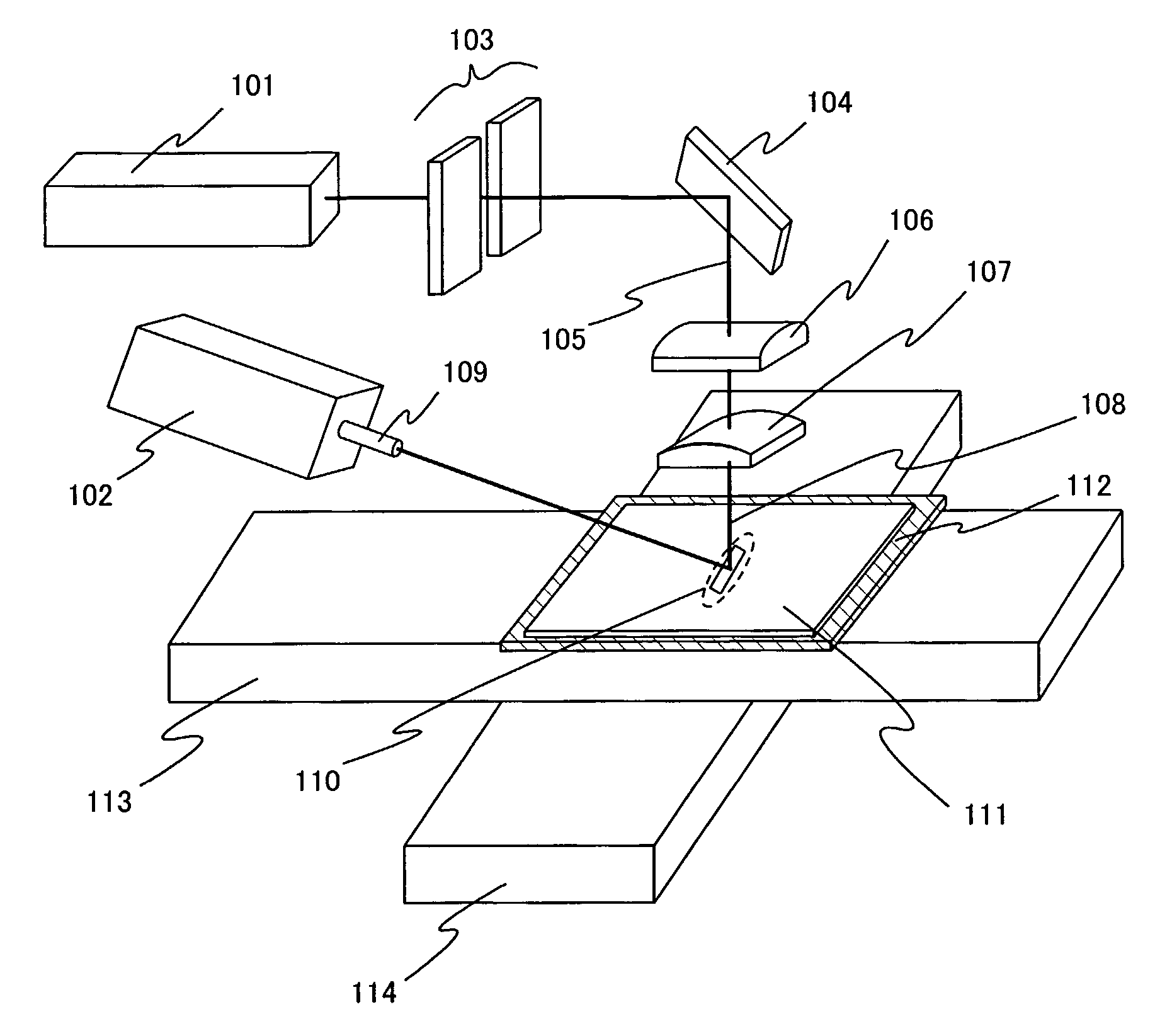

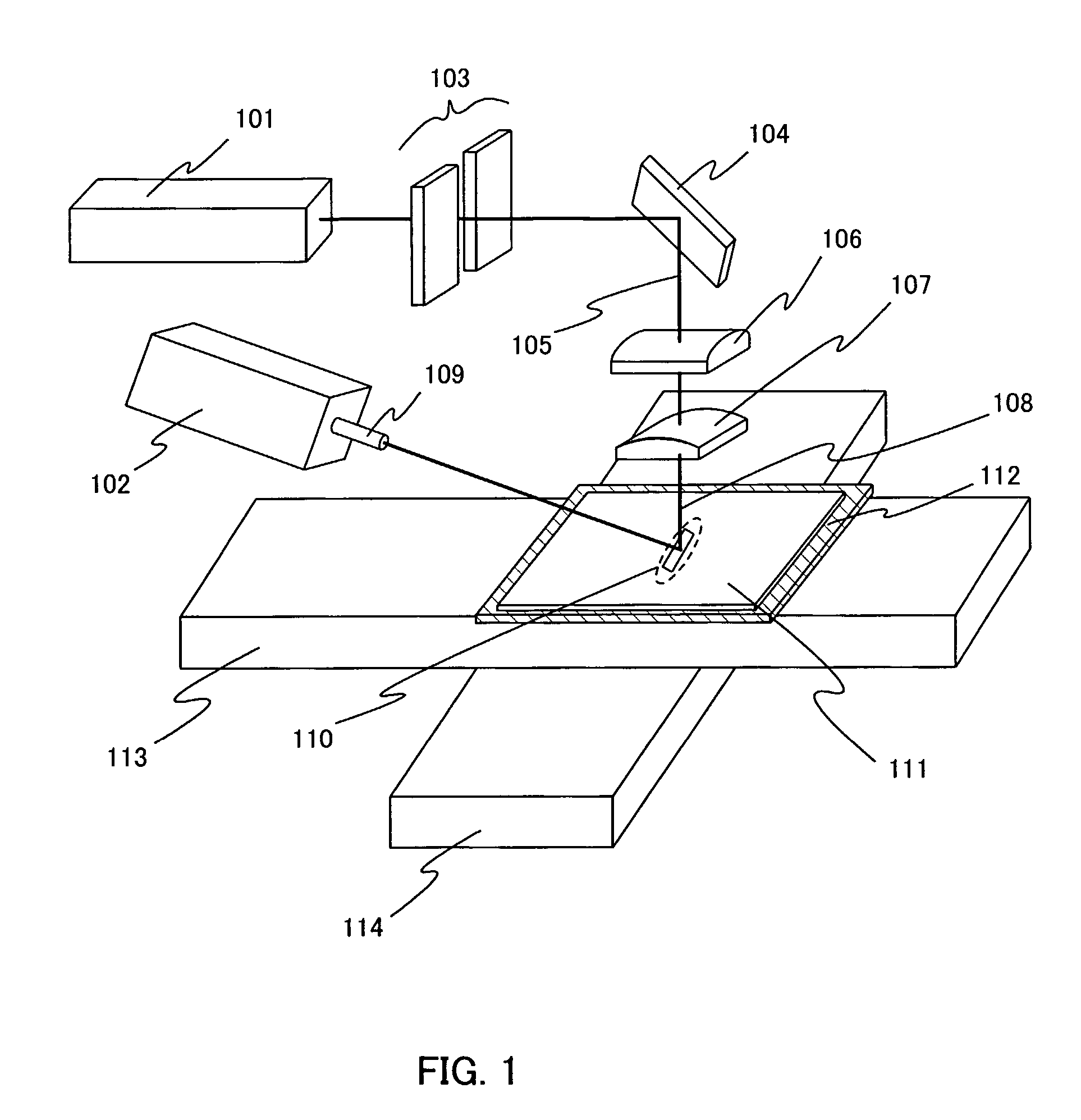

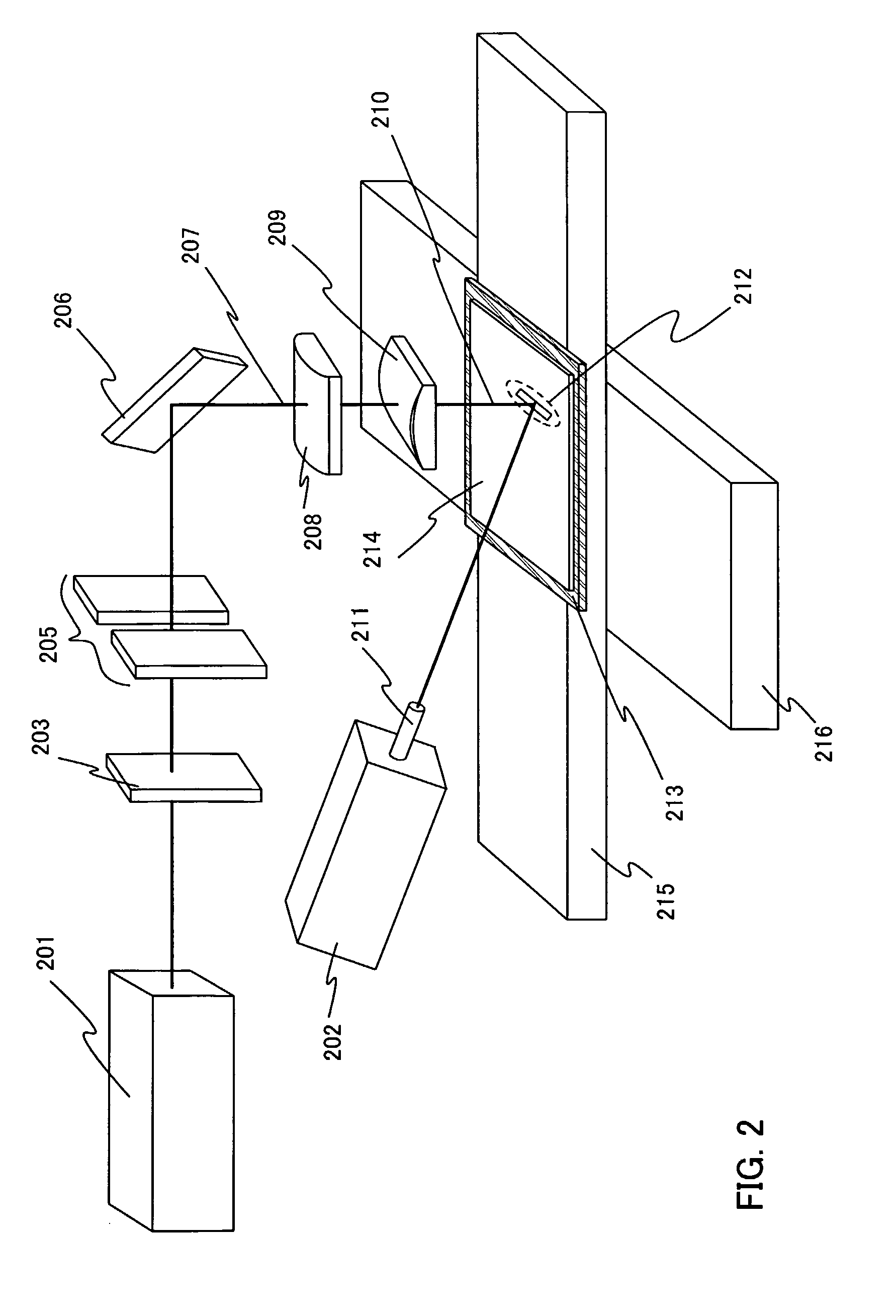

Laser irradiation apparatus and laser irradiation method

InactiveUS20070158315A1Irradiate the whole surface of the irradiation surface efficientlyConstant beam widthSolid-state devicesSemiconductor/solid-state device manufacturingCondensing lensSemiconductor

It is an object of the present invention to provide a laser irradiation apparatus and a laser irradiation method for conducting a laser process homogeneously to the whole surface of a semiconductor film. A first laser beam emitted from a first laser oscillator passes through a slit and a condensing lens and then enters an irradiation surface. At the same time, a second laser beam emitted from a second laser oscillator is delivered so as to overlap the first laser beam on the irradiation surface. Further, the laser beams are scanned relative to the irradiation surface to anneal the irradiation surface homogeneously.

Owner:SEMICON ENERGY LAB CO LTD

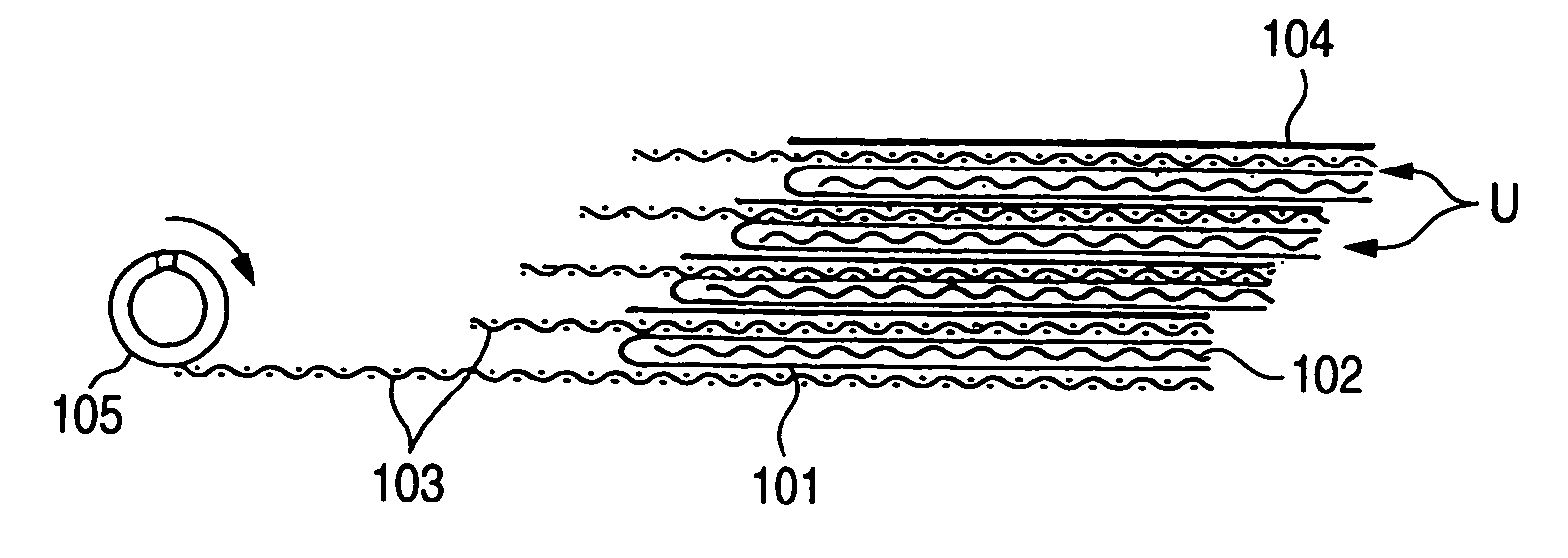

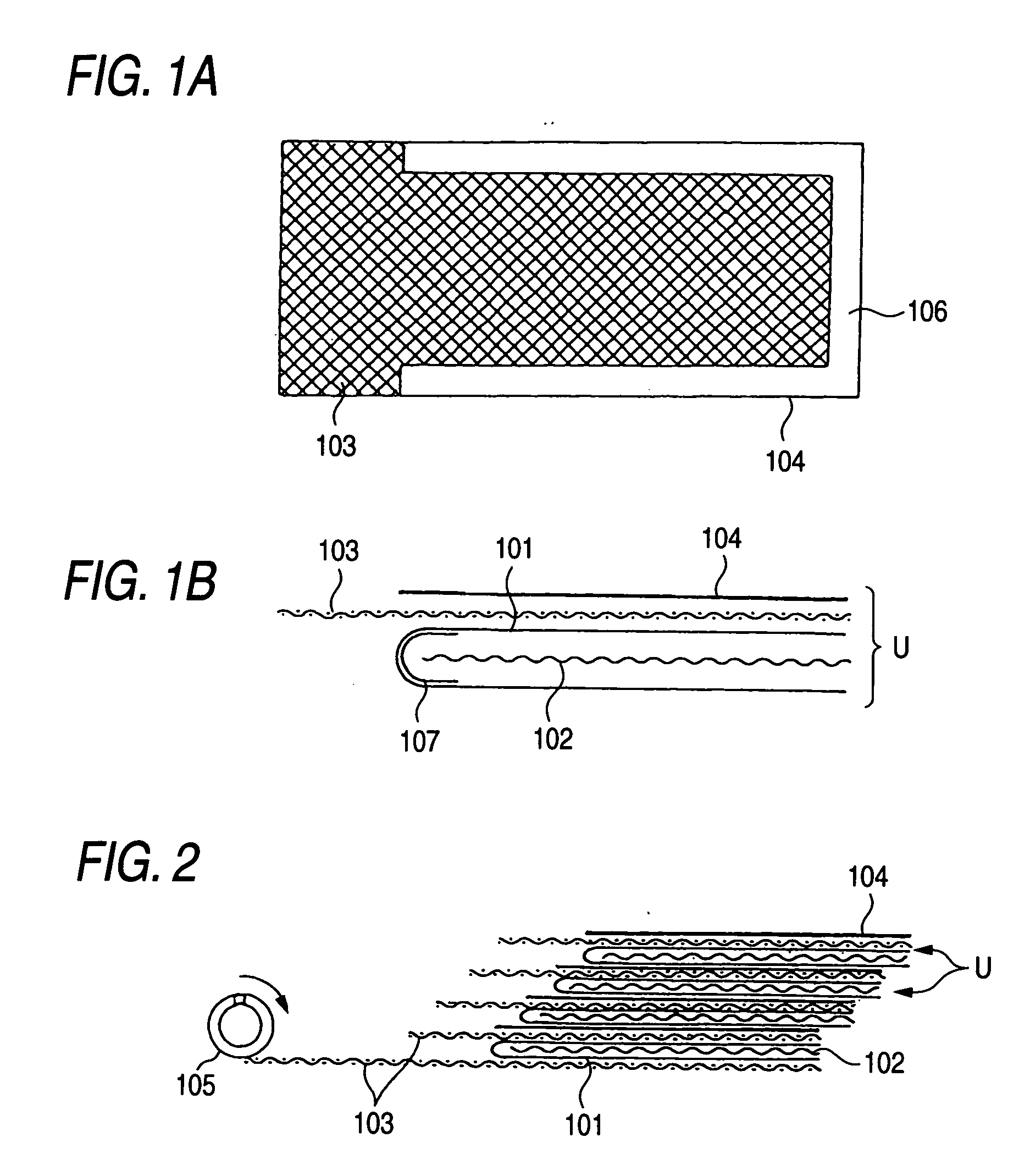

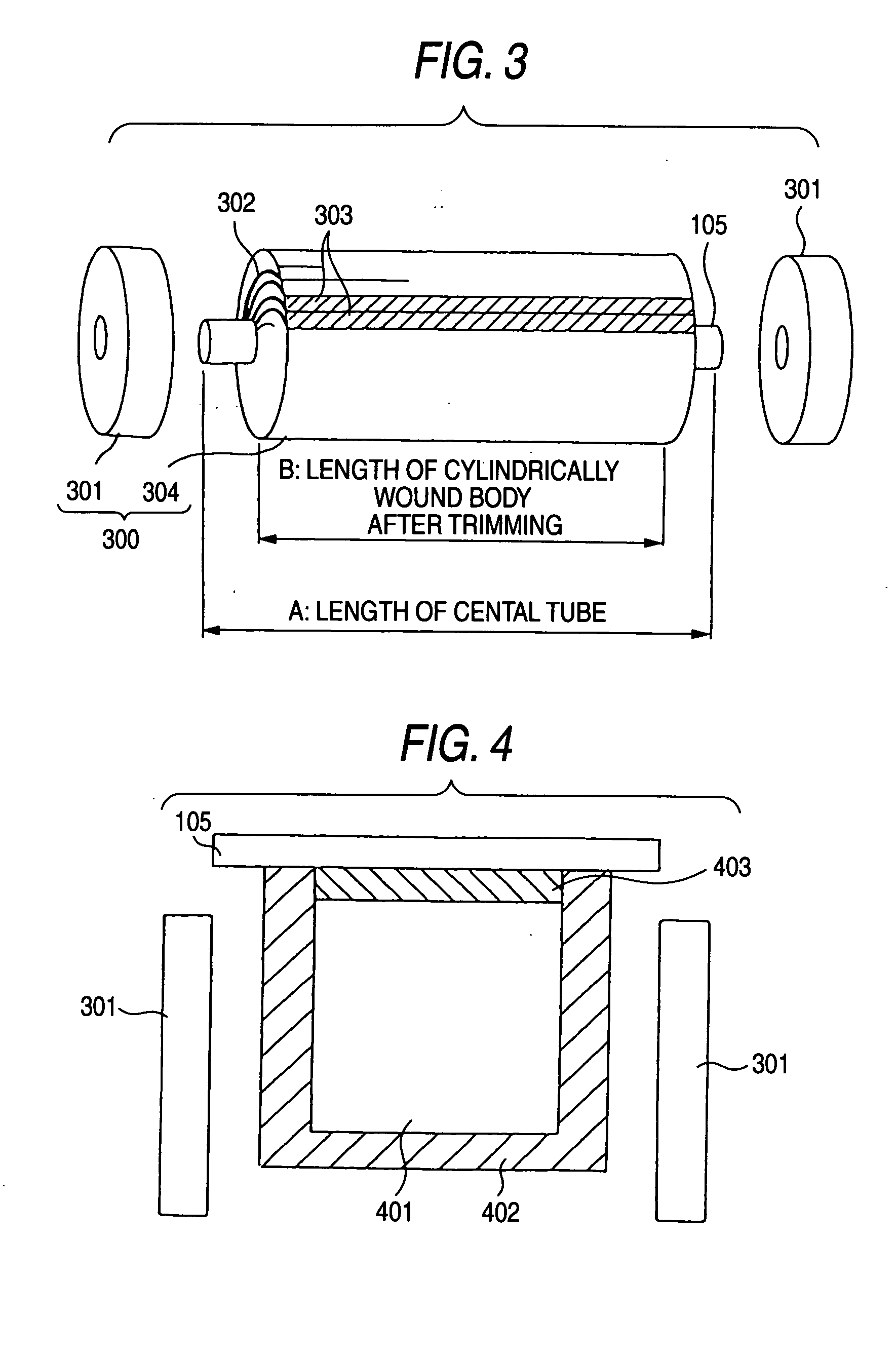

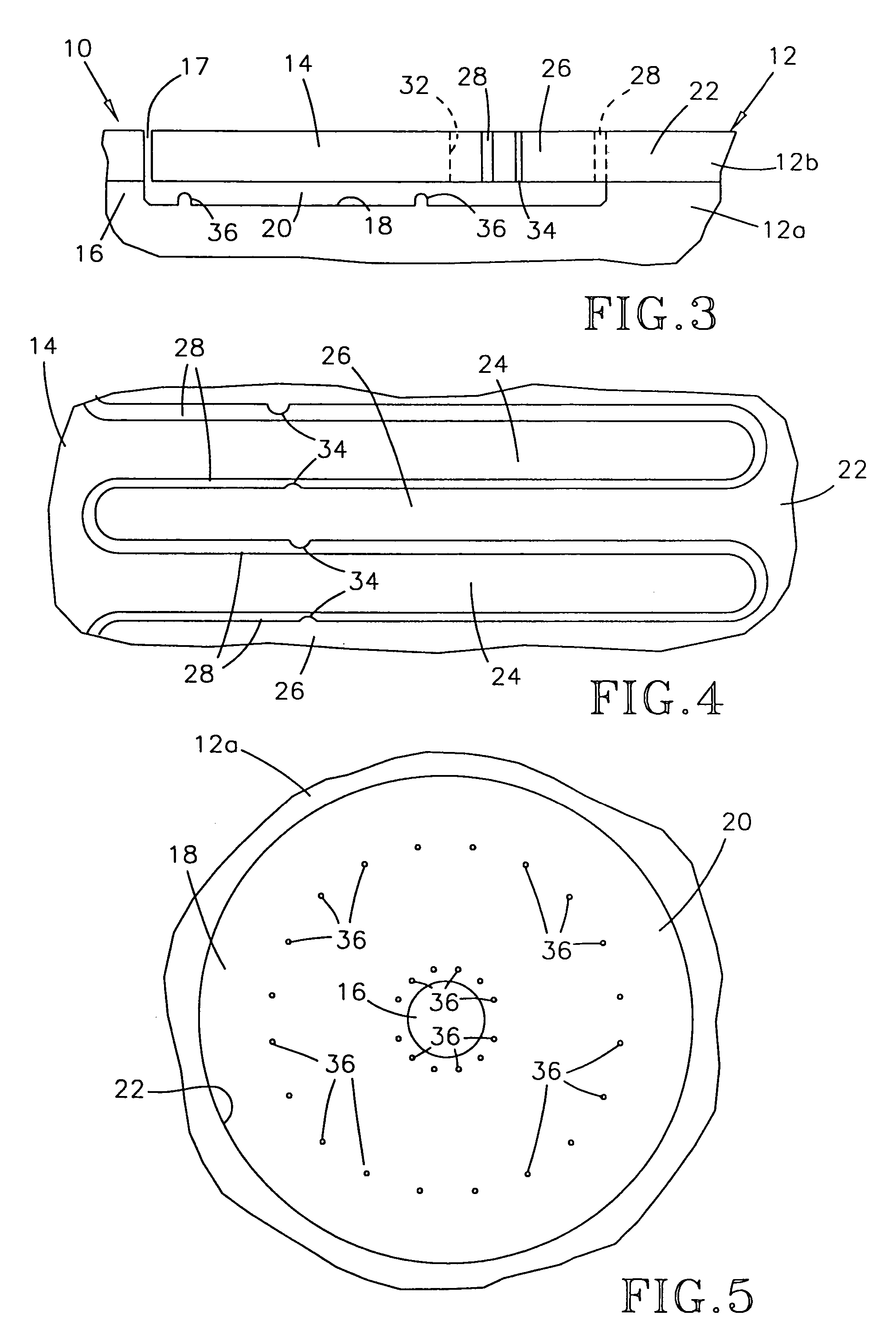

Spiral membrane element and method of manufacturing the same

InactiveUS20050077229A1Reduce total pressure lossReduce manufacturing costSemi-permeable membranesDispersed particle filtrationAdhesiveMembrane surface

A spiral membrane element having an enlarged effective membrane surface area without having its separation performance lowered, while maintaining the sealing property of any sealing portion of a cylindrically wound body, and a manufacturing method of the same are disclosed. The spiral membrane element includes a cylindrically wound body comprising a perforated central tube and, spirally wound therearound, a separation membrane, a feed-side passage material and a permeation-side passage material in a laminated state, and a sealing portion for preventing a feed-side fluid and a permeation-side fluid from being mixed together, wherein the sealing portion formed at each of both ends of the cylindrically wound body is spirally formed with a substantially constant width by an adhesive and has a trimmed section formed on its whole end surface, and the cylindrically wound body has a ratio of its length to the length of the central tube of 0.96 to 1.00, and a ratio of an ineffective membrane surface area to the entire membrane surface area of 0.02 to 0.10.

Owner:NITTO DENKO CORP

Electron beam layer manufacturing using scanning electron monitored closed loop control

ActiveUS8598523B2Avoid oversaturationConstant widthAdditive manufacturing apparatusMaterial analysis using wave/particle radiationClosed loopTrailing edge

A process (and apparatus for performing the process) for layer manufacturing a three-dimensional work piece comprising the steps of: feeding raw material in a solid state to a first predetermined location; exposing the raw material to an electron beam to liquefy the raw material; depositing the raw material onto a substrate as a molten pool deposit, the deposit having a forward edge region in an x-y plane with a forward edge region width and a trailing edge region in the x-y plane with a trailing edge region width, under at least one first processing condition; monitoring the molten pool deposit for at least one preselected condition using detecting of scatter from a scanning electron beam contemporaneously with the depositing step; solidifying the molten pool deposit; automatically altering the first processing condition to a different processing condition based upon information obtained from the comparing step; and repeating steps at one or more second locations for building up layer by layer, generally along a z-axis that is orthogonal to the x-y plane, a three-dimensional work piece.

Owner:SCIAKY SA

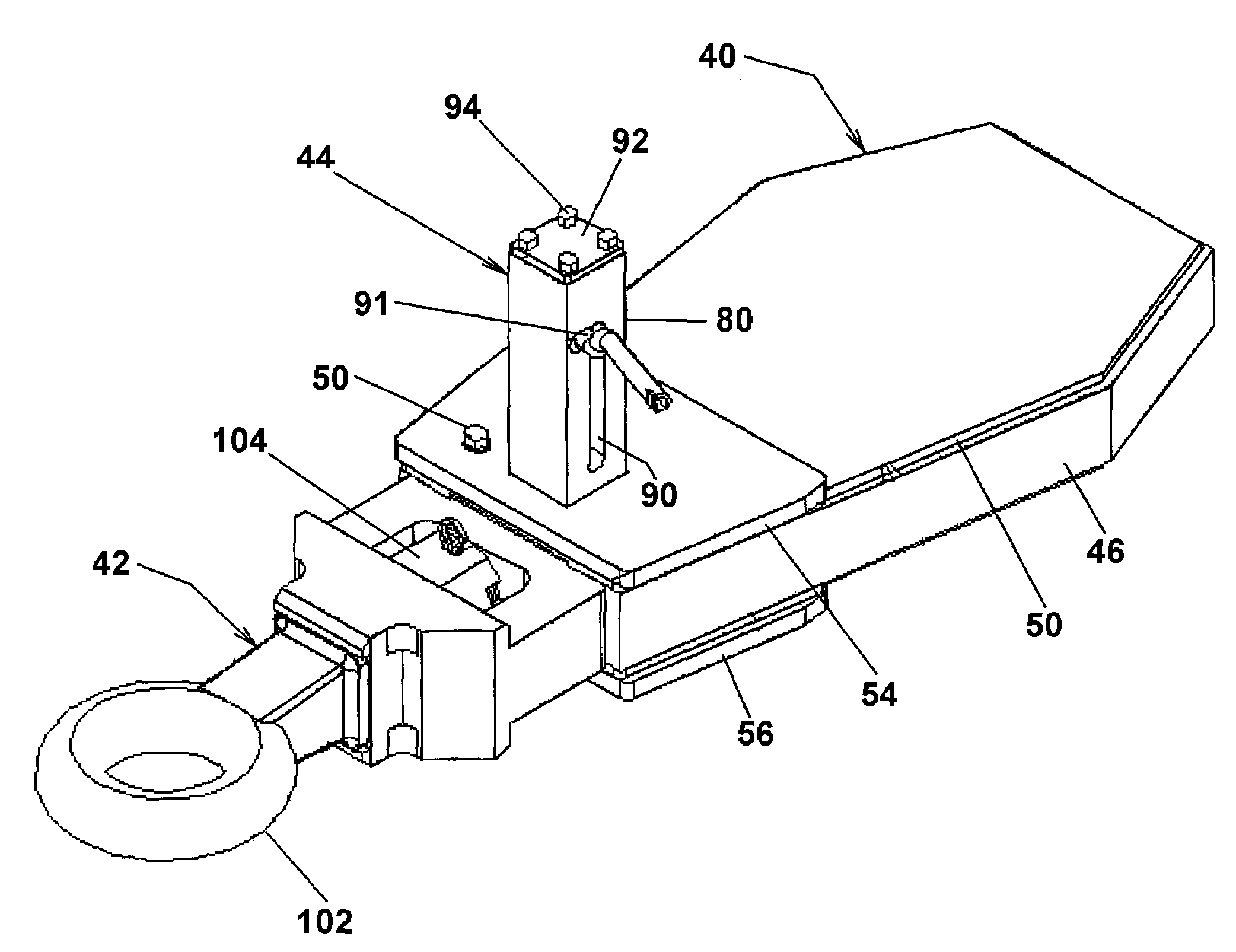

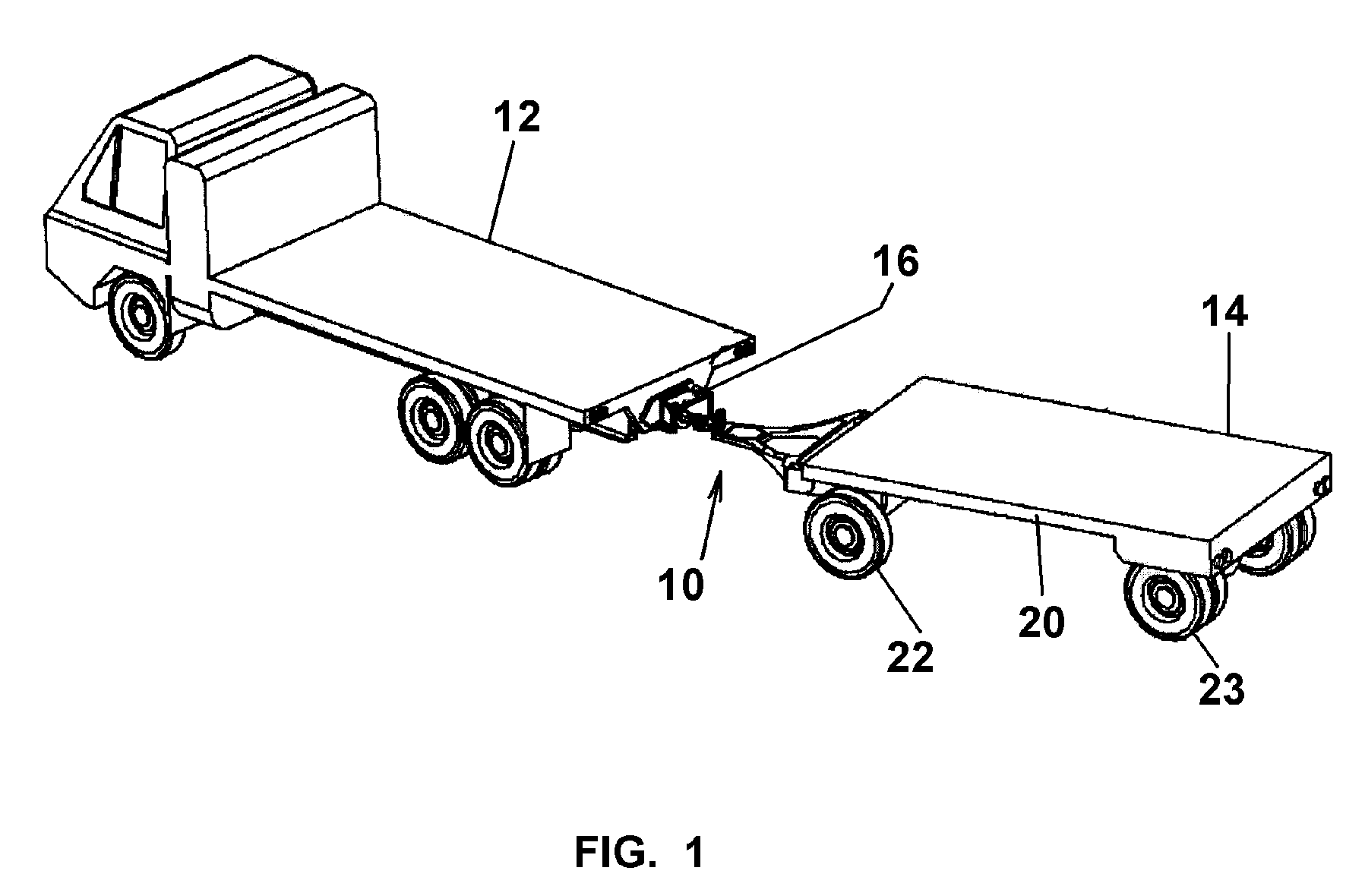

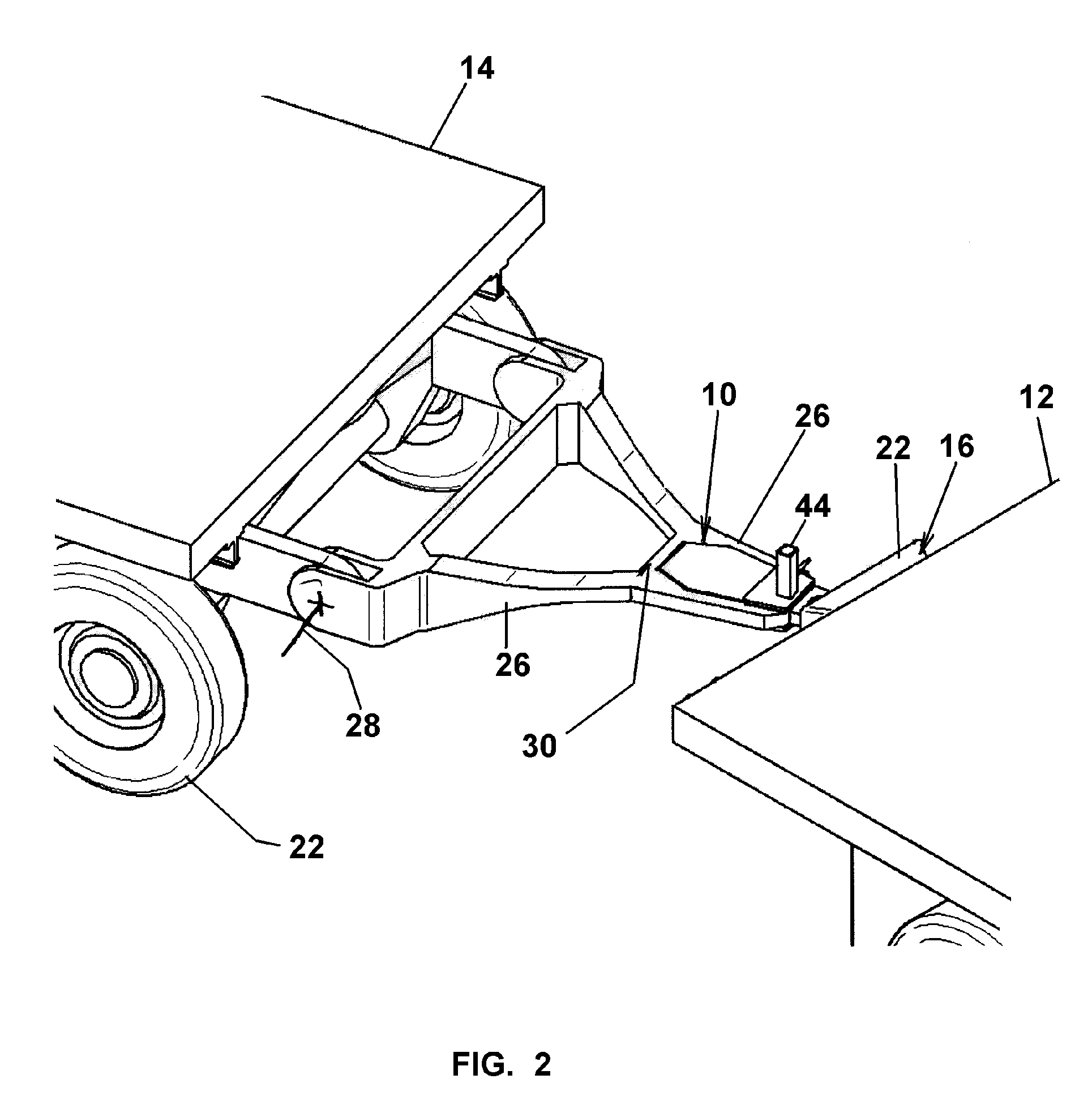

Telescoping and swiveling hitch assembly

A hitch assembly for connecting a towed vehicle to a towing vehicle include a housing mounted on the towing tongue of the towed vehicle having a tow bar mounted in an internal cavity having a restricted throat. Tow bar can be extended and pivoted to position a hitching eyelet on a variably proximately located towed vehicle. The tow arm coacts with the walls of the cavity to provide a torque on the tongue upon forward or rearward movement of the towing vehicle. Upon rearward movement of the towed vehicle, the tow bar attains an aligned nested position in the cavity and a lock assembly is actuated for locking the tow arm to the housing.

Owner:TELESWIVEL

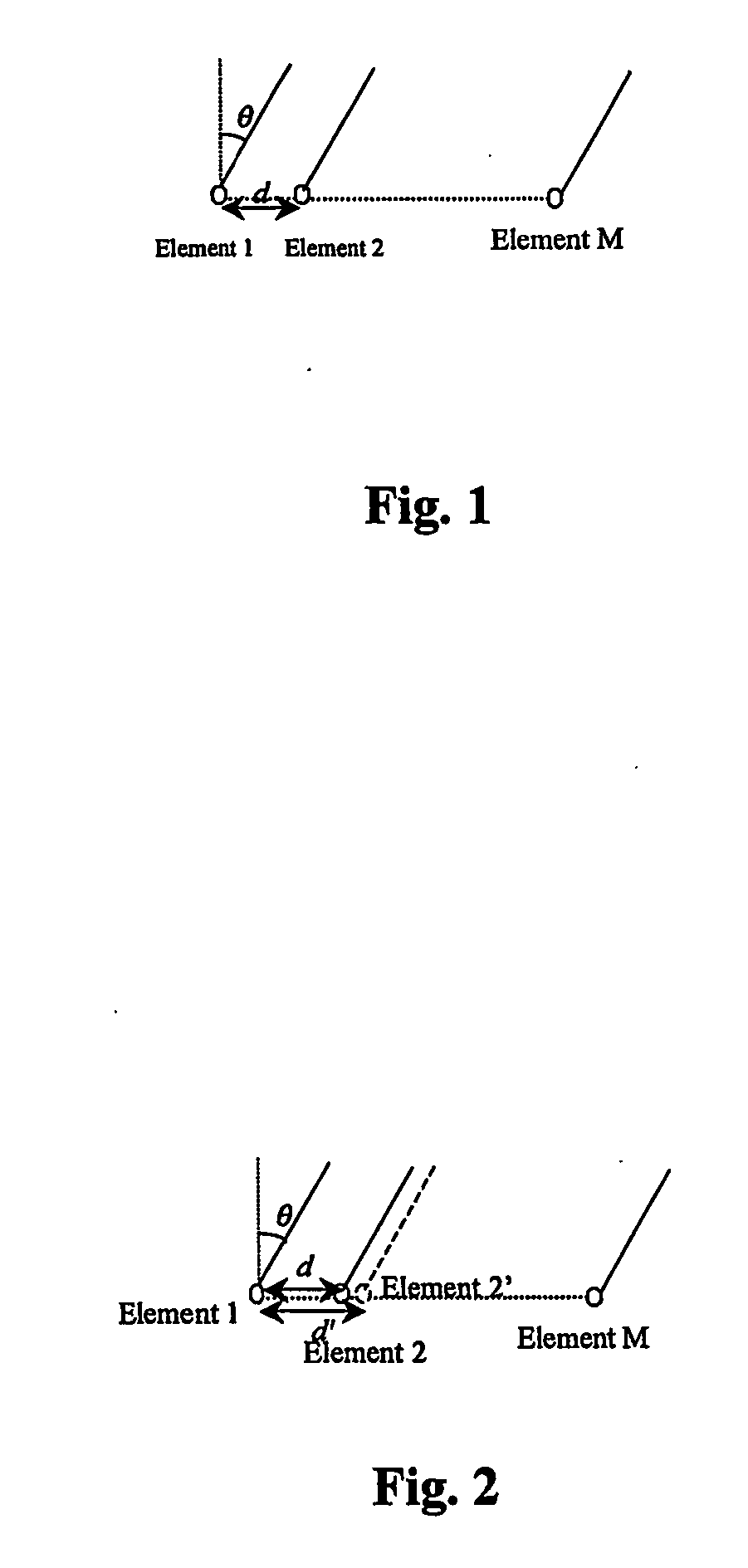

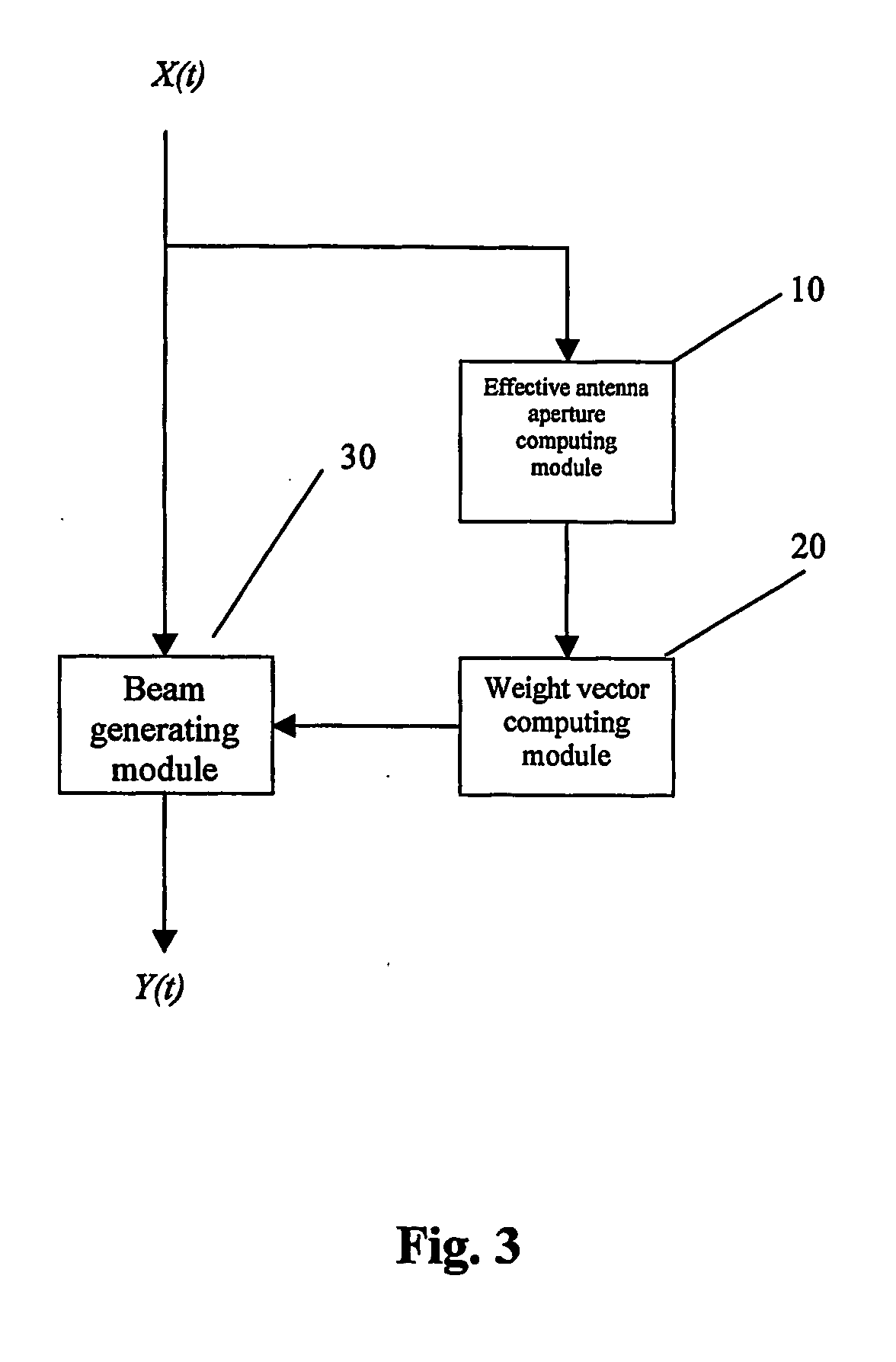

Method and apparatus for beamforming based on broadband antenna

ActiveUS20060181456A1Remove distortionConstant widthRadio wave direction/deviation determination systemsSubstation equipmentCommunication qualityBroadband

A beamforming method based on broadband antenna is provided, comprising: detecting the frequency of input signals of an antenna; determining the effective antenna aperture between elements of the antenna array according to the detected frequency; computing the weight vector of each element of the antenna array to the signals according to the determined effective antenna aperture and the transmission function of the antenna array; multiplying the input signals with said weight vector of each element of the antenna array to the signals, combining them and outputting the beam signals. By performing weighting operation respectively to the input signals after a series of delaying operation, and then combining them, the single digital signals can be acquired. This effectively reduces the odds produced by the antenna between transmitting signals and receiving signals, and thus dramatically improves the communication quality.

Owner:UNILOC 2017 LLC

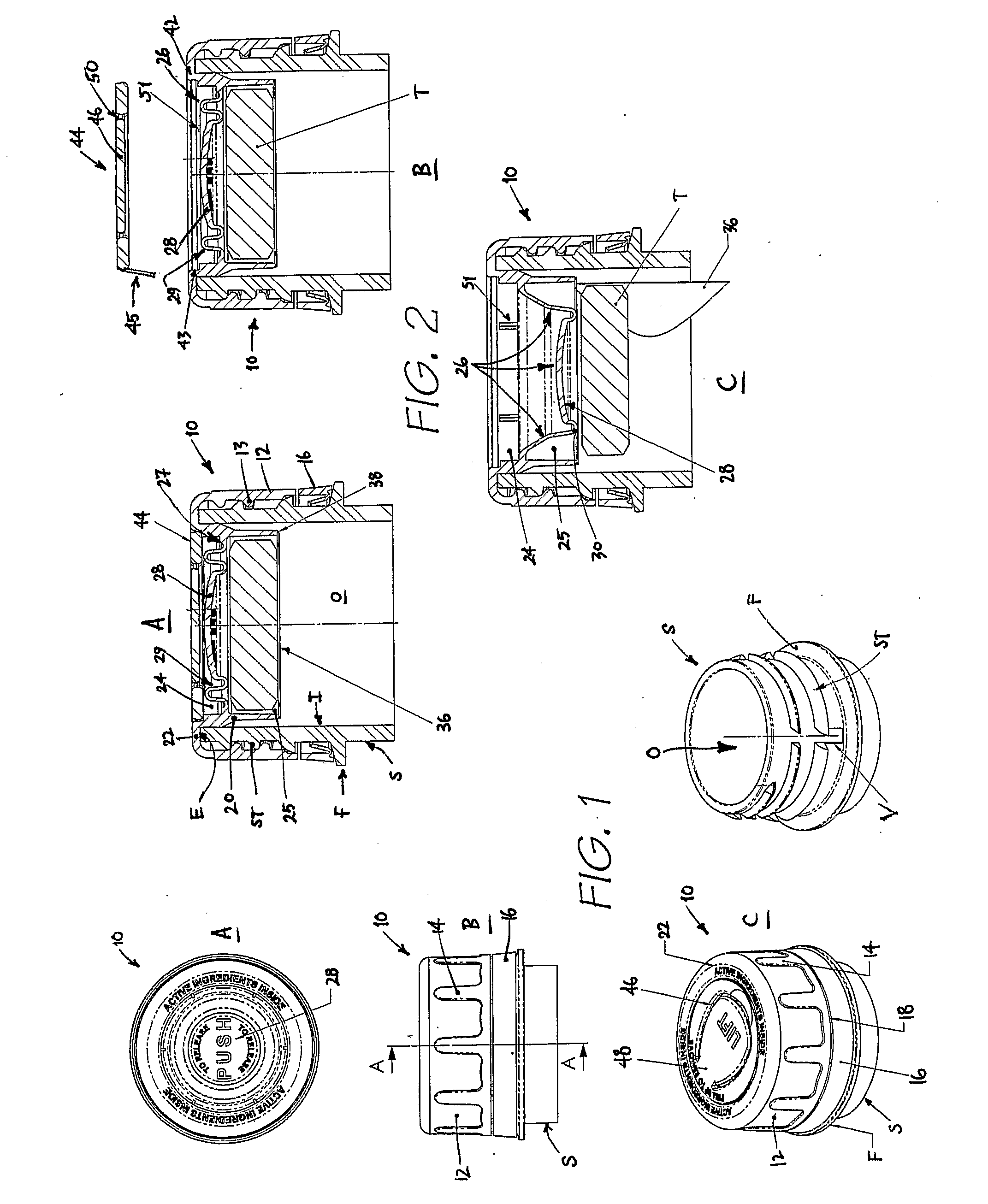

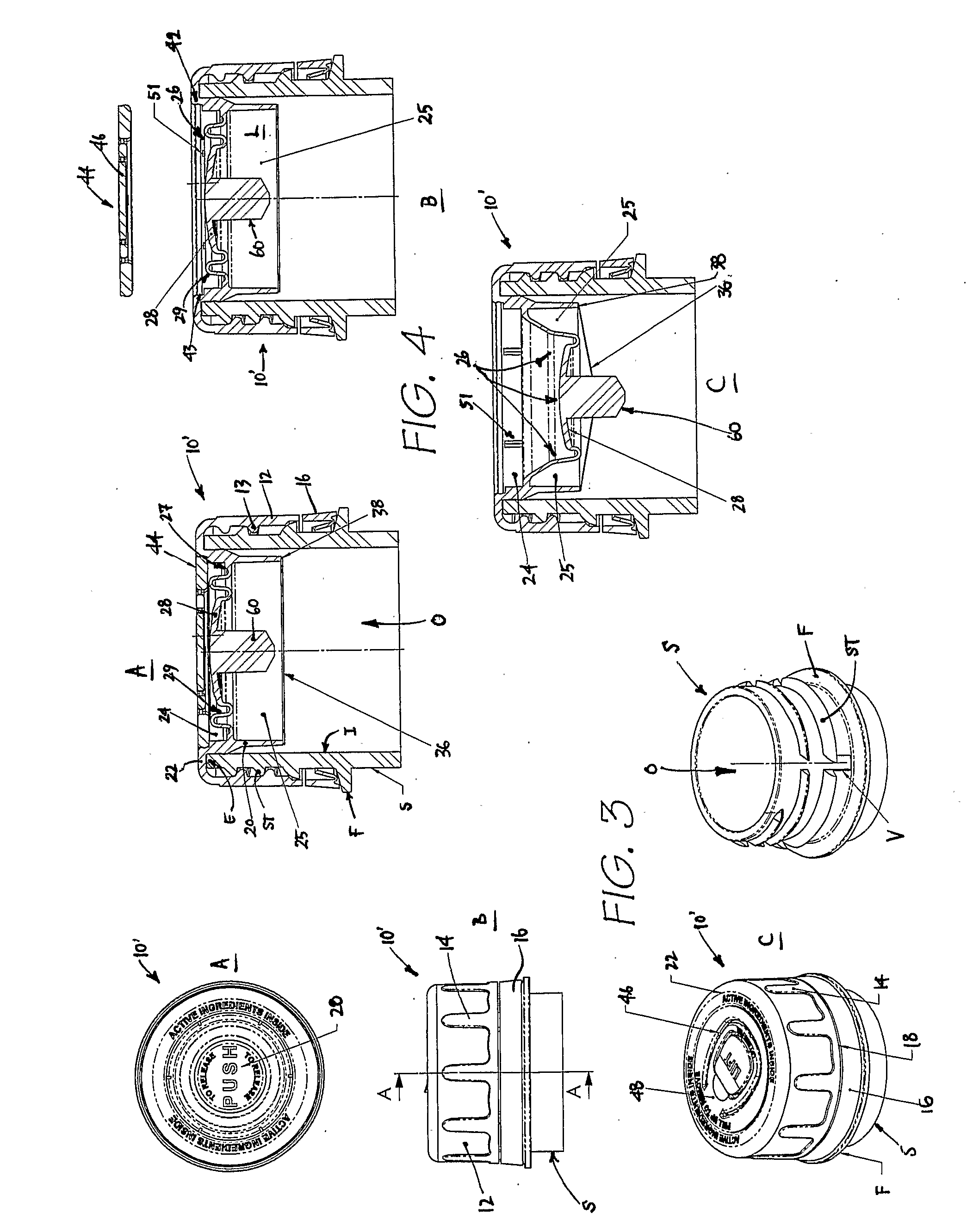

Closure

ActiveUS20090242561A1Considerable in operationEasy constructionCapsClosure using stoppersEngineeringBellows

A closure (10) for mounting at an opening (O) of a container spout (S) comprises a compartment (32) in which material such as a tablet (T) can be positioned. The compartment comprises a wall (26) that comprises a first region (28) that is surrounded by a second bellows-like region (30) that enables the first region to be displaced from a first position to a second position to cause the material to be released from the compartment. The wall can comprise a protrusion (X) that extends into the compartment such that, when the wall is displaced to the second position, the protrusion can cause the material to be released from the compartment. Also, when the wall is displaced to the second position the first region can act directly on the material to force it out of the compartment.

Owner:SOPHINITY PTY LTD (ATF WELLMAN CONSOLIDATED TRUST)

Device for clamping a fluidic component

ActiveUS20050194472A1Constant widthSpray nozzlesVibration suppression adjustmentsElastomerEngineering

A fluidic component consisting of silicon / glass, for example, is arranged in an elastomeric shaped part made of silicon rubber, for example, the contour of which is matched to the outer contour of the component and to the inner contour of a holder. The elastomeric shaped part is chamfered towards the fluidic component on its pressure side. When the holder is assembled the elastomeric shaped part is deformed by a projection provided on the mating part and is put under uniformly distributed internal tension, after which the elastomeric shaped part surrounds the fluidic component to its full height. This “floating mounting” means that there are no unacceptable local tension peaks and no deformation of the component. The mounting is sealed against the fluid even when the fluid pressure fluctuates repeatedly from a very low level to several 100 bar.

Owner:BOEHRINGER INGELHEIM INT GMBH

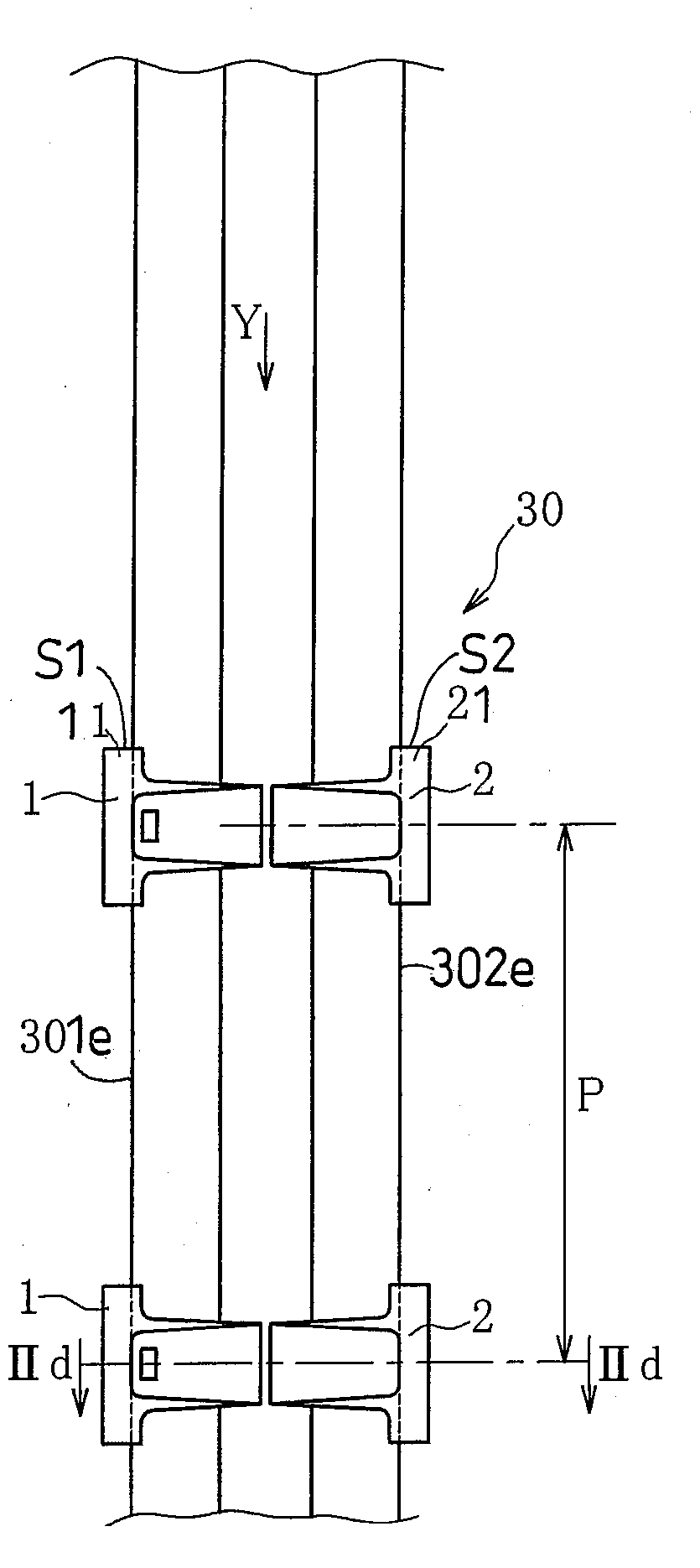

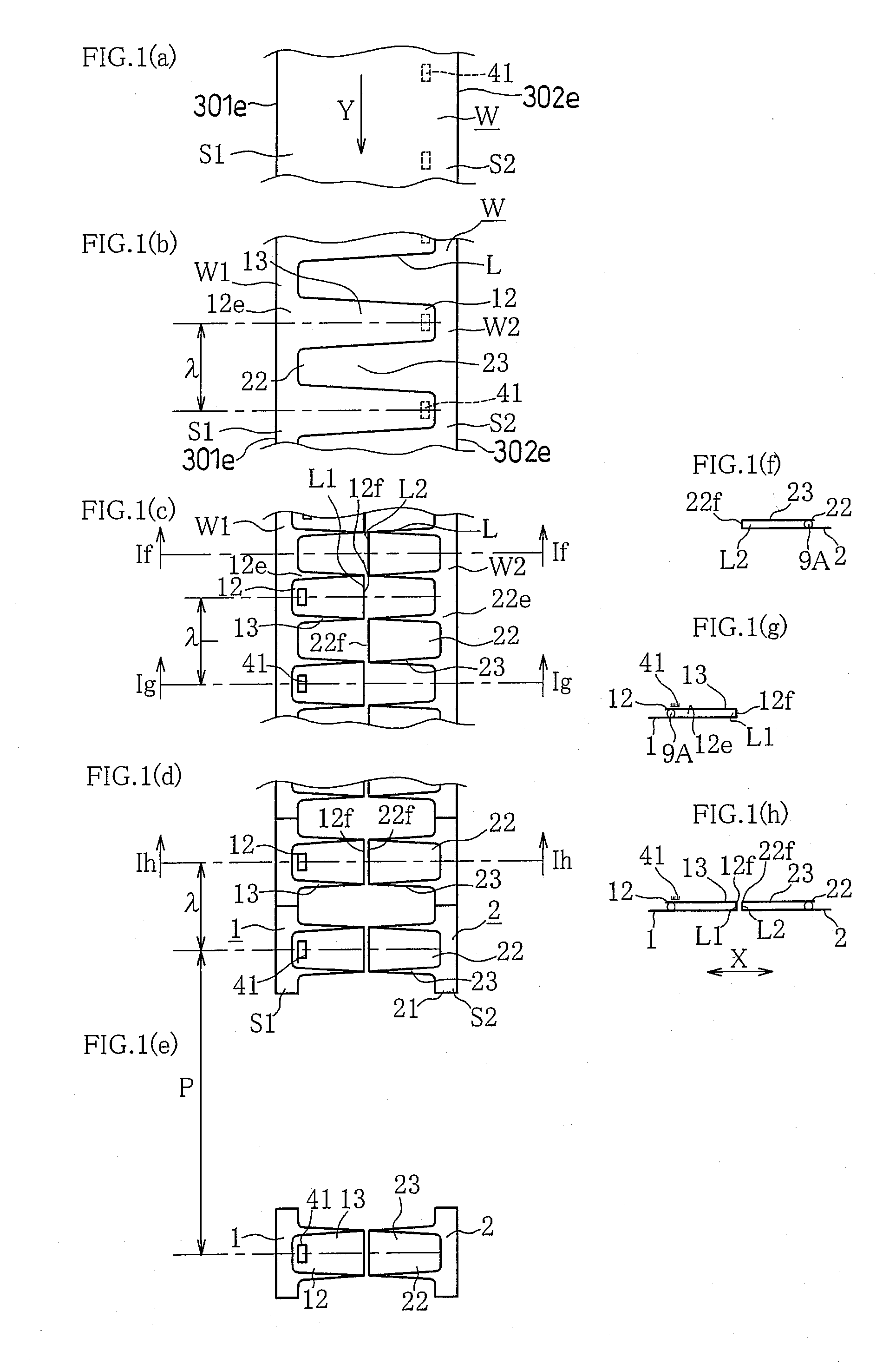

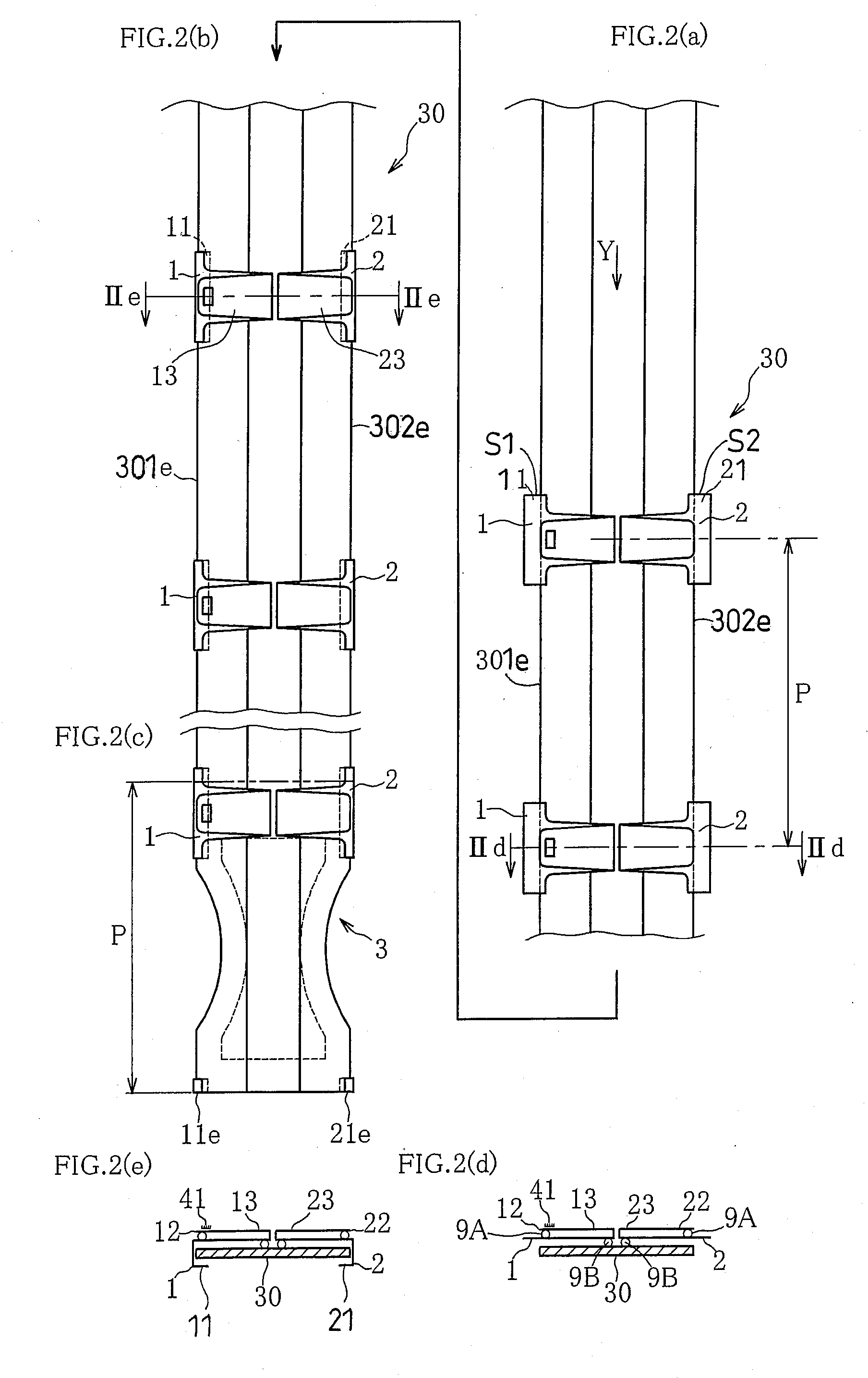

Method for producing diaper

InactiveUS20090126864A1Improve appearanceIncrease widthLayered productsAbsorbent padsEngineeringLeather belt

A method for producing a diaper of the present invention includes the steps of: folding back a first strip-shaped portion 13 and a second strip-shaped portion 23; successively forming pairs of first and second belts 1 and 2 by cutting first and second separate webs W1 and W2; placing pairs of the first and second belts 1 and 2 at a predetermined interval P in a carrying direction Y of a continuous piece; temporarily attaching the first and second belts 1 and 2 to a portion of the continuous piece to be a back portion; fixing the belts 1 and 2 to the continuous piece; and severing the continuous piece with the belts 1 and 2 fixed thereon at a predetermined pitch into individual diapers.

Owner:ZUIKO CORP

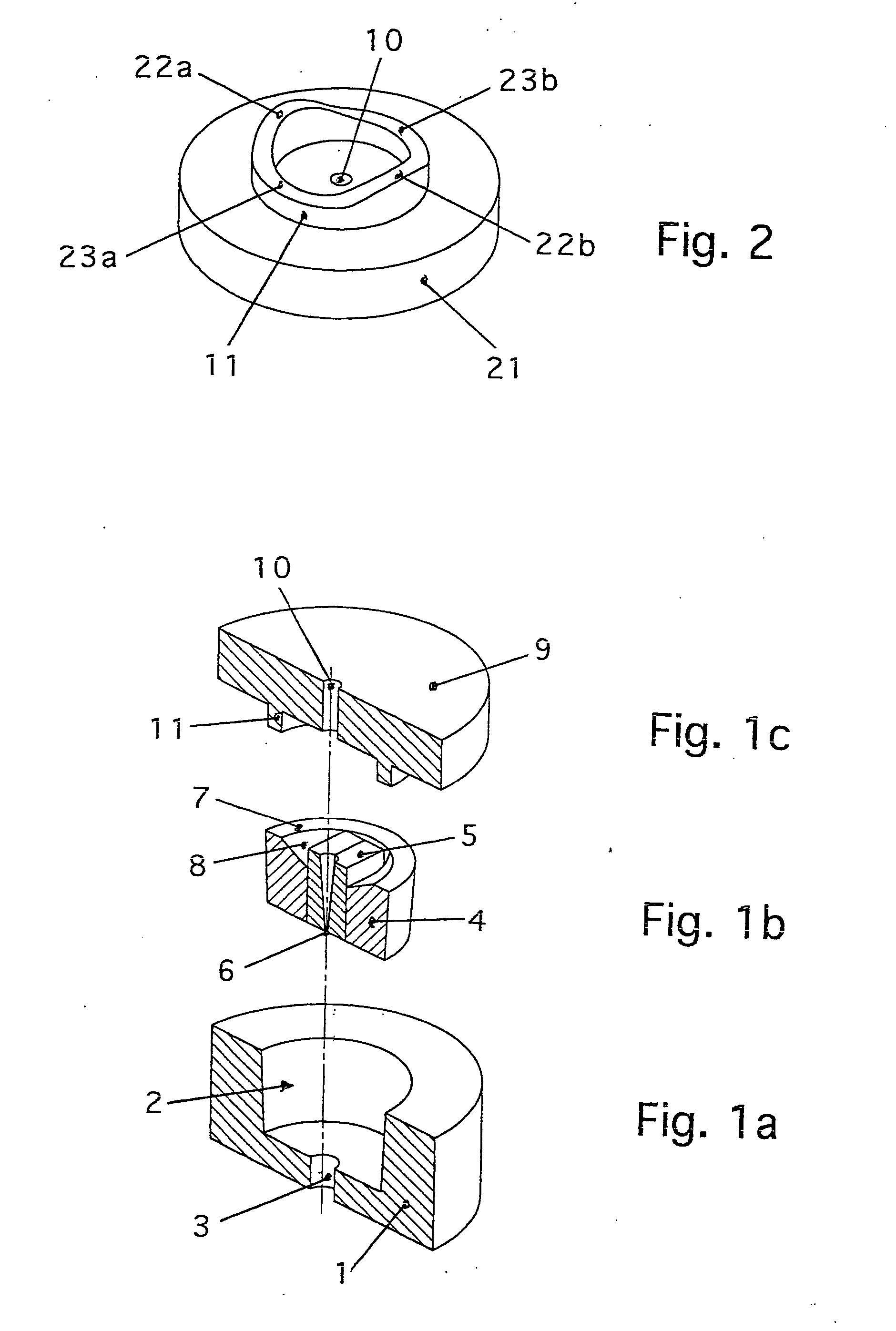

Thermionic electron emitter and x-ray souce including same

InactiveUS20100195797A1Excellent propertyMinimal focal spot sizeX-ray tube electrodesLamp incadescent bodiesX-rayAtomic physics

A thermionic electron emitter (1) is proposed comprising an inner part (2) including a heatable flat emission surface (3) and an outer part (4) including a surrounding surface (6) substantially enclosing the emission surface and a heating arrangement for heating the emission surface to a temperature for thermionic electron emission. The outer part is mechanically connected to the inner part in a connection region (10) apart from the emission surface. Furthermore, the surrounding surface is thermally isolated, e.g. by a gap (14), from the emission surface in an isolation region apart from the connection region. By providing a surrounding surface enclosing the emission surface which may be on a similar electrical potential as the emission surface but which can have a substantially lower temperature than the emission surface without influencing the temperature distribution within the emission surface, an improved electron emission distribution and homogeneity can be obtained.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

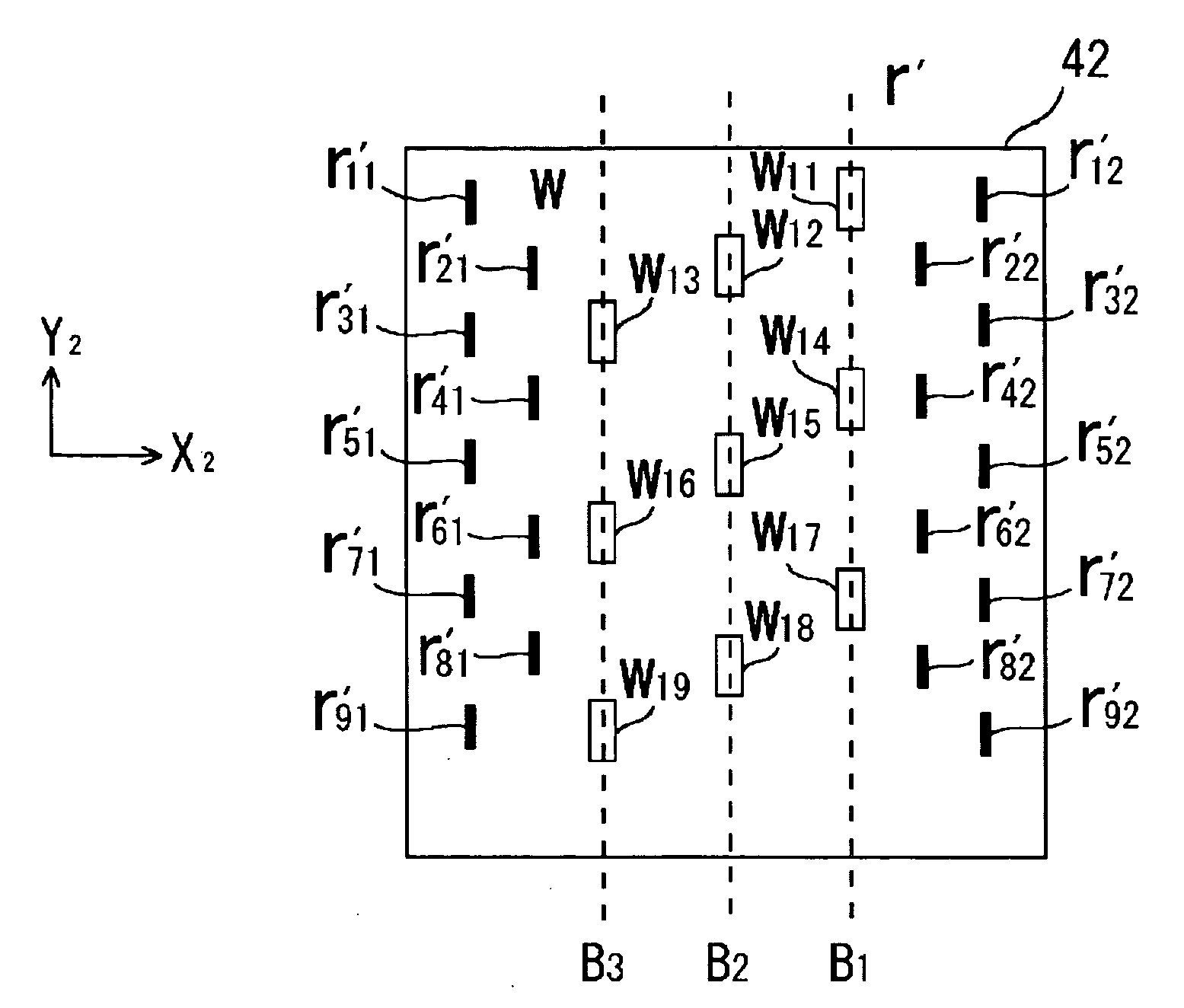

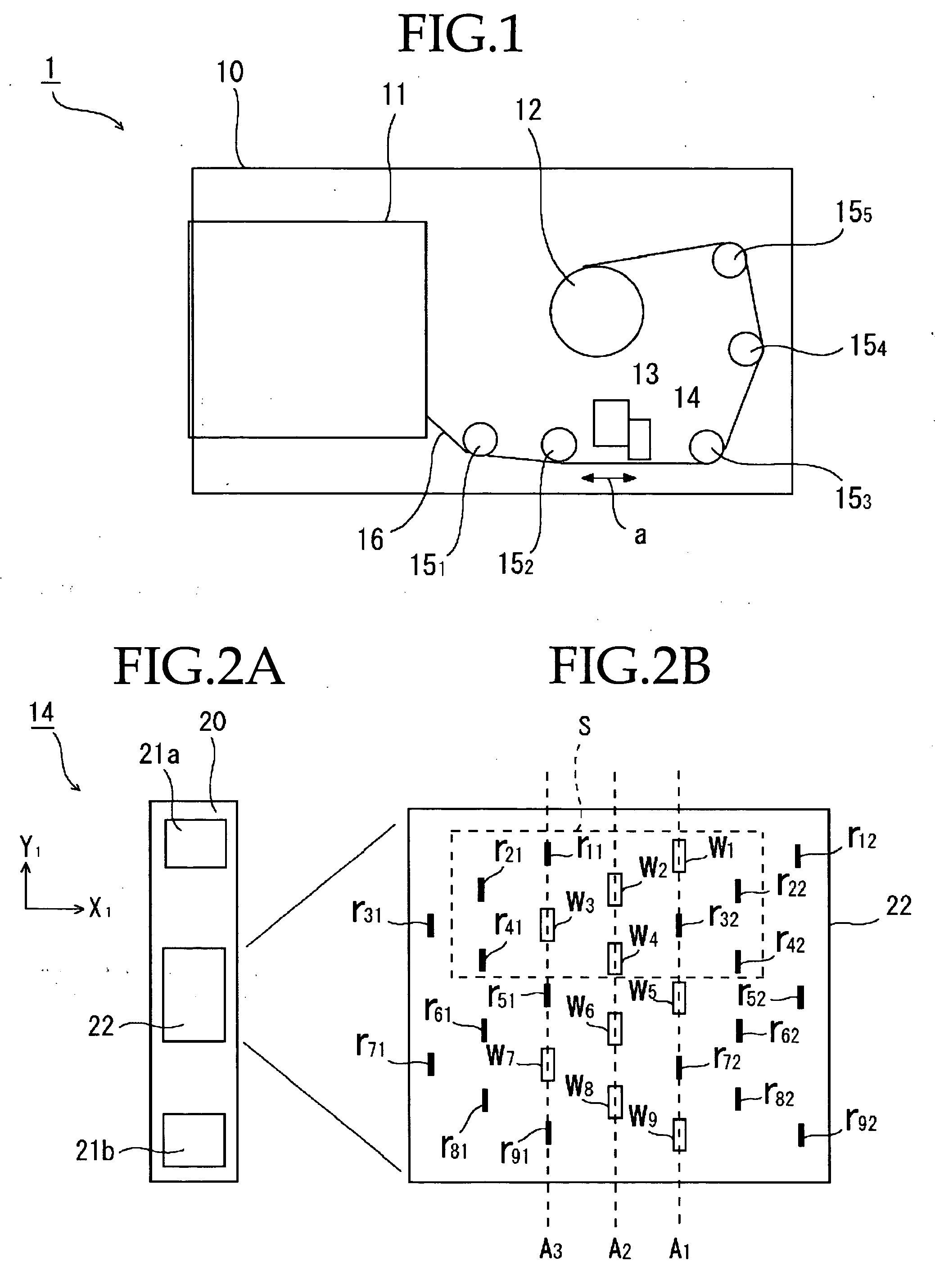

Tape recording system and head device

ActiveUS20050007700A1Reduce overlap areaImprove recording densityManufacturing heads with multiple gapsManufacture unitary devices of plural headsSignal onMagnetic tape

There is provided a tape recording system and head device. A tape recording system and head device include a plurality of recording sections for recording data signals on a recording medium wherein one recording section of the plurality of recording sections and another recording section arranged so as to adjoin the one recording section are disposed such that the one recording section and the another recording section are shifted from each other in a running direction and a width direction of the recording medium, and wherein the one recording section and another recording section simultaneously record a data signal on adjacent recording tracks on the recording medium.

Owner:SONY CORP

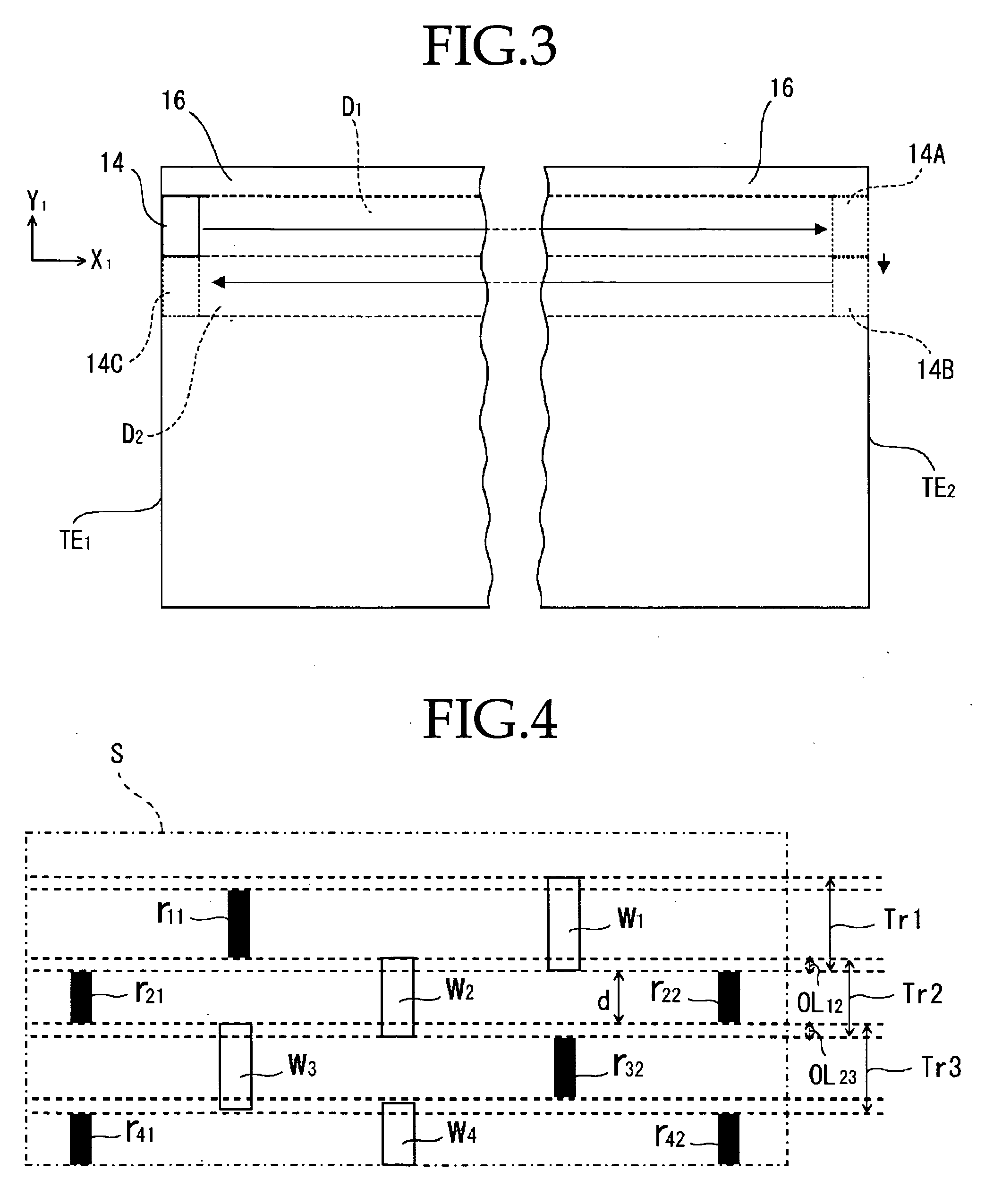

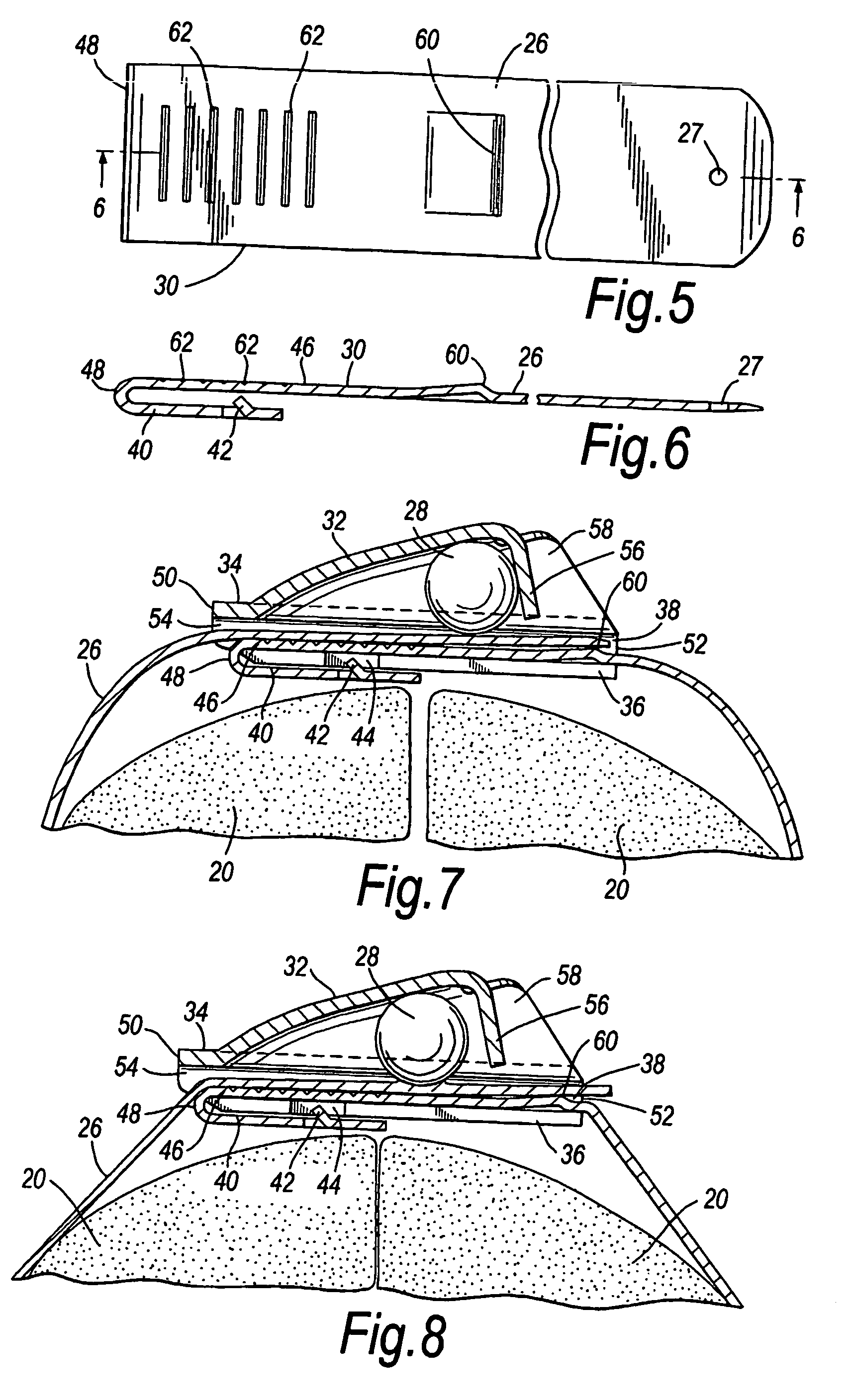

Suture band

InactiveUS20070055258A1Easy threadingPrevent movementSuture equipmentsInternal osteosythesisLocking mechanismEngineering

The present invention provides a suture band device comprising an elongated flexible band having first and second ends, a needle attached to the first end of the band, a buckle attached proximate the second end of the band for receiving and locking the band, characterised in the that buckle comprises a locking mechanism which enables the band to be locked at any point along its length.

Owner:HANSEN DORIS HJORTH

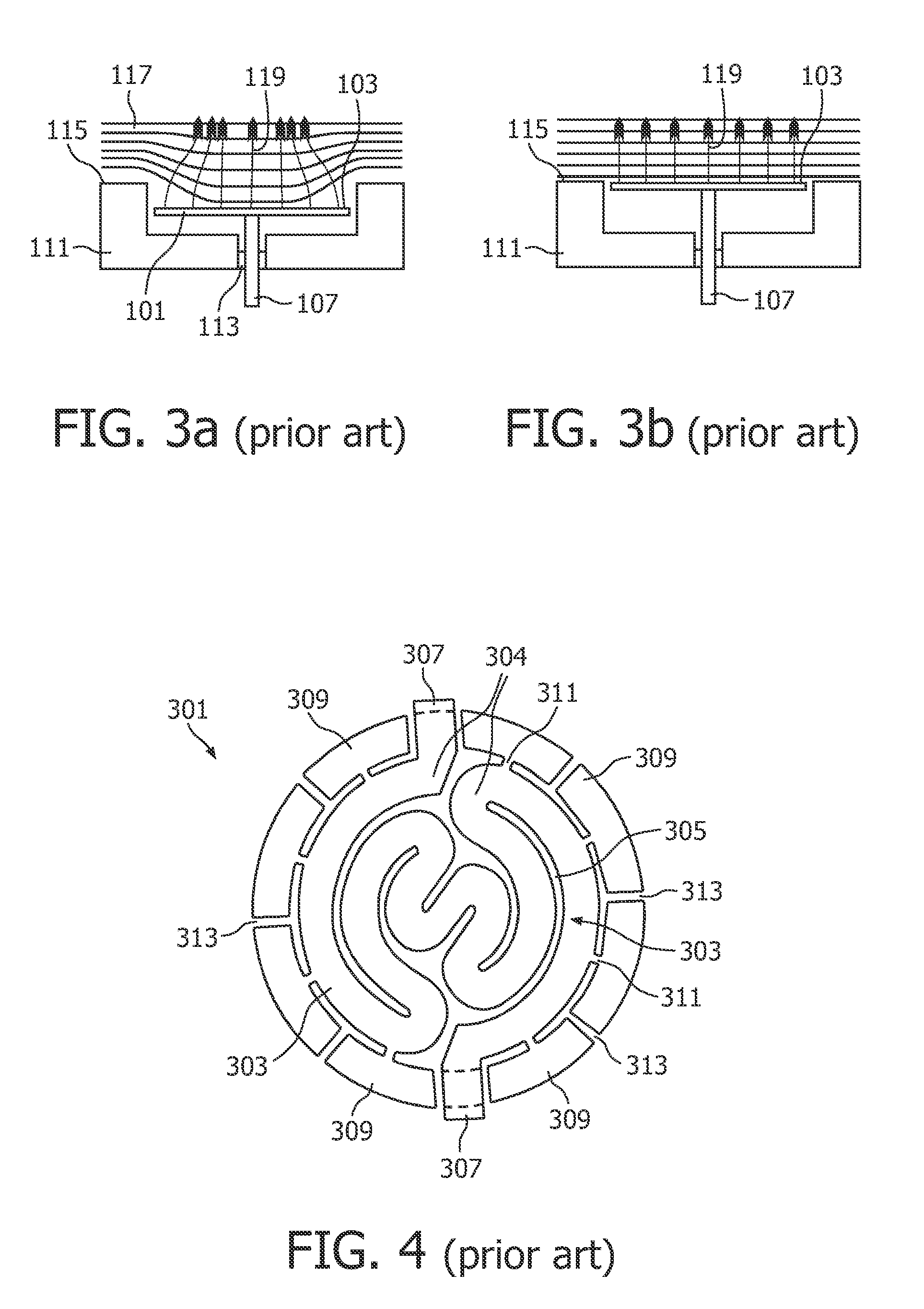

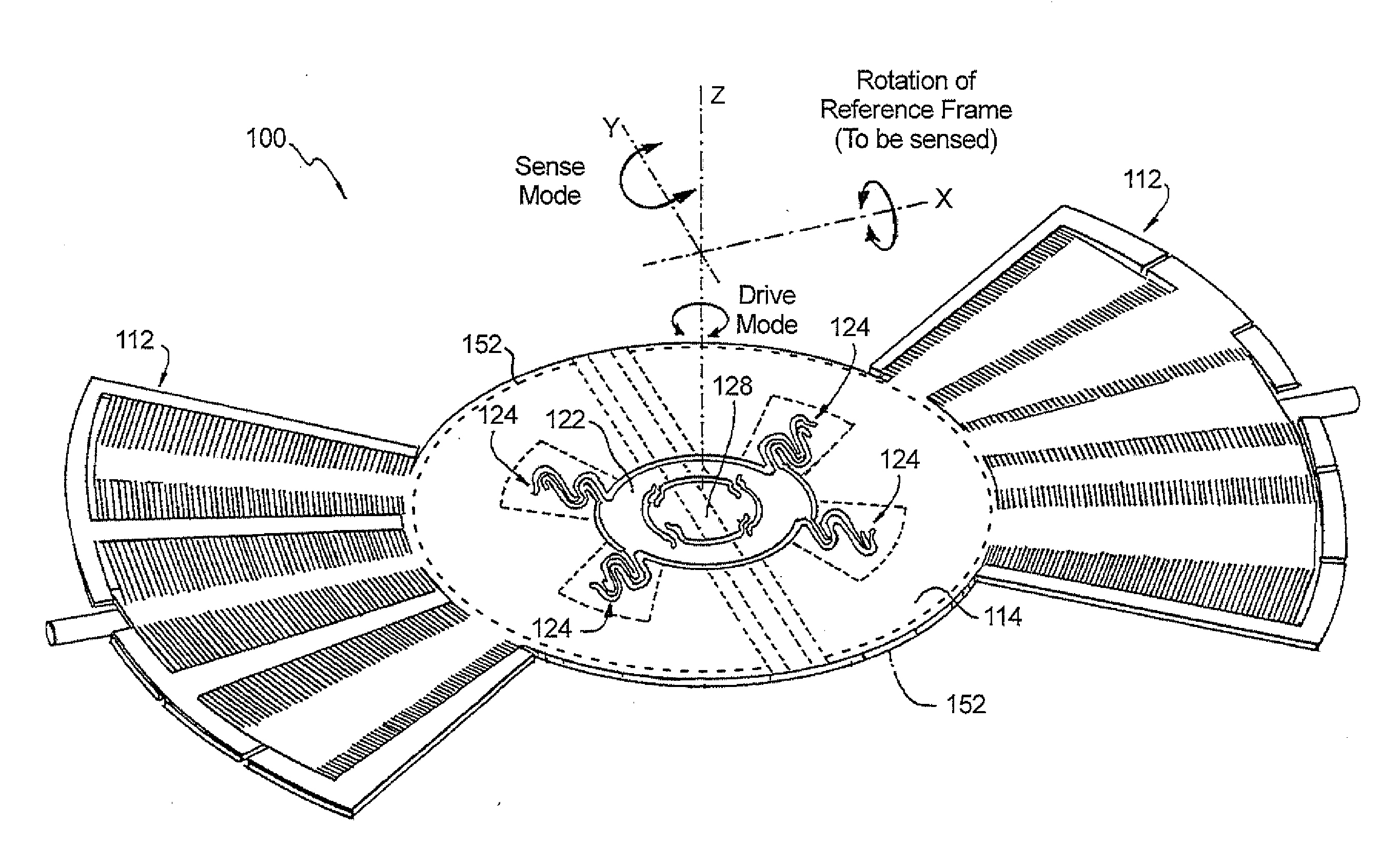

MEMS gyros with quadrature reducing springs

ActiveUS20120096943A1Reduce errorConstant widthAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsQuadrature errorMass balance

Spring set configurations that include an advantageous combination of spring geometries are disclosed. Spring elements having curved and straight sections, orientation of spring element anchor points with respect to the common radius, orientation of spring element segments with respect to a specific axis, balance of the length of spring elements about the common radius, and mass balance about the common radius can be used to mitigate unwanted out of plane motion. The spring set provides planar motion while reducing undesired out of plane motion making MEMS devices substantially insensitive to the process-induced etch angle variations of the spring elements. The spring set can be used in a MEMS gyro device which maintains the desired resonant modes and consistently low quadrature error even with process variations in manufacturing causing undesirable etch angles.

Owner:ROSEMOUNT AEROSPACE

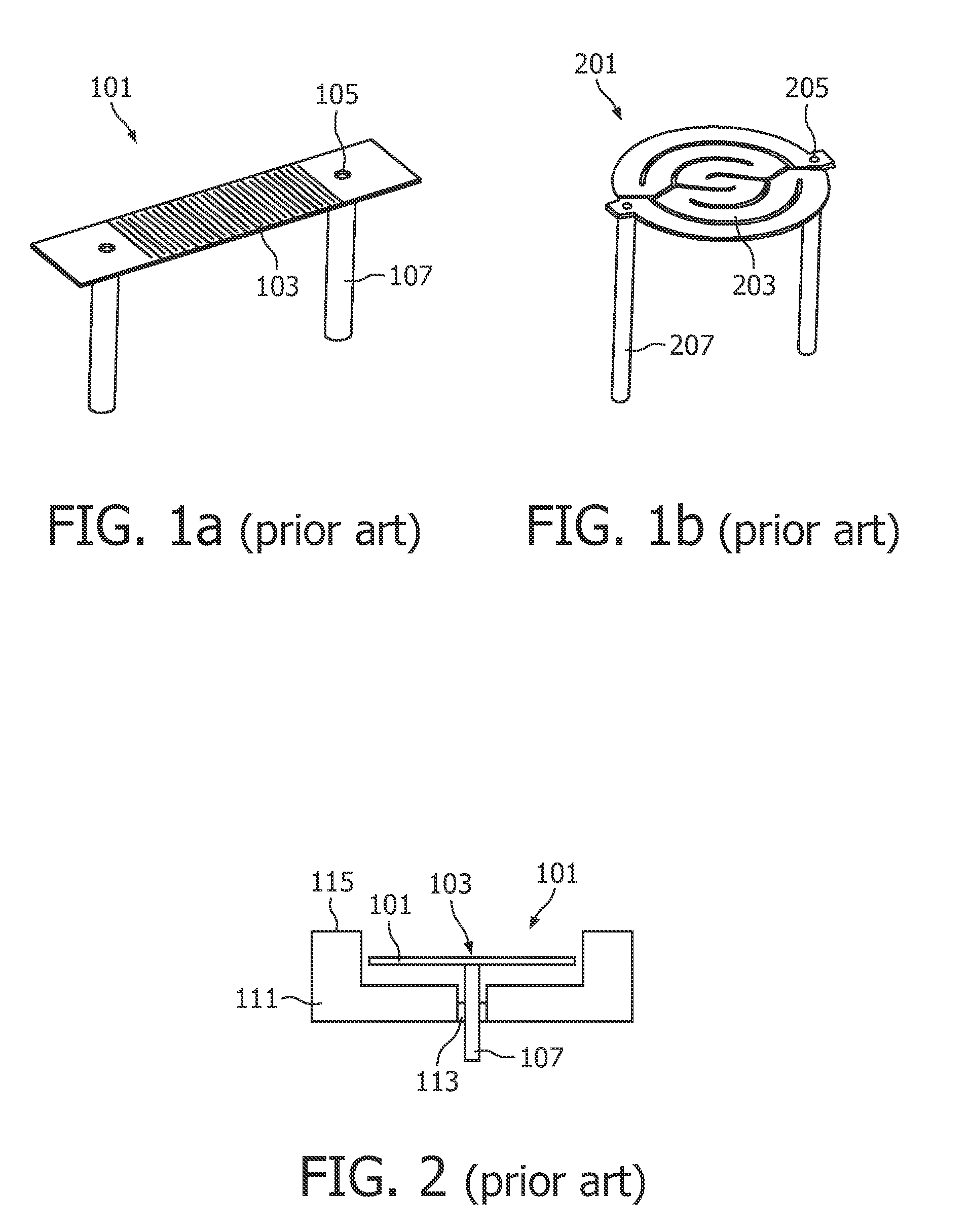

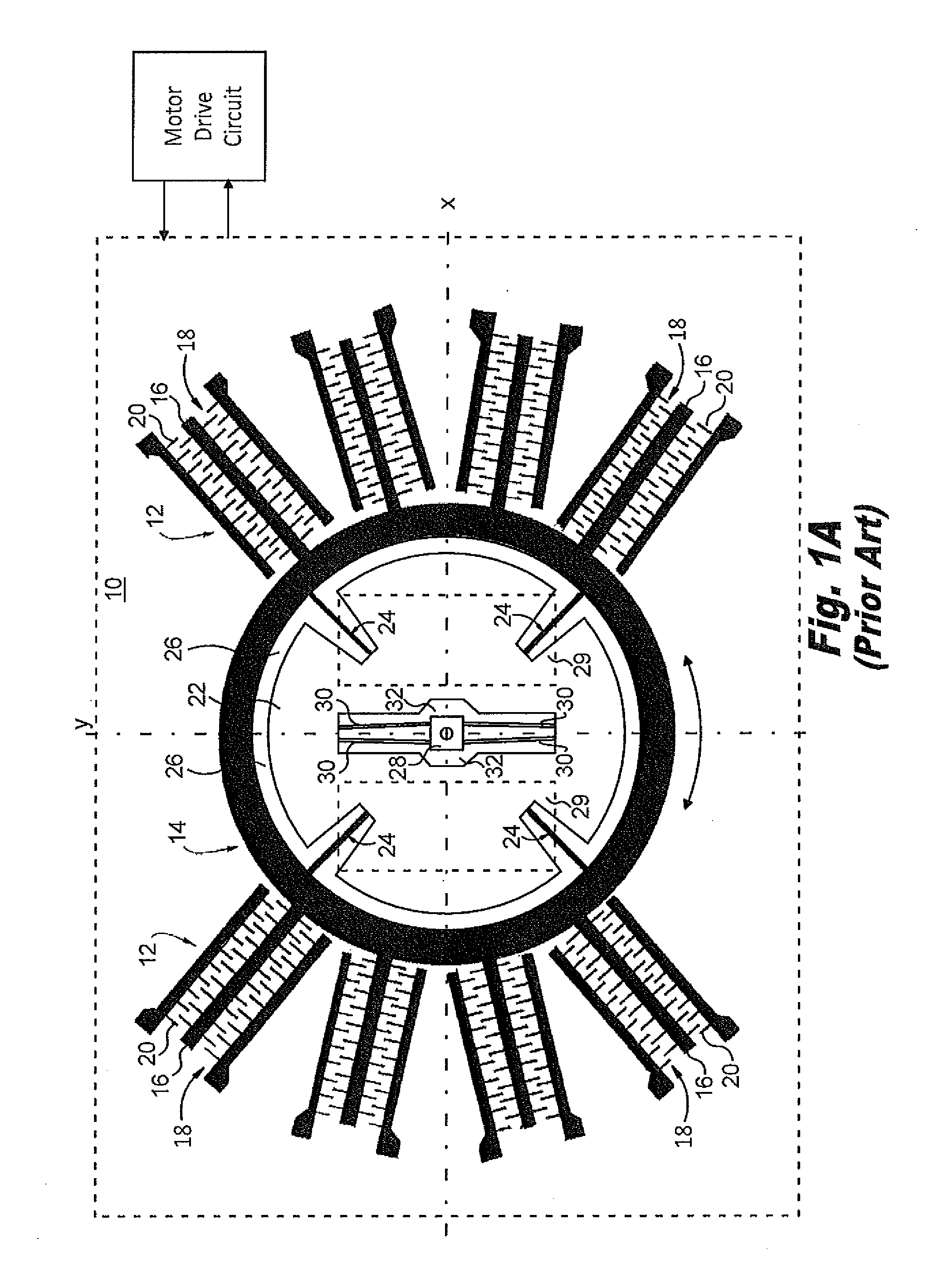

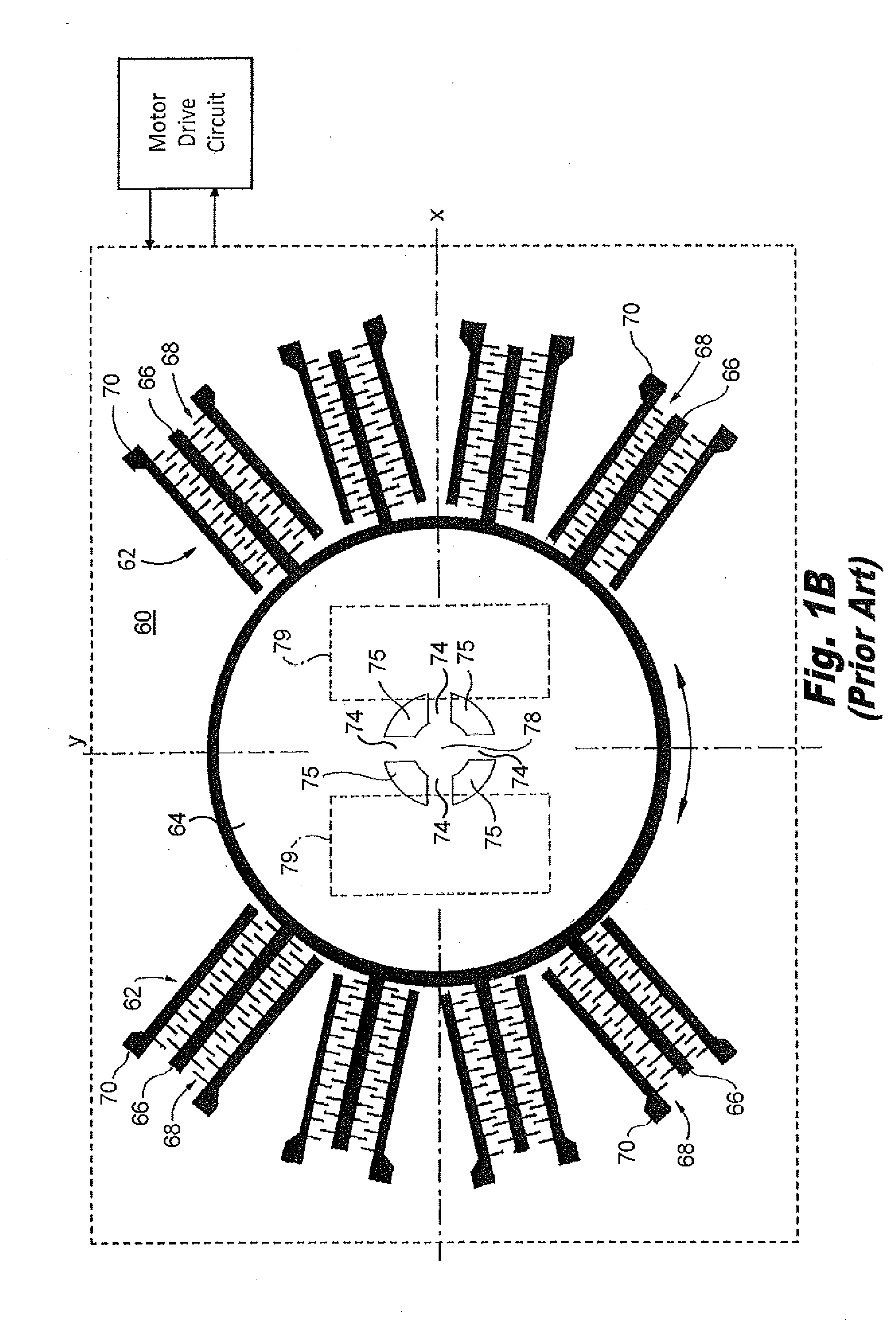

Deep reactive ion etching process and microelectromechanical devices formed thereby

InactiveUS7077007B2Uniform widthConstant gap widthAcceleration measurement using interia forcesDecorative surface effectsDevice formEngineering

A process for forming a microelectromechanical system (MEMS) device by a deep reactive ion etching (DRIE) process during which a substrate overlying a cavity is etched to form trenches that breach the cavity to delineate suspended structures. A first general feature of the process is to define suspended structures with a DRIE process, such that the dimensions desired for the suspended structures are obtained. A second general feature is the proper location of specialized features, such as stiction bumps, vulnerable to erosion caused by the DRIE process. Yet another general feature is to control the environment surrounding suspended structures delineated by DRIE in order to obtain their desired dimensions. A significant problem identified and solved by the invention is the propensity for the DRIE process to etch certain suspended features at different rates. In addition to etching wider trenches more rapidly than narrower trenches, the DRIE process erodes suspended structures more rapidly at greater distances from anchor sites of the substrate being etched. At the masking level, the greater propensity for backside and lateral erosion of certain structures away from substrate anchor sites is exploited so that, at the completion of the etch process, suspended structures have acquired their respective desired widths.

Owner:GOOGLE LLC

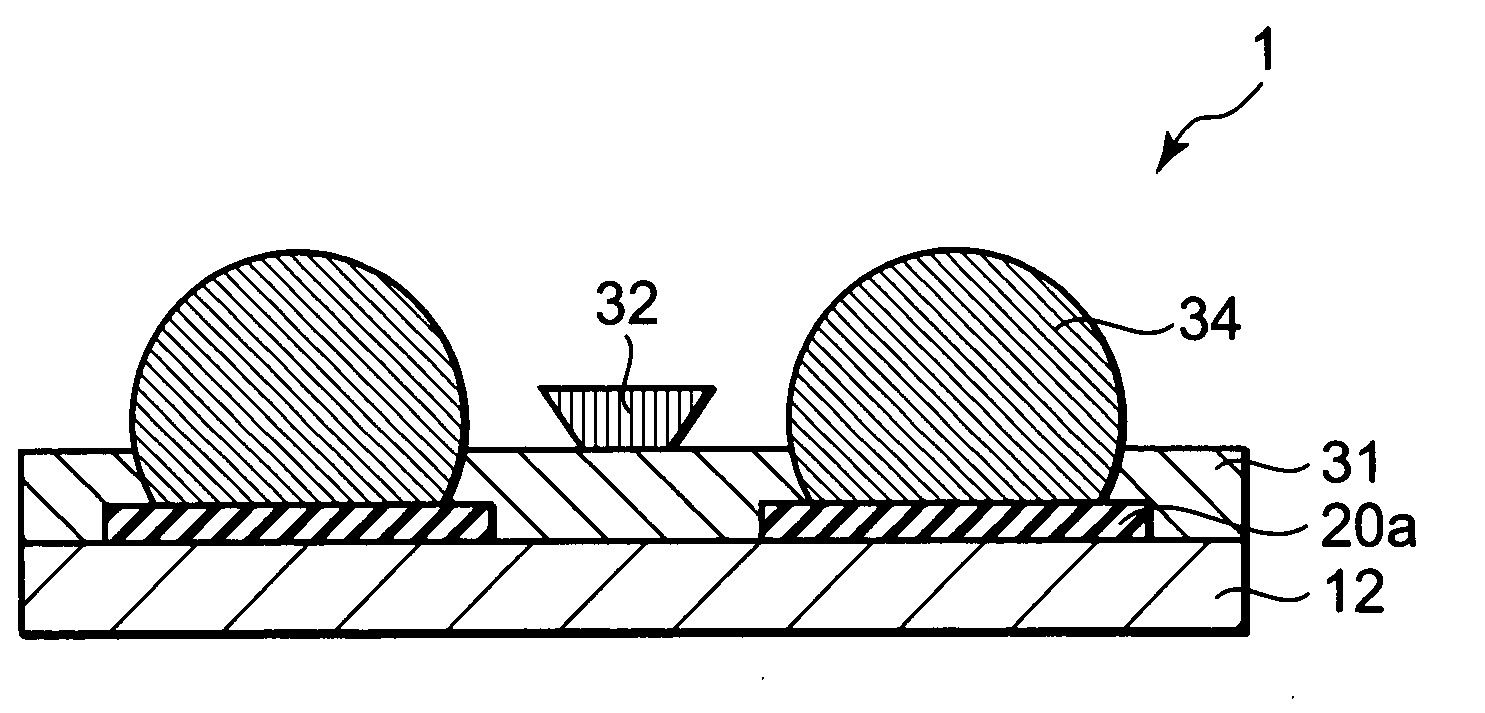

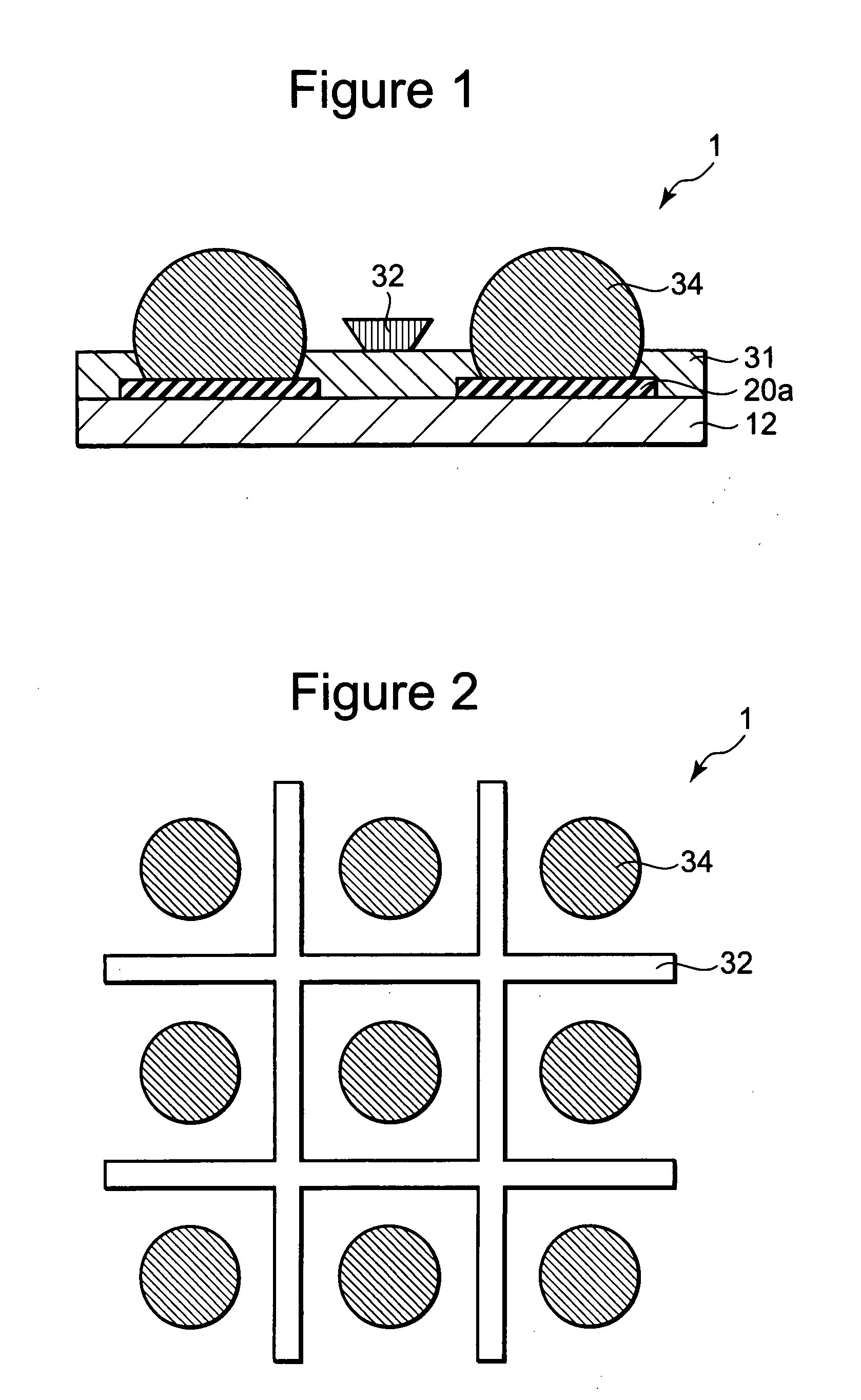

Printed wiring board having plural solder resist layers and method for production thereof

InactiveUS20080135279A1High adhesivenessConstant widthLiquid surface applicatorsSecond resist patternSolder maskResist

A printed wiring board includes: a substrate main body; a solder resist layer provided on the substrate main body and having a first opening in which a part of the solder bump is formed; and a solder resist layer provided on the solder resist layer and having a second opening through which the solder bump is formed. The shape of the second opening is non-analogous to the shape of the first opening when viewed as plane-wise.

Owner:RENESAS ELECTRONICS CORP

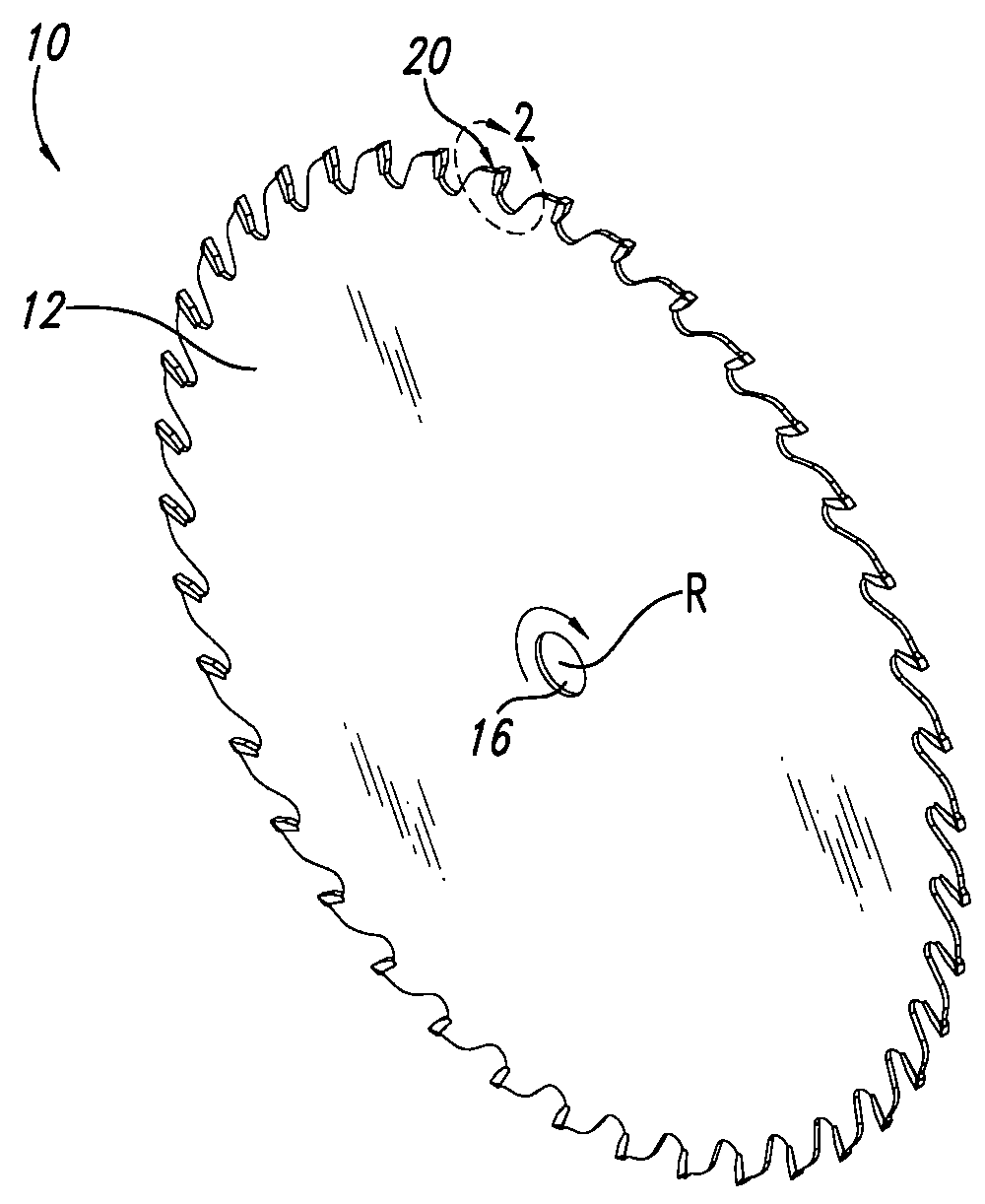

Saw blade and method of manufacturing the same

InactiveUS20100126326A1Constant widthGain is not constantMetal sawing devicesMetal sawing tool makingUpper toothCircular saw

A circular saw blade includes a substantially circular body having a plurality of protruding tip support regions spaced around the periphery thereof, each tip support region including at least a seat for supporting a cutting tip. The tip support region may further include a substantially planar upper tooth face, a grindable tip reinforcement portion and / or a lower tip angle less than 90 degrees. A cutting tip is secured to the seat of each tip support region preferably with a top face of each cutting tip substantially parallel to and offset from an upper tooth face of each tip support region. Each cutting tip of the circular saw blade is further configured to maintain a cutting edge at a substantially constant width when material is removed from the top face thereof. A method of manufacturing a saw blade is also provided.

Owner:CLOUTIER MICHAEL F

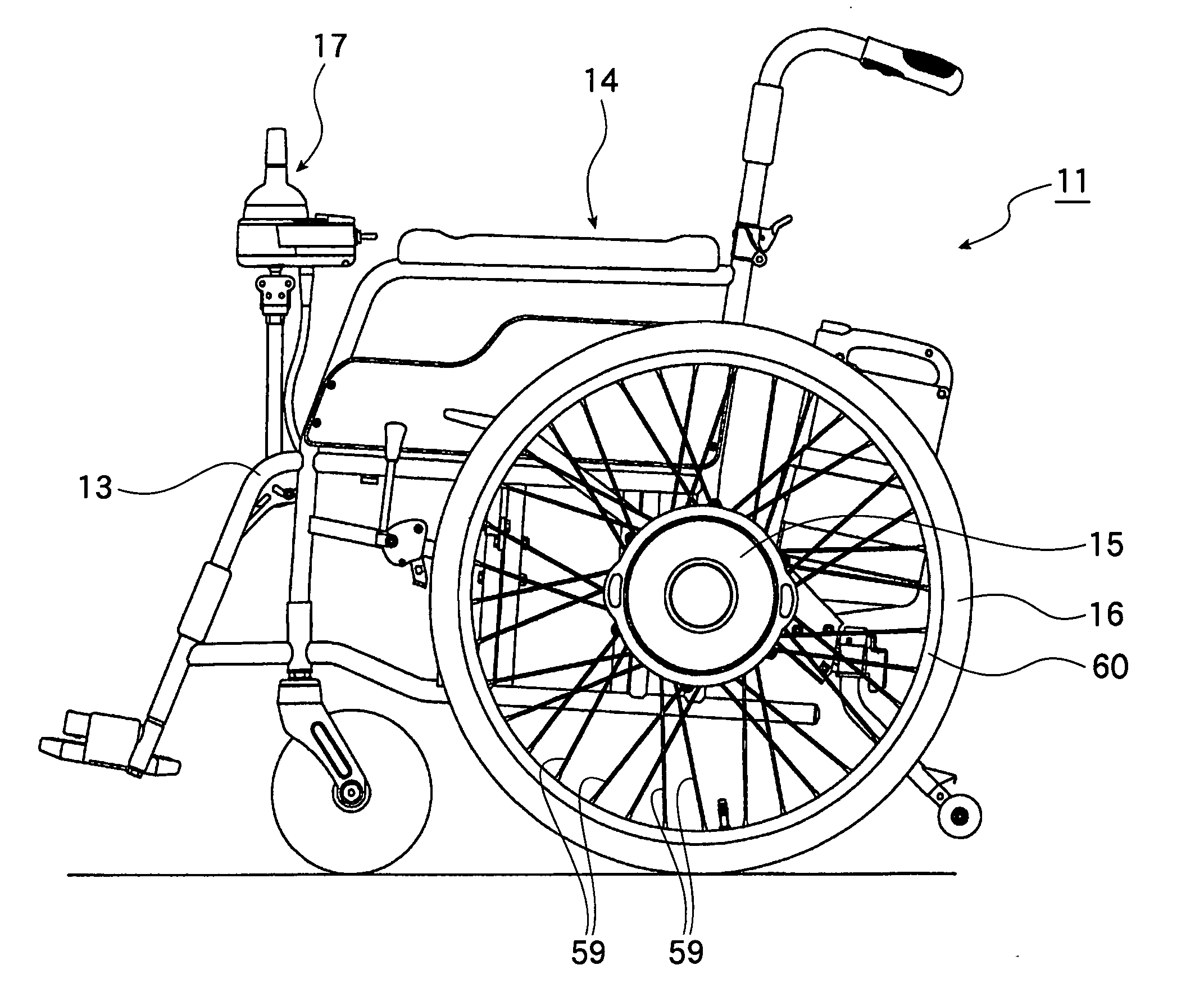

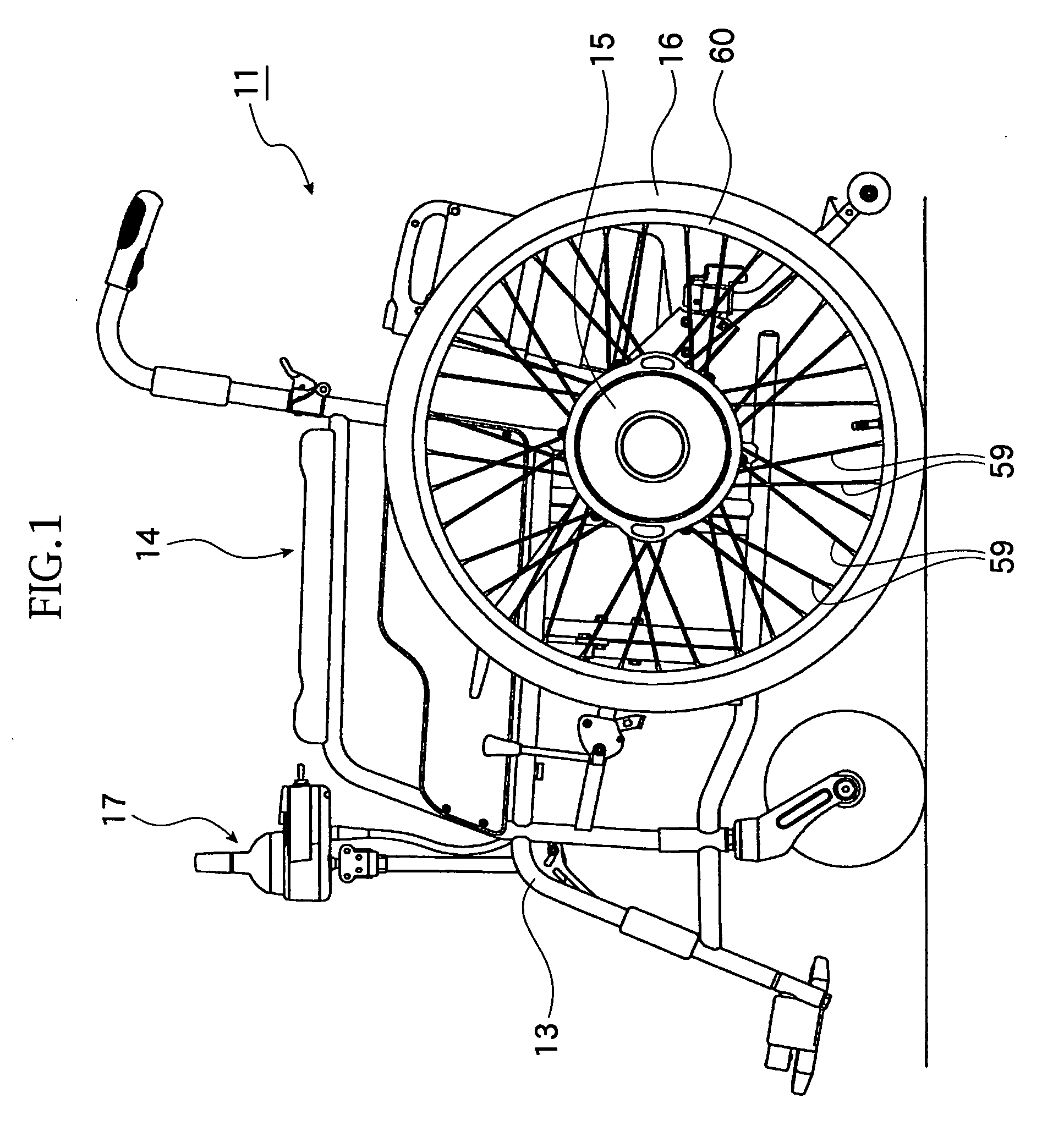

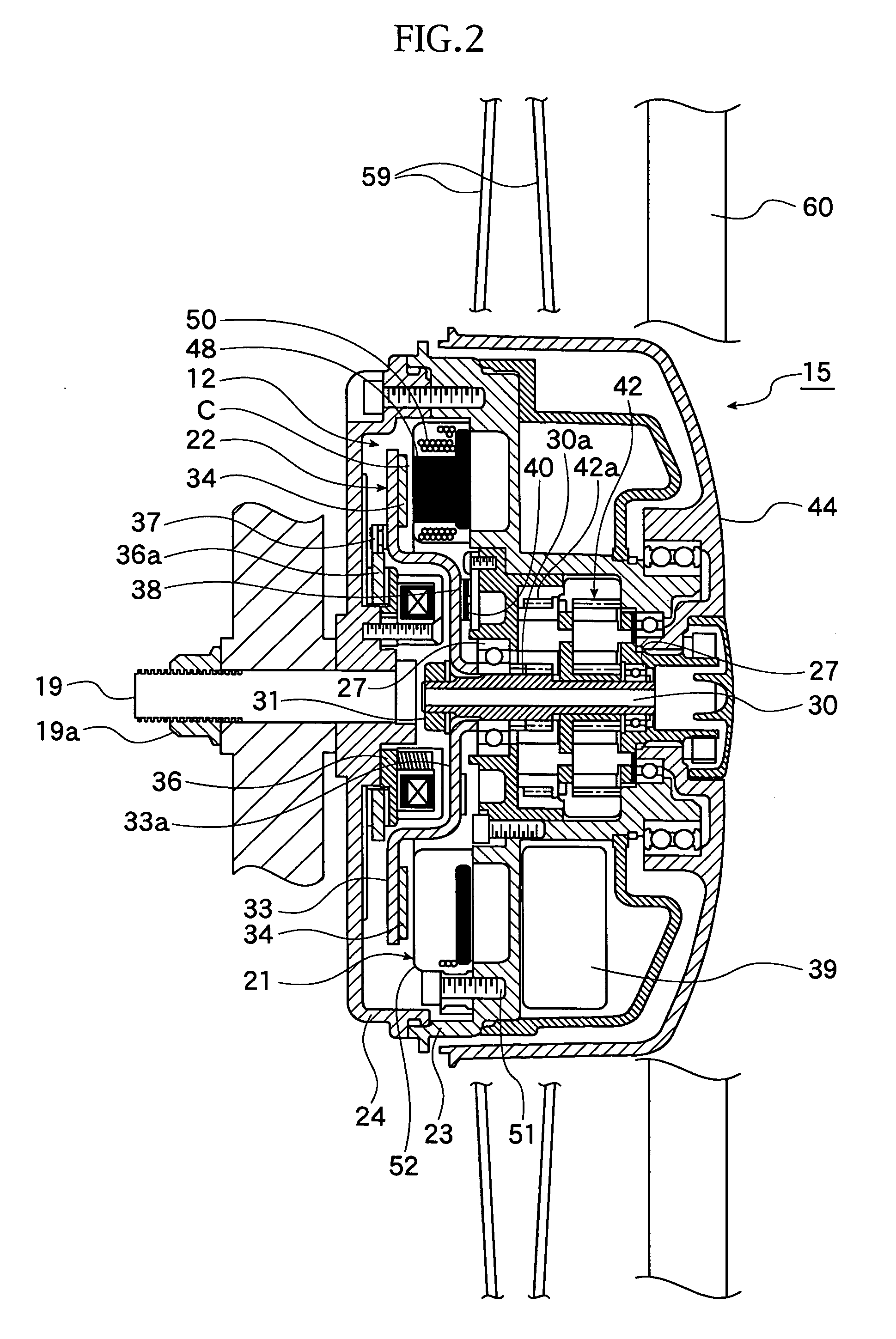

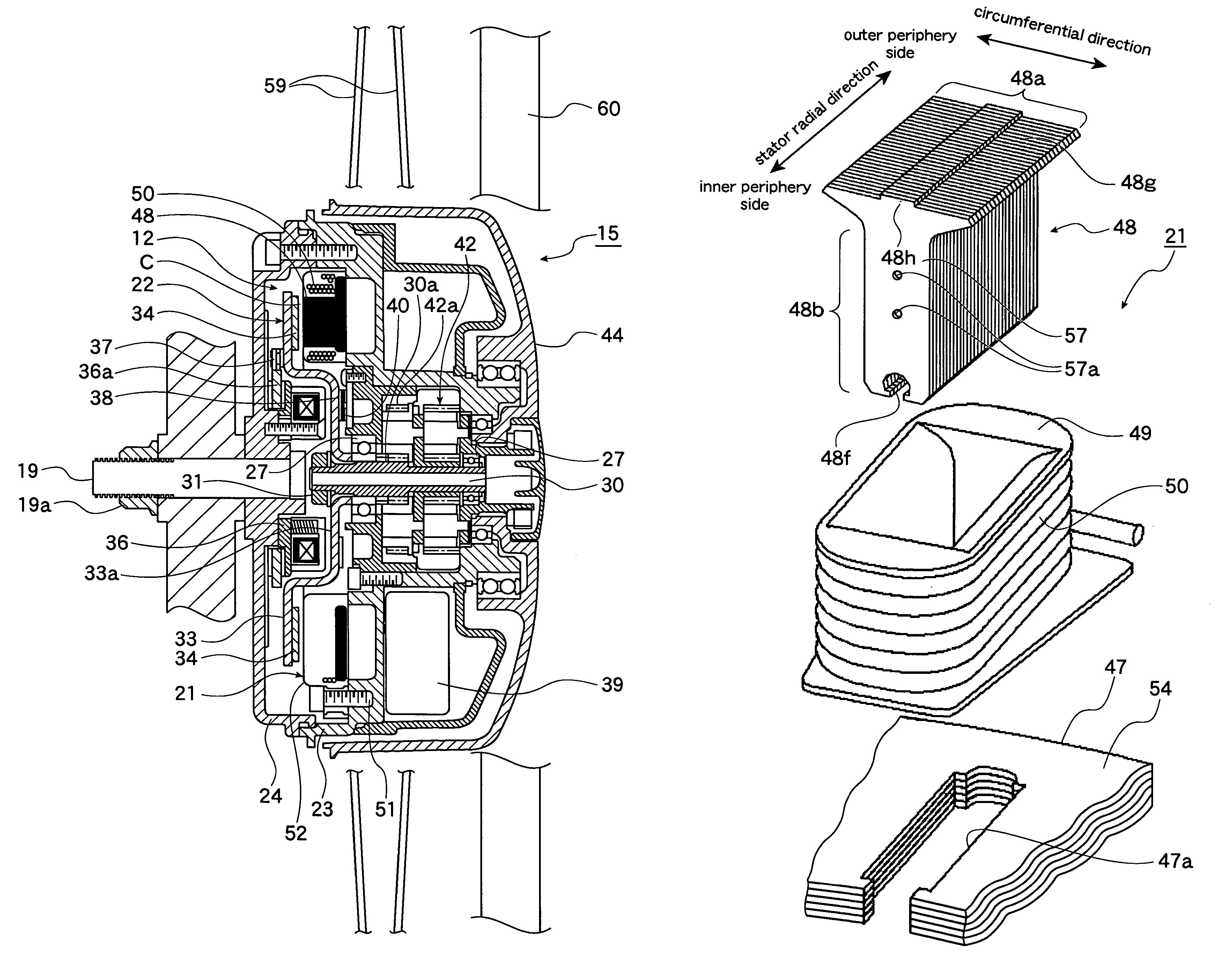

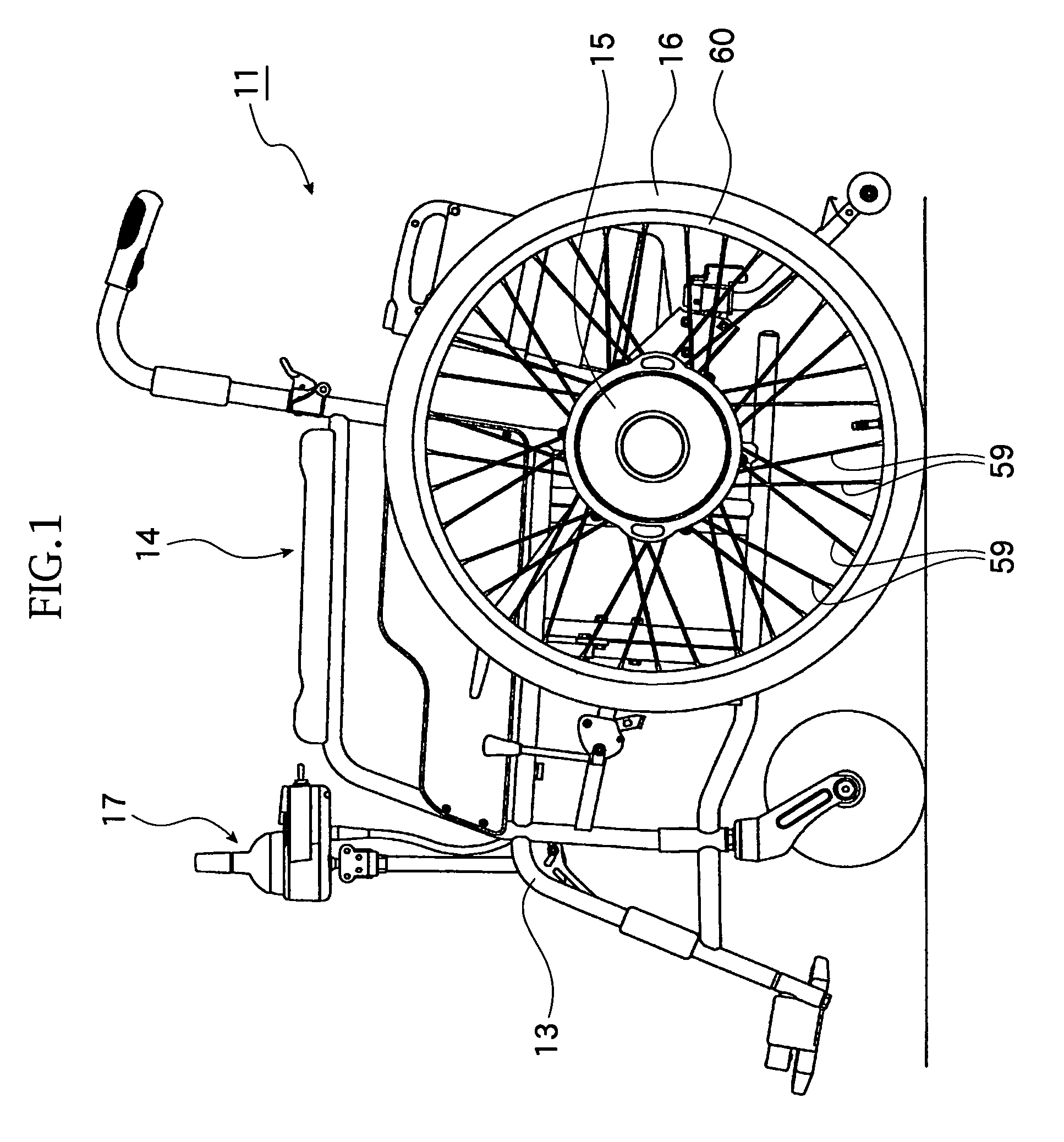

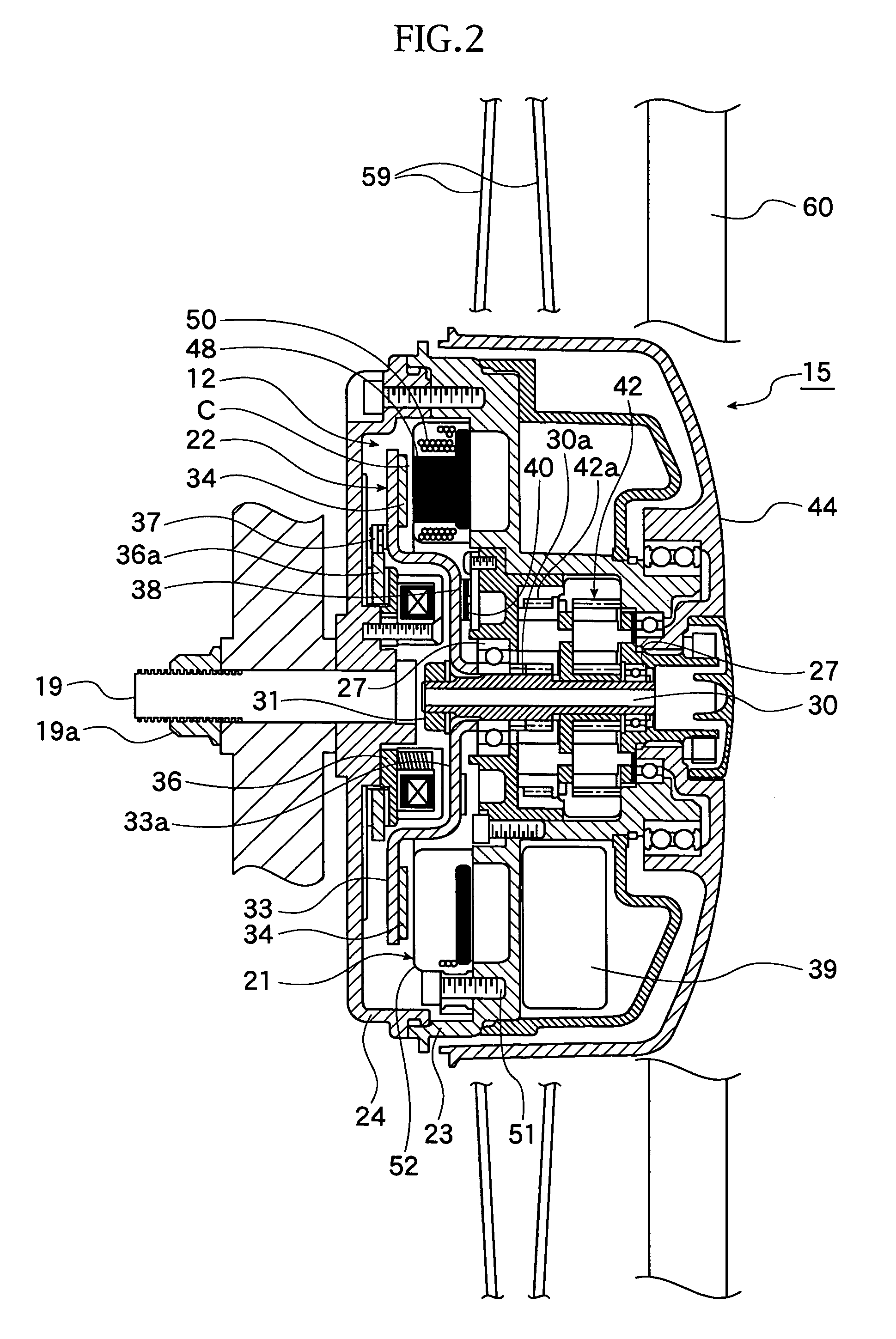

Rotary electric machine and electric wheelchair mounted with rotary electric machine

InactiveUS20070020985A1Minimally suppressing induction current lossConstant widthSpeed controllerMagnetic circuit rotating partsWheelchairElectric machine

A rotary electric machine comprises a stator including a plurality of teeth which are wound up by coils and a stator yoke core connecting the respective teeth, and a rotor provided with magnets disposed so as to oppose to the teeth, respectively, with a space therebetween. Each of the teeth (tooth) is formed into T shape by laminating a plurality of magnetic steel plates and has a head portion and a leg portion, the head portion being a wider portion of the T-shape which is opposed to the magnet, the leg portion including a coil wind-up portion which has a substantially constant width and an insert portion which is inserted into the stator yoke core, and the coil wind-up portion is formed with a plurality of fitting portions for fitting and fixing the laminated magnetic steel plates together, the fitting portions being arranged so as to align along a center line of the coil wind-up portion.

Owner:YAMAHA MOTOR CO LTD

Laser irradiation apparatus and laser irradiation method

InactiveUS7772523B2Reduce energy densityConstant widthSolid-state devicesSemiconductor/solid-state device manufacturingIrradiationSemiconductor

It is an object of the present invention to provide a laser irradiation apparatus and a laser irradiation method for conducting a laser process homogeneously to the whole surface of a semiconductor film. A first laser beam emitted from a first laser oscillator passes through a slit and a condensing lens and then enters an irradiation surface. At the same time, a second laser beam emitted from a second laser oscillator is delivered so as to overlap the first laser beam on the irradiation surface. Further, the laser beams are scanned relative to the irradiation surface to anneal the irradiation surface homogeneously.

Owner:SEMICON ENERGY LAB CO LTD

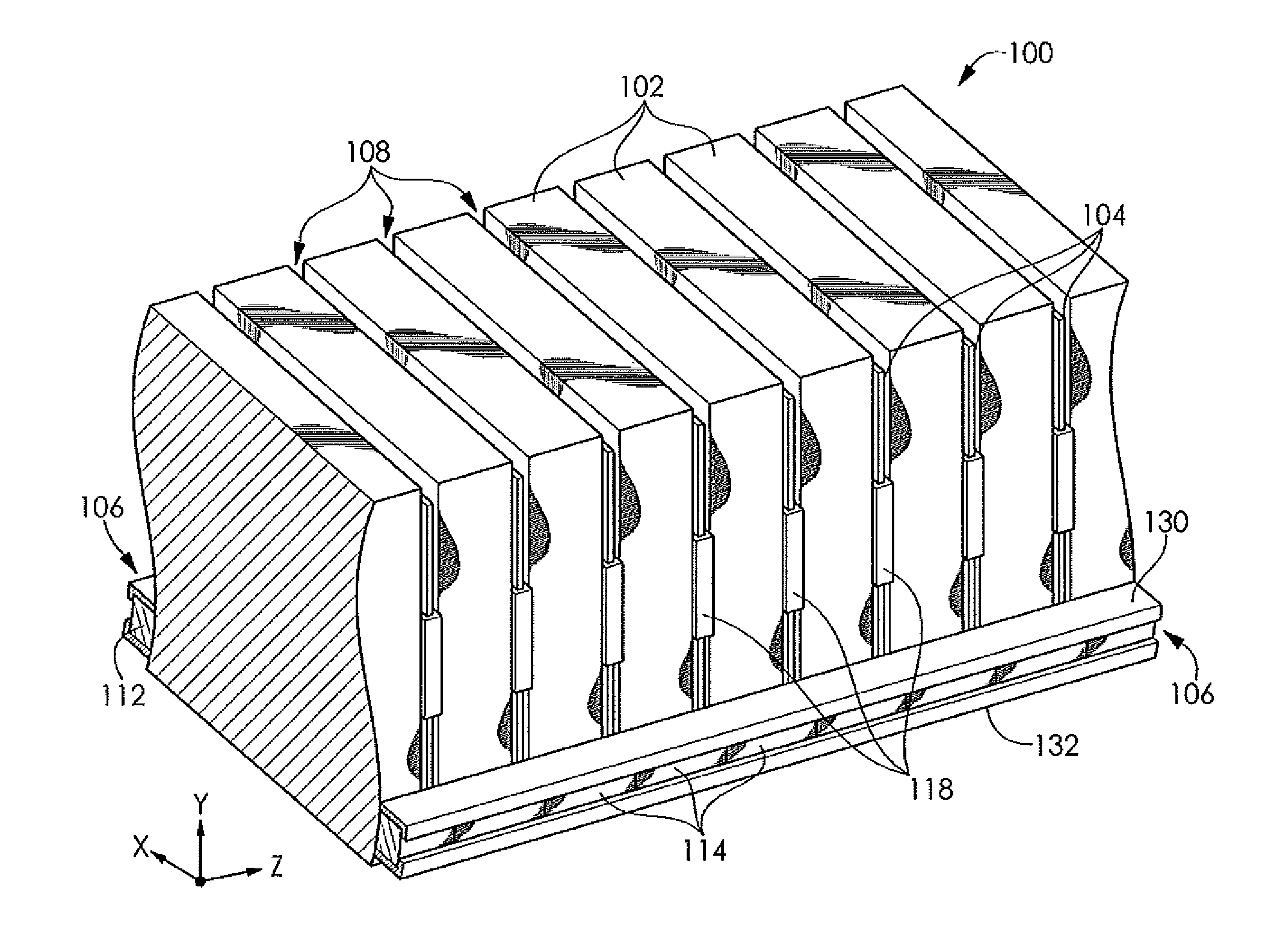

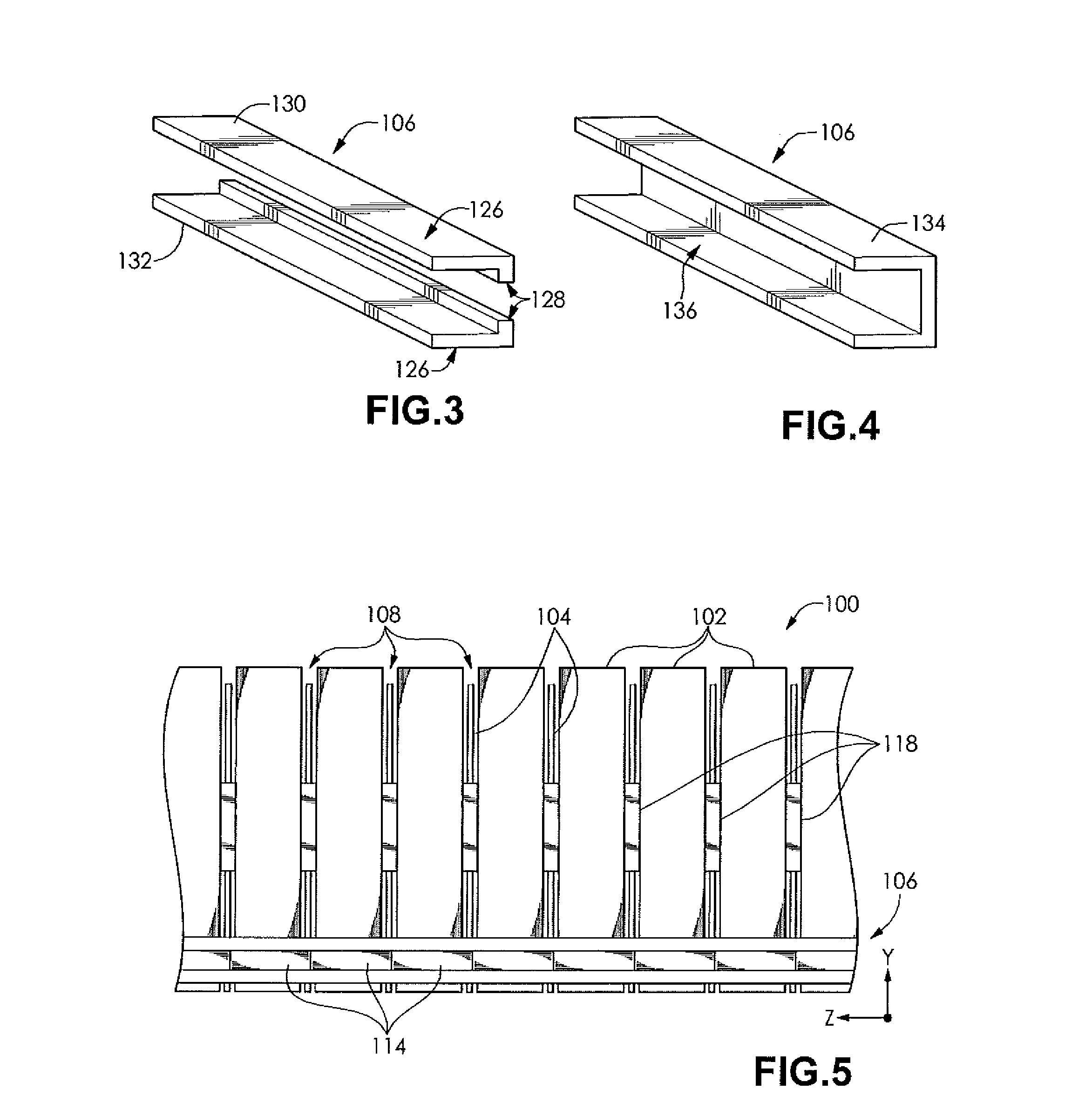

Battery cell module with sliding repeating elements

InactiveUS20130157098A1Constant widthPrimary cell to battery groupingCell temperature controlSpacer couplingBattery cell

A battery cell module includes a battery cell, a sliding repeating element, and a guide rail. The repeating element is disposed adjacent the battery cell. A gap is defined between the battery cell and the repeating element. The repeating element has a main body with at least one spacer coupled thereto. The guide rail cooperates with the at least one spacer and permits the repeating element to move with an expansion of the battery cell. The cooperation of the guide rail with the at least one spacer thereby militates against an overcompression of the battery cell.

Owner:GM GLOBAL TECH OPERATIONS LLC

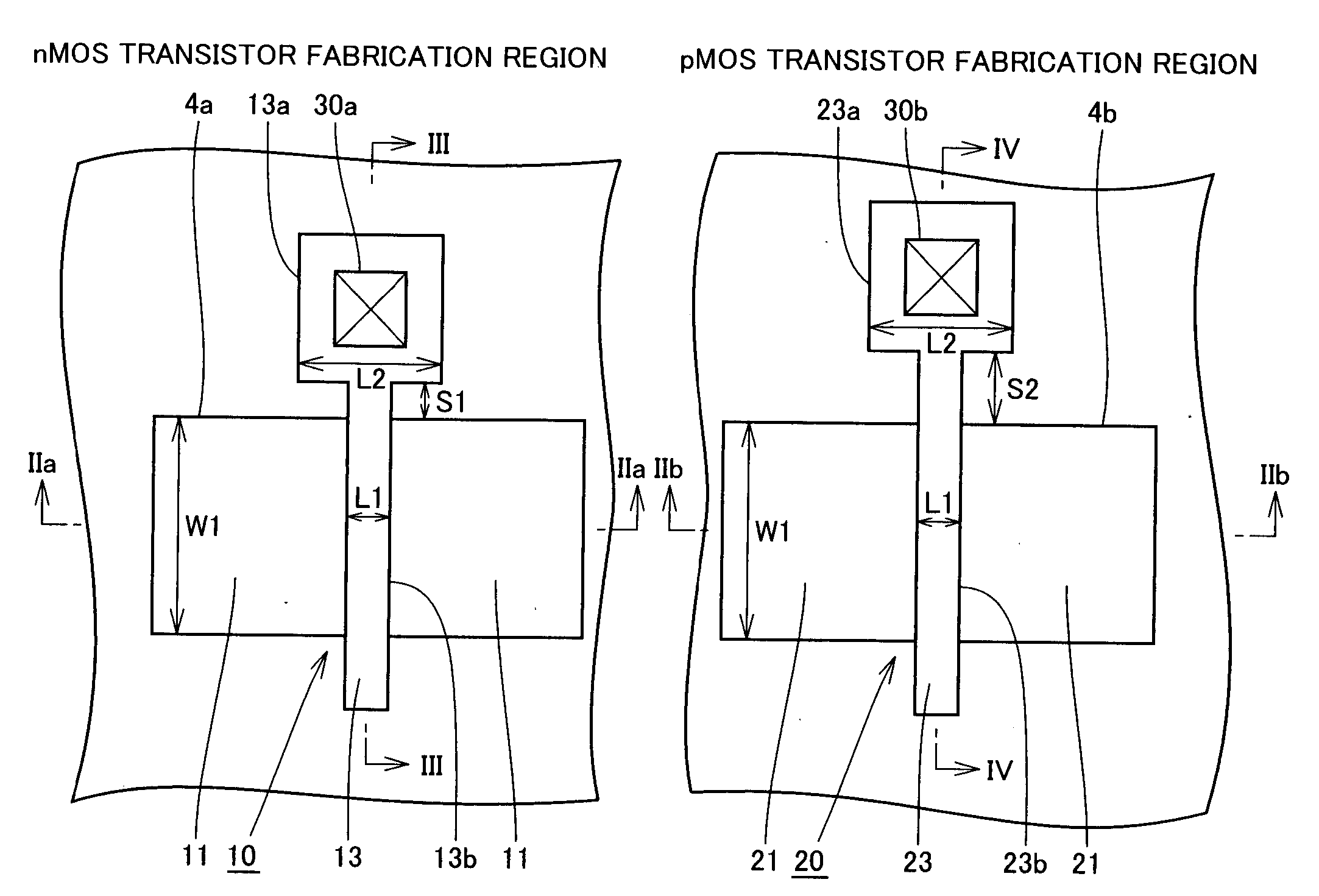

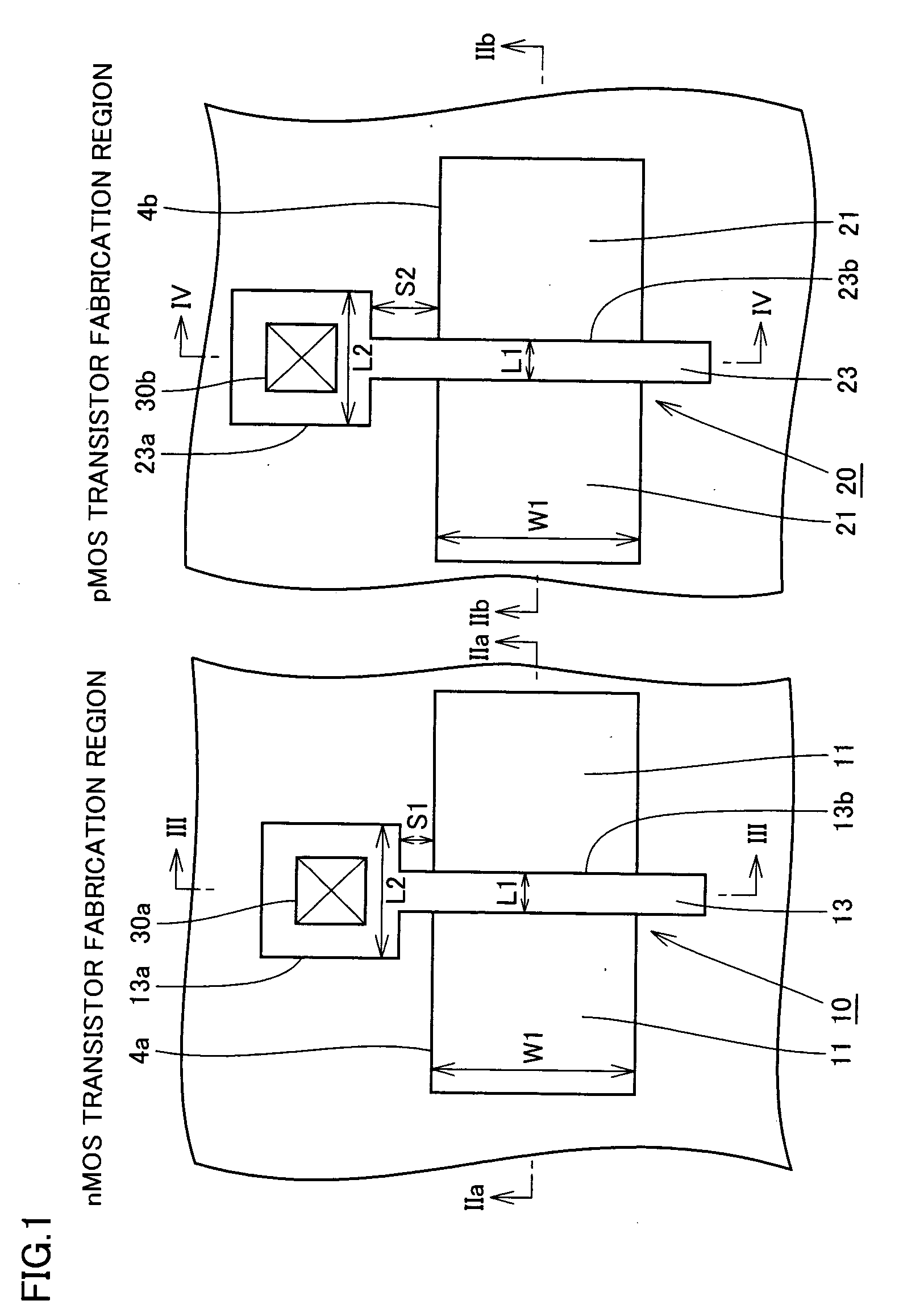

Semiconductor device

InactiveUS20060006474A1Highly integratedLittle effectTransistorSolid-state devicesContact padDevice material

In an active region a pair of source / drain regions of an nMOS transistor is provided. Between the paired source / drain regions the semiconductor substrate has a region provided with a gate electrode layer with a gate oxide film interposed. The gate electrode layer extends on both the active region and an element isolation structure and also has a contact pad portion on the element isolation structure, and the active region and the contact pad as seen in a plane are spaced by less than 0.5 μm.

Owner:RENESAS ELECTRONICS CORP

Fuel cell cathode flow field

Owner:LOOP ENERGY INC

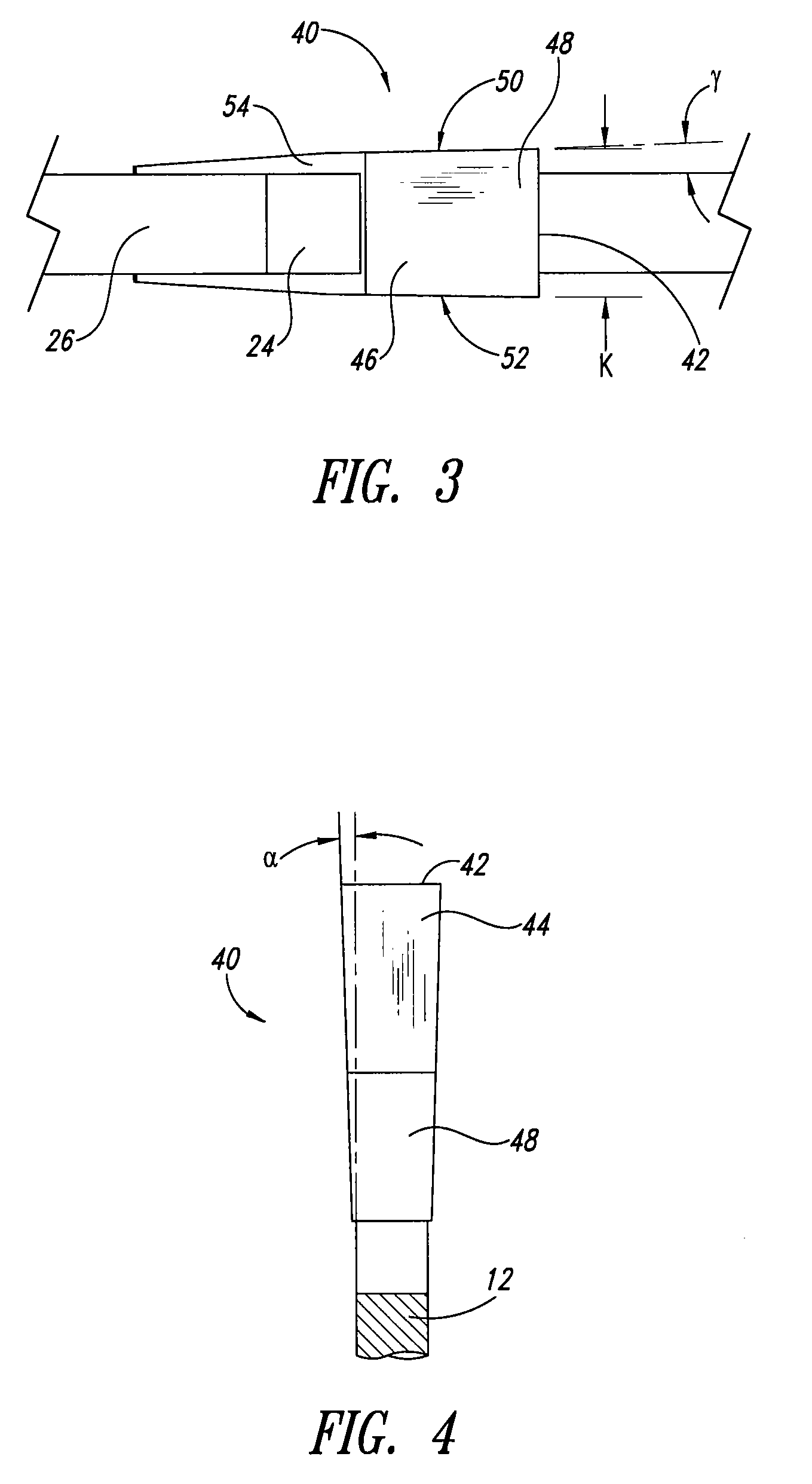

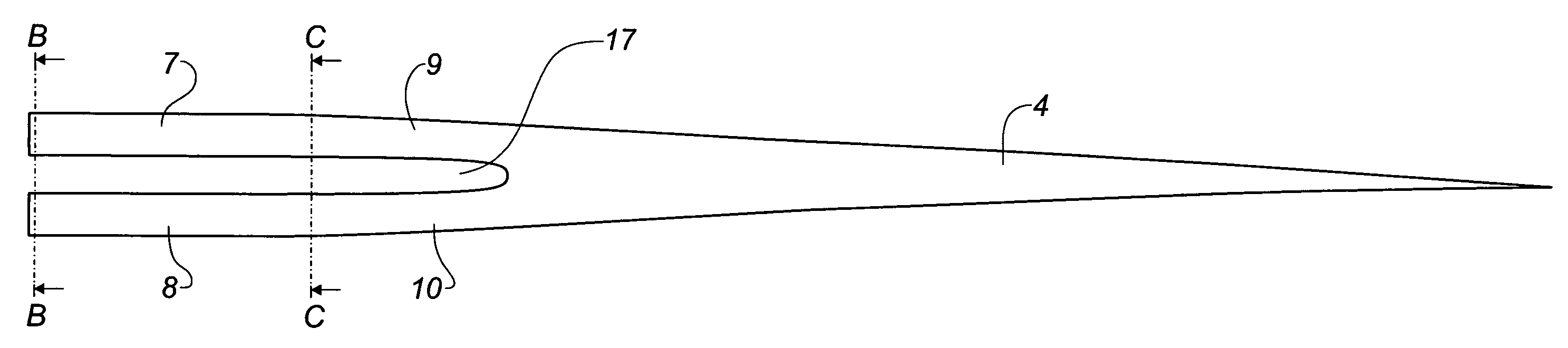

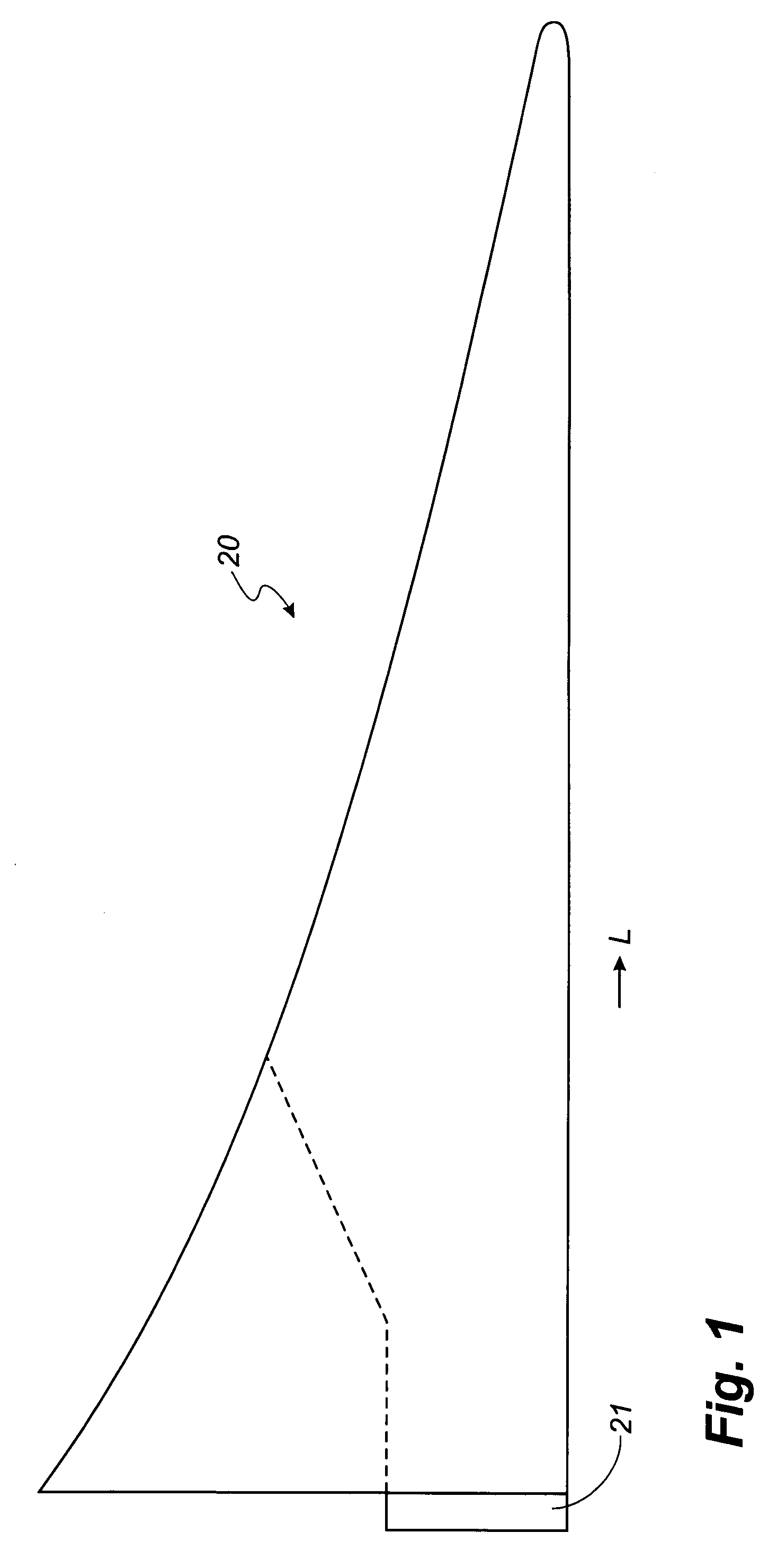

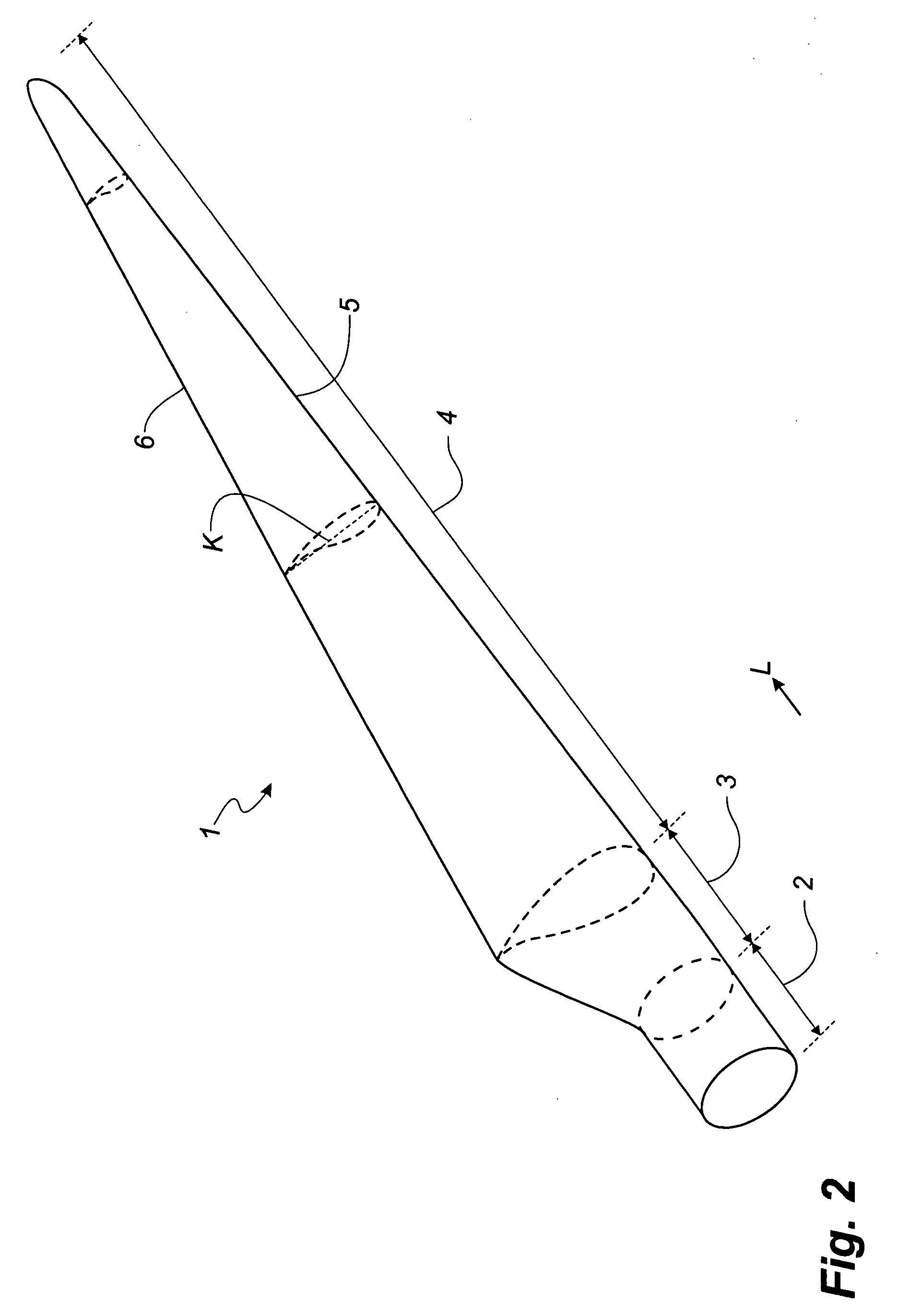

Blade for a wind Turbine Rotor

A blade (1) for a rotor of a wind turbine having a substantially horizontal′ rotor shaft, said rotor comprising a hub, from which the blade extends substantially radially from said rotor when mounted. The blade (1) has a chord plane (K) extending between the leading edge (5) and the trailing edge (S) of the blade (1). The blade (1) comprises a root area (2) closest to the hub, an airfoil area (4) furthest away from the hub and a transition area (3) between the root area (2) and the airfoil area (4), and comprises a single airfoil along substantially the entire airfoil area (4). The blade (1) comprises at least a first root segment (7) and a second root segment (8) along substantially the entire root area (2), said segments being arranged with a mutual distance, as seen transverse to the chord plane (K). At least one of the root segments (7, 8) has an airfoil profile.

Owner:LM GLASSFIBER

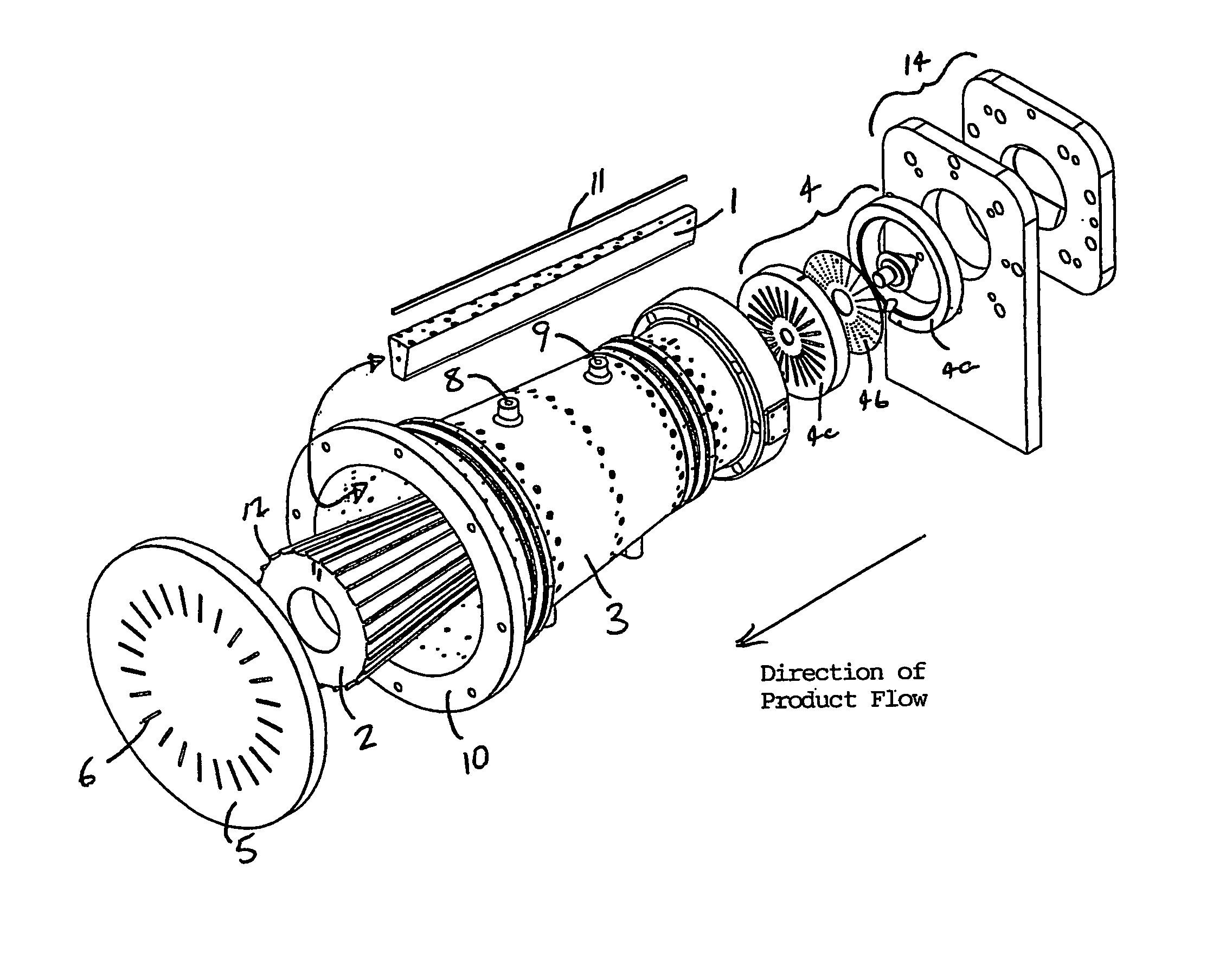

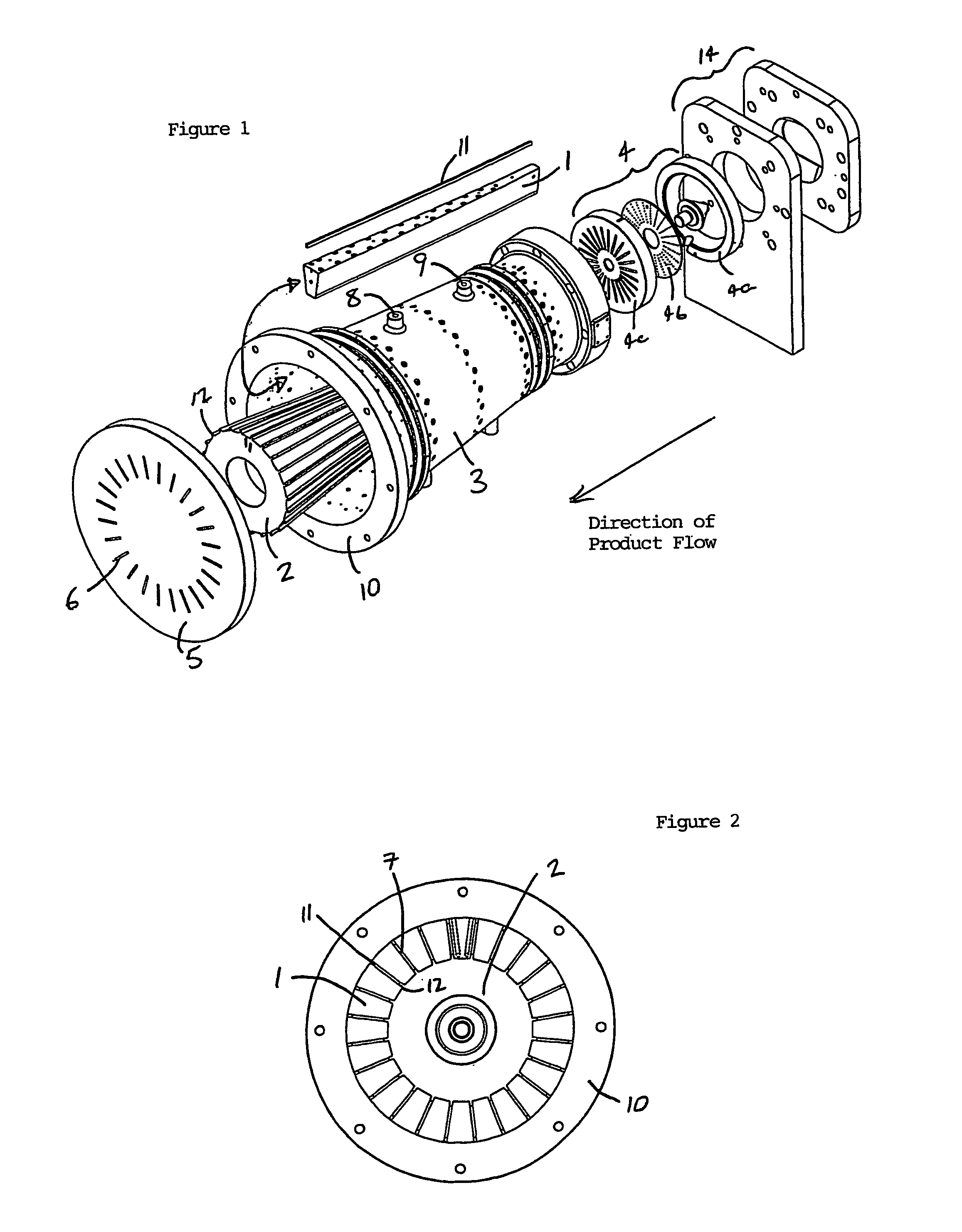

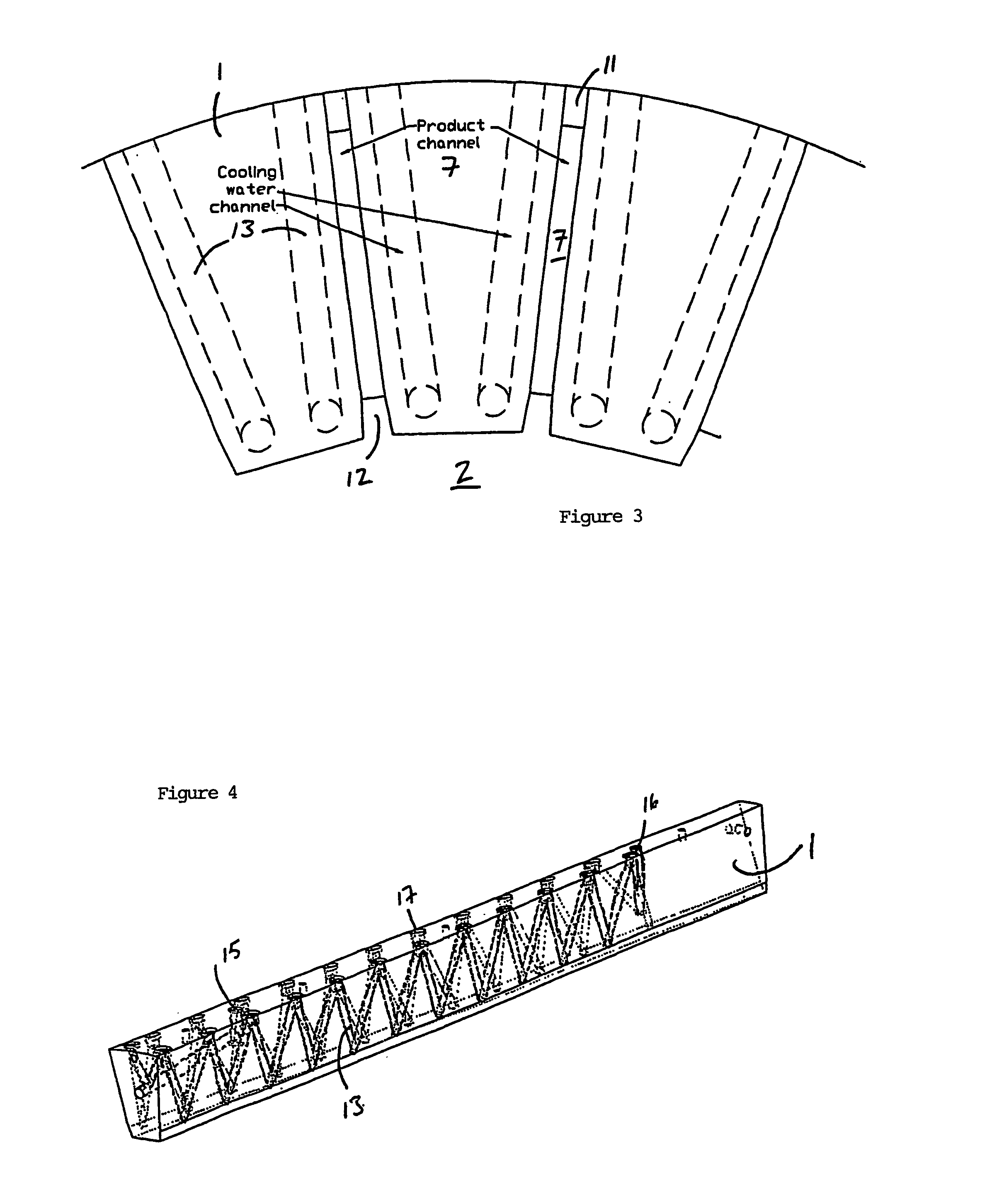

Multi-channel cooling die

InactiveUS7275927B2Reduces extrudate flow path distanceReduced operational downtimeConfectioneryMeat processingEngineeringFood extrusion

A cooling die, for use in the manufacture of extruded food products, the cooling die including: a plurality of core members forming a main body portion of the cooling die between die inlet and outlet ends and arranged about an axis of the die in neighboring relationship; a plurality of extrudate flow channels extending through the cooling die from the inlet end to the outlet end, defined by gaps between neighboring ones of said core members; at least one bore in each said core member through which coolant may flow; an enclosing structure adapted to secure the core members against radial movement relative to the die axis; means for connecting the cooling die to an outlet of a food extruder, a cooling fluid source and a cooling fluid receptacle; and extrudate flow distribution means, located adjacent the inlet end, adapted to direct extrudate from the outlet of the food extruder into selected ones of said extrudate flow channels.

Owner:MARS INC

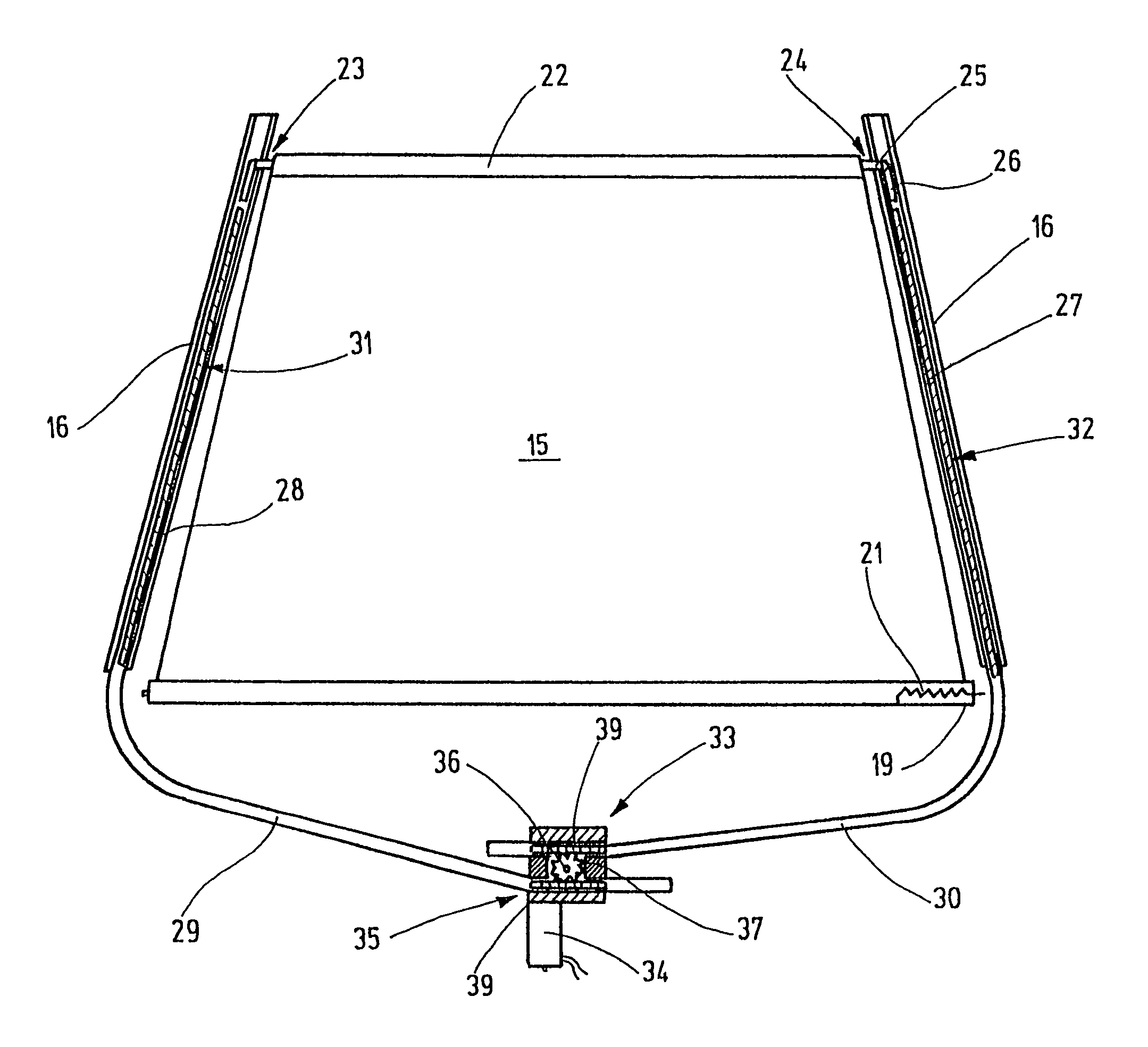

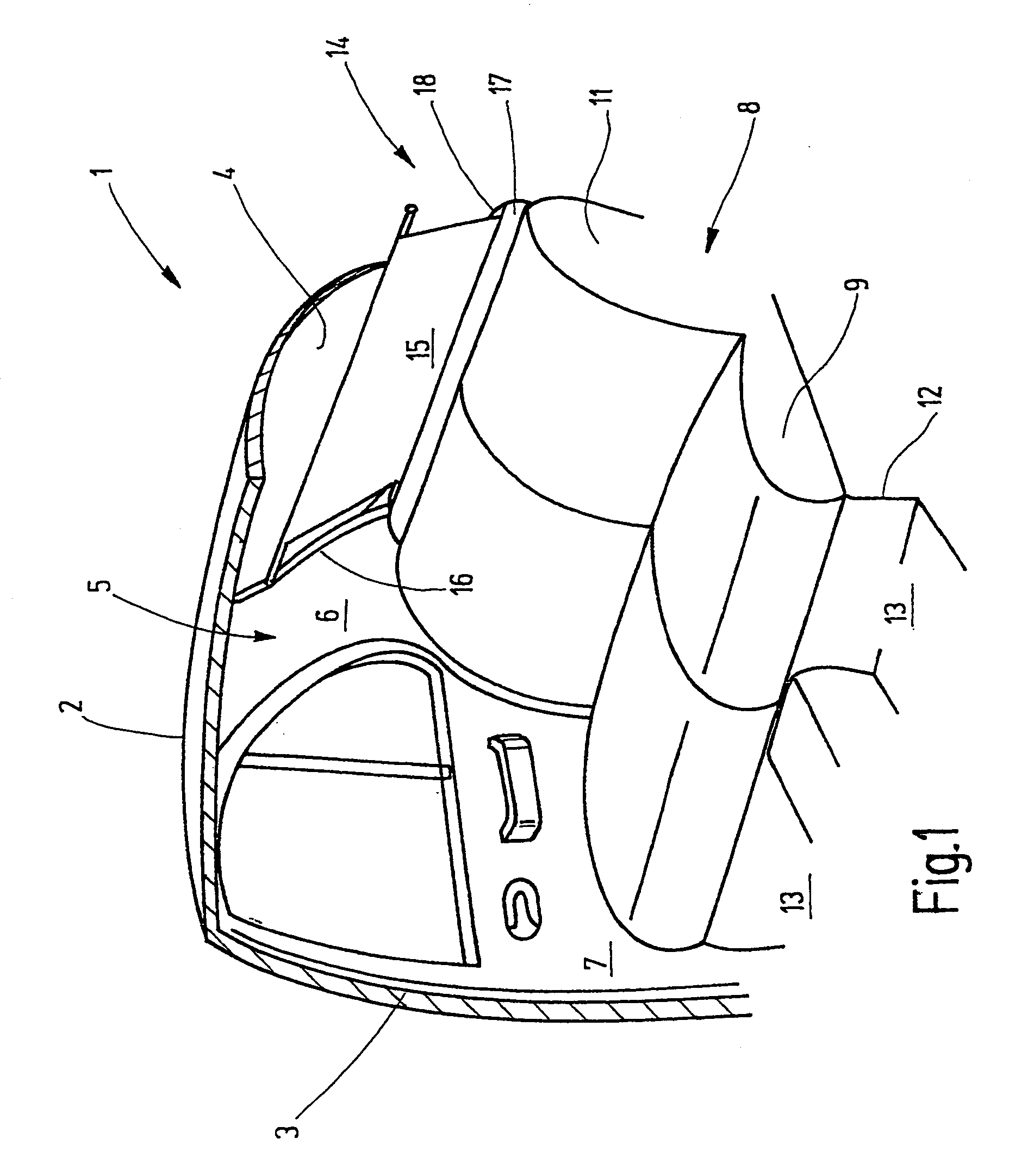

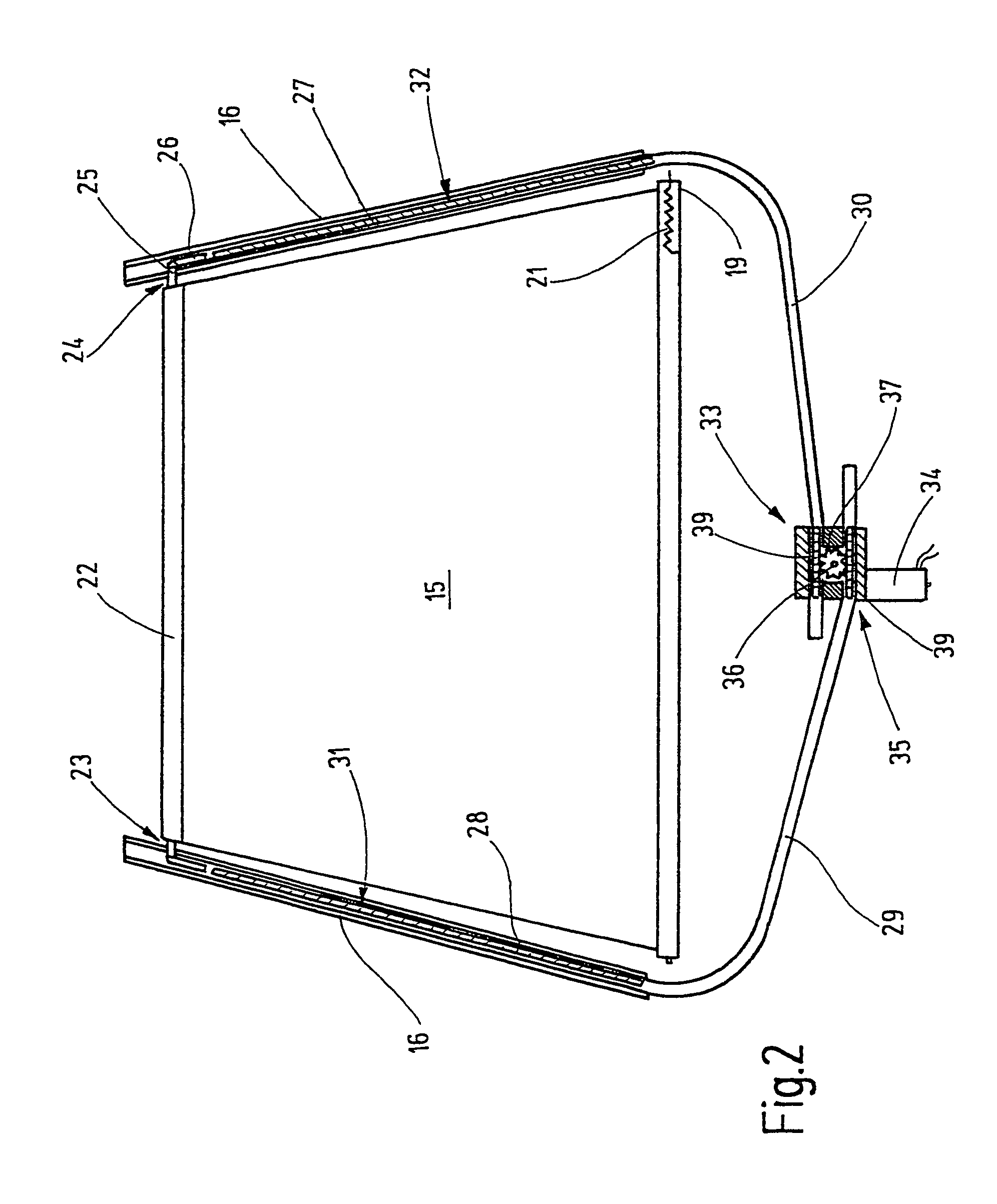

Injection-molded plastic guide rail

Owner:BOS

Rotary electric machine and electric wheelchair mounted with rotary electric machine

InactiveUS7528521B2Minimally suppressing induction current lossConstant widthSpeed controllerMagnetic circuit rotating partsWheelchairElectric machine

Owner:YAMAHA MOTOR CO LTD

Method for forming uniformly-variable-height component through laser

ActiveCN106216678ARealize closed-loop controlConstant widthAdditive manufacturing apparatusIncreasing energy efficiencyLoop controlClosed loop

The invention relates to a method for forming a uniformly-variable-height component through laser. According to the method, each cladding layer is segmented through normal direction layering, then, the difference value between the actual stacking height of each small segment of each layer and the ideal stacking height of the small segment is measured and calculated, the scanning speed of each small segment of the next cladding layer is corrected through calculating, and thus closed-loop control of the cladding layer height is achieved; the cladding layers with continuously variable heights can be automatically formed through the method for forming the uniformly-variable-height component through the laser, meanwhile, the width of the cladding layers is kept to be constant, the bevel step effect is eliminated, the complexity and the forming efficiency of the laser 3D forming component are improved, and the forming quality is ensured. Compared with the prior art, the uniformly-variable-height component formed through the method is high in stability and precision, a lot of earlier-stage cladding layer orthogonal tests are omitted, a large amount of time can be saved, and a large amount of cost can be reduced. The forming process is completed fully automatically, process parameters can be subjected to self adaptation and correction according to feedback data of a layer-height control sensor, and manual intervention can be avoided.

Owner:SUZHOU UNIV

MEMS gyros with quadrature reducing springs

ActiveUS8539832B2Constant widthReduce sensitivityAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsOut of plane motionEngineering

Spring set configurations that include an advantageous combination of spring geometries are disclosed. Spring elements having curved and straight sections, orientation of spring element anchor points with respect to the common radius, orientation of spring element segments with respect to a specific axis, balance of the length of spring elements about the common radius, and mass balance about the common radius can be used to mitigate unwanted out of plane motion. The spring set provides planar motion while reducing undesired out of plane motion making MEMS devices substantially insensitive to the process-induced etch angle variations of the spring elements. The spring set can be used in a MEMS gyro device which maintains the desired resonant modes and consistently low quadrature error even with process variations in manufacturing causing undesirable etch angles.

Owner:ROSEMOUNT AEROSPACE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com