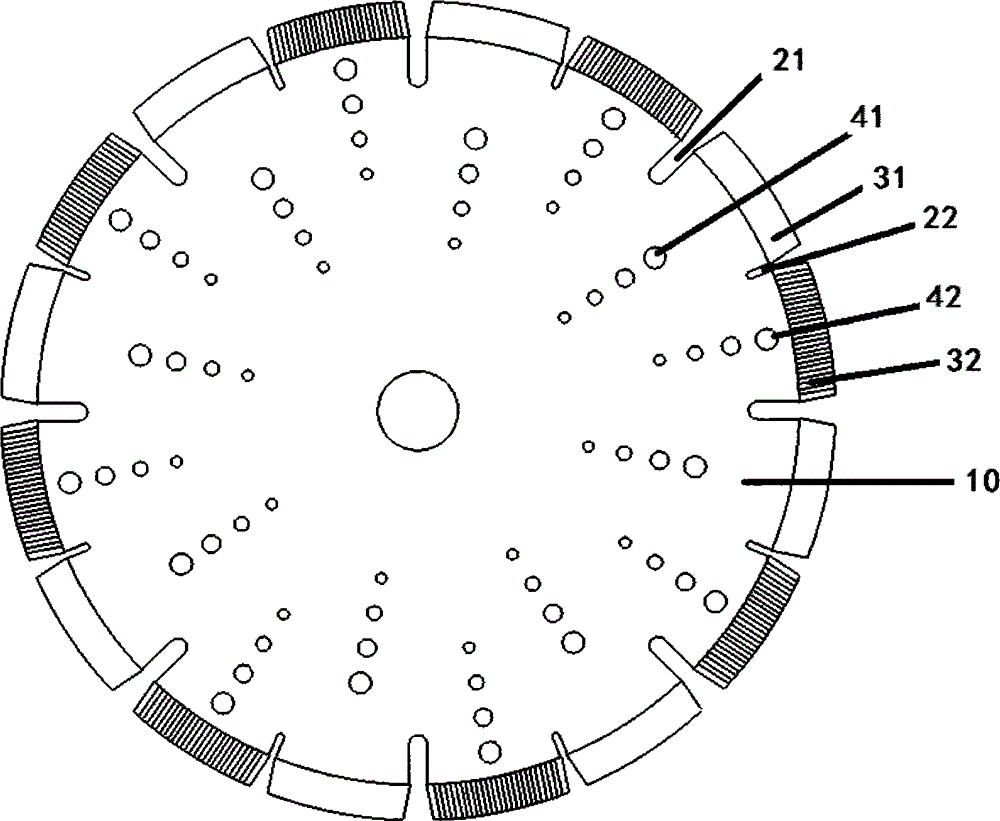

Dry and wet dual-purpose laser welding diamond saw blade

A diamond saw blade and laser welding technology, which is applied in stone processing tools, stone processing equipment, manufacturing tools, etc., can solve problems such as harsh environments, and achieve the effects of not easy to fall off, good safety performance, and stable cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Take 2.7kg of copper powder, 4.16kg of iron powder, 0.5kg of nickel powder, 1.5kg of cobalt powder, 0.7kg of tin powder, and 0.15kg of rare earth alloy powder, put them into the mixing tank and mix for 30 minutes, then add 0.13kg of liquid paraffin, diamond 0.16kg (compressive strength 25Kg, particle size 35 / 40), continue mixing for 3 hours, pour the powder into the mold for cold pressing, hot pressing sintering (sintering temperature is 800°C, pressure 320kg / cm 2 ), grind the cutter head with the grinding wheel and the abrasive belt, put the cutter head and the substrate together on the corresponding substrate position according to the drawings, adjust the light spot of the laser welding machine to the appropriate position between the cutter head and the substrate, and start the laser welding machine to weld, so that The cutter head and the substrate are welded together at the moment of laser penetration, and then 600N / mm 2 Intensity Standards Welding strength testing ...

Embodiment 2

[0034] Take 3.1kg of copper powder, 4.15kg of iron powder, 0.8kg of nickel powder, 1.1kg of cobalt powder, 0.4kg of tin powder, and 0.15kg of rare earth alloy powder, put them into the mixing tank and mix for 30 minutes, then add 0.10kg of liquid paraffin, diamond 0.20kg (compressive strength 25Kg, particle size 35 / 40), continue mixing for 3 hours, pour the powder into the mold for cold pressing, hot pressing sintering (sintering temperature is 800°C, pressure 320kg / cm 2 ), grind the cutter head with the grinding wheel and the abrasive belt, put the cutter head and the substrate together on the corresponding substrate position according to the drawings, adjust the light spot of the laser welding machine to the appropriate position between the cutter head and the substrate, and start the laser welding machine to weld, so that The cutter head and the substrate are welded together at the moment of laser penetration, and then 600N / mm 2Intensity Standards Welding strength testing i...

Embodiment 3

[0036] Take 2.9kg of copper powder, 4.3kg of iron powder, 0.65kg of nickel powder, 1.2kg of cobalt powder, 0.5kg of tin powder, and 0.16kg of rare earth alloy powder, put them into the mixing tank and mix for 30 minutes, then add 0.11kg of liquid paraffin, diamond 0.18kg (compressive strength 25Kg, particle size 35 / 40), continue mixing for 3 hours, pour the powder into the mold for cold pressing, hot pressing sintering (sintering temperature is 800°C, pressure 320kg / cm 2 ), grind the cutter head with the grinding wheel and the abrasive belt, put the cutter head and the substrate together on the corresponding substrate position according to the drawings, adjust the light spot of the laser welding machine to the appropriate position between the cutter head and the substrate, and start the laser welding machine to weld, so that The cutter head and the substrate are welded together at the moment of laser penetration, and then 600N / mm 2 Intensity Standards Welding strength testing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com