Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Accurate and stable transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

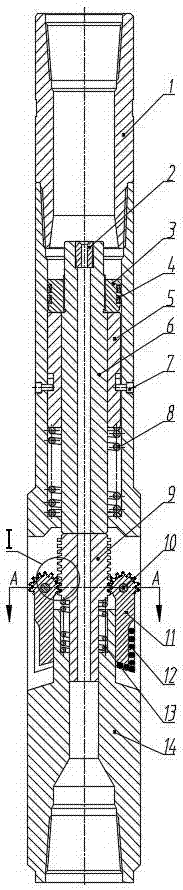

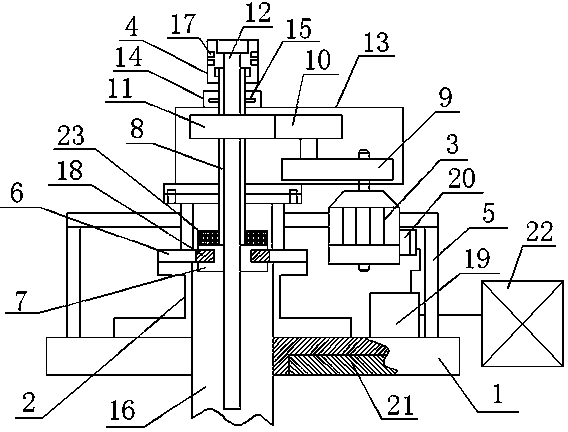

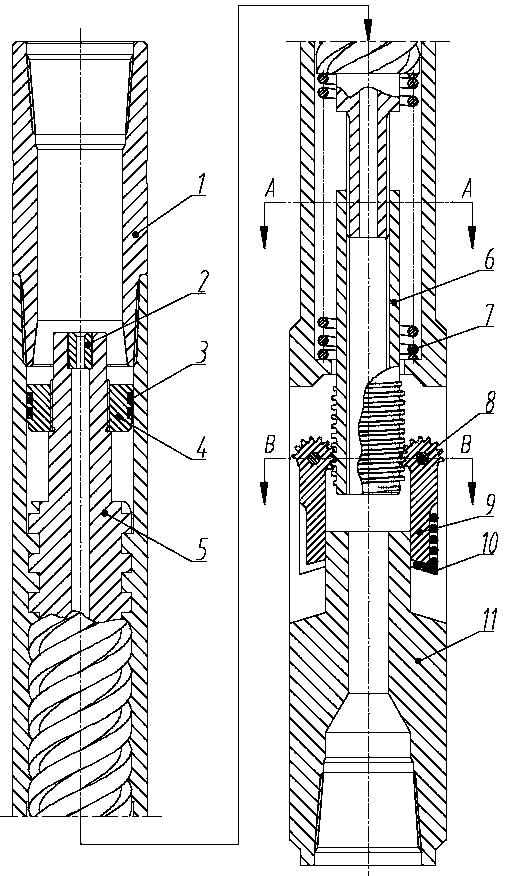

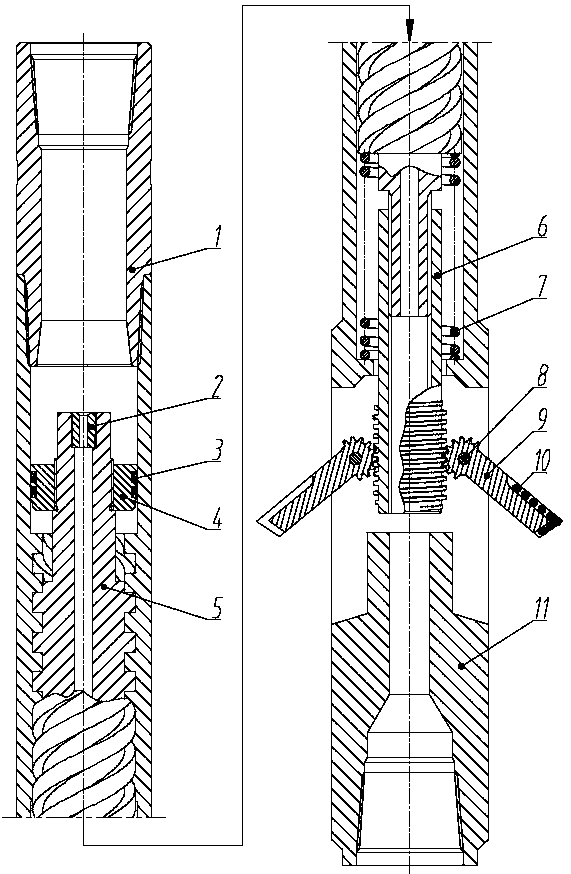

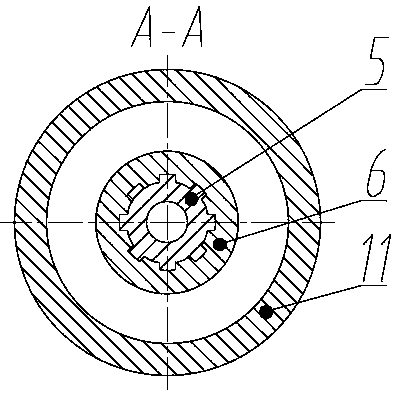

Variable-diameter hydraulic cutter capable of realizing continuous cutting of sleevings with different diameters through gear and rack transmission

InactiveCN107218007ASimple structureAccurately control the opening angleBorehole/well accessoriesGear wheelUpper joint

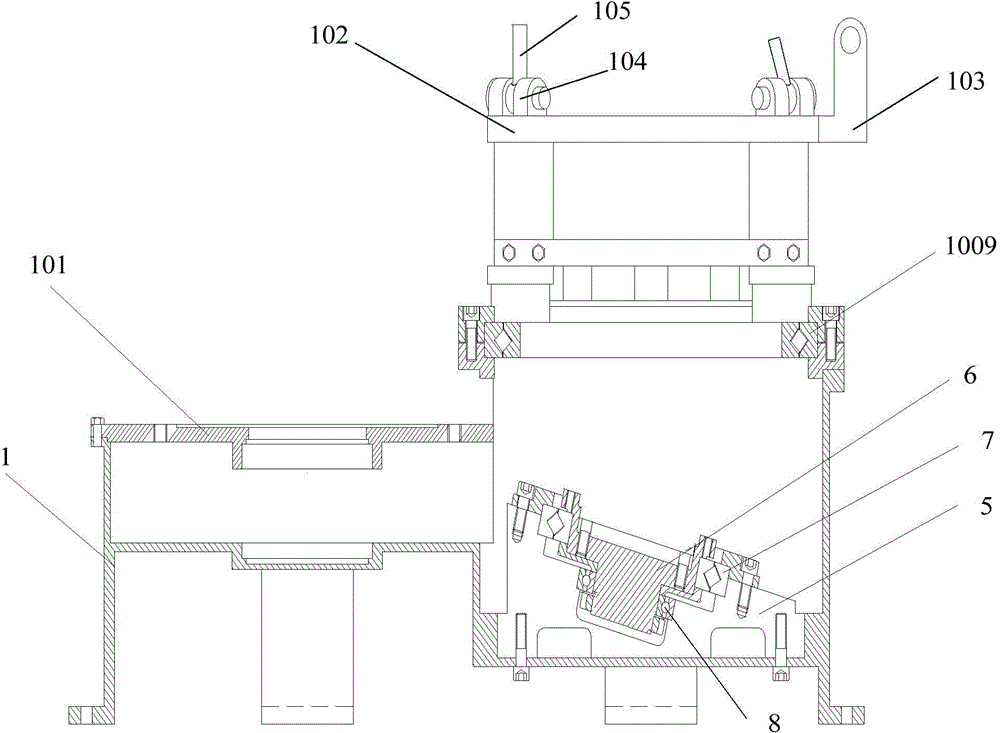

The invention relates to a variable-diameter hydraulic cutter capable of realizing continuous cutting of sleevings with different diameters through gear and rack transmission in the abandoned well operation process. The technical scheme of the cutter is that an upper joint is connected with a housing by threads; a spraying nozzle is located in a piston push rod and connected with the push rod by the threads; an upper spring, a turning mechanism and a piston are mounted on the piston push rod sequentially and arranged inside the housing; cutter knives are arranged uniformly in the circumferential direction and connected with the housing by hinge pins, gear structures of the upper parts of the cutter knife bodies are meshed with a cylindrical rack, the rack and the gears can transmit, and too large displacement of the cutter knives is limited while the opening degrees of the cutter knives are accurately controlled. According to the variable-diameter hydraulic cutter, the piston and the turning mechanism are pushed by the throttling action, gear and rack transmission is matched so as to realize continuous cutting of the sleevings with different diameters, trip times are reduced, the abandoned well operation time is saved, and the sleeving cutting efficiency and the operation reliability in the abandoned well operation process are improved greatly.

Owner:SOUTHWEST PETROLEUM UNIV

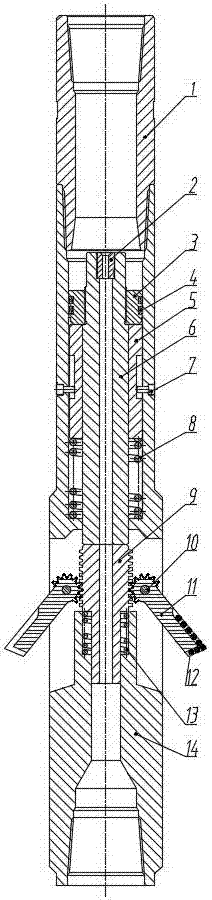

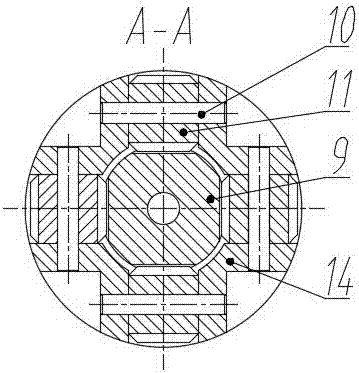

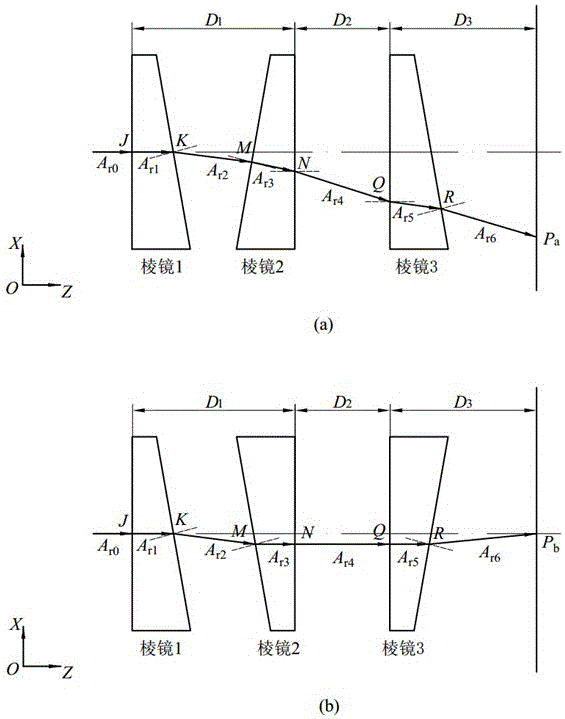

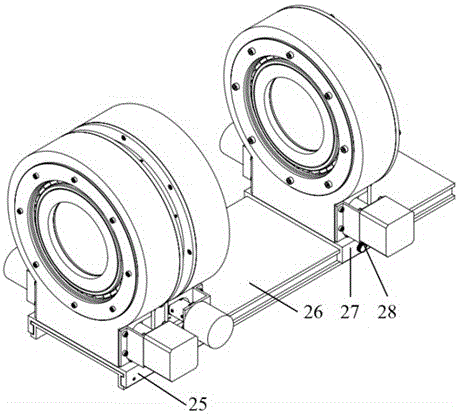

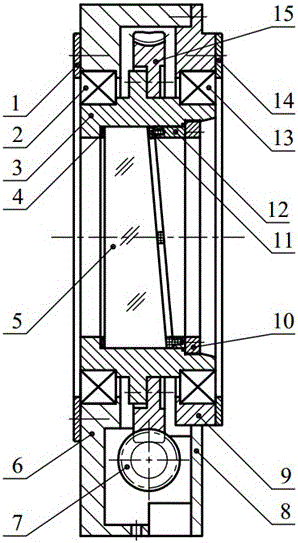

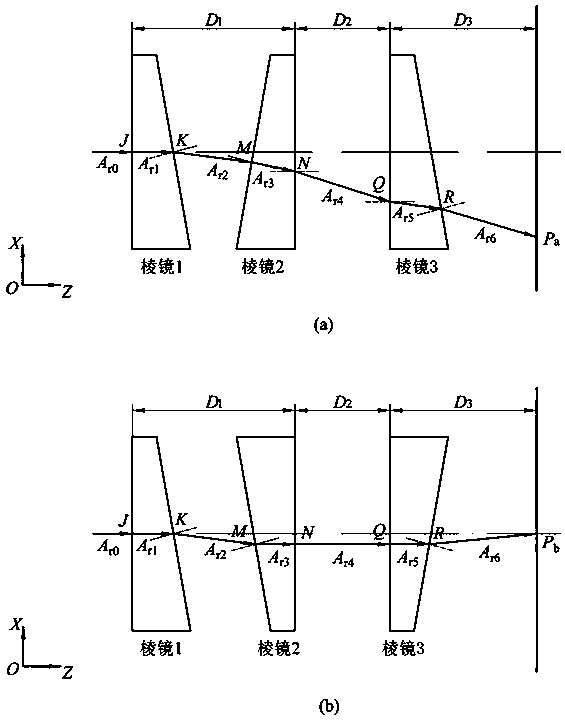

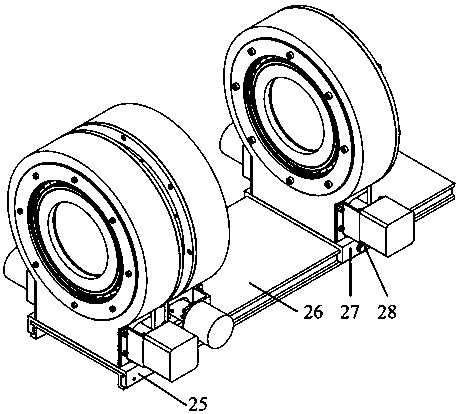

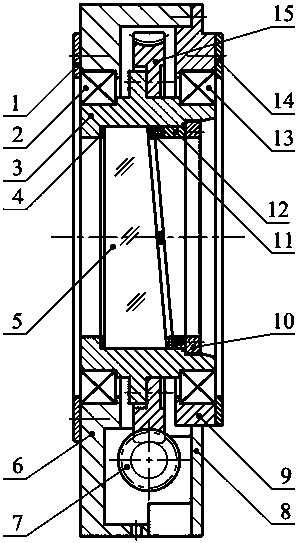

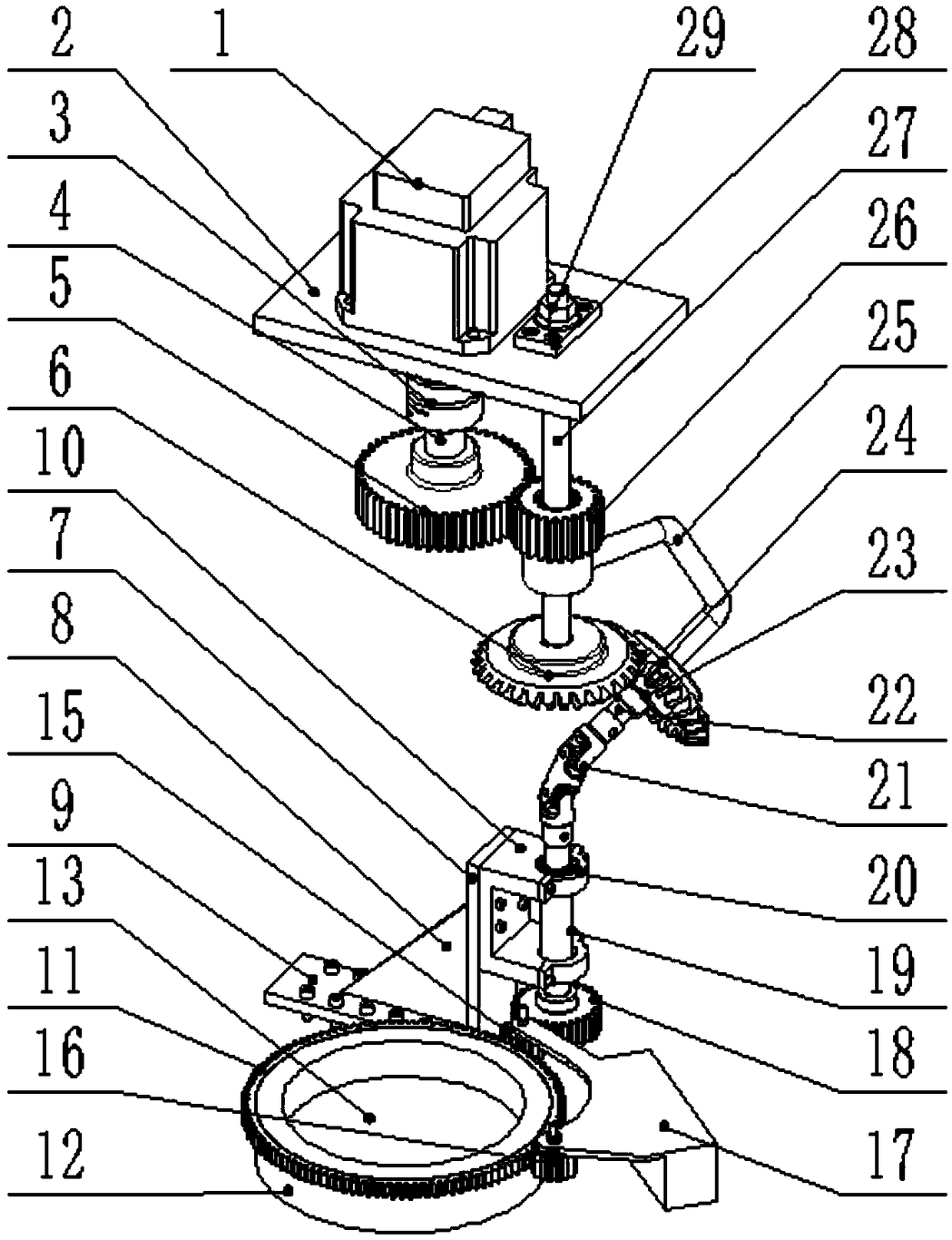

Rotating triple-prism beam scanning device

InactiveCN106249405AControl rotation angleAvoid empty backOptical elementsCouplingRolling-element bearing

The invention relates to a rotating triple-prism beam scanning device comprising a rotating double-prism system, a rotating single-prism system, a guide rail, an adjustable support, and a fixed support. The rotating single-prism system comprises a base component, a prism and frame assembly, and a worm-and-gear mechanism. The prism and frame assembly comprises a flat washer, a wedge prism, a rubber pad, a wedge retainer ring, a threaded retainer ring, and a frame. The base component comprises a base, a base baffle, and a base insert. The worm-and-gear mechanism comprises a rotary motor, a motor stand, a coupling, a worm, a bearing support, a rolling bearing, a worm gear, an encoder support, and a rotary encoder. The rotating double-prism system is formed by assembling two rotating single-prism systems together. In the invention, the three wedge prisms are driven by the worm-and-gear mechanisms to do full-circumferential rotation, transmission is stable and accurate, and the scanning precision and stability of dynamic beams can be ensured; the prisms are independent of one another in rotation control, and diversified scanning modes can be achieved; and by introducing the third prism to the double-prism system, the scanning field of beams is enlarged significantly, and the problem that a double-prism system has scanning blind areas and control singular points is solved effectively.

Owner:TONGJI UNIV

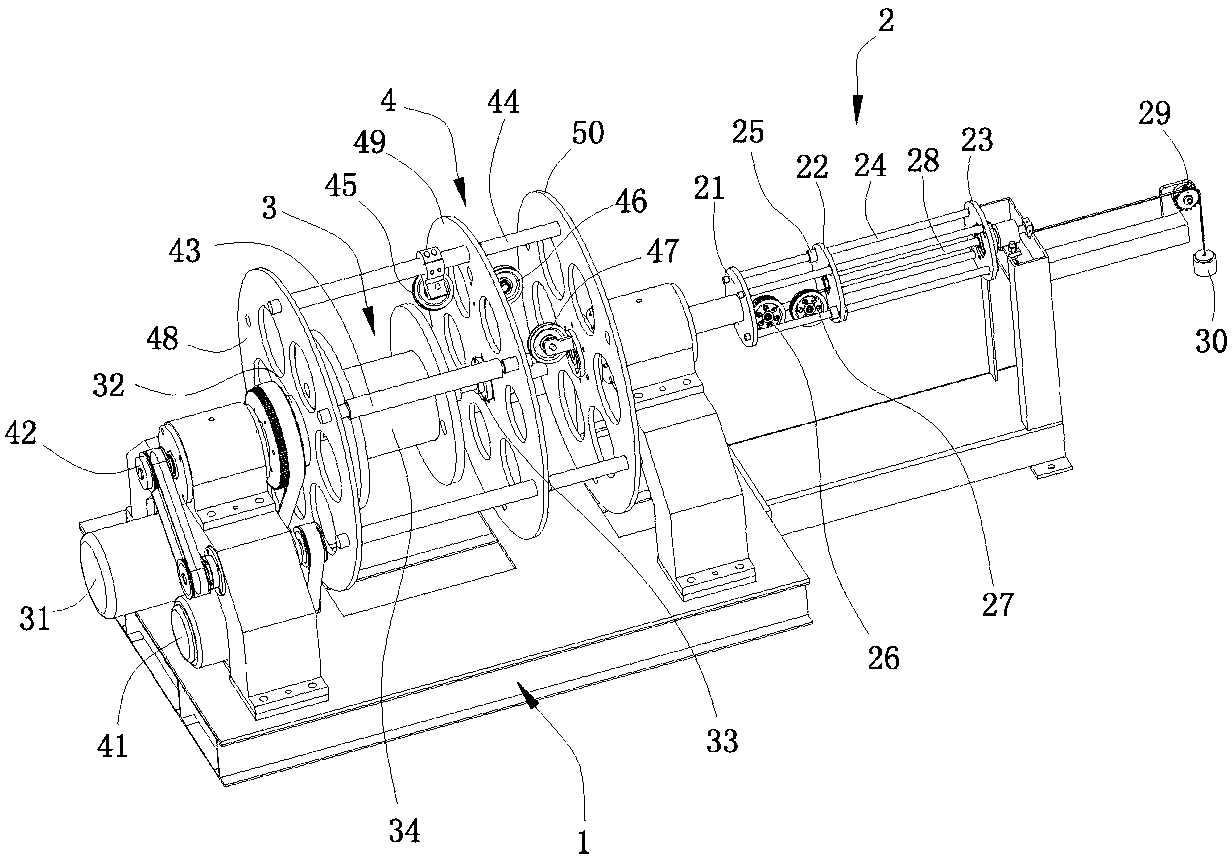

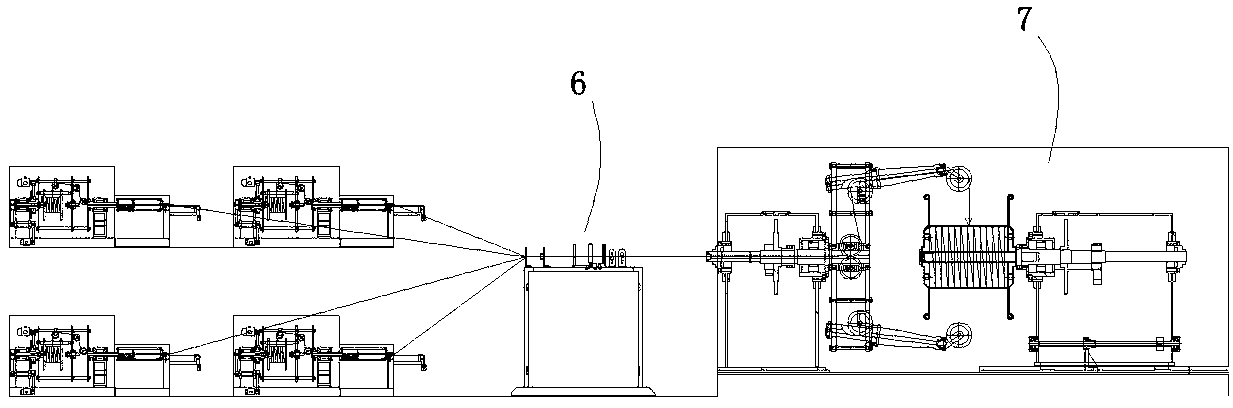

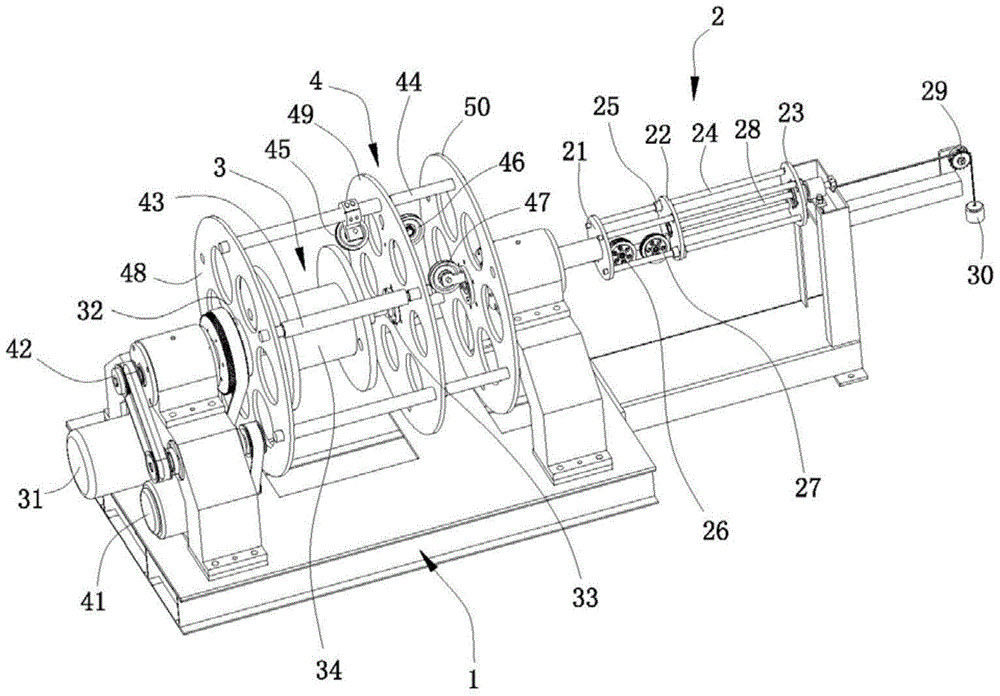

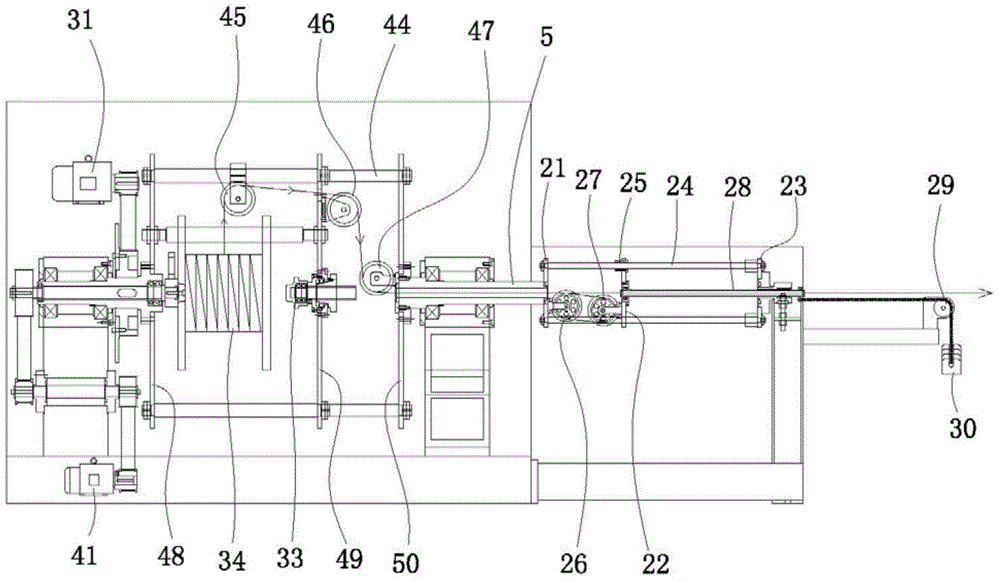

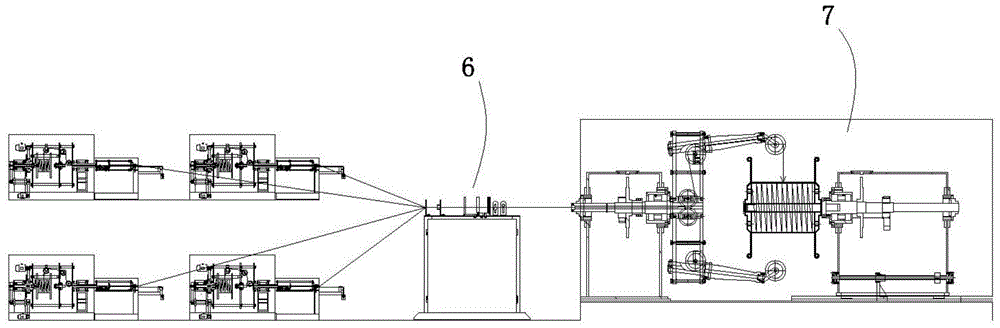

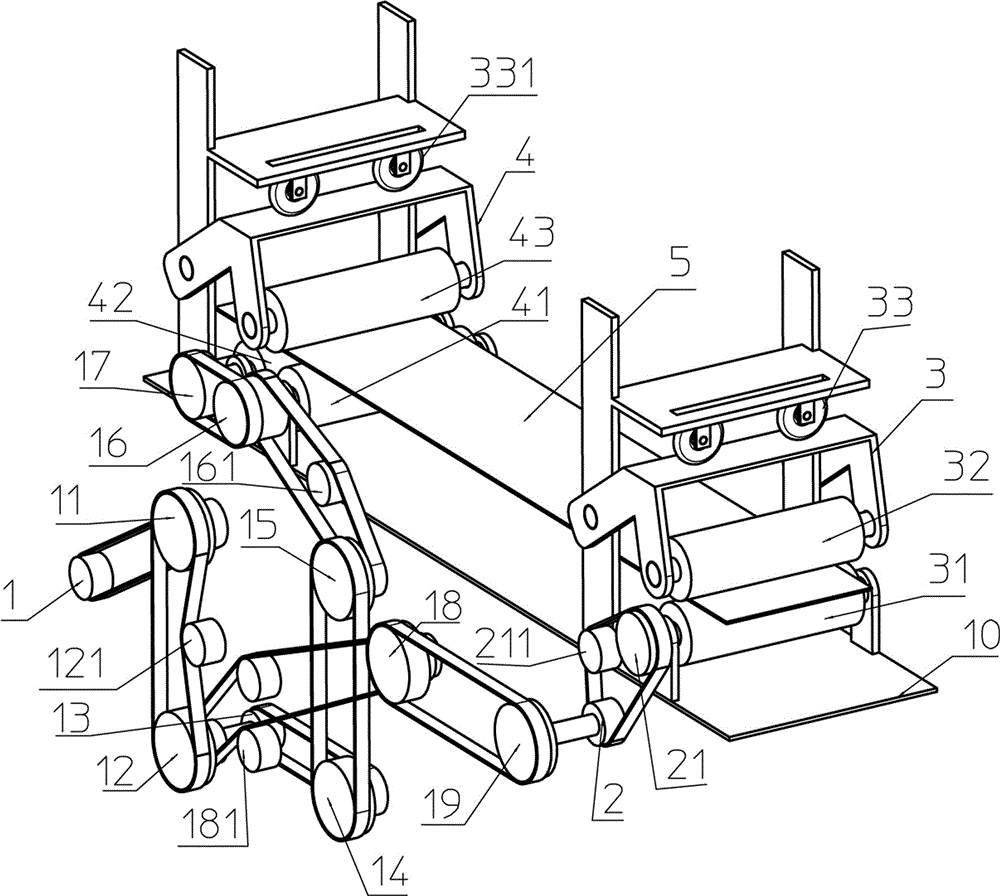

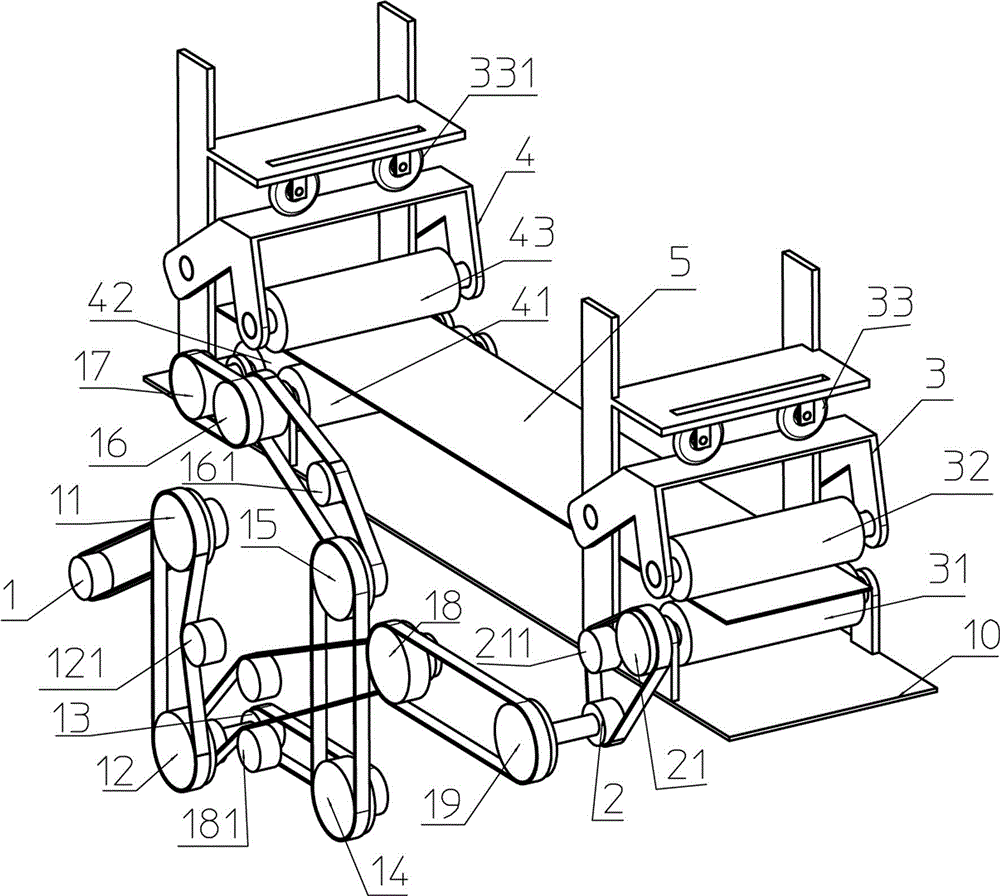

Active back-twist constant-force pay-off machine and production method thereof

ActiveCN103106982AReasonable structural designIngenious structural designCable/conductor manufactureConstant forceUltimate tensile strength

The invention discloses an active back-twist constant-force pay-off machine which comprises a machine frame, a back-twist pay-off device and a rotating tension device, wherein the back-twist pay-off device comprises a pay-off mechanism and a back-twist mechanism. The invention further discloses a production method of the active back-twist constant-force pay-off machine. The active back-twist constant-force pay-off machine is reasonable and ingenious in structural design and capable of quickly feeding a cable core to a stranding machine in a balanced mode with predetermined constant tension; at the same time, the rotating tension device and the stranding machine move in the same direction at the same rotation speed, and therefore the cable core can be effectively prevented from being damaged due to twist; in addition, regulating accuracy of the tension is high, the tension of the cable core can be automatically detected and adjusted in the whole production process, and therefore the tension of the cable core can always remain constant, and constant-tension cable feeding in a true sense is realized; and the active back-twist constant-force pay-off machine is convenient to operate, greatly lowers labor intensity, guarantees the quality of products, and is beneficial to improvement of the competitiveness of an enterprise. The production method of the active back-twist constant-force pay-off machine is simple in process, low in cost, easy to implement, and through the production method, the active back-twist constant-force pay-off machine can be produced rapidly.

Owner:DONGGUAN JINGTIE MACHINERY

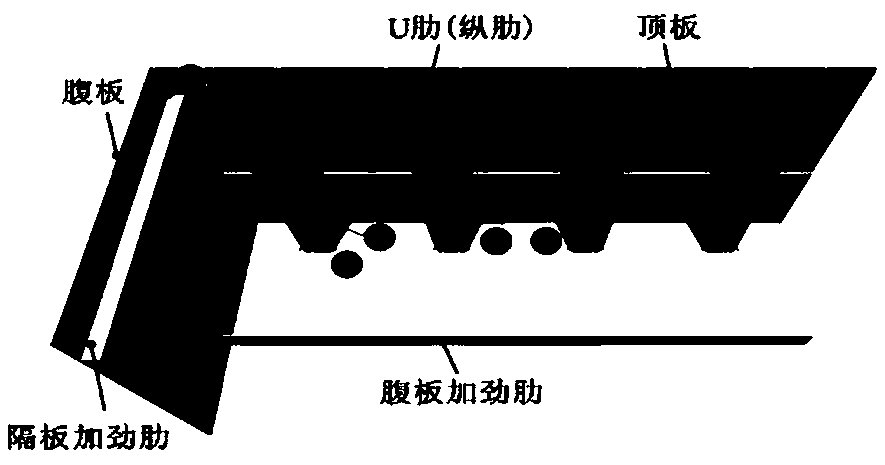

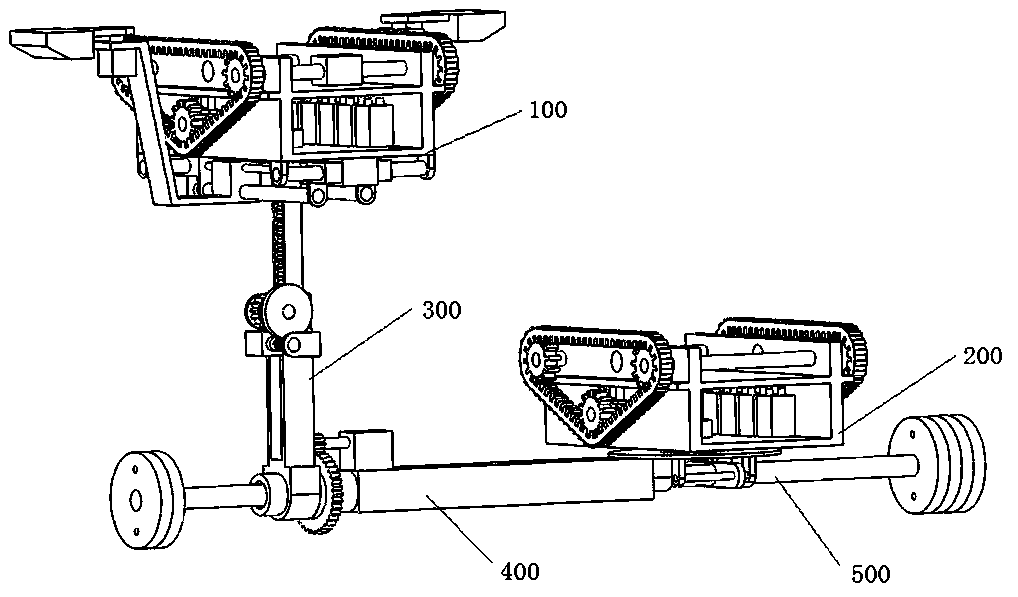

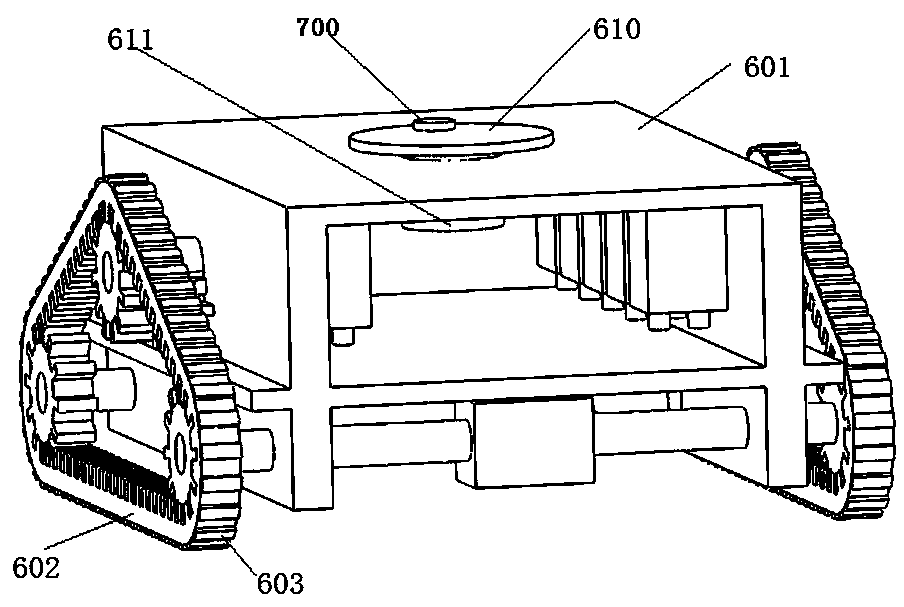

Intelligent orthotropic steel bridge deck fatigue cracking detection robot

PendingCN111021244ATake full advantage of self-lockingFully automated inspection processAnalysing solids using sonic/ultrasonic/infrasonic wavesBridge structural detailsBridge deckStructural engineering

The invention, which relates to the technical field of orthotropic steel bridge deck fatigue crack detection, discloses an intelligent orthotropic steel bridge deck fatigue crack detection robot comprising a top plate walking detection device, a longitudinal rib walking device, an electric drive telescopic mechanism and an electric drive swing mechanism. The top plate walking detection device andthe longitudinal rib walking device are provided with crawlers respectively; a plurality of electromagnets are arranged on the outer sides of crawler belts of the crawlers to achieve adsorption of thecrawler belts on a top plate or longitudinal ribs. An ultrasonic detector is arranged on the top plate walking detection device and can move close to or away from a crawler; the top plate walking detection device is connected with the electric drive telescopic mechanism, the joint of the top plate walking detection device and the electric drive telescopic mechanism can rotate, the electric driveswing mechanism is connected with the other end of the electric drive telescopic mechanism and can swing at the joint, and the longitudinal rib walking device is connected with the other end of the electric drive swing mechanism and can rotate. The robot can complete automatic detection of the orthotropic steel bridge deck slab, the traditional manual detection mode is changed, the manpower can besaved effectively, the detection efficiency is high; and the detection data are reliable.

Owner:川南城际铁路有限责任公司

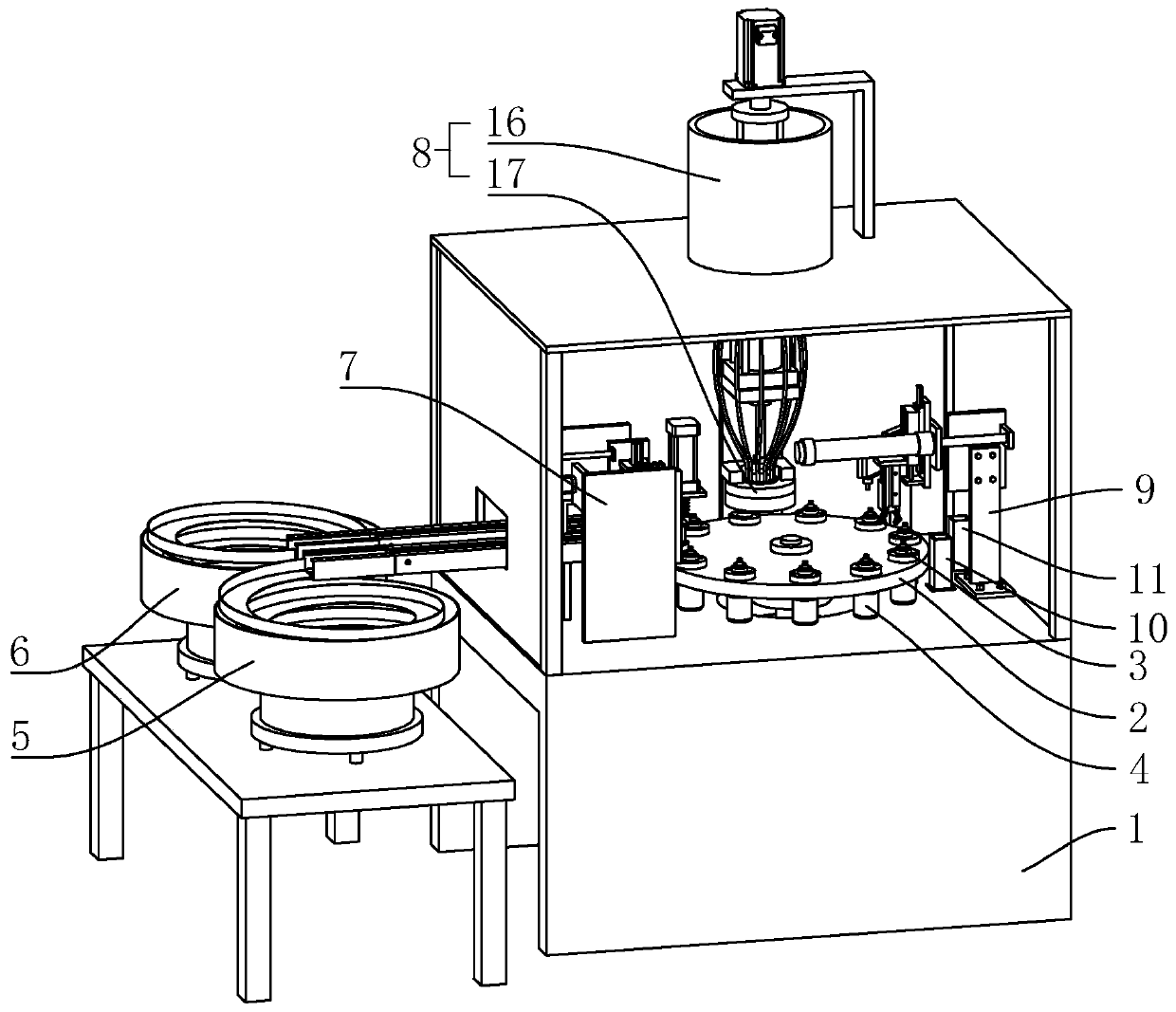

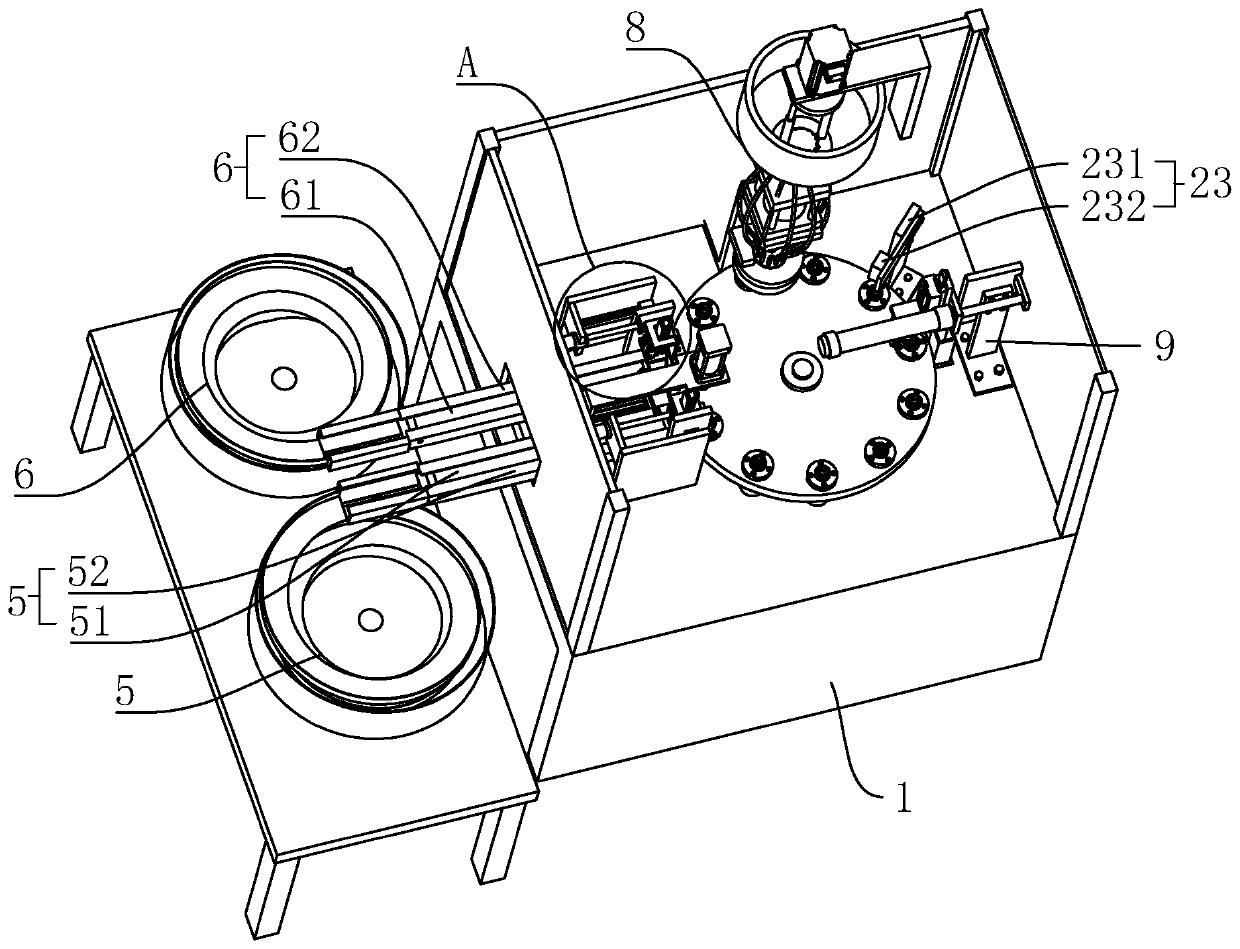

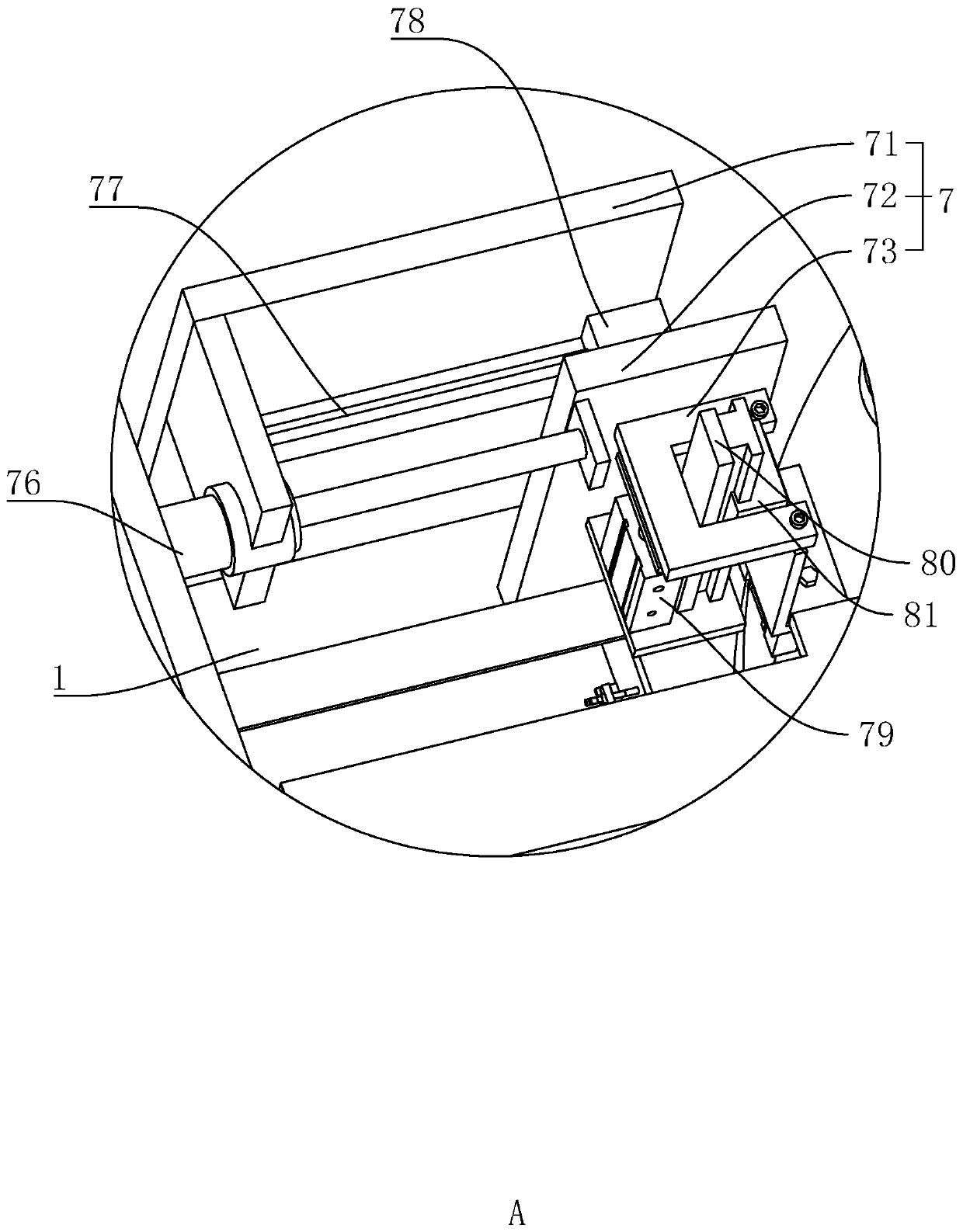

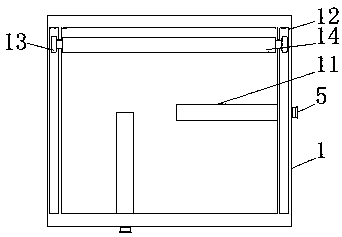

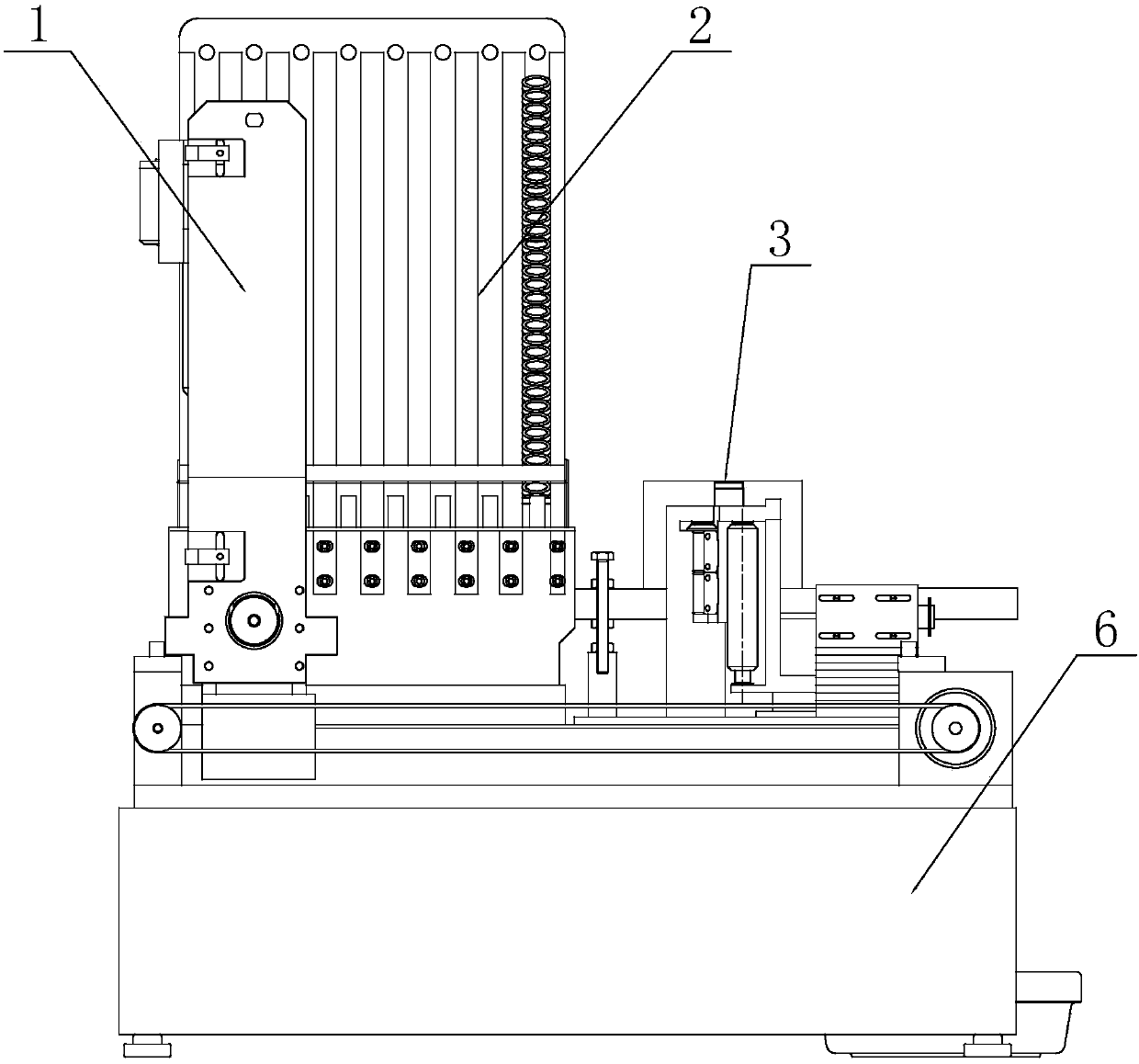

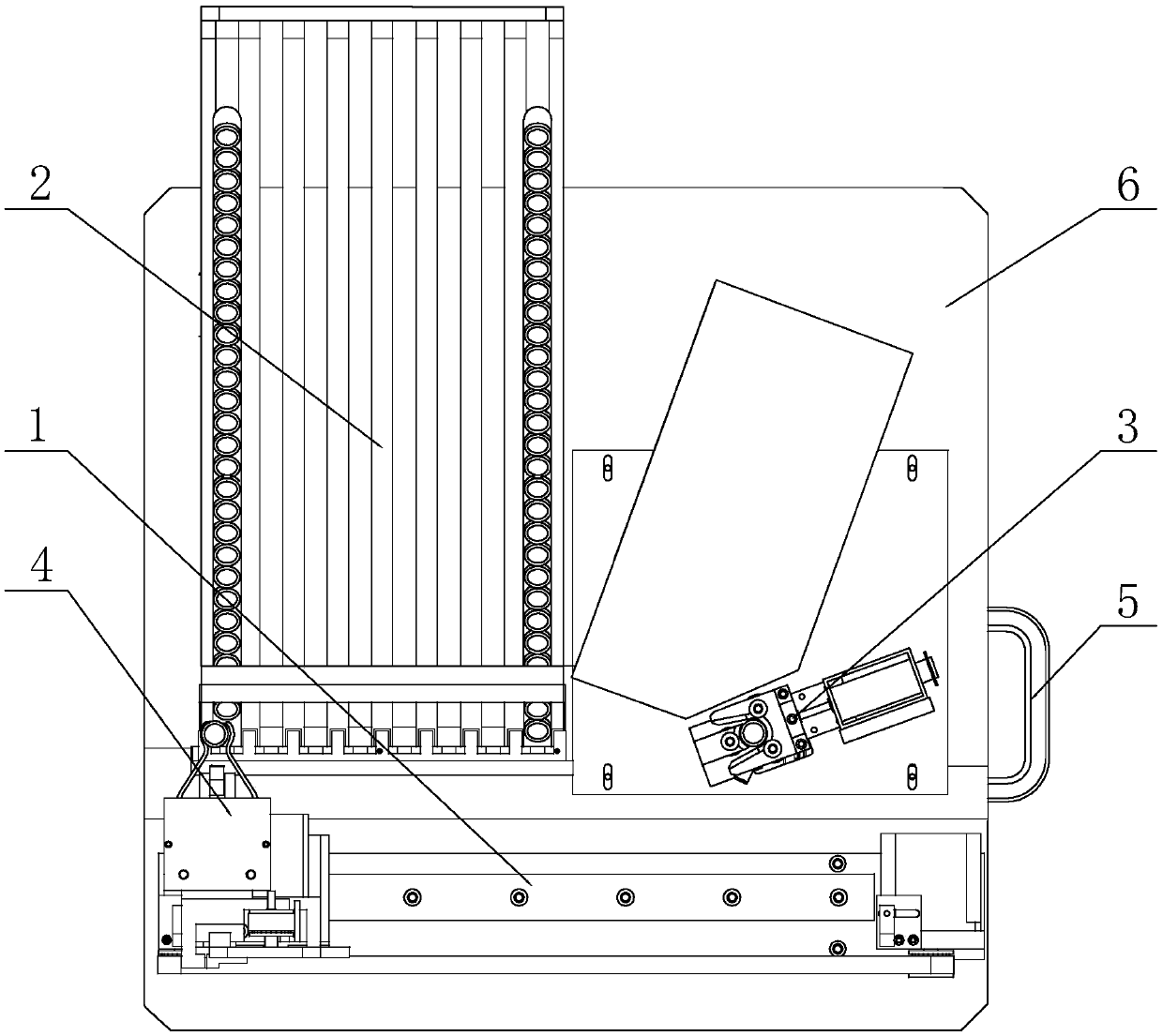

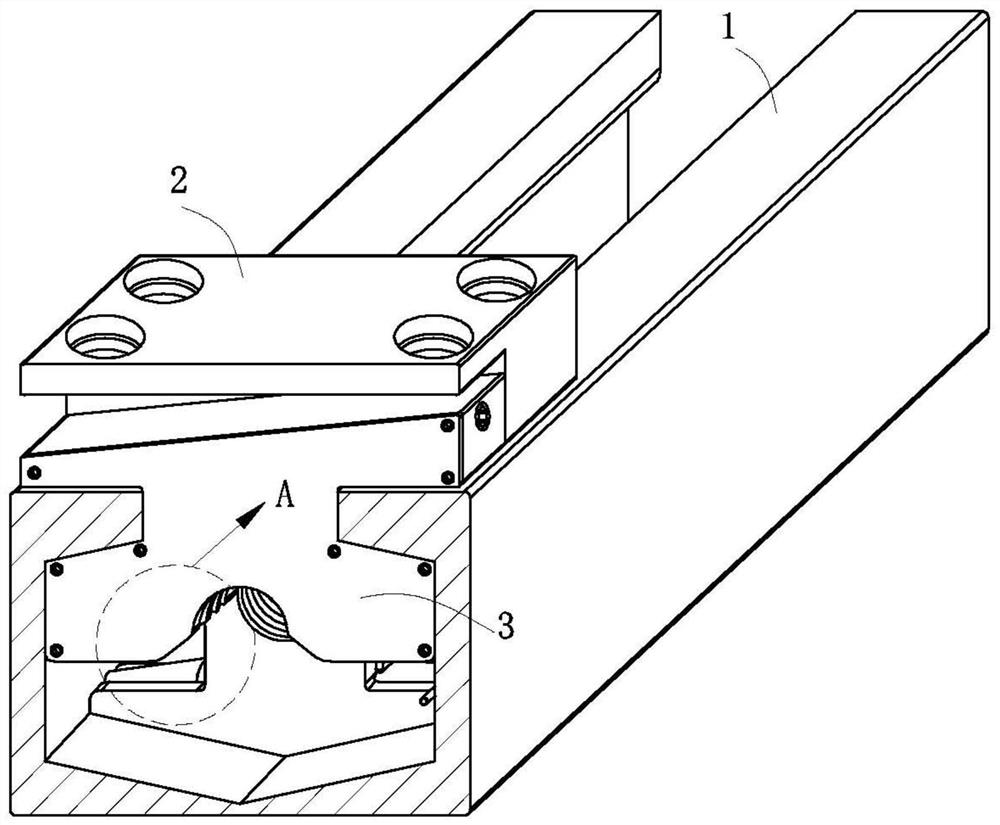

Needle bearing integrated assembling device

InactiveCN111271383ARealize automated assemblyPlay a limiting roleBearing componentsNeedle roller bearingWorkbench

The invention relates to a needle bearing integrated assembling device. The needle bearing integrated assembling device comprises a rack, wherein a workbench is rotatably connected to the rack; a workpiece placing boss is connected to the workbench; a retainer conveying device and a bearing outer ring conveying device are arranged on one side of the workbench; two groups of loading devices are arranged on one side of the workbench; and a needle bearing assembling device and a bearing unloading device are sequentially arranged on the rack. According to the needle bearing integrated assembling device disclosed by the invention, the retainer conveying device and the bearing outer ring conveying device are separately used for conveying a retainer and a bearing outer ring; the two groups of loading devices are used for loading the retainer and the bearing outer ring; when the workbench rotates, the retainer synchronously rotates to the lower end of the needle bearing assembling device; theneedle bearing assembling device can realize automatic assembling of a needle bearing, the retainer and the bearing outer ring; and the bearing unloading device is used for unloading the needle bearing, so that synchronous automatic assembling of a plurality of bearings is realized, and bearing assembling efficiency can be greatly improved.

Owner:SUZHOU JINCHENG BEARING

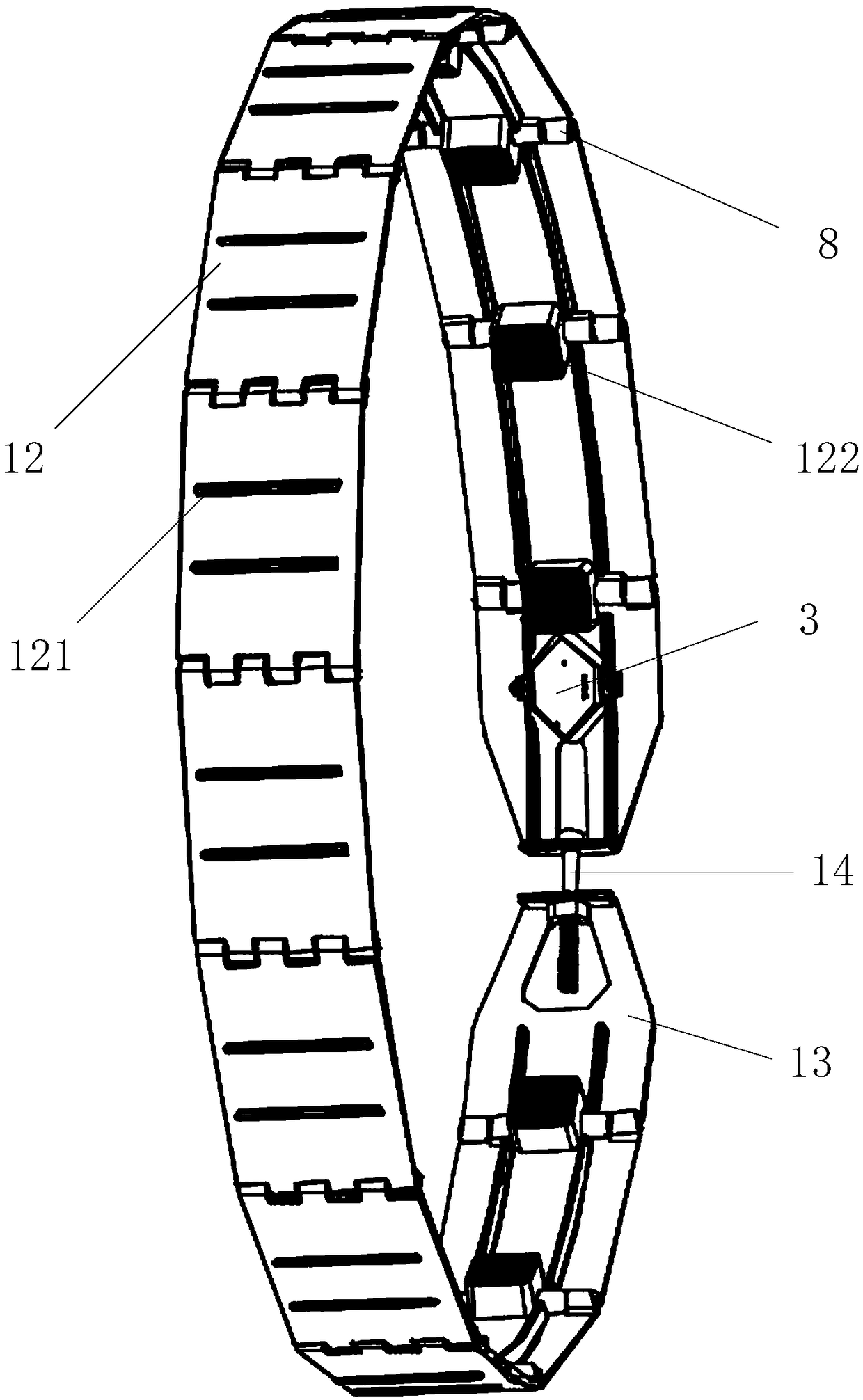

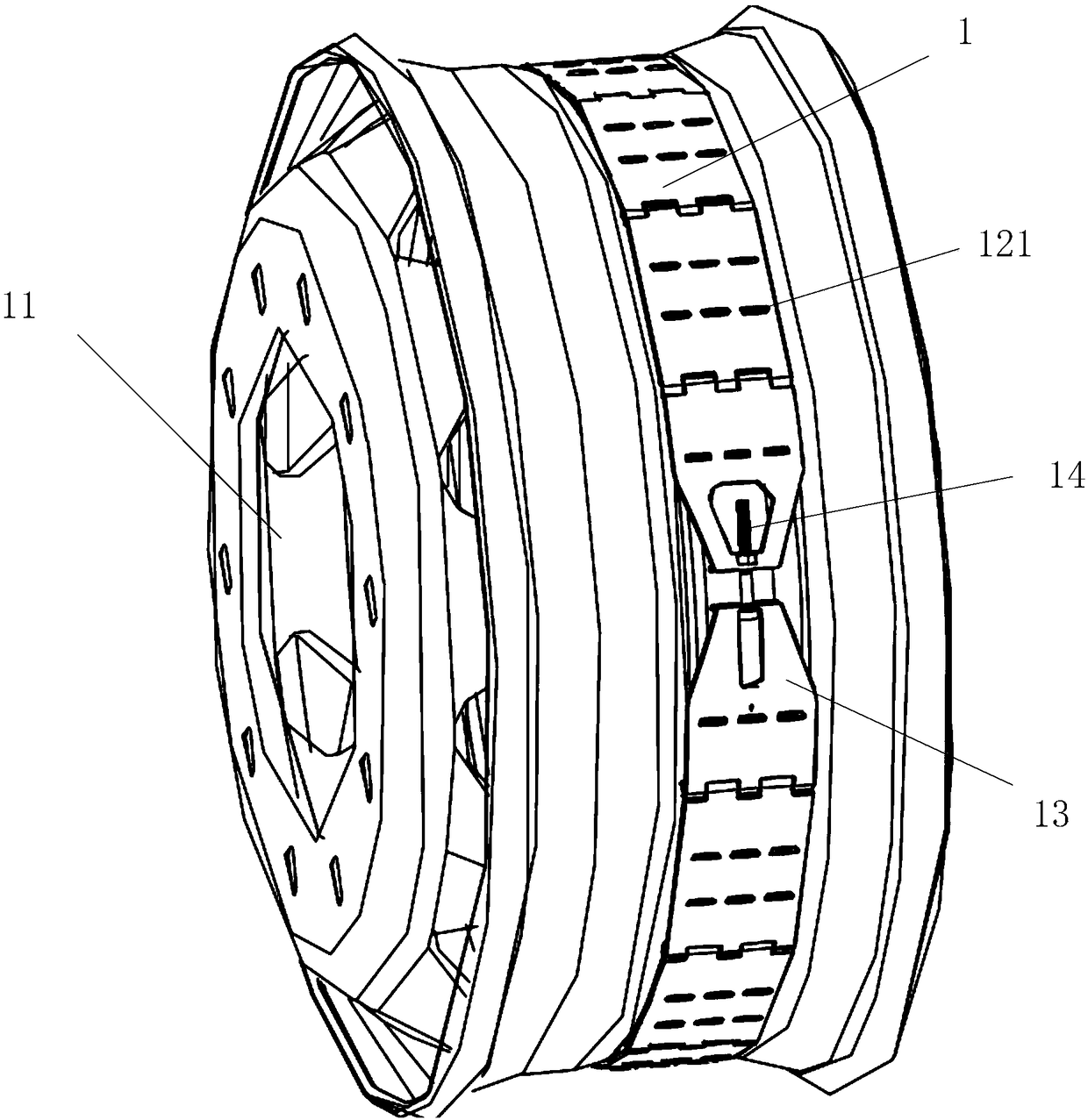

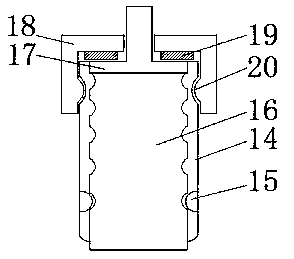

Tire temperature and tire pressure monitoring and deflated tire anti-drop supporting device

PendingCN108146160ARealize the function of anti-off supportAvoid abnormal wearTyre measurementsBurstingTemperature stress

The invention discloses a tire temperature and tire pressure monitoring and deflated tire anti-drop supporting device. The tire temperature and tire pressure monitoring and deflated tire anti-drop supporting device comprises a supporting assembly and a temperature and pressure sensing and radio frequency module, wherein the supporting assembly is formed by sequentially connecting a plurality of supporting pieces surrounding the outside circumference of a hub in series; the supporting pieces arranged on two ends of the supporting assembly are respectively connected with one locking piece; the two locking pieces are fixedly connected through an adjustable locking bolt; a pin shaft hole hinged to the corresponding supporting piece is formed in one end of each locking piece; the temperature and pressure sensing and radio frequency module is arranged in a sealed shell; the sealed shell is arranged on one locking piece. According to the tire temperature and tire pressure monitoring and deflated tire anti-drop supporting device disclosed by the invention, a tire pressure and tire temperature sensor and a deflated tire emergency supporting piece are integrated, so that simultaneous promotion of active prevention and passive defense can be realized, the risk of tire bursting can be reduced to the maximum, the tire bursting is avoided, and the safety performance of a vehicle is greatly improved.

Owner:北京龙卓科技有限公司

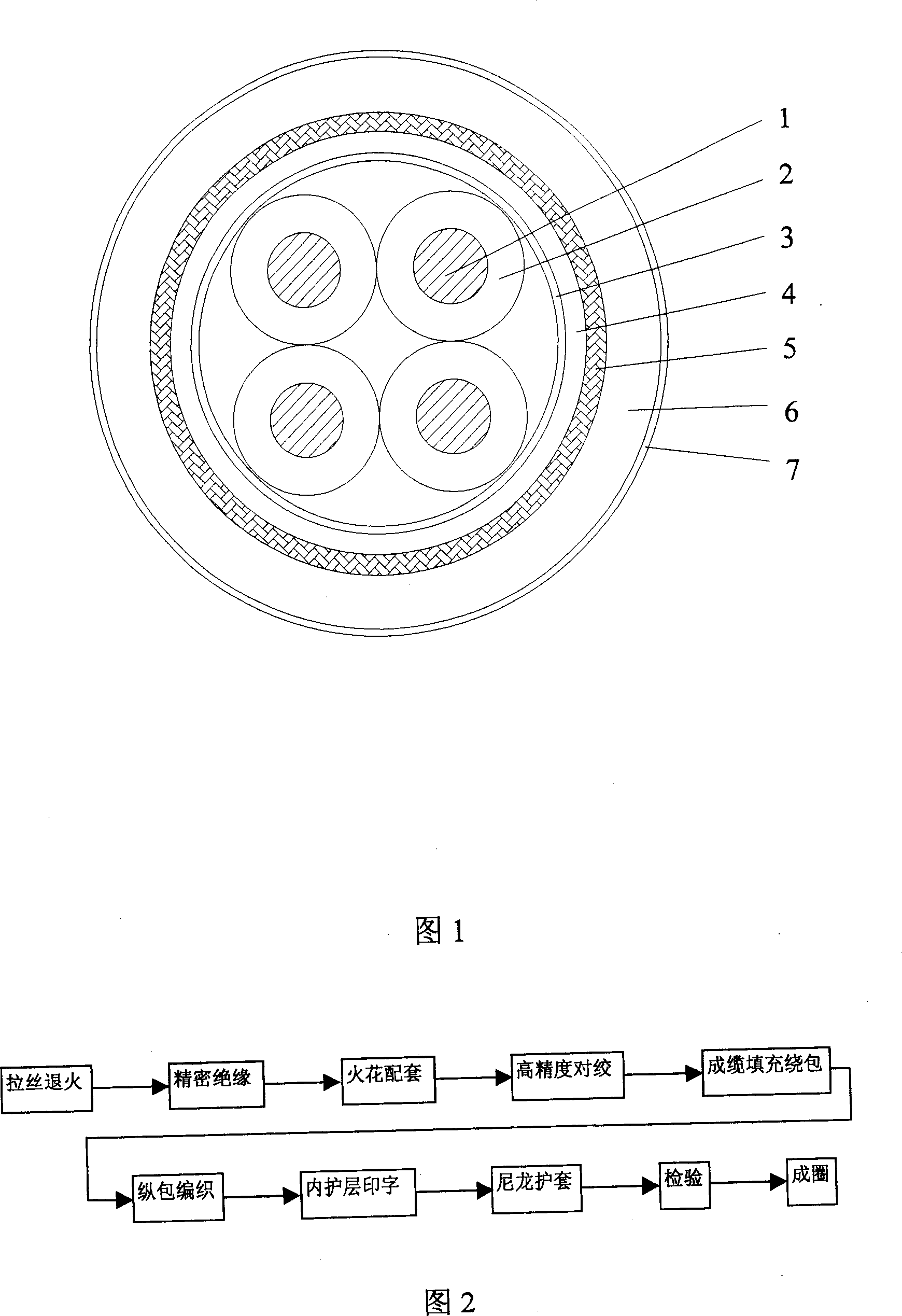

Bus cable for building intelligent control system

InactiveCN101145410AAdapt to wiring needsAccurate and stable transmissionPlastic/resin/waxes insulatorsInsulated cablesElectrical conductorTransport system

The invention relates to a bus cable used for a building intelligent control system and is characterized in that the bus cable has a four-core structure, wherein the cable core is formed by twisting two wire pairs (red-black and yellow-white pairs); the cable comprises, from the inside to the outside, a conductor, a high-density polyethylene insulating inner protective layer and an outer jacket layer; one of the two wire pairs is used to transmit a DC 24 V power to the system and digital signals as well and the other one is the spare pair; the bus cable is adapted to the on-off, control, monitoring and signal information transmission of buildings; the data transmission rate of the bus cable is more than or equal to 960KB / S; and the rated voltage of the bus cable is 0.6 / 1kV. The inventive bus cable used for the control system is safe and reliable to serve as the power line for digital control lines.

Owner:SHANGHAI YALONG IND

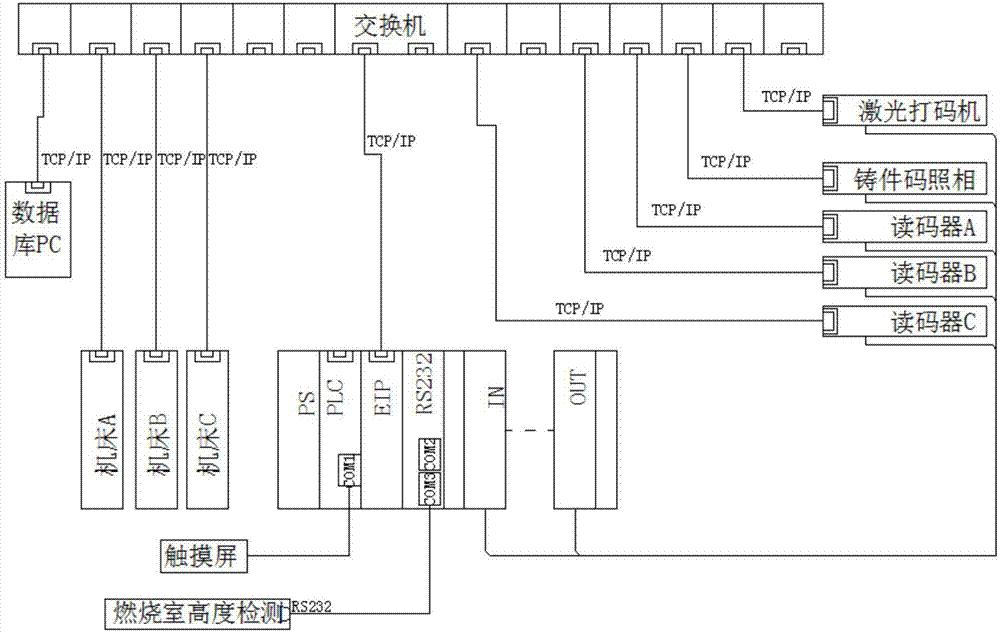

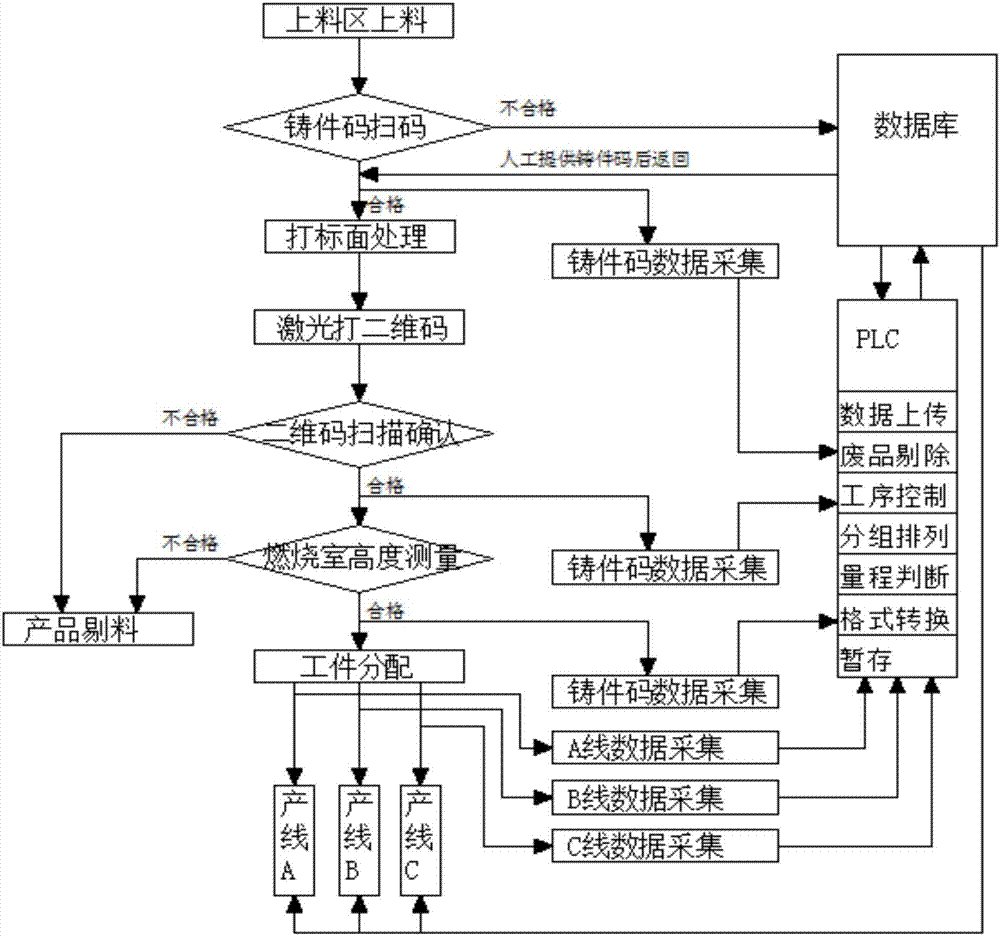

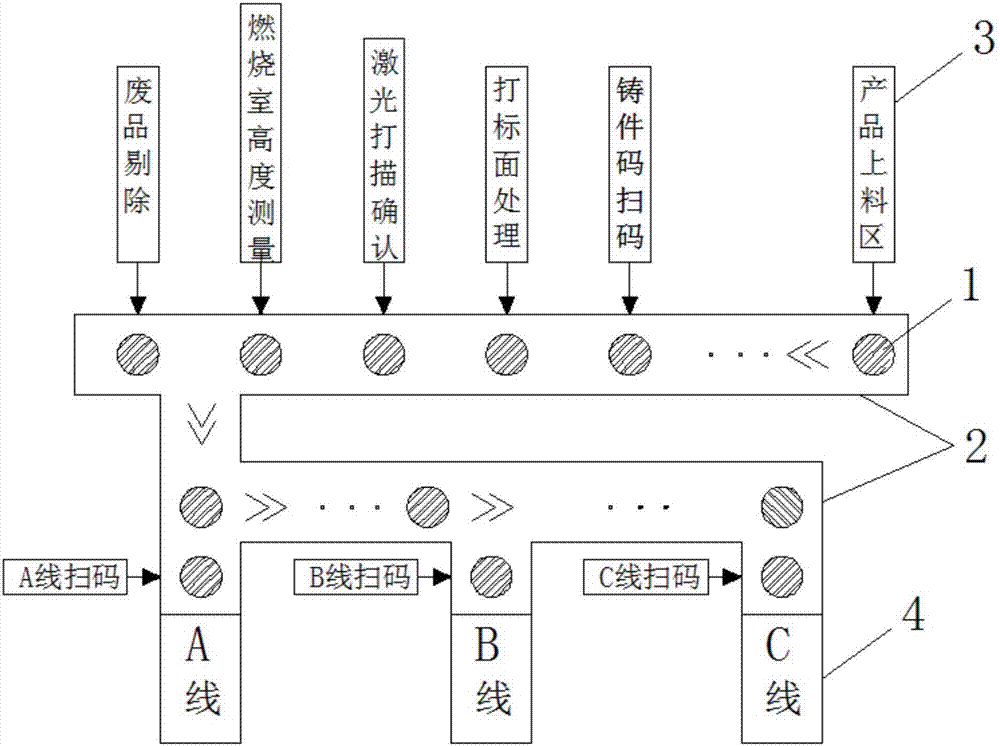

Data acquisition and error prevention PLC control method in cylinder cover conveying process

ActiveCN107357273AGuaranteed continuous productionConvenient production site managementTotal factory controlProgramme total factory controlCombustion chamberData acquisition

The invention relates to the machining field and particularly relates to a data acquisition and error prevention PLC control method which is utilized when cylinder cover blank members are sequentially conveyed on a conveying line. Before an engine cylinder cover enters a machine tool for processing, the blank members are conveyed by a conveying device from a feeding area to the machine tool, the cylinder covers on the conveying line sequentially realize casting code scanning, marking surface processing, laser two-dimensional code printing, two-dimensional code confirmation, combustion chamber height measurement and dimension over-error waste discharge operations; each function operation is distributed according to certain rules, firstly, casting code scanning operation and marking surface processing operation, secondly, laser two-dimensional code printing operation, combustion chamber height measurement operation and dimension over-error waste discharge operation which are continuously arranged, and products must sequentially have the multiple operations. The method is advantaged in that data acquisition and transmission accuracy is high, production is convenient, and relatively good use and promotion values are realized.

Owner:NINGXIA KOCEL MACHINE TOOL ACCESSORIES

Cleaning device for mobile phone screen

InactiveCN109848162AAccurate and stable transmissionEasy to replaceLiquid surface applicatorsHousehold cleanersGear wheelCircular cone

The invention discloses a cleaning device for a mobile phone screen. The cleaning device comprises a frame, wherein a support is fixedly connected to the interior of the frame; a bearing sleeve is fixedly connected to the top end of the support, a rotating shaft is rotationally connected to the interior of the bearing sleeve, and a rotating button is fixedly connected to one end of the rotating shaft; and a conical gear is fixedly connected to one end of the rotating shaft, a threaded rod is fixedly connected to the interior of the conical gear in a sleeve mode, the two ends of the threaded rod are rotationally connected to bearing blocks, and the surface of the threaded rod is fixedly connected to a limiting block. According to the cleaning device for the mobile phone screen, the rotatingbutton and the conical gear are arranged, the rotating button is rotated to drive the conical gear and thus supporting plates are enabled to move up and down, the position between the supporting plates and a cleaning piece is positioned due to the fact that the thickness of the mobile phones are different, the transmission is stable and accurate, the mobile phone screens with different sizes canbe cleaned, and therefore the purpose of wide application range is achieved.

Owner:罗仲文

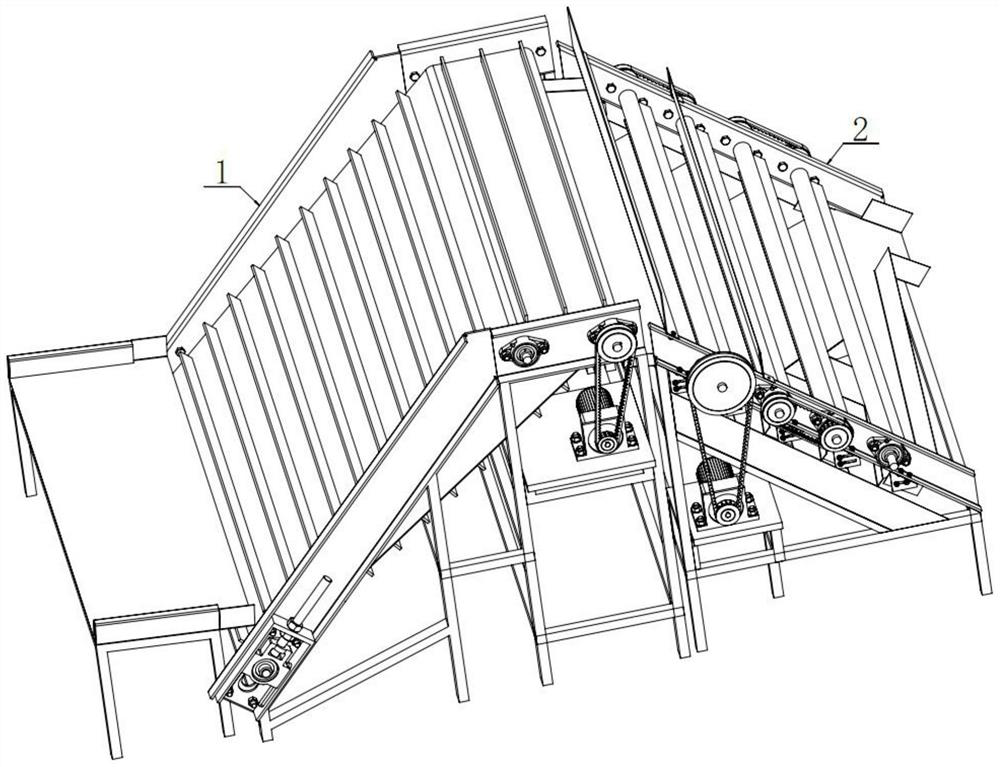

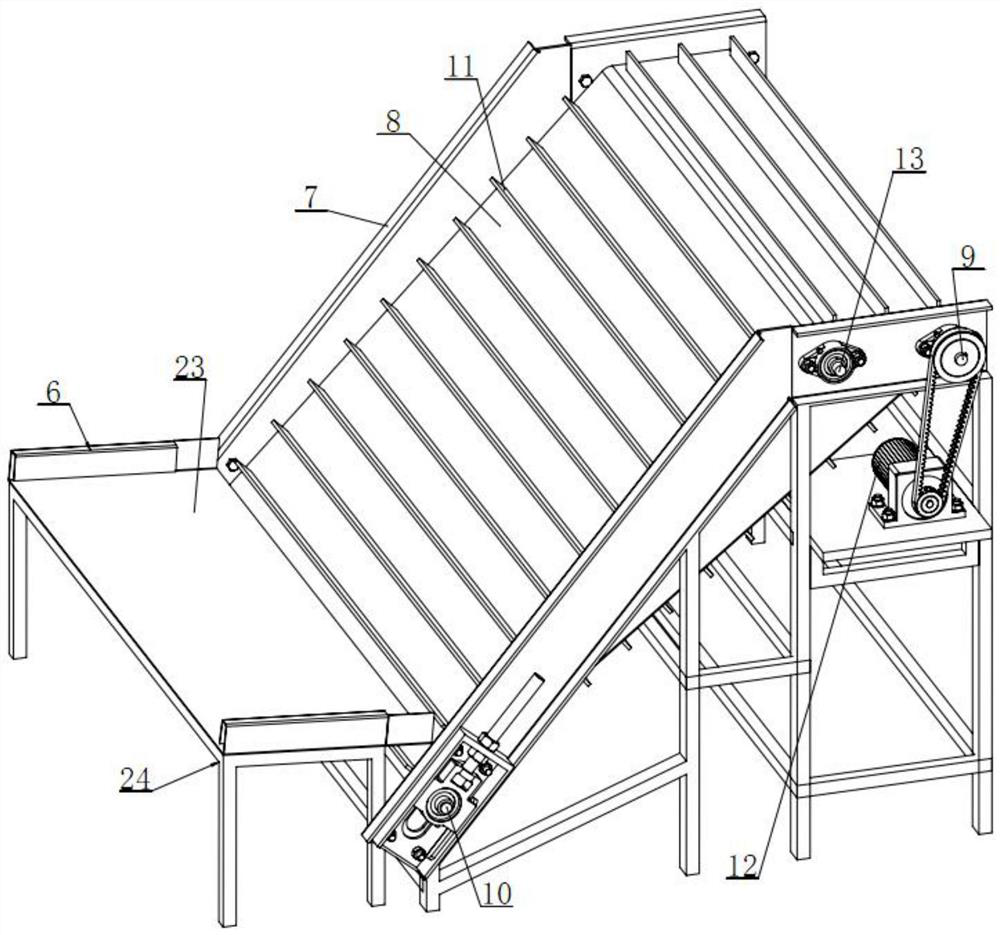

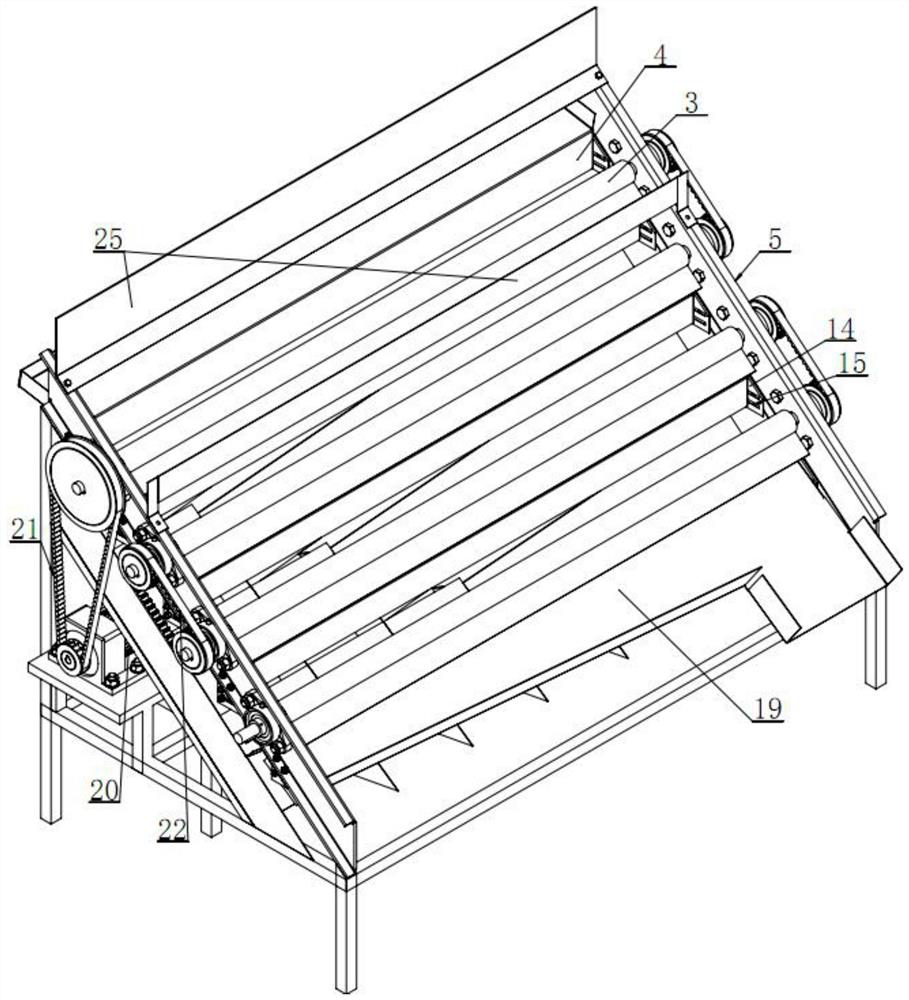

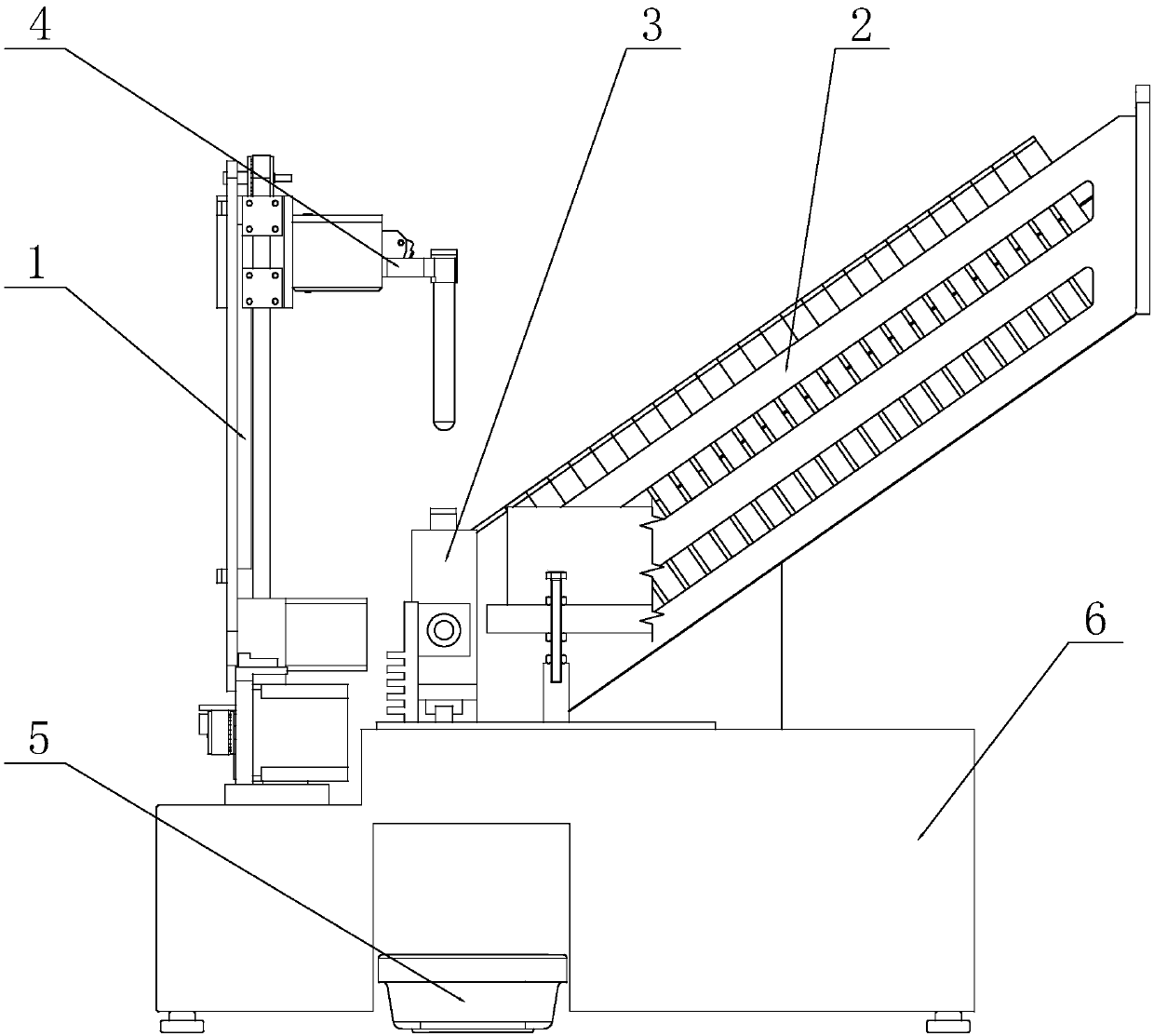

Fruit grading and sorting device

ActiveCN111822357AImprove sorting efficiencySorting saves time and effortGradingAgricultural engineeringStructural engineering

The invention discloses a fruit grading and sorting device. The fruit grading and sorting device comprises an inclined feeding system and a sorting mechanism installed at the discharging end of the feeding system, wherein the sorting mechanism comprises a plurality of rollers and baffles; the rollers are evenly arranged on the slope face of an inclined rack at intervals and rotationally connectedwith the inclined rack; the horizontal inner side of each roller is provided with one baffle; the gaps between each pair of baffles and the corresponding roller from top to bottom are sequentially increased; a shifting piece is arranged in the radial length direction of each roller; the length of the part, stretching out of the corresponding roller, of each shifting piece is smaller than the corresponding gap; a material collecting device is installed in the inclined rack; and the rollers are connected with a drive mechanism. The feeding system is adopted for feeding fruits to the sorting mechanism, the different gaps between the plurality of pairs of rollers and the baffles from top to bottom are adopted in the sorting mechanism, and grading and sorting of the fruits different in size areachieved; and the sorting efficiency is high, time and labor are saved during sorting, the sorting efficiency is high, and sorting is accurate.

Owner:GUIZHOU UNIV

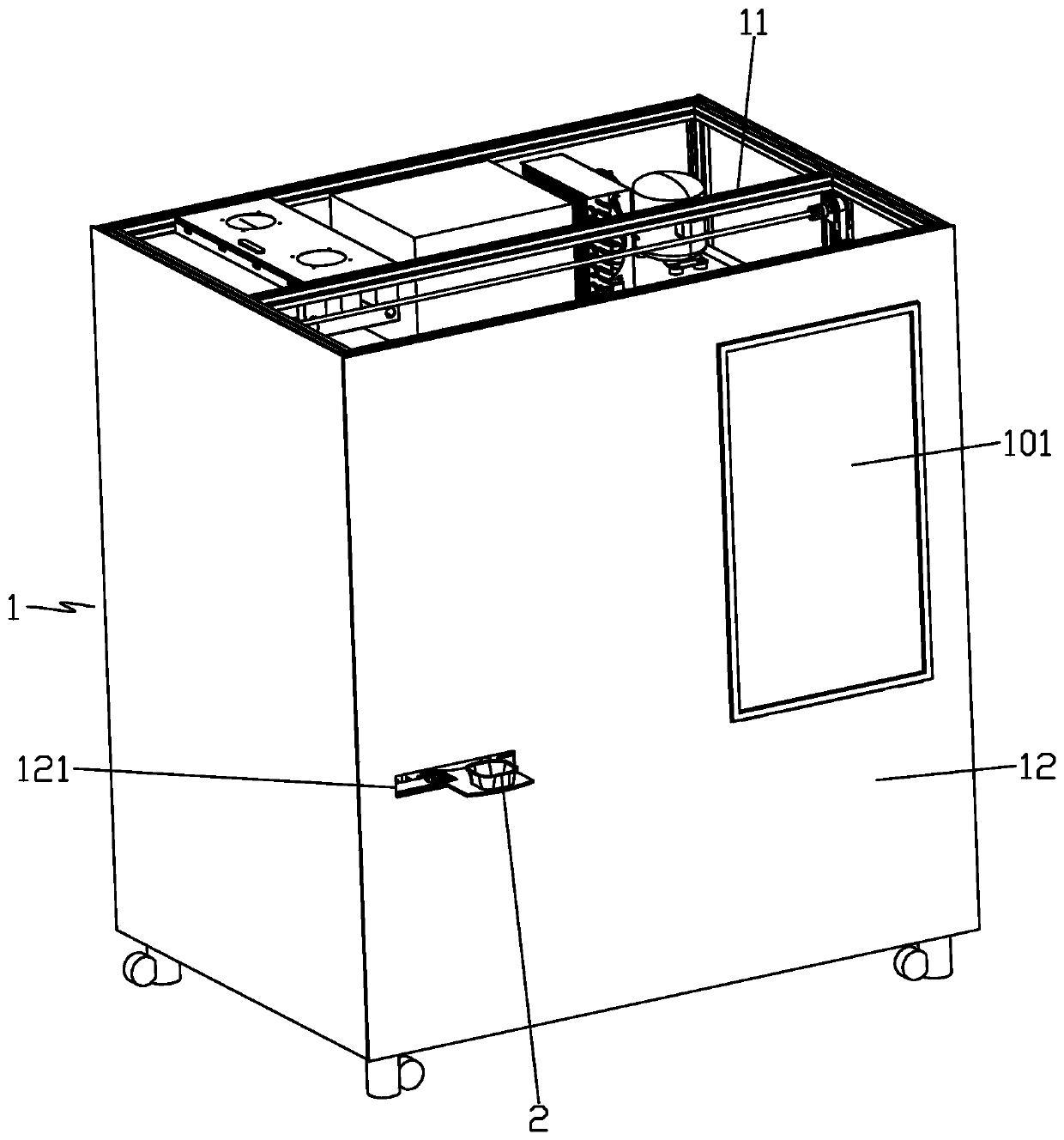

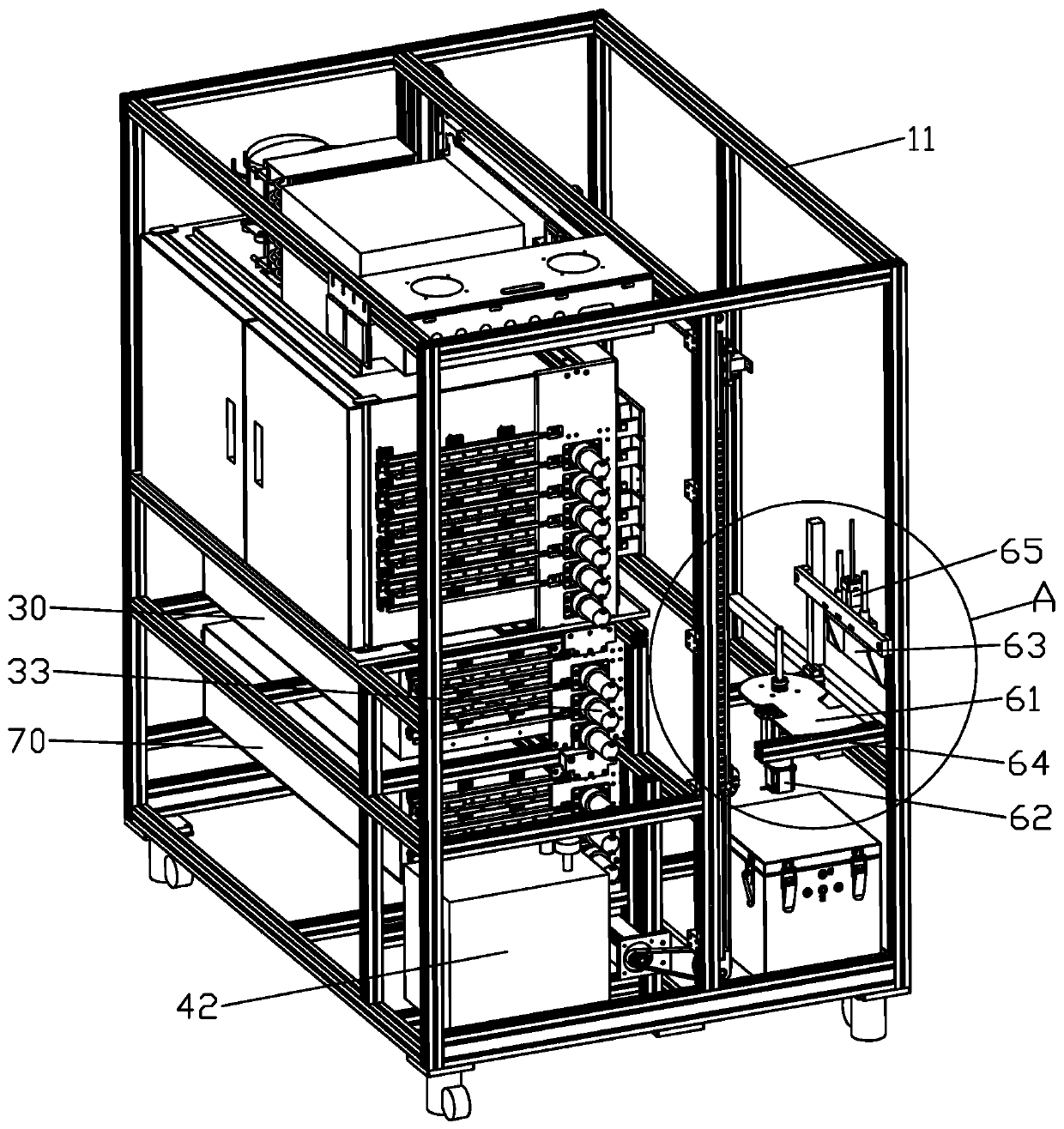

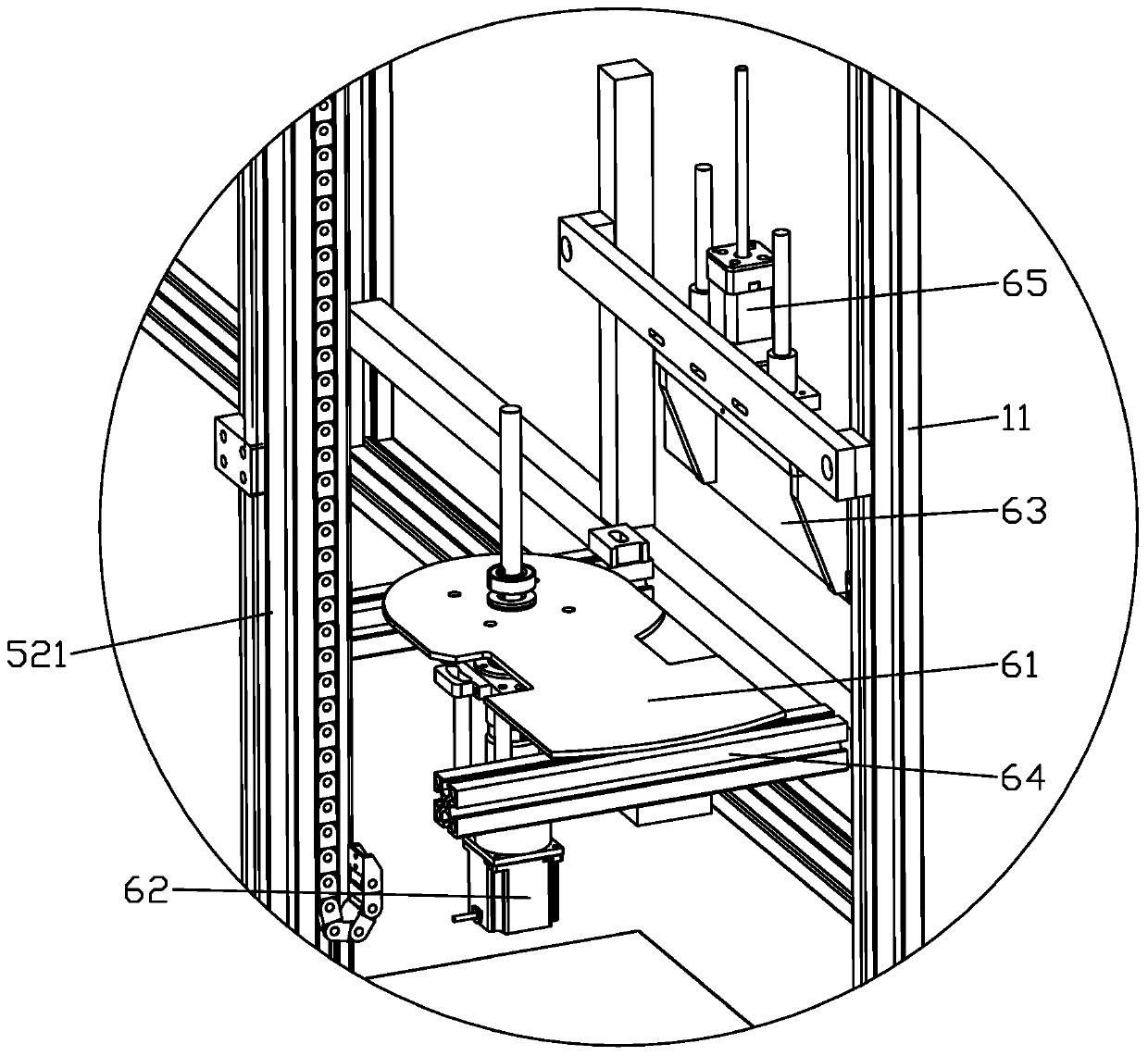

Automatic food steaming and vending machine

PendingCN110338645ACompact structureAccurate and stable transmissionSteam cooking vesselsApparatus for dispensing fluids/granular materialsFood contact materialsControl system

The invention discloses an automatic food steaming and vending machine; the automatic food steaming and vending machine comprises a machine body with a control system, wherein a storage space capableof containing a food container is arranged in the machine body, a feeding device capable of adding a liquid material into the food container, a steaming device capable of steaming the food in the foodcontainer, and a carrying system, wherein the carrying system is controlled by the control system, so that the food container can be conveyed among in the storage space, the feeding position of the feeding device and the steaming device, and the food container in the steaming device can be conveyed to a meal taking position. According to the requirements of users, the corresponding food containeris taken out, a proper amount of liquid material is added into the liquid material, and then the food container is put into the steaming device for automatic steaming and automatic vending, so that the machine has high market prospect.

Owner:深圳极客开饭科技有限公司

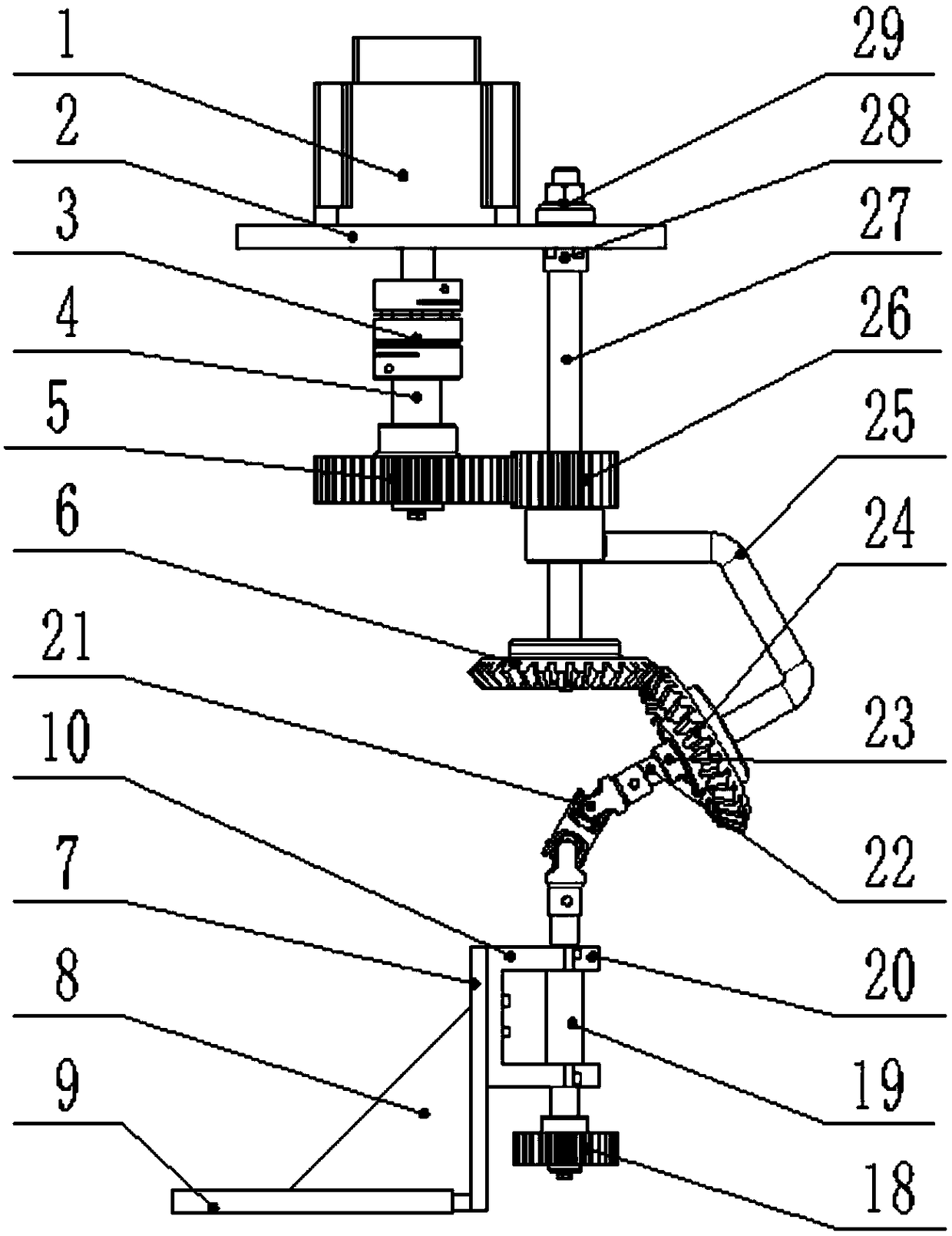

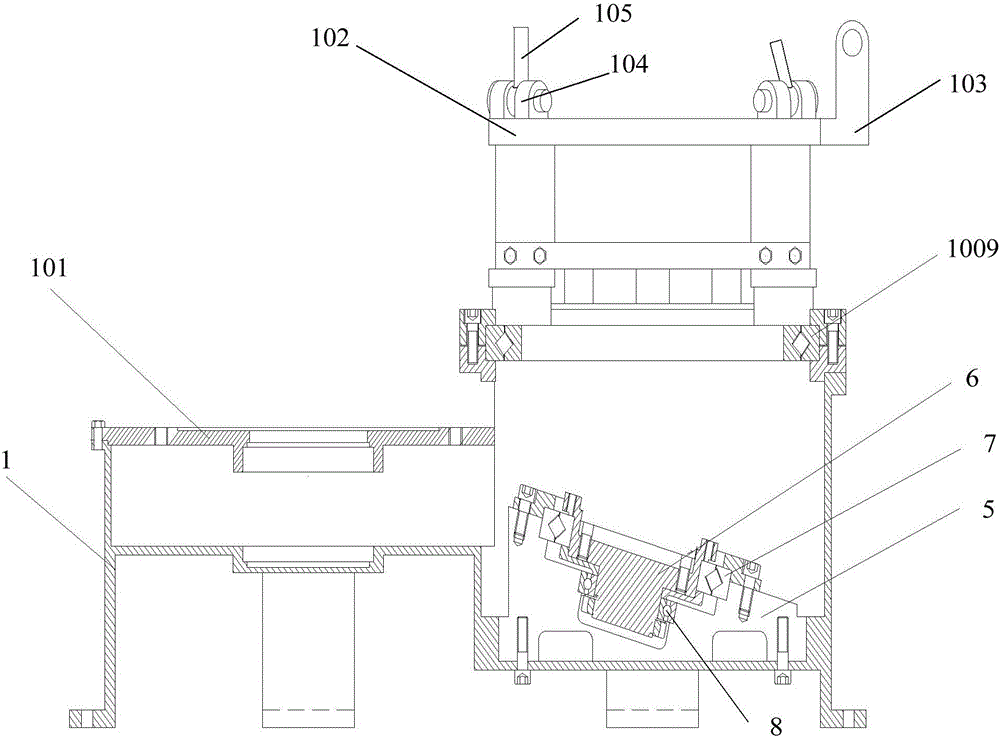

Mining pneumatic-conveying universal joint piston type concrete spraying machine

InactiveCN104564108AIncrease displacementIncrease output torqueUnderground chambersTunnel liningCouplingUniversal joint

The invention provides a mining pneumatic-conveying universal joint piston type concrete spraying machine. The problems of large size and low efficiency of an existing spraying machine are solved. The mining pneumatic-conveying universal joint piston type concrete spraying machine comprises a machine frame, wherein a rotor cylinder barrel is arranged on the machine frame, a plurality of material storage channels are formed in the rotor cylinder barrel, piston modules penetrate through the material storage channels, an oblique table base is arranged under the rotor cylinder barrel, a rotating seat rotating along the oblique axis is arranged on the oblique table base, a straight gear is fixedly connected to the top face of the rotating seat, the piston modules are connected with the straight gear through a double-cross universal coupling, a spline shaft penetrates into the central position of the rotor cylinder barrel and is connected with the rotating seat through a single-cross universal coupling, and an air distribution disc is arranged above the rotor cylinder barrel and is communicated with a hopper and an air box. A power mechanism is arranged on the machine frame, the driving end of the power mechanism is connected with a bevel gear, and the bevel gear is in meshed connection with the straight gear. The mining pneumatic-conveying universal joint piston type concrete spraying machine is small in size, simple in structure, capable of saving energy and protecting environment, abrasion-resistant, low in operation cost and high in efficiency.

Owner:SHANDONG UNIV OF SCI & TECH

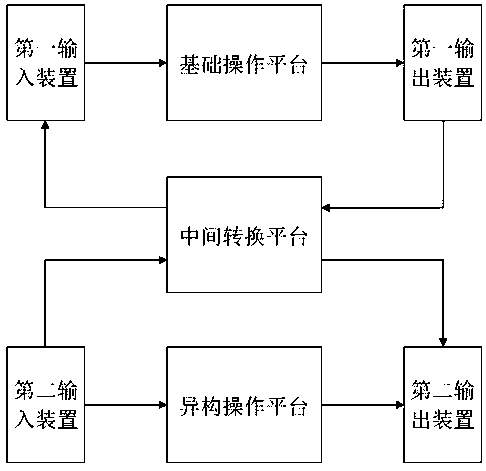

Intermediate mimicry system and mimicry method thereof

ActiveCN109992544AImprove interoperabilityFast deliveryElectric digital data processingRemote controlOutput device

The invention relates to an intermediate mimicry system. The system comprises a basic operation platform and a heterogeneous operation platform, an intermediate conversion platform is also arranged between the basic operation platform and the heterogeneous operation platform; according to the invention, information can be input into the input device of one operation platform; meanwhile, corresponding output information is obtained through synchronous observation in the output devices of the two operation platforms at the same time; therefore, data and information intercommunication between thetwo operation platforms can be effectively achieved regardless of different types of data and information between the different operation platforms, and remote control and information synchronous sharing of one heterogeneous operation platform to the other heterogeneous operation platform are achieved on the basis of data and information intercommunication between the two operation platforms.

Owner:ZHENJIANG NO 4 PEOPLES HOSPITAL

Axicon beam scanning device

InactiveCN106249405BGuaranteed accuracy requirementsGuaranteed Stability RequirementsOptical elementsCouplingLight beam

The invention relates to a rotating triple-prism beam scanning device comprising a rotating double-prism system, a rotating single-prism system, a guide rail, an adjustable support, and a fixed support. The rotating single-prism system comprises a base component, a prism and frame assembly, and a worm-and-gear mechanism. The prism and frame assembly comprises a flat washer, a wedge prism, a rubber pad, a wedge retainer ring, a threaded retainer ring, and a frame. The base component comprises a base, a base baffle, and a base insert. The worm-and-gear mechanism comprises a rotary motor, a motor stand, a coupling, a worm, a bearing support, a rolling bearing, a worm gear, an encoder support, and a rotary encoder. The rotating double-prism system is formed by assembling two rotating single-prism systems together. In the invention, the three wedge prisms are driven by the worm-and-gear mechanisms to do full-circumferential rotation, transmission is stable and accurate, and the scanning precision and stability of dynamic beams can be ensured; the prisms are independent of one another in rotation control, and diversified scanning modes can be achieved; and by introducing the third prism to the double-prism system, the scanning field of beams is enlarged significantly, and the problem that a double-prism system has scanning blind areas and control singular points is solved effectively.

Owner:TONGJI UNIV

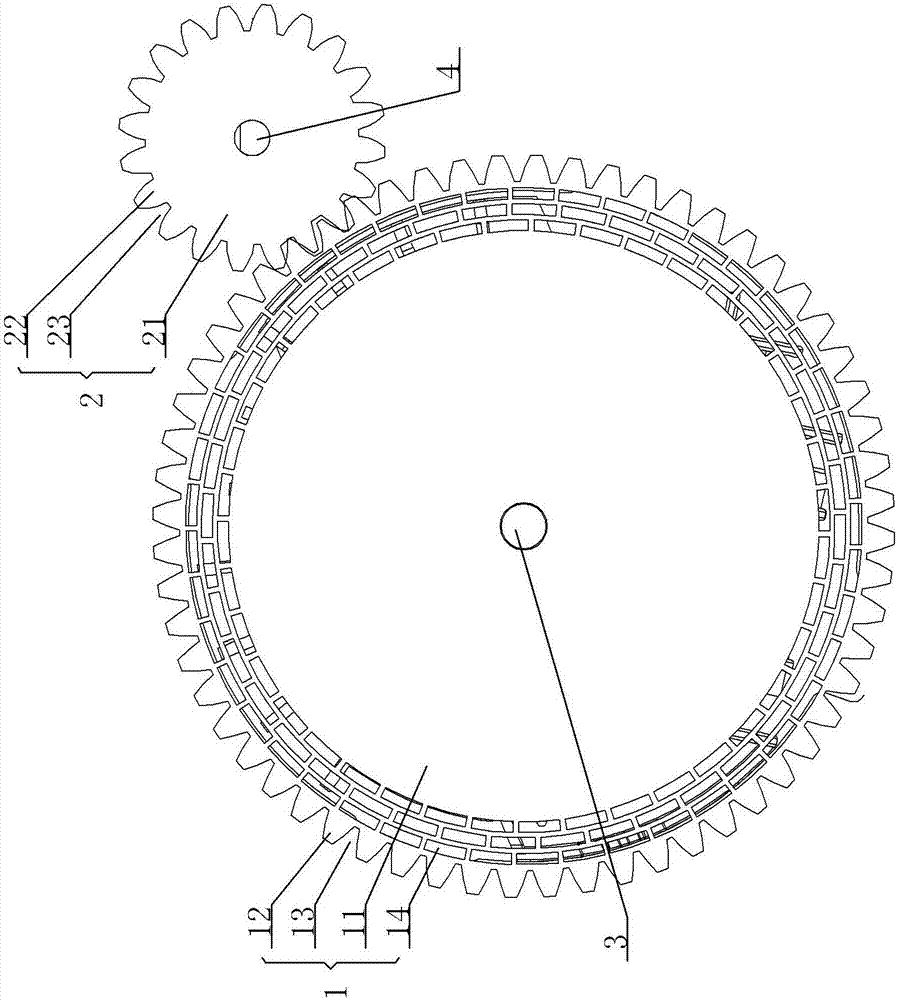

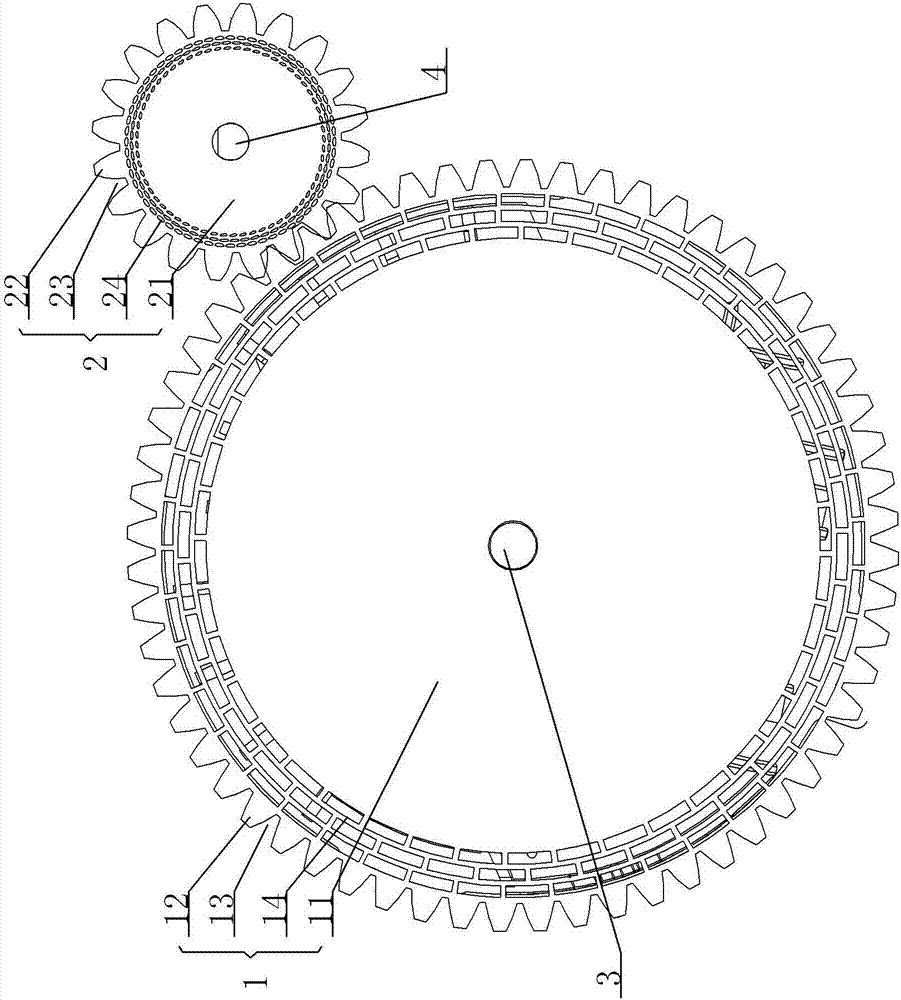

Structural flexible gear speed reduction transmission structure

InactiveCN107191543ASmooth transmissionAccurate and stable transmissionPortable liftingToothed gearingsEngineeringMutual engagement

The invention provides a structural flexible gear speed reduction transmission structure. Plastic gears in the mutual engagement state are kept in the stable extrusion state all the time in the engagement process, stable accurate gear transmission is ensured, and the transmission precision and the gear service life are ensured; the structure comprises two plastic gears including the first gear and the second gear; a first rotating shaft is sleeved with the first gear, a second rotating shaft is sleeved with the second gear, the first gear and the second gear are arranged in an engagement connection manner, the first gear comprises a first body, a first outer ring tooth and a first outer ring tooth groove, the second gear comprises a second body, a second outer ring tooth and a second outer ring tooth groove, first air hole structures which are not continuous are arranged between the outer ring face formed by the first outer ring tooth and the first outer ring tooth groove and the outer ring face of the first body, the first air hole structures penetrate the thickness direction of the first body, and the multiple first air hole structures are arranged from the radial direction of the inner end of the first outer ring tooth to the outer ring face of the first body

Owner:SUZHOU IND PARK KAYMAX PRECISION ENG

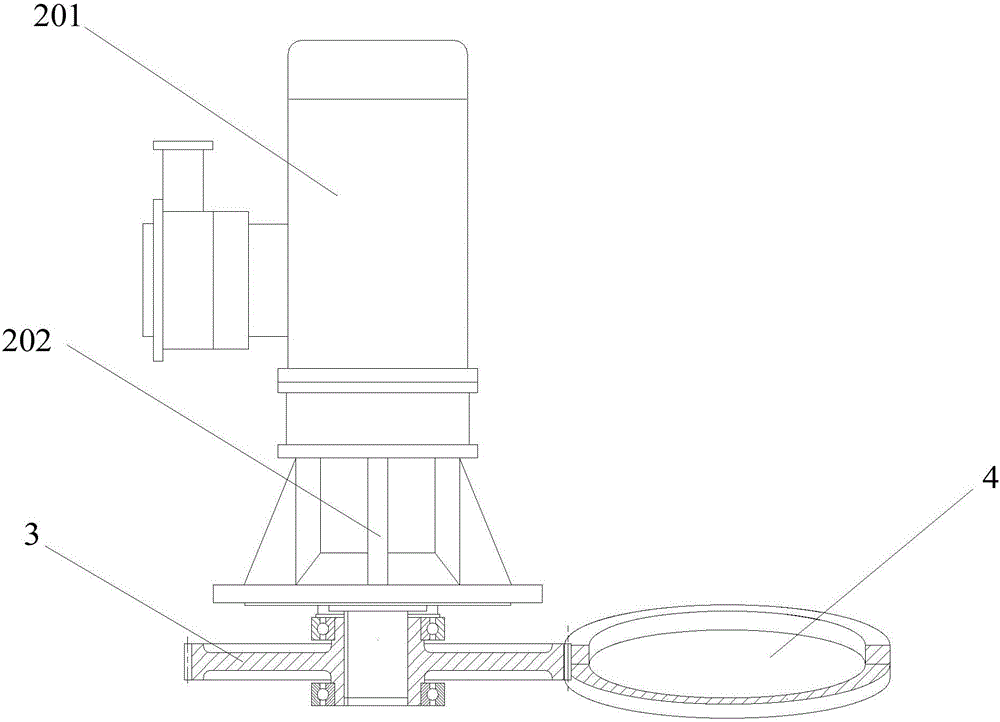

Ground direct-drive screw pump oil extracting device

InactiveCN103967760AMake sure it doesn't leakConvenience to workFlexible member pumpsPositive-displacement liquid enginesEngineeringBlowout preventer

The invention provides a ground direct-drive screw pump oil extracting device which comprises a base, a load-bearing frame, a drive device and a sealing connection sleeve. The load-bearing frame is installed on the base, the base is provided with a machine frame for fixing the load-bearing frame, the load-bearing frame is provided with a blowout preventer, the blowout preventer is provided with a sealing pipe sleeve, the load-bearing frame is provided with a rotary shaft, the drive device is installed on the machine frame, the output end of the drive device is connected with a speed changing box, the output end of the speed changing box is connected with a driving gear, the rotary shaft is provided with a driven gear matched with the driving gear, a polished rod penetrates through the rotary shaft, a protective cover is arranged on the load-bearing frame, a coded disc shell is arranged above the protective cover, a coded disc is arranged in the coded disc shell, the sealing connection sleeve is installed at the upper end of the rotary shaft, and a square clamp matched with the polished rod is arranged in the sealing connection sleeve. The oil extracting device is simple in structure, convenient to use and install, easy to operate, low in energy consumption, efficient and stable in operation, good in sealing effect, low in manufacturing cost, wide in application range, long in service life, safe and reliable.

Owner:何帅松

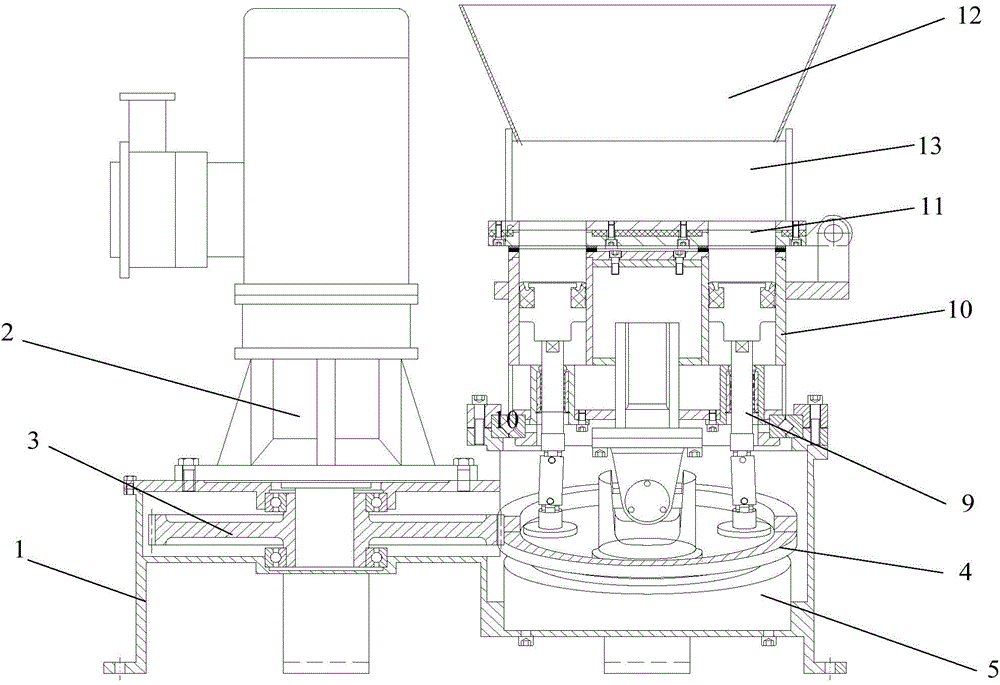

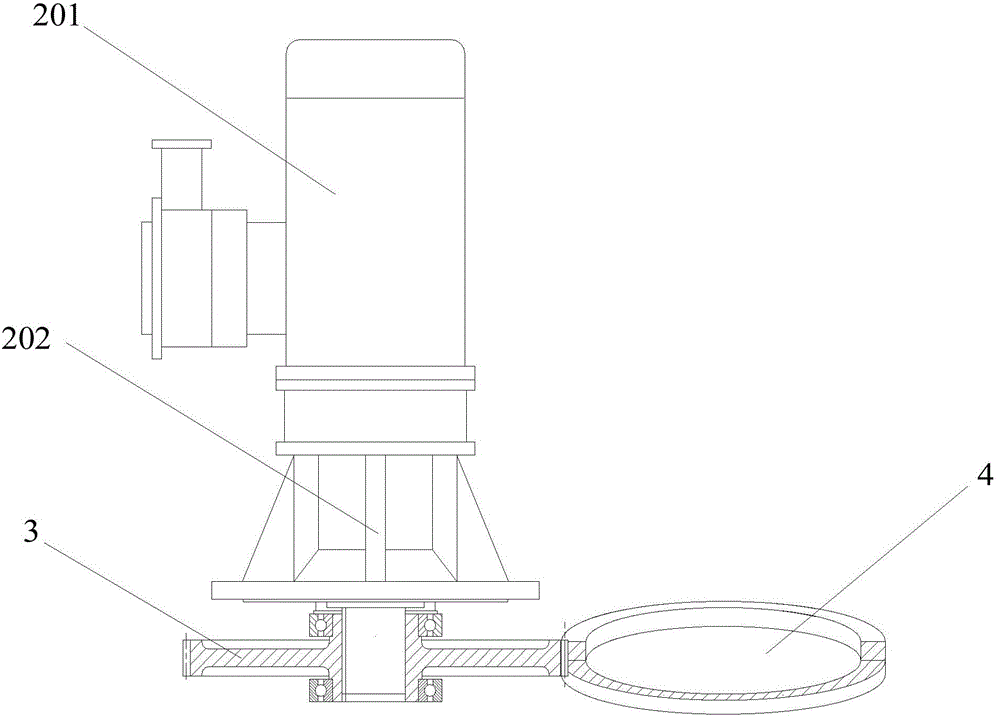

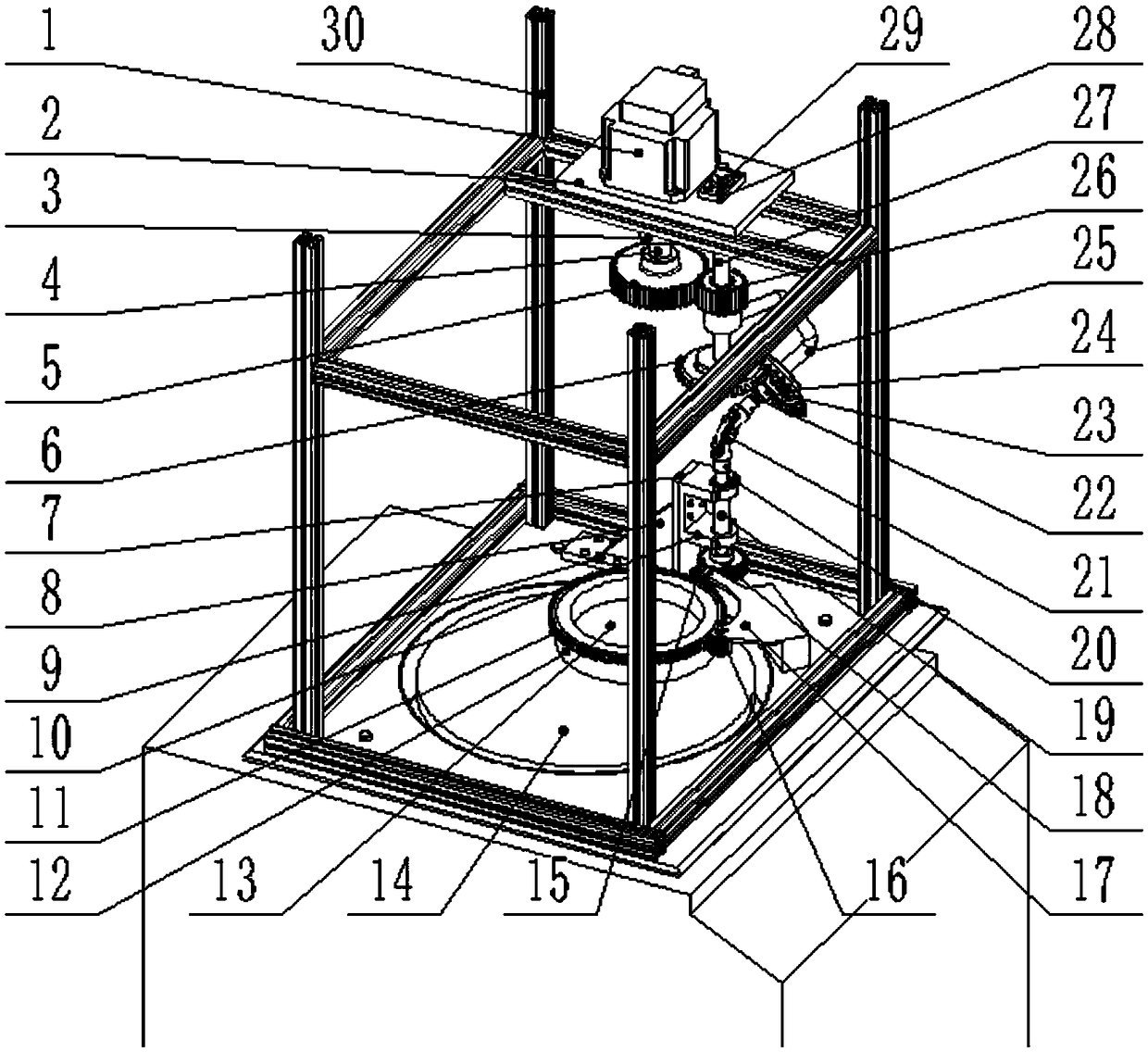

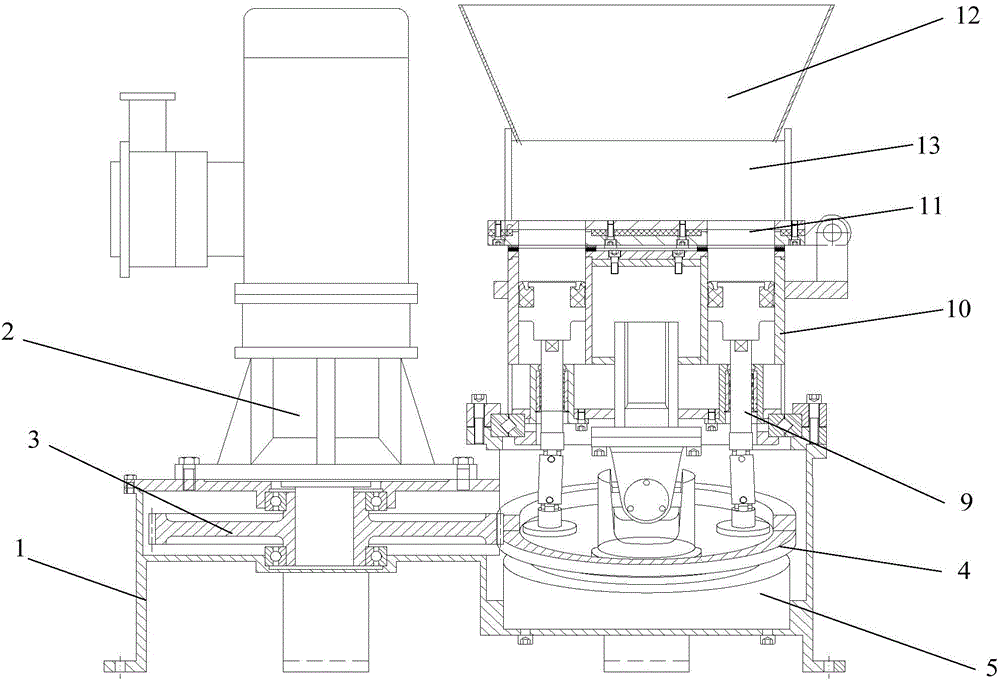

Novel high-precision shape-controlled plane grinding drive device

PendingCN108608315ACompact structureAccurate and stable transmissionGrinding drivesLapping machinesEngineeringMachining

A novel high-precision shape-controlled plane grinding drive device comprises a servo motor, a shaft I, a gear I, a shaft II, a gear II, a planet carrier, a bevel gear I, a bevel gear II, a shaft III,a double-cross axle type universal coupler, a shaft IV, a fixing bracket, a gear III, a guide gear I, a guide gear II, a holder, a gear ring, a trimming ring used for trimming a grinding disc and ensuring the planeness of the gear disc, a workpiece tray and a rack; the gear I is fixedly installed at the lower end of the shaft I; the gear II is installed on the middle of the shaft II in a sleevingmode through an internal rolling bearing and is engaged with the gear I; the upper end of the planet carrier is fixedly connected with a hub of the gear II in a welding mode; and the bevel gear I, the bevel gear II and the planet carrier form a planet wheel system. According to the novel high-precision shape-controlled plane grinding drive device, the grinding machining efficiency and workpiece machining surface quality can be remarkably improved by adjusting the speed ratio to be the irrational number value within the certain rotation speed range.

Owner:ZHEJIANG UNIV OF TECH

Mine air-supplied universal joint rotor piston concrete sprayer

InactiveCN104564108BIncrease displacementIncrease output torqueUnderground chambersTunnel liningUniversal jointCoupling

The invention provides a mining pneumatic-conveying universal joint piston type concrete spraying machine. The problems of large size and low efficiency of an existing spraying machine are solved. The mining pneumatic-conveying universal joint piston type concrete spraying machine comprises a machine frame, wherein a rotor cylinder barrel is arranged on the machine frame, a plurality of material storage channels are formed in the rotor cylinder barrel, piston modules penetrate through the material storage channels, an oblique table base is arranged under the rotor cylinder barrel, a rotating seat rotating along the oblique axis is arranged on the oblique table base, a straight gear is fixedly connected to the top face of the rotating seat, the piston modules are connected with the straight gear through a double-cross universal coupling, a spline shaft penetrates into the central position of the rotor cylinder barrel and is connected with the rotating seat through a single-cross universal coupling, and an air distribution disc is arranged above the rotor cylinder barrel and is communicated with a hopper and an air box. A power mechanism is arranged on the machine frame, the driving end of the power mechanism is connected with a bevel gear, and the bevel gear is in meshed connection with the straight gear. The mining pneumatic-conveying universal joint piston type concrete spraying machine is small in size, simple in structure, capable of saving energy and protecting environment, abrasion-resistant, low in operation cost and high in efficiency.

Owner:SHANDONG UNIV OF SCI & TECH

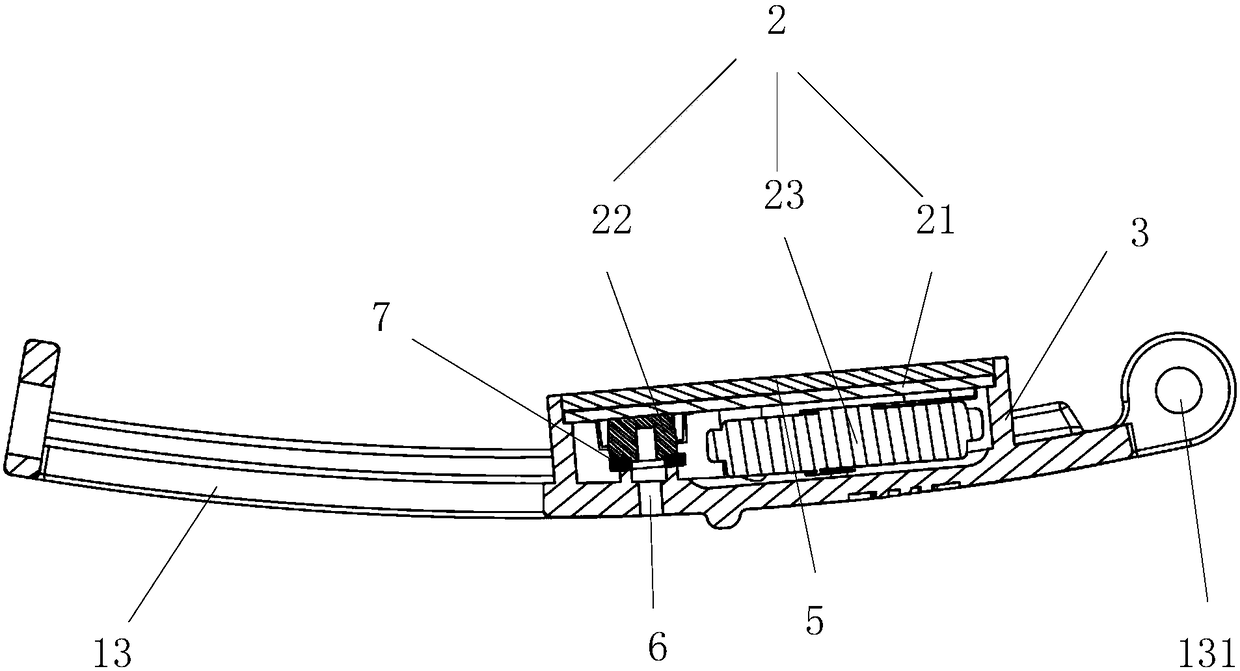

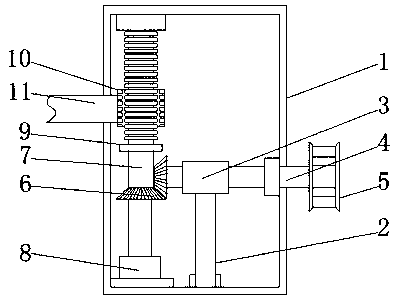

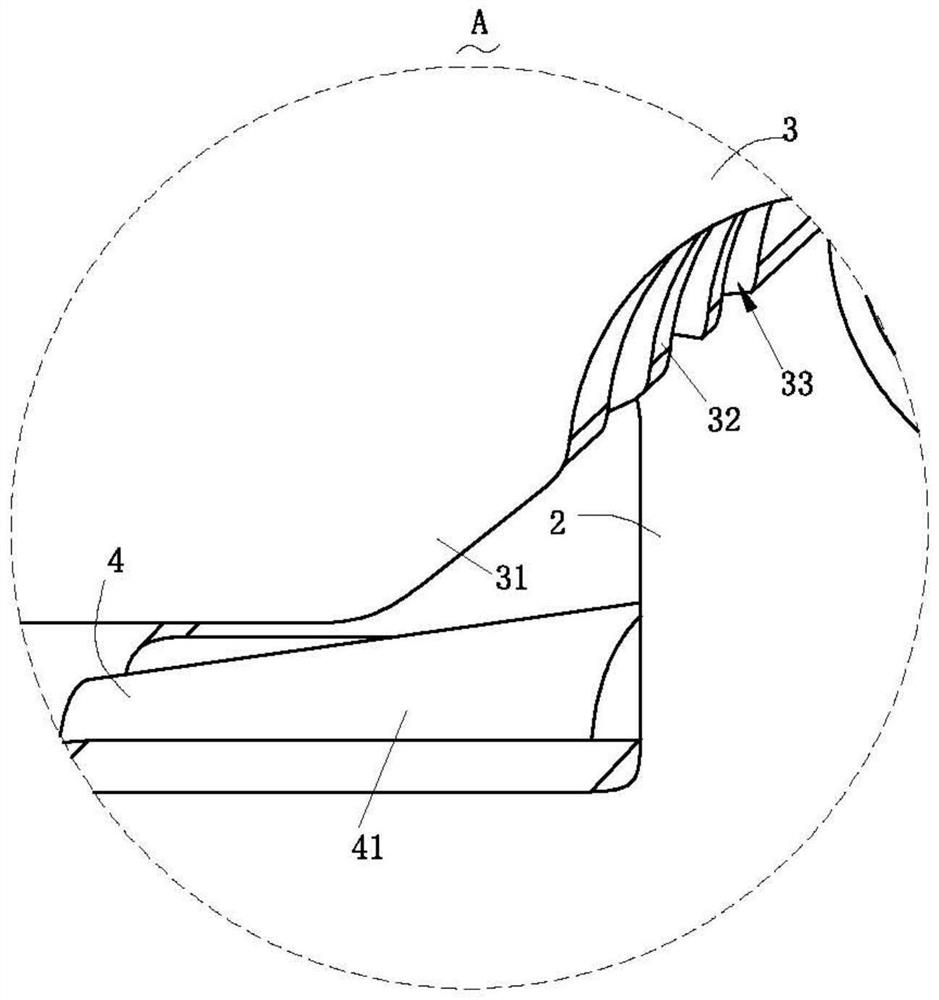

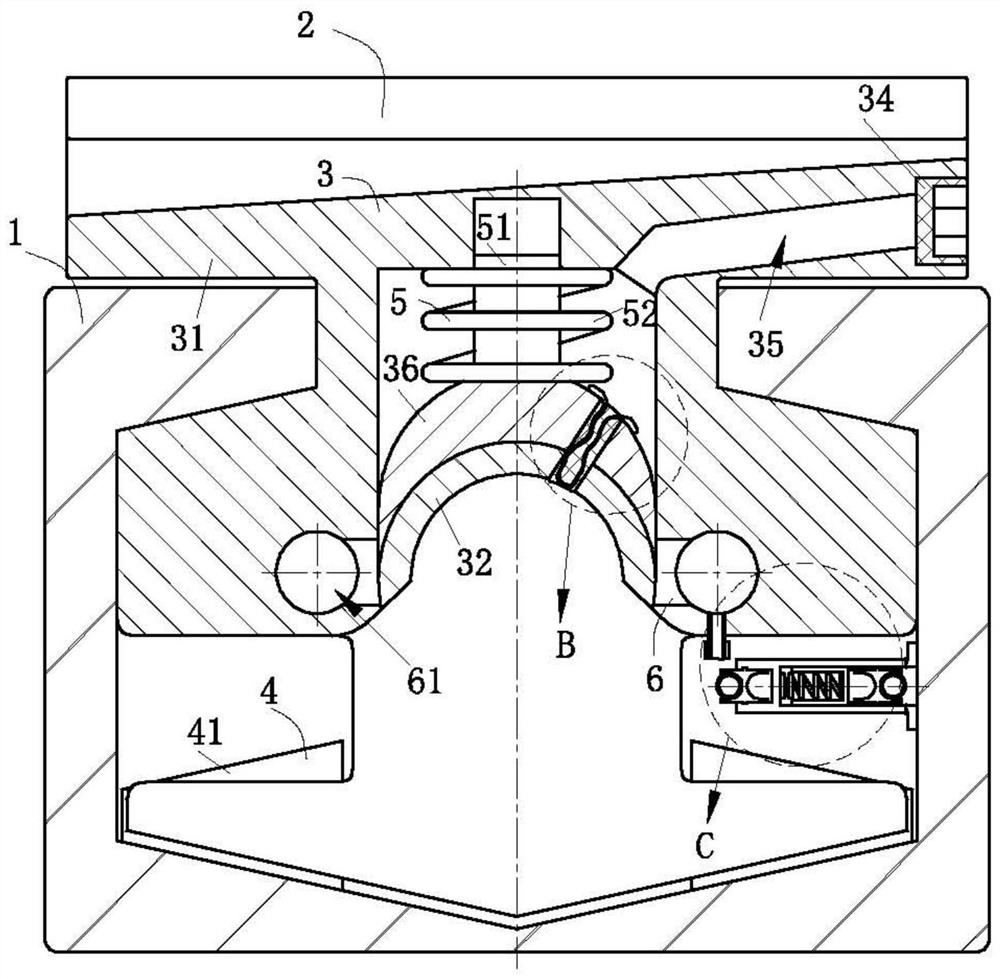

A variable-diameter hydraulic cutter for cutting casings with different diameters using multi-head screw drive

ActiveCN107191150BAccurately control the opening angleImprove wear resistanceBorehole/well accessoriesLinear motionScrew thread

The invention relates to a variable-diameter hydraulic cutter for cutting sleeve pipes different in diameter through multi-start screw transmission, and the variable-diameter hydraulic cutter is used for operation of abandoned wells. The variable-diameter hydraulic cutter is characterized in that an upper connector is in threaded connection with a housing, and a nozzle is located in a mandrel and connected with the mandrel through a thread; a piston is installed at the upper end of the mandrel in a threaded connection mode, and the piston, the mandrel and a spring are put in the housing; the mandrel is provided with a spiral groove, and the mandrel and the housing are matched to form a multi-start screw pair; a worm is located on the lower portion of the mandrel and is matched with the mandrel through a spline; cutter bodies are uniformly arranged in the circumferential direction and connected with the housing through hinge pins, a worm wheel on the upper portion of the cutter bodies are meshed with the worm, and rotation of the worm and the worm wheel is achieved. Through the mandrel, linear motion is transformed into rotary motion and transferred to the worm, the worm wheel is driven to rotate, the opening angles of the cutter bodies are thus controlled, continuous cutting of the sleeve pipes different in diameter can be achieved, the number of times of tripping operation is reduced, and the sleeve pipe cutting efficiency and operation reliability in the operation of abandoned wells are largely improved.

Owner:徐州精一泵业有限公司

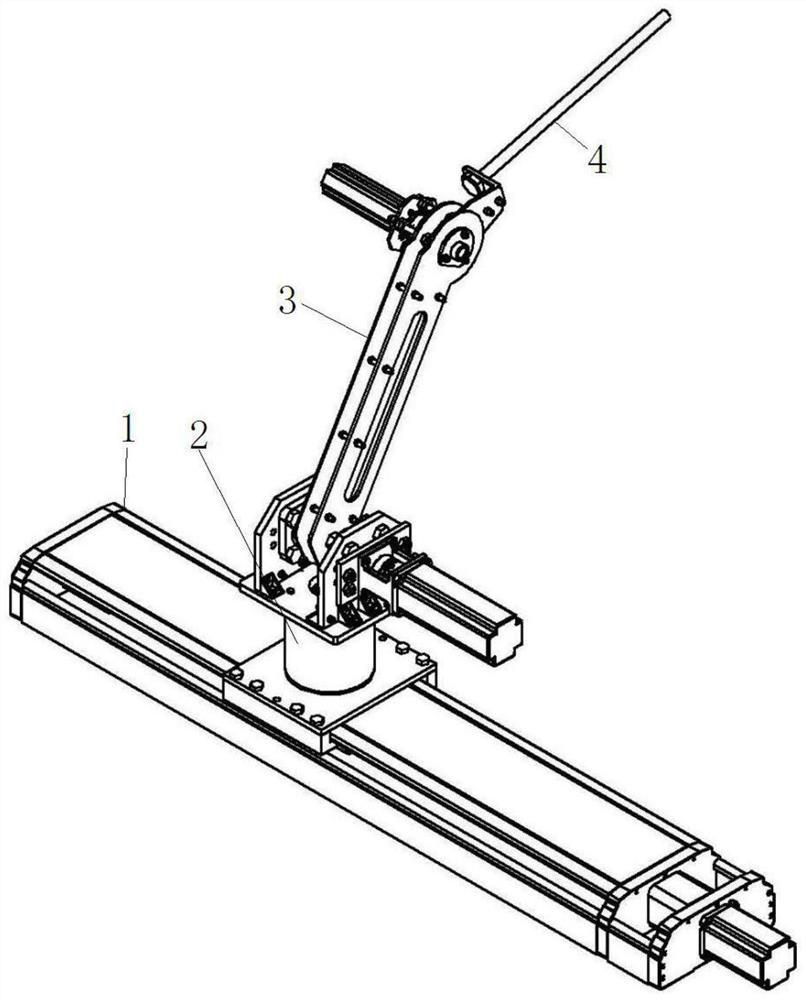

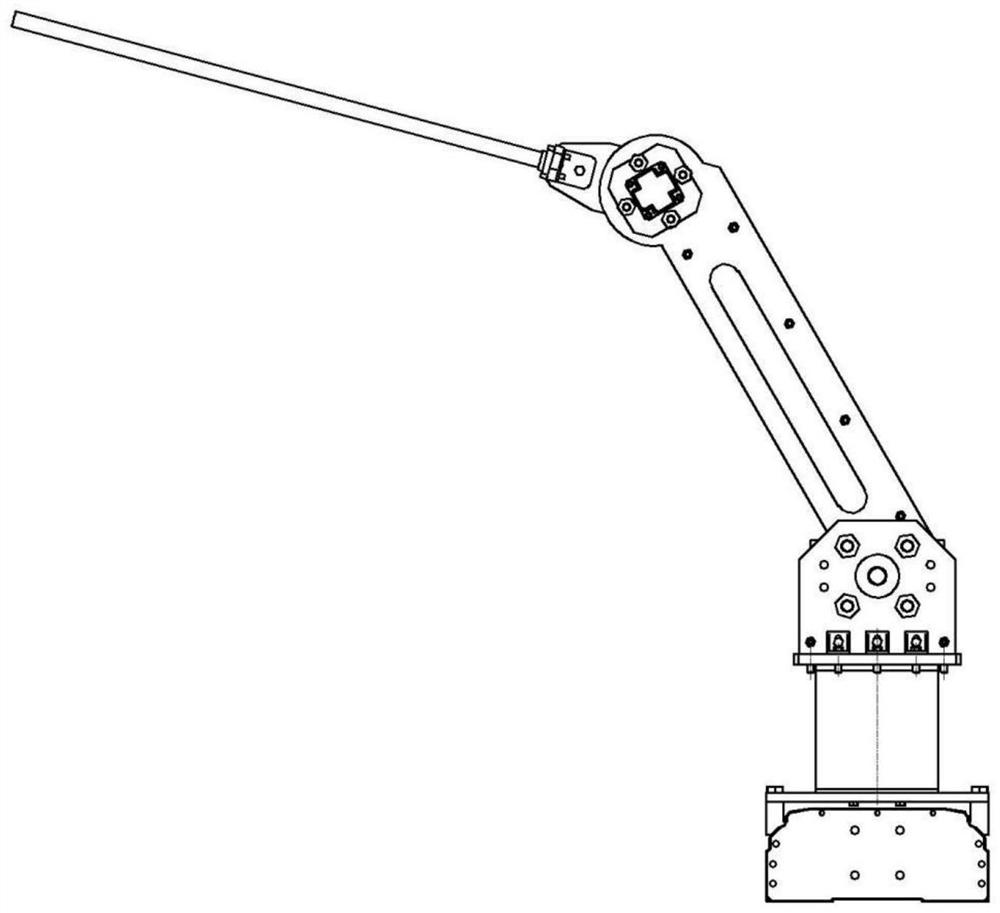

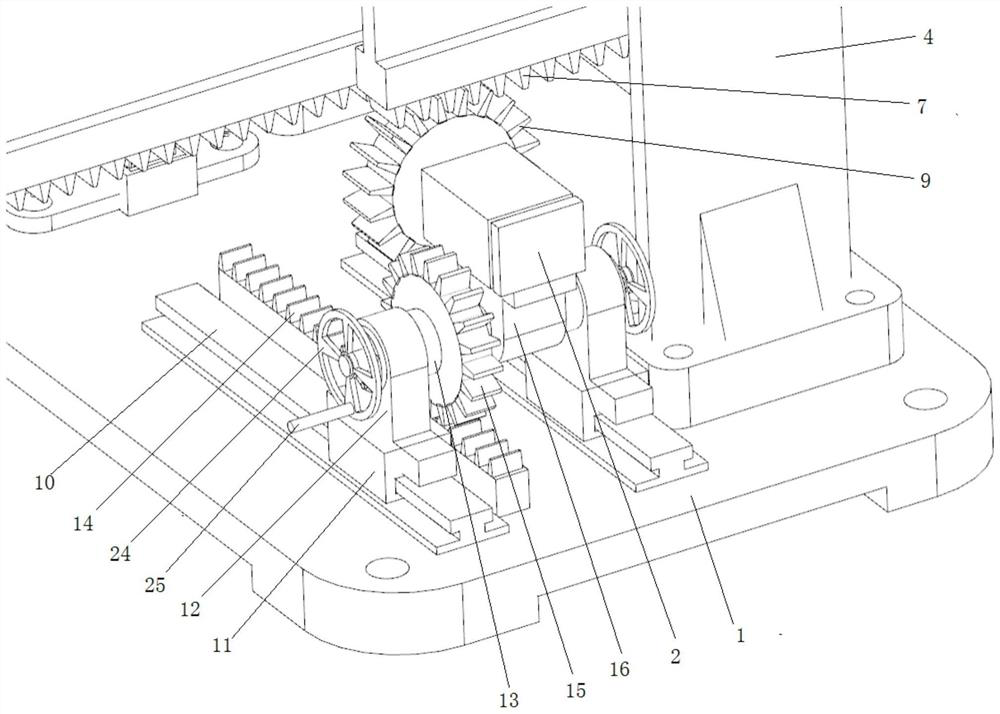

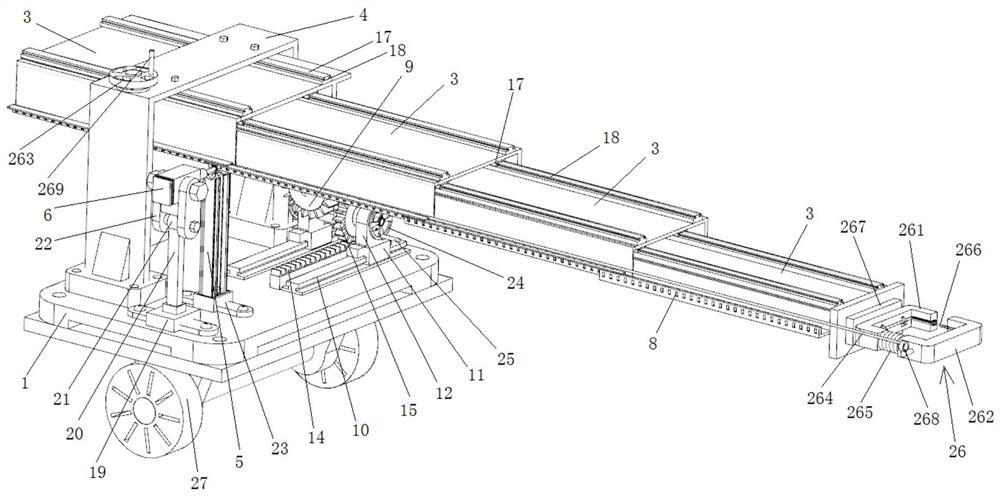

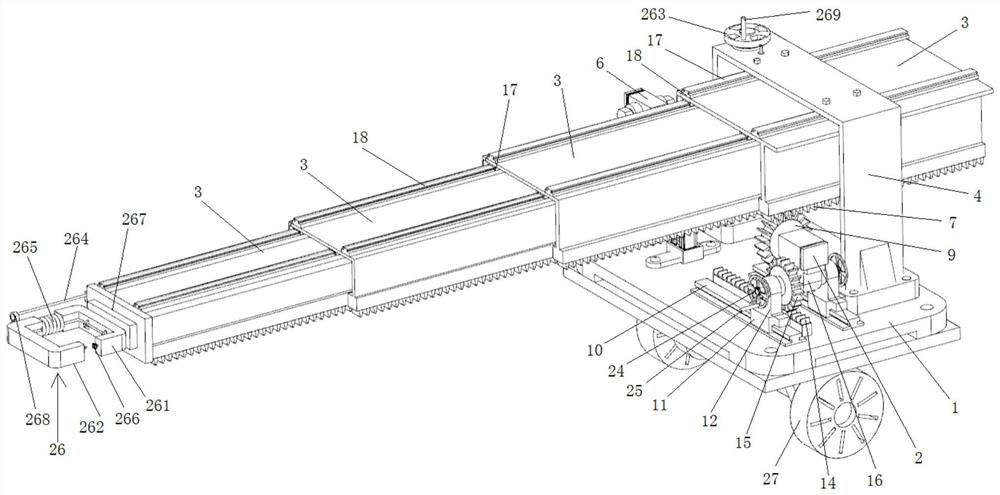

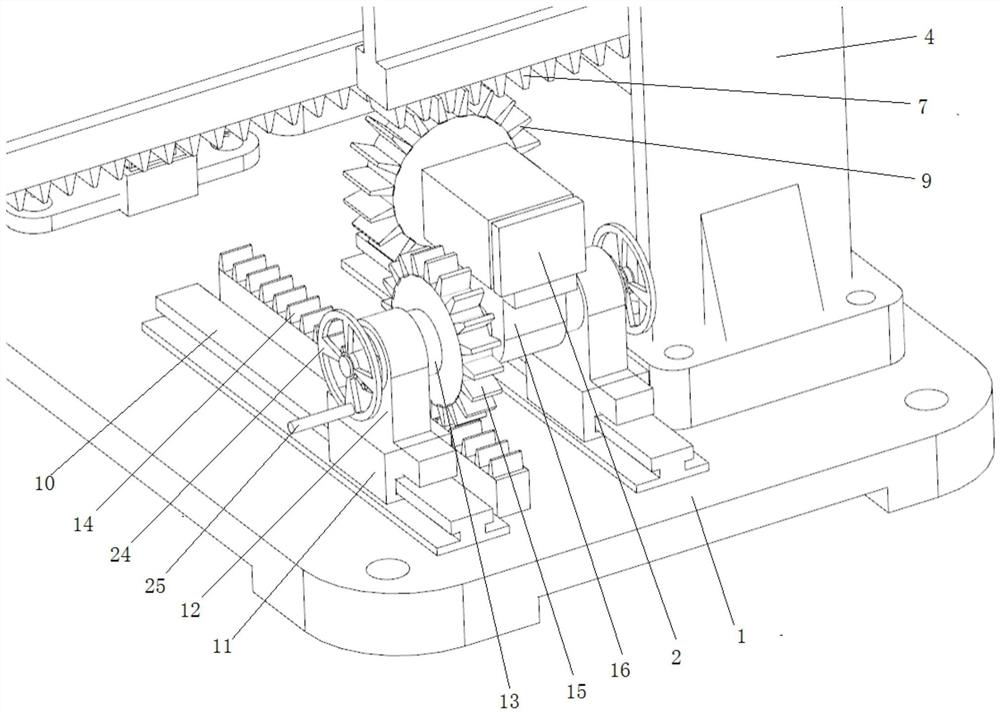

Large-stroke four-degree-of-freedom rigid-flexible coupling mechanical arm

The invention discloses a large-stroke four-degree-of-freedom rigid-flexible coupling mechanical arm. The large-stroke four-degree-of-freedom rigid-flexible coupling mechanical arm comprises a linearsliding table, an electric rotating table, a rigid arm body and a flexible arm body, wherein the lower end of the electric rotating table is fixedly connected to a sliding plate on the linear slidingtable, the upper portion of the electric rotating table is rotationally connected to one end of the rigid arm body through a rigid arm joint motor transmission mechanism, and the other end of the rigid arm body is rotationally connected to the flexible arm body through a flexible arm joint motor transmission mechanism. According to the large-stroke four-degree-of-freedom rigid-flexible coupling mechanical arm, the rigid arm body is formed by splicing, so that the weight of the rigid arm body is easier to reduce, the inertia is reduced, the weight of the rigid arm body and the control over thewhole four-degree-of-freedom mechanical arm are more convenient to balance, deformation is not prone to occurrence in the stress direction, and meanwhile the joint structure is easier to design, manufacture and install; and in the flexible mechanism motion planning and vibration active suppression in the intelligent manufacturing research, the replaceability of the joint structure is higher, the design of the joint structure is simplified through the spliced mechanical arm, the transmission efficiency is improved, and the weight is reduced.

Owner:GUIZHOU UNIV

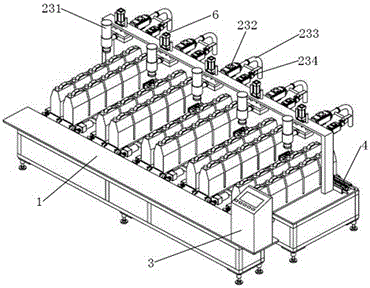

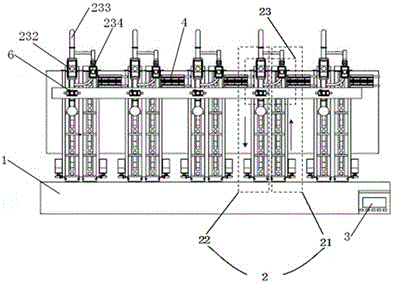

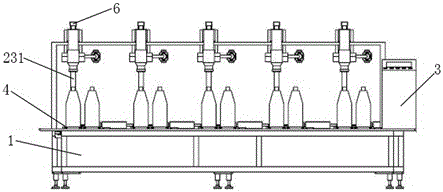

Novel semi-automatic filling machine

InactiveCN105947957AAvoid pollutionAccurate and stable transmissionBarrels/casks fillingControl systemSemi automatic

A novel semi-automatic filling machine comprises a rack, a filling system and a control system. The filling system is arranged on a platform of the rack. The control system controls operation of the filling system. The filling system is composed of a plurality of filling assembly lines. Each filling assembly line comprises an empty bucket area, a heavy bucket area and a filling area, wherein the empty bucket area and the heavy bucket area are arranged side by side and each provided with a conveying belt, the tail end of the conveying belt of the empty bucket area is rotationally connected to the starting end of the conveying belt of the heavy bucket area, and the filling area is located above the heavy bucket area. Empty filling buckets are conveyed to the heavy bucket areas from the empty bucket areas through the conveying belts and stay for filling after being recognized by detection devices. The novel semi-automatic filling machine is suitable for simultaneous precise filling of a large batch of different kinds of ceramic ink and is easy to adjust and operate and more convenient to clean, and filling efficiency is improved. The empty bucket areas, the heavy bucket areas and the filling areas are divided, the aims of accurate and stable conveying of the filling buckets and semi-automatic filling of the ceramic ink are achieved, manual cost is reduced, and filling is quick and precise.

Owner:佛山市理想家科技有限公司

Constant-tension wire conveying mechanism and making method thereof

InactiveCN104681205AReasonable structural designIngenious structural designCable/conductor manufactureUltimate tensile strengthWire twister

The invention discloses a constant-tension wire conveying mechanism comprising a frame body, a linkage wire pay-off device, and a rotary tension device. The linkage wire pay-off device comprises a wire pay-off mechanism and a back-twisting mechanism. The invention further discloses a method for making the constant-tension wire conveying mechanism. The constant-tension wire conveying mechanism provided by the invention is reasonable and ingenious in structure design, and capable of quickly conveying a wire core to a stranding machine in a balanced mode with predetermined constant tension; at the same time, the rotary tension device and the stranding machine move in the same direction at the same speed, so that the wire core can be effectively prevented from being damaged by twisting; in addition, the accuracy of tension regulation is high, the tension of the wire core is automatically detected and adjusted in the whole production process, the tension of the wire core can always remain constant, and constant-tension wire conveying in a true sense is realized; and the constant-tension wire conveying mechanism is convenient to operate, the labor intensity is greatly lowered, the quality of products is ensured, and the mechanism is conducive to the improvement of competitiveness of enterprises. The making method provided by the invention is simple in process, low in cost and easy to implement, and can be adopted to quickly prepare the constant-tension wire conveying mechanism.

Owner:蔡静君

Labeling machine

InactiveCN109693848ACompact structureImprove ergonomicsConveyor partsLabelling machinesEngineeringBlood sampling

The invention belongs to labeling devices, and especially relates to a labeling machine. The machine includes a cross-shaped slide table, a material cabin mechanism, a labeling mechanism, a manipulator and a material receiving box; the manipulator can convey a blood sampling test tube to the labeling mechanism through the cross-shaped slide table after grabbing the blood sampling test tube under the controlling of a central control device, so that the labelled blood sampling test tube can fall into the material receiving box; the manipulator selects an electromagnetic manipulator and incudes two mechanical clamping hands in opposite arrangement; grabbing parts on the front ends of the two mechanical clamping hands can fit with the profile of the blood sampling test tube, and the rear endsof the mechanical clamping hands are in rotatory assembling with rotating shafts; the mechanical clamping hands can be controlled by a power input device to do opposite or reverse rotation so that thegrabbing or loosening of the blood sampling test tube can be realized; and the power input device includes an electromagnet arranged between the middle parts of the two mechanical clamping hands andreset springs connected between the two mechanical clamping hands. Thus, technical problems in the prior art of low work efficiency, complex structure and poor universality can be effectively solved,and therefore, the machine has advantages of being high in working efficiency, compact in structure and good in adaptability.

Owner:石家庄泽厚科技有限公司

Main drafting unit in top cutting machine

The invention discloses a main drafting device of a wool top cut-off machine. The main drafting device of the wool top cut-off machine comprises a machine frame. A front drafting roll set is installed at the front portion of the machine frame and comprises a front compression roll and a front pull roll. A rear drafting roll set is installed at the rear portion of the machine frame and comprises a rear compression roll, a first rear pull roll and a second rear pull roll, wherein the first rear pull roll and the second rear pull roll are arranged in parallel; the rear compression roll is located above the first rear pull roll and the second rear pull roll, and the rear compression roller, the first rear pull roll and the second rear pull roll are distributed in the shape like a character 'pin'. The machine frame is provided with a rear drive device and a front drive device. The rear drive device can drive the first rear pull roll and the second rear pull roll to rotate in the same direction. The front drive device can drive the front pull roll, the first rear pull roll and the second rear pull roll to rotate in the same direction. Wool tops are pulled by the front pull roll, the first rear pull roll and the second rear pull roll to move from the front drafting roll set to the rear drafting roll set. The main drafting device of the wool top cut-off machine is reliable in operation, low in noise and good in wool top drafting effect.

Owner:ZHANGJIAGANG RONGCHANG POLYESTER TOPS

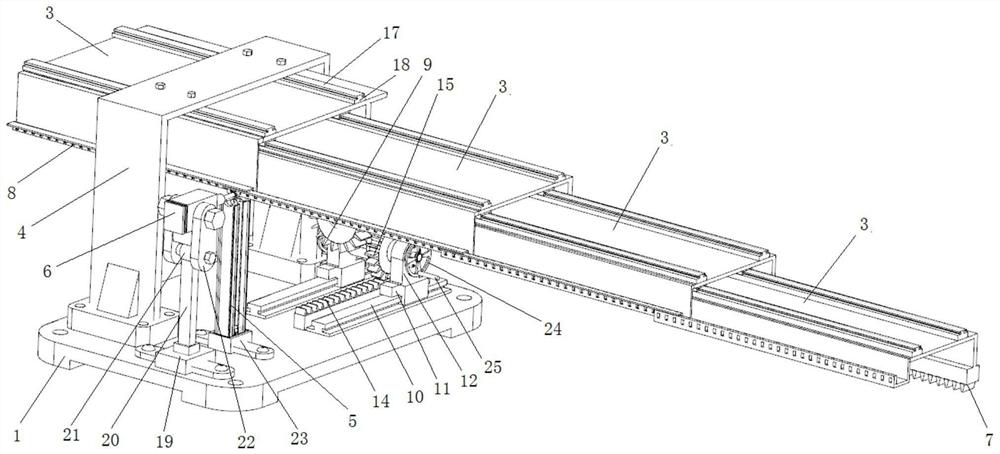

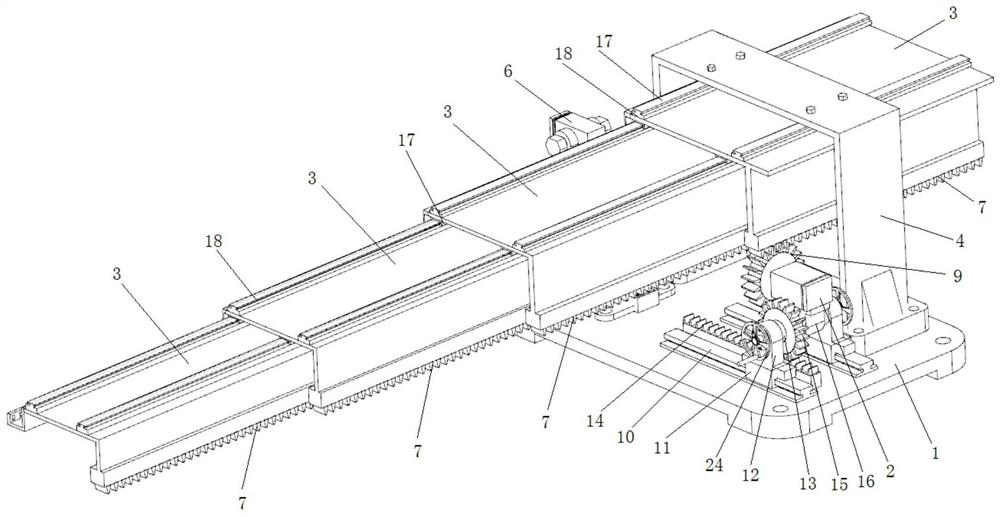

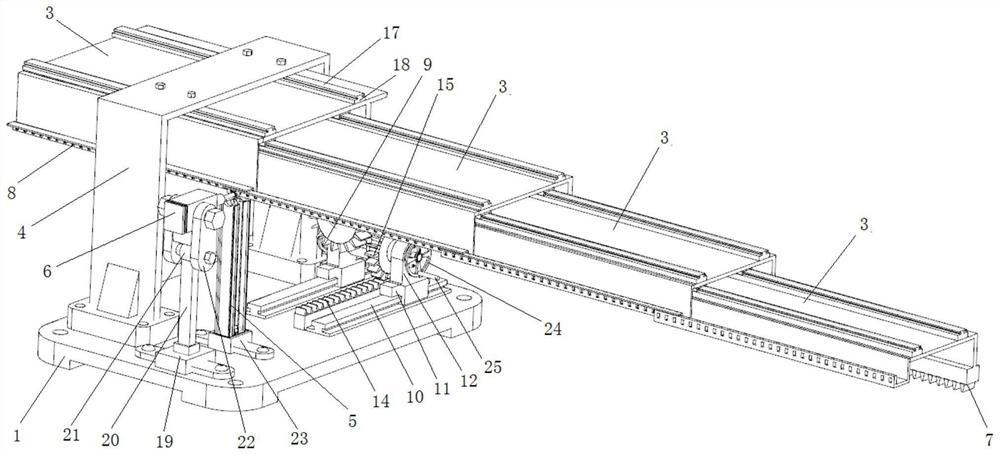

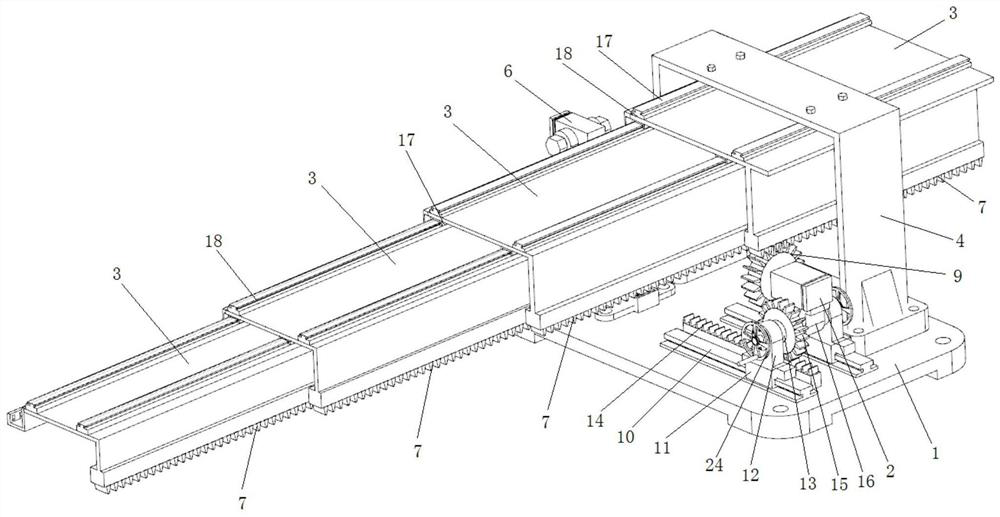

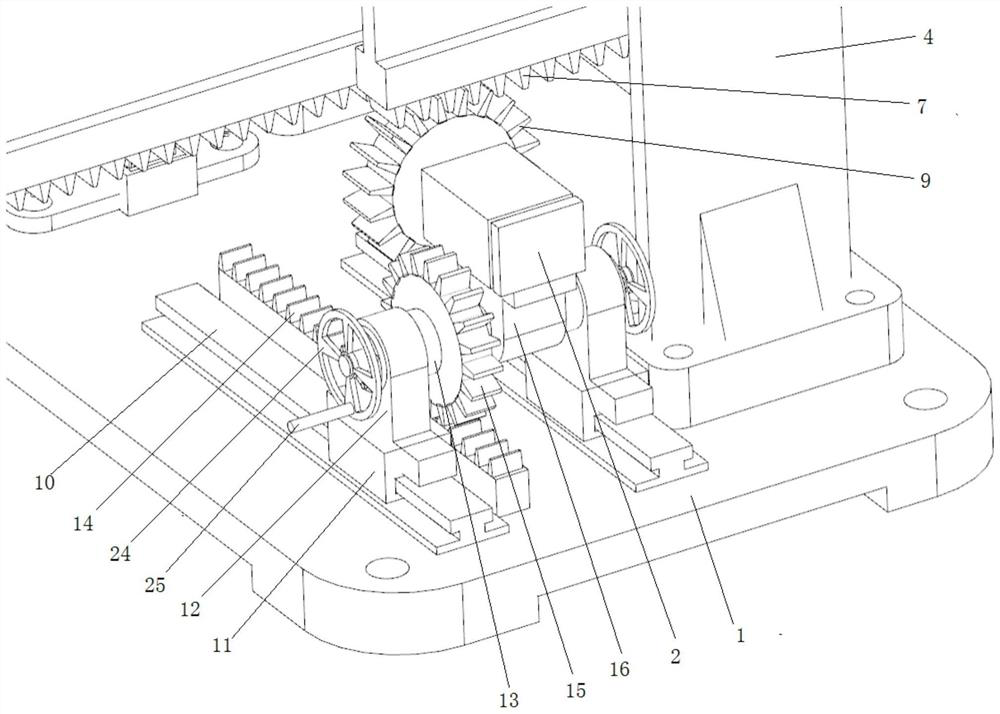

Flexion and extension device based on directional wheel strip meshing transmission and using method

The invention discloses a flexion and extension device based on directional wheel strip meshing transmission and a using method. A gantry support is fixed to a base, a groove penetrating to the two ends of each flexion and extension body is formed in the bottom of each flexion and extension body, and a first rack is fixed to the bottom of one side of each flexion and extension body in the groove extending direction. A plurality of positioning holes are formed in the side wall of the other side of each flexion and extension body along the extension direction of the grooves. The first flexion and extension body is connected to the gantry support in a sliding mode, the first flexion and extension body is connected into a groove of the first flexion and extension body in a sliding mode, and soon, the nth flexion and extension body is connected into a groove of the n-1th flexion and extension body in a sliding mode. Driving devices are arranged on the base in a sliding mode, first gears are connected to output shafts of the driving devices, and the first gears can be meshed with first racks on any flexion and extension body. Fastener containing boxes and screwing devices are fixed to the base, the screwing devices are located on the sides, provided with positioning holes, of the flexion and extension bodies, the fastener containing boxes are located between the screwing devices andthe flexion and extension bodies. The flexion and extension transmission effect of the flexion and extension device based on the directional wheel strip meshing transmission and the using method is better.

Owner:YUEXI COUNTY GREAT WALL MACHINERY

An unmanned high-altitude strapping machine with rack and pinion meshing transmission and its use method

ActiveCN112591182BImprove reliabilityAvoid malfunctioningBundling machine detailsFriction gearingsStrappingGear wheel

The invention discloses an unmanned high-altitude strapping machine with rack and pinion meshing transmission and its use method. The strapping execution structure includes a U-shaped first strapping hook, a U-shaped second strapping hook, a winding turntable and a pull rope. The first strapping The U-shaped mouth of the hook and the second binding hook is set oppositely, and one end of the first binding hook is connected with one end of the second binding hook through the first elastic member, and the first binding hook is fixed on the protruding end of the nth flexion and extension body The winding turntable is set on the gantry bracket for rotation, one end of the pull rope is wound and set on the winding turntable, and the other end is connected to the second binding hook near the first elastic member, the first binding hook and the second binding hook are provided with Groove, binding strap is installed in the groove. The binding machine of the invention has good reliability.

Owner:HEFEI WISDOM DRAGON MACHINERY DESIGN CO LTD

Main drafting device of wool top cut-off machine

The invention discloses a main drafting device of a wool top cut-off machine. The main drafting device of the wool top cut-off machine comprises a machine frame. A front drafting roll set is installed at the front portion of the machine frame and comprises a front compression roll and a front pull roll. A rear drafting roll set is installed at the rear portion of the machine frame and comprises a rear compression roll, a first rear pull roll and a second rear pull roll, wherein the first rear pull roll and the second rear pull roll are arranged in parallel; the rear compression roll is located above the first rear pull roll and the second rear pull roll, and the rear compression roller, the first rear pull roll and the second rear pull roll are distributed in the shape like a character 'pin'. The machine frame is provided with a rear drive device and a front drive device. The rear drive device can drive the first rear pull roll and the second rear pull roll to rotate in the same direction. The front drive device can drive the front pull roll, the first rear pull roll and the second rear pull roll to rotate in the same direction. Wool tops are pulled by the front pull roll, the first rear pull roll and the second rear pull roll to move from the front drafting roll set to the rear drafting roll set. The main drafting device of the wool top cut-off machine is reliable in operation, low in noise and good in wool top drafting effect.

Owner:ZHANGJIAGANG RONGCHANG POLYESTER TOPS

A CNC machine tool capable of lubricating linear slide rails

ActiveCN112059641BReduce wearReduce side pressureLarge fixed membersMaintainance and safety accessoriesNumerical controlEngineering

The invention relates to the field of CNC machine tool accessories, specifically a CNC machine tool capable of lubricating a linear slide rail, including a slide rail body, a slider, a lubricating structure, a first guiding structure, a pressure relief structure, a cleaning structure and a second Guide structure; the side wall of the slider is provided with a lubricating structure for lubricating the screw rod and preliminary cleaning of dust, and a pressure relief structure is provided inside the lubricating structure, so that when the screw rod slides between the driving slider and the slide rail body , so that the lubricating structure can automatically carry out preliminary dust removal and lubricating oil on the screw rod, and at the same time cooperate with the use of the pressure relief structure, so that the bonding effect between the lubricating structure and the screw rod is better, and it is convenient to quickly lubricate the screw rod; The end of the cleaning structure passes through the second guiding structure used to guide the cleaning structure on the slide rail body, which is convenient to absorb dust and waste on the screw rod through the negative pressure vacuum of the cleaning structure. The setting of the second guiding structure makes cleaning The structural transmission is more stable, which in turn makes the cleaning effect of the screw rod better.

Owner:云南锦润数控机械制造有限责任公司

A flexion and extension device based on directional wheel meshing transmission and its application method

The invention discloses a flexion and extension device based on directional wheel bar meshing transmission and a use method. The gantry bracket is fixed on the base, and the bottom of each flexion and extension body is provided with grooves extending to both ends of itself. The bottom of each flexion and extension body is along the The first rack is fixed in the extending direction of the groove, and several positioning holes are opened on the other side wall of each flexing and extending body along the extending direction of the groove; the first flexing and extending body is slidably connected to the gantry bracket, and the first flexing and extending body The sliding connection is in the groove of the first flexor-extension body, and so on, the n-th flexor-extension body is slidingly connected in the groove of the n-1 flexor-extension body; The first gear, the first gear can be meshed with the first rack on any flexion and extension body; the fastener receiving box and the screwing device are fixed on the base, and the screwing device is located on the side where the positioning hole is opened on the flexion and extension body, The fastener accommodating box is located between the screwing device and the flexion and extension body, and the flexion and extension transmission effect of the present invention is better.

Owner:YUEXI COUNTY GREAT WALL MACHINERY

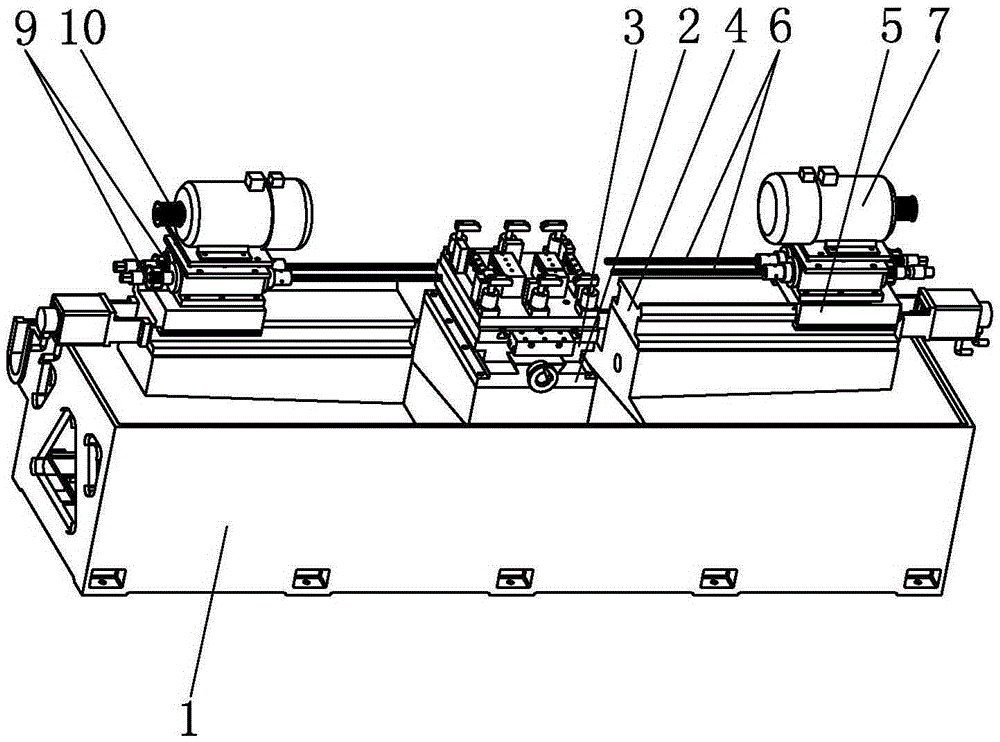

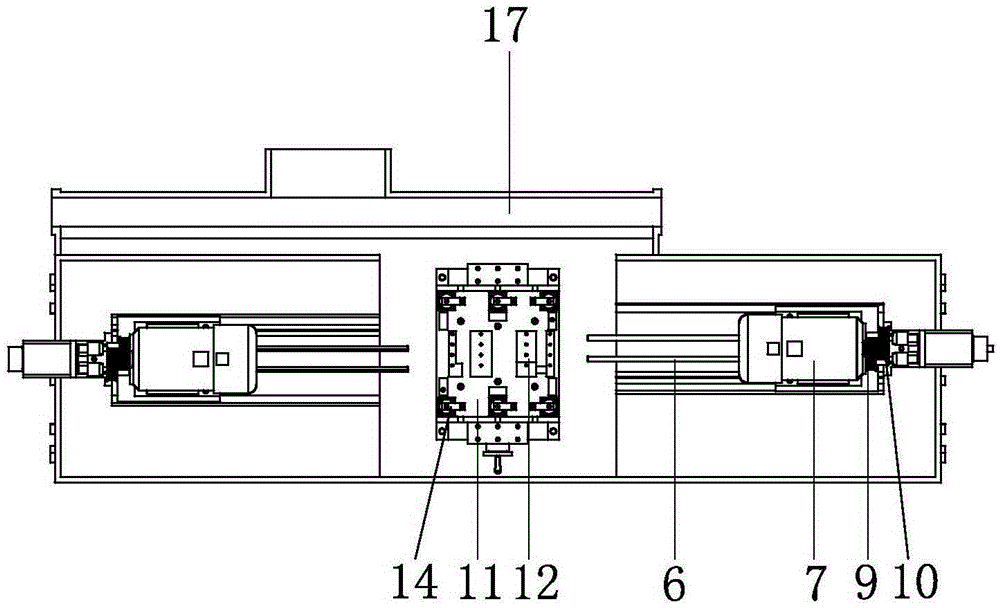

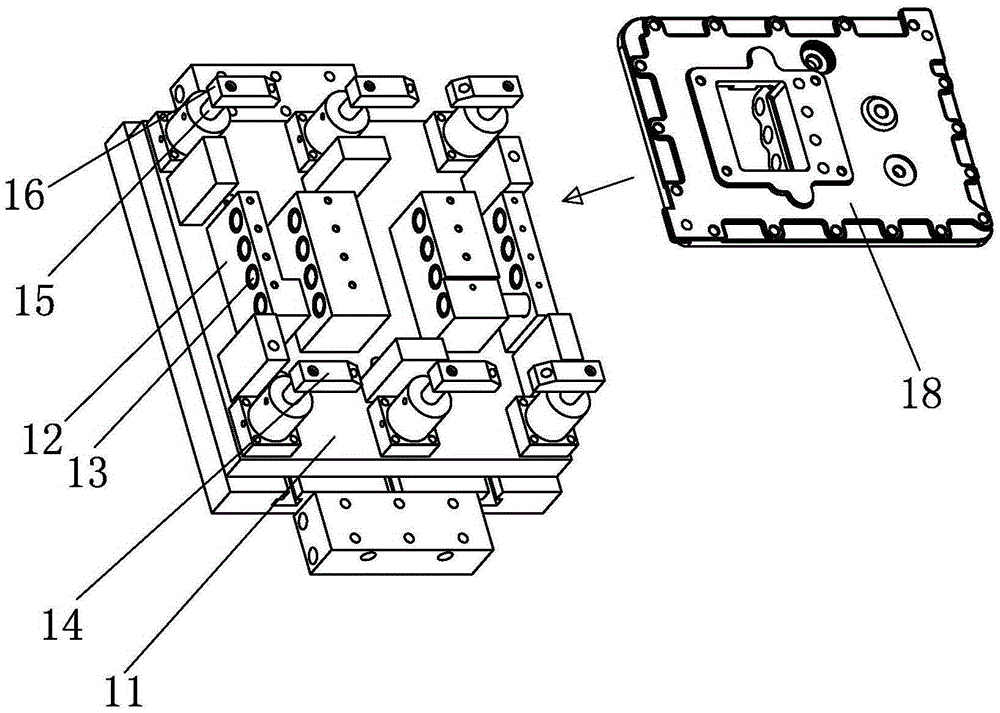

Four axis deep hole drilling machine

InactiveCN103192109BAccurate and stable transmissionNo slidingPositioning apparatusBoring/drilling componentsHigh volume manufacturingEngineering

The invention provides a four-spindle deep-hole drilling machine and belongs to the technical field of tools. The four-spindle deep-hole drilling machine solves the problems of expensive equipment, high machining costs, the low machining efficiency and the like due to the fact that multi-hole and multi-direction drilling of workpieces is difficult to complete once on ordinary tools and multiple times of clamping and machining is required. The four-spindle deep-hole drilling machine comprises a machine body, a clamp is arranged in the middle of the machine body, transverse guide rails are arranged on two sides of the clamp respectively, transverse sliding tables capable of sliding along the transverse guide rails are arranged on the transverse guide rails respectively, and workpiece drilling mechanisms are arranged on the two transverse sliding tables respectively. A plurality of straight long drills are arranged on each transverse sliding table and driven synchronously through motors on the transverse sliding tables. Compared with 30 minutes required for machining of a vehicle gear box product, only 5 to 7 minutes are required by the four-spindle deep-hole drilling machine, the production time is greatly saved, and the four-spindle deep-hole drilling machine has the advantages of being capable of reducing the production time greatly, suitable for large batch production and the like.

Owner:ZHEJIANG YINGTENG MACHINE TOOL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com