Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

310 results about "Wire twister" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

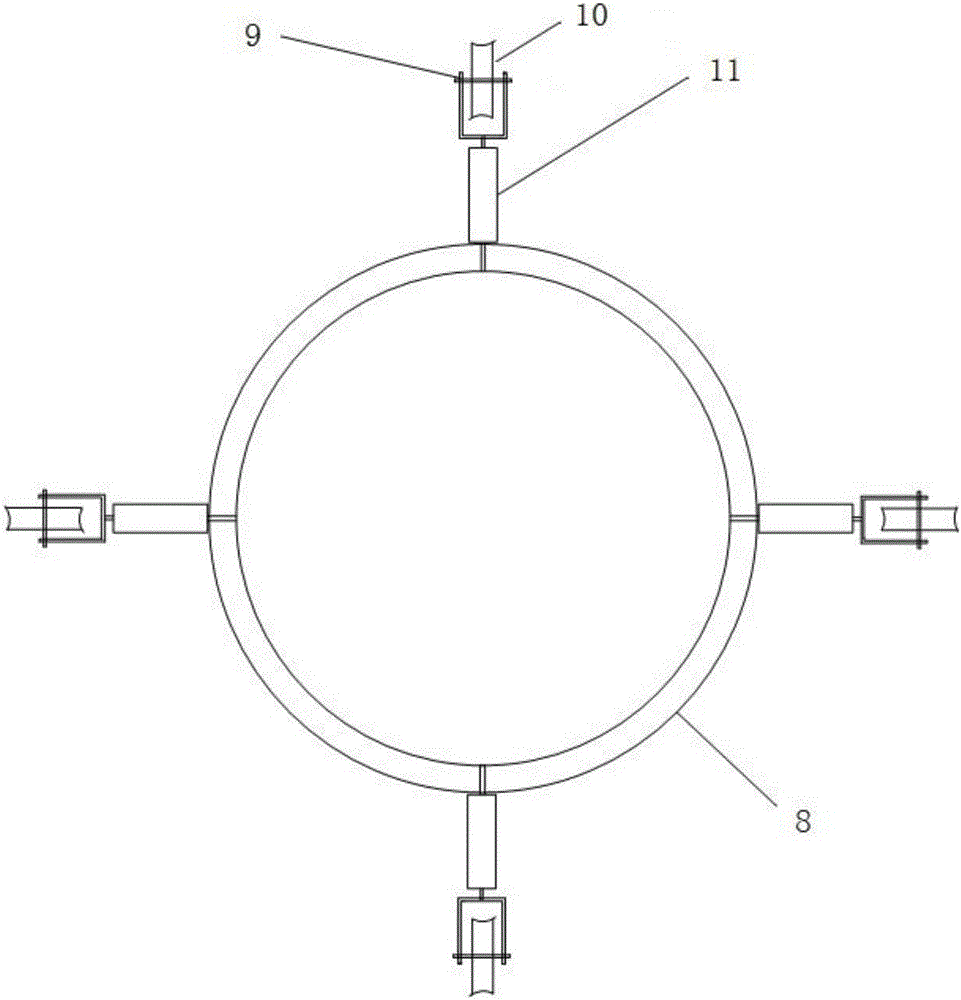

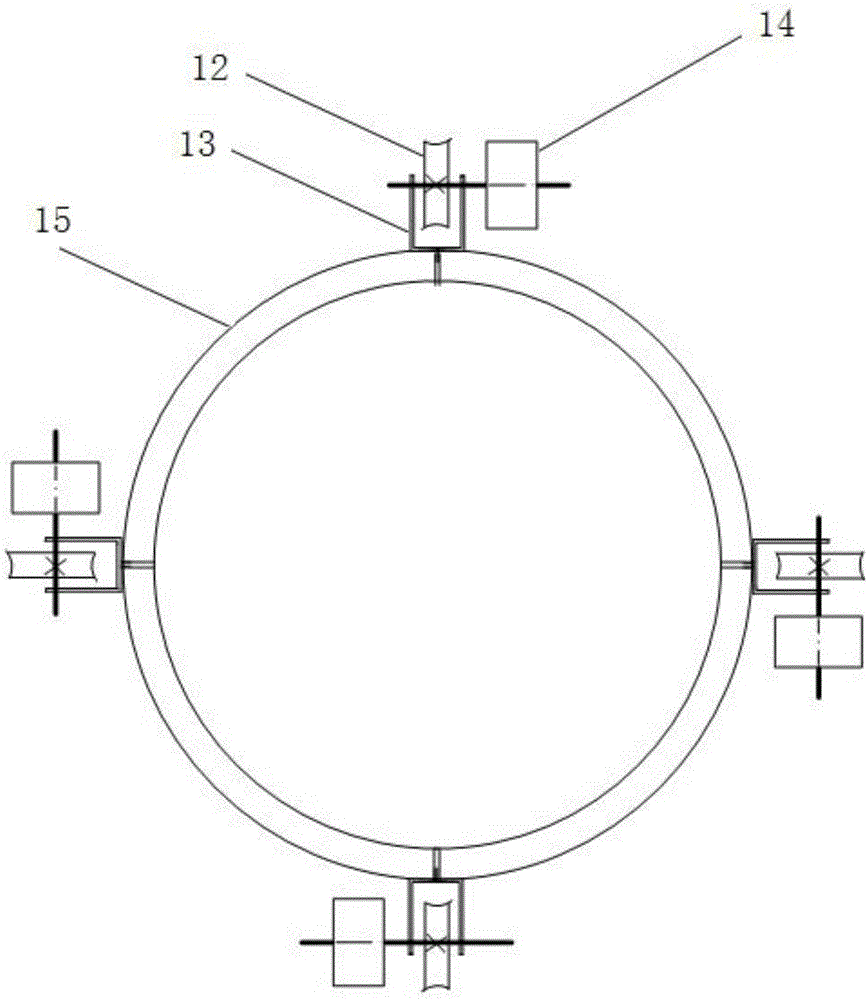

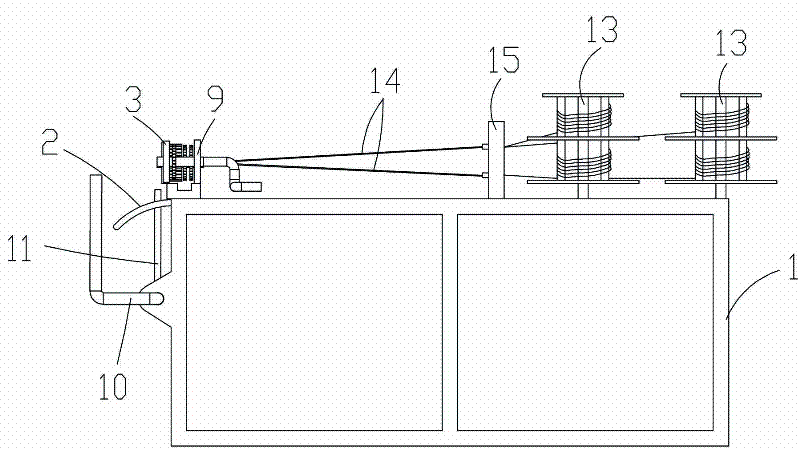

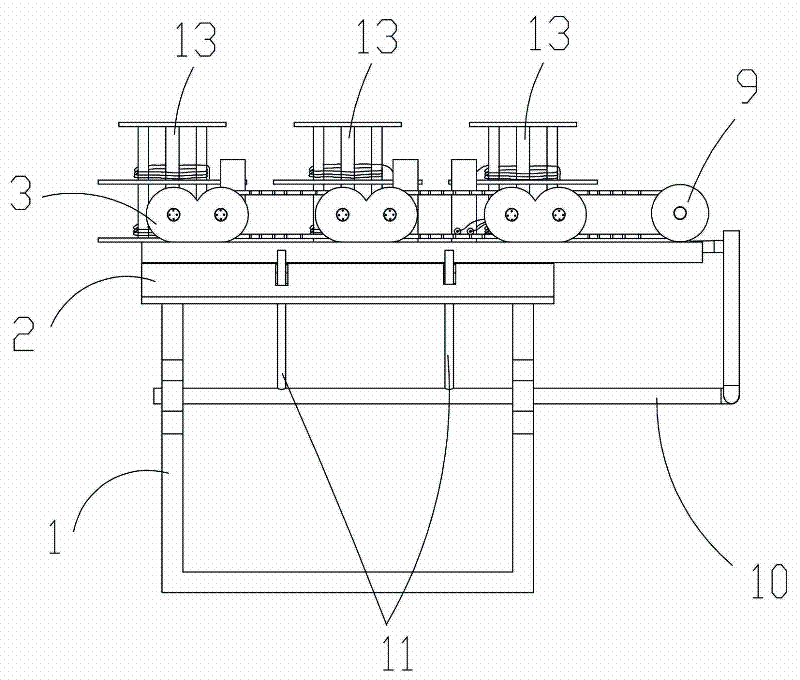

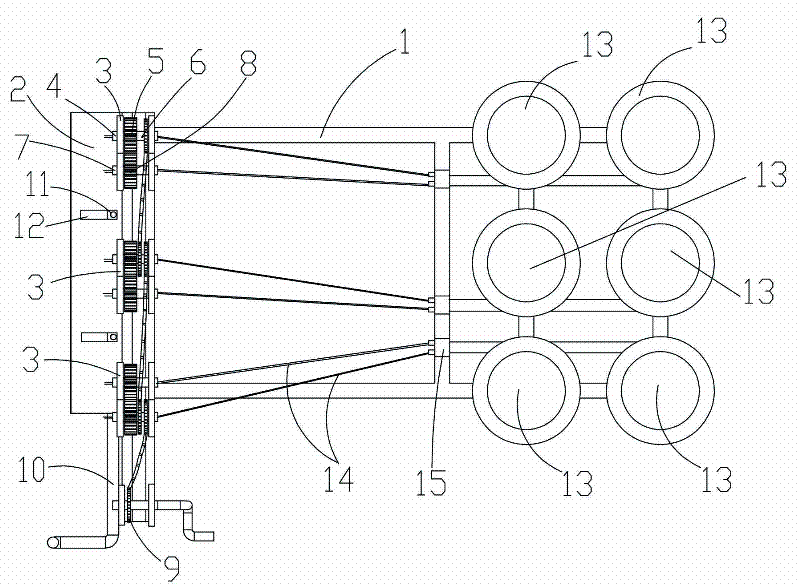

Wire winding machine

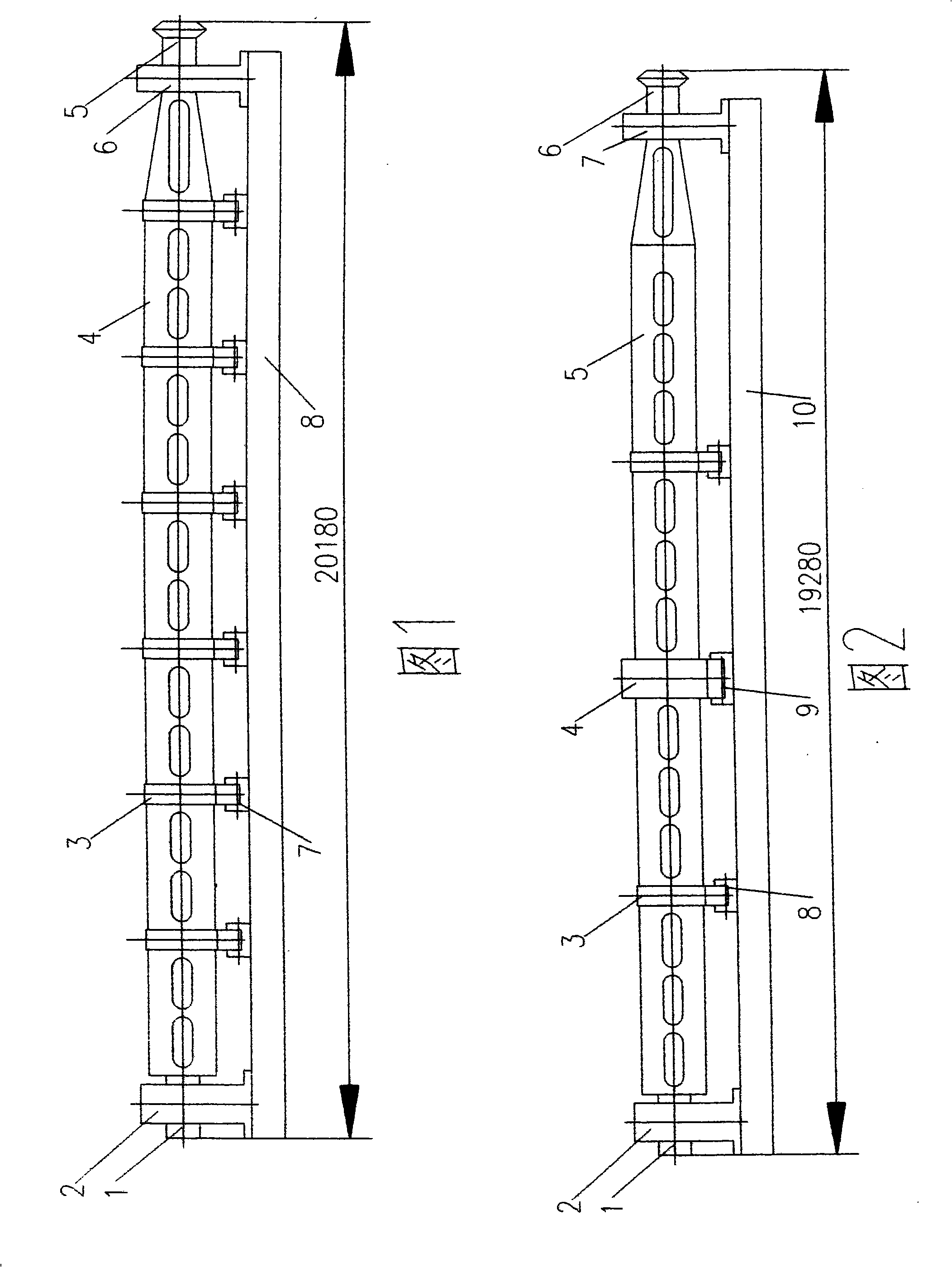

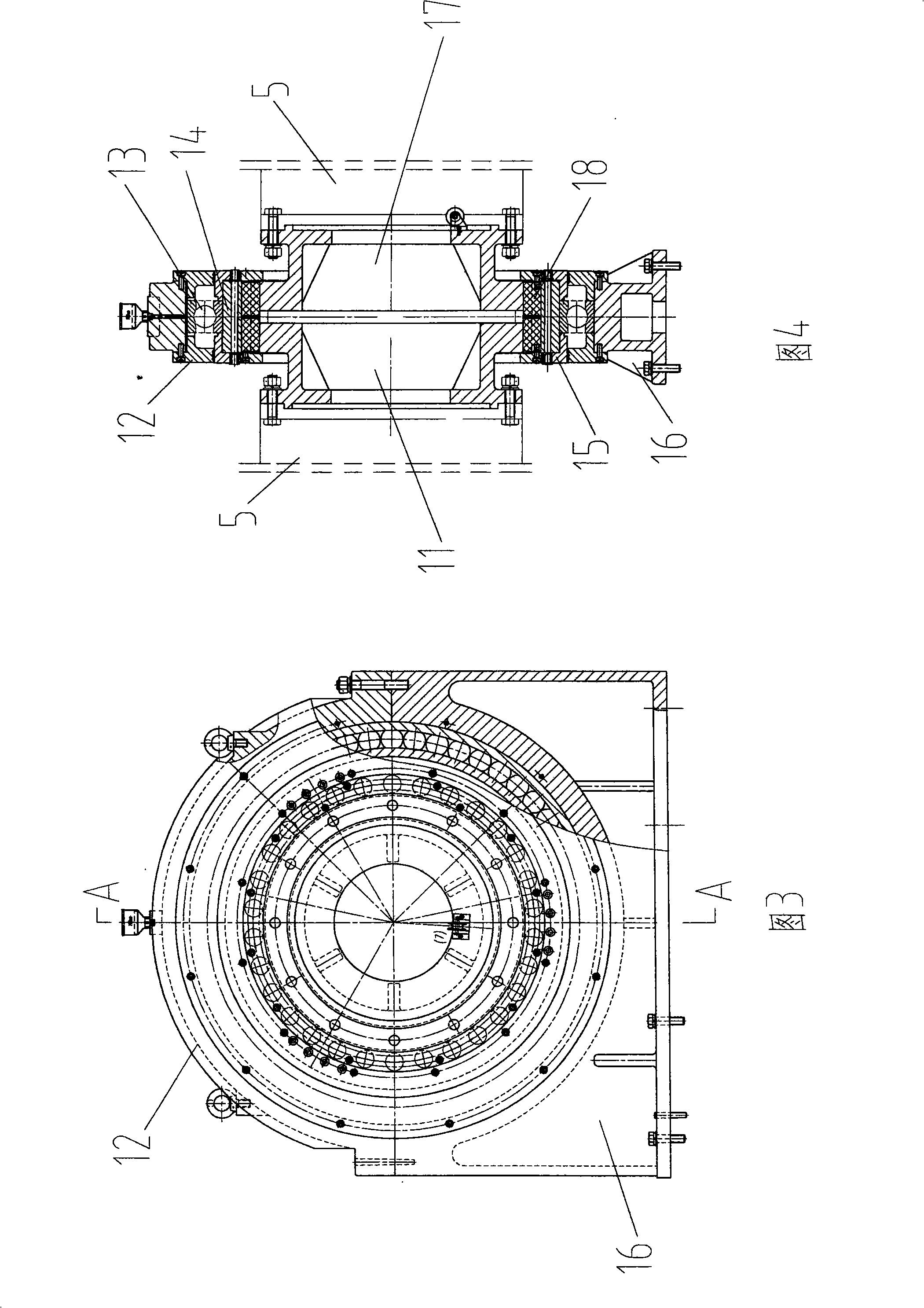

InactiveCN101359525AReasonable layoutIncrease the number ofCable/conductor manufactureWinding machineWire twister

The invention relates to a wire strander which is particularly applicable for cable production. The strander comprises a frame and a wiring disc arranged on the frame. A rotating shaft which can rotate relatively with respect to the frame is fixed at the center of the wiring disc and is connected with a drive mechanism. A take-up device fixed on the frame is installed at the side of the wiring disc. The strander is characterized in that a plurality of coil holders are installed at two sides of the wiring disc; the heads of the wire coils on the coil holders at one side of the wiring disc can run through the wiring disc and reach the other side of the wiring disc. Compared with prior art, the strander has the advantages that: 1, the coil holders are reasonable in arrangement, thus increasing the number of the coil holders; the whole structure is compact in structure and low in cost and is easy to operate; 2, the feed pitch can be flexibly adjusted according to needs and the wires arranged on the strander will not be mixed up, so work stability is good and efficiency is high; 3, the feed pitch can be adjusted according to needs, so various products with different specifications can be produced, thereby the wire strander is widely applicable.

Owner:CHANGZHOU HENGFENG SPECIAL CONDUCTOR CO LTD

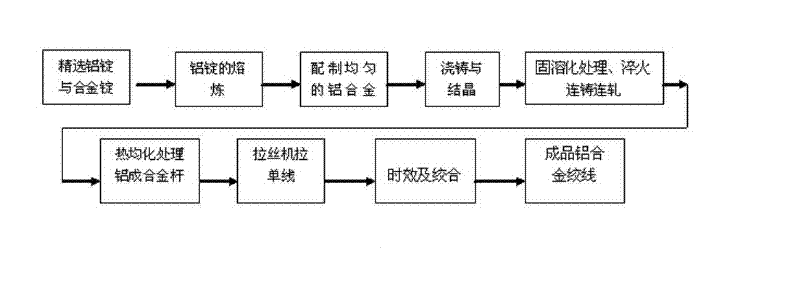

Method for manufacturing medium-strength aluminum alloy wire with electric conductivity of 59 percent

ActiveCN102162050AQuick checkControl contentManufacturing extensible conductors/cablesMetal/alloy conductorsAluminium matrixIngot

The invention discloses a method for manufacturing a medium-strength aluminum alloy wire with the electric conductivity of 59 percent (International Annealed Copper Standard, IACS), and relates to a method for manufacturing a medium-strength aluminum alloy wire with high conductivity. The method is characterized by comprising the following steps of: (1) selecting an aluminum matrix and an aluminum intermediate alloy ingot; (2) performing on-the-spot sample analysis and adjustment, namely putting the selected aluminum ingot into a shaft furnace, melting to form molten aluminum, and refining by using a refining agent; (3) casting and crystallizing, namely allowing molten aluminum alloy in a kettle furnace to pass through a runner and filtering by using a ceramic filtering plate, adding rare earth to ensure that the content of the rare earth is 0.05 to 0.15 percent, feeding into an aluminum alloy continuous casting machine, performing continuous casting to form an aluminum alloy cast ingot, and rolling a medium-strength alloy rod by using an aluminum alloy continuous mill; (4) performing solid solution treatment and quenching, namely performing thermal homogenization treatment on the aluminum alloy rod; and (5) drawing, aging and twisting, namely drawing the aluminum alloy rod treated in the previous working procedure into an aluminum alloy wire with the required diameter on an aluminum alloy wire drawing machine, and twisting on a frame type wire twisting machine to obtain the medium-strength aluminum alloy wire with the electric conductivity of 59 percent IACS.

Owner:JIANGSU ZHONGTIAN TECH CO LTD +1

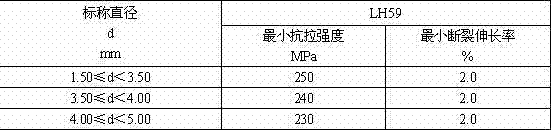

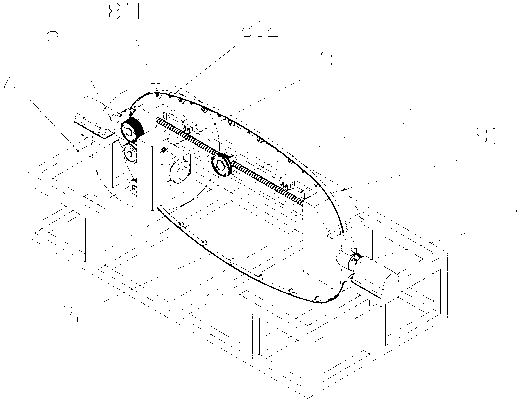

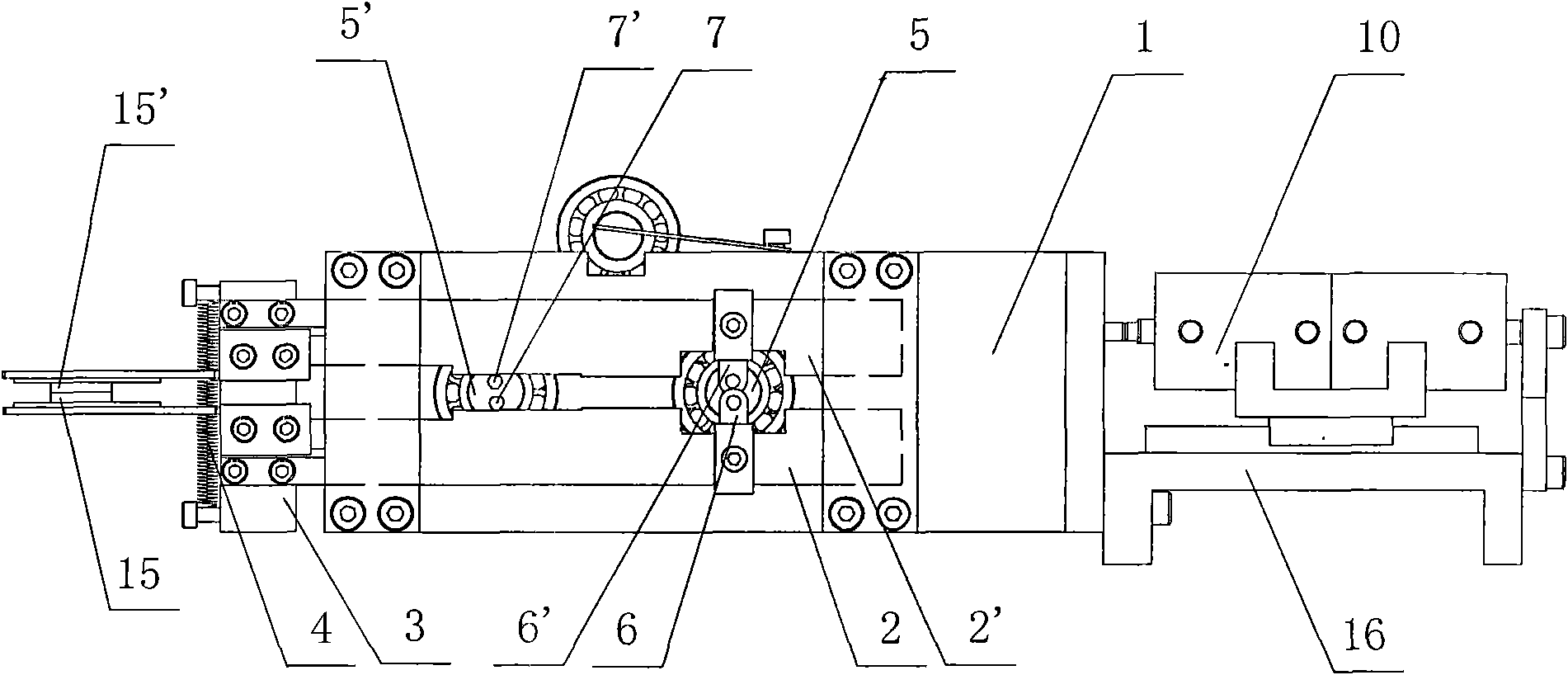

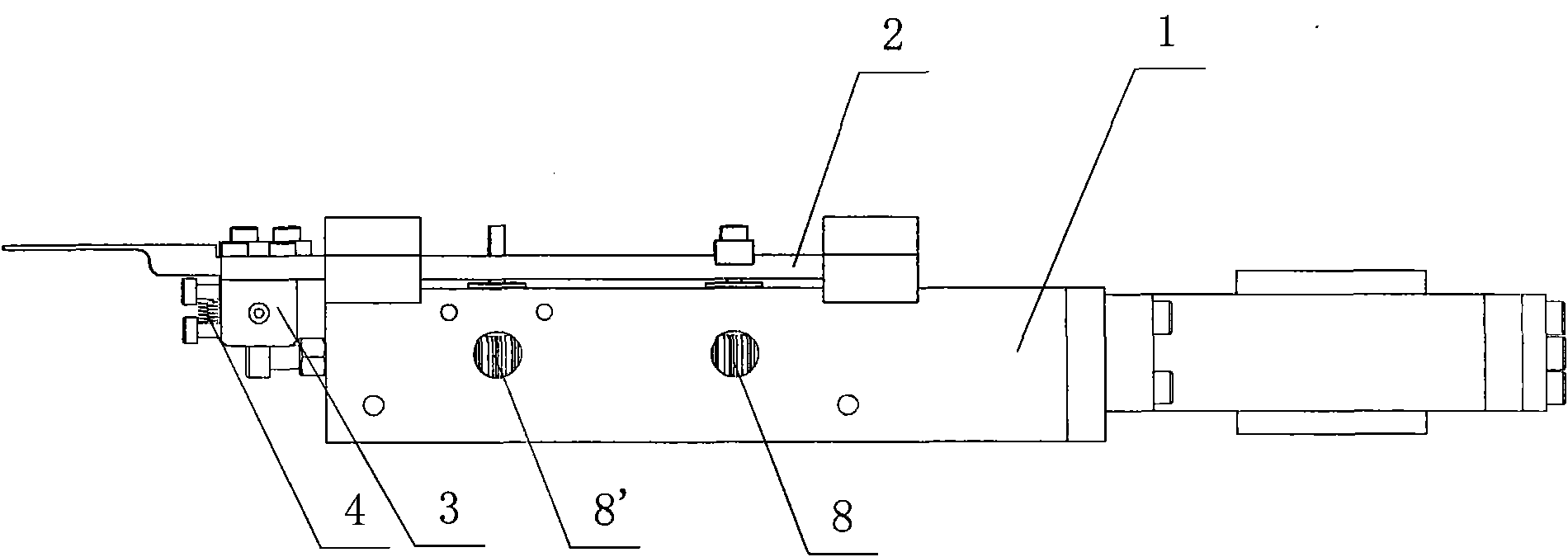

Four-pitch wire twisting machine capable of realizing continuous production

InactiveCN101599323AImprove stranding efficiencySmall sizeCable/conductor manufactureTextile cablesElectrical conductorFuselage

The invention discloses a four-pitch wire twisting machine capable of realizing continuous production, comprising a machine body, a driving mechanism, a cradle, a wire-in main shaft, a wire-out main shaft, two twisting bow brackets, a pair of twisting bows, a first wire twisting guide wheel, a second wire twisting guide wheel and a traction device, wherein the pair of twisting bows are respectively used as a wire-in twisting bow and a wire-out twisting bow, that is, a counter weight twisting bow of the prior art is used as the wire-out twisting bow so as to ensure a core wire passes through the two twisting bows to realize four-pitch wire twisting; meanwhile, in order to ensure the core wire can walk along the wire-out twisting bow, a wire-out guide wheel, a third wire twisting guide wheel and a fourth wire twisting guide wheel are additionally arranged, so as to ensure multistrand conductors or core wires in the twisting machine first enter from the wire-in main shaft and finally exit from the wire-out main shaft by passing through the first wire twisting guide wheel, the wire-in twisting bow, the second twisting wire guide wheel, the traction device, the wire-out guide wheel, the third wire twisting guide wheel, the wire-out twisting bow and the fourth wire twisting guide wheel. The wire twisting machine is high in efficiency and low in loss, can realize continuous production, and can be used as a single machine or be used for united machine production.

Owner:向继光

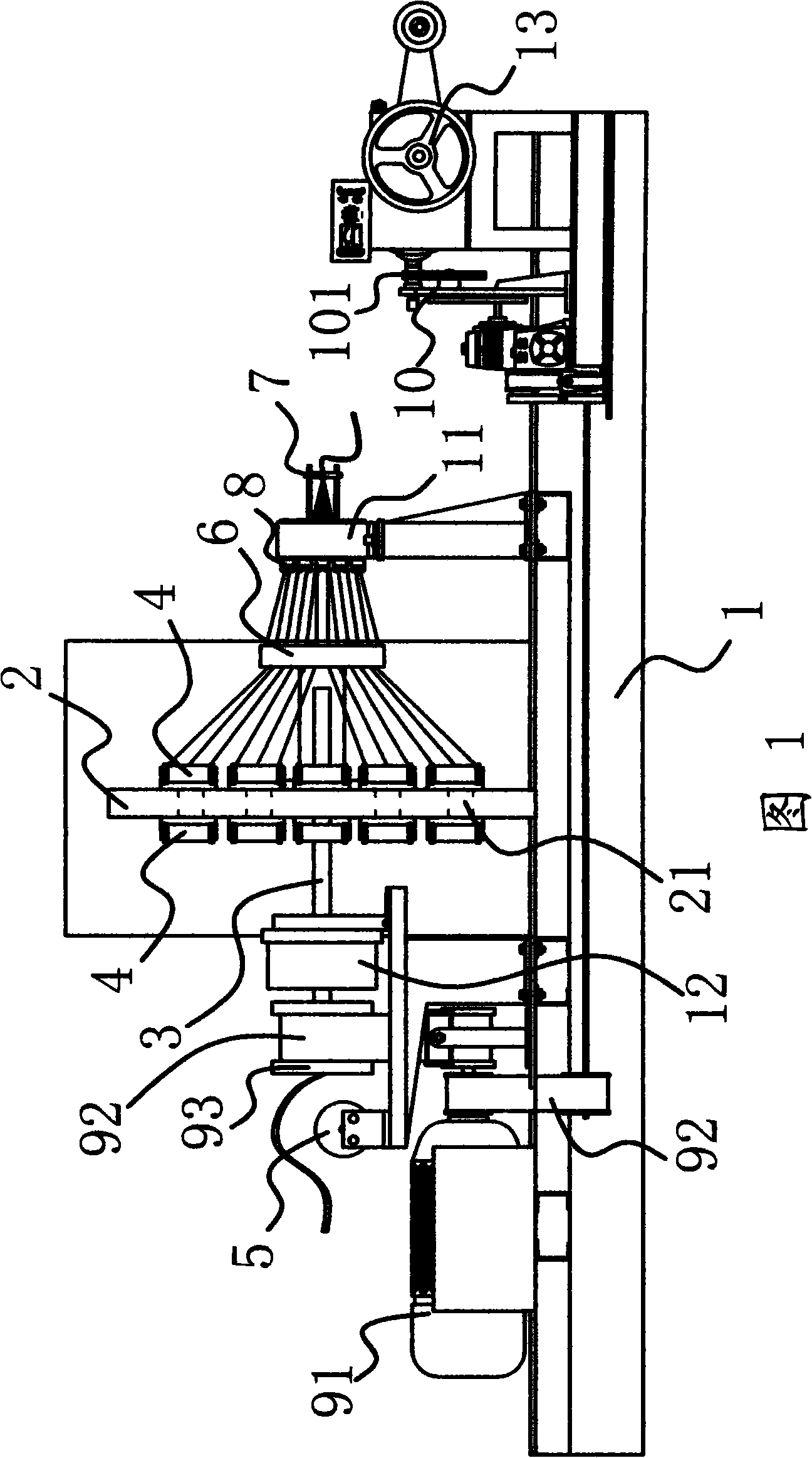

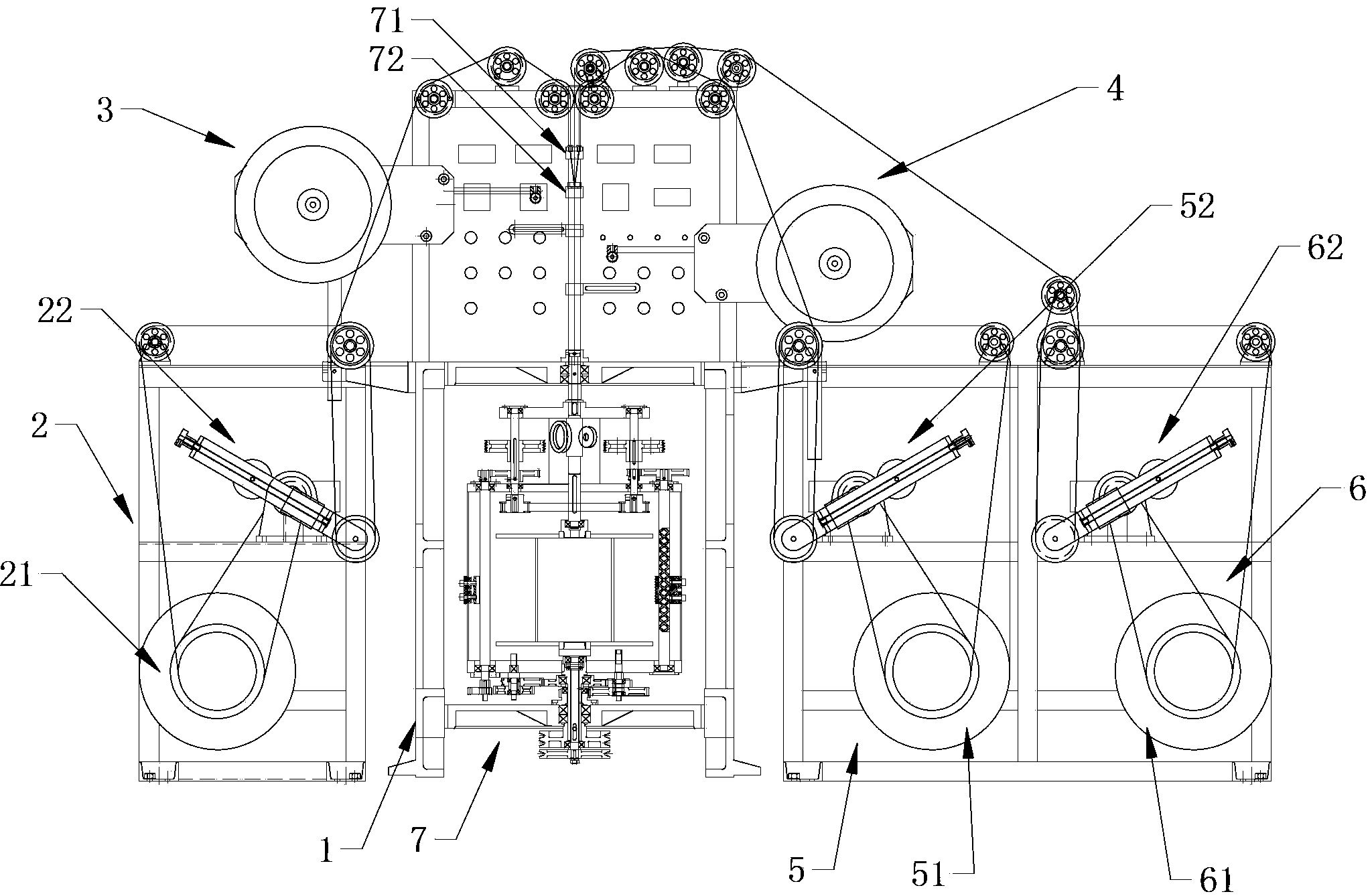

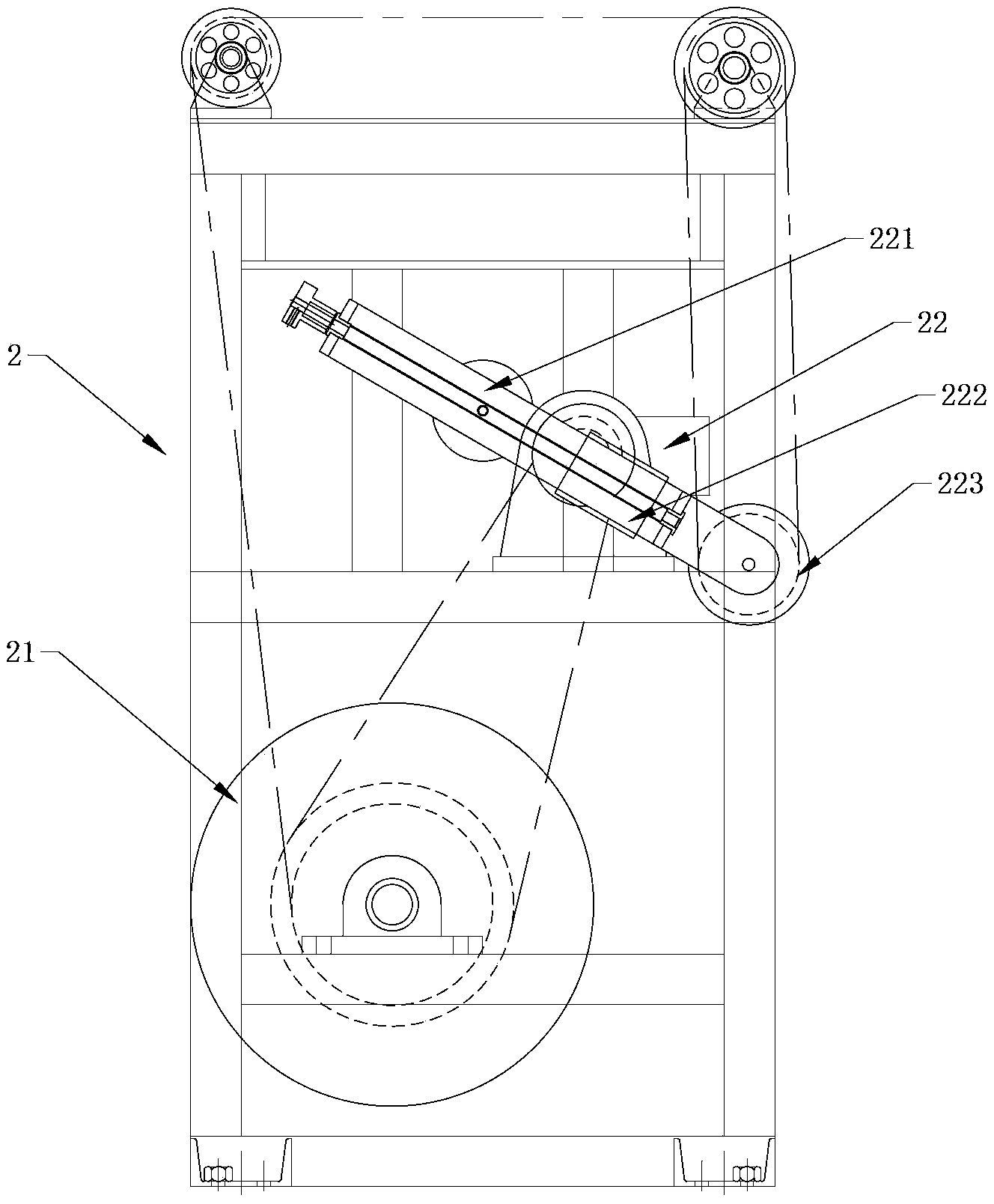

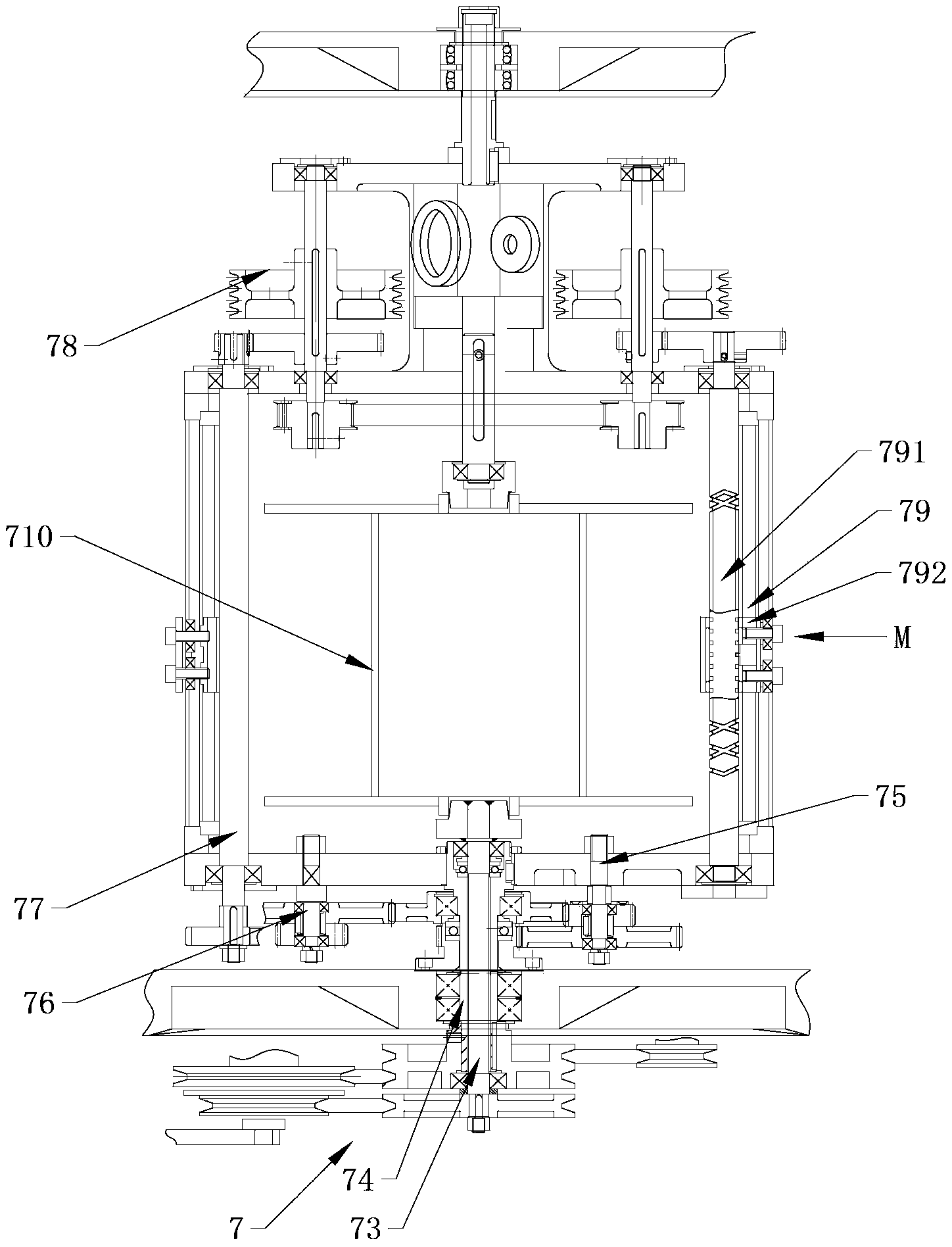

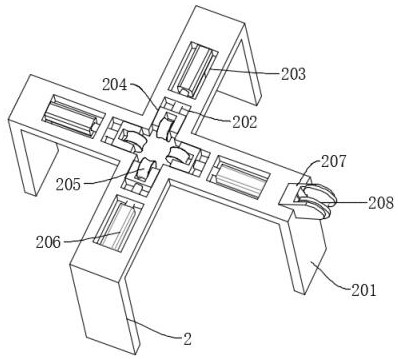

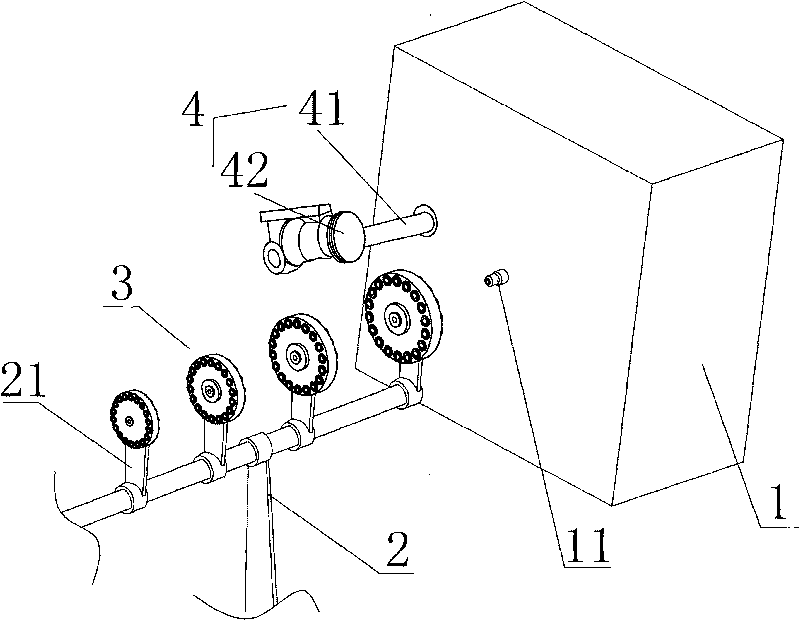

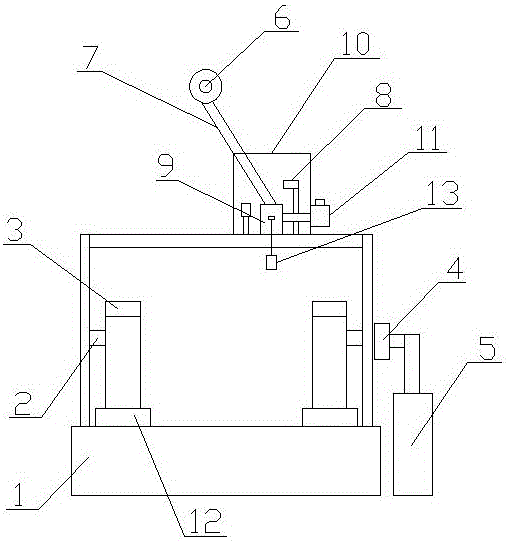

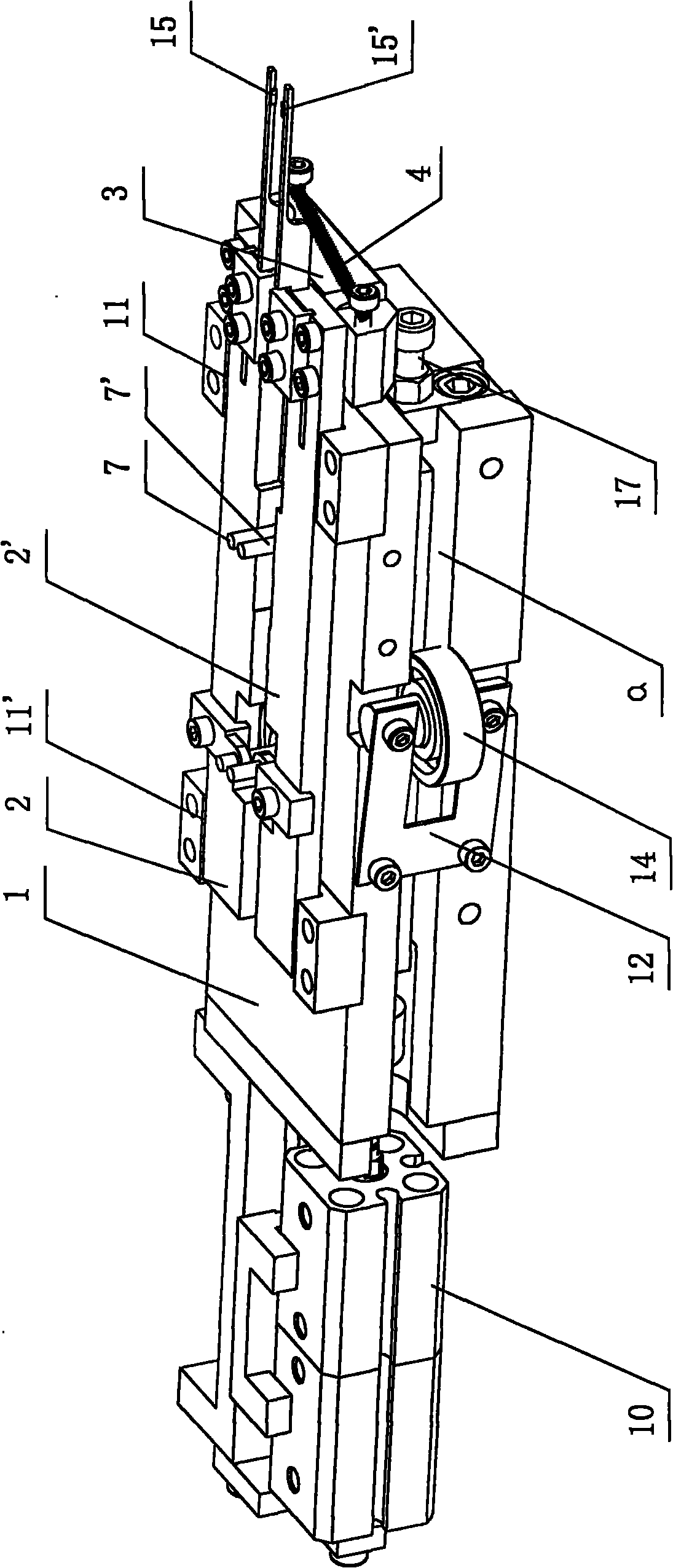

Vertical-type wire stranding machine of high-definition multimedia interface (HDMI) cables

ActiveCN103413618ASuitable for automated productionReasonable driveCable/conductor manufacturePaper sheetTension control

The invention discloses a vertical-type wire stranding machine of high-definition multimedia interface (HDMI) cables. The vertical-type wire stranding machine comprises a rack, a first wire core releasing mechanism, a second wire core releasing mechanism, a ground wire releasing mechanism, a wire stranding main machine, a first paper layer wrapping mechanism and a second paper layer wrapping mechanism; the first wire core releasing mechanism makes a wire core in the high-definition multimedia interface (HDMI) cable pass through a first tension control device and thereafter makes the wire core enter a wire concentrating board and a narrowing and modeling model; the second wire core releasing mechanism makes the other wire core in the high-definition multimedia interface (HDMI) cable pass through a second tension control device and makes the wire core enter the second wire concentrating board and the narrowing and modeling model; the ground wire releasing mechanism makes a ground wire in the high-definition multimedia interface (HDMI) cable pass through a third tension control device and thereafter enables the ground wire to enter the wire concentrating board and the narrowing and modeling model; the wire stranding main machine winds up two wire cores and one ground wire; the first paper layer wrapping mechanism wraps a first player of paper on the cable which is subjected to narrowing and modeling; and the second paper layer wrapping mechanism wraps a second layer of paper on the cable which is wrapped with the first layer of paper. The vertical-type wire stranding machine of the high-definition multimedia interface (HDMI) cable of the invention is advantageous in simple structure and high production efficiency, and can be applicable to completing wire stranding and wrapping processes of the high-definition multimedia interface (HDMI) cable.

Owner:JIANGSU JIACHENG TECH

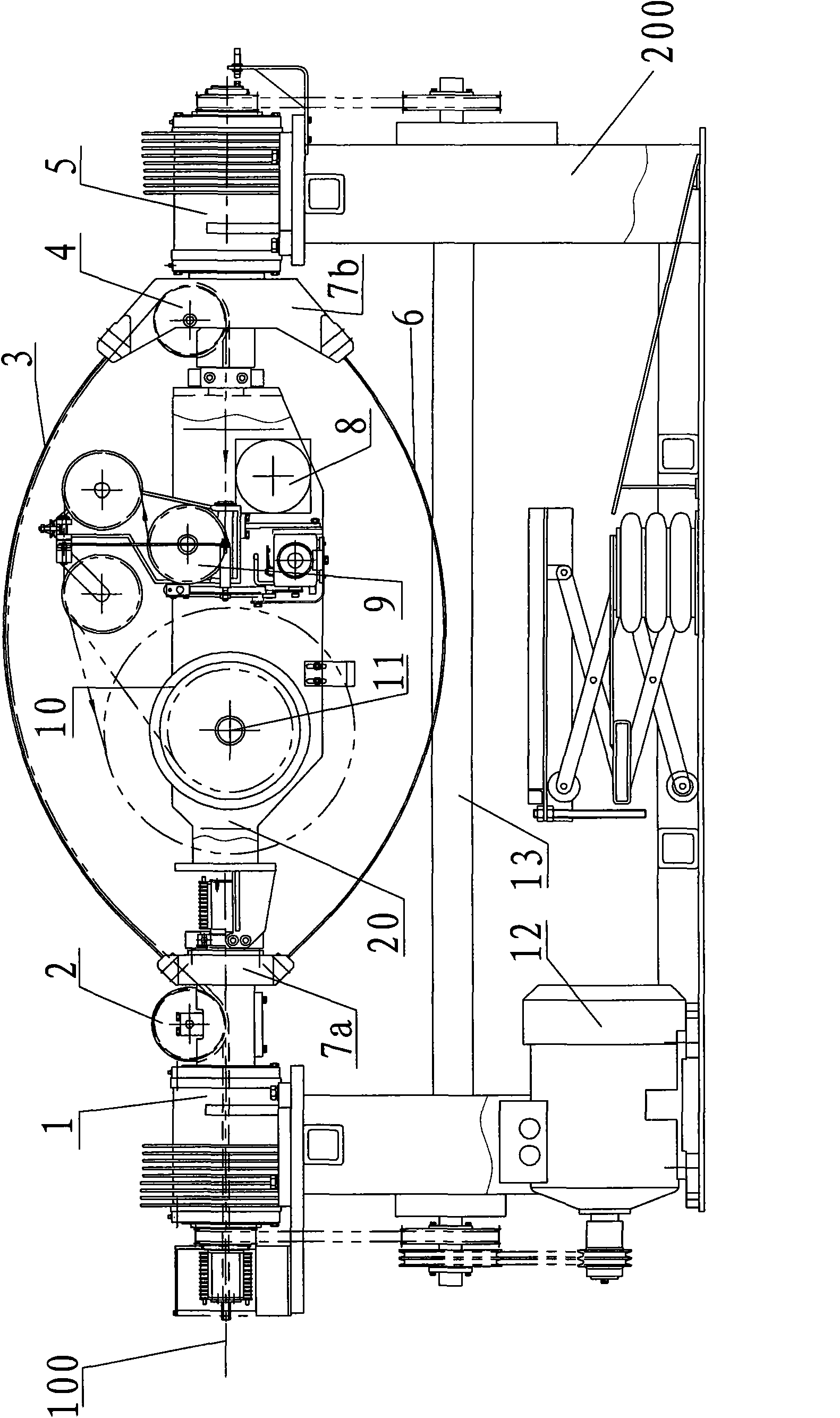

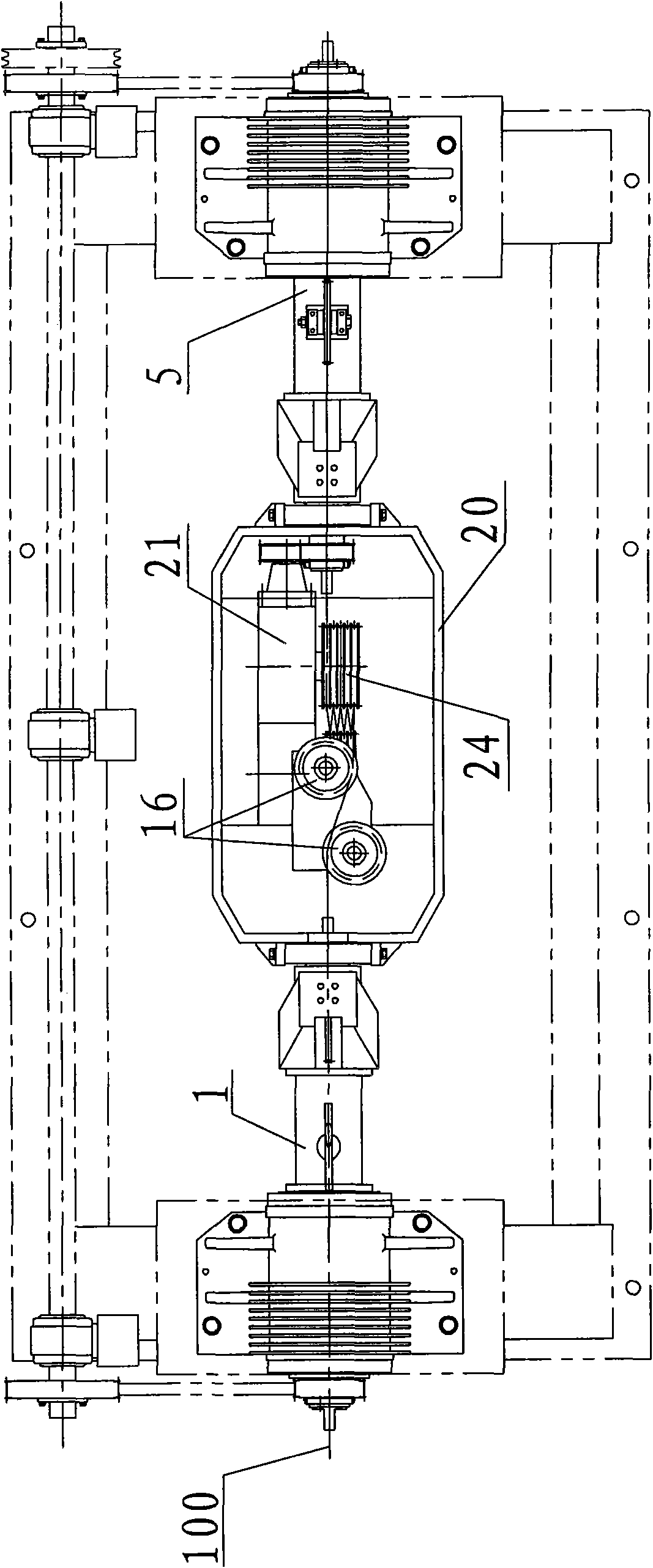

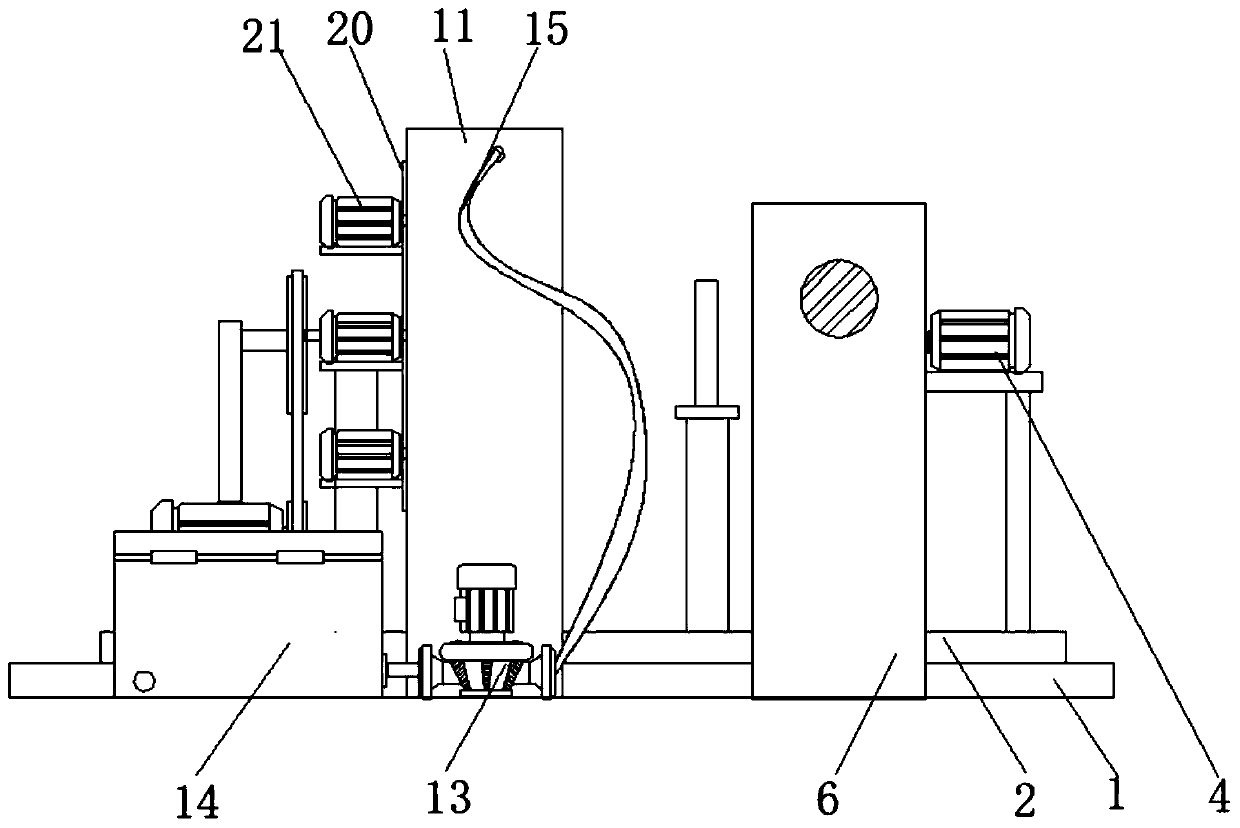

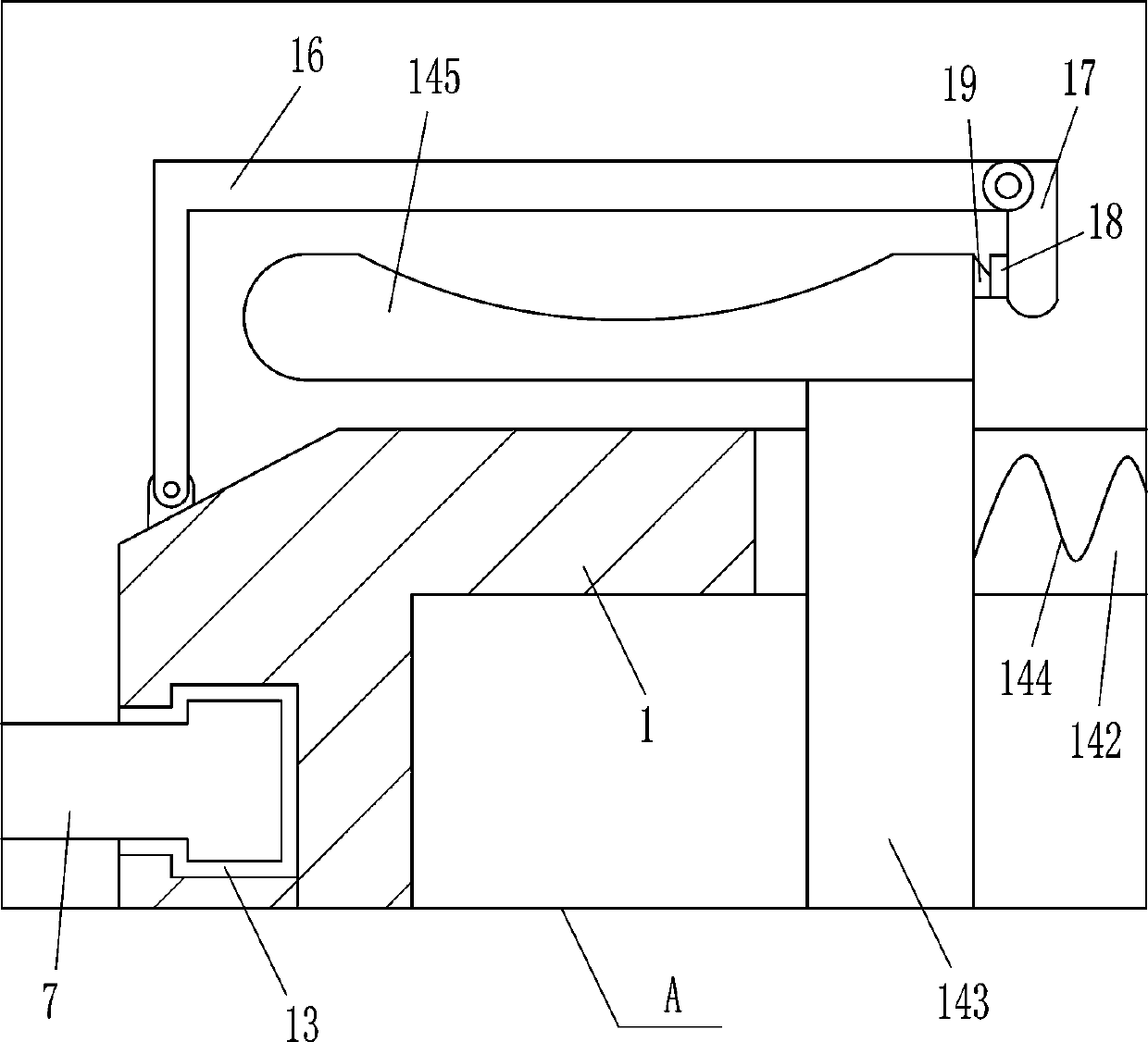

Active back-twist constant-force pay-off machine and production method thereof

ActiveCN103106982AReasonable structural designIngenious structural designCable/conductor manufactureConstant forceUltimate tensile strength

The invention discloses an active back-twist constant-force pay-off machine which comprises a machine frame, a back-twist pay-off device and a rotating tension device, wherein the back-twist pay-off device comprises a pay-off mechanism and a back-twist mechanism. The invention further discloses a production method of the active back-twist constant-force pay-off machine. The active back-twist constant-force pay-off machine is reasonable and ingenious in structural design and capable of quickly feeding a cable core to a stranding machine in a balanced mode with predetermined constant tension; at the same time, the rotating tension device and the stranding machine move in the same direction at the same rotation speed, and therefore the cable core can be effectively prevented from being damaged due to twist; in addition, regulating accuracy of the tension is high, the tension of the cable core can be automatically detected and adjusted in the whole production process, and therefore the tension of the cable core can always remain constant, and constant-tension cable feeding in a true sense is realized; and the active back-twist constant-force pay-off machine is convenient to operate, greatly lowers labor intensity, guarantees the quality of products, and is beneficial to improvement of the competitiveness of an enterprise. The production method of the active back-twist constant-force pay-off machine is simple in process, low in cost, easy to implement, and through the production method, the active back-twist constant-force pay-off machine can be produced rapidly.

Owner:DONGGUAN JINGTIE MACHINERY

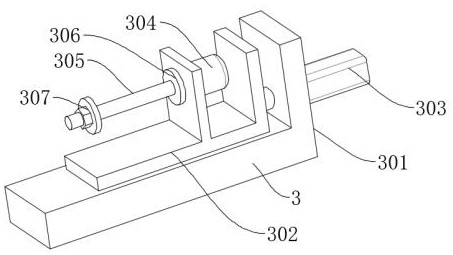

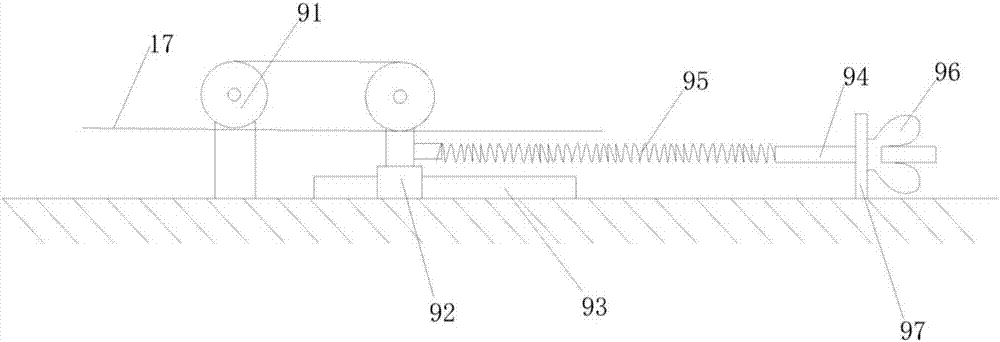

Conducting wire tension adjusting device of stranding machine

ActiveCN101599324AAvoid redundancyQuality assuranceCable/conductor manufactureWire tensionEngineering

The invention relates to a conducting wire tension adjusting device of a stranding machine, and belongs to the technical field of wire and cable processing devices. The stranding machine comprises a frame, wherein a group of swing frames are arranged in the length direction of the frame at intervals; and each swing frame is provided with a pay-off disk. The device is characterized in that: the conducting wire tension adjusting device comprises a friction disk with a brake shoe slot, a friction disc braking device and a baffle pin; the friction disk is arranged on a pay-off disk shaft of the pay-off disk; the friction disk braking device is arranged on the friction disk and contacts the baffle pin; the baffle pin is fixed on the swing frame; and the pay-off disk shaft is positioned in a seat cavity of a pay-off disk seat on the swing frame. The device has the advantages that: the tension of a conducting wire payed off from the pay-off disk can be controlled by braking the friction disk to avoid redundancy of the conducting wire so as to ensure the quality of the stranded conducting wire.

Owner:JIANGSU ZHONGLI GRP CO LTD +4

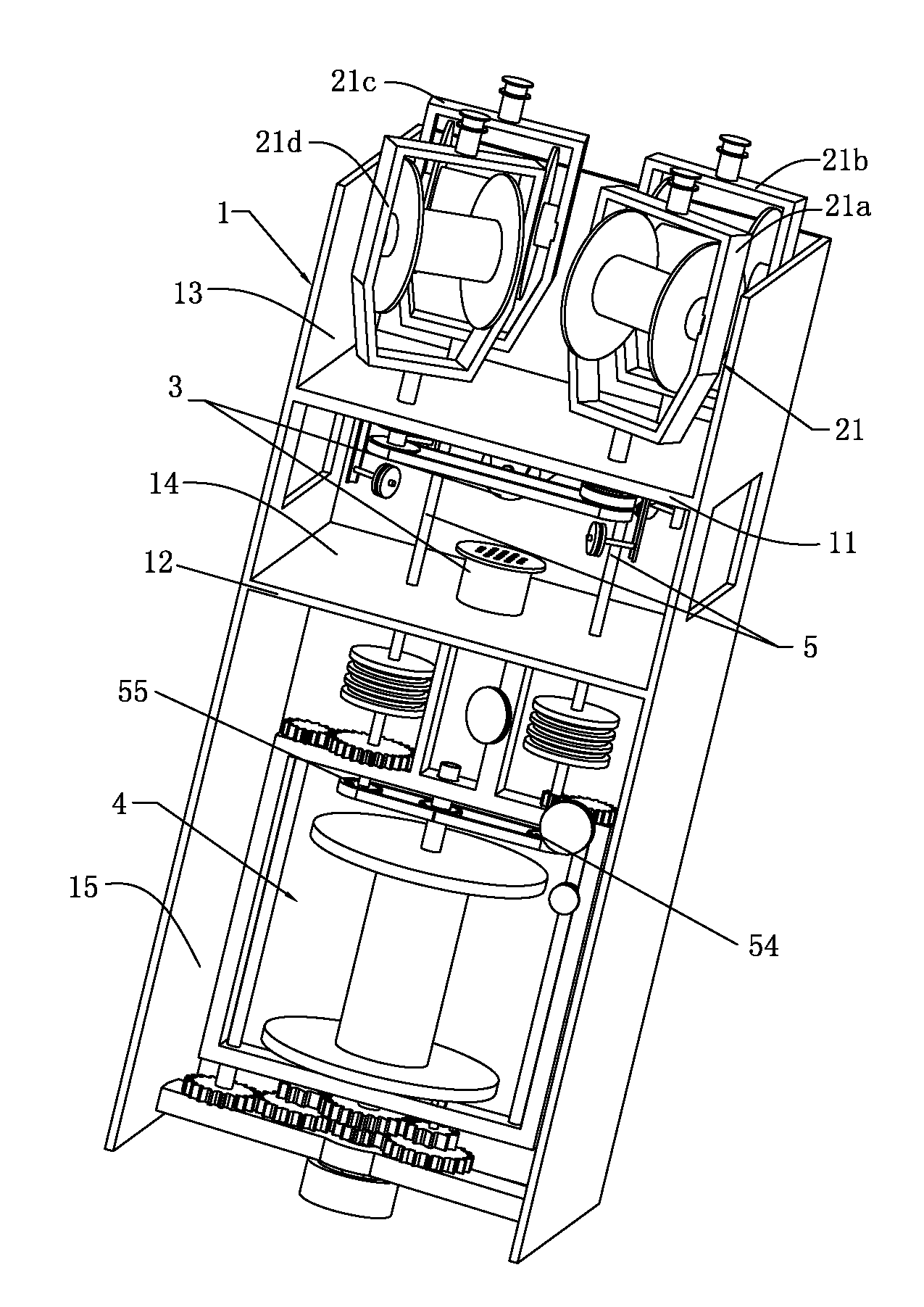

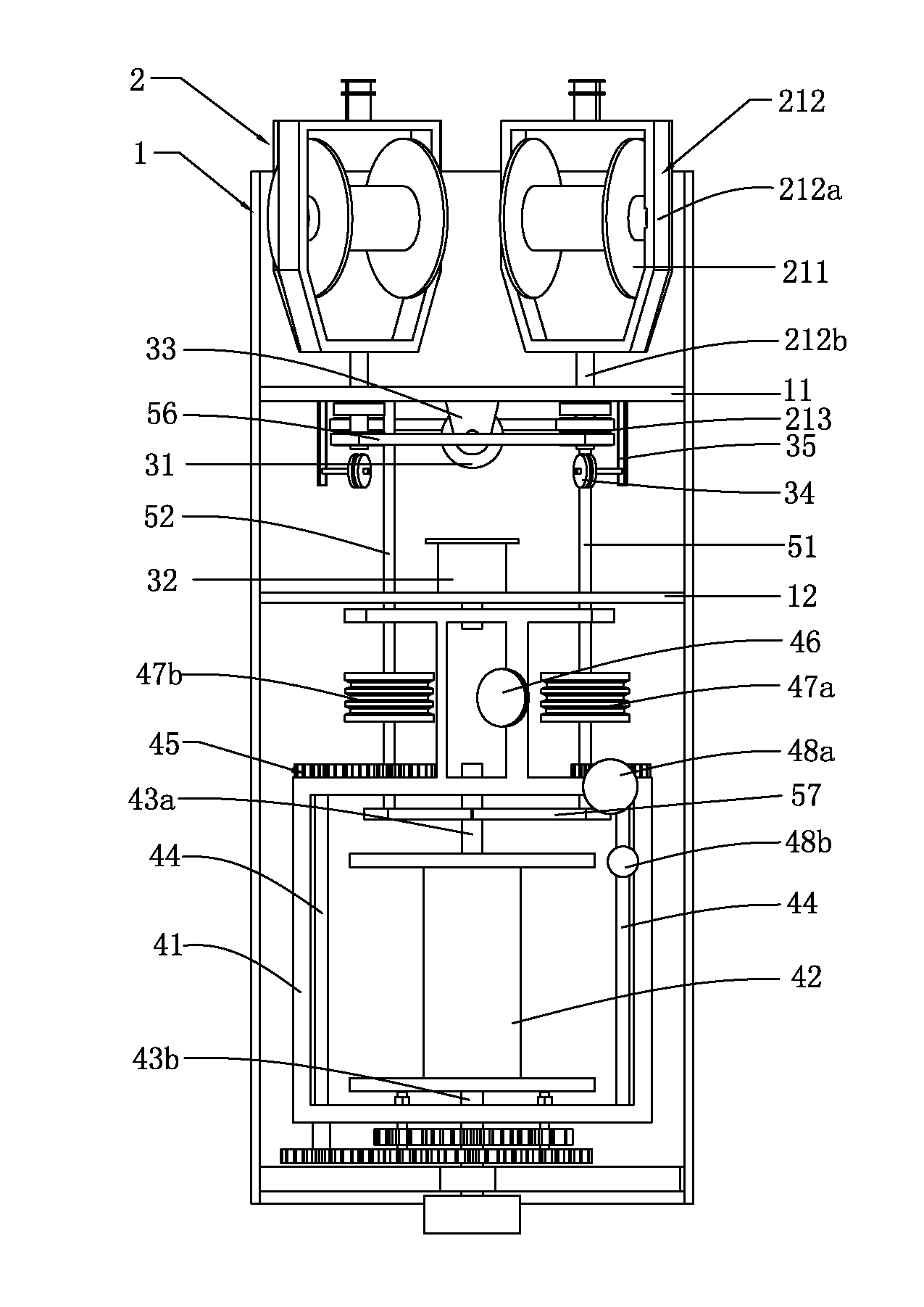

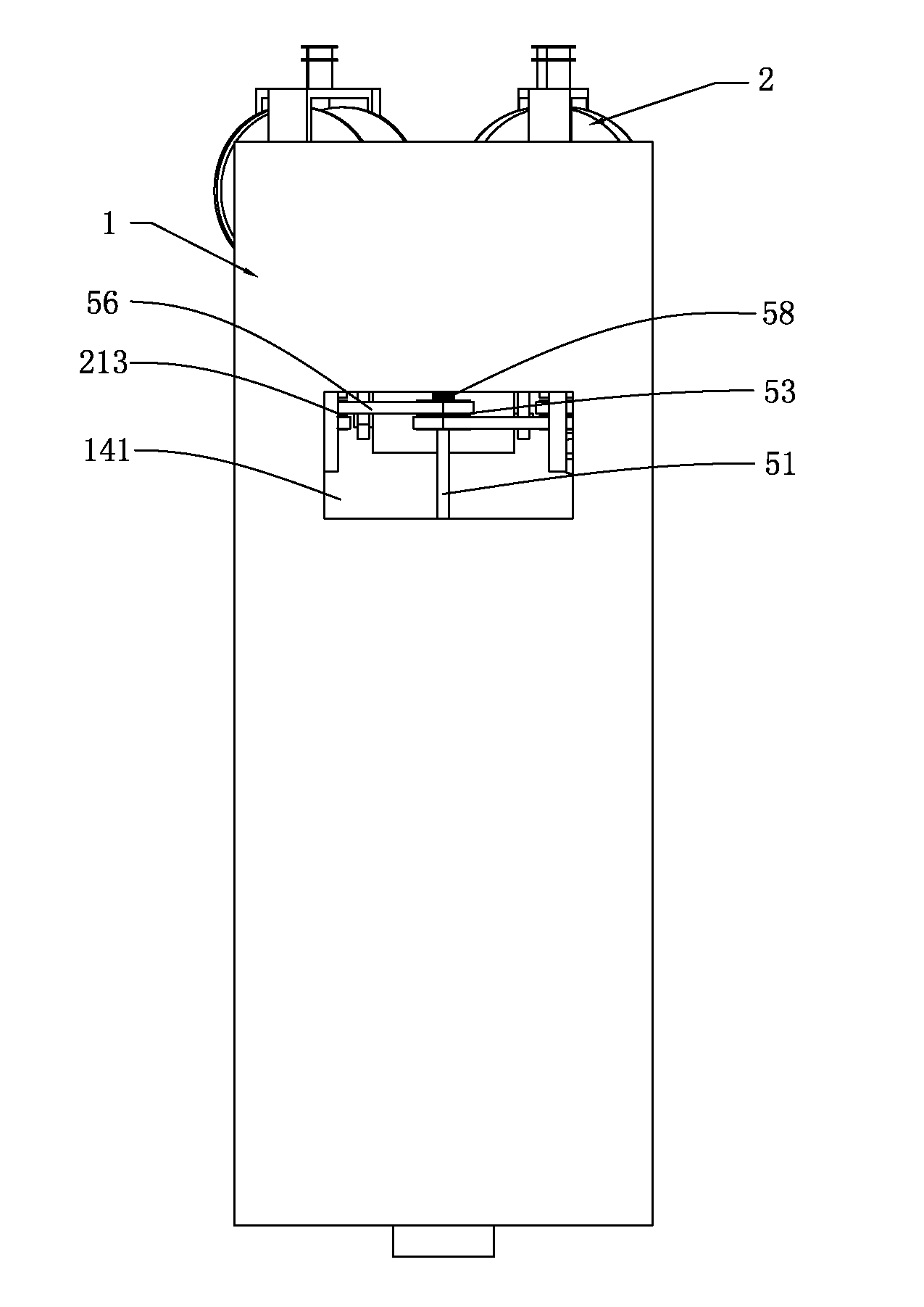

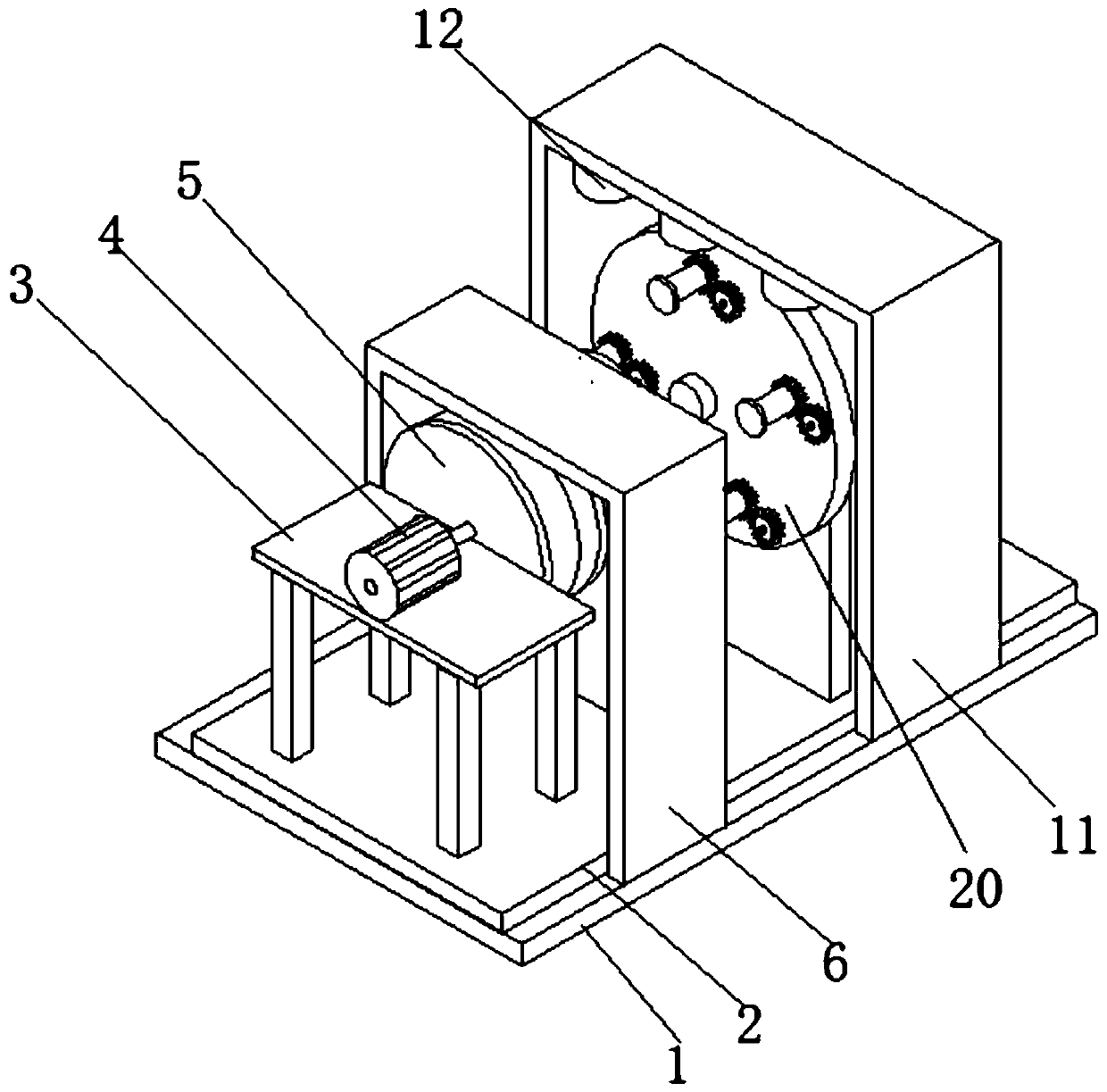

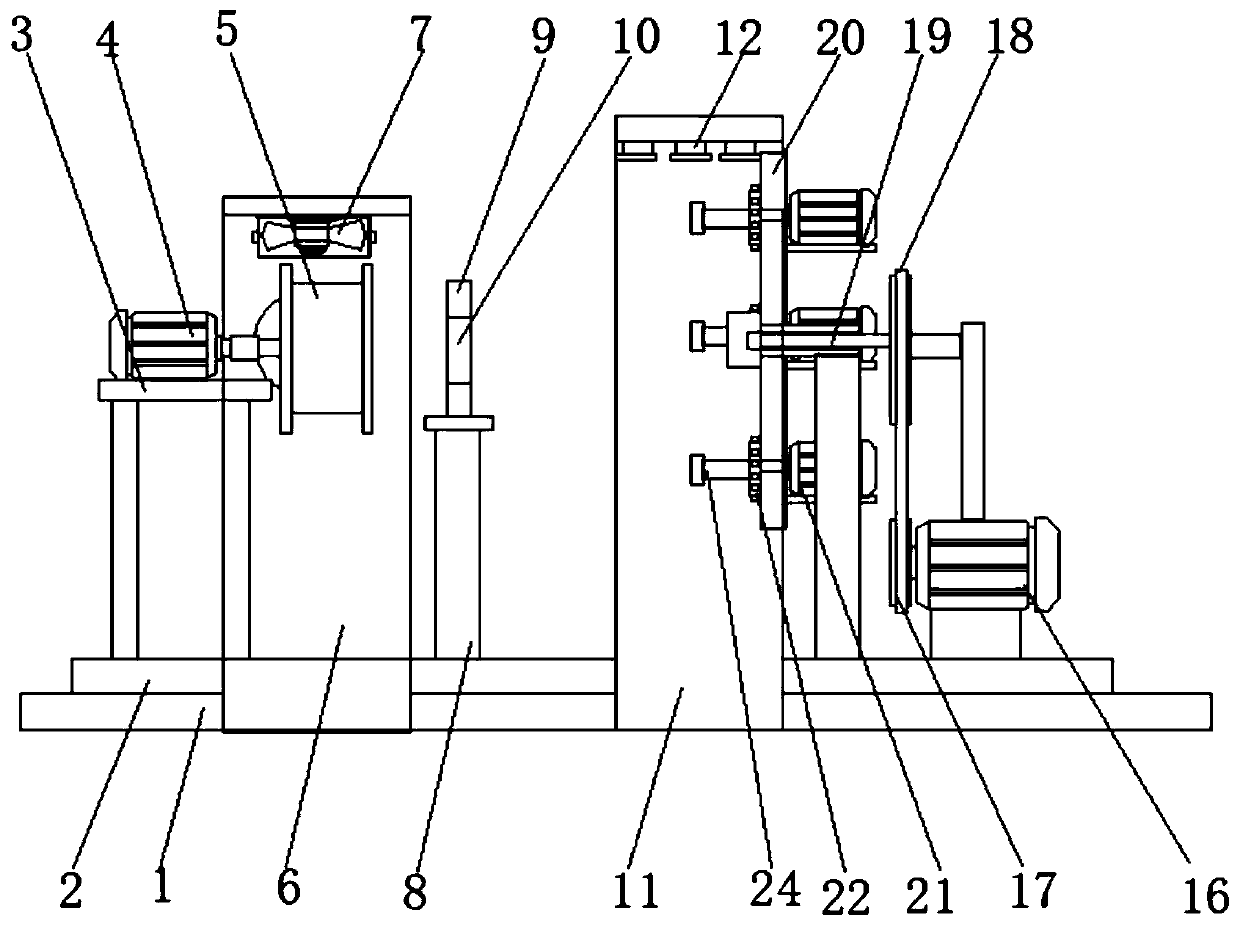

Back twist strander

ActiveCN102354583AEliminate torsional stressThere will be no jumping phenomenonCable/conductor manufactureTransmitted powerGear wheel

The invention relates to the technical field of stranders, in particular to a back twist strander capable of eliminating torsion stress. The back twist strander comprises a stand, a feeding device, a stranding device, a transmission device and a coiling device, wherein the stand is provided with a first working plate and a second working plate which divide the stand into three working chambers. The back twist strander provided by the invention achieves the aim of eliminating torsion stress generated in the total stranding process of wires through controlling the rotating speed of a feeding end to be consistent with the rotating speed at a coiling end by using the same transmission device. The transmission device of the back twist strander transmits power through a synchronous transmissionrod as well as a synchronous gear and a synchronous belt which are in the same specification. The back twist strander is simple and compact in structure, capable of totally stranding a plurality of wires, varied in stranding way and high in stranding quality, and no jumping phenomenon is caused in the total stranding process of the wires.

Owner:HUBEI YINGTONG ELECTRONICS +1

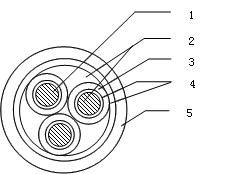

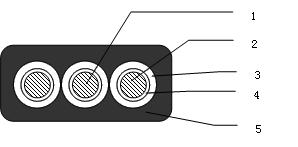

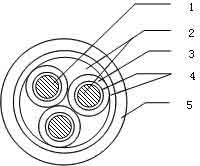

Longitudinal water-sealing degaussing cable and manufacturing process for same

InactiveCN102509582AReduce distractionsImprove water absorptionClimate change adaptationFlat/ribbon cablesLow smoke zero halogenElectrical conductor

The invention discloses a longitudinal water-sealing degaussing cable. The longitudinal water-sealing degaussing cable is characterized by comprising three cores which are arranged in a delta shape or linearly. A plurality of tin plated copper wires are twisted to form a conductor in the center of each core of the cable by an electric wire and cable twisting machine. A waterproof adhesive is filled in gaps between every two of the plurality of tin plated copper wires. A first layer of wrapped waterproof tape is arranged on the periphery of the conductor. An insulating layer made of an insulating material ethylene propylene rubber is arranged on the periphery of the first layer of wrapped waterproof tape. A second layer of wrapped waterproof tape is arranged on the periphery of the insulating layer. A sheath is arranged on the periphery of the second layer of wrapped waterproof tape. The waterproof adhesive is filled in gaps between every two of the three cores which are arranged in the delta shape. The longitudinal water-sealing degaussing cable has the advantages that: by a multi-core structure, troubles in the multi-turn winding laying of the conventional single-core structure are avoided, and the longitudinal water-sealing degaussing cable is convenient to mount and lay; the longitudinal water-sealing degaussing cable can be used for compensating for own induced magnetic field of a naval ship, and is small in interference and good in degaussing effect, and a generated magnetic field is regular and easy to control; and the longitudinal water-sealing degaussing cable is low-smoke, halogen-free and low-toxicity.

Owner:NANJING QUANXIN CABLE TECH

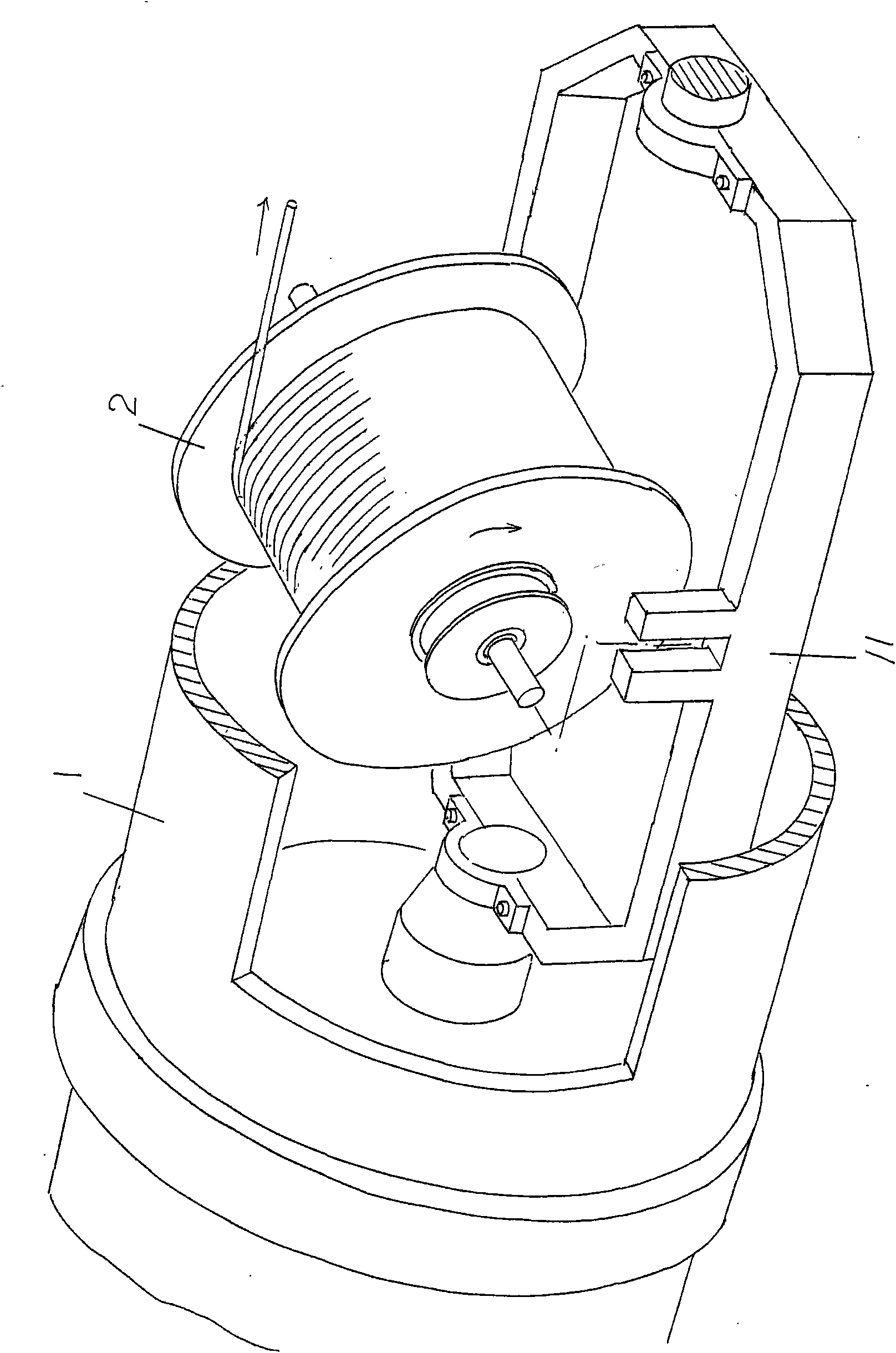

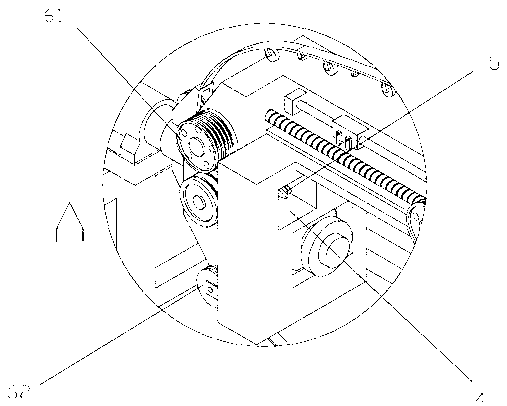

Winding structure of automatic wire twisting machine

InactiveCN103219094ASubsequent take-up work is stableTake-up works smoothlyCable/conductor manufactureTextile cablesMachineElectric cables

The invention provides a winding structure of an automatic wire twisting machine, and belongs to the technical field of twisting and producing of cables and wires. The winding structure comprises a wire feeding main shaft, a twisting bow, a wire discharging main shaft and a wire collecting support arranged on the twisting bow. A port is arranged on a position, connected with the wire discharging main shaft, of the wire collecting support. A drawing inclined wheel is arranged at the position of the port. A drawing device and a wire collecting device are further arranged on the wire collecting support. Due to the drawing inclined wheel, twisted wires are stable when entering the drawing device from the twisting bow, wire passing resistance is reduced, operation of equipment is more stable, and production efficiency is improved.

Owner:ZHEJIANG BAOLONG MACHINERY

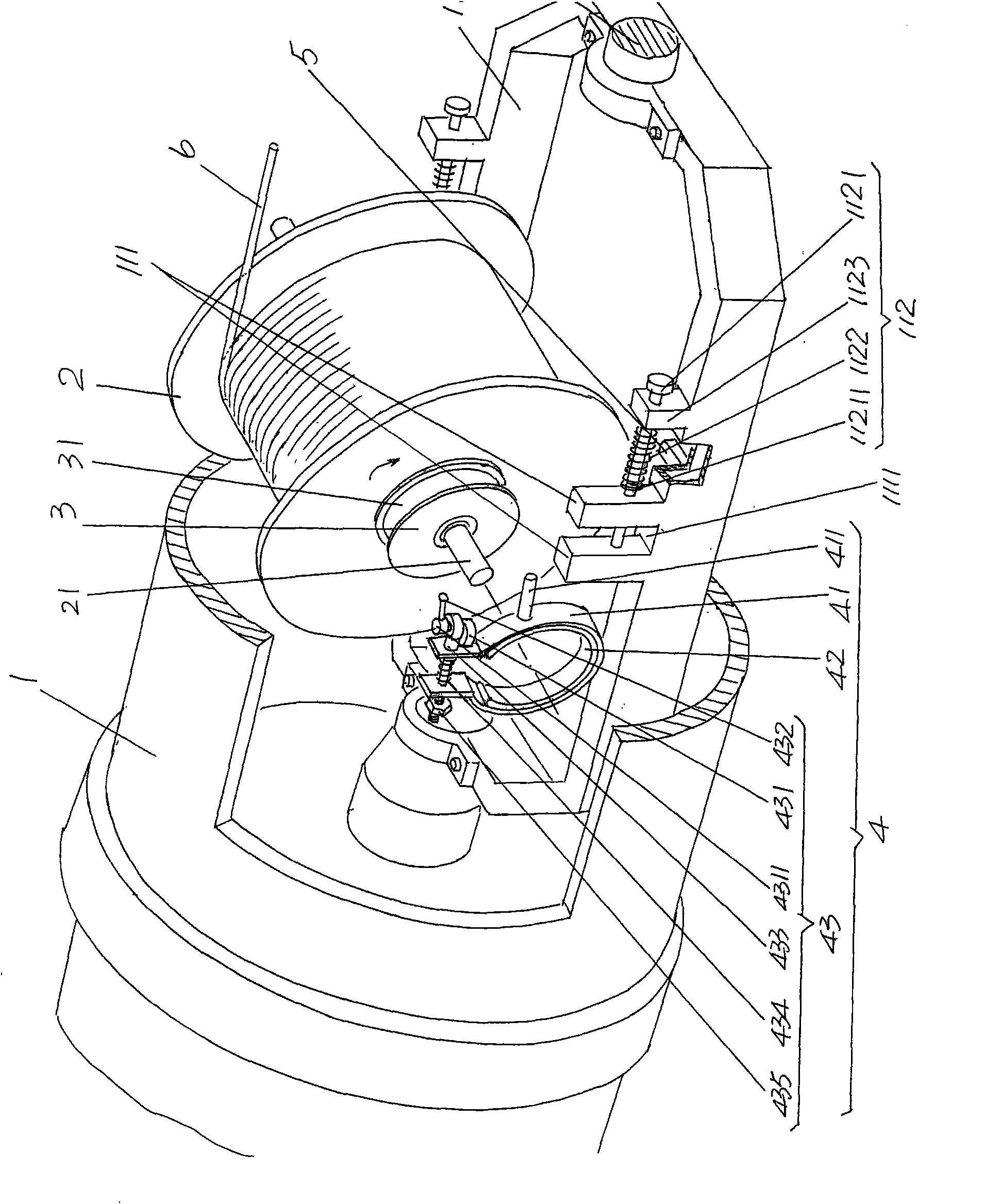

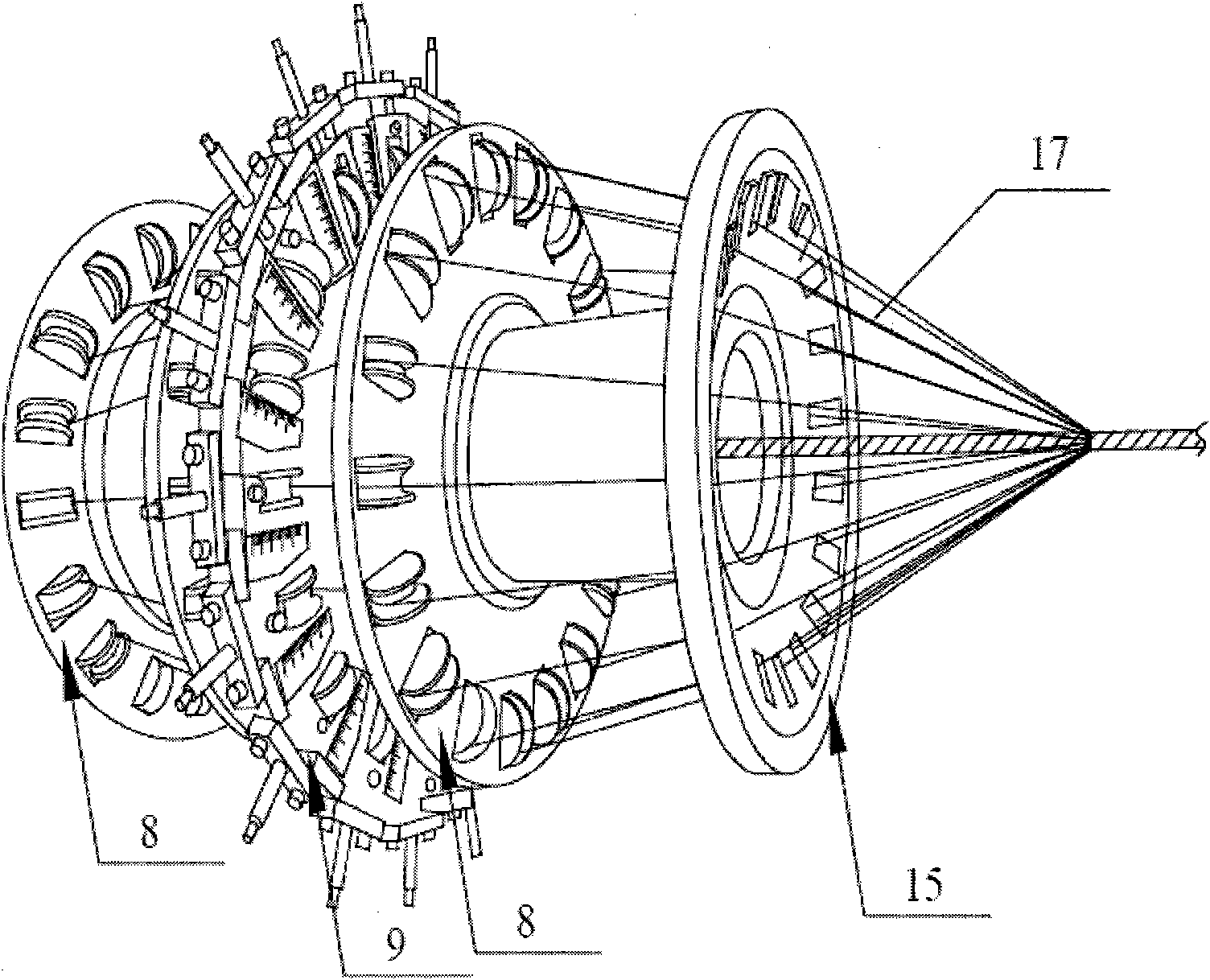

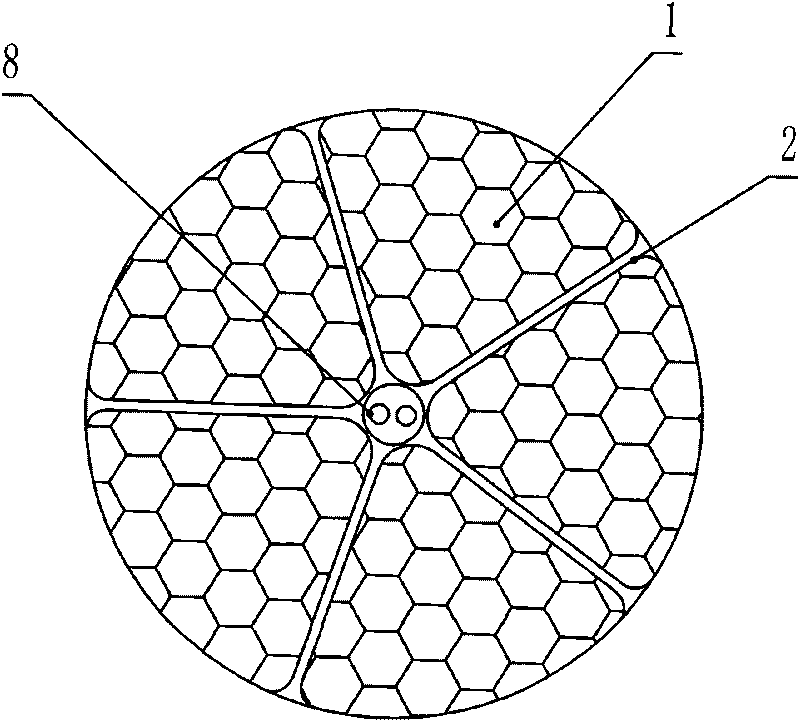

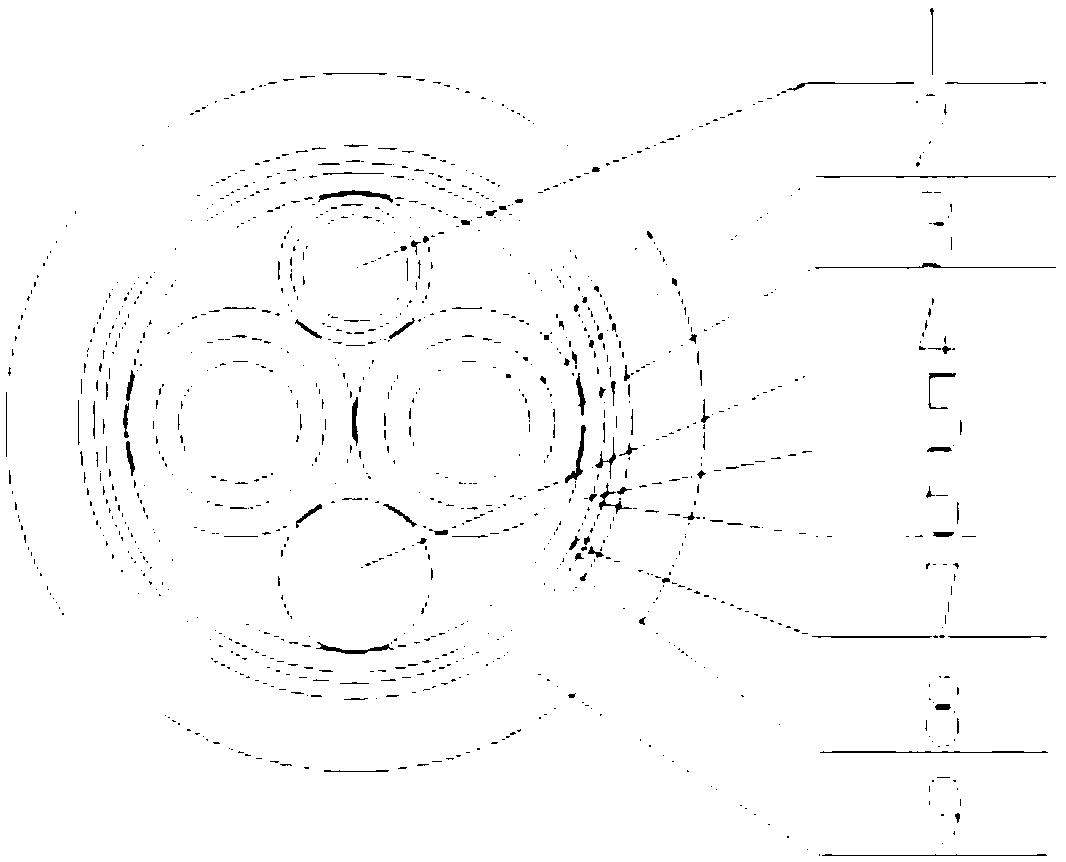

Wire twister

InactiveCN101950637ANot looseSimple structureRope making machinesCable/conductor manufactureWire wheelWire twister

The invention discloses a wire twister which comprises four twisted wire disks arranged on the same hollow shaft, wherein, the concentric periphery of each twisted wire disk is provide with a plurality of conducting wire wheels and / or slotted holes; the conducting wire wheels comprise fixed conducting wire wheels and movable conducting wire wheels, the fixed conducting wire wheels are connected with the twisted wire disks through rollers on the conducting wire wheels, and the movable conducting wire wheels are connected on a sliding block through rollers; the sliding block is matched with a sliding rail block, one side of the sliding rail block is fixed on a connecting plate, and the connecting plate is fixed on the hollow shaft; the axis of the shaft is perpendicular to the radial line of each twisted wire disk; and the end part of the sliding block is provided with an adjusting rod, and the adjusting rod adjusts the sliding block to slide along the radial direction of the connecting plate through an adjusting component arranged on the sliding rail block and / or the connecting plate. By adopting the wire twister, before cables or ropes are twisted, a plurality of the cables are plastically deformed in advance; and in addition, the cables of various specifications can be produced by adjusting the distance among the twisted wire disks and positions of the movable conducting wire wheels.

Owner:江阴华电新材料有限公司

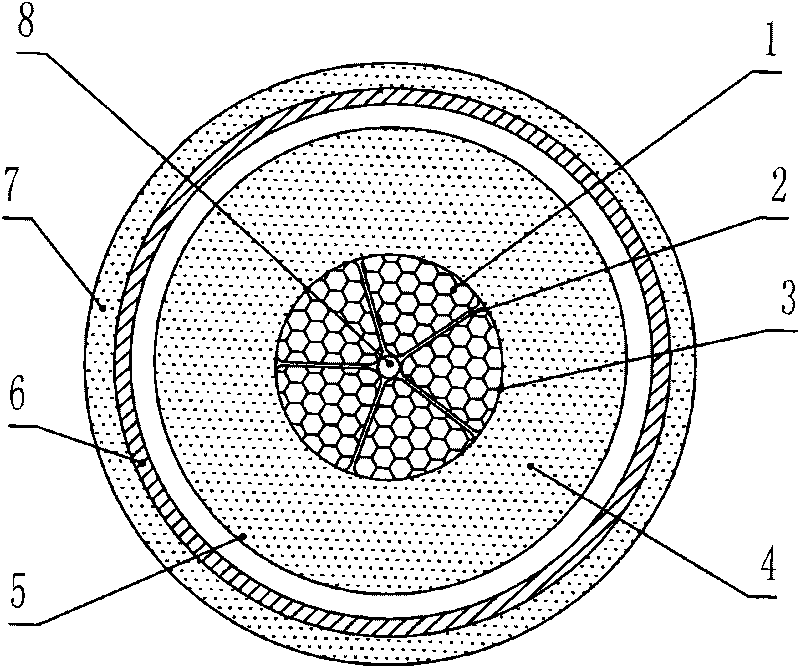

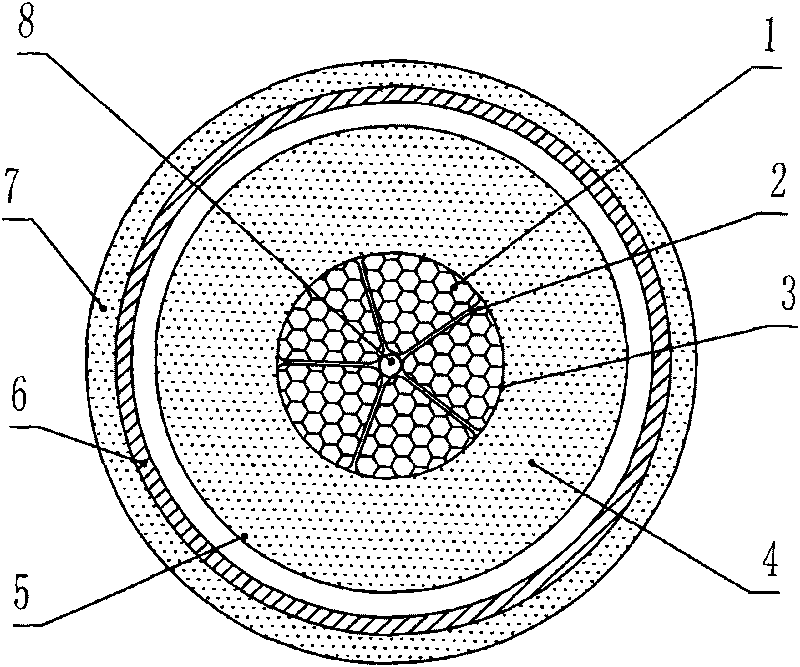

Method for twisting fibers in center of composite power cable conductor

InactiveCN101714433AReduce aging speedUse the transmission abilityCommunication cablesCable/conductor manufactureFiberElectrical conductor

The invention relates to a method for twisting fibers in the center of a composite power cable conductor, solving the lasting problem of arranging optical fiber in the center of the cable conductor, which is unsolved all along by technical staff in the field. The invention utilizes the conventional frame-type wire-twisting machine, twists compacted and molded fan-shaped conductor units into a round segment conductor by fan-shaped filming, and twists the optical fiber with a stainless steel sleeve into a space enclosed by the round segment conductor center at the same time, and sequentially arranges a semi-conductive shielding layer, a crosslinked polyethylene insulator, an insulated semi-conductive shielding layer, a metal sheath and a plastic sheath on the periphery of the round segment conductor to prepare a composite power cable. The invention has simple process flows and together successfully twists the optical fiber with the stainless steel sleeve in the conductor center of the cable core on a basis of unchanging the prior cable manufacture process flows so that the product reaches the aims of accurately realizing the online measurement of practical cable temperature rise, exerting the transmission capability of the cable to the maximum extent and ensuring the safe operation of a power cable line.

Owner:SHENYANG FURUKAWA CABLE

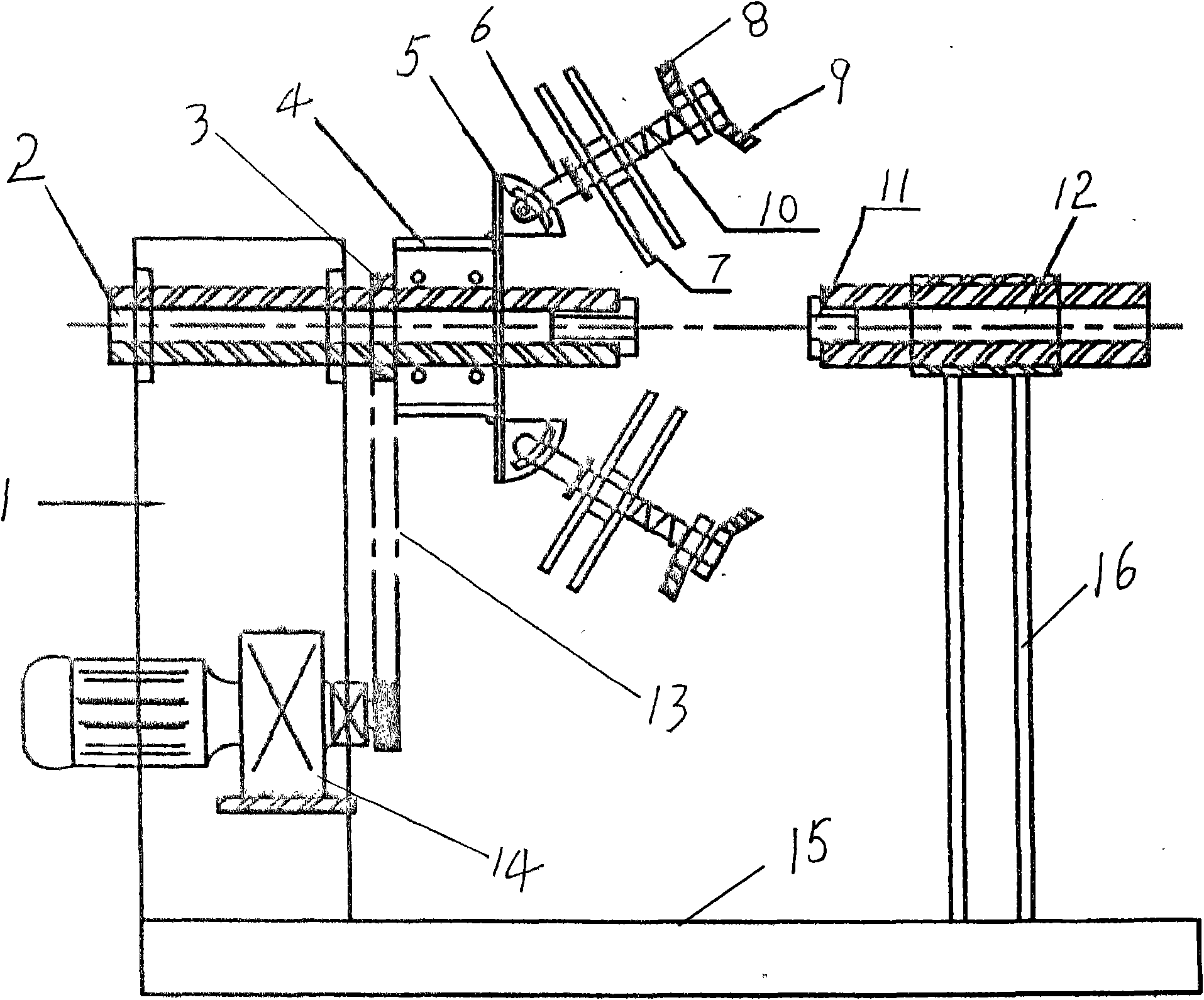

Stranding machine lapping device

InactiveCN101630548AImprove processing efficiencyReduce processCable/conductor manufactureDrive wheelElectrical conductor

The invention relates to a stranding machine lapping device, wherein, a case is installed at the front end of a long strip type base, and a stand column is installed at the back end of the long strip type base; a multitronic slip motor is installed in the case; a front cable tube is installed on the upper end of the case; a back cable tube is installed on the stand column; a driving wheel is arranged on the front cable tube and is connected with a drive wheel of a motor by a driving belt; a lapping head is installed on the front cable tube; two lapping shafts stretching backward in a splayed form are symmetrically installed at both sides of the rear part of the lapping head through two fixing seats; each fixing seat is provided with an angle regulator; the middle part of each lapping shaft is provided with a lapping rack; prolongations of panel faces of the two lapping racks correspond to the connection between the front cable tube and the back cable tube; an inner handle and an outer handle are respectively arranged at the outer side of each lapping rack; and an alignment module is arranged on the front tube orifice of the back cable tube. The device not only can process all types of cable lapping conductors or control cable laps, but also has high processing efficiency, reduces equipment and space and reduces cost.

Owner:XINXIANG POWER SUPPLY COMPANY STATE GRID HENAN ELECTRIC POWER

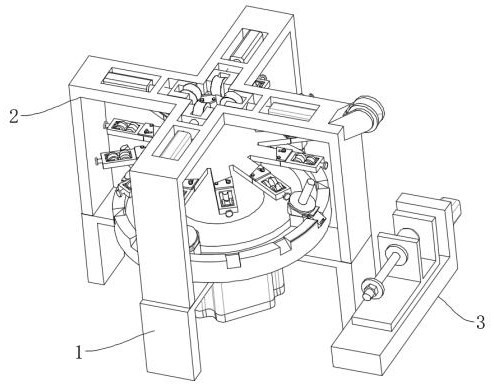

Anti-wear stranding device for electric wire production line

ActiveCN112489888APrevent disengagementSolve wear and tearCable/conductor manufactureProduction lineElectric machine

The invention discloses an anti-wear stranding device for an electric wire production line, the anti-wear stranding device comprises a winding mechanism, a stranding mechanism and a guide mechanism, the stranding mechanism comprises a support frame, a driving motor, a rotating table, an annular sliding groove, a fixing assembly, a stand column and a support plate, and the center of the bottom of the support frame is connected with the driving motor through a bolt; the output end of the driving motor penetrates through the support frame, stretches into the inner side of the rotating table and is connected with the rotating table through a key, the annular sliding groove and a plurality of clamping grooves are formed in the top of the rotating table, the clamping grooves are located in the outer side of the annular sliding groove, and the fixing assembly is connected to the inner side of the annular sliding groove in a sliding mode. Through the arrangement of the rotating structure and the wire guide assembly, the electric wire is prevented from being separated from the fixed wire guide wheel, and meanwhile, the problem that the electric wire is abraded before being stranded is solved due to rolling connection between the fixed wire guide wheel and the electric wire; and the guide mechanism is arranged, so that the problem that the electric wire is abraded after being stranded issolved.

Owner:衡阳市捷讯实业有限公司

Automatic stranding machine for cable production

ActiveCN111243796ARealize continuous workAvoid affecting the stranding processInsulating conductors/cablesDrive wheelElectric machinery

The invention discloses an automatic stranding machine for cable production, and relates to the field of cable production. The automatic stranding machine comprises a base. The top end of the base isconnected with a connecting seat; the top end of the connecting seat is connected with a mounting seat; a winding motor is mounted at the top end of the mounting seat; a winding roller is connected with the output end of the winding motor; a first mounting bin is connected with one side of the top end of the base; a drying fan is mounted in the first mounting bin; a bottom column is connected withthe position, located at the top end of the connecting seat, of one side of the mounting seat; and a communicating block is connected with the top end of the bottom column. According to the invention, the winding motor, the winding roller, a stranding motor, a driving wheel, a driven wheel, a connecting shaft, a rotating disc and connecting columns are arranged;, the stranding motor drives the rotating disc to rotate so as to drive cables on the outer sides of six sets of connecting columns to rotate; the twisted cables are driven by the winding motor and the winding roller to be wound; continuous work is achieved; the cables being twisted do not need to be disconnected; and therefore the influence on the twisting process is avoided.

Owner:南通辰乐工业科技有限公司

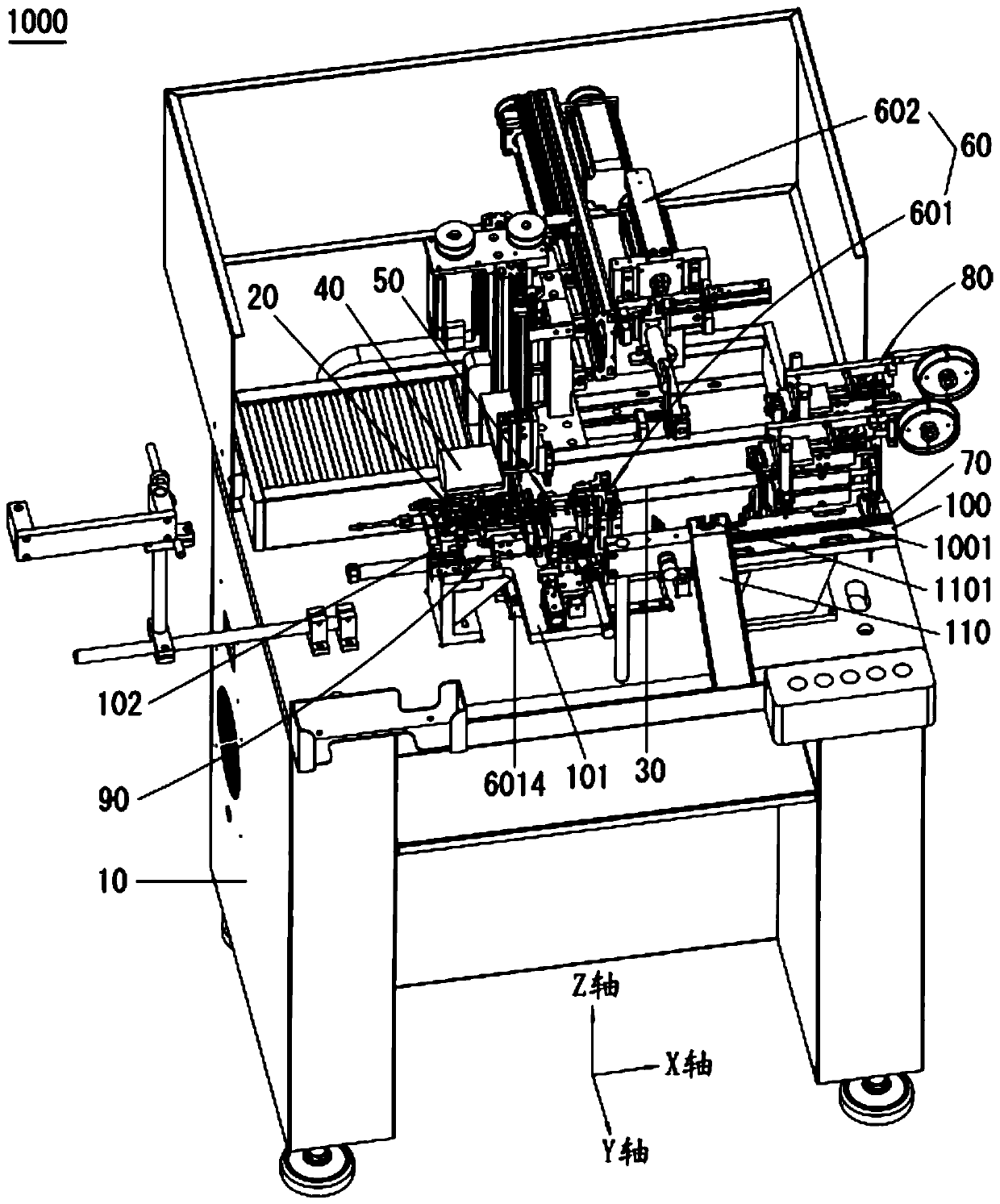

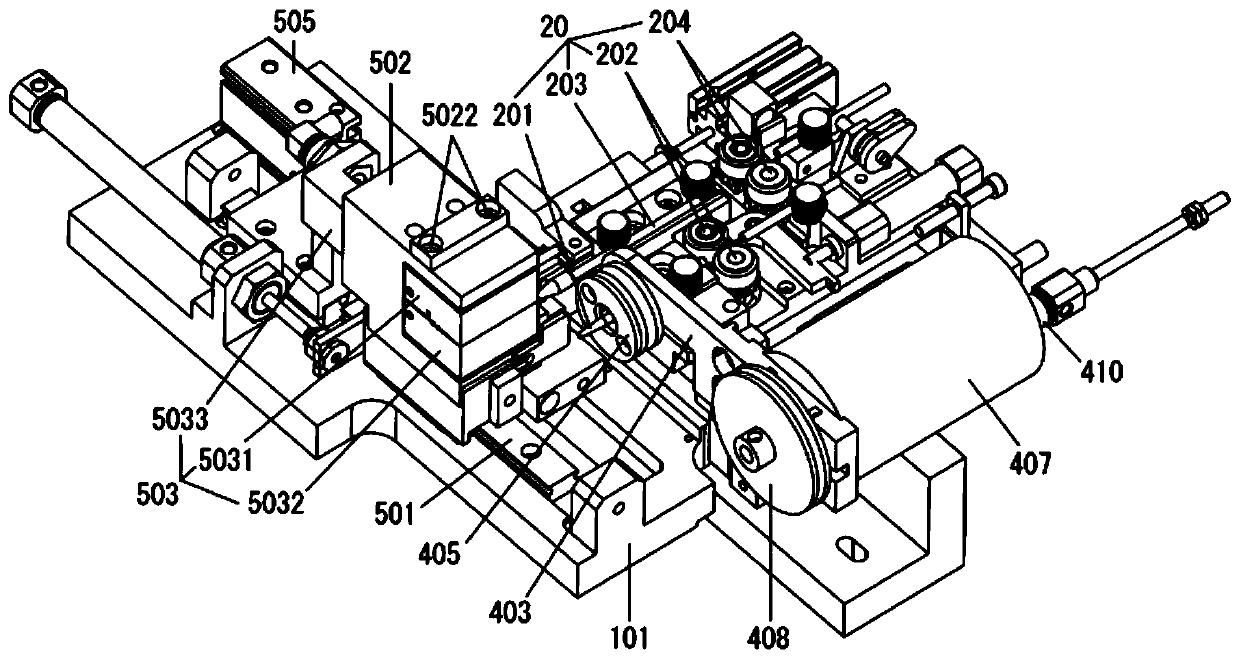

Stranded wire penetrating sleeve winding and rubber coating machine

PendingCN111477454AImprove work efficiencyReduce operating efficiencyCoils manufactureWire rodEngineering

The invention discloses a stranded wire penetrating sleeve winding and rubber coating machine. The stranded wire penetrating sleeve winding and rubber coating machine comprises a rack, a main controller, a wire feeding and pipe feeding mechanism, a wire stranding mechanism, a sleeve penetrating mechanism, a wire winding and sleeve winding and fixing mechanism, a rubber coating mechanism and a sleeve opening expanding mechanism. The stranded wire penetrating sleeve winding and rubber coating machine is advantageous in that automatic wire feeding and pipe feeding can be realized, a plurality ofwires which are wound together are automatically stranded so as not to be bifurcated, a sleeve is automatically arranged outside the wire rod which is stranded and twisted into a whole in a penetrating manner, winding, sleeve winding and fixing and automatic rubber coating are automatically carried out on the coil framework, the whole line production is coherent and good in continuity, the coil framework assembling production period can be greatly shortened, the sleeve opening expanding mechanism is used for expanding a sleeve opening in the rear end of a sleeve, and a wire rod can more conveniently penetrate into the sleeve opening expanding mechanism, so the stranded wire penetrating sleeve winding and rubber coating machine is high in practicability, good in using effect and capable ofbeing widely popularized and effectively popularized.

Owner:深圳市鹏达金电子设备有限公司

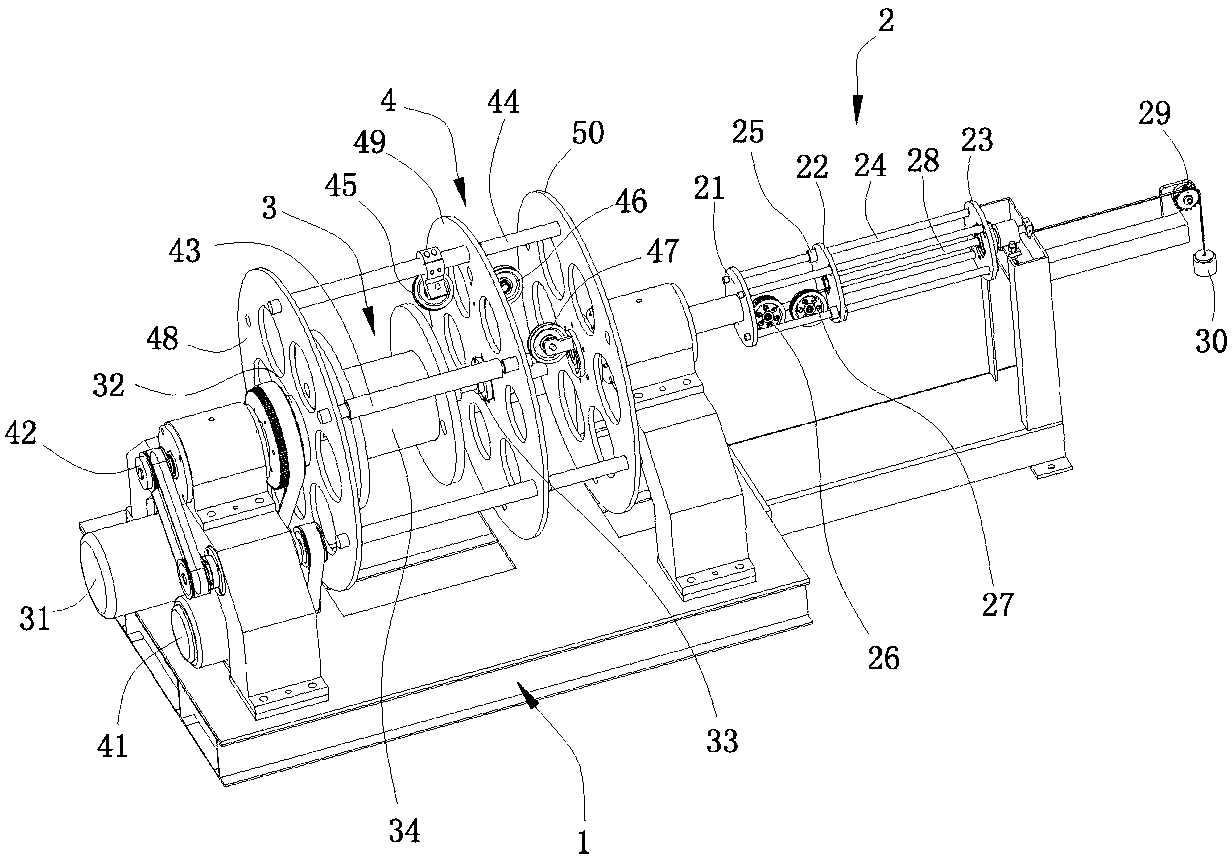

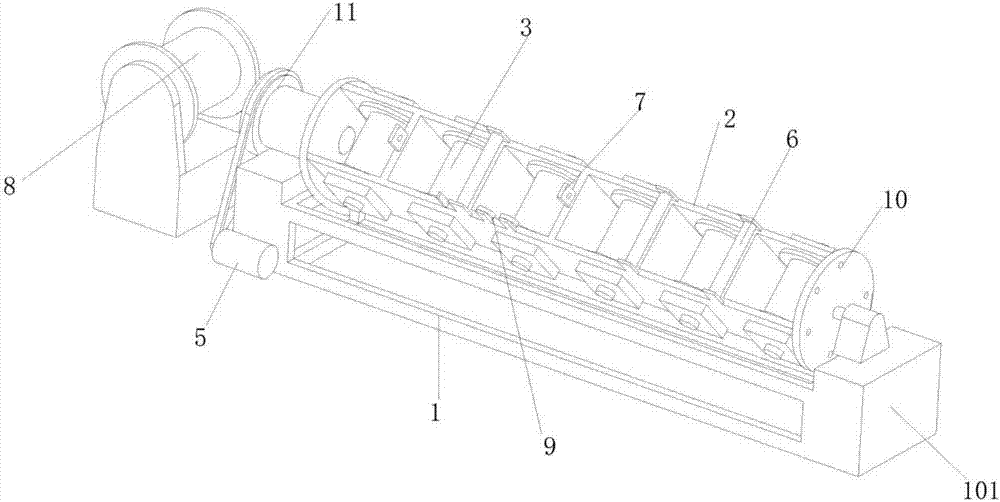

Concentric high-speed stranding machine

PendingCN107039128AReduce resistanceTo achieve twist and actionCable/conductor manufactureStructural engineeringMachine

The invention discloses a concentric high-speed stranding machine, which comprises a rack and a stranding system arranged on the rack. The concentric high-speed stranding machine also comprises a traction machine and a take-up machine, which are used for carrying out traction and take-up and rolling on the stranded cables in sequence. The concentric high-speed stranding machine is characterized in that the stranding system comprises a bracket rotatably connected with the rack through bearing pedestals at the two ends; the bracket is uniformly equipped with a plurality of paying-off wheels in the same line direction; the paying-off wheels can rotate automatically and can also rotate synchronously with the bracket; and one side surface, opposite to an end frame, at the tail end of the bracket is uniformly provided with cable outlets. The provided concentric high-speed stranding machine is unique in structure; in the stranding machine, the bracket drives the paying-off wheels to rotate together, and the paying-off wheels are arranged uniformly in the same line direction, so that the bracket is smaller in overall structure; and therefore, the stranding machine is small in space occupation, fast in stranding speed and low in energy consumption.

Owner:邵现明

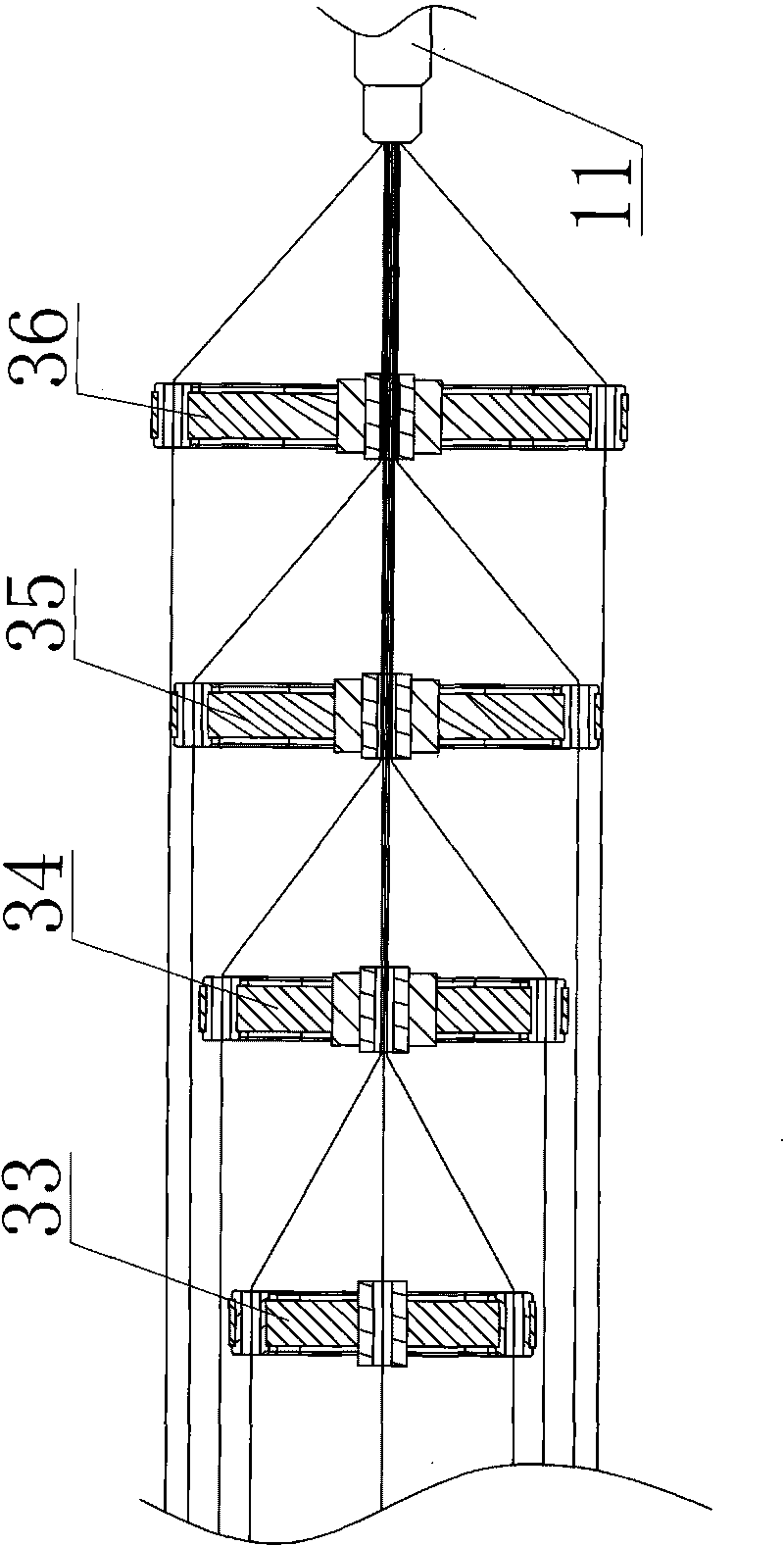

Multilayer and multi-strand wire twisting method and device implementing same

InactiveCN101728031AQuick layeringFast, even layeringCable/conductor manufactureEngineeringMechanical engineering

The invention discloses a multilayer and multi-strand wire twisting method. A device comprises a wire twisting machine and a bracket which is arranged at the wire twisting opening of the wire twisting machine. The method comprises the following steps: 1. preparing wire guide disks; 2. preparing wire guide holes; 3. preparing a wire collection hole; and 4. preparing a wire collection group: arranging the prepared wire guide disks in line according to the order from small radius to large radius and fixing the wire guide disks on the bracket, wherein the wire guide disk with the largest radius is arranged close to one end of the wire twisting opening of the wire twisting machine. The method provided by the invention can rapidly and uniformly twist and joint the multilayer and multi-strand wires of the same type or of different types in multiple layers. The device provided by the invention is simple in structure and convenient in operation and can automatically twist and joint the multilayer and multi-strand wires of the same type or of different types in multiple layers by only starting the wire twisting machine, thus greatly reducing the labor intensity, ensuring the product quality and being beneficial to improving the enterprise competitiveness.

Owner:LINOYA ELECTRONIC TECHNOLOGY CO LTD +1

Method for manufacturing prestress steel strand coated with nichrome powder

ActiveCN103639402AHigh strengthImprove toughness and strengthMolten spray coatingRope making machinesWire rodPre stress

The invention discloses a method for manufacturing a prestress steel strand coated with nichrome powder. The method for manufacturing the prestress steel strand coated with the nichrome powder comprises the following steps that (1) the nichrome powder comprises, by weight, 0.5-3.2% of Re, 48-54% of Ni, 18-32% of Cr, 1.6-5.5% of Si, 0.3-0.8% of S, 0.5-2.2% of C, 10-16% of Fe, 1.2-10% of Mn, and 1-2.5% of composite rear earth; (2) a plurality of wire rod steel wires are fed into a heating furnace; (3) the nichrome powder is evenly sprayed on the surfaces of the wire rod steel wires through a spray gun; (4) the wire rod steel wires are stranded through a stranding machine to form the steel strand which is of a steel wire rope shape; (5) the steel strand enters a quenching device; (6) the nichrome powder is evenly sprayed on the surface of the steel strand again through the spray gun; (7) the steel strand enters a layer winder to be packaged. According to the method for manufacturing the prestress steel strand coated with the nichrome powder, the strength, wear resistance and corrosion resistance of the steel strand are improved.

Owner:TIANSHUN GROUP

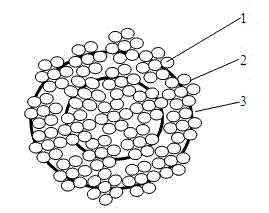

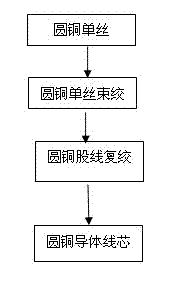

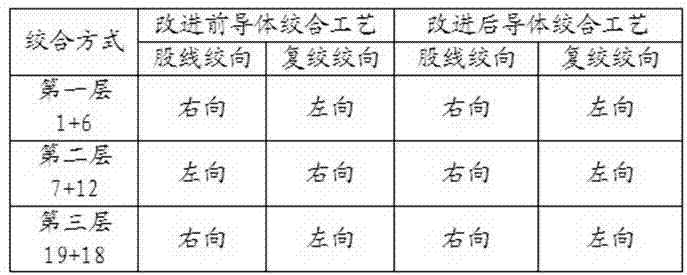

Improved stranding process of cable copper conductors

InactiveCN103117137AGood flexibilitySuitable for bendingCable/conductor manufactureCopper conductorCopper wire

The invention relates to an improved stranding process of cable copper conductors. The improved stranding process of the cable copper conductors includes the steps of: (1) utilizing a wire bunching machine to bunch and strand single round copper wires all rightwards to produce round copper strand wires, and (2) utilizing a wire twisting machine to divide the round copper strand wires into layers and restrand the round copper strand wires all leftwards to produce round copper conductor wire cores. According to the improved stranding process of the cable copper conductors, the single round copper wires are all stranded rightwards when in bunching and stranding, and the round copper strand wires are stranded all leftwards when in restranding. Therefore, the flexibility of the conductors is improved, the electrical property and the mechanical property are stable, and the conductor is applicable to the bending, twisting and movable use of the cable.

Owner:TIANJIN TIANLAN GROUP

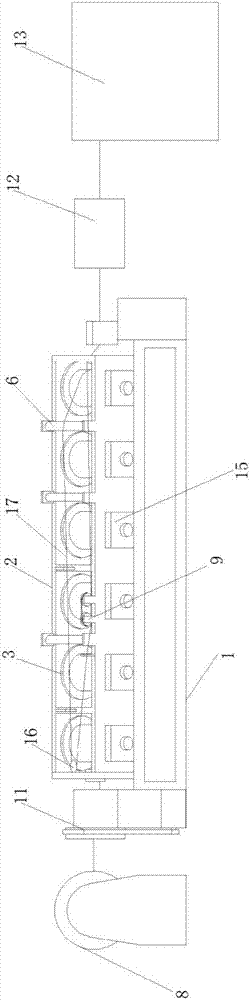

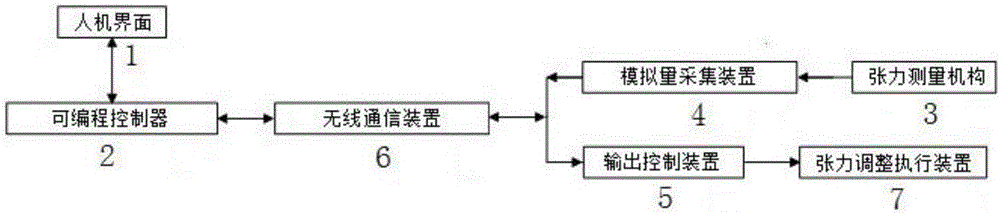

Stranding machine stranding tension automatic monitoring system

ActiveCN105955157AUniform tensionMeet the requirements of special mechanical properties such as torsion resistanceProgramme controlComputer controlQuality levelHuman–machine interface

The invention discloses a stranding machine stranding tension automatic monitoring system. The system comprises a human-computer interface, a programmable controller, a tension measuring mechanism, an analog quantity collection device, a wireless communication device, an output control device and a tension adjustment executing device. The human-computer interface transmits set operation state parameters to the programmable controller and displays the process data of the programmable controller in real time. Measuring data of the tension measuring mechanism is collected by the analog quantity collection device and is transmitted to the programmable controller through the wireless communication device. The programmable controller transmits control signals to the output control device through the wireless communication device so as to control the tension adjustment executing device to adjust the tension of stranded wire core. The system has the advantages that the magnitude of the tension on each stranded wire core is measured and controlled in real time in the operation process of a stranding machine, the tension on each stranded wire core is stabilized and balanced and is maintained in a set process requirement range, the requirements of special mechanical performance on cables are met, and the quality level of the products is improved.

Owner:ZHEJIANG WANMA SPECIAL CABLE TECH CO LTD +2

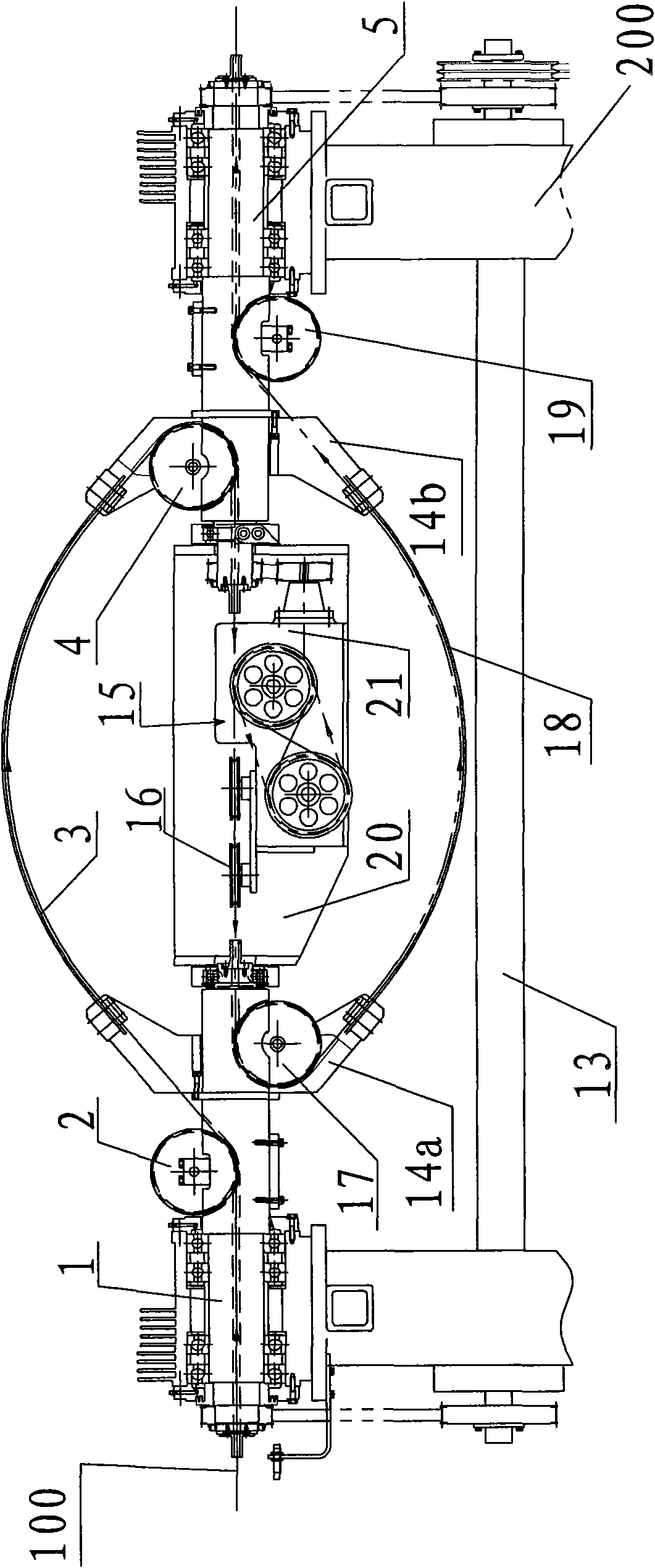

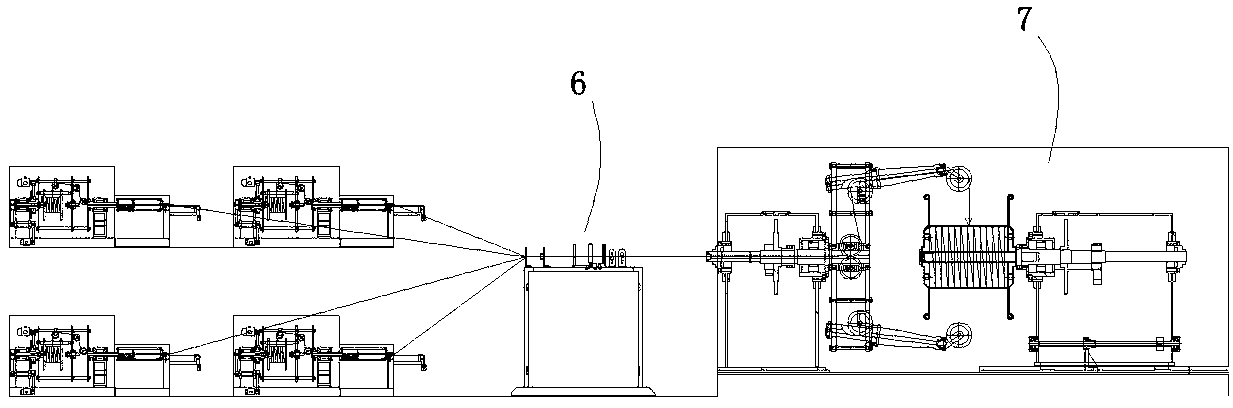

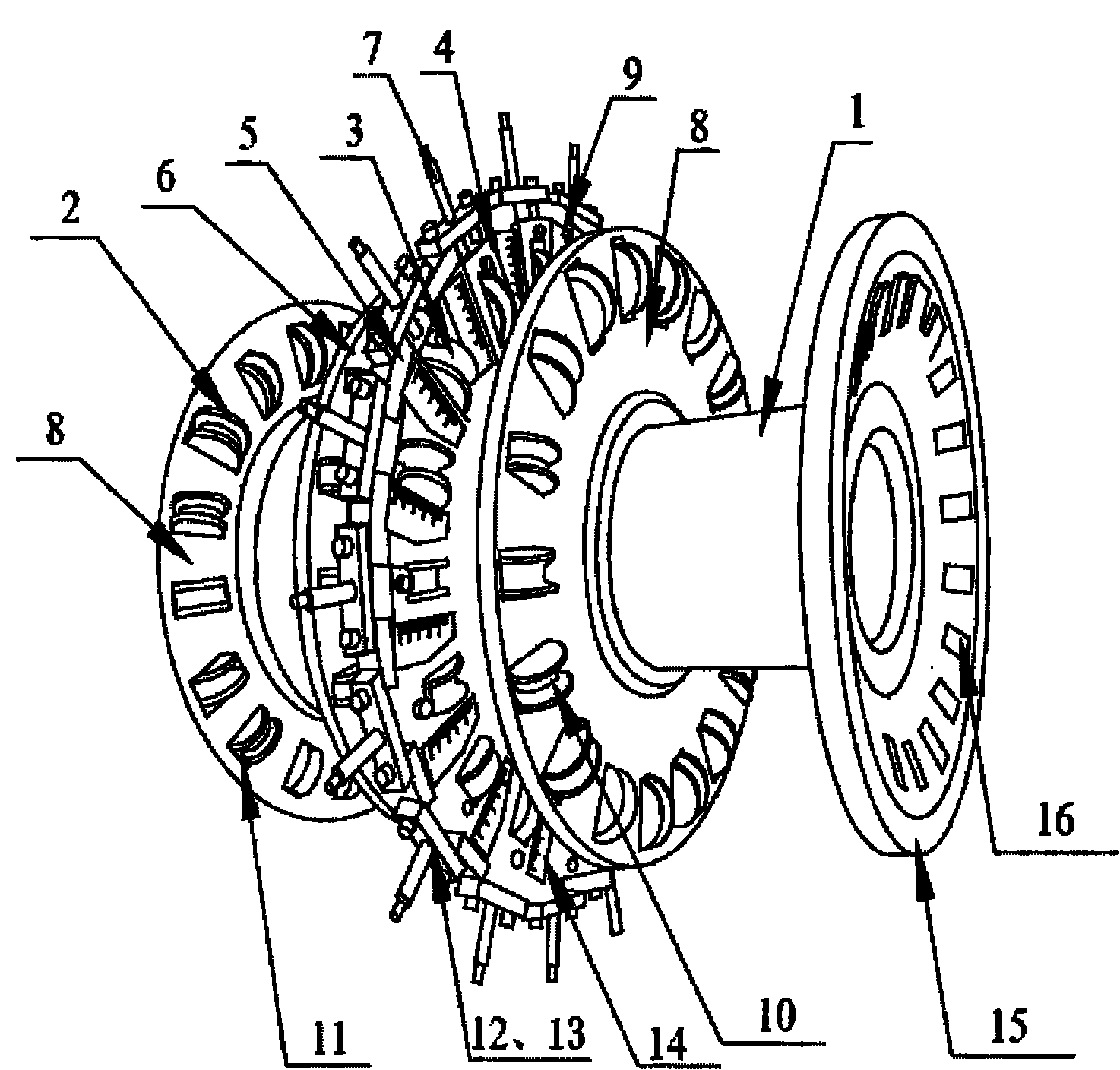

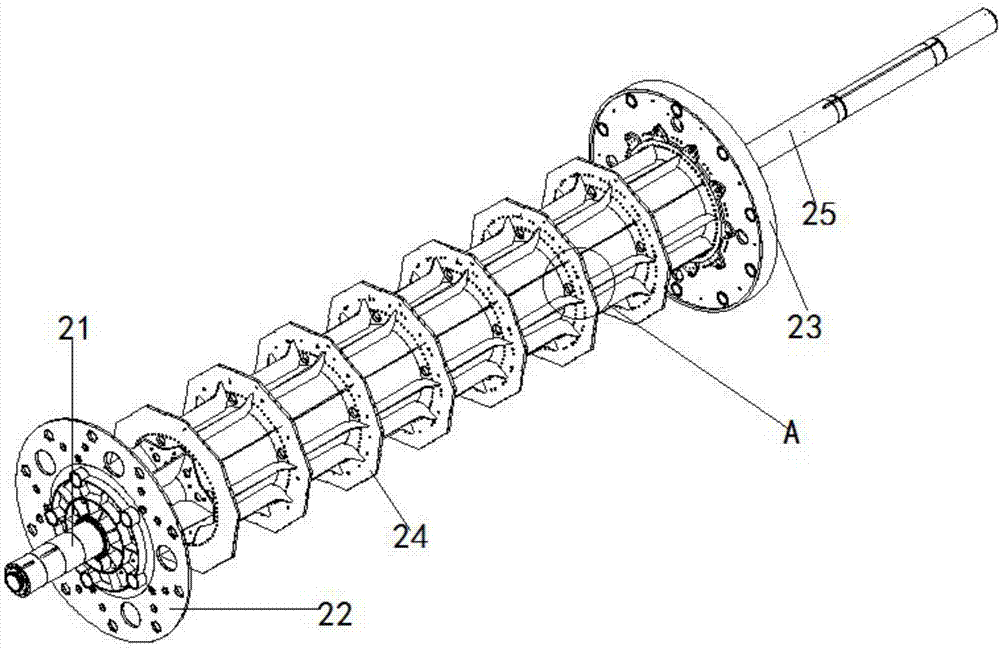

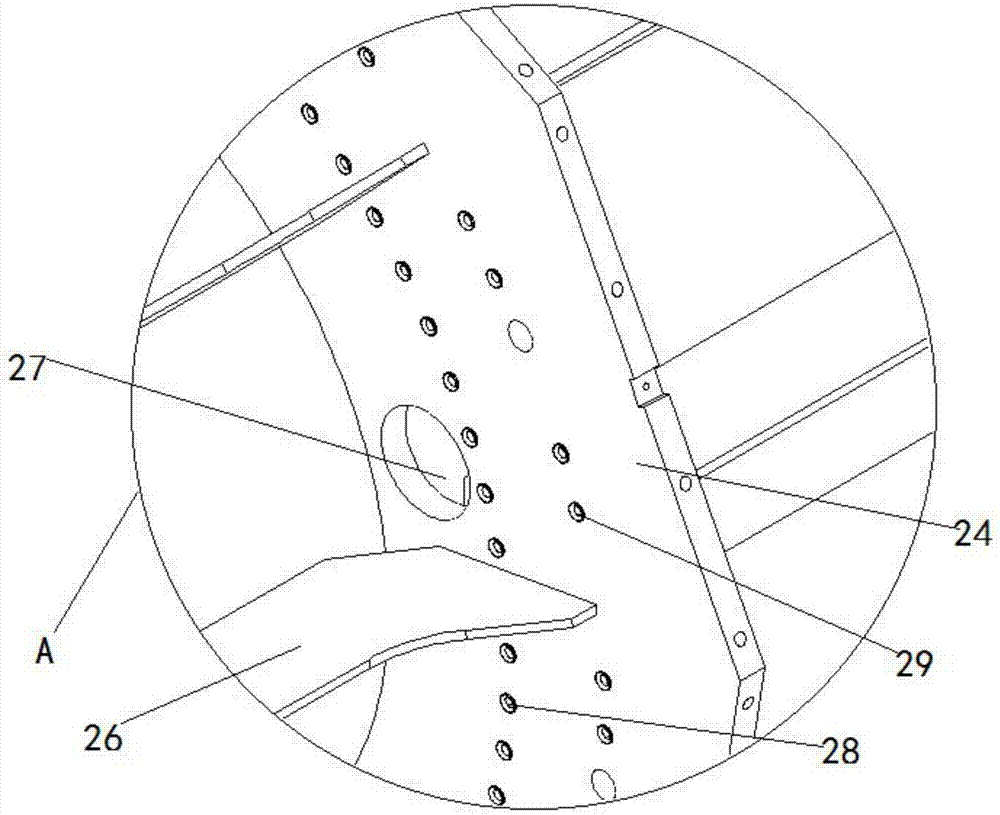

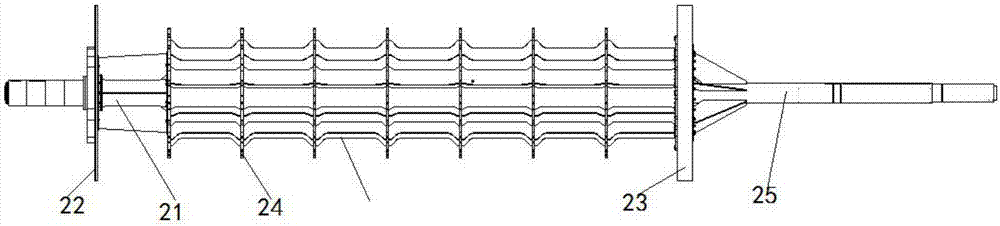

Novel multi-winch cage stranding machine

ActiveCN107275010AChange the shortcomings of insufficient quantityImprove stranding efficiencyCable/conductor manufactureEngineeringUltimate tensile strength

The invention discloses a novel multi-winch cage stranding machine including a spindle assembly. The spindle assembly includes a spindle. A rotating disc is mounted at the input end of the spindle. The output end of the spindle is coaxially connected with a pre-twisting shaft through a pre-twisting disc. A plurality of winches are equidistantly distributed along the axial direction between the rotating disc and the pre-twisting disc. Connecting plates are uniformly distributed along the circumferential direction between adjacent winches. A first wire hole group, a second wire hole group and a third wire hole group are arranged sequentially along the radius direction on the surface of each winch. Through clever design of the spindle, the rotating disc and the pre-twisting disc, the shortcoming that the traditional stranding machine has insufficient winches is changed. The novel multi-winch cage stranding machine has a simple and compact structure, and is of higher stranding efficiency. Tight, solid and reliable stranding is ensured. High mechanical strength is achieved. The novel multi-winch cage stranding machine has good economic and promotion values.

Owner:HEFEI SMARTER TECH GROUP CORP

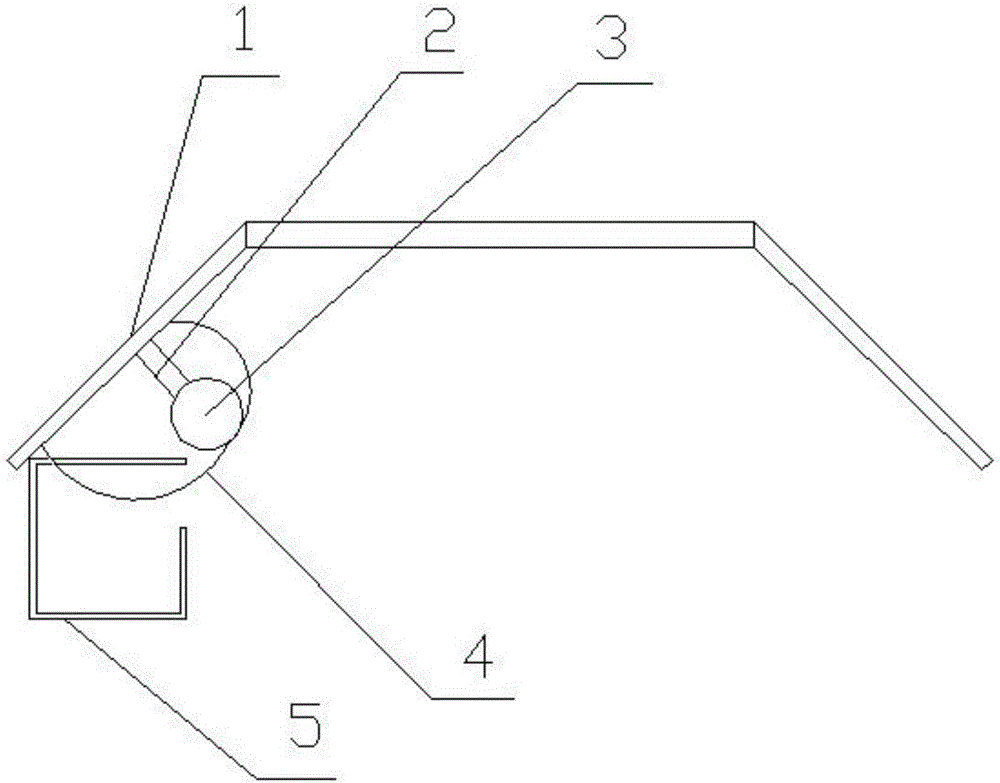

Feeding and routing apparatus used in copper wire stranding

ActiveCN105938743AAvoid breakingFeeding speed adjustmentCable/conductor manufactureCopper wireGear wheel

Te invention provides a feeding and routing apparatus used in copper wire stranding. The feeding and routing apparatus comprises a base, wherein a bracket is arranged on the base; a placement groove is formed in the bracket; the placement groove is used for placing a wire-collecting rod; a rotary gear is arranged on the right side of the placement groove; the rotary gear rotates under the drive of a rotary motor which is arranged below the rotary gear; a routing wheel is arranged above the bracket; the routing wheel is connected with the bracket though a speed regulation rod; contact sensors are arranged at the lower end of the speed regulation rod and on the bracket; the number of the contact sensors is two, and the two contact sensors are arranged above and below the speed regulation rod respectively; an angle adjustment apparatus is arranged between the speed regulation rod and the bracket; and the angle adjustment apparatus is electrically connected with the rotary motor. The bracket is used for supporting and placing a material-discharging rod; the material discharging speed is controlled by the rotary gear and the rotary motor; due to the combination of the routing wheel, the speed regulation rod and the contact sensors, the required speed of the copper wires is detected when a stranding machine is in operation; and meanwhile, the material discharging speed is adjusted, and the condition that the copper wires are pulled to be broken in the feeding process is avoided, so that the working efficiency is improved.

Owner:WUHU SHUNCHENG ELECTRONICS

Nail-prevention collector for automobile tire

A nail-prevention collector for an automobile tire comprises a storage box, a wire twister and a stranded wire, wherein the storage box is arranged on a splash guard on the front side of an automobile wheel; the wire twister is arranged above the storage box; and the stranded wire is matched with the wire twister. An electric magnet is arranged on the stranded wire. One end of the stranded wire sequentially penetrates through the side wall and the top of the storage box to be connected with the other end of the stranded wire. A through hole matched with the electric magnet is formed in the side wall of the storage box. When the collector is in use, the electric magnet is kept working constantly, and when the automobile tire encounters iron nails or other metal barriers, due to the fact that the collector is arranged on the front splash guard, the metal objects can be attracted in time through the electric magnet; and then a pressure sensor induces that a weight exists on the electric magnet, a motor is started, the wire twister operates, the electric magnet is taken to the position of an opening of the storage box, when the electric magnet passes through the opening of the storage box, an inductor at the opening induces the electric magnet when the electric magnet passes through the opening, then the electric magnet is controlled by a single-chip microcomputer to be deenergized, and the metal objects fall into the storage box.

Owner:HUAINAN UNITED UNIVERSITY +1

Hand-held stranding machine applied to enameled wire

The invention relates to a stranding machine, and in particular relates to a hand-held stranding machine applied to an enameled wire. The technical problem of the invention is how to design the hand-held stranding machine applied to the enameled wire, which can replace manual twisting of the enameled wire, save labor, can evenly twist the enameled wire, and has high work efficiency. The hand-heldstranding machine applied to the enameled wire comprises a cylinder body, a guide sleeve, a circular rod, a first gear and the like. The guide sleeve is fixedly connected with the top left side of thecylinder body. The circular rod is slidably arranged in the guide sleeve. The left end of the circular rod penetrates the middle of the left side of the cylinder body. The first gear is fixedly connected with the right end of the circular rod. According to the invention, by pushing a push plate to the right, a splint processes and clamps the enameled wire; a drive motor is initiated, and the splint is rotated to drive the enameled wire to be rotated and twisted; the enameled wire becomes a twist knot; manpower does not need to continuously rotate and twist the enameled wire, which is relatively labor-saving; the twisted enameled wire is more uniform; and the work efficiency is high.

Owner:恒达传动禹城有限公司

Stranding machine for cable production

ActiveCN111785451AAchieve fixationEasy to fixFilament handlingCable/conductor manufactureStructural engineeringElectric cables

The invention discloses a stranding machine for cable production. The stranding machine comprises a base, a stranding device, a coiling device and a communication block, wherein the stranding device and the coiling device are fixed on the base; the communication block is located between the stranding device and the coiling device, the bottom face of the communication block is fixedly connected with a supporting rod, the lower end of the supporting rod is fixed to the base, a control box is further fixed to the base, the stranding device comprises a stranding box, and a stranding cavity is formed in the stranding box. According to the stranding machine, the pay-off wheel placed on a pay-off rod can be fixed conveniently, when a cable on the pay-off wheel is used up and needs to be replaced,a valve on a rotary disc is opened at the moment, compressed air is exhausted, a sliding block is collected into an air channel under the action of the spring, and the pay-off wheel is convenient toreplace.

Owner:JING FENG GRP

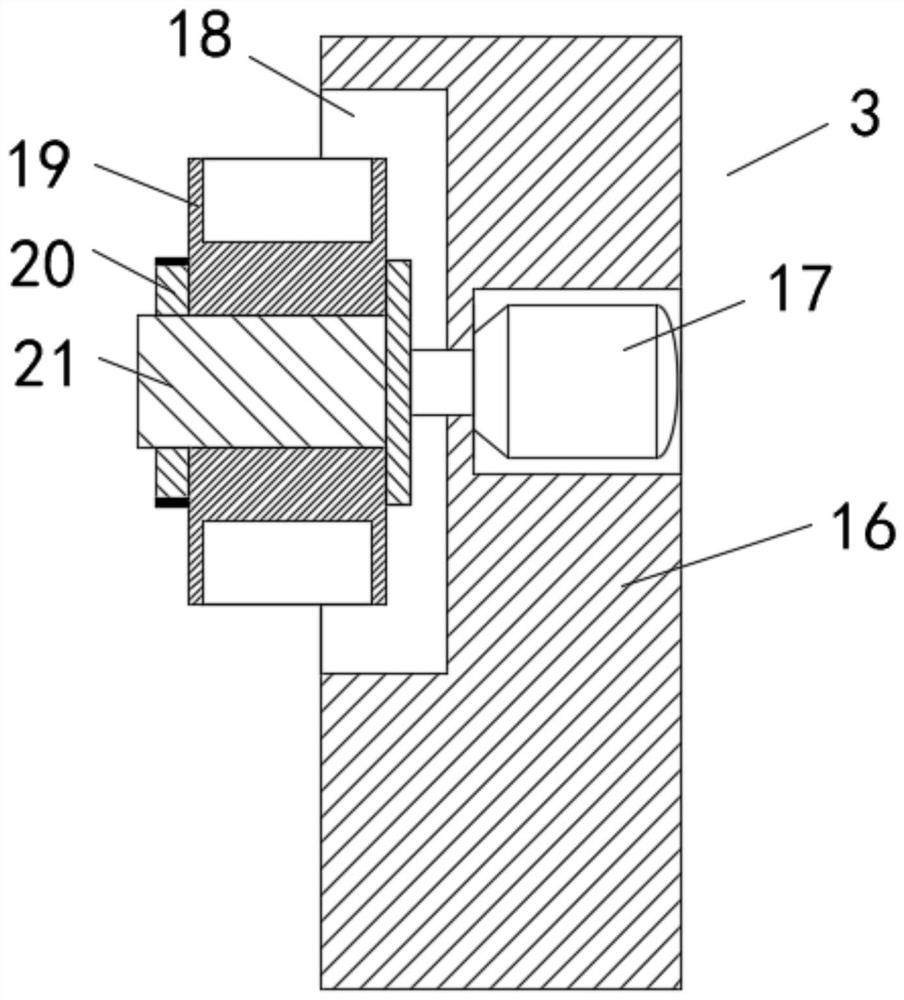

Voltage-stabilizing driving device of wire twister

InactiveCN101847916ALow movement resistanceGuaranteed working accuracyManufacturing dynamo-electric machinesEngineeringCylinder block

The invention discloses a coil wire twisting device which is characterized by comprising a pedestal, a left twisting arm, a right twisting arm, a twisting arm power mechanism, a reset cylinder and a compression spring, wherein the twisting arm power mechanism is provided with a first rotating wheel which is installed on the pedestal through a bearing, and a left rotating arm and a right rotating arm are installed on the first rotating wheel, one end of the first rotating wheel is connected with the first rotating wheel, the other end is articulated with the left twisting arm, one end of the right rotating arm is connected with the first rotating wheel, and the other end is articulated with the right twisting arm; the cylinder body of the reset cylinder is fixed on the left twisting arm, and a piston push rod of the reset cylinder is fixedly connected with the right twisting arm; and the compression spring is connected between the cylinder body and the piston push rod of the reset cylinder. The invention has the advantages that an original coil can be rapidly and effectively twisted and pressed, the consistency of products can be improved, a stable and reliable coil sheet is provided for a subsequent rounding process, and the coil wire twisting device is stable and reliable and has the advantages of long service life and high precision.

Owner:CHONGQING KNVAN ELECTRONICS

Manual bamboo fence baffle knitting machine

InactiveCN102371607AUnified specificationsSimple structureCane mechanical workingSprocketSlide plate

The invention discloses a manual bamboo fence baffle knitting machine, comprising a machine frame, a knitting mechanism which is arranged on the machine frame, an arc-shaped sliding plate, a kick-out mechanism and an iron wire turntable assembly; the knitting mechanism at least comprises three groups of parallel wire twisters; and each group of the wire twisters consist of a lower base, a driving wire twisting shaft which is connected onto the lower base in a matching mode, a driving gear and a double-chain wheel which are connected onto the driving wire twisting shaft in the matching mode, a driven wire twisting shaft which is connected onto the lower base in the matching mode, and a driven gear which is matched on the driven wire twisting shaft; the double-chain wheels on the two adjacent wire twisters are matched and connected through a chain; two axial wire passing slots are arranged on cylindrical surfaces of both the driving wire twisting shaft and the driven wire twisting shaft; a plurality of galvanized iron wires penetrate through the wire passing slots one by one. The manual bamboo fence baffle knitting machine has a simple structure and low manufacturing cost; as mechanical transmission and twisted knitting are adopted, knitted bamboo fences have consistent specifications and stable quality; and as manual driving is adopted, a knitting speed can be manually controlled; thereby, the knitting machine not only has simple operation, but also has high safety and reliability and high production efficiency.

Owner:重庆市江津区渝铁竹帘加工厂 +2

Fire-proof-data-bus preparation technology and cable

InactiveCN108565046AImprove the living environmentImprove and enhance physical and mechanical propertiesNon-insulated conductorsPlastic/resin/waxes insulatorsCopper conductorCross-link

The invention discloses a fire-proof-data-bus preparation technology and a cable. In the fire-proof-data-bus preparation technology, tinned copper conductors are stranded through a wire-and-cable stranding machine or a bunching machine, skin-foam-skin low-medium-loss polyethylene insulation is extruded through a cable extruding machine outside the conductors, and is subjected to irradiation crosslinking through an electron accelcrator to serve as insulation layers, low-medium-loss polyethylene is extruded through cable equipment, and is subjected to irradiation crosslinking through the electron accelcrator to serve as insulation wire cores and filling cores, the insulation wire cores are wrapped with calcined mica tapes, and the insulation wire cores wrapped with the calcined mica tapes and the filling cores are stranded together through a cable former; the calcined mica tapes and a combined shielding layer are arranged on outer layers of insulation layers wrapped with the calcined mica tapes and the filling cores, the combined shielding layer is formed by longitudinally wrapping aluminum foils and is formed by weaving tinned copper wires through a weaving machine, and a drain wireis arranged between two layers of shields; a low-smoke-zero-halogen cross-linked polyolefin material is extruded outside the shields and is irradiated through the electron accelcrator to serve as a protection layer. The cable has the fire-proof capacity of the flame-retardant and the fire-proof cable, and when the cable is directly and continuously burned through flames, a short circuit or an open circuit does not occur.

Owner:NANJING QUANXIN CABLE TECH

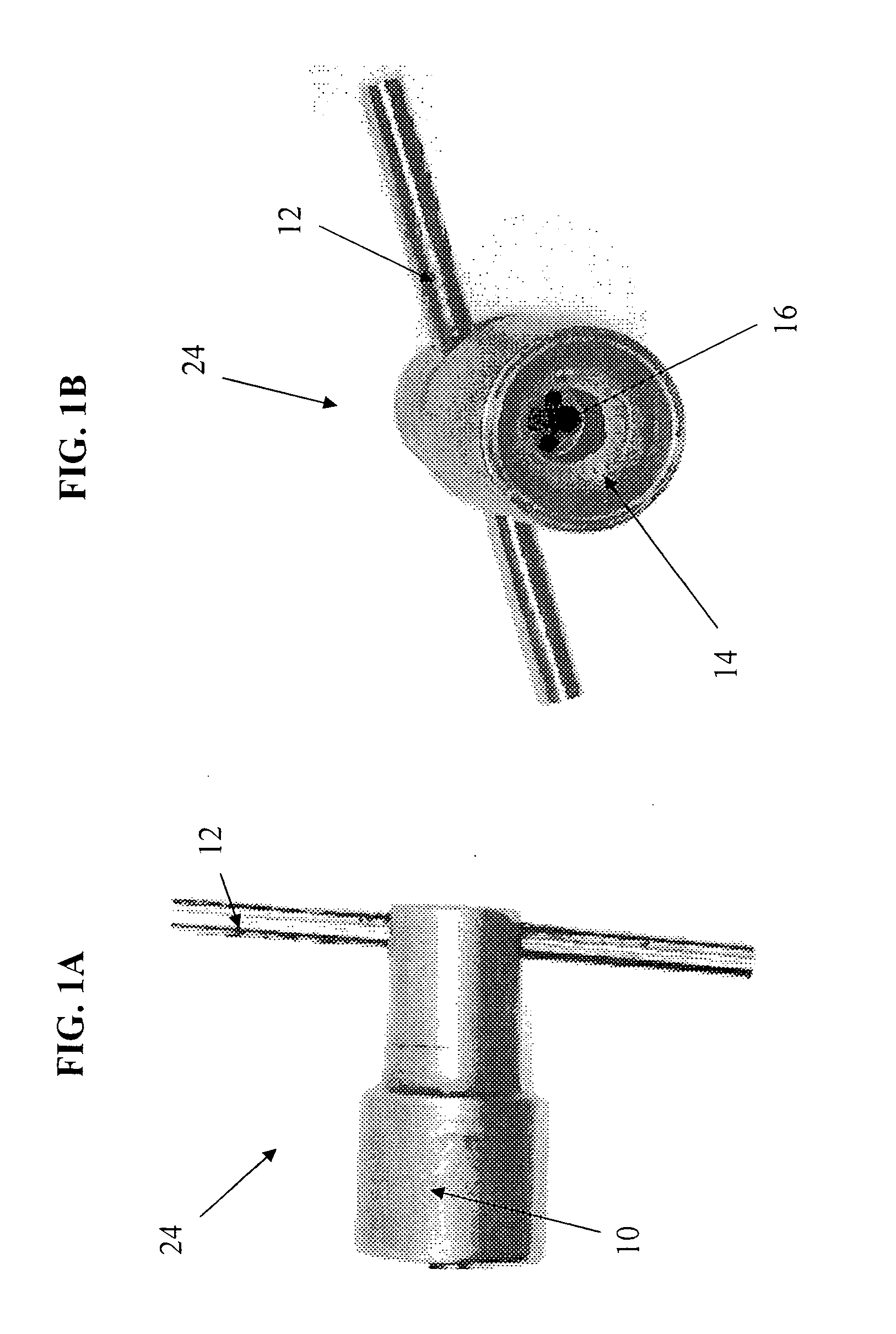

E-Z wire twister

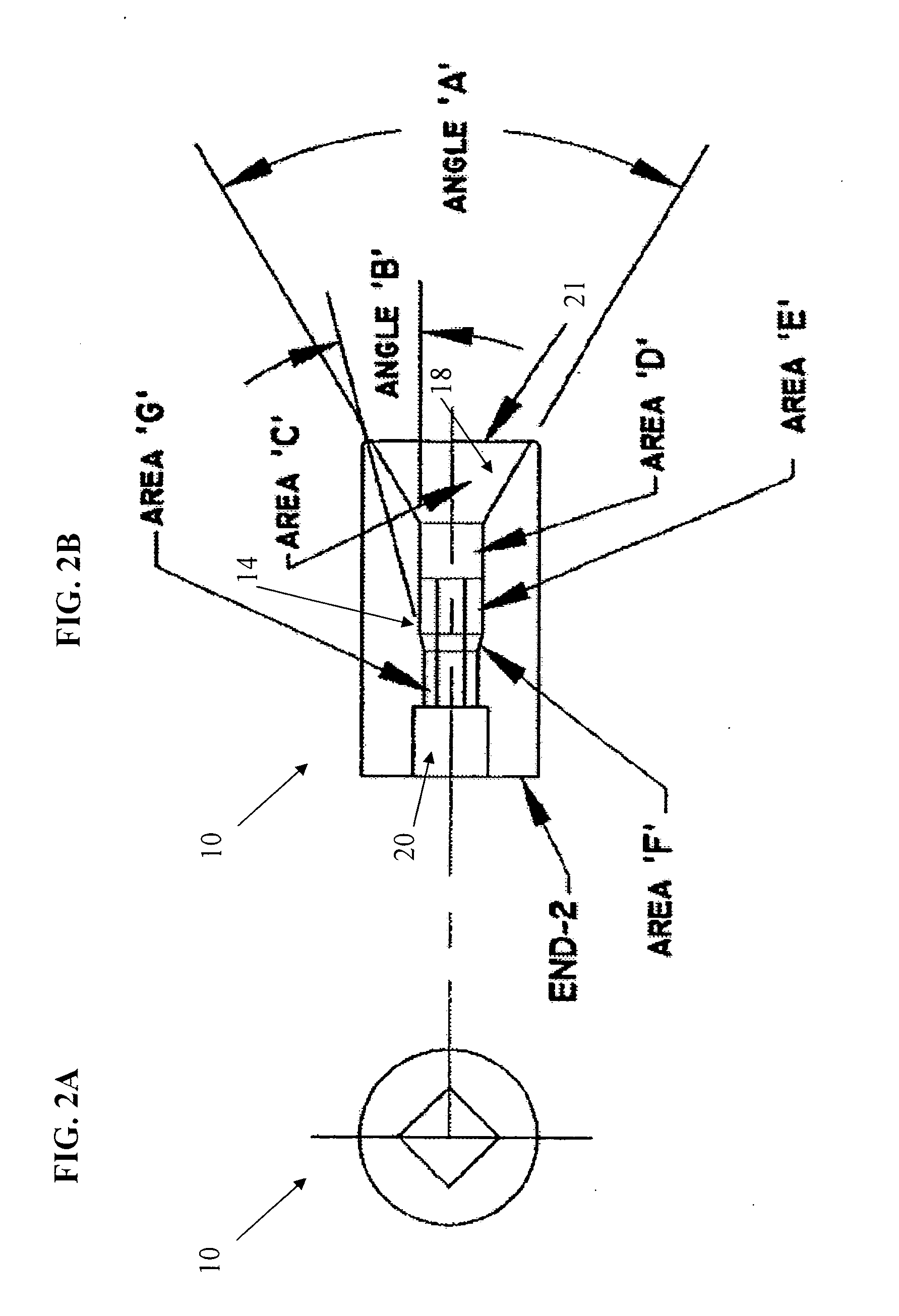

InactiveUS20070215233A1Widen meansLine/current collector detailsConnections effected by permanent deformationWire rodFixed position

The present invention relates to a tool for twisting a plurality of wires together. The tool includes a body portion having a cavity that includes a plurality of contiguous openings to receive a plurality of wires. The tool also includes a gripping portion for gripping the tool. The body portion holds the plurality of wires in a fixed position relative to one another. Rotation of the gripping portion in a clockwise or counterclockwise direction rotates the body portion in a clockwise or counter clockwise direction thereby twisting the plurality of wires together. The gripping portion may be a rod that can be is inserted substantially perpendicularly into the body portion.

Owner:DEFRANCE ROBERT VICTOR

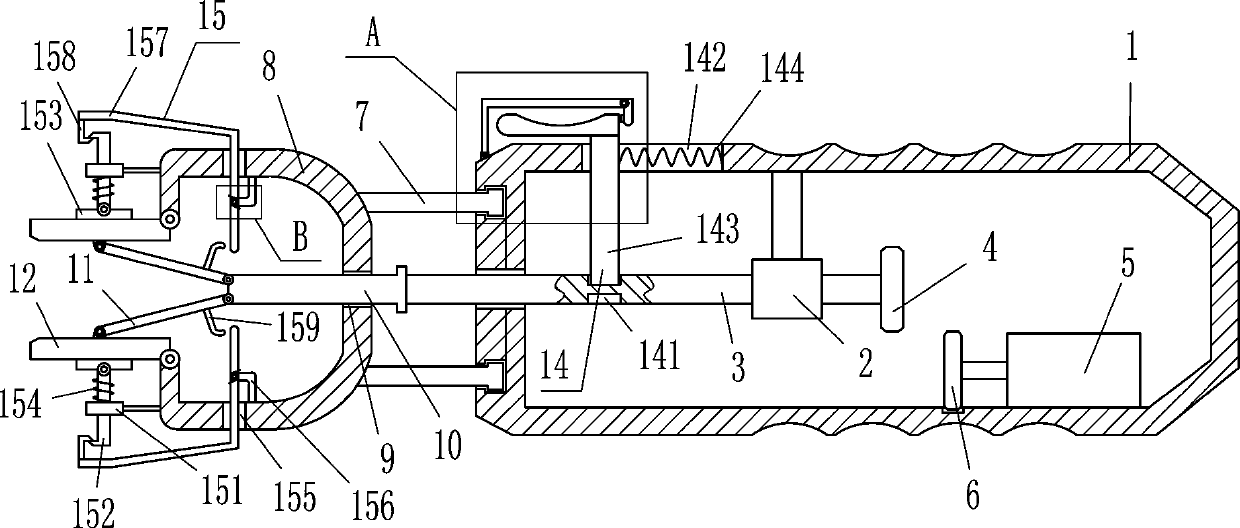

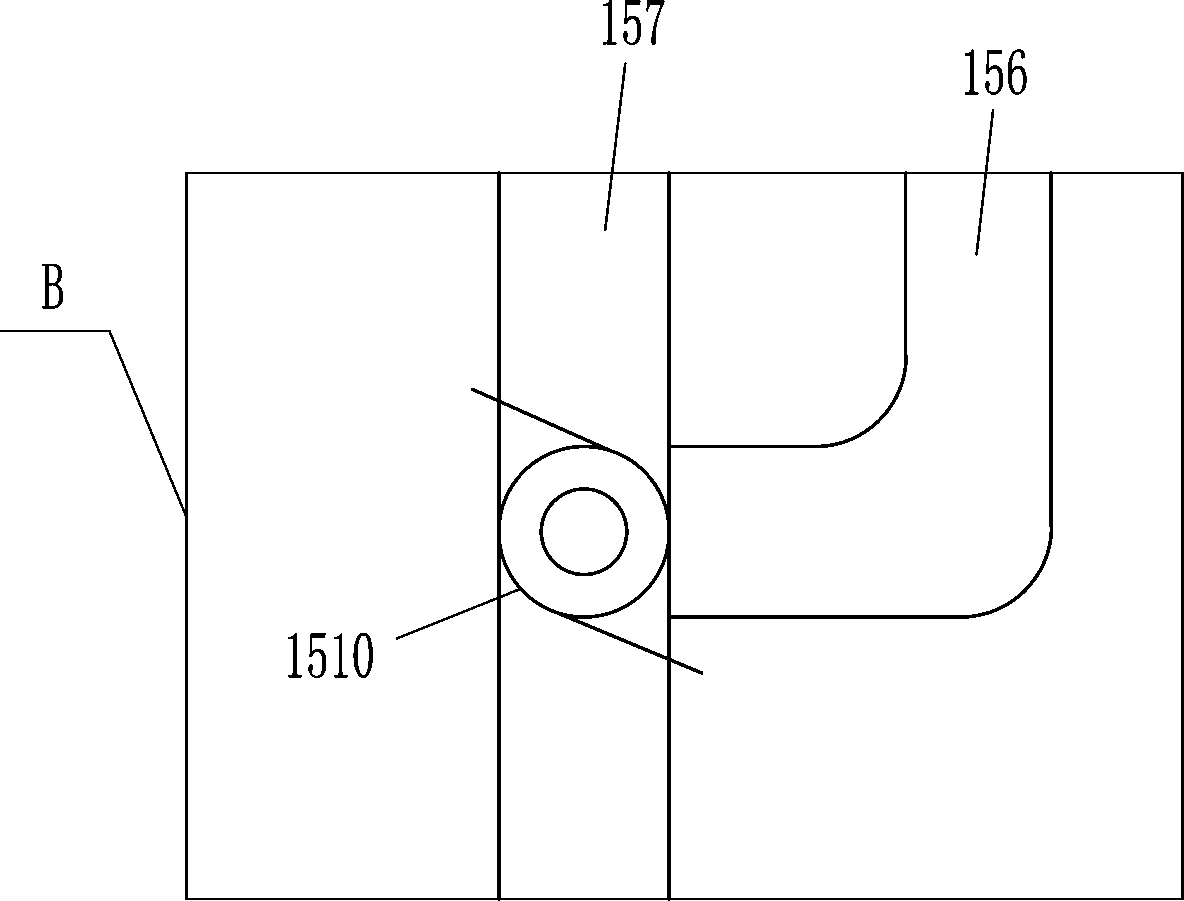

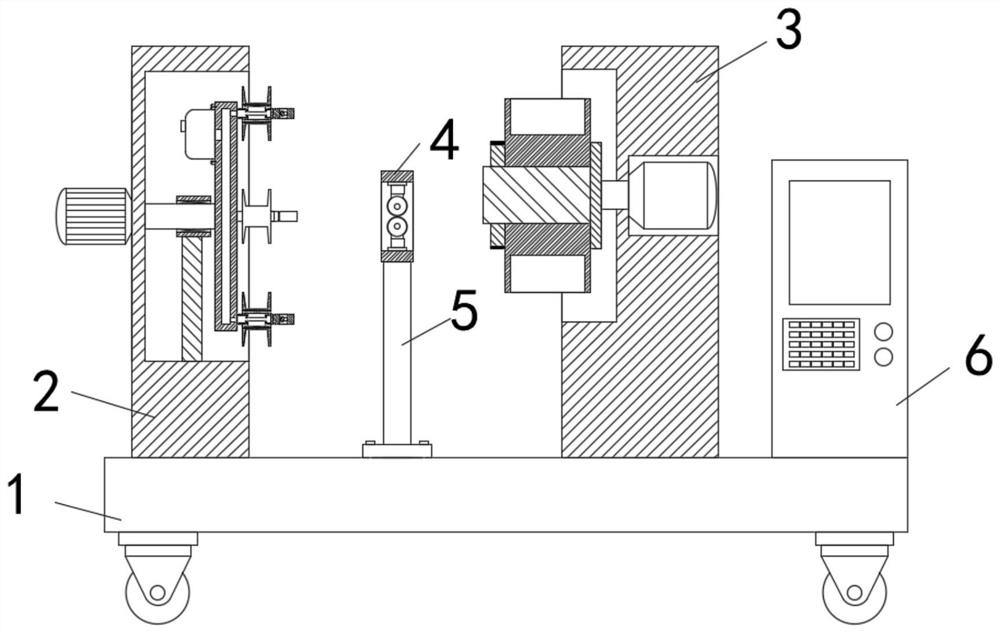

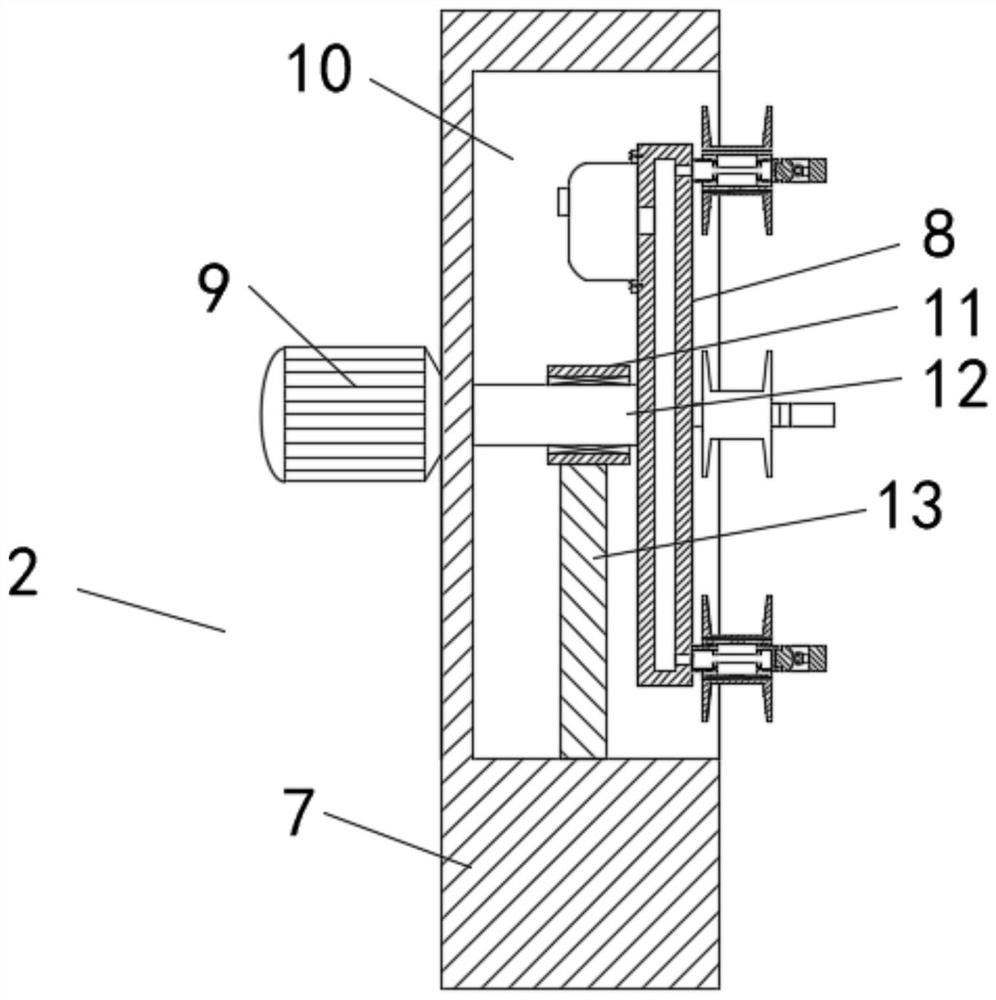

Flexible transmission tubular wire twisting machine

The invention discloses a flexible driving tube stranding machine which comprises a rotating stranding body, a gear box end bearing pedestal, a tail end bearing pedestal, support riding wheels and a base; the gear box end bearing pedestal and the tail end bearing pedestal are arranged at the two ends of the base and oppositely correspond to each other; the two ends of the rotating stranding body are respectively provided with a supporting axle; the supporting axles are supported on the gear box end bearing pedestal and the tail end bearing pedestal; the waist part of the rotating stranding body is provided with a plurality of riding wheel runways axially distributed; the support riding wheels are arranged on the base and have the same number as the riding wheel runways; each support riding wheel correspondingly supports a riding wheel runway; the rotating stranding body is formed by connecting a plurality of tube sections; a connection point is arranged between every two adjacent tube sections, and at least one connection point is connected by using a flexible pin coupling; the coupling is provided with a bearing and a bearing pedestal; the bearing pedestal is supported on the base, and the bearing is a deep groove ball bearing. Compared with the existing tube stranding machine, the flexible driving tube stranding machine can further improve the technical performance of the stranding machine and improve the rotation speed and the production efficiency under the preconditions of simplifying the structure, reducing the precisions of processing, assembly, installation, debugging and maintenance.

Owner:德阳东佳港智能装备制造股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com