Wire winding machine

A stranding machine and stranding technology, applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve the problems of bulky stranding machines, inconvenient operation, increased equipment costs, etc. Good stability and the effect of increasing the number of wire racks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

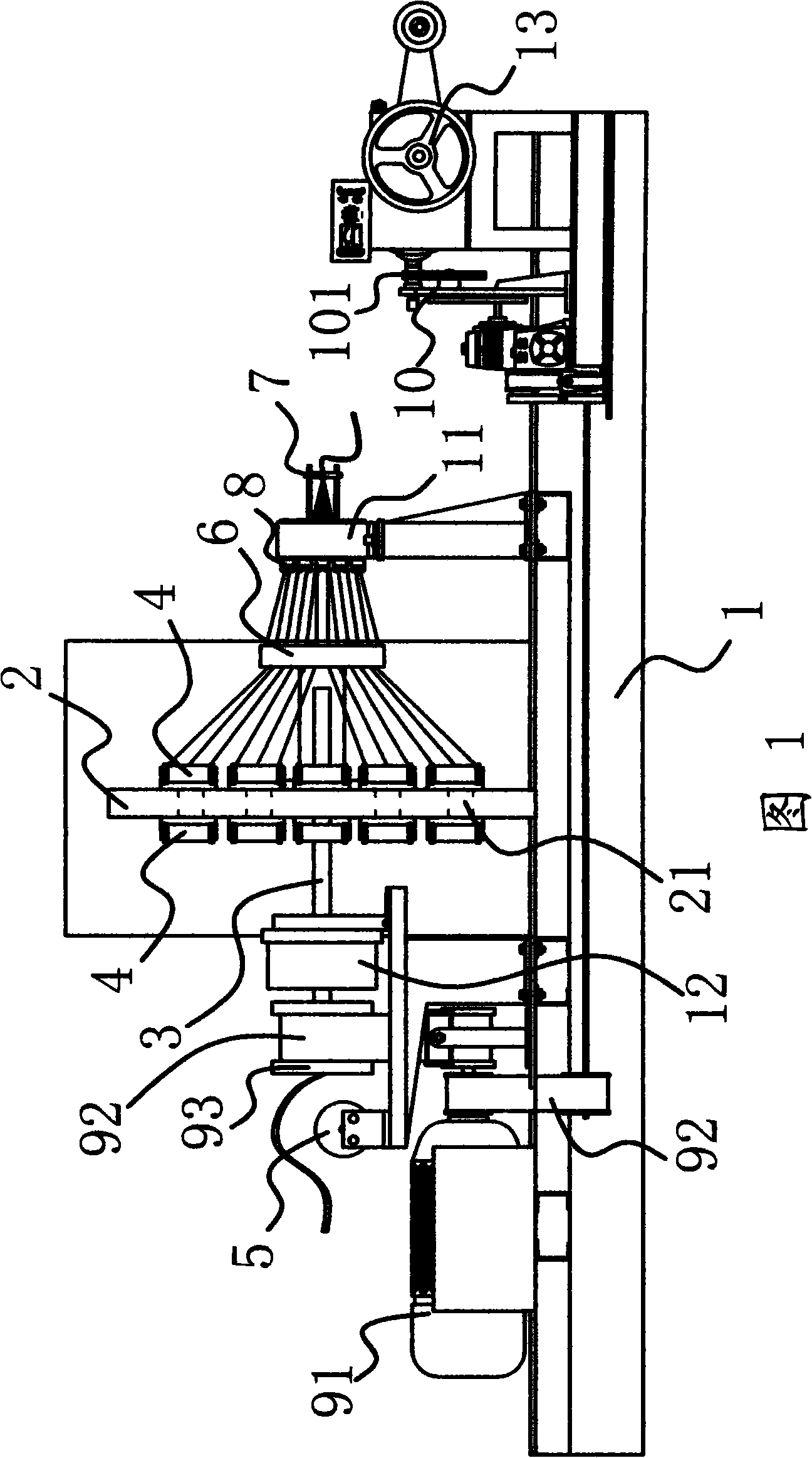

[0020] As shown in FIG. 1 , the stranding machine includes a frame 1, a wire reel plate 2 arranged on the frame 1, and a rotating shaft 3 that can rotate relative to the frame 1 is fixed in the center of the wire installation plate 2. The One end of the rotating shaft 3 is connected with the driving mechanism, and the other end is rotatably connected with the twisted wire seat 11 on the frame 1 . One end of the above-mentioned rotating shaft 3 passes through the stranded wire seat 11 and a stranded wire eye mold 7 is installed at the end of the rotating shaft 3 . A wire take-up device fixed on the frame 1 is provided on the side of the wire reel plate 2 . The wire take-up device includes a wire take-up reel 13 fixed on the frame 1 . A wire baffle 6 fixed on the rotating shaft 3 is provided between the wire reel plate 2 and the wire take-up device. The stranding eye mold 7 , the stranding seat 11 , and the wire baffle 6 are located on the same side of the wiring reel plate 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com