Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about "Loading equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

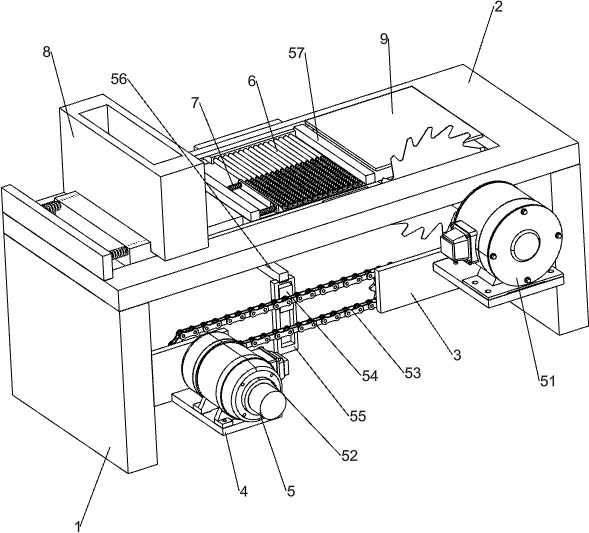

Timber selecting and chopping method and selection chopping saw therefor

InactiveCN1827319AIncrease productivityImprove operating rateLoading equipmentAdjusting equipmentComputer science

The invention discloses a timber optimized truncate method and relative optimized truncate saw. First, inputting the saw data list which comprises target saw length and quality parameters into the computer; when the sawed timber that longitudinally supplied passes the position relative to the detecting device, the detecting device reads the information of sawed timber into the computer, and the computer according to the input saw data list and said information to select the optimized sawing method; the saw machine according to said method processes truncating on the timber. Two sides of said truncate machine individually have a feeding platform and a finished product classifying platform; wherein, said feeding platform has a detecting device; said finished product classifying platform has a finished product classifying device; and a waste removing device is arranged between them.

Owner:JIANGSU JIANGJIA MACHINERY

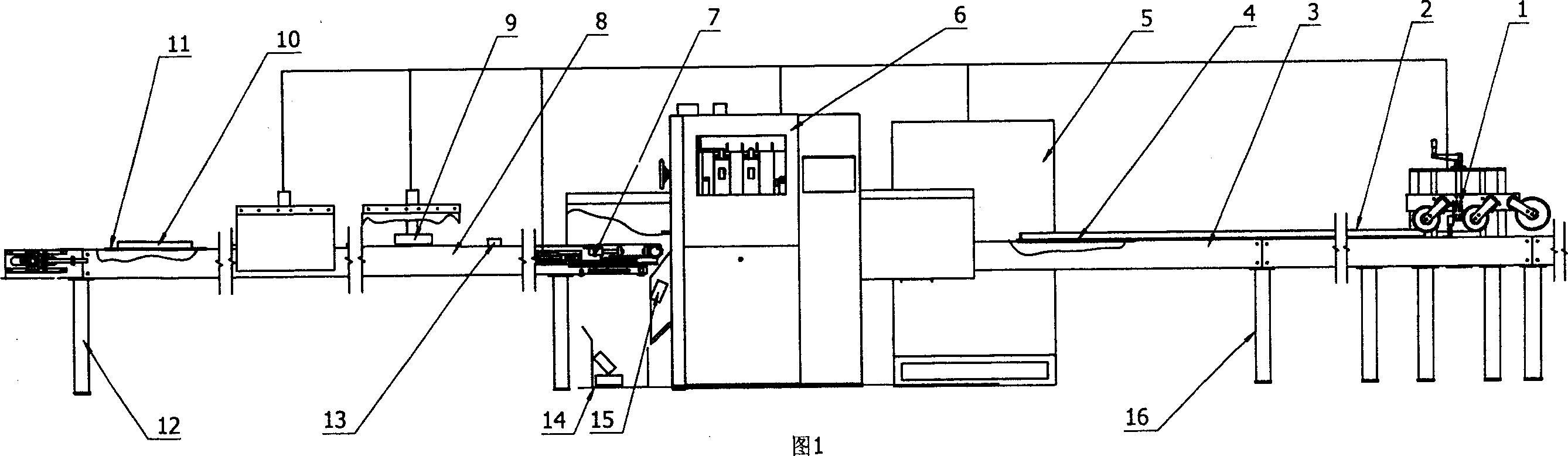

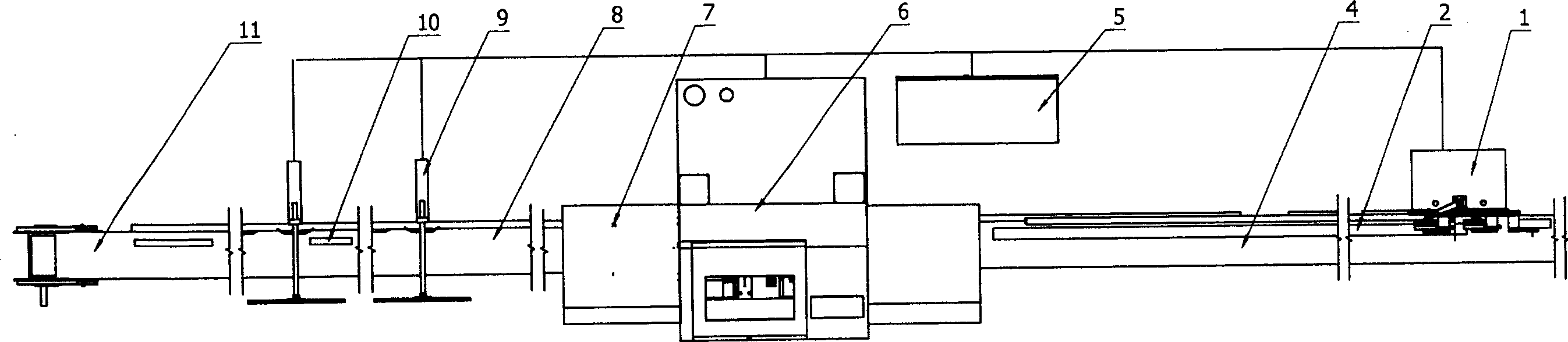

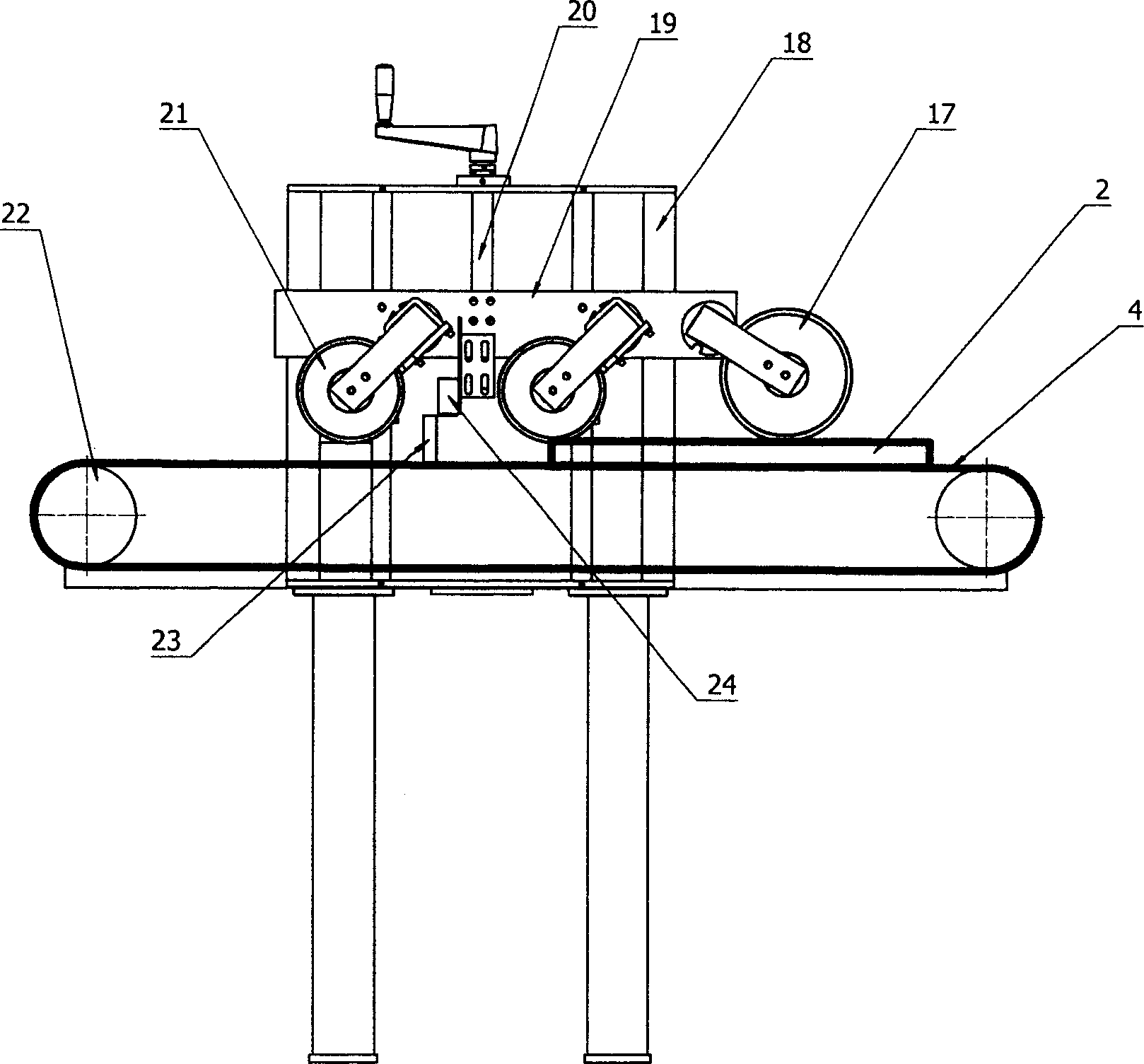

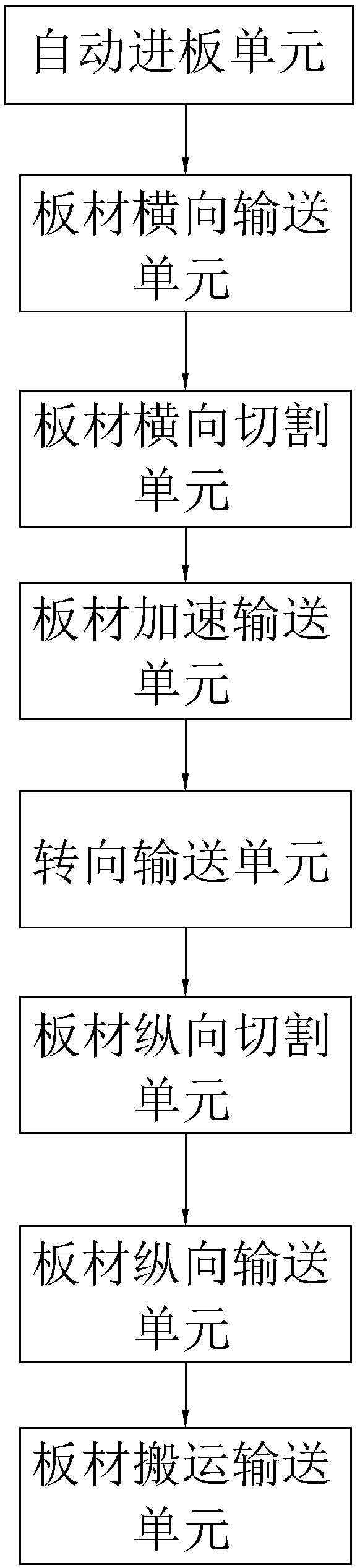

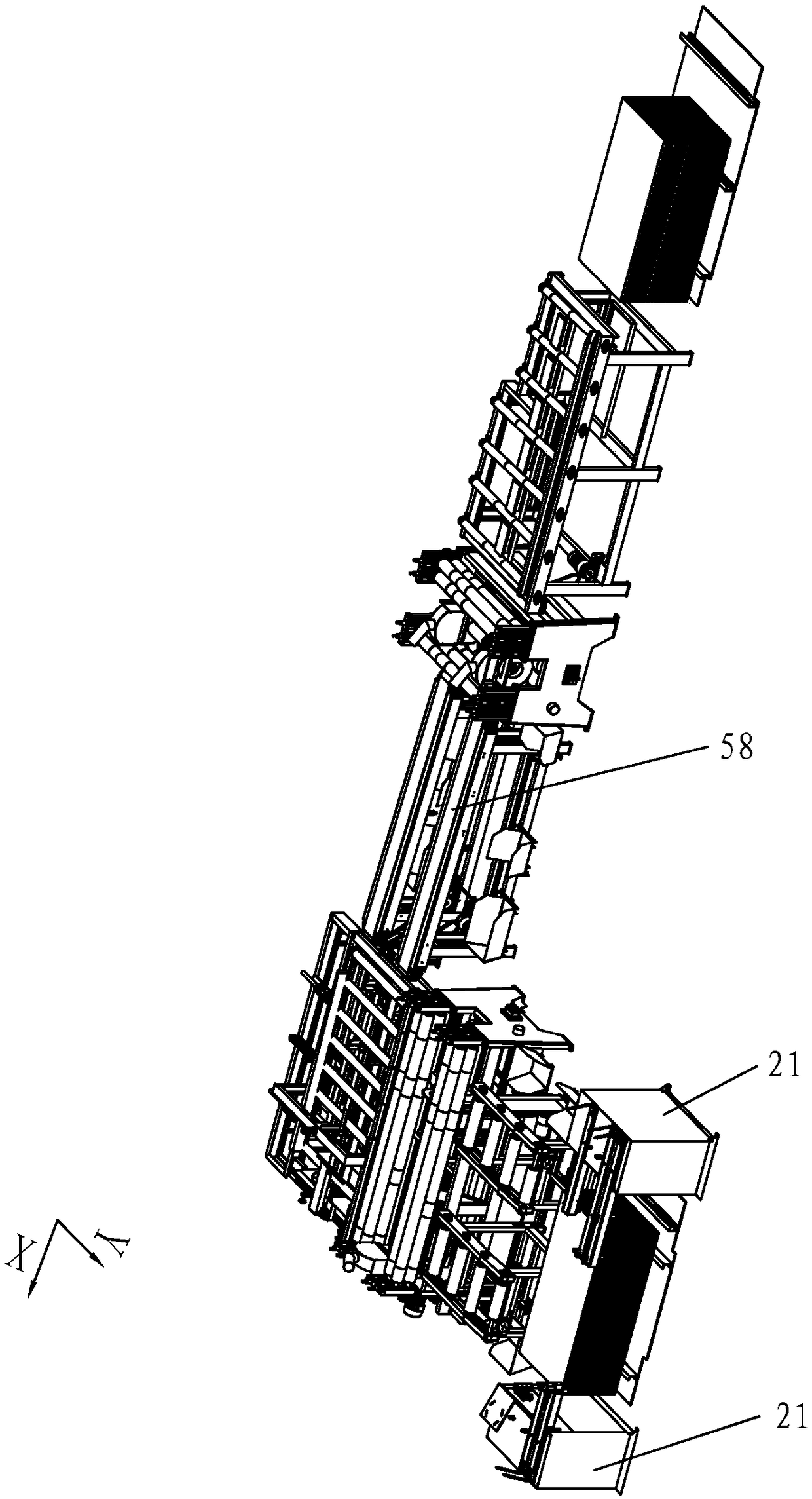

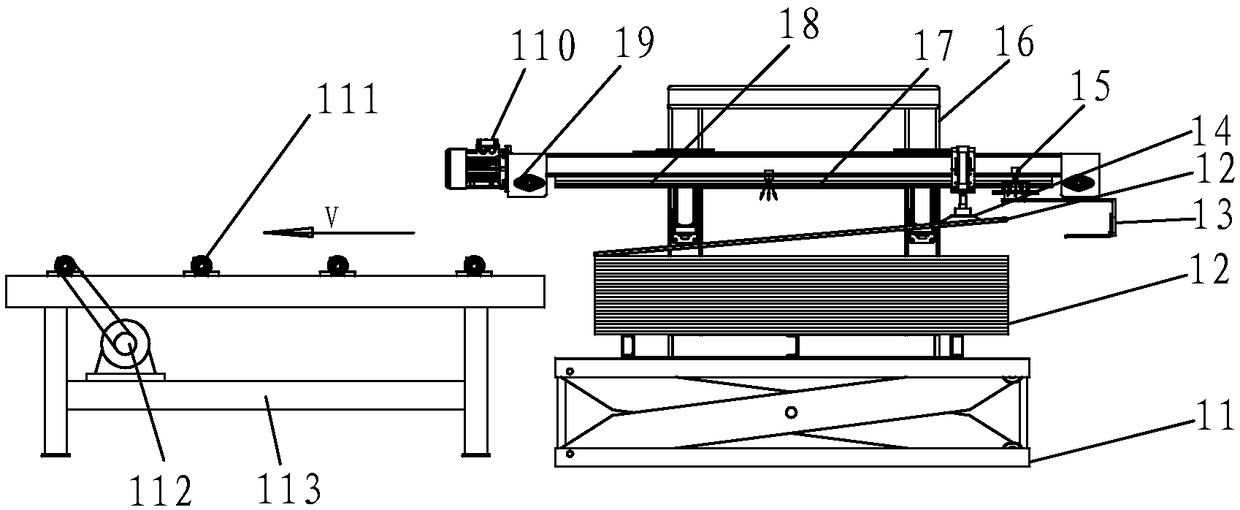

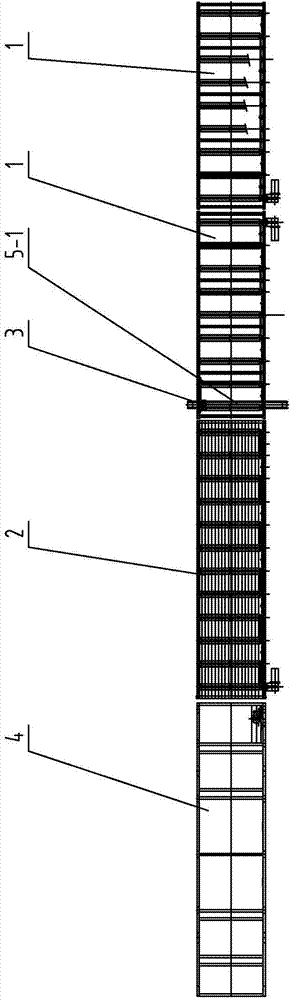

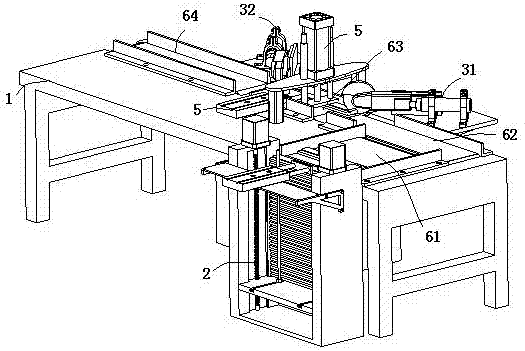

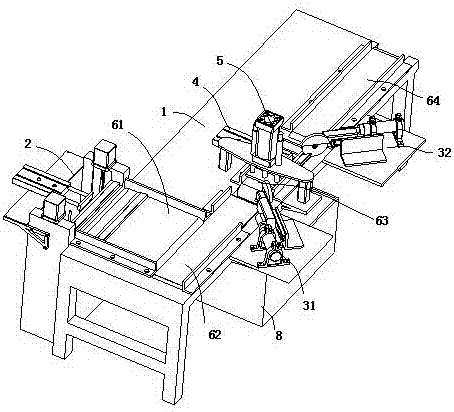

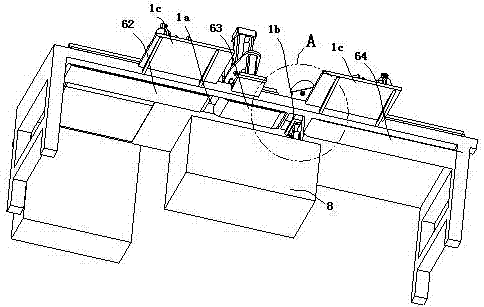

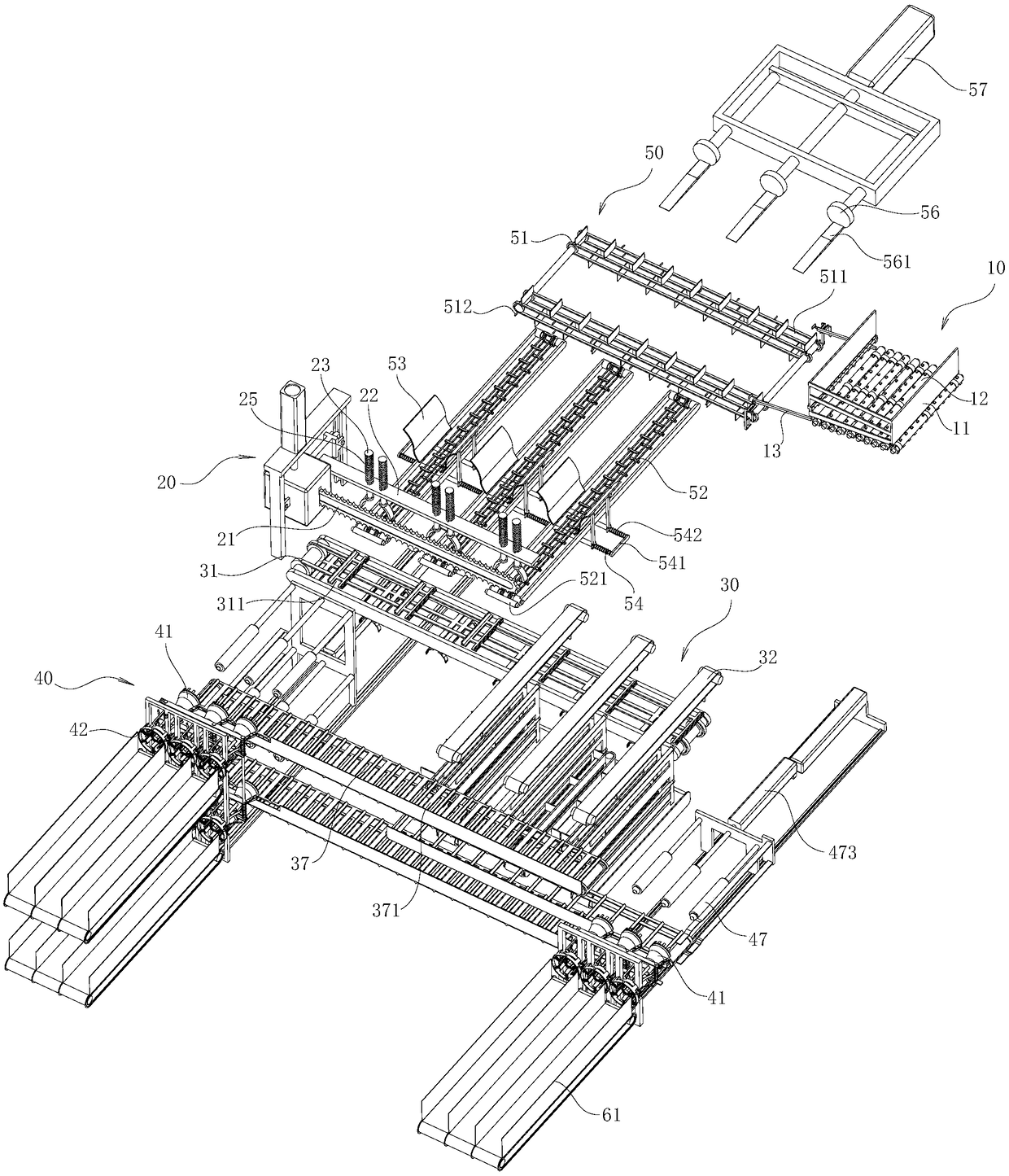

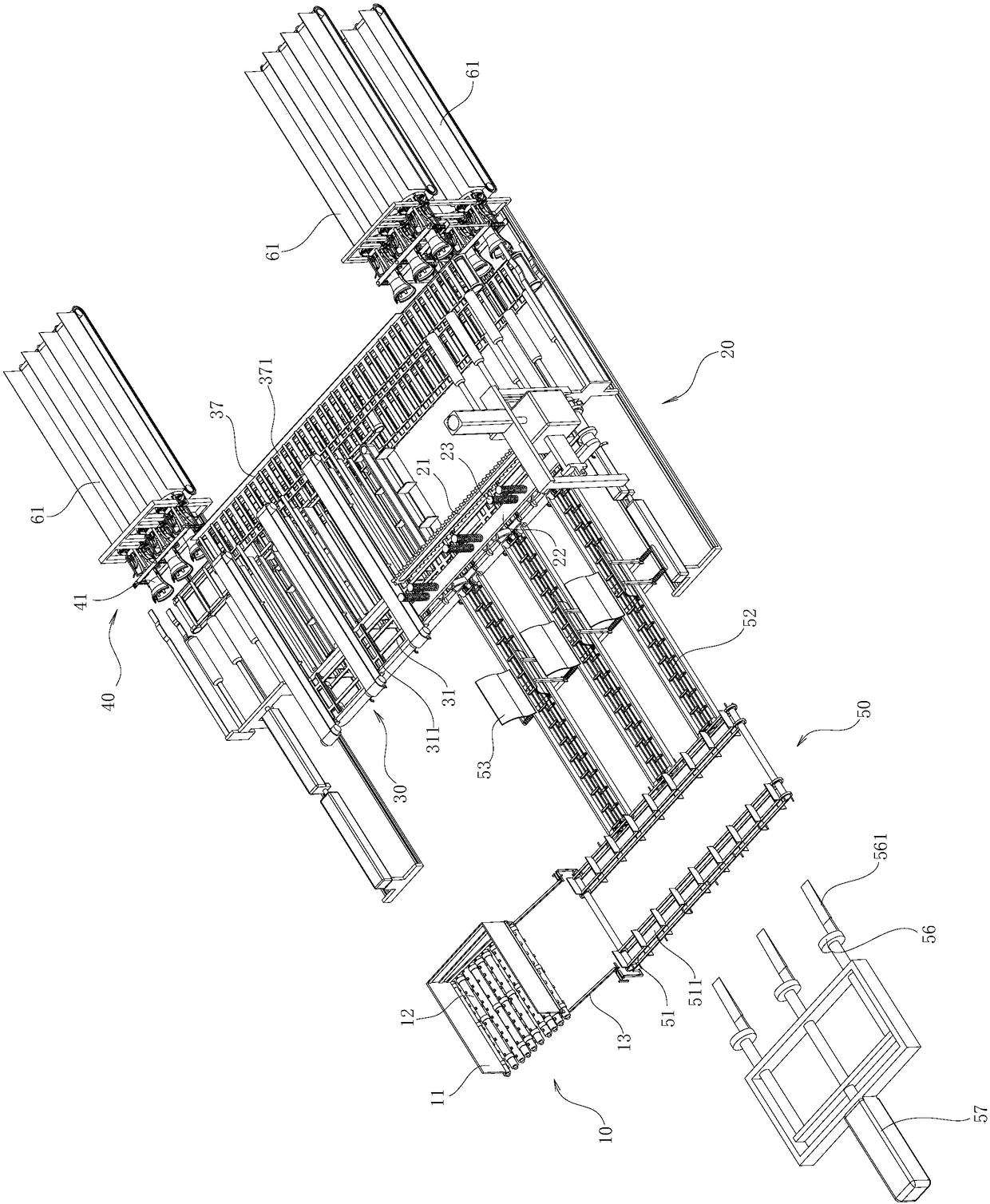

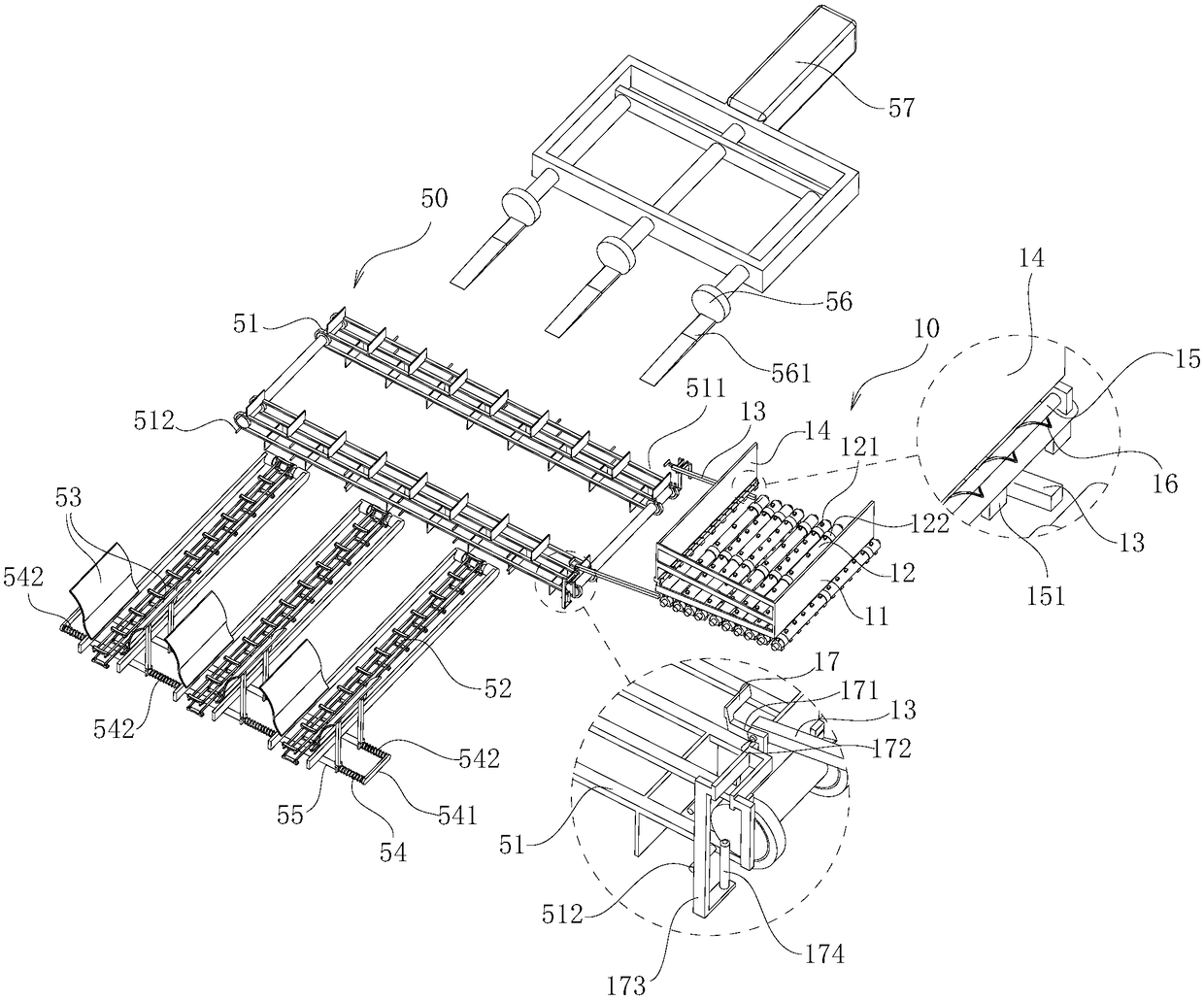

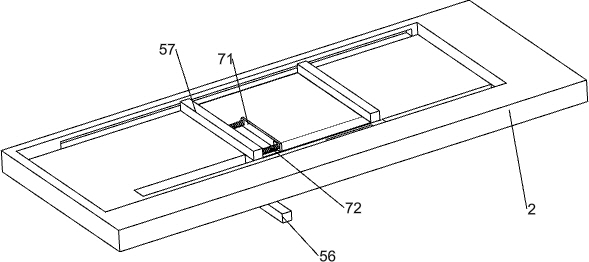

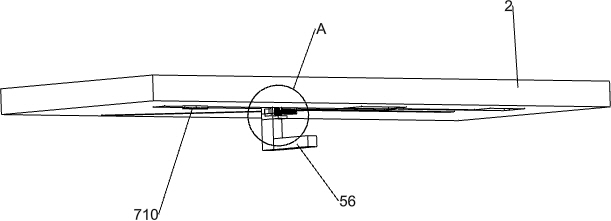

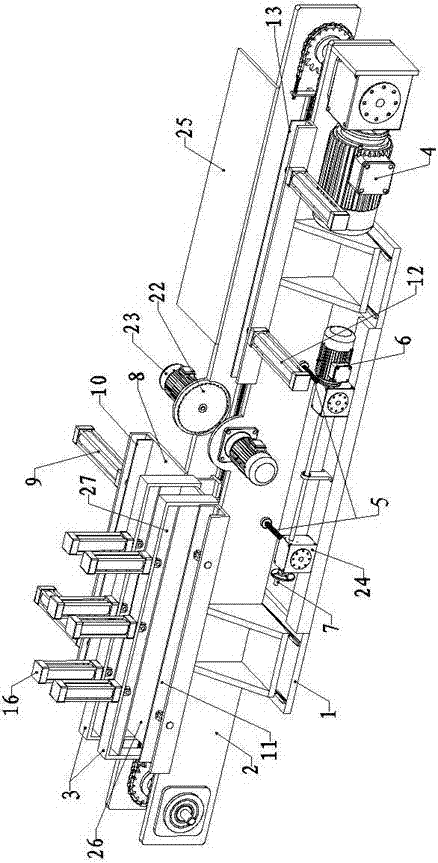

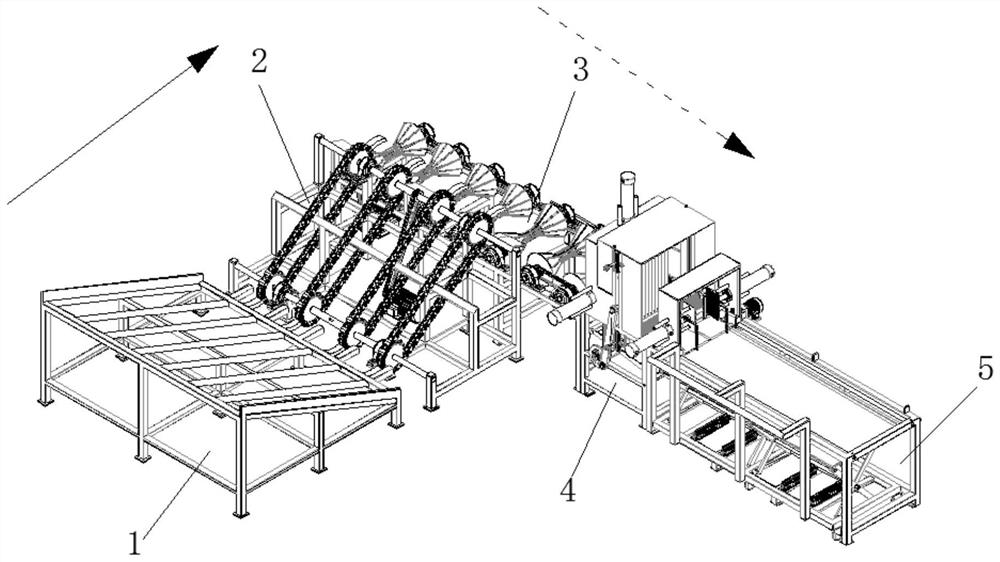

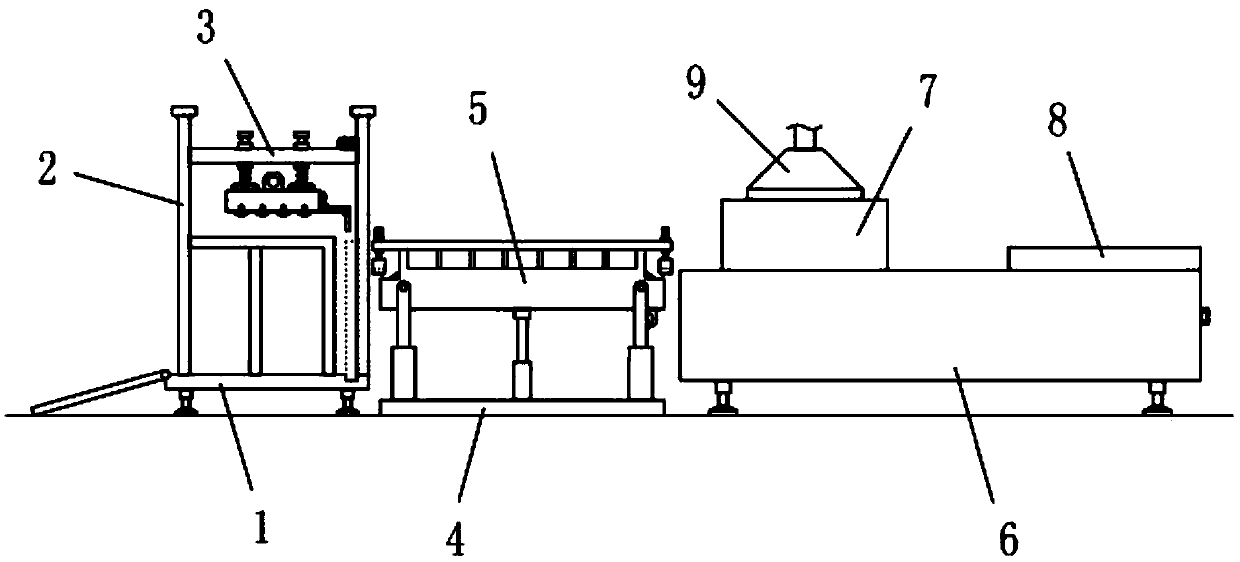

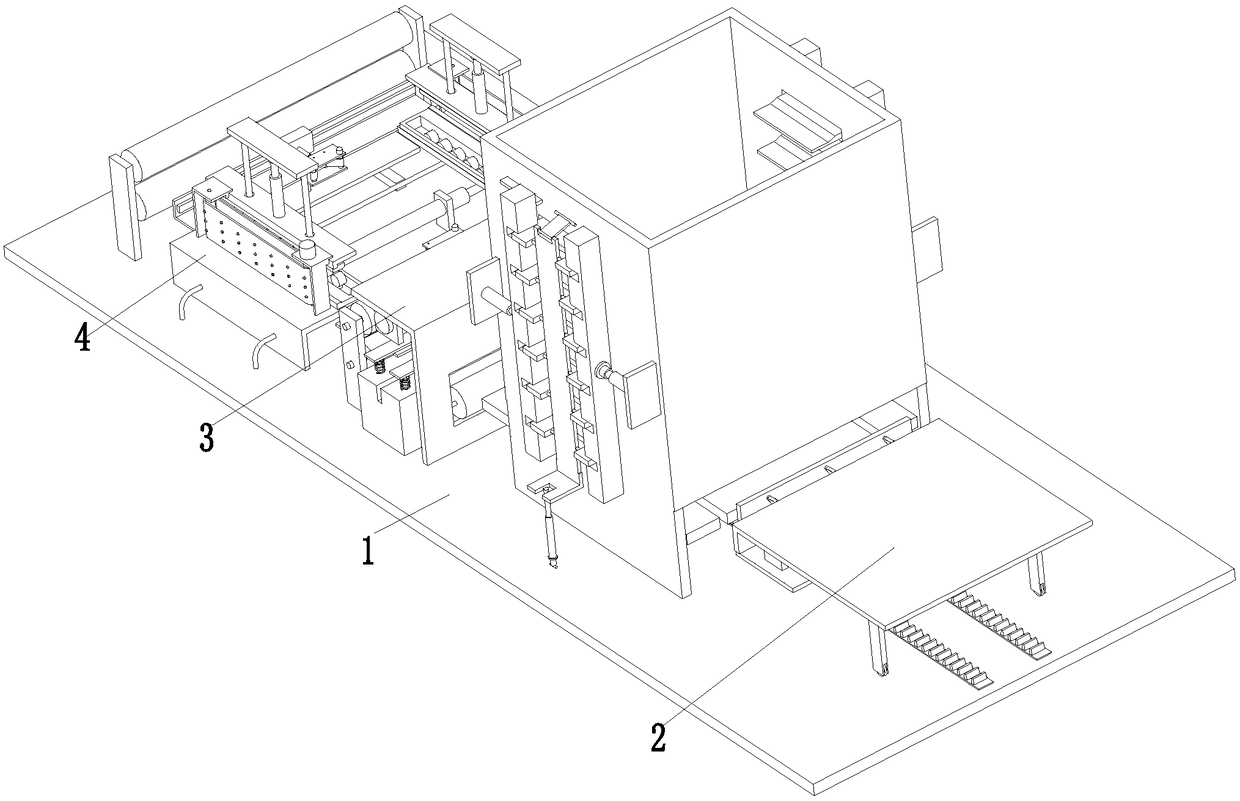

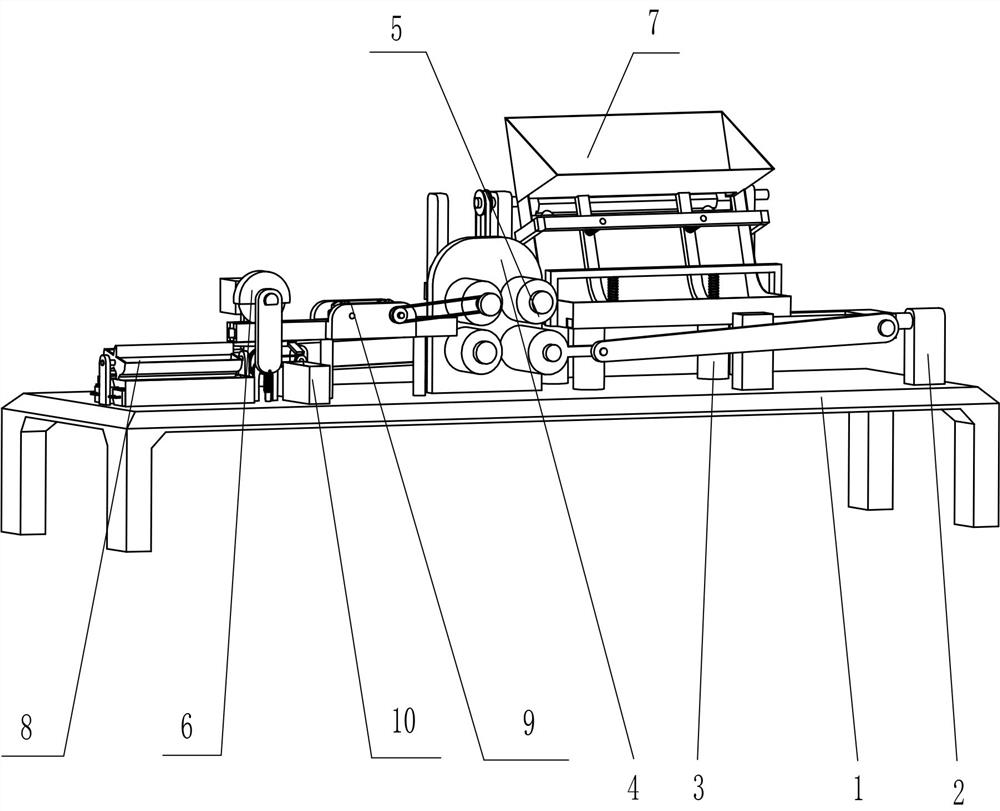

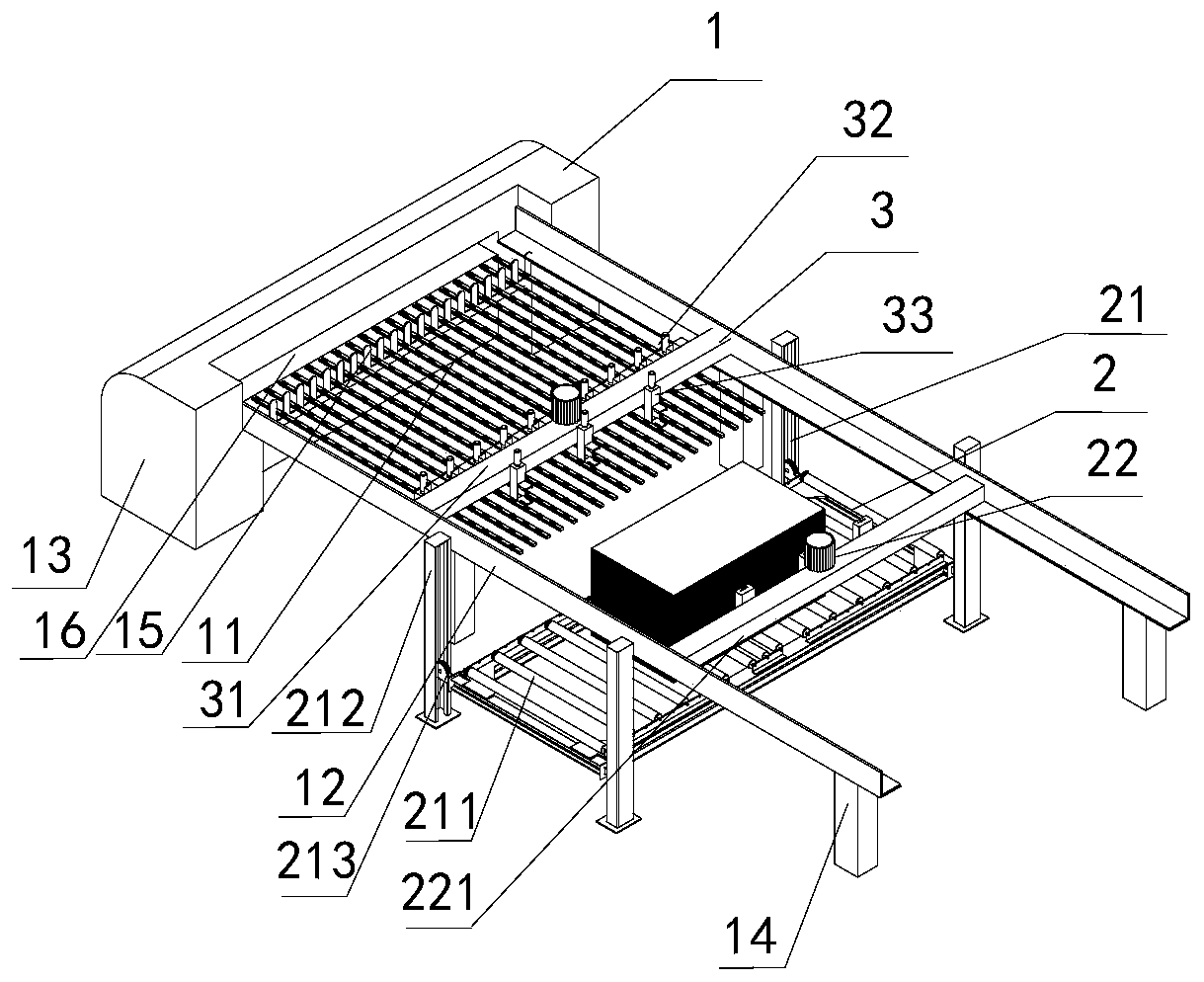

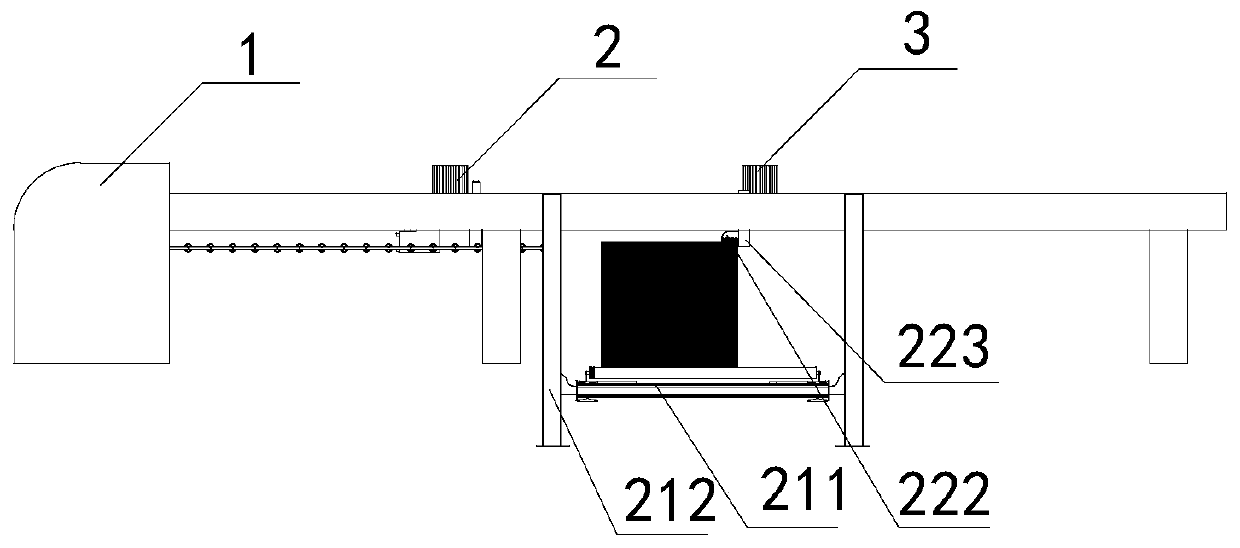

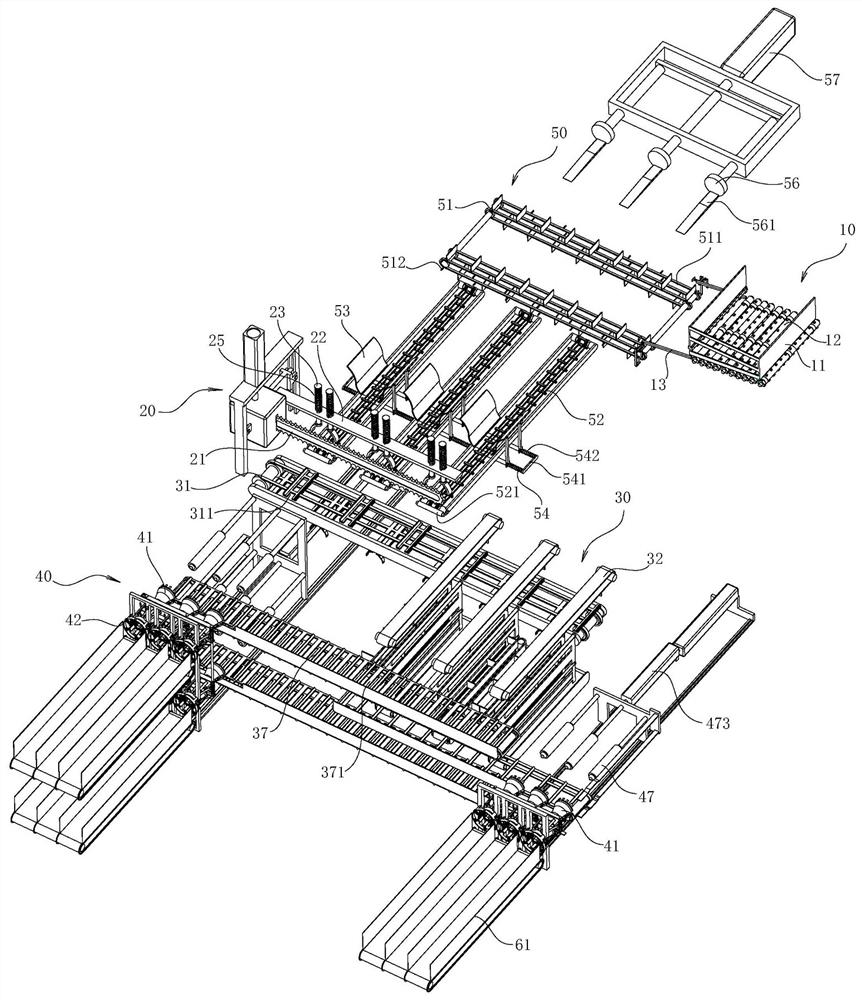

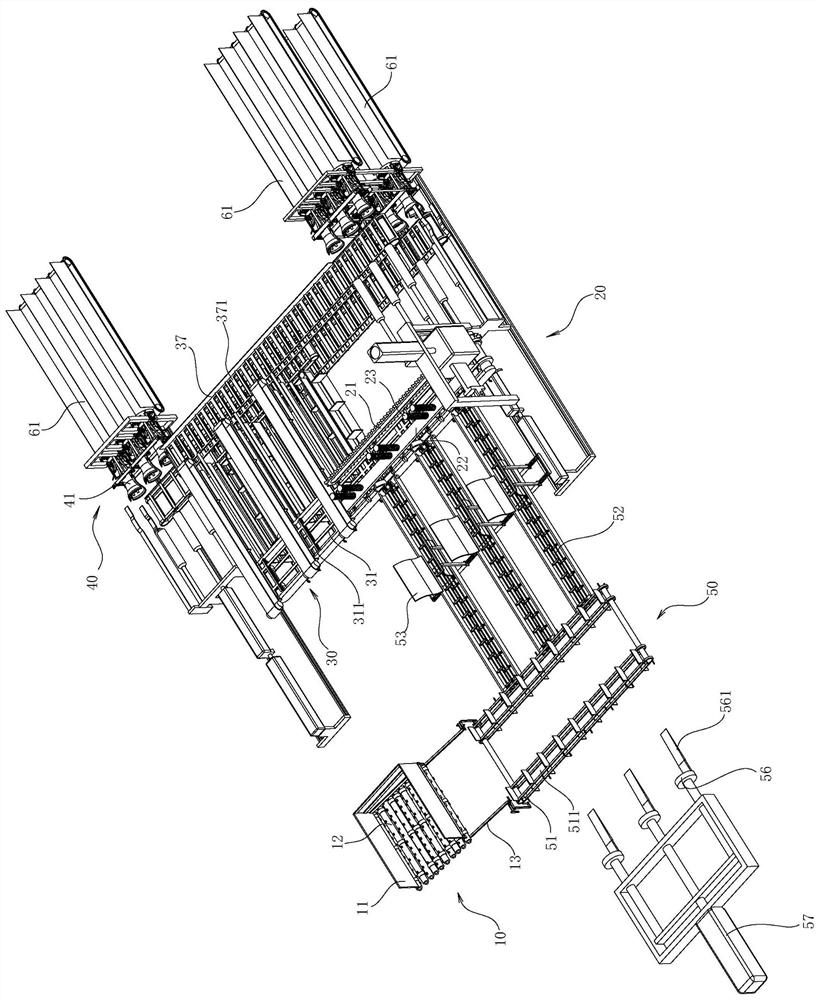

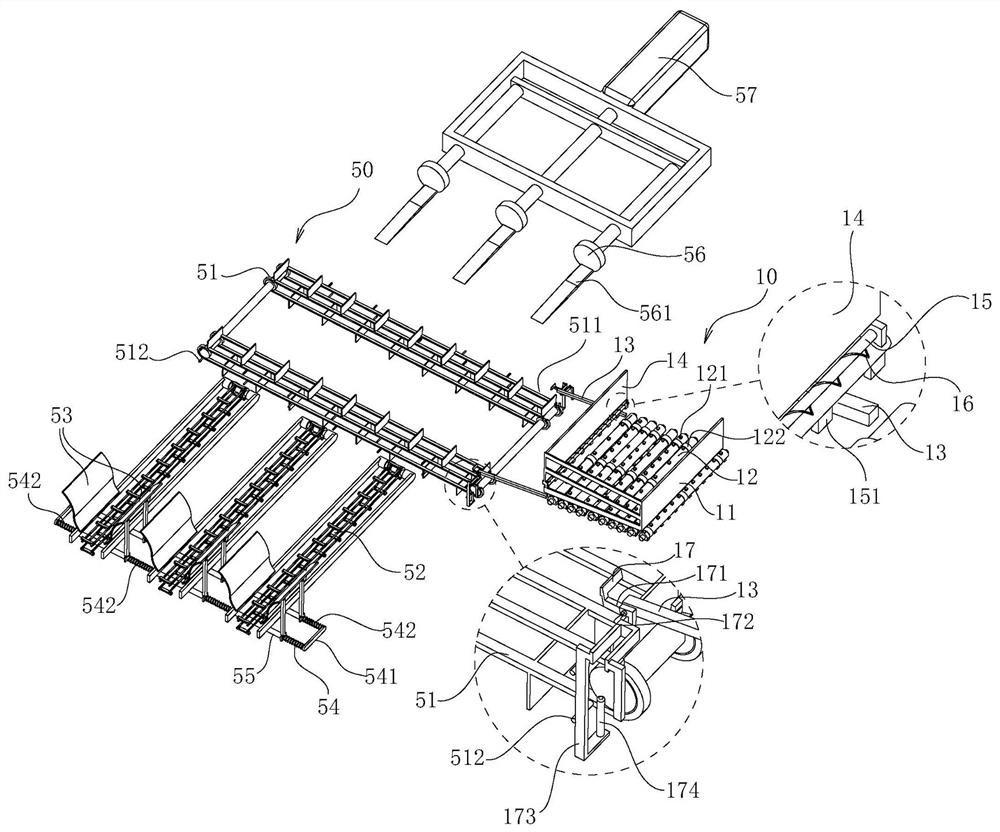

Board processing production line for highly automatically conveying boards

PendingCN109129724ACut Rate Improvement TuningImprove processing efficiencyFeeding devicesLoading equipmentProduction lineDischarge rate

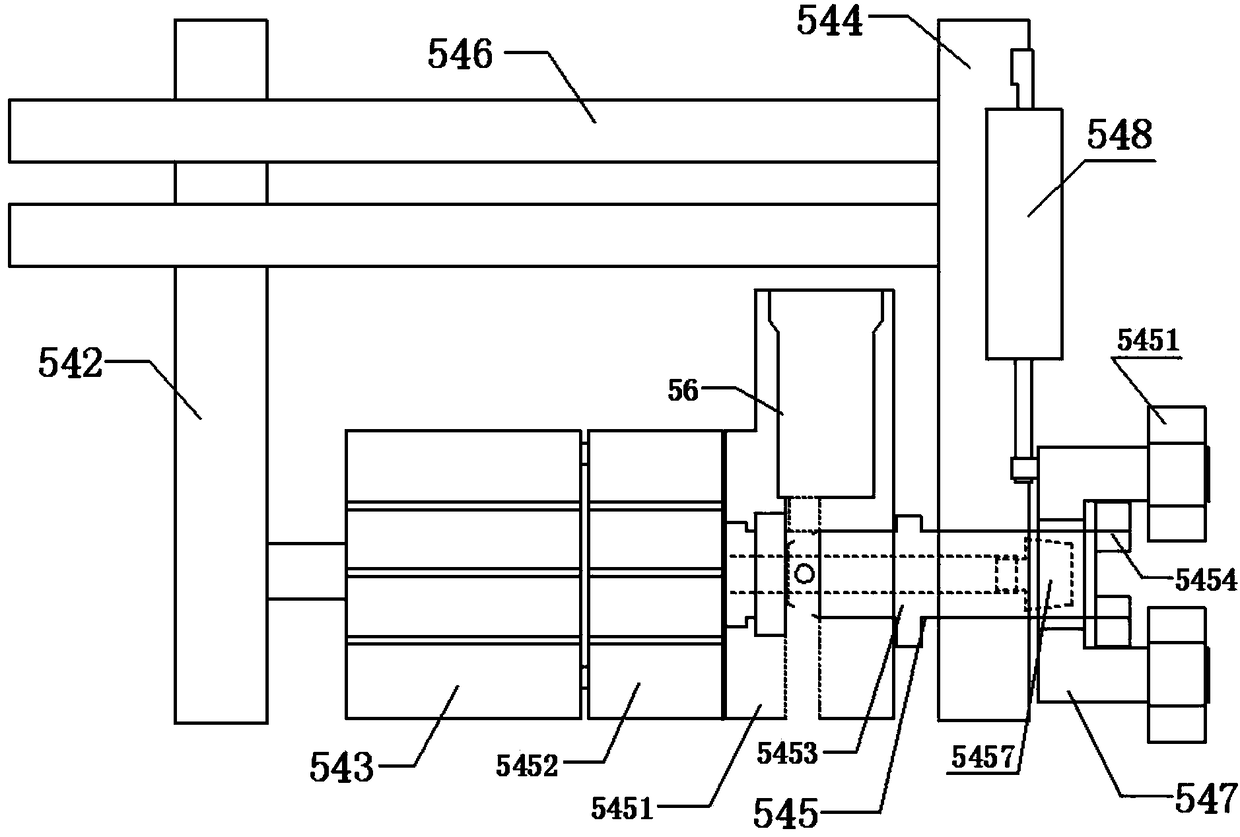

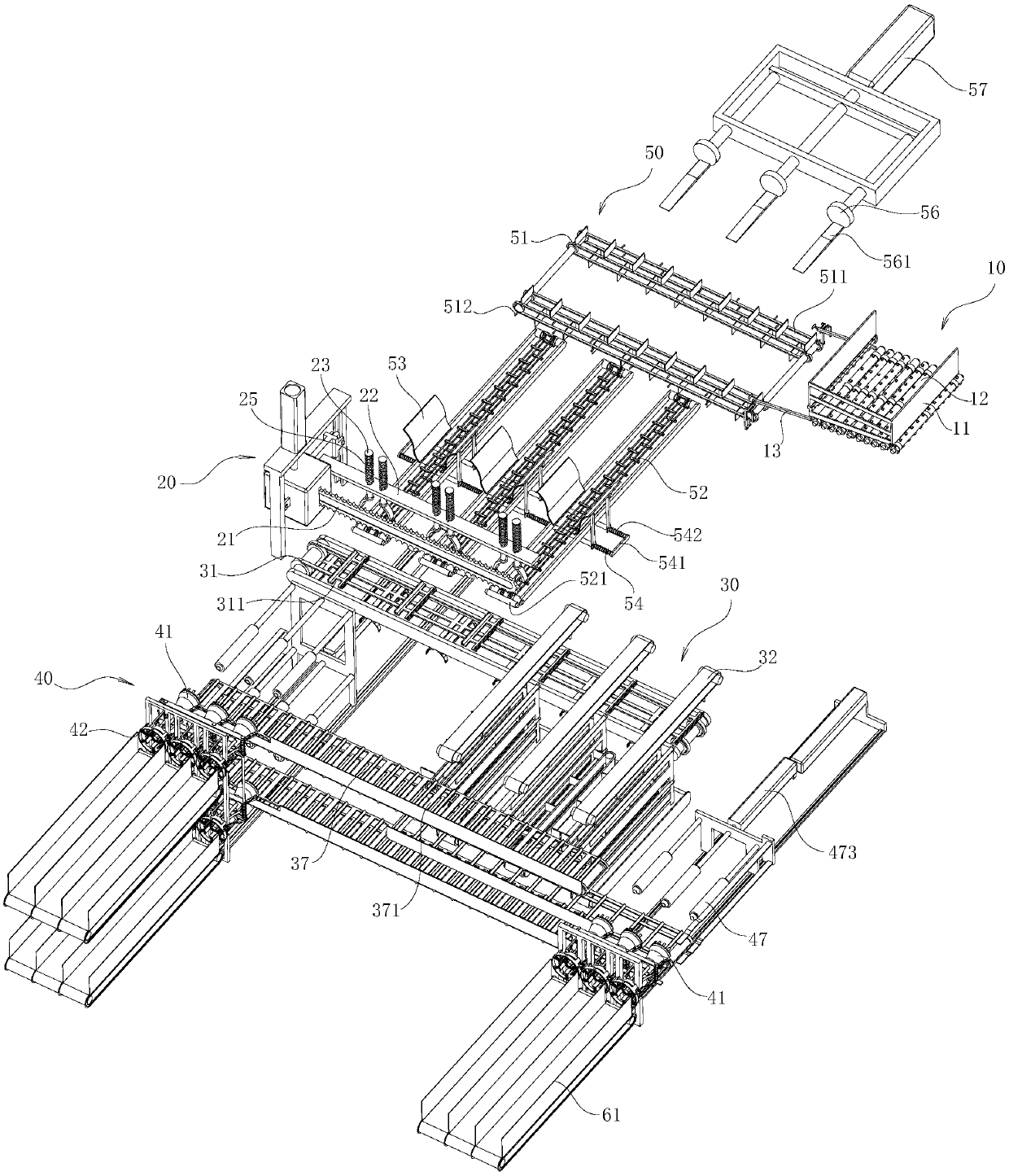

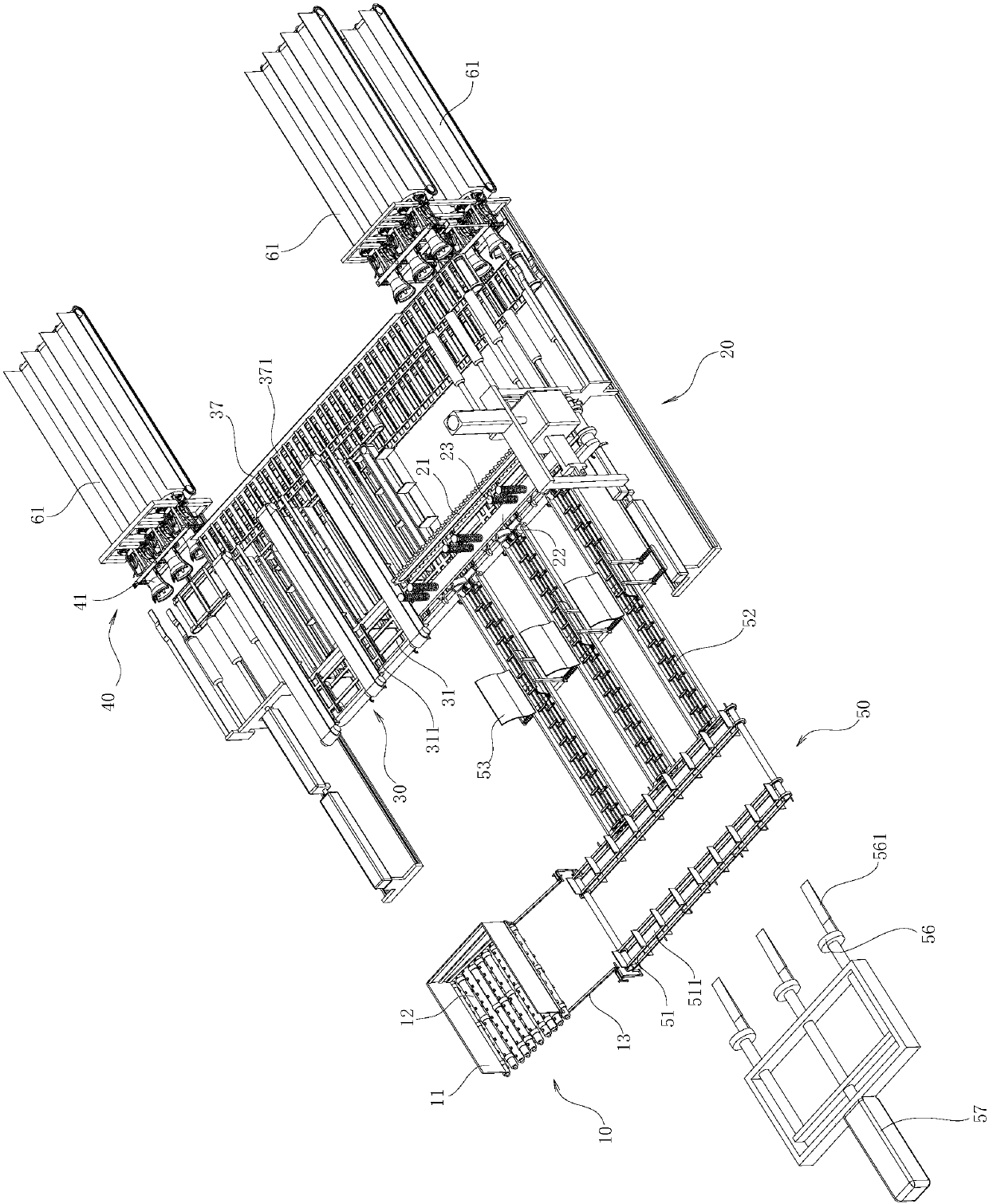

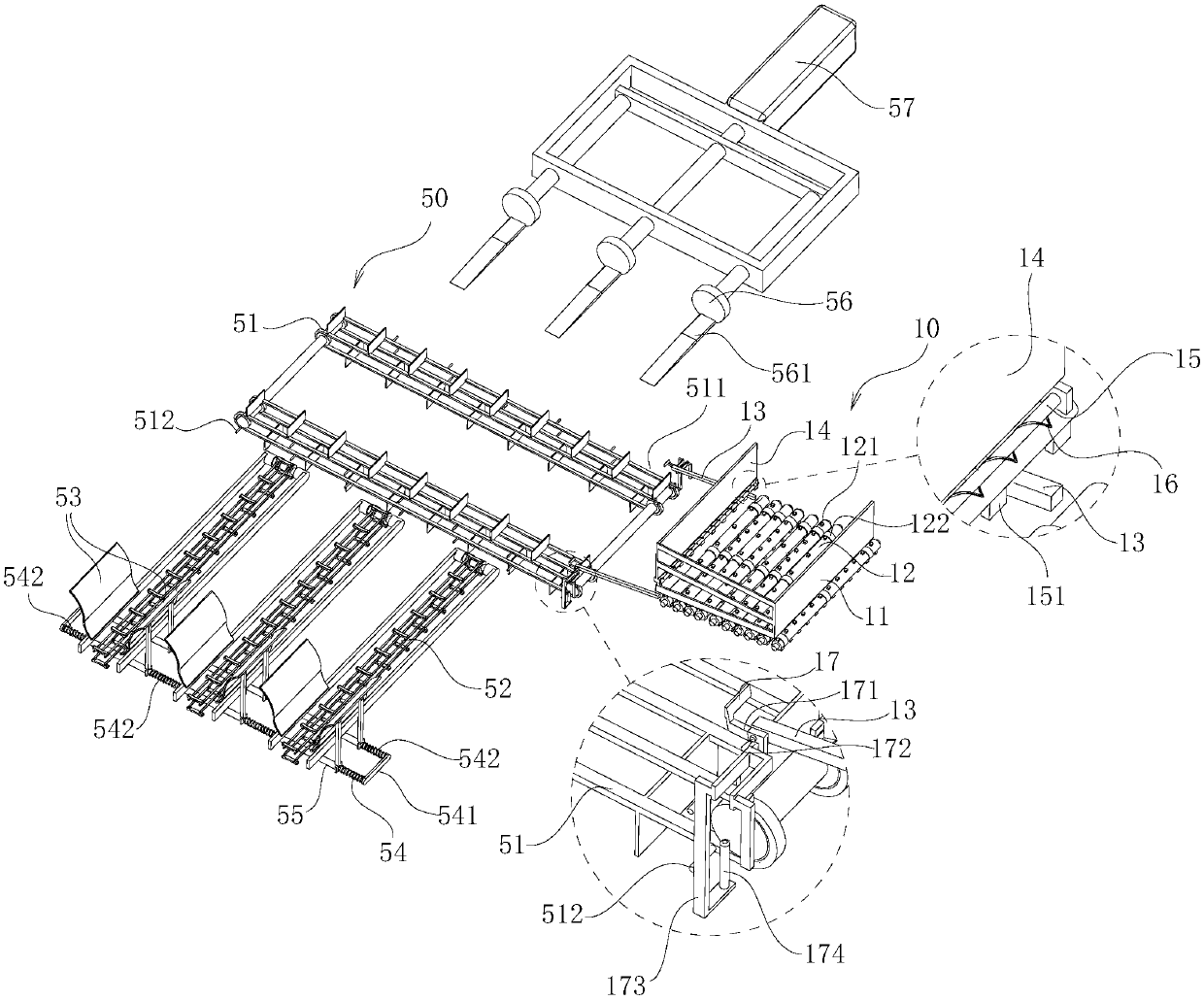

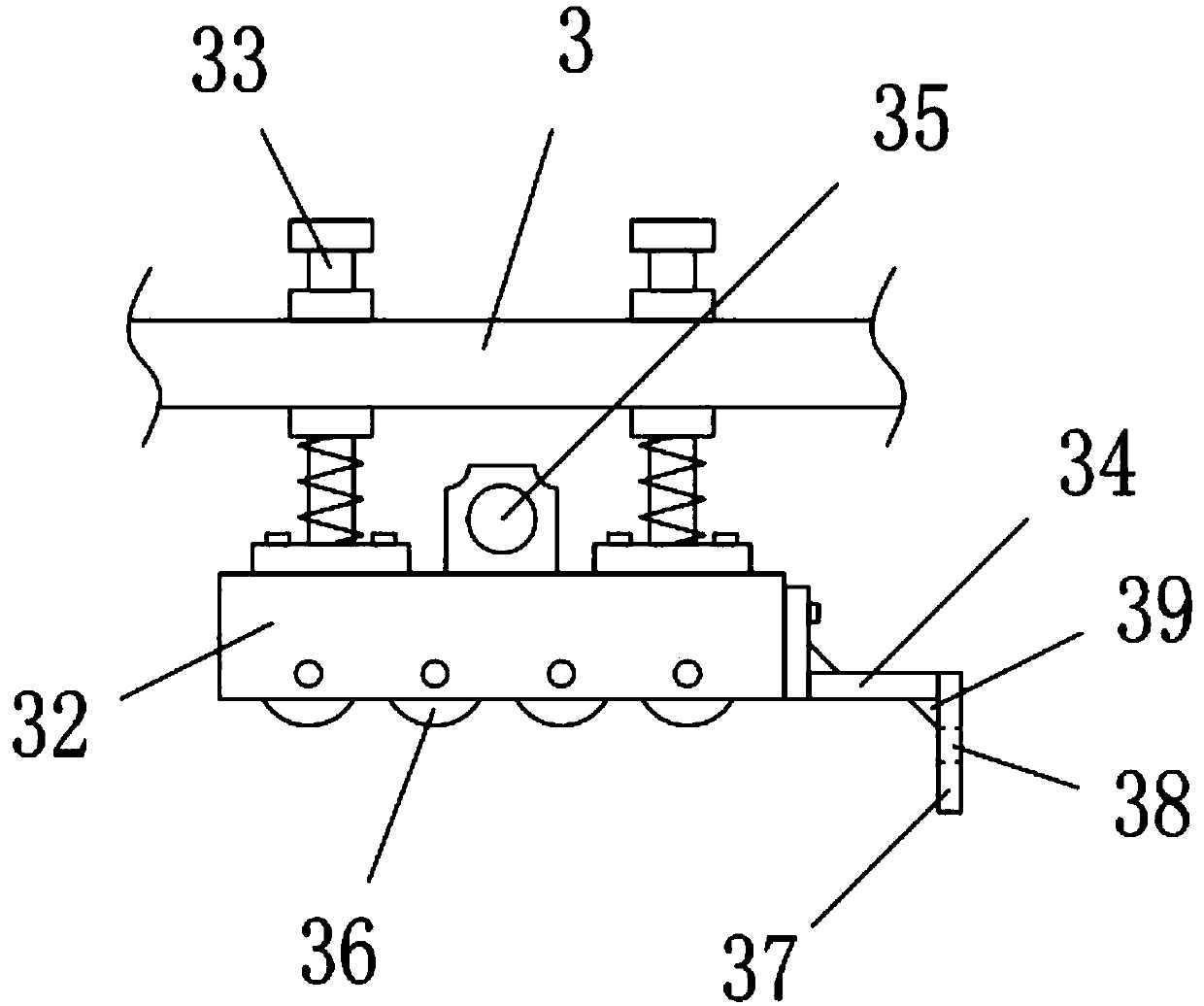

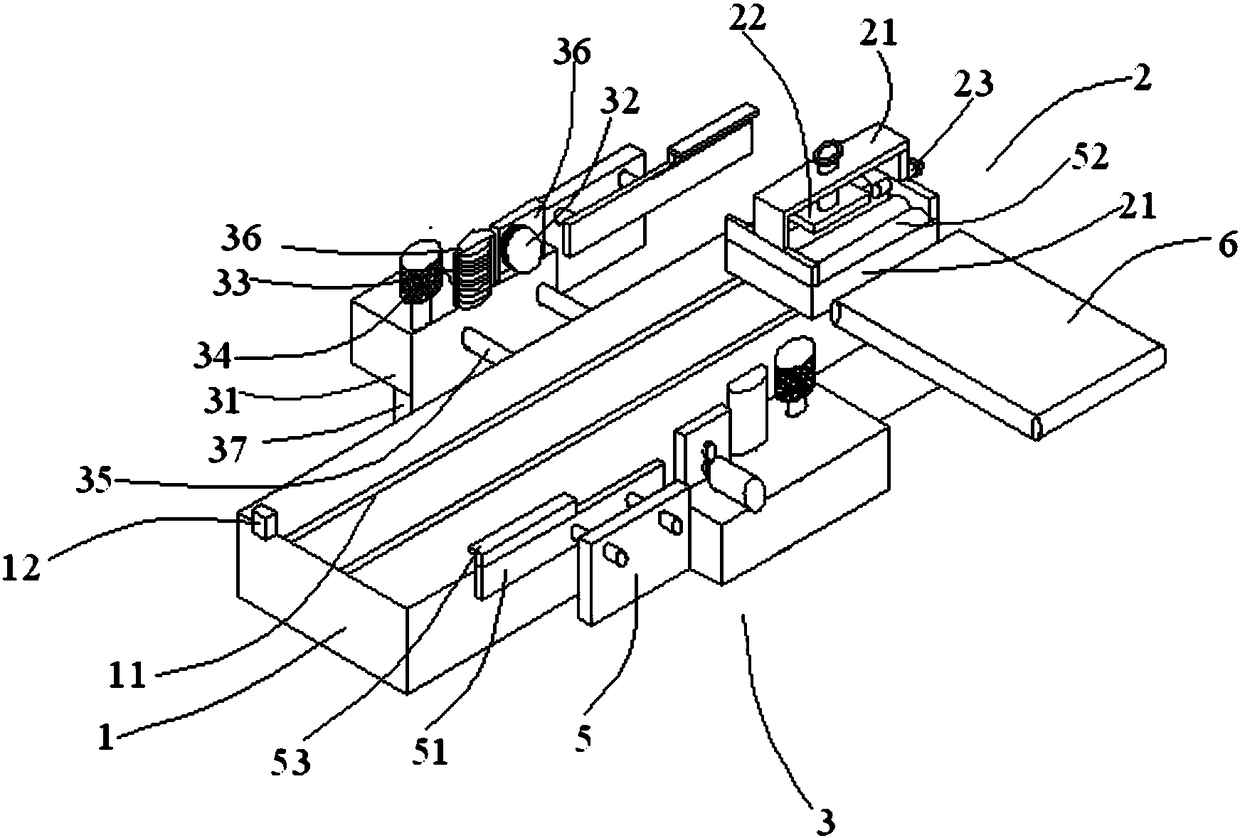

The invention discloses a board processing production line for highly automatically conveying boards. The board processing production line comprises an automatic board feeding unit, a transverse boardcutting unit, a longitudinal board conveying unit and a board carrying and conveying unit; the automatic board feeding unit comprises a board feeding device with a feeding frame; the board carrying and conveying unit comprises positioning stack aligners and a carriage assembly; a transport frame is arranged on the carriage assembly; the feeding frame is connected with the transverse board conveying unit; the transport frame is connected with the longitudinal board conveying unit; and the two positioning stack aligners are arranged on two sides of the transport frame. Both board feeding beforecutting and board discharging after cutting are conducted automatically, safety is achieved, the automatic board feeding unit and the board conveying unit are located on the initial point and the stop point of the whole production line respectively, the board feeding rate and the board discharging rate are both improved, the cutting rate of the production line is improved and adjusted, and thus the processing efficiency of the whole production line is improved.

Owner:福建兴恒机械科技有限公司

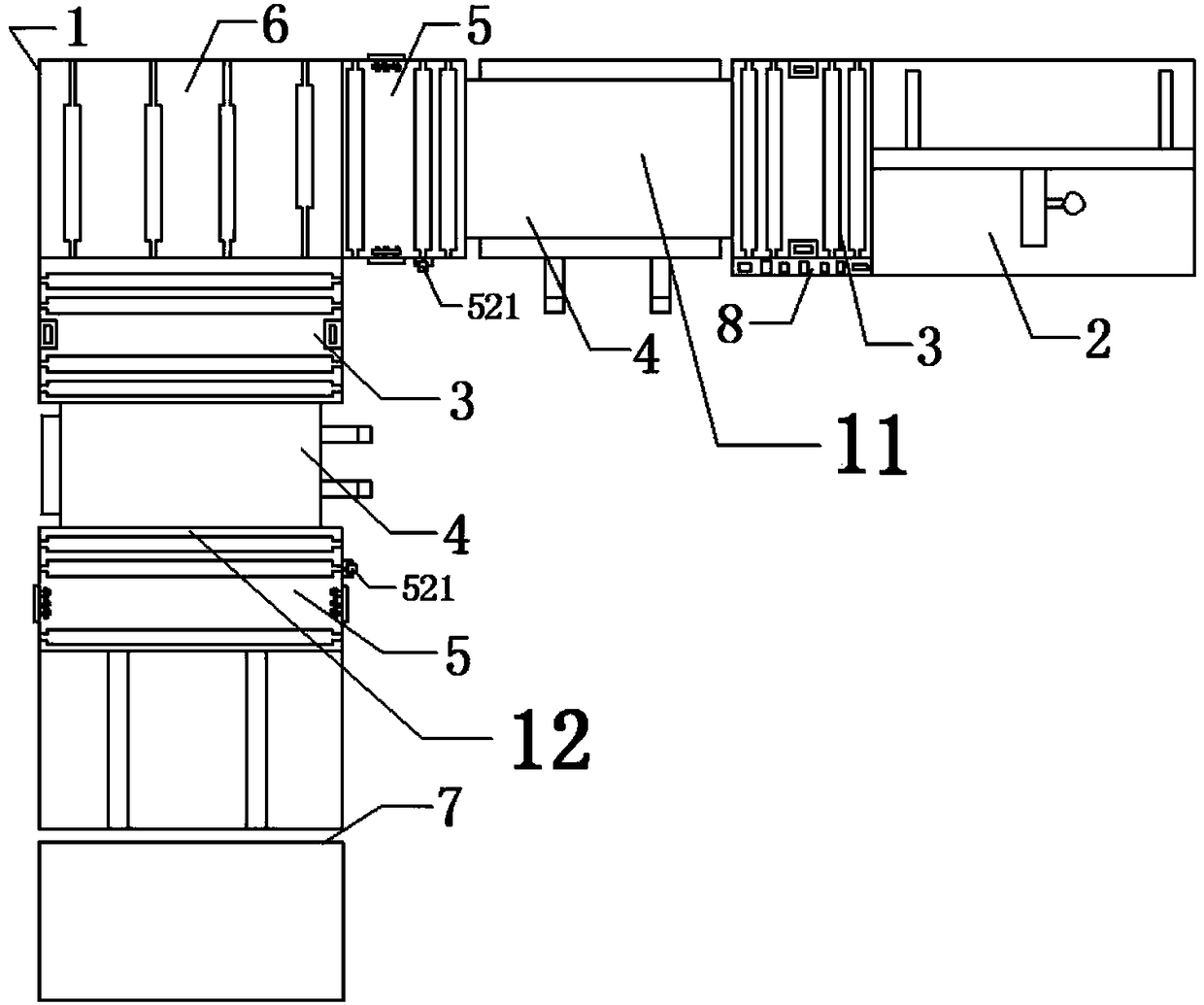

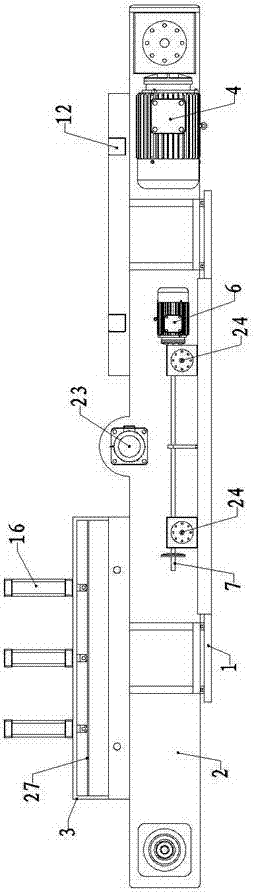

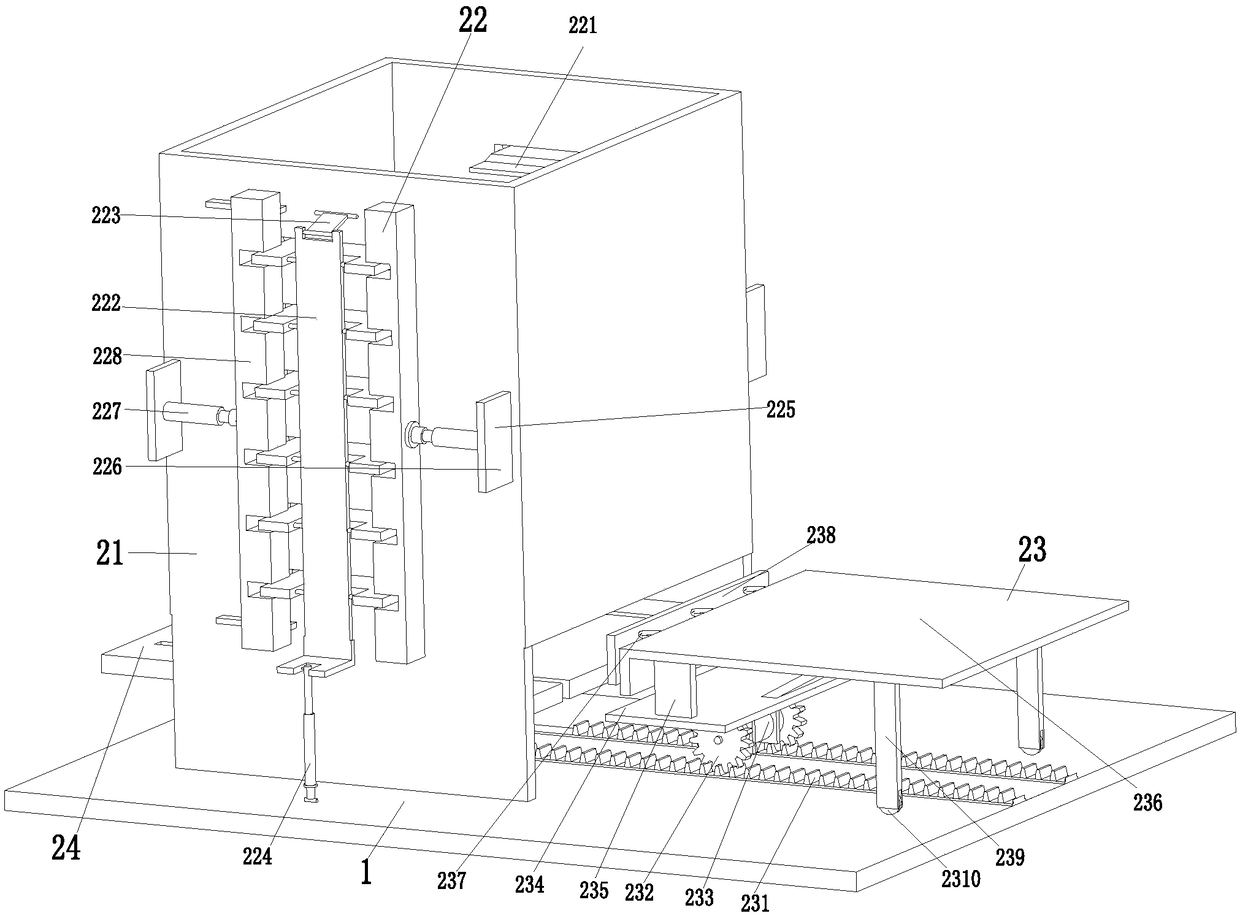

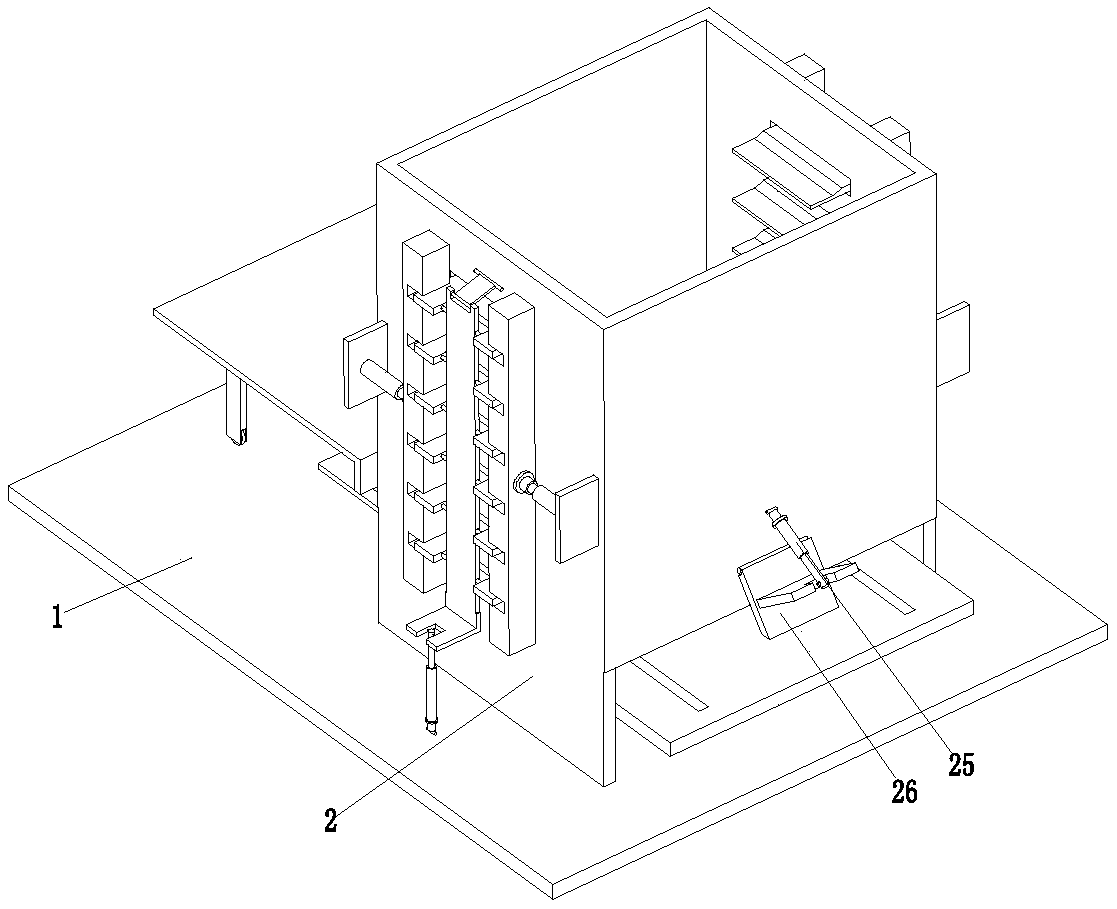

Longitudinal and transverse saw cutting device

ActiveCN106003253ARealize continuous automatic productionIncrease productivityFeeding devicesLoading equipmentEngineeringMachining

The invention provides a longitudinal and transverse saw cutting device comprising a transverse cutting mechanism and a longitudinal cutting mechanism. The feeding end of the transverse cutting mechanism communicates with a feeding mechanism; a plate material is supplied to the transverse cutting mechanism through the feeding mechanism; the transverse cutting mechanism performs transverse saw cutting treatment on the plate material; a conveying mechanism is arranged between the transverse cutting mechanism and the longitudinal cutting mechanism; the discharging end of the transverse cutting mechanism communicates with the feeding end of the longitudinal cutting mechanism through the conveying mechanism; the plate material subjected to the transverse saw cutting treatment of the transverse cutting mechanism enters the longitudinal cutting mechanism and is subjected to longitudinal saw cutting treatment through the longitudinal cutting mechanism; the feeding mechanism comprises a primary position material supporting platform and a secondary position material supporting platform; the primary position material supporting platform communicates with a feeding device which supplies the plate material to the primary position material supporting platform; the secondary position material supporting platform communicates with the primary position material supporting platform which transfers the plate material to the secondary position material supporting platform; and the primary position material supporting platform comprises a set of primary position supporting plates, and the secondary position material supporting platform comprises a set of secondary position supporting plates. The device adopts a door sleeve plate as a main machining object and is reasonable in structure, high in production efficiency and high in machining precision.

Owner:MENGTIAN HOUSEHOLD GRP CO LTD

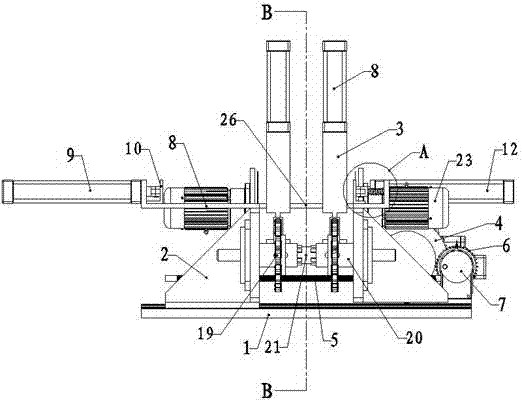

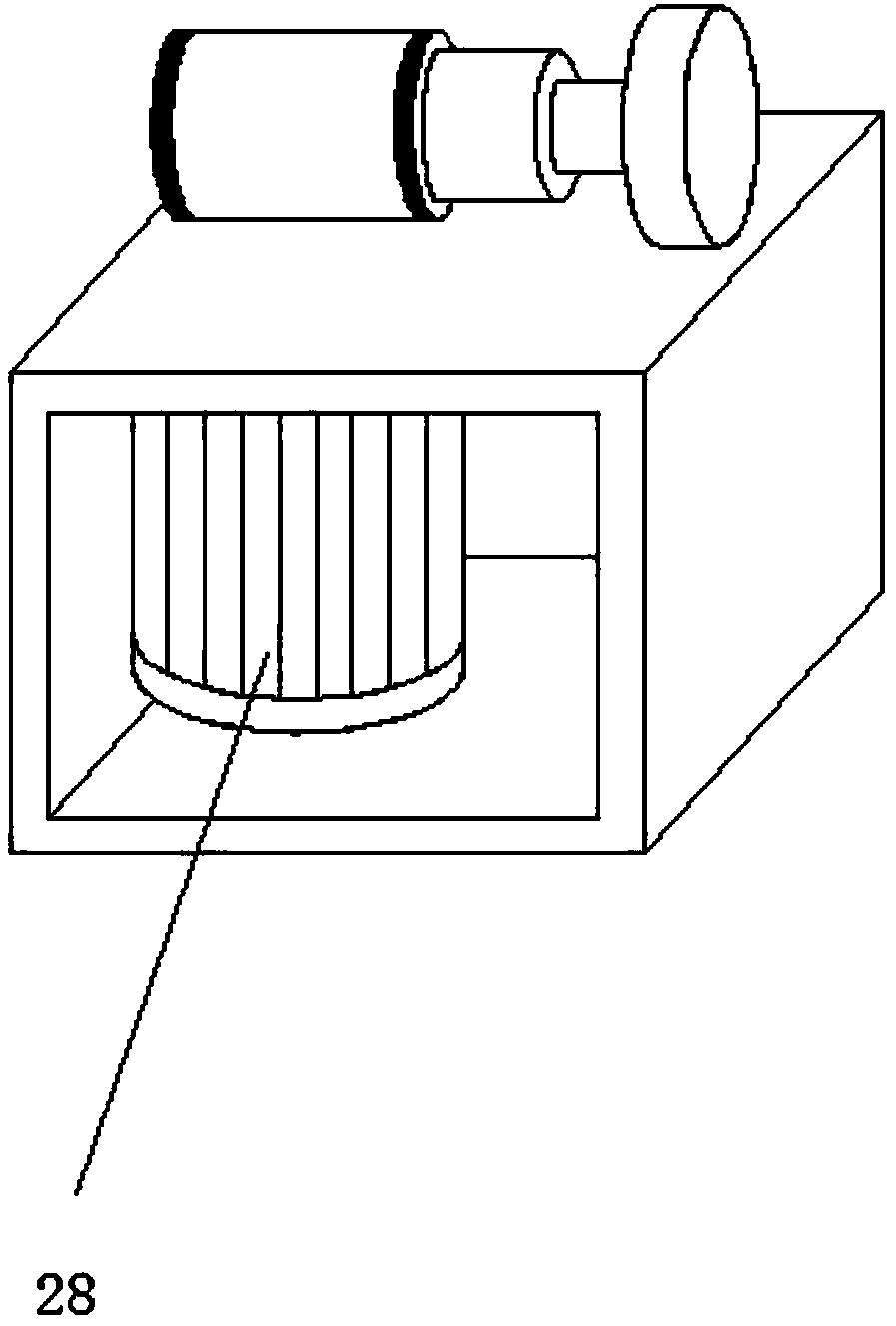

Full-automatic wood feeder

InactiveCN104493906AReduce in quantityReduce labor intensityLoading equipmentDe-stacking articlesSolid woodEngineering

The invention relates to the field of wood processing machinery, in particular to a full-automatic wood feeder, and aims to solve the problem that the wood feeding process in the existing solid-wood door / window processing field is not automated, leading to low productivity and high labor intensity for operators. The full-automatic wood feeder comprises a conveying mechanism, a lifting mechanism, a feeding mechanism, a stirring mechanism, a portal frame and a control cabinet; the conveying mechanism, the lifting mechanism and the stirring mechanism are arranged in order along the lengthwise direction; the portal frame is perpendicularly fixed to a joint of the conveying mechanism and the lifting mechanism; the feeding mechanism is disposed on a mounting beam of the portal frame; the conveying mechanism, the lifting mechanism, the feeding mechanism and the stirring mechanism are all connected with the control cabinet through power cords. The full-automatic wood feeder is used for feeding wood materials in the solid-wood door / window processing field.

Owner:HARBIN SAYYAS WINDOWS

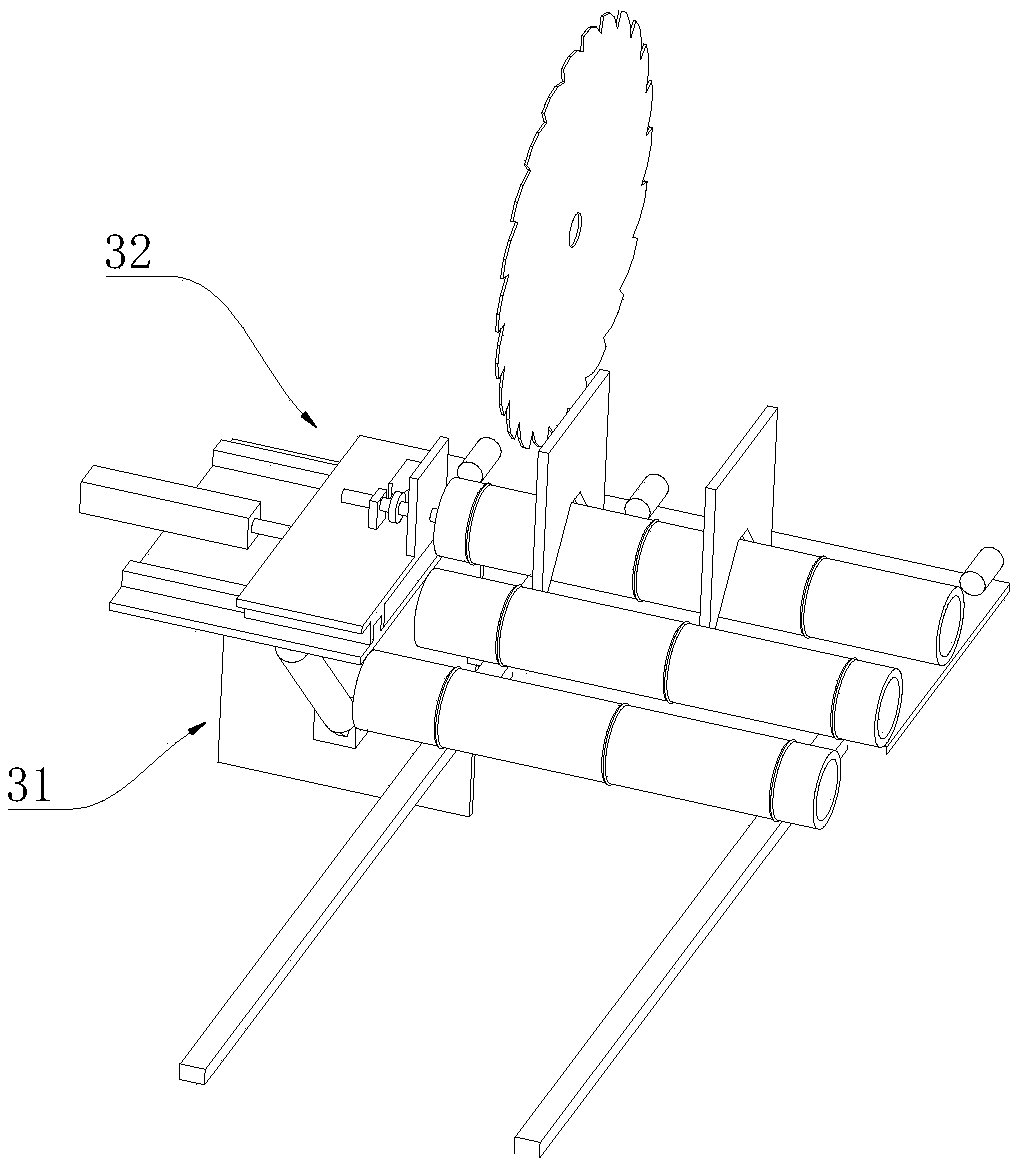

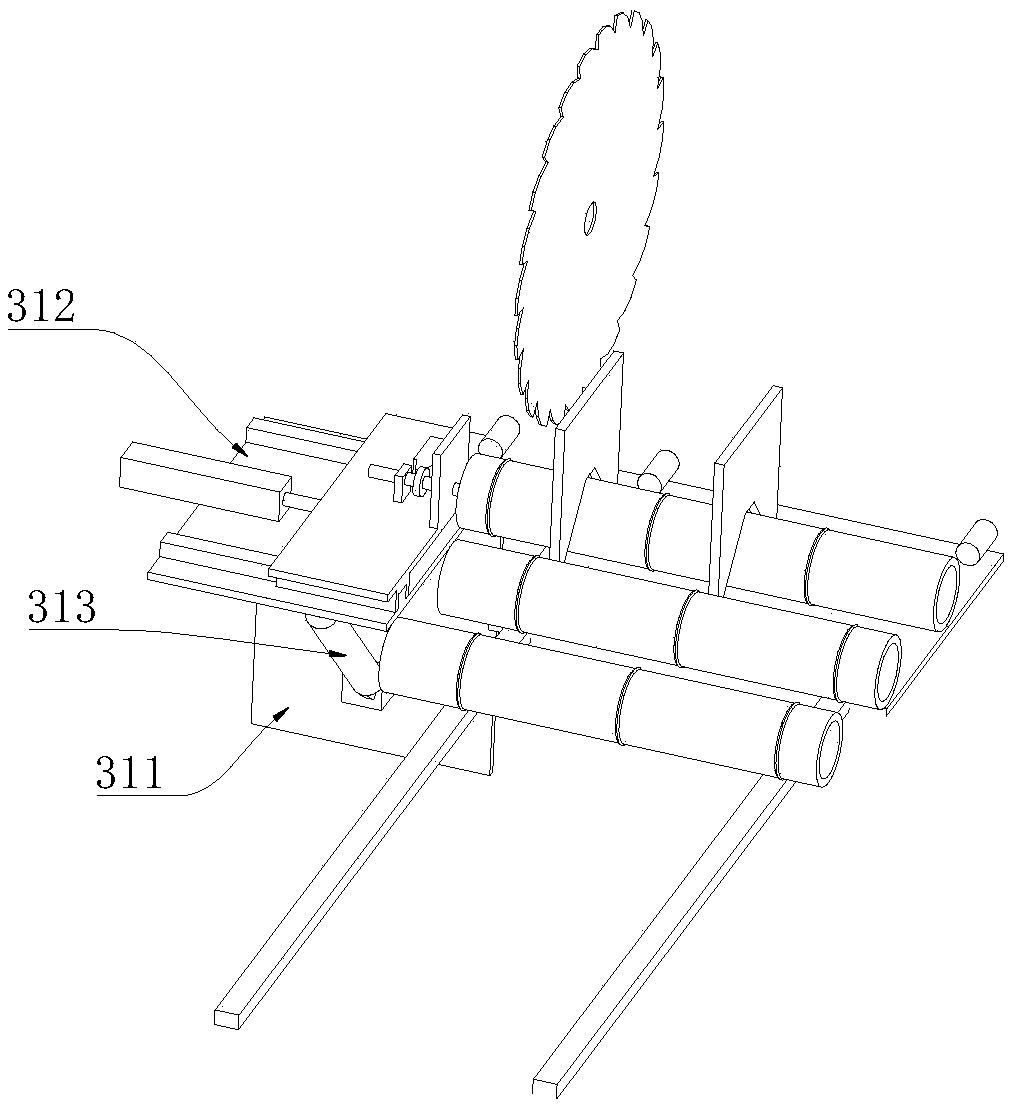

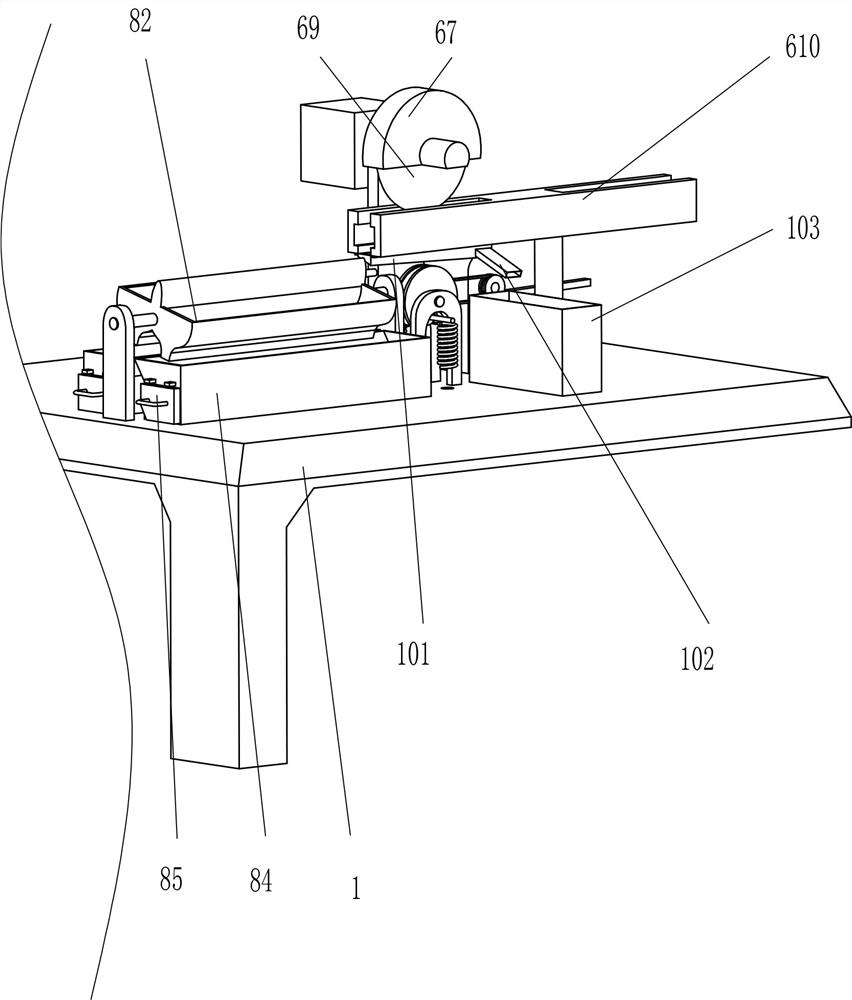

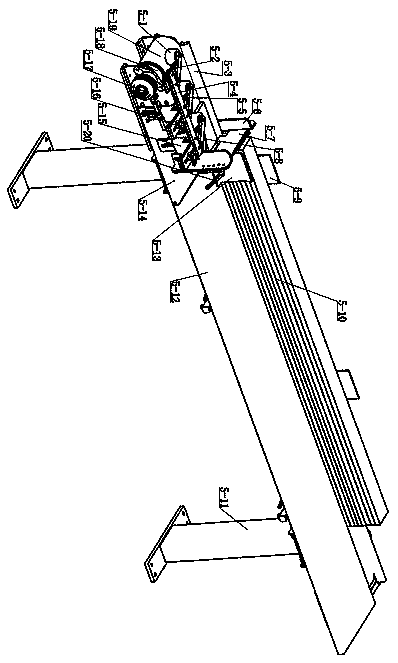

Wood transporting and cutting integrated mechanism

InactiveCN107127829AIncrease the number ofNo need for manual markingGuide fencesFeeding devicesEngineeringWorkbench

The invention discloses a wood transporting and cutting integrated mechanism. The wood transporting and cutting integrated mechanism comprises a workbench, a cutting device and a wood transporting device. The wood transporting device is close to the wood feeding start end of the workbench or the wood transporting device makes contact with the wood feeding start end of the workbench. The wood transporting device comprises a slope type conveying device and a horizontal conveying platform. The workbench is provided with wood supporting frames. The multiple wood supporting frames in the same row are distributed from the wood feeding start end of the workbench to the wood feeding stop end of the workbench in the length direction of the workbench at intervals. A fixed length baffle is arranged at the wood feeding stop end of the workbench, and a pushing mechanism is arranged between the horizontal conveying platform and the workbench. The pushing mechanism is used for pushing woods to the position abutting against the fixed length baffle. The wood transporting and cutting integrated mechanism has the beneficial effects that the length fixing working procedure is easy and convenient, the cutting defective percentage is low, tool abrasion is slight, the cutting speed is high, and the multiple woods can be cut at the same time.

Owner:薛忠来

Full-automatic double-end cutting photo frame corner cutting machine

InactiveCN106965253AReduce precisionRealize automatic corner cuttingGuide fencesFeeding devicesEngineeringWorkbench

The invention relates to the field of photo frame corner cutting machines, in particular to a full-automatic double-end cutting photo frame corner cutting machine. The full-automatic double-end cutting photo frame corner cutting machine comprises a workbench. A conveying device is arranged on the workbench. A feeding device is arranged at the initial end of the conveying device. A cutting device is further arranged on the workbench and comprises a first cutting device body and a second cutting device body. The first cutting device body and the second cutting device body are arranged perpendicularly and form a 45-degree angle with the conveying device. A first clamp arranged vertically and a second clamp arranged horizontally are arranged on the part, located between the first cutting device body and the second cutting device body, on the workbench. The first clamp and the second clamp can jointly jack and fix a photo frame onto the conveying device in the working state. Automatic corner cutting of the photo frame is achieved, manpower sources are saved, and the production efficiency and product quality are improved.

Owner:东莞市勤唯机械科技有限公司

Segment cutting device

InactiveCN109159213AAchieve positioningAvoid unevennessFeeding devicesGripping devicesEngineeringMechanical engineering

The invention relates to a segment cutting device. The segment cutting device comprises a chain saw arranged at the discharging end of a guiding conveying chain, and the length direction of the chainsaw is perpendicular to the discharging end of the guiding conveying chain; a pressing mechanism is further arranged above the discharging end of the guiding conveying chain; the chain saw moves up and down and correspondingly the pressing mechanism carries out the decompressing and pressing actions on raw wood; the chain saw is connected with a lifting mechanism; a power mechanism drives the chain saw to rotate; when the lifting mechanism descends, the power mechanism performs driving, and therefore segment cutting operation on the raw wood at the guiding conveying end of the guiding conveying chain is achieved; when the lifting mechanism ascends, the power mechanism is closed; when the chain saw carries out segment cutting on the raw wood, the pressing mechanism carries out pressing on the raw wood, and therefore positioning on the raw wood can be effectively achieved; and it is avoided that when the chain saw carries out saw cutting operation on the raw wood, the raw wood deviates,and consequently the notch position of the raw wood is not flat.

Owner:NANJING LISHUI HIGH-TECH VENTURE CAPITAL MANAGEMENT CO LTD

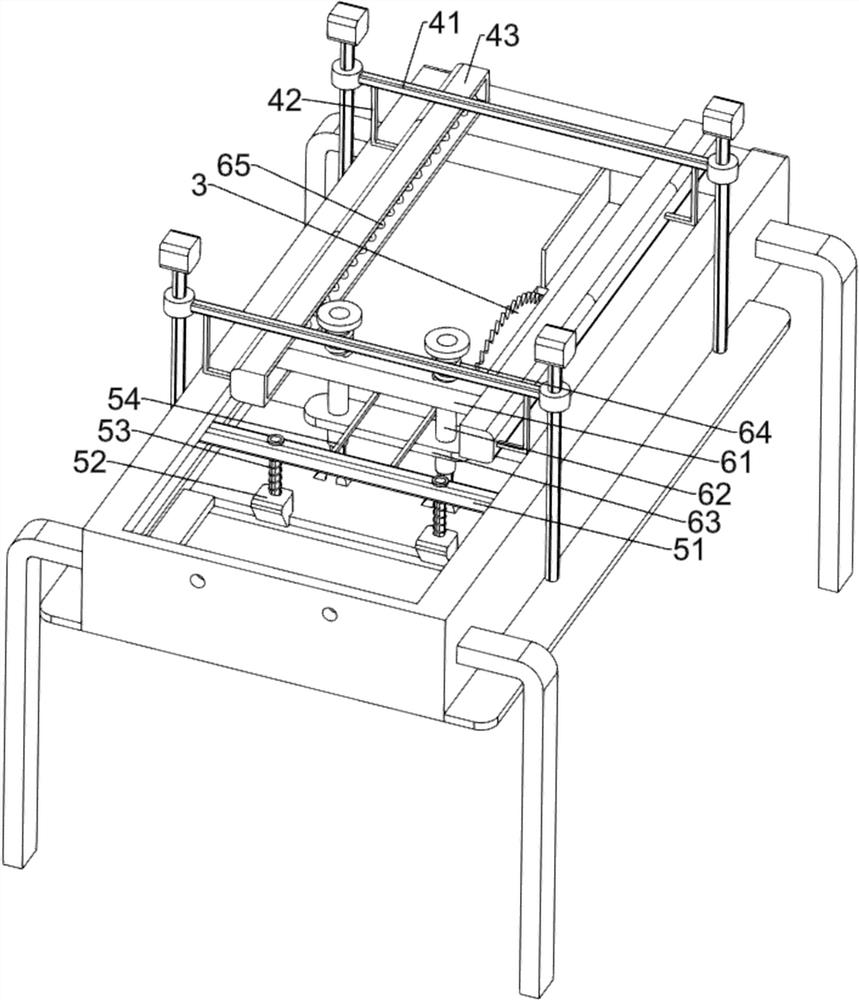

Dicing device for boards with different lengths

InactiveCN111906851AReduce labor intensityAvoid shakingFeeding devicesGripping devicesMechanical engineeringWood plank

Owner:赵三秀

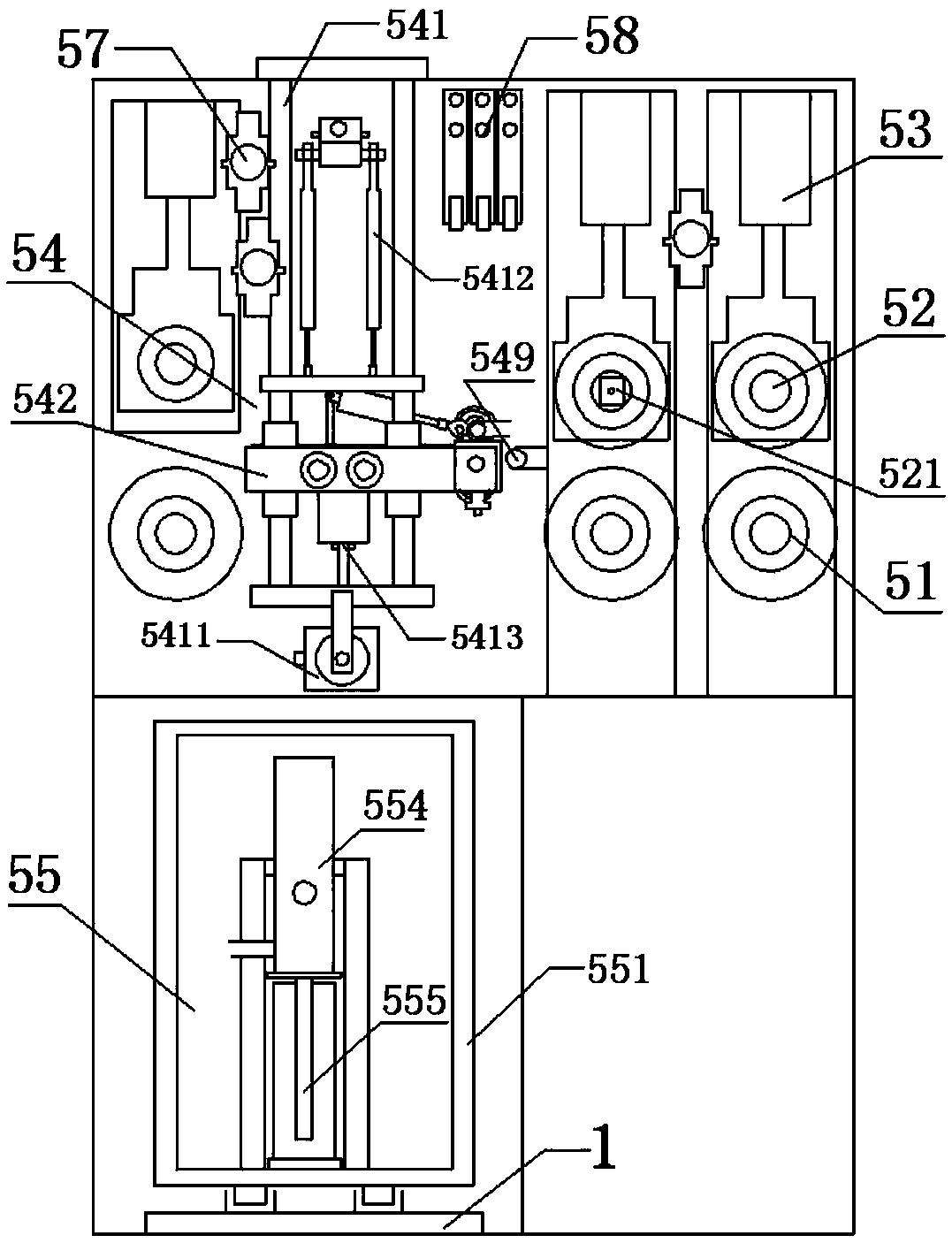

Automatic edge trimming machine for pressing plate

PendingCN108582382ARealize automated productionImprove processing speedOther plywood/veneer working apparatusLoading equipmentEngineeringAutomation

The invention discloses an automatic edge trimming machine for a pressing plate. The automatic edge trimming machine comprises a rack, a transverse side processing mechanism, a longitudinal side processing mechanism, a loading mechanism, a pushing plate mechanism, a stacking mechanism and a PLC, wherein the loading mechanism, the transverse side processing mechanism, the pushing plate mechanism, the longitudinal side processing mechanism and the stacking mechanism are sequentially arranged on the bracket; each of the transverse side processing mechanism and the longitudinal side processing mechanism is equipped with an edge sawing mechanism, a waste mechanism and an edge supplementing mechanism; and the PLC is arranged on the rack and is electrically connected with each mechanism. The automatic edge trimming machine realizes automatic production for edge sawing and edge supplementing of the pressing plate, and realizes automatic loading, edge sawing, waste collecting, edge supplementing, pushing plate edge-changing and stacking; and the edge supplementing mechanism of the device presses a filling material into a gap of the pressing plate through an injection way, the edge-supplemented plate is flat in appearance, and the filling material is not liable to drop, is good in waterproof performance and is long in service life. The edge-sawing edge-supplementing mechanism is high indegree of automation, is good in processing quality, and improves edge trimming efficiency of the pressing plate.

Owner:唐海波

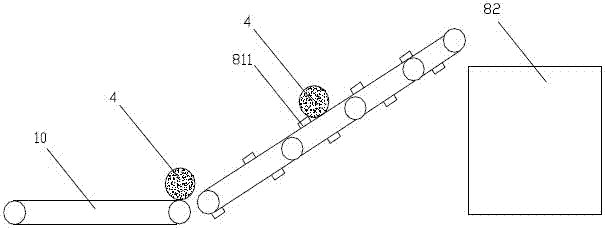

Stacking device

ActiveCN109250466ACode implementationConveyorsFeeding devicesElectrical and Electronics engineeringSingle row

The invention relates to a stacking device, which comprises a first conveying crawler arranged at the outlet position of peeling devices, a second conveying crawler is arranged below the discharge endof the first conveying crawler, a material receiving inclined plate is arranged at the discharge port of the second conveying crawler, a material receiving cross rod is arranged at the bottom end ofthe material receiving inclined plate, the side of the material receiving cross rod is provided with a segment material receiving mechanism, the segment material receiving mechanism is used for receiving the segments arranged on the material receiving cross rod and transferring the segments to the position of a material receiving frame, after peeled by the peeling device at each stage, the segments are exported through the first conveying crawler, the second conveying crawler exports the segments to the position of the material receiving inclined plate, the segments slide down to the materialreceiving cross rod through the material receiving inclined plate, and are stacked in a single row, after the material receiving cross rod is fully provided with the segments, a segment receiving mechanism is started, so that the receiving of the segments on the receiving cross rod is carried out, and the segments are conveyed to the position of the material receiving frame, so as to achieve the stacking of the segments, and when the material receiving frame is fully filled with the segments and is transported to an airing room for naturally drying, usable planting base wood can be obtained.

Owner:王步熬

Plate cutting machine

The invention relates to the technical field of plate machining equipment, in particular to a plate cutting machine. The plate cutting machine comprises a base, gap adjusting brackets, a feed bracket, a loading mechanism, a discharge mechanism, a positioning mechanism, a clamping mechanism and a cutting mechanism; the two gap adjusting brackets are symmetrically mounted on the base in a linear sliding manner; a gap adjusting mechanism is arranged between the two gap adjusting brackets; the feed bracket is mounted on the gap adjusting brackets in a linear sliding manner, and is driven through a feed motor; the cutting mechanism and the clamping mechanism are both arranged on the feed bracket; the loading mechanism and the positioning mechanism are both arranged at loading ends of the gap adjusting brackets, and are respectively mounted on the two gap adjusting brackets; and the discharge mechanism is arranged at discharge ends of the gap adjusting brackets. The plate cutting machine has the advantages of time and labor saving, safety, high efficiency, high precision and adaption to wide machining size range.

Owner:山东同利玻纤制品有限公司

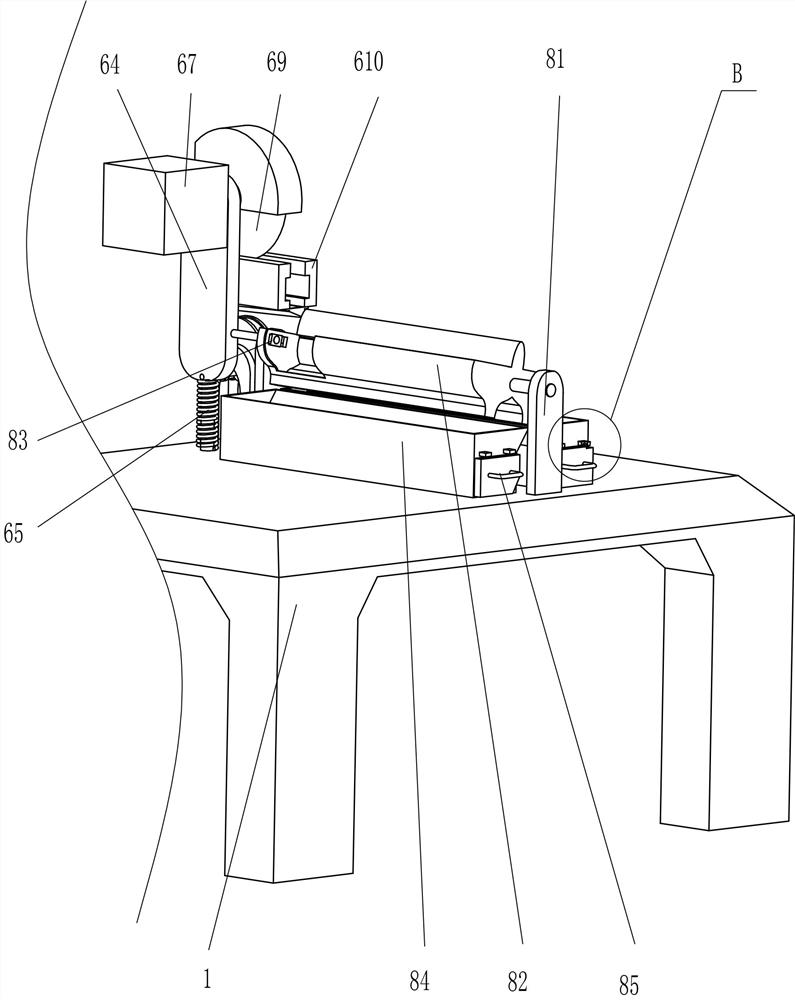

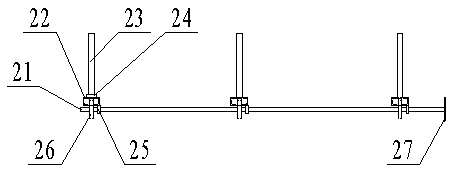

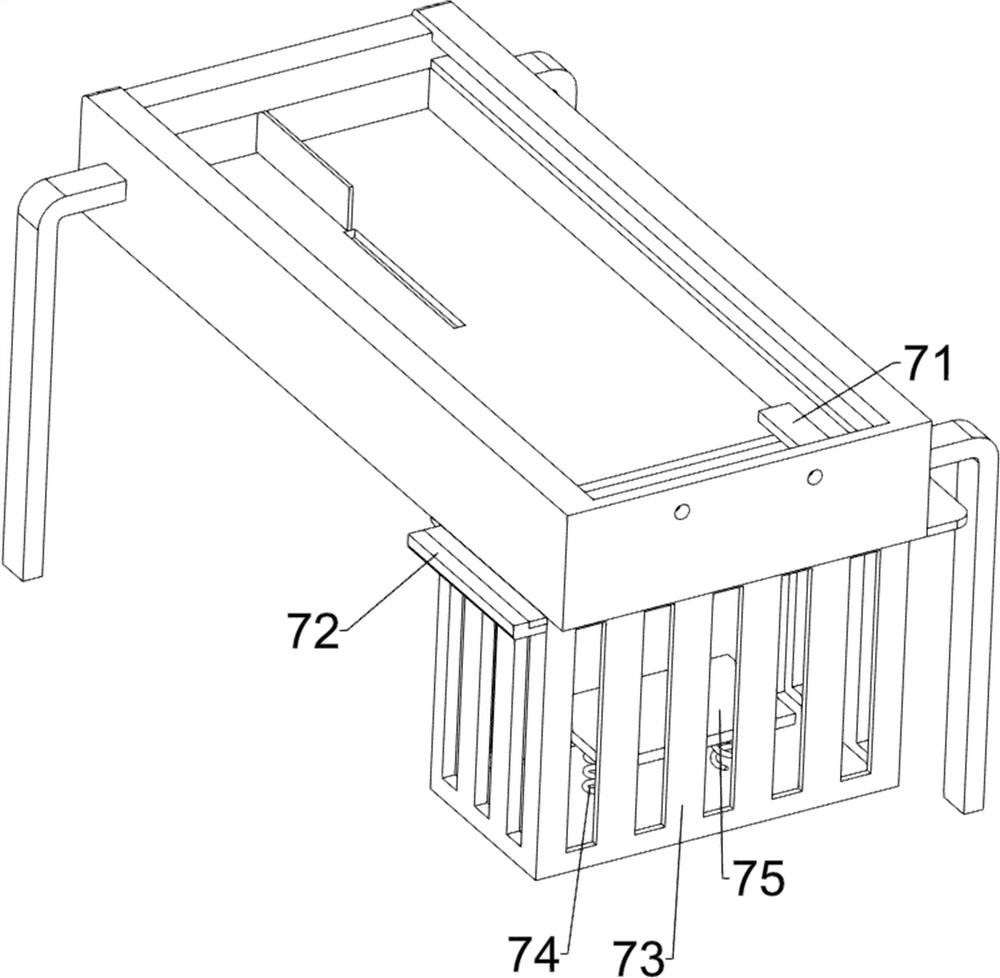

Board thickness-adjustable type frame sawing machine

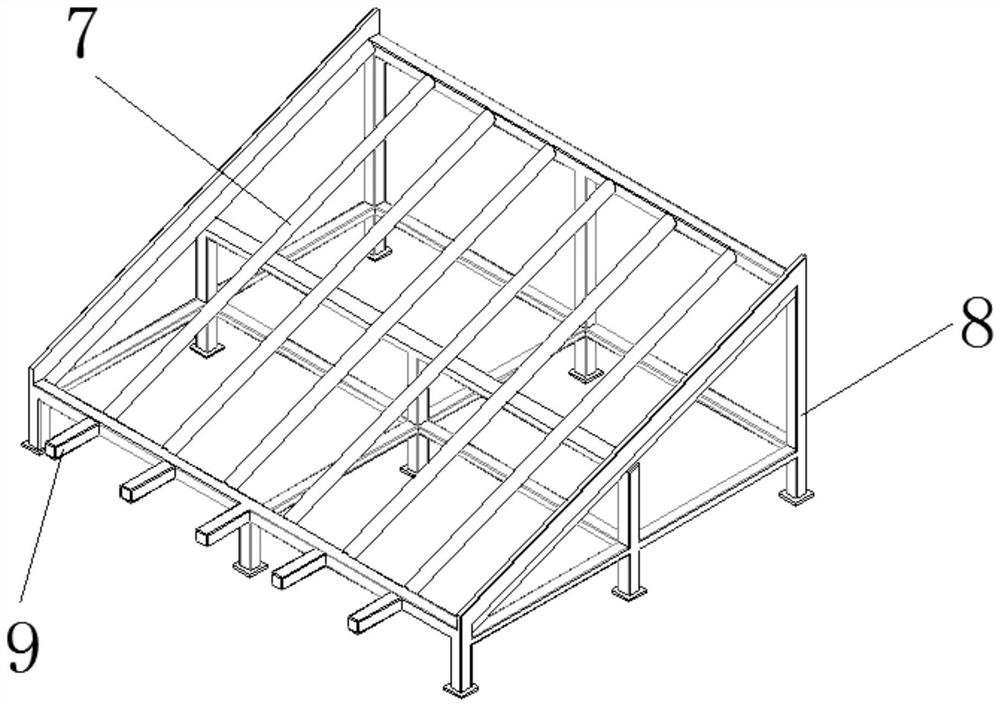

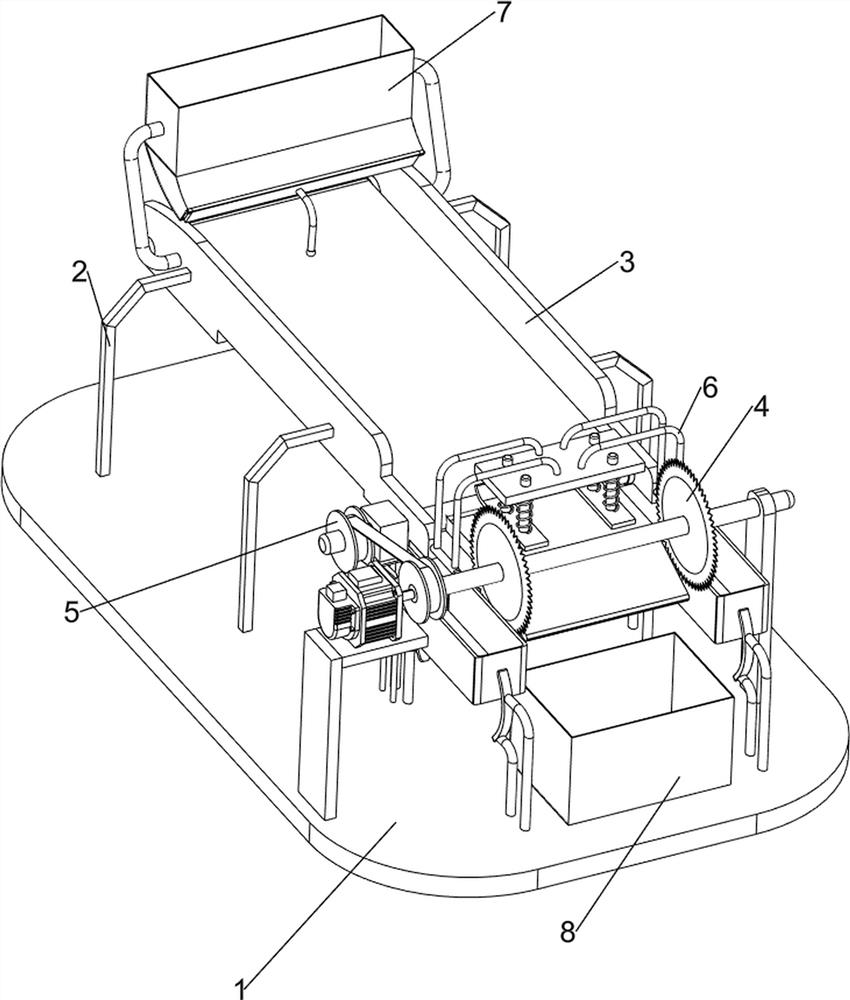

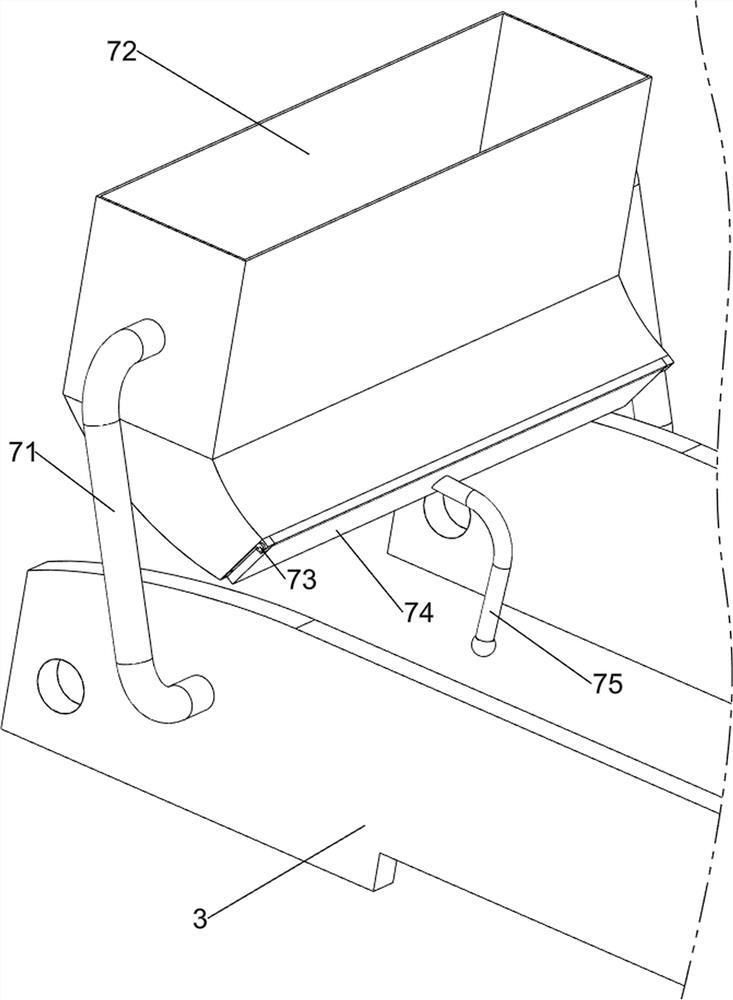

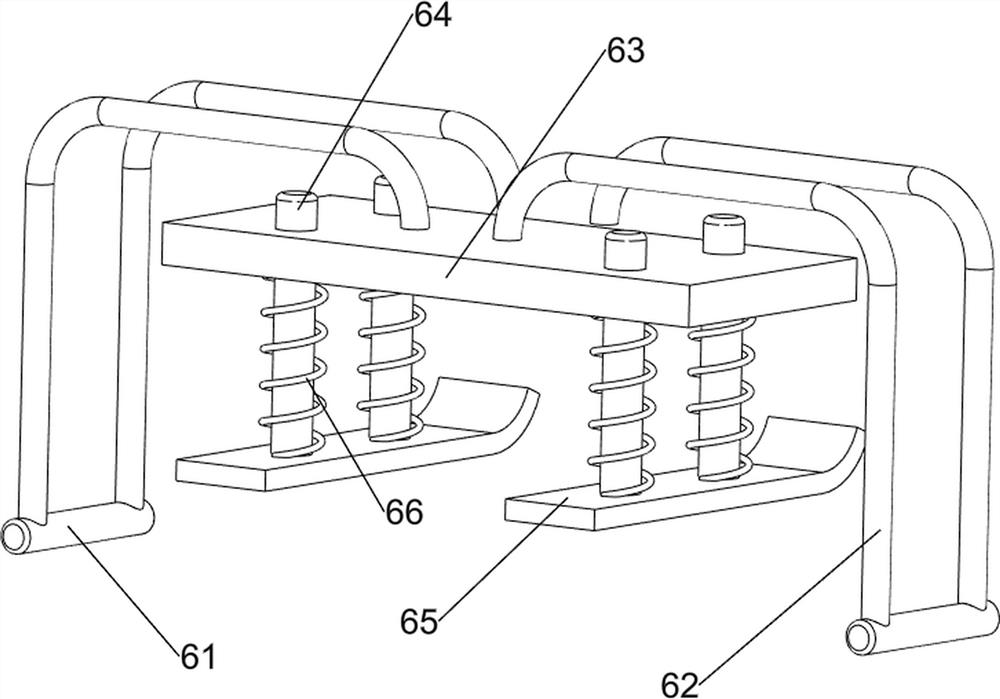

PendingCN113103372AAdjustable spacingDischarge in timeFeeding devicesLoading equipmentMechanical engineeringWood plank

The invention relates to a board thickness-adjustable type frame sawing machine. The machine comprises a wood accumulating frame, a wood taking device, a propelling device, a clamping and sawing device and a collecting and conveying device. The wood accumulating frame is provided with a slope structure enabling wood to roll down forwards in the transverse direction, and the wood taking device is located at the front side of the wood accumulating frame in the transverse direction, hooks the wood and is lifted forwards by a preset height in the transverse direction. The propelling device is located at the front side of the wood taking device in the transverse direction and used for bearing wood and conveying the wood forwards in the longitudinal direction. The clamping and sawing device is located at the front side of the propelling device in the longitudinal direction, clamps the wood to be pushed, cuts the wood into boards and conveys the boards forwards in the longitudinal direction, and a distance adjusting mechanism for adjusting the thickness of the boards cut by the clamping and sawing device is arranged on the clamping and sawing device; and the collecting and conveying device is located at the front side of the clamping and sawing device in the longitudinal direction and collects and transfers the boards. According to the frame sawing machine, the distance adjusting mechanism is adopted to adjust the thickness of the finally-machined boards, so that the boards with various thicknesses can be sawed by one machine, the working efficiency is improved, and the time and the labor cost are saved.

Owner:ZIYUAN COUNTY DUOLISHI WOODWORKING MACHINERY +1

Wood cutting machining line

InactiveCN109093766AReduce labor intensityReduce processing timeGuide fencesFeeding devicesElectric machineryMachining process

The invention discloses a wood cutting machining line. The wood cutting machining line includes a feeding device, a delivering device and a cutting device which are arranged in sequence, wherein the feeding device includes a feeding base plate, feeding vertical columns, a feeding lifting plate and a feeding assembly, the feeding vertical columns are arranged at the corners of the feeding base plate, the feeding lifting plate is slidably matched with the vertical columns, the feeding lifting plate is provided with a feeding lifting motor, and the feeding assembly is arranged on the feeding lifting plate; the delivering device includes a delivering base and a lifting delivering platform, the delivering base is provided with a guiding supporting column and a delivering lifting cylinder, and the lifting delivering platform is provided with a conveyor belt mechanism; and the cutting device comprises a rack, and a cutting mechanism and a dust removing mechanism are arranged on the rack. According to the wood cutting machining line, the functions of automatic wood feeding, delivering, cutting and sawing and dust removing are realized, manual intervention is not required in the machining process, the labor intensity is lowered, the machining time is shortened, the production efficiency is improved, automatic machining of a machine is achieved, the accuracy is ensured, and the quality of products is improved.

Owner:SUZHOU DA ER CHANG MACHINERY CO LTD

Efficient wedge-joint-board tenoning machine

PendingCN108098944AAvoid incomplete splicingPrevent tiltingEdge grinding machinesFeeding devicesAutomatic controlReciprocating motion

The invention relates to the technical field of wood processing devices, in particular to an efficient wedge-joint-board tenoning machine. The efficient wedge-joint-board tenoning machine comprises amachine base, a feeding frame and a tenoning device; the feeding frame can do reciprocating movement on the machine base through a transmission chain and is used for fixing wood slabs; the tenoning device comprises storing boxes, the two storing boxes are correspondingly located on the two sides of the machine base and connected through a telescopic device, and the storing boxes are provided withtrimming-flat saw blades, tenoning cutters and roughness removing brushes; and an aligning device can conduct aligning before tenoning of the wood slabs. According to the efficient wedge-joint-board tenoning machine, a PLC is used as a control system, flexibility is high, tenoning can be conducted on the long wood slabs or the wood slabs with different lengths, roughness of a mortise can be reduced, and safety accidents are avoided by adopting automatic control.

Owner:柳城县迪森人造板有限公司

Environment-friendly processing assembly line for building materials

InactiveCN108466350AReduce processing efficiencyRealize the function of automatic processingEdge grinding machinesGrinding carriagesProcess efficiencyEngineering

The invention relates to an environment-friendly processing assembly line for building materials. The environment-friendly processing assembly line comprises a bottom plate, wherein a limiting and pushing device, a stable cutting device and a grinding conveying device which are sequentially mounted on the bottom plate from front to rear; the limiting and pushing device comprises a limiting workingframe mounted on the bottom plate; a pushing inlet is formed in the rear side of the lower end of the limiting working frame; and two limiting auxiliary mechanisms are arranged on the limiting working frame. The environment-friendly processing assembly line for the building materials can solve the problems that material waste is caused, processing efficiency of straw tiles is reduced, manual straw tile cutting is unstable, straw tiles quickly vibrate in a cutting process and need to manually fix, operations are complex and cutting precision is low and poor as the straw tiles need to manuallycut and process, corners of the straw tiles need to grind, processing number of the straw tiles needs to manually control, and manual controlling and processing number is inaccurate in an existing process of manually processing and processing straw tiles.

Owner:王冰建

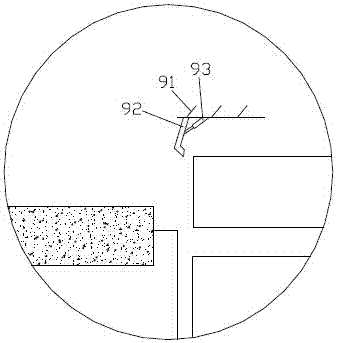

Bamboo sawing equipment

ActiveCN108748491AIncrease profitReduce scrap rateBio-packagingFeeding devicesEngineeringRejection rate

The invention relates to bamboo sawing equipment which comprises a bamboo sawing mechanism, a positioning mechanism and a sorted screening device, wherein the bamboo sawing mechanism is used for saw-cutting bamboo stumps and fixed length sections of raw bamboo; the positioning mechanism is used for determining the initial positions of the fixed length sections, so that the saw-cutting mechanism is used for saw-cutting the fixed length sections; and the sorted screening device is provided with a bamboo joint detection mechanism, wherein the bamboo joint detection mechanism is inserted into bamboo inner cavities, close to the small ends, of the fixed length sections for detecting bamboo joints, and the sorted screening device carries out sorted screening of the fixed length sections according to the bamboo joint detection result. According to the bamboo sawing equipment and a method provided by the invention, the fixed length sections can be saw-cut automatically, the bamboo joints at the small ends of the fixed length sections are detected, and the fixed length sections are screened in a sorted manner according to the condition that whether the bamboo joints at the small ends of the fixed length sections are available or not, so that the rejection rate in a bamboo breaking and slicing step as the bamboo joints are available at the small ends of the fixed length sections is reduced, and the utilization ratio of materials is improved.

Owner:HUNAN ACAD OF FORESTRY

Batch cutting forming device for disposable chopsticks

ActiveCN112659293AEasy to cutImprove work efficiencyFeeding devicesCane mechanical workingMechanical engineeringIndustrial engineering

The invention relates to a cutting forming device, in particular to a batch cutting forming device for disposable chopsticks. It is needed to design the batch cutting forming device for disposable chopsticks, which makes it convenient for people to cut bamboo boards into disposable chopsticks, saves time and labor, has high working efficiency, and avoids the situation that injury is likely to occur. The batch cutting forming device for disposable chopsticks comprises a base and supporting columns, wherein supporting seats are symmetrically installed on one side of the base, and the four supporting columns are installed on the base. According to the batch cutting forming device for disposable chopsticks, a bamboo board is placed a feeding mechanism, the feeding mechanism and a cutting mechanism are started to operate, the feeding mechanism operates to drive the bamboo board to move leftwards, the bamboo board moves leftwards into the cutting mechanism, meanwhile, the feeding mechanism operates to drive the cutting mechanism to move up and down, and the cutting mechanism moves downwards to perform cutting forming on the bamboo board. Thus, people can conveniently cut bamboo boards into disposable chopsticks, time and labor are saved, and the working efficiency is high.

Owner:宜春市华韵实业有限公司

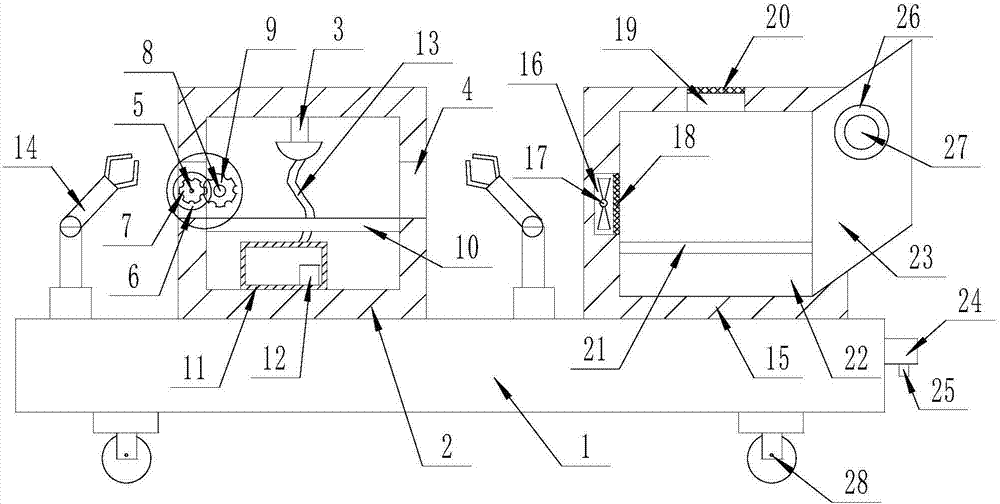

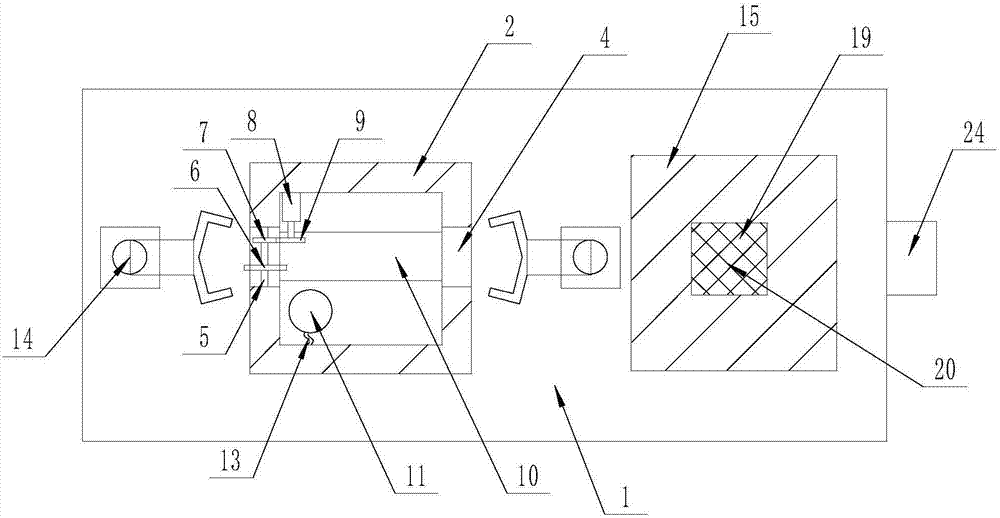

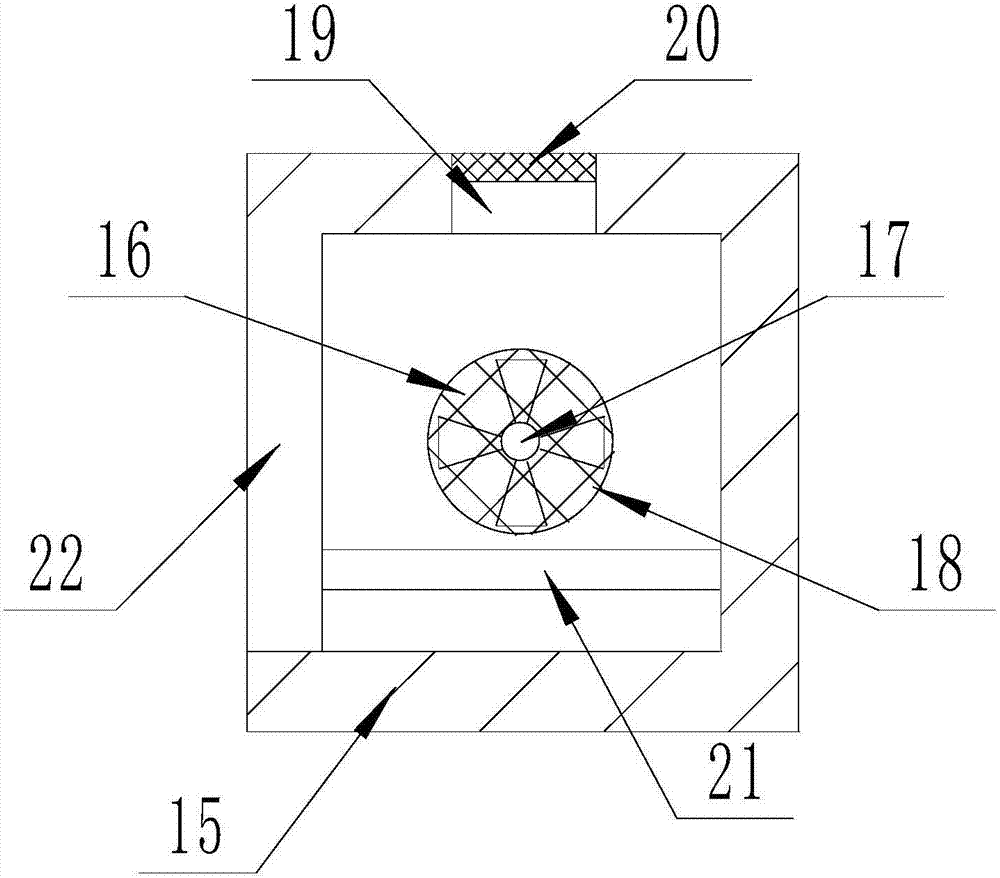

Cutting, paint spraying and air drying device

InactiveCN107029927ANo deformationEasy to operatePretreated surfacesLoading equipmentEngineeringMechanical engineering

The invention discloses a cutting, paint spraying and air drying device which comprises a rectangular working table. A cutting and paint spraying system is arranged on the upper surface of the rectangular working table, an air drying box is arranged on the upper surface of the rectangular working table and on one side of a mechanical clamping handle, a set of round grooves are machined in the center of the surface of the inner side of the air drying box, draught fans are arranged in the round grooves, protection nets are arranged at openings of the round grooves, a ventilation opening is machined in the center of the upper surface of the interior of the air drying box, and a screen net is embedded in the ventilation opening; a layer plate is arranged in the air drying box, an opening is machined in the front surface of the air drying box, an electric stopping door is arranged at the position of the opening, and a controller is arranged on the surface of one side of the rectangular working table; and an electric supply connector is arranged on the controller and is electrically connected with the controller, and the controller is electrically connected with the cutting and paint spraying system, the mechanical clamping handle, the draught fans and the electric stopping door. The cutting, paint spraying and air drying device has the beneficial effects that operation is simple, indirect contact between operators and a cutter and between the operators and sprayed paint is avoided through automatic running, and cutting, paint spraying and air drying device is convenient and practical.

Owner:湖北鑫民建设集团有限公司

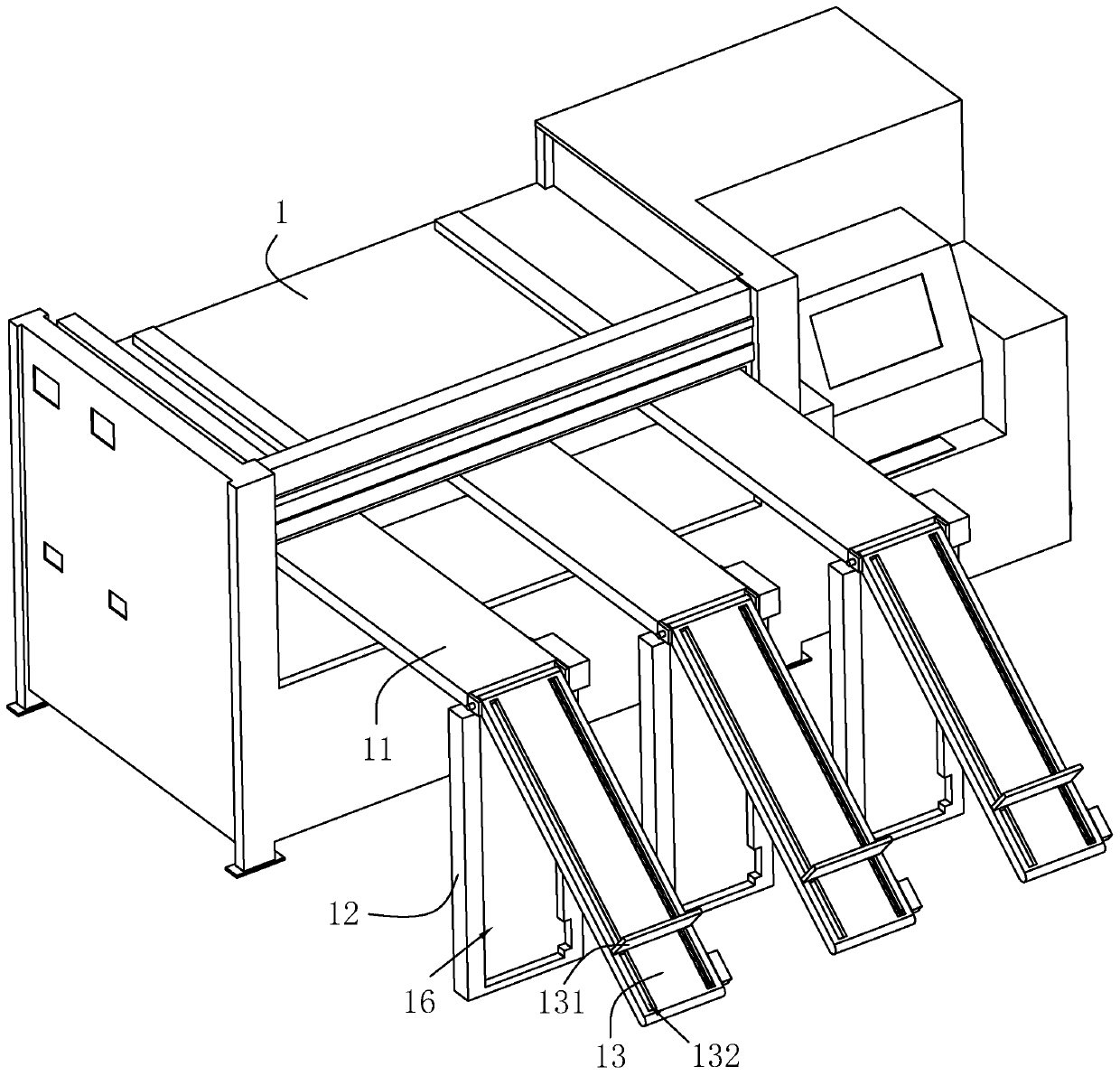

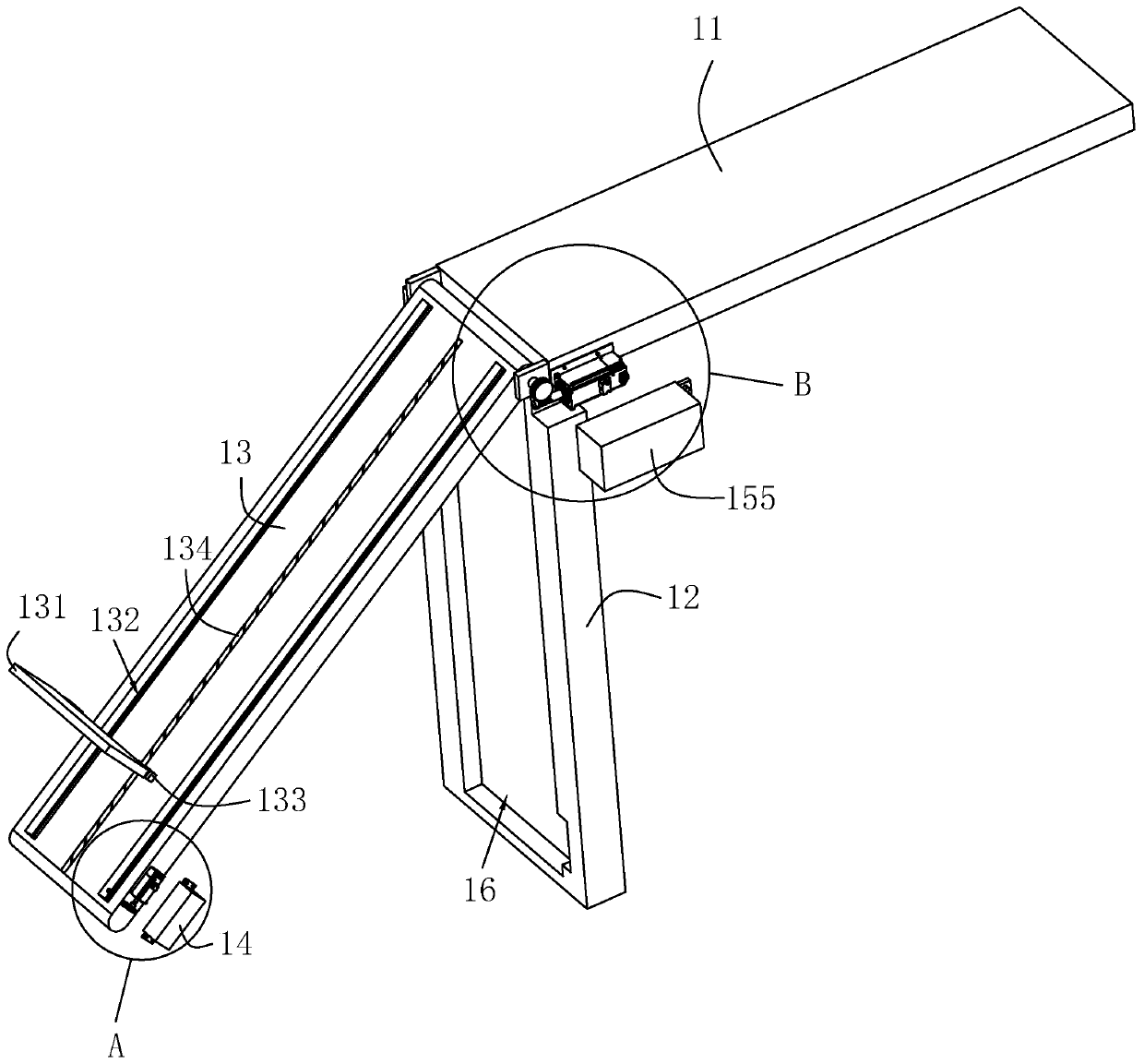

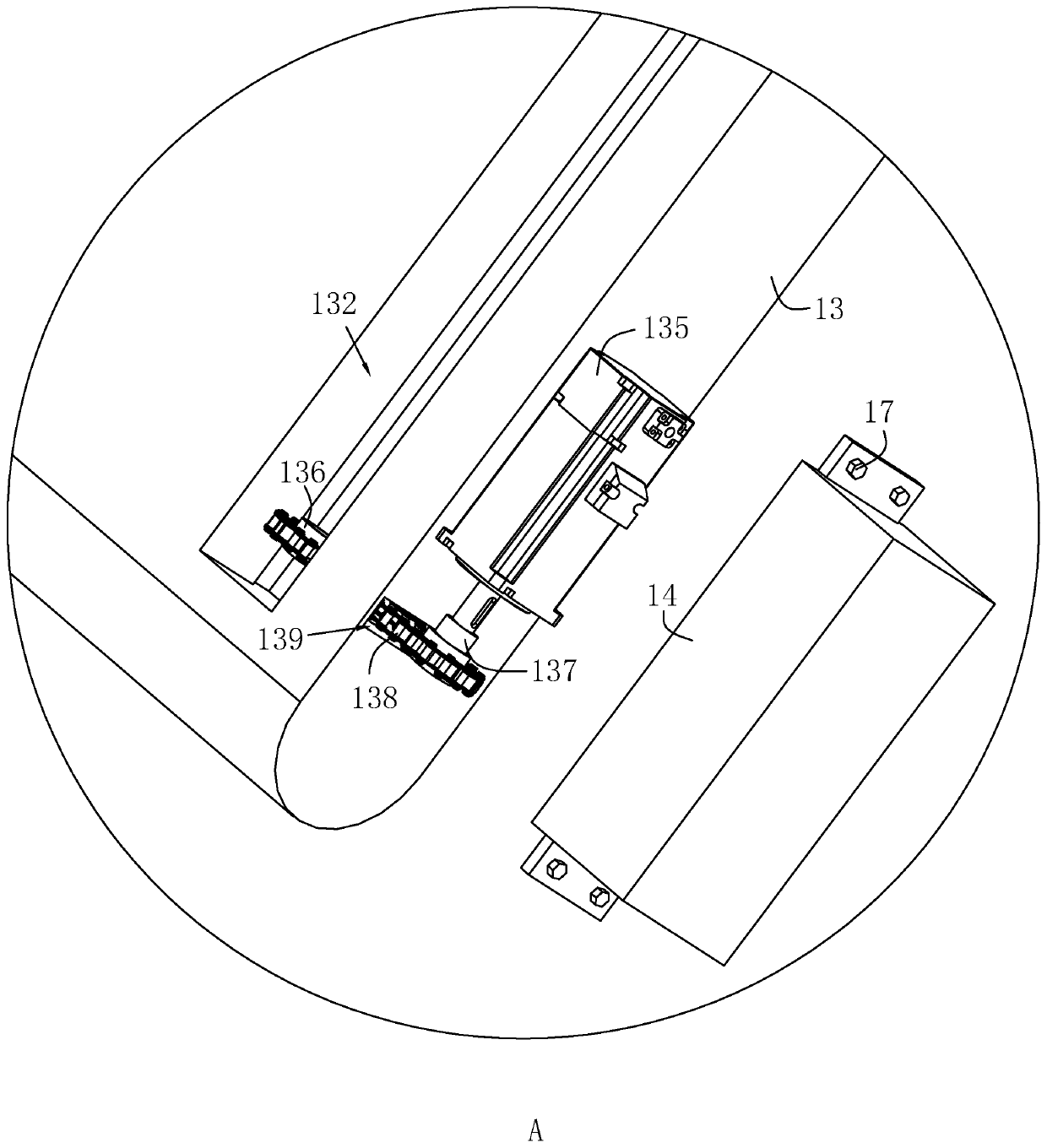

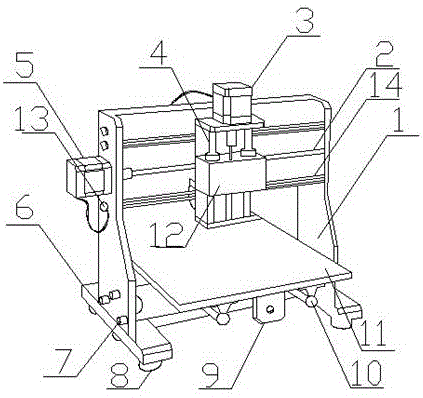

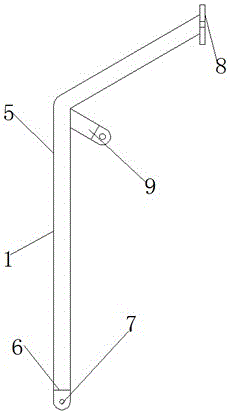

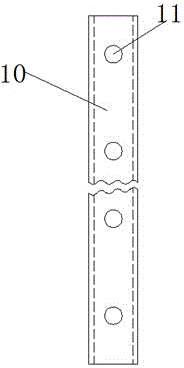

CNC saw convenient for feeding

ActiveCN110450231ASave human effortAvoid taking up spaceFeeding devicesLoading equipmentWood machiningEngineering

The invention relates to a CNC saw convenient for feeding, and belongs to the technical field of wood machining equipment. The CNC saw comprises a machine body, wherein a plurality of conveying tablesare arranged on the machine body at intervals, the edge, away from the machine body, of facing the ground, of the conveying table is obliquely extended and provided with conveying plates, moving plates are arranged on the conveying plates perpendicular to the conveying plates, and sliding grooves are formed in the conveying plates and located on two sides of the conveying plates, sliding blocks slidably connected in the sliding grooves are arranged on the moving plates and located on the two sides of the moving plates, and first driving parts used for driving the sliding blocks to move in thesliding grooves are arranged in the sliding grooves, when the woods need to be transported to the conveying tables, the woods are placed on the surface, facing the conveying tables, of the moving plates, at the moment, the sliding blocks are driven by the first driving parts to move in the sliding grooves to drive the woods on the moving plates to move to the position of the conveying tables, andthe operator can push the woods to the conveying tables by pushing the woods, so that manpower is saved.

Owner:成都梵凰家具有限公司

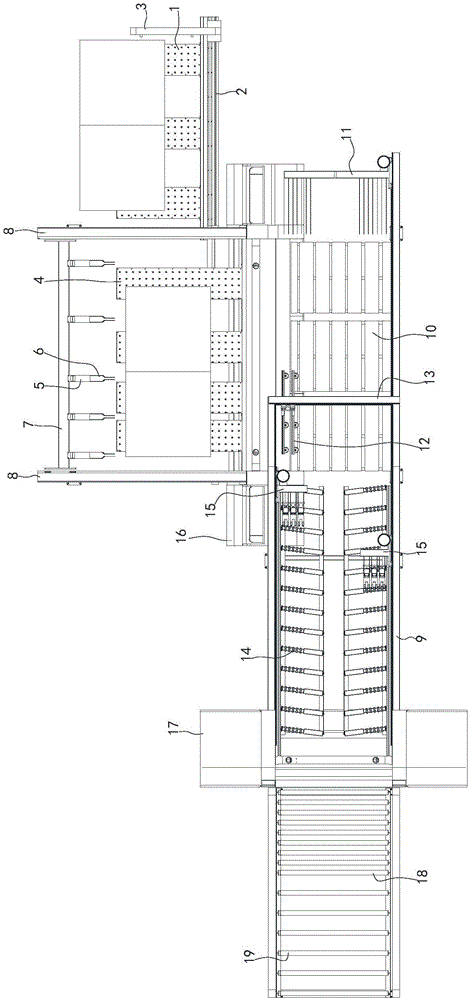

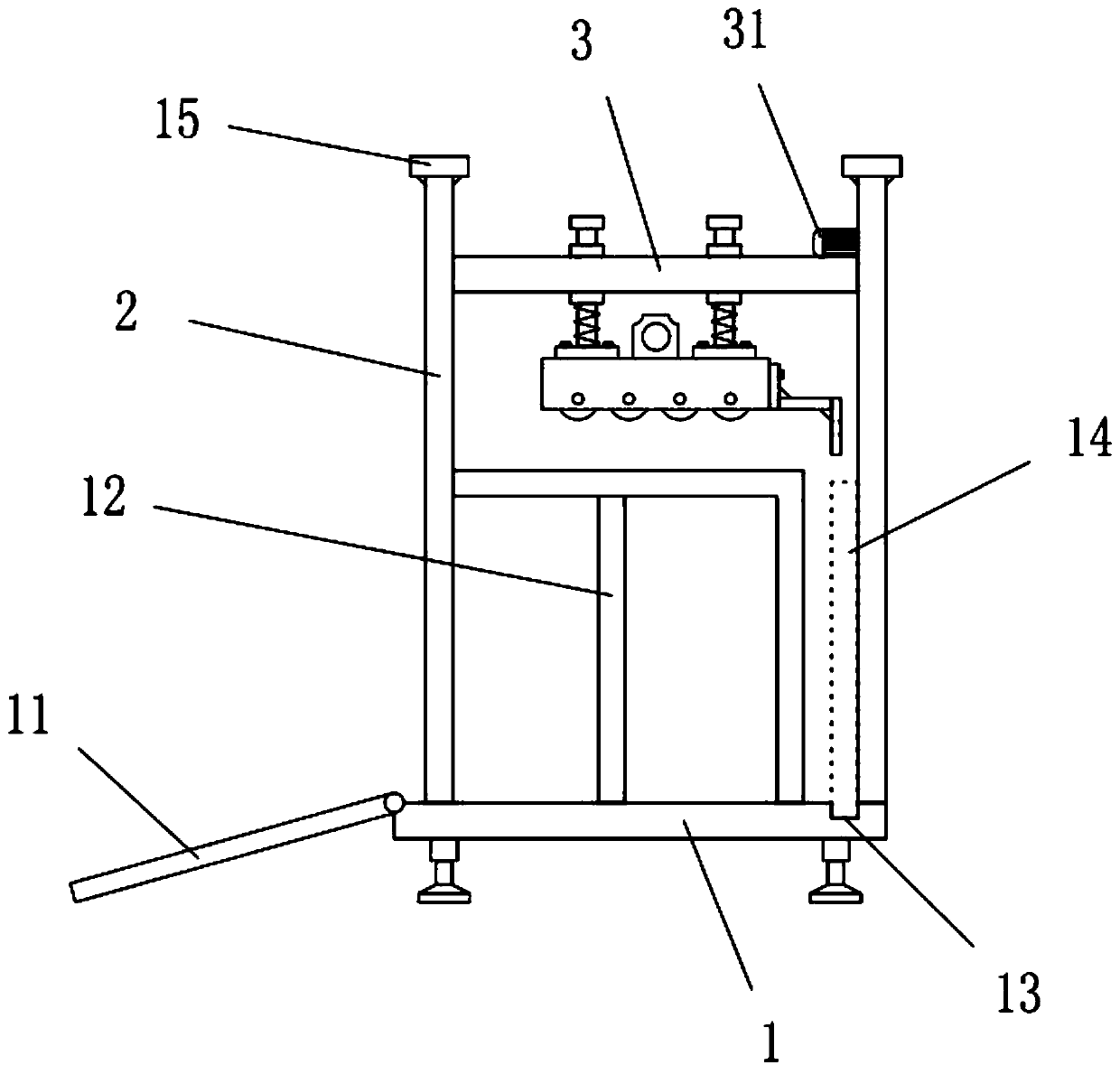

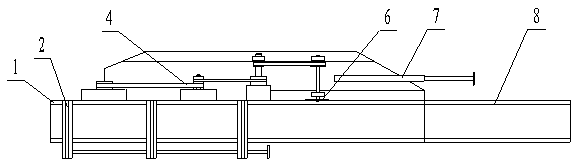

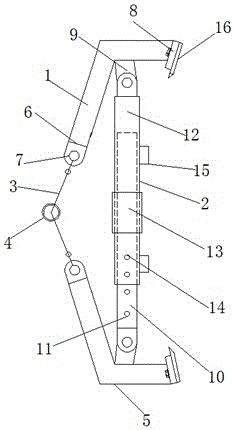

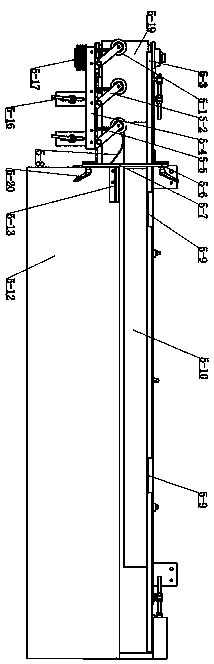

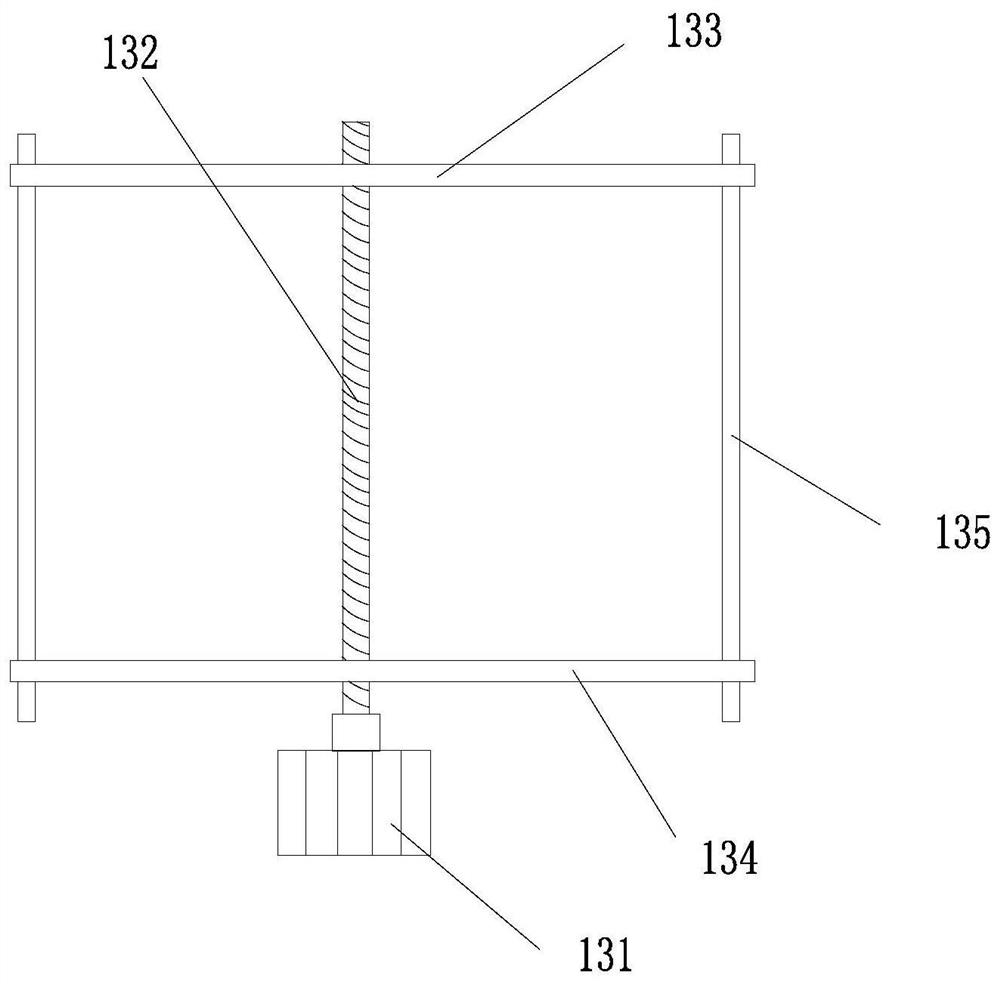

Thin plate rear end automatic loading system for electronic saw

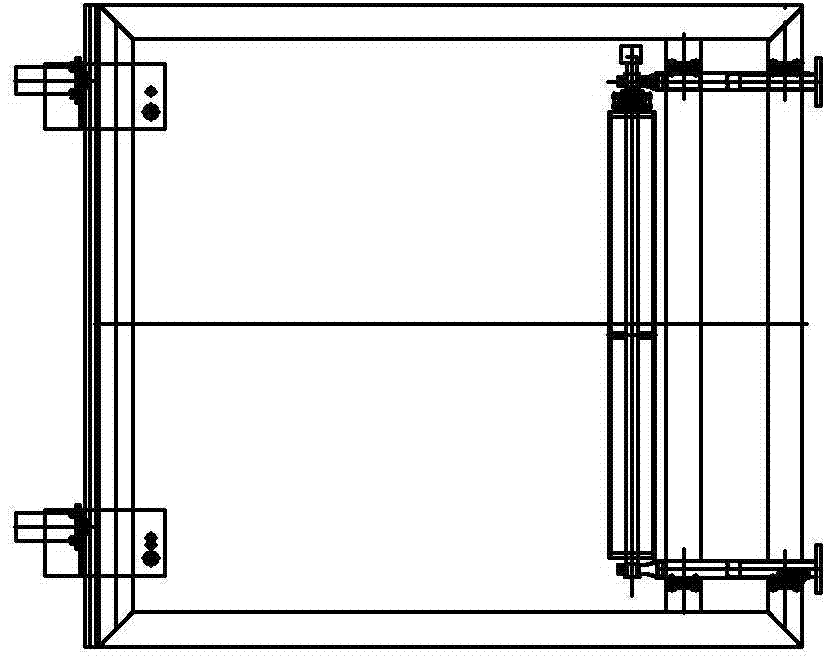

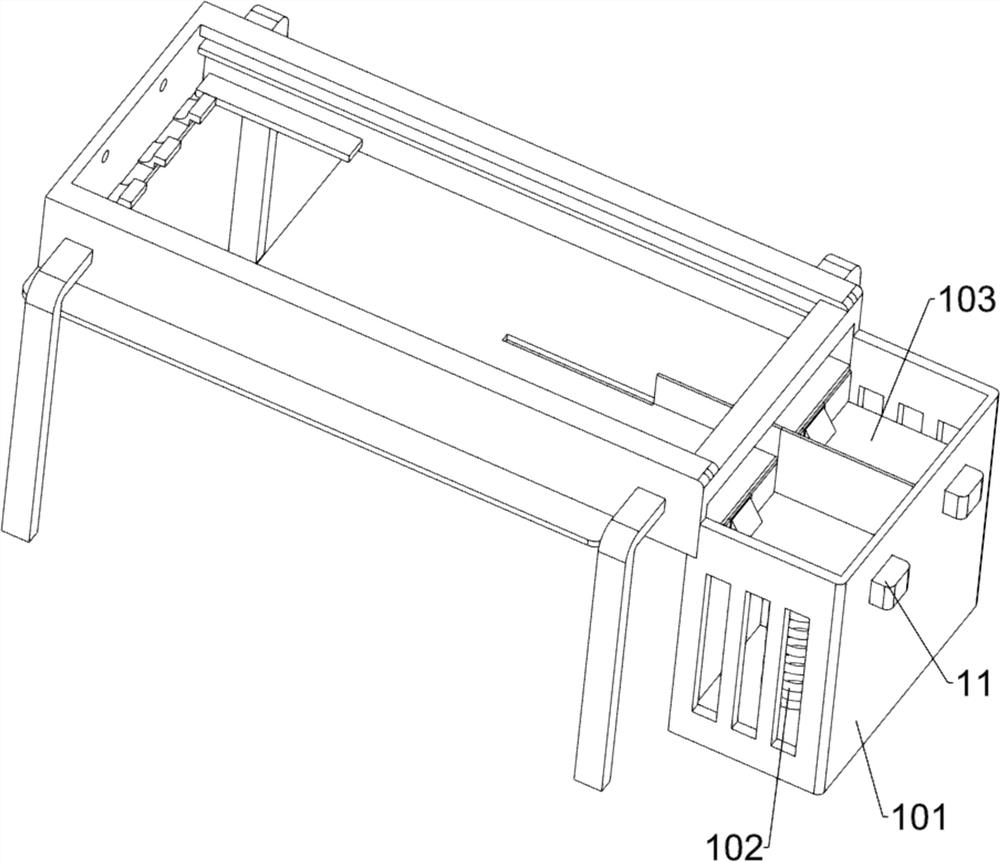

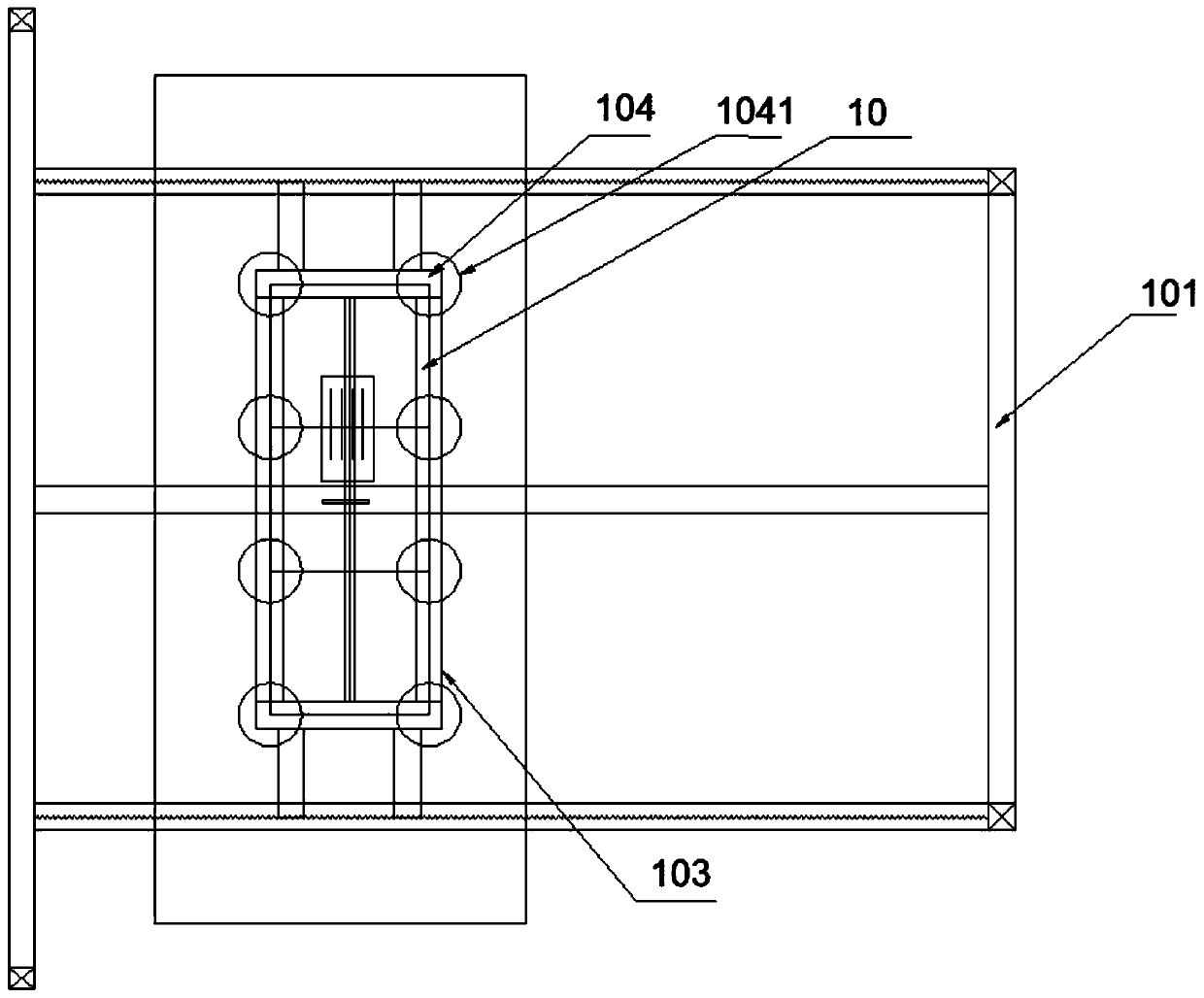

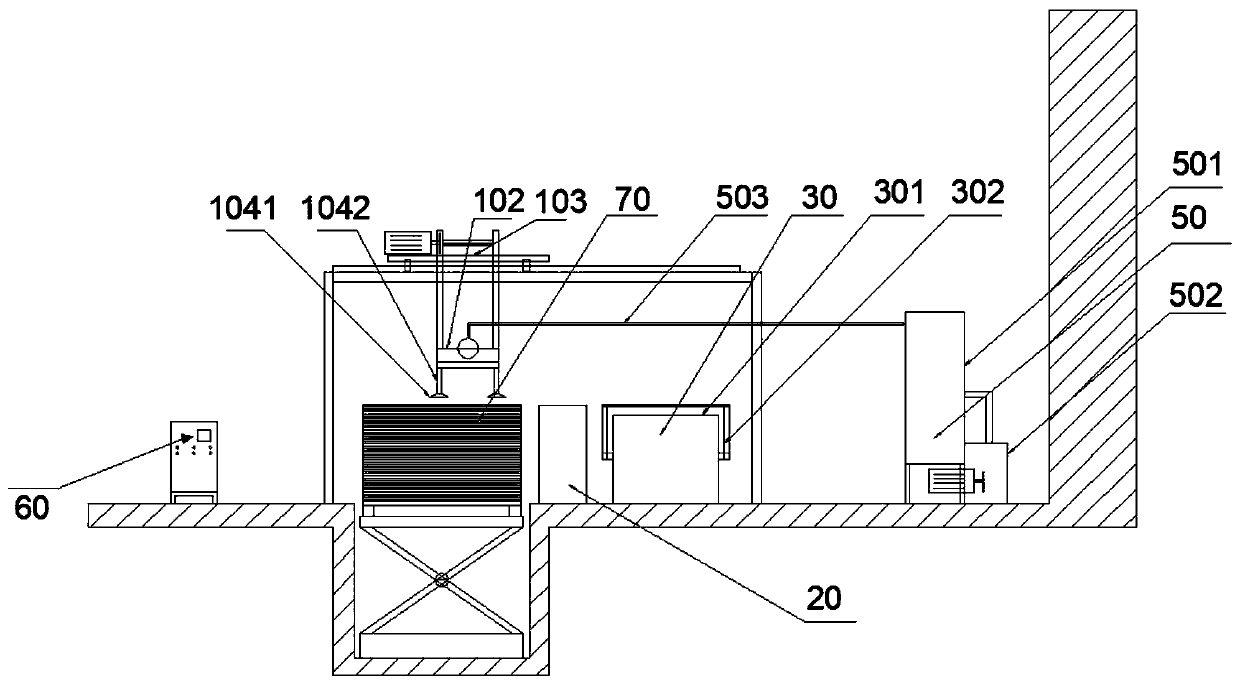

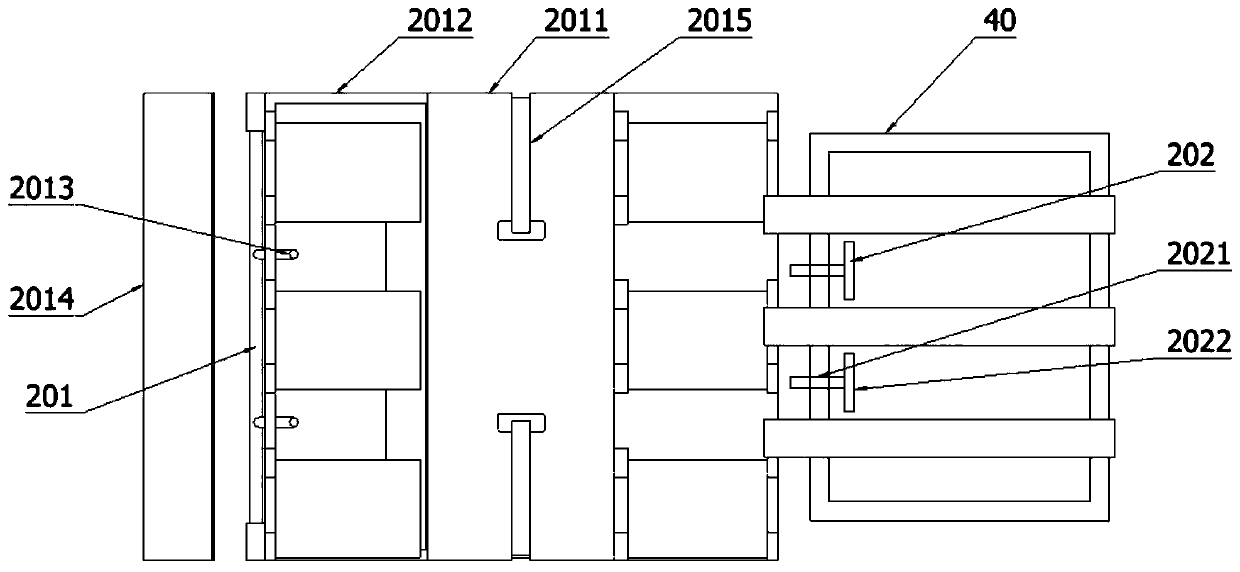

PendingCN111376352APrecise determination of lifting heightHigh precisionFeeding devicesLoading equipmentStructural engineeringMechanical engineering

The invention discloses a thin plate rear end automatic loading system for an electronic saw. The system comprises a rack, an auxiliary feeding unit, a main feeding unit, a power system and an intelligent control system. A conveying plate is fixed to the rack, a pair of longitudinal beams are fixed to the two sides of the rack, the main feeding unit is fixed to the rack through the longitudinal beams, the auxiliary feeding unit is located on the front end of the rack, through the intelligent control system, the power system is controlled, a plate is pushed to the conveying plate from the auxiliary feeding unit and is conveyed out through the main feeding unit, the auxiliary feeding unit is mounted, a height measuring plate clamping device is mounted in the auxiliary feeding unit, under theeffect of a magnetic railing ruler, the lifting height of the plate can be precisely fixed, precision of the thin plate in the loading process can be improved, the damage to the thin plate can be reduced to the maximum degree, and safety and high efficiency in the work process can be improved.

Owner:泰州市龙洋木业有限公司

Working platform with hydraulic pump

InactiveCN106346562AWon't spillEven by forceWood feeding arangementsFeeding devicesHydraulic pumpEngineering

The invention discloses a workbench with a hydraulic pump, which comprises a baffle plate, a beam, a No. 1 power source, a piston rod, a No. 2 power source, a metal base, a fixing nut, a suction cup, a connecting plate, a moving rack, and a feeding Forks, hydraulic pumps, wiring holes, trusses. The beneficial effects of the present invention are: the side and the back of the stable and efficient cantilever workbench are provided with baffles to ensure that the material will not be spilled when taking materials; the piston rod and the truss are connected to the No. 1 power source, and the two-way braking system ensures The force is uniform and the structure performance is stable; one side of the reclaiming fork is equipped with a metal connecting plate connected to the double moving rack, and the moving rack is connected to the second power source, which makes the moving speed of the reclaiming fork faster and improves the machine efficiency; The base, the metal bottom is used to set the suction cup below, which ensures the stability of the machine during operation; the beam is set in the middle of the baffle, and the metal base is set at the bottom, which strengthens the structural stability of the entire working platform.

Owner:江苏江北泵业制造有限公司

Wood cutting conveying device

The invention discloses a wood cutting conveying device. The wood cutting conveying device comprises a wood box, a worktable, a telescopic pump, a telescopic push rod, a push head, a wood groove, binding bandages, a PLC touch screen, a piston rod, an electric saw, a tilt table, a groove, a sawdust box, a conveying belt, a container, a fuel tank, a processing box, a starter, a cylinder, a through hole, jackstays, an L-shaped bracket, pliers, a mechanical arm, a positioning sensor, logic circuit chips, a single chip, a motor, an oil inlet, a cock, a fixing block, a perforation and a lock catch.The wood cutting conveying device is innovative in design and has practical functions, wood is transported to the wood cutting conveying device by the installed mechanical arm instead of manual handling, the wood is cut into small pieces of wood of uniform size under cutting of the electronically controlled electric saw, and the small pieces of wood are transported into the container by the conveying belt; and the whole process can be realized by manually operating the PLC touch screen, therefore, the degree of intelligence is particularly high, the design is ingenious and innovative, and spreading use is recommended.

Owner:TAIZHOU DINGTUO IND DESIGN CO LTD

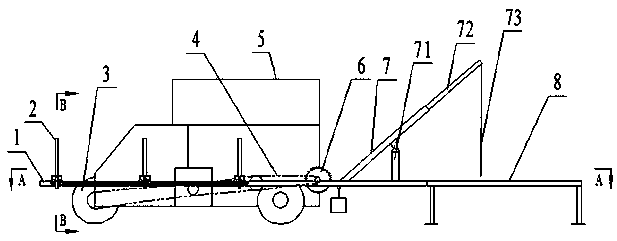

Movable log saw board device

The invention discloses a movable log saw board device. The device comprises a vehicle frame, a travelling mechanism is arranged at the bottom of the vehicle frame, a cab is arranged at the front end of the vehicle frame, a tool kit is arranged on the top of the vehicle frame, a fixed rail is arranged on one side of the vehicle frame, the length of the fixed rail is matched with that of a vehicle body, a movable rail is movably arranged on the tail of the fixed rail, and a wood clamping platform mechanism is movably installed above the fixed rail and can slide leftwards and rightwards on the fixed rail and the movable rail; a log hoisting mechanism is arranged on the tail of the vehicle frame in the direction parallel with the rails, a log saw board mechanism is arranged on the portion, on the inner side of the fixed rail, of the vehicle frame, and a power device driving the vehicle frame to move and the log saw board mechanism to run is arranged at the bottom of the vehicle frame. According to the movable log saw board device, field transfer is convenient, functions are complete, manufacturing is easy, manufacturing cost is low, operation efficiency is high, and production cost is low.

Owner:章能昌

Wood board cutting equipment for furniture production

InactiveCN112809838APrevent flying outCutting stabilityFeeding devicesLoading equipmentMechanical engineeringWood plank

The invention relates to cutting equipment, in particular to wood board cutting equipment for furniture production. According to the wood board cutting equipment for furniture production, wood boards can be automatically cut, manual edge changing is not needed, time and labor are saved, and the efficiency is high. In order to achieve the technical aims, the invention provides the wood board cutting equipment for furniture production. The equipment comprises a bottom plate connected with supporting legs, a first baffle connected to the supporting legs, a cutting mechanism connected to the bottom plate, and a conveying mechanism connected to the first baffle. According to the wood board cutting equipment, the wood boards are conveyed and cut through cooperation of the cutting mechanism and the conveying mechanism, cutting is more stable through a pressing mechanism, the wood boards are prevented from flying out, and the working efficiency is improved.

Owner:邓红梅

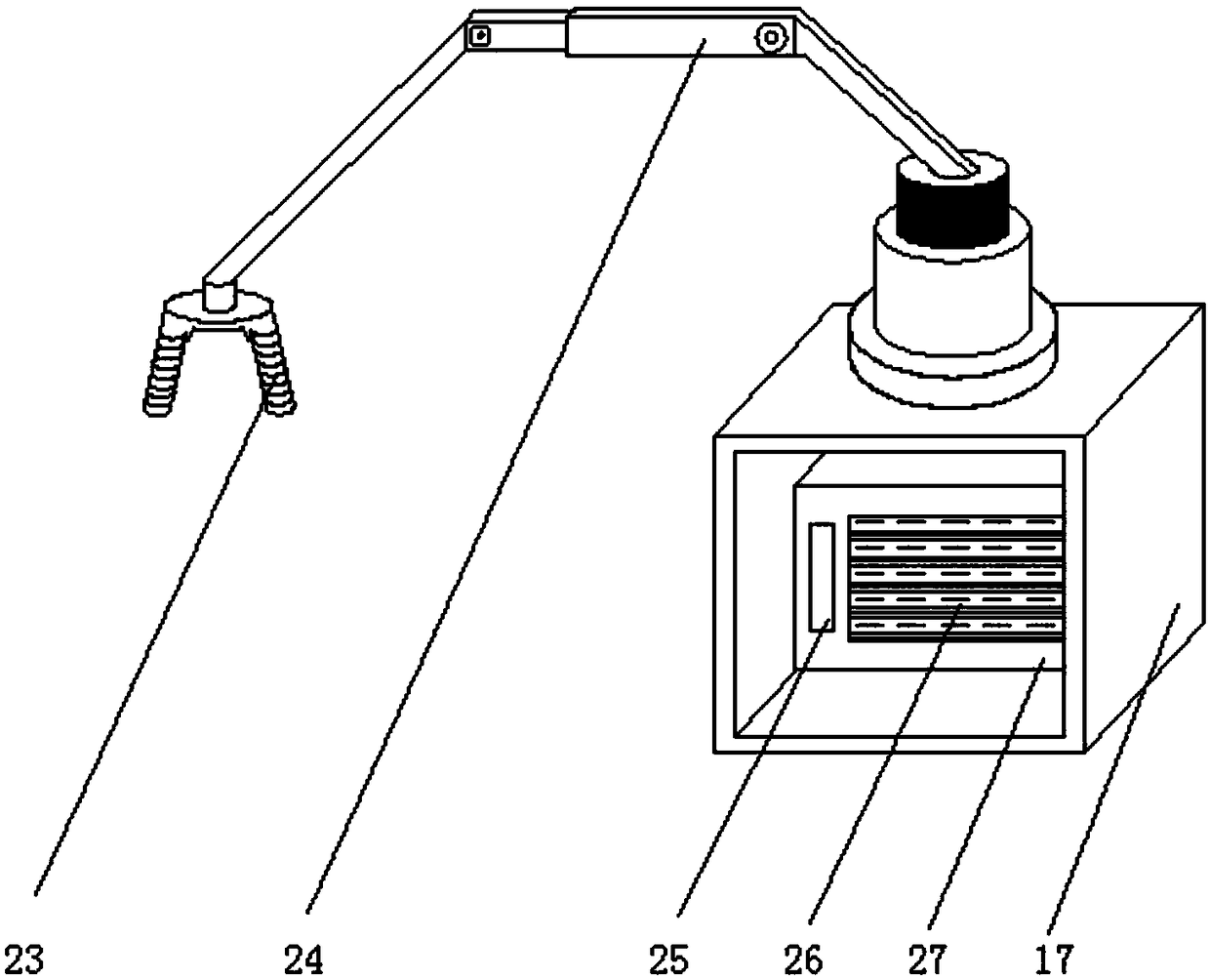

Special wood lifting and grabbing fixture applicable to wood processing in small and medium-sized enterprises

InactiveCN106313189AControl gripControl releaseLoading equipmentBand sawsArchitectural engineeringWood processing

The invention discloses a special wood lifting and grabbing fixture applicable to wood processing in small and medium-sized enterprises. The fixture comprises two connecting rods, wherein steel wire ropes are mounted at the ends, close to each other, of the two connecting rods, the steel wire ropes are sleeved with hanging loops, wood binding tooth plates are mounted at the ends, far away from each other, of the two connecting rods, and an adjusting support is mounted between the two connecting rods; each of the two connecting rods comprises an L-shaped support rod, a groove is formed in one end of the L-shaped support rod, a rotating shaft is mounted in the groove and connected with the corresponding steel wire rope, a tooth plate mounting seat is mounted at the other end of the L-shaped support rod and connected with the corresponding wood binding tooth plate through screws, and a connecting hinge is mounted on one side, close to the adjusting support, of the L-shaped support rod. The fixture is simple and quick to operate, simple in structure, low in production cost, high in adaptability and capable of lifting wood in different sizes, falling off of the wood during lifting is prevented, the safety of operators and equipment is guaranteed, the loading time and labor are saved, and the loading efficiency and machining production benefits of the wood are improved.

Owner:东台市唐洋带锯机械有限责任公司

Uniform cutting equipment for wood board for furniture production

ActiveCN112372746AReduce manual fixationAchieve cutting effectFeeding devicesGripping devicesMechanical engineeringWood plank

Owner:江门市甲鹏益木业有限公司

Full-automatic panel processing all-in-one machine and using method thereof

PendingCN110405854ARealize automatic productionImprove feeding efficiencyFeeding devicesLoading equipmentRelative motionMechanical equipment

The invention discloses a full-automatic panel processing all-in-one machine, and relates to the field of panel processing conveying mechanical equipment. The full-automatic panel processing all-in-one machine comprises a feeding part, a material inlet part and a cut-off part. The feeding part is arranged on a plane and is used for grabbing panels. The material inlet part is arranged on the plane,the material inlet part is arranged on the plane and is arranged in a containing space partially. The material inlet part is arranged parallel to the plane. The cut-off part is arranged at the periphery of the feeding part. The cut-off part is connected with the feeding part. The cut-off part is detachably connected with the material inlet part. The cut-off part is arranged above the material inlet part. Relative motion refers to any one of the situations including movement of the cut-off part towards the material inlet part and or movement of the material inlet part towards the cut-off part.According to the a full-automatic panel processing all-in-one machine, panel feeding can be implemented in the panel processing process so that manual interference is reduced, the panel feeding efficiency is improved, and furthermore, and it is achieved that panels are cut after the panels are automatically fed, in other words, it is achieved that panel processing is automatic.

Owner:张家港市盛港绿色防火建材有限公司

Palletizing device

ActiveCN109250466BCode implementationConveyorsFeeding devicesAgricultural engineeringStructural engineering

The invention relates to a stacking device, which comprises a first conveying crawler arranged at the outlet position of peeling devices, a second conveying crawler is arranged below the discharge endof the first conveying crawler, a material receiving inclined plate is arranged at the discharge port of the second conveying crawler, a material receiving cross rod is arranged at the bottom end ofthe material receiving inclined plate, the side of the material receiving cross rod is provided with a segment material receiving mechanism, the segment material receiving mechanism is used for receiving the segments arranged on the material receiving cross rod and transferring the segments to the position of a material receiving frame, after peeled by the peeling device at each stage, the segments are exported through the first conveying crawler, the second conveying crawler exports the segments to the position of the material receiving inclined plate, the segments slide down to the materialreceiving cross rod through the material receiving inclined plate, and are stacked in a single row, after the material receiving cross rod is fully provided with the segments, a segment receiving mechanism is started, so that the receiving of the segments on the receiving cross rod is carried out, and the segments are conveyed to the position of the material receiving frame, so as to achieve the stacking of the segments, and when the material receiving frame is fully filled with the segments and is transported to an airing room for naturally drying, usable planting base wood can be obtained.

Owner:王步熬

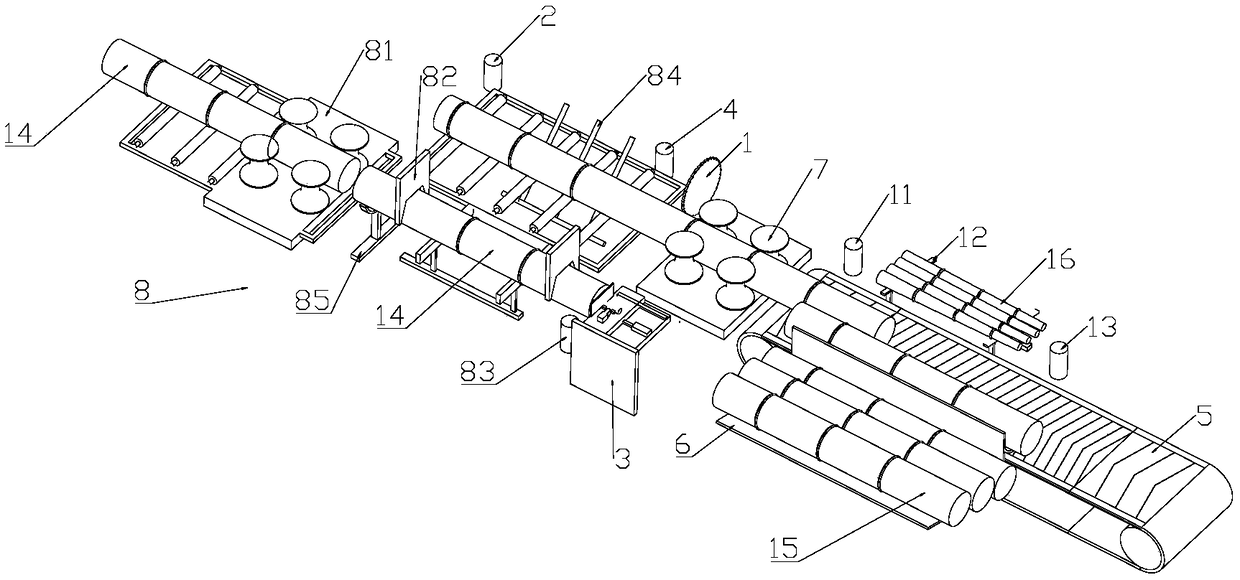

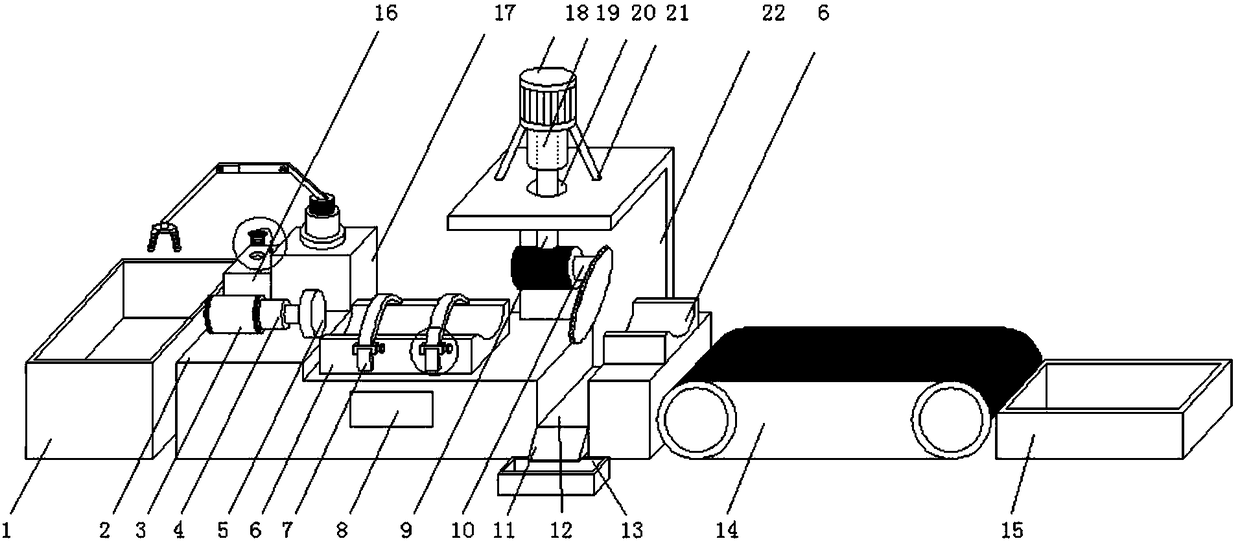

High speed optimized truncating and finish planing production line

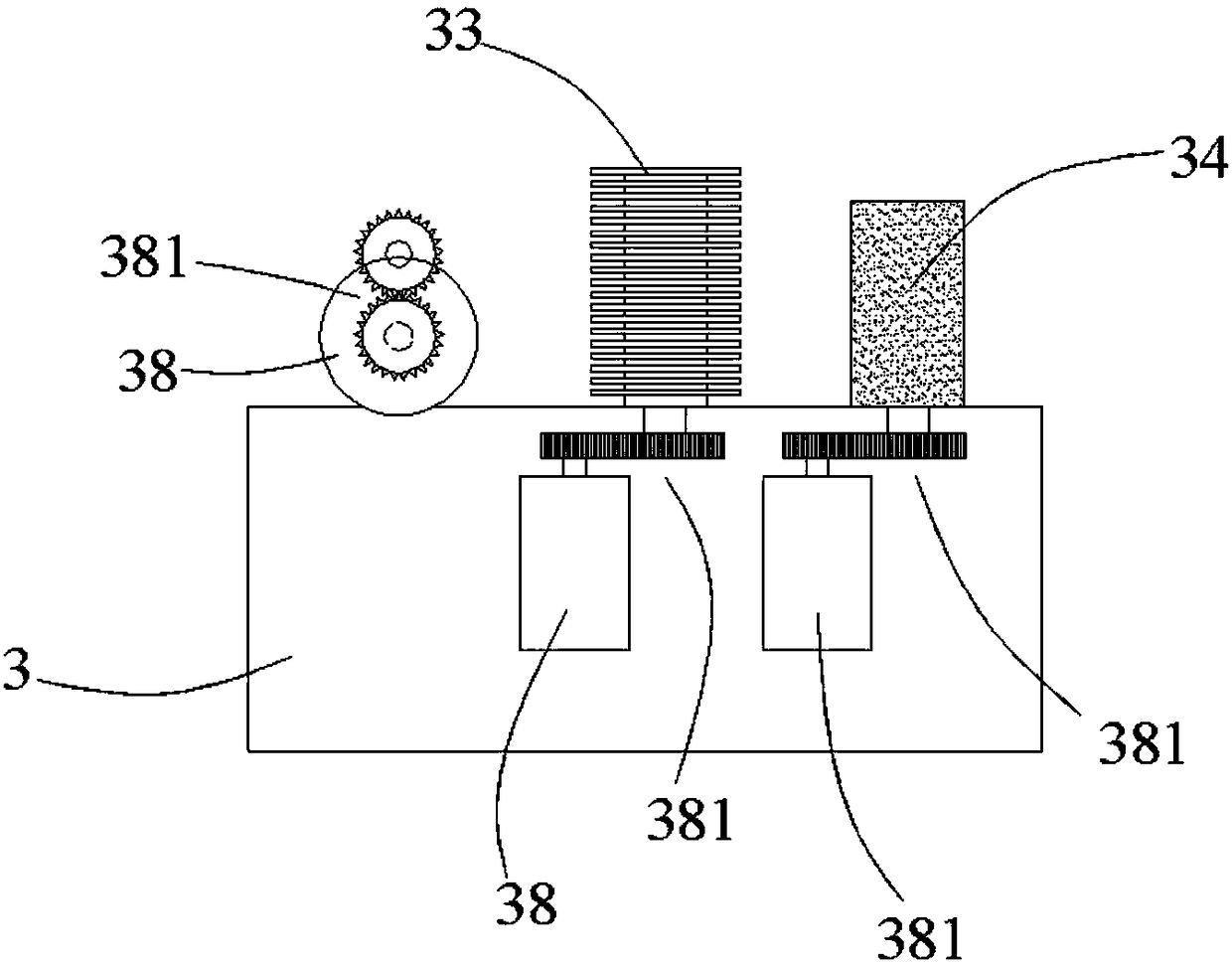

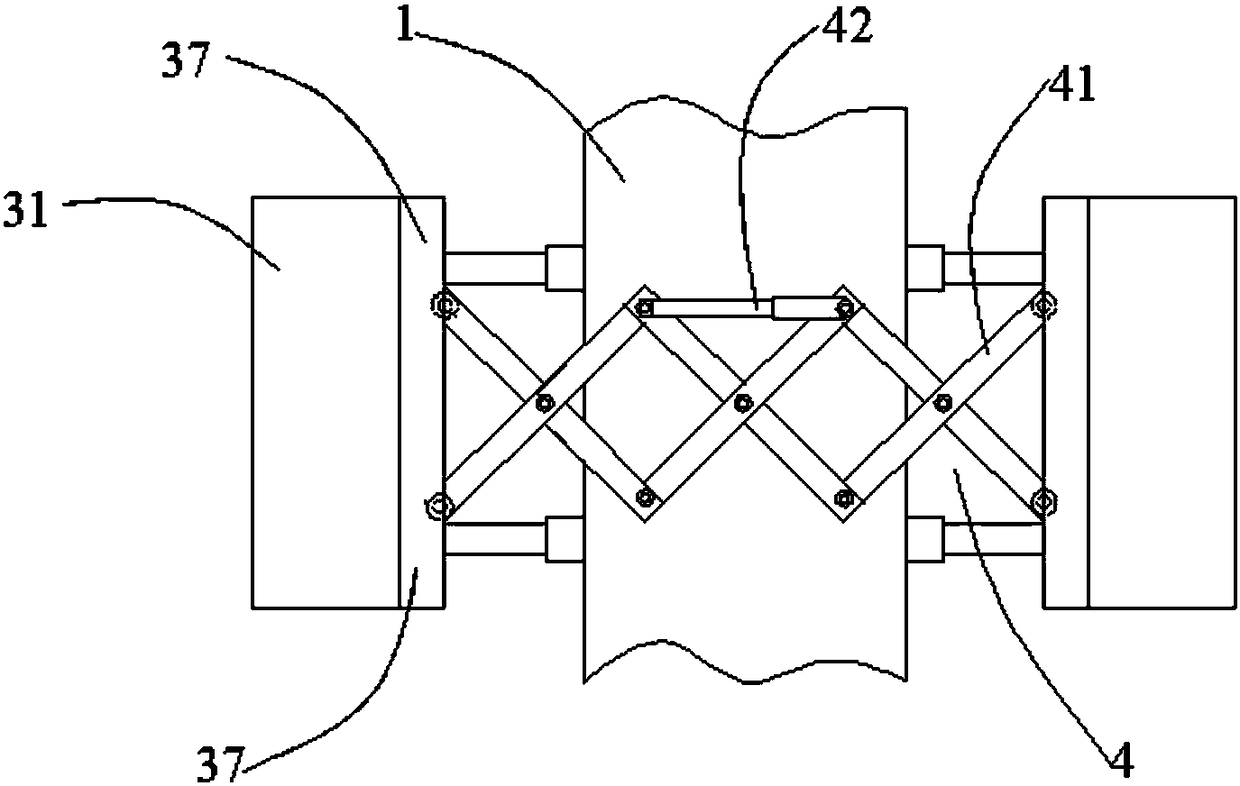

PendingCN109203085AAccurate and stable grippingExact stability constraintsWood feeding arangementsFeeding devicesProduction lineEngineering

The invention discloses a high speed optimized truncating and finish planing production line. The high speed optimized truncating and finish planing production line comprises an optimized truncating saw and a planing and milling machine. The optimized truncating saw is connected to the planing and milling machine through a truncated material conveying device. A feeding conveying device is connected to the feeding end of the optimized truncating saw, and a sorting pusher is also arranged on the truncated material conveying device. The ratio of a gap B between a material control gear and a feeding conveyor belt of the feeding conveying device to the thickness H of a wood material B / H is 1.8-1.2. A front conveyor belt and a back conveyor belt are arranged on an output material rack of the truncated material conveying device, and a material scraping roller is arranged between the front conveyor belt and the back conveyor belt; a coarse planing lower planer tool, a finish planing lower planer tool and an upper planer tool of the planing and milling machine are successively arranged from front to back along a wood material feeding channel. A follow-up pinch roller rack is connected to the piston rod end of a follow-up pinch roller air cylinder, a presser foot follow-up pinch roller is rotatably supported at the lower end of a presser foot follow-up pinch roller slide, and a wood material guiding and conveying device is also mounted at the front end of the body. The production line not only is good in processing quality, but also is high in production efficiency.

Owner:JIANGSU JIANGJIA MACHINERY

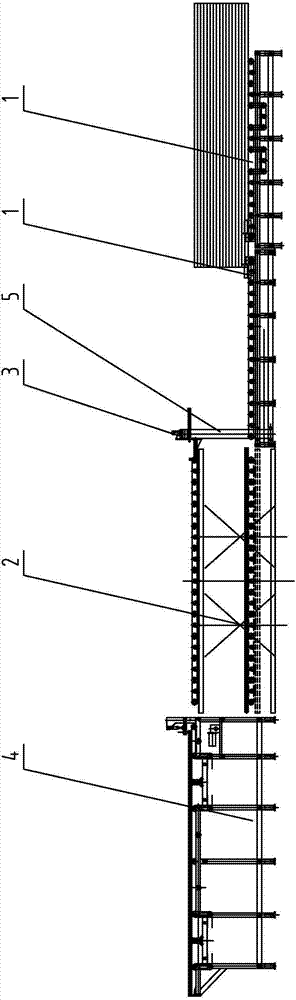

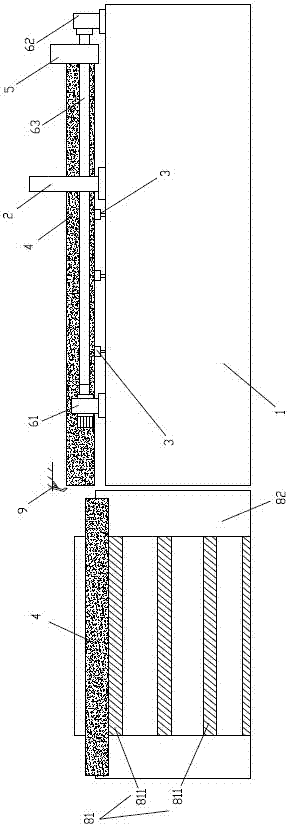

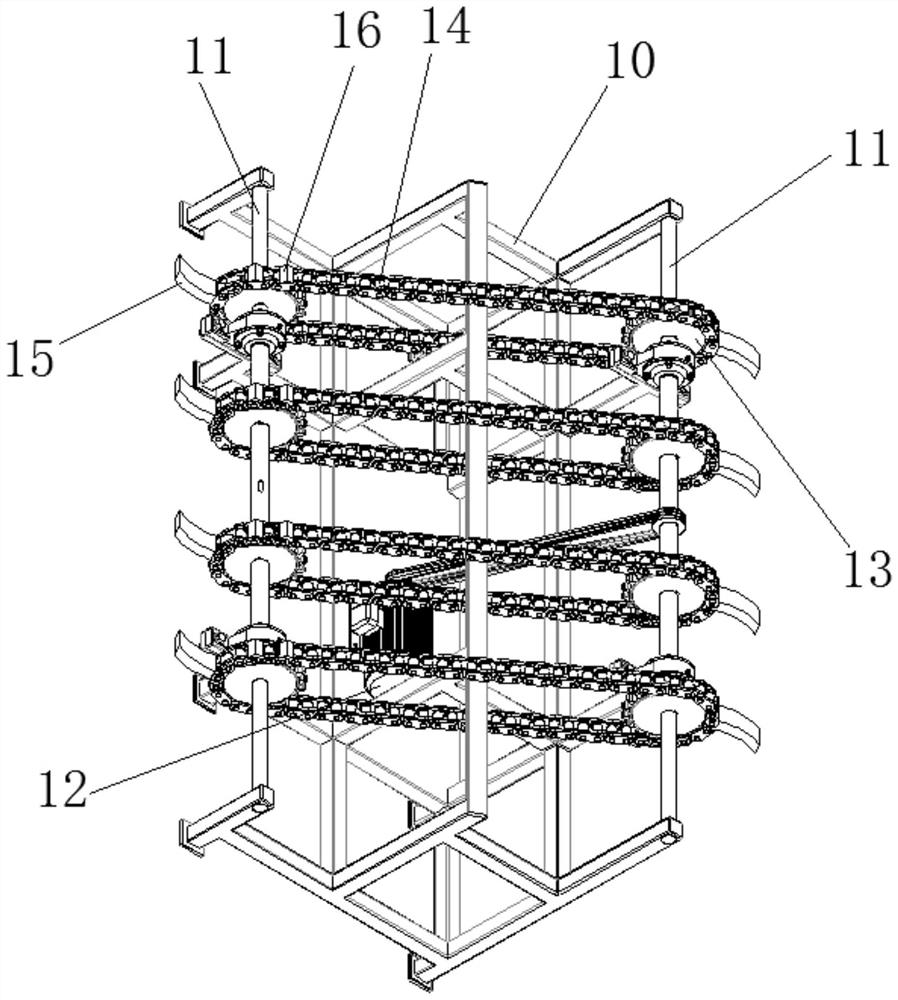

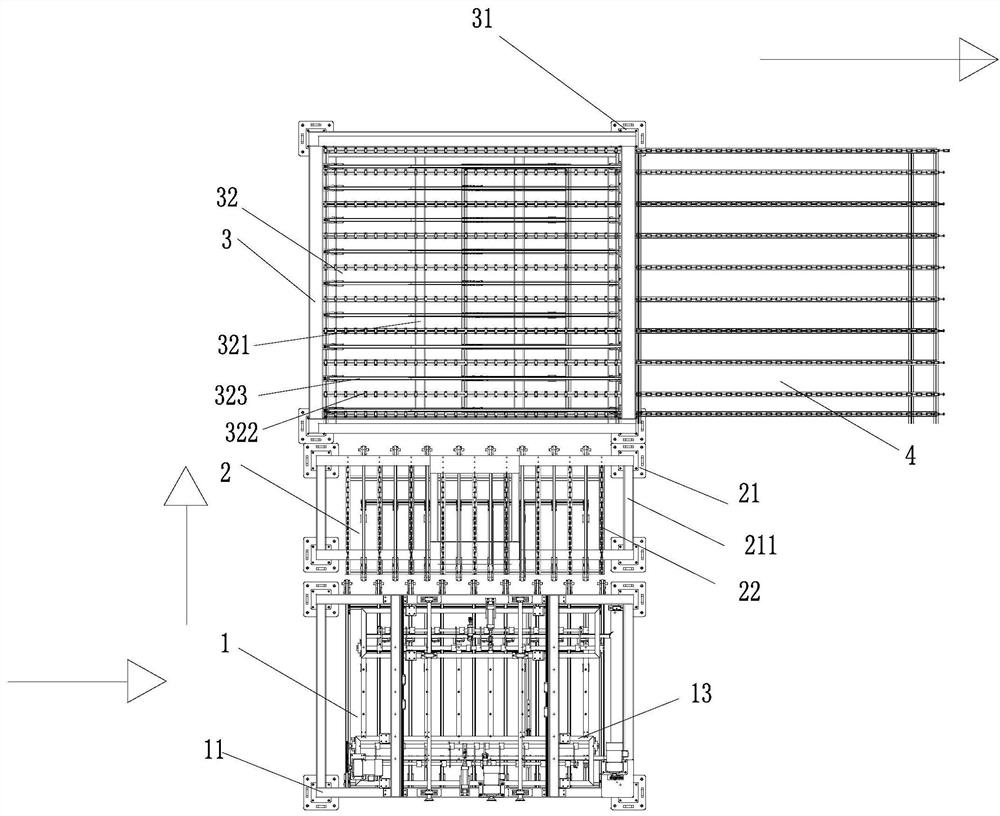

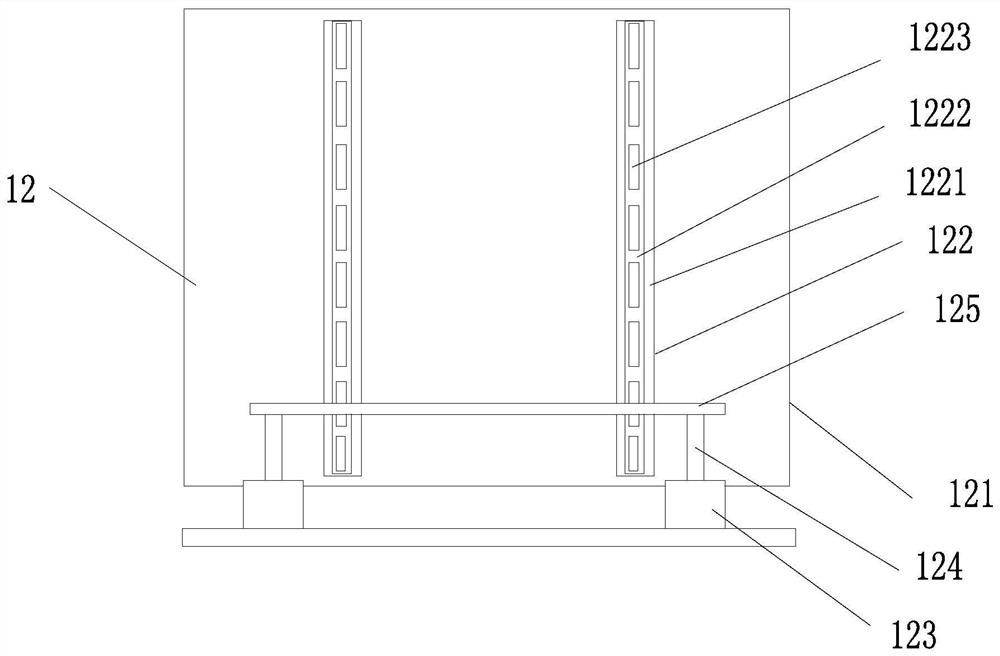

Plate online cutting and feeding system on large plate coating operation line

InactiveCN113276220AImprove sawing efficiencyImprove sawing qualityFeeding devicesLoading equipmentStructural engineeringMechanical engineering

The invention discloses a plate online cutting and feeding system on a large plate coating operation line. The plate online cutting and feeding system comprises a plate stacking device, a buffer transition translation device positioned at the downstream of the plate stacking device, a feeding device and an intelligent control system. The feeding device is connected with a plate sawing device through a feeding plate, and the intelligent control system controls the operation of the plate stacking device, the buffer transition translation device and the feeding device. According to the plate online cutting and feeding system on the large plate coating operation line, plates can be automatically conveyed to the cutting system after being coated, so that on one hand, the manual work of large plate coating discharging and cutting feeding is saved; and on the other hand, plate surface damage in the feeding and discharging process is avoided. By designing a plate stacking machine, the coated plates can be stacked in groups and controlled by a set program, the number of the stacked plates in each group is consistent, the stacked plates in each group are conveyed to the feeding device through the buffer transition translation device, the stacked plates in each group are sawn together, and the sawing quality of the plates is improved while the sawing efficiency of the plates is improved.

Owner:泰州市龙洋木业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com