Batch cutting forming device for disposable chopsticks

A one-time, mass-produced technology, applied in the direction of feeding devices, charging devices, sawing components, etc., can solve the problems of low work efficiency, laborious, easy to cut hands, etc., and achieve the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

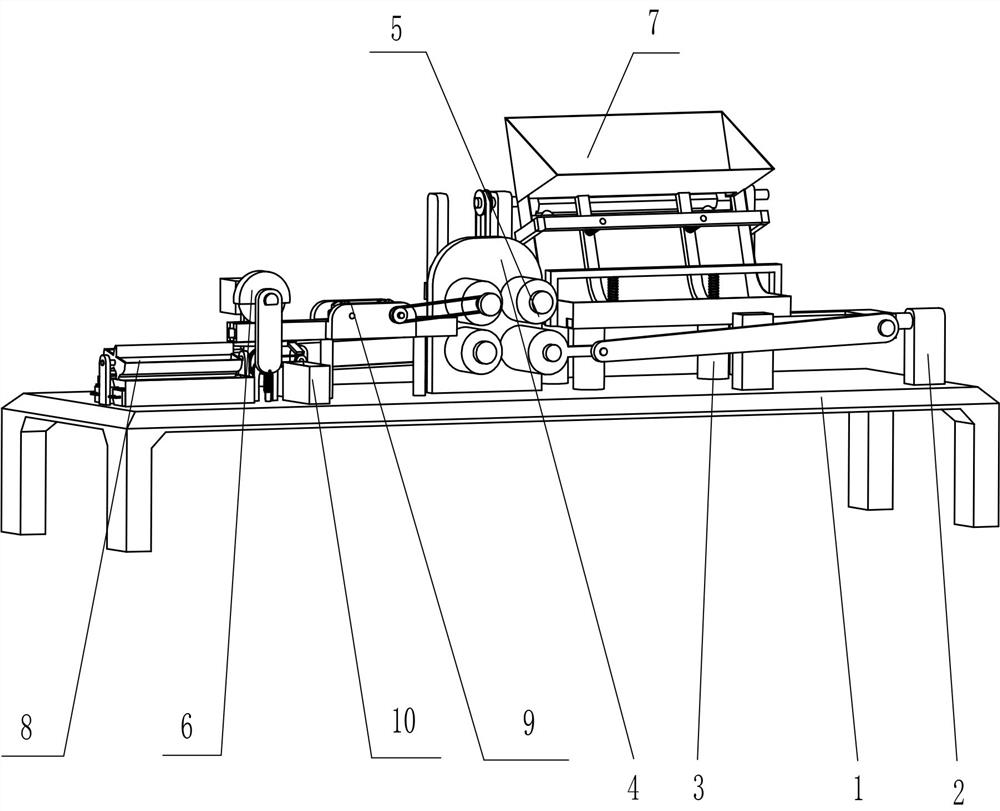

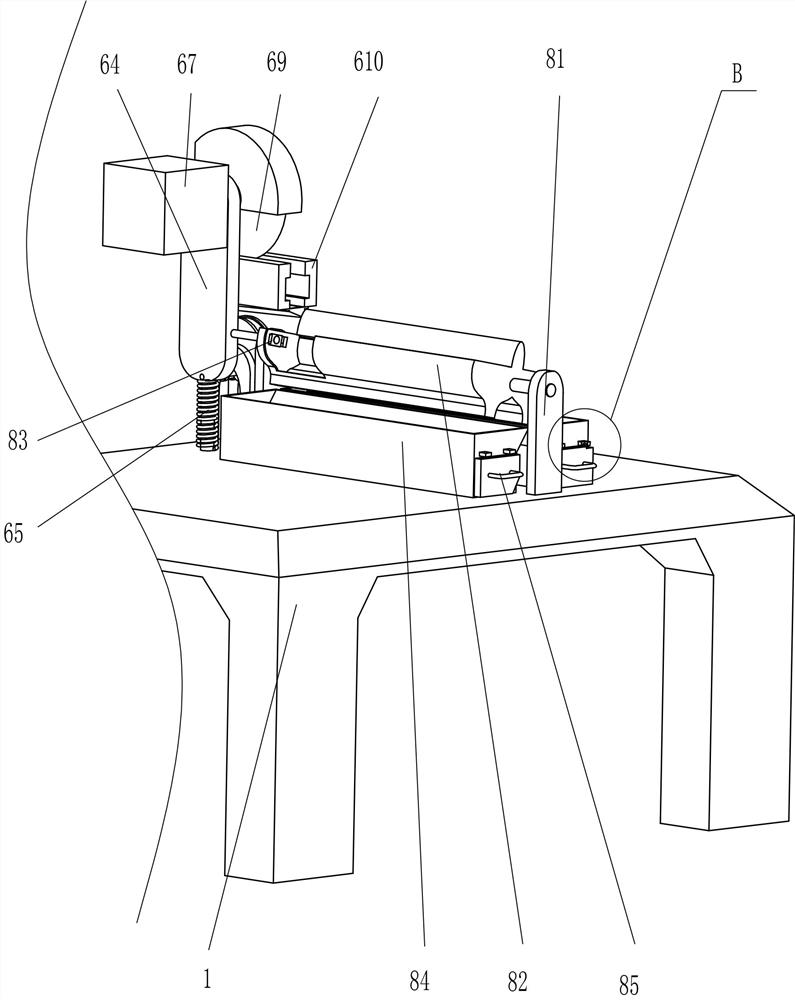

[0027] A device for cutting and forming batches of disposable chopsticks, such as Figure 1-Figure 5 As shown, it includes a base 1, a support base 2, a support column 3, a mounting plate 4, a feeding mechanism 5, and a cutting mechanism 6. There are four supporting columns 3 fixedly connected to the side intervals, and a mounting plate 4 is fixedly connected to the top of the base 1. A feeding mechanism 5 is provided between the base 1, the mounting plate 4 and the supporting columns 3, and a feeding mechanism 5 is installed between the base 1 and the feeding mechanism 5. A cutting mechanism 6 is provided.

[0028] The feeding mechanism 5 includes a servo motor 51, a driving shaft 52, an installation shaft 53, an acceleration transmission assembly 54, a gear transmission assembly 55, a rubber wheel 56, a transmission pillar 57, a movable connecting plate 58, a feeding push block 59, and a slide rail 510 And feeding plate 511, base 1 top middle rear part is fixedly connected ...

Embodiment 2

[0034] On the basis of Example 1, such as figure 1 , figure 2 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, a feed mechanism 7 is also included, and the feed mechanism 7 includes an H-shaped mounting frame 71, a transmission worm 72, a worm wheel 73, a third transmission assembly 74, a feed wheel 75, a feed hopper 76, a fixed mount 77 and Spring pressure plate 78, base 1 top middle rear part is fixedly connected with H type installation frame 71, and upper right mounting shaft 53 rear end is fixedly connected with drive worm 72, and H type mounting frame 71 top rotation type is provided with worm gear 73, and worm gear 73 and transmission The worm 72 is engaged, and the upper right side of the H-shaped mounting frame 71 is rotated to be provided with a feed wheel 75. A third transmission assembly 74 is connected between the left circumference of the feed wheel 75 and the right circumference of the worm wheel 73. The upper part of the feeding plate 511 A fee...

Embodiment 3

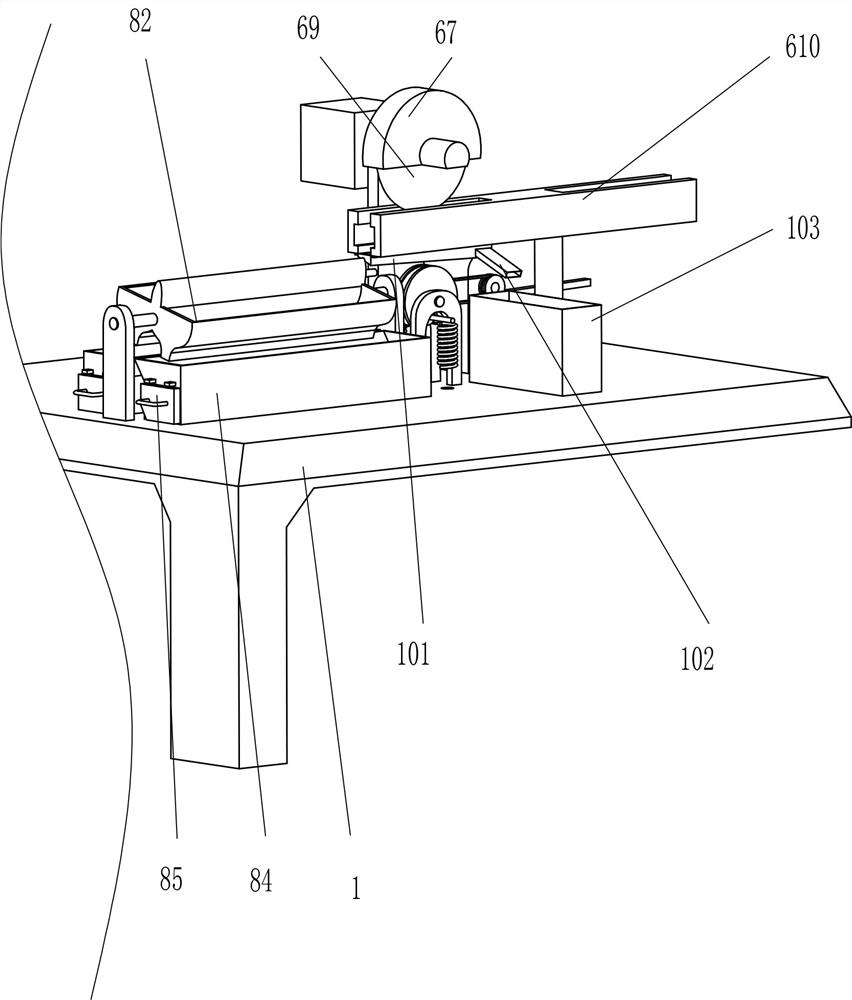

[0039] On the basis of embodiment 1 and embodiment 2, such as figure 1 , figure 2 and Figure 7 As shown, guide mechanism 9 is also included, and guide mechanism 9 includes the fourth transmission assembly 91, elastic sheave 92 and synchronous assembly 93, and the left and right symmetrical rotation type is provided with elastic sheave 92 in the middle part of the outer surface of square tube 610 of material transmission, right A fourth transmission assembly 91 is connected between the front circumference of the square elastic sheave 92 and the front circumference of the upper left mounting shaft 53 , and a synchronization assembly 93 is connected between the rear circumference of the left and right elastic sheaves 92 .

[0040] Also includes a waste collection mechanism 10, the waste collection mechanism 10 includes a material baffle plate 101, a waste material discharge square tube 102 and a waste material collection box 103, the left side of the material transmission squa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com