Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3559results about "Cane mechanical working" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

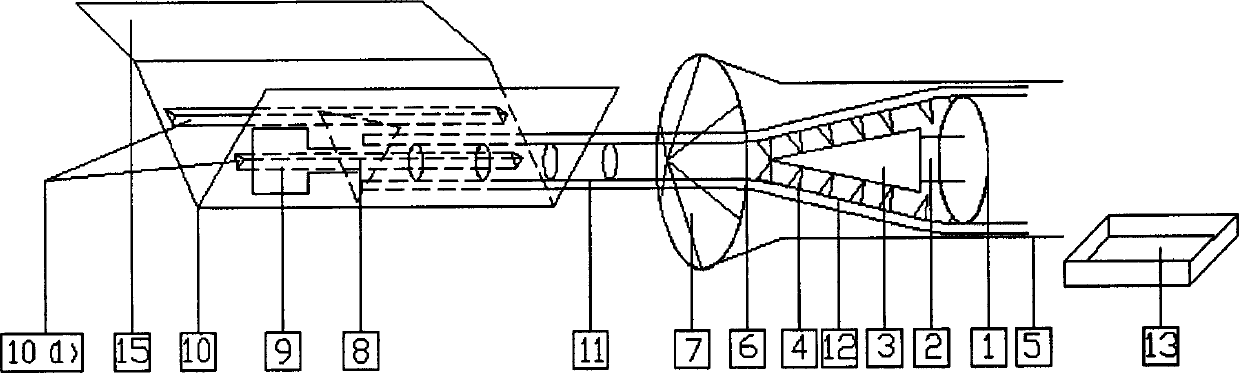

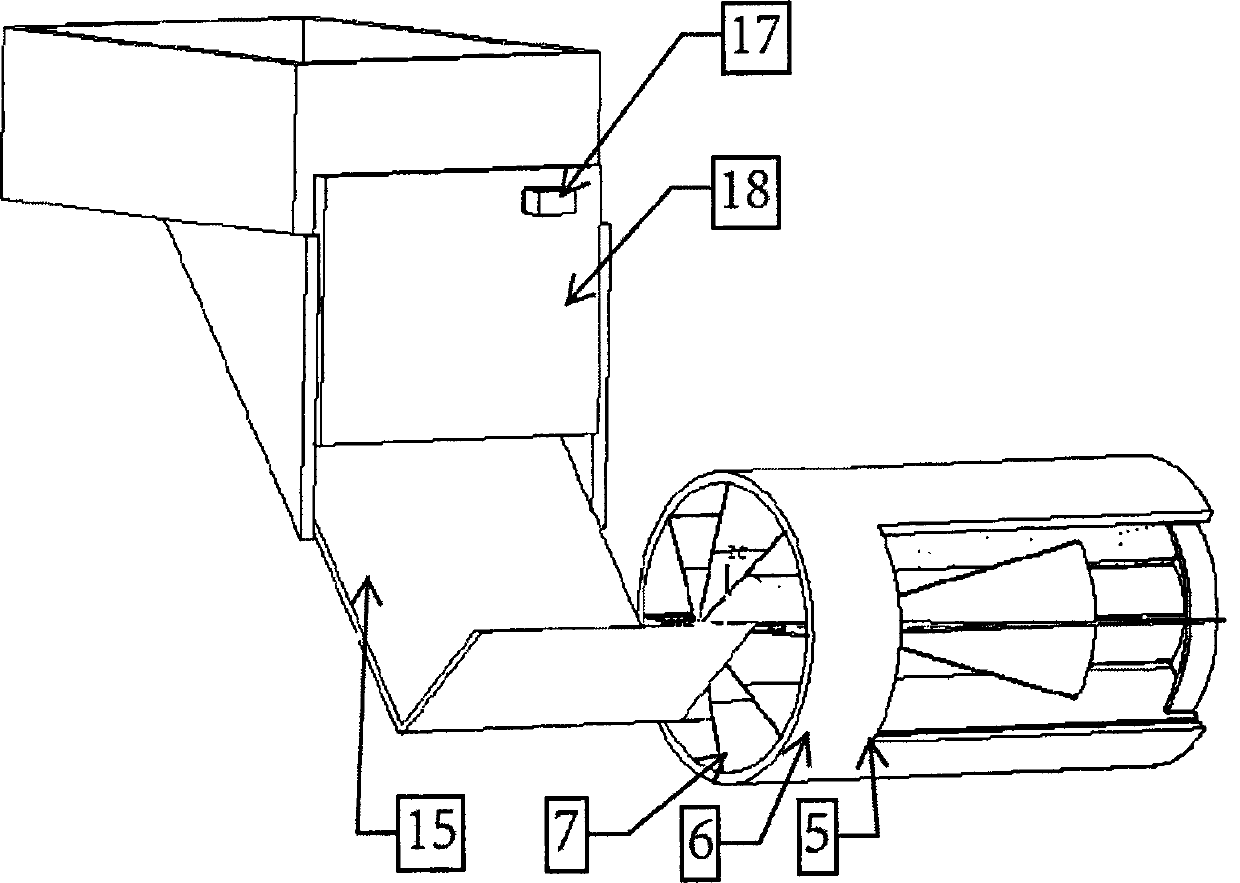

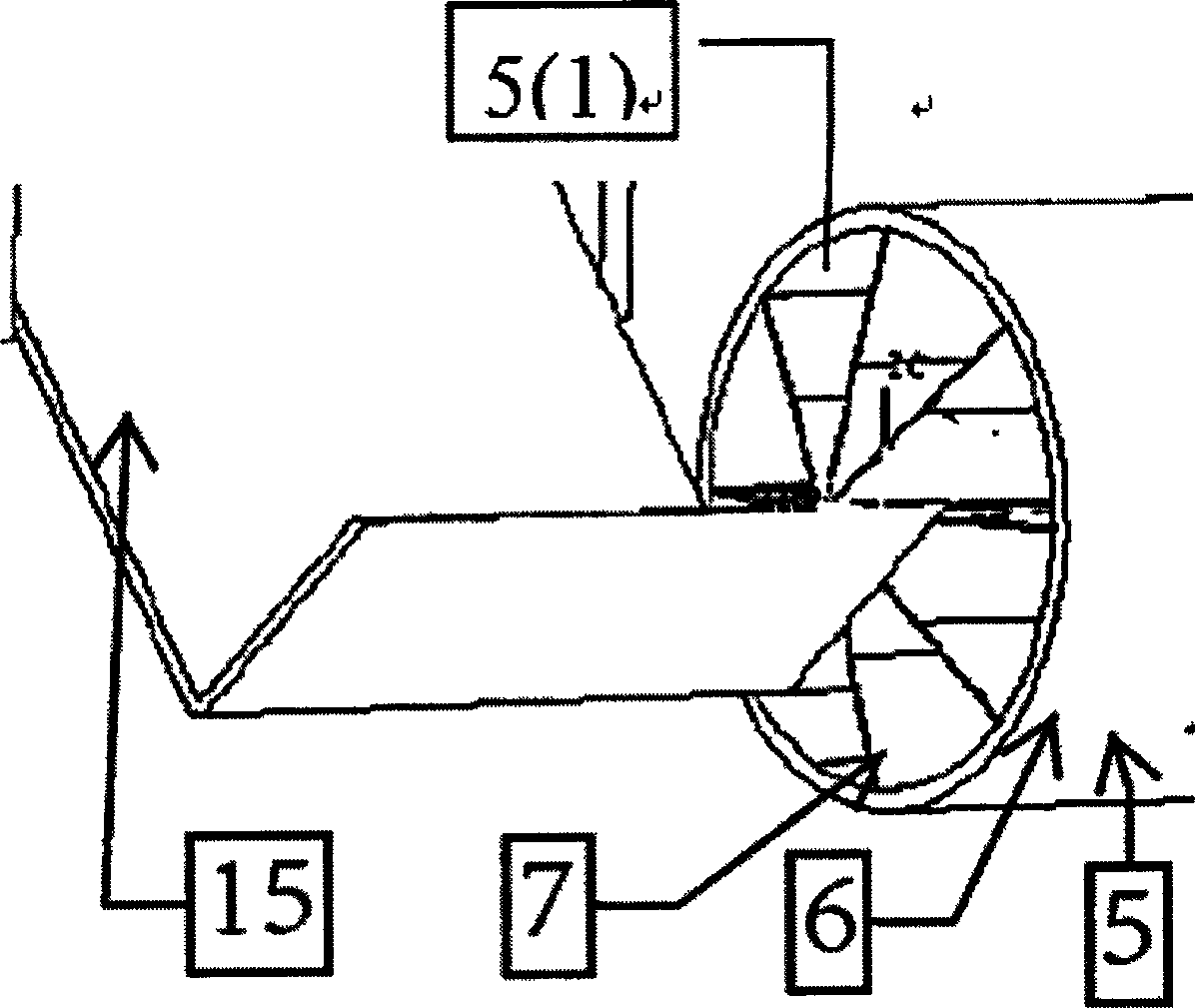

Slitting and bamboo joint removing integrated machine for bamboo billet cylinder

InactiveCN103009446AOutstanding innovationEasy to operateTree debarkingCane mechanical workingCircular coneEngineering

As a traditional bamboo joint removing method is low in degree of mechanization and production efficiency, and consumes time and labor, the invention discloses a slitting and bamboo joint removing integrated machine for a bamboo billet cylinder, which aims to improve the production efficiency of bamboo processing, belongs to the technical field of processing machinery of bamboo products, and comprises a circular cutter, a solid cylinder, a solid circular cone, an outer cylinder, outer cylinder inner plates, an annular cutterhead, a cutter, a movable baffle plate, a power device, a fixing device, a receiving device, a feeding device and other devices that all form a complete machine. The slitting and bamboo joint removing integrated machine for the bamboo billet cylinder is a novel bamboo joint removing machine for the bamboo billet cylinder, and slits the bamboo billet cylinder and removes bamboo joints at the same time, so as to achieve the purposes of labor conservation and production time conservation, and meet the processing requirement for batch production at the same time.

Owner:GUANGXI UNIV

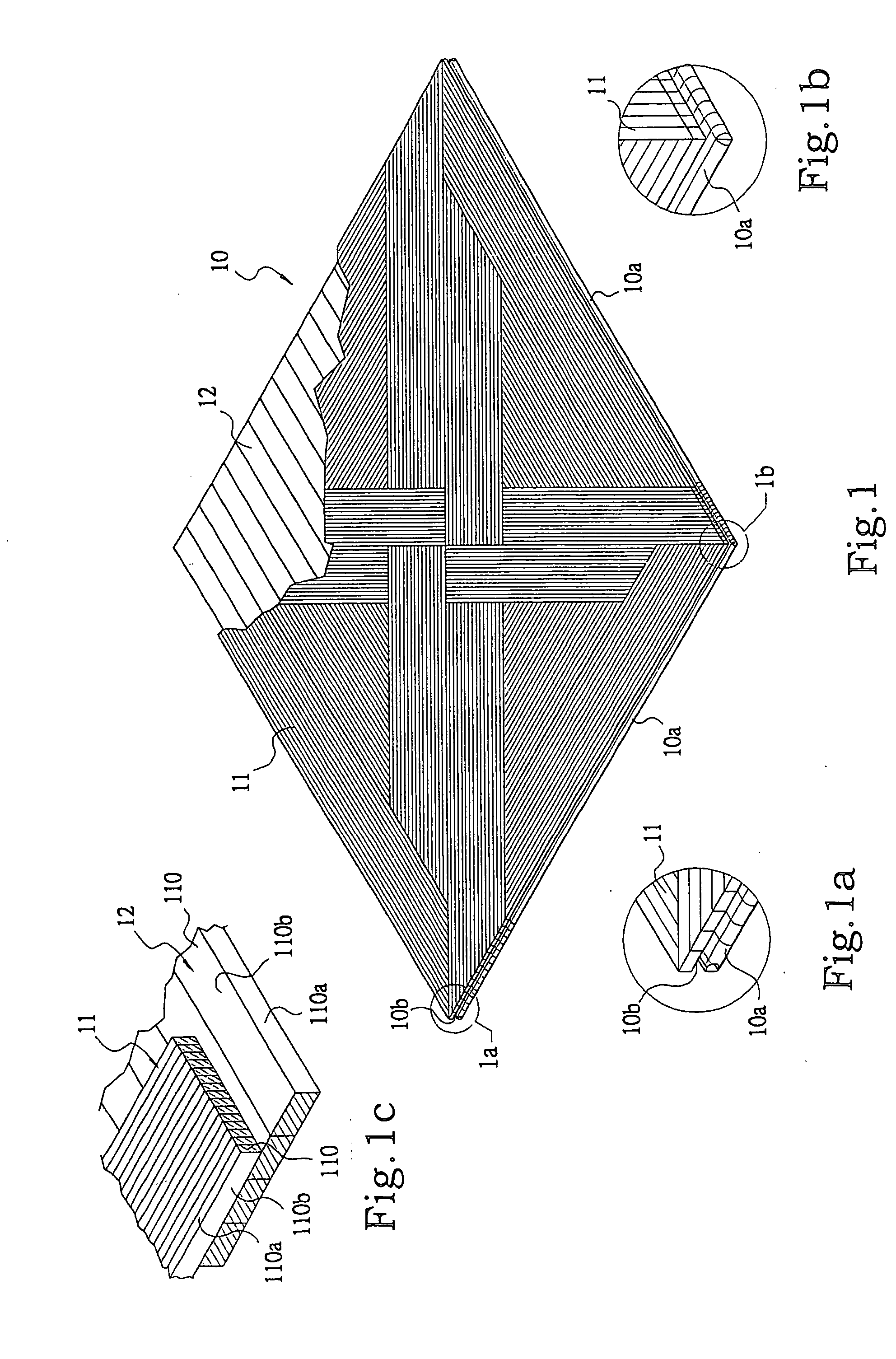

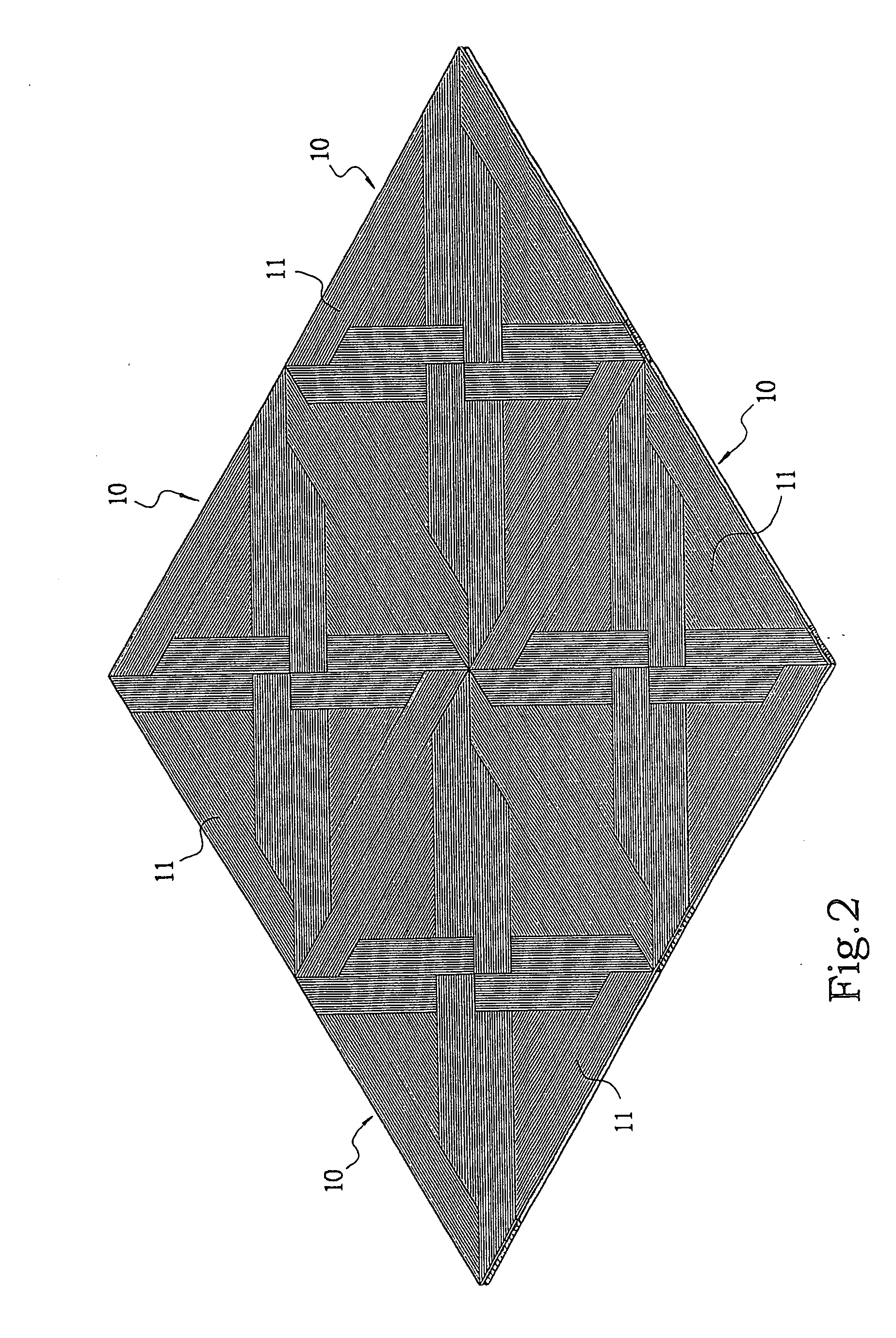

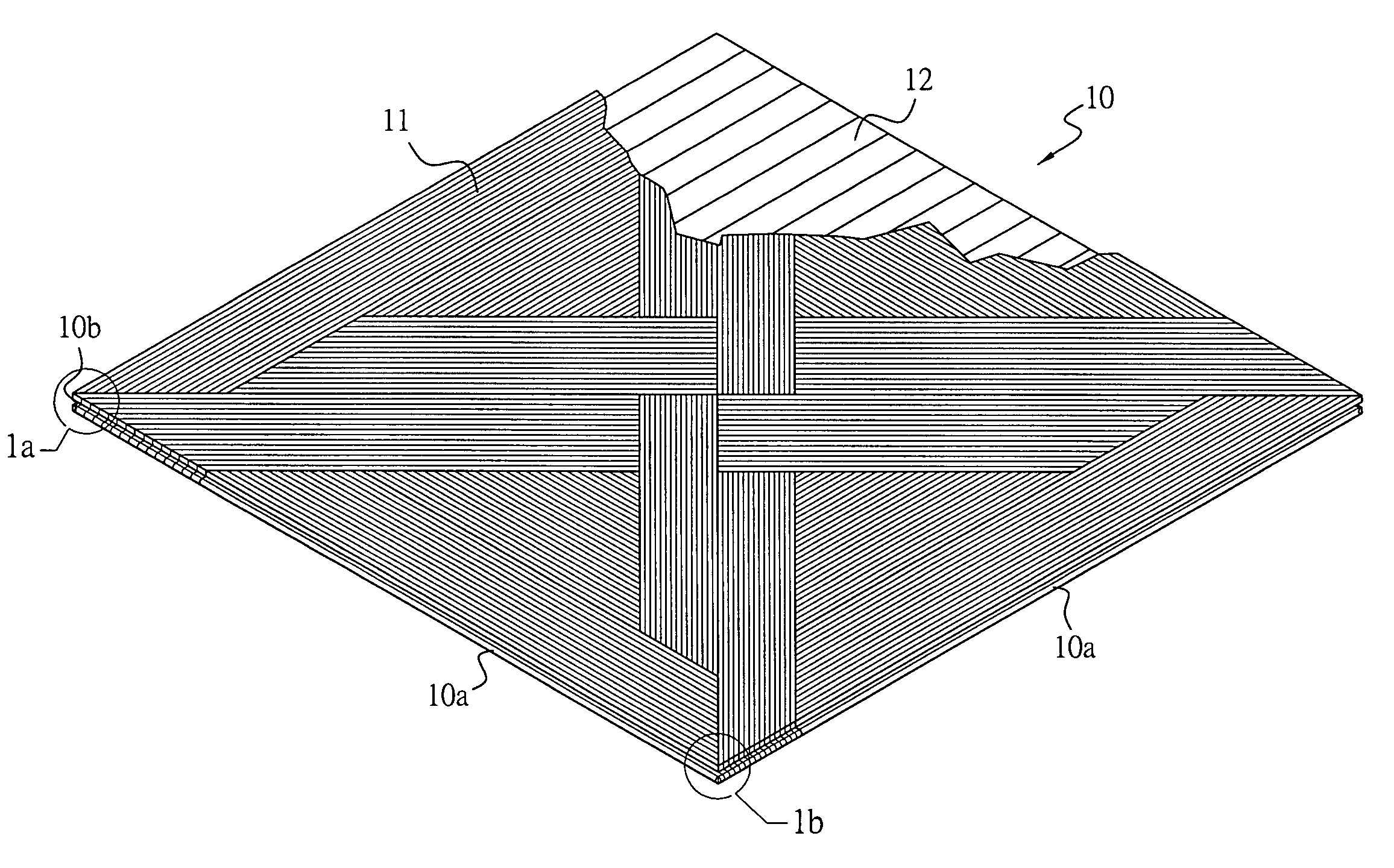

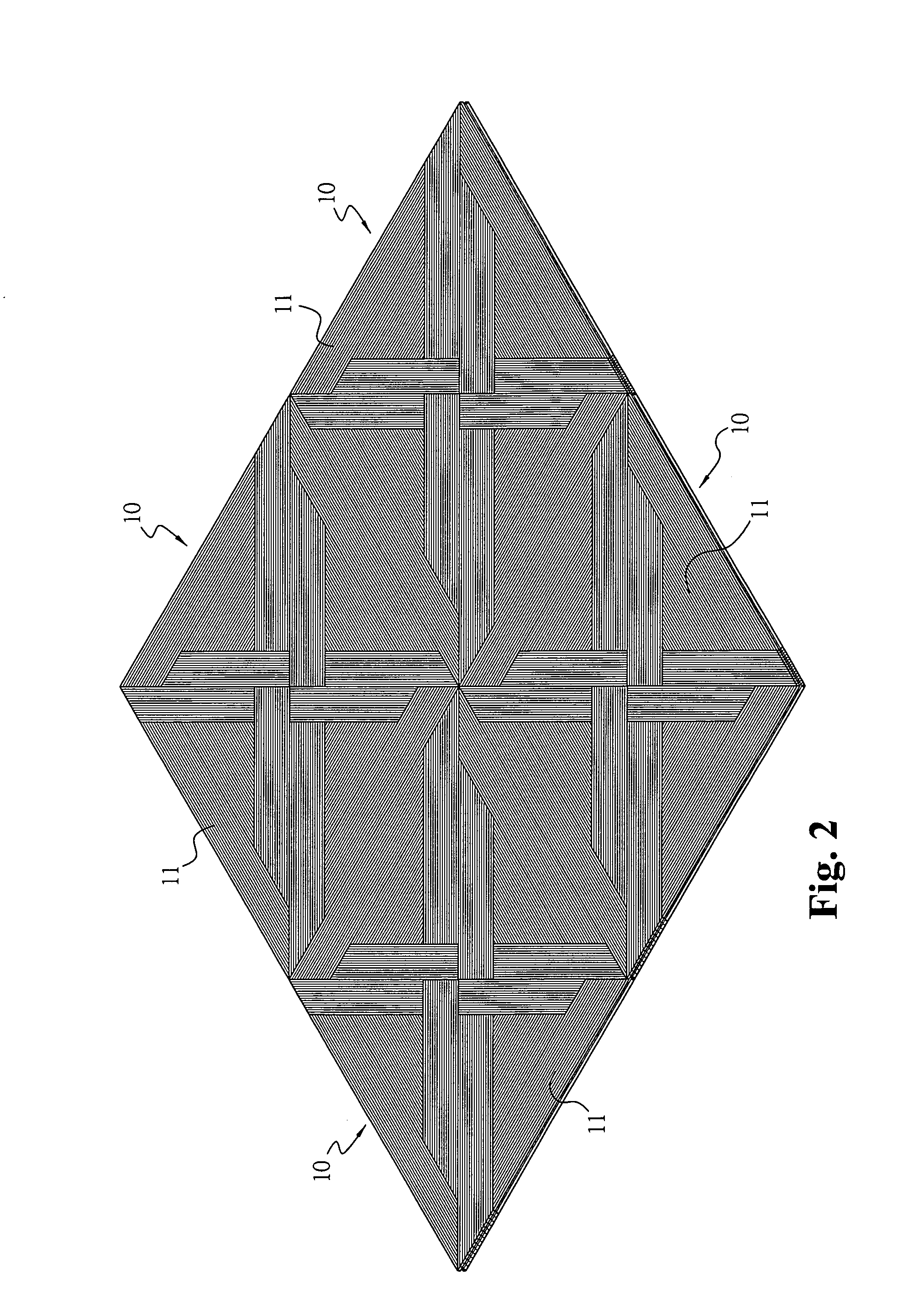

Bamboo mat board and method for producing the same

ActiveUS20050161116A1Increase stiffnessHigh economic valueCane mechanical workingWood veneer joiningSurface layerEngineering

A bamboo mat board element with a double-layered construction, a constant dimension, each of the elements is formed with a projecting tenon at each of two adjacent sides, respectively, and a concave mortise at each of the other two adjacent sides, respectively, for inter-tenoning the elements of the mat board, in which a surface layer of the mat board is obtained by matting a plurality of mat board stuffs having different orientations, shapes, and sizes, while each of the mat board stuffs is obtained by matting a plurality of lumbers having a parallel orientation, respectively, to form a plurality of patterns having parallel stripes by specially matting at the longitudinal section thickness of the lumbers. A method for producing the bamboo mat board at least comprises steps as follows: cutting step, boiling for blanching step, drying step, rough shaving, bottom layer pre-forming step, adhesive applying and pressing step, pattern selecting step, matting step, and refined shaving, etc. The sandwich mat board is then formed by pressing.

Owner:CHANG AO YU

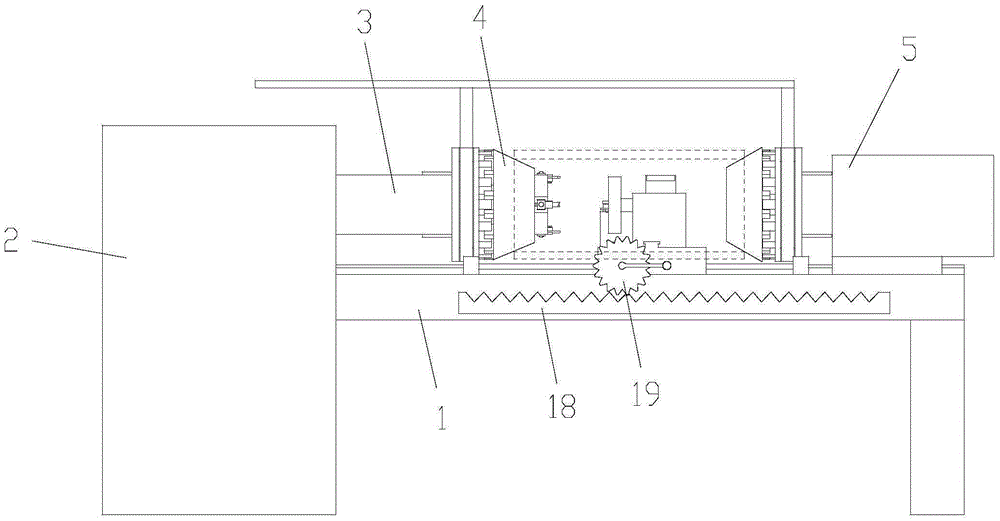

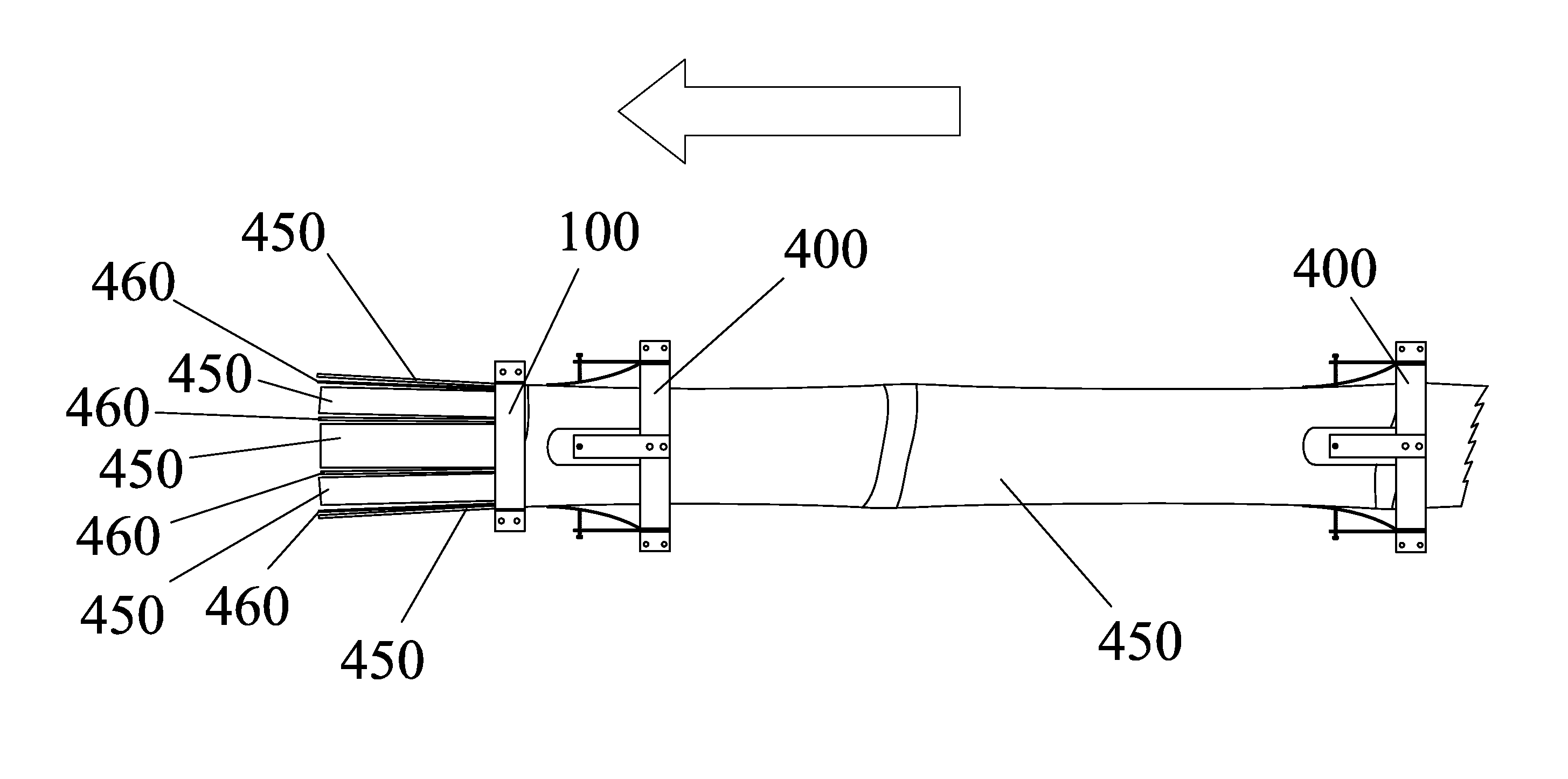

Whole bamboo flattening method and processing equipment

ActiveCN105235030AImprove processing qualityNovel structureCane mechanical workingEngineeringWood processing

The invention provides a whole bamboo flattening method. The method includes the following steps that firstly, old bamboo which is 3-5 years is selected, after branches are removed, the bamboo is sawn into a bamboo tube with the corresponding length; secondly, the bamboo tube is arranged on the bamboo wood processing equipment, an outer bamboo joint and an inner bamboo joint are removed, bamboo green with the thickness of 2-3 mm is removed, and a groove is formed in the bamboo tube; thirdly, the bamboo tube obtained in the second step is placed in an oven, baked for 5-10 min at the temperature of 300 DEG C to 500 DEG C, and softened; fourthly, the softened bamboo tube is placed on a flattening machine to be flattened, cooled for 20-30 min, and flattened into a bamboo plate in a cold pressing manner; fifthly, bamboo inner skin on the inner surface of the flattened bamboo plate is removed by 3-5 mm in a planing manner, and the outer surface and the periphery of the bamboo plate are ground to be smooth; and sixthly, the bamboo plate is baked for 5-6 hours in a baking room at the temperature of 30 DEG C, baked for 10-11 hours after temperature is raised to 40 DEG C, baked for 2-3 hours when temperature is raised to 50 DEG C, and manufactured into whole bamboo. The outer bamboo joint, the bamboo green and the inner bamboo joint of the bamboo tube are automatically cut off, working efficiency is high, and the processing quality of the bamboo tube is improved.

Owner:LIUZHOU LONGTAI BAMBOO IND CO LTD

Bamboo wood-grain plate and the preparing method

InactiveCN101036999AShun goodIncreased shear strengthWood treatment detailsCane mechanical workingSolid woodEngineering

The invention discloses a wood grain board made of bamboo and manufacturing method, the wood grain board made of bamboo includes a faceplate made by bonding and pressing the bamboo pieces arrangement, the bamboo pieces are arranged with inclination less than 90 degrees to the board plane, the inclination is adjusted and set based on the grain of required boards. The bamboo boards made by the invention technique project, because the faceplate is pressed by form of inclined arrangement of the bamboo, so the grain of faceplate has solid wood grain of top grade; because the core plate and base plate use interlaced in length and breadth arrangement form of bamboo mat, bamboo curtain, bamboo filament and piece plate, the multiple indexes of shear strength, bending intensity and elastic modulus for long and cross grain of the whole boards are better.

Owner:张世庆

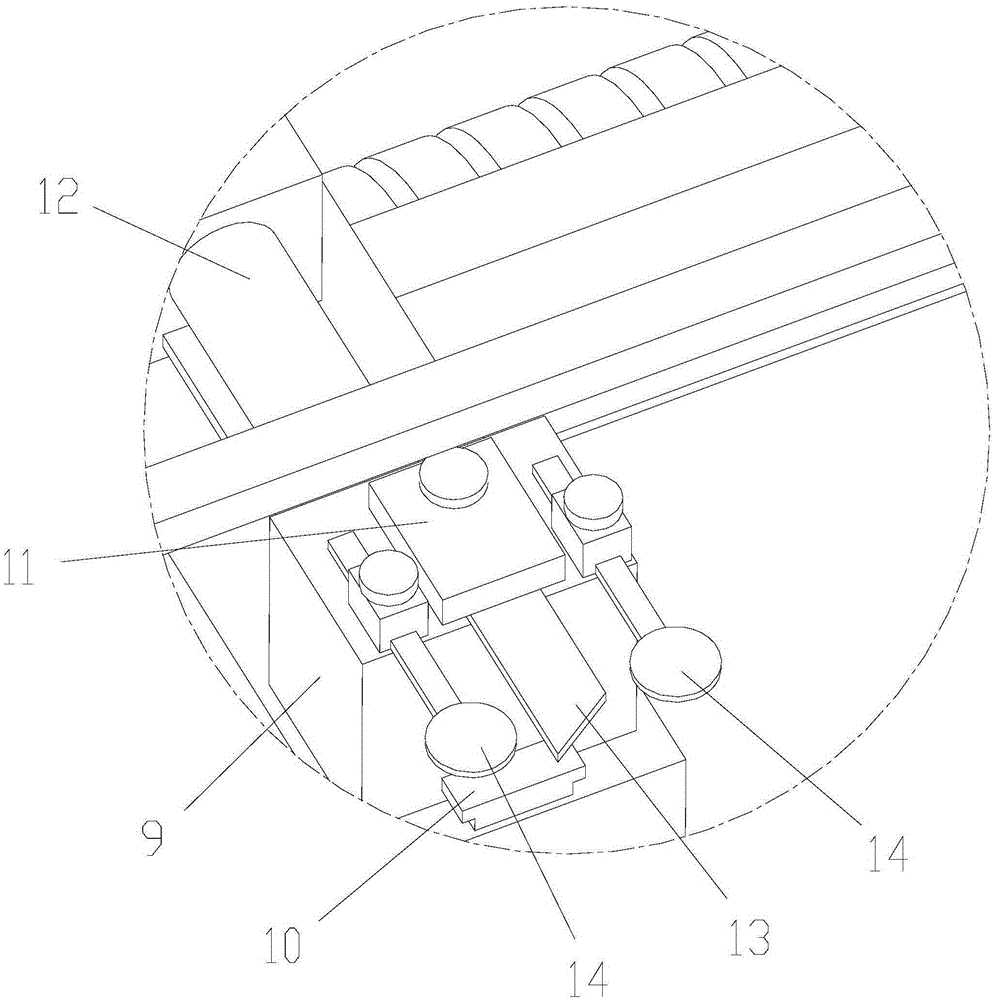

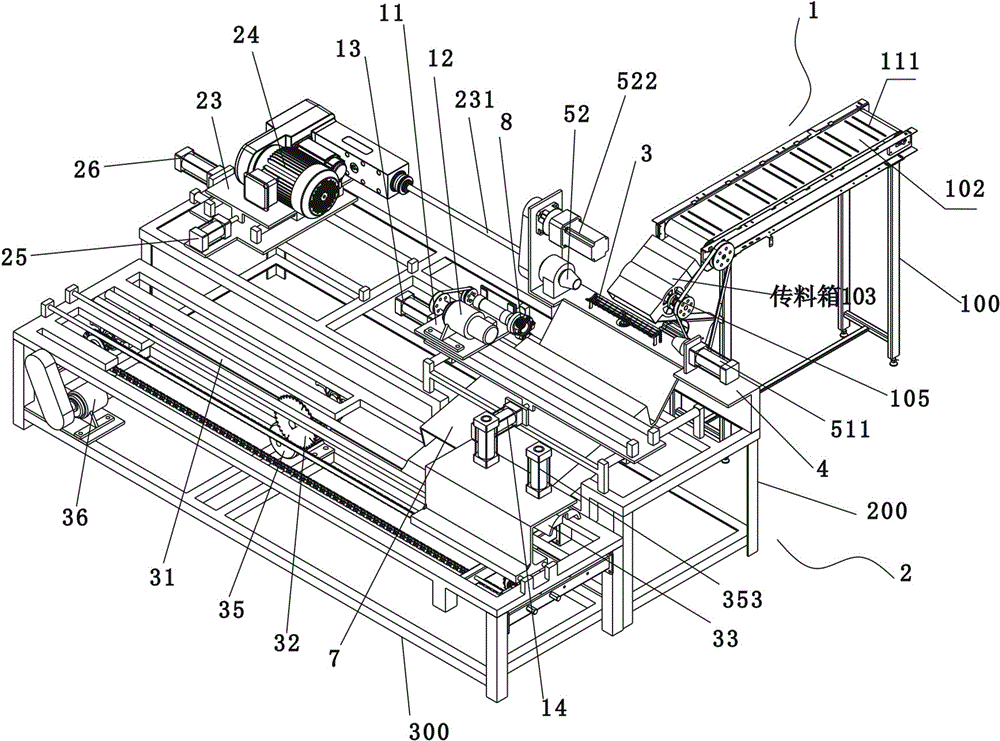

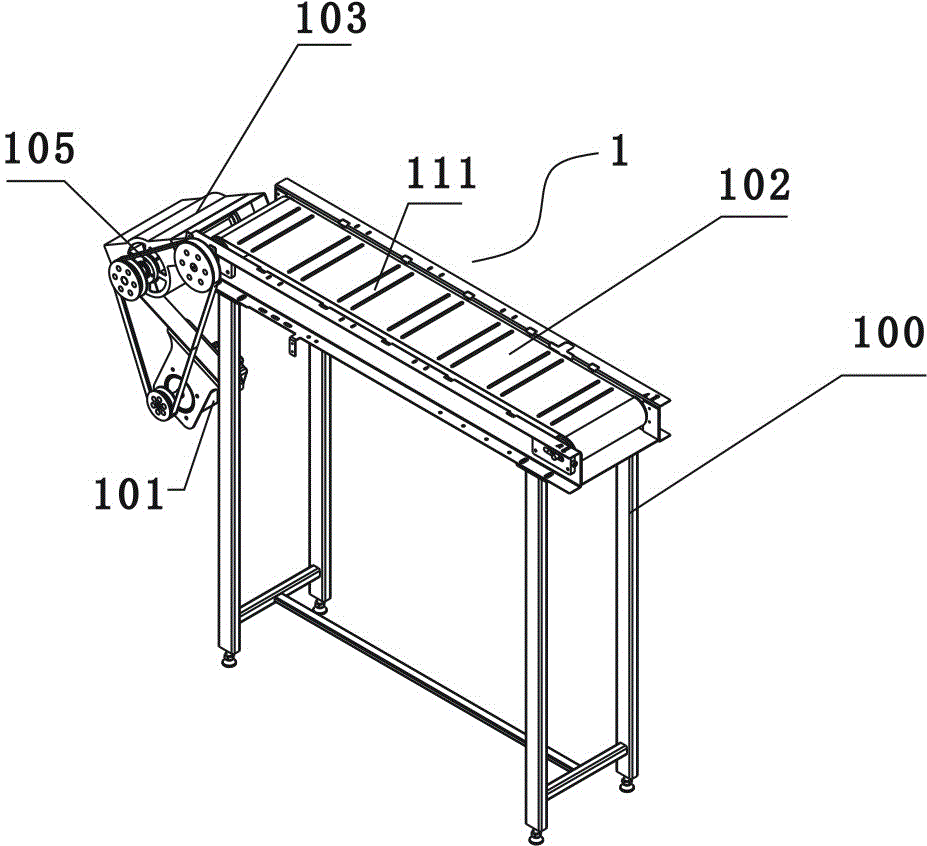

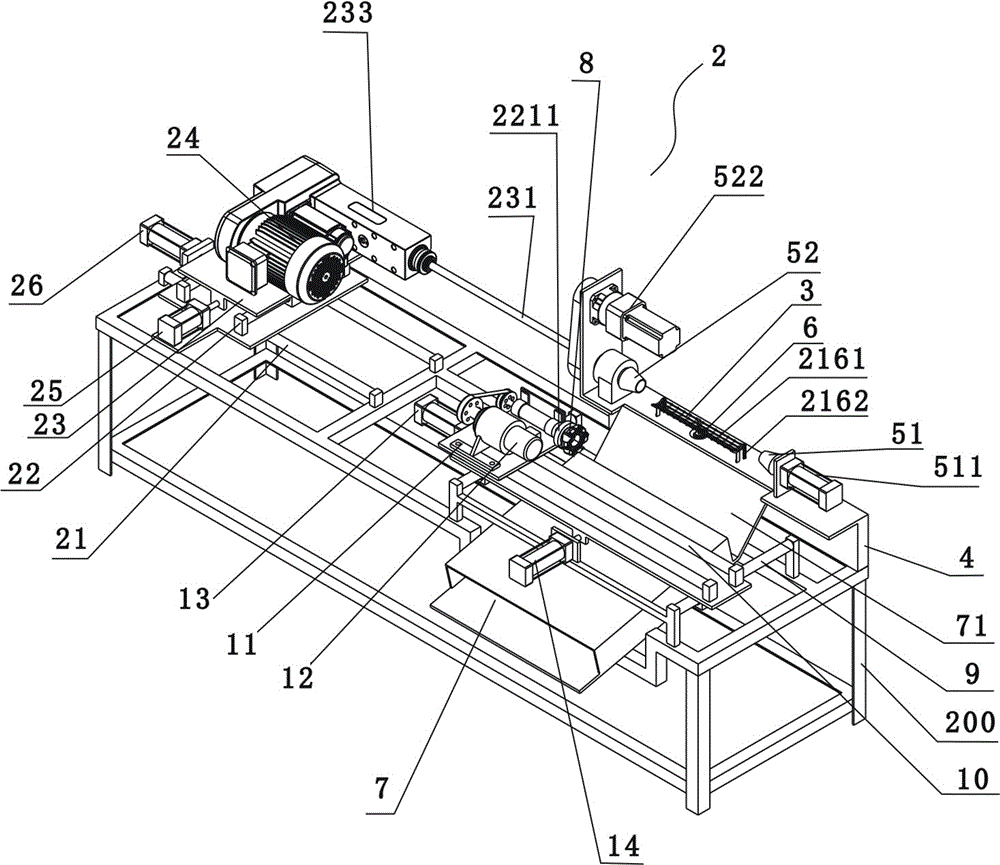

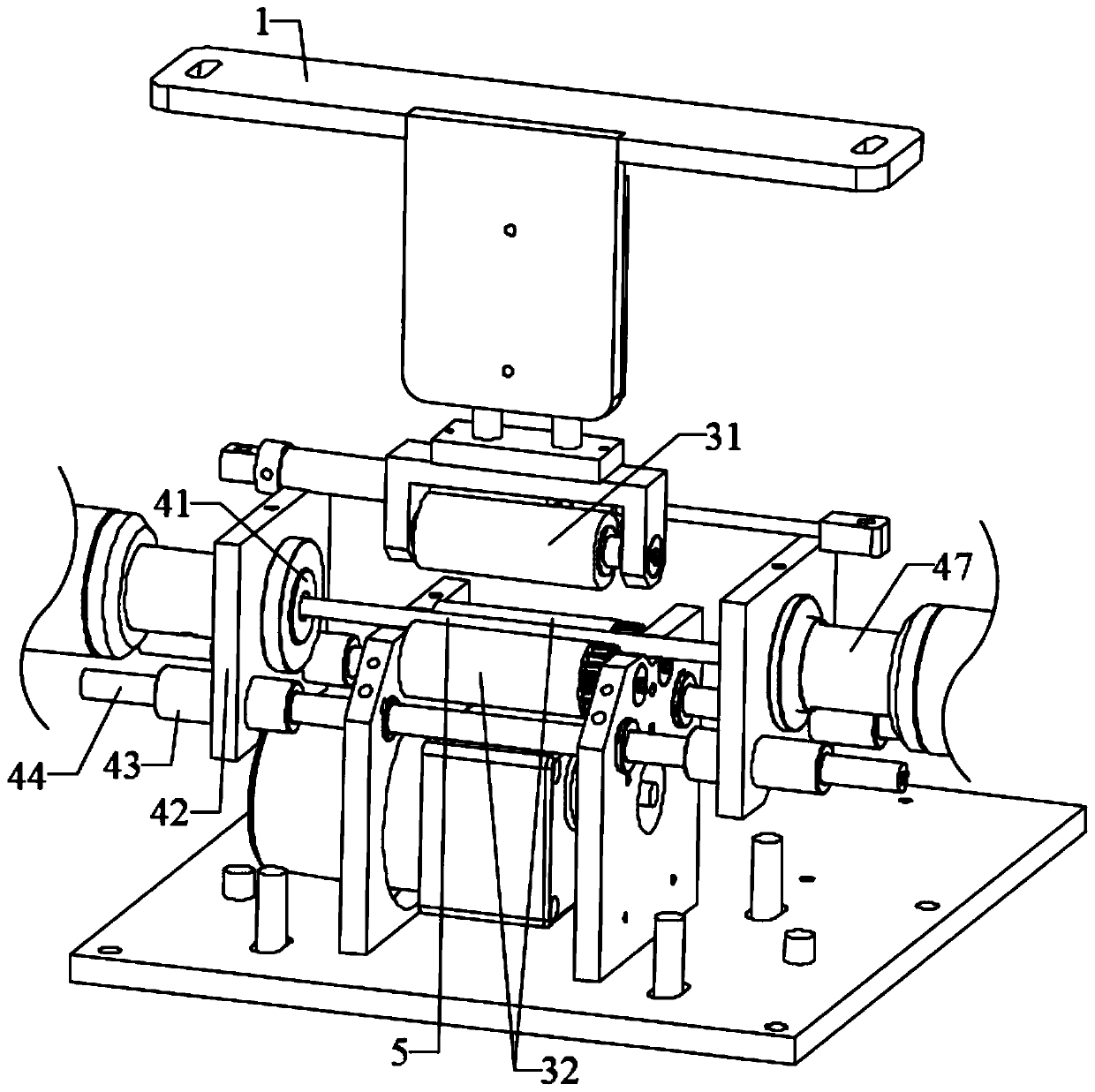

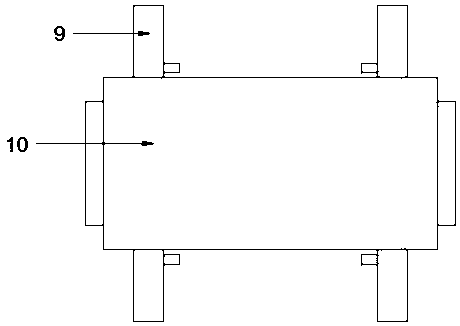

Automatic bundle splitting and lay-feeding device and control method thereof

ActiveCN105171863ARealize automatic beam separation and pavingEasy to handleCane mechanical workingButt jointEconomic benefits

Disclosed is an automatic bundle splitting and lay-feeding device. According to the device, a motor is installed below a machine frame and connected with a feeding transmission mechanism and a conveying part which are installed above the machine frame, and side baffles are installed at the two sides of the conveying part; a hopper is installed on the machine frame, a pressing plate guiding part is arranged on the upper portion of the interior of the hopper, and a pressing mechanism is arranged on the pressing plate guiding part; a feeding roller part is installed on the machine frame, part of composing mechanisms are arranged in the hopper, and an upper movable scraper blade part is installed on the hopper and attached to a lower fixed scraper blade installed on the machine frame; the feeding roller part is in butt joint with the lower fixed scraper blade to achieve bundle splitting separation of straw, straw finally falls on the conveying part and is conveyed to a straw braiding machine through a conveyer belt provided with conveying spike teeth, and then automatic bundle splitting separation and lay-feeding of straw are achieved. The working efficiency of the straw braiding machine is effectively improved, labor intensity is relieved, processing and recycling of straw are facilitated, and greater economic benefits are created.

Owner:HUNAN AGRICULTURAL UNIV

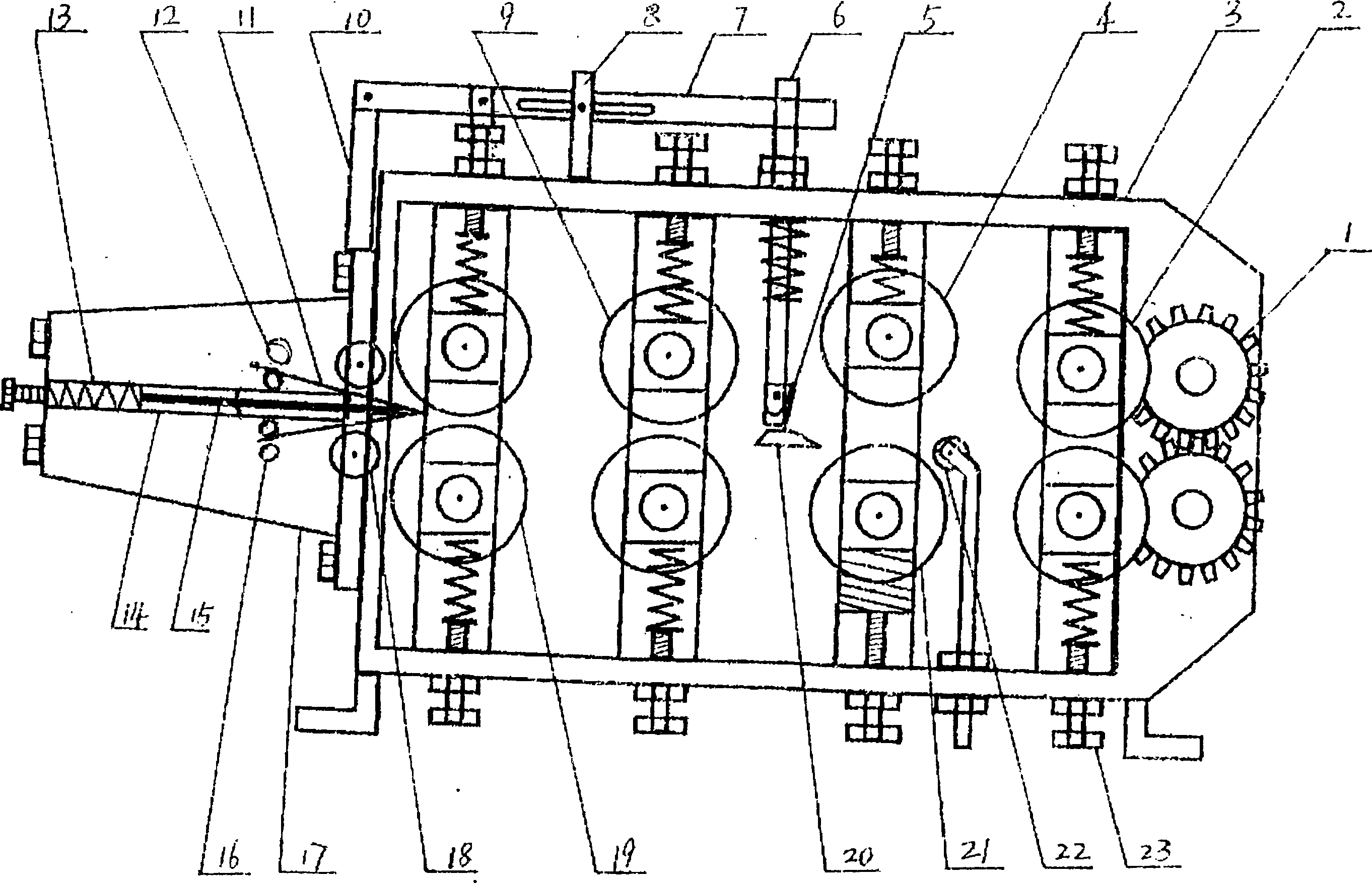

New type thin bamboo strip splitting machine

InactiveCN1785619AImprove quality requirementsControl uniformityCane mechanical workingVeneer manufactureMechanical engineering

A bamboo strip making machine is composed of plate-type machine frame, feeding gears, bamboo splitting plate, spring and regulating screw bolt, blade, movable rod, blade supporter, and bamboo strip driving gears. It features that the wheel attached to planer, green joint remover, auxiliary unit and operation regulator are additionally used.

Owner:周云龙

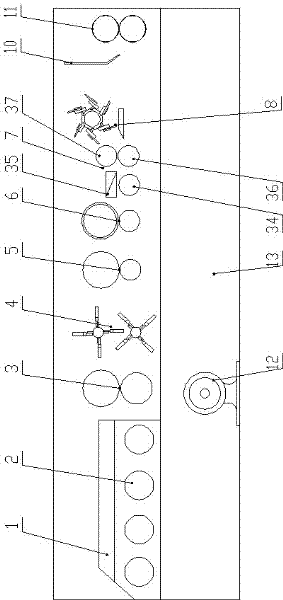

Peel-pith-leaf separator of maize straw

InactiveCN102528865AAchieve separationTake advantage ofCane mechanical workingEngineeringEnergy consumption

The invention discloses a peel-pith-leaf separator of a maize straw. The separator comprises a rack (13) and a power mechanism (12) arranged on the rack and is characterized in that a guiding conveying mechanism, a leaf removing mechanism, a peel-stripping mechanism and an output mechanism are arranged on the rack (13) from front to back and are all in transmission connection with the power mechanism (12). The separator disclosed by the invention specially aims at leaf-removing and pith-stripping works so as to realize the function of peel-pith-leaf thorough separation, and further the peel, the pith and the leaf of the maize straw can be respectively and effectively utilized; besides, the separator disclosed by the invention has the advantages of small mechanical vibration, low noise, less energy consumption, strong practicability, good market prospect and worthy of popularization and application.

Owner:HENAN AGRICULTURAL UNIVERSITY

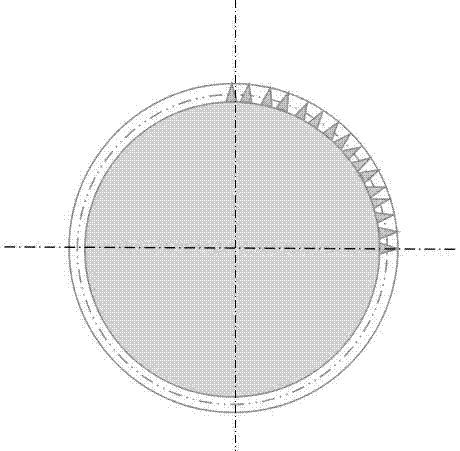

Bamboo splitter

A bamboo splitter has an outer support ring with an interior mounted inner ring blade. A plurality of base blades are radially arranged around the inner ring blade and both the inner ring blade and the base blades have v-shaped cutting surfaces. Attached to each base blade is a pair of slat blades that attach to the base blades at a vertex and have a left and right slat blade. The angle between the vertex and the left and right blades is chosen so that adjacent left slat blades are parallel to adjacent right slat blade forming a parallel cutting space which produces bamboo slats that have orthogonal edges which makes them much more amenable to traditional building methods. A different number of slat blades may be used depending on the size of the bamboo being used and the size and number of the slats being produced.

Owner:BAMBOO TECH

Bamboo mat board and method for producing the same

ActiveUS7021346B2Increase stiffnessHigh economic valueCane mechanical workingWood veneer joiningSurface layerMechanical engineering

A bamboo mat board element with a double-layered construction, a constant dimension, each of the elements is formed with a projecting tenon at each of two adjacent sides, respectively, and a concave mortise at each of the other two adjacent sides, respectively, for inter-tenoning the elements of the mat board, in which a surface layer of the mat board is obtained by matting a plurality of mat board stuffs having different orientations, shapes, and sizes, while each of the mat board stuffs is obtained by matting a plurality of lumbers having a parallel orientation, respectively, to form a plurality of patterns having parallel stripes by specially matting at the longitudinal section thickness of the lumbers. A method for producing the bamboo mat board at least comprises steps as follows: cutting step, boiling for blanching step, drying step, rough shaving, bottom layer pre-forming step, adhesive applying and pressing step, pattern selecting step, matting step, and refined shaving, etc. The sandwich mat board is then formed by pressing.

Owner:CHANG AO YU

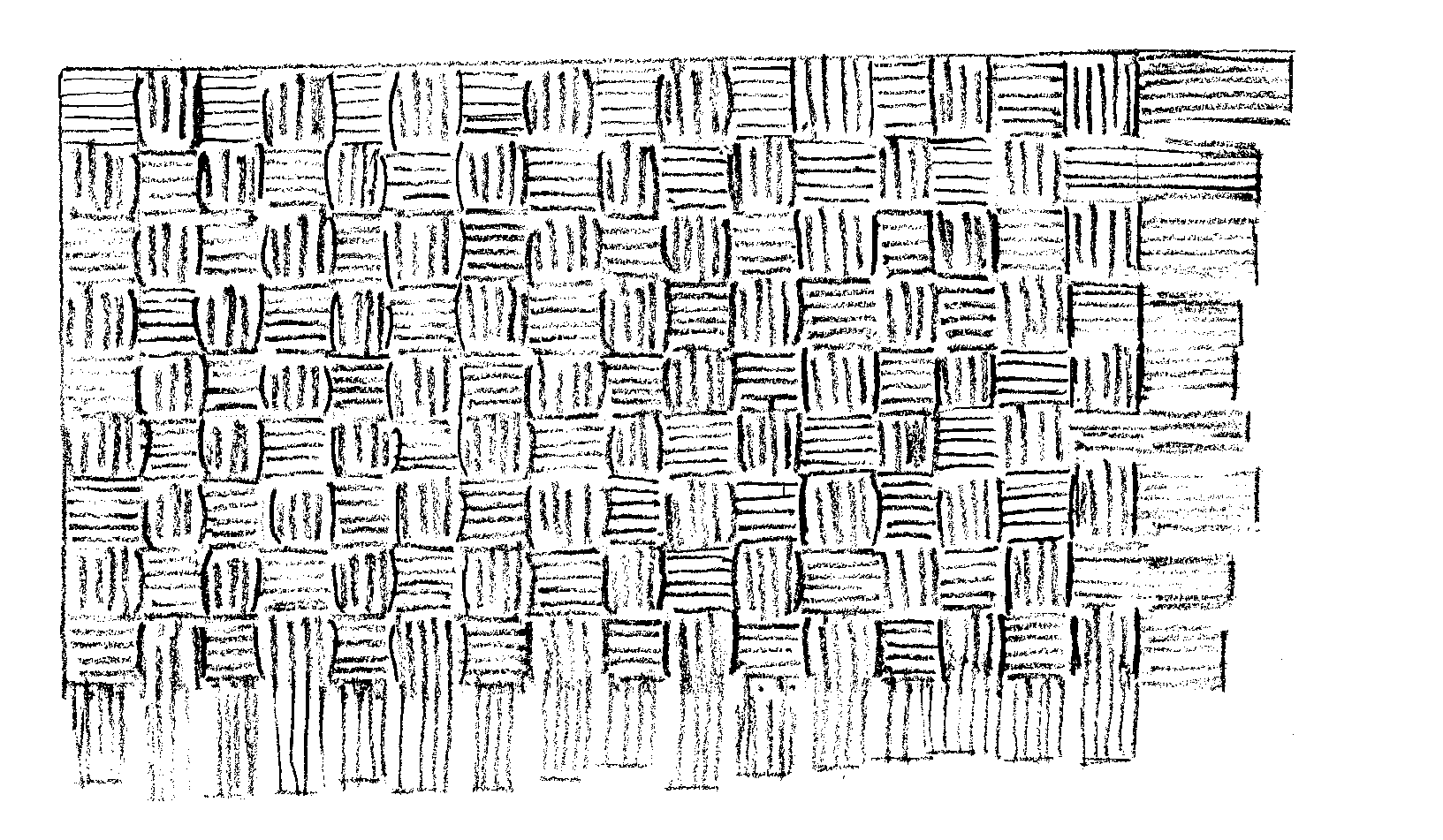

Method for Making Plywood and Dimensional Lumber from Arundo Donax L. or Bamboo

ActiveUS20070125446A1Reduce dependenceConstruction materialCane mechanical workingEngineeringFire retardant

A method of producing a virtually fireproof plywood from perennial grasses such as Arundo donax Ligneous, various bamboo strains, or a blend thereof, by first weaving the stalks of these plants into a mat and then layering these mats and binding each layer with any one of several commercial resins mixed with potash for the purpose of enhancing the board's fire retardant quality. The result is the formation of a finished product with structural board attributes and an exceptionally high flash point in relation to other manufactured board products made from forest materials.

Owner:ABDULNASER ABDULMALIK +1

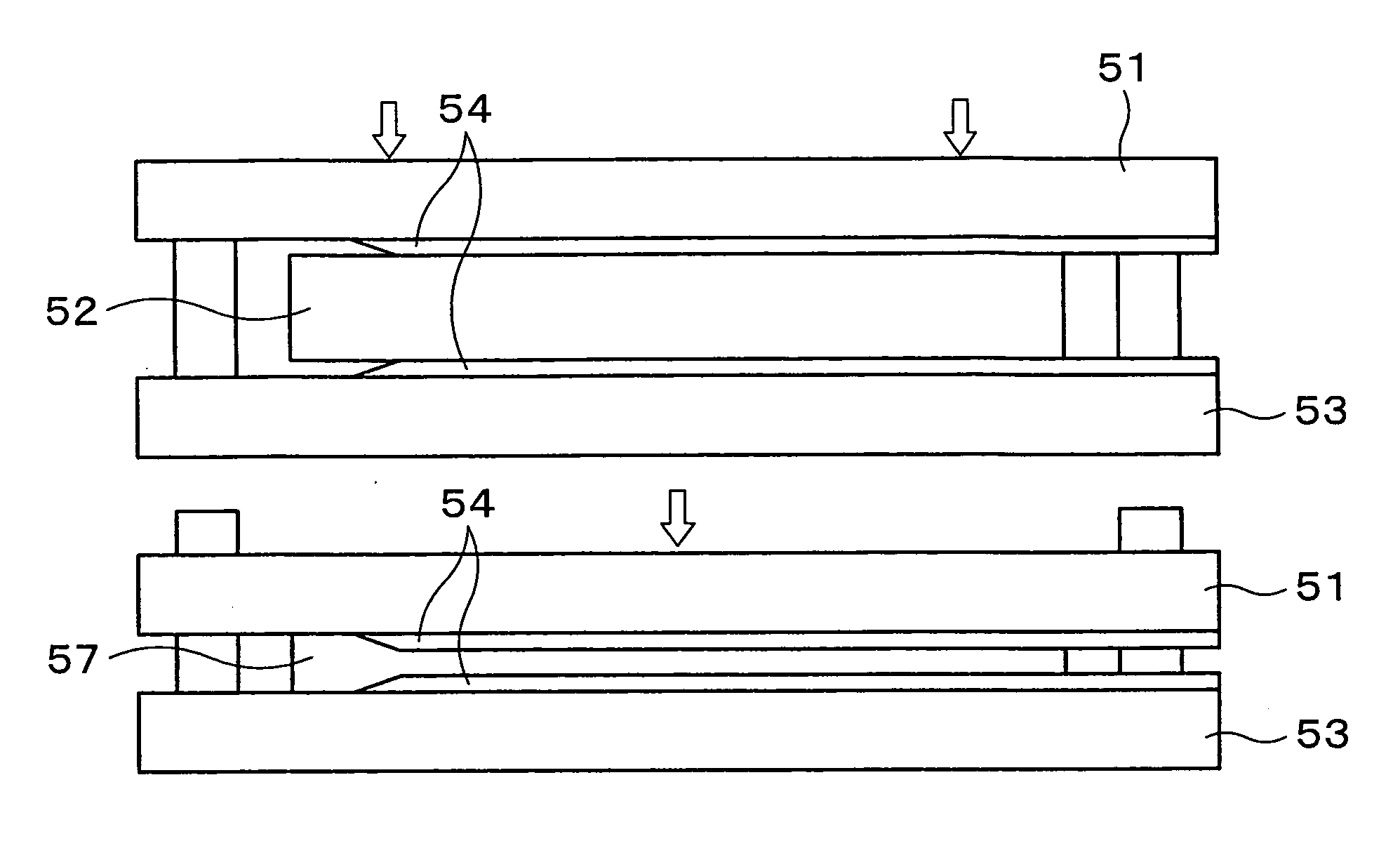

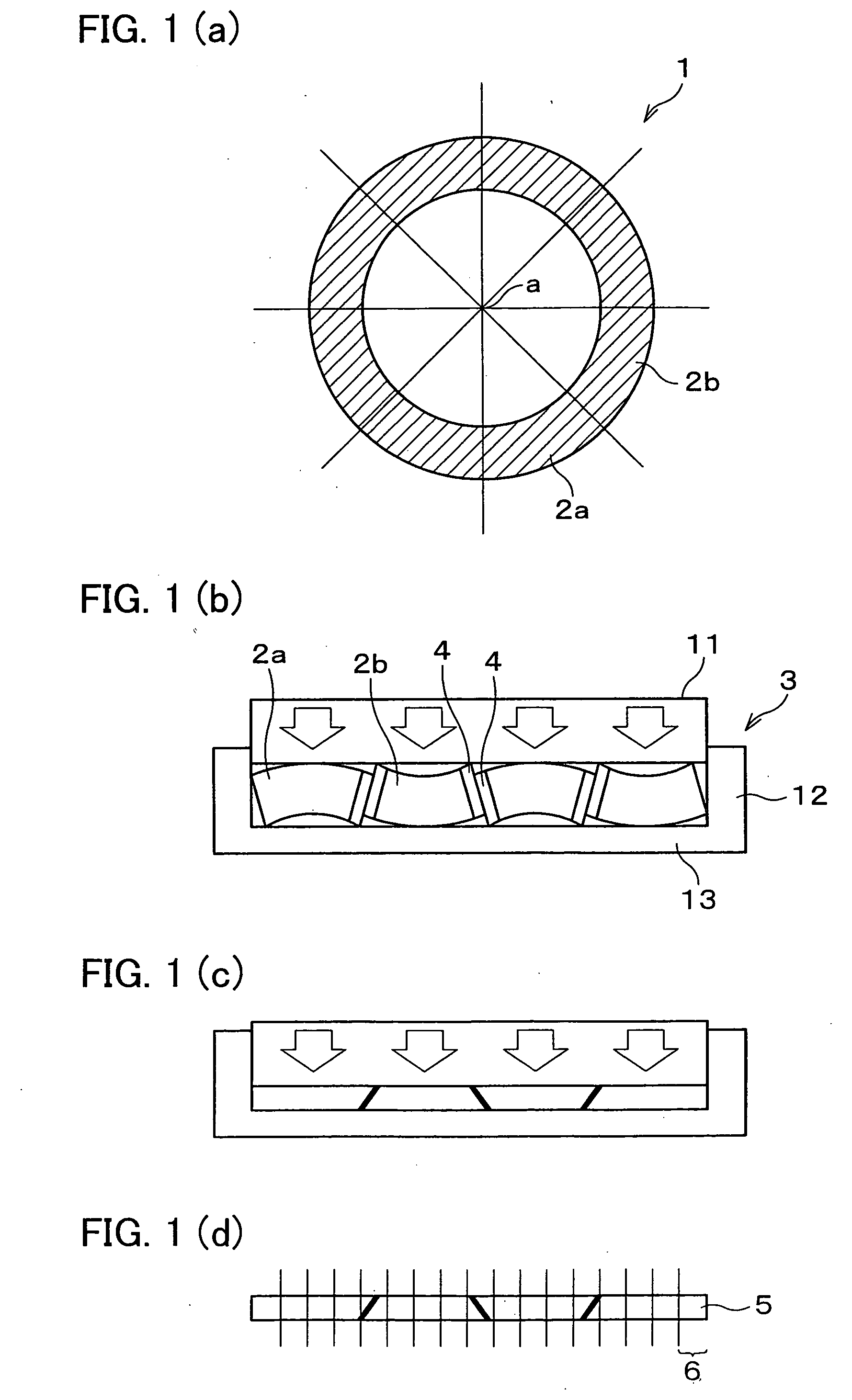

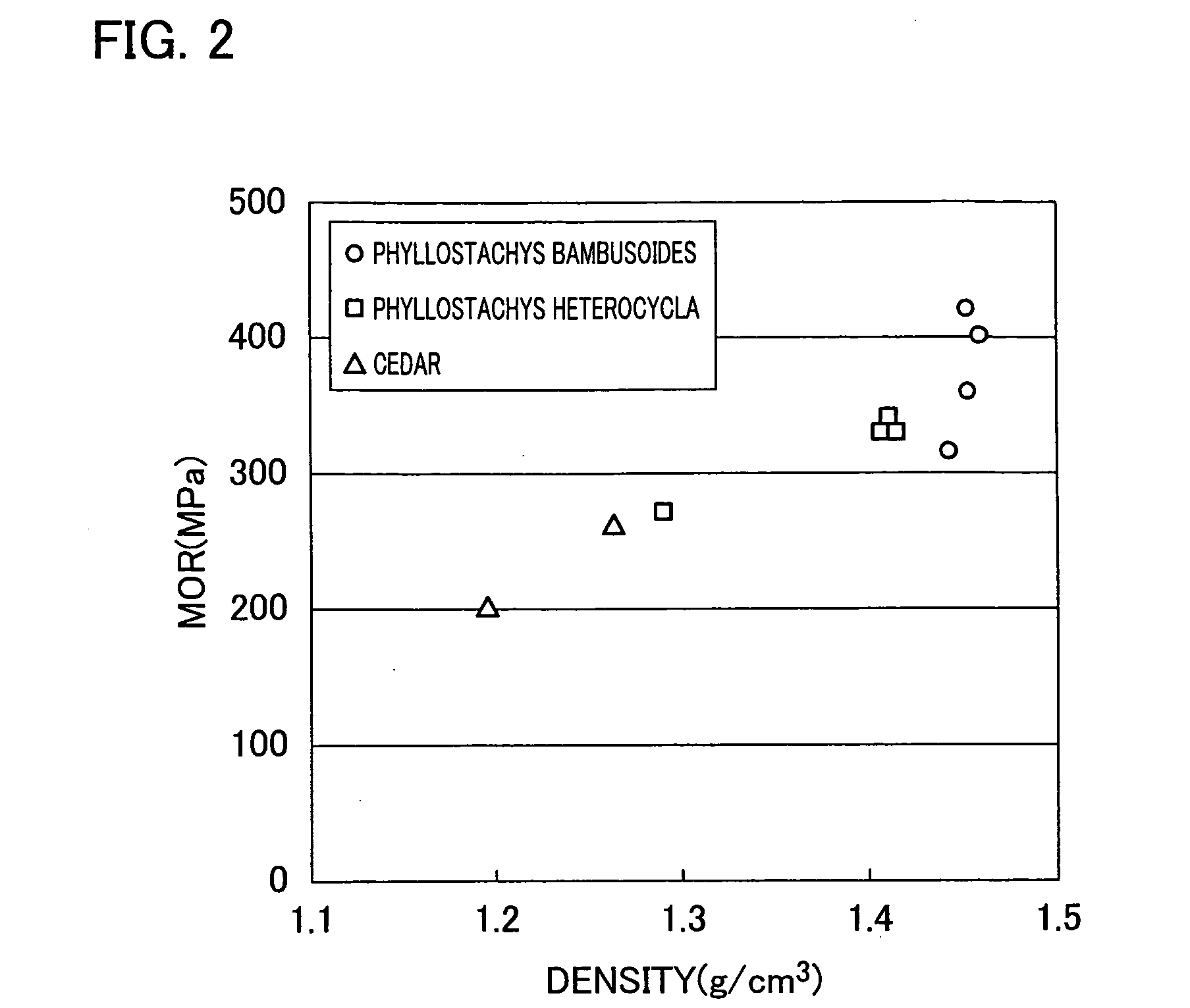

Wooden nail-like connector, compressed bamboo material, and method of manufacturing the connector and the material

InactiveUS20060060263A1High strengthHigh densityStapling toolsCane mechanical workingFiberEngineering

A method is disclosed for manufacturing bamboo nails. The method includes horizontally laying down small bamboo plates, obtained by cutting a bamboo piece radially from the center axis thereof, in a press. The small bamboo plates are then pressed perpendicularly to the fibers to produce a compressed flat plate. Finally, the compressed flat plate is cut in the shape of a multangular column. Thus the strength of a wooden material is increased.

Owner:JAPAN SCI & TECH CORP

Bamboo slicer

A bamboo split opening machine comprises a frame and a bamboo strip feeder on the frame, and a bamboo strip inlet and an opening device respectively mounted on two sides of the bamboo strip feeder. The opening device comprises a blade relative to the outlet of the bamboo strip feeder, wherein the blade is fixed at the end of one flexible rod whose back part is connected with a swing rod. The swing rod can accelerate the flexible rod to move to the bamboo strip feeder. Based on high density and rigidity of bamboo fiber, the invention is designed to simulate the blade feeding operation when cutting the bamboo, to obtain straight shape at the bamboo joint, therefore the inventive bamboo split has high quality.

Owner:周云龙

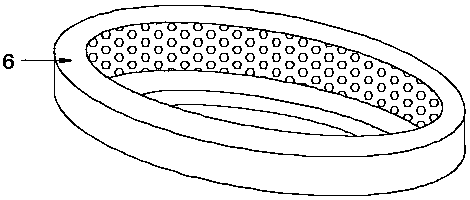

Production method for high-temperature heat treatment of bamboo bunch

ActiveCN105690512ASimple production processProduction process is environmentally friendlyWood compressionCane mechanical workingHigh pressureMechanical property

The invention discloses a production method for high-temperature heat treatment of a bamboo bunch. The production method comprises the following steps: (1) preparation of bamboo chips; (2) softening treatment; (3) rolling compaction; (4) a heat treatment process; and (5) cooling and humidifying treatment. The production method is simple in production process, high in production efficiency, short in processing period, free of heat-source equipment cooling, and low in energy consumption and waste; heat transfer oil is adopted as a heat source; compared with high-temperature and high-pressure saturated steam, the heat transfer oil has the advantages that not much waste gas is generated during bamboo bunch preparation, and the production process is environmentally friendly; and meanwhile, when the bamboo bunch is subjected to high-temperature heat treatment in an atmosphere of ammonia gas, the prepared bamboo bunch is uniform is defibering effect, high in permeability and uniform in bamboo color, the difference between physical and mechanical properties is relatively small, and the anti-distortion and anti-cracking properties of reconstituted bamboo timber can be improved.

Owner:ZHEJIANG FORESTRY UNIVERSITY

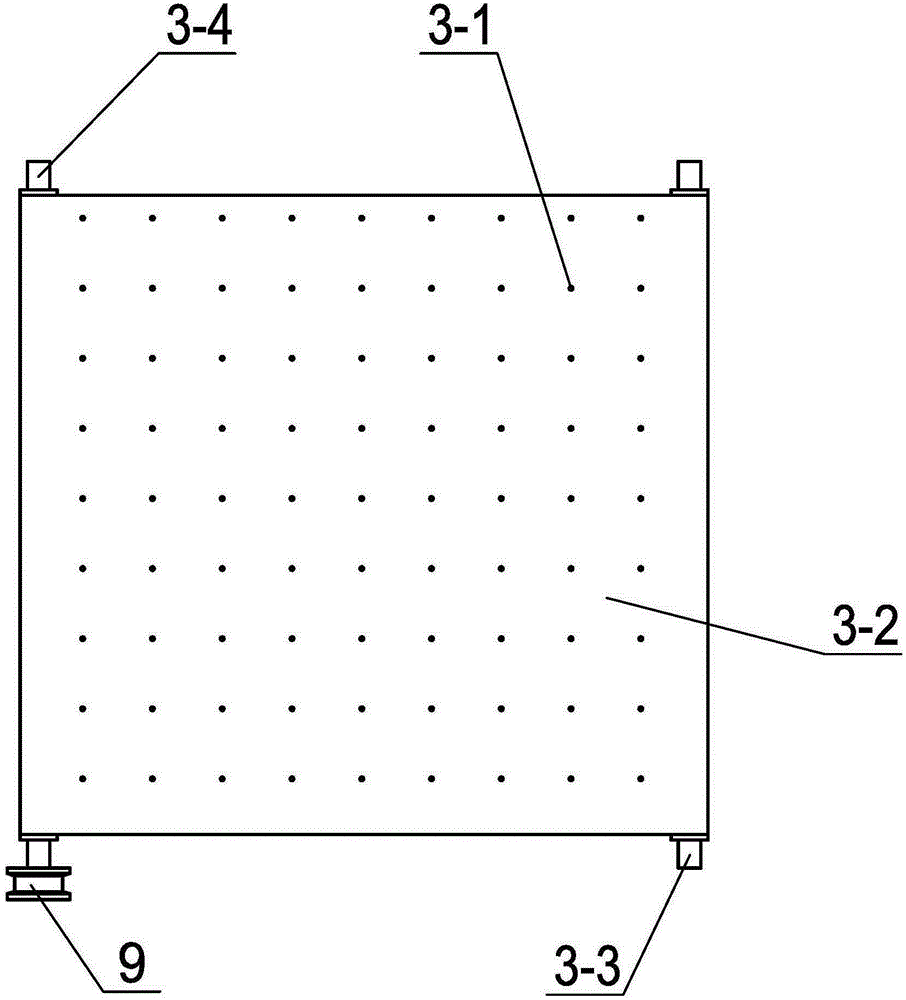

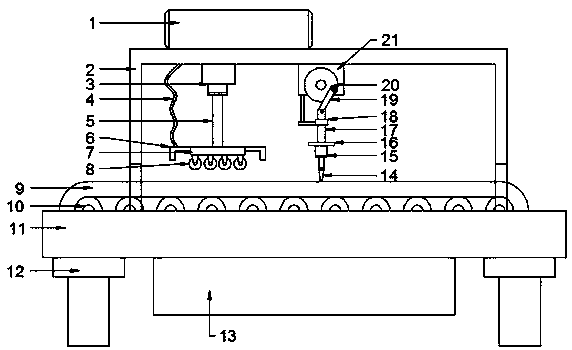

Inner segment removing machine

ActiveCN104942926AEasy to interveneAvoid scratchesCane mechanical workingPlant material mechanical workingEngineeringPunching

The invention discloses an inner segment removing machine. The machine comprises a rack, wherein an inner segment removing scraper assembly is erected on the rack and comprises a knife rest, a segment punching knife mounted at the front end of the knife rest, inner segment scrapers mounted on sides of the knife rest and located behind the segment punching knife, elastic propping pieces for driving the inner segment scrapers to get away from the sides of the knife rest as well as limiting pieces for preventing the inner segment scrapers from separating from the knife rest; blunt propping parts for propping are arranged at ends, far away from the knife rest, of the inner segment scrapers; the segment punching knife rotates and forms breaches in inner segments, and the inner segment scrapers rotate and grind and scrape the breached inner segments; the inner segment scrapers can be attached to the inner wall of a bamboo for grinding and scrape bamboo segment residues left after the segment punching knife passes; the blunt propping parts are propped against the inner wall of the bamboo to prevent the inner segment scrapers from excessively scraping the inner side of the bamboo under the action of the elastic propping pieces. The machine can be adapted to bamboos with different shapes and can fully scrape bamboo segments under the condition that no bamboo body is hurt.

Owner:FUJIAN LONTAI BAMBOO HOUSEHOLD CO LTD

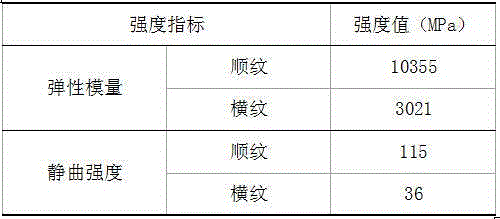

Manufacturing method of bamboo-wood composite laminated timber

InactiveCN105196368AImprove longitudinal strengthReduce horizontalCane mechanical workingWood veneer joiningComposite laminatesFiber array

The invention provides a manufacturing method of a bamboo-wood composite laminated timber and belongs to the technical field of bamboo-wood processing. The manufacturing method comprises the following process steps: (1) preparing raw materials; (2) drying; (3) braiding bamboo bundles; (4) immersing in glue; (5) drying; (6) assembling; (7) prepressing; (8) hot pressing; and (9) ageing. Compared with a traditional process for manufacturing recombined bamboo by adopting a mold pressing manner, mechanization is realized in a manufacturing process of a bamboo bundle single board; the spreading of a plate blank is similar with the spreading of a plywood; and compared with the spreading of a recombined bamboo plate blank, the spreading is relatively simple, and the production efficiency is relatively high. Meanwhile, a traditional recombined bamboo product has the same fiber array direction so that the longitudinal strength of the product is remarkably higher than transverse strength. According to the bamboo-wood composite material manufactured by the manufacturing method, the method is carried out by symmetrically assembling the bamboo bundle single board and a wood single board, so that the difference of the transverse strength and the longitudinal strength of the material is reduced and the transverse strength is remarkably improved.

Owner:国家林业局竹子研究开发中心 +1

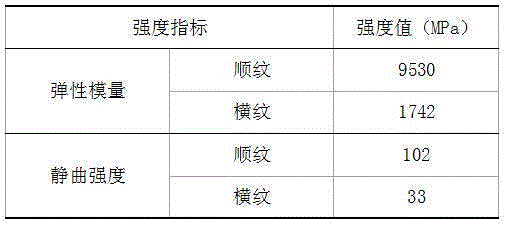

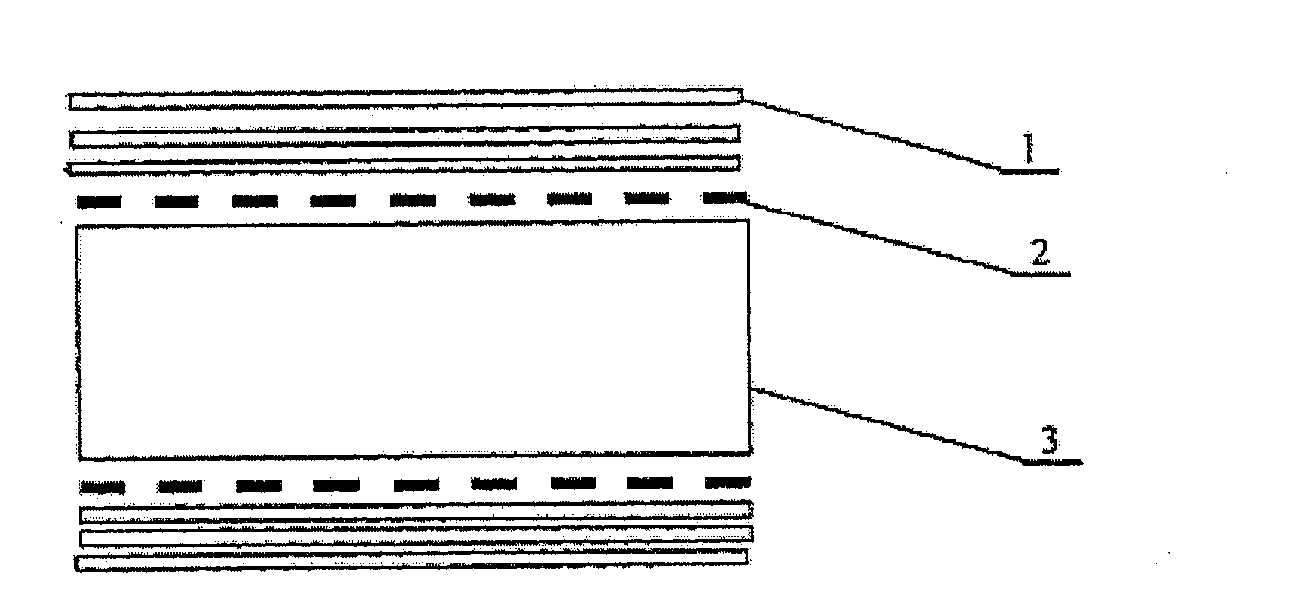

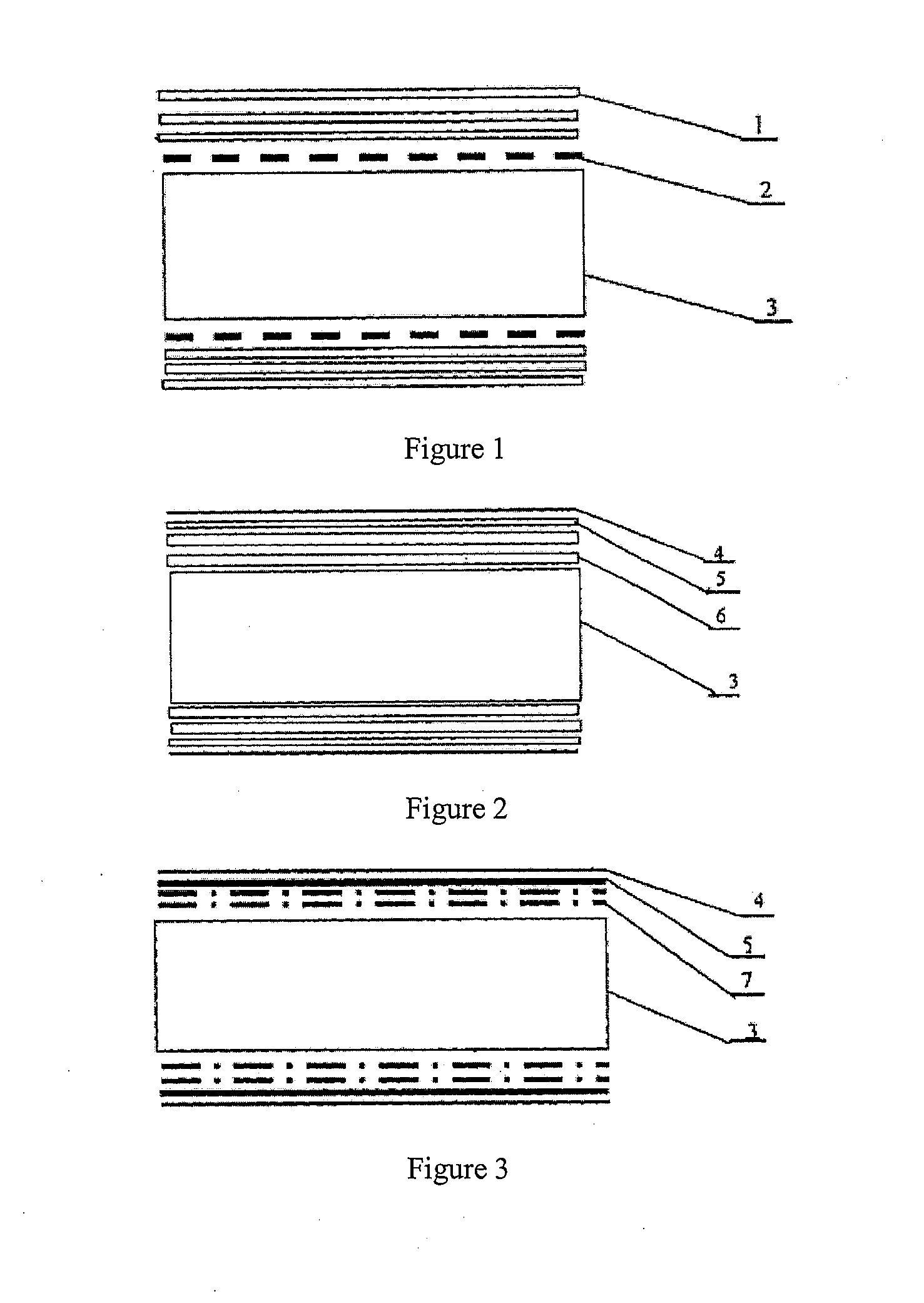

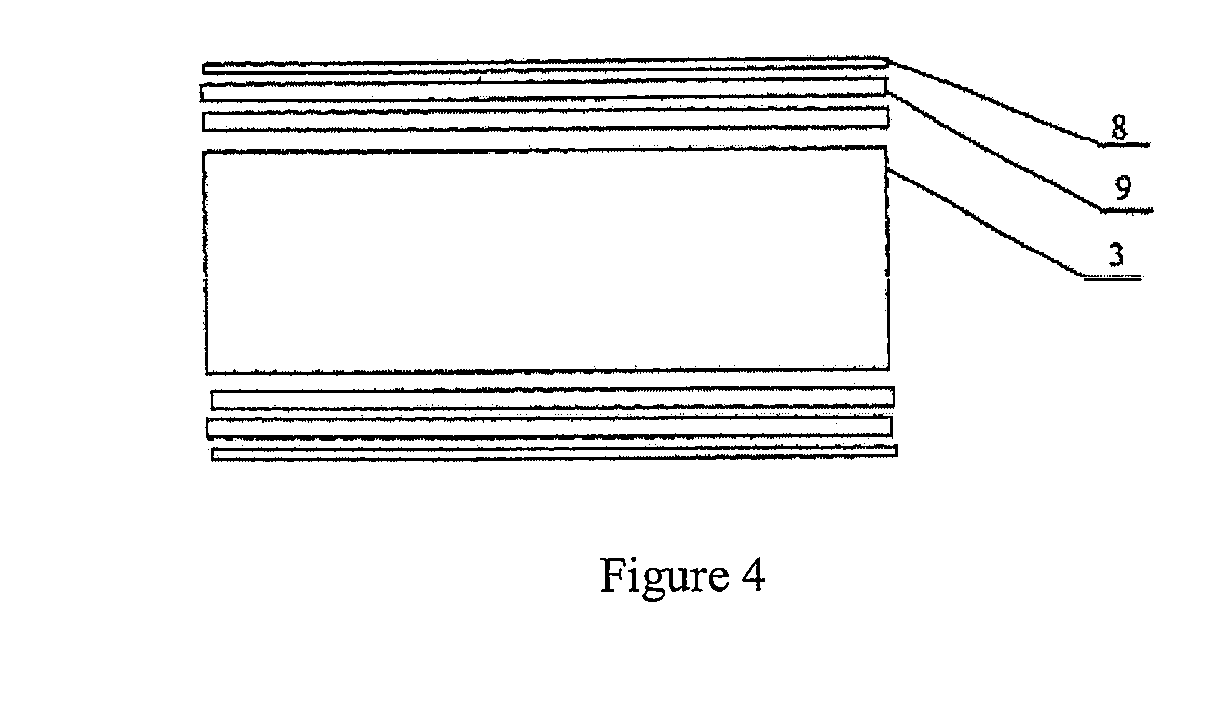

Container flooring material and method of manufacture

InactiveUS20100015389A1Efficient use ofOvercome shortageLamination ancillary operationsLayered product treatmentSoutheast asiaResin coating

The present invention relates to a composite container floorboard having a structural strand-based board as the core material and its fabrication method thereof. It is characterized wherein the composite container floorboard, using a structural strand-based board as a core material, comprises 2 to 4 layers of wooden veneers coated or impregnated with resin, respectively, on a top and a bottom of the surface overlay materials; or comprises one piece of impregnated paper, one piece of resin-impregnated bamboo-woven mat, and 1 to 3 pieces of double-side resin-coated or resin-impregnated wooden veneers, respectively, from an exterior to an interior of the surface overlay materials; or comprises one Keruing or Apitong wooden veneer of Southeast Asia, or other wooden veneer with similar properties and 1 to 3 pieces of double-side resin-coated or resin-impregnated wooden veneers [or partially or entirely replacing wooden veneer(s) with resin-impregnated bamboo curtain(s) or bamboo-woven mat(s)], respectively, from an exterior to an interior of the surface overlay materials.

Owner:ALBERTA INNOVATES TECH FUTURES

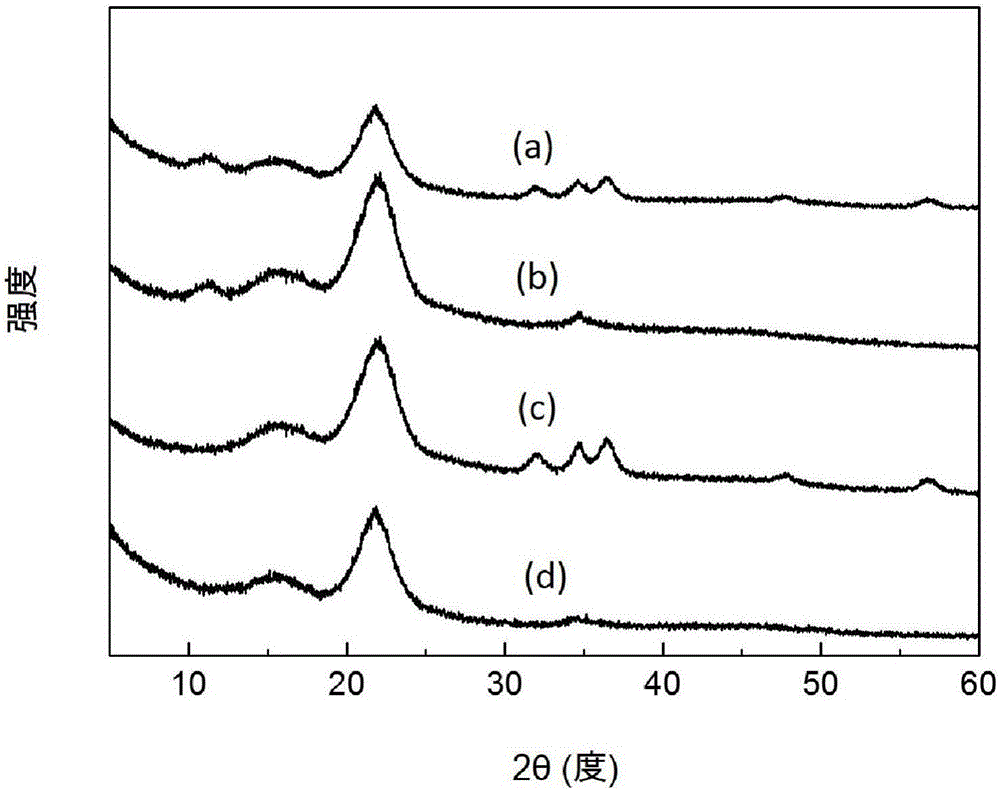

Antibacterial bamboo composite material and preparation method

ActiveCN106142243AEasy to fixImprove antibacterial propertiesCane mechanical workingReed/straw treatmentGrapheneZinc

The invention discloses a preparation method of an oxide graphene nanosheet / zinc oxide / bamboo composite material. The method deeply combines zinc oxide and an oxide graphene nanosheet in a bamboo through a hydrothermal reaction to obtain the oxide graphene nanosheet / zinc oxide / bamboo composite material with an excellent antibacterial effect. The method is simple in process, green, environment-friendly and low in cost, is different from a traditional nanometer inorganic matter modification surface treatment method, prepares an oxide graphene / zinc oxide modified bamboo composite material through a method of combining pretreatment with the hydrothermal method, penetrates oxide graphene and zinc oxide in the material, is not easy to lose effective components, and is excellent and long in antibacterial effect. The bamboo can keep better antibacterial performance in later secondary processing.

Owner:INT CENT FOR BAMBOO & RATTAN +1

Method for processing bamboo sectional material

InactiveCN101708618AStress reliefImprove anti-corrosion performanceWood treatment detailsCane mechanical workingCarbonizationHigh pressure

The invention discloses a processing method, which can form a bamboo sectional material having rich texture, sufficiently eliminates the internal stress of bamboo chips, enhances the antiseptic property of the bamboo chips and can adjust the colour of the bamboo chip through a carbonization process at 150 to 180 DEG C. The processing method comprises the following steps: after twisting retiform bamboo chips into twist strip-shaped bamboo cables, weaving the bamboo cables into a bamboo braid; immersing the bamboo braid into a glue; and thermo-curing the bamboo braid under a high pressure to obtain a texture as a precious wood can be obtained. The number of strands and weaving methods are different, so the texture of the sectional material changes correspondingly; the original form of the bamboo is changed radically through the high pressure treatment of the process; bamboo fires are recombined into a novel bamboo sectional material; and various physical performance indexes exceeding that of the wood are obtained. The method for processing the bamboo sectional material performs precompression on the bamboo braid before thermo-curing the bamboo braid under the high pressure, which reduces the stroke of an oil cylinder of a mould press, reduces the height of equipment, saves the cost of the equipment, and improves the production efficiency. The bamboo sectional material prepared by the process method can replace the precious wood facing depletion, can be used for houses, floor boards, doors and windows and building materials, and has good market prospect.

Owner:周东华

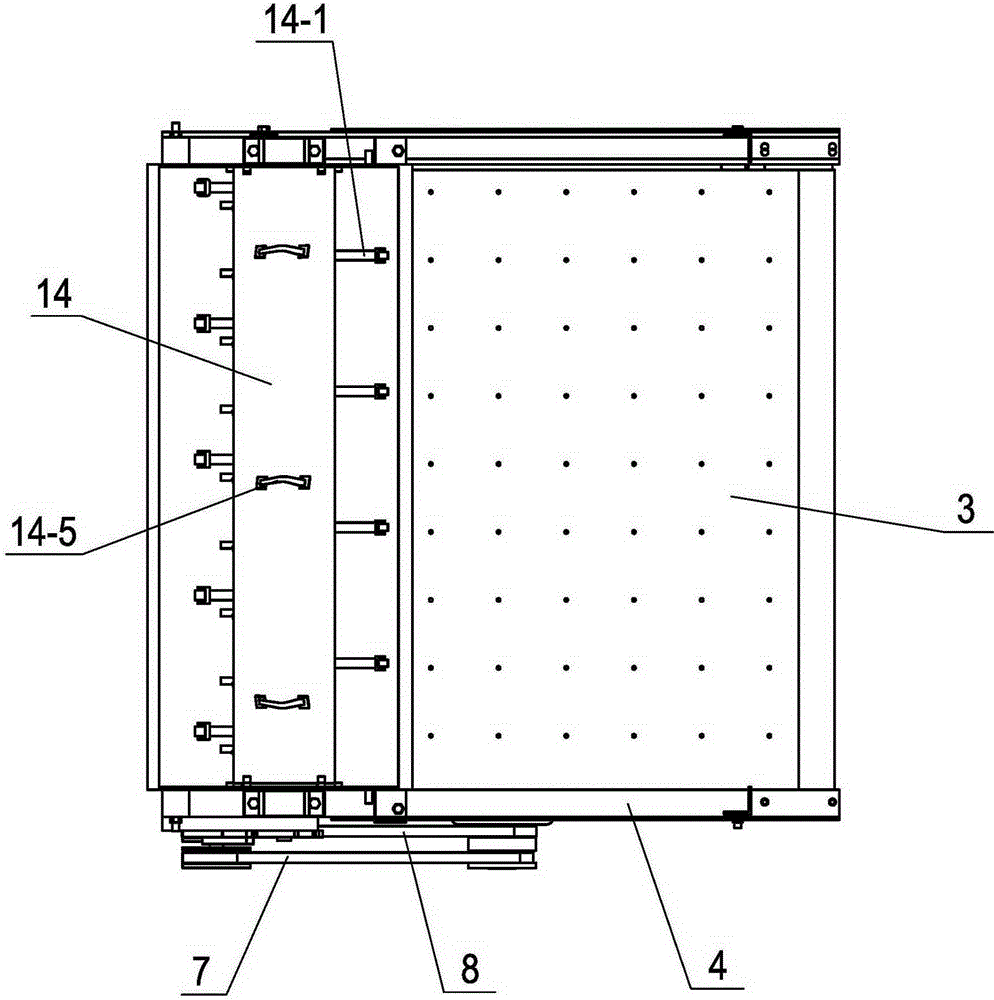

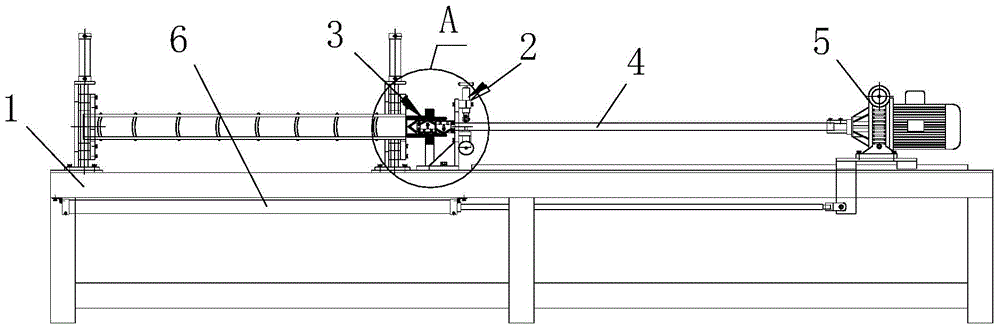

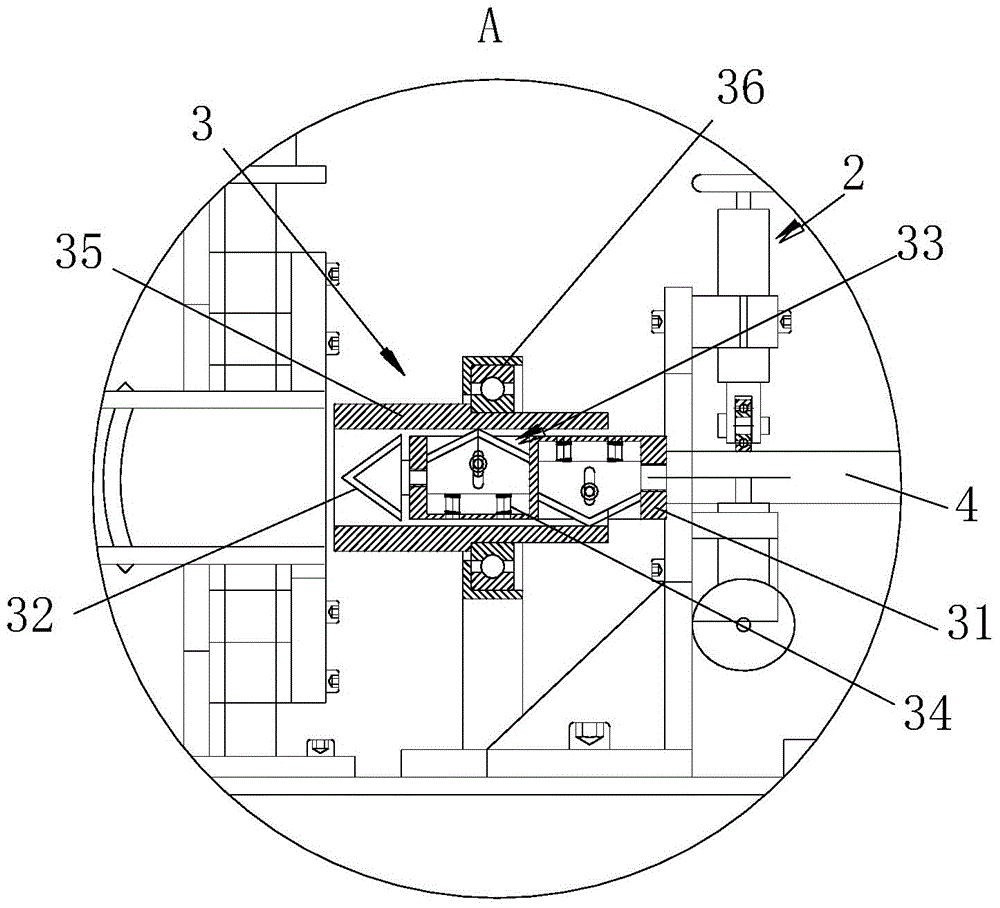

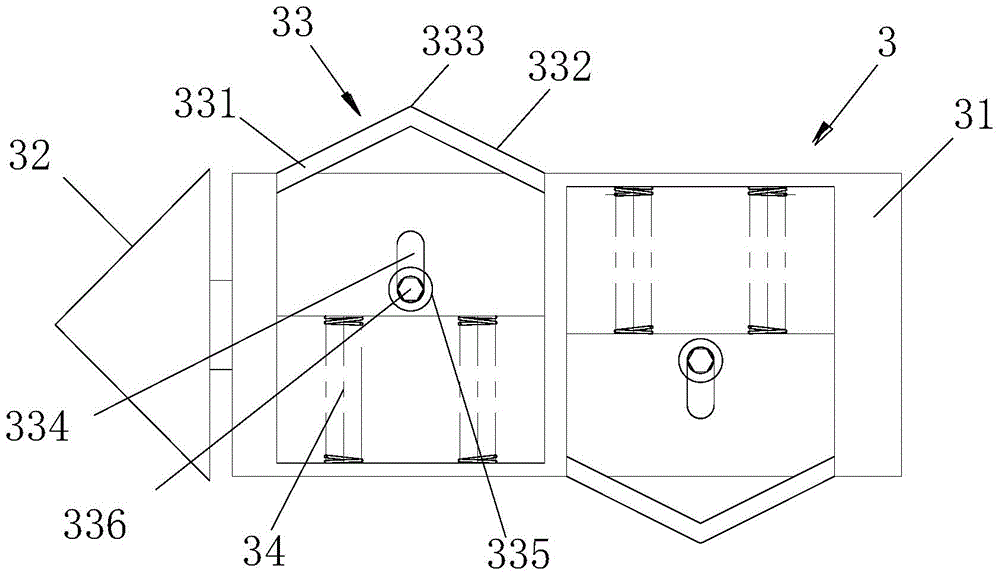

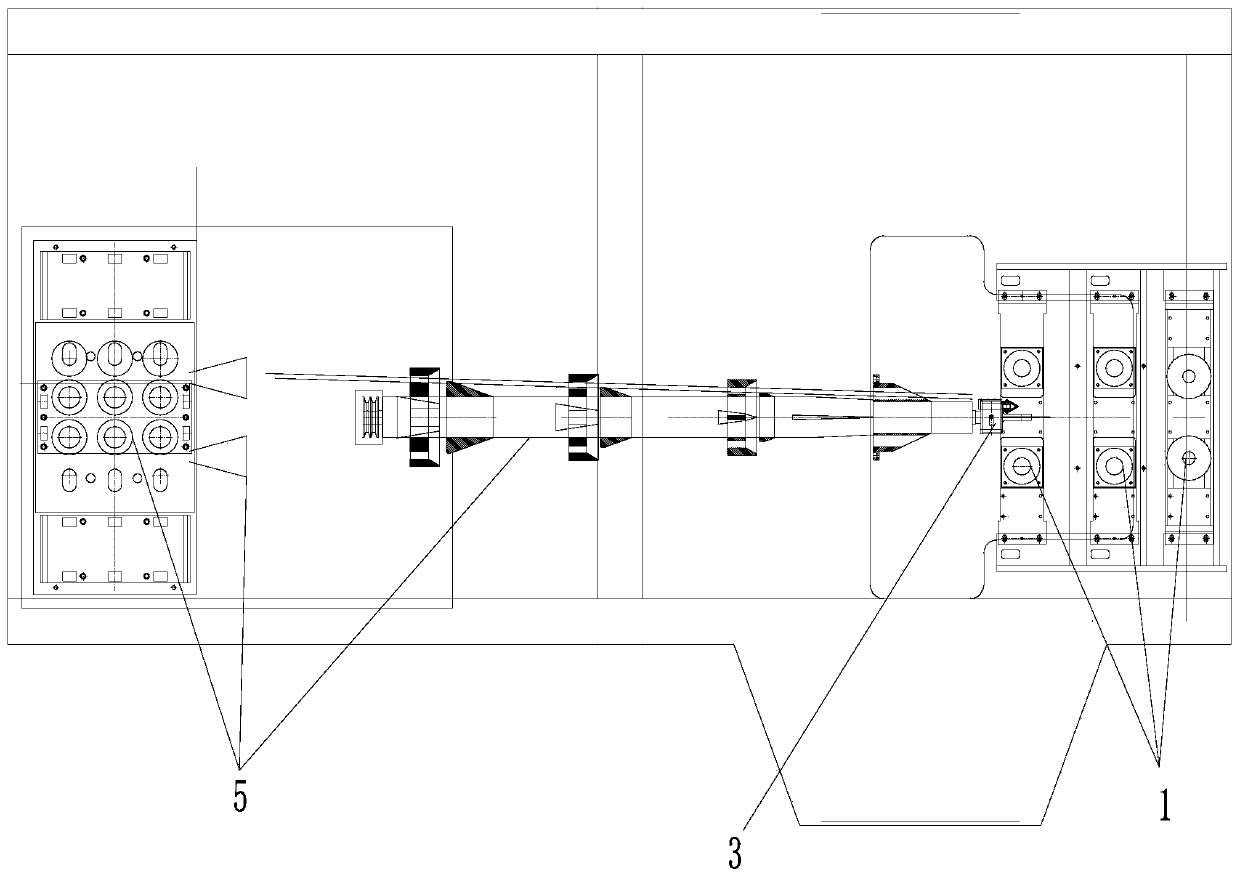

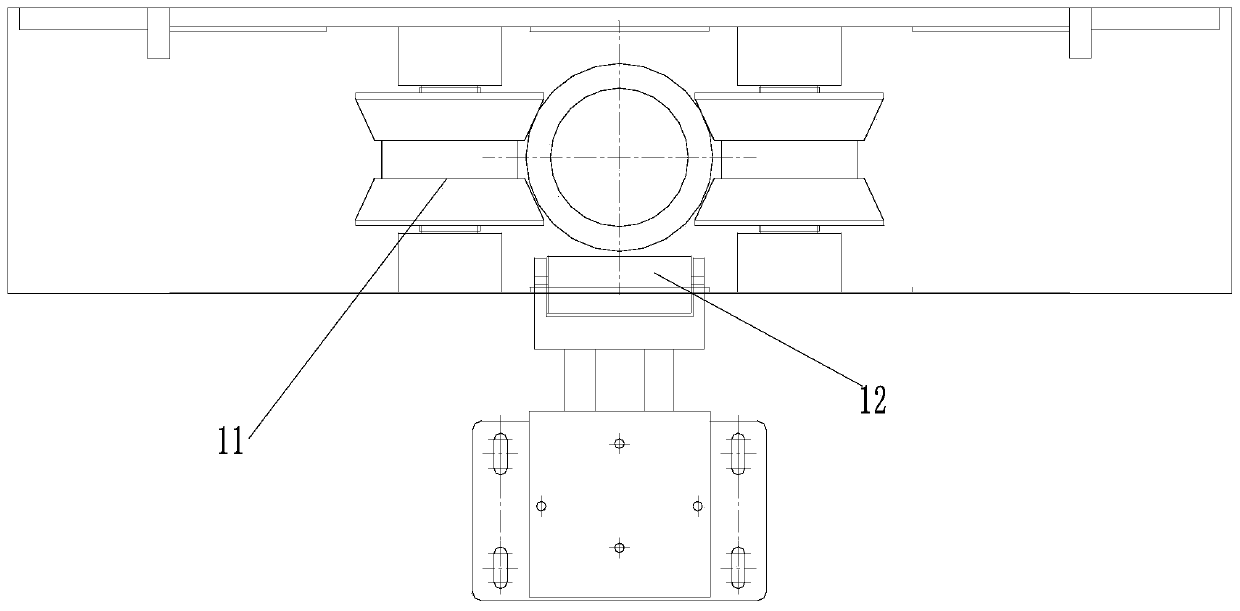

Bamboo tube automatic production device and production method

ActiveCN104960048ARealize automated productionFree laborCane mechanical workingWood working apparatusElectricityControl system

The invention discloses a bamboo tube automatic production device and production method. The device comprises a control system, a feeding system, an impurity removing system and a grooving system. The feeding system comprises a first rack, a conveying device is fixedly connected to the first rack, and the conveying device is electrically connected with the control system. The impurity removing system comprises a second rack, and a clamp device, an outer green removing device and an inner joint beating device are fixedly installed on the second rack. The grooving system comprises a third rack, and a grooving device is fixedly installed on the third rack and is electrically connected with the control system. The whole production device is controlled through a PLC, full-automatic production is achieved, all procedures are closely matched, assembly line type production including bamboo green removing, inner joint removing and grooving of raw materials is achieved, workforce is greatly liberated, and work efficiency is improved.

Owner:ZHEJIANG JIUCHUAN BAMBOO & WOOD

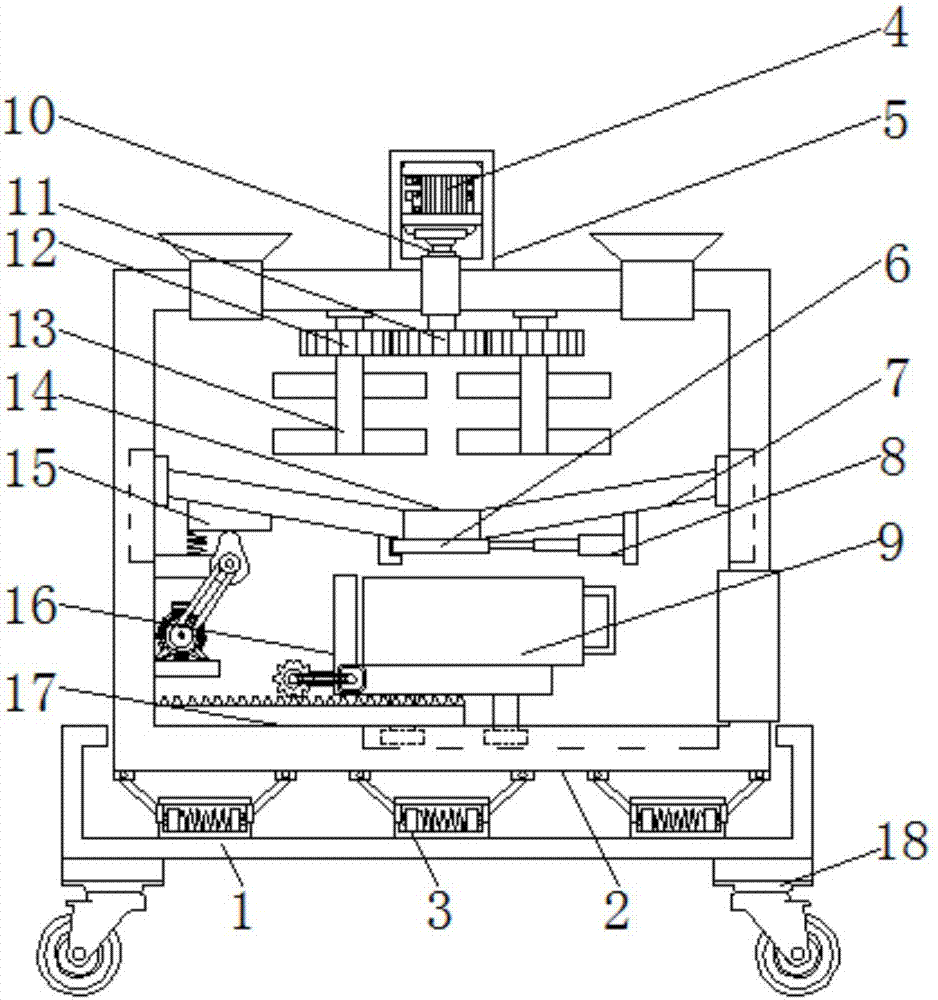

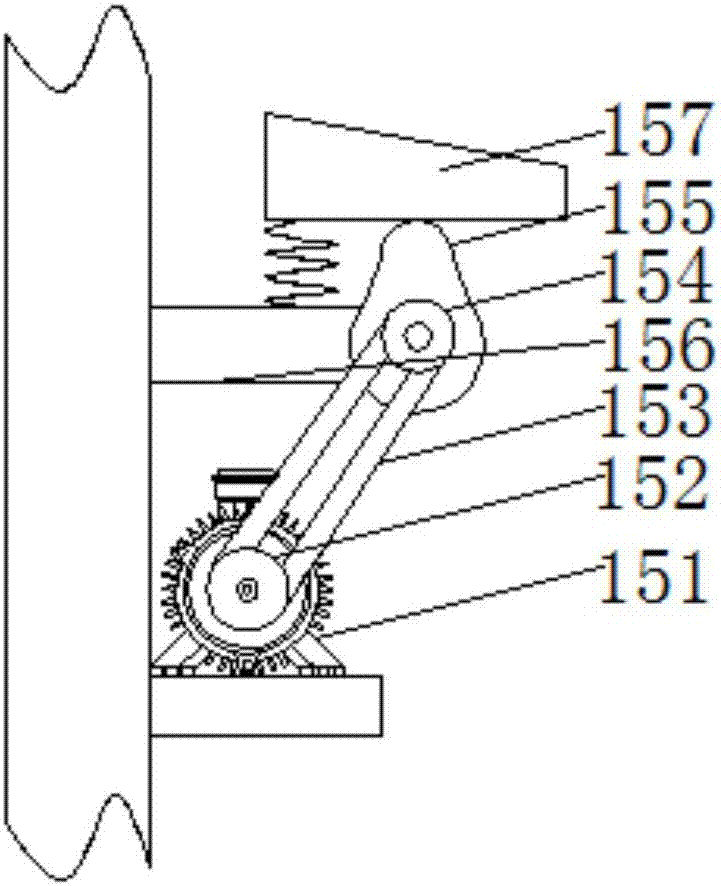

Glue preparation device for processing bamboo products

InactiveCN107414993AGood mixabilityImprove efficiencyTransportation and packagingRotary stirring mixersCouplingBiochemical engineering

The invention discloses a glue preparation device for processing bamboo products. The glue preparation device comprises bases, wherein a box body is arranged on the tops of the bases in a penetrated manner, and a damping device is fixedly connected between the bottom of the box body and the bottom of the inner cavity of each base; the top of the box body is fixedly connected with a motor box, and the interior of the motor box is fixedly connected with a first motor; and the output shaft of the first motor is fixedly connected with a rotating shaft through a coupler. The invention relates to the technical field of bamboo product processing. According to the glue preparation device for processing bamboo products, raw materials are shaken while the raw materials are stirred and mixed, so that the stirring and mixing effect of the raw materials is better, and the efficiency is higher; the raw materials are shaken during discharging, the raw materials are prevented from remaining inside the device, after the raw materials are stirred and mixed, the raw materials are automatically fallen into a material storage box, and the material storage box is sent out by a moving device, so that the workload of workers is alleviated, the device can be moved freely, the device is convenient to use, and the work efficiency is improved.

Owner:安吉县安信信息有限公司

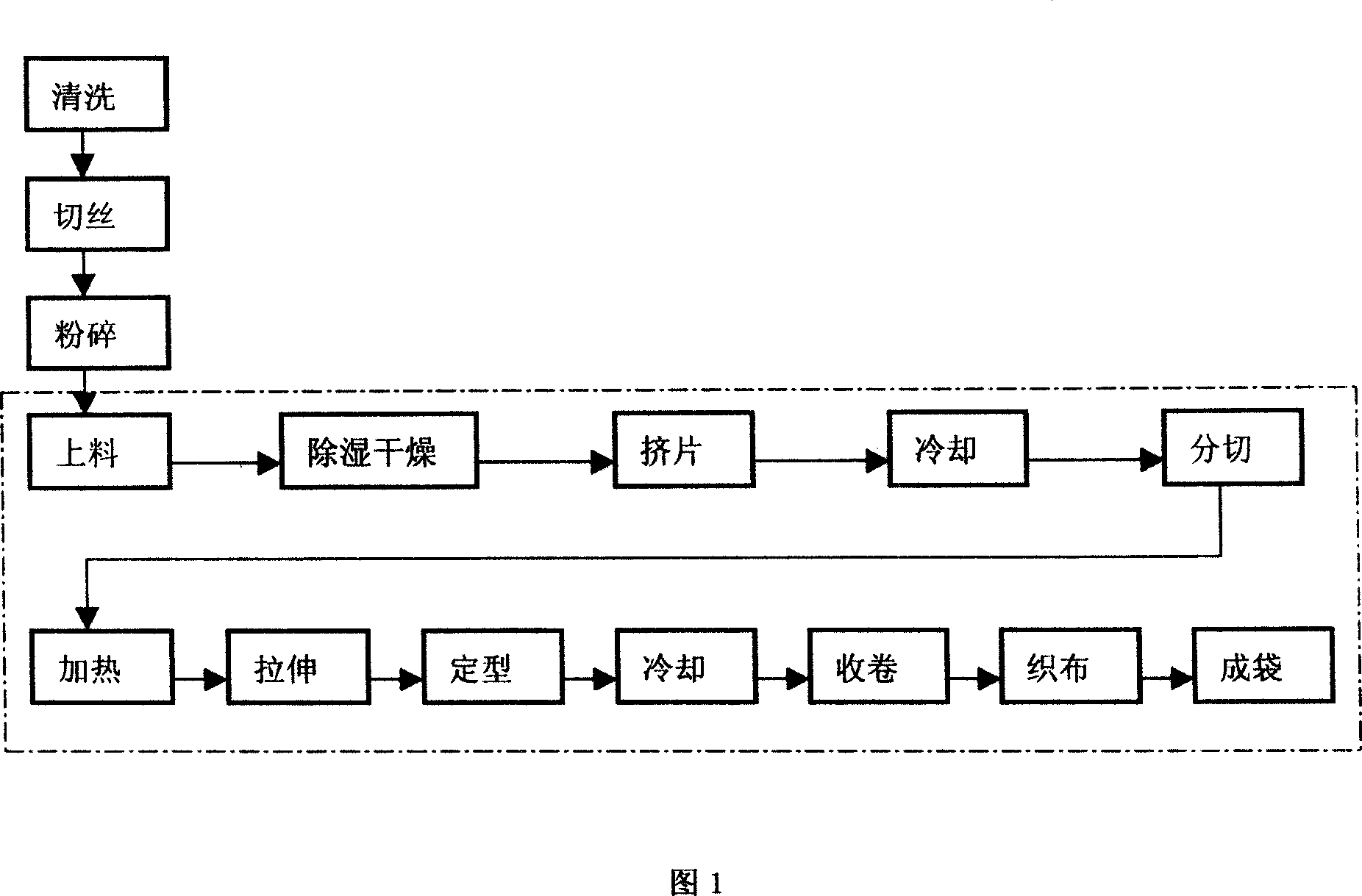

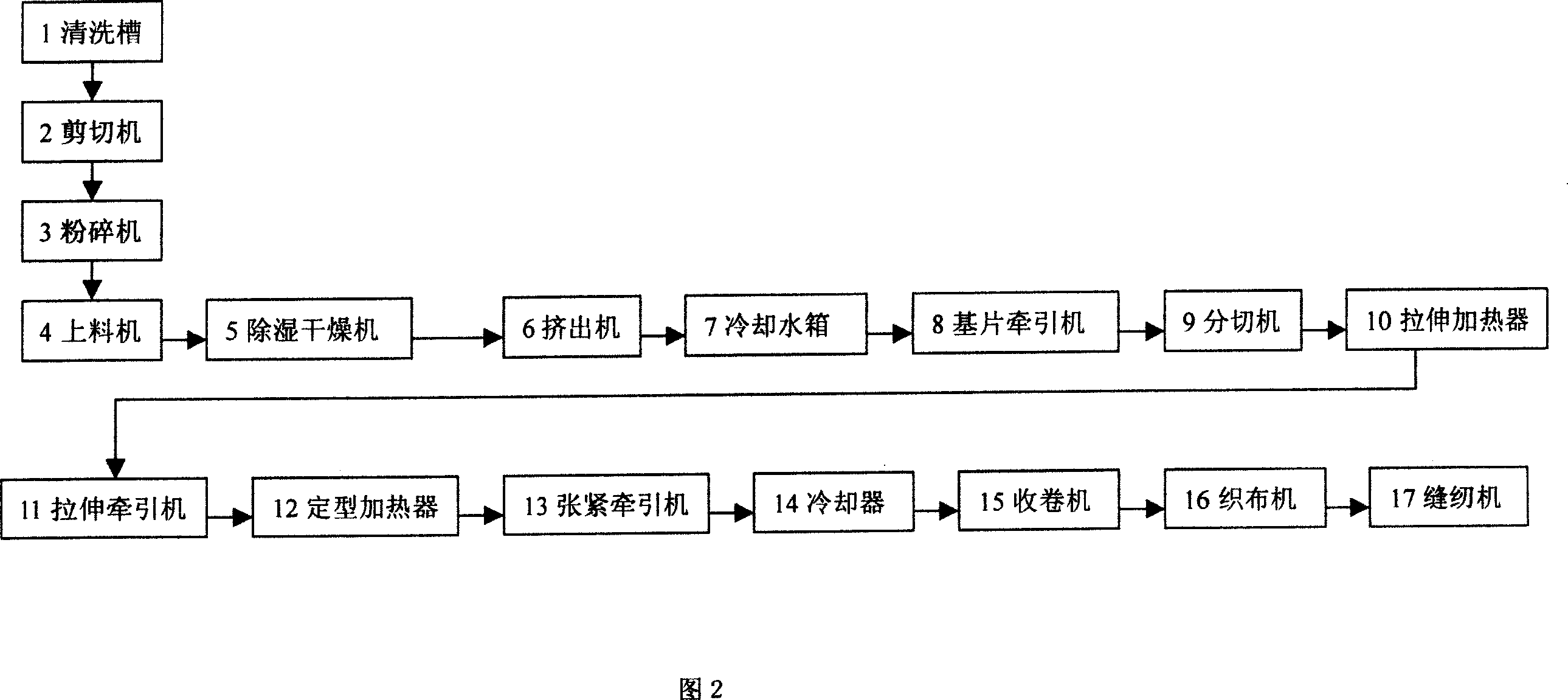

Braided bag and its production technology and device

InactiveCN100999264AGood weather resistanceNot brittlePlastic recyclingBagsPolyethylene glycolWater cooling

The present invention relates to a braided bag produced by using waste and old PET (polyethylene glycol terephthalate) products as raw material, its production process and equipment. Its production process includes the following steps: (1) cleaning waste and old polyethylene glycol terephthalate product, pulverizing and drying; (2), extruding the pulverized raw material into base sheet, cooling said base sheet by using water; (3), cutting said base sheet into band material; (4), heating said band material and wire-drawing; (5), heating the wire, tensioning and setting, cooling to normal temperature; (6), using said wire to weave fabric; and (7), cutting and making bag.

Owner:周世均

Rattan bamboo plus material and preparation method thereof

InactiveCN101264679AWide range of usesImprove breathabilityLamination ancillary operationsCane mechanical workingUltravioletBiomedical engineering

The invention provides a cany bamboo fabric and preparation method, which comprises a cany skin layer or a bamboo skin layer (1) and a lapping cloth layer (2); wherein, the cany skin layer or the bamboo skin layer (1) are produced through the scraping and silking or drawing out and planishing treatments; the cany skin layer or the bamboo skin layer (1) are compounded with the lapping cloth layer (2) together. The cany bamboo fabric is characterized in that (a) the processes of degreasing, purifying, stewing, acid treatment and bleaching treatment are added between the process of silking or drawing out and the process of planishing, (b) the cany skin or the bamboo skin are weaved into the cany skin layer or the bamboo skin layer (1), and (c) the processes of softening finishing and hot compression and fixation are processed as the cany skin layer or the bamboo skin layer (1) are compounded with the lapping cloth layer (2) together. The cany bamboo fabric has the advantages of beautiful appearance, good performance of ultraviolet resistance, soft texture, uneasy to fold, free of yellowing, easy to clean, being applicable to the production of clothing, bedding articles, high grade car pad set, slipcover, window curtain, carpet, and shoes and hats, and versatility.

Owner:周觉民

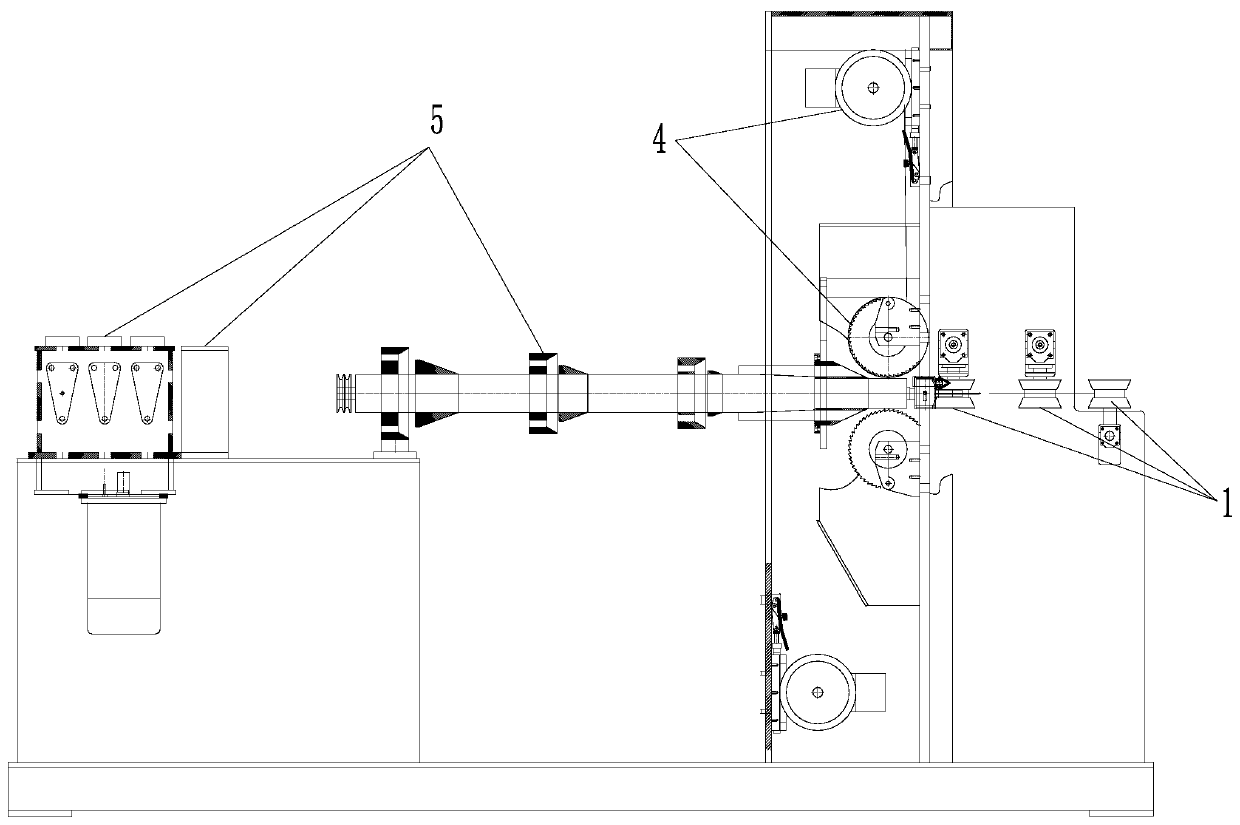

Bamboo stick clamping and drilling equipment for bamboo straw manufacturing

InactiveCN111168790AImprove processing efficiencyImprove yieldStationary drilling machinesCane mechanical workingWood machiningProcess engineering

The invention relates to the technical field of bamboo and wood machining, in particular to bamboo stick clamping and drilling equipment for bamboo straw manufacturing. The equipment comprises a conveying device, a clamping device and a drilling device which are arranged on a rack, wherein the conveying device is arranged on one side of the clamping device and used for conveying a bamboo stick tothe clamping device, and the drilling device is used for drilling the bamboo stick clamped by the clamping device. According to the bamboo stick clamping and drilling equipment for bamboo straw manufacturing, the machining efficiency of the bamboo straw is greatly improved, and the equipment is simple in mechanism and easy to disassemble and maintain; the formed bamboo stick can be directly drilled, and compared with a traditional bamboo straw manufacturing mode, the efficiency is higher; and through the straightening and fixing effect of a taper sleeve and a clamping roller on the bamboo stick, the bamboo stick is always in a rotating state in the drilling process, it is guaranteed that a drill bit advances straightly in the bamboo stick, the problem that the drill bit drills through thebamboo stick due to the insufficient straightness of the bamboo stick or the structure of a sunny side and a nightside is avoided, and the yield of bamboo straw machining is greatly increased.

Owner:邵武市意创机械有限公司

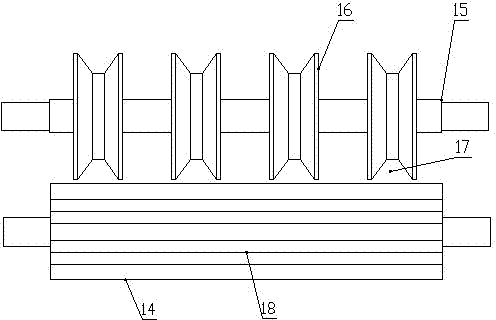

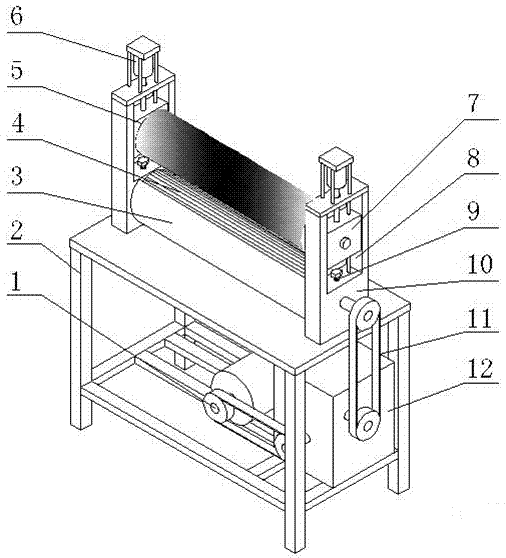

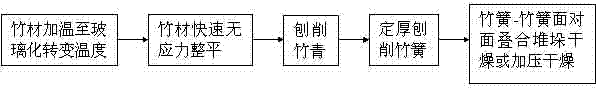

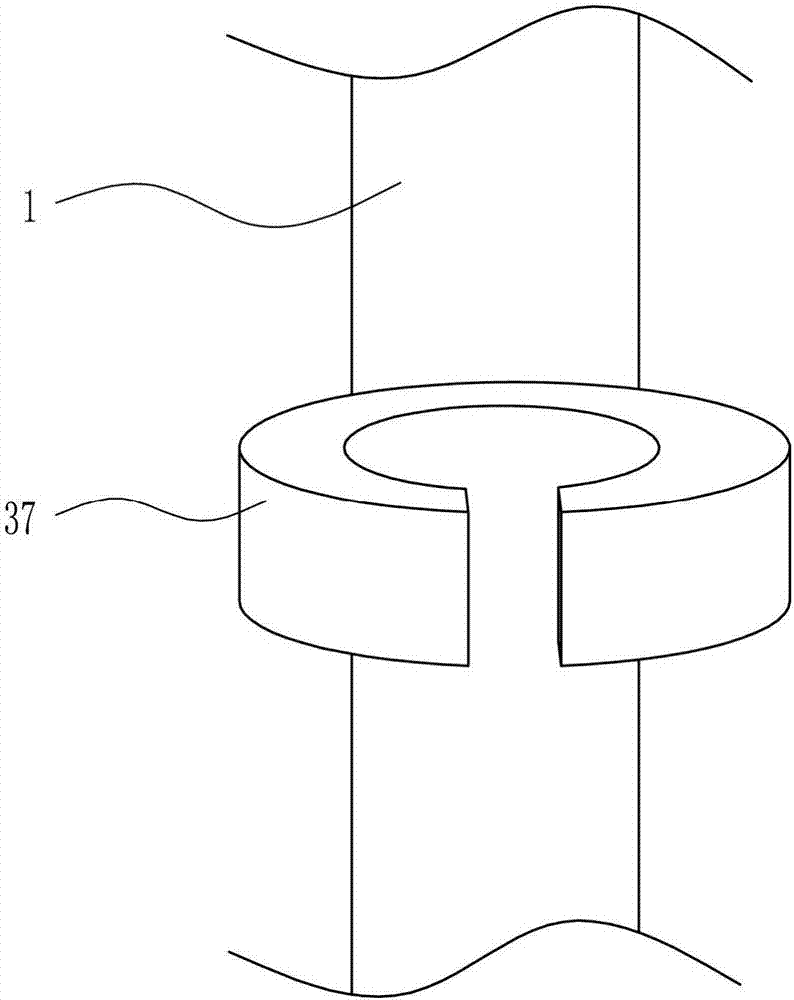

Unstressed flattening device and method for cylindrical bamboo wood with bamboo green and tabasheer

InactiveCN103786198ASimple and scientific structureEasy maintenanceCane mechanical workingEngineeringGlass transition

The invention discloses an unstressed flattening device and method for cylindrical bamboo wood with bamboo green and tabasheer. The device structurally comprises a motor, a motor base, a protective cover, a knife roll, a flattening roll, an air cylinder, a flattering roll bearing sliding base, a sliding groove, a limiting bolt, a knife roll bearing fixing base, a chain and a gearbox. The flattening method comprises the steps of (1) heating the bamboo wood to reach the glass-transition temperature, (2) rapidly flattening the bamboo wood in an unstressed mode, (3) planing the bamboo green, (4) planing the tabasheer with the fixed thickness, and (5) conducting drying through overlapping and stacking in a tabasheer face-to-face mode or pressure drying. The unstressed flattening device and method for the cylindrical bamboo wood with the bamboo green and the tabasheer have the advantages that only one pair of rolls, namely the upper flattening roll and the lower knife roll are needed, the structure is simple, maintenance is convenient, operation is easy, the device and method can be suitable for flattening bamboo cylinders with different diameters, and the flattening effect is good; flattening of the heated bamboo cylinders in a heating tank is rapidly finished within 3 min to 5 min, fixed-thickness planing is conducted, most cracks of the tabasheer face are planed away when the tabasheer is planed, the tabasheer is in the adhesive face when finished products are formed, and the appearance and the strength are not affected.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Method for producing multi-layer board using poplar board, enzyme treated lumber and stalk fibre

InactiveCN101439525AExpand sourceImprove bonding performanceCane mechanical workingWood veneer joiningFiberHigh density

The invention relates to a method for manufacturing a multilayer board by a poplar veneer, enzyme treated wood and straw fiber. The method is characterized by comprising the following steps: (1) manufacturing wood fiber; (2) manufacturing the straw fiber; (3) processing the wood and the straw fiber by enzyme; (4) manufacturing a high-density fiber board; and (5) assembling and compregnating the poplar veneer and the fiber board into the multilayer board. The method has the advantages of improving the bonding performance by the enzyme treated wood and straw fiber, manufacturing the high-density fiber board by the enzyme treated wood and straw fiber, being capable of enlarging material sources of the multilayer board by manufacturing the multilayer board by replacing part of the veneers, and using the wood felling and processing remainders and crop straw materials. The enzyme treated wood and straw fiber improve the wetting property of the multilayer board (a surface contact angle is reduced by 10-20%), improve the bonding performance and reduces the application amount of urea formaldehyde resin adhesive by 6-8%. Generally, the application amount of urea formaldehyde resin adhesive is 10-14%.

Owner:NANJING FORESTRY UNIV

Bamboo chip trepanning and grinding integrated automation device

InactiveCN108312025ARealize transmission grindingImprove grinding efficiencyStationary drilling machinesCane mechanical workingHydraulic cylinderArchitectural engineering

The invention discloses a bamboo chip trepanning and grinding integrated automation device. The bamboo chip trepanning and grinding integrated automation device comprises grinding rollers, a workbenchand a drill bit. A conveying belt is arranged at the upper end of the workbench. In cooperation with the conveying belt, the upper end of the workbench is provided with a cavity. The conveying belt is provided with a baffle. A fixing cover is fixed to the upper end of the workbench. The four grinding rollers are arranged and are distributed on a first fixing plate in an array manner. A dust suction cover is fixed to the outer side of the first fixing plate, and the upper end of the first fixing plate is fixed to a push rod. The push rod is fixed to a hydraulic cylinder, and the drill bit is fixed to an output shaft of a first motor. The bamboo chip trepanning and grinding integrated automation device is high in grinding efficiency and quality; and meanwhile, in the grinding process, the dust suction cover can suck away fine dust generated during grinding

Owner:安吉森虎机械有限公司

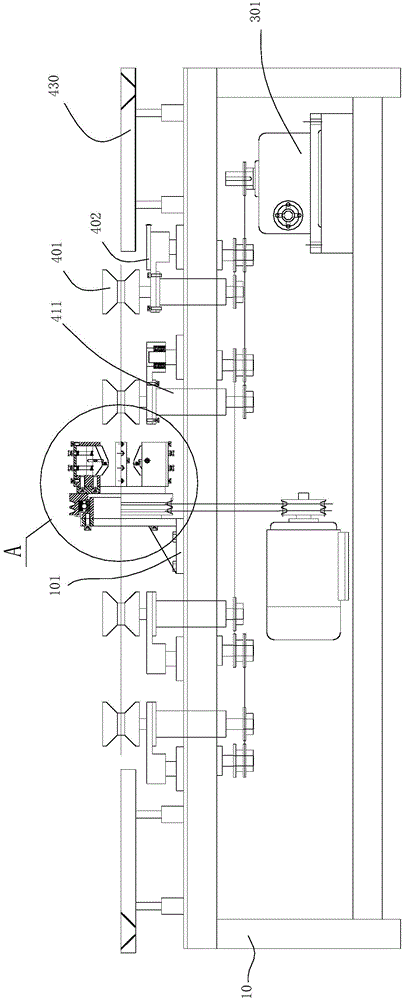

Bamboo board production system capable of efficiently utilizing round bamboos

PendingCN109834783AGood effectRealize automatic adjustment processingCane mechanical workingWood working apparatusEngineeringSegmentation system

The invention provides a bamboo board production system capable of efficiently utilizing round bamboos. The bamboo board production system comprises a bamboo segmentation system which is used for cutting round bamboos in sequence, a bamboo section diameter sorting device which is used for sorting the bamboo sections according to the diameter, a round bamboo multi-piece profiling segmentation system which is used for slitting the bamboo sections, a bamboo strip four-side finish milling system which is used for performing four-side planing on the bamboo chips carbonized and a bamboo strip row plate splicing device which is used for slicing the bamboo chips and bamboo strips. According to the bamboo board production system capable of efficiently utilizing round bamboos, the processing efficiency of round bamboos can be improved, and the waste of round bamboos can be reduced.

Owner:FUJIAN DUS WOOD IND

Bamboo equal-length cutting equipment for making pencil rods

The invention relates to cutting equipment, in particular to bamboo equal-length cutting equipment for making pencil rods. The invention aims at solving the technical problem of providing the bamboo equal-length cutting equipment for making the pencil rods, wherein the bamboo equal-length cutting equipment is accurate in cutting length and capable of making the pencil rods with the equal length. In order to solve the above-mentioned technical problem, the bamboo equal-length cutting equipment for making the pencil rods is provided and comprises an installing rack, supporting rods, a placing device, a cutting device and the like, wherein the supporting rods are arranged at the center of the bottom in the installing rack in a bilaterally symmetrical manner, the placing device is arranged at the top ends of the supporting rods, and the cutting device is arranged on the top in the installing rack. According to the bamboo equal-length cutting equipment for making the pencil rods, by means of the placing device, bamboo can be placed uniformly; by means of the cutting device, equal-length cutting can be conducted on the bamboo; and then by means of matching of a pedal and a fourth stay rope, working can be achieved more conveniently.

Owner:HUZHOU SHANLIAN YONGHEFENG PEN HOUSE

Processing technology for moso bamboo for bamboo-woven basket

InactiveCN105904556AHigh strengthImprove toughnessPressure wood treatmentWood treatment detailsFiberHigh pressure

The invention provides a processing technology for moso bamboo for a bamboo-woven basket. The processing technology comprises the following steps that the moso bamboo freshly cut is placed into a refrigeration house with the temperature ranging from 10 DEG C to 15 DEG C to be frozen; the frozen moso bamboo is taken out and subjected to high-temperature processing for 30-60 min, the processing temperature ranges from 120 DEG C to 150 DEG C, and then the moso bamboo is placed in a closed pressure processing tank to be subjected to high-pressure processing; and the root of the moso bamboo subjected to high-pressure processing is cut away, bamboo breaking is conducted through a bamboo breaking machine, a bamboo skin is formed and tailored according to the specification of a needed bamboo-woven product, then, the tailored bamboo skin is dried, and the water content of the bamboo skin is not larger than 4%. The operation of the processing technology is easy to achieve. The moso bamboo processed through the processing technology is used for weaving the bamboo-woven product, the mould proof, high-temperature resisting and severe cold resisting capability and the anti-yield strength of the bamboo-woven product can be greatly improved, and the connection strength of bamboo fiber is obviously improved.

Owner:FUNAN FANGLIU ARTS & CRAFTS CO LTD

Green bamboo skin removal machine

The invention relates to a green bamboo skin removal machine. The machine comprises a rack, a green bamboo skin removal cutter assembly fixedly mounted on the rack and multiple conveying mechanisms driven by a motor and used for pushing bamboos into the green bamboo skin removal cutter assembly, wherein the multiple conveying mechanisms are fixed on the rack and uniformly distributed on two sides of the green bamboo skin removal cutter assembly; the conveying mechanisms correspond to the green bamboo skin removal assembly in position; each conveying mechanism comprises a pair of movable devices mounted on the rack, driving wheels mounted on the movable devices respectively as well as two gears in transmission connection with a driving wheel chain; the two gears of each conveying mechanism are located on one side of the driving wheels and are mutually meshed; each movable device comprises a pivot, a sliding rod with one end fixedly connected with the pivot as well as a sliding rod support fixedly connected with the rack; each sliding rod is sleeved with a spring; a reset spring is located between each pivot and the corresponding sliding rod support. The green bamboo skin removal machine can push bamboos to the green bamboo skin removal cutter assembly smoothly and does not deviate, the feeding speed is high, the adaptability is high, the green bamboo skin removal effect is good, and the production and processing efficiency can be substantially improved.

Owner:杭州新竹文化创意有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com