Bamboo stick clamping and drilling equipment for bamboo straw manufacturing

A technology of drilling equipment and bamboo straws, which is applied in the direction of mechanical equipment, fixed drilling machines, sugarcane machining, etc., can solve the problems of cumbersome production methods and unfavorable production efficiency due to multiple equipment, and achieve easy disassembly and maintenance, and improve processing efficiency and efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

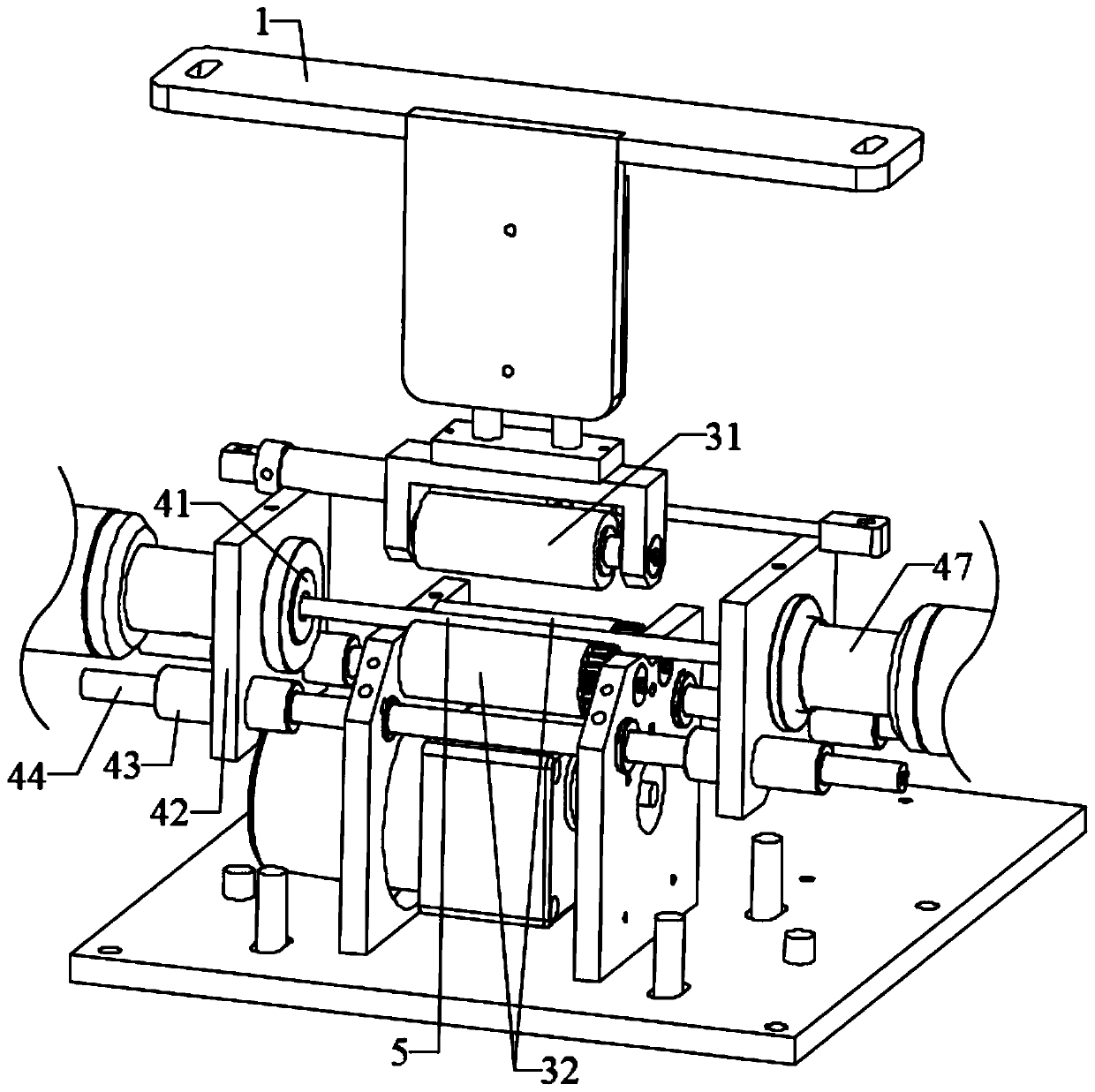

[0047] A kind of bamboo sucking tube acts as bamboo rod clamping drilling equipment, comprises clamping device 3 and drilling device 4 that are arranged on frame 1, and described drilling device 4 pairs of bamboo sticks 5 that are clamped by clamping device 3 carry out drilling;

[0048] The clamping mechanism clamps the bamboo stick 5 and drives it to rotate along the axis direction of the bamboo stick 5;

[0049] Described drilling mechanism comprises drill bit 47 and two taper sleeves 41, and two described taper sleeves 41 are rotatably arranged on the frame 1 and oppositely arranged, and two described taper sleeves 41 are sleeved on the two ends of bamboo stick 5 respectively and Rotate together with bamboo stick 5, the cone head part of two described taper sleeves 41 is all provided with the feed hole of drill bit 47, one side of two described taper sleeves 41 is respectively provided with a drill bit 47, and described feed hole diameter Less than the diameter of the bam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com