Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1270results about "Adhesive application devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

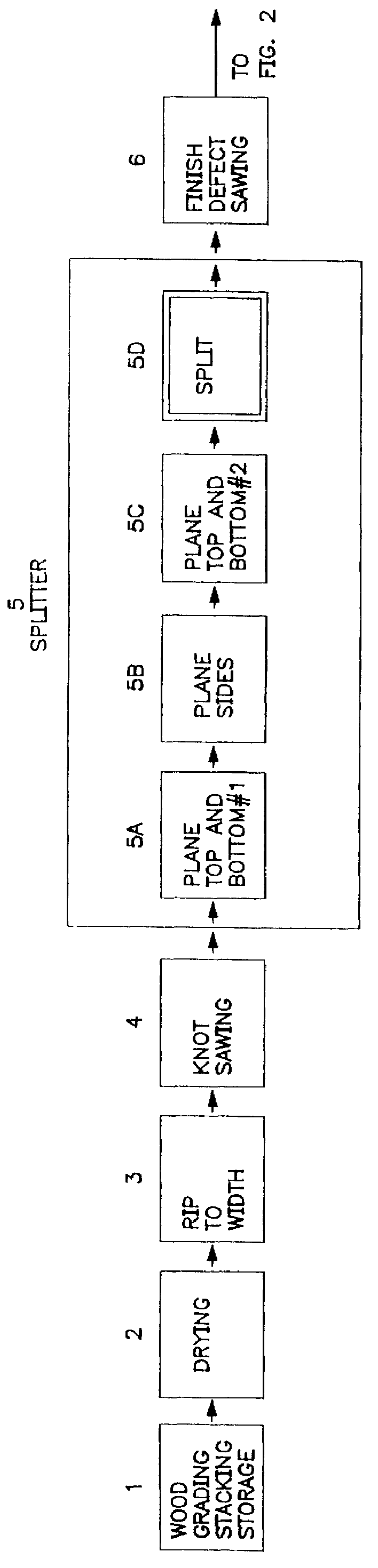

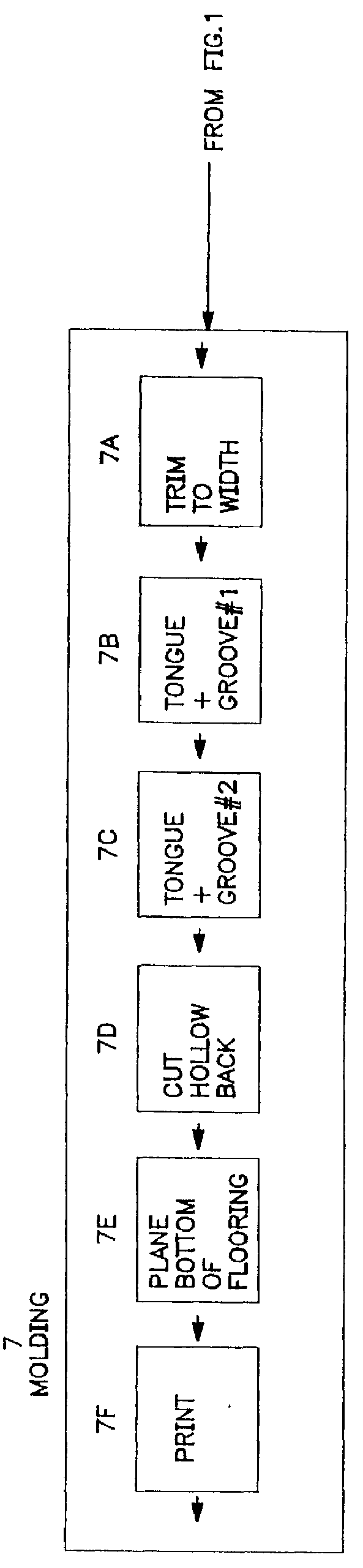

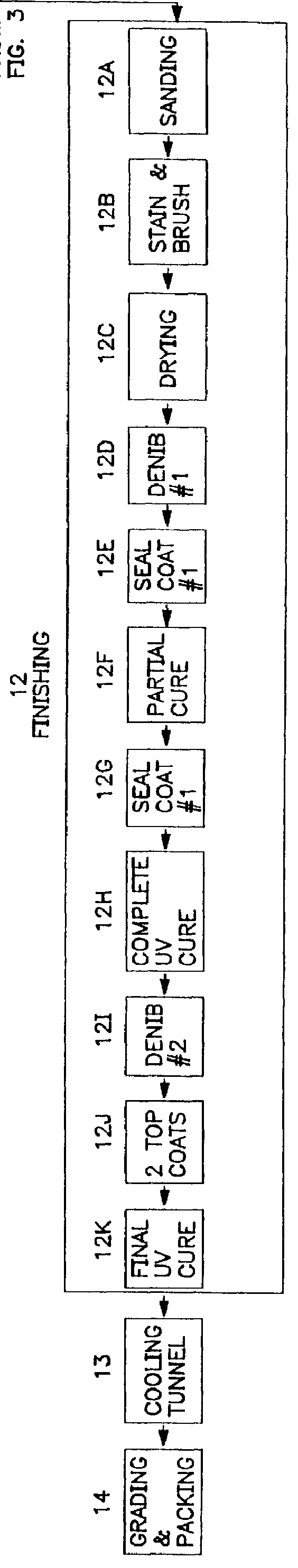

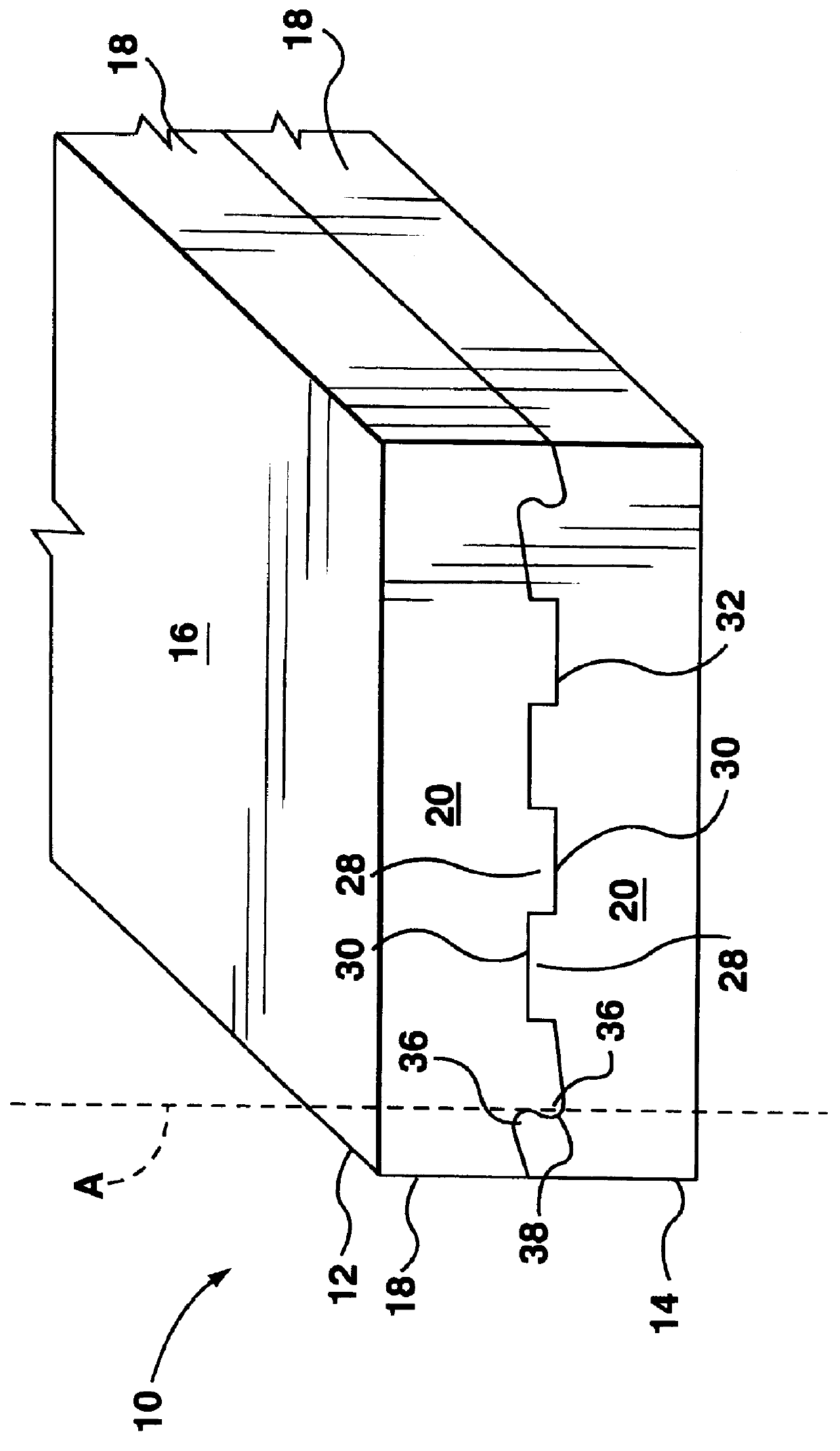

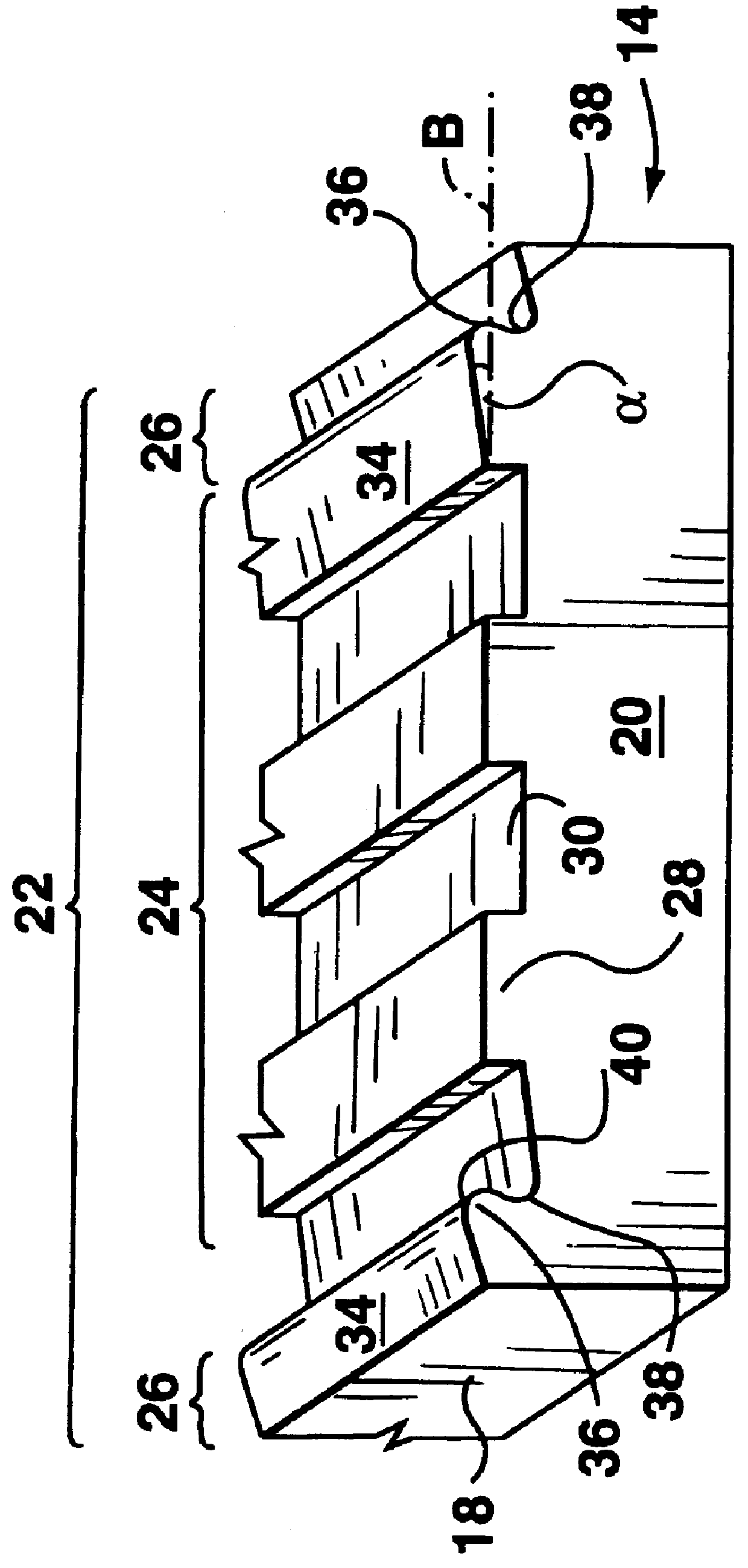

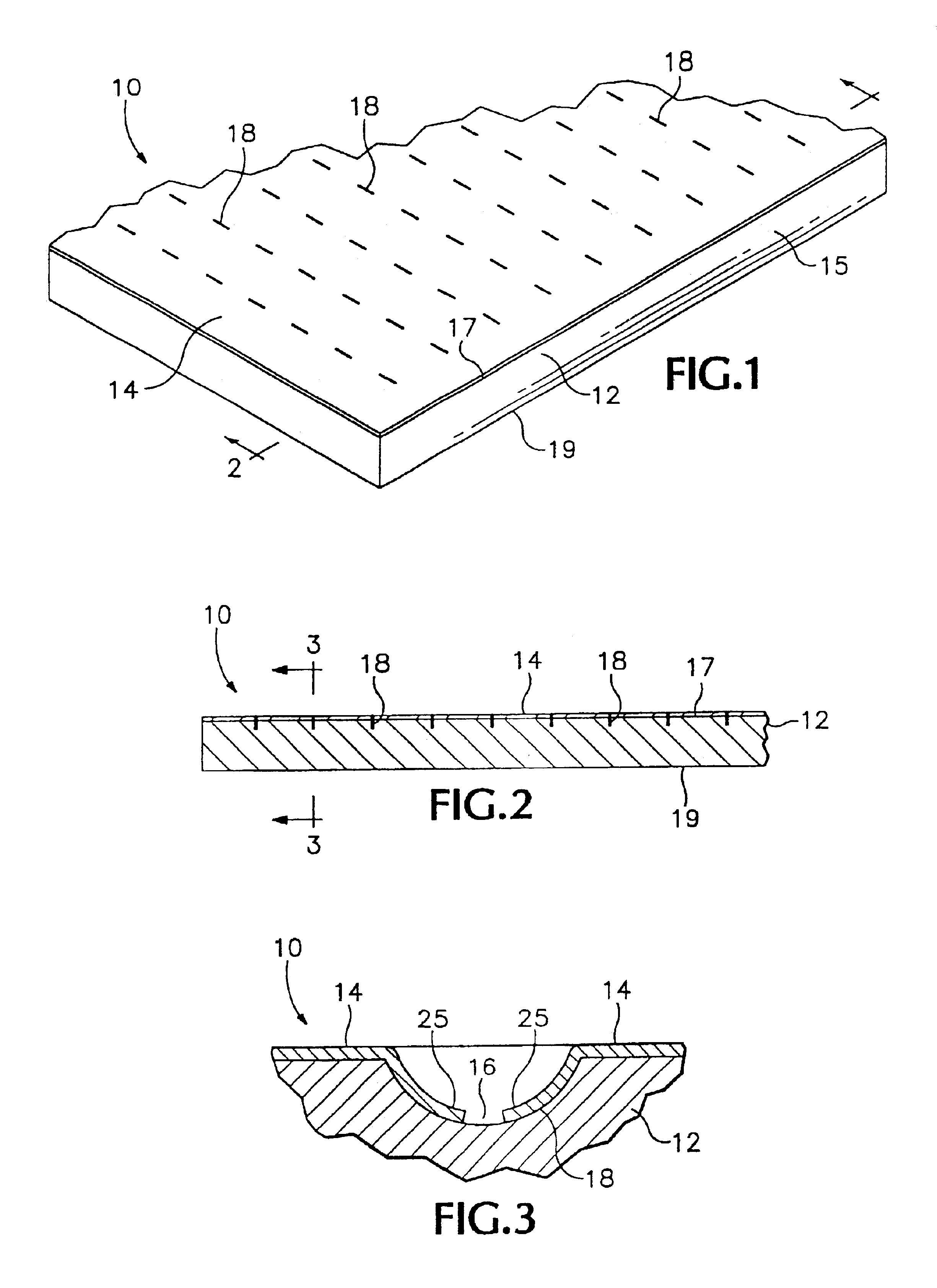

Low profile hardwood flooring strip and method of manufacture

InactiveUS6148884AConsiderable quantityImprove rigidityDovetailed workMulti-purpose machinesCircular sawTongue and groove

A method of producing a hardwood flooring product, including the steps of processing a strip of raw wood into a blank having a predetermined thickness and width, and top and bottom surfaces defining parallel planes relative to each other, and splitting the blank along the width of the blank from one side to the other to form two low profile flooring strips having the same width as the blank and a thickness less than one-half the thickness of the blank. The splitting step includes the steps of providing first and second circular saw blades mounted on spaced-apart vertical axes for rotation in a single plane intermediate and parallel to the planes of the top and bottom surfaces of the blank and positioning the blank on conveying means upstream from the saw blades with the plane of rotation of the saw blades intermediate and parallel to the planes of the top and bottom surfaces of the blank for movement of the blank from an upstream position to a downstream position relative to the saw blades. The blank is moved downstream into the plane of rotation of the saw blades during rotation of the saw blades thereby horizontally splitting the blank to form first and second low-profile flooring strips. Interlocking members, such as molded, mating tongue and groove members, are molded into first and second longitudinally-extending side edges of the flooring strips for securing together the flooring strips when placed side-to-side to form a floor.

Owner:ARMSTRONG HARDWOOD FLOORING CO +2

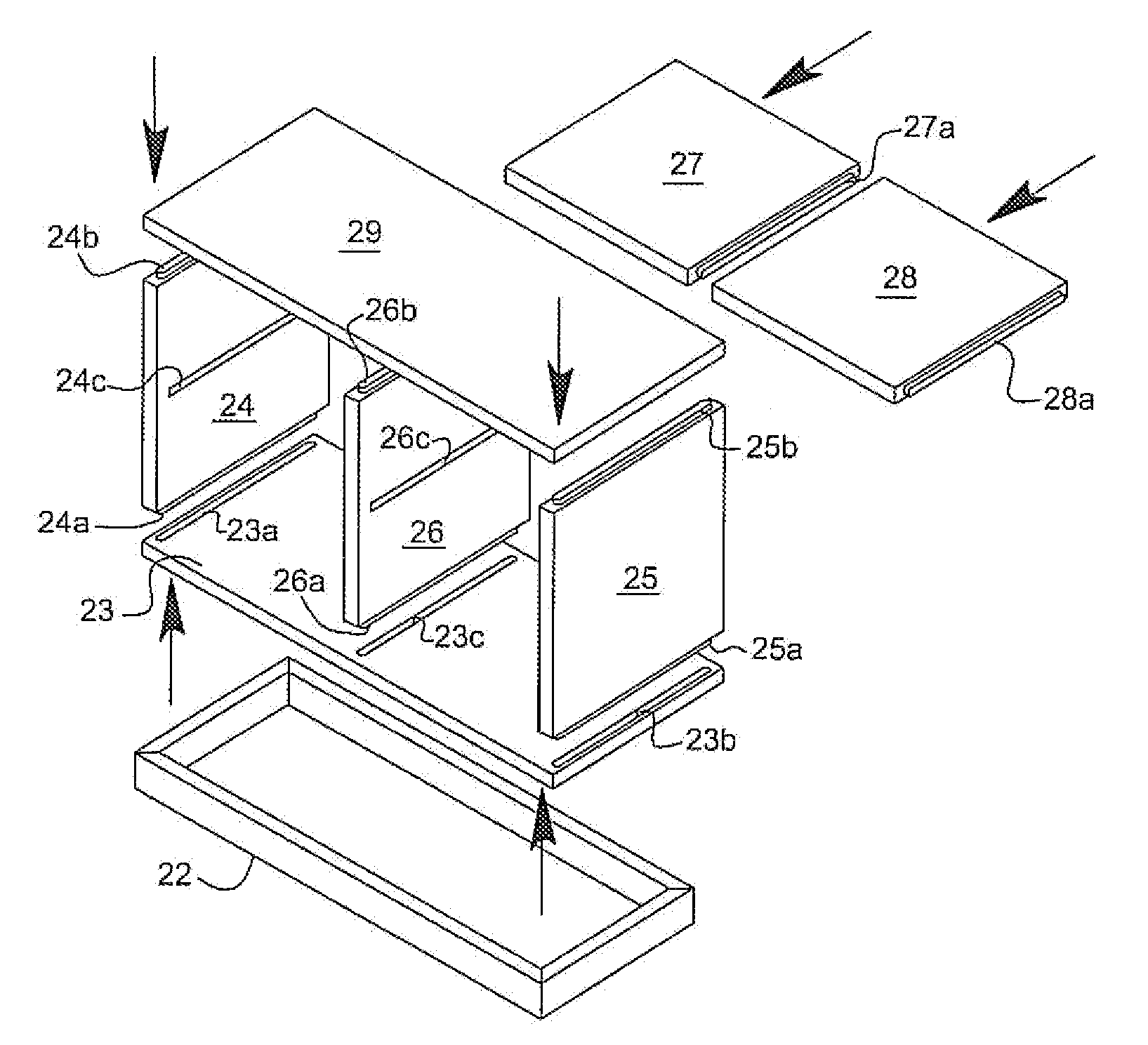

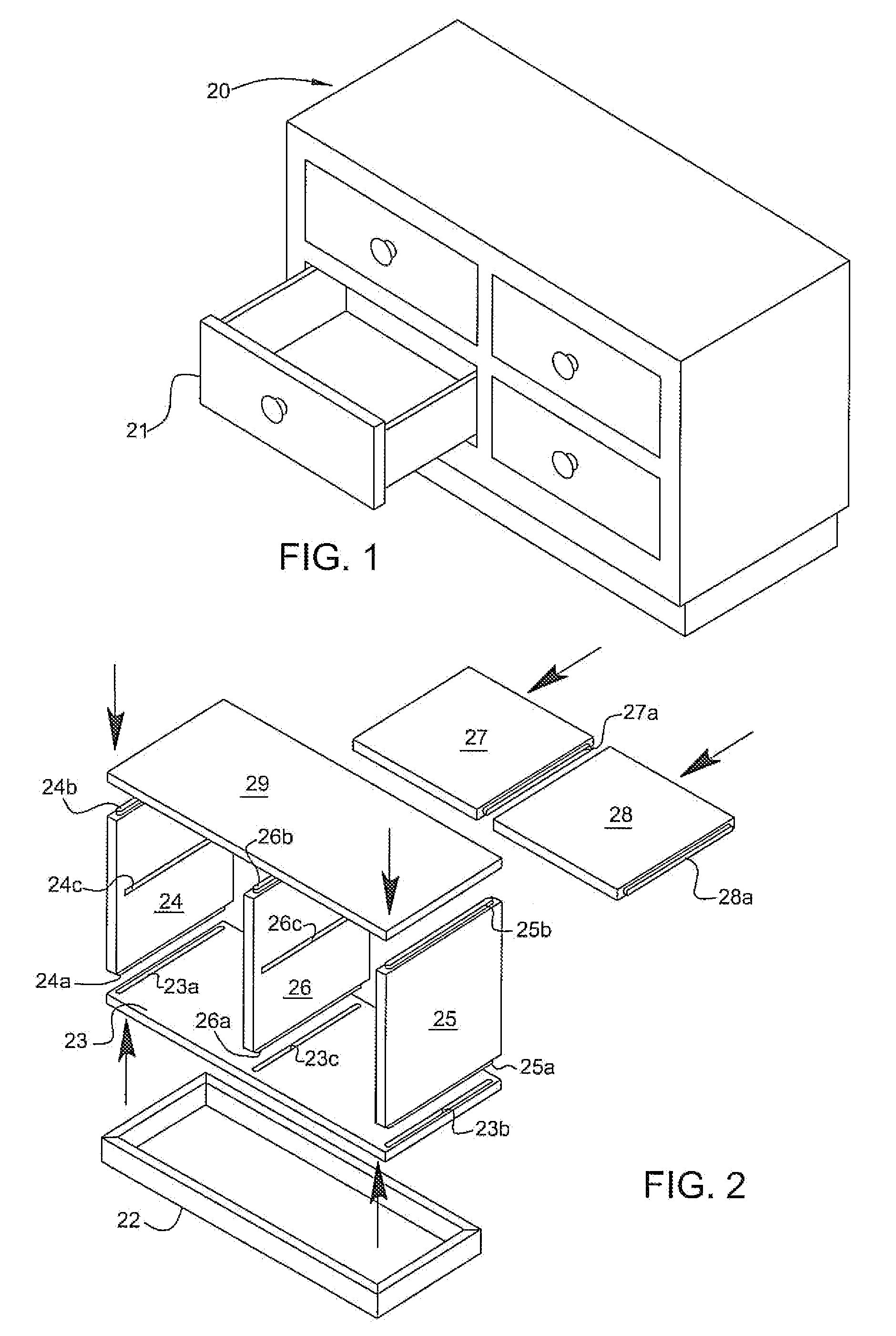

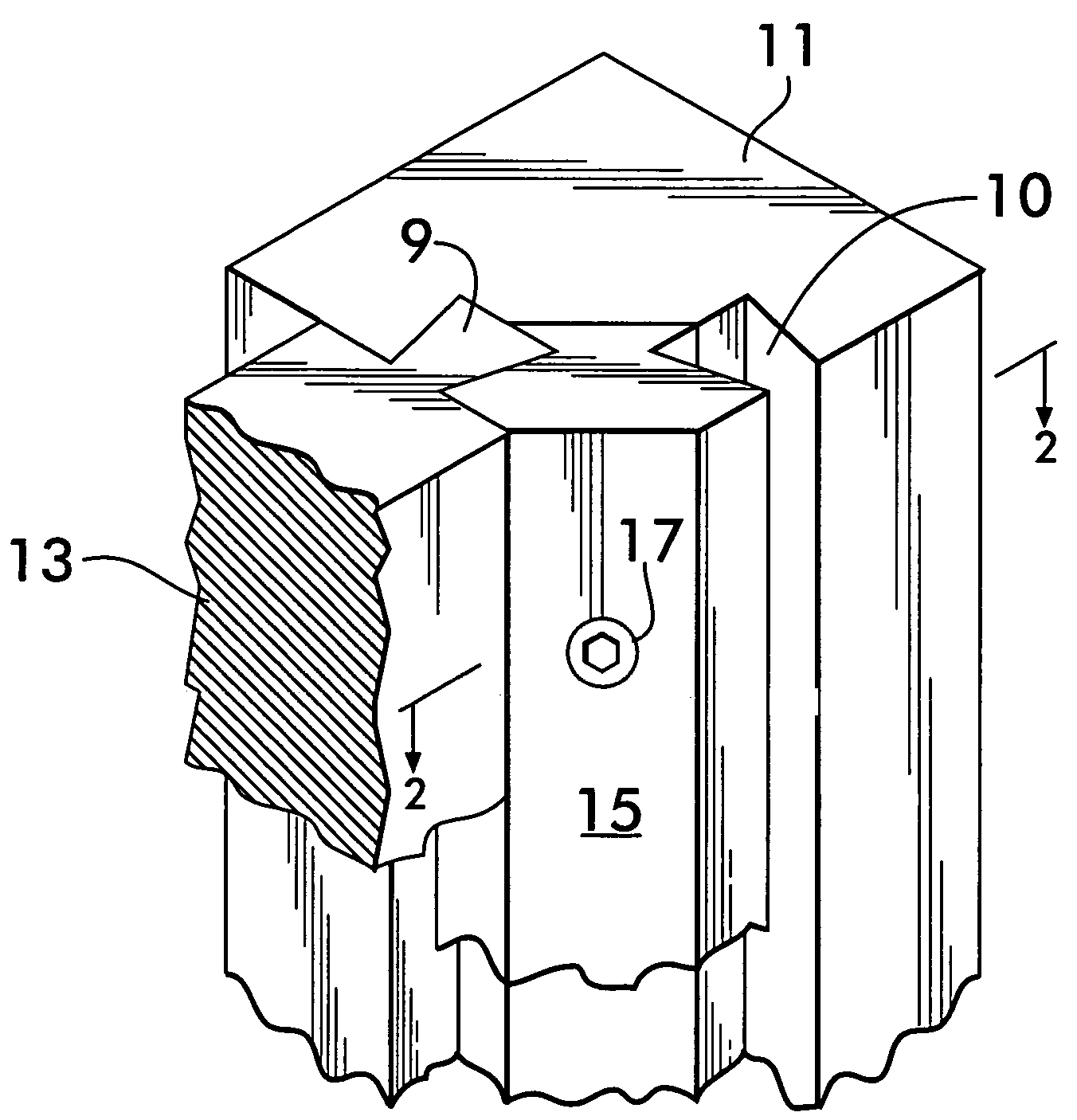

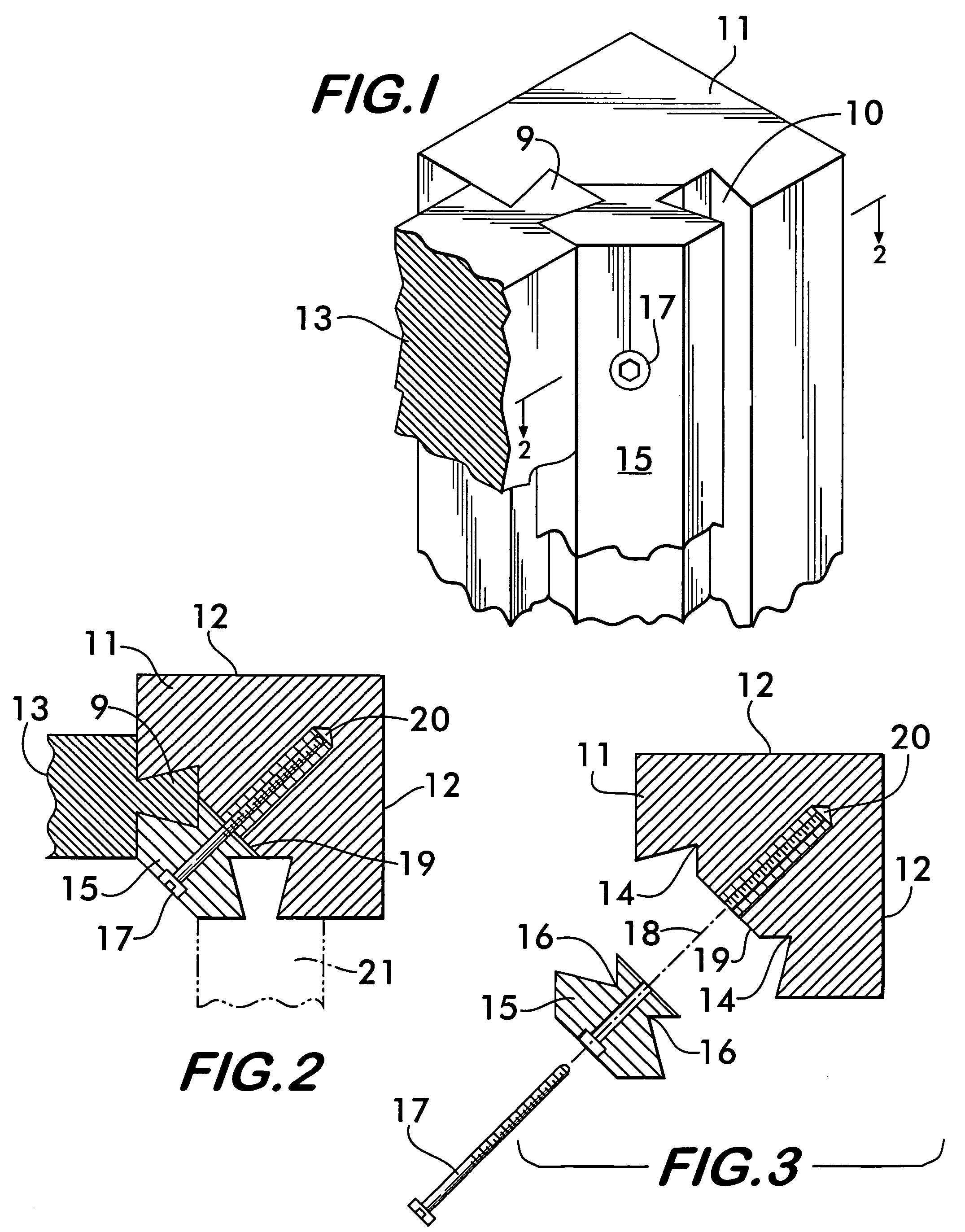

Structure and method of assembly thereof

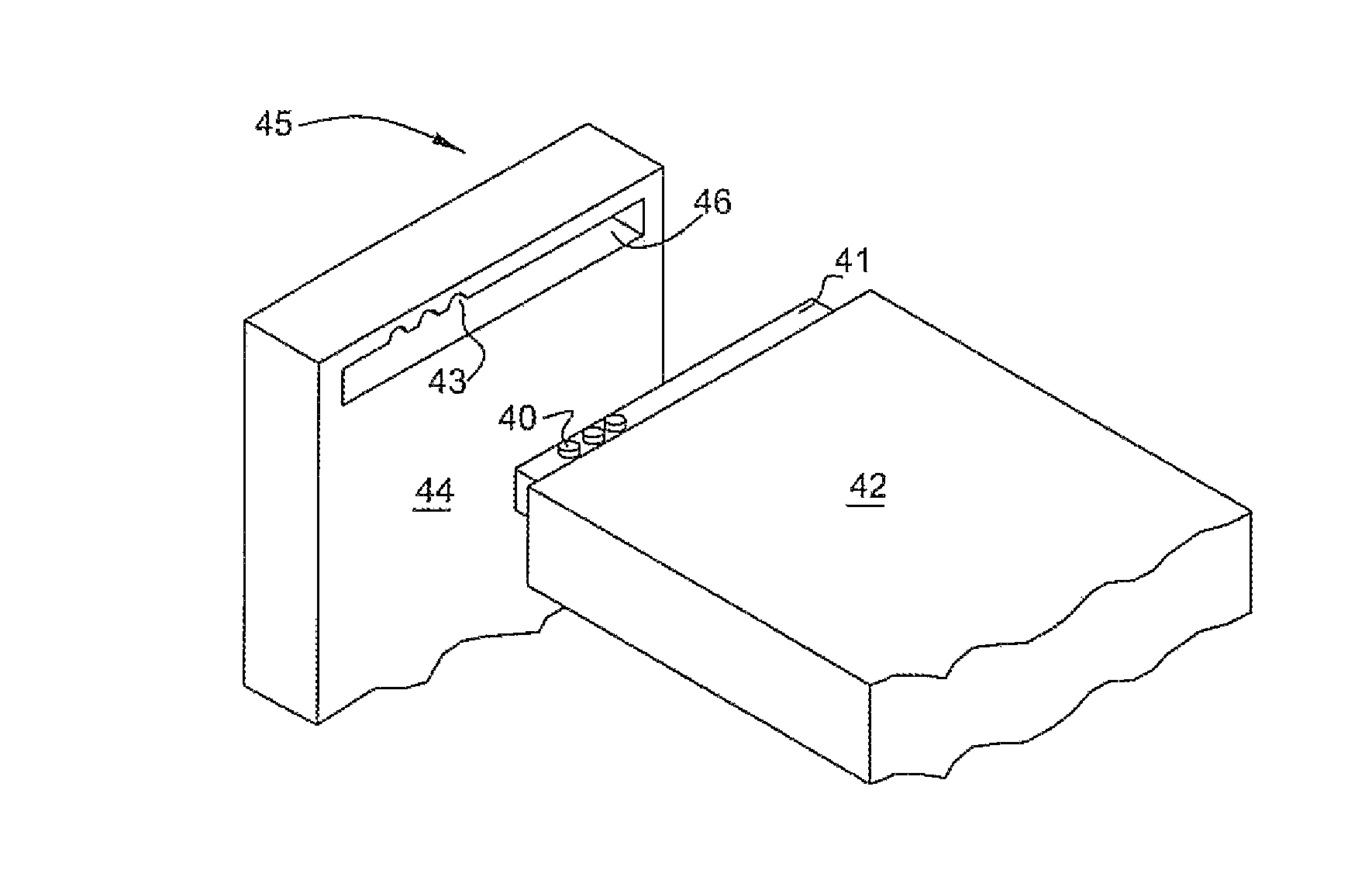

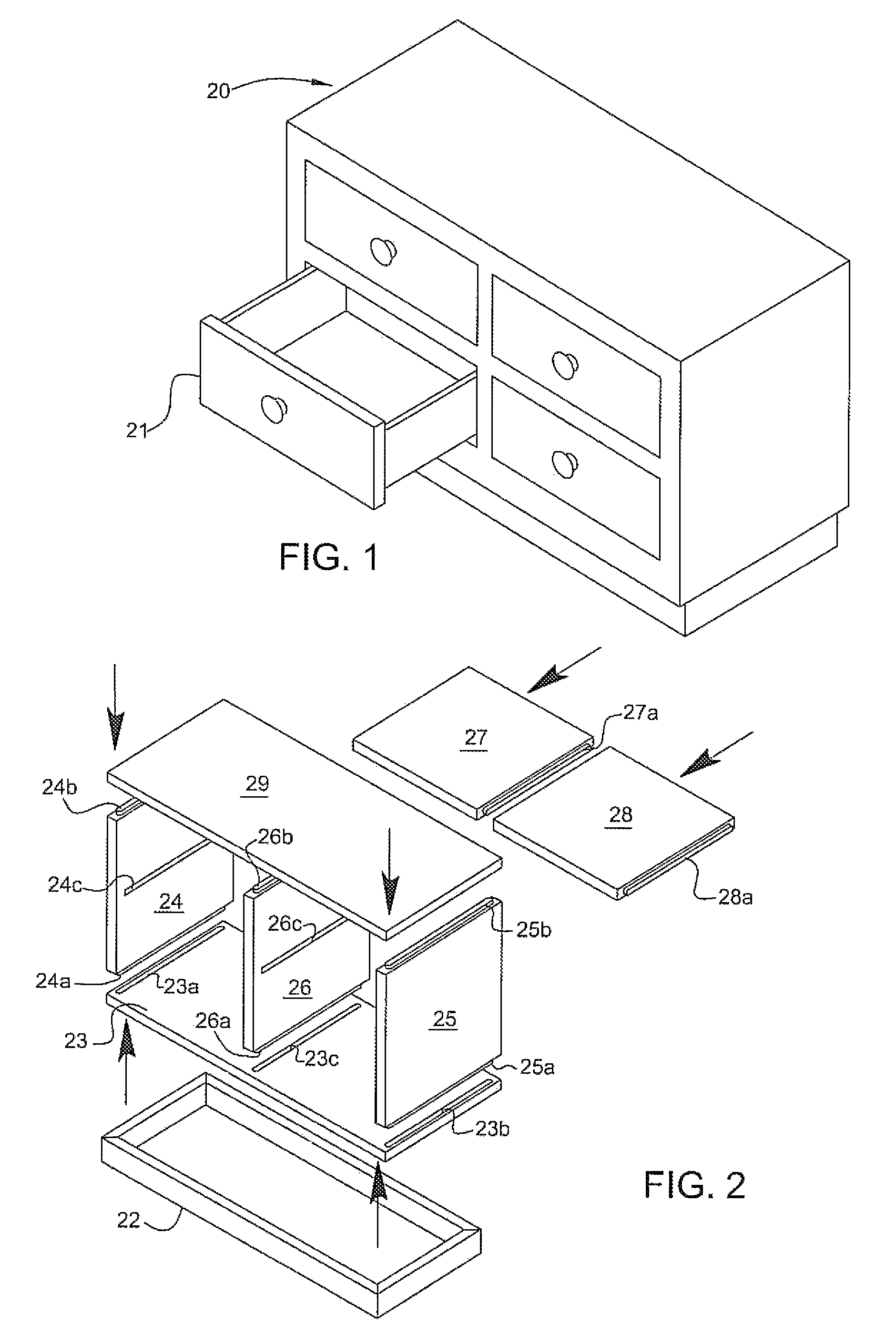

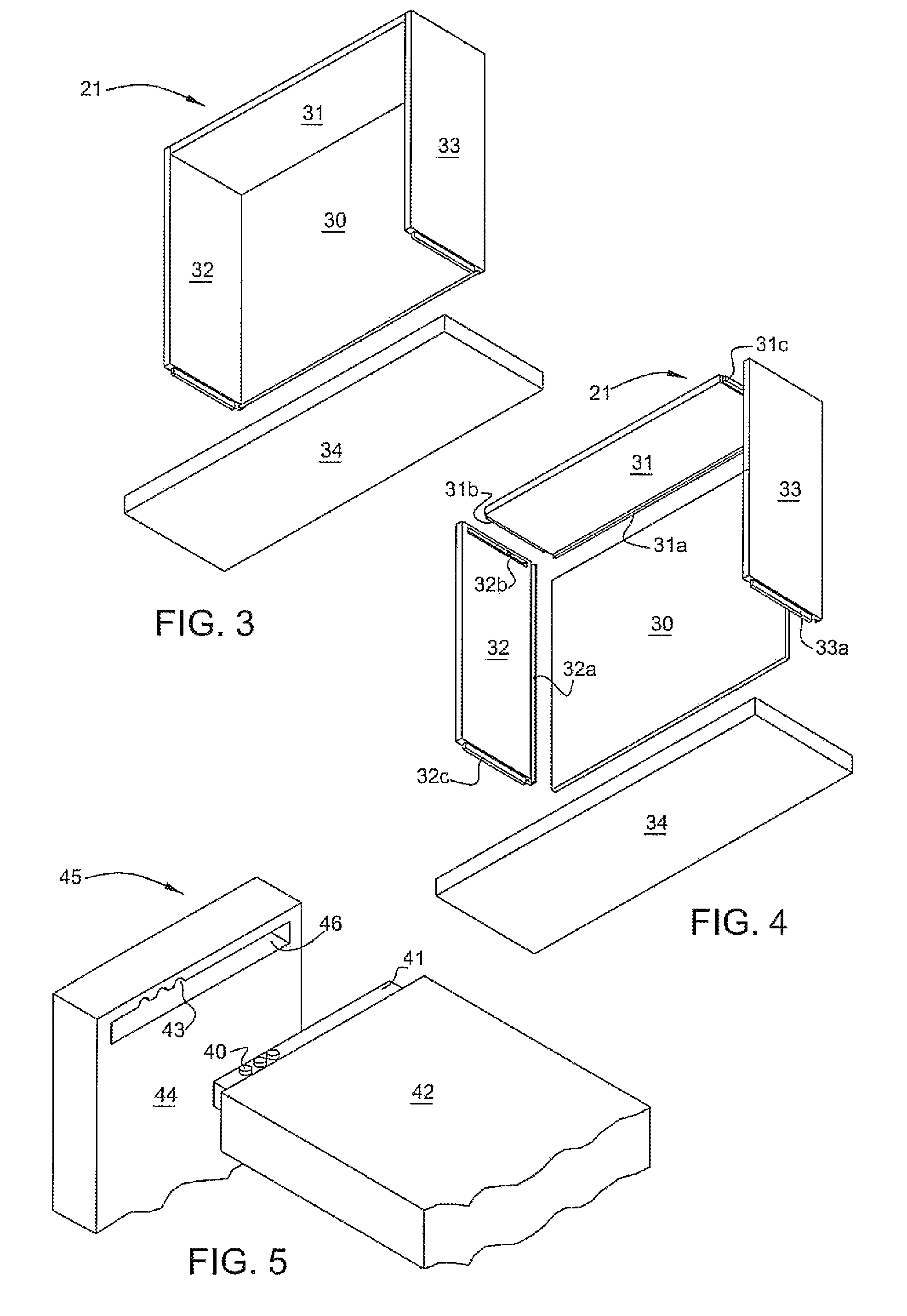

A method of forming an assembly including a first workpiece having a surface provided with a mortise and a second workpiece provided with a tenon inserted into the mortise joining the workpieces together in which the second workpiece is disposed in a certain orientation relative to the first workpiece to provide a certain disposition of the workpieces when joined together, generally consisting of providing identifying marks on the surface of the first workpiece and the tenon of the second workpiece at locations assuming a certain disposition when the second workpiece is disposed in a certain orientation and the tenon is registered with the mortise; positioning the second workpiece relative to the first workpiece wherein the second workpiece is disposed in the certain orientation relative to the first workpiece, the tenon is registered with the mortise and the marks are disposed in the certain mark disposition; and displacing the second workpiece toward the first workpiece and inserting the tenon into the mortise.

Owner:THERMWOOD CORPORATION

Vaccum support and transfer of flexible material

A transfer assembly and method for transferring a flexible sheet of material which is subject to wrinkling, folding and / or creasing. The assembly and method includes a vacuum manifold having a cavity which is connected to an evacuation source for drawing a vacuum on the cavity, and an opening on the manifold of a given size and shape and communicating with the cavity. A sheet of porous material for supporting the flexible sheet of material for transfer thereon covers the opening and has a plurality of fine pores extending therethrough. The pores are profusely and uniformly distributed entirely over an area of the sheet of porous material which area is at least substantially of the same size and shape as the flexible sheet of material which is to be transferred thereon, so that substantially the entire area of the flexible sheet of material which is to be transferred is exposed to the pores. The pores are subjected to the vacuum in the manifold cavity in the substantial absence of impairment of communication of the vacuum to the pores to uniformly pickup and hold the flexible sheet of material for transfer without folding, wrinkling or creasing of the flexible sheet of material.

Owner:TROPICANA PROD INC

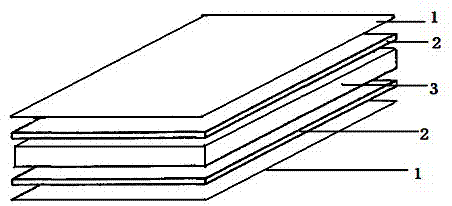

Method for producing plywood with glueing on one side and plywood mould

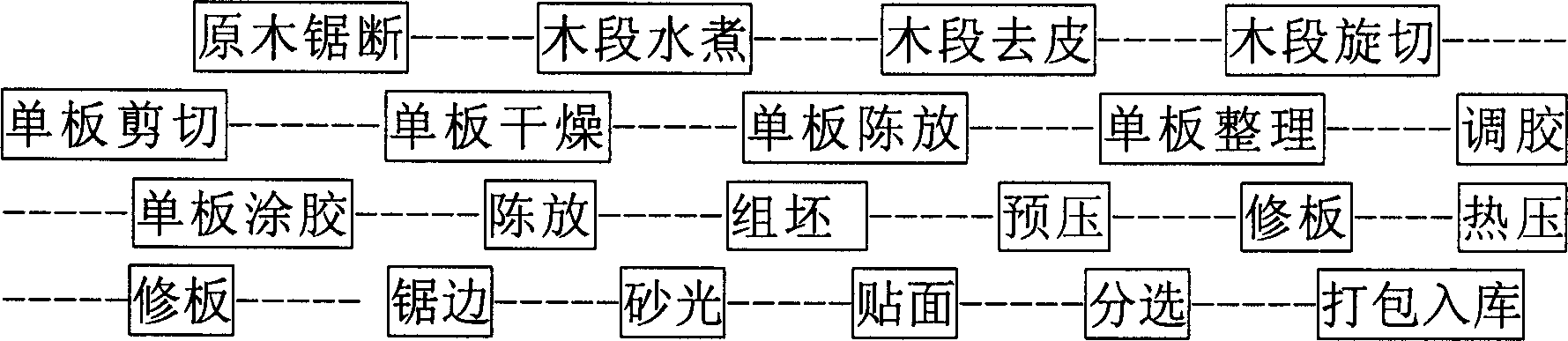

A method for producing the plywood with the wood plys whose one surface is coated by resin includes such steps as sawing log short, boiling in water, removing bark, spinning cutting, cutting fly, drying, ageing, coating resin on one surface of each ply, ageing, laminating, pre-pressing, trimming, hot pressing, trimming, sawing edge, sticking a paper immersed in resin, and classifying.

Owner:哈尔滨市香坊区人造板胶粘剂研究所 +1

Structure and method of assembly thereof

A method of forming an assembly including a first workpiece having a surface provided with a mortise and a second workpiece provided with a tenon inserted into the mortise joining the workpieces together in which the second workpiece is disposed in a certain orientation relative to the first workpiece to provide a certain disposition of the workpieces when joined together, generally consisting of providing identifying marks on the surface of the first workpiece and the tenon of the second workpiece at locations assuming a certain disposition when the second workpiece is disposed in a certain orientation and the tenon is registered with the mortise; positioning the second workpiece relative to the first workpiece wherein the second workpiece is disposed in the certain orientation relative to the first workpiece, the tenon is registered with the mortise and the marks are disposed in the certain mark disposition; and displacing the second workpiece toward the first workpiece and inserting the tenon into the mortise.

Owner:THERMWOOD CORPORATION

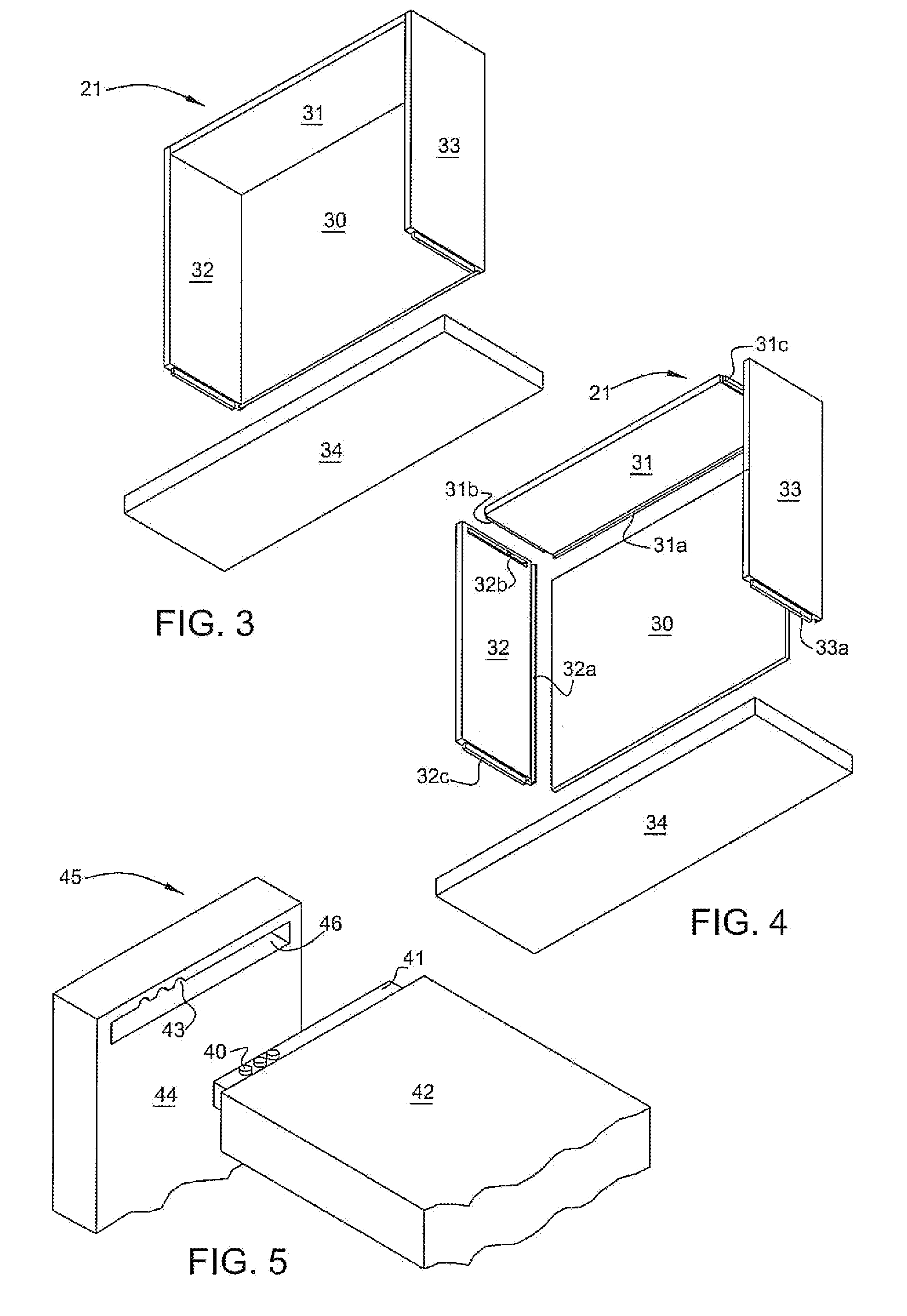

Method for Joining Workpieces Together and Product Made Thereby

A method of forming a joint between first and second workpieces generally consisting of forming a recess in one of such workpieces, provided with at least one side wall having a serrated cross-sectional configuration with inwardly projecting, distortable segments; providing a portion in the other of such workpieces, insertable into such recess, having a cross-sectional configuration sufficient to engage and distort such segments as such portion is inserted into such recess; and inserting such portion of the other workpiece into such recess, causing the segments to distort and thus provide an interference fit between such workpieces.

Owner:THERMWOOD CORPORATION

Preparation process and application of water resistant starch-base timber adhesive

InactiveCN100999651AAvoid damageImprove water resistanceAdhesive application devicesGraft polymer adhesivesPolymer scienceWater resistant

The present invention belongs to the field of adhesive technology, and provides one kind of starch-base timber adhesive with excellent water resistance and its preparation process and application. The starch-base timber adhesive with excellent water resistance has wide material source, no environmental pollution and high adhesion strength, and may be used widely in timber adhesion.

Owner:JIANGNAN UNIV

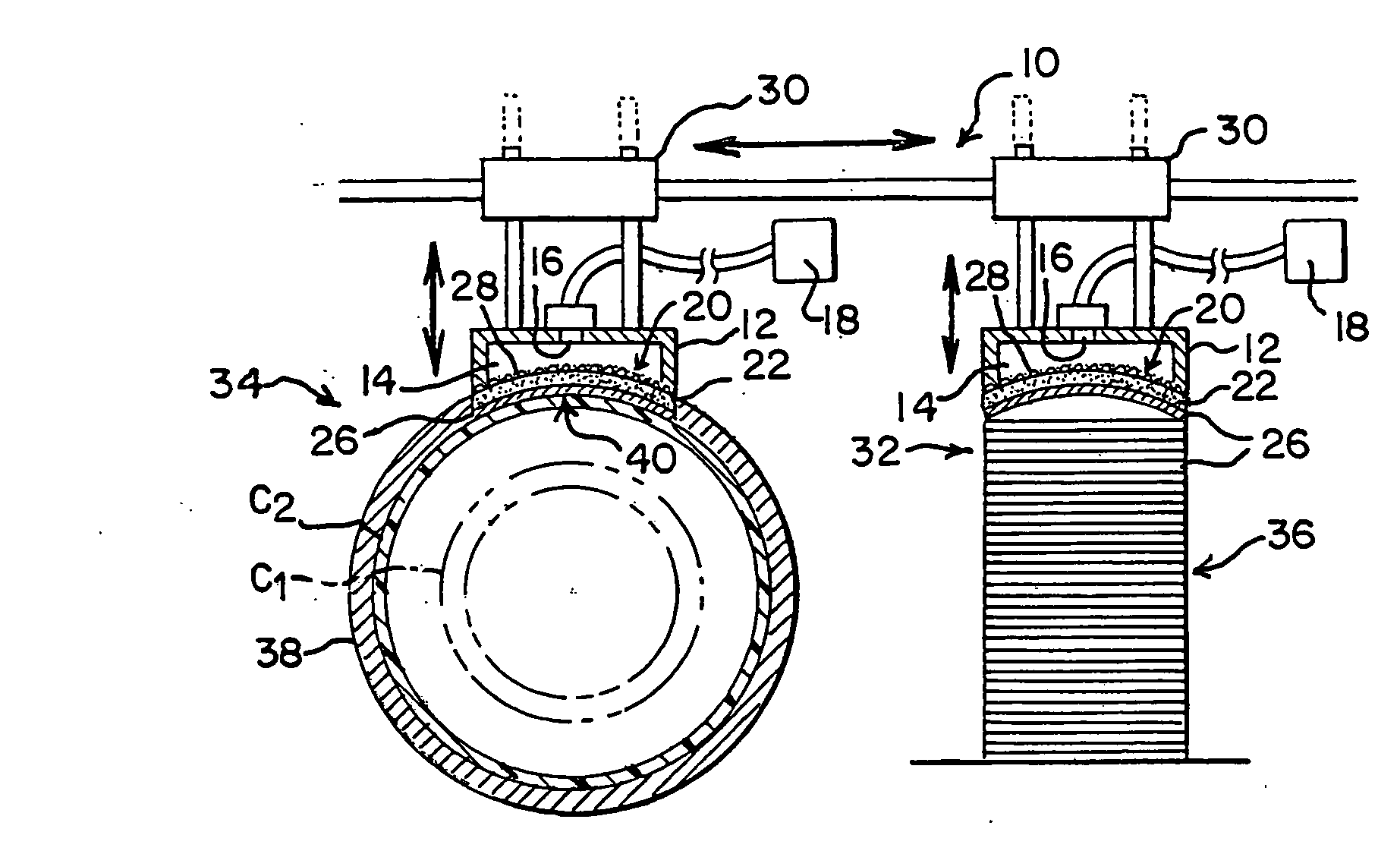

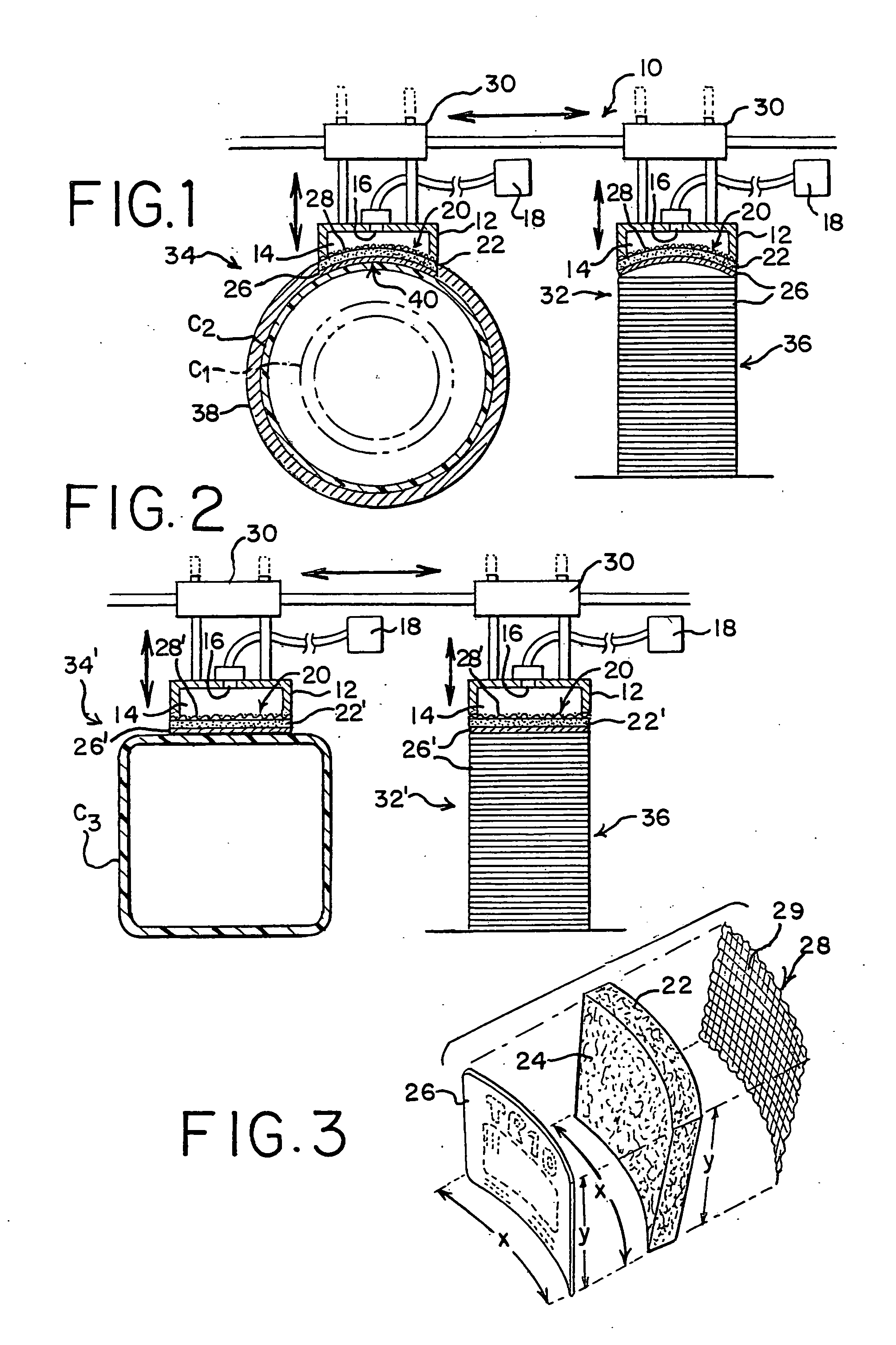

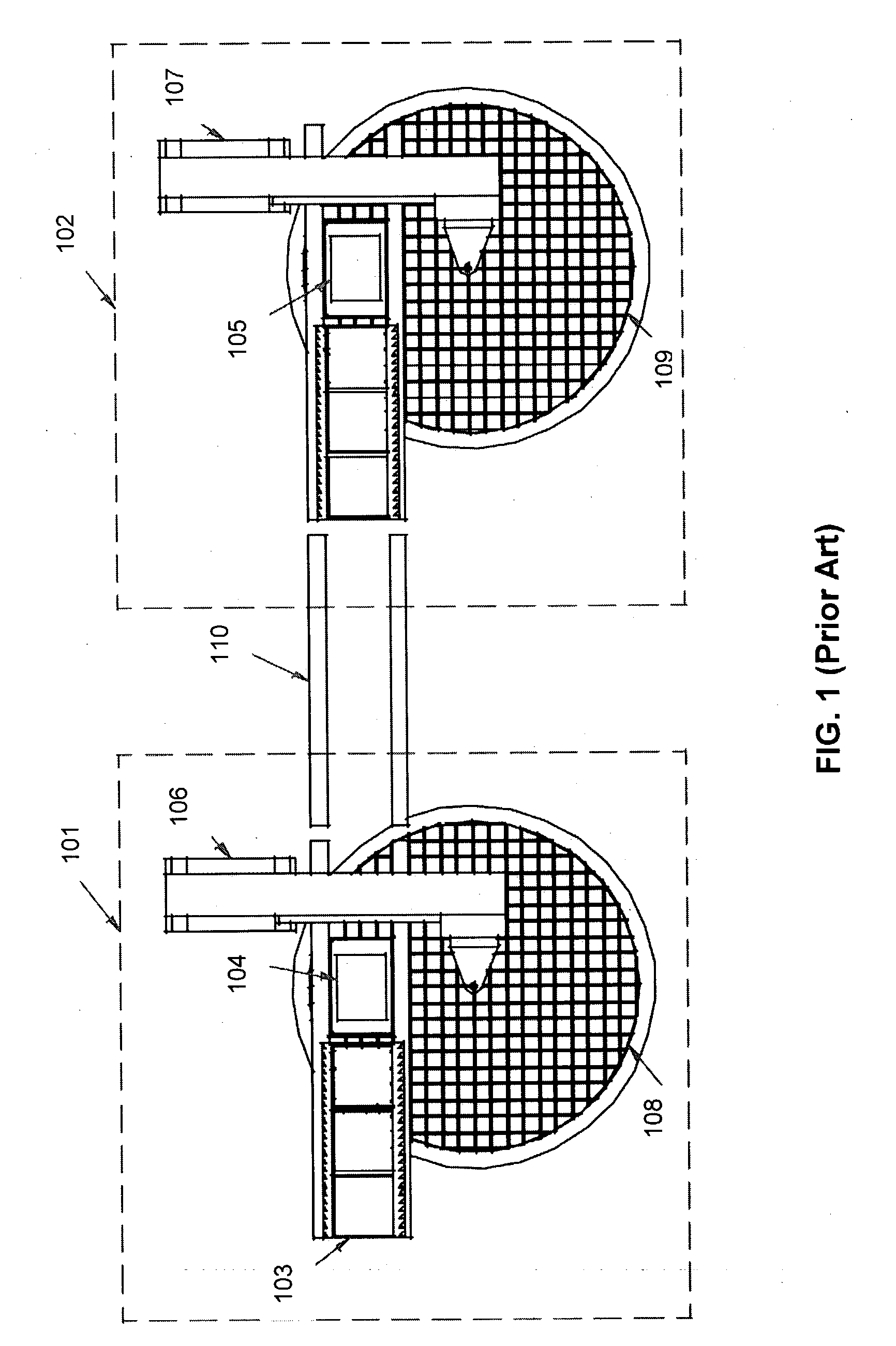

Semiconductor apparatus with multiple delivery devices for components

InactiveUS20040244915A1Improve throughputMechanical working/deformationCovering/liningsMultiple deliveryEngineering

An apparatus is provided for transferring components from a pick-up position amongst a supply of components to a placement position on a receptor, such as a die pad, during semiconductor processing. It includes a first delivery device and a second delivery device operative to alternatively transfer the components from the pick-up position to the placement position. The second delivery device is arranged opposite the first delivery device about a line passing through the pick-up position and the placement position.

Owner:ASM ASSEMBLY AUTOMATION LTD

Method and apparatus for producing labeled, plastic foam containers, and product of same

InactiveUS8105459B2Low densityLow stiffnessMechanical working/deformationAdhesive processes with adhesive heatingEngineeringHardness

Owner:GRUPO CONVERMEX DE C V

Softwood-ceiling / hardwood-floor structure comprised of a single set of bonded boards

A structure comprising a softwood-ceiling / hardwood-floor formed of a single set of adjacent boards. Each of the boards including a hardwood layer bonded to a softwood layer, the board having a first edge and a second edge, the first edge having a tongue, the second edge having a groove, the first edge having a first chamfer on the softwood layer, the second edge having a second chamfer on the softwood layer. All boards securely attached to carrying beams that span the walls between two levels within a building.

Owner:STANHOPE THOMAS SPENCER

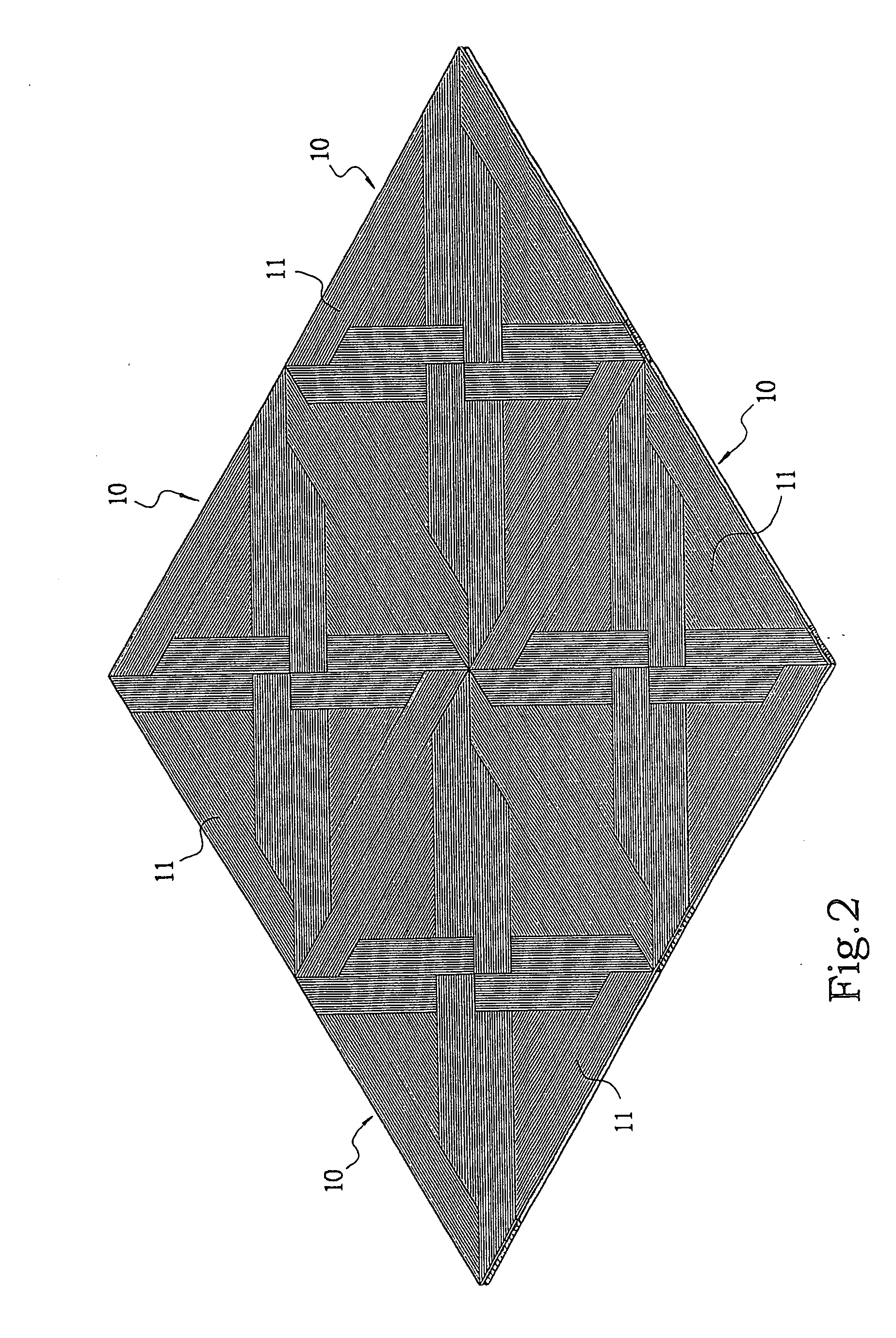

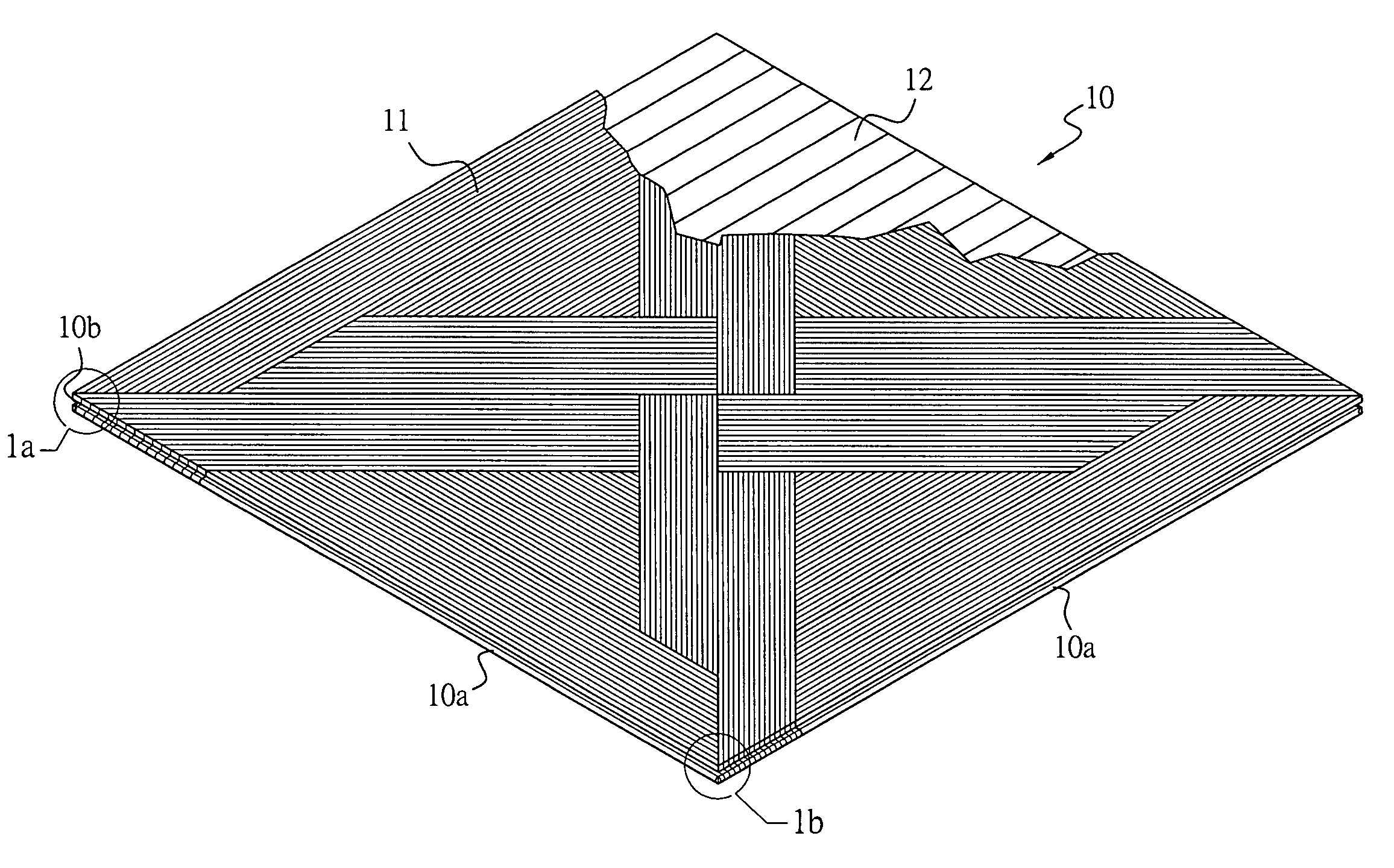

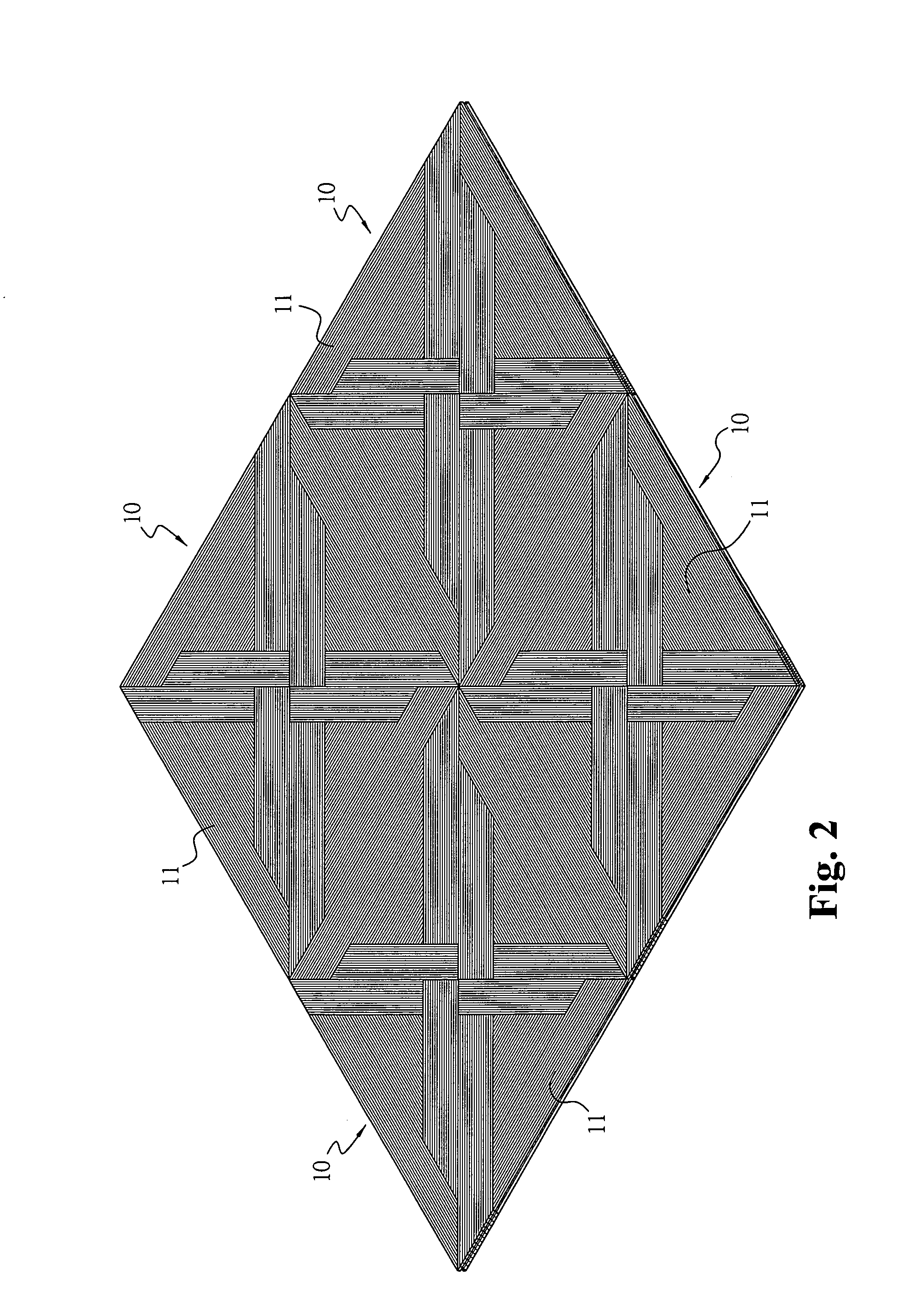

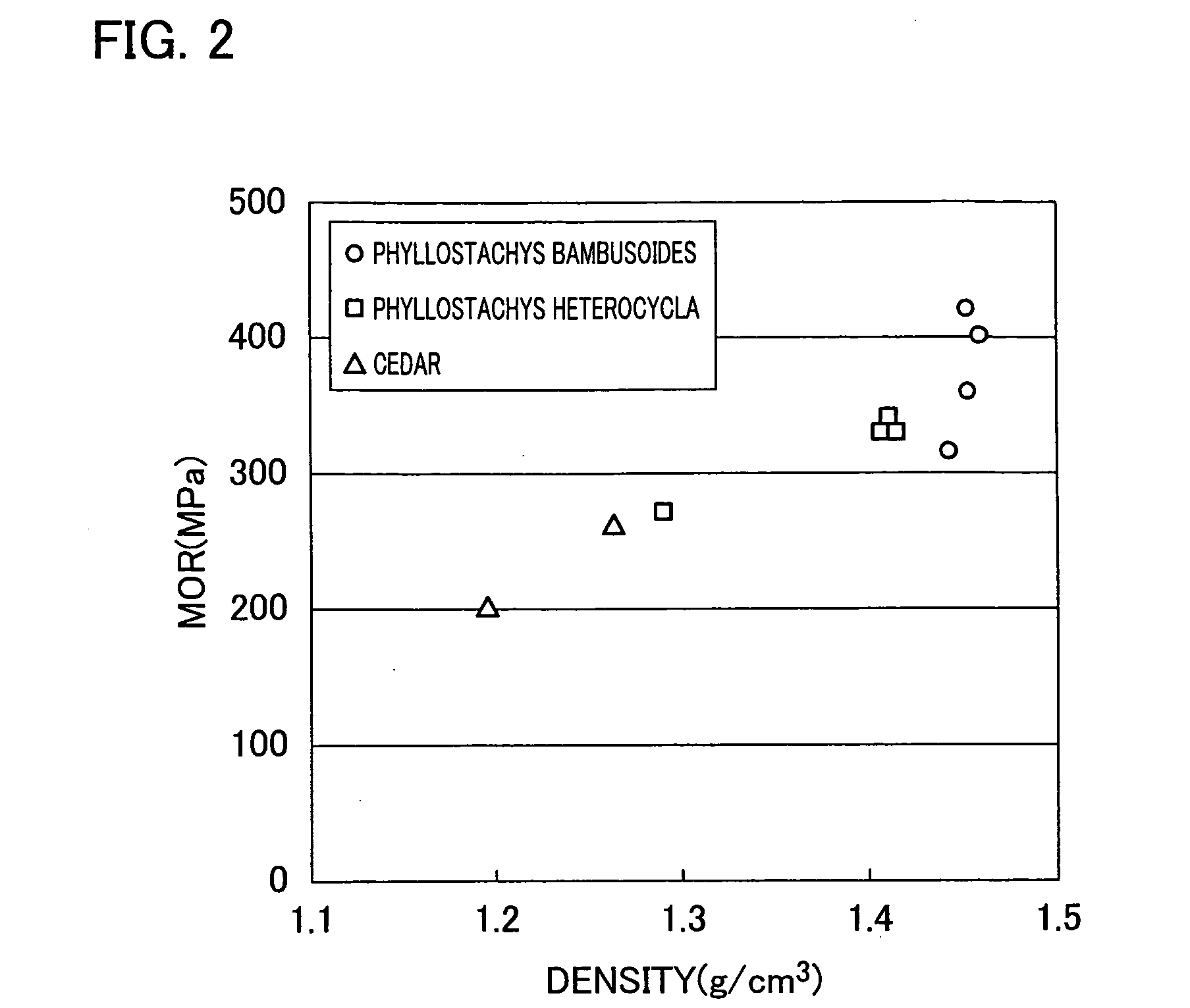

Bamboo mat board and method for producing the same

ActiveUS20050161116A1Increase stiffnessHigh economic valueCane mechanical workingWood veneer joiningSurface layerEngineering

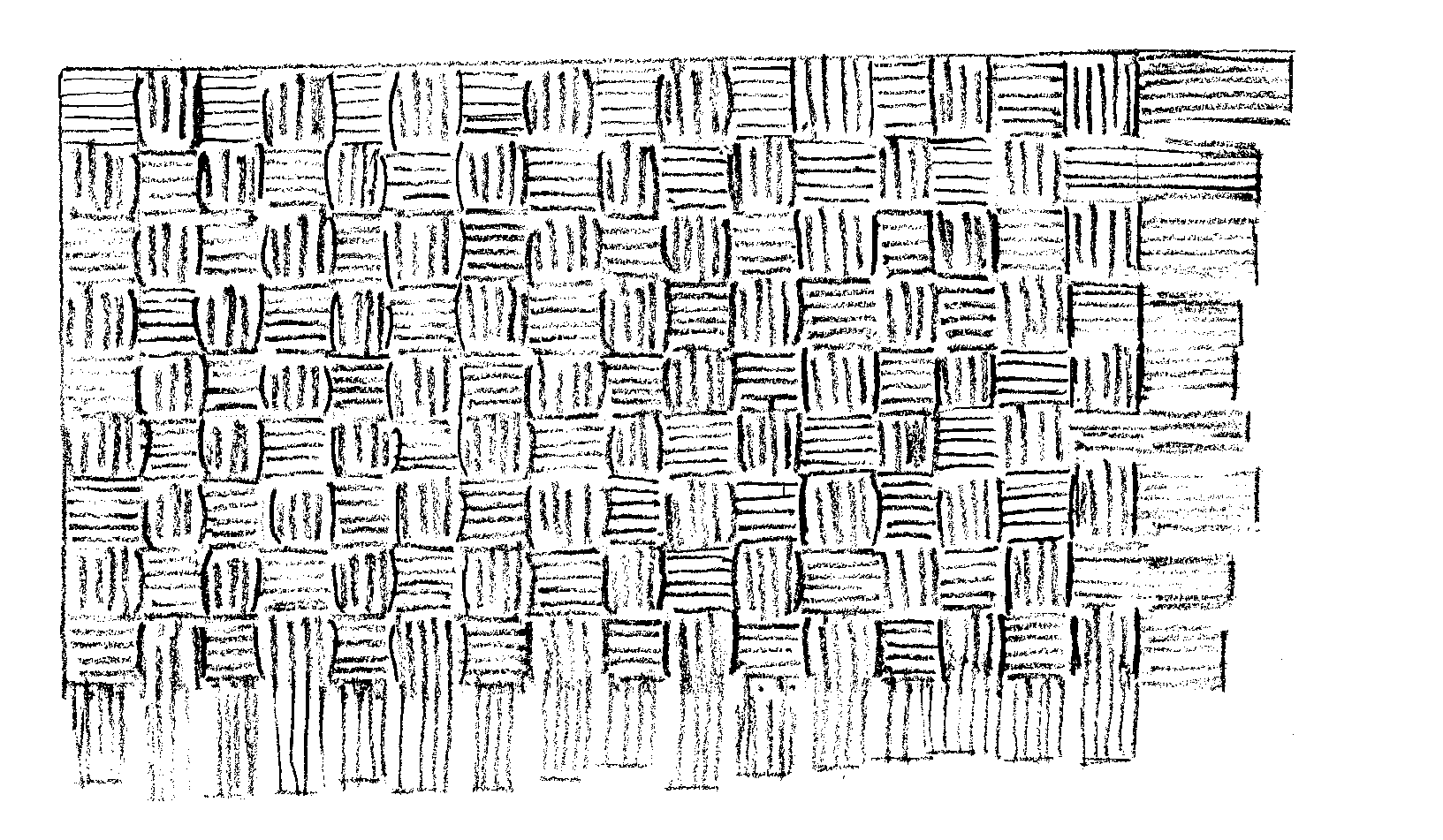

A bamboo mat board element with a double-layered construction, a constant dimension, each of the elements is formed with a projecting tenon at each of two adjacent sides, respectively, and a concave mortise at each of the other two adjacent sides, respectively, for inter-tenoning the elements of the mat board, in which a surface layer of the mat board is obtained by matting a plurality of mat board stuffs having different orientations, shapes, and sizes, while each of the mat board stuffs is obtained by matting a plurality of lumbers having a parallel orientation, respectively, to form a plurality of patterns having parallel stripes by specially matting at the longitudinal section thickness of the lumbers. A method for producing the bamboo mat board at least comprises steps as follows: cutting step, boiling for blanching step, drying step, rough shaving, bottom layer pre-forming step, adhesive applying and pressing step, pattern selecting step, matting step, and refined shaving, etc. The sandwich mat board is then formed by pressing.

Owner:CHANG AO YU

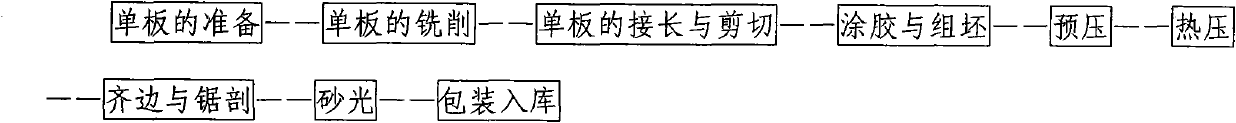

Preparation method of environmental protection type solid-wood composite floor

InactiveCN101396839ATake advantage ofReduce pollutionOther plywood/veneer working apparatusWood treatment detailsSolid woodEngineering

The invention relates to a preparation method for an engineered flooring, in particular to a preparation method for an environment-friendly engineered flooring, belonging to the wood manufacturing industry. The invention aims at providing a preparation method for an environment-friendly engineered flooring which has strong non-deformability, high processing efficiency and can fully use resources, thus overcoming the deficiencies of the prior art. Due to the adoption of the technical program, the invention has the advantages of making full use of wood resources, improving labor efficiency and relieving the pollution of formaldehyde to the environment.

Owner:汤可新

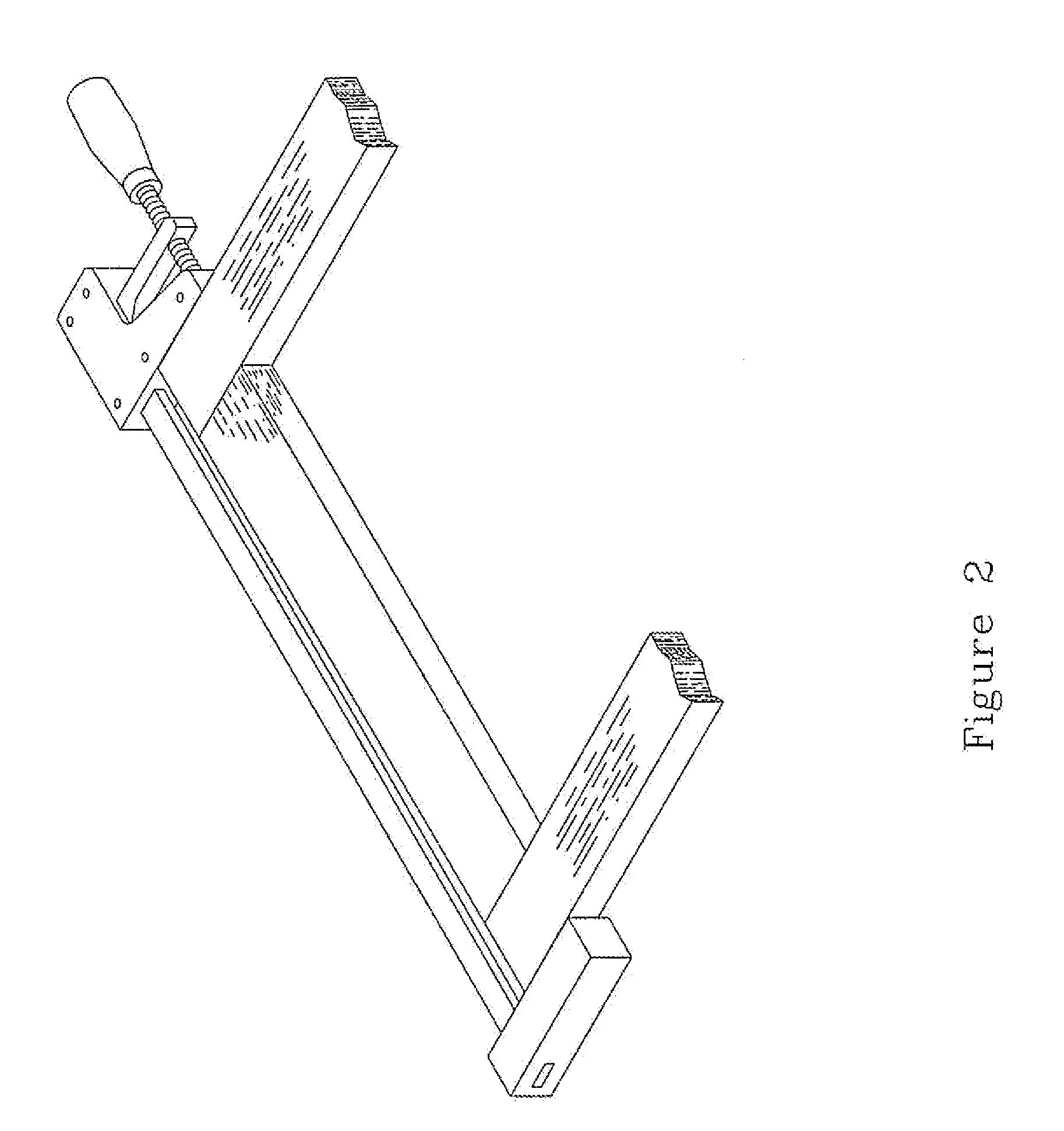

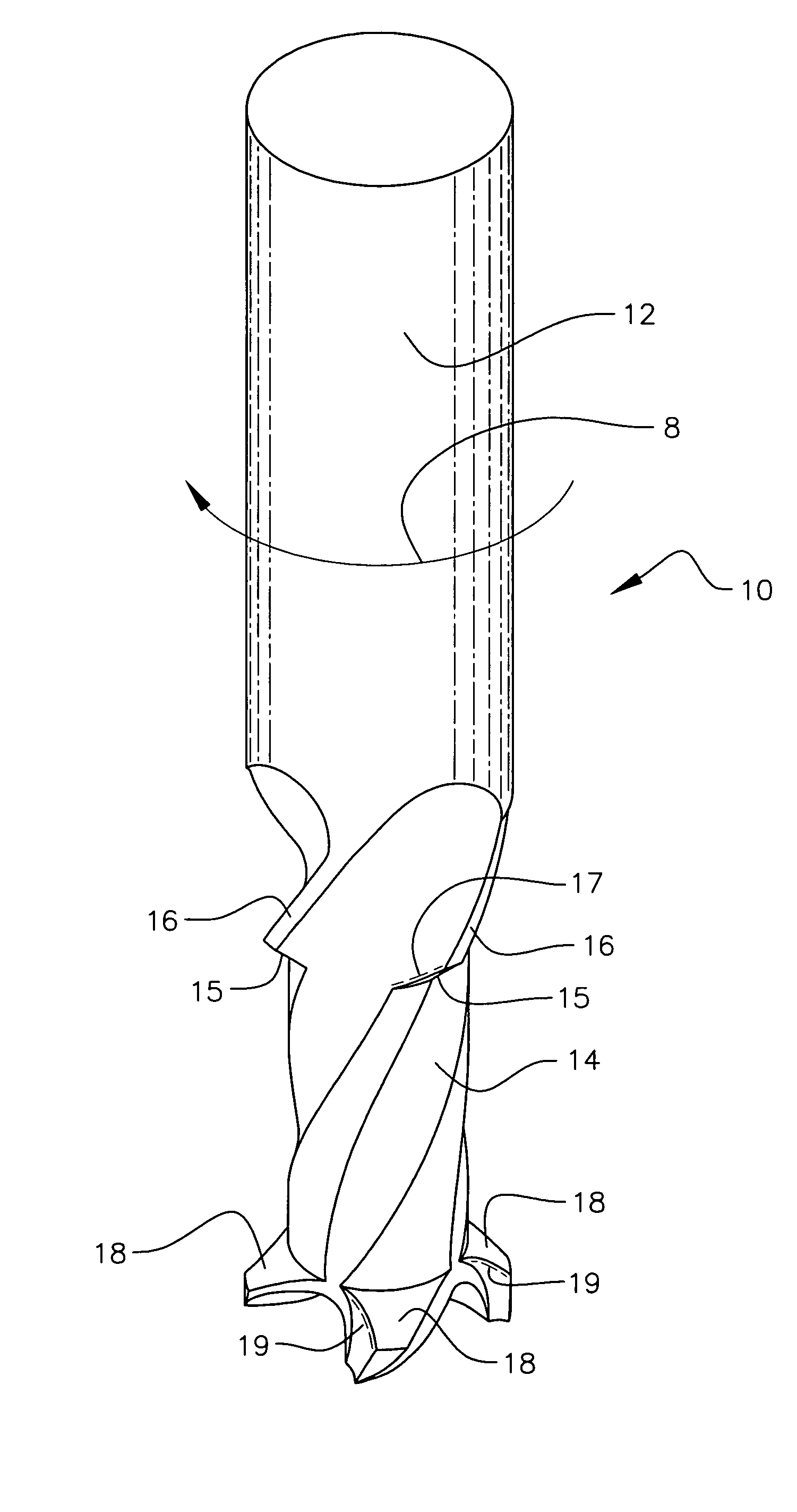

Two edge deburring tool

Owner:CLAYTON STEPHEN D

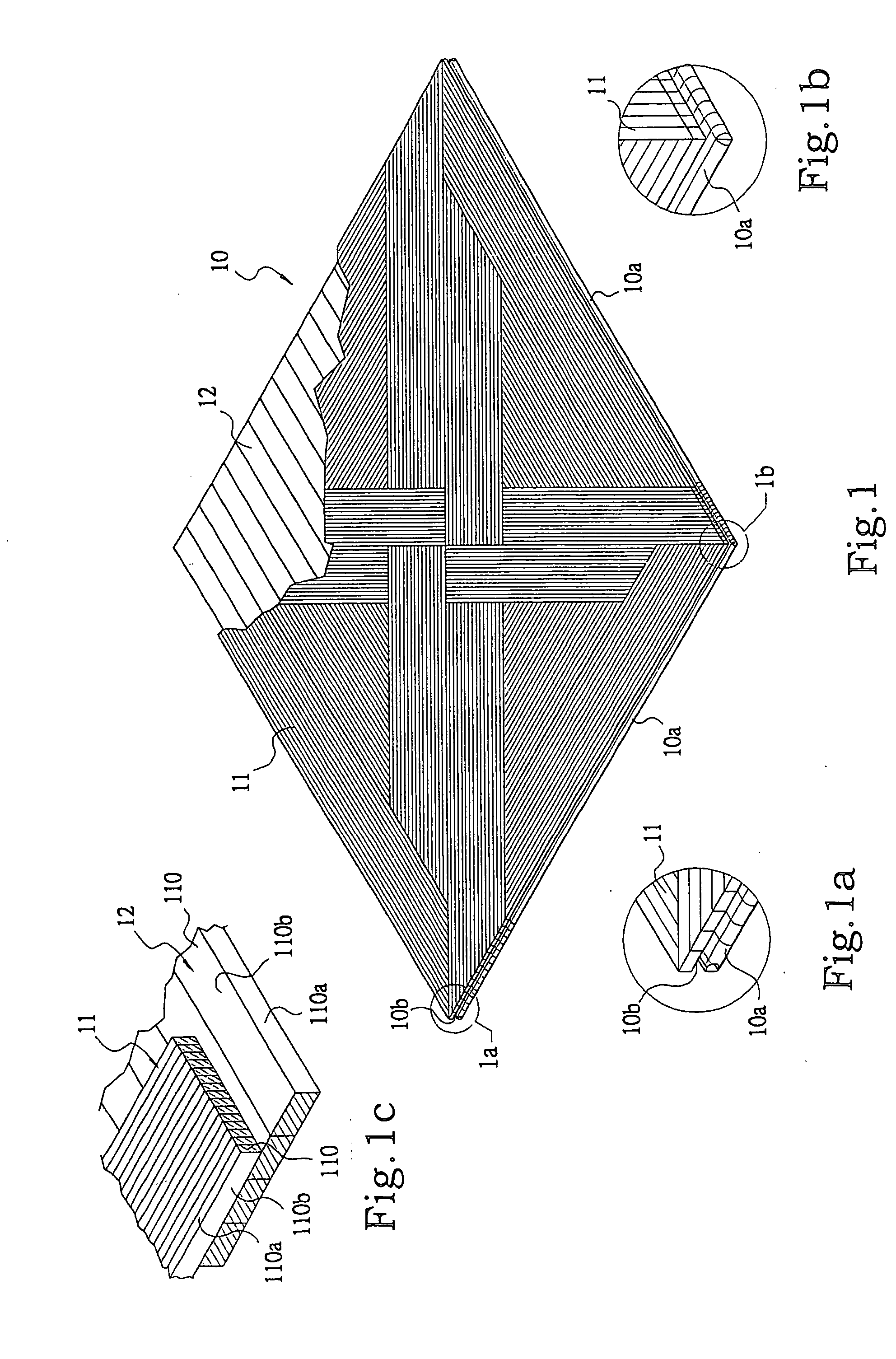

Bamboo mat board and method for producing the same

ActiveUS7021346B2Increase stiffnessHigh economic valueCane mechanical workingWood veneer joiningSurface layerMechanical engineering

A bamboo mat board element with a double-layered construction, a constant dimension, each of the elements is formed with a projecting tenon at each of two adjacent sides, respectively, and a concave mortise at each of the other two adjacent sides, respectively, for inter-tenoning the elements of the mat board, in which a surface layer of the mat board is obtained by matting a plurality of mat board stuffs having different orientations, shapes, and sizes, while each of the mat board stuffs is obtained by matting a plurality of lumbers having a parallel orientation, respectively, to form a plurality of patterns having parallel stripes by specially matting at the longitudinal section thickness of the lumbers. A method for producing the bamboo mat board at least comprises steps as follows: cutting step, boiling for blanching step, drying step, rough shaving, bottom layer pre-forming step, adhesive applying and pressing step, pattern selecting step, matting step, and refined shaving, etc. The sandwich mat board is then formed by pressing.

Owner:CHANG AO YU

Wood article and method of manufacture

InactiveUS6125607ALow costElement becomes smallTongue/grooves making apparatusWallsAdhesiveEngineering

A wood member comprises first and second opposed members made of wood and secured together. Each of the first and second members has spaced sides and a surface extending between the sides. The surfaces include a first portion contoured to define a contact surface which extends in more than one plane, the first portions defining a space therebetween for receiving an adhesive for securing the first and second members together; a second portion contoured to restrict the flow of the adhesive to a position outward from the sides when the first and second members are brought into engagement; and, opposed engagement members configured to lockingly engage without substantial deformation of the engagement members and secure the first and second members together as the adhesive dries.

Owner:POCE JOHN DI

Method for Making Plywood and Dimensional Lumber from Arundo Donax L. or Bamboo

ActiveUS20070125446A1Reduce dependenceConstruction materialCane mechanical workingEngineeringFire retardant

A method of producing a virtually fireproof plywood from perennial grasses such as Arundo donax Ligneous, various bamboo strains, or a blend thereof, by first weaving the stalks of these plants into a mat and then layering these mats and binding each layer with any one of several commercial resins mixed with potash for the purpose of enhancing the board's fire retardant quality. The result is the formation of a finished product with structural board attributes and an exceptionally high flash point in relation to other manufactured board products made from forest materials.

Owner:ABDULNASER ABDULMALIK +1

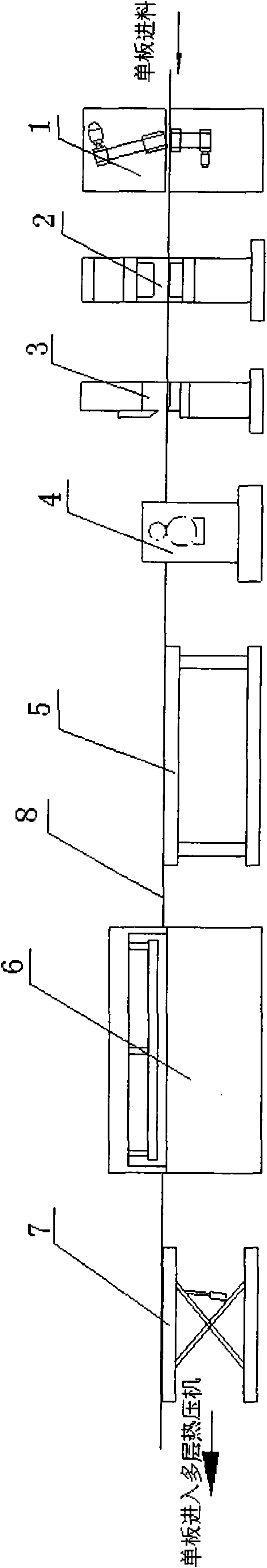

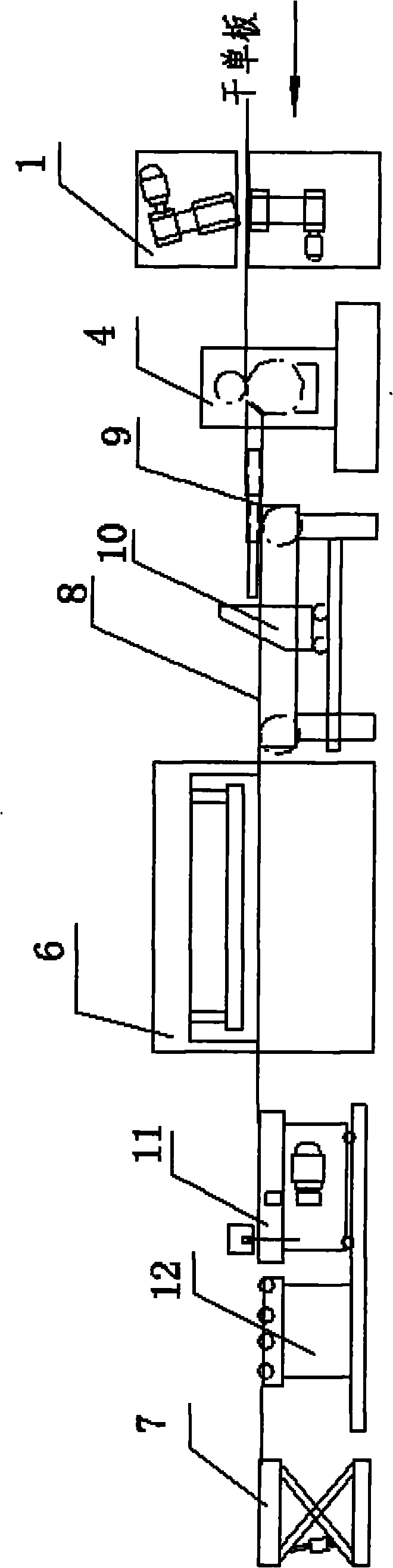

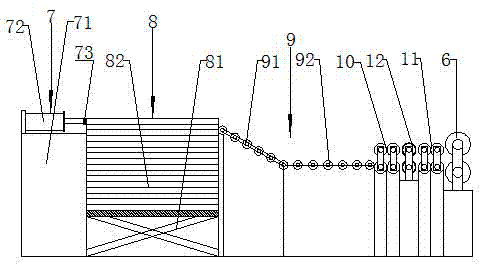

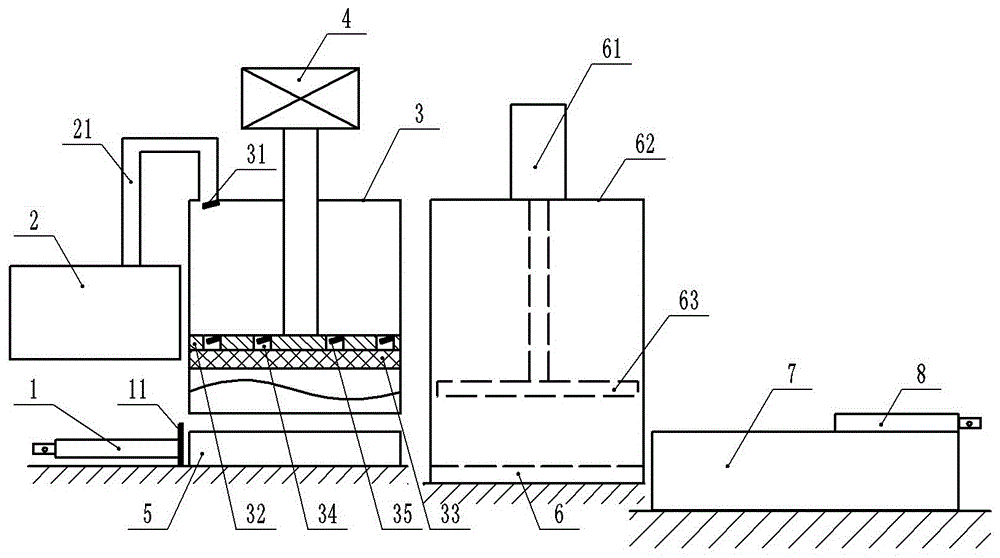

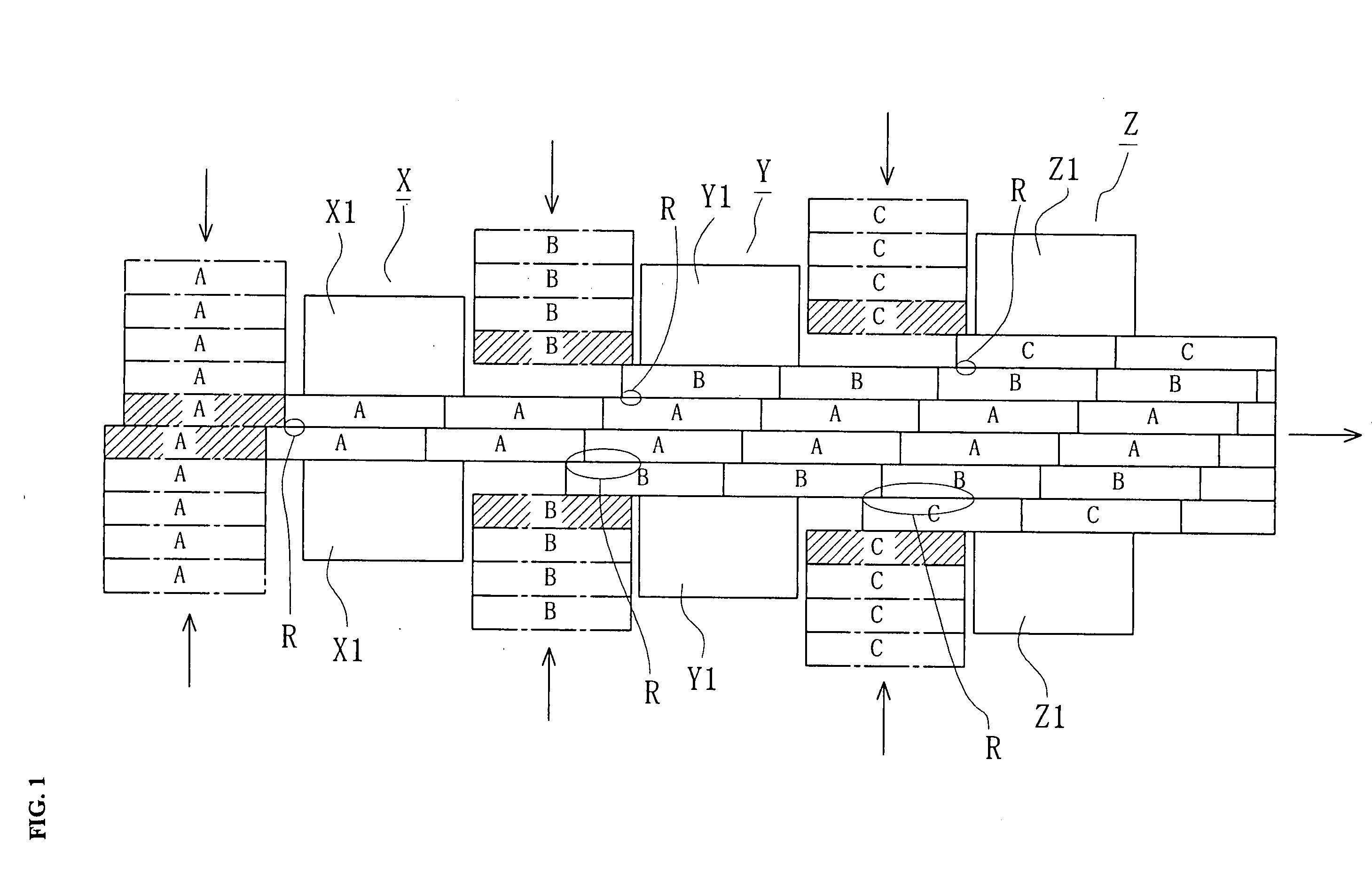

Complete production equipment for laminated veneer lumbers

InactiveCN101947801AReduce investmentPrecise positioningPlywood pressesVeneer pressesNumerical controlProduction line

The invention discloses complete production equipment for laminated veneer lumbers, which comprise an abrasive belt slant milling machine, a glue spreading machine, a veneer performing press, a material storing table and a multilayer thermal press. The complete production equipment is characterized by arranging a telescopic feeder and a numerical control locating assembly machine in sequence between the glue spreading machine and the veneer performing press, and a movable cutting saw and a conveying roller are arranged in sequence between the veneer performing press and the material storing table, wherein the abrasive belt slant milling machine, the glue spreading machine, the telescopic feeder, the numerical control locating assembly machine, the veneer performing press, the movable cutting saw, the conveying roller, the material storing table and the multilayer thermal press are connected in sequence to form a production line through an operating platform. Compared with the traditional complete production equipment for laminated veneer lumbers, the invention saves equipment investment, the location of the lumbers is very accurate due to the adoption of the numerical control locating assembly machine, production efficiency and product quality are obviously improved, assembled veneers can be infinitely prolonged, the production field of the laminated veneer lumbers is widened, and meanwhile, the degree of automation is also obviously increased.

Owner:NANJING FORESTRY UNIV

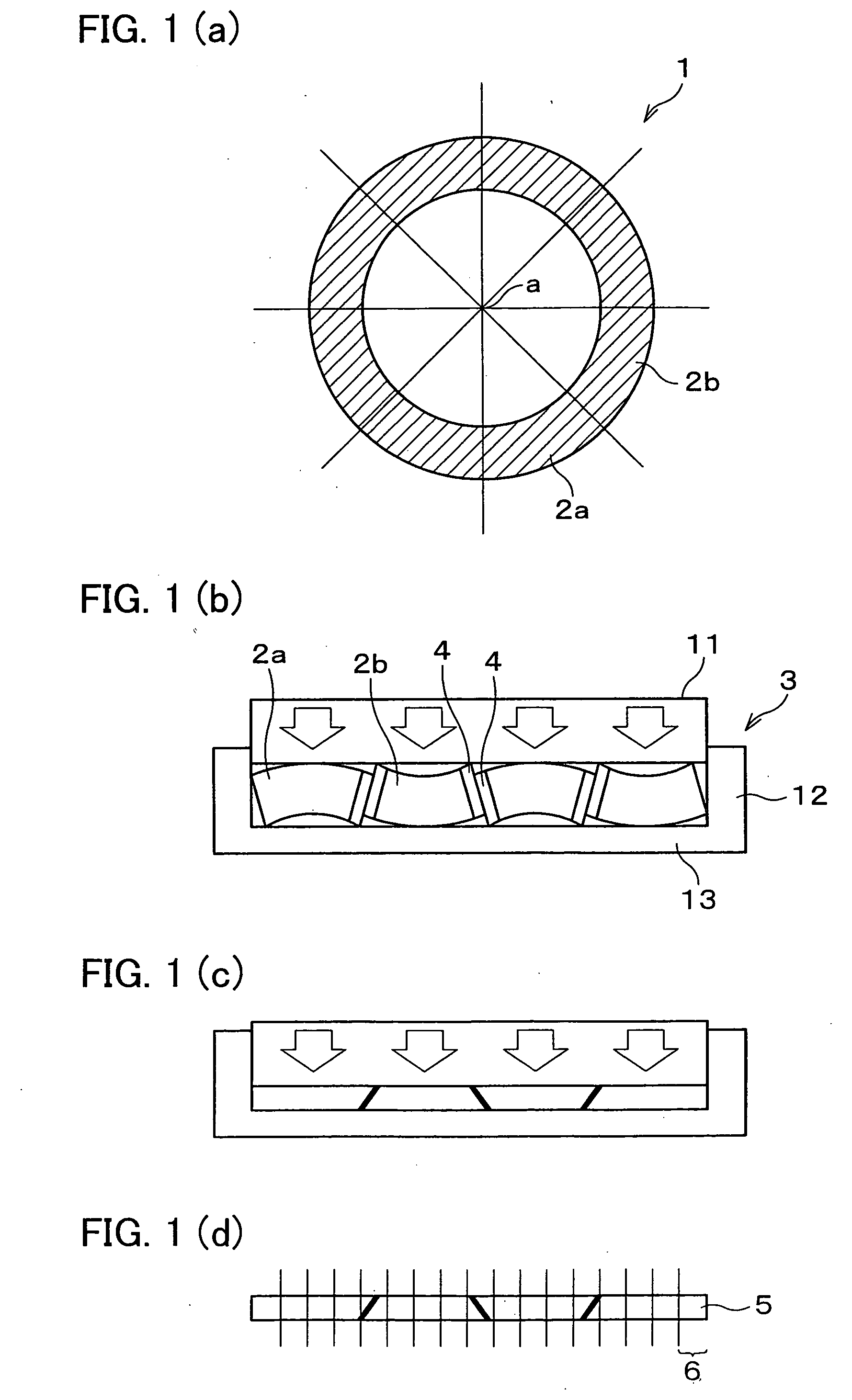

Wooden nail-like connector, compressed bamboo material, and method of manufacturing the connector and the material

InactiveUS20060060263A1High strengthHigh densityStapling toolsCane mechanical workingFiberEngineering

A method is disclosed for manufacturing bamboo nails. The method includes horizontally laying down small bamboo plates, obtained by cutting a bamboo piece radially from the center axis thereof, in a press. The small bamboo plates are then pressed perpendicularly to the fibers to produce a compressed flat plate. Finally, the compressed flat plate is cut in the shape of a multangular column. Thus the strength of a wooden material is increased.

Owner:JAPAN SCI & TECH CORP

Layer-by-layer automatic feeding, marking and gluing integrated equipment for sheet materials

ActiveCN104708689AFast processingSpread evenlyOther plywood/veneer working apparatusAdhesive application devicesProduction lineEngineering

The invention discloses layer-by-layer automatic feeding, marking and gluing integrated equipment for sheet materials. The layer-by-layer automatic feeding, marking and gluing integrated equipment for the sheet materials comprises a marking device and a gluing device; the gluing device is arranged on one side of the marking device and a layer-by-layer automatic feeding device is arranged on the other side of the marking device; the layer-by-layer automatic feeding device comprises a pushing mechanism, a hoisting mechanism and a sliding mechanism in sequence; and the gluing device comprises a supporting framework, a stirring mechanism arranged at the upper end of the supporting framework, a material scattering mechanism arranged at the bottom of a transverse beam of the supporting framework, and a compression roller gluing mechanism arranged under the supporting framework. According to the layer-by-layer automatic feeding, marking and gluing integrated equipment, marking and gluing are integrated, transmission and interruption of machines are reduced in the process and the consistency of a production line is improved; and the machining time of the whole sheet material is shortened, materials can be automatically fed layer by layer, the transmission is buffered, the gluing can be automatically realized and the gluing is uniform.

Owner:JIANGSU KENTIER WOOD

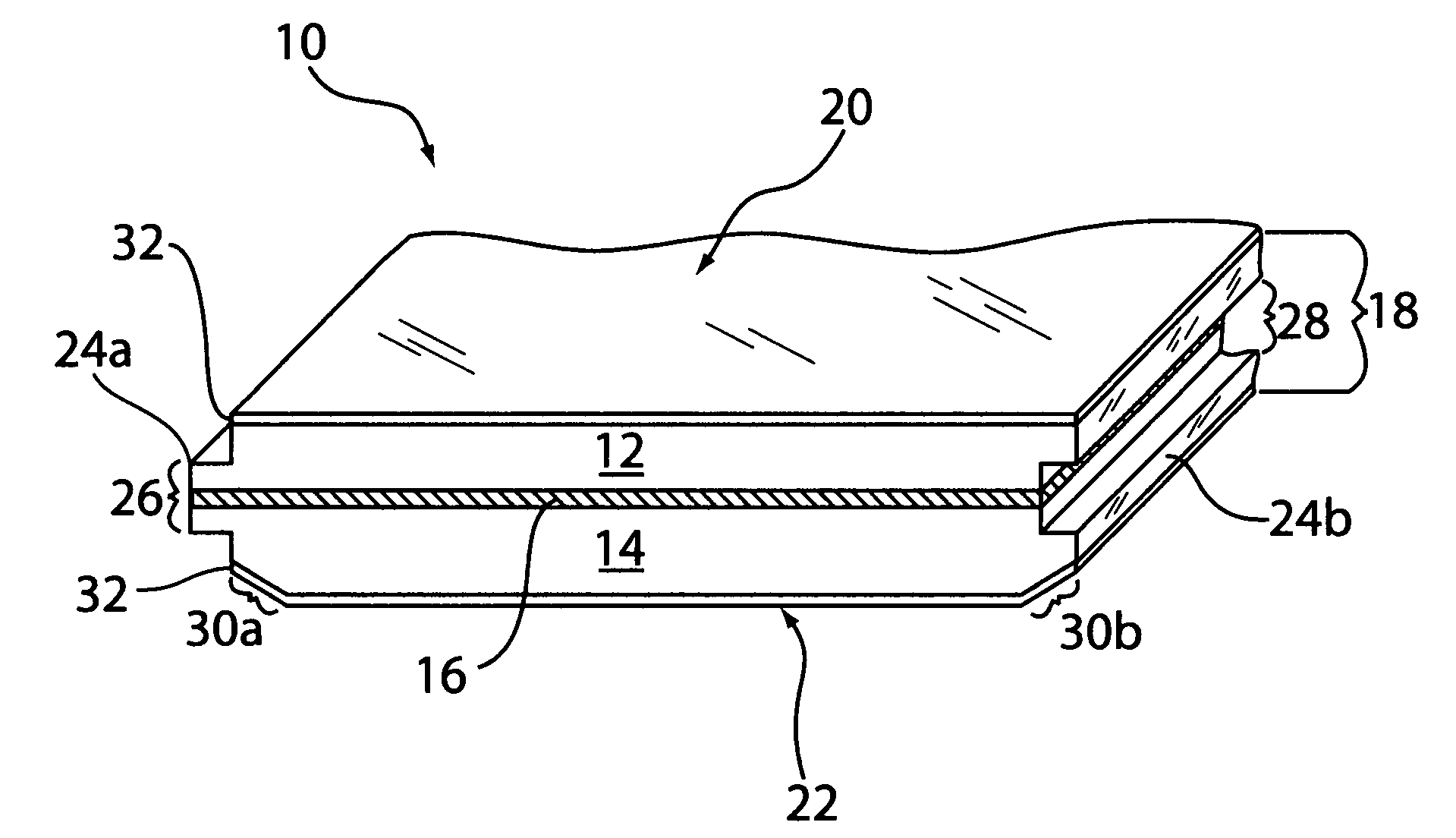

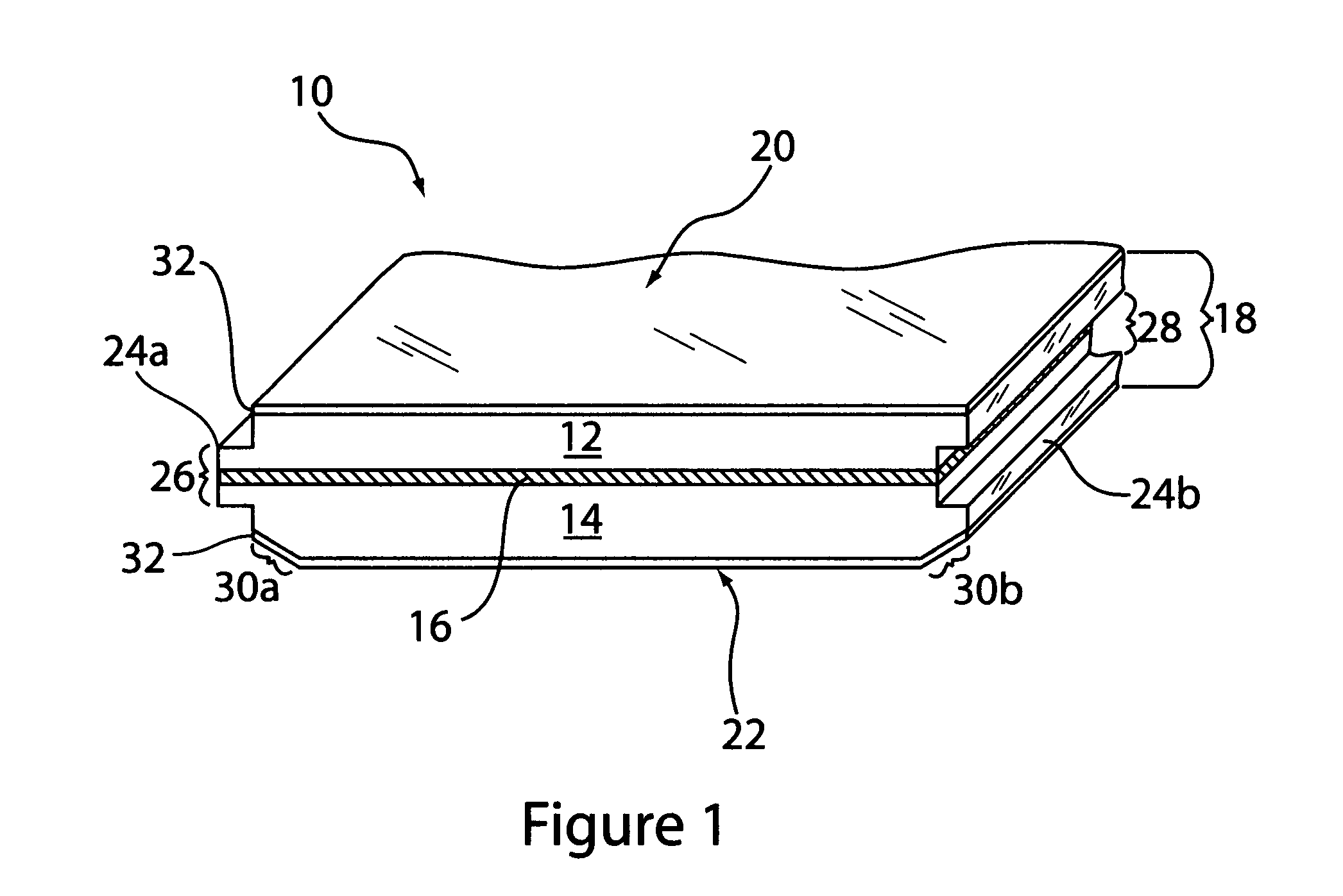

Low emissivity products and methods for making same

The method of this invention adheres a low emissivity radiant barrier material to an underlying lignocellulosic substrate within the primary manufacturing operation of the underlying lignocellulosic substrate. Thus, a radiant barrier covered substrate is formed by integrally joining the radiant barrier covering to a mat of lignocellulosic material during consolidation thereof with a first adhesive bonding material to form an underlying substrate. The integral joining operation can, for example, be accomplished by bonding the radiant barrier covering to a lignocellulosic mat in a product formation press. This is typically accomplished using a second adhesive bonding material for adhesion of the radiant barrier material to the lignocellulosic mat, and a first adhesive bonding material for consolidating the lignocellulosic mat to form a lignocellulosic substrate. More specifically, this invention is directed to a method whereby a low emissivity radiant barrier material is joined in situ to a mat of lignocellulosic particles using a second adhesive material, during the consolidation of the lignocellulosic particles and a first adhesive bonding material to form an underlying substrate, an integral laminated radiant barrier covered lignocellulosic product being produced.

Owner:GANG NAIL SYST

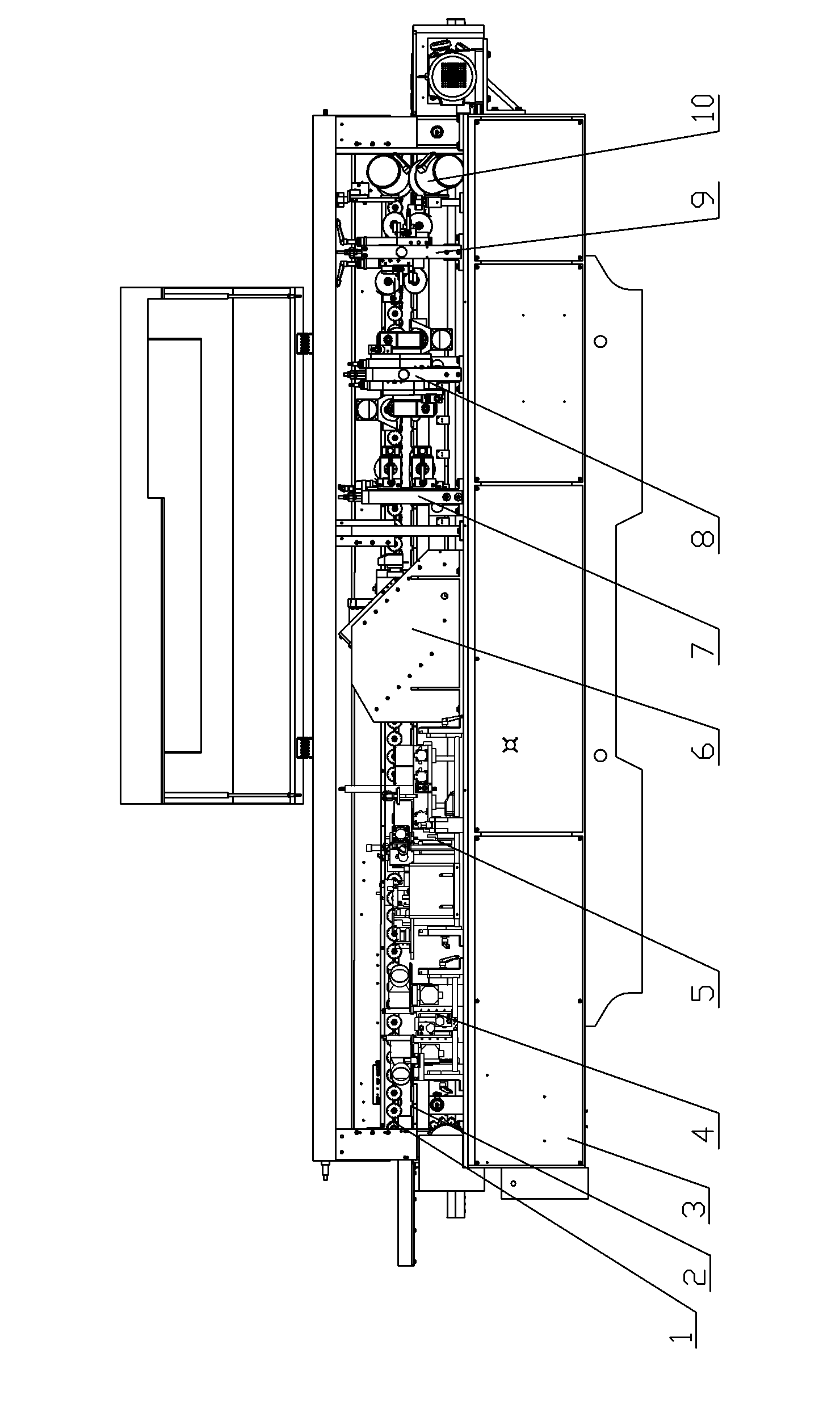

Automatic bevel edge bonding machine

ActiveCN102092075AImprove edge banding efficiencyImprove qualityPolishing machinesDomestic articlesMechanical engineeringWood plank

The invention relates to an automatic bevel edge bonding machine. The machine comprises a roller pressing device (1), a chain delivery device (2), a frame (3), a bevel edge conveying belt, glue, a cut tape, a tape pressing device (5), a front and back coarse trimming device (6), an upper and lower coarse trimming device (7), an upper and lower refining device (8), an upper and lower scraping device (9) and an upper and lower polishing device (10), wherein the roller pressing device (1) is arranged on the frame (3) and is opposite to the chain delivery device (2) up and down; and the bevel edge conveying belt, the glue, the cut tape, the tape pressing device (5), the front and back coarse trimming device (6), the upper and lower coarse trimming device (7), the upper and lower refining device (8), the upper and lower scrapping device (9) and the upper and lower polishing device (10) are arranged on the same side of the frame (3) in sequence, and close to the chain conveying device (2). The automatic bevel edge sealing machine can seal a bevel edge automatically, has the advantages of high sealing efficiency, high quality and adjustable sealing angle, and can automatically perform wood board pre-milling.

Owner:NANXING MACHINERY CO LTD

Releasable dovetail corner joint

InactiveUS7255511B2Facilitates adjustment and assemblyIncrease spacingScaffold connectionsDoors/windowsEngineeringMirror image

Owner:DOLAN KEVIN P

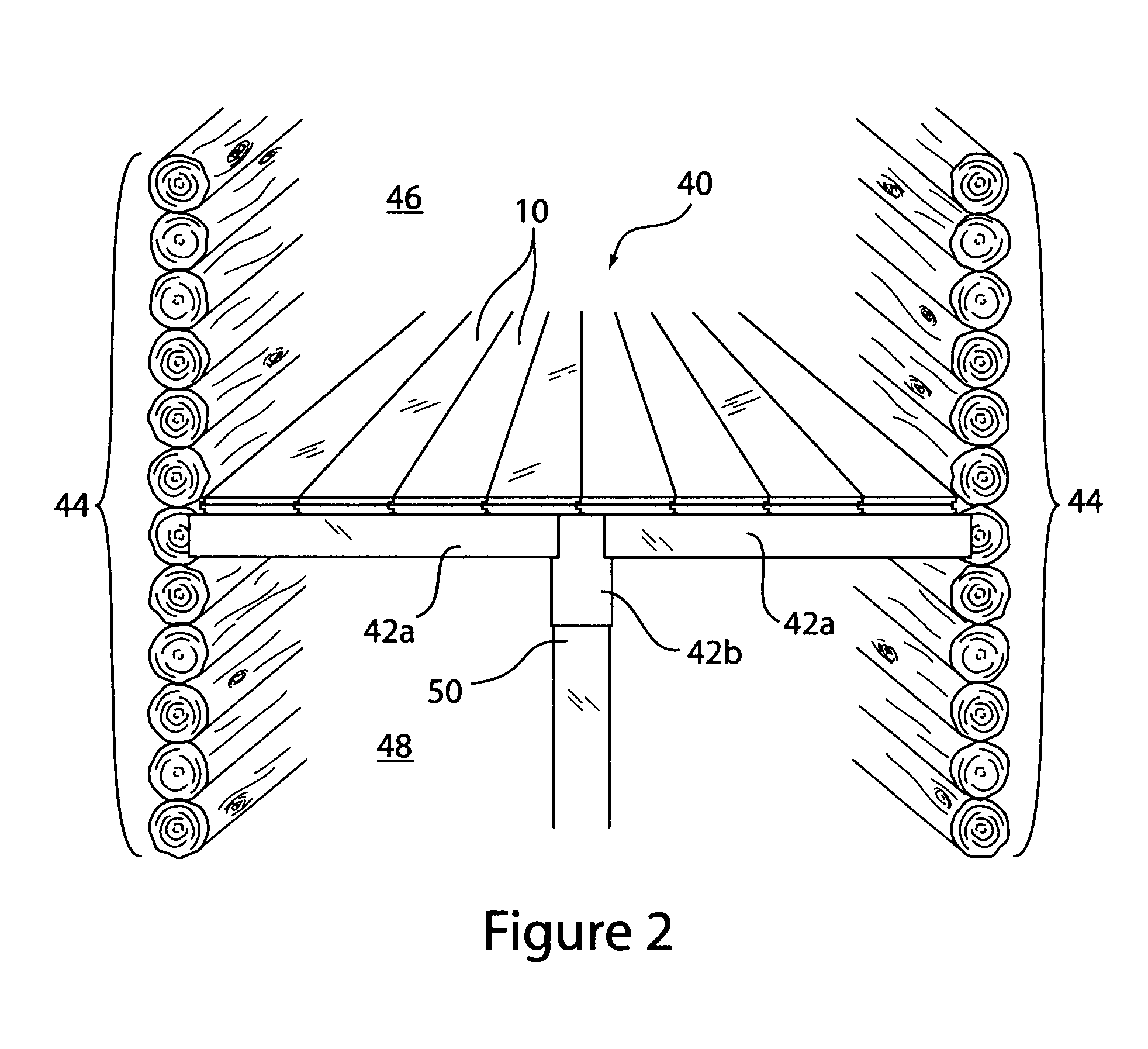

Wood mat and apparatus and method for assembling same

InactiveUS20080028703A1Improve rigidityHigh strengthStapling toolsConstruction materialEngineeringRivet

A wood mat has a first layer of timbers extending parallel to one another in a longitudinal direction and a second layer timbers spanning across the first timbers parallel to one another and transversely to the first timbers such that each second timber intersects a plurality of the first timbers at respective intersecting locations of the mat; and a plurality of pressed fasteners mounted at selected intersecting locations through drilled holes formed by either a rivet fastener or a press fit fastener having opposed ends compressively joining the timbers therebetween.

Owner:BRANDSTROM RANDEL

Plate press machine with glue coating function

ActiveCN106738100AAccelerate solidificationLighten the laborPlywood pressesMulti-purpose machinesWood machiningPulp and paper industry

The invention belongs to the technical field of wood working equipment, and particularly discloses a plate press machine with glue coating function. The plate press machine comprises a first horizontal push hydrocylinder, a glue coating device, a plate presser and a feeder from left to right, wherein the glue coating device comprises a bracket, a glue tank, an air cylinder and a glue supply tank; the glue supply tank is a tank body with an opening on the lower end; the glue supply tank is fixed to the bracket; a piston is arranged in the glue supply tank, and driven by the air cylinder; the air cylinder is positioned above the glue supply tank; the side wall of the glue supply tank communicates with a glue suction pipe; one end of the glue suction pipe is positioned in the glue tank; the joint between the glue suction pipe and glue supply tank is provided with a first one-way valve; the piston is provided with a through hole, and the through hole is provided with a one-way valve; the lower surface of the piston is provided with a sponge layer; the feeder comprises an elevating table and a second horizontal push hydrocylinder; and the second horizontal push hydrocylinder is positioned on the elevating table. By adopting the technical scheme, the wood plate can be pressed immediately after finishing glue coating, and the glue coating and pressing processes are continuous, so the production efficiency is high.

Owner:重庆汇升套装门有限公司

Labeling machine

InactiveUS6634400B2Avoids incessant go-and-return tripSimple designMechanical working/deformationManual label dispensersEngineeringLabelling machine

The invention provides a labeling machine comprising a structure, a labeling head capable of pivoting relative to the structure about a pivot axis, the labeling head being fitted with gripper means for gripping a label holding it in a plane that is substantially normal to the pivot axis of the labeling head, and placing means carried by the labeling head and adapted to take the label held by the gripper means and place it on an article to be labeled that is present on the labeling machine. According to the invention, the gripper means hold a label in such a manner that a corner thereof coincides substantially with the point of intersection of the pivot axis and the plane of the label.

Owner:NS TESTUT

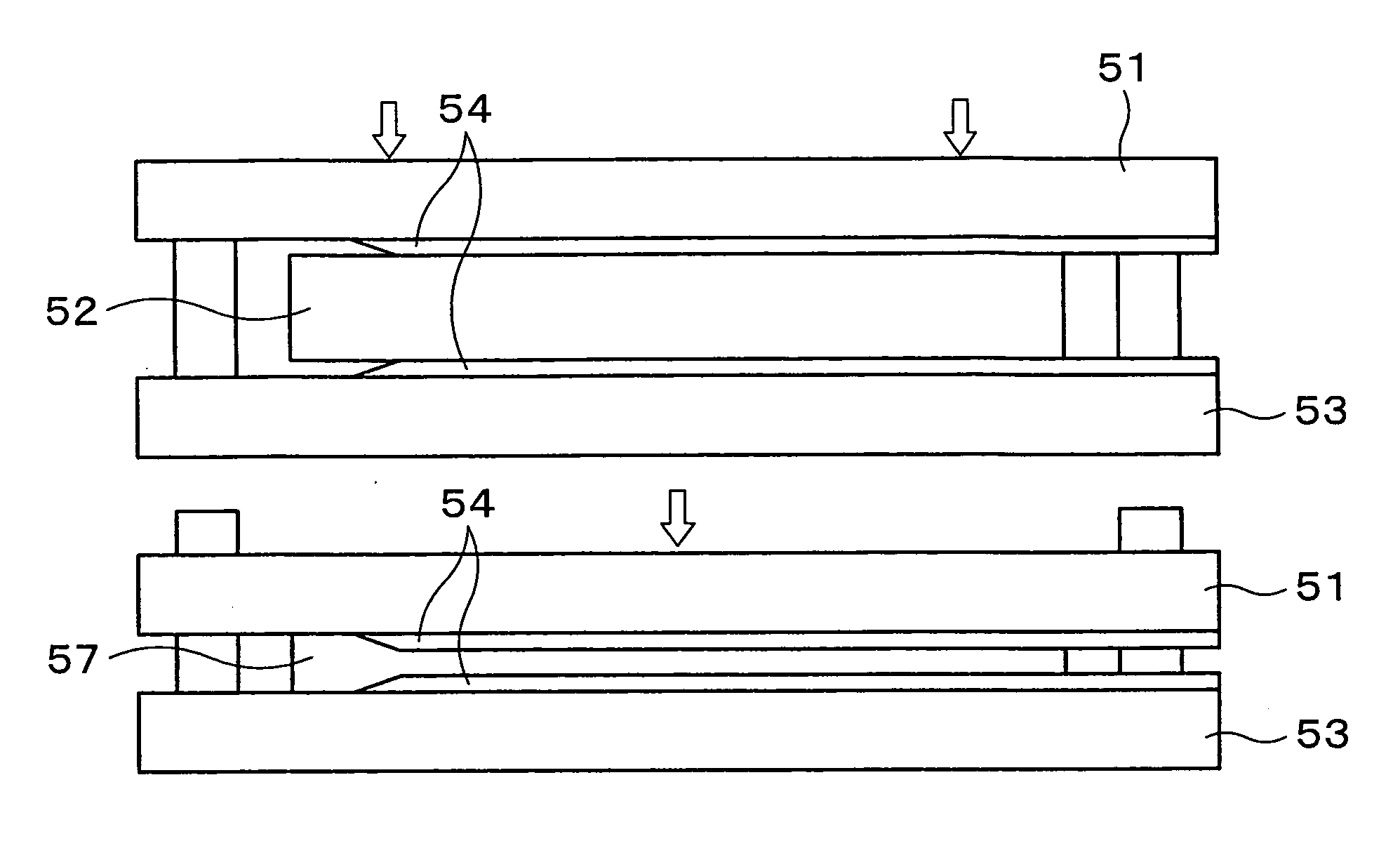

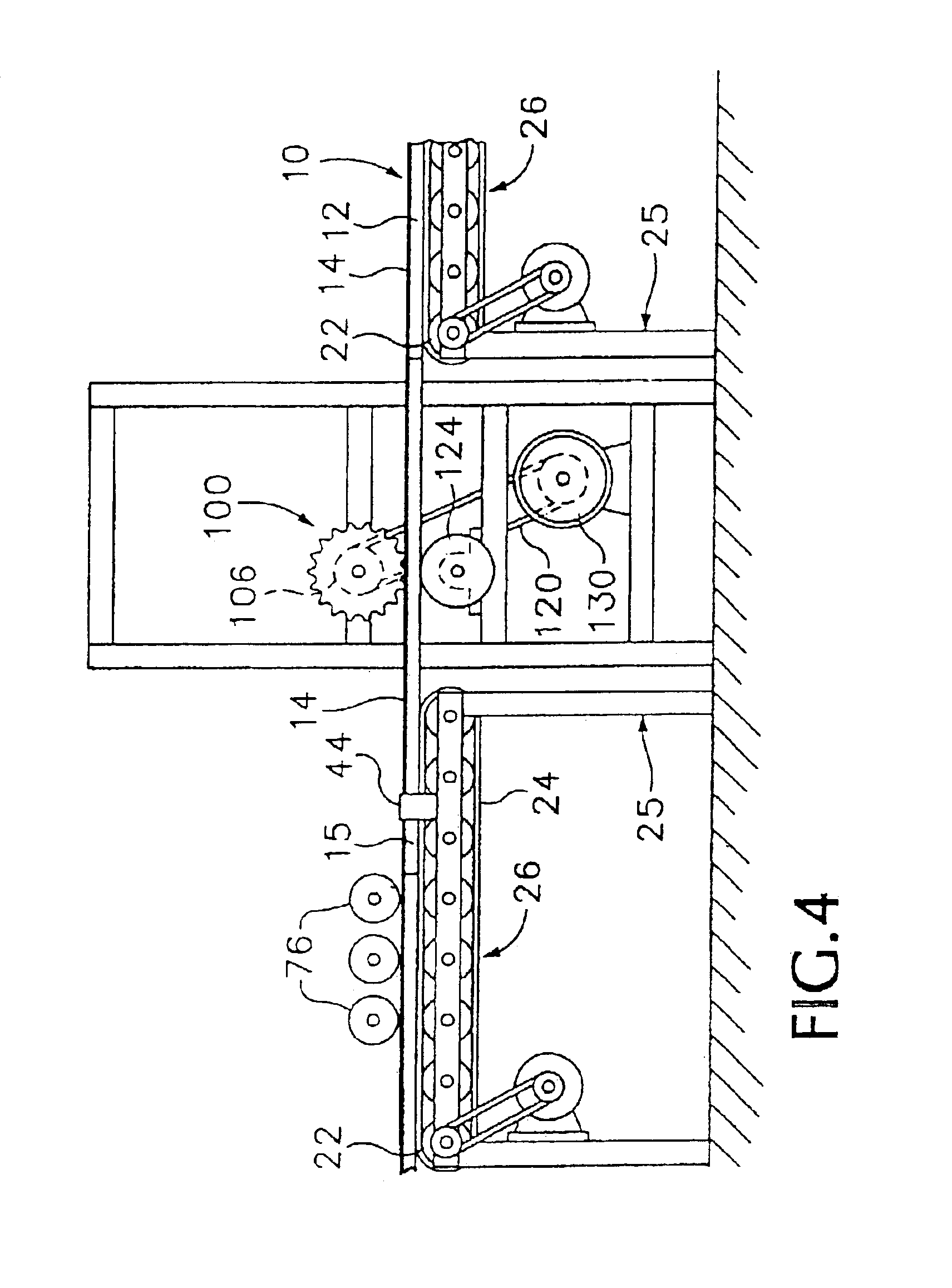

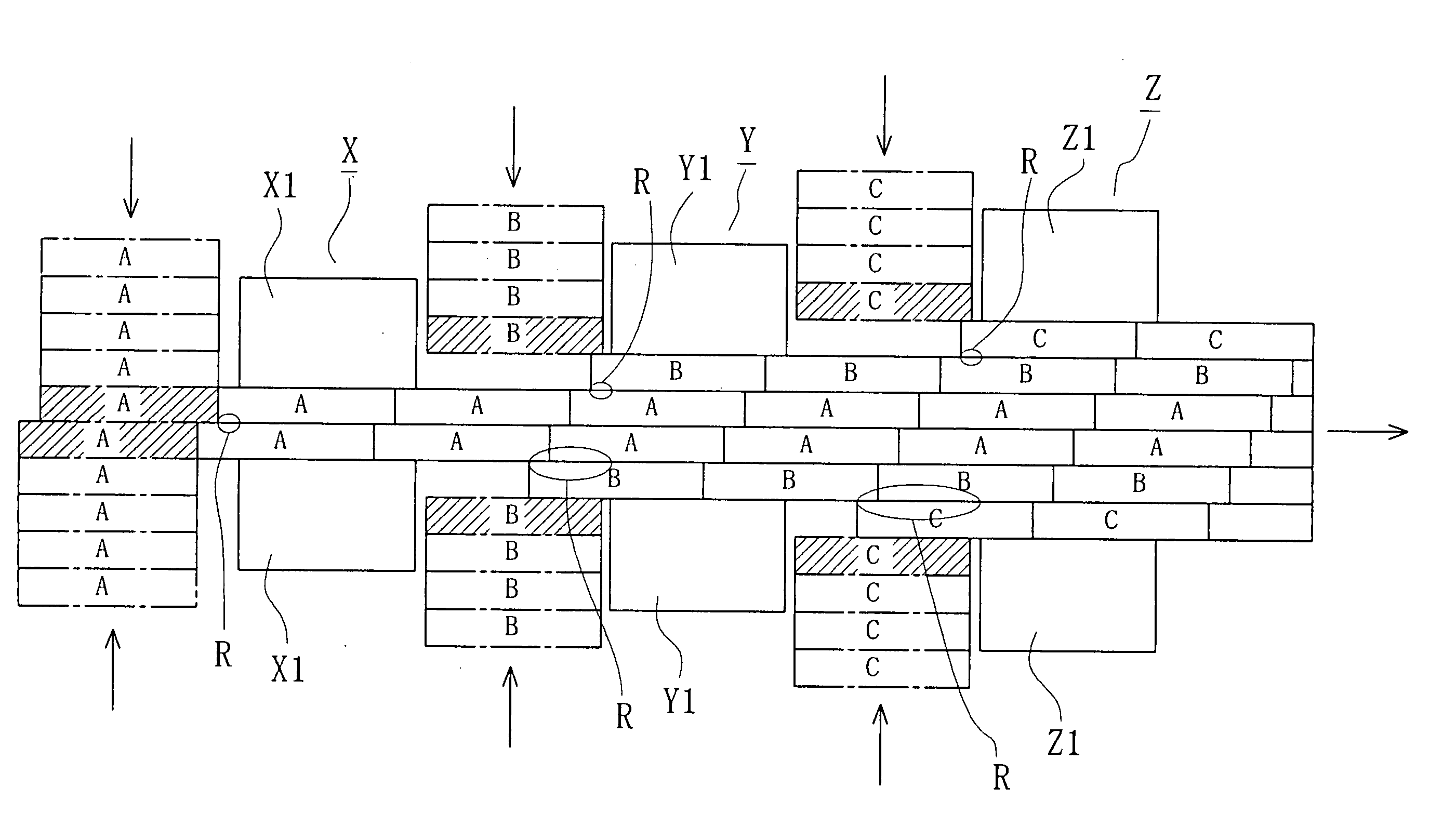

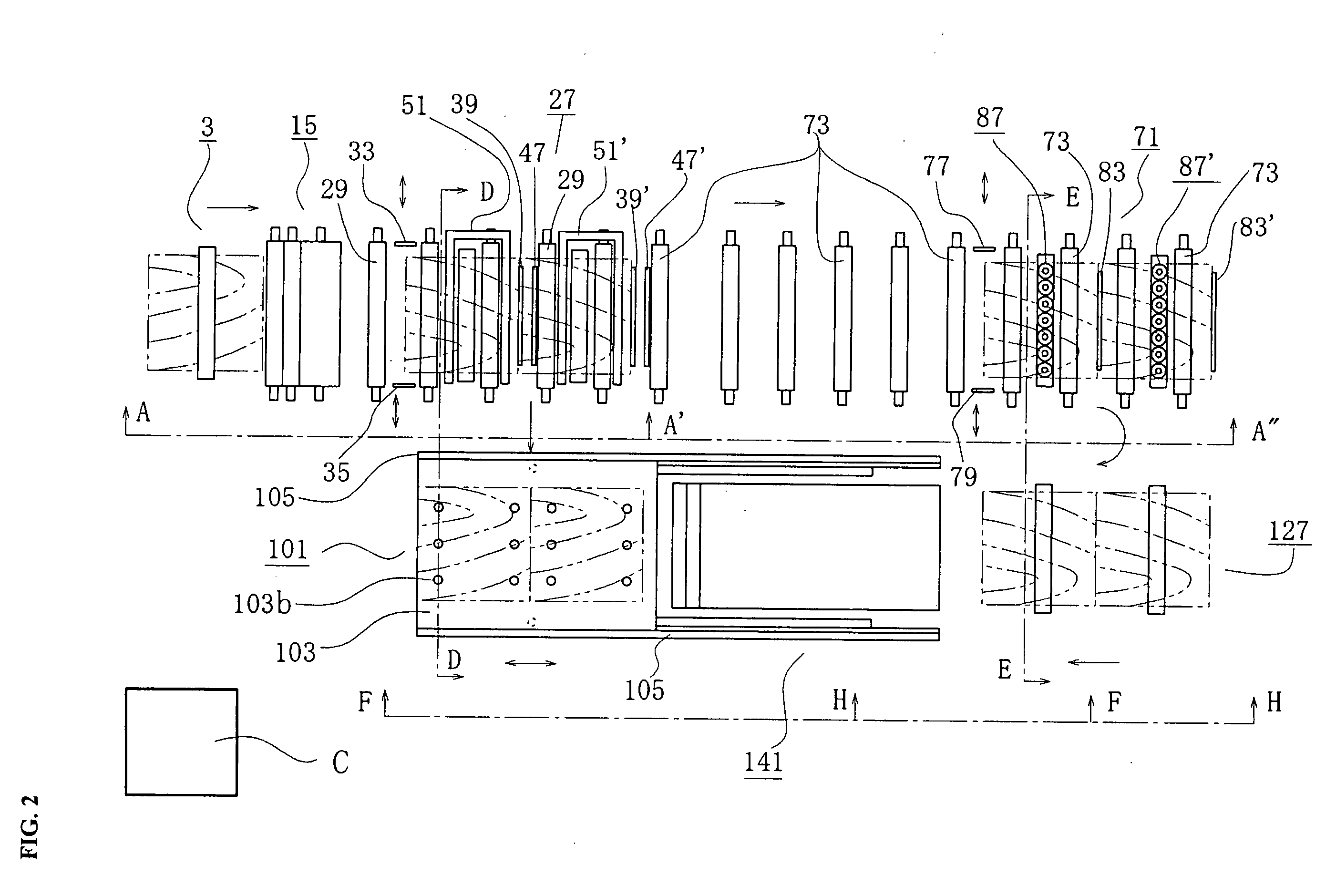

Method and apparatus of manufacturing glued laminated wood

A method and apparatus of manufacturing glued laminated wood such as laminated veneer lumber (LVL) are disclosed. The glued laminated wood is made of a number of wood sheets such as veneer sheets which are laminated together by a hot press with a thermosetting adhesive into a continuous length of multiple-layered board of the glued laminated wood wherein wood sheets in each layer of the multiple-layered board are arranged in a staggered relation in the lengthwise direction of the board to wood sheets in an adjacent layer. The hot press has a pair of heating plates arranged substantially in facing relation to each other and an auxiliary heating plate disposed adjacent to one end of each heating plate. The auxiliary heating plate is adapted to press part of wood sheet which extends out beyond the above end of the heating plate.

Owner:MEINAN MASCH WORKS INC

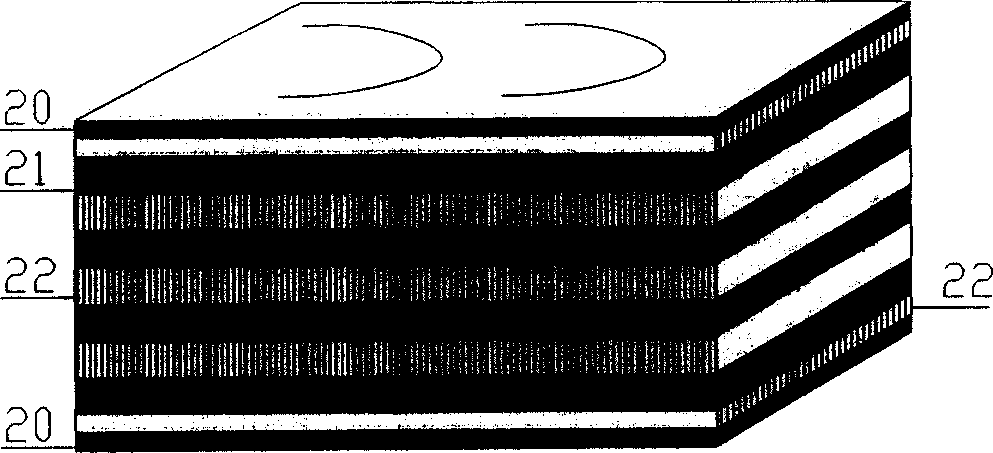

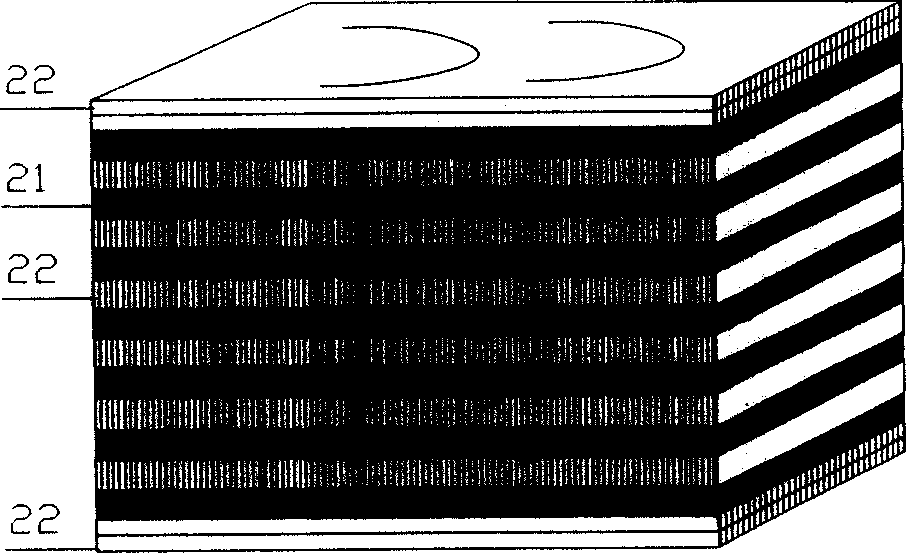

Adhesive-bonded panel made of bamboo and wood and its prodn. method

ActiveCN1903529AEnsure stable qualityIncrease profitAldehyde/ketone condensation polymer adhesivesWood veneer joiningAdhesiveEngineering

A plyboard is made up of multiple wood plys and multiple bamboo plys through alternative laminating and hot pressing.

Owner:中集新型环保材料股份有限公司

Dowel connection system and method

An embodiment of the connection system is for connecting a plurality of components together. One embodiment of a method of the system provides a dowel having first and second portions. Each of the portions has first and second ends, the first and second portions being connected to one another at their second ends. At least one portion of the first and second portions has at least three dowel sections of successively decreasing diameters. One of these dowel sections has a side wall and an end wall that forms the first end of the at least one portion and each of the other dowel sections has a side wall and step wall. A first component has a first opening configured to substantially fit the first portion, and a second component has a second opening configured to substantially fit the second portion. An adhesive material is then applied on at least part of the first portion, and the first portion is inserted into the first opening in the first component. Adhesive material is then also applied on at least a part of the second portion, and the second portion is inserted into the second opening in the second component, thereby connecting together the two components.

Owner:MILLER DOWEL

Preparation method of ecological plate

InactiveCN102198675AReduce usageConserve non-renewable resourcesSynthetic resin layered productsWood veneer joiningRenewable resourceNon-renewable resource

The invention discloses a preparation method of an ecological plate, which comprises the following steps of: step 1, preparing melamine impregnated cellophane paper, wherein glue content is increased by 15-20% in the preparation process in comparison with a traditional formula; step 2, attaching the melamine impregnated cellophane paper on special-shaped veneers; step 3, preparing an intermediate substrate; step 4, respectively adhering the veneers attached with the melamine impregnated cellophane paper to two surfaces of the intermediate substrates, and pressing and heating the two surfaces of the intermediate substrate to get the ecological plate. In the preparation method provided by the invention, a grainy paper for printing substitutes a natural wood material to serve as a decorative finish of the plate, so that usage amount of wood is greatly reduced, and non-renewable resource is saved; oil paint is substituted after the surface of the plate is impregnated by melamine, so that cost on processing is greatly saved, processing time is greatly shortened, and environmental performance of the preparation method is far better than that of the conventional production method; and the prepared ecological plate is excellent in surface abrasive resistance, scratch resistance, stain resistance and fire resistance, and is fashionable in design and color expression, so that the prepared ecological plate can meet the requirements of different consumers.

Owner:上海荷雨木业有限公司

Adhesive Coating Device With Discharge Adjustment Mechanism

An adhesive coating device is provided with an adhesive reservoir; two opposite adjustment rollers at bottom of the reservoir; a pattern roller between the adjustment rollers and having a pattern formed thereon; a resilient roller under the pattern roller; a roller member under the resilient roller; two pivotal, co-rotated links on a side of the reservoir and operatively connected to the adjustment rollers respectively; and a spring biased adjustment screw pivotably secured to an end of one link. Clockwise rotation of the adjustment screw rotates the links at different directions, thereby decreasing a gap between the pattern roller and each adjustment roller.

Owner:HUANG YU CHENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com