Method for producing plywood with glueing on one side and plywood mould

A production method and technology for plywood, applied in the field of wood processing, can solve the problems of non-reuse, low utilization rate of wood, low production efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

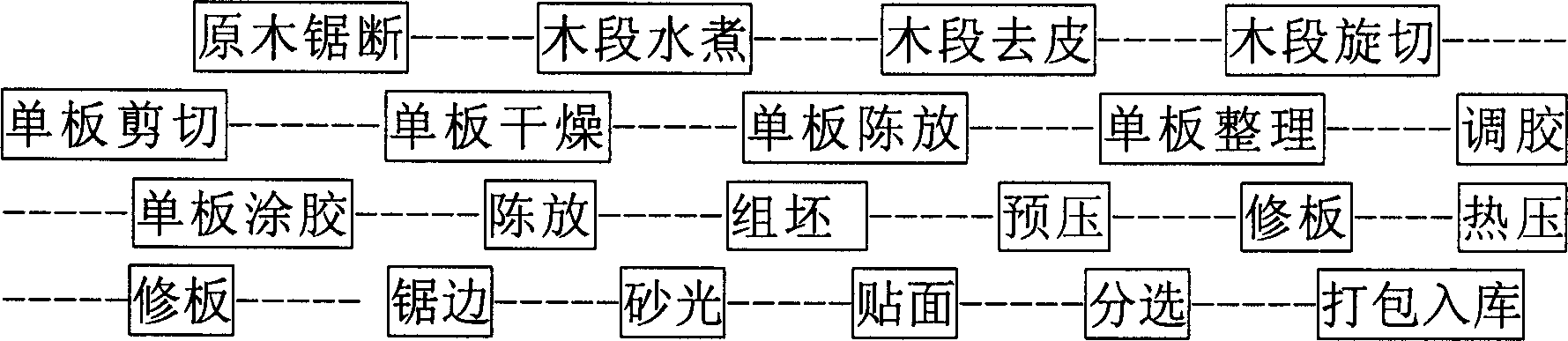

Method used

Image

Examples

Embodiment Construction

[0098] The technological feature of the present invention is that each layer of veneer of the plywood is coated with glue on one side, and the shape and size of the veneer are not limited, and they can be overlapped with each other when forming blanks, so that each veneer can be connected with the adjacent The veneers can be glued together, which improves the bonding strength of the boards. The waste small pieces of veneers are used to reduce the diameter to 1.5 cubic meters of logs to produce 1 cubic meter of plywood formwork, which greatly improves the utilization rate of wood by 56%.

[0099] In order to make the surface of the template smooth, water-resistant and durable, the present invention pastes a layer of resin-impregnated paper mold on the base material of veneer glued plywood to make it smooth and durable.

[0100] The single-side gluing process has the following advantages:

[0101] The traditional double-sided gluing process produces plywood with odd-numbered lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com