Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3324 results about "Single plate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

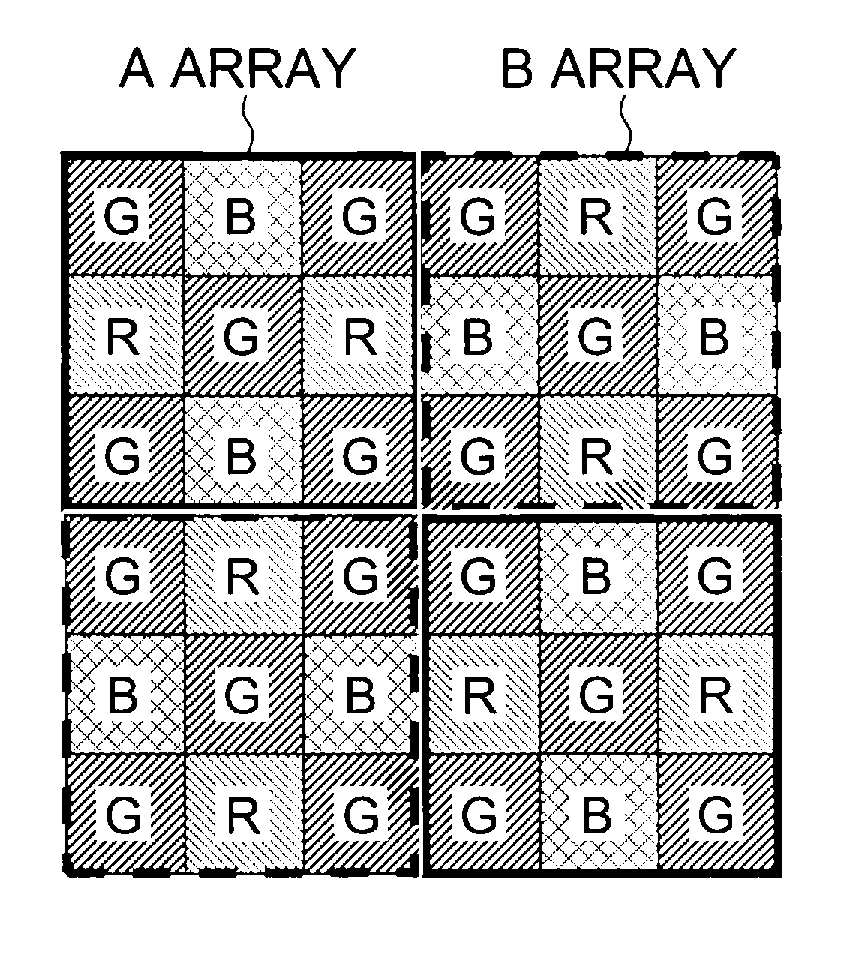

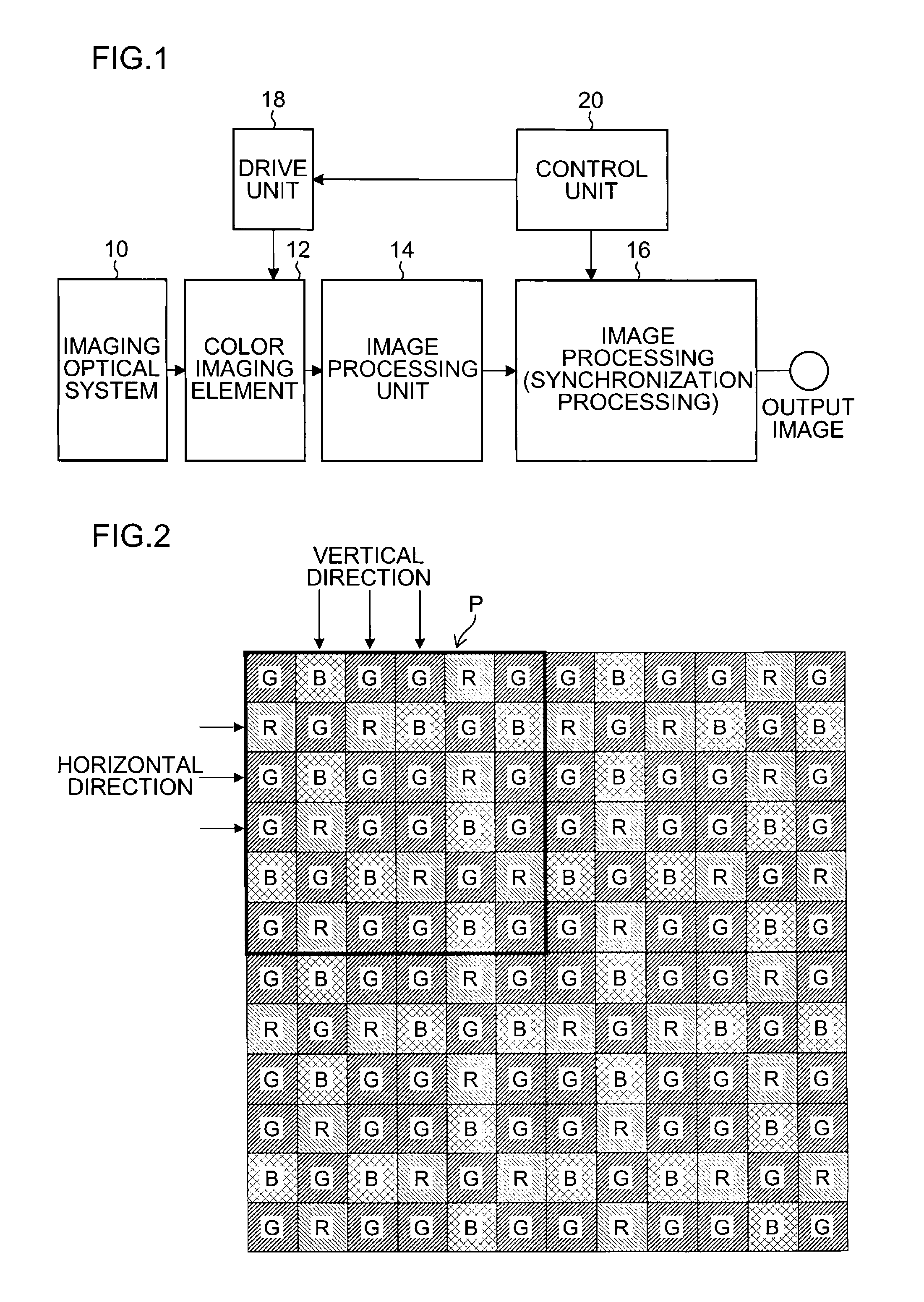

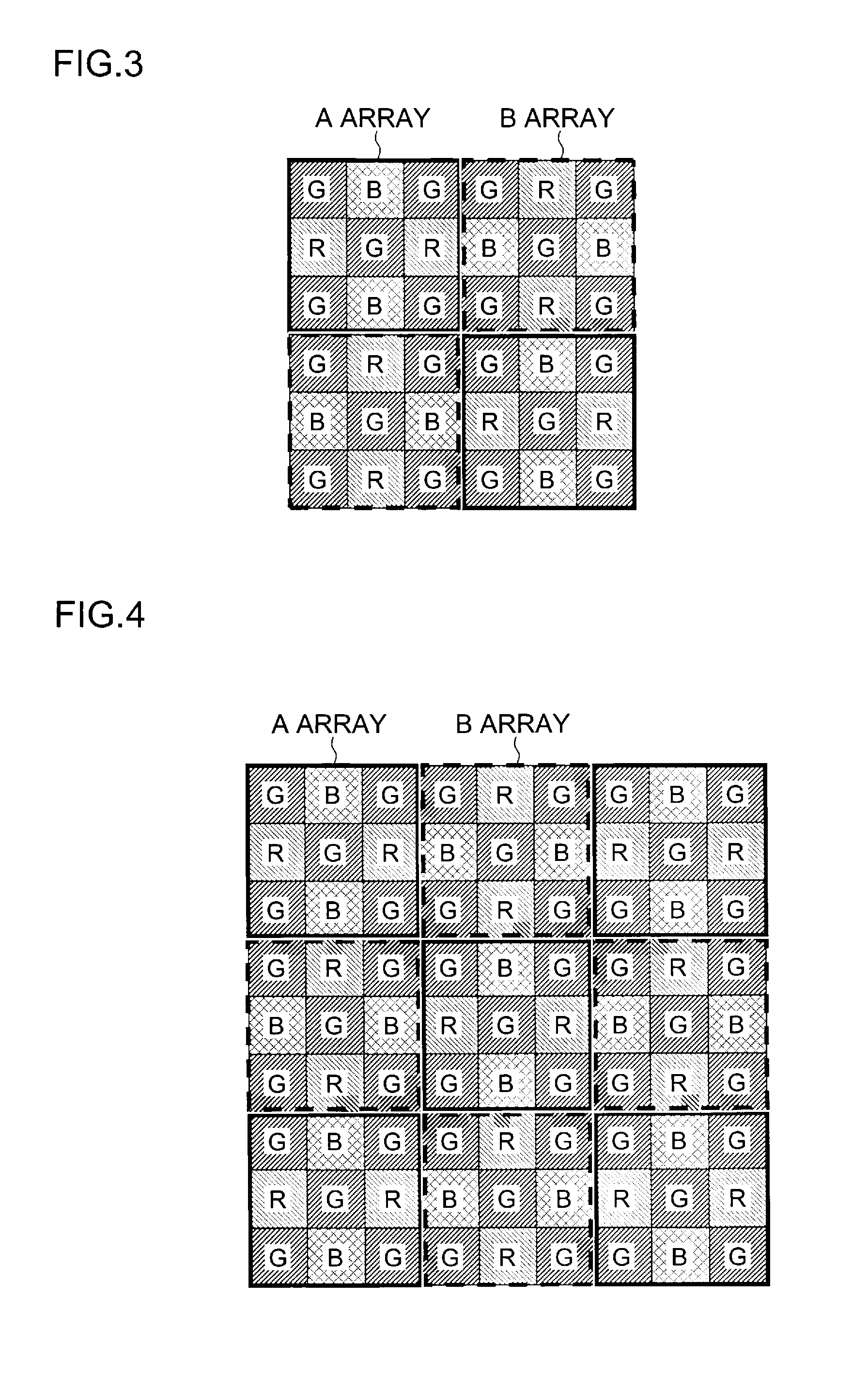

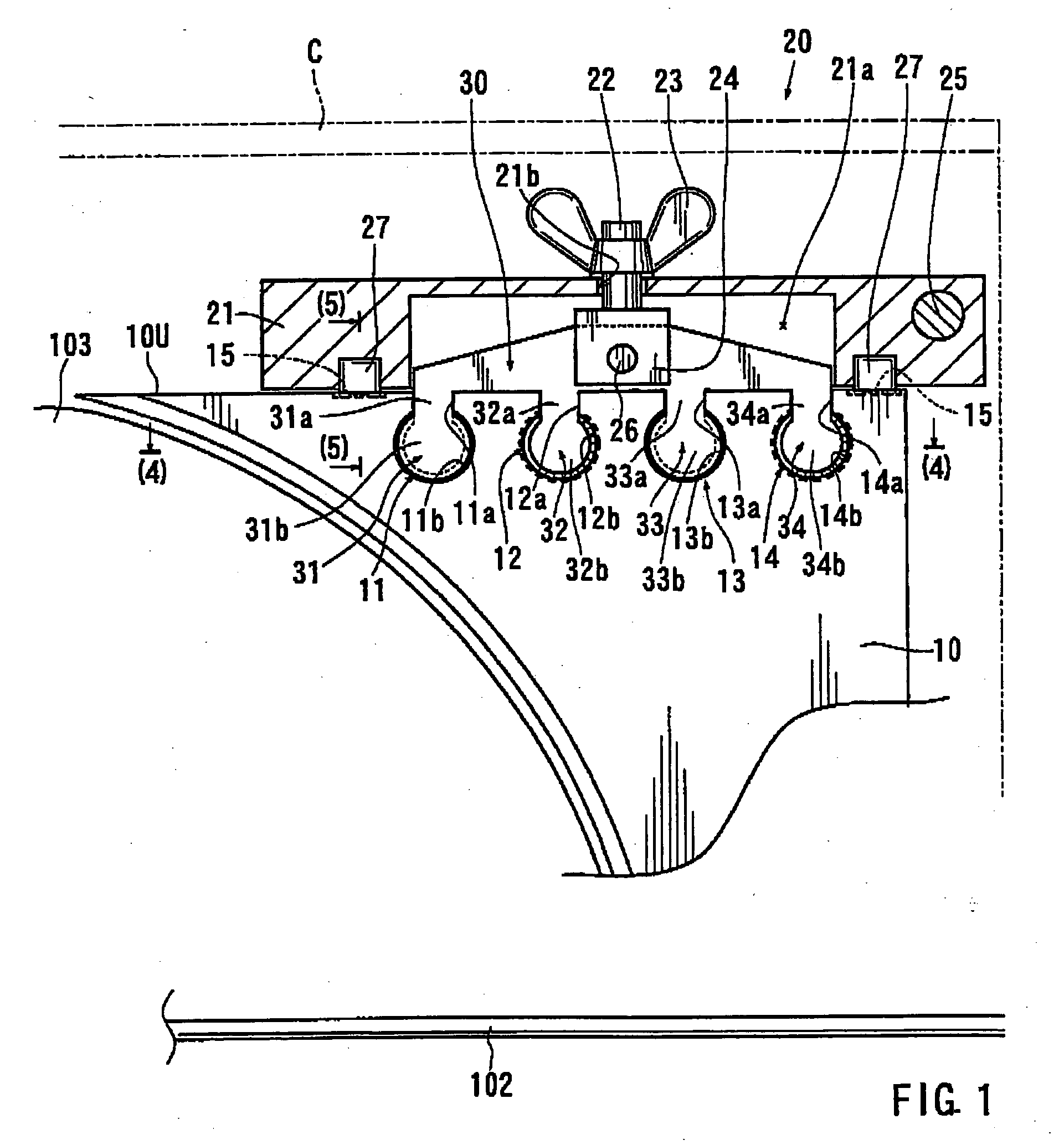

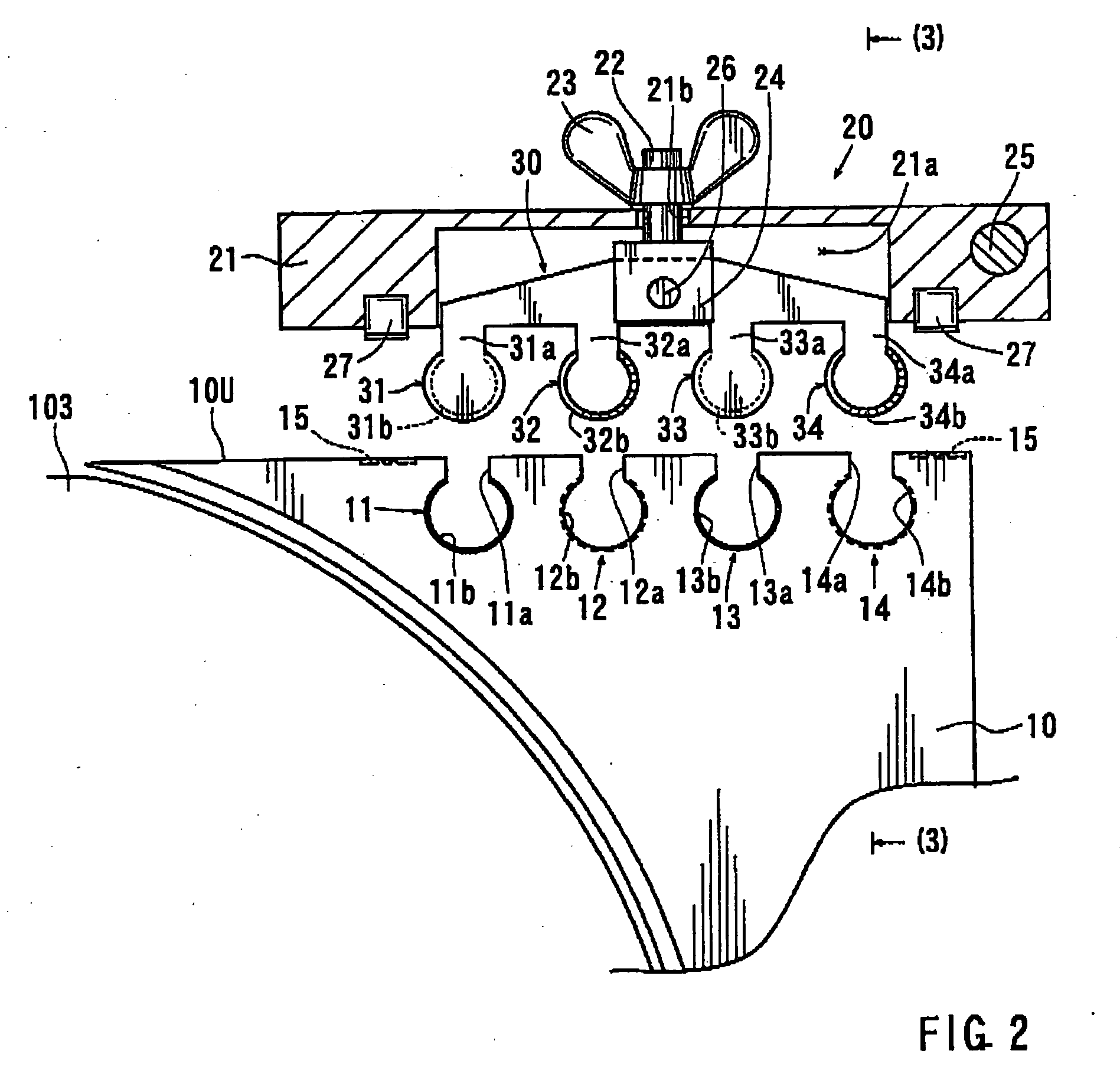

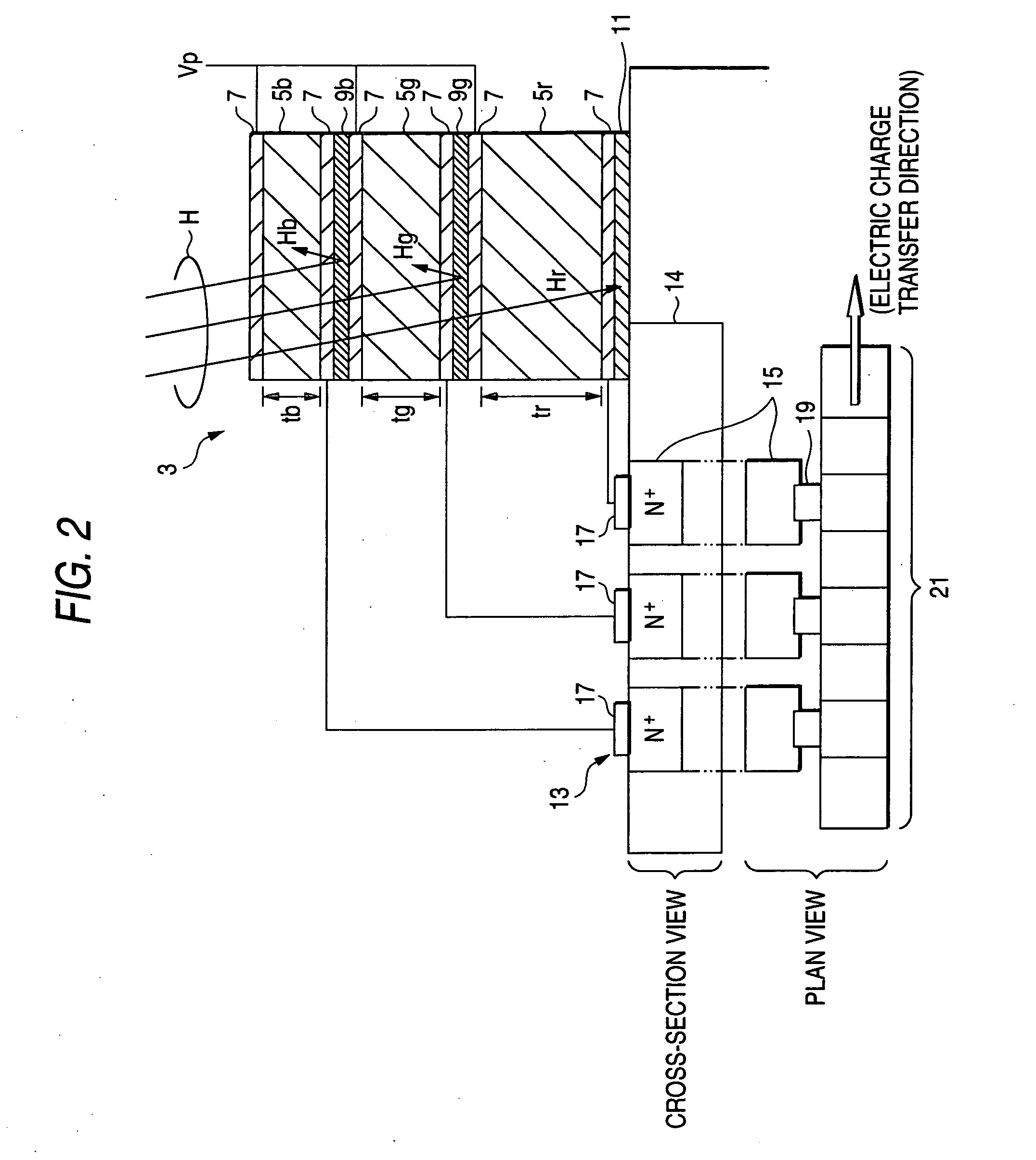

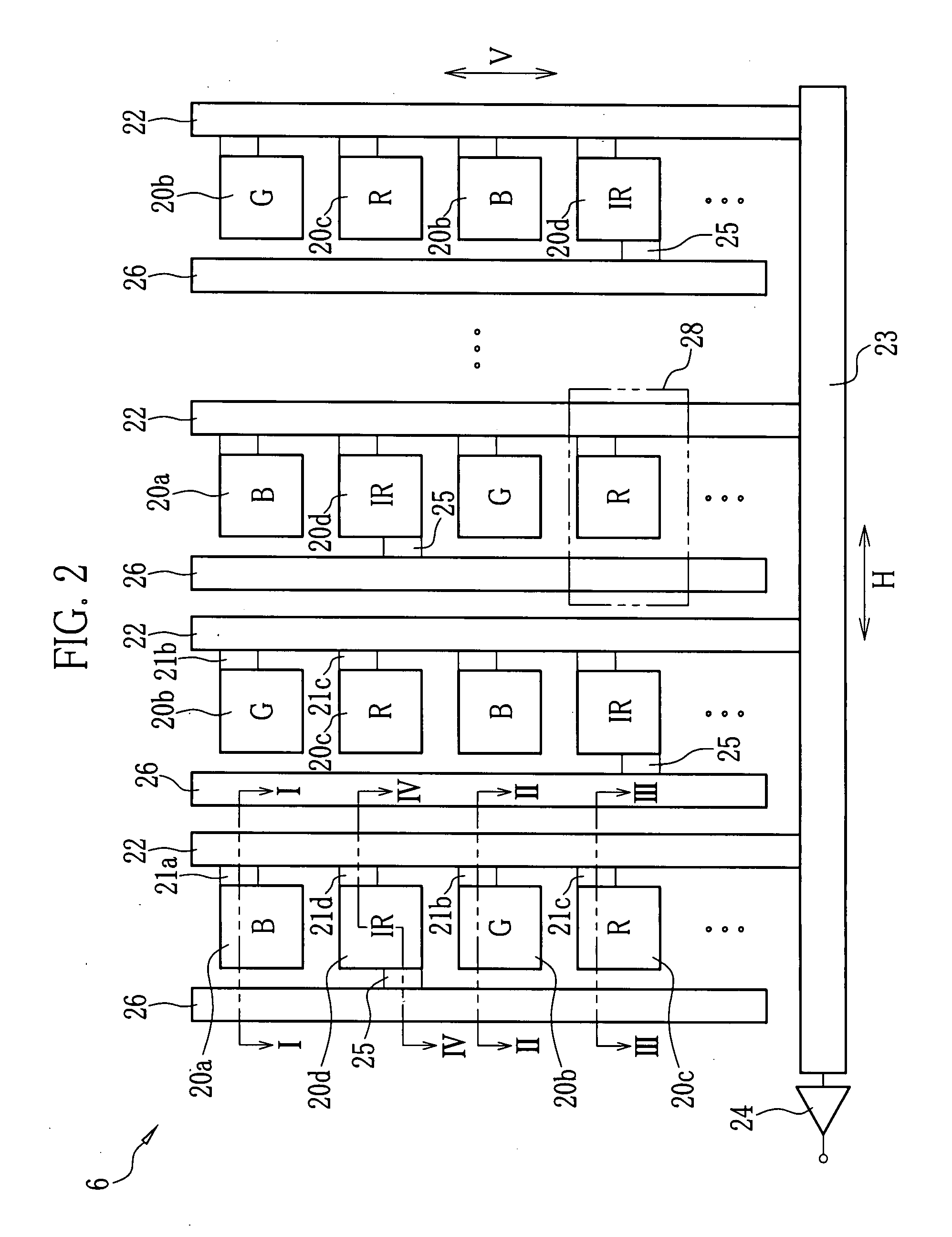

Color imaging apparatus

ActiveUS20120293695A1Accurate estimateSuppress generationTelevision system detailsTelevision system scanning detailsColor imageAverage filter

A color imaging apparatus comprising: a single-plate color imaging element including color filters arranged on pixels arranged in horizontal and vertical directions where all colors are arranged in each line in the directions; weighted average filters with filter coefficients set in a local area extracted from a mosaic image acquired from the color imaging element corresponding to the weighted average filters so that proportions of sums of the filter coefficients of each color in the lines in the horizontal and vertical directions are equal; a weighted average calculation unit that calculates weighted average values of each color; a demosaicking processing unit that calculates a pixel value of another color at a pixel position of a target pixel of demosaicking processing and that interpolates a pixel value of the target pixel based on a color ratio or a color difference of the calculated weighted average values to calculate the pixel value.

Owner:FUJIFILM CORP

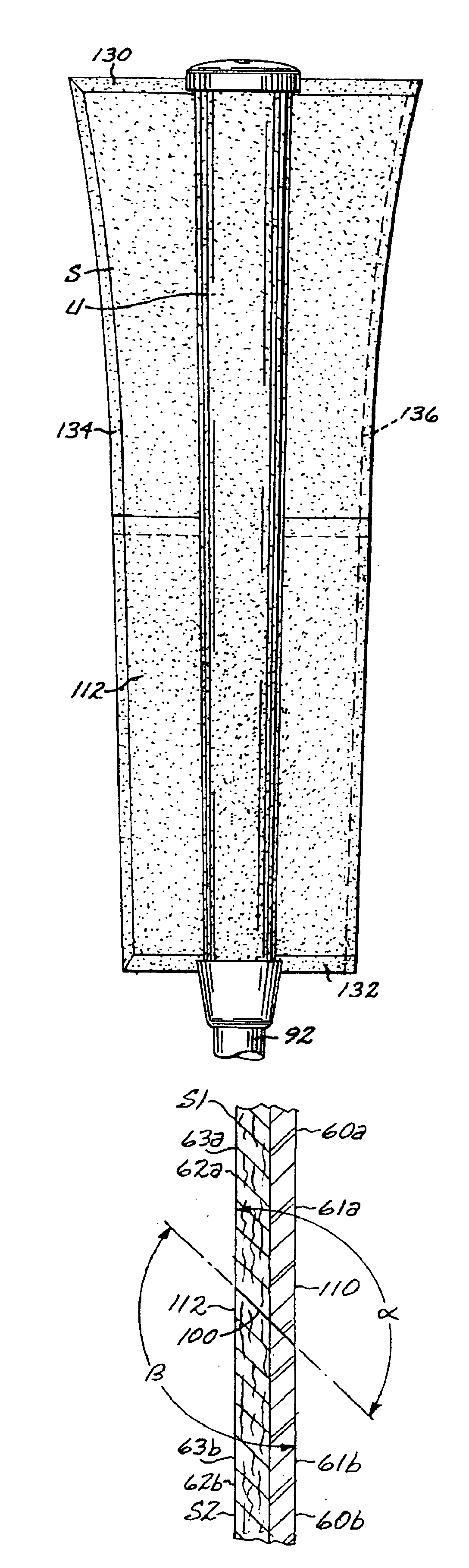

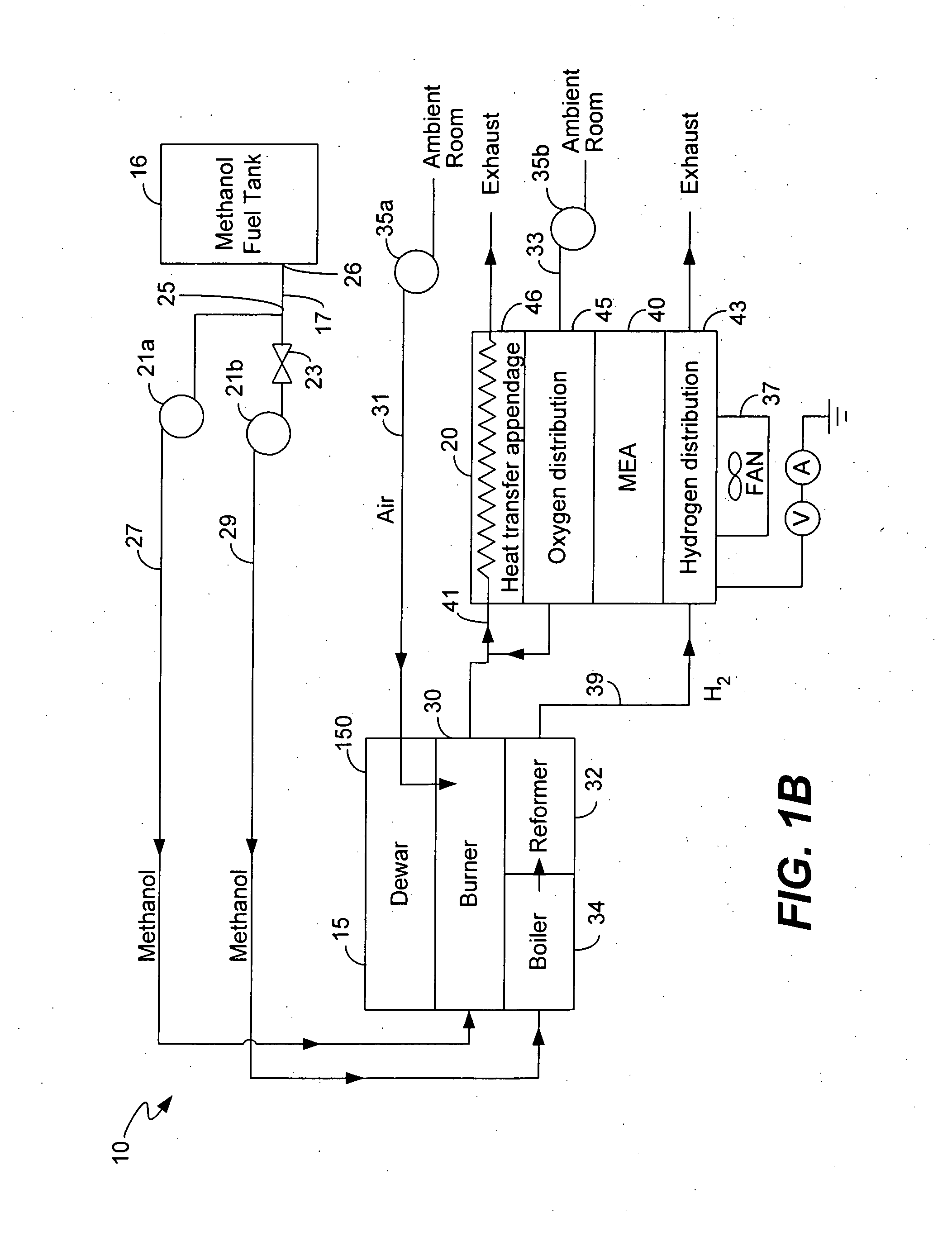

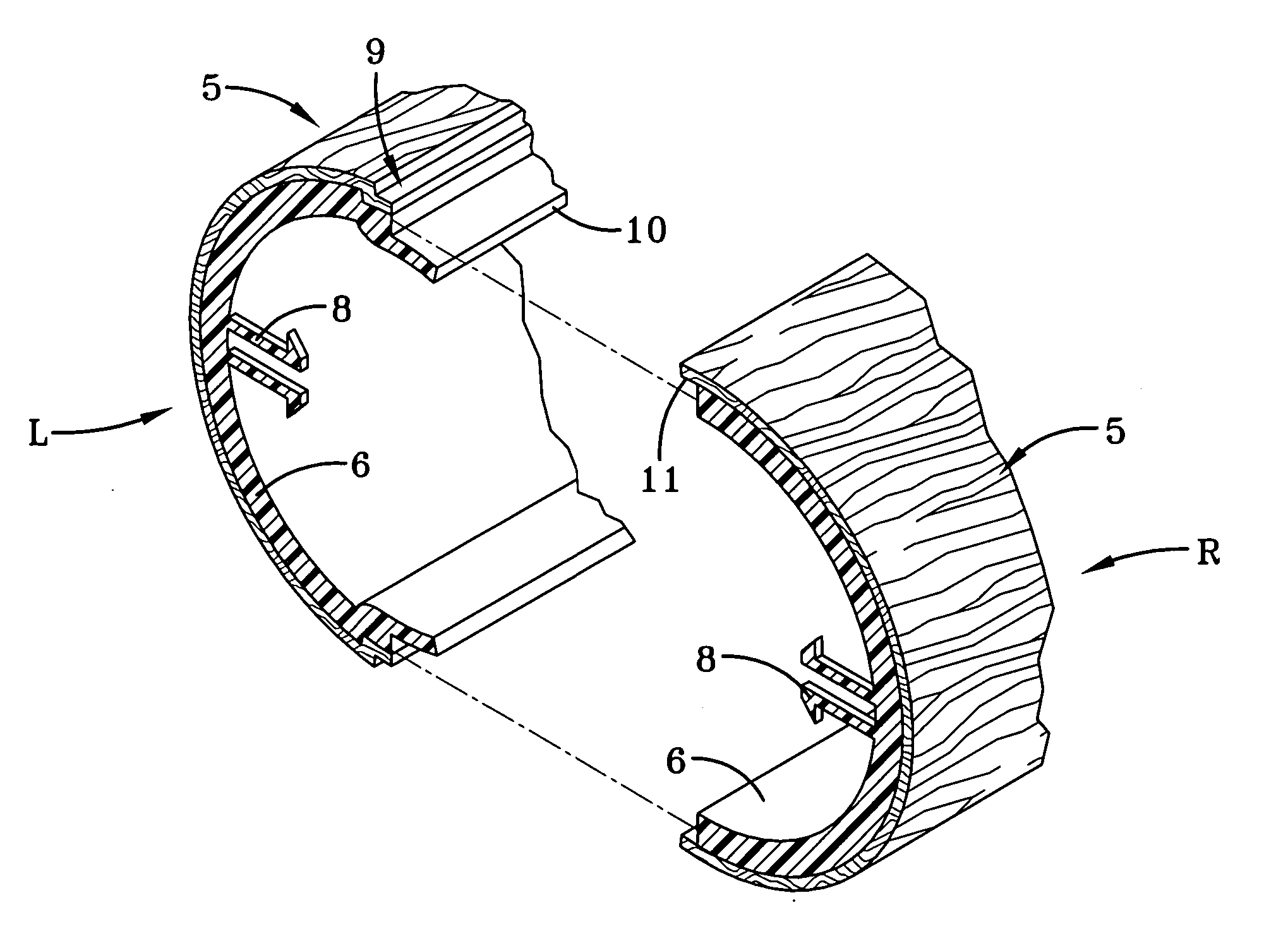

Multi-segment single panel grip

ActiveUS6843732B1Same resistance to shockOvercome disadvantagesWallsSynthetic resin layered productsSingle plateEngineering

A grip for the handle of a golf club having multiple two layer panels that are wrapped about an underlisting sleeve. The edges of the panels are adhesively sealed together. The grip reduces impact and shock and provides a feeling of tackiness in the manner of a spirally wrapped polyurethane-felt grip while allowing the use of multiple color panels and easy instillation onto a golf club shaft.

Owner:WINN INC

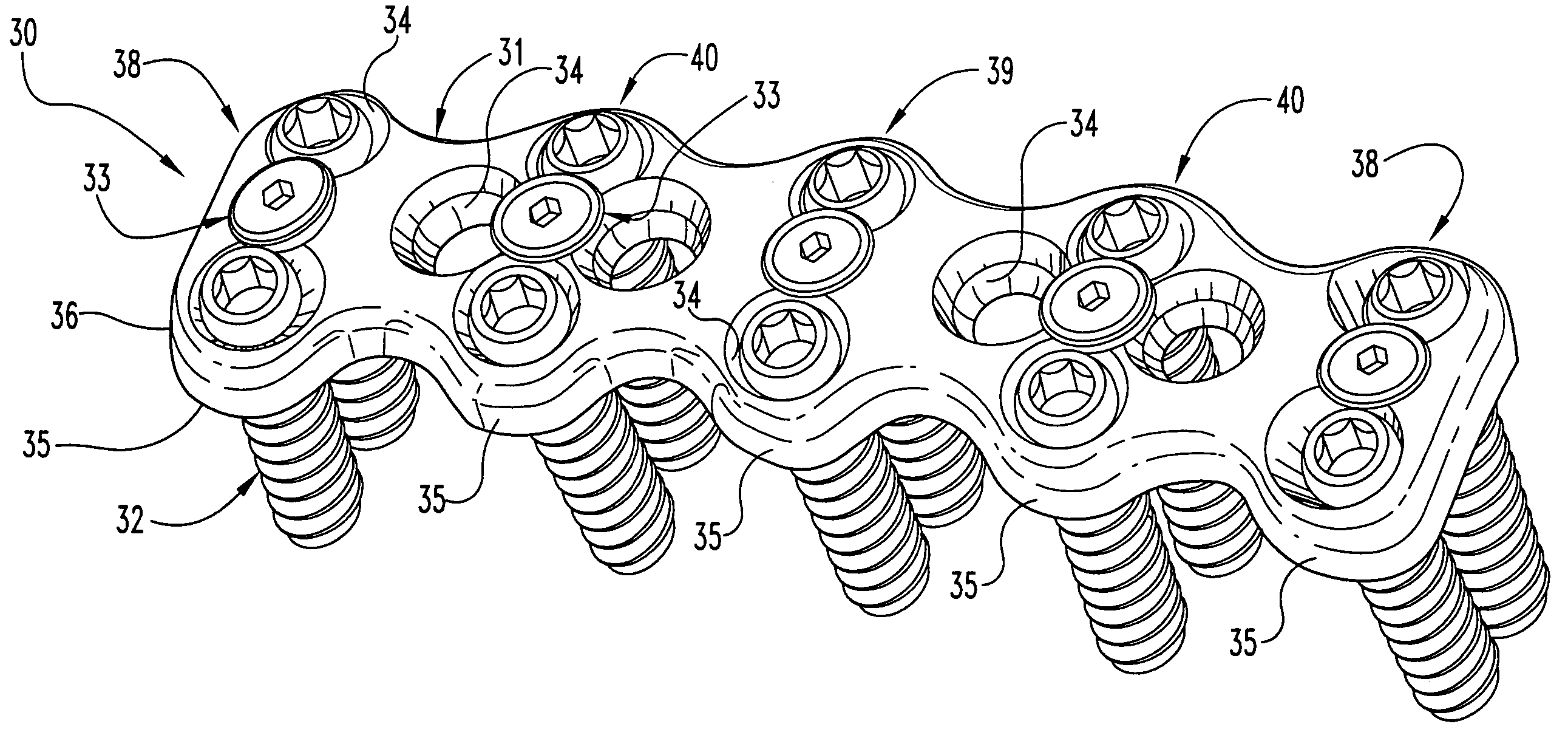

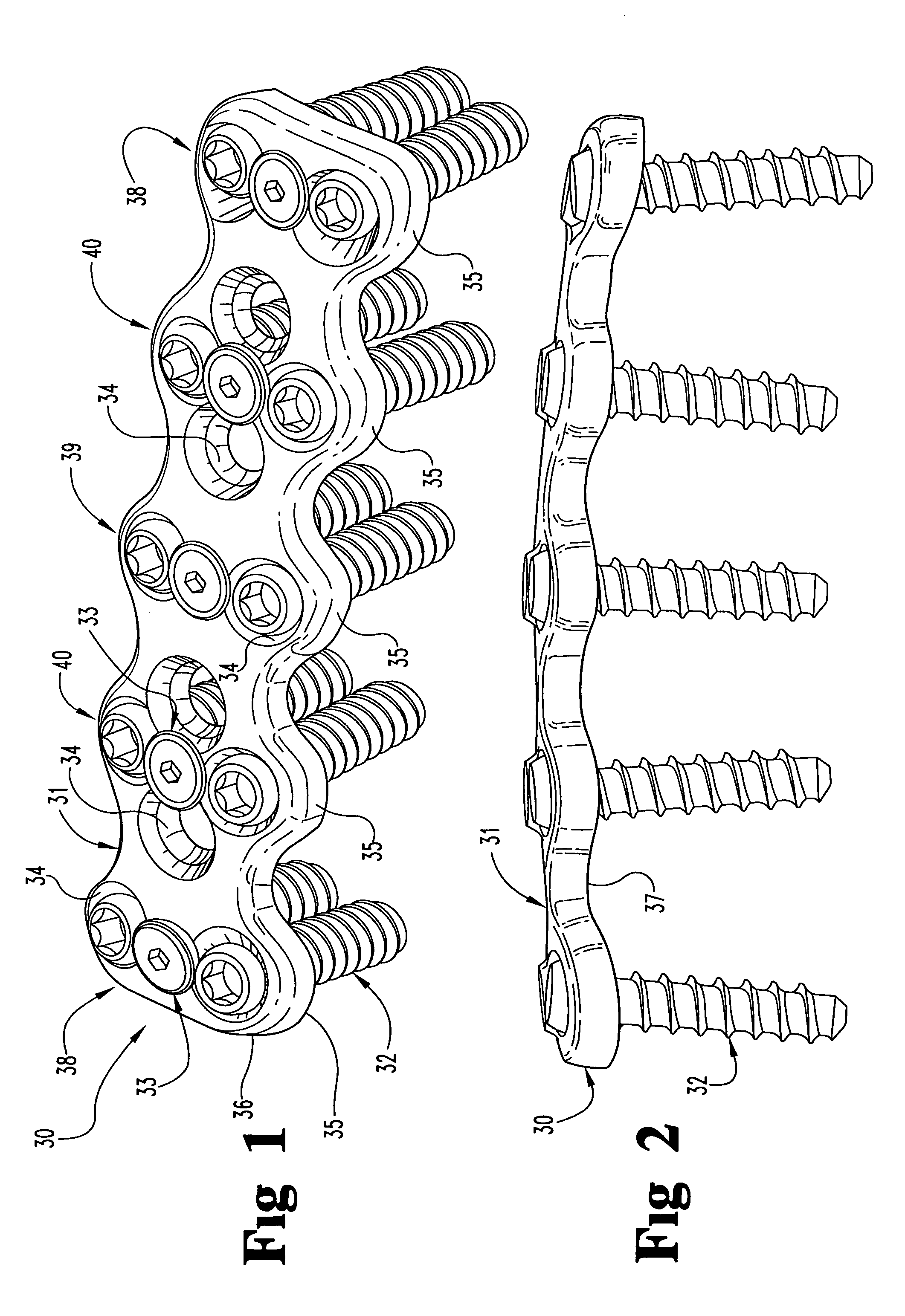

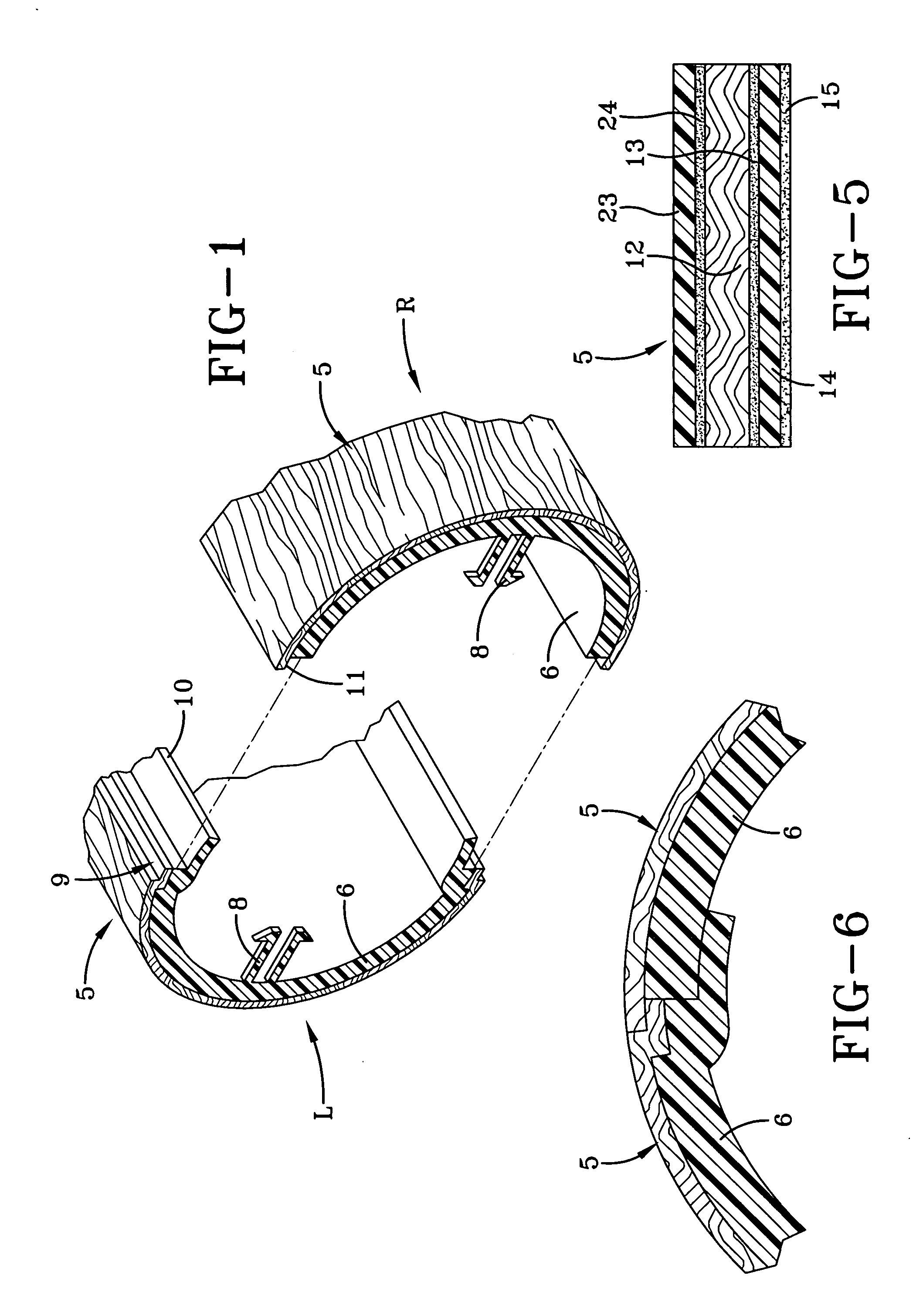

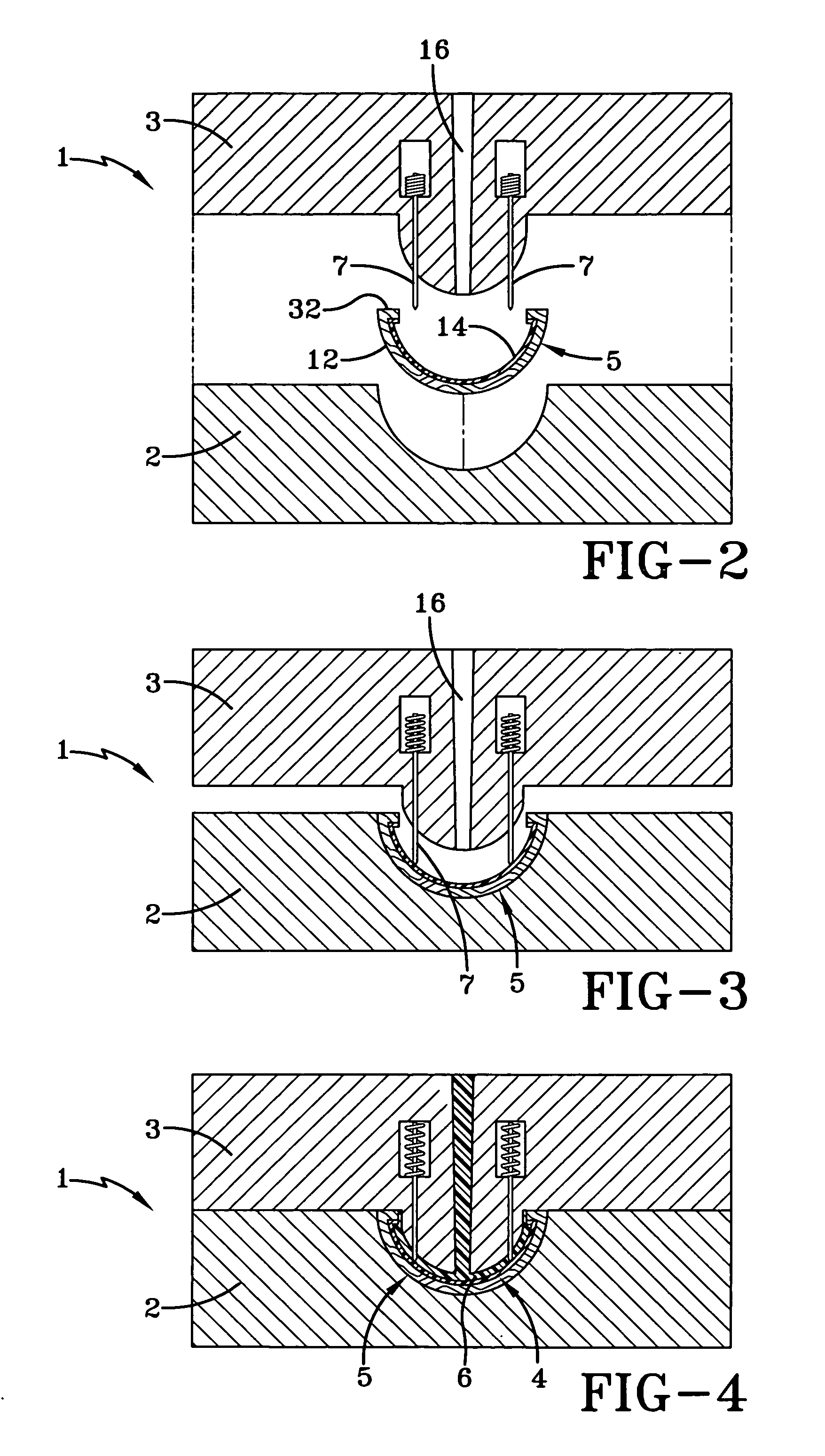

Anterior cervical plating system

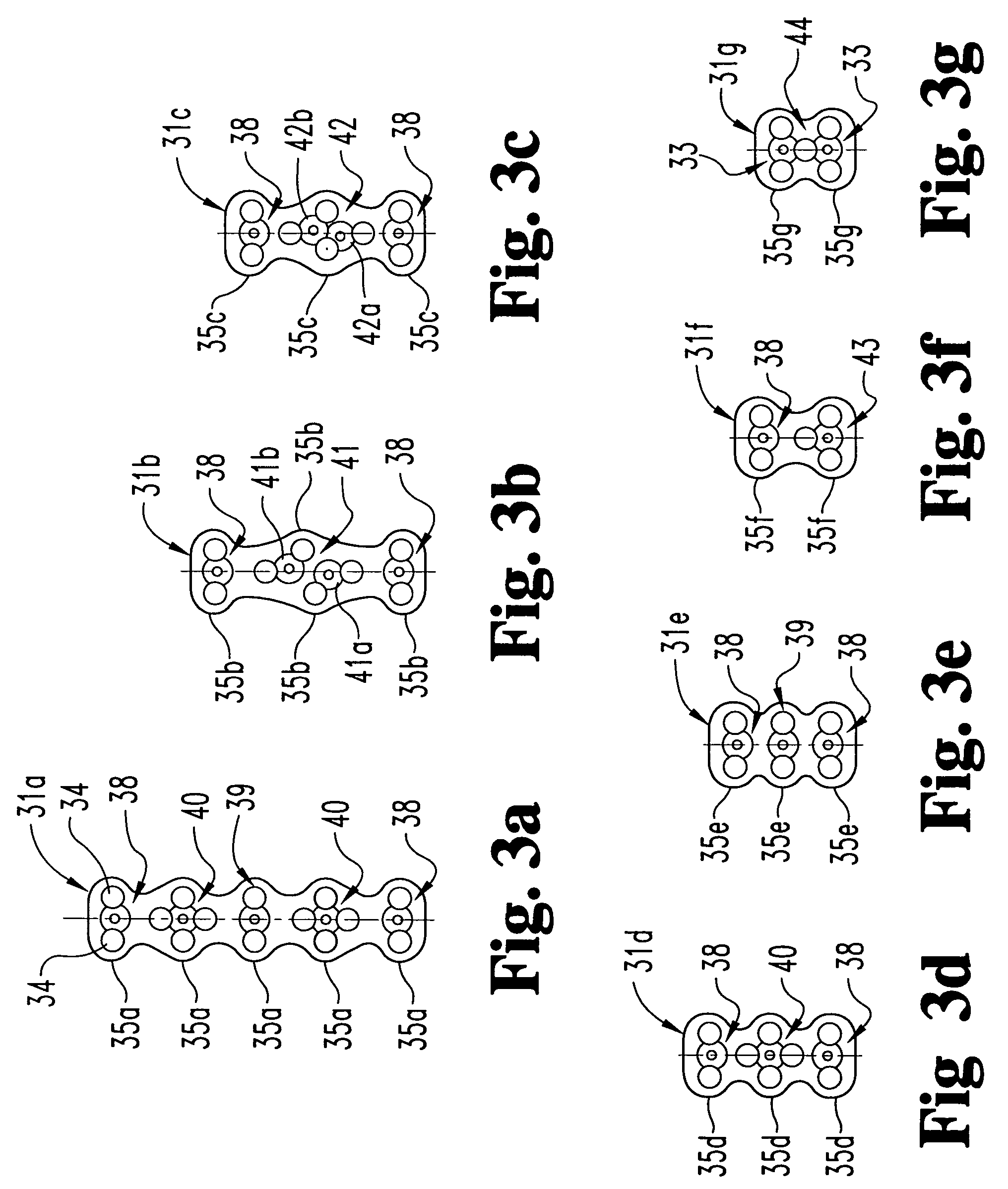

In one embodiment of the invention, an anterior fixation system includes a plate defining a plurality of screw holes, a number of screws and a number of locking assemblies for fixing the screws to the plate. The system includes two bone screws a fixed angle screw and a variable angle screw, that are configured to extend through the same screw openings in the fixation plate. The surgeon can select either the fixed or variable angled screws to be implanted with a single plate and can place either type of screw into any of the screw holes along the plate. The fixation plate according to the invention can include several screw holes in various patterns that provide the surgeon with great flexibility in the placement of bone screws depending upon the spinal anatomy and pathology. The invention further contemplates a locking assembly to lock one or more bone screws within a respective screw hole. In one embodiment, the locking assembly includes a washer that is held to the plate by a staked locking screw. The washer includes an outer surface that overlaps one or more screw holes. The washer is initially loosely held to the plate by the locking screw so that various tools and bone screws can be passed through the screw holes. In one embodiment of the washer, the washer includes cut-outs corresponding to the screw holes, along with a notch and key configuration for setting the locking washer in its locked configuration.

Owner:SDGI HLDG

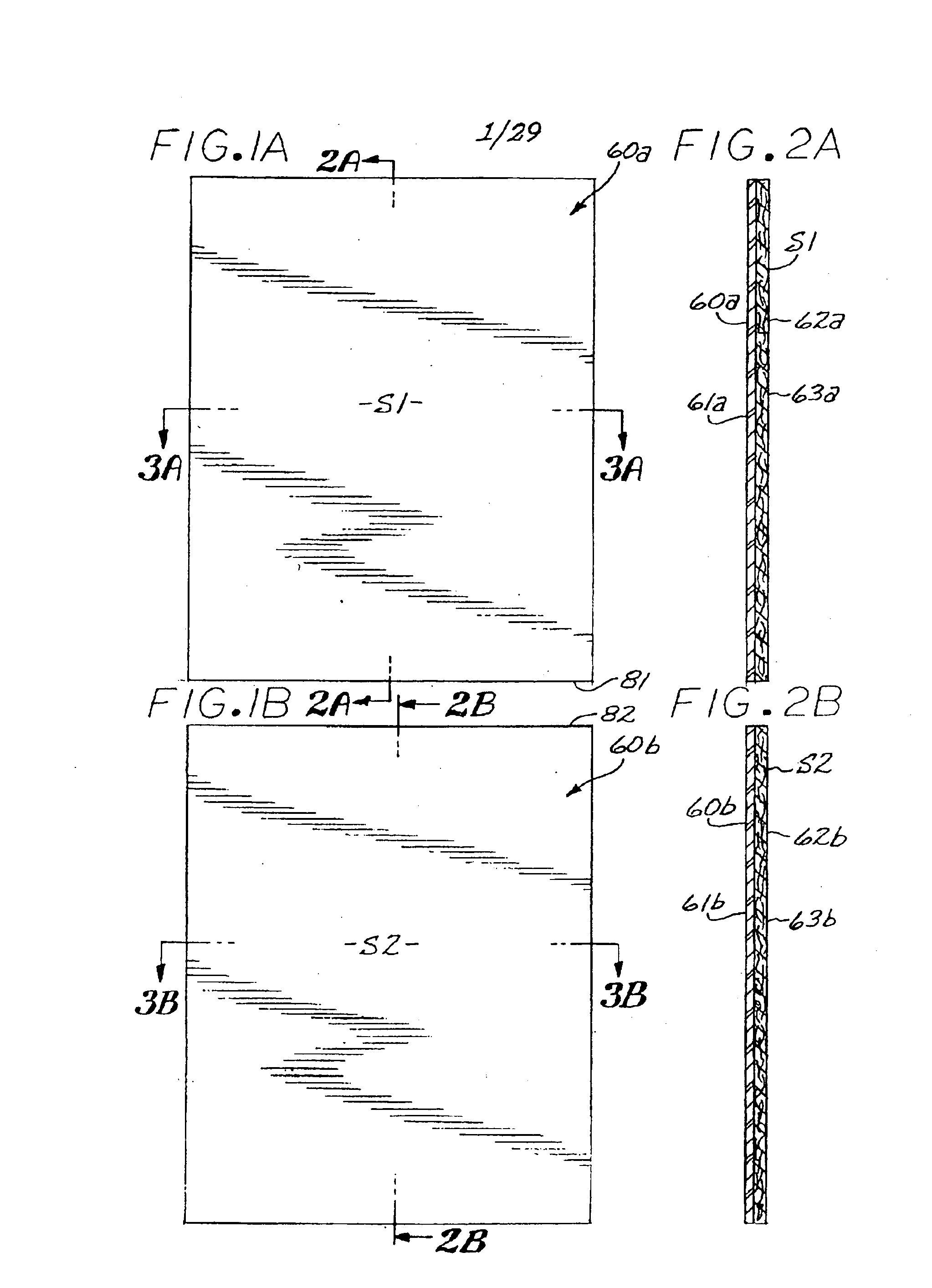

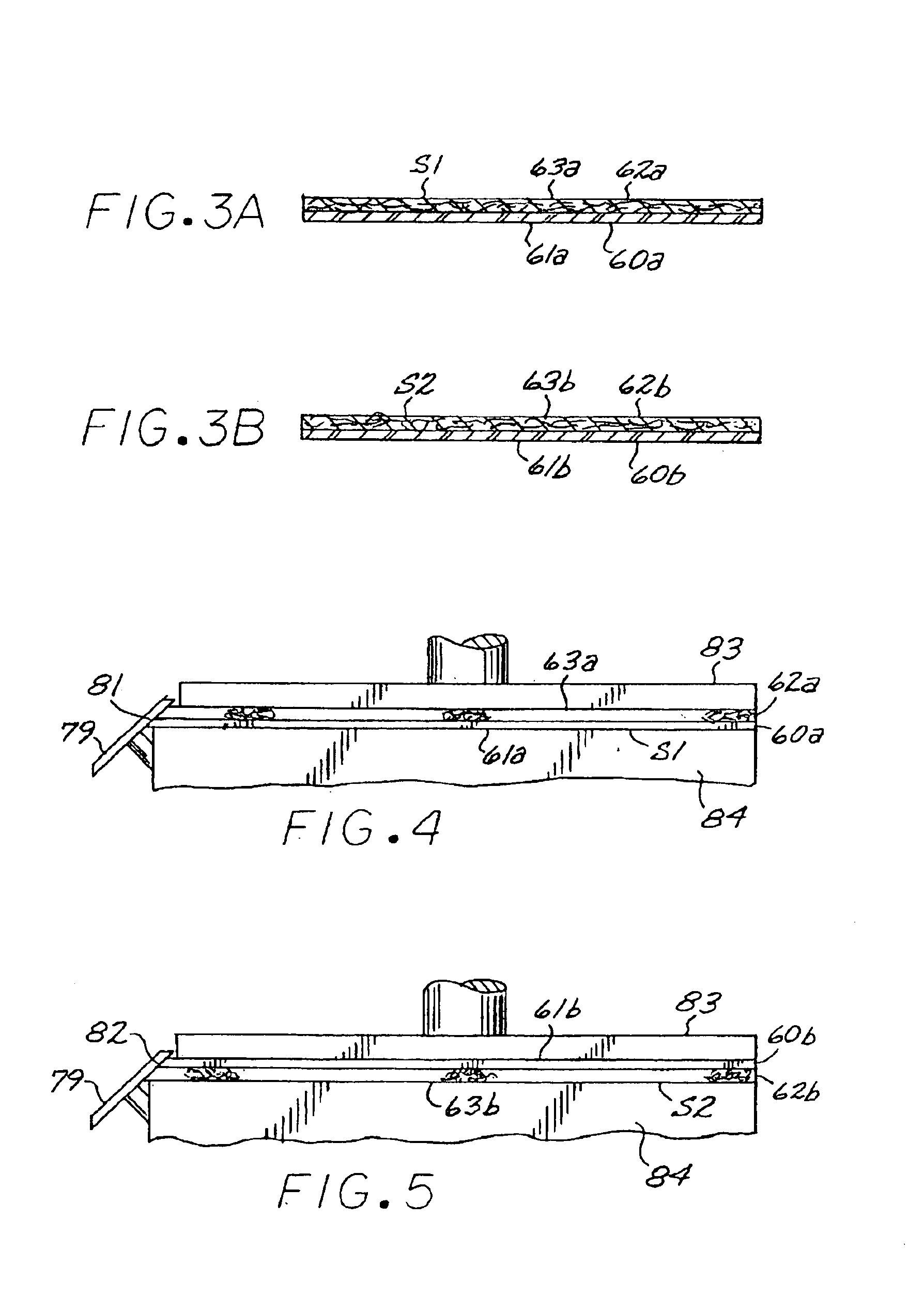

Single automatic document feeder sensor for media leading edge and top cover being opened detection

InactiveUS7139108B2Low costReduce the numberSolid-state devicesMaterial analysis by optical meansLeading edgeSingle plate

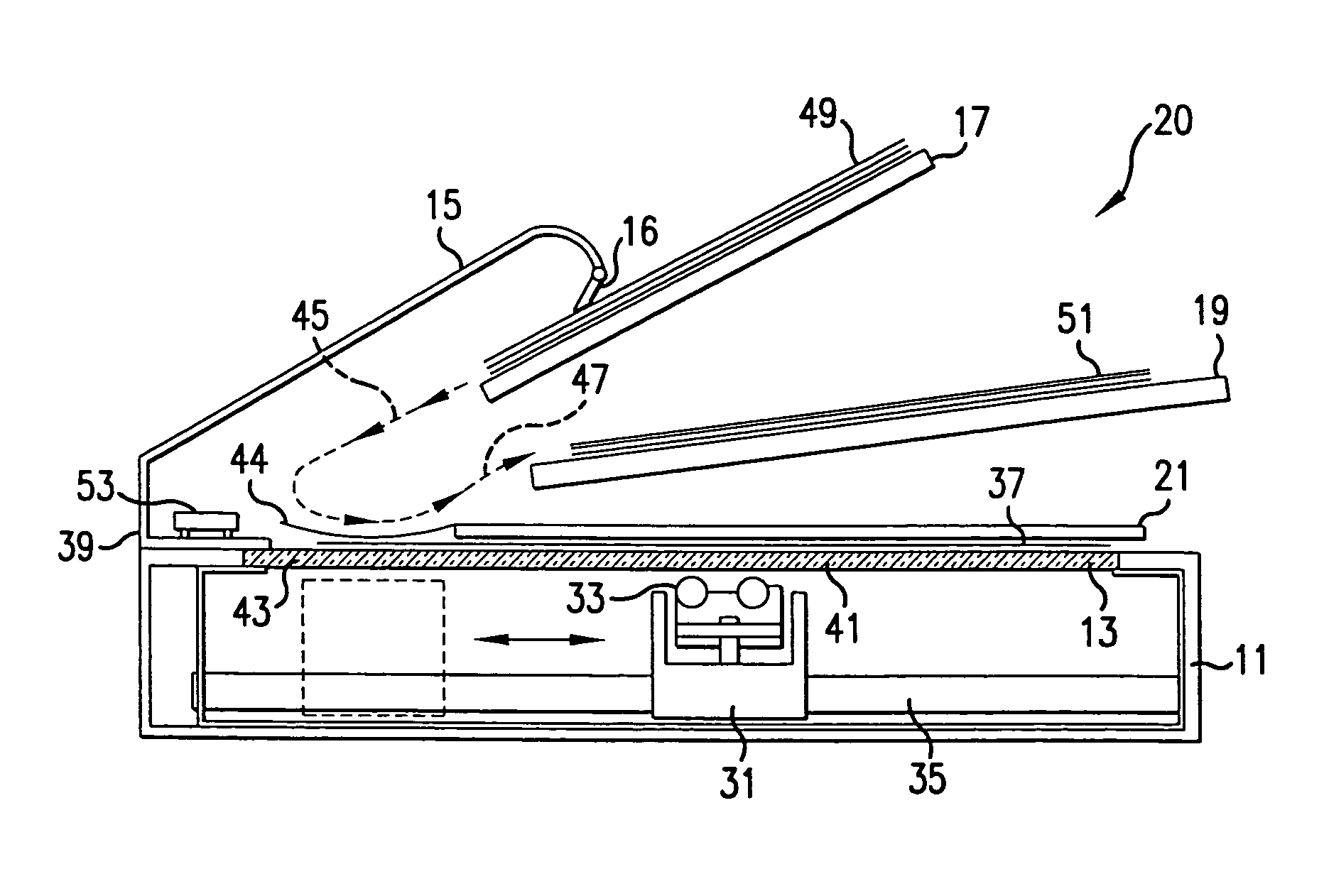

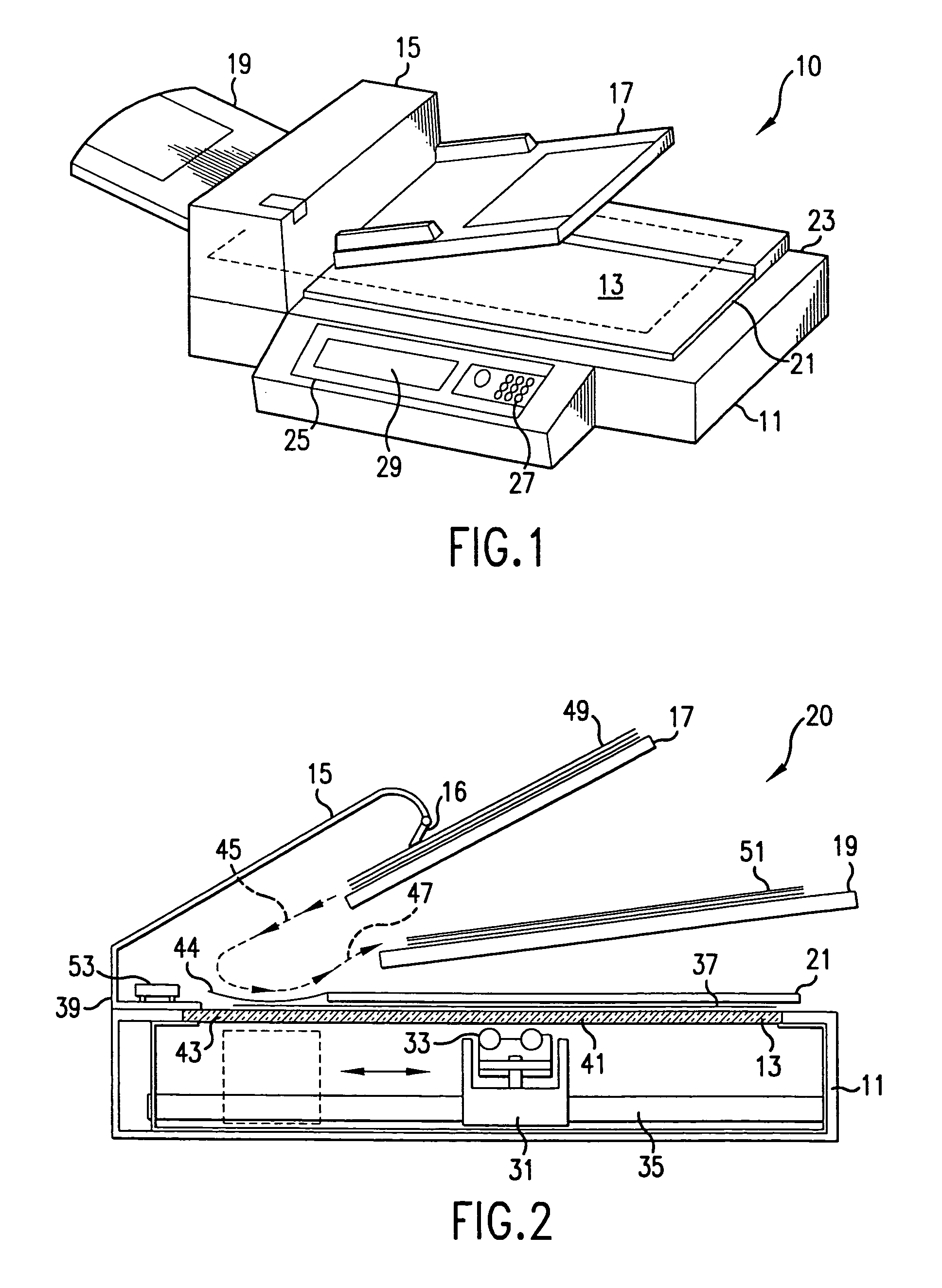

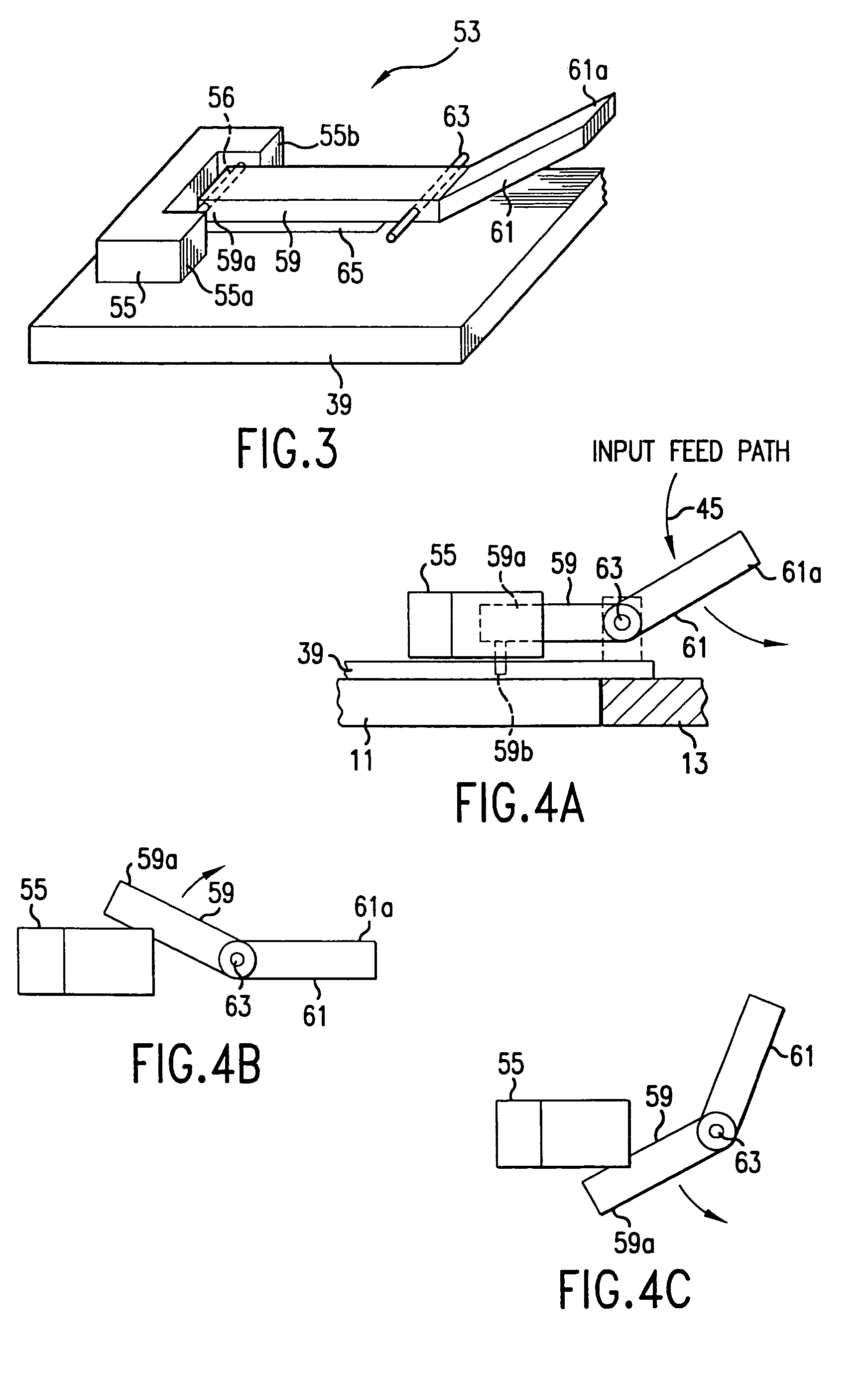

A single plate flatbed scanner utilizing a single sensor to detect both opening of a lid covering the plate and the leading edge of an automatically fed document. The flatbed scanner includes a contact glass plate defining a flatbed scanning area where a document to be scanned may be manually positioned. An automatic document feeder (ADF) scan window where ADF-fed documents are scanned is defined within the flatbed scanning area. An image sensor is maintained at a fixed position in the ADF scan window while scanning ADF-fed documents. To scan a manually fed document, the image sensor moves under the flatbed scanning area so as to scan an image of the document. Since the ADF scan window and the flatbed scanning area both are defined in the same area of the contact glass plate, a document inadvertently left on the contact glass blocks the ADF scan window and prevents the scanning of an ADF fed document. A single sensor is utilized to detect the opening of the ADF which uncovers the contact glass to allow manual placement of a document. Detecting the opening of the glass plate cover is used to determine whether or not a document has been left on the glass plate after scanning. The same sensor is also utilized to detect the leading edge of an ADF fed document to initiate the scanning process at the precise time the document reaches the ADF scan window.

Owner:HEWLETT PACKARD DEV CO LP

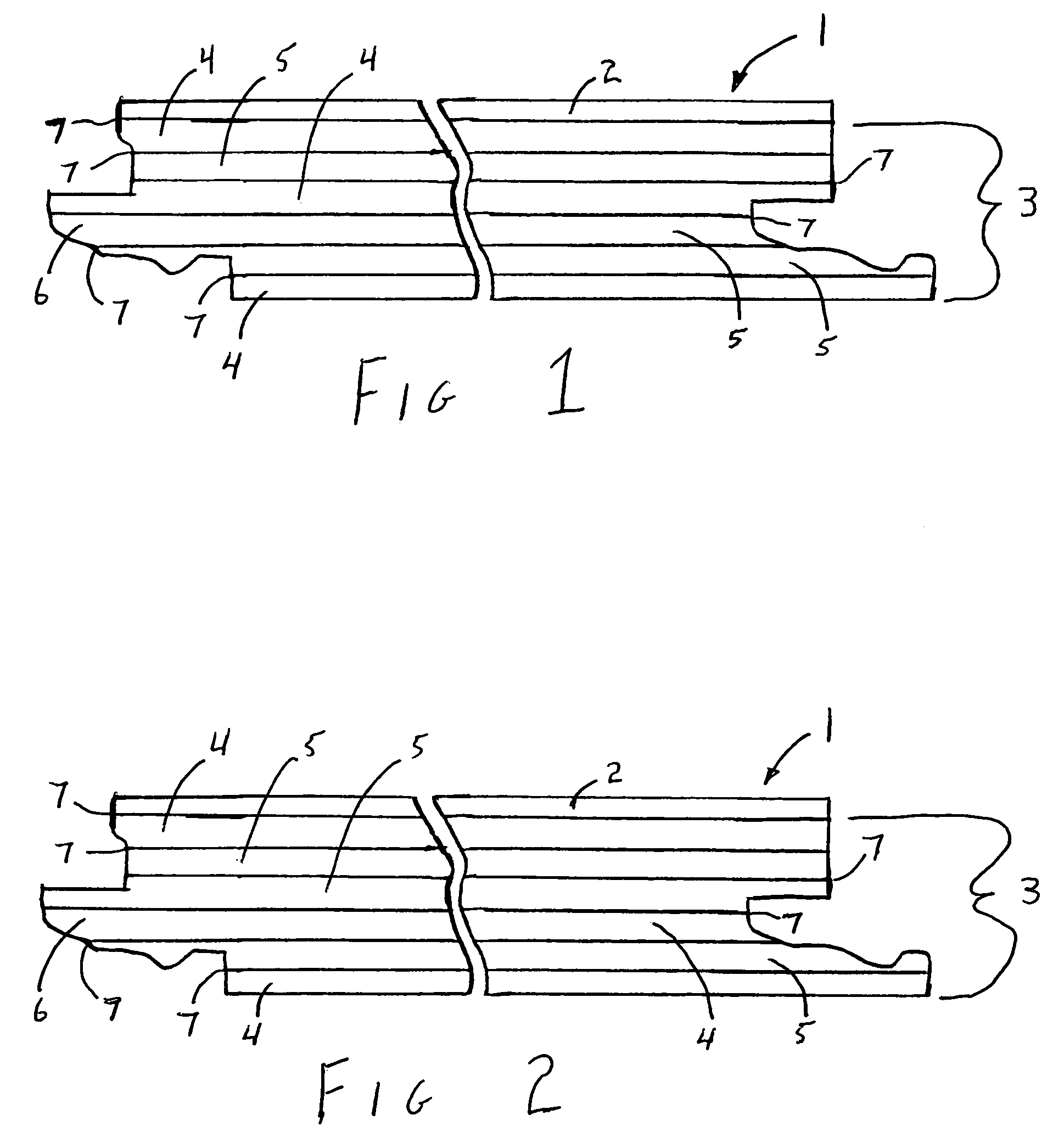

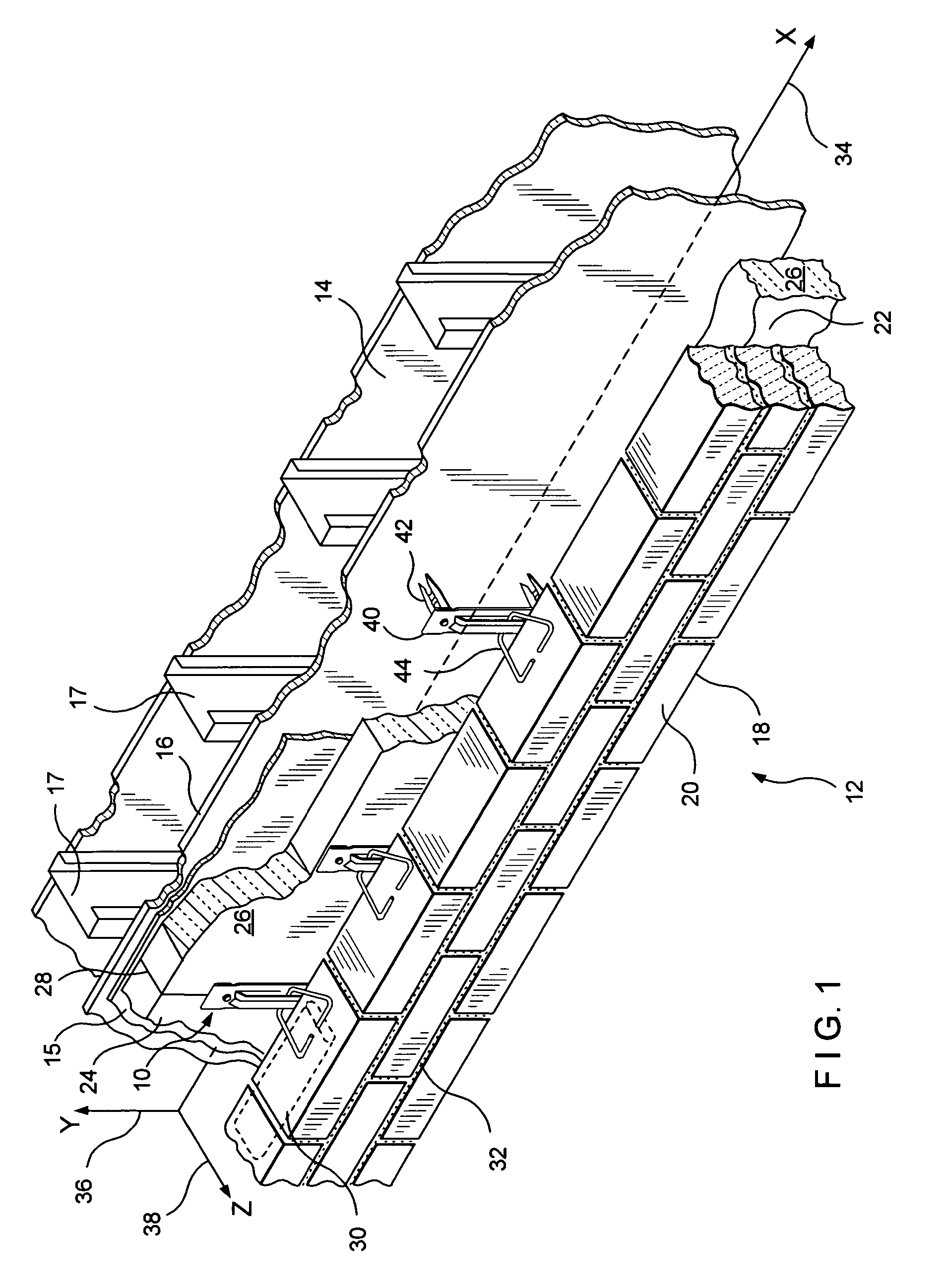

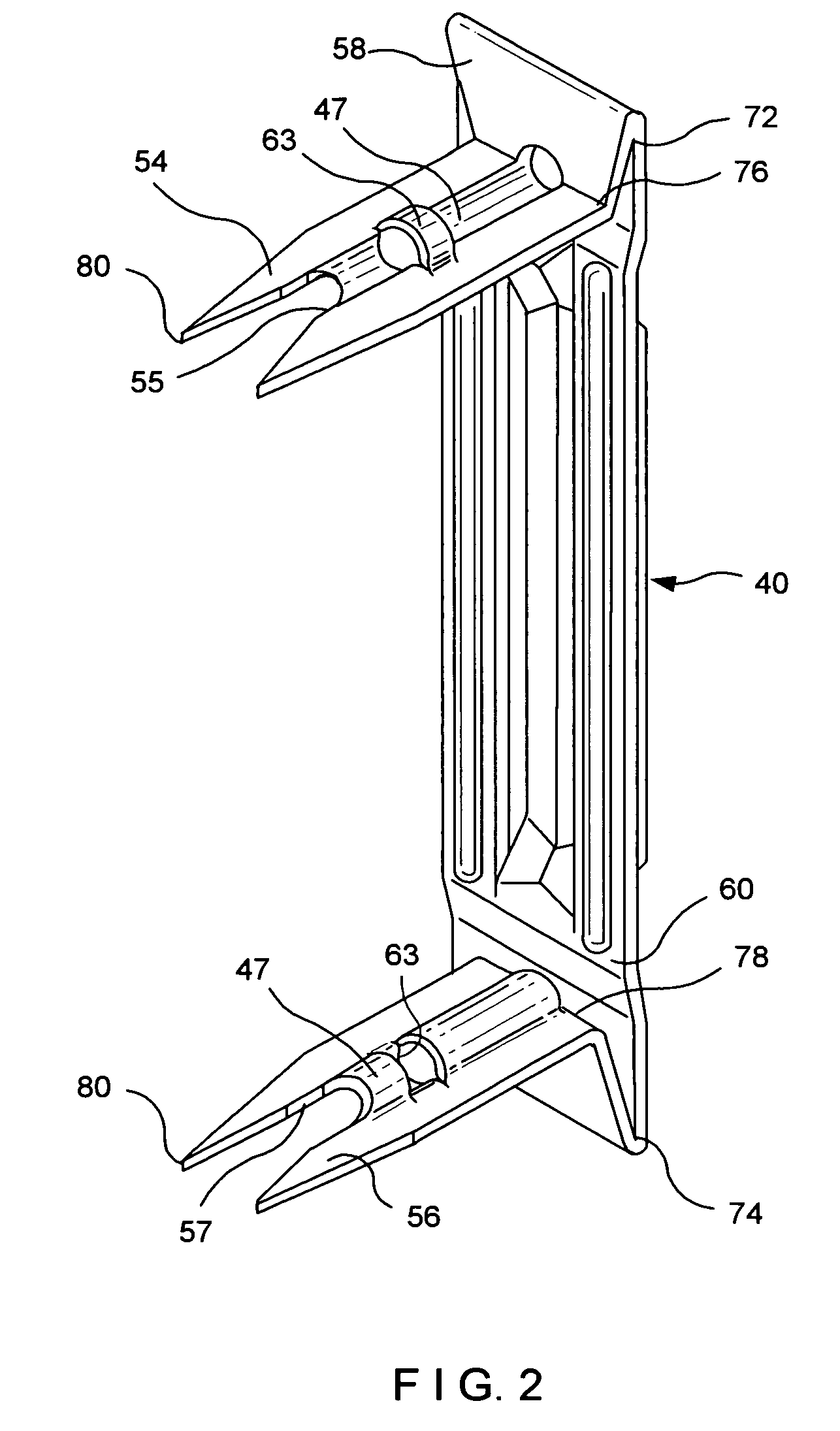

Mountings for riving knives of table saws

ActiveUS20050211034A1Easy to implementEasy to operateMetal sawing devicesGuide fencesSingle plateEngineering

A device for mounting a cover of a cutting blade to a riving knife may have an engaging member for releasably engaging at least a part of the riving knife from both sides, in a direction of thickness of the riving knife. The engaging member is manually operable without any additional tools. A device for mounting a riving knife to a table saw may include a manually operable lock member and a biasing member. The biasing member is arranged and constructed to normally bias the lock member towards a lock position. The riving knife may be divided into a first knife portion and a second knife portion. A positioning device may position the first knife portion and the second knife portion substantially within a single plate.

Owner:MAKITA CORP

Wood adhesive and method of preparing thereof

InactiveUS20100258033A1Drying rate of adhesiveLow pour pointProtein waste adhesivesStarch adhesivesHigh densityAdhesive

A wood adhesive having a) 100 weight parts of water; b) between 3 and 45 weight parts of a proteinaceous material; c) between 0.01 and 15 weight parts of an acidity regulator; d) between 0.01 and 15 weight parts of an aromatic compound; e) between 0.01 and 15 weight parts of a curing agent; f) between 0.01 and 15 weight parts of a preservative; g) between 0 and 15 weight parts of a viscosity modifier; h) between 0 and 10 weight parts of a filler; and i) between 0 and 15 weight parts of a drier. The wood adhesive can be used for preparation of plywood, blockboard, oriented strand board (OSB), flakeboard, fiberboard, veneer plywood, middle density fibreboard, high density fibreboard, hardboard, flooring substrate, LVL, and so on. A method for preparing the wood adhesive is also provided.

Owner:YANG GUANG +1

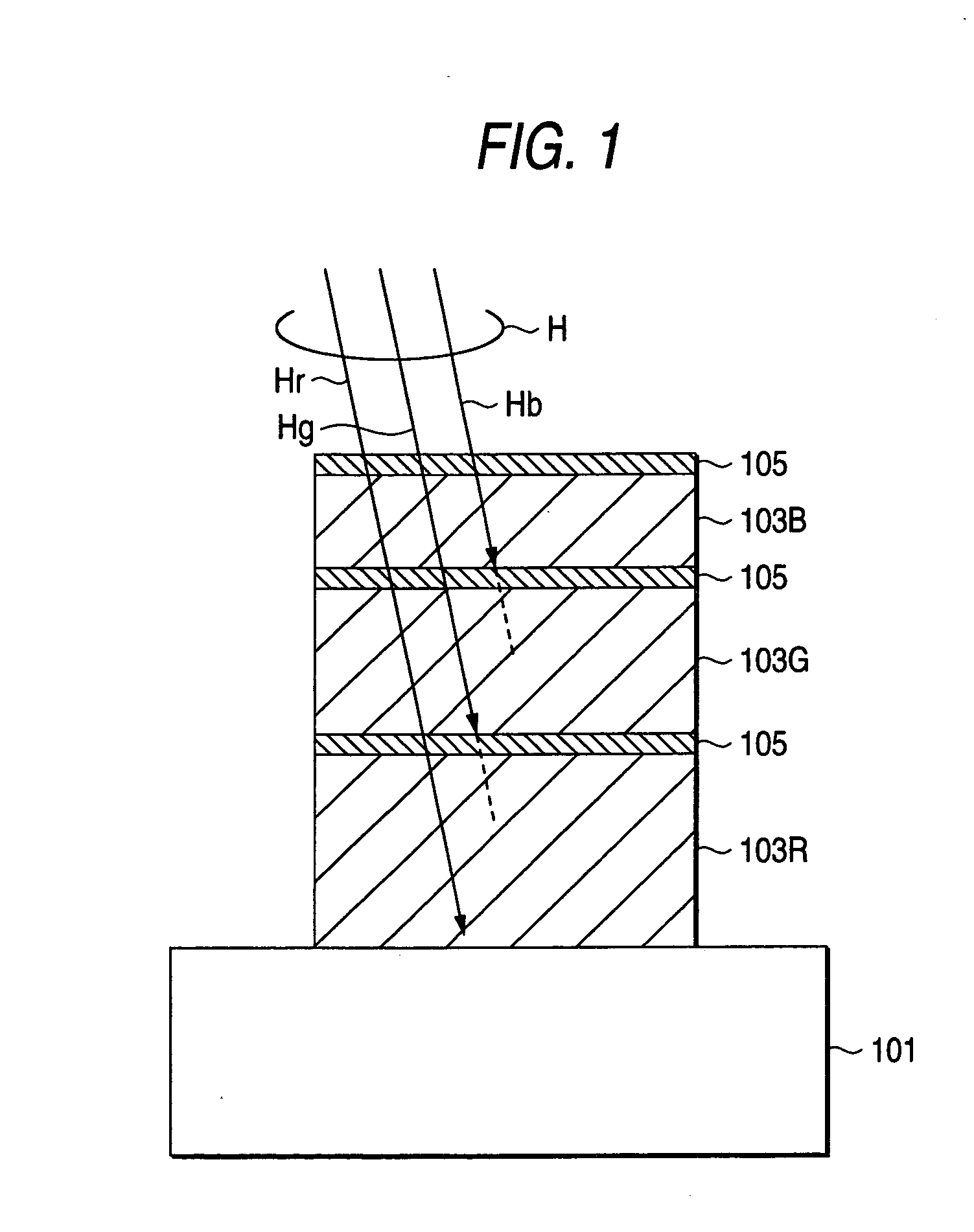

Strengthened, light weight wallboard and method and apparatus for making the same

InactiveUS6319312B1Easy to optimizeReduce amountConstruction materialCeramic shaping plantsSingle plateFlexural strength

A novel wallboard composition is disclosed comprising a unique combination of synthetic binders selected for their ability to establish a strengthened permanent bond in the final dry state for use in a wallboard composition comprising primarily gypsum, and in a wallboard composition comprising an expanded mineral such as Perlite which largely reduces the amount of gypsum over current gypsum wallboard formulations, thus reducing the weight while maintaining the strength of the wallboard structure. In a preferred embodiment, the lightweight, strengthened wallboard of the present invention also comprises an optional covering veneer that is applied to the top ply of the face paper to provide increased strength, moisture resistance, and fire retardency, and the back paper top ply is treated to provide increased flexural strength. Additionally, this invention relates to the unique manufacturing process to produce the wallboard composition of the present invention in order to create a lightweight, strengthened, moisture resistant, and fire retardant wallboard used to cover walls and ceilings in construction applications. Still further, this invention relates to the apparatus for manufacturing the wallboard composition of the present invention, including a method and apparatus for economically converting a standard gypsum wallboard manufacturing facility into a facility for manufacturing wallboard of the present invention.

Owner:INNOVATIVE TECH ENTERPRISES

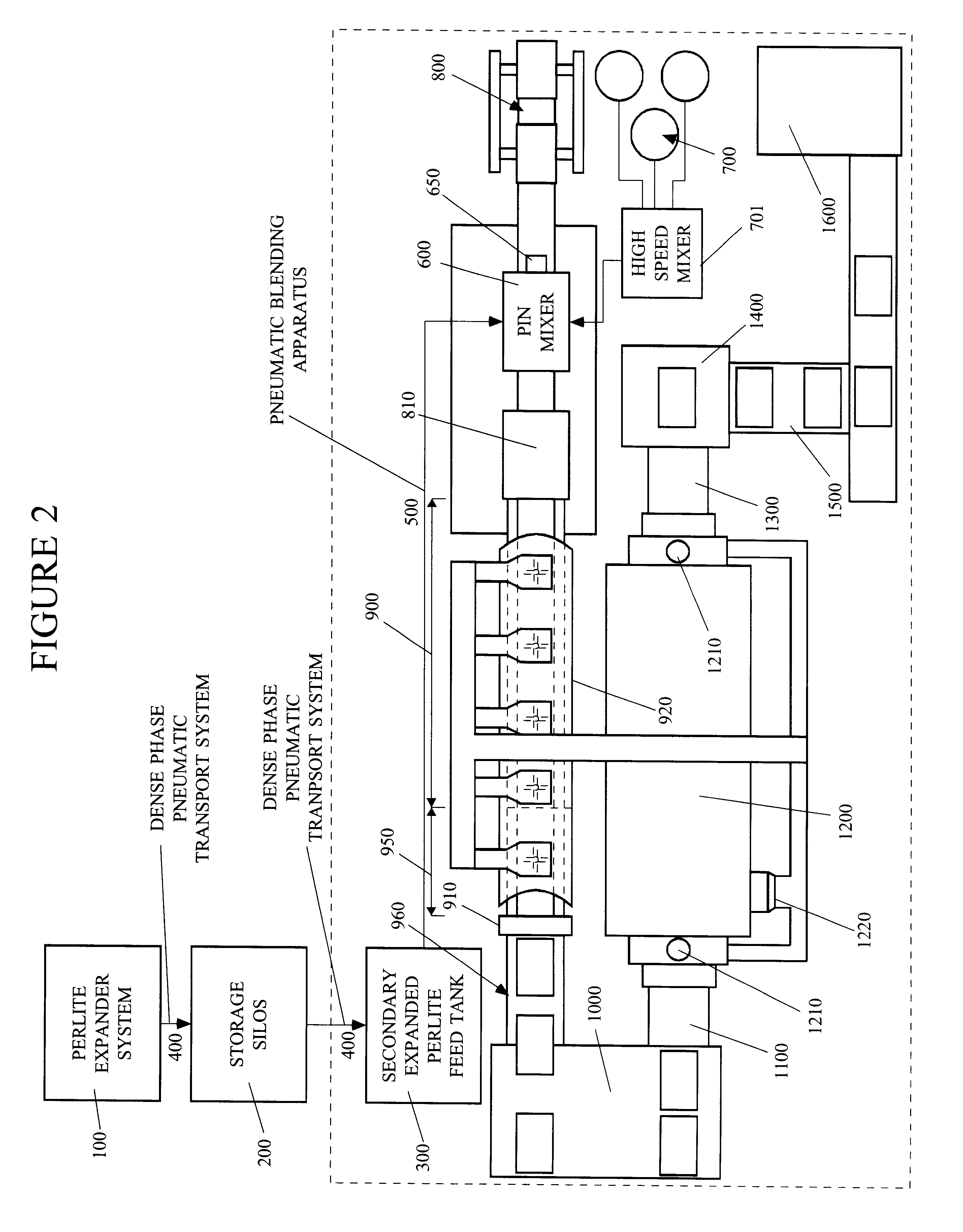

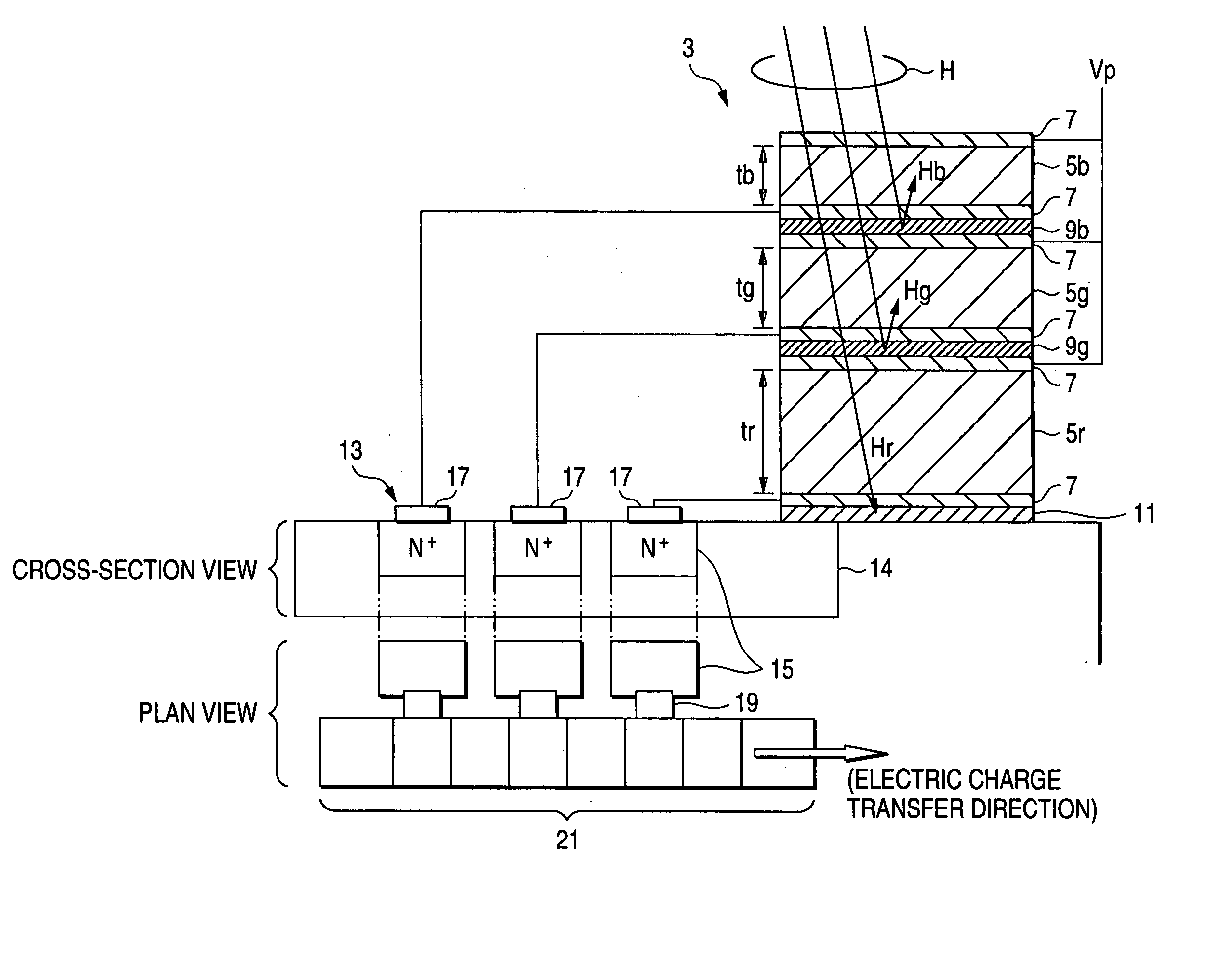

Solid-state imaging device

ActiveUS20040259010A1High color resolutionHigh sensitivityTelevision system detailsSolid-state devicesImage resolutionSingle plate

A solid-state imaging device including a substrate corresponding to a pixel. The substrate carries thereon a light receiving section, which is a stack of, in this order, a photoconductive layer for absorbing light in a wavelength region for red, a photoconductive layer for absorbing light in a wavelength region for green, and a photoconductive layer for absorbing light in a wavelength region for blue. A transparent electrode layer is provided on each of the photoconductive layers. The transparent electrode layer placed above the photoconductive layer and the transparent electrode layer placed below the photoconductive layer are sandwiching a translucent reflective layer for reflecting the light in the green wavelength region. Similarly, a translucent reflective layer is sandwiched between the transparent electrode layer placed above the photoconductive layer and the transparent electrode layer placed below the photoconductive layer for reflecting the light in the blue wavelength region. With such a structure, successfully provided is a single-plate color solid-state imaging device of a photoconductive-layer-stacked type achieving the higher color resolution and the better sensitivity.

Owner:SONY SEMICON SOLUTIONS CORP

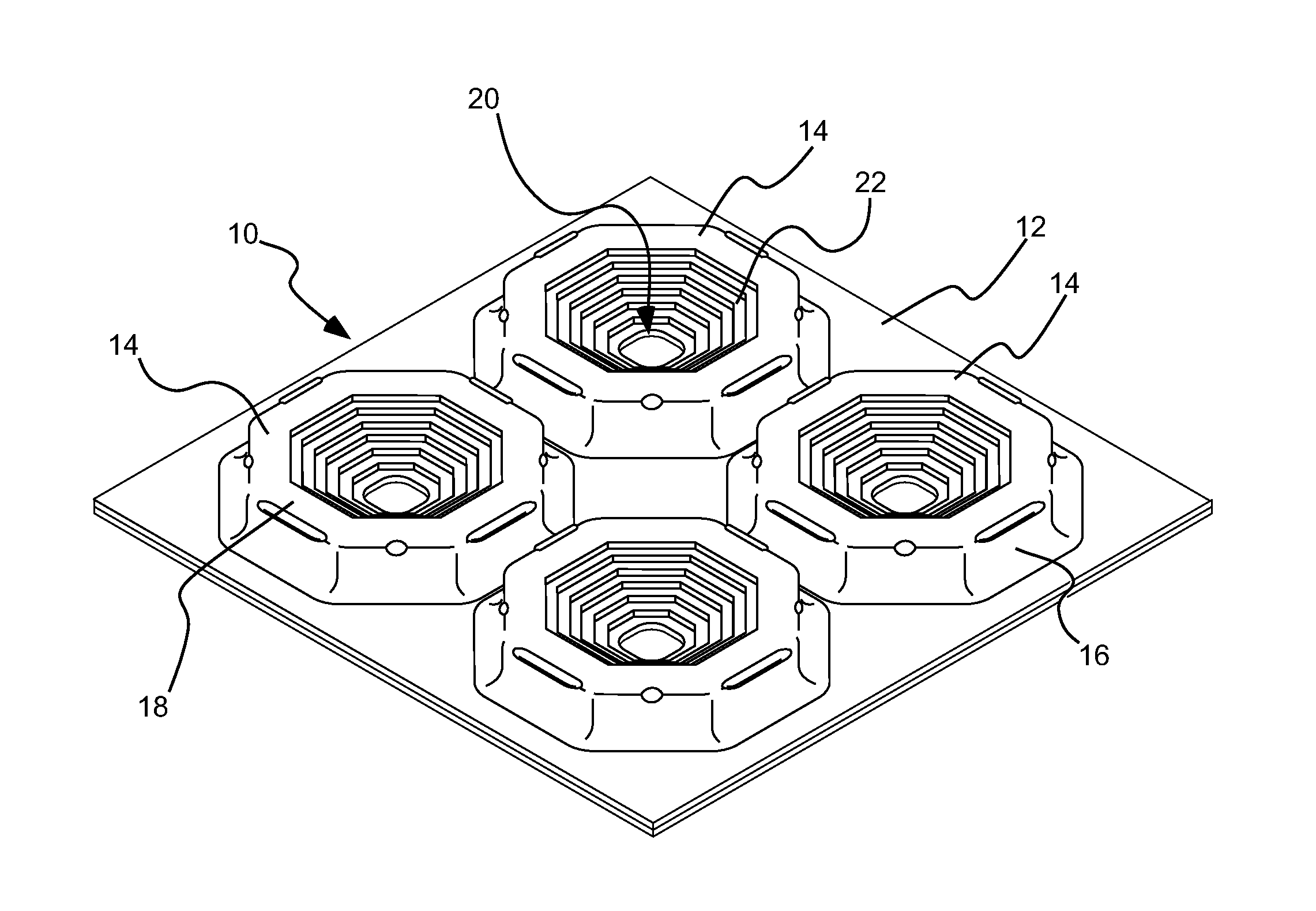

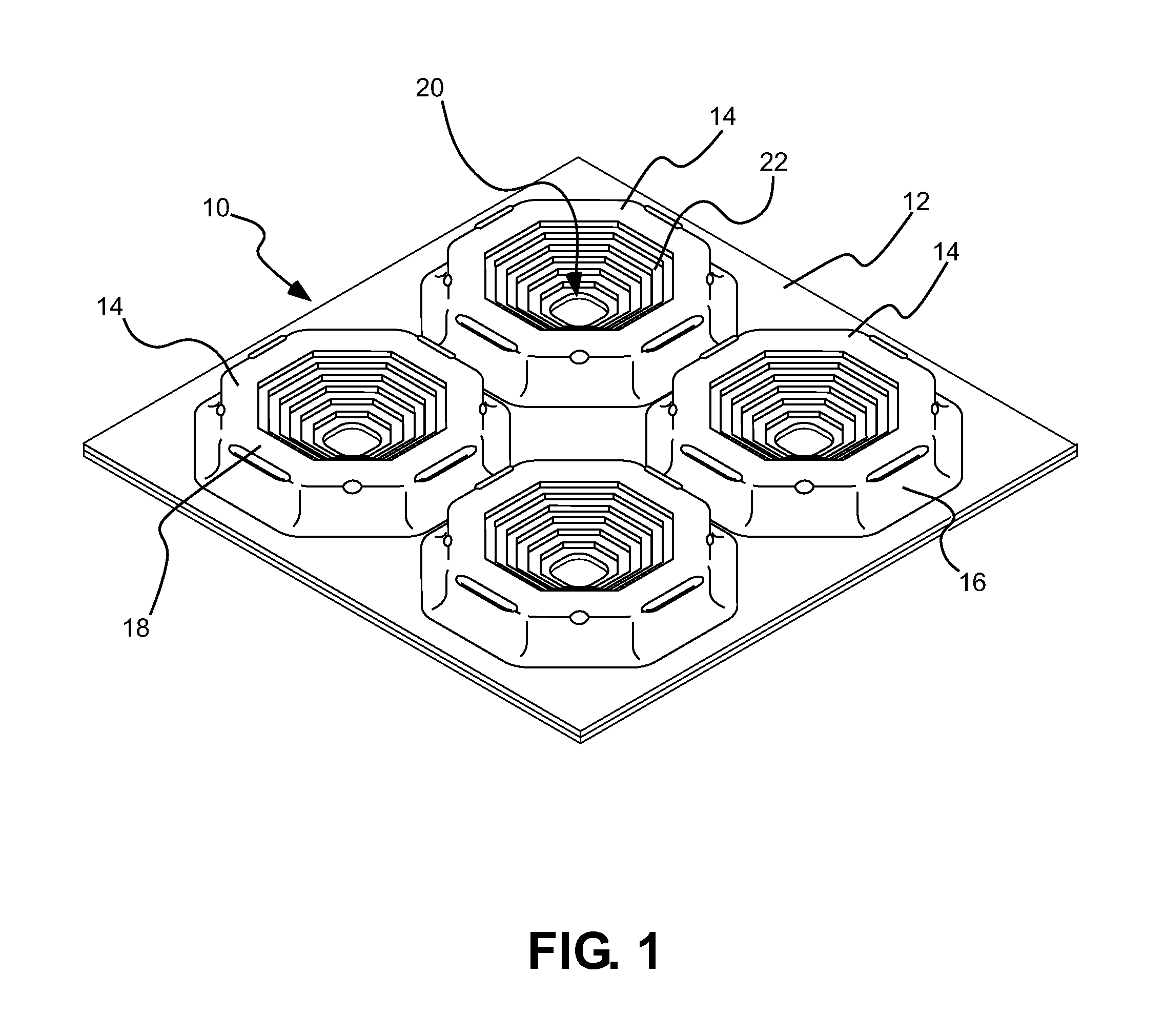

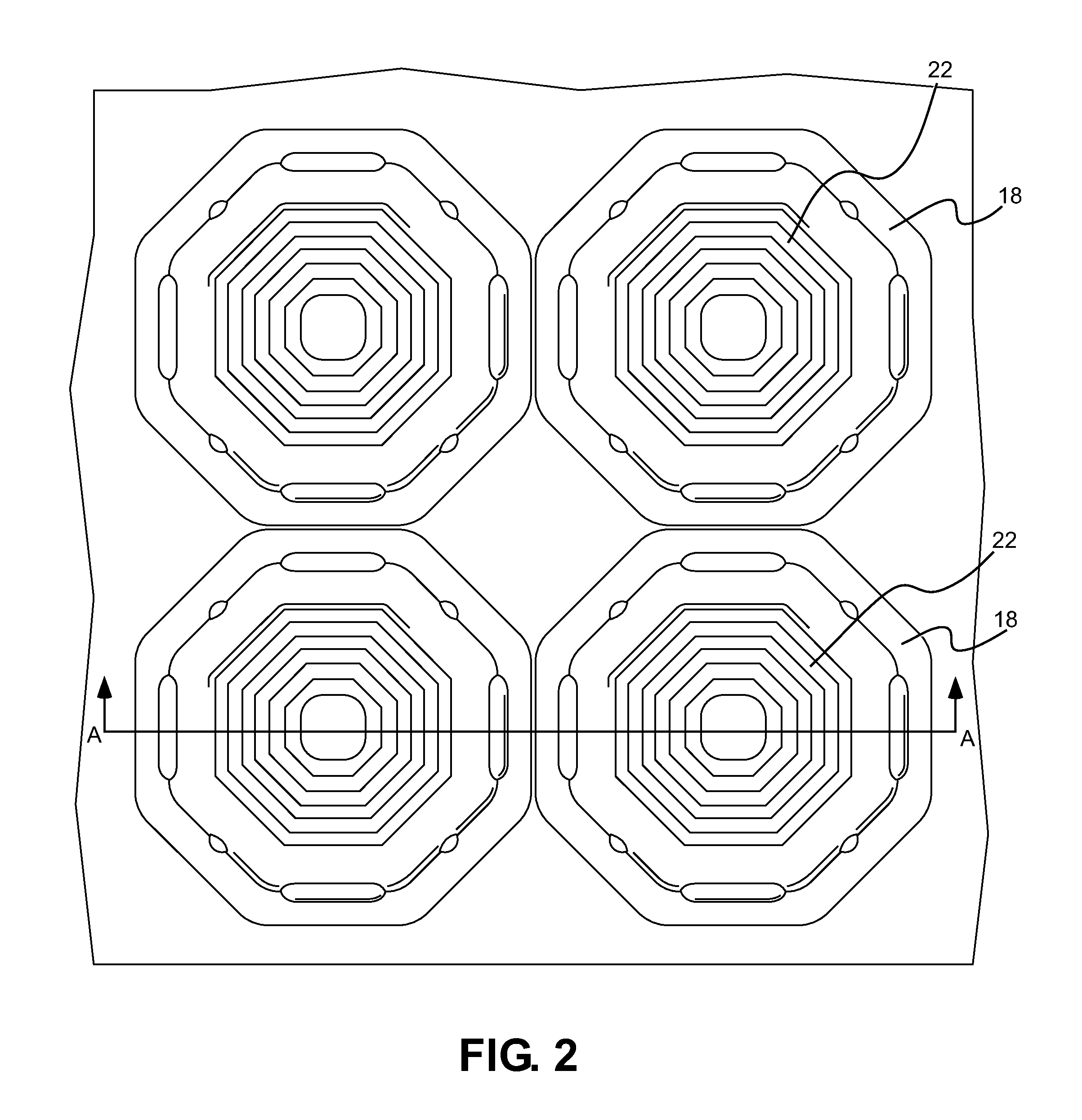

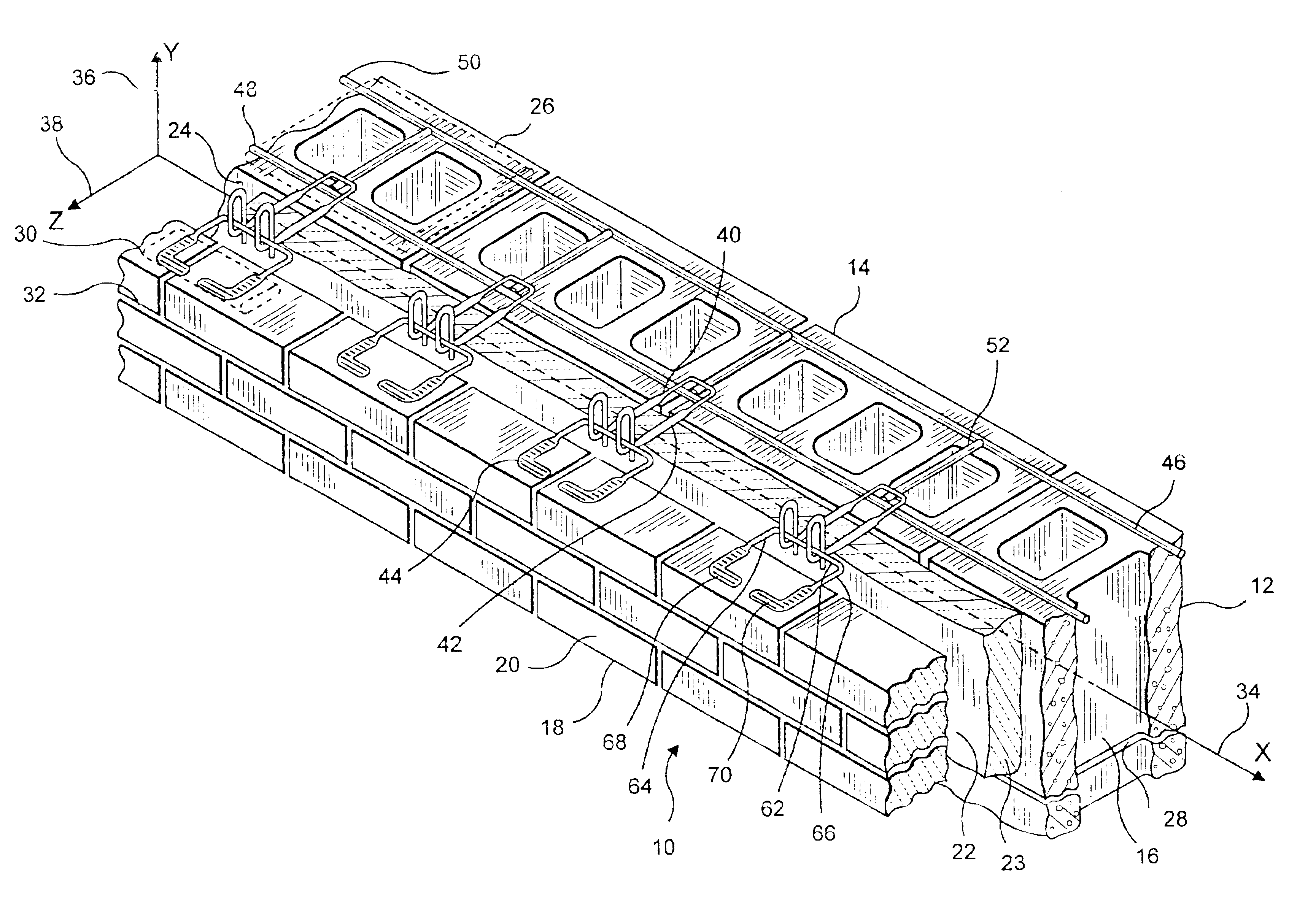

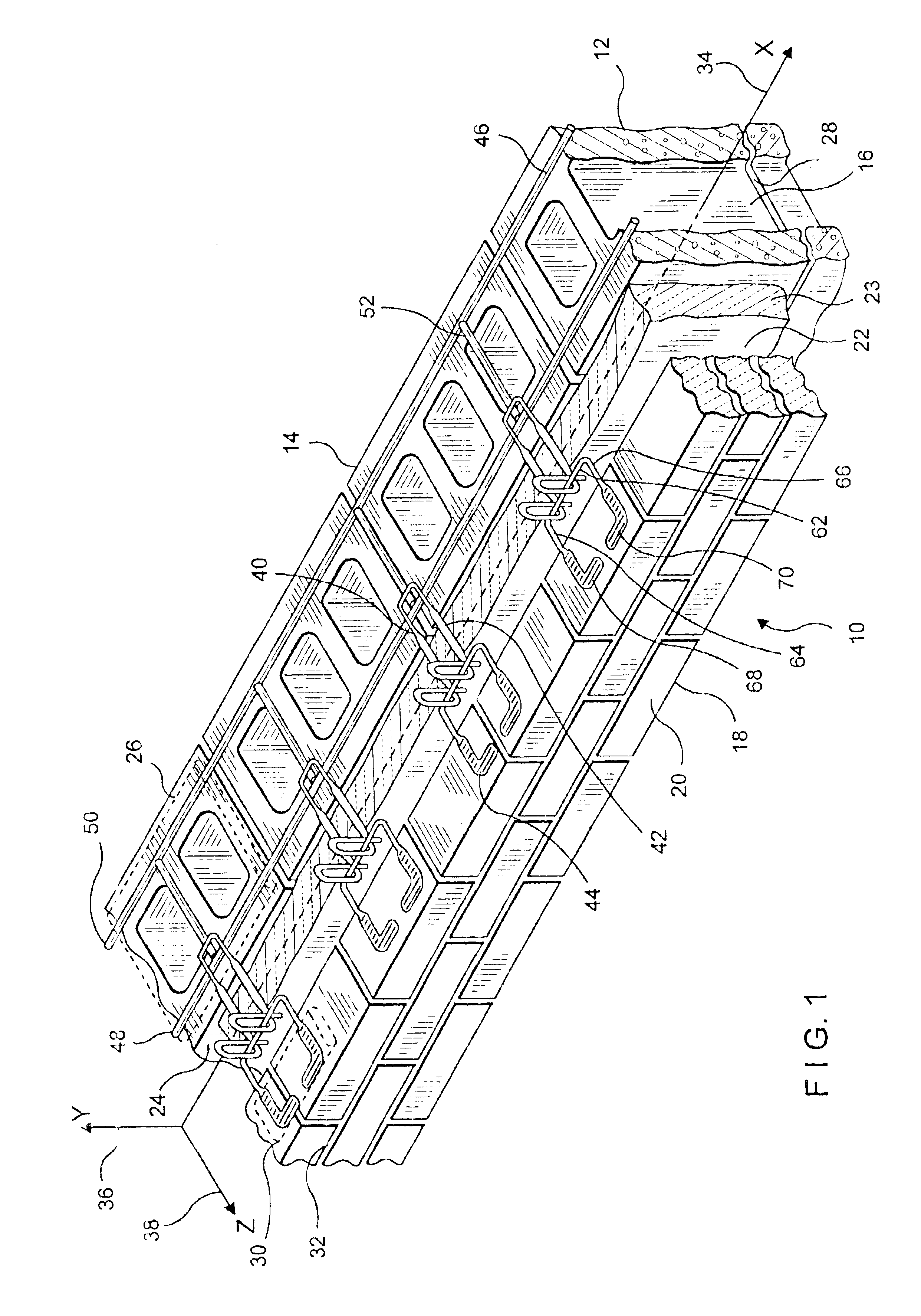

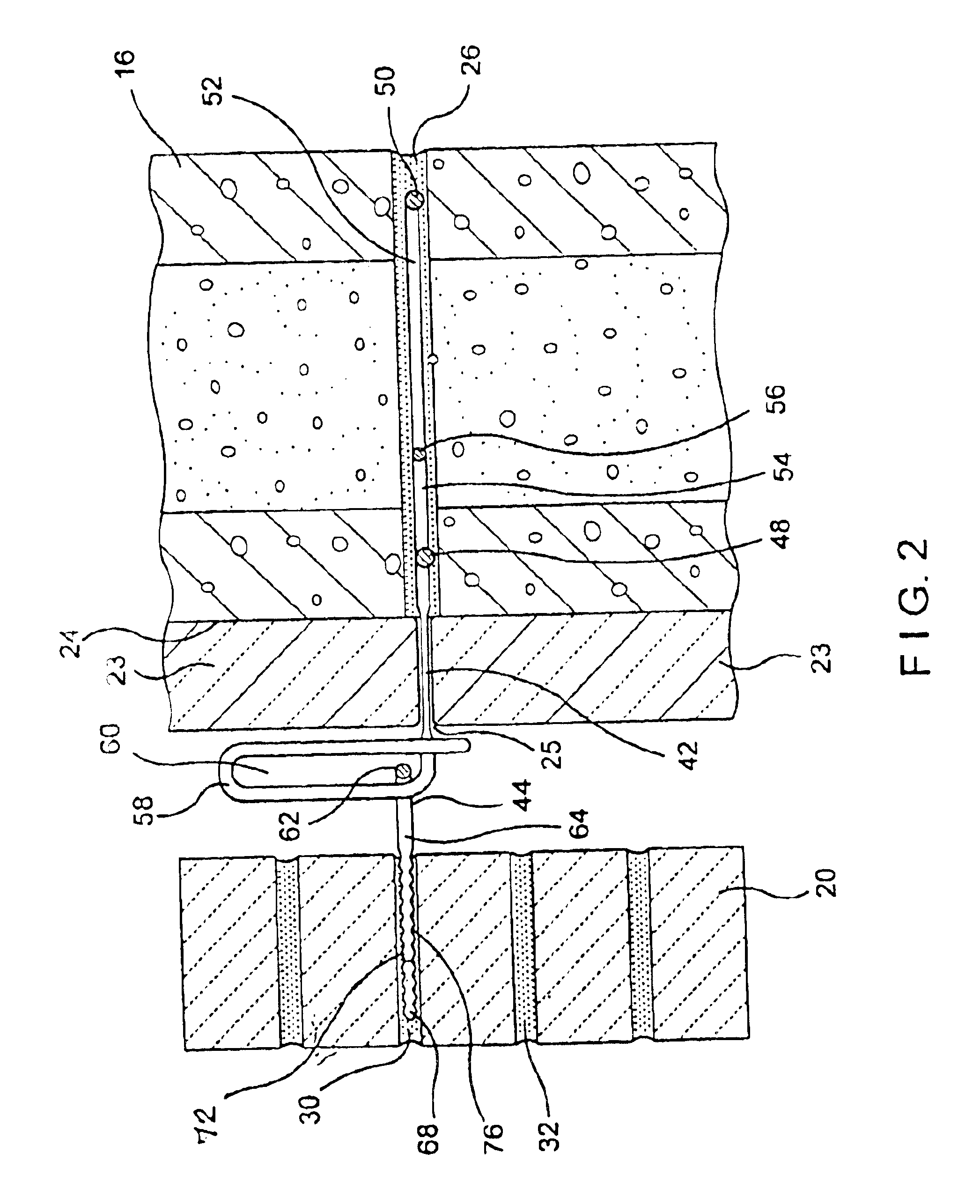

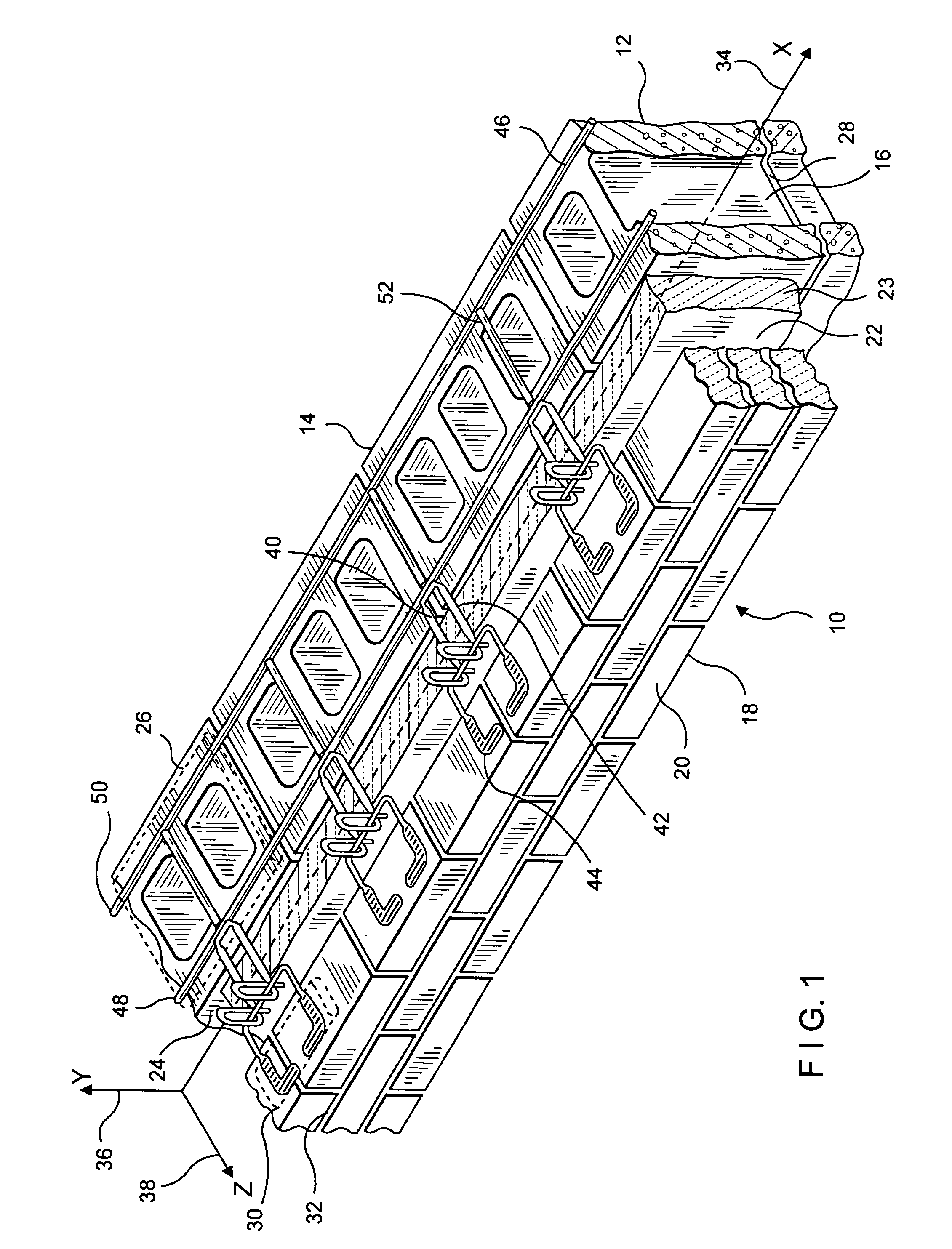

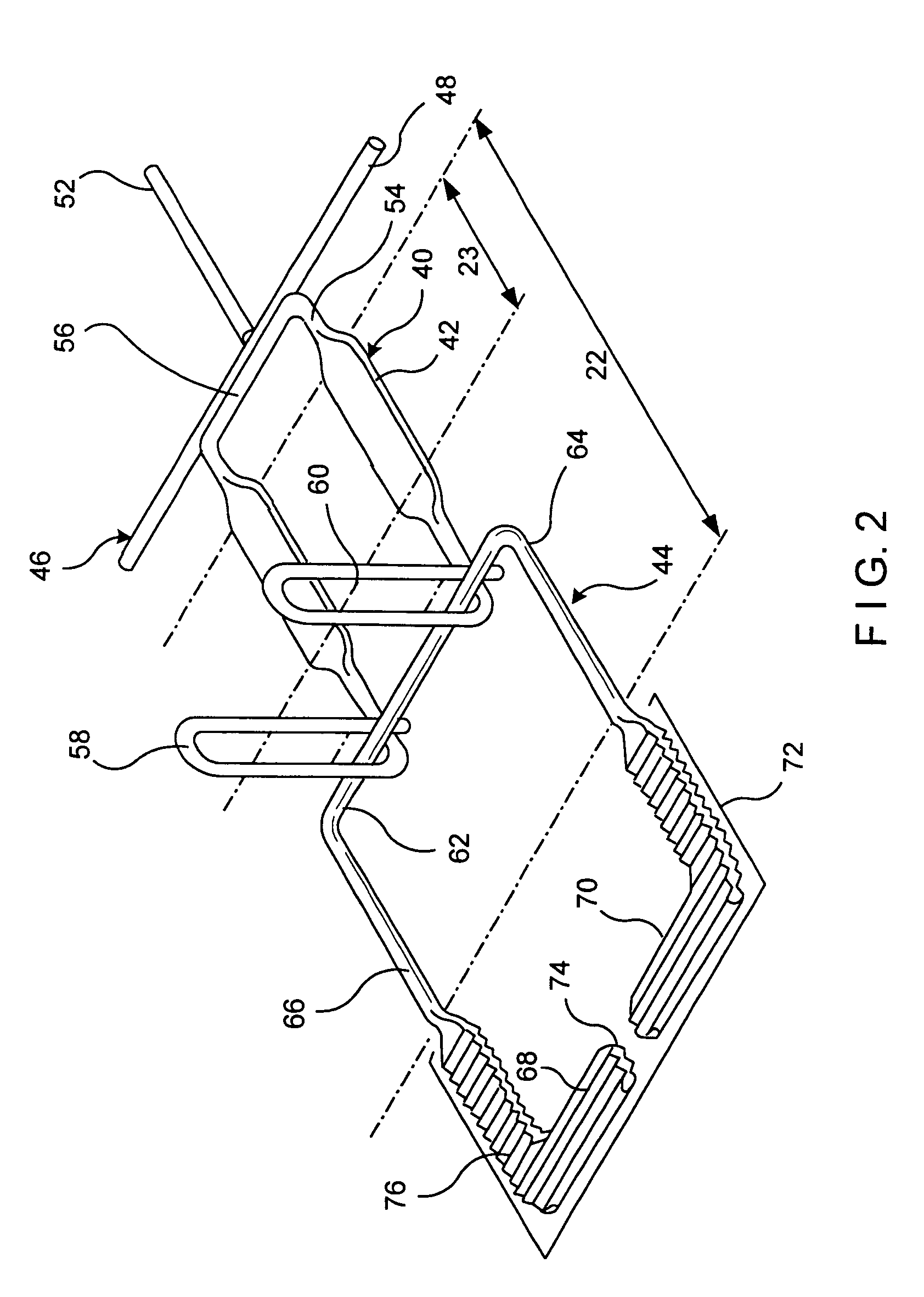

Veneer Underlayment

An underlayment for use between a veneer material and a foundation surface comprises a base layer and a series of supports extending upwardly from the base layer. The supports are configured to create voids in a layer of bonding material used to adhere the veneer material to the underlayment. Each of the supports includes at least one outer wall extending upwardly from the base layer and terminating at an upper lip, a bowl area defined adjacent a center of the support; and an internal wall extending downwardly from the upper lip toward the center of the support to at least partially define the bowl area within each of the supports.

Owner:SCHLUTER SYST LP

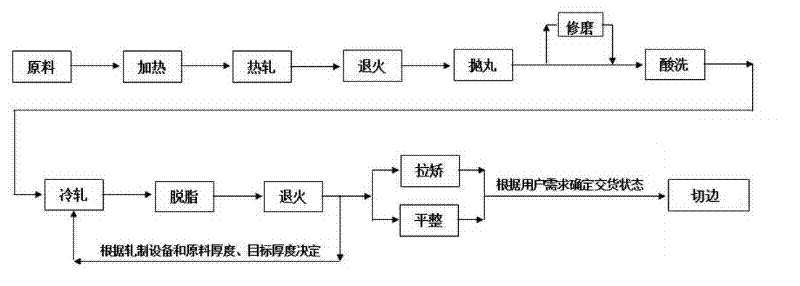

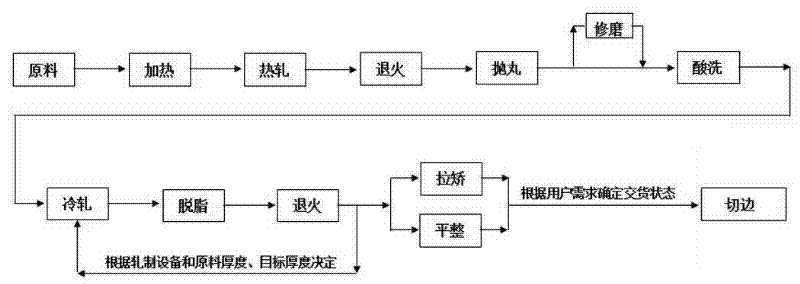

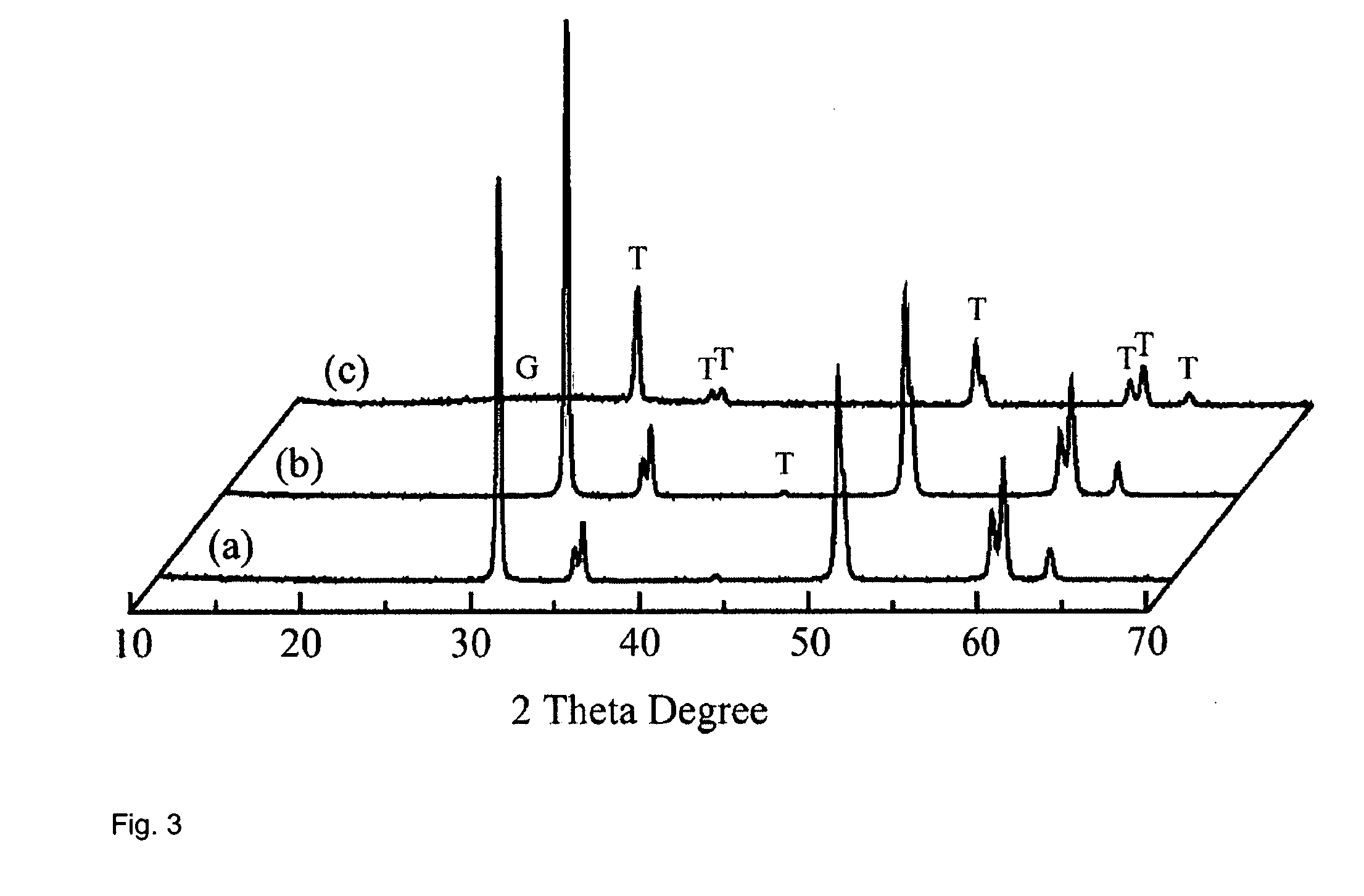

Processing method of titanium and titanium alloy strip coils

ActiveCN102310314ASolve the shortage of titanium-free surface processing technologyImprove processing efficiencyWork treatment devicesMetal rolling arrangementsSingle plateTitanium

The invention provides a processing method of titanium and titanium alloy strip coils, which comprises the steps of raw material preparation, heating, rolling, annealing, shot blasting treatment, coping, pickling, cold rolling, derosination, annealing, straightening or flattening, edge scraping, and product obtaining. According to the method, existing large steel rolling equipment of various types in the steel processing industry is fully utilized, the defect that no titanium material surface processing and treatment technology exists in the steel processing industry is overcome, the advantages of the steel processing industry are combined with the uniqueness of the titanium material processing industry, and the essential leap of titanium material processing from single plate rolling to long strip rolling plus collection and coiling is completed. By using the method, goods can be delivered in a coiled state as well as a flat plate state, the titanium material processing efficiency is improved, the titanium material processing yield is increased, and conditions are created and high quality raw materials are provided for the processing of titanium welded pipes with various diametersand longer lengths, so high efficiency, energy conservation and economization of titanium material processing are realized.

Owner:YUNNAN TITANIUM IND

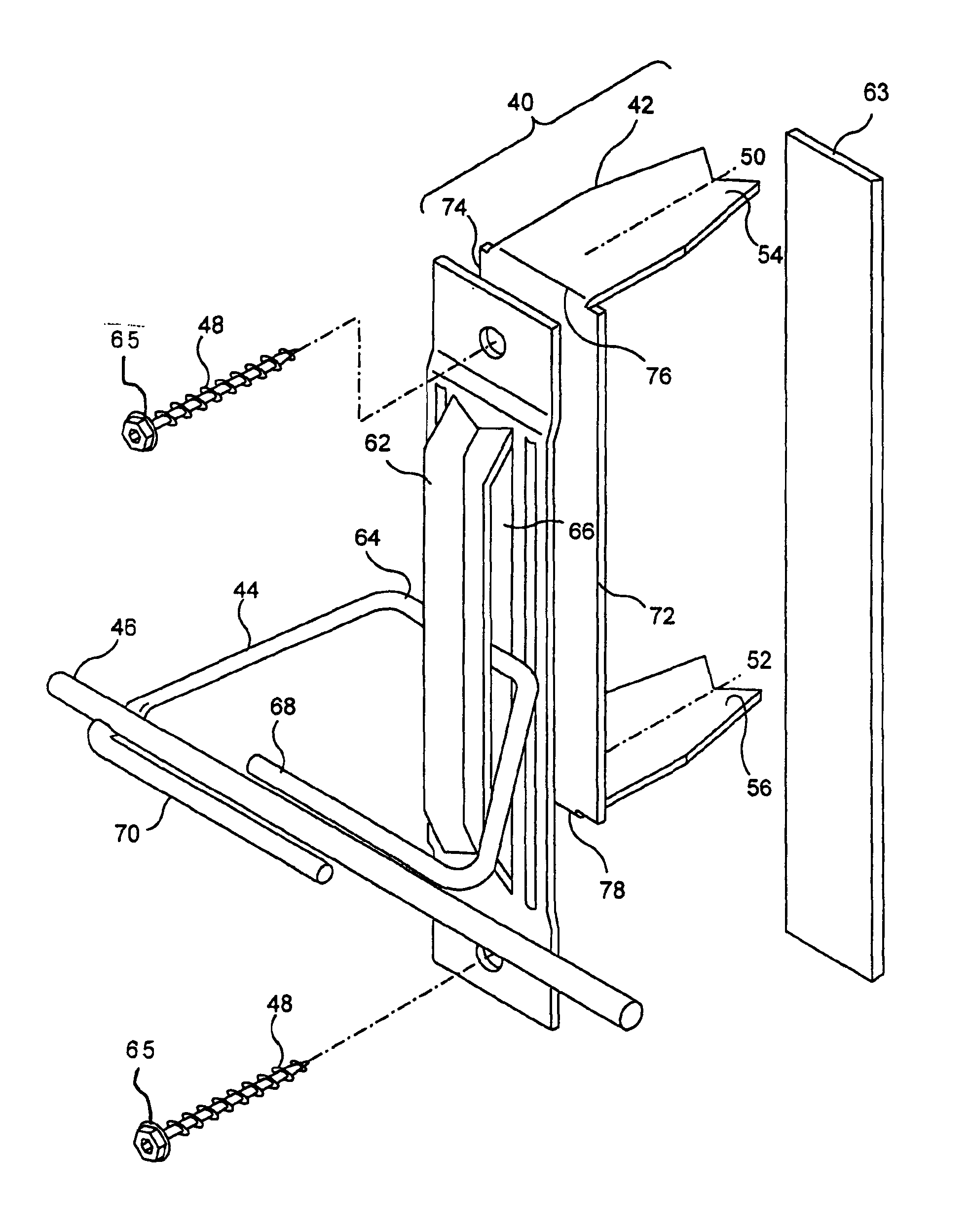

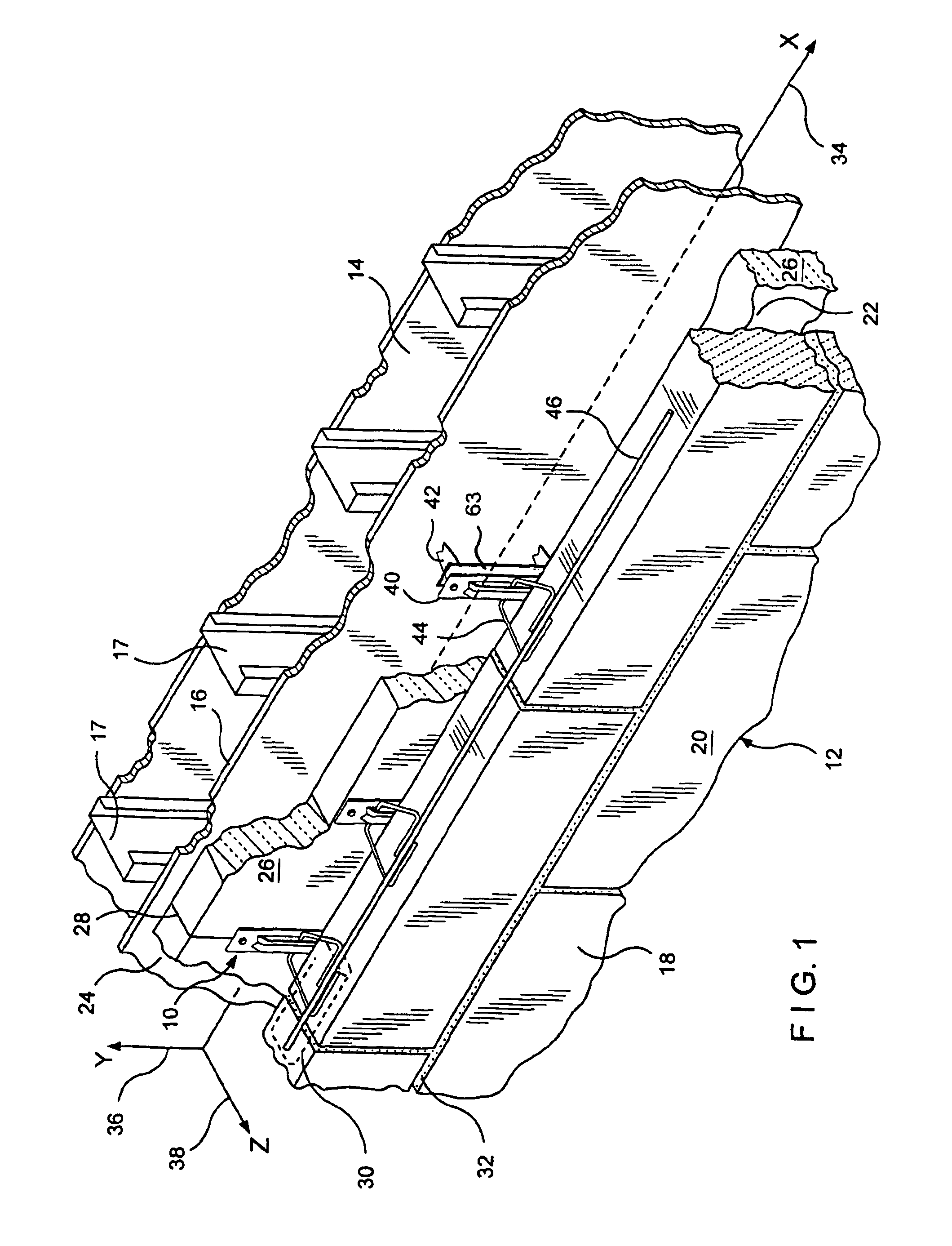

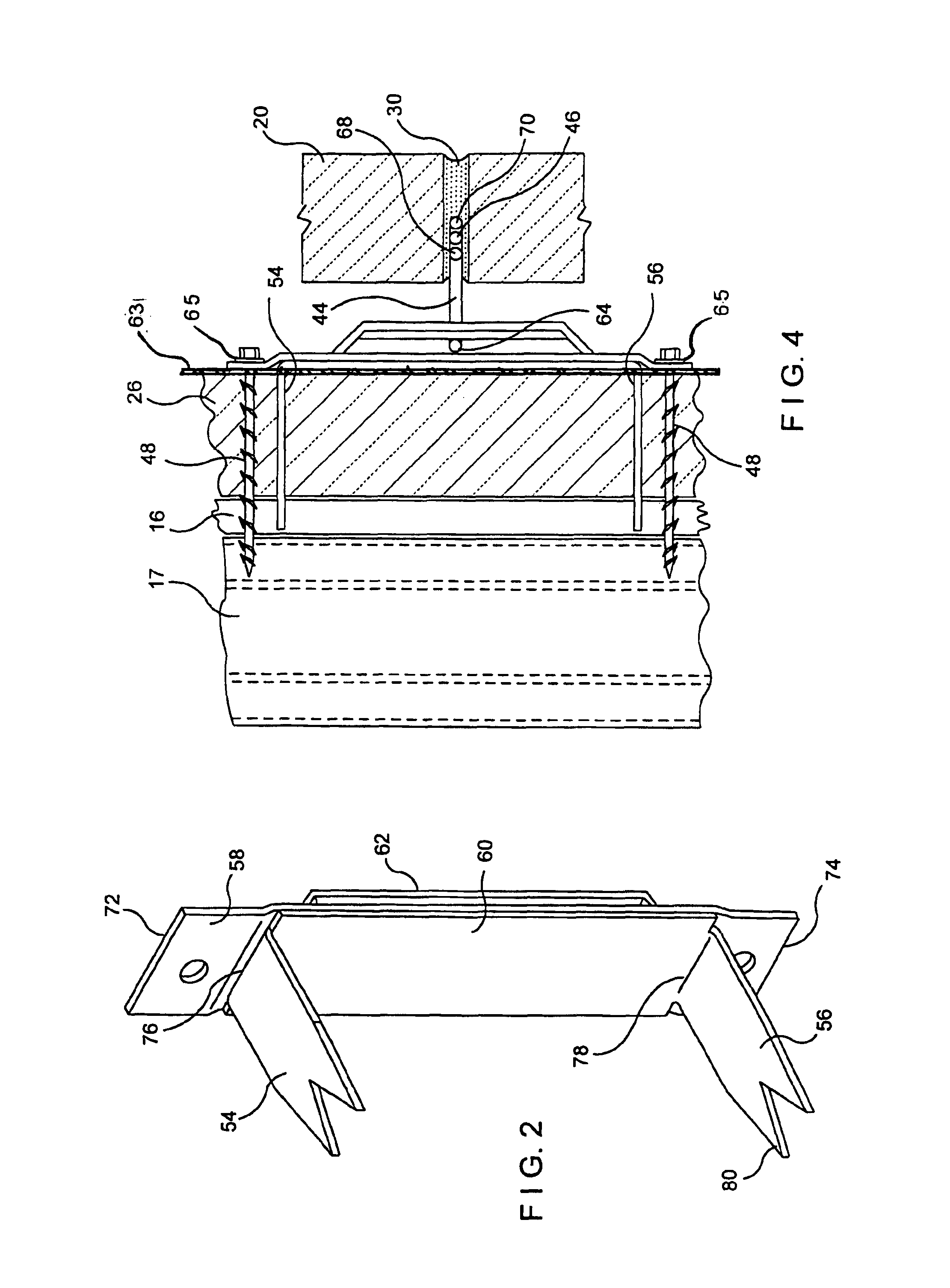

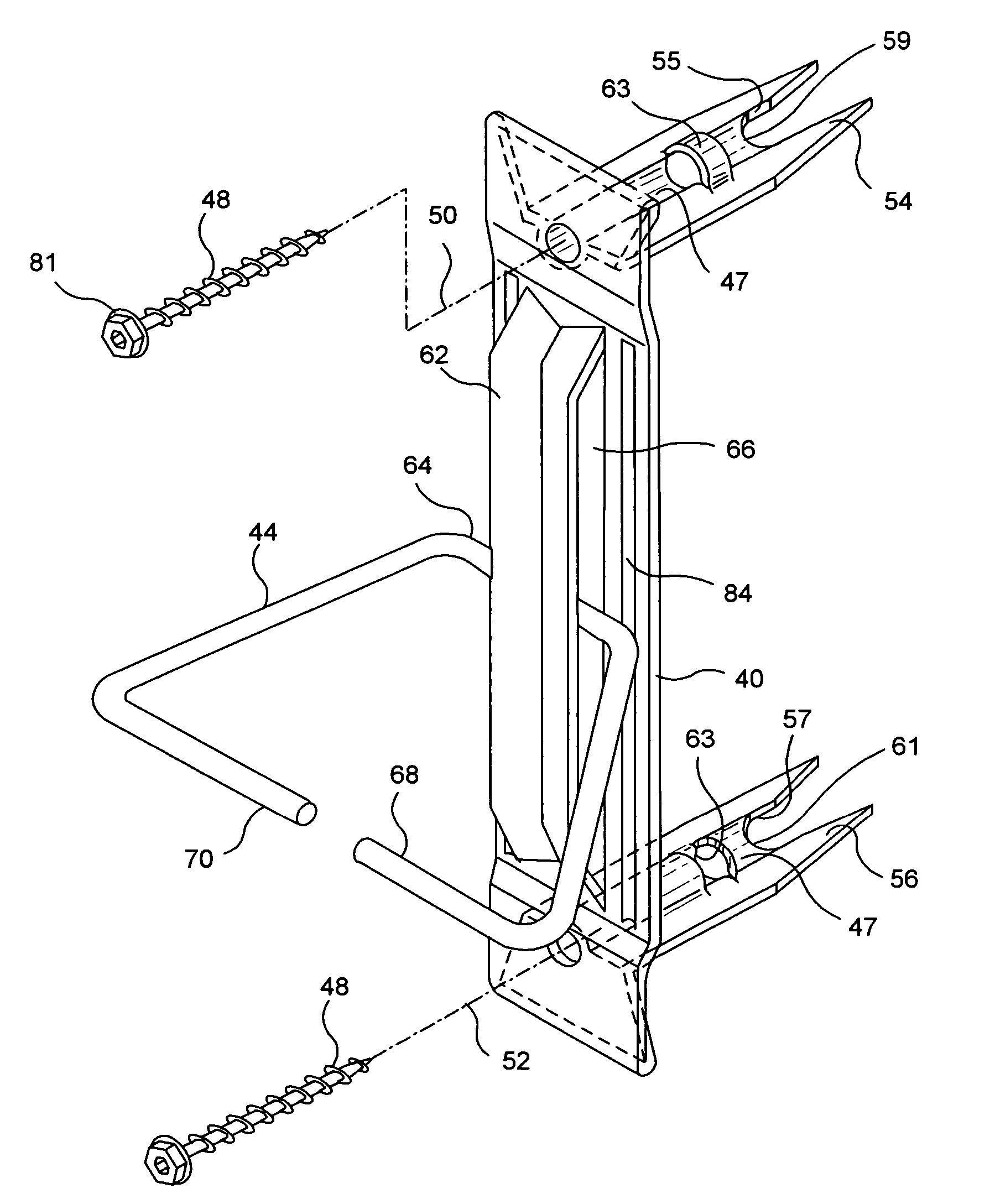

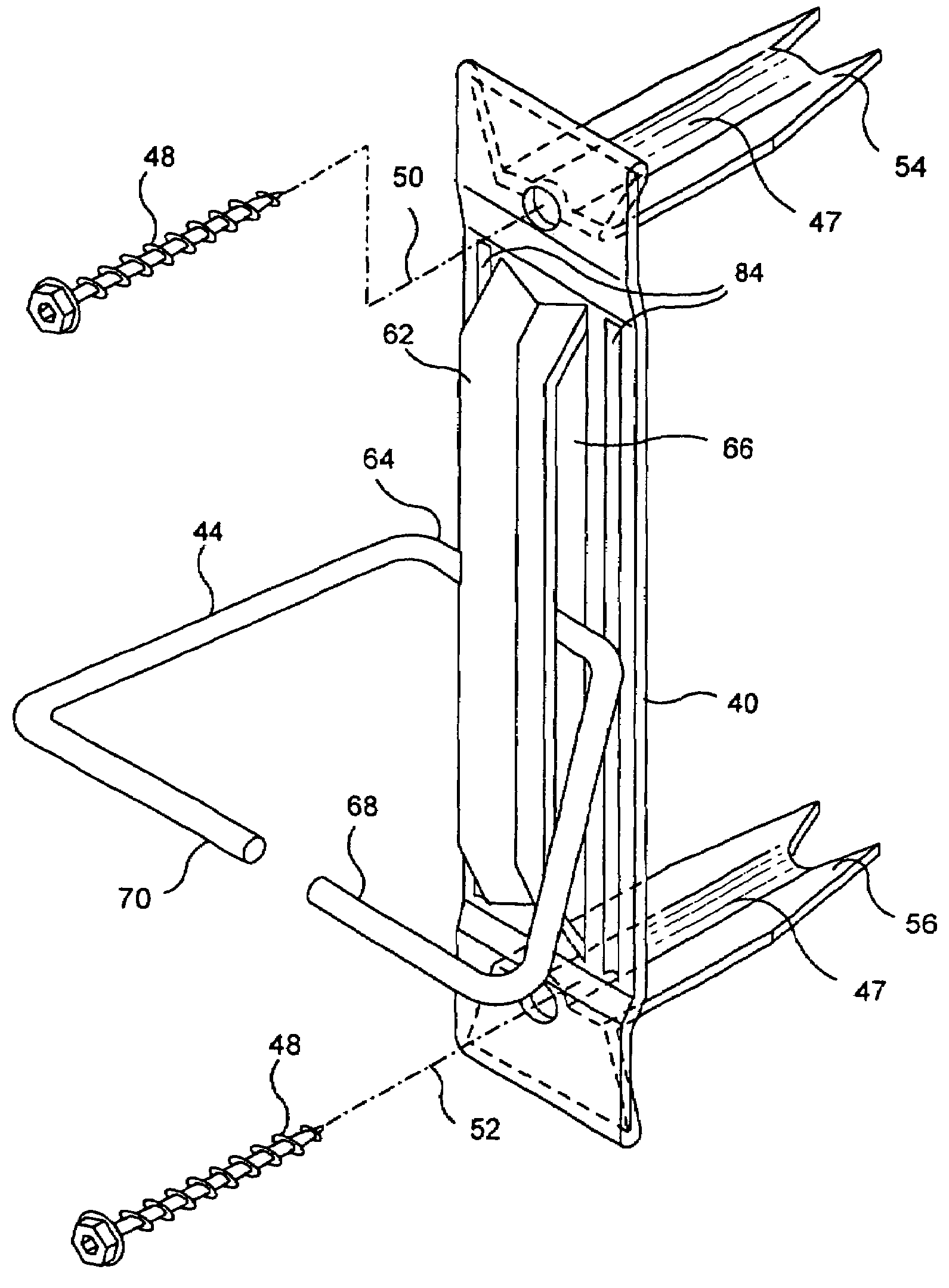

Wall anchor constructs and surface-mounted anchoring systems utilizing the same

Wall anchor constructs and anchoring systems employing the same are disclosed. Each anchor is a sheetmetal construct utilizable with various wire formative veneer ties. In the wall anchor structures, the junctures of the legs and the base of the wall anchor are located inboard from the periphery of the wall anchor base. With the surfaces of the leg base and the anchor base coplanar, the leg insertion point is, upon installation, sealed thereby. This sealing precludes penetration of air, Moisture, and water vapor into the wall structure. Various embodiments showing wall anchor configurations with suitable veneer ties are provided.

Owner:HOHMANN & BARNARD INC

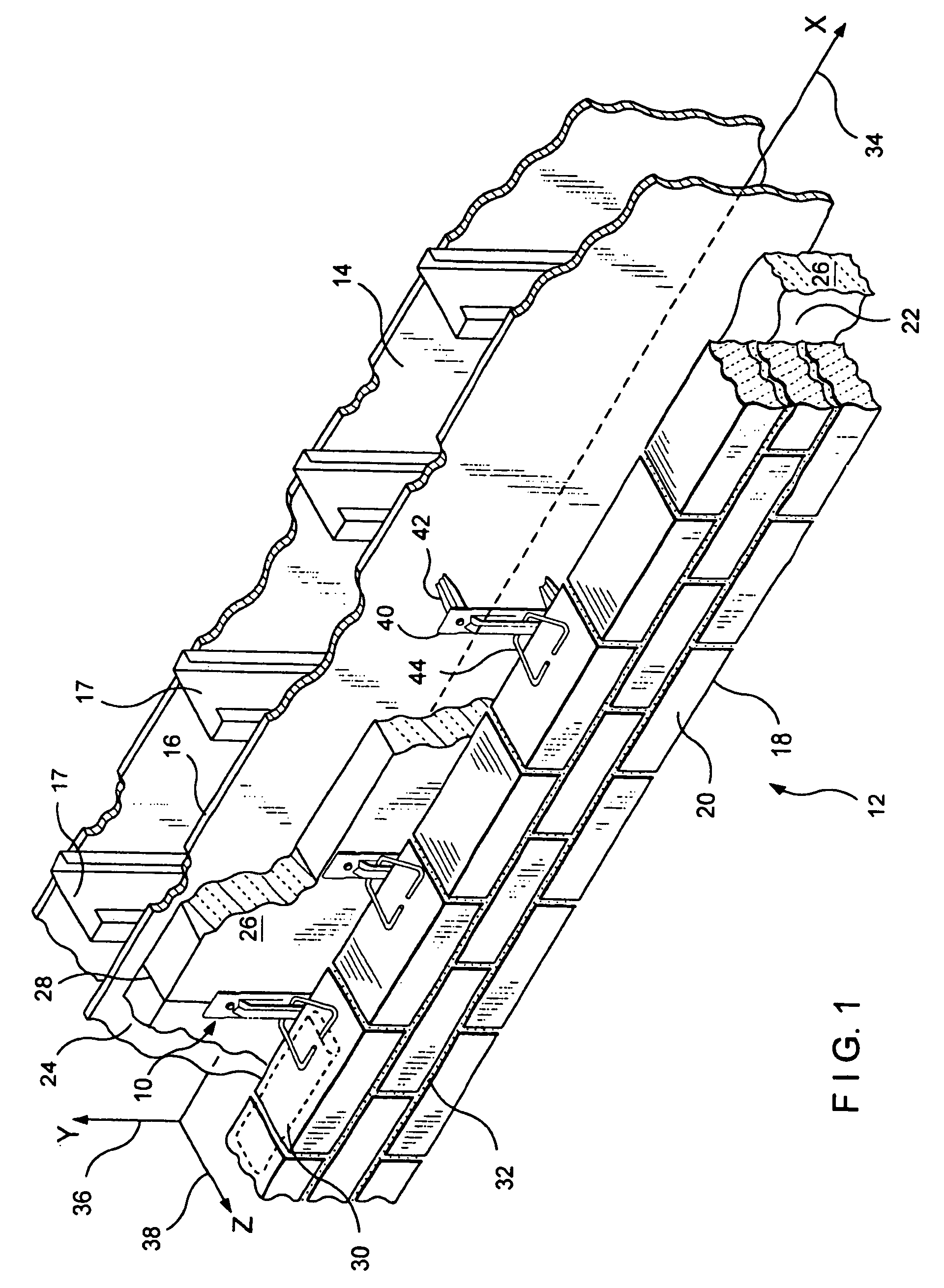

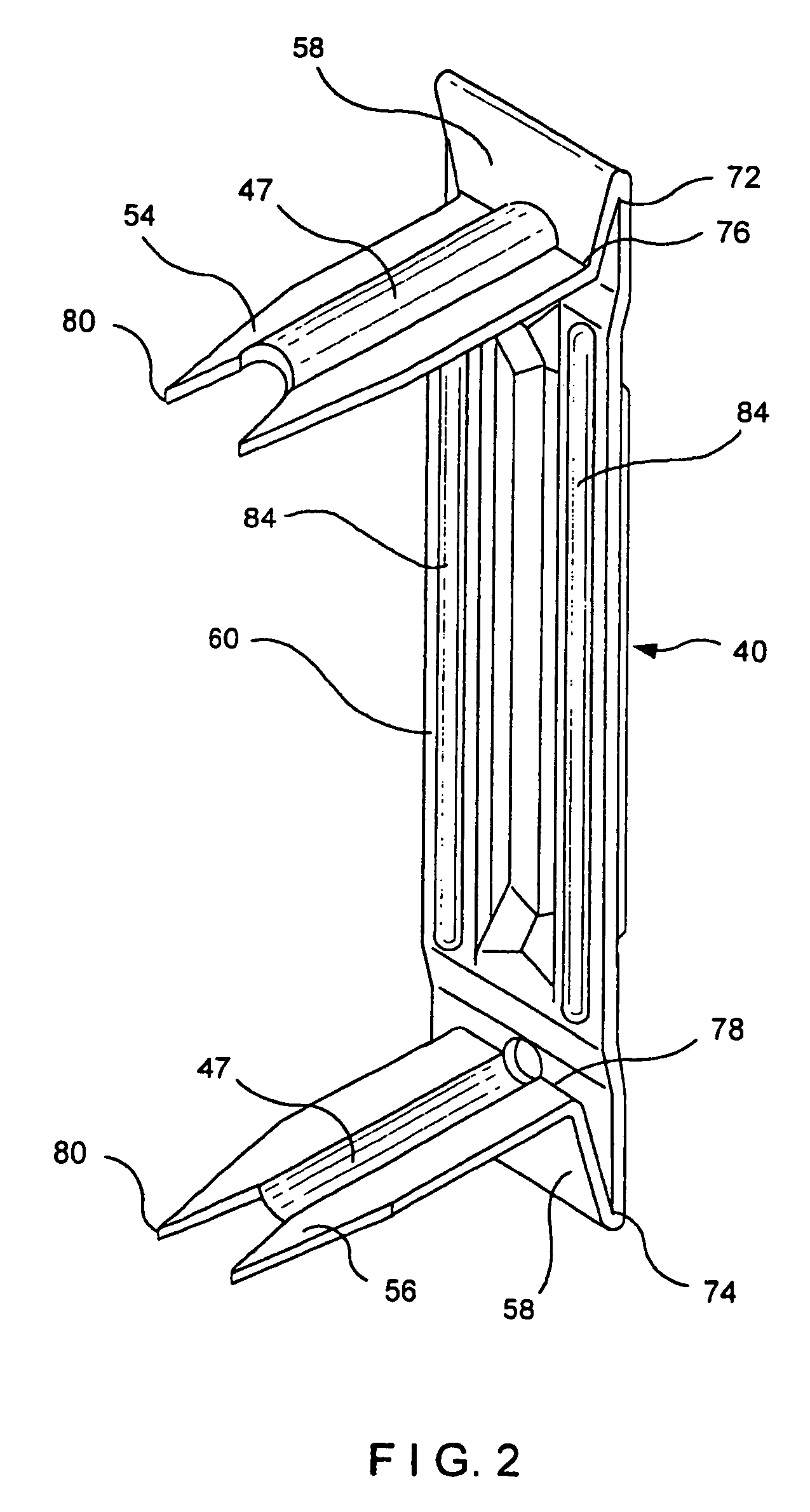

True-joint anchoring systems for cavity walls

InactiveUS6851239B1Improve evenlyReadily maintained verticalityStrutsConstruction materialMetal alloySingle plate

A high-span anchoring system is described for a cavity wall incorporating a wall reinforcement combined with a wall tie which together serve a wall construct having a larger-than-normal cavity. Further the various embodiments combine wire formatives which are compressively reduced in height by the cold-working thereof. Among the embodiments is a veneer anchoring system with a low-profile wall tie for use in a heavily insulated wall. The compressively reduced in height wall anchors protrude into the cavity through the seams, between insulation strips, which seams seal thereabout and maintain the integrity of the insulation by minimizing air leakage. Further, the eye wires extend across the insulation into the cavity between the wythes, and each accommodates the threading thereinto of a wire facing anchor or wall tie with either a pintle inserted through the eye or the open end of the veneer tie. The veneer tie is then positioned so that the insertion end is embedded in the facing wall. The close control of overall heights permits the mortar of the bed joints to flow over and about the wall reinforcement and wall tie combination inserted in the inner wythe and insertion end of the wall in the outer wythe. Because the wire formatives hereof employ extra strong material and benefit from the cold-working of the metal alloys, the high-span anchoring system meets the unusual requirements demanded thereof.

Owner:HOHMANN & BARNARD INC

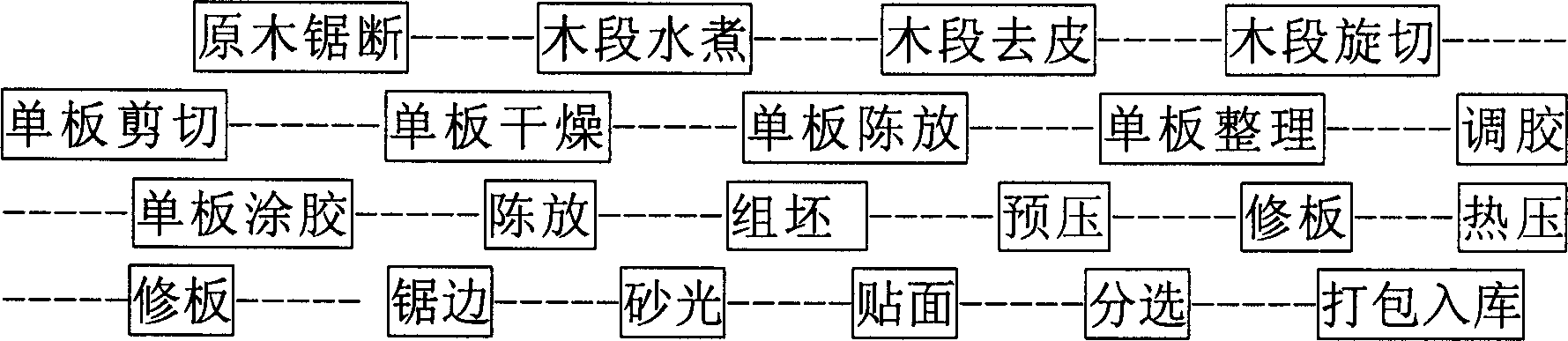

Method for producing plywood with glueing on one side and plywood mould

A method for producing the plywood with the wood plys whose one surface is coated by resin includes such steps as sawing log short, boiling in water, removing bark, spinning cutting, cutting fly, drying, ageing, coating resin on one surface of each ply, ageing, laminating, pre-pressing, trimming, hot pressing, trimming, sawing edge, sticking a paper immersed in resin, and classifying.

Owner:哈尔滨市香坊区人造板胶粘剂研究所 +1

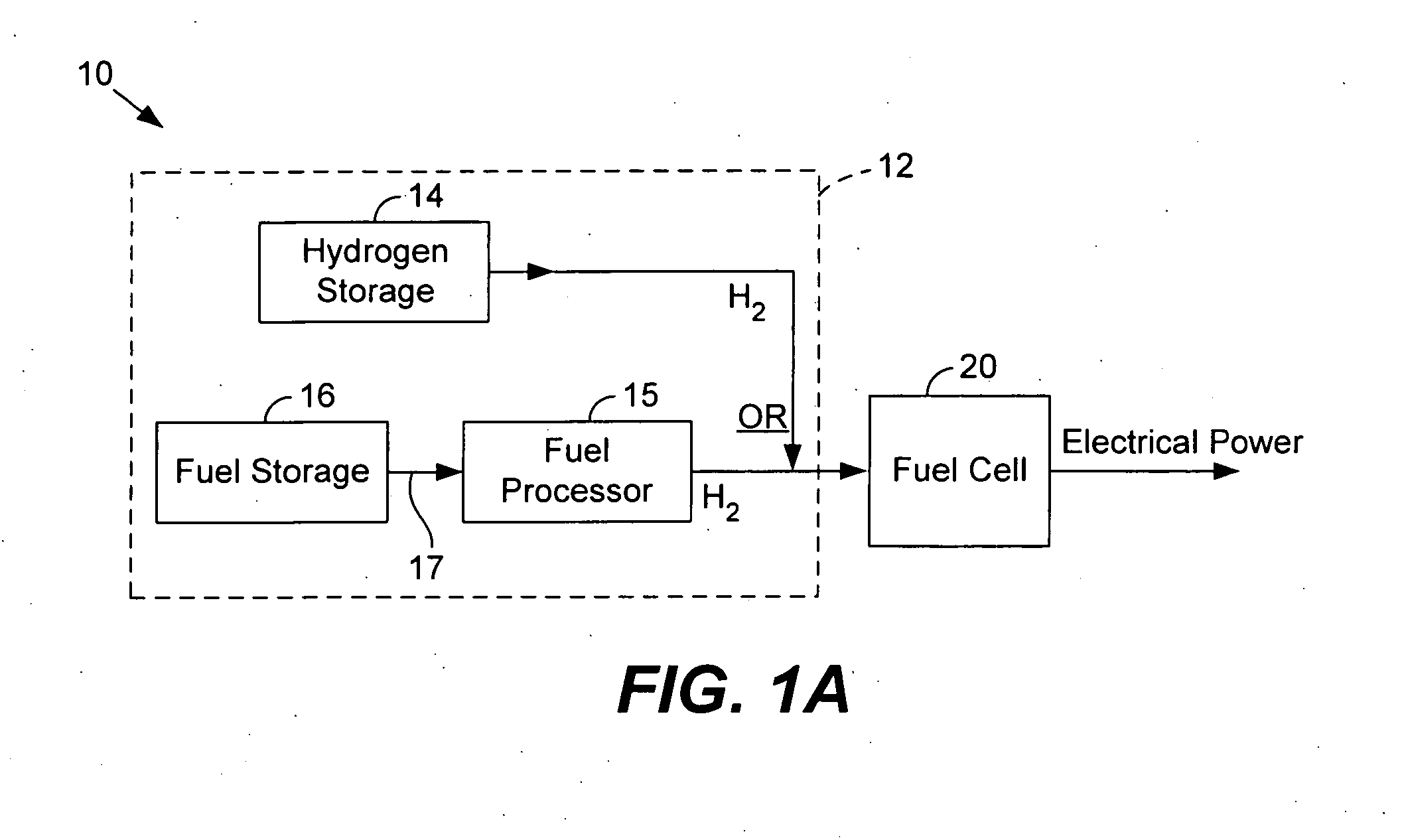

Micro fuel cell thermal management

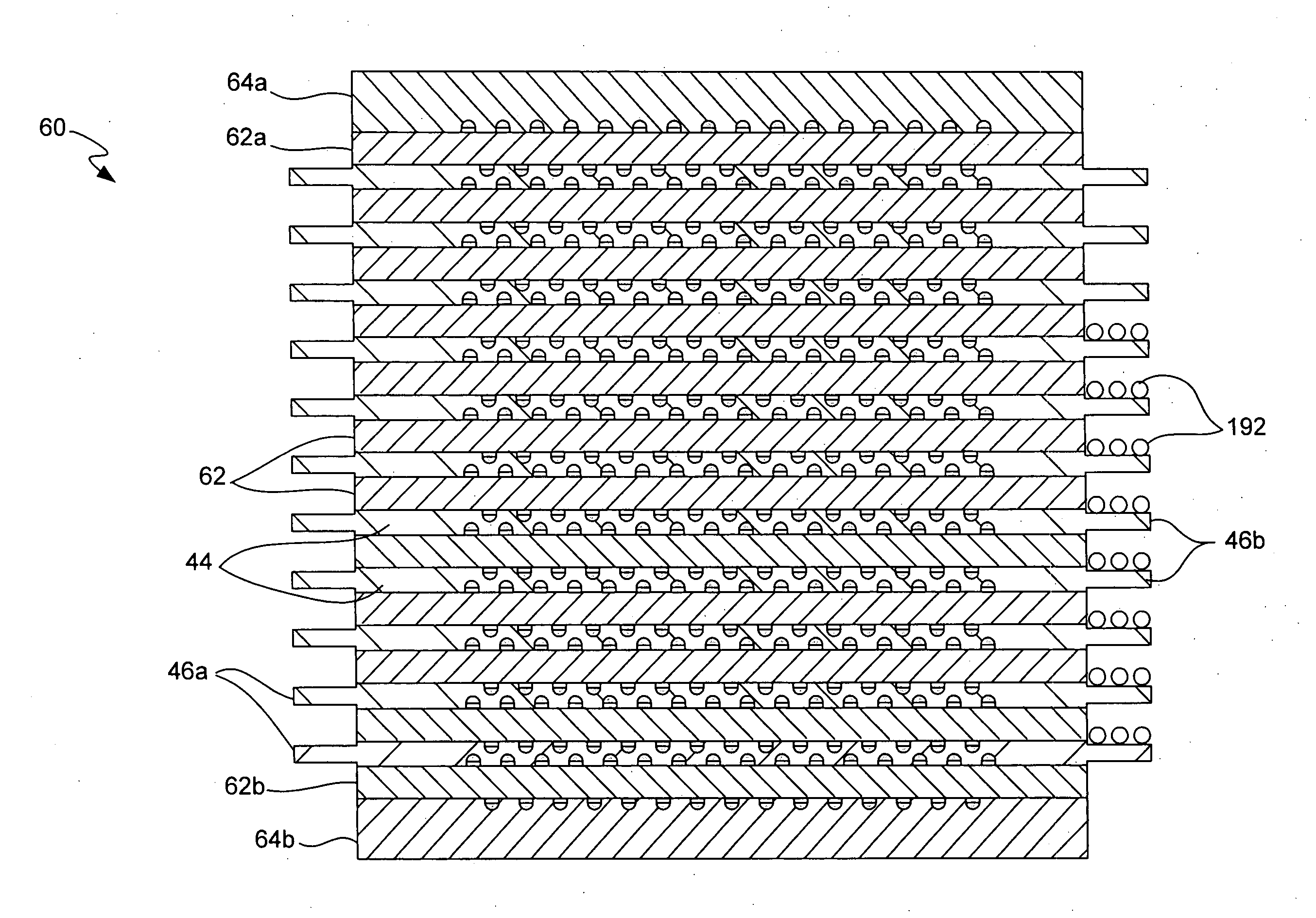

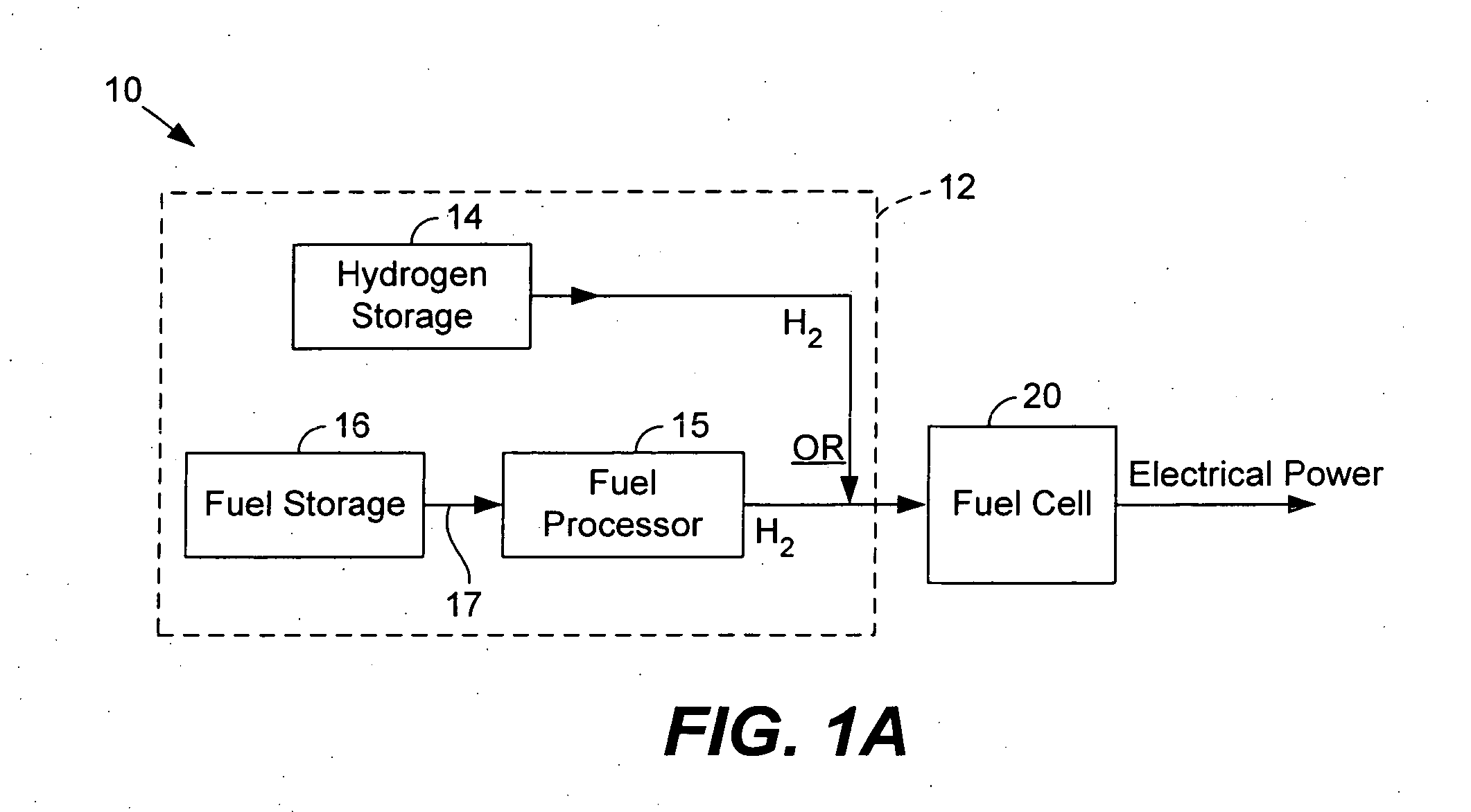

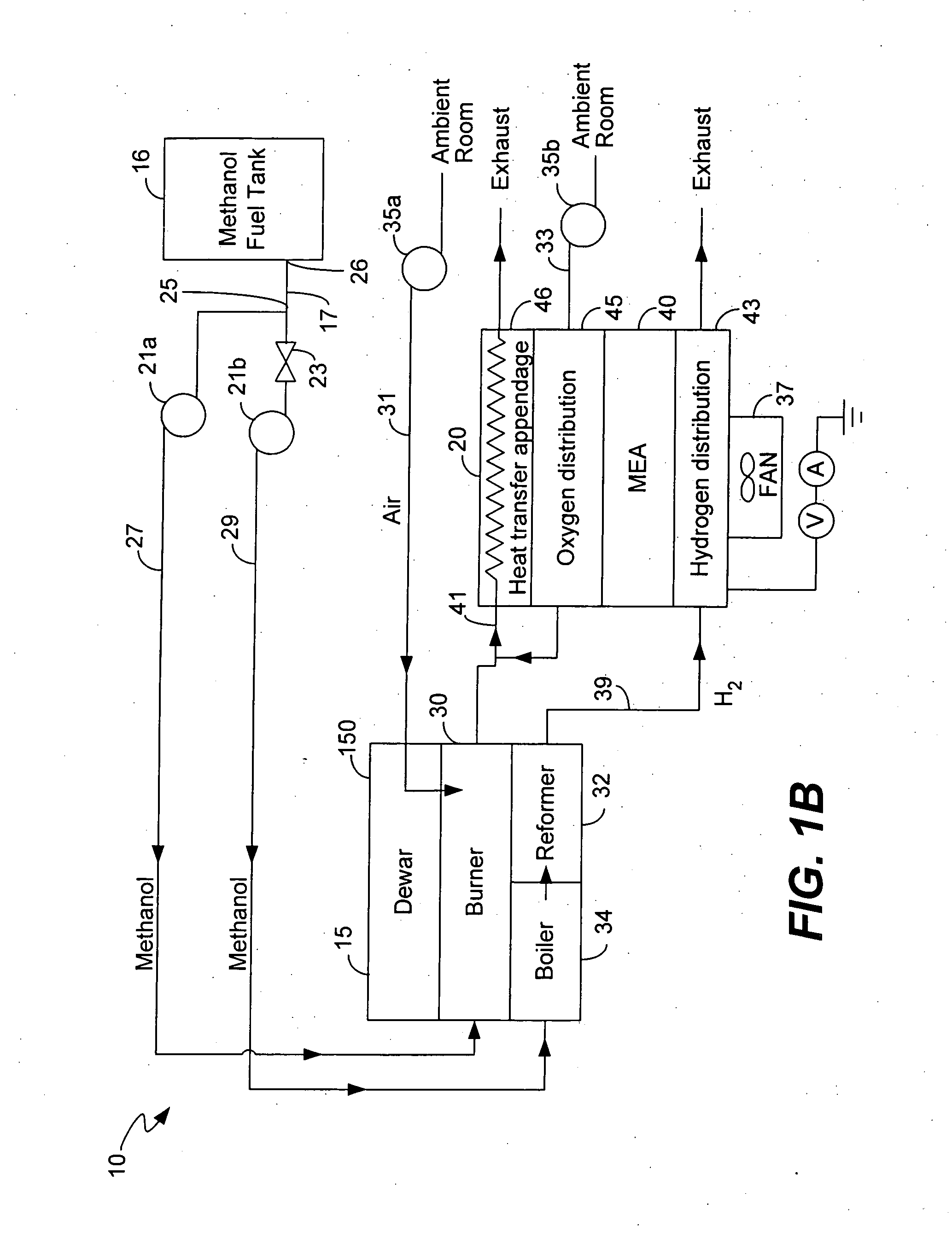

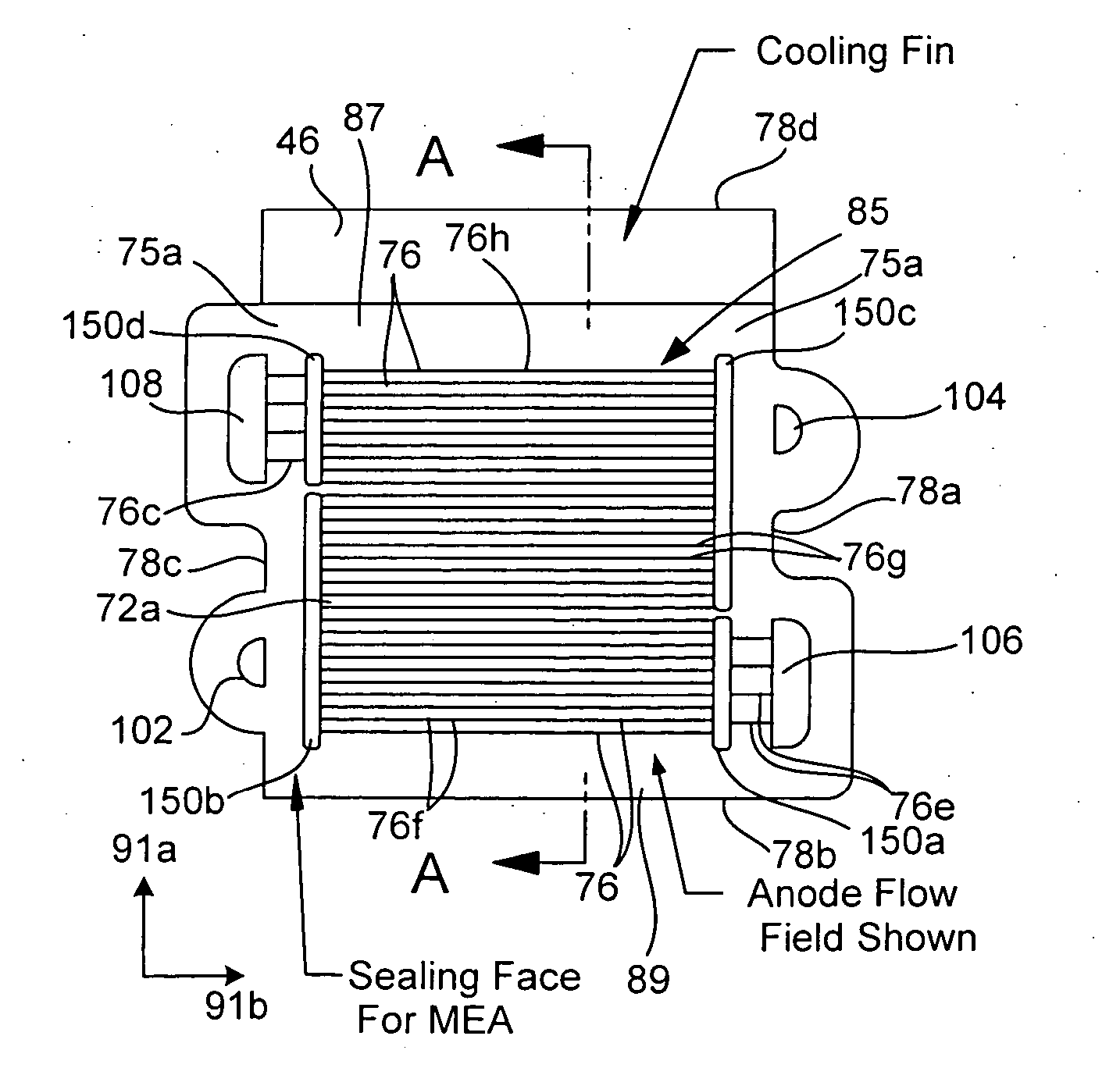

ActiveUS20050008911A1Improves fuel cell thermal managementFacilitates thermal communicationFuel cell heat exchangeFuel cells groupingSingle plateEngineering

The present invention relates to fuel cells and components used within a fuel cell. Heat transfer appendages are described that improve fuel cell thermal management. Each heat transfer appendage is arranged on an external portion of a bi-polar plate and permits conductive heat transfer between inner portions of the bi-polar plate and outer portions of the bi-polar plate proximate to the appendage. The heat transfer appendage may be used for heating or cooling inner portions of a fuel cell stack. Improved thermal management provided by cooling the heat transfer appendages also permits new channel field designs that distribute the reactant gases to a membrane electrode assembly. Flow buffers are described that improve delivery of reactant gases and removal of reaction products. Single plate bi-polar plates may also include staggered channel designs that reduce the thickness of the single plate.

Owner:ULTRACELL LLC

Micro fuel cell architecture

InactiveUS20050014059A1Improved thermal managementFacilitate communicationFuel cell heat exchangeLayered productsSingle plateEngineering

The present invention relates to fuel cells and components used within a fuel cell. Heat transfer appendages are described that improve fuel cell thermal management. Each heat transfer appendage is arranged on an external portion of a bi-polar plate and permits conductive heat transfer between inner portions of the bi-polar plate and outer portions of the bi-polar plate proximate to the appendage. The heat transfer appendage may be used for heating or cooling inner portions of a fuel cell stack. Improved thermal management provided by cooling the heat transfer appendages also permits new channel field designs that distribute the reactant gases to a membrane electrode assembly. Flow buffers are described that improve delivery of reactant gases and removal of reaction products. Single plate bi-polar plates may also include staggered channel designs that reduce the thickness of the single plate.

Owner:ULTRACELL LLC

Decorative components for motor vehicle interiors

InactiveUS20050276874A1Increase flexibilityImprove adhesionEnvelopes/bags making machineryMouldsSingle plateEngineering

A method of manufacturing a decorative components for vehicle interiors, comprises the steps of pre-forming a sheet of formable veneer material under pressure and heath, positioning the pre-formed sheet in a mold half of an injection mold comprising a cavity; holding the sheet in position on the mold half, closing said mold and injecting into the cavity one or more thermoplastic materials on the back of the veneer sheet to provide a support layer.

Owner:KEY SAFETY SYST

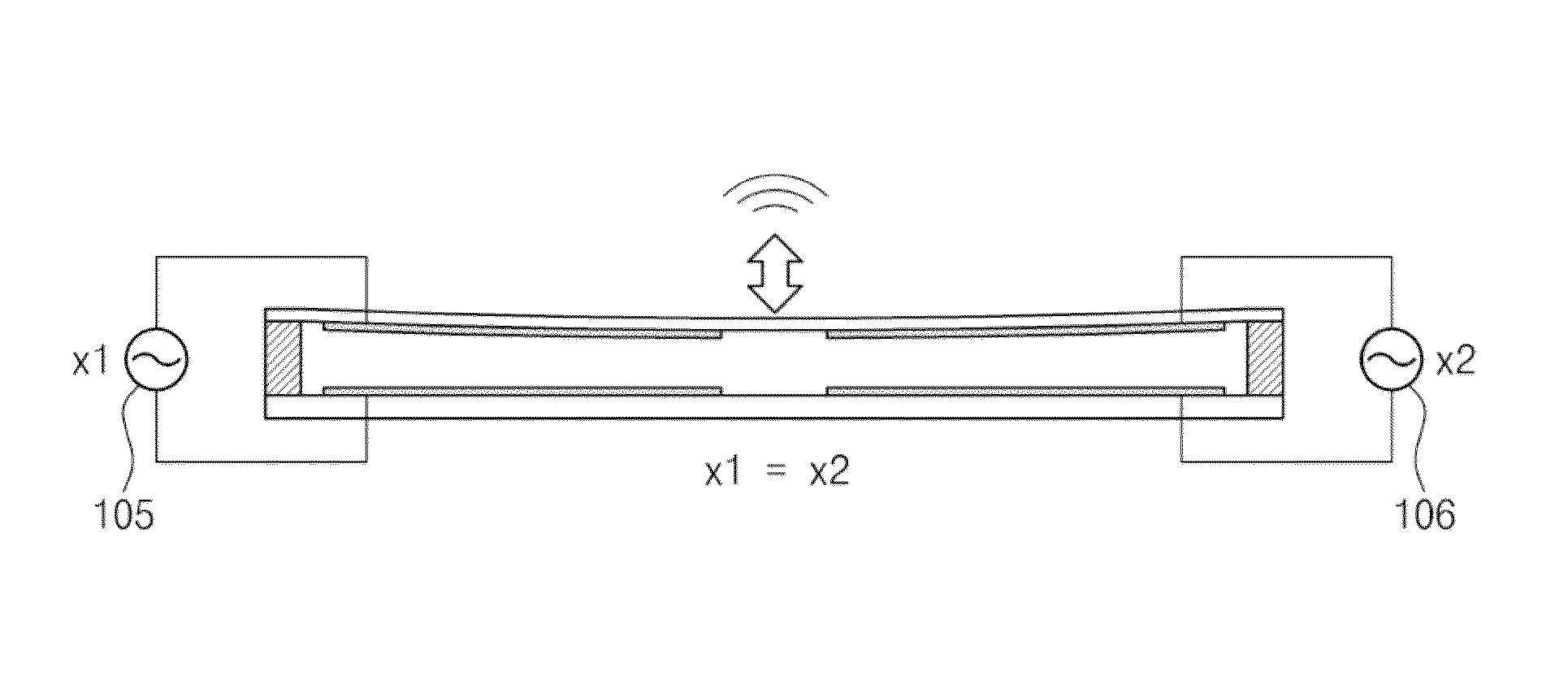

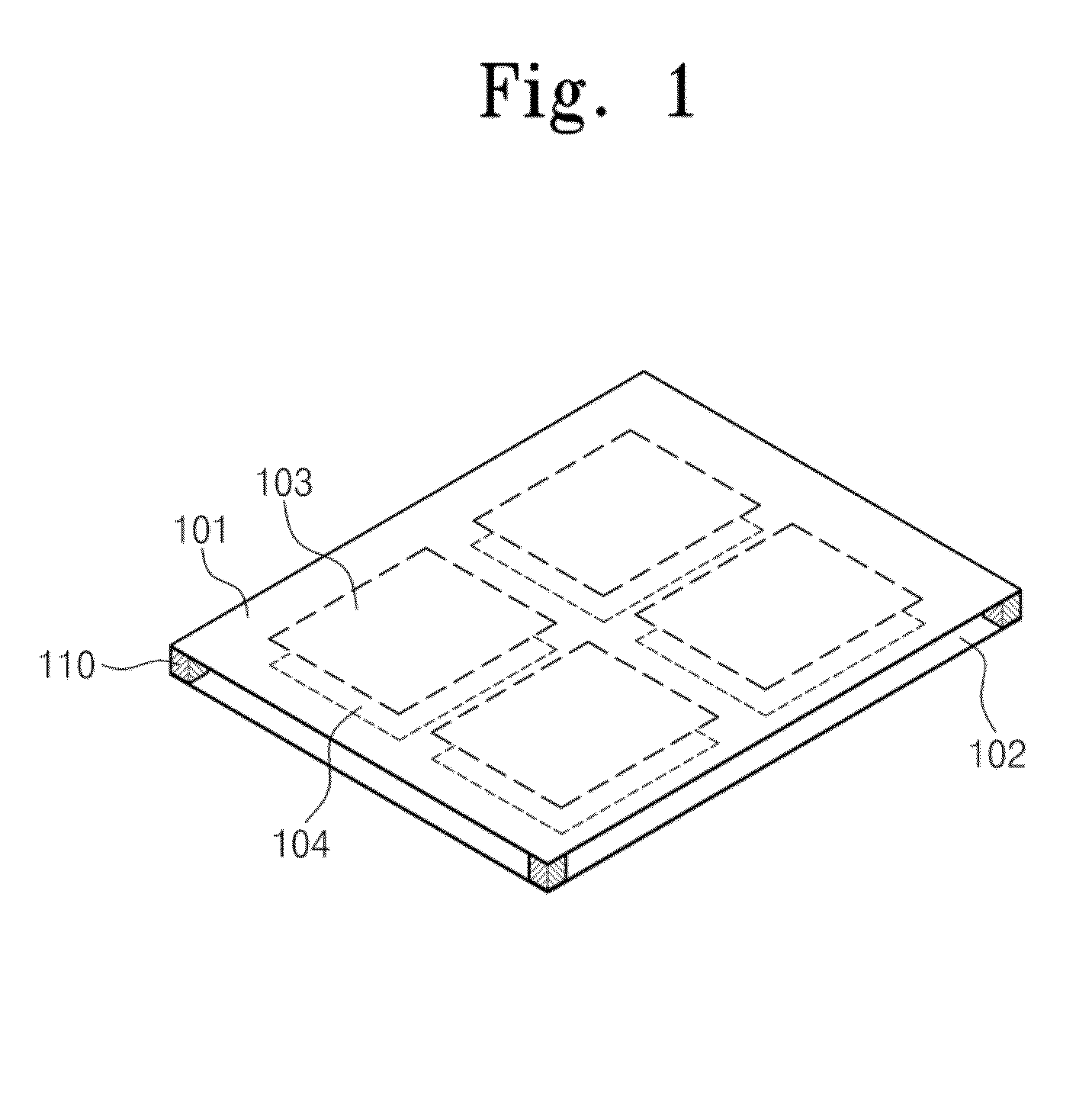

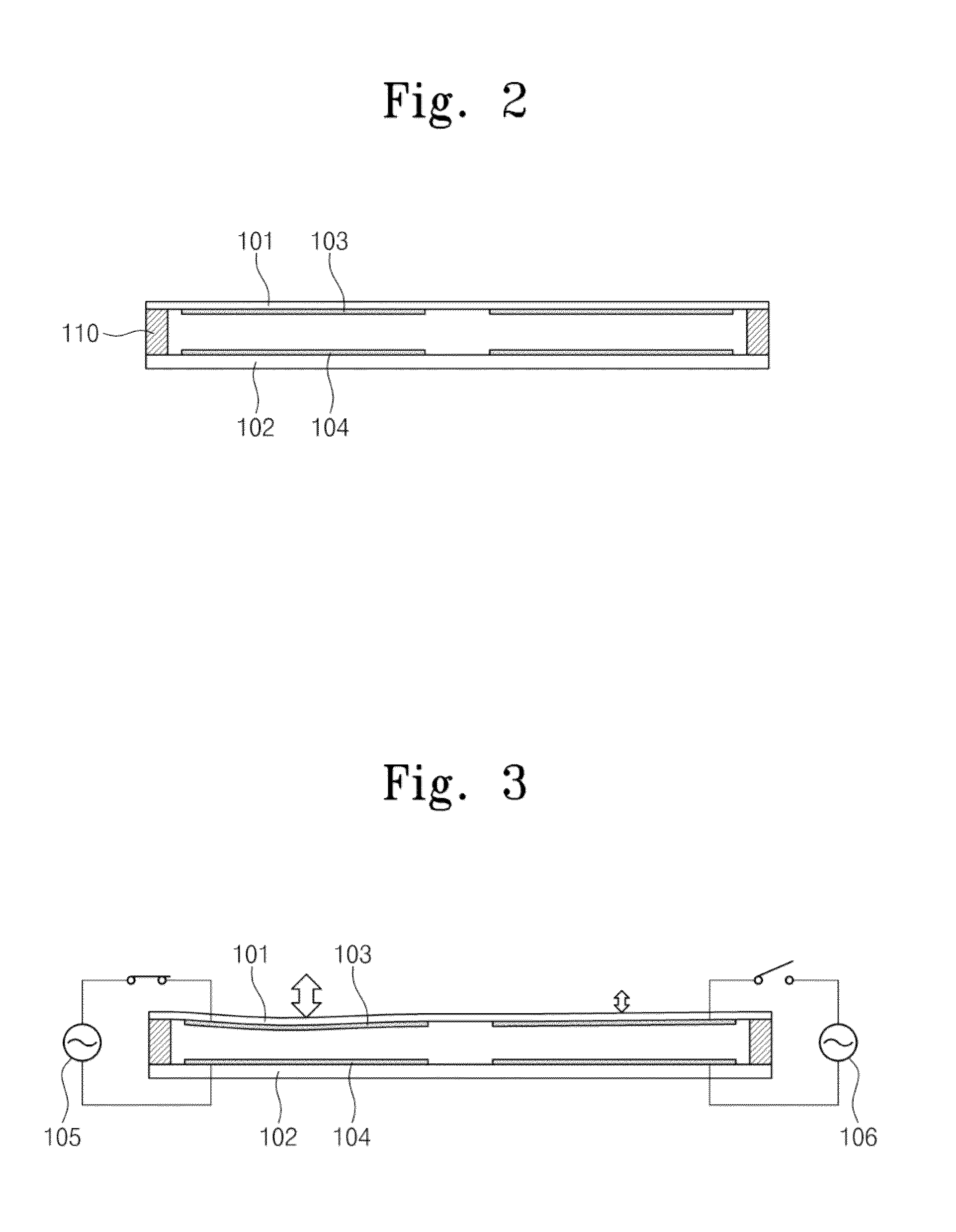

Film haptic system having multiple operation points

Provided is a thin film type actuator having multi-operation points, capable of various feels of touch or sounds. The film type actuator includes an upper plate and a lower plate, formed of a single plate. Between the upper plate and the lower plate, pairs of electrode parts capable of attracting one another via an electrostatic force. Since each of the pairs of electrode parts functions as an operation point and the upper plate and the lower plate are formed of the single plate, movements of the respective operation points in such a way that a new physical movement different from an original individual movement is generated to generate a haptic feel or a sound. It is possible to generate various haptic feels or sounds by modulating and combining amplitudes and frequencies of the respective operation points.

Owner:ELECTRONICS & TELECOMM RES INST

Plywood laminate having improved dimensional stability and resistance to warping and delamination

A plywood laminate having dimensional stability and resistance to warping and delamination is formed from a plurality of higher quality plies and a plurality of lower quality plies. The higher quality plies may be of hardwood and the lower quality plies may be of softwood or lower quality hardwoods, or the higher quality plies may have a veneer grade of better than ANSI / HPVA HP-1-2000 veneer grade C and the lower quality plies may have a veneer grade of no greater than ANSI / HPVA HP-1-2000 veneer grade C. The exposed plies are of the higher quality. In most embodiments, at least two adjacent interior plies are of the lower quality. In those embodiments having a tongue and groove or click-lock edge configuration, the tongue comprises portions of at least two plies and at least one of the plies is a higher quality ply.

Owner:AHF LLC

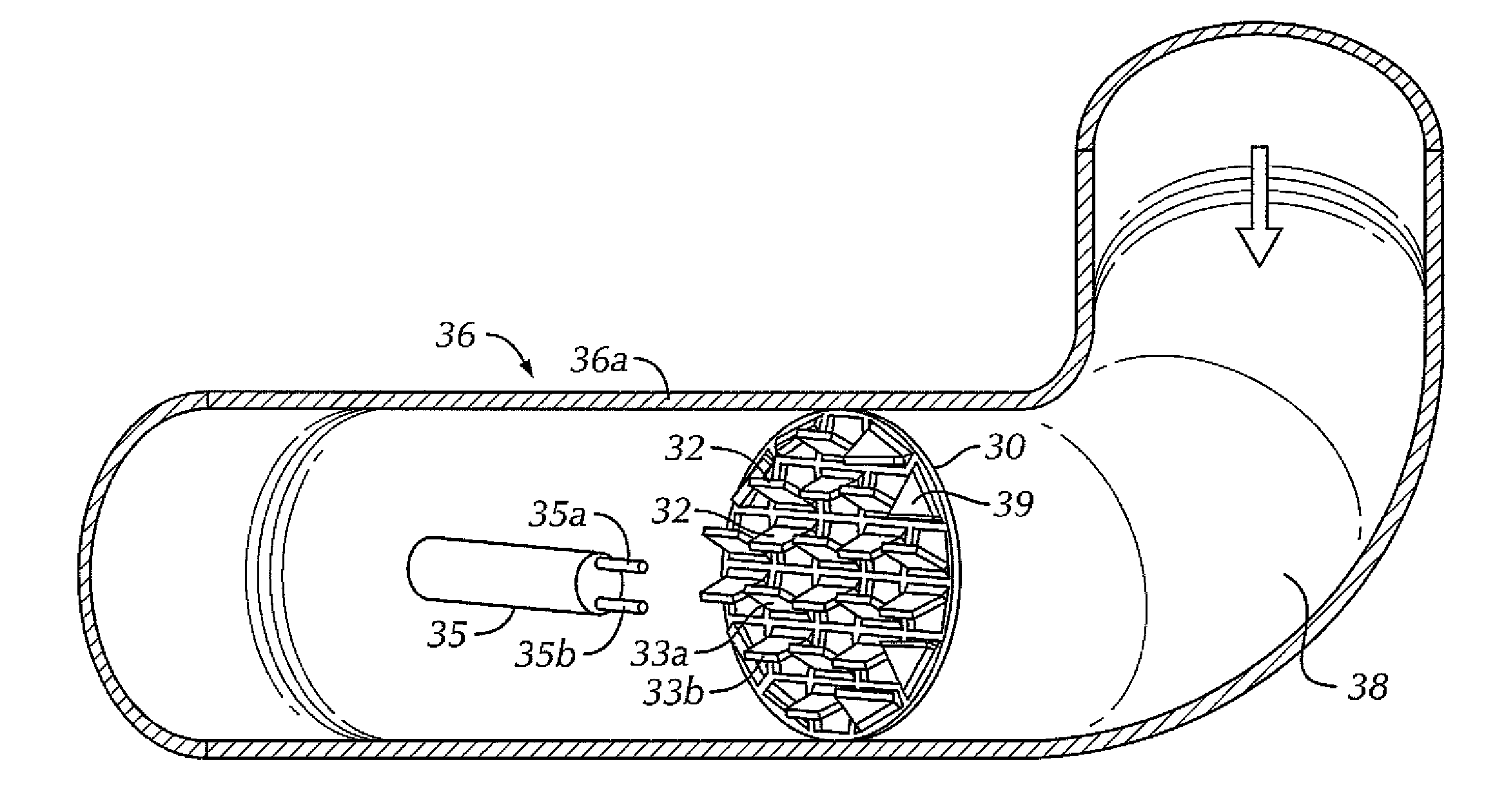

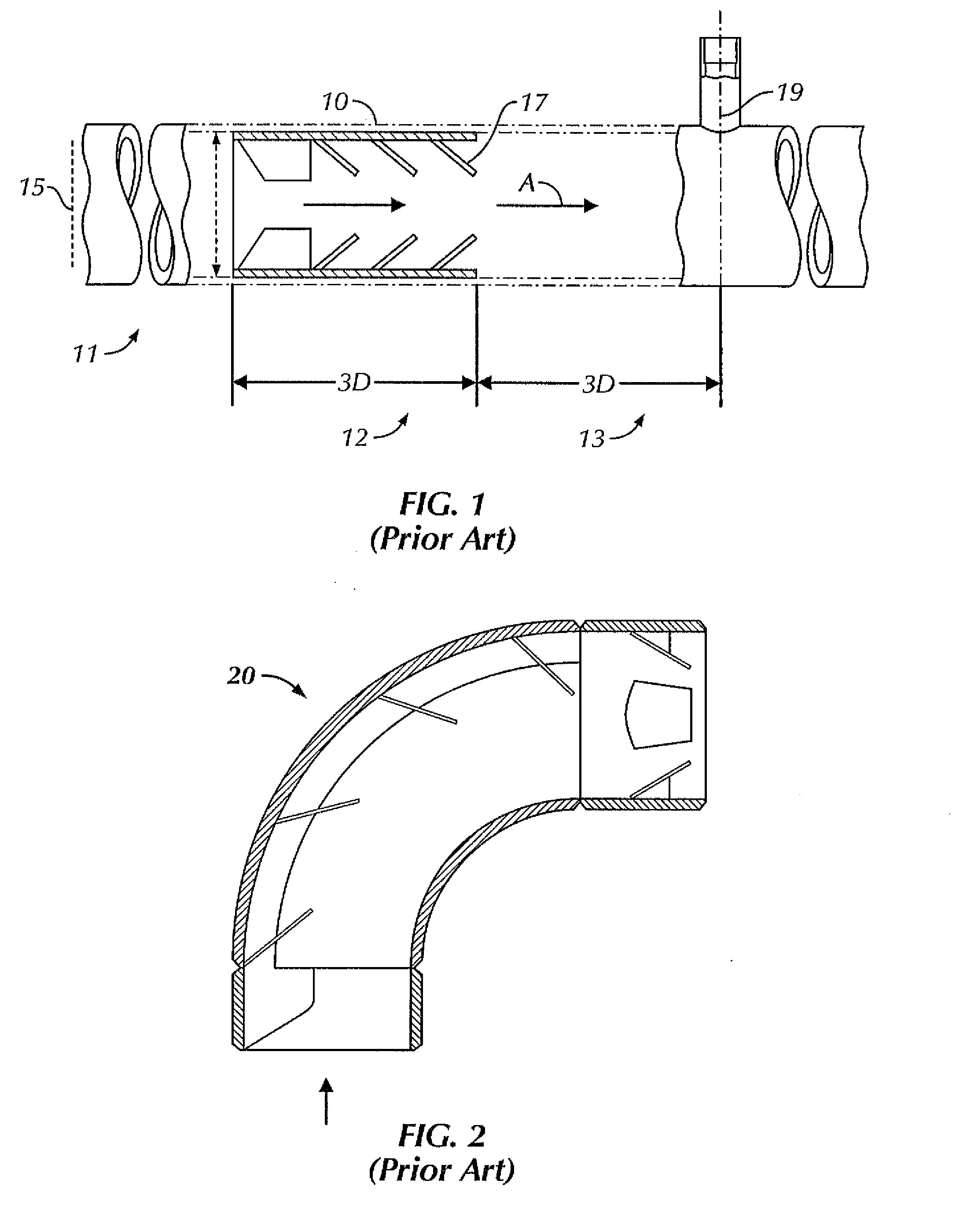

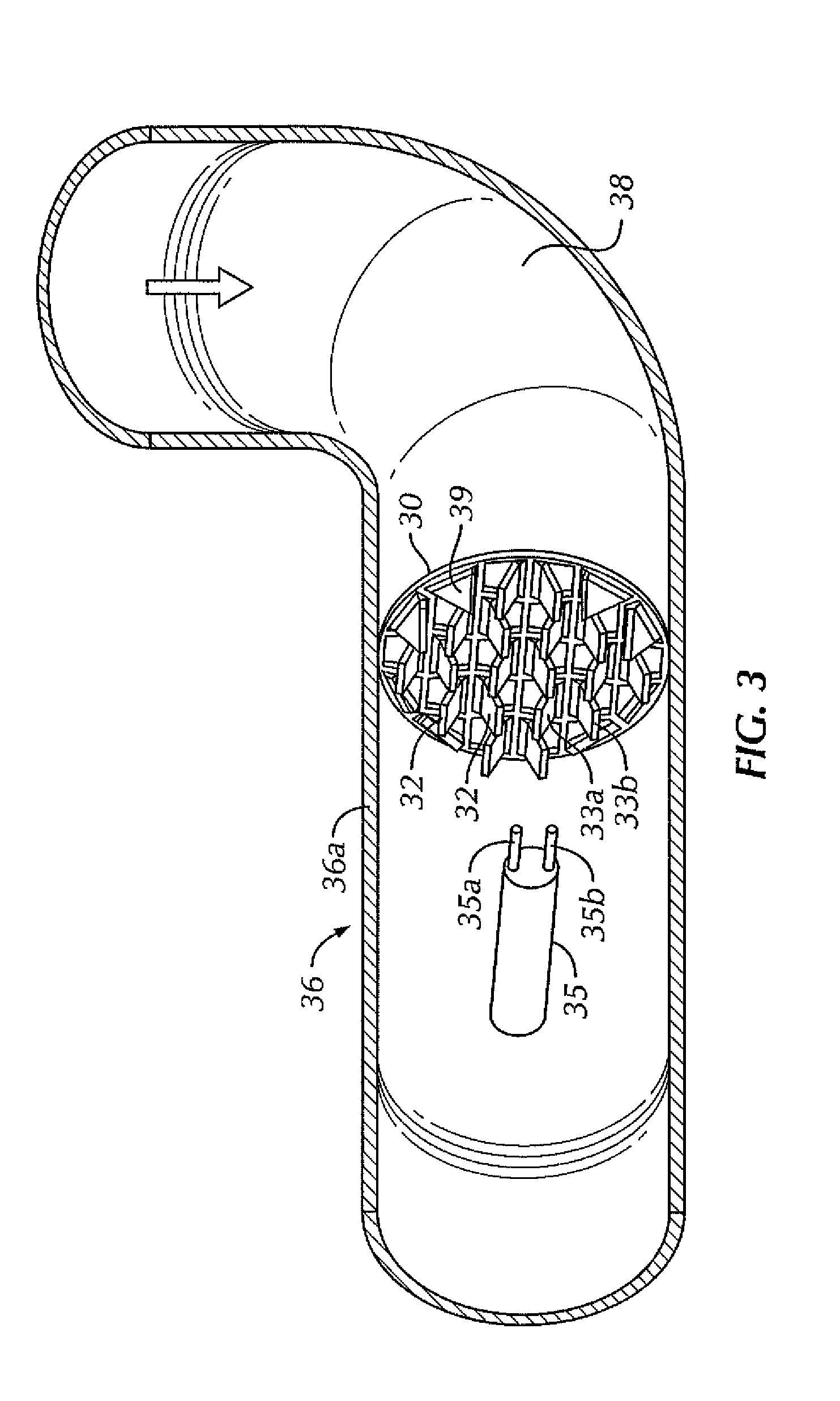

Flow mixer and conditioner

ActiveUS20110174407A1Reduce shipping costsReduce material costsFluid heatersFlow mixersSingle plateDistortion

A flow mixer and conditioner for use within a conduit conditions flowing media within the conduit to provide a swirl-free, symmetric, and reproducible velocity profile regardless of upstream flow distortions, disturbances, or anomalies. Tabs are cut from a single plate and bent or affixed to provide mixing and conditioning of the flowing media. Single tabs or tab pairs emanating from common vertices can be formed so that they diverge in, or against, the direction of flowing media. The flow conditioner requires as little as three pipe diameters downstream and upstream to mix and condition the flow stream allowing close placement to elbows, valves, tees, and other disturbances typically seen in industrial plants.

Owner:FLUID COMPONENTS INTERNATIONAL

Notched surface-mounted anchors and wall anchor systems using the same

InactiveUS7562506B2Reduce openingHigh strengthStrutsFoundation engineeringWater vaporSurface mounting

Owner:HOHMANN & BARNARD INC

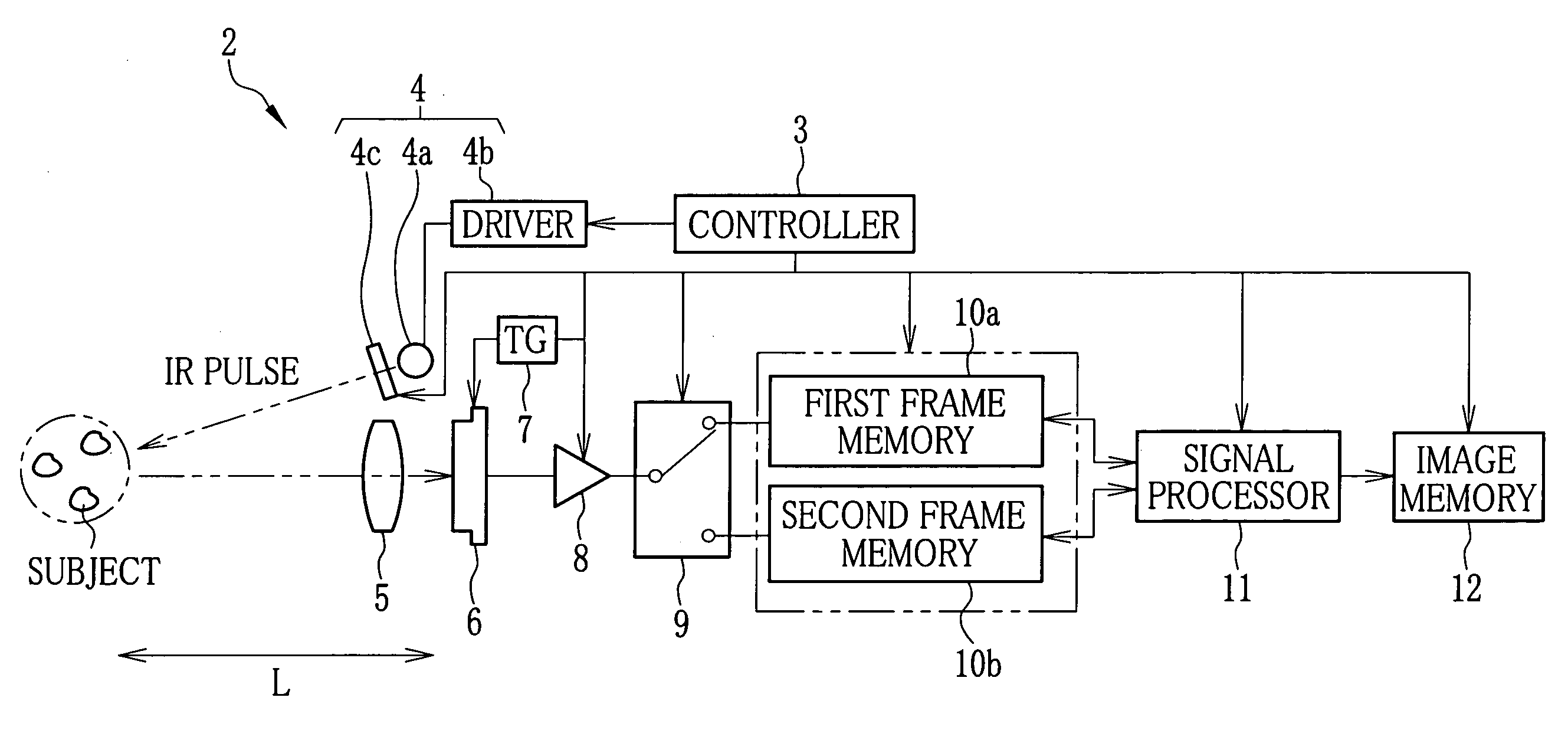

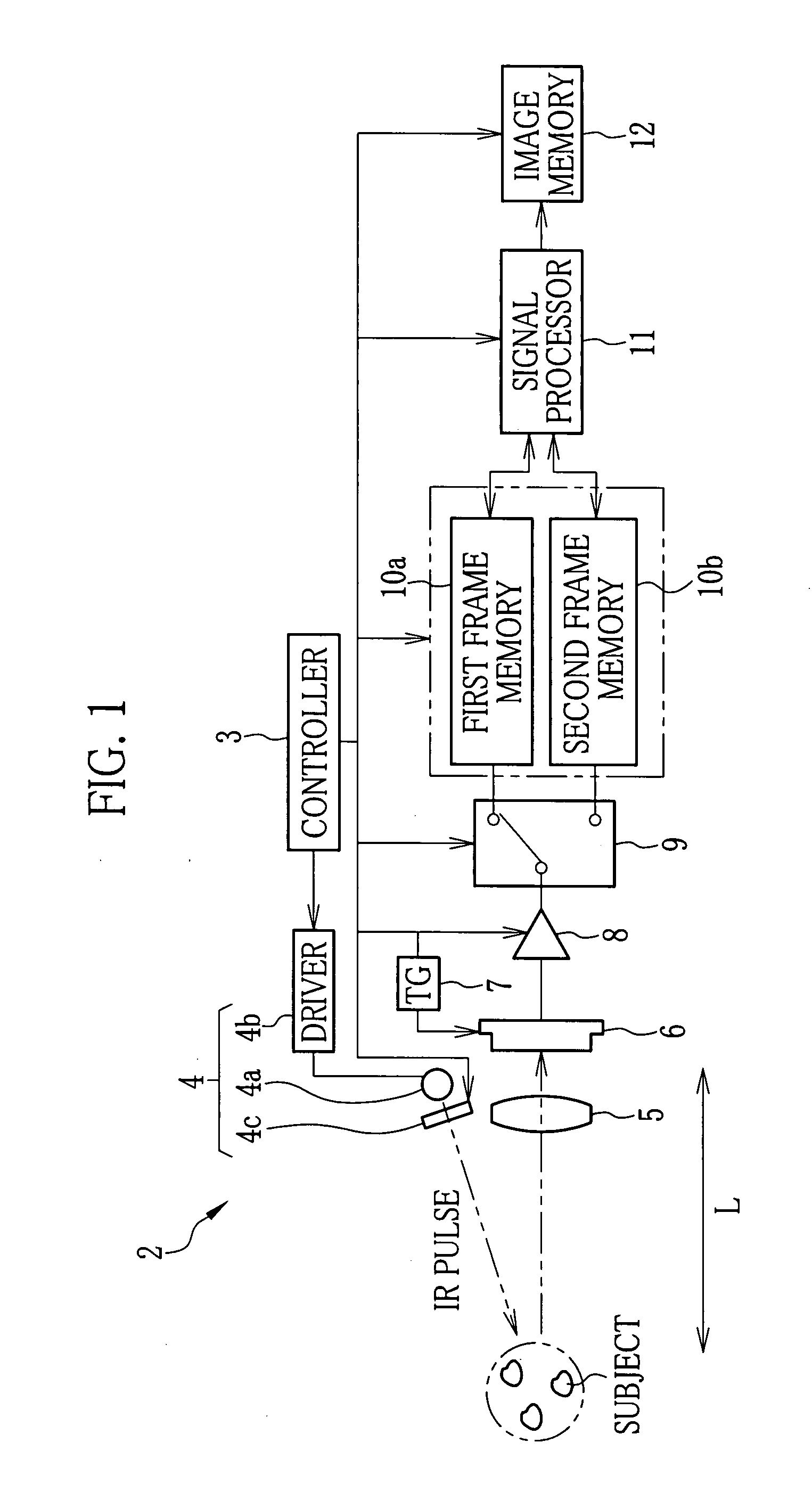

Range image system for obtaining subject image of predetermined distance position

InactiveUS20080122933A1Simple structureIncrease costTelevision system detailsOptical rangefindersSingle plateImage system

A solid-state imaging device has a single plate structure and is capable of imaging of visible light and infrared light. While imaging of the visible light and the infrared light is performed by the imaging device every one-frame scanning period, an IR pulse is emitted, every other one-frame scanning period, to a space to be shot. A visible-light image is produced every one-frame scanning period. A range image from which influence to be caused by infrared component of the ambient light is removed is produced every other one-frame scanning period by subtracting an IR pixel image (S2IR), which is obtained by imaging of non-emission time of the IR pulse, from an IR pixel signal (S1IR), which is obtained by imaging of emission time of the IR pulse.

Owner:FUJIFILM CORP

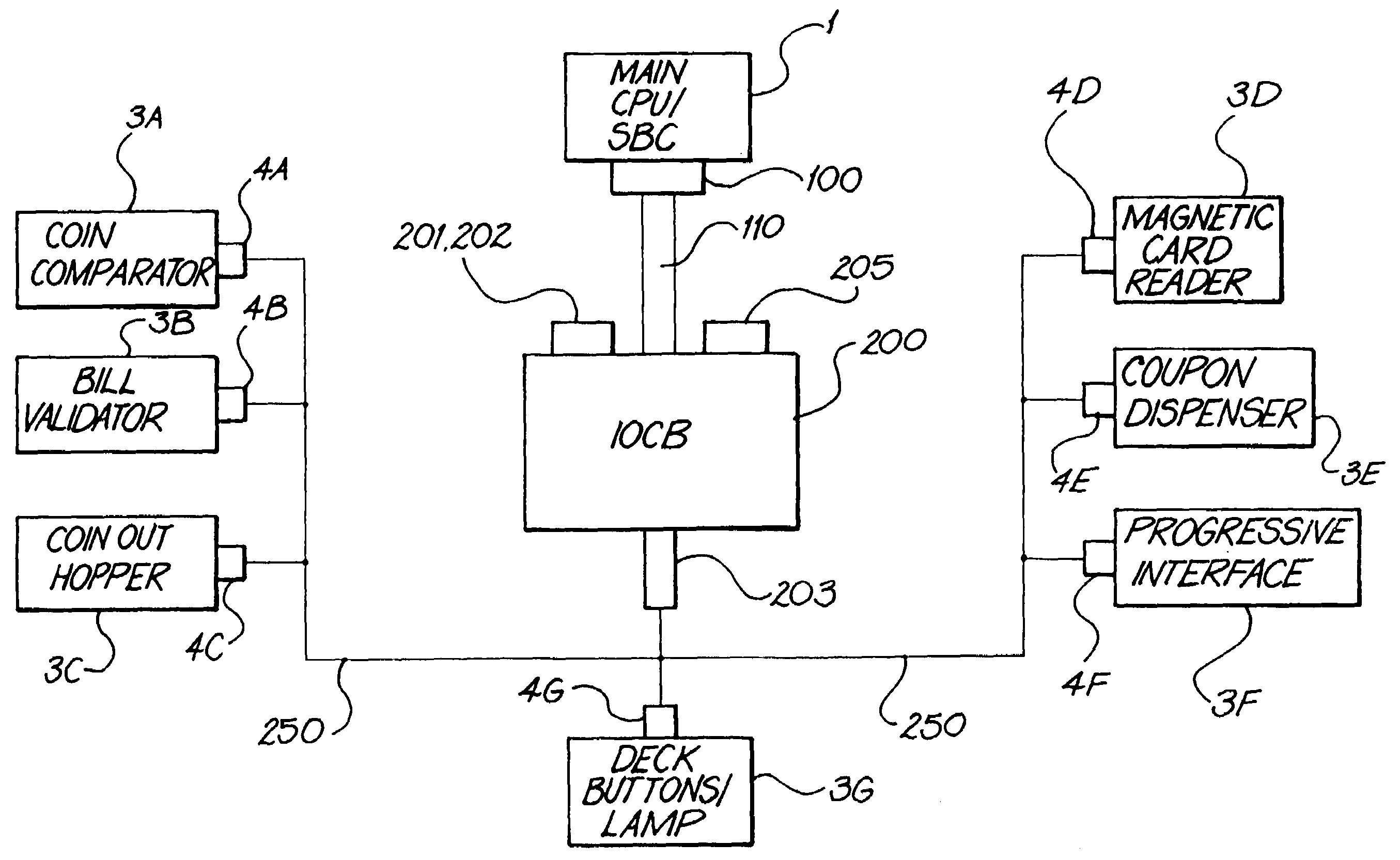

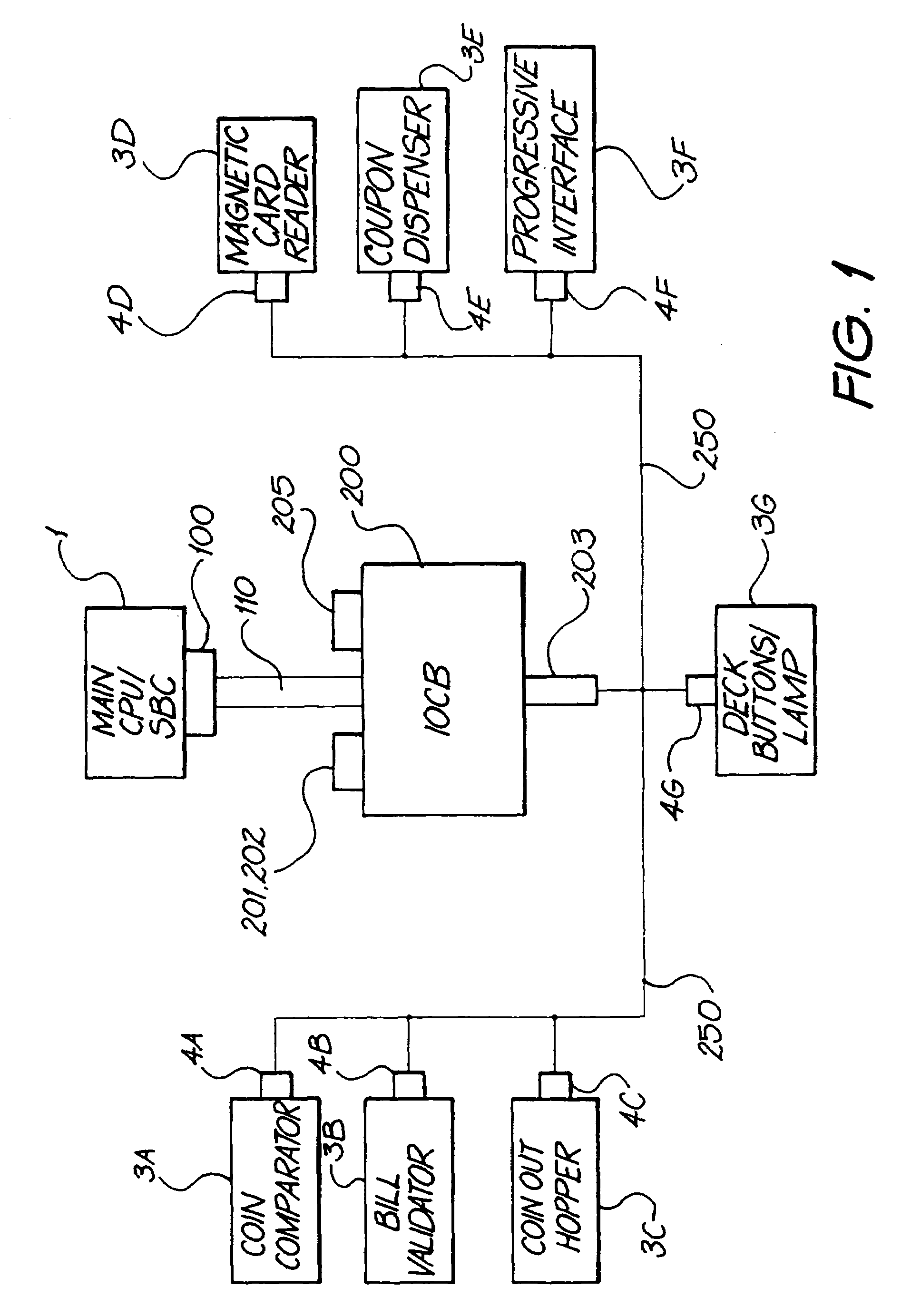

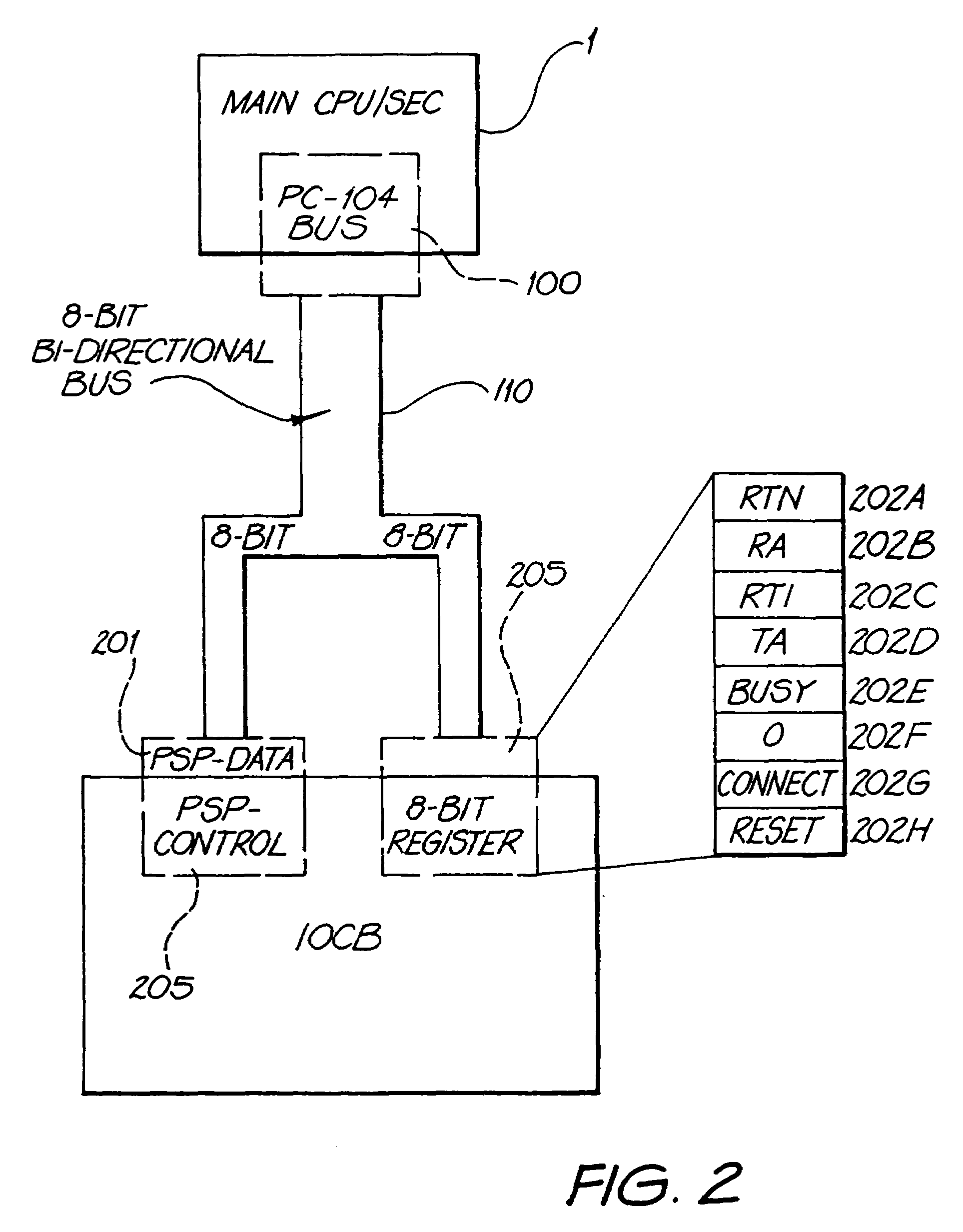

Secured inter-processor and virtual device communications system for use in a gaming system

InactiveUS7093040B1Reliable dataFacilitate communicationDigital computer detailsInternal/peripheral component protectionCommunications systemMultidrop bus

The invention comprises an electronically secured inter-processor and virtual device communications system, with an input / output controller board, a multi-drop bus interface to multiple devices, and a parallel interface to an industry standard single board computer. The invention assigns a bus address and virtual identification number to each device and controls communications between the main central processing unit and the devices through a Plug-n-Play protocol.

Owner:ARISTOCRAT TECH AUSTRALIA PTY LTD

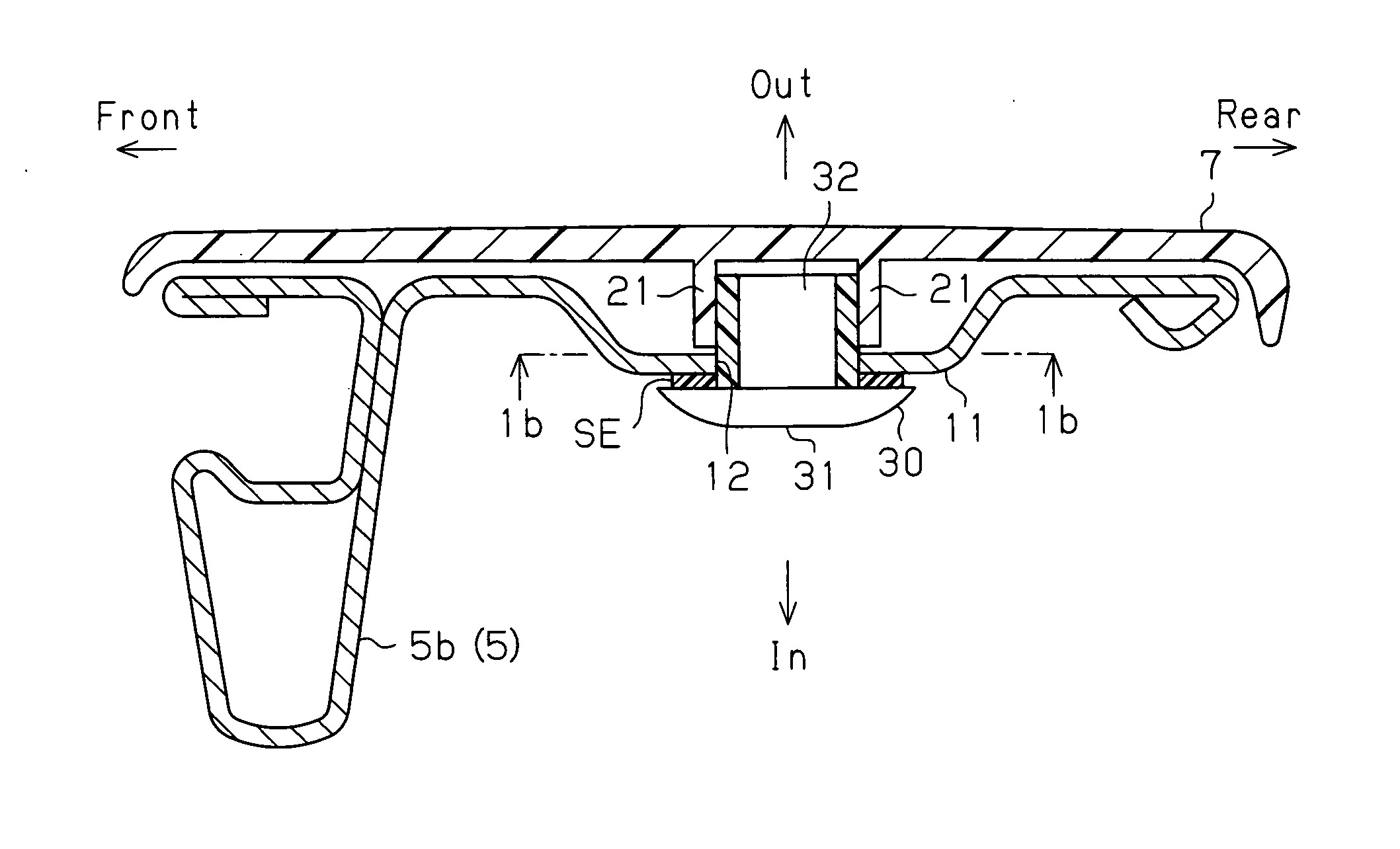

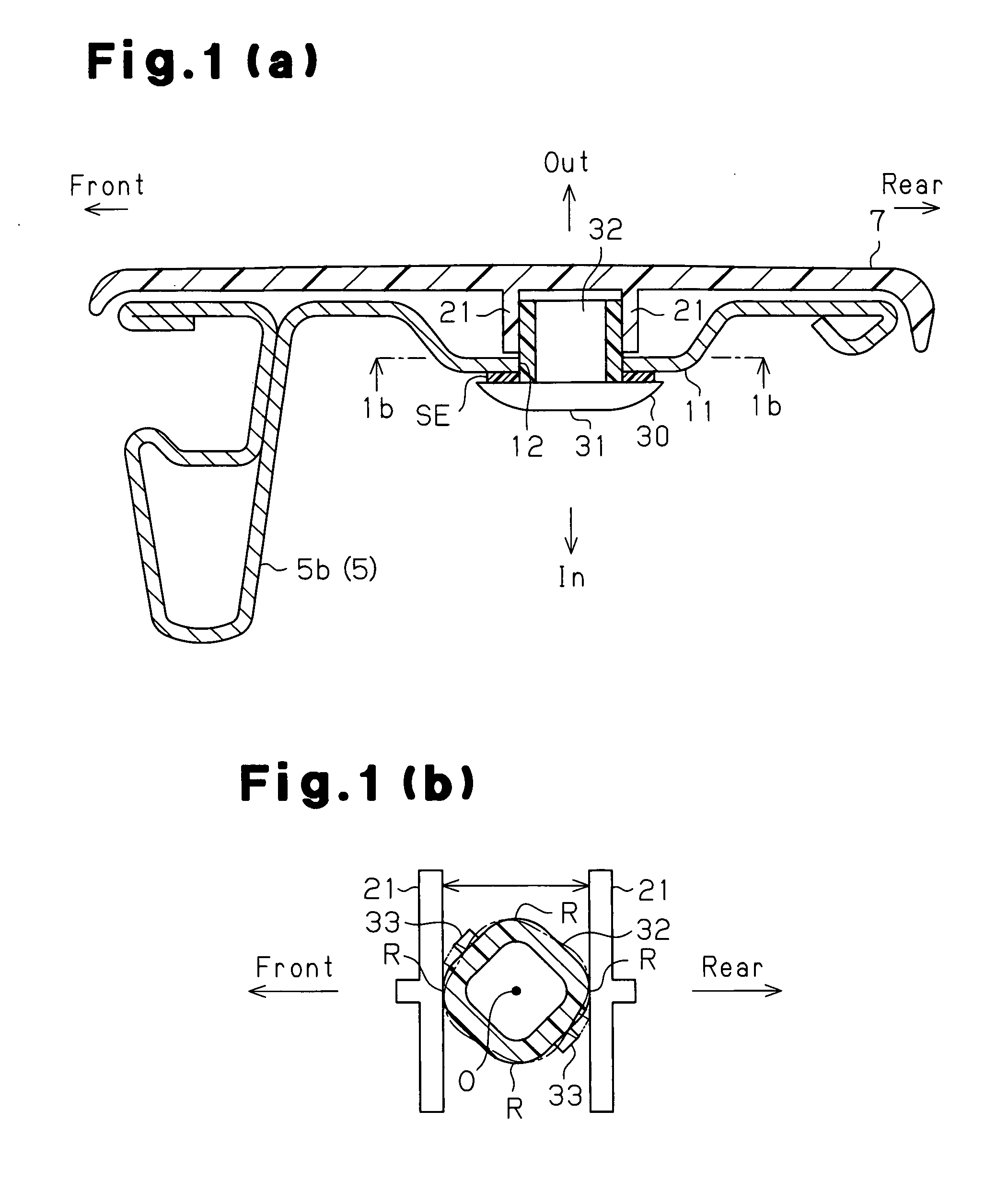

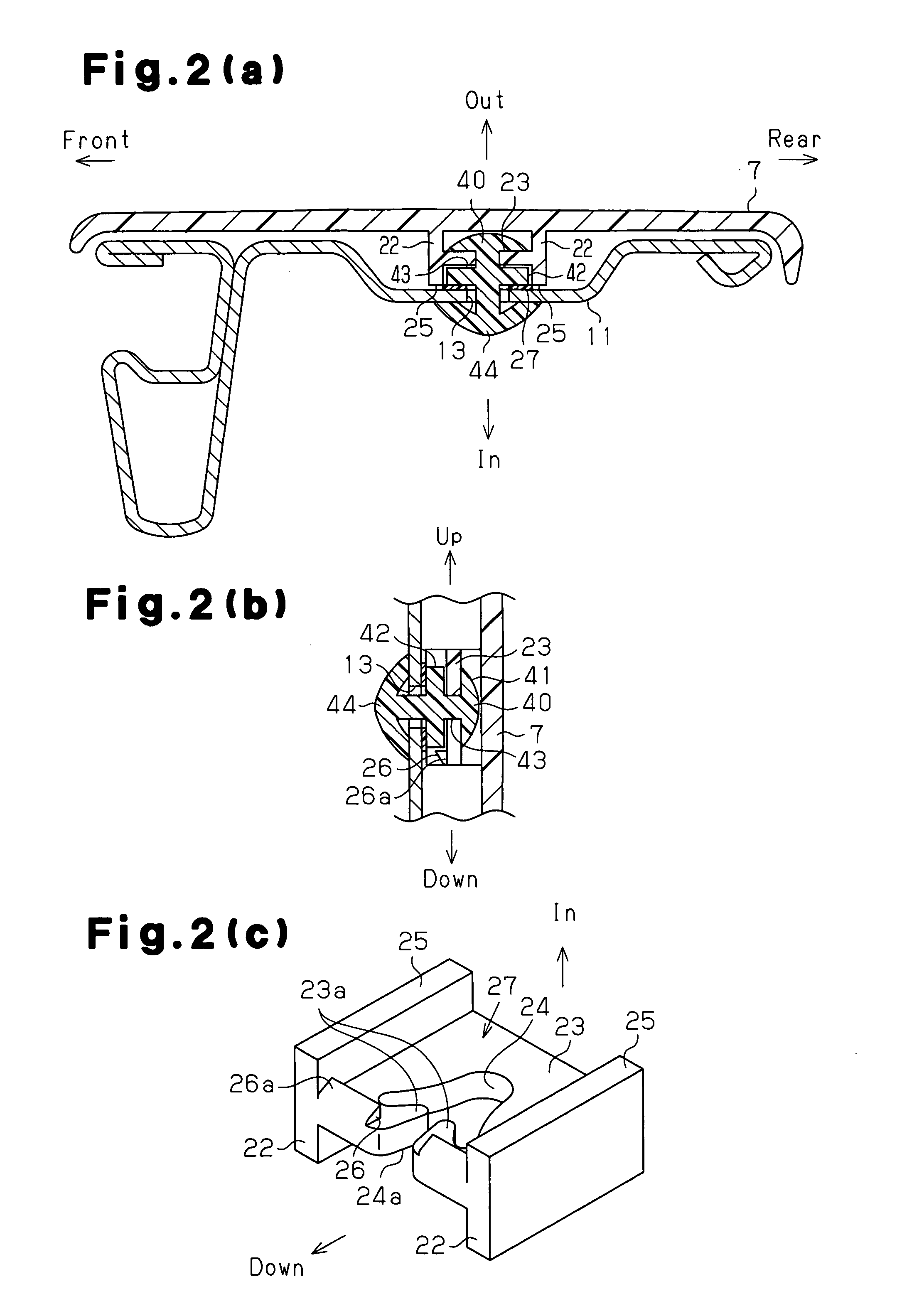

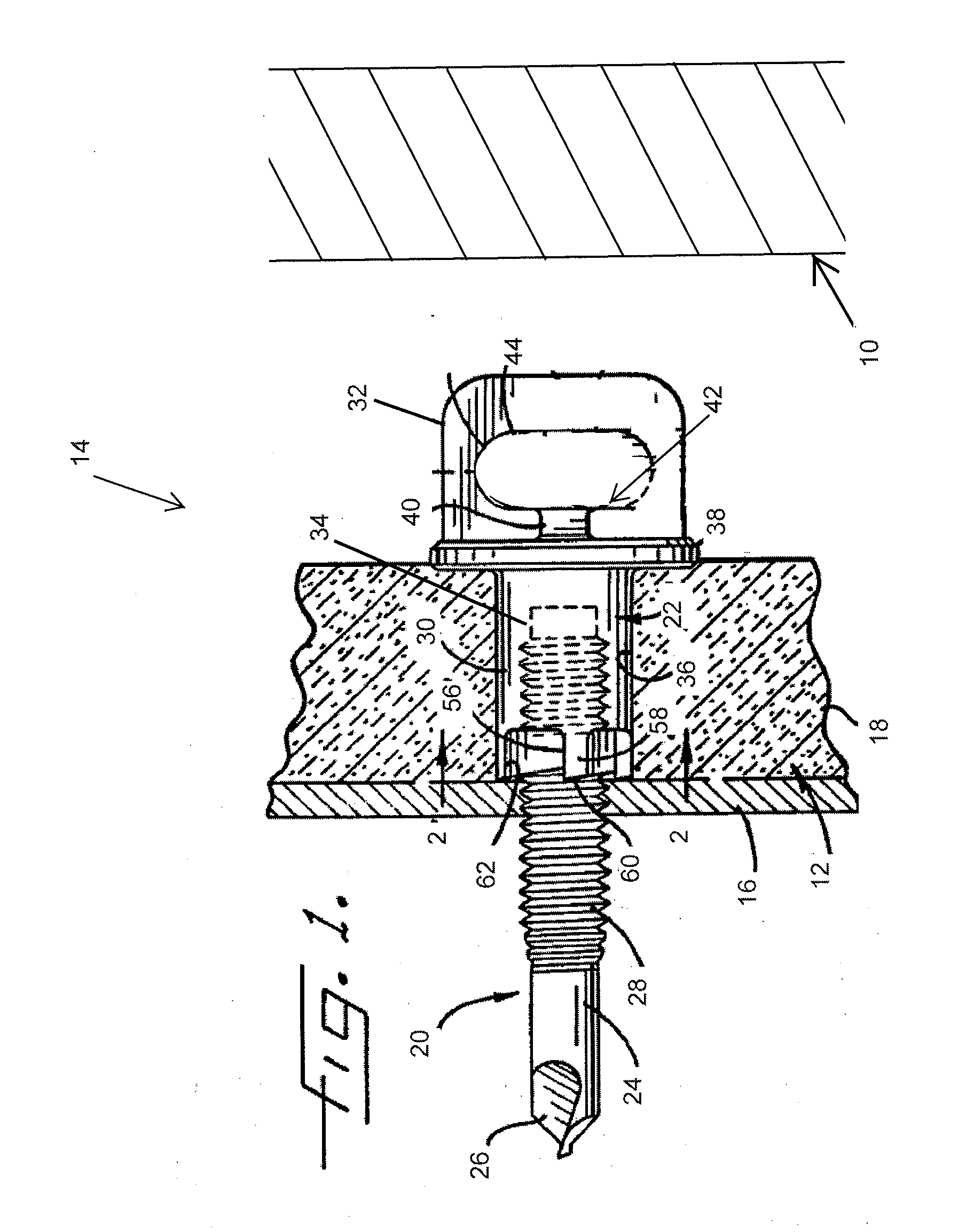

Trim attachment structure

ActiveUS20110296764A1Improves aesthetic appealReduced angular positionSheet joiningFriction grip releasable fasteningsDiagonalSingle plate

A trim attachment structure includes a door frame, trim and a clip. The door frame has an attachment part, which is formed by a single plate, and a fitting hole. The fitting hole has a square shape in which the diagonals thereof are aligned with specific directions. The trim has a pair of ribs which extend towards the inner side in the width direction of the vehicle, respectively facing a pair of end parts of the fitting hole. The clip is installed in the fitting hole. The clip includes a head part, a tube part and a latching hook. The tube part has a tip end part which projects from the fitting hole to the outer side of the attachment part in the width direction of the vehicle. Angled parts of the tip end part are held between the ribs. The latching hook is latched at the peripheral edge of the fitting hole on the outer side of the attachment part in the width direction of the vehicle.

Owner:AISIN SEIKI KK +1

High-strength surface-mounted anchors and wall anchor systems using the same

Owner:HOHMANN & BARNARD INC

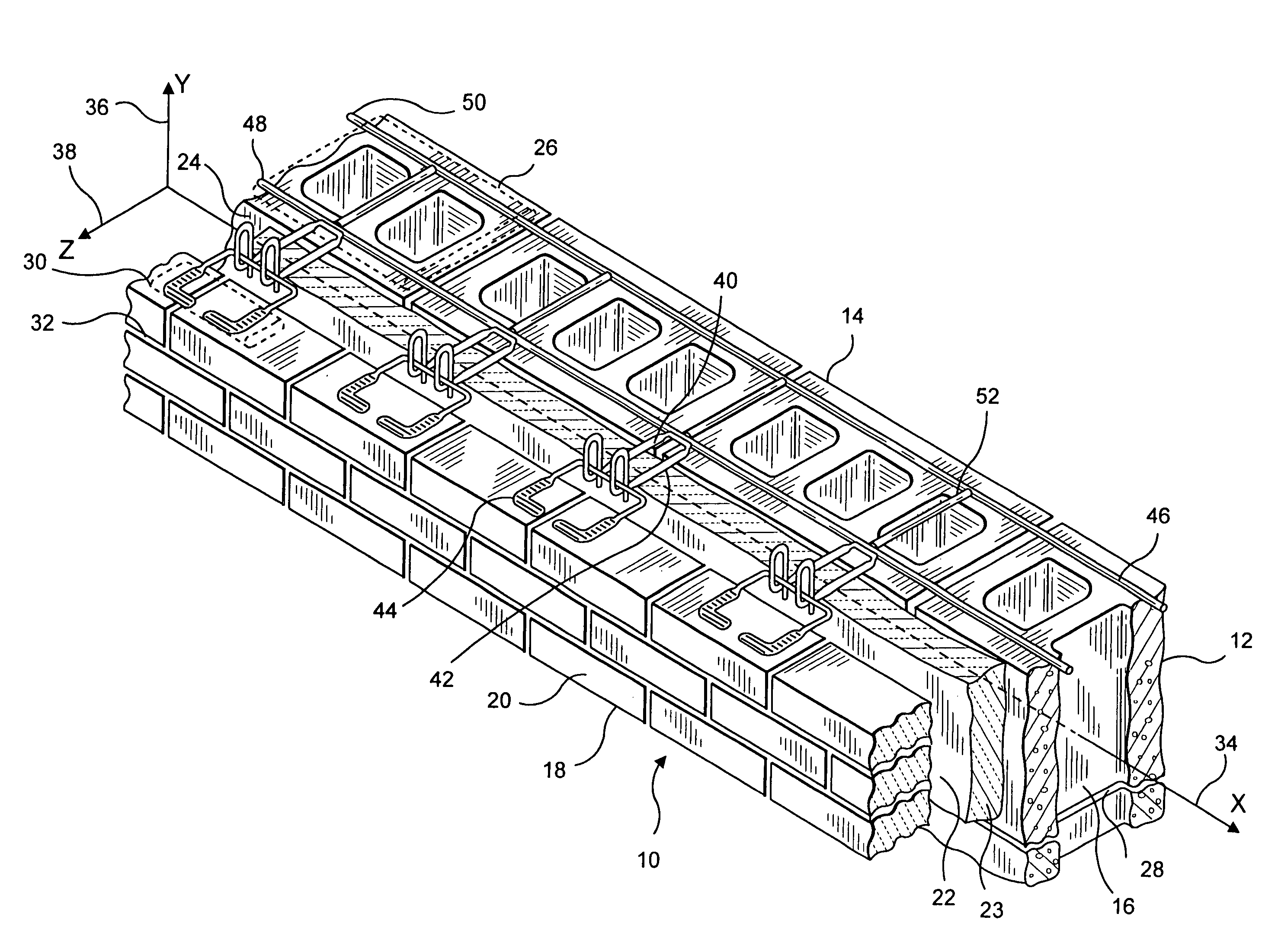

Anchors and reinforcements for masonry walls

InactiveUS8122663B1Labor savingIncrease the cross-sectional areaConstruction materialBuilding reinforcementsSingle plateEngineering

Anchor and reinforcement devices for a cavity wall are disclosed. The devices are combined with interlocking veneer anchors, and with veneer reinforcements to form unique anchoring systems. All the components of the system are wire formatives, including therewithin truss or ladder reinforcements and the eye extensions. The wall anchor portion of the device is fusibly attached to the exterior of the truss or ladder reinforcement by various metalworking techniques. Beyond the portions of the wire formatives inserted in the backup wall, the wire formatives are optionally reduced in height by cold-working thereof. The combined wall anchor and reinforcement devices are compressively reduced in height for spanning insulation mounted on the exterior of the backup wall. The low-profile portions are disposed between thick strips of insulation and maintain the insulative integrity thereof by preventing air leakage.

Owner:HOHMANN & BARNARD INC

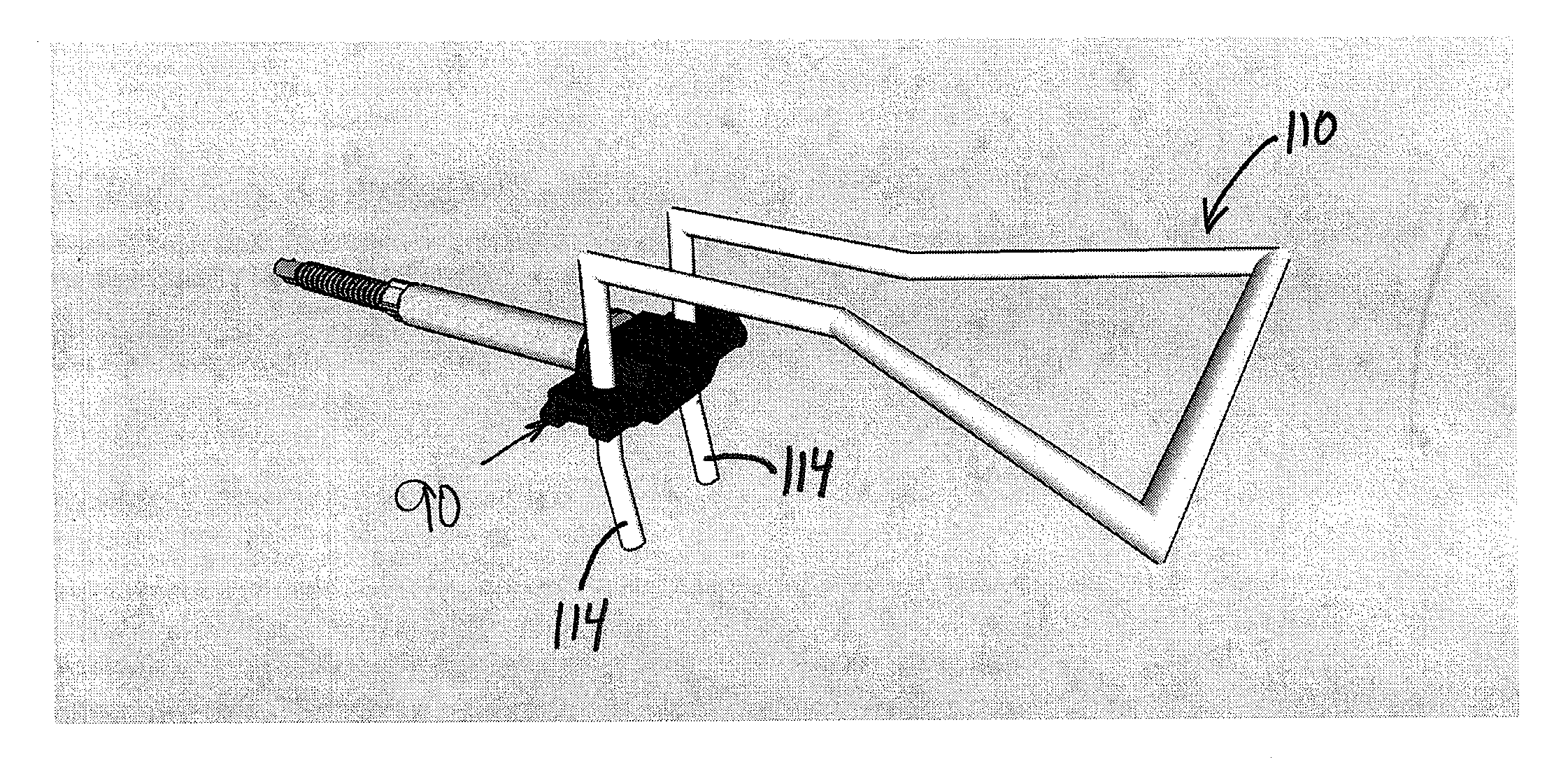

Thermal clip attachment apparatus for masonry anchors and methods thereof

A thermal clip attachment apparatus and methods for using the thermal clip attachment with a masonry veneer anchor system are disclosed. The thermal clip attachment may be a composite piece that attaches to the part of a stud that protrudes from an inner structural supportive wall after the stud is advanced into the wall. The thermal clip attachment serves as a thermal break between the stud and an outer masonry veneer wall. Further, the thermal clip attachment also serves as an attachment point for a wire tie, which allows a positive lateral load connection to be established between the outer masonry veneer wall and the inner structural supportive wall.

Owner:MECHANICAL PLASTICS CORP

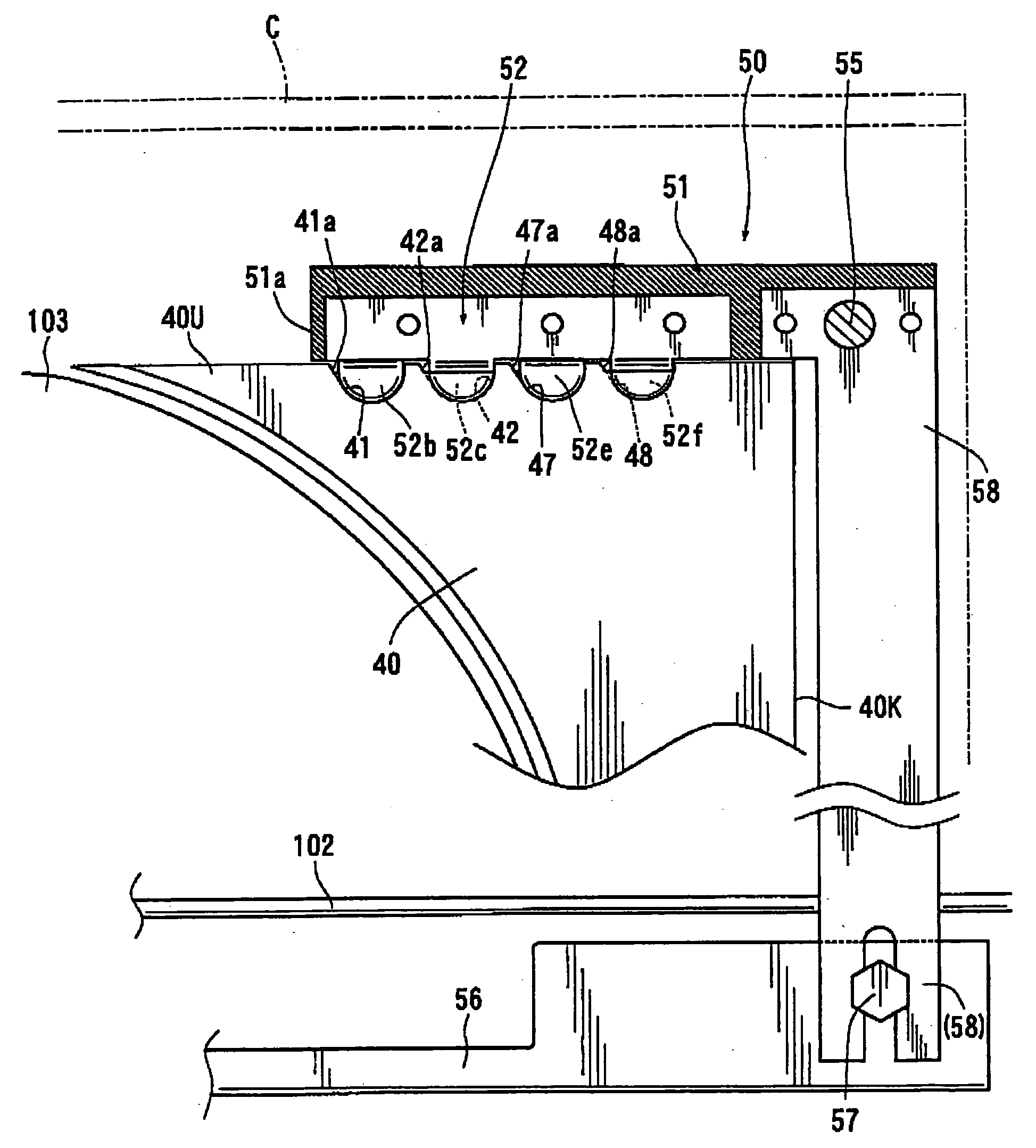

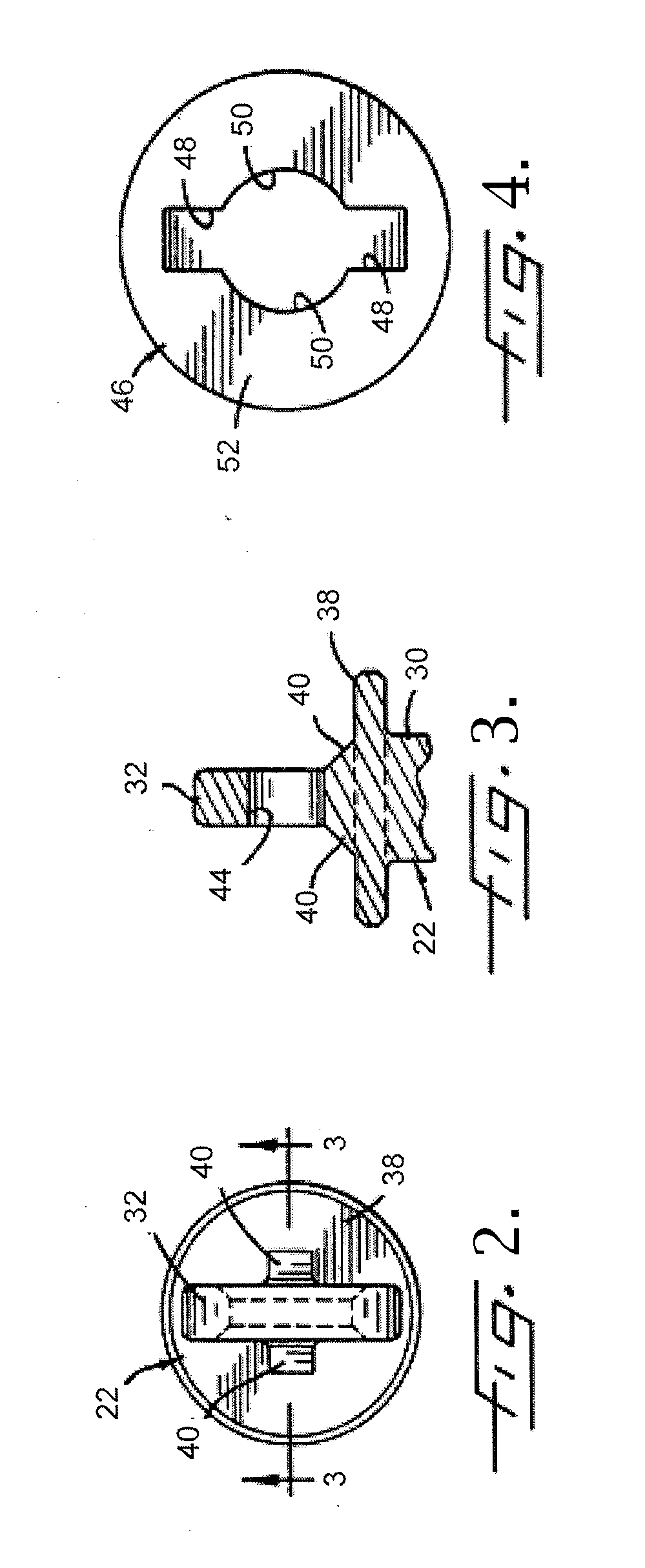

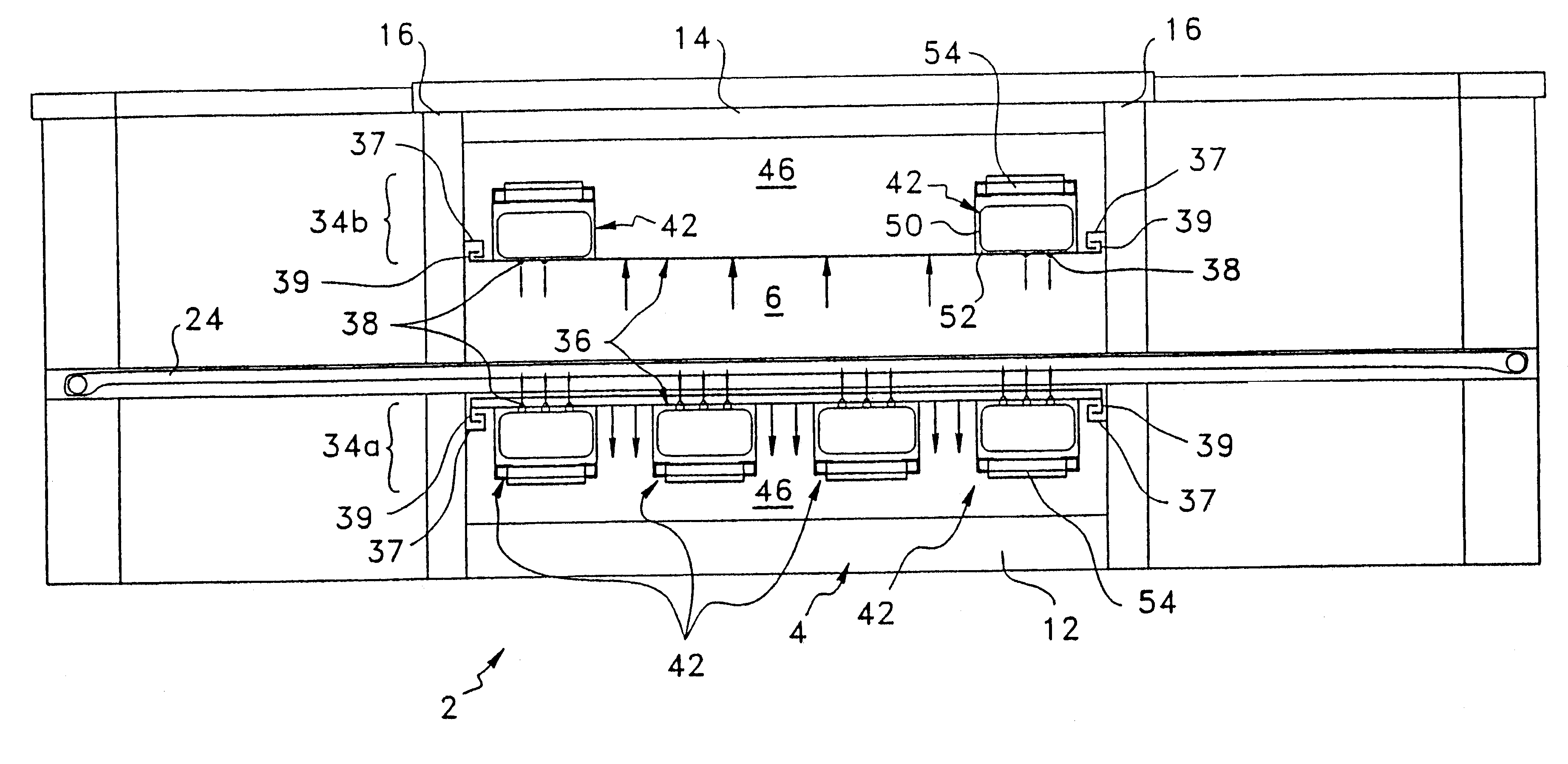

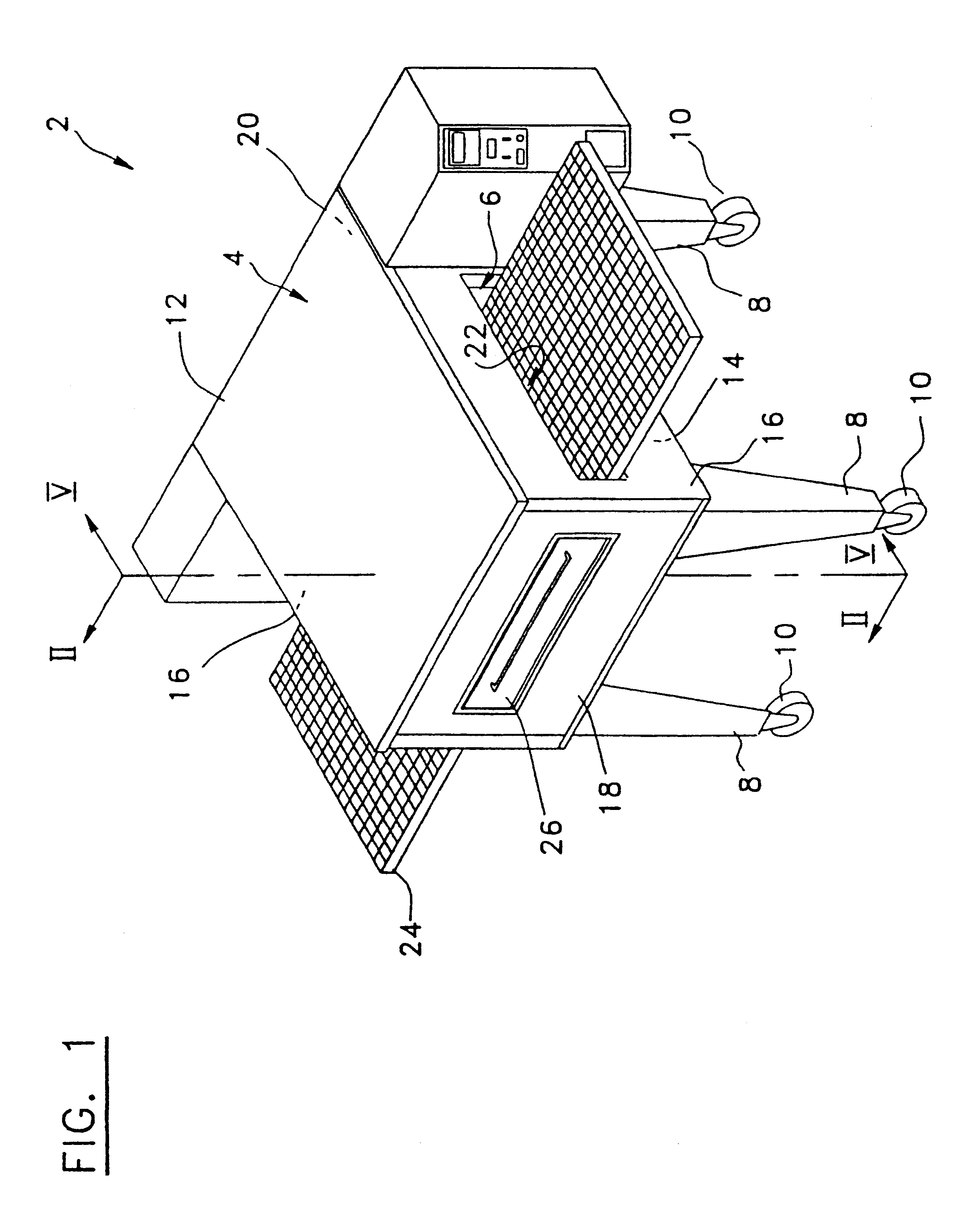

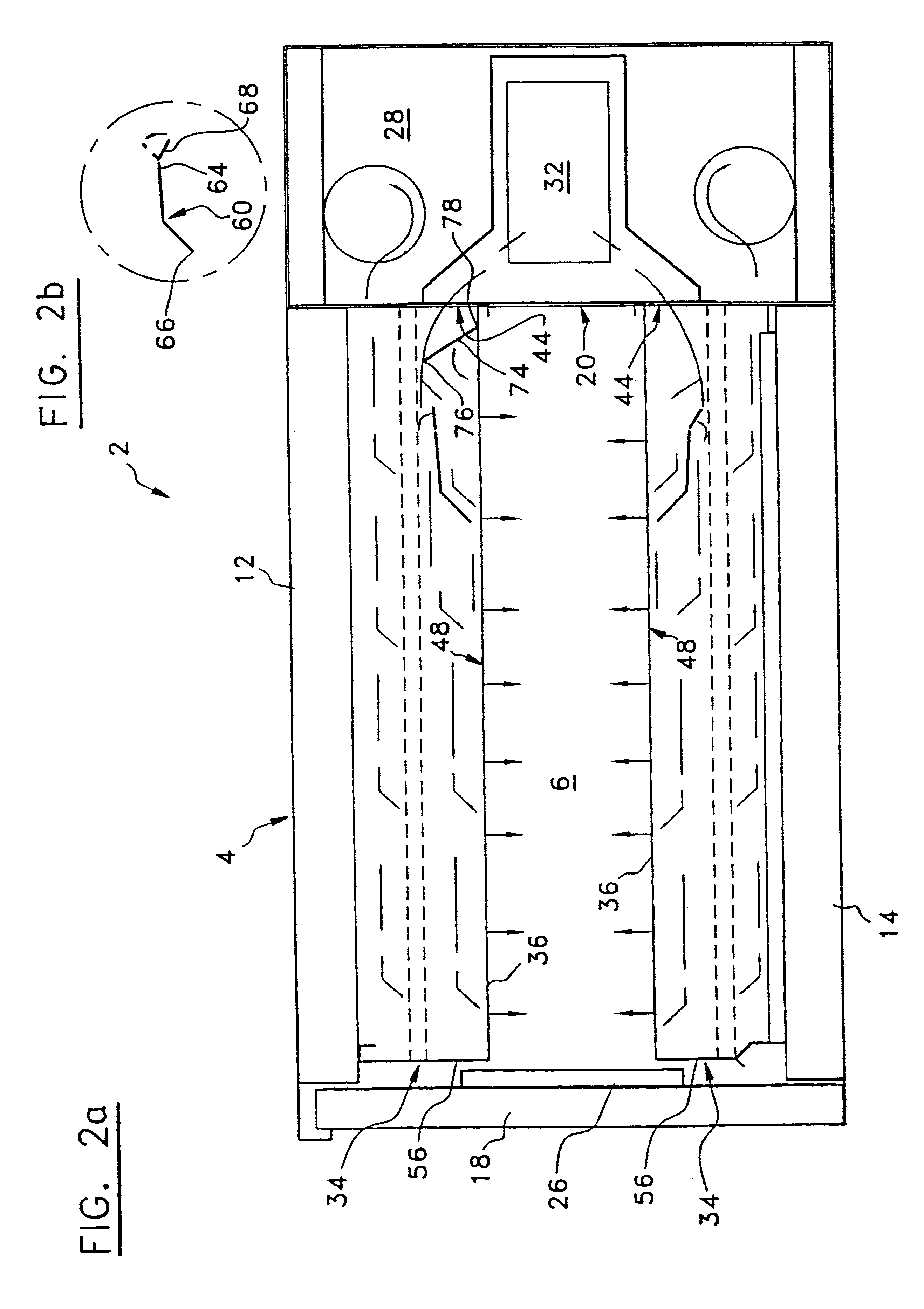

Blown air distributor for a convection oven

InactiveUS6192877B1Rapidly and easily dismountedImprove distributionBiocideDomestic stoves or rangesSingle plateDistributor

A blown air distributor for use in a convection oven having a blower that draws air from the baking chamber, a heat source to heat the drawn air and a plenum downstream from the blower to recirculate the heated air in the baking chamber. The blown air distributor has a plurality of finger ducts mounted in parallel on a single plate, which is removable from the baking chamber. Each finger duct has an air inlet to receive the heated air from the plenum and a plurality of air outlets to dispense the heated air in the baking chamber. The single plate has opposite side edges each slidably receivable in a guide way provided on a corresponding sidewall of the chamber. The single plate also has a plurality of air inlets that receive the air from the baking chamber and drawn by the blower. The blown air distributor is easily and rapidly installable without incorrectly placing each finger duct in the baking chamber. The blown air distributor is also easily dismantled for cleaning.

Owner:ZESTO FOOD EQUIP MFG

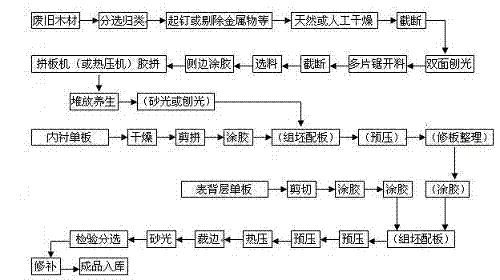

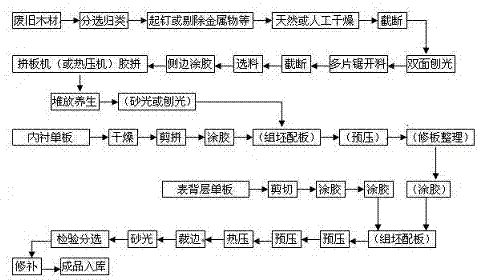

Method for producing recombinant composite board by using waste wood

InactiveCN102229159AFlat surfaceUniform thicknessOther plywood/veneer working apparatusLaminationSolid woodPulp and paper industry

The invention discloses a method for producing a recombinant composite board by using waste wood. The method comprises the following steps of: (1) preparation of a core board, (2) veneer finishing, (3) board blank gluing, blank matching and pre-pressing, (4) hot pressing, (5) trimming and sanding, and (6) inspection, grading and repair. The method has the advantages that: the square board of certain specification is manufactured by making full use of the waste wood, the core layer is spliced by using glue, two layers of veneers are covered on two sides of the core layer respectively, the recombinant composite board with five-layer structure is manufactured by hot pressing, and the reclaimed waste wood is used for substituting solid wood, so the material channel is broadened; low carbon, environment friendliness, greenness and resource property of the recombinant composite board are highlighted; the comprehensive utilization rate of the waste wood is improved, and the additional value and the technological content of the waste wood product are increased; and high use of small material, preferential use of poor material, fine use of coarse material and elaborate use of weak materialare realized in the waste wood.

Owner:玉环市众创人才科技创新服务中心

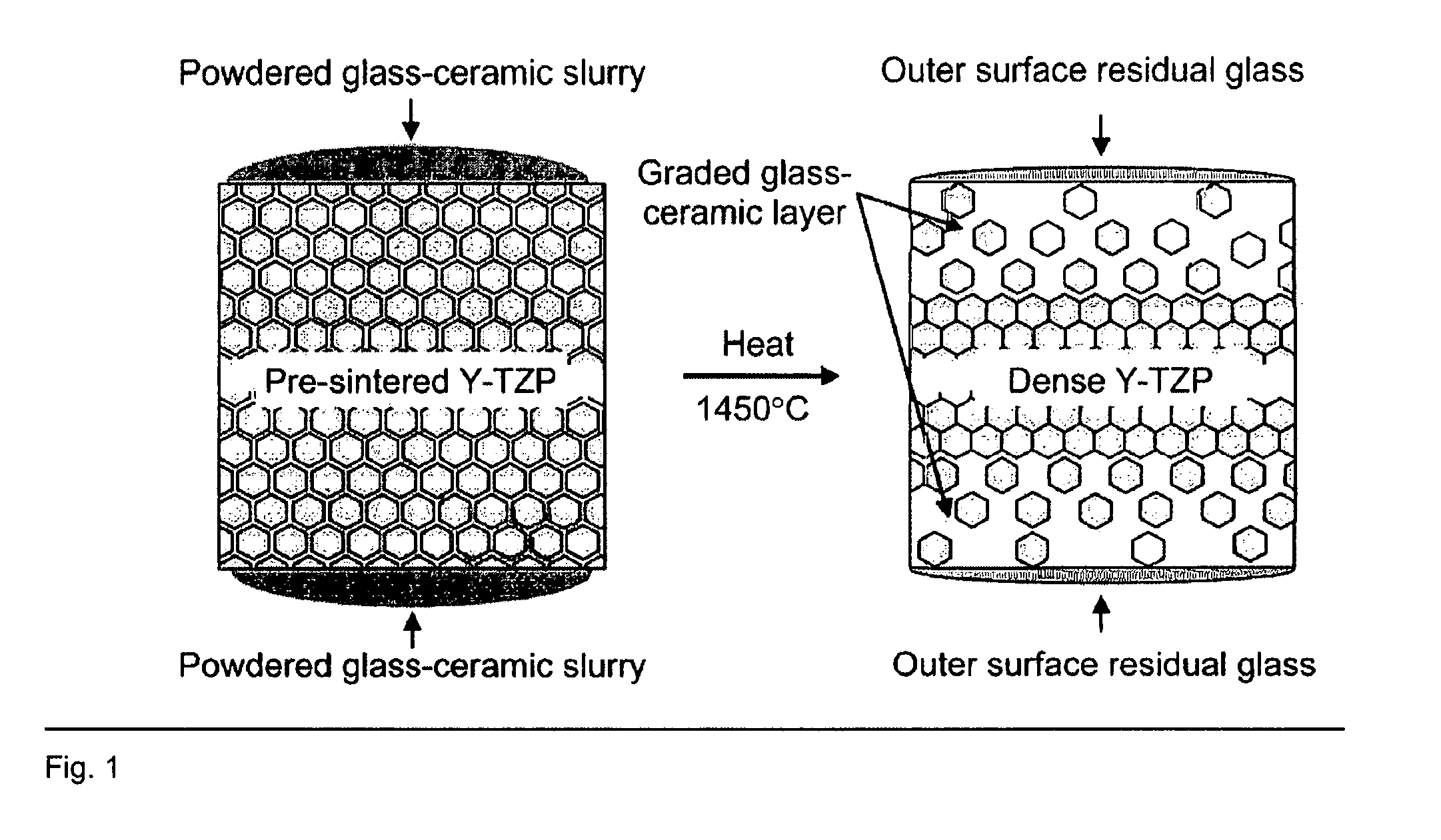

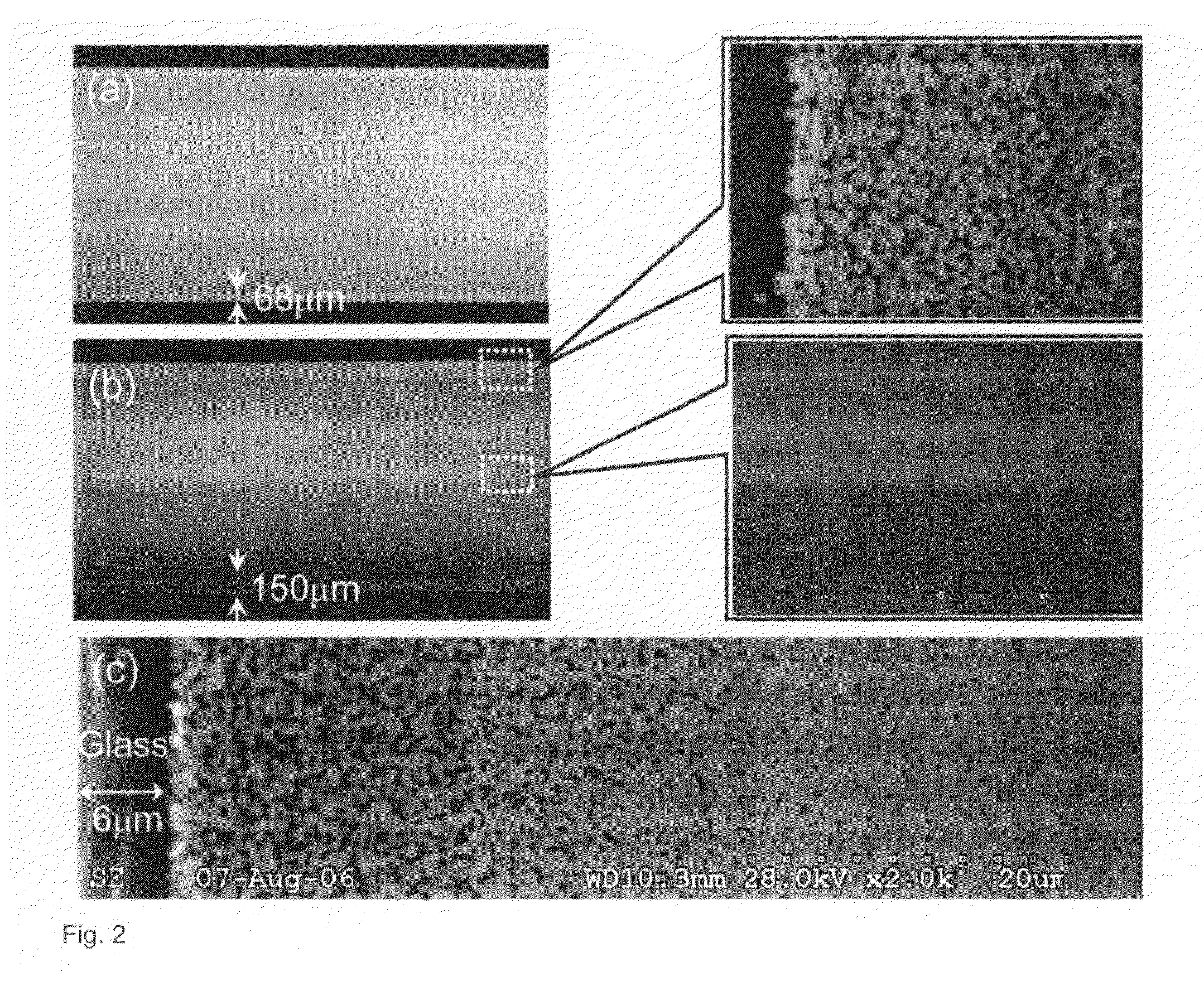

Graded glass/zirconia/glass structures for damage resistant ceramic dental and orthopedic prostheses

The present invention provides a functionally graded glass / ceramic / glass sandwich system for use in damage resistant, ceramic and orthopedic prosthesis. The functionally graded glass / substrate / glass composite structure comprises an outer residual glass layer, a graded glass-ceramic layer, and a dense interior ceramic. The functionally graded glass / substrate / glass composite structure may further comprise a veneer on an exterior surface. The present invention also provides a method for preparing a functionally graded glass / ceramic / glass sandwich system. A powdered glass-ceramic composition is applied to the accessible surfaces of a presintered zirconia substrate to thereby substantially cover the substrate surfaces. The glass of the composition has a CTE similar to that of the substrate material. The glass-ceramic composition is infiltrated into and densifies the substrate by heating the assembly to at least the sintering temperature of the substrate.

Owner:NEW YORK UNIV

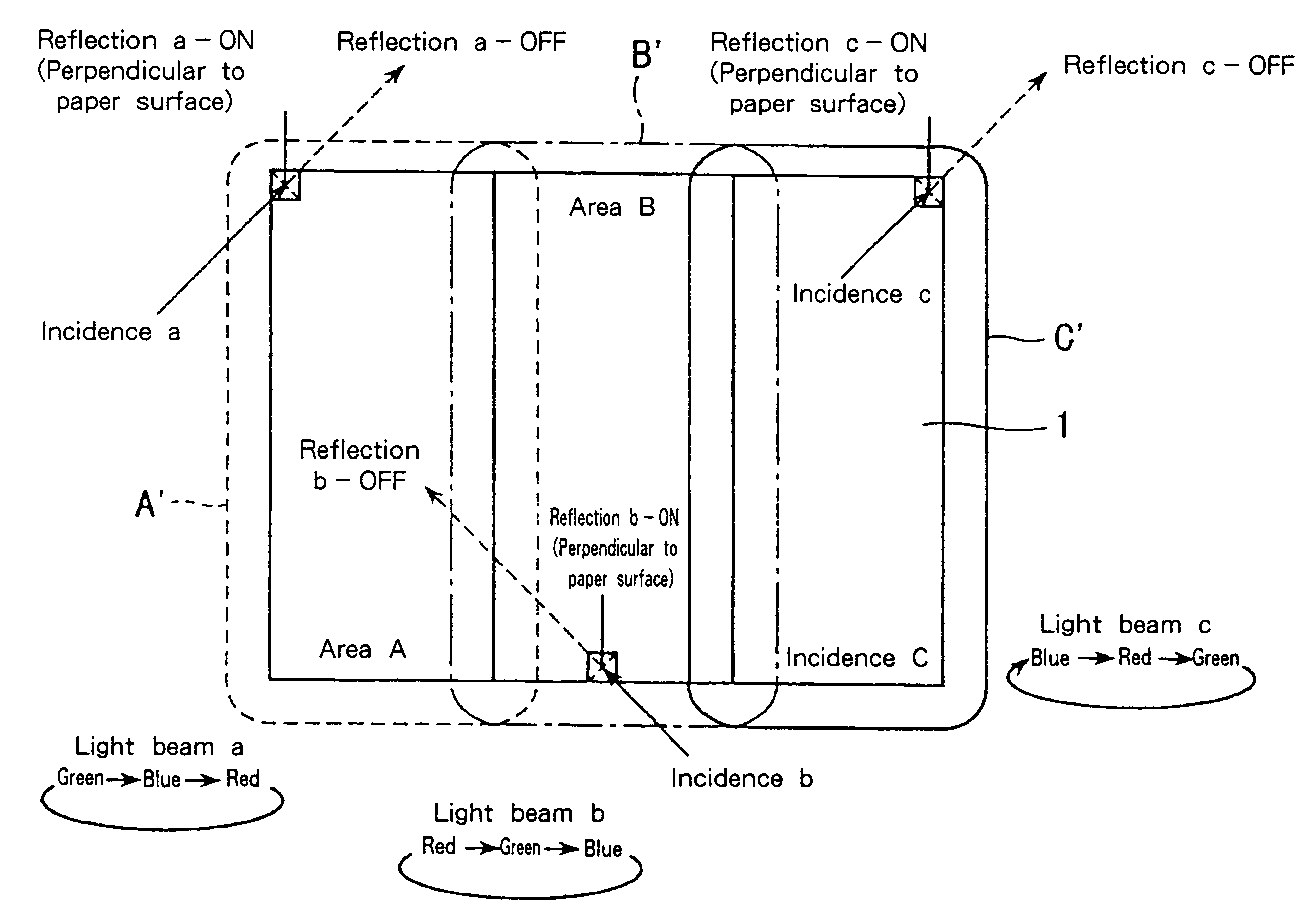

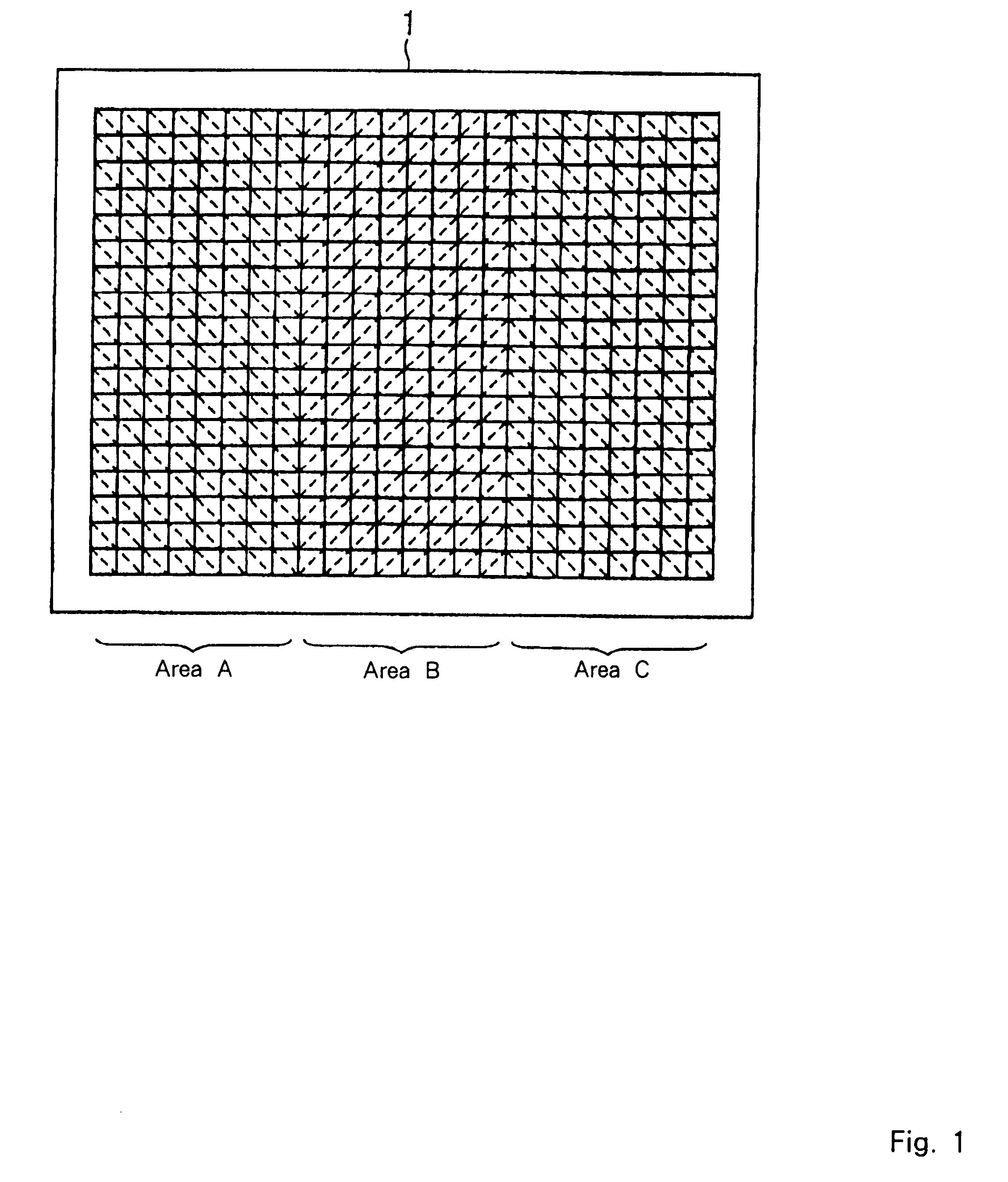

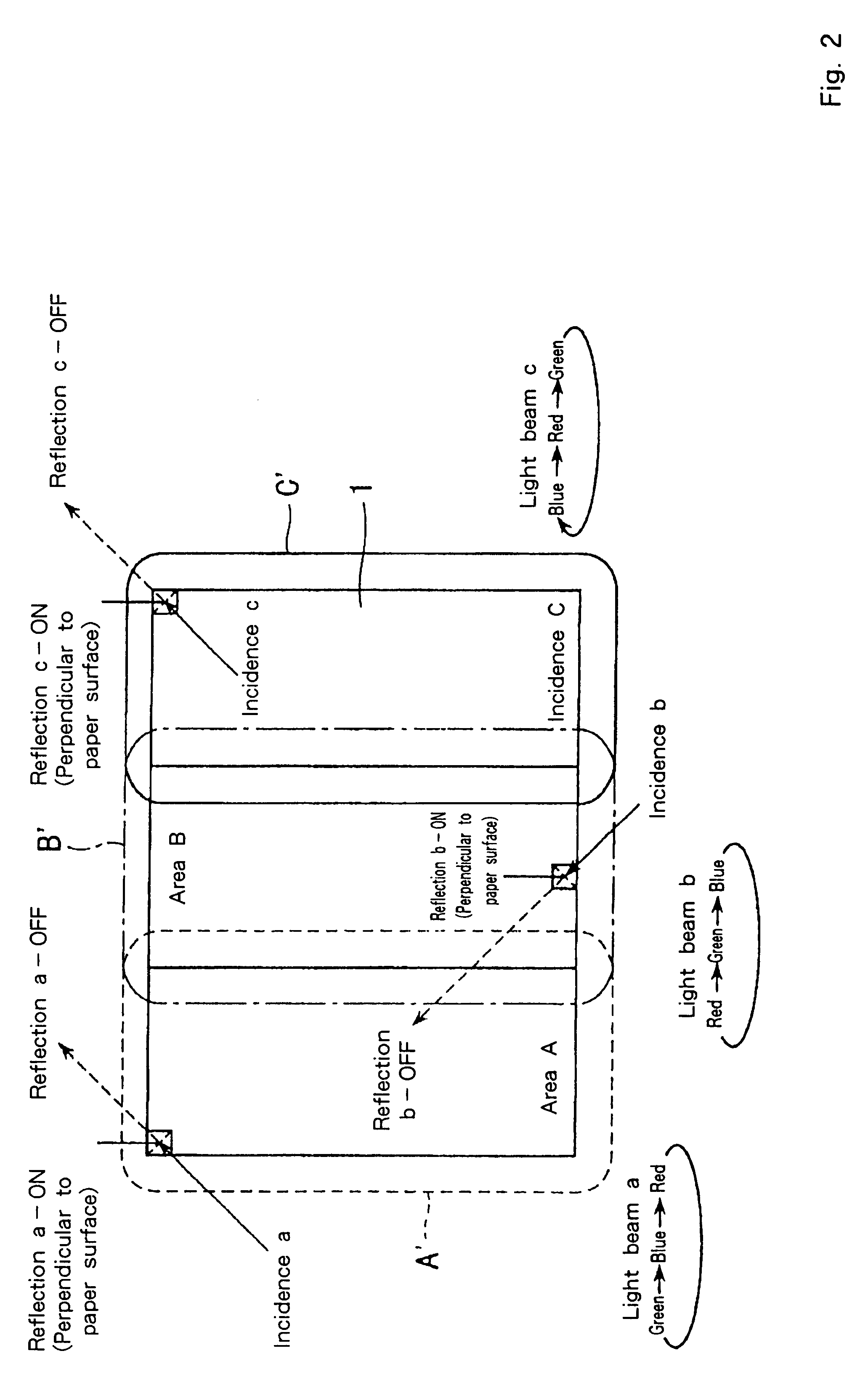

Digital micro mirror device and single-panel color projector using it

InactiveUS6457833B1Securely display colorHigh strengthTelevision system detailsProjectorsDigital micro mirror deviceSingle plate

A digital micro mirror device (and a single-panel color projector using a digital micro mirror device) includes a reflection surface including an array of micro mirrors. The reflection surface is divided into two or more areas, and the axis direction about which a mirror of the array of micro mirrors rotates in one area is the same for all of the micro mirrors in the area. The single-panel color projector includes a white light source, a color separator for separating a white light from the white light source into two or more light beams, the digital micro mirror device reflecting the two or more light beams, an illumination light establishing unit for illuminating the two or more light beams from the color separator, and a projection unit for collecting and projecting light reflected from the digital micro mirror device.

Owner:IBM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com