Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1769 results about "Wood product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fire retardant compositions and methods for preserving wood products

Wood preservative compositions are disclosed. Treatment of lumber, plywood, and other wood products with a novel composition comprising the boron source composition, a melamine binder resin, and a urea casein activator resin protects lumber, plywood, and other wood products from attack by termites, fungi, fire and flame. The preservative can be formed by combining a source of boron such as boric acid and the water-soluble salts thereof, a melamine binder resin, and a urea casein resin. A wood preservative is characterized by a weight ratio of the urea casing activator resin to the melamine binder resin ranging from about 1:20 to 1:4 and a weight ratio of the boron source composition to the melamine binder resin ranging from about 1.3:1 to 9.6:1.

Owner:LOPEZ RICHARD A

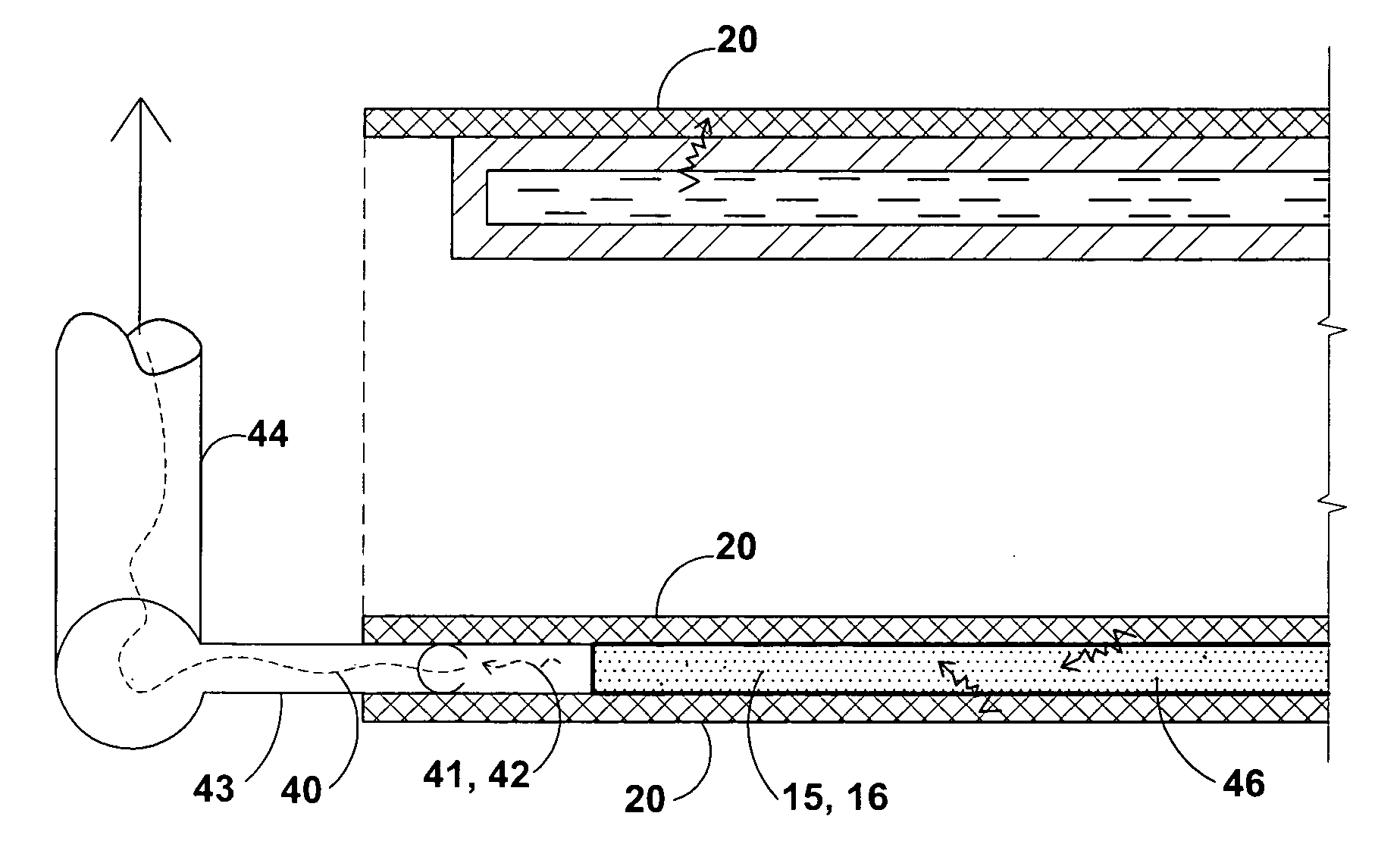

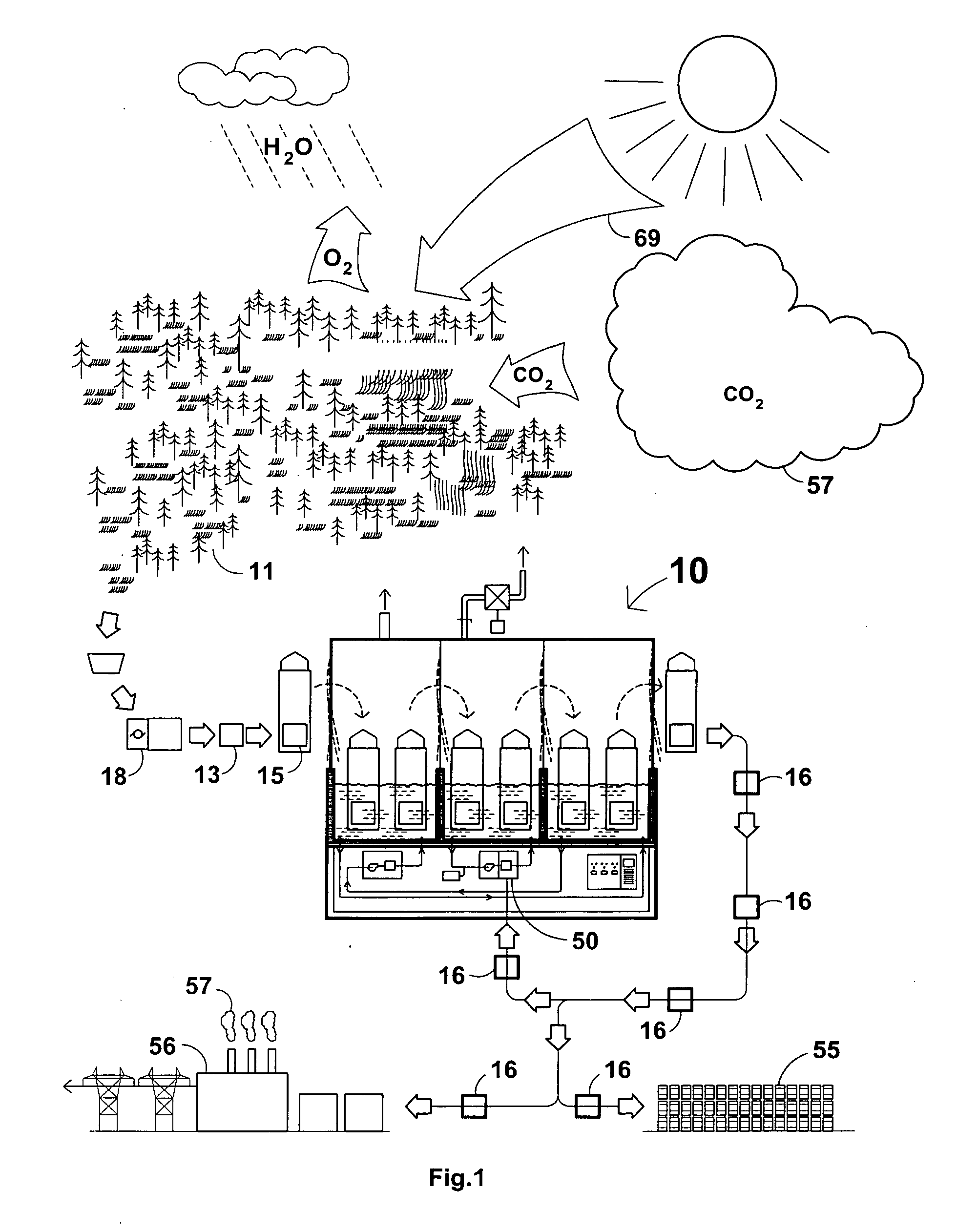

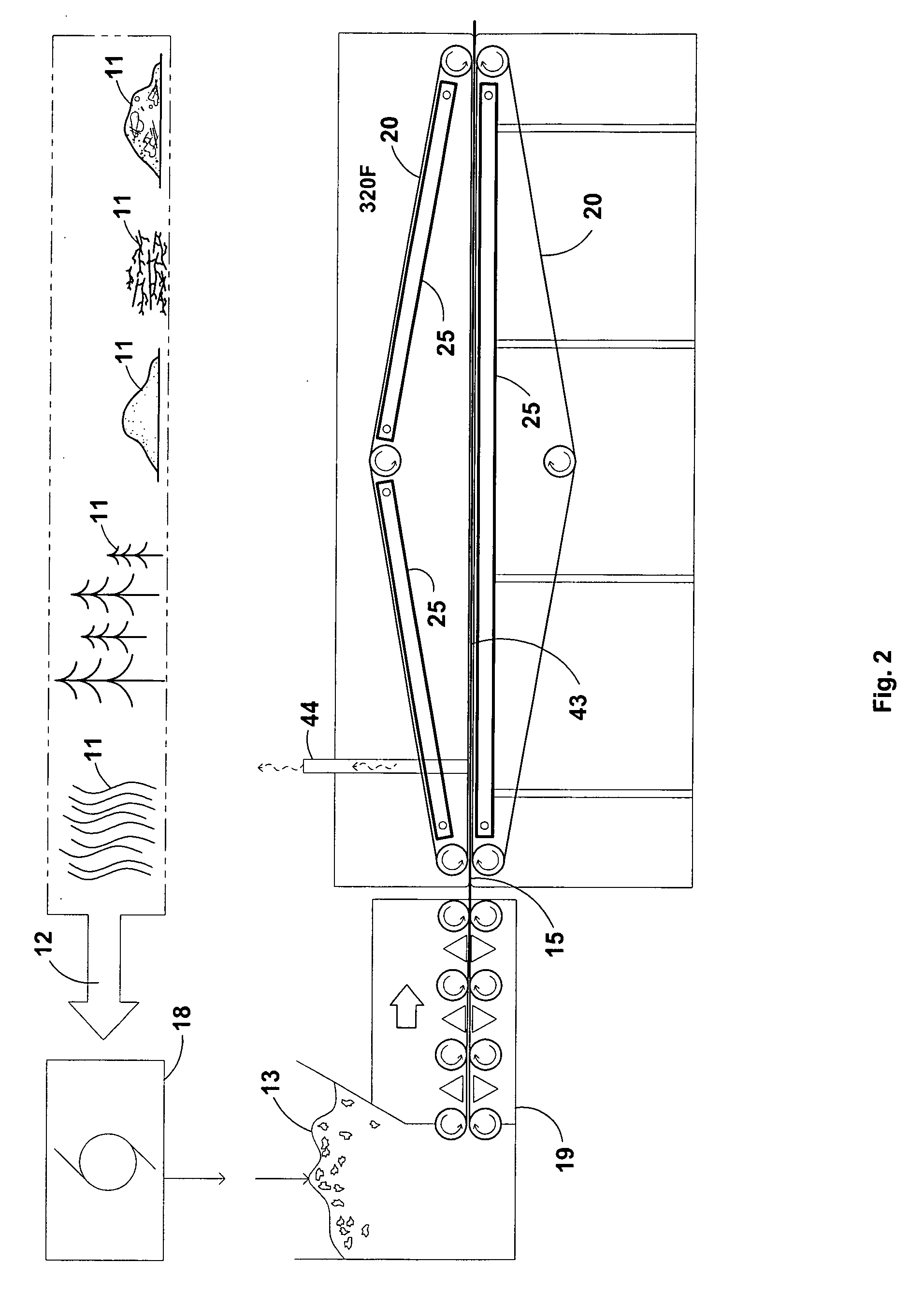

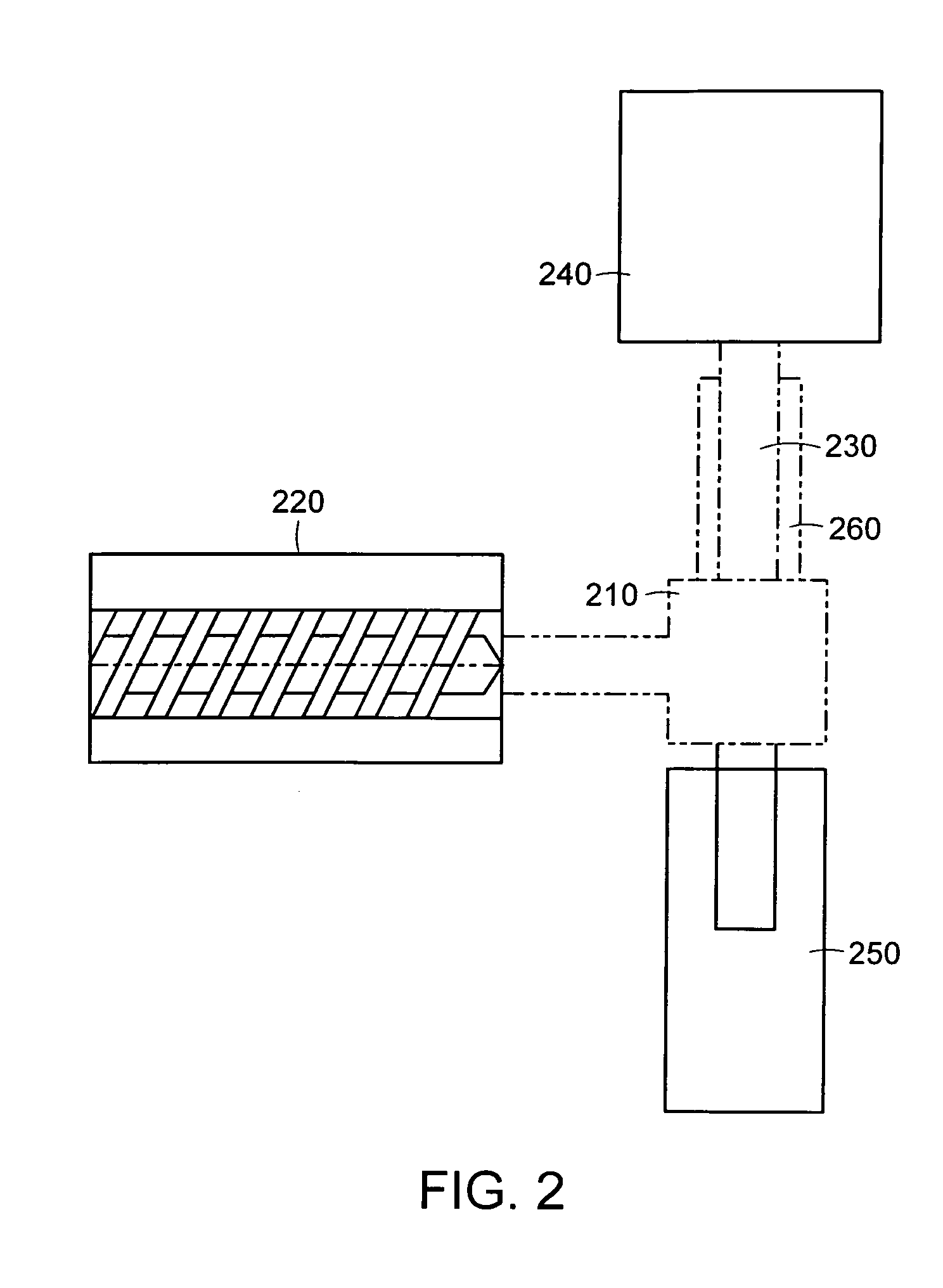

Method and apparatus for biomass torrefaction using conduction heating

InactiveUS20080223269A1Reduce air pollutionEasy to storeDrying solid materials with heatBiofuelsThermal contactConveyor belt

A method for torrefaction of wood which includes providing a first endless conveyor belt; heating the first endless belt; and positioning a planar wood product on the first belt to heat the wood product by conduction to achieve torrefaction. Other forms provide a second endless belt that disposed in sandwich relation to wood to be torrefied. Some embodiments of the method provide a metal chamber having opposed planar sides dimensioned and configured for receiving a wood sheet with the respective opposed sides of the wood sheet in intimate thermal contact with respective opposed sides of the metal chamber. Other embodiments include the apparatus for torrefaction of an associated wood sheet.

Owner:PAOLUCCIO JOHN A

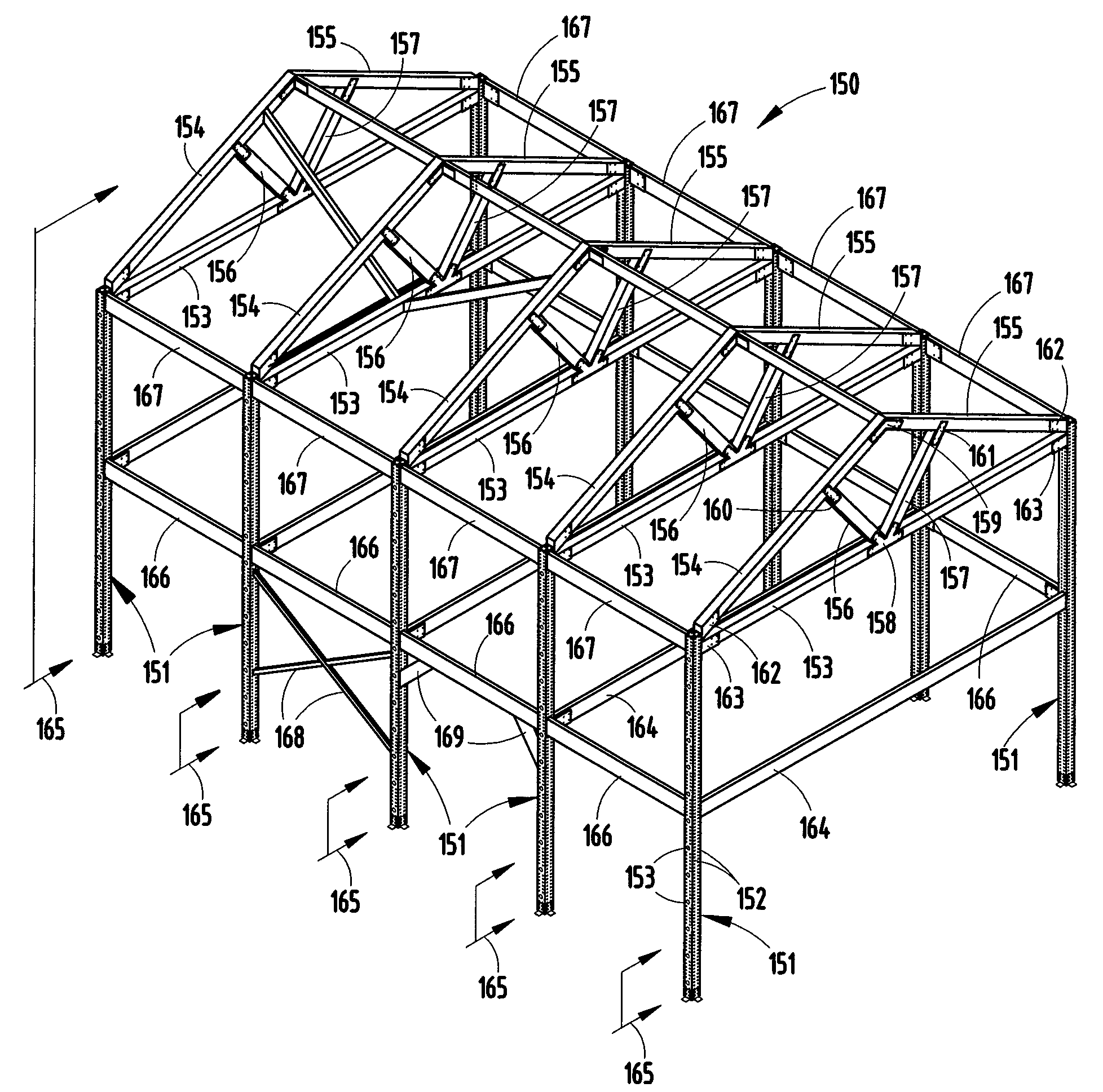

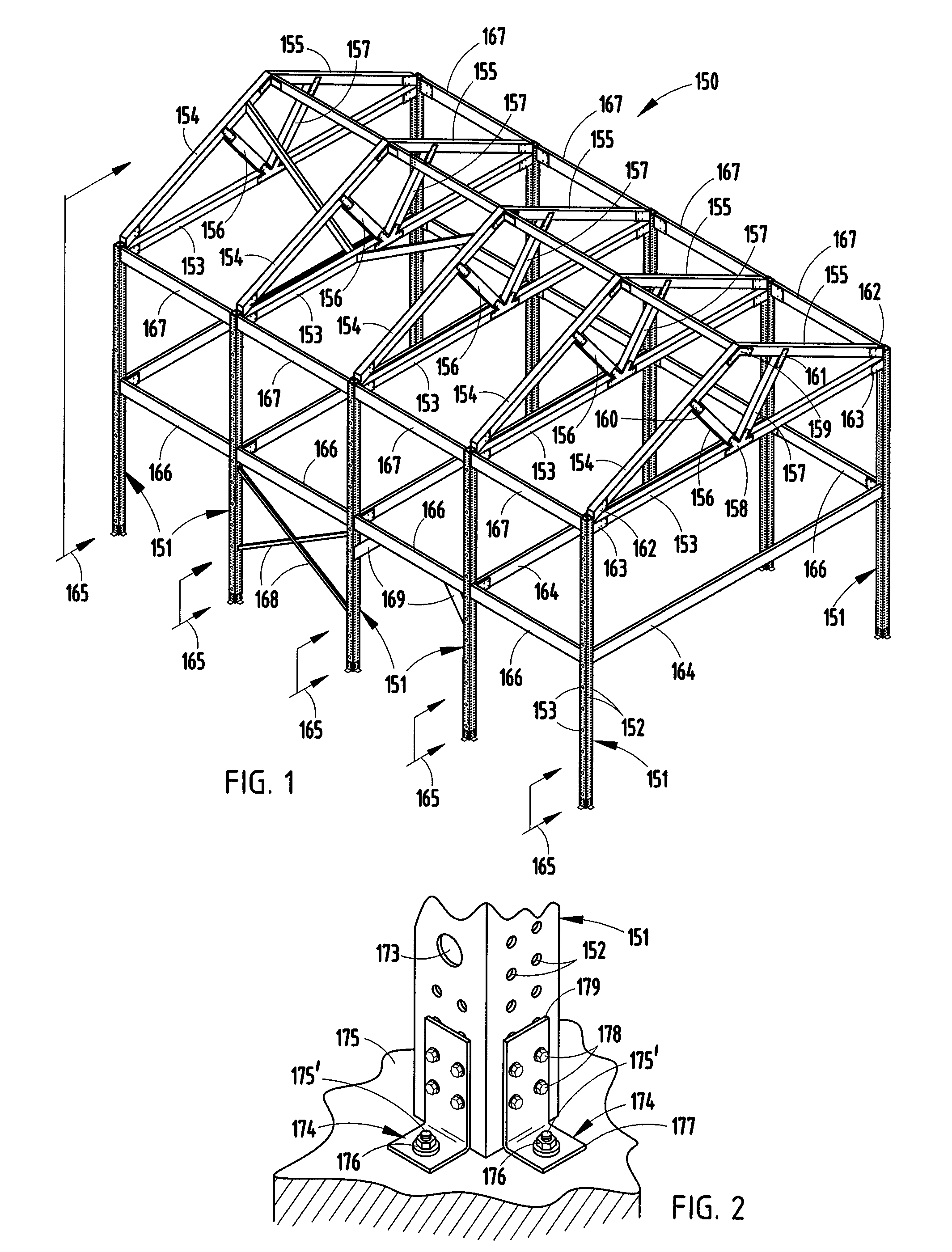

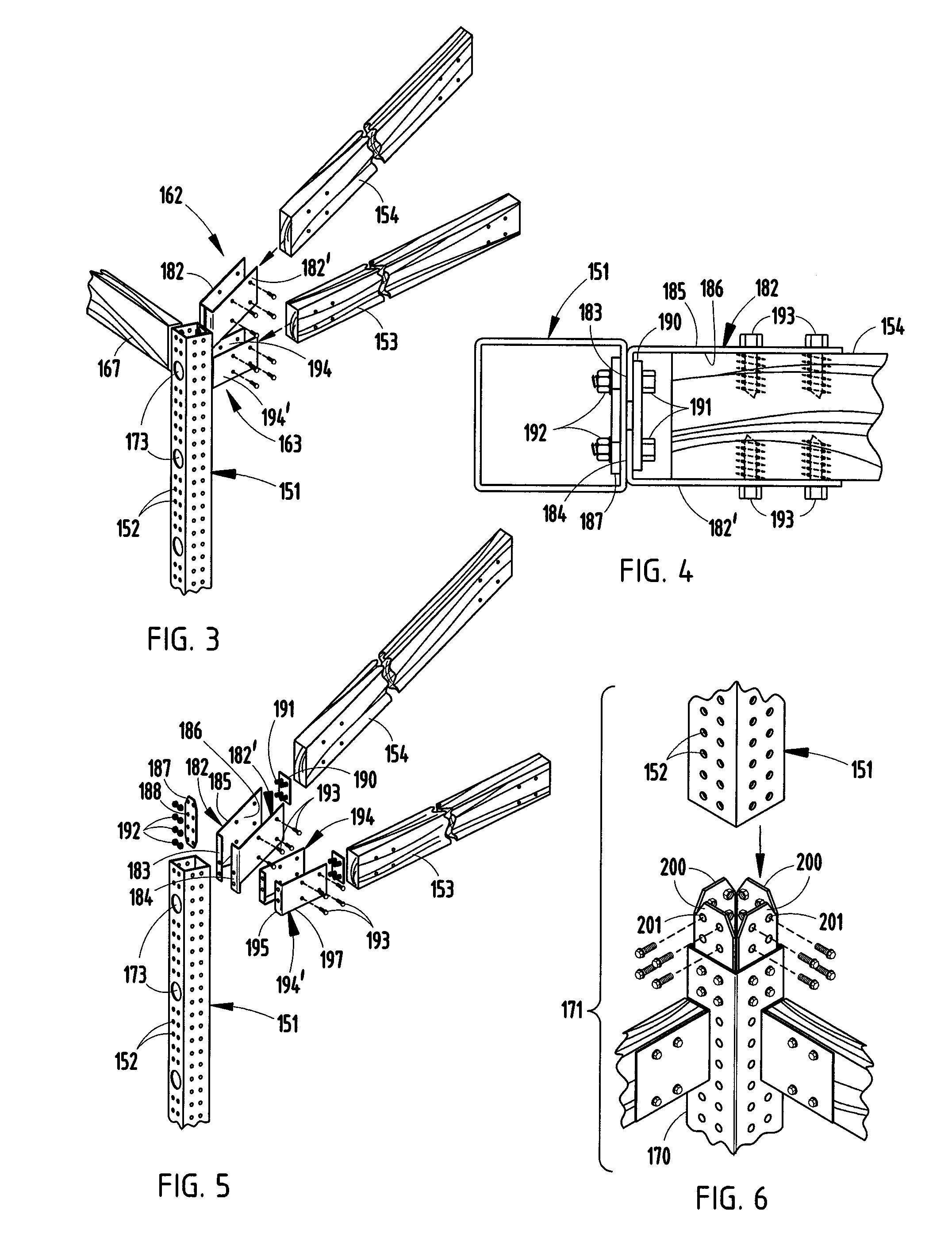

Flexible modular building framework

InactiveUS20080178551A1Save considerable costEfficient assemblyBuilding repairsTowersArchitectural engineeringLag

A building framework includes metal columns (e.g., tubular or I-beam), wood-product beams, and bracket connectors for joining the beams to the columns to form a building joint of sufficient strength and durability for buildings suitable for human occupation. First mechanical fasteners (such as bolts and nuts) secure a selected connector to the column, and second mechanical fasteners (such as lag bolts) secure a selected beam to the connector. The columns include double rows of holes. A plurality of different connectors with differently angled flanges are provided, such that beams can be connected at a wide variety of different angles. Further, the system allows columns and / or beams to be cut at the construction site, or at a building supply company. Thus, basic building components can be inventoried in a manner not previously possible, yet the system supports a wide variety of different building frames for on-site customization and adaptability.

Owner:PORTER WILLIAM H

Completely degraded plant powder modified thermoplastics composite material and preparation method thereof

ActiveCN101760037AHas physical and chemical propertiesEasy to processThermoplastic compositesPolypropylene

The invention discloses a completely degraded plant powder modified thermoplastics composite material and preparation method thereof, which consists of the components with the weight portions as follows: 100 portions of degradable thermoplastics resin, 1-400 portions of plant powder, 0.1-40 portions of dispersing agent, 0.5-60 portions of impact modifier, 0-40 portions of inorganic filler as well as 0.1-10 portions of stabilizing agent. The degraded thermoplastics resin has similar physiochemical performances with universal polyethylene and polypropylene, has excellent processing performances, and can be commixed with plant powder to prepare thermoplastics wood plastic composite materials. The obtained thermoplastics wood plastic composite materials can be completely degraded into carbon dioxide and water in natural environment under the effects of broadly existed microbes like germs, actinomycetes, etc. Compared with wood products, the composite material has the characteristics of good durability and dimensional stability, easy forming, small water absorbability, and corrosion resistance; compared with plastic, the composite material has the characteristics of low cost and high rigidity. The completely degraded plant powder modified thermoplastics composite material can be used for producing the shells of electric apparatuses like TV, sound, copier, printer, etc, and can also be applied on other workpieces used for injection.

Owner:GUANGDONG KINGFA TECH CO LTD +2

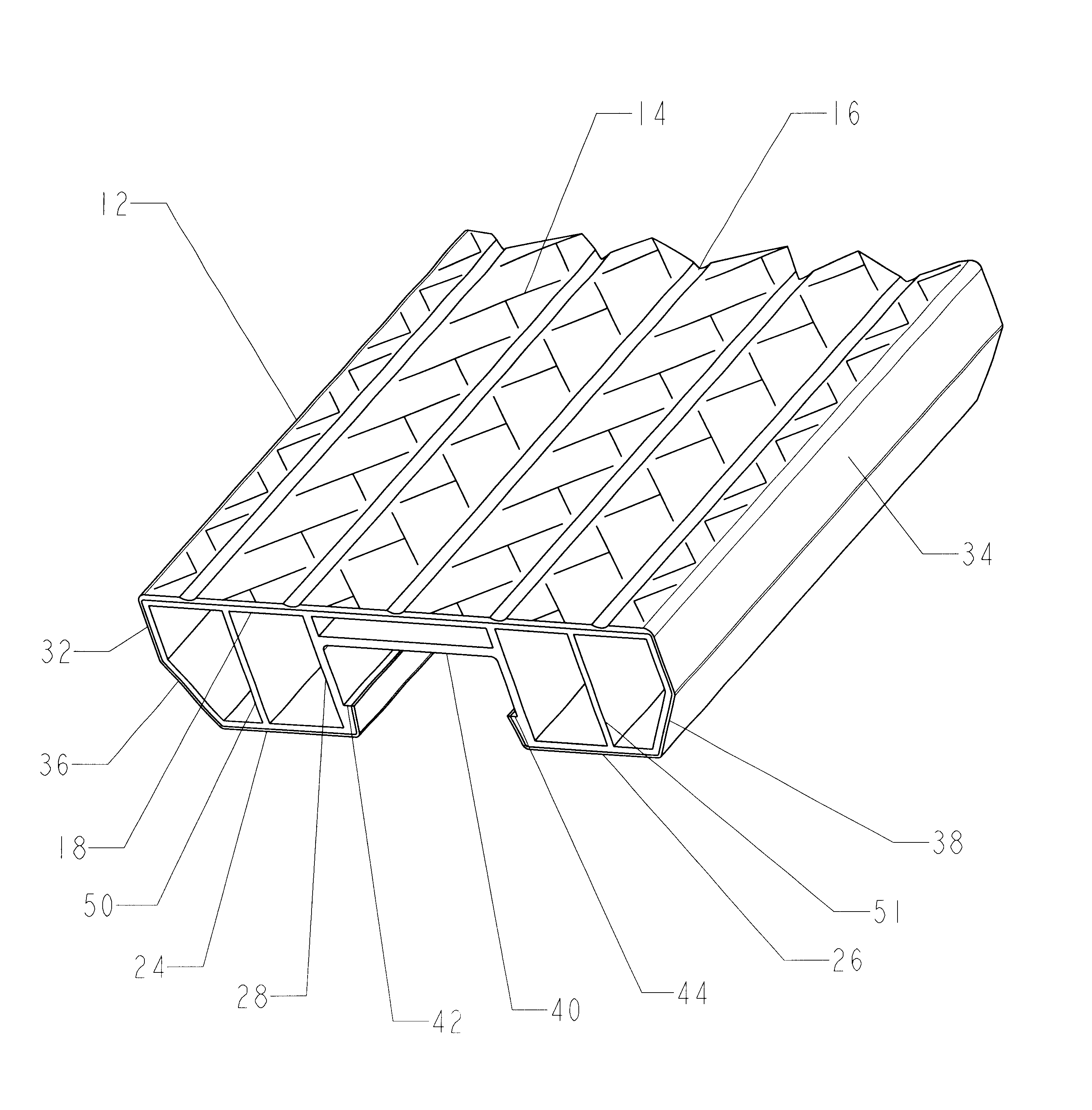

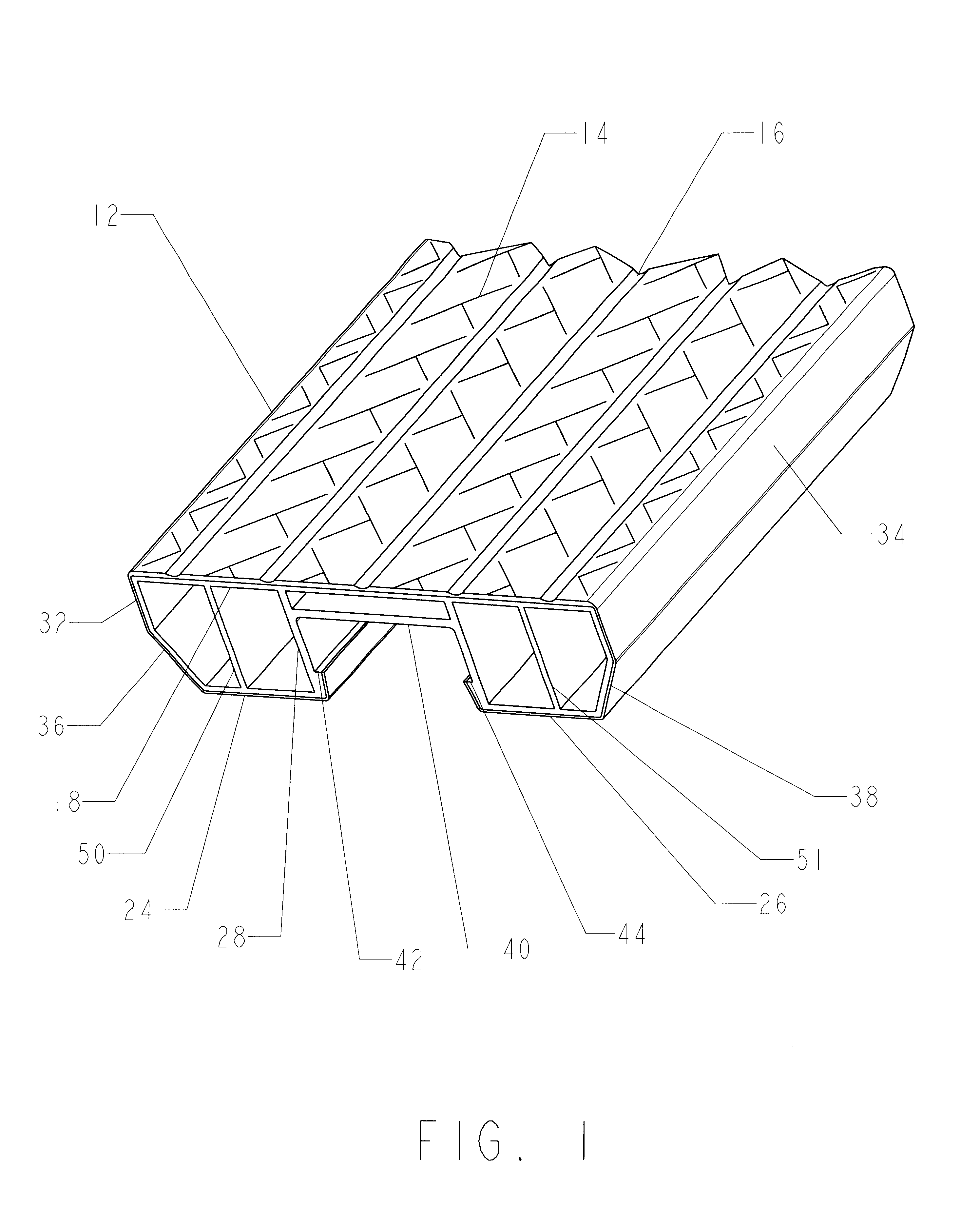

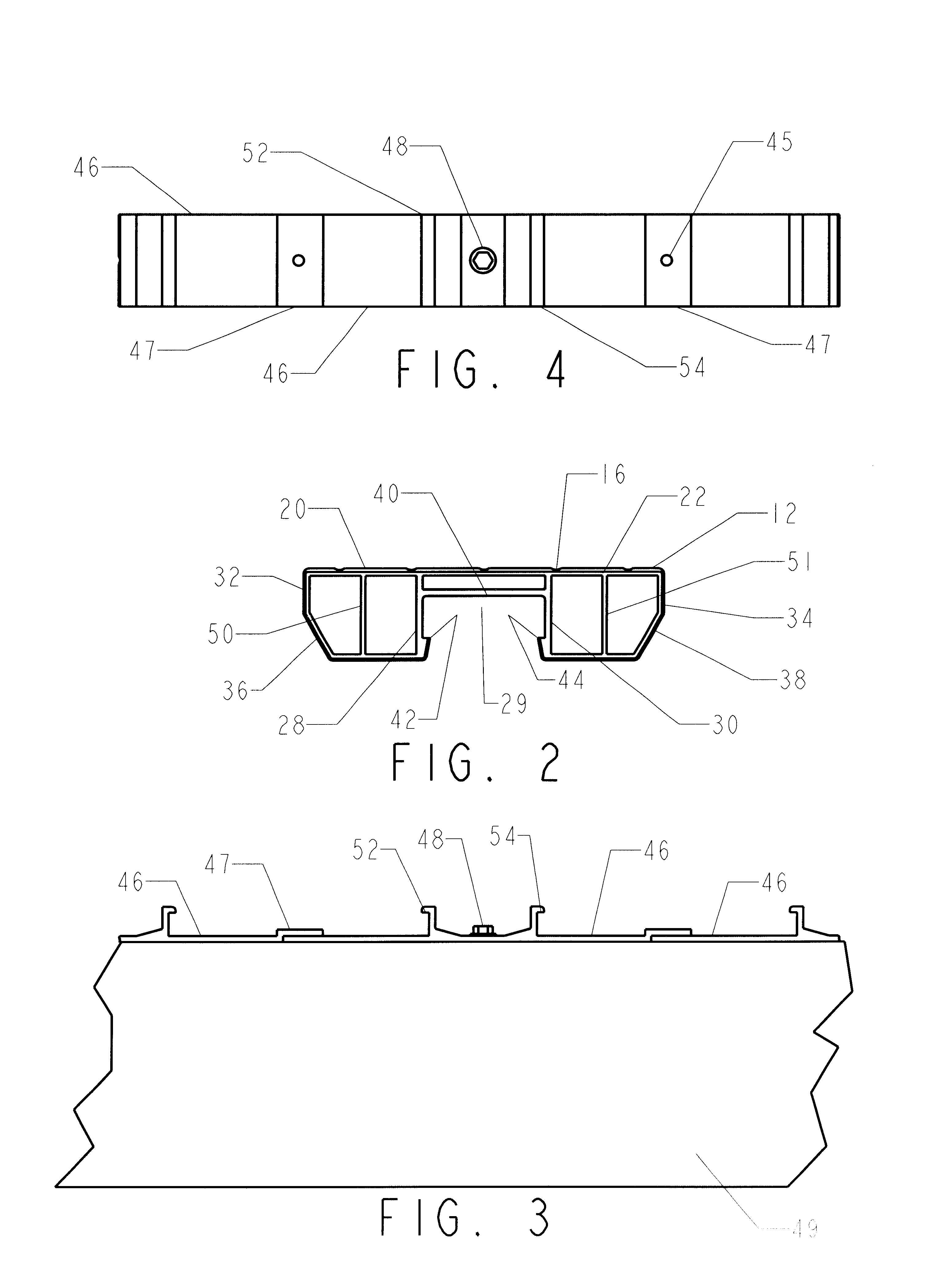

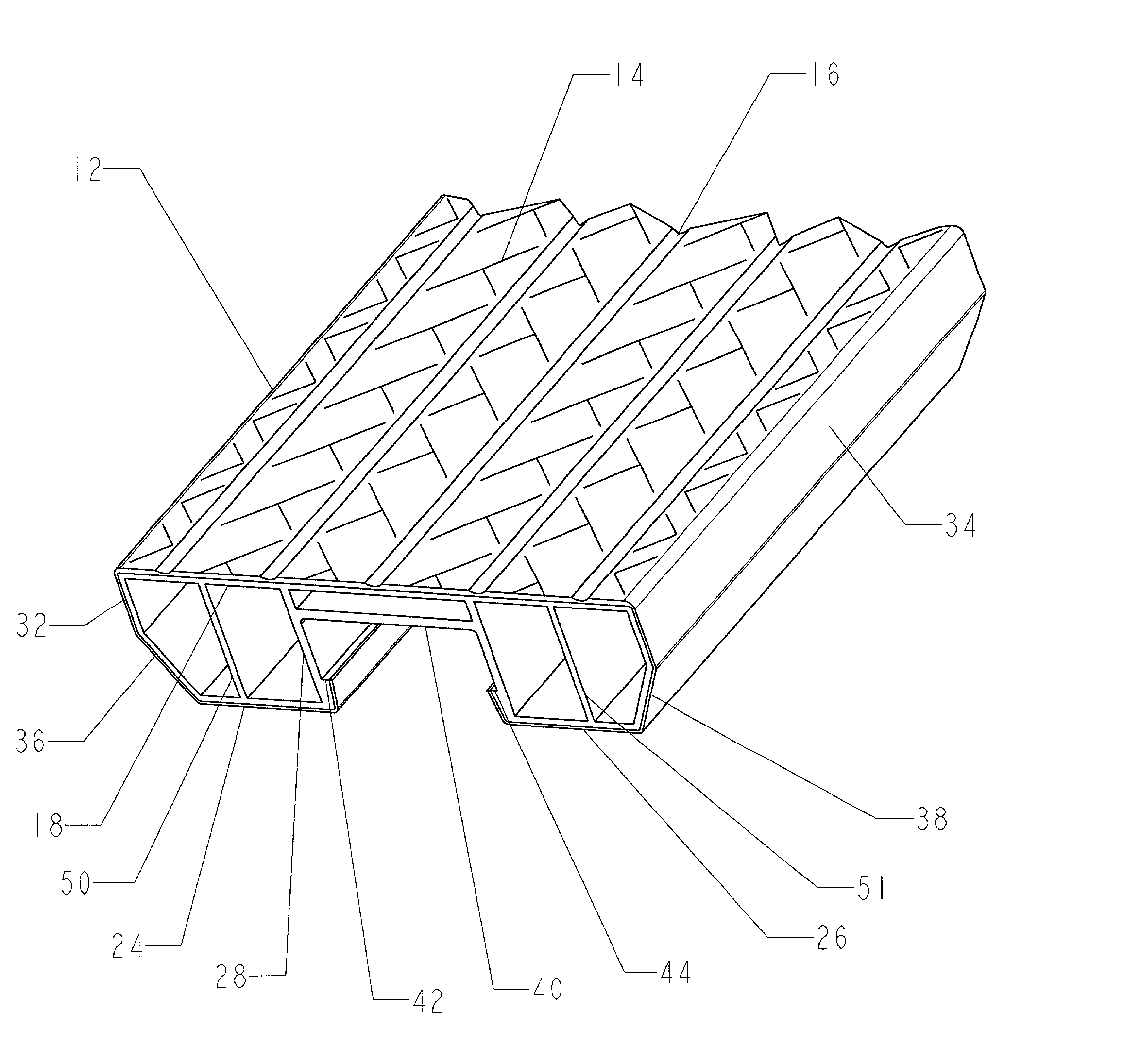

Deck plank extrusion and retaining clip

A deck plank (12) readily attaches to an engagement clip (46) when force is applied over the plank. When a plurality of clips are attached to underlying joists in parallel with the joists, and a plurality of deck planks are oriented to the clip perpendicular to the joist and pushed down over clips, a secure deck structure is provided. Each clip has a pair of horizontal flanges (52 and 54), which snap over a plurality of ledges (42 and 44) in a channel under each plank. The deck planks (12) are embossed (14) so as to form a slip resistant surface to be walked upon. The plastic extruded deck plank (12) resists rot, deterioration and insect infection found in current wood products. The deck plank assembly is simple enough so that a homeowner or do-it-yourselfer can install or alter it with minimal effort and direction.

Owner:LEINES RICHARD ALAN

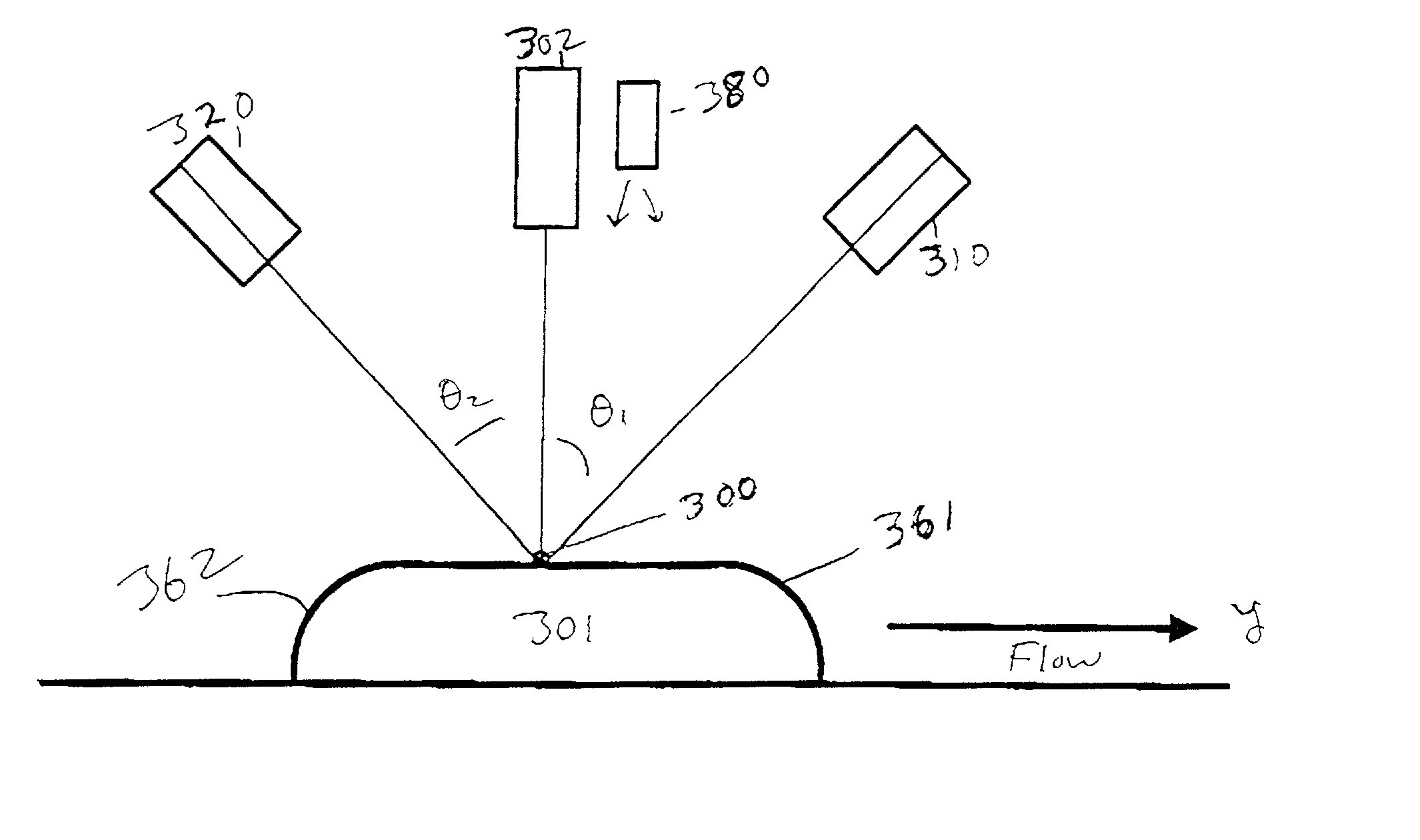

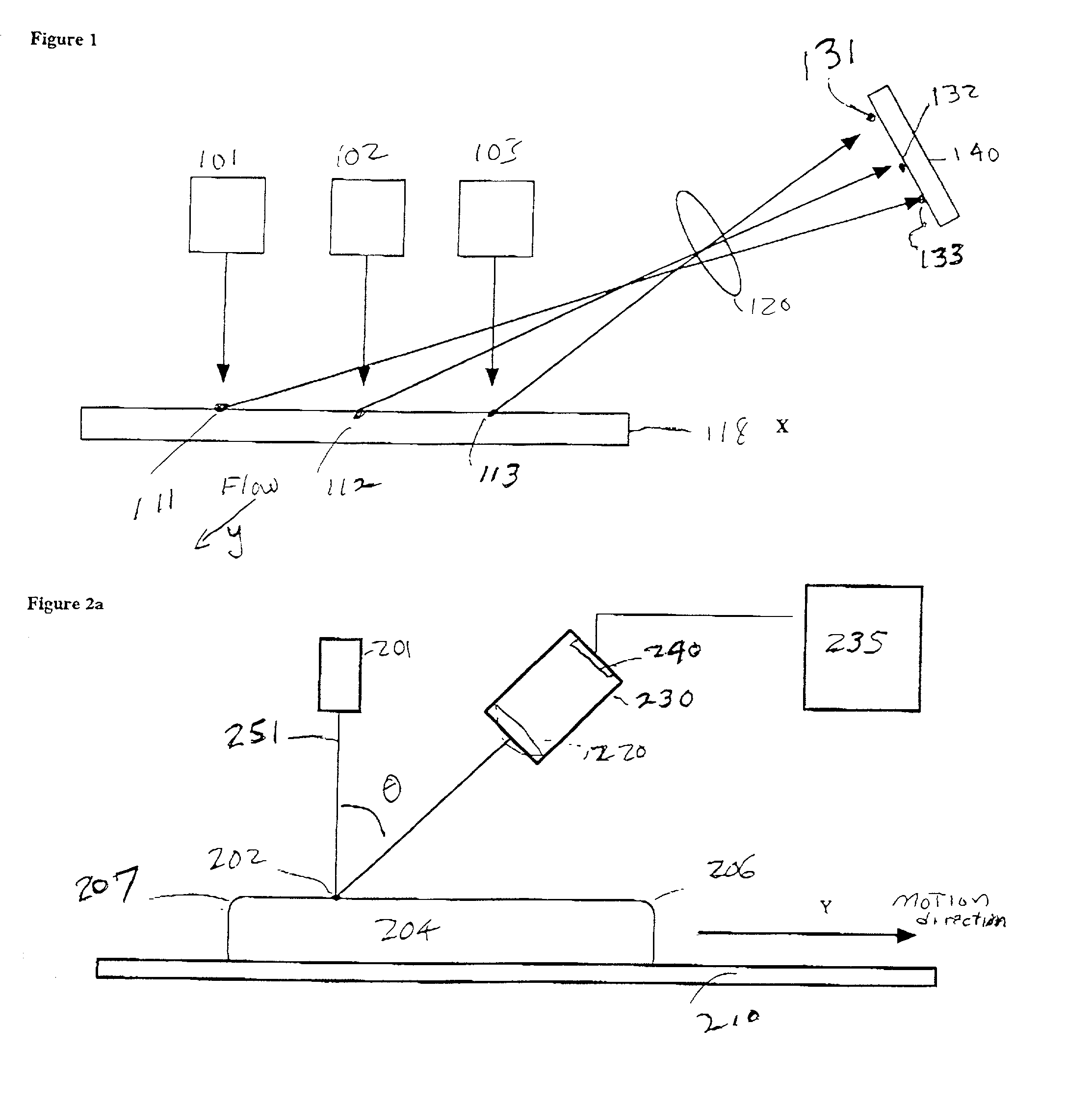

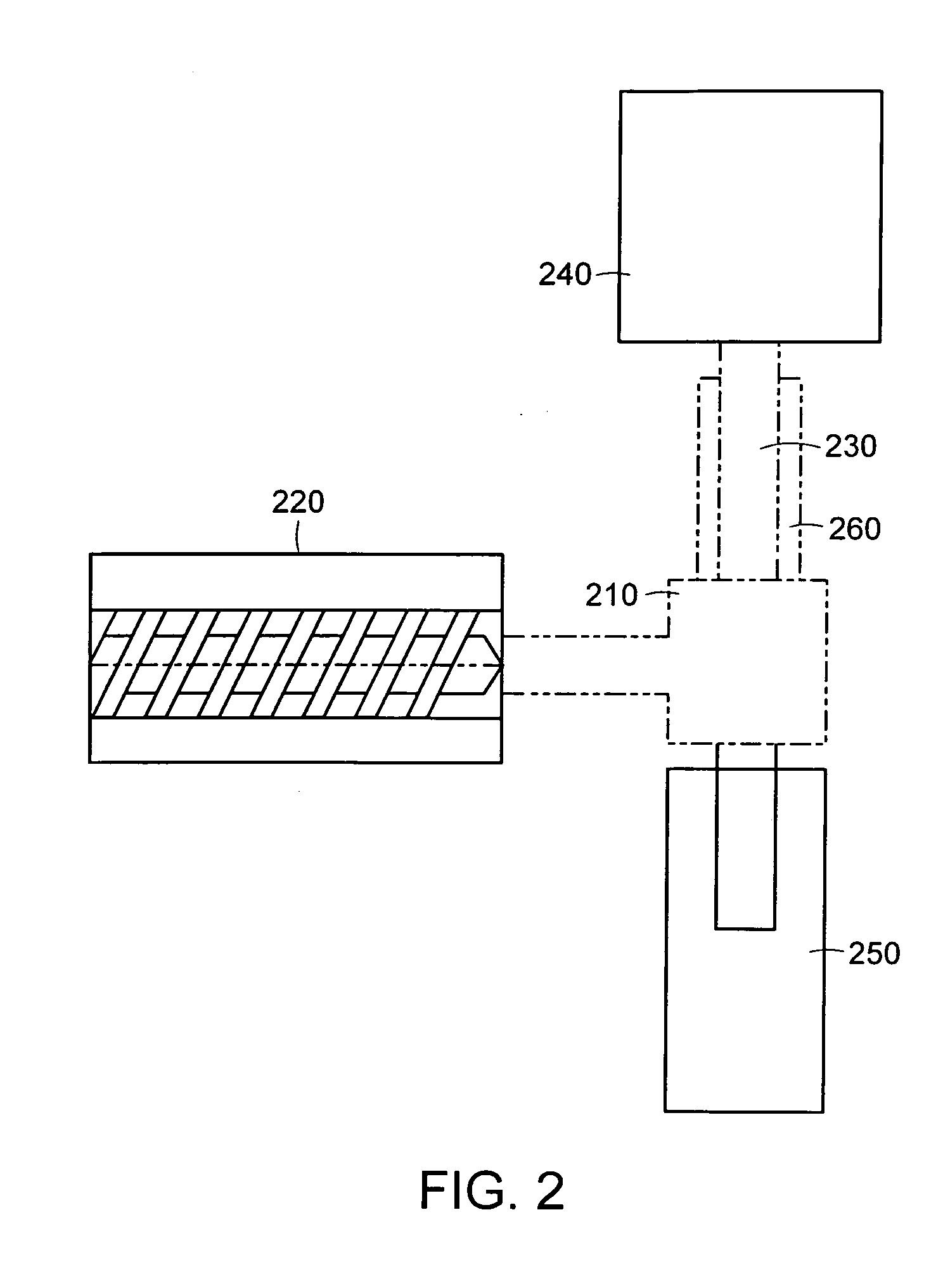

Method and apparatus for scanning lumber and other objects

InactiveUS20020024677A1Acceptable accuracyLow costInvestigating moving sheetsUsing optical meansElectro-optical sensorHigh velocity

Disclosed herein are TV Camera based and other electro-optical sensors and systems, providing affordable methods and apparatus for high speed determination of dimensions and other features of objects. Particular embodiments capable of fast and reliable acquisition of features of moving objects such as boards and wood products are disclosed. Preferred embodiments utilize laser triangulation range detection with at least two cameras viewing the same laser spot or line projected on the object.

Owner:LMI TECH

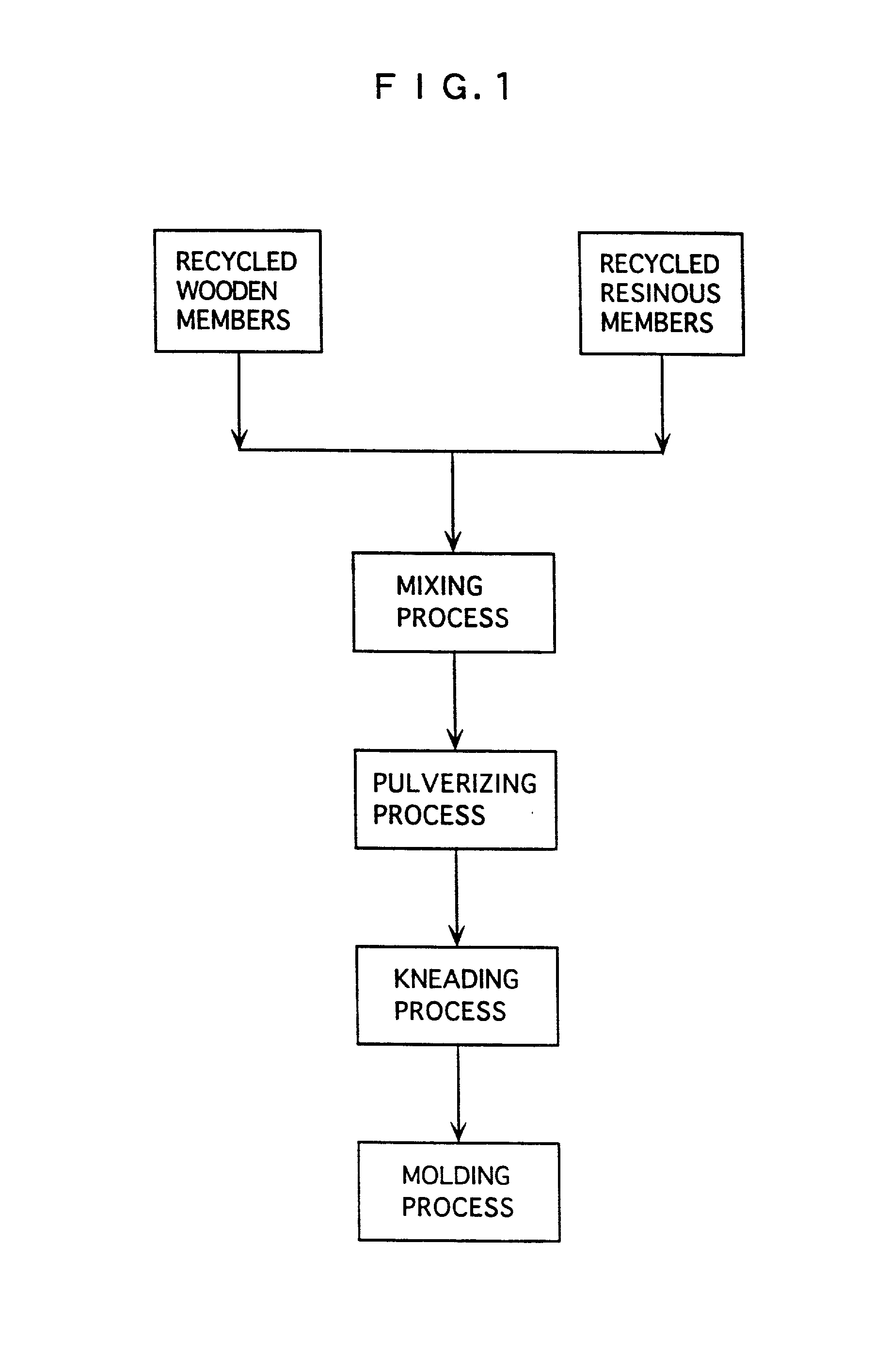

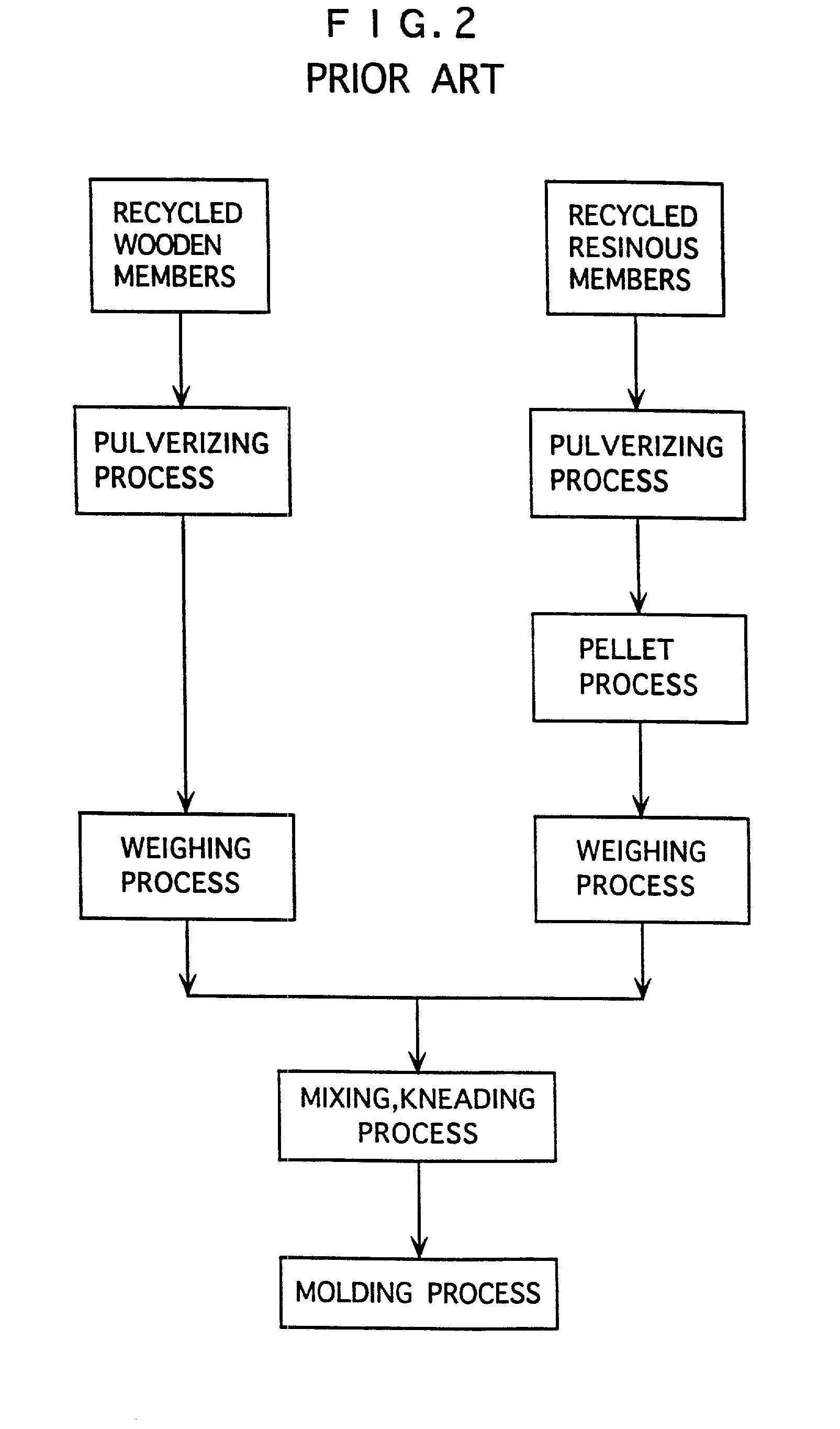

Cement bonded wood chip product, resin bonded wood chip product, simulated wood product

InactiveUS20010009309A1Reduce the numberReduce processFlat articlesDomestic articlesMixed materialsInjection moulding

A manufacturing method for providing a cement bonded wood chip product, a resin bonded wood chip product and a simulated wood product, in which recycled wooden members and recycled resinous members are pulverized after having been mixed. Accordingly, a mixing process and a pulverizing process can be integrated into one single line, reducing the space as well as laborious work and efficient operation in a plant. A manufacturing method of a simulated wood product utilizing pulverized powders obtained from recycled building members as raw material, in which the building members comprise recycled wooden members made of wooden materials and resinous members made of resinous materials, the manufacturing method further comprising a mixing process for mixing the recycled wooden members, a pulverization process for pulverizing the mixed materials obtained in the mixing process to form pulverized powder, a kneading process for kneading the pulverized powders obtained by the pulverizing process, and a molding process for molding the kneaded materials obtained in the kneading process either by an extrusion or injection molding.

Owner:MISAWA HOMES CO LTD

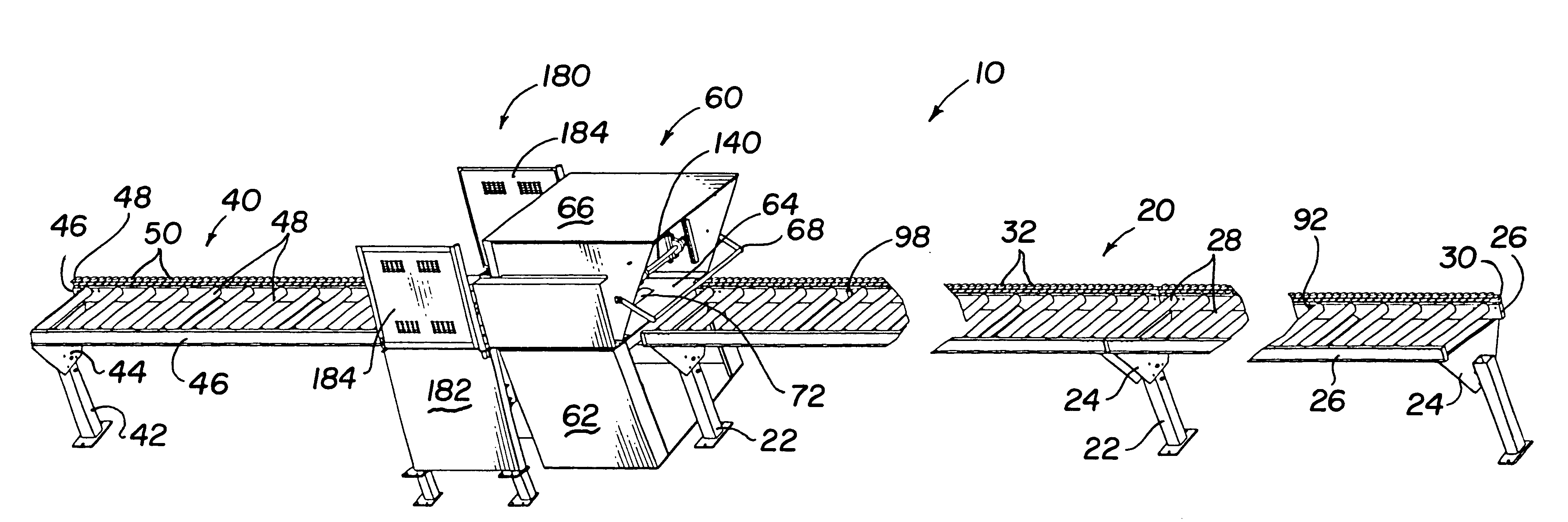

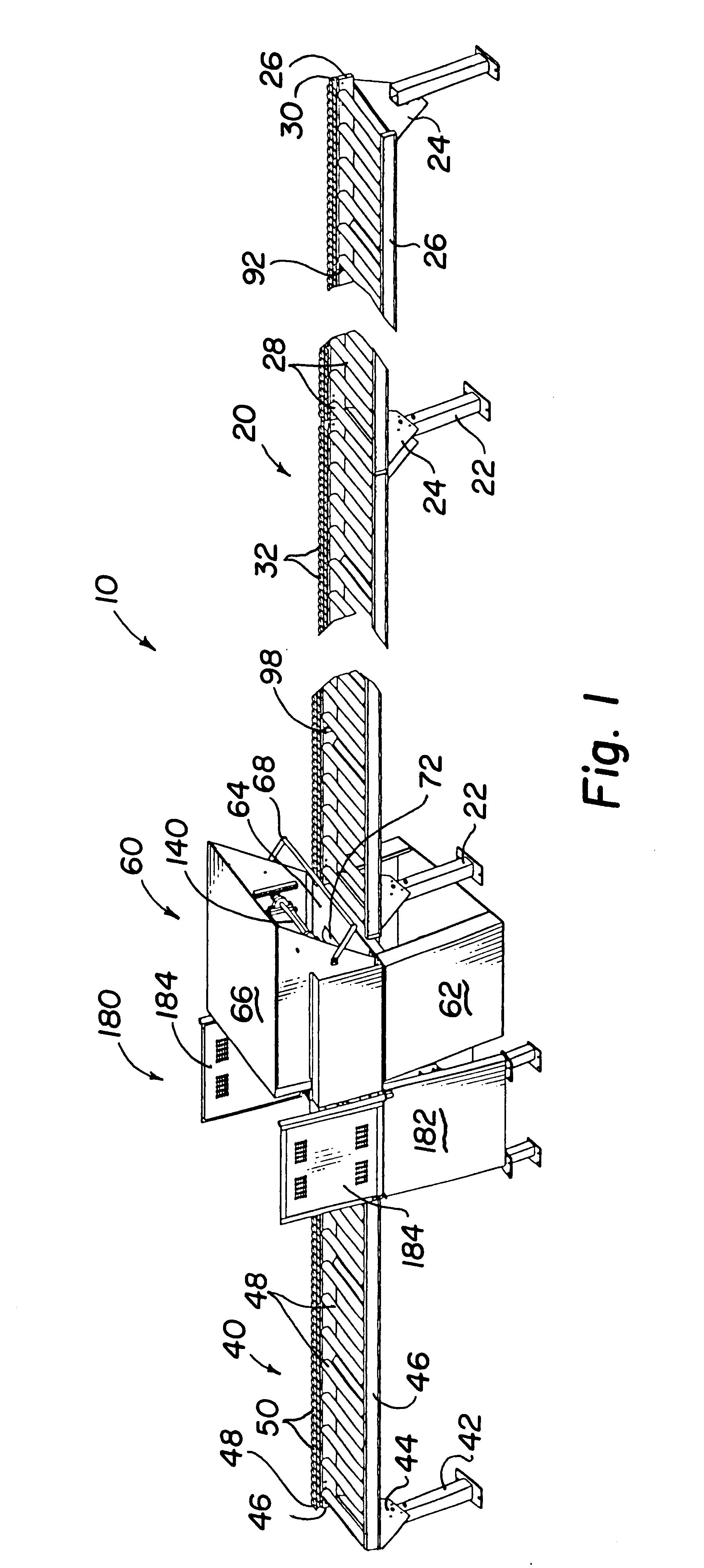

Engineered wood products cutting method and apparatus

InactiveUS6263773B1Automatic control devicesPrecision positioning equipmentEngineeringEngineered wood

The invention is a method and apparatus for processing an Engine Wood Product member. The member is moved to a home position in a driving unit and the length of the EWP member is automatically measured by moving the EWP member from the home position while engaging the EWP member with a measuring assembly including a measuring wheel having a smooth hard facing, the facing contacting the EWP member. The member is moved to a first cutting position and cut to a predetermined length. Activating one or more position sensor devices, at least one of the position sensor devices positioned such that the EWP member engages the position sensor device while the member is in the home position, the length of the member is determined as it is moved from the home position. Moving the EWP member is accomplished by clamping the EWP member between at least one driver roller and at least one pressure roller, each driver roller aligned with a corresponding pressure roller, and rotating the at least one driver roller to move the EWP member. First and second driver rollers may be spaced apart and positioned on opposite sides of the measuring wheel. An outfeed table and infeed table with angled rollers may further be employed.

Owner:ILLINOIS TOOL WORKS INC

Non-wood fiber plastic composites

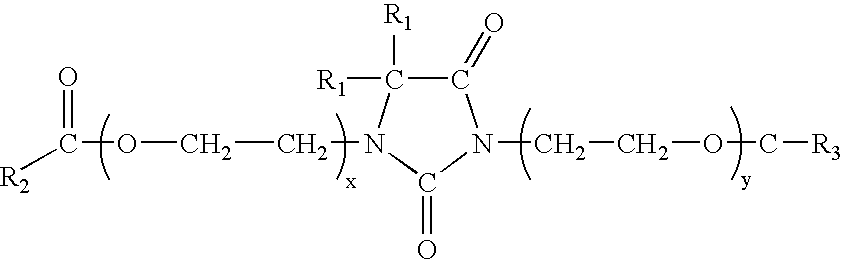

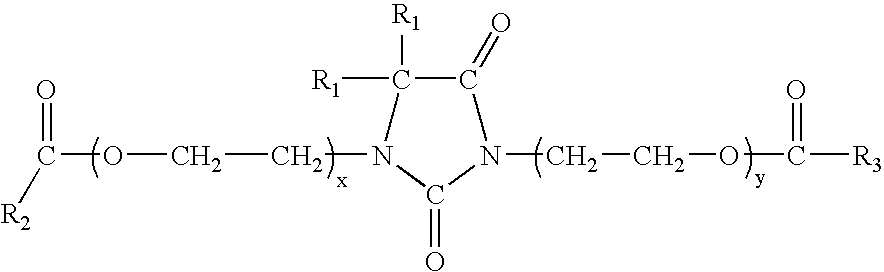

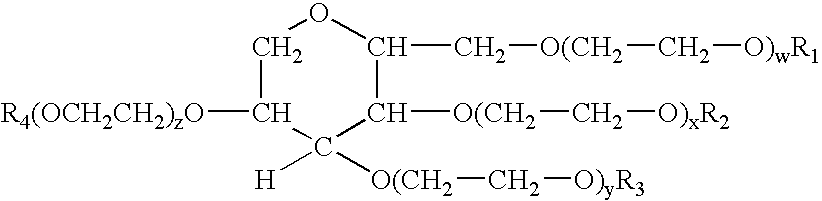

This invention is directed to an extrudable compound, an extrusion method using a polymer, a cellulosic fiber, and at least one lubricant selected from the group consisting of ethoxylated esters of hydantoins, ethoxylated esters of sorbitol and sorbitan, and ethylene bisamides made from fatty acids containing 6-10 carbons and composites manufactured through such processes which simulate conventional wood products. Another embodiment of the invention is directed to a composition containing polymer, a cellulosic fiber from an agricultural waste product and a lubricant containing a mixture of an alkylene bisamide derived from a C10-C18 is fatty acid and an alkaline earth salt of a fatty acid.

Owner:ARXADA LLC

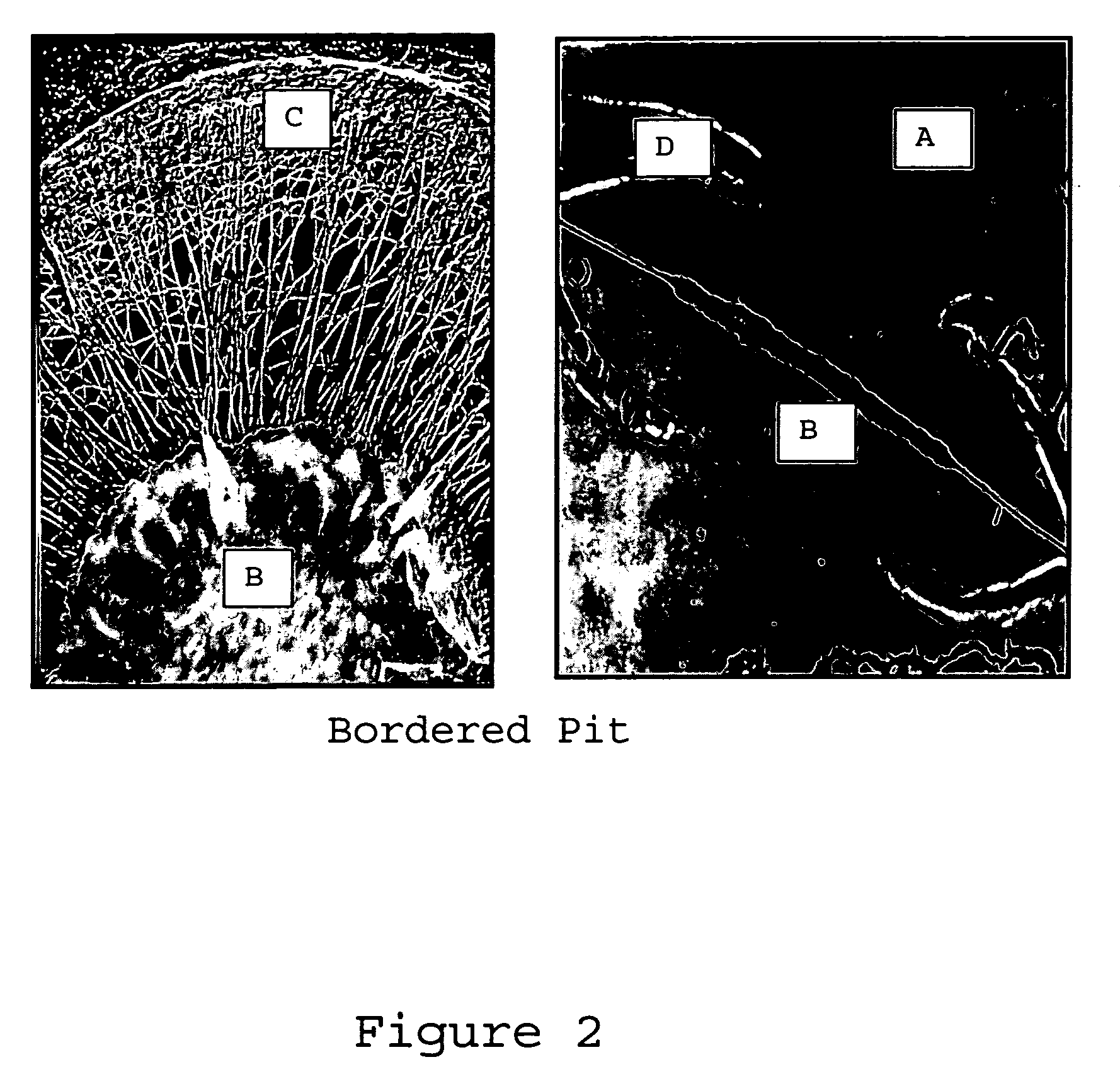

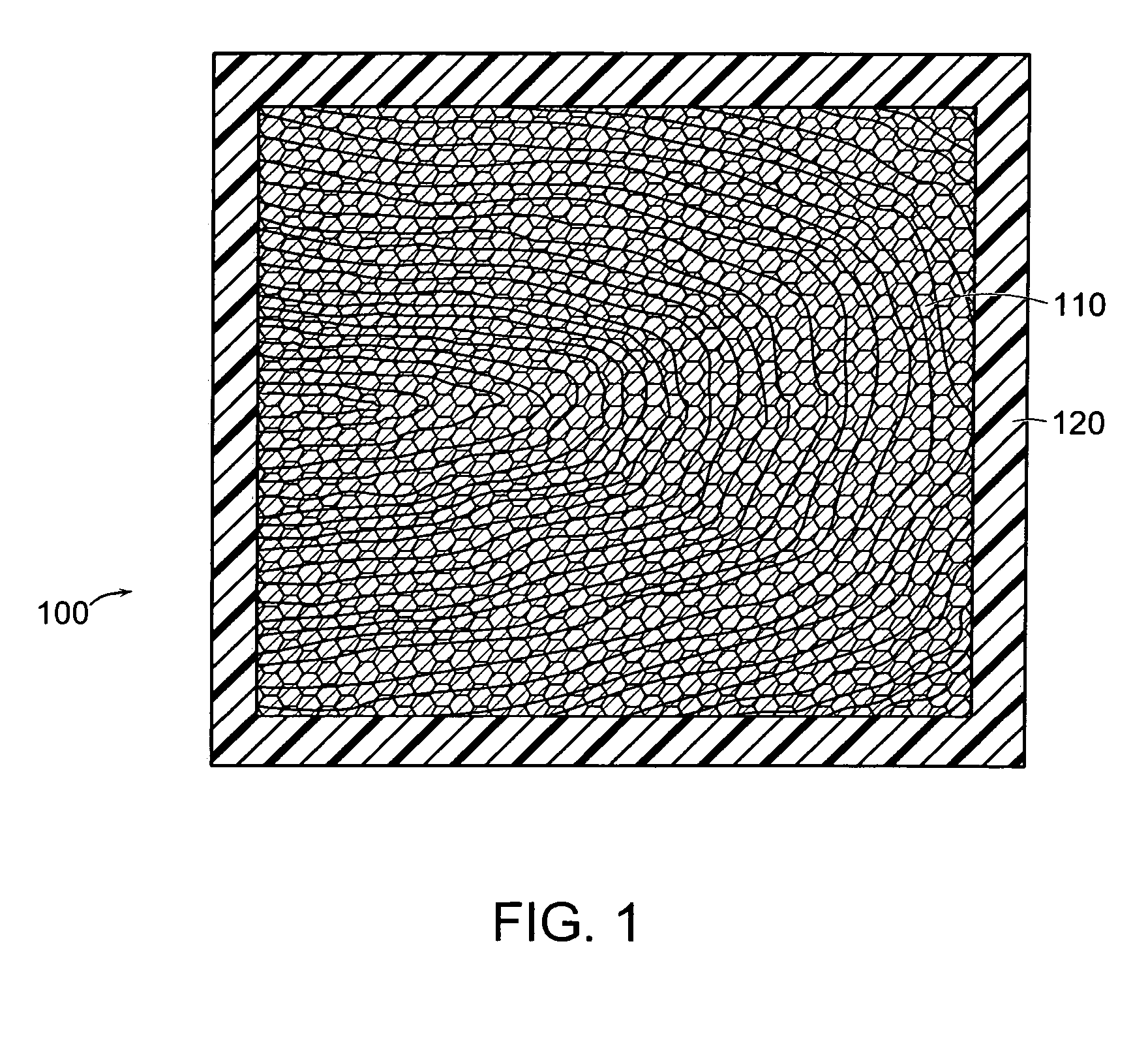

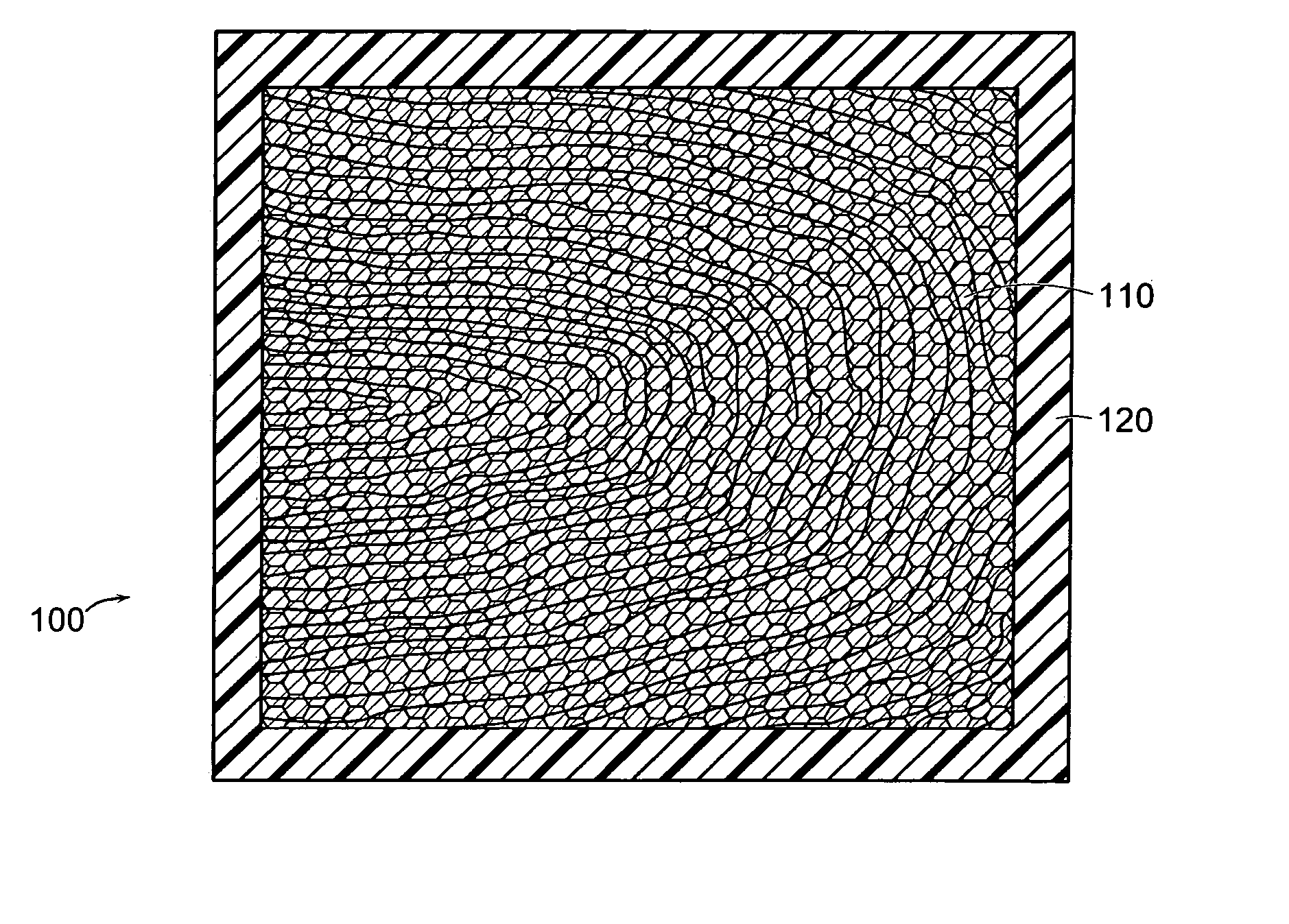

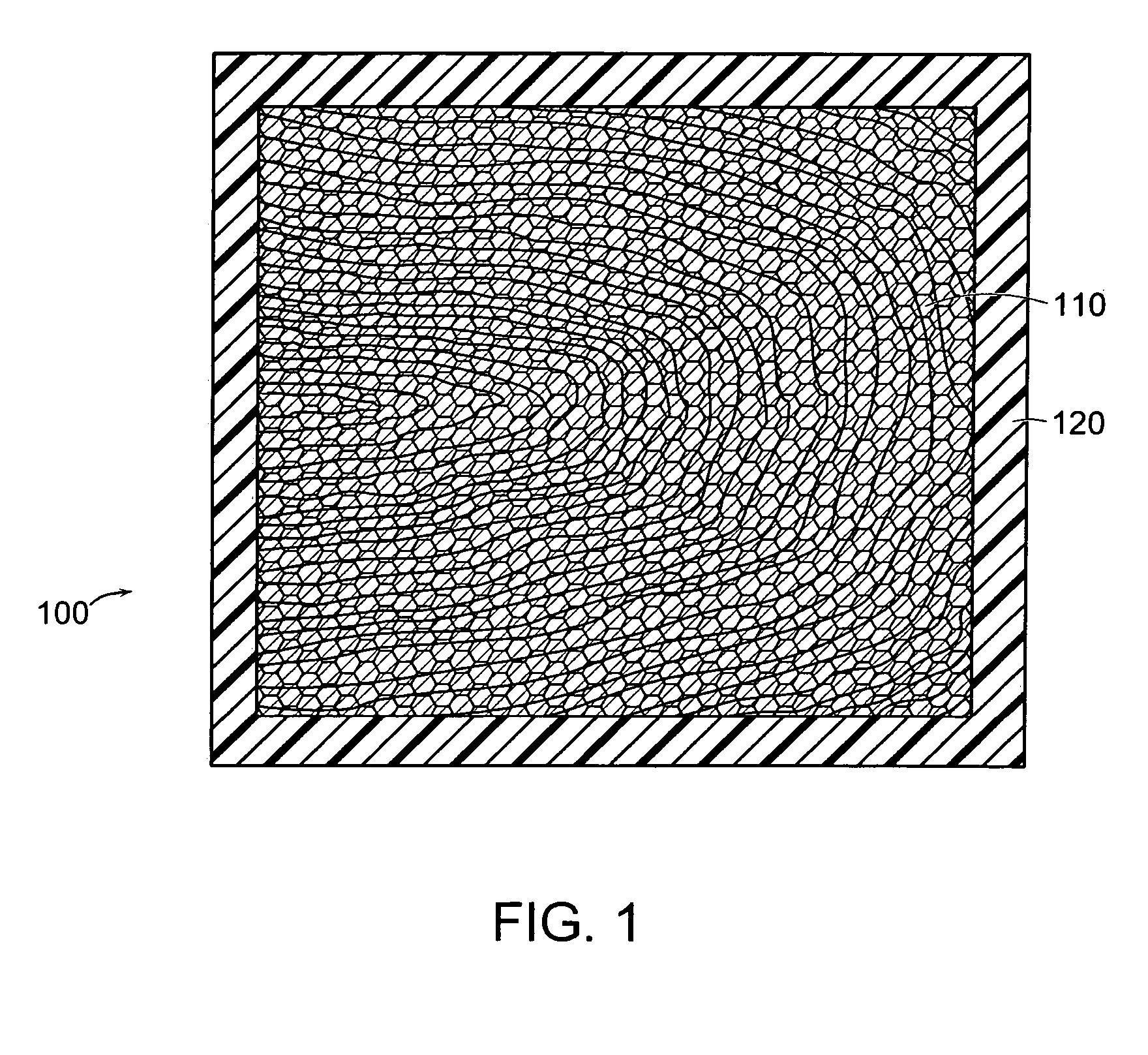

Engineered wood product

InactiveUS20100310893A1Lamination ancillary operationsSynthetic resin layered productsWood veneerCellulose fiber

Engineered wood products, methods of making the products, laminates including the products, and articles of manufacture which include the engineered products or composites, are disclosed. The products include wood and / or other cellulosic fibers, and can include non-cellulosic fibers, all or part of which can be derived from post-industrial and / or post-consumer materials. The products also include a binding agent, such as a latex dispersion, as well as hydrophobic materials, processing aids, colorants, and the like. The product can be in the form of a sheet, a three dimensional article or a plurality of laminated sheets, and can include one or more additional layers, such as top coat layers, reinforcing layers, cushioning layers, wood veneer layers, and / or additional product layers. The products can be used as flooring, and in construction, cabinetry, and the like.

Owner:SSI HOLDCO INC A DELAWARE +1

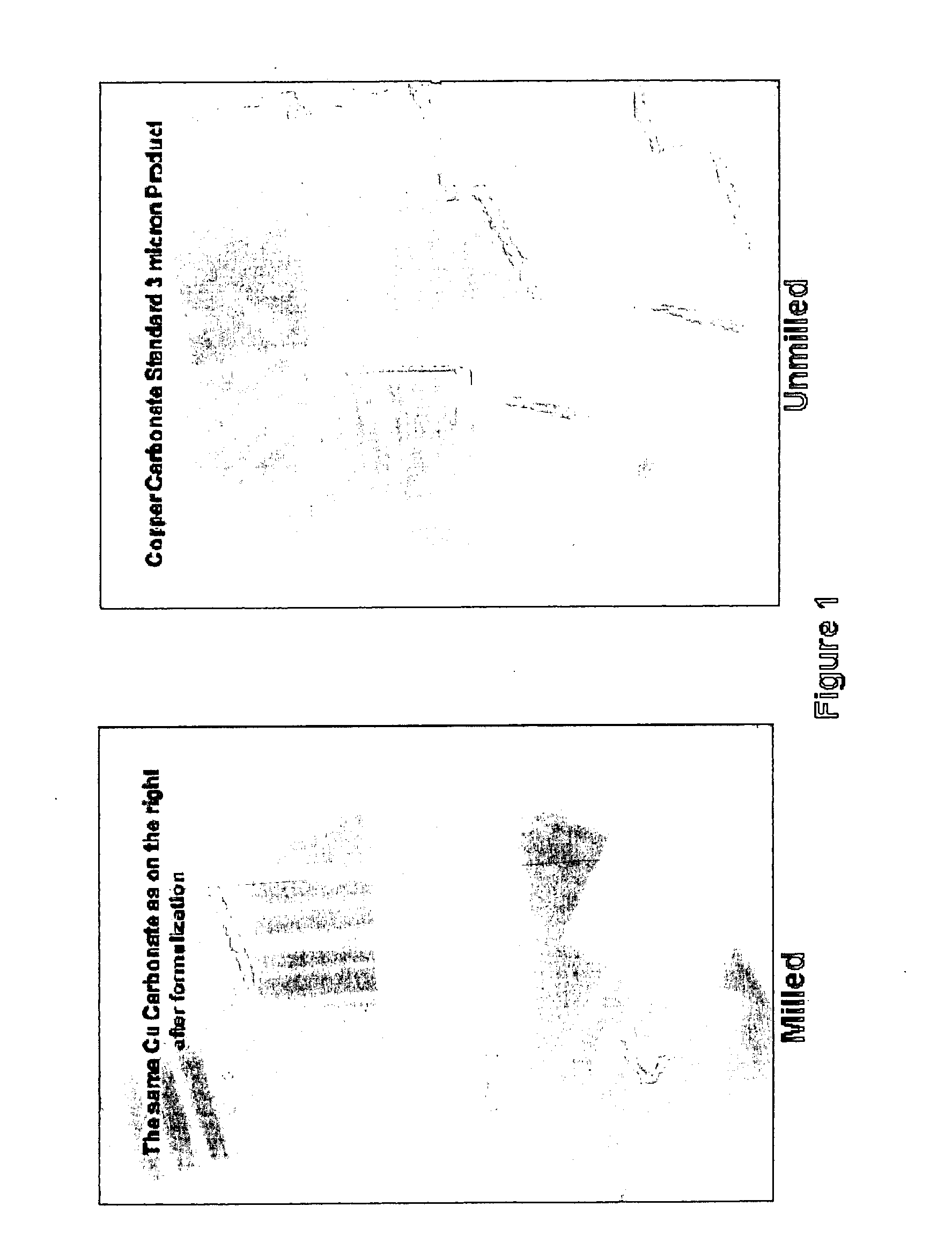

Particulate wood preservative and method for producing same

InactiveUS20050252408A1Reduce the amount requiredWide particle size distributionBiocideAntifouling/underwater paintsCopper(II) hydroxideBasic copper carbonate

A wood preservative includes injectable particles comprising one or more sparingly soluble copper salts. The copper-based particles are sufficiently insoluble so as to not be easily removed by leaching but are sufficiently soluble to exhibit toxicity to primary organisms primarily responsible for the decay of the wood. Exemplary particles contain for example copper hydroxide, basic copper carbonate, copper carbonate, basic copper sulfates including particularly tribasic copper sulfate, basic copper nitrates, copper oxychlorides, copper borates, basic copper borates, and mixtures thereof. The particles typically have a size distribution in which at least 50% of particles have a diameter smaller than 0.25 μm, 0.2 μm, or 0.15 μm. At least about 20% and even more than 75% of the weight of the particles may be composed of the substantially crystalline copper salt. Wood or a wood product may be impregnated with copper-based particles of the invention.

Owner:OSMOSE

Method of manufacture and treatment of wood with injectable particulate iron oxide

InactiveUS20060075923A1Reduces UV-promoted degradation of the wood substrateAppearance hasFireproof paintsBiocideParticulatesPreservative

A wood preservative includes injectable particles comprising one or more sparingly soluble iron salts. The iron-based particles are sufficiently insoluble so as to not be easily removed by leaching but are sufficiently soluble to exhibit toxicity to primary organisms primarily responsible for the decay of the wood. Wood or a wood product may be impregnated with iron-based particles of the invention.

Owner:OSMOSE

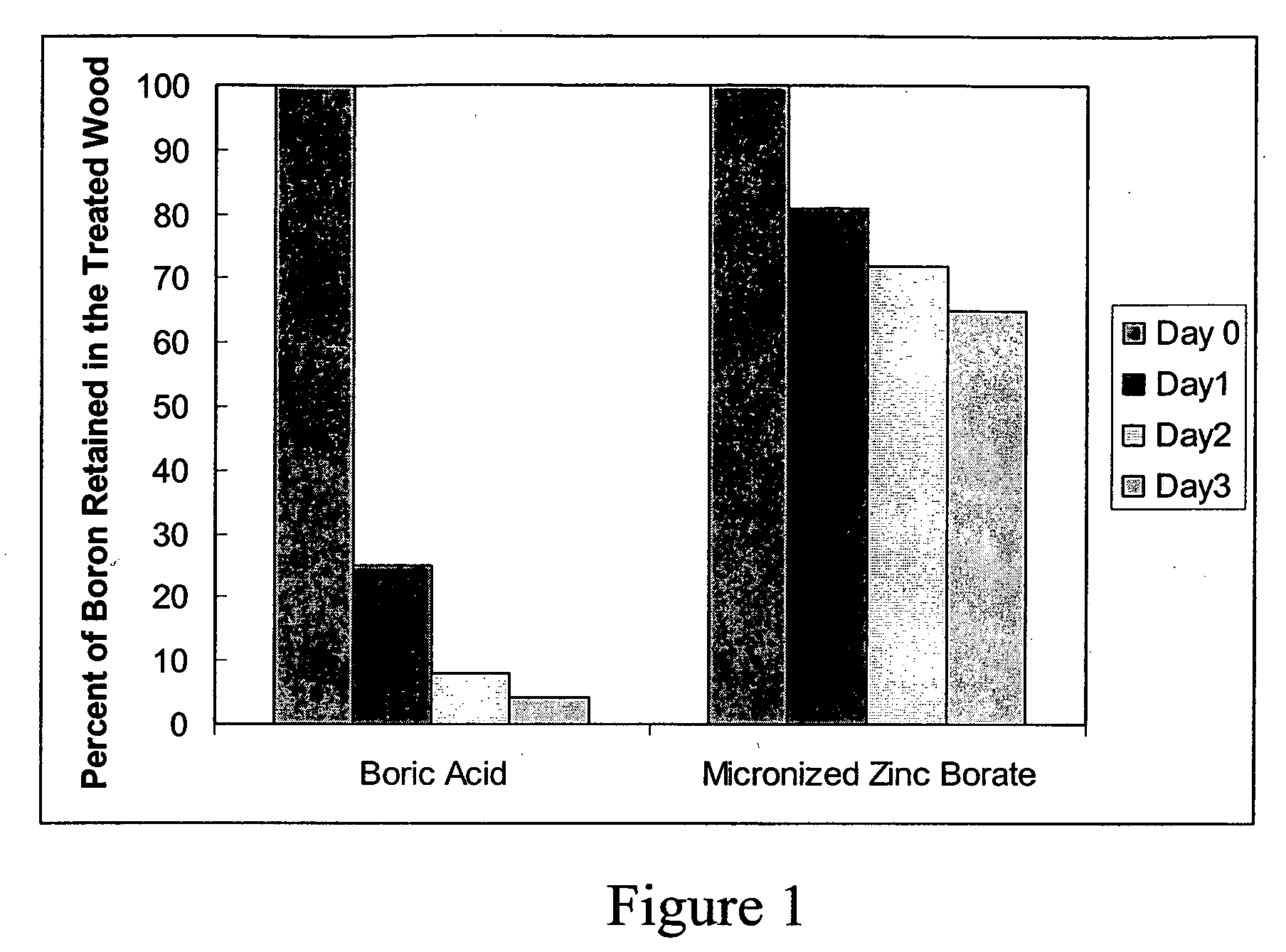

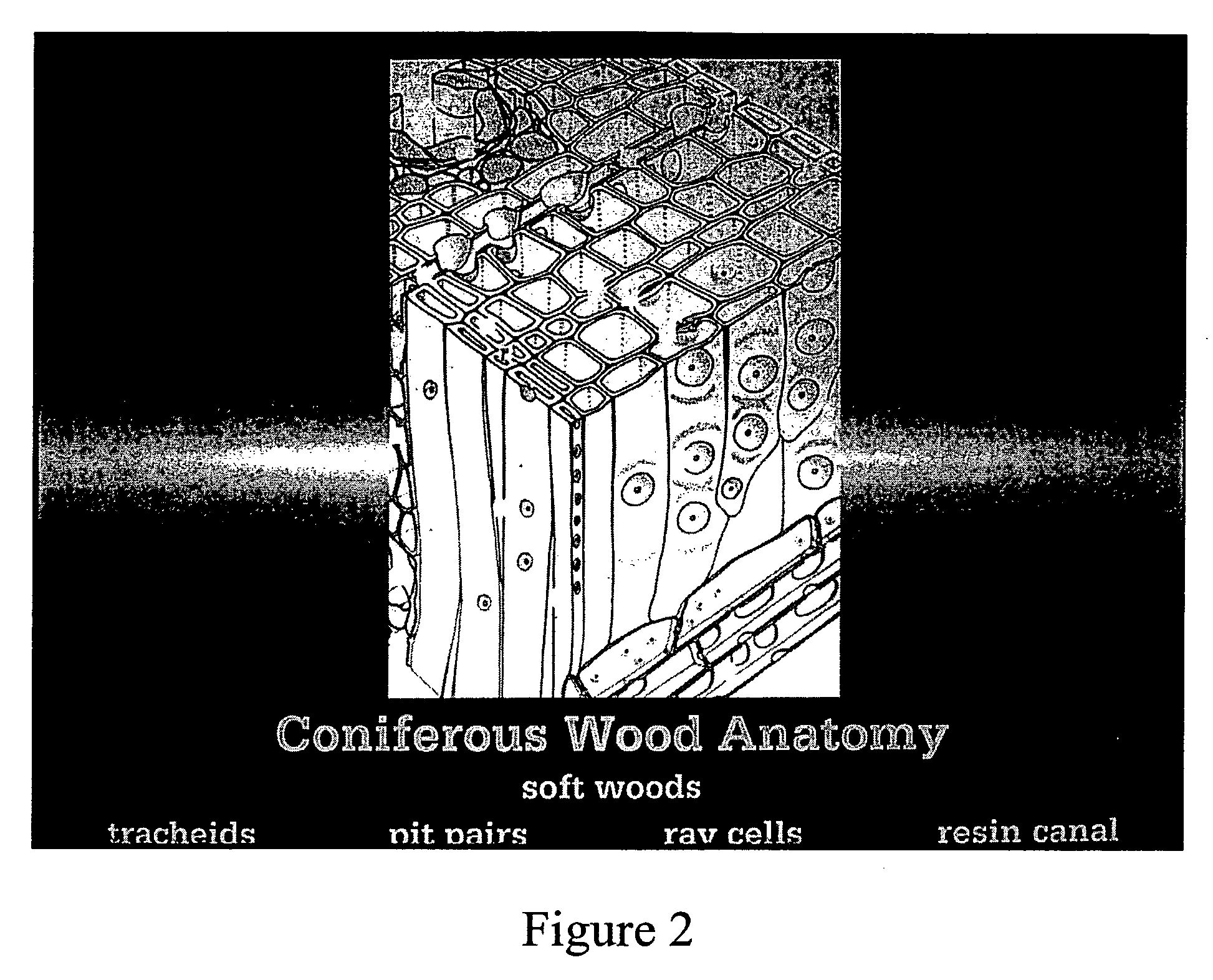

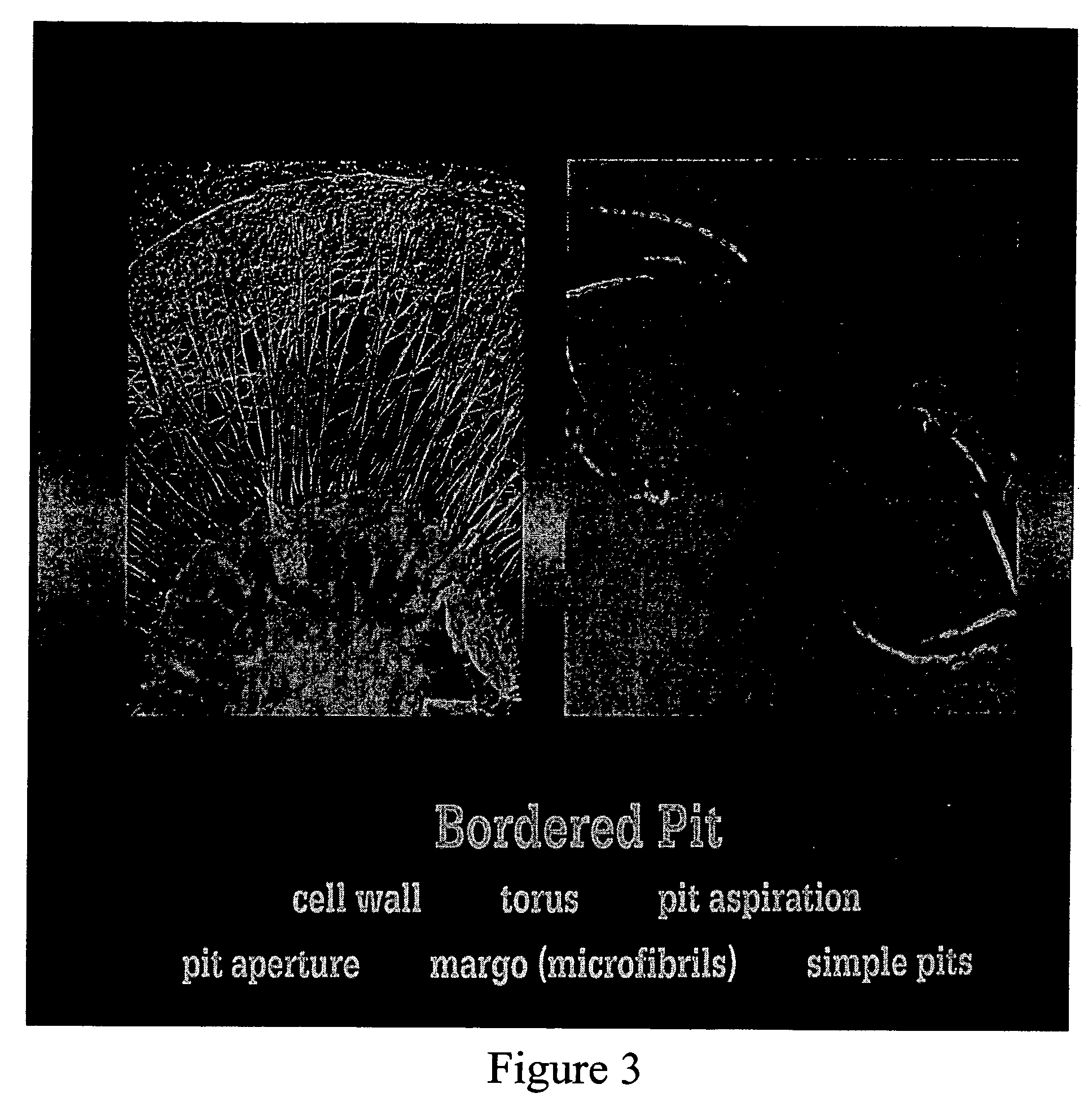

Micronized wood preservative formulations comprising boron compounds

InactiveUS20060257578A1Improving decay- and insect and fire-resistanceAccelerated decayFireproof paintsAntifouling/underwater paintsPreservativeFire retardant

The present invention provides wood preservative and flame retardant compositions having low leachability comprising micronized boron compounds and, optionally, one or more organic biocides which may be micronized. Also provided is a method for applying the composition to wood and wood products comprising impregnating the wood with the composition.

Owner:OSMOSE

Composition And Process For Coloring Wood

InactiveUS20070131136A1Uniform colorGood outdoor weather resistanceHeavy metal active ingredientsBiocidePigment dispersionPigment

Provided is a method for coloring and, optionally, preserving wood and wood products. The method comprises application of pigment dispersions, and optionally biocide dispersions, to wood such that the wood is impregnated. A composition for coloring and, optionally, preserving wood is disclosed, comprising dispersions of micronized pigment and, optionally, micronized biocide.

Owner:OSMOSE

Compositions and methods for treating cellulose-based materials with micronized additives

InactiveUS20050265893A1Increase costIncrease residueBiocideDrying using combination processesCelluloseMaterials science

Owner:OSMOSE +1

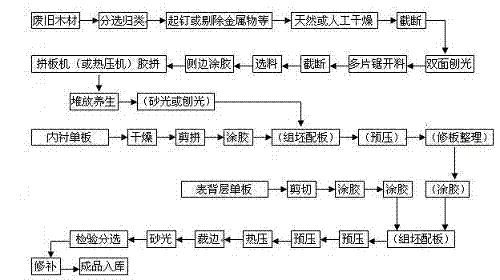

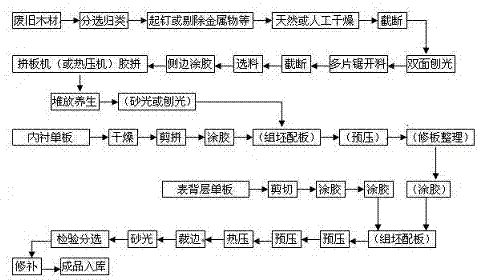

Method for producing recombinant composite board by using waste wood

InactiveCN102229159AFlat surfaceUniform thicknessOther plywood/veneer working apparatusLaminationSolid woodPulp and paper industry

The invention discloses a method for producing a recombinant composite board by using waste wood. The method comprises the following steps of: (1) preparation of a core board, (2) veneer finishing, (3) board blank gluing, blank matching and pre-pressing, (4) hot pressing, (5) trimming and sanding, and (6) inspection, grading and repair. The method has the advantages that: the square board of certain specification is manufactured by making full use of the waste wood, the core layer is spliced by using glue, two layers of veneers are covered on two sides of the core layer respectively, the recombinant composite board with five-layer structure is manufactured by hot pressing, and the reclaimed waste wood is used for substituting solid wood, so the material channel is broadened; low carbon, environment friendliness, greenness and resource property of the recombinant composite board are highlighted; the comprehensive utilization rate of the waste wood is improved, and the additional value and the technological content of the waste wood product are increased; and high use of small material, preferential use of poor material, fine use of coarse material and elaborate use of weak materialare realized in the waste wood.

Owner:玉环市众创人才科技创新服务中心

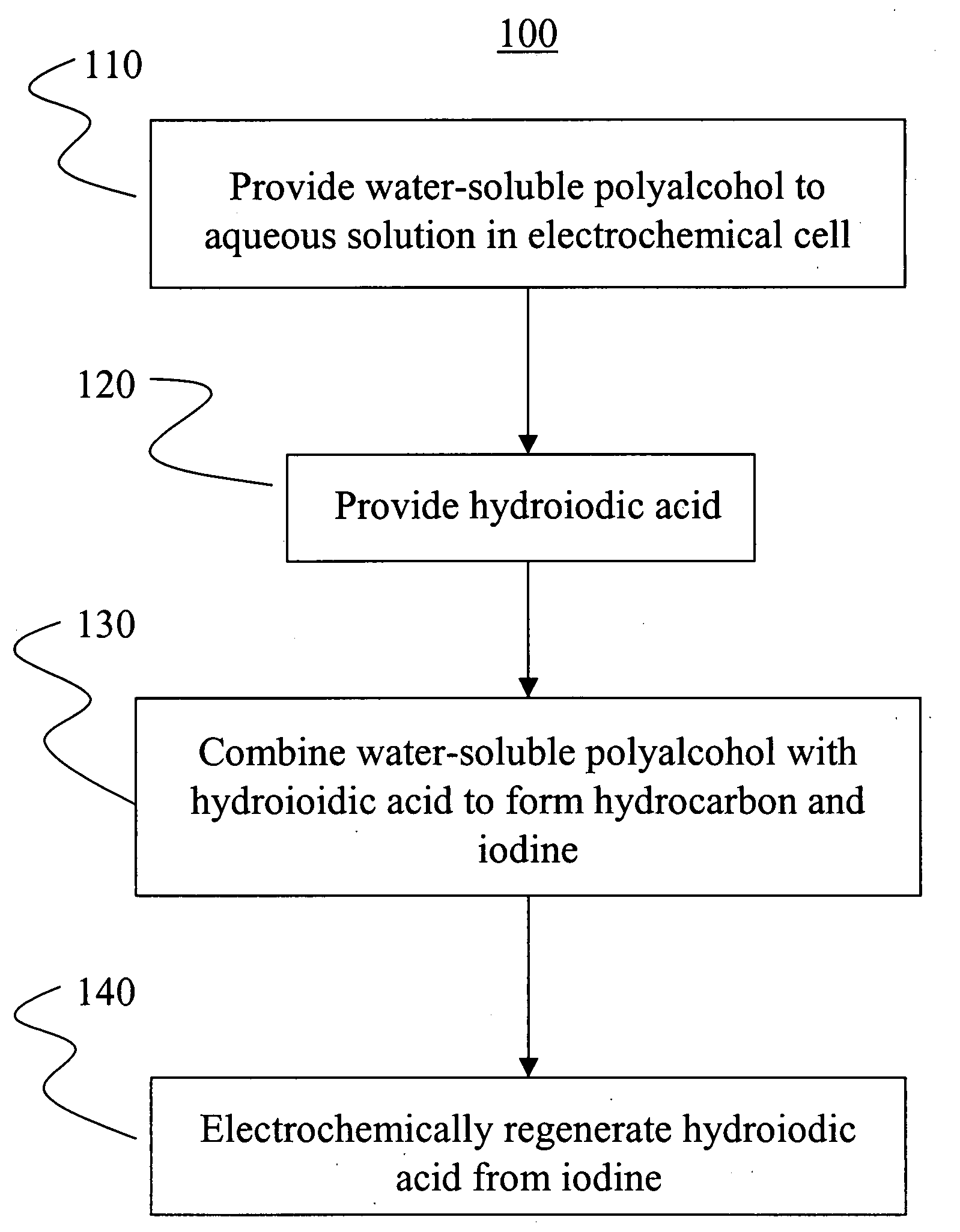

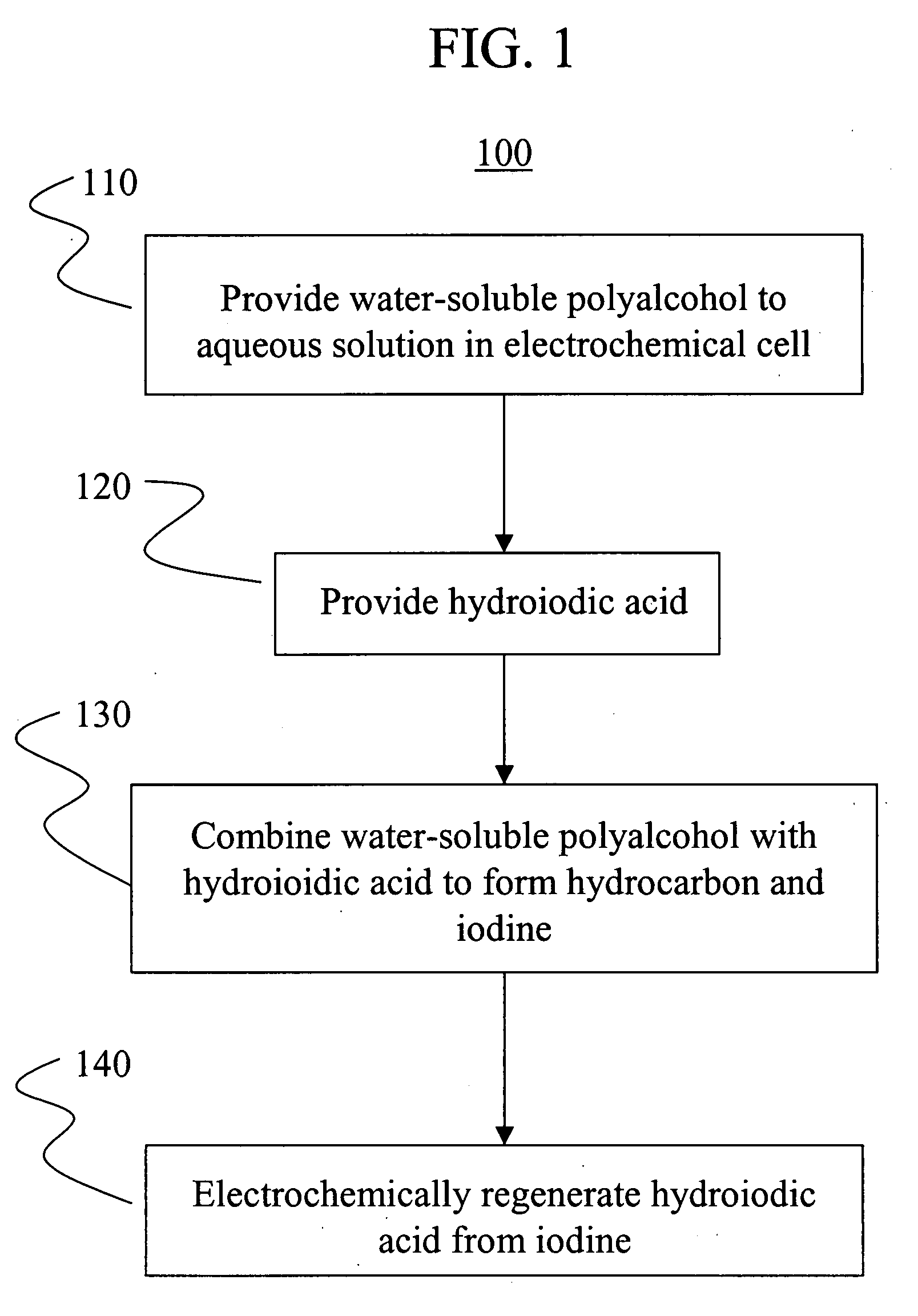

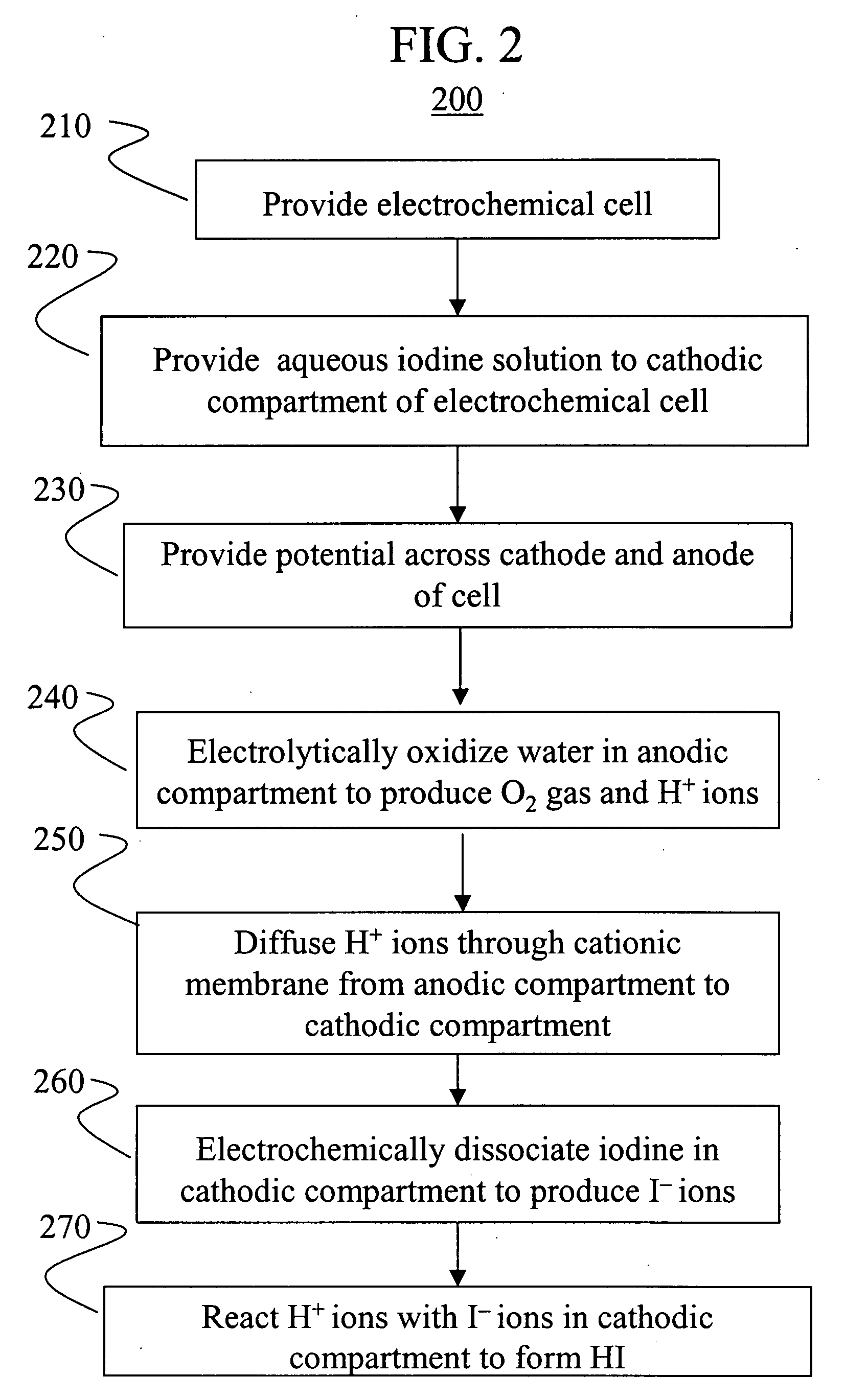

Electrochemical conversion of polyalcohols to hydrocarbons

A method of making hydrocarbons from polyalcohols, such as carbohydrates. The polyalcohols and carbohydrates may be provided from biomass, including paper, cardboard or urban generated paper product waste; wood and wood products, including forest slash and deadfall; agricultural waste; and the like. The polyalcohols and carbohydrates are combined with hydroiodic acid in aqueous solution to form the hydrocarbon and elemental iodine. Hydroiodic acid is then electrochemically regenerated by reducing the elemental iodine in a parallel reaction. A method of electrochemically generating hydroiodic acid from elemental iodine in aqueous solution is also described.

Owner:RGT UNIV OF CALIFORNIA

Polyvinyl chloride composition

The present invention relates to a polyvinyl chloride (PVC) / wood composition and more particularly to a PVC / wood composite suitable for the manufacture of window blinds and other PVC / wood products. A compound containing wood powder is added to a PVC base, and a high concentration of titanium oxide, e.g., from about 5 to about 20 wt %, is added to the mixture to make it white. Additional pigments can be added to make the formulation any desired color.

Owner:KAM TECH HLDG

Micronized organic preservative formulations

A wood preservative composition comprising micronized particles of organic biocide is provided. The composition comprises a dispersion comprising particles in the range of 0.001 to 25 microns. Also provided is a method for the application of the preservative composition to wood. In addition, wood products which have been treated with the preservative composition are also provided.

Owner:OSMOSE +1

Production of gasoline from fermentable feedstocks

ActiveUS20100137647A1High speedHigh oil contentOrganic compound preparationBiofuelsBiodieselKetonic acids

Methods are disclosed for forming heptan-4-one, and, optionally, heptan-4-ol, from fermentable sugars. The sugars are fermented using a bacteria or yeast that predominantly forms butyric acid. The butyric acid is subjected to catalytic ketonization conditions to form heptan-4-one, with concomitant loss of water and carbon dioxide. The heptan-4-one can be subjected to catalytic hydrogenation to form heptan-4-ol, an either of these can be included in gasoline compositions. In one aspect, the fermentable sugars are derived from lignocellulosic materials such as wood products, switchgrass, or agricultural wastes, which are delignified to form lignin, cellulose and hemicellulose. The cellulose and hemicellulose can be depolymerized to form glycose and xylose, either or both of which can be fermented by the bacteria. Thus, the methods described herein can convert biomass to a fuel composition or fuel additive, which can be used in a conventional gasoline engine, unlike traditional fuels such as ethanol or biodiesel.

Owner:CPS BIOFUELS INC

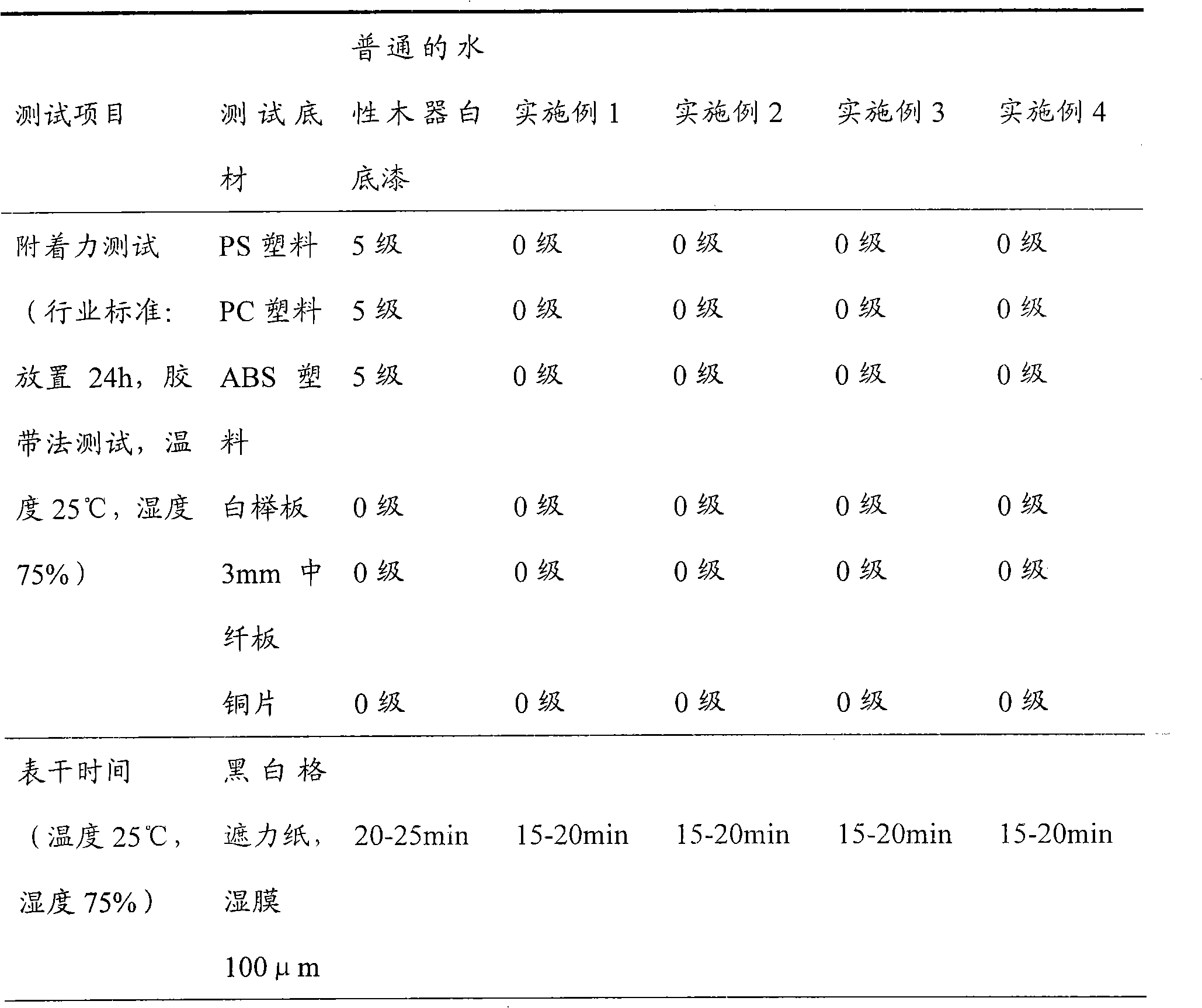

Multifunctional water-based white primer and preparation method thereof

The invention discloses multifunctional water-based white primer, which comprises the following components: titanium dioxide, talcum powder and calcium carbonate, and is characterized by comprising acrylic emulsion A and acrylic emulsion B, wherein acrylic emulsion A is styrene-acrylate emulsion which is self-crosslinked at the room temperature, and acrylic emulsion B is modified acrylic emulsion. The multifunctional water-based white primer provided by the invention can be constructed on a variety of wood product substrates, but also can be constructed on a variety of plastic substrates, at the same time, can be applied on the copper sheets, breaks through the situation of the simplification of the water-based white primer, and the performances meet the various requirements water-based wood white bottom and water-based plastic white bottom.

Owner:CHINA PAINT MFG CO SHENZHEN

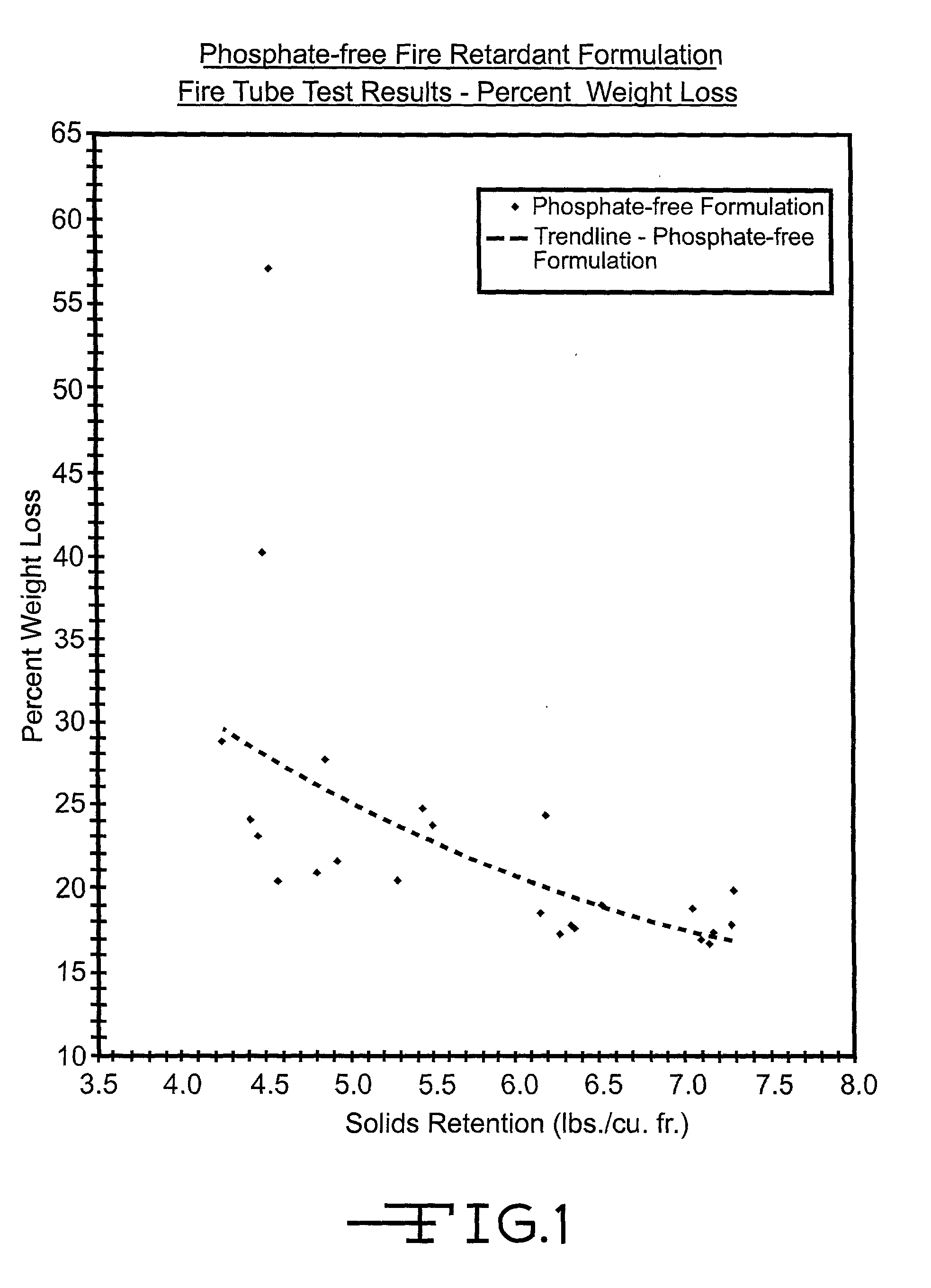

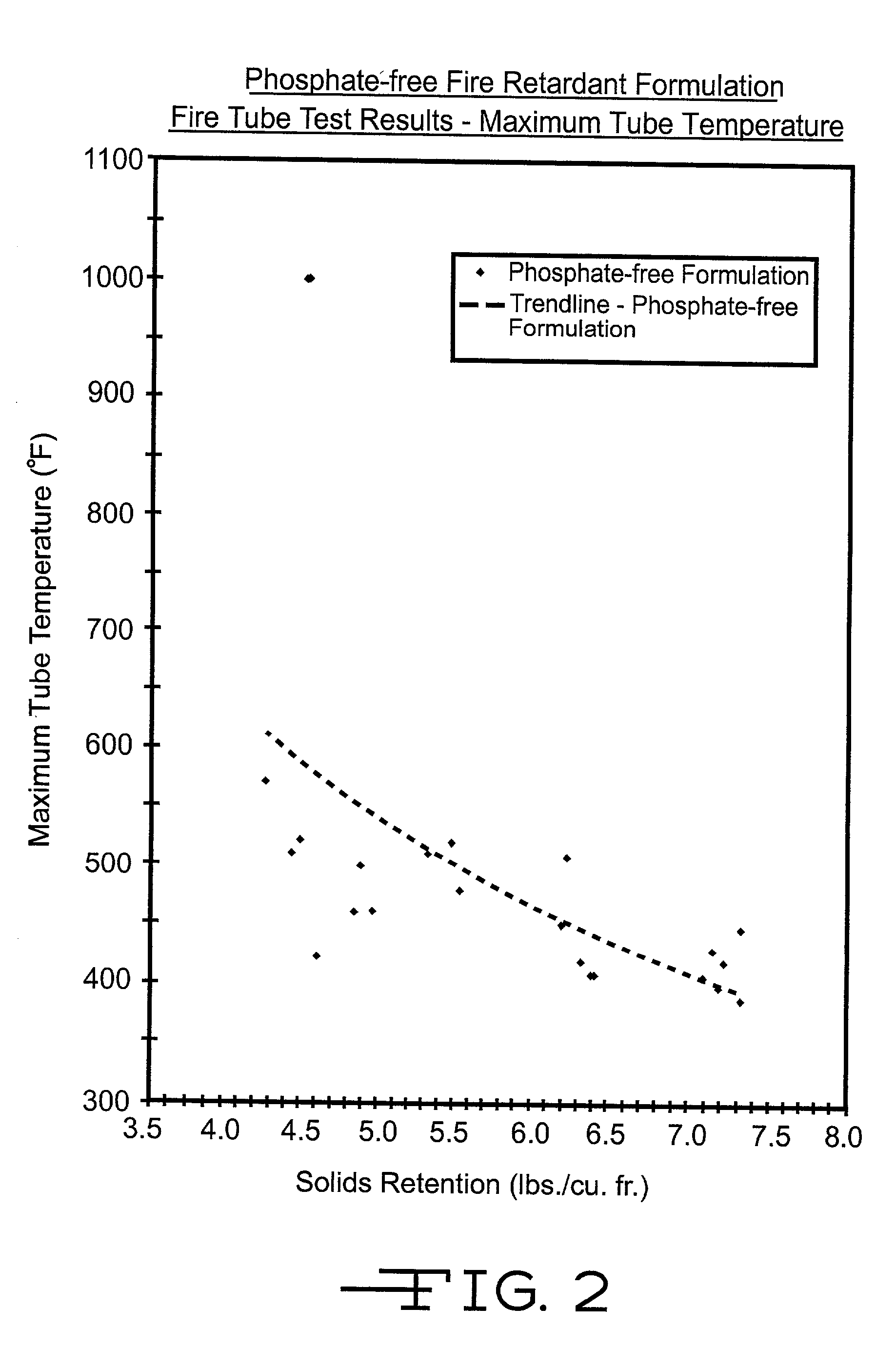

Phosphate free fire retardant composition

A phosphate and ammonia free composition for treating an object (i.e., lumber, plywood and other wood products) is described. The treating solution may be applied to the object by dipping, soaking, brushing, spraying, etc., however, vacuum and / or pressure techniques may be used to impregnate the object according to the method of this invention, including both the empty-cell process and the full-cell process. The composition achieves fire retardant qualities without object degradation when the treated object is subjected to heat and humidity over time. The composition of this invention includes nitrogen in a predetermined ratio to boron.

Owner:KOPPERS PERFORMANCE CHEM

Water repellent composition for improving wood product dimensional stability

InactiveUS20070037001A1Increased swelling resistanceImprove material stabilityWax coatingsOther chemical processesWaxWater repellent

Provided are compositions for improving the water-resistance and dimensional stability of wood and wood products. The compositions comprises wax and oil components, and can be applied as liquid compositions comprising little or no water. Also provided are methods for the application of the compositions to wood.

Owner:OSMOSE

Wooden wares surface archaizing treatment technology

InactiveCN1730255AEasy to produceVariety of colorsWood treatment detailsPretreated surfacesLacquerDiluent

The invention relates technology of surface treatment of wooden wares, comprising the following steps: drying the wood and blanking according to the requirement, processing and charring; brushing or spraying the archaized color priming paint which is compounded by diluent and mixture of yellow paint, red paint, black paint, and white paint in proper proportion, after drying, repairing the surface of the wood, then spraying the priming paint repeatedly twice or thrice, making it dry naturally; sanding the said wooden wares by fineness abrasive cloth, taking out the paint around 20%; spraying the press polish archaized paint to the surface of the wooden wares. The invention processes simple technology, good effect of imitation antique, convenience production, economy and utility.

Owner:DAKANG HLDG GROUP

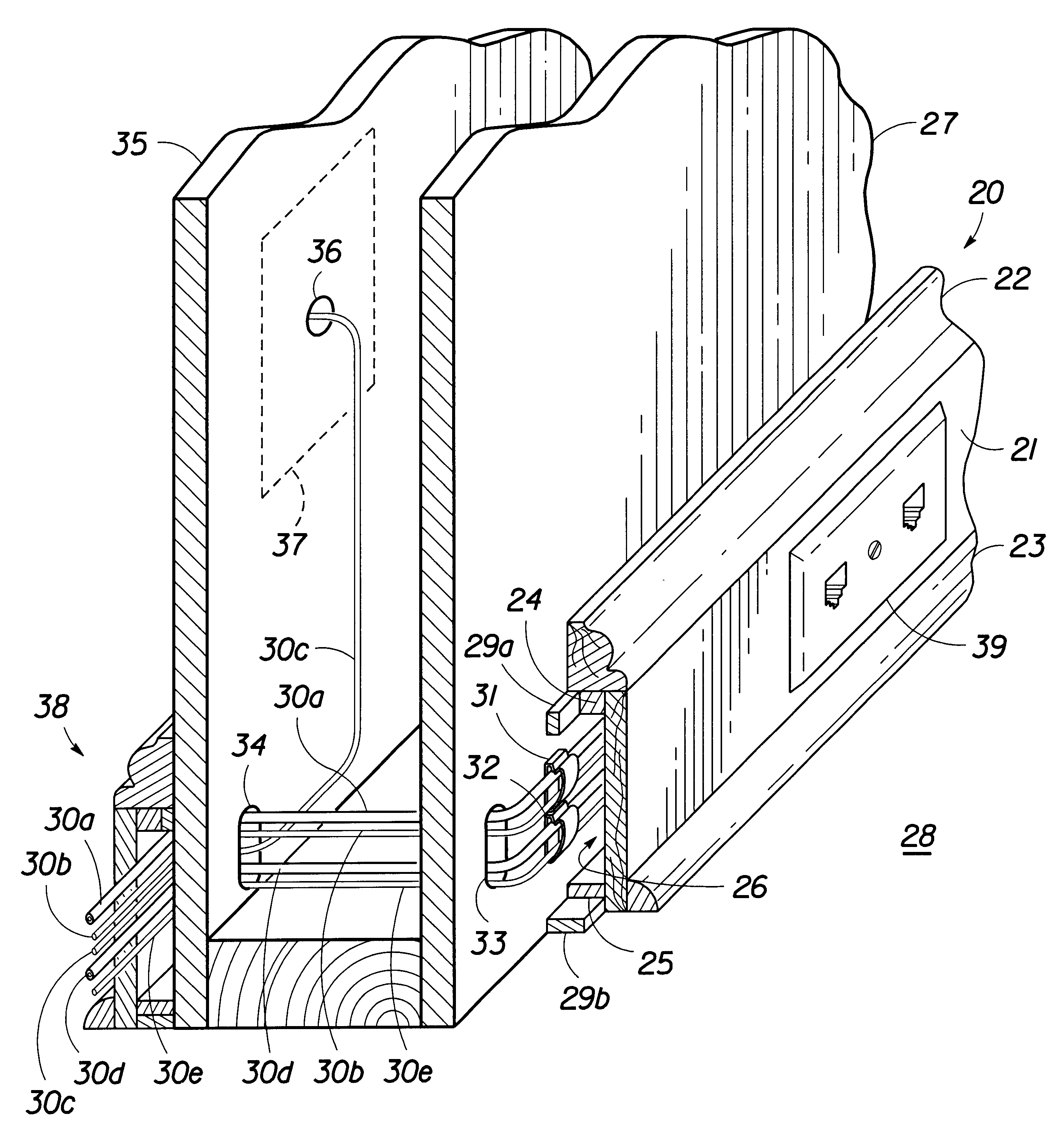

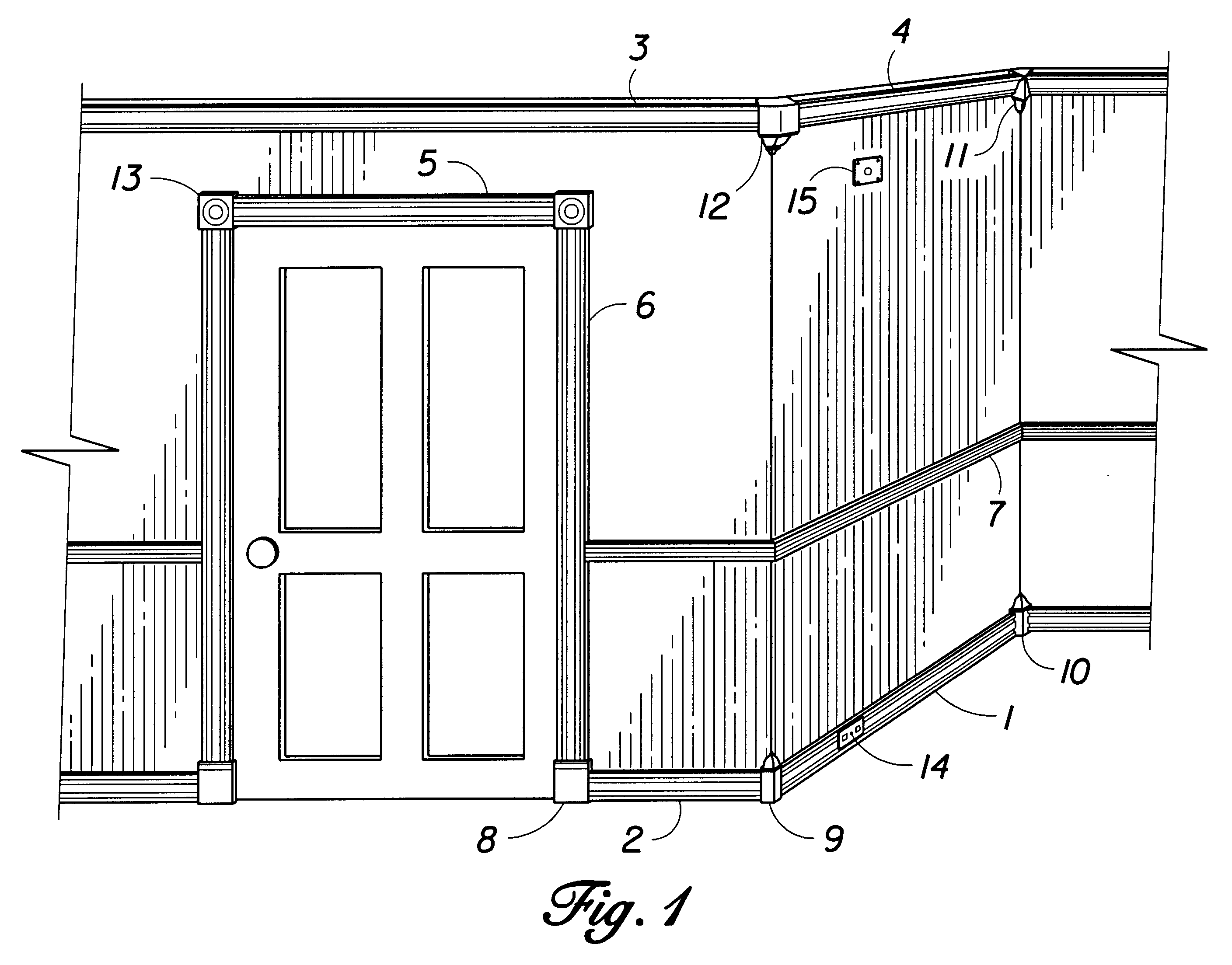

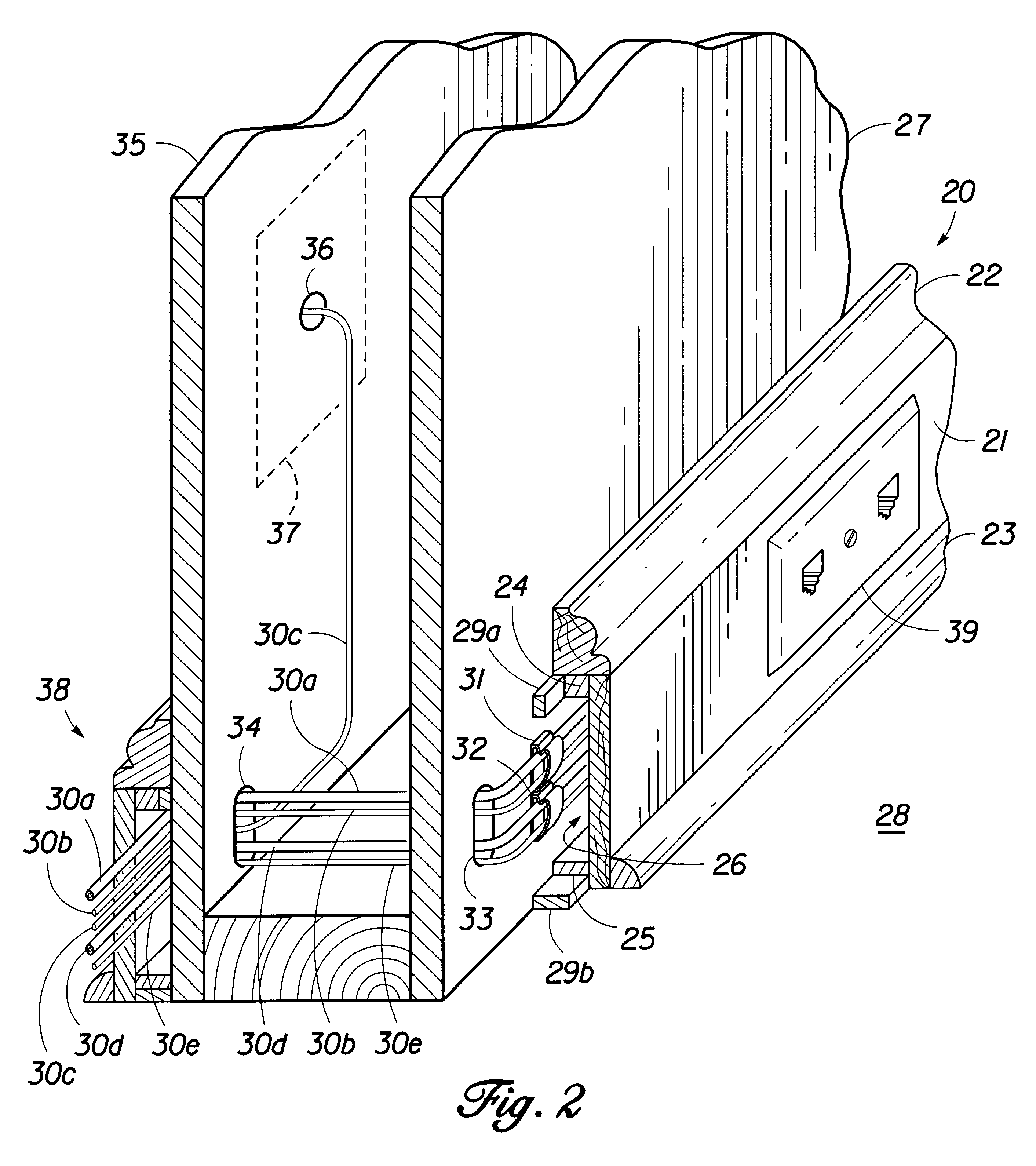

Architectural moldings for protecting, concealing and accessing indoor wiring and cables

A system of architectural moldings that, when installed, form a passage for electrical wiring, coaxial cables, fiber optic cables, and associated devices used in the transmission of low-voltage power, communication, and control signals. The architectural moldings may also be used to cover and improve the aesthetic appeal of pre-existing wiring raceways and conduits. The system as a whole may be installed during construction of new a home or building or when retrofitting an existing structure. The moldings can be removably mounted on the interior surfaces of residential and commercial structures in a manner that allows for easy removal and replacement of some or all of the molding without disturbing the enclosed wiring and cables or harming finished surfaces. The moldings may be made of wood, polyurethane, fiberboard, or any material that is suitable to manufacture pieces that resemble baseboards, cornice moldings, chair rails, casings, or other interior millwork for homes or commercial structures. The system of moldings greatly facilitates any upgrades or modifications to the number, type, or placement of wiring, cables, outlets, jacks, or associated devices.

Owner:SEAMANS JAMES D

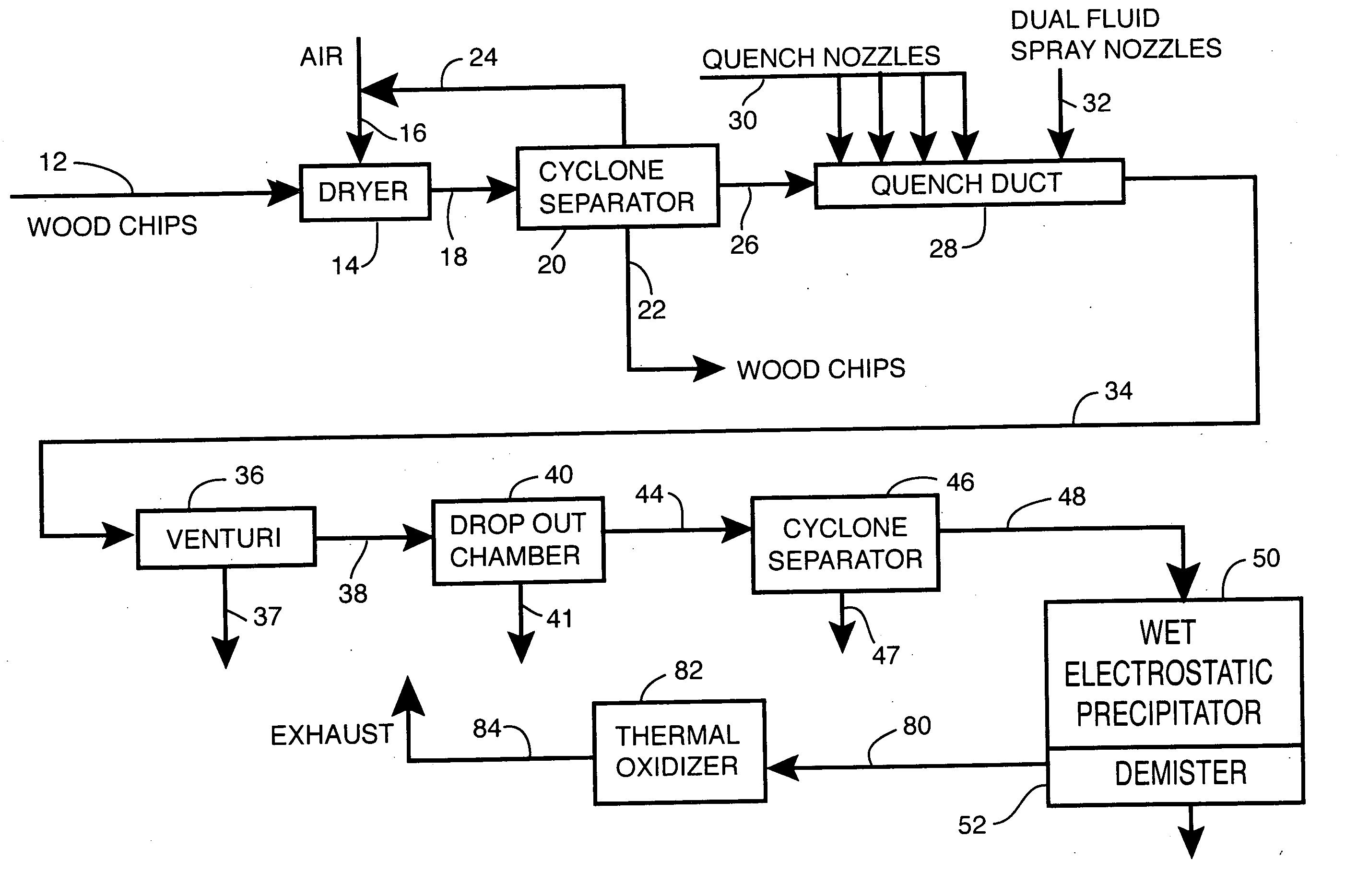

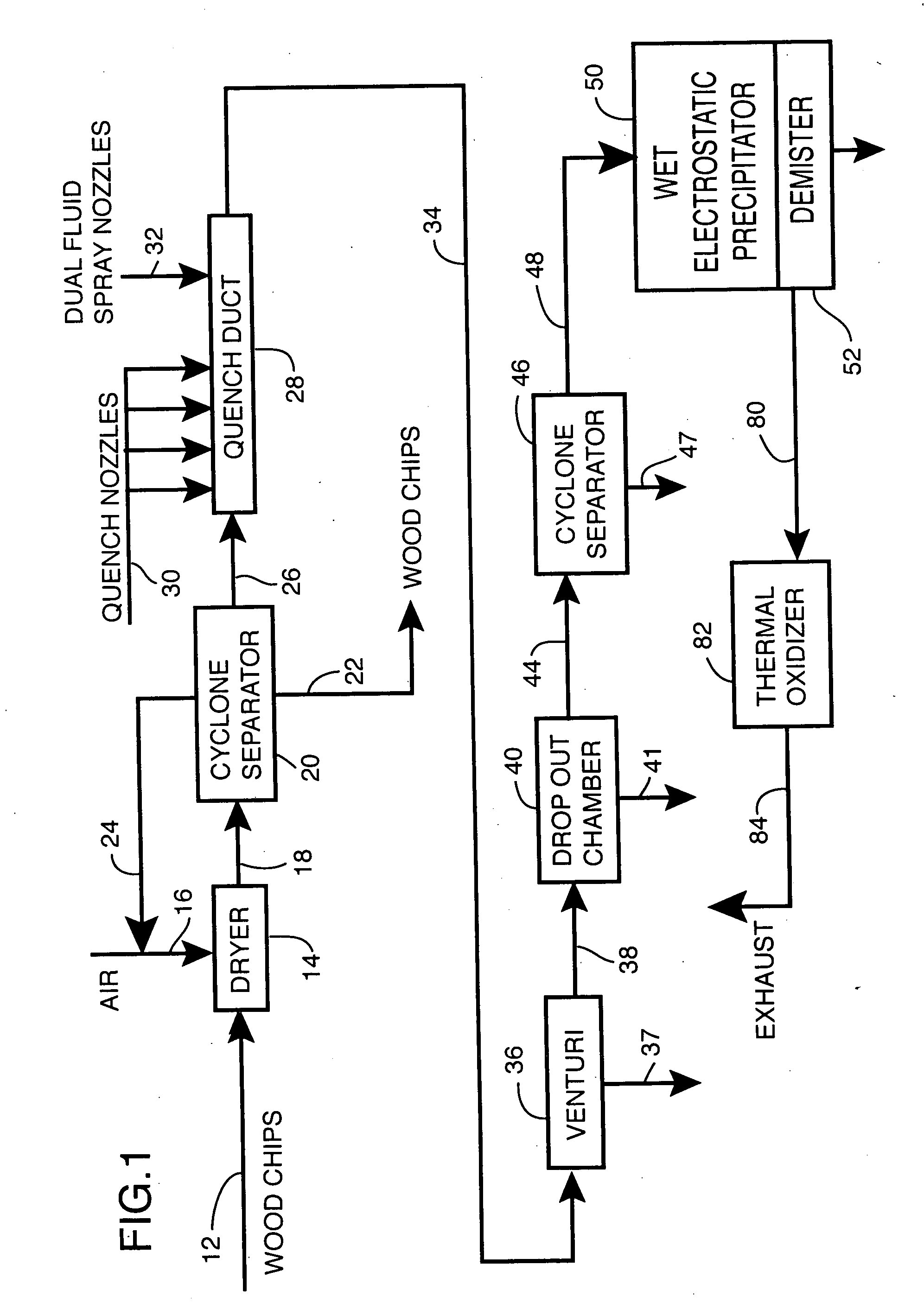

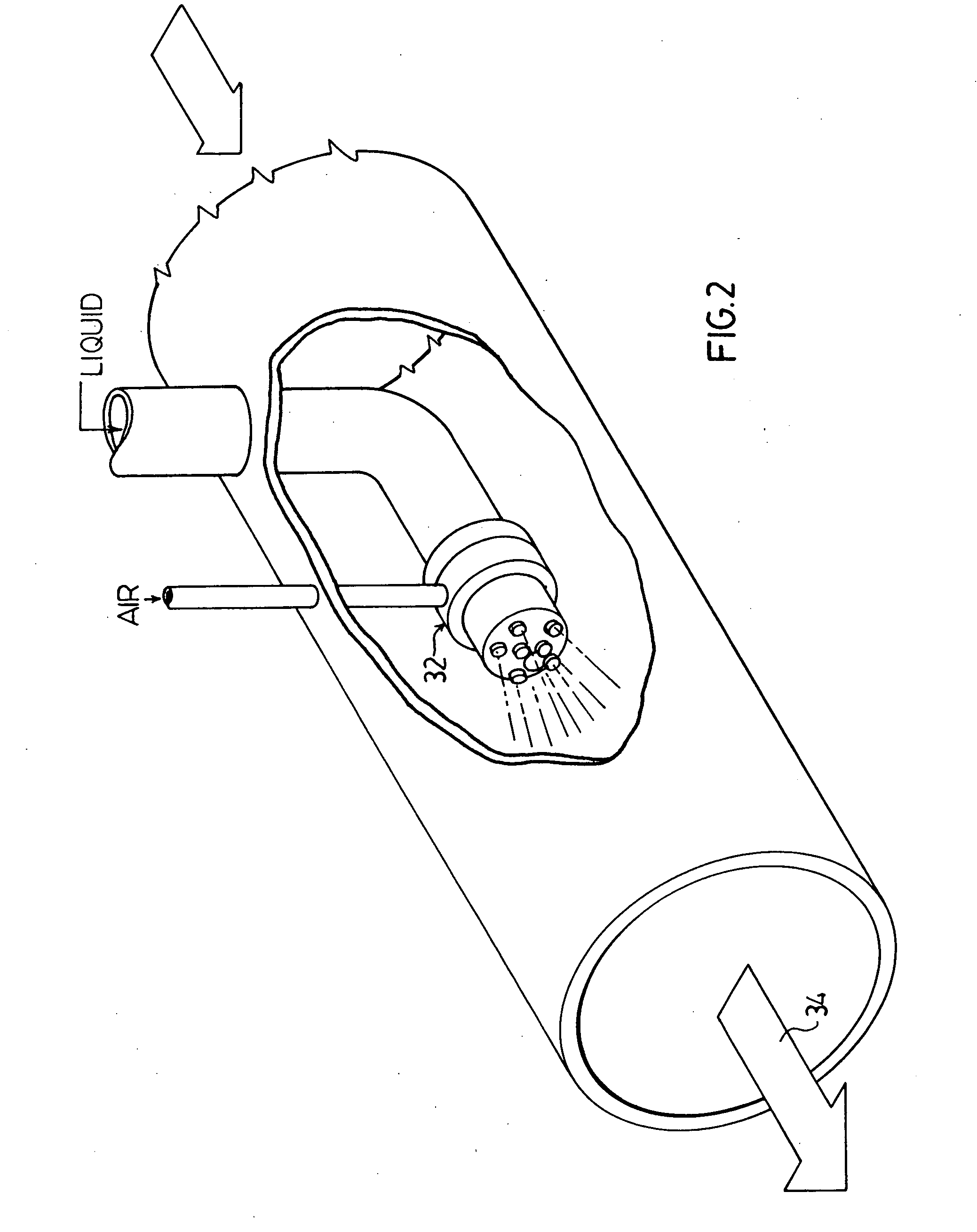

Pollution control in wood products dryer

InactiveUS20050229780A1Reduce gas flowEmission reductionCombination devicesDrying solid materials with heatParticulatesCombustor

Contaminant laden gas streams from wood product dryer operations, and other sources, are purified. The gas stream first is saturated with moisture by contacting the gas stream with fine liquid droplets which entrain particulates. The gas stream then is subjected to a plurality of separate particulate and liquid droplet removal steps before a droplet-free gas stream having substantially reduced particulate contaminant levels is passed to a burner for removal of volatile organic compounds from the gas stream.

Owner:MEGTEC TURBOSONIC

Deck plank extrusion and retaining clip

A deck plank (12) readily attaches to an engagement clip (46) when force is applied over the plank. When a plurality of clips are attached to underlying joists in parallel with the joists, and a plurality of deck planks are oriented to the clip perpendicular to the joist and pushed down over clips, a secure deck structure is provided. Each clip has a pair of horizontal flanges (52 and 54), which snap over a plurality of ledges (42 and 44) in a channel under each plank. The deck planks (12) are embossed (14) so as to form a slip resistant surface to be walked upon. The plastic extruded deck plank (12) resists rot, deterioration and insect infection found in current wood products. The deck plank assembly is simple enough so that a homeowner or do-it-yourselfer can install or alter it with minimal effort and direction.

Owner:LEINES RICHARD ALAN

Composite coated/encapsulated wood products and methods to produce the same

InactiveUS20050106406A1Lose weightHigh strengthRecord information storageCeramic layered productsBuilding productMaterials science

Composite coated wood products, and methods to produce such products, are described by embodiments of the invention. Composite layers may comprise polymer and fillers, such as organic fillers and inorganic fillers. The composite layers may also be foamed in some embodiments of the invention. Such composite coated wood products may be structural or non-structural pieces that may provide safe, economical, easy to manufacture construction products that may be utilized with wood composites, and other plastic composites. Such products may also promote uniformity of appearance in objects constructed with the composite coated wood products in a variety of applications.

Owner:LUMBERTEK

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com