Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

414 results about "Building product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

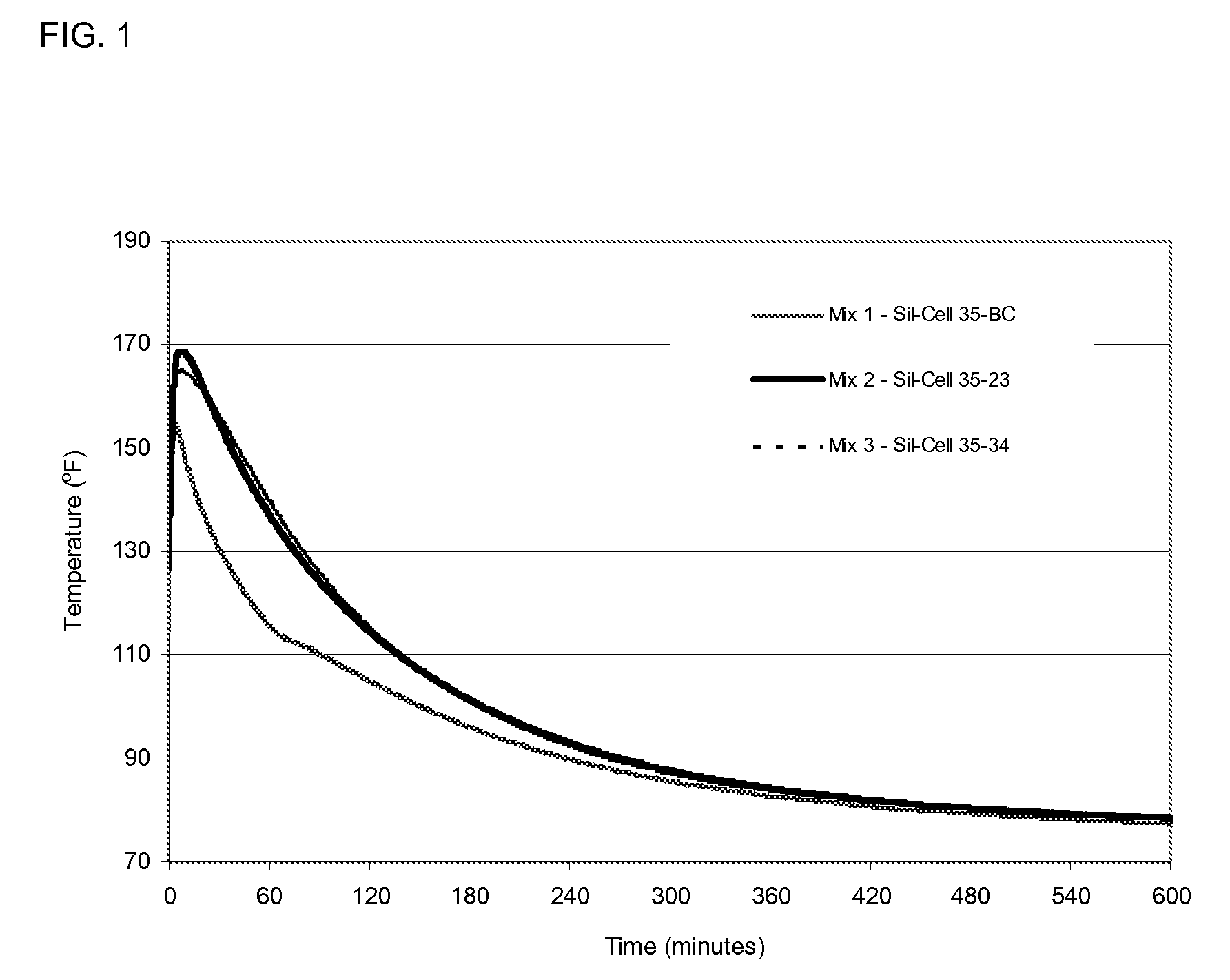

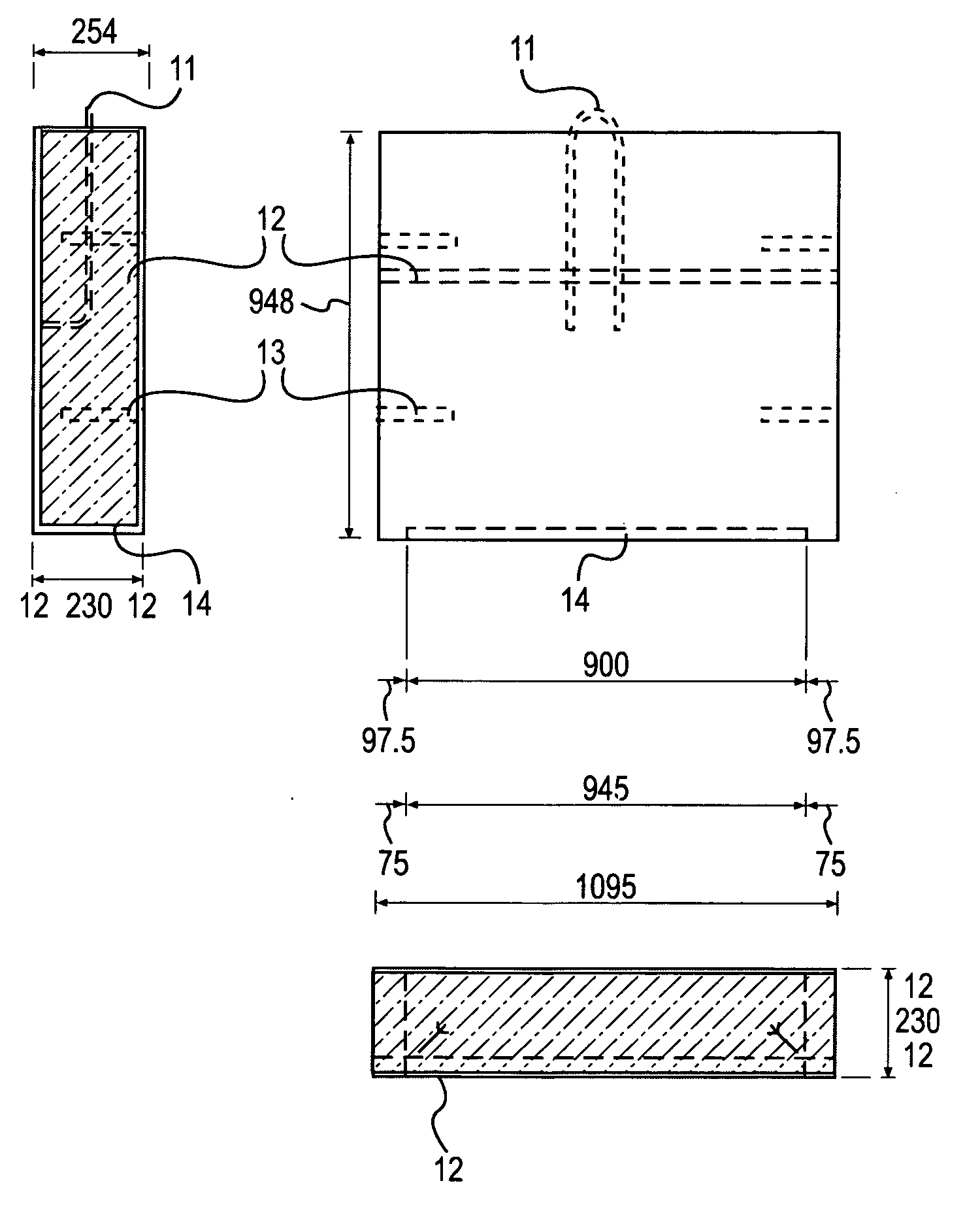

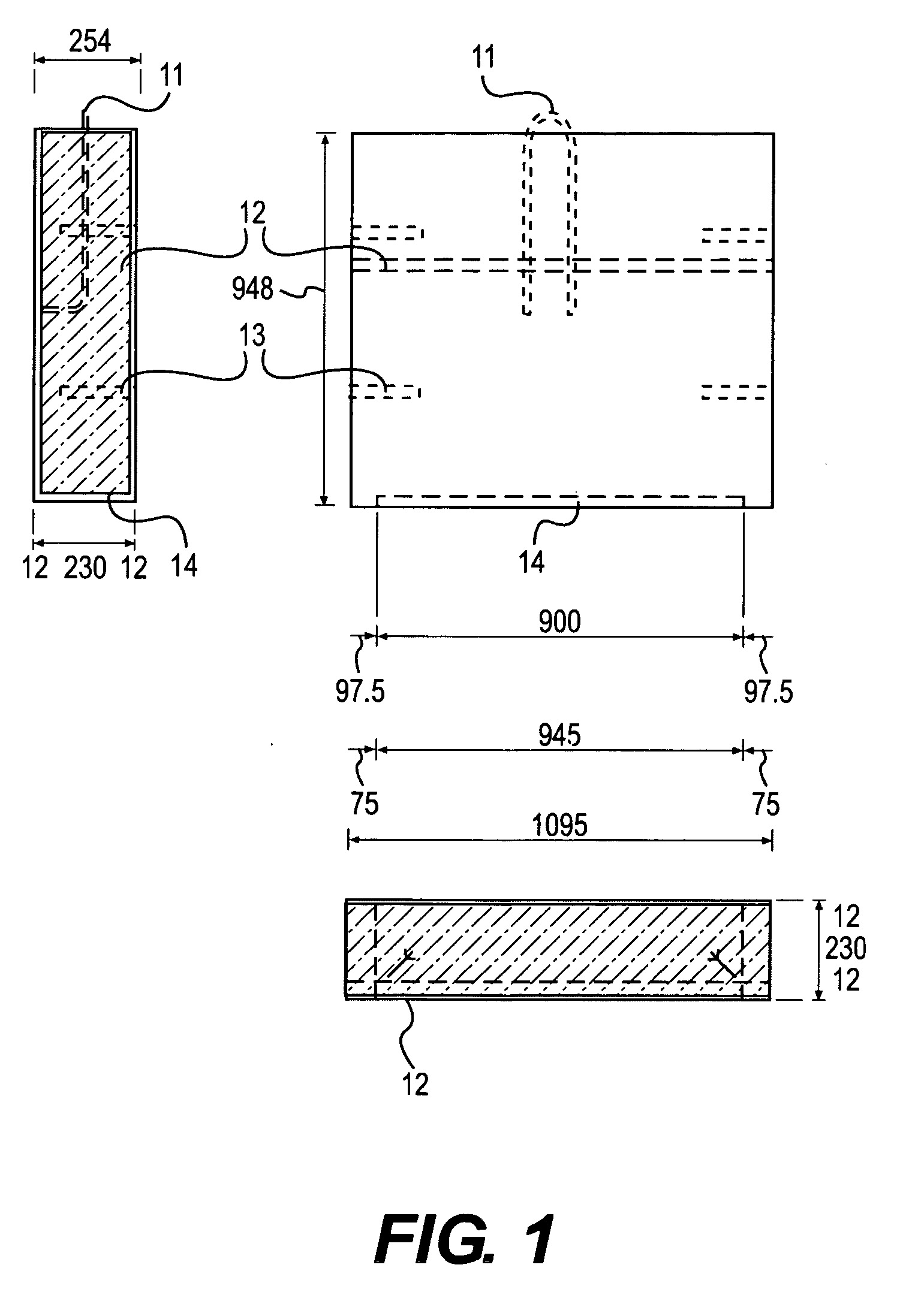

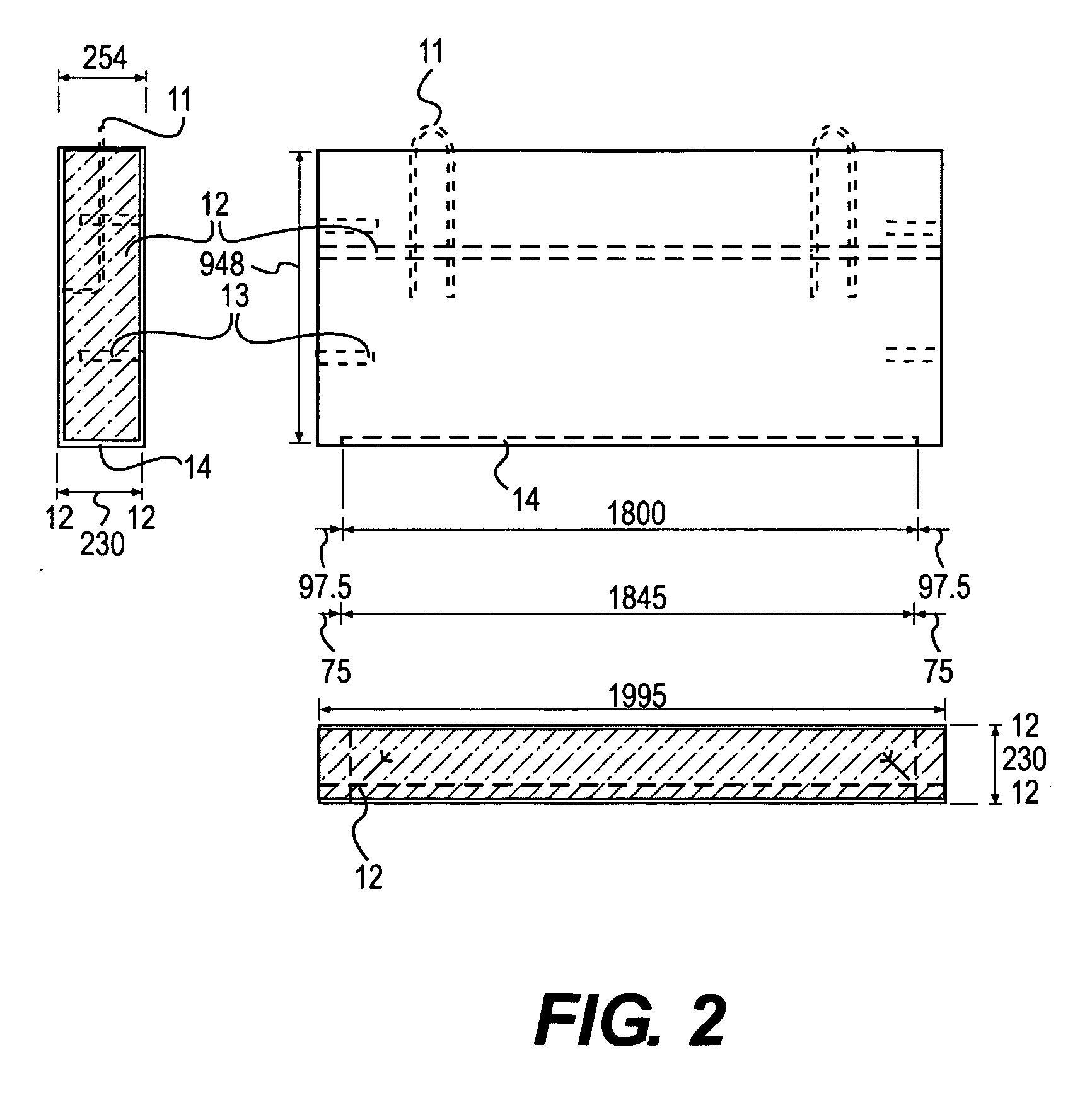

Lightweight cementitious compositions and building products and methods for making same

Cementitious compositions and methods for making same, in which the cementitious compositions include 35-60 wt. % cementitious reactive powder (also termed Portland cement-based binder), 2-10 wt. % expanded and chemically coated perlite filler, 20-40 wt. % water, entrained air, and optional additives such as water reducing agents, chemical set-accelerators, and chemical set-retarders. In addition, the lightweight cementitious compositions may contain 0-25 wt. % on a wet basis secondary fillers such as expanded clay, shale aggregate, and pumice.

Owner:UNITED STATES GYPSUM CO

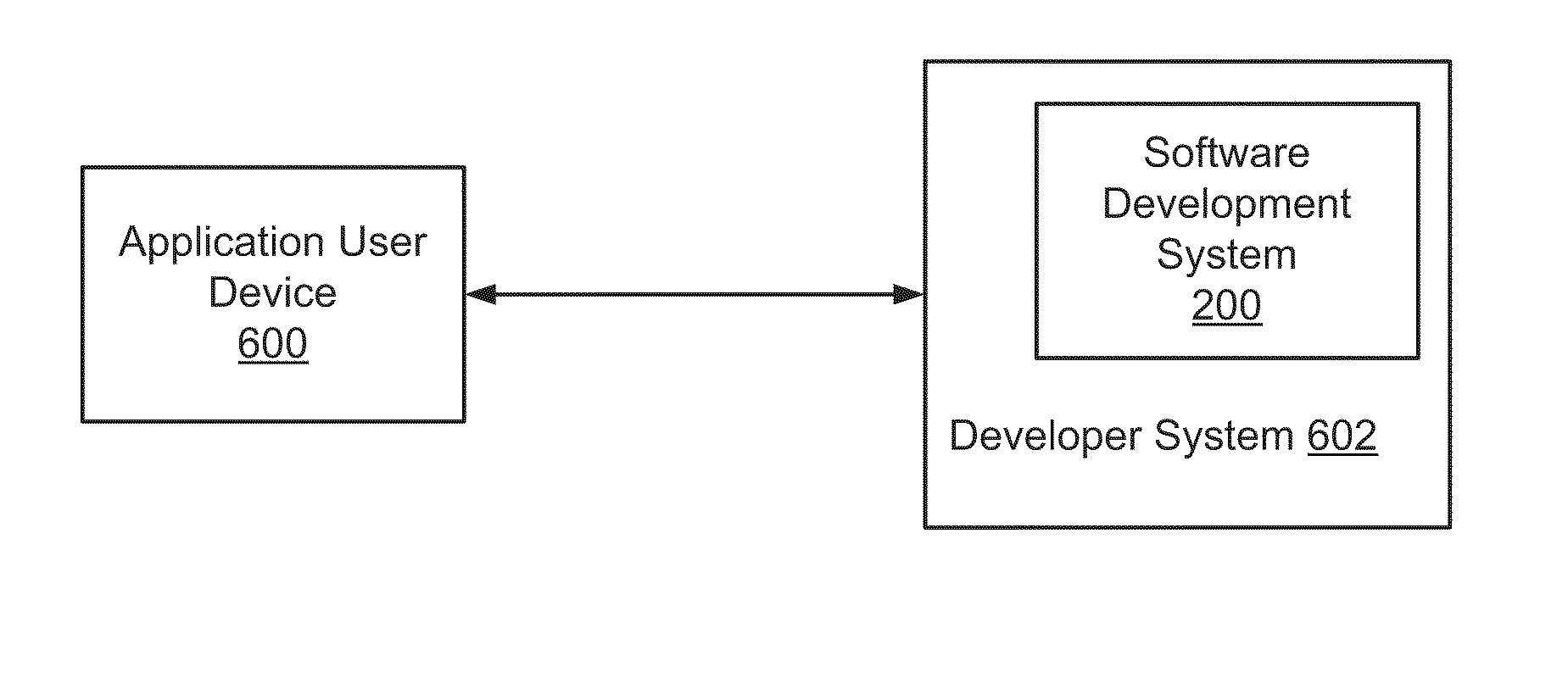

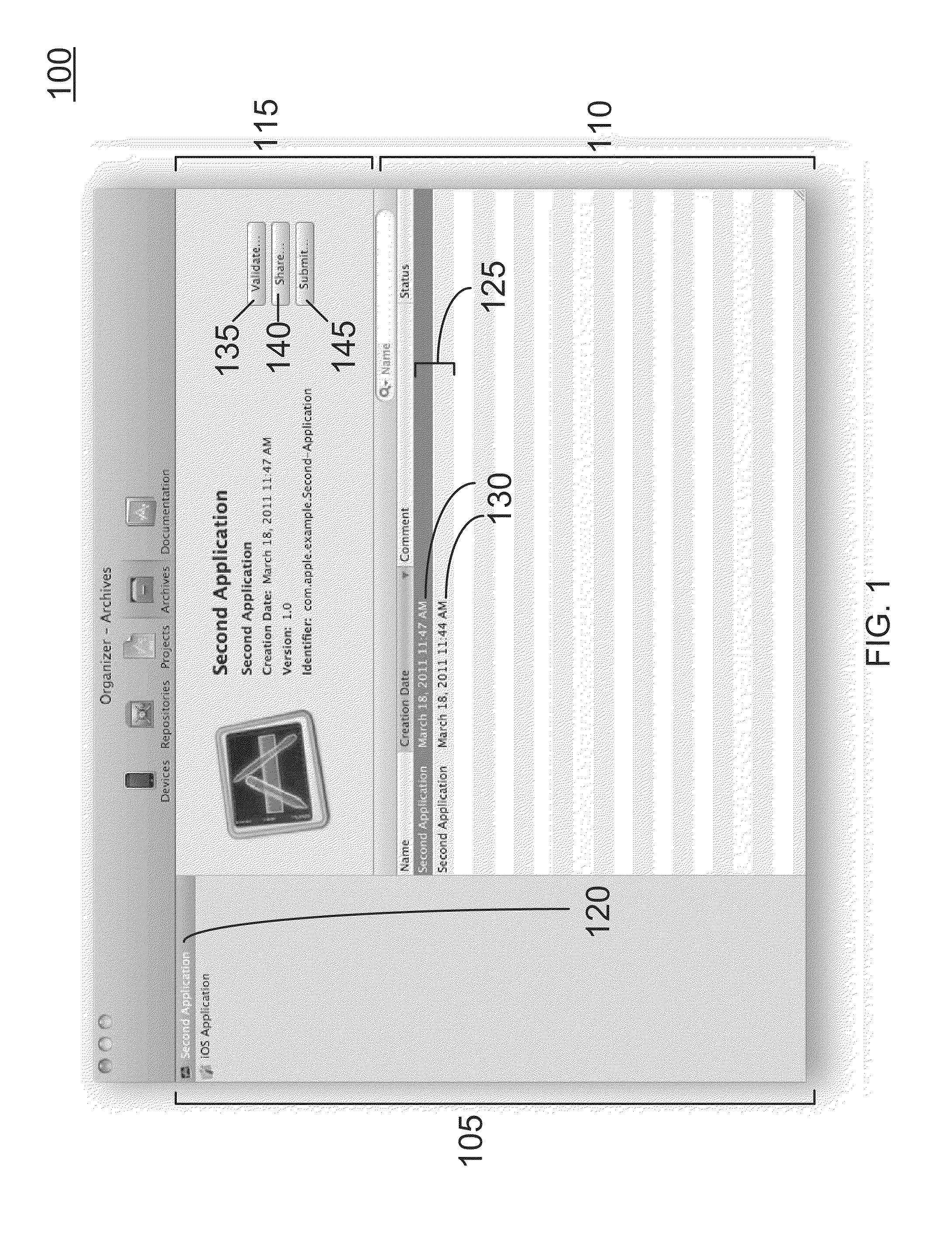

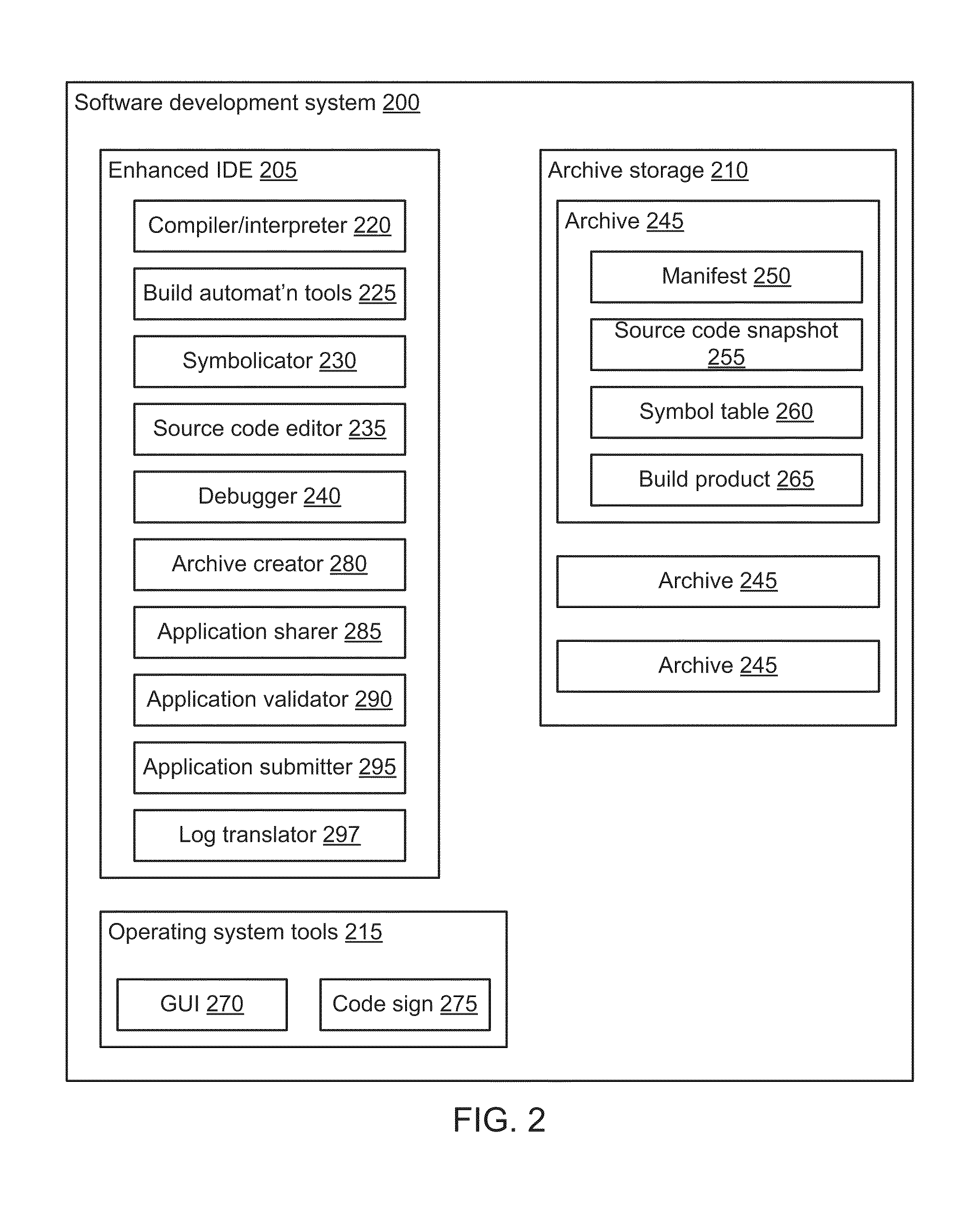

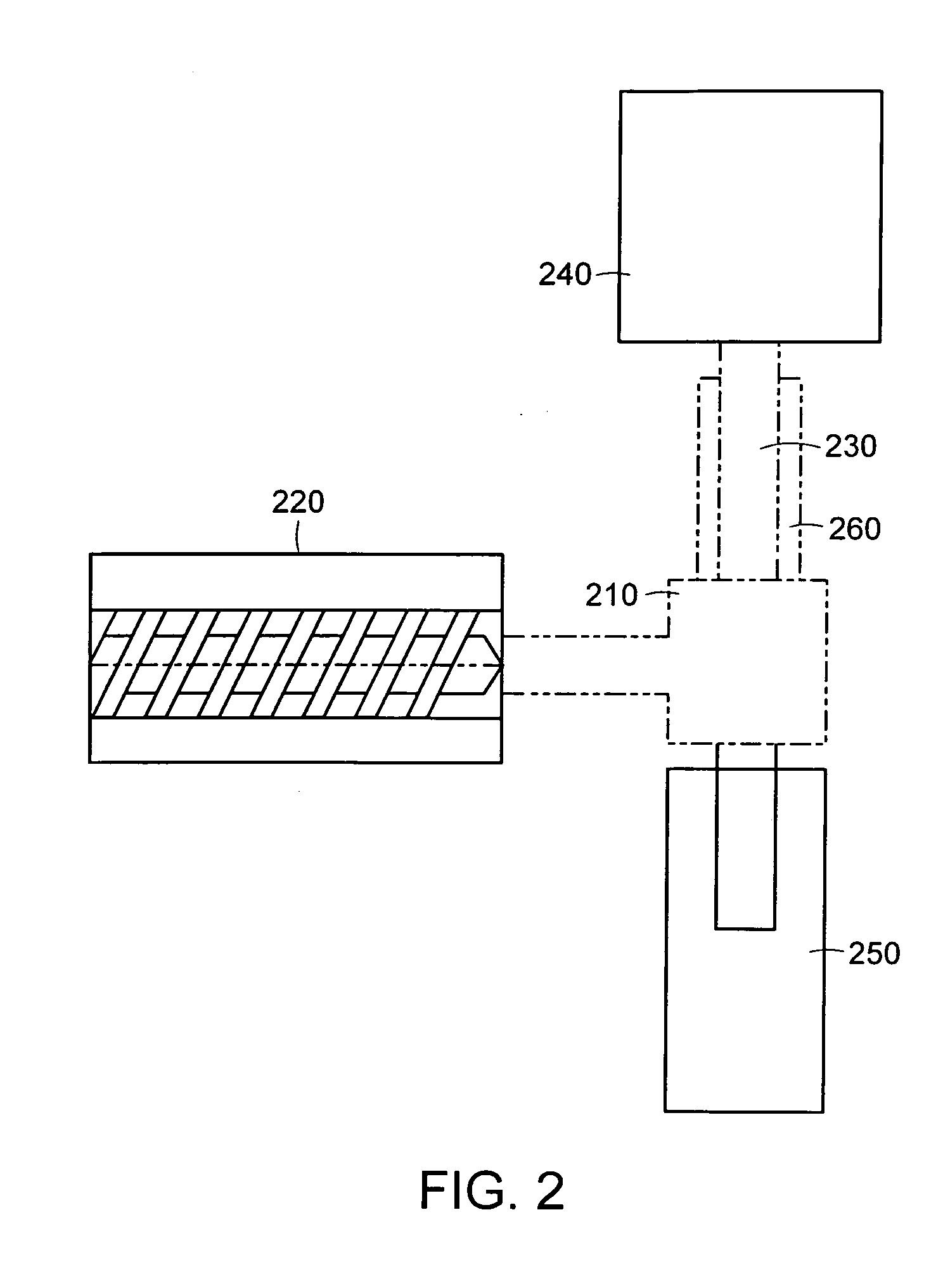

Archiving a Build Product

An enhanced integrated development environment (IDE) is able to archive a build product and / or work with an archived build product in various ways. In one embodiment, a build product archive includes a manifest, a source code snapshot, a symbol table, and a build product. The manifest contains meta-data about the archive. The source code snapshot is a copy of the source code that was used in the build process. The symbol table is a copy of the symbol table that was generated by the build process. The build product is a copy of the build product that was generated by the build process. A developer can use the enhanced IDE to help share a build product with others and / or to understand system logs and reports that describe operation of the build product (e.g., crash logs and memory logs).

Owner:APPLE INC

Construction products and method of making same

InactiveUS20070062143A1Eliminate needShorten construction timeSolid waste managementWallsBuilding productCement board

A highly durable and easy to use prefabricated construction product is disclosed having a cellular concrete component sandwiched between two cement boards, wherein the cellular concrete component comprises cement, fly ash, an activating agent and water, and the cement boards comprise cement, fly ash, an activating agent, sand, silica fume, a water reducer agent, a reinforcing fiber, and water.

Owner:NOUSHAD RAFIE LOTFI

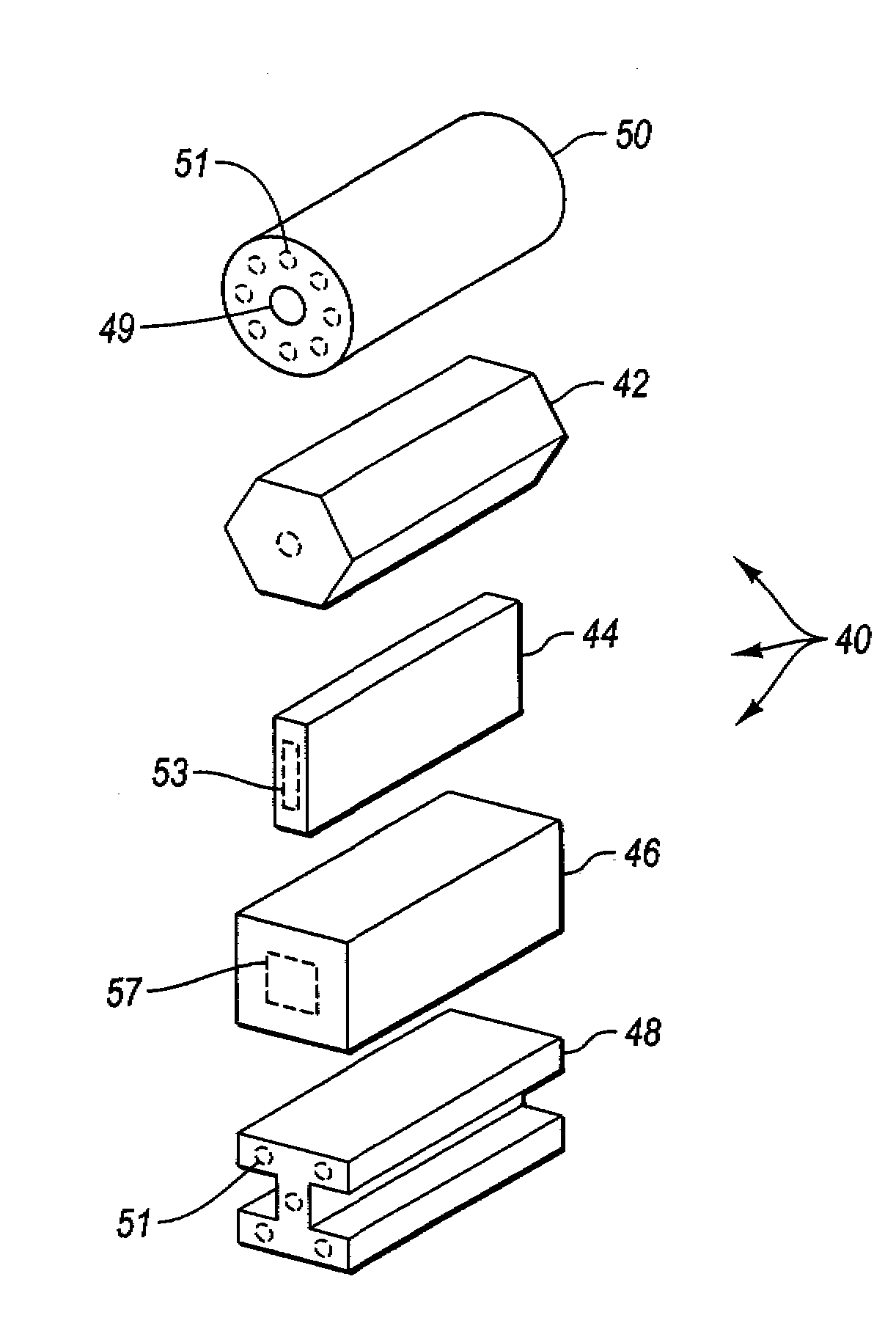

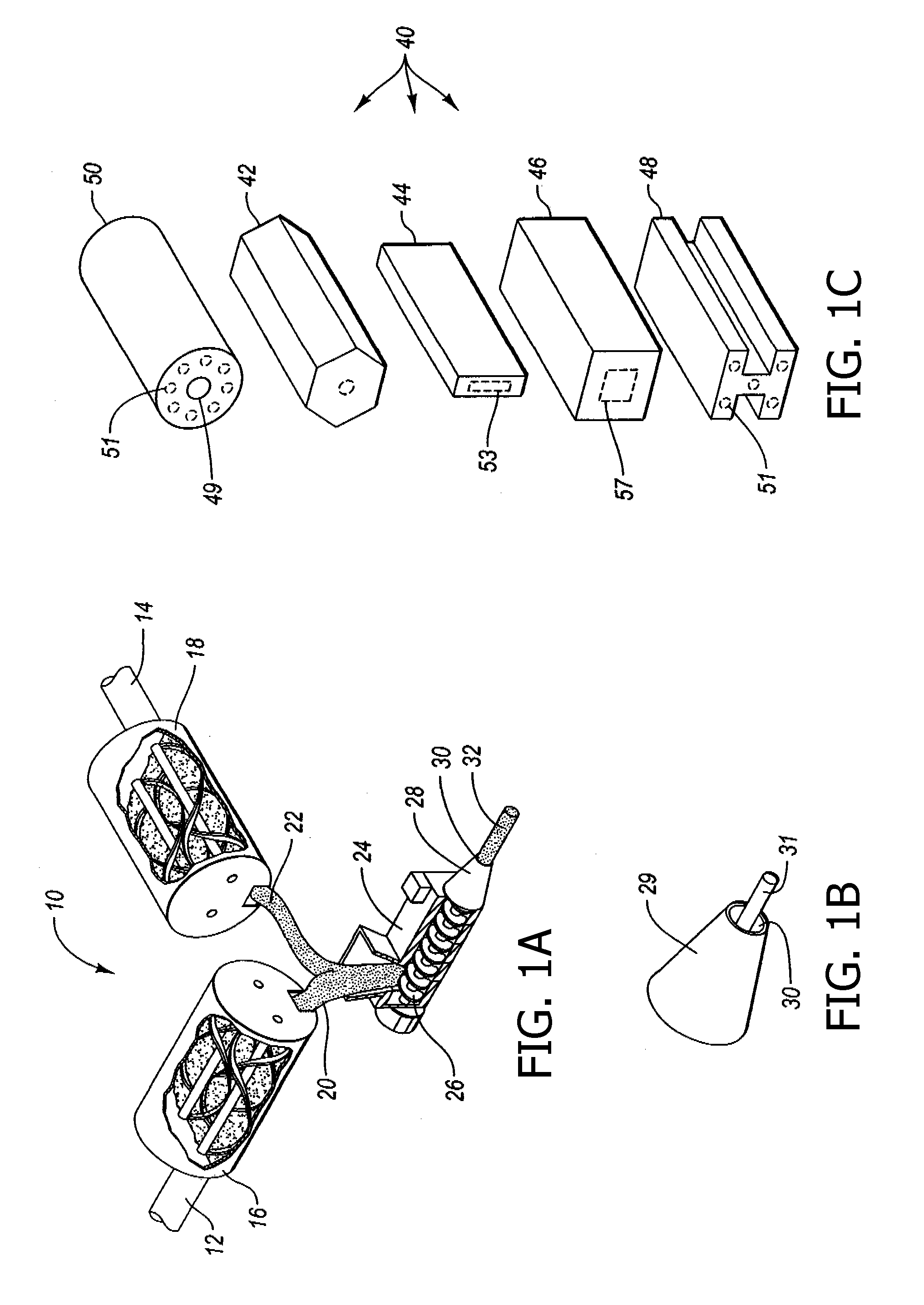

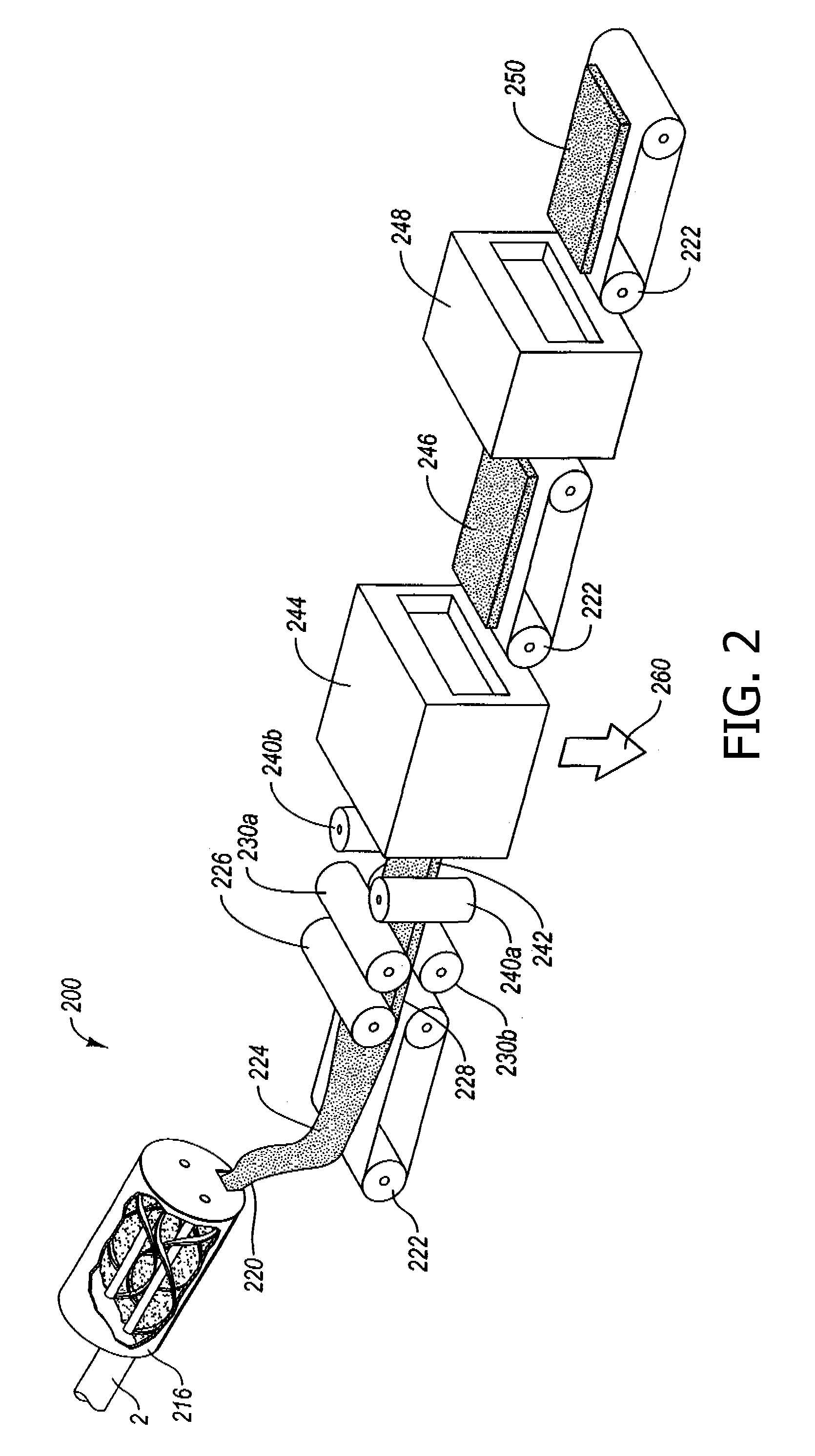

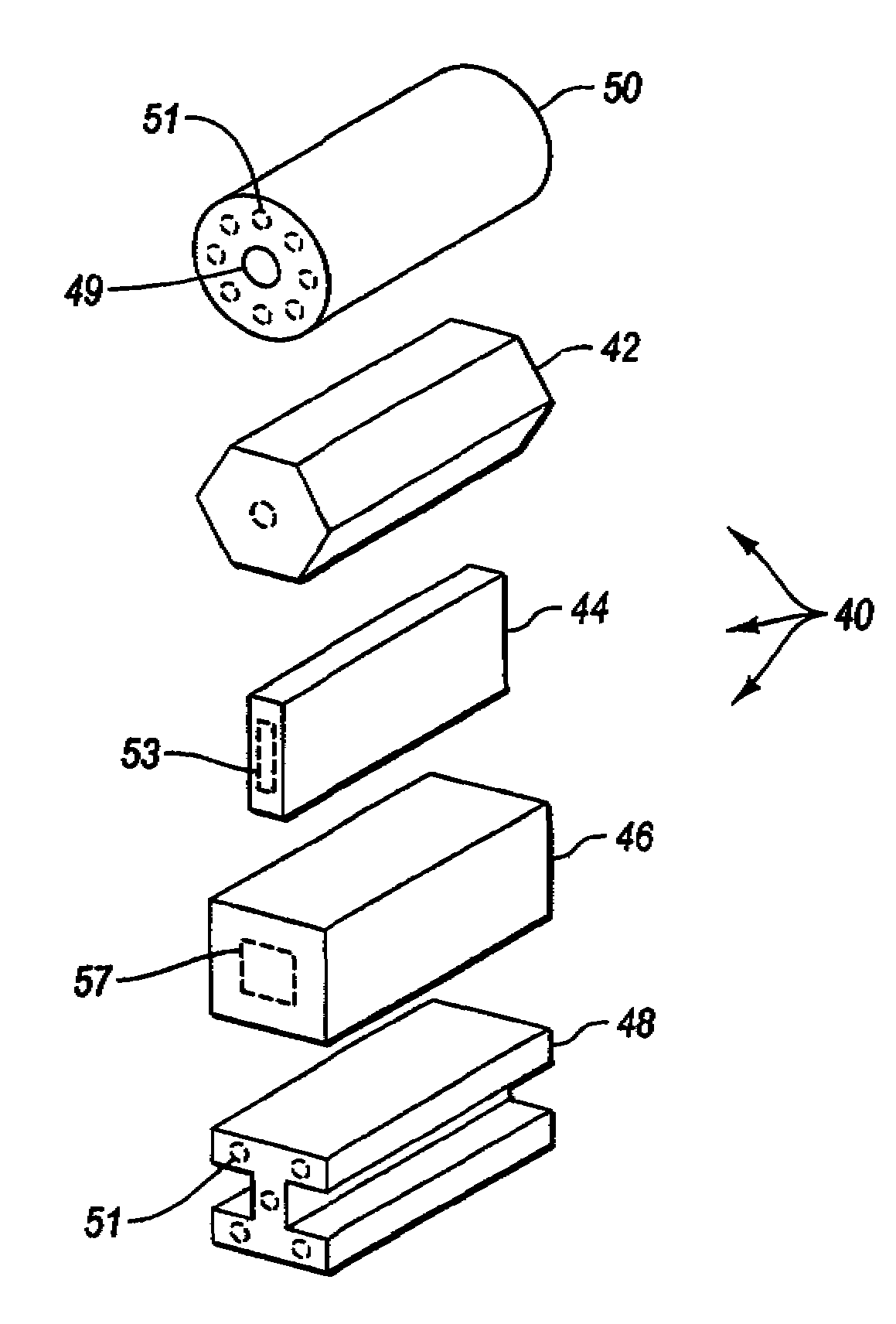

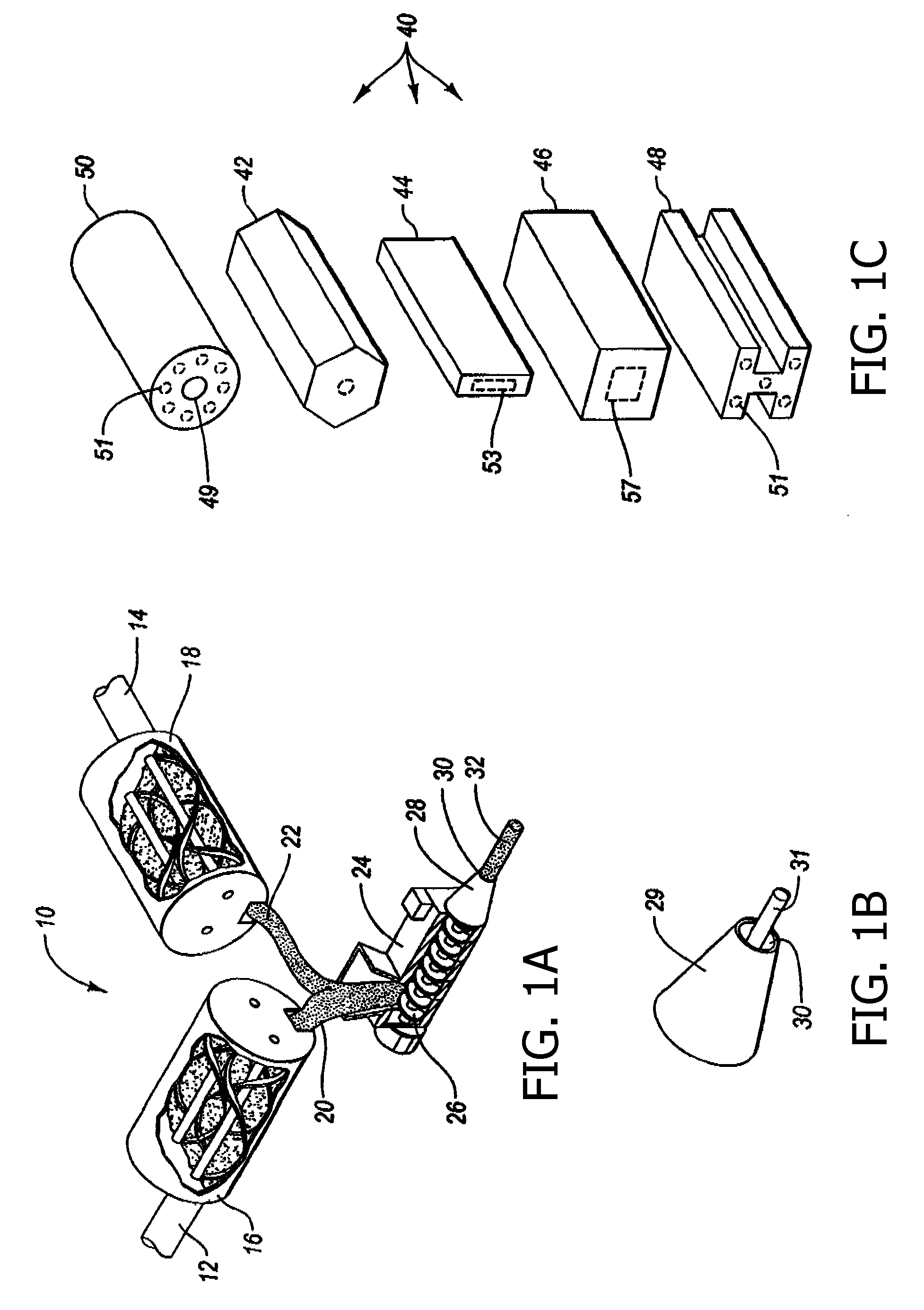

Cementitious composites having wood-like properties and methods of manufacture

InactiveUS20080099122A1Harder to saw, nail or screwLow densityPlastic recyclingLaminationPorosityBuilding product

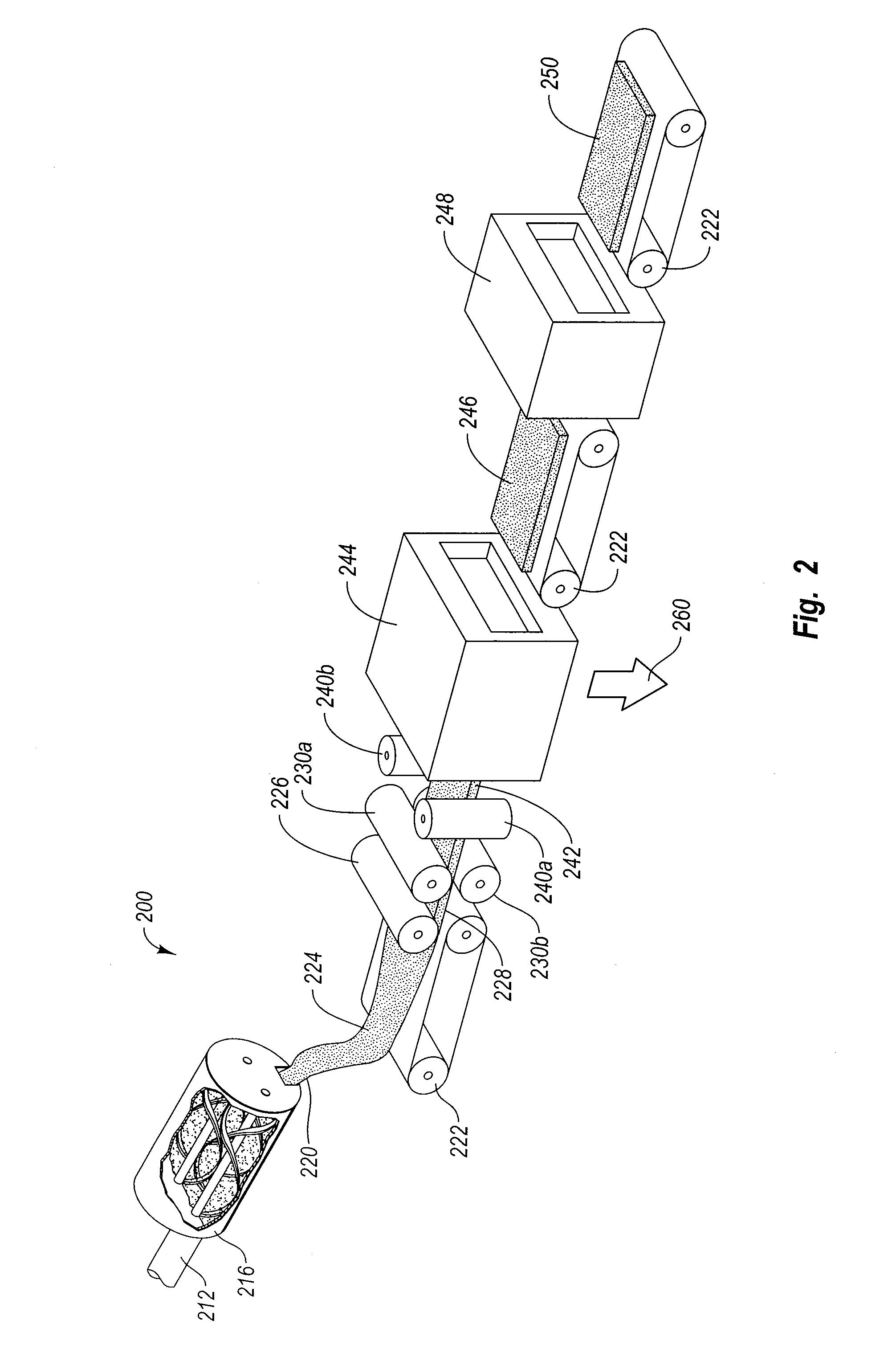

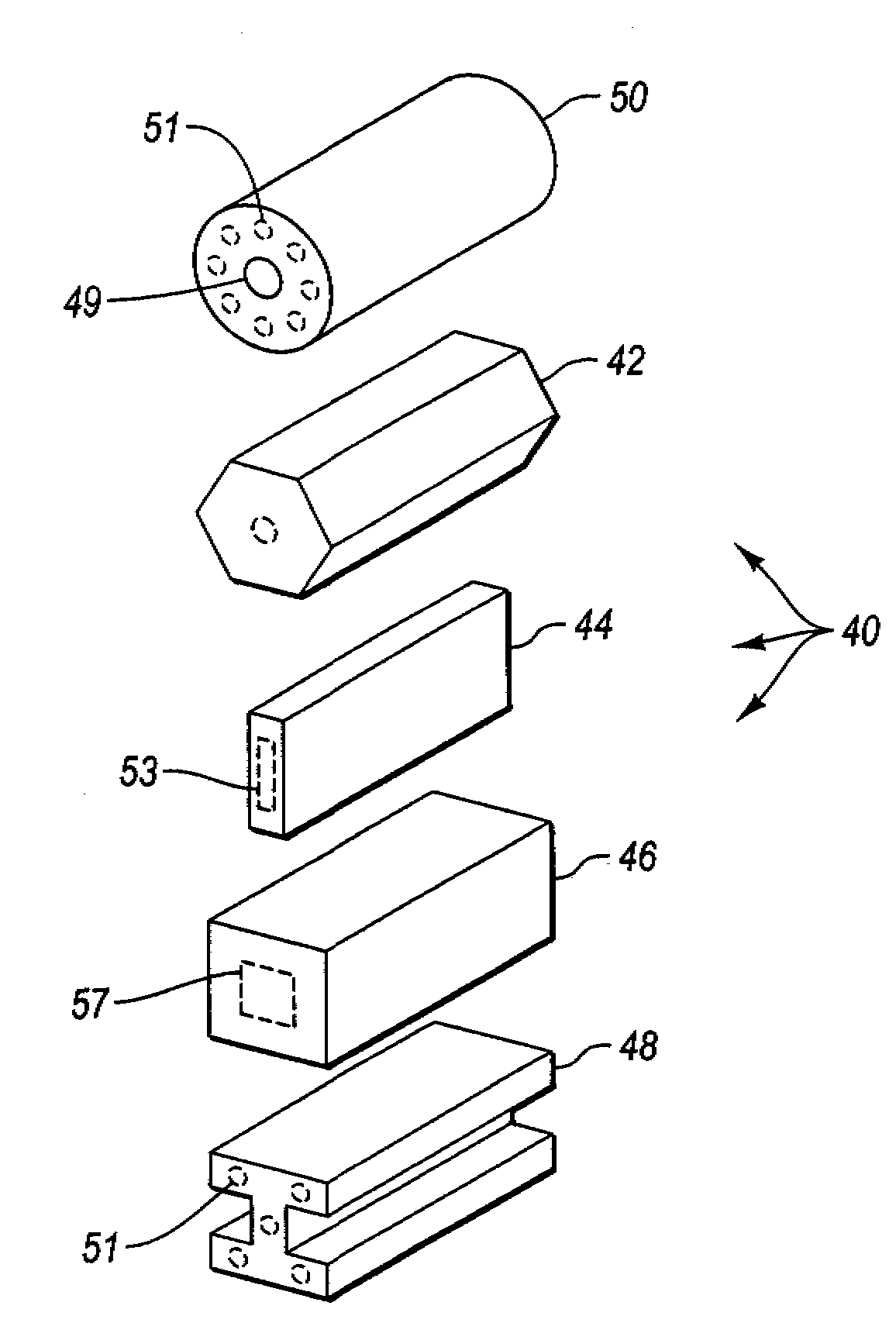

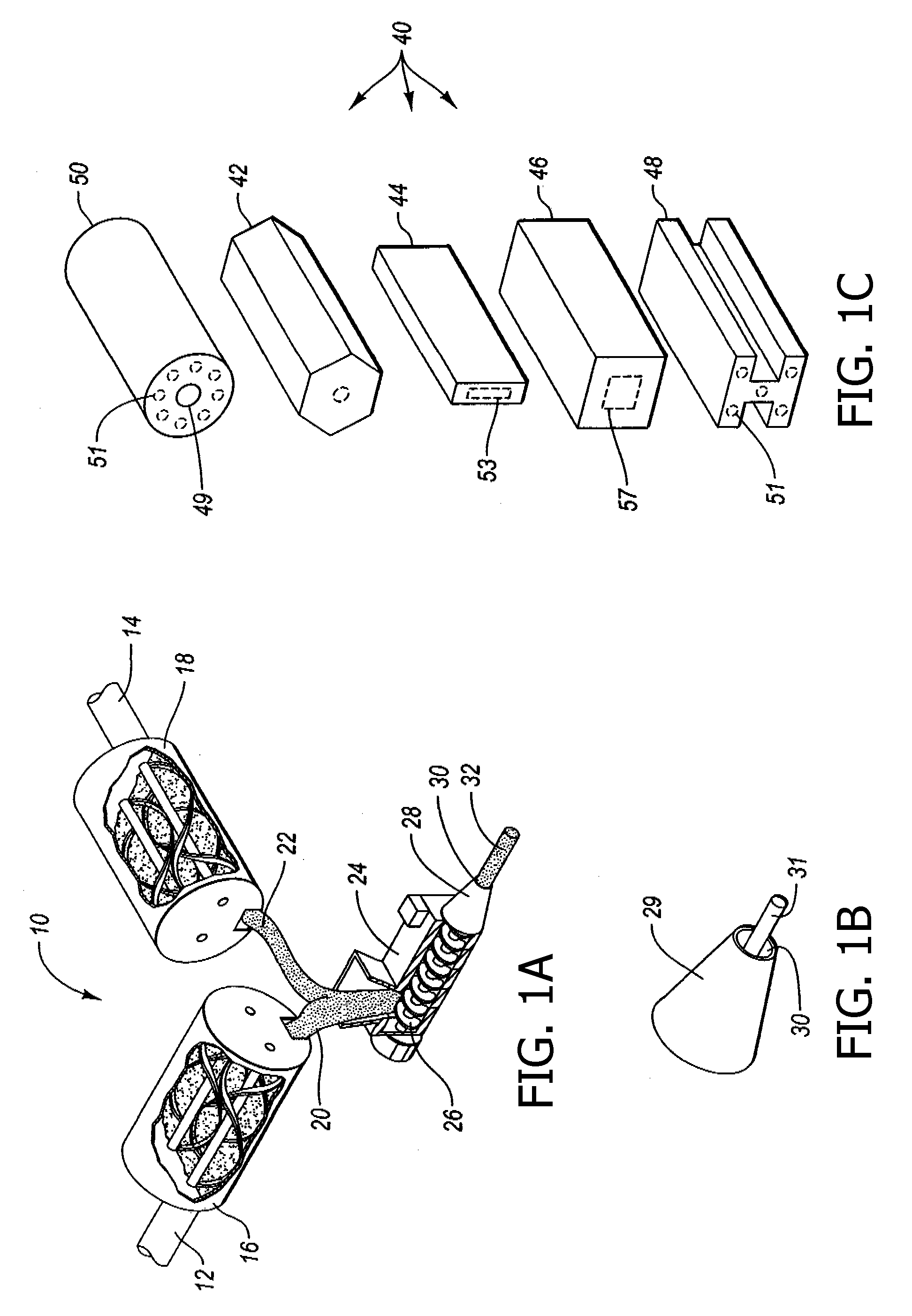

A method of manufacturing a cementitious composite includes: (1) forming mixing an extrudable cementitious composition by first forming a fibrous mixture comprising fibers, water and a rheology modifying agent and then adding hydraulic cement; (2) extruding the extrudable cementitious composition into a green extrudate, wherein the green extrudate is characterized by being form-stable and retaining substantially a predefined cross-sectional shape; (3) removing a portion of the water by evaporation to reduce density and increase porosity; and (4) causing or allowing the hydraulic cement to hydrate to form the cementitious composite. Such a process yields a cementitious composite that is suitable for use as a wood substitute. The wood-like building products can be sawed, nailed and screwed like ordinary wood.

Owner:E KHASHOGGI INDS

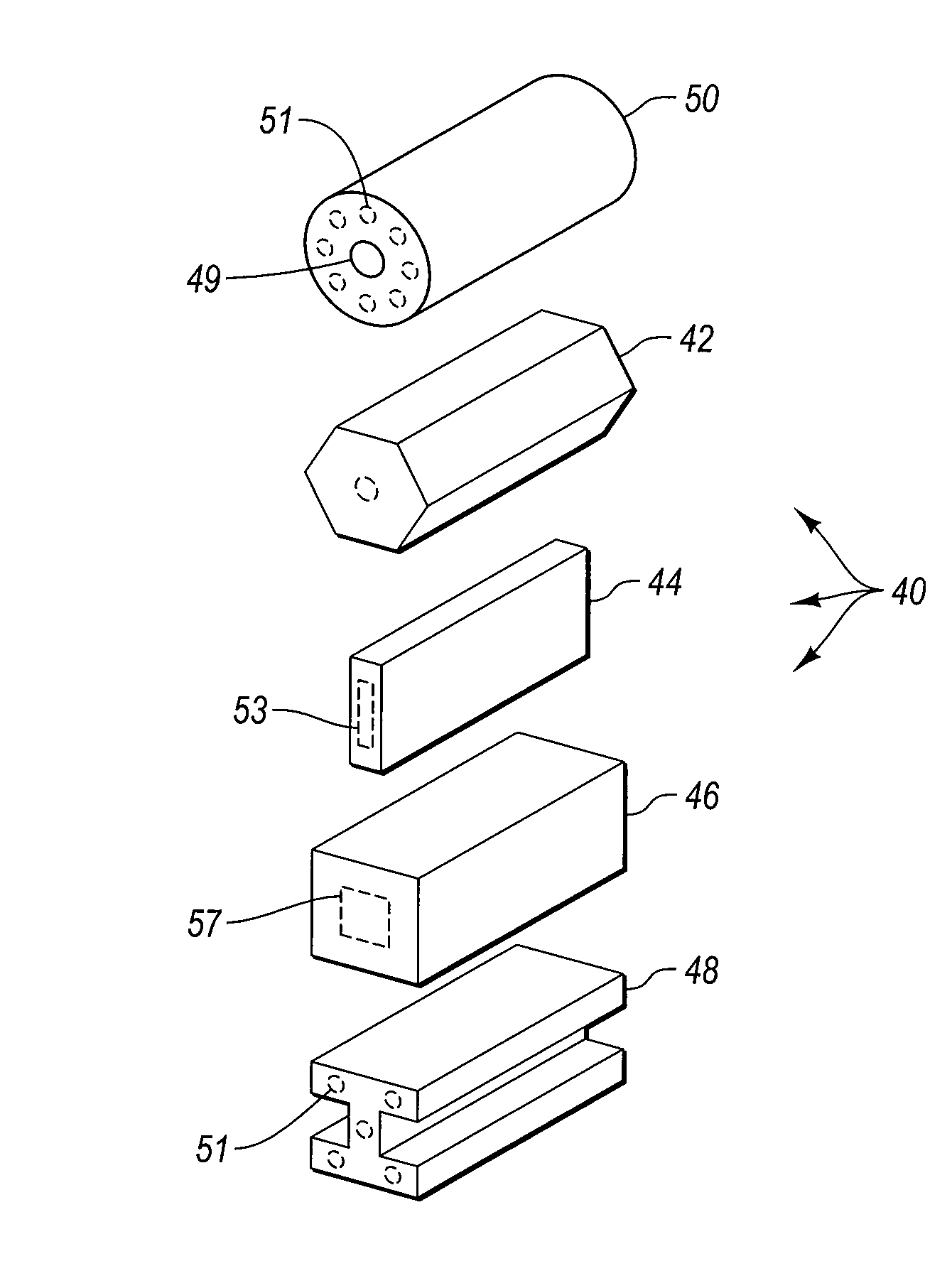

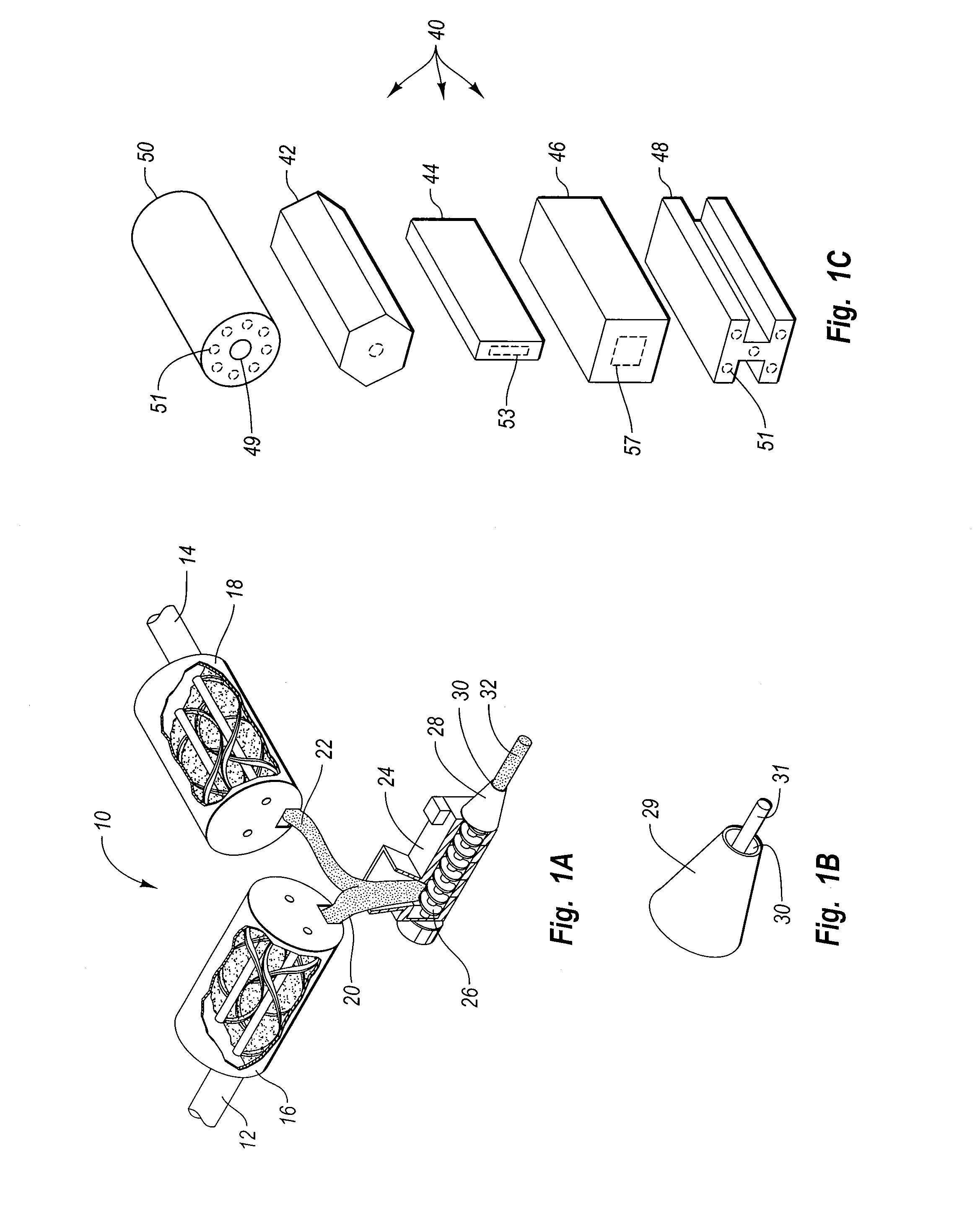

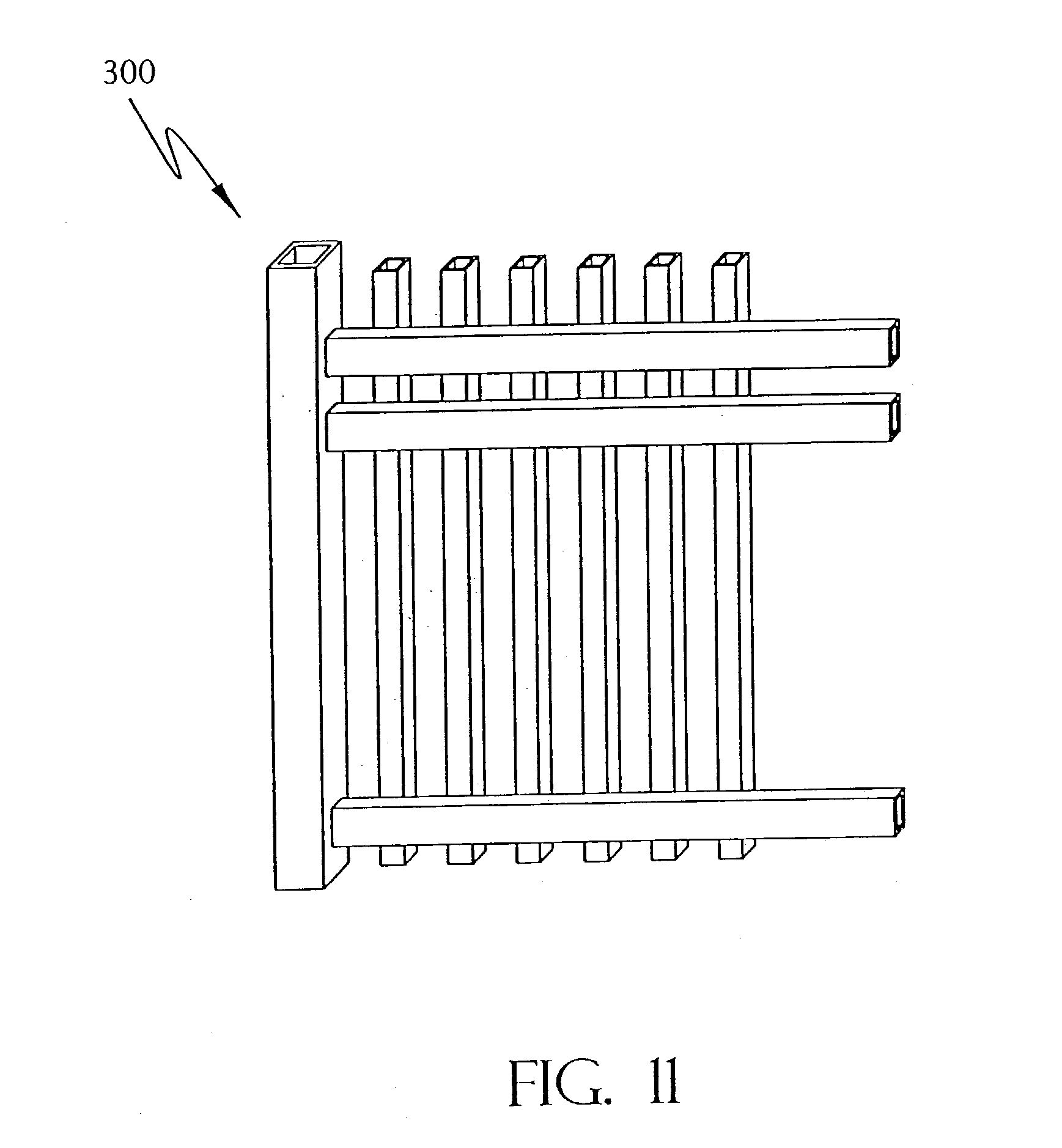

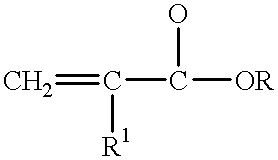

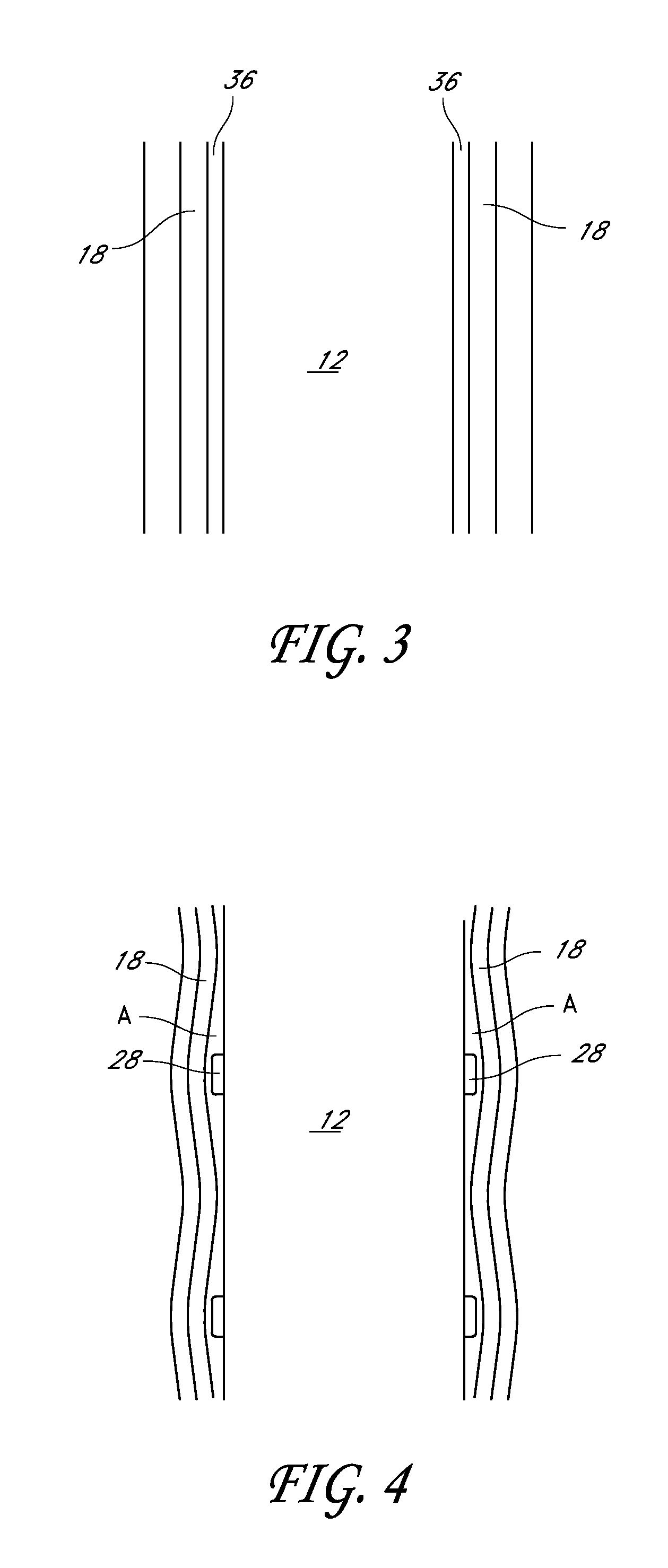

Plastic rail system and other building products reinforced with polymer matrix composites

InactiveUS20040009338A1Reduce air pressureBalustersSynthetic resin layered productsBuilding productUltimate tensile strength

Polymeric building materials are provided which include a composite reinforcement comprising continuous filaments of fibers substantially oriented in at least a first direction within a polymeric matrix. The composite reinforcement includes a higher tensile strength and a lower rigidity than aluminum. The building material further includes a capstock polymeric material disposed substantially over the composite reinforcement. The building material is resistant to heat deformation and corrosion. This invention also includes methods for constructing such polymeric composite building materials, including in the preferred embodiments, pultrusion and extrusion steps.

Owner:CERTAINTEED CORP

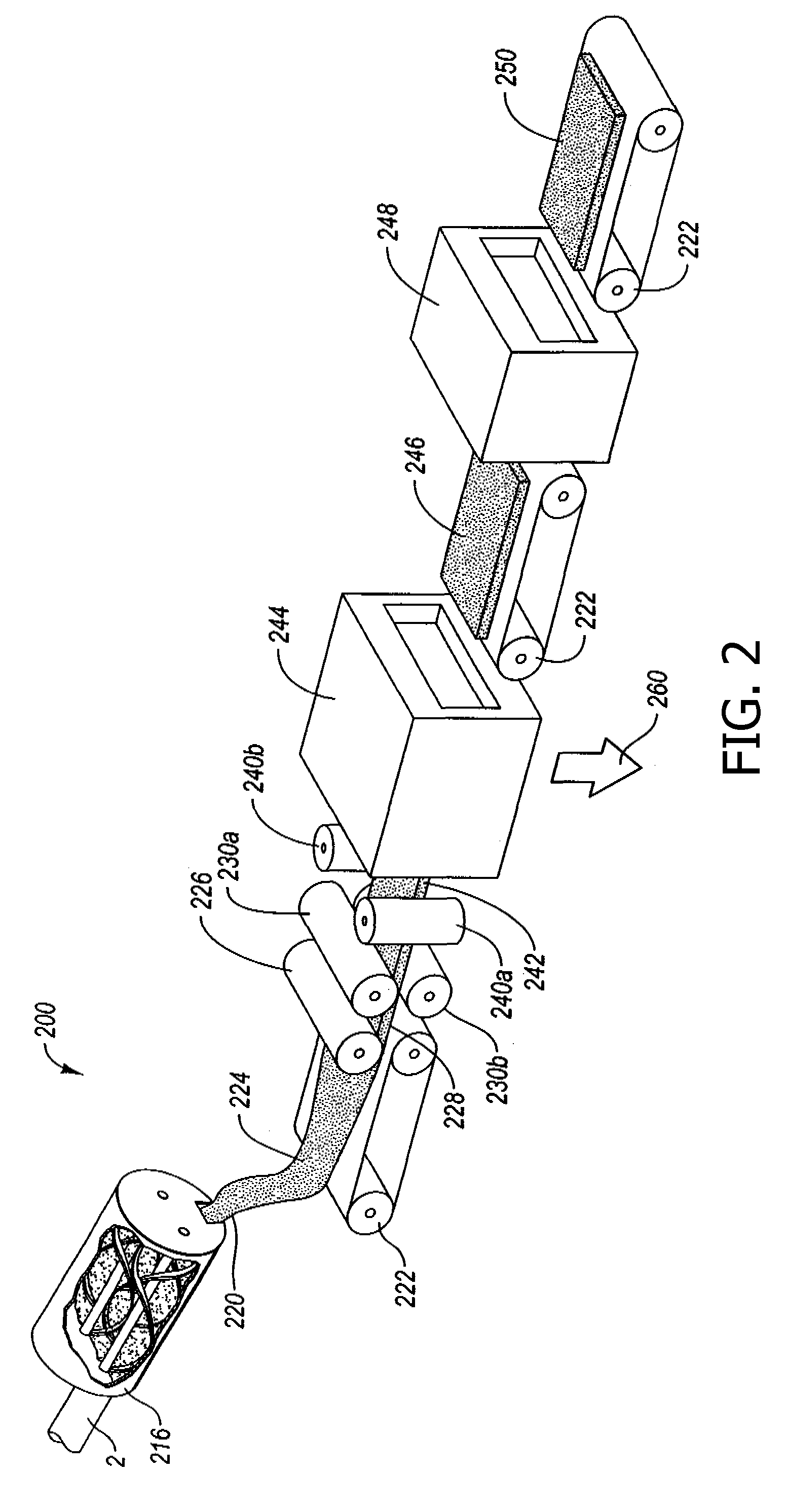

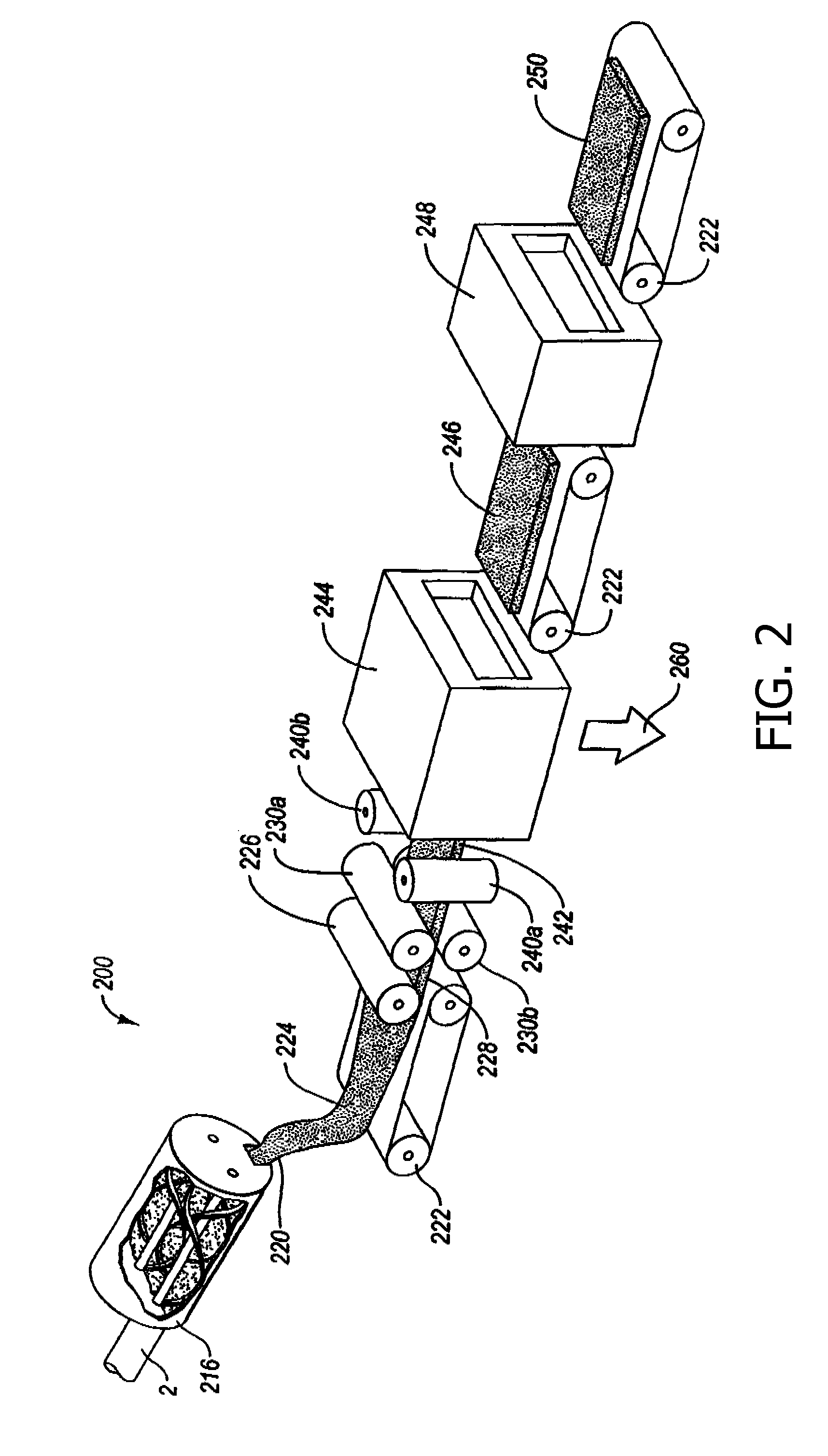

Extruded fiber reinforced cementitious products having wood-like properties and ultrahigh strength and methods for making the same

InactiveUS20100136269A1High yield stressImmediate form stabilityLayered productsPlastic recyclingPorosityFlexural strength

A method of manufacturing a cementitious composite including: (1) mixing an extrudable cementitious composition by first forming a fibrous mixture comprising fibers, water and a rheology modifying agent and then adding hydraulic cement; (2) extruding the extrudable cementitious composition into a green extrudate, wherein the green extrudate is characterized by being form-stable and retaining substantially a predefined cross-sectional shape; (3) removing a portion of the water by evaporation to reduce density and increase porosity; and (4) heating the green extrudate at a temperature from greater than 65° C. to less than 99° C. is disclosed. Such a process yields a cementitious composite that is suitable for use as a wood substitute. Particularly, by using higher curing temperatures for preparing the cementitious building products, the building products have a lower bulk density and a higher flexural strength as compared to conventional products. The wood-like building products can be sawed, nailed and screwed like ordinary wood.

Owner:E KHASHOGGI INDS

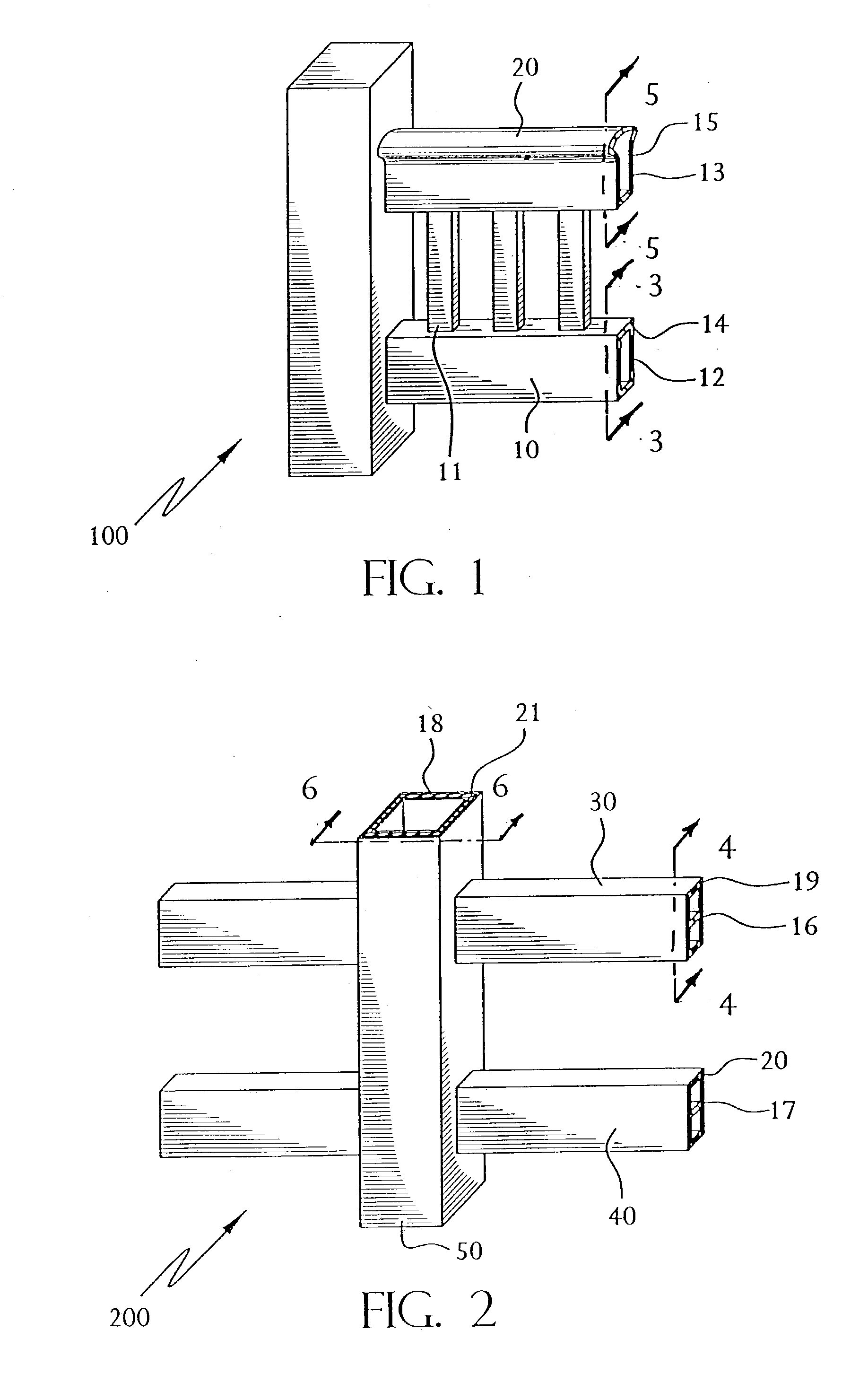

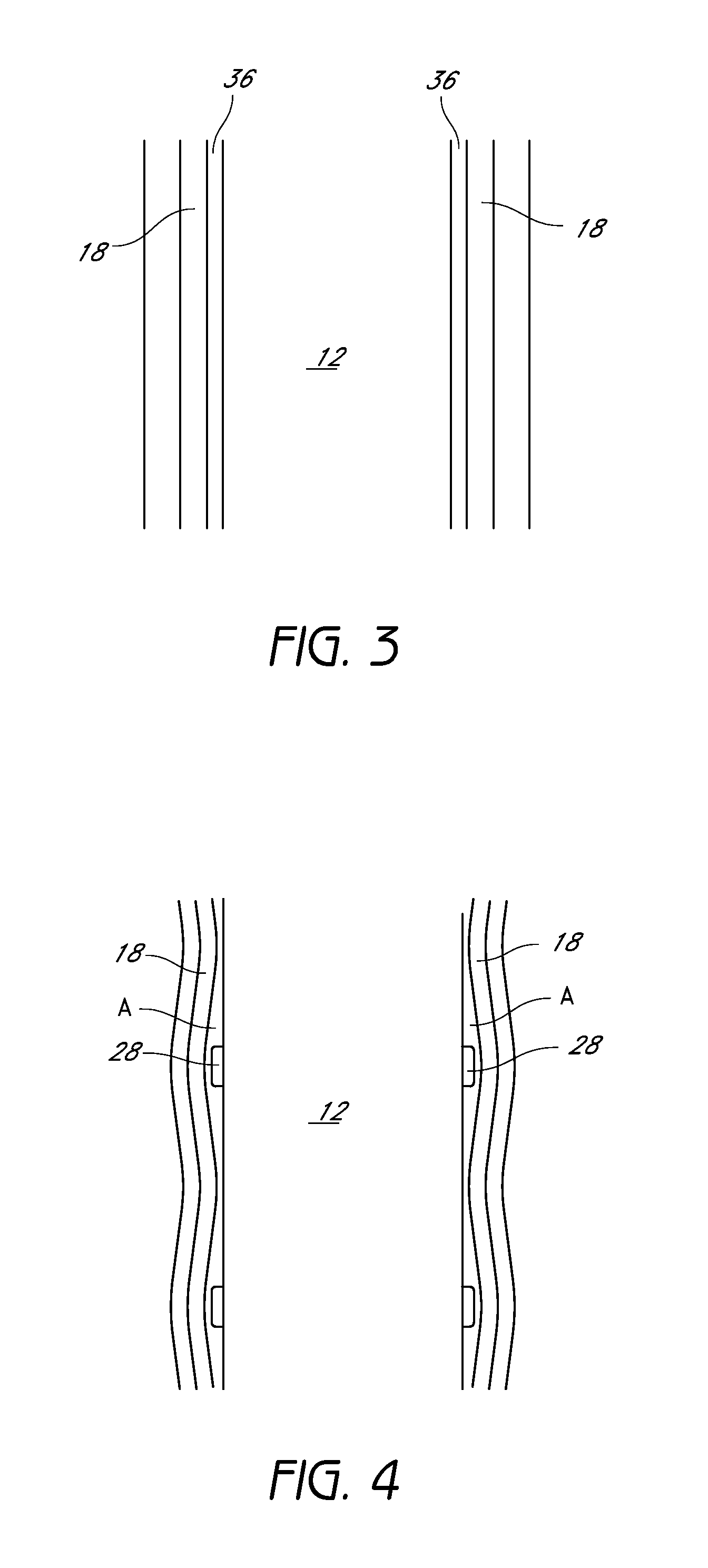

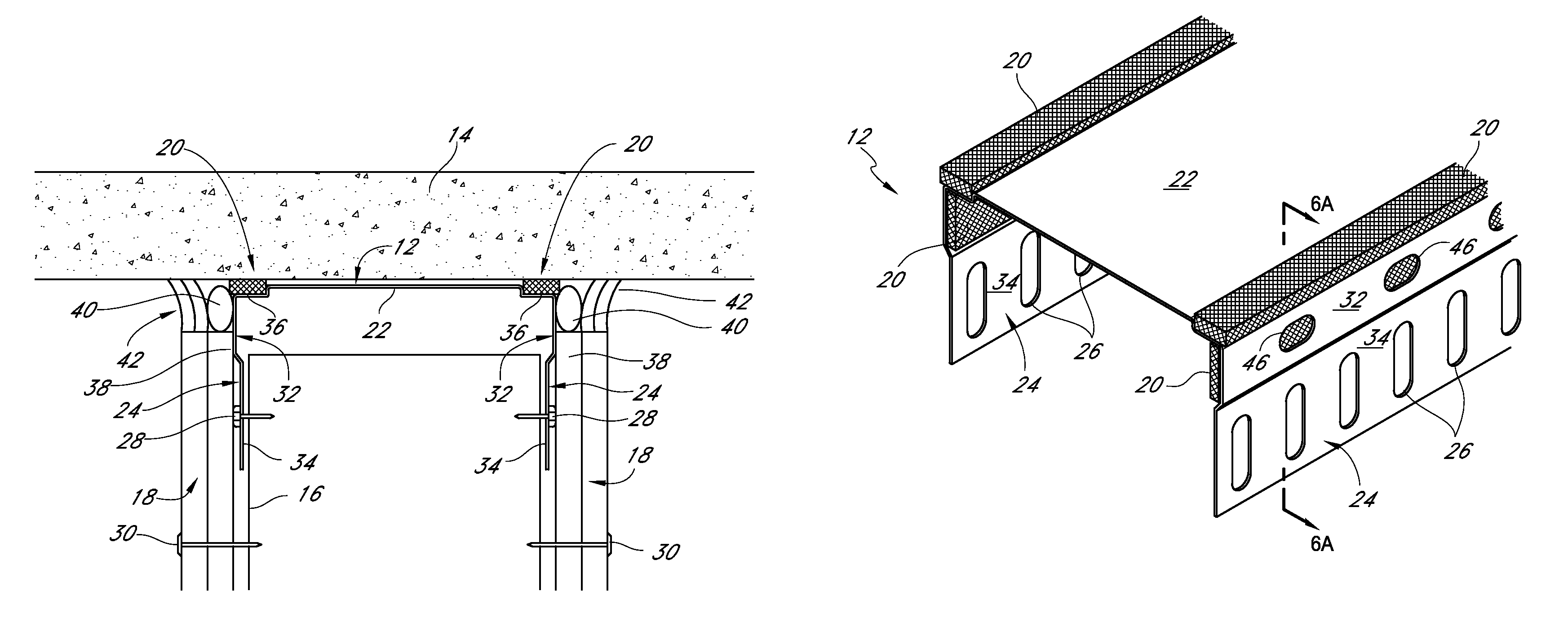

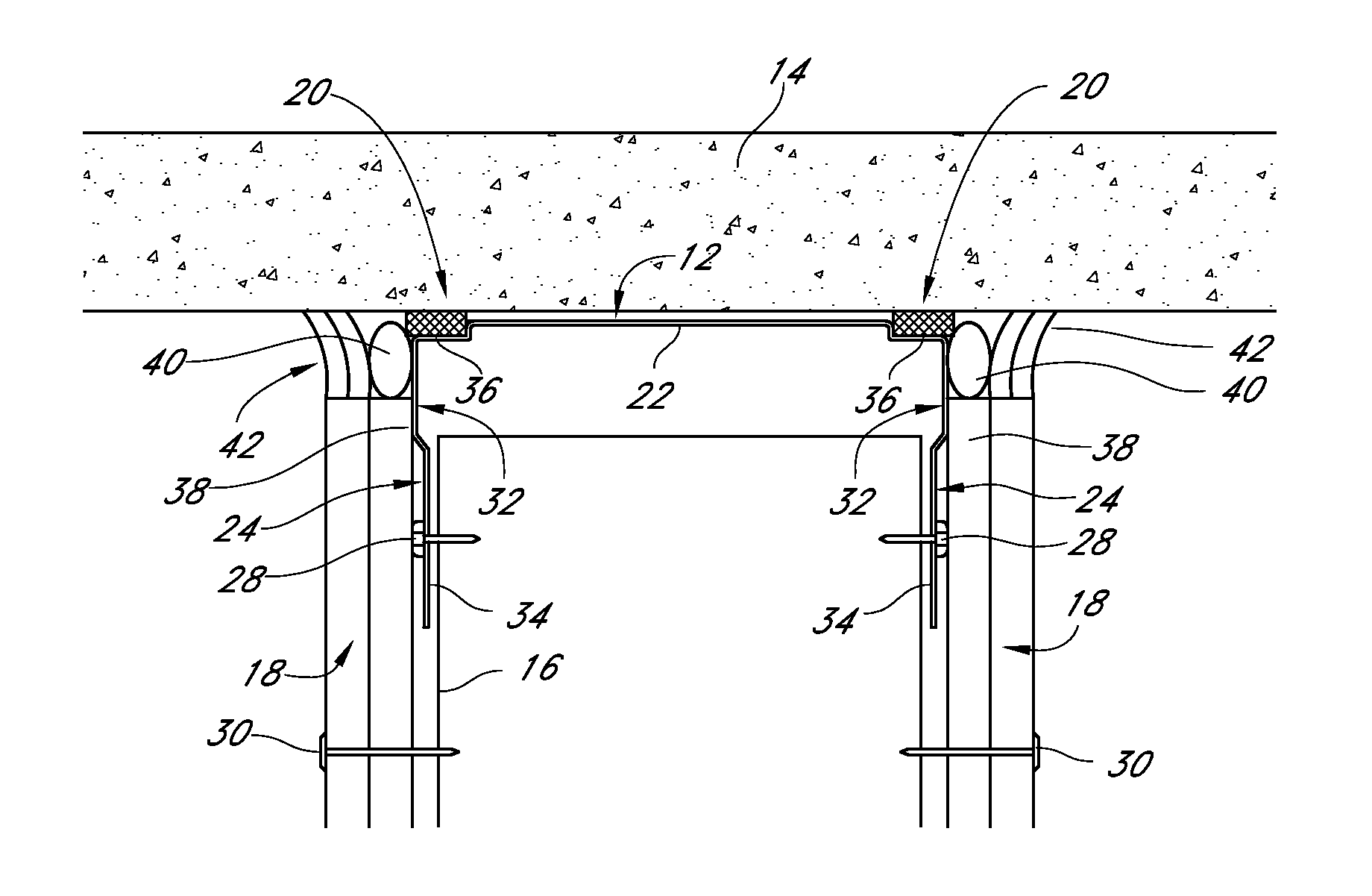

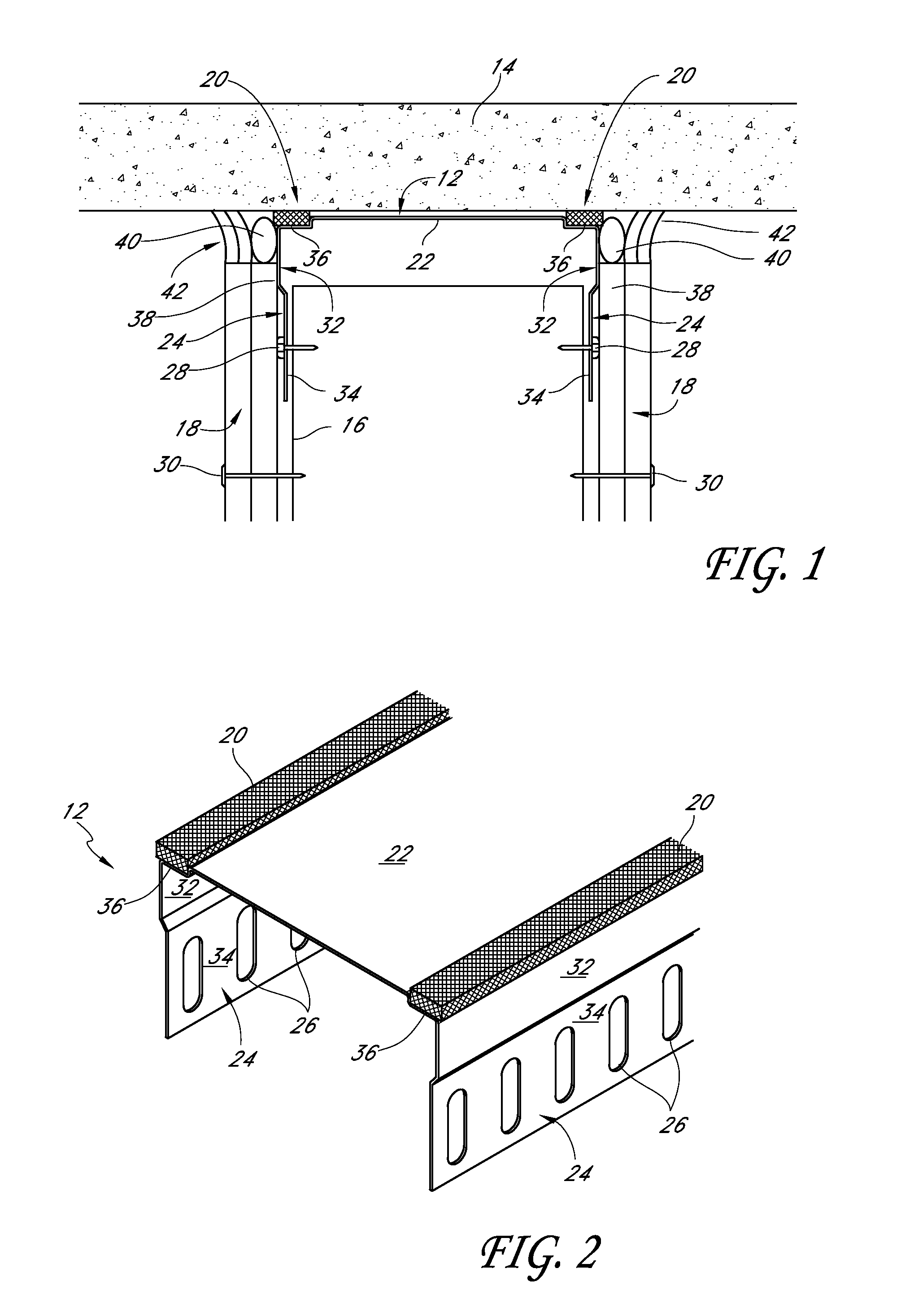

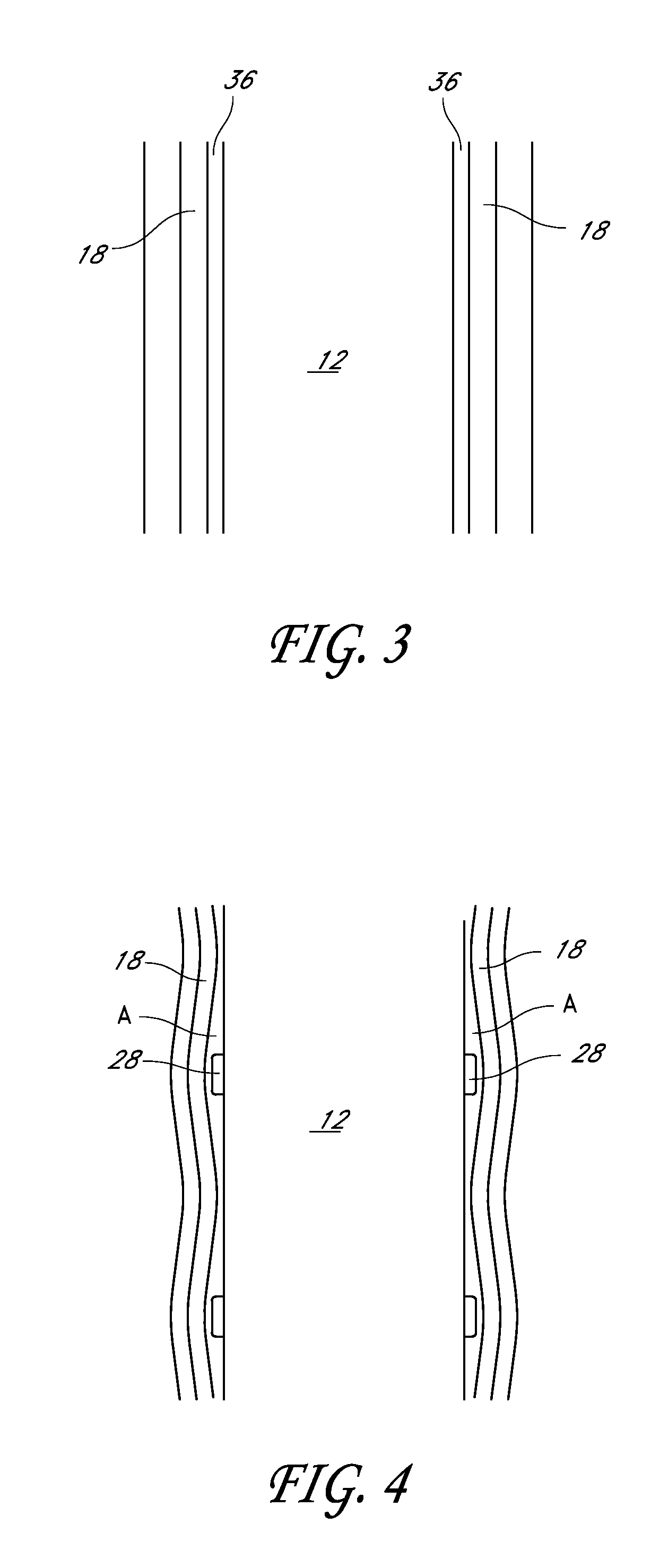

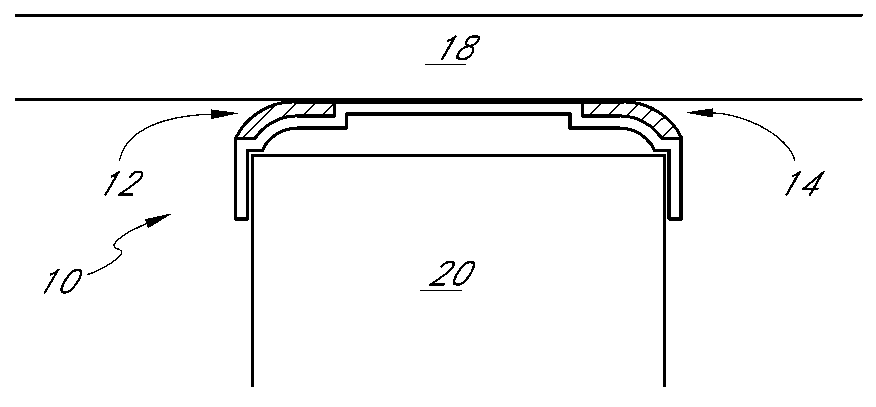

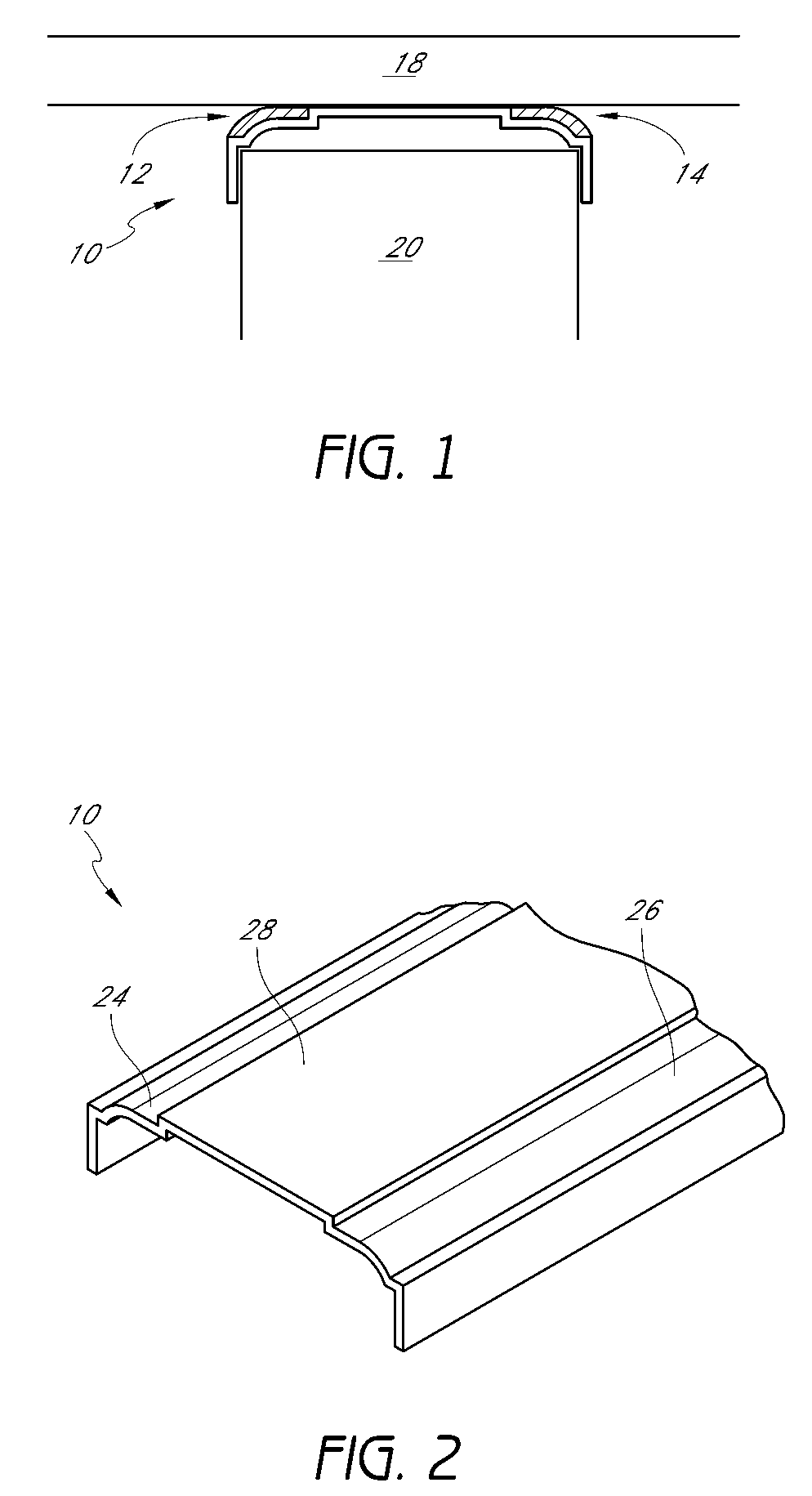

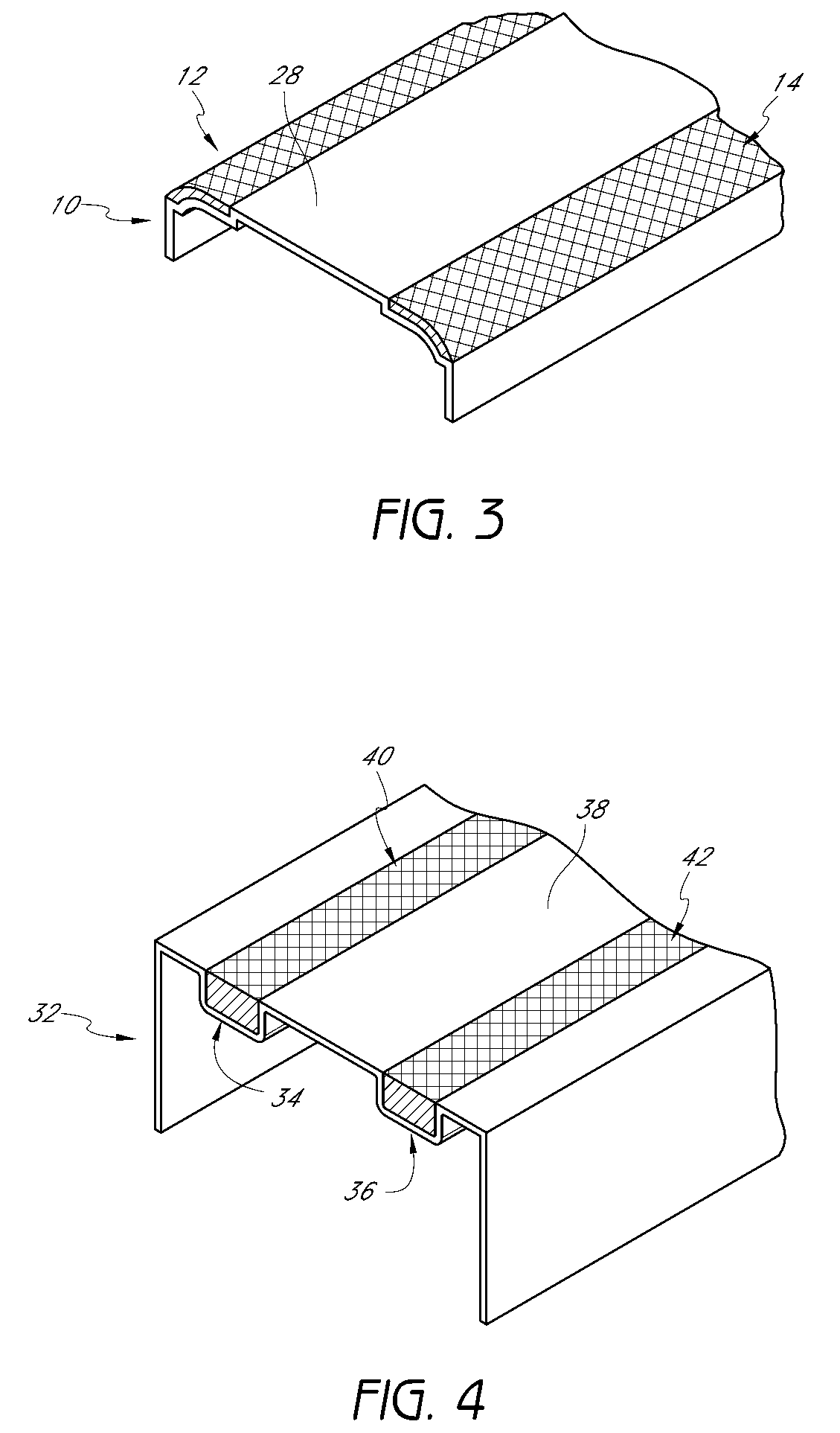

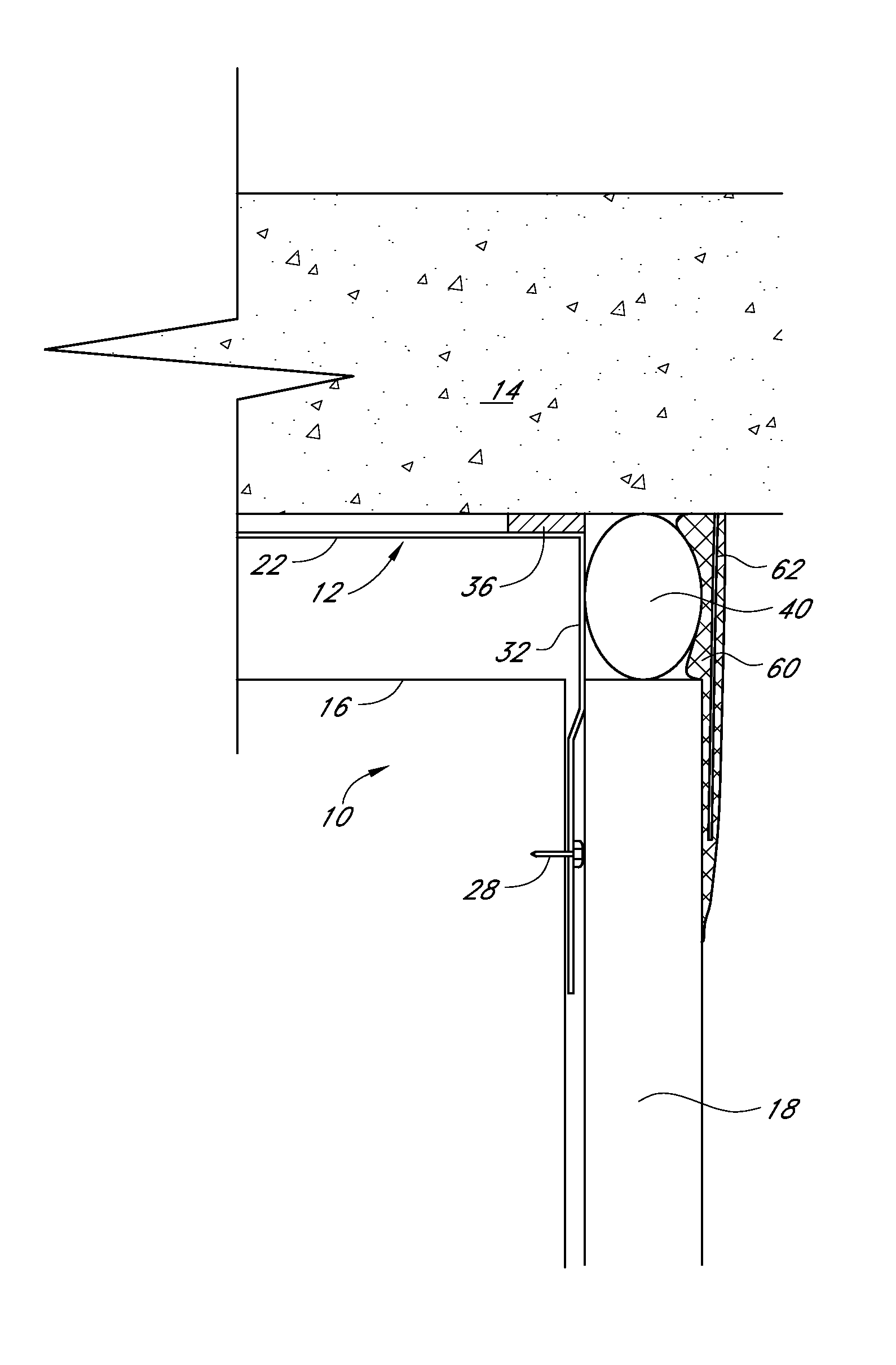

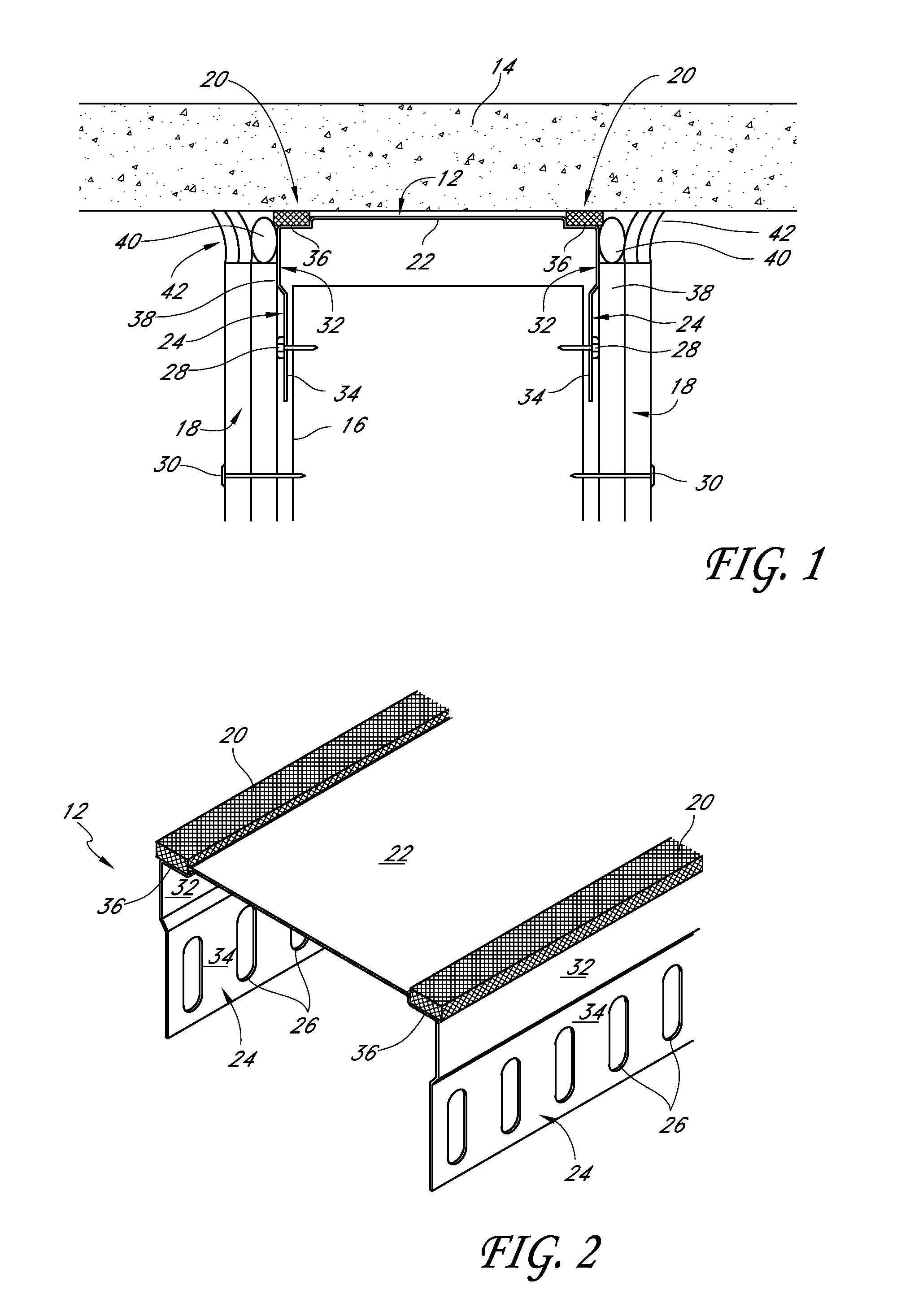

Fire-rated wall construction product

The present invention is directed toward fire-rated wall construction components for use in building construction. The invention provides wall components and systems which have fire-retardant characteristics, as well as wall components which allow for needed ventilation in a building throughout times when no fire is present. Embodiments include tracks for holding studs which incorporate various geometries capable of receiving intumescent material. When the intumescent material becomes hot, it expands rapidly and fills its surrounding area, blocking fire, heat, and smoke from traveling to other areas of a building.

Owner:CEMCO LLC

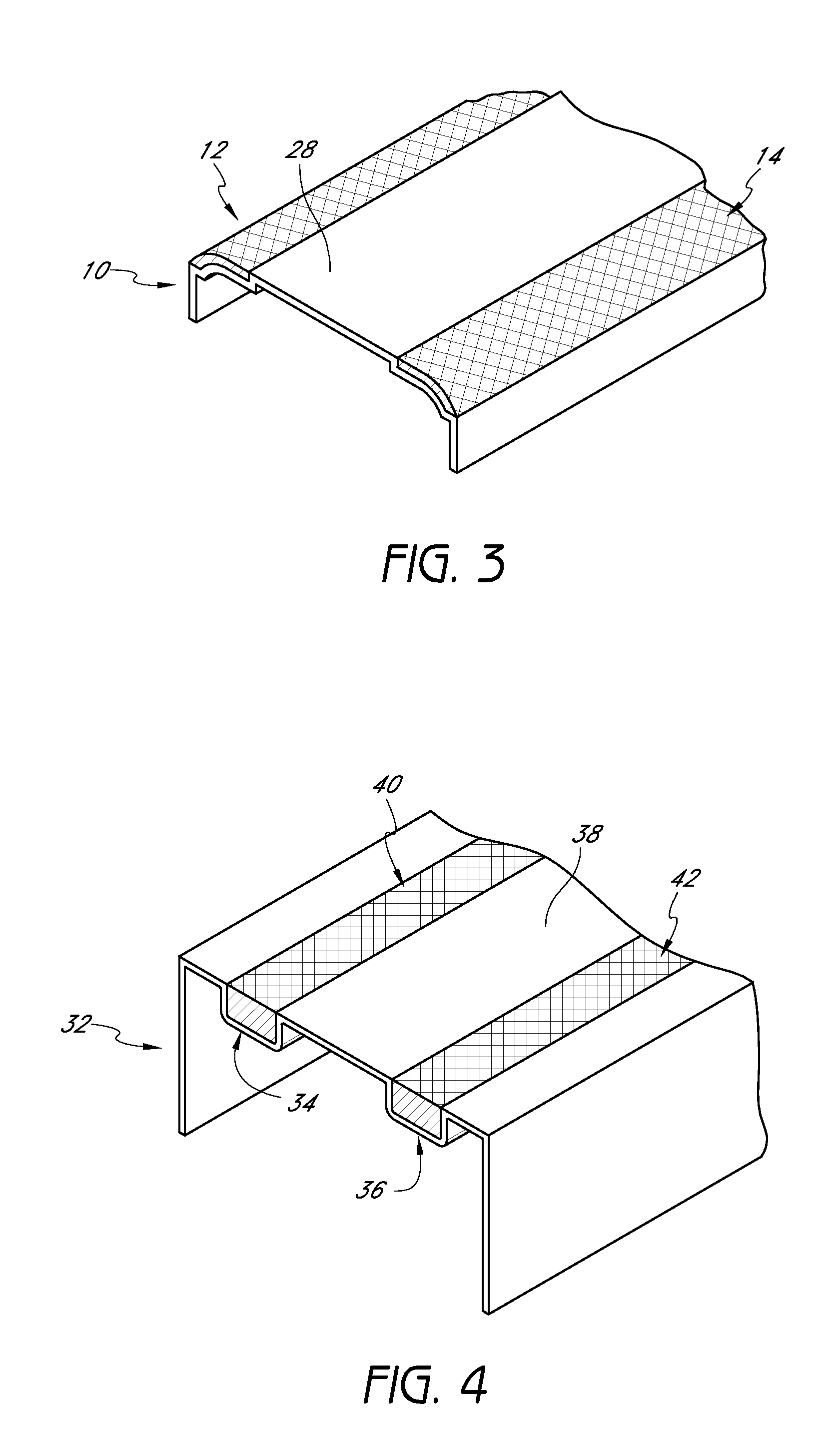

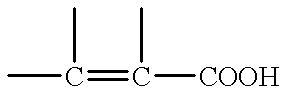

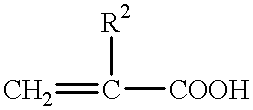

Weatherable building products

InactiveUS6383652B1Eliminate accumulated volatileAvoid blistersSynthetic resin layered productsCellulosic plastic layered productsBuilding productSolid wood

The present invention relates to a weatherable building product comprising a wood member. The wood member has at least a portion which is coated with a coating composition comprising an interpenetrating polymer network of an acrylic latex and a vinylidene chloride polymer. The wood member comprises solid wood or fiber-based materials.

Owner:TTTECH

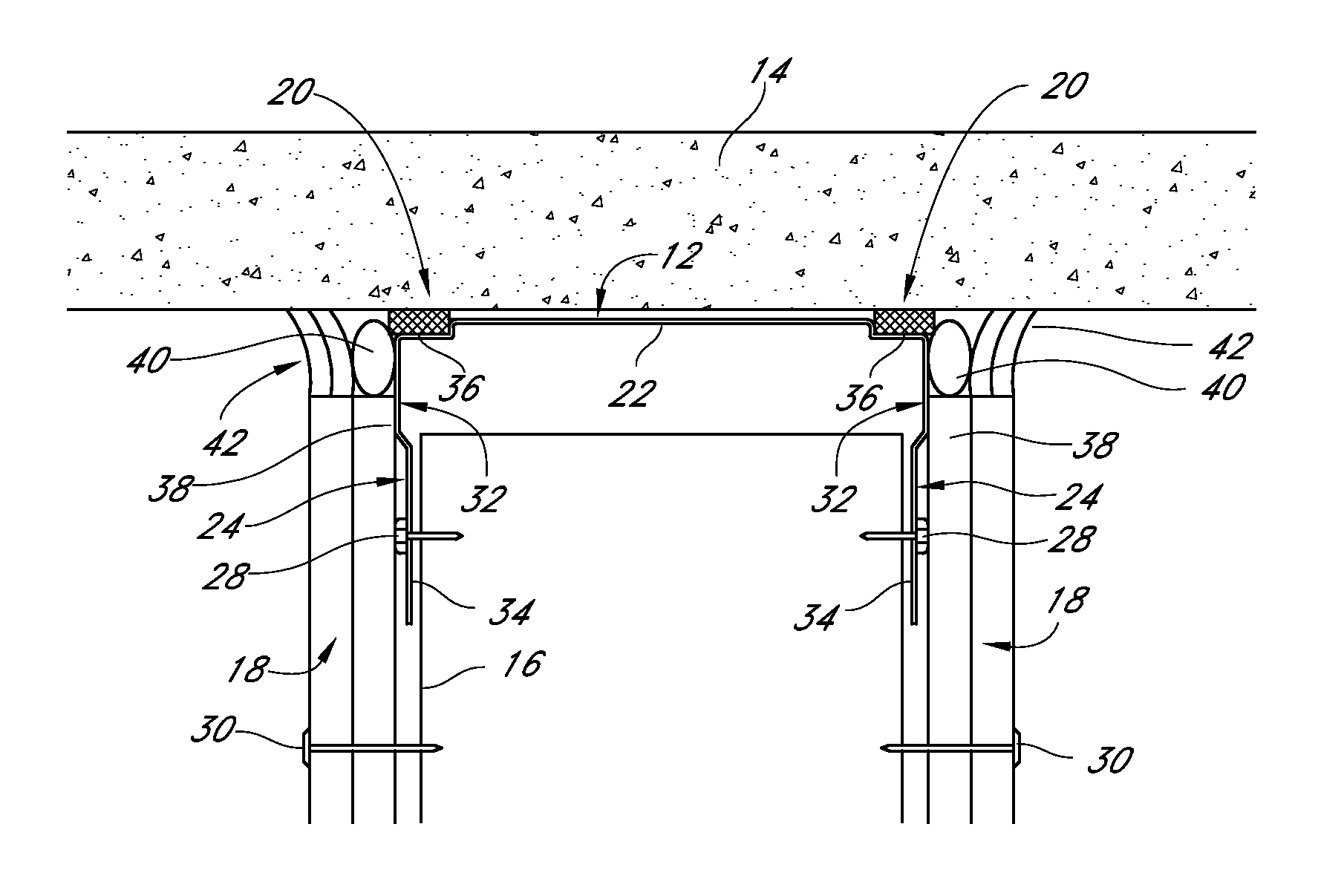

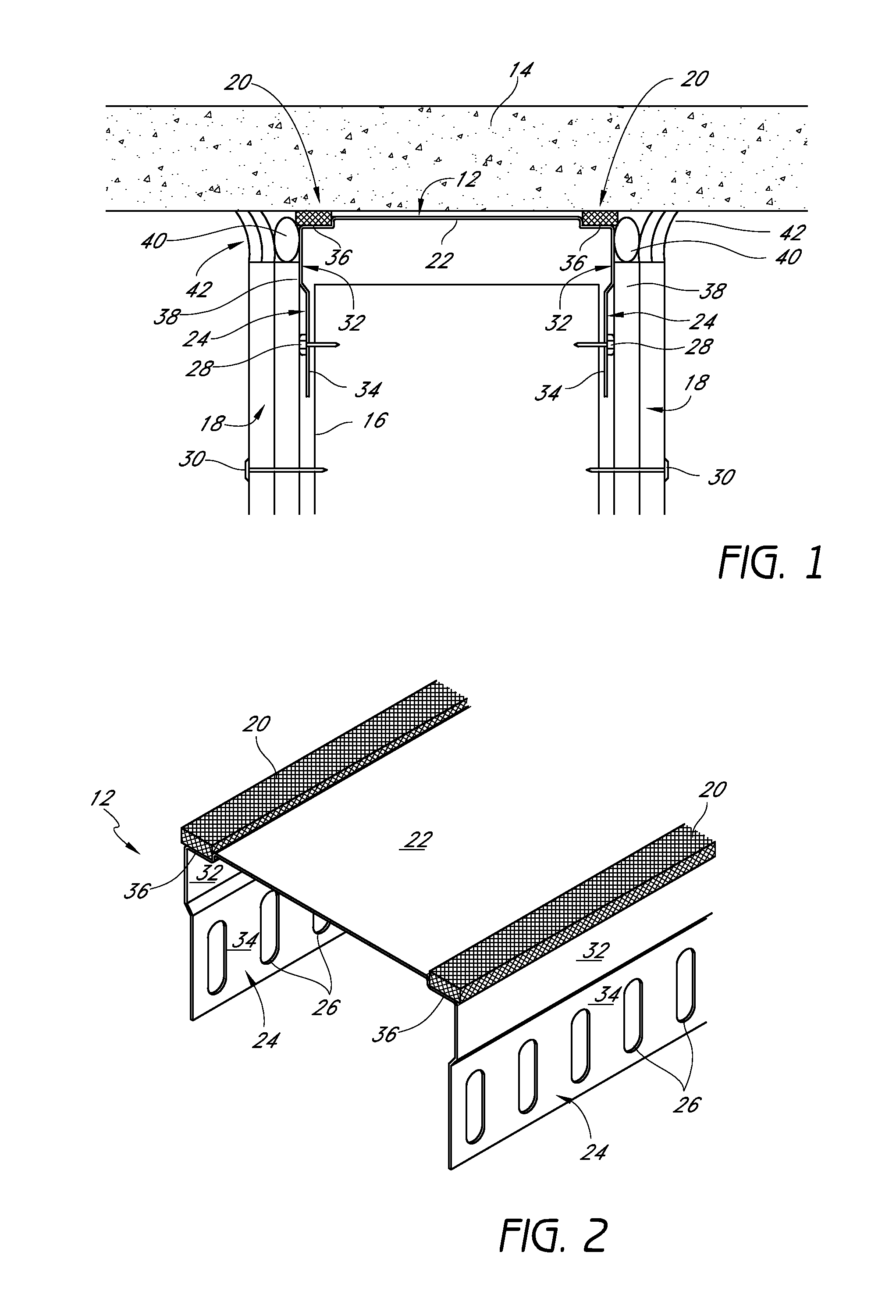

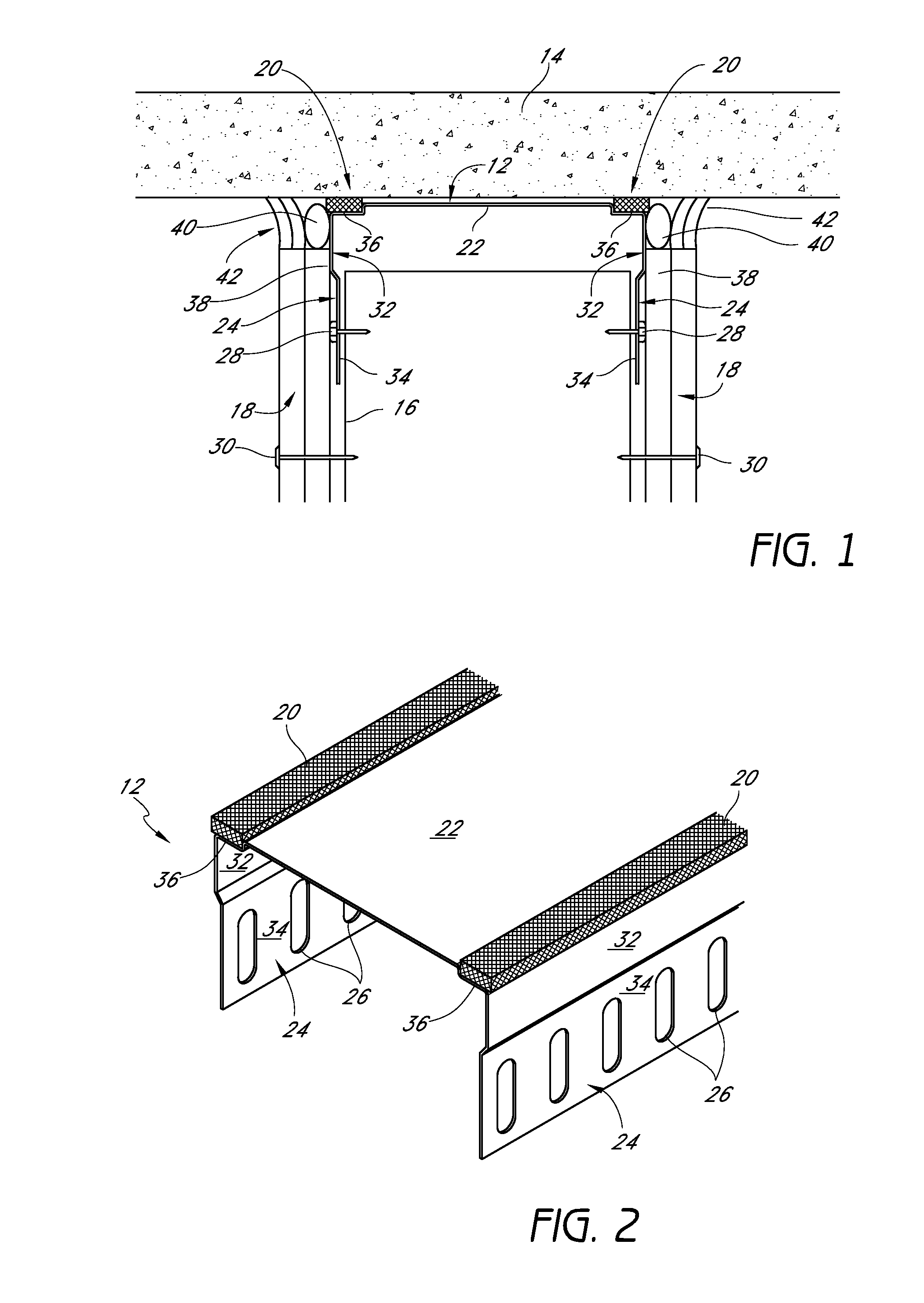

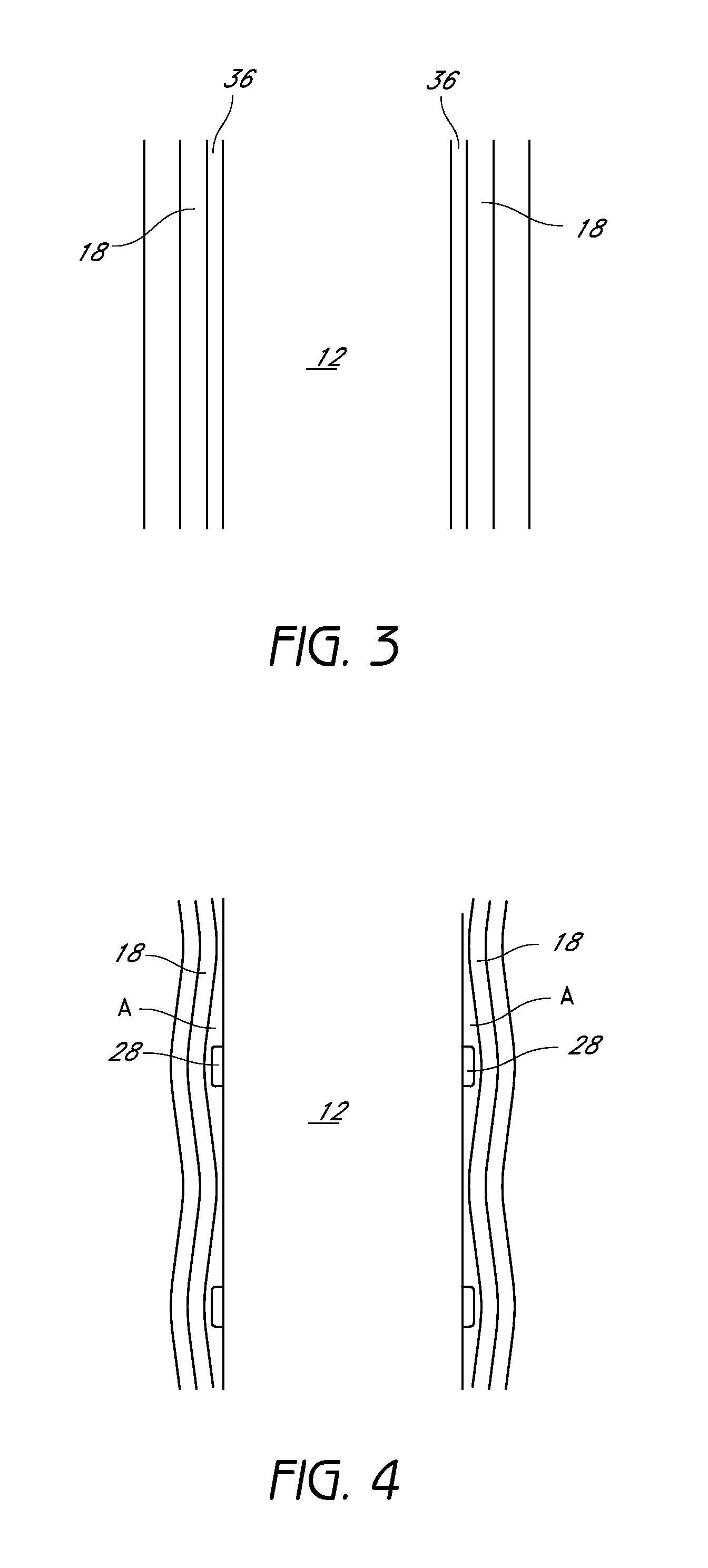

Fire-rated wall construction product

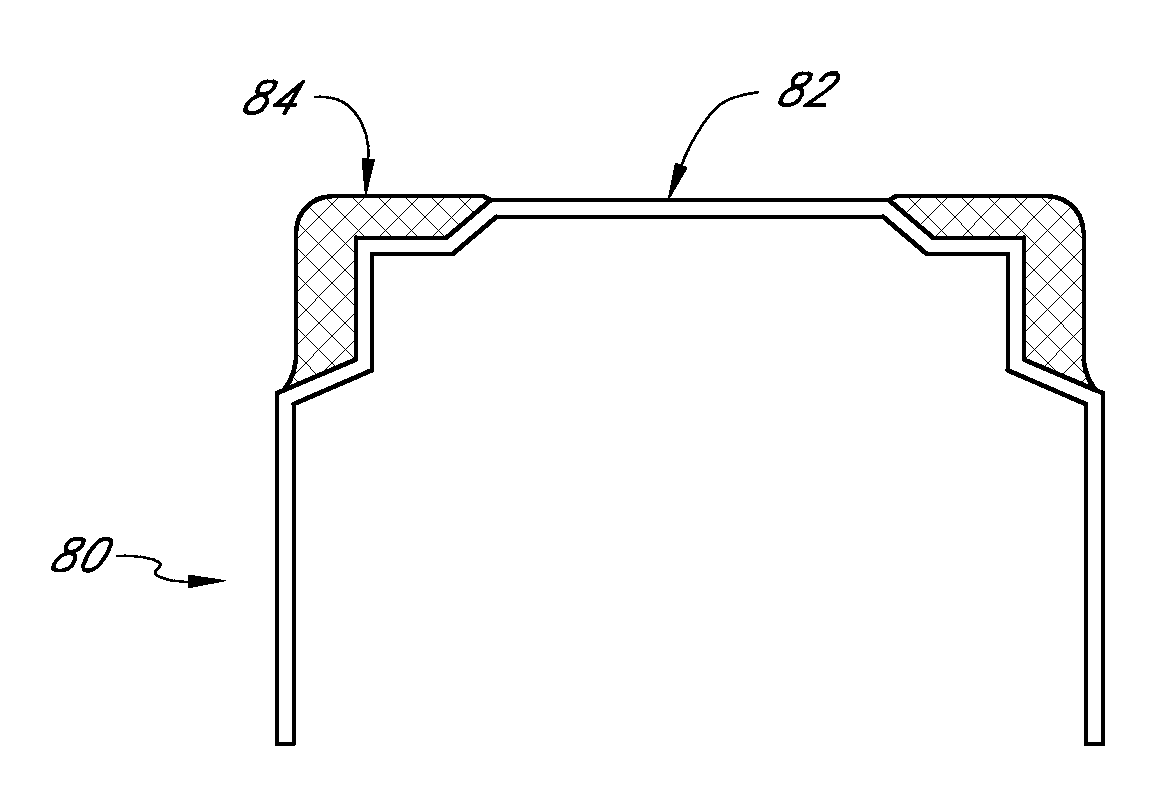

ActiveUS20110247281A1Roof covering using slabs/sheetsRoof covering using tiles/slatesBuilding productFire retardant

The present application is directed toward fire-rated wall construction components and wall systems for use in building construction. Embodiments can include tracks for holding studs which incorporate various geometries capable of receiving fire-retardant material, including but not limited to intumescent material. The fire-retardant material can be attached to the tracks such that the fire-retardant material expands and seals gaps and / or areas between the tracks and wall components such as ceilings, floors, and drywall.

Owner:CEMCO LLC

Halogen-free flame-retardant polyolefin injection-grade wood-plastic composite and preparation method thereof

The invention discloses a halogen-free flame-retardant polyolefin injection-grade wood-plastic composite and a preparation method thereof. The halogen-free flame-retardant polyolefin injection-grade wood-plastic composite comprises the following components in percentage by mass: 25 to 70 percent of polyolefin resin, 5 to 50 percent of plant fiber, 0.5 to 20 percent of compatilizer, 0 to 30 percent of flexibilizer, 0.5 to 8 percent of dispersant, 5 to 40 percent of fire retardant and synergist and 0 to 1 percent of antioxidant. Compared with the conventional wood-plastic composite, the halogen-free flame-retardant polyolefin injection-grade wood-plastic composite prepared by the invention has the characteristics of simple production flow, less fire retardant dosage, good halogen-free flame-retardant effect, wide molding mode range and the like, and is suitable for various injection-molded products such as shells of electrical appliance products, furniture, materials for automobiles, artworks, building products with complex construction and the like.

Owner:KINGFA SCI & TECH CO LTD +1

Fire-rated wall construction product

ActiveUS8640415B2Roof covering using slabs/sheetsRoof covering using tiles/slatesBuilding productFire retardant

Owner:CEMCO LLC

Fire-rated wall construction product

Fire-rated wall construction components and wall systems for use in building construction. Embodiments can include tracks for holding studs which incorporate various geometries capable of receiving fire-retardant material, including but not limited to intumescent material. The fire-retardant material can be attached to the tracks such that the fire-retardant material expands and seals gaps and / or areas between the tracks and wall components such as ceilings, floors, and drywall. Various assemblies and methods can be used to cover the deflection gap.

Owner:CEMCO LLC

Fire-rated wall construction product

The present application is directed toward fire-rated wall construction components and wall systems for use in building construction. Embodiments can include tracks for holding studs which incorporate various geometries capable of receiving fire-retardant material, flat straps for use between tracks and fluted wall components, fire sponges for use in fluted wall components, and tracks with protruding grooves or other structures which prevent unwanted air movement between a wallboard component and the track.

Owner:CEMCO LLC

Fire-rated wall construction product

Fire-rated wall construction components and wall systems for use in building construction. Embodiments can include tracks for holding studs which incorporate various geometries capable of receiving fire-retardant material, including but not limited to intumescent material. The fire-retardant material can be attached to the tracks such that the fire-retardant material expands and seals gaps and / or areas between the tracks and wall components such as ceilings, floors, and drywall. Various assemblies and methods can be used to cover the deflection gap.

Owner:CEMCO LLC

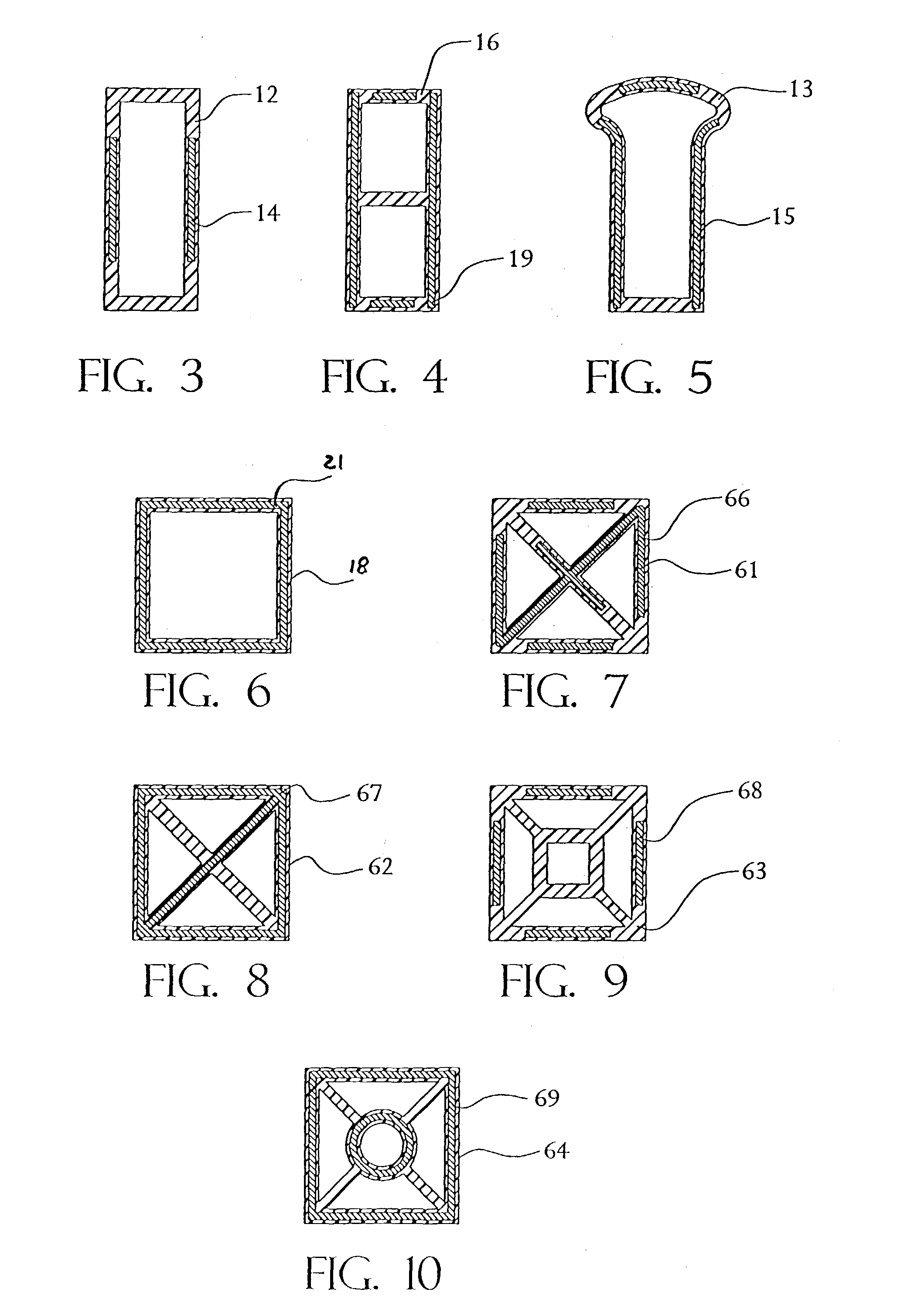

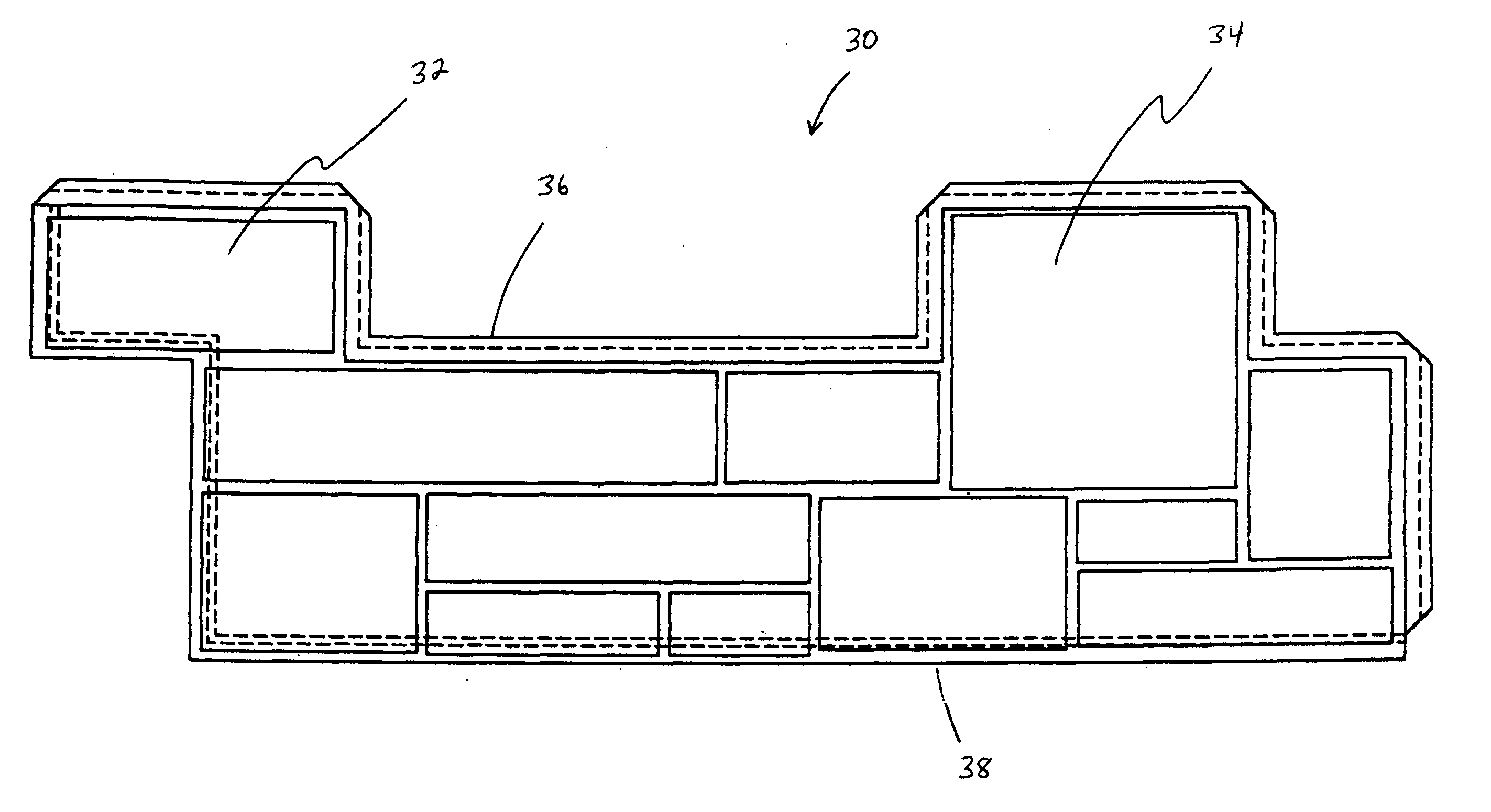

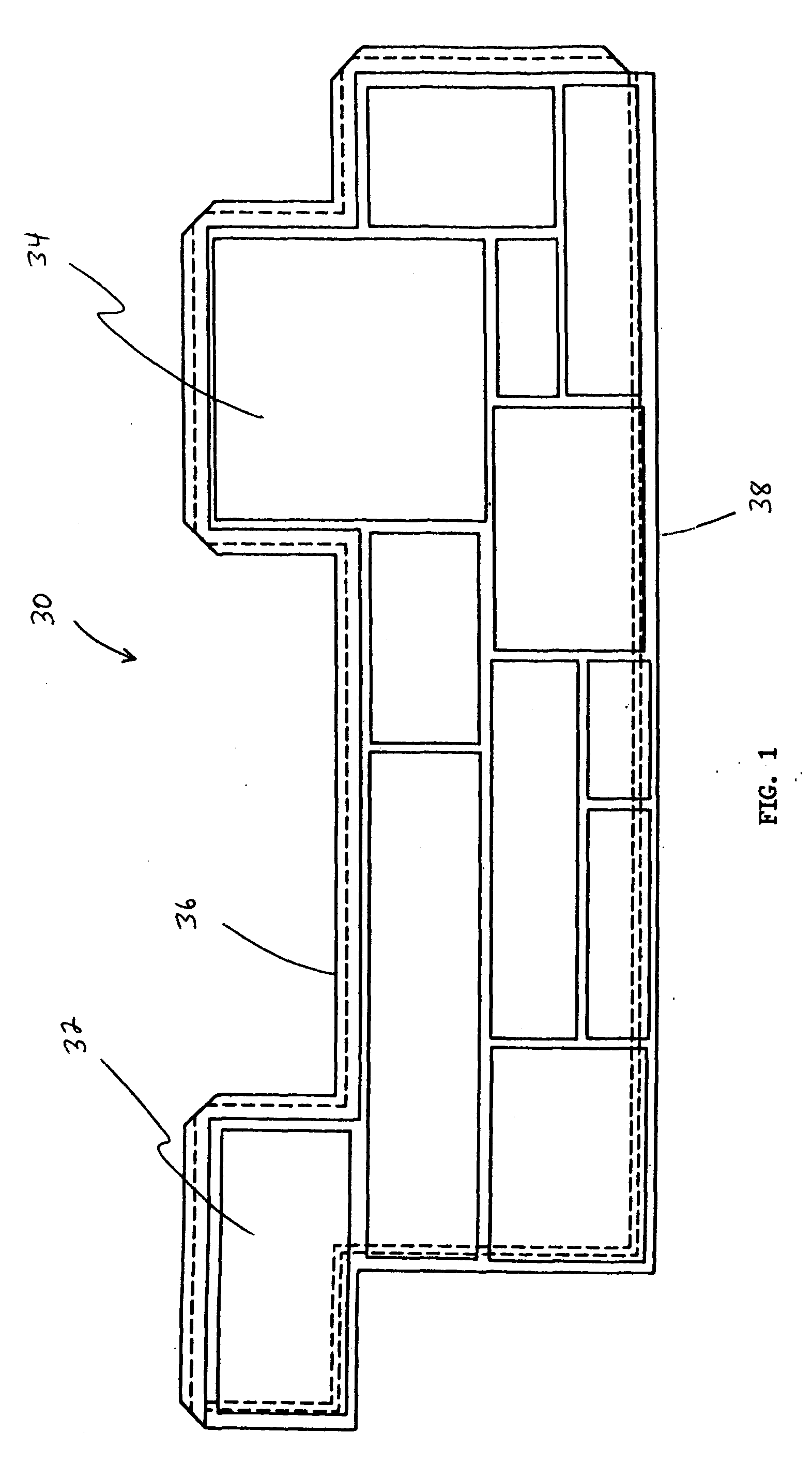

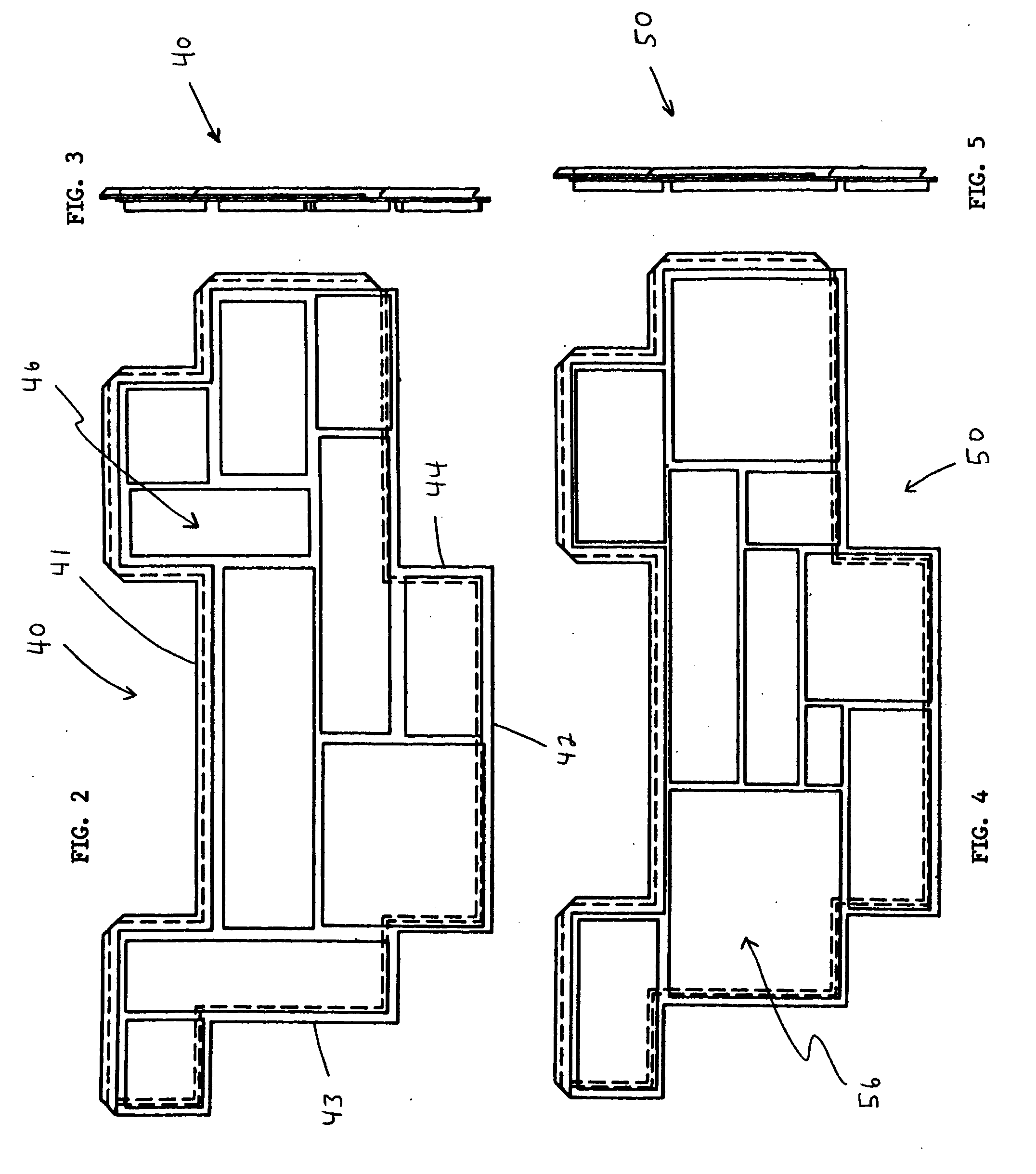

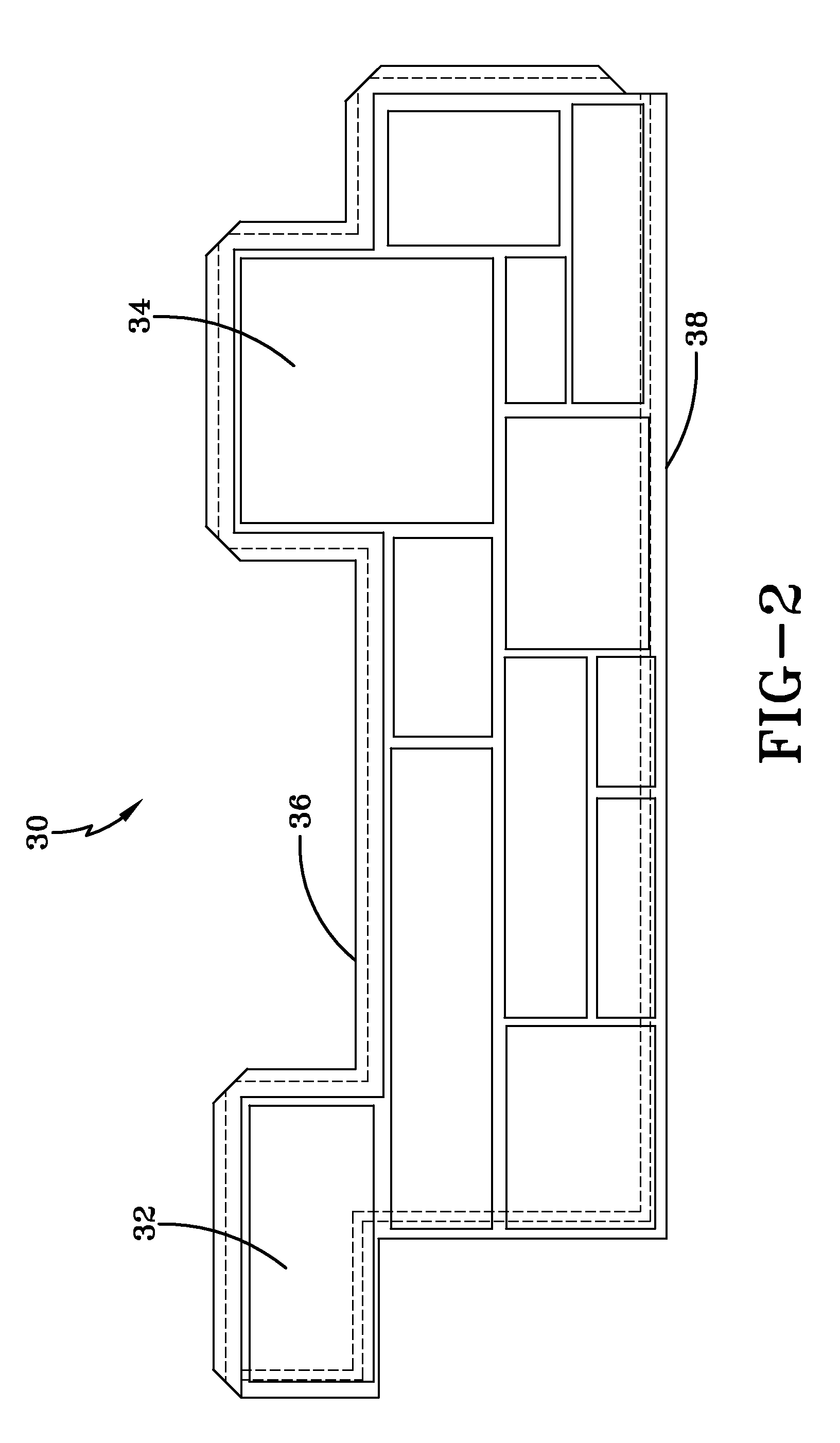

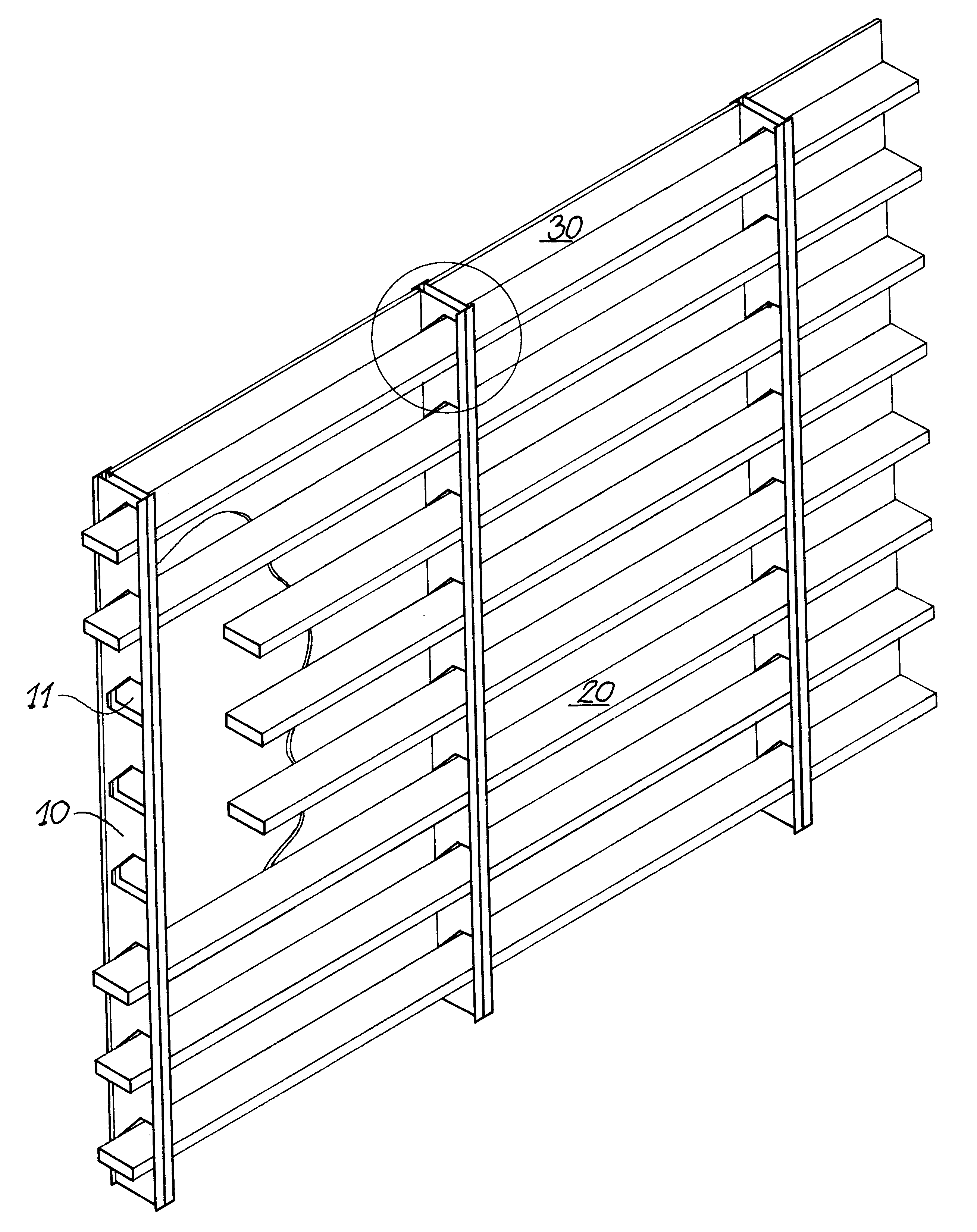

Simulated stone, brick, and masonry panels and wall structures

InactiveUS20060197257A1OptimizationEasy transitionCovering/liningsNatural patternsBuilding productBrick

Products and methods that may enhance the manufacturing, structure, appearance, assembly, or installation of synthetic building or construction products. In particular, exemplary embodiments include panels, wall structures, and other panel assemblies that may have contoured or textured surfaces to simulate the appearances of other building or construction products. For instance, exemplary embodiments of panels, wall structures, and other panel assemblies may have contoured and textured surfaces that may simulate the appearances of conventional building or construction materials including, but not limited to, stone, bricks, masonry, concrete, stucco, wood, other conventional building materials, and combinations of any of these materials.

Owner:EXTERIOR PORTFOLIO

Lightweight cementitious compositions and building products and methods for making same

Cementitious compositions and methods for making same, in which the cementitious compositions include 35-60 wt. % cementitious reactive powder (also termed Portland cement-based binder), 2-10 wt. % expanded and chemically coated perlite filler, 20-40 wt. % water, entrained air, and optional additives such as water reducing agents, chemical set-accelerators, and chemical set-retarders. In addition, the lightweight cementitious compositions may contain 0-25 wt. % on a wet basis secondary fillers such as expanded clay, shale aggregate, and pumice.

Owner:UNITED STATES GYPSUM CO

Special-purpose board for building and producing method thereof

ActiveCN101168610AProtect the environmentOvercome fear of waterBuilding constructionsSlagPolyvinyl chloride

The invention relates to a building product and the generating method thereof, in particular to a construction special-purpose plate and the manufacturing method thereof. The invention is made of the following raw material according to the parts by weight: 20 to 50 percent of thermoplastic resin comprising polyvinyl chloride, polyethylene and polypropylene, 50 to 80 percent of bulking agent comprising iron ore waste tailing sand, calcium carbonate and slag, and additive occupying 0.05 to 5 percent of the gross weight of the thermoplastic resin and the bulking agent and comprising plasticizer, heat stabilizer and lubricating agent. The product is made by adopting a stone molding and extrusion moulding way, no pollution is produced, no distortion exists, the product is moistureproof and fireproof, the processing waste and the disposed plate of the product can be recycled and newly processed to ensure zero waste, the damage to the environment cannot be caused, and the product is made into a hollow plate structure which has the advantages that the elasticity and the sound insulation effect are good and the heat transfer effect is good, therefore, the invention is very suitable for the heating of a geothermic pipeline, and the difficult problem that a wooden compound floor plate in the present market cannot be used for the heating of the northern geothermic building because of the distortion due to the heating or poor heat insulation heating effect is solved.

Owner:唐山金三顺装饰材料有限公司

Styrene-based non-halogen flame-retardant injection-grade wood-plastic composite material and preparation method thereof

ActiveCN101864118AImprove liquidityGive full play to the flame retardant effectBuilding productHalogen

The invention discloses a styrene-based non-halogen flame-retardant injection-grade wood-plastic composite material and a preparation method thereof. The wood-plastic composite material comprises the following components by mass percentage: 25% to 60% of styrene-based resin, 5% to 50% of vegetable fiber, 0.5% to 20% of compatibilizer, 0% to 30% of toughener, 0.5% to 8% of dispersant, 5% to 40% offlame retardant and flame-retardant synergist and 0% to 1% of antioxidant. Compared with the existing wood-plastic composite material, the styrene-based non-halogen flame-retardant injection-grade wood-plastic composite material prepared by the invention has the characteristics of simple production procedure, lower flame-retardant consumption, good non-halogen flame-retardant effect and wide range of forming manners. Therefore, the invention is suitable for various injection-molded parts, such as the housing of electrical products, furnishings, automobile materials, artworks, complex-structured building products and the like.

Owner:KINGFA SCI & TECH CO LTD +2

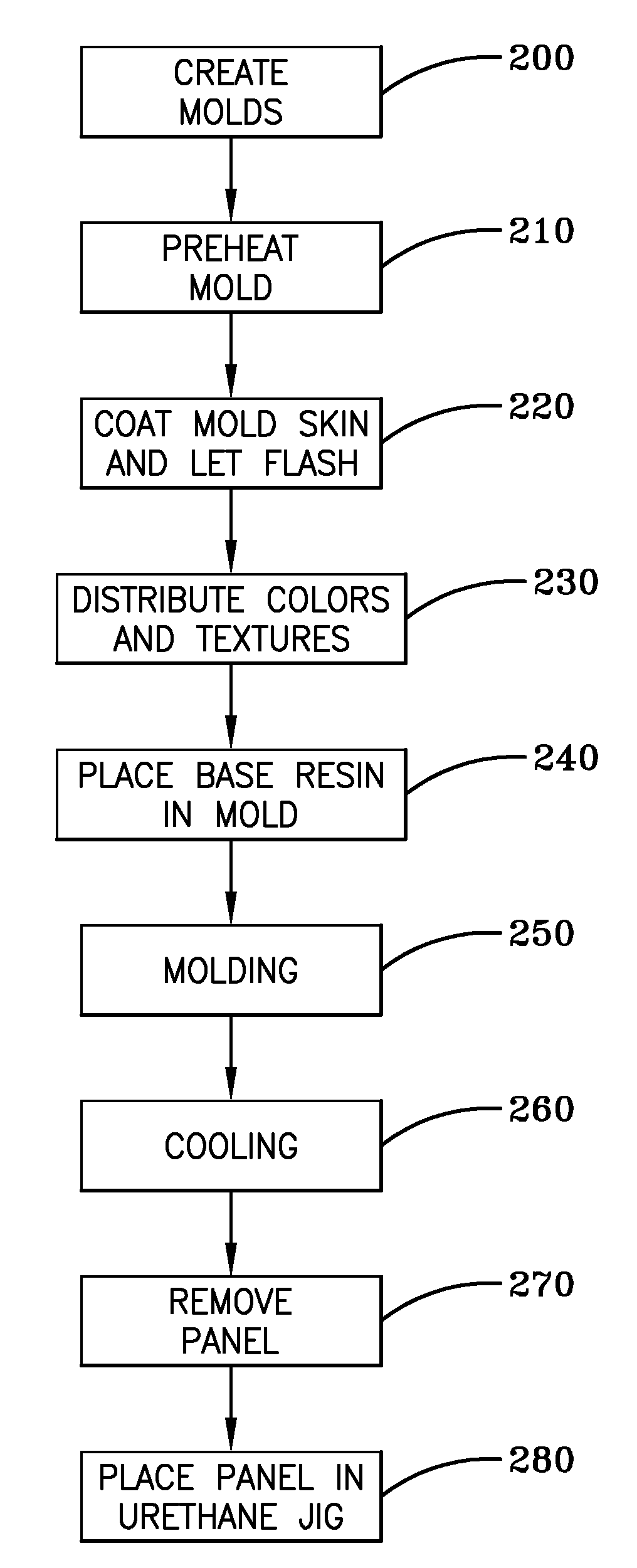

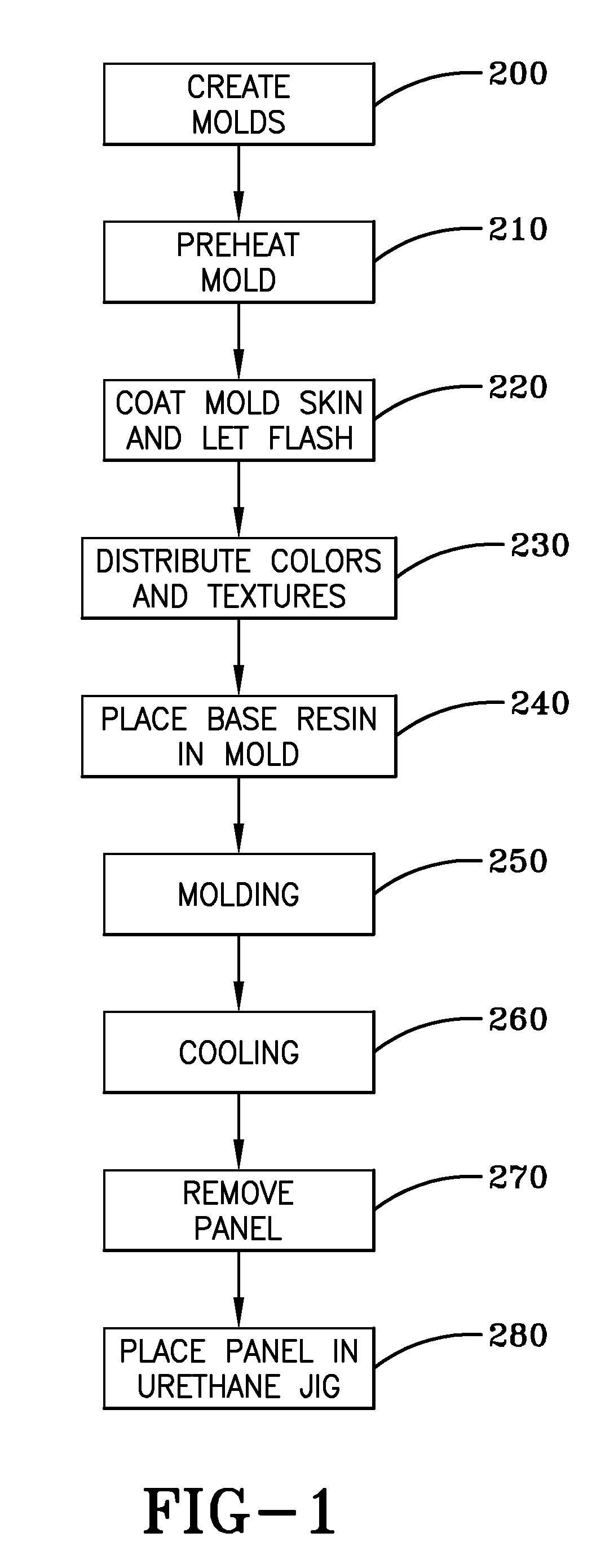

Method of manufacturing simulated stone, brick, and masonry panels and wall structures

InactiveUS20070227087A1Minimize limitationEasy to assembleCovering/liningsNatural patternsBuilding productBrick

Simulated stone, masonry and brick textured products such as siding panels are obtained when specially selected materials are properly admixed and formed via molding techniques. For instance, exemplary methods of manufacturing embodiments of panels, wall structures, and other products that may have contoured and textured surfaces and may simulate the appearances of conventional building or construction materials including, but not limited to, stone, bricks, masonry, concrete, stucco, wood, other conventional building materials, and combinations of any of these materials are disclosed. Such products are manufactured from suitable molds according to a prescribed process methodology using synthetic polymeric materials in addition to other materials such as coloring and texturing materials. Prerequisite surface textures may be produced that effectively simulate actual stone, masonry and brick panels. Methods described herein may enhance the manufacturing, structure, appearance, assembly, or installation of synthetic building or construction products. In particular, exemplary embodiments include panels, wall structures, and other panel assemblies that may have contoured or textured surfaces to simulate the appearances of other building or construction products. The disclosed invention is not limited to products in the building or construction industries and may be applied in the manufacture of a wide variety of products in other industries.

Owner:EXTERIOR PORTFOLIO

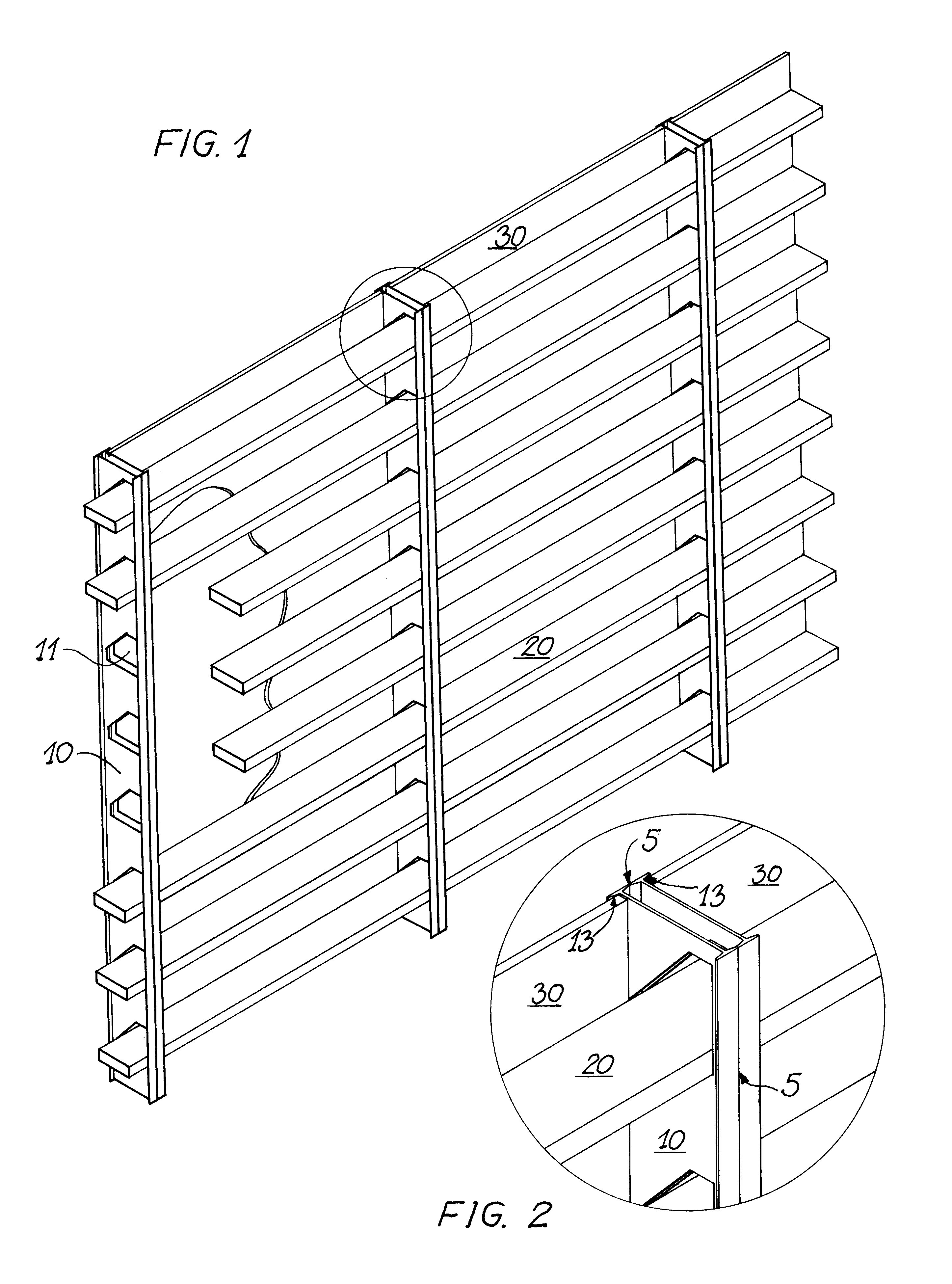

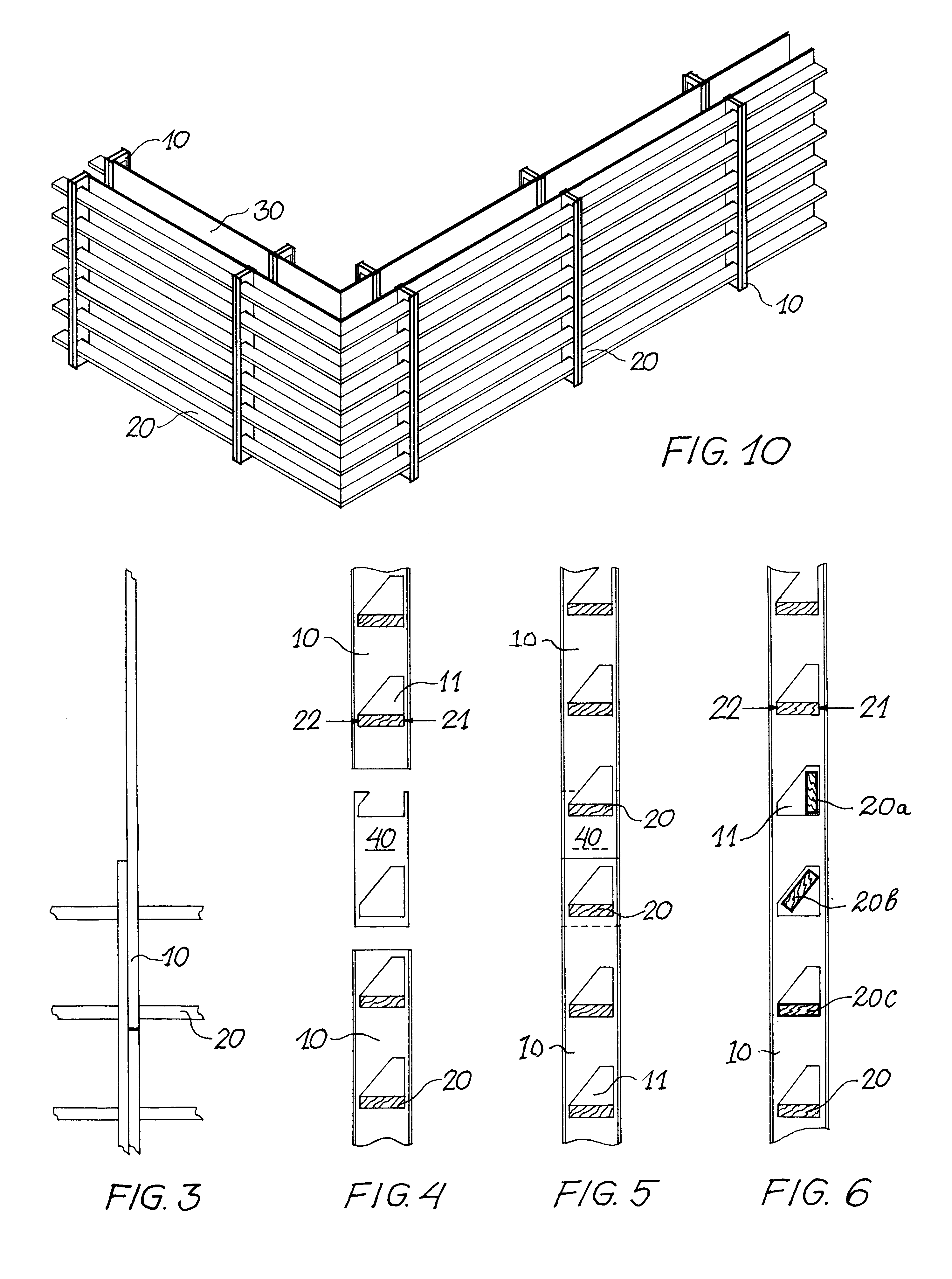

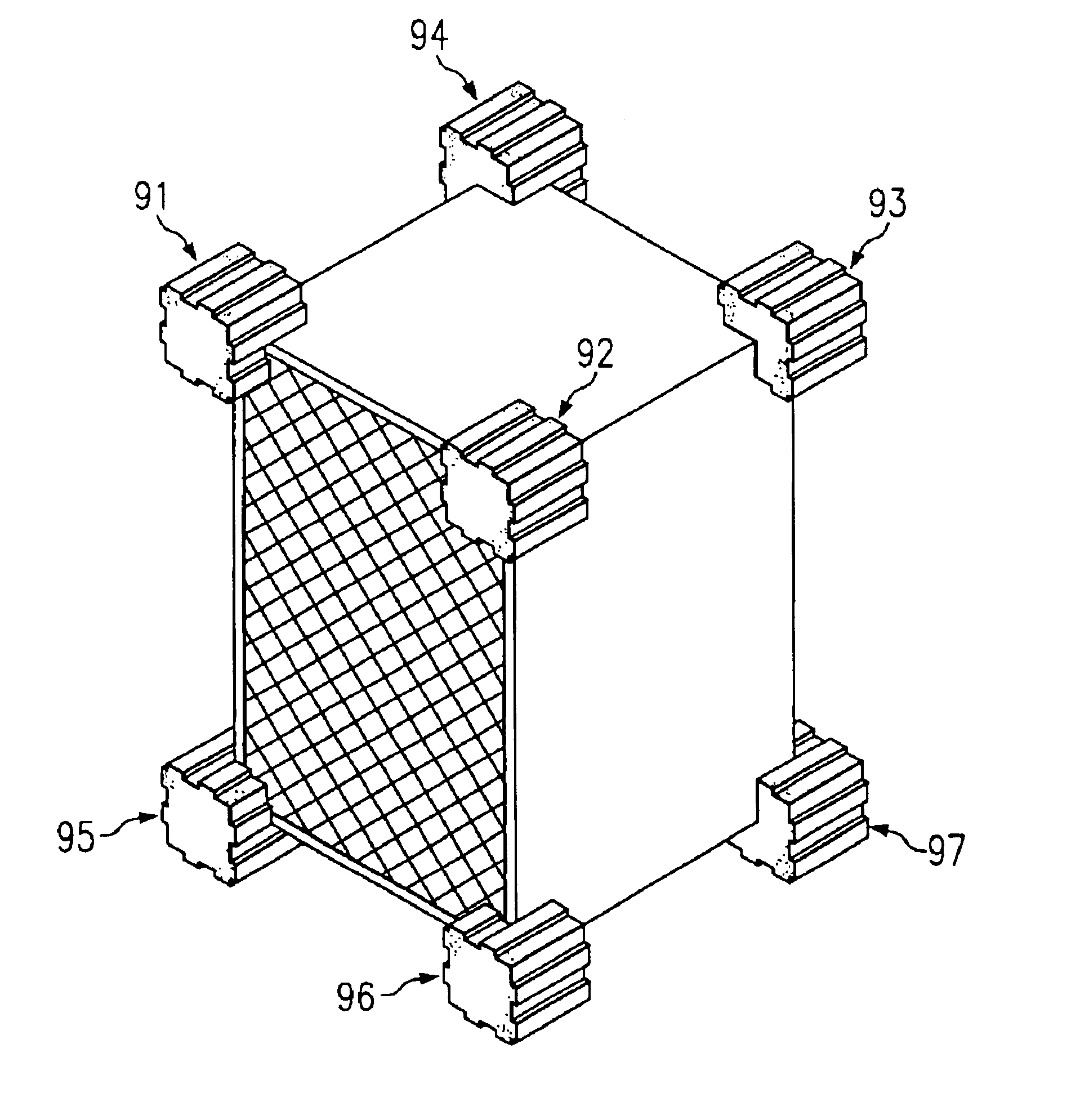

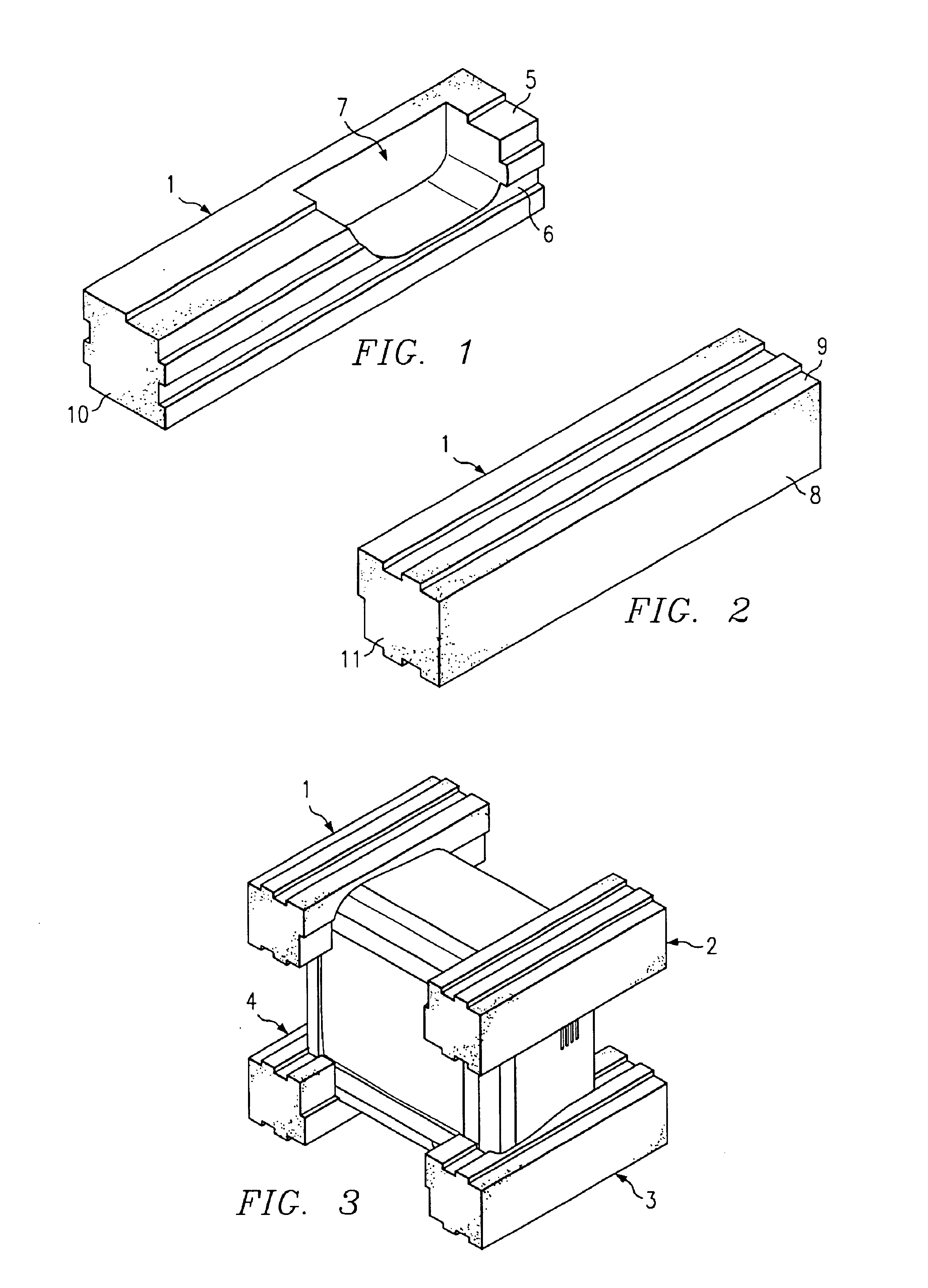

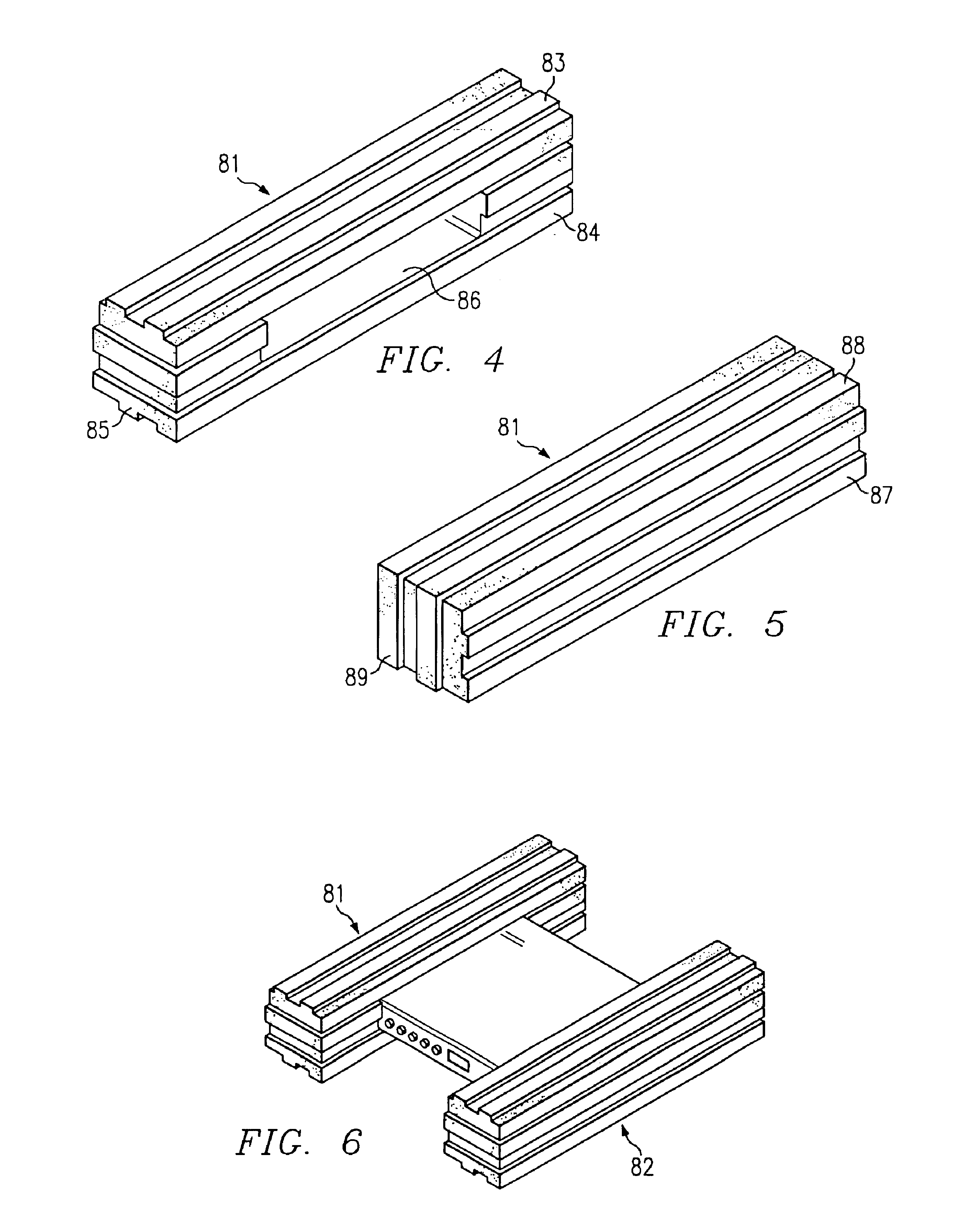

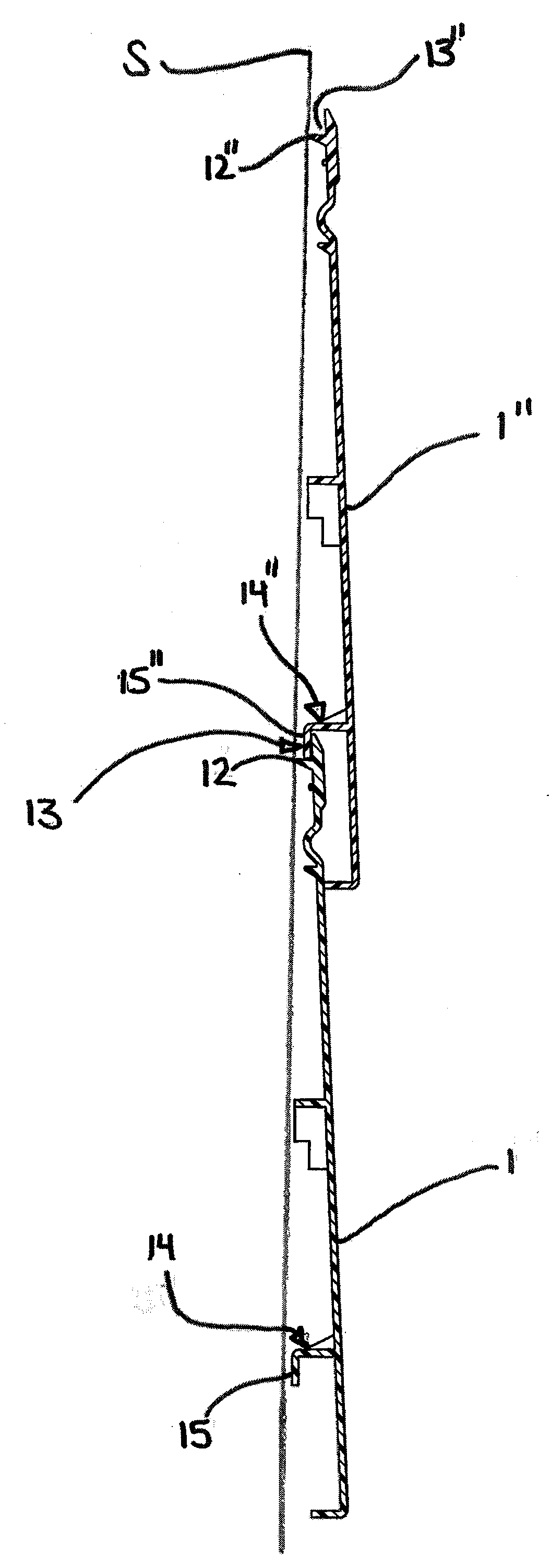

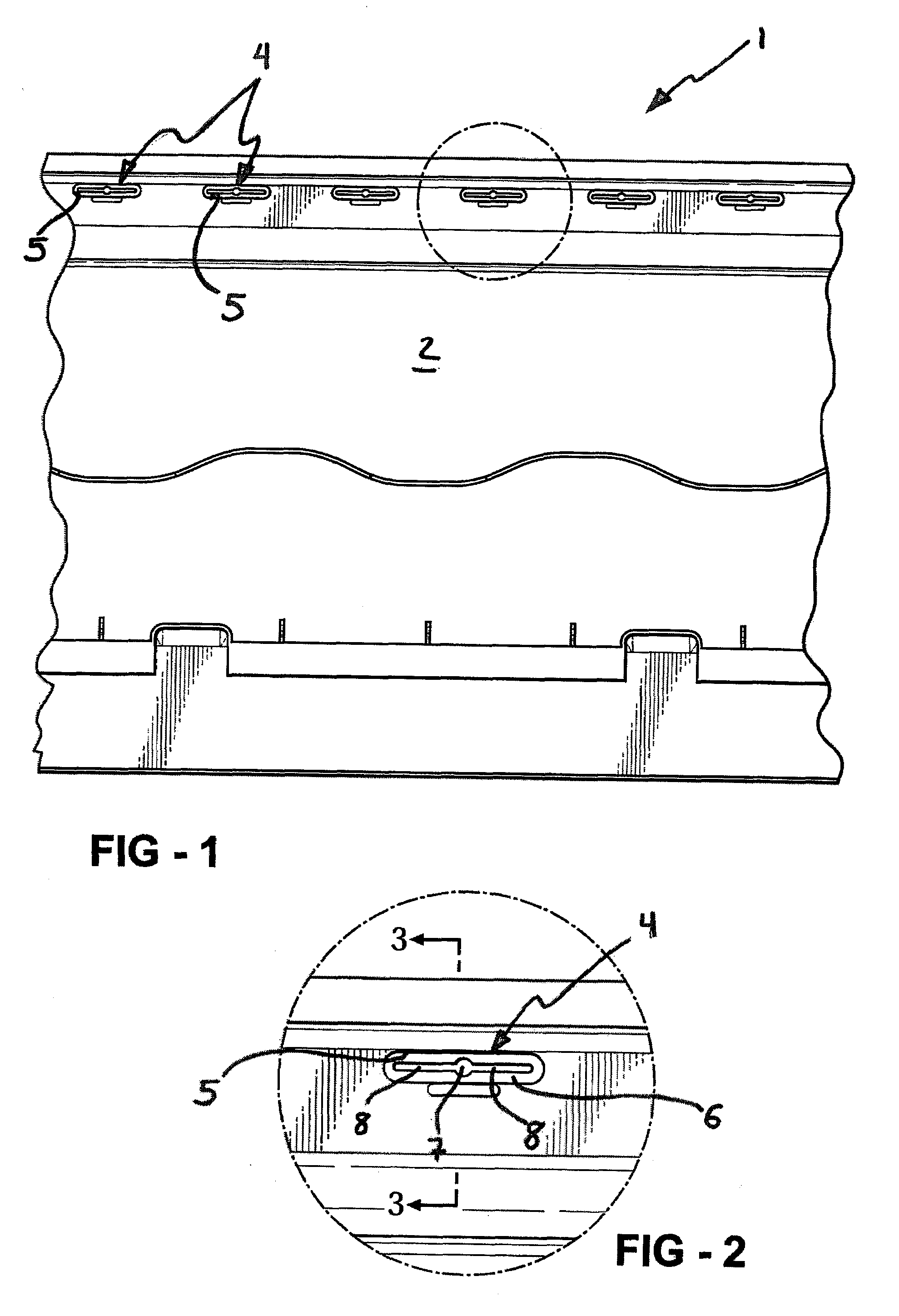

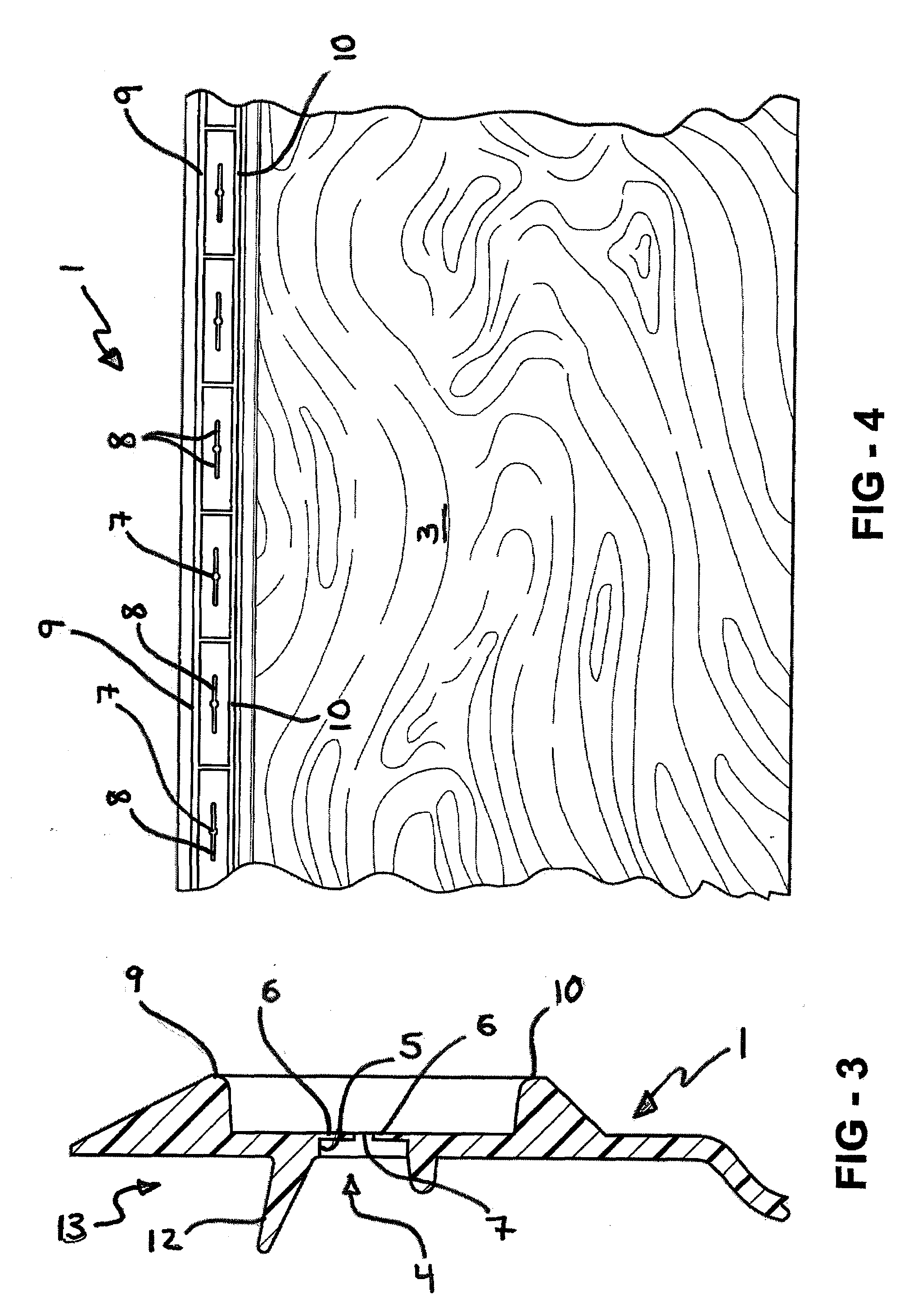

Sub-rigid fast-form barrier system

The invention disclosed herein is remarkable in its simplicity and promises wide commercial application as the labor costs for construction become increasingly prohibitive. The extraordinary absence of nails, screws, bolts, welds or any other fastening device allows these barriers to compete with many conventional barrier systems, such as those employed for fencing, vehicular trailer beds, removable stages, and scale models or toys of all fabrications mentioned plus many more. In this age time is money and the erection speed this barrier system offers may well revolutionize conventional "post and beam" framing. The invention is specifically aimed at eccentric beam loading where barriers must be economically fabricated to withstand hurricane force winds, earthquake reactions, or liquid concrete pressure in a sub-rigid manner. The Fast-Form System will offer insurers building products that will protect their interests for any and all applications. When the barriers disclosed herein are utilized for concrete formwork, contractors will have a new option that embraces standard building products, with barrier fabrication accomplished in half the time of the systems that precede it.

Owner:NELSON THOMAS PAGE

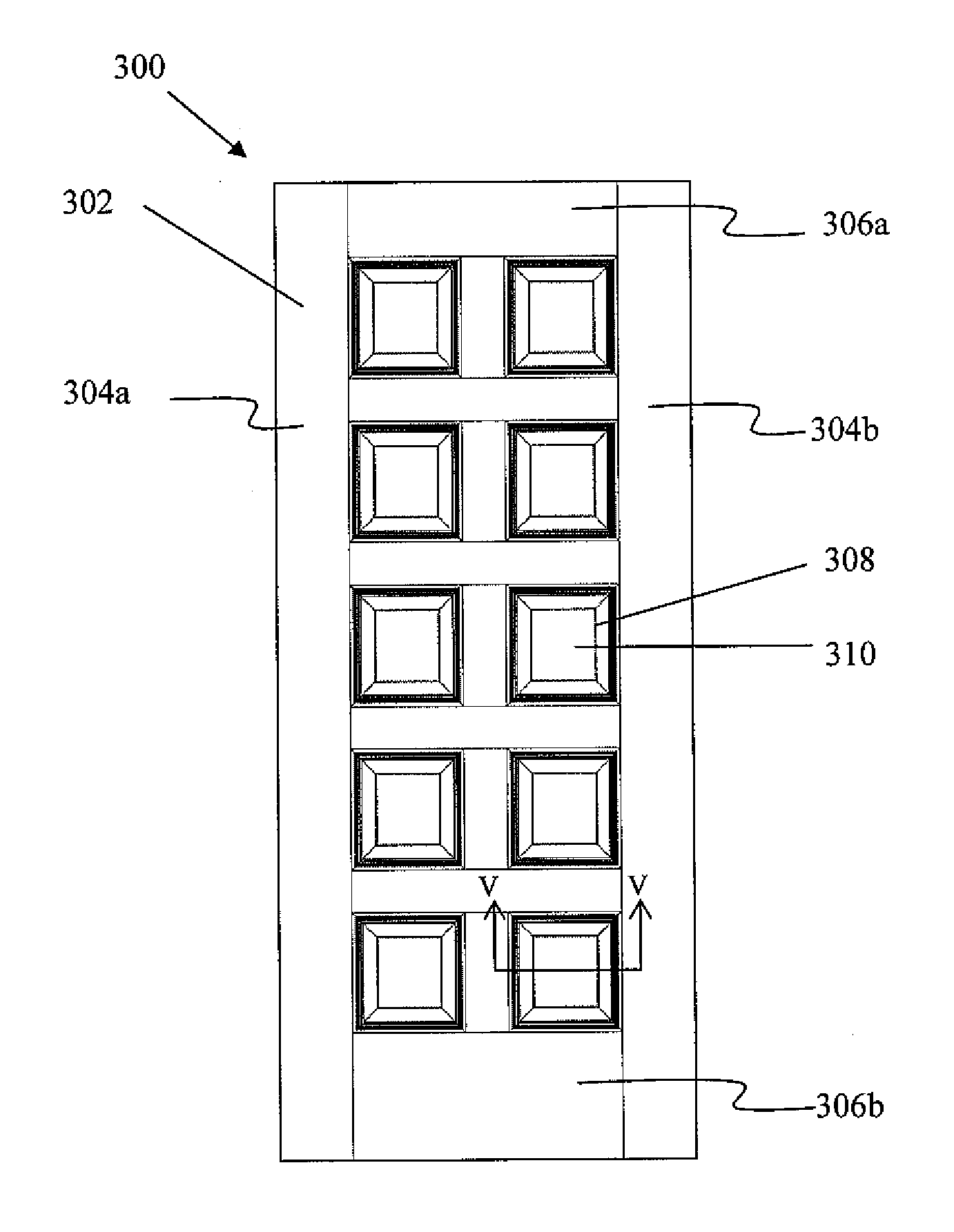

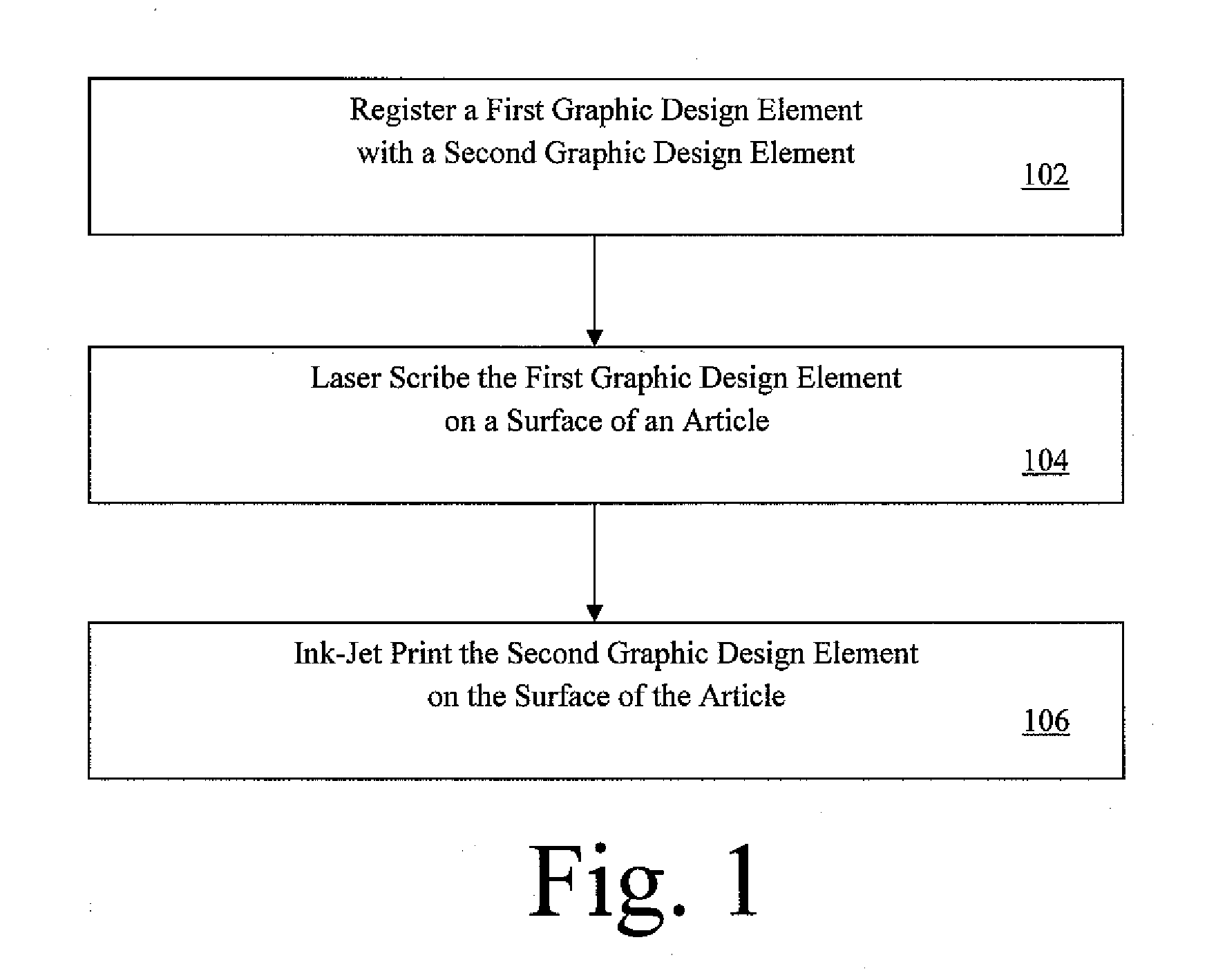

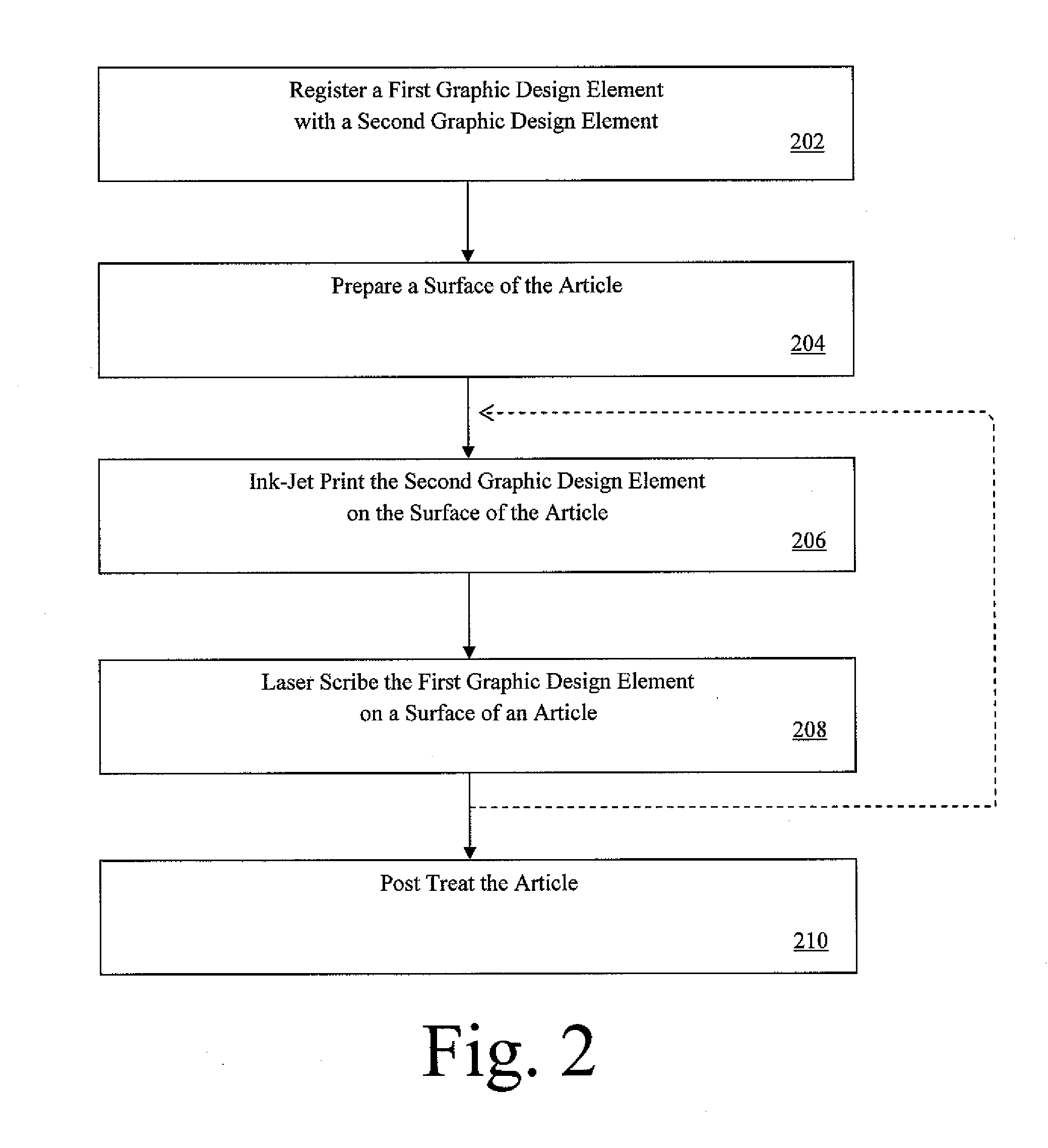

Surface marked articles, related methods and systems

InactiveUS20100183822A1Quality improvementRadiation applicationsSewing apparatusBuilding productEngineering

A method of surface marking an article, especially a building product, is provided. One described method includes the steps of laser marking a first graphic design element on a surface of an article and ink-jet printing a second graphic design element in registry with the first graphic design element on the surface of the article to create a high quality overall graphic design. Also provided are articles made according to this method, and systems for carrying out the method.

Owner:MASONITE CORP

Uniform interlocking foam packing material/building material apparatus and method

InactiveUS6840372B2Reduce productionReduces ecological impactRoof covering using slabs/sheetsRoof covering using tiles/slatesBuilding productElectrical conductor

A foam structure for protecting a product in a package can interlock with another foam structure, concrete or wood to form a structural unit of building material. The foam structure can be made of two nested parts, which can be made of differing materials.A structural unit that can be used as building material can be made from packing material. A foam structure that can be used to pack a product in a package is interlocked with another foam structure, wood or concrete to form the unit of building material. The structural units can be used in construction products or in flotation products. The structural units can be used as part of a wall form and can be attached to the wall or to the other side of the wall form with connectors. The structural units can have conduits. The conduits can pass electrical conductors, air, fluids, ducts or pipes.

Owner:HOAMFOAM ALLIANCE

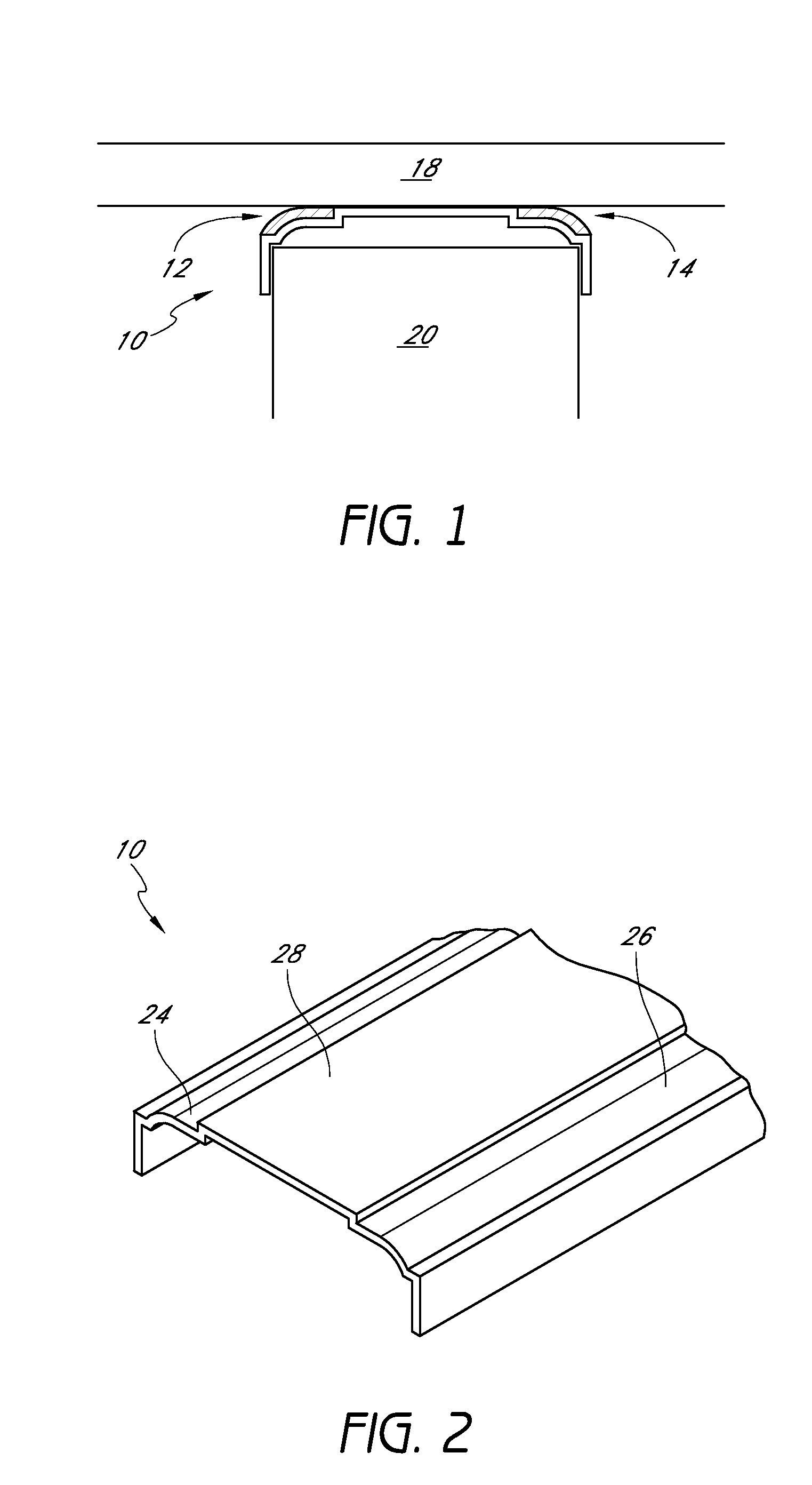

Polymer building products

ActiveUS20100088988A1Permit some movementRoof covering using tiles/slatesConstruction materialBuilding productRelative motion

Owner:NOVIK INC

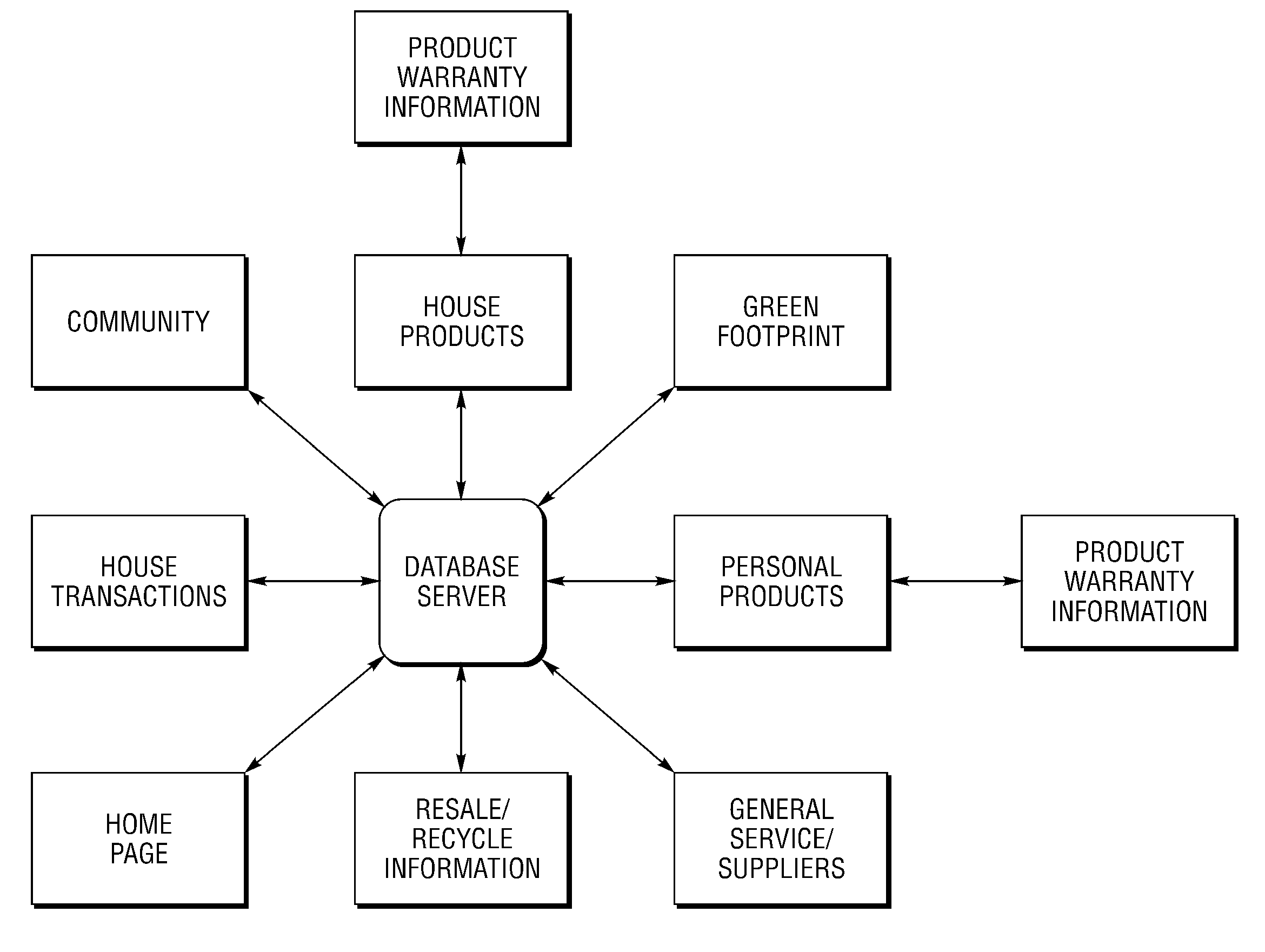

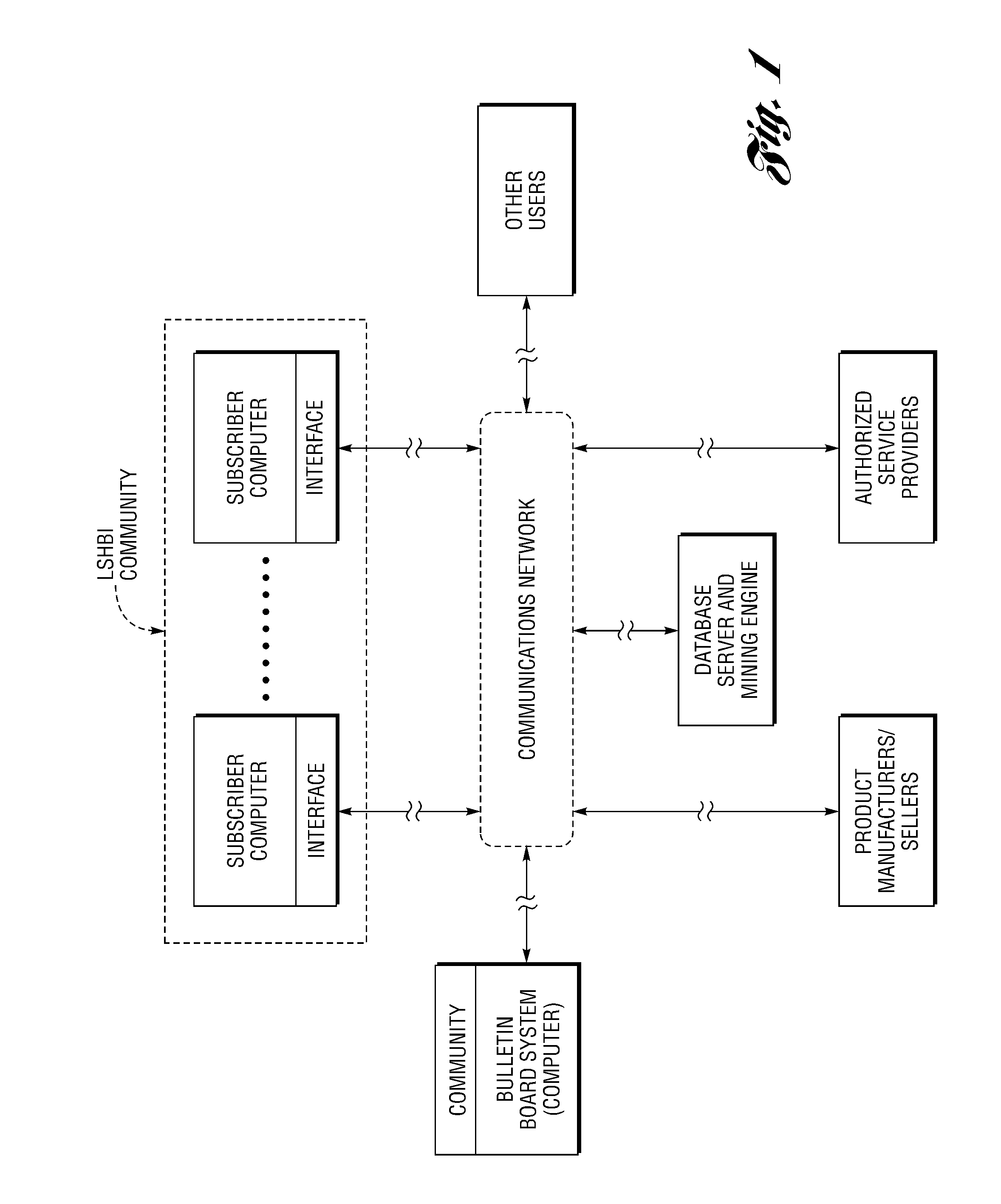

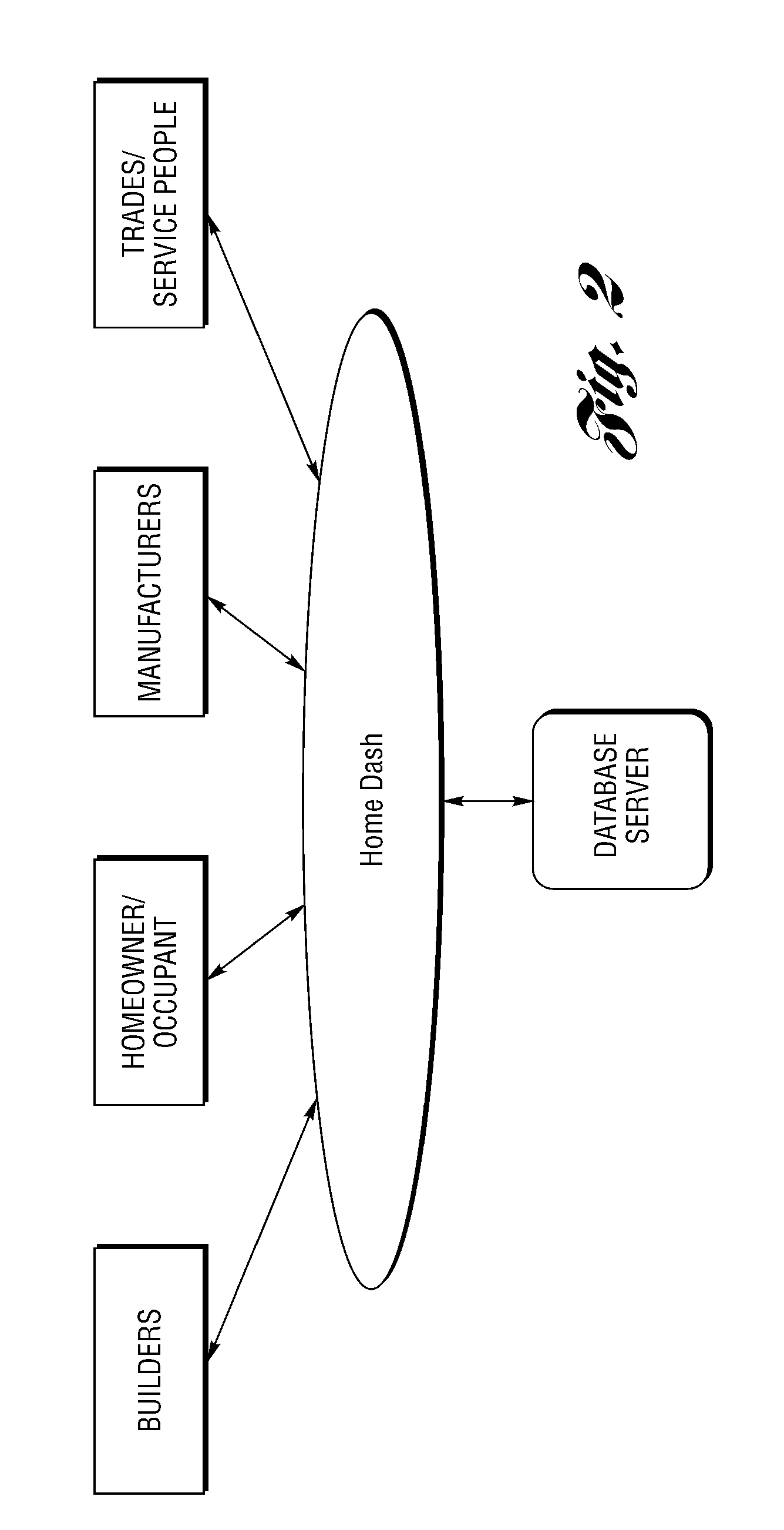

Scalable method and system for connecting, tracking and facilitating warranty, maintenance, service and replacement of products within a community of residential housing and/or commercial building inventories or units over a communications network

A scalable method and system are provided for connecting, tracking and facilitating warranties, recalls, maintenance, repair and upgrade / replacement and purchase of new products within a community of large-scale, homogeneous building inventories (LSHBI) or units over a communications network. The method includes providing a database of electronic data at a computer site. The data includes building product data that uniquely identifies building products common to and contained within each housing unit in a community of subscribing building units. The electronic data also includes service provider data that identifies service providers for the building products and warranty data that identifies warranties and warranty dates for at least one of the building products and services provided by the service providers. The method further includes analyzing the electronic data to determine whether an action to facilitate the maintenance, repair or replacement of at least one building product is to be performed.

Owner:MOSHER DOYLE W

Extruded fiber reinforced cementitious products having wood-like properties and ultrahigh strength and methods for making the same

InactiveUS20120276310A1Low densityReduce hardnessEnvelopes/bags making machineryCeramic extrusion diesPorosityBuilding product

A method of manufacturing a cementitious composite including: (1) mixing an extrudable cementitious composition by first forming a fibrous mixture comprising fibers, water and a rheology modifying agent and then adding hydraulic cement; (2) extruding the extrudable cementitious composition into a green extrudate, wherein the green extrudate is characterized by being form-stable and retaining substantially a predefined cross-sectional shape; (3) removing a portion of the water by evaporation to reduce density and increase porosity; and (4) heating the green extrudate at a temperature from greater than 65° C. to less than 99° C. is disclosed. Such a process yields a cementitious composite that is suitable for use as a wood substitute. Particularly, by using higher curing temperatures for preparing the cementitious building products, the building products have a lower bulk density and a higher flexural strength as compared to conventional products. The wood-like building products can be sawed, nailed and screwed like ordinary wood.

Owner:E KHASHOGGI INDS

Extruded fiber reinforced cementitious products having stone-like properties and methods of making the same

InactiveUS20110120349A1Improve flexural strengthHigh tensile strengthConstruction materialSolid waste managementBuilding productCement composites

A cementitious composite product that can function as a substitute for stone and solid surface materials, such as granite, marble, and engineered stone is provided. Furthermore methods for manufacturing the cementitious composite product using an extrudable cementitious composition that can be extruded or otherwise shaped into stone-like building products that can be used as a substitute for many known stone products is disclosed. In one embodiment, the cementitious composite products can be manufactured more cheaply to be as tough or tougher and more durable than stone and solid surface materials.

Owner:E KHASHOGGI INDS

Dry composition based on mineral binder and intended for the preparation of a hardenable wet formulation for the construction industry

ActiveUS20140371351A1Easy to getEasy to useTransportation and packagingMixing methodsBuilding productFoaming agent

Owner:PAREXGROUP SA

Incombustible composition, incombustible construction product using incombustible composition, and method of producing incombustible construction product

InactiveUS20050066859A1High hardnessHigh strengthSolid waste managementCeramicwareFiberFire retardant

Disclosed is an incombustible composition, an incombustible construction product using the incombustible composition, and a method of producing the incombustible construction product. The incombustible composition includes 1 to 80 wt % of organic or inorganic fiber, 1 to 80 wt % of fly ash or bottom ash, 1 to 80 wt % of fire-proofing agent, and 1 to 60 wt % of fire-retardant curing agent. Additionally, the method includes mixing components, constituting the incombustible composition, with each other, and shaping the incombustible composition using a roller press or an autoclave. Therefore, the incombustible composition is advantageous in that it is environmentally-friendly because it contains waste materials, and that it has excellent hardness, strength, and water resistance. Other advantages are that its production costs are relatively low, and that it has excellent incombustibility, depending on the contents of the components constituting the incombustible composition.

Owner:CHOI JUN HAN

Composite coated/encapsulated wood products and methods to produce the same

InactiveUS20050106406A1Lose weightHigh strengthRecord information storageCeramic layered productsBuilding productMaterials science

Composite coated wood products, and methods to produce such products, are described by embodiments of the invention. Composite layers may comprise polymer and fillers, such as organic fillers and inorganic fillers. The composite layers may also be foamed in some embodiments of the invention. Such composite coated wood products may be structural or non-structural pieces that may provide safe, economical, easy to manufacture construction products that may be utilized with wood composites, and other plastic composites. Such products may also promote uniformity of appearance in objects constructed with the composite coated wood products in a variety of applications.

Owner:LUMBERTEK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com