Construction products and method of making same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

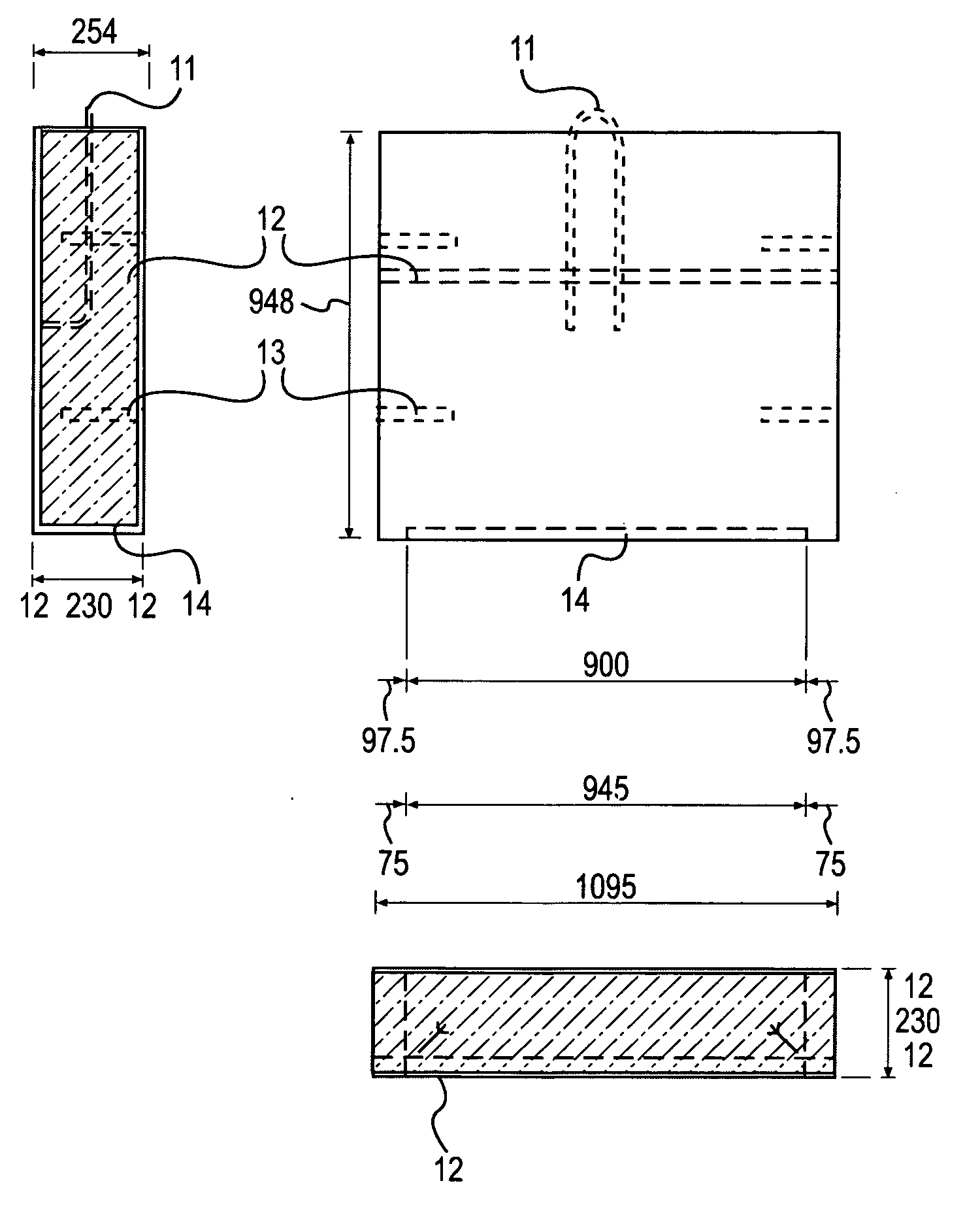

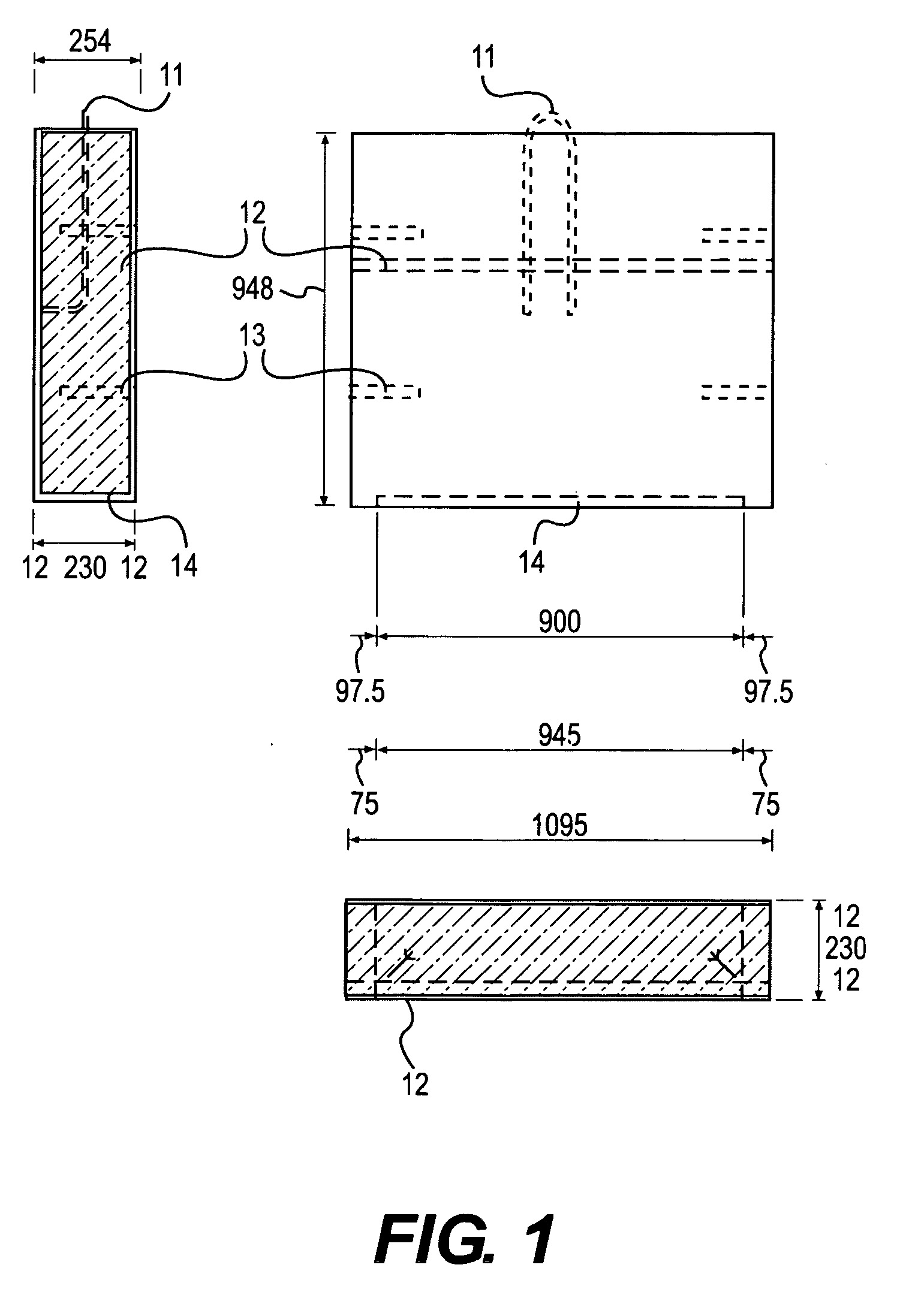

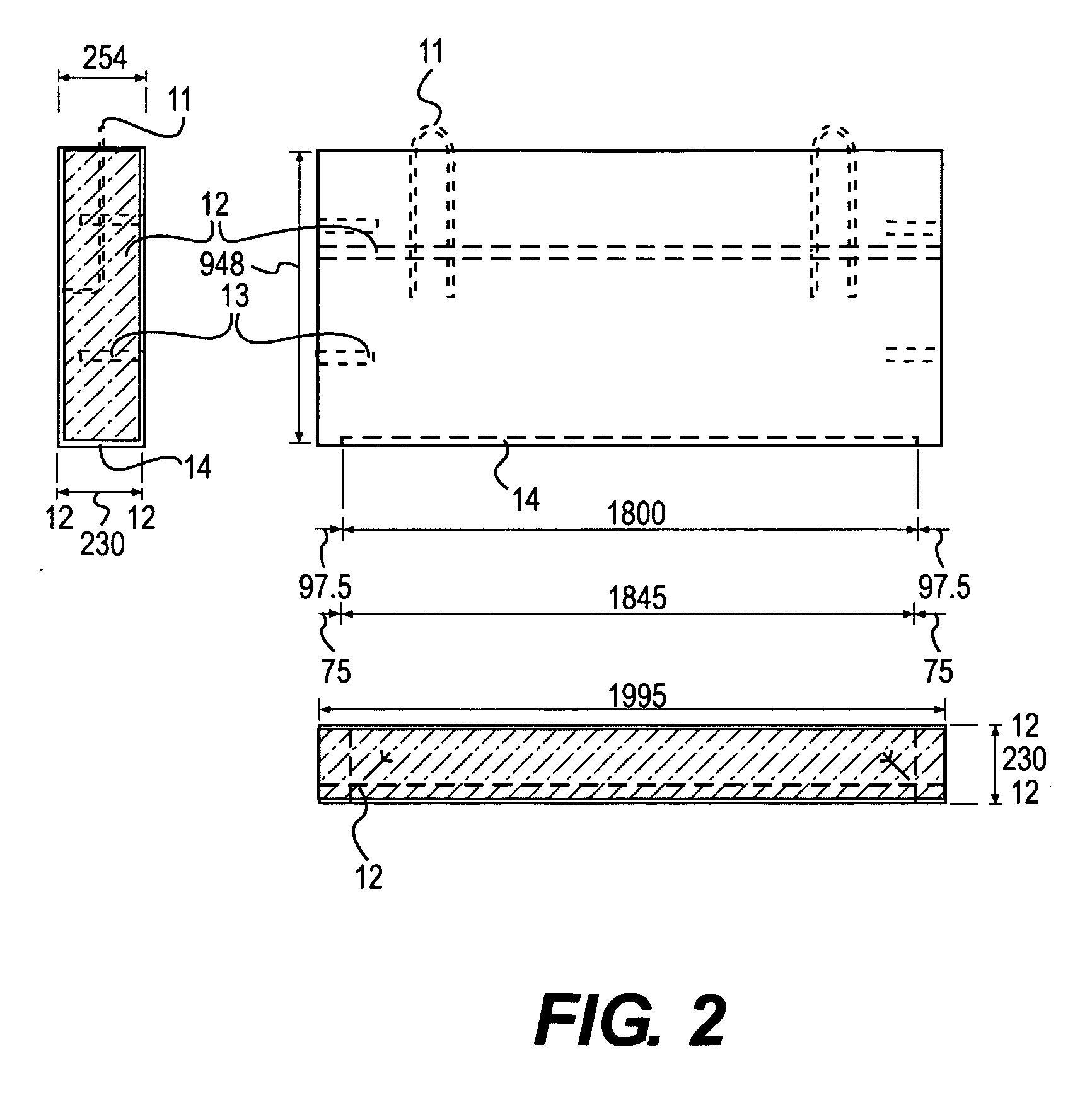

Image

Examples

example 1

Effect of Initial Moisture Content and Type of Surface Finish Layers on the Energy Performance of a Residential House with Cellular Concrete Walls.

[0114] The hygrothermal behavior of an external wall made of two cement boards and one cellular concrete in the inside was numerically simulated for the first years of building use. A state-of-the art model applied for coupled heat, air, and moisture transfer in deforming porous building materials. Climatic data for a typical meteorological year for Toronto, Canada were applied for the definition of external boundary conditions. Four different cases for finish layers—interior and exterior wall surfaces, with and without a vapor-retardant paint—were considered. Based on the simulation results, space and time-averaged values of moisture content, thermal conductivity, apparent density, and specific heat of the cellular concrete layer were calculated for each month. These averaged material properties were used for a DOE-2.1E simulation of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com