Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

307results about How to "Shorten the curing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

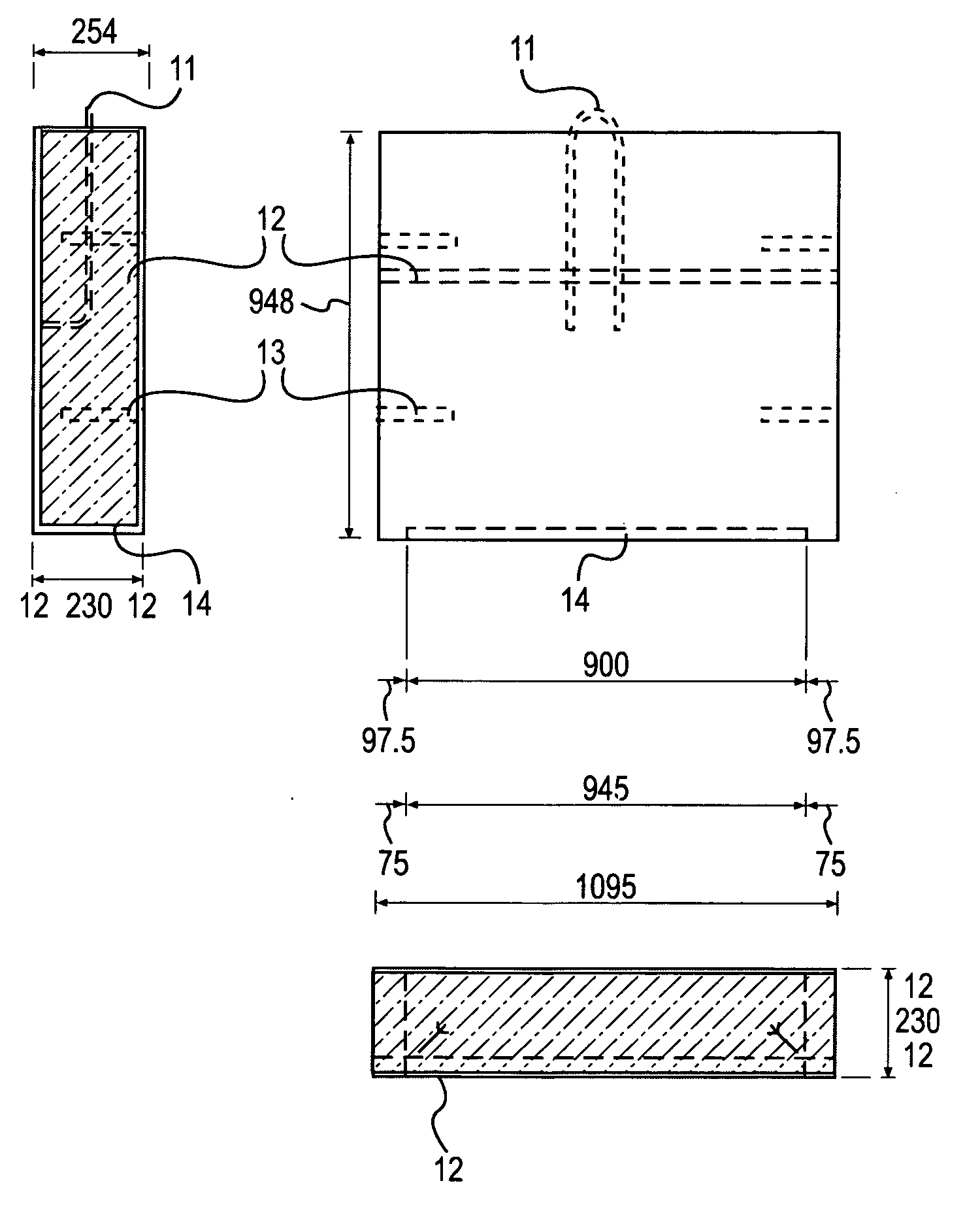

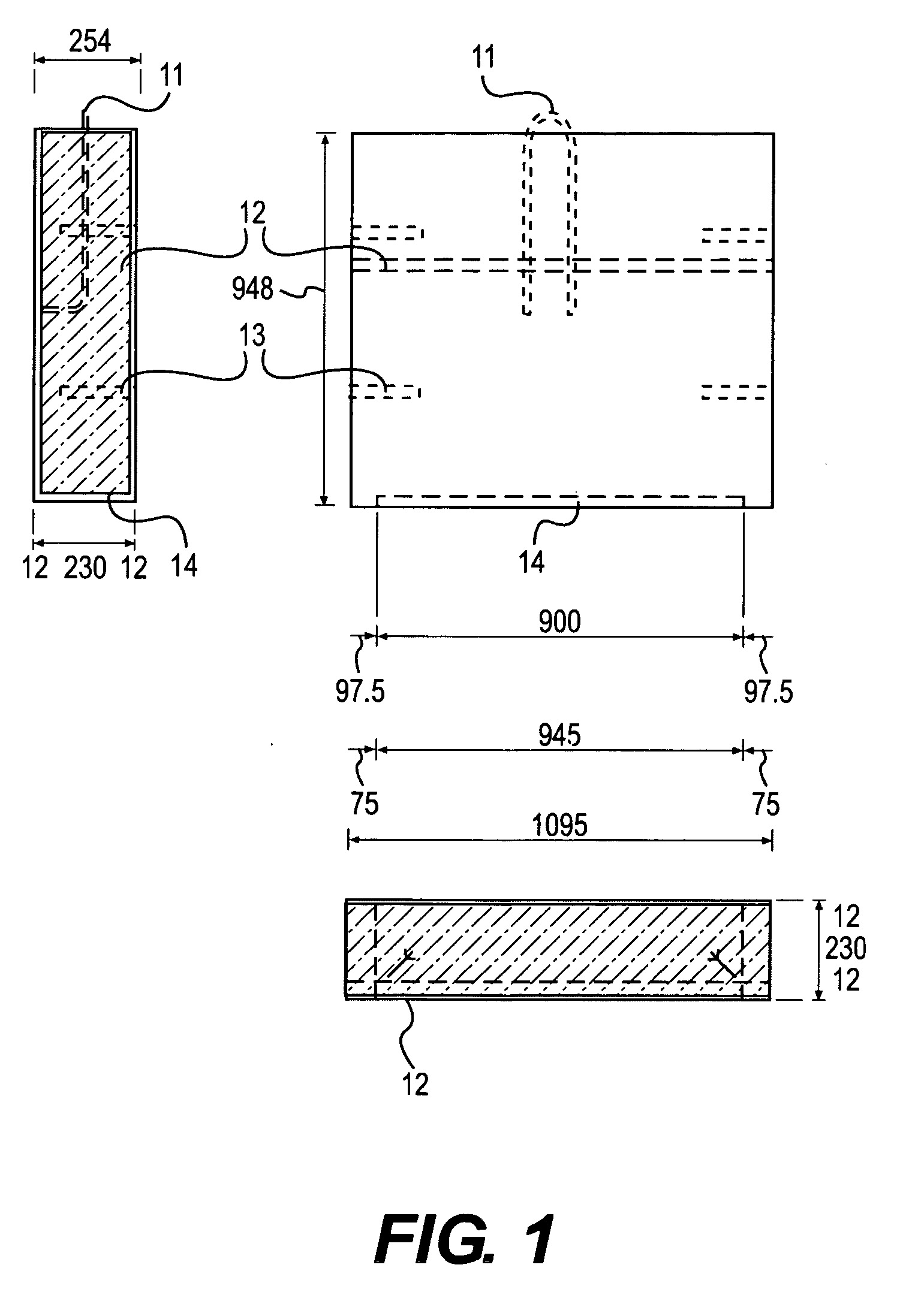

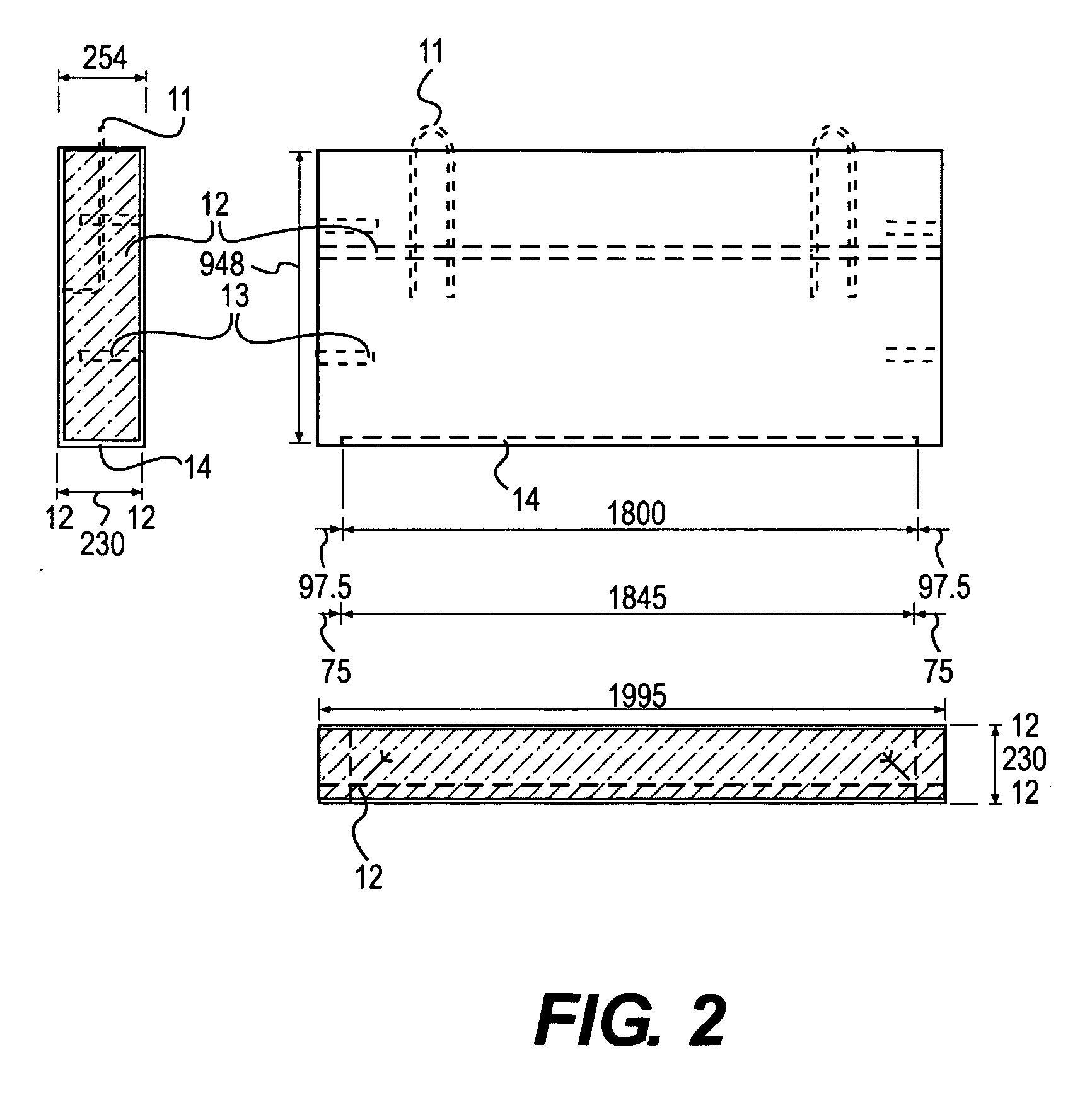

Construction products and method of making same

InactiveUS20070062143A1Eliminate needShorten construction timeSolid waste managementWallsBuilding productCement board

A highly durable and easy to use prefabricated construction product is disclosed having a cellular concrete component sandwiched between two cement boards, wherein the cellular concrete component comprises cement, fly ash, an activating agent and water, and the cement boards comprise cement, fly ash, an activating agent, sand, silica fume, a water reducer agent, a reinforcing fiber, and water.

Owner:NOUSHAD RAFIE LOTFI

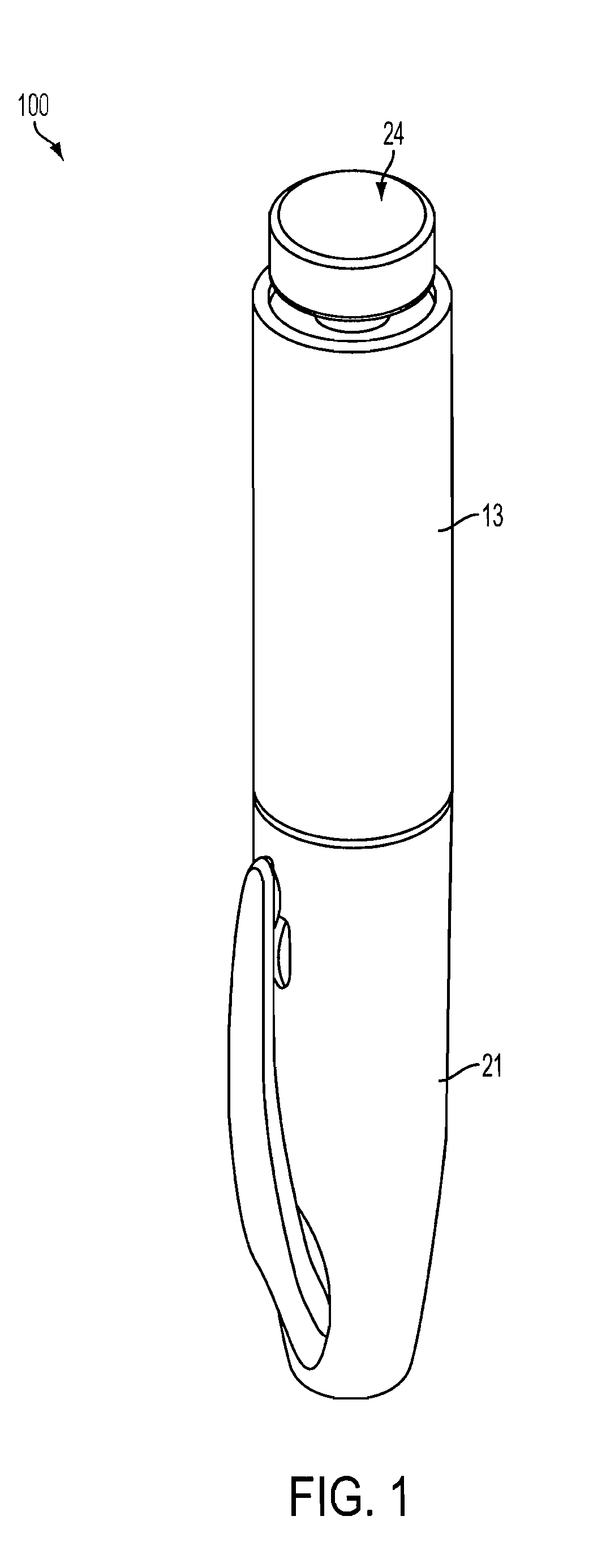

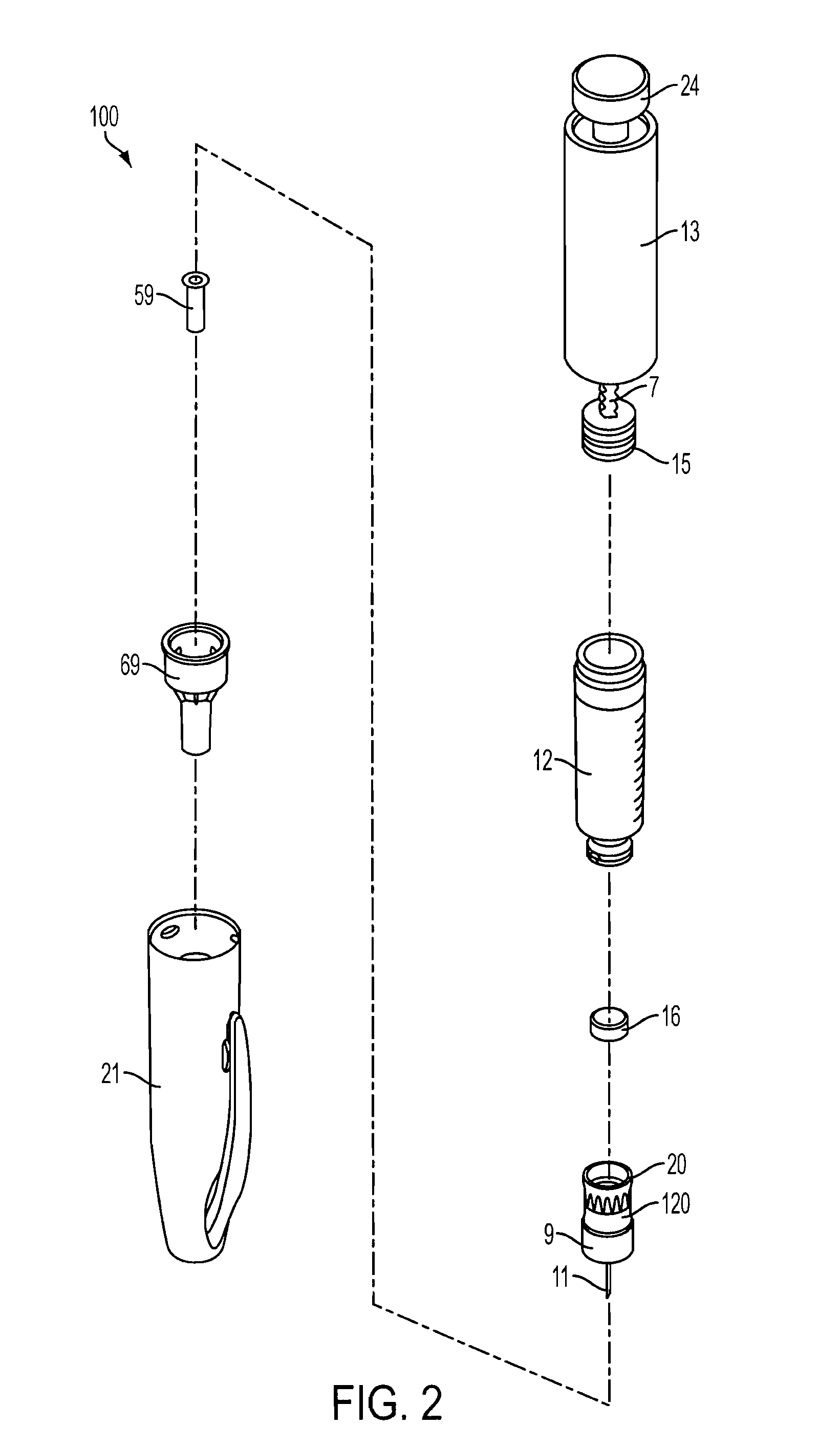

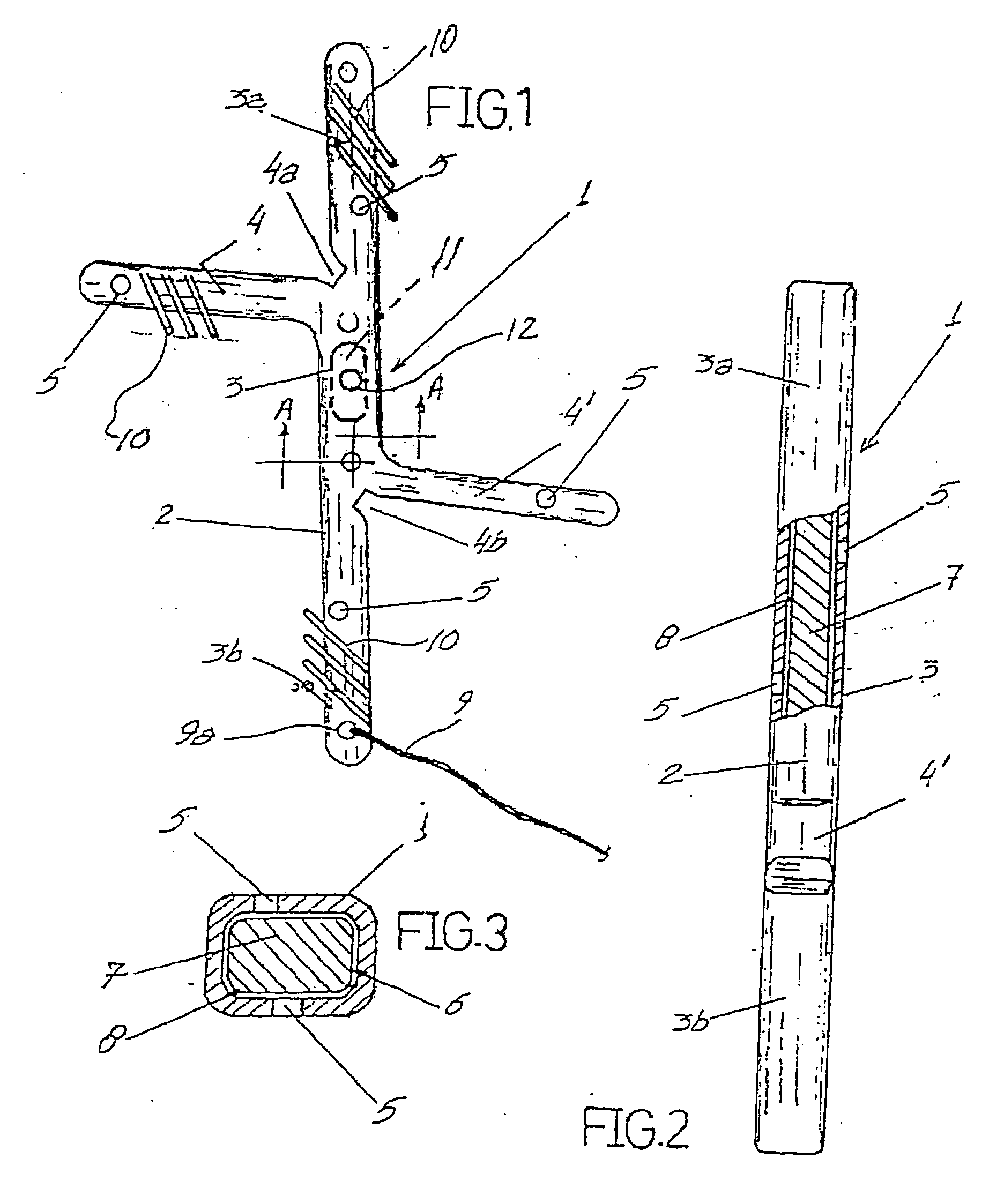

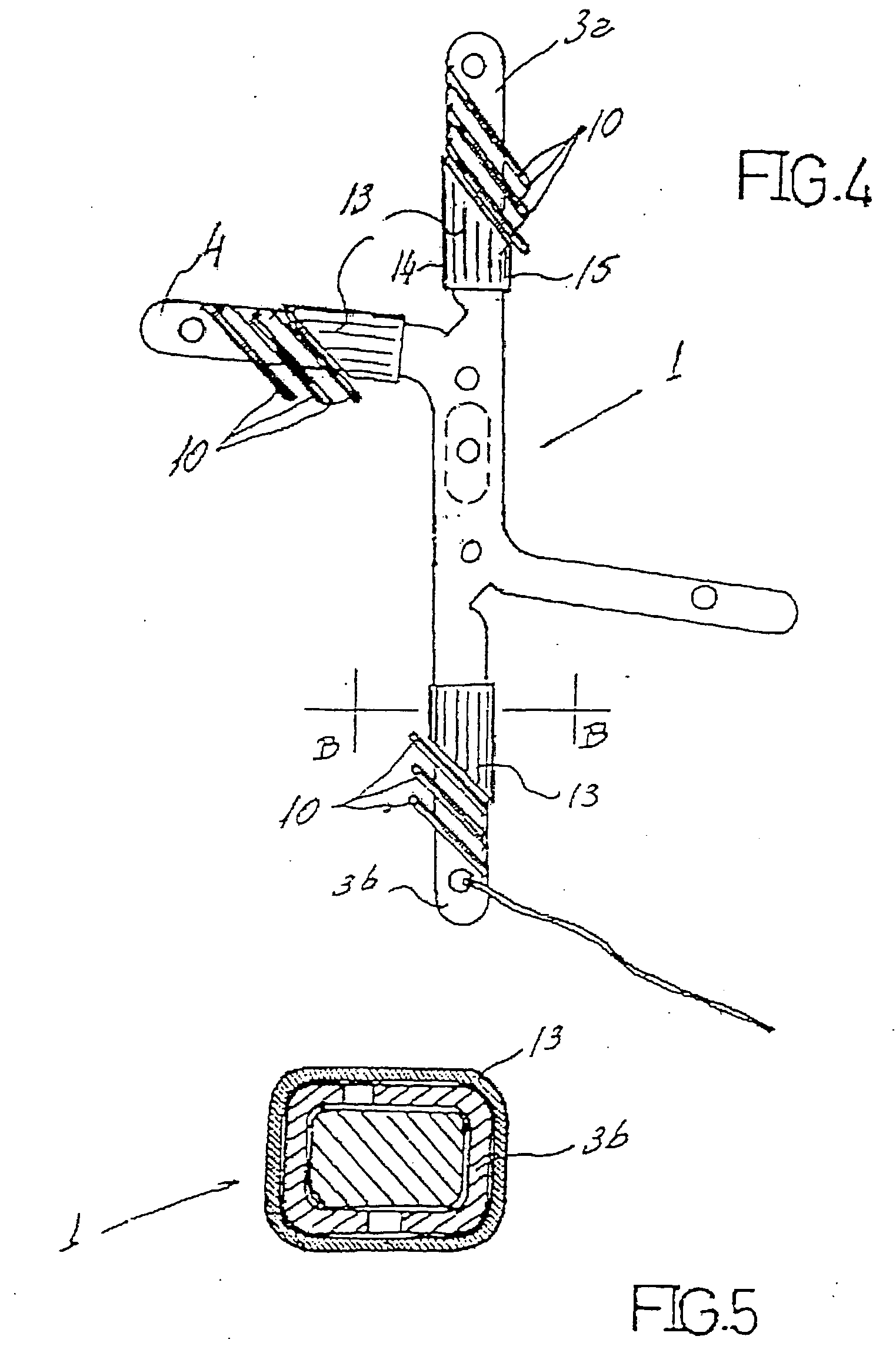

Pen Needle Hub Having Increased Contact Area

ActiveUS20090069755A1Improve comfortIncrease surface areaInfusion syringesInfusion needlesSkin contactUltimate tensile strength

A pen needle assembly having a hub with an increased surface area that contacts a patient's skin is provided. The increased contact area of the hub with the patient's skin during injection of a cannula decreases the pressure exerted against the patient's skin, thereby increasing the comfort of the patient. A bonding adhesive is disposed on an outer surface of the hub, thereby decreasing the required curing time of the adhesive. Additionally, the increased contact area, between the cannula adhesive and hub increases the strength of the bond therebetween.

Owner:EMBECTA CORP

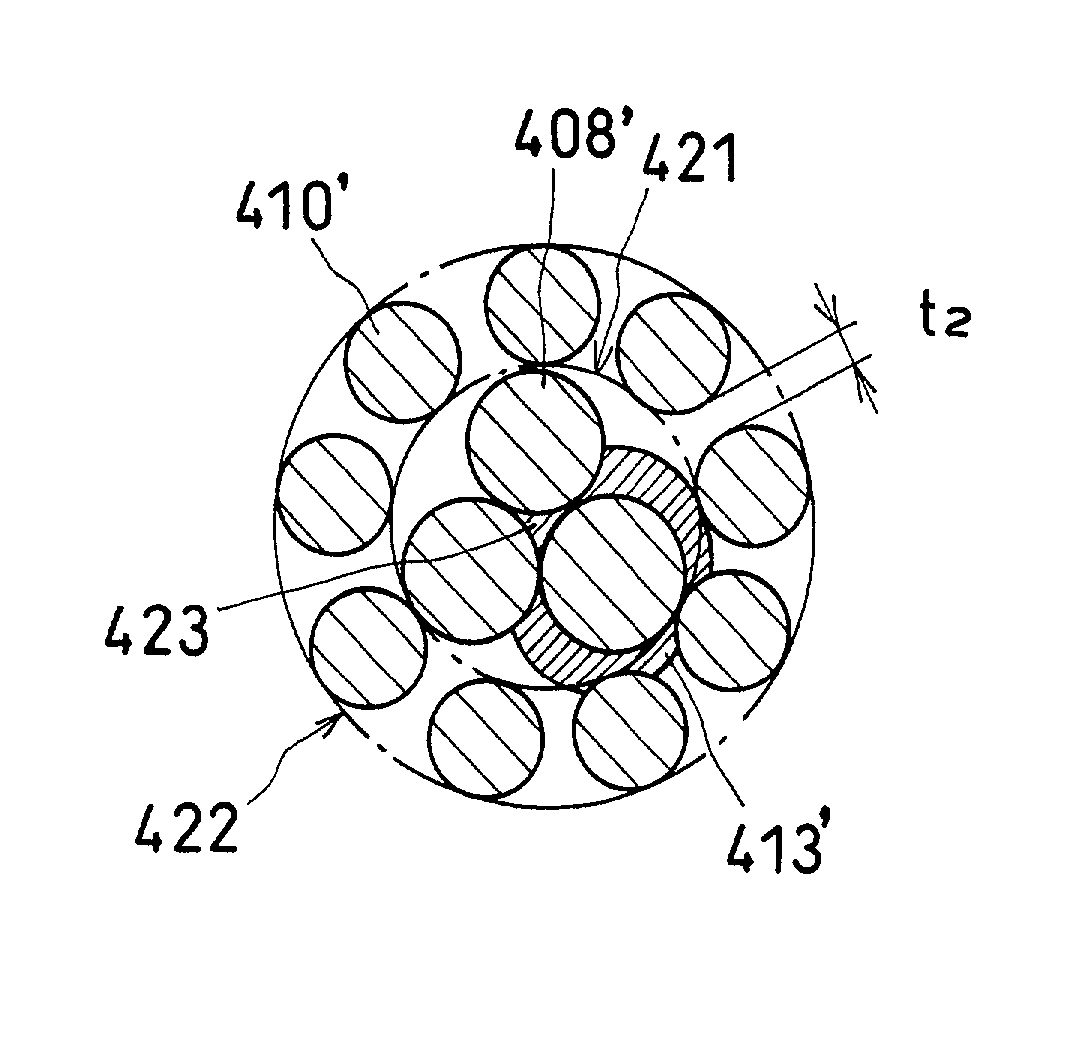

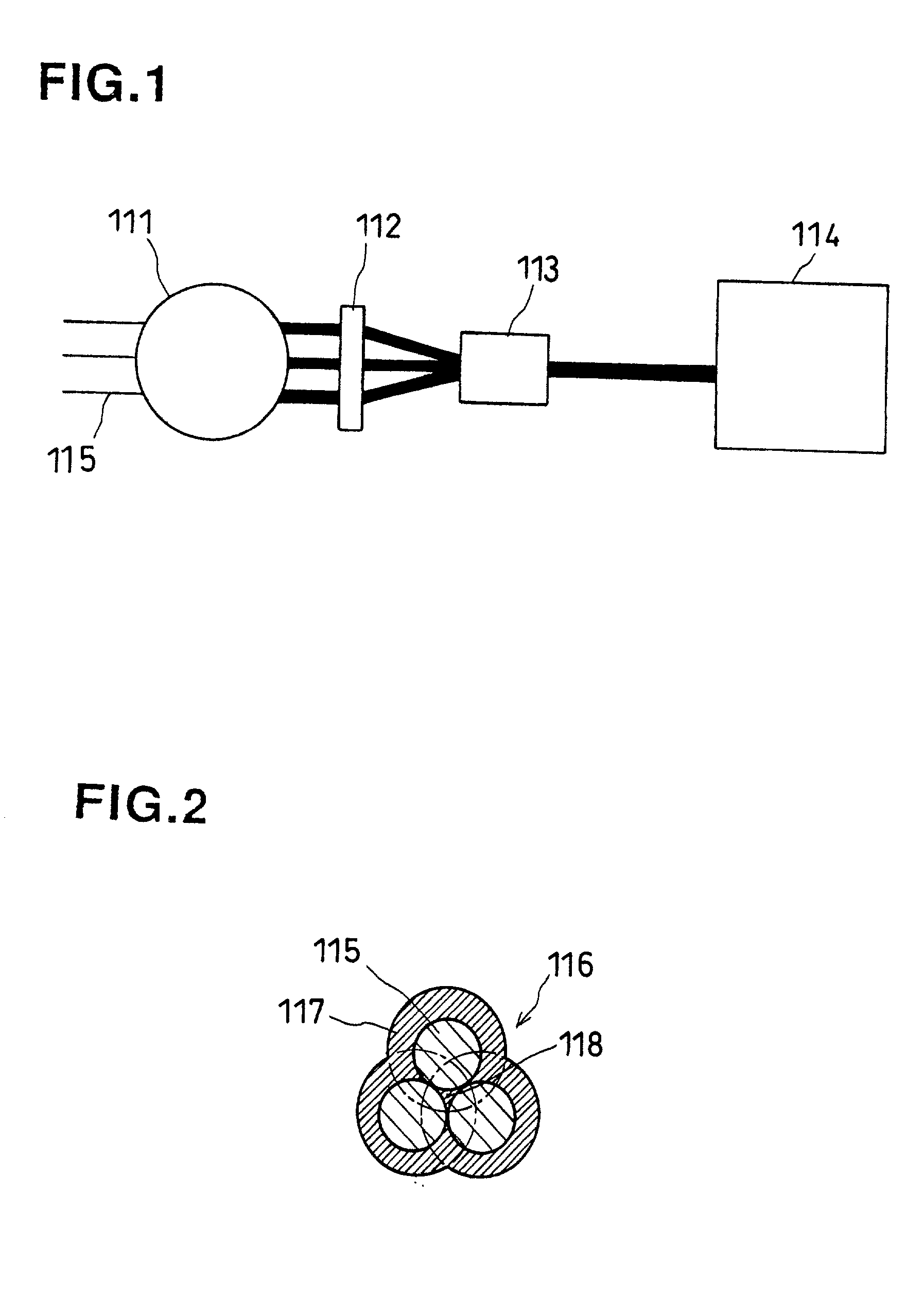

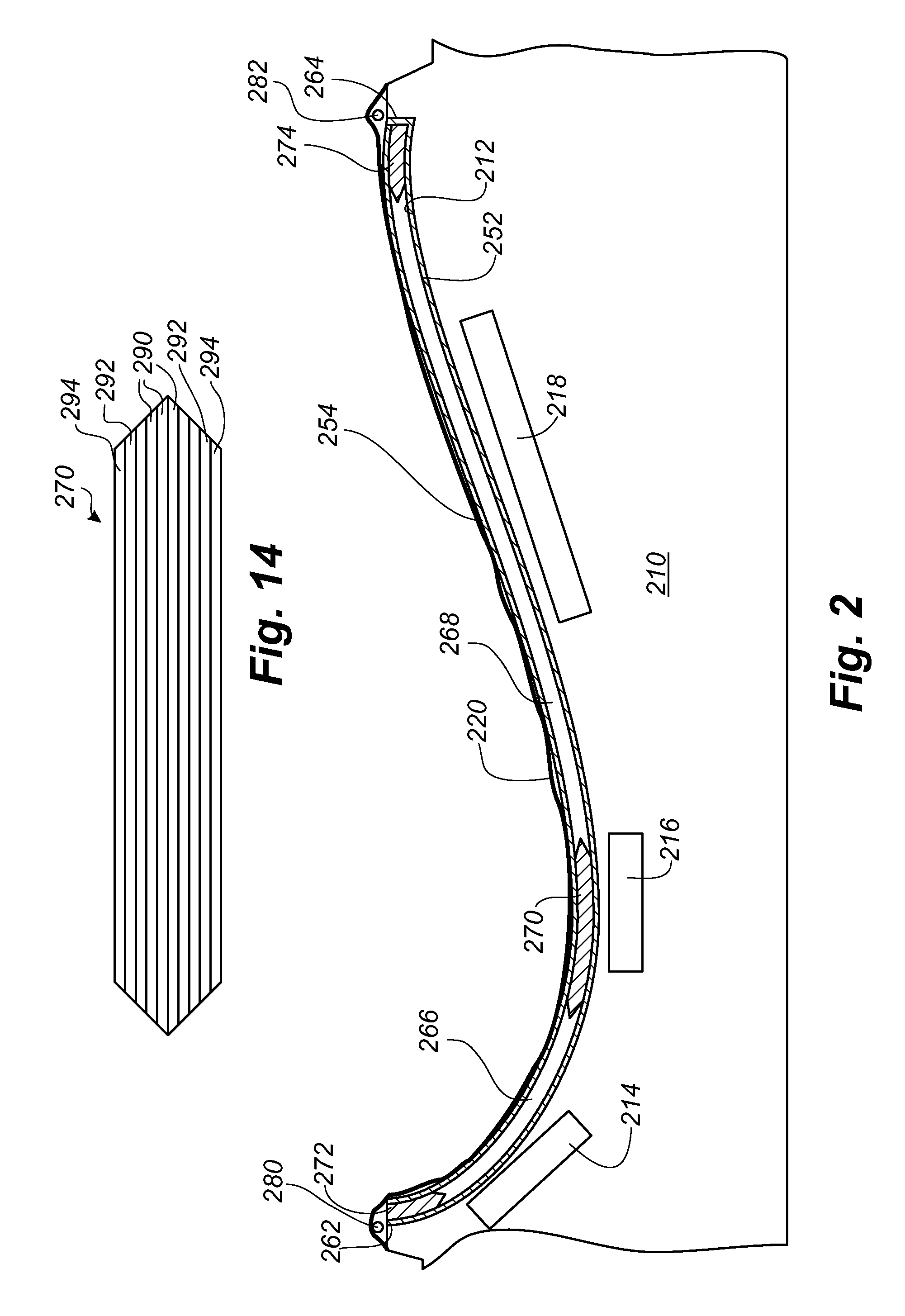

Elastomer and steel cord composite and process for producing the same

InactiveUS20020160213A1Reduce componentsSave energyPneumatic tyre reinforcementsRope making machinesElastomerMaterials science

In order that spaces, including a space in the central portion, inside a steel cord used as a reinforcement by being embedded in a tire or the like are filled with an uncured rubber, the uncured rubber is coated on plural steel filaments 115 which are then stranded in case of a single layer steel cord, the uncured rubber is coated on all of plural core filaments 329 which are then stranded along with outer layer filaments 330 in the same direction at the same pitch in case of a 2-layer steel cord of 1 stranding process, and the uncured rubber is coated on all or 2 to 4 core filaments 218 or on at least one of 3 or 4 steel filaments 408, 408' to form a core strand and outer layer filaments 410, 410' are stranded therearound in case of 2-layer steel cord of 2 stranding process. Consequently, it is possible to exhibit satisfactory corrosion resistance and satisfactory fatigue resistance as a steel cord, shorten a curing time in tire component assembling or the like to attain energy saving and prolong the life of a steel cord itself and the life of a tire or the like using the same as a reinforcement. Further, production can be performed at low cost.

Owner:YOKOHAMA RUBBER CO LTD +1

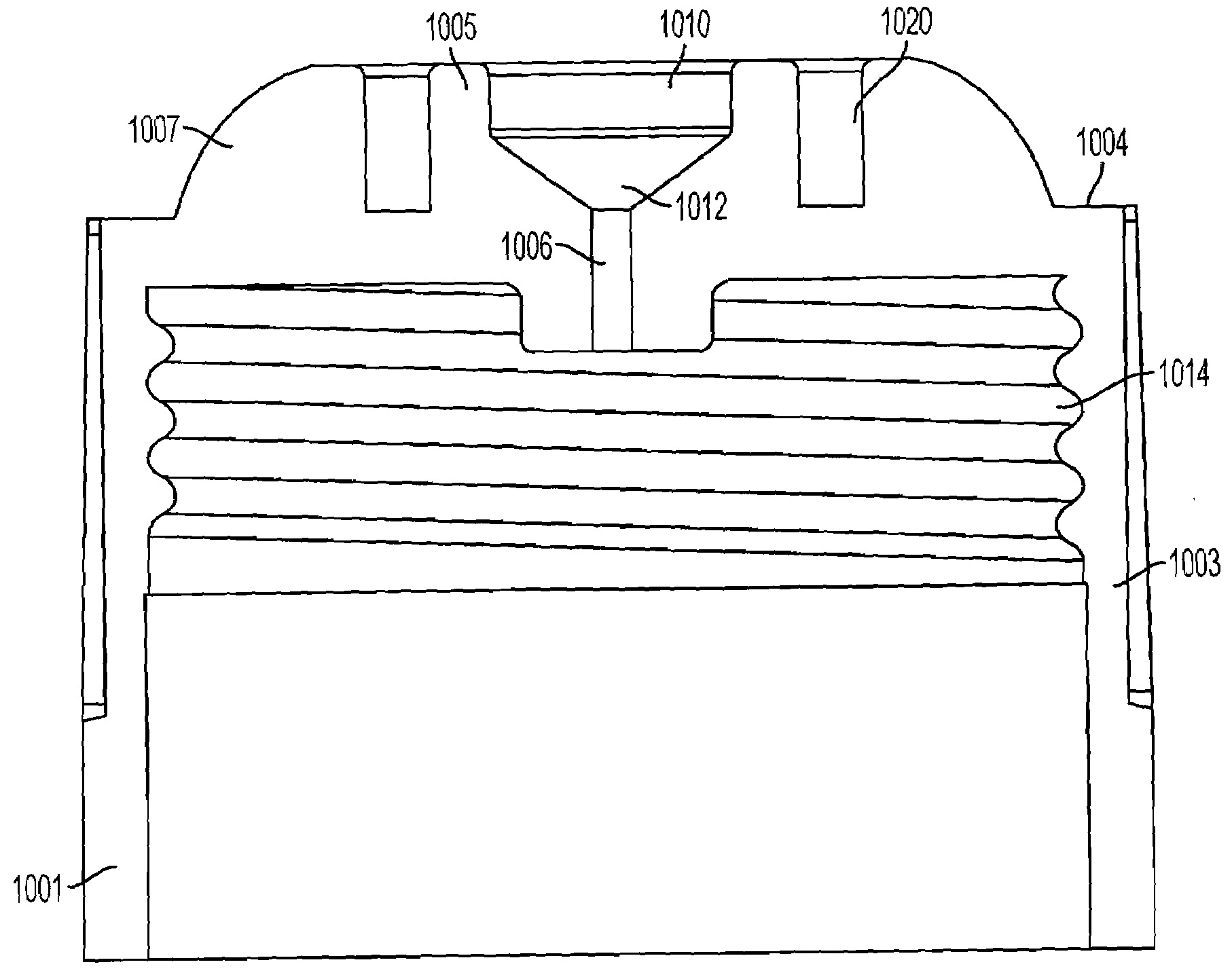

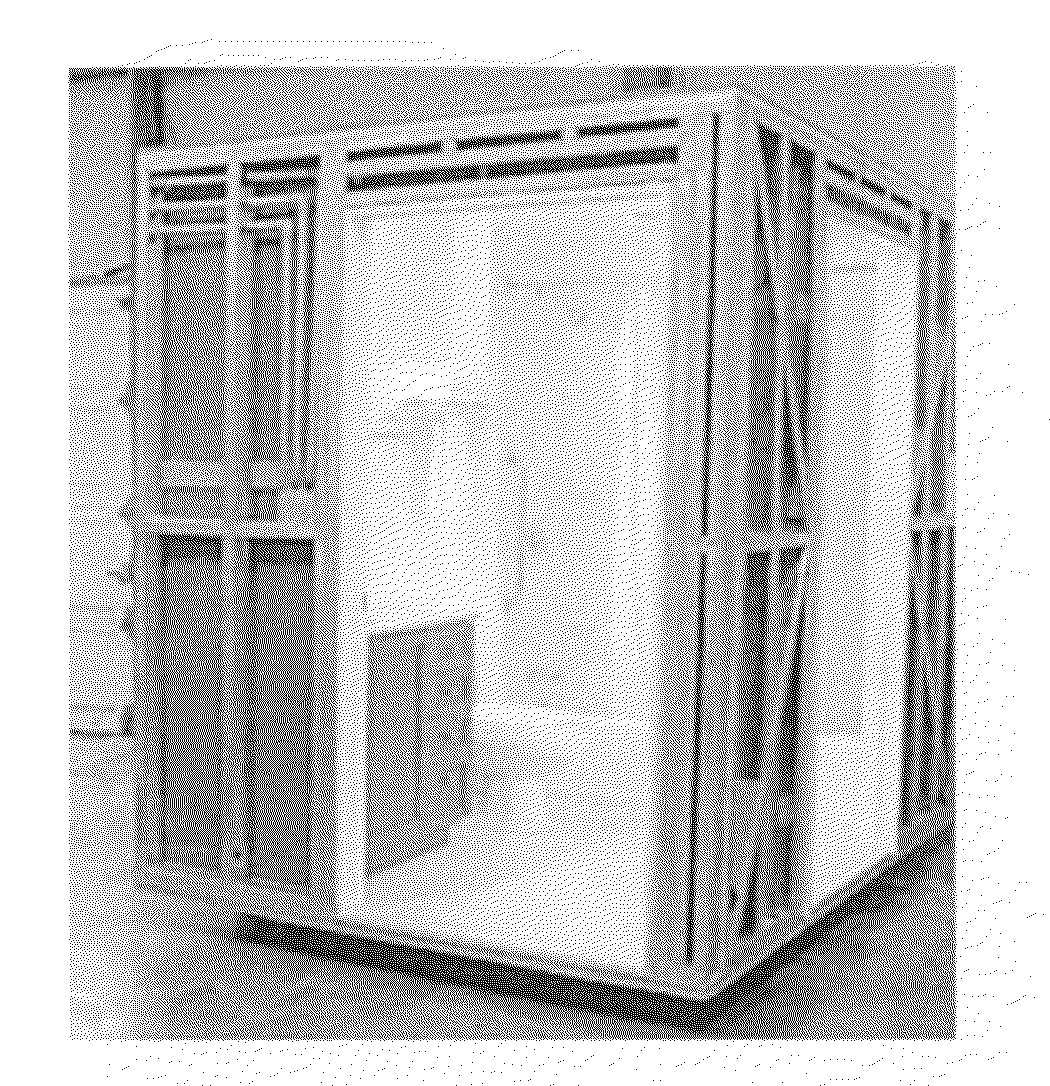

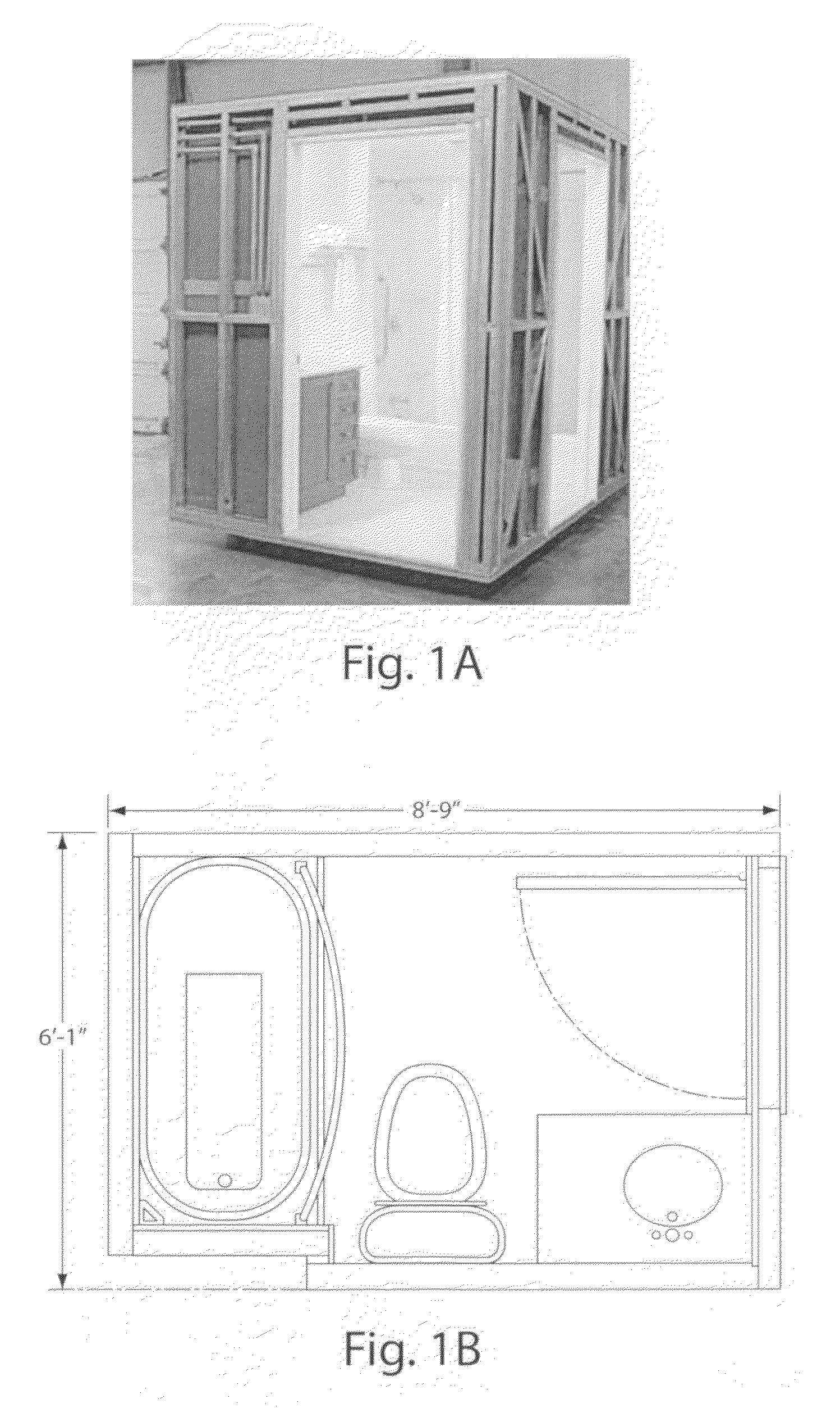

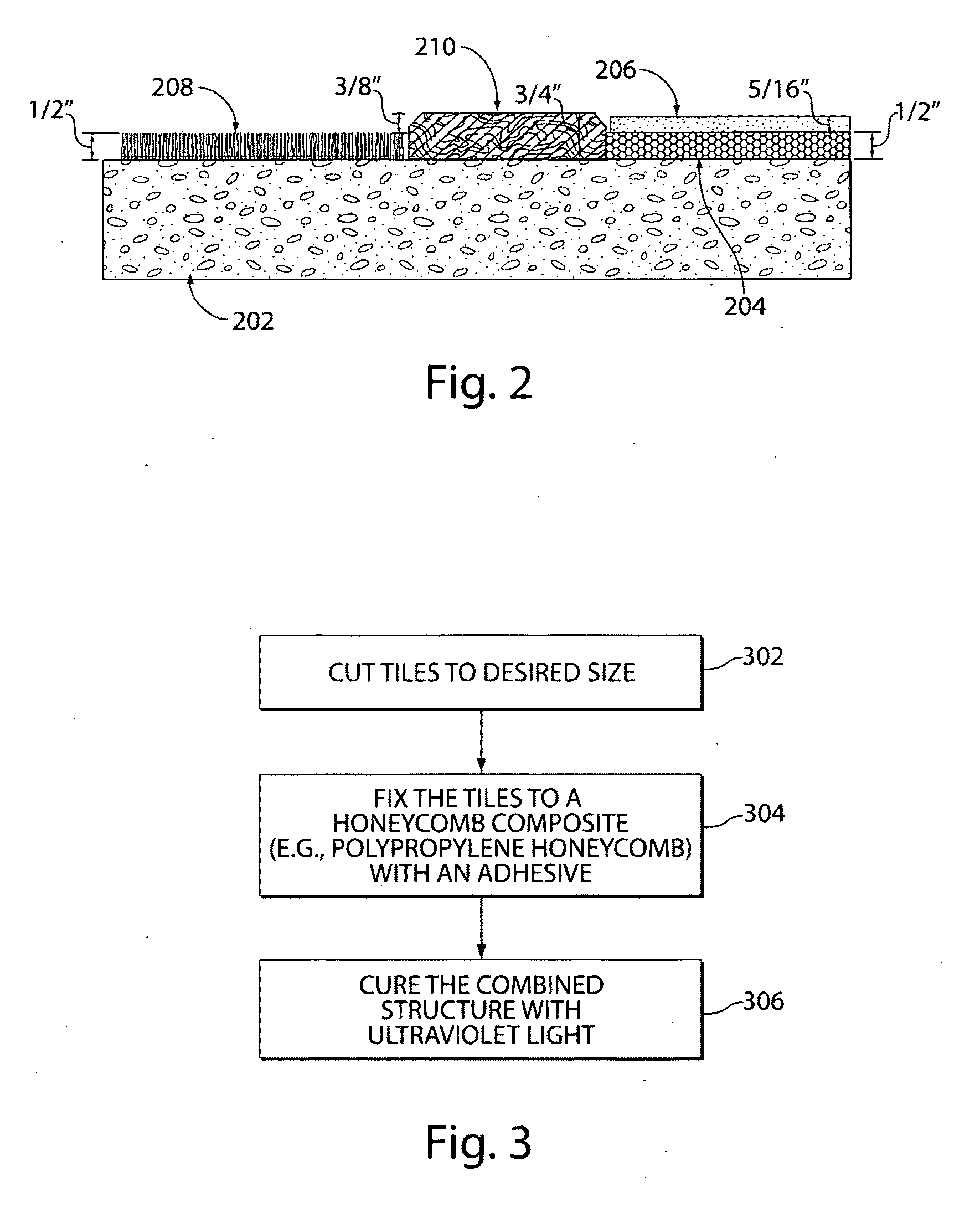

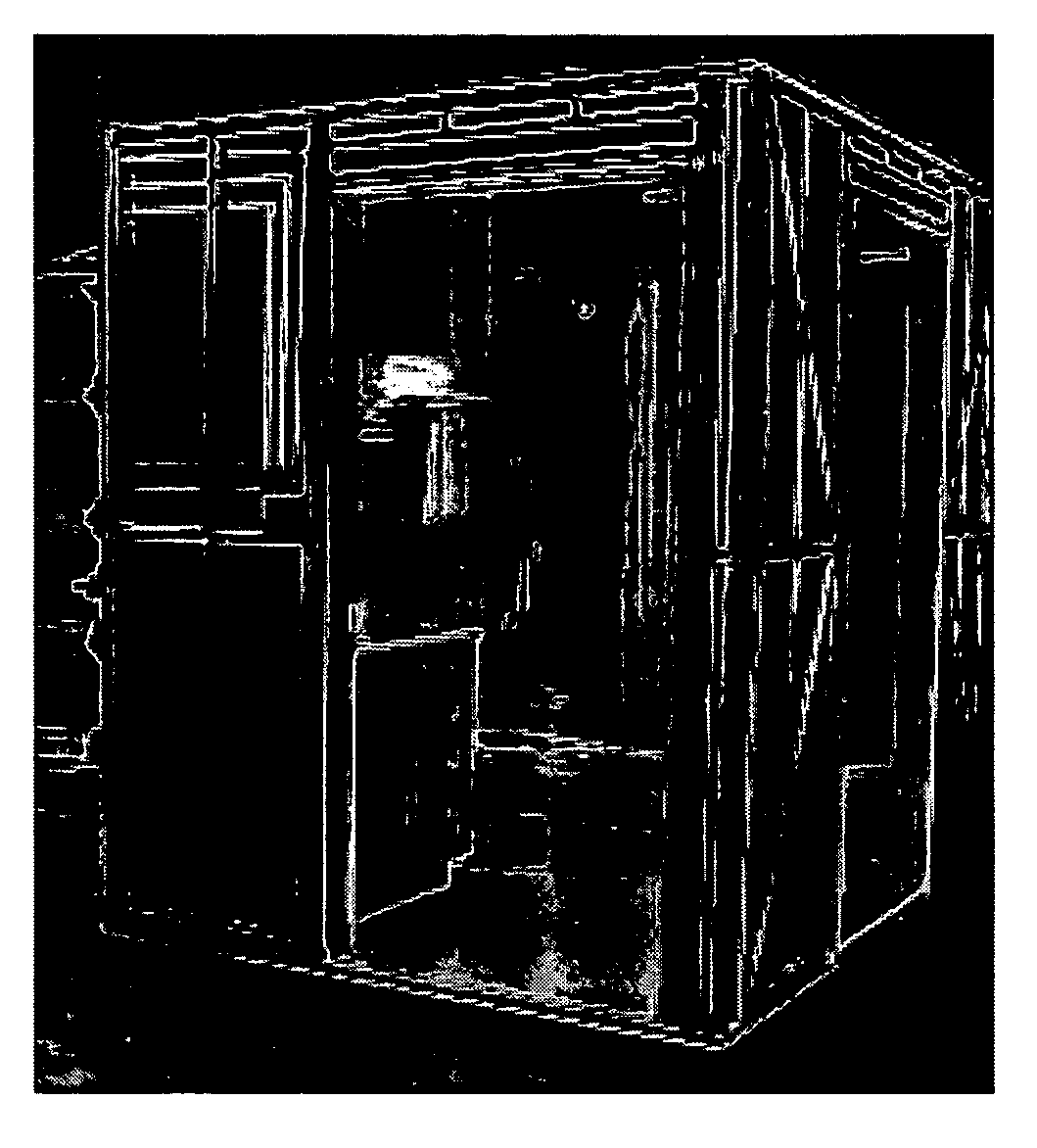

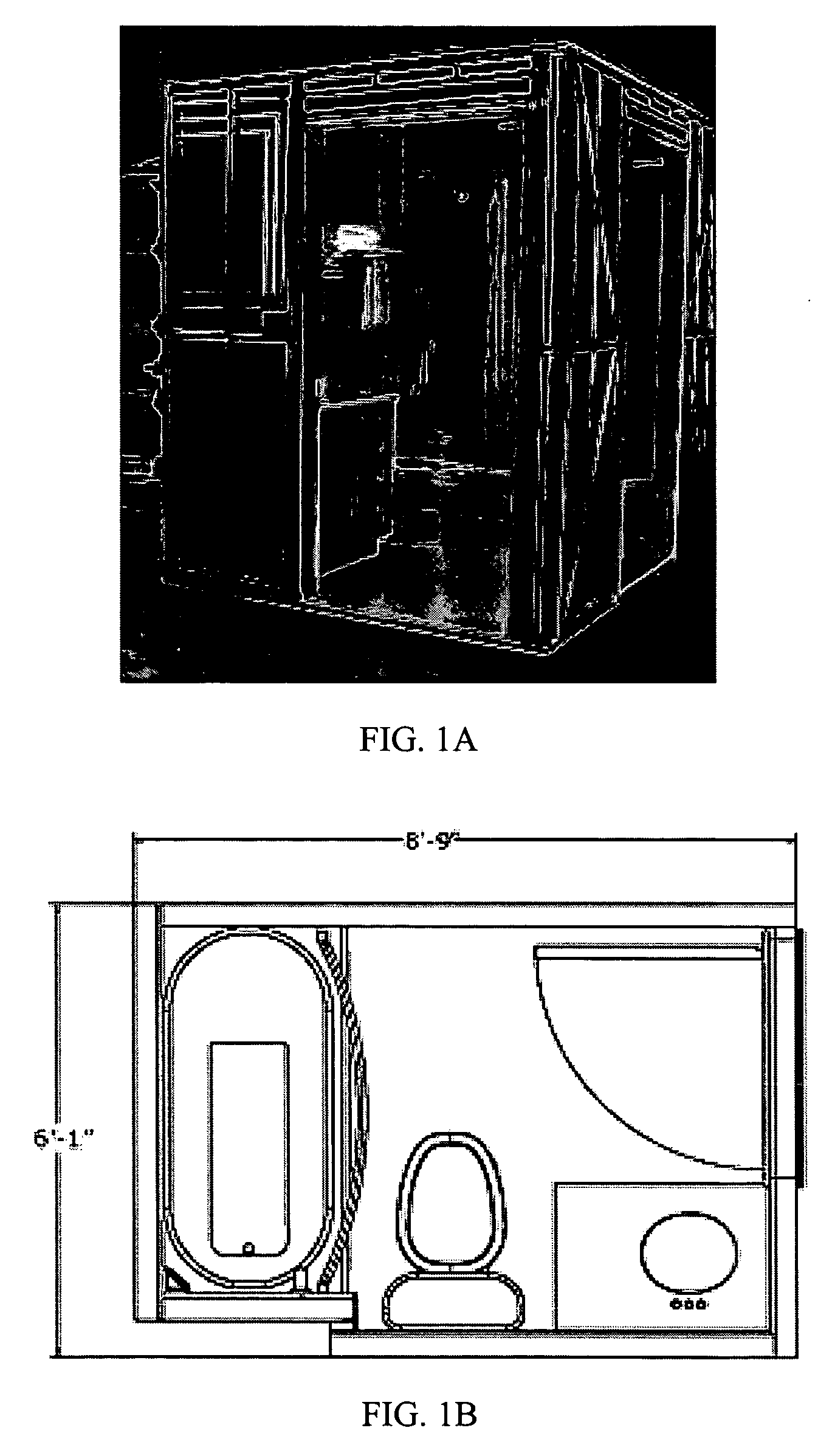

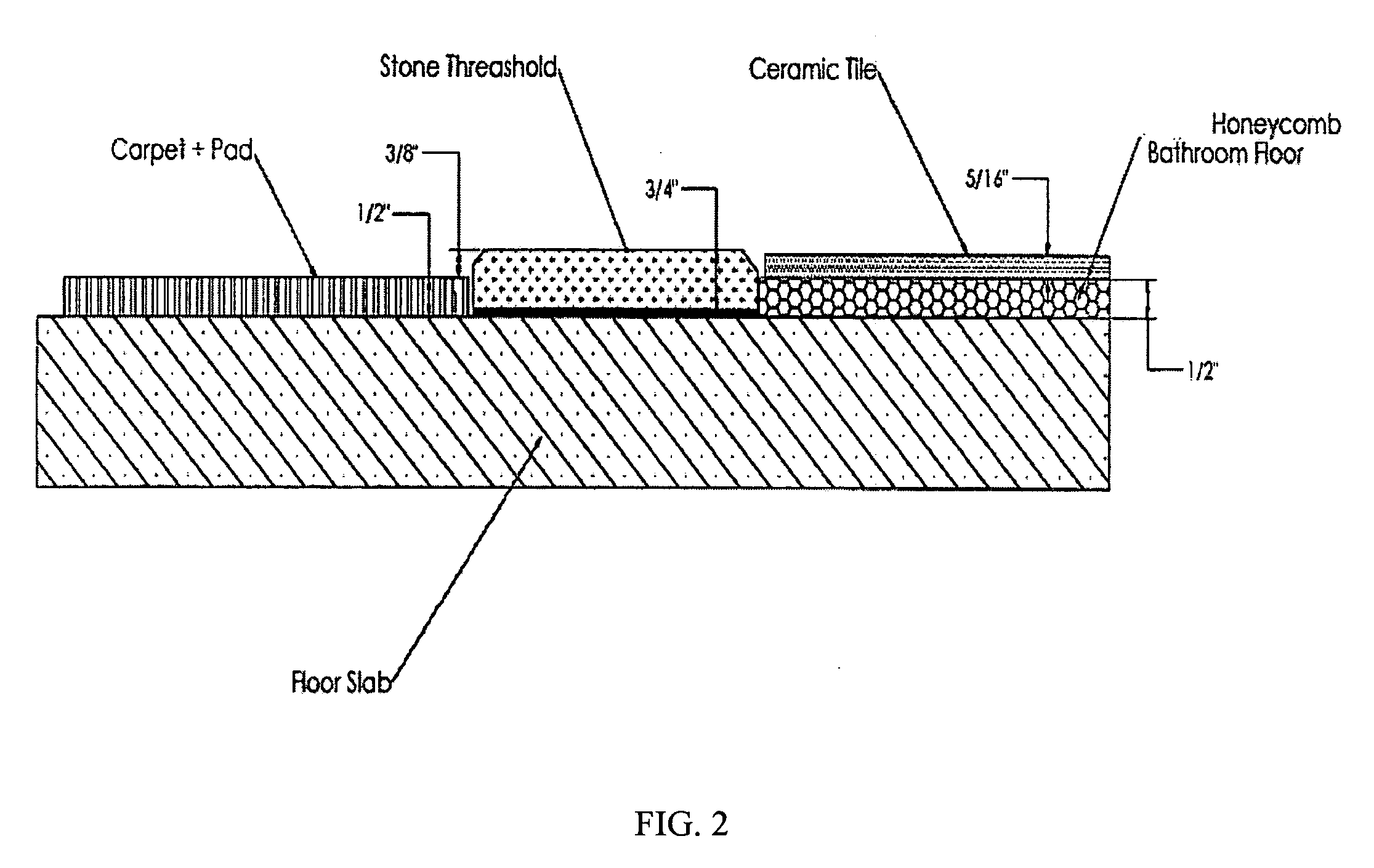

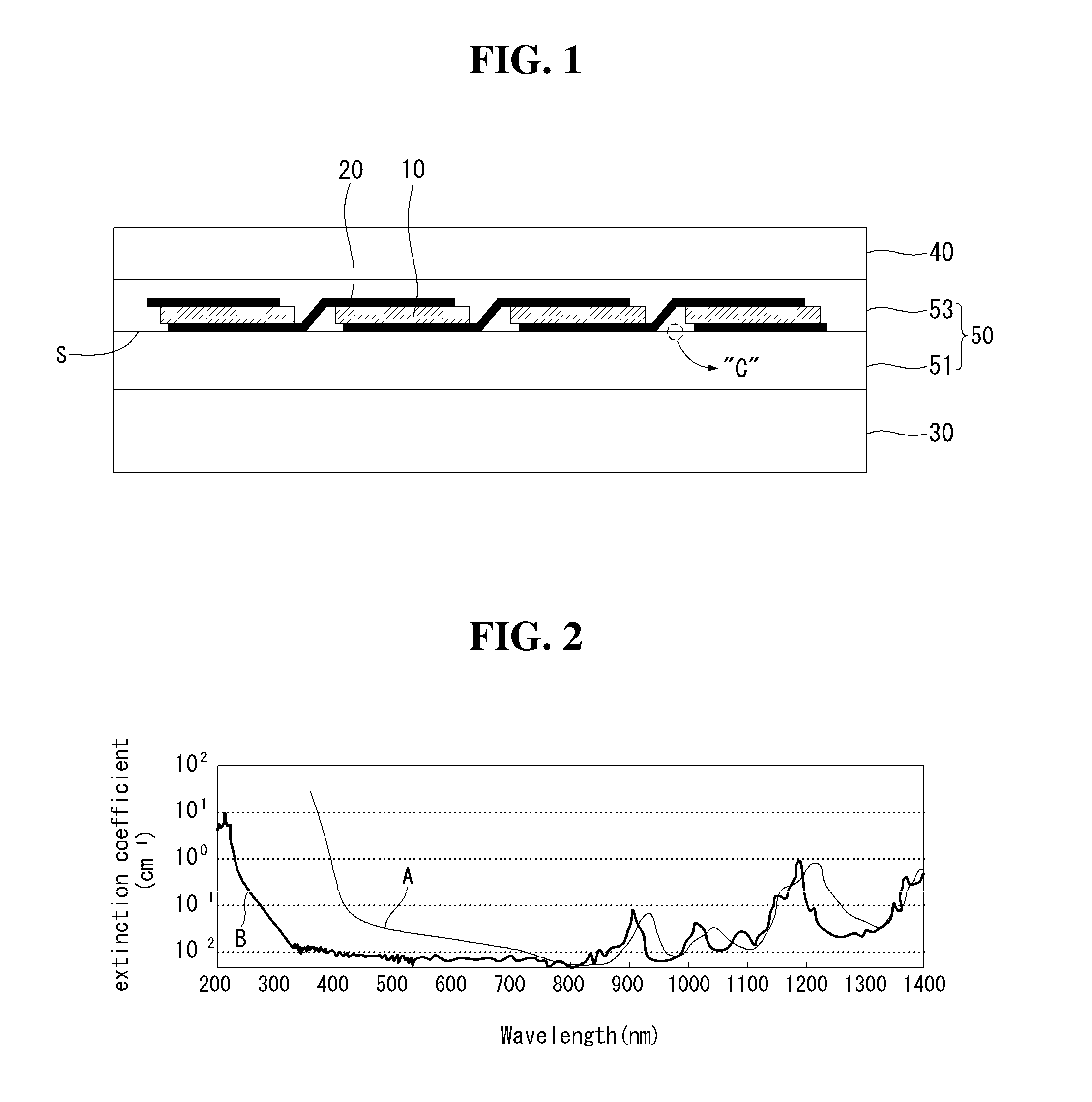

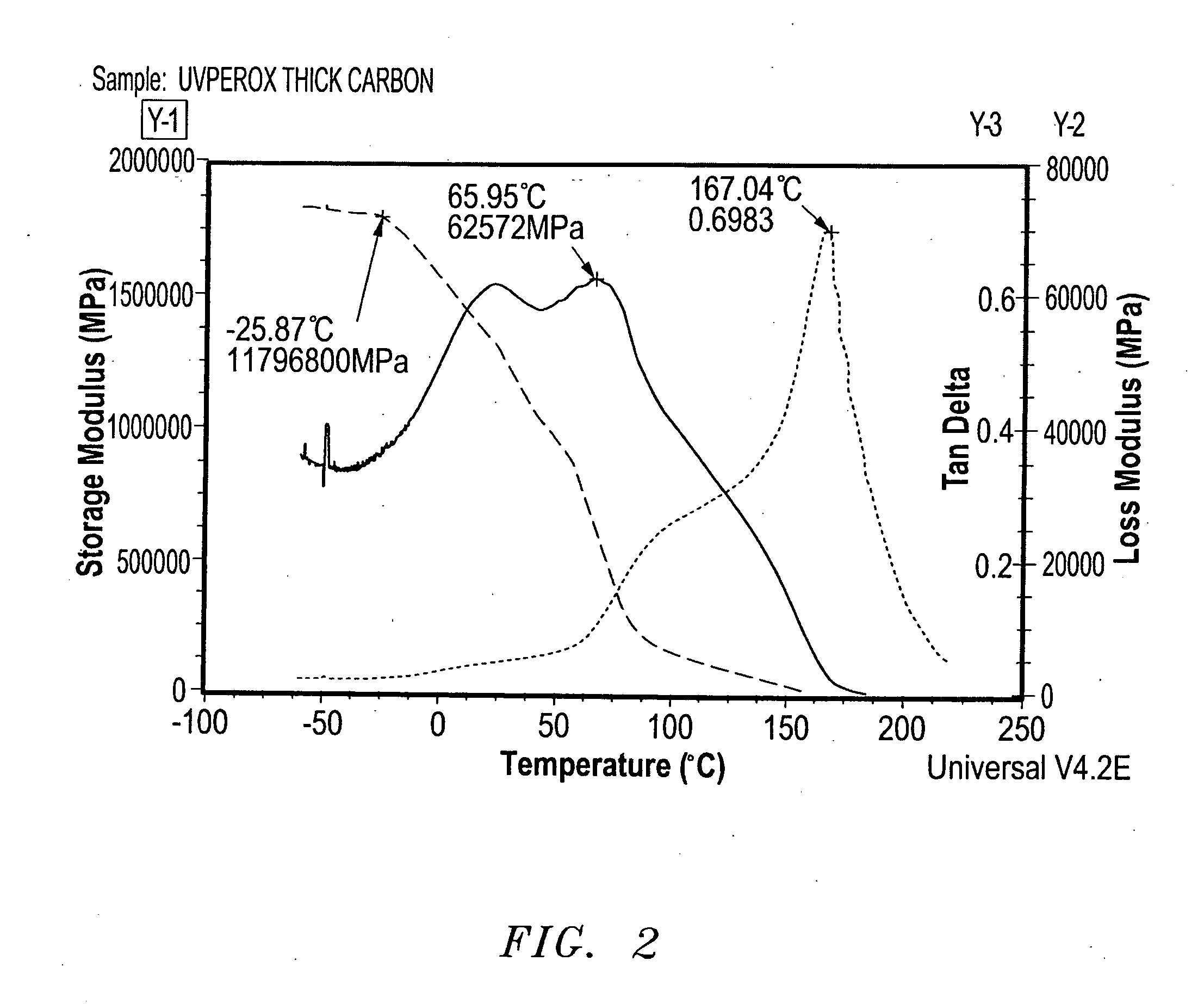

Prefabricated bathroom assembly and methods of its manufacture and installation

InactiveUS20090100769A1Maximal aesthetic qualityMaximum comfortBathsDouchesEngineeringPrefabrication

A prefabricated bathroom assembly and methods for its manufacture and installation are disclosed. For example, a prefabricated tub and / or shower assembly may be provided. In some embodiments, the prefabricated assembly may include at least a bathtub or a shower pan, tile surround(s), and a ceiling. The prefabricated assembly may be constructed substantially entirely off-site relative to a construction site and shipped to the construction site, for example, in substantially a single piece. Finishing face trim for making a seamless transition from the prefabricated assembly to the adjoining walls and ceiling may also be provided. In other embodiments, at least partially prefabricated panels (e.g., 3 wall panels and 1 ceiling panel), a tub or shower pan, the face trim, and / or other components may be shipped separately to the construction site for on-site assembly.

Owner:EGGROCK

Binder for mineral wool products

Owner:ROCKWOOL INT AS

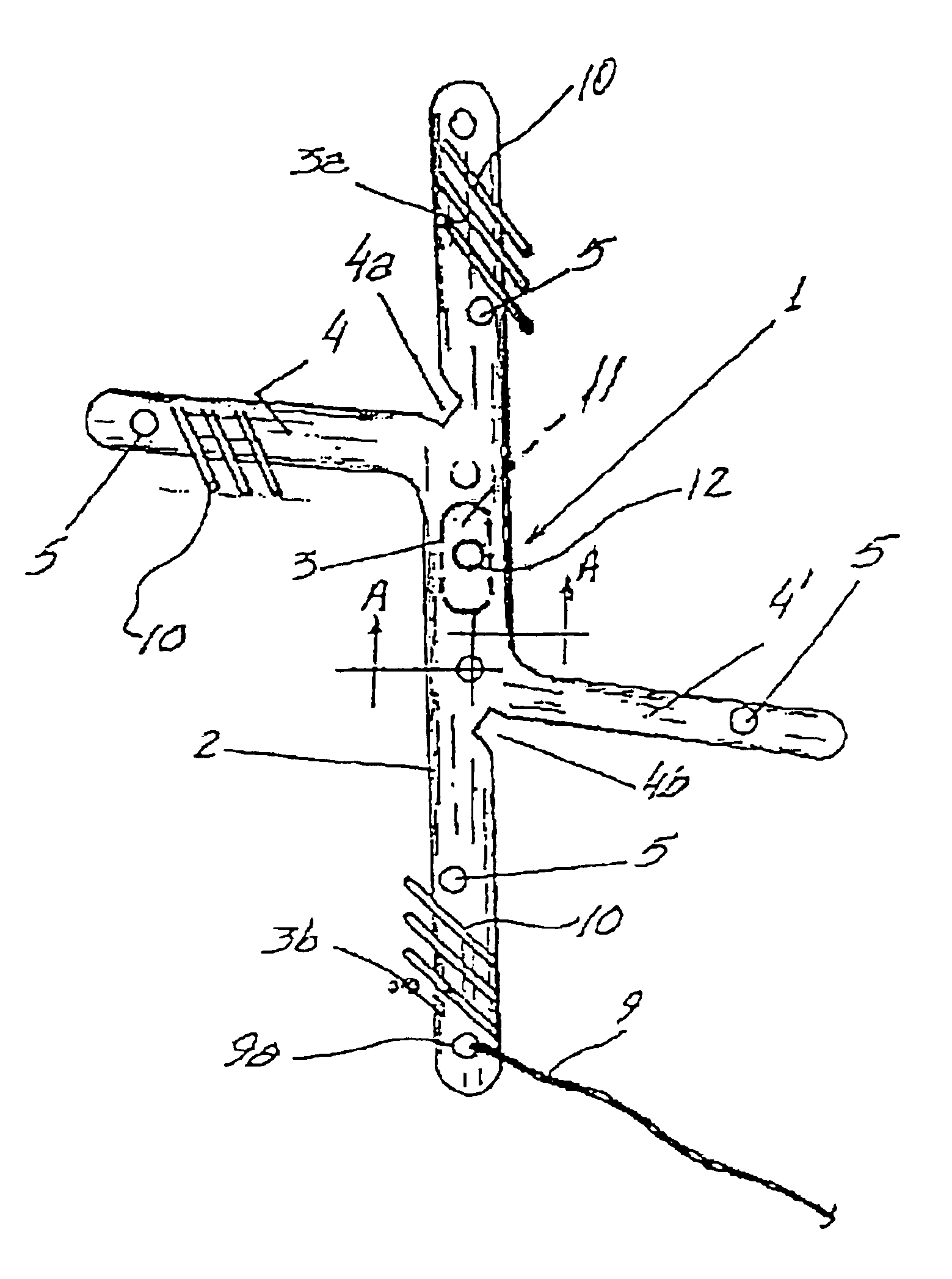

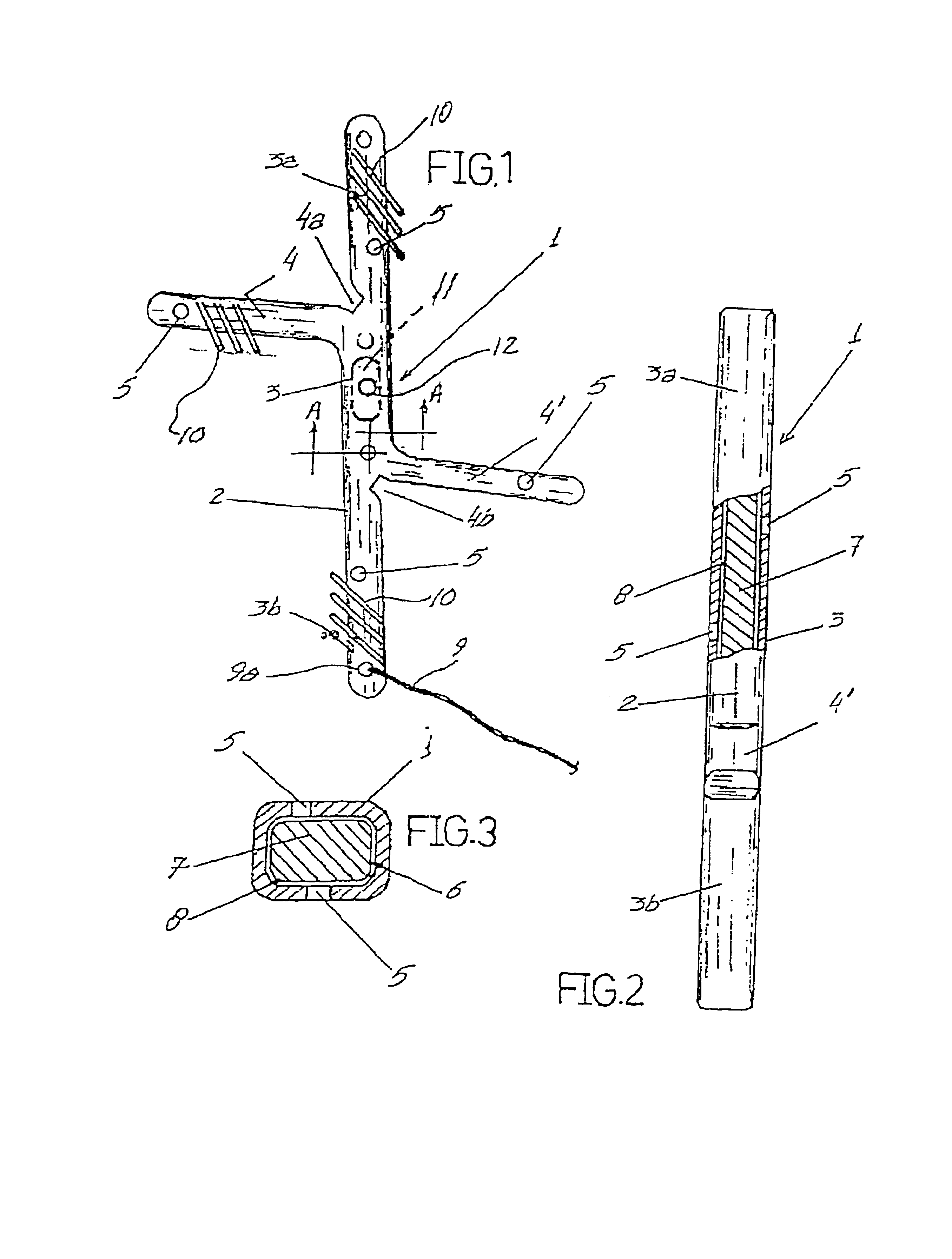

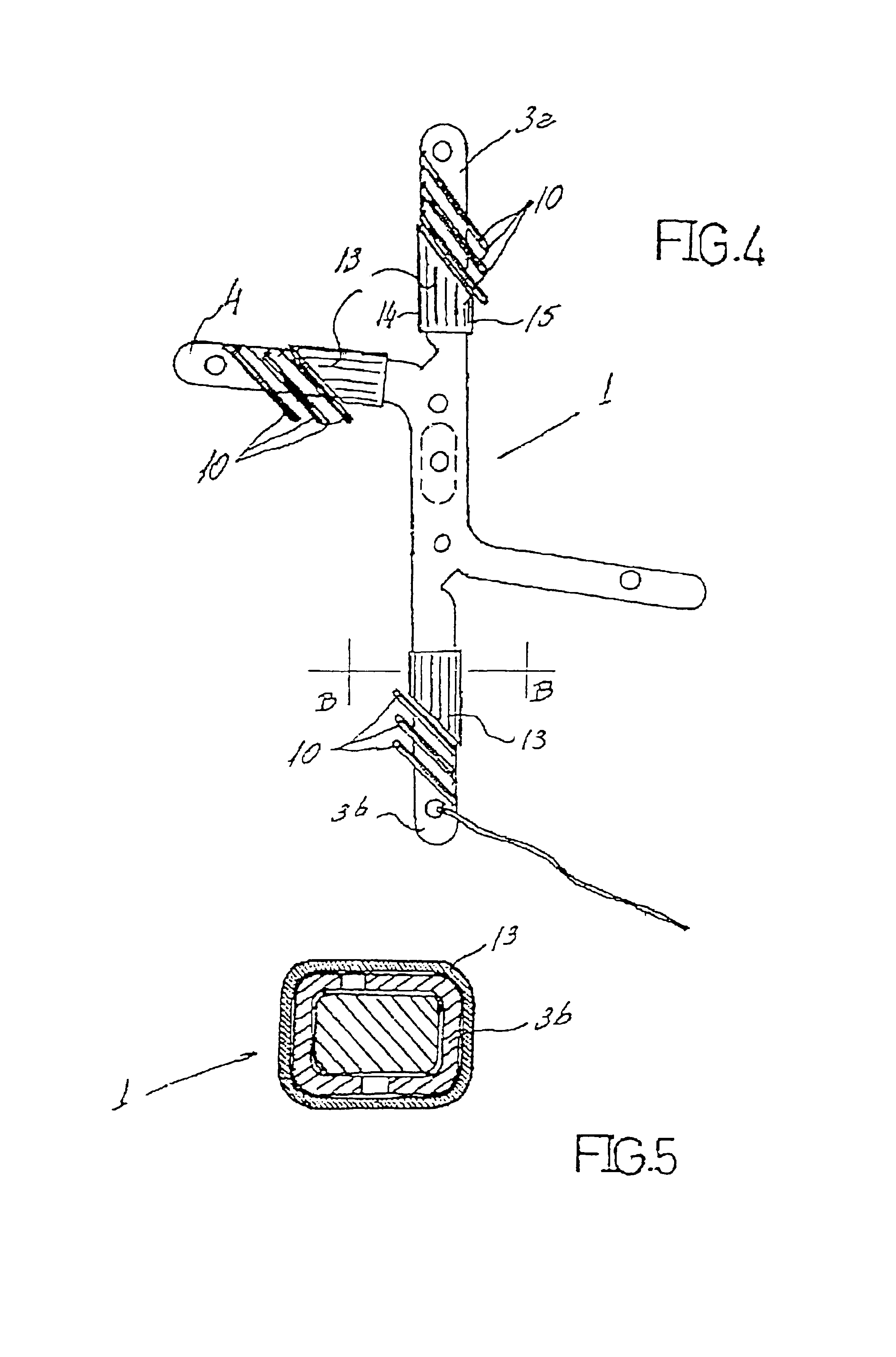

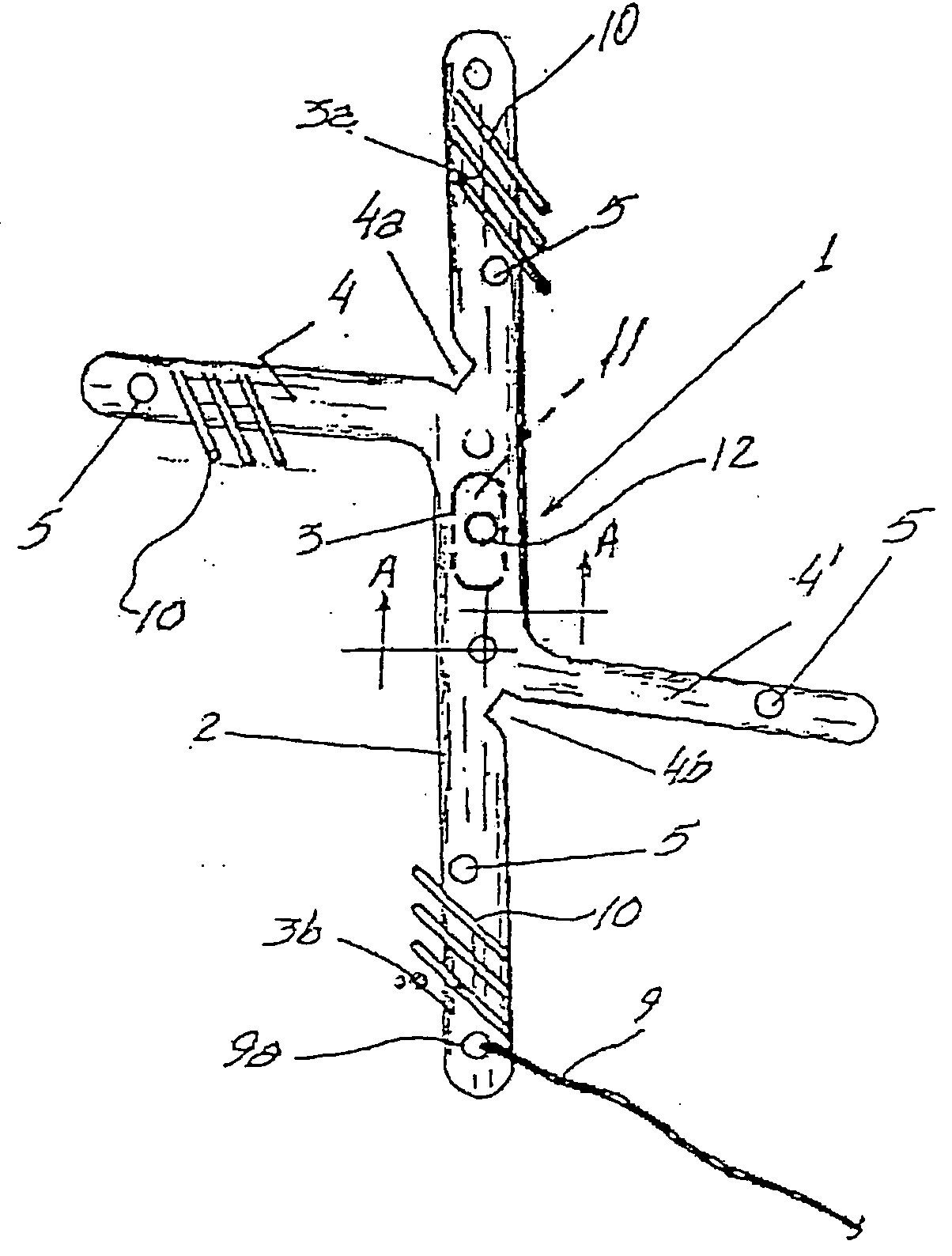

Intravaginal devices containing progesterone for estrus synchronization and related proceses

InactiveUS6939558B2Solve the lack of flexibilitySolving the Insufficiency of ElasticityAnimal reproductionPharmaceutical delivery mechanismMedicineEstrus synchronization

Embodiments of the present invention generally relate to devices and processes related to estrus synchronization. Particular embodiments of devices and processes of the present invention slowly release progesterone over a period of time for estrus synchronization.

Owner:AKZO NOBEL NV

Intravaginal devices containing progesterone for estrus synchronization and related proceses

InactiveUS20050021009A1Solve the lack of flexibilitySolving the Insufficiency of ElasticityAnimal reproductionFemale contraceptivesMedicineEstrus synchronization

Embodiments of the present invention generally relate to devices and processes related to estrus synchronization. Particular embodiments of devices and processes of the present invention slowly release progesterone over a period of time for estrus synchronization.

Owner:AKZO NOBEL NV

Prefabricated bathroom assembly and methods of its manufacture and installation

InactiveUS20070294954A1Maximal aesthetic qualityMaximum comfortSpecial buildingBuilding constructionsComputer Aided DesignToilet

A prefabricated bathroom assembly and methods for its manufacture and installation are disclosed. The prefabricated bathroom assembly preferably includes at least some of the same or similar building materials (e.g., stud construction, tile finishing, wallpaper, and floor-mounted toilets) traditionally used for on-site construction, in order to provide maximal aesthetic quality and comfort as well as the ability for a purchaser to customize the design. The bathroom assembly is preferably pre-fabricated substantially in its entirety off-site for delivery to the site in a single piece, and needing only fastening into place and connection to utilities at the site in order to complete the installation. In an embodiment, a prefabricated bathroom with a low-profile floor is provided that complies with applicable provisions of the Americans with Disabilities Act (“ADA”). In another embodiment, Computer Aided Design (“CAD”) technology is used in the design of the prefabricated bathroom assembly.

Owner:EGGROCK

High-frequency welding of non-polar thermoplastic rubbers

The present invention relates to a high-frequency weldable thermoplastic rubber composition, to a method of rendering non-polar thermoplastic rubbers high-frequency weldable, to a high-frequency weldable shaped article obtainable from the composition according to the invention, to a method for manufacturing said shaped articles and to a method of high-frequency welding of said articles. Furthermore, the present invention relates to shaped high-frequency welded articles obtainable by the method according to the present invention.

Owner:ADVANCED ELASTOMER SYST LP

Curable sealant composition

A radiation curable, flexible, paintable composition produced from epoxy compounds and one or more polyol(s) has enhanced durability, thick and thin film adhesion, resistance to mold growth and dimensional changes while reducing solvent emissions. The composition can reduce, if not eliminate, runs and drips during the thermal bake cycles which are associated with using conventional compositions in automotive applications.

Owner:DENOVUS

SMC sheets and its prepn. method

InactiveCN1903563AShorten the curing timeLow molding temperatureSynthetic resin layered productsGlass/slag layered productsGlass fiberHigh surface

A SMC sheet with high surface quality and luster is composed of both surficial PE films and a core material prepared from glass fibers through immersing them in the resin paste which is proportionally from unsaturated polyester resin, low-shrinkage additive, internal demoulding agent, calcium carbonate, styrene, trigger and magnesium oxide.

Owner:北京玻钢院复合材料有限公司

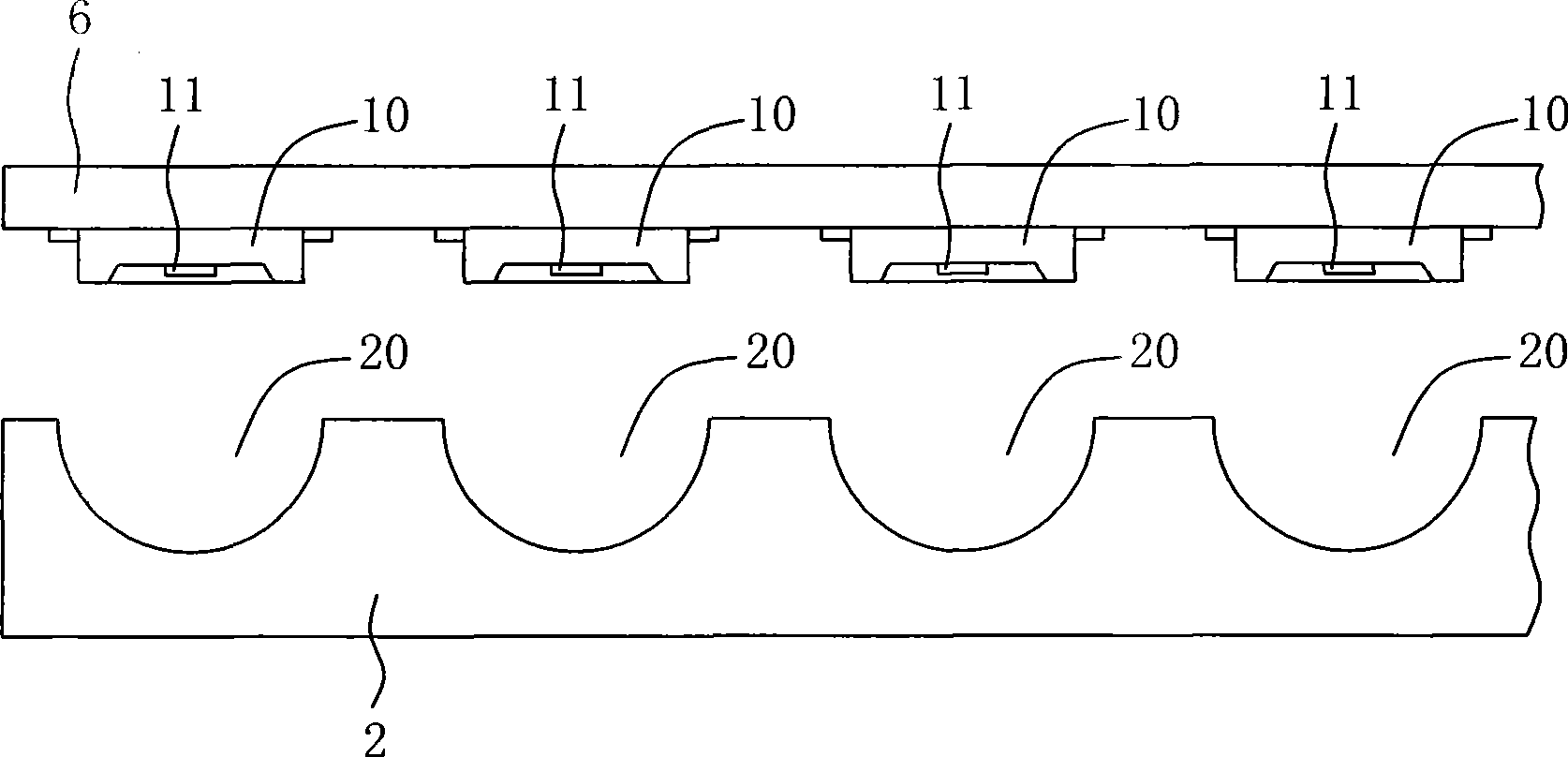

Forming method of resin lens in LED module

InactiveCN101386194AShorten the curing timeLow costPoint-like light sourceOptical articlesEpoxyPlastic materials

The invention provides a method for forming resin lenses in an LED component, which comprises the following steps: manufacturing a mould corresponding to the lens by a material with light transmittance, which contains plastic materials, such as PP, PET, PC, PE, or glass and the like; selecting liquid light-transmittance resin material for forming the lens, such as polyurethane, epoxide resin, silica gel, polyacrylic resin or co-polymer thereof and the like; quickly solidifying the liquid light-transmittance resin under irradiation of electron beam, or adding light trigger in the materials to solidify the liquid light-transmittance resin under irradiation of ultraviolet ray. By being combined with the LED component, the resin can be injected in the mould corresponding to the lens, and the resin material inside the mould is irradiated by the electron beam or the ultraviolet ray from the outside of the light-transmittance mould, so that the resin material can be quickly solidified and formed into the lens. Therefore, the solidifying process of the lens can be accelerated, and the solidified forming time of the resin can be effectively shortened.

Owner:ISOTECH PRODS

Treated rubber and products made therefrom

InactiveUS6896964B2High tensile strengthHigh elongationButtonsRecord carriersPolymer scienceUltimate tensile strength

Treated rubber is made from ground rubber and a polyurethane resin. Products made by mixing treated rubber with additional polyurethane resin, molding and curing the polyurethane have higher tensile strengths and / or elongations than similar products made from untreated rubber. The method using treated rubber uses less polyurethane binder to produce products of equivalent strengths. The molding time is also reduced because of the reduced amount of polyurethane binder used.

Owner:RYVEC

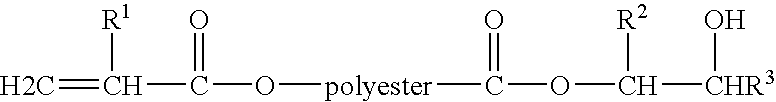

Adhesive useful for film laminating applications

InactiveUS20070088145A1Broaden applicationEasy to handleAdhesive processesPolyureas/polyurethane adhesivesPolyesterEpoxy

An adhesive that is capable of being curing in at least two stages is prepared by combining at least one isocyanate-functionalized polyurethane prepolymer, at least one hardener, and at least one (meth)acrylate-functionalized compound selected from the group consisting of polyester (meth)acrylates containing hydroxyl functional groups, adducts of epoxy-functionalized poly(meth)acrylic resins and (meth)acrylic acids, polybutadiene (meth)acrylates, and polyoxyalkylene ether mono(meth)acrylates. Such adhesives are particular useful as two part laminating adhesives in the assembly of flexible laminates.

Owner:HENKEL CORP

Paste curing additive

InactiveUS20060093912A1Increase productionShorten the curing timeLead-acid accumulator electrodesNon-aqueous electrolyte accumulator electrodesPolymer scienceLead oxide

The disclosed invention relates to additives for use in, such as, battery pastes and in polymers. The additive is the reaction product of sulphuric acid, water and leady oxide. The additive may be used in a mixture of sulphuric acid, water and leady oxide to produce a modified battery paste that, when pasted onto battery plates, yields plates of improved performance. The additive also may be used as a stabilizer for chlorine containing polymers such as polyvinyl chloride.

Owner:MAYER GEORGE E

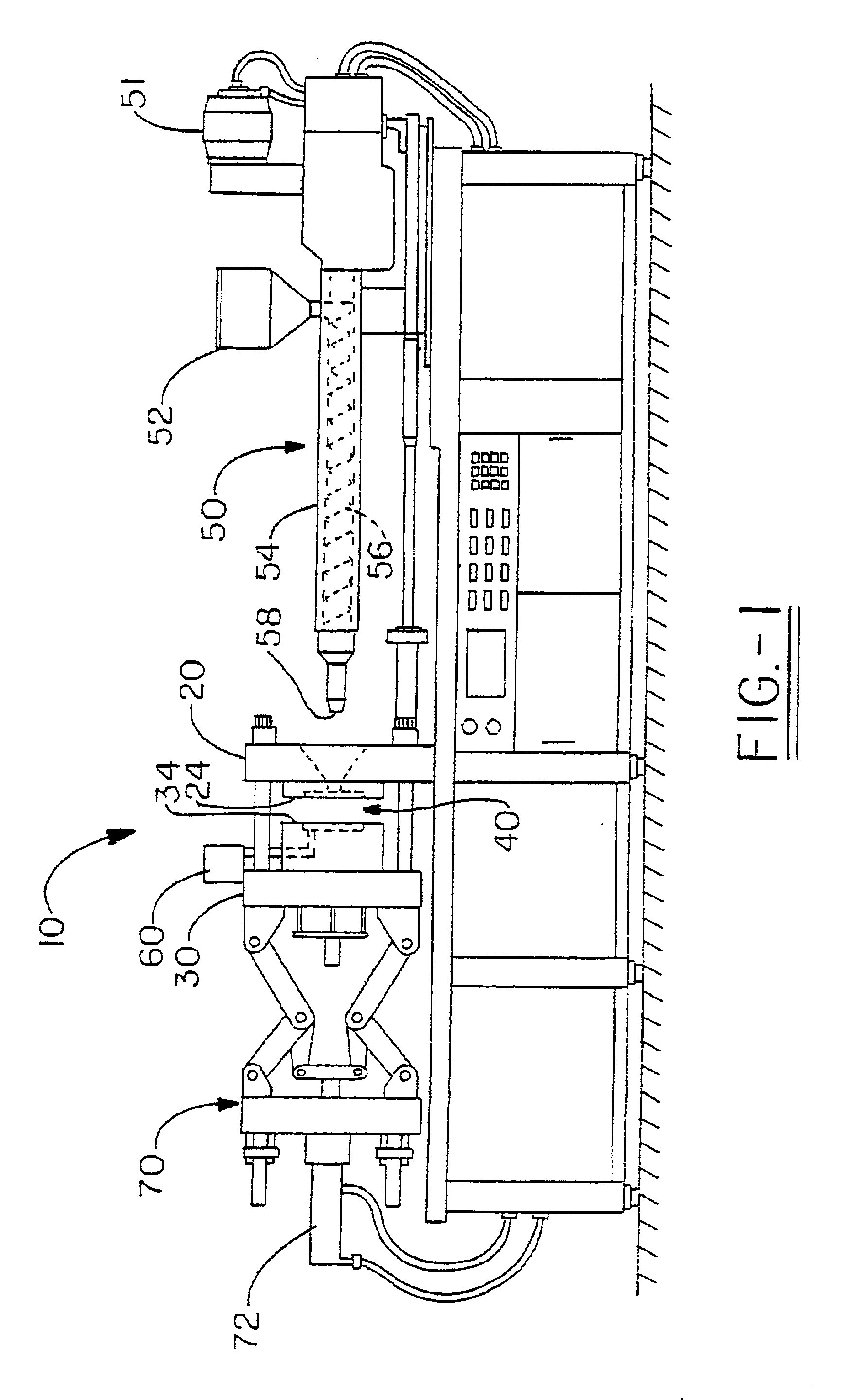

Method of manufacturing a wind turbine blade comprising steel wire reinforced matrix material

ActiveUS20110164987A1Short cycleObtained waterFinal product manufactureWood working apparatusTurbine bladeWind force

A method of manufacturing a shell construction part of a wind turbine blade, the shell construction part being made of a fibre reinforced polymer material including a polymer matrix and fibre reinforcement material embedded in the polymer matrix. The method comprises the steps of a) providing a forming structure comprising a mould cavity and having a longitudinal direction, b) placing the fibre reinforcement material in mould cavity, c) providing a resin in the mould cavity simultaneously with and / or subsequently to step b), and d) curing the resin in order to form the composite structure, wherein at least 20% by volume of the fibre reinforcement material consists of metallic wires.

Owner:LM GLASSFIBER

Method for making optical device structures

InactiveUS20040101782A1Process environmental protectionLight transmission lossElectrographic processes using photoelectrophoresisElectrographic process apparatusRefractive indexTopography

A method of forming an optical device structure having a first region and a second region. The method comprises: providing a polymerizable composite comprising a polymer binder and an uncured monomer, depositing the polymerizable composite on a substrate to form a layer, patterning the layer to define an exposed area and an unexposed area of the layer, irradiating the exposed area of layer, and volatilizing the uncured monomer to form the optical device structure. The step of volatilizing the uncured monomer forms a surface topography and a compositional change between the first region and the second region. The compositional change creates a gradient in refractive index between the first region and the second region.

Owner:GENERAL ELECTRIC CO

Method for reduction of tobacco specific nitrosamines

InactiveUS20050121046A1Good colorShorten the curing timeTobacco preparationTobacco treatmentBicarbonateChemistry

Tobacco is treated before or during curing to lower or eliminate bacterial populations and / or activity, fungal growth, and / or tobacco-specific nitrosamine or bacterial endotoxin levels in the cured tobacco, wherein the tobacco is treated with an effective amount of a wash solution. Air-cured tobacco may be cured in four weeks or less when treated with a wash solution of bicarbonate salts.

Owner:PHILIP MORRIS USA INC

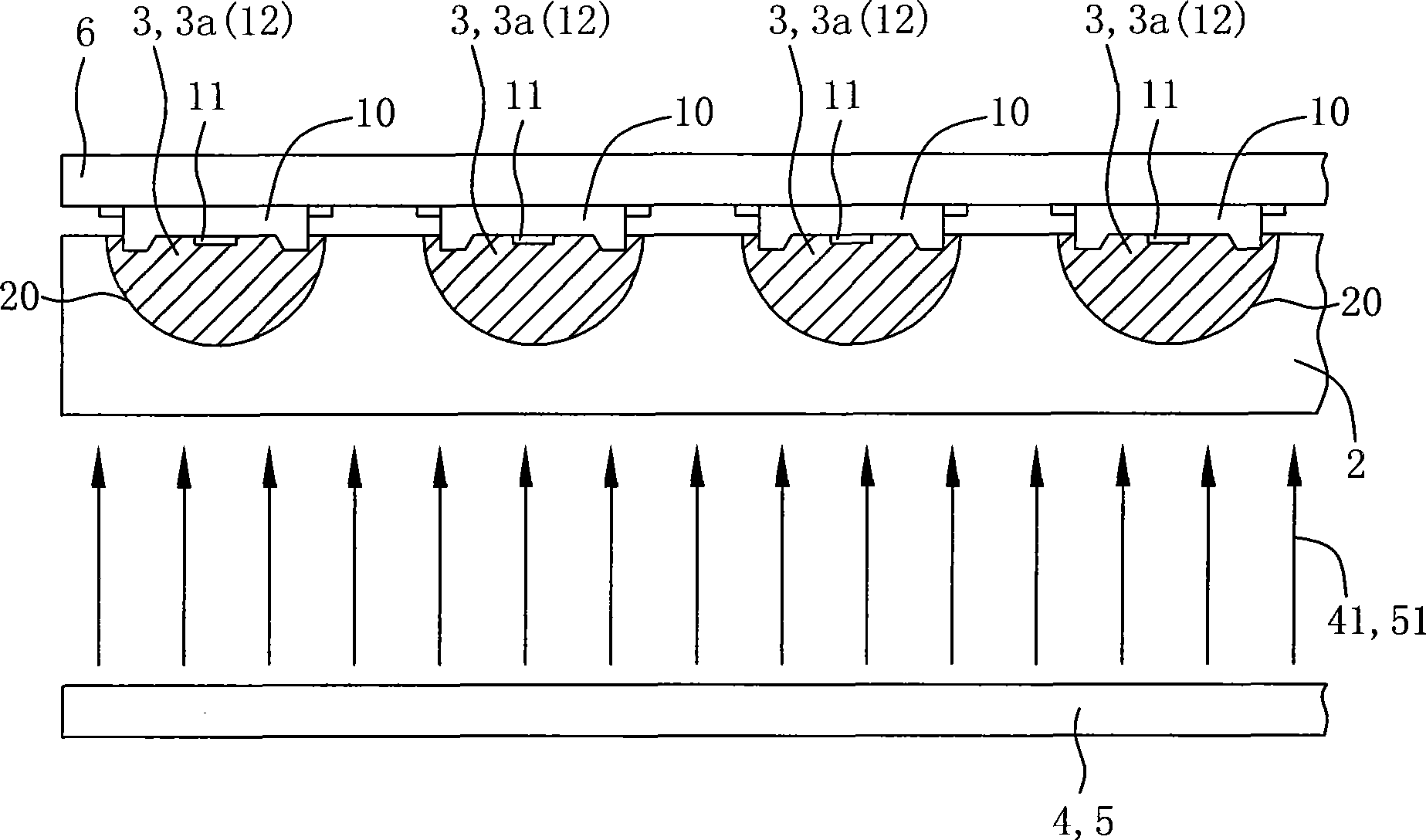

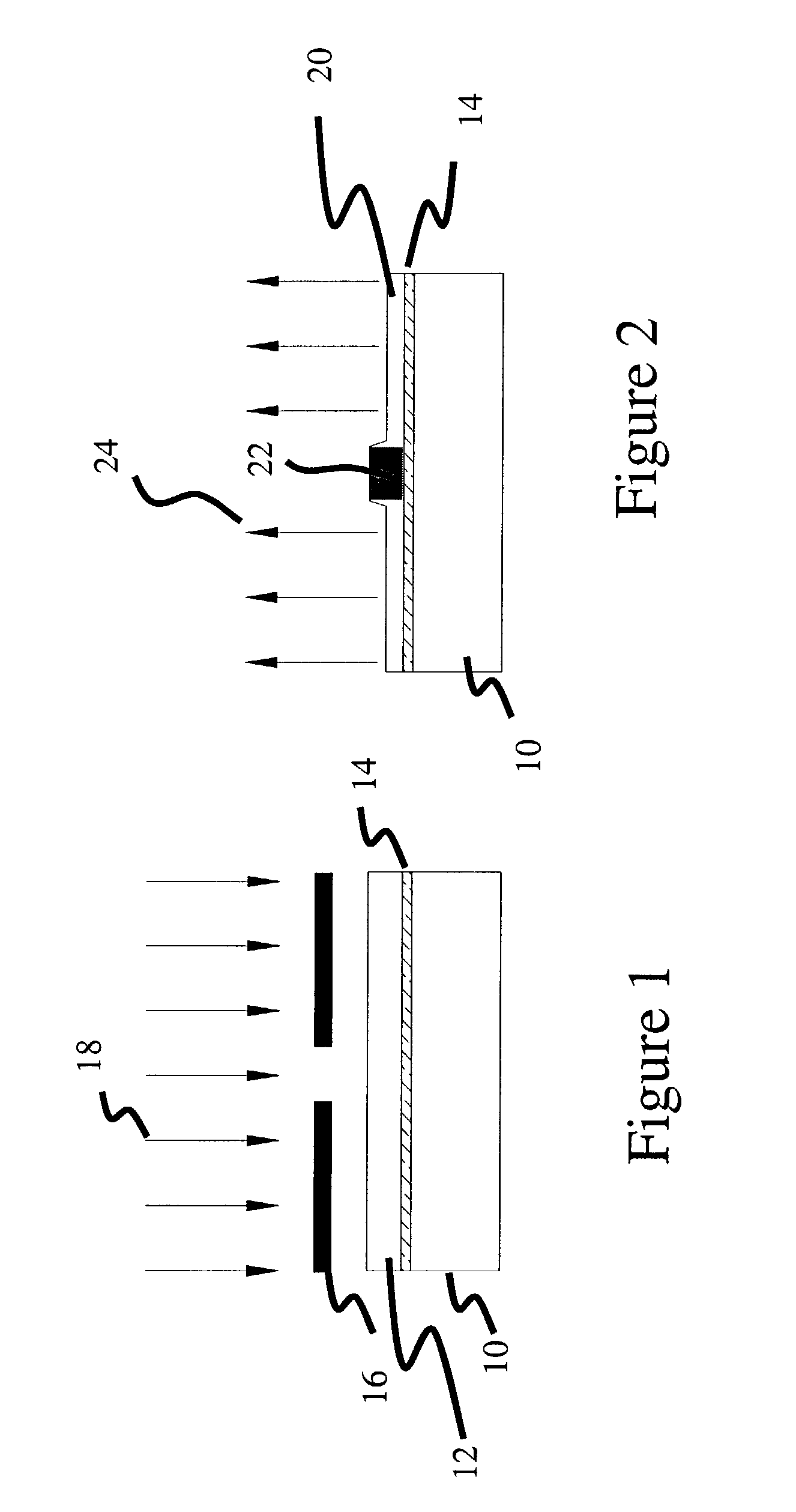

Bifacial solar cell module

InactiveUS20120048353A1Improve efficiencyLow curing temperaturePV power plantsPhotovoltaic energy generationTetrafluoroethyleneOptical transmittance

A bifacial solar cell module comprises: a plurality of bifacial solar cells; a light transmitting first substrate positioned at a first surface side of the bifacial solar cells; a light transmitting second substrate positioned at a second surface side of the bifacial solar cells; and a seal member positioned between the first substrate and the second substrate and made of a sealing material of at least one layer, wherein at least one of the first substrate and the second substrate is made of an ethylene tetrafluoroethylene copolymer (ETFE) copolymer in which light transmittance is 85% or more and light absorptance is 5% or less in an entire wavelength band.

Owner:LG ELECTRONICS INC

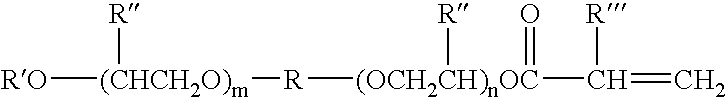

In-mold appearance coatings for nylon and nylon based thermoplastic substrates

InactiveUS6863981B2Extend curing timeShorten the curing timeLiquid surface applicatorsSynthetic resin layered productsPolymer chemistryOligomer

An in-mold coating composition particularly useful for in-mold coating of molded nylon based substrates comprises a coreactive addition polymerizable composition of urethane-acrylate oligomer having at least two acrylate and / or methacrylate terminal groups, at least 0.2% of a sulfonic acid functional acrylate or methacrylate, at least 0.2% of acrylic and / or methacrylic acid, with the balance being coreactive polymerizable diacrylate(s) and / or ethylenically unsaturated monomer(s).

Owner:OMNOVA SOLUTIONS INC

Photocurable primer composition and coating method by use of the same

InactiveUS6844029B2Shorten the curing timeImprove work efficiencyLiquid surface applicatorsPolyurea/polyurethane coatingsOligomerMeth-

A photocurable primer composition containing (A) an acrylic resin having through an urethane linkage a polymerizable unsaturated group on its side chain and containing the polymerizable unsaturated group in an amount of 0.2 to 2.0 mol / kg in a solid content of the resin (A), (B) an urethane (meth)acrylate oligomer containing at least one polymerizable unsaturated group in one molecule, and (E) a photopolymerization initiator, and a coating method.

Owner:KANSAI PAINT CO LTD

Pressure bearing and leakage blocking agent

InactiveCN105349125ASmall specific surface areaCuring time controllableDrilling compositionFilling materialsMass ratio

The invention discloses a pressure bearing and leakage blocking agent, which solves the problems of difficult retention, easy mixing, poor caking property and pollution of a drilling fluid of the routine leakage blocking agents. The pressure bearing and leakage blocking agent comprises the following components: an amorphous form aluminosilicate curing agent, an activator, a retarder and an inertia filling material; a ratio of components is calculated according to a following mode: modulus is 1.0-1.4, the activator with mass concentration being 10-20% is taken as a liquid phase, a mass ratio (water cement ratio) of the liquid phase to the curing agent is 0.8-1.2; the addition of the retarder accounts for 0-1% of total amount of the above slurry. The pressure bearing and leakage blocking agent has the advantages of adjustable solidification time, high solidification intensity, large bearing, is not restricted by a leakage channel, so that effective plugging is formed to a leakage layer.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

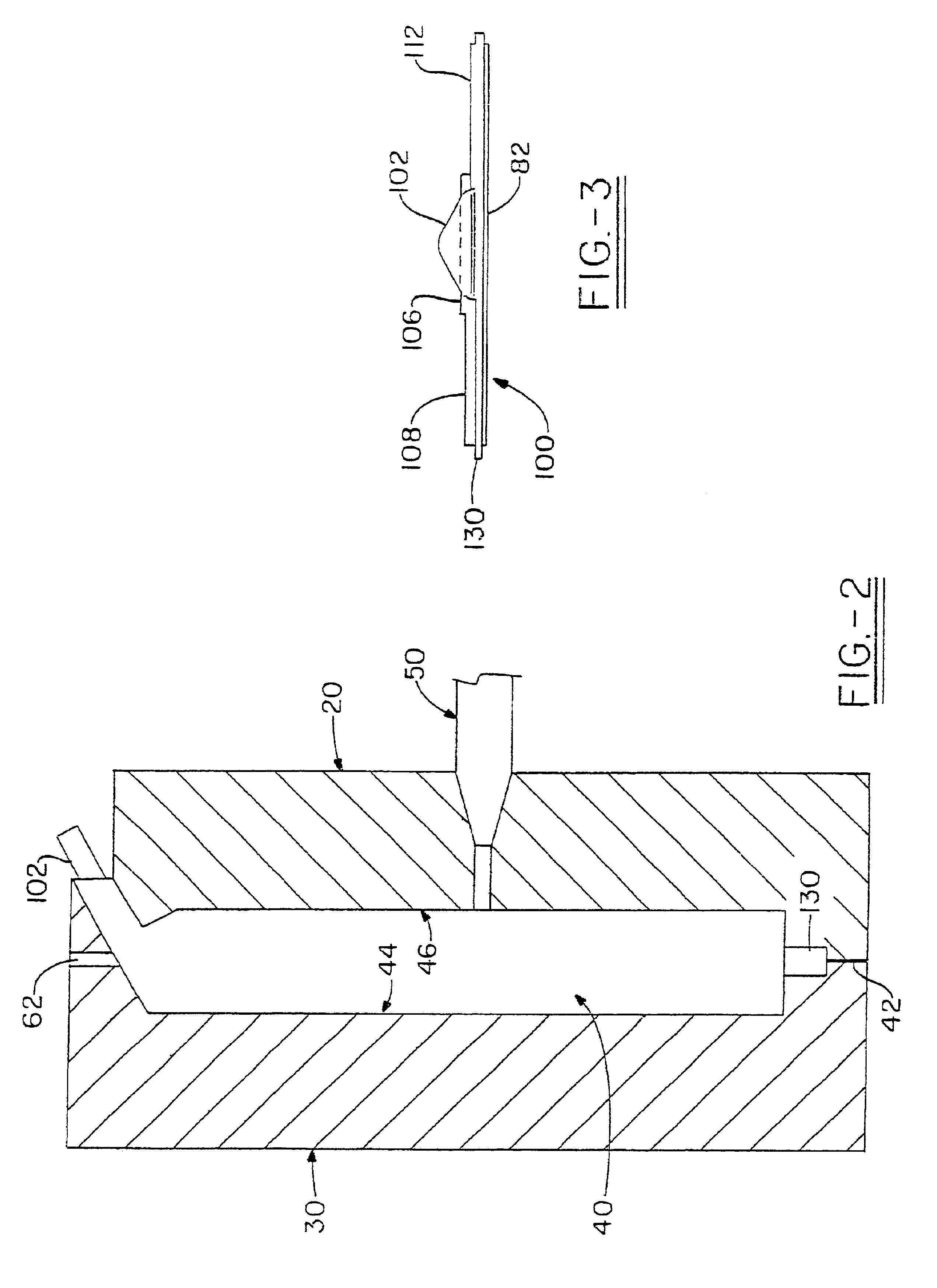

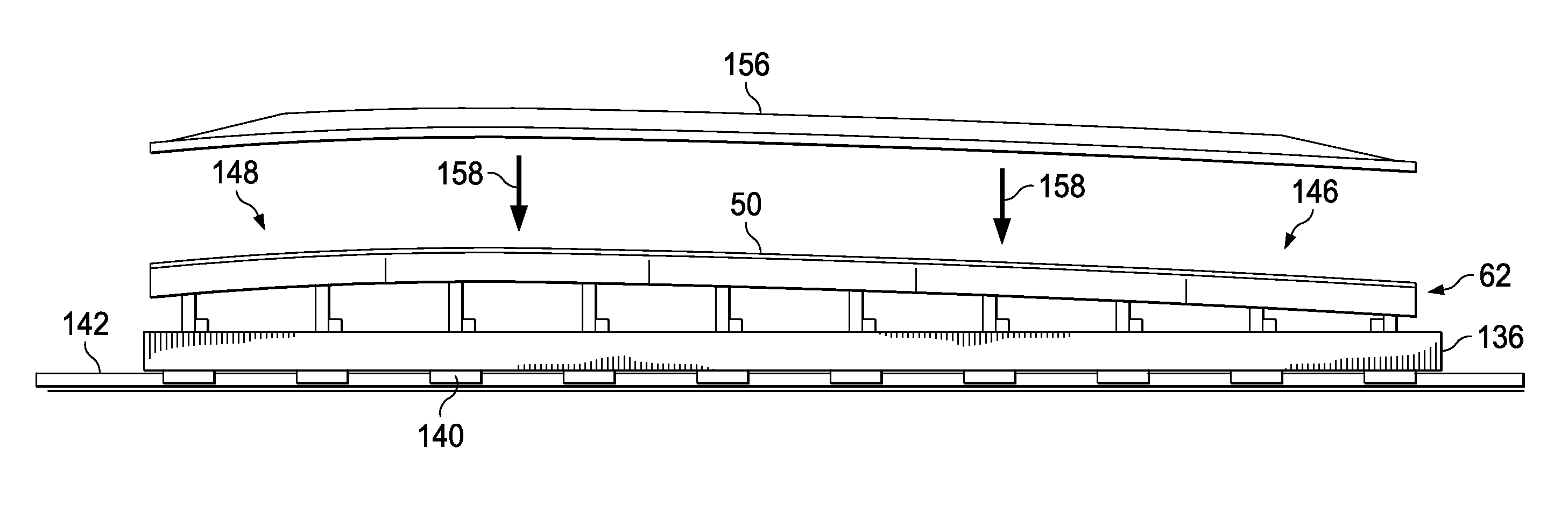

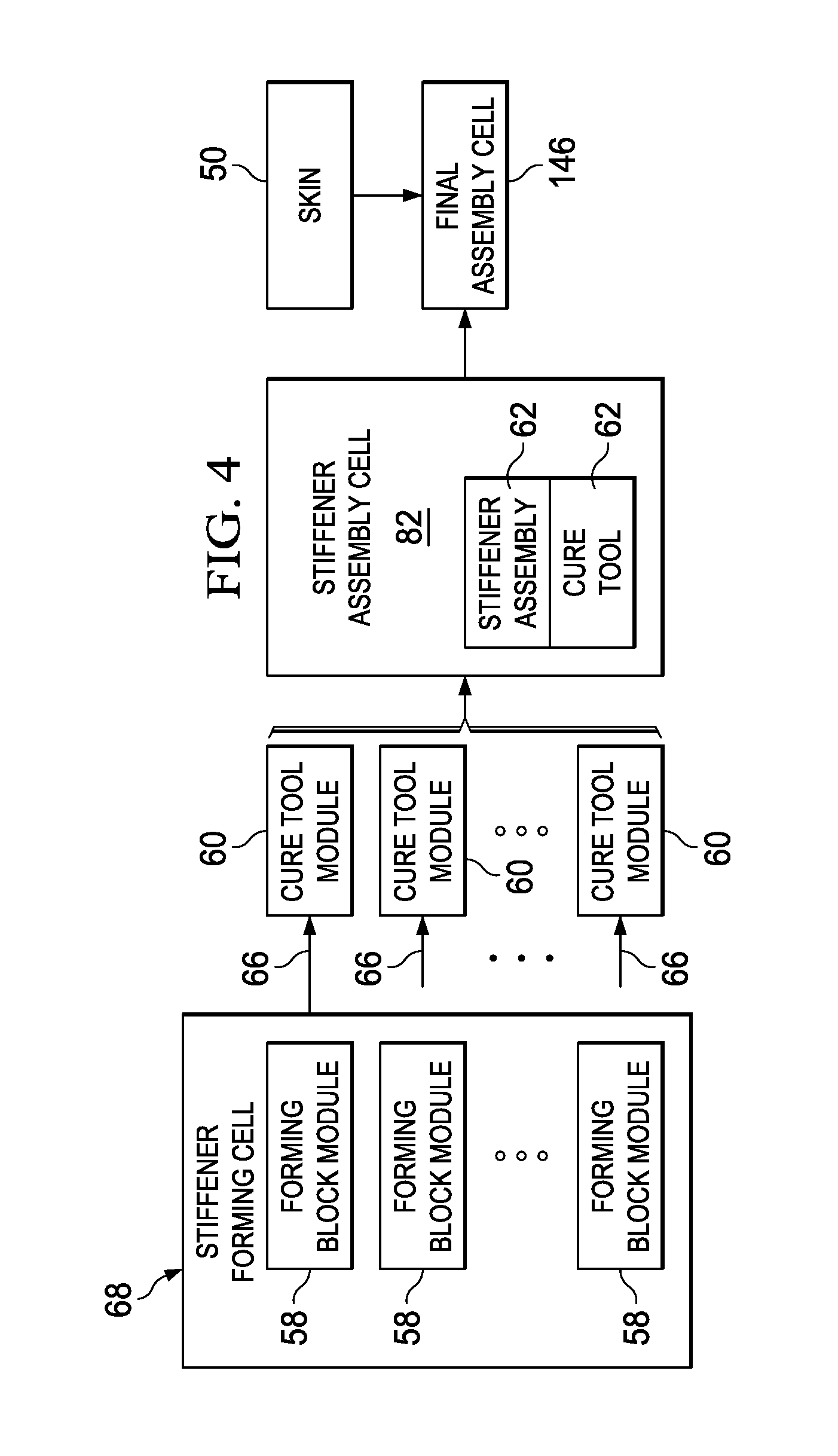

Fabrication of Stiffened Composite Panels

ActiveUS20140374013A1Reduce tooling costsReduce assembly floor space requirementLaminationLamination apparatusComposite skinMechanical engineering

A stiffened composite panel is fabricated using modular tooling. Composite pre-preg is laid up and formed over forming block modules each of which is assembled by co-linearly arranging a plurality of forming block segments. The formed stiffeners are respectively transferred to individual cure tool modules that are assembled by co-linearly arranging a plurality of cure tool module segments. The stiffeners are assembled by arranging the cure tool modules side-by-side, and a composite skin is placed on the assembled stiffeners. The panel is vacuum bagged using a segmented vacuum bag.

Owner:THE BOEING CO

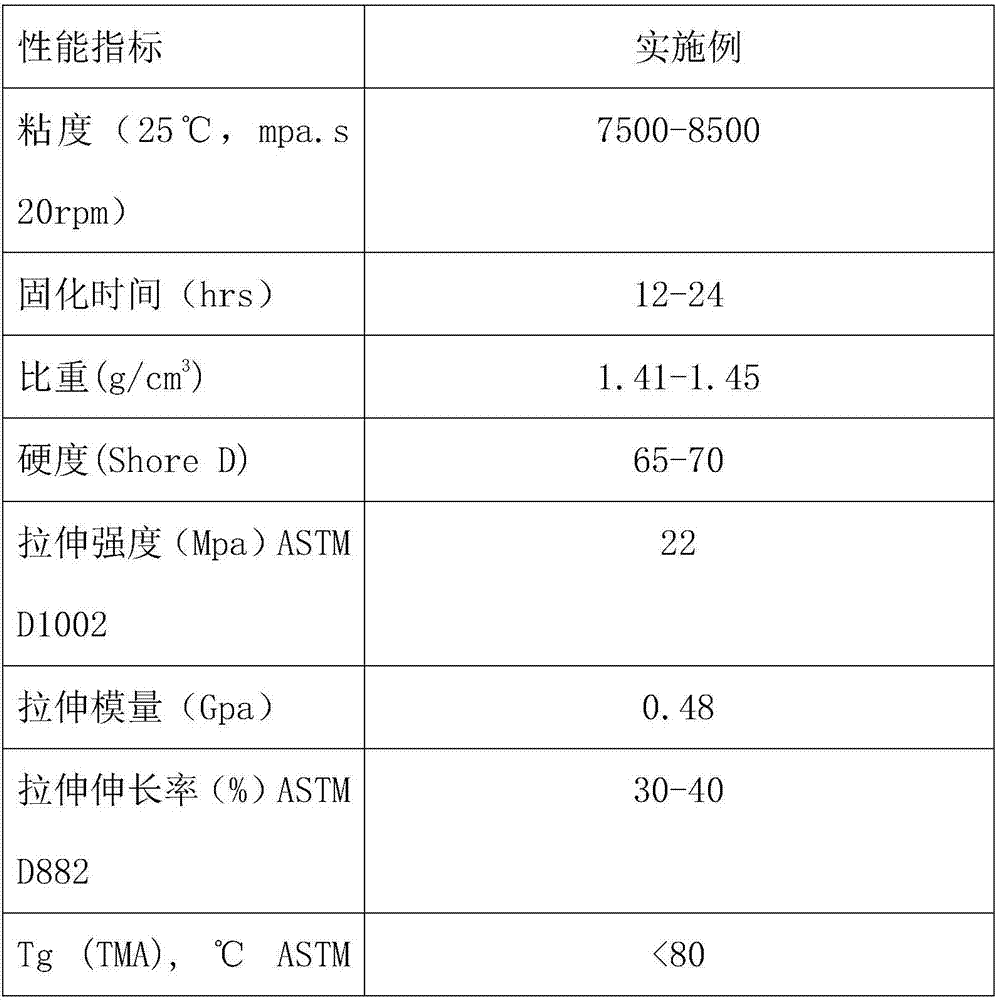

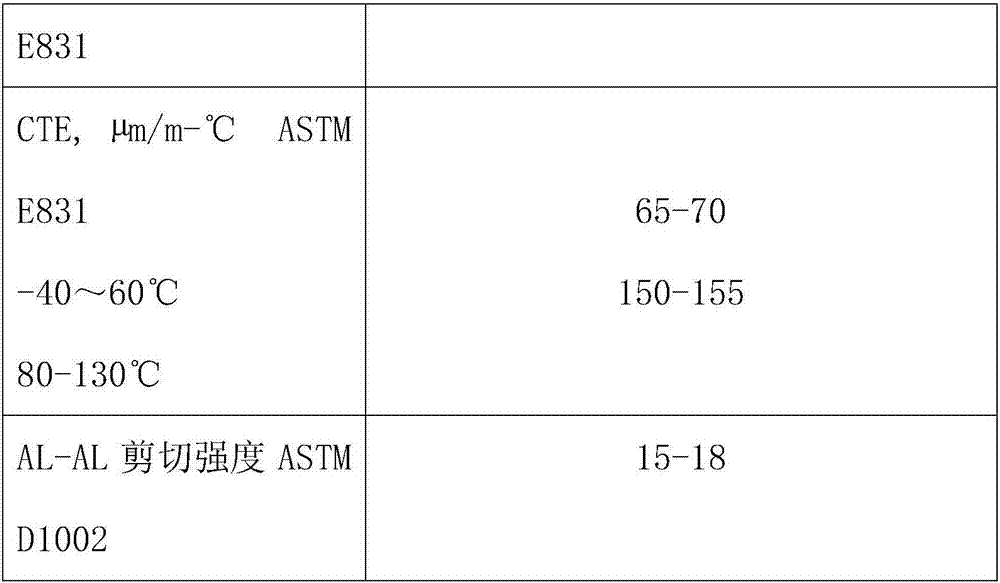

Epoxy resin pouring sealant and preparation method thereof

InactiveCN107163888AImprove crack resistanceImprove stabilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyAging resistance

The present invention relates to an epoxy resin pouring sealant and a preparation method thereof, the epoxy resin pouring sealant includes A and B components, the A component includes, by weight, 40-70 parts of bisphenol F epoxy resin, 20-50 parts of an active polyurethane toughening agent, 10-20 parts of an active diluent, 30-50 parts of an inorganic filler and 1-10 parts of an additive; the B component includes, by weight, 40-70 parts of modified alicyclic amine; 30-60 parts of polyetheramine and 3-10 parts of a promoter. The weight ratio of A to B is 2-4:1. The epoxy resin pouring sealant has better aging resistance and strong resistance to cold and hot impact, and meets the high temperature and cold impact requirement of electronic sealing.

Owner:COLLTECH DONGGUAN BONDING TECH CO LTD

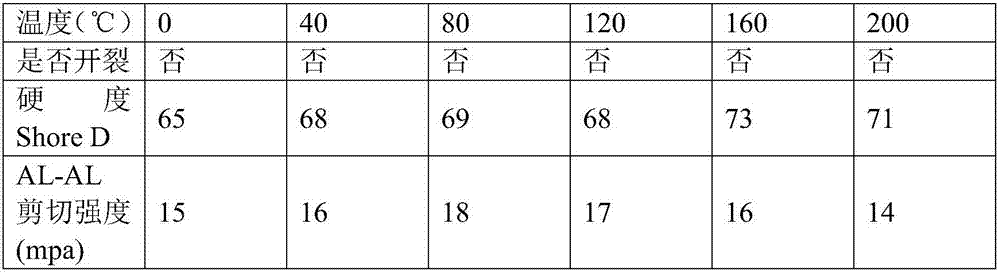

Ultraviolet light curing compositions for composite repair

Methods and compositions concerning an ultraviolet light curable formulation useful for repairing composite materials including the repair of a hole in the exterior of an airplane. The formulation may contain an acrylic oligomer, an acrylic monomer, an organic peroxide, a dialkylaniline promoter, a photoinitiator. The formulation can include a filler such as carbon fabric or Kevlar fabric.

Owner:TEXAS RES INT

Method of maxillary sinus bone grafting for placement of implant

A method of maxillary sinus bone grafting for placement of an implant in which upon placement of the implant, a vertical hole is formed and enlarged with ease in a maxillary sinus floor, a maxillary membrane is easily lifted in an always-stable state using a piezotome and gel type bone graft material while preventing the membrane from becoming damaged, and even the bone graft material of coarse bone meal is uniformly diffused and infused, thereby ensuring that the implant is placed in a fast, safe manner while allowing a patient to keep relaxed and alleviating the pain the patient feels, resulting in shortening a curing time and maximizing effects of the placement of the implant.

Owner:LEE DAL HO

High-frequency welding of non-polar thermoplastic rubbers

The present invention relates to a high-frequency weldable thermoplastic rubber composition, to a method of rendering non-polar thermoplastic rubbers high-frequency weldable, to a high-frequency weldable shaped article obtainable from the composition according to the invention, to a method for manufacturing said shaped articles and to a method of high-frequency welding of said articles. Furthermore, the present invention relates to shaped high-frequency welded articles obtainable by the method according to the present invention.

Owner:ADVANCED ELASTOMER SYST LP

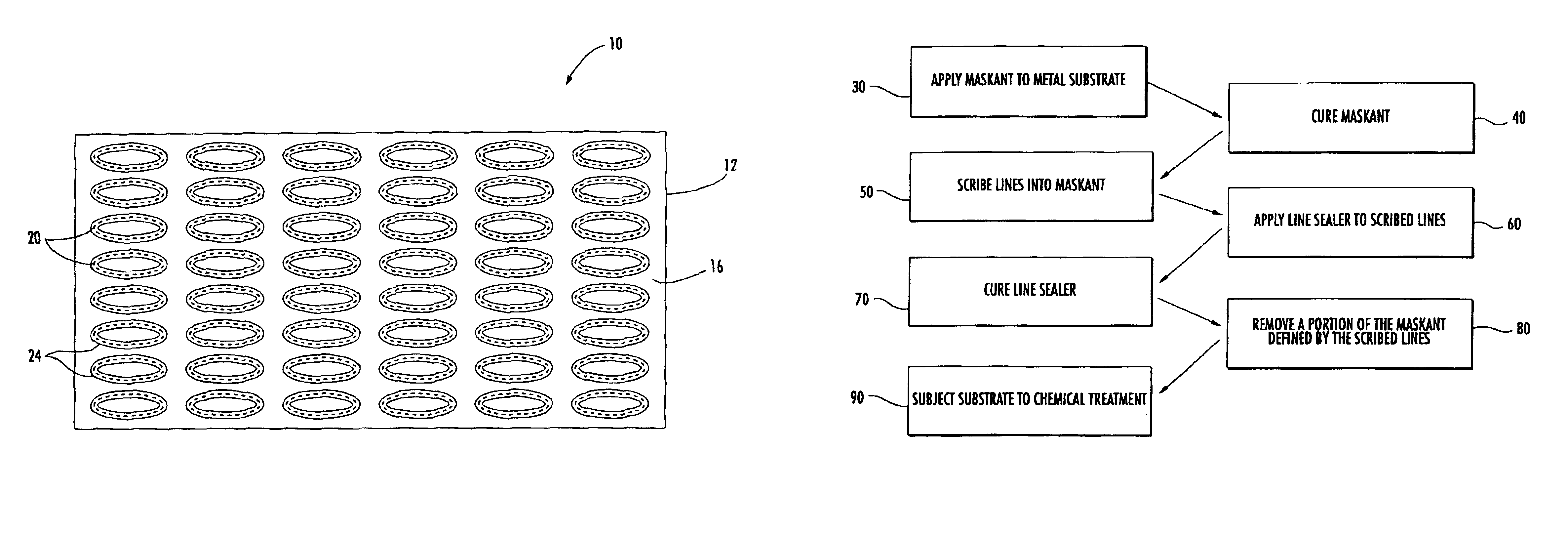

Radiation curable maskant and line sealer for protecting metal substrates

InactiveUS6951623B2Increase processing efficiencyFew toxicity and environmental concernAnodisationElectrolytic inorganic material coatingSolventMetal substrate

The invention provides a coated metal substrate comprising a metal substrate having an outer surface, a maskant film adhered to at least a portion of the outer surface of the metal substrate, the maskant film having a pattern of scribed lines therein, and a line sealant composition applied to the scribed lines in a maskant film. Both the maskant film and the line sealant composition are preferably radiation cured and substantially solvent-free. The invention also provides a method of protecting a metal substrate from chemical exposure by utilizing the radiation-cured maskant film and line sealant composition.

Owner:THE BOEING CO

Dust suppression agent

InactiveUS20100284741A1Extend your lifeIncreased load-bearing capacityIn situ pavingsOther chemical processesAcetic acidPolyvinyl acetate

A composition for dust suppression including an acrylic polymer, a polyvinyl acetate polymer, glycerin, and water is herein disclosed.

Owner:MIDWEST IND SUPPLY INC

Method for Producing Molded Silicone Rubber Products Using Liquid Silicone Rubber

Described is a method for producing a molded silicone rubber product using a liquid silicone rubber (LSR) base comprising at least one vinyl siloxane polymer, at least one hydride crosslinker, and optionally at least one injection molding inhibitor. The single LSR base is fed into a feed line, and into the feed line are fed an inhibitor master batch comprising at least one liquid injection molding inhibitor and at least one vinyl siloxane polymer, and a catalyst master batch comprising at least one catalyst and at least one vinyl siloxane polymer. The invention is further directed to: said LSR base; said inhibitor master batch; said catalyst master batch; and a molded silicone rubber article produced by the methods and compositions described herein.

Owner:BLUSR SILICONES USA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com