Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51 results about "Chemical exposure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

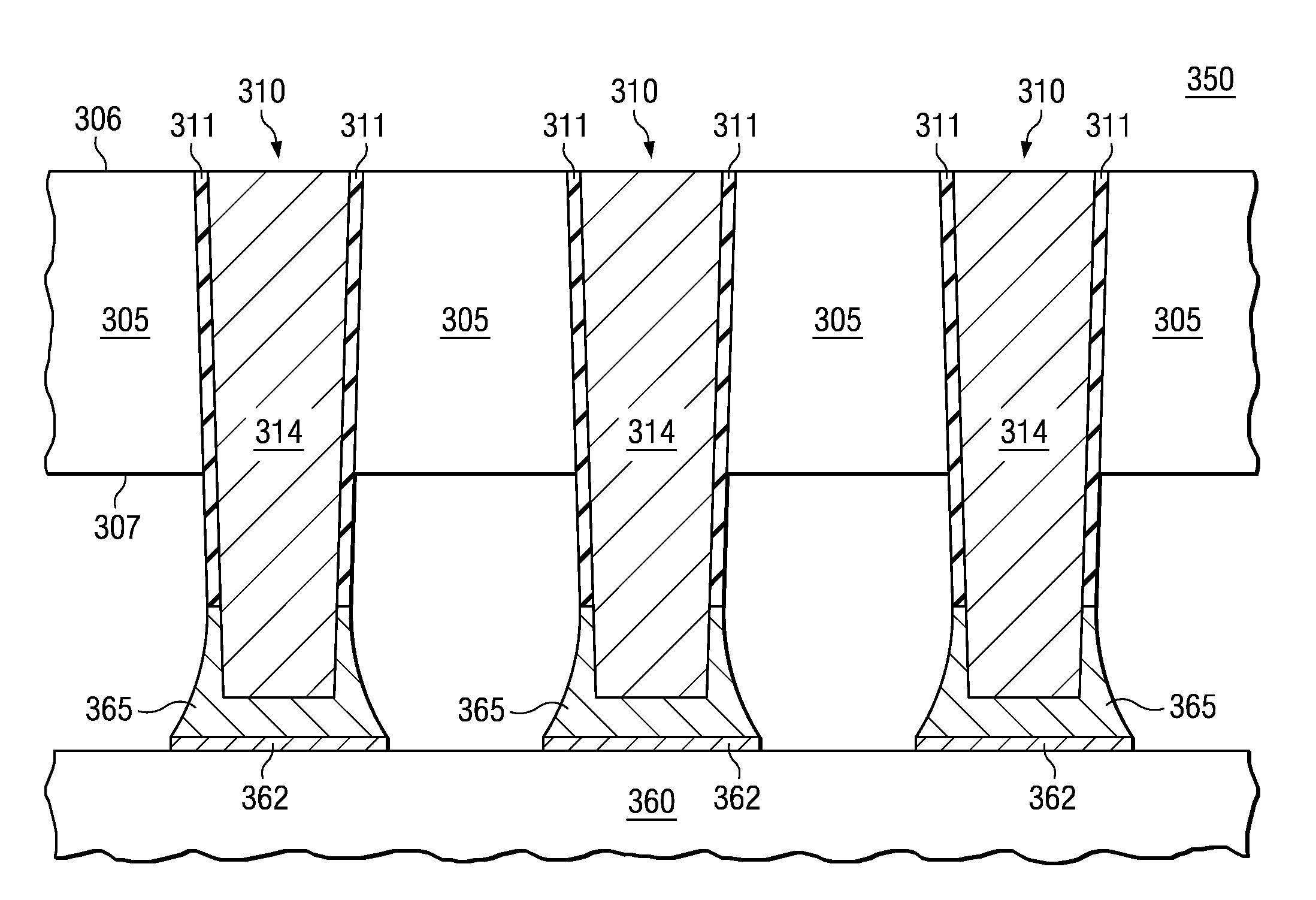

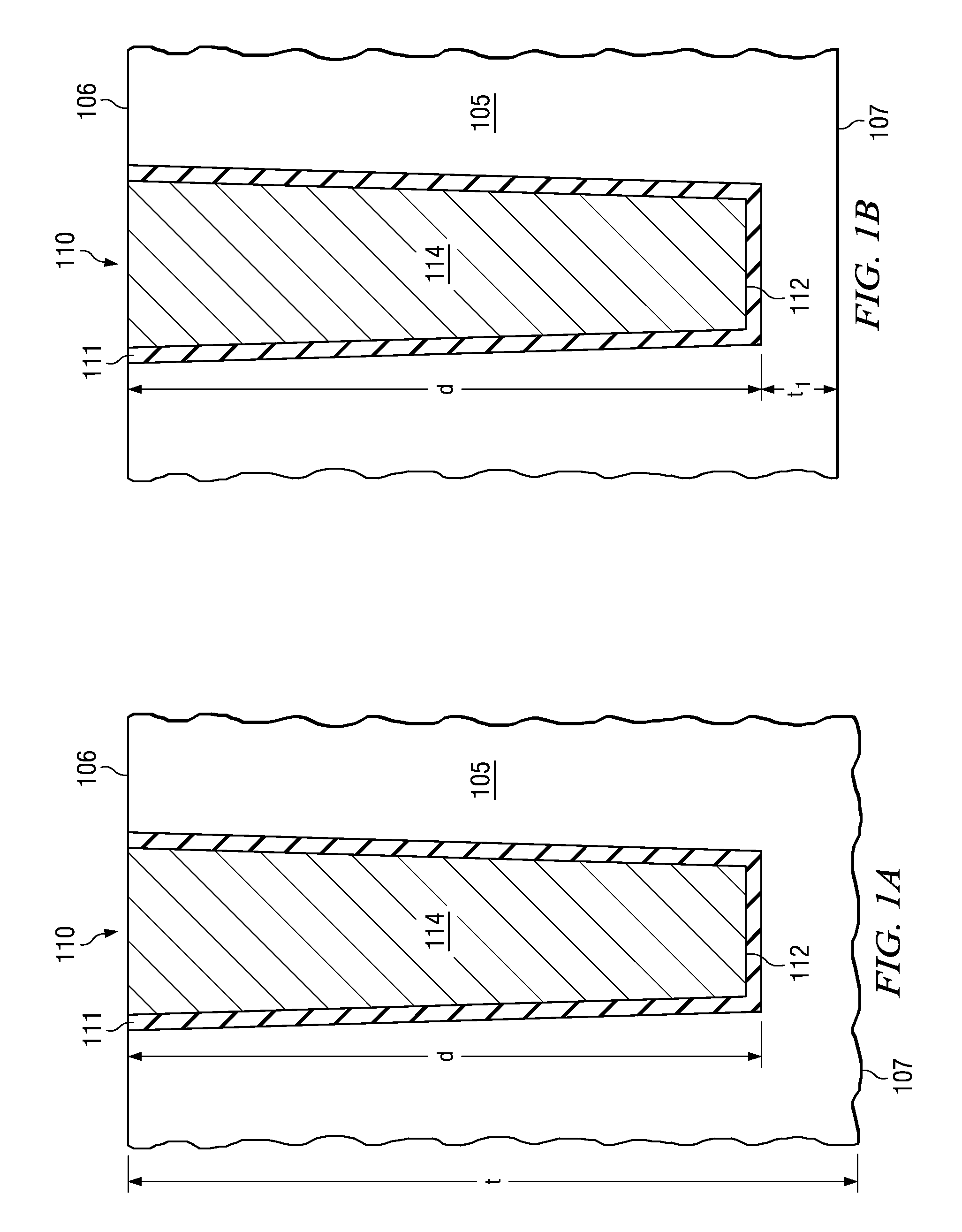

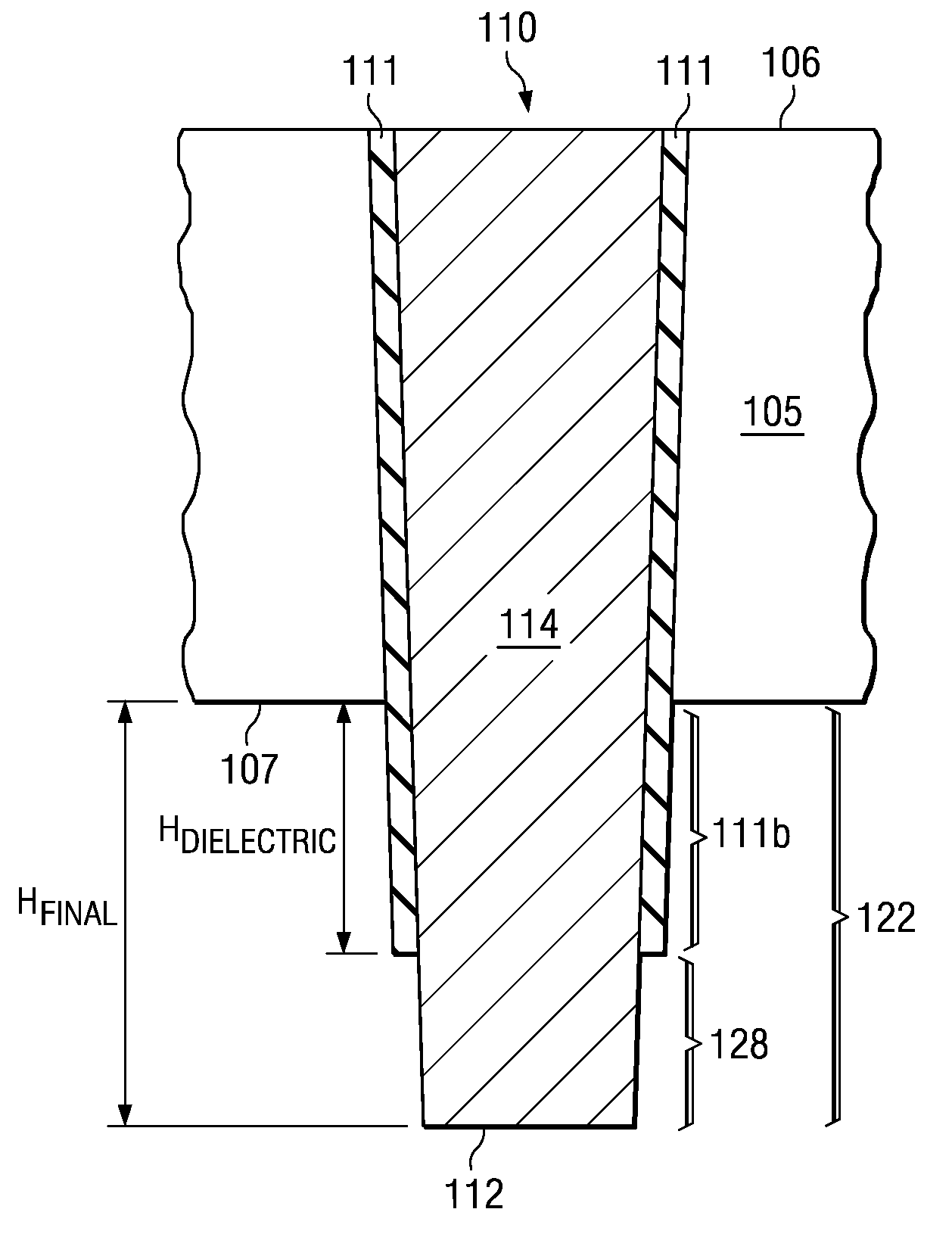

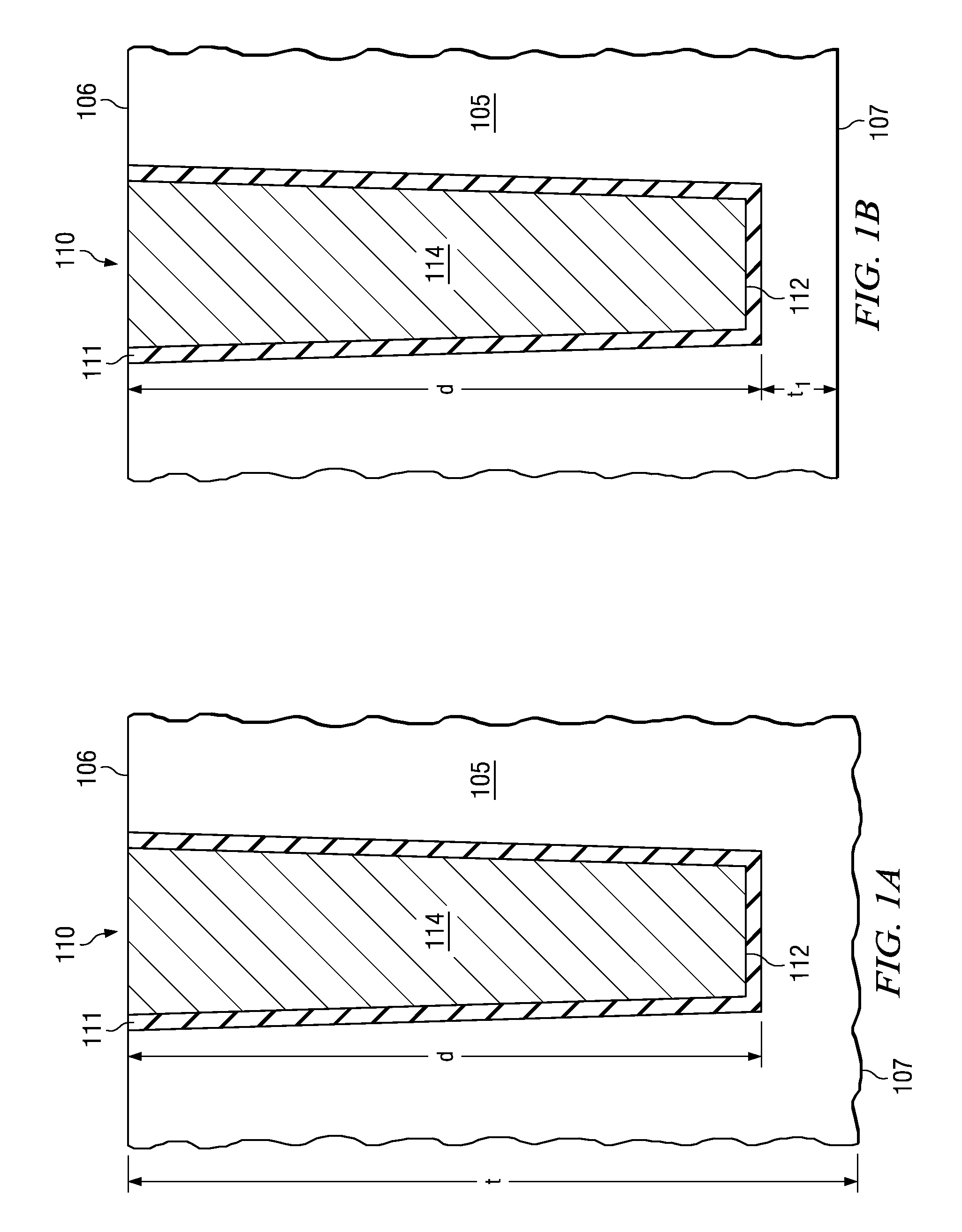

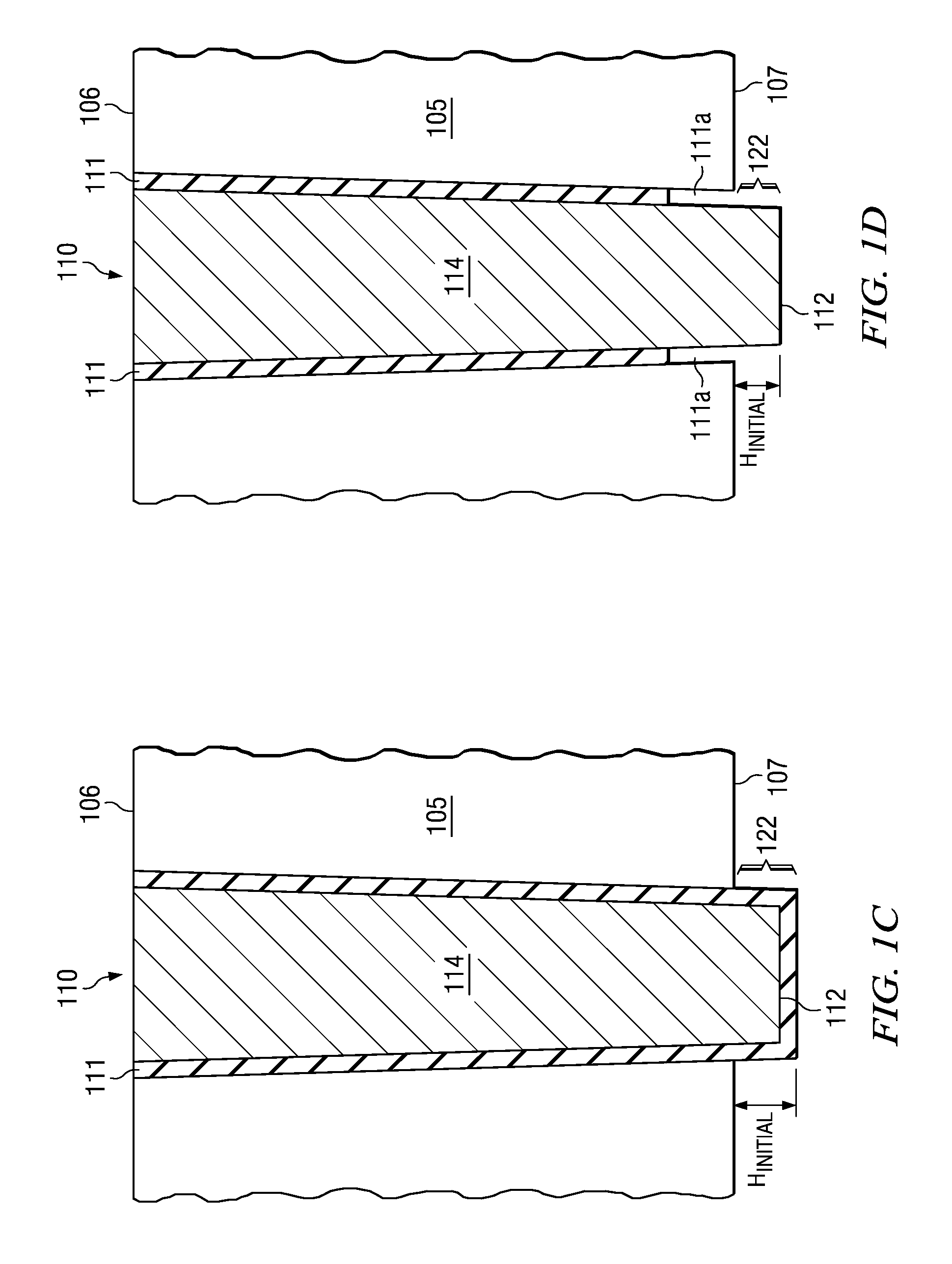

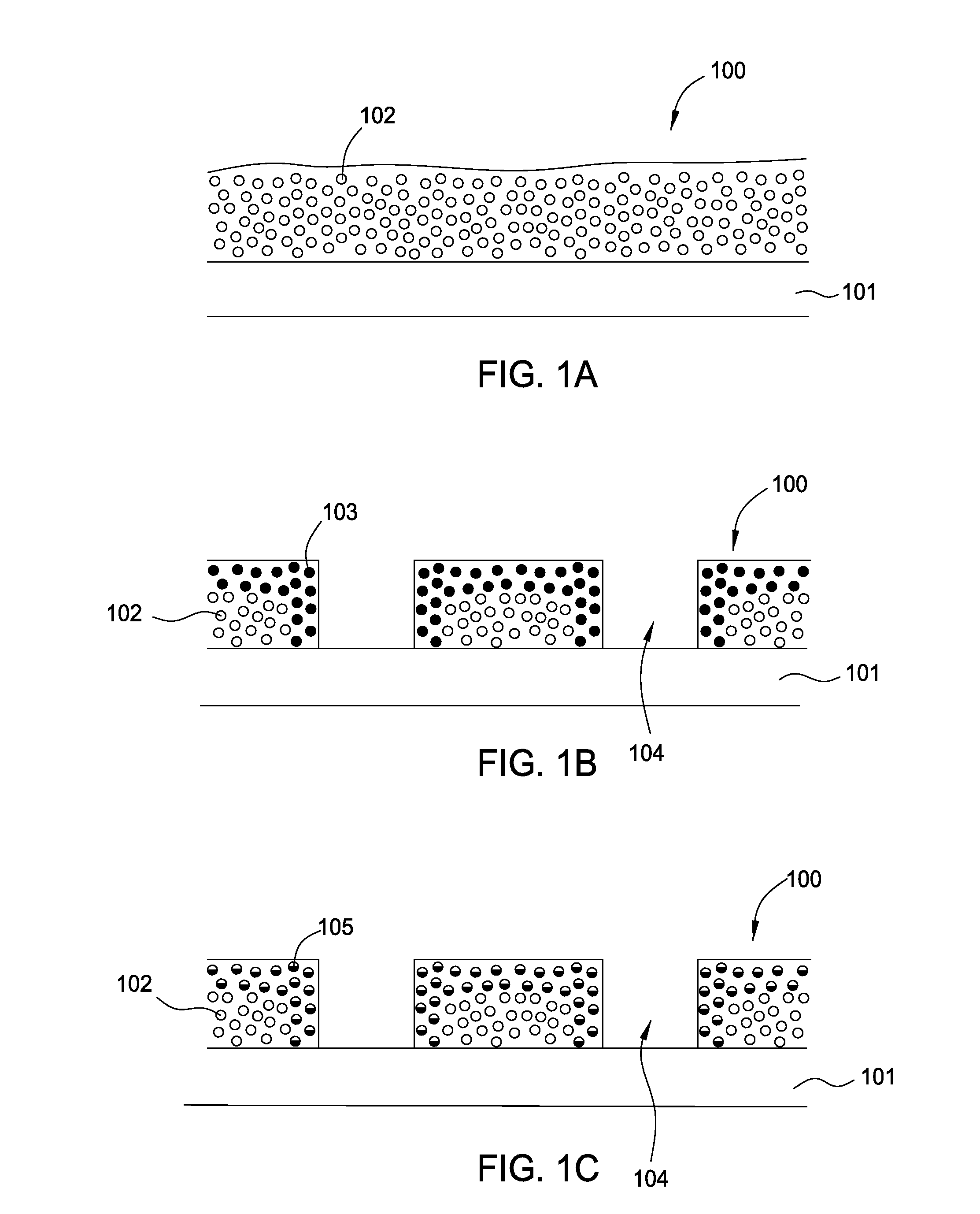

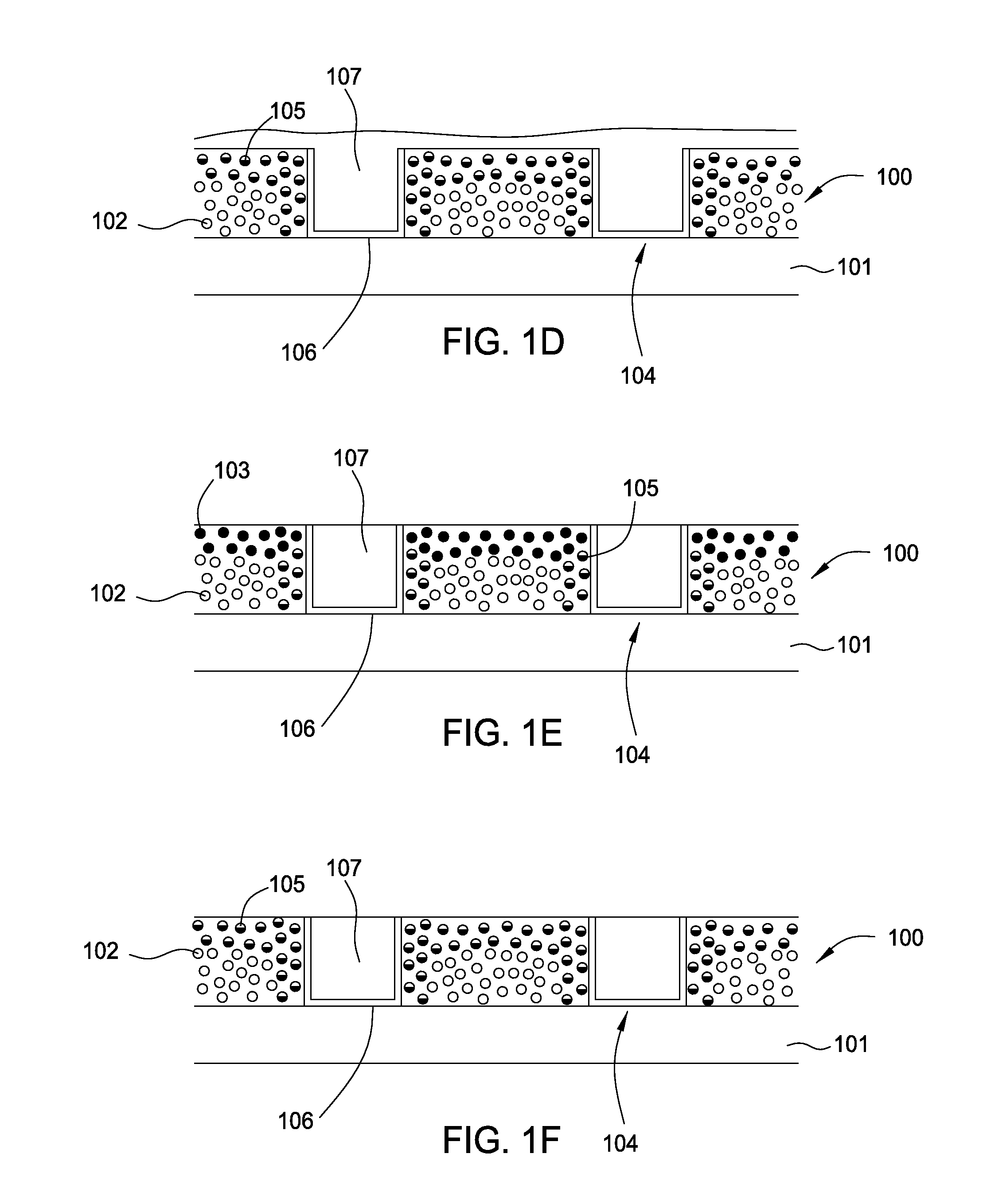

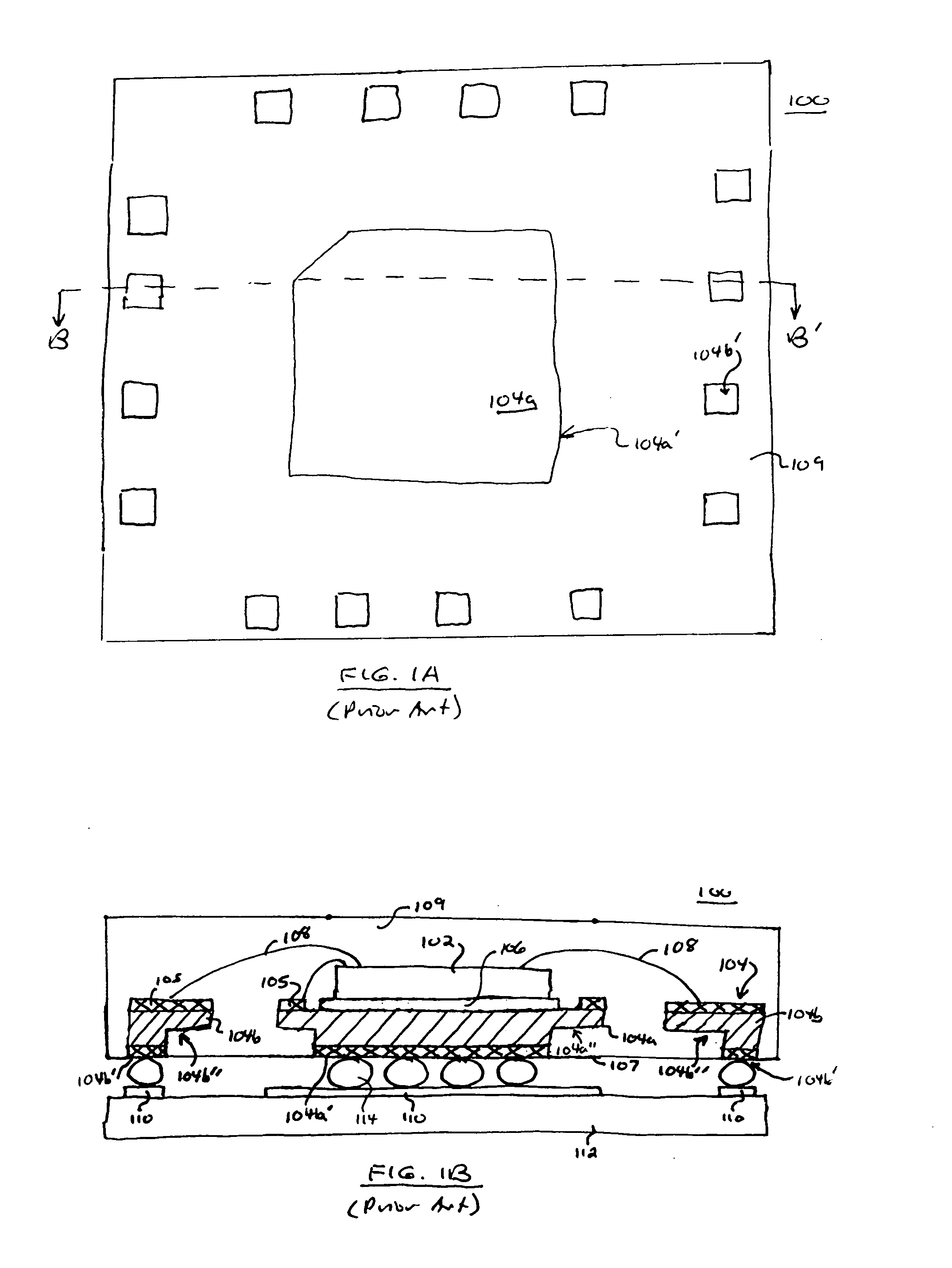

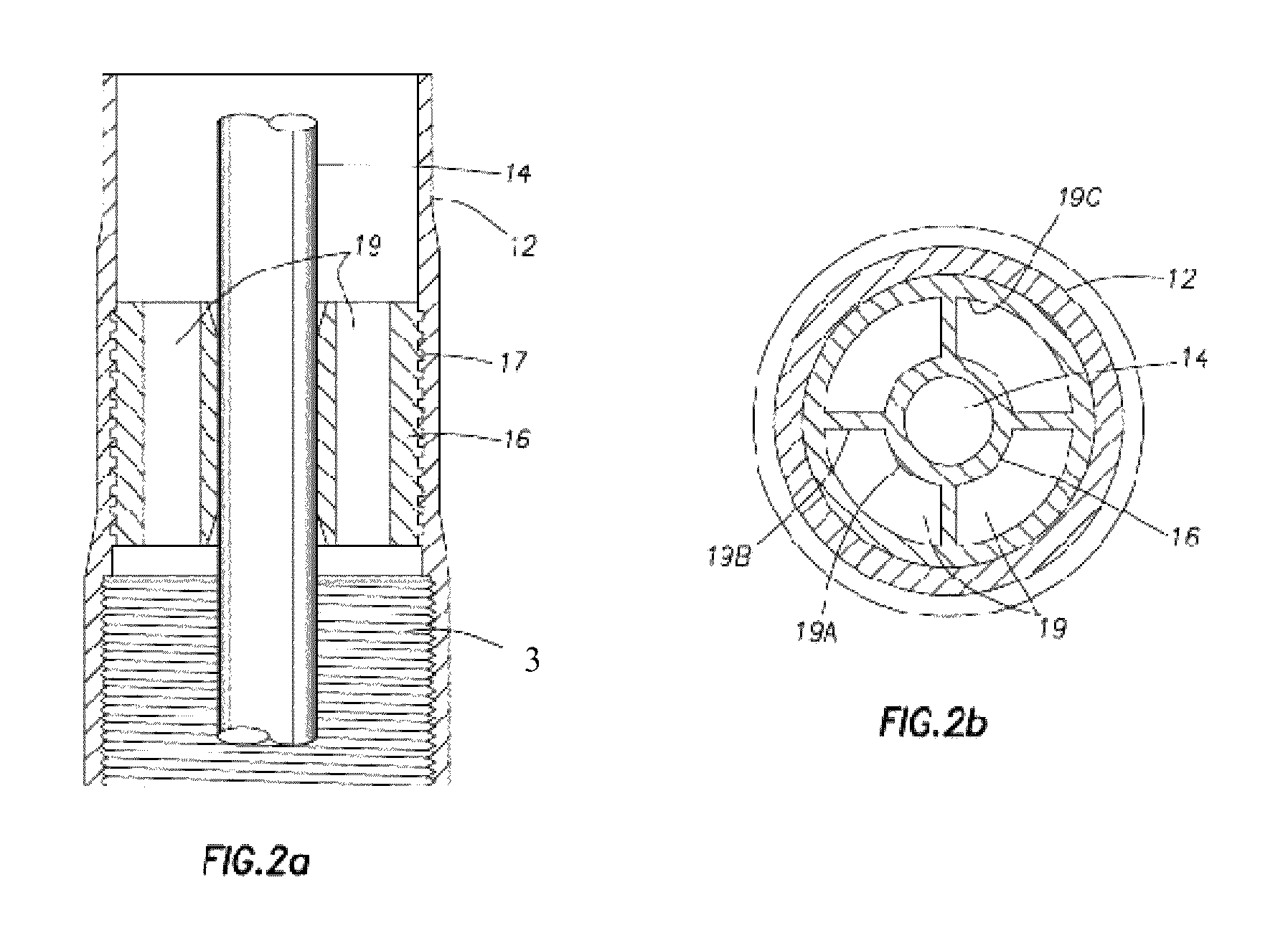

Tsvs having chemically exposed TSV tips for integrated circuit devices

ActiveUS20090278238A1Lower performance requirementsReduce yieldSemiconductor/solid-state device detailsSolid-state devicesEtchingChemical exposure

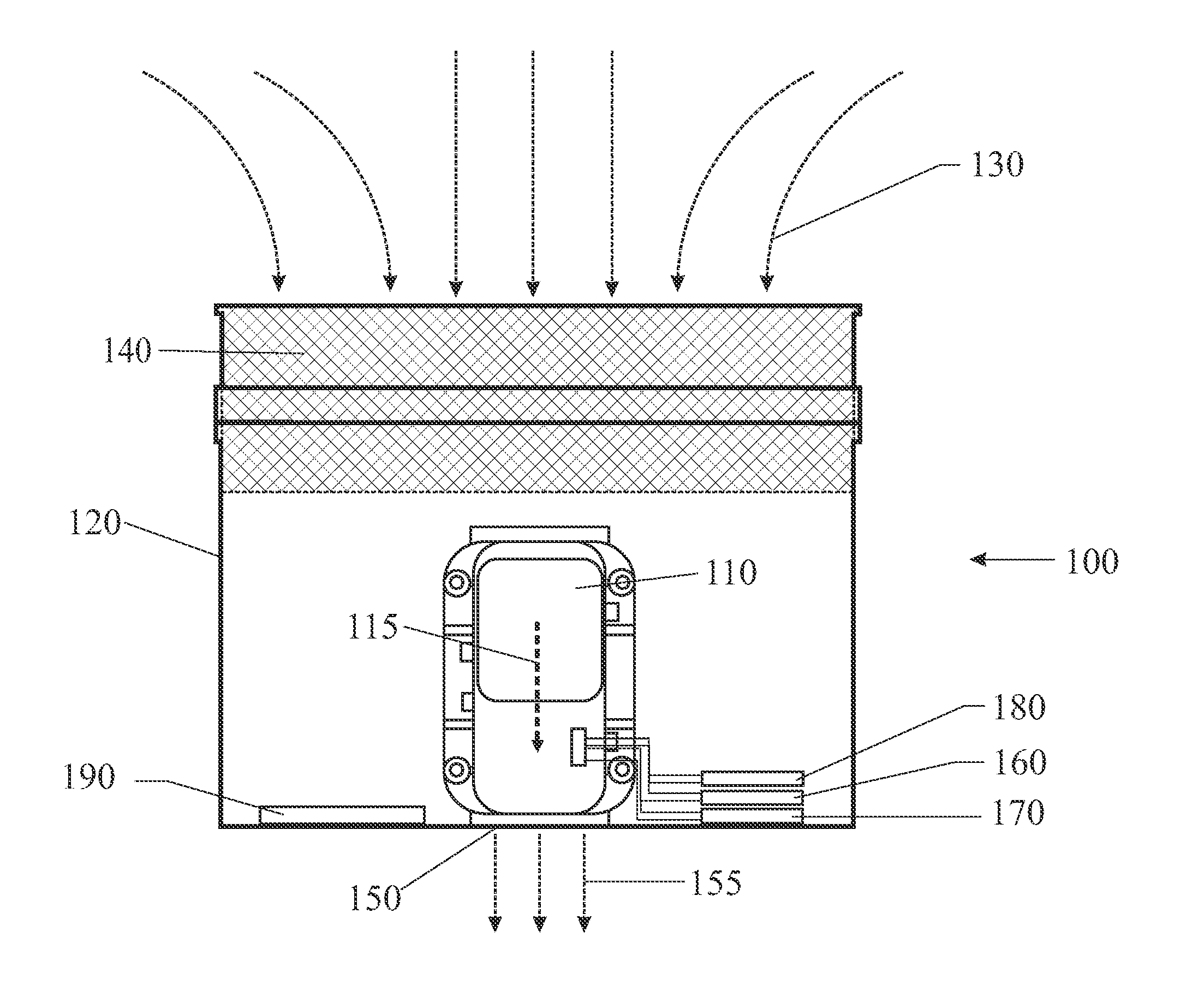

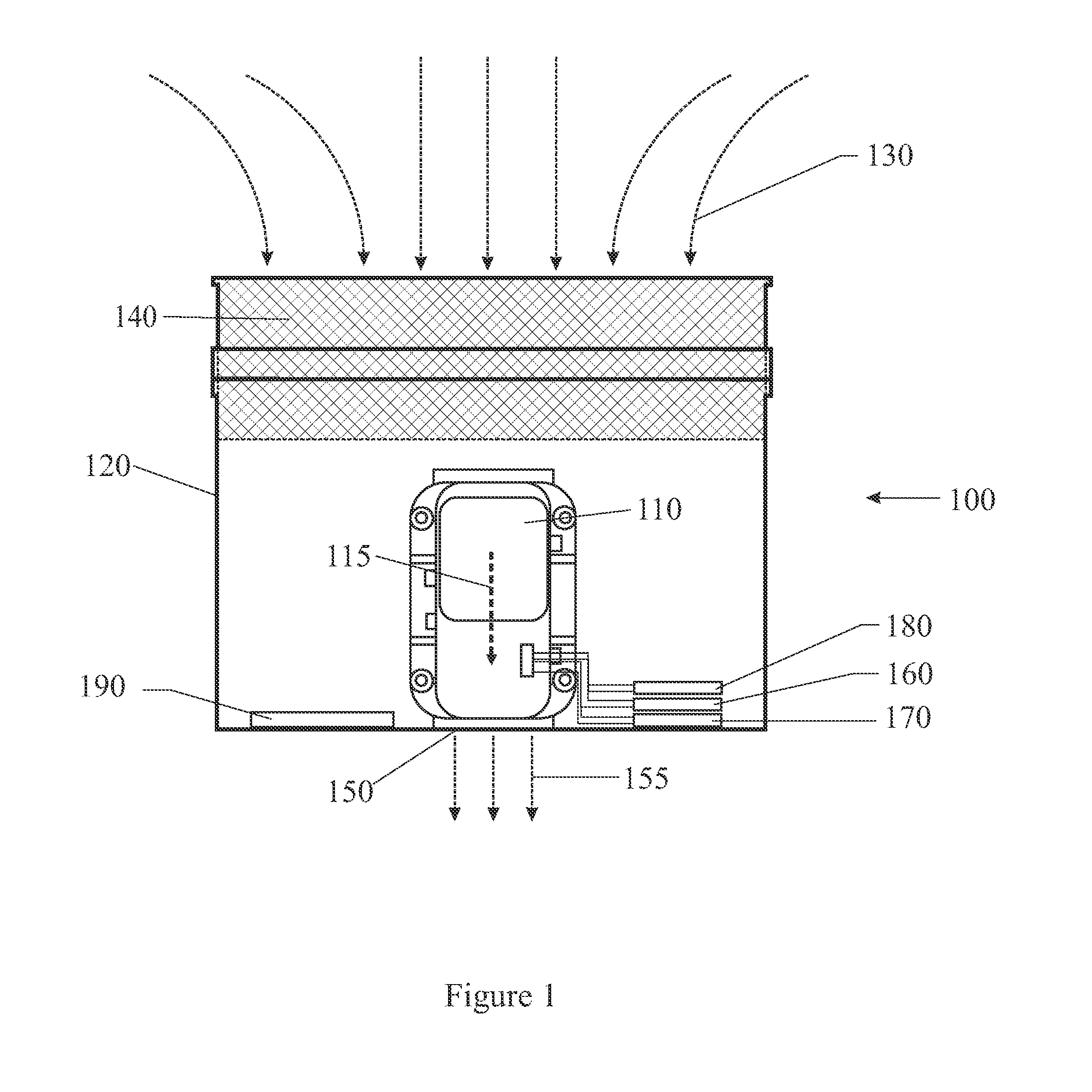

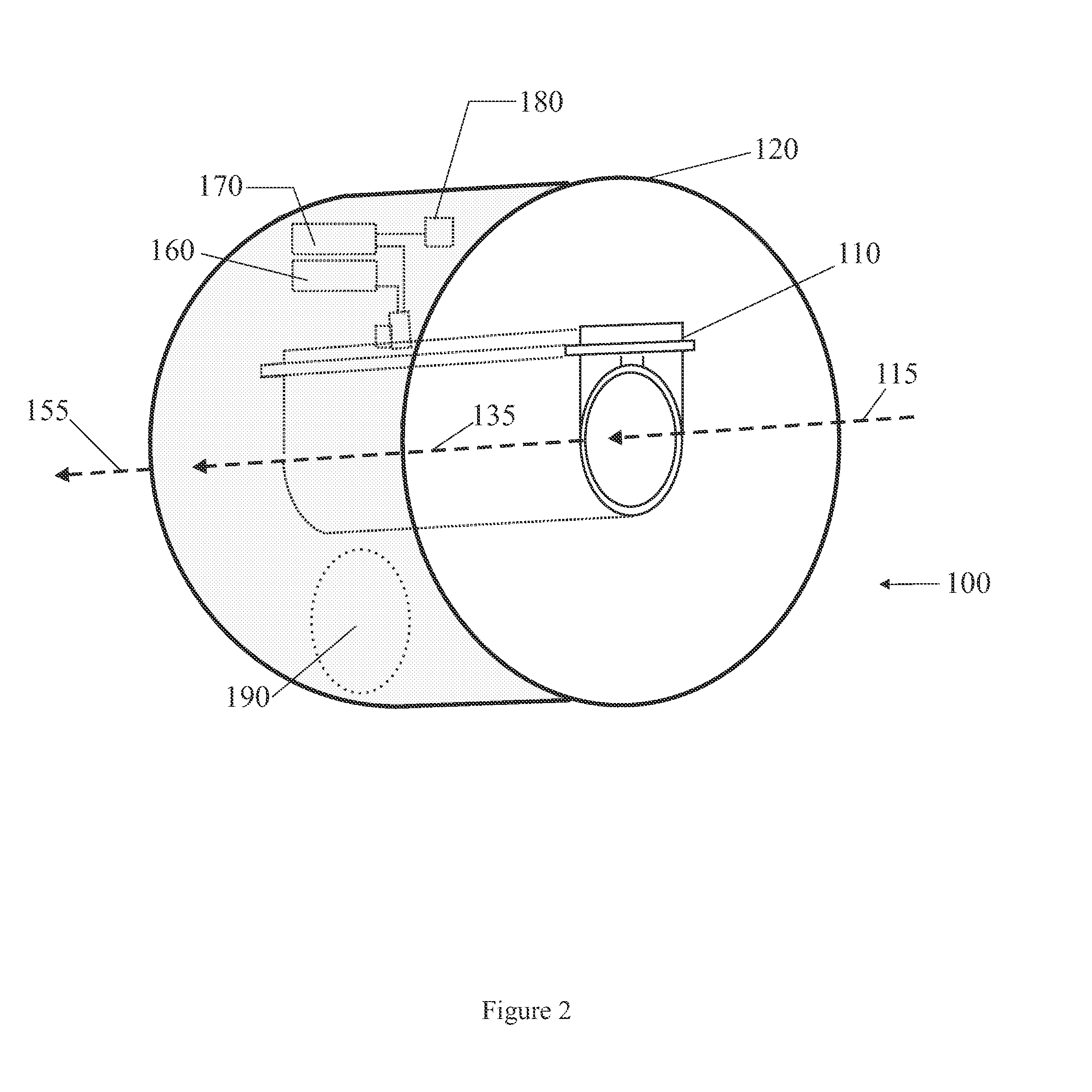

A method for fabricating ICs including via-first through substrate vias (TSVs) and ICs and electronic assemblies therefrom. A substrate having a substrate thickness including a top semiconductor surface and a bottom surface is provided including at least one embedded TSV including a dielectric liner and an electrically conductive filler material formed on the dielectric liner. A portion of the bottom surface of the substrate is mechanically removed to approach but not reach the embedded TSV tip. A protective substrate layer having a protective layer thickness remains over the tip of the embedded TSV after the mechanical removing. Chemical etching exclusive of mechanical etching for removing the protective substrate layer is used form an integral TSV tip that has an exposed tip portion that generally protrudes from the bottom surface of the substrate. The chemical etching is generally a three step chemical etch.

Owner:TEXAS INSTR INC

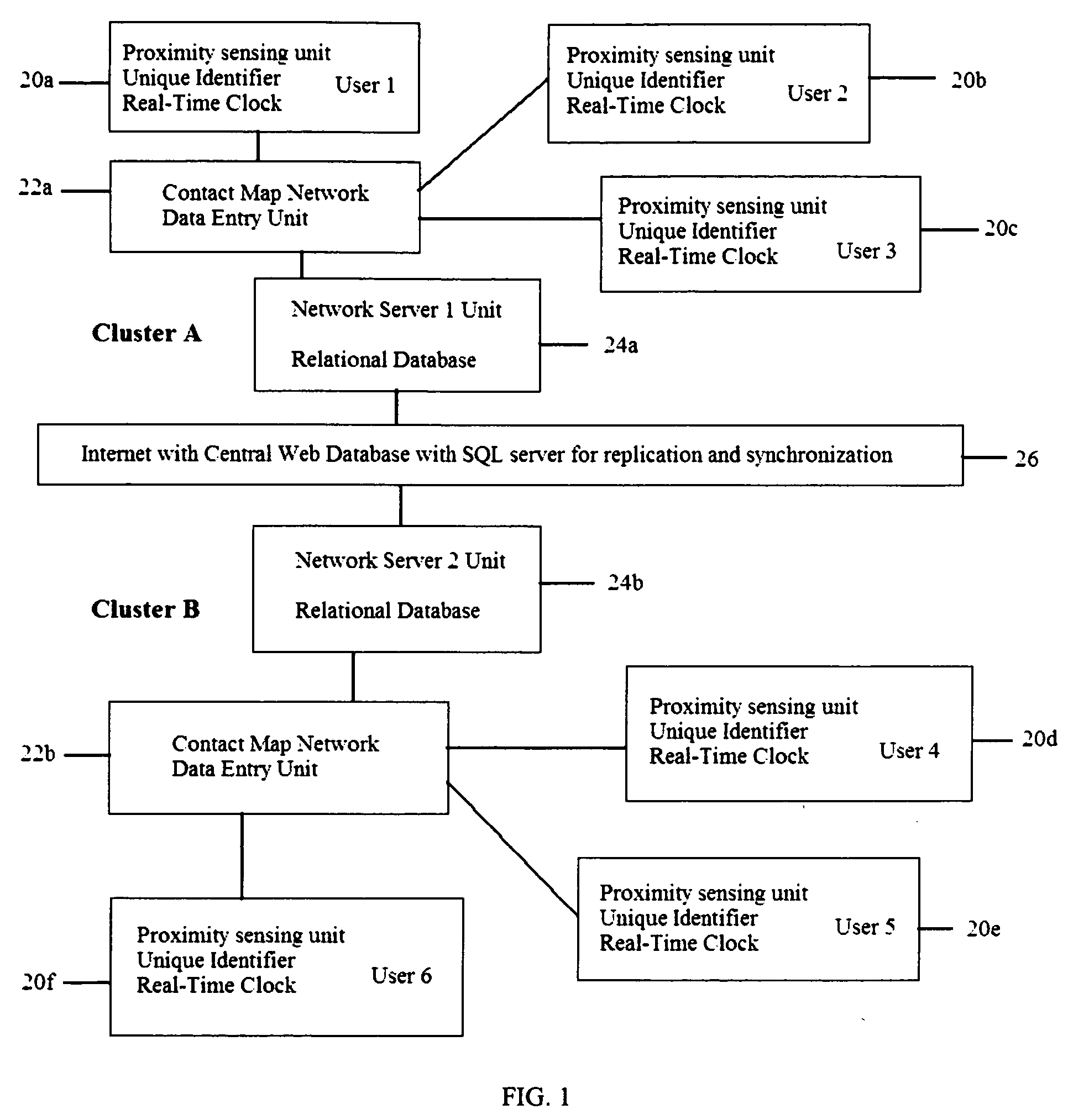

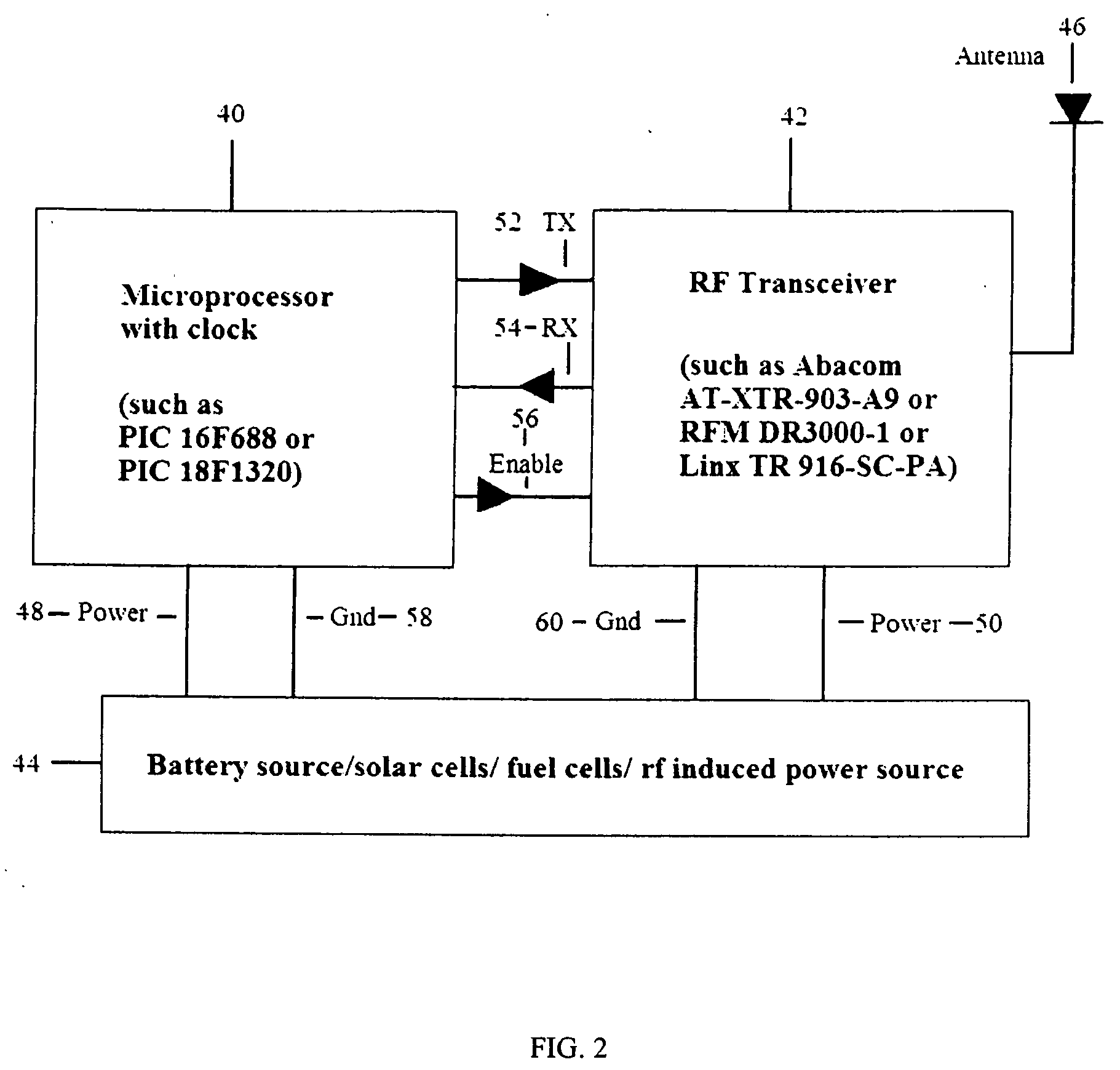

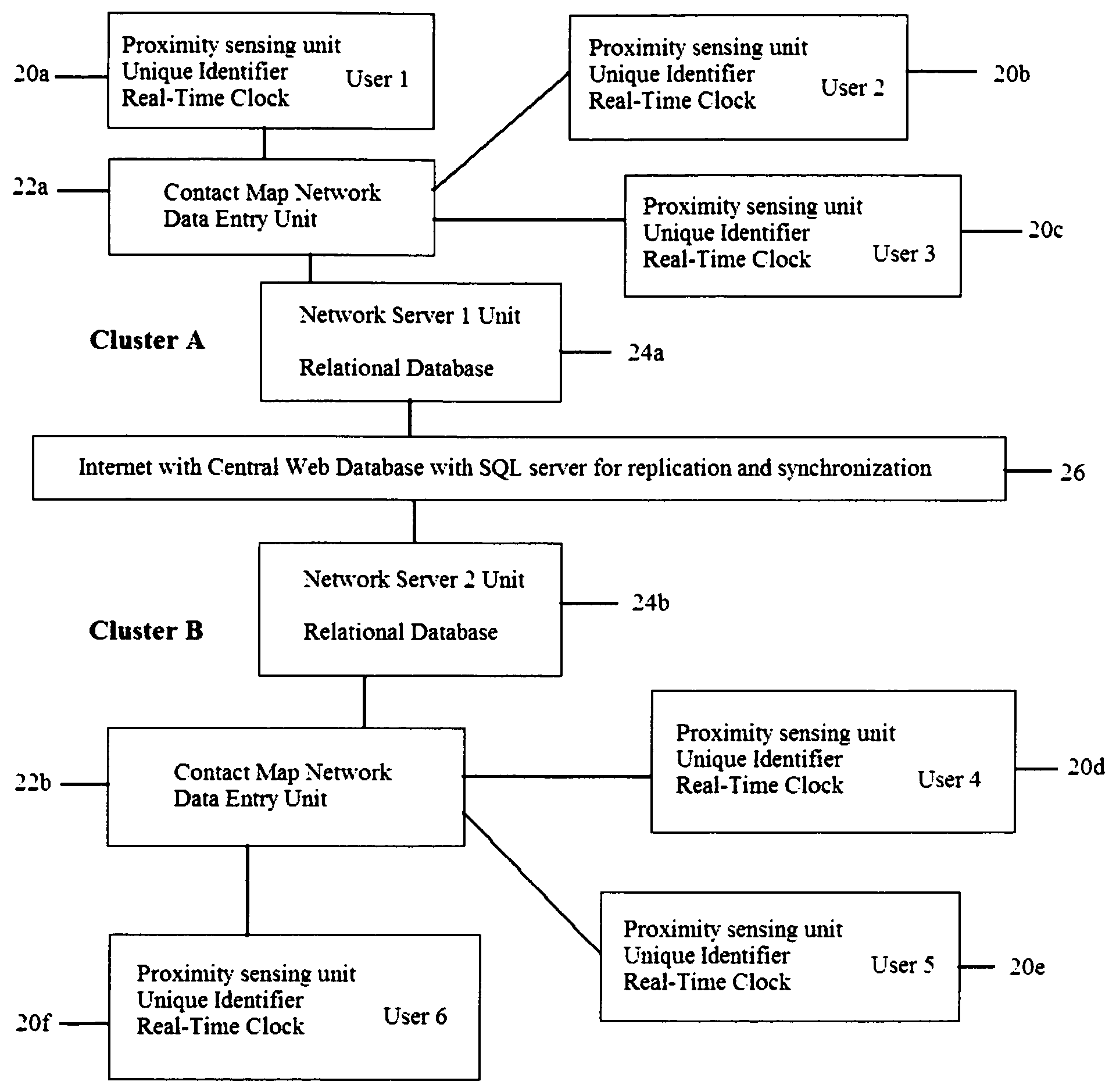

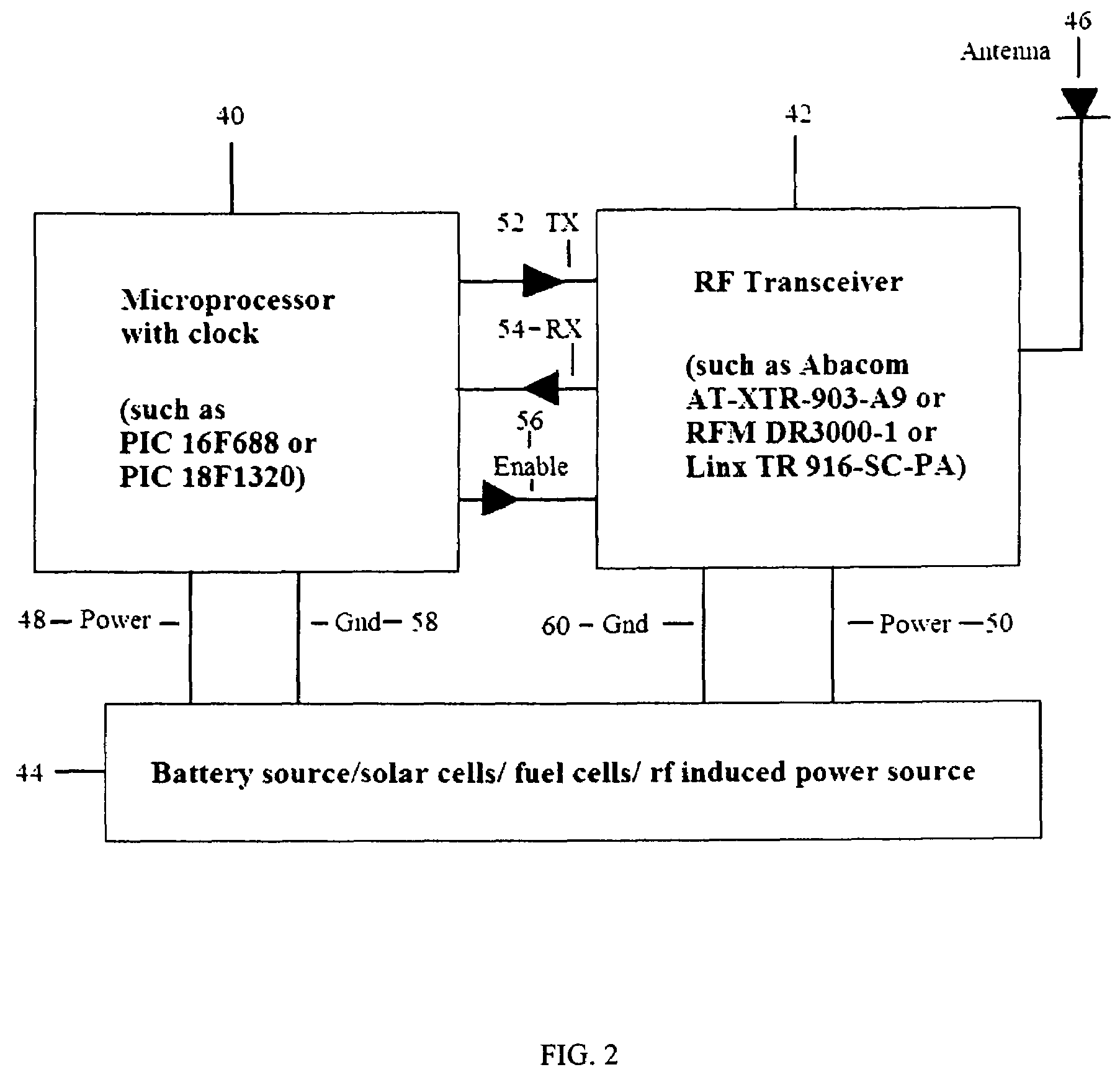

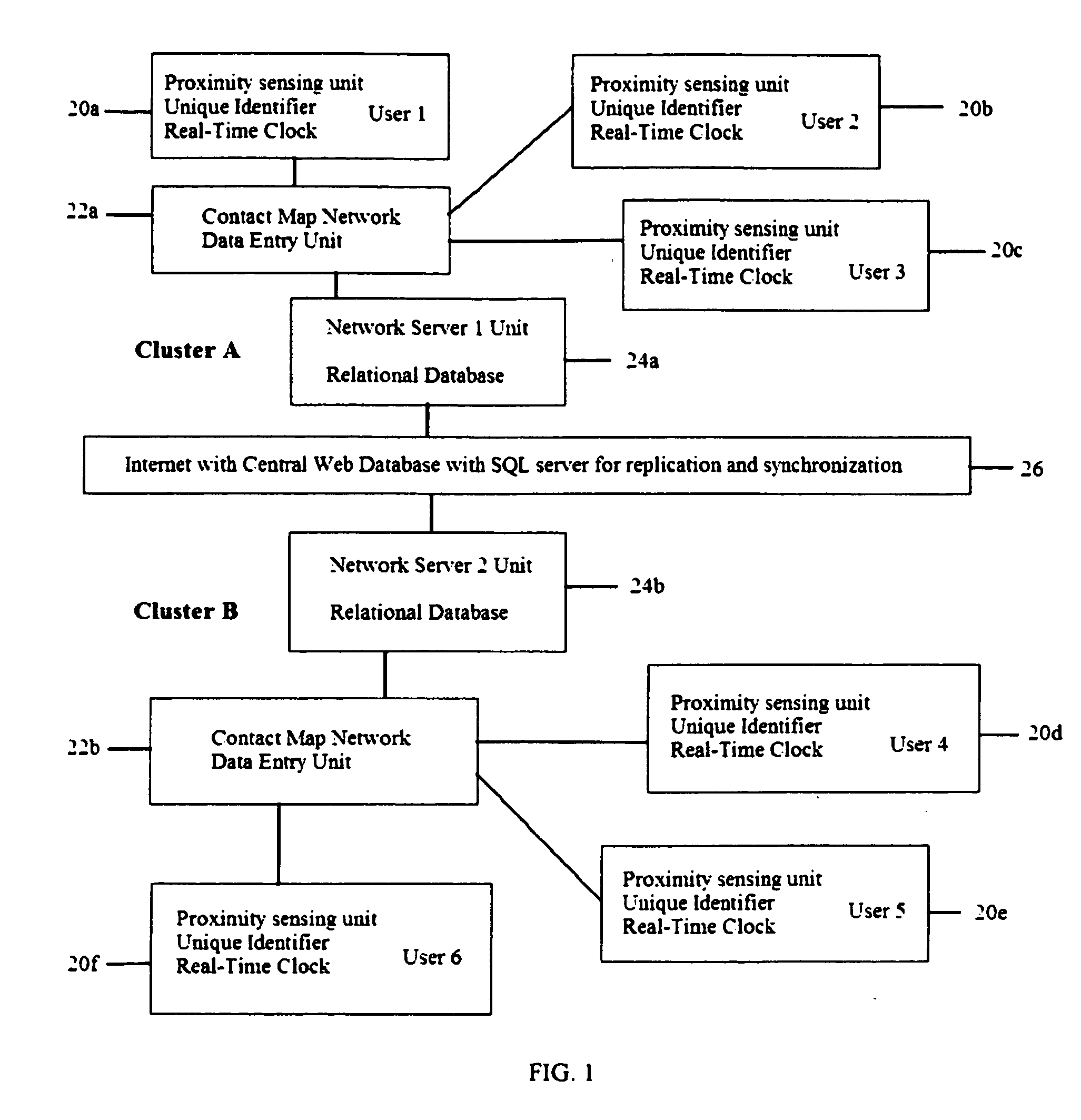

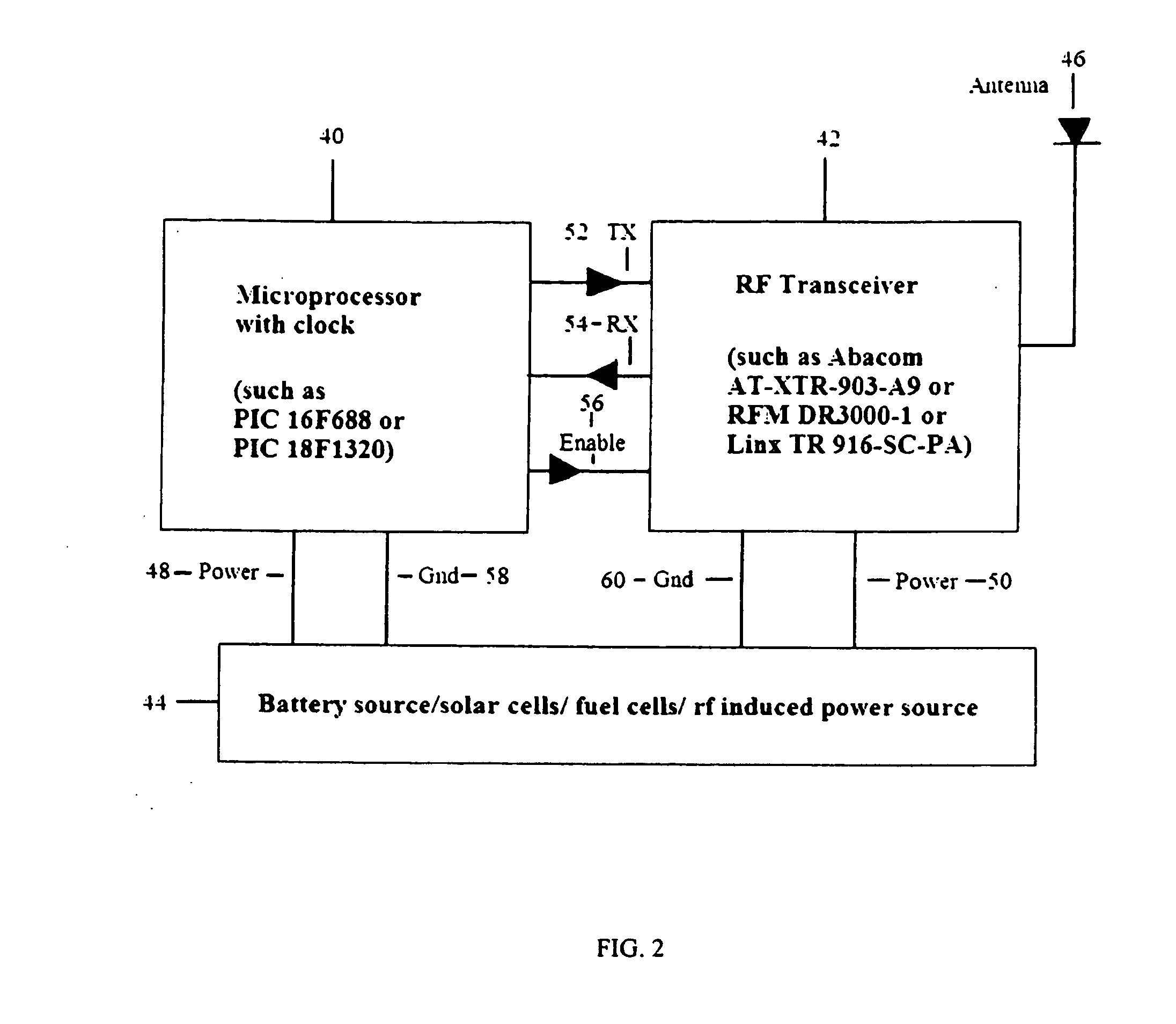

System and method for creating a proximity map of plurality of living beings and objects

A proximity network map defines who and what objects have come in contact of each other including location and time. This map selects the list people who have come in contact with known infected people based on contagious disease epidemiology criteria to control its spread, or to prevent radiation poisoning, limit bio-chemicals exposure, etc. These people then undergo testing and quarantine procedures. It monitors hygiene practices and reduces nosocomial infections in hospitals and mitigates the pandemic flu threat by controlling contamination. It controls people interaction, information flow in a high security environment, control crime or gang activities. Each person or object carrying a proximity-sensing unit with unique ID records all units it encountered over a period of time. This information is stored with time stamp in a relational database and transferred to network servers. The databases are then replication throughout via a central web database server for retrieval and analysis.

Owner:WONG CHON MENG

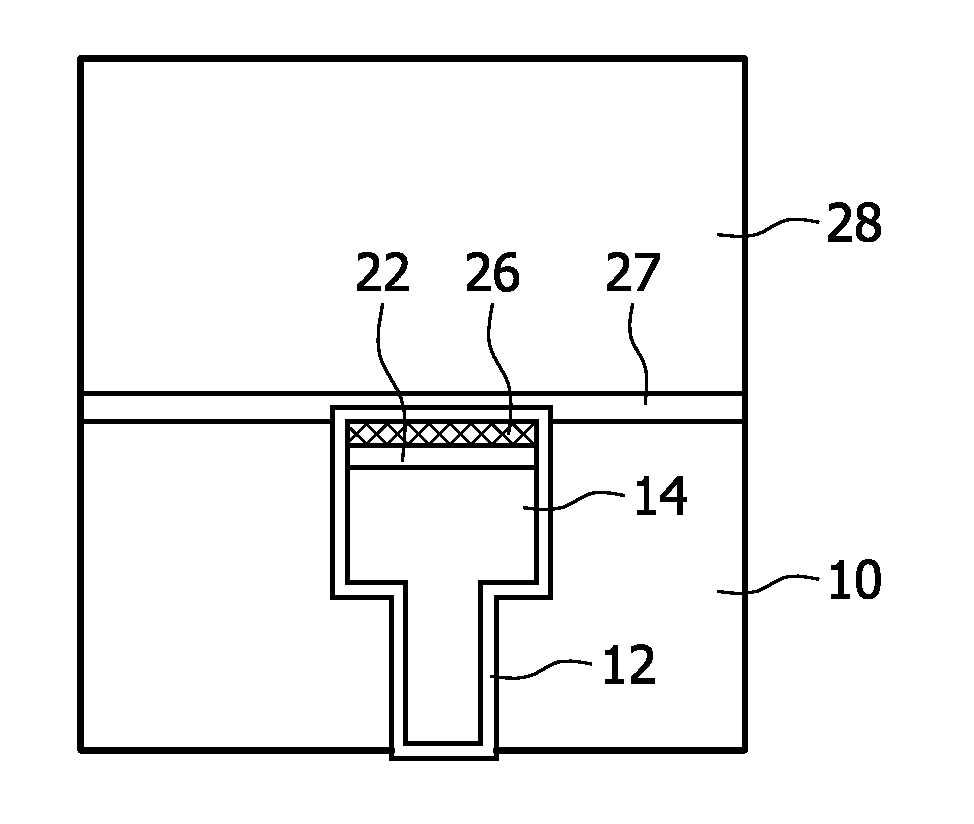

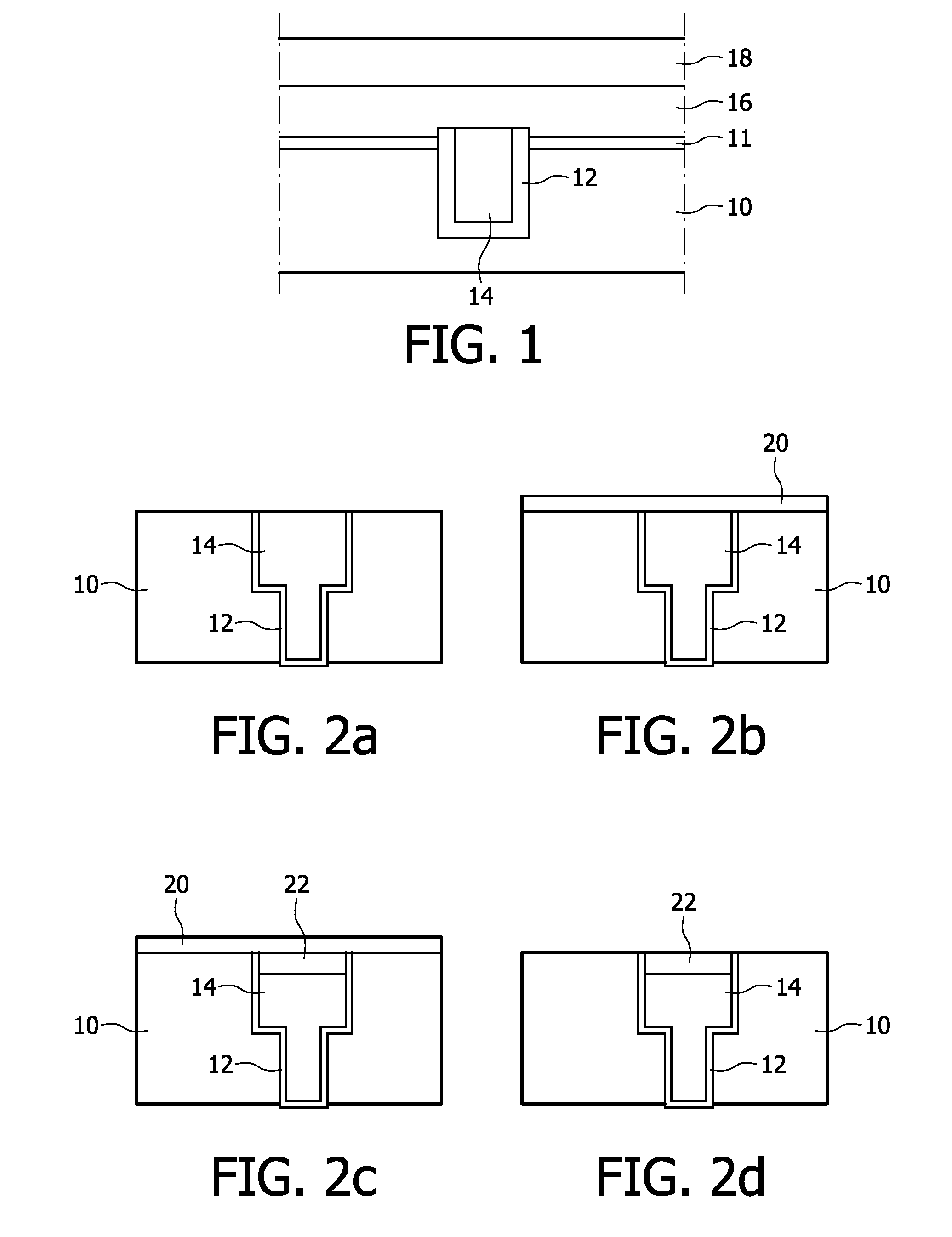

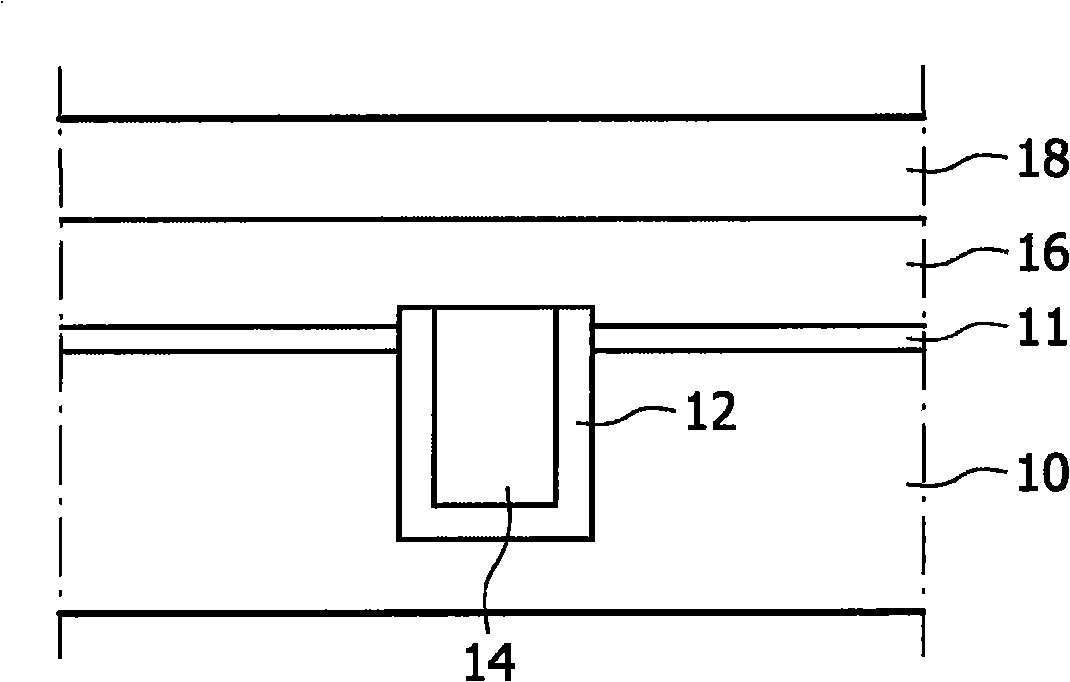

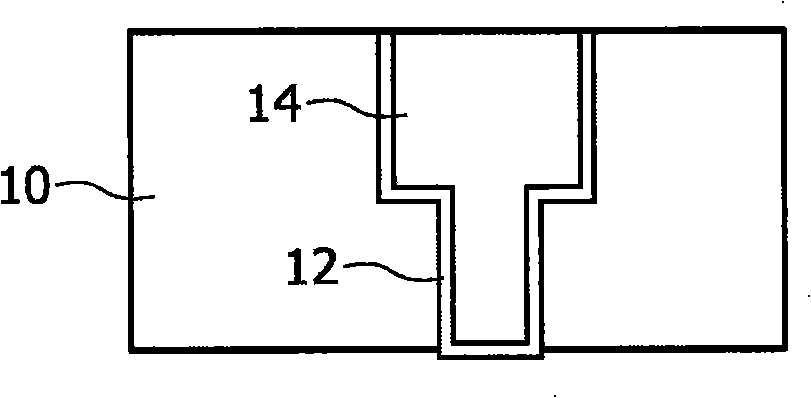

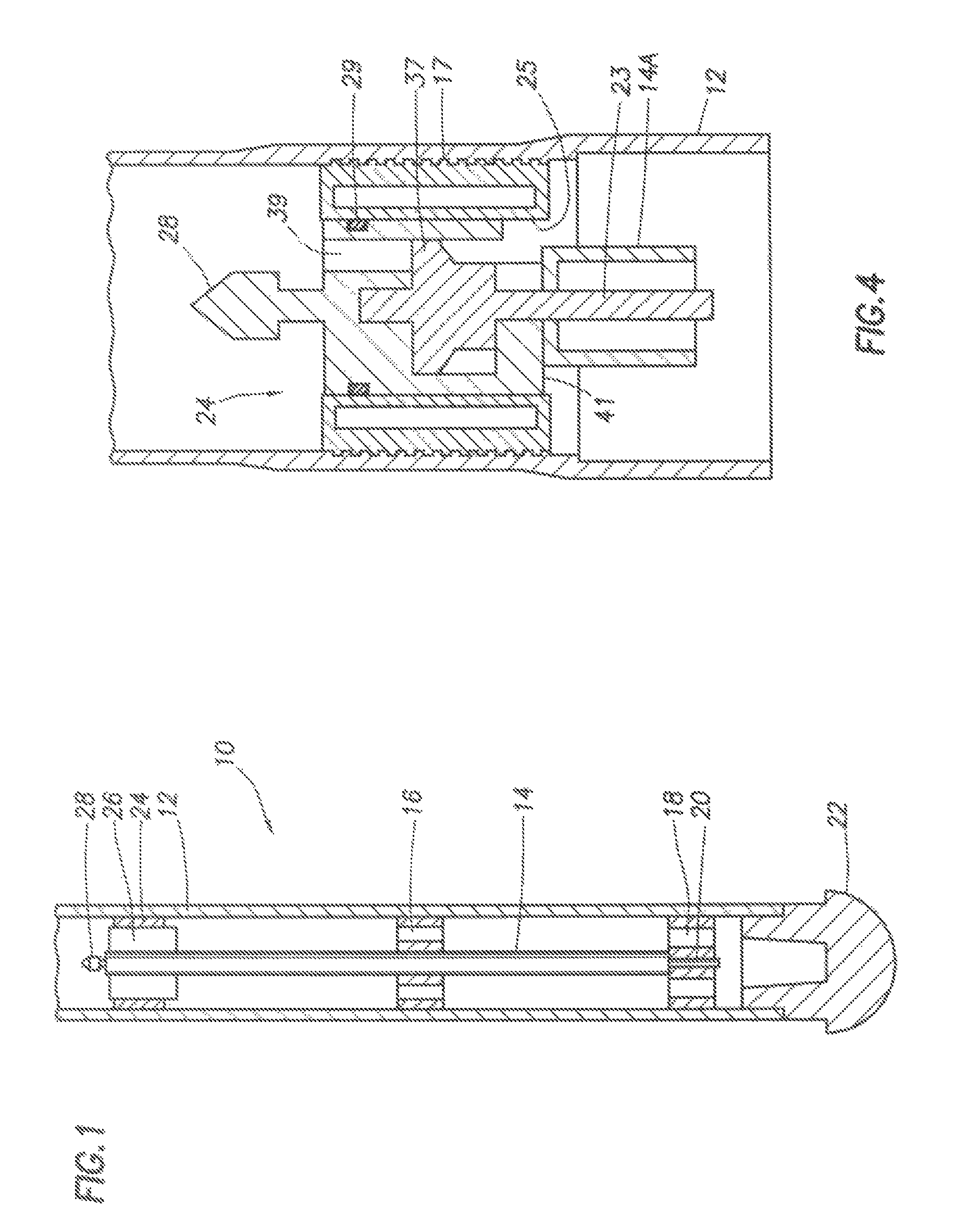

Method of Forming a Self Aligned Copper Capping Layer

InactiveUS20080311739A1Prevent further spreadPreventing inter-metal line leakageSemiconductor/solid-state device detailsSolid-state devicesCopper interconnectChemical exposure

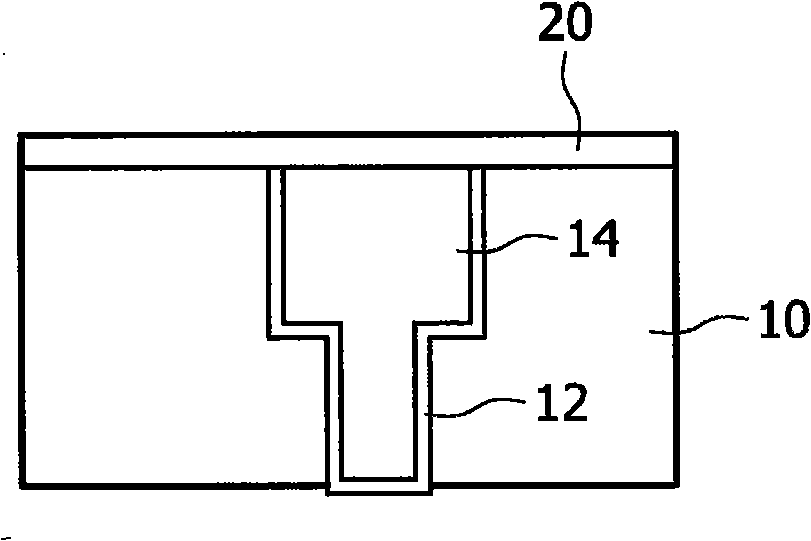

A method of forming a capping layer on a copper interconnect line (14). The method comprises providing a layer (20) of Aluminium over the interconnect line (14) and the dielectric layer (10) in which it is embedded. This may be achieved by deposition or chemical exposure. The structure is then subjected to a process, such as annealing or further chemical exposure, in an environment containing, for example, Nitrogen atoms, so as to cause indiffusion of Al into the copper line (14) and nitridation to form a diffusion barrier 26 of the intermetallic compound CuAlN.

Owner:NXP BV

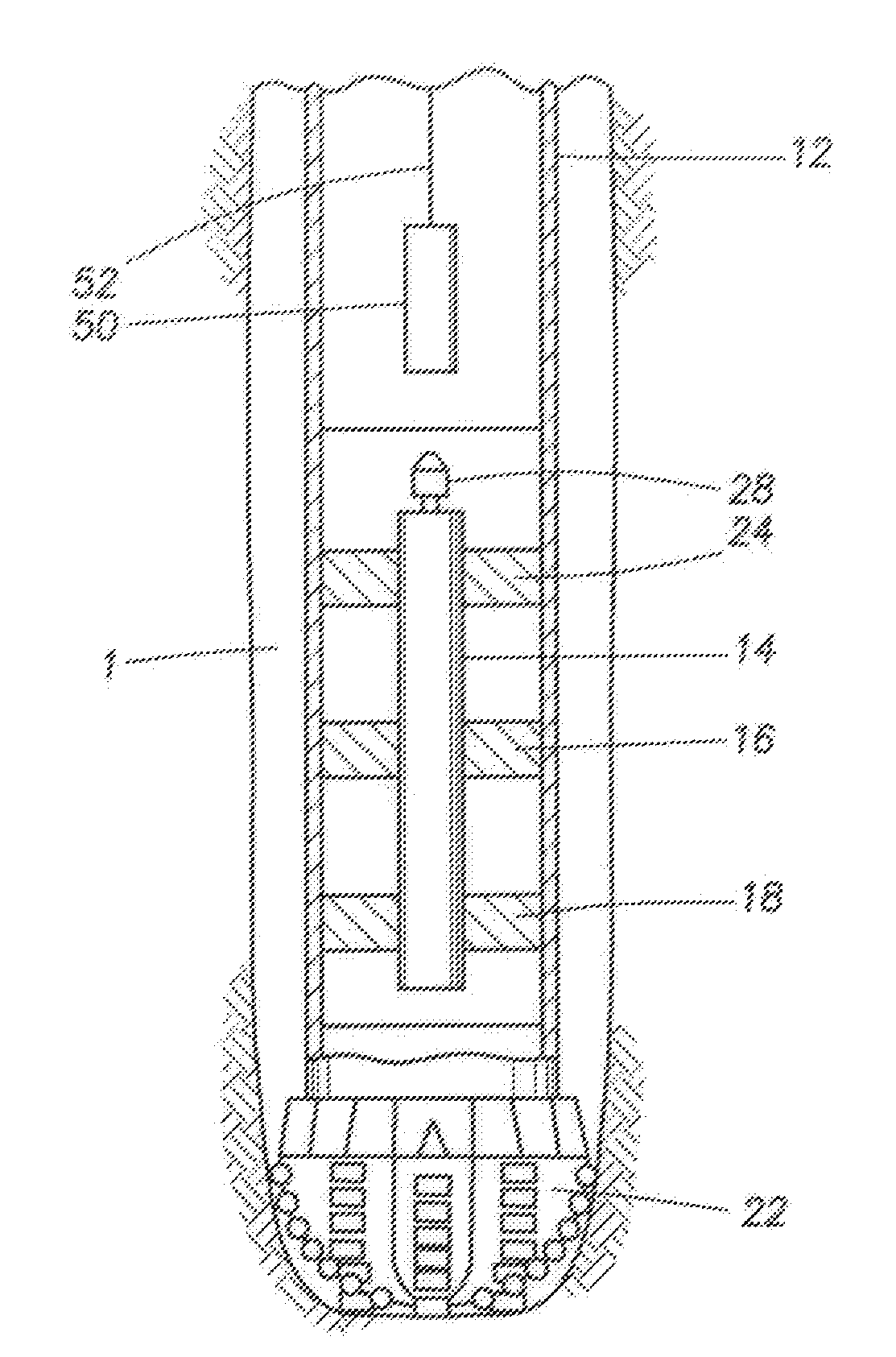

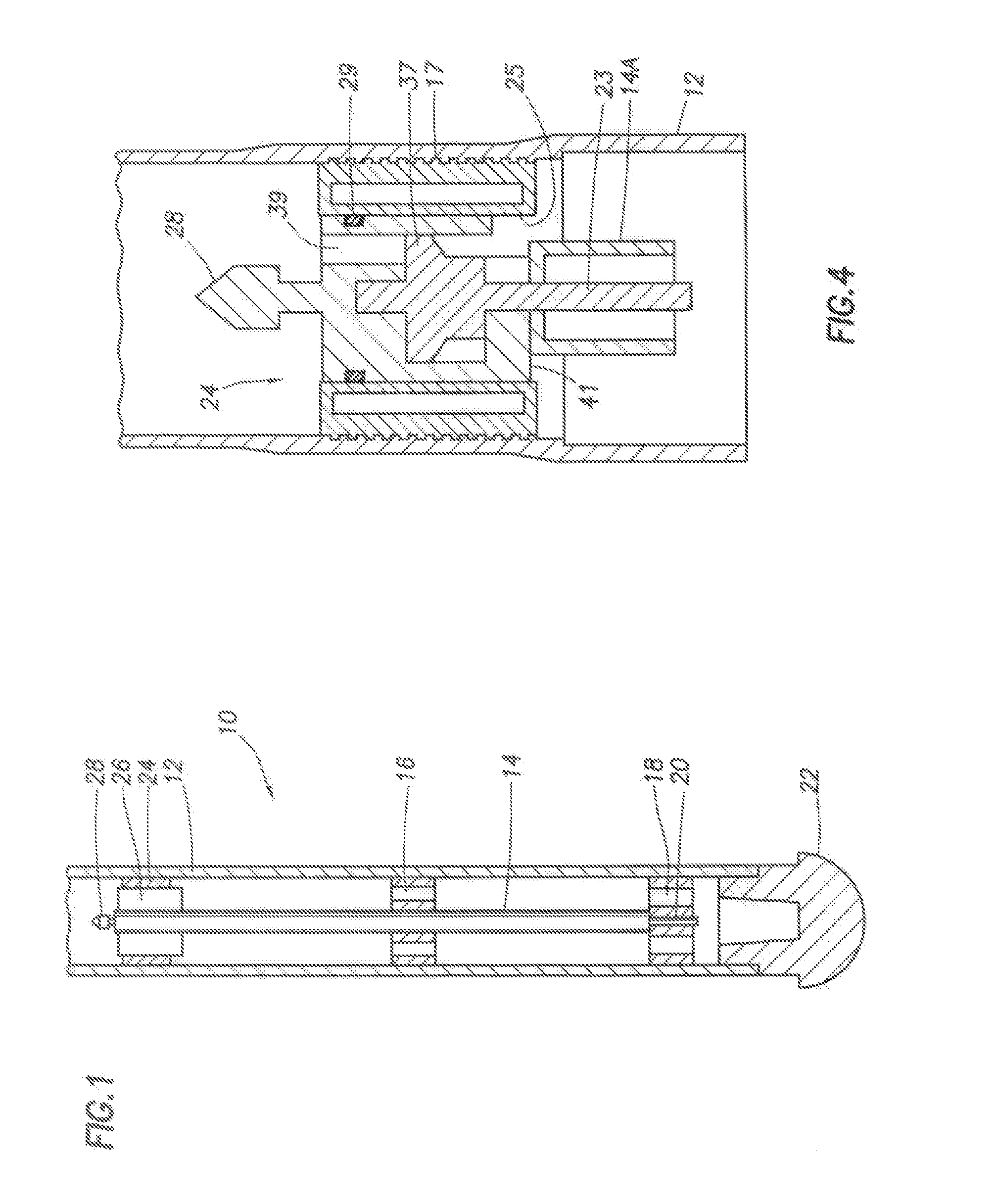

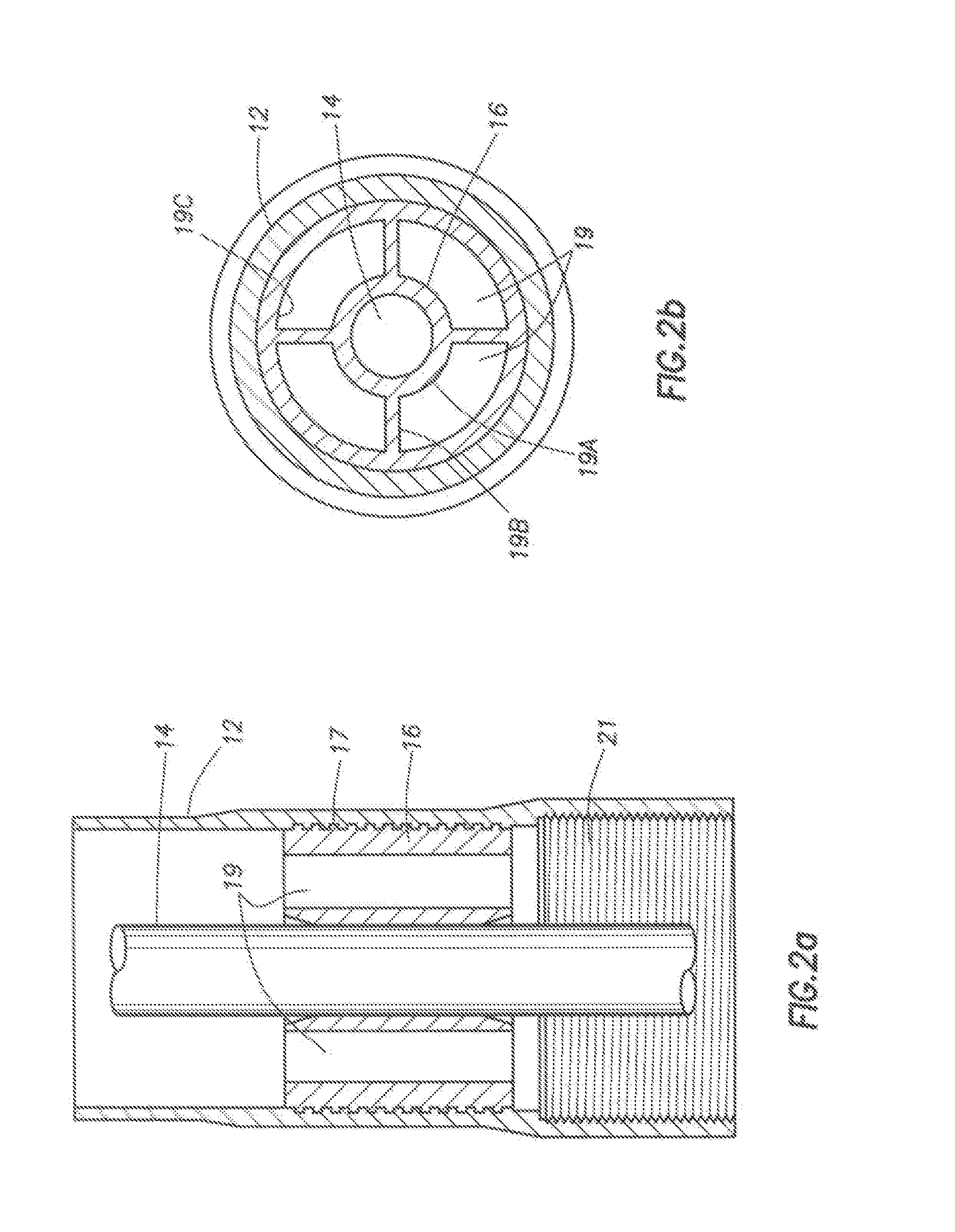

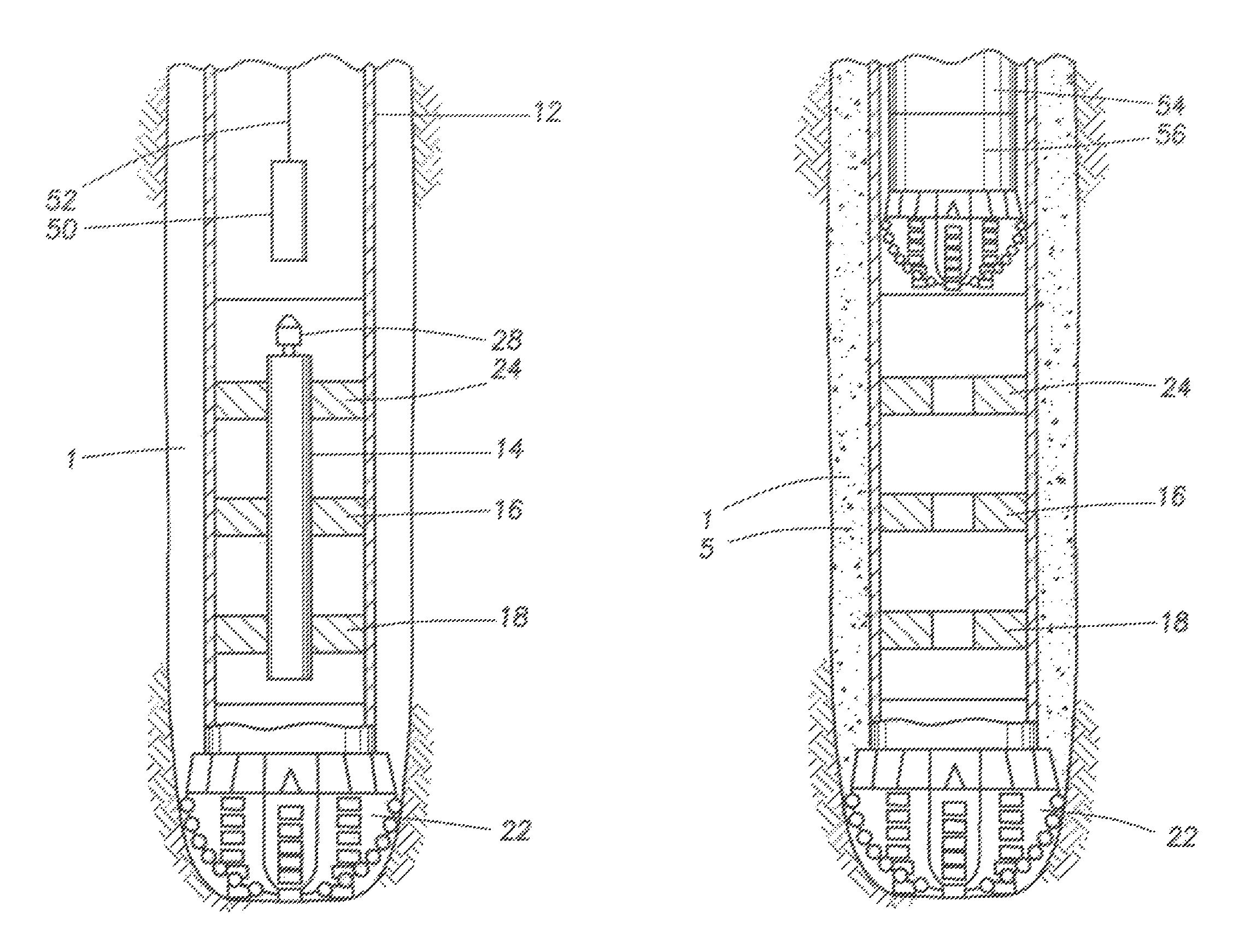

System and method for making drilling parameter and or formation evaluation measurements during casing drilling

A casing drilling system includes a casing having a drill bit at one end. The drill bit is capable of drilling subsurface formations and formed from a material removable by drilling or chemical exposure. The chemical is substantially harmless to the casing. The system includes a centralizer affixed to an interior of the casing. The centralizer includes a receptacle therein for engaging a measurement while drilling tool. The centralizer is formed from a material removable by drilling or chemical exposure, wherein the chemical is substantially harmless to the casing. The system includes a measurement while drilling tool configured to move along the interior of the casing and to engage with the centralizer. The tool includes a device to measure a drilling parameter or a formation parameter. The tool including a latch at an upper end thereof for engagement with a retrieval tool moved through the interior of the casing.

Owner:SCHLUMBERGER TECH CORP

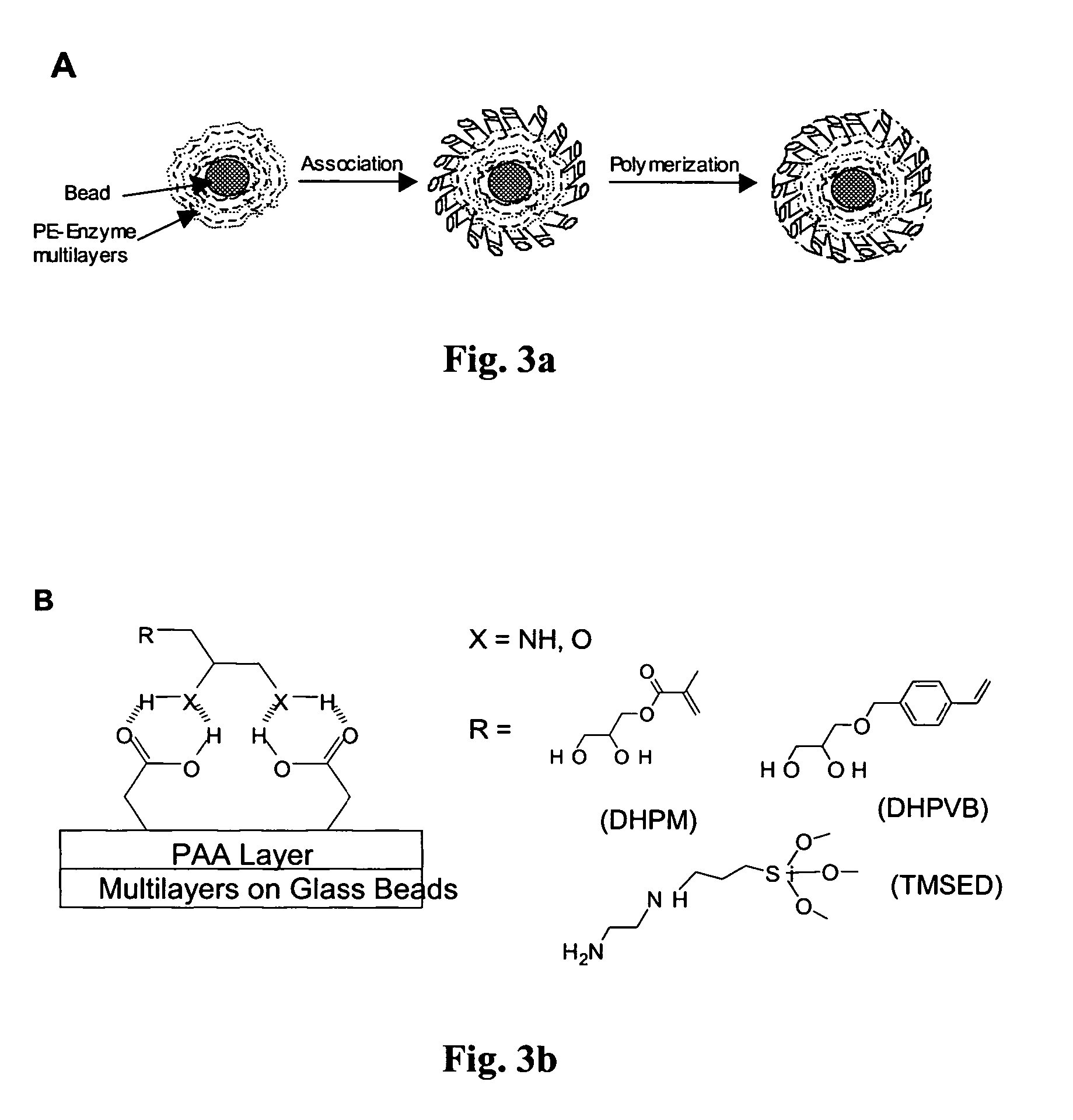

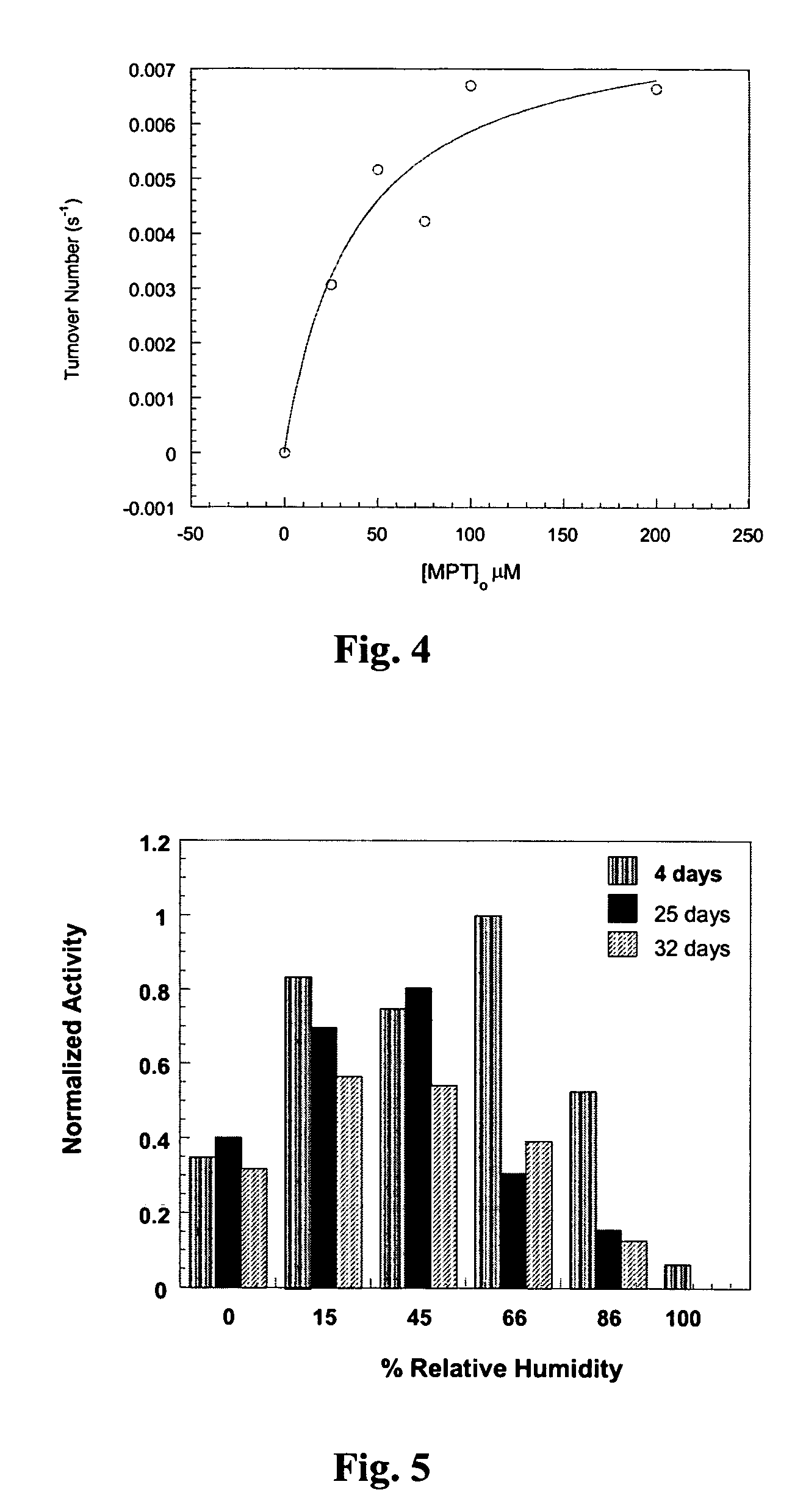

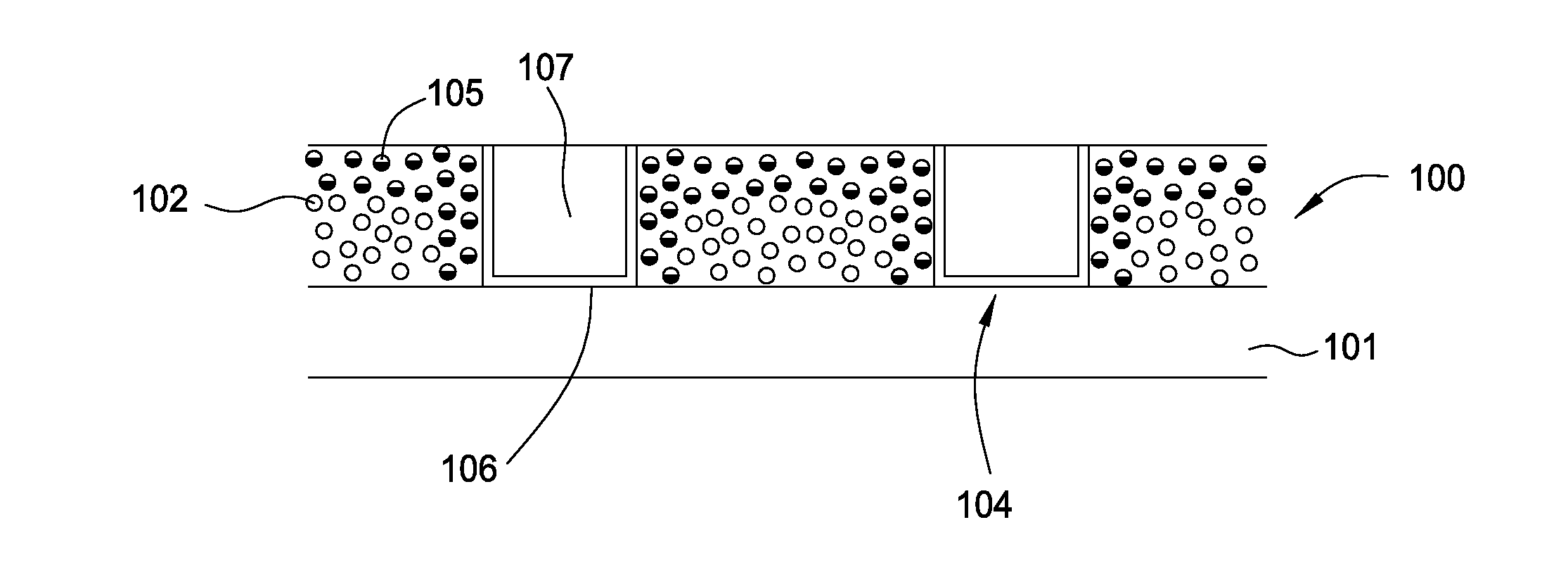

Catalytic surfaces for active protection from toxins

InactiveUS7067294B2High catalytic activityIncrease contactPeptide/protein ingredientsHydrolasesPolyelectrolyteChemical exposure

A bioactive catalytic material is disclosed for providing protection from chemical exposure. The material is composed of enzymes immobilized within polyelectrolyte multilayers and a polymerizable end-capping layer to render stability to enzymes. Also disclosed is the related method for making a bioactive catalytic material and their deposition on substrates of varying size, shape and flexibility for providing active protection from chemical exposure.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

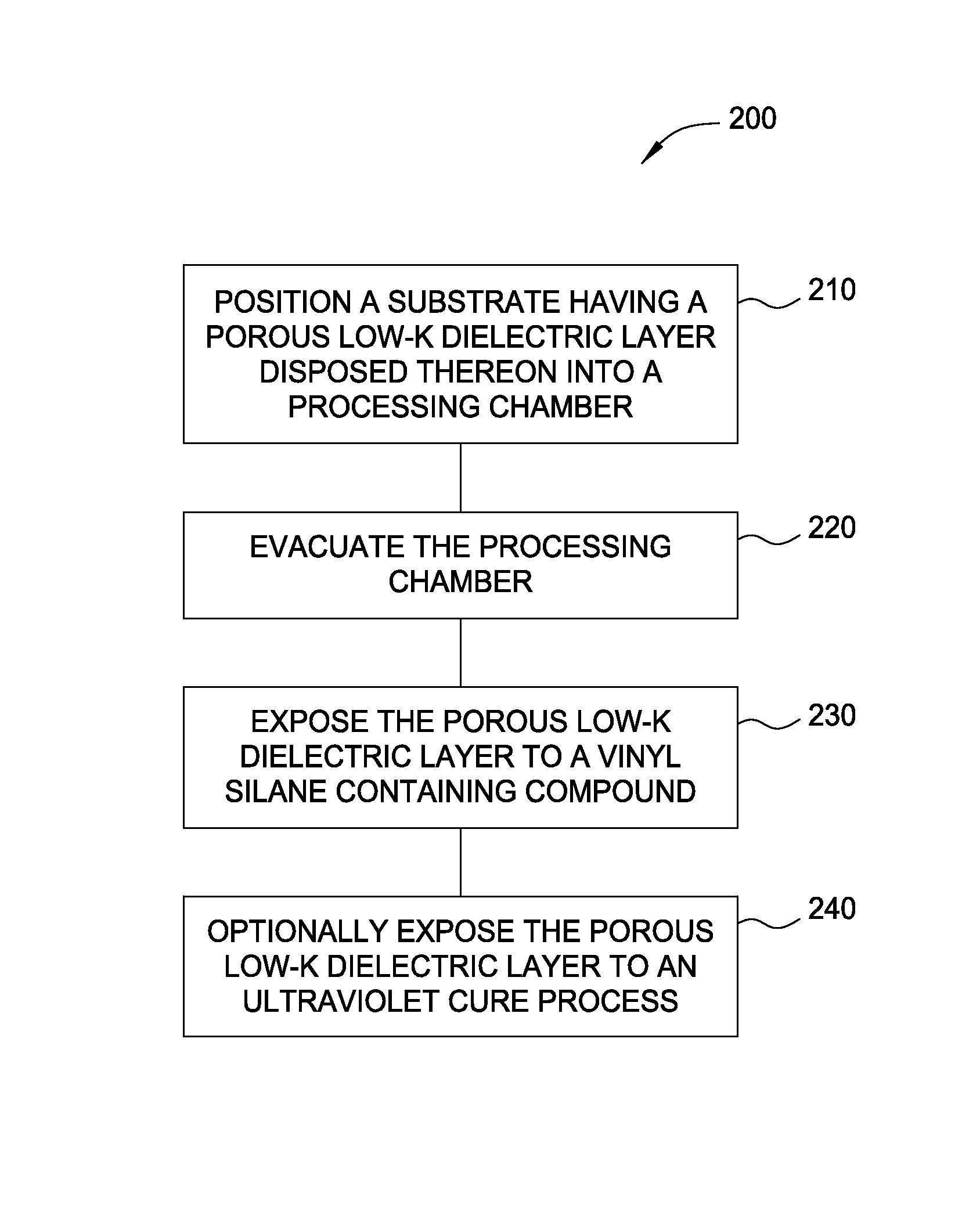

Low-k dielectric damage repair by vapor-phase chemical exposure

ActiveUS20140004717A1Dielectric constant be lowerSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseSilanes

A method for repairing and lowering the dielectric constant of low-k dielectric layers used in semiconductor fabrication is provided. In one implementation, a method of repairing a damaged low-k dielectric layer comprising exposing the porous low-k dielectric layer to a vinyl silane containing compound and optionally exposing the porous low-k dielectric layer to an ultraviolet (UV) cure process.

Owner:APPLIED MATERIALS INC

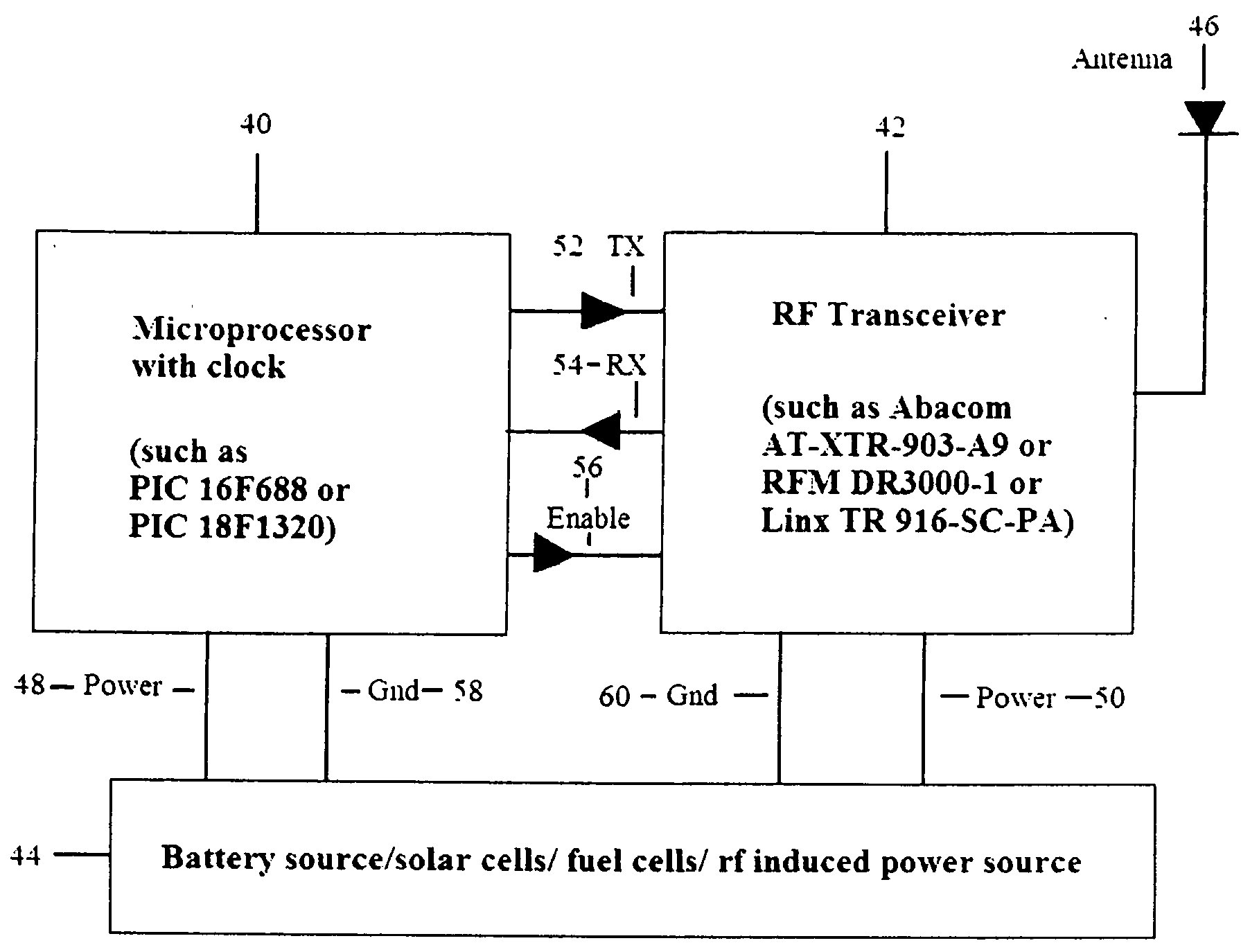

System and method for creating a proximity map of plurality of living beings and objects

A proximity network map defines who and what objects have come in contact of each other including location and time. This map selects the list people who have come in contact with known infected people based on contagious disease epidemiology criteria to control its spread, or to prevent radiation poisoning, limit bio-chemicals exposure, etc. These people then undergo testing and quarantine procedures. It monitors hygiene practices and reduces nosocomial infections in hospitals and mitigates the pandemic flu threat by controlling contamination. It controls people interaction, information flow in a high security environment, control crime or gang activities. Each person or object carrying a proximity-sensing unit with unique ID records all units it encountered over a period of time. This information is stored with time stamp in a relational database and transferred to network servers. The databases are then replication throughout via a central web database server for retrieval and analysis.

Owner:WONG CHON MENG

System and method for creating a proximity map of living beings and objects

A contact or proximity network map defines who and what objects have come in contact of each other including location and time. This map selects the list people who have come in contact with known infected people based on contagious disease epidemiology criteria for the purpose of control its spread, or to prevent radiation poisoning, limit bio-chemicals exposure, etc. This selected list of people then undergoes testing and quarantine procedures. It can monitor hygiene practices and reduce nosocomial infections in hospitals and mitigate the pandemic flu threat by controlling spread and control contamination. It controls people interaction, information flow in a high security environment, control crime or gang activities. Each person or object has a proximity-sensing device with unique ID, which is recorded by the encountered units during contact. This information is stored with time stamp in a relational database. It generates contact maps with real time replication of its database via a central web database for retrieval and analysis at any site.

Owner:WONG CHON MENG

TSVS having chemically exposed TSV tips for integrated circuit devices

ActiveUS7833895B2Lower performance requirementsReduce yieldSemiconductor/solid-state device detailsSolid-state devicesEtchingChemical exposure

A method for fabricating ICs including via-first through substrate vias (TSVs) and ICs and electronic assemblies therefrom. A substrate having a substrate thickness including a top semiconductor surface and a bottom surface is provided including at least one embedded TSV including a dielectric liner and an electrically conductive filler material formed on the dielectric liner. A portion of the bottom surface of the substrate is mechanically removed to approach but not reach the embedded TSV tip. A protective substrate layer having a protective layer thickness remains over the tip of the embedded TSV after the mechanical removing. Chemical etching exclusive of mechanical etching for removing the protective substrate layer is used form an integral TSV tip that has an exposed tip portion that generally protrudes from the bottom surface of the substrate. The chemical etching is generally a three step chemical etch.

Owner:TEXAS INSTR INC

Surface treatments for underfill control

InactiveUS20070099346A1Reduce and eliminate bleed outLow wettabilitySolid-state devicesSemiconductor/solid-state device manufacturingChemical exposureFilling materials

Methods to reduce or eliminate the bleed out of underfill material. Surface treatments to selective areas on a chip carrier substrate surface create a non-wettable surface or a reduced wettability surface in the areas where the underfill should not flow. The substrate surface is subjected to surface treatments such as media blasting or chemical exposure which will roughen the exposed surface.

Owner:IBM CORP

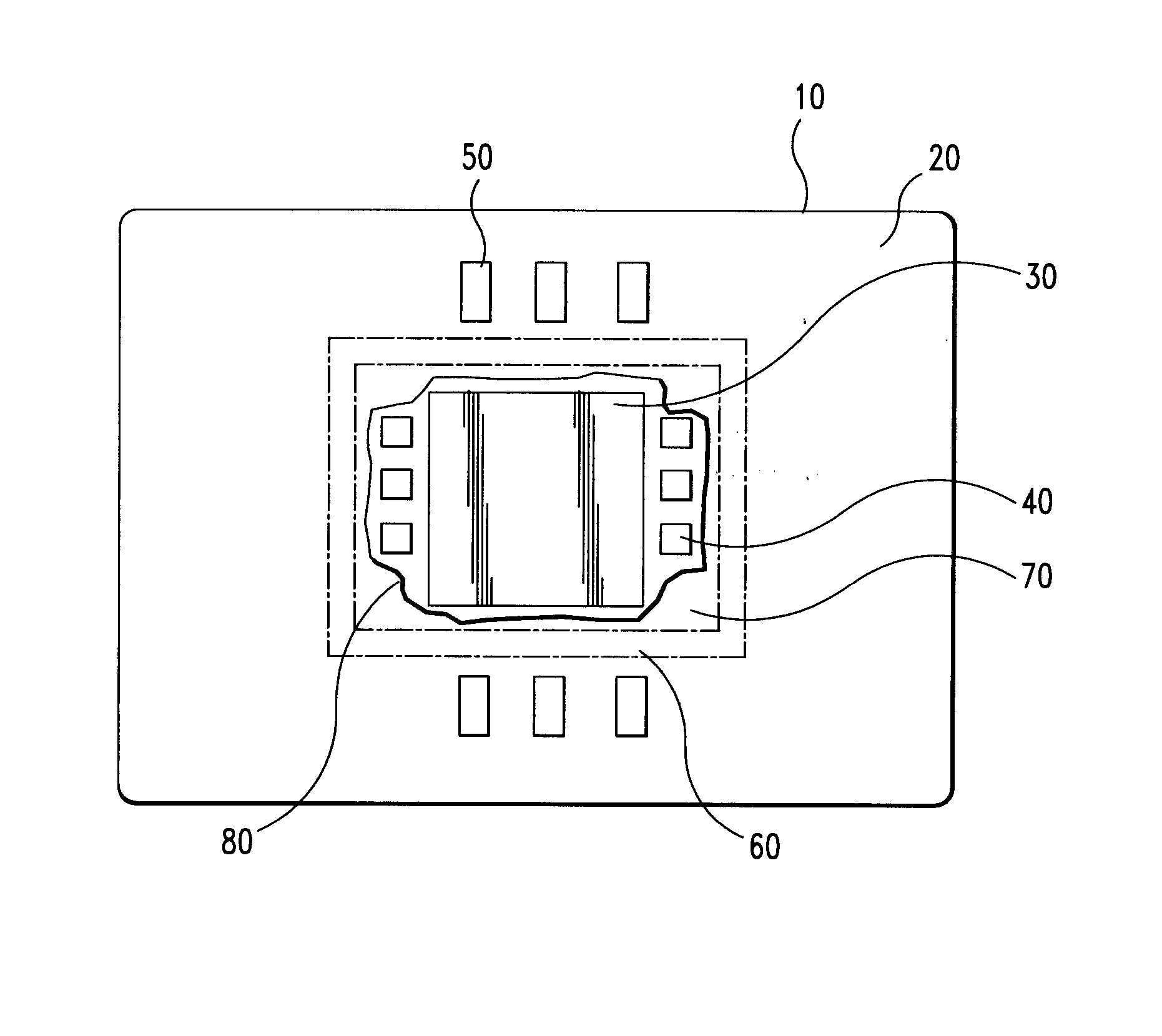

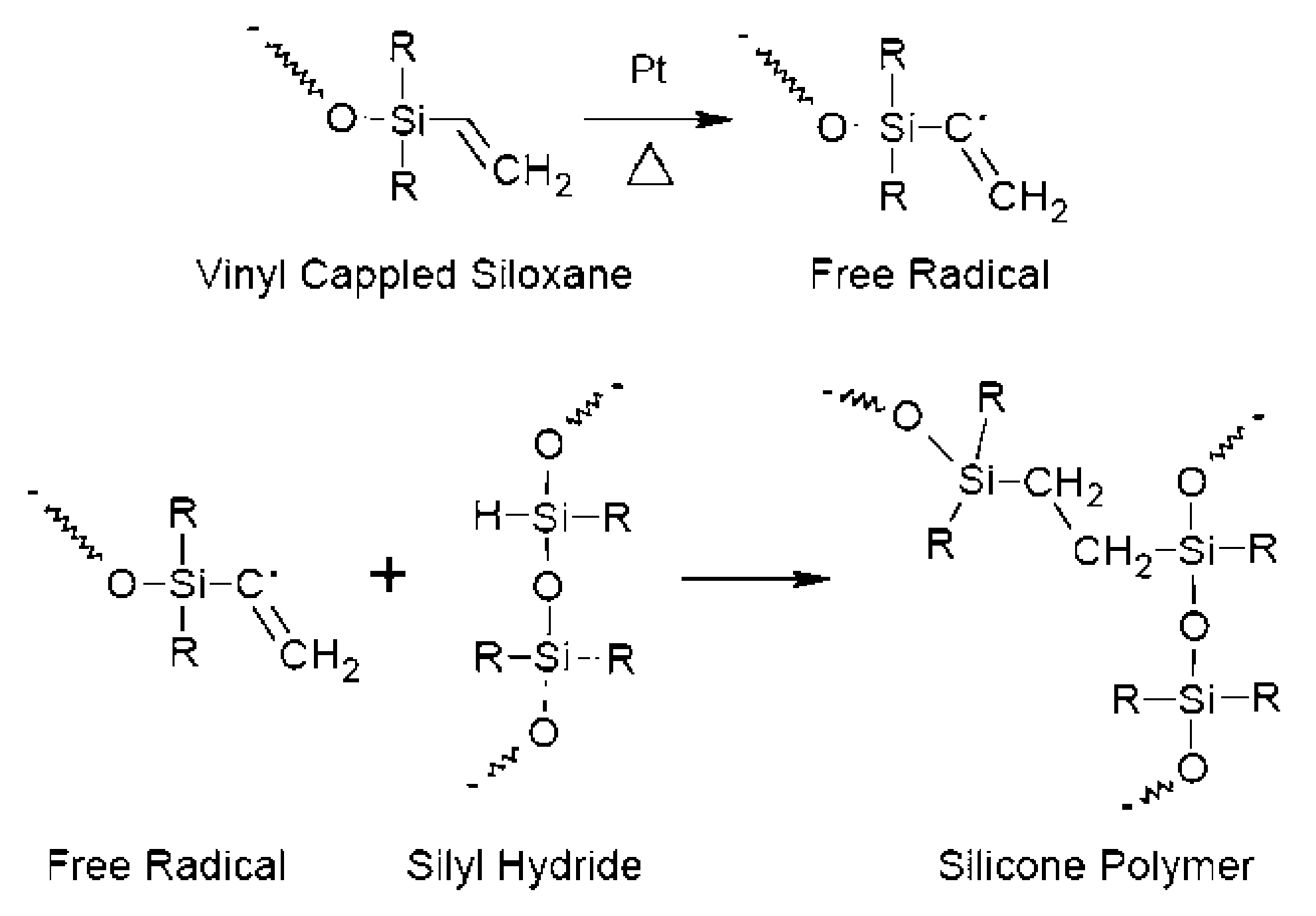

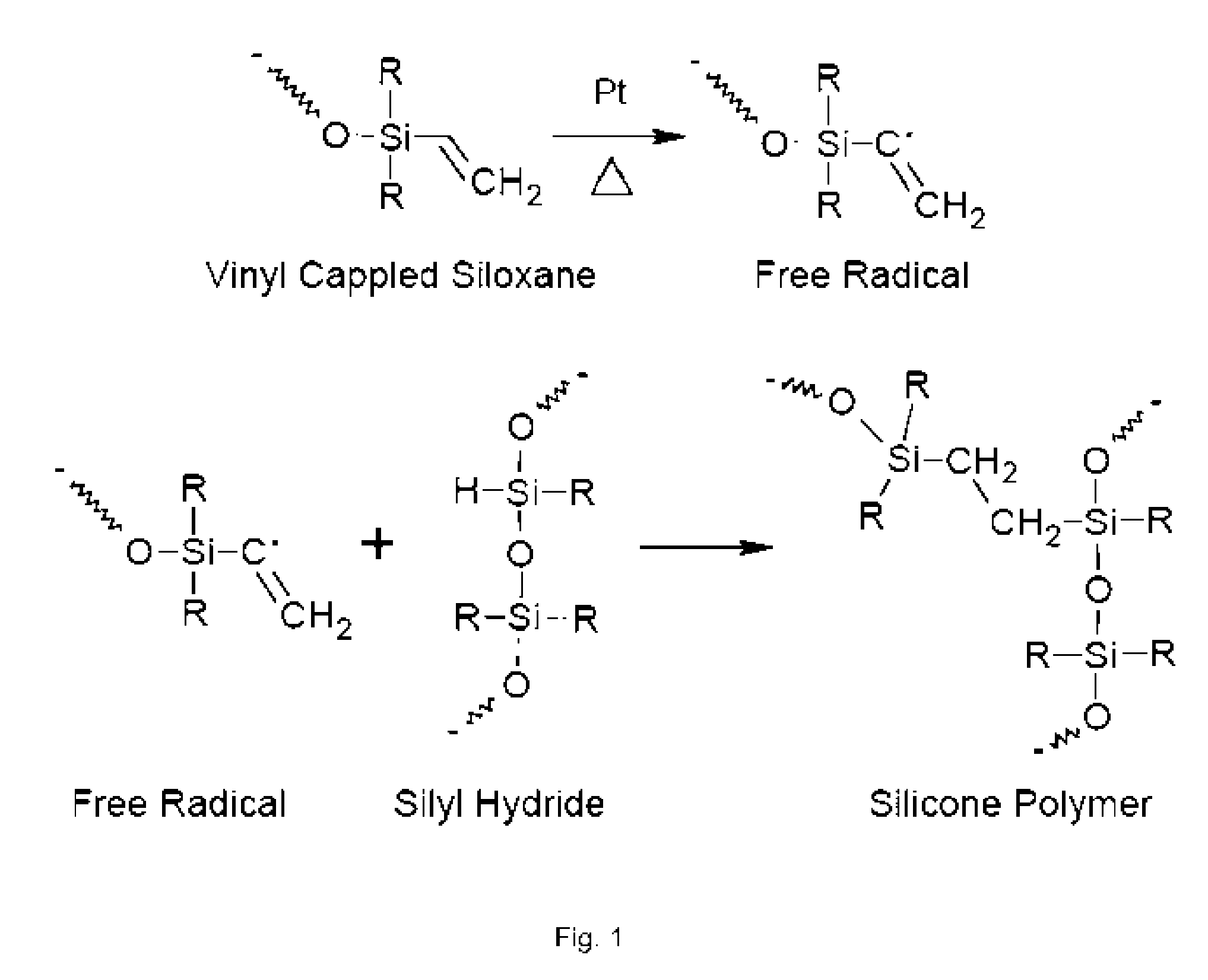

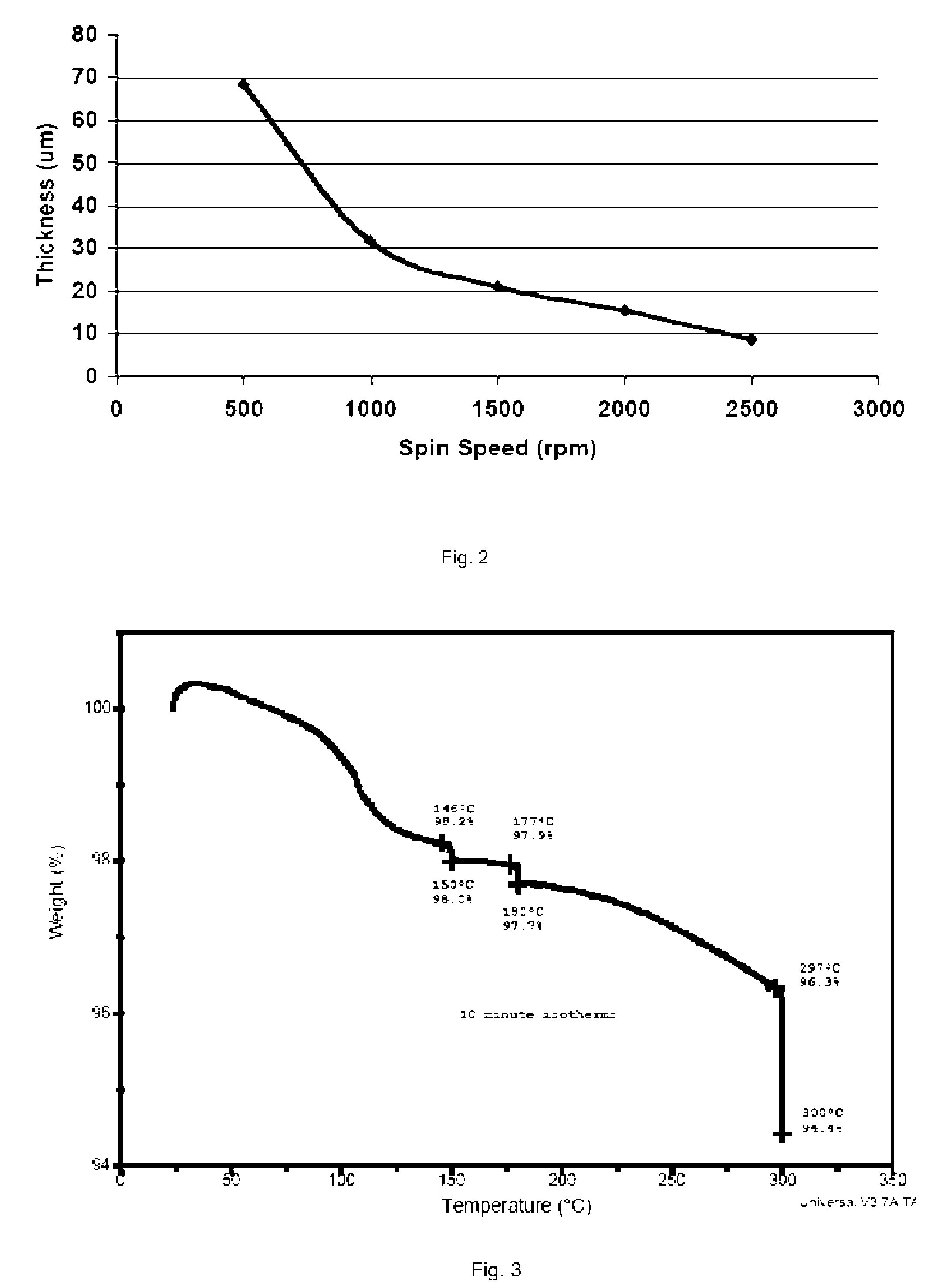

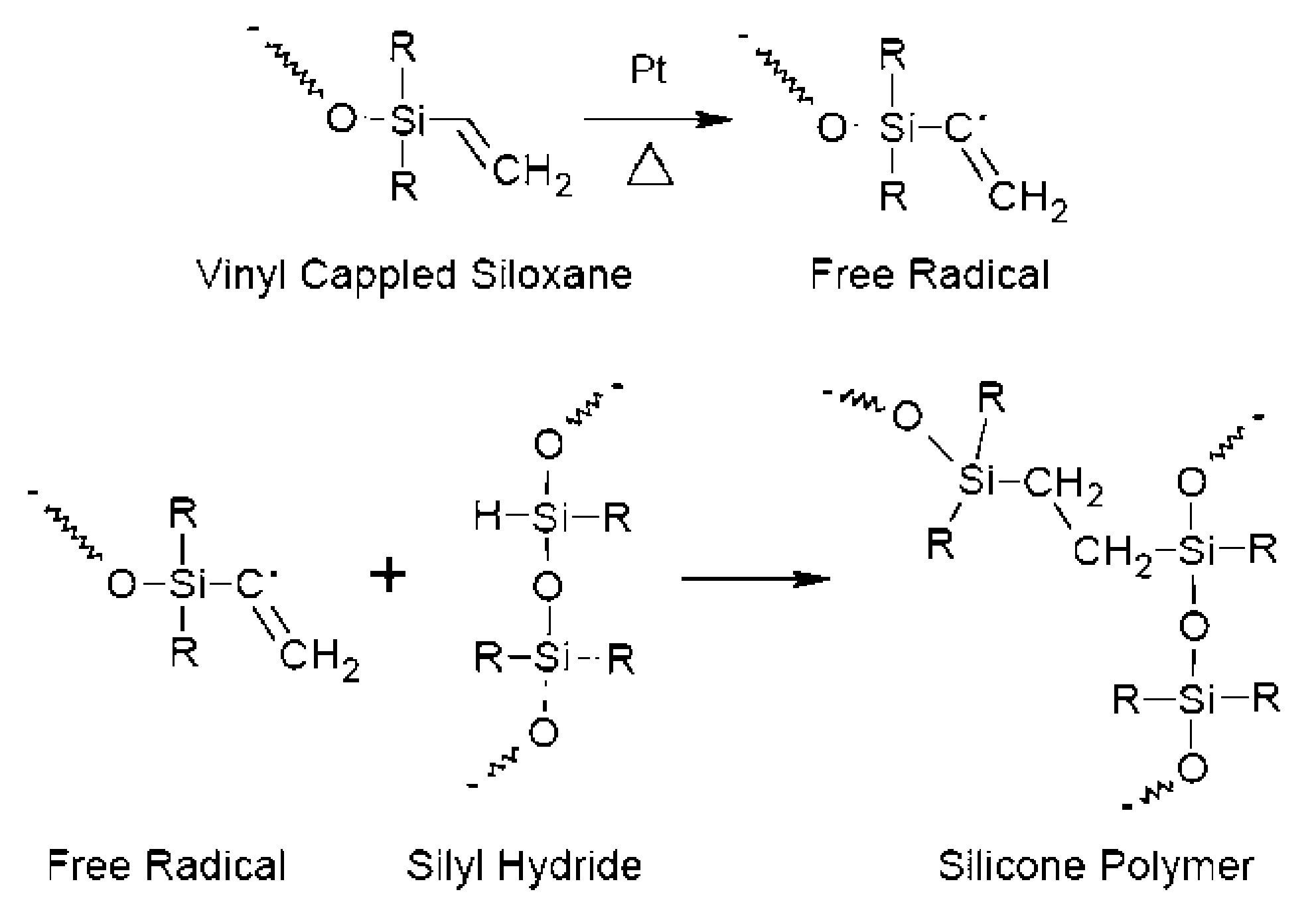

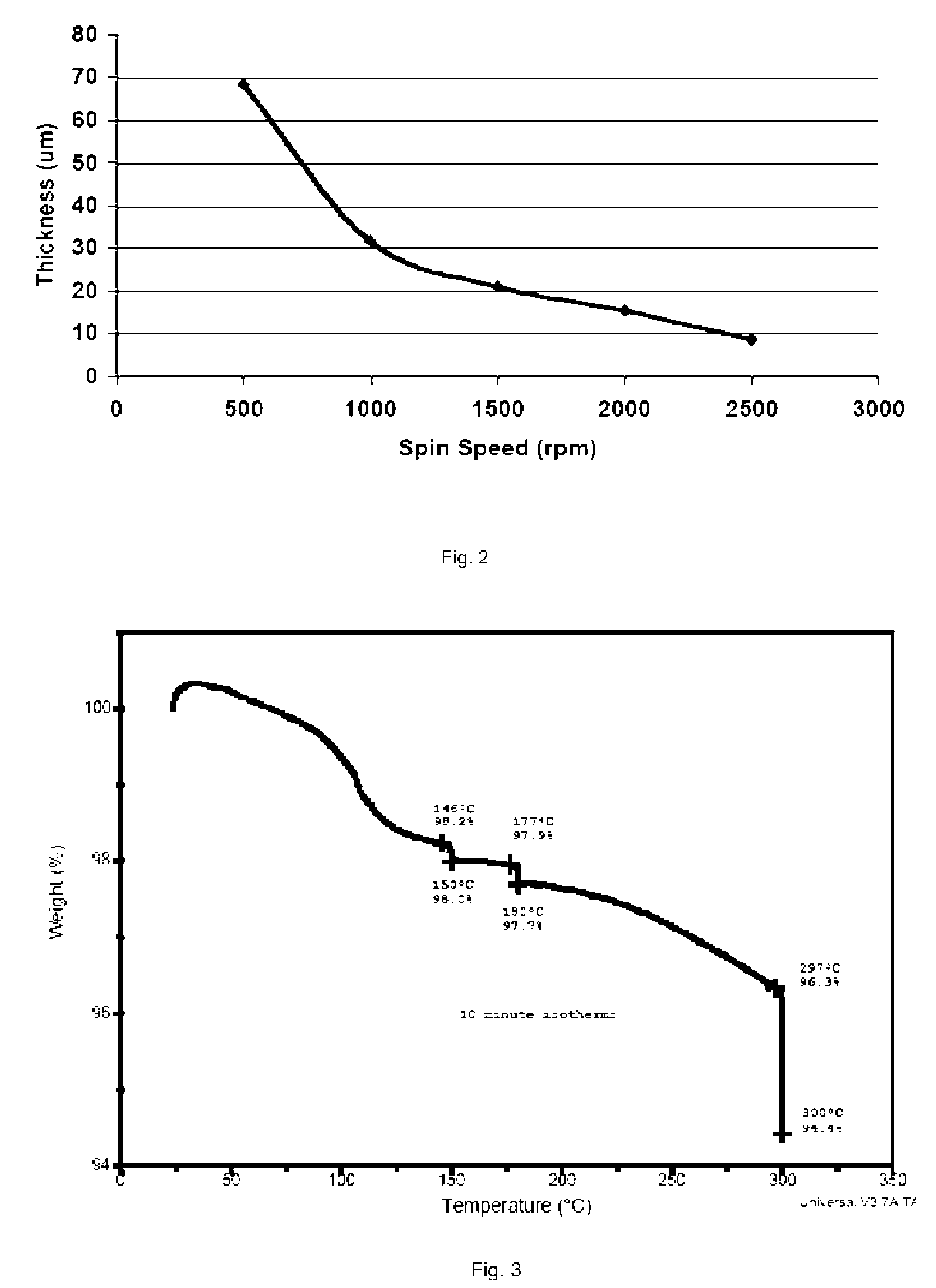

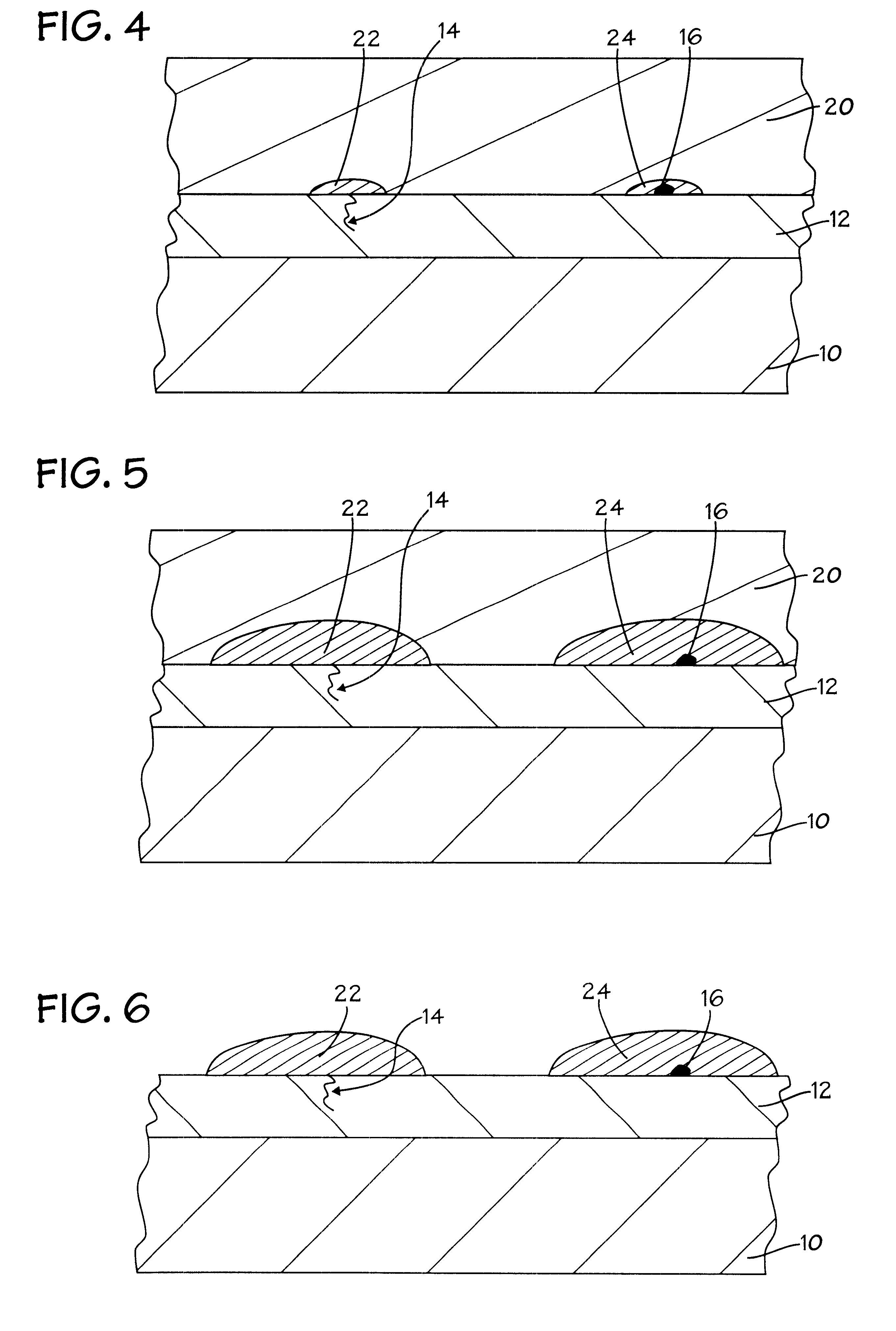

High temperature and chemical resistant process for wafer thinning and backside processing

InactiveUS7232770B2Easy to installSemiconductor/solid-state device manufacturingMonomerThermal oxide

A process which uses a silicone resin to form a wafer-to-carrier bonded package that enables wafer thinning and backside processing while the cured resin exhibits high chemical and thermal resistance. The process is versatile in that the constructed wafer package allows for a wide range of chemical exposures to include dilute acid and base etchants, resist and residue strippers, electroplating chemistries, and also providing use in a range of deposition and etch processes that may exceed 300° C. The process utilizes a mixture of silicone monomers that when applied to semiconductor wafers by a spin-coat application, the result is a planarization of the front side device area, and when a subsequent thin coat is applied will facilitate bonding of the wafer-to-carrier package when heat and pressure are applied. The cured silicone bonded wafer-to-carrier package allows for wafer thinning consistent to industry objectives. Backside processing may include thermal oxide deposition, installed vias, and subsequent metallization in plating baths. Upon completion of a thinned and processed wafer, detachment occurs as described in prior art. Specialty chemical systems which completely dissolves the cured silicone and allows the wafer substrate to be easily rinsed and dried and become available for subsequent processing or final dicing and packaging.

Owner:KMG ELECTRONICS CHEM

High Temperature and Chemical Resistant Process for Wafer Thinning and Backside Processing

A process which uses a silicone resin to form a wafer-to-carrier bonded package that enables wafer thinning and backside processing while the cured resin exhibits high chemical and thermal resistance. The process is versatile in that the constructed wafer package allows for a wide range of chemical exposures to include dilute acid and base etchants, resist and residue strippers, electroplating chemistries, and also providing use in a range of deposition and etch processes that may exceed 300° C. The process utilizes a mixture of silicone monomers that when applied to semiconductor wafers by a spin-coat application, the result is a planarization of the frontside device area, and when a subsequent thin coat is applied will facilitate bonding of the wafer-to-carrier package when heat and pressure are applied. The cured silicone bonded wafer-to-carrier package allows for wafer thinning consistent to industry objectives. Backside processing may include thermal oxide deposition, installed vias, and subsequent metallization in plating baths. Upon completion of a thinned and processed wafer, detachment occurs as described in prior art. Specialty chemical systems which completely dissolves the cured silicone and allows the wafer substrate to be easily rinsed and dried and become available for subsequent processing or final dicing and packaging.

Owner:KMG ELECTRONICS CHEM

Method of detecting film defects using chemical exposure of photoresist films

InactiveUS6440621B1Semiconductor/solid-state device testing/measurementPhotomechanical apparatusSolubilityResist

Various methods of inspecting a semiconductor workpiece for defects are provided. In one aspect, a method of inspecting a surface of a semiconductor workpiece for defects is provided that includes applying a negative-tone photoresist film to the surface and baking the negative-tone photoresist film to release solvent therefrom and to facilitate release of catalyzing substances held by the defects into the negative-tone photoresist film. The catalyzing substances react chemically with at least one moiety of the photoresist film to thereby lower the solubility of one or more portions of the negative-tone photoresist film in a developer. The negative-tone photoresist film is developed with the developer and the surface is inspected for the portions of the negative-tone photoresist film remaining after the developing process. The remaining portions of the negative-tone photoresist film are indicative of the locations of the defects.

Owner:SDGI HLDG +1

Exposure monitoring

A filter medium of an air purifying respirator captures one or more substances from the air in a worker's environment as the worked breathes. Air contaminants captured by the respirator filter media can be subsequently analyzed and measured. An air flow meter placed at an air channel of the respirator measures air flow and / or total air volume inspired by the worker wearing the respirator. Personal chemical exposure of the worker can be assessed from the filter media measurements and air flow data.

Owner:IND HYGIENE RESOURCES

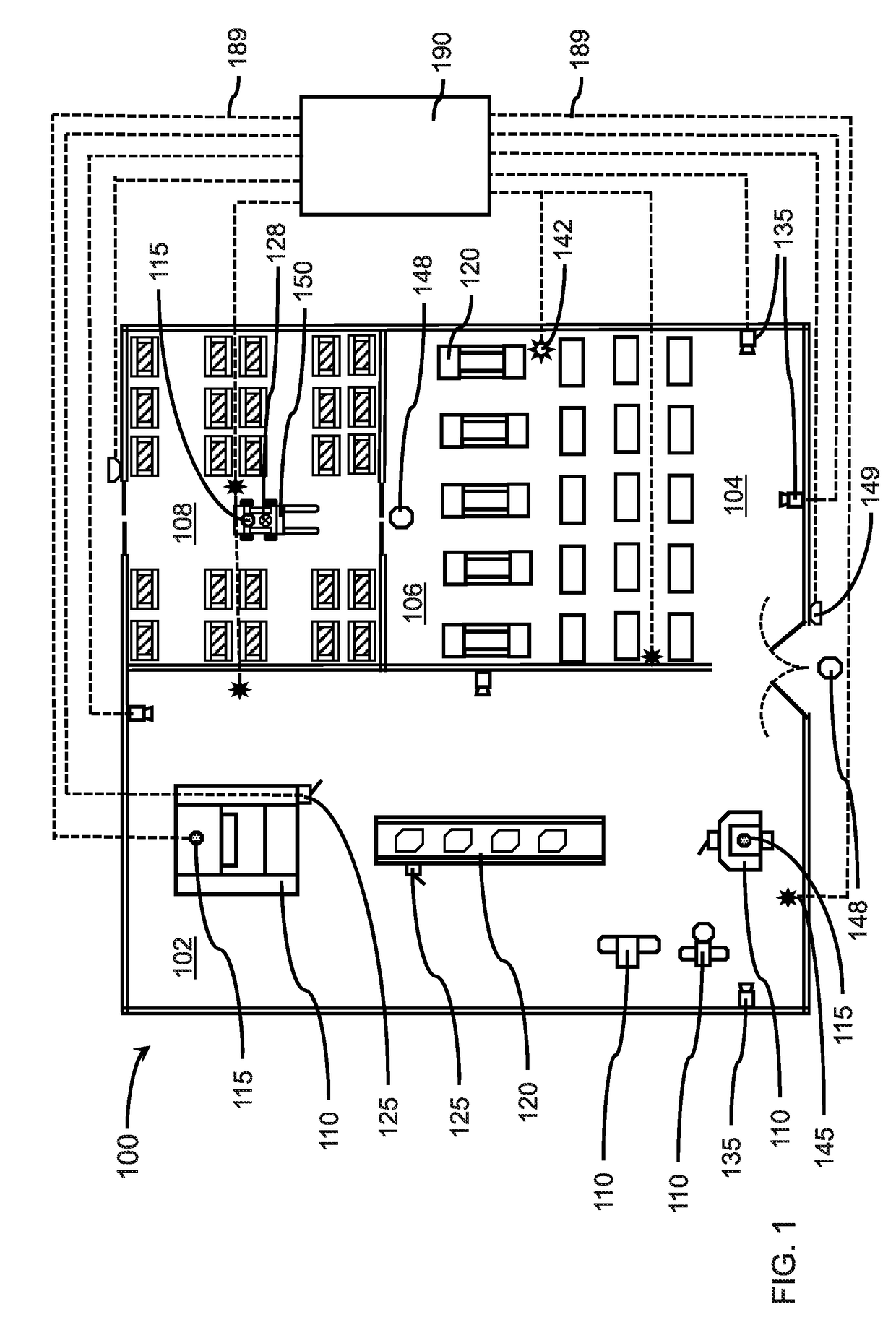

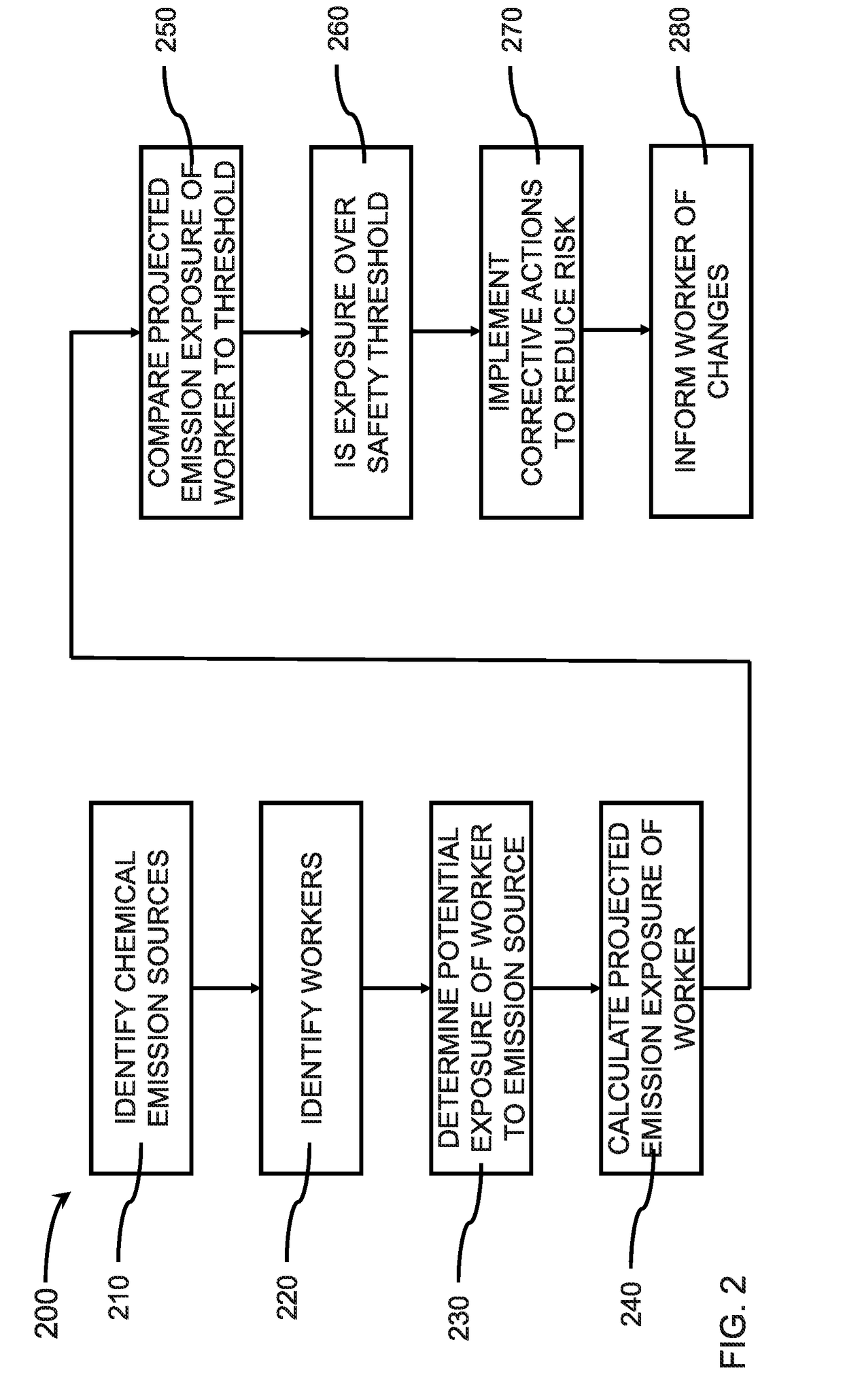

Predicting harmful chemical exposures and implementing corrective actions prior to overexposure

ActiveUS20170185905A1Avoid contactProbabilistic networksAlarmsPersonal protective equipmentChemical exposure

A method of avoiding harmful chemical emission concentration levels, the method comprising implementing a cognitive suite of workplace hygiene and injury predictors (WHIP) that has learned to identify chemical emission sources and indicators of harmful chemical emission concentration levels, detecting an indicator, and implementing a corrective action by at least one of altering the operation of a chemical emissions source, modifying a time of a scheduled task, or changing prescribed personal protective equipment.

Owner:IBM CORP

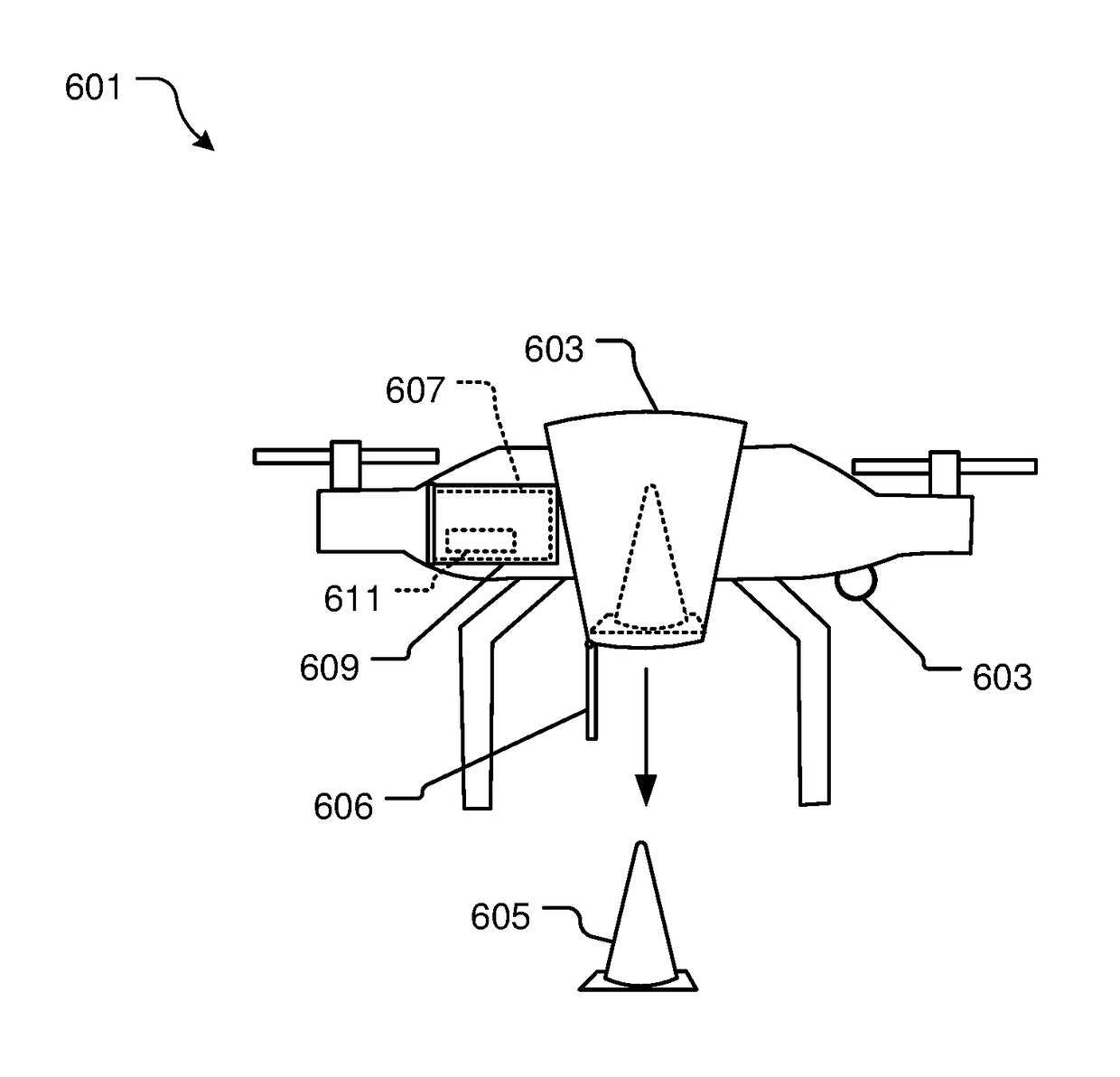

Unmanned aerial vehicle system and method of use

InactiveUS10055984B1Aircraft componentsArrangements for variable traffic instructionsWeather conditionVisibility

An unmanned aerial vehicle (UAV) system includes a command center having a computing device an unmanned aerial vehicle (UAV) with a body, the UAV to communicate wirelessly with the command center via a network, the UAV having a control system with a power source, a geospatial tracking device, and a multi-channel communication portal; a camera secured to the body and in communication with the control system; and one or more equipment attachment sites; site assessment tools to attach to or within the one or more equipment attachment sites, each of the site assessment tools to record a data associated with an emergency site, such as weather conditions, road conditions, traffic, visibility, radiation, and chemical exposure; the UAV is to receive commands from the command center to deploy to the emergency site; and the UAV is to receive the data and transmit the data to the command center via the multi-channel communication portal.

Owner:SCHAEFFER LEE +3

Method of forming a self aligned copper capping layer

InactiveCN101317261AImprove adhesionResistivity degradationSemiconductor/solid-state device detailsSolid-state devicesCopper interconnectChemical exposure

A method of forming a capping layer on a copper interconnect line (14). The method comprises providing a layer (20) of Aluminium over the interconnect line (14) and the dielectric layer (10) in which it is embedded. This may be achieved by deposition or chemical exposure. The structure is then subjected to a process, such as annealing or further chemical exposure, in an environment containing, for example, Nitrogen atoms, so as to cause indiffusion of Al into the copper line (14) and nitridation to form a diffusion barrier 26 of the intermetallic compound CuAlN.

Owner:NXP BV

Coating system having long-term durability and chemical resistance

ActiveUS8742004B1Increased durabilityNon-fibrous pulp additionSynthetic resin layered productsCoating systemChemical exposure

A highly durable coating composition particularly suited for use on printed articles requiring protection from exposure to the natural elements, chemical exposure, or abrasion. The coating composition generally comprises a fluoropolymer resin, an acrylic polyol resin and a melamine resin. Optionally, a polyisocyanate crosslinking agent may also be included to accelerate curing of the coating.

Owner:DONALD D SLOAN TRUSTEE OF THE DONALD D SLOAN TRUST AND HIS SUCCESSORS UNDER THE FIFTEENTH AMENDMENT TO & COMPLETE RESTATEMENT OF THE DONALD D SLOAN TRUST DATED DECEMBER 17 2013

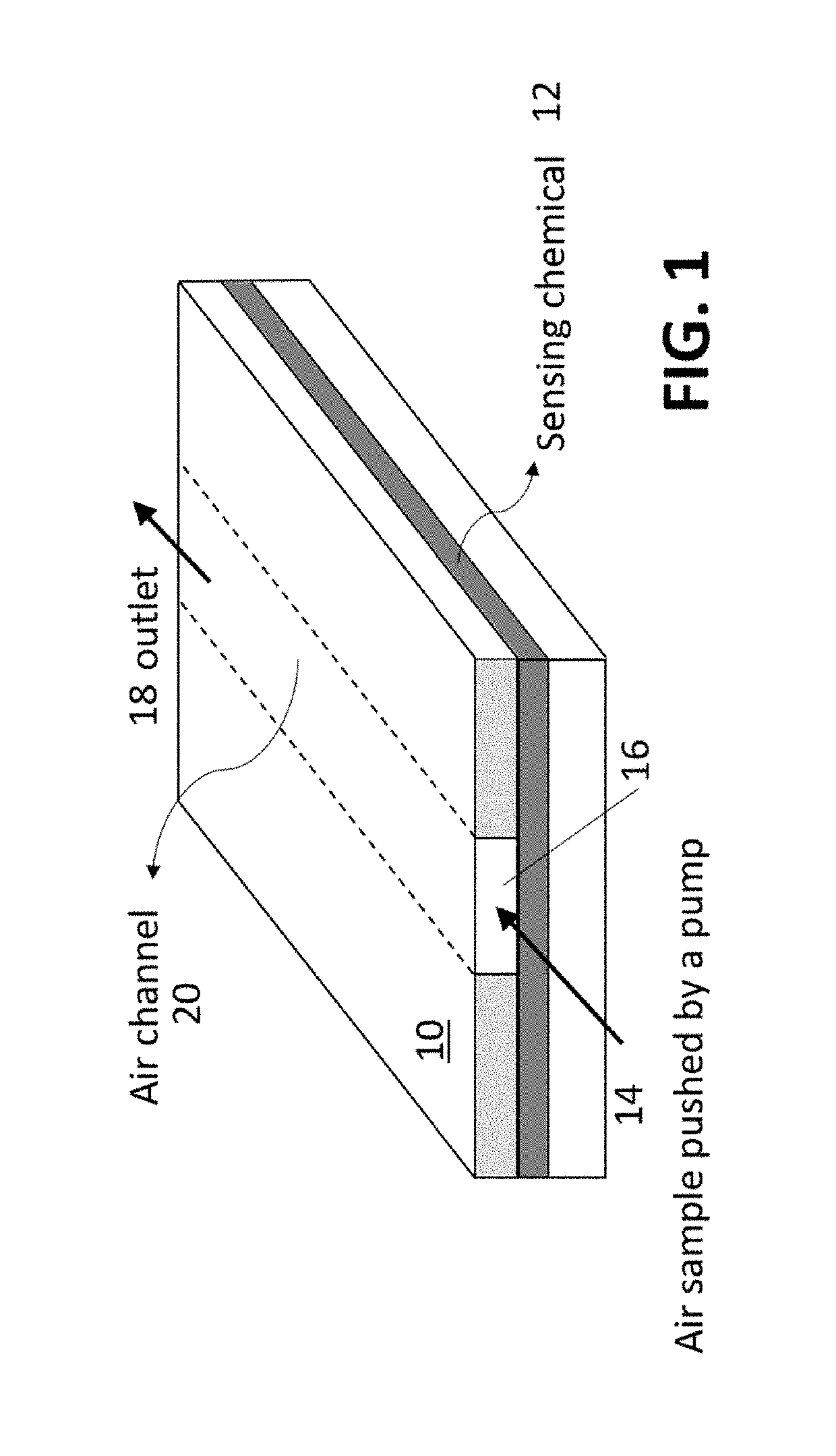

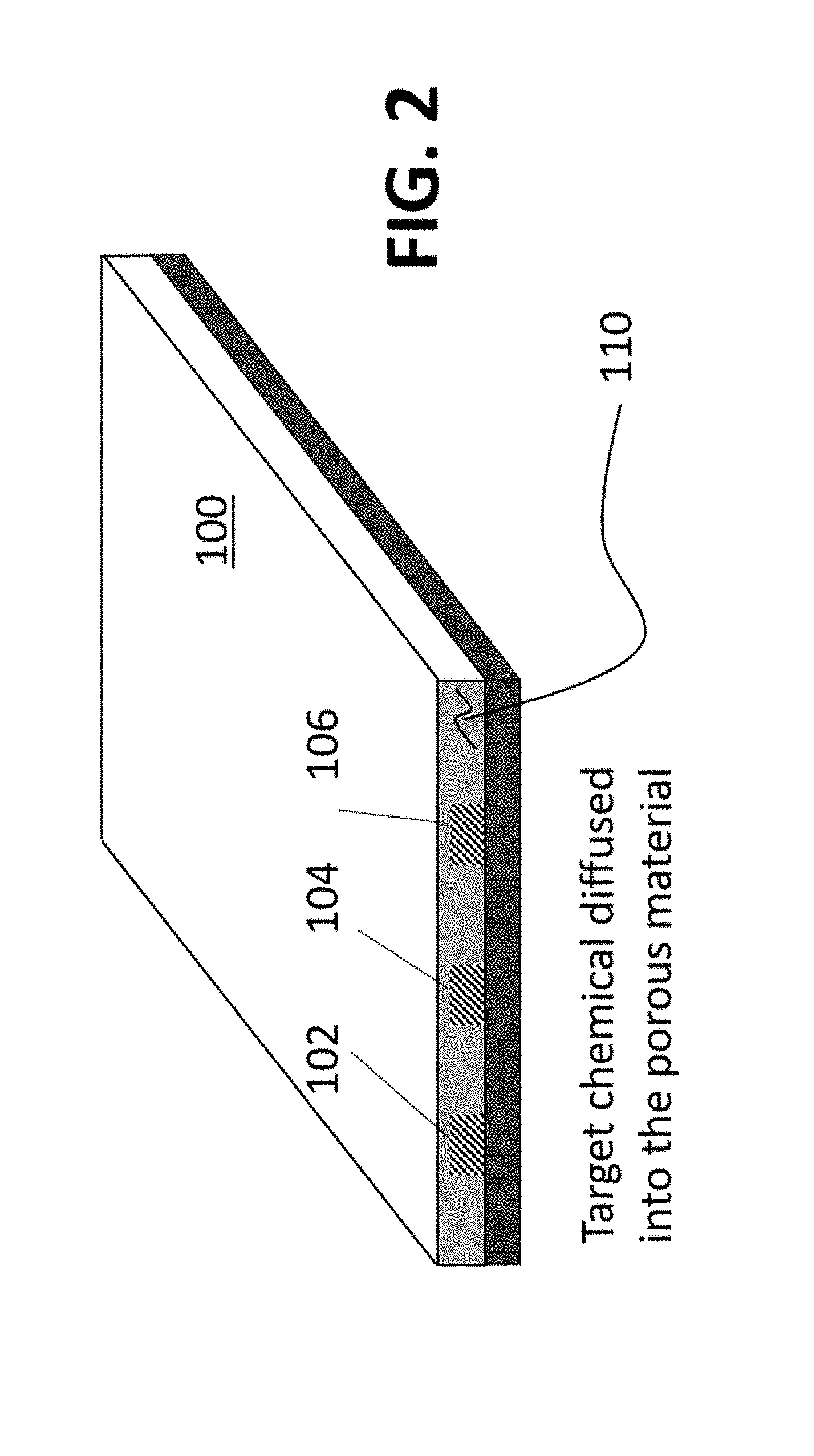

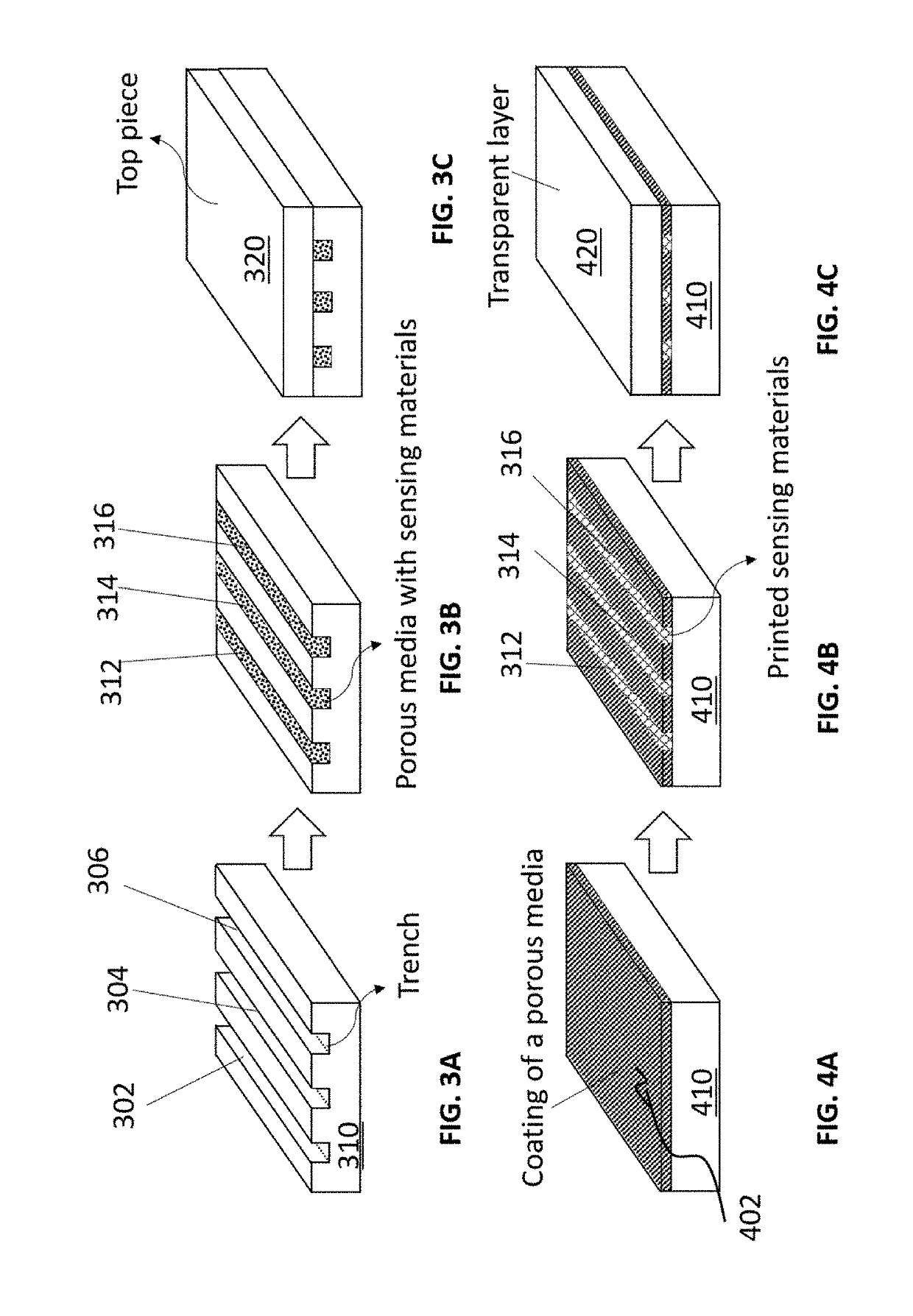

Method and apparatus for continuous gas monitoring using micro-colorimetric sensing and optical tracking of color spatial distribution

ActiveUS20190094146A1Not identifyMaterial analysis by observing effect on chemical indicatorAir quality improvementColor imagePorous medium

A micro-colorimetric sensor for sensing target chemicals that converts time sequence information into a spatial distribution of color. By tracking the spatial color distribution, chemical exposure over time is thus detected, which overcomes the limitation of traditional colorimetric sensors. A porous media is coated on a top surface of the substrate. Multiple sensing chemicals are fused in parallel linear channels into the porous media coating. A plate is affixed over the substrate top surface to cover the plurality of parallel linear channels. An air sample is diffused along the porous media to get a clear pattern of spatial color distribution and color images are captured. Optical parameters like gradient of spatial color distribution, intensity, and absorbance, etc., can be tracked to calculate analytes concentrations.

Owner:ARIZONA STATE UNIVERSITY

Low-k dielectric damage repair by vapor-phase chemical exposure

ActiveUS8877659B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseSilanes

A method for repairing and lowering the dielectric constant of low-k dielectric layers used in semiconductor fabrication is provided. In one implementation, a method of repairing a damaged low-k dielectric layer comprising exposing the porous low-k dielectric layer to a vinyl silane containing compound and optionally exposing the porous low-k dielectric layer to an ultraviolet (UV) cure process.

Owner:APPLIED MATERIALS INC

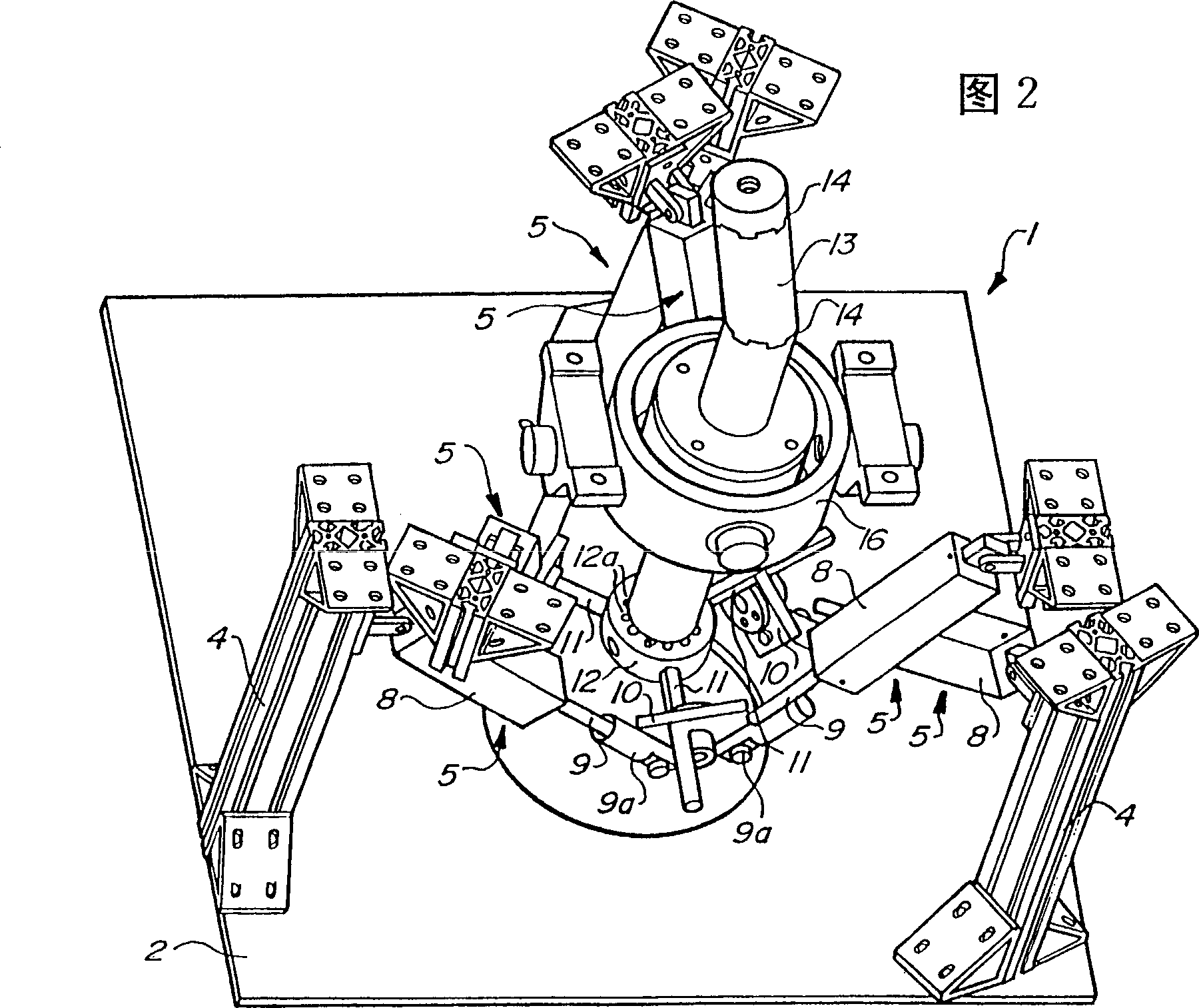

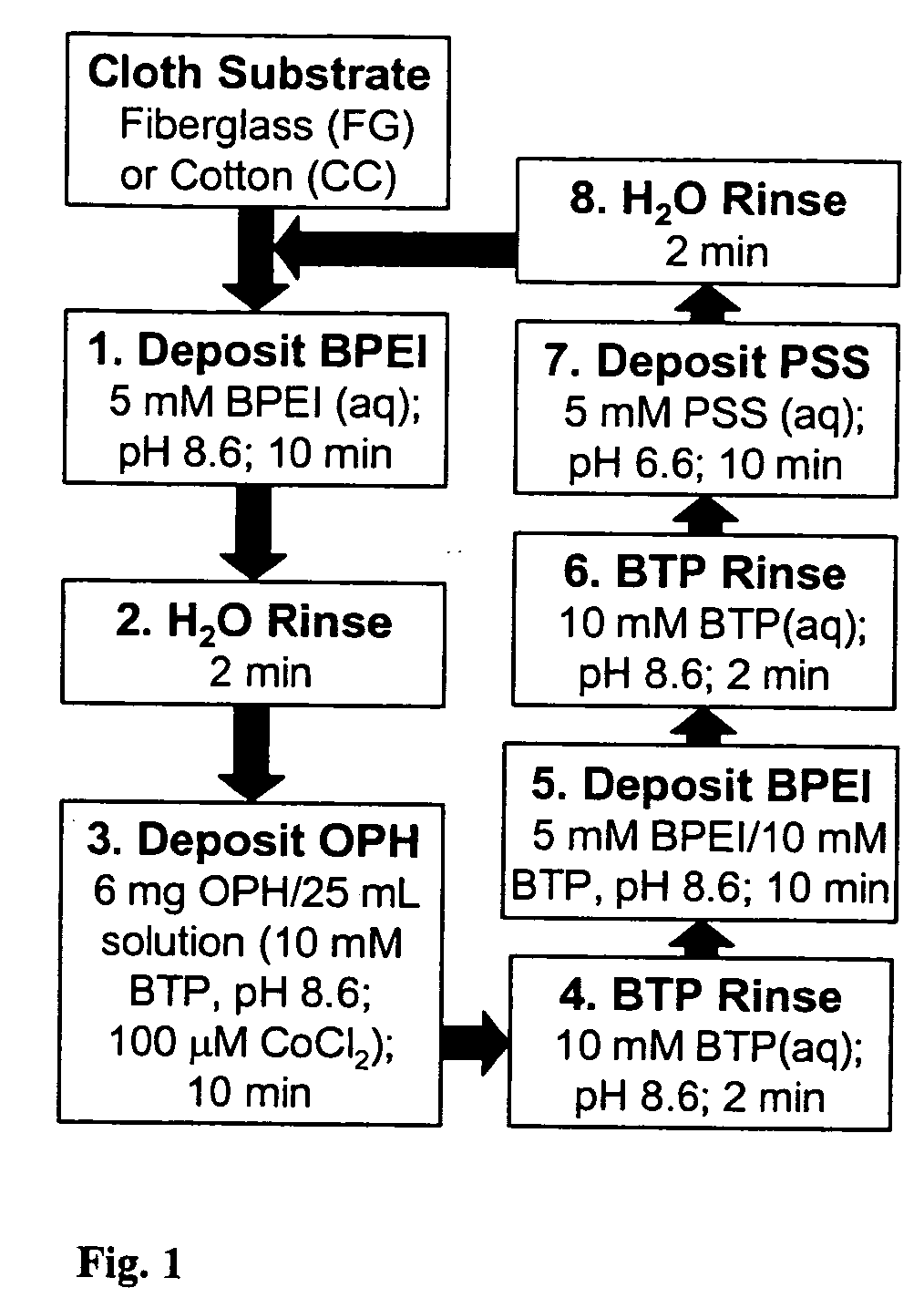

Method and apparatus for optimizing the design of a product

InactiveCN1270689AData processing applicationsAnalysing solids using sonic/ultrasonic/infrasonic wavesChemical reactionChemical exposure

Method and apparatus is described for optimizing the design of products, such as but not limited to mechanical products, by simultaneously subjecting the products to multiple stimuli, such as but not limited to temperature, vibration, pressure, ultraviolet radiation, chemical exposure, humidity, mechanical cycling, and mechanical loading.

Owner:NTERA INC

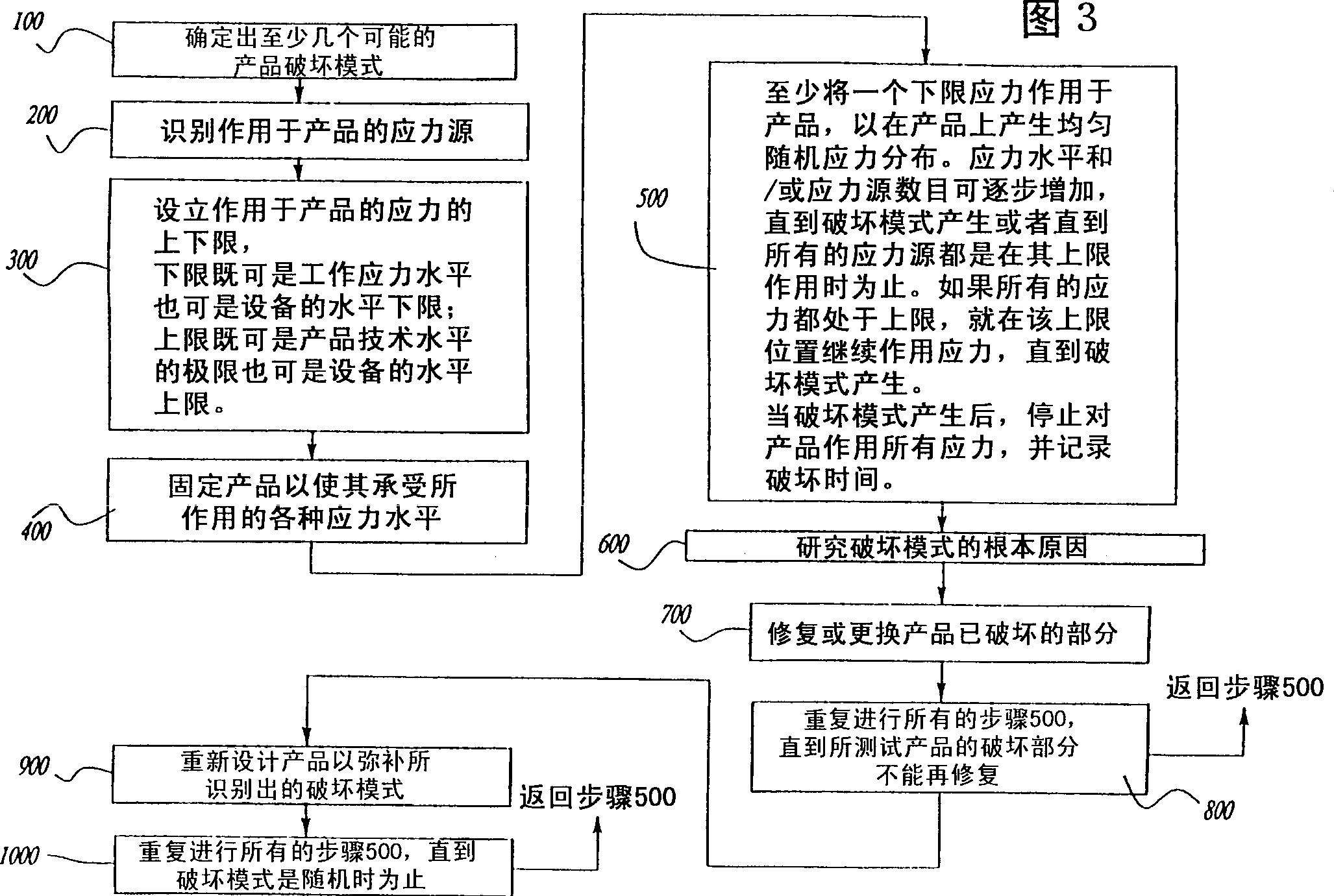

Catalytic enzyme-modified textiles for active protection from toxins

InactiveUS20050136523A1Do not damage the environmentEffective protectionHydrolasesPeptide/protein ingredientsPolyelectrolyteChemical exposure

Catalytic enzyme-modified textiles are disclosed for providing protection from chemical exposure. The textiles are composed of a cloth substrate, at least one polyelectrolyte layer, at least one enzyme layer to degrade the chemical agent, and at least one capping layer. Also disclosed is the related method for making catalytic enzyme-modified textiles.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

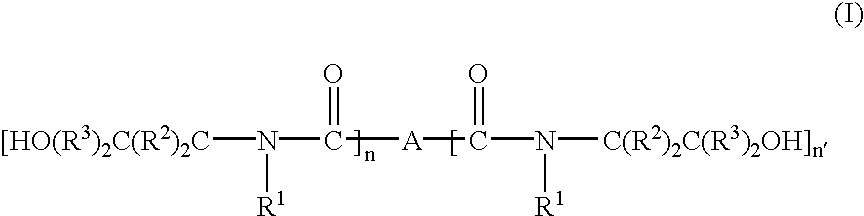

Use of beta-hydroxyalkylamide in ambient and low bake liquid coatings

InactiveUS6503999B1Improve the immunityIncreases the rate at which the desired level of hardnessOther chemical processesSynthetic resin layered productsPolyesterPolymer chemistry

An aqueous coating composition comprising an active hydrogen-containing polymer, an isocyanate, and beta-hydroxyalkylamide is disclosed. The polymer can be any number of polymers containing hydroxyl, amine and / or thiol groups, such as an acrylic polyol, a polyester polyol, and mixtures thereof. The hydroxylalkylamide has been shown to decrease the time in which the coating achieves hardness and, in the case of the polyester polyol system, increases the hardness that is achieved. The present compositions also provide resistance to chemical exposure. Methods for coating a substrate and the substrates coated thereby are also disclosed.

Owner:PPG IND OHIO INC

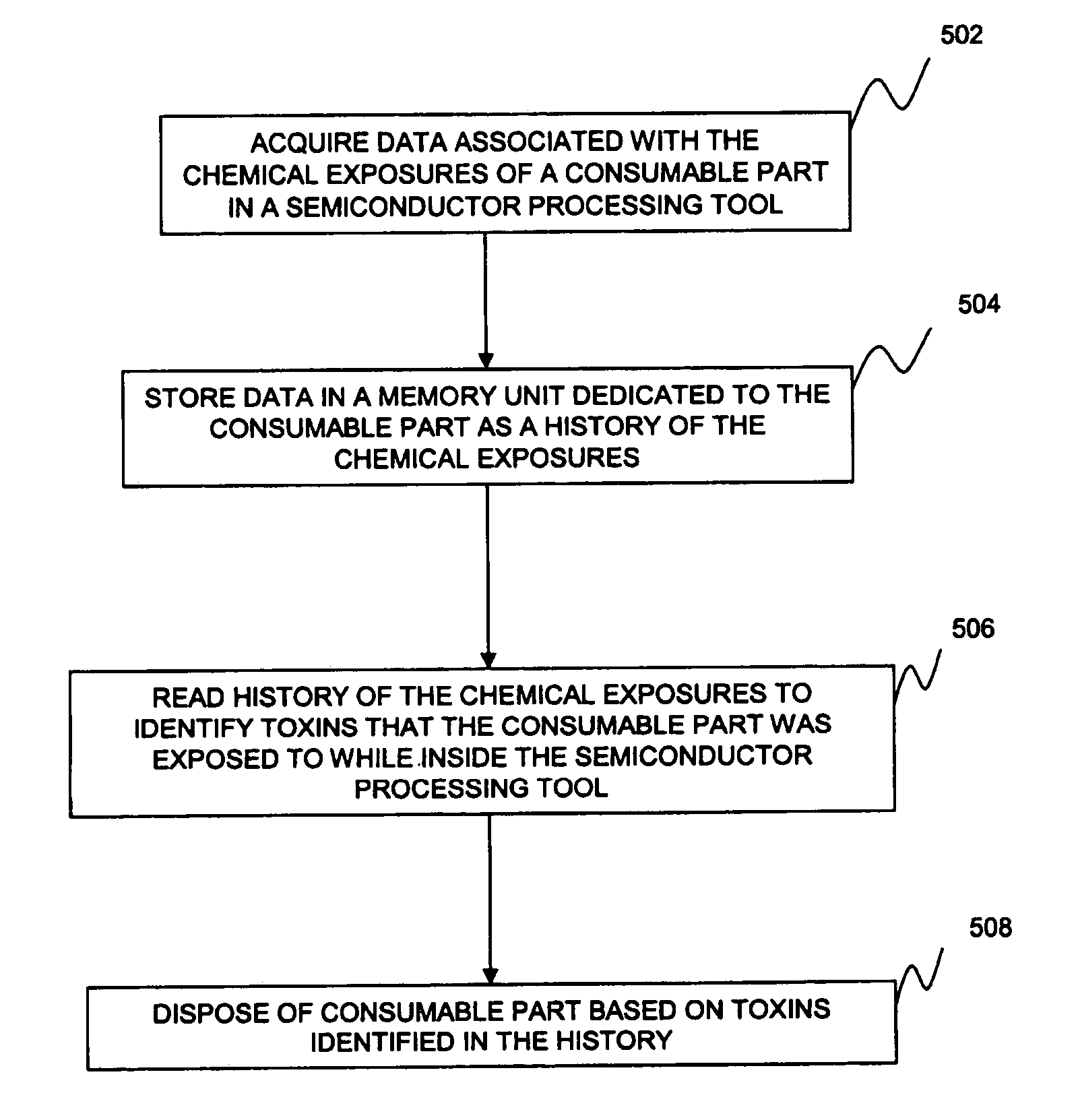

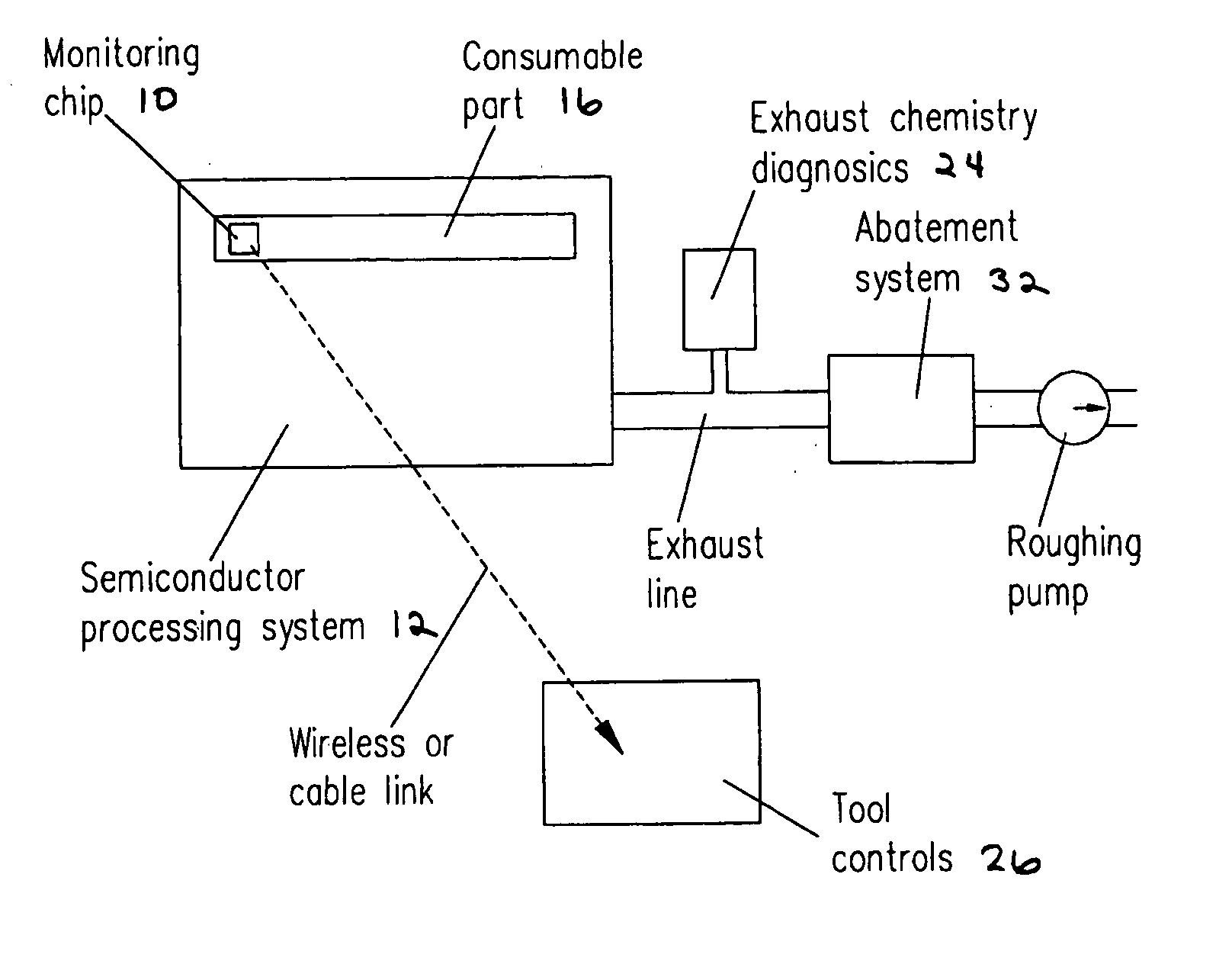

Method and apparatus for determining chemistry of part's residual contamination

InactiveUS7020583B2Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingChemical compositionChemical exposure

Owner:TOKYO ELECTRON LTD

Catalytic enzyme-modified textiles for active protection from toxins

InactiveUS20070014838A1Do not damage the environmentEffective protectionHydrolasesPeptide/protein ingredientsPolyelectrolyteChemical exposure

Catalytic enzyme-modified textiles are disclosed for providing protection from chemical exposure. The textiles are composed of a cloth substrate, at least one polyelectrolyte layer, at least one enzyme layer to degrade the chemical agent, and at least one capping layer. Also disclosed is the related method for making catalytic enzyme-modified textiles.

Owner:U S A AS REPRESENTED BY THE SEC OF THE NAVY CHIEF OF NAVAL RES OFFICE OF COUNSEL ATTN CODE OOCCIP THE

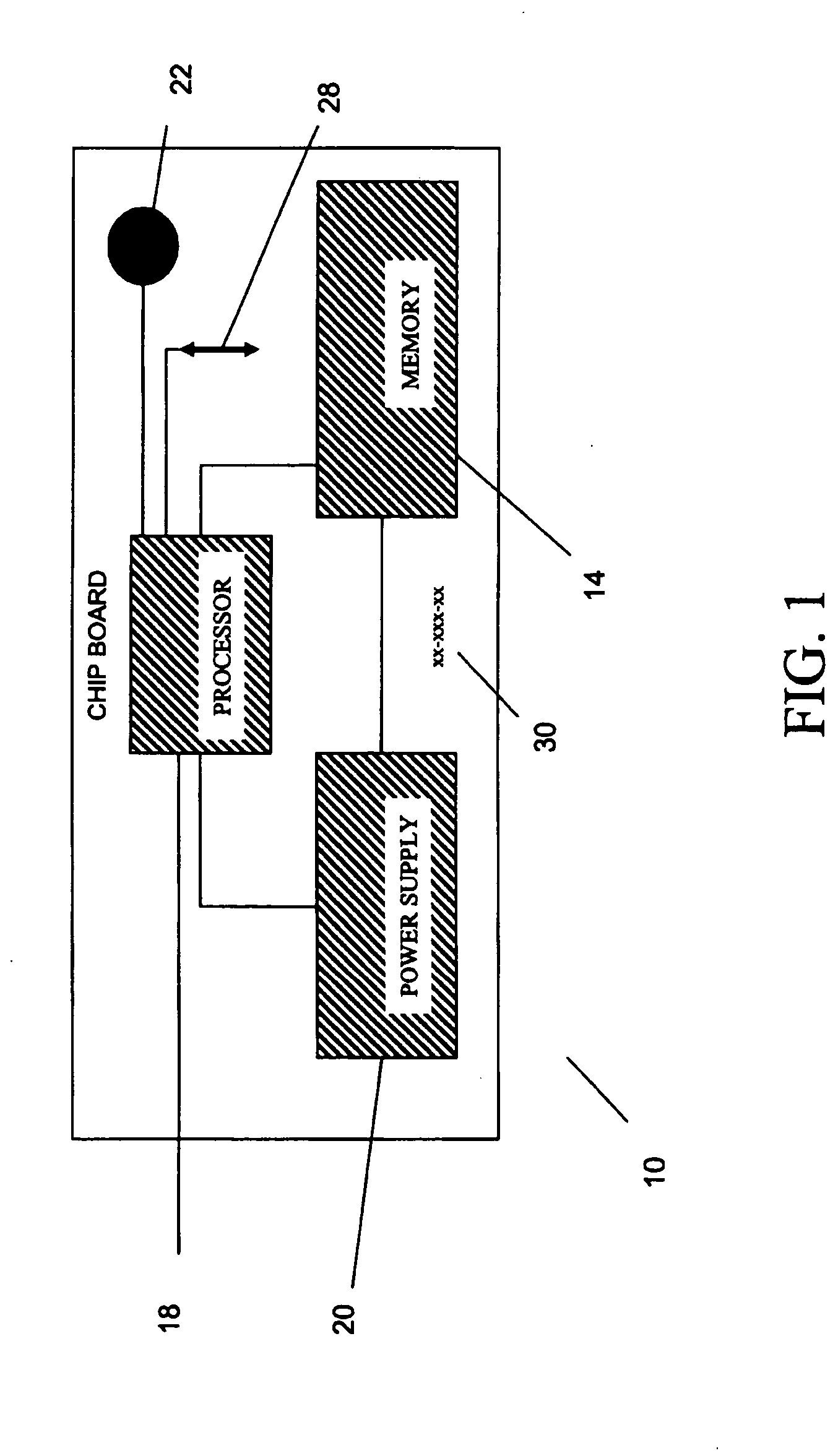

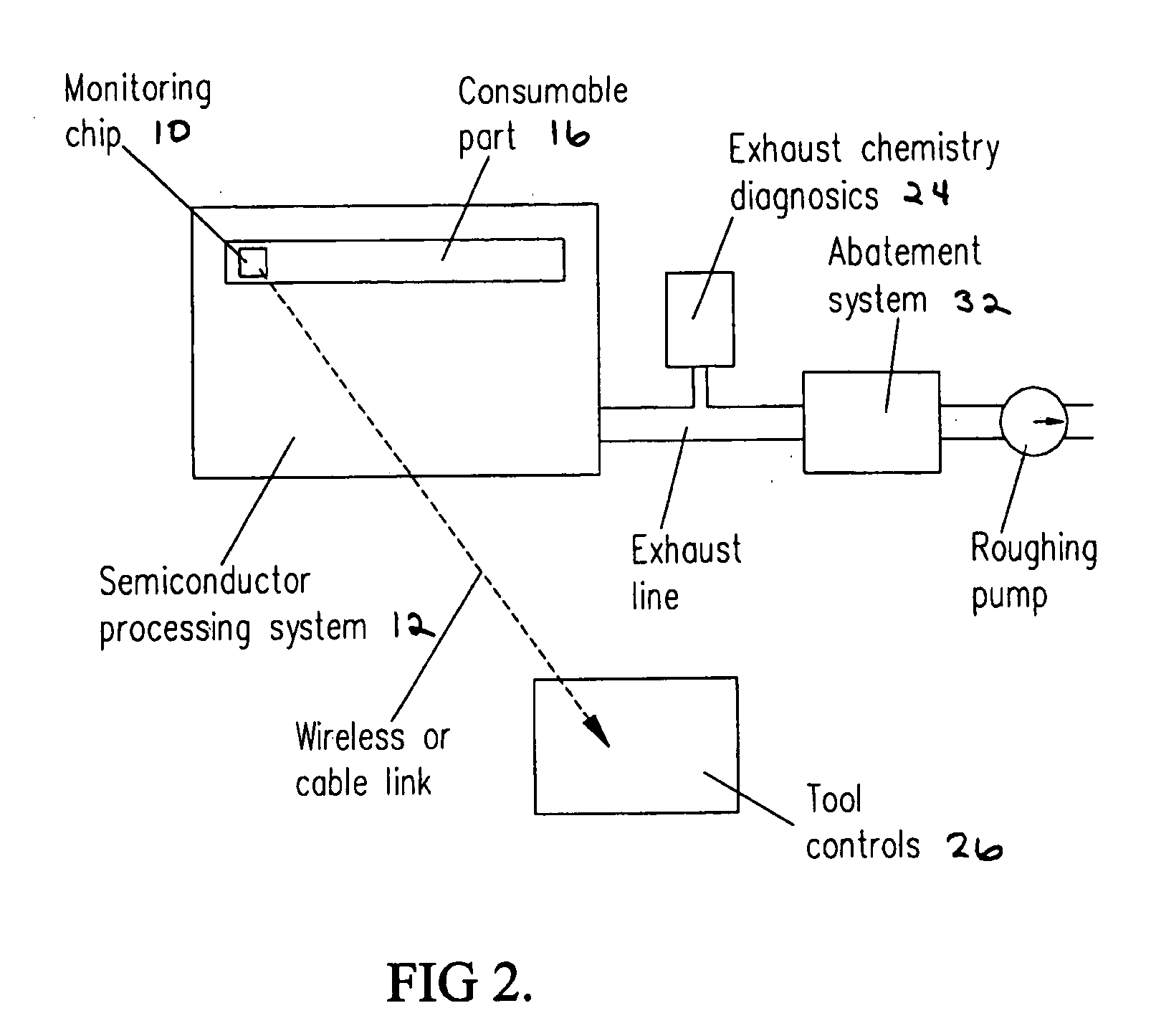

Method and apparatus for determining chemistry of part's residual contamination

InactiveUS20050171702A1Semiconductor/solid-state device testing/measurementDigital computer detailsChemical compositionChemical exposure

An electronic monitoring device that archives chemical exposures of a consumable part inside a semiconductor processing tool. The monitoring device includes a memory unit dedicated to the consumable part and which stores a history of the chemical exposures of the consumable part, a processor in communication with the memory unit, and a power supply circuit that supplies power to the processor and the memory unit.

Owner:TOKYO ELECTRON LTD

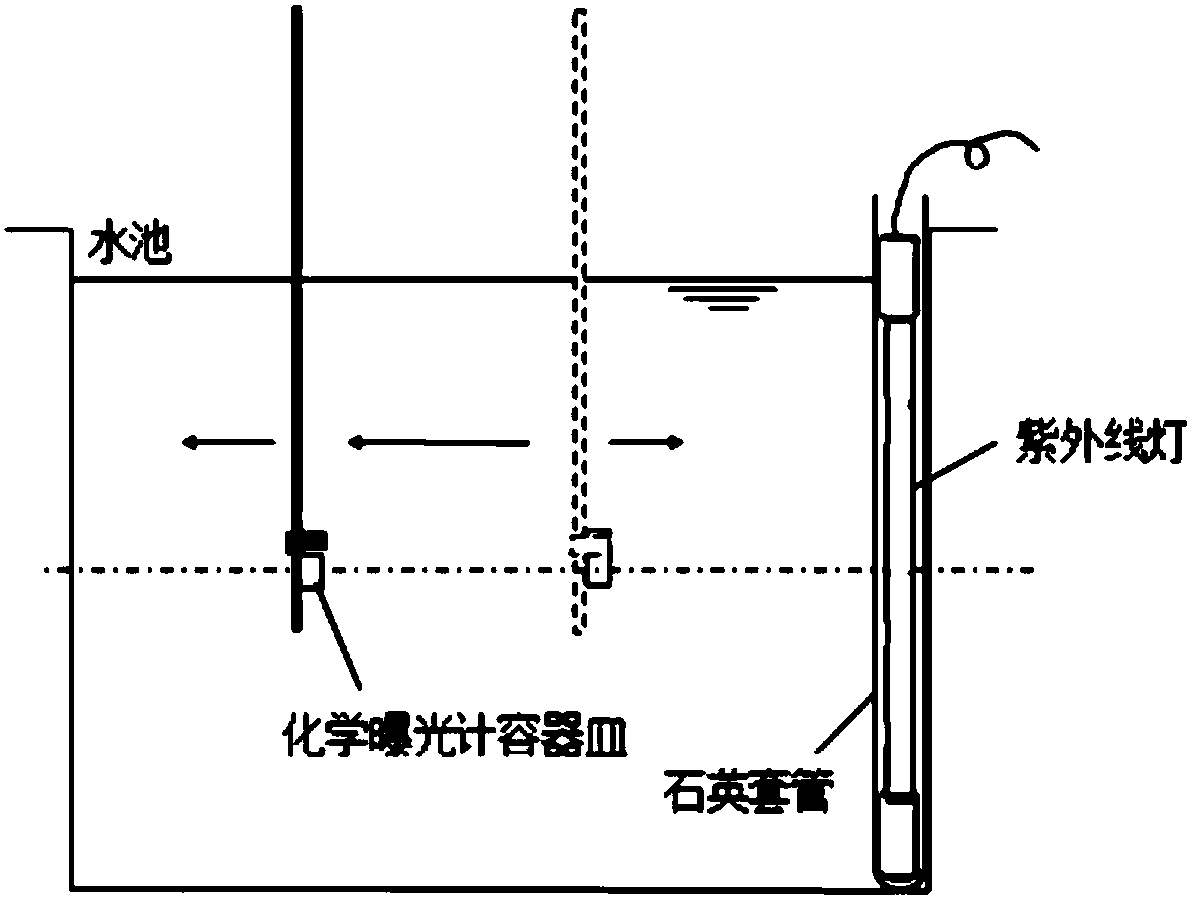

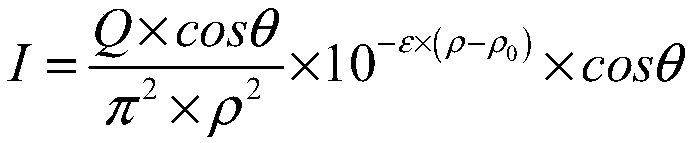

Method and system for measuring emission power of ultraviolet lamp in water

The invention discloses a method for measuring the emission power of an ultraviolet lamp in water. The method comprises the following steps of: placing an ultraviolet lamp arranged in a quartz sleevein water, and placing a chemical exposure meter on a perpendicular bisector of the ultraviolet lamp; recording absorbance values of the ultraviolet lamp collected by the chemical exposure meter beforeand after irradiation by controlling positions of the chemical exposure meter at different distances from the ultraviolet lamp; calculating a radiation illuminance curve of the ultraviolet lamp withthe change of distance by a system; fitting the radiation illuminance curve with a radiation illuminance curve calculated by a radiation illuminance calculation formula by the system to obtain the emission power of the ultraviolet lamp. The invention also discloses a system for measuring the emission power of the ultraviolet lamp in water. The method and the system provided by the invention can measure the actual ultraviolet emission power of the combination of the underwater ultraviolet lamp and the quartz sleeve, the cost is low, the operation method is simple and the measurement can be carried out in a conventional laboratory, so that the method and the system can be widely applied to the field of ultraviolet lamps.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

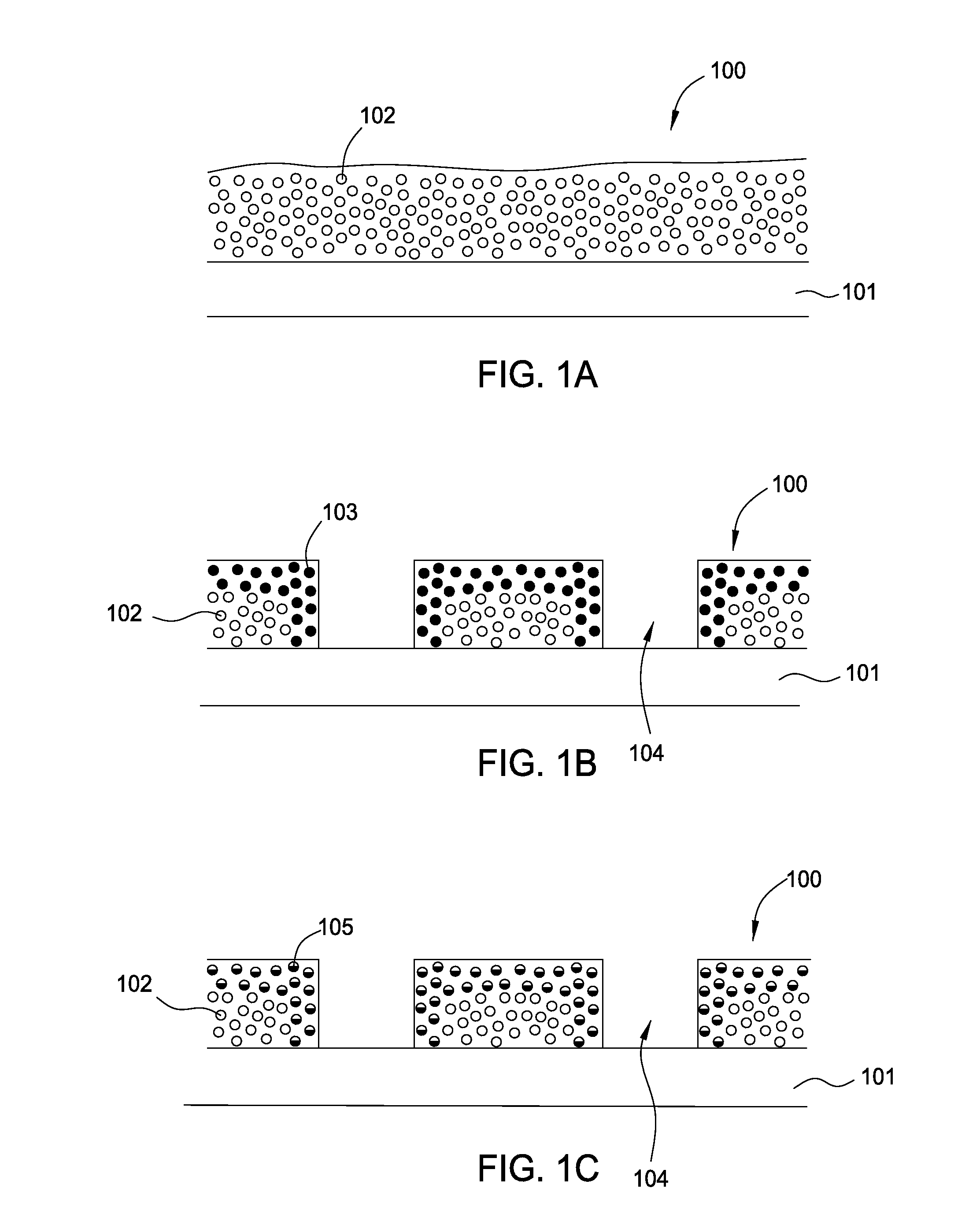

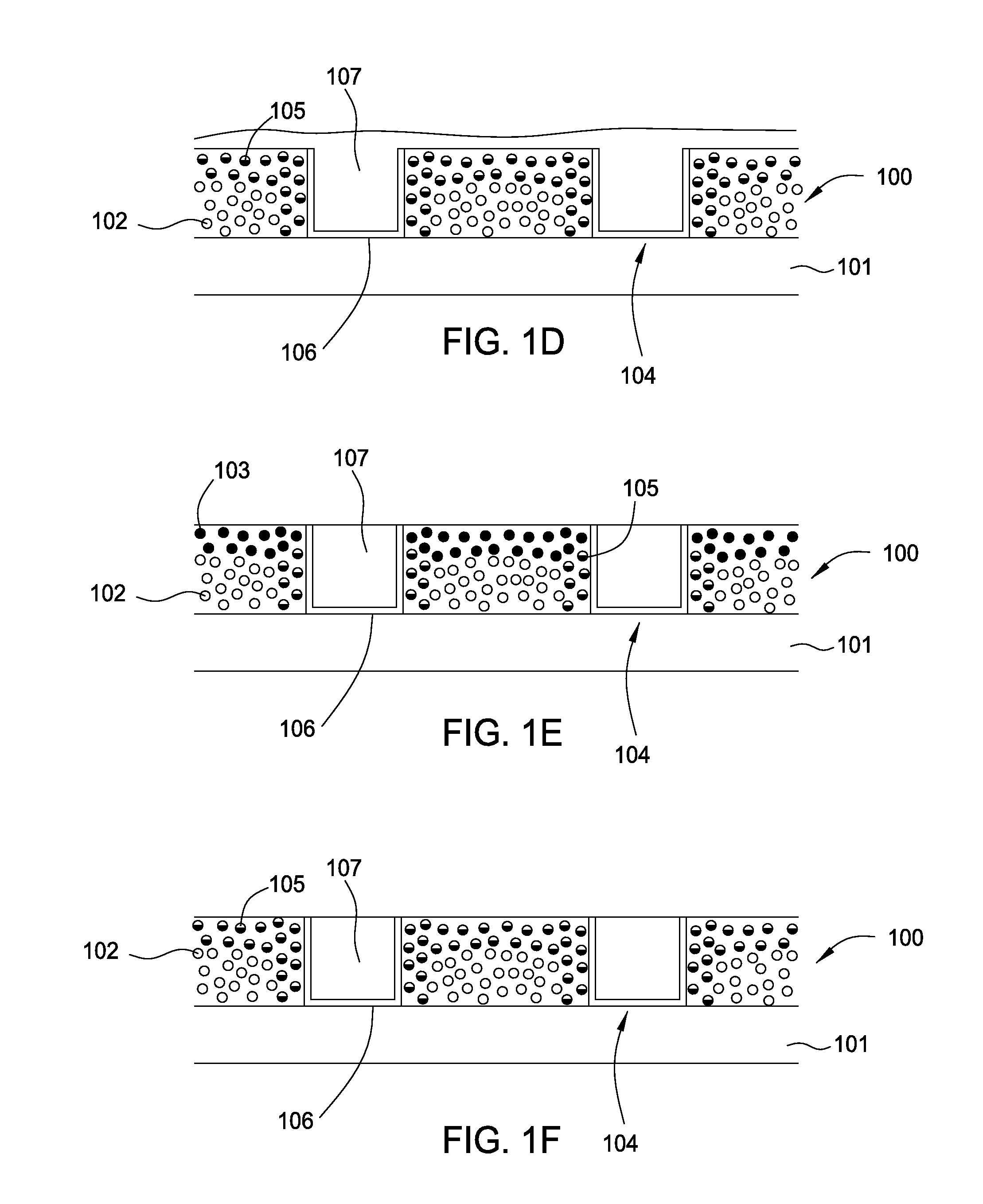

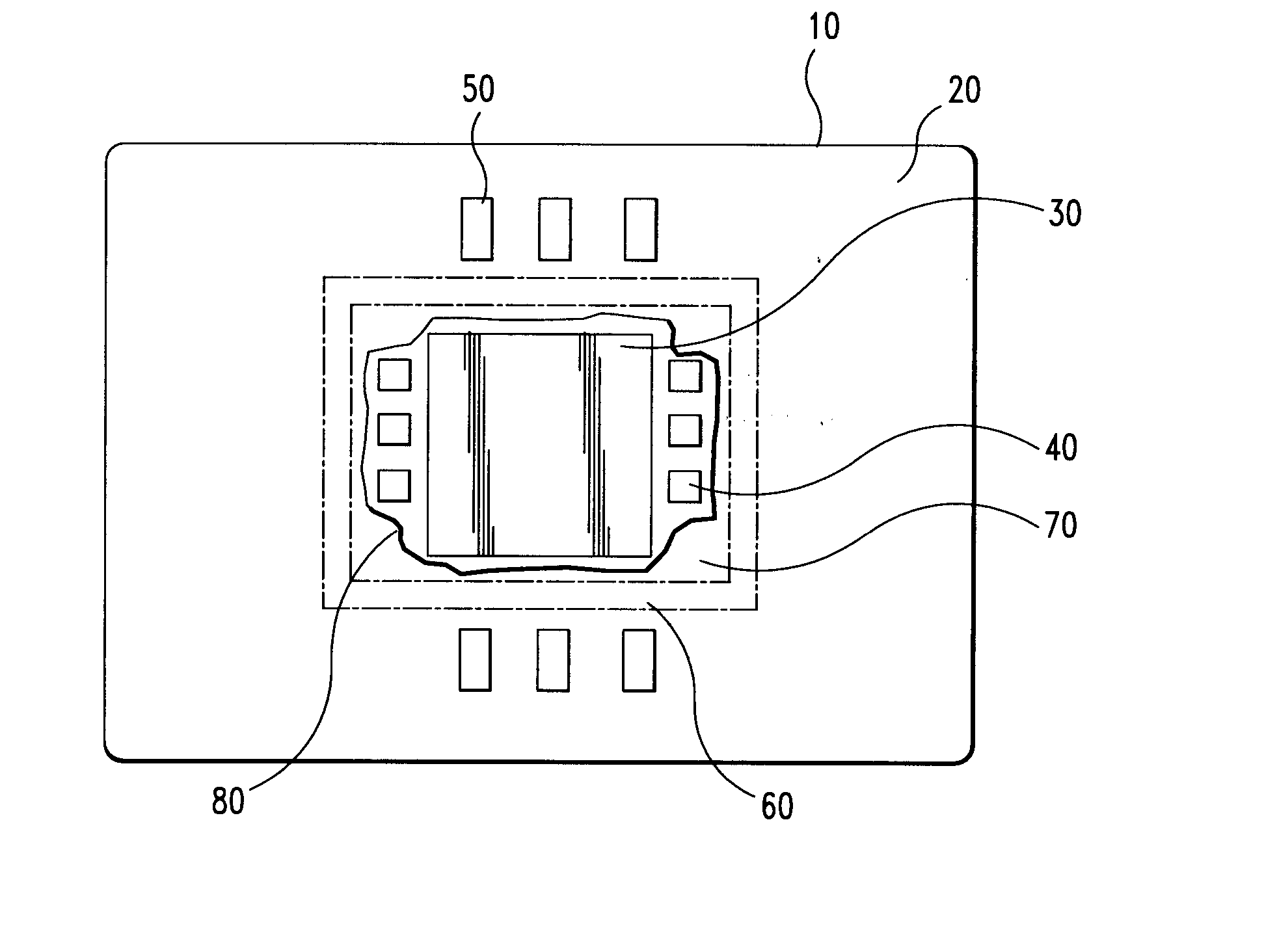

Chemical-enhanced package singulation process

Singulation of individual electronic packages fabricated as part of a common matrix, is accomplished by mask patterning and chemical exposure in combination with physical sawing. In one embodiment of a singulation process in accordance with the present invention, an initial, shallow saw cut into inter-package regions of the matrix exposes underlying metal to subsequent chemical etching steps. In an alternative embodiment, a separate photoresist mask may be patterned over the matrix to selectively expose metal in inter-package regions to chemical etching.

Owner:GEM SERVICES

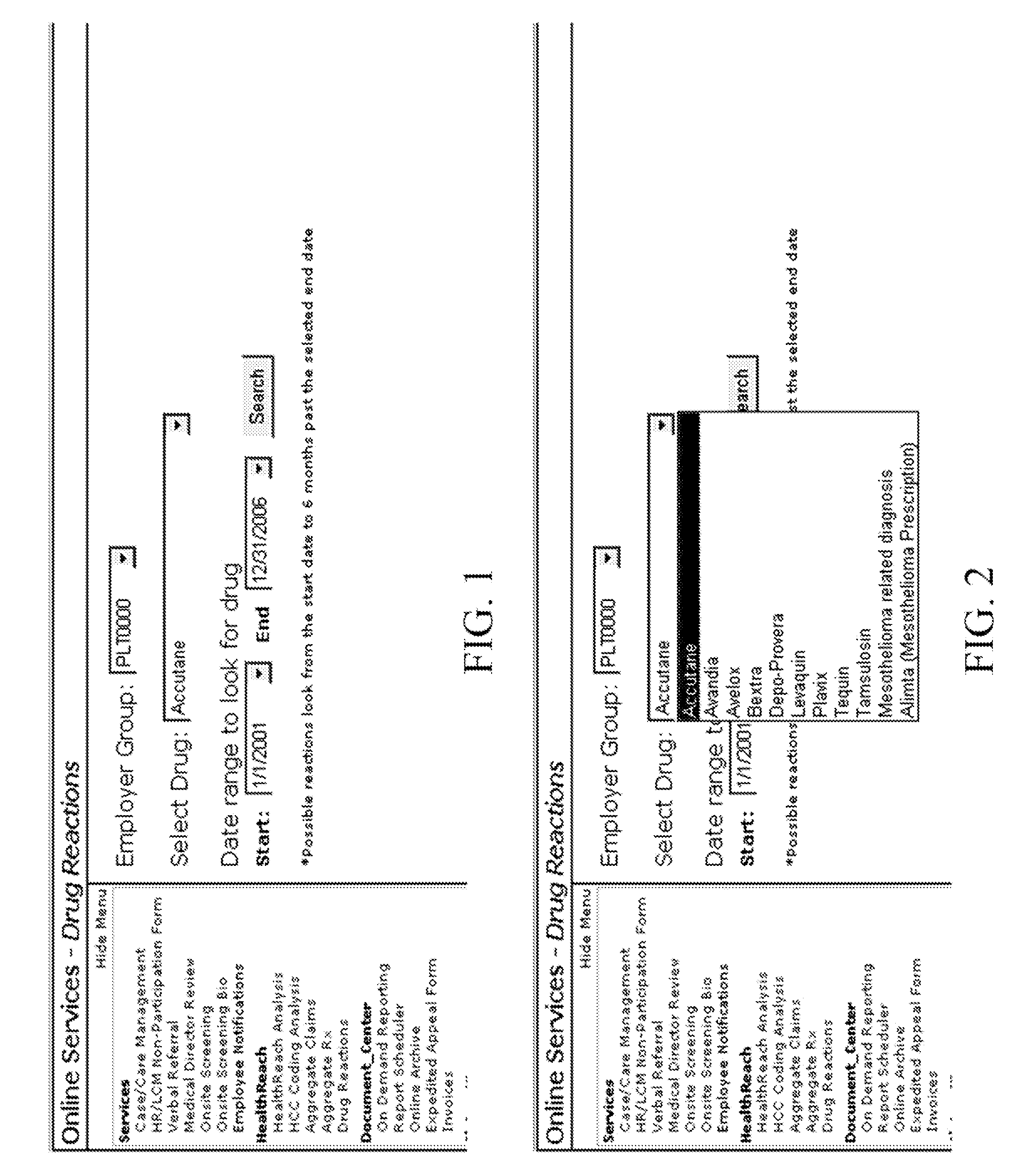

Health plan subrogation system

A software system for providing assistance to third party healthcare payors and others in recouping funds to which they have a subrogation right. The system generally comprises a web enabled computer server and a dynamic information gathering module for instructing a processor to search a health insurance claims database for all claims of record meeting a specified criteria and display, and a search window for allowing a user to enter a selected black box drug and date range for searching said health insurance claims database. The software application can identify individuals who took a particular drug and had an adverse outcome, and can identify specific diagnoses which can be imputed back to drugs or chemical exposure (such as mesothelioma caused by exposure to asbestos, and liver toxicity caused by acetominophen (including combination drugs containing acetaminophen). The software system assists health insurers in collecting funds subject to a subrogation claim.

Owner:HEALTHCARE STRATEGIES

System and method for making drilling parameter and or formation evaluation measurements during casing drilling

A casing drilling system includes a casing having a drill bit at one end. The drill bit is capable of drilling subsurface formations and formed from a material removable by drilling or chemical exposure. The chemical is substantially harmless to the casing. The system includes a centralizer affixed to an interior of the casing. The centralizer includes a receptacle therein for engaging a measurement while drilling tool. The centralizer is formed from a material removable by drilling or chemical exposure, wherein the chemical is substantially harmless to the casing. The system includes a measurement while drilling tool configured to move along the interior of the casing and to engage with the centralizer. The tool includes a device to measure a drilling parameter or a formation parameter. The tool including a latch at an upper end thereof for engagement with a retrieval tool moved through the interior of the casing.

Owner:SCHLUMBERGER TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com