Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

394 results about "Vinyl siloxane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyvinyl siloxane (PVS), also called poly-vinyl siloxane, vinyl polysiloxane, or vinylpolysiloxane, is an addition-reaction silicone elastomer (an addition silicone). It is a viscous liquid that cures (solidifies) quickly into a rubber-like solid, taking the shape of whatever surface it was lying against while curing.

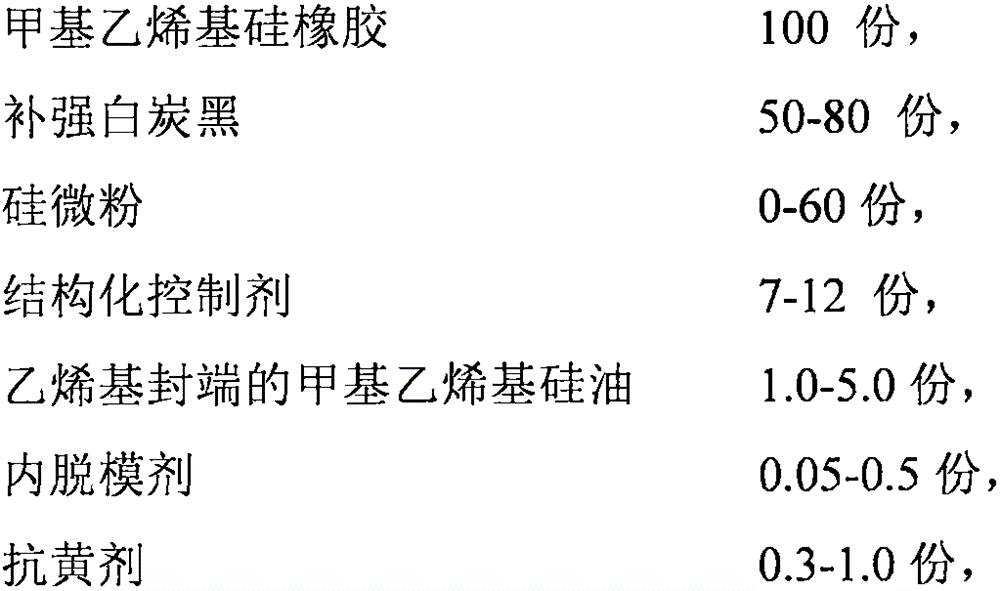

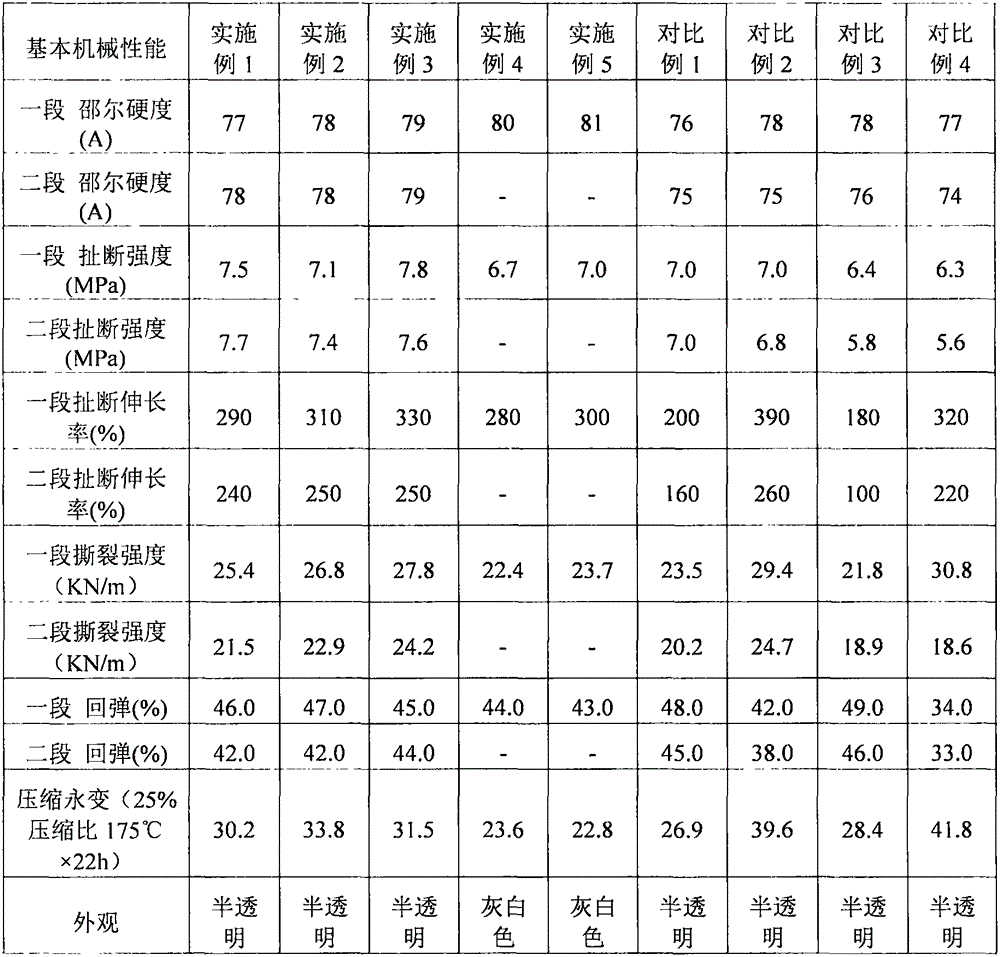

High-hardness extruded silicone rubber composition and preparation method thereof

The invention provides high-hardness extruded silicone rubber composition. The silicone rubber takes methyl vinyl siloxane with the average molecular weight of 0.55-0.75 million and the average vinyl molar content of 0.4-0.55% as rubber master batch, and reinforced white carbon black, silica powder, a structurized control agent, vinyl-terminated methyl vinyl silicone oil, an internal releasing agent, an anti-yellowing agent, magnesium oxide and cerium oxide are added. The prepared silicone rubber has high hardness, high resilience, relatively high elongation and high tear resistance after high temperature vulcanization and can be applicable to silicone products such as an industrial rubber-covered roller, a pressing wheel, a sealing ring and a sealing element.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Interface materials and methods of production and use thereof

InactiveUS20080044670A1Improve cooling effectImprove thermal performanceLayered productsSemiconductor/solid-state device detailsElastomerIndium

An interface material comprising a resin mixture and at least one solder material is herein described. The resin material may comprise any suitable resin material, but it is preferred that the resin material be silicone-based comprising one or more compounds such as vinyl silicone, vinyl Q resin, hydride functional siloxane and platinum-vinylsiloxane. The solder material may comprise any suitable solder material, such as indium, silver, copper, aluminum and alloys thereof, silver coated copper, and silver coated aluminum, but it is preferred that the solder material comprise indium or indium-based compounds and / or alloys. The interface material, or polymer solder, has the capability of enhancing heat dissipation in high power semiconductor devices and maintains stable thermal performance. The interface material may be formulated by mixing the components together to produce a paste which may be applied by dispensing methods to any particular surface and cured at room temperature or elevated temperature. It can be also formulated as a highly compliant, cured, tacky elastomeric film or sheet for other interface applications where it can be preapplied, for example on heat sinks, or in any other interface situations.

Owner:NGUYEN MY

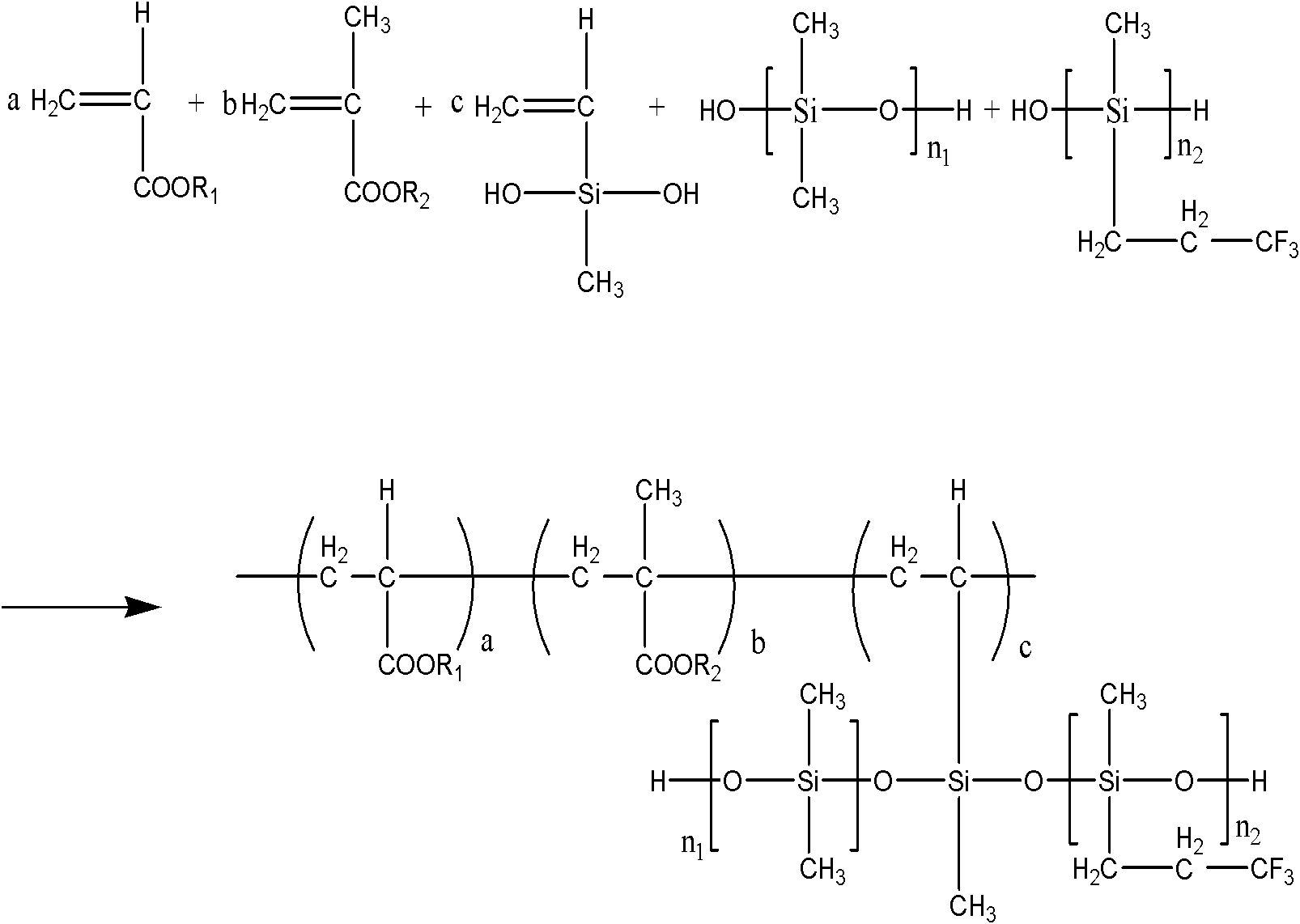

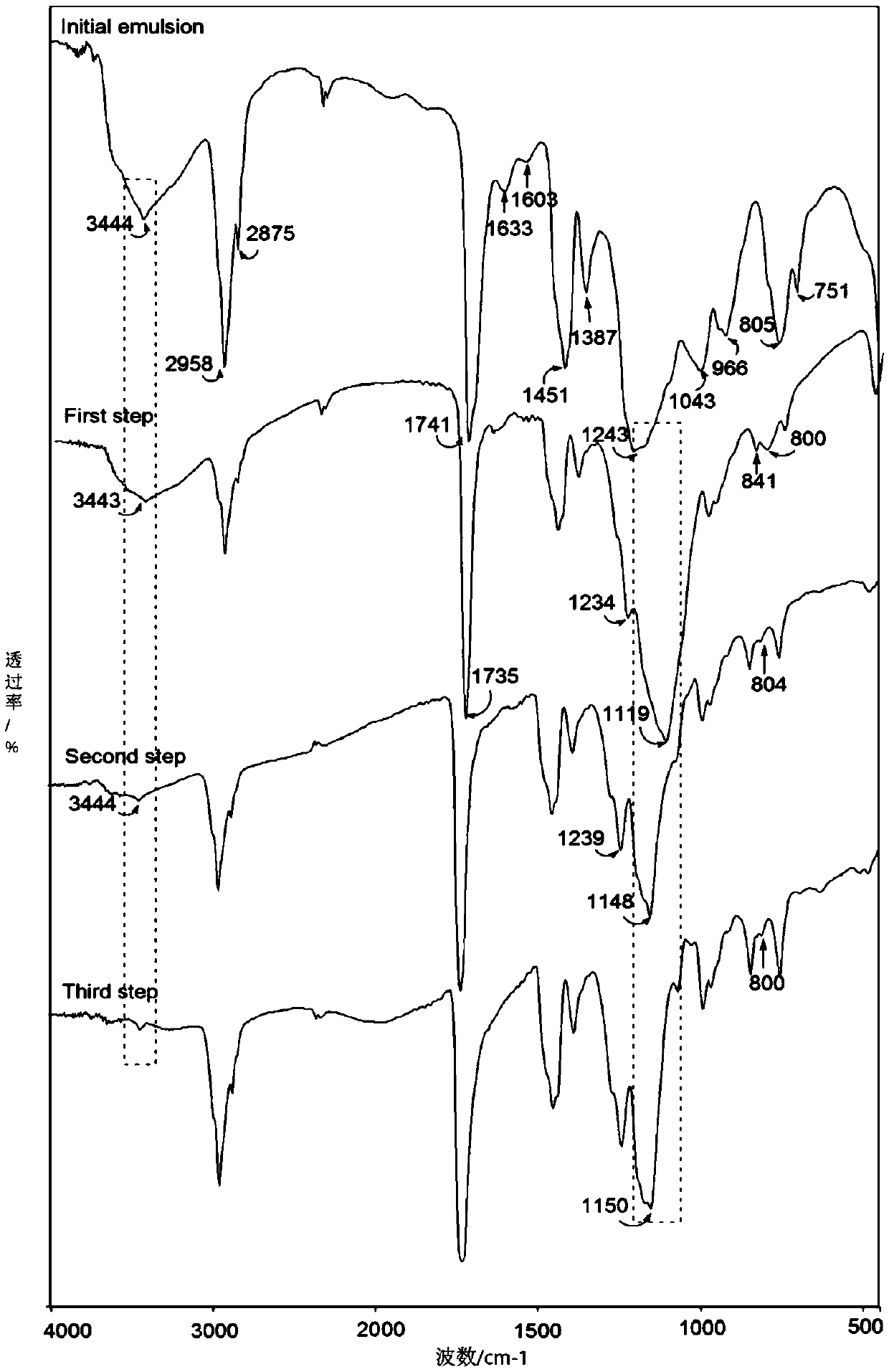

Method for preparing fluorine-containing silicon acrylate emulsion

ActiveCN102127186AStable and excellent water and oil repellencyWide variety of sourcesNon-fibrous pulp additionFibre treatmentEmulsionEmulsion polymerization

The invention belongs to the field of modification of acrylate and in particular relates to a method for preparing fluorine-containing silicon acrylate emulsion by an emulsion polymerization method. The method comprises the following steps of: 1) mixing octamethylcyclotetrasiloxane, trifluoropropylmethyl ring trisiloxane, vinyl siloxane, an acrylate monomer, a composite emulsifier, an initiator, a pH conditioning agent and distilled water to perform pre-emulsification to obtain pre-emulsified liquid; 2) stirring part of the pre-emulsified liquid under the atmosphere of inert gas, heating at the temperature T1, adding the residual pre-emulsified liquid into a reaction system dropwise, and heating at the temperature T2; and 3) cooling to room temperature under stirring, filtering by using a 200-mesh filter screen to obtain the fluorine-containing silicon acrylate emulsion. In the preparation method, the reaction process is mild and easy to control; and the product has excellent waterproof and oilproof properties.

Owner:苏州优诺塑业有限公司

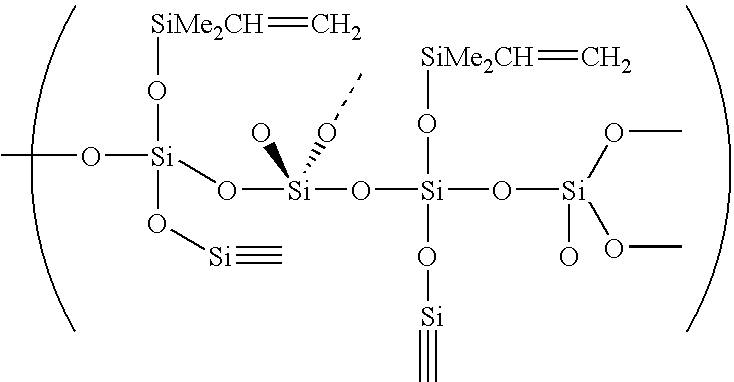

Vinyl silicon resin for reinforcing organic silicon pouring sealant and preparation method thereof

The invention discloses a vinyl silicon resin for reinforcing an organic silicon pouring sealant and a preparation method thereof. The preparation method comprises the following steps of: adding an appropriate amount of hexamethyl disiloxane and tetramethyl divinylsiloxane into a mixture of hydrochloric acid, an organic solvent and water to perform reaction for some time and then adding tetraethoxysilane and bis-functional or trifunctional siloxane to perform reaction; adding a certain amount of hexamethyl disiloxane and tetramethyl divinylsiloxane according to circumstances, standing and demixing after the reaction is finished, washing lower mixed liquor with deionized water until the liquor is neutral, and drying the liquor to obtain the vinyl silicon resin. The spherical core of the silicon resin prepared by the method, namely SiO2 has high content, and the spherical shell is tightly encircled by an R3SiO0.5 layer, so the silicon resin has good reinforcing effect; and the resin hashigh solubility or dispersibility in silicon rubber, can be separately used as a reinforcing filler for the organic silicon pouring sealant, and can also be matched with other fillers, so that the organic silicon pouring sealant with required performance can be obtained.

Owner:GUANGZHOU GLORYSTAR CHEM +1

Synthesis of densified siloxate ceramic by liquified polysiloxane

Synthesis of compact silobone ceramic from liquefied silicone is carried out by mixing silicone of hydrogen content 1.55 wt% with tetramethyl-tetravinyl cyclo-tetrasilicone in proportion of 1:2-2:1, magnetic agitating to obtain mixture, adding into vinyl-silicone ligand platinum complex catalyst, mixing, pouring it into mould, putting it into vacuum baker, cross-linking to form at 20-100 degree, drying formed blank, de-molding, raising temperature to 600-1300 degree under argon or nitrogen atmosphere and lowering temperature to room temperature to obtain final product. It's simple and controllable, has no need for pressure and different shapes.

Owner:TIANJIN UNIV

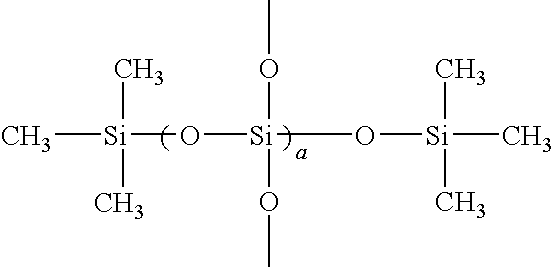

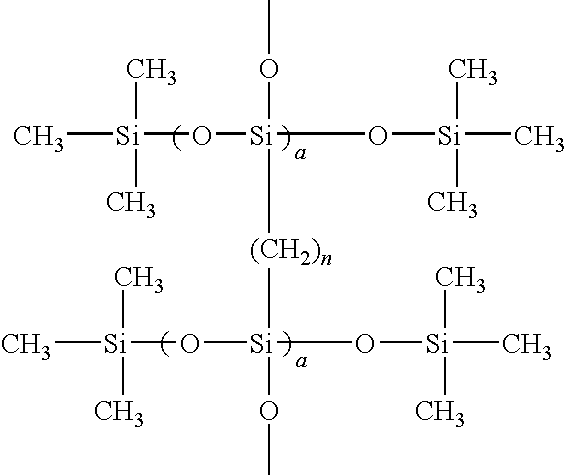

Linear silicone resins in personal care applications

InactiveUS20070196309A1Easy to wearImprove adhesionCosmetic preparationsBiocideHydrogenCompound (substance)

The present invention relates to the use in personal care products of a series of novel silicone polymers (referred to as linear silicone resin) that by are made by the hydrosilylation reaction of a terminal vinyl silicone and a terminal silanic hydrogen polymer. The properties make the compounds very useful in a variety of personal care applications including personal care.

Owner:SILTECH

Organic silicon modified phenyl emulsion pressure-sensitive adhesive with high release force and low residue as well as preparation method thereof and application

InactiveCN104342073AImprove peel forceHigh initial tackFilm/foil adhesivesEster polymer adhesivesEmulsionAging resistance

The invention belongs to the technical field of pressure-sensitive adhesive for packaging an electronic product, and discloses organic silicon modified phenyl emulsion pressure-sensitive adhesive with high release force and low residue and a preparation method thereof. The method comprises the following steps: firstly synthesizing polyacrylate seed emulsion, adding organic silicon by utilizing an after-dropping technology, facilitating the ring-opening reaction of an epoxy group with carboxyl on a polymer chain and an amino group on a reactive emulsifier to obtain organic silicon modified phenyl emulsion through the treatment after heating an adhesive film. By increasing cross-linking points of carboxyl and hydroxy, the cohesion can be further enhanced. By adopting the method, the introduction of siloxane which does not contain two bonds is realized, the weakness of the low conversion rate caused by different cohesion rates when vinyl siloxane and acrylate monomer are copolymerized can be overcome, the difficulty of the reduced polymer stability caused by the hydrolysis of the organic silicon can be solved, the complicated procedure that the cohesion can be improved by additionally adding the cross-linking agent is avoided, the low residual adhesion under high initial adhesion and high stripping strength can be realized, and the water resistance and high-temperature aging resistance can be improved.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI +1

Silicone modified polyacrylate and its prepn and application

InactiveCN1887926AImprove heat resistanceGood chemical resistanceCoatingsAcrylonitrileAcrylate polymer

The present invention relates to water soluble organosilicon modified polyacrylate and its preparation process. The organosilicon modified polyacrylate has number average molecular weight of 33,000-70,000, and is prepared through the first free radical polymerization with monomers, including (methyl) acrylate 15-85 wt%, hydroxyl group containing acrylate 6-18 wt%, (methyl) acrylic acid 5-17 wt%, styrene 0-25 wt%, acrylonitrile 0-15 wt%, Veova 0-30 wt% and vinyl siloxane 1-20 wt%, under the action of initiator inside alcohol or alcohol ether medium, and the subsequent neutralization with ammonia or organic amine to produce salt. The polymer of the present invention has high storage stability, high water resistance, high chemical resistance, excellent heat resistance and electric insulating performance, and may be used widely as filming material for various paint products.

Owner:SHENZHEN HANLONG TECH DEV

(Methyl) acrylic resin with high organic silicon content and preparation method thereof

The invention discloses (methyl) acrylic resin with high organic silicon content and a preparation method thereof. The preparation method of the (methyl) acrylic resin comprises the following steps of: enabling octamethylcyclotetrasiloxane, an anionic emulsifier, a non-ionic emulsifier and water to react for 3 hours to 9 hours at 70 DEG C to 90 DEG C; adding siloxane containing unsaturated double bond to react for 3 hours to 9 hours at 75 DEG C to 90 DEG C; breaking the emulsion by alcohol to obtain long-chain siloxy vinyl siloxane; and enabling the obtained long-chain siloxy vinyl siloxane, (methyl) acrylic resin monomer, non-reactive organic solvent and initiator to react at 60 DEG C to 75 DEG C to obtain the (methyl) acrylic resin with high organic silicon content. The resin is introduced with the long-chain siloxy vinyl siloxane, so the resin has good water resistance; and the appropriate (methyl) acrylic resin monomer is selected, so that the elongation at break and tensile strength of a film which is coated with the (methyl) acrylic resin are increased.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Organosilicon insulating impregnating varnish and preparation method thereof

InactiveCN101649158AThe degree of cross-linking is controllableLow viscosityCoatingsSolventSilsesquioxane

The invention discloses an organosilicon insulating impregnating varnish and a preparation method thereof. The organosilicon insulating impregnating varnish comprises a component A and a component B in a weight ratio of 1:1, wherein the component A comprises 100 parts of polymethylphenylvinylsiloxane and 0.9-1.5 parts of platinum catalyst and the component B comprises 30-75 parts of polyhedral oligomeric silsesquioxane with ethylene group and 40-60 parts of hyperbranched polysiloxane with Si-H bond. The polymethylphenylvinylsiloxane synthesized in the preparation method of the invention adoptsethanol as solvent and is no non-toxic and non-harmful; when the prepared impregnating varnish is solidified, no by-product with low molecular weight is discharged, thus not affecting the electric performance of the insulating material; in addition the impregnating varnish has good post impregnation effect, high temperature resistance and environmental friend.

Owner:SUZHOU UNIV

Room temperature vulcanized organosilicon pouring sealant for LED

ActiveCN101381516AExtended service lifeSimple preparation processOther chemical processesSemiconductor devicesAdhesiveRefractive index

The invention relates to a room temperature vulcanized (RTV) organosilicon potting adhesive for an LED. The potting adhesive is a bi-component potting adhesive, wherein a component A is formed by mixing vinyl terminated polymethylphenyl sioxane, vinyl dimethyl methylsiloxy terminated PDMS, polymethyl hydrogen phenyl siloxane and methyl-butynol as inhibitor in the weight ratio of 100:10-30:5-20:0.05-1; and a component B is formed by mixing vinyl terminated polymethylphenyl sioxane, vinyl dimethyl methylsiloxy terminated PDMS and methyl vinyl siloxane coordinated platinum catalyst in the weight ratio of 100:10-30:0.5-5. The RTV organosilicon potting adhesive for the LED has the advantages of good heat resistance, wet fastness, light transmittance up to 99 percent, refractive index up to 1.47 to 1.55, good packaging effect, capability of prolonging the life span of the LED, as well as simple manufacture process.

Owner:SHANGHAI UNIV

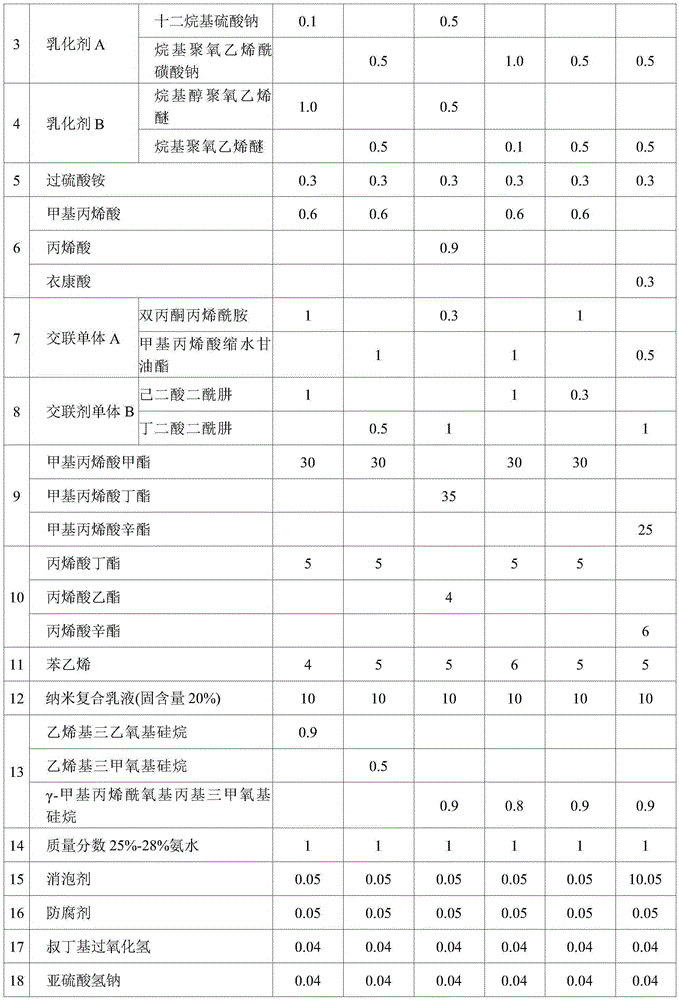

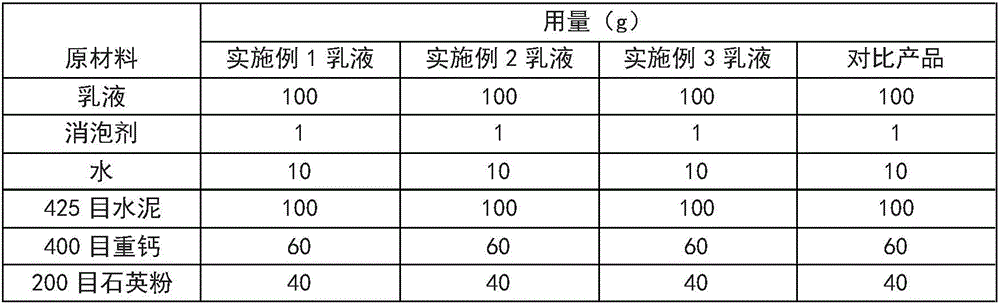

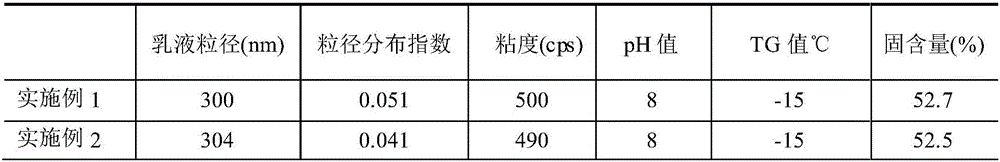

Room temperature multiple self-crosslinking nano acrylate copolymer emulsion and preparation method and water-based woodenware paint using emulsion as base material

The invention discloses a room temperature multiple self-crosslinking nano acrylate copolymer emulsion and a preparation method thereof and water-based woodenware paint using the emulsion as a base material, preparation synthesis components of the room temperature multiple self-crosslinking nano acrylate copolymer emulsion include vinyl-unsaturated carboxylic acid, methacrylate, acrylate, styrene, a modified SiO2 and acrylate monomer dispersion liquid, a crosslinking monomer A, vinyl siloxane, a crosslinking monomer B and the like, and by use of three methods of introduction of three components of modified nano-SiO2, the cross linking monomers and the vinyl siloxane for crosslinking through the preparation of the room temperature multiple self-crosslinking nano acrylate copolymer emulsion, the three crosslinking methods are in mutual coordination, so that finally the water-based woodenware paint prepared from the emulsion as the base material forms a dense protective film, and has excellent water resistance, alcohol resistance, scratch resistance, high temperature after-tack resistance and relatively high hardness, and the paint film properties can be comparable to that of solvent-based furniture paint.

Owner:HENGSHUI XINGUANG CHEM

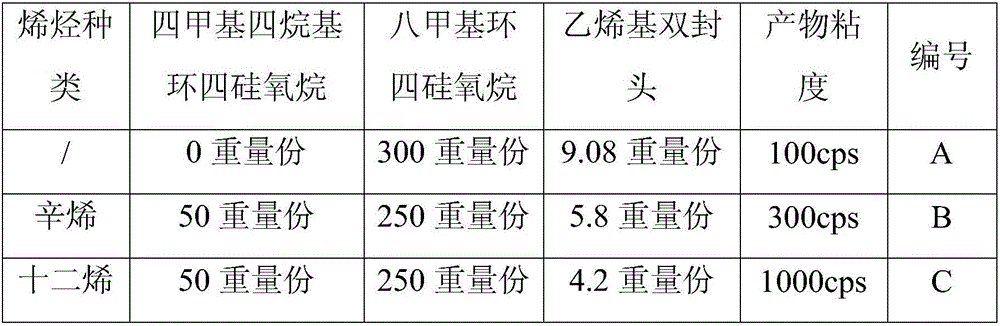

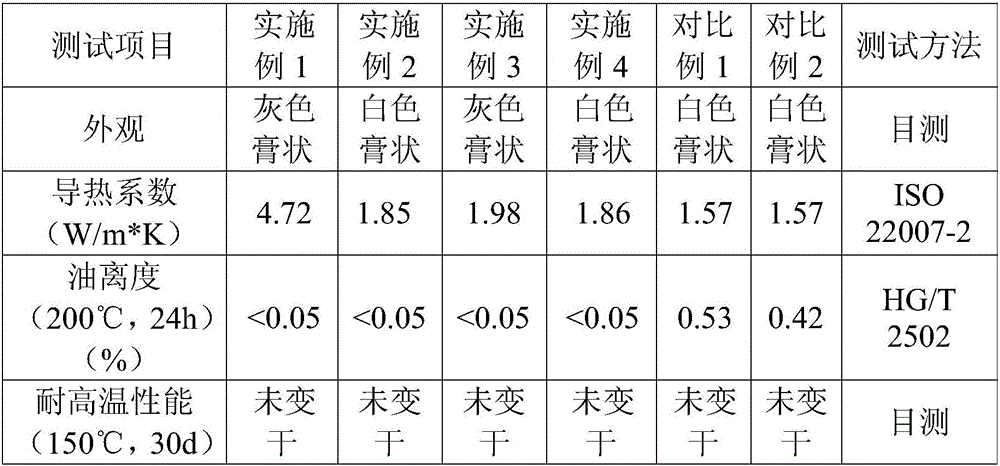

Heat-conducting silicone grease composition with low oil separation degree and preparation method thereof

The invention discloses a heat-conducting silicone grease composition with low oil separation degree and a preparation method thereof. The heat-conducting silicone grease composition with low oil separation degree includes: by weight, 30-40 parts of vinyl silicone oil, 0.1-1.0 part of hydrogen-containing silicone oil, 0.05-0.1 part of an inhibitor, 0.01-0.05 part of platinum-vinyl siloxane complex, and 100-500 parts of heat-conducting filler. The silicone oil in the heat-conducting silicone grease composition with low oil separation degree is difficult to transfer, and the oil separation degree is less than 0.05% (200 DEG C, 24h, HG / T 2502). The composition has secular stable thermolysis when using in the electron component, and has no harmful effect on the electron component because of the transference of the silicone oil.

Owner:CHENGDU GUIBAO SCI & TECH

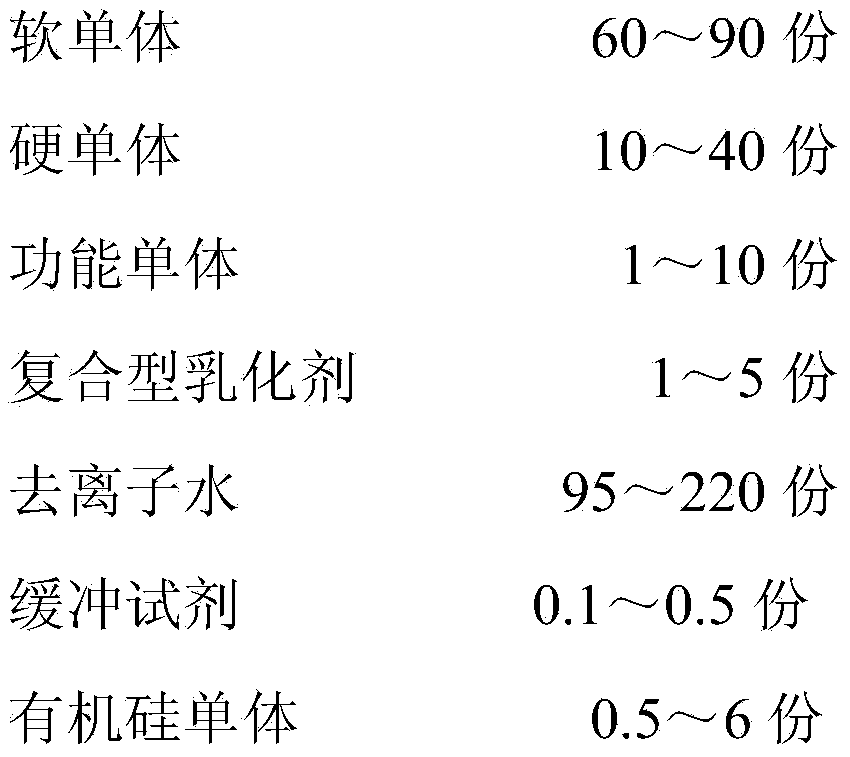

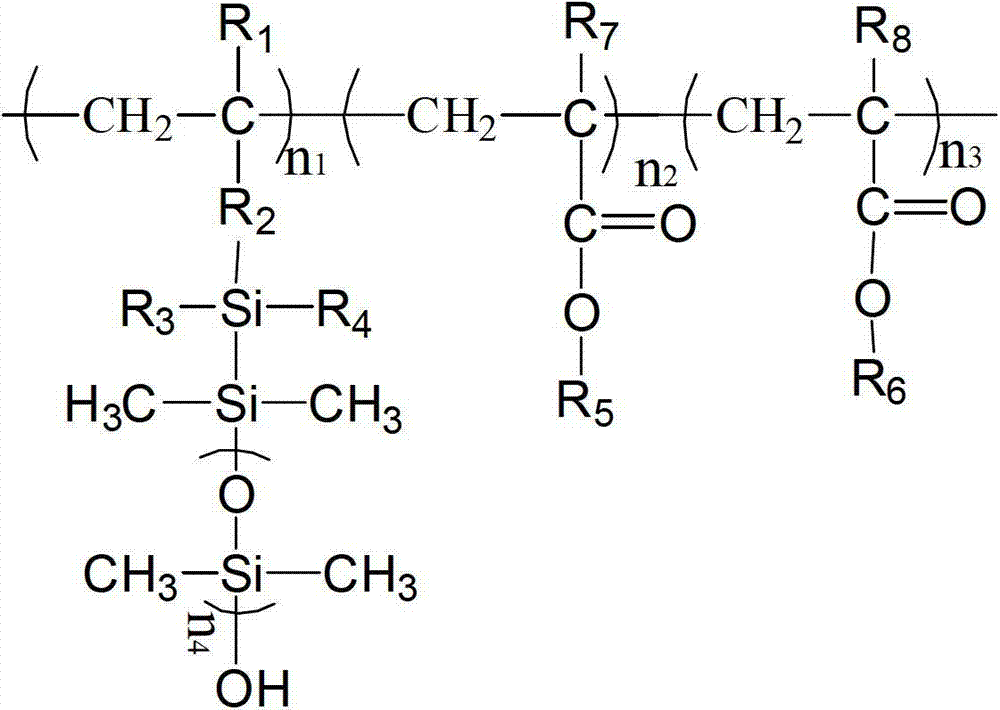

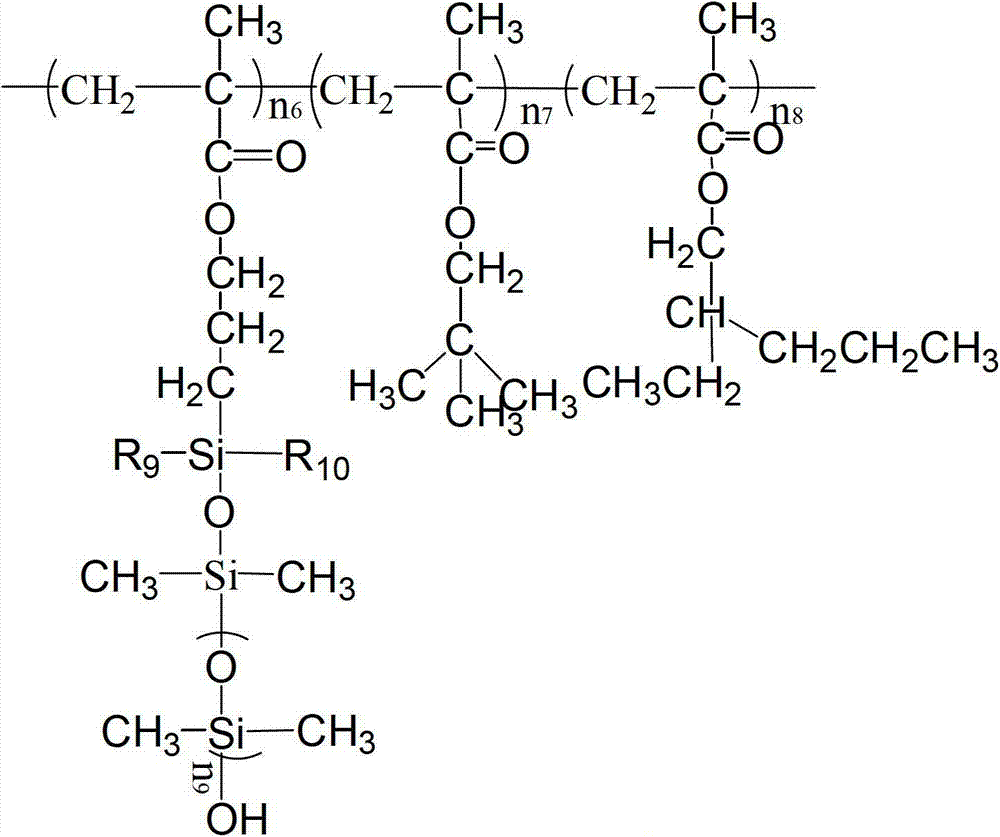

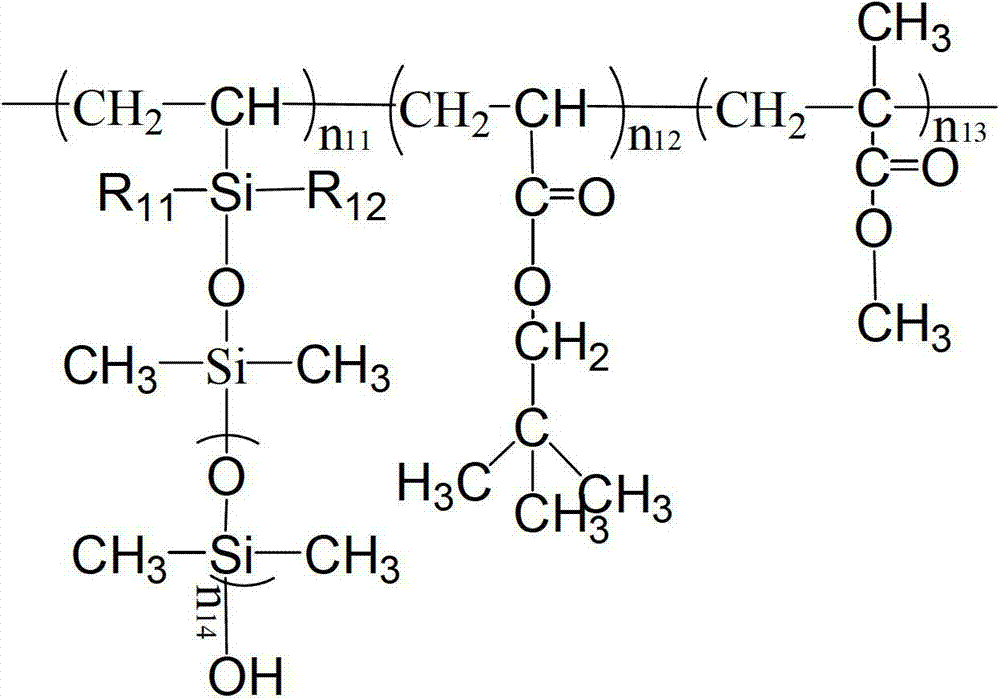

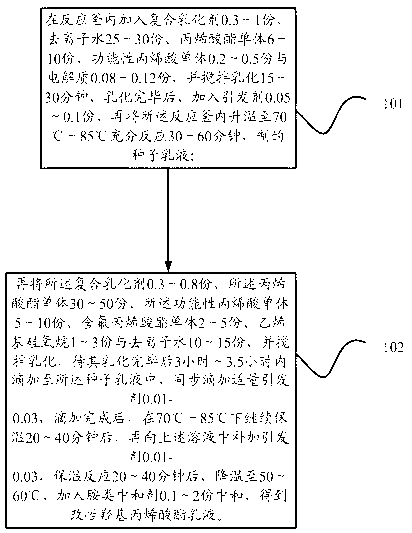

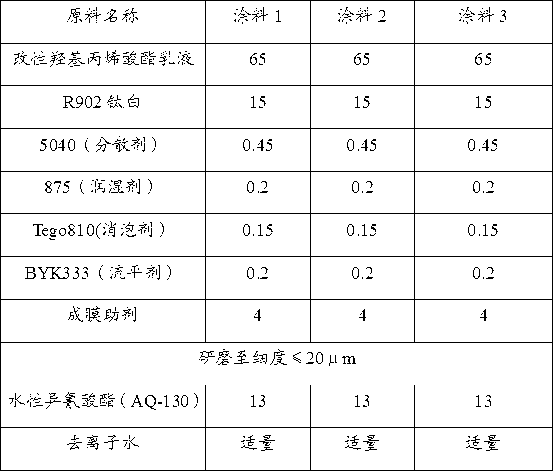

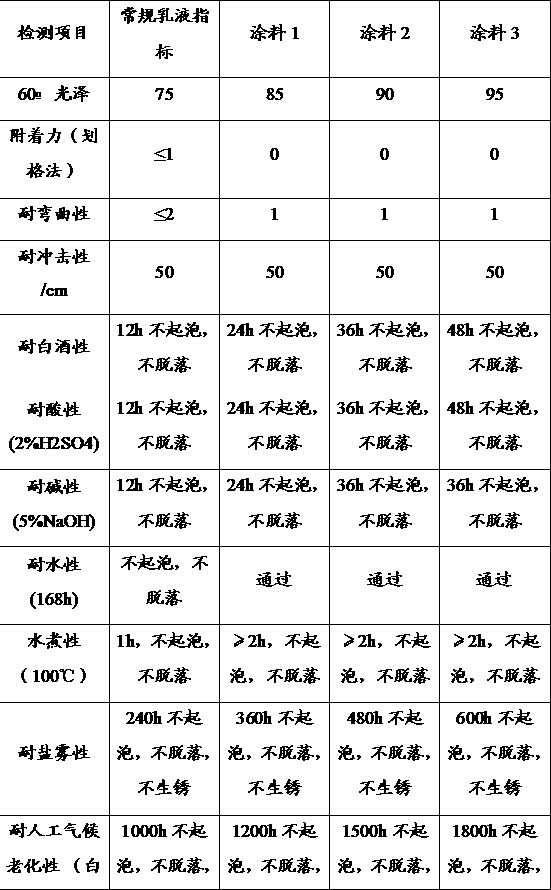

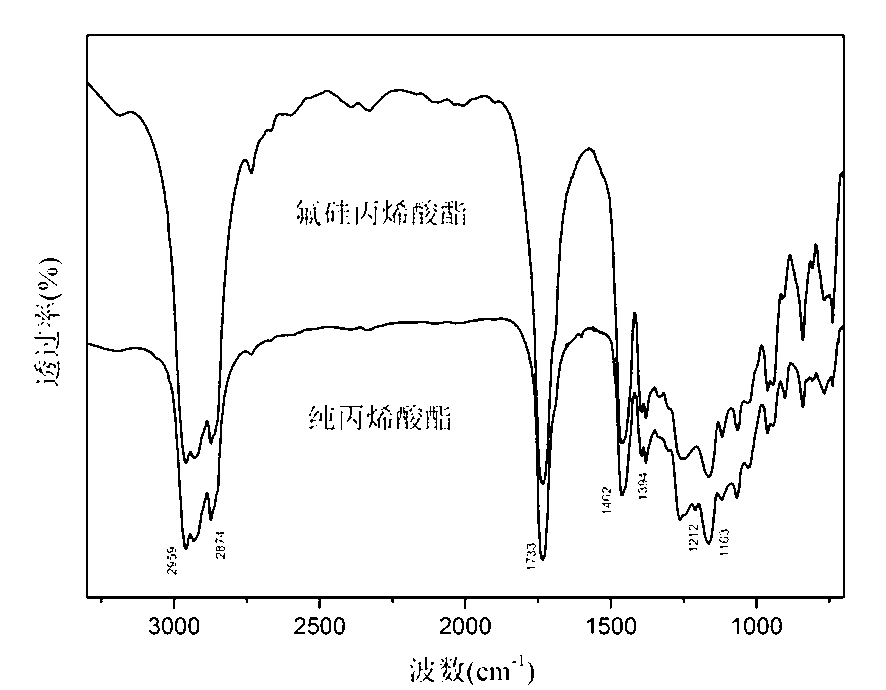

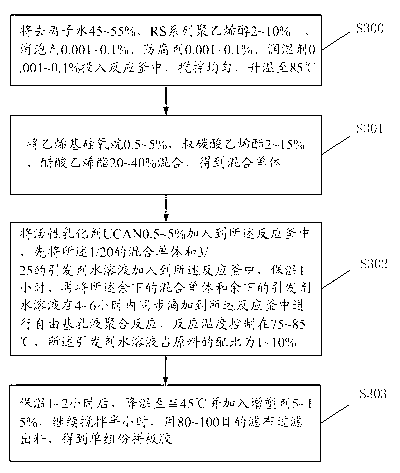

Modified hydroxyacrylate emulsion and preparation method thereof

ActiveCN103059210AGood weather resistanceGood chemical resistancePolyurea/polyurethane coatingsPolymer scienceAcrylic monomers

The invention discloses a modified hydroxyacrylate emulsion and a preparation method thereof. The modified hydroxyacrylate emulsion comprises 0.6-1.8 parts of composite emulsifier, 35-45 parts of deionized water, 36-50 parts of acrylate monomer, 0.2-0.5 part of functional acrylic monomer, 0.08-0.12 part of electrolyte, 0.05-0.2 part of initiator, 5-10 parts of functional acrylic monomer, 2-5 parts of fluorine-containing acrylate monomer, 1-3 parts of vinyl siloxane and 0.1-2 parts of amine neutralizer. The polymerizable fluorine-containing acrylate monomer is introduced in the emulsion polymerization process, and the polymerizable vinyl siloxane is introduced in the later polymerization period, so that the modified hydroxyacrylate emulsion has the advantages of high durability, weather resistance, corrosion resistance, self-cleaning performance, acid resistance, alkali resistance, strong adhesiveness, high decoration performance, high paint film fullness and the like.

Owner:泰兴市华盛银洋新材料科技有限公司

Fluorosilicone acrylates copolymer emulsion as well as preparation method and application thereof

InactiveCN103242479AGood storage stabilityImprove stabilityBuilding insulationsEmulsionGlass transition

The invention relates to a fluorosilicone acrylates copolymer emulsion as well as a preparation method and application thereof. Acrylate monomer, cationic emulsifier, nonionic emulgator and initiator are mixed so as to obtain the mixed emulsion, part of the mixed emulsion reacts through stirring at 75-80 DEG C so as to obtain light blue seed emulsion, vinyl siloxane and trifluoro propyl group trimethyl ring trisiloxanes are added into the left mixed emulsion for pre-emulsification, and the pre-emulsification emulsion is dropped into the seed emulsion for reaction after the temperature rises to 81-86 DEG C, so that cationoid fluorosilicone acrylates copolymer emulsion is obtained. The prepared cationoid fluorosilicone acrylates copolymer emulsion has the characteristics of good stability and low glass-transition temperature, can be applied to modification of road asphalt emulsion, and is beneficial to maintenance of road asphalt in alpine region.

Owner:江苏阜光工程新技术有限公司

Amine-free waterproof emulsion, preparing method thereof and waterproof coating containing amine-free waterproof emulsion

ActiveCN105949381AHigh hardnessHigh tensile strengthCoatingsHydrophilic monomerPhosphoric Acid Esters

The invention discloses amine-free waterproof emulsion, and belongs to the technical field of waterproof coatings. The amine-free waterproof emulsion comprises, by weight, 40-50 parts of deionized water, 0.6-12.0 parts of emulsifying agent, 0.02-20 parts of phosphoric acid ester monomers, 0.05-40 parts of hydrophilic monomers, 0.05-60 parts of hydrophobic monomers, 0.05-20 parts of polymerization stabilizer, 0.02-5 parts of vinyl silicone, 0.02-5 parts of initiating agent, 0.02-5 parts of chain transfer agent, 0.02-5 parts of pH buffering agent, 0.02-5 parts of antifoaming agent, 0.02-5 parts of preservative and 0.02-5 parts of alkali liquid. The invention further provides a preparing method of the amine-free waterproof emulsion and a waterproof coating containing the amine-free waterproof emulsion. The waterproof emulsion and the waterproof coating are environmentally friendly and free of pollution, and pungent smells such as ammonia smells are not generated.

Owner:HENGSHUI XINGUANG CHEM +1

Waterproof coating containing polyether-modified silicon-acrylic soft resin and preparation method thereof

The invention provides waterproof coating containing a polyether-modified silicon-acrylic soft resin and a preparation method thereof. The waterproof coating is prepared by mixing the following raw materials in percentage by mass: 30 to 70 percent of polyether-modified silicon-acrylic soft resin, 25 to 65 percent of pigment filler, 1 to 8 percent of aqueous aid and the balance of water; and the polyether-modified silicon-acrylic soft resin is prepared from 5 to 30 mass percent of polyether polymer emulsifier, 5 to 15 mass percent of vinyl siloxane, 30 to 70 mass percent of acrylate monomer and the balance of water. The waterproof coating has high comprehensive performance, high adhesive force, high water resistance and high corrosion resistance and has a very wide market prospect in an environment-friendly society and high practicality.

Owner:武汉力诺投资控股集团有限公司

Silicon-containing acrylate-polyester resin, and finish coat and application thereof

InactiveCN102850536AImprove stain resistanceImprove self-cleaning functionPolyurea/polyurethane coatingsFunctional monomerCarboxylic acid

The invention relates to a silicon-containing acrylate-polyester resin which is prepared by carrying out free-radical polymerization and polycondensation on functional monomers composed of organic silison monomer (especially vinyl siloxane monomer) and multiple (methyl) acrylic acid (acrylate) monomers, polybasic carboxylic acids and polybasic alcohols. By increasing the quantity and varieties of the polymerization monomers, the prepared resin effectively combines the advantages of the organic silicon resin, acrylate resin and polyester resin, so that the coat prepared by using the resin as the base material not only has excellent functions of pollution resistance and self-cleaning, but also has the advantages of excellent corrosion resistance, high / low temperature stability, weather resistance, wear resistance, shock resistance, chemical medium resistance, corrosion resistance and solvent resistance as well as sufficient hardness, flexibility, brightness, fullness and the like.

Owner:常州市弘可利办公用品有限公司 +1

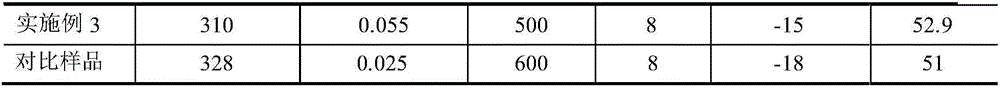

Organic silicon composition and application thereof

ActiveCN104449550AExcellent physical and chemical propertiesImprove liquidityNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsVulcanizationLight-emitting diode

The invention discloses an organic silicon composition and application thereof. The organic silicon composition comprises at least one vinyl siloxane polymer capable of curing by silicon hydrogenation addition reaction, at least one hydrogen-radical siloxane polymer, at least one vinyl POSS (polyhedral oligomeric silsesquioxane), organic-group-modified nano silicon dioxide, a silicon hydrogenation addition curing catalyst and other basic components, and can further comprise a silicon hydrogenation addition reaction inhibitor, a binding accelerator and the like. The organic silicon composition has favorable physical and chemical comprehensive properties (including favorable flowability, high curing speed, high curing ratio, high curing hardness, high light transmittance and the like), has the characteristics of high vulcanization resistance, low aging speed, stable performance and the like, is suitable to be used as binding and packaging materials for optical and electronic devices, and is especially suitable to be used as a packaging material for LEDs (light-emitting diodes) and other semiconductor light-emitting elements.

Owner:FLORY OPTOELECTRONICS MATERIALS SUZHOU CO LTD

Personal Care and Dermatologic Compositions

Owner:PERLE ADAM +2

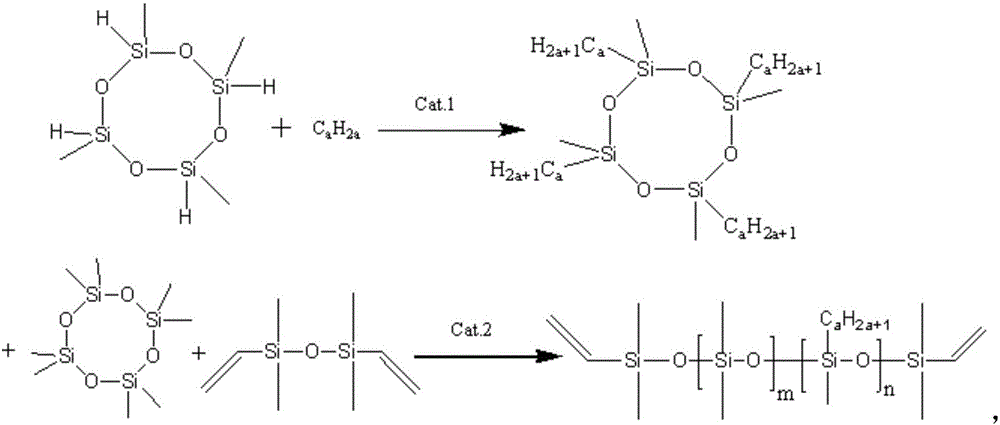

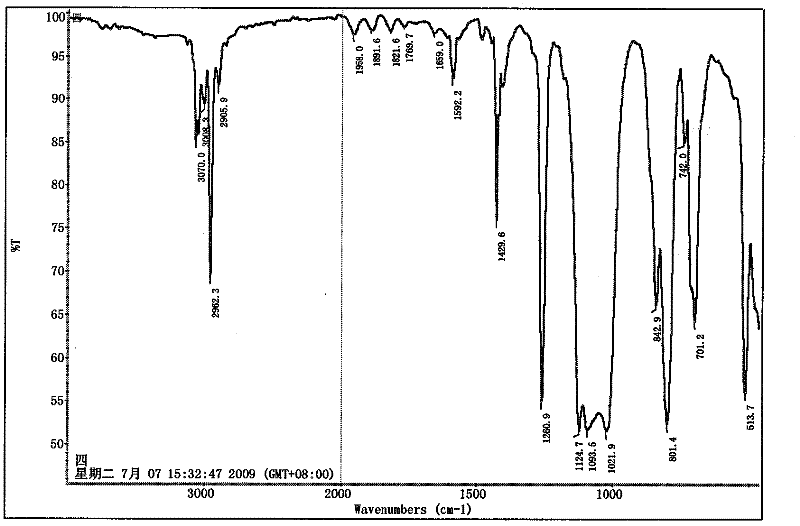

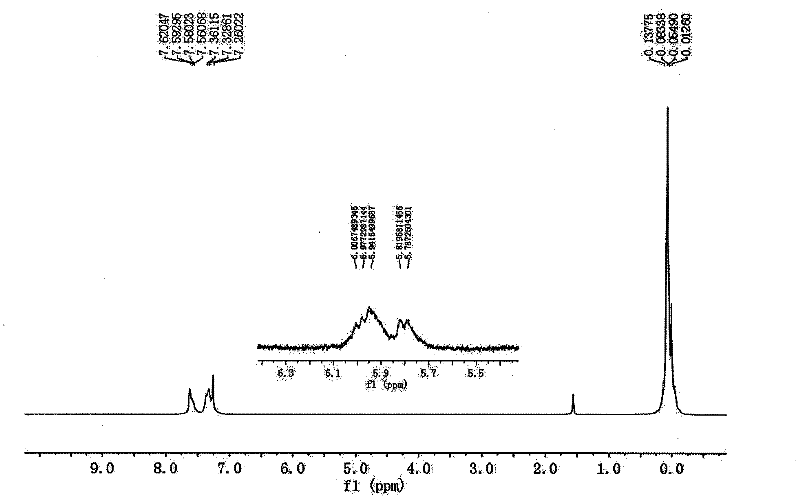

Copolymerized high-performance damping silicon rubber and preparation method thereof

The invention discloses copolymerized high-performance damping silicon rubber and a preparation method thereof. The preparation method is characterized by comprising the following steps of: adding 100 parts by mole of octamethylcy-clotetrasiloxane, 0.001-1 part by mole of tetram-ethy1tetravinylcyclotetrasiloxane, 1-50 parts by mole of octaphenyl cyclotetrasiloxane and 1-500 parts by mole of hybrid ring containing methylphenyl siloxane chain links into a reactor; dehydrating by forming nitrogen bubbles at the temperature of between 55 DEG C and 65 DEG C under the protection of nitrogen gas for 1-3 hours; adding 0.01-5 percent by weight of catalyst; continually drying nitrogen bubbles; adding 0.00001-1 part by millimole of end-capping reagent when the viscosity rises; undergoing a balanced reaction at the temperature of between 90 DEG C and 110 DEG C for 7-8 hours; raising the temperature to 145-165 DEG C after the reaction; preserving heat for 1-2 hours; decomposing and breaking the catalyst; raising the temperature to 180-200 DEG C finally; separating low molecular substances out at reduced pressure under the vacuum degree of 6-12 Mpa until distillate is eliminated fully; cooling to room temperature and discharging; and stopping reducing pressure to obtain polymethyl phenyl ethylene siloxane. Phenyl siloxane rubber further prepared from the copolymer has superior damping capacity and mechanical property.

Owner:SICHUAN UNIV

Antimicrobial moldproof agent for silk fabrics

ActiveCN103757893AWon't breakHas antibacterial and antifungal effectsAnimal fibresFiberPhosphoric acid

The invention discloses an antimicrobial moldproof agent for silk fabrics, which is prepared from the following components in parts by weight: 8-12 parts of citric acid, 7-11 parts of polyoxyethylene trimethyl ammonium chloride, 6-10 parts of vinyl siloxane, 5-9 parts of chitosan quaternary ammonium salt, 4-8 parts of tetrasodium metaphosphate, 3-7 parts of tin tetrachloride, 3-7 parts of potassium oxalate, 3-7 parts of sodium alginate, 5-9 parts of phenyl salicylate and 10-14 parts of amyl acetate. The antimicrobial moldproof agent has favorable antimicrobial and moldproof effects; the finished fabric has favorable washing fastness and soft feeling; and the preparation technique is simple, is nontoxic and harmless to the human body, and can not destroy the cocoon fibers in the silk fabric.

Owner:上海福晏精细化工有限公司

Polyacrylate/nano SiO2 hybrid emulsion with high coating film hardness and tolerance and preparation method for polyacrylate/nano SiO2 hybrid emulsion and application of polyacrylate/nano SiO2 hybrid emulsion

The present invention discloses a polyacrylate / nano SiO2 hybrid emulsion with high coating film hardness and tolerance and a preparation method for the polyacrylate / nano SiO2 hybrid emulsion and an application of the polyacrylate / nano SiO2 hybrid emulsion. The preparation method comprises: by virtue of a semi-continuous seed emulsion polymerization process, firstly preparing a vinyl silicone modified polyacrylate emulsion; and then blending the emulsion with a silica sol, cosolvent and other auxiliaries to prepare the polyacrylate / nano SiO2 hybrid emulsion with a high silicon content. Concentration with the cosolvent can enable siloxy on organic polymer chains and silicon hydroxyl of the silica sol to perform a sol-gel reaction when a film is formed, and self-assembly on the coating film surface occurs to generate a compact glassy coating film, thereby improving the hardness, chemical resistance and thermal resistance of the coating film. The PAE / SiO2 hybrid emulsion provided by the present invention has the characteristics of good storage stability, high silicon content of the coating film, high hardness of the coating film and excellent chemical resistance.

Owner:SOUTH CHINA UNIV OF TECH +1

Method for synthesizing vinyl phenyl silicone oil

The invention discloses a method for synthesizing vinyl phenyl silicone oil. The method comprises the following steps of: A, measuring and placing hydroxyl-terminated low-polymerization degree phenyl siloxane, methyl yclosiloxane, and a vinyl silicone terminating agent into a reaction container; raising the temperature to be between 150 and 180 DEG C; fully stirring until a mixture is semitransparent; adding an alkali catalyst into the mixture; and continuously stirring for 6 to 10 hours to obtain reaction liquid; B, cooling the reaction liquid in the step A to room temperature; adding an acid neutralizer; continuously stirring for 2 to 5 hours; adding a soluble carbonate; and leaching for 2 to 4 times after stirring for 2 to 5 hours to obtain a filtrate; and C, removing low-boiling-point substance from the filtrate of the step B in vacuum at the temperature of between 160 and 180 DEG C; and finally obtaining transparent high-refractive index vinyl phenyl silicone oil. The vinyl phenyl silicone oil synthesized by the method has the characteristics of high refractive index (25 DEG C, 1.54), high transparency, good high-temperature stability and high reactivity.

Owner:东莞市贝特利新材料有限公司

Organosilicon ingredient toughened methyl silicone resin and preparation method thereof

ActiveCN104910807AHigh hardnessHigh temperature resistanceCoatingsTemperature resistanceVinyl siloxane

The invention relates to organosilicon component toughened methyl silicone resin and a preparation method thereof. The resin contains the ingredients in gram by weight: 2-30g of organosilicon component, 20-40g of deionized water or acidic silica sol, 30-80g of methyl trialkoxysilane, 0-30g of tetra-alkoxysilane, 0-15g of phenyl trialkoxysilane, 0-10g of dimethyl dialkoxysilane, 0-10g of silane coupling agent, 0-10g of acidic catalyst, 0.02-0.5g of curing agent, 0-15g of ethanol or isopropanol and 0-0.5g of leveling agent, wherein the organosilicon component is synthesized from terminal-hydrogen silicone oil and vinyl siloxane in the presence of a catalyst. The resin disclosed by the invention has the biggest advantage that a film formed material is endowed with very good flexibility, wet-heat resistance and high-temperature resistance while high hardness for the methylsilicone resin is maintained. The preparation method is simple, is good in environmental friendliness and facilitates large-scale production. The surface protection effect for hard or flexible transparent and opaque plastic parts is good.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

Water-based hydrophobic nano-resin, glass thermal insulating coating and preparation method

ActiveCN101845124AImprove stain resistanceImprove aging resistanceCoatingsWater basedThermal insulation

The invention relates to a thermal insulating coating widely applied to glass substrates, in particular to a water-based hydrophobic nano-resin, a glass thermal insulation coating and a preparation method. The waterborne hydrophobic nano-resin is prepared by mixing and reacting 10 to 40 percent of the solution of vinyl nano-oxide, 0.5 to 4.0 weight percent of emulsifier, 30 to 60 weight percent of acrylate monomer, 5 to 30 weight percent of fluoroacrylate monomer, 3 to 12 weight percent of vinyl siloxane, 0.1 to 4 weight percent of initiator, 0.5 to 2 weight percent of neutralizer and 5 to 30 weight percent of de-ionized water. The method comprises the following steps of: from the standpoint of chemical grafting, first preparing a nano-oxide containing vinyl; then synthesizing the hydrophobic nano-resin by copolymerizing the nano-oxide with a free radical of a fluoro (silicon) acrylic monomer; and finally preparing the hydrophobic glass thermal insulating coating by using the resin. The glass thermal insulating coating has the advantages of high comprehensive performance, thermal insulation, contamination resistance and aging resistance, and wide market prospect in the environmentally-friendly society.

Owner:武汉双虎涂料股份有限公司

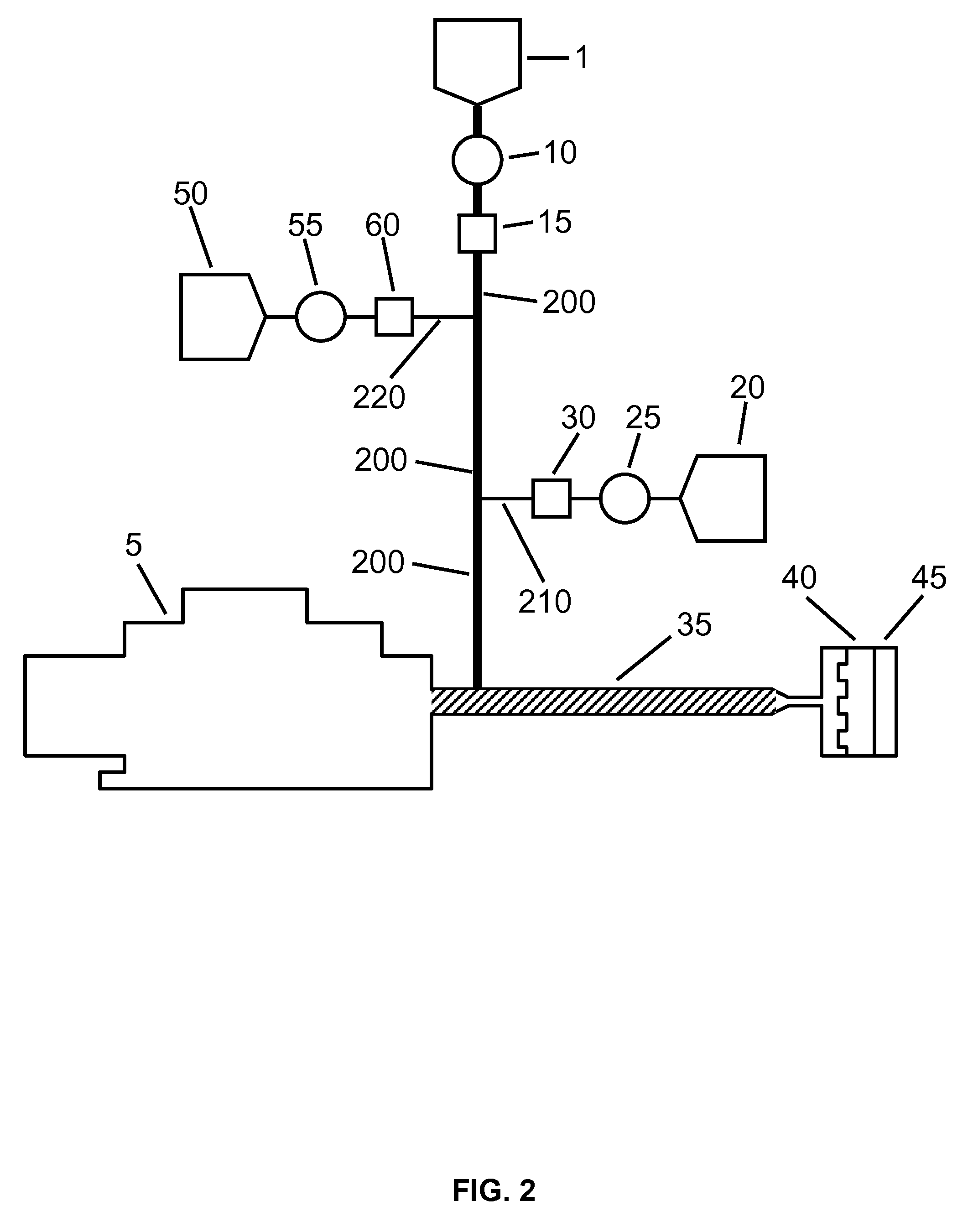

Method for Producing Molded Silicone Rubber Products Using Liquid Silicone Rubber

Described is a method for producing a molded silicone rubber product using a liquid silicone rubber (LSR) base comprising at least one vinyl siloxane polymer, at least one hydride crosslinker, and optionally at least one injection molding inhibitor. The single LSR base is fed into a feed line, and into the feed line are fed an inhibitor master batch comprising at least one liquid injection molding inhibitor and at least one vinyl siloxane polymer, and a catalyst master batch comprising at least one catalyst and at least one vinyl siloxane polymer. The invention is further directed to: said LSR base; said inhibitor master batch; said catalyst master batch; and a molded silicone rubber article produced by the methods and compositions described herein.

Owner:BLUSR SILICONES USA CORP

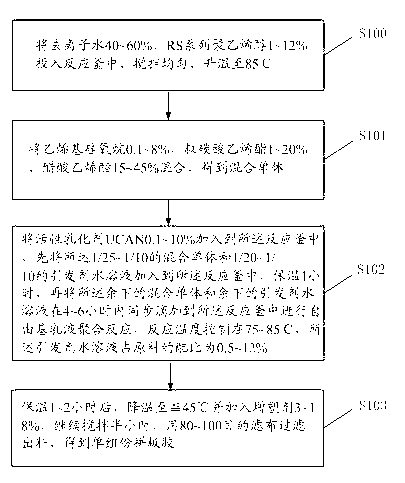

Single-component puzzle glue and preparation method thereof

ActiveCN102863927AExtend the life cycleEasy to useMonocarboxylic acid ester polymer adhesivesPolyvinyl alcoholResource saving

The invention discloses a single-component puzzle glue. The single-component puzzle glue disclosed herein comprises the following main ingredients: 15-45% of vinyl acetate, 0.1-8% of vinyl siloxane, 1-20% of vinyl versatate, 0.1-10% of active emulsifier UCAN, 1-12% of RS series polyving akohol, 40-60% of deionized water, 3-18% of plasticizer, and 0.5-12% of initiator. Correspondingly, the invention further discloses a preparation method of the single-component puzzle glue. According to the invention, by applying the invention, the single-component puzzle glue has the advantages of convenient usage, no need for using it right after it is ready, recoverable property, resource saving, no organic solvent included, no formaldehyde included, no isocyanate included, environmental protection, no toxicity, high bonding strength, and good water tolerance.

Owner:FOSHAN HAITE CHEM TECH

Dual-cured high-performance LED packaging material and preparation method thereof

ActiveCN103408947AHigh refractive indexImprove performanceSemiconductor devicesHydrosilylationSilicon dioxide

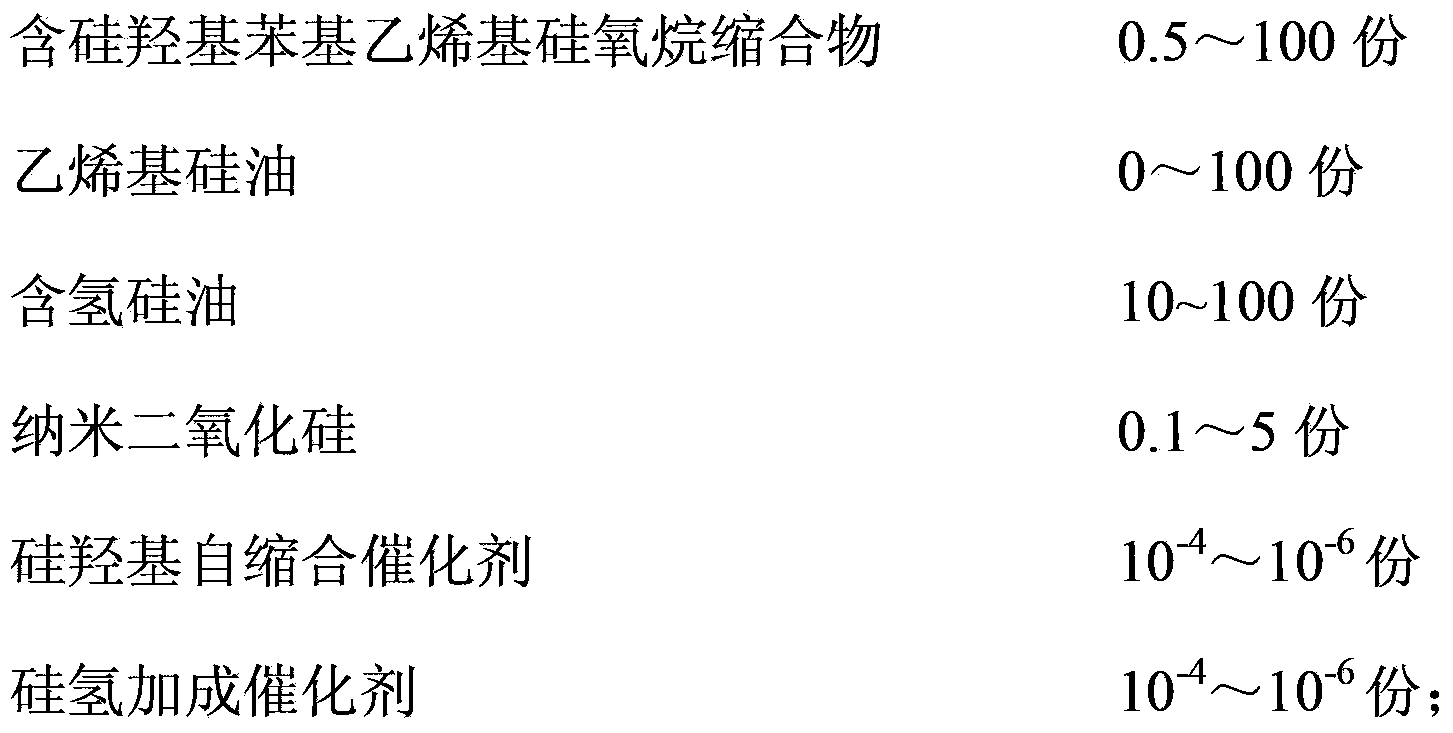

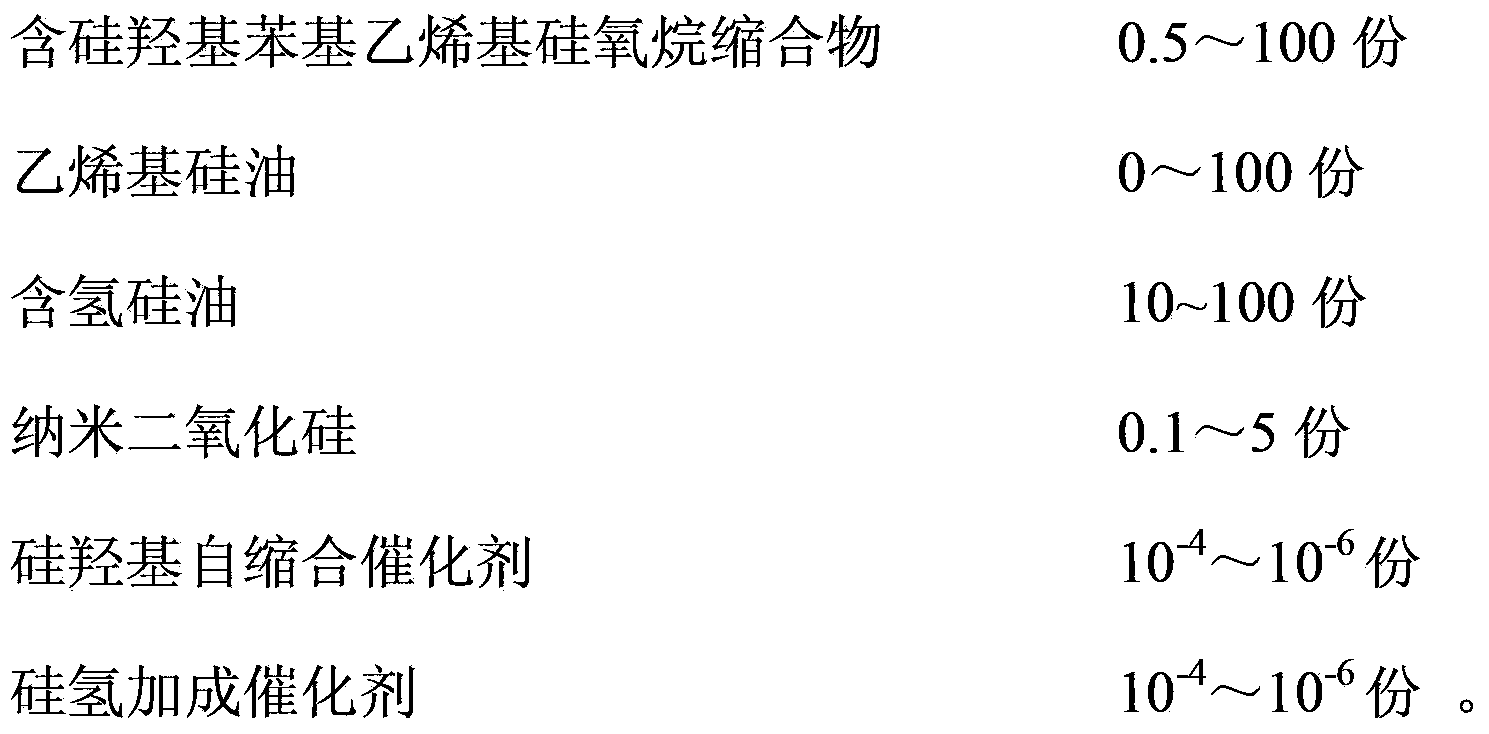

The invention relates to the field of organosilicon packaging materials, and discloses a dual-cured high-performance LED packaging material and a preparation method thereof. The preparation method of the packing material comprises the following steps: uniformly mixing the following components in parts by weight: 0.5-100 parts of condensation compound containing silicon hydroxyl phenyl vinyl siloxane, 0 to 100 parts of vinyl silicone oil, 10 to 100 parts of hydrogen-containing silicone oil, 0.1 to 5 parts of nano silica, 10<-4> to 10<-6> part of silicon hydroxyl self-condensation catalyst and 10<-4> to 10<-6> part of hydrosilylation catalyst; performing reaction for 0.1-0.5 hour at the temperature of 90-120 DEG C to realize hydrosilylation curing reaction; then rising the temperature up to 130-150 DEG C for reaction for 1-5 hours to realize condensation of silicon hydroxyl so as to obtain the product. The obtained material has high light transmittance, high refraction indexes and excellent high-temperature resistance and anti-ultraviolet ageing performance, and is suitable for substrate equipment, touchpads, LCD components and the like, which utilize the LED packing materials.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Two-component addition type room temperature vulcanized silicone rubber for manufacturing handprint mold and footprint mold

The invention discloses a two-component addition type room temperature vulcanized silicone rubber for manufacturing a handprint mold and a footprint mold, which comprises a basic component and a catalyst component, wherein the volume ratio of the basic component to the catalyst component is 1-3:1; the basic component comprises the following raw materials: 40-80% of vinyl silicone oil, 0.5-10% of methyl hydrogen silicone fluid of cross-linking agent, 0.01-0.5% of inhibitor, 3-15% of releasing agent, 1-10% of plasticizer and 10-60% packing; and the catalyst component comprises the following raw materials: 40-80% of vinyl silicone oil, 3-15% of methyl vinyl siloxane coordination platinum complex, 3-15% of releasing agent, 1-10% of plasticizer and 10-60% of packing. The invention has convenience and safety.

Owner:合肥凯蒙新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com