Room temperature multiple self-crosslinking nano acrylate copolymer emulsion and preparation method and water-based woodenware paint using emulsion as base material

An acrylate, self-crosslinking technology, applied in the coating and other directions, can solve the problems of decreased adhesion, decreased water resistance, increased internal stress between the paint film and the substrate, and achieves enhanced hardness, increased hardness, and high scratch resistance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

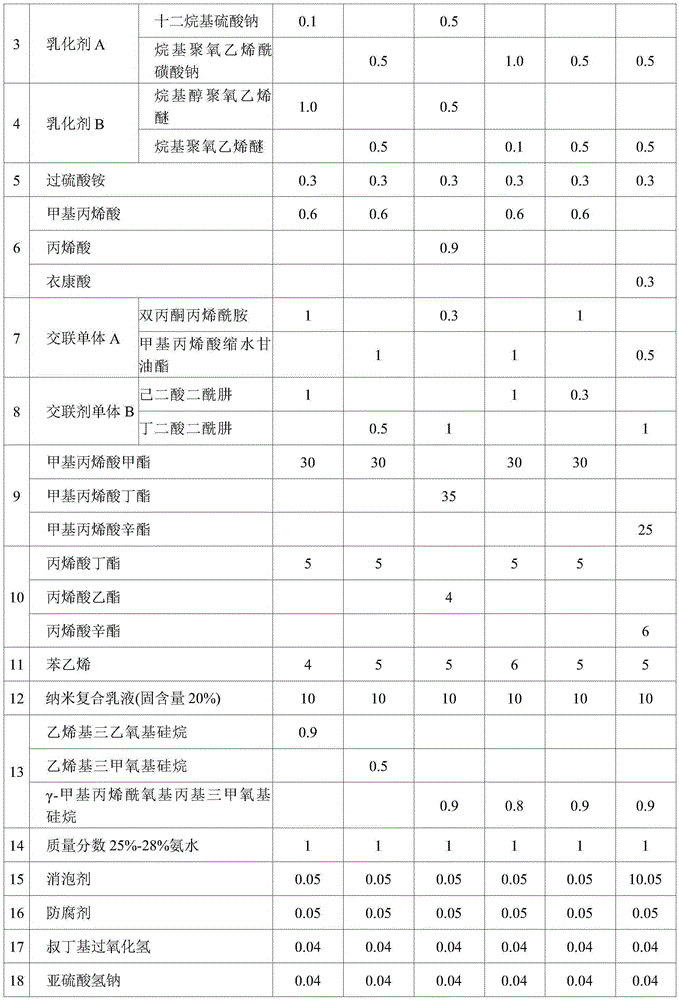

[0033] Prepare multiple self-crosslinking nanometer acrylate copolymer emulsions at room temperature, and the dosage of each component is shown in Table 1:

[0034] Table 1

[0035]

[0036]

[0037] (1) Preparation of monomer pre-emulsion: deionized water, emulsifier A, emulsifier B, and methacrylic acid, methyl methacrylate, butyl acrylate, styrene and crosslinking agent A described in Table 1 Put into the monomer pre-emulsification tank in turn, high-speed stirring and emulsification for 1 hour to form monomer pre-emulsion;

[0038] (2) Preparation of multiple self-crosslinking nanometer acrylate copolymer emulsions at room temperature: add deionized water to the polymerization kettle, metered nanocomposite emulsions, start stirring, raise the temperature to 80°C-84°C, and after stabilizing for 15 minutes, add the step ( When the monomer pre-emulsion and ammonium persulfate solution prepared in 1) are added dropwise to 1 / 5 of the remaining monomer pre-emulsion, stop ...

Embodiment 7

[0047] The water-based wood lacquer was prepared by using the room temperature multiple self-crosslinking acrylate copolymer emulsion synthesized in Examples 1-6 above as a base material. The specific components and consumption of the water-based wood lacquer are shown in Table 3.

[0048] table 3

[0049]

[0050] (1) Add the emulsion, dispersant, wetting agent, leveling agent, anti-scratch agent and zinc stearate in a stirred tank in the formula amount shown in the table and add it to the above stirred tank, at a speed of 900r / min and stir for 10 min to obtain a uniform dispersion;

[0051] (2) In another stirred tank, take the formula amount of film-forming aids dipropylene glycol methyl ether (DPM), dipropylene glycol butyl ether (DPnB), deionized water and thickener RS-8W (polyurethane modified type) and add Stir in a stirred tank for 10 minutes to obtain a mixed solution;

[0052] (3) Slowly add the mixed solution in the stirred tank in step (2) to the stirred tan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com