Modified hydroxyacrylate emulsion and preparation method thereof

A technology of hydroxyacrylate and hydroxybutyl methacrylate, which is applied in the field of modified hydroxyacrylate emulsion and its preparation, can solve the problems of low gloss, poor comprehensive performance and poor resistance of modified hydroxyacrylate emulsion, etc. Achieve the effects of high fullness of the paint film, low cost and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

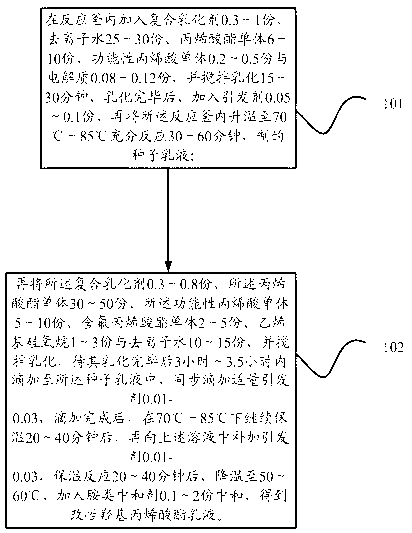

[0027] The present invention also provides a kind of preparation method of modified hydroxyacrylate emulsion, such as figure 1 As shown, it includes the following steps:

[0028] Step 101: Add 0.3-1 part of composite emulsifier, 25-30 parts of deionized water, 6-10 parts of acrylate monomer, 0.2-0.5 part of functional acrylic monomer and 0.08-0.12 part of electrolyte into the reactor, and Stir and emulsify for 15 to 30 minutes. After the emulsification is complete, add 0.05 to 0.1 part of initiator, and then raise the temperature in the reactor to 70°C to 85°C and fully react for 30 to 60 minutes to obtain a seed emulsion;

[0029] Step 102: Add 0.3-0.8 parts of the composite emulsifier, 30-50 parts of the acrylate monomer, 5-10 parts of the functional acrylic monomer, 2-5 parts of fluorine-containing acrylate monomer, ethylene Add 1-3 parts of base siloxane and 10-15 parts of deionized water into the emulsification tank to stir and emulsify. After the emulsification is compl...

Embodiment 1

[0033] In the reaction kettle, add 0.6 parts of composite emulsifier, 28 parts of deionized water, 6 parts of methyl methacrylate, 0.8 parts of butyl acrylate, 0.4 parts of methacrylic acid and 0.1 part of electrolyte in advance; start stirring and emulsifying for 15 minutes, emulsifying After completion, 0.06 part of initiator was added, and the temperature in the reactor was raised to 80° C. for 30 minutes to obtain a seed emulsion.

[0034] Then add 0.5 parts of compound emulsifier, 21 parts of methyl methacrylate, 13.2 parts of butyl acrylate, 0.6 parts of methacrylic acid monomer, 6 parts of hydroxyethyl methacrylate, 2 parts of hexafluorobutyl methacrylate, ethylene Add 1 part of triethoxysiloxane and 16 parts of deionized water into the dripping emulsification tank to stir and emulsify. After 3 hours to 3.5 hours after emulsification, add it dropwise to the said reaction kettle. For seed emulsion, add 0.03 parts of initiator solution synchronously. After the addition is...

Embodiment 2

[0036] In the reaction kettle, add 0.6 parts of composite emulsifier, 28 parts of deionized water, 6 parts of methyl methacrylate, 0.8 parts of butyl acrylate, 0.4 parts of methacrylic acid and 0.1 part of electrolyte in advance; start stirring and emulsifying for 15 minutes, emulsifying After completion, 0.06 part of initiator was added, and the temperature in the reactor was raised to 80° C. for 30 minutes to obtain a seed emulsion.

[0037] Then add 0.5 parts of compound emulsifier, 20 parts of methyl methacrylate, 12.2 parts of butyl acrylate, 0.6 parts of methacrylic acid monomer, 6 parts of hydroxyethyl methacrylate, 4 parts of hexafluorobutyl methacrylate, ethylene Add 1 part of base triethoxysiloxane and 16 parts of deionized water into the dripping emulsification tank to stir and emulsify. After 3 hours to 3.5 hours after emulsification, add it dropwise to the reaction kettle. Seed emulsion, add 0.03 parts of initiator solution synchronously. After the addition is com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com