Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

390results about How to "Improve peel force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

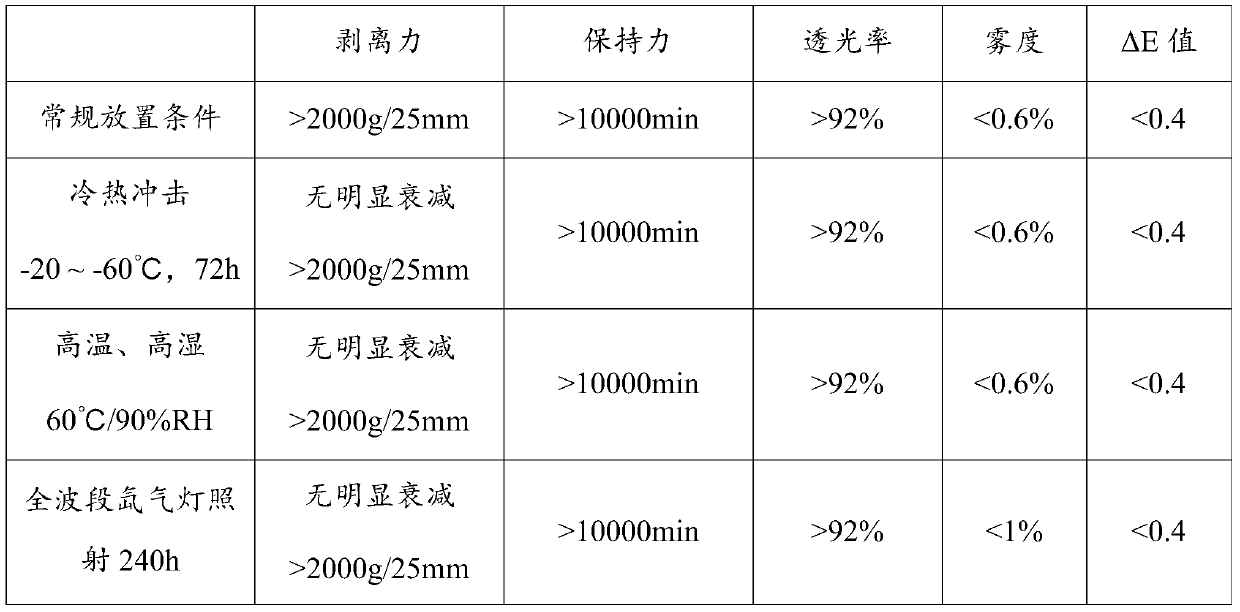

Heat-resistant UV visbreaking glue composition and UV visbreaking protective film

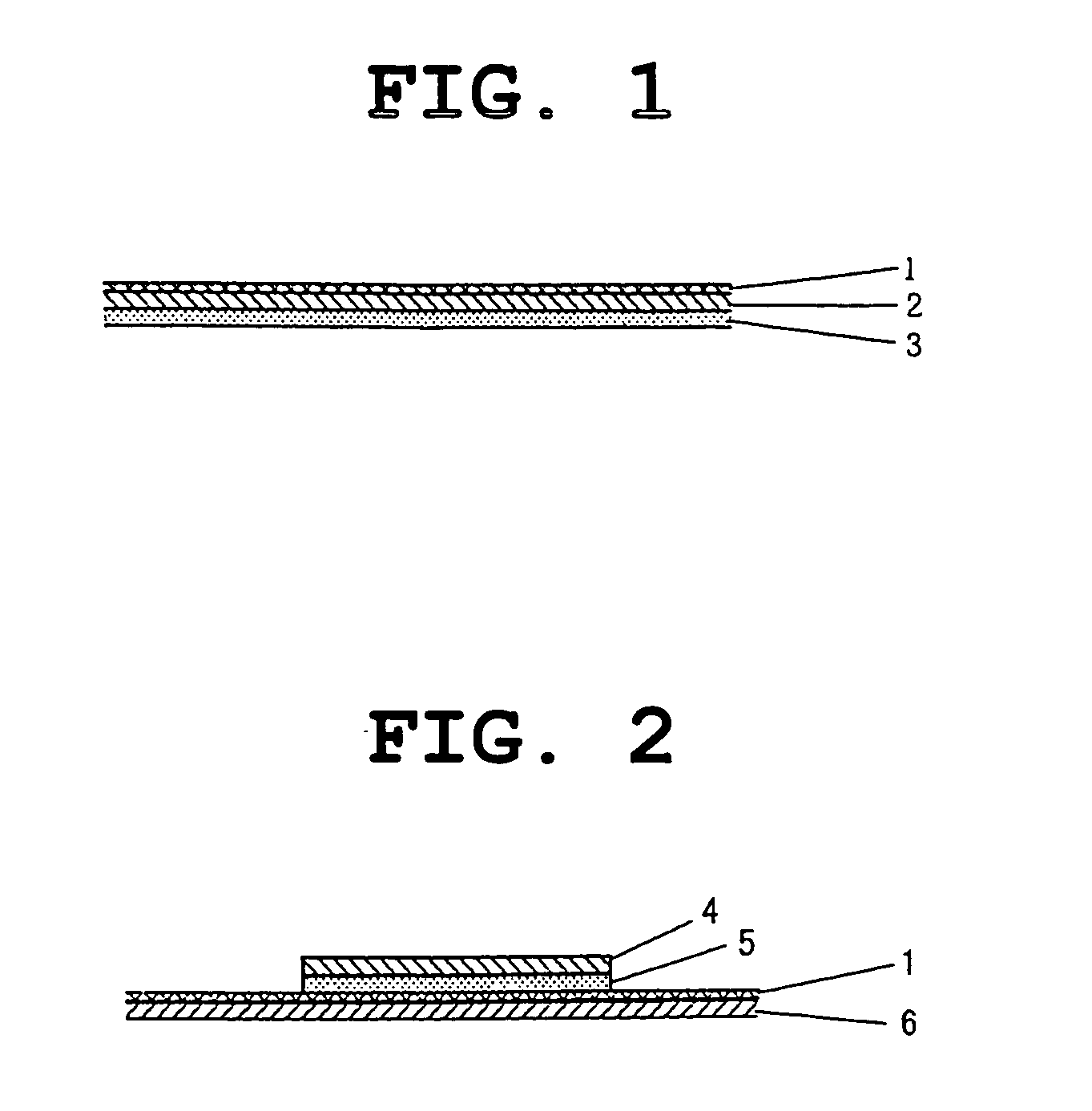

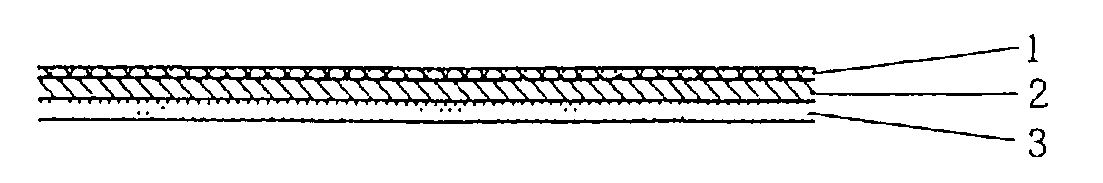

InactiveCN105778806AImprove peel forceSmall peeling forceFilm/foil adhesivesPolyureas/polyurethane adhesivesCross-linkTectorial membrane

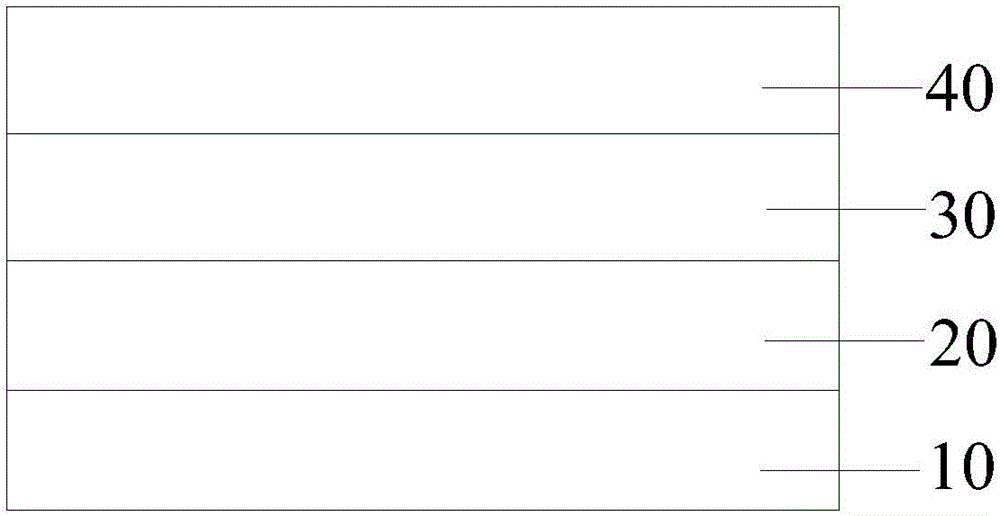

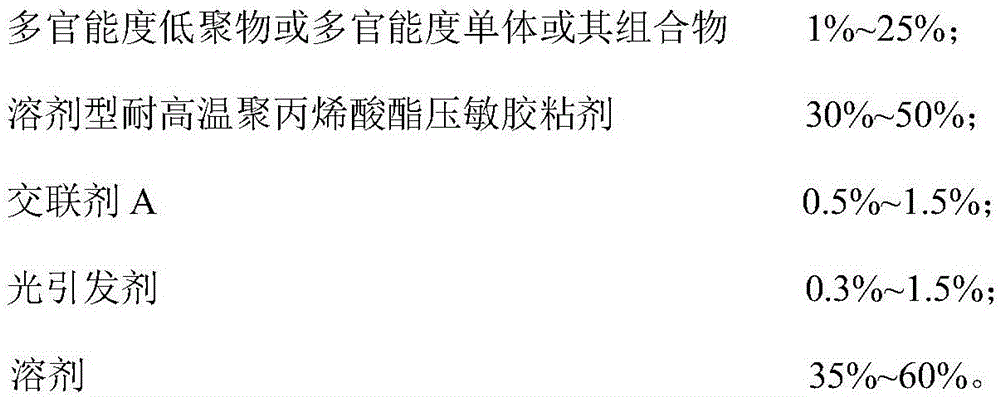

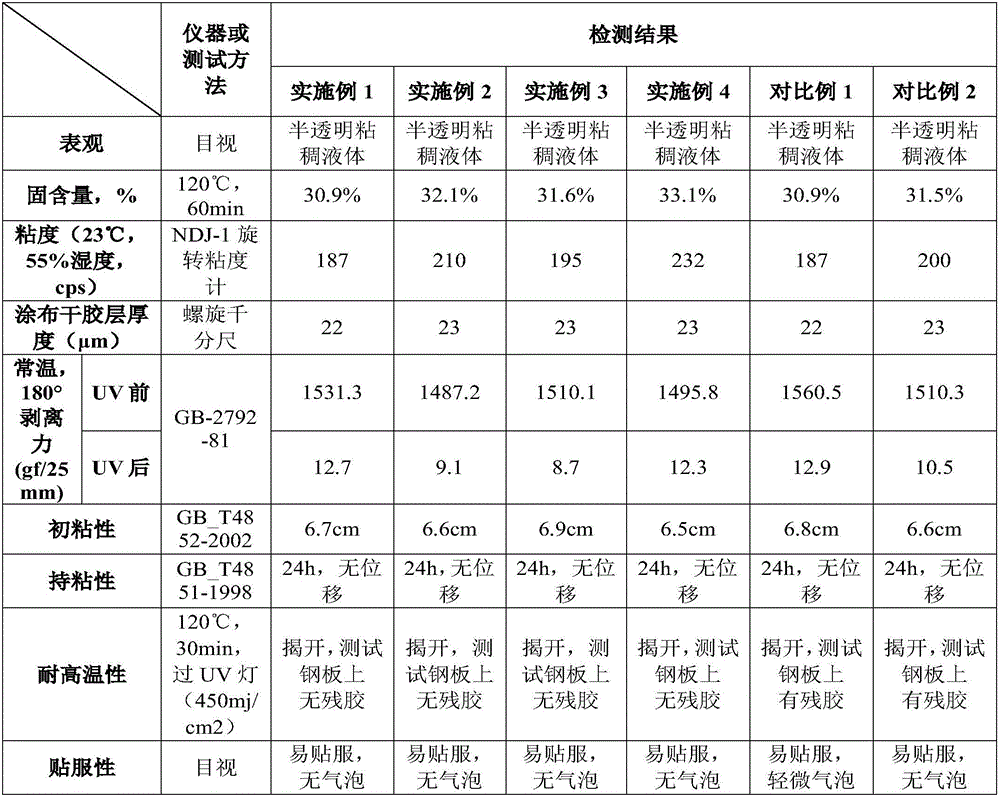

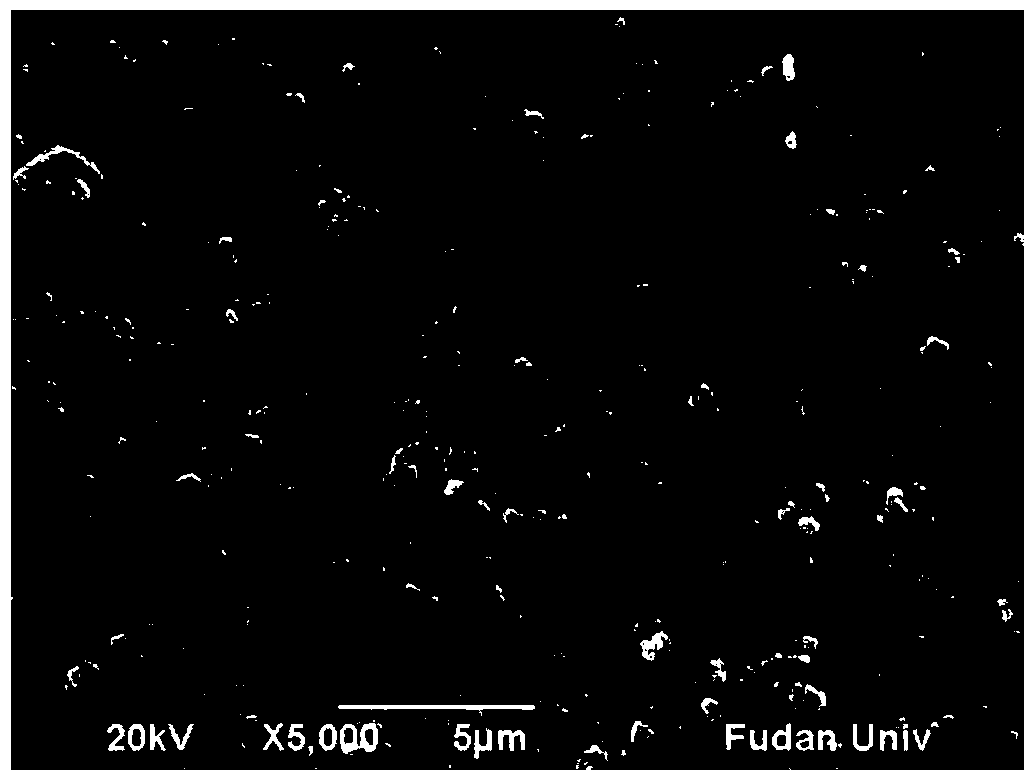

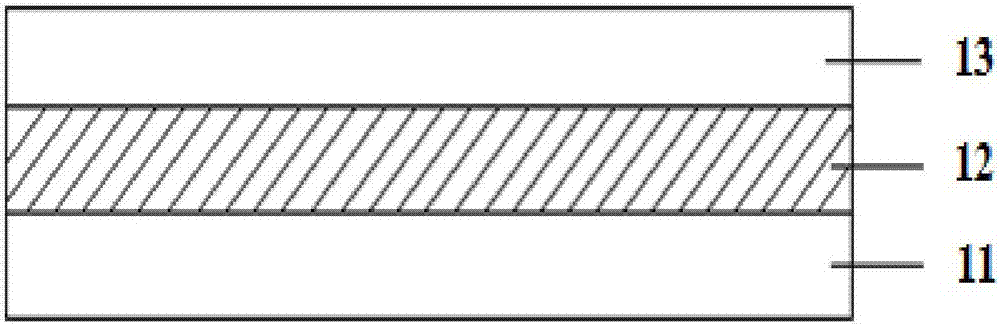

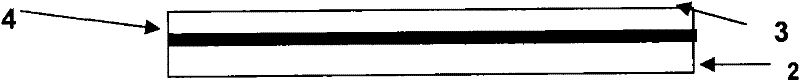

The invention discloses a heat-resistant UV visbreaking glue composition and a UV visbreaking protective film prepared with this composition. This composition is made from the following materials according to parts by weight: 1-25% of a polyfunctional oligomer or polyfunctional monomer or its composition, 30-50% of a solvent type high-temperature-resistant polyacrylate pressure-sensitive glue, 0.5-1.5% of a cross-linking agent, 0.3-1.5% of a photo-initiator, and 35-60% of a solvent. The heat-resistant UV visbreaking protective film comprises a base (10), a bottom coating layer (20) applied to the surface of the base (10), a UV visbreaking glue layer (30) applied to the bottom coating layer (20), and a release film (40). The heat-resistant UV visbreaking protective film prepared herein can resist a high temperature of 120 DEG C and has the advantages of high UV pre-illumination release force, low UV post-illumination release force and no glue residue.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Hot-melt silicone based ostomy and wound care skin attachment adhesives

InactiveUS20070179461A1Simple processImprove peel forceSurgical adhesivesNon-surgical orthopedic devicesWound careHot melt

An ostomy or wound care appliance including an ostomy or wound care device for attachment to the body with an adhesive. The adhesive including a hot-melt silicone pressure sensitive adhesive composition and a reinforcing member.

Owner:CONVATEC TECH INC

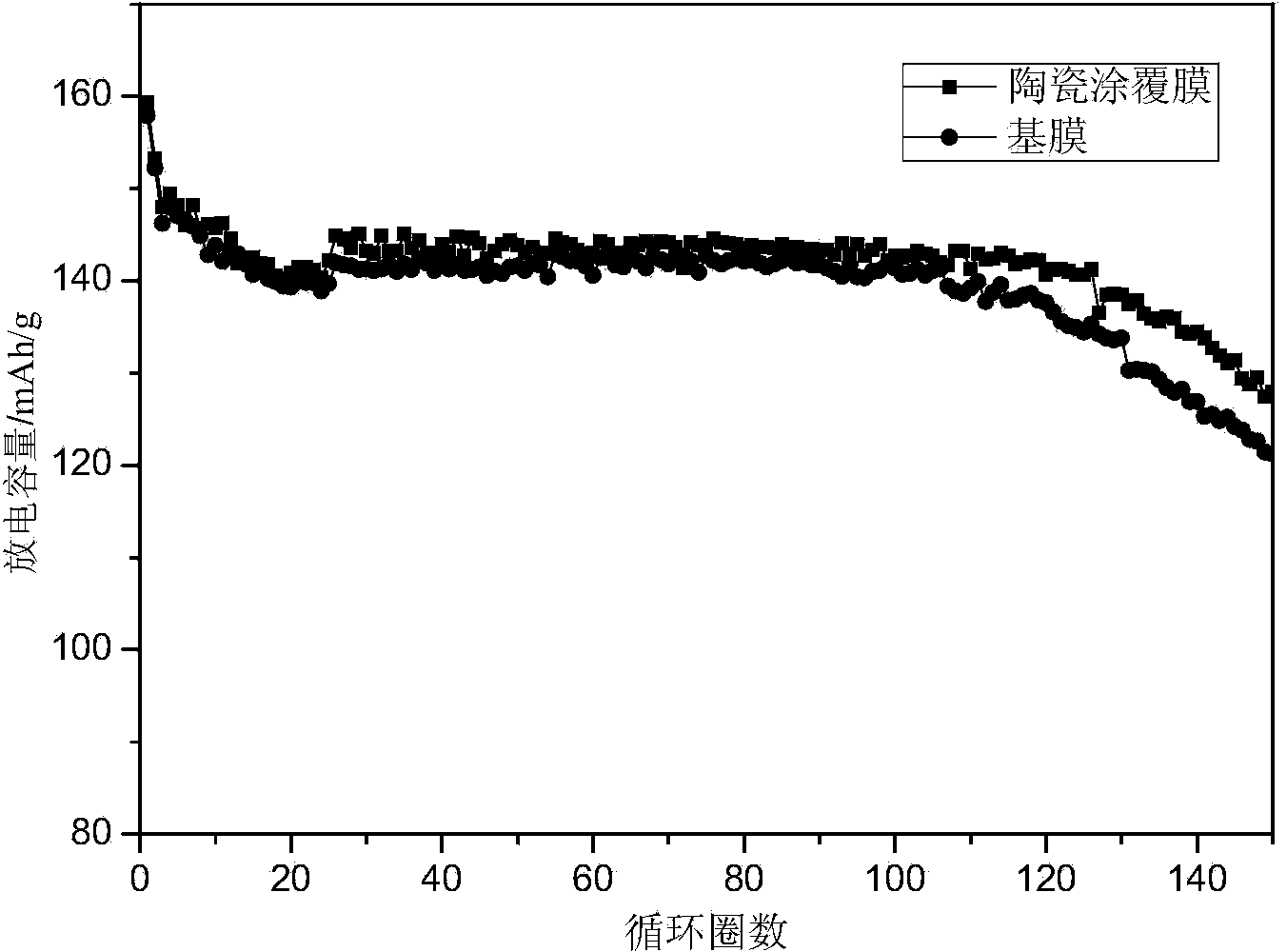

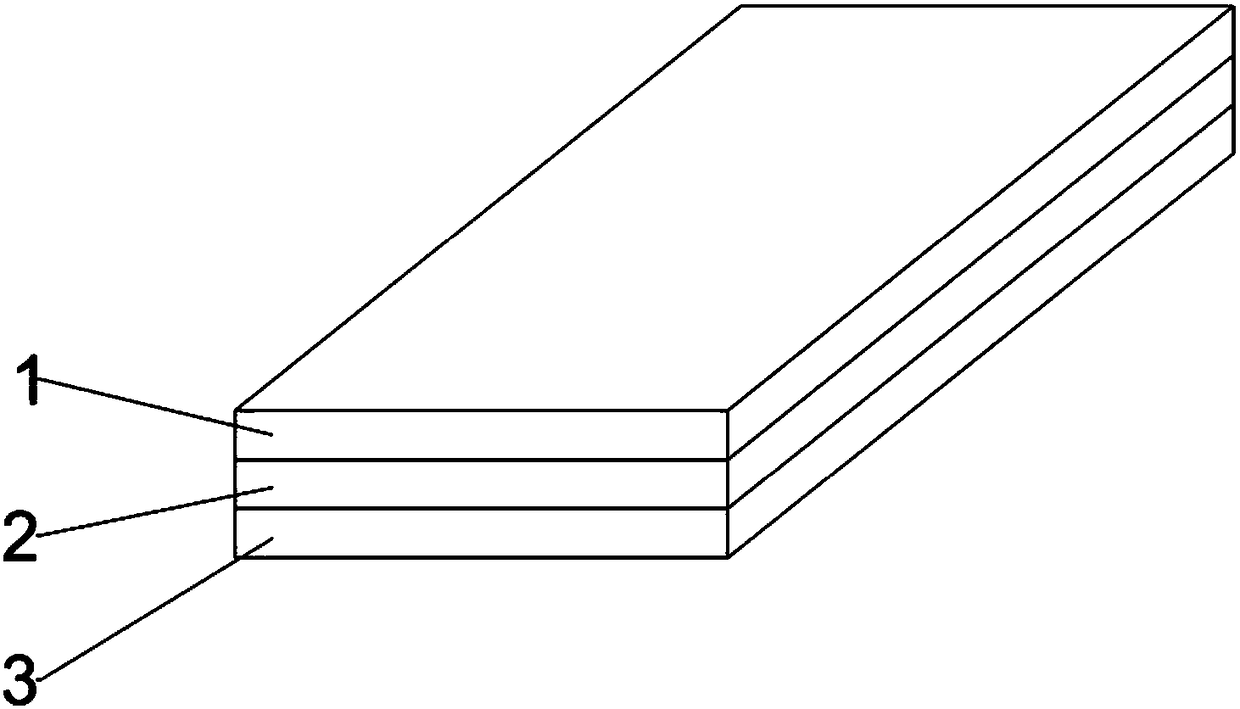

Ceramic coating diaphragm for lithium battery and preparation method of ceramic coating diaphragm

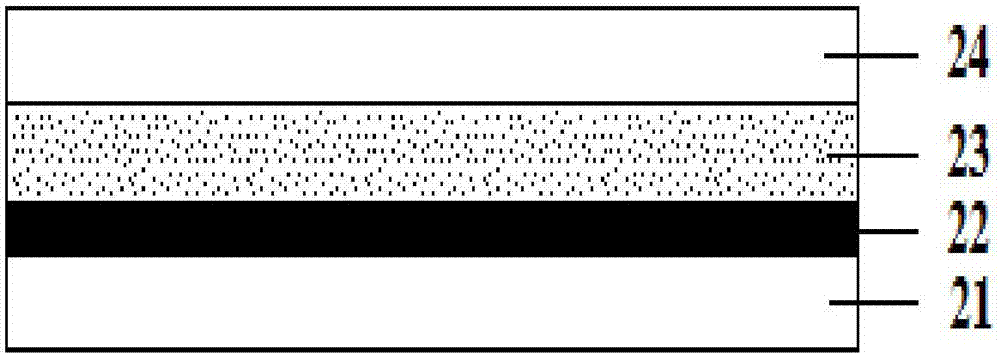

InactiveCN104269509AGood air permeabilityImprove peel forceCell component detailsCeramic coatingDiameter ratio

The invention discloses a ceramic coating diaphragm for a lithium battery and a preparation method of the ceramic coating diaphragm, and belongs to the technical field of batteries. The ceramic coating diaphragm comprises a ceramic coating and a substrate diaphragm, wherein the ceramic coating is prepared by uniformly coating the substrate diaphragm with water-based ceramic coating slurry; the ceramic coating slurry comprises components in percentage by weight as follows: 10%-30% of aluminum oxide, 0.5%-3% of a bonding agent, 0.2%-1.0% of an additive and 0.01%-0.1% of an auxiliary; and the aluminum oxide is nanometer aluminum oxide powder with the grain diameter ratio D1 / D2 of 0.10-0.20. According to the technical scheme, the safety of the ceramic coating diaphragm is improved, the wetting ability of electrolyte is improved, and the cycle life of the battery can be prolonged when the ceramic coating diaphragm is applied to the lithium battery.

Owner:SHANGHAI ELECTRICGROUP CORP

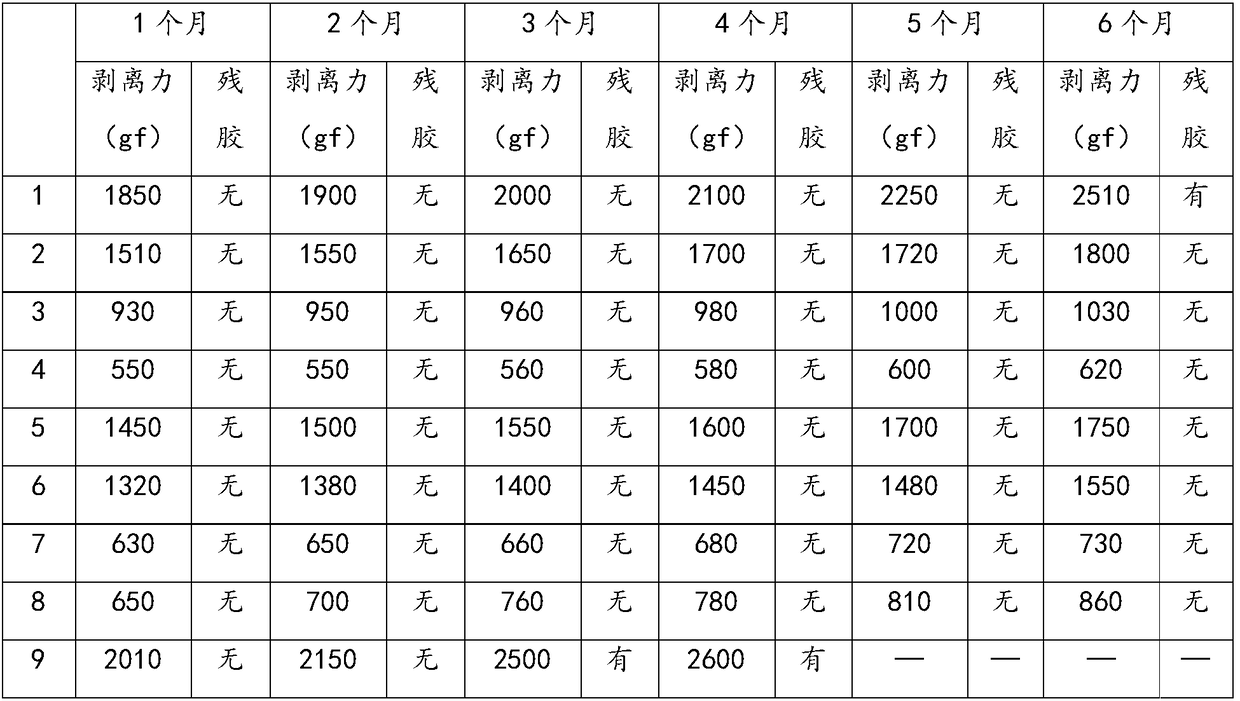

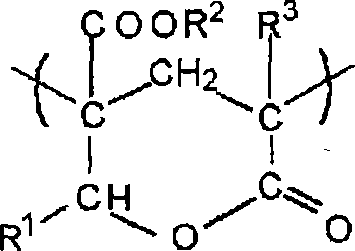

Ultraviolet (UV) viscosity-reducing composition as well as UV viscosity-reducing film and preparation method thereof

InactiveCN108276923AImprove adhesionImprove peel forceNon-macromolecular adhesive additivesPressure sensitive film/foil adhesivesSolventPressure sensitive

The invention relates to the technical field of protective films, in particular to an ultraviolet (UV) viscosity-reducing composition as well as a UV viscosity-reducing film and a preparation method thereof. The UV viscosity-reducing composition is mainly prepared from the following raw materials by weight percent: 20-50% of acrylate pressure-sensitive adhesive resin, 1-30% of a polyfunctional oligomer and / or a polyfunctional monomer, 0.3-2% of a cross-linking agent, 0.1-5% of a thermal initiator, 0.5-5% of a photoinitiator and 25-60% of a solvent. The UV viscosity-reducing film comprises a base material layer, a UV viscosity-reducing layer and a release film layer which are sequentially stacked, wherein the UV viscosity-reducing layer is formed by coating the surface of the base materiallayer with the UV viscosity-reducing composition, drying and curing. The UV viscosity-reducing composition has excellent bonding force; before being irradiated with UV, the UV viscosity-reducing composition has high bonding force and stripping force; after being irradiated with UV, the UV viscosity-reducing composition has low bonding force and stripping force; furthermore, after being stored fora long time, the UV viscosity-reducing composition has no residual glue.

Owner:SUZHOU CHENGBANG DALI MATERIAL TECH

Heat-resistant UV viscosity breaking film and preparation method thereof

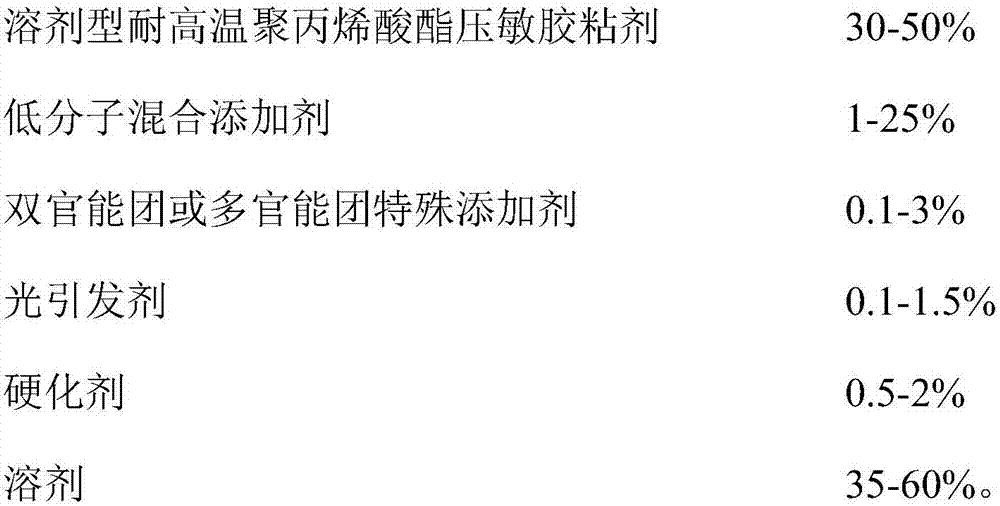

ActiveCN106995665AImprove peel forceImprove adhesionMacromolecular adhesive additivesOrganic non-macromolecular adhesiveTemperature resistancePressure sensitive

The invention provides a heat-resistant UV viscosity breaking film. The heat-resistant UV viscosity breaking film comprises a substrate layer, a UV photosensitive adhesive layer and a release film layer sequentially. The invention further provides a preparation method of the UV photosensitive adhesive layer. The UV photosensitive adhesive layer comprises the ingredients in percentage by weight: 30% to 50% of solvent type high-temperature resistant polyacrylate pressure-sensitive adhesive, 1% to 25% of micromolecular mixed additives, 0.1% to 3% of difunctional or polyfunctional special additive, 0.1% to 1.5% of photoinitiator, 0.5% to 2% of curing agent and 35% to 60% of solvent. The invention further provides a preparation method of the heat-resistant UV viscosity breaking film. According to the heat-resistant UV viscosity breaking film and the preparation method thereof, the sealing performance and high-temperature resistance of a UV photosensitive adhesive to corona PET substrates are improved, base coat treatment technologies are reduced, and the product structure is optimized.

Owner:新纶电子材料(常州)有限公司

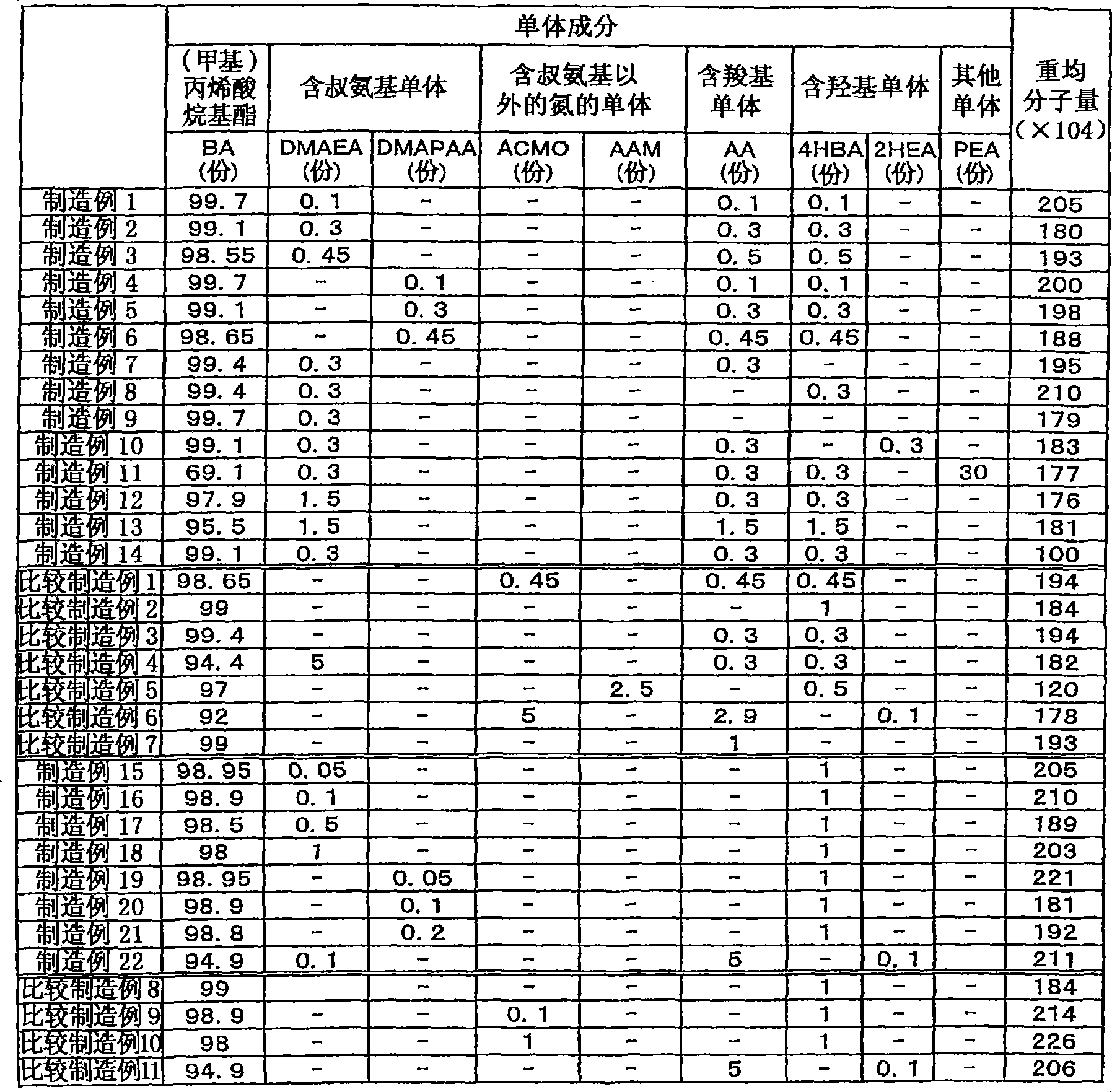

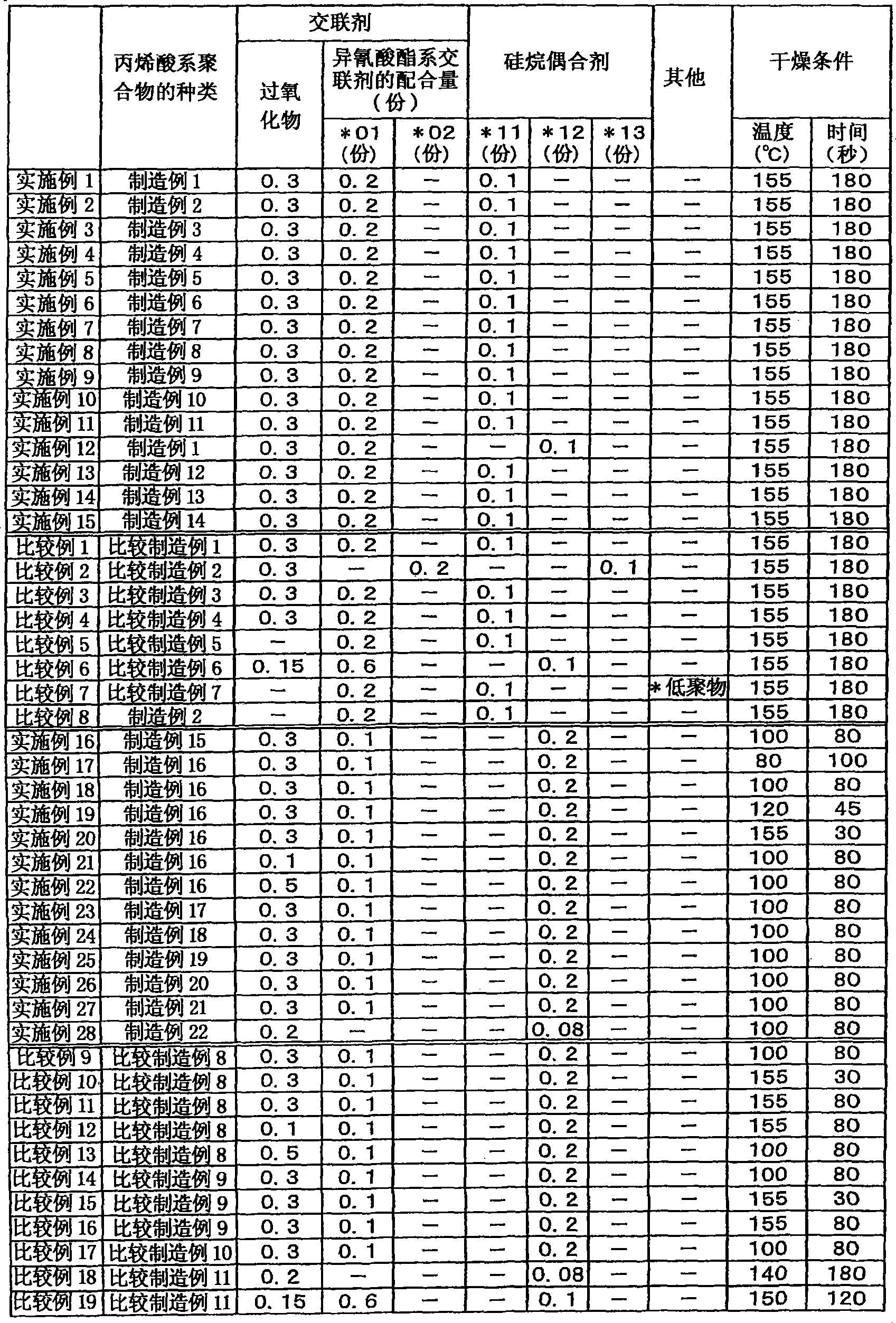

Pressure-sensitive adhesive composition for optical film, pressure-sensitive adhesive layer for optical film, production method thereof, pressure-sensitive adhesive optical film and image display

ActiveCN101418198AExcellent productivityImprove machinabilityFilm/foil adhesivesPolarising elementsMeth-Optical thin film

A pressure-sensitive adhesive composition can form an pressure-sensitive adhesive layer that has satisfactory reworkability such that optical films can be easily peeled from liquid crystal panels with no adhesive residue and also has satisfactory processability such that it can be worked without pressure-sensitive adhesive fouling or dropout. The pressure-sensitive adhesive composition for an optical film of the present invention comprises 100 parts by weight of a (meth)acrylic polymer comprising 45 to 99.99% by weight of an alkyl (meth)acrylate monomer unit and 0.01 to 2% by weight of a tertiary amino group-containing monomer unit; and 0.01 to 2 parts by weight of a peroxide as a crosslinking agent.

Owner:NITTO DENKO CORP

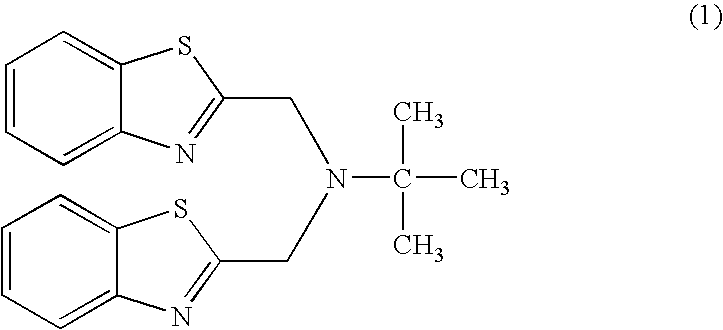

Rubber composition for covering steel cord and pneumatic tire

InactiveUS20100200141A1Reduce adhesionReduce forceSpecial tyresPneumatic tyre reinforcementsNitrogenEngineering

A rubber composition for covering a steel cord is used to form a rubber-steel cord composite used as a reinforcing material of a pneumatic tire and the like. The rubber composition includes 100 parts by weight of a diene rubber, from 0.3 to 1.5 parts by weight of N-t-butyl-2-benzothiazole sulfenimide, and from 5 to 20 parts by weight of active zinc oxide having a specific surface area by nitrogen adsorption using BET method of 20 m2 / g or more.

Owner:TOYO TIRE & RUBBER CO LTD

Pressure-sensitive adhesive members and processes for producing the same

InactiveUS20040224117A1Lightly peelableRetention stabilityLamination ancillary operationsAdhesive articlesFractionationElution

Owner:NITTO DENKO CORP

Transfer print type decorative film suitable for cold wave technology

ActiveCN102658742AImprove peel forceGuaranteed cleanlinessRosin coatingsThermographyGraphicsPlastic packaging

The invention discloses a transfer print type decorative film suitable for a cold wave technology. The transfer print type decorative film comprises a base material, a release layer, a metal layer and a bonding layer, wherein the release layer comprises the following components in part by weight: 600 to 2,000 parts of acrylic resin, 100 to 400 parts of rosin resin, 30 to 120 parts of amino resin, 3 to 50 parts of aid and 2,000 to 3,000 parts of solvent. According to the decorative film, stripping force between the release layer and the base material can reach more than 100 grams, powder cannot fall in the cold wave process, and graphics and words are high in definition; and the decorative film can be widely applied to decorative processing of surfaces of plastic films, plastic packaging products and the like in a package printing industry.

Owner:BAODING LUCKY INNOVATIVE MATERIALS

Method for preparing modified double-component high-temperature-resistant waterborne polyurethane pressure-sensitive adhesive

InactiveCN103435760AGood pressure sensitivityImprove water resistanceGraft polymer adhesivesEpoxyPolyurethane dispersion

The invention discloses a method for preparing a modified double-component high-temperature-resistant waterborne polyurethane pressure-sensitive adhesive. The method comprises the following steps: adding polyisocyanate and low polymer polyhydric alcohol into reaction equipment, further adding a hydrophilic chain extender to react to obtain a polyurethane prepolymer, subsequently adding acrylic ester containing hydroxyl and a modified epoxy resin so as to obtain the modified polyurethane prepolymer; further adding a neutralizer to neutralize, adding water, subsequently dispersing by using a high-speed dispersing machine so as to obtain a modified waterborne polyurethane dispersoid; uniformly dripping acrylate monomer, a modified rosin resin and an initiating agent so as to obtain a modified waterborne polyurethane dispersoid; further adding a defoaming agent, and finally adding a curing agent additionally so as to obtain the modified double-component high-temperature-resistant waterborne polyurethane pressure-sensitive adhesive. The pressure-sensitive adhesive prepared through the method is high in primary adhesion property, release force, adhesion lasting property and high-temperature adhesion lasting property; a high-temperature-resistant pressure-sensitive adhesive tape prepared from the adhesive can meet the requirements of automobile and electronic industries. According to the invention, the preparation process is simple, the production period is short and the operation cost is low.

Owner:SOUTH CHINA UNIV OF TECH

Pressure-sensitive adhesive members and processes for producing the same

InactiveUS20030091817A1Lightly peelableRetention stabilityLamination ancillary operationsAdhesive articlesFractionationElution

A process includes (i) the steps of adhering a pressure-sensitive adhesive layer supported on a base material to a release layer containing a mixture of a polyethylene and an ethylene / alpha-olefin copolymer and aging the resultant structure at 40 to 75° C. for 6 hours or more or (ii) the steps of adhering a pressure-sensitive adhesive layer supported on a base material to a release layer containing a linear ethylene-based resin in which the content of components eluted at 30° C. or lower measured by the temperature rising elution fractionation method is 3 to 30 wt % and aging the resultant structure at 55 to 75° C. for 6 hours or more, to thereby regulate the pressure-sensitive adhesive layer so as to have a peel force of 0.5 to 5 N / 50 mm when peeled from the release layer at an angle of 180° and a rate of 2 m / min together with the support base material.

Owner:NITTO DENKO CORP

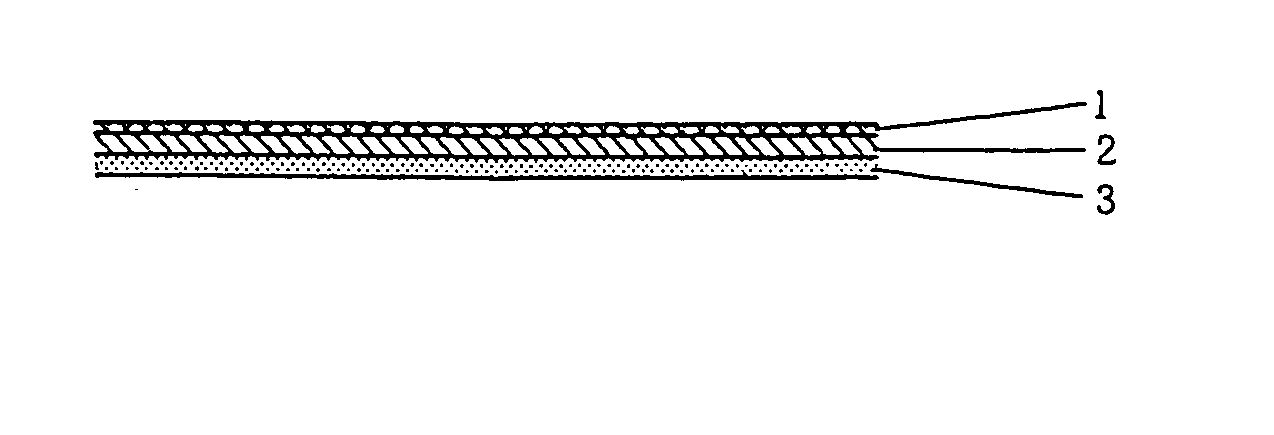

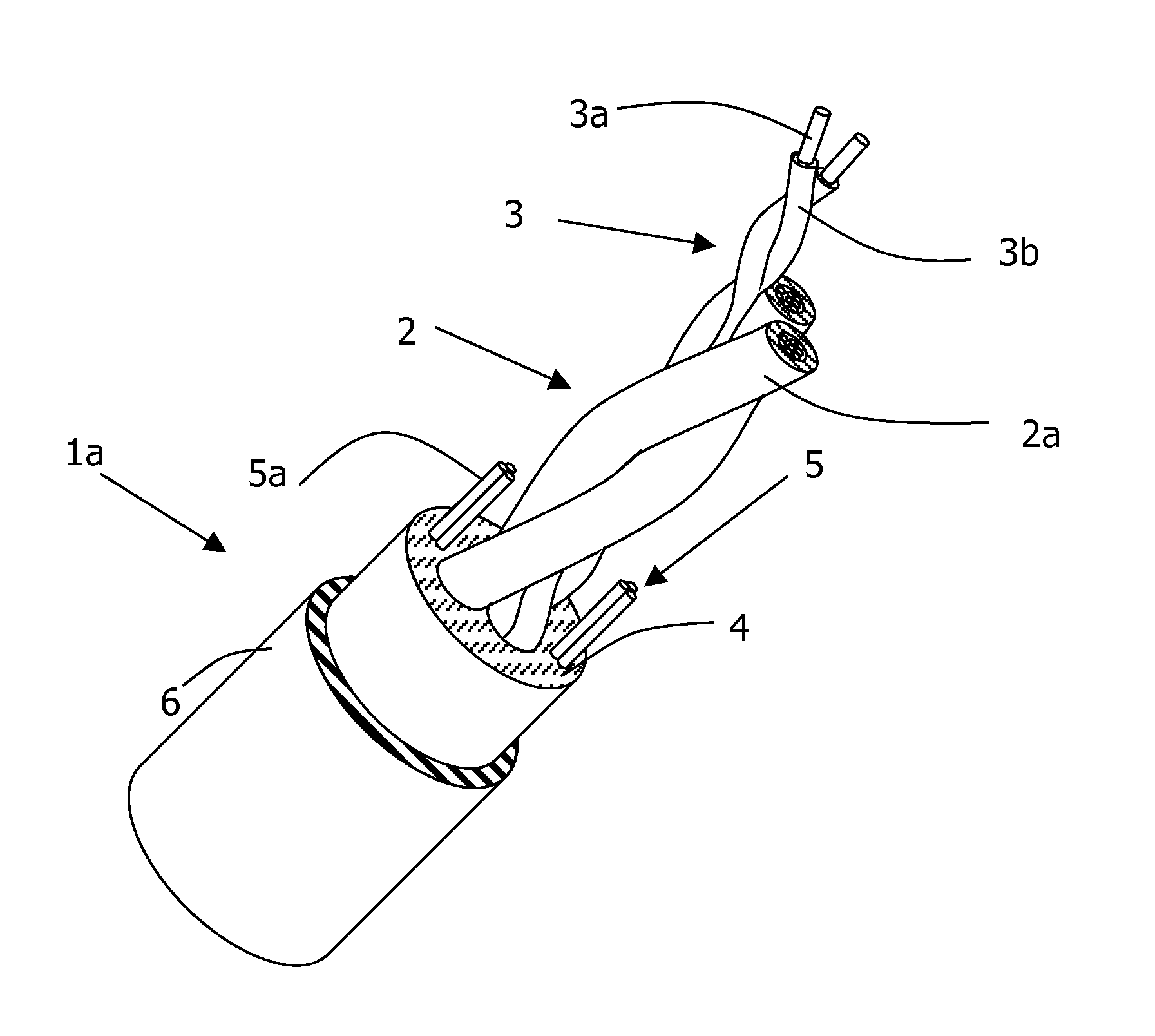

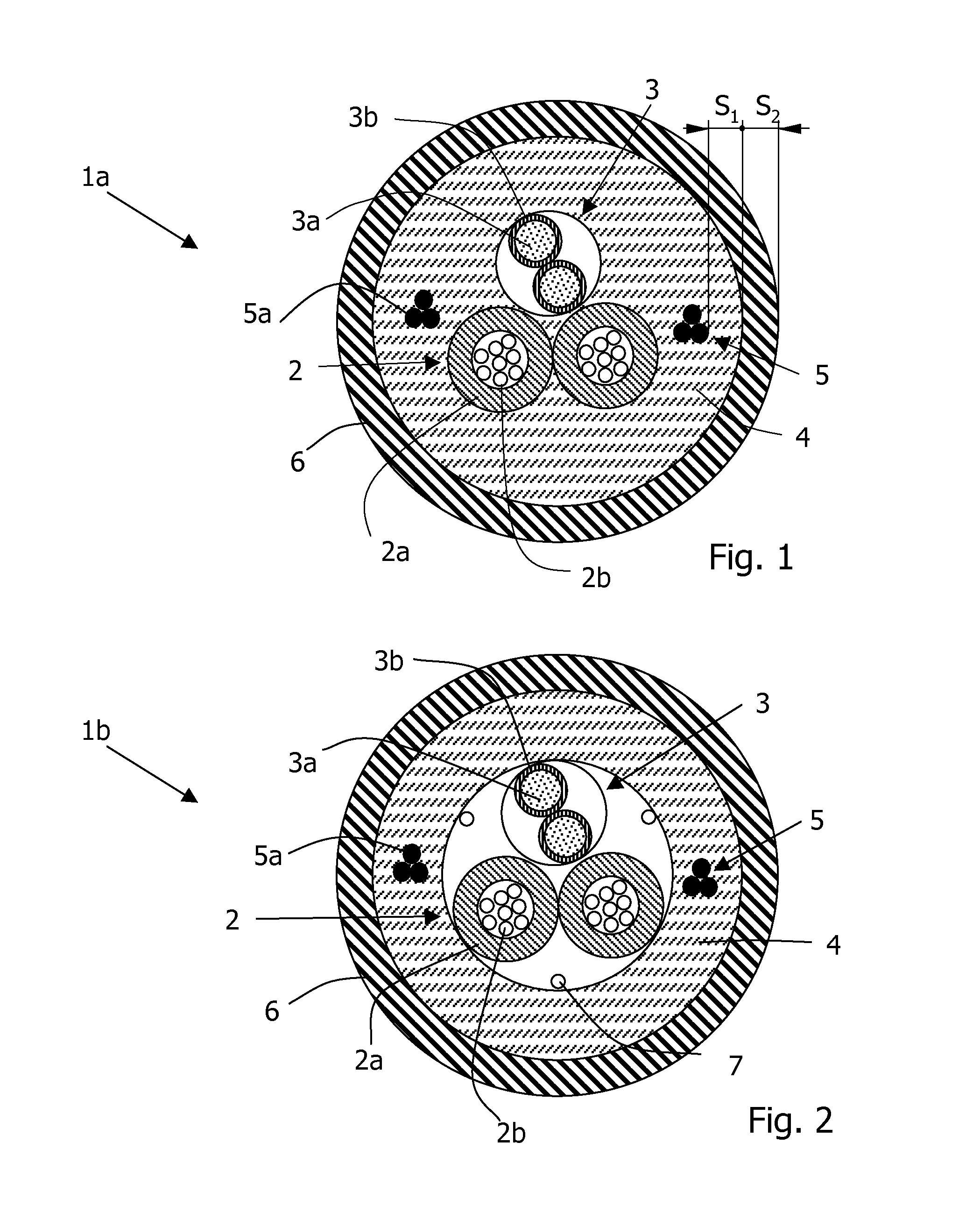

Multipurpose optical fibre drop cable

ActiveUS20140241677A1Relief the optical fibre strain stressLimiting strain resistanceOptical articlesFibre mechanical structuresTelecommunications cableEngineering

A telecommunication cable includes at least one optical fibre unit surrounded by a low fire hazard halogen free polymeric inner sheath that is covered by and in contact with a peelable, environmentally resistant polymer outer sheath. At least two discrete strength members are embedded into the low fire hazard halogen free polymeric inner sheath. The cable is intended for outdoor and indoor use.

Owner:PRYSMIAN TELECOM CABLES & SYST UK +1

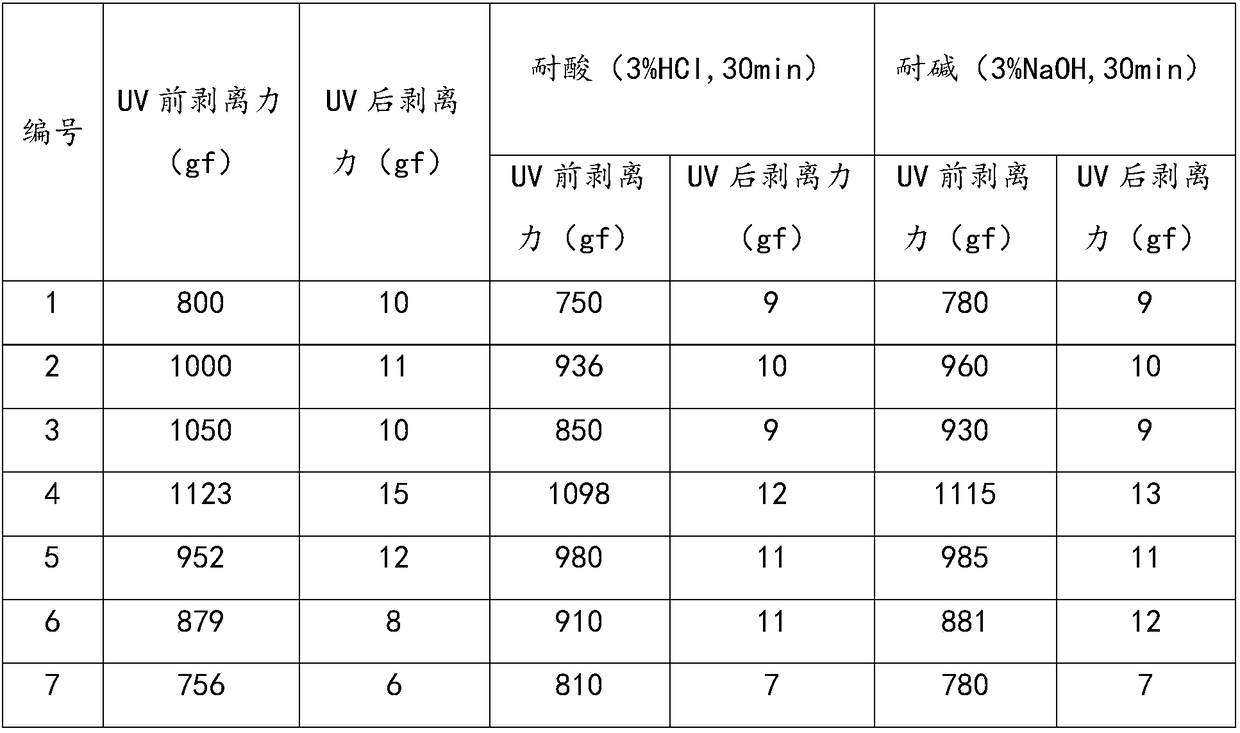

Acid and alkali resistant UV visbreaking composition, UV visbreaking film and preparation method thereof

InactiveCN108300352AImprove adhesionImprove peel forceNon-macromolecular adhesive additivesMacromolecular adhesive additivesTectorial membraneOligomer

The invention relates to the technical field of protective films, in particular to an acid and alkali resistant UV visbreaking composition, a UV visbreaking film and a preparation method thereof. Theacid and alkali resistant UV visbreaking composition is prepared from the following raw materials in percentages by weight: 25% to 45% of a polyacrylate pressure sensitive adhesive, 1% to 20% of a multifunctional oligomer and / or a multifunctional monomer, 0.1% to 1.5% of a photoinitiator, 0.1% to 2% of a curing agent and 30% to 60% of a solvent. The UV visbreaking film comprises a base material layer, a UV visbreaking layer and a release film layer which are laminated in sequence, wherein the UV visbreaking layer is obtained by coating the UV visbreaking composition on the surface of the basematerial layer and baking. The UV visbreaking composition is high in adhesive force and high in release force before UV irradiation and low adhesive force and low in UV release force after UV irradiation, and has excellent acid and alkali resistance.

Owner:SUZHOU CHENGBANG DALI MATERIAL TECH

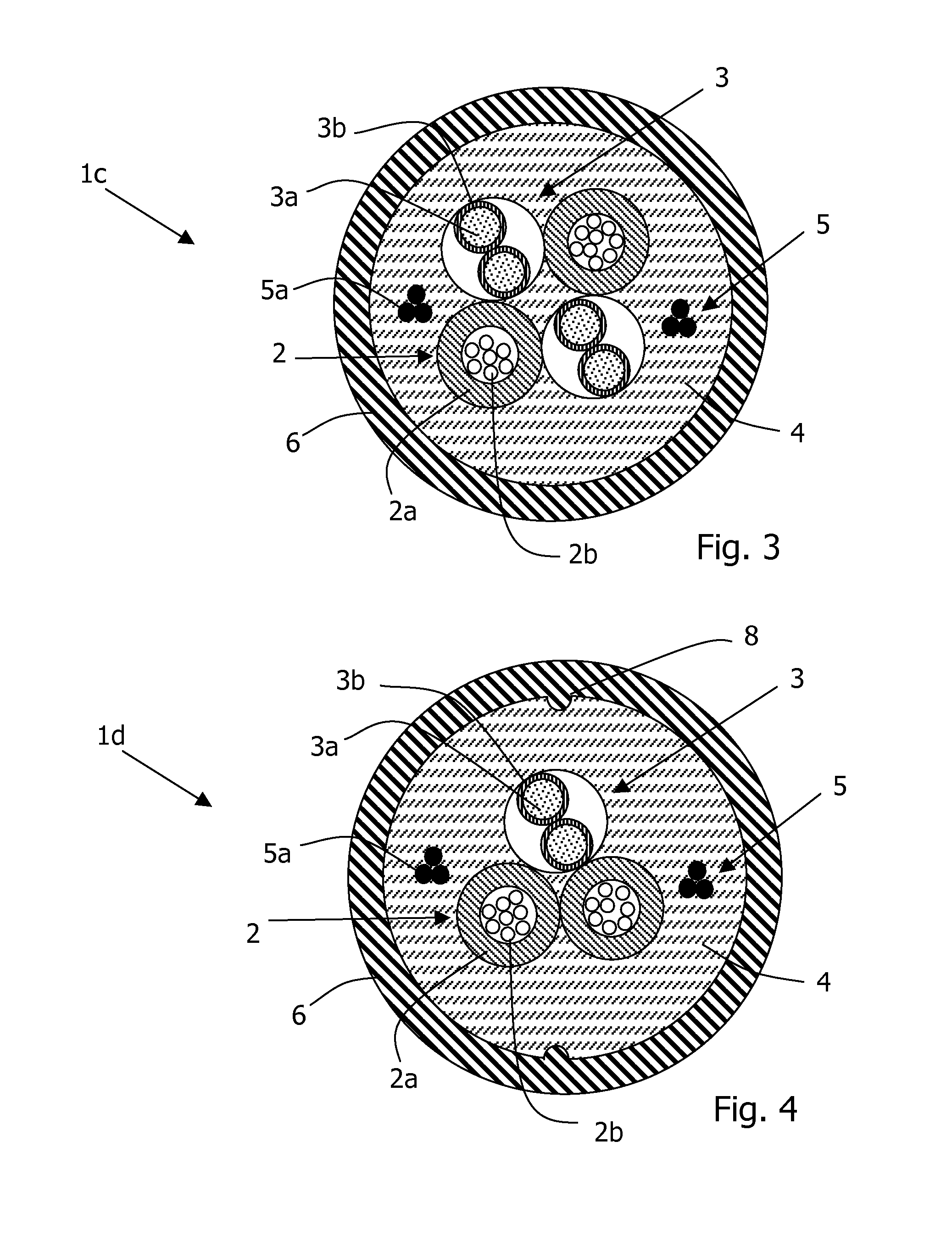

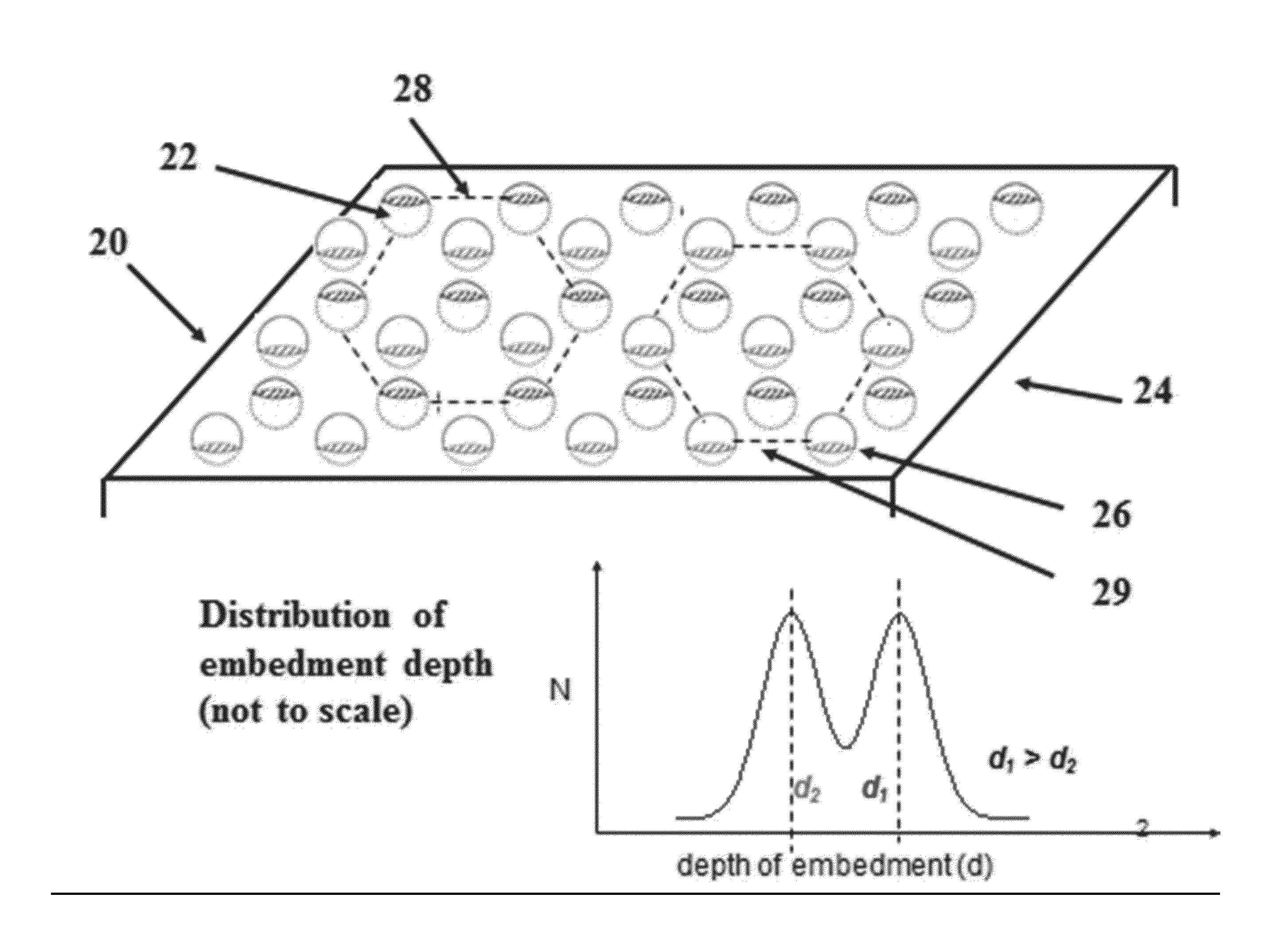

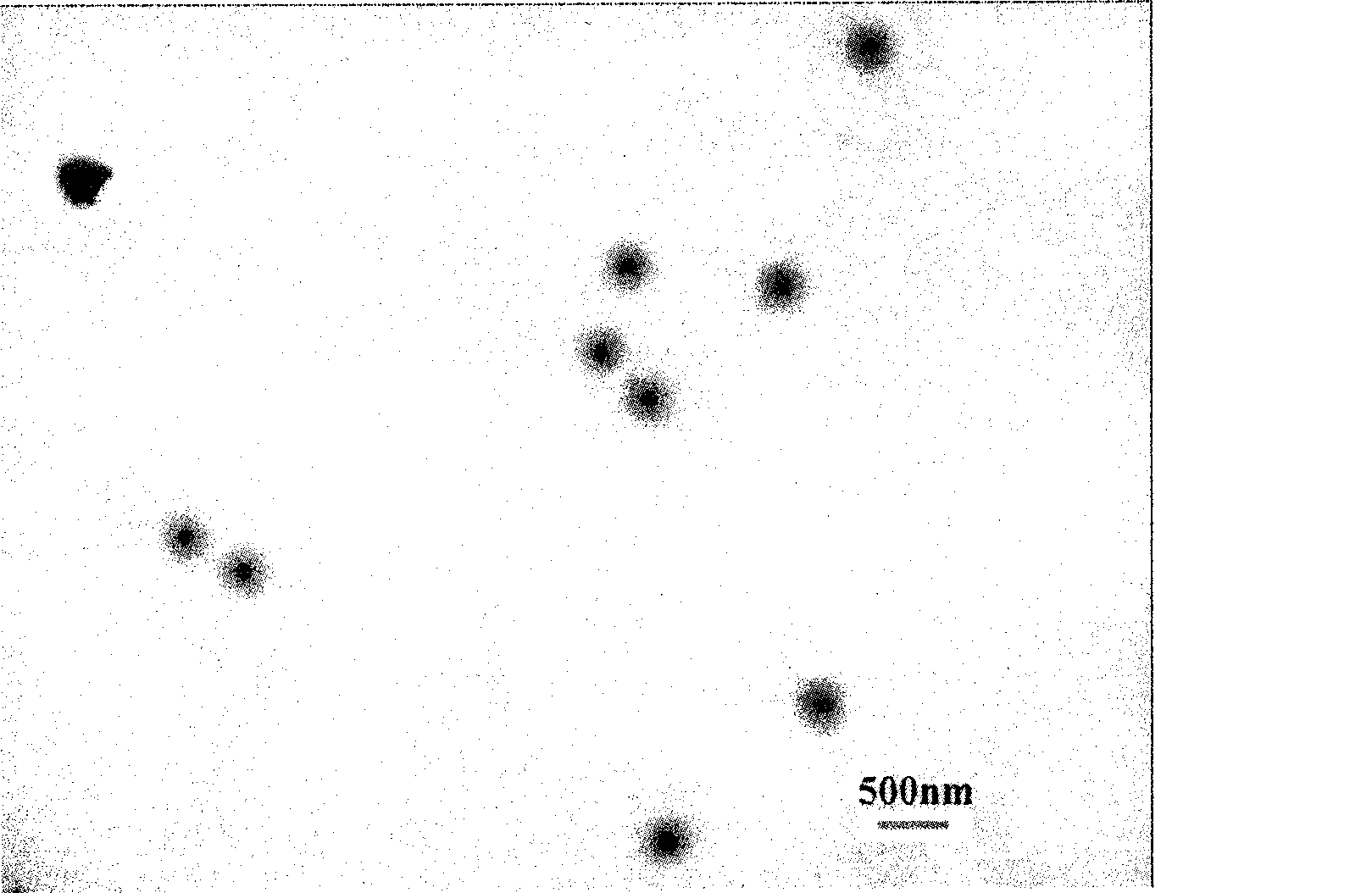

FIXED ARRAY ACFs WITH MULTI-TIER PARTIALLY EMBEDDED PARTICLE MORPHOLOGY AND THEIR MANUFACTURING PROCESSES

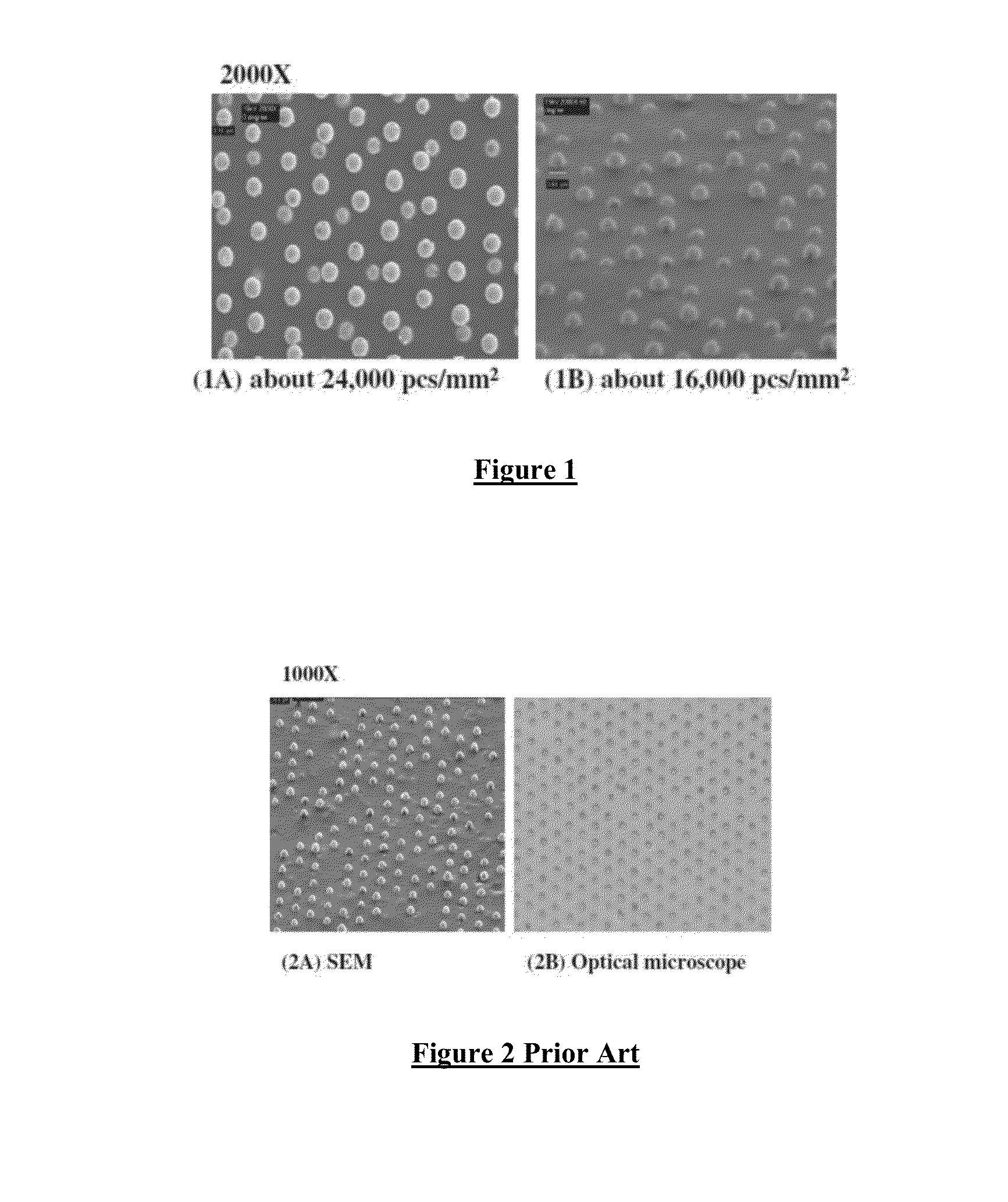

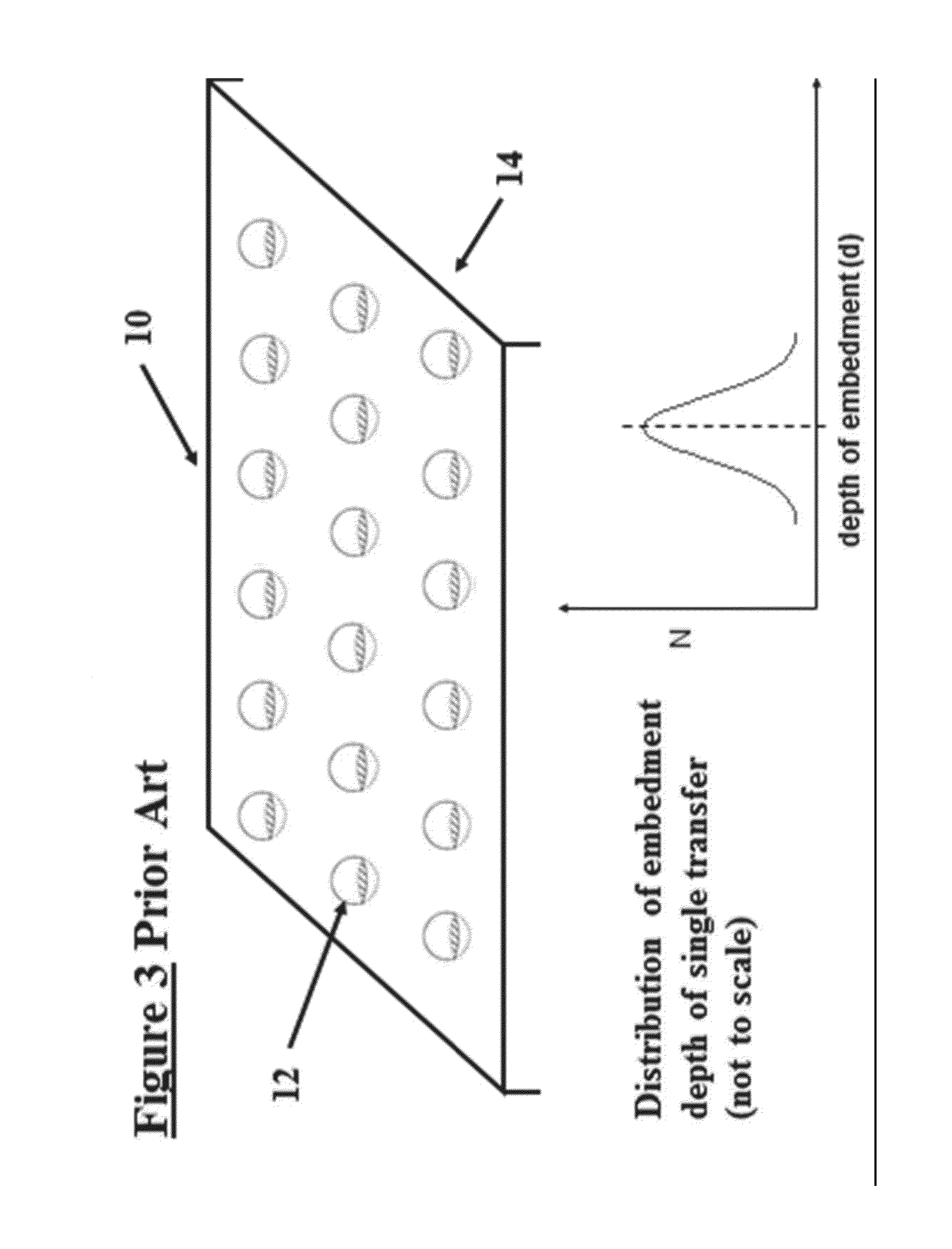

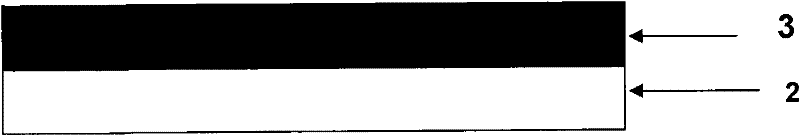

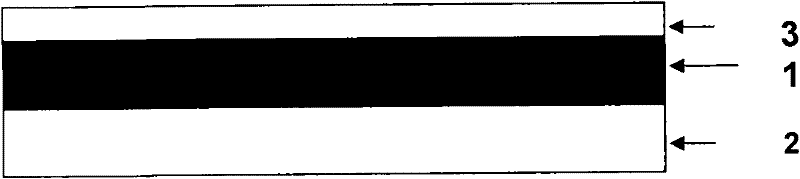

InactiveUS20140141195A1Increase catch rateIncrease contact resistanceFilm/foil adhesivesLayered productsAnisotropic conductive filmRandom array

An anisotropic conductive film (ACF) comprising: (a) an adhesive layer having a substantially uniform thickness; and (b) a plurality of conductive particles individually adhered to the adhesive layer, wherein the conductive particles include a first non-random array of particle sites partially embedded at a first depth within the adhesive layer and a second fixed non-random array or dispersion of conductive particles partially embedded at a second depth or a dispersion of conductive particles fully embedded within the adhesive layer, wherein the first depth and the second depth are distinctly different. The ACF may be supplied as a sheet, a continuous film or as a roll and the multi-tier morphology may be present throughout the length of the product or in select areas.

Owner:TRILLION SCI INC

Electromagnetic shielding adhesive tape

InactiveCN102241950AImprove peel forceImprove shielding effectMagnetic/electric field screeningSynthetic resin layered productsEngineeringElectromagnetic shielding

The invention provides an electromagnetic shielding adhesive tape, which comprises a resin film layer, an electromagnetic shielding layer with a sandwich laminated structure, a first adhesive layer bonded with one surface of the resin film layer, a second adhesive layer and a conductive metal layer positioned between the first adhesive layer and the second adhesive layer, wherein the electromagnetic shielding layer is laminated with the resin film layer.

Owner:3M INNOVATIVE PROPERTIES CO

Flexible all-coating soft film and preparation method thereof

ActiveCN107936860AEvenlyGood flexibilityPolyureas/polyurethane adhesivesPressure sensitive film/foil adhesivesTectorial membraneEngineering

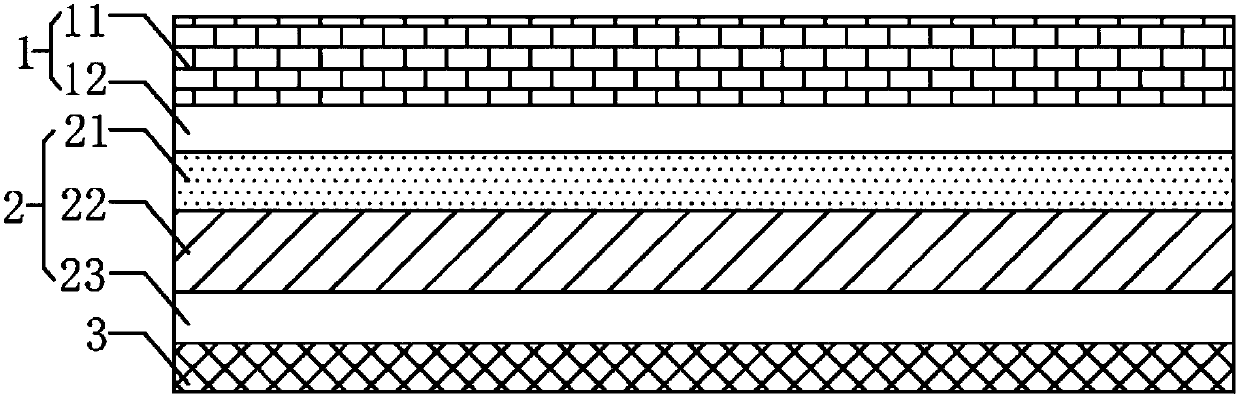

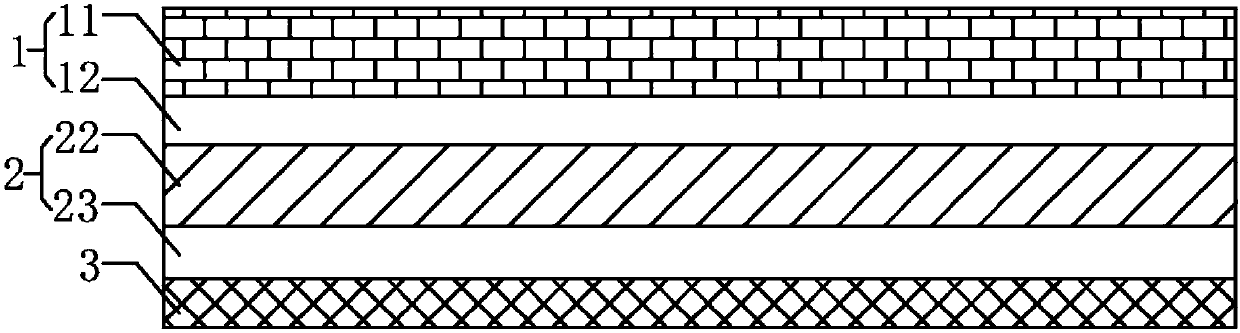

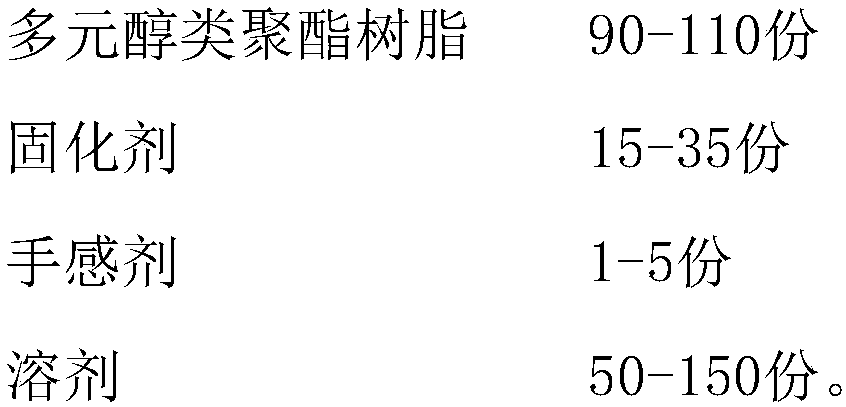

The invention relates to the technical field of protective films, and particularly relates to a flexible all-coating soft film and a preparation method thereof. The flexible all-coating soft film comprises a film protecting layer, a using layer and a stripping layer which are sequentially adhered from top to bottom; the protecting film layer comprises a base material layer and a film protecting glue layer which are sequentially adhered from top to bottom; the using layer comprises a self-repairing layer, a flexible soft film layer and a using glue layer which are sequentially adhered from topto bottom; the lower surface of the film protecting glue layer is adhered to the upper surface of the self-repairing layer; and the lower surface of the using layer is adhered to the upper surface ofthe stripping layer. The flexible all-coating soft film provided by the invention has smooth hand feeling and large stripping force, a curved screen can be all coated, relatively good resilience and self-repairing effect can be achieved, scratch marks can be repaired automatically, and the service life of the flexible all-coating soft film is prolonged. The preparation method provided by the invention is simple, the operation control is convenient, conventional production processes are simplified, the production efficiency is high, the production cost is low, the prepared product is high in yield and stable in quality, and the preparation method is suitable for large-scale industrial production.

Owner:NALI OPTICAL MATERIAL DONGGUAN

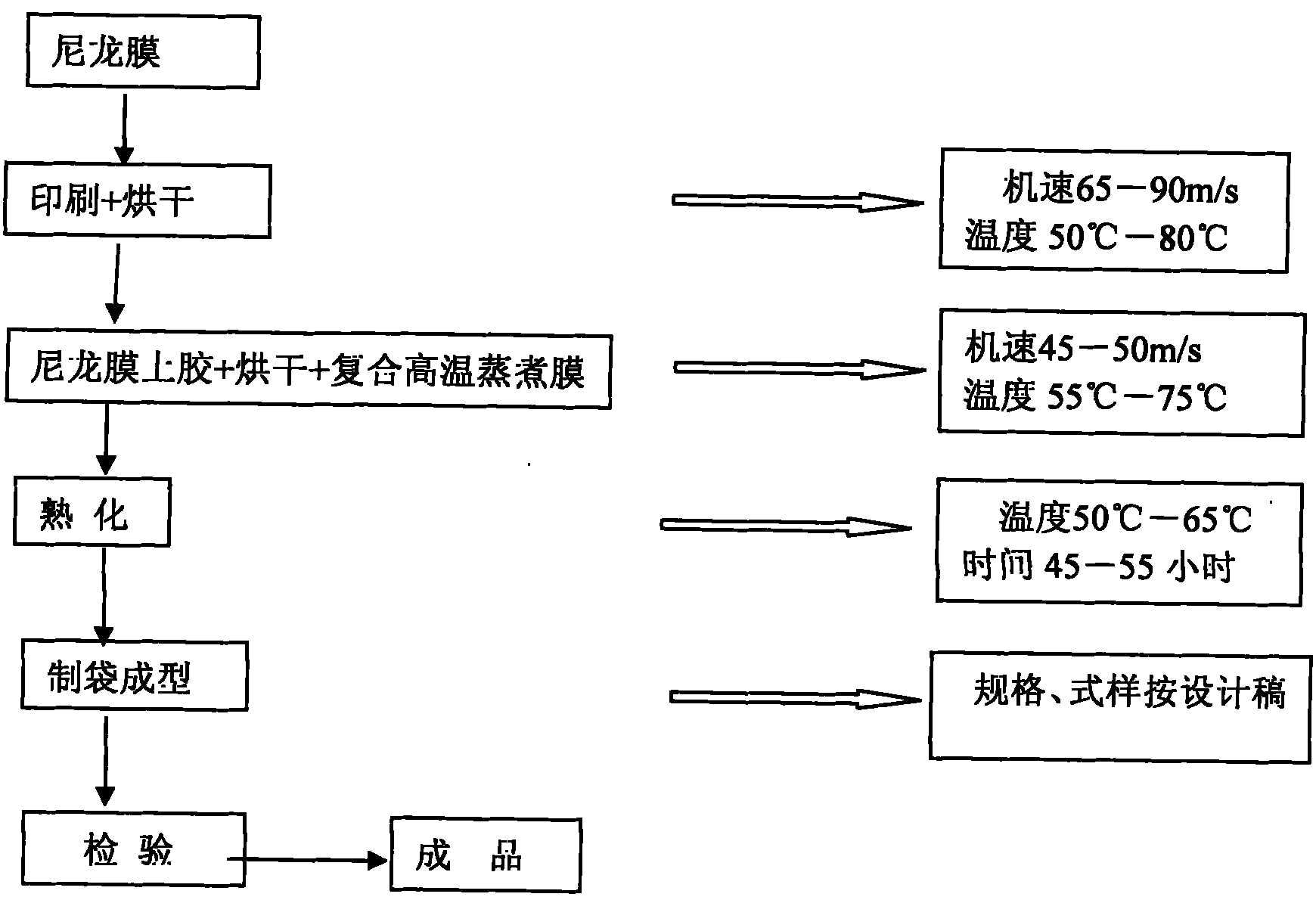

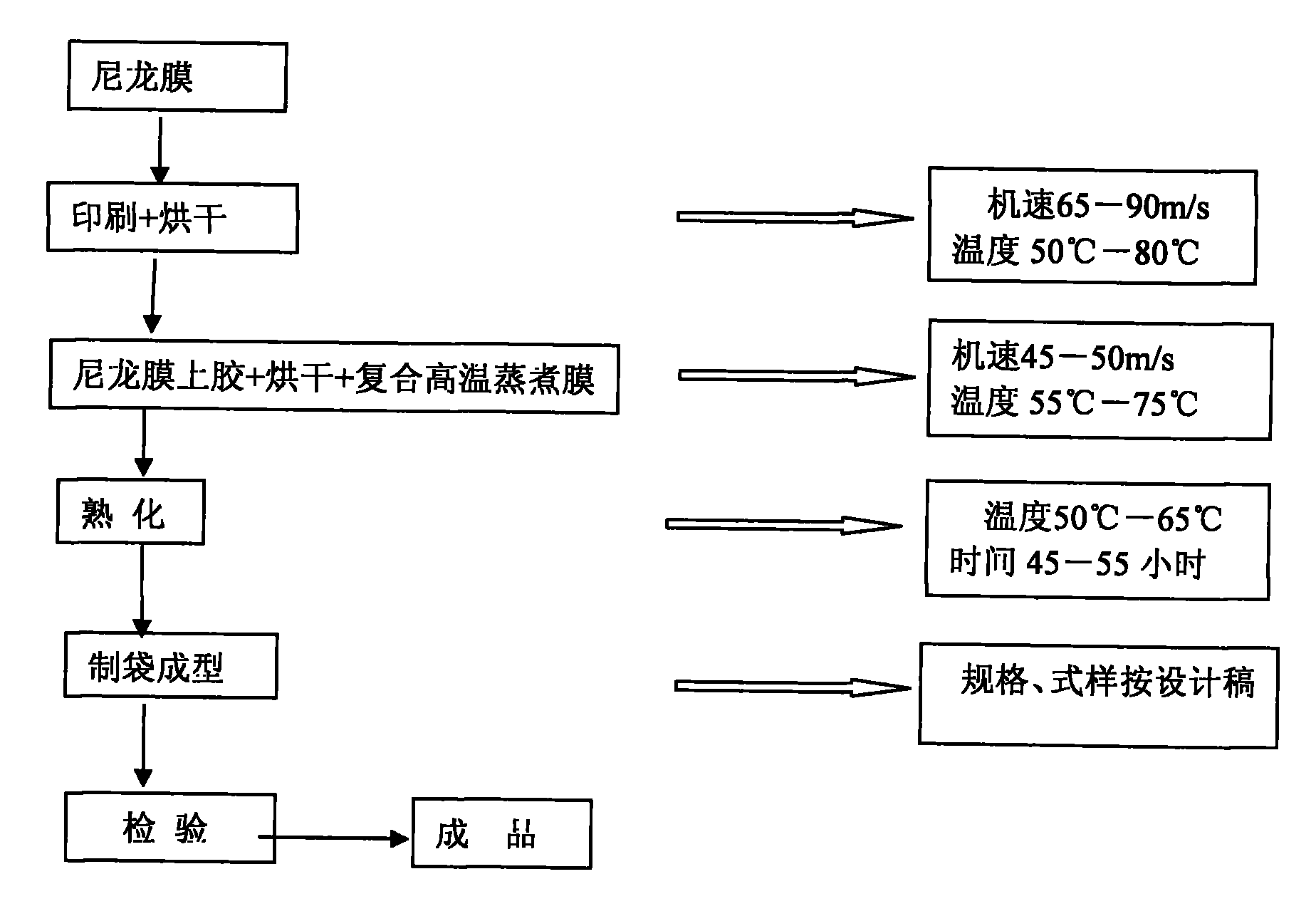

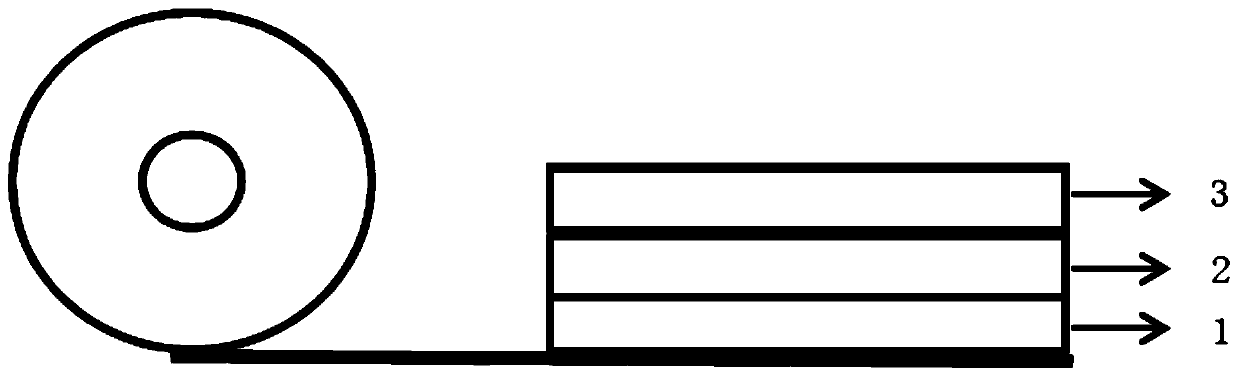

Manufacturing method of vacuum cooking and packaging bag for food

InactiveCN101837855AIncrease air flowImprove toughness and strengthLamination ancillary operationsBagsCompound aEngineering

The invention relates to a manufacturing method of a vacuum cooking and packaging bag for food, which comprises the following steps: selecting and proportioning raw materials and controlling the process flow; compounding a BOPA with an RCPP; firstly, delivering the printed BOPA into a compounding process; and proportioning a polyurethane glue and a solvent by weight; stirring uniformly and gluing on the BOPA; and manufacturing and forming a bag by heating in a drying tunnel, aging at constant temperature and heat sealing. After the food is packaged in vacuum, the vacuum package can resist high-temperature cooking and sterilizing at 135 DEG C for 30 minutes, and the packaging bag can not loose or leak air, can ensure the quality of the food and prolong the preservation and quality guarantee period of the food.

Owner:赵秀雄

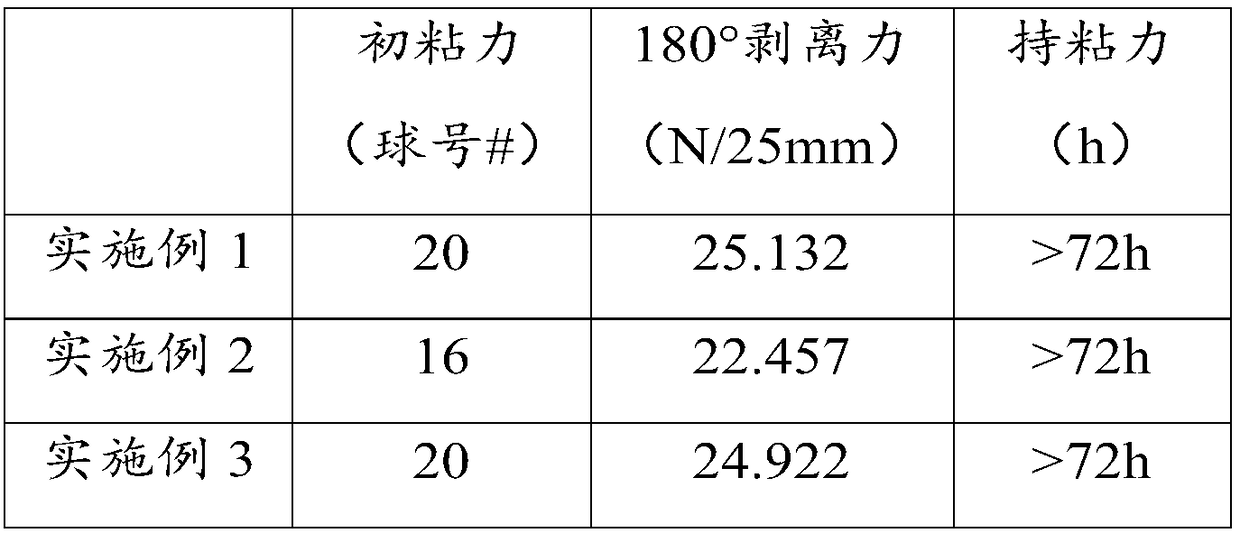

High-viscosity yellowing-resistant explosion-proof film adhesive, adhesive tape and preparation method of adhesive tape

ActiveCN110527464ALight colorImprove antioxidant capacityNon-macromolecular adhesive additivesFilm/foil adhesivesIsooctyl acrylateEthyl acetate

The invention discloses a high-viscosity yellowing-resistant explosion-proof film adhesive. The explosion-proof film adhesive comprises the following components in parts by weight: 100 parts of acrylic acid adhesive, 5-10 parts of tackifying resin, 0.15-0.6 part of a curing agent and 50-90 parts of a solvent, wherein the acrylic acid adhesive is prepared by reacting the following components in parts by weight: 26-30 parts of isooctyl acrylate, 3-5 parts of acrylic acid, 0.5-1 part of hydroxyethyl acrylate, 5-10 parts of methyl acrylate, 53-65 parts of ethyl acetate and 0.5-1 part of azobisisobutyronitrile; the solvent is one or more selected from ethyl acetate, toluene and butanone; and the tackifying resin is hydrogenated resin. The invention also provides a high-viscosity yellowing-resistant adhesive tape prepared from the adhesive. The high-viscosity yellowing-resistant explosion-proof film adhesive has colorless transparent appearance, and can still ensure sufficient peeling forceaccording to different coating thicknesses. Under the condition of high-temperature aging, the explosion-proof film adhesive is not yellowing in appearance, and peeling force is basically not attenuated.

Owner:CROWN TAICANG ADHESIVE PROD CO LTD

Pressure-sensitive adhesive tape, preparation method thereof, and resin composition used for preparing pressure-sensitive adhesive tape

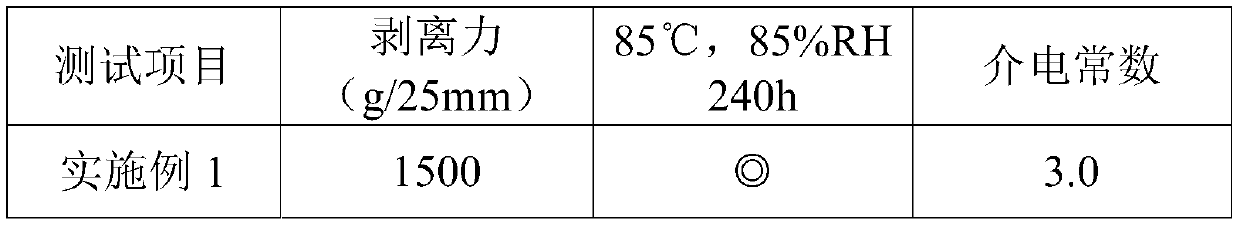

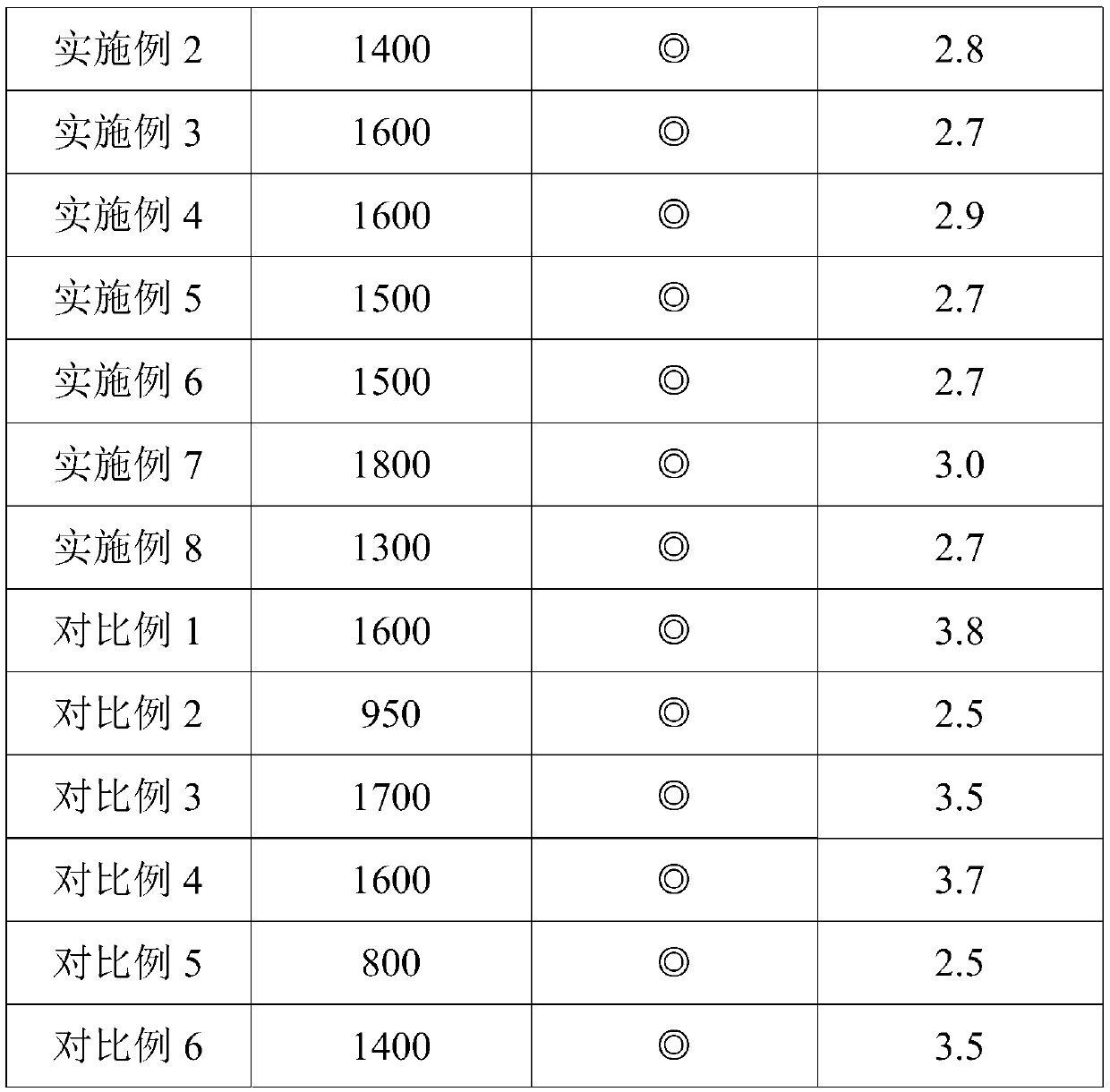

ActiveCN110467890AImprove peel forceLow dielectric constantAmide/imide polymer adhesivesEster polymer adhesivesDielectricFunctional monomer

The invention belongs to the field of optical adhesive tape, and discloses a p pressure-sensitive adhesive tape, a preparation method thereof, and a resin composition used for preparing the pressure-sensitive adhesive tape. The resin composition comprises, by mass, polyacrylic resin of 90 to 98%; a photopolymerizable monomer of 0 to 6%; a photoinitiator of 0 to 2%; and a curing agent of 0.01 to 2%, wherein the polyacrylic resin is prepared through polymerization of a soft monomer, a hard monomer, and a functional monomer; the functional monomer comprises at least one selected from a hydroxy containing monomer, a carboxyl containing monomer, an epoxide group containing monomer, and a nitrogen containing monomer. The adding amount of the different kinds of monomers in the resin composition is controlled, so that the resin composition of different properties is obtained; and combination of the resin composition of different properties is capable of producing the pressure-sensitive adhesive tape high in peeling strength and low in dielectric constant.

Owner:广州慧谷功能材料有限公司

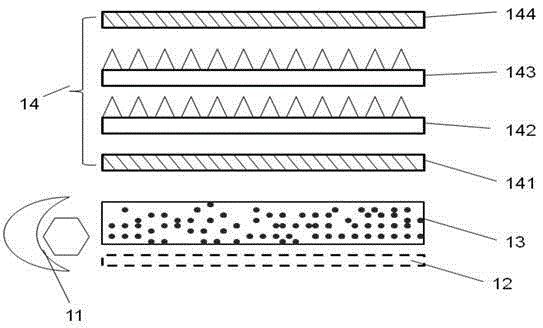

Basal membrane of composite brightness enhancement film

ActiveCN105353431AHigh hardnessIncrease surface tensionNon-linear opticsOptical elementsTectorial membraneUltraviolet lights

The invention discloses a basal membrane of a composite brightness enhancement film. The basal membrane comprises a support body and an antistick protection layer coating the surface of the support body, wherein the antistick protection layer is formed by solidifying a coating liquid composed of an ultraviolet light solidification resin and diffusion particles under the condition of ultraviolet light, and the haze scope ranges from 40% to 90%. The coating liquid of the antistick protection layer is prepared by the following components in parts by weight: 5 to 40 parts of a high-functionality polyurethaneacrylate prepolymer, 10 to 40 parts of an activated monomer, 1 to 5 parts of a photoinitiator, 0.5 to 3 parts of a levelling agent, 0.5 to 3 parts of a dispersing auxiliary and 20 to 60 parts of an organic solvent. According to the composite brightness enhancement film provided by the invention, when a protective membrane is laid for the brightness enhancement film, the protective membrane can be smoothly attached, and the problem of leftovers of residual gum is eliminated; and besides, the antistick protection layer has an atomization diffusion effect and can be applied to the basal membrane of the composite brightness enhancement film.

Owner:HEFEI LUCKY SCI & TECH IND

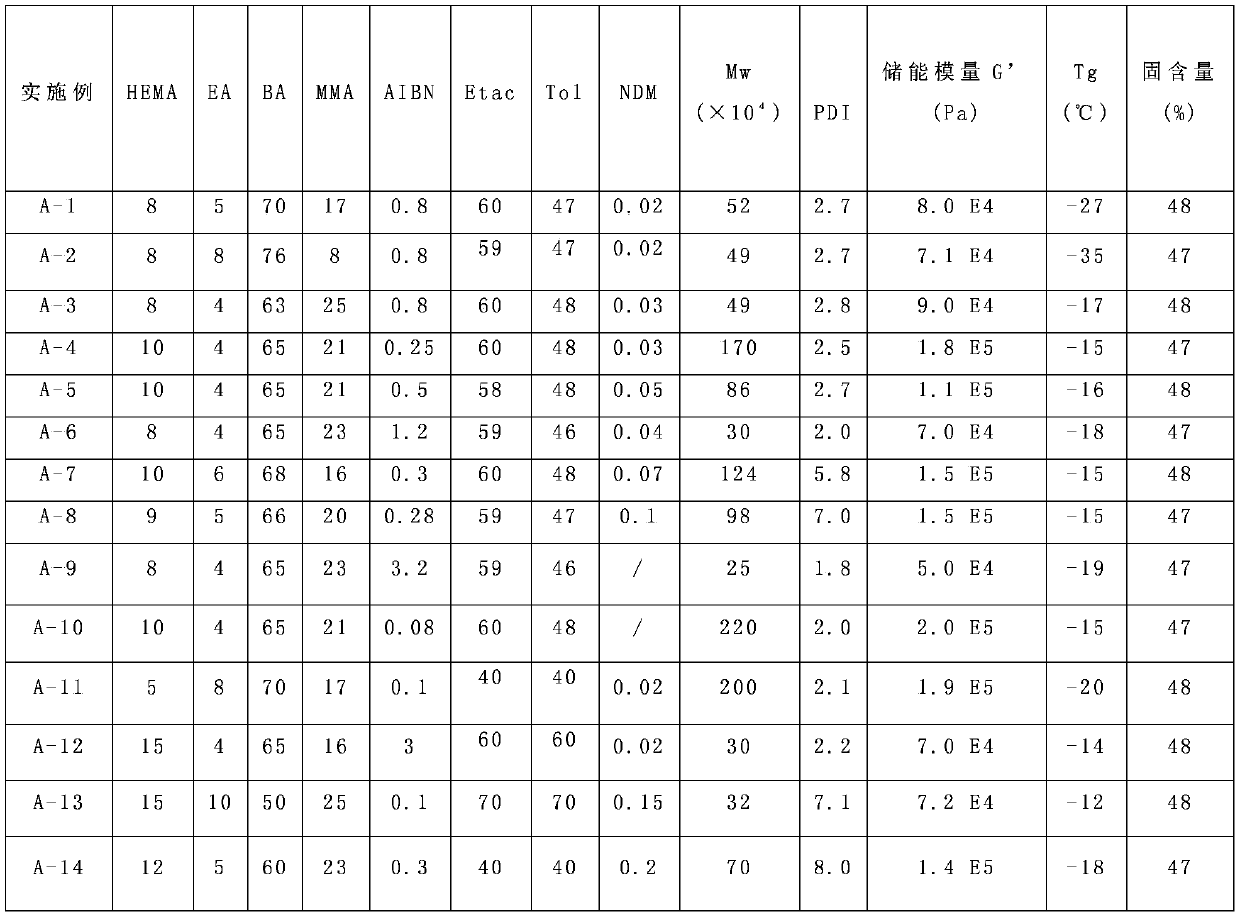

Thinly-coated high-viscosity pressure-sensitive adhesive, and pressure-sensitive adhesive tape

ActiveCN110819273AHigh bonding strengthStrong initial adhesionMacromolecular adhesive additivesEster polymer adhesivesPolymer scienceAdhesive glue

The invention discloses a thinly-coated high-viscosity pressure-sensitive adhesive. The thinly-coated high-viscosity pressure-sensitive adhesive comprises the following components by weight: 100 partsof acrylate resin slurry, 0.1-3 parts of a curing agent and 15-50 parts of tackifying resin, wherein the acrylate resin slurry has a weight-average molecular weight of (30-200)*10<4> g / mol and a molecular weight distribution index PDI of 2.0 to 8.0; and the tackifying resin has a softening point of 10 DEG C to 140 DEG C and relative molecular mass of 300 g / mol to 2000 g / mol. On the basis of 100 parts of acrylate resin slurry, the tackifying resin comprises 10-25 parts of rosin resin and 5-25 parts of terpene resin. The pressure-sensitive adhesive has excellent initial adhesion and excellent stripping force, and good fluidity; and a prepared pressure-sensitive adhesive tape is thin in thickness and high in nanocrystalline bonding strength.

Owner:SUZHOU FINESET MATERIAL TECH CO LTD

Acrylate structural adhesive being resistant against solvent scrubbing

InactiveCN107603497AGlue evenlyMix rubber evenlyNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyAdhesive

The invention relates to an acrylate structural adhesive being resistant against solvent scrubbing, which includes a component A and a component B; the component A is composed of: an acrylate monomer,methacrylic acid, toughening rubber, toughening filler, an accelerant, a stabilizer and a coupling agent; the component B is composed of: an oxidizing agent, epoxy resin, a plasticizer, filler and pigments. The component A and the component B are uniformly stirred according to the volume ratio of 10:1 to produce the acrylate structural adhesive. The acrylate structural adhesive is resistant against solvent scrubbing, is high in thixotropy and is good in infiltrability on an adhesion interface. In addition, after solidification, an adhesive layer is good in toughness and is high in adhesion force between anodised alumina, Al / Mg alloy, an electrophoresis ED layer, ABS / PC and the like plastic alloy, etc.

Owner:YANTAI DARBOND TECH

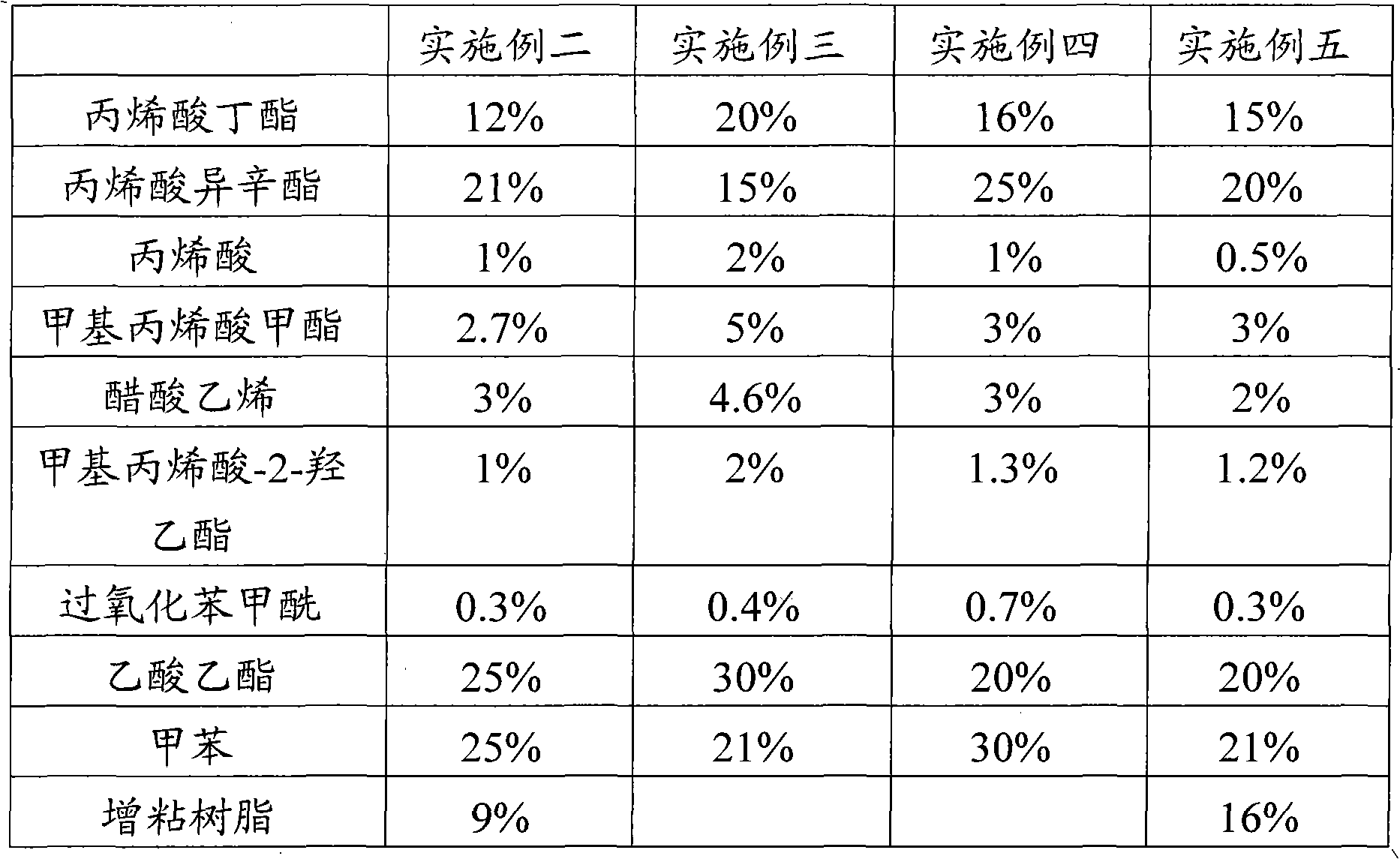

Pressure-sensitive adhesive for PET (Polyester) adhesive tapes and preparation method thereof

InactiveCN102040930ANo pollution in the processIncrease stickinessFilm/foil adhesivesEster polymer adhesivesPolyesterIsooctyl acrylate

The invention discloses a pressure-sensitive adhesive for PET (Polyester) adhesive tapes and a preparation method thereof. The preparation method comprises the following steps of: uniformly mixing 10-20% butyl acrylate, 15-30% of ethyl hexyl acrylate, 0.5-2% of acrylic acid, 2-5% methyl methacrylate, 2-5% vinyl acetate, 0.5-2% methacrylate-2-hydroxyethyl ester, 20-30% toluene and 20-30% ethyl acetate; heating to 80-85 DEG C in a reaction kettle, and then adding benzoyl peroxide 1-3 times in a heat holding process, wherein the heat holding time is 2-10h; and finally, adding tackifying resin as required on adhesiveness. In the invention, the prepared pressure-sensitive adhesive has high stripping resistance between 1000g and 2000g, and has no adhesive remained to pollute an adhered object in a tearing process.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

Acrylate pressure sensitive adhesive and preparation method thereof, and electronic product

ActiveCN109266257AGood adhesionImprove high temperature resistanceMacromolecular adhesive additivesAmide/imide polymer adhesivesPolymer scienceTemperature resistance

The invention provides an acrylate pressure sensitive adhesive and a preparation method thereof, and an electronic product, belonging to the technical field of polymer materials. The acrylate pressuresensitive adhesive is prepared from the following raw materials in parts by weight: 70-80 parts of soft monomer, 18-28 parts of hard monomer, 5-15 parts of crosslinking monomer, 3-7 parts of heat resistant monomer, 0.3-1 part of initiator, 3-6 parts of tackifying resin, and solvent. The acrylate pressure sensitive adhesive obtained by optimizing proportion of each monomer and adding a specific amount of tackifying resin has a high adhesive property and high temperature resistance, has good initial adhesion, peeling force and holding force, better balances all adhesion properties, and can be applied to electronics, electrical appliance, military and aerospace fields having special requirements on high temperature resistance of adhesive.

Owner:GUANGZHOU DUBAGN MATERIAL SCI & TECH

Waterborne polyurethane hot melt adhesive as well as preparation method and application thereof

InactiveCN104927747AReduce liquidityEasy to usePolyureas/polyurethane adhesivesPolymer sciencePtru catalyst

The invention belongs to the technical field of hot melt adhesives, and discloses a waterborne polyurethane hot melt adhesive as well as a preparation method and application thereof. The preparation method comprises the following steps: (1) adding polyether polyol in a reaction kettle, heating to 120-130 DEG C, and carrying out heat preservation, water removal and cooling; (2) under the condition of stirring, dropwise adding a catalyst into the reaction kettle and then adding polyisocyanate, heating to 80-88 DEG C, and carrying out a heat preservation reaction to obtain a mixture; (3) dropwise adding a carboxylic monomer solution into the mixture, adjusting the temperature, and carrying out heat preservation reaction to obtain a crude product; (4) adding acetone into the crude product, increasing the rotating speed of a stirrer, cooling to 35-40 DEG C, adding a neutralizing agent for neutralization, taking out the obtained material, adding distilled water, and conducting high-speed shearing emulsification and rotating evaporation to obtain the waterborne polyurethane hot melt adhesive. The waterborne polyurethane hot melt adhesive provided by the invention is low in melt temperature, and high in solid content and stripping force, and remains in a liquid state at normal temperature; meanwhile, the preparation method is mild in reaction condition and low in energy consumption; the waterborne polyurethane hot melt adhesive is applied to the field of adhesives.

Owner:SOUTH CHINA UNIV OF TECH

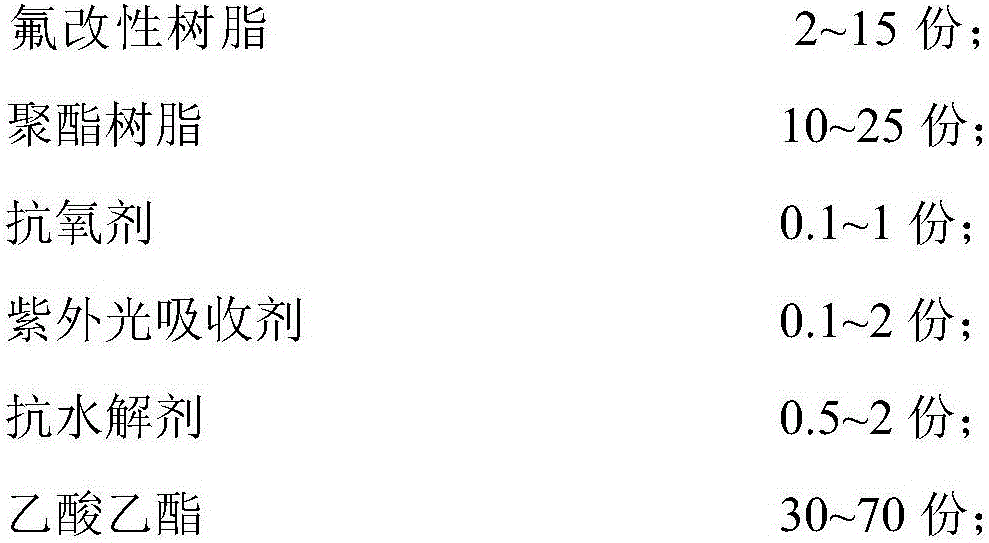

Adhesive composition for solar cell backplane and preparation method thereof

InactiveCN106244081AReduce surface tensionGood wettingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPrepolymerChemistry

The invention provides an adhesive composition for a solar cell backplane and a preparation method thereof. The adhesive composition is composed of a prepolymer component and a curable component, wherein the prepolymer component contains the following raw materials: fluorine-modified resin, polyester resin, an antioxidant, an ultraviolet absorber, an anti-hydrolysis agent and ethyl acetate; and the curable component is a hexamethylene diisocyanate trimer. The preparation method of the adhesive composition comprises the step of respectively preparing the prepolymer component and the curable component. A preparation method of the prepolymer component comprises the step of uniformly mixing the above raw materials. When in use, the prepolymer component and the curable component are mixed according to the weight ratio of (15-18): 1. The invention has the following advantages: contact area is increased to raise the whole peel strength of the backplane; by adding fluororesin into the adhesive, aging resistance of the backplane can be further enhanced, and dual ''85'' test lasts over 3,000 hours.

Owner:SHANGHAI WEIKAI CHEM +2

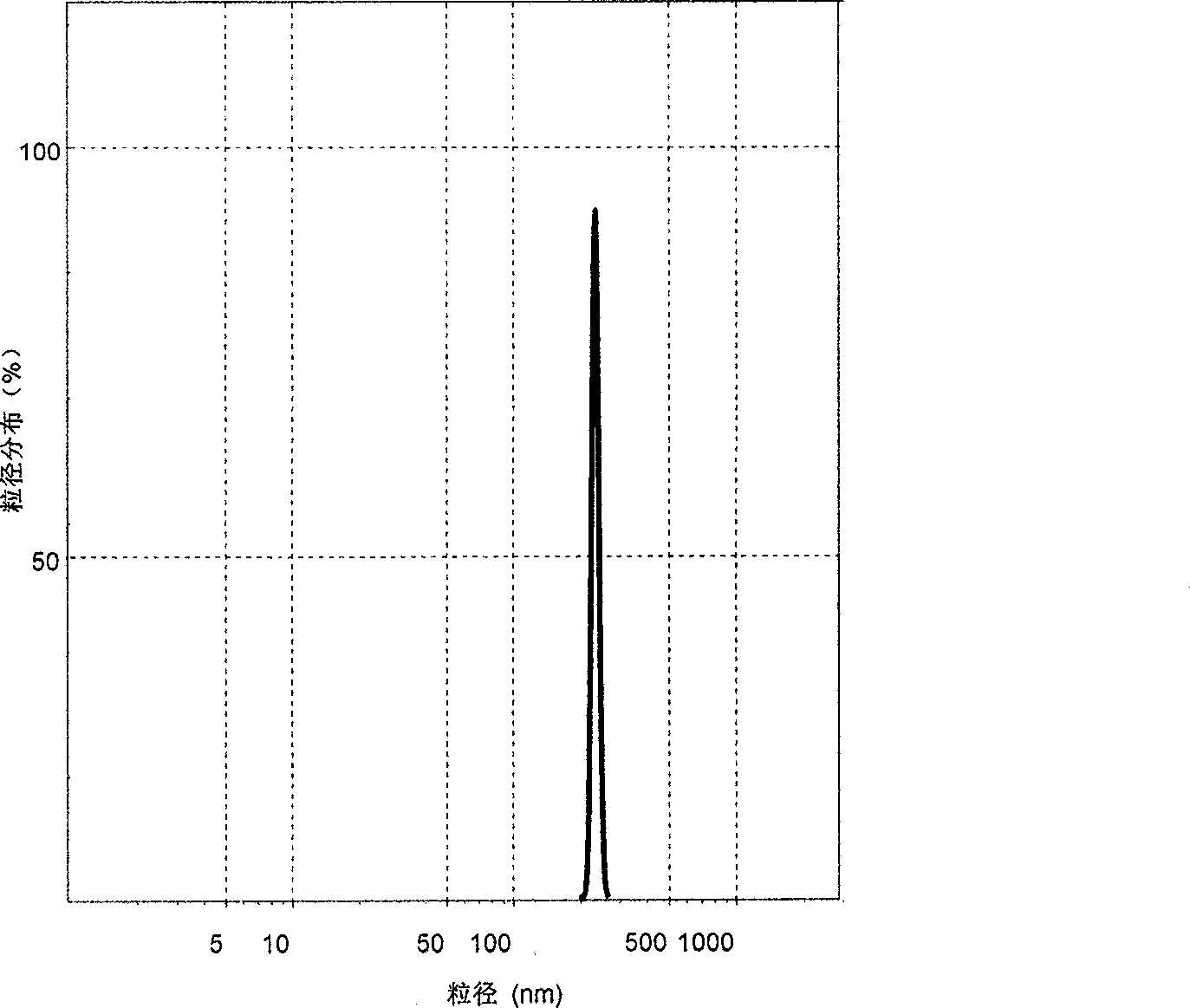

Preparation of acrylic ester copolymer emulsion for pressure-sensitive adhesive

ActiveCN101412783AGood pressure sensitivityImprove performanceEster polymer adhesivesEmulsionOrganic inorganic

The invention relates to a method for preparing an acrylate polymer emulsion used for a pressure sensitive adhesive, which belongs to an adhesive based on acrylate polymer. The method for preparing the acrylate polymer emulsion used for the pressure sensitive adhesive comprises the following steps: (1) preparation of a seed emulsion; (2) pre-emulsification of shell layer monomers; and (3) gradient feeding of a shell layer. The method adopts the seed emulsion polymerization technology to drip a hard monomer, namely methyl methacrylate (MMA) into the shell layer, so that the concentration is subjected to discontinuous change and the organic-inorganic acrylate polymer emulsion provided with an obvious core-shell structure is prepared, wherein nano silicon dioxide is taken as a core and a copolymer of acrylic ester and acrylic monomers is taken as the shell layer; and the hard monomer of the shell layer is subjected to concentration gradient change. The acrylate polymer emulsion can be used as the pressure sensitive adhesive after drying and film forming; the prepared pressure sensitive adhesive has the advantages of high continuous viscous force and reduction of the residual gum content under the condition of gum peeling; and the initial adhesion and the peeling strength can be improved when the continuous viscous force is larger.

Owner:HEBEI UNIV OF TECH

Adhesion layer for adhesive tape as well as preparation method and application thereof

ActiveCN109306252AHigh elastic plasticityImprove cohesionMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPolytetramethylene terephthalatePolyolefin

The invention provides an adhesion layer for an adhesive tape. The adhesion layer is prepared from the following raw materials in parts by weight: 40 to 60 parts of a thermoplastic elastomer, 40 to 60parts of tackifying resin, 10 to 20 parts of a reinforcing agent, 10 to 25 parts of a softening agent, 0.2 to 5 parts of an antioxidant and 0.1 to 5 parts of filler, wherein the thermoplastic elastomer is selected from one or more of a styrene block copolymer, a polyolefin block copolymer, an acrylic block copolymer, polyisobutene, thermoplastic polyurethane, butyl rubber and ethylene propylene diene monomer; the reinforcing agent is selected from one or more of polystyrene, polyphenylene ether, polyethylene glycol terephthalate and polybutylene terephthalate. According to the adhesion layerprovided by the invention, the components with specific content are adopted to realize a good compatible effect; the cohesion force is improved on the basis that the adhesion layer has high-elasticityplasticity, so that the adhesion layer has the properties of high peeling force, high temperature resistance, tension without breaking and no removal of residual glue.

Owner:安徽屹珹新材料科技有限公司

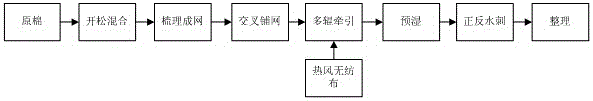

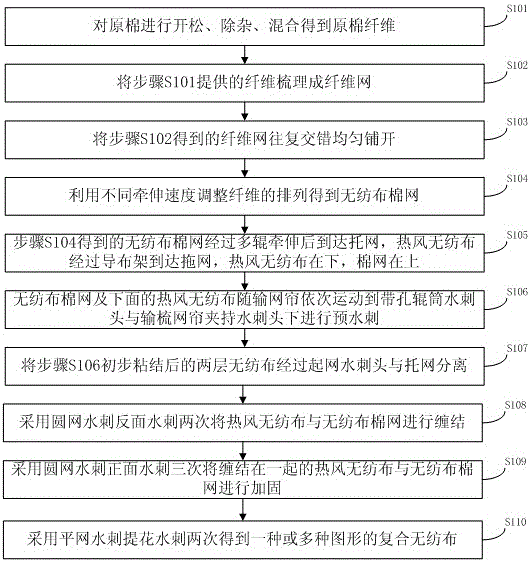

Compounding method of hot air through nonwoven fabric and all cotton nonwoven fabric and production system thereof

ActiveCN106393945AComposite process advantagesRemove the phenomenon of bleedingLamination ancillary operationsLaminationPulp and paper industryNonwoven fabric

The invention discloses a compounding method of hot air through nonwoven fabric and all cotton nonwoven fabric, and belongs to the technical field of nonwoven fabric production. The method comprises the following steps: taking hot air through nonwoven fabric as the bottom layer, laminating a nonwoven fabric-cotton mesh on the hot air through fabric, and carrying out pre-wetting and front-back spunlace laminating to obtain the product. According to the method, a spunlace method is used to replace chemical adhering to compound chemical fiber nonwoven fabric and all cotton spunlace nonwoven fabric; the advantages of all cotton nonwoven fabric such as softness, water absorbing property, breathability, and the like, are preserved, at the same time, the advantages of hot air through nonwoven fabric such as high filling power, good elasticity, soft hand feeling, strong warm keeping performance, air penetrating and water penetrating performance, and the like are also preserved; moreover, the glue leakage is prevented, and the peeling strength meets the requirement.

Owner:WINNER MEDICAL (HUANGGANG) CO LTD

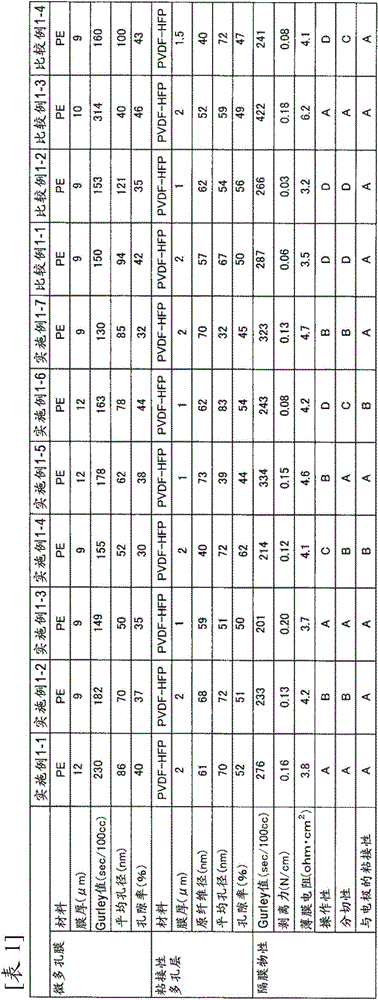

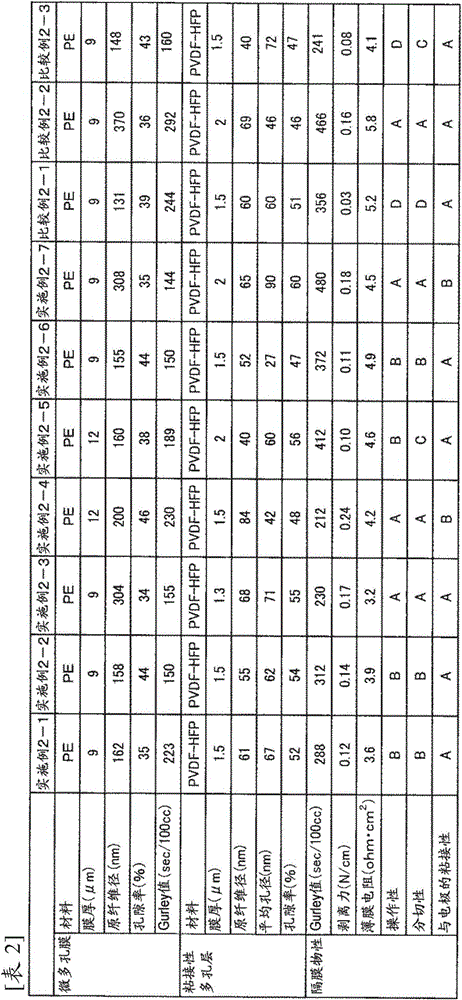

Nonaqueous-secondary-battery separator and nonaqueous secondary battery

InactiveCN104620417AImprove peel forceFull ion permeabilitySecondary cellsCell component detailsElectrical batteryPhysical chemistry

A nonaqueous-secondary-battery separator provided with the following: a microporous membrane containing a fibrillar resin; and an adhesive porous layer that is provided on one or both sides of the microporous membrane and contains a fibrillar polyvinylidene-fluoride resin. Either the mean pore diameter determined from the specific surface area of the microporous membrane is between 50 and 90 nm, inclusive, or the fibril diameter determined from the specific surface area of the microporous membrane is between 150 and 350 nm, inclusive.

Owner:TEIJIN LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com