Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

344results about How to "Glue evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength glass fiber-reinforced plastic pipeline and production method thereof

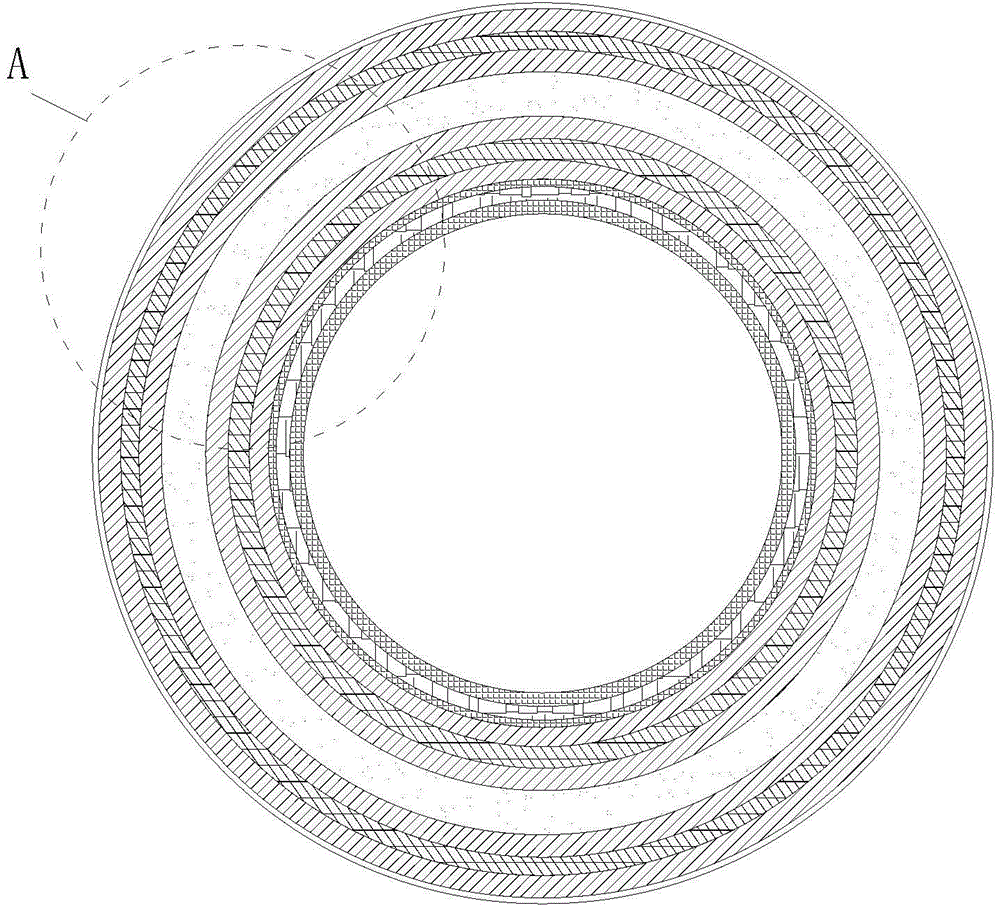

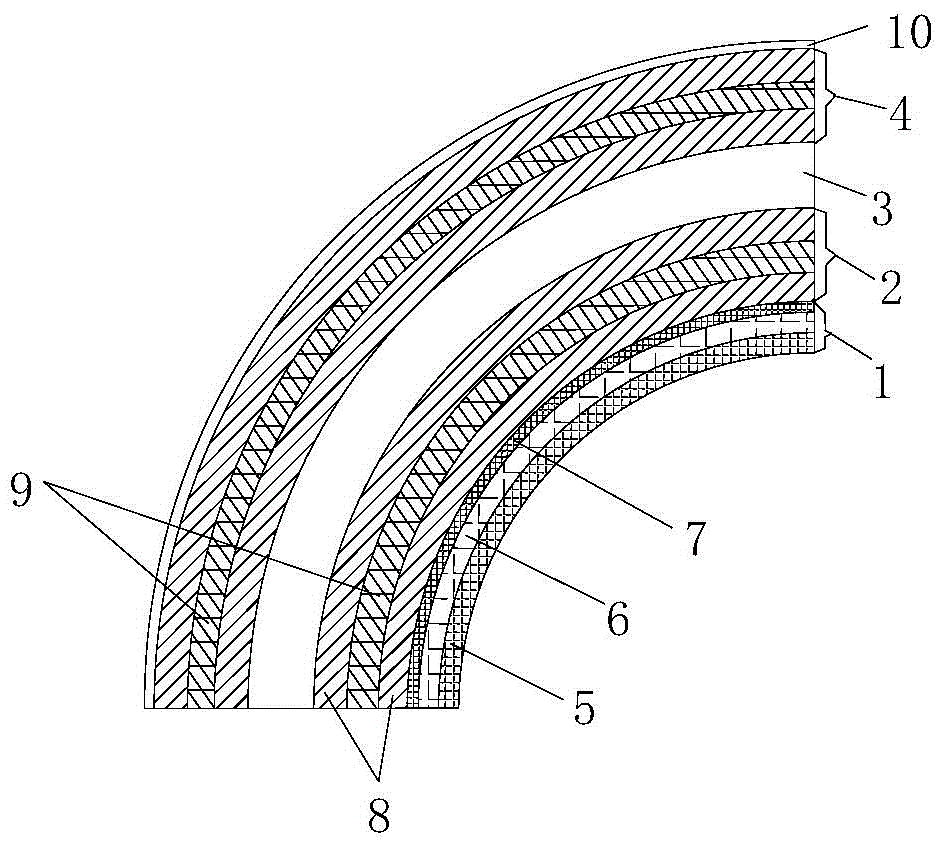

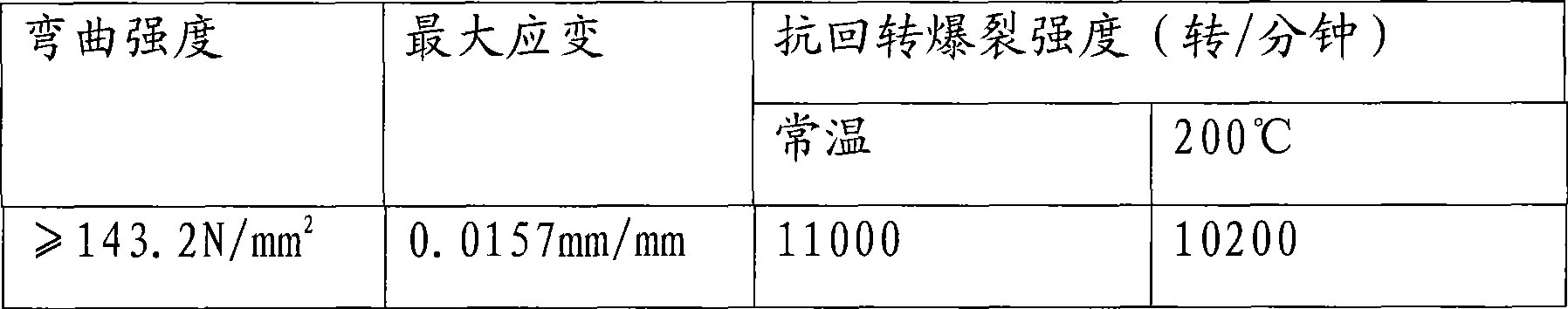

The invention discloses a high-strength glass fiber reinforced plastic pipeline and a production method thereof, and belongs to the technical field of glass fiber reinforced plastic pipelines and production methods thereof. The high-strength glass fiber reinforced plastic pipeline is a circular pipeline, and is characterized by comprising a lining layer, an inner structural layer, a middle sand inclusion layer and an outer structural layer, wherein the lining layer is formed by soaking and bonding a glass fiber surface felt layer, a glass fiber knitted felt layer and a grid cloth layer in sequence through lining resin from inside to outside; the inner structural layer and the outer structural layer are constructed by one or more glass fiber yarn annular winding layers and one or more glass fiber yarn crossed winding layers; the annular winding layers and the crossed winding layers are formed at intervals; the middle sand inclusion layer consists of upper layer sand inclusion cloth, lower layer sand inclusion cloth and a sand material compressed and clamped between the upper layer sand inclusion cloth and the lower layer sand inclusion cloth; the sand material is formed by mixing quartz sand and sand adhesion resin. The pipeline has the advantages of high compressive strength, high axial tensile strength, large pipe diameter span, light weight, high hydraulic performance, freeness from scaling, insulation, flame retardance and corrosion resistance.

Owner:HUNAN XIAOXIANGYUAN TECH DEV

Method for car clutch face sheet production

InactiveCN101429977ALow priceImprove adsorption capacityAldehyde/ketone condensation polymer adhesivesFriction clutchesAdhesiveFilling materials

The invention relates to a method for producing automobile clutch facing patches, which adopts an organic vegetable fiber and other fibers to weave the organic vegetable fiber and other fibers into twill fabrics as a framework material, simultaneously mixes and stirs bonding materials such as water soluble phenol resin, filling materials and water to be prepared into slurry. The method utilizes a natural wood vegetable fiber to replace an inorganic fiber material, and the natural wood vegetable fiber is reproducible and has no pollution. The water soluble phenol resin is used to replace rubber and is taken as a bonding adhesive for preparing the clutch facing patches. Industrial naptha is not used any more. Therefore, compared with the prior art, the method has the following advantages: firstly, the method has the characteristic of environmental protection; and secondly, the method is favorable for reducing the production cost of the automobile clutch facing patches, and solving the problem of product performance fluctuation.

Owner:ZHEJIANG DUALRAY FRICTION MATERIAL

Gum dipping, stentering forming method of earthwork grid cloth

InactiveCN1789540AGuaranteed not to shrinkGuaranteed FounderLiquid surface applicatorsTextile selvedgesMesh gridTowing

The invention relates gumming stretching shaped method, comprising the following steps: accumulating, gumming, stretching and drying, discharging cloth, cooling, towing, accumulating and winding; putting the grid into impregnating groove; before accumulating, carrying out hemming and straightening weft; after accumulating, setting the draught device which is composed at least a drawoff roller, and after stretching and drying, setting cloth discharge and cooling draught device to cool and draw the grid. The method is simple and the grid is not out of shape.

Owner:管昆明

Moisturecuring polyurethane hot-melt adhesive suitable for adhering narrow frame of mobile phone, and preparation method of moisturecuring polyurethane hot-melt adhesive

InactiveCN106753179AModerate viscosityGood compatibilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention discloses a moisturecuring polyurethane hot-melt adhesive suitable for adhering a narrow frame of a mobile phone, and a preparation method of the polyurethane hot-melt adhesive. The polyurethane hot-melt adhesive is prepared by enabling polyether polyol, polyester polyol and diisocyanate to react, and adding acrylic resin, an antioxidant, tackifying resin, phosphoric acid, a catalyst and a silane coupling agent at the same time to obtain the single-component moisturecuring polyurethane hot-melt adhesive. The moisturecuring polyurethane hot-melt adhesive prepared by using the method disclosed by the invention has adjustable opening time, can be cured fast, and is free of gel and high in mobility during adhesive applying. The moisturecuring polyurethane hot-melt adhesive can be applied smoothly by using a 23# needle under a 110 DEG C heating condition, and is specially suitable for structure assembly in a production line of the narrow frame of the mobile phone.

Owner:NANTONG GAOMENG NEW MATERIAL

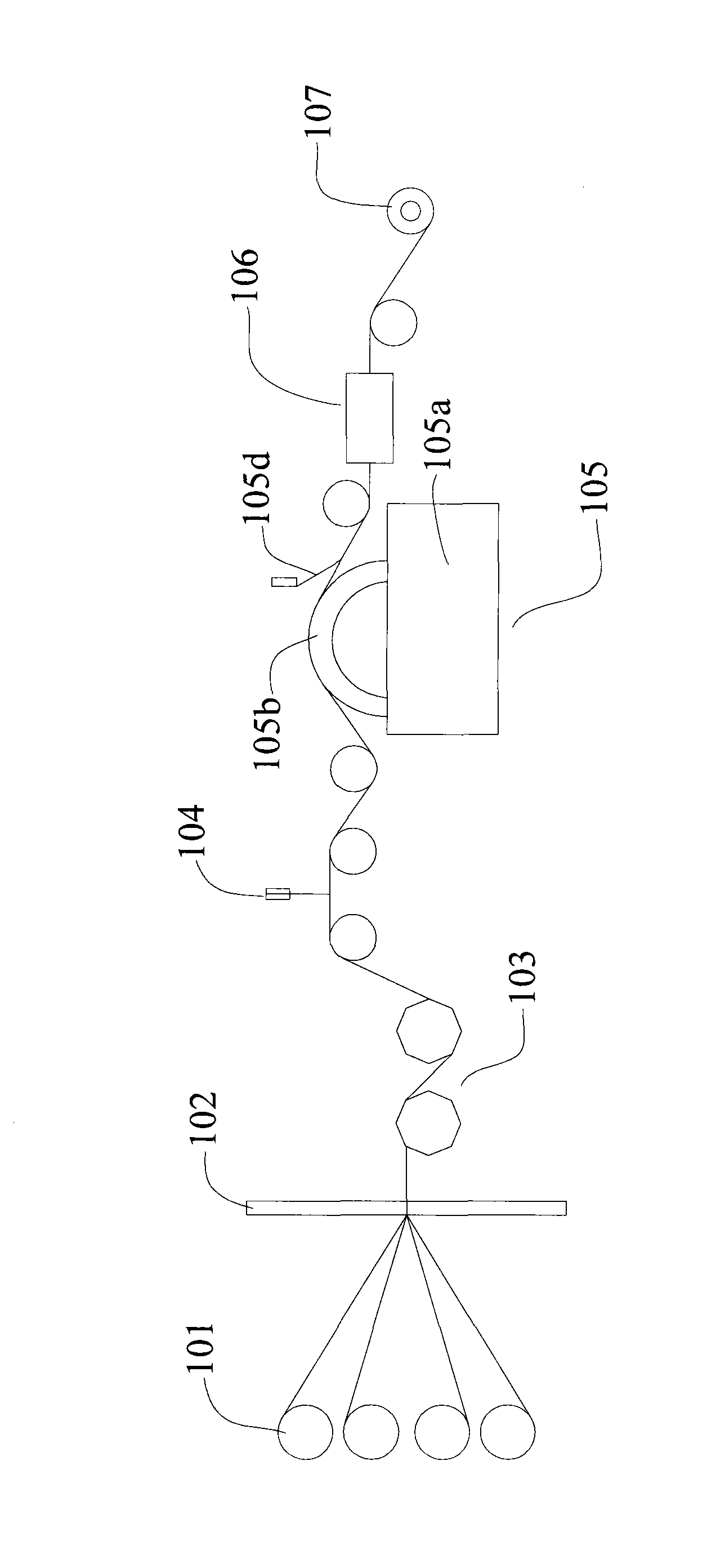

In-situ polymerization composite surface sizing system and surface sizing craft for needle punching non-woven fabrics

ActiveCN103111404AMeet quality requirementsReduce viscosityFibre treatmentPretreated surfacesIn situ polymerizationSynthetic Polymeric Macromolecules

The invention discloses an in-situ polymerization composite surface sizing system and a surface sizing craft for needle punching non-woven fabrics, namely a chemical process that organic monomers are polymerized to form high polymer materials and a flame planting composite process that non-woven fabrics are soaked by the organic monomers are combined in the same production line in a situ mode. The surface sizing system comprises a glue producing device, a glue seeping / flame planting sizing device and a drying device. The surface sizing craft achieved through the surface sizing system comprises the steps of (1) adding an emulsifying agent, a buffer agent and some water inside a burdening pot, stirring, evenly mixing the emulsifying agent, the buffer agent and the water, adding butyl mehtacrylate and methyl metacrylate, stirring, adding an initiating agent, stirring for an hour in a temperature range of 60 to 70 DEG C to form prepolymer, adding remaining water, stirring, evenly mixing the remaining water and the prepolymer, obtaining water miscible liquid, cooling the water miscible liquid to room temperature, introducing the water miscible liquid to a mixing pot, adding a polysaccharide compound into the mixing pot, mixing the polysaccharide compound with the water miscible liquid in a continuously stirred mode, forming suspension liquid; (2) treating the needle punching non-woven fabrics in a sizing mode through the glue seeping / flame planting sizing device; and (3) drying the needle punching non-woven fabrics and finalizing the design.

Owner:SHANDONG UNIV

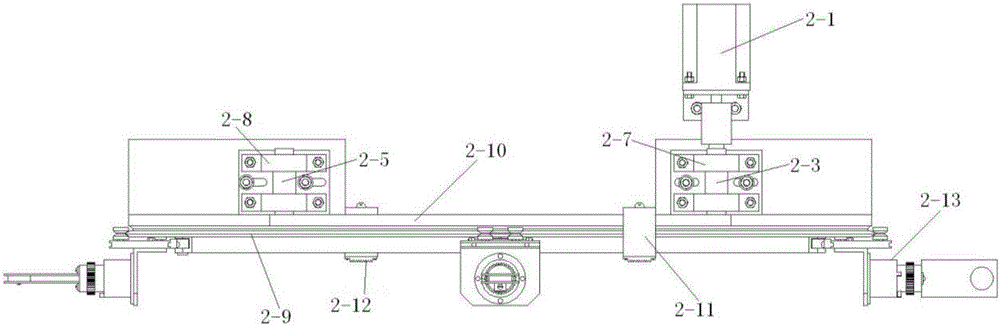

Gum dipping device and method for testing of tensile property of carbon fiber multifilaments

InactiveCN105806683AGlue evenlyThe amount of gluing is controllablePreparing sample for investigationFiberYarn

The invention provides a gum dipping device and method for testing of the tensile property of carbon fiber multifilaments.The device comprises a test box, an unwinding mechanism for fixing a fiber spindle, a porcelain eye, a drive roller, a yarn unfolding assembly, a gum dipping tank, a gum extruding assembly and a yarn collecting frame.The test box is fully closed.The unwinding mechanism, the porcelain eye, the drive roller, the yarn unfolding assembly, the gum dipping tank, the gum extruding assembly and the yarn collecting frame are all located in the test box, the drive roller is arranged at the inlet end of the gum dipping tank, and the gum extruding assembly is arranged at the outlet end of the gum dipping tank.According to the gum dipping device and method for testing of the tensile property of the carbon fiber multifilaments, carbon fibers are gummed evenly, the gumming amount is controllable, harm to the body of an operator can be relieved, and environment friendliness and safe operation are promoted.

Owner:HENGSHEN

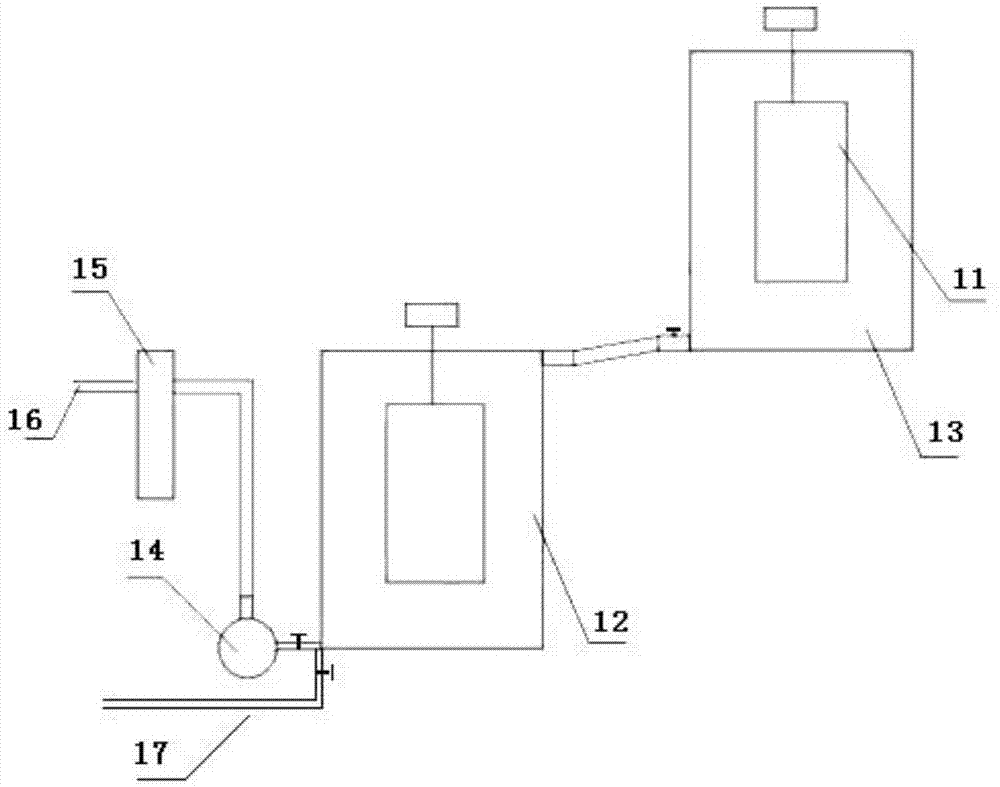

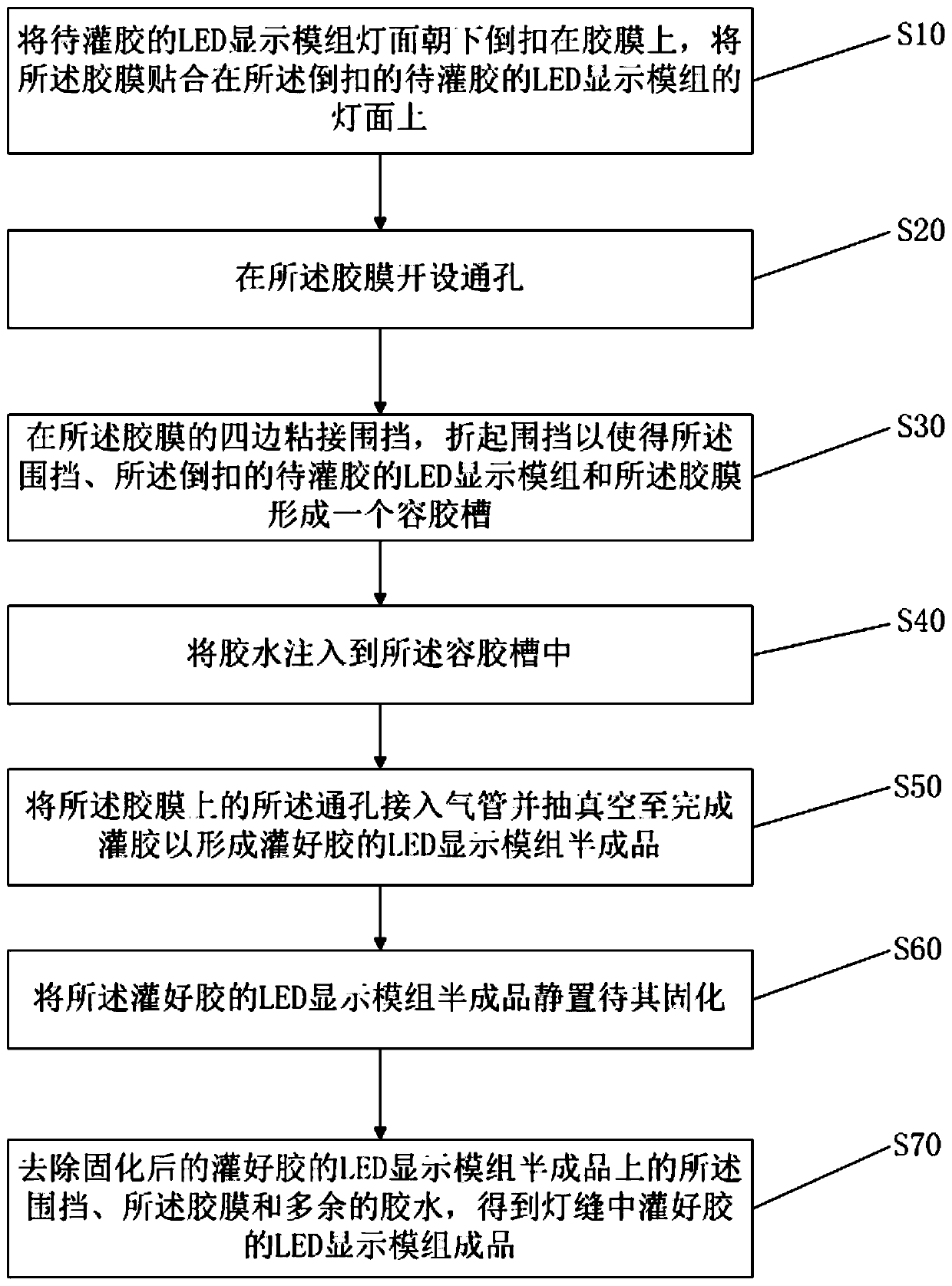

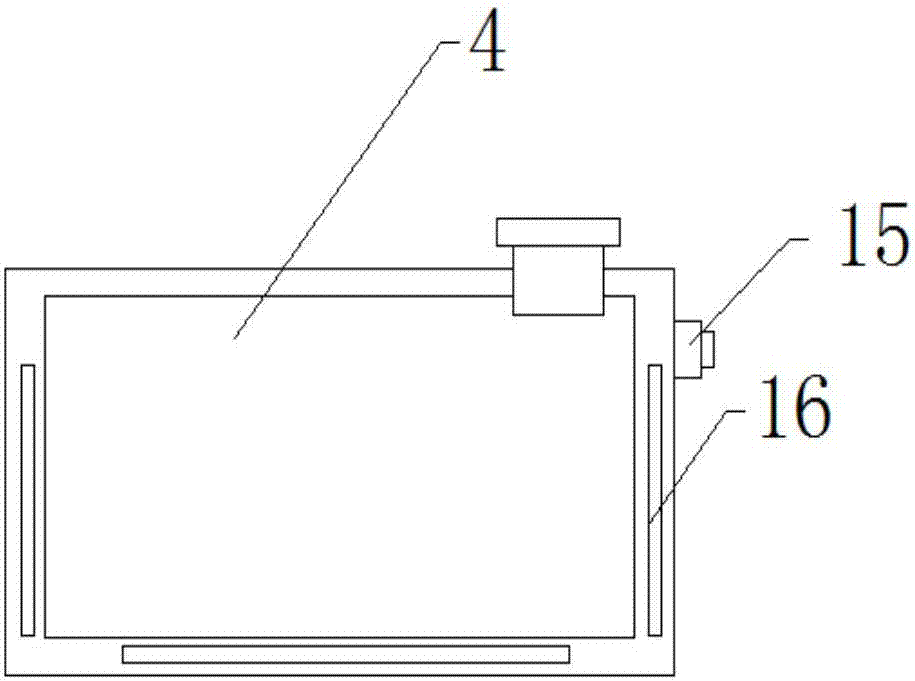

LED display module lamp seam glue pouring process

InactiveCN110956902AImprove liquidityGlue thickness is thickIdentification meansLED displayAdhesive glue

The invention discloses an LED display module lamp seam glue pouring process, and belongs to the technical field of LED display screens. The glue pouring process comprises the steps that the lamp faceof the LED display module to be subjected to glue pouring is downwards buckled on a glue film in an inverted mode, and the glue film is attached to the lamp face of the LED display module to be subjected to glue pouring in an inverted mode; a through hole is formed in the adhesive film; fences are adhered to the four sides of the adhesive film, and the fences are folded to enable the fences, theinverted LED display module to be filled with the adhesive and the adhesive film to form an adhesive containing groove; glue is injected into the glue containing groove; connecting an air pipe into the through hole and vacuumizing until glue filling is completed to form a semi-finished product of the LED display module filled with glue; and the LED display module semi-finished product filled withthe glue is stood until the LED display module semi-finished product is cured. According to the whole process, only existing simple equipment needs to be adopted, the fluidity of glue in the lamp seams is good, meanwhile, the LED display module finished product with the lamp seams filled with the glue and thicker and more uniform glue filling thickness can be obtained with lower cost and higher efficiency, and the front face of the LED display module has the anti-collision, damp-proof and waterproof capacity.

Owner:UNILUMIN GRP

Glue-pouring machine

ActiveCN102921598AAvoid air gapGlue evenlyLiquid surface applicatorsCoatingsColloidCentrifugal force

The invention relates to a glue-pouring machine which comprises a glue-pouring fixing rod and a glue-pouring product fixing mechanism. A glue-pouring product is provided with a glue-pouring hole; the glue-pouring machine also comprises a rotating platform; the fixing mechanism is installed on the rotating platform and is used for fixing the glue-pouring product, so that the glue-pouring hole is aligned with a rotating shaft of the rotating platform; and the rotating platform is used for driving the glue-pouring product to carry out fixed-point rotation around the glue-pouring hole. Thus, when glue is poured, colloids poured through the glue-pouring hole diffuse towards the periphery under the action of rotating centrifugal force and are gradually accumulated and encapsulated from the edge to the center (such as an axis of rotation); and by utilizing the centrifugal force, air gaps among the colloids can be effectively avoided, so that the glue is uniformly poured. The glue-pouring machine can be widely applied to glue-pouring various products glue-poured through the hole.

Owner:SHENZHEN ZHENHUA MICROELECTRONICS

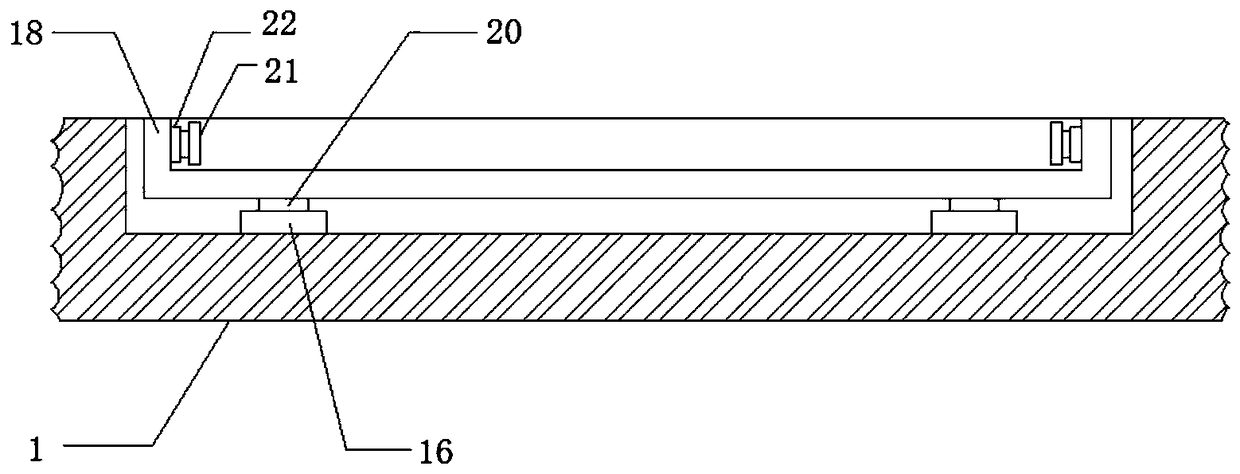

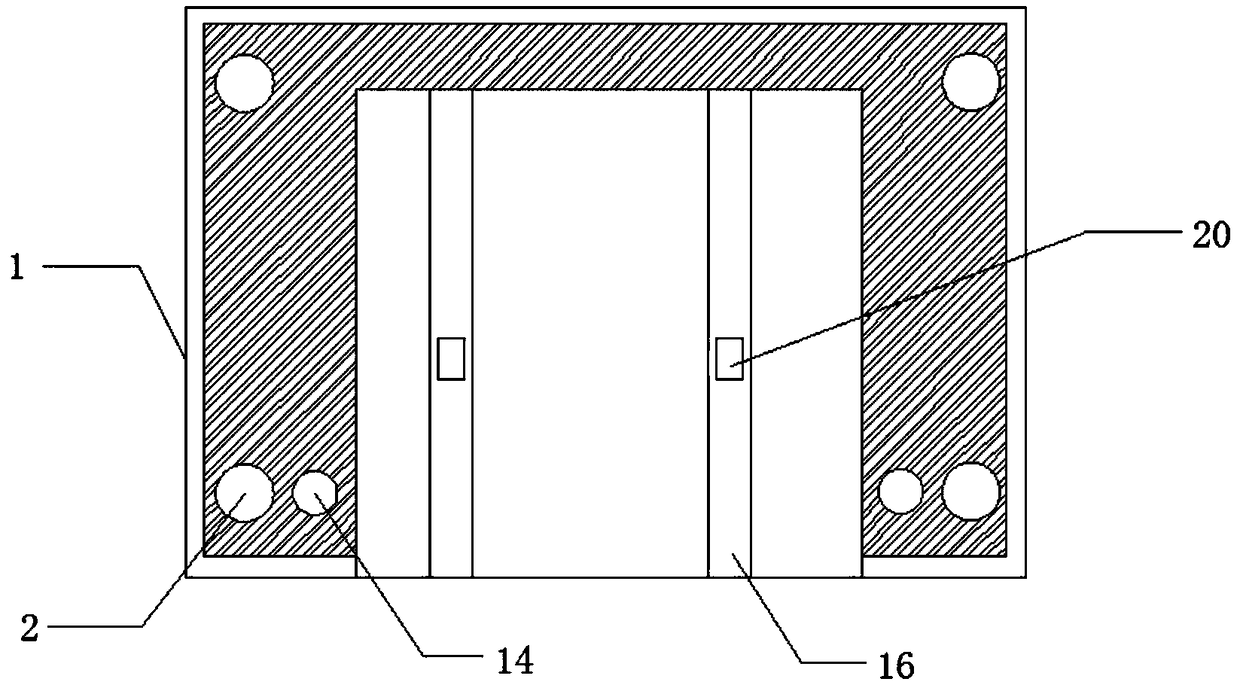

Plate glue spreading device

InactiveCN107377292AGlue evenlySpeed up air flowPretreated surfacesCleaning using toolsEngineeringHot-melt adhesive

The invention discloses a plate glue spreading device. The plate glue spreading device comprises a main frame; the top end of the main frame is provided with a glue spreading bin and a cleaning bin from left to right in sequence; a pressing roller is fixedly installed in an inner cavity of the glue spreading bin, a glue tank is fixedly welded to the position, located under the pressing roller, of the main frame, and a glue spreading roller is installed in an inner cavity of the glue tank; when the glue spreading roller is aligned to the pressing roller, a supporting rolling shaft set and a transmission rolling shaft set are installed on the positions, located on the left side and the right side of the glue tank, of the main frame in a horizontal alignment mode through brackets correspondingly, and a ventilation and heat dissipation fan parallel to the supporting rolling shaft set is fixedly installed below the supporting rolling shaft set; an upwards-inclined glue scraping plate is welded to the right side wall of the glue tank; a glue storage box is installed at the top of the glue spreading bin; and one of supporting feet at the bottom of the main frame is fixedly provided with a motor. The plate glue spreading device is easy to operate and capable of quickly spreading glue over a plate and quickly cooling the hot glue spread on the plate, so that the cooling speed of the hot glue is increased, and the working efficiency is improved.

Owner:LIANGXI HAOXING IND DESIGN OFFICE

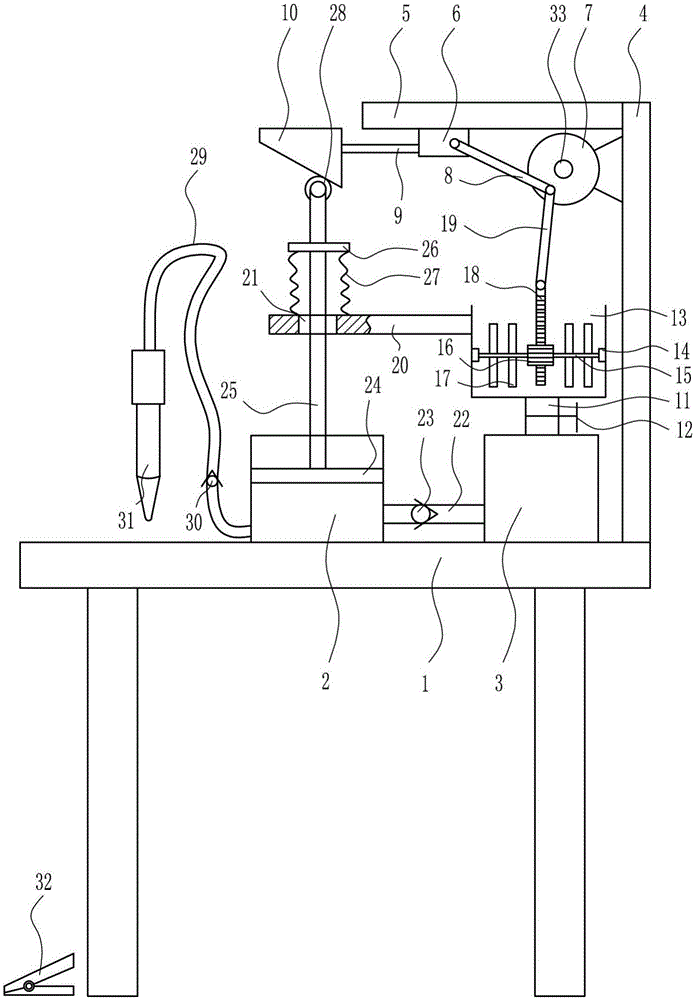

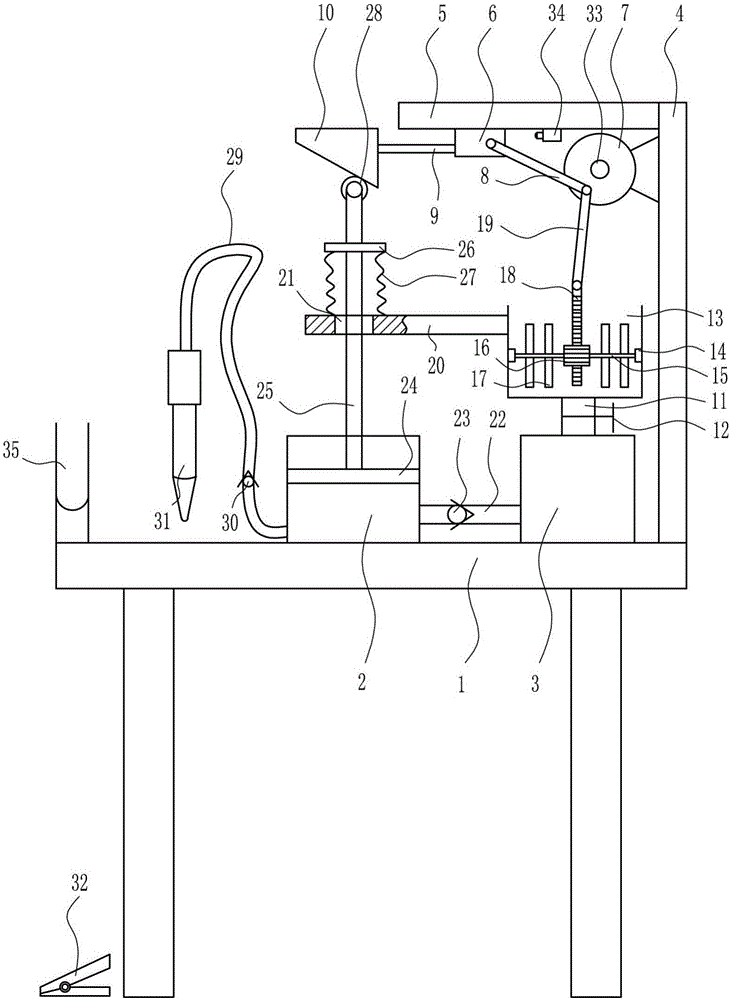

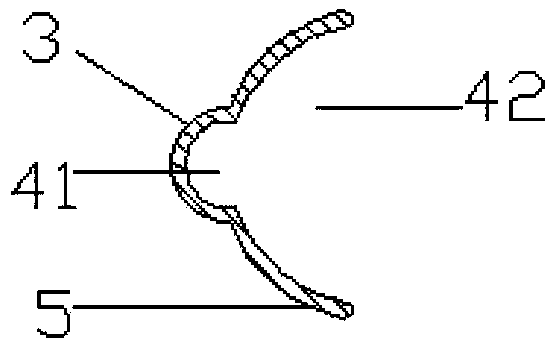

A highly-efficient sole glue applying device used in shoe factories

The invention relates to a sole glue applying device used in shoe factories, in particular to a highly-efficient sole glue applying device used in shoe factories. The highly-efficient sole glue applying device used in shoe factories has the advantages of uniform glue applying, high glue applying speed and glue saving. The highly-efficient sole glue applying device comprises a support frame, a compression cylinder, a transfer box, a support, a slide rail, a slider, a disc, a first connecting rod, a strut, a wedge-shaped block, a connecting pipe, an electronic control valve, a stirring tank, bearing bases, a rotating shaft, a gear, stirring rods, a rack, a guide rod, a liquid outlet pipe, a first check valve, a piston, a push rod, a fixing plate, a spring, a contact wheel, a hose, a glue gun, a pedal and a motor. The motor rotates to drive the stirring rods to rotate, so that glue is stirred; by using the push rod and the piston, glue enters the glue gun; the highly-efficient sole glue applying device achieves the effects of uniform glue applying, high glue applying speed and glue saving.

Owner:张浩杰

Glue gun

InactiveCN103406241AReduce wasteGlue evenlyLiquid surface applicatorsCoatingsPulp and paper industryFlange

The invention discloses a glue gun which comprises a glue nozzle, wherein a glue feeding hole is formed in the glue nozzle; a scraper blade is arranged at the head of the glue nozzle; a glue body accommodating cavity is formed in the lower end of the scraper blade; two sides of the glue body accommodating cavity extend towards the head of a nozzle body to form cambered flanges; a through hole is formed in the scraper blade; the lower end of the through hole is communicated with the glue body accommodating cavity; the upper end of the through hole is communicated with the end face of the upper end of the scraper blade; the through hole in the upper end of the scraper blade is connected with a hollow hose; the other end of the hollow hose is connected with a glue body collection device. When the glue gun is used for dispensing glue, redundant glue bodies in a slit can be scraped to another slit with a small amount of glue bodies under the action of the scraper blade, and the residual glue bodies are sucked into the glue body collection device. Therefore, the glue gun has the beneficial effects that the glue dispension is uniform, the redundant glue bodies can be recycled, the waste of glue bodies is effectively reduced, and the cost is reduced.

Owner:ZHEJIANG HAOQING AUTOMOBILE MFG CO LTD +1

Acrylate structural adhesive being resistant against solvent scrubbing

InactiveCN107603497AGlue evenlyMix rubber evenlyNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyAdhesive

The invention relates to an acrylate structural adhesive being resistant against solvent scrubbing, which includes a component A and a component B; the component A is composed of: an acrylate monomer,methacrylic acid, toughening rubber, toughening filler, an accelerant, a stabilizer and a coupling agent; the component B is composed of: an oxidizing agent, epoxy resin, a plasticizer, filler and pigments. The component A and the component B are uniformly stirred according to the volume ratio of 10:1 to produce the acrylate structural adhesive. The acrylate structural adhesive is resistant against solvent scrubbing, is high in thixotropy and is good in infiltrability on an adhesion interface. In addition, after solidification, an adhesive layer is good in toughness and is high in adhesion force between anodised alumina, Al / Mg alloy, an electrophoresis ED layer, ABS / PC and the like plastic alloy, etc.

Owner:YANTAI DARBOND TECH

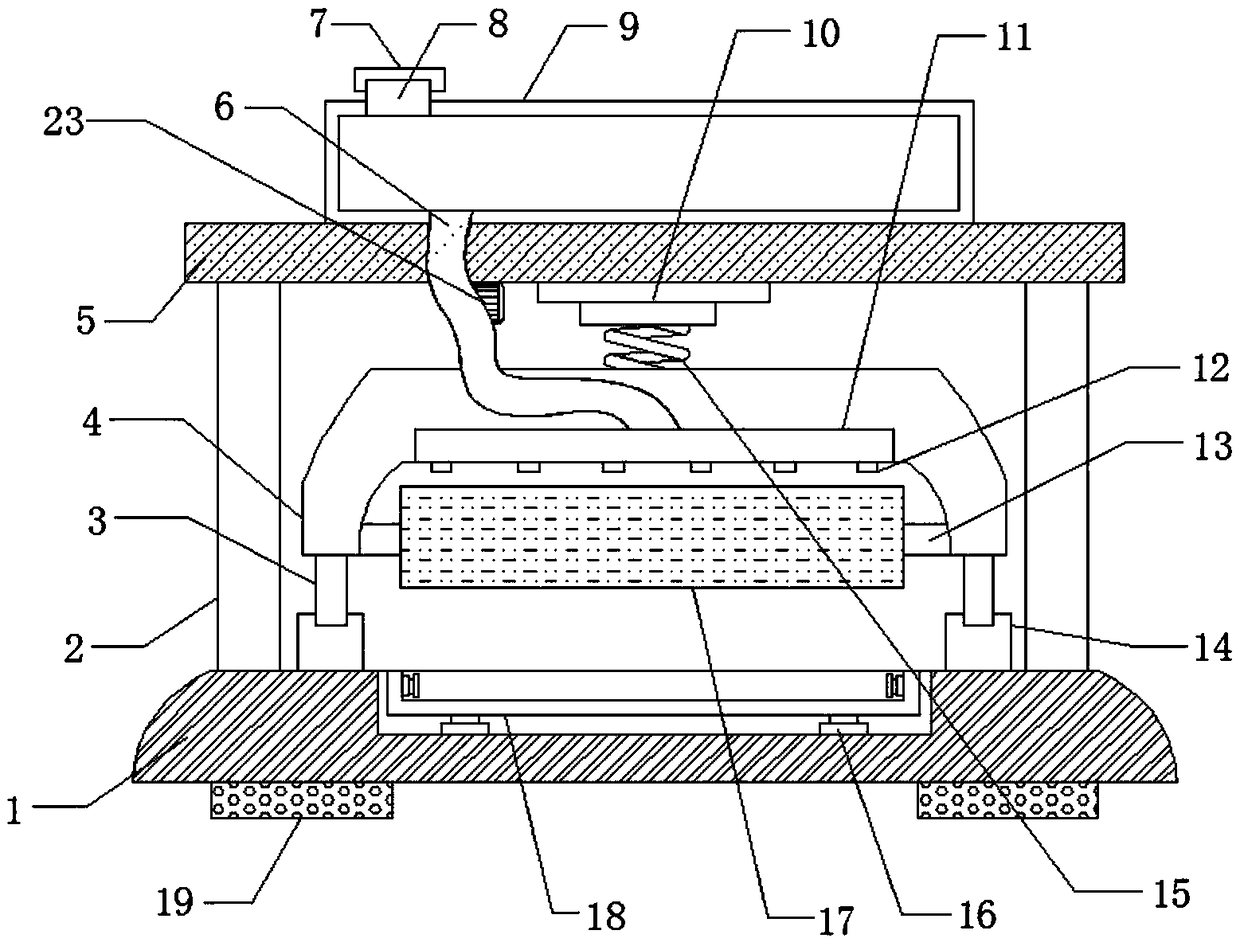

Glue pressing device for wood furniture processing

InactiveCN108943204AAvoid affecting the glue effectEasy to fixWood veneer joiningAdhesive application devicesHydraulic cylinderStable fixation

The invention discloses a glue pressing device for wood furniture processing. The glue pressing device comprises a supporting base, the outer walls of top four corners of the supporting base are all connected with vertically-arranged supporting columns through bolts, the top outer walls of the four supporting columns are all connected with one same horizontally-arranged supporting top plate through the bolts, the top central outer wall of the supporting top plate is connected with a glue storage box through the bolts, the outer wall of one side of the bottom of the glue storage box is connected with a glue guide flexible pipe through the bolts, and the bottom central outer wall of the supporting top plate is connected with a vertically-arranged hydraulic cylinder through the bolts. According to the glue pressing device for the wood furniture processing provided by the invention, by means of the manners that electric stretching and contracting rods and fixing clamping plates are provided and the fixing clamping plates are driven to move by the electric stretching and contracting rods, wood furniture plate materials of different sizes can be fixed, the quite stable fixing effect is achieved, and the situation that the plate materials are loosened to affect the glue pressing effect in later glue pressing is avoided.

Owner:湖北乔木森家具有限公司

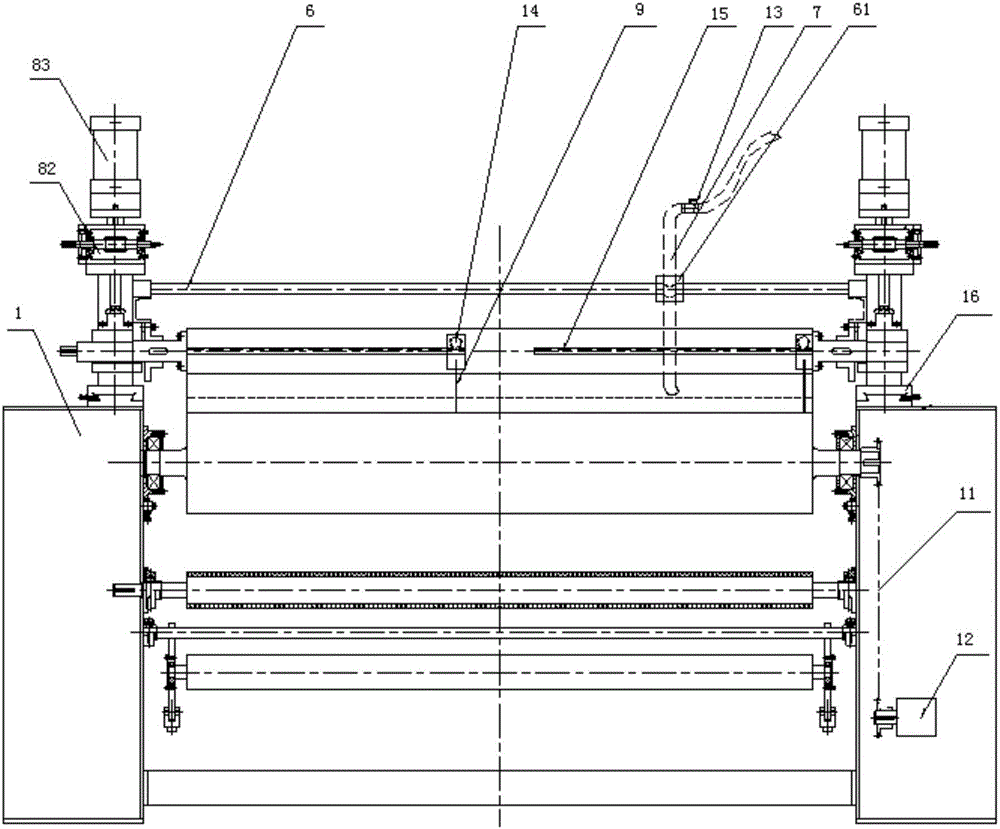

Fabric compounding apparatus

ActiveCN110802909AUnwinding is smooth and orderlyEfficient and smooth coatingSpraying apparatusLaminationElectric machineryMechanical equipment

The invention discloses a fabric compounding apparatus, and belongs to the field of textile processing machinery and equipment. In the apparatus, the middle of an unwinding turntable is horizontally and fixedly provided with an unwinding bearing rod, the terminal end of a pressure disc rotation rod at the upper side of the unwinding turntable is vertically and rotationally connected with a dampingrotation wheel, a pressure rod slide block is arranged on a rotation guide rod in a sliding manner, a cloth guide bearing plate is tilted downwards and fixedly arranged on a composite support frame at the lower side of the unwinding bearing rod, a feeding roller is horizontally arranged at the upper side of the cloth guide bearing plate, a plurality of gluing nozzles are arranged at the lower side of a glue spraying guide pipe, an upper material guide roller and a lower material guide roller are arranged in a compression fit manner, an upper pressing support frame and a lower pressing supportframe are arranged on the composite support frame in order from top to bottom, and a cloth pulling motor and a cloth pulling roller are connected by a cloth pulling chain in a transmission manner. The structure design of the apparatus is reasonable, the continuous and smooth compounding of the fabric can be performed rapidly and efficiently during the material transfer process, the efficiency andquality of fabric compounding are improved, the automation degree is high, and the needs of processing and use are met.

Owner:TONGXIANG YUESHUN WRAP KNITTING

Sponge grinding block production line and method

ActiveCN106695584AIncrease productivityReduce labor costsAbrasion apparatusElectroplatingMethods of production

The invention provides a sponge grinding block production line. The sponge grinding block production line comprises an uncoiling device, a surface treatment device, a sand embedding device, a drying device and a sponge combination device which are sequentially arranged in the thin film operation direction. The invention further provides a sponge grinding block production method. The method adopts the above devices and includes the following steps of uncoiling, surface treatment, static sand embedding, drying and sponge combination. Continuous and automatic machining can be sequentially finished on the same production line, the occupied space is small, a specially-assigned person on duty is not needed in all the processes, therefore, the labor force is saved, the labor intensity is relieved, and the production efficiency is improved; a thin film is subjected to surface treatment through the production method, the surface of the thin film is rough, the adsorption capacity can be improved, and gluing is more uniform; and by means of a metal layer electroplated on the surface of the thin film, the strength of the thin film is improved, gluing and sand embedding are facilitated, and the product quality is further guaranteed.

Owner:湖北重泰研磨工具有限公司

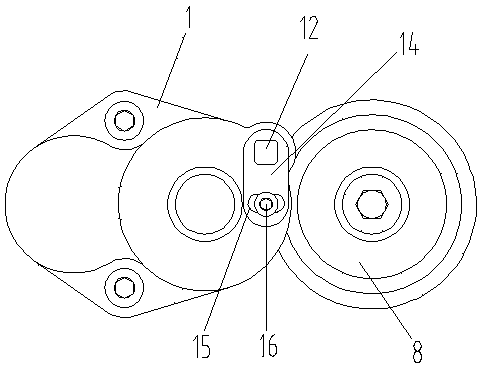

Gluing device with uniform glue feeding

InactiveCN103418524AEven glue supplyGlue evenlyLiquid surface applicatorsCoatingsPulp and paper industry

The invention discloses a gluing device with uniform glue feeding, which comprises a glue adjusting seat and a glue spreader seat, wherein a glue inlet cavity and a glue suction cavity are arranged in the glue adjusting seat, and are communicated with each other through a glue inlet in the bottom side of the glue inlet cavity; a glue suction roller is arranged in the glue suction cavity; a gluing shaft is arranged on the glue spreader seat; a glue spreader is arranged on the gluing shaft; a group of meshed gears are arranged at the outer ends of the glue suction roller and the glue spreader; a glue guiding sleeve is arranged at the end, opposite to the gears, of the glue suction roller; staggered reticulate patterns are arranged on the circumferential surface of the glue guiding sleeve; a spiral groove is formed in the inner wall, corresponding to the glue guiding sleeve, of the glue suction cavity; a glue suction sleeve is arranged in the middle of the glue suction roller; a gluing notch is formed in the side wall of the glue suction cavity in a position corresponding to the glue suction sleeve; the circumferential surface of the glue suction sleeve is tangent to that of the glue spreader in the position of the gluing notch. Therefore, the gluing device has the advantages of uniform glue feeding and discharging, so as to ensure uniform gluing.

Owner:NINGBO POLYTECHNIC

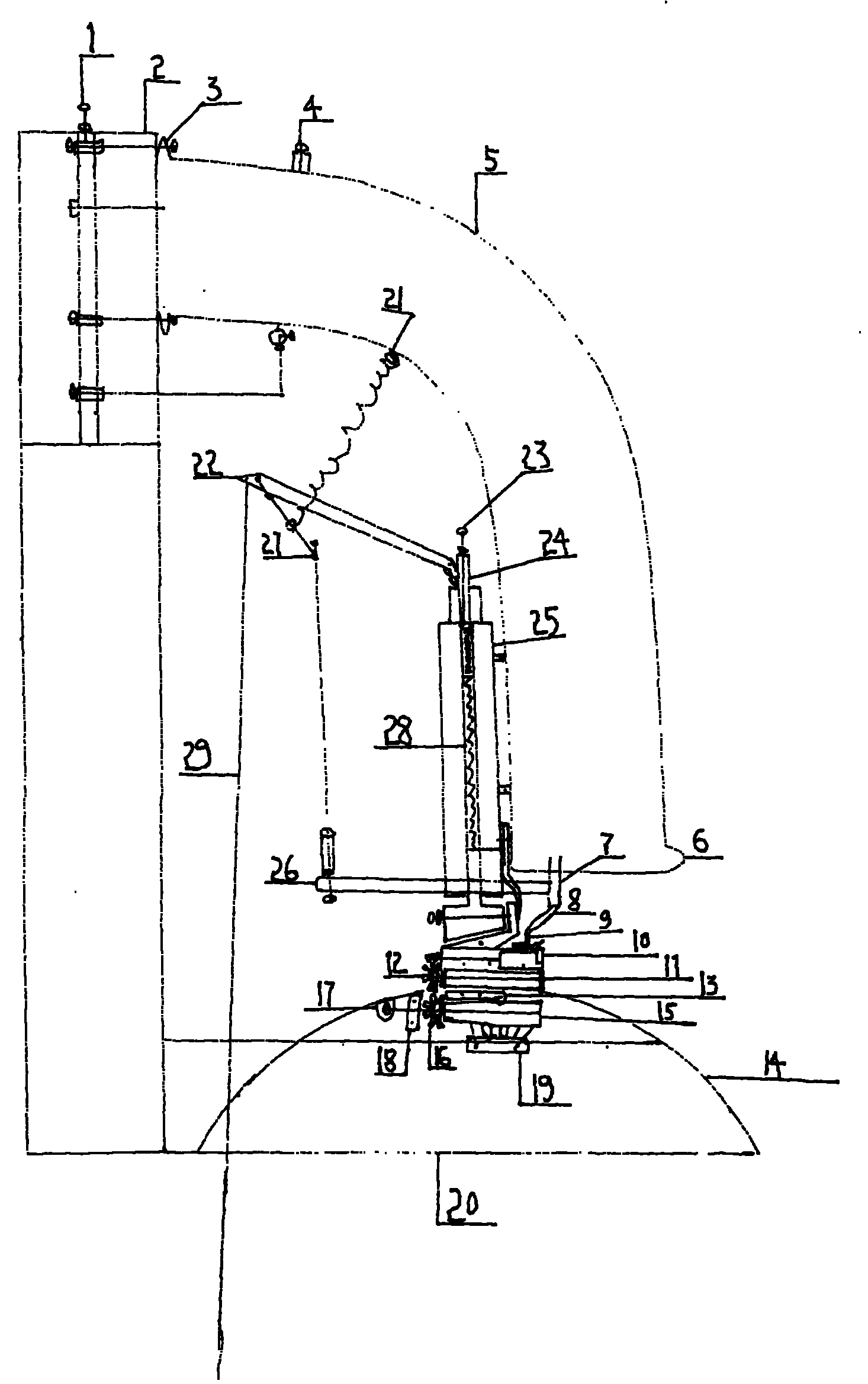

Vertical form inculcating technology of lathy hard surface component of bamboo compound material windmill leaf blade

InactiveCN101229689ASolve the problem of indoctrinationGlue evenlyDomestic articlesEngineeringShell element

The invention relates to a process for erectly instilling a slender shell element in a blade of a wind turbine with bamboo compound material, which includes a cleaning die, an assembling die, a fixed die, wrapped glass cloth, wrapped demoulding cloth, wrapped diversion net, a winding spiral pipe, instilling substrate glue material, hardener and demoulding. The erect instilling method solves the instilling problems of one-time forming of the slender shell element in the blade of the wind turbine; at the same time, by using gravity, the glue is uniformly pasted, thus, avoiding glue accumulation caused by horizontal placement of the instillation, deflection due to male die as well as difficult cloth wrapping and avoids the glue accumulation; the produces has relatively high coaxiality; besides, the inner surface of the products has high precision and the invention is in particular applied to the inner surface of the products with high requirements.

Owner:无锡天奇竹风科技有限公司

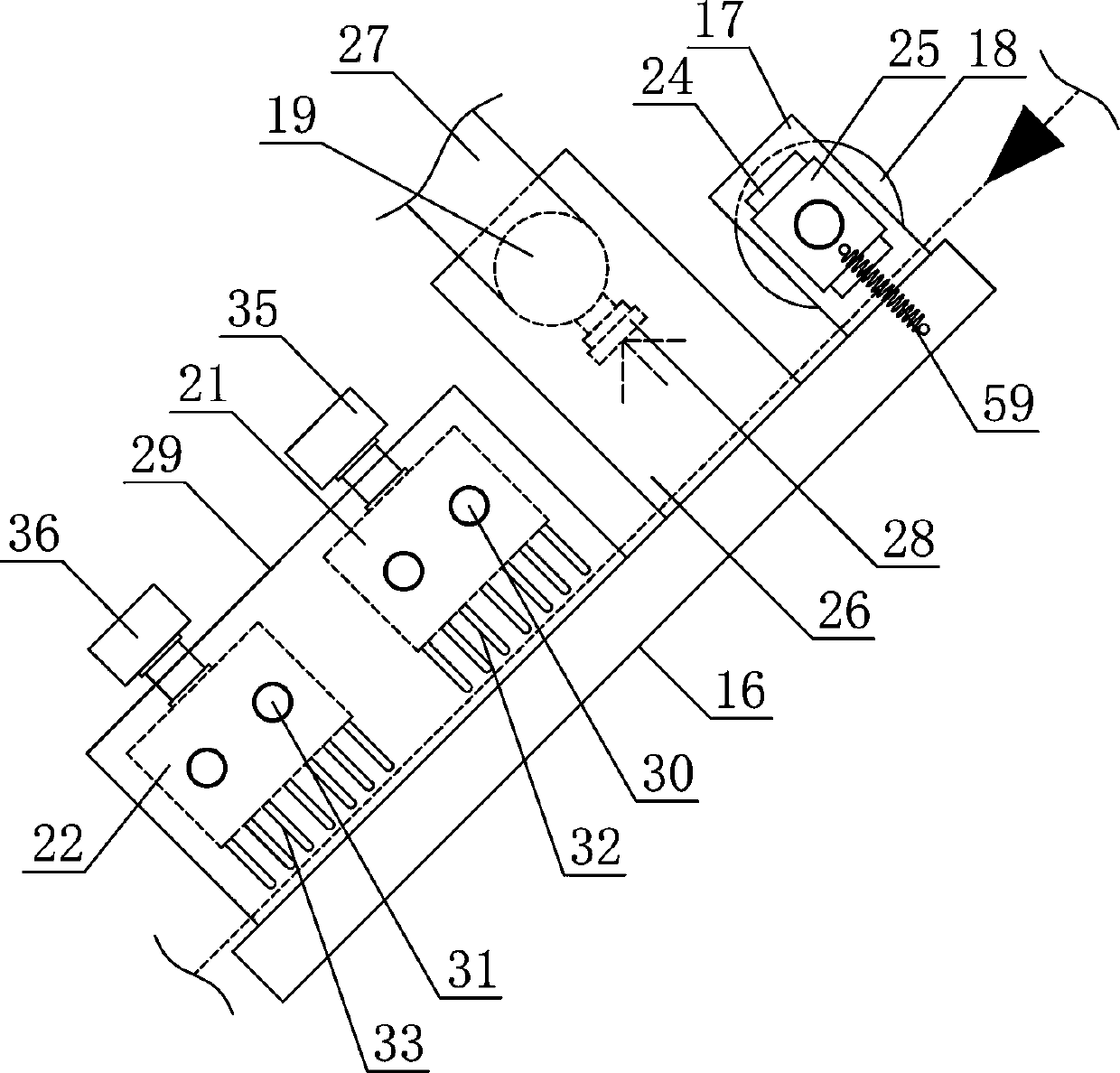

Automatic loading machine of strain gauge of terminals

ActiveCN107747580ACompact structureHigh degree of automationMaterial gluingElectrical/magnetic solid deformation measurementHuman–machine interfaceEngineering

The present invention relates to an automatic loading machine of strain gauges of terminals. The automatic loading machine comprises a main body rack and a rack base plate. An upper end of the rack base plate is provided with a terminal feeding device. The tail end of the terminal feeding device is butted with a terminal conveying slideway device. One side of the terminal conveying slideway deviceis successively provided with a dispensing device, a strain gauge blanking device and a terminal fixing device from left to right, and the other side of the terminal conveying slideway device is successively provided with a strain gauge conveying device, a pressing device and a human-computer interface. The dispensing device is connected to a strain gauge feeding device. The strain gauge conveying device is positioned between the dispensing device and the strain gauge blanking device. The terminals are conveyed by the terminal conveying slideway device, the strain gauges are clamped by a material receiving head of a front and back clamping mechanism and moved below a dispensing head to achieve dispensing, the strain gauges are conveyed below the strain gauge blanking device by a left andright moving mechanism, a blanking head of the strain gauge blanking device descends and passes through inner rings of the strain gauges, the material receiving head is withdrawn, the strain gauges are lowered on the terminals along the blanking head, the whole structure is compact, and the degree of automation is high.

Owner:安徽明亮面业股份有限公司

Book gluing system

The invention discloses a book gluing system, and aims to overcome the defects of low efficiency and unsatisfactory gluing effect in the existing book gluing system. In order to realize the above goals, the invention discloses a book gluing system. The system comprises a book conveying transmission mechanism, an automatic gluing mechanism, a drying mechanism and a compacting mechanism, wherein the book conveying transmission mechanism is connected with the compacting mechanism; the automatic gluing mechanism and the drying mechanism are arranged on the book conveying transmission mechanism; the automatic gluing mechanism comprises gluing rollers and brushes; and the gluing rollers are connected with the brushes in a synchronous rotation mode. The book gluing system ensures stable transmission, no press mark, even gluing, adjustable gluing thickness, favorable drying effect and flat and compact book core in the book gluing process.

Owner:东莞城市装钉器材有限公司

Spunlace non-woven fabric composite filter material and manufacturing method thereof

ActiveCN101804274AEasy to fold and shapeEasy to glueSynthetic resin layered productsLaminationWoven fabric compositeComposite filter

The invention discloses a spunlace non-woven fabric composite filter material and a manufacturing method thereof. The manufacturing method of the composite filter material comprises the following steps that: spunlace non-woven fabric which is obtained after the starching treatment is unwound, the surface of the spunlace non-woven fabric is coated, the coat is of oil-based polyurethane with the solid content of 30 to 75 percent, polyfluortetraethylene film is smoothed by a hot ironing roller after being unwound, the spunlace non-woven fabric and the polyfluortetraethylene film are compounded through the compression of pressing rolls, the pressure of the pressing roll is 3 to 10 kg, at the same time the composite material is heated and dried, the drying temperature is 70 to 170 DEG C, and the composite material is rolled to form the finished product after the compounding. Finally the filter material which is formed by compounding the spunlace non-woven fabric and the polyfluortetraethylene film is obtained, the base weight of the composite product is 102 to 258 g / m2, the filter resistant force is 40 to 280 Pa, the filter efficiency is 85 to 99.995 percent, and the stiffness is 1500 to 4500 mg. The filter material has low filter resistant force and high filter efficiency, is easy to fold and for, and can be made into different filters with different shapes.

Owner:杭州路先非织造股份有限公司

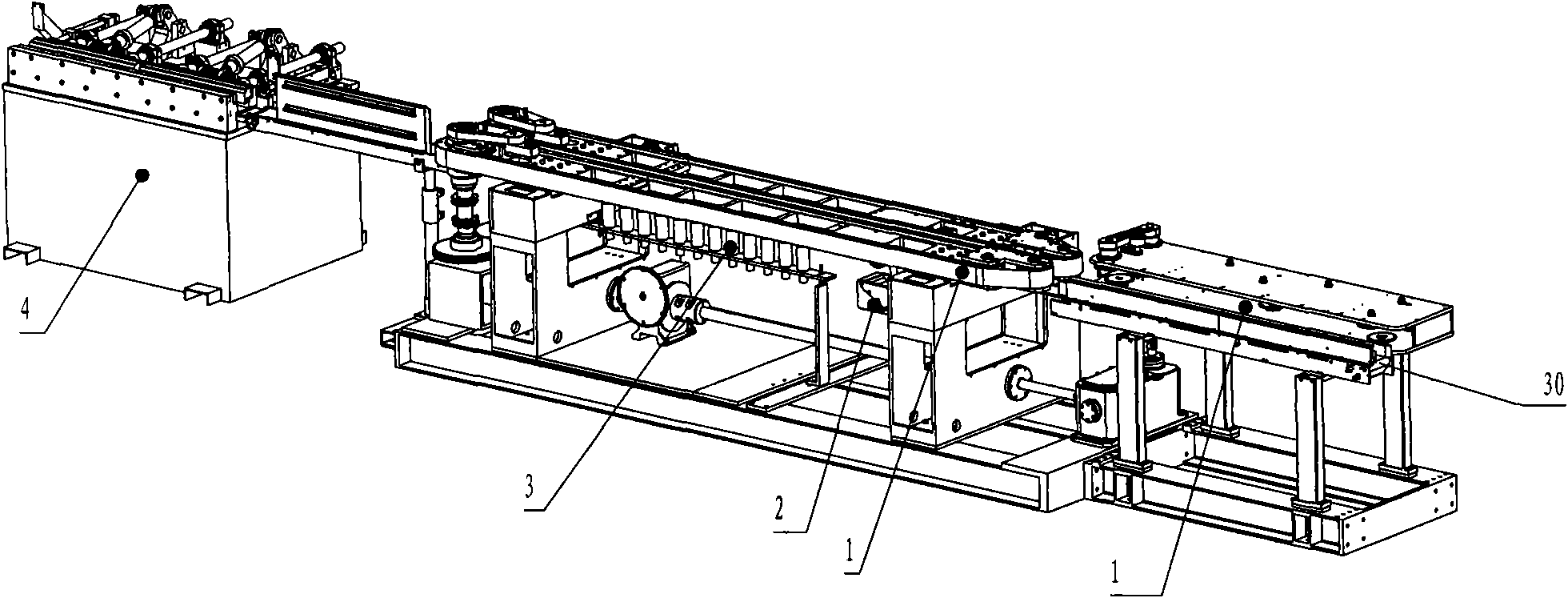

Production line for polyethylene fiber single-oriented presoaked belts

The invention discloses a production line for polyethylene fiber single-oriented presoaked belts, which orderly comprises a yarn creel used for supporting spindles, a static electricity generator, a static electricity eliminator, a glue applicator and a drying apparatus, wherein the static electricity generator comprises rubbing bodies which rub fibers to make the fibers take static electricity; the glue applicator comprises a glue applying groove, and an applicator roll arranged on the glue applying groove; and the outer surface of the applicator roll is provided with a plurality of grooves. The production line for the polyethylene fiber single-oriented presoaked belts is suitable for continuously preparing the polyethylene fiber single-oriented presoaked belts. The applicator roll of which the surface is provided with glue storage grooves can apply glue to two sides of the presoaked belts simultaneously so as to improve the work efficiency and optimize the preparation process.

Owner:杨珍芬

Automatic gluing machine

The invention discloses an automatic gluing machine. The automatic gluing machine includes a frame, a transmission device and a gluing device. The frame includes a chassis (1) located on both sides of the transmission device. The gluing device is supported, and the box is used to fix the transmission device; the transmission device includes an axially parallel adjustment roller (2), a guide roller (3), and a gluing bottom roller (4); the gluing device includes a rodless cylinder (6 ), the rubber hose (7), the scraper (8) on the cylinder slider (61), and the rubber baffle (9) fixed on the front of the scraper (8). The automatic gluing machine of the present invention has uniform and stable gluing, reduces labor in the production line, and greatly improves production efficiency and product qualified rate.

Owner:沈阳东铄电材有限公司

Composite water-based emulsion sizing agent for carbon fibers, and preparation method for sizing agent

The invention discloses a composite water-based emulsion sizing agent for carbon fibers, and a preparation method for the sizing agent. The composite water-based emulsion sizing agent is prepared from water-based modified epoxy resin emulsion, thermoplastic resin and a toughening additive according to a ratio. The prepared water-based emulsion sizing agent is excellent in compatibility, high in adsorption and carbon fiber wettability, and long in storage time; after sizing, the carbon fibers are uniform in sizing amount, and stable in gum content, fuzziness, ductility, hardness, width coefficient and friction coefficient; compared with a single sizing agent, the interlaminar shear strength of a sample strip adopting the sizing agent is improved by 10%, and the fabric performance of both wet method prepreg cloth and woven cloth by use of the sizing agent is excellent.

Owner:ZHONGFU SHENYING CARBON FIBER

Method for improving gluing uniformity of heavy bamboo and improving bonding strength

InactiveCN102528860AGlue evenlyImprove and increase bond strengthLamination ancillary operationsLaminationFiberPhenolic aldehyde

The invention discloses a method for improving gluing uniformity of heavy bamboo and improving bonding strength. The method comprises the following steps of: designing a bamboo bunch extrusion kneading machine; drying bamboo bunches: artificially or naturally drying the processed bamboo filament bunches; gluing the bamboo filament bunches: binding the bamboo filament bunches, completely soaking the bamboo filament bunches, then taking the bamboo filament bunches out immediately, airing the glue for 30 seconds, conveying the bamboo filament bunches to the bamboo bunch extrusion kneading machine, extruding so that thick bamboo filaments in the bamboo bunches crack, gluing the cracked part at the same time, and recycling the extruded phenolic aldehyde glue; performing secondary drying on the extruded and kneaded bamboo bunches; spreading: spreading the secondary dried bamboo bunches to form blanks of certain specification in the fiber direction and the width direction; and forming: conveying the spread bamboo bunches to a hot press for hot pressing and curing forming, or conveying the bamboo bunches to a die, locking the die in a cold press and then conveying the bamboo bunches to a forming chamber for heating and curing forming, and thus obtaining heavy bamboo square boards or boards. By the method, the aims of improving the gluing uniformity of the heavy bamboo and improving the bonding strength of the heavy bamboo are fulfilled.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Gluing device

InactiveCN102500517AGuarantee the right amountGlue evenlyLiquid surface applicatorsCoatingsEngineeringPulp and paper industry

The invention provides a gluing device. The gluing device comprises an anilox roller, a gluing roller and a glue disc, wherein the anilox roller is immersed into the glue disc and driven by a motor; the gluing roller is positioned above the anilox roller and is in linear contact with the anilox roller; the gluing roller is arranged in the middle of a moveable rod; one end of the moveable rod is hinged with a frame and the other end of the moveable rod is connected with a piston rod of an air cylinder; and a pressure sensor is arranged on the air cylinder. According to the gluing device, the air cylinder is used for adjusting pressure of the gluing roller, and the sensor is used for detecting the pressure, so that pressure at the two ends is balanced, and proper gluing quantity and gluing uniformity are guaranteed.

Owner:WUXI JIANGSU WEIFENG PRINTING MACHINE

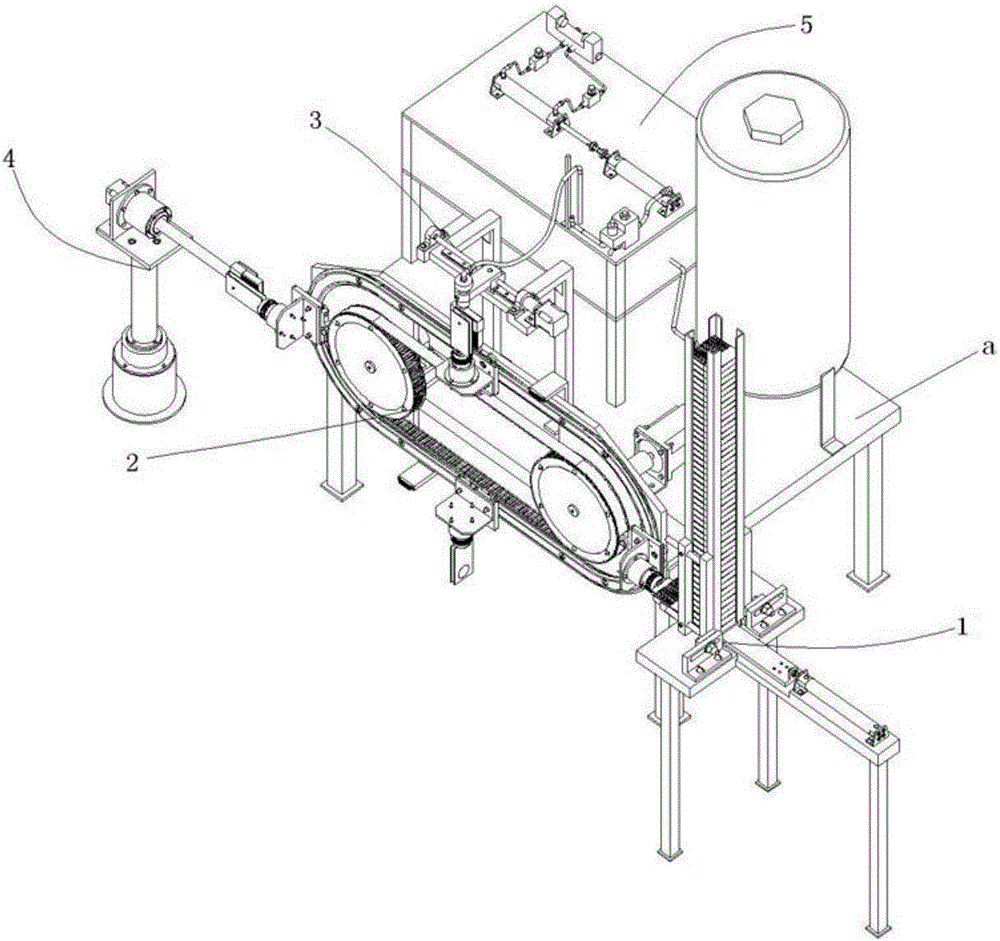

Automatic glue pouring system and method for paint brush

ActiveCN106423733AEasy to unloadImprove working environmentLiquid surface applicatorsCoatingsABSORPTION BASEControl system

The invention discloses an automatic glue pouring system and method for a paint brush. The system comprises a device fixing platform, a feed assembly, a transfer assembly, a glue pouring assembly, a discharge assembly, a pneumatic system and a control system. The feed assembly, the transfer assembly, the glue pouring assembly and the discharge assembly are connected with the pneumatic system and the control system; the feed assembly drives a push plate through a push cylinder to push a brush head in a storage tank to a material inlet of the transfer assembly, the transfer assembly drives a movable absorption base through a transmission belt to slide along a rolling guide rail, and therefore transfer and glue pouring of the brush head are achieved; the glue pouring assembly drives a glue pouring head through a stepping motor to achieve uniform glue pouring of the brush head; and receiving and discharge of the brush head are achieved through a receiving iron piece, a transverse cylinder and a longitudinal cylinder. The automatic glue pouring system and method can be suitable for glue pouring of paint brushes of various models, the automation degree is high, operation is convenient, the glue pouring efficiency and quality can be improved through the paint brush while labor is saved, and therefore the production cost is lowered.

Owner:XUZHOU NORMAL UNIVERSITY

Paperboard gluing machine

InactiveCN105499061AGlue evenlyImprove gluing effectLiquid surface applicatorsCoatingsArchitectural engineeringPaperboard

The invention discloses a paperboard gluing machine which comprises a rack. The top faces of the two sides of a table plate of the rack are fixedly provided with two vertical plates, the bottom faces of the two sides of the table plate are fixedly provided with two support plates, the two ends of a lower transmission press roll are hinged to the two support plates, the lower transmission press roll is inserted into a long through groove formed in the middle of the table plate in a sleeved mode, and the upper portion of the lower transmission press roll stretches out the top face of the table plate; the upper portions and the lower portions of the outer side walls of the vertical plates are fixedly provided with connecting plates, the two ends of an adjusting screw rod are hinged to every two connecting plates, and the upper ends of the adjusting screw rods stretch out of the connecting plates located on the upper portions and are fixedly provided with rotary plates; the middles of the vertical plates are provided with vertical adjusting through grooves, the two ends of an upper transmission press roll penetrate through the vertical adjusting through grooves and are hinged to two adjusting blocks, and the two adjusting blocks are connected to the interiors of the corresponding adjusting screw rods in a screwed mode. According to the paperboard gluing machine, synchronous lifting and falling of the upper transmission press roll and a gluing tank can be achieved, therefore, the gluing uniformity is guaranteed, and the gluing effect is improved.

Owner:福建三利达环保科技有限公司

Bicomponent dip solution for bonding polyester chord thread and rubber and preparation process of bicomponent dip solution

ActiveCN103031102AEvenly dispersedGood water solubilityPolyureas/polyurethane adhesivesEpoxy resin adhesivesEpoxyPolyester

The invention provides a bicomponent dip solution for bonding a polyester chord thread and rubber and a preparation process of the bicomponent dip solution. The dip solution is composed a component A and a component B, wherein the component A comprises the raw materials in parts by mass: 120-170 parts of diisocyanate, 40-60 parts of dihydric alcohol, 5-7 parts of trihydric alcohol, 25-30 parts of hydrophilic solvent, 80-85 parts of sealing agent, 13-15 parts of neutralizer and 300-500 parts of deionized water, and the component A is prepared through processes such as pre-polymerization, sealing, neutralization, emulsification and the like; and the component B comprises 100 parts of epoxy resin, 3 parts of modifying agent, 1 part of methanoic acid and 1 part of emulsifier, and the component B is prepared through processes such as modification, neutralization, emulsification and the like. The product is good in stability, strong in bonding power, convenient to use, simple in preparation process, easy to operate and environment-friendly. The product is mainly used for bonding the polyester chord thread and the rubber.

Owner:SICHUAN AILUN TECH

LED lamp bead encapsulation technology

InactiveCN105374921AIncreased durabilityHigh luminous intensitySemiconductor devicesEngineeringLED lamp

Owner:ANHUI FUN OPTOELECTRONICS TECH

Latexing machine for edgefolds of leather shoe upper

The invention relates to the footwear field of human necessities, in particular to a latexing machine for edgefolds of leather shoe uppers which is also used for other leather products such as hats, clothes, gloves, leather sheaths and the like. The latexing machine is composed of a flow velocity mechanism for controlling the flow velocity of glue, a flow quality mechanism for controlling the flow quality of glue and a transfer mechanism for controlling the leather shoe uppers; and the mechanisms coordinately work so as to achieve uniform gluing for the leather shoe uppers. By using the successfully trial-produced latexing machine, not only the coated glue is uniform, but also the work efficiency is increased by about five times, thereby reducing labor intensity, saving labor time and materials and preventing evaporation of the glue.

Owner:魏巧国

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com