Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1906results about How to "Moderate hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

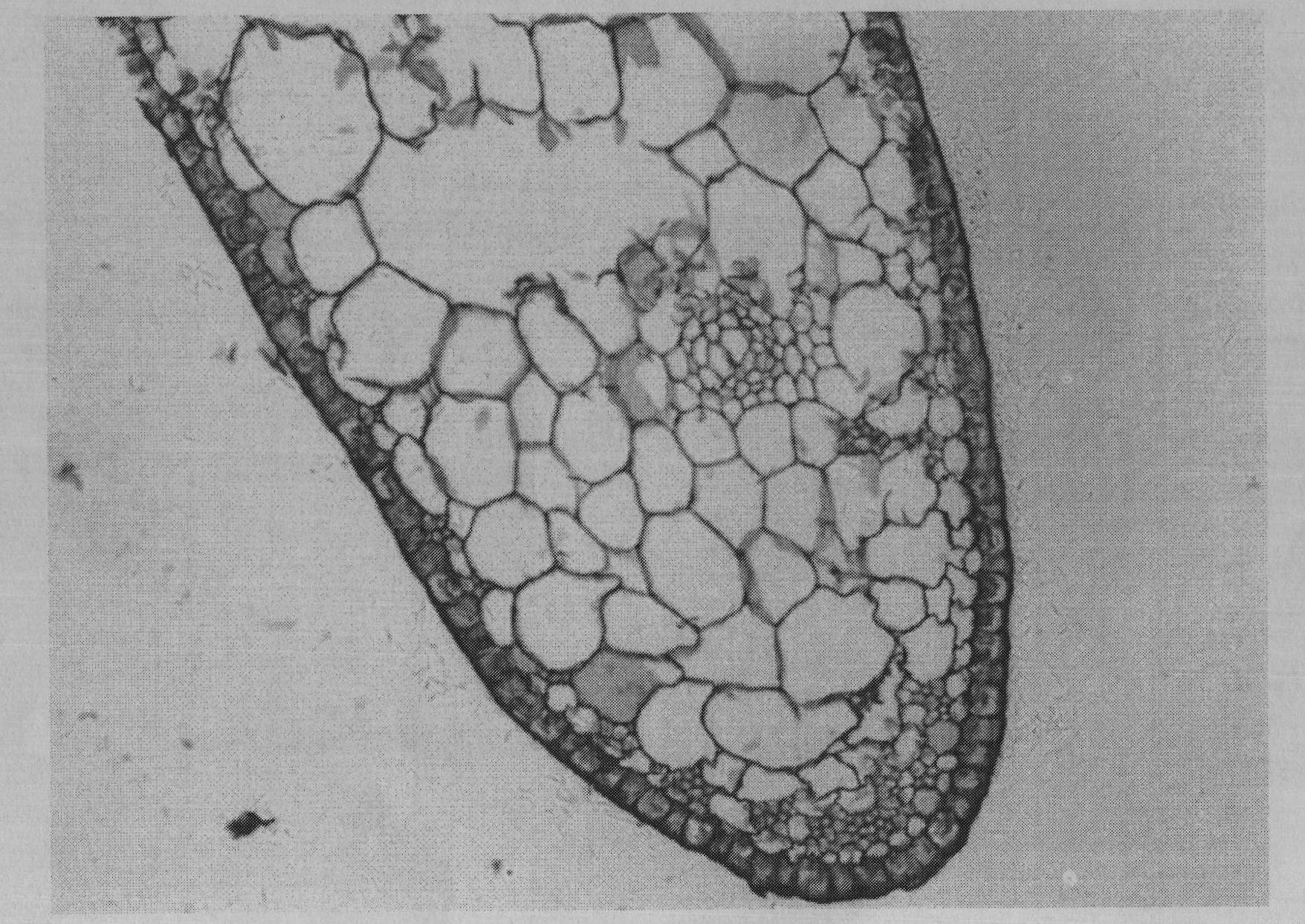

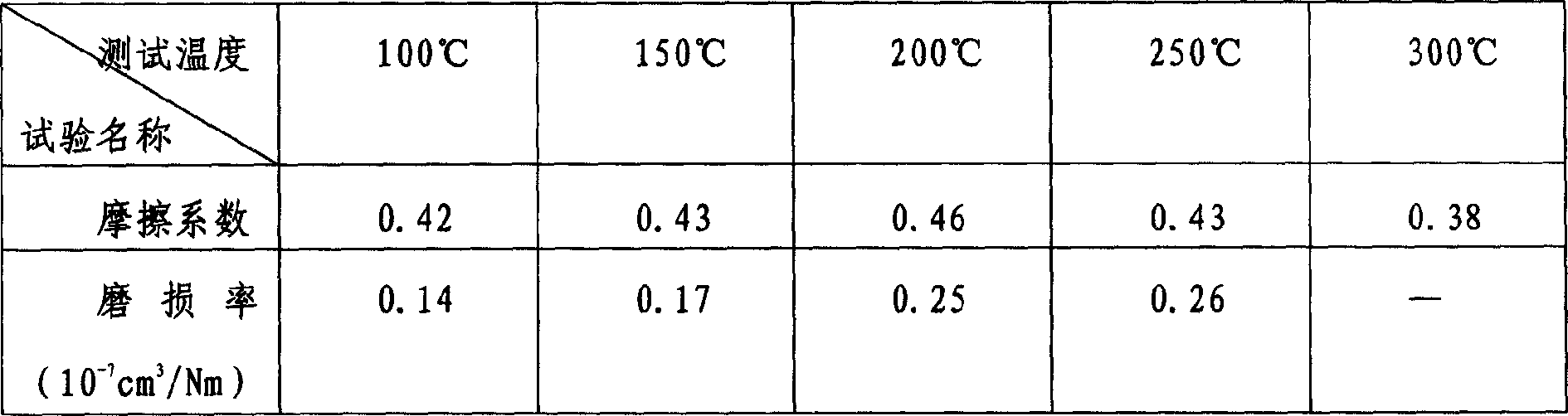

Manufacturing method of paraffin sections of zostera marina embryo

ActiveCN102116711AAvoid deformationModerate hardnessWithdrawing sample devicesPreparing sample for investigationParaffin waxEmbryo

The invention discloses a manufacturing method of paraffin sections of zostera marina embryo, comprising the following steps: (1) material drawing and fixation: zostera marina seeds are taken and the fruit skin is stripped, and after endosperm is removed, an integral zostera marina embryo is soaked in FAA (free amino acids) fixing solution and is fixed for more than 48 hours; (2) dehydration: the zostera marina embryo is taken out from the fixing solution and is soaked in alcohol for dehydration; (3) waxing and embedding: paraffin is added gradually in a vessel containing the zostera marina embryo and dimethylbenzene, and conventional paraffin embedding is carried out to obtain the wax blocks containing the zostera marina embryo; (4) slicing, spreading and drying: the wax blocks coated with the zostera marina embryo is fixed on a wheel rotation type slicing machine for carrying out continuous slicing of the paraffin, so as to obtain wax bands and enable the wax bands to be attached to an object slide; (5) dewaxing, rehydration and dyeing of hematoxylin dye solution; (6) slicing, dehydration and dyeing of eosin and alcohol; and (7) transparence and mounting are carried out to manufacture a permanent section. In the manufacturing method disclosed by the invention, the paraffin sections of the zostera marina embryo, which have clear dyeing and an integral texture structure, can be obtained.

Owner:SHANDONG ORIENTAL OCEAN SCI TECH

Automotiv non-asbestos high strength braking friction disk, and its prodn. method

InactiveCN1563735AImprove heat resistanceEnhancement effect is goodFriction liningHeat resistanceMetal fibers

The wearing piece of non-asbestos high srength material applies the high molecular compound, phenolic ressin as the agglomerant. The metal fiber or organic fiber is strengthen component. The stuffing applies regulator with frictional properties and barium sulfate, black lead, alumina as accessory ingredient. The production possesses excellent characteristic of physical chemical and mechanical and thermo-stability.

Owner:APPLIED PHYSICS INST OF GUANGXI ACADEMY OF SCI

Cigarette water capsule with water and hydrotropic substance as core materials and manufacturing method of cigarette water capsule with water and hydrotropic substance as core materials

ActiveCN104305521AValid packageHave mechanical strengthTobacco smoke filtersEssential-oils/perfumesFood gradeWater soluble

The invention relates to a water capsule with water and hydrotropic substance as core materials and a manufacturing method of the water capsule. The water capsule is composed of a certain number of water capsule wall materials and the core materials, wherein the water capsule wall materials are compositions of long-chain ester materials and food-grade coagulant aids in specific proportion; the core materials are compositions of pure water, water-soluble substance and the hydrotropic substance. The water capsule is not used as an existing capsule capable of containing oil-soluble flavor substance only, the water and water substance can be included in the water capsule, and meanwhile the single-layer wrapped water capsule is achieved due to the fact that the wall materials are made of the long-chain ester materials and the specific coagulant aids. The water capsule is relatively simple in process; multi-layer wrapping is not needed; the commercial production is easily achieved; raw materials are easily obtained; the water capsule is easy to operate.

Owner:SHANGHAI HUABAO BIOLOGICAL TECH

High refraction and high adhesion large power LED packaging organosilicon material and preparation method thereof

ActiveCN102936414ASolve the problem of incomplete hydrolysis and condensationReduce air permeabilitySemiconductor devicesChemical synthesisPtru catalyst

The present invention relates to a high refraction and high adhesion large power LED packaging organosilicon material and a chemical synthesis method thereof. The organosilicon packaging material is prepared by carrying out mixing matching on a component A and a component B according to a mass ratio of 1:1, wherein the component A comprises vinyl phenyl polysiloxane, vinyl phenyl silicone oil, a platinum-containing polysiloxane catalyst and a tackifier, the component B comprises hydrogen-containing phenyl polysiloxane, dihydrideterminated phenyl polysiloxane, vinyl phenyl polysiloxane and an inhibitor, the tackifier is prepared by carrying out addition on isocyanate, methoxy silane and epoxy silane, and provides strong adhesion for PPA and a silver surface, the curing agent is prepared by compounding hydrogen-containing phenyl polysiloxane and dihydrideterminated phenyl polysiloxane, and a compounding mass ratio is preferably 4:1-2, such that the packaging material has moderate hardness and flexibility after curing so as to effectively solve contradiction of strength and cracking of the cured adhesive. With the present invention, the organosilicon packaging material with characteristics of refraction of 1.54, suitability for industrialization and fully meeting of large power LED packaging requirements can be obtained.

Owner:湖北环宇化工有限公司

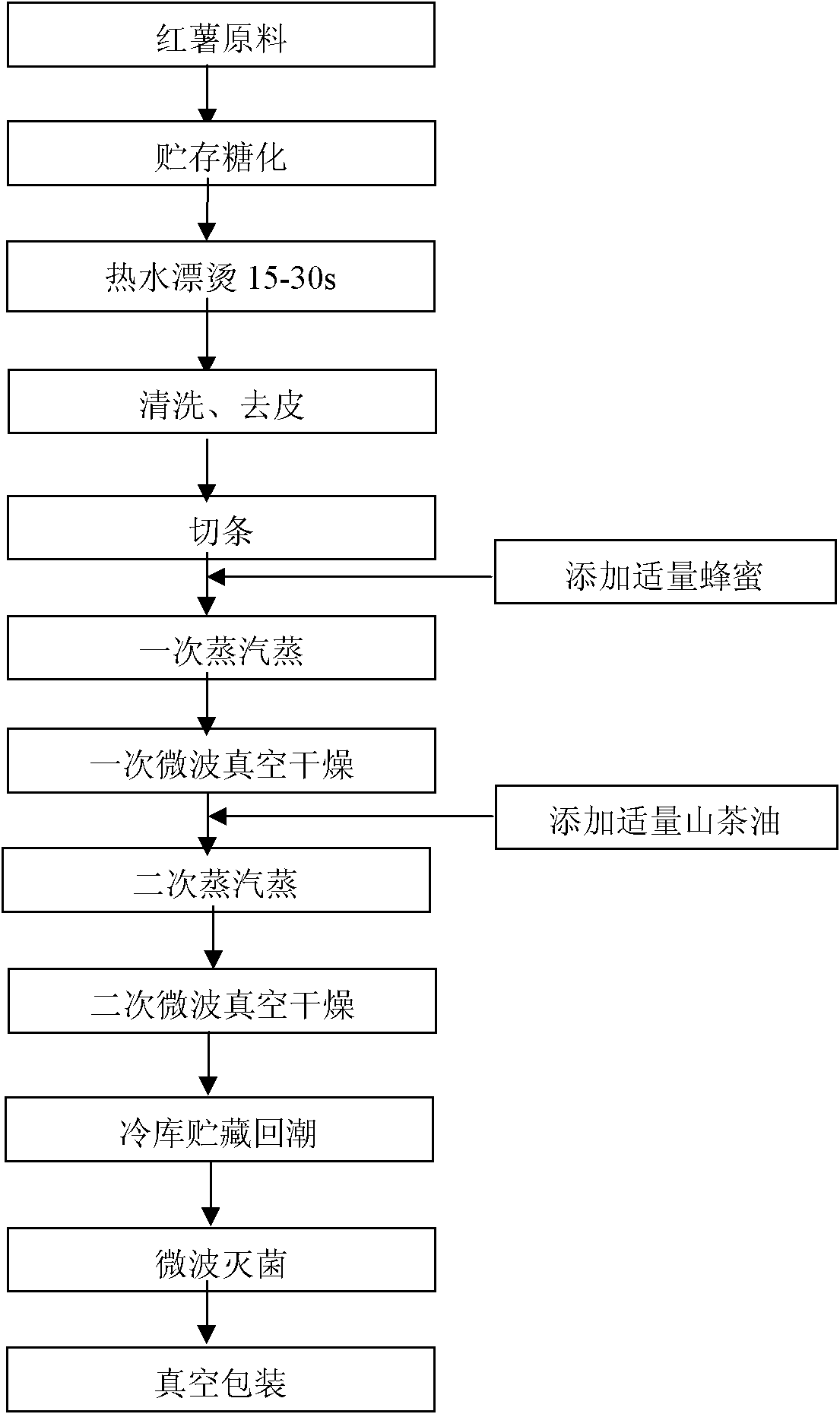

Method for processing instant dried sweet potato

The invention provides a method for processing an instant dried sweet potato, which comprises the following steps of: carrying out storage and saccharification pretreatment on a fresh sweet potato; cleaning the sweet potato, removing the peel of the fresh sweet potato and cutting the sweet potato into strips; blanching for 15-30 seconds; leaching; adding 1-3 percent by mass of honey; steaming for 30-45 minutes in steam; drying to the water content of 32-36 percent at 60-70 DEG C in microwave vacuum; adding 0.2-0.4 percent by mass of mountain naphthalene oil; steaming for 15-30 minutes in steam; drying to the water content of 14-18 percent at 50-60 DEG C in microwave vacuum; storing and dampening to the water content of 20-24 percent at 4-8 DEG C in a refrigeration house; and carrying out microwave sterilization at 30-40 DEG C for 3-6 minutes; and packaging in vacuum. By adopting the processing method of the invention, the produced instant dried sweet potato has flexible texture and certain toughness and can be chewed by all people regardless of age and sex; the product has uniform color, presents red gloss and has the potato flavor deserved by the variety, palatable sweetness, no any food additive, short vacuum microwave drying time and less loss of nutrition components; the product has the normal temperature quality guarantee period for 9 months and the refrigeration quality guarantee period for 12 months; the quality standard of the product meets the following condition: the total bacterial amount is not more than 1,000 CFU / g, the mould is not more than 50 CFU / G, the escherichia coli is not more than 30 MPN / 100g, and pathogenic bacteria are not detected; in addition, the energy consumed for producing the instant dried sweet potato is reduced by more than 30 percent compared with the energy consumed for producing the instant dried sweet potato by hot air drying.

Owner:ZHEJIANG UNIV OF TECH

Formulation technology of compound feed for carps

ActiveCN101912053AReasonable choiceGood crushing finenessFood processingClimate change adaptationCalcium biphosphateAnimal science

The invention relates to a formulation technology of the compound feed for carps. The compound feed is prepared from the following raw materials in percentage by weight: 20-30 percent of soybean meal CP 46%, 18-23 percent of cottonseed meal CP 45 %, 12-18 percent of rapeseed cake, 4-10 percent of imported fish meal, 13-20 percent of wheat, 4-9 percent of rice bran, 2-10 percent of maize gluten feed, 1.6-3 percent of soybean oil, 1-2 percent of calcium biphosphate, 0.1-0.3 percent of salt, 0.15-0.3 percent of choline chloride 50% of content and 0.7-1.3 percent of carp premix compound, and the sum of the components is 100 percent. The compound feed for carps, which is prepared by the formulation of the compound feed for carps, enables carps to grow rapidly and have high single birth and strong disease resistance and has low bait factor, decreased culture cost and obvious economic benefits.

Owner:YUXI KUAIDADUO ANIMAL HUSBANDRY TECH

Polyester paint of high solid for coiled material and lithographed sheet

InactiveCN1415682AIncreased irregularitySmall molecular weightLiquid surface applicatorsPolyester coatingsChemistryBoiling point

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

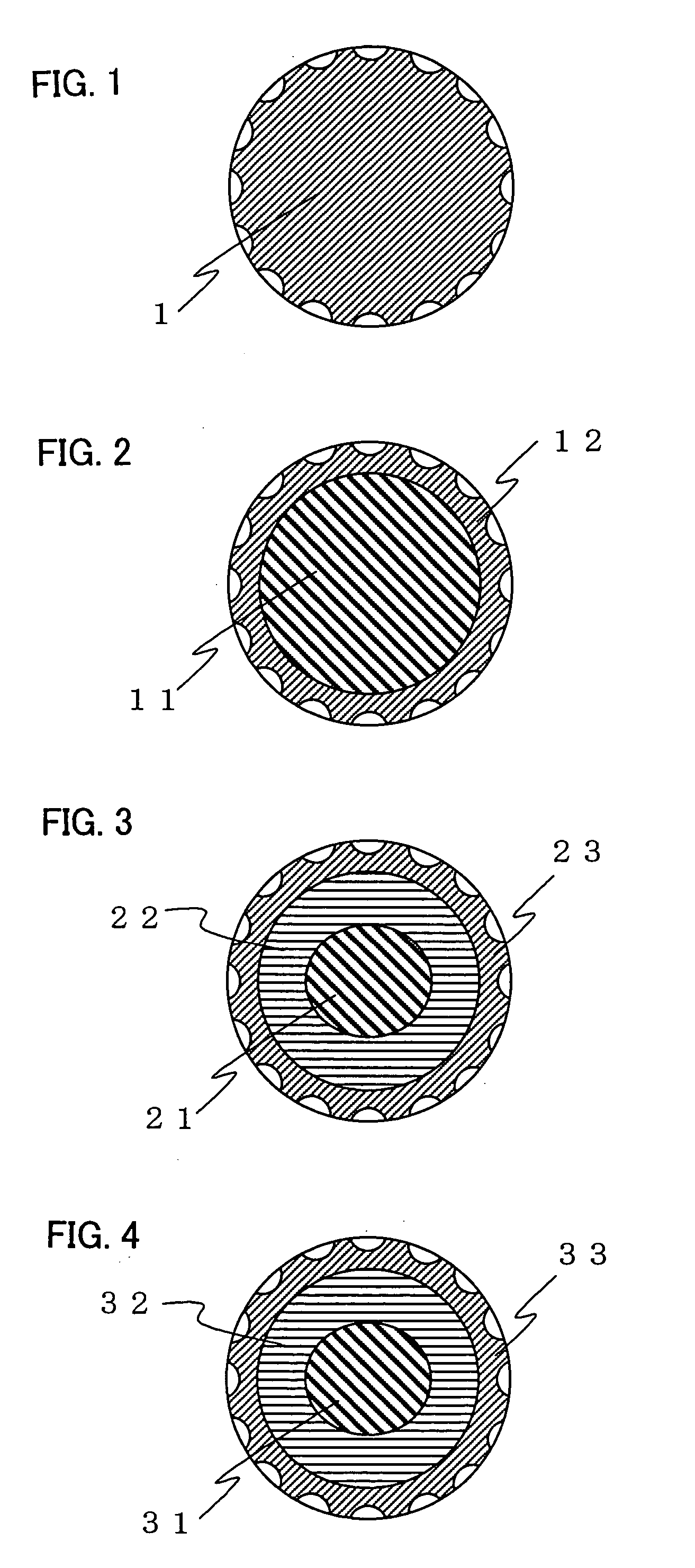

Golf ball

InactiveUS20040152540A1Large particle sizeImprove the overall coefficientGolf ballsSolid ballsPolymer scienceHardness

A golf ball achieving both excellent hit feeling and good restitution performance by using a rubber composition having moderate hardness and sufficient restitution performance is provided. The golf ball includes a rubber composition obtained by blending 10 to 50 parts by mass of a co-crosslinking agent and 0.1 to 6 parts by mass of a crosslinking initiator with 100 parts by mass of a rubber component. The rubber component contains at least 80 mass percent of hydrogenated polybutadiene having a double bond residual rate of 80 to 99% or preferably 85 to 99%, and cis-1,4-structure content rate of not smaller than 90% or preferably not smaller than 95%. Polybutadiene is obtained by hydrogenating a part of its double bonds.

Owner:DUNLOP SPORTS CO LTD

Instant spiced shredded beef food

The invention discloses an instant spiced shredded beef food, which is prepared from the following raw materials in parts by weight: 100,000 parts of beef, 2300 parts of edible salt, 1800 parts of white sugar, 1500 parts of aginomoto and 50 parts of vitamin C, and is prepared from the following spiced ingredients in parts by weight: 3,000 parts of red oil, 500 parts of five-spice oil, 40 parts of ethyl maltol, 1500 parts of beef cream, 1500 parts of chicken cream, 60 parts of ginger oil, 60 parts of scallion oil, 500 parts of five spice powder and 2,0000 parts of spice water. The preparation method comprises the following steps: preparing fresh meat, tumbling, pickling, charging, marinating, frying with hot oil, mixing raw materials and seasoning; carrying out vacuum packing and sterilization treatment; and cleaning, treating, airing, cooling, inspecting and warehousing. The invention aims at providing the instant spiced shredded beef food. The beef is uniformly seasoned and pickled, is good in flavor and taste, moderate in taste, neither too hard, nor too soft, and easy to chew and eat; most fresh taste of beef is reserved; the color of the beef is close to normal color; no toner needs to be externally added; and the food is relatively healthy.

Owner:XINHUANG XIAOFEINIU FOOD

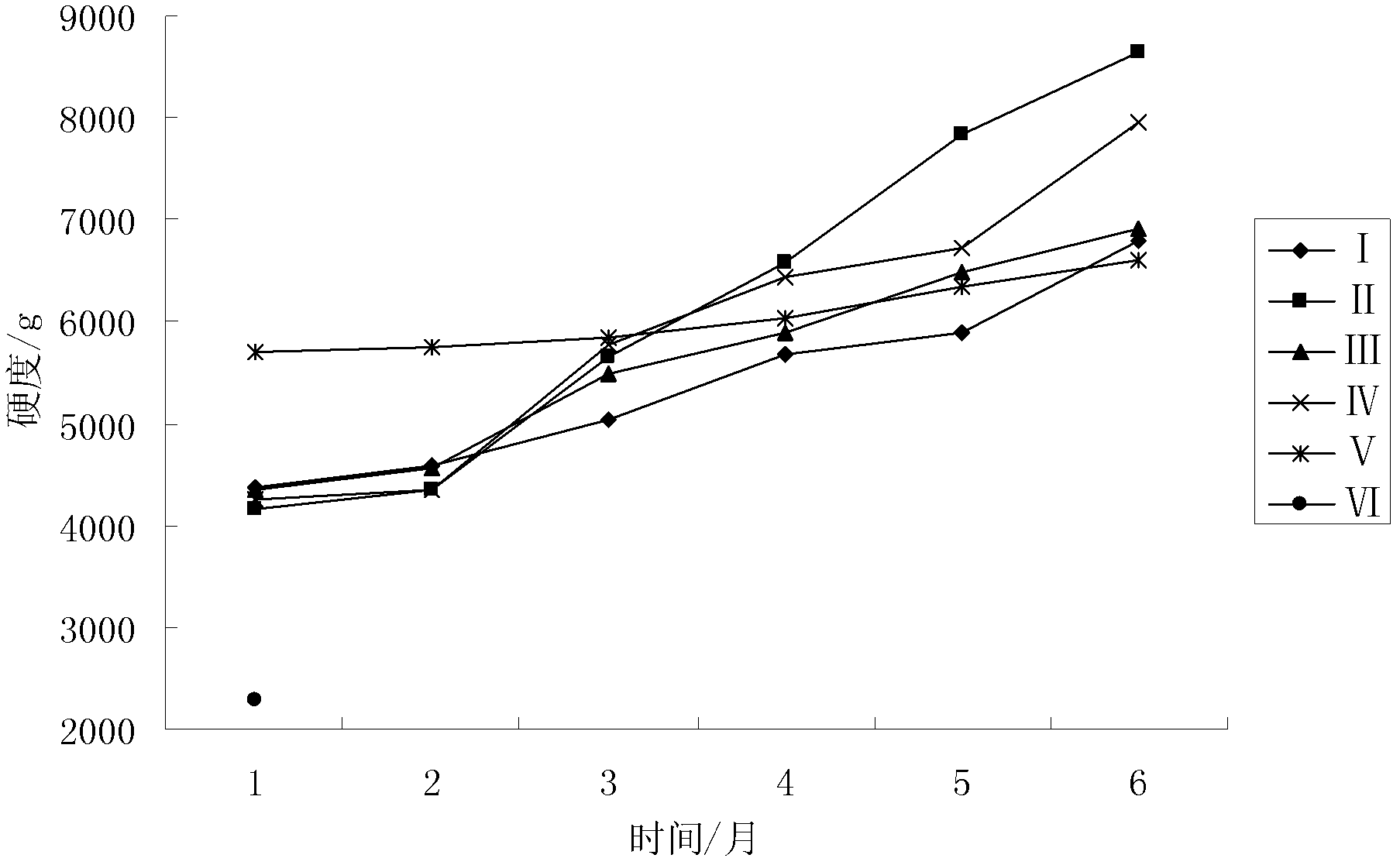

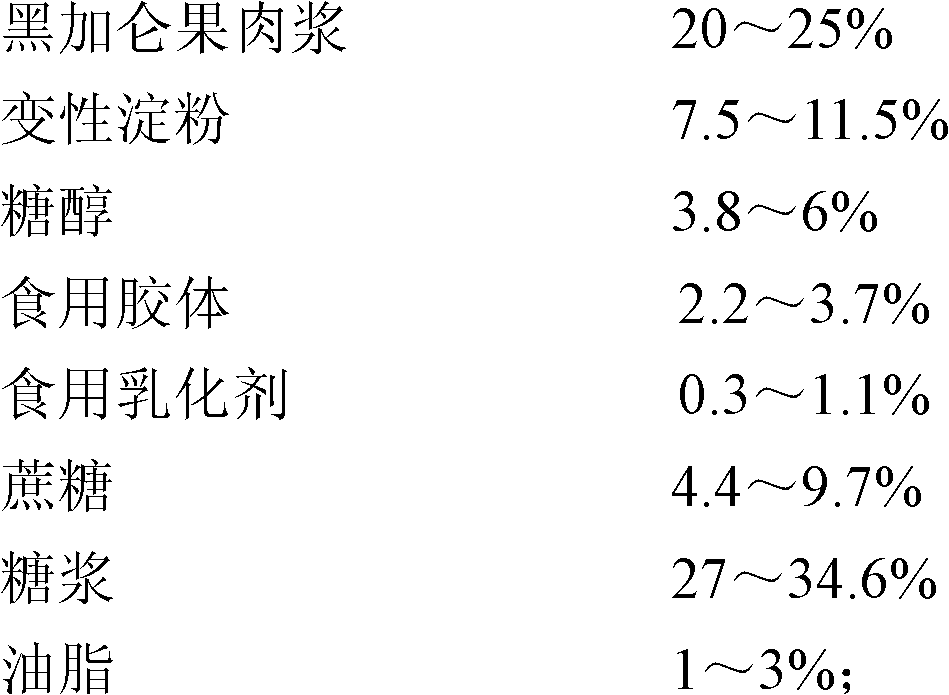

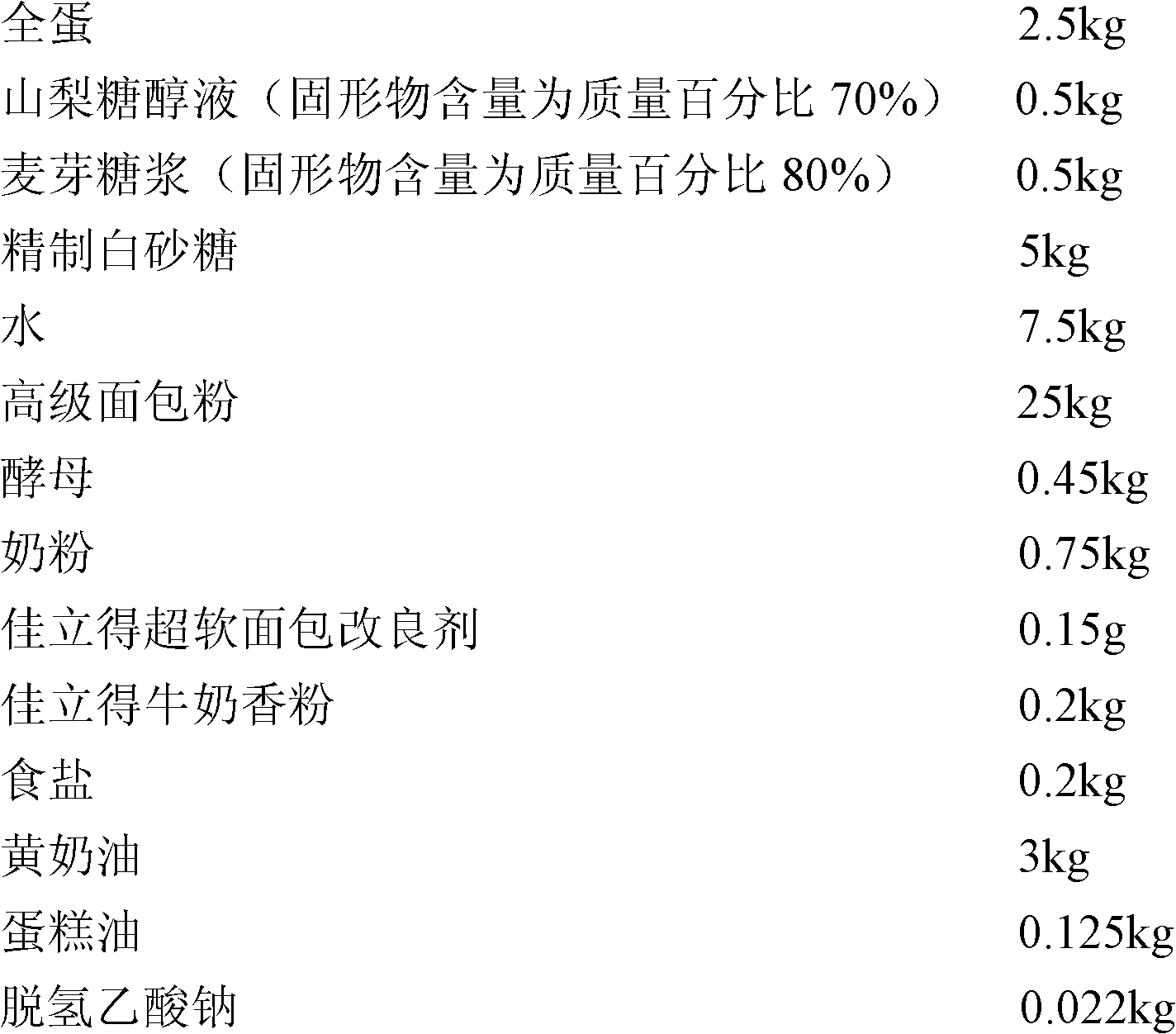

Black currant jam for bread with long shelf life and preparation method thereof

The invention discloses black currant jam for bread with a long quality guarantee period and a preparation method thereof. The black currant jam mainly comprises the following components: 20 to 25 percent of flesh and pulp of black currant, 7.5 to 11.5 percent of modified starch, 3.8 to 6 percent of sugar alcohol, 2.2 to 3.7 percent of edible colloid, 0.3 to 1.1 percent of edible emulsifier, 4.4 to 9.7 percent of sucrose, 27 to 34.6 percent of syrup and 1 to 3 percent of grease. The preparation method comprises the following steps of: mixing the modified starch, the sugar alcohol, the edible colloid, the edible emulsifier, a preservative and the sucrose and stirring uniformly; adding water, the syrup and the grease, raising the temperature to 90 to 95 DEG C, and keeping the temperature until the gelatinization is complete; adding the flesh and pulp of the black currants, continuing to stir and keep the temperature, and controlling the content of a solid matter to 65 to 68 percent; andreducing the temperature, and adding an acidity regulator and an edible essence to obtain the black currant jam for the bread with the long quality guarantee period. The black currant jam for the bread with the long quality guarantee period has the advantages that: the jam has soft texture, moist mouthfeel, rich taste, high water content and low water activity, and is baking-resistant, the sugar degree is 65 to 70 degrees, the water activity is 0.75 to 0.8, and the quality guarantee period of finished bread containing the jam is 3 to 6 months.

Owner:广州合诚实业有限公司

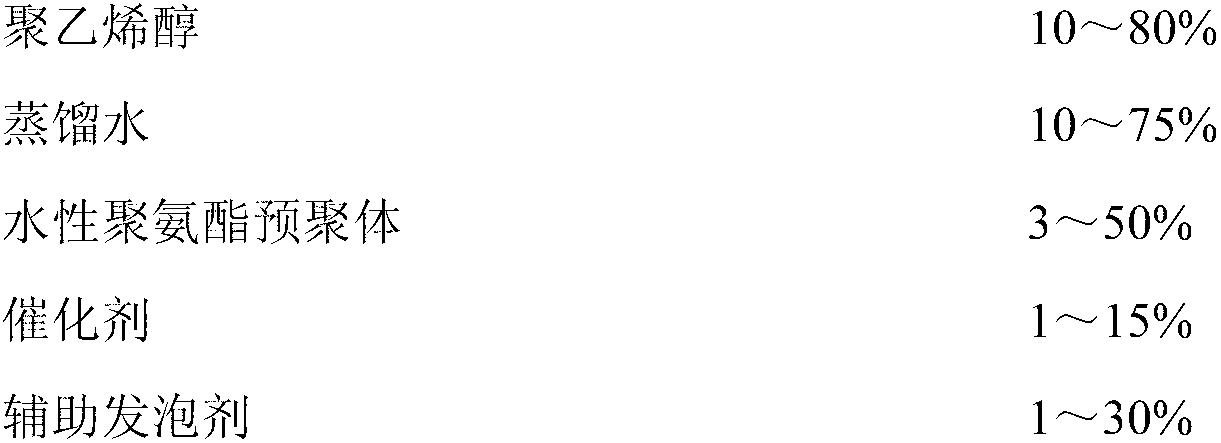

Method for preparing polyvinyl alcohol and polyurethane super absorbent sponge

The invention discloses a method for preparing a polyvinyl alcohol and polyurethane super absorbent sponge. The method includes mixing polyvinyl alcohol with distilled water at first, dissolving the polyvinyl alcohol for 20 to 30 minutes under the condition that the water bath temperature ranges from 50 DEG C to 95 DEG C and rotational speed ranges from 400r / min to 600r / min to obtain polyvinyl alcohol aqueous solution; and then heating the polyvinyl alcohol aqueous solution until the temperature of the polyvinyl alcohol aqueous solution ranges from 30 DEG C to 100 DEG C, adding water-based polyurethane prepolymer, catalysts and auxiliary foaming agents into the polyvinyl alcohol aqueous solution, stirring and uniformly mixing the mixture under the condition of rotational speed ranging from 400r / min to 600r / min, enabling the mixture to react for 5 minutes to 10 minutes, and solidifying the mixture for 2 to 4 hours at the temperature ranging from 30 DEG C to 100 DEG C to obtain the sponge with the water absorbent rate higher than 9.8. The water absorbent rate of the obtained sponge is increased to 10-20 times from the original 6-8 times of an existing polyvinyl acetal sponge, the water absorbing velocity of the sponge is increased to 8g / ming from the original 4g / ming, and the polyvinyl alcohol and polyurethane super absorbent sponge has a broad development prospect in fields of aquatic product processing, food, clinical medicine, water treatment and the like.

Owner:SOUTH CHINA UNIV OF TECH

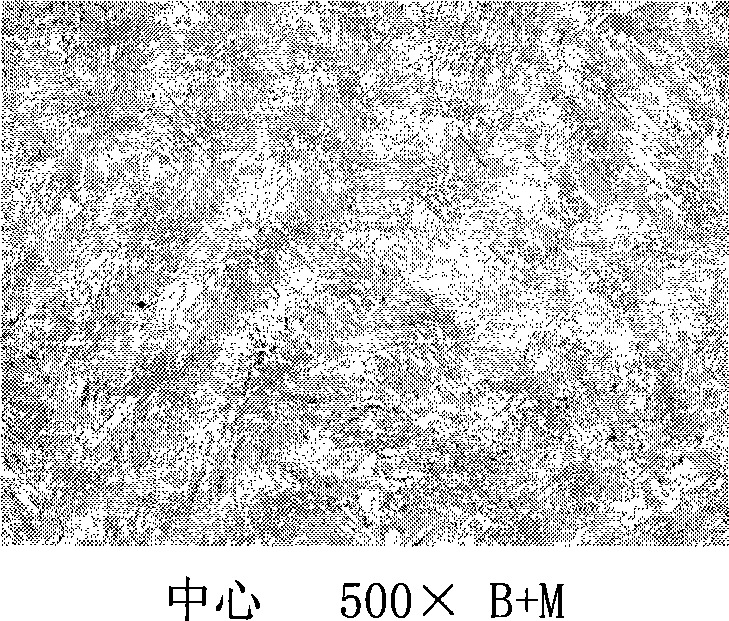

Method for manufacturing high-strength hot rolled bulletproof steel plate

The invention discloses a method for manufacturing a high-strength hot rolled bulletproof steel plate, and belongs to the technical field of metal materials. The bulletproof steel plate comprises the following components: 0.08-0.12% of C, 0.7-1.3% of Si, 1.30-1.8% of Mn, 0.01-0.06% of Al, less than or equal to 0.02% of P, less than or equal to 0.004% of S, less than or equal to 0.004% of N, less than or equal to 0.015% of O, 0.3-1.0% of Gr, less than or equal to 0.2% of Ti and Nb, 0.0015-0.0025% of B and the balance of Fe and inevitable impurities. The method for manufacturing the high-strength hot rolled bulletproof steel plate comprises the following steps: 1, smelting the components to cast a continuous casting billet with qualified components, feeding the continuous casting billet into a heating furnace and heating; 2, performing hot rolling on the heated billet; 3, cooling the hot rolled continuous casting billet; 4, coiling the cooled continuous casting billet to obtain a hot rolled plate; 5, performing thermal treatment on the hot rolled plate to obtain the bulletproof steel plate. The high-strength hot rolled bulletproof steel plate disclosed by the invention is high in ductility and moderate in hardness, meanwhile, the alloy cost is relatively low, the process is easy in implementation, and the welding performance of the bulletproof steel plate is good.

Owner:SHOUGANG CORPORATION

Production process of instant Chinese chestnut kernels and product

The invention relates to a production process of instant Chinese chestnut kernels and a product, which belong to the field of the deep processing of agricultural products. The production process comprises the following main technological processes: taking Chinese chestnuts with high water content, low reducing sugar, low starch and low fruit breaking rate as a raw material, processing instant Chinese chestnut kernels, sieving the raw material, classifying, removing outer peels, blanching, removing inner peels, quick-freezing, unfreezing, saccharifying, steaming, pasting, packaging and sterilizing. The instant Chinese chestnut kernels produced by the method have golden color, low fruit breaking rate and proper sweetness, are fragrant, glutinous and delicious and can be used as leisure foods for eating.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

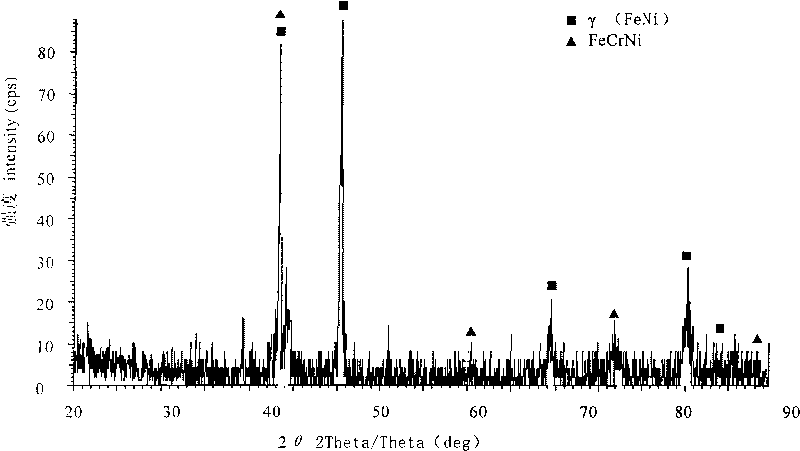

Iron-based alloy powder material for plasma cladding quick forming

InactiveCN101709469AImprove toughnessModerate hardnessMetallic material coating processesHardnessWear resistance

The invention discloses an iron-based alloy powder material for plasma cladding quick forming, which comprises the following alloy components in percentage by weight: 0.05-0.15 percent of C, 4-8 percent of Ni,10-15 percent of Cr, 0.1-1 percent of B, 0.8-1.2 percent of Si, 0.8-1.2 percent of Mo, 0.25-0.70 percent of Nb, 0.25-3.5 percent of mixed RE(containing 47 percent of Ce, 26 percent of La,18 percent of Nd and 5 percent of Pr in percentage by mass) and the balance of Fe. The iron-based alloy powder with the components is especially suitable for plasma cladding quick forming, and a cladding layer has medium hardness and wear-resistance. The iron-based alloy powder has little tendency to crack and other cladding defects under the condition of multi-layer cladding, and the cladding process is excellent with low powder cost. The powder can be also used for restoring work-piece size or used as a bottom layer before a functional cladding layer is formed during plasma single-layer cladding repair, and can be applied to wider application needs.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Processing method of instant lightly baked spicy squid

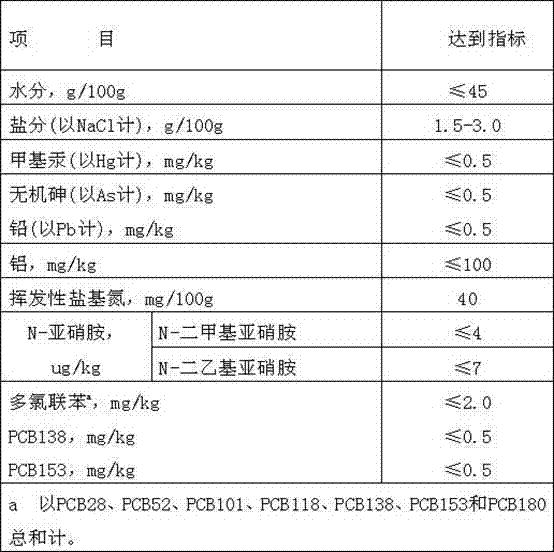

The invention relates to a processing method of instant lightly baked spicy squid, and the method comprises the following steps that fresh squid, or fresh frozen and thawed squid is selected as a raw material and cleaned; the head and the internal organs are removed; then the squid is cut and sliced, cooked, uniformly mixed with seasoning and cured, dried and baked until the water content is 40 percent + / -0.8 percent; and the slices are packaged, sealed and sterilized to obtain an instant lightly baked spicy squid finished product. The processing method has reasonable procedures and is simple in preparation. The seasoning for curing is mixed scientifically, so that the dainty flavor and palatability of the squid food are improved. The lightly baked spicy squid food which is prepared through the method has soft texture, maintains the nutrition of the squid as well as the original color and the appearance of the fresh squid to the largest extent, has long storage life, can be eaten conveniently only after a package is opened, the taste is dainty in hardness, saline taste and sweetness and delicious, and has the special aroma of seafood.

Owner:RONGCHENG HONGWEI FOOD

Production method for low carbon high sulfur free-cutting steel with excellent sulfide modality

The invention discloses a production method for low carbon high sulfur free-cutting steel with excellent sulfide modality. Under the precondition that all the conventional production conditions are not changed and no other alloying element is added, measures are taken to control total oxygen content at 150-200 ppm, crystallizer water-carrying capacity at 1700-1900 L / min, second cooling zone specific water flow at 0.7-0.9 L / kg, heating furnace temperature at 1230-1280 DEG C, starting rolling temperature at 1100-1130 DEG C, finishing rolling temperature at 1050-1120 DEG C and the like, so as to solve the problem of low cutting performance of low carbon high sulfur free-cutting steel caused by poor sulfide modality in the prior art. Sulfide in free-cutting steel hot rolling steel wires produced by the invention has the characteristics that the mean diameter is greater than or equal to 3 Mu m, the unit area number is greater than or equal to 1000 / mm<2>, the area ratio is greater than or equal to 1.1 %, the sulfide with the length-width ratio greater than or equal to 10 is below 25 %.

Owner:ZHANGJIAGANG RONGSHENG SPECIAL STEEL CO LTD

Water-based mold release and preparation method thereof and release paper prepared by utilizing water-based mold release

The invention discloses a water-based mold release and a preparation method thereof and release paper prepared by utilizing the water-based mold release. The mold release comprises the following raw materials by weight: 1 to 50 parts of organosilicone monomer, 1 to 50 parts of vinyl end-capping agent, 1 to 50 parts of alkyd resin, 1 to 10 parts of emulsifying agent, 1 to 10 parts of catalytic agent, 100 to 160 parts of deionized water, 0.1 to 10 parts of pH value conditioning agent, 1 to 10 parts of cross-linking agent and 0.01 to 1 part of platinum-based catalytic agent. The mold release has the advantages that the raw materials are cheap and easy to get; the preparation method is simple; the used mold release layer takes water as a dispersing agent; no organic solvent is released; the mold release is safe and environment-friendly; the release paper prepared by utilizing the mold release is short in thermosetting time, and is suitable for industrialized production; the prepared release paper is good in property.

Owner:浙江池河科技有限公司

Quenching and tempering type abrasion resistant steel and heat treating method thereof

InactiveCN101451218AReasonable toughness matchingModerate hardnessHeat treatment process controlChemical compositionWear resistant

The invention relates to quenching and tempering type wear resistant steel and a heat treatment method thereof. The steel comprises the following chemical components by weight percentage: less than or equal to 0.22 percent of C, less than or equal to 0.80 percent of Si, less than or equal to 1.60 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.010 percent of S, less than or equal to 0.60 percent of Ni, less than or equal to 1.00 percent of Cr, less than or equal to 0.50 percent of Mo, 0.02 to 0.03 percent of Nb,0.04 to 0.06 percent of V, 0.020 to 0.045 percent of Al, 0.015 to 0.030 percent of Ti, less than or equal to 0.004 percent of B, and the balance being Fe and unavoidable impurities. The steel plate has reasonable obdurability matching, proper hardness, even full-thickness hardness and the mechanical properties reaching the expected design requirements. The steel plate production process has easy operation and high adaptability. The steel plates of various batches have stable and even performance and can reach the requirements for volume production. As the tempering time in a quenching machine is longer, the tempering time can be appropriately shortened in the subsequent production through tests, thereby reducing the cost.

Owner:WUYANG IRON & STEEL

Polyurethane pouring sealant as well as preparation method and pouring process thereof

InactiveCN102212325AImprove liquidityLow viscosityOther chemical processesPolyureas/polyurethane adhesivesPolymer sciencePolyol

The invention relates to a polyurethane pouring sealant. The polyurethane pouring sealant comprises the following raw material components in parts by weight: 100-350 parts of polyether polyol, 40-70 parts of isocyanate, 20-60 parts of plasticizer and 0.01-0.5 parts of catalyst and is prepared by a method comprising the following steps: (a) mixing the polyether polyol with the plasticizer in the proportion and placing the mixture in a closed container, vacuuming for 1-3 hours while rotating at the temperature of 100-130 DEG C, and then cooling to 35-60 DGE C; and (b) mixing the isocyanate, the catalyst with the product prepared in the step (a) in the proportion and then placing the mixture in the closed container, stirring at high speed and vacuuming for 1-10 minutes, and stopping stirring when the pouring sealant releases a small amount of heat and is semitransparent. The polyurethane pouring sealant has excellent flowability and low viscosity, and is easer to penetrate to tiny apertures, thereby being beneficial to tight filling inside a poured material.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

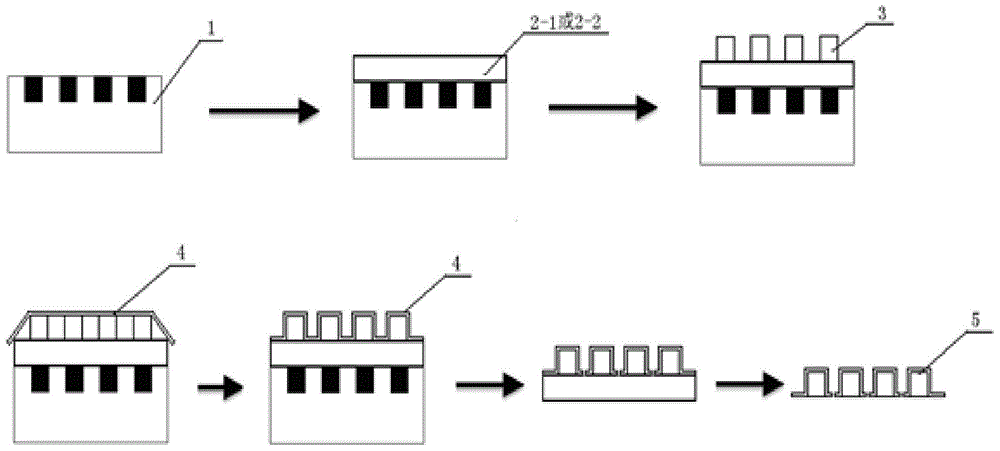

Preparation method for inverted LED white-light chip of chip scale package

ActiveCN104900783AHigh batch stabilityConsistent color temperatureSemiconductor devicesPhosphorEngineering

The invention discloses a preparation method for an inverted LED white-light chip of chip scale package, and the method comprises the following steps: temporarily fixing an UV solidifying adhesive tape (2-1) on the upper surface of a die bonding positioning light cover (1); setting flip chips (3) on the upper surface of the UV solidified adhesive tape (2-1) according to the position of the die bonding positioning light cover (1); employing a fluorescent glue film (4) to cover the flip chips (3); carrying out vacuumizing and heating, and enabling the fluorescent glue film (4) to be solidified and packaged on the flip chips (3); carrying out cutting along gaps among the all packaged flip chips (3); removing the die bonding positioning light cover (1); carrying out UV irradiation and enabling the UV solidified adhesive tape (2-1) to be solidified, and obtaining the inverted LED white-light chip (5) of chip scale package. The method simplifies the technological flow, avoids glue mixing and dispensing in the original technology, improves the production efficiency and yield, and greatly reduces the production cost. The method completely avoids the sinking of phosphor, enables the batch stability of the inverted LED white-light chips (5) to be high, and enabling the color temperature of the inverted LED white-light chips (5) to be consistent.

Owner:TECORE SYNCHEM

Various grains chewing slice and preparation method thereof

The invention discloses miscellaneous grain chewable tablet which belongs to the technical field of agricultural product deep processing, and a preparation method thereof. The raw materials of the miscellaneous grain chewable tablet are oat, tartary buckwheat, pumpkin powder and auxiliary materials. The better preparation scope of the raw materials by the weigh portion is as follows: 20 percent to 35 percent of oat, 10 percent to 30 percent of tartary buckwheat, 10 percent to 30 percent of pumpkin powder and 5 percent to 60 percent of auxiliary materials. The preparation method comprises the following steps: (1) the oat and the tartary buckwheat are baked and ground; (2) the ground raw materials are mixed with the pumpkin powder and the auxiliary materials to prepare soft materials and particles; (3) the granulated raw materials are dried; (4)the dried raw material particles are pressed into finished products. The chewable tablet prepared by the invention has appropriate hardness, good taste, unique flavor, stable product quality, rich rutin, phaseomannite and Beta-hyskon, low heat, high nutrition, and can prevent diabetes, high blood pressure, etc. to some degree.

Owner:CHINA AGRI UNIV

Water-based multipurpose painting pen

The invention provides a kind of comination which is used for producing multi-purpose water painting pens, including the following components: stearic acid, hydrogenated oil, wax, emulsifier, pigment, and filler. The invention also provides a kind of multi purpose water painting pens based on the combination and their preparation. The multi purpose water painting pens have the properties such as water-soluble, water cleansing, and they can paint on the glass, Ci brick, plastic surface, EVA material and smooth articles.

Owner:LOTUS STATIONERY

Manufacturing method of anti-yield foundation bolt

ActiveCN103128506AModerate hardnessImprove the lubrication effectCooling temperatureChemical composition

The invention discloses a manufacturing method of an anti-yield foundation bolt. A processing step includes: a, casting a rod blank, wherein the rod blank comprises chemical components, by weight, 0.196%<=C<=0.250%, 0.20%<=Si<=1.90%, 0.35%<=Mn<=1.35%, 0.010%<=P<=0.030%, 0.010%<=S<=0.030%, 1.50%<=Cr<=1.50%, trace amount <=B<=0.0018%, 0.012%<=Cu<=0.030% and the balance Ferrum and inevitable impurities; and cooling temperature of casting molded blank to 350 DEG C, heating to 670-780 DEG C, keeping warm for 3-5 hours, cooling a furnace to 300 DEG C, keeping warm for 3 hours, heating to 650-760 DEG C, keeping warm for 10 hours, cooling to 400 DEG C at 45 DEG C / hour, and cooling to 150 DEG C at 25 DEG C / hour. The manufacturing method of the anti-yield foundation bolt adopts cold extrusion technology bolt processing, improves strength of the bolt, reaches a hardness value and a strength value required by the anti-yield foundation bolt, solves delay breakage and fatigue breakage of the bolt under high strength, is reliable to connect in use and not prone to break, prolongs service life of the bolt, and meets using requirements of various industries in society on high-strength bolts.

Owner:浙江同力重型机械制造有限公司

Formula and preparation method for non-toxic and environment-friendly polyvinyl chloride high-foaming glue for bottle cap

The invention discloses a formula and a preparation method for non-toxic and environment-friendly polyvinyl chloride high-foaming glue for bottle caps. In the formula, the foaming glue comprises the following components in part by weight: 90 to 100 parts of polyvinyl chloride resin, 60 to 70 parts of acetyl tributyl citrate, 1.8 to 2.4 parts of foaming agent, 0.6 to 1 part of dimethyl silicon oiland 10 to 30 parts of heavy calcium carbonate. In the formula, by regulating and controlling the plasticizing action of polyvinyl chloride (PVC) sealant strictly, the plasticizing action of the PVC sealant is matched with the decomposition temperature of the foaming agent, so the prepared PVC high foaming glue is high in foaming magnification, uniform in foaming density, appropriate in softness and hardness and good in a sealing effect, and basically reaches the performance of conventional sealing gaskets in which azodicarbonamide is taken as the foaming agent. The high-foaming glue is non-toxic, low in production cost, easy to produce and good in a using effect.

Owner:国家复合改性聚合物材料工程技术研究中心

Anti-static polyurethane material for manufacturing shoe soles, shoe sole manufacturing method and manufacturing method of dual-density polyurethane safety shoe soles

ActiveCN102504519AImprove anti-static performanceGood anti-static performanceSolesDefoaming AgentsIsocyanate compound

The invention discloses an anti-static polyurethane material for manufacturing shoe soles, a shoe sole manufacturing method and a manufacturing method of dual-density polyurethane safety shoe soles. The anti-static polyurethane material consists of a component A and a component B which are mixed and poured, the component A includes polyatomic alcohol, catalyst, foaming agent, anti-static agent, carbon fiber powder, chain extender and defoaming agent; and the component B is isocyanate. The shoe sole manufacturing method includes steps of baking and drying the polyatomic alcohol and the isocyanate, mixing the rest compositions in the component A and the baked polyatomic alcohol uniformly to form material A, and mixing the material A with the isocyanate of the component B to obtain shoe soles made of anti-static polyurethane materials by pouring forming. The dual-density polyurethane safety shoe soles can be manufactured by secondary pouring by selecting foaming agents in different quantity. The polyurethane materials are high in anti-static performance, and the manufactured shoe soles are proper in hardness. Shoe soles manufactured by the manufacturing methods are fine in demouldingand high in production efficiency.

Owner:深圳市新纶超净科技有限公司

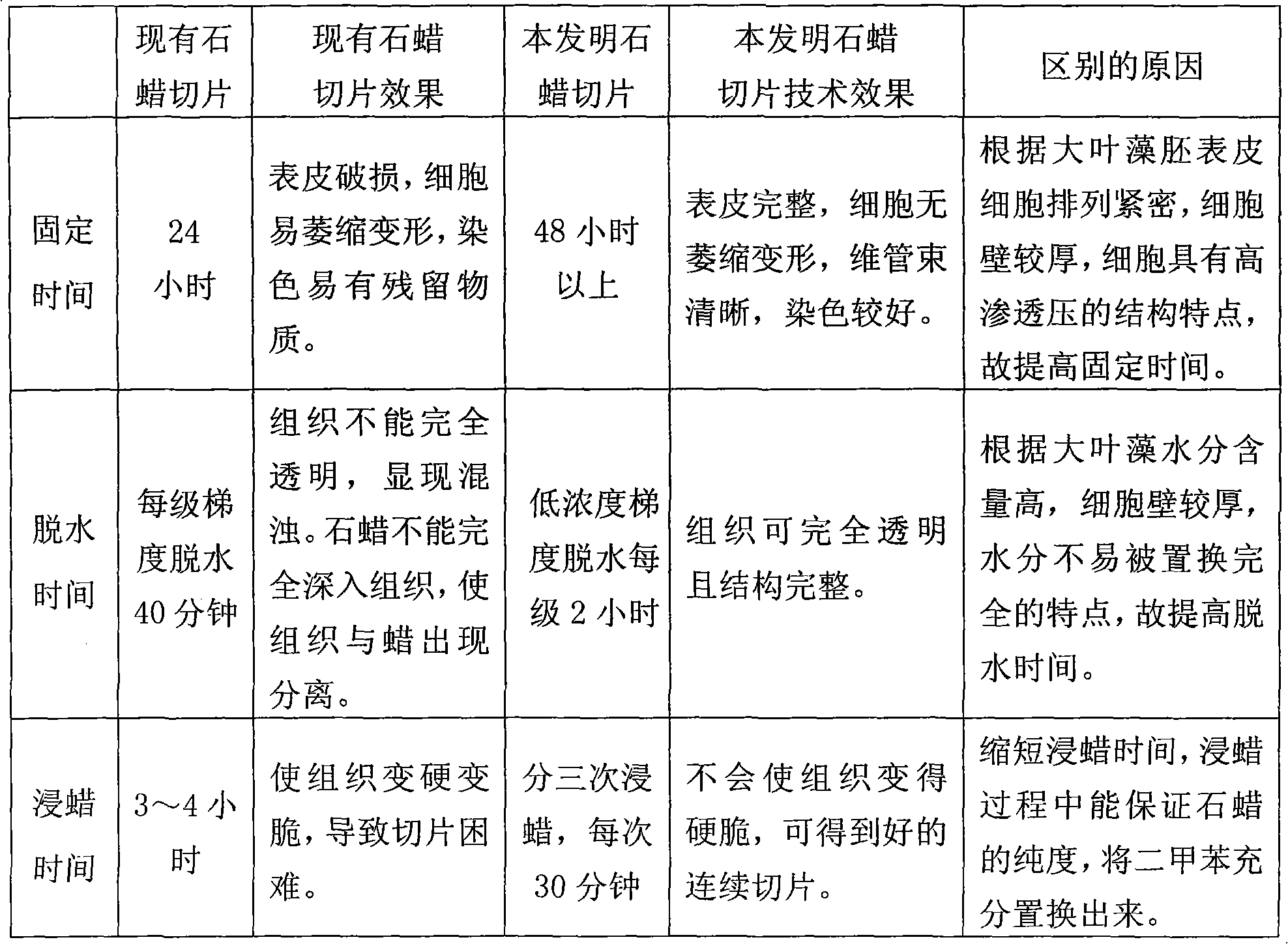

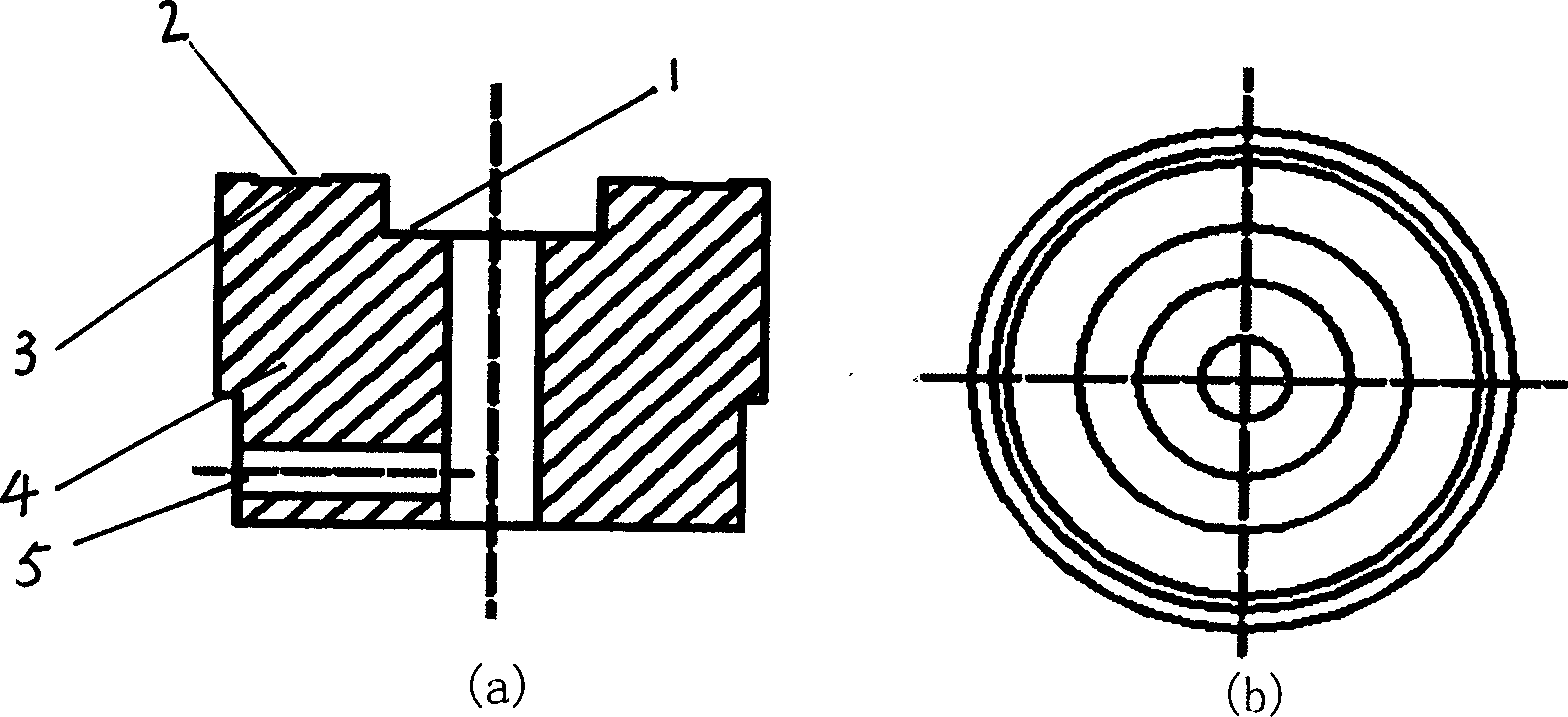

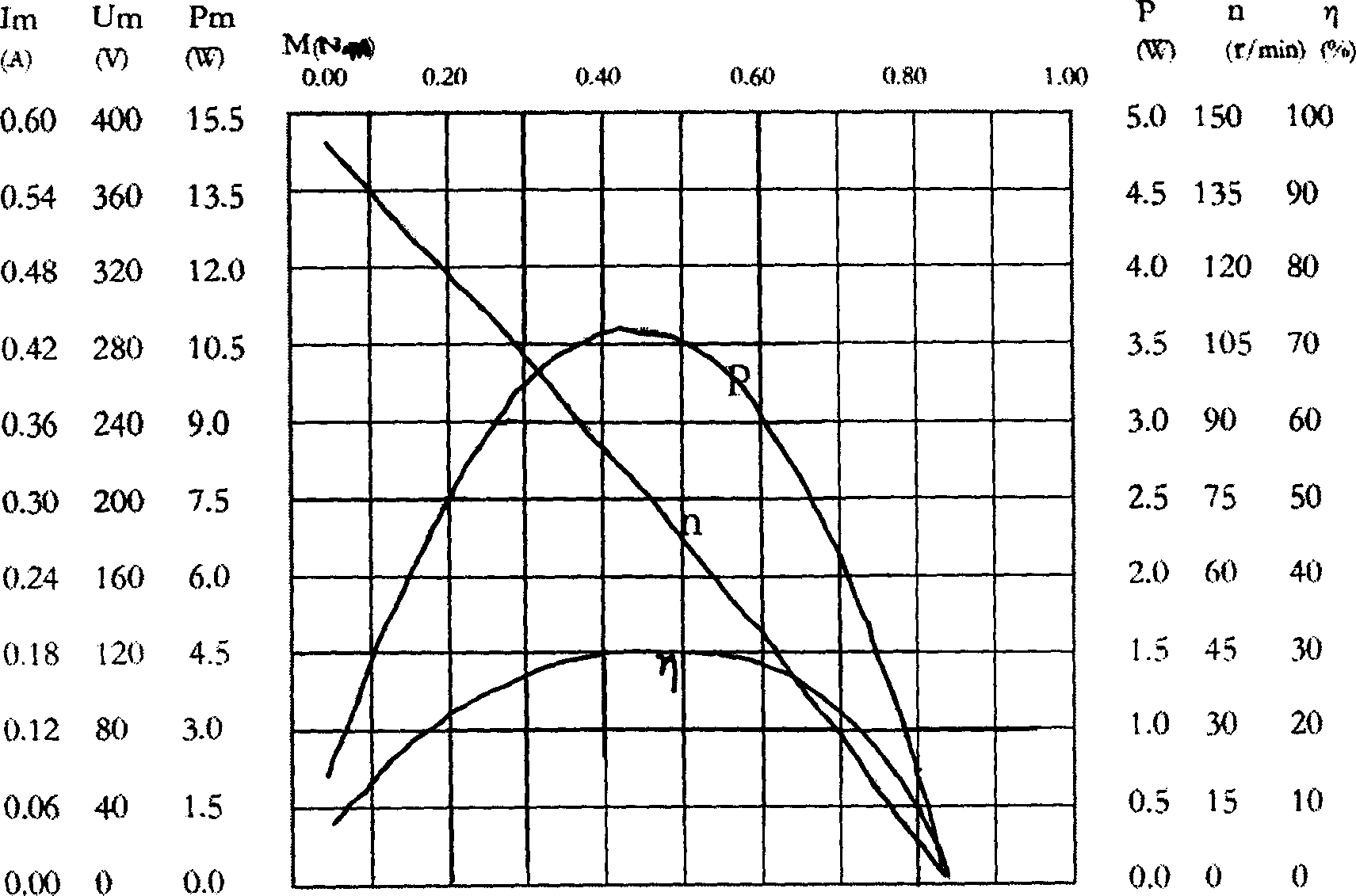

Supersonic motor thermosetting resin base friction material and friction layer manufacturing method and auxiliary tool

The invention relates to an ultrasound dynamo thermosetting resin radical friction material and friction layer making method and the assistant tools. The material is made up of 35-80% thermosetting resin, 0-34% curing agent, 5-15% nanometer antifriction powder, 5-15% carbon fiber, 0-10% copper oxide, 0-5% polytetrafluoroethylene, 5-10% copper powder, 2-10% graphite, 0-5% nitrile butadiene rubber, and 0-10% mineral substance. The invention has excellent wear resistance, suitable rigidity, good output characteristic, etc. And the method is low cost and simple. The assistant tool is made up of moving bar and base.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

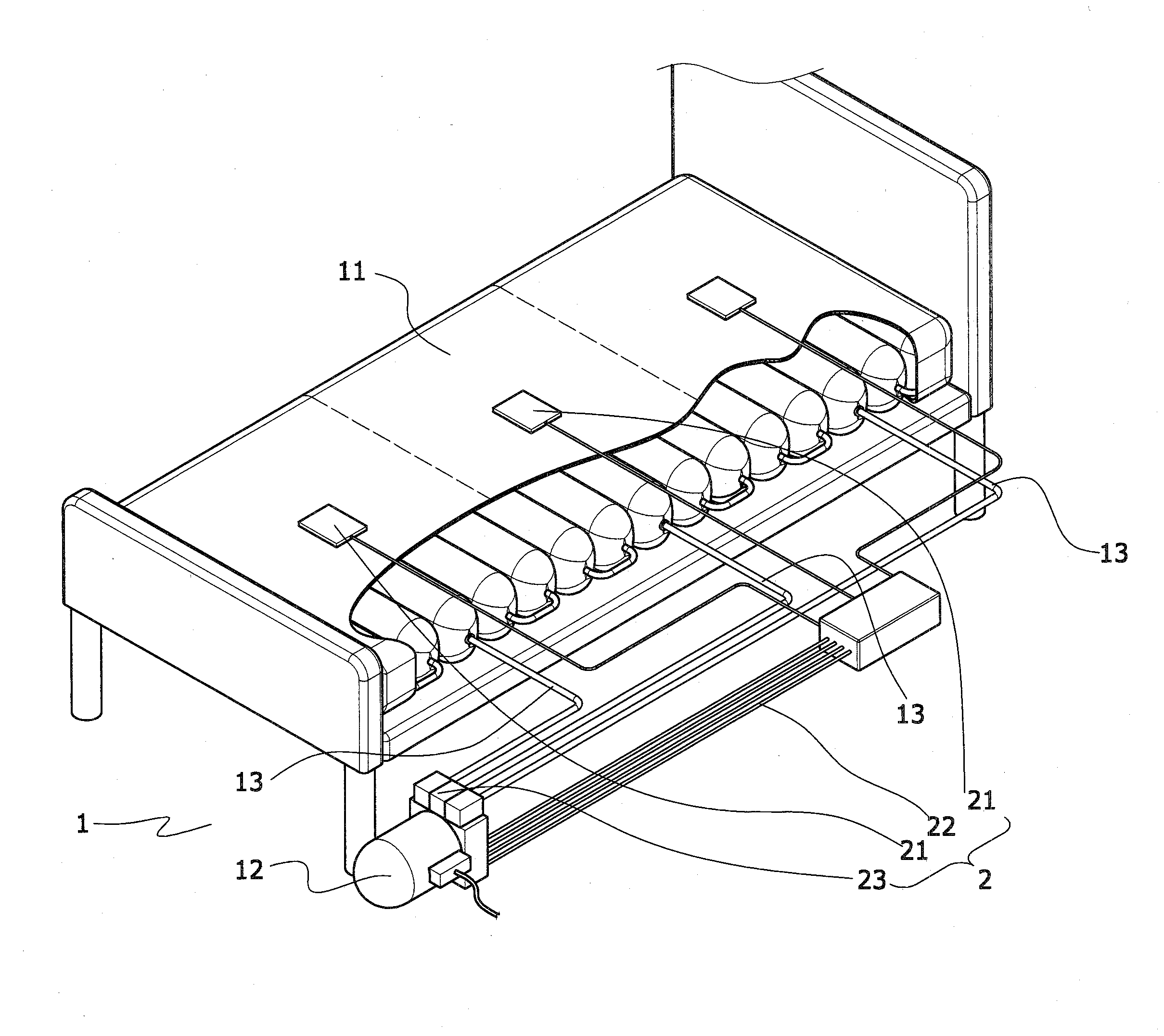

Structure of automatic pressure adjustable air bed

InactiveUS20100064443A1Automatic adjustment of firmnessModerate hardnessStuffed mattressesSpring mattressesControl systemAir pump

An improved structure of automatic pressure adjustable air bed mainly includes an air mattress, an air pump, and air pipes arranged therebetween, as well as a control system disposed on the air bed. The control system includes multiple pressure sensors disposed on the air mattress for acquiring pressure signals, and a main control unit for controlling actions of the air pump or electrical controlled valves thereon, thereby achieving the automatic adjustment of firmness of the air mattress.

Owner:CAREMED SUPPLY

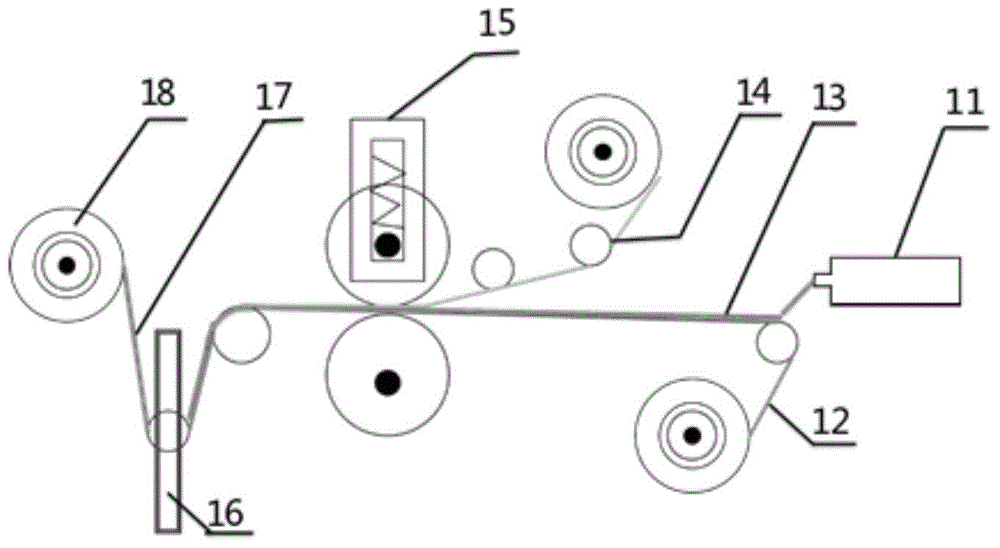

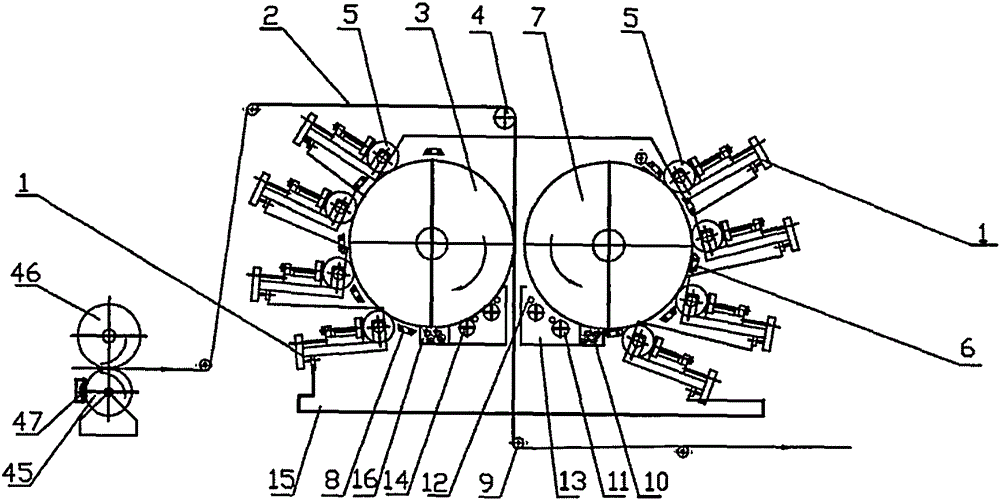

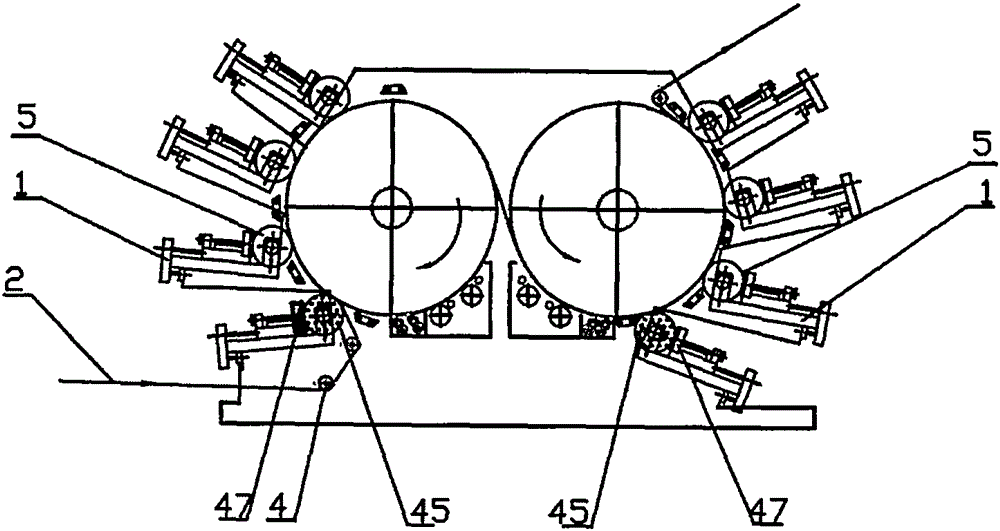

Dual-purpose printing equipment with functions of transfer printing and direct printing

InactiveCN105058968AModerate hardnessSmall compression deformationTransfer printingScreen printersEngineeringDirect printing

The invention discloses dual-purpose printing equipment with the functions of transfer printing and direct printing. The equipment consists of a preprocessing device and a printing device, wherein the preprocessing device consists of a reticulate pattern roller (45) and a bearing roller (46); the printing device consists of a front main roller and a rear main roller, and each main roller is matched with printing plate rollers, roller barrel washing devices and roller barrel drying devices. The dual-purpose printing equipment disclosed by the invention adopts integrated dual-purpose design with the functions of the transfer printing and the direct printing and can meet requirements for low cost and high speed of the direct printing, and the dual-purpose printing equipment can also meet requirements for high fineness of the transfer printing.

Owner:NEWTECH TEXTILE TECH DEV SHANGHAI

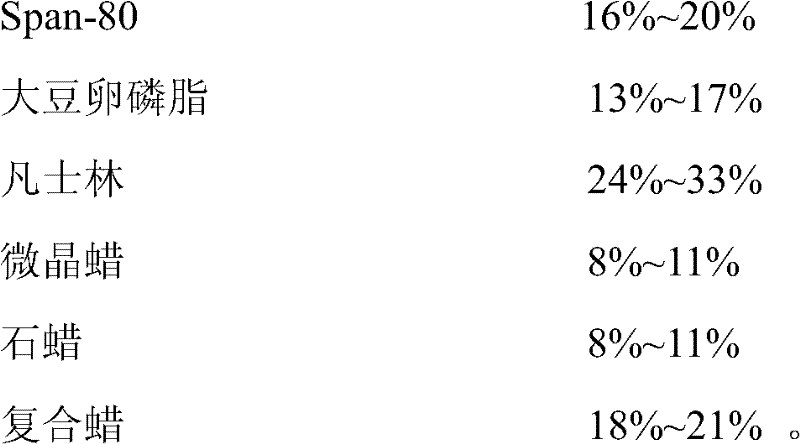

Special composite oil phase for emulsion explosive and preparation method thereof

ActiveCN102584501AExtensive sources of raw materialsLow costNon-explosive/non-thermic compositionsParaffin waxEmulsion explosive

The invention provides a special composite oil phase for an emulsion explosive and a preparation method thereof, which belong to the technical field of explosive composition. The composite oil phase comprises Span-80, soybean lecithin, vaseline, a microcrystalline wax, a paraffin wax and a composite wax, wherein during producing the emulsion explosive, an emulsion and a blending wax are melted after being mixed or mixed after being melted according to a mass ratio of 1:2 so as to obtain the special composite oil phase for the emulsion explosive. By using the composite oil phase provided by the invention, the problems of low performance, over-quickness for damping detonation capacity as well as short storage period of the traditional emulsion explosive are solved; and the special composite oil phase for the emulsion explosive, provided by the invention, can be used for producing the special composite oil phase materials for the emulsion explosive.

Owner:SHANDONG TIANBAO CHEM

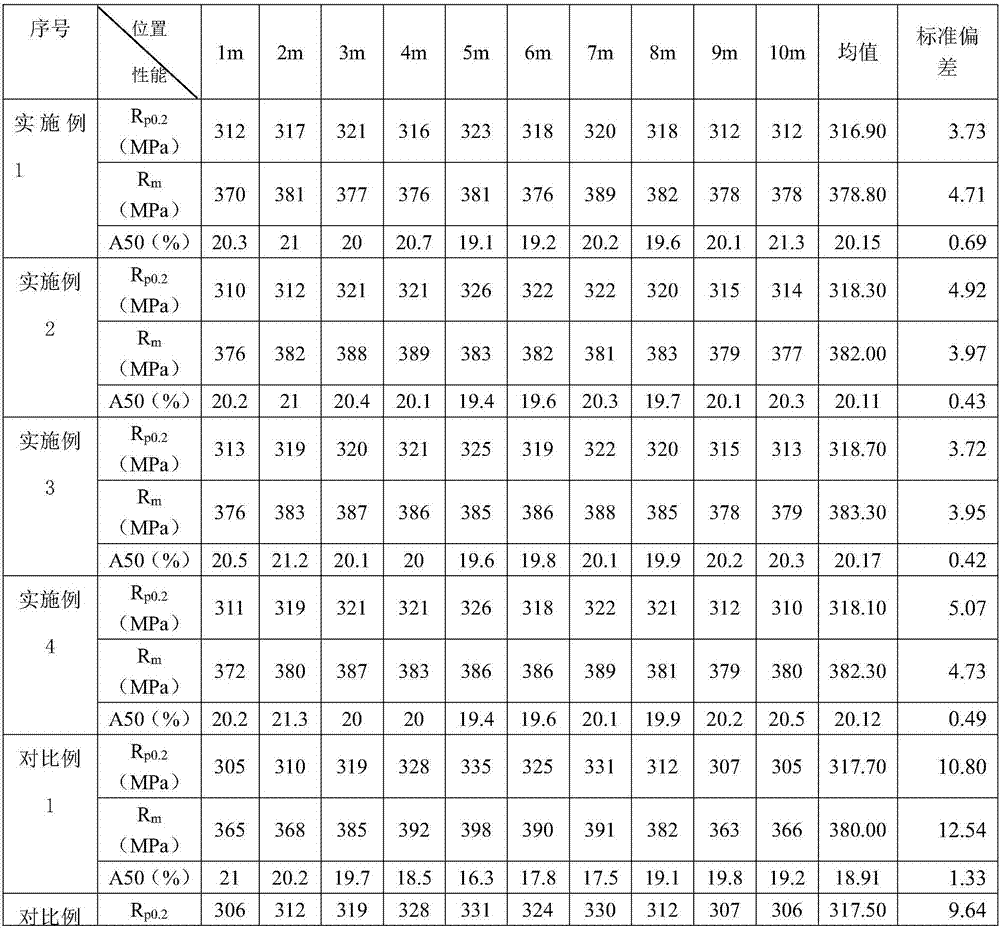

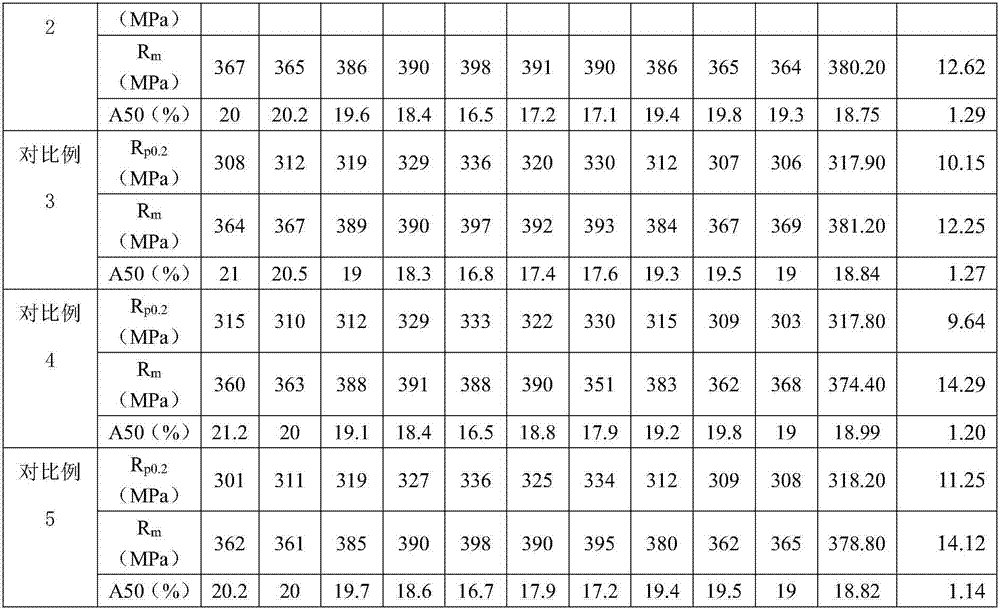

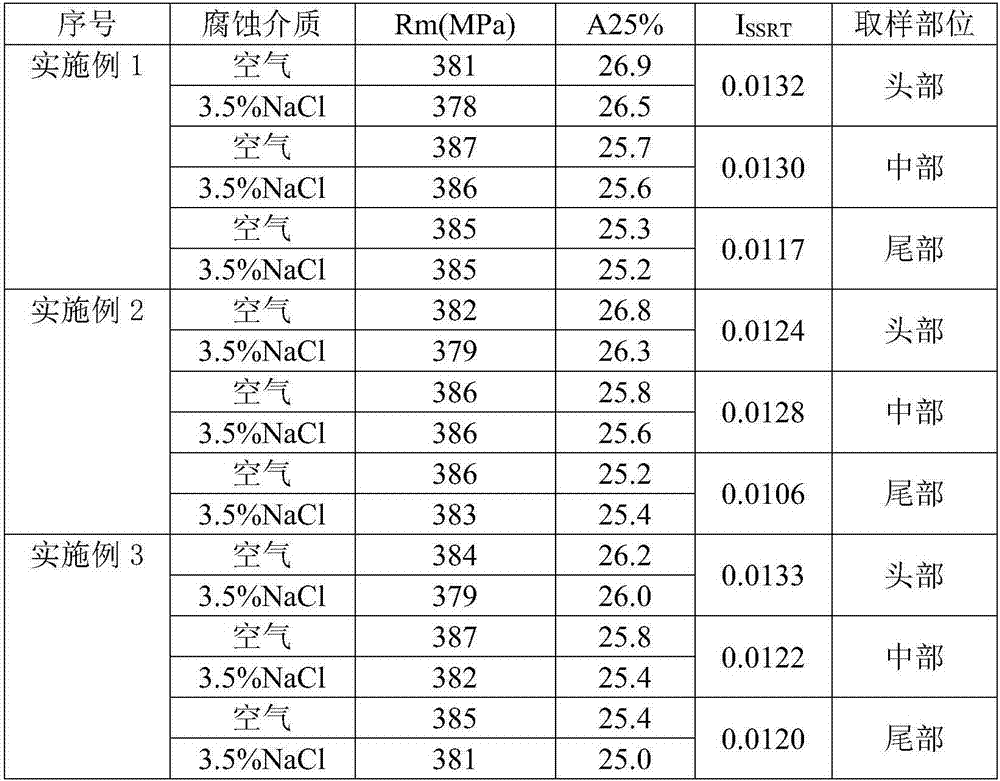

Preparation process of Al-Zn-Mg alloy profile for high-speed train body

The invention relates to a preparation process of a Al-Zn-Mg alloy profile for a high-speed train body. The preparation process comprises the following steps that (1), extruding is carried out; (2), roll bottom continuous solution hardening is carried out; (3), stretching is carried out; (4), plate type three-stage aging oven for aviation aging treatment is carried out; (5), finished product saw cutting is carried out; and (6), packaging and storing are carried out. According to the preparation process of the Al-Zn-Mg alloy profile for the high-speed train body, roll bottom continuous solution hardening and plate type three-stage aging oven for aviation aging treatment are adopted for production, and thermal treatment precision can be greatly improved. Meanwhile, a gradient heating method is adopted during extrusion, the Al-Zn-Mg profile head and tail temperature difference is precisely controlled, the Al-Zn-Mg alloy profile head, middle and tail performance difference is reduced, and therefore the performance stability of the Al-Zn-Mg alloy profile is guaranteed.

Owner:广西南南铝加工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com