Supersonic motor thermosetting resin base friction material and friction layer manufacturing method and auxiliary tool

A technology of friction materials and ultrasonic motors, applied in the field of ultrasonic motors, can solve problems such as low surface tension and difficult stator friction layers, and achieve the effects of suitable hardness, excellent output characteristics, and superior wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

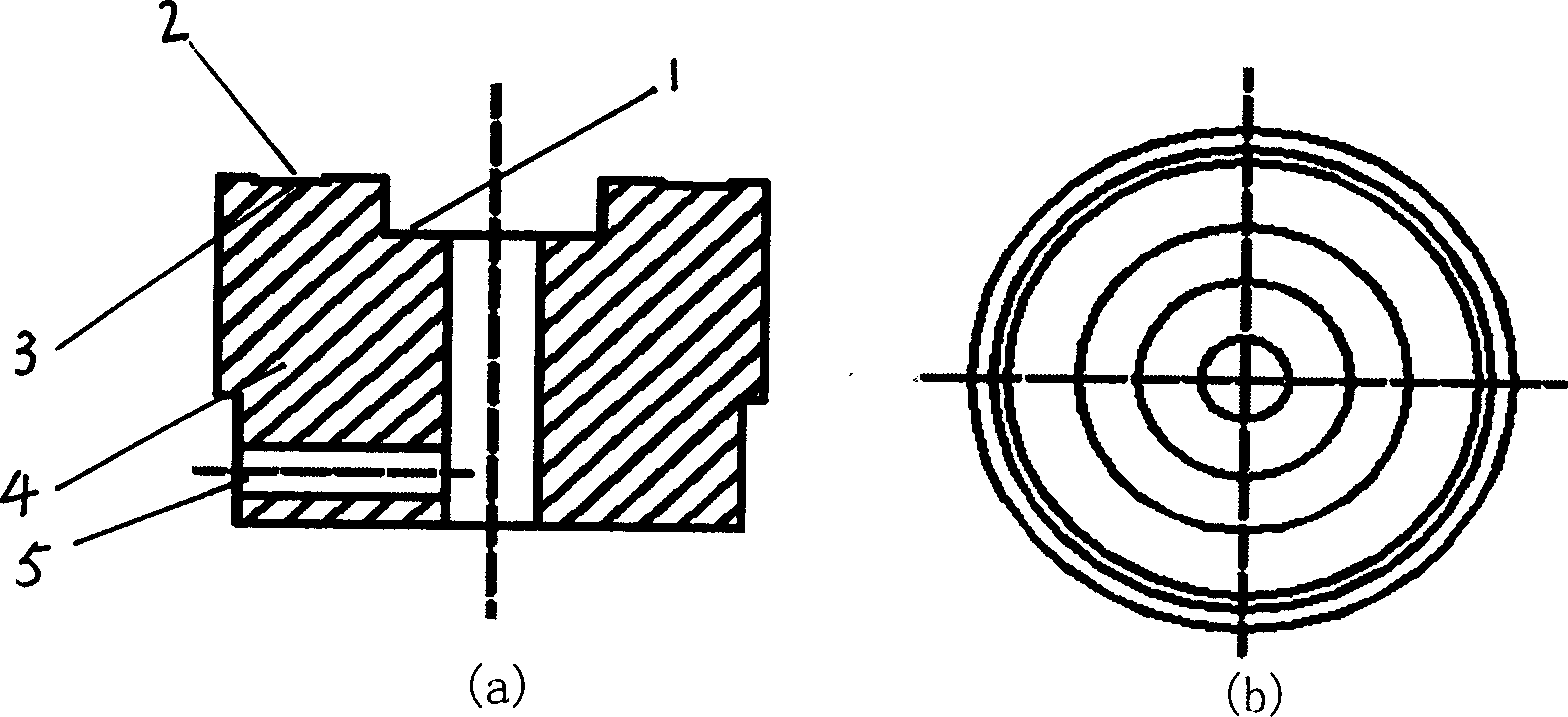

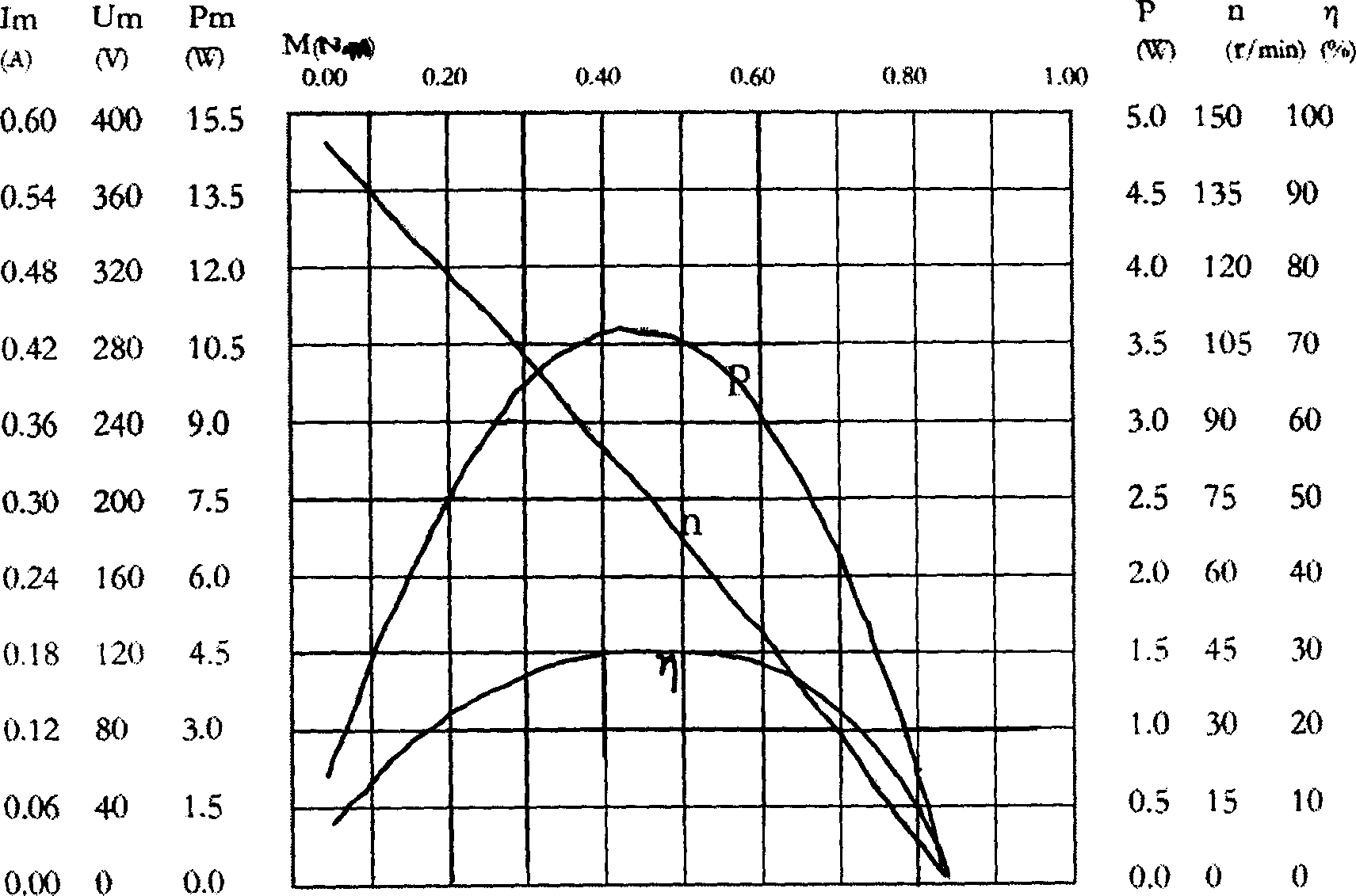

Image

Examples

specific Embodiment approach 1

[0031] Embodiment 1: A thermosetting resin-based friction material for an ultrasonic motor, its composition and mass percentage: 47% epoxy resin, 33% curing agent, 15% nano wear-resistant powder, 10% carbon fiber and 5% copper powder.

[0032] The method for making the friction layer of the ultrasonic motor by using the above-mentioned materials comprises the following steps:

[0033] 1. At room temperature, mix the epoxy resin-based ultrasonic motor friction material according to the above ingredients and mass ratio, and stir evenly;

[0034] 2. Directly stick and coat the prepared material on the specially designed rotor or stator test piece which has not yet been formed;

[0035] 3. Put the rotor or stator coated with friction material at a temperature of 30°C to 45°C, vibrate, level and remove the gas in the material through an ultrasonic vibrator;

[0036] 4. Put the test piece in the oven and bake it at 50-90°C for 30-180 minutes;

[0037] 5. Machining the grilled test...

specific Embodiment approach 2

[0041] Embodiment 2: A thermosetting resin-based ultrasonic motor friction material, its composition and mass percentage: 38.2% epoxy resin and 26.8% curing agent, 12.5% nano wear-resistant powder, 12.5% carbon fiber and 10% copper powder. In this embodiment, copper powder is added to improve the heat dissipation of the friction layer. The fabrication method of the friction layer of the ultrasonic motor is similar to that in Embodiment 1.

specific Embodiment approach 3

[0042] Specific embodiment 3: A thermosetting resin-based ultrasonic motor friction material, its composition and mass percentage: 38.2% epoxy resin and 26.8% curing agent, 5% nano wear-resistant powder, 15% carbon fiber, 5% copper oxide and poly Tetrafluoroethylene 5%, copper powder 5%. In this embodiment, polytetrafluoroethylene is added in Embodiment 1 to reduce the hardness of the material and reduce the wear on the counter surface. The fabrication method of the friction layer of the ultrasonic motor is similar to that in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com