Centrifugally cast composite roller and method for manufacturing same

A technology of centrifugal casting and composite rolls, which is applied in the manufacture of tools, chemical instruments and methods, rolls, etc., can solve the problems of increased manufacturing costs, deterioration of processability, foreign matter intrusion, etc., and achieves easy machining, excellent wear resistance, Effect of manufacturing cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3 and comparative example 1 and 2

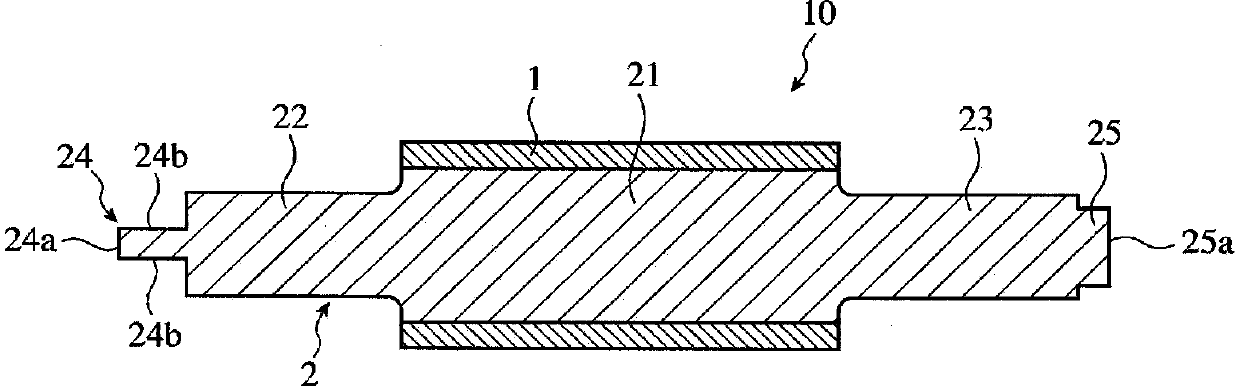

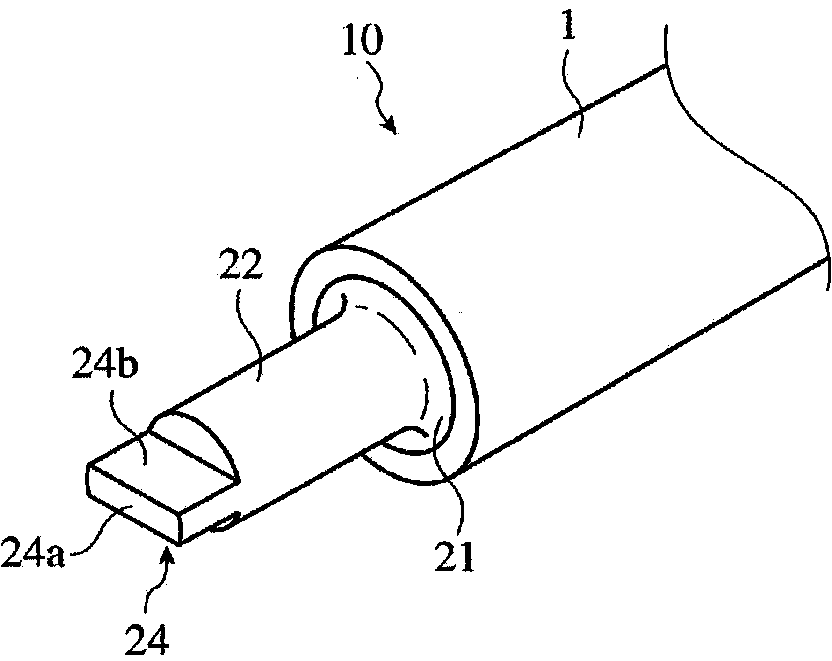

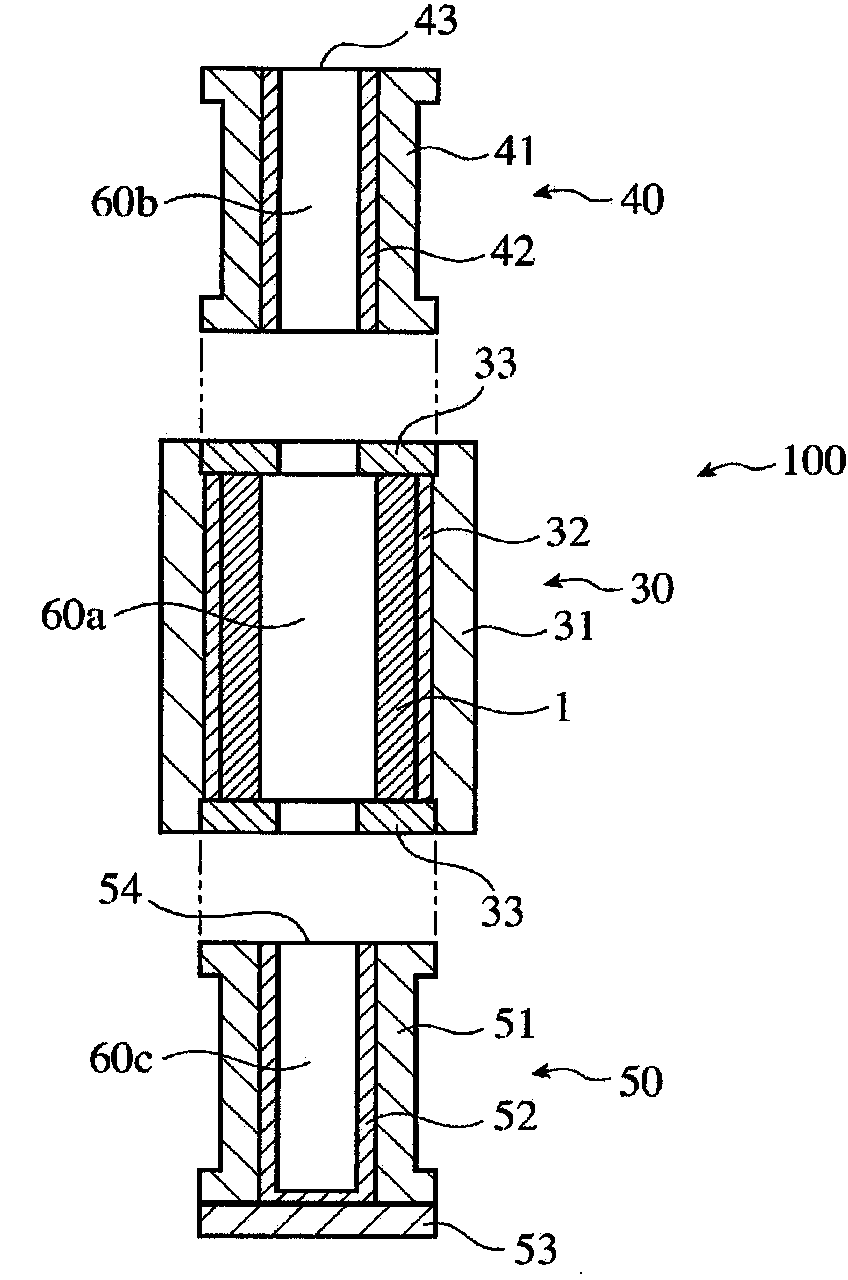

[0121] A cylindrical mold 30 (800 mm in inner diameter, 2500 mm in length) having the structure shown in FIG. After the outer layer 1 is solidified, the cylindrical mold 30 with the outer layer 1 (thickness: 90 mm) formed on the inner surface is erected, and placed on the hollow lower mold 50 (inner diameter: 600 mm, length: 1500 mm) for forming the drive side shaft portion 22 A cylindrical casting mold 30 is vertically arranged, and a hollow upper mold 40 (inner diameter 600mm, length 2000mm) for forming the driven side shaft portion 23 is vertically arranged on the cylindrical casting mold 30, thereby constituting the static mold shown in Fig. 3 (b). Place casting mold 100 for casting.

[0122] A nodular cast iron melt having the composition shown in Table 1 was poured from the upper opening 43 into the cavity 60 of the static casting mold 100 . The liquid level of the nodular cast iron melt is determined by the lower mold 50 for forming the driving side shaft portion 22, the...

Embodiment 4

[0125] After forming an intermediate layer (thickness: 20 mm) of the composition shown in Table 1 on the inner surface of the outer layer 1, the cylindrical mold 30 was erected, and a composite roll was formed in the same manner as in Example 1. As a result of ultrasonic inspection, it was confirmed that the outer layer 1, the middle layer, and the inner layer 2 were firmly welded together.

[0126] For Examples 1 to 4 and Comparative Examples 1 and 2, the casting temperatures of the outer layer, inner layer, and intermediate layer, and the lower mold 50 for forming the drive side shaft portion 22, the cylindrical mold 30 for forming the core portion 21, and the Table 2 shows the average rising speed of the inner layer melt surface in the upper die 40 for forming the movable side shaft portion 23 . The average rate of rise of the molten surface of the inner layer was calculated by measuring the weight of the molten inner layer and measuring the casting time. In addition, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com