Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

259results about How to "Reduced dimensional accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

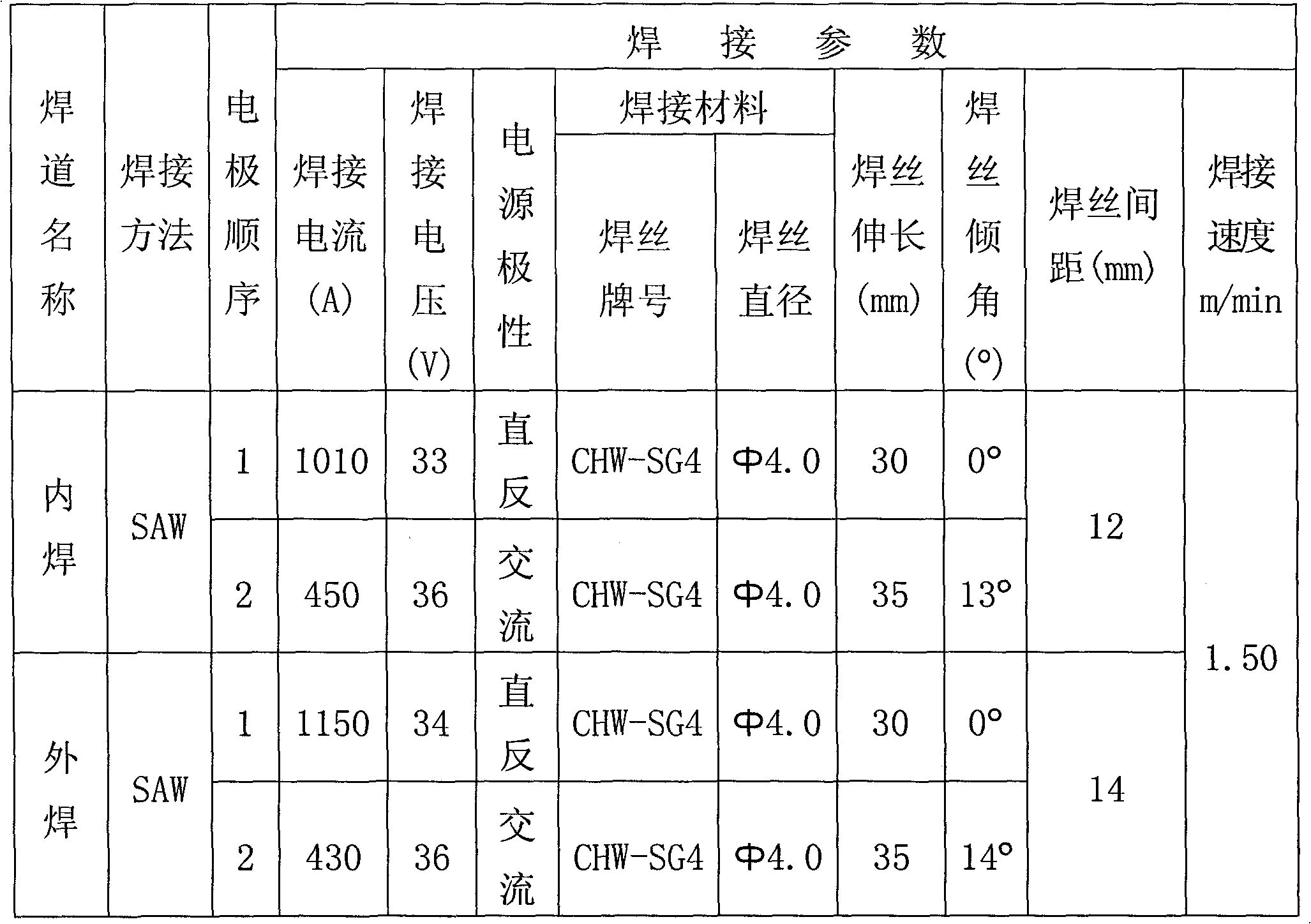

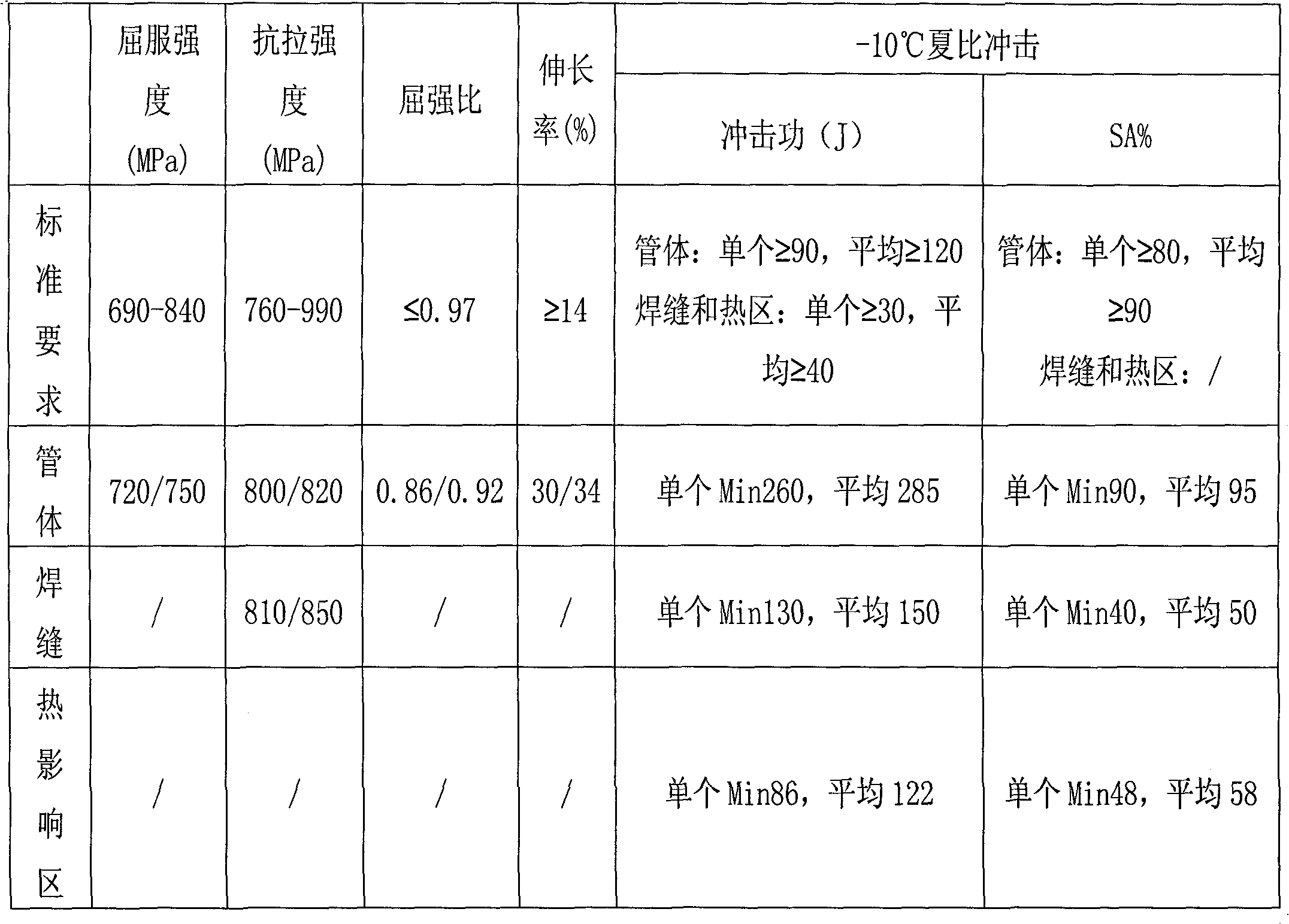

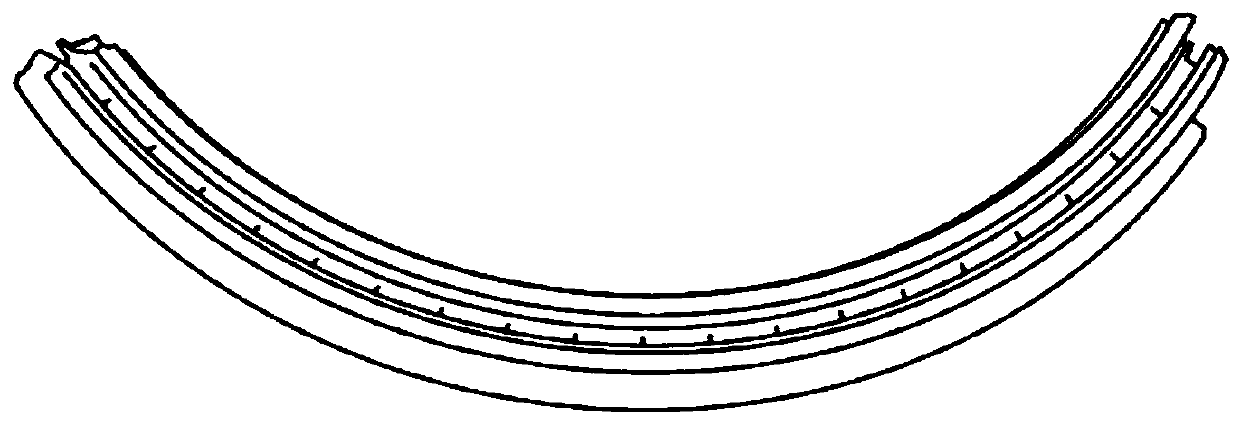

Method for manufacturing high-strength X80 steel spiral welded pipe

InactiveCN101205587AReduced dimensional accuracyImprove docking efficiencyArc welding apparatusWelding/cutting media/materialsUltrasound testSteel plates

The invention discloses a method for manufacturing a high-strength (X 80) steel spiral weld pipe. The weld pipe adopts a parent metal of X 80 rolled steel plate, and the chemical compositions of weld pipe are: 0.02 to 0.09 percent of C, 0.10 to 0.42 percent of Si, 1.50 to 1.85 percent of Mn, less than or equal to 0.022 percent of P, less than or equal to 0.005 percent of S, less than or equal to 0.45 percent of Cr, less than or equal to 0.50 percent of Ni, less than or equal to 0.30 percent of Cu, less than or equal to 0.35 percent of Mo, less than or equal to 0.025 percent of Ti, less than or equal to 0.11 percent of Nb, less than or equal to 0.06 percent of V, less than or equal to 0.06 percent of Al, less than or equal to 0.008 percent of N, less than or equal to 0.0005 percent of B, and less than or equal to 0.23 percent of Pcm. The manufacturing procedures includes: decoiling, leveling, edge milling, prebending, molding, internal welding, external welding, pipe end expending, hierarchical ultrasonic examination of parent metal, X-ray examination of welded seam, hydraulic pressure test, ultrasonic examination of welded seam, pipe end chamfering, finished product examination, etc. The (X 80) steel spiral weld pipe( ID: 1219mm, thickness:18.4mm) manufactured by the invention successfully solves the problem of poor stability and unsatisfactory welded seam performance, etc. in the manufacturing process of the high-strength (X 80) steel spiral weld pipe, thereby greatly improving the pass-rate and working efficiency.

Owner:CNPC BOHAI EQUIP MFG +1

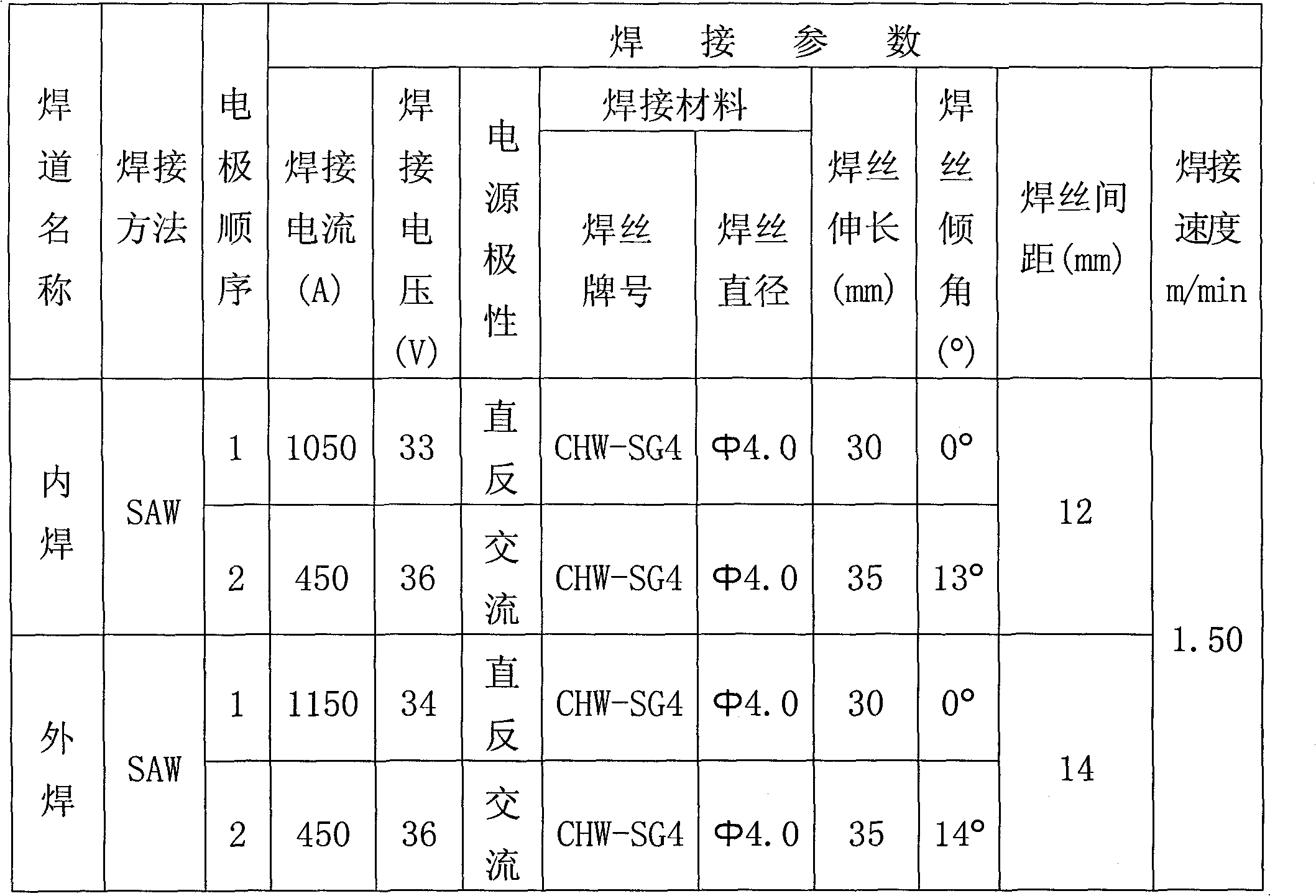

Method for manufacturing high-strength X100 steel grade spiral seam submerged arc welded pipe

ActiveCN101797600ATo achieve effective detectionFully automatedArc welding apparatusMilling equipment detailsProduct inspectionX-ray

The invention discloses a method for manufacturing a high-strength X100 steel grade spiral seam submerged arc welded pipe. The method comprises the following steps: uncoiling, flattening, edge milling, pre-springing, molding, inside welding, outside welding, pipe end belling, base metal layering ultrasonic examination, weld seam X ray inspection, hydrostatic test, weld seam ultrasonic inspection, pipe end chamfering and finished product inspection. In the technical steps of the preparation method, double edge milling process, pre-springing process and pipe end belling process are added so as to successfully solve the technical problems that the high-strength X100 steel grade spiral seam submerged arc welded pipe has poor molding stability, the welding joint performance cannot meet technical requirement and the like.

Owner:NORTH CHINA GASOLINEEUM STEEL PIPE +3

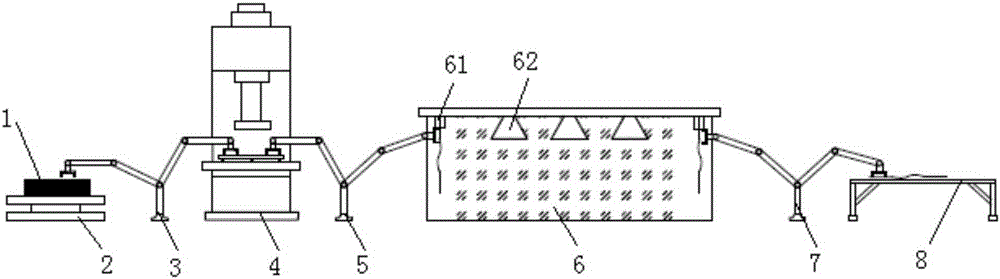

Multi-station continuous hot stamping production line and method

ActiveCN105215160AGuaranteed surface qualityReduce lossesShaping toolsMetal-working feeding devicesHot stampingProduction line

The invention discloses a multi-station continuous hot stamping production line and method. The production line comprises a material loading table, a feeding robot, a press unit, a material conveying robot, a quenching device, a material unloading robot and a conveyor belt which are arranged in sequence. The press unit comprises a heating device, a mould device and at least one press used for installation of the mould device; the heating device is used for wholly or locally heating a prefabricated blank to obtain a hot blank, and the mould device is used for conducting stamping forming, pressure maintaining setting and trimming and punching on the hot blank to obtain a hot stamped part. The rapid heating, stamping forming, pressure maintaining setting, trimming and punching and quenching can be continuously completed, so that the heating efficiency is improved, and the transportation process before punching of the hot blank is also avoided. For steel plates, stamped parts are blanked at a high temperature, increasing of cutting difficulty caused by generation of a martensitic structure at normal temperature is avoided, the blanking force is reduced, and the optimal blanked edge can be obtained.

Owner:WUHAN UNIV OF TECH

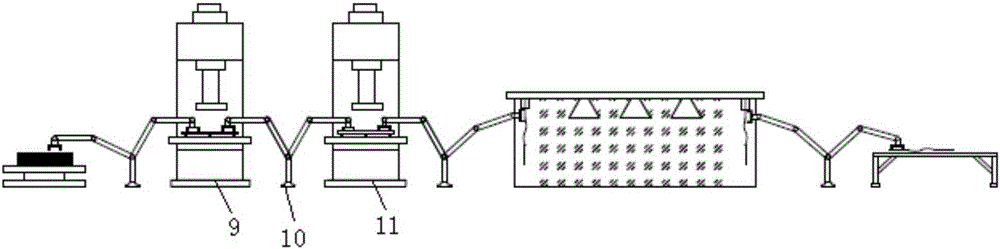

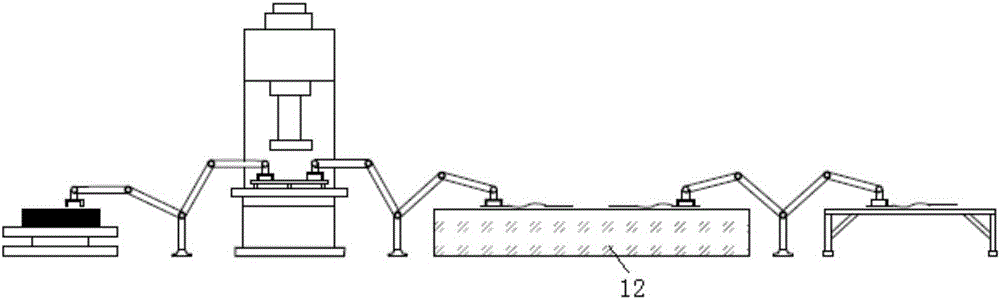

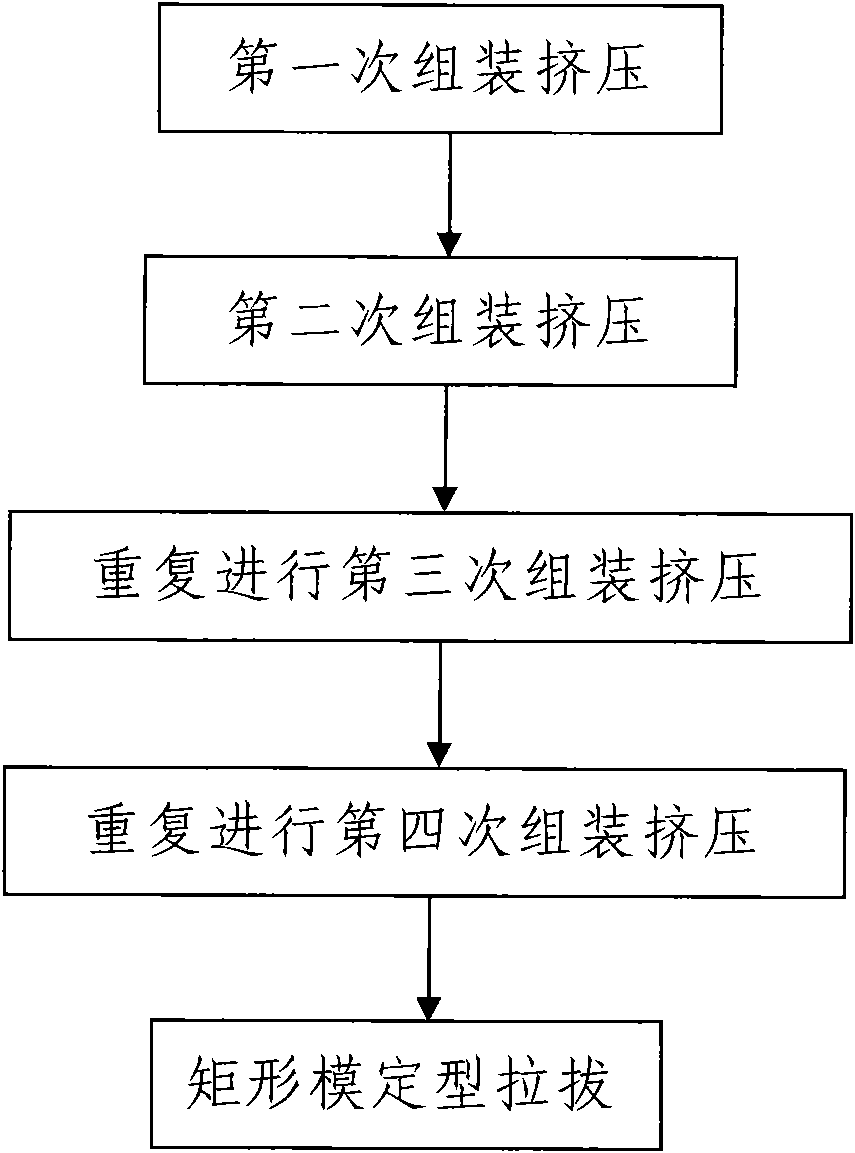

Preparation method of Cu-Nb multi-core composite wire with rectangular cross-section

InactiveCN101872660AThe process steps are simpleShort processSuperconductors/hyperconductorsManufacturing extensible conductors/cablesL&D processExtrusion

The invention discloses a preparation method of a Cu-Nb multi-core composite wire with the rectangular cross-section, which comprises the following steps: firstly, carrying out first extrusion assembly and drawing for a single pure Nb rod and a first outer oxygen-free copper sheathing; secondly, carrying out second extrusion assembly and obtaining a first Cu-Nb multi-core composite filament; secondly, according to the extrusion assembly method and related process parameters in the step 2, repeatedly carrying out third extrusion assembly; thirdly, according to the extrusion assembly method and related process parameters in the step 2, repeatedly carrying out fourth extrusion assembly; and finally, setting and drawing by a rectangular mold. The invention has simple process step, short process, high production efficiency, low preparation cost and good use effect, and the produced Cu-Nb multi-core composite wire has superior performance; and the invention is suitable for mass production, can better control the dimensional accuracy of the rectangular cross-section, and can machine any size and length of hundred-million-magnitude-order Cu-Nb multi-core composite wires with the rectangular cross-section.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

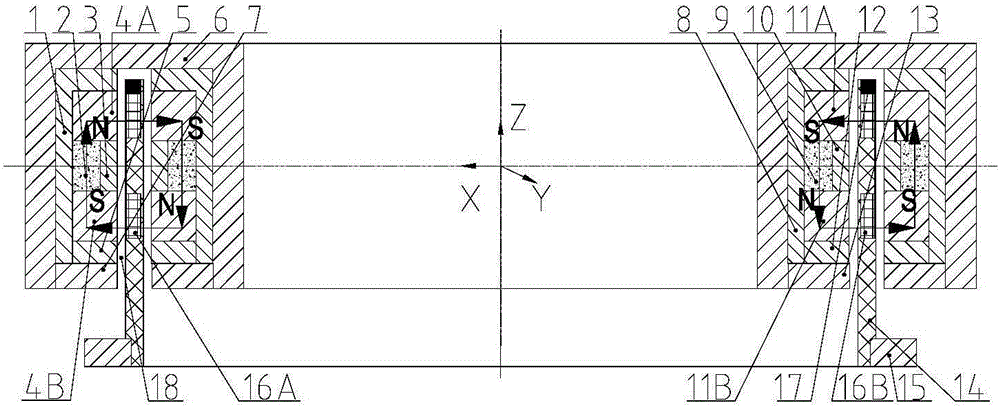

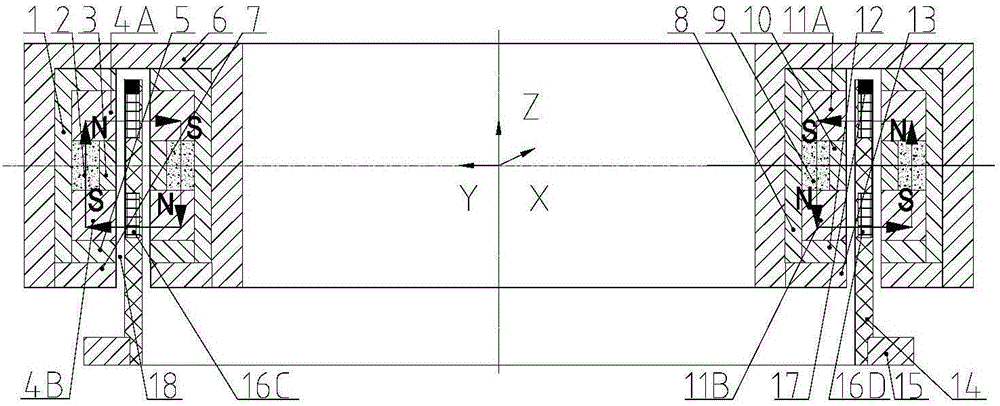

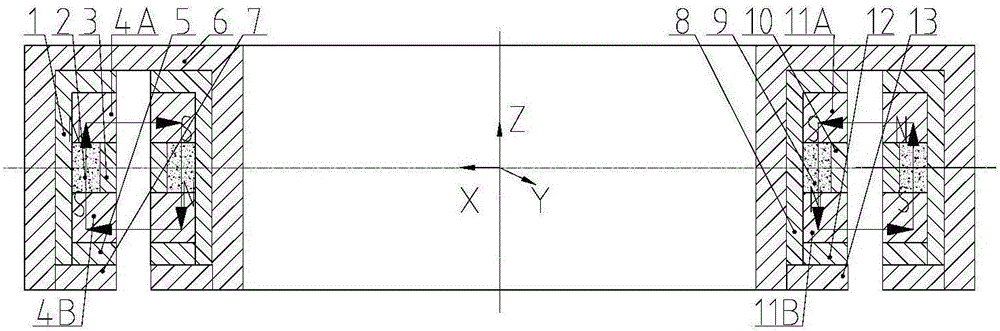

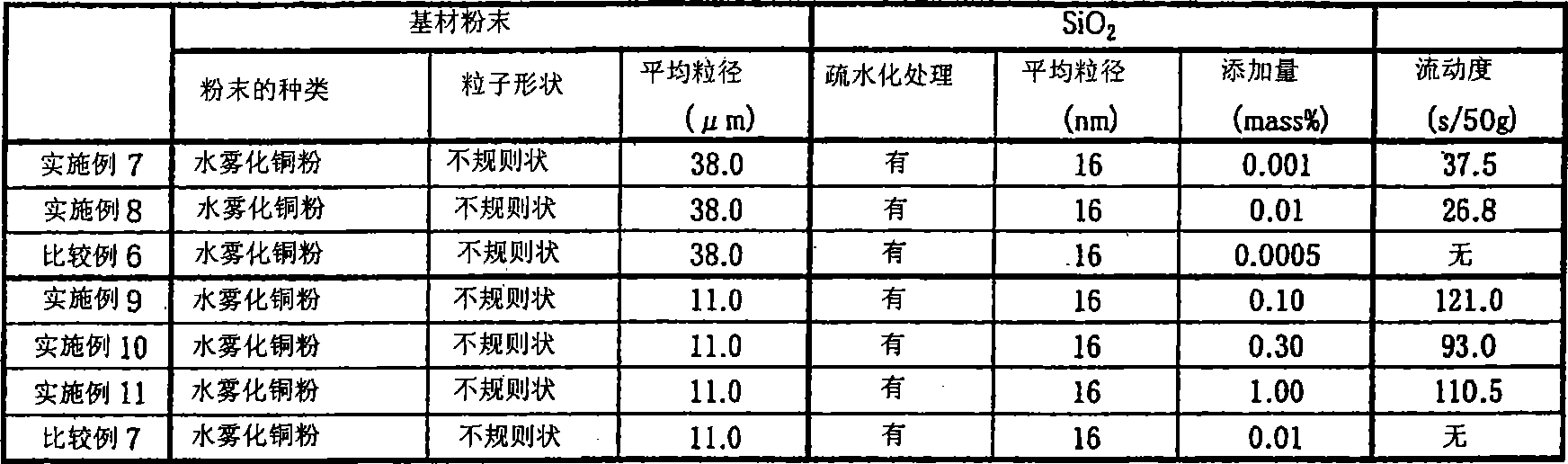

Lorentz force type magnetic bearing capable of realizing double permanent magnet deflection

ActiveCN106090010AReduce lapsReduced dimensional accuracyMagnetic bearingsMagnetic bearingMagnetic poles

The invention discloses a Lorentz force type magnetic bearing capable of realizing double permanent magnet deflection. The bearing comprises a rotor system and a stator system, wherein the rotor system mainly comprises an outer mounting sleeve, outer magnetic steel, an outer magnetism isolating ring, an outer upper magnetism conducting ring, an outer lower magnetism conducting ring, an outer lower magnetism conducting ring lock nut, a turntable, an outer assembly lock nut, an inner mounting sleeve, inner magnetic steel, an inner magnetism isolating ring, an inner upper magnetism conducting ring, an inner lower magnetism conducting ring, an inner lower magnetism conducting ring lock nut and an inner assembly lock nut; the stator system mainly comprises a stator framework, an aluminum substrate, a winding and epoxy resin glue. The magnetic steel axial magnetization scheme is adopted, the number of magnetic steel turns is reduced, the gap flux density fluctuation caused by uneven magnetomotive force of the magnetic steel is reduced, the paramagnetic effect is realized by the aid of the magnetism conducting rings, the gap flux density fluctuation caused by assembly of the outer magnetic steel and the inner magnetic steel is further reduced, and high-precision deflection control torque can be realized. Besides, a magnetism conducting material is used as a magnetic pole material, precision machining of a magnetic pole surface is facilitated, and requirements for size precision and surface roughness of the magnetic steel are reduced.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

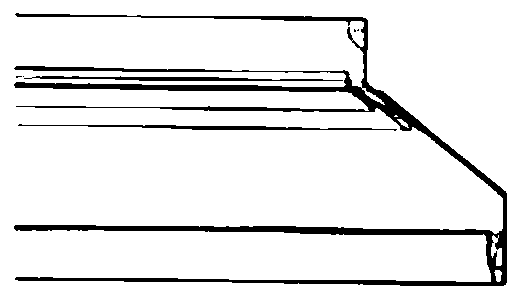

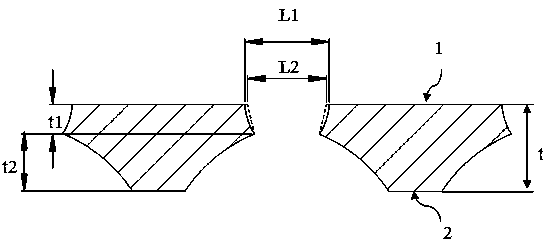

Alloy liquid extrusion casting forming device and process method thereof

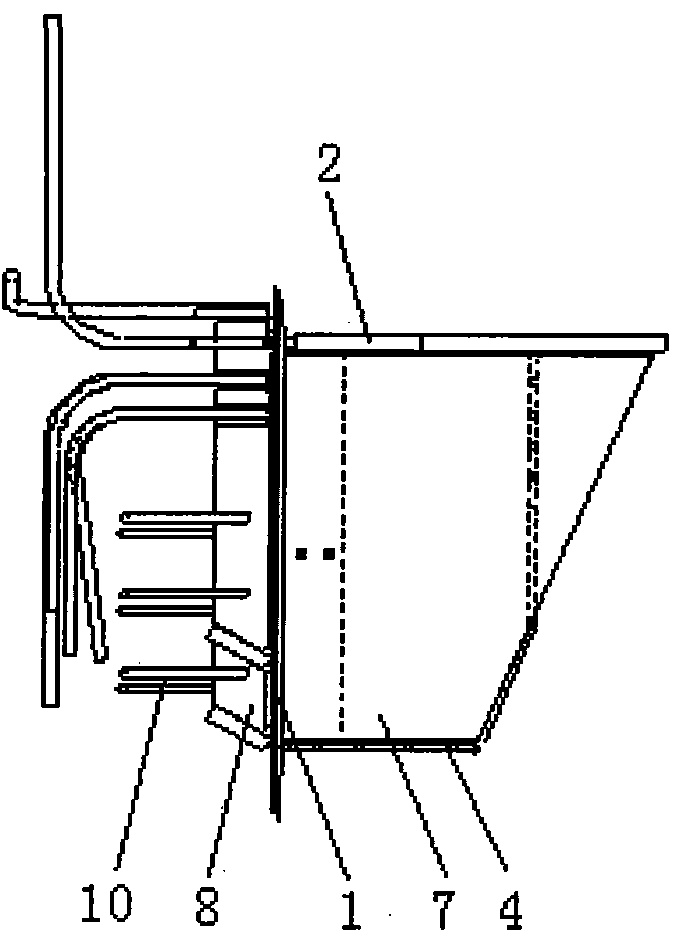

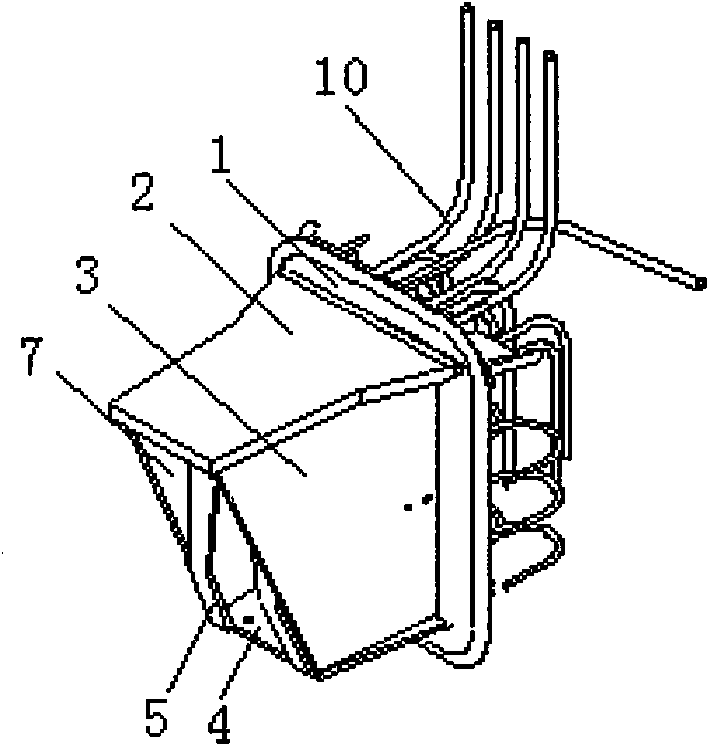

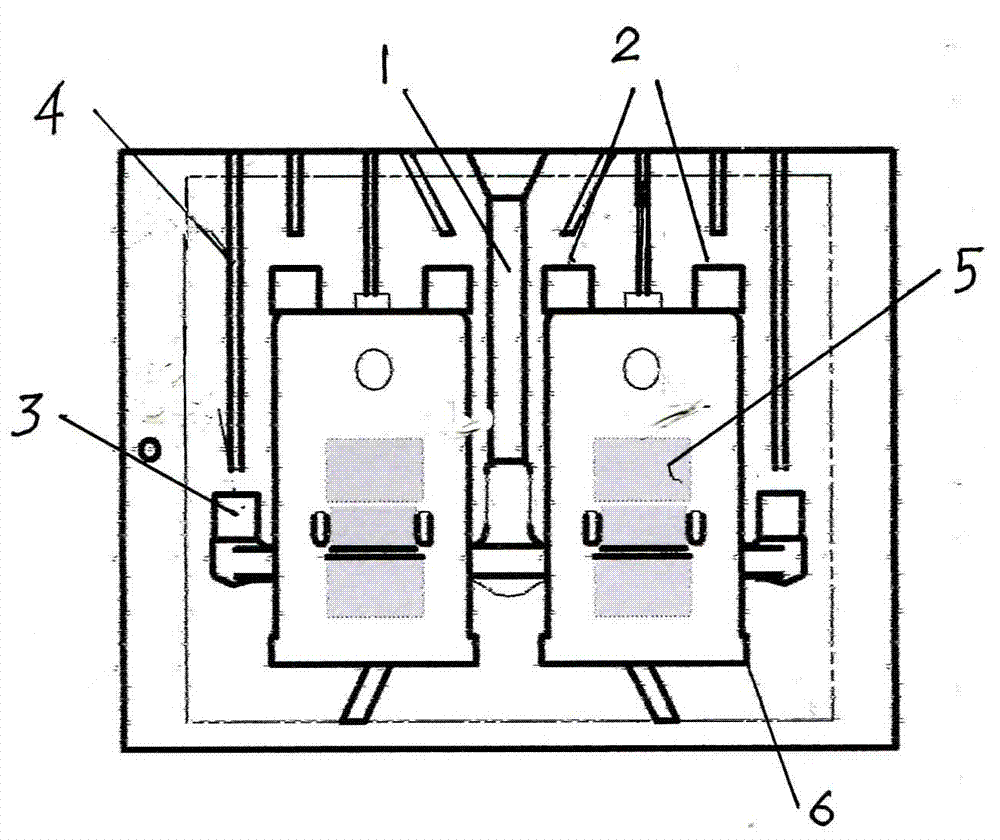

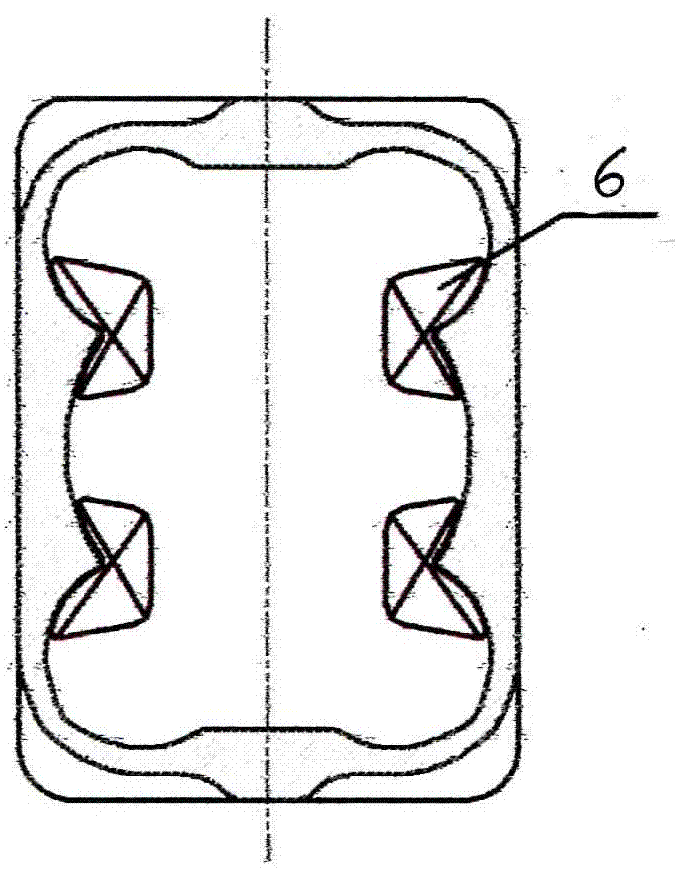

The invention discloses an alloy liquid extrusion casting forming device which comprises a hammerhead (1), a static die (2), a movable die (3) and a pouring slot (4). The device adopts the technical scheme that a declined and downward funnel-shaped pouring slot occupied by both the movable die and the static die arranged respectively by half is arranged on the parting plane on one side of a vertical die casting mould; a cylinder chamber type feed liquid chamber and the piston type hammerhead with a sealing knife is arranged on the static die; the hammerhead is controlled to be pushed up, and simultaneously the sealing knife seals the pouring slot. Firstly, feed liquid is filled into the a die cavity at high speed with low pressure, then the semisolid feed filled into the die cavity is extruded at low speed with high pressure, and the semisolid feed is gradually condensed to be formed under high-pressure low-speed extrusion. The alloy liquid extrusion casting forming device and the process method thereof integrate full casting functions of low-pressure filling and high-pressure extrusion into a whole, ensure that forming of alloy casting achieves the purposes of no gas entrapment, no cast seam, no mis-run, no forging crack, no fash, compact texture, fine crystal grain, high mechanical property, capability of performing thermal treatment and sealing, high dimensional accuracy, energy saving and low cost.

Owner:中建投(绍兴)机械科技有限公司

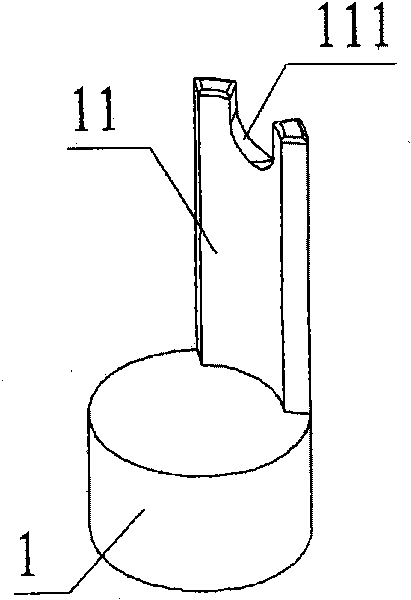

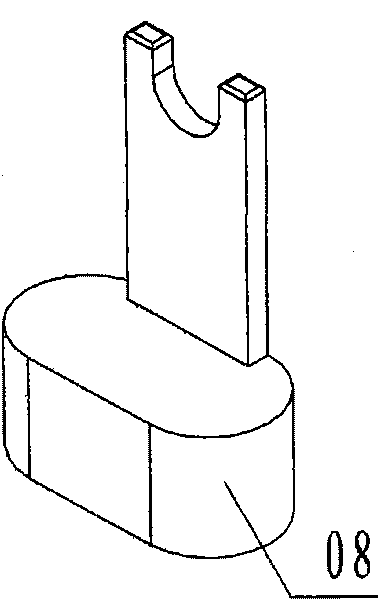

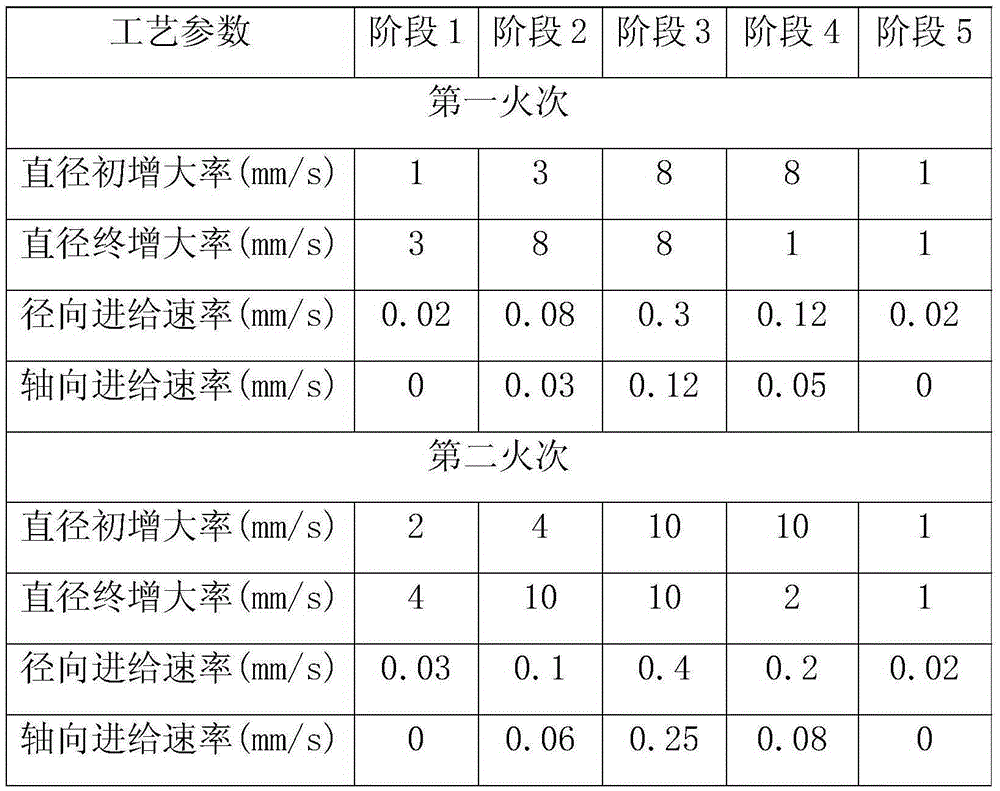

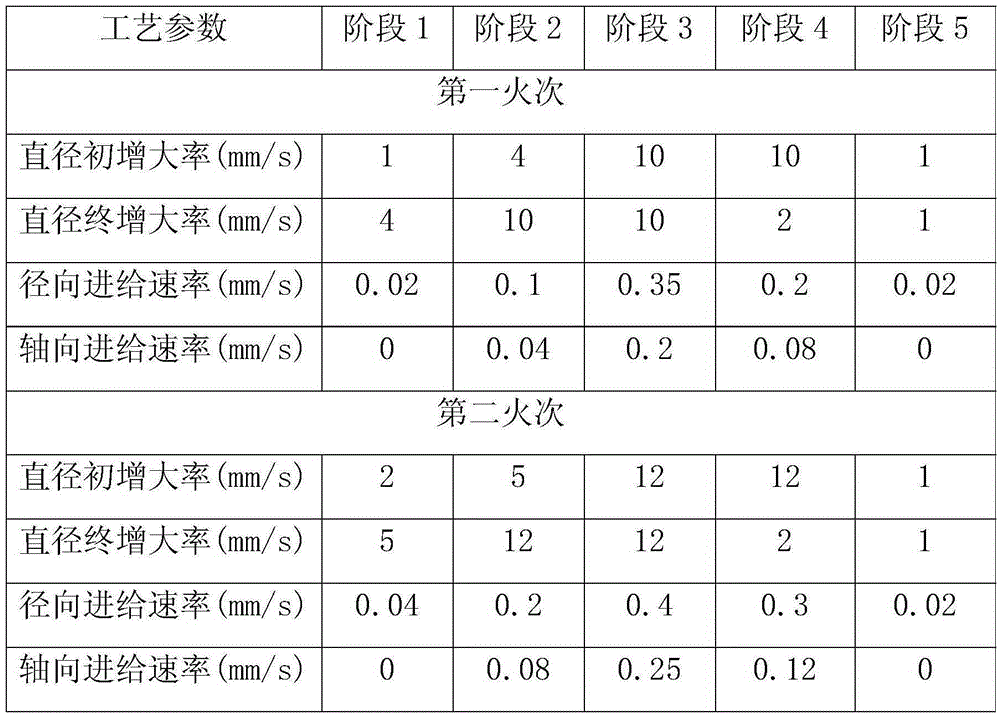

Rolling production method for integral aluminum alloy ring of super-large diameter

The invention belongs to the technical field of ring rolling forming and particularly relates to a rolling production method for an integral aluminum alloy ring of the super-large diameter. According to the technical scheme of the invention, a ring rolling forming technology is adopted, and through control over the rolling deformation temperature, the diameter increasement rate, the radial and axial feed rates, the radial and axial rolling reductions, the rolling ratio, the core roller diameter and the ring rolling heating number of an aluminum alloy ring piece of the super-large specification, the stable and continuous rolling process of the integral aluminum alloy ring of the super-large diameter is achieved, the size precision, the ovality and the radial and axial deformation quantities of the ring piece are effectively controlled, the product quality consistency is improved, the product percent of pass is increased, and technical index requirements of products are met.

Owner:CAPITAL AEROSPACE MACHINERY +1

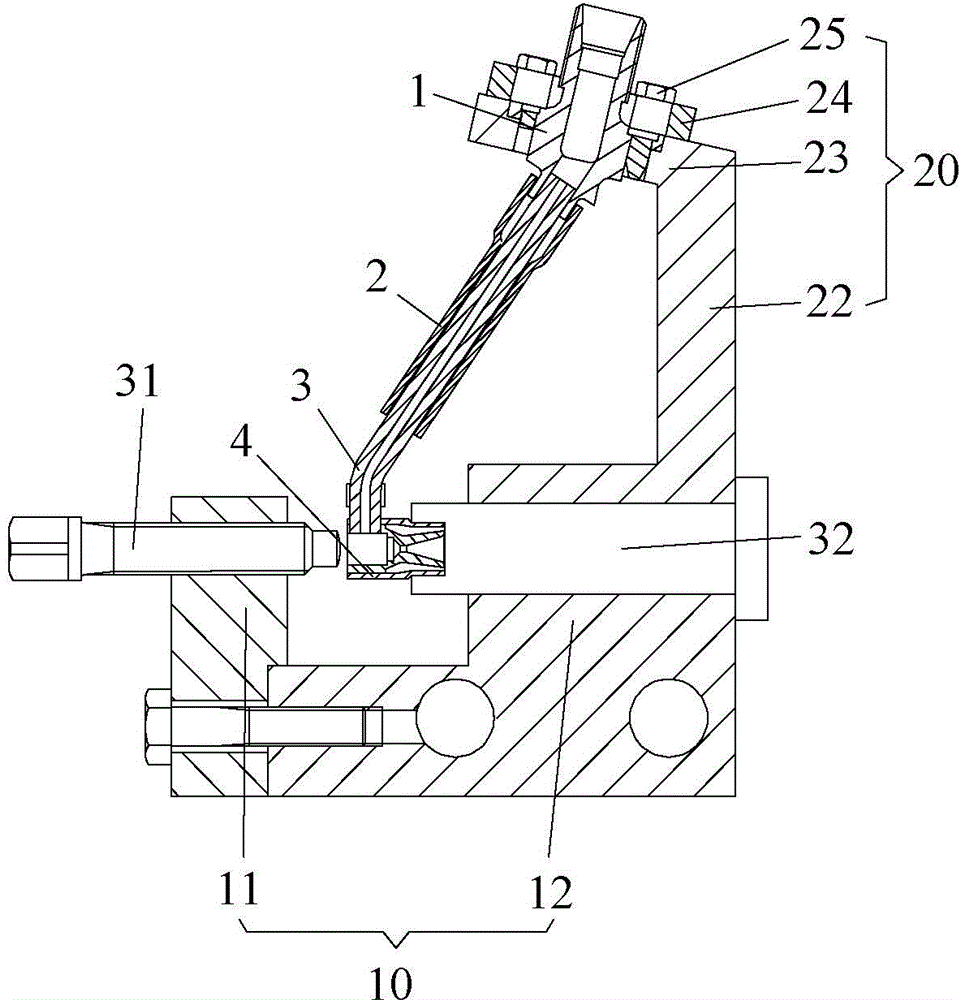

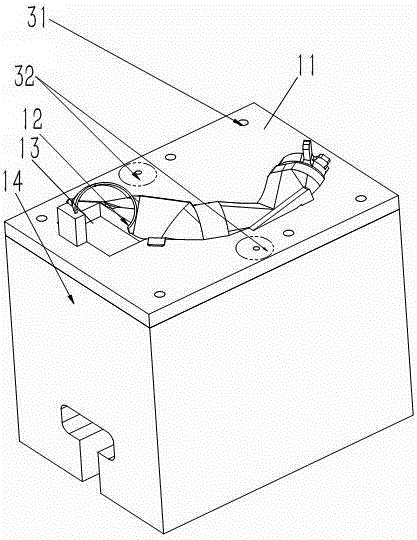

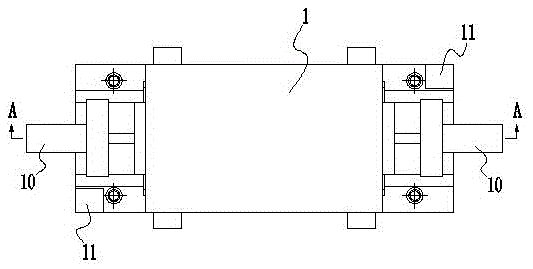

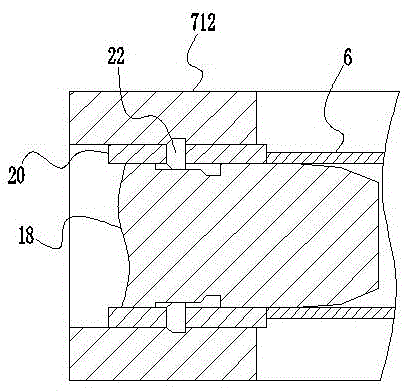

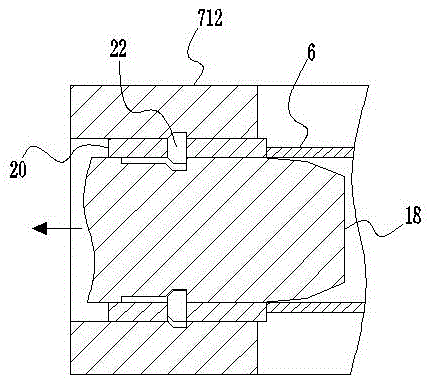

Fixing fixture and machining method for fuel spray nozzles

ActiveCN104097008AEffectively fixedConditions that limit deformationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachining

The invention provides a fixing fixture and a machining method for fuel spray nozzles. The fixing fixture for the fuel spray nozzles comprises a supporting assembly (10), a positioning assembly (20) and a clamping assembly (30). The positioning assembly (20) is arranged on the supporting assembly (10) and is provided with a supporting hole (21) which is matched with a spray nozzle seat (1) of each fuel spray nozzle; the clamping assembly (30) is arranged on the supporting assembly (10) and comprises a first clamping part (31) and a second clamping part (32), and a shell (4) of each fuel spray nozzle can be clamped by the first clamping part (31) and the second clamping part (32) from two opposite directions. According to the technical scheme, the fixing fixture and the machining method have the advantage that the problem of high braze welding difficulty due to complicated structures of fuel spray nozzles in the prior art can be effectively solved.

Owner:CHINA HANGFA SOUTH IND CO LTD

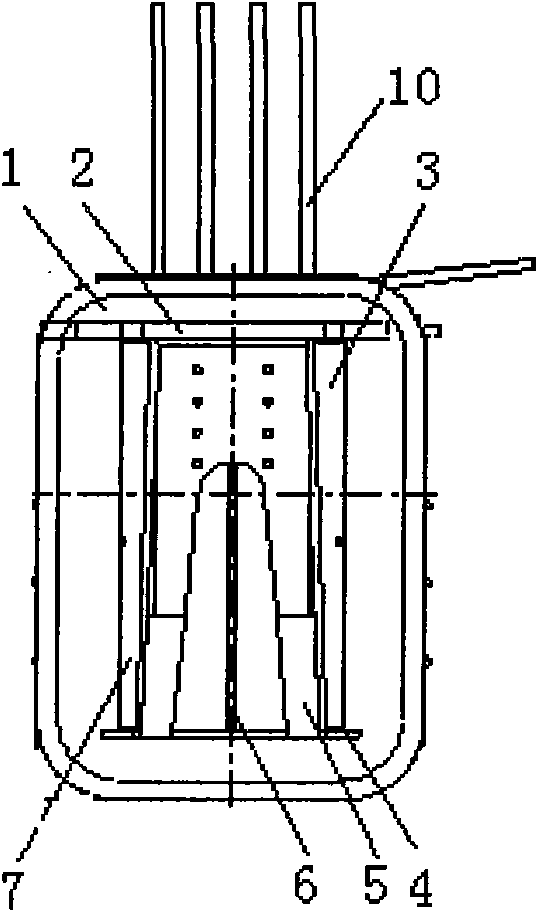

Selective laser melting manufacturing process for annular array blade guide

ActiveCN110202142AReduced dimensional accuracyControl stress deformationAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingAfter treatment

The invention relates to a selective laser melting manufacturing process for an annular array blade guide. The process comprises the steps of 1, model segment processing, specifically, an annular array blade guide three-dimensional model is equally divided into multiple sections; 2, material selection and setting of process parameters; 3, determining of a placing mode and designing of a support structure; 4, correcting of the size precision; 5, selective laser melting forming; 6, after-treatment, specifically, parts together with a base plate are placed into a vacuum heat treatment furnace, warm is kept for one hour at the temperature of 800 DEG C to eliminate residual stress, and then the parts are cut and the support structure is removed; and 7, welding, specifically, all the segmented parts are fixed on a welding fixture and welding is carried out to obtain an integral annular array blade guide part in an argon-arc welding or laser welding mode. The part size precision, stress deformation and surface roughness are well controlled in the process, mechanical performance of the parts is superior to traditional castings, the manufacturing cycle is short, and the efficiency is high.

Owner:航发优材(镇江)增材制造有限公司

Screw-thread steel rolling production line and production method thereof

ActiveCN110947759AReduced dimensional accuracyAchieving controlled rollingTemperature control deviceWork treatment devicesManufacturing lineIndustrial engineering

The invention relates to a screw-thread steel rolling production line, which comprises a roughing mill set, an intermediate mill set, a pre-water-cooling device and a finishing mill set, which are sequentially arranged in the rolled piece running direction. The intermediate mill set comprises a slitting rolling section which is a middle section of the intermediate mill set. The slitting rolling section comprises at least one roller with a slitting rolling pass, and two flying shears before finish rolling are arranged between the intermediate mill set and the finishing mill set side by side. According to the screw-thread steel rolling production line, the slitting rolling section is arranged in the intermediate mill set, that is, slitting rolling of screw-thread steel is completed in the intermediate rolling process; the two slit screw-thread steel bars are cooled through the pre-water-cooling device and then enter the finishing mill set for rolling, and screw-thread steel controlled rolling can be achieved in a true sense; and the slitting rolling section is arranged in the middle section of the intermediate mill set, and after slitting rolling, a rolled piece is rolled by a plurality of subsequent intermediate rolling mills and a plurality of finishing mills, so that the size precision of the rolled piece can be effectively controlled.

Owner:WISDRI ENG & RES INC LTD

Neutron absorbing material rapid semi-solid state temperature zone forming method

The invention relates to a neutron absorbing material rapid semi-solid state temperature zone forming method, and belongs to the technical field of semi-solid state forming. The method is suitable forsemi-solid state forming plate blanks of particle (nano and micro scale) reinforced metal base composites. The method comprises the steps that a ball milling technology is adopted to prepare boron carbide and aluminum alloy mixed powder, and through isostatic cool pressing, a green body is obtained; technologies of hot pressing sintering, hot isostatic pressing and the like are carried out on solid and liquid two-phase semi-solid state temperature zone of an aluminum alloy, a high-compactness composite with ceramic particles evenly dispersed and distributed in an aluminum alloy base body isobtained, hot forging pressing, hot extrusion or hot rolling treatment is carried out on the aluminum alloy base body deformation temperature zone, heat treatment is carried out, and a high-compactness aluminum-based boron carbide neutron absorbing material with the uniform structure is made. Non-metallic materials are easily added, the preparing time is short, the material compactness is high, micrograph morphology is good, and production cost is low.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Ring crane corbel for nuclear power station and manufacturing method thereof

ActiveCN101875475AReasonable structureMeet support requirementsLoad-engaging girdersBuilding constructionsNuclear powerArchitectural engineering

The invention relates to a ring crane corbel for a nuclear power station and a manufacturing method thereof, belonging to the technical field of building construction facilities. In the ring crane corbel, a box-type frame main body comprises a rectangular main body plate, wherein an upper cover plate and a lower cover plate are respectively soldered and fixed on one side of the main body plate; a left lateral plate, a right lateral plate and a middle stiffened plate are soldered between the upper cover plate and the lower cover plate; the left lateral plate, the right lateral plate and the middle stiffened plate are soldered with the main body plate; the two ends of one side of the lower cover plate are soldered with the two bottom edges of an external baffle; the upper part of the external baffle extends between the left lateral plate and the right lateral plate after the upper part of the external baffle is bent; the two lateral edges of the upper part of the external baffle are respectively soldered with the inner surfaces of the left lateral plate and the right lateral plate; the other side of the main body plate is soldered with a bent bar; and horizontal and vertical stiffened plates are respectively soldered on corresponding positions on the main body plate, which are soldered with the upper cover plate, the lower cover plate, the left lateral plate, the right lateral plate and the middle stiffened plate. After the ring crane corbel is adopted, the use requirement can be met, and reasonable assembly and soldering sequence are adopted, so the final quality of the ring crane corbel component can be ensured.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

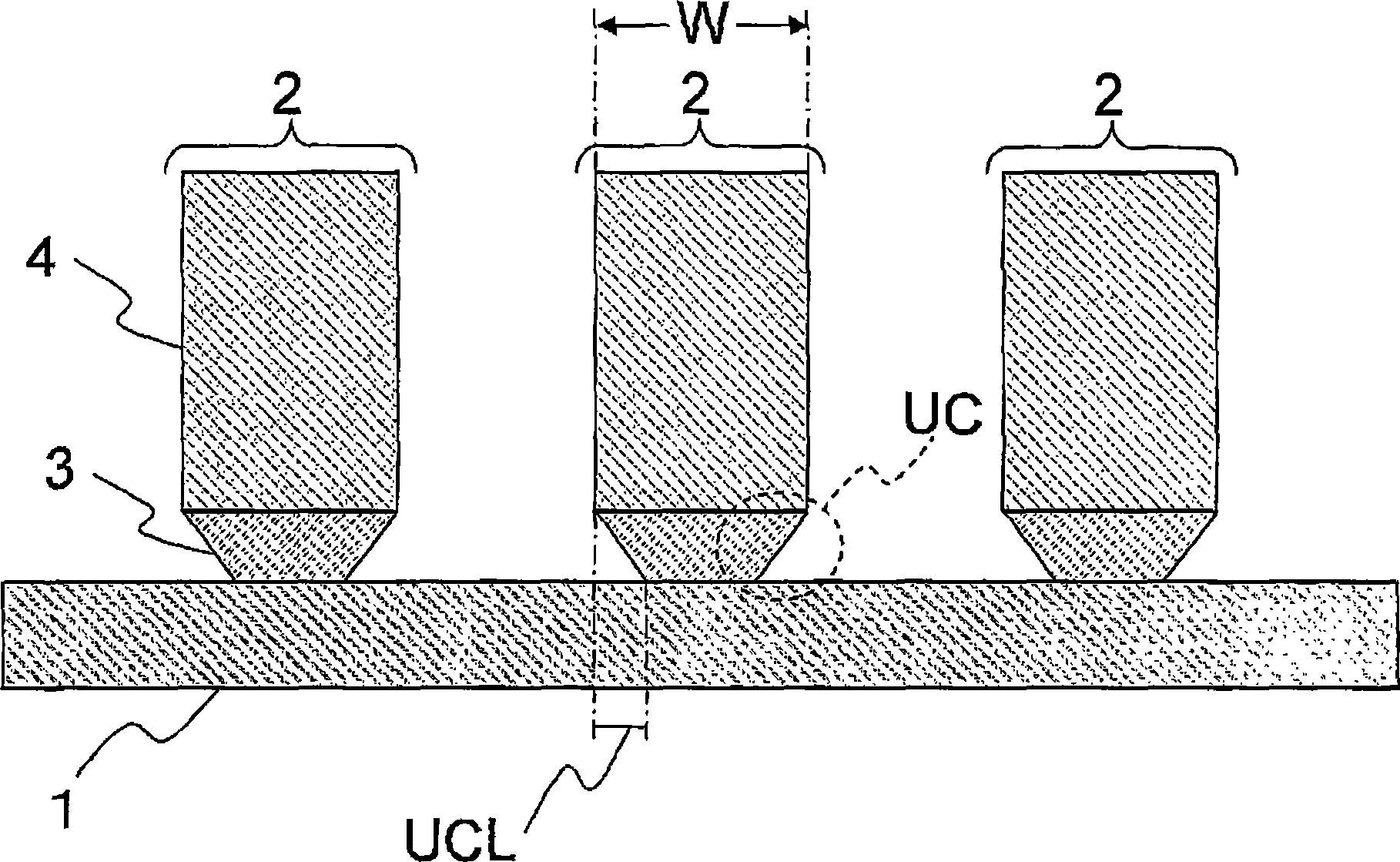

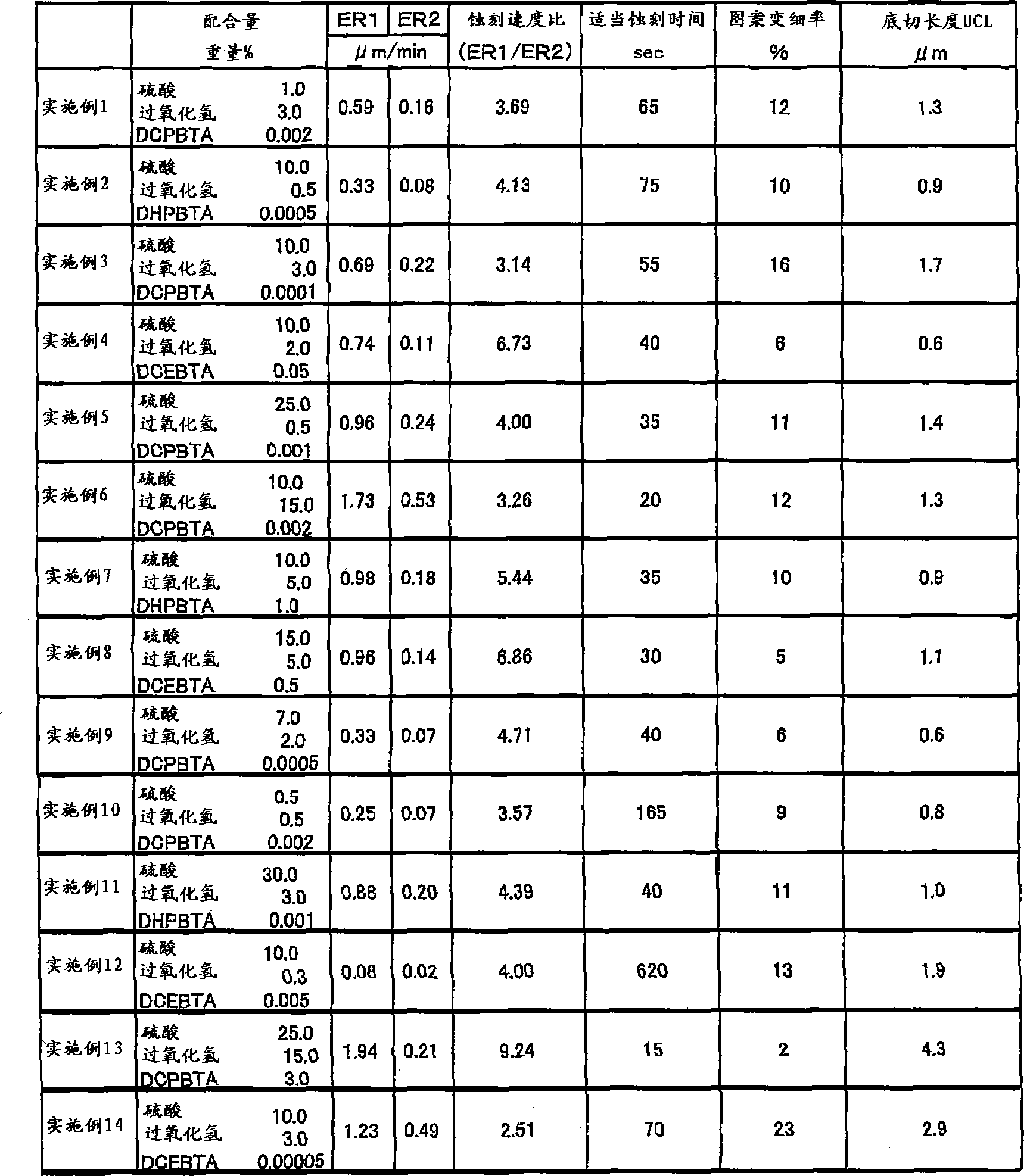

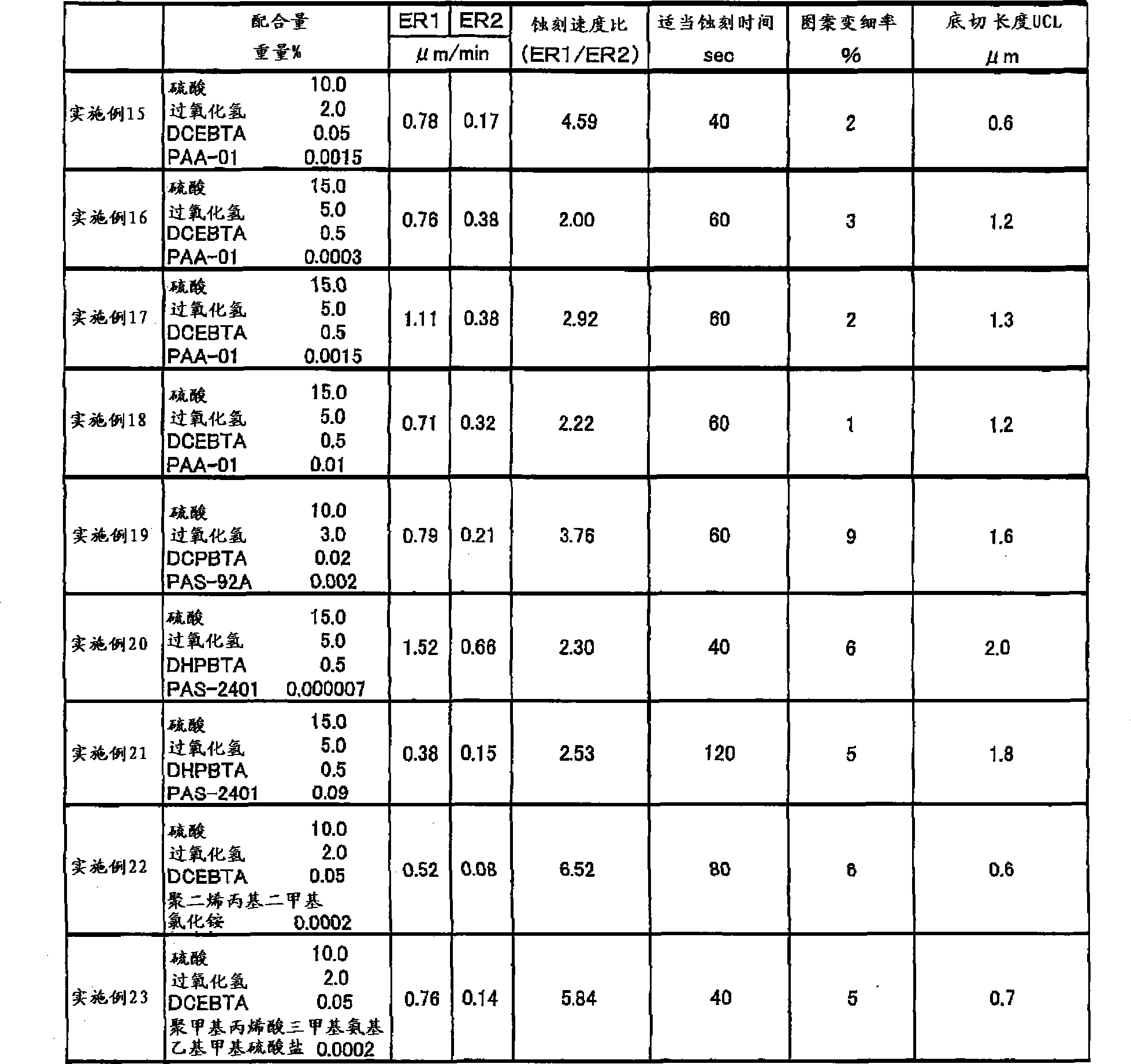

Etchant

ActiveCN101445933AAvoid corrosionGood etchingConductive material chemical/electrolytical removalSurface treatment compositionsNitrogenBenzotriazole

The present invention provides an etchant, capable of preventing dimensional precision of a wiring pattern from reducing when removing a chemical copper plate in a half addition process. A first etchant of the invention is characterized in that it is a copper etchant containing sulphuric acid, hydogen peroxide and water, and containing more than two benzotriazole derivates containing at least oneof carboxyl and dydroxyl in a molecule. A second etchant of the invention is characterized in that it is a copper etchant containing sulphuric acid, hydogen peroxide and water, and containing pyrrolehaving heteroatom of nitrogen atom only in a loop, and polyprotic acid having more than two carboxyl or salts thereof.

Owner:MEC CO LTD

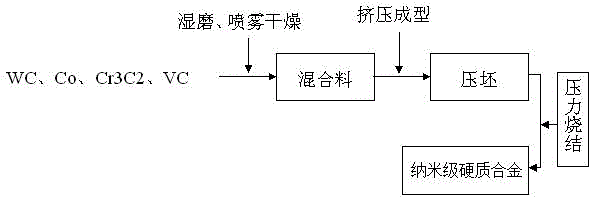

Preparation method of nanoscale hard alloy

The invention discloses a preparation method of a nanoscale hard alloy. According to the preparation method, the nanoscale hard alloy with a grain size less than 0.4 micrometer is prepared through the procedures of blending, ball-milling, spray-drying, extrusion forming and pressure sintering by taking WC powder with a Fsss particle size less than 0.2 micrometer and Co powder with a Fsss particle size less than 0.8 micrometer as raw materials and vanadium carbide and chromium carbide as inhibitors. The nanoscale hard alloy is integral in metallographic structure, has the characteristics of high hardness, high strength and the like, and can be used for processing a high-hardness material with HRC hardness higher than 60 degrees; in addition, a cutter processed by adopting the nanoscale hard alloy can be prolonged in service life by nearly 30% and increased in cutting speed by 10%.

Owner:JIANGXI RARE EARTH & RARE METALS TUNGSTEN GRP

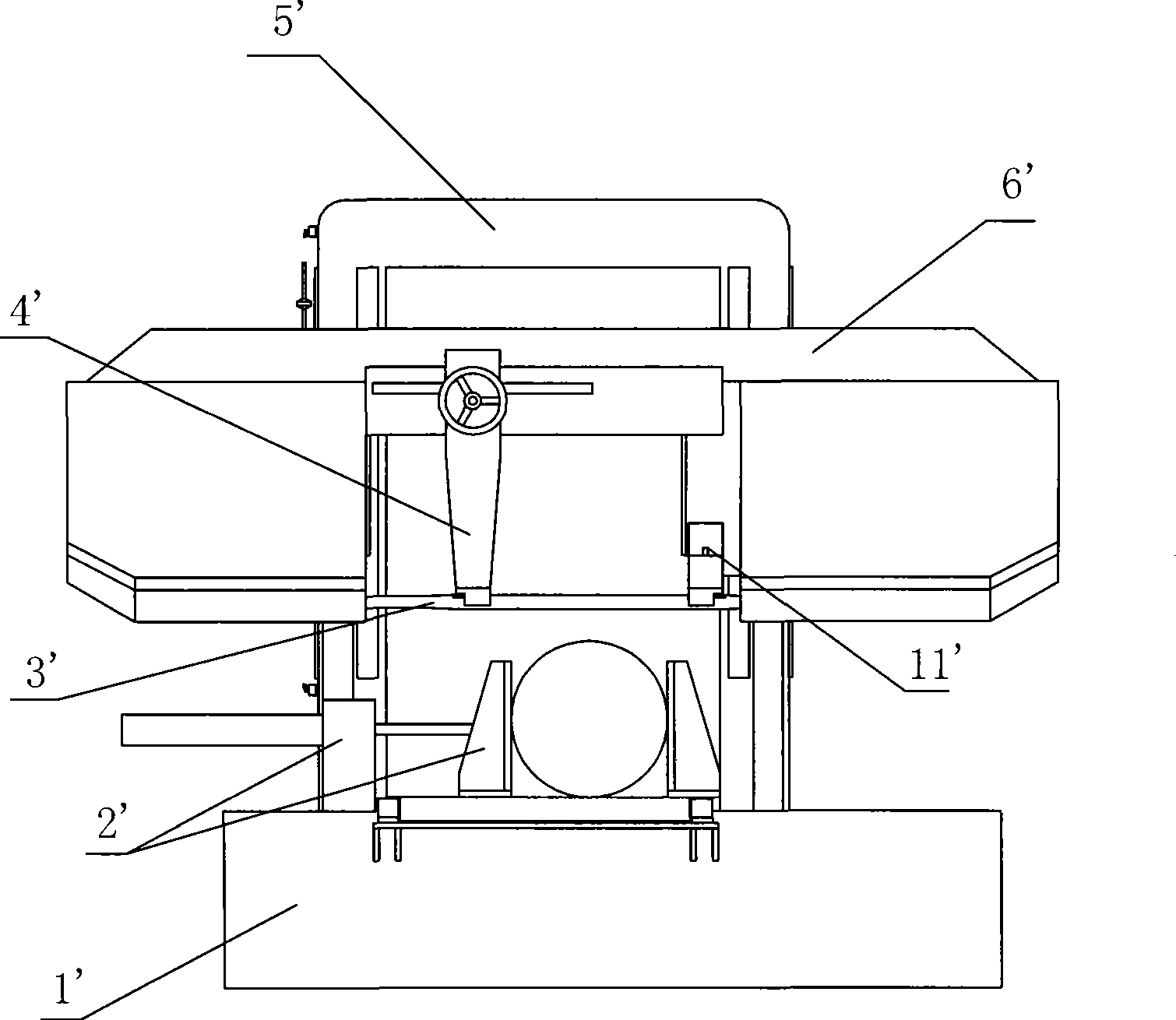

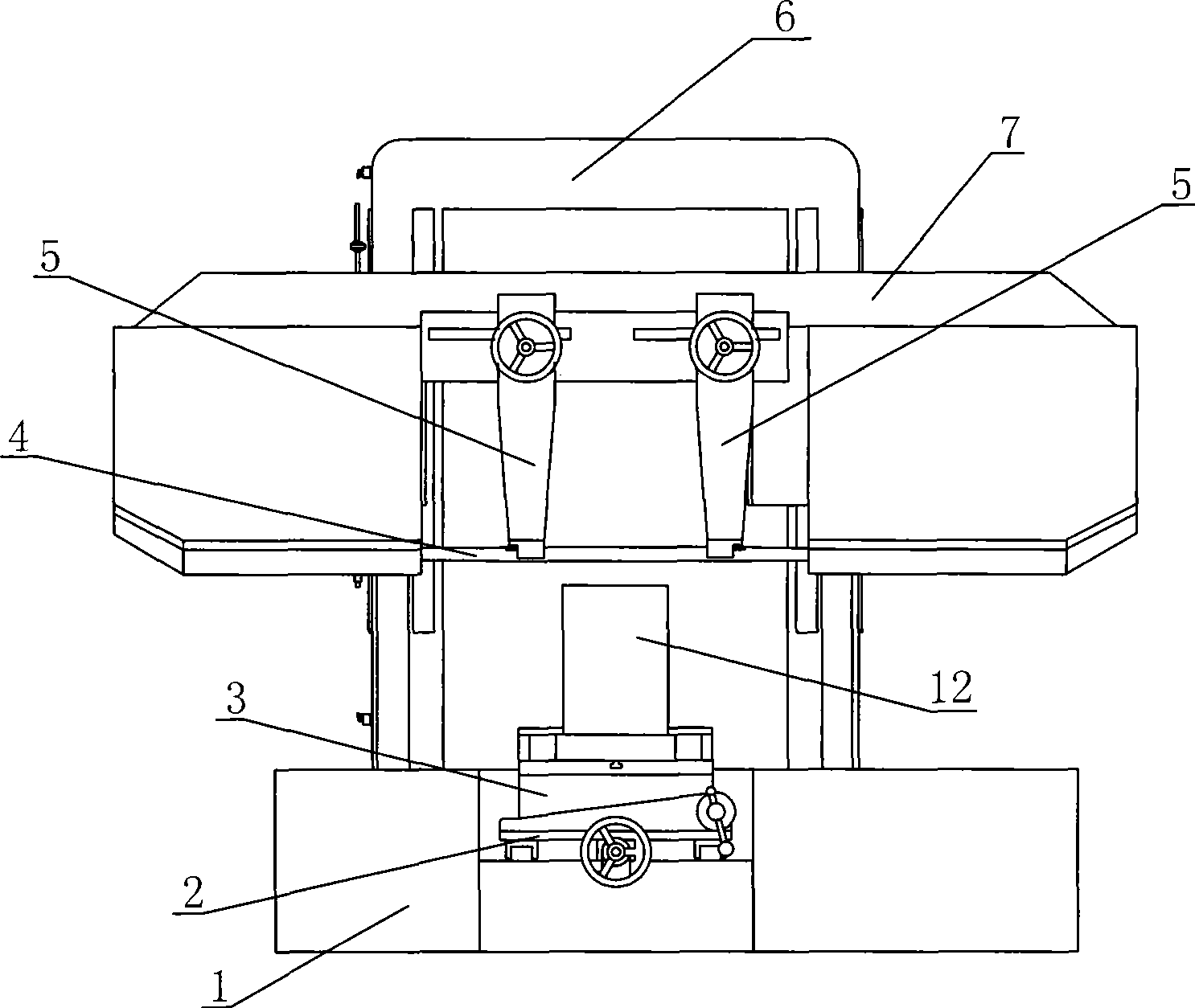

Deep groove processing method

The invention relates to a method for machining a deep groove. The method specifically comprises the following steps: establishing a deep groove machining device comprising a pedestal, a power part, a cutting part, a deep microadusting part, and the like; clamping a machining workpiece on the deep groove machining device; adjusting the position of a groove joint on the workpiece to be machined; machining the first groove joint of a first deep groove by a cutting method; after cutting to be tested is finished, using a deep microadusting part for microadjustment and position limit according to actual machining depth; carrying out cutting again till the machining of the first groove joint is finished; rotating and adjusting a rotary disc, so that the rotary disc is rotated for certain angle; carrying out the cutting machining from the second groove joint to the final groove joint sequentially; after the groove joints of two sides of all the deep grooves are totally machined, detaching the workpiece to be machined; cutting off groove bottom between the groove joints of two sides of all the deep grooves; and completing the machining of all the deep grooves. The method has a simple manufacturing process, simple equipment, low energy consumption and prominent manufacturing cost advantage; and the production efficiency can reach as high as 4 to 5 times of that of the prior machining method.

Owner:SUZHOU DONGLING VIBRATION TEST INSTR

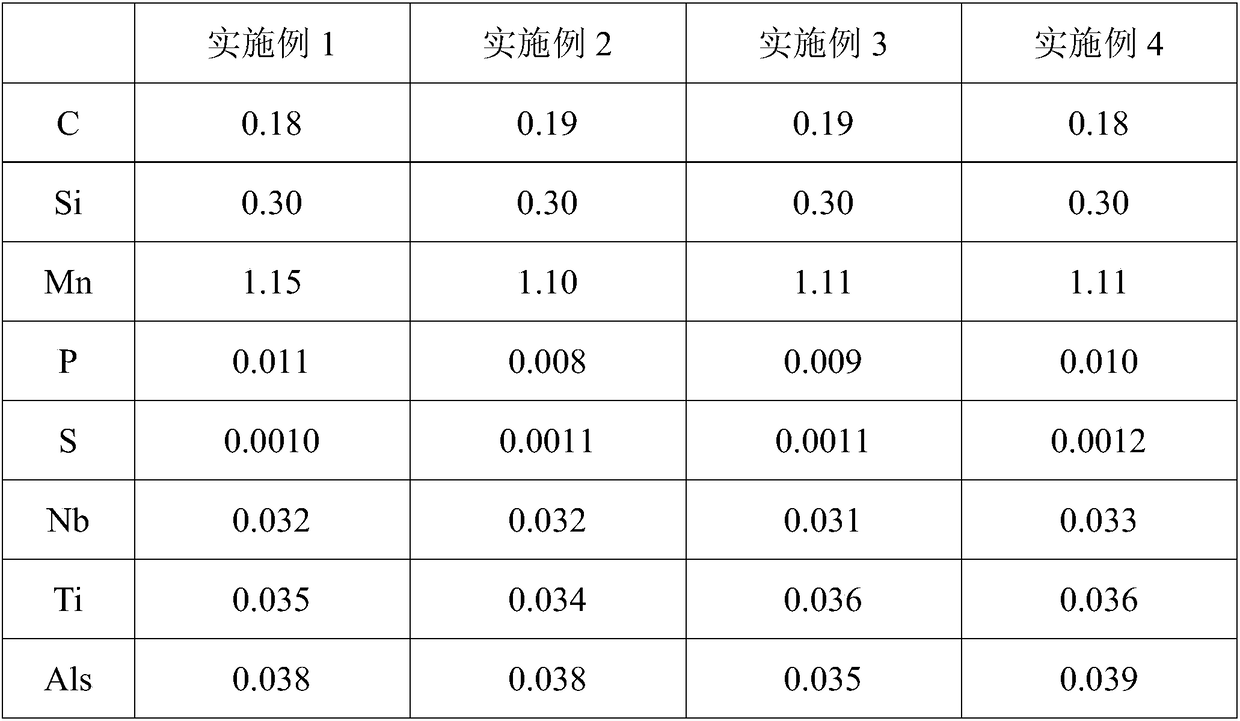

Niobium-titanium-chromium-boron alloyed wear-resistant steel and preparation method thereof

The invention discloses a niobium-titanium-chromium-boron alloyed wear-resistant steel. The niobium-titanium-chromium-boron alloyed wear-resistant steel comprises, by weight, 0.15-0.30% of C, 0.40% orless of Si, 0.60-1.60% of Mn, 0.015% or less of P, 0.0015% of S, 0.010-0.050% of Nb, 0.0025-0.40% of Cr, 0.010-0.040% of Ti, 0.015-0.040% of Als, 0.0025-0.040% of Ni, 0.0010-0.0040% of Cu, 0.0010-0.0050% of Ca, 0.0010-0.0030% of B, 0.006% or less of N, 0.004% or less of O, 0.00020% or less of H, and the balance of iron and inevitable impurities. A preparation method of the niobium-titanium-chromium-boron alloyed wear-resistant steel comprises the following steps: hot metal pretreatment, converter smelting, alloy fine adjustment, LF refining, RH refining, continuous casting, stacking slow cooling, hot rolling, cross cutting and flattening, and heat treatment for obtaining the finished product. The niobium-titanium-chromium-boron alloyed wear-resistant steel is a martensite structure, and has excellent mechanical properties and excellent wear resistance, the Rm value is 1250-1500 MPa, the A50 value is 7-15%, the HBW value is 425-500, the thickness size tolerance is within -0.15 to +0.15mm, and the lowest thickness of a wear-resistant plate produced from the steel can be 2.0 mm.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

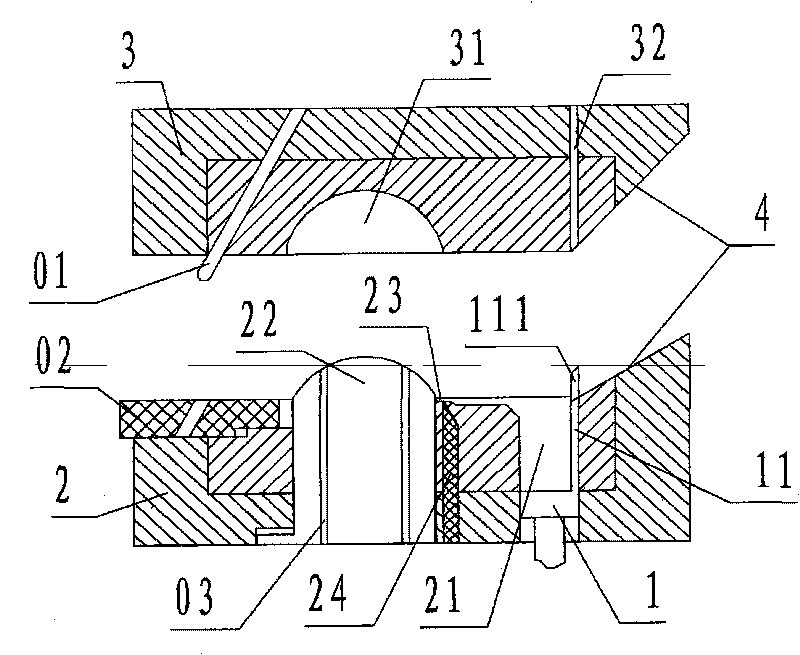

Self-aligning support assembly for rotatable cylindrical components

ActiveUS20100163705A1Easy alignmentReduced dimensional accuracyPortable framesMachines/enginesEngineeringLubricant

An apparatus and method suitable for supporting a cylindrical component. The apparatus includes a pedestal having an upper surface with a semispherical concave shape, and a carriage supported on the upper surface of the pedestal. The carriage has a lower surface and an oppositely-disposed upper surface with elements for contacting and rotatably supporting the cylindrical component. The lower surface of the carriage engages the upper surface of the pedestal and has a semispherical convex shape complementary to the semispherical concave shape of the upper surface of the pedestal. The apparatus further includes a reservoir at and recessed in the upper surface of the pedestal, and a feature for delivering a lubricant to the lubricant reservoir. The lower surface of the carriage and the upper surface of the pedestal define an enclosure around the reservoir.

Owner:GENERAL ELECTRIC CO

Injection compression molding composite mould

The invention provides an injection compression molding composite mould. On the basis of a common valve type hot runner injection mould, a compression gap is reserved between a cavity plate and a core insert fixing plate; a slide block is pushed by a compression hydraulic cylinder mounted on a movable mould seat plate to slide horizontally on the movable mould seat plate; the horizontal movement is converted into movement vertical to mould splitting surfaces of other parts except the cavity plate, namely a fixed slide block, a pressure plate and a movable mould side through a contacted surface of a movable slide block and the fixed slide block; and finally, movement relative to the reserved compression gap is formed between a core insert and the cavity plate. A common injection molding machine does not have a secondary mould closing function and the composite mould can realize an injection compression molding process on the common injection molding machine, so that the precision of a product is improved on the basis of existing equipment and control system, and the application range of the common injection molding machine is enlarged.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

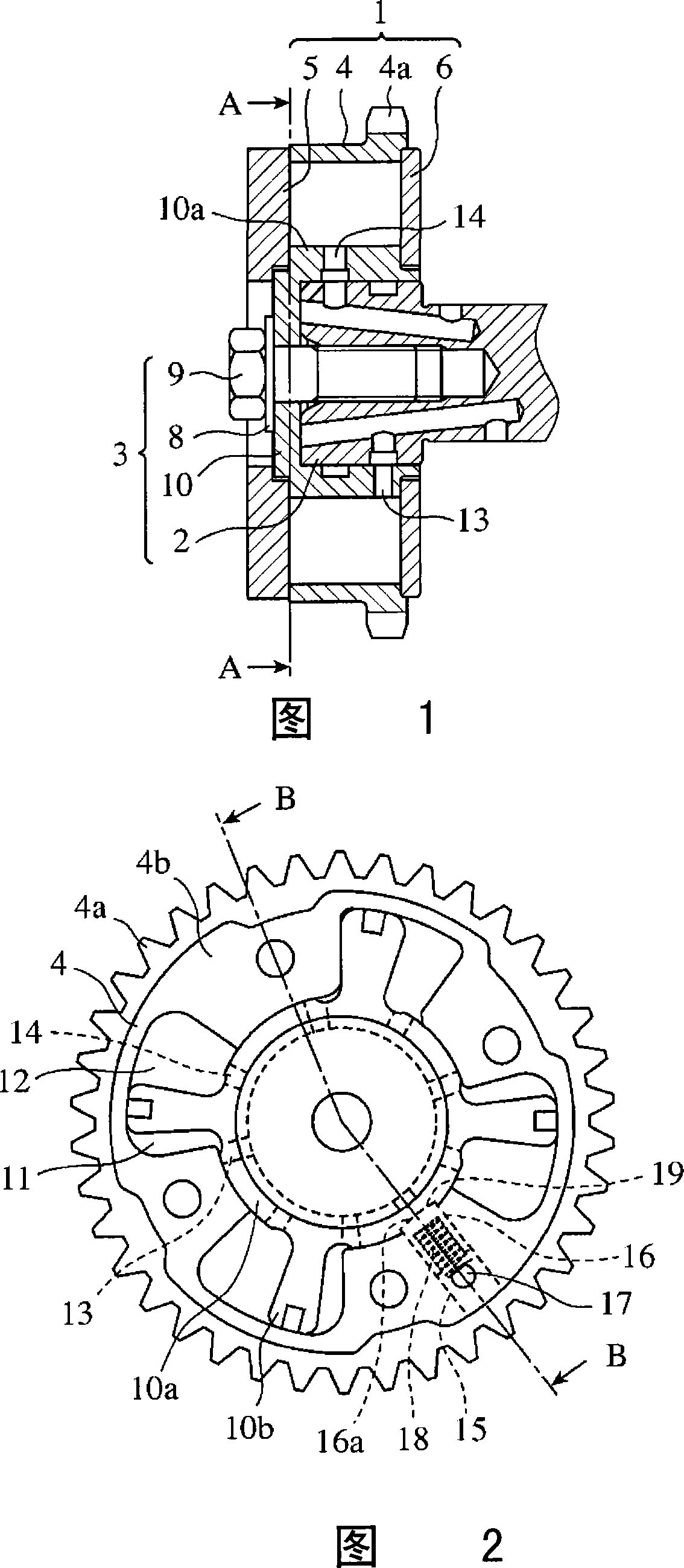

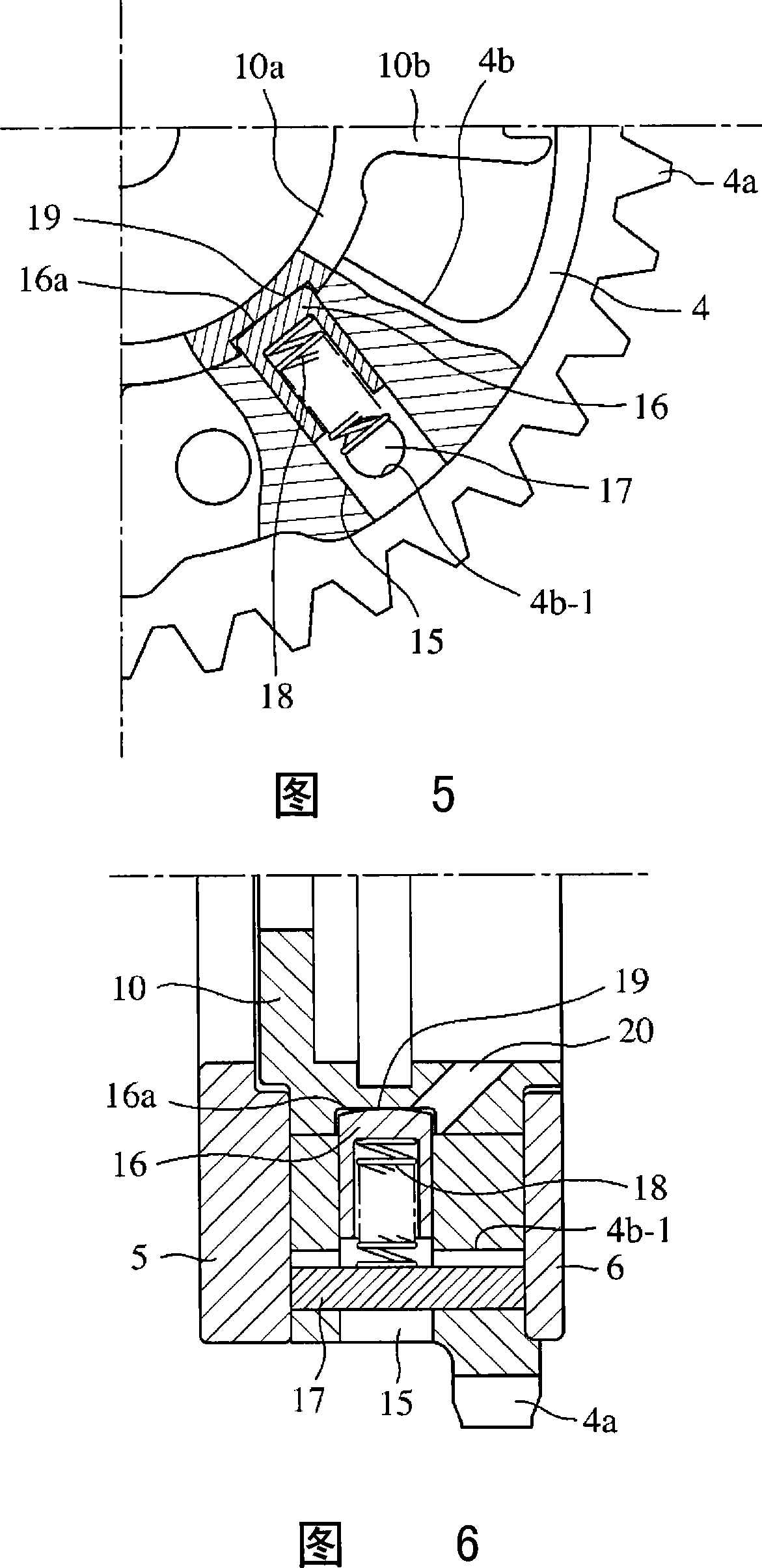

Valve timing regulation device

InactiveCN101248255AEasy to prepareEasy to manufactureValve arrangementsMachines/enginesCoil springEngineering

A valve timing regulation device having a first rotating body co-rotating with a crankshaft; a second rotating body integrally fixed to an intake or exhaust camshaft; a first hole radially penetrating through a shoe formed inside the first rotating body; a second hole formed in the shoe, intersecting with the first hole; a coil spring pressing a lock pin received in the first hole to engage the lock pin with a recess formed in the outer periphery of the second rotating body; and a shaft inserted in the second hole for preventing jumping out of the coil spring.

Owner:MITSUBISHI ELECTRIC CORP

Electronic thermometer

ActiveCN101074893AReduced dimensional accuracyReduce assembly accuracyThermometer detailsThermometers using electric/magnetic elementsMechanical engineeringElectronic thermometers

The electronic thermometer of this invention includes a supporting portion which supports the vicinity of the periphery on one face of a vibration plate, and a buzzer cover having plasticity of pressing the vibration plate against the supporting portion by pressing the vicinity of the periphery of the other face of the vibration plate and further includes a mechanism which presses the vicinity of the center of the buzzer cover on an opposite side to a side provided with the vibration plate in the buzzer cover so as to flex the buzzer cover, thereby pressing the vicinity of the periphery on the other face of the vibration plate with elastic reaction force of the buzzer cover.

Owner:OMRON HEALTHCARE CO LTD

Casting process for square shell of buffer of high-speed railway vehicle

InactiveCN103480797AImprove compactnessImprove surface qualityFoundry mouldsFoundry coresDimensional precisionCasting

The invention provides a casting process for a square shell of the buffer of a high-speed railway vehicle. According to the process, a casting system, risers, chills, molding and core-making methods and each technological parameter are optimized, the principles of progressive solidification are followed, so internal compactness of a casting is improved, cracks are reduced, surface quality of a cast blank is improved, dimensional precision is better controlled, and a good effect is obtained. Detection is carried out according to American inspection standard ASTME-446, and five surfaces all reaches grade 1 to 2 in radiographic inspection.

Owner:TIANJIN JINPU RAIL TRAFFIC EQUIP PARTS

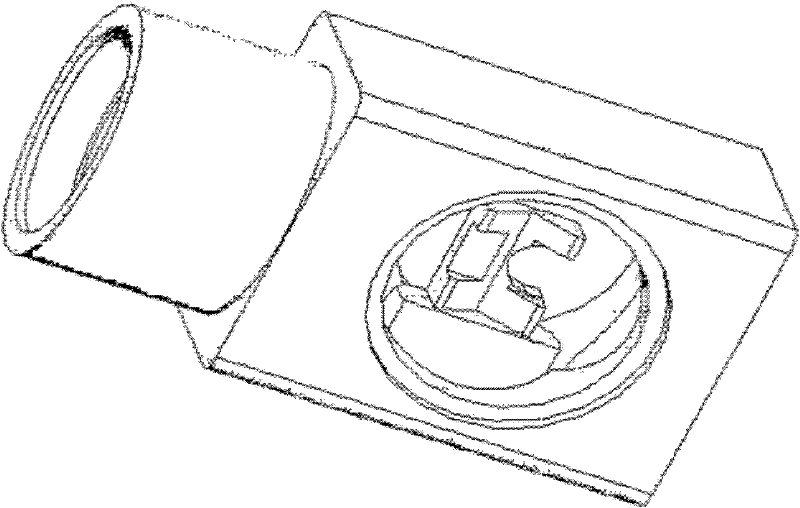

One-step molding process for optical communication assembly seat

The invention discloses a one-step molding process for an optical communication assembly seat. The one-step molding process comprises the steps of: preparation of a raw material, wherein a powder raw material is 304 stainless steel powder; preparation of a binder: mixing 70-80wt% of PW (Paraffin Wax), 5-20wt% of PE (Polyethylene) and 10-20wt% of SA (Stearic Acid) for 1-2 hours at the temperature of 140-160 DEG C; preparation of feeding: weighing the binder and the 304 stainless steel powder according to the volume ratio of (50-60):(60-50) and mixing for 1.5-2 hours at the temperature of 130-165 DEG C at the mixer rotation speed of 40-60r / min; injection molding: adding prepared feed into an injection molding machine for injection molding to obtain a blank, wherein the injection temperatureis 120-165 DEG C, the injection pressure is 60-120MPa and the mold temperature is 30-60 DEG C; treatment of the blank: dissolving a component PE of the blank, then drying the blank and degreasing theblank; and sintering of the blank: performing a sintering process by heating to high temperature of 1100-1350 DEG C at the temperature raise speed of 8-12 DEG C / min, preserving the temperature for 30-600min and cooling along with a furnace. According to the invention, assembly seat products with 45 degrees of inclined surface and high dimension precision and surface precision can be obtained by the injection molding.

Owner:湖南英捷高科技有限责任公司

Production method for high-performance special-shaped iron-cobalt soft magnetic alloy parts

The invention discloses a production method for high-performance special-shaped iron-cobalt soft magnetic alloy parts and belongs to the field of magnetic materials. The production method includes: adopting powder particles as raw materials, and placing the raw materials in a high-energy ball-milling machine for ball milling for 1-40 hours prior to evenly mixing ball milling powder with a forming agent so as to enable a mixture of the powder particles and the forming agent to infuse or flow into a mold for formation under good liquidity conditions to obtain green bodies of parts with complicated shapes; removing the forming agent from the obtained green bodies, obtaining pretreating pieces via sintering, and placing the pretreating pieces under high temperature for treatment prior to final heat treatment to obtain final products. An alloy is even in texture and excellent in performance with saturation flux density Bs greater than 2.3T, maximum permeability greater than 5mH / m and coercivity force less than 110A / m, the parts with the final shapes can be directly prepared, resources and energy sources are saved, and manufacturing cost is lowered.

Owner:UNIV OF SCI & TECH BEIJING

Processing method of clamshell type thin-walled part

ActiveCN105312644AAvoid Dimensional AccuracyReduced dimensional accuracyMilling equipment detailsIndustrial engineeringProcessing accuracy

The invention discloses a processing method of a clamshell type thin-walled part. The processing method of the clamshell type thin-walled part comprises the following steps: step one, processing a process handle with a part blank on a substrate and forming a stress releasing notch in the process handle, in which the part blank has a bridge section which crosses over the stress releasing notch; step two, positioning and clamping the process handle on a tool, processing a convex surface, a concave surface and a mounting boss on the part blank to form a finished part and enabling the process handle to be integrally connected to the periphery of the finished part all the time; and step three, removing the process handle around the finished part to obtain a complete finished part. Through the processing method of the clamshell type thin-walled part, the stress releasing notch is formed in the process handle so as to release the processing stress applied to the part blank and the process handle in the cutting processing process, so that the influence of the processing stress on the size accuracy and the shape accuracy in the part forming process is avoided; the influence of the processing stress on the size accuracy of the part forming process is reduced; the processing accuracy of the finished part is improved.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

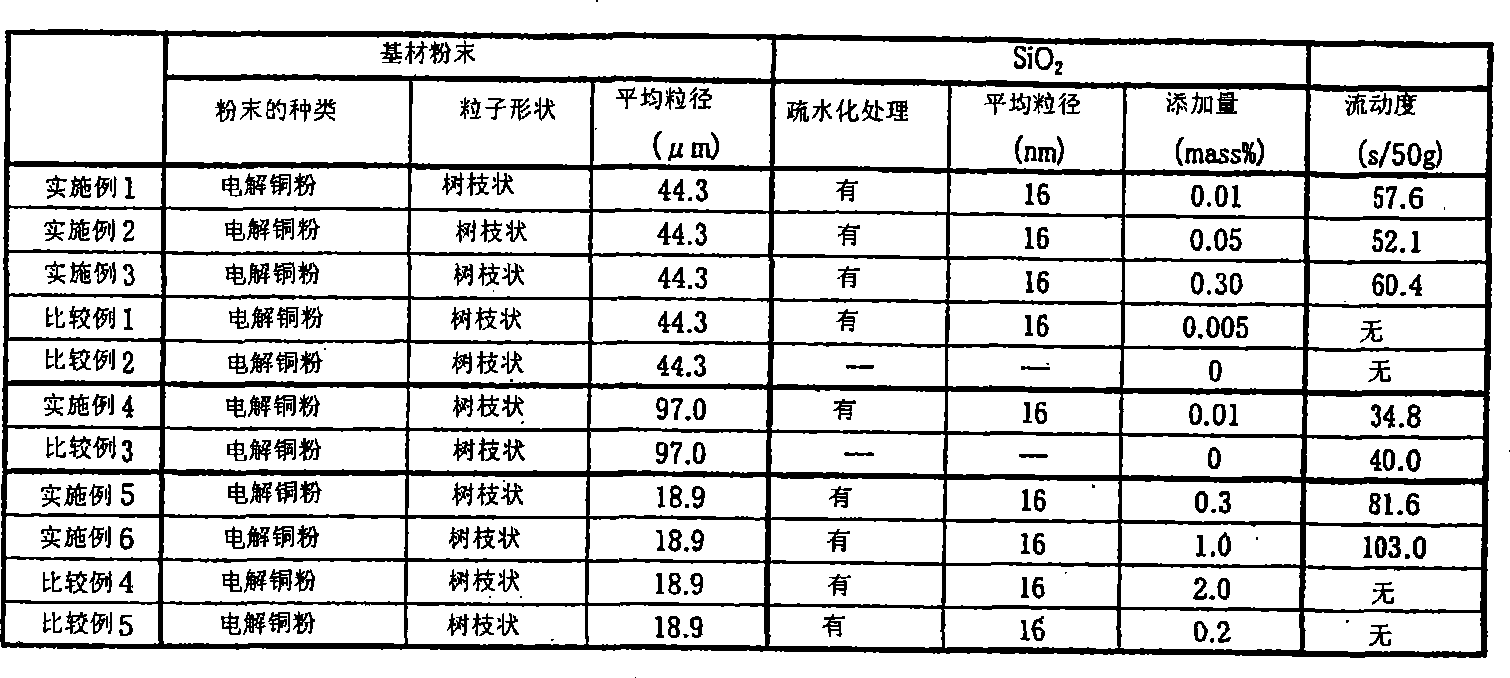

Copper based metal powder

The invention provides copper based metal powders with excellent fluidity suitable as raw material for powder metallurgy, specifically copper based metal powders added and mixed with hydrophobic SiO2 or Al2O3 or TiO2 or MgO or their mixture as fluidity improvement materials with an average grain diameter of 40nm or below and an addition ratio of 1.0 wt.% or below. Organic silicon compound and so on are suitably used for the hydrophobic treatment.

Owner:FUKUKA METAL FOIL & POWDER CO LTD

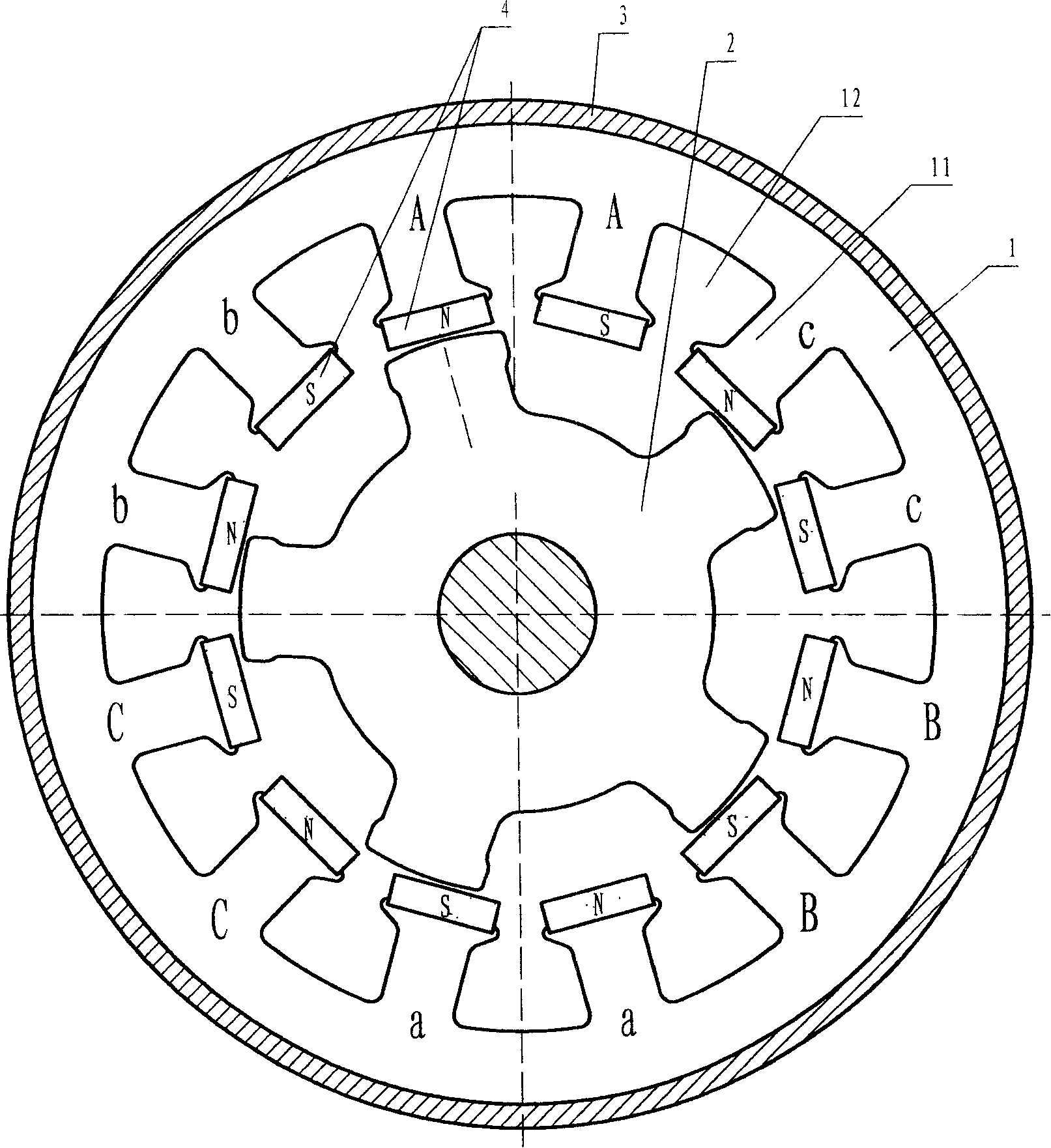

Single salient pole permanent magnetic paster bias magnetic motor scheme

InactiveCN101197510AIncrease the number of effective teethReduced torque ripple at low speedsMagnetic circuit stationary partsManufacturing stator/rotor bodiesPermanent magnet motorReluctance motor

The invention relates to a monosalient pole permanent magnet patch magnetic bias motor proposal, and is characterized in that rotors retain the salient pole structure which is common in reluctance motors; permanent magnets are pasted in sequence along the circumferential direction in air gap surface of stator core. Similar to changing rotors of common permanent magnet motor to reluctant rotors, and moving permanent magnet from rotors to stators, the invention provides a new type motor.The invention refers to the magnetic steel surface pasting technique of common permanent magnet motor, combines magnetic bias principle of main circuit and cogging magnetic bias reluctance motor, and has the advantages of advanced technique and good manufacturability. As no magnetic steel is pasted on rotors, the new type motor is more suitable for high speed rotation situation. Combined with driving control circuit, the switched magnetic bias speed control motor system has wide range of variable-speed and food performance price ratio.

Owner:苏州扬名机电有限公司 +1

Shuttering hardening agents

InactiveCN105312486AAvoid pollutionFast hardeningFoundry mouldsFoundry coresEconomic benefitsChloride

The invention relates to shuttering hardening agents. The shuttering hardening agents mainly include, by weight, 10-15% of hexahydrate crystallization of aluminum chloride, 22-25% of dihydrate flaky calcium chloride, 1.5-2% of anhydrous boric acid, 0.1-0.15% of permeating agents and the balance clear water. The hexahydrate crystallization of aluminum chloride and the dihydrate flaky calcium chloride serve as the main materials of the hardening agents, so that the defect that the work conditions are seriously worsened as ammonium chloride is used as the main materials of shuttering hardening agents is fundamentally overcome, and the other properties are better than those of the ammonium chloride hardening agents. The shuttering hardening agents have the characteristics of being high in hardening speed, shortening the process and shortening the production period, avoid environmental pollution and obviously improve economic benefits.

Owner:TIANJIN RONGHENG GROUP

Preparation technology for mask plate

InactiveCN104213071AControl thicknessAvoid occlusionVacuum evaporation coatingSputtering coatingEvaporationMaterials science

A disclosed preparation technology for a mask plate comprises: firstly electroforming an electroformed layer through an electroforming technology, and then etching an etched groove with certain depth at the opening side of the electroformed layer through an etching technology, wherein the electroforming technology comprises first film pasting, first exposuring, first developing, electroforming and first film removing, and the etching technology comprises secondary film pasting, secondary exposuring, secondary developing, etching, and secondary film removing. The mask plate prepared by employing the provided technology has the opening formed by combining of an electroforming opening and the etched groove, the electroforming opening has smooth sidewall and is easy for demolding, the effective deposition opening precision is easily controlled, and the opening precision is improved; and the etched groove prepared by using the etching technology on the basis of an electroformed opening forms a bowl-shaped hole wall and is combined with the electroformed opening, due to the fact that the bowl-shaped hole wall has a large conicity, shielding of the hole wall to an evaporation material during evaporation is avoided, and the evaporation film-forming rate is improved.

Owner:KUN SHAN POWER STENCIL

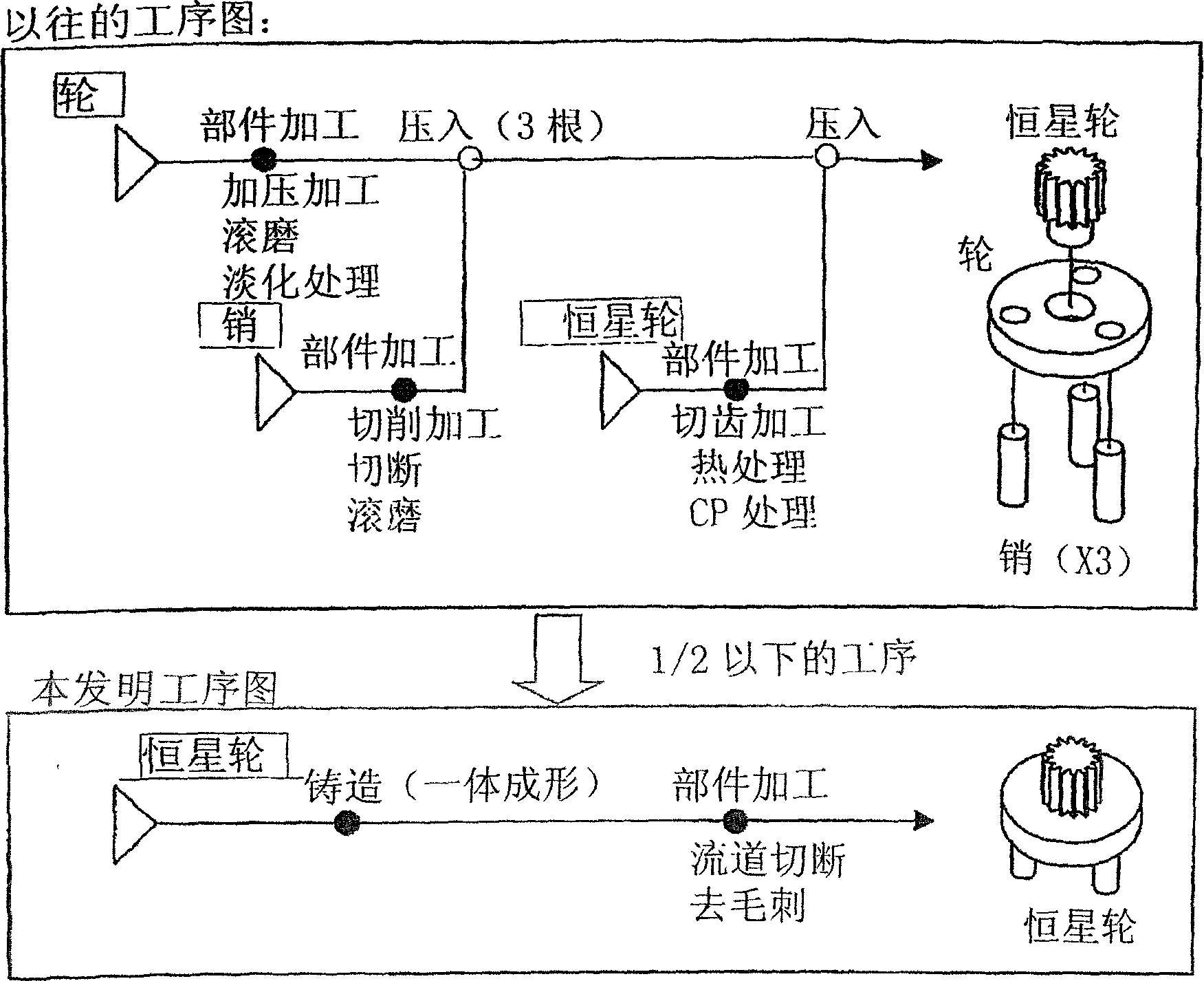

Precision gear, its gear mechanism and production method of precision gear

InactiveCN1846085AReduce surface roughnessReduced dimensional accuracyGearworksMaterial nanotechnologyIron groupGear wheel

The present invention provides a metal precision gear and a gear mechanism, which have high hardness, high strength, high surface smoothness, and processability by using a new material gear that is not found in conventional resin molded gears or tool steel metal gears. Excellent high-precision metal precision gears and gear mechanisms. The gear is composed of vitreous metal alloy composed of Fe, Co, Ni, Cu, Ti, Zr, and Hf, which are mainly composed of iron group elements. A disordered structure with broad peaks and no regularity forms a precision gear with a modulus of 0.2 or less.

Owner:NAMIKI PRECISION JEWEL CO LTD +2

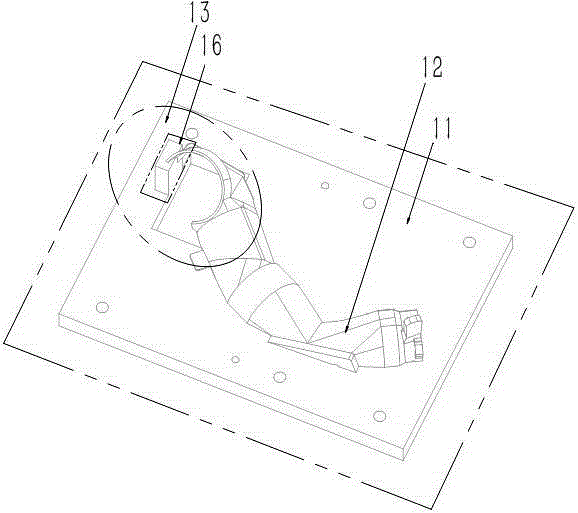

Integral riveting tool for I-shaped automobile thrust rod body and riveting method of integral riveting tool

ActiveCN106670327AAvoid the phenomenon of axial extensionGuaranteed processing efficiencyVehicle componentsHydraulic cylinderEngineering

The invention discloses an integral riveting tool for an I-shaped automobile thrust rod body and a riveting method of the integral riveting tool. The tool comprises an upper installing plate, a lower installing plate, a floating plate, upper riveting dies and lower riveting dies, wherein the upper riveting dies and the lower riveting dies are arranged on the upper installing plate and the lower installing plate correspondingly, and the two upper riveting dies and the two lower riveting dies are arranged. The tool further comprises two ball head sliding bases connected to the floating plate in a sliding manner, and two equal-height blocks arranged on the floating plate. Two sliding base power cylinders are further fixedly connected to the floating plate. Under driving of the two sliding base power cylinders, the two ball head sliding bases can move close to each other or away from each other relatively along the floating plate. The two ball head sliding bases can drive two ball heads to be connected to the two ends of a pipe in a sleeving manner. The floating plate is further provided with a vertical power cylinder, the lower riveting dies penetrate the floating plate, the floating plate can move back and forth in the vertical direction under the action of the vertical power cylinder, and hydraulic cylinders or air cylinders are adopted as the sliding base power cylinders and the vertical power cylinder. Through the integral riveting tool and the riveting method, the quality of the thrust rod body is guaranteed, and integral riveting can be finished at a time.

Owner:BOGE RUBBER&PLASTICS ZHUZHOU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com