Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

217results about How to "Fast hardening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cement-based composite material for powder-bonding three-dimensional (3D) printing, and powder-bonding 3D printing method applying cement-based composite material

ActiveCN106800391AAppropriate hardening speedAppropriate water distribution effectAdditive manufacturing apparatusPolymer adhesivePhosphate

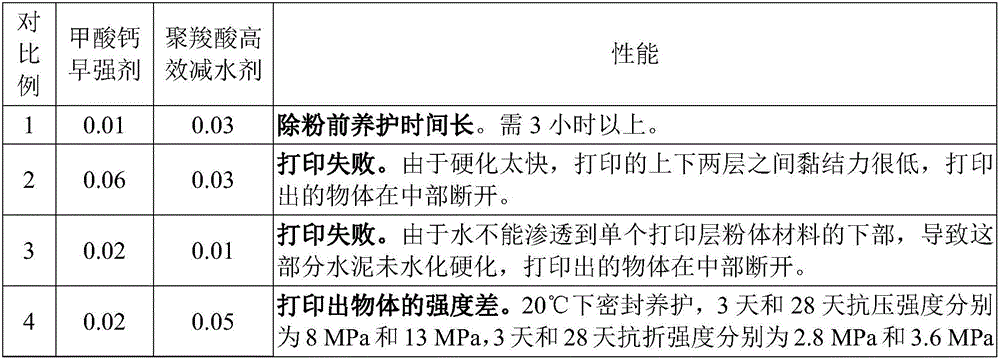

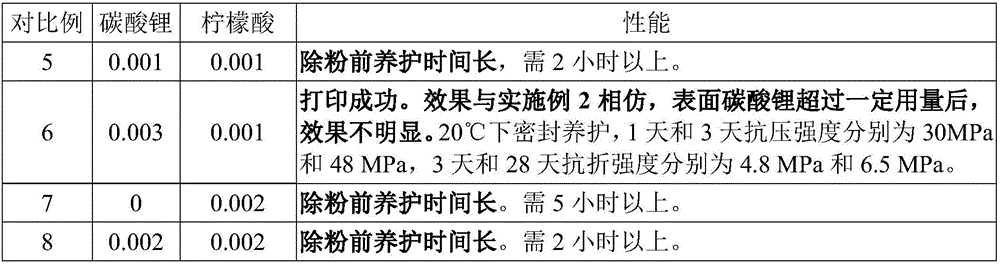

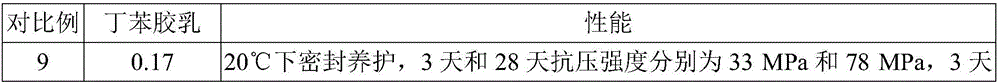

The invention provides a cement-based composite material for powder-bonding three-dimensional (3D) printing. The material is prepared from the following components in parts by weight: 1 part of cement, 0-5 parts of sand, 0-5 parts of a mineral admixture, 0-0.2 part of an expanding agent, 0-0.2 part of a toughening agent, 0-0.2 part of mineral pigment, 0.1-0.5 part of water, 0-0.25 part of polymer emulsion, 0.001-0.05 part of an additive and 0-0.03 part of fibers, wherein the cement is selected from one or a mixture of more in silicate cements, sulphoaluminate cement, high belite sulphoaluminate cement, aluminate cement, fluoroaluminate cement, aluminosilicate cement, phosphate cement or magnesium oxide cement; the additive is selected from one or a mixture of more in a water reducing agent, an early strength agent or a coagulating regulating agent. After being contacted with water, the cement-based composite material can be hardened, thus not needing a great deal of polymer adhesive; the cement-based composite material is rapid and controllable in hardening speed; the cement-based composite material is small in deformation in the hardening process, thus being suitable for a powder-bonding 3D printing technology. The invention also provides a method for carrying out powder-bonding 3D printing by using the cement-based composite material.

Owner:万玉君

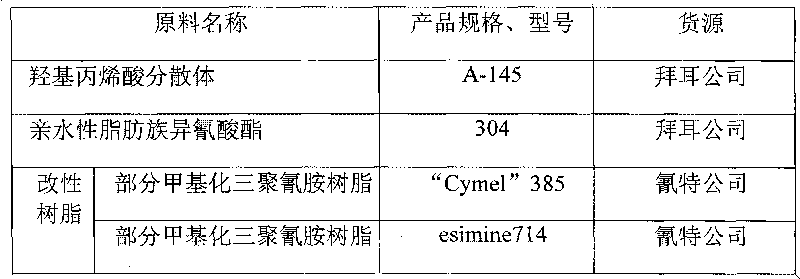

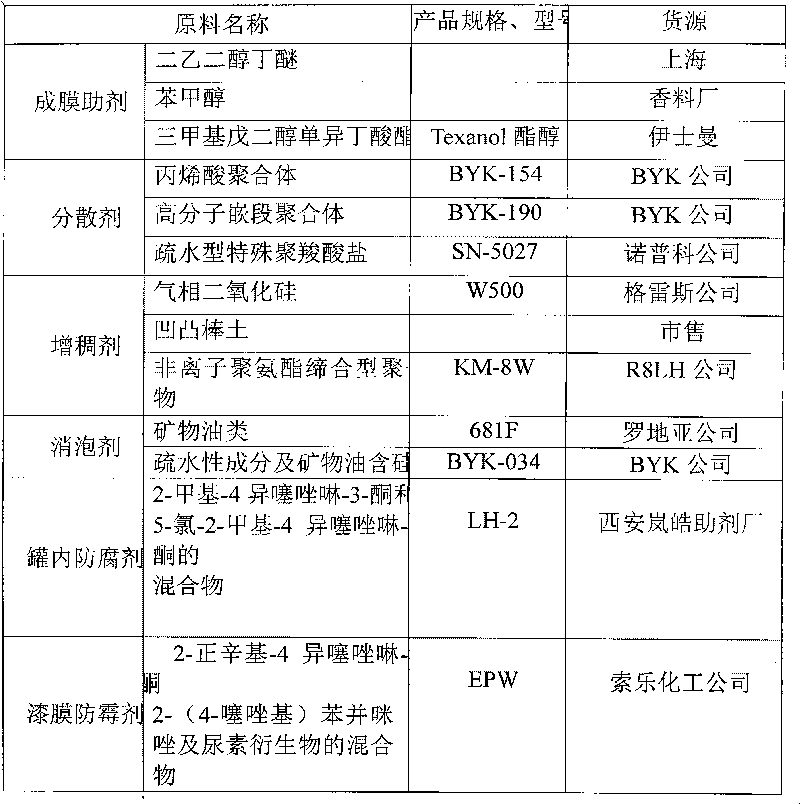

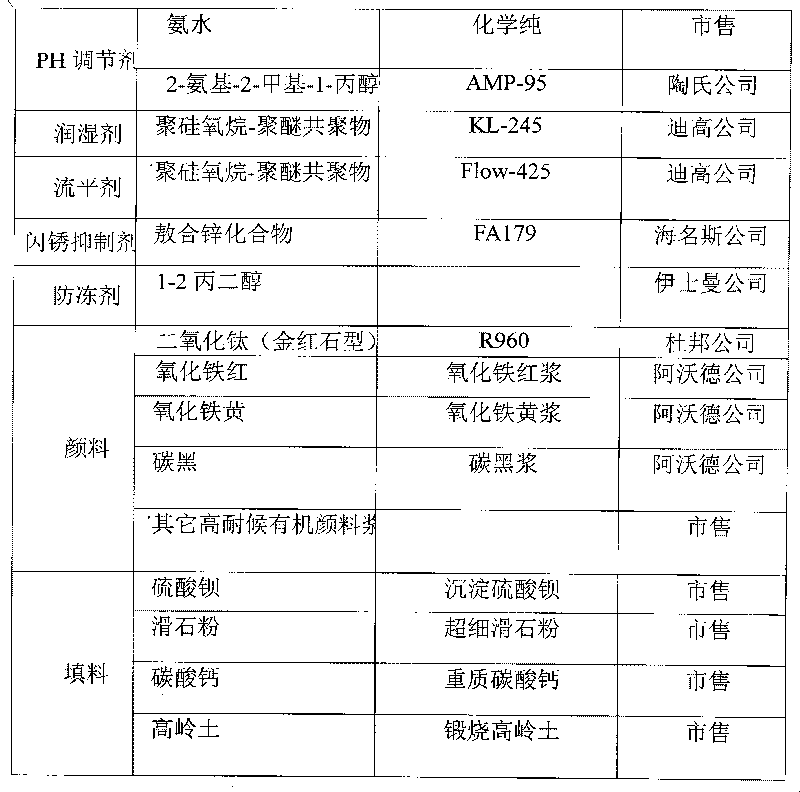

Water-based two-pack polyurethane preservative coating and preparation method thereof

ActiveCN101701128AHigh glossGood chemical resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedDipropylene glycol monomethyl ether acetate

The invention relates to the preservative coating technology, in particular to a water-based two-pack polyurethane preservative coating and a preparation method thereof. The water-based two-pack polyurethane preservative coating comprises two parts, namely paint vehicle and curing agent, wherein the paint vehicle is prepared from water-based hydroxylated acrylic dispersion, modified resin, pigment, filler, additive and water, the curing agent part comprises hydrophilic aliphatic isocyanate, dodecyl ester and propylene glycol methyl ether acetate. When using the coating of the invention, the weight ratio of the paint vehicle to the curing agent is 74-85:15-26 and the coating can solve the defects of the existing preservative coating.

Owner:JIANGSU LANLING POLYMER MATERIAL CO LTD

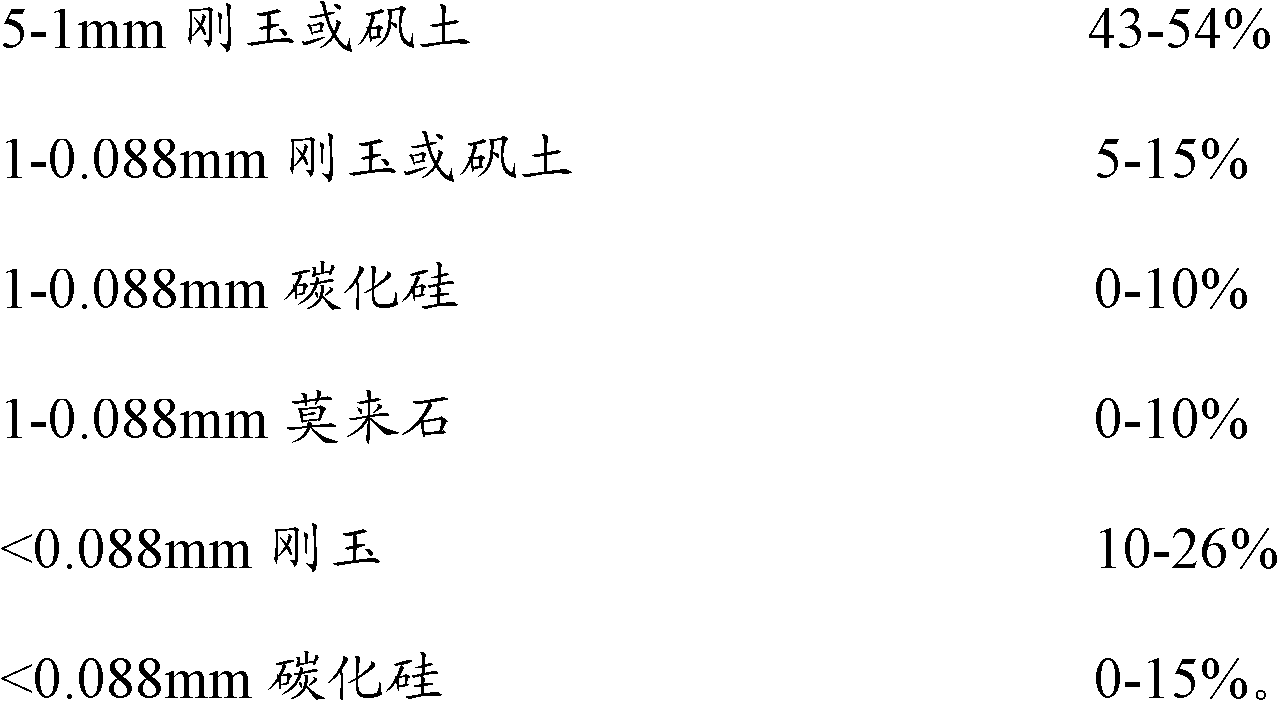

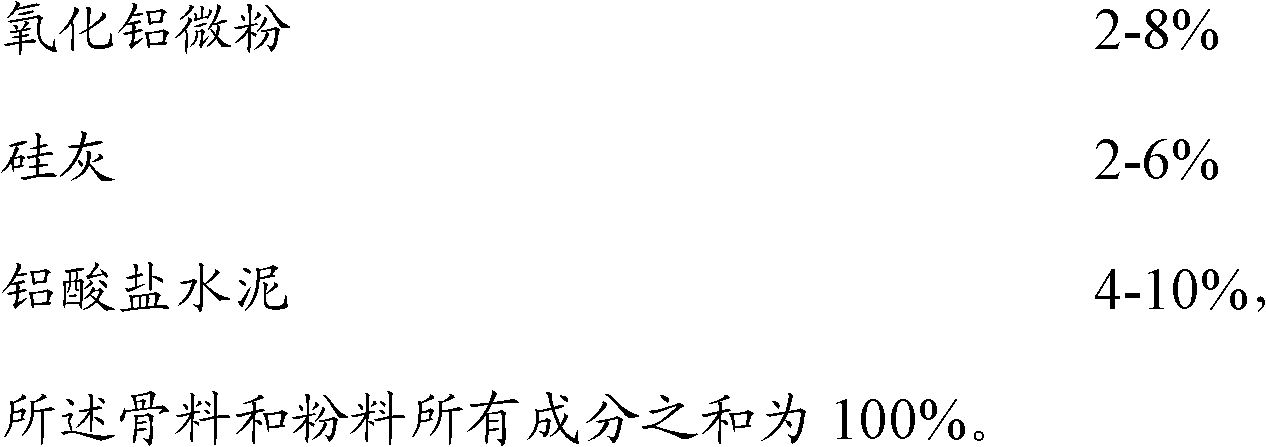

Composite bonding low-temperature constructional castable refractory

The invention relates to a composite bonding low-temperature constructional castable refractory, which can be used for high-temperature kiln engineering. According to the castable refractory, corundum, alumina, mullite and silicon carbide are used as an aggregate, silica sol is used as a bonding agent, aluminate cement is used as a curing agent and a bonding aid, and alumina micro powder, wollastonite, a deflocculant, a retarder, water and the like are added. The composite bonding low-temperature constructional castable refractory has high low-temperature constructional performance, high performance of high-temperature resistance, erosion resistance, thermal shock resistance and high mechanical performance, and meets the requirements of overhauling in winter on the premise that the service life of the castable refractory is not influenced.

Owner:ANHUI RUITAI NEW MATERIALS TECH

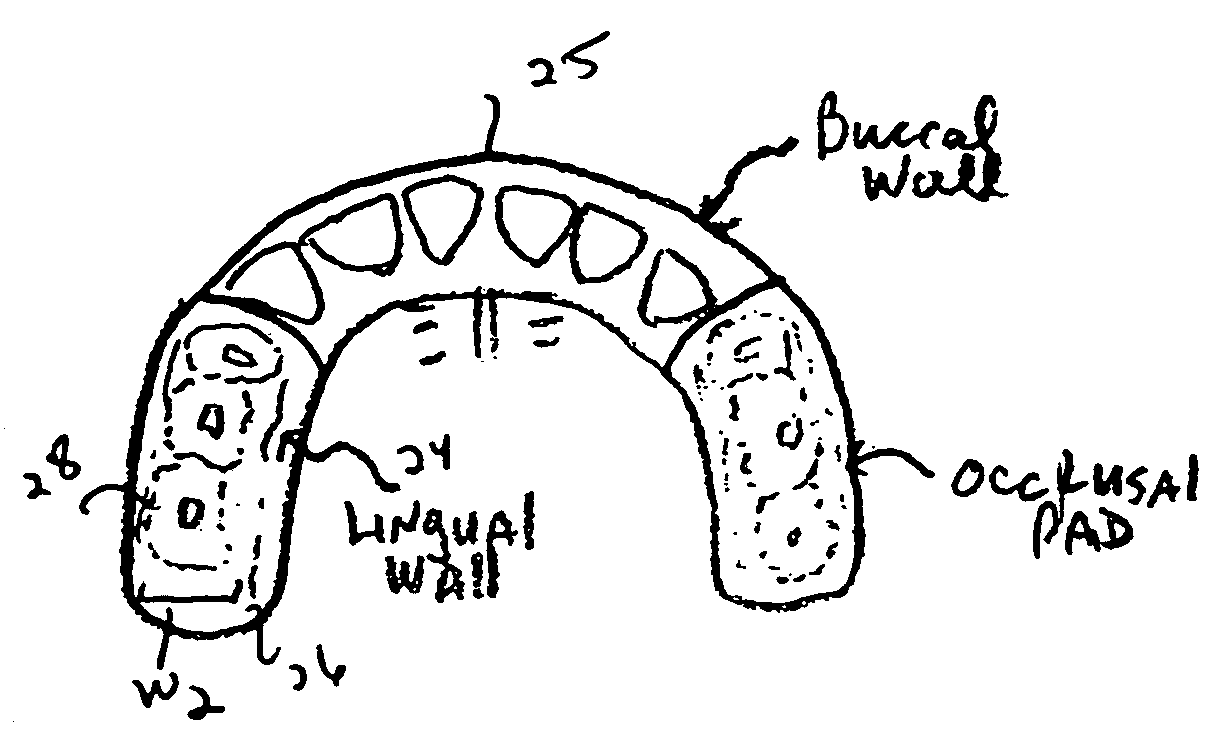

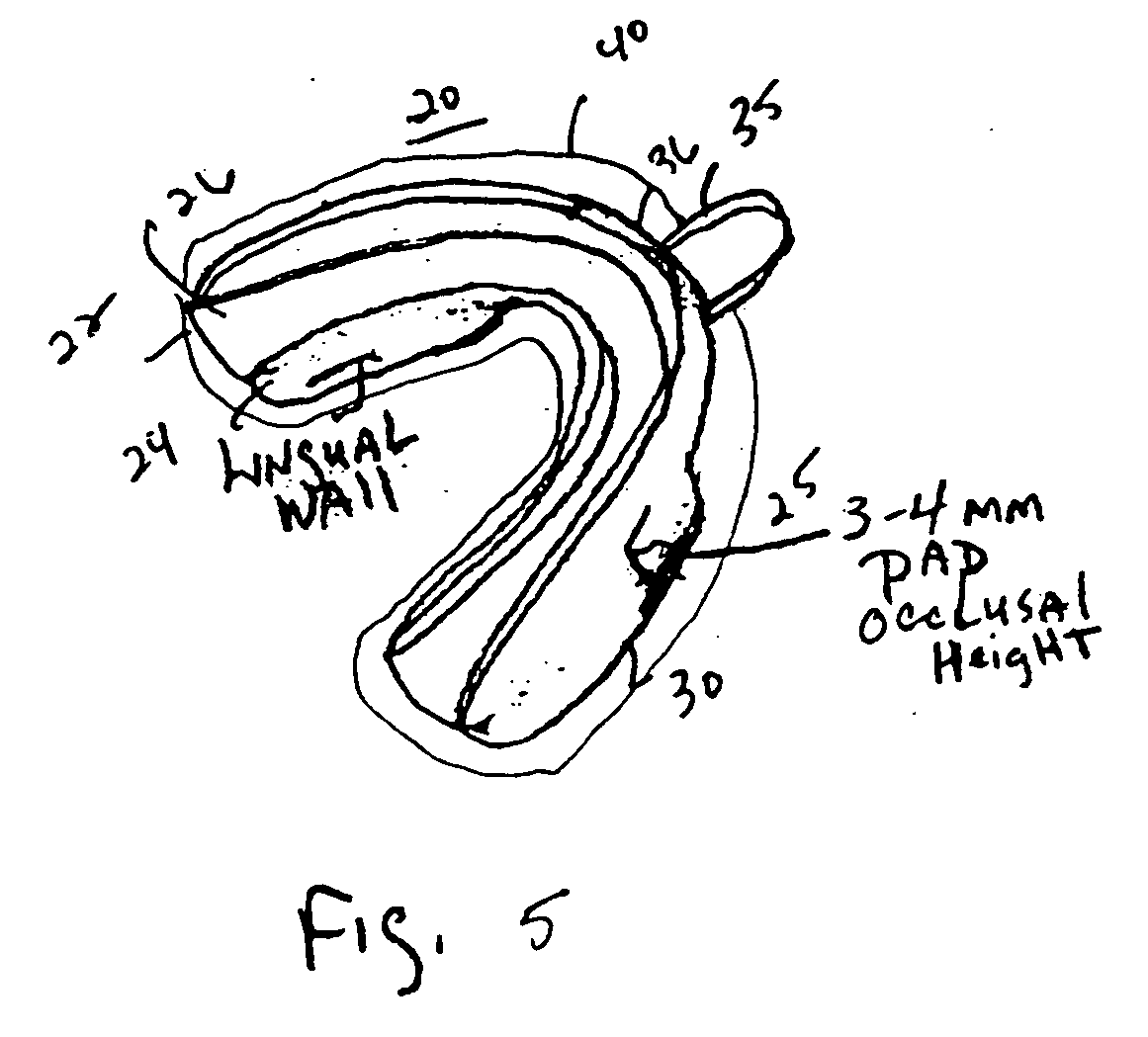

Dental appliance and mouthguard formed of polyolefin elastomer

ActiveUS20050256276A1High materialIncrease in temperatureImpression capsTeeth fillingOlefin polymerizationPolypropylene

A self-customizable dental appliance adapted to lie within the mouth of a person including occlusal pads with a connecting arch or a u-shaped style base with upstanding labial and lingual walls. The appliance is formed of a semi-crystalline polyolefin polymer or crystallizable blend. In one embodiment, the appliance is formed of elastomeric propylene-ethylene polypropylene, optionally including high density polypropylene. An optional occlusal lifting pad can be used in the self-customizable dental appliance.

Owner:DENTAL CHOICE HLDG LLC

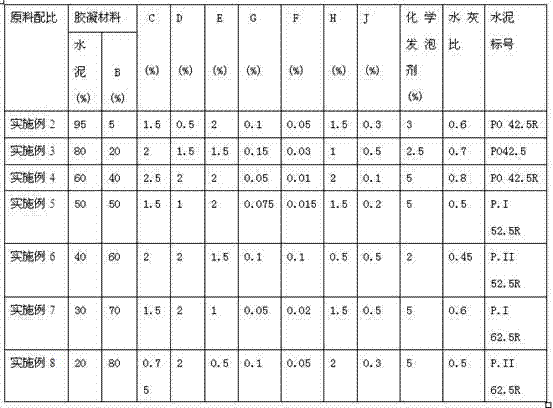

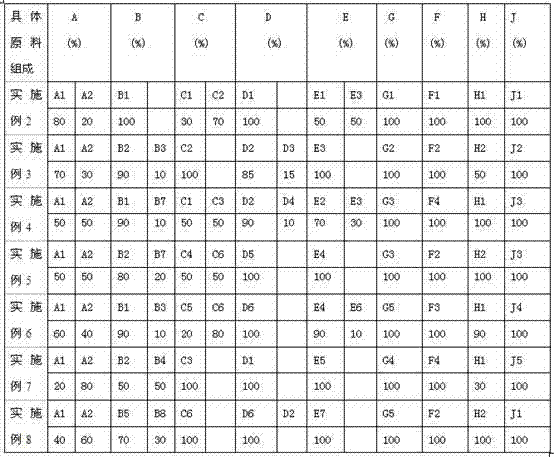

Inorganic foaming thermal-insulation mortar and preparation method thereof

The present invention provides an inorganic foaming thermal-insulation mortar and a preparation method thereof, and belongs to the technical field of building material preparation. The thermal-insulation mortar comprises a cementing material, expanded perlite particles, a macromolecule polymer, a coagulant, an early strength agent, a physical foaming agent, a chemical foaming agent hydrogen peroxide, a chemical foaming agent foaming catalyst, a hydrophobic agent, reinforced short fibers and water. According to the present invention, the inorganic foaming thermal-insulation mortar can be directly coated on the wall and the roof requiring the thermal-insulation treatment, the thickness of the inorganic thermal-insulation mortar layer can be adjusted within 10-100 mm, screeding finishing construction is performed before the cementing material is subjected to final setting, and hardening is performed to obtain the inorganic thermal-insulation mortar layer with characteristics of good durability, good water resistance and good heat insulation, wherein the inorganic thermal-insulation mortar layer never sheds, and has the same service life as the building being subjected to thermal-insulation by the inorganic thermal-insulation mortar layer; and the raw material cost is low, and significant economic benefits and environmental benefits are provided.

Owner:安徽融博科技有限公司

Inorganic composite heat insulation material and preparation method thereof

ActiveCN102093030ADecreased volumetric water absorptionStable physical and chemical propertiesFiberCellulose

The invention relates to an inorganic composite heat insulation material, which is prepared from the following raw materials in part by weight: 100 parts of common silicate cement, 10 to 30 parts of quick hardening sulfate aluminum cement, 10 to 30 parts of gypsum powder, 10 to 40 parts of admixture, 20 to 40 parts of mineral fiber, 150 to 200 parts of vitrified micro bubbles, 4 to 8 parts of re-dispersible latex powder, 2 to 4 parts of cellulose ether, 0.1 to 0.3 part of starch ether, 0.2 to 1.0 part of water reducing agent, 0.2 to 0.6 part of retarder, 1 to 3 parts of early strength agent, 0.5 to 3 parts of water repellent, and 0.02 to 0.06 part of air entraining agent. The raw materials are mixed uniformly to prepare dry powder, and the dry powder and water are mixed in a weight ratio of 1: (0.8-1.2) and stirred to form slurry for use. The inorganic composite heat insulation material has good workability, quick strength development, high construction efficiency, good adhesive property, low drying shrinkage, heat insulation, hydrophobic property, fire resistance and durability.

Owner:辽宁际洲环保节能建材有限公司

Metakaolin-based polymer foam concrete and preparation method thereof

The invention relates to metakaolin-based polymer foam concrete and a preparation method thereof. Metakaolin, coal ash and a coagulation accelerating agent are added into a mixing machine in proportion to be mixed to be uniform, an alkali excitant and water are added in proportion, and mixing is carried out to prepare slurry; while the slurry is prepared, a foaming agent is diluted with water in proportion of 1: 15, a high-speed mixing machine or a vacuum foaming machine is adopted for preparing fine and stable foam; and according to density design requirement, the prepared foam is blended into the uniformly mixed slurry in volume ratio to be mixed and foamed, wherein the volume ratio of the foam to the slurry is (1-4):1, and mixing is carried out for 2.5-3min until the foam is uniformly dispersed in the slurry, thus freshly blended metakaolin-based polymer foam concrete is prepared. Compared with the traditional cement-based foam concrete taking silicate cement as a main cementing material, the metakaolin-based polymer foam concrete has the characteristics of environmental friendliness, higher strength, low thermal conductivity, good heat insulating property and the like, and can be used for producing various foam concrete products.

Owner:CHONGQING UNIV

Anti-freeze aerated concrete brick

The invention discloses an anti-freeze aerated concrete brick. The anti-freeze aerated concrete brick is prepared from the following raw materials in parts by weight: 35-40 parts of fly ash, 15-20 parts of cement, 15-20 parts of wollastonite powder, 5-10 parts of modified straw ash, 2-4 parts of gypsum, 0.05-0.1 part of aluminum powder, 2-4 parts of urea, 0.01-0.03 part of oxyparaffin soap, 1-2 parts of sugar calcium, 4-6 parts of calcium formate, 0.1-0.5 part of polyethylene wax powder, 4-6 parts of calcium carbonate, 0.2-0.4 part of calcium nitrate, 0.1-0.2 part of sodium acetate and right amount of water.

Owner:潘逸东

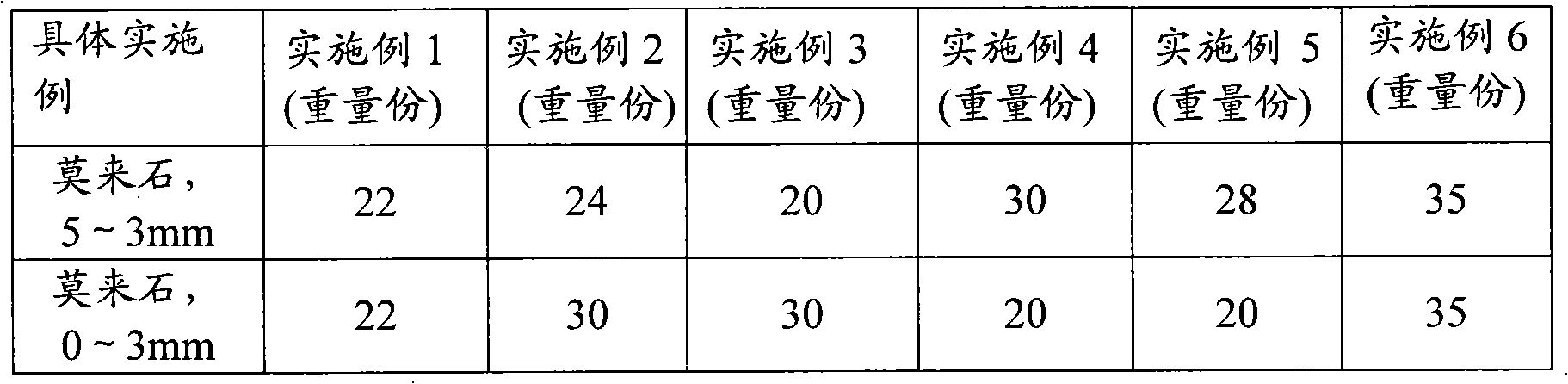

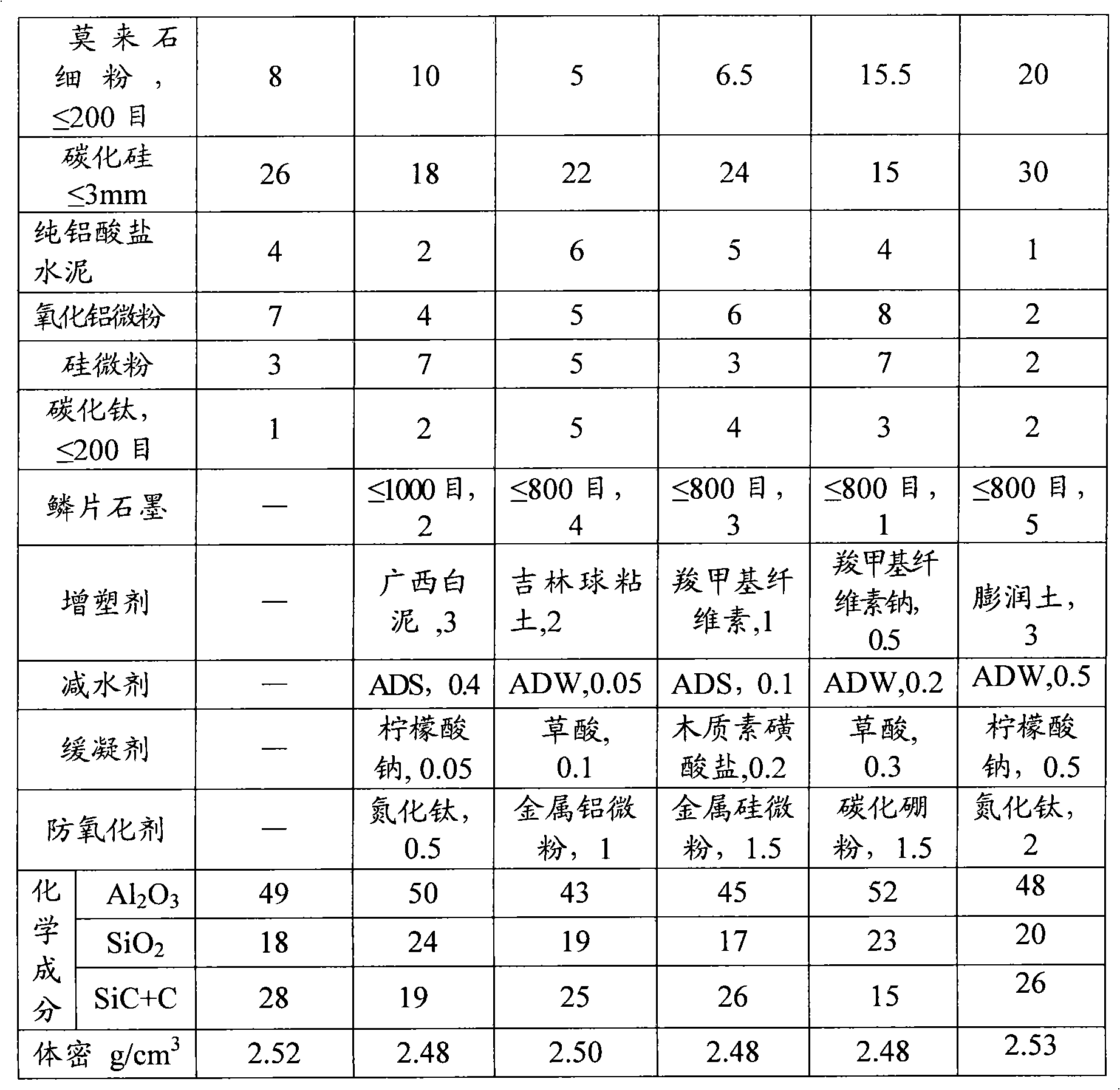

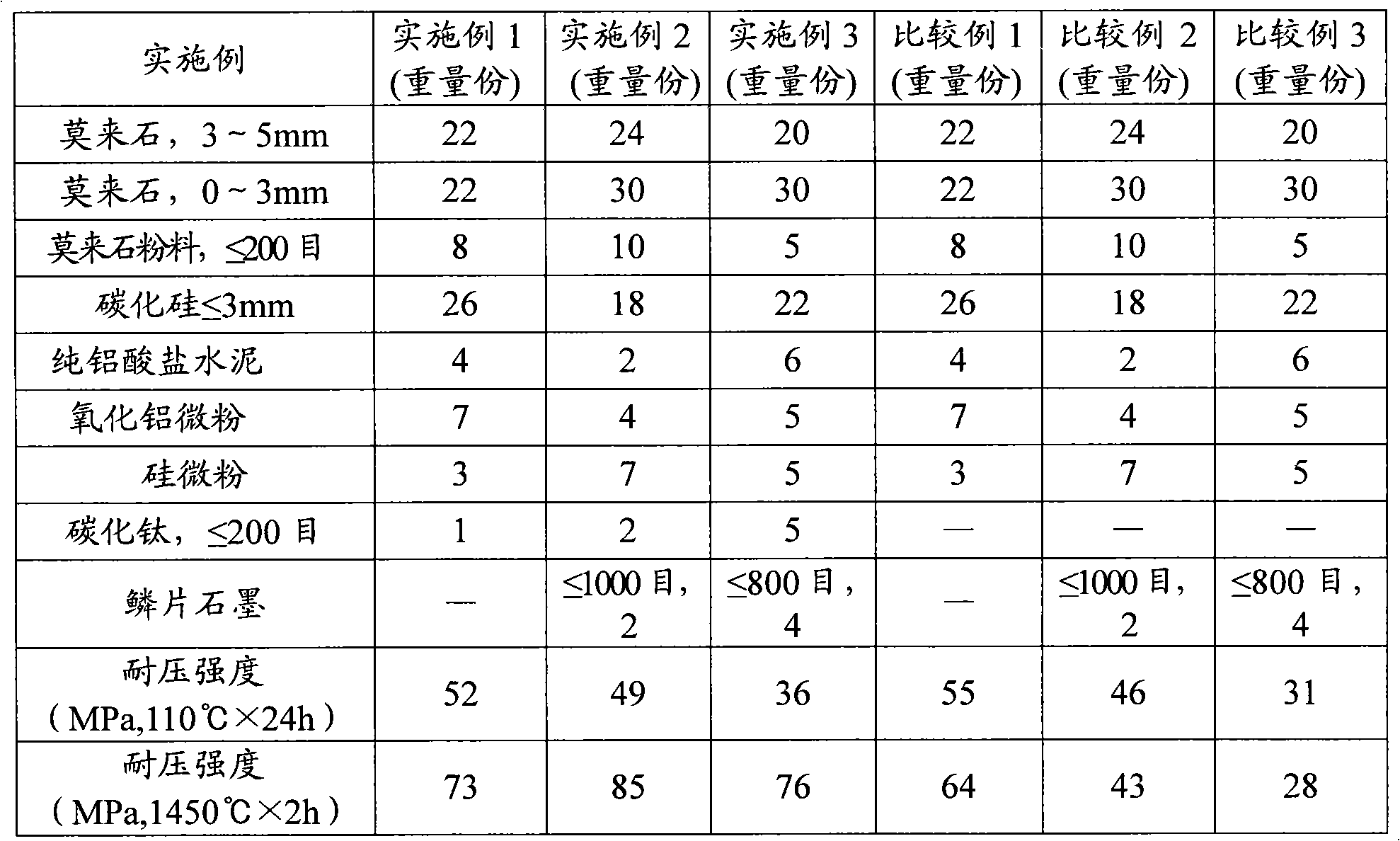

Torpedo can spouting material and spouting method thereof

ActiveCN102040386AImprove adhesion performanceImproved density and plasticityMelt-holding vesselsTitanium carbideChemical composition

The invention provides a torpedo can spouting material and a spouting method thereof. The torpedo can spouting material comprises the following components in parts by weight: 20-35 parts of mullite particles with the particle size of 3-5mm, 20-35 parts of mullite particles with the particle size of 0-3mm, 5-20 parts of mullite fine powder not greater than 200 meshes, 15-30 parts of silicon carbide with the particle size not greater than 3mm, 1-6 parts of pure aluminate cement, 2-8 parts of aluminum oxide micro powder not greater than 320 meshes, 2-7 parts of silicon micro powder and 1-5 parts of titanium carbide not greater than 200 meshes; and the torpedo can spouting material mainly comprises the following chemical components in percentage by weight: 40-65% of Al2O3, 15-25% of SiO2 and 15-30% of SiC+C. The invention also further provides the spouting method of the spouting material. The torpedo can spouting material provided by the invention has favorable corrosive resistance and antioxidation.

Owner:PUYANG REFRACTORIES GRP CO LTD

Thermosetting phosphate casting binder as well as preparation method and application method thereof

The invention provides a thermosetting phosphate casting binder. The thermosetting phosphate casting binder is prepared from the following raw materials in percentage by weight: 50 percent to 57 percent of industrial phosphoric acid, 9 percent to 12 percent of aluminum hydroxide, 0.75 percent to 2.18 percent of boric acid, 0.66 percent to 2.48 percent of citric acid, 0.075 percent to 0.57 percentof silicic acid, 0.075 percent to 0.47 percent of a water-soluble high molecular material, 0.75 percent to 3.53 percent of magnesium carbonate, 3.5 percent to 6.5 percent of magnesium chloride, 0.035percent to 0.19 percent of a silane coupling agent and the balance of pure water. According to the thermosetting phosphate casting binder provided by the invention, organic acid, inorganic acid and the water-soluble high molecular material are used for modifying a phosphoric acid binder, so that the aim of remarkably improving the performance of heat-curing sand by the phosphoric acid binder is realized; the thermosetting phosphate casting binder provided by the invention has the advantages of high binding strength, rapid curing speed and good moisture resistance and has a wide application prospect in a casting industry.

Owner:HUBEI UNIV OF TECH

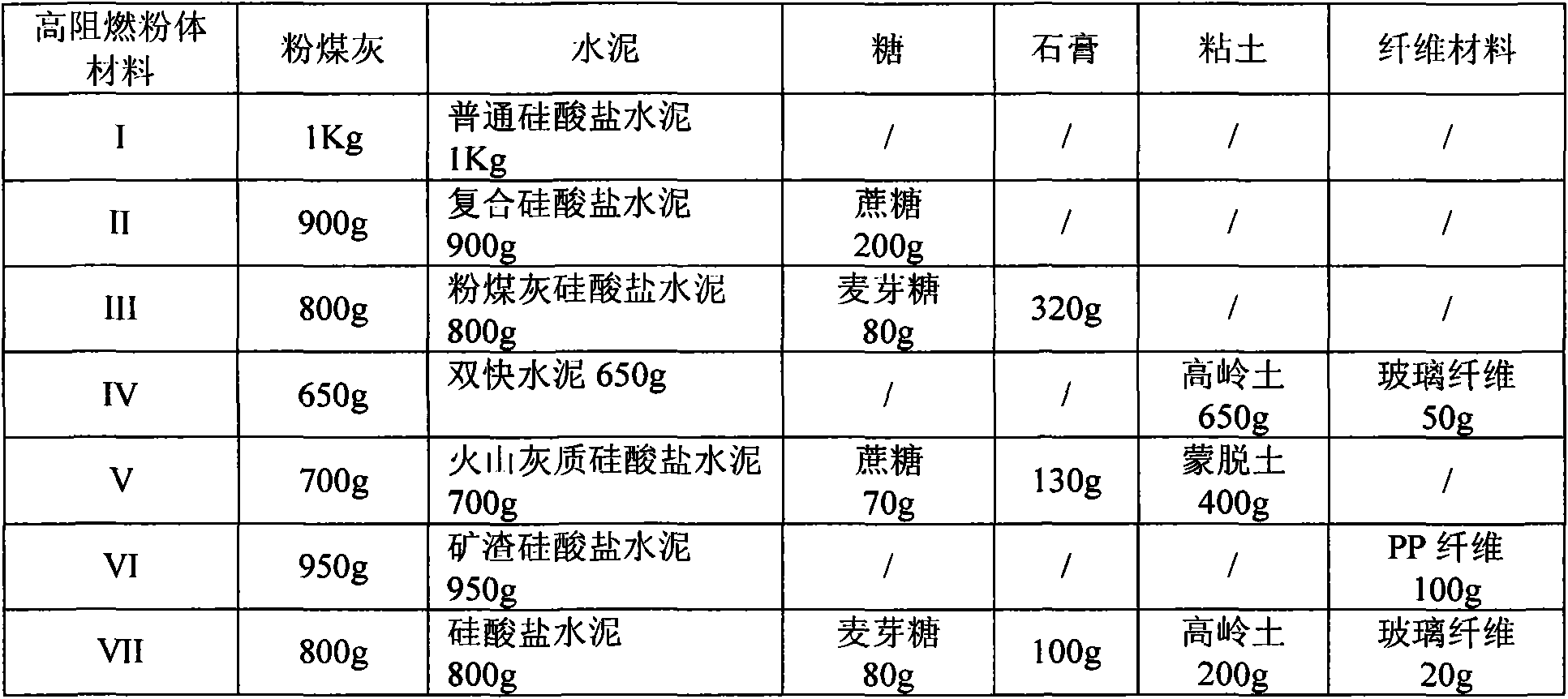

Spray-coating sealing material for coal rock mass

The invention provides a spray-coating sealing material for coal rock mass, belonging to the technical field of organic / inorganic compound materials. The spray-coating sealing material for the coal rock mass is a complex of high-molecular emulsion and high-flame-retardant powder materials, without any toxic and harmful substances, free of springback for construction, safe and environmental protective. When sprayed at vertical surfaces and top surfaces, the material does not flow and sag, and is good in overall effect. After curing, the coating has advantages of strong adhesion stress, high tensile strength, large tensile deformation, and excellent sealing performance. The material can be used for surface protection of the coal rock mass, air leakage prevention, gas leakage prevention, and rapid surface protection and moistureproof treatment after tunneling of swelling rock.

Owner:山东固安特新材料科技股份有限公司

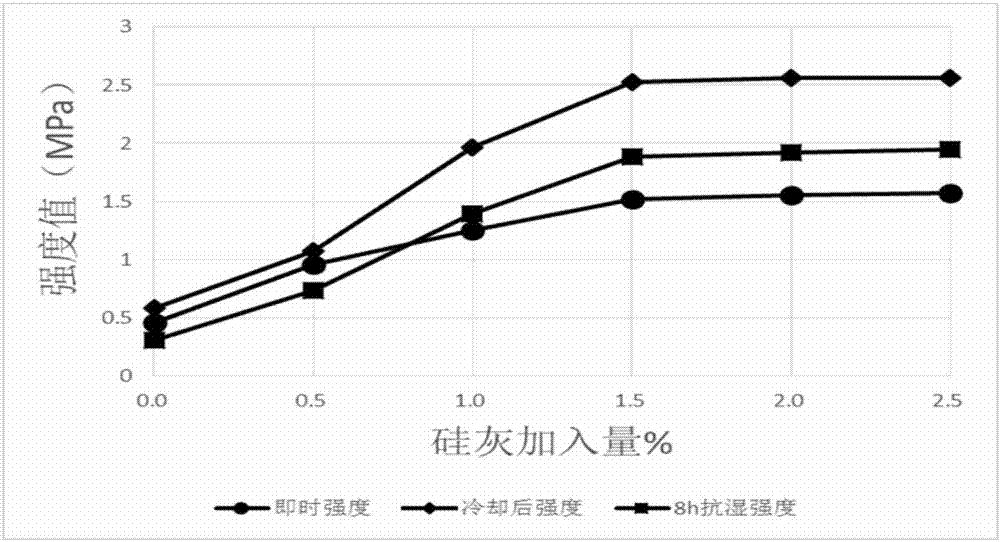

Preparation of coated sand by use of phosphate inorganic binder and molding method thereof

ActiveCN104289661AGood collapsibilityRealize recyclingFoundry mouldsFoundry coresGranularityWater vapor

The invention discloses preparation of coated sand by the use of a phosphate inorganic binder and a molding method thereof. Preparation of the coated sand comprises the following steps: uniformly mixing the phosphate inorganic binder and quartz sand; heating and drying to a semi-dry state; adding calcium stearate with the granularity being 600 meshes and uniformly mixing; and drying and cooling so as to obtain the phosphate inorganic binder coated sand which is in a dry arenaceous state. During molding of the coated sand, the coated sand undergoes hydration only by high temperature steam, the binder is dissolved, sand grains are connected, and finally hot-air is blown for drying and curing molding. The hardening speed is fast. During preparation and curing molding of the coated sand, smell or any harmful gas or substance is not generated. The sand mould has low gas-forming property, is harmless to the health of workers, causes no pollution to the environment and is energy-saving and environmentally friendly. The coated sand provided by the invention has characteristics of high strength, high temperature resistance, low gas evolution, no curing agent required for molding and good storage stability.

Owner:HUBEI UNIV OF TECH +1

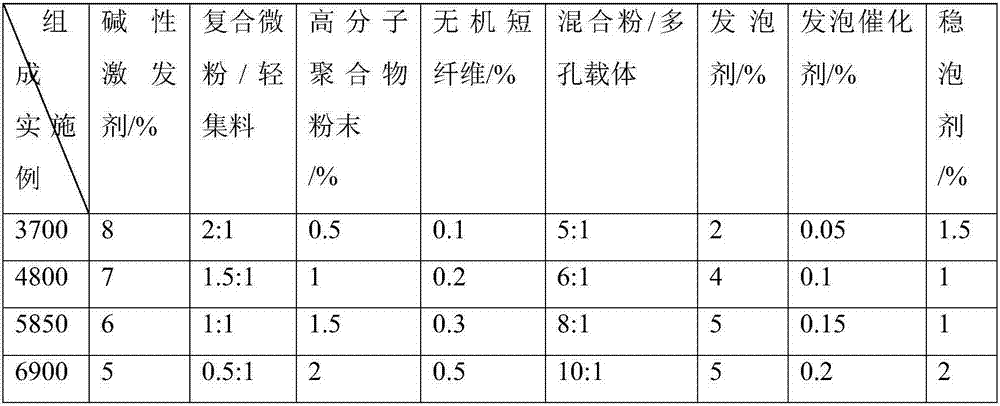

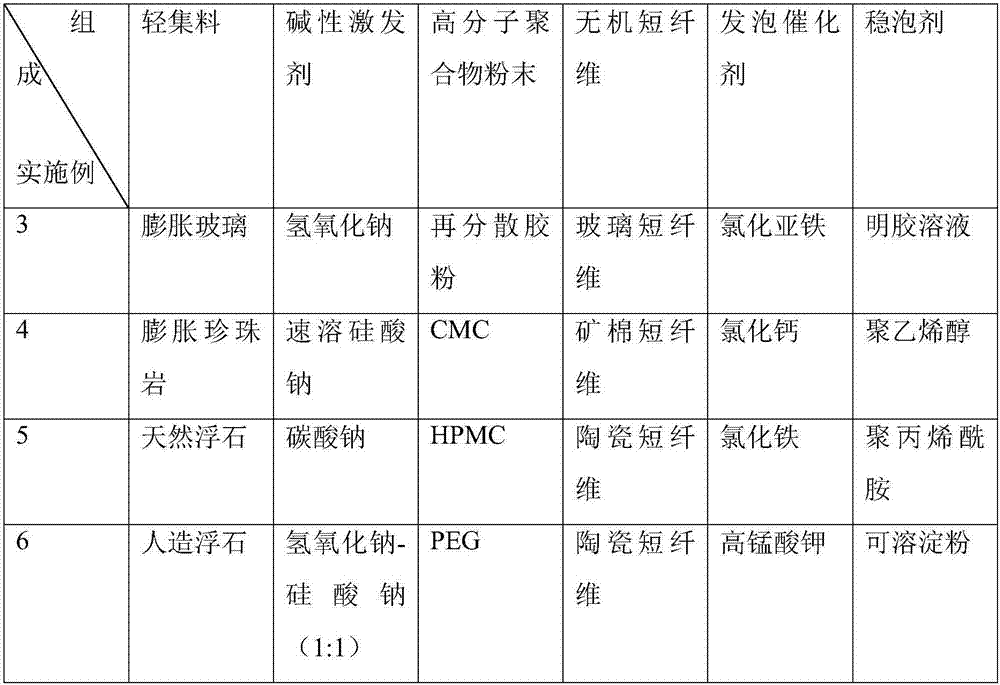

Geopolymer foamed light aggregate concrete and preparation method thereof

The invention discloses geopolymer foamed light aggregate concrete. The material is composed of slag-fly ash composite micro powder, an alkali activator, inorganic super-light aggregate, high-molecular polymer powder, inorganic staple fibers, a hydrogen peroxide chemical foaming agent, a foaming catalyst, an inorganic porous carrier and a foam stabilizer. The method for preparing the geopolymer foamed light aggregate concrete comprises the following steps: mixing and manufacturing various components according to a certain ratio. The problems that the strength of the conventional cement-based foam concrete material is greatly decreased when used for high-temperature insulation and foams and bubbles difficultly grow due to too fast setting of slag-based geopolymer foamed cement and the like can be effectively solved. Therefore, the durability of the foamed light aggregate geopolymer concrete layer is obviously improved, and the light aggregate concrete can be used for promoting energy-saving insulation of low-temperature and normal-pressure building envelopes, decreasing the dead weight of walls and reducing CO2 emission, contributes to improving ecological and economic benefits and is extremely convenient in construction. The construction cost and material cost can be greatly reduced.

Owner:MAANSHAN MCC17 ENG TECH CO LTD

Fluxing apparatus of LCD glass melting furnace

InactiveCN101381197AHigh clarification temperatureClarification temperature is goodGlass furnace apparatusGlass productionViscosityGlass production

The invention relates to a liquid-crystal glass tank furnace fluxing device and a method for solving the difficult problems that liquid-crystal glass is high in melting temperature, high in high temperature viscosity, low in melting rate and high in volatility when melting. A tank bottom between a charging opening and a bubble of a tank furnace is provided with a row of electrodes; the tank bottom in a clarification area close to a liquid flow hole is provided with a row of electrodes as well; and a pure oxygen burner jetting flame into the furnace is arranged on the tank furnace. The device aids in melting through a plurality of fluxing modes, homogenizes the temperature of molten glass, raises the internal temperature of the molten glass, speeds up convection, accelerates glass clarification process, reduces crystallization tendency, and can obtain the glass with higher quality. Therefore, the device is especially applicable to the liquid-crystal glass production harsh in requirement on glass quality.

Owner:HENAN ANFEI ELECTRONICS GLASS

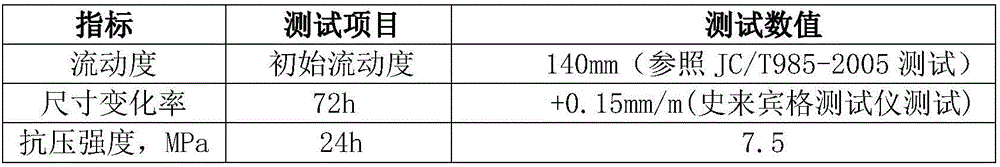

Binary system quick-drying thick-layer cement self-leveling mortar

The invention belongs to the technical field of building materials and specifically discloses binary system quick-drying thick-layer cement self-leveling mortar. The binary system quick-drying thick-layer cement self-leveling mortar is mainly composed of the following ingredients (by weight): 25-30% of ordinary Portland cement, 5-8% of sulfoaluminate cement, 1.5-3% of calcium oxide, 2-5% of fine sinking beads and 40-45% of dried river sand of 12-140 meshes, etc. According to the binary system quick-drying thick-layer cement self-leveling mortar, one-time construction thickness reaches 50 mm, existing ground artificial plaster can be directly replaced, construction speed is fast, construction period is greatly shortened, and flatness is high. After construction, the ground can be directly coated with floor paint, and wooden floorboards and PVC boards can be paved or large-sized flat bricks can be directly paved by the use of a glue for tiles by a thin-layer full adhesion method.

Owner:河南一方建材集团有限公司

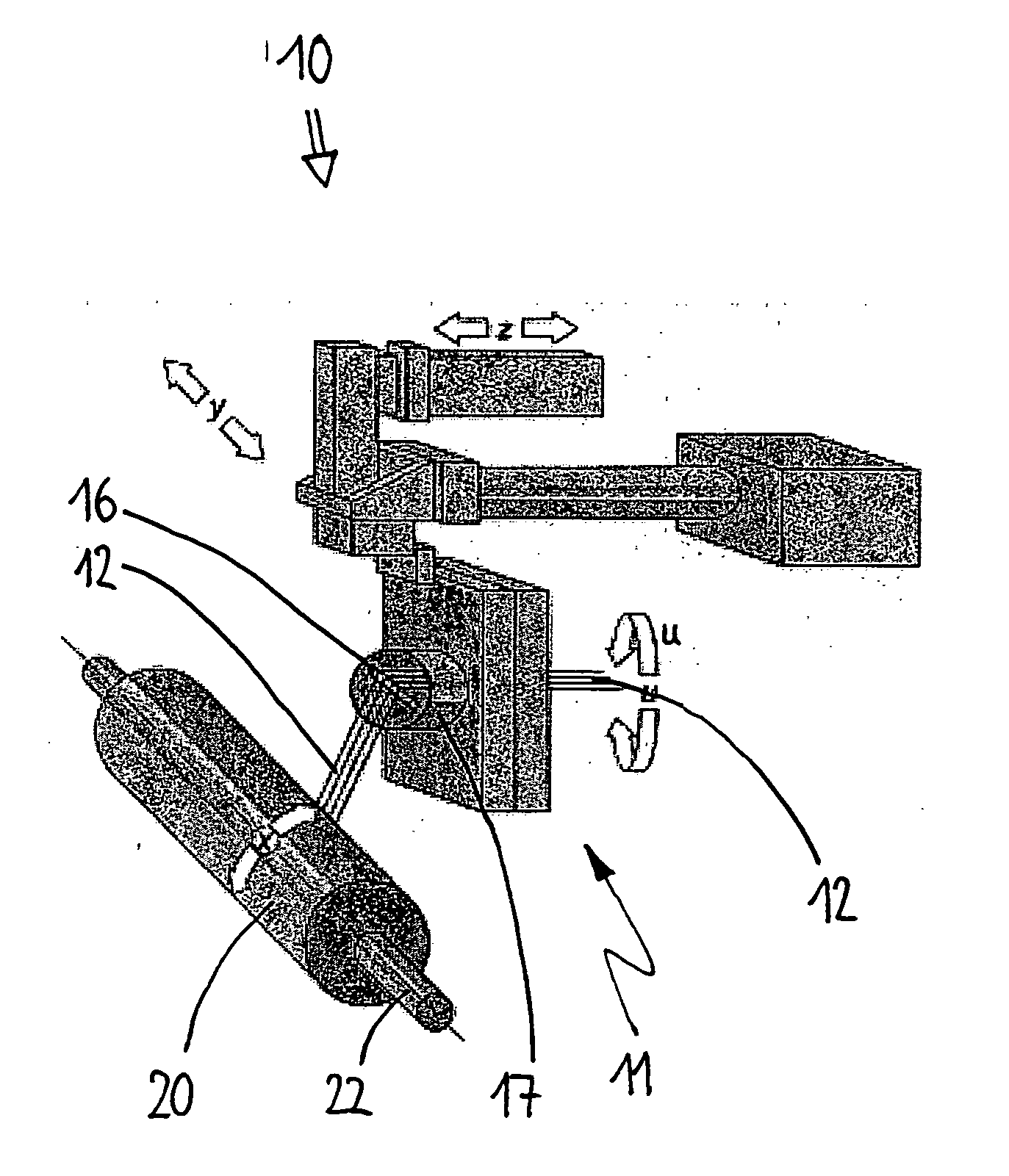

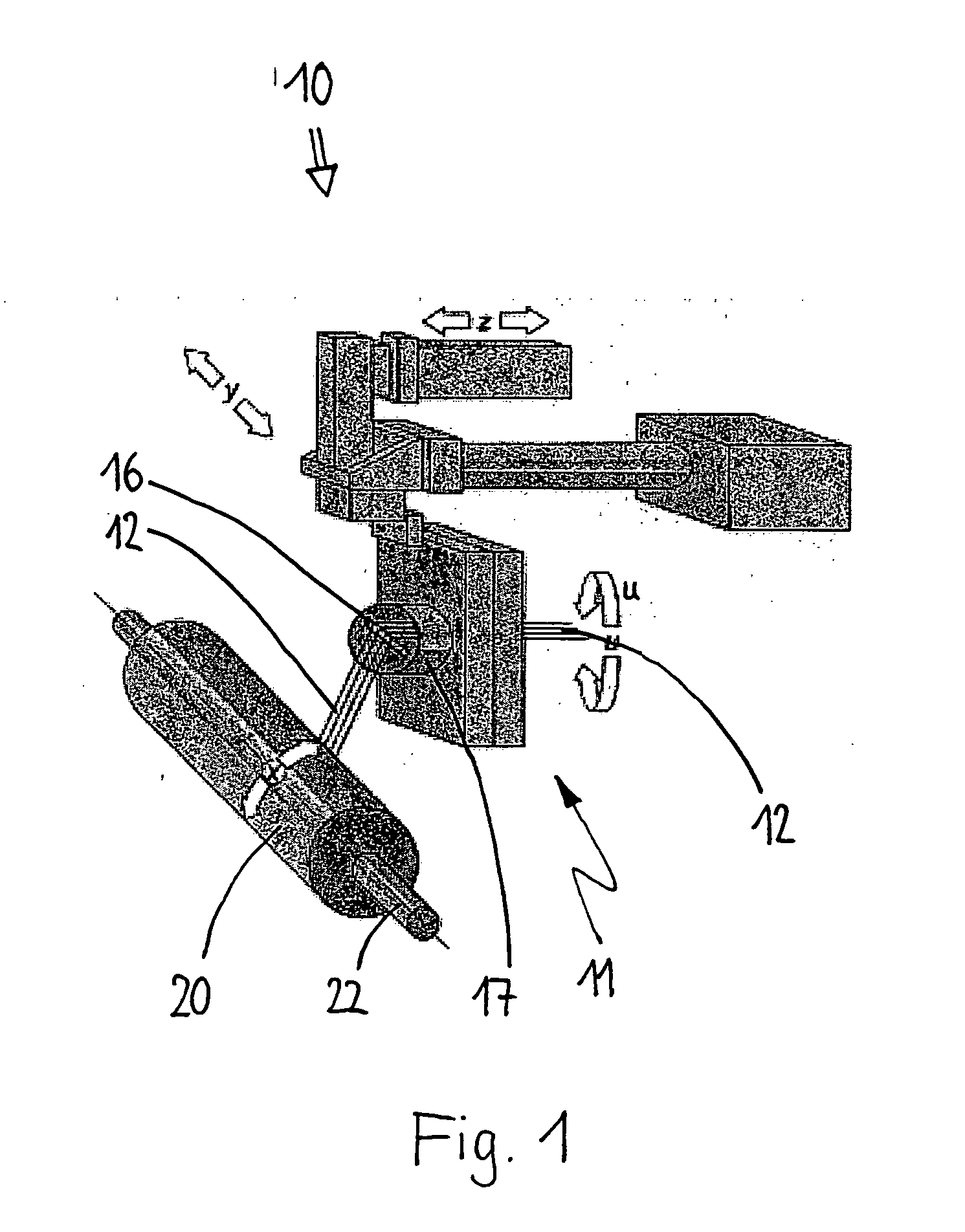

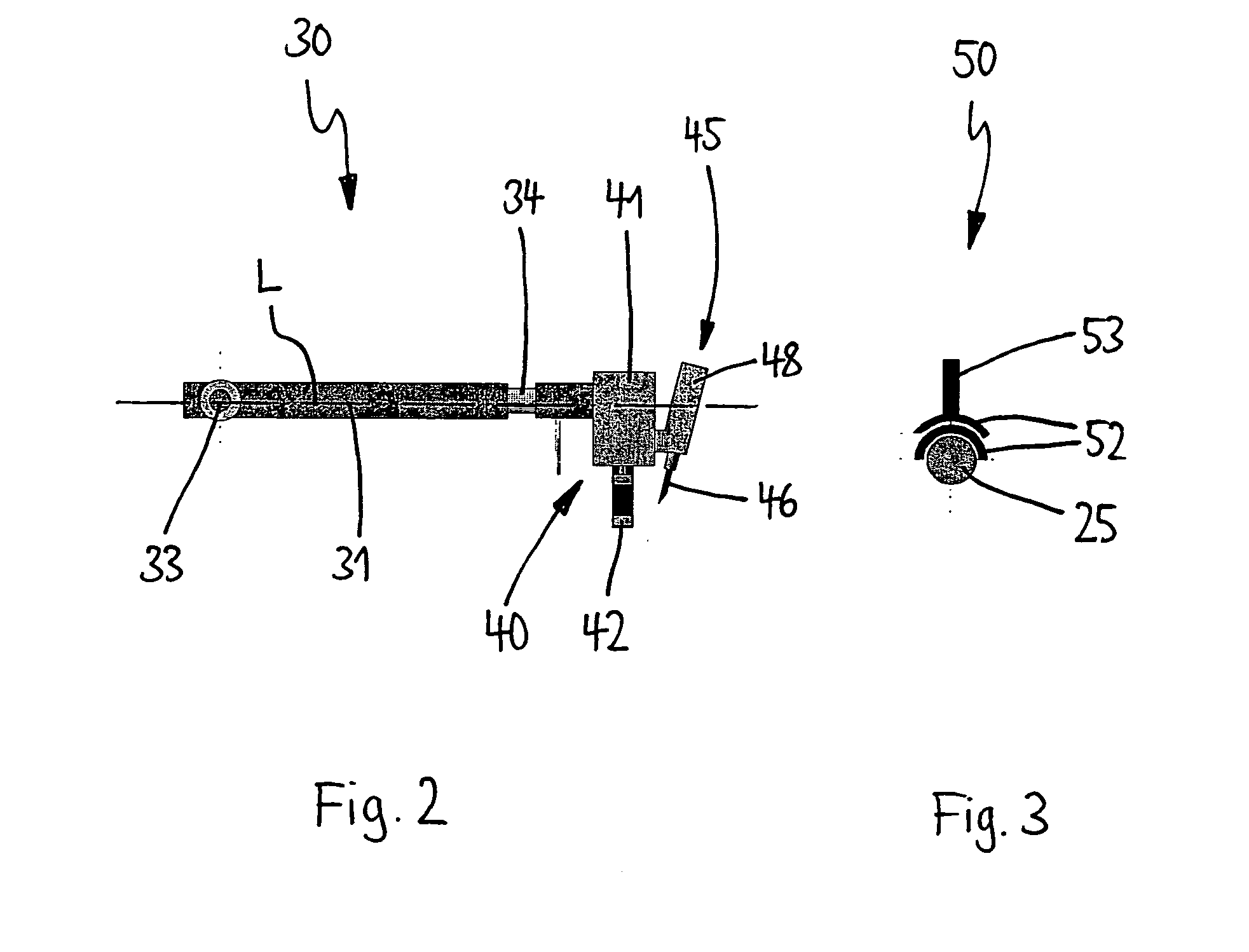

System for separating and linking composite fibers

ActiveUS20050184188A1Promote disseminationAvoid injuryFilament handlingDocument insertersFiber bundleEngineering

A system and process for separating and linking composite fibers, fiber bundles and the like in a filament winding installation (10) for the manufacture of rotationally symmetric wound packages (70) has a feeding device (11) for a fiber strand (12) impregnated with a matrix material which is wound on a rotatably driven base element (20). The system has at least one separating device (30) for cutting the fiber strand (12) and contacting the package-sided end (13) of the fiber strand (12) on the completed wound package (70). Also provided is at least one binding device (50) for linking the free end (14) of the fiber strand (12) with an adjacent new non-wound base element (20).

Owner:EHA SPEZIALMASCHENBAU

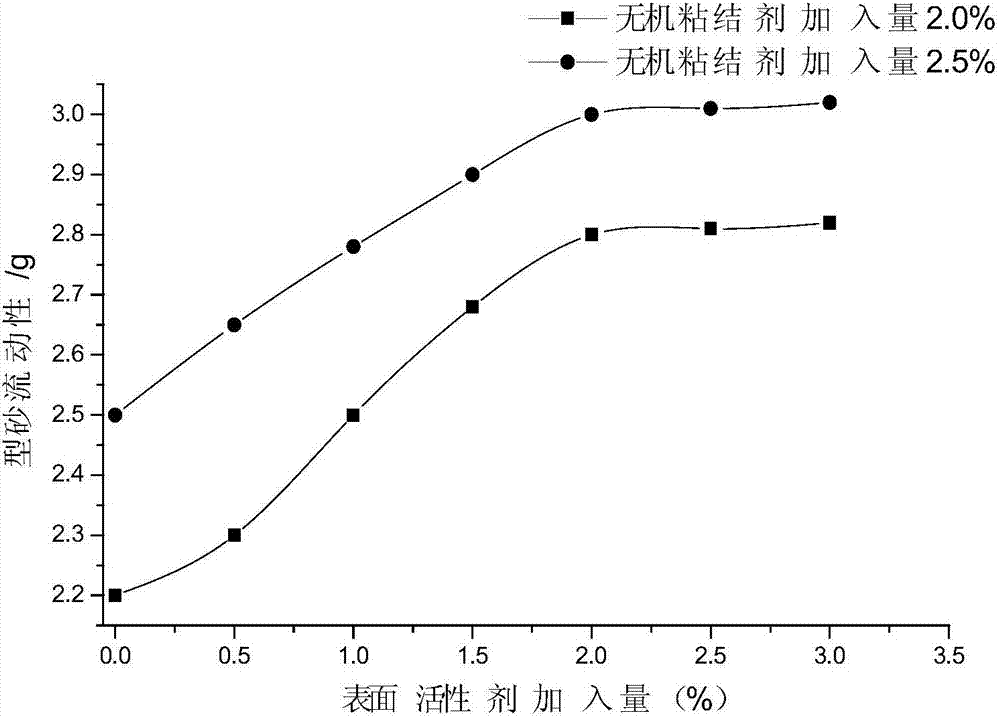

High-modulus inorganic binder

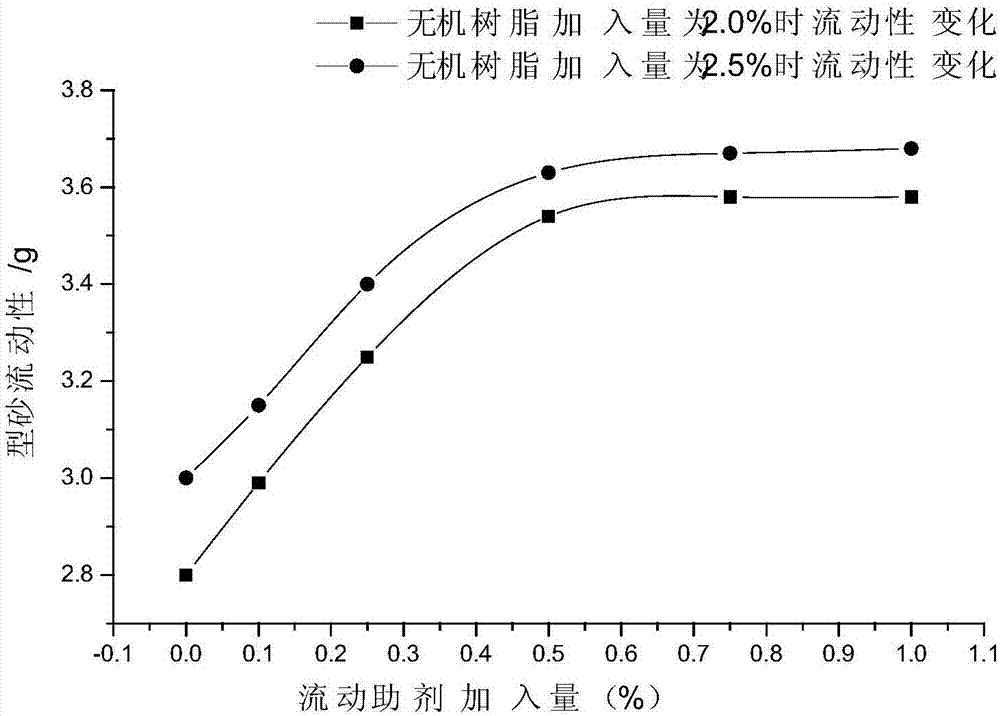

ActiveCN106862480AImprove liquidityImprove moisture resistanceFoundry mouldsFoundry coresNano siliconPhosphate

The invention belongs to the field of inorganic binders for casting, and particularly discloses a high-modulus inorganic binder. The high-modulus inorganic binder comprises the following materials, by weight, 5-25 parts of anionic surfactants, 1-75 parts of flow promoting agents, 10-25 parts of accelerative activators, 5 parts of curing agents, 30 parts of nano silicon oxide, 20 parts of nano zinc oxide, 20 parts of hydrogenated starch, 10 parts of phosphate and 5 parts of carbonate. With the adoption of the high-modulus inorganic binder, the liquidity, the moisture resistance, the strength, a hardening rate, the collapsibility and the like of inorganic binder bonded sand can be improved effectively.

Owner:CHINA FIRST AUTOMOBILE

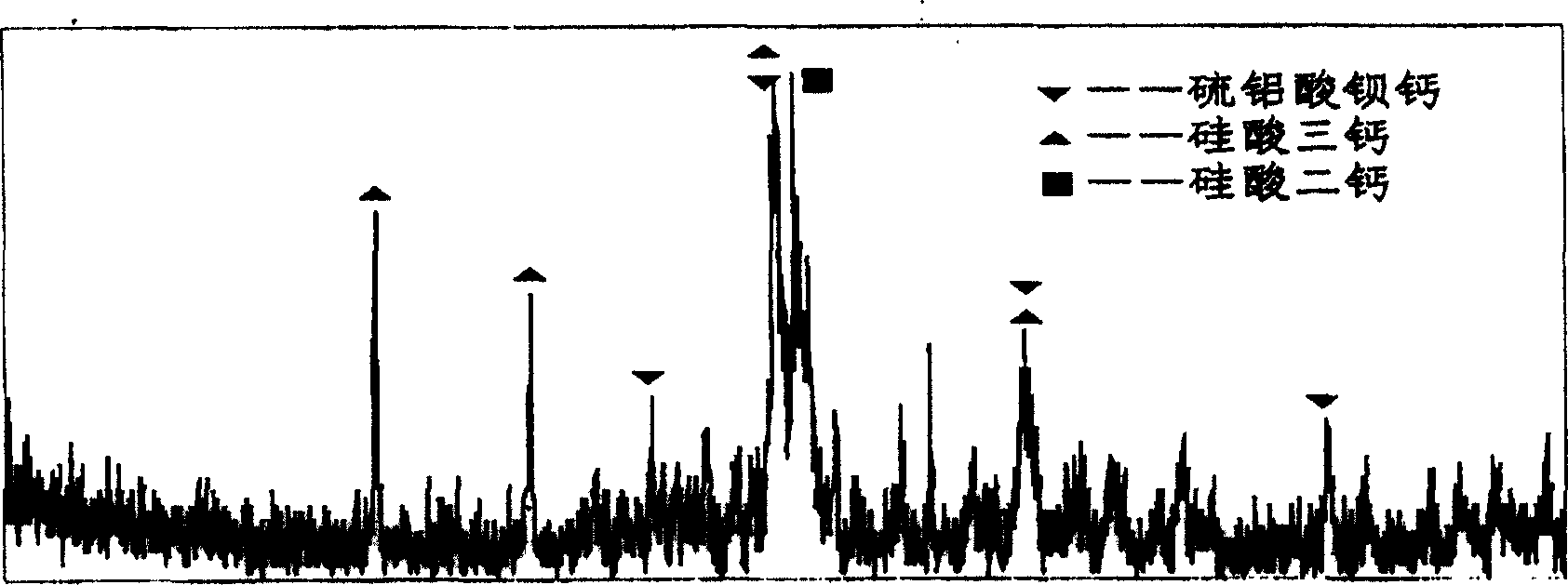

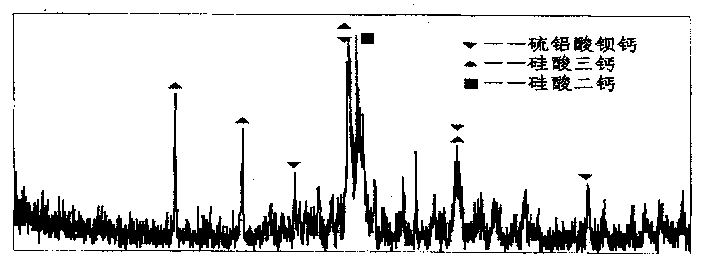

Alite-barium calcium sulfur aluminate cement

An Alinty-barium calcium thioaluminate cement contains barium calcium thioaluminate (3-38 wt.%), tricalcium aluminate (3-20), tricalcium silicate (30-60), dicalcium silicate (15-40), and ferroaluminate (3-20). Its advantages are low burning temp, high early strength and hardening speed, and low cost.

Owner:UNIV OF JINAN

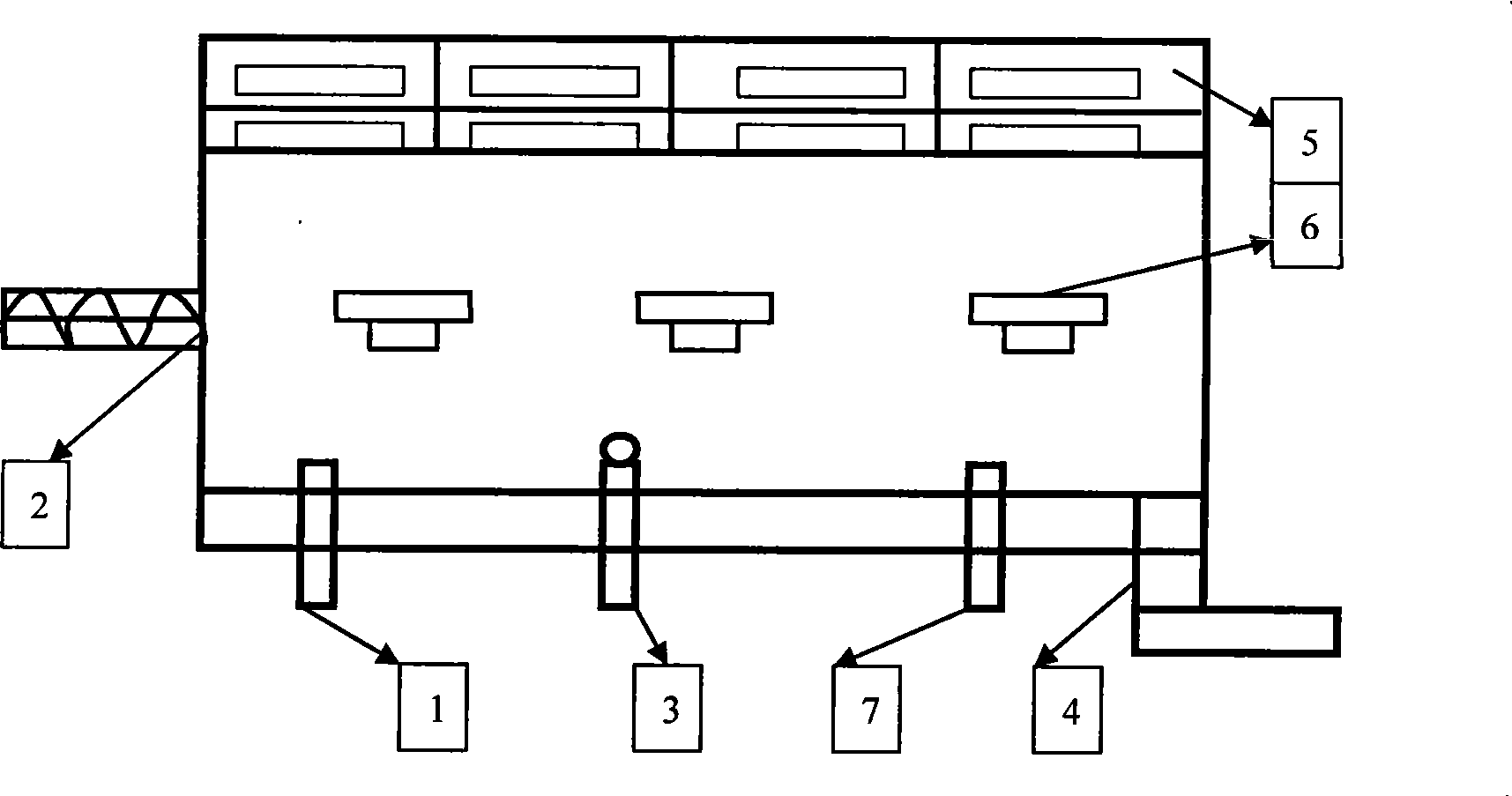

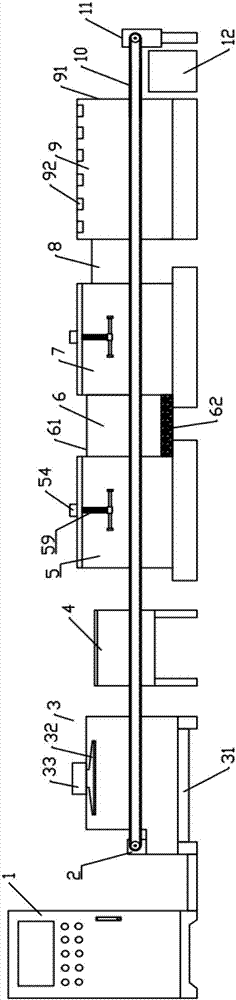

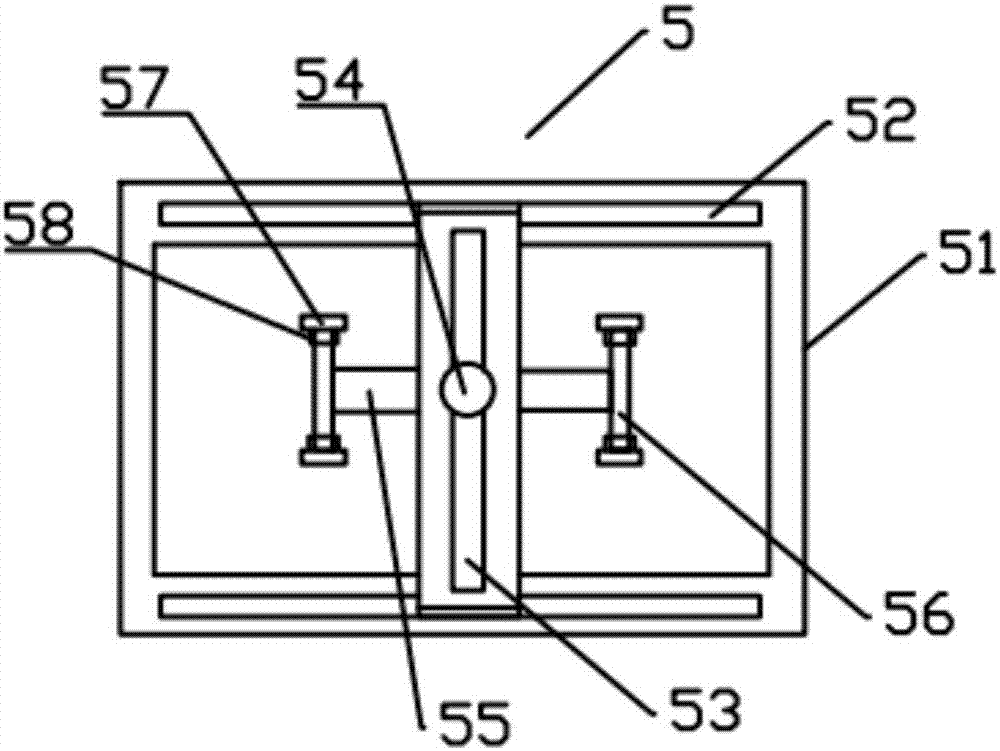

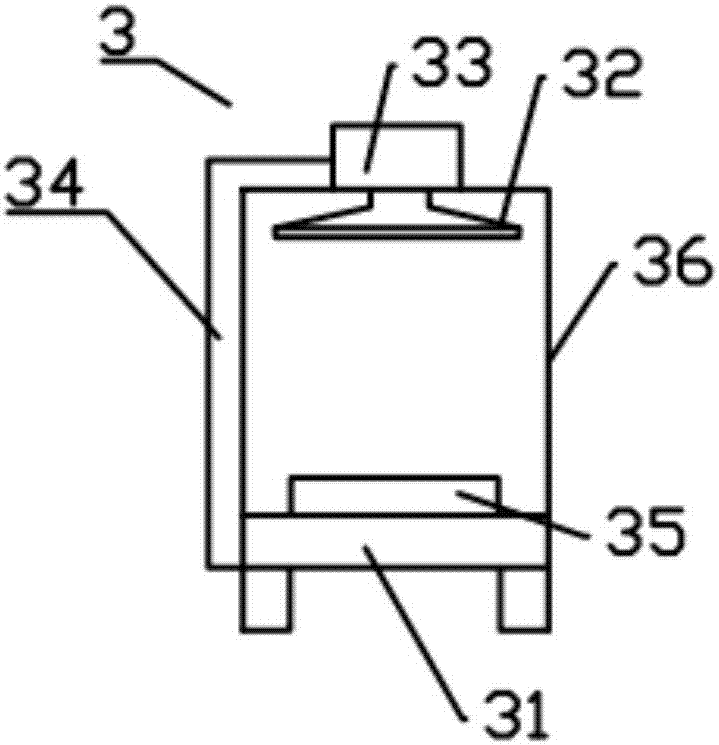

Environment-friendly and efficient UV paint spraying line and technology thereof

InactiveCN107470073AImprove cleanlinessFast hardeningPretreated surfacesCoatingsUV curingEngineering

The invention discloses an environment-friendly and efficient UV paint spraying line. The environment-friendly and efficient UV paint spraying line comprises an electric control cabinet, a first motor, an automatic dust removing device, a preheating device, a UV primer paint spraying device, a first tunnel, a UV finish paint spraying device, a second tunnel, a UV curing device, a material driving belt, a second motor and a material storing box; and the first motor, the automatic dust removing device, the preheating device, the UV primer paint spraying device, the first tunnel, the UV finish paint spraying device, the second tunnel, the UV curing device and the second motor are electrically connected with the electric control cabinet, the material driving belt is arranged between the first motor and the second motor, and the automatic dust removing device, the preheating device, the UV primer paint spraying device, the first tunnel, the UV finish paint spraying device, the second tunnel and the UV curing device are sequentially arranged from left to right and connected through the material driving belt. According to the environment-friendly and efficient UV paint spraying line and a technology thereof, UV paint is sprayed to a workpiece, and then a product which is high in surface hardness, wear resistance and glossiness is obtained.

Owner:太仓市众翔精密五金有限公司

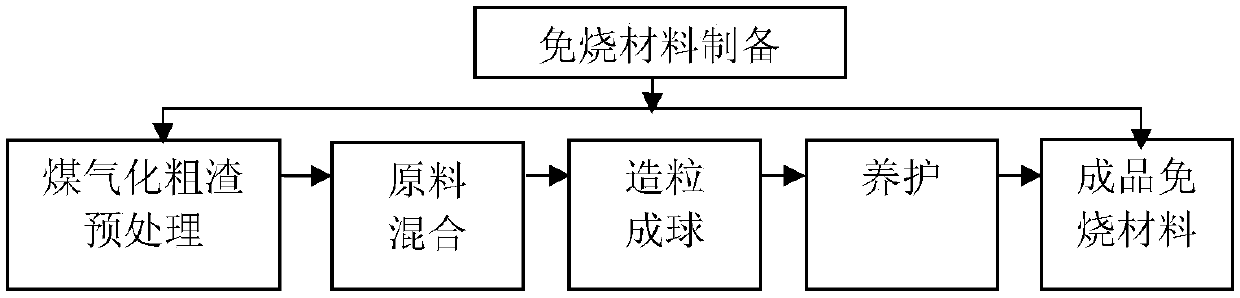

Coal gasification coarse slag non-fired material and preparation method thereof

The invention provides a non-fired material. The non-fired material comprises, by weight, 63-75 parts of coal gasification coarse slag, 15-25 parts of cement and 10-12 parts of quartz sands; and a mass ratio of the coal gasification coarse slag to the cement is (4-5):1 or (2-2.52):1. Compared with materials in the prior art, the non-fired material has the following advantages: the coal gasification coarse slag, cement and quartz sands are mixed according to a certain ratio, the quartz sands are used to supplement glass in the coal gasification coarse slag, and the cement is used to improve theactivity of the coal gasification coarse slag, so the hardening speed of the non-fired material is accelerated, and the strength of the non-fired material is increased.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

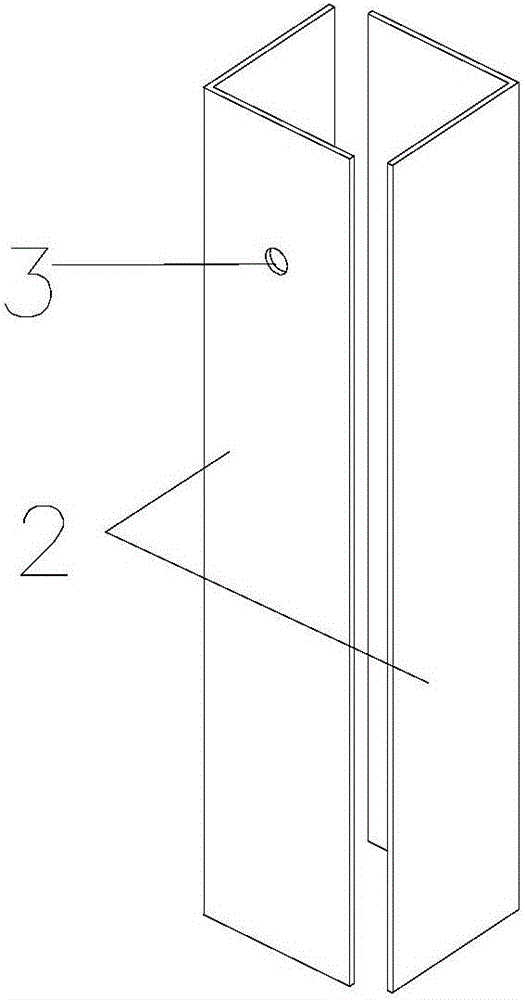

The steel-tube grouting quick-stabilizing column structure and construction method

ActiveCN106337570APrevent local bucklingAvoid high demandsBuilding repairsReinforced concrete columnRebar

The present invention relates to the field of stabilization with the aid of reinforced-concrete column structures, in particular to a steel-tube grouting quick-stabilization column structure and construction method. The cross-section of steel-tube grouting quick-stabilization column structure may be either round or square. A round-section steel-tube grouting quick-stabilizing column structure comprises two outer-casing semi-round steel tubes and ring-type restriction stirrups, and a square-section steel-tube grouting quick-stabilizing column structure comprises two outer-casing semi-round steel tubes and square restriction stirrups. The two outer casing steel tubes adopted by the present invention can double as formwork so as to avoid field formwork construction. The construction techniques only require installing and securing the semi-steel tubes on the field and injecting the high-strength grouting material, so the operating process is quite simple. Welding the two semi-steel tubes after the grouting material is injected can avoid the partial buckling of steel-tube wall caused by welding operation and the high requirements for skilled welders; therefore, it is quite simple and easy to implement the stabilization technique.

Owner:浙江书韬建设有限公司

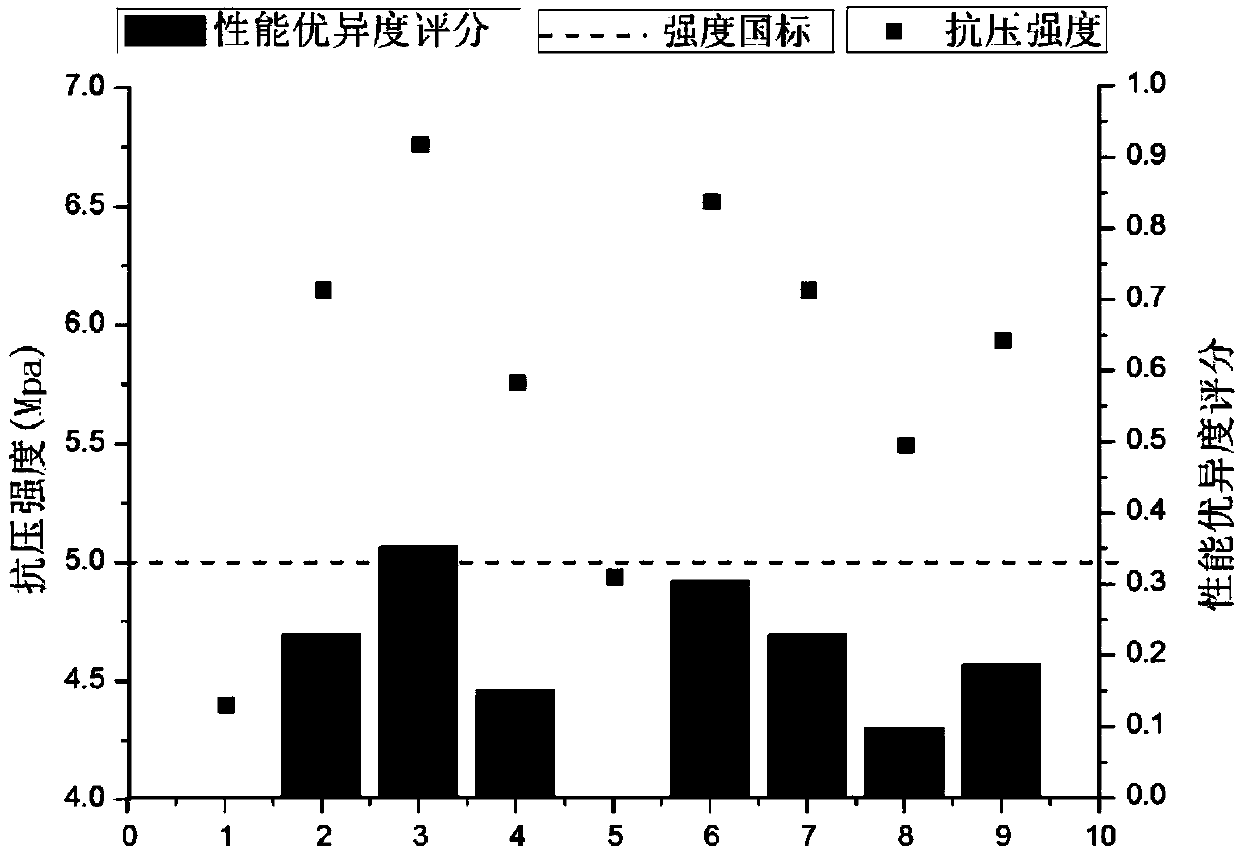

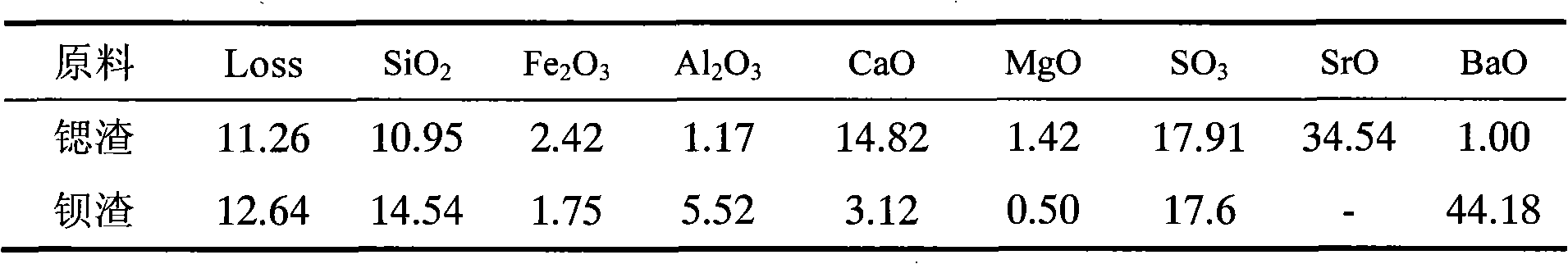

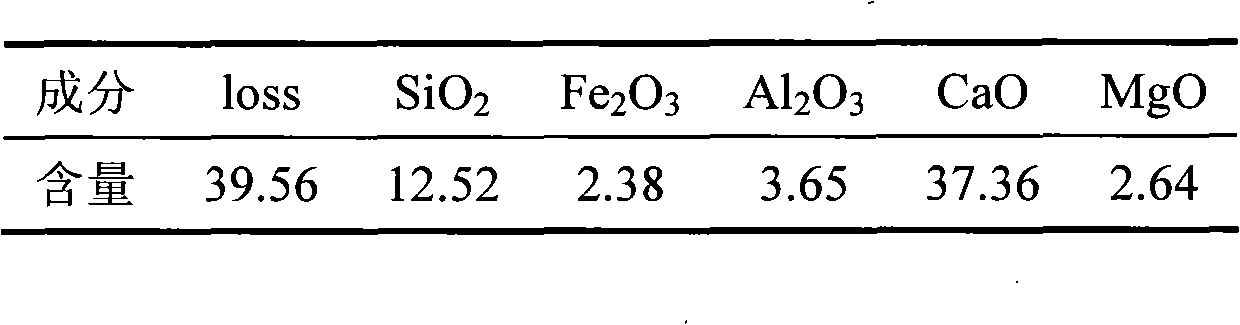

Strontium-barium cement calcination composite mineralizer

The invention relates to a strontium-barium cement calcination composite mineralizer, which is mainly made of strontium slag and barium slag, wherein both the weight percentage of the strontium slag and the weight percentage of the barium slag are 15 to 85 percent; the strontium slag is waste residue for producing strontium carbonate, and the weight percentage of SrO is required to be 25 to 40 percent; and the barium slag is waste residue for producing barium carbonate, and the weight percentage of BaO is required to be 20 to 50 percent. The invention utilizes the strontium slag and the barium slag as raw materials to synthesize the composite mineralizer, and achieves the aims of improving the cement strength, accelerating the hydrating and hardening of cement, improving the yield of kilns, reducing the cement cost, saving energy and resources, and reducing environmental pollution through the activation and mineralization of the composite mineralizer during the calcination of cement clinker.

Owner:UNIV OF JINAN

Binding agent, preparation method and grinding wheel

The invention relates to a binding agent, a preparation method and a grinding wheel, and belongs to the technical field of abrasives and grinding tools. The binding agent is mainly prepared from the following raw materials by mass percent: 70% to 85% of gypsum, 1% to 12% of glass fiber powder and 8% to 18% of clay. According to the binding agent, the raw materials coact with each other in a limited dosage proportion range, so that a compound high-temperature sintered product has relatively high strength, proper hardness and good plasticity; during preparation of the grinding wheel, the binding agent is mixed with water according to a suitable proportion, the forming speed is high, sintering is not carried out in the follow-up steps, and only natural drying or accelerated drying is required; sintering is not required, and the hardening speed is high, so that various problems like cracking and foaming occurring in traditional ceramic bond sintering are avoided; the binding agent is applicable to grinding wheels for low-speed and high-precision grinding, and the prepared grinding wheel is sharp and is high in grinding efficiency; the binding agent is applicable to various abrasives, the holding force for the abrasives is good, and the binding agent has universality; and the raw materials of the binding agent are easy to obtain, the cost is low, and the binding agent is applicable to large-scale industrial production.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

3D printed solid waste concrete member and preparation method

ActiveCN111233407AFast hardeningImprove buildabilityAdditive manufacturing apparatusRebarConstruction engineering

The invention relates to a 3D printed solid waste concrete member and a preparation method. The concrete member comprises a 3D printed mortar template and a concrete inner core which is filled in thetemplate and can be implanted with reinforcing steel bars, the 3D printed mortar template is made of 3D printing mortar with low shrinkage and high durability, and the concrete filled in the 3D printed mortar template has good fluidity, can realize self-compaction and has small later shrinkage. The 3D printed mortar template can realize quick hardening, early strength and low shrinkage and can beused as a permanent template of a component; the use amount of common wood and steel templates is reduced; the construction speed is accelerated, the internally filled concrete can be matched with reinforcing steel bars for use; the problem that reinforcing steel bars cannot be implanted into a 3D printed component is solved, the concrete inner core and the 3D printed mortar template have good bonding strength, a large amount of glass fiber reinforced plastic solid waste is consumed, solid waste resource recycling and 3D printing intelligent construction are combined, and actual engineering application of 3D printing concrete is promoted.

Owner:HEBEI UNIV OF TECH

Special flooring waterborne polyurethane sub-gloss varnish product and preparation method and application thereof

ActiveCN106147566AExtended opening hoursExtend construction timePolyurea/polyurethane coatingsSurface finishNational standard

The invention relates to a special flooring waterborne polyurethane sub-gloss varnish product and a preparation method and application thereof. Particularly, the varnish product comprises a first container and a second container; the first container comprises a component A which is prepared from, by weight, 40-70 parts of polyacrylate dispersoid, 0.01-5 parts of siloxane dispersing agent, 0.01-5 parts of organosilicone defoaming agent and 0.01-5 parts of non-organosilicone defoaming agent; the second container comprises a component B which is prepared from 10-35 parts by weight of isocyanate curing agent. The invention further discloses the preparation method and application of the varnish product. The varnish product is excellent in surface finishing effect and chemical resistance, other comprehensive properties are balanced, and the varnish product can well meet various indexes of requirements of the national standard.

Owner:NIPPON PAINT CHINA

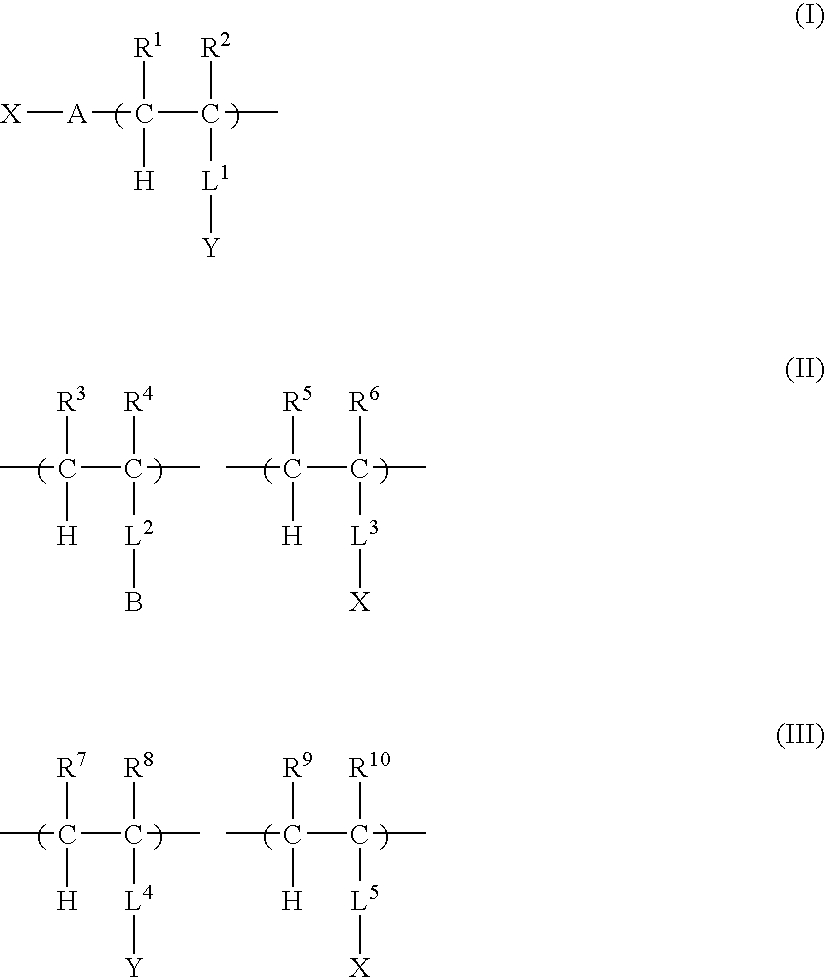

Two-liquid composition, hydrophilic composition and hydrophilic member

InactiveUS20090029179A1High temporal stabilityFast hardeningCoatingsThin material handlingHydrophilic polymersLiquid composition

A two-liquid composition, includes (A) a first liquid composition that contains a hydrophilic polymer having a hydrolyzable silyl group; and (B) a second liquid composition that contains a catalyst capable of accelerating reaction of the hydrolyzable silyl group, and a hydrophilic member is formed by mixing the first liquid composition (A) and the second liquid composition (B), coating a substrate with the resultant mixture and drying the mixture coated.

Owner:FUJIFILM CORP

Shuttering hardening agents

InactiveCN105312486AAvoid pollutionFast hardeningFoundry mouldsFoundry coresEconomic benefitsChloride

The invention relates to shuttering hardening agents. The shuttering hardening agents mainly include, by weight, 10-15% of hexahydrate crystallization of aluminum chloride, 22-25% of dihydrate flaky calcium chloride, 1.5-2% of anhydrous boric acid, 0.1-0.15% of permeating agents and the balance clear water. The hexahydrate crystallization of aluminum chloride and the dihydrate flaky calcium chloride serve as the main materials of the hardening agents, so that the defect that the work conditions are seriously worsened as ammonium chloride is used as the main materials of shuttering hardening agents is fundamentally overcome, and the other properties are better than those of the ammonium chloride hardening agents. The shuttering hardening agents have the characteristics of being high in hardening speed, shortening the process and shortening the production period, avoid environmental pollution and obviously improve economic benefits.

Owner:TIANJIN RONGHENG GROUP

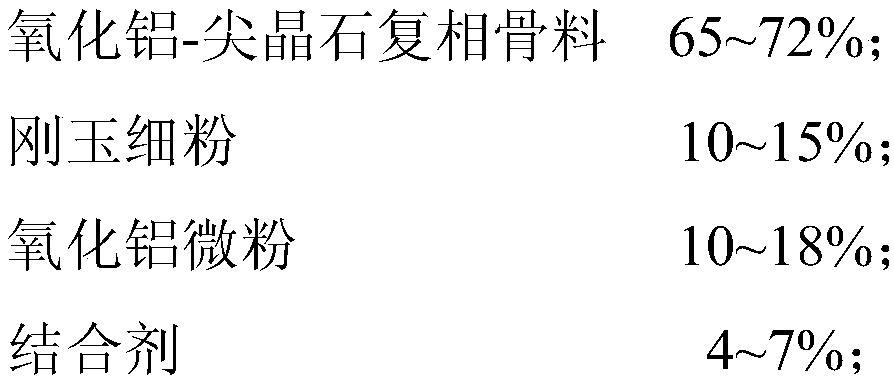

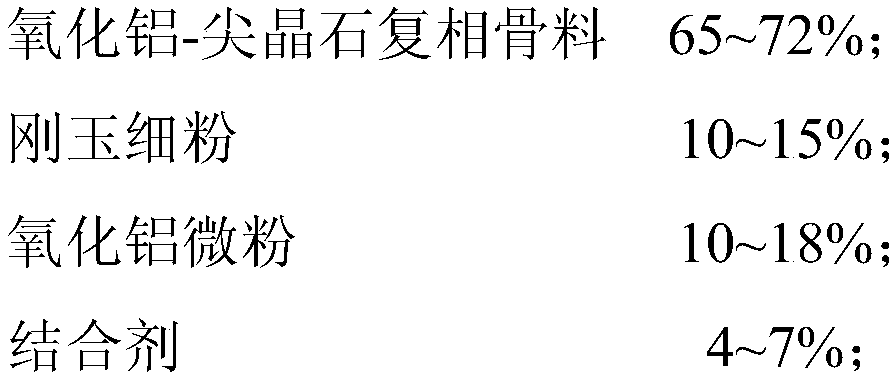

Castable for steel ladle integral casting working lining

The invention discloses a castable for a steel ladle integral casting working lining. The castable is prepared by mixing raw materials including, by weight, 65-72% of aluminum oxide-spinel complex phase aggregates, 10-15% of corundum fine powder, 10-18% of alumina micro-powder, 4-7% of binding agents, 0.1-1% of additional dispersing agents, 0.01-0.1% of additional detonation inhibitors and 0.01-0.2% of additional bleeding prevention agents. Aluminum oxide-spinel complex phase materials serve as the aggregates to prepare the castable for the steel ladle integral casting working lining, and thecastable is excellent in slag corrosion resistance and penetration resistance, low in cost, good in thermal shock resistance, slight in expansion and long in service life and solves the problems of poor slag corrosion resistance and penetration resistance as current castables for steel ladle integral casting working linings extensively use corundum or alumina as an aggregate.

Owner:WUGANG REFRACTORY CO LTD

Building solid waste mixed cement soil

InactiveCN112624670AReduce occupancyAchieve recyclingSolid waste managementEnvironmental engineeringCurtain wall

The invention discloses building solid waste mixed cement soil, which comprises building solid waste, soil and a soil body curing agent; according to the building solid waste mixed cement soil, inorganic nonmetal building solid waste and soil which are obtained nearby are used as main materials, the soil body curing agent is used as a secondary material, a certain proportion of water is added, and then through ground mechanical transmission and uniform stirring, a building material with fluidity and certain strength after hardening is formed, and the material can be widely applied to foundation reinforcement, groove backfill, roadbeds, foundation pit supporting curtain walls and mine goaf backfill; the composition and dosage are determined and adjusted according to different requirements of the component properties of soil and the strength of finished products.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD +2

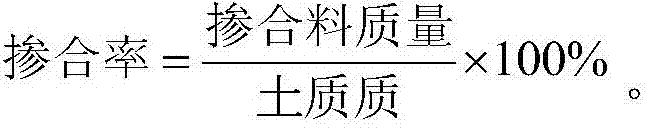

Construction method using modified collapsible loess as roadbed filler

The invention relates to a construction method using modified collapsible loess as roadbed filler and is designed for realizing roadbed filling by using modified loess. The construction method using the modified collapsible loess as the roadbed filler comprises construction survey and setting out, feeding, primary leveling, cement spreading, mechanical mixing, secondary leveling, roller compactionand compaction degree detection, wherein the filler is cement-incorporated loess, in which the cement is incorporated into the loess in an admixing method, and the admixture content is 4%, 5% or 6%.According to the invention, special treatment measures are taken on collapsible loess that could not be used in the past, to make the collapsible loess to be used as the roadbed filler, thus the organic combination of farmland, ecological protection and sustainable development of waste recycling is realized, and the construction method is of great significance to the treatment of roadbed engineering in loess areas.

Owner:JIANGSU SINOROAD ENG TECH RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com