Inorganic foaming thermal-insulation mortar and preparation method thereof

A technology of thermal insulation mortar and inorganic foaming, applied in ceramic products, other household appliances, applications, etc., can solve the problems of reducing the bulk density of inorganic thermal insulation mortar, unsatisfactory weather resistance and durability of thermal insulation mortar, and high cost of thermal insulation mortar. , to achieve the effect of fast setting and hardening speed, light wet weight and dry bulk weight, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: a kind of inorganic foaming thermal insulation mortar, it is composed of: cementitious material; Expanded perlite particle; Polymer; Coagulation accelerator; Early strength agent; Blowing catalyst for blowing agent; water repellent; reinforced short fiber and water composition.

[0031] An inorganic foaming thermal insulation mortar, the mass ratio of the cementitious material to the expanded perlite particles in the composition is 1:1, the high molecular polymer accounts for 0.1% of the mass of the cementitious material; 0.5%; early strength agent accounts for 0.5% of the mass of the gelling material; physical foaming agent accounts for 0.01% of the mass of the gelling material; chemical foaming agent accounts for 5% of the mass of the gelling material; the foaming catalyst of the chemical foaming agent accounts for 0.05% of the mass of the cementitious material; water repellent accounts for 2% of the mass of the cementitious material; reinforcing sho...

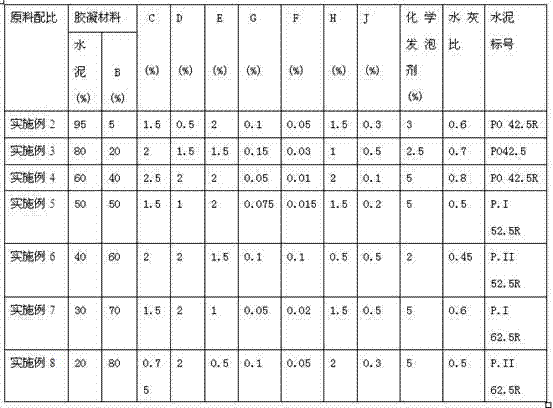

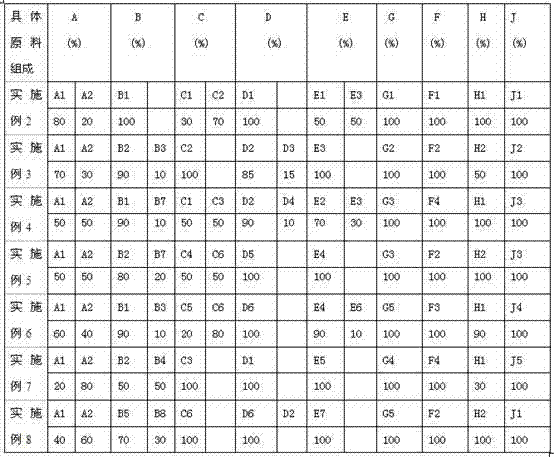

specific Embodiment 2

[0051] In specific embodiment 2, obtain a kind of inorganic foaming thermal insulation mortar that directly smears construction on the exterior wall, can directly smear and construct on the roof that needs thermal insulation treatment, and the thickness of inorganic foaming thermal insulation mortar layer is 40 millimeters, and is finally set in cementitious material Scrape and smooth before construction, and then harden for 10 hours to become an inorganic thermal insulation mortar layer with good durability, water resistance and heat insulation. The 28d compressive strength of the mortar layer is 3.0MPa, and the dry density is 400kg / m 3 , the absolute dry thermal conductivity is 0.09W / (m.K), which can make the insulated wall meet the requirement of 65% building energy saving.

specific Embodiment 3

[0052] In the specific embodiment 3, a kind of inorganic foaming thermal insulation mortar directly applied to the external wall is obtained, which can be directly applied to the wall body that needs thermal insulation treatment. The thickness of the inorganic foamed thermal insulation mortar layer is 40 mm. Scrape and smooth the construction before setting, and then harden for 10 hours to become an inorganic thermal insulation mortar layer with good durability, water resistance and heat insulation. The 28d compressive strength of the mortar layer is 2.8MPa, and the dry density is 350kg / m 3 , the absolute dry thermal conductivity is 0.08W / (m.K), which can make the insulated wall meet the requirement of building energy saving of 65%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com