Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

175 results about "Belite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Belite is an industrial mineral important in Portland cement manufacture. Its main constituent is dicalcium silicate, Ca₂SiO₄, sometimes formulated as 2 CaO · SiO₂ (C₂S in cement chemist notation).

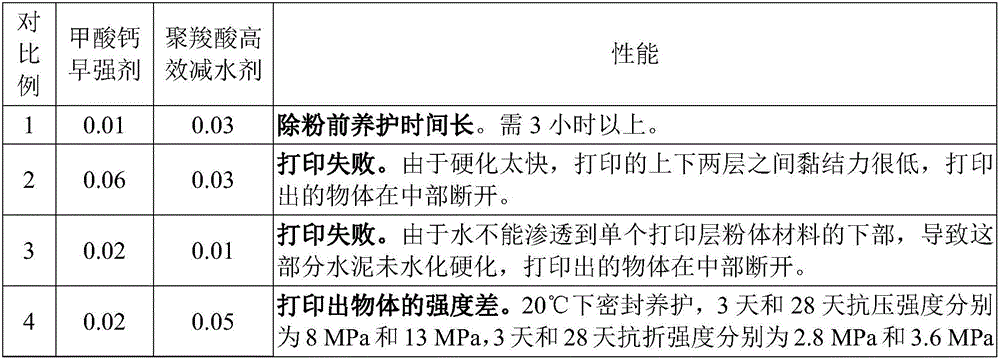

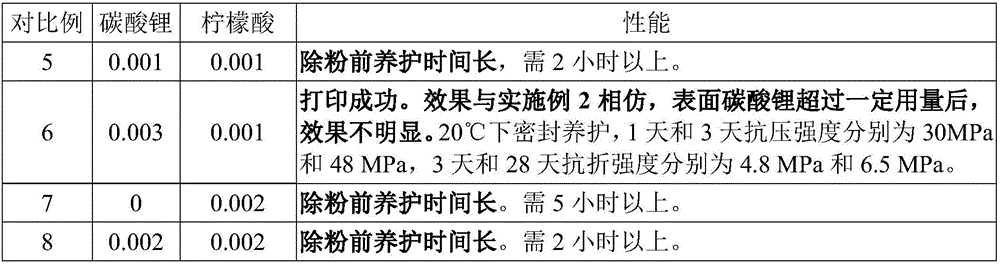

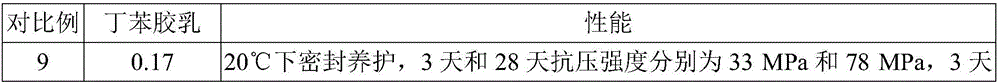

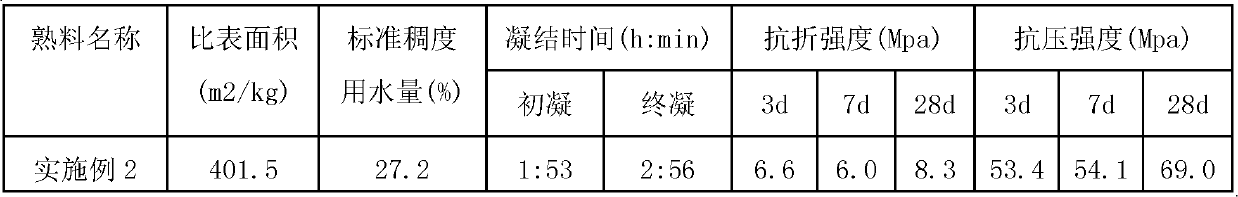

Cement-based composite material for powder-bonding three-dimensional (3D) printing, and powder-bonding 3D printing method applying cement-based composite material

ActiveCN106800391AAppropriate hardening speedAppropriate water distribution effectAdditive manufacturing apparatusPolymer adhesivePhosphate

The invention provides a cement-based composite material for powder-bonding three-dimensional (3D) printing. The material is prepared from the following components in parts by weight: 1 part of cement, 0-5 parts of sand, 0-5 parts of a mineral admixture, 0-0.2 part of an expanding agent, 0-0.2 part of a toughening agent, 0-0.2 part of mineral pigment, 0.1-0.5 part of water, 0-0.25 part of polymer emulsion, 0.001-0.05 part of an additive and 0-0.03 part of fibers, wherein the cement is selected from one or a mixture of more in silicate cements, sulphoaluminate cement, high belite sulphoaluminate cement, aluminate cement, fluoroaluminate cement, aluminosilicate cement, phosphate cement or magnesium oxide cement; the additive is selected from one or a mixture of more in a water reducing agent, an early strength agent or a coagulating regulating agent. After being contacted with water, the cement-based composite material can be hardened, thus not needing a great deal of polymer adhesive; the cement-based composite material is rapid and controllable in hardening speed; the cement-based composite material is small in deformation in the hardening process, thus being suitable for a powder-bonding 3D printing technology. The invention also provides a method for carrying out powder-bonding 3D printing by using the cement-based composite material.

Owner:万玉君

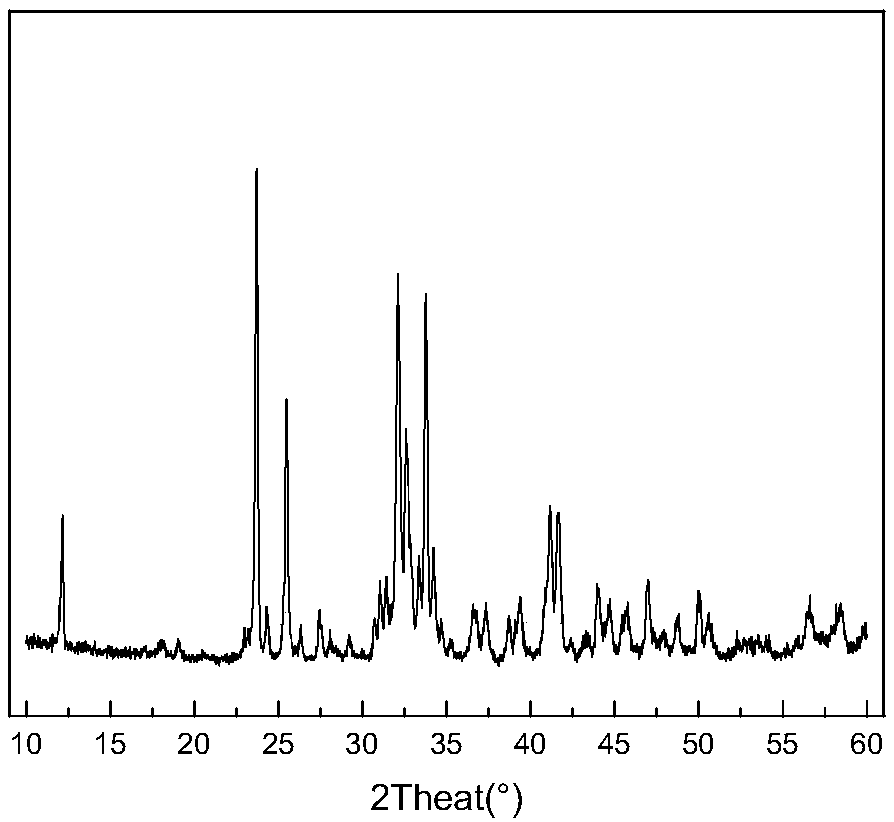

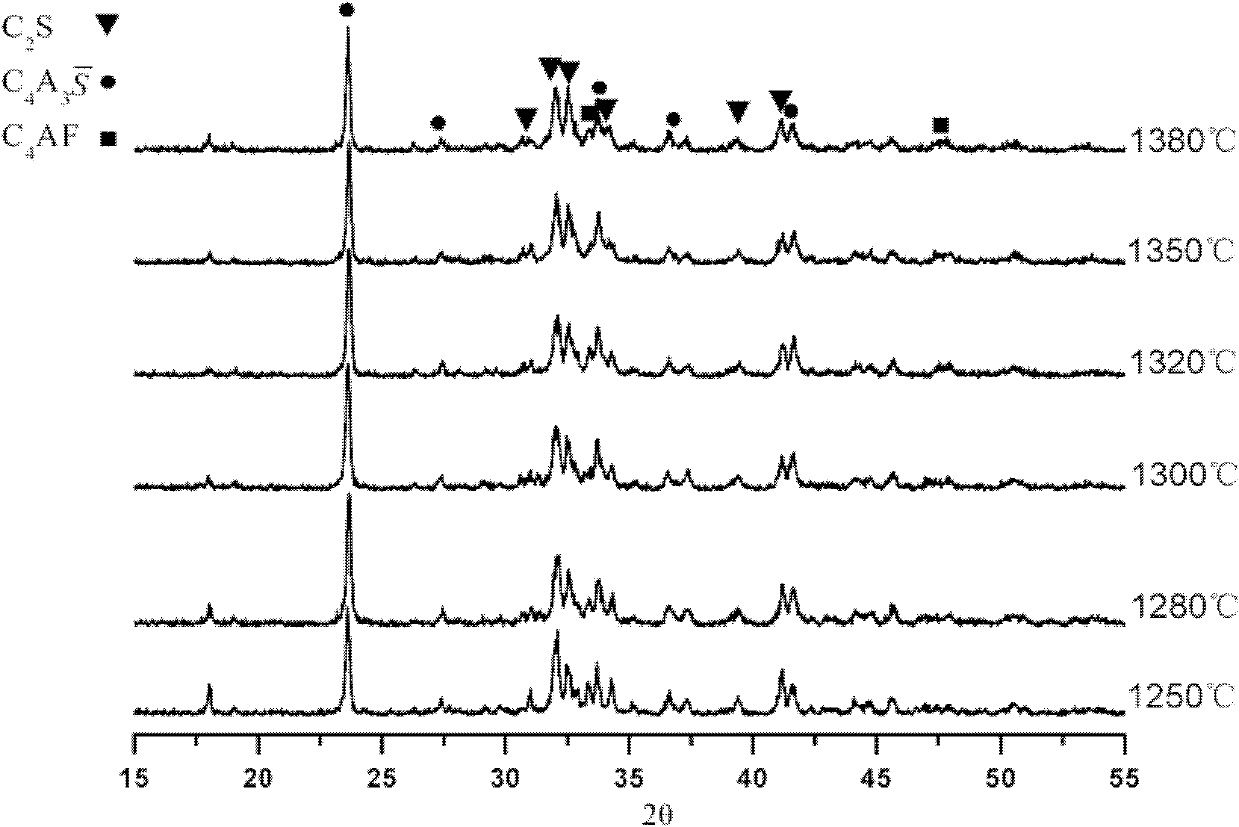

Active belite-sulphate aluminum cement clinker and preparation method for active belite-sulphate aluminum cement clinker

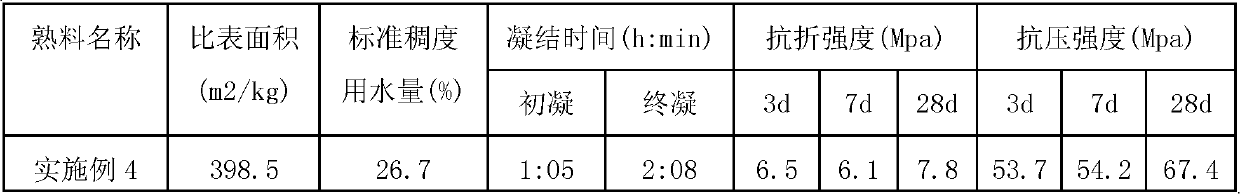

ActiveCN102584045AChange work performanceReduce manufacturing costCement productionAmorphous phaseMaceral

The invention discloses active belite-sulphate aluminum cement clinker, which comprises the following mineral compositions in weight percentage: 25-30 percent of beta-type C2S, 25-30 percent of a-type C2S, 28-40 percent of C4A3S`, 4-12 percent of C4AF and 4-8 percent of amorphous-phase substance. The control of different forms and the change of number of the C2S in the clinker are controlled mainly through special setting on clinker ingredient rate values. The invention also discloses a preparation method for the active belite-sulphate aluminum cement clinker. Compared with traditional common silicate cement clinker, the active belite-sulphate aluminum cement clinker has the advantages that more industrial solid waste residues are used in raw materials by the active belite-sulphate aluminum cement clinker, and thereby, the production cost is reduced, the use proportion of limestone is greatly reduced, and the carbon dioxide emission in clinker production is obviously reduced. Under the condition that the water demand and the setting time of the obtained clinker are basically the same as that of the common silicate cement clinker, the strength of the obtained clinker is superior to that of the common silicate cement clinker.

Owner:TIANJIN CEMENT IND DESIGN & RES INST +1

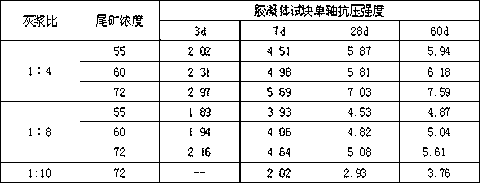

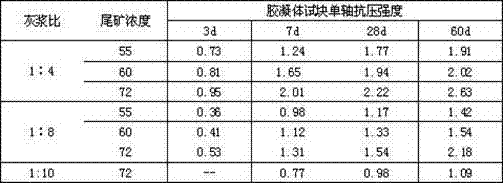

Binding material for filling fine-grain tailings

The invention discloses a binding material for filling fine-grain tailings. The binding material is prepared by milling and mixing the following components in percentage by mass: 15-40% of belite-sulphate aluminum cement, 2-10% of gypsum, 2-8% of quick lime, 40-70% of superfine-grain slag powder, 2-10% of coal ash, 1-6% of activating agent, 0.1-0.5% of activating accelerant, 0.1-0.5% of coagulant, and 0.1-0.5% of water reducer, wherein the activating agent is Na2SiO3, the activating accelerant is sodium fluosilicate, and the coagulant is any one or a mixture of two or more of LiOH, LiCO3 and LiCl; and the water reducer is a naphthalene water reducer or a polycarboxylic acid water reducer. According to the binding material for filling the fine-grain tailings, the problems that -0.074-mm fine-grain tailings and high-silt-content tailings are difficultly solidified and are low in strength after being solidified, and the strength of a filling body can meet a strength requirement on cut and fill of a mine on the filling body by using the binding material; the liquidity of slurry can be improved, and roof-contacting performance of the filling body can be improved; and the water retention capacity can be improved, and the water seepage of the slurry is reduced.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Method for comprehensive utilization of red mud, phosphogypsum and coal gangue

A method for comprehensive utilization of red mud, phosphogypsum and coal gangue comprises the following steps: red mud, phosphogypsum and coal gangue are used as main original burning materials, a correction material is taken as a secondary original burning material, a homogeneous moisture material is prepared through two-stage batching process and is shaped or dried and crushed, and then a clinker product including main ingredients of dicalcium silicate, calcium sulphoaluminate and calcium sulphoferrite is prepared through calcination. The clinker produced by the method can be not only directly sold as a product but also further processed into a cementing material or product for sale by utilizing the prior art. The method provided by the invention is simple in process and low in investment, the production scale can be either big or small, a rapid hardening early strength clinker produced by the method is wide in use and relatively higher in value, not only are lots of clay resources and non-renewable burning coal saved, but also environmental pollution caused by waste pollutants are effectively reduced, secondary disasters is prevented, and high industrial competitiveness and favorable investment economical efficiency are realized.

Owner:长沙紫宸科技开发有限公司

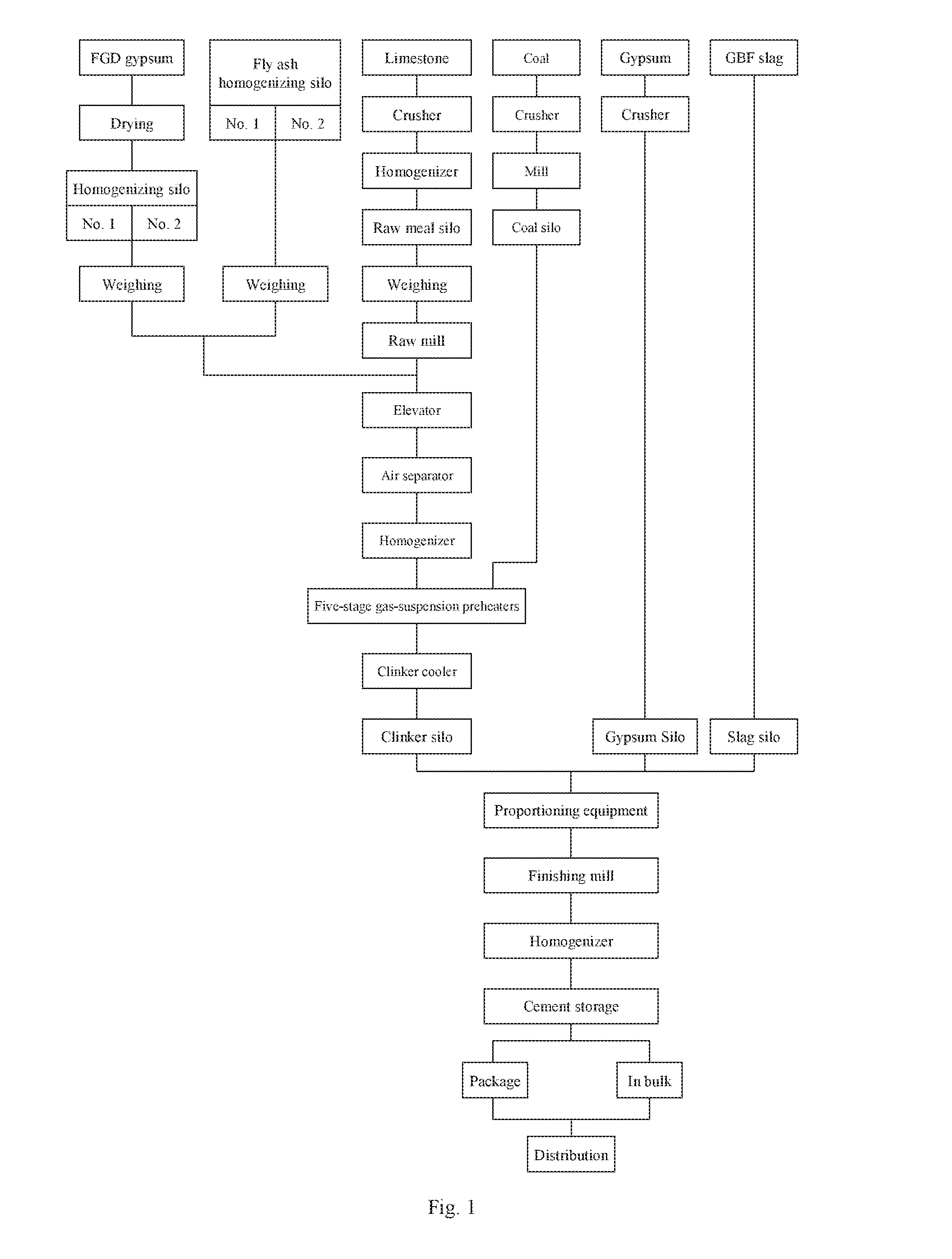

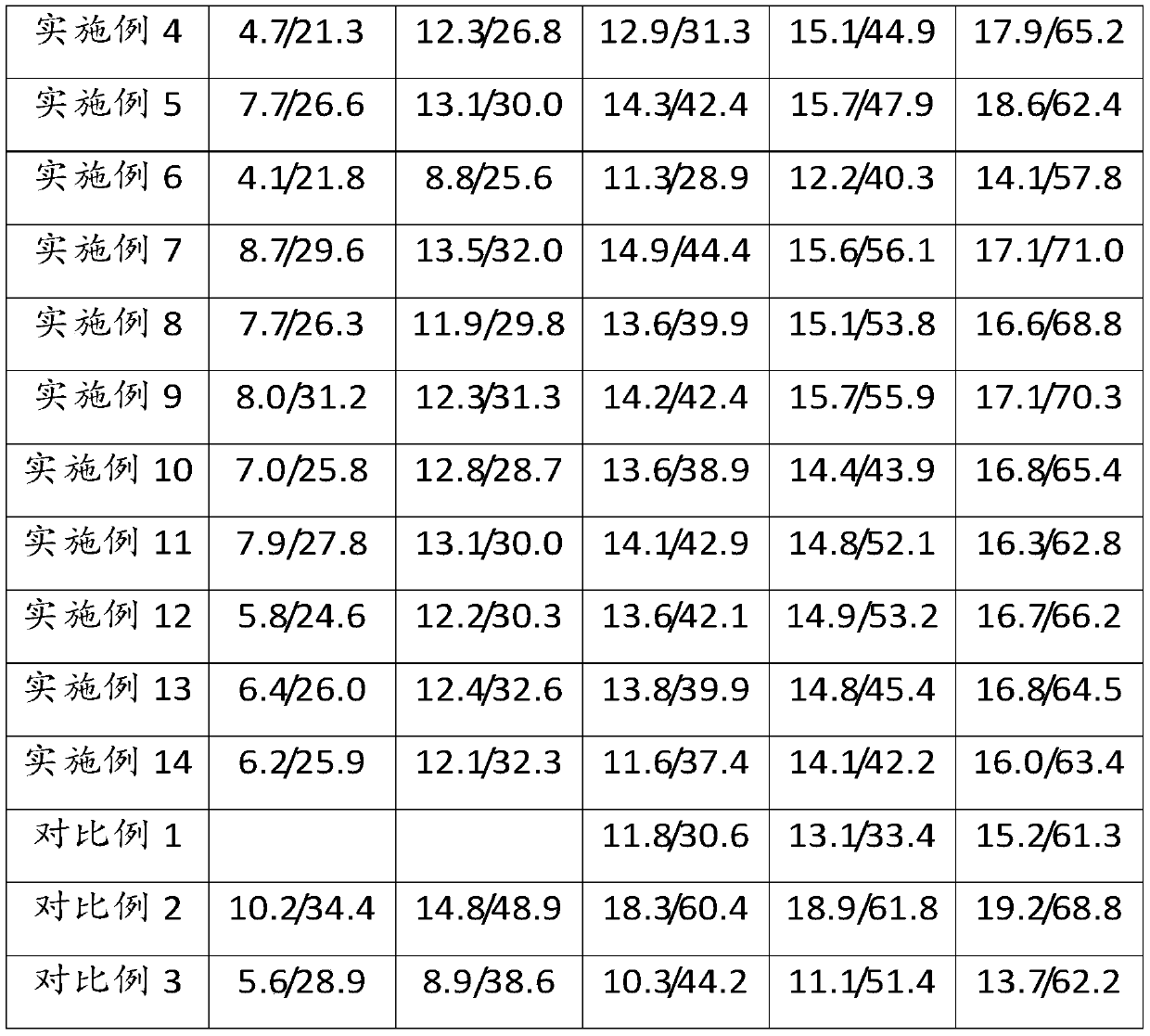

Rapid-setting and hardening, high-belite sulfoaluminate cement clinker as well as application and production process thereof

ActiveUS20170050882A1Increase heightHigh-strength rapid-hardeningSolid waste managementCement productionChemical compositionSlag

The invention discloses a rapid-hardening high-belite calcium sulfoaluminate cement clinker and relates generally to a rapid-hardening high-belite calcium sulfoaluminate cement clinker and methods to use and to manufacture the clinker. The clinker of the present invention comprises 20% to 35% by weight of C4A3S 3% to 9% by weight of C4AF, 37% to 47% by weight of C2S, 0.5% to 4.6% by weight of f-Ca° and 14% to 26.3% by weight of CaSO4. The chemical compositions of the clinker are 12.9% to 16.1% by weight of SiO2, 12% to 19% by weight of Al2O3, 1% to 3% by weight of Fe2O3, 49% to 54% by weight of CaO and 12% to 18.43% by weight of SO3. It is manufactured by calcining, at a temperature of 1300° C.±50° C. in a rotary kiln, the raw meal, comprising 33% to 62% by weight of limestone, 10.5% to 28% by weight of fly ash, and 19% to 45% by weight of FGD gypsum. A group of rapid-hardening high-strength cements of various strength classes can be manufactured by mixing and grinding 26% to 97% by weight of clinker, 3% to 19% by weight of anhydrite and 0% to 55% by weight of granulated blast furnace slag.

Owner:TANGSHAN POLAR BEAR BUILDING MATERIAL

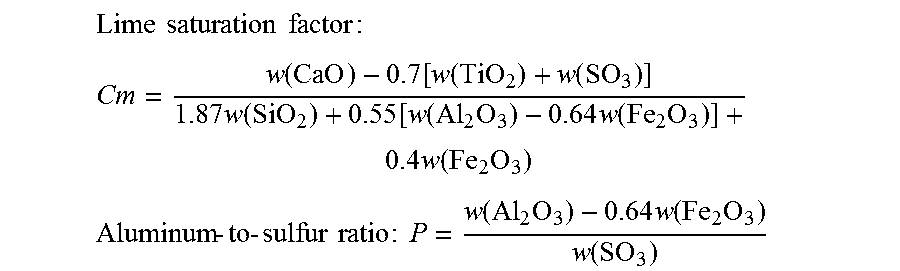

White fast-setting, fast-hardening and high-belite sulphoaluminate cement clinker, and application and production technology thereof

The invention relates to a white fast-setting, fast-hardening and high-belite sulphoaluminate cement clinker, and also relates to an application and a production technology thereof. The mineral component of the cement clinker comprises 0.5-4.6% of f-CaO; the chemical component of the cement clinker comprises 12.9-16.1wt% of SiO2, 12-19wt% of Al2O3, 0.15-1.0wt% of Fe2O3, 49-53wt% of CaO and 12-18.5wt% of SO3; and the clinker rate range Cm is 1.01-1.137, and P is 0.62-1.44. The clinker is produced through calcining 30-50wt% of limestone, 26-46wt% of slag powder and 21.1-40wt% of desulfurized gypsum in a rotary kiln at 1250-1350DEG C. 26-97% Of the clinker, 3-19% of anhydrite and 0-55% of the slag powder, or 5-25% of the clinker, 14.4-19.0% of the anhydrite and 55.8-79% of the slag powder are mixed and ground to form white fast-setting, fast-hardening and high-belite sulphoaluminate cement and high-late strength and high-belite sulphoaluminate cement.

Owner:TANGSHAN POLAR BEAR BUILDING MATERIAL +1

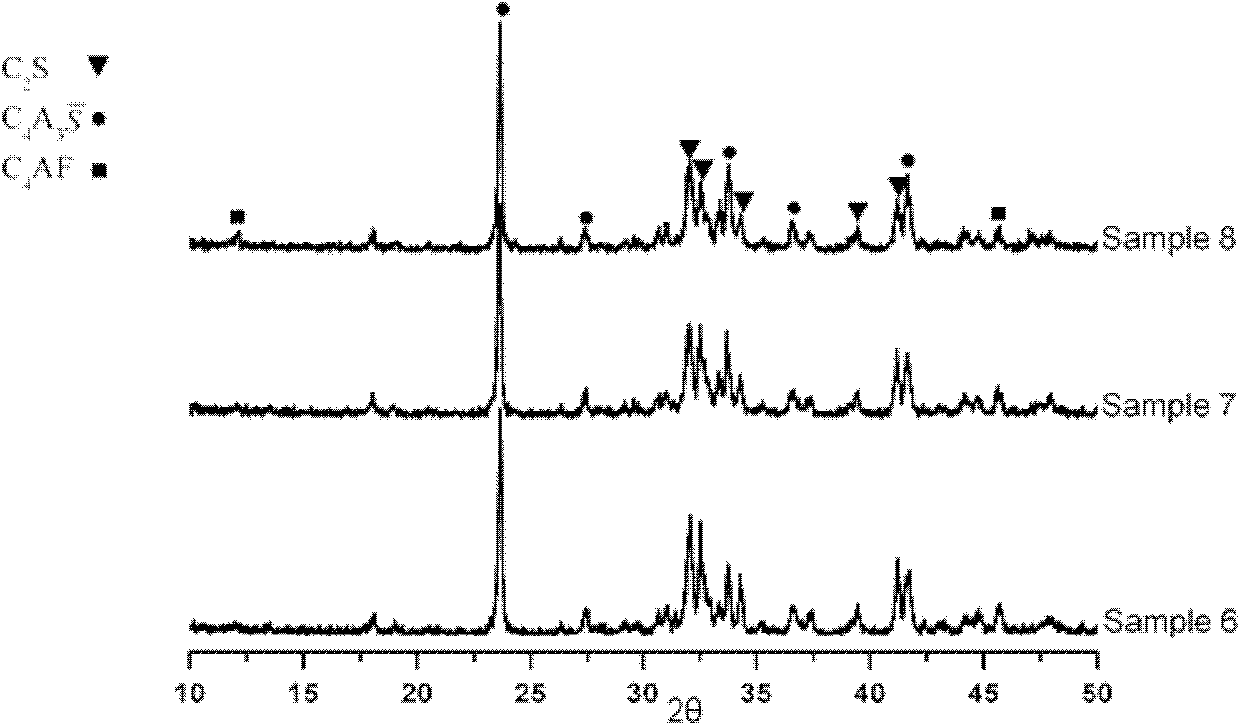

High iron aluminate-belite-sulfoaluminate cement clinker and preparation method thereof

ActiveCN107721214AIncrease iron oxide contentImprove wear resistanceCement productionCalcium in biologyWear resistance

The invention discloses a high iron aluminate-belite-sulfoaluminate cement clinker and a preparation method thereof. The high iron aluminate-belite-sulfoaluminate cement clinker comprises the following components in percentages by mass: 25 to 35% of C4A3S<->, 32 to 42% of C2S, 10% to 30% of C4AF and 15 to 25% of f-CaSO4; and besides, the cement clinker also comprises CT. The invention also discloses a preparation method for the cement clinker. The preparation method comprises the following steps: respectively subjecting a calcareous raw material, a salic raw material, a ferruginous raw material and a gypsum component to drying, crushing and grinding, and carrying out weighing and mixing in proportion, adding a certain amount of water and carrying out uniform mixing, carrying out press molding so as to obtain sample blocks, then carrying out calcination at 950 DEG C for 30 min, then immediately transferring the calcined sample blocks into a high-temperature furnace with a temperature of1275 DEG C to 1350 DEG C, continuing calcination for 30 to 60 min, and carrying out air-blast cooling so as to obtain the clinker. The preparation method provided by the invention gets rid of the modulus limit of traditional sulfoaluminate cement, and improves the content of free gypsum on the basis of high iron aluminate and high belite; and the clinker prepared by using the preparation method provided by the invention has mechanical properties capable of meeting requirements of sulfoaluminate cement 525, and has good wear resistance.

Owner:BEIJING UNIV OF TECH

Gelatinizing agent suitable for unclassified tailing filling

The invention discloses a gelatinizing agent suitable for unclassified tailing filling. The gelatinizing agent is prepared by grinding and mixing the following components by mass percent: 15-40% of belite-sulphate aluminium cement, 2-10% of gypsum, 0-8% of limestone, 40-70% of superfine slag powder, 0-10% of coal ash, 1-8% of an activating agent, 0.1-0.5% of an activation promoter, 0.1-0.5% of a coagulation accelerator and 0.1-0.5% of a water reducing agent. The gelatinizing agent suitable for the unclassified tailing filling disclosed by the invention solves the problems of difficult solidification and poor strength after solidification of unclassified tailings and classified tailings being -200meshes; through the gelatinizing agent, the filling material can meet strength demand required by mine filling mining, the fluidity of slurry is improved, injection performance of the filling material is improved, water retention capacity is improved, and slurry bleeding is relieved.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Concrete pavement repairing material and preparation method and application thereof

PendingCN109851304AImprove performanceExcellent hourly strengthIn situ pavingsFiberFlexural strength

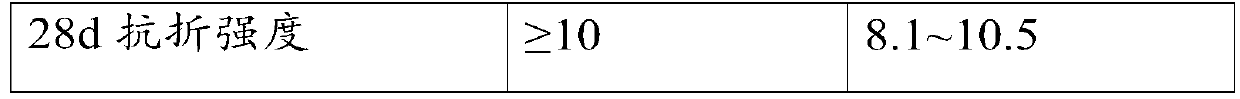

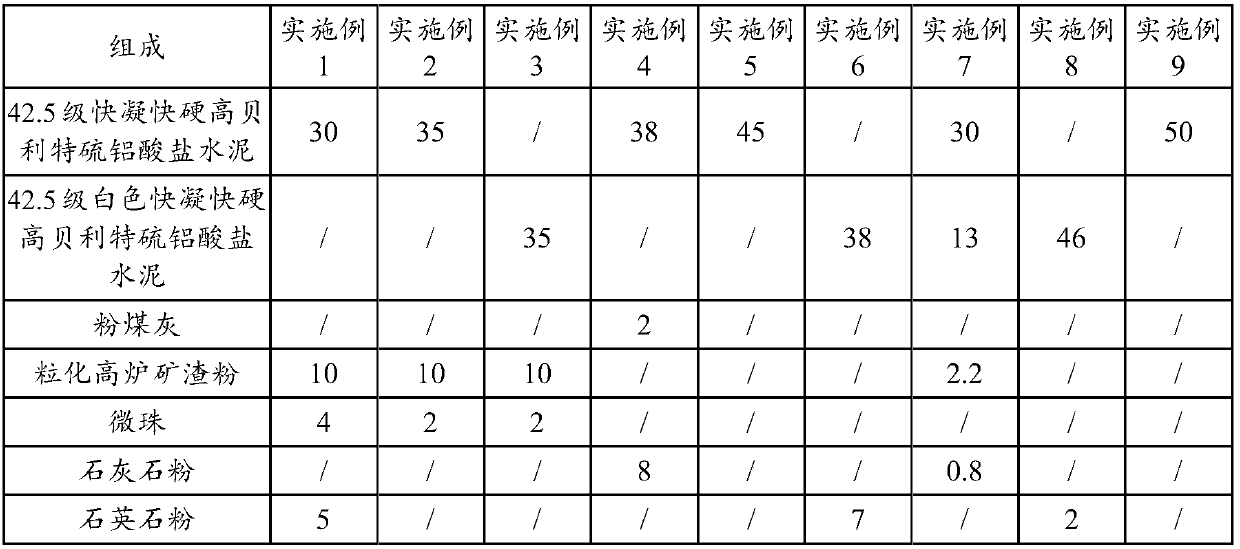

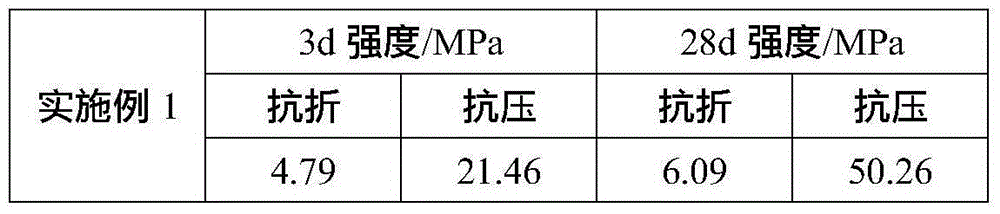

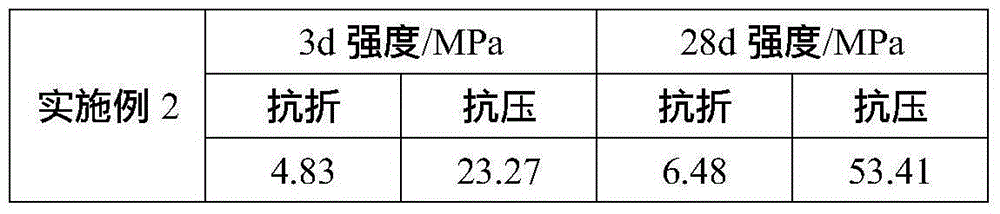

The invention provides a concrete pavement repairing material and a preparation method and application thereof, and belongs to the technical field of concrete pavement repairing materials. The concrete pavement repairing material comprises the following raw materials in parts by weight: 37-53 parts of rapid-solidification and quick-hardening high belite sulpho-aluminate cement, 35-58 parts of a fine aggregate, 0.15-0.5 part of a water reducing agent, 1-6 parts of fiber, 0.05-0.2 part of an anti-foaming agent, 0.02-0.3 part of a solidification accelerator, 2-8 parts of rubber powder and / or 0.01-8 parts of an emulsion. The concrete pavement repairing material has excellent hour strength, higher flexural strength and tensile bond strength, and has good waterproof and crack resistant, impermeability and frost resistant properties, so that the repairing material is suitable for the rapid repairing of the concrete surface layer of highways, airports and other buildings.

Owner:TANGSHAN POLAR BEAR BUILDING MATERIAL

Low-energy-consumption and low-emission cement and preparation method and application thereof

InactiveCN102249576AImprove performanceWith the advantages of energy saving and emission reductionClinker productionCoesiteResource consumption

The invention discloses low-energy-consumption and low-emission cement and a preparation method and application thereof. Cement clinker mainly comprises the following minerals in parts by weight: 35-65 parts of C2S, 20-50 parts C4A3S and 5-15 parts of C4AF. A corresponding green stock consists of the following components in parts by weight: 30-60 parts of CaO, 25-35 parts of SiO, 5-35 parts of Al2O3, 1-6 parts of SO3 and 1-10 parts of Fe2O3. The cement clinker is a product which is prepared by calcining limestone, alumina and clay or sandstone and gypsum serving as raw materials at the temperature between 1,280 DEG C and 1,300 DEG C for 45-70 minutes by combining the advantages of low calcium content, low-temperature baking and high later strength of a belite mineral, low-temperature baking and high later strength of anhydrous calcium sulphoaluminate, and the like. The cement product has the advantages of excellent performance, low energy and resource consumption and low carbon dioxide emission, can play an important role in the field of construction, and has a wide application prospect.

Owner:CHINA BUILDING MATERIALS ACAD

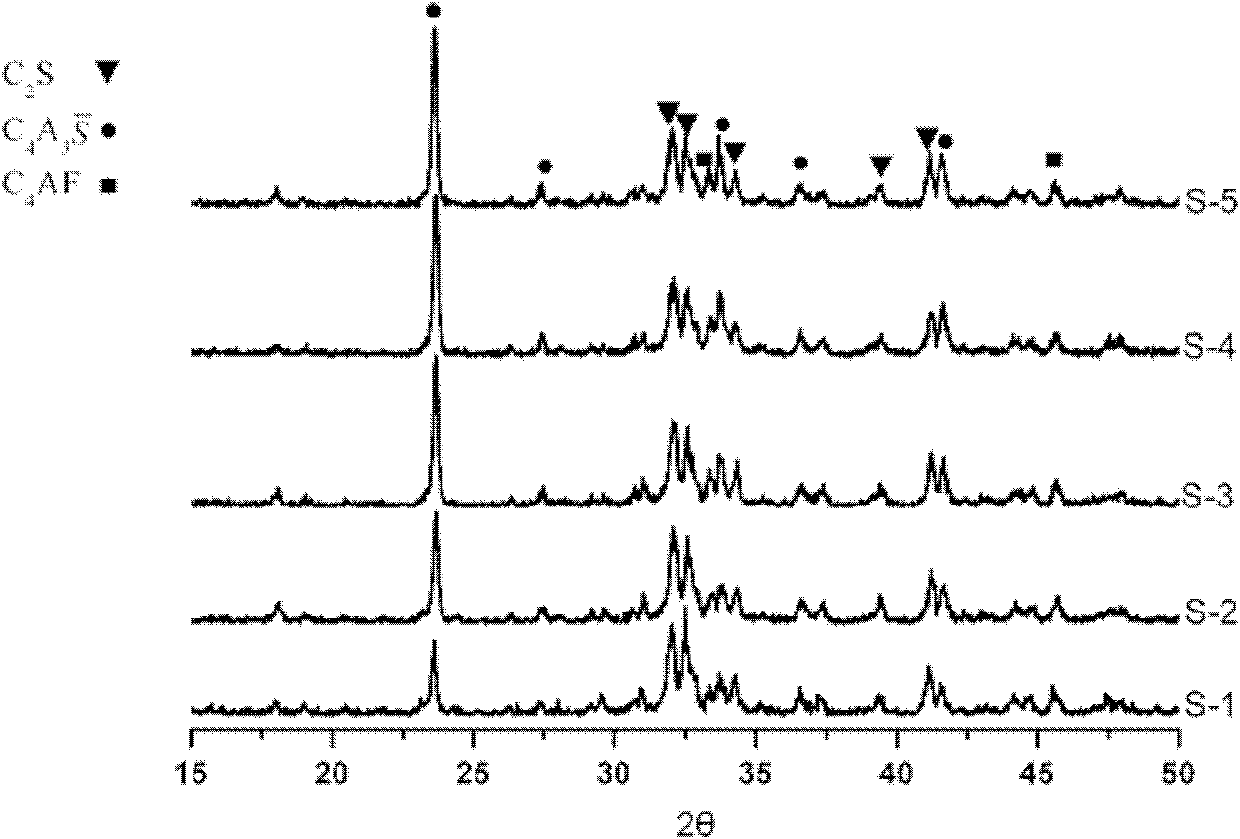

Belite-sulphoaluminate-ferrous aluminate cement and preparation method thereof

ActiveCN105060745ALow firing temperatureImprove performanceCement productionToxic industrial wasteMaterials science

The invention discloses belite-sulphoaluminate-ferrous aluminate cement which comprises the following components by mass percent: 38-70% of beta-C2S, 27-37% of C4A3S-(refer to the description) and 3-25% of C4AF. The invention further discloses a preparation method of the belite-sulphoaluminate-ferrous aluminate cement. The preparation method comprises the following steps: with industrial waste residue and industrial gypsum as the raw materials, mixing the raw materials with aluminous corrective addition namely bauxite or tailing bauxite, forming, performing hydrothermal reaction, crushing, calcining and grinding to obtain the belite-sulphoaluminate-ferrous aluminate cement. According to the invention, the low-carbon belite-sulphoaluminate-ferrous aluminate cement is prepared at low temperature; in addition, limestone is not used, so that no carbon dioxide is generated to increase the environmental pressure; moreover, the calcining temperature is low, so that the energy consumption is low, and the preparation method is a low-carbon and environment friendly preparation method.

Owner:天瑞集团萧县水泥有限公司

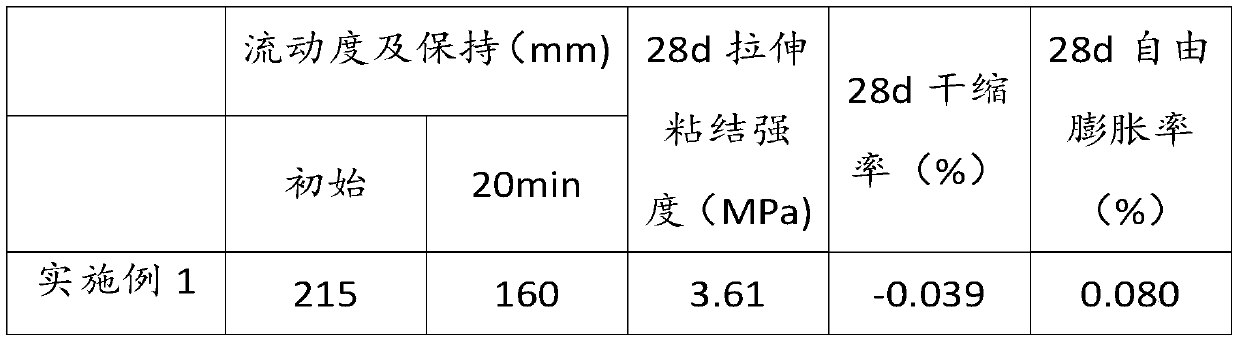

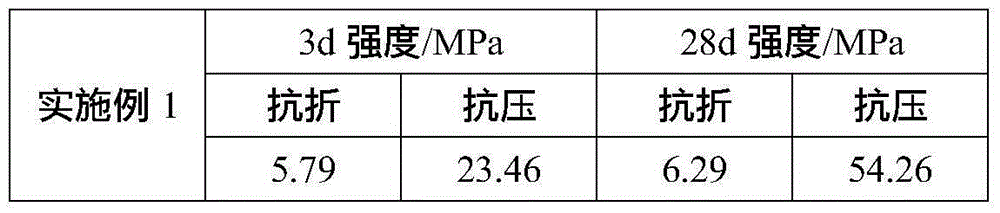

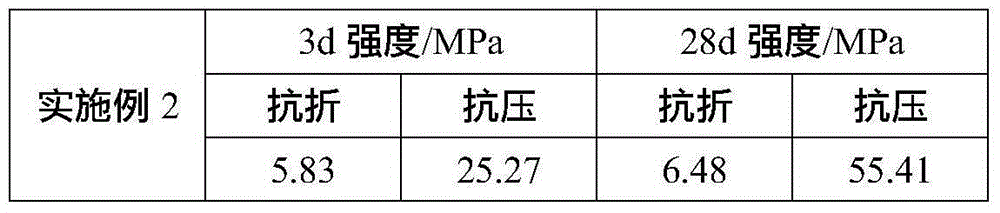

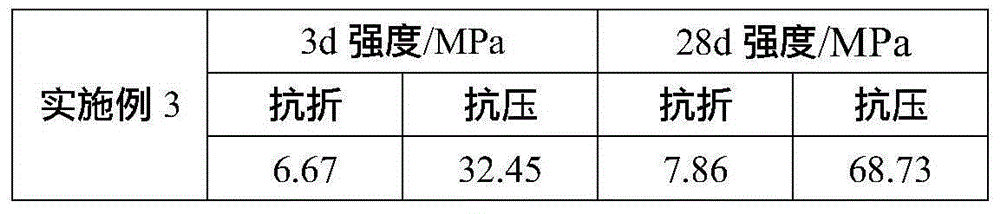

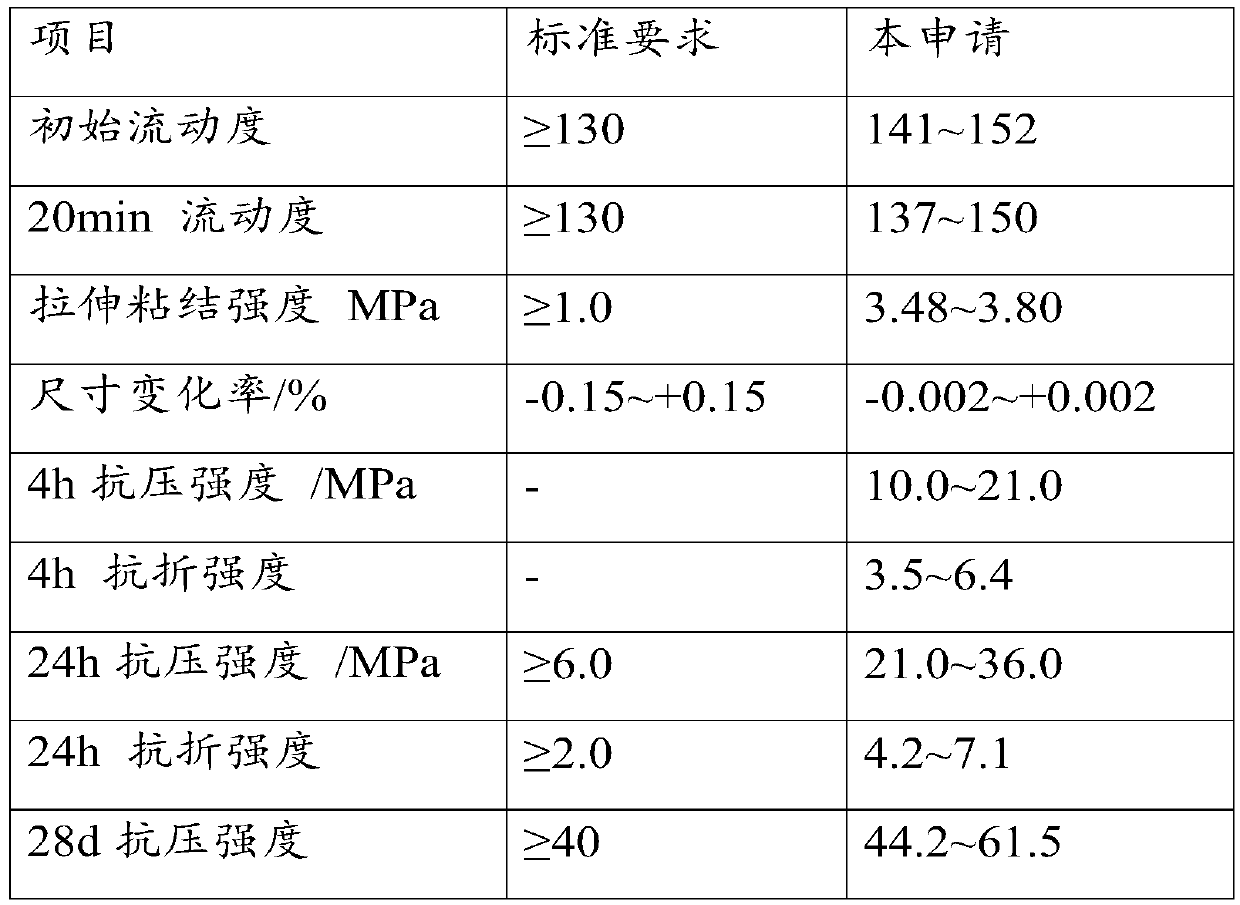

Quick-hardening anti-cracking cement-based self-leveling mortar powder, slurry, mortar and preparation method thereof

PendingCN109836106AImprove initial fluidityNo significant decrease in fluidity after 20 minutesAcid corrosionSlurry

The invention provides quick-hardening anti-cracking cement-based self-leveling mortar powder, slurry, mortar and a preparation method, and relates to the field of building materials. The mortar powder comprises the following raw materials in percentage by weight: 30%-50% of quick-cementing and -hardening high-belite sulphoaluminate cement, 46.19%-51.97% of a fine aggregate, 0.15%-0.3% of a waterreducing agent, 0%-0.04% of a thickening agent, 0.05%-0.2% of a defoaming agent, 0.5%-3.5% of latex powder, 0.075%-0.25% of a retarder and 0.15%-0.3% of a coagulation accelerator. The self-leveling mortar has the excellent properties of acid corrosion resistance, small shrinkage, high tensile bonding strength, high setting and hardening speed and the like, and is suitable for self-leveling floors,industrial floors, civil floors, artistic floors and the like in an acid salt environment.

Owner:TANGSHAN POLAR BEAR BUILDING MATERIAL

Preparation method of sulfoaluminate Belite cement

ActiveCN105060744ALow firing temperatureImprove performanceCement productionCalcinationToxic industrial waste

The invention discloses a preparation method of sulfoaluminate Belite cement. The preparation method comprises the following steps: taking industrial waste residues and industrial gypsum as raw materials, taking bauxite or bauxite tailings as a corrective material, adding water for grinding after mixing, molding, carrying out hydrothermal reaction, and then, smashing, calcining and grinding, so as to obtain sulfoaluminate Belite cement, wherein the main components of the sulfoaluminate Belite cement are C4A3S<-> and beta-C2S. According to the invention, the sintering temperature of the sulfoaluminate Belite cement is reduced through the hydrothermal reaction performed in advance, the energy consumption is reduced, the performance of the sulfoaluminate Belite cement is improved through a proper ratio and a proper technology, and the fact that the low-carbon sulfoaluminate Belite cement is prepared under low temperature; besides, limestone is not used, the generation of carbon dioxide is avoided, the environmental pressure is increased, and the energy consumption is low due to low calcination temperature; therefore, the preparation method of the sulfoaluminate Belite cement is low-carbon and environment-friendly.

Owner:YANCHENG INST OF TECH

Process for producing pozzolanes, synthetic blast furnace slags, belite or alite clinkers, or pig iron alloys from oxidic slags

InactiveUS6395054B1Little structural expenditureOperational securityGlass furnace apparatusGlass shaping apparatusAlloyBelite

A process that produces pozzolanes, synthetic blast furnace slags, belite, or alite clinkers, as well as pig iron alloys, from oxidic liquid slag. The oxidic liquid slag is reduced above an iron bath in a reactor containing submerged tuyeres. Carbon is blown through the submerged tuyeres and into the iron bath to maintain the iron bath at a carbon content of between 2.5 wt % and 4.6 wt %.

Owner:HOLCIM

Low-shrinkage ultra-high performance concrete and preparation method thereof

ActiveCN111285629ASmall self-shrinkage valueReduce the risk of later crackingCement productionAluminateWater reducer

The invention relates to low-shrinkage ultra-high performance concrete, which is prepared from the following raw materials in parts by weight: 800 to 900 parts of a special composite cementing material; 50 to 80 parts of silica fume; 200 to 250 parts of I-grade fly ash; 140 to 160 parts of copper-plated steel fibers; 15-20 parts of a water reducing agent; 1000 to 1100 parts of quartz sand; 160-180parts of water. The special composite cementing material is prepared by uniformly dry-mixing the following raw materials in parts by weight: 75-85 parts of Portland cement clinker powder; 10 to 20 parts of expansive high-belite calcium sulfoaluminate cement clinker powder; 5-10 parts of anhydrite powder. According to the invention, the UHPC self-shrinkage value is small; and the 7d self-shrinkage value ranges from 300 ppm to 350 ppm, the later cracking risk of the UHPC material is reduced, component deformation is reduced, the ultrahigh strength and durability are achieved, the 1d compressive strength reaches 60 MPa to 70 MPa, the 28d compressive strength reaches 160 MPa to 180 MPa, the liquidity is good, and the preparation cost is reduced.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

Method for preparing special cement by circulating fluidized bed combustion ash

ActiveCN101913786AReduce manufacturing costSolve resource problemsCement productionMixed materialsToxic industrial waste

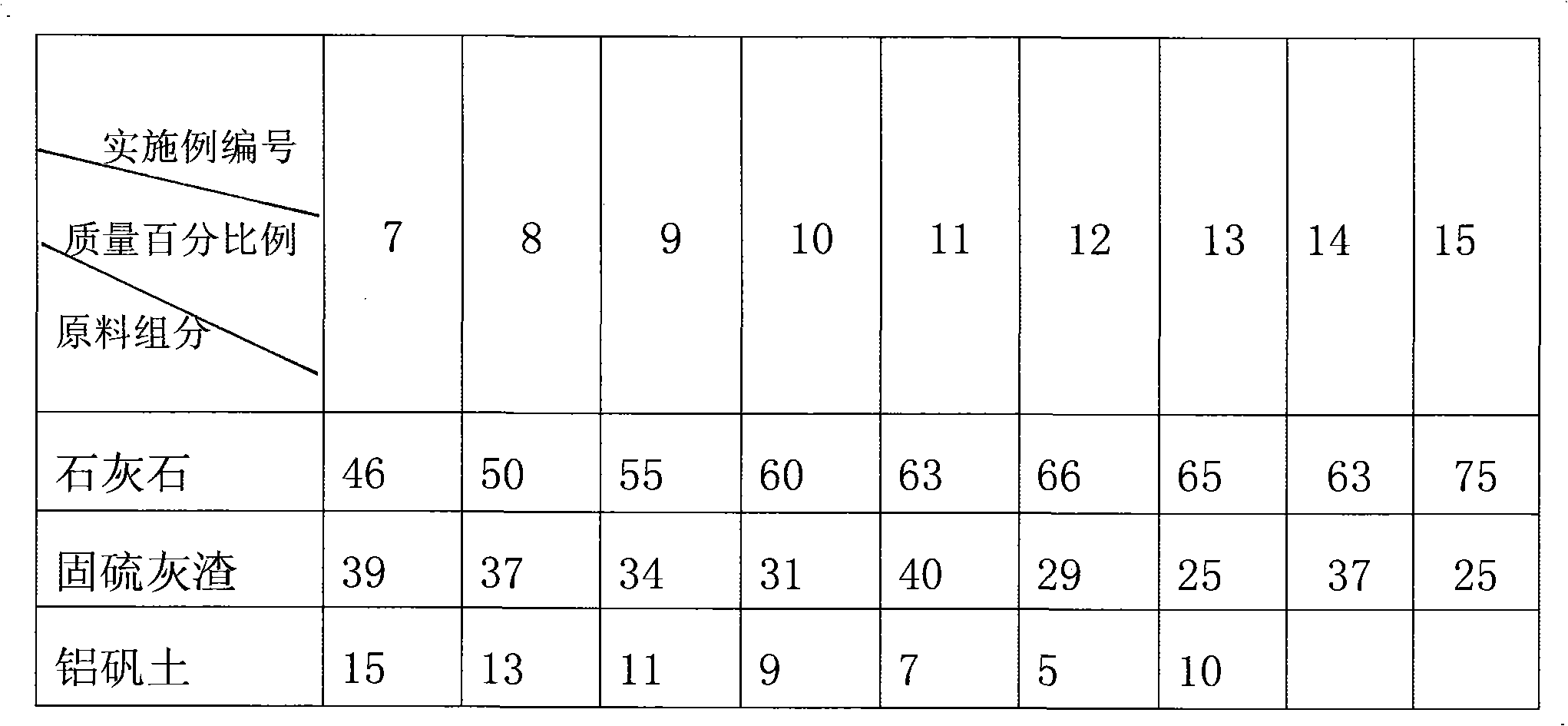

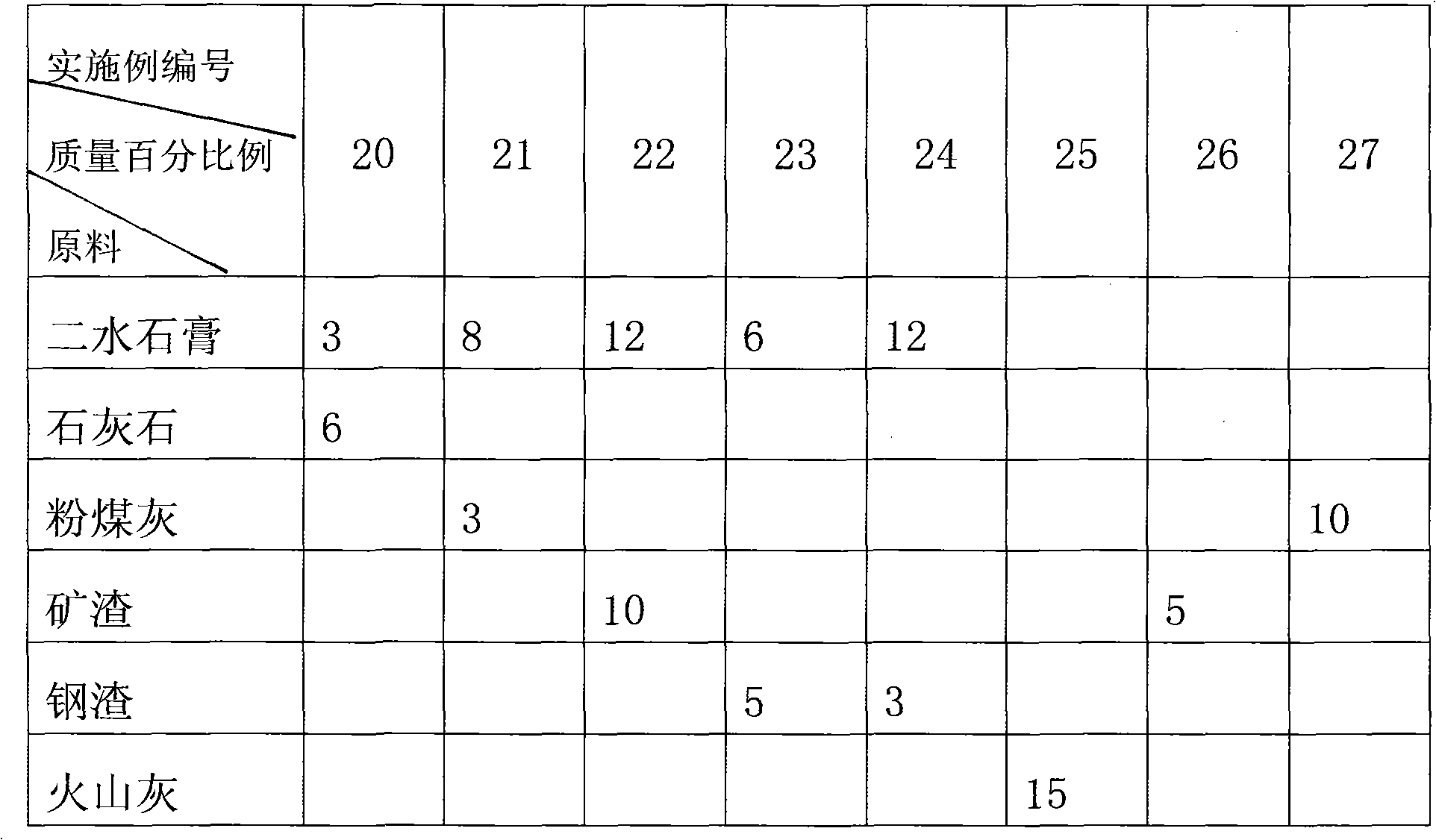

The invention discloses a method for preparing special cement by circulating fluidized bed combustion ashes, comprising the following steps: raw materials are taken out, which comprise the following components in percentage by weight: 45-75 wt% of limestone, 25-40 wt% of fluidized bed combustion ash and 0-15 wt% of bauxite; the raw materials are broken and levigated to be evenly mixed to prepare a mixed material; the mixed material is calcined at the temperature of 1100-1450 DEG C for 10-90 min, cooled and prepared into clinker; dihydrate gypsum which accounts for 0-15 wt% of cement is added into the clinker; and all the materials are mixed and levigated to prepare the special cement. The invention takes industrial waste residue-fluidized bed combustion ash as the raw material to prepare the special cement which takes Belite, calcium sulphoaluminate and iron phase as main minerals. The invention utilizes a great quantity of waste, lowers cement production cost, improves environment protection benefit, has low calcining heat and lowers energy consumption, and the prepared cement has favorable construction workability.

Owner:SOUTHWEAT UNIV OF SCI & TECH

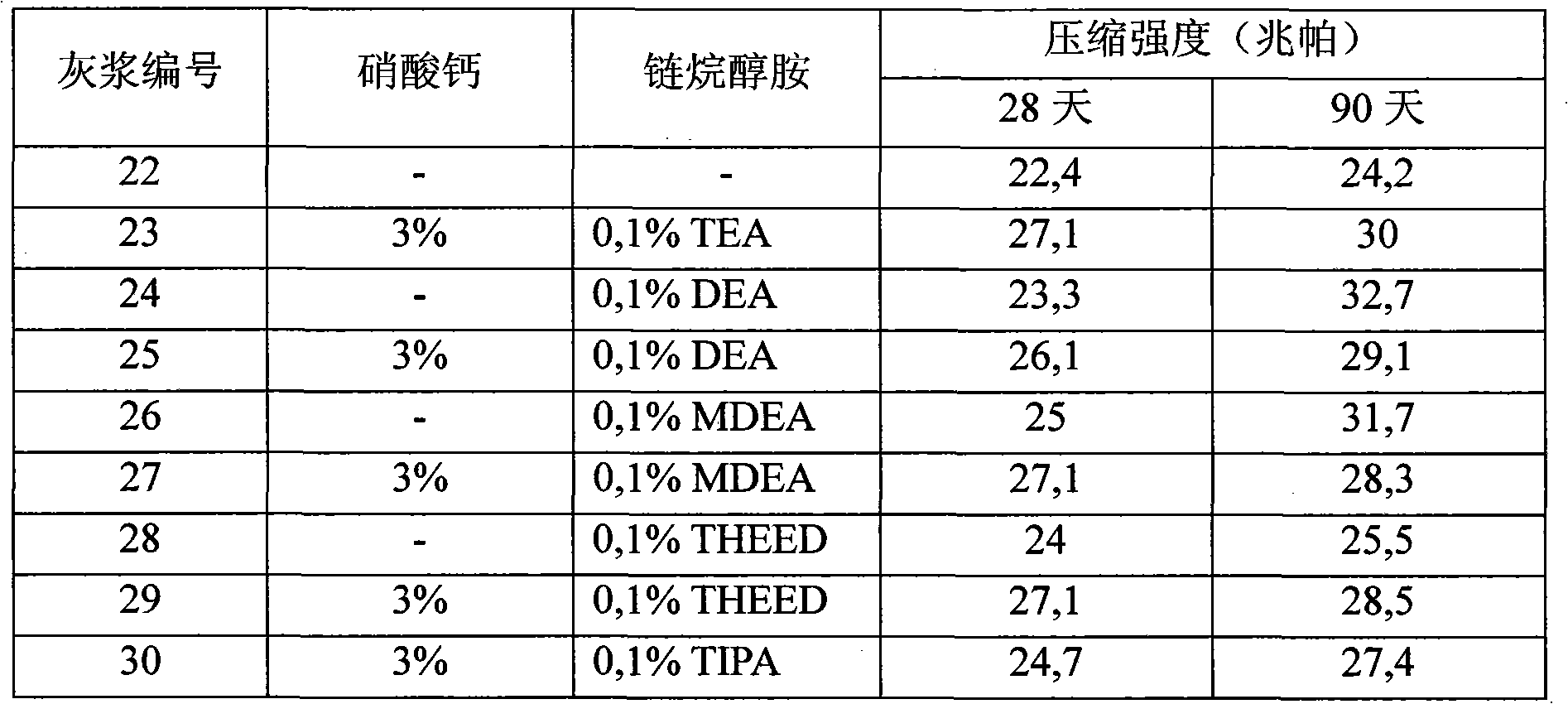

Additives for cement

The invention provides a belite-calcium sulphoaluminate-ferrite (BCSAF) cement composition comprising: a BCSAF clinker which clinker has the following mineralogical composition, based on the total weight of the clinker: 5 to 25%, preferably 10 to 20%, of a calcium aluminoferrite phase having the general formula C2AxF(1-X), wherein X is from 0.2 to 0.8; 15 to 35% of a calcium sulphoaluminate phase; 40 to 75% of belite (C2S); from 0.01 to 10% in total of one or more minor phases selected from calcium sulphates, alkali metal sulphates, perovskite, calcium aluminates, gehlenite, free lime and periclase and / or a vitreous phase; and an alkanolamine.

Owner:HOLCIM

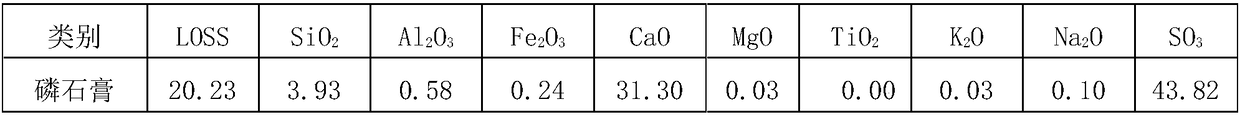

Method for calcining Belite sulphoaluminate cement clinker by using phosphogypsum and cement clinker

ActiveCN108892401ASolve the problem of resource utilizationMeet ingredient requirementsCement productionPhosphogypsumGypsum

The invention discloses a method for calcining Belite sulphoaluminate cement clinker by using phosphogypsum and the cement clinker, and belongs to the field of cement. The method for calcining the Belite sulphoaluminate cement clinker by using phosphogypsum comprises the following steps of 1, weighing, by mass, 75-80% phosphogypsum, 10-15% of aluminum raw materials and 10-15% of siliceous raw materials, and conducting mixing and grinding to obtain a cement raw material; 2, preheating the cement raw material at 1,000-1,100 DEG C, conducting desulfurization for 160-180 minutes, and calcining thecement raw material at 1,320-1,350 DEG C for 60-80 minutes until the clinker mineral is completely formed. The method for calcining the Belite sulphoaluminate cement clinker by using phosphogypsum and the cement clinker have the advantages that the original calcium raw material is not used in the accessory material, and phosphogypsum is utilized to the maximum degree.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

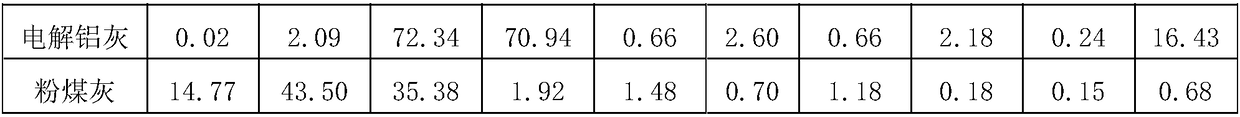

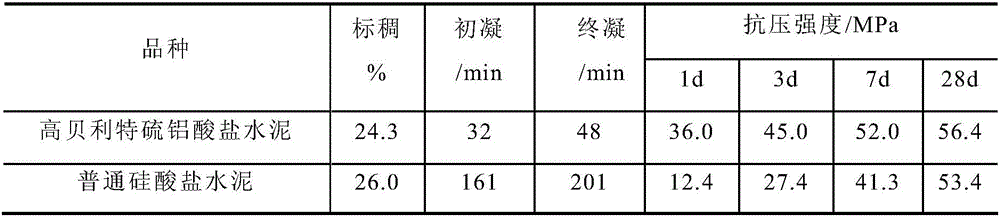

High Belite sulphoaluminate cement prepared by coal gangue

The invention provides a high Belite sulphoaluminate cement prepared by industrial waste residue, the used raw meals, which are limestone, industrial waste residue coal gangue and ardealite, are added with retarder according to a conventional preparation method in case that the roasting temperature is controlled in the range of 1400+ / -20 DEG C, and the high Belite sulphoaluminate cement can be prepared under the operations in accordance with specific implementation steps. The main effective ingredients in the raw meals are: 20.71%-21.53% of SiO2, 15.78%-16.53% of Al2O3, 2.27%-2.35% of Fe2O3 and 51.98%-55.21% of CaO. The prepared high Belite sulphoaluminate cement is superior to 52.5R common Portland cement in the aspect of performance.

Owner:BEIJING UNIV OF TECH

Low-carbon cement clinker and preparation method and application thereof

ActiveCN105669056AIncreases hydration activityIncrease late strengthCement productionRed mudHigh activity

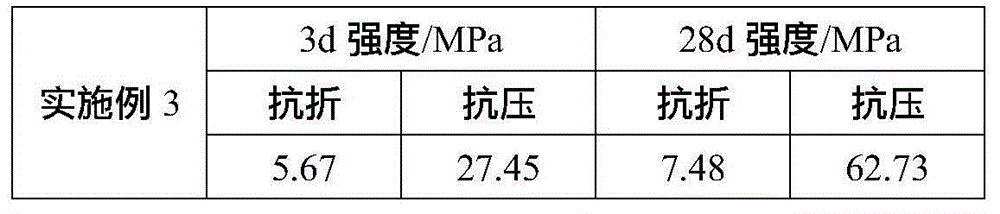

The invention discloses low-carbon cement clinker and a preparation method and application thereof.Raw materials for preparing the cement clinker are a silicon-aluminum containing material, limestone and industrial tailings, and the silicon-aluminum containing material is one of or a mixture of low-grade alumina, fly ash, red mud and gangue.The preparation method includes: well mixing the raw materials, and grinding, wherein a requirement on grain diameter after grinding is that screen residue of a 0.08-mm square-hole screen is less than 15%; calcining the raw materials after being ground at calcining temperature of 1150-1350 DEG C for 10-40 min, and cooling to obtain the low-carbon cement clinker.Content of high-activity beta type dicalcium silicate is greater than or equal to 50%, content of calcium sulfosilicate is 5-15%, and content of calcium sulfoaluminate is 15-25%.A finished cement product can be prepared by adding 0.01-10% of gypsum and 0.01-10% of limestone into the cement clinker.According to existing national detection standards, standard mortar of the cement is higher than 30 MPa in 3-day compressive strength and is 60+ / -5 MPa in 28-day compressive strength.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

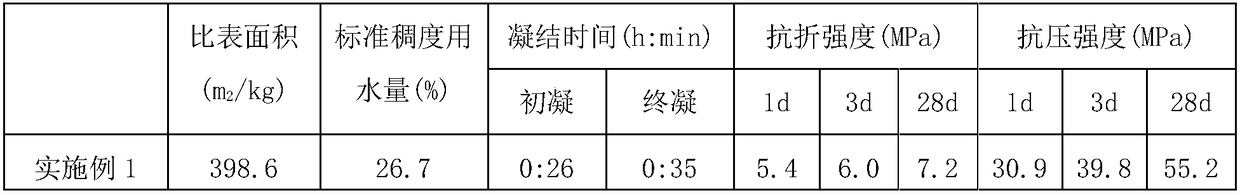

Method for preparing calcium sulphosilicate-Belite-sulfoaluminate cement clinker at low temperature

The invention relates to a method for preparing calcium sulphosilicate-Belite-sulfoaluminate cement clinker at low temperature, and belongs to the technical field of building materials. The method comprises the following steps: crushing a siliceous raw material, a calcium raw material, an aluminum raw material and industrial gypsum respectively; then, proportioning according to a mass ratio of (25.67-39.31):(18.4-39.21):(4.64-20.53):(16.4-24.59), and performing ball milling for 24-72h to obtain a raw material; pressing the raw material into square pieces, then calcinating the square piece at 900-1200 DEG C, preserving heat for 1-3h, taking out for quenching, and then grinding to obtain the calcium sulphosilicate-Belite-sulfoaluminate cement clinker. According to the method, industrial waste residues are used as the main raw materials; by a mechanochemical method, the activity of a material is improved, the potential barrier of a chemical reaction is lowered, change of the texture, thestructure and the performance of the material is induced more efficiently, and the calcination temperature of calcium sulphosilicate-Belite-sulfoaluminate cement is reduced; the method is low in energy consumption and environmentally friendly.

Owner:YANCHENG INST OF TECH

High belite sulphoaluminate cement based self-leveling mortar

The invention discloses high belite sulphoaluminate cement based self-leveling mortar. The mortar comprises the following powder raw materials in parts by weight: 30-40 parts of high belite sulphoaluminate cement, 5-7 parts of anhydrite, 12-15 parts of heavy calcium powder, 40.5-45 parts of river sand, 2-2.5 parts of emulsion powder, 0.35-0.45 part of water reducing agent, 0.35-0.45 part of defoaming agent, 0.1-0.2 part of cellulose ether, 0.1-0.2 part of tartaric acid, and 0.05-0.1 part of lithium carbonate. According to the high belite sulphoaluminate cement based self-leveling mortar, the high belite sulphoaluminate cement is used as the only cement-based gel material, so that the performances are outstanding, and various additives can be specifically selected, and as a result, the adaptability of the gel material and the various additives can be obviously improved; the preparation technology processes of the self-leveling mortar can be greatly simplified, and moreover, the product performance stability can be greatly improved; meanwhile, the cost can be decreased.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

Method for preparing rapid hardening high-early-strength cement clinker

ActiveCN102936104ACompletely absorbedSolve the problem of resource utilizationClinker productionAmorphous phaseUltimate tensile strength

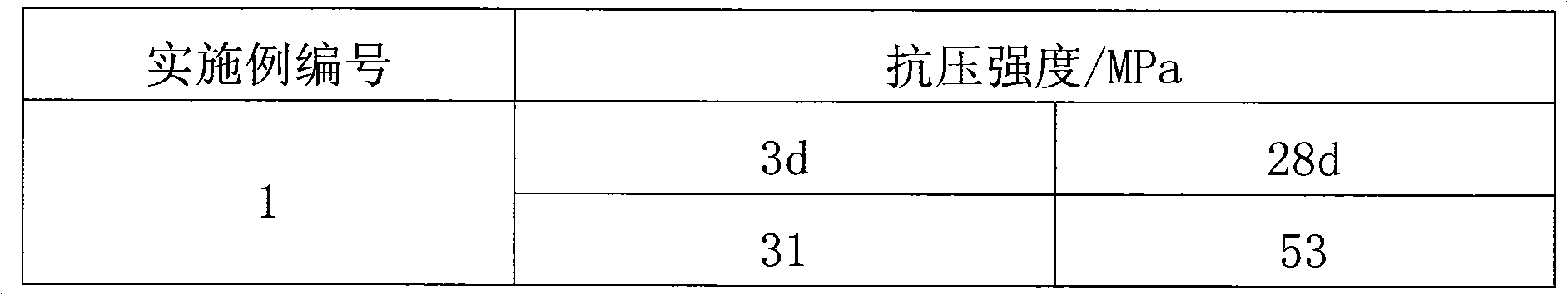

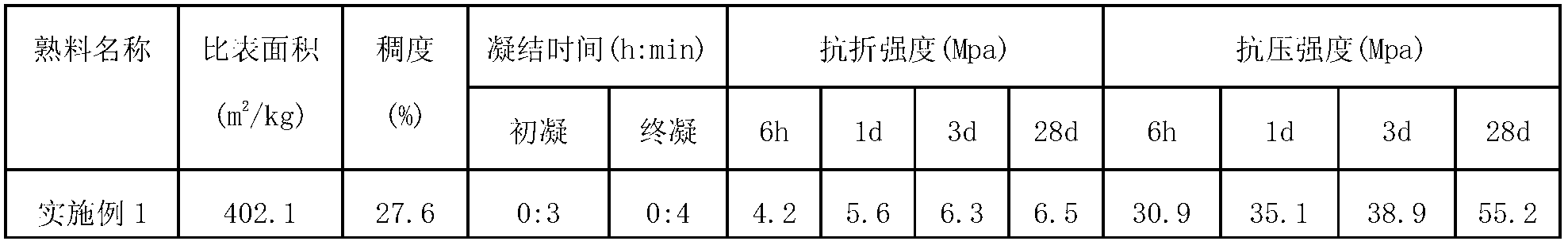

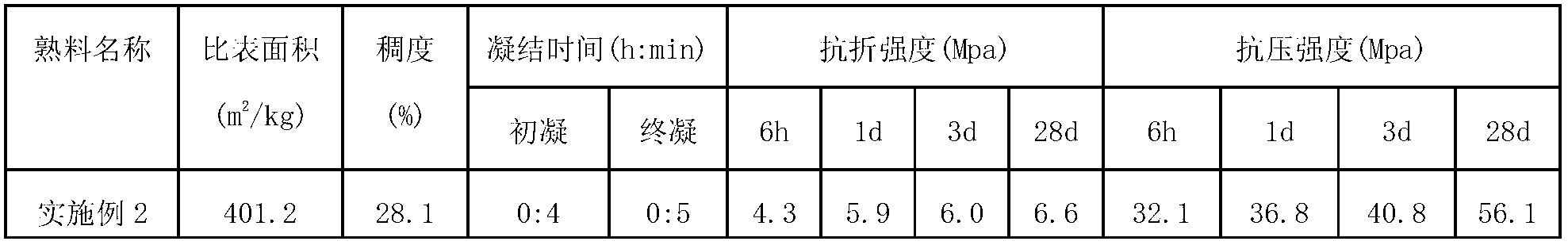

The invention provides a method for preparing rapid hardening high-early-strength cement clinker. Limestone, monohydrallite milltailings, ordinary coal ash and gypsum serve as raw amterials, rapid hardening high-early-strength Belite sulphate aluminium cement clinker is calcined at the temperatures of 1350+ / -20 DEG C, the clinker comprises, by weight, 50-52% of C2S, 28-30% of C4A3S and 16-18% of C4AF and a small quantity of amorphous phase substances. According to the method, most of the used aluminous materials are monohydrallite milltailings which are industrial residues which are discharged by aluminium factories, the initial setting time of the obtained clinker is less than 5 minutes, more than 30MPa of the strength of 6 hours can be achieved, and at the same time, the 28d strength of the clinker can reach about 55 MPa.

Owner:TIANJIN CEMENT IND DESIGN & RES INST +1

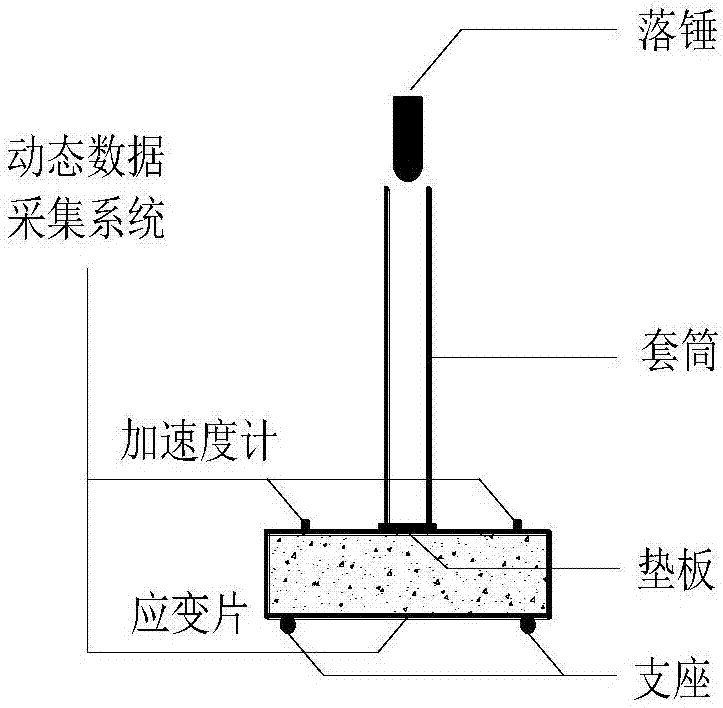

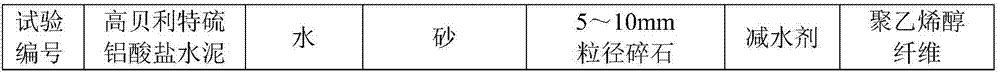

Fiber concrete for quick repair of airfield pavement, preparation and application

The invention relates to fiber concrete for quick repair of an airfield pavement, preparation and an application and belongs to the technical field of concrete. The weight of high-belite sulphate aluminum cement accounts for 16.0-20.0% of the total weight of a repair material; the weight of sand accounts for 21.5-34.1% of the total weight of the repair material; the weight of gravel accounts for 42.7-55.3% of the total weight of the repair material; a water-cement ratio is 0.31-0.42; a polyvinyl alcohol fiber is 12-15mm in length and 45 micrometers in diameter; the volume of the polyvinyl alcohol fiber accounts for 0.6-1.0% of the total volume of the repair material; and an effective solid mixing amount of a water reducer is 0.12-0.19% of the mass of the high-belite sulphate aluminum cement. A preparation method comprises the steps of pouring a cementing material and the sand in raw materials into a stirrer for uniform stirring, slowly pouring a mixed solution of the water reducer and the water into the stirrer, adding the polyvinyl alcohol fiber after a mixture is changed into colloid from a particle, and performing quick casting after uniform dispersion. The fiber concrete can be used for the quick repair of the broken airfield pavement.

Owner:BEIJING UNIV OF TECH

High performance sulfo-aluminous clinker

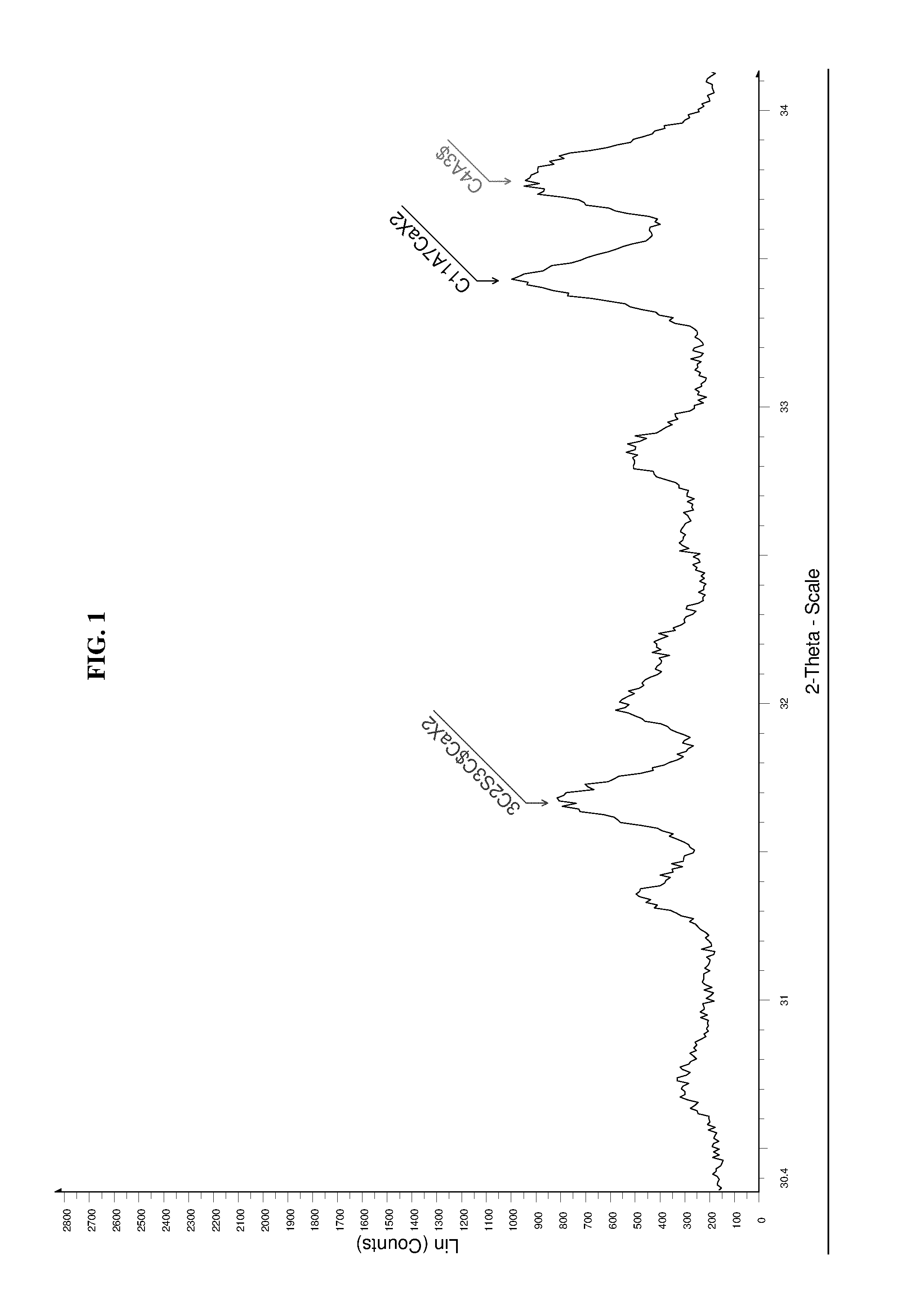

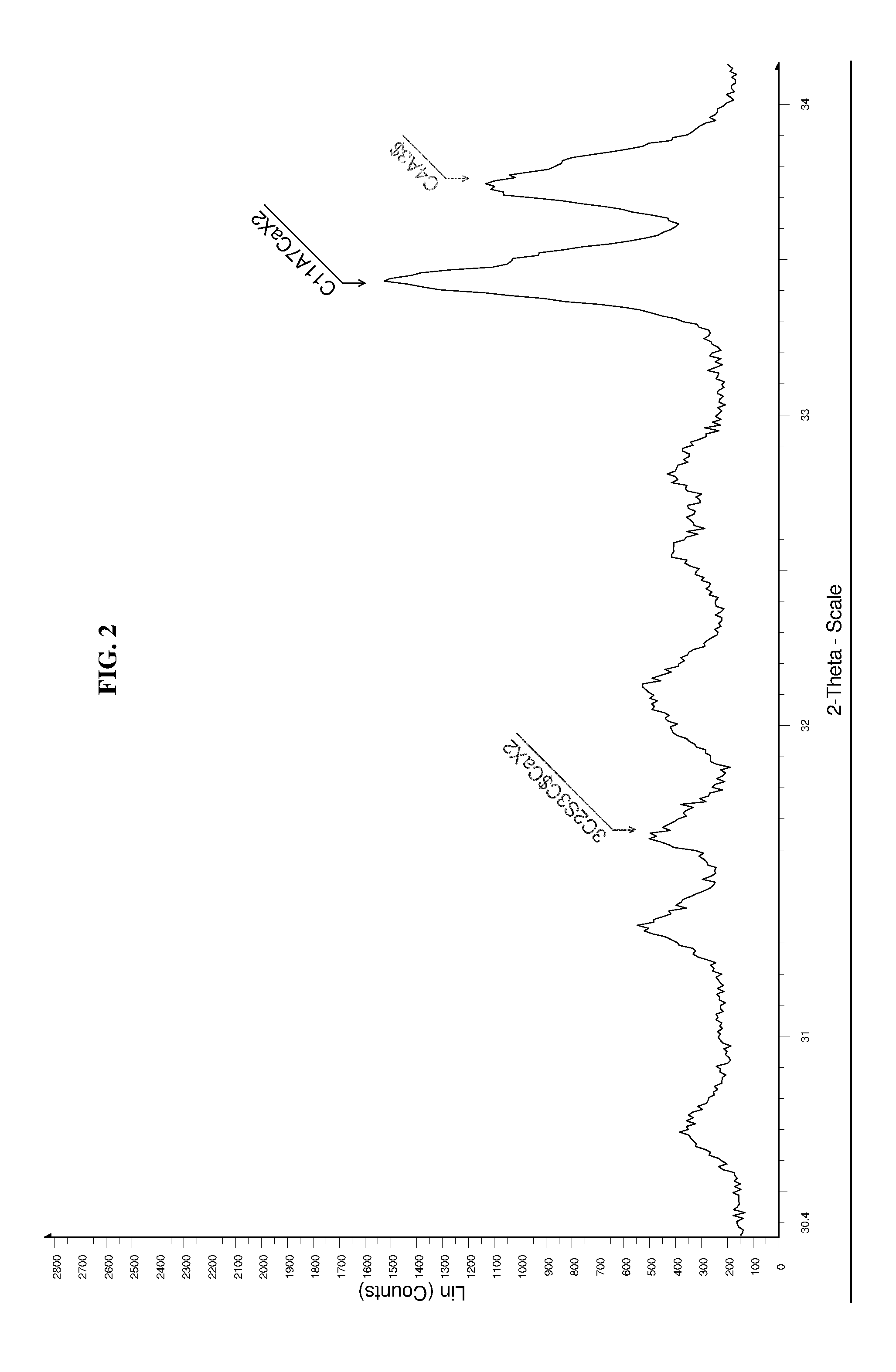

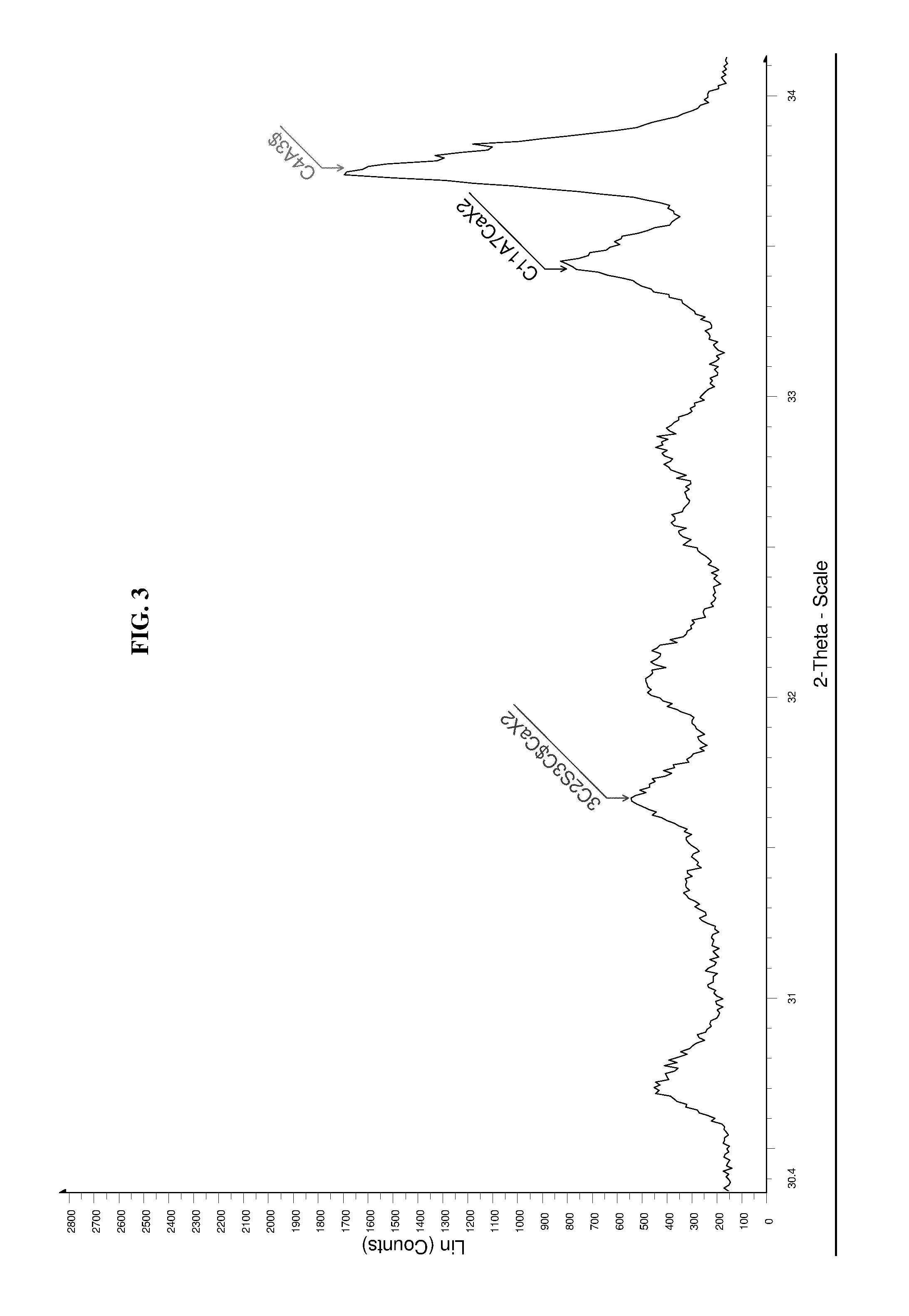

The invention relates to a sulfo-aluminous clinker with optimal setting time and short term compressive strengths, comprising a mixture of the following phases: —calcium sulfoaluminate, or C4A3$, in amounts higher than 50% by weight of the mixture, —belite, or C25, in amounts between 2 and 23%, —3C25 3C$ CaX2, X being fluorine or chlorine, between 3 and 15% —C11A7CaX2, X being fluorine or chlorine, between 2 and 12%, both fluorine and chlorine being altogether present in the mixture, and phase C5S2$ being absent. The invention also relates to a method for preparing this sulfo-aluminous clinker, and hydraulic binders comprising this clinker.

Owner:ITALCEMENTI

Wear-resistant concrete for heavy-haul railway sleepers and preparation method of wear-resistant concrete

InactiveCN110395949AReduce in quantityLess micro defectsBallastwayWear resistantCompressive strength

The invention relates to wear-resistant concrete for heavy-haul railway sleepers and a preparation method of the wear-resistant concrete. The wear-resistant concrete is composed of the following components: in parts by mass, 350-600 parts of high belite cement, 0.5-10 parts of a nano-nucleating agent, 0-100 parts of a mineral admixture, 10-60 parts of a polymer, 500-800 parts of fine aggregate, 1100-1400 parts of coarse aggregate, 1-6 parts of a water reducing agent and 100-145 parts of water. The internal pore structure of the wear-resistant concrete for heavy-haul railway sleepers is refined, the defects in the interface transition zone are improved obviously, the compactness is good, the bonding performance between a cement hydration product and the aggregate interface is improved obviously, and the compressive strength, toughness and wear resistance of the concrete are improved significantly.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

Production method of high-speed railway track board not requiring steam curing and special concrete

InactiveCN106966672AImprove quality and efficiencyIncrease productivityBallastwaySlagUltimate tensile strength

The invention discloses a production method of high-speed railway track board not requiring steam curing and special concrete. The concrete is formed by mixing and stirring the following components in parts by weight: 360 to 400 parts of PO42.5 level R ordinary Portland cement, 40 to 100 parts of a slag powder, 20 to 40 parts of high belite sulphoaluminate cement, 1 to 2 parts of an exciting agent, 1 to 2 parts of an early strength agent, 1 to 1.5 parts of a water reducer, 1 part of a resistance and seepage control composite material, 699.86 parts of sands, 1167 to 1177.14 parts of stones, 87.5 to 88.5 parts of water. The method comprises the following steps: directly putting concrete into a curing box with the temperature of 20 plus or minus 2 DEG C and the humidity of 98 plus or minus 2 percent after the concrete is poured, so as to enable the concrete to be cured for 24 hours; performing relaxation and demolding after the strength of the concrete reaches greater than 80 percent of design strength, and putting the concrete into water to cure the concrete for 24 hours. The method and the concrete have the advantages that steam curing is not required, and the production efficiency of the railway track board is improved.

Owner:陈绪利

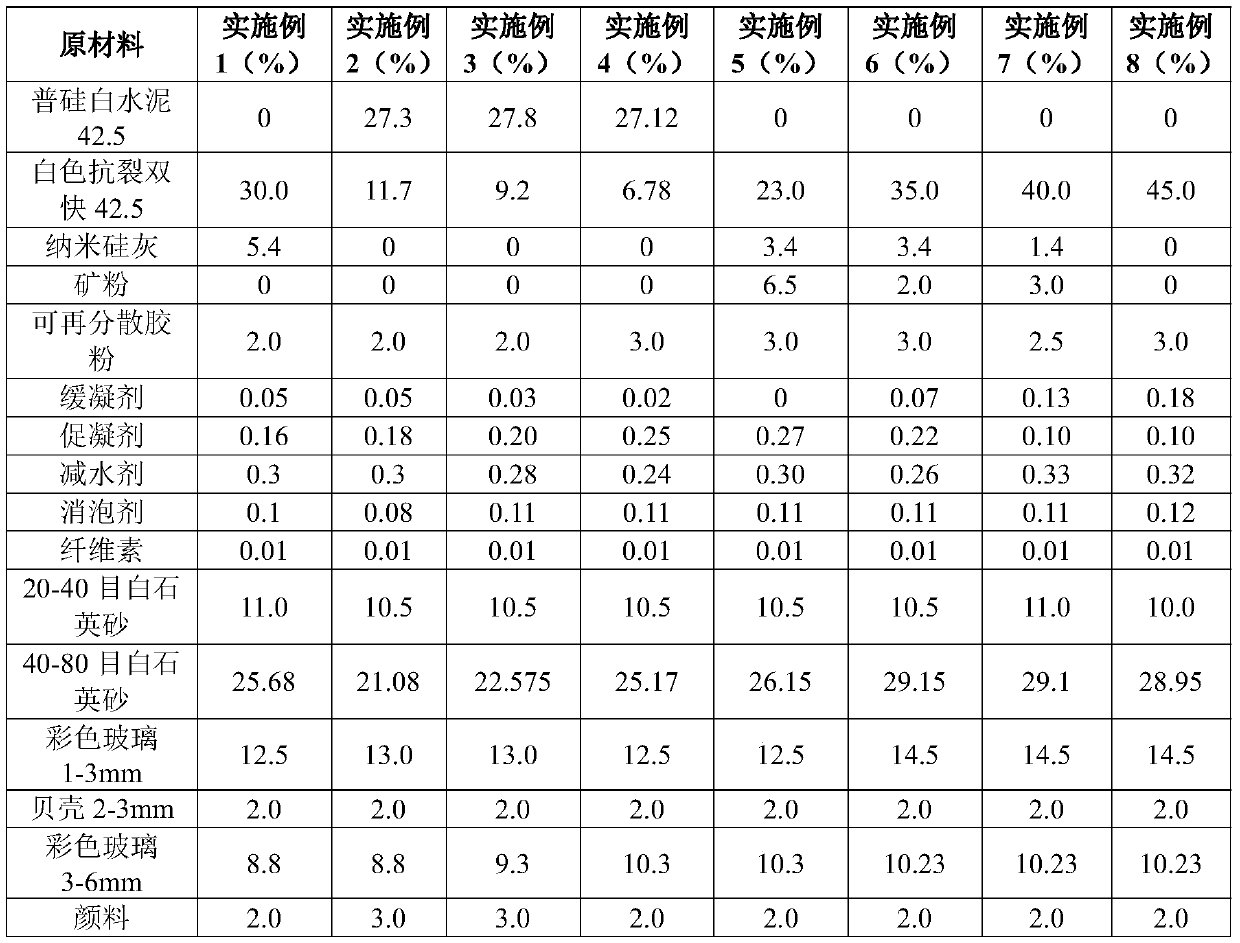

Surface layer mortar, grindstone, board and preparation method of grindstone and board

The invention discloses surface layer mortar, grindstone, a board and a preparation method of the grindstone and the board, and relates to the technical field of stone materials. The surface layer mortar is prepared from the following components in percent by mass: 20-45% of cement, 55-67% of aggregate, 0-5.4% of nanometer silica fume, 0-6.5% of mineral powder, 2-3% of dispersible rubber powder, 0-0.2% of a retarder, 0.1-0.3% of a coagulant, 0.1-0.3% of a water reducing agent, 0.05-0.3% of a defoaming agent, 0.01-0.02% of a thickening agent and 2-3% of pigment; the cement comprises high belitesulfoaluminate cement and optional ordinary cement, wherein the mass of the high belite sulfoaluminate cement accounts for 20-100% of the mass of the cement; and the water-material ratio of the surface layer mortar is 0.08-0.1. The fluidity, breaking and compressive strength and free expansion rate of the surface layer mortar meet related index requirements; and the grindstone or board prepared by adopting the surface layer mortar is small in size shrinkage, does not deform, does not crack, and has no alkali efflorescence.

Owner:TANGSHAN POLAR BEAR BUILDING MATERIAL

High-iron Belite sulphoaluminate cement clinker and preparation method thereof

The invention discloses a high-iron Belite sulphoaluminate cement clinker and a preparation method thereof. The high-iron Belite sulphoaluminate cement clinker comprises, in weight percent, 55-65% ofcalcium materials, 5-35% of siliceous materials, 0-20% of aluminous materials, 5-35% of iron-aluminum materials and 5-15% of gypsum materials. Mineral components of the clinker comprise, in weight, 10-30% of C4A3S, 40-55% of C2S and 10-35% of C4AF. According to the clinker, the calcium materials, the gypsum materials and the like with poor taste serve as raw materials to prepare the cement clinker, the cement clinker has the advantages that the early strength and the later strength of the cement clinker are higher than these of ordinary Portland cement, specific mineral components of the clinker decide low overall hydration heat of the clinker, and the clinker has good volume stability.

Owner:SOUTHWEAT UNIV OF SCI & TECH +1

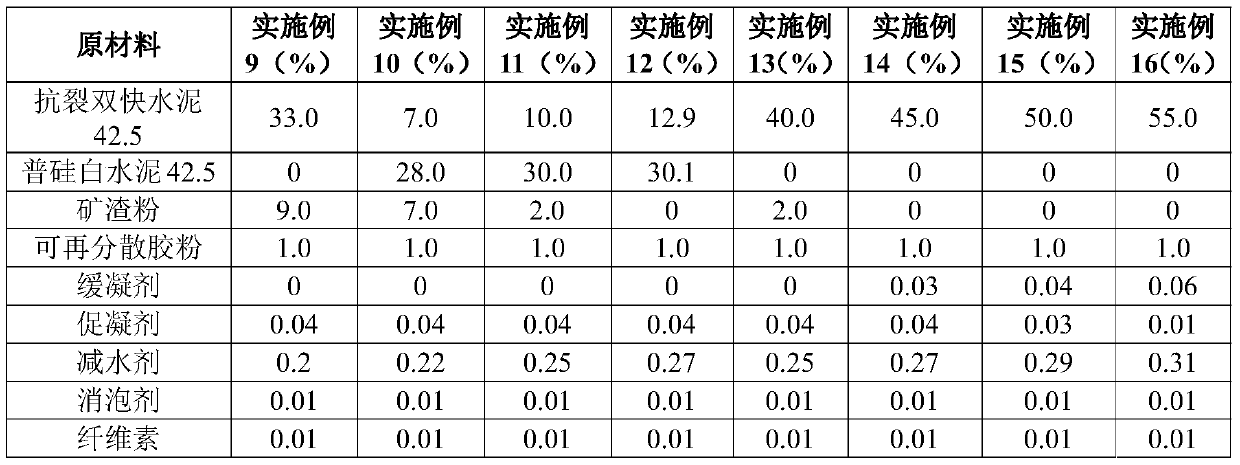

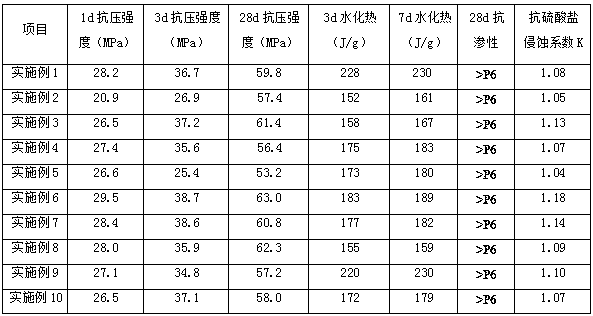

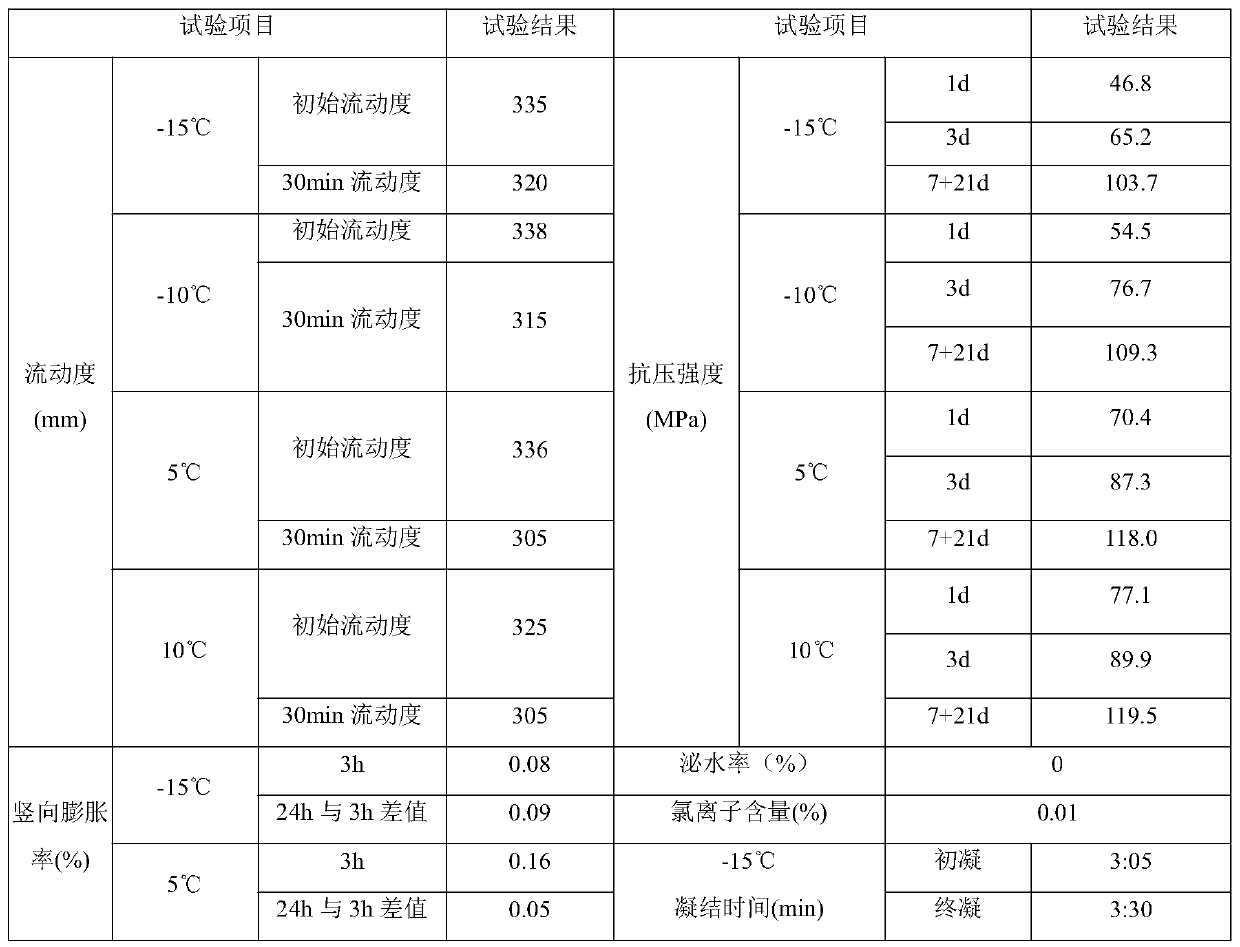

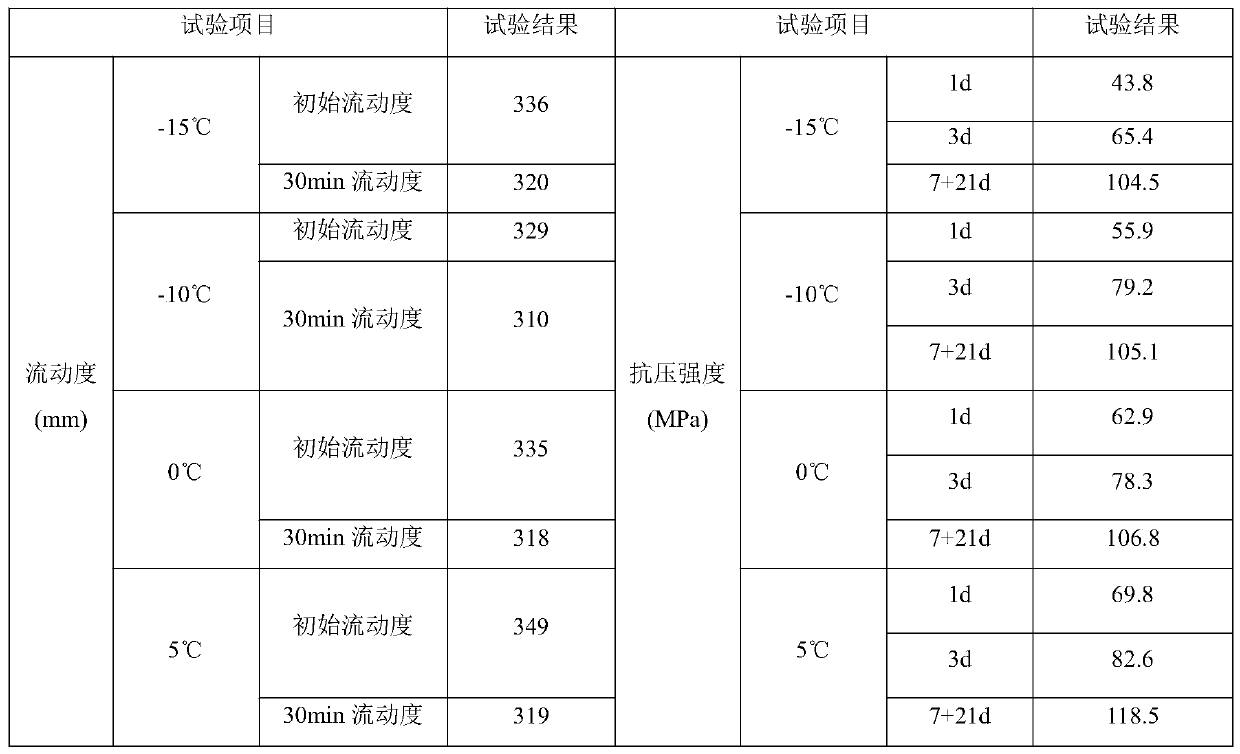

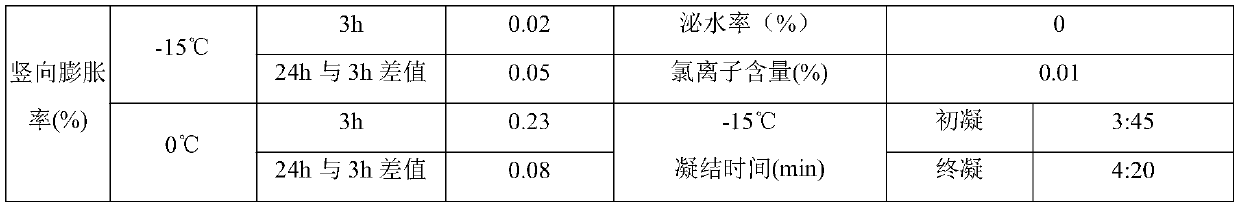

Sleeve grouting material for low-temperature steel bar connection and using method thereof

The invention relates to a sleeve grouting material for low-temperature steel bar connection and a using method thereof. Fast-setting, fast-hardening and high-belite sulphoaluminate cement, Portland cement, ultrahigh-strength sulphoaluminate cement, gypsum, an admixture, aggregate, nanocrystalline nucleuses, an antifreeze agent, a powder polycarboxylic acid high-performance water reducing agent, apolyether defoamer, an expanding agent, cellulose ether and a viscosity reducer are used as raw materials, and the ultralow-temperature construction requirement of-15 DEG C to 10 DEG C can be met.

Owner:CNBM ZHONGYAN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com