Concrete pavement repairing material and preparation method and application thereof

A technology for concrete pavement and repairing materials, which is applied to cohesive pavement paved on site, roads, roads, etc., and can solve problems such as high shrinkage rate, long age of base concrete, and low dimensional change rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

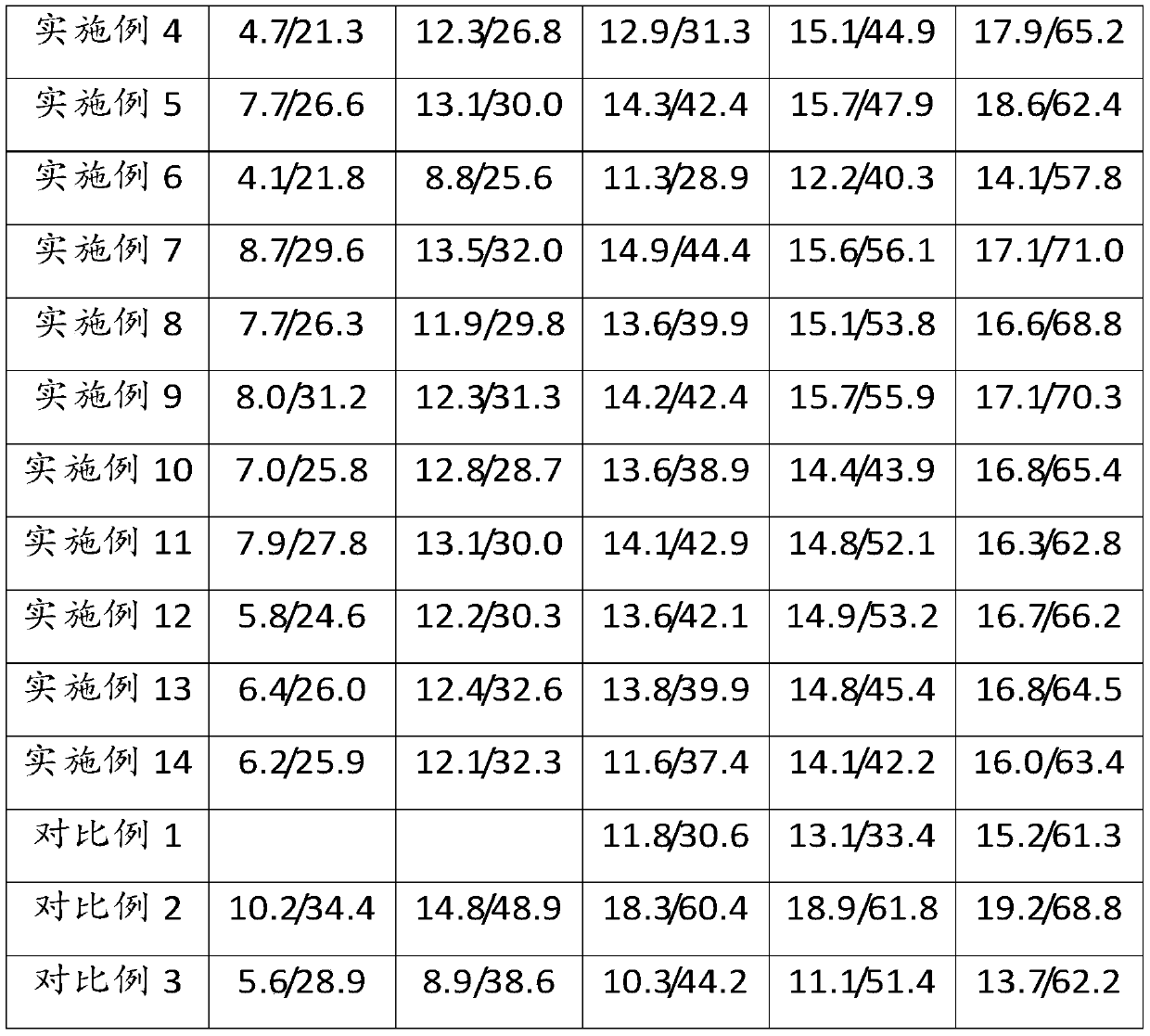

Examples

preparation example Construction

[0074] According to a second aspect of the present invention, a method for preparing the above-mentioned concrete pavement repair material is provided, comprising the following steps:

[0075] The raw materials of the concrete pavement patching material are mixed to obtain the concrete pavement patching material.

[0076] Preferably, the fast-setting rapid-hardening high-belite sulfoaluminate cement, fine aggregate, water reducer, defoamer, coagulant, rubber powder and / or milk are stirred with water for 1-3 minutes before adding the fiber Continue stirring for 1-3 minutes to obtain repair mortars with different flow properties.

[0077] Preferably, during the repair work, the mortar can be leveled automatically with a little auxiliary measures, and it can also be repaired on the concrete surface in the form of manual or mechanical troweling.

[0078] According to the third aspect of the present invention, there is provided the application of the above-mentioned concrete pavem...

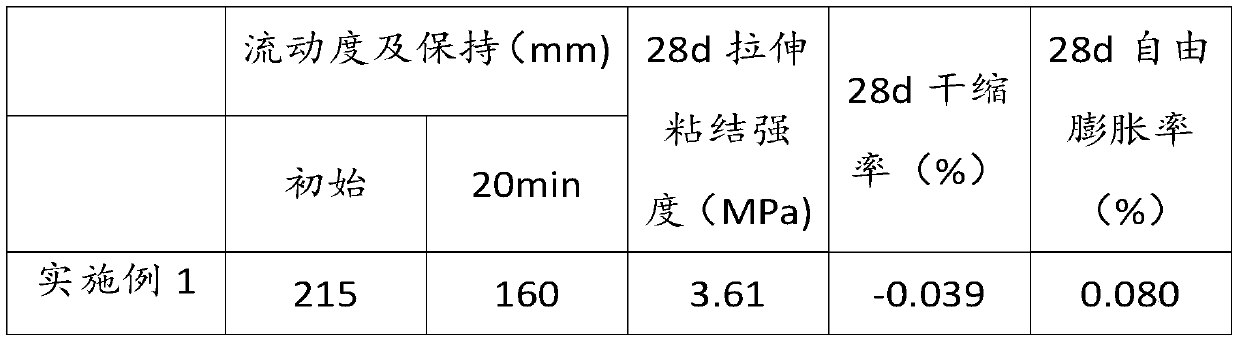

Embodiment 1

[0082] One, a kind of concrete pavement patching material, comprise the raw material of following weight portion:

[0083]53 parts of fast setting and rapid hardening high belite sulfoaluminate cement, 36.85 parts of fine aggregate, 0.5 part of water reducer, 6 parts of fiber, 0.15 part of defoamer, 0.2 part of coagulation accelerator, 0.3 part of retarder and 2 parts of rubber powder. The ratio of water to material is 0.12:1.

[0084] The fast-setting, rapid-hardening, high-beilite sulfoaluminate cement is a 42.5-grade white anti-cracking double-rapid cement.

[0085] The fine aggregate is 11.0 parts by weight of 1.25mm quartz sand, 5.85 parts by weight of 2mm quartz sand, 14.0 parts by weight of 0.1mm river sand and 6.0 parts by weight of 2mm silica sand.

[0086] The water reducing agent is 0.36 parts by weight of C900 water reducing agent, 0.04 parts by weight of FL-51 water reducing agent and 0.10 parts by weight of SM water reducing agent.

[0087] The fiber is Taisha...

Embodiment 2

[0094] A concrete pavement patching material, comprising the following raw materials in parts by weight:

[0095] 32.0 parts by weight of 82.5 grade white ultra-high-strength double-fast cement, 10.0 parts by weight of 42.5 grade high-strength double-fast cement, 22.0 parts by weight of 1.25mm quartz sand, 31.0 parts by weight of 0.1mm river sand, 0.33 parts by weight of 2651F water reducer , 1.50 parts by weight of 12mm PVA fibers, 0.08 parts by weight of P801 defoamer, 0.02 parts by weight of LC, 3.50 parts by weight of 5010 rubber powder, 0.06 parts by weight of tartaric acid, and microbeads of 4.0 parts by weight.

[0096] The ratio of water to material is 0.11:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com