Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

81results about How to "Good early strength effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof

The invention relates to a high-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof, belonging to the field of construction materials. The invention aims to provide a high-early-strength antifreezing polycarboxylic-acid composite water reducing agent and application thereof. The high-early-strength antifreezing polycarboxylic-acid composite water reducing agent is prepared from the following raw materials in parts by weight: 17.5-32.5 parts of polycarboxylic-acid water reducing agent, 1-3 parts of sodium lignosulfonate, 7-36 parts of early-strength admixture, 2-8 parts of antifreezing agent, 0-0.5 part of air entraining agent and 20-72.5 parts of water. The early-strength admixture is composed of 1-8 parts by weight of organic early-strength component and 6-28 parts by weight of inorganic early-strength component. The high-early-strength antifreezing polycarboxylic-acid composite water reducing agent has the advantages of high early strength, favorable anti-freeze-thawing effect and the like.

Owner:CHINA 19TH METALLURGICAL CORP CHENGDU CONSTR +1

High-strength and high-toughness geopolymer material and preparation method thereof

ActiveCN111018435AHigh bonding strengthImprove mechanical propertiesCement productionFiberKaolin clay

The invention discloses a high-strength and high-toughness geopolymer material. The high-strength and high-toughness geopolymer material comprises, by weight, 500-700 parts of silicon-aluminum mineralraw materials, 600-800 parts of an alkali activator, 70-150 parts of a nanoscale efficient modifier, 2-5 parts of super absorbent resin, 2-6 parts of a hybrid fiber, 4-10 parts of a surfactant, 700-1000 parts of fine aggregates and 100-150 parts of deionized water, the silicon-aluminum mineral raw materials comprise 200-300 parts of metakaolin, 150-200 parts of fly ash, 50-100 parts of red mud, 40-60 parts of mineral slag, 40-60 parts of silica fume and 20-40 parts of Portland cement, and the nanoscale efficient modifier comprises 20-50 parts of condensed phosphate, 20-40 parts of nano-silica, 20-40 parts of nano-alumina and 10-20 parts of zeolite. The invention further discloses a preparation method of the high-strength and high-toughness geopolymer material. The problems of large earlyself-shrinkage and easy cracking of the geopolymer are solved, and the obtained geopolymer has strong toughness and high strength.

Owner:ZHEJIANG UNIV

Compound concrete admixture with early strength and water reduction functions, and preparation method and application thereof

ActiveCN104030595AExcellent early strength performance and water reducing effectThe preparation process is simpleMother liquorCement Material

The invention discloses a compound concrete admixture with early strength and water reduction functions. The compound concrete admixture is mainly prepared by 10-20 parts by mass of a polycarboxylate water-reducer, 1-5 parts by mass of a surfactant, 5-40 parts by mass of an early strength agent, 2 or less parts by mass of an air entraining agent, and 20-100 parts by mass of water. The preparation method of the compound concrete admixture comprises the following steps: processing a polycarboxylate water-reducer mother liquor to prepare a solution, mixing the polycarboxylate water-reducer solution with the early strength agent, the surfactant, the air entraining agent and water according in proportion, and uniformly stirring. The application of the concrete admixture is realized through the following steps: stirring the concrete admixture and standard sand; taking cement and water, and carrying out low-speed uniform mixing; mixing the above two materials, carrying out low-speed stirring, then carrying out high-speed stirring, intermediately stopping, and then continuously carrying out high-speed stirring; and adding the finally obtained mixture into a mold, and maintaining, wherein the addition of the polycarboxylate water-reducer is not greater than 1% of the amount of a cement mortar. The compound concrete admixture has the advantages of simple preparation method, fast effectiveness, wide application range, low cost and good effect.

Owner:重庆市宝霸石材有限公司

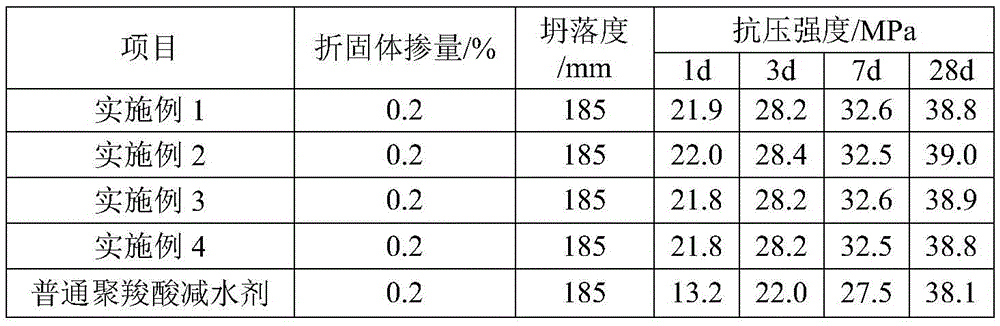

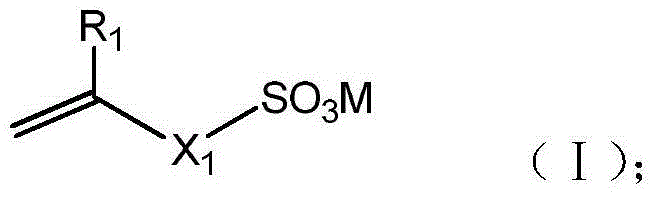

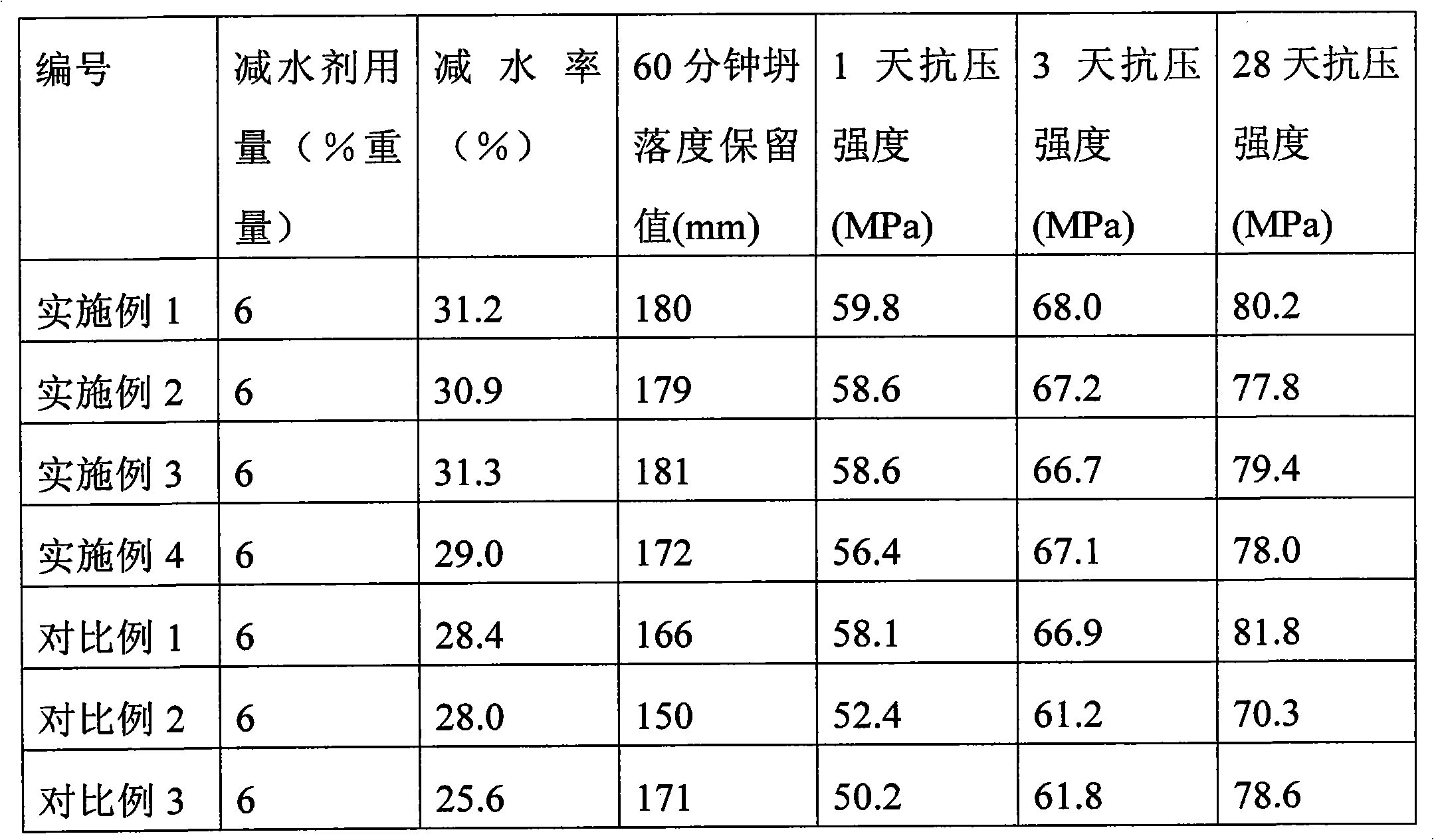

Early-strength ethers polycarboxylic acid water reducing agent and preparation method thereof

The invention relates to an early-strength ethers polycarboxylic acid water reducing agent and a preparation method thereof, belonging to the technical field of construction concrete additives. The preparation method of the early-strength ethers polycarboxylic acid water reducing agent comprises the steps: mixing and dissolving TPEG with a molecular weight of 6000 to 8000 and deionized water at the normal temperature, then adding a catalyst, then successively dropwise adding a solution A formed by mixing acrylic acid, sulphosalts unsaturated monomers and deionized water and a solution B formed by mixing an initiator, a chain transfer agent and deionized water to perform the water-based polymerization reaction, stirring after the dropwise addition, and finally adding an alkaline liquid to perform the neutralization to obtain the early-strength ethers polycarboxylic acid water reducing agent. A great amount of rigid benzene rings and sulfonate radicals are introduced into the molecular structure of the water reducing agent, so that the content of carboxylic groups having a delayed coagulation effect in the polycarboxylic acid molecules is greatly reduced, the early strength effect of the polycarboxylic acid water reducing agent molecules is greatly improved, a certain water reducing performance is achieved, and the application prospect is wide.

Owner:湖北鑫城普瑞化学科技有限公司

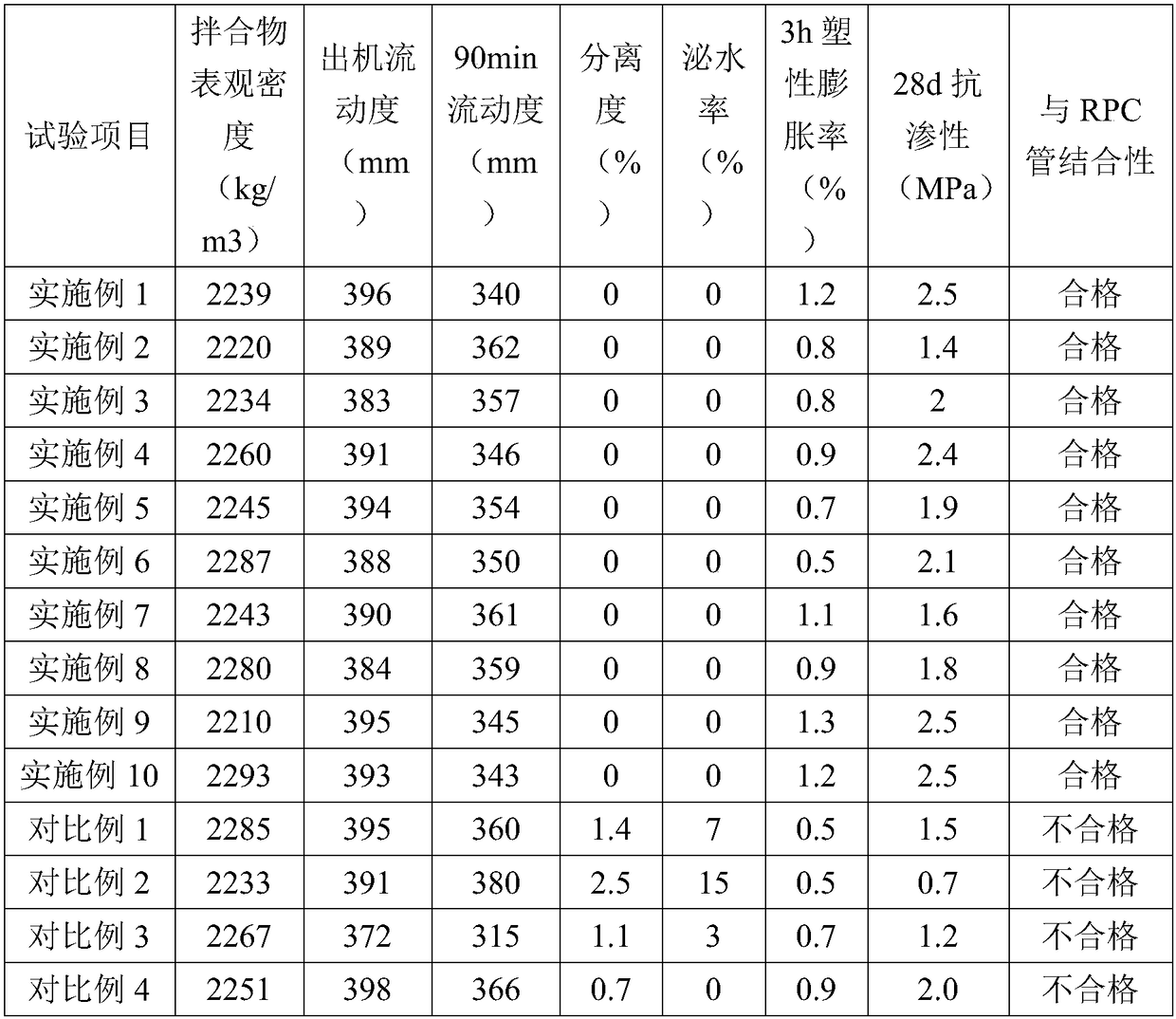

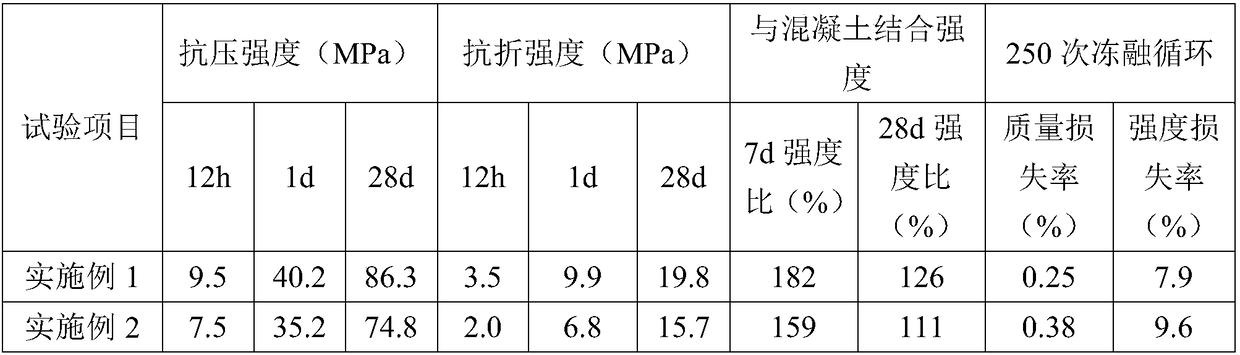

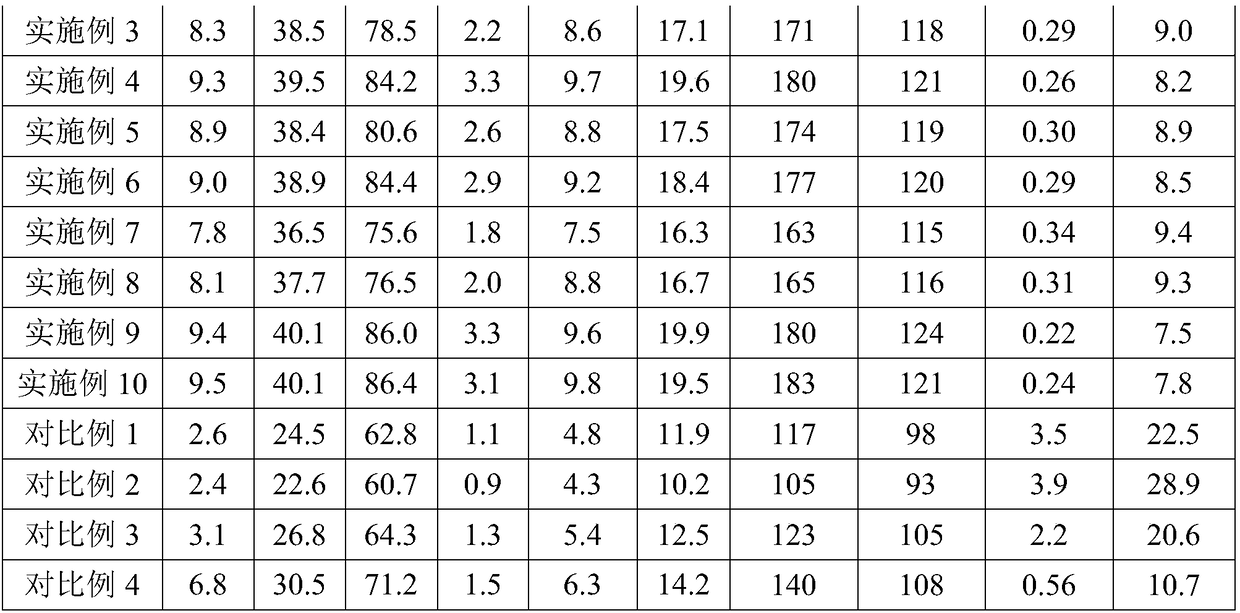

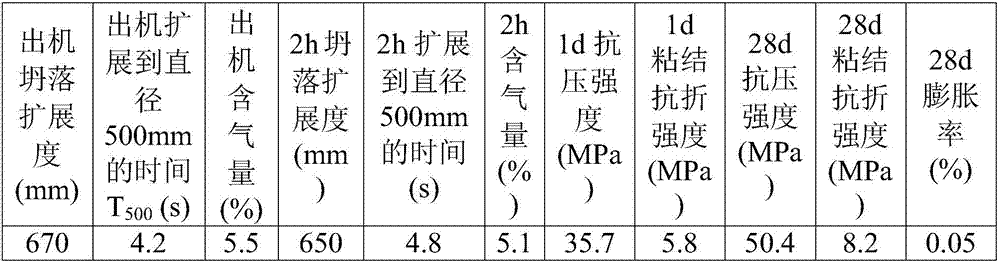

Micro-expansion grouting material for grouting tunnel lining vault with mold

The invention discloses a micro-expansion grouting material for grouting a tunnel lining vault with a mold. The micro-expansion grouting material is made of, by mass, 52.5-60% of cement, 35-40% of graded aggregate, 2-3% of viscosity modifier, 0.02-4% of expansion agent, 0.03-0.43% of early strength agent, 0.2-0.26% of water reducing agent, 0.01-0.03% of water retention agent and 0.01-0.02% of defoaming agent; the cement is one or more of Portland cement, ordinary Portland cement and sulphate aluminium cement, and the strength level of the cement is not lower than 42.5; the water retention agent is one or more of a cellulose ether polymer compound and biopolysaccharide gum. The micro-expansion grouting material for grouting the tunnel lining vault with the mold has better fluidity and micro-expansion performance, and the bonding strength with concrete and the bonding performance with RPC grouting pipes can be significantly improved.

Owner:WUHAN YUANJIN BUILDING MATERIALS TECH CO LTD

Green expansive cementing material based on salt chemical industry solid waste and building garbage, preparation method and applications thereof

InactiveCN105152553AGood expansion performanceGood affinity for mudMaterial fill-upClinker productionSteelmakingChemical industry

The present invention discloses a green expansive cementing material based on salt chemical industry solid waste and building garbage, and a preparation method thereof, wherein salt-containing chemical industry waste (salt mud, carbide slag and mirabilite), building garbage (gravel, broken bricks and concrete blocks), steelmaking plant waste residue (water residue and steel residue) and power plant desulfuration gypsum are matched with an expander, a water reducer, a soluble calcium salt and other components, and fine grinding and uniform mixing are performed to prepare the green expansive cementing material. According to the present invention, the salt mud, the carbide slag, the mirabilite and other solid waste produced by the salt chemical industry enterprise are digested while the building garbage, the desulfuration gypsum, the water residue and other solid water are subjected to the resource utilization, such that the green expansive cementing material is the green environmental protection cementing material; and the green expansive cementing material has characteristics of good expansion property, good fluidity, good consolidation property, good early strength, active tightening and effective earth's surface sinking control, is the cementing material for mine, and is particularly suitable for the filling mining of coal mines or non-coal mines.

Owner:胡相明

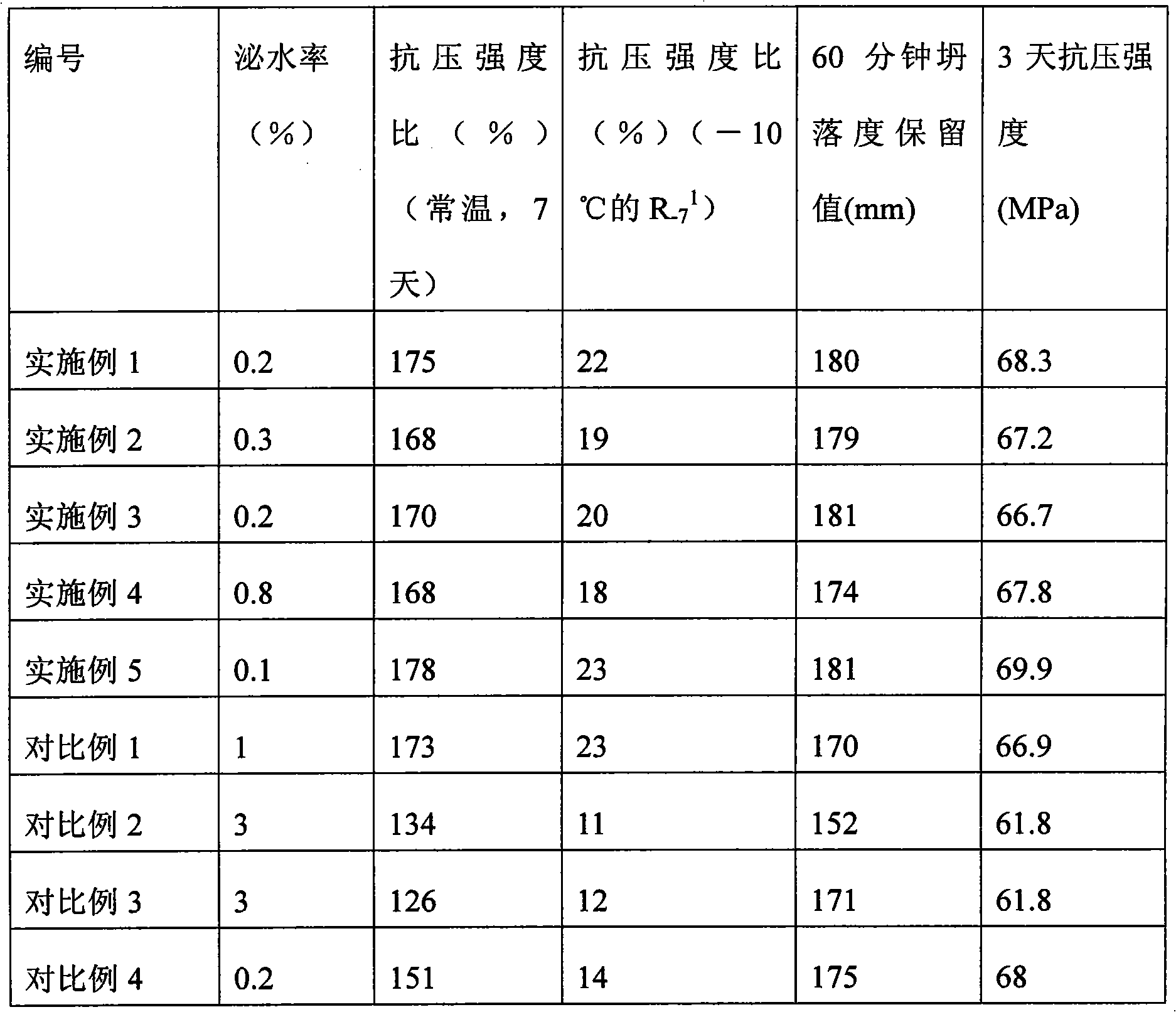

Additive for improving early strength of cement based material as well as preparation method and application of additive

The invention provides an additive for improving early strength of a cement based material. The additive is prepared by the reaction of an ionic copolymer and silane, wherein the ionic copolymer is prepared by the reaction of a monomer A, a monomer B, a monomer C and a monomer D. The invention further provides a preparation method of the additive for improving early strength of the cement based material and application of the additive in improvement of the early strength of the cement based material. The additive is simple in preparation process, convenient to use, low in cost and relatively high in water reduction rate, accelerates the hydration of the cement in the early stage, improves the early strength of the cement based material, particularly shows an obvious effect on improving the early strength of the cement based material at a low temperature environment, is relatively high in adaptability to the raw materials, has a good super early strength improving effect for different cement, and does not have any adverse effect on the future strength and durability.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

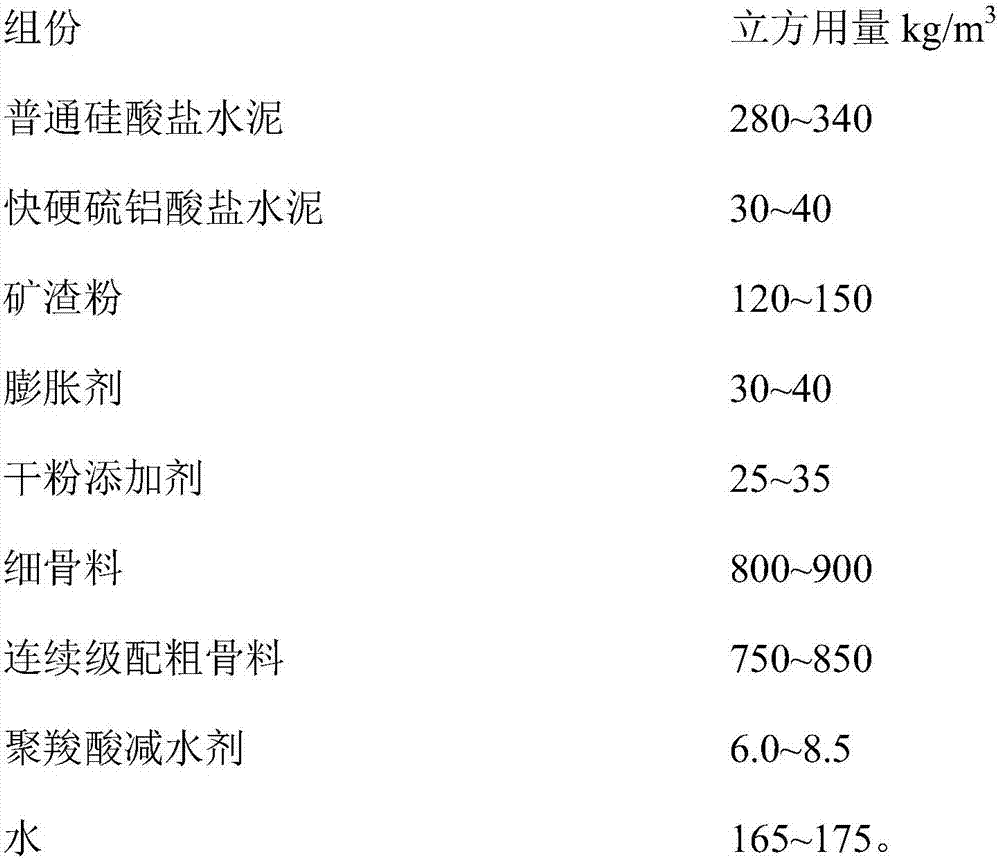

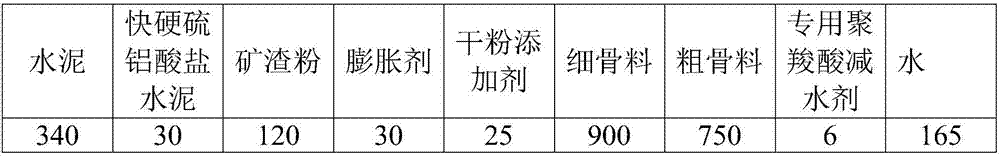

Self-compacting concrete for concrete repairing and preparation method of self-compacting concrete for concrete repairing

The invention discloses self-compacting concrete for concrete repairing and a preparation method of the self-compacting concrete for concrete repairing. Per cubic meter of the concrete is prepared from 280-340kg of ordinary Portland cement, 30-40kg of quick-hardening sulfate aluminum cement, 120-150kg of slag powder, 30-40kg of an expanding agent, 25-35kg of a dry powder additive, 800-900kg of fine aggregate, 750-850kg of continuously graded aggregate, 6.0-8.5kg of a special polycarboxylate superplasticizer and 165-175kg of water. The self-compacting concrete for concrete repairing is preparedby well mixing of ordinary Portland cement, quick-hardening sulfate aluminum cement, slag powder, the expanding agent, the dry powder additive, fine aggregate and coarse aggregate according to a certain stirring process. The self-compacting concrete for concrete repairing is high in strength of bonding to old concrete, high in early strength, capable of slightly expanding and especially applicable to repairing of dense reinforcement cement concrete structures and CRTS III type slab ballastless track filling layers by self-compacting concrete filling layers.

Owner:ANHUI ZHONGTIE ENGINEER MATERIAL SCI & TECH CO LTD +1

High-temperature-resistant stone powder adsorption-resistant slump-retaining polycarboxylate superplasticizer and preparation method thereof

ActiveCN113461873AImprove water reducing performanceGood slump retention performanceSolid waste managementPhosphateEnvironmental geology

The invention discloses a high-temperature-resistant stone powder adsorption-resistant slump-retaining polycarboxylate superplasticizer and a preparation method thereof. The polycarboxylate superplasticizer is prepared from the following components in parts by weight: 320 to 360 parts of unsaturated polyether macromonomer, 20 to 30 parts of unsaturated monocarboxylic acid, 6 to 10 parts of maleimide alkyl acid, 5 to 8 parts of unsaturated phosphate, 2 to 5 parts of unsaturated amino acid monoester, 2.5 to 5.0 parts of oxidant, 0.5 to 1.0 part of reducing agent and 1 to 3 parts of chain transfer agent. The pH value of the water reducing agent is 5.0-7.0, and the solid content of the water reducing agent is 40%-42%. The polycarboxylic acid water reducing agent can effectively solve the problems of insufficient initial fluidity of concrete, too fast slump loss and poor workability of a concrete mixture caused by incapability of simultaneously meeting high temperature resistance and limestone powder adsorption resistance of the existing water reducing agent, and has great significance in widening the engineering application field of the water reducing agent.

Owner:SICHUAN TONGZHOU CHEM TECH

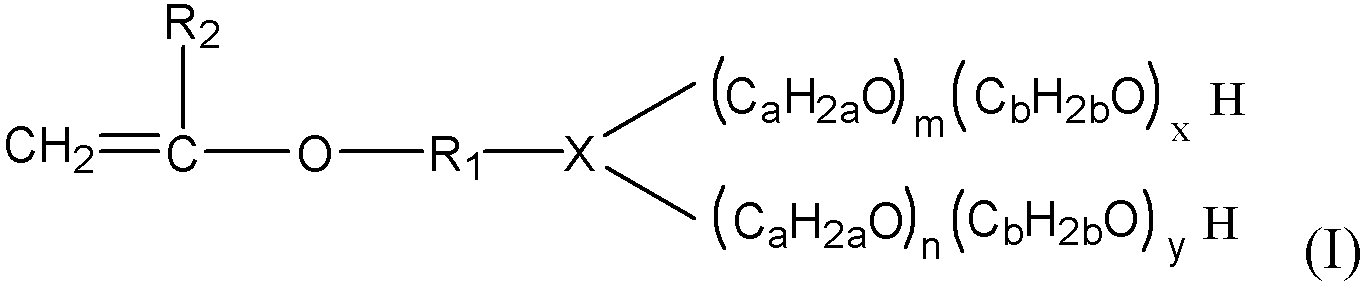

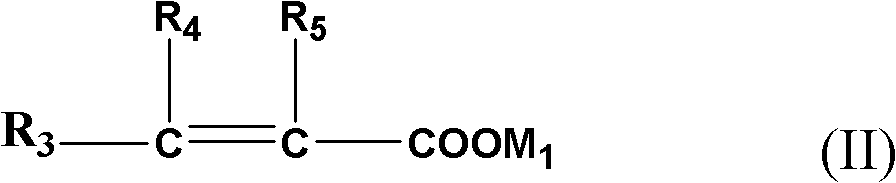

Terminal alkenyl polyether and preparation method and application thereof

The invention discloses a terminal alkenyl polyether which has a weight-average molecular weight of 15,000-45,000 and is a binary random copolymer obtained by copolymerization of monomers A and B, wherein the monomer A has the structure shown as the following formula (I), the monomer B has the structure shown as the following formula (II), and the symbols in the formulae are defined as the specifications. The invention further discloses a method for preparing the terminal alkenyl polyether, which comprises a step of performing free radical copolymerization of the monomers A and B in an aqueous solution. When the terminal alkenyl polyether disclosed by the invention is used as a concrete water reducer, the terminal alkenyl polyether has the characteristics of stable performance, high early strength, high water-reducing rate and excellent slump resistance. Besides, in the preparation method disclosed by the invention, the raw materials are easily available, the process is simple and environment-friendly, and the energy consumption is reduced.

Owner:LIAONING OXIRANCHEM INC

Early strength polycarboxylic acid water reducing agent and preparation method thereof, and cement admixture

The invention provides an early strength polycarboxylic acid water reducing agent and a preparation method thereof, and a cement admixture, wherein the early strength polycarboxylic acid water reducing agent includes a copolymer formed by polymerization of a monomer A and a monomer B, and the weight percentages of the two monomers are respectively 75%-90% and 10%-25%; the monomer A has the structural formula described in the specification, wherein R1 and R2 are alkenyl containing 3-6 carbon atoms, R3O can be the same or different and is an oxyalkylene group containing 2-18 carbon atoms, R4 is -H or hydrocarbyl containing 1-30 carbon atoms, and p is an integer or fraction of 1-300; the monomer B is one or more of acrylic acid, methacrylic acid, maleic acid, maleic anhydride, fumaric acid, citraconic acid and / or salts and / or esters thereof. Through introducing the new polymerization monomers, the early strength polycarboxylic acid water reducing agent having the advantages of high water reducing rate, short setting time, good early strength effect and stable performance is obtained; when used in precast concrete, the early strength polycarboxylic acid water reducing agent can significantly improve the early strength of concrete, thereby demolding early, improving the production efficiency, and reducing the production energy consumption of the precast concrete.

Owner:联泓新材料科技股份有限公司 +1

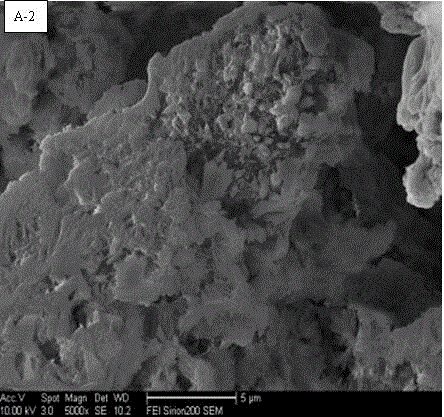

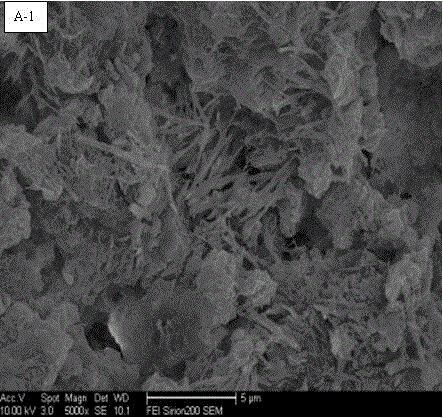

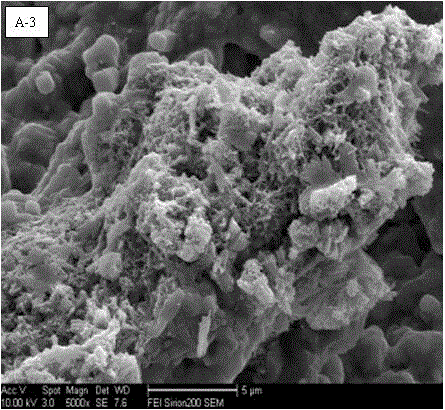

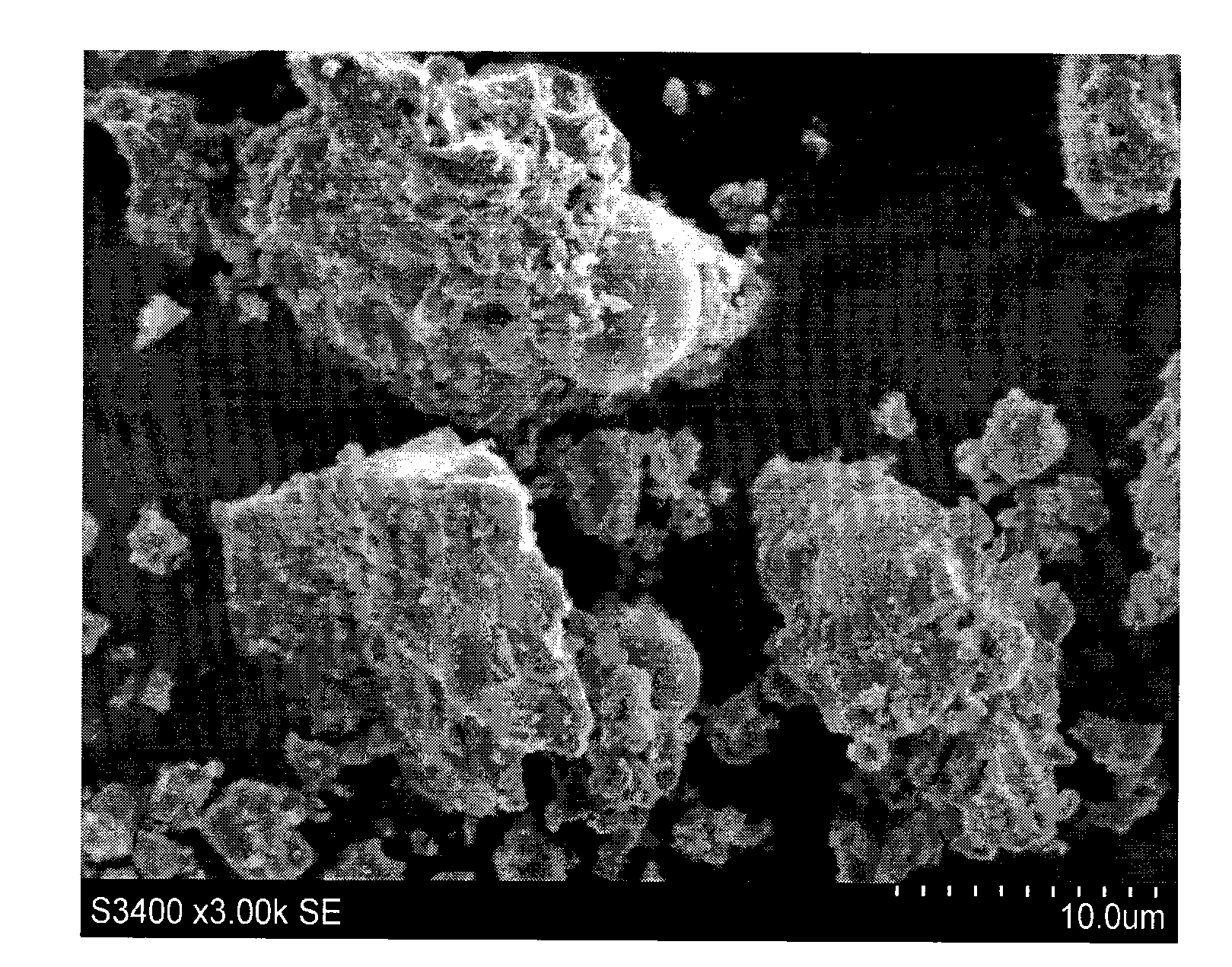

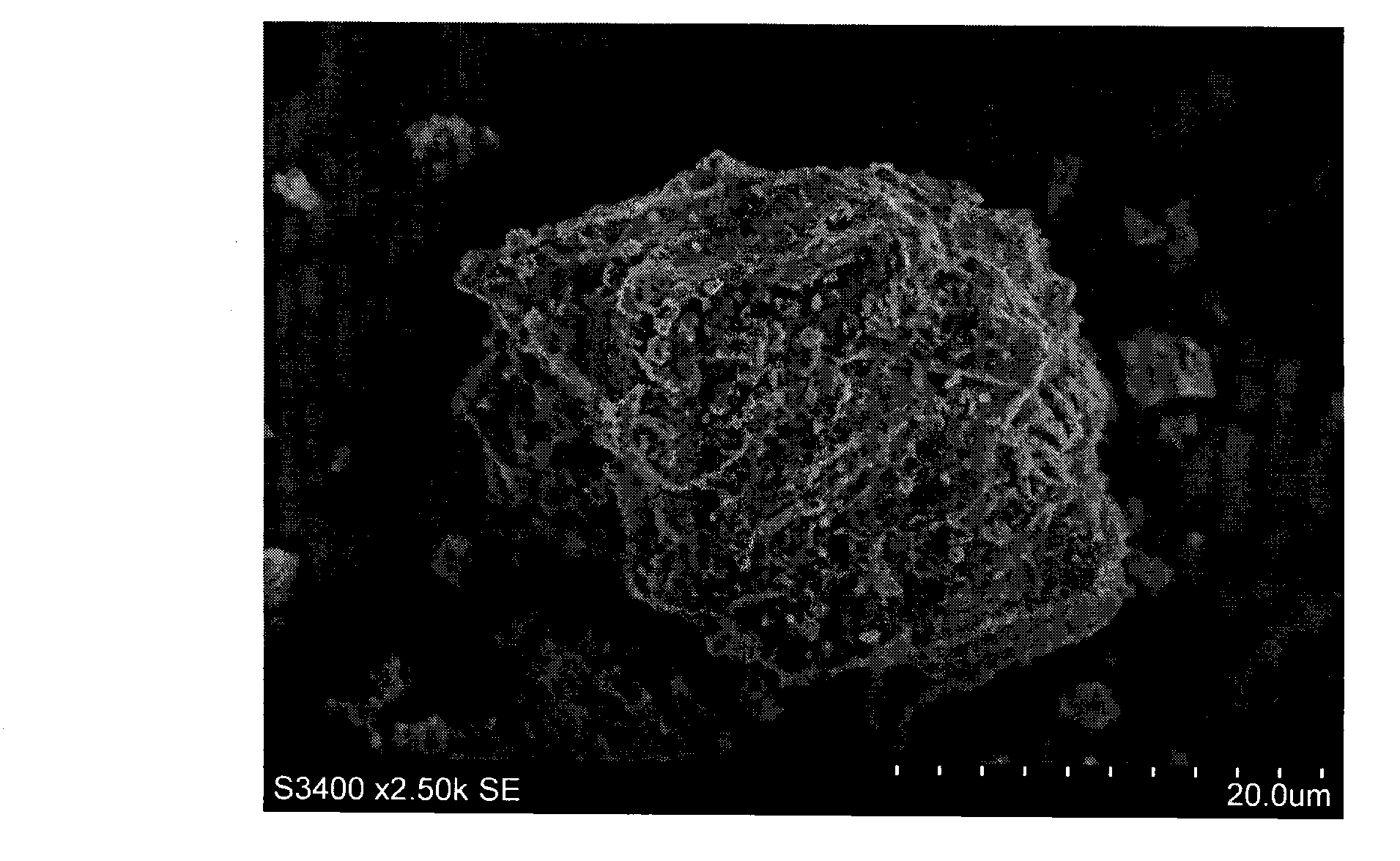

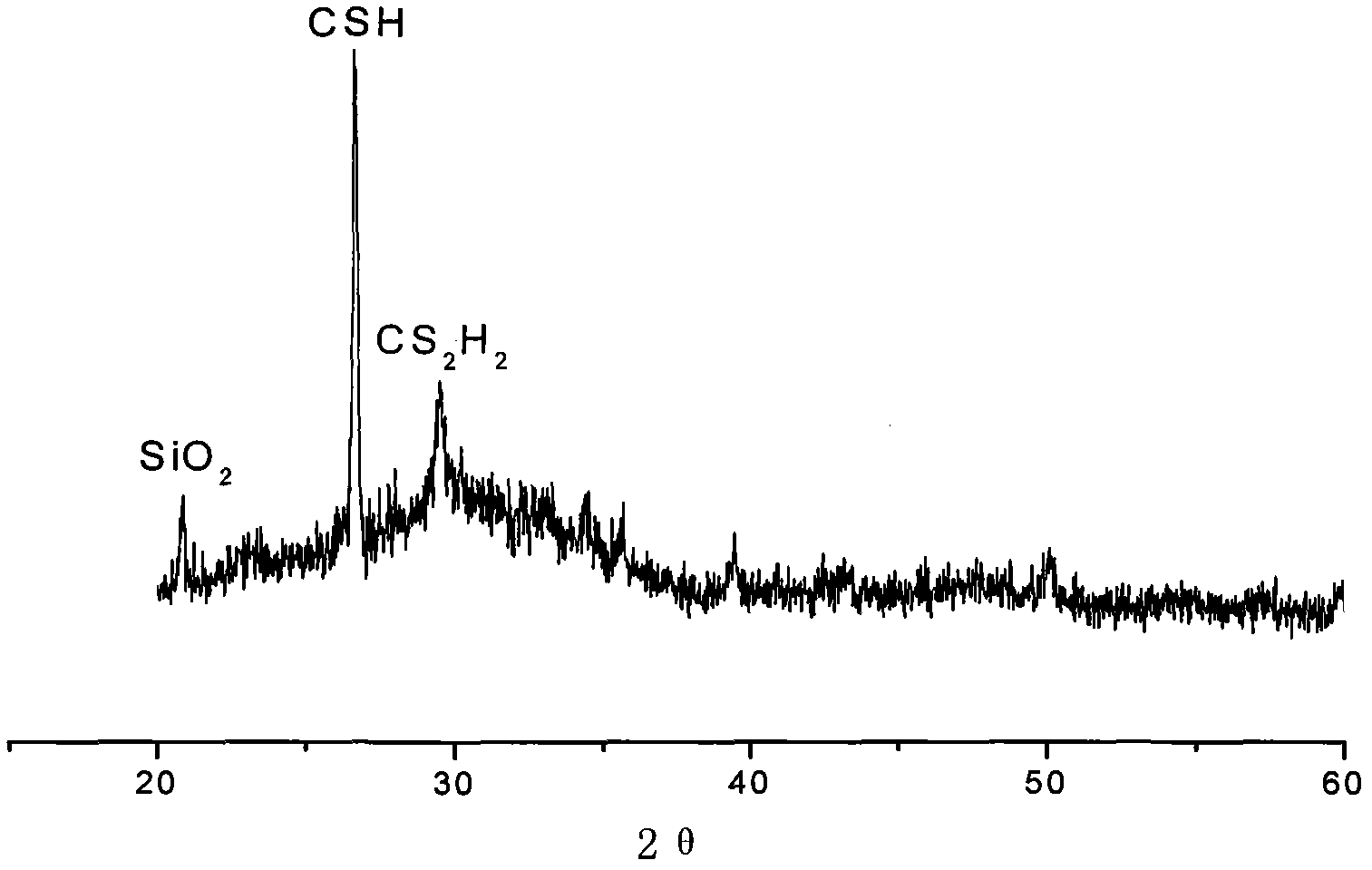

Coupling agent modified nano hydrated calcium silicate crystal nucleus early strength agent and preparation method thereof

The invention discloses a coupling agent modified nano hydrated calcium silicate crystal nucleus early strength agent and a preparation method. The coupling agent modified nano hydrated calcium silicate crystal nucleus early strength agent comprises the following components in percentage by mass: 1-10% of dispersing agent, 0.05-1% of coupling agent, 5-30% of hydrated CSH synthesized from a soluble calcium source and a soluble silicon source through solution precipitation, adn the balance of deionized water. The molar ratio of calcium to silicon is 0.5-2.0. The preparation method comprises the following steps of taking an aqueous solution of a polycarboxylic acid dispersing agent and a silane coupling agent as a base material, and simultaneously dropwise adding a soluble calcium source aqueous solution and a soluble silicon source aqueous solution into the base material to obtain the nano calcium silicate hydrate crystal nucleus early strength agent. The coupling agent modified nano hydrated calcium silicate crystal nucleus early strength agent can quickly promote cement hydration and shorten the setting time, the hour strength of concrete is greatly improved, and the middle and later strength is slightly improved. The method is suitable for different rubber material systems and different temperature conditions.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

Method for producing low combustion composite cement from waste concrete cement stone phase

ActiveCN106904847AEliminate sticking problemsEfficient grindingClinker productionNatural resourceCombustion

A method for producing low combustion composite cement from a waste concrete cement stone phase belongs to the field of cement production, solves the problem of resource utilization of the waste concrete cement stone phase, and can also realize large dosage use of industrial waste residues. The low combustion composite cement comprises the following raw materials by weight: 50%-70% of dehydrated cement stone powder, 2%-5% of dihydrate gypsum, 1.5%-3% of anhydrous sodium sulphate, 25%-40% of mineral powder and 0%-20% of other mixtures. The low combustion composite cement has the advantages of simple preparation process, the waste concrete cement stone phase is efficiently used, the cement production cost is greatly reduced by low temperature firing technology, consumption of natural resources and environmental pollution can be effectively reduced, and the method has obvious low carbon environmental-friendly effects and remarkable comprehensive benefits.

Owner:CHINA UNIV OF MINING & TECH +1

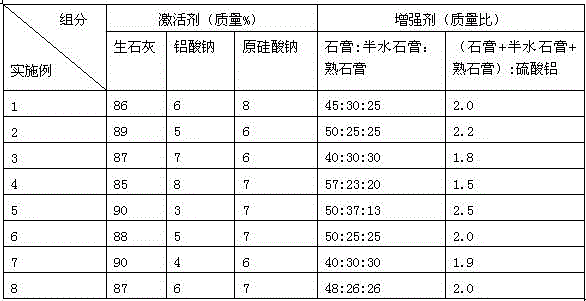

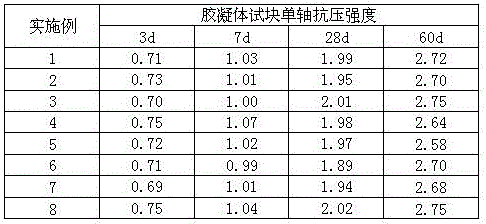

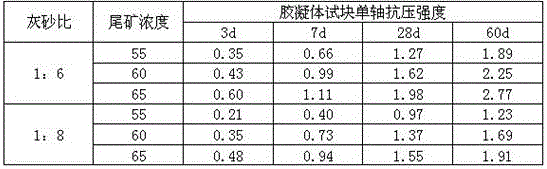

Cementing agent for micro-fine-particle tailing cementing filling

The invention discloses a cementing agent for micro-fine-particle tailing cementing filling. The cementing agent is prepared in the mode that following components are matched, mixed and ground to powder with the specific area of 600 m<2> / kg-800 m<2> / kg, and comprises, by mass, 75%-85% of superfine slag powder, 6%-12% of activating agent, 0.5%-0.8% of activating accelerant, 0.3%-0.6% of accelerating agent, 0.1%-0.3% of pumping agent and 6.65%-12.5% of reinforcing agent. The superfine slag powder is the S105 grade, and the specific area of the superfine slag powder is larger than or equal to 600 m<2> / kg; the activating agent is a mixed compound of quick lime, sodium aluminate and sodium orthosilicate, the activating accelerant is sodium fluoride, the accelerating agent is a mixed compound of sodium thiocyanate and anhydrous calcium chloride, the pumping agent is a nonionic surfactant, and the reinforcing agent is a mixed compound of plaster stone, semi-hydrated gypsum, calcined gypsum and aluminum sulfate. The cementing agent has the advantages of being short in setting time, high in early strength and strength, low in cost, easy to convey and produce and simple in technology.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

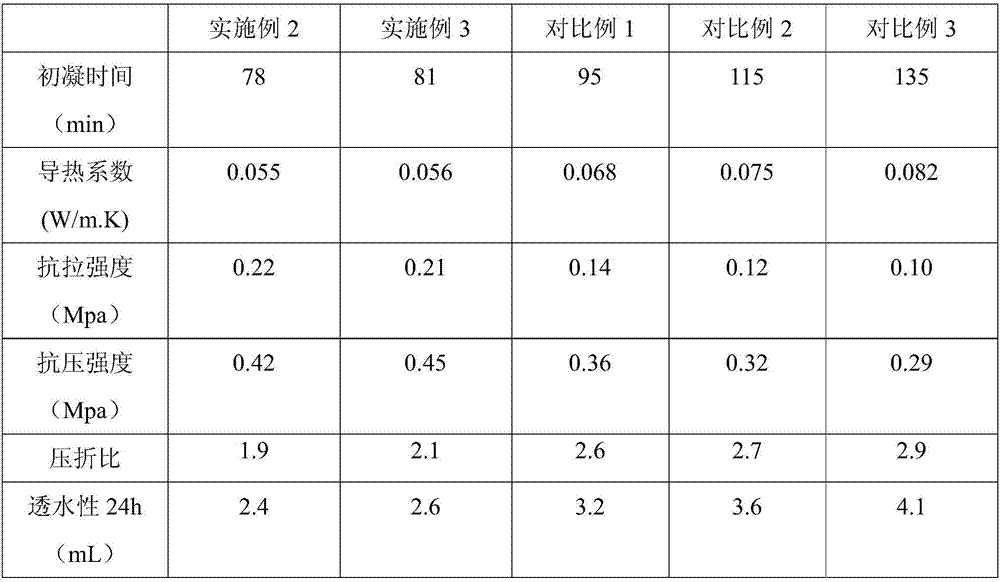

Cement-based grouting material containing modified melamine water reducer and preparation method thereof

The invention provides a modified melamine water reducer-containing cement-based grouting material and a preparation method thereof. The grouting material comprises: by weight, 350 to 500 parts of cement clinkers, 80 to 130 parts of fly ash, 20 to 30 parts of an expanding agent, 80 to 120 parts of gypsum, 1 to 2 parts of a pH regulator, 8 to 15 parts of a modified melamine water reducer and 300 to 500 parts of quartz sand, wherein the modified melamine water reducer is prepared from phenol, urea, an aminobenzenesulfonate, formaldehyde, melamine, sodium pyrosulfite, sodium hydroxide, triethanolamine, an acid catalyst and a solvent. The modified melamine water reducer-containing cement-based grouting material has the advantages of high strength, low cost and excellent early strength performances.

Owner:广州滕泰建材科技有限公司

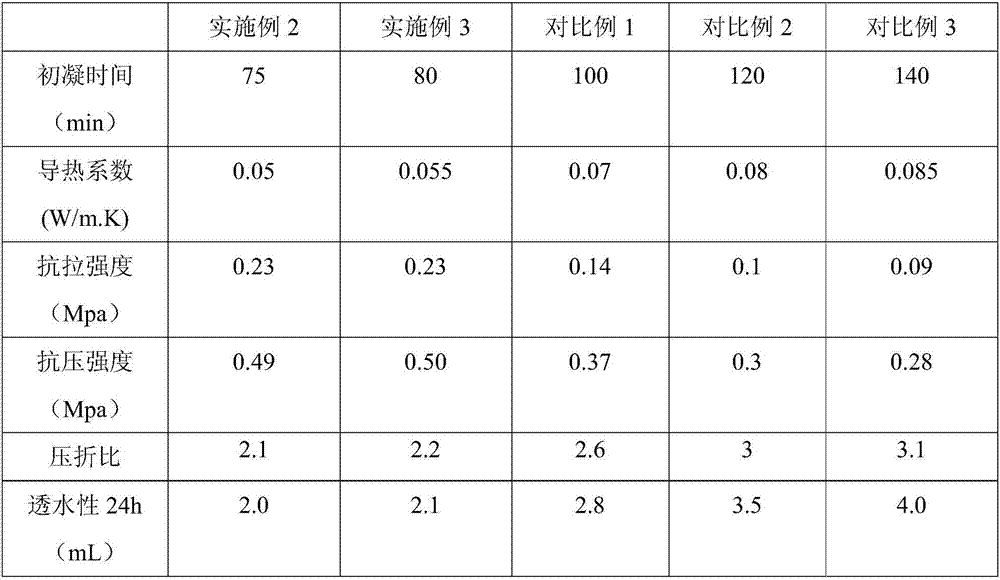

Composite mortar and manufacturing method thereof

The invention provides composite mortar and a manufacturing method thereof, and belongs to the field of production of building materials. In the composited mortar, cement, mineral sand, coal ash and glass beads are taken as aggregates, and carboxymethyl cellulose sodium, wood fibers, gelatine powder, a water-retaining agent, a water reducing agent and a water repellent are taken as additives. The manufacturing method comprises the following steps: first, sequentially putting cement, additives, glass beads and coal ash into a reaction kettle, premixing the mixture for a certain time, putting an obtained substance and mineral sand into a stirrer, stirring the mixture and cooling, so as to obtain the composite mortar. The invention provides the composite mortar and the manufacturing method thereof; the composite mortar has the advantages of being safe and non-toxic and reducing energy consumption, is good in peaceability, crack resistance, thermal insulation and waterproofing, high in strength, corrosion resistance and adhesion, light in weight and convenient in construction, is beneficial to mechanical construction, and has the characteristics of saving working hours and lowering construction cost.

Owner:广西绿地涂装工程有限公司

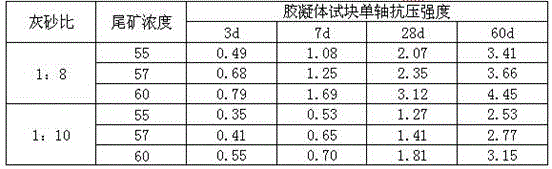

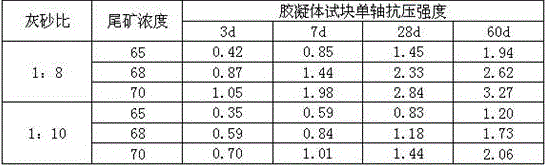

Gel material for ultra-fine tailing filling and dry heaping

InactiveCN105776911AGood early strength and cementing propertiesImprove filling utilizationCement productionSodium silicateAluminium salts

The invention discloses a gel material for ultra-fine tailing filling and dry heaping.The gel material is prepared from, by mass, 70-90% of blast furnace water granulated slag fine powder, 3-15% of an activating agent, 0.5-0.8% of an activation promoter, 0.3-0.6% of coagulant, 0.1-0.3% of a pumping aid and 5-15% of a reinforcing agent through the steps of matching, mixing and grinding.The activating agent is a mixed compound composed of quick lime, sodium aluminate and sodium orthosilicate.The activation promoter is sodium fluoride.The coagulant is a mixed compound of sodium thiocyanate and anhydrous calcium chloride.The pumping aid is non-ionic surfactant.The reinforcing agent is a mixed compound composed of gypsum, semi-hydrated gypsum, calcined gypsum and aluminum sulfate.The gel material solves the problem that ultra-fine and fine-particle tailing and tailing slurry are difficult to cure and low in strength after curing, and the gel material is low in cost and easy to construct, and has the double characteristics of high early strength and high later strength.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

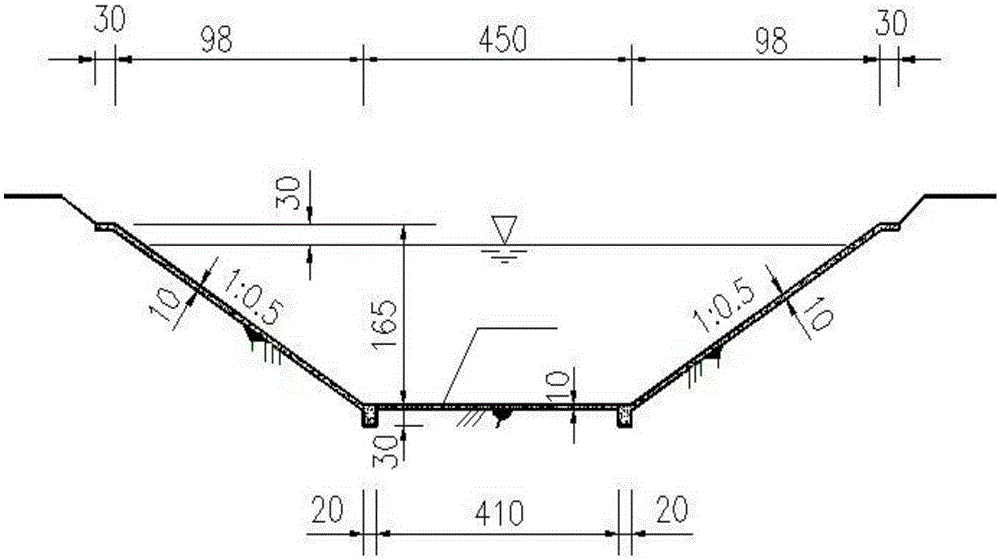

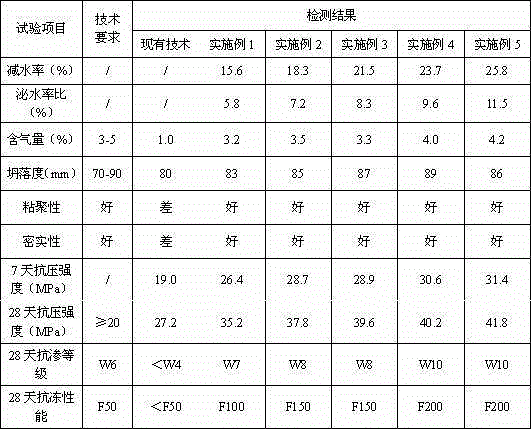

Channel side slope cast in situ concrete composite additive and preparation method thereof

The invention discloses a channel side slope cast in situ concrete composite additive, and a preparation method thereof. The channel side slope cast in situ concrete composite additive comprises, by weight, 25 to 50 parts of a water reducing agent, 1 to 5 parts of an air entraining agent, 5 to 15 parts of a thickening agent, 4 to 20 parts of an early strength agent, and 20 to 60 parts of water. The channel side slope cast in situ concrete composite additive obvious water reducing effect, air entraining effect, thickening effect, and early strength effect, is capable of increasing strength, compactibility, impermeability, and crack resistance of channel side slope concrete greatly, improving construction quality, and prolonging project service life. According to application processes of the channel side slope cast in situ concrete composite additive in channel side slope cast in situ concrete, the admixing amount of the channel side slope cast in situ concrete composite additive only accounts for 0.5 to 1.5% of the total mass of cement in the concrete; cost is relatively low; economic benefit is excellent; and the channel side slope cast in situ concrete composite additive is suitable for large-scale popularization.

Owner:广西壮族自治区水利科学研究院

Environment-friendly concrete water reducer and preparation method thereof

InactiveCN109279804ASimple manufacturing methodRaw materials are easy to getSuccinic acidWater reducer

The invention provides an environment-friendly concrete water reducer. The concrete water reducer comprises the following components in parts by weight: 30-40 parts of a triethanolamine oleic soap-based polyacrylic acid copolymer, 10-15 parts of modified activated clay, 5-10 parts of 4-aminophenyl fucoside, 4-6 parts of polyether amine, 10-15 parts of isopropanol and 30-40 parts of water, whereinthe triethanolamine oleic soap-based polyacrylic acid copolymer is prepared by copolymerization of triethanolamine oleic soap, (2R,3S,4S)-rel-2-carboxyl-4-(1-methylvinyl)-3-pyrrolidine acetic acid, sulfo succinic acid-1-(2-propenyl)-4-tridecylester sodium salt and N-acryloyltris(hydroxymethyl)aminomethane. The invention further discloses a preparation method of the environment-friendly concrete water reducer. The environment-friendly concrete water reducer disclosed by the invention has the advantages that comprehensive performance is excellent, the water reducing effect is more obvious, the mixing amount is smaller, plasticizing performance is more excellent, cost is lower, influence on the environment is smaller, and use is safer and more environmentally friendly.

Owner:魏菊宁

Slag-coal ash compound solid exciter and preparation method thereof

The invention relates to a slag-coal ash compound solid exciter and a preparation method thereof, and belongs to the field of cement and concrete building materials. The preparation method for the slag-coal ash compound solid exciter comprises the steps as follows: carrying out compound modification on sodium hydroxide, sodium carbonate and low-modulus liquid water glass as well as a modifying agent-polyacrylamide or polyphosphate, ageing and digesting in vacuum condition, drying and grinding. The slag-coal ash compound solid exciter overcomes the defects of poor stability of the traditional solid base exciter and difficult field construction of the traditional liquid exciter, has the advantages of good stability, unsuitability for moisture absorption or air slaking and a wide range of material sources, and can be directly mixed and ground with the slag and the coal ash to prepare high-strength hydraulic cementing materials. The cement can be fully replaced with the cementing material obtained by the excitation of the exciter in the concrete, so that the concrete strength can be enhanced by about 20-30%, and the concrete durability can be improved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Construction technique for composite mortar

ActiveCN106906967AImprove workabilityGood early strength effectCovering/liningsFiberCarboxymethyl cellulose

The invention provides a construction technique for composite mortar and belongs to the technical field of buildings. The construction technique specifically comprises the following steps that a polished wall face is washed firstly, and the wall face is subjected to hair spraying treatment through a wall body interface agent, wherein the wall body interface agent is prepared by blending cement, sand, an additive and water, and the additive comprises carboxymethyl cellulose sodium, wood fibers, flexible rubber powder, a water-retaining agent, a water reducing agent and a water repellent; then the wall body surface is subjected to anchoring; and finally the wall face is subjected to composite mortar layered spraying through a dedicated mortar spray gun, and water spraying maintenance is noticed, wherein the composite mortar comprises cement, mineral sand, prefabricated coal powder ash, glazed hollow beads and an additive. According to the construction technique for the composite mortar, the anti-cracking and waterproof effects of the composite mortar can be improved, the used composite mortar has the advantages of being safe and innoxious and has the characteristics of being good in workability and capable of achieving the anti-cracking, heat-insulation, heat-preservation, waterproof, high-strength and corrosion-resistance effects, and building cost can further be reduced.

Owner:广西绿地涂装工程有限公司

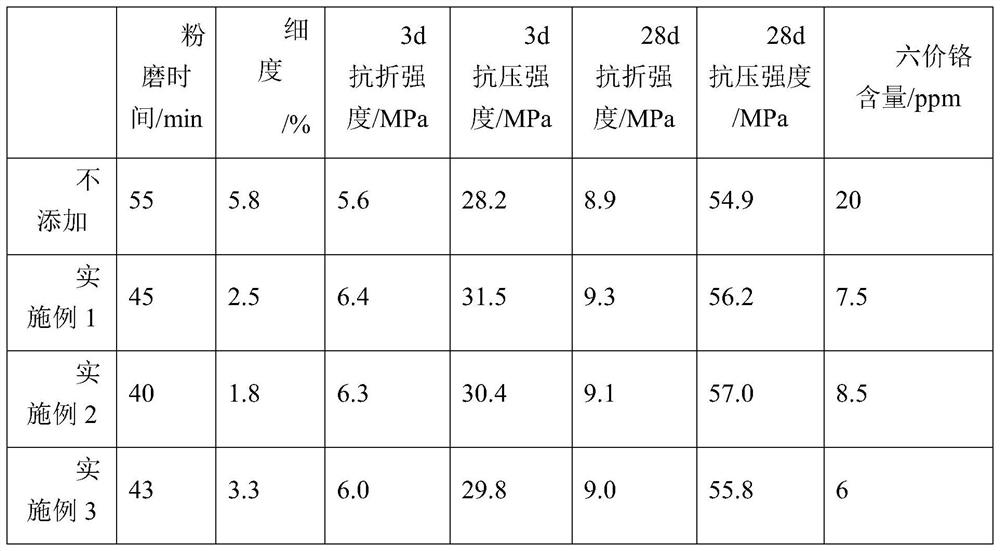

Formula and preparation process of novel powder cement grinding aid

InactiveCN112645628AShorten the timeInhibit hygroscopicityMANGANESE ACETATEAnhydrous Calcium Sulfate

The invention relates to the technical field of cement grinding aids, and discloses a formula and preparation process of a novel cement grinding aid which comprises the following raw materials in parts by weight: 3-5 parts of alkylol amine, 5-10 parts of potassium humate, 2-5 parts of sodium thiocyanate, 20-35 parts of anhydrous sodium sulphate, 25-35 parts of silica fume, 10-25 parts of hexavalent chromium reducing agent and 7-10 parts of stabilizer. According to the novel powder cement grinding aid, the chemical stability and the reduction efficiency are greatly improved, the defect that ferrous sulfate and manganese acetate are easy to deliquesce while the hygroscopicity of anhydrous calcium sulfate is overcome, the oxidation resistance of ferrous sulfate is greatly improved, the cement grinding time is shortened, the energy consumption is greatly reduced, the cement grinding aid has the advantages of favorable chromium removal property, favorable grinding aid property, favorable early strength and favorable chemical stability, does not contain chlorine salt, is environment-friendly, has wide application range, is worthy of wide-range popularization and use, brings great convenience to capital construction engineering in China, and greatly enhances the physical strength of the cement after being poured or completely dried.

Owner:TANGSHAN DUNSHI DRY POWDER BUILDING MATERIAL

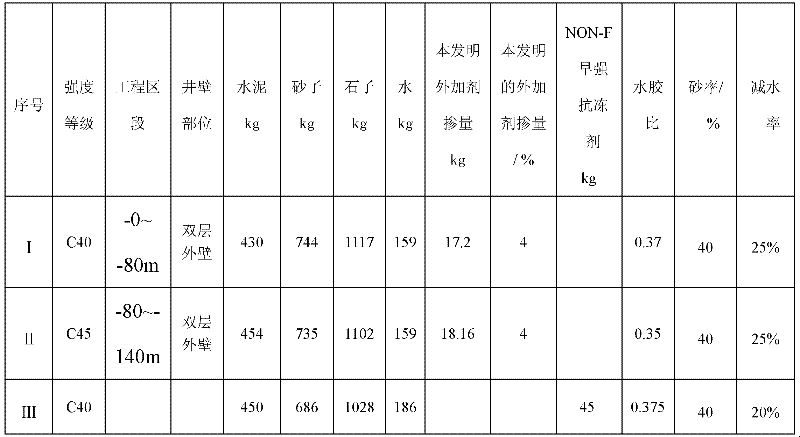

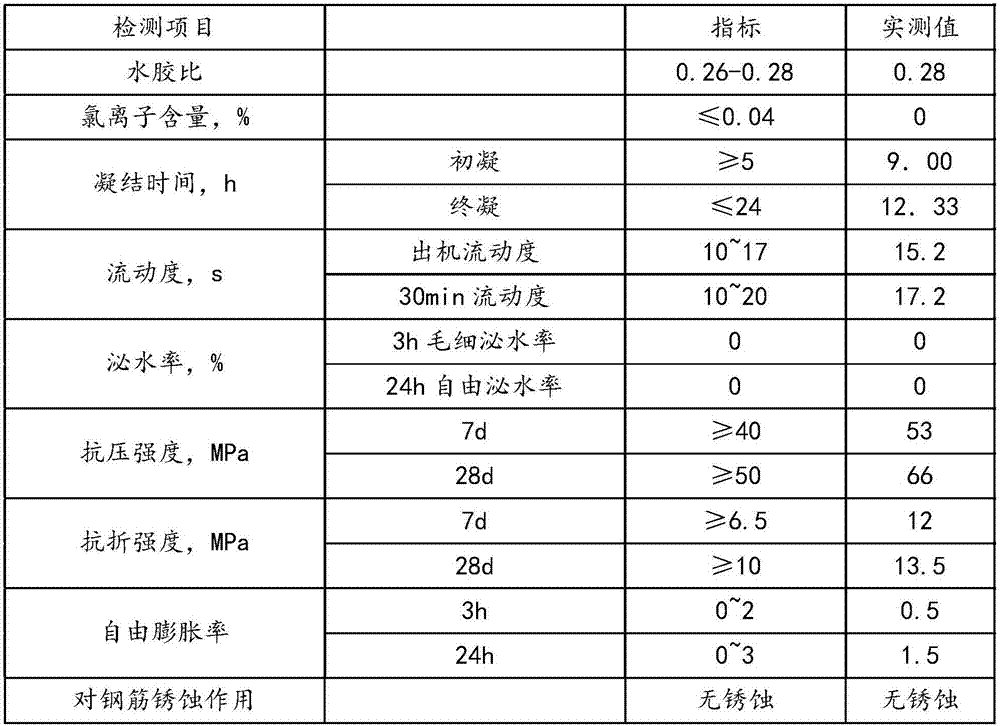

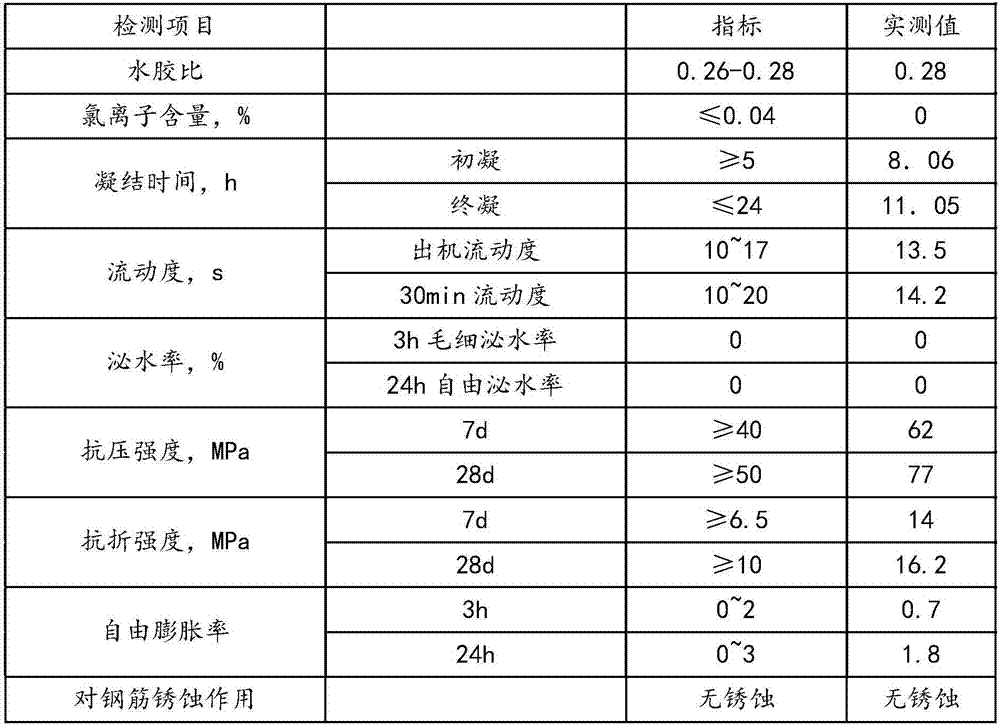

Water-reducing and early-strength antifreeze

The invention discloses a water-reducing and early-strength antifreeze agent, which is composed of the following raw materials by weight percentage: 18-25% of naphthalene series high-efficiency water-reducer, 13-20% of early-strength agent, and 5-13% of antifreeze calcium nitrite %, mineral admixture fly ash 53-60%, and the early strength agent is sulfate. Stir the naphthalene-based high-efficiency water reducer and the mineral admixture fly ash for 3 minutes, then add the early strength agent and antifreeze in turn and stir for 7 minutes. The water-reducing and early-strength antifreeze agent of the present invention can significantly improve the early strength of concrete in construction under low negative temperature conditions, reduce cracks, and improve the durability of the well wall, thereby meeting the requirements for reducing the strength of the well wall, cracking resistance, waterproofing, early strength, and improving Durability requirements.

Owner:HANDAN JUNQIANG MINE TECH

Preparation method of early strength prestress duct grouting material

The invention discloses a preparation method of an early strength prestress duct grouting material and solves the problems that in the existing grouting materials, the fluidity is poor, laying and cracking occur and the like. The technical scheme is that the early strength prestress duct grouting material comprises the composites of 0.15%-0.25% of water reducer, 20%-30% of cullet, 5%-10% of cinerite, 0.3%-0.4% of Welangum, 2%-6% of micro-expanding agent, 0.02%-0.1% of defoamer and 53.25%-72.53% of cement; the water-binder ratio is 0.28; the preparation method comprises the steps that the cullet and the cinerite are put into a wet mill, the water-material weight ratio is 1:2, ball-milling is performed until the median size is smaller than 1 micrometer, then cement and surplus water are put into the wet mill sequentially, the architecture grade Welangum, the micro-expanding agent, the defoamer and the water reducer are added and stirred uniformly after wet-milling stirring, and the early strength prestress duct grouting material is obtained. According to the preparation method of the early strength prestress duct grouting material, the method is easy, the production cost is low, the prepared grouting material has ultrafast fluidity, can prevent layering, is free of shrinkage and has micro-expansion and early strength performance.

Owner:HUBEI UNIV OF TECH

Concrete admixture and preparation method

ActiveCN108503251APromote green developmentGood water reduction effectOrganic acidGreen Tea Polyphenols

The invention provides a concrete admixture and a preparation method. Tea is ground, water is added, the mixture is boiled, and an exciting agent, namely, a tea extracting solution is obtained for later use; theophylline, tea polyphenol and the exciting agent, namely, the tea extracting solution are weighed in a weight ratio, mixed and stirred uniformly; the concrete admixture is obtained throughintermittent mixing under the ultrasonic condition. Effective components of tea are mainly taken as a basis, natural components including theophylline and tea polyphenol in tea are sufficiently utilized for admixture preparation, the tea extracting solution is taken as the excitant, and excitation is performed through multiple amino acids, vitamins, organic acid, lipopolysaccharide, saponin, sterol and the like in the tea extracting solution. The water reducing function and the early strength function of the natural components of the tea on concrete are played, and the concrete admixture has very high social value and ecological value.

Owner:长春昌驰环保科技有限公司

Elastic cement-based self-leveling mortar and preparation method thereof

The invention discloses elastic cement-based self-leveling mortar. The elastic cement-based self-leveling mortar comprises early-strength cement master batch, common cement, waste tire particles, sand, water reducing agent, cellulose and dispersible latex powder. Sodium-silicon emulsion is added into the mortar when the mortar is used. A preparation method of the self-leveling mortar includes: evenly mixing the early-strength cement master batch, the common cement, the waste tire particles and the sand, sequentially adding the water reducing agent, the cellulose and the dispersible latex powder, evenly mixing and stirring all the raw materials, adding the sodium-silicon emulsion during site construction, and stirring. The elastic cement-based self-leveling mortar has the advantages the high permeability and stability of the sodium-silicon emulsion and the early strength and micro-expansibility of the early-strength cement master batch are utilized, an appropriate amount of compound additives are added after the sodium-silicon emulsion and the early-strength cement master batch are mixed according to a certain proportion to regulate the fluidity, crack resistance and operability of the mortar, properties such as early strength and rapid hardening, high fluidity, high bonding strength, crack resistance and durability of the mortar are achieved, and the crack resistance can effectively prevent terrace from cracking.

Owner:SHANGHAI YUXI NEW MATERIAL TECH

Environment-friendly composite early-strength water reducing agent and preparation method thereof

The invention discloses an environment-friendly composite early-strength water reducing agent, which is characterized by including the following components in parts by weight: 15 to 20 parts of 3-(1-naphthyl) acrylic acid / 3-[N, N-dimethyl-[2-(2-methylprop-2-enoyloxy) ethyl] ammonium] propane-1-sulfonic acid inner salt / 4-vinyl-2, 3-dihydrobenzofuran / alliin copolymer; 4 to 8 parts of hyperbranched polylysine; 2-5 parts of sodium alginate; 4 to 7 parts of celestite; 1-3 parts of spar; 1 to 3 parts of N-(3-triethoxysilylpropyl) glucosamide; and 30-40 parts of water. The invention also discloses apreparation method of the environment-friendly composite early strength water reducing agent. The environment-friendly composite early-strength water reducing agent disclosed by the invention is remarkable in early-strength water reducing effect, small in mixing amount, capable of effectively improving the compressive strength of concrete, reducing the shrinkage rate of the concrete and shorteningthe production period of the concrete, free of obvious negative effects on the comprehensive performance of the concrete, and green and environment-friendly in preparation and use processes.

Owner:赵良文

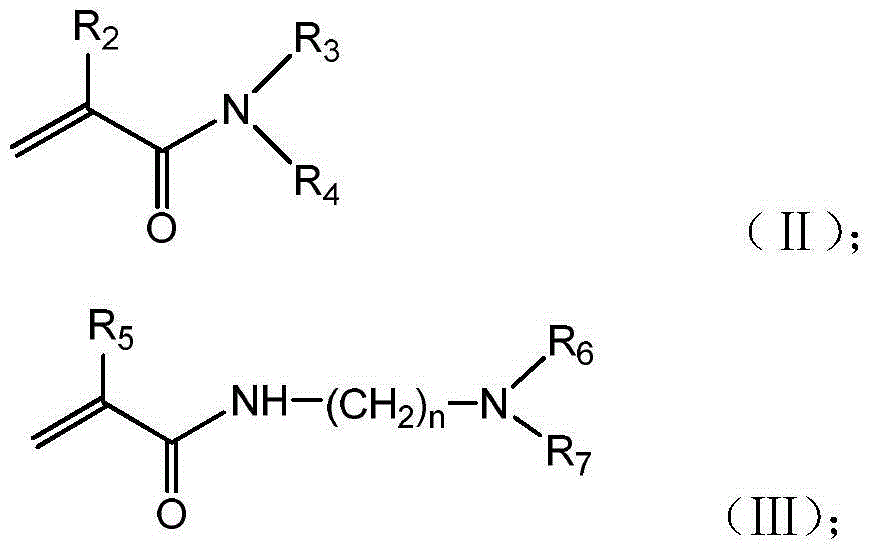

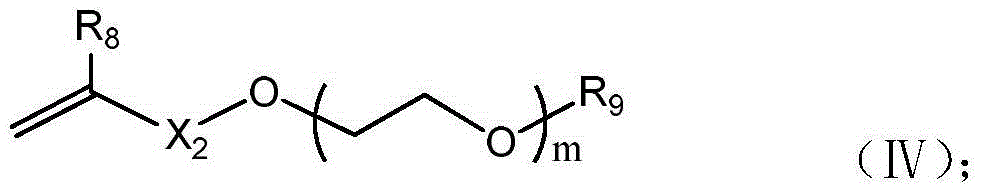

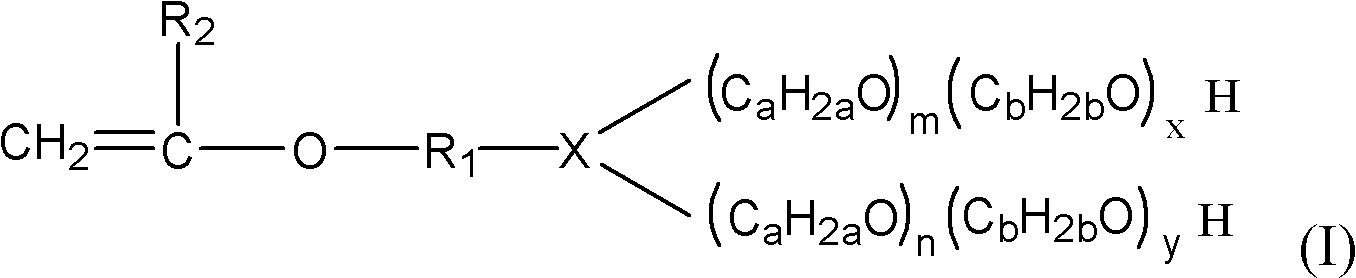

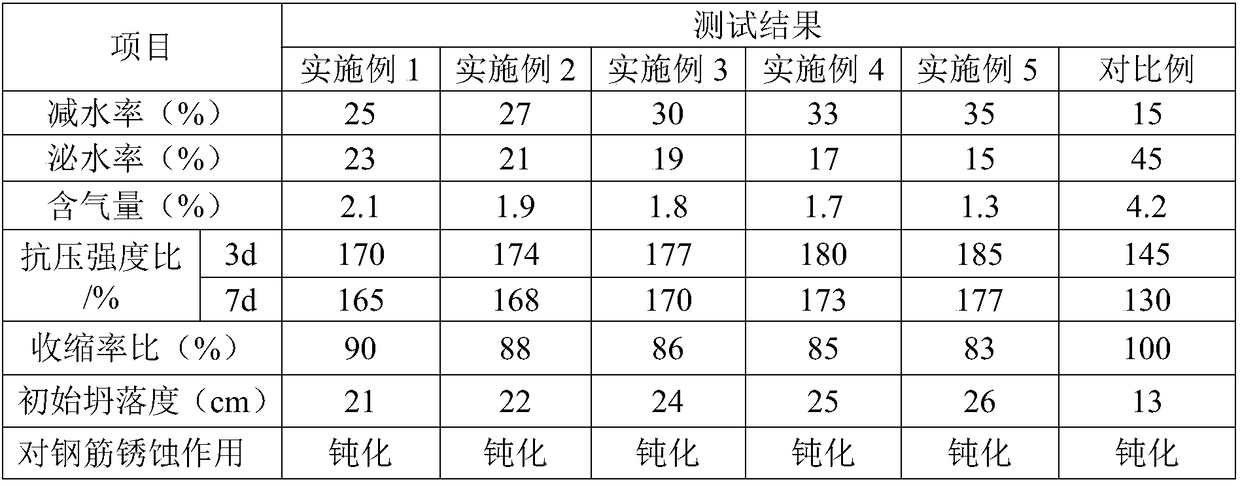

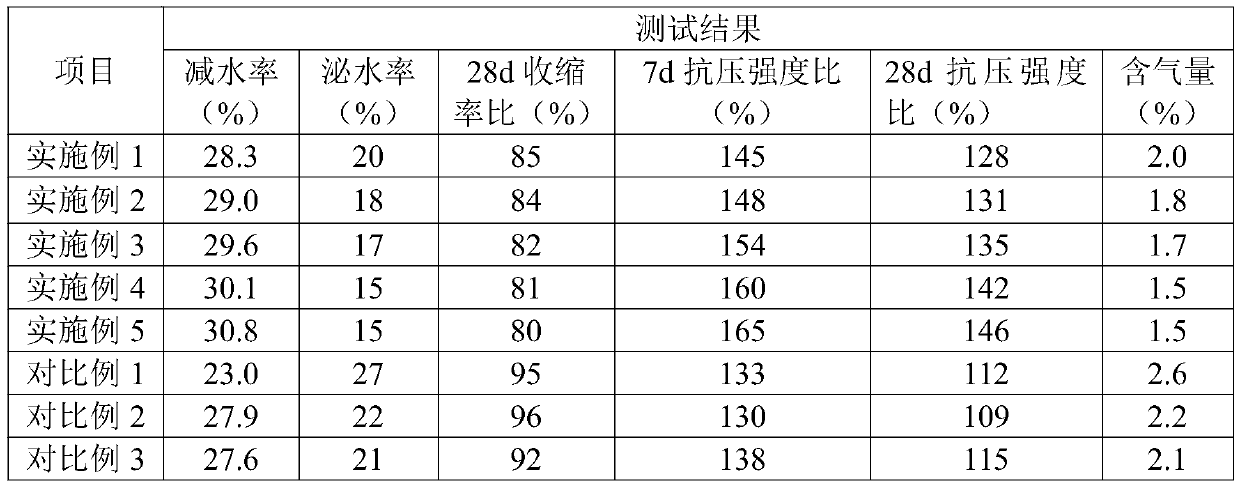

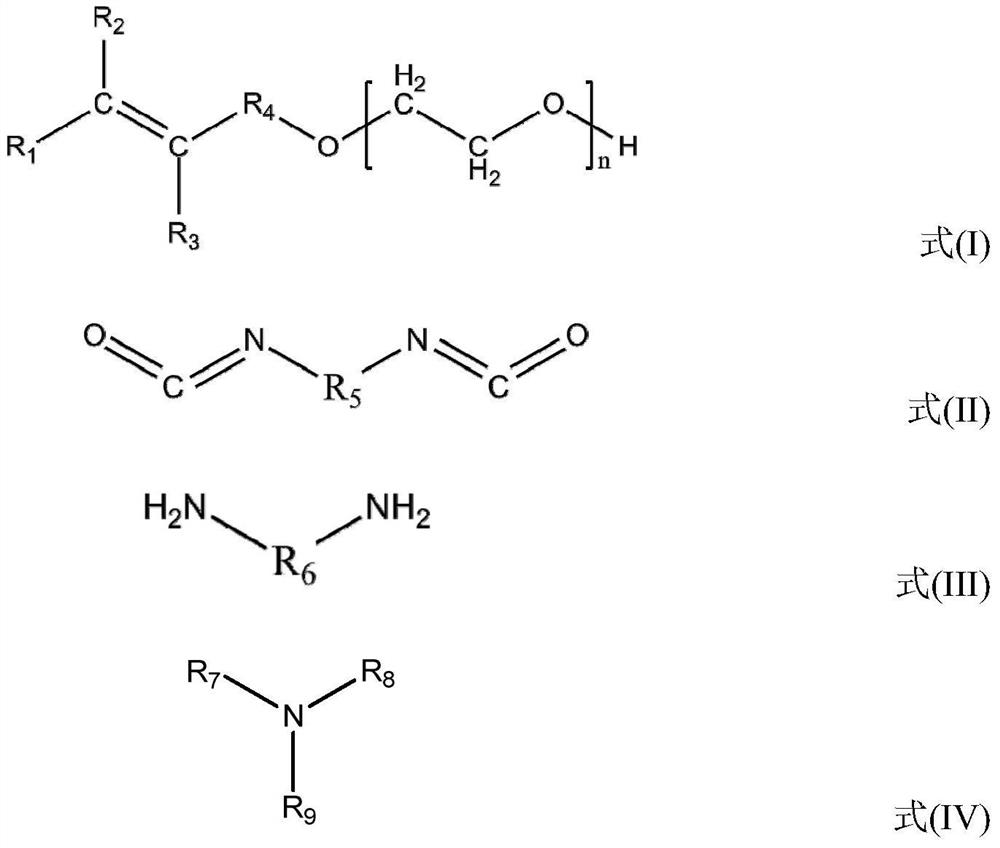

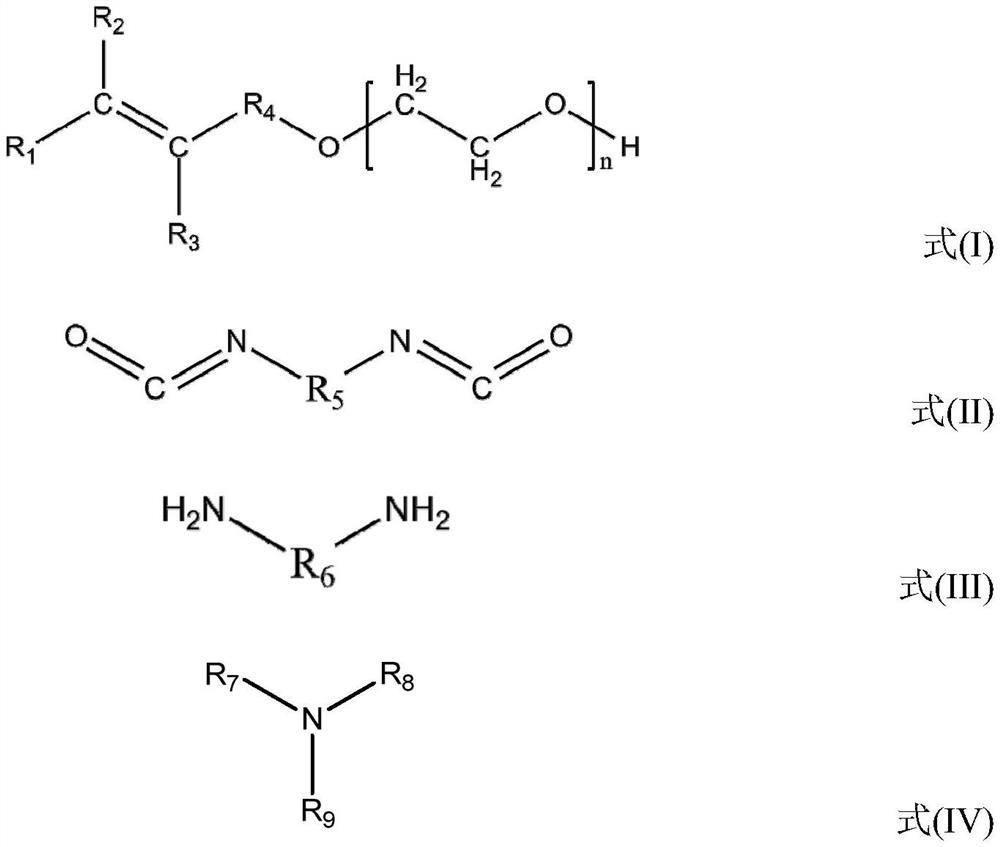

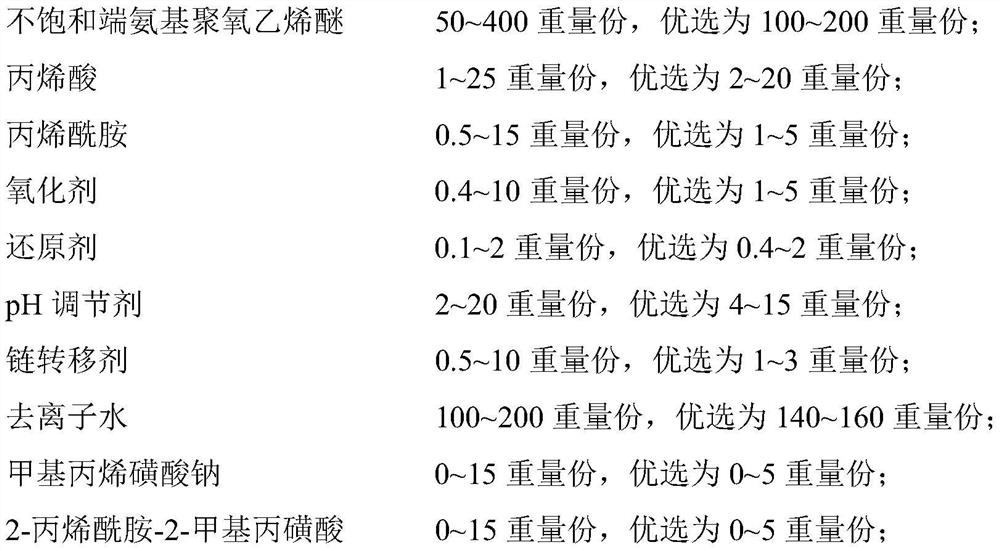

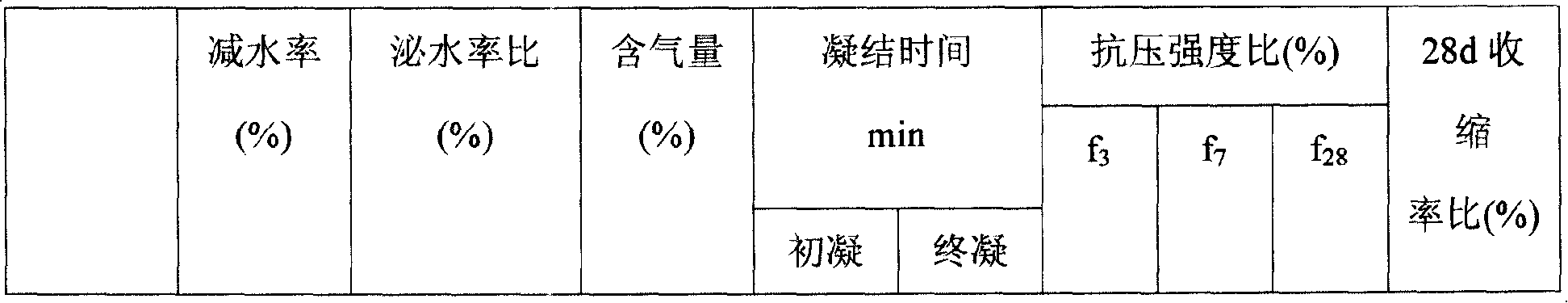

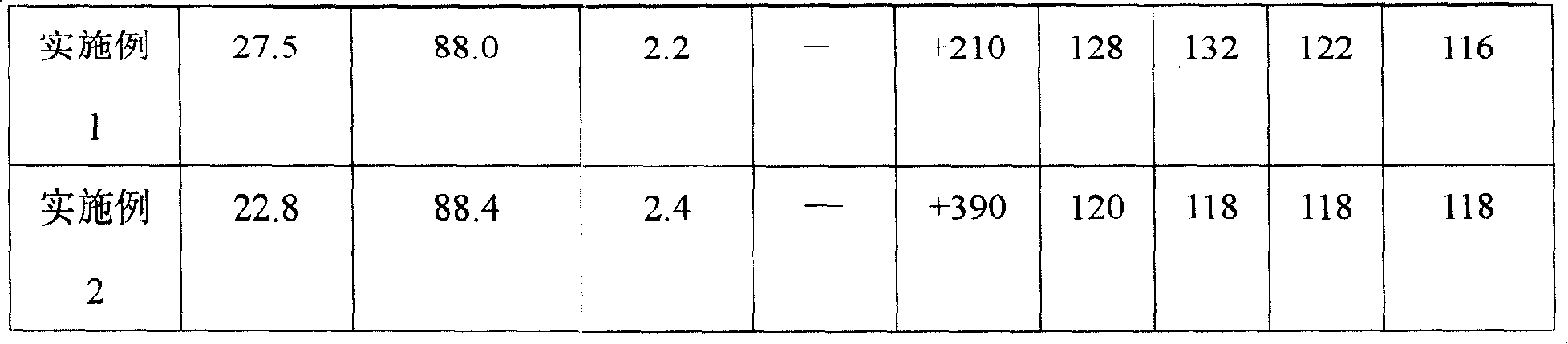

Unsaturated amino polyoxyethylene ether and polycarboxylate superplasticizer as well as synthesis method and application thereof

ActiveCN112625232AGood early strength effectOvercoming the problem of introducing early-strength groupsSolid waste managementPolymer scienceSuperplasticizer

The invention provides unsaturated amino polyoxyethylene ether and a synthesis method thereof, a polycarboxylate superplasticizer containing the unsaturated amino polyoxyethylene ether and a preparation method thereof, and application of the unsaturated amino polyoxyethylene ether and the synthesis method thereof and the polycarboxylate superplasticizer and the preparation method thereof in the field of buildings. The unsaturated amino polyoxyethylene ether is prepared from the following raw materials: unsaturated polyoxyethylene ether as shown in a formula (I), diisocyanate as shown in a formula (II), and an amino compound as shown in a formula (III) and / or a formula (IV). The polycarboxylate superplasticizer prepared from the unsaturated amino polyoxyethylene ether has better early strength and water reducing and slump retaining properties.

Owner:SHANXI SUNWAY INTION TRADE CO LTD

Efficient retarding and water reducing agent for concrete

The present invention relates to one kind of efficient retarding and water reducing agent for concrete suitable for commercial concrete, pumped concrete and bulk concrete. The efficient retarding and water reducing agent consists of water reducing agent 0-90 wt%, retarder I 1-15 wt%, retarder II 0.5-25 wt% and shrinkage reducing agent 0.05-0.2 wt%. The efficient retarding and water reducing agent has simple preparation process, and has the effects of delaying the setting of concrete, raising early strength, reducing water, etc.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

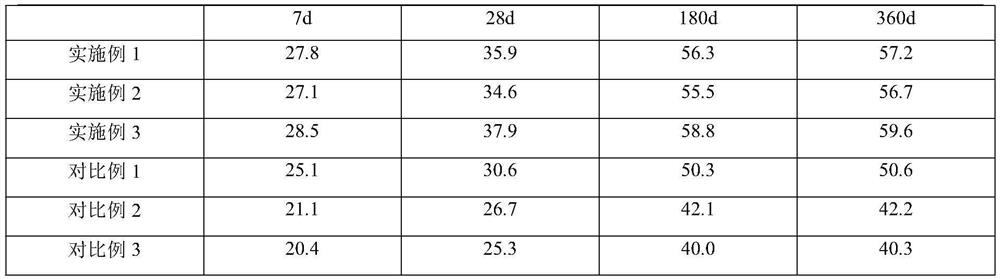

Concrete admixture and preparation method thereof

The invention provides a concrete admixture and a preparation method thereof. The preparation method comprises the following steps: preparing calcium silicate and magnesium silicate nanoparticles by taking a magnesium nitrate aqueous solution, a sodium silicate aqueous solution, tetraethyl orthosilicate, calcium nitrate and the like as raw materials; modifying the halloysite nanotube by using N-([beta]-aminoethyl-[gamma]-aminopropyl triethoxysilane to obtain a modified halloysite nanotube, and reacting the modified halloysite nanotube with the epoxidized bark powder to obtain modified bark powder; and finally, taking acrylamide and N-(4-aminophenyl)acrylamide as raw materials to carry out polymerization reaction, and adding calcium silicate and magnesium silicate nanoparticles and the modified bark powder in the polymerization process. The concrete admixture is helpful for greatly accelerating early hydration of cement, has a good early strength effect, has a very good adsorption and solidification effect on chloride ions, and prevents concrete from being eroded and damaged by the chloride ions.

Owner:凌池英

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com