Composite mortar and manufacturing method thereof

A composite mortar and a production method technology, applied in the field of building material production, can solve the problems of unstable quality, low early strength, easy breakage, etc., and achieve the effects of good adsorption, not easy to agglomerate, and lighter weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

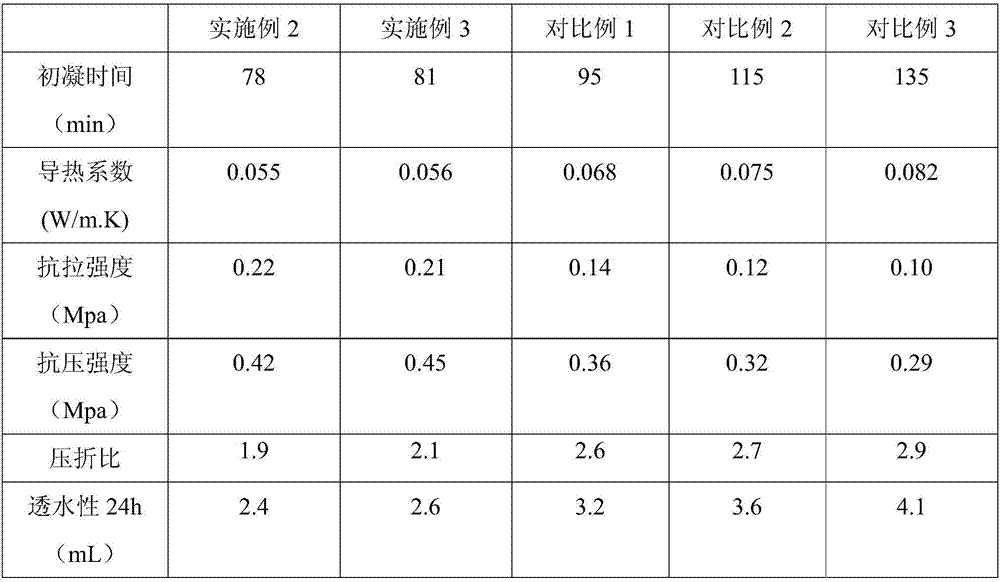

Examples

Embodiment 1

[0037] A method for making composite mortar, comprising the following steps:

[0038] (1) Selection of raw materials: choose cement, mineral sand, fly ash and vitrified microspheres as aggregates, sodium hydroxymethyl cellulose, wood fiber, rubber powder, water retaining agent, water reducing agent and water repellent as admixtures ;in,

[0039] The water-retaining agent is made by mixing methyl hydroxyethyl cellulose ether, guar gum ether, and sepiolite according to a mass ratio of 1:0.6:1;

[0040] The water reducer is made by mixing calcium lignosulfonate, sodium lignosulfonate, and naphthalenesulfonic acid formaldehyde condensate in a mass ratio of 1:1:1;

[0041] The hydrophobic agent is made by mixing polysiloxane and isobutyltriethoxysilane according to a mass ratio of 1:1.5;

[0042] The rubber powder is made by mixing styrene-butadiene copolymer, vinyl tertiary carbonate-vinyl acetate copolymer, vinyl laurate-acetic acid copolymer according to the mass ratio of 1:0.7:...

Embodiment 2

[0052] A method for making composite mortar, comprising the following steps:

[0053] (1) Selection of raw materials: choose cement, mineral sand, fly ash and vitrified microspheres as aggregates, sodium hydroxymethyl cellulose, wood fiber, rubber powder, water retaining agent, water reducing agent and water repellent as admixtures ;in,

[0054] The water-retaining agent is made by mixing methyl hydroxyethyl cellulose ether, guar gum ether, and sepiolite according to a mass ratio of 2:0.8:1;

[0055] The water reducer is made by mixing calcium lignosulfonate, sodium lignosulfonate, and naphthalenesulfonic acid formaldehyde condensate in a mass ratio of 1:1:1.5;

[0056] The hydrophobic agent is made by mixing polysiloxane and isobutyltriethoxysilane according to a mass ratio of 1:2;

[0057] The rubber powder is made by mixing styrene-butadiene copolymer, vinyl tertiary carbonate-vinyl acetate copolymer, vinyl laurate-acetic acid copolymer according to the mass ratio of 1.2:...

Embodiment 3

[0067] A method for making composite mortar, comprising the following steps:

[0068] (1) Selection of raw materials: choose cement, mineral sand, fly ash and vitrified microspheres as aggregates, sodium hydroxymethyl cellulose, wood fiber, rubber powder, water retaining agent, water reducing agent and water repellent as admixtures ;in,

[0069] The water-retaining agent is made by mixing methyl hydroxyethyl cellulose ether, guar gum ether, and sepiolite according to a mass ratio of 1.5:0.7:1;

[0070] The water reducer is made by mixing calcium lignosulfonate, sodium lignosulfonate, and naphthalenesulfonic acid formaldehyde condensate in a mass ratio of 1:1:1.2;

[0071] The hydrophobic agent is made by mixing polysiloxane and isobutyltriethoxysilane according to the mass ratio of 1:1.6;

[0072] The rubber powder is made by mixing styrene-butadiene copolymer, vinyl tertiary carbonate-vinyl acetate copolymer, vinyl laurate-acetic acid copolymer according to the mass ratio o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com