Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

817 results about "MANGANESE ACETATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Conversion of carbohydrates to hydroxymethylfurfural (HMF) and derivatives

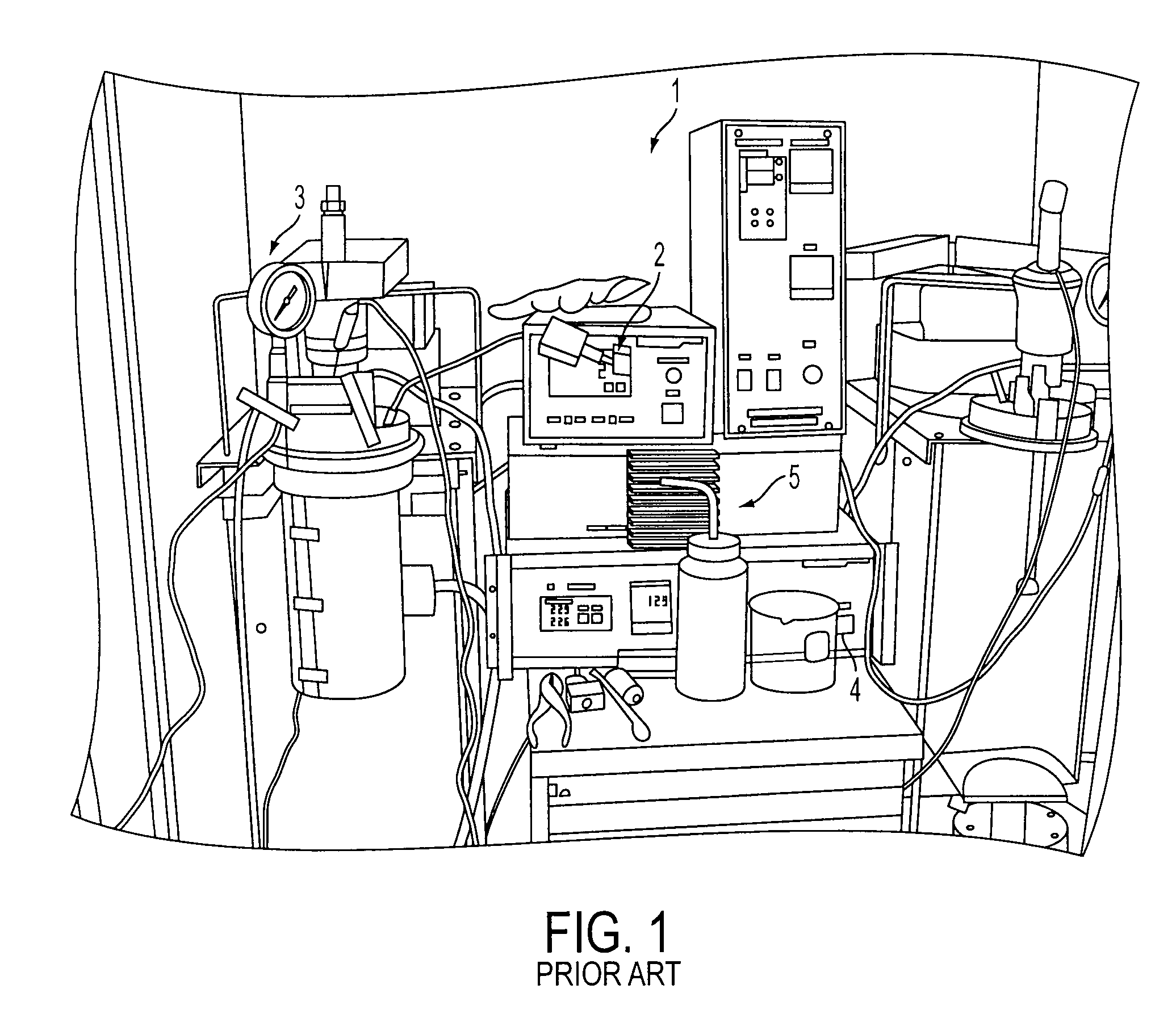

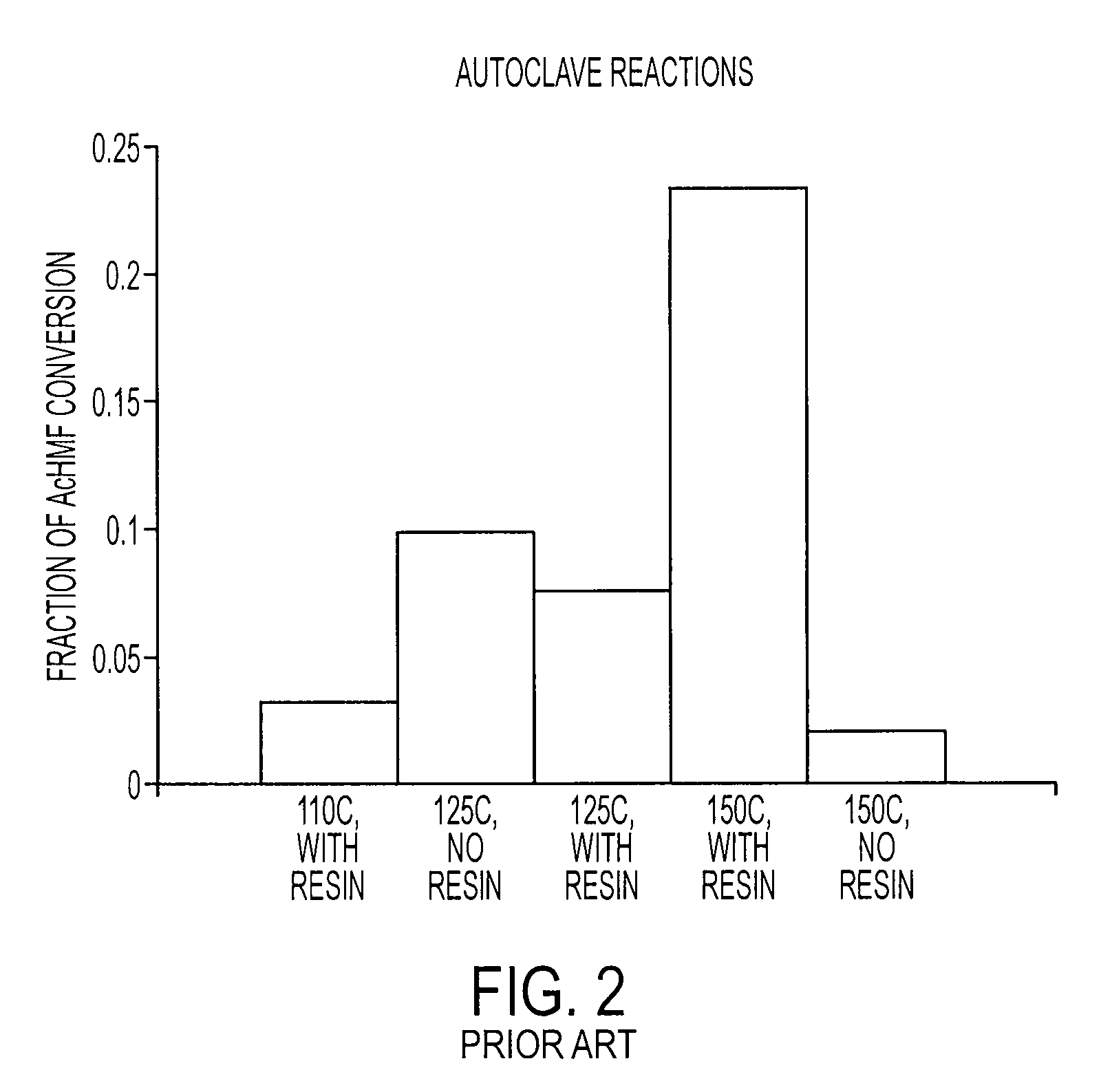

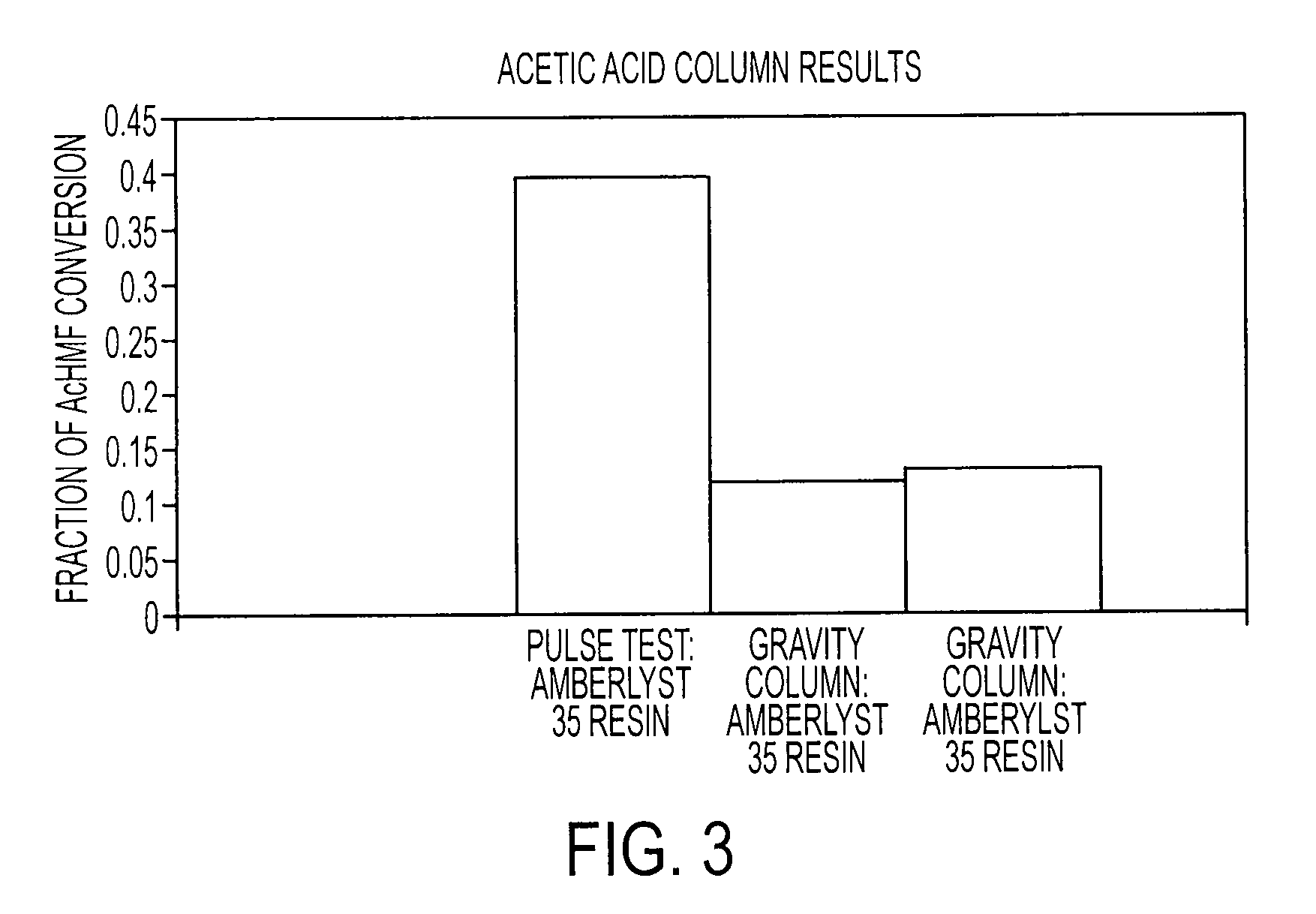

InactiveUS20090156841A1Increase conversion rateStable formOrganic compound preparationCarboxylic compound preparationMANGANESE ACETATEFuran

A method of producing substantially pure HMF, HMF esters and other derivatives from a carbohydrate source by contacting the carbohydrate source with a solid phase catalyst. A carbohydrate starting material is heated in a solvent in a column and continuously flowed through a solid phase catalyst in the presence of an organic acid, or heated with the organic acid and a solid catalyst in solution to form a HMF ester. Heating without organic acid forms HMF. The resulting product is purified by filtration to remove the unreacted starting materials and catalyst. The HMF ester or a mixture of HMF and HMF ester may then be oxidized to 2,5-furandicarboxylic acid (FDCA) by combining the HMF ester with an organic acid, cobalt acetate, manganese acetate and sodium bromide under pressure. Alternatively, the HMF ester may be reduced to form a furan or tetrahydrofuran diol.

Owner:ARCHER DANIELS MIDLAND CO

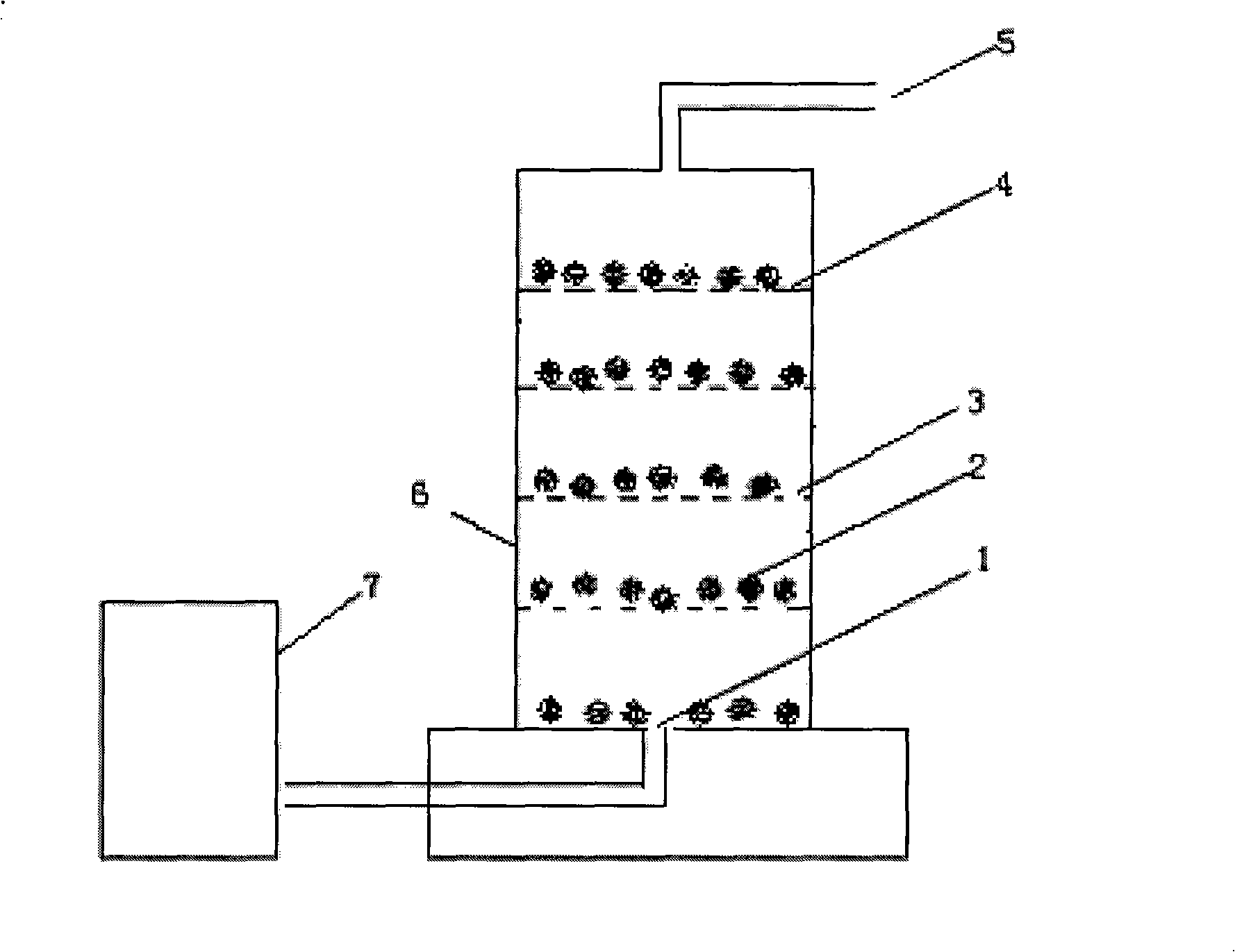

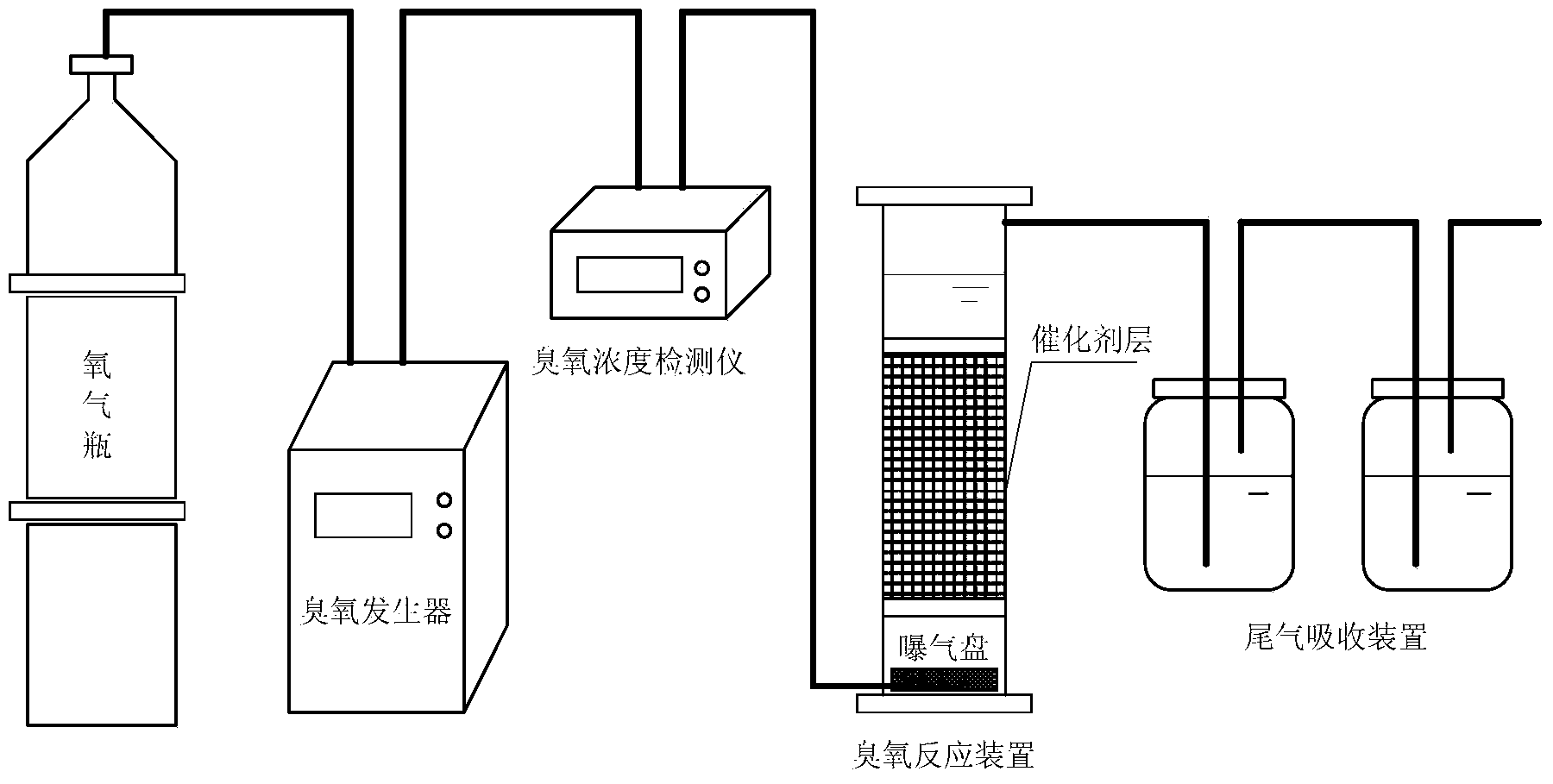

Method for producing MnO2 supported catalyst as well as method of using the same and apparatus for treating waste water

InactiveCN101406831AGood granularityEasy to recycleMolecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsMANGANESE ACETATESesquioxide

The invention discloses a method for preparing MnO2 supported catalysts, an application method thereof and a wastewater treatment device. The preparation method comprises the following steps: manganese acetate is prepared into a solution; one of activated carbon, active aluminium sesquioxide, white silica gel, a molecular sieve, zeolite or diatomite is taken as a carrier and dipped in the solution; and supported solid catalysts are prepared through dipping, evaporation, concentration, drying and roasting. A reactor of the wastewater treatment device is divided into a plurality of reaction spaces by baffles, and the catalysts exist as fluidized beds on every baffle. When the MnO2 supported catalysts prepared by the method are used in the reaction of degrading refractory organic matter through ozone catalytic oxidation, the contact time among the MnO2 supported catalysts, wastewater and ozone is between10 and 120 minutes, and the mass ratio of the adding amount of the catalysts to the wastewater in the reaction is between 1 to 200 and 1 to 20. The MnO2 supported catalysts prepared by the method have the characteristics of easy recovery, high repeat utilization property and high efficiency of catalyzing and degrading refractory organic matters.

Owner:GUANGDONG UNIV OF TECH

Catalyst for preparing mixing alcohol with low carbon from synthesis gas and its preparing method

InactiveCN1431049AGuaranteed stabilityGuaranteed lifeOrganic compound preparationHydroxy compound preparationHigh resistanceMANGANESE ACETATE

A catalyst for preparing low-carbon alcohol mixture from synthetic gas contains Mo (2-40 %), Ni (4-10%), Mn (0.1-5.0%), K (5-15%), S (20-40%) and bentone, and is prepared through reaction of ammoniumsulfide solution or hydrogen sulfide gas on ammonium molybdate, adding concentrated acetic acid, thermal stirring, cooling for deposition, adding deionized water for dissolving doposit to obtain solution of ammonium thiomolybdate, dropping the solution along with the mixed solution of nickel acetate and manganese acetate in acetic acid to form black deposit, filtering, washing, baking, mixing with bentone, and tabletting. Its advantages are high resistance to S and no carbon deposit.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Cellular activated carbon-based denitration catalyst as well as preparation and application thereof

InactiveCN102078753ALarge specific surface areaWell-developed pore structureCatalyst carriersDispersed particle separationMANGANESE ACETATEActivated carbon

The invention discloses a catalyst for smoke denitration. The catalyst comprises the following components in percentage by weight: 77-96% of cellular activated carbon carrier, 1.3-6.5% of MnO and 2.4-18.8% of CeO2, wherein the mixture of the MnO and the CeO2 serves as an active component. The preparation method is as follows: mixing activated carbon with an organic binder, a forming auxiliary and water, carrying out vacuum extrusion molding, drying, and carbonizing, thus obtaining the cellular activated carbon carrier; and preparing the catalyst by using an isopknic impregnation method based on a mixed liquid of magnganous nitrate or manganese acetate and cerous nitrate, wherein the mixed liquid serves as an impregnation liquid. The cellular activated carbon-based denitration catalyst has the advantages of high specific surface area of cellular activated carbon, developed pore structure and small bed pressure drop, and when being used in smoke denitration, the cellular activated carbon-based denitration catalyst has high denitration activity at the wide temperature range of 80-200 DEG C.

Owner:EAST CHINA UNIV OF SCI & TECH

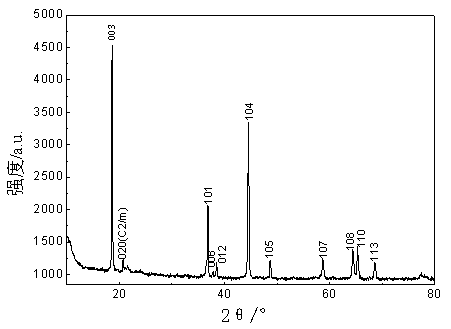

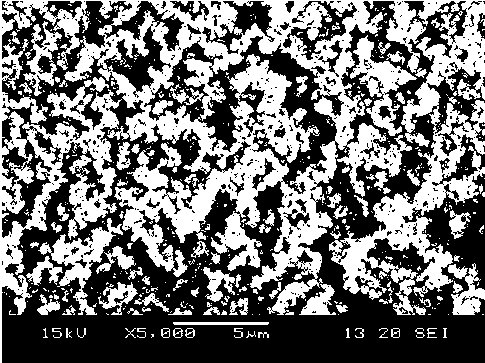

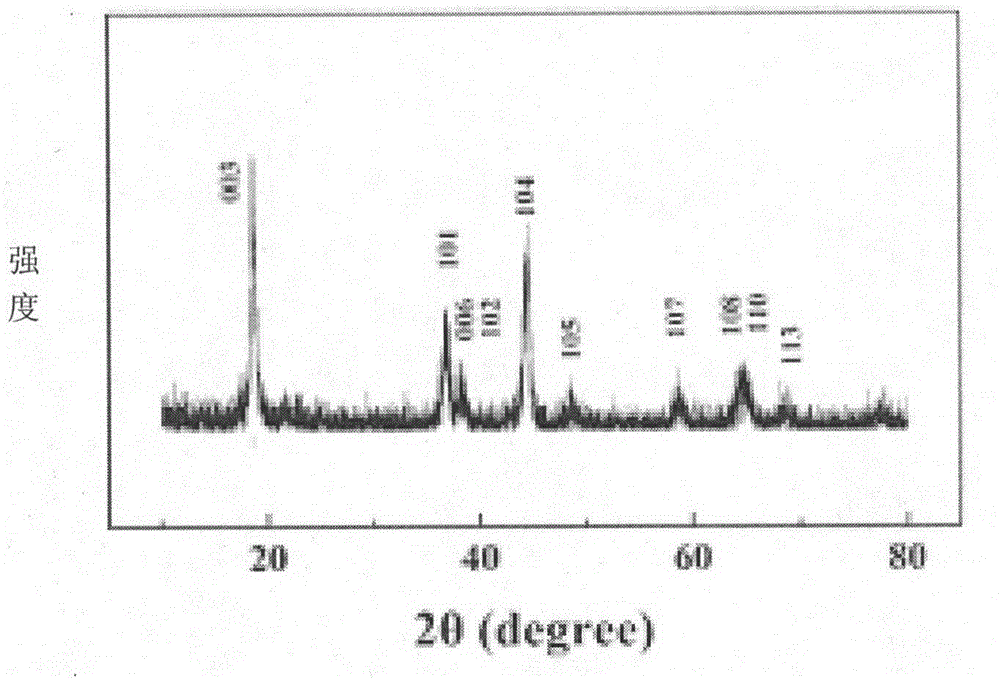

Lithium-enriched ternary anode material of power lithium-ion battery and preparation method of lithium-enriched ternary anode material

InactiveCN103280574AIncrease capacityPromote circulationCell electrodesMANGANESE ACETATEPhysical chemistry

The invention discloses a lithium-enriched ternary anode material of a power lithium-ion battery and a preparation method of the lithium-enriched ternary anode material. The molecule formula of the lithium-enriched ternary anode material of the power lithium-ion battery is Li1.2Ni0.13Co0.13Mn0.54O2. The preparation method comprises the following steps of: dissolving lithium acetate, cobaltous acetate, nickel acetate and manganese acetate in deionized water according to the molar ratio of Li: Co: Ni: Mn: O being 1.2: 0.13: 0.13: 0.54: 2 to obtain a solution 1; adding citric acid according to the ratio of the molar weight of the citric acid to the total molar weight of Ni, Co and Mn being 1:1 to obtain a solution 2; dropwise adding the solution 2 into the solution 1, and then adjusting the pH value to 9, continuously stirring the solution at the temperature of 80 DEG C until purple gel is formed, and then sequentially drying, ball milling, calcining segment by segment and grinding to obtain the lithium-enriched ternary anode material of the power lithium-ion battery with large discharging specific capacity and good cycling performance.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

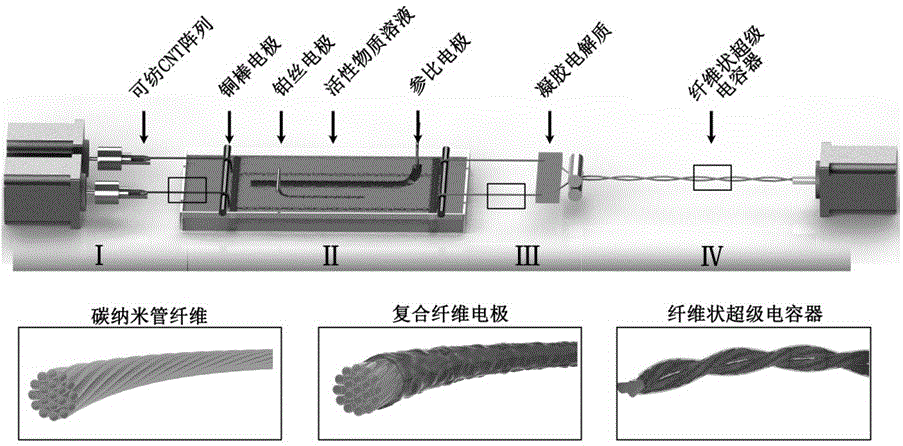

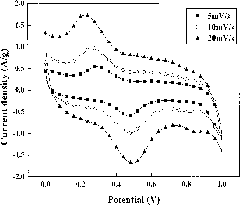

Method for preparing composite fiber-shaped capacitors continuously

InactiveCN105140048AContinuous preparationFast preparationHybrid/EDL manufactureMANGANESE ACETATEFiber

The invention belongs to the technical field of flexible energy storage and wearable devices, and specifically relates to a method for preparing composite fiber-shaped capacitors continuously. According to the invention, a spinnable carbon nanotube array serves as an initial material, and carbon nanotube fiber is obtained by means of dry spinning; the obtained carbon nanotube fiber is subjected to a solution mixed with fake capacitance active substances, such as an oxidized graphene aqueous solution, a manganese acetate aqueous solution, a aniline aqueous solution and a pyrroles aqueous solution, and a specific voltage is applied to the carbon nanotube fiber so as to enable the fake capacitance active substances to be deposited or aggregated on the surface of the carbon nanotube fiber; the continuously prepared carbon nanotube fiber is subjected to a phosphoric acid / polyvinyl alcohol gel electrolyte to obtain composite fiber electrodes; and finally two identical composite fiber electrodes are wound to obtain the fiber-shaped composite super capacitor. According to the invention, the continuous preparation of the fiber-shaped composite super capacitor is realized, the method is simple to operate and is applicable to large-scale production, and the prepared composite fiber-shaped super capacitor is good in flexibility and can be used in the field of flexible energy storage and wearable devices.

Owner:FUDAN UNIV

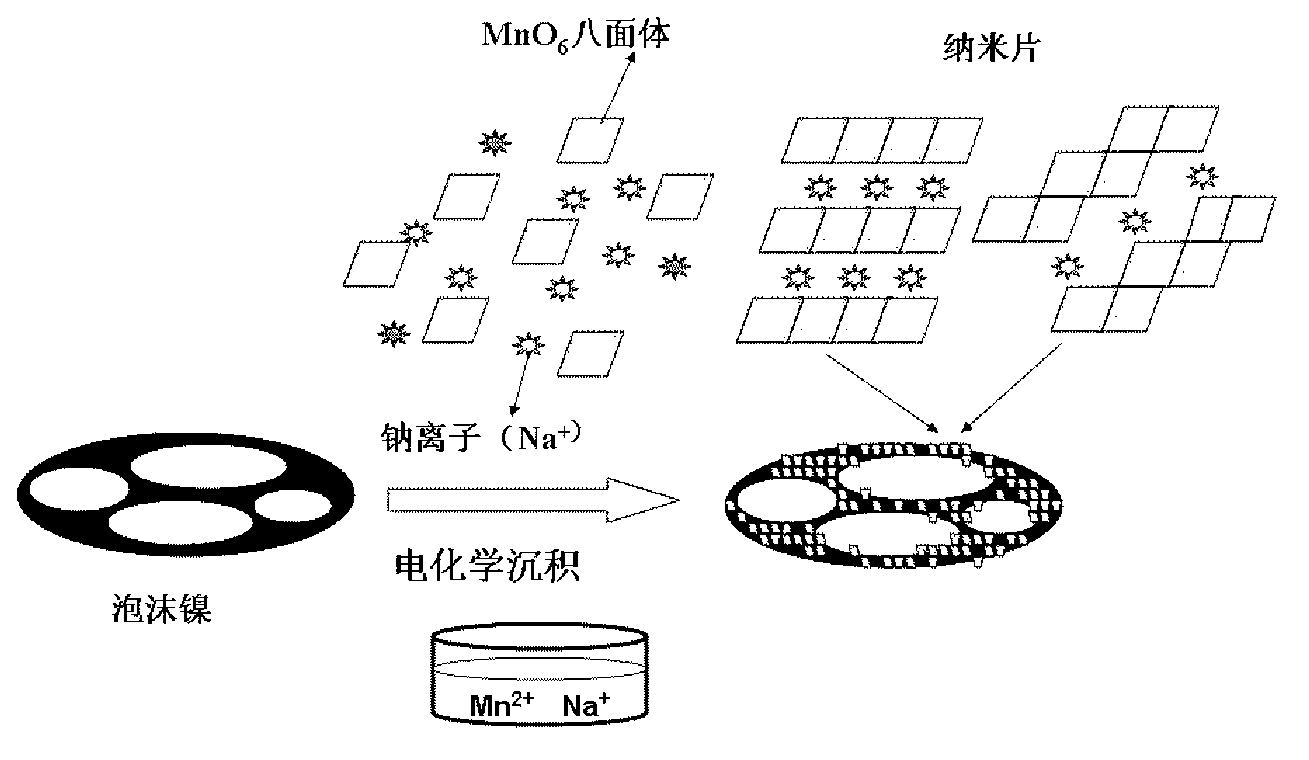

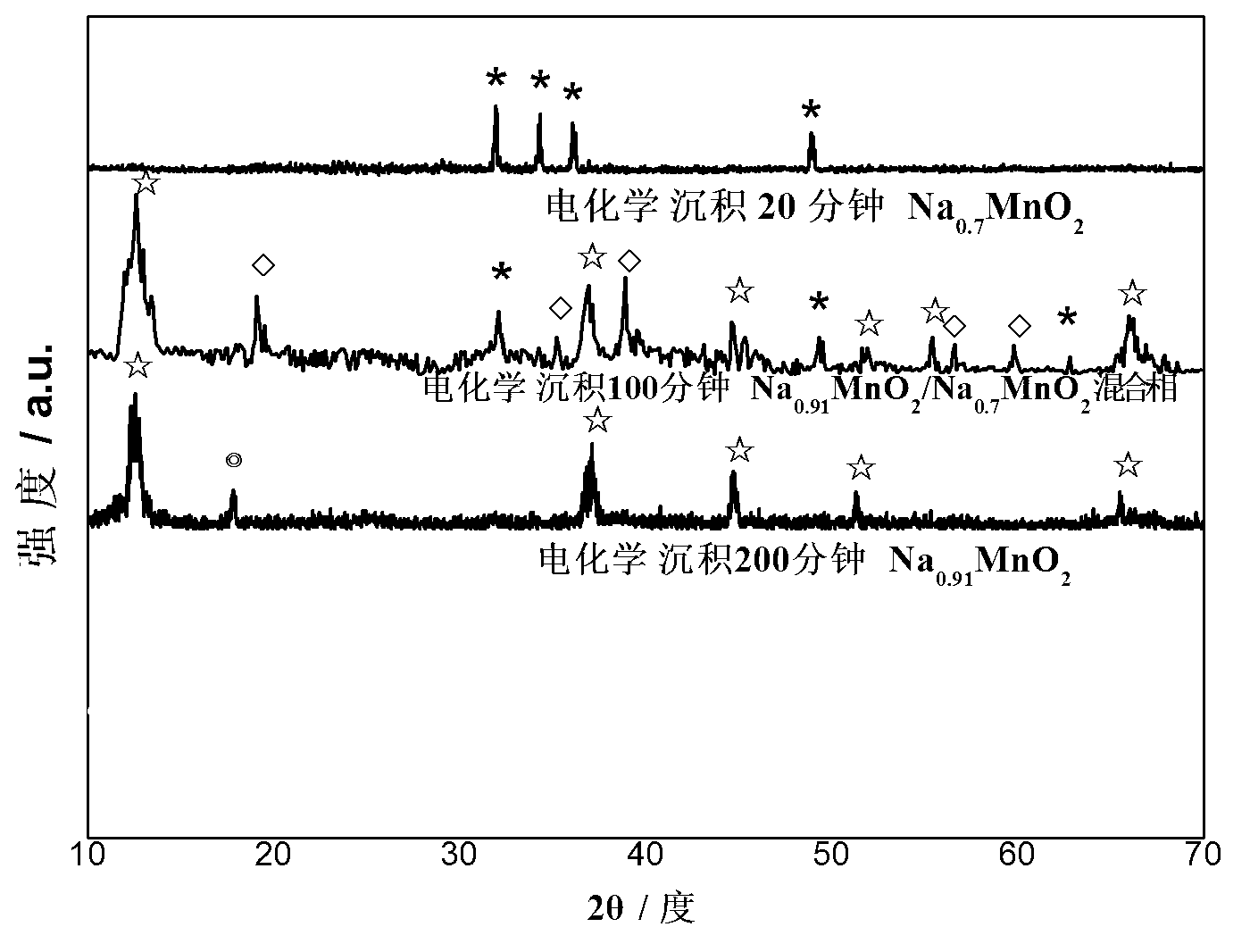

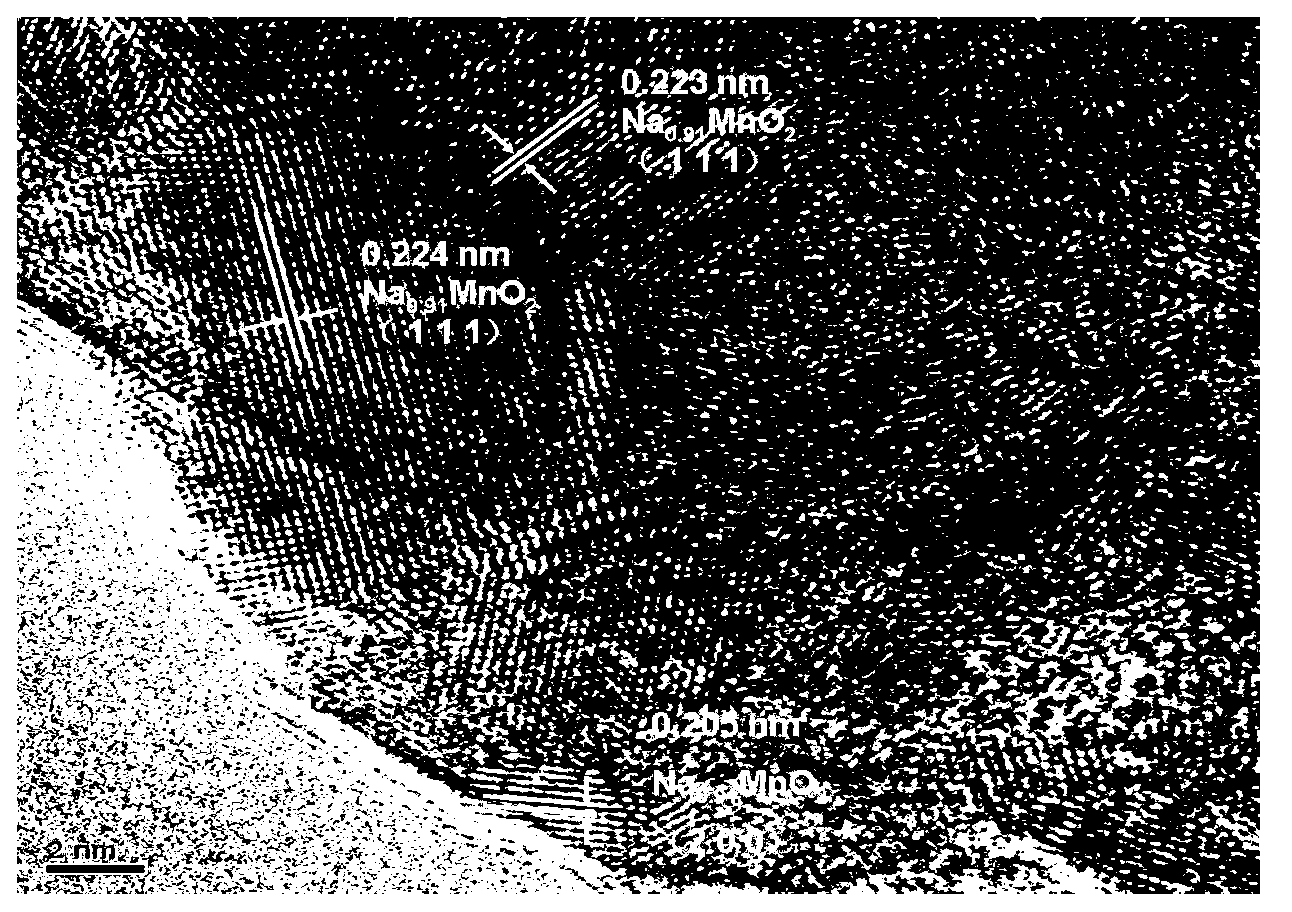

Sodion-embedded manganese dioxide nanometer sheet electrode as well as preparation method and application of electrode

ActiveCN103065806AImprove conductivityEnsure structural stabilityHybrid capacitor electrodesHybrid/EDL manufactureMANGANESE ACETATEStopped work

The invention relates to a sodion-embedded manganese dioxide nanometer sheet electrode as well as a preparation method and an application of the electrode. The electrode can be used as the active material of a supercapacitor and comprises sodion-embedded manganese dioxide nanometer sheets evenly distributed on the surface of a foamed nickel substrate. The preparation method comprises the following steps of: (1) mixing sodium sulfate and manganese acetate to prepare an electrochemical deposition precursor solution; (2) setting up an electrochemical deposition platform through a three-electrode method and taking the foamed nickel substrate after pretreatment as a working electrode, a platinum electrode as a counter electrode and a saturated calomel electrode as a reference electrode; (3) soaking the electrodes in the electrochemical deposition precursor solution at same depth; (4) opening an electrochemical workstation, setting the working electrode to the anode, setting the working mode to a timing potential mode, and starting up the electrochemical workstation; (5) taking out and washing the working electrode after the electrochemical workstation stops working; and (6) drying to obtain the sodion-embedded manganese dioxide nanometer sheet electrode. The sodion-embedded manganese dioxide nanometer film electrode as well as the preparation method and the application of the electrode disclosed by the invention have the characteristics of simple technique, mild reaction condition and excellent electrochemical performance of materials.

Owner:WUHAN UNIV OF TECH

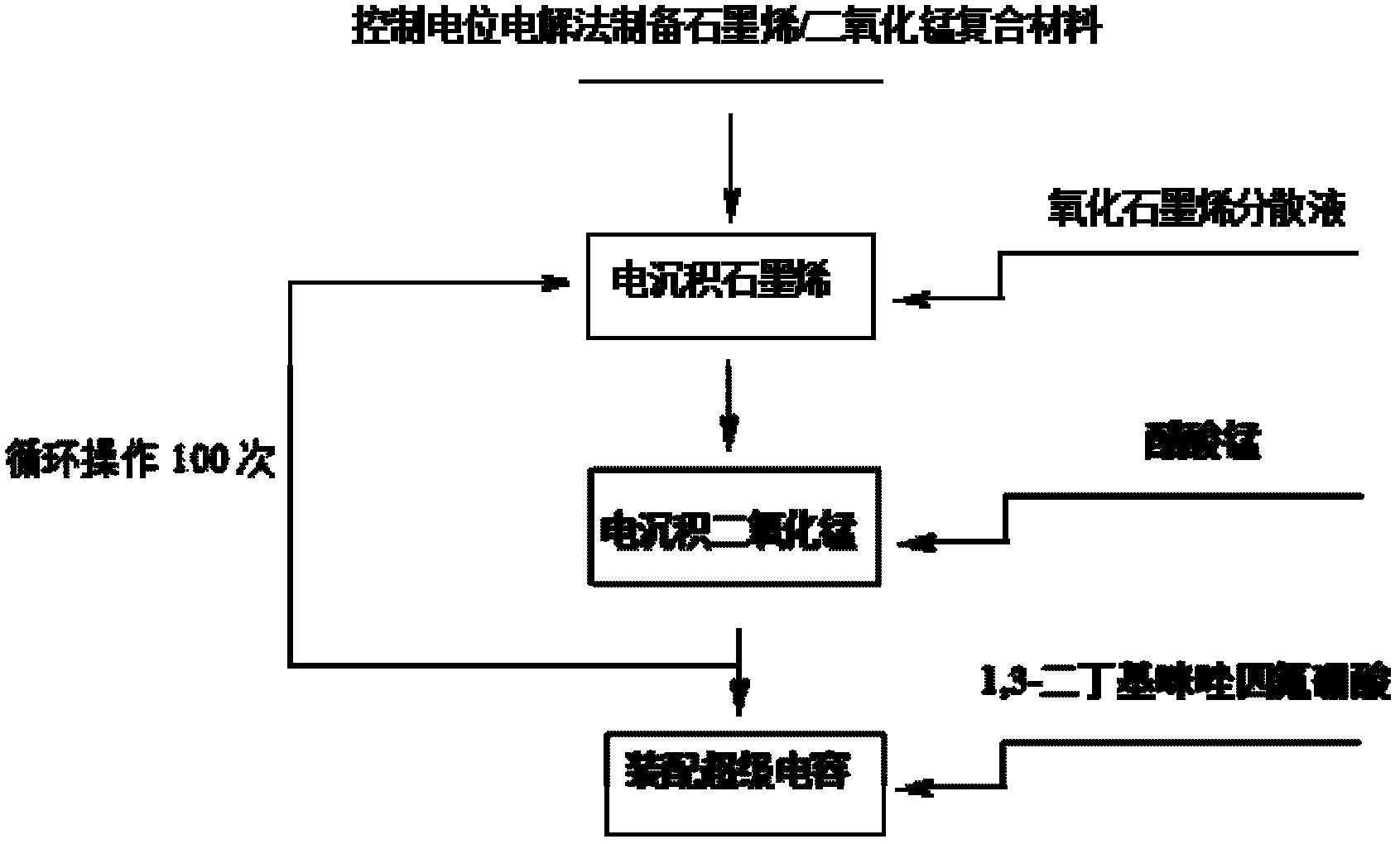

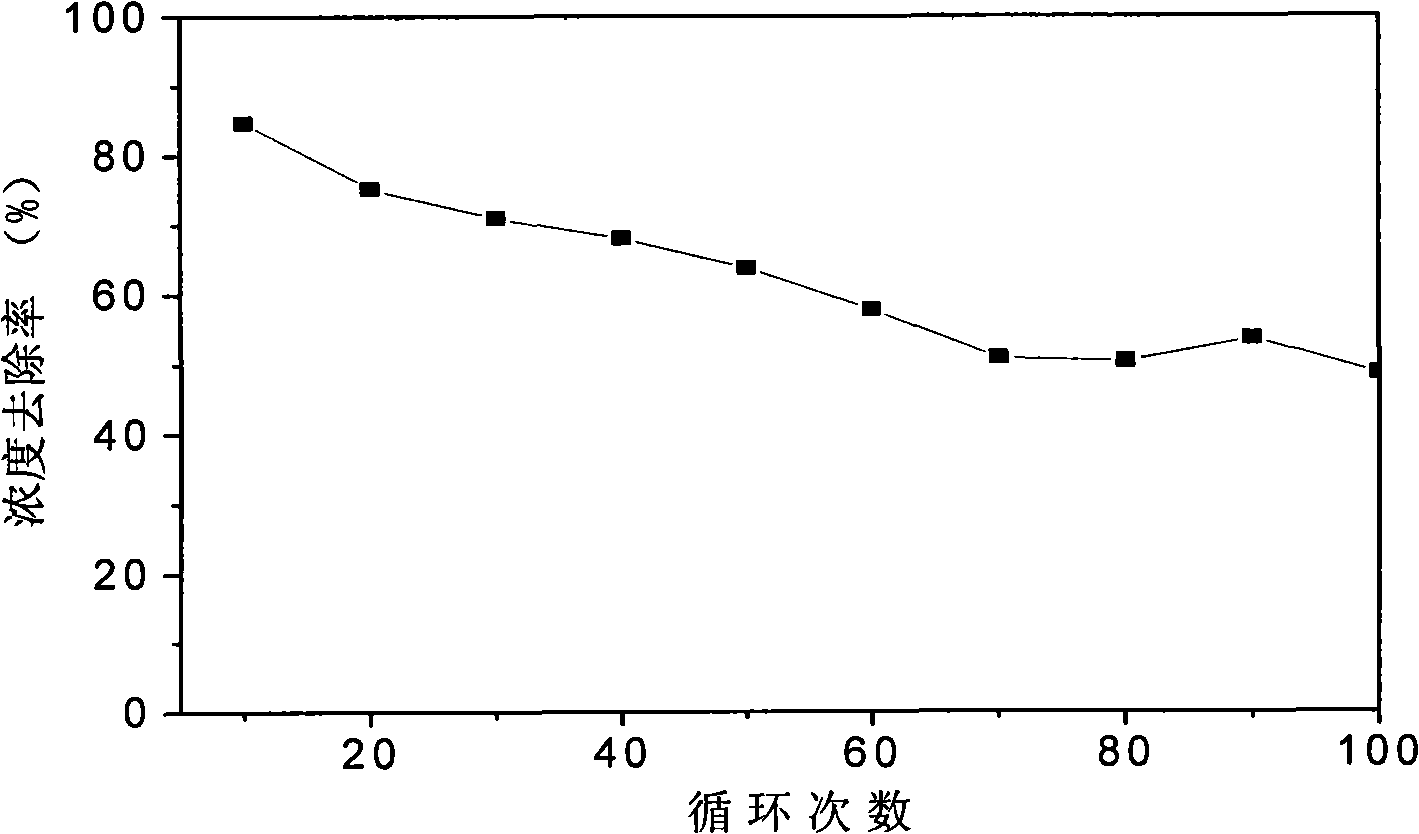

Method for electrochemically preparing graphene/manganese dioxide composite material, and application of graphene/manganese dioxide composite material

ActiveCN102568847ASmall particle sizeControl distribution densityElectrolytic capacitorsMANGANESE ACETATESupporting electrolyte

The invention relates to a method for electrochemically preparing a graphene / manganese dioxide composite material, and application of the graphene / manganese dioxide composite material, and belongs to the technical field of electrochemistry. The method comprises the following steps of: taking sodium carbonate as a supporting electrolyte; reducing a graphene oxide into graphene by a controlled potential electrolysis method, and uniformly fixing the graphene on a surface of an electrode; and precisely controlling the thickness of a graphene coating layer according to the concentration of the graphene oxide, potential, temperature and time during electro-deposition; respectively taking manganese acetate and sodium sulfate as a manganese precursor and a supporting electrolyte; adjusting the acidity of the electrolyte by sulfuric acid, performing controlled potential electrolysis, electrically depositing manganese dioxide on the surface of the graphene, and precisely controlling the particle size and the distribution density of the manganese dioxide; and repeating the operation for 100 times, and preparing the graphene / manganese dioxide composite material. Test shows that the obtained graphene / manganese dioxide composite material is an electrode or a super assembly capacitor, in which ionic liquid is used as the electrolyte; the capacity is more than 500 F / g; and after the super assembly capacitor is cyclically charged and discharged for 1,000 times, the capacity can still be kept over 99 percent.

Owner:JIANGSU SUNPOWER

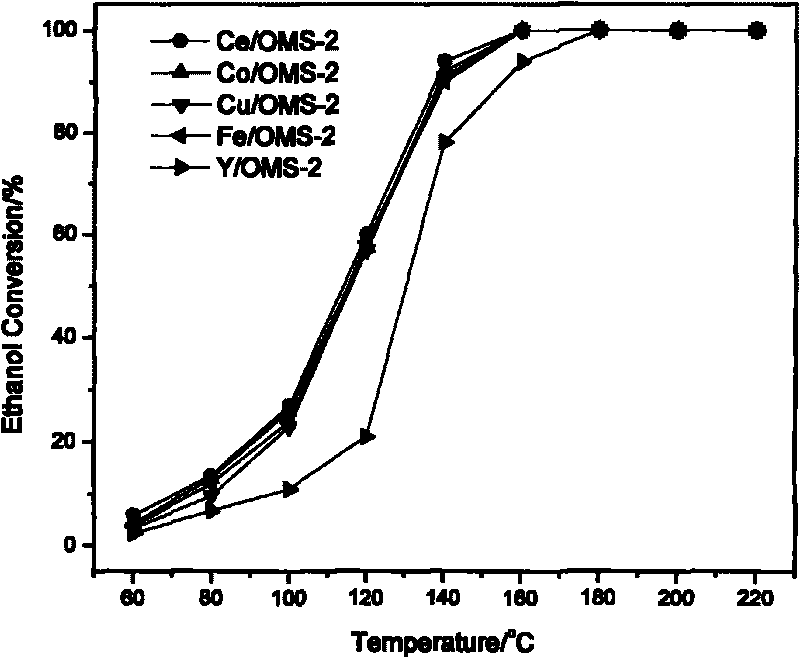

Metal oxide-loaded molecular sieve catalyst and preparation method thereof

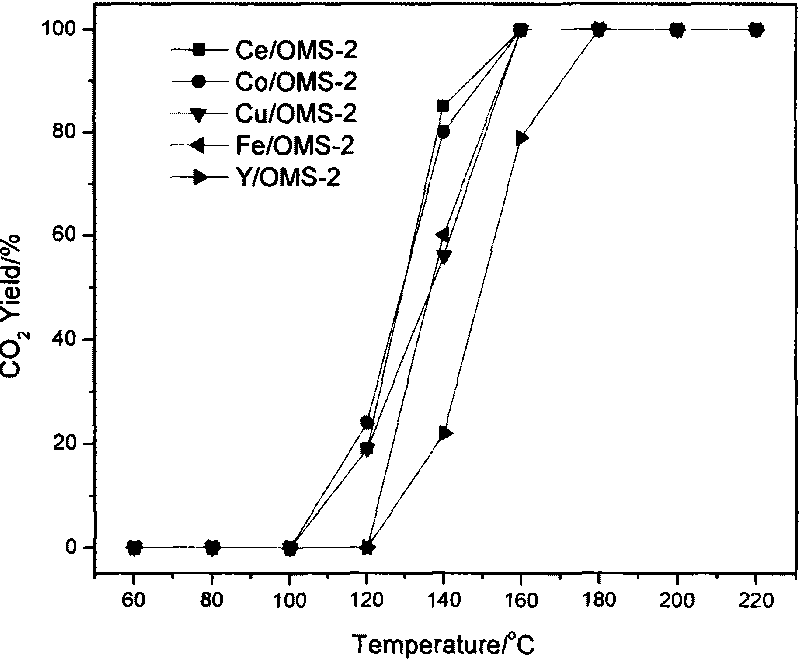

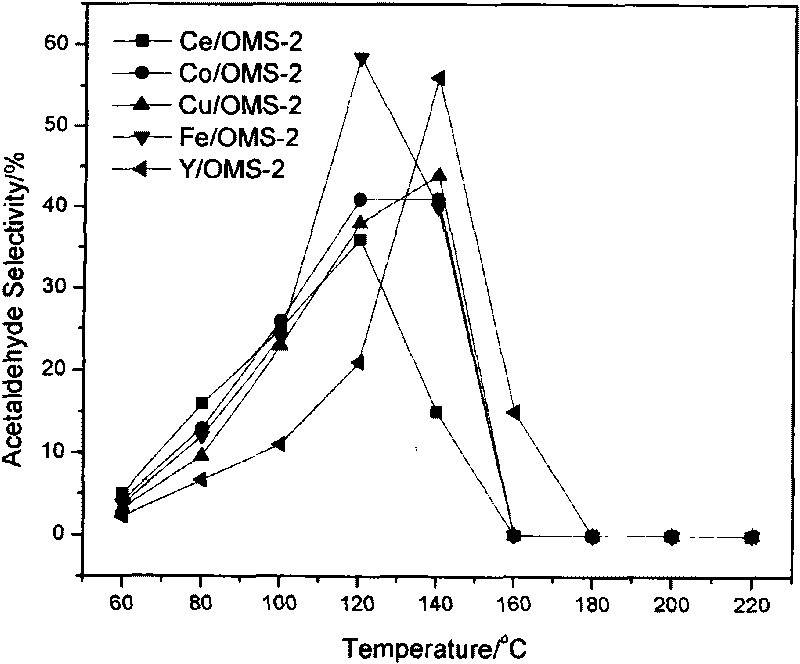

ActiveCN101711990AStrong oxidizingReduce exhaust temperatureMolecular sieve catalystsDispersed particle separationMANGANESE ACETATECerium

A metal oxide-loaded molecular sieve catalyst comprises pure cryptomelane type manganese dioxide and transition metal. A method for preparing the molecular sieve catalyst comprises the following steps: 1, preparing solution of potassium permanganate; 2, preparing solution of manganese acetate; 3, adding the solution obtained by the step one into a three-neck flask, and heating, condensing and refluxing the solution; 4, adding the solution obtained by the step two into the three-neck flask of the step three, condensing and refluxing the solution, filtering and drying the obtained black pasty sediment, and roasting the sediment to obtain an octahedral manganese oxide molecular sieve catalyst (OMS-2) solid; 5, adding cerium ammonium nitrate, cobalt nitrate hexahydrate, copper nitrate trihydrate, ferric nitrate nonahydrate or yttrium nitrate into deionized water to form solution; and 6, mixing the solid taken from the step four and the solution in the step five, soaking cerium on the octahedral manganese oxide molecular sieve catalyst (OMS-2) solid, and drying and roasting the obtained solid to obtain the metal oxide-loaded molecular sieve catalyst. The metal oxide-loaded molecular sieve catalyst has the characteristics of high purification efficiency, low price and good thermal stability.

Owner:TSINGHUA UNIV

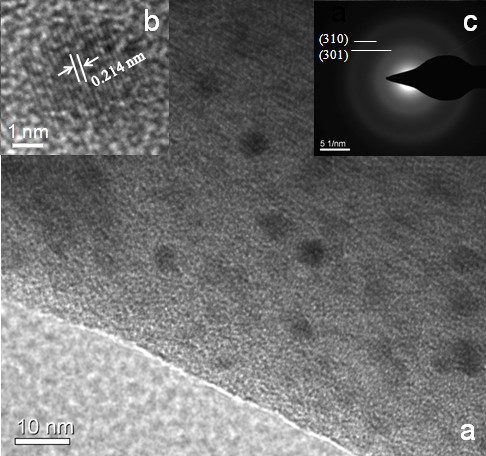

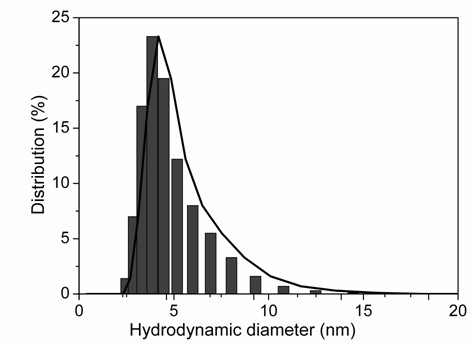

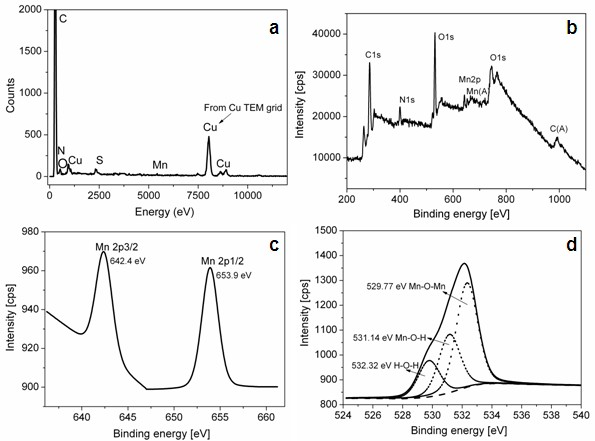

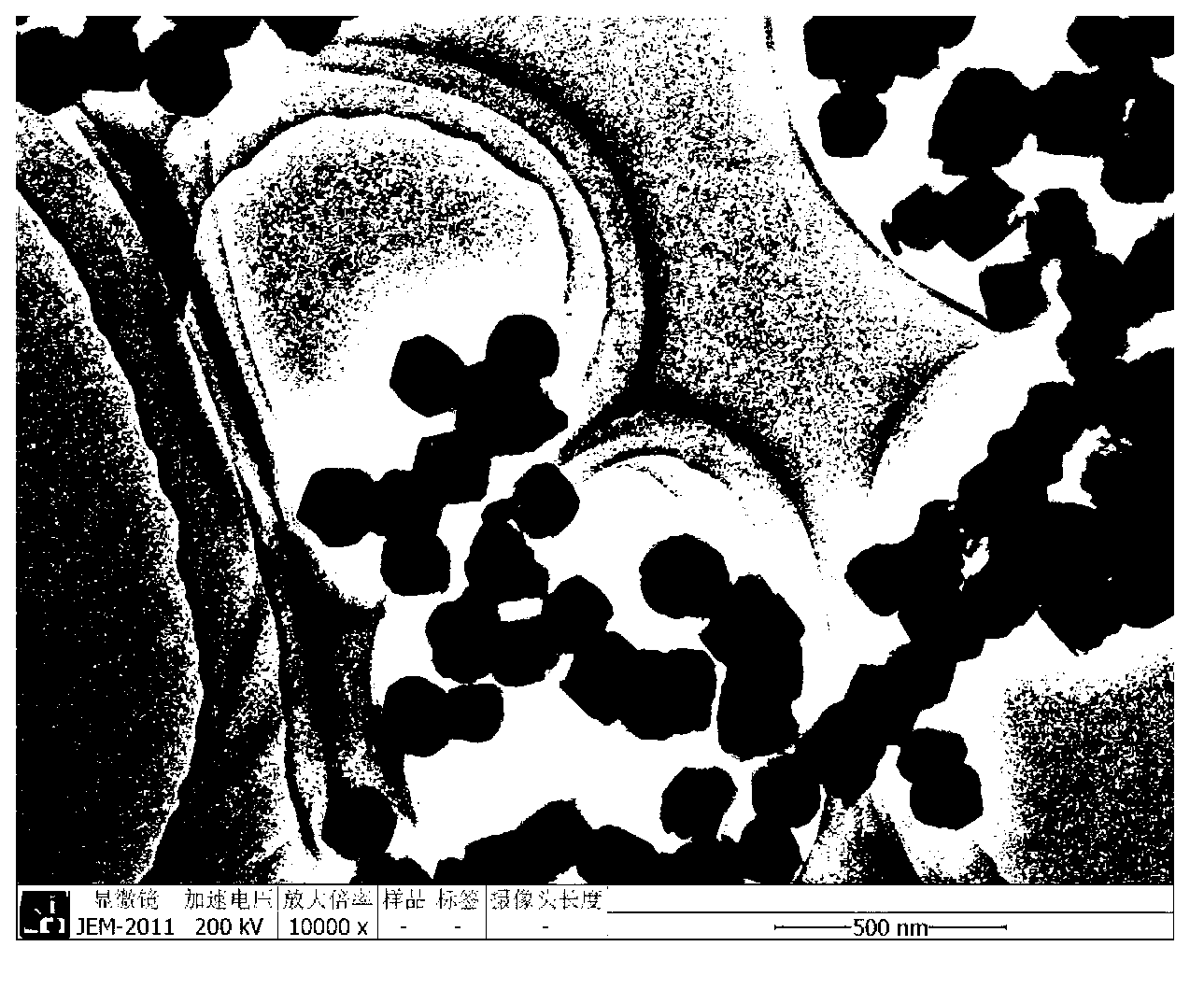

Method for preparing manganese dioxide nanoparticles with bovine serum albumin as template

InactiveCN102515276AUniform particle sizeGood dispersionNanotechnologyManganese oxides/hydroxidesMANGANESE ACETATEBiocompatibility Testing

The invention provides a preparation method for controlling to synthesize manganese dioxide nanoparticles with bovine serum albumin as a biological template, which belongs to the technical field of manganese dioxide synthesis and nano materials. A process has the following steps that: a certain amount of bovine serum albumin is dissolved in phosphate buffer solution, manganese acetate solution is added in, the mixed solution is mixed and reacts for 2min, then sodium hydroxide is added in, the pH value is adjusted to be strong alkaline, the reaction is carried out for 6h to 8h at room temperature, and the manganese dioxide nanoparticles with the grain size of 4.8nm are obtained after 2 days of dialysis and high-speed centrifugal separation. The method has the advantages that: the preparation method is simple, the reaction conditions are mild, the cost is low, little reagent is required, the use is environmental-friendly, and the manganese dioxide nanoparticles with good dispersibility, good stability, good biocompatibility, smaller grain size, consistent dimension and uniform shape and appearance are obtained. We think the manganese dioxide nanoparticles with smaller and uniform grain size have huge potential application prospect in absorption, catalysis, bio-marking and other fields.

Owner:SICHUAN UNIV

Method for recovering organic acid and cobalt-manganese metal in terephthalic acid oxidized residues

ActiveCN102503813AOrganic-compounds/hydrides/coordination-complexes catalystsChemical recyclingMANGANESE ACETATEBenzoic acid

The invention belongs to the technology for recovering organic acid and catalyst from terephthalic acid oxidized residues, which includes the steps of firstly, discharging high-temperature oxidized residues from a pure terephthalic acid (PTA for short) production device, controlling the solid content within the range from 20% to 45% and implementing primary filtering separation within the temperature range from 55 DEG C to 90 DEG C, and directly vending separated solid for manufacturing resin or paint or returning the separated solid to an oxidation reactor for use, wherein primary filtrate is treated according to the process: (I) adding oxalic acid to obtain cobalt-manganese oxalate precipitation, obtaining cobalt-manganese oxalate by means of filtering separation, further cooling the filtrate by means of filtering separation, utilizing the separated solid for extracting benzoic acid and delivering the filtrate to a waste water treating device; or (II) directly cooling the primary filtrate for secondary filtering separation, utilizing the separated solid for extracting benzoic acid, adding oxalic acid into secondary filtrate to obtain cobalt-manganese oxalate precipitation, obtaining cobalt-manganese oxalate by means of filtering separation and delivering the filtrate to a waste water treating device; and secondly, carrying out reaction of the cobalt-manganese oxalate obtained from (I) or (II) with oxidant such as hydrogen peroxide, peroxyacetic acid, bromine, manganate, permanganic acid, manganese dioxide or / and hydrobromic acid, utilizing cobalt acetate aqueous liquor, cobalt bromide aqueous liquor, manganese acetate aqueous liquor, manganese bromide aqueous liquor, acetic acid or / and pure water as dissolvent, then carrying out reaction of the cobalt-manganese oxalate with metallic cobalt, metallic manganese or / and hydrobromic acid after the cobalt-manganese oxalate is completely dissolved, and obtaining homogeneous phase liquor containing cobalt-manganese bromide ions by means of purification and filtration, wherein the mixed liquor can be directly mixed with cobalt acetate, manganese acetate, cobalt bromide, manganese bromide, acetic acid or water to serve as oxidation catalyst for the terephthalic acid.

Owner:浙江上虞利星化工有限公司

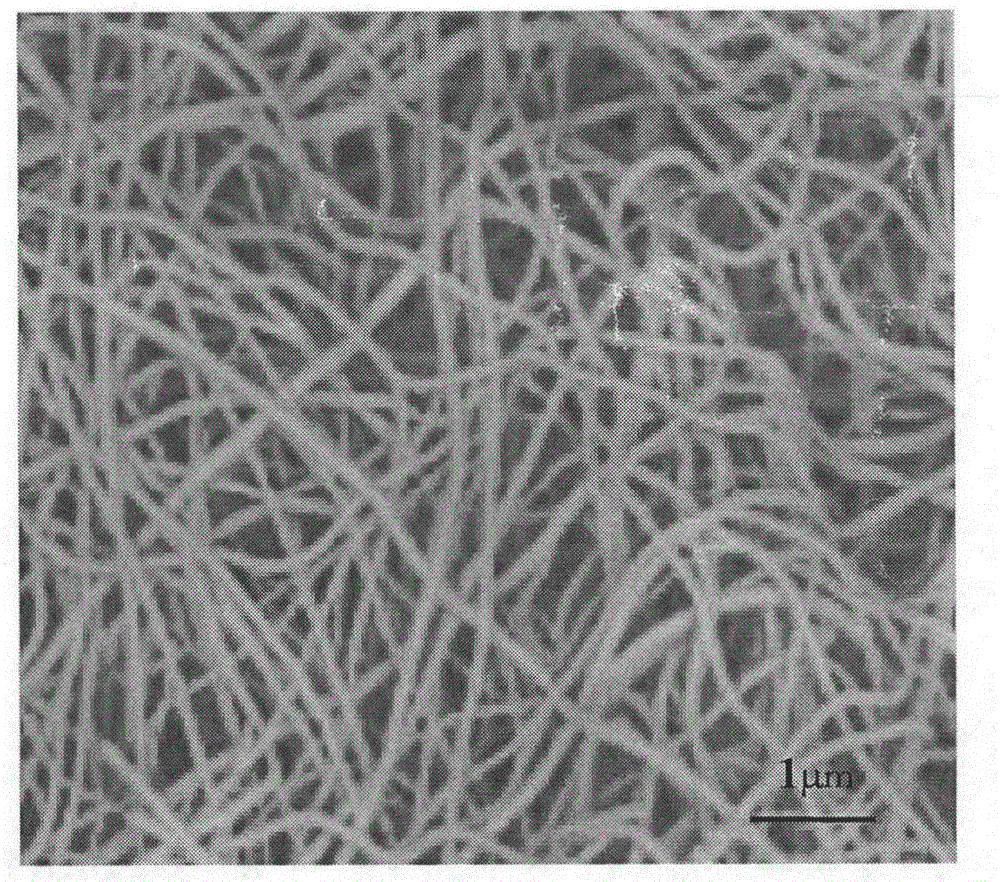

Nano thread-shaped manganese dioxide load carbon silica aerogel as well as preparation method and application thereof

InactiveCN101281821AHigh removal rateThe process steps are simpleElectrolytic capacitorsWater/sewage treatment by electrochemical methodsFiberPorosity

The present invention relates to nanometer fiber-shaped manganese dioxide borne carbon aerogel, a method for producing the aerogel, and an application of the aerogel. The method employs a coprecipitation method, i.e., carbon aerogel grains are dipped in potassium permanganate solution, and manganese acetate solution is added into the potassium permanganate solution drop by drop, then, the precipitate is filtered, washed, and dried. In the resulting nanometer fiber-shaped manganese dioxide borne carbon aerogel, the carbon aerogel is in a three-dimensional mesh structure formed by nanometer grains bonded together; the manganese dioxide in uniform nanometer fiber-shaped distribution; the pore size of the carbon aerogel is 20-30nm; the diameter of the fiber-shaped manganese dioxide is about 5-25nm; wherein, manganese dioxide accounts for 20-50 percent of the total mass. The method utilizes both the high specific surface area, high porosity, and good electrical conductivity features of carbon aerogel and the high specific surface area and high reactivity features of the manganese dioxide in nanometer-level distribution. The nanometer fiber-shaped manganese dioxide borne carbon aerogel can be used in environmental protection and energy domains, such as organic wastewater treatment by three-dimensional electric catalytic oxidation, and manufacturing of electrode materials for super capacitors.

Owner:SUN YAT SEN UNIV

Desulphurization and denitration catalyst and preparation method thereof

InactiveCN101791561AWide variety of sourcesEasy accessDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsMANGANESE ACETATECopper nitrate

The invention discloses a low-temperature high-activity desulphurization and denitration catalyst, which comprises the following components in percentage by weight: 5-10% of CuO, 5-10% of Fe2O3, 5-10% of MnO2 and 70-80% of Al2O3. The preparation method of the catalyst comprises the following steps: (1) taking appropriate 95 wt% of Al2O3 particles, drying the particles in a muffle furnace to remove crystal water; (2) preparing copper nitrate, ferric nitrate and manganese acetate impregnating solutions; (3) mixing a carrier and the impregnating solutions, impregnating, heating, decompressing, rotating for evaporation and removing moisture in the mixture; and (4) preparing the carrier via drying, calcination and activation. The prepared catalyst has good activity at low temperature, can desulfurize and denitrate simultaneously, has low material cost and can be recycled, and by-products can be recycled without secondary pollution.

Owner:HUAZHONG UNIV OF SCI & TECH

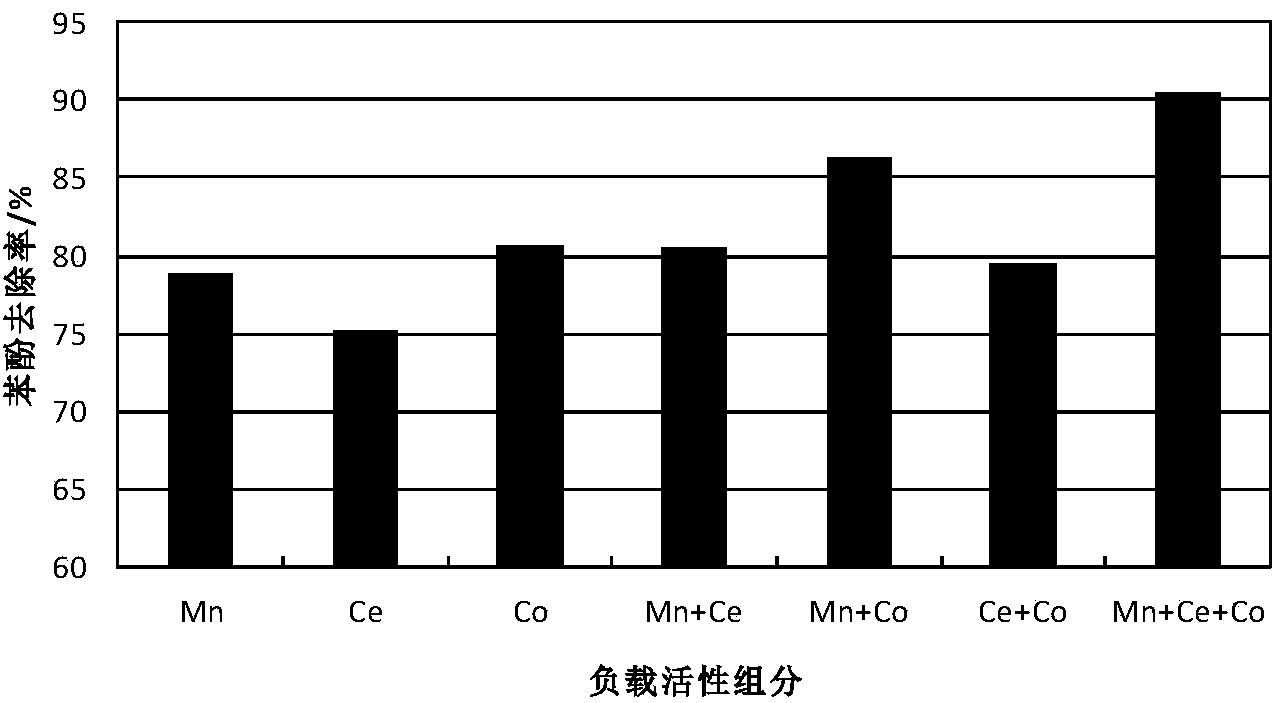

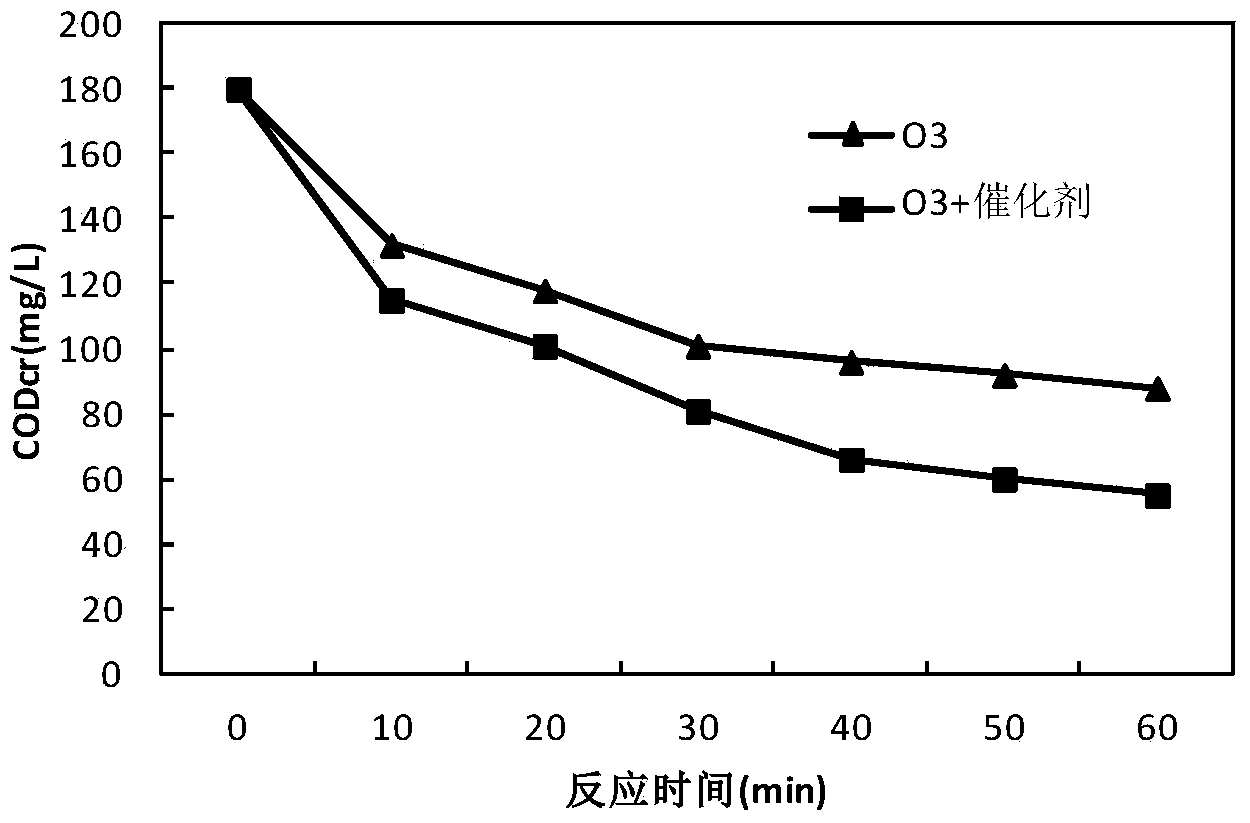

Preparation method for MnO2-CeO2-CoO/AC ternary supported catalyst for treatment of phenolic wastewater

ActiveCN104307534AEfficient catalytic degradationAccelerate the process of catalytic oxidationWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsMANGANESE ACETATECerium

The invention discloses a preparation method for an MnO2-CeO2-CoO / AC ternary supported catalyst for treatment of phenolic wastewater. The catalyst is prepared by that manganese dioxide, cerium oxide and cobalt oxide are loaded to a carrier activated carbon; the method comprises the following steps: preparing a mixed solution of manganese acetate, cerium acetate and cobaltous acetate with the concentration of 10%-30%, wherein the mass ratio of manganese to cerium to cobalt is (2-10):(1-3):1; adding a binder and the mixed solution into raw material coal dust, wherein the weight ratio of the raw material coal dust to the mixed solution to the binder is 100:(1-20):(20-30), mixing the components, and using an extruding die to extrude the mixture into carbon strips through a forming machine or pelletizing through a pelletizing machine, and sequentially performing air drying, carbonization, activation and aftertreatment on formed carbon strips or carbon balls, so that the ternary supported activated carbon catalyst with the grain size of 2-5 mm is finally obtained. In preparation, secondary pollution to the environment cannot be caused, and the prepared catalyst is good in catalytic effect, low in preparation cost and long in service life, and achieves higher application value.

Owner:TIANJIN UNITED ENVIRONMENTAL ENG DESIGN

Preparation method of manganese dioxide one-dimensional nanomaterial

InactiveCN101798118ARaw materials are easy to getLow costNanostructure manufactureElectrolytic capacitorsMANGANESE ACETATEDistilled water

The invention discloses a preparation method of manganese dioxide one-dimensional nanomaterial. The method comprises the following steps: 1. dissolving potassium permanganate in distilled water or deionized water, stirring to obtain a purple-red solution, wherein the concentration is 0.05mol / L-2.0mol / L; 2. dissolving manganese acetate in distilled water or deionized water, stirring to obtain a colorless and transparent solution, wherein the concentration is 0.05mol / L-3.0mol / L; 3. mixing and stirring the solution A and B obtained in the step 1 and 2, transferring the obtained solution in a stainless steel hydrothermal reaction tank with a polytetrafluoroethylene lining, reacting at 50-200 DEG C for 1-36h; and 4. after the reaction, performing natural cooling, and filtering, washing and drying the precipitate in turn to obtain the manganese dioxide one-dimensional nanomaterial. The method has the advantages that the process is simple, the raw materials are accessible, the cost is low, the pollution is low and is easy to perform purification treatment, the method is suitable for industrialization, etc.

Owner:XIANGTAN UNIV +1

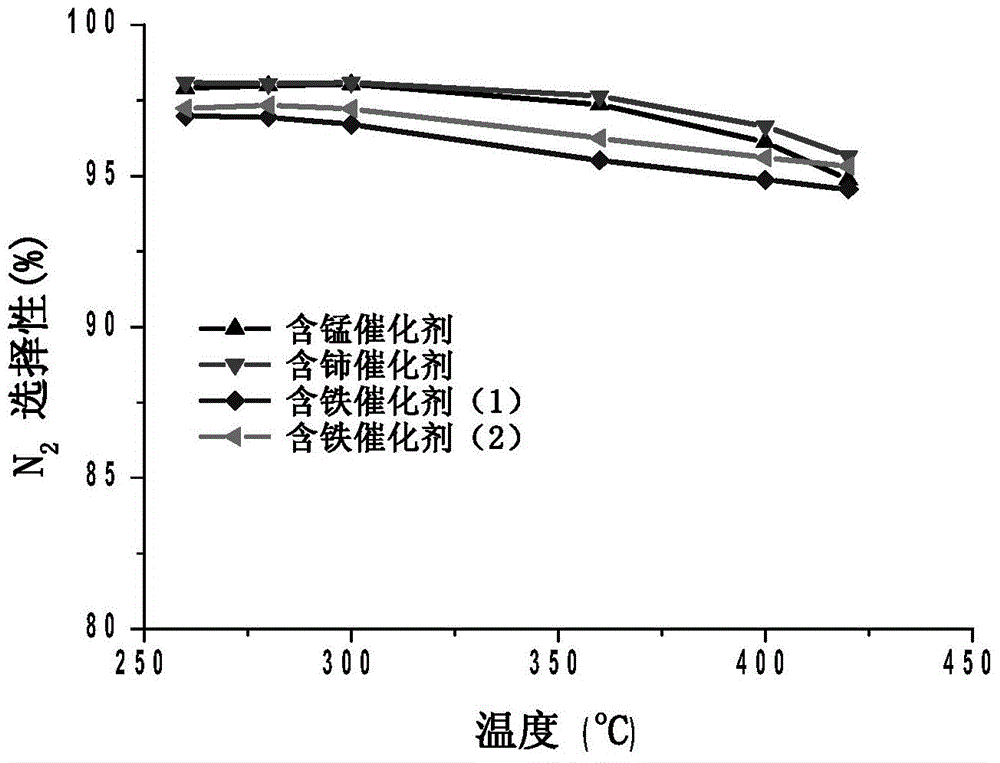

Denitration catalyst for wide temperature window under high sulfur condition and preparation method thereof

ActiveCN104525216ASimple processImprove denitrification activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsMANGANESE ACETATERare earth

The invention discloses a denitration catalyst for a wide temperature window under a high sulfur condition and a preparation method thereof. The catalyst is prepared from the following components in percentage by weight of the denitration catalyst: 1wt% of vanadium pentoxide, 6wt% of tungsten trioxide, 5wt% of one of manganese oxide, cerium oxide, ferric oxide without sulfur or ferric oxide with sulfur, and the balance of titanium dioxide. The preparation method comprises the following step: adjusting a commercial V2O5-WO3 / TiO2 catalyst by adding traditional metals iron and manganese and rare earth cerium, specifically, in the preparation process of the catalyst, adding ferric nitrate, ferric sulfate, manganese acetate or cerous nitrate to obtain the highly active catalyst which has good SO2 poisoning resistance and has the denitration activity over 80% under the condition that the temperature is 260-420 DEG C in a relatively wide high-temperature region and the SO2 concentration is high (1000ppm).

Owner:江苏中创清源科技有限公司

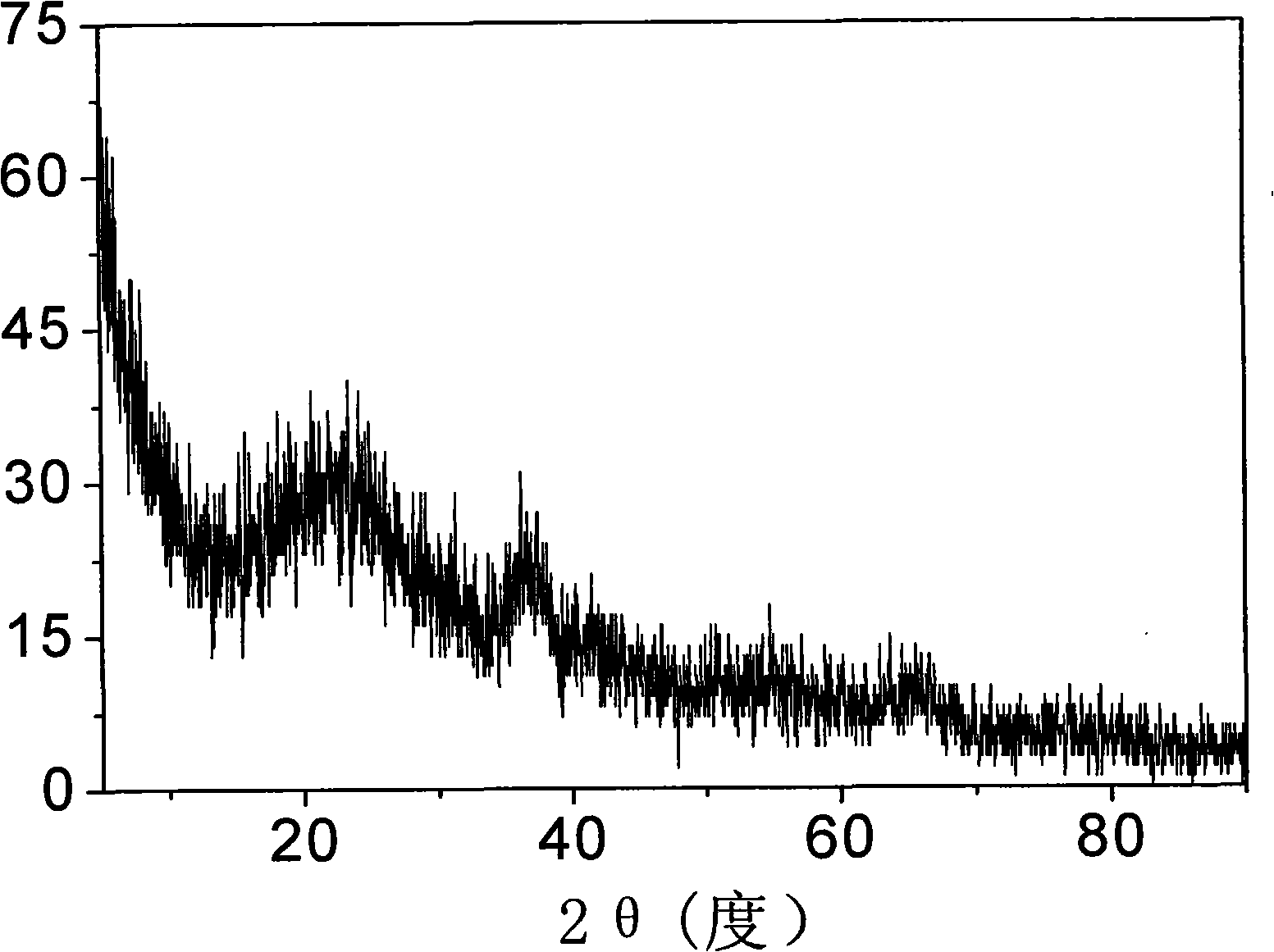

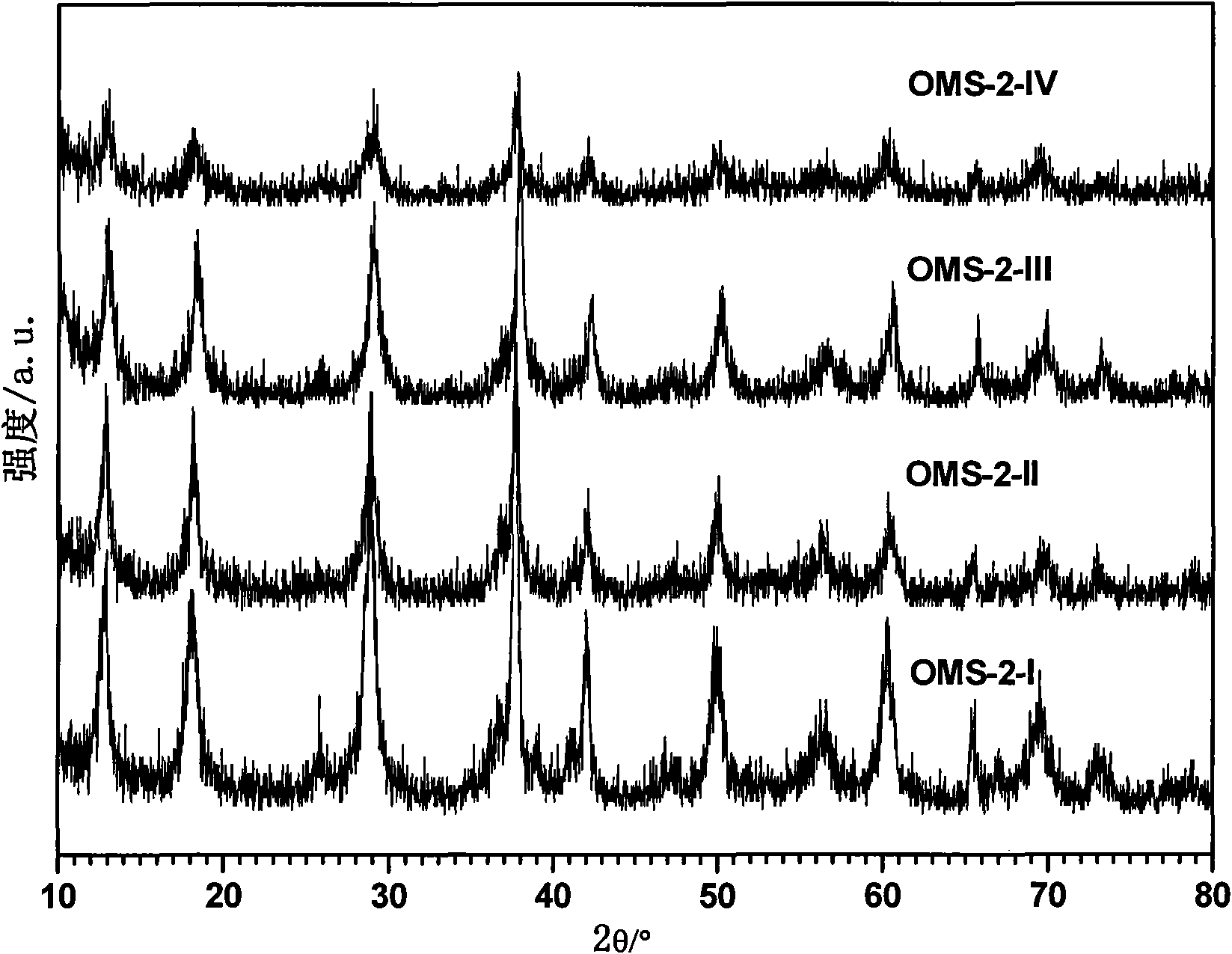

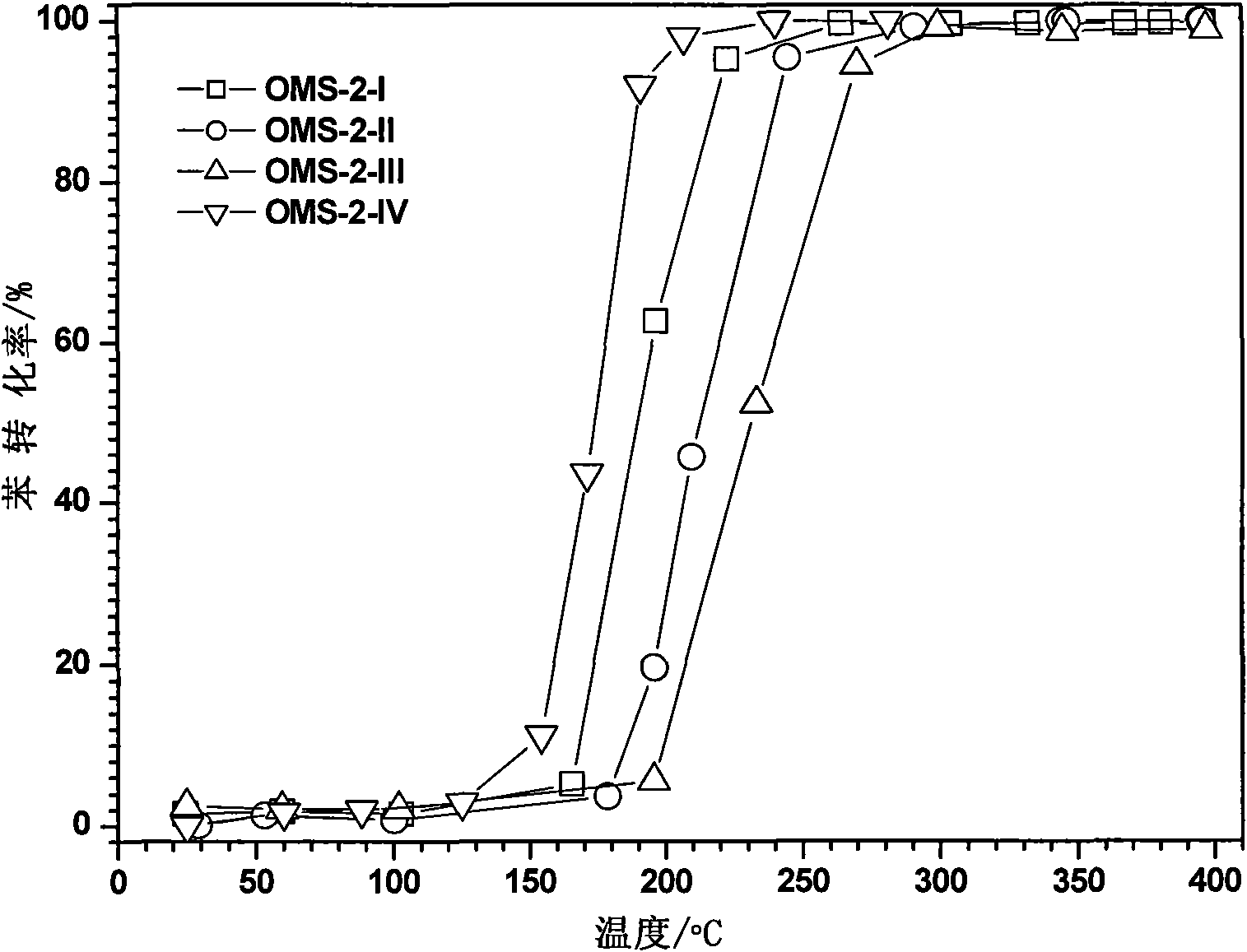

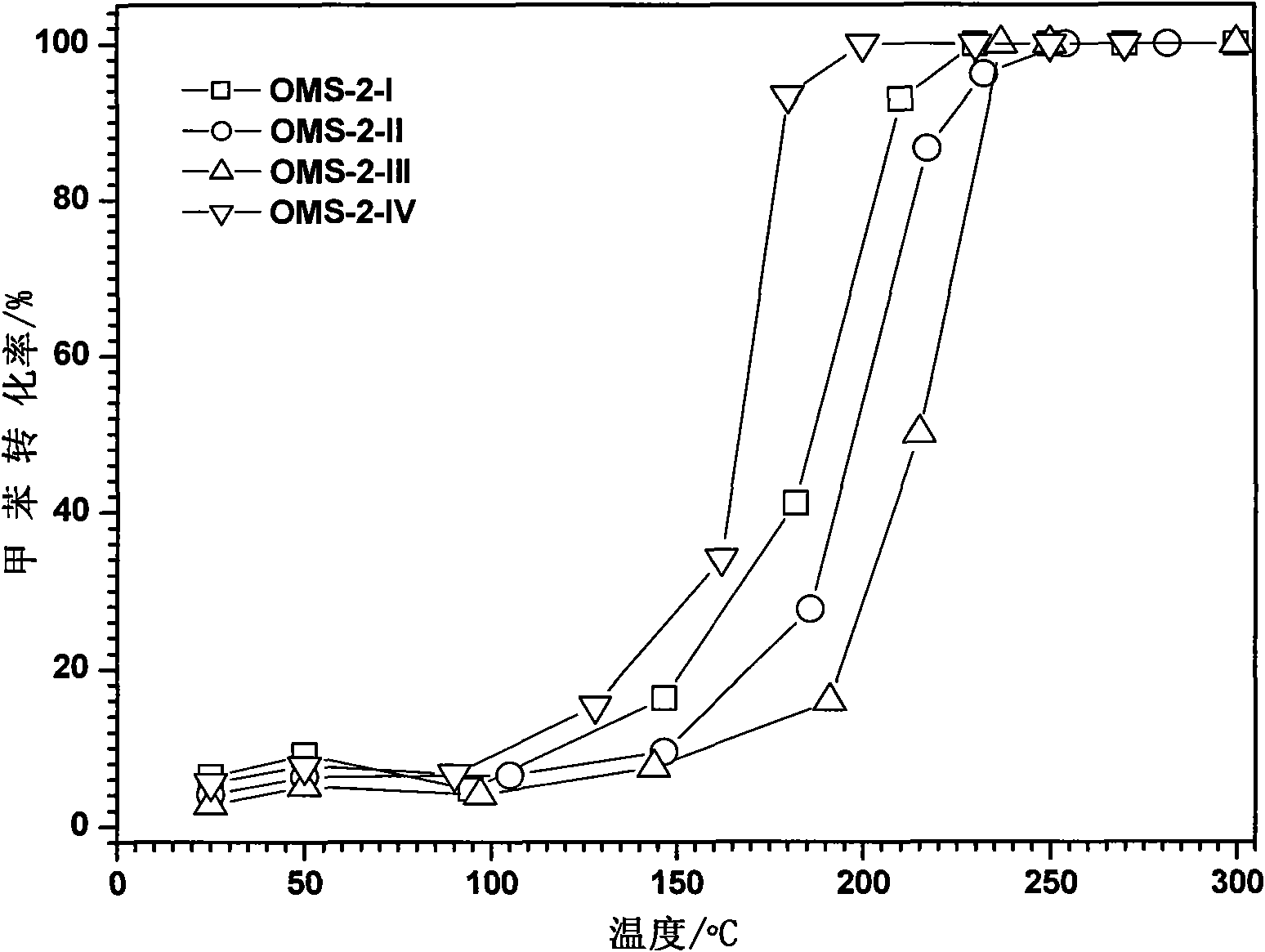

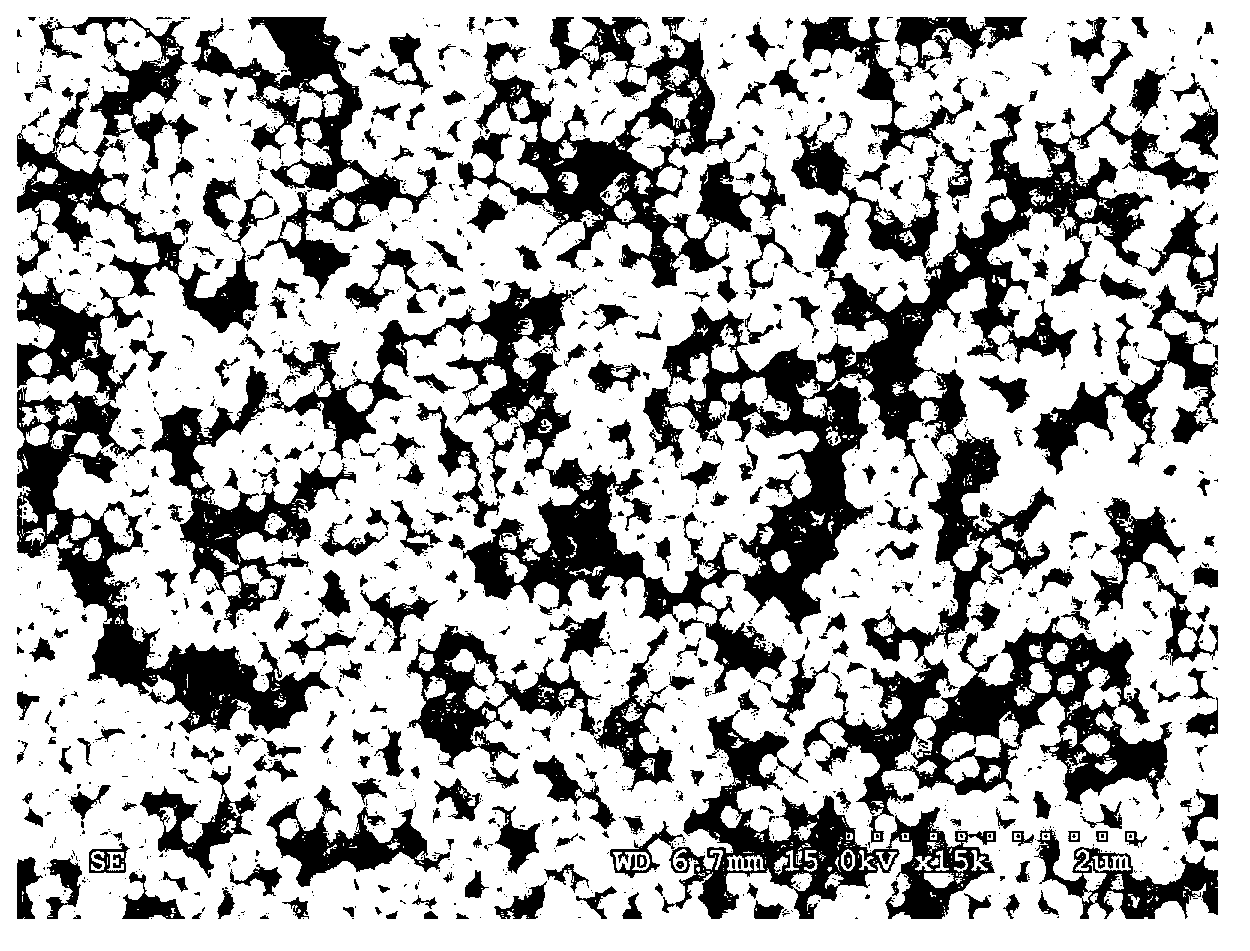

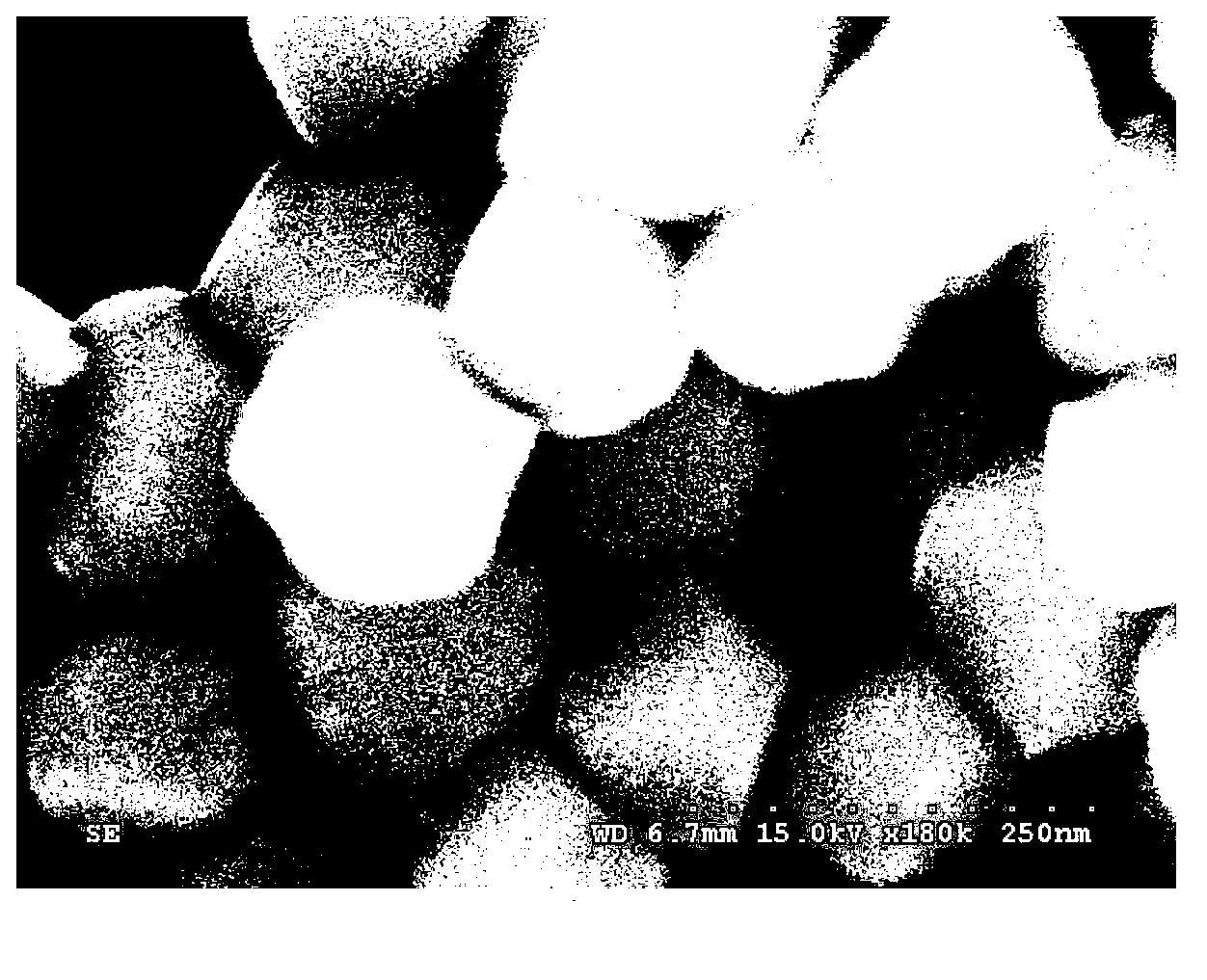

OMS-2 catalyst used in elimination of benzene series at low temperature and preparation and application

InactiveCN101927179AEasy to makeHigh and low temperature catalytic combustion to eliminate activityMolecular sieve catalystsDispersed particle separationMANGANESE ACETATEMolecular sieve

The invention discloses an OMS-2catalyst used in the elimination of benzene series at the low temperature, preparation and application. The catalyst is a manganese oxide octahedral molecular sieve and has a molecular formula of KMn8O16.nH2O. The material is prepared by using a reflux method which comprises the following steps of: preparing buffer solution of KAc-HAc with a pH value of 3.7 to 5.6; adding the buffer solution into PVP-containing Mn(Ac)2 solution; adding solution of KMnO4; stirring; refluxing; aging by sealing; filtering; washing with water; drying; baking; and performing other processing. The catalyst of the invention has the advantages of higher specific area and heat stability, high activity and high stability when the catalyst is applied to the elimination of the benzene series through low-temperature catalytic combustion, capacity of keeping the elimination ratio of the benzene series over 90 percent and not changed within 100 hours, cheap used raw material, namely manganese acetate, simple preparation process, no load of other metals or noble metals,.

Owner:BEIJING UNIV OF TECH

Manganese cobalt composite oxide (MnCo2O4) magnetic nanocrystal and preparation method thereof

ActiveCN103073072AReduce the introductionEasy to separateNanotechnologyCobalt compoundsMANGANESE ACETATEHigh pressure

The invention belongs to the technical field of active substances of inorganic oxide of nickel, cobalt or ferrum, and particularly relates to a manganese cobalt composite oxide (MnCo2O4) magnetic nanocrystal and a preparation method thereof. The preparation method adopts a hydrothermal synthesis method and comprises the following steps of (1) weighing a certain amount of potassium permanganate, manganese acetate and cobalt acetate on the condition that a molar ratio of nKMnO4 to nMn(Ac)2 to nCo(Ac)2 is 2:3:10, adding pure water, uniformly stirring, obtaining a reaction mixture, (2) shifting the reaction mixture into a polytetrafluoroethylene-stainless steel high-pressure reaction kettle, sealing the high-pressure reaction kettle, placing in an oven, keeping warm at 150-200 DEG C for a certain time, conducting hydrothermal reaction for 10-24h, taking out the high-pressure reaction kettle, and (3) opening the high-pressure reaction kettle after cooling, conducting centrifugal separation on a reactant, using the pure water to wash a sample, obtaining a black precipitate, conducting vacuum drying, and obtaining the MnCo2O4 magnetic nanocrystal. The method is simple and easy, and the obtained MnCo2O4 magnetic nanocrystal is uniform in particle size, regular in shape, good in crystallinity, and controllable in atom proportioning and has a good magnetic property.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Mesoporous manganese oxide nano granule and preparation method thereof

InactiveCN101597085AImprove protectionSimple preparation processManganese oxides/hydroxidesMANGANESE ACETATESesquioxide

The invention relates to a mesoporous manganese oxide nano material and a preparation method thereof. In the invention, a uniformly distributed mesopore with the aperture of 2 to 10 nanometers and a mixture of oxyhydrogen manganese oxide and manganic manganous oxide or a mangano-manganic octoxide monocrystal granule or a manganese sesquioxide monocrystal granule with the granule particle diameter controlled within the range of 20 to 80 nanometers are prepared by the hydrothermal function of manganese metal, manganese acetate and ammonia and the subsequent calcination control, and the uniformly distributed mesoporous, the mixture of oxyhydrogen manganese oxide and manganic manganous oxide, the mangano-manganic octoxide monocrystal granule and the manganese sesquioxide monocrystal granule play a catalytic action to a toluene combustion reaction. The invention has simple preparation method, loose synthesizing condition, easy repetition and cheap raw materials and can carry out large-scale production.

Owner:HEBEI UNIV OF TECH

Preparation method of beta-hydroxyphosphonate derivatives

InactiveCN104370960ARich typeRaw materials are easy to getGroup 5/15 element organic compoundsMANGANESE ACETATEEthylic acid

The invention discloses a preparation method of beta-hydroxyphosphonate derivatives. The preparation method comprises that an arylethene derivative, a phosphorus reagent and manganese acetate are dissolved in a solvent and the solution undergoes a reaction at a temperature of 20-60 DEG C to produce the beta-hydroxyphosphonate derivative. Under the action of ammonia water, a beta-aminophosphonate derivative is prepared from the beta-hydroxyphosphonate derivative. The preparation method utilizes the arylethene derivative as an initiator and utilizes multiple easily available raw materials. The beta-hydroxyphosphonate derivatives belong to multiple types and can be directly used and can be used for other further reactions. The preparation method has a short synthesis route, mild reaction conditions, simple reaction and aftertreatment processes and a high yield and is suitable for large-scale production.

Owner:翁后科

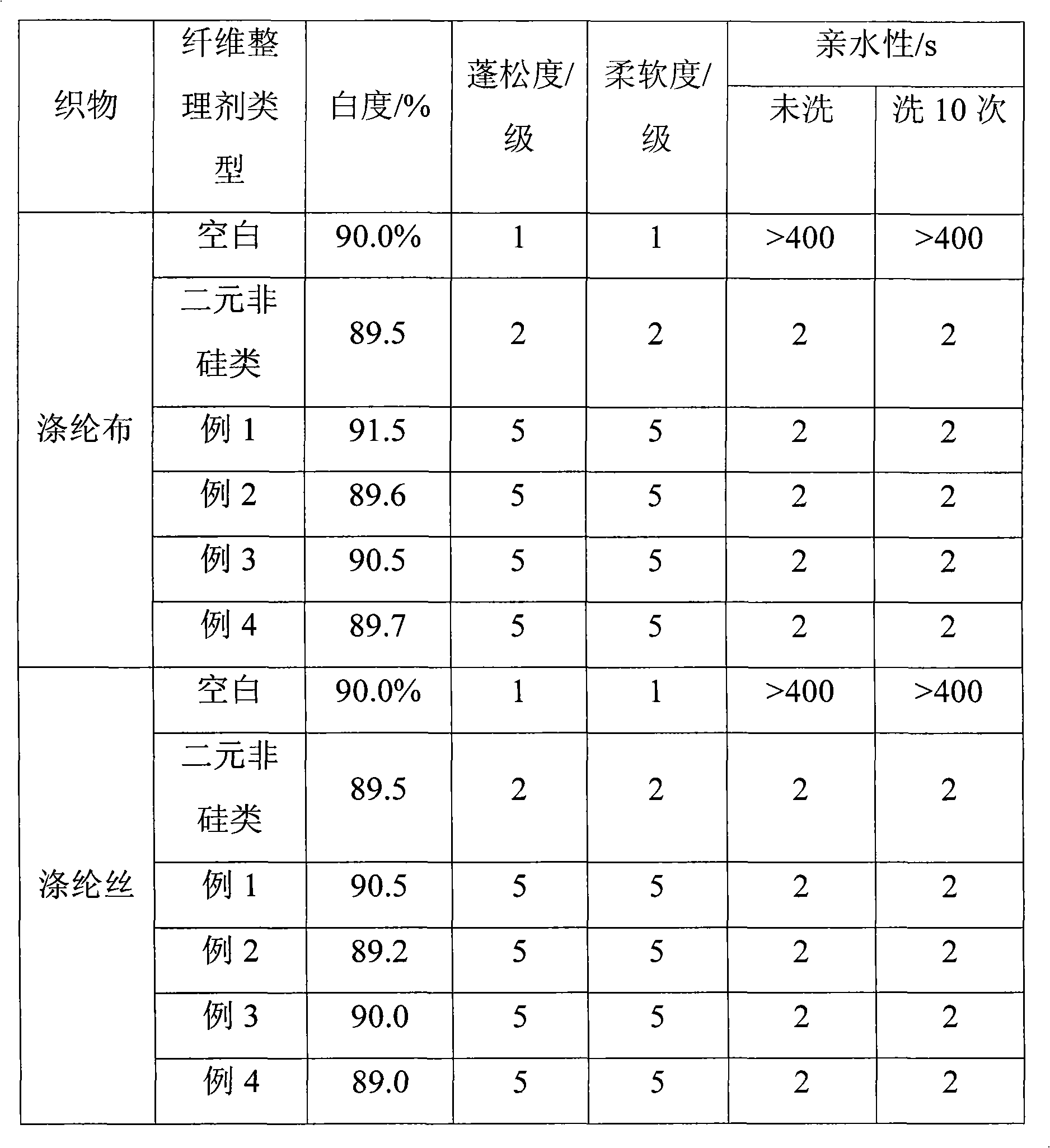

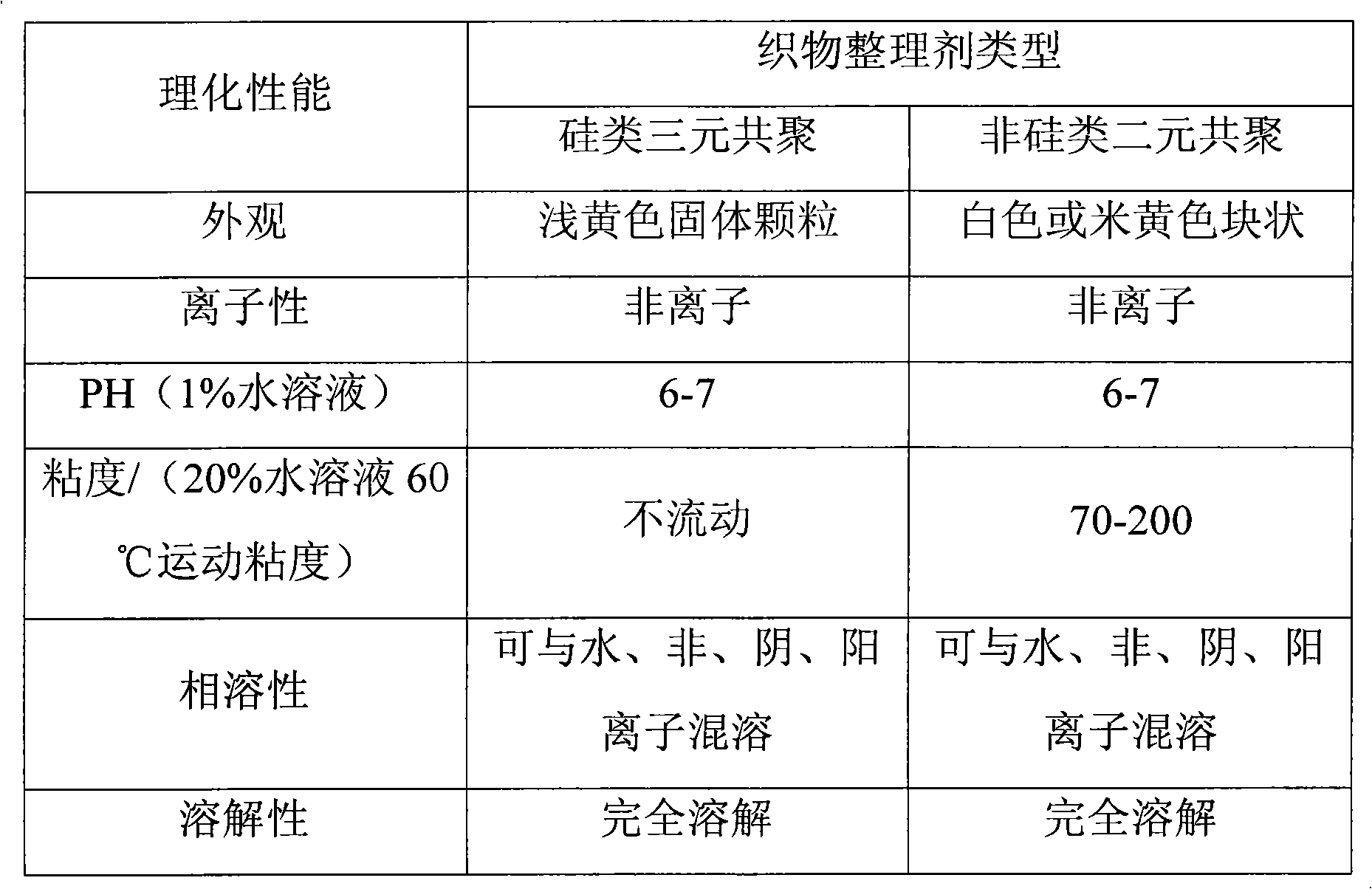

Method for preparing polyester and polyether modified silicone oil ternary copolymer textile finishing agent

The invention relates to a method for preparing a polyester and polyether modified silicone oil ternary copolymer textile finishing agent, and belongs to the field of the synthesis of ternary copolymer synthetic fiber finishing agents. The method comprises the following steps of: performing a hydrosilylation reaction of allyl polyether and hydrogen-containing silicone oil under the action of a chloroplatinic acid catalyst to form polyether modified silicone oil; and performing a polycondensation reaction of the polyether modified silicone oil and dimethyl terephthalate, glycol and polyethylene glycol under the action of antimonous oxide, manganese acetate, n-tetrabutyl titanate and triphenyl phosphate to obtain the polyester and polyether modified silicone oil ternary copolymer multifunctional textile finishing agent. The textile finishing agent can make textiles very absorbent, antistatic and washable and touch very soft.

Owner:LIAONING KELONG FINE CHEM

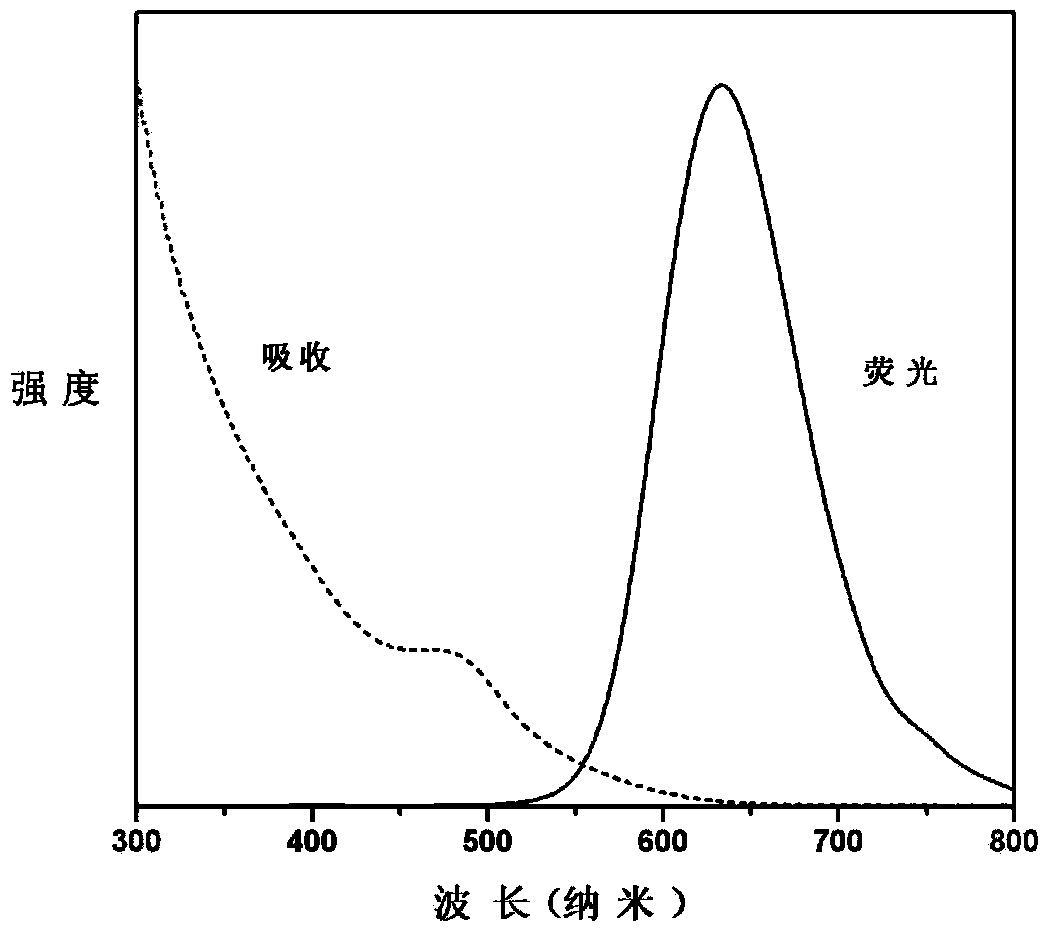

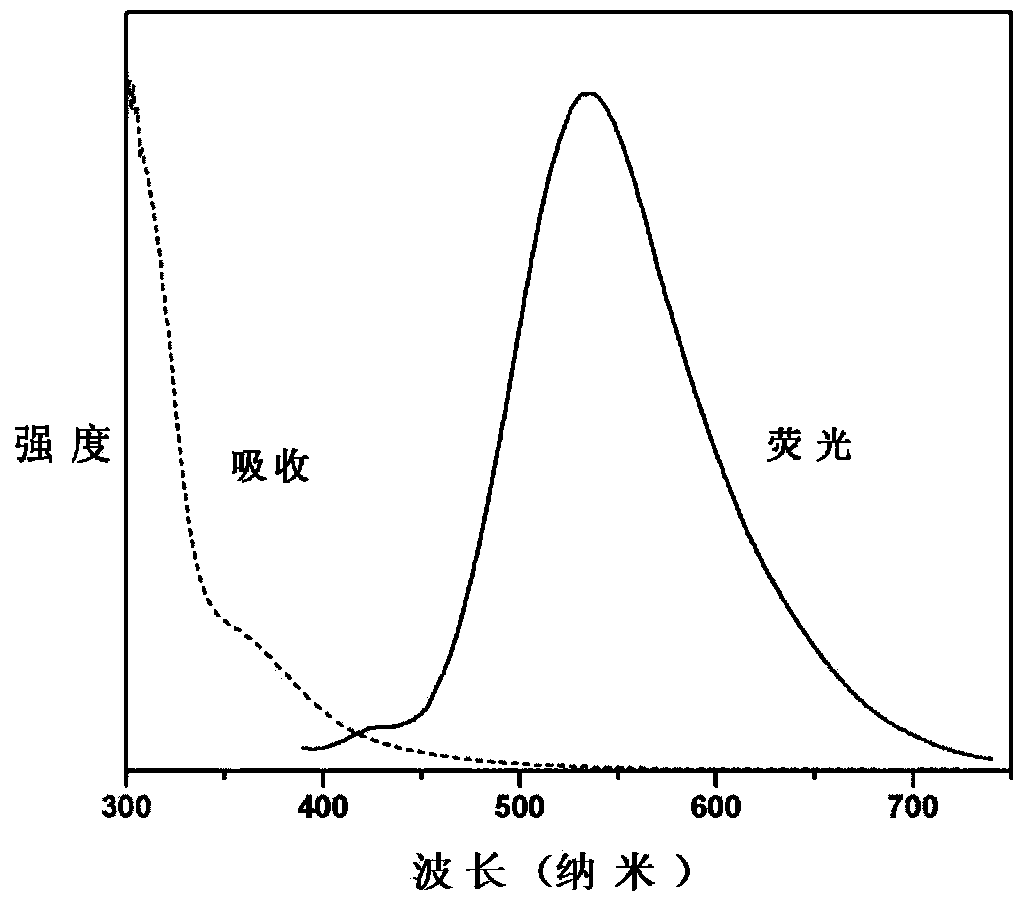

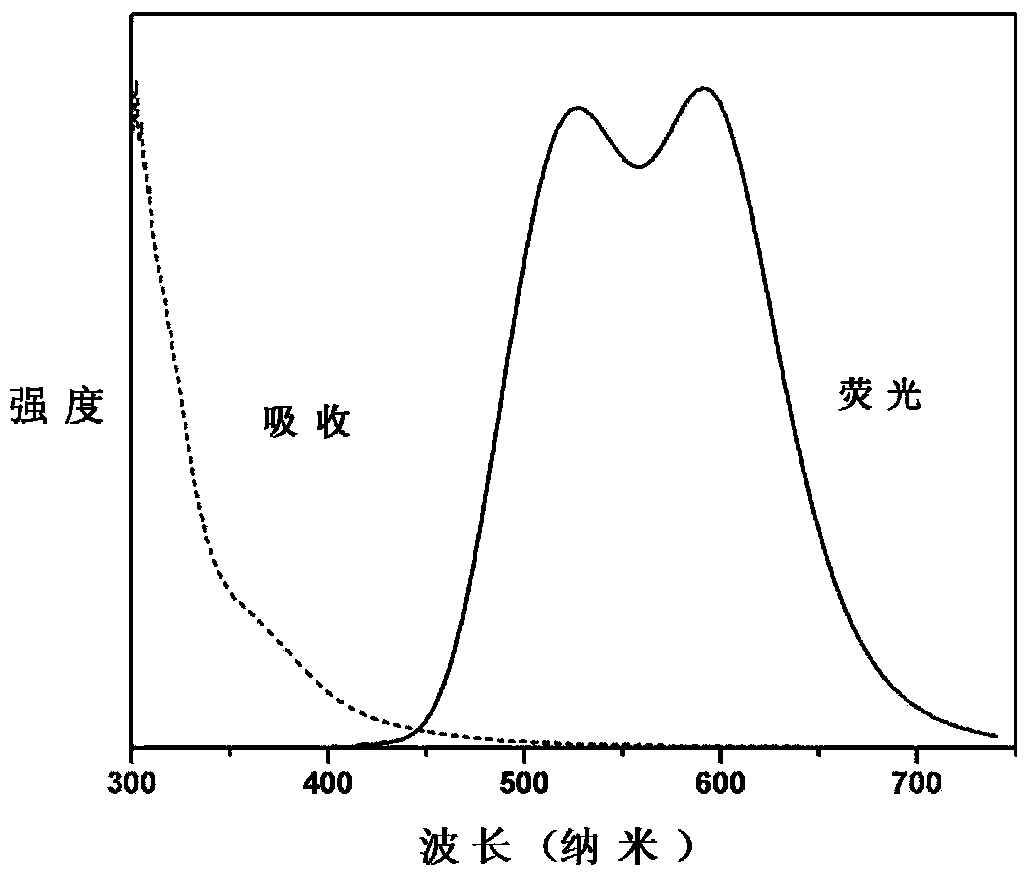

Preparation method of bicolor fluorescent semiconductor nanomaterial based on Mn-doped CuInS2/ZnS

InactiveCN103773364AEasy to manufactureGood optical performanceMaterial nanotechnologyLuminescent compositionsMANGANESE ACETATEIndium

The invention relates to a preparation method of a bicolor fluorescent semiconductor nanomaterial based on Mn-doped CuInS2 / ZnS. The preparation method comprises the following steps: (1) preparing CuInS2 / ZnS quantum dots, purifying the CuInS2 / ZnS quantum dots and then dissolving the CuInS2 / ZnS quantum dots in n-hexane; (2) adding the CuInS2 / ZnS quantum dots obtained by the step (1) into octadecene (ODE), heating to 150 DEG C under an argon gas environment, injecting a mixed solution of Mn(Ac)2 (manganese acetate) and oleylamine and maintaining for 1 hour at the 150 DEG C; then heating to 240 DEG C, injecting the mixed solution of Zn(Ac)2, oleic acid / DDT (Dichloro-Diphenyl-Trichloromethane) and the ODE and reacting for 1 hour at 240 DEG C; and cooling to a room temperature, thereby obtaining the quantum dot nanomaterial of CuInS2 and ZnS: Mn / ZnS. The quantum dot nanomaterial can be used for replacing yellow fluorescent powder to be prepared into a white LED (Light Emitting Diode). The Mn-doped CuInS2 / ZnS quantum dots are of a nanomaterial which is nontoxic and environment-friendly, and has two fluorescence peak positions within a visible light range, wherein the peak positions are between 525nm and 590nm or so; the relative strength of the two fluorescence peaks can be regulated by regulating the content of the Mn.

Owner:SOUTHEAST UNIV

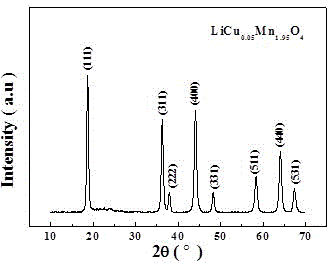

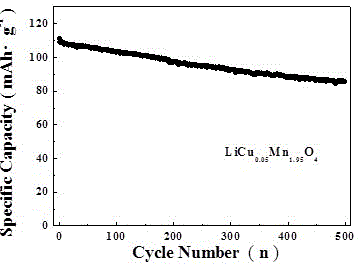

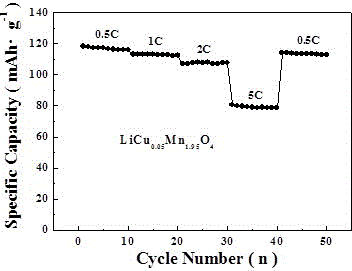

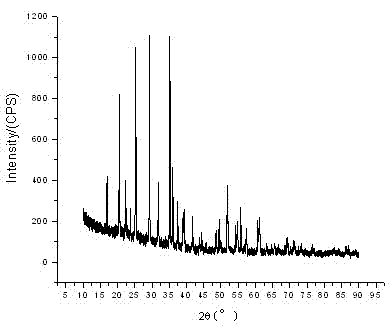

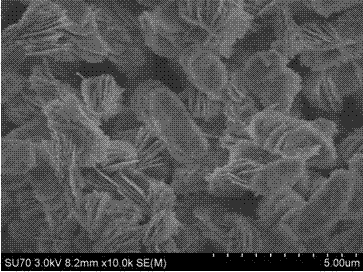

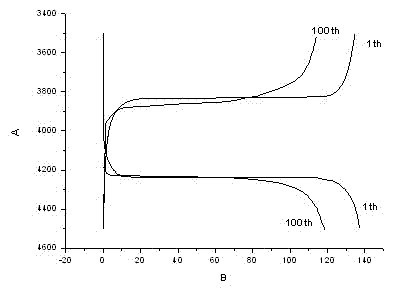

One-step method for preparing high-magnification copper-doped lithium manganese dioxide lithium ion battery positive electrode material

The invention discloses a preparation method of lithium manganese dioxide lithium ion battery positive electrode material with high magnification and excellent cyclic performance. The method particularly comprises the following steps of putting the reactants of lithium nitrate, manganese acetate and copper acetate into a crucible, adding a proper amount of nitric acid, combusting in a muffle furnace, and preserving heat, thereby obtaining the spinel LiCu0.05Mn1.95O2 electrode material. The preparation method of the LiCu0.05Mn1.95O4 lithium ion battery positive electrode material, which is disclosed by the invention, has the characteristics of operation simplicity, rapid synthesis speed, low cost and scale production is easy to achieve.

Owner:YUNNAN MINZU UNIV

Preparation method for manganese phosphate lithium nanosheet

InactiveCN102903918AGood dispersionFacilitated DiffusionCell electrodesMANGANESE ACETATEPolyethylene glycol

The invention relates to a preparation method for a manganese phosphate lithium nanosheet. According to the preparation method, glycol and water are used as a solvent, and polyethylene glycol is introduced, so that the formation of crystal nucleus and the growth of crystal are influenced, and as a result, the thermosynthesis of the solvent of the manganese phosphate lithium nanosheet can be achieved. The preparation method comprises the following steps of: dissolving ascorbic acid in the water / glycol solvent; then dissolving into phosphoric acid and manganese acetate in sequence; dropwise adding the water / glycol solution of manganese acetate to the previous solution containing phosphoric acid, lithium acetate and ascorbic acid; then introducing proper polyethylene glycol; fully mixing to obtain a precursor for water / solvent thermal reaction; transferring the precursor into a reaction kettle system to be sealed; thermally processing at 160 to 240 DEC G; and carrying out thermal reaction to the solvent to obtain the manganese phosphate lithium nanosheet. By adopting the preparation method, products are stable in quality, high in purity and high in dispersion of particles; the lithium ions can be dispersed well; the electrochemical performance of a lithium ion battery can be improved; and the preparation method is simple in technical process, easy to control, free of pollution, low in cost, and easy for mass production.

Owner:ZHEJIANG UNIV

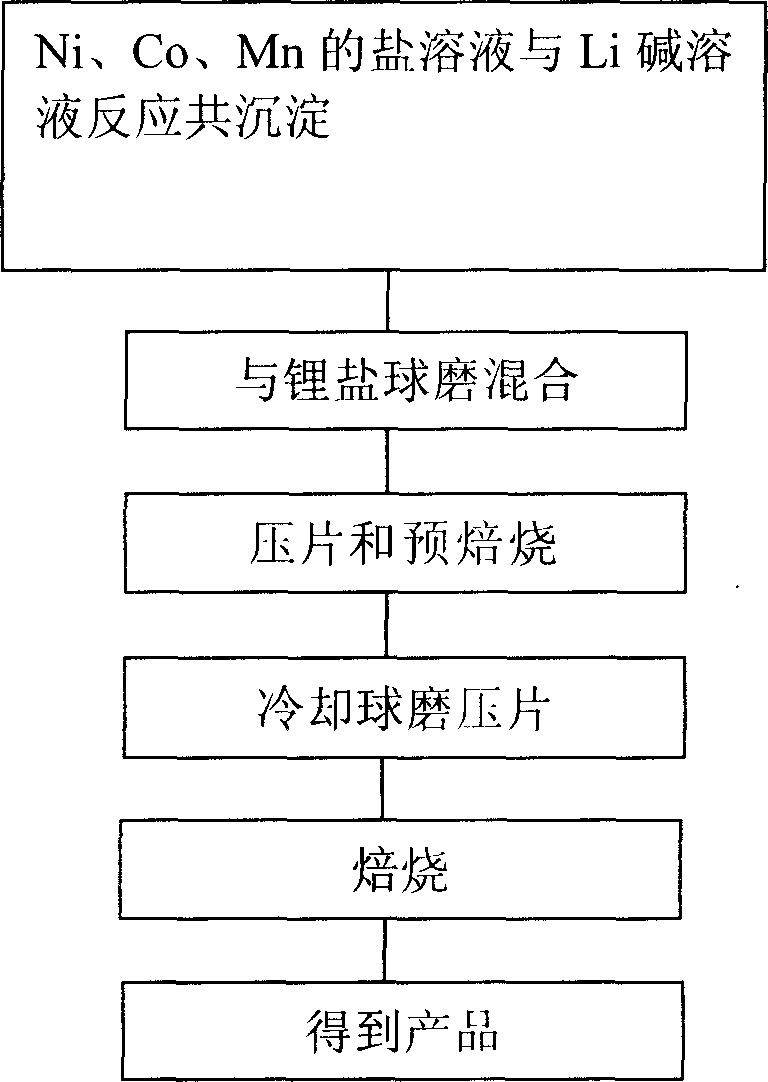

Method for producing anode active material containing lithium, magnesium compound oxide

InactiveCN1741302AStructural Precise TailoringSimple structureElectrode manufacturing processesLithium compoundsMANGANESE ACETATENickel salt

A method for preparing positive electrode multielement active material containing lithium / manganese composite oxide includes directly using lithium hydroxide coprecipitation to prepare M ( OH )2 , mixing it with lithium salt in grinding , forming plate by pressing , prebaking , cooled ball grinding , forming plate by pressing and backing . In the method , applied nickel salt is nickel acetate or nickel nitrate , applied cobalt salt is cobalt acetate or cobalt nitrate, applied manganese salt is manganese nitrate or manganese acetate and applied lithium salt is lithium carbonate or lithium acetate .

Owner:HEBEI UNIV OF TECH

Nitrogen-doped carbon-coated manganous-manganic oxide composite material, as well as preparation method and application thereof

InactiveCN108520944AImprove stabilityImprove conductivityCell electrodesSecondary cellsMANGANESE ACETATEManganous-manganic oxide

The invention belongs to the field of materials for lithium ion batteries, and discloses a nitrogen-doped carbon-coated manganous-manganic oxide composite material, as well as a preparation method andapplication thereof. The preparation method comprises the steps of dissolving manganese acetate and ammonium bicarbonate into ethylene glycol, carrying out solvent heat treatment at the temperature of 180 to 220 DEG C, and obtaining manganese carbonate; reacting with dopamine hydrochloride, and obtaining a manganese carbonate / polydopamine composite material; then calcining under an inert atmosphere, and finally oxidizing in a muffle furnace to obtain the nitrogen-doped carbon-coated manganous-manganic oxide composite material. The preparation method provided by the invention is simple and lowin cost; the prepared nitrogen-doped carbon-coated manganous-manganic oxide composite material is stable in structure and good in electrical conductivity, and has excellent rate performance and cyclic stability when being used as a lithium ion battery cathode material.

Owner:SOUTH CHINA UNIV OF TECH

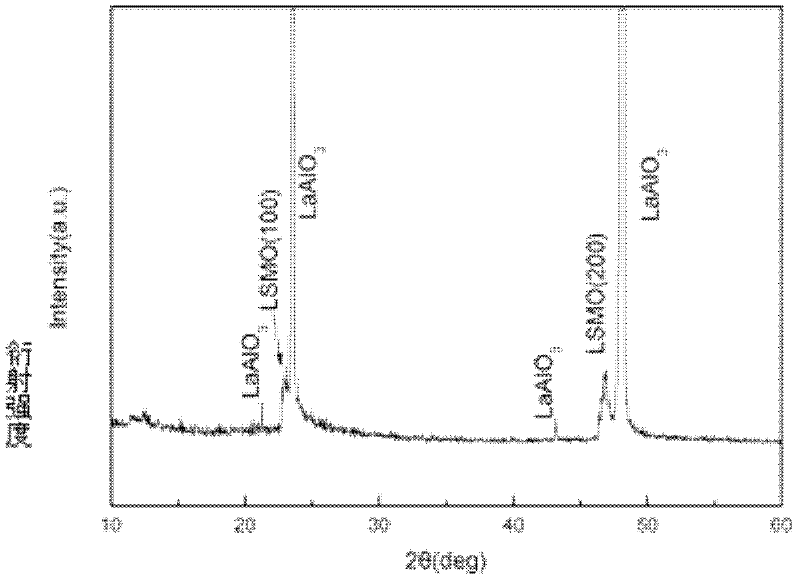

Method for preparing high-temperature superconducting coating conductor LaSrMnO3 buffering layer film

InactiveCN102509763ALow priceEasy to useSuperconductor device manufacture/treatmentMANGANESE ACETATEElectrical conductor

The invention discloses a method for preparing a high-temperature superconducting coating conductor La0.7Sr0.3MnO3 buffering layer film, and belongs to the technical field of high-temperature superconducting materials preparation. The film prepared by the method is smooth and compact, and is favorable in texture, and triplex functions of La0.7Sr0.3MnO3 as a conducting buffering layer film, namely isolation, extension and electric current transmission, can be adequately exerted. The method comprises the following steps: dissolving analytically pure lanthanum oxide (La2O3) in acetic acid (the mol ratio of the acetic acid to cations being 10: 1) in a cation ratio of La: Sr: Mn=0.7: 0.3: 1; after the analytically pure lanthanum oxide is completely dissolved, putting the obtained solution in an infrared drying box, and after the solution is baked into a white solid, taking out the white solid; mixing and dissolving strontium acetate and manganese acetate with the prepared white solid (namely lanthanum acetate) in propionic acid in the cation ratio of La: Sr: Mn=0.7: 0.3: 1 to form an anhydrous solution; adding polyvinyl butyral (PVB) in the anhydrous solution to prepare into a colloid with good film forming property; and coating the colloid on a substrate, drying the coated substrate, and then, putting the dried substrate in a sintering furnace to be sintered to form a phase, so as to obtain a lanthanum-strontium-manganese oxide La0.7Sr0.3MnO3 high-temperature superconducting coating conductor buffering layer. The cost of the method is low; the manufacturing process is simple; the operation is easy to control; and the environment is not polluted.

Owner:SOUTHWEST JIAOTONG UNIV

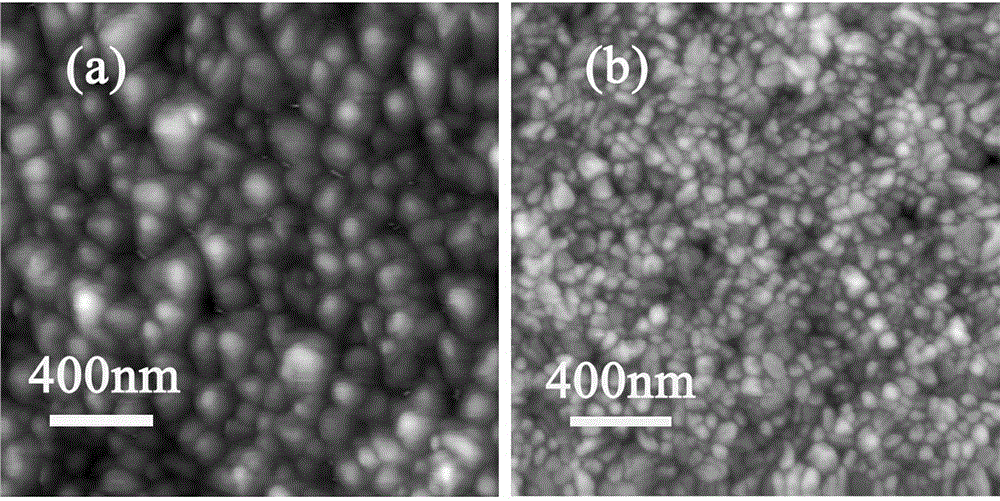

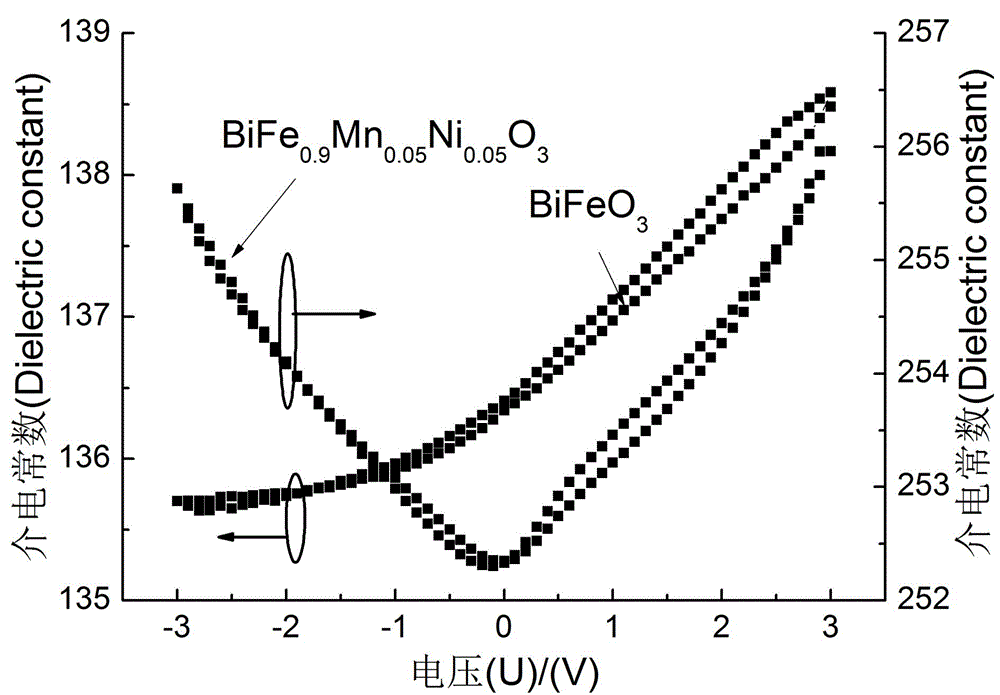

Method for preparing manganese, nickel codoped bismuth ferrite film by sol-gel process

The invention discloses a method for preparing manganese, nickel codoped bismuth ferrite film by a sol-gel process. The method comprises the steps of weighing material ferric nitrate, bismuth nitrate, manganese acetate and nickel acetate according to a general formula BiFe(1-2x)MnxNixO3 (x is smaller than or equal to 0.05 and greater than or equal to 0.0125); adding glacial acetic acid to agitate for 30 minutes at 80 DEG C; and adding ethylene glycol monomethyl ether to agitate for 180 minutes at room temperature to prepare into a liquid precursor of which the concentration is 0.1-0.2mol / L. The final sample is obtained by preparing a wet film on indium tin oxide / glass or a platinum substrate by a spin-coating method, pre-annealing, finally annealing the film, and repeating the pre-annealing and film annealing processes for 10-20 times. The method has the characteristics that the impurity phase in bismuth ferrite can be effectively restrained; the grain size and the root-mean-square roughness of the film surface are reduced; the insulating property, ferroelectric properties, the ferromagnetic property and the optical property of the sample are improved; and the method is simple in production technology, good in reproducibility, and low in cost.

Owner:XINJIANG UNIVERSITY

Preparation method for synthesizing LiNi1/3Co1/3Mn1/3O2 nanometer fiber by using electro-spinning technique

InactiveCN103560243ALarge specific surface areaControllable diameterCell electrodesSecondary cellsFiberMANGANESE ACETATE

The invention discloses a preparation method for synthesizing a LiNi1 / 3Co1 / 3Mn1 / 3O2 nanometer fiber by using an electro-spinning technique, and belongs to the technical field of lithium ion battery electrode materials and preparation of the materials. The preparation method comprises the steps: preparing a precursor solution by using raw materials of lithium nitrate, nickel nitrate, cobalt nitrate, manganese acetate, deionized water, polyacrylic acid and polyvinylpyrrolidone (PVP) as raw materials, preparing a PVP / LiNi1 / 3Co1 / 3Mn1 / 3O2 composite fiber through using an electro-spinning technique, insulating, sintering, and cooling to a room temperature to obtain the LiNi1 / 3Co1 / 3Mn1 / 3O2 nanometer fiber. The preparation method is simple in process, convenient to operate, low in cost and slight in pollution. An anode material of the LiNi1 / 3Co1 / 3Mn1 / 3O2 nanometer fiber prepared by using the preparation method provided by the invention has a good electrochemical performance.

Owner:TIANJIN POLYTECHNIC UNIV

Modified nickel cobalt manganese ternary composite electrode material coated on oxide surface and preparation method thereof

ActiveCN107331852AAvoid corrosionReduce surface resistanceSecondary cellsPositive electrodesMANGANESE ACETATENiobium

The invention provides a modified nickel cobalt manganese ternary composite electrode material coated on an oxide surface and a preparation method thereof. A coating layer of the composite electrode material is prepared from two or three metal oxides MxOy, wherein M is niobium, zirconium or yttrium; the thickness of the coating layer is 0.5-50nm and the weight percent in the composite electrode material is 1%-10%; the prepared nickel cobalt manganese composite electrode material has an alpha-NaFeO2 layered structure. Nickel acetate, cobalt acetate, manganese acetate and lithium acetate are taken as raw materials, the metal oxides are served as surface coating matters and the high-temperature sintering and in-situ coating combined technology is adopted for preparing the high-performance composite electrode material. The coating layer of the composite electrode material can prevent the metal ions in active materials from dissolving, can resist against the corrosion of HF to active materials and can reduce the surface impedance and promote the cycling stability. The preparation process is simple, the operation is easy, the production period is short, the equipment requirement is low and industrial development and popularization and application are benefited.

Owner:ENERGY RESOURCES INST HEBEI ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com