Method for electrochemically preparing graphene/manganese dioxide composite material, and application of graphene/manganese dioxide composite material

A manganese dioxide and composite material technology, applied in the field of electrochemistry, can solve the problems of serious graphene agglomeration, serious environmental pollution, poor dispersibility of composite materials, etc., and achieve the effect of good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

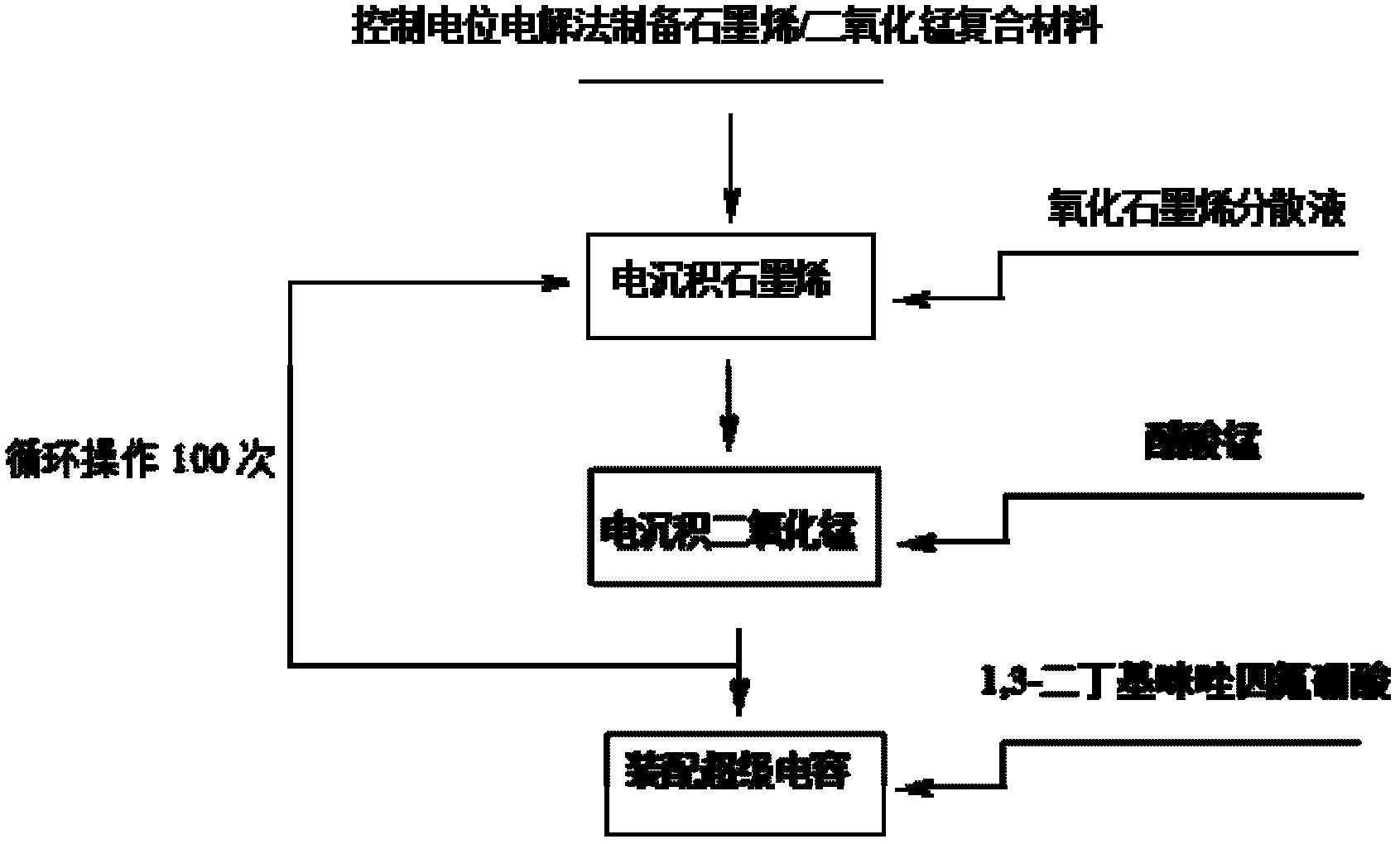

Embodiment 1

[0029] Put 10mg of graphite oxide into a beaker, add 100mL of deionized water and 1.2g of sodium carbonate, ultrasonically oscillate for 10 minutes, select a potential value of -0.9V, and perform constant potential electrolysis at a temperature of 0°C for 10 seconds, take out the electrode, and wash it with deionized water ,dry. Put the prepared graphene-modified electrode into an electrolytic cell containing 0.001mol / L manganese acetate, 0.01mol / L sodium sulfate and 1.0mol / L sulfuric acid solution, select a potential value of 0.9V and a temperature of 0°C for constant potential Electrolyze for 10 seconds, take out the electrode, wash with deionized water, and dry. Repeat the electrodeposition operation 100 times, use the obtained graphene / manganese dioxide composite material as the working electrode and counter electrode, and the acetocyanide solution of 0.1mol / L 1,3-dibutylimidazole tetrafluoroborate as the electrolyte Assembled with a supercapacitor, its capacitance is 155...

Embodiment 2

[0031] Put 10mg of graphite oxide into a beaker, add 200mL of deionized water and 2.0g of sodium carbonate, ultrasonically oscillate for 20 minutes, select a potential value of -1.0V, and perform constant potential electrolysis at a temperature of 20°C for 20 seconds, take out the electrode, and wash it with deionized water ,dry. Put the prepared graphene-modified electrode into an electrolytic cell containing 0.002mol / L manganese acetate, 0.02mol / L sodium sulfate and 0.5mol / L sulfuric acid solution, select a potential value of 0.9V and a temperature of 0°C for constant potential Electrolyze for 10 seconds, take out the electrode, wash with deionized water, and dry. Repeat the electrodeposition operation 100 times, use the obtained graphene / manganese dioxide composite material as the working electrode and the counter electrode, and the acetocyanide solution of 0.2mol / L1,3-dibutylimidazole tetrafluoroborate as the electrolyte assembly The supercapacitor has a capacitance of 12...

Embodiment 3

[0033] Put 10mg of graphite oxide into a beaker, add 200mL of deionized water, oscillate ultrasonically for 20 minutes, select the potential value of -0.9V, and perform constant potential electrolysis at 0°C for 10 seconds, take out the electrode, wash it with deionized water, and dry it. Put the prepared graphene-modified electrode into an electrolytic cell containing 0.002mol / L manganese sulfate, 0.06mol / L sodium sulfate and 0.2mol / L sulfuric acid solution, select a potential value of 1.2V and a temperature of 0°C for constant potential Electrolyze for 20 seconds, take out the electrode, wash with deionized water, and dry. Repeat the electrodeposition operation 100 times, use the obtained graphene / manganese dioxide composite material as the working electrode and the counter electrode, and the ethanol solution of 1.0mol / L 1,3-dibutylimidazole tetrafluoroborate as the electrolyte assembly The supercapacitor has a capacitance of 2710F / g, and after charging and discharging 1000 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com