Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about How to "Increase operating voltage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

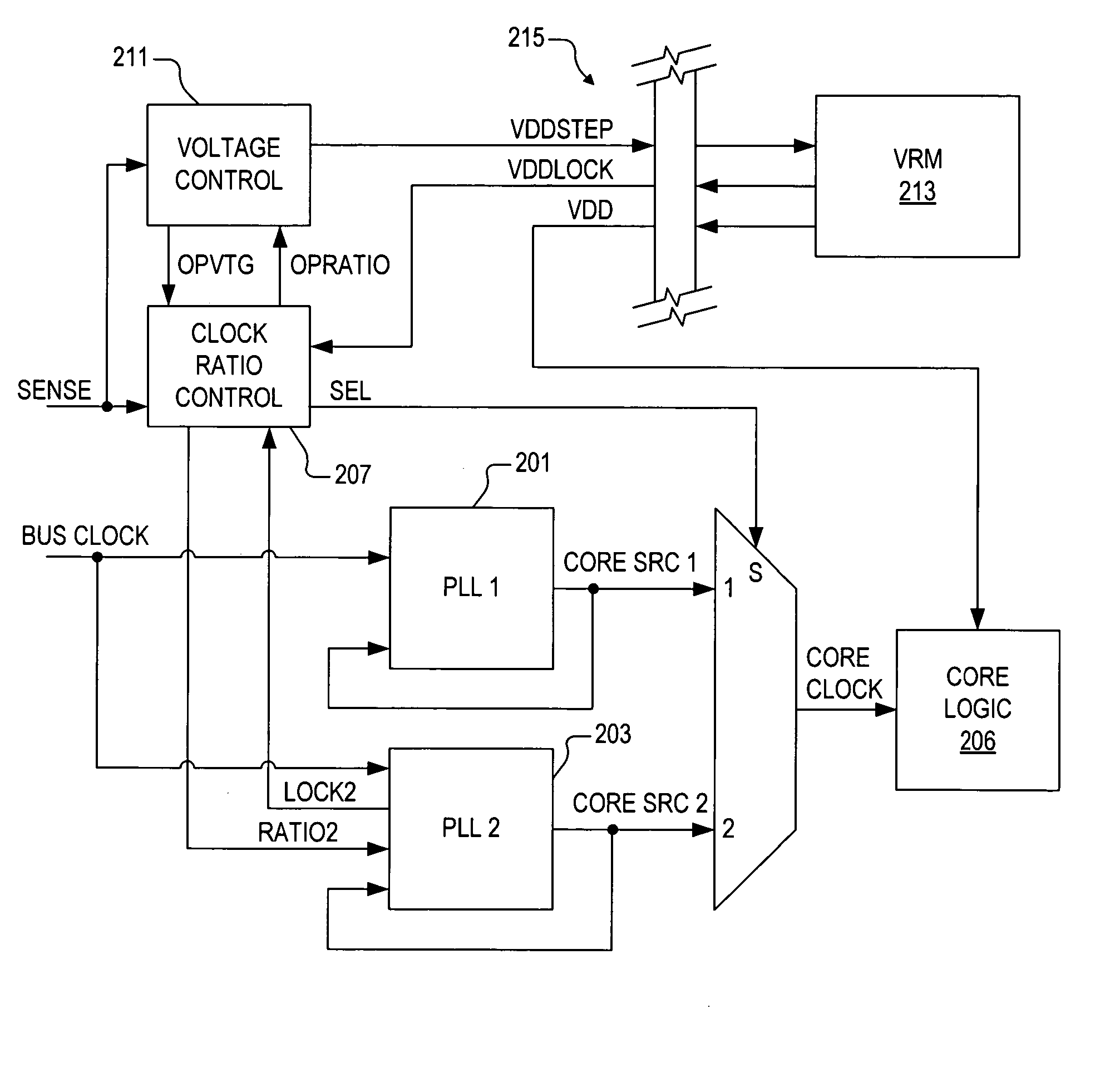

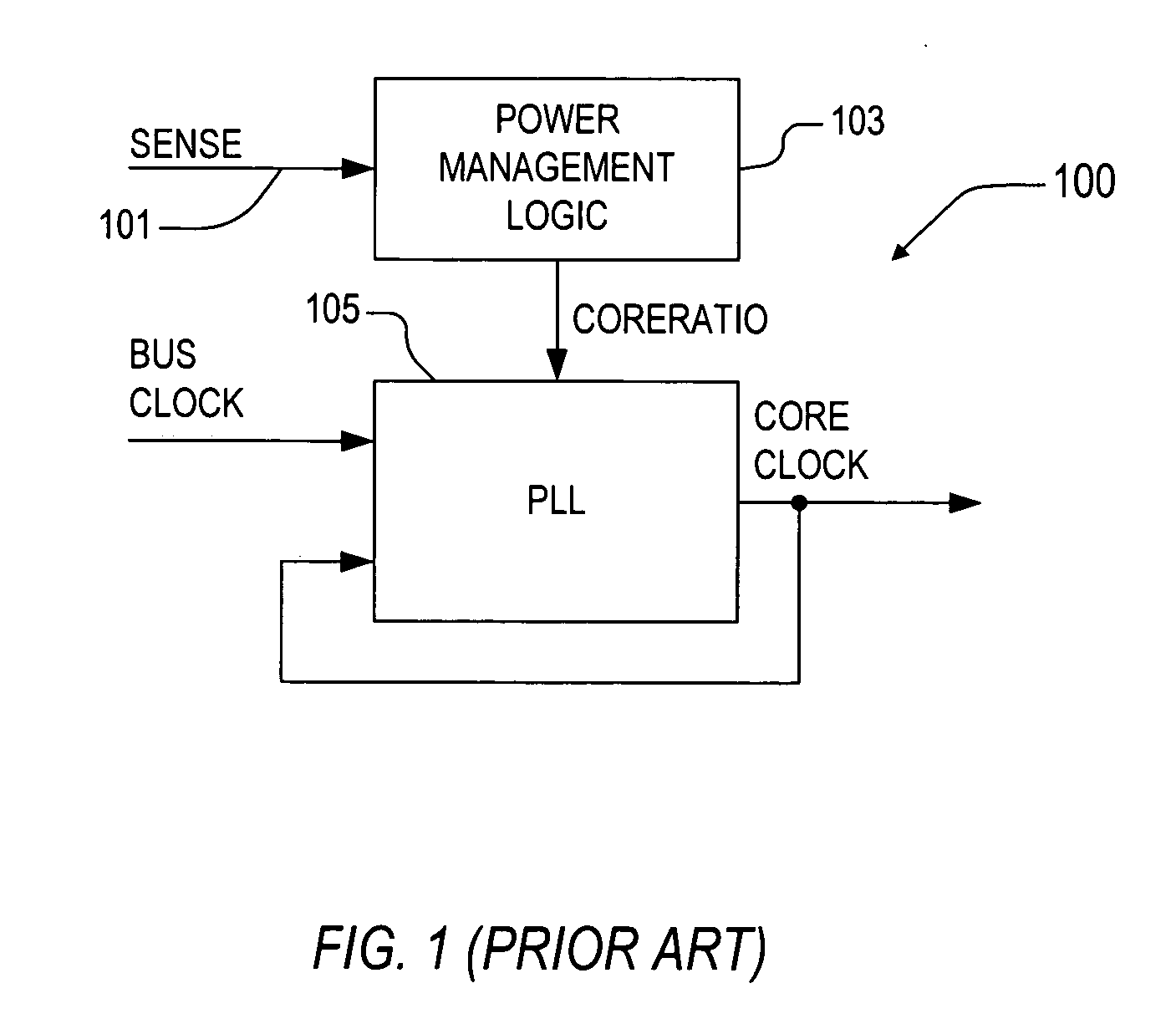

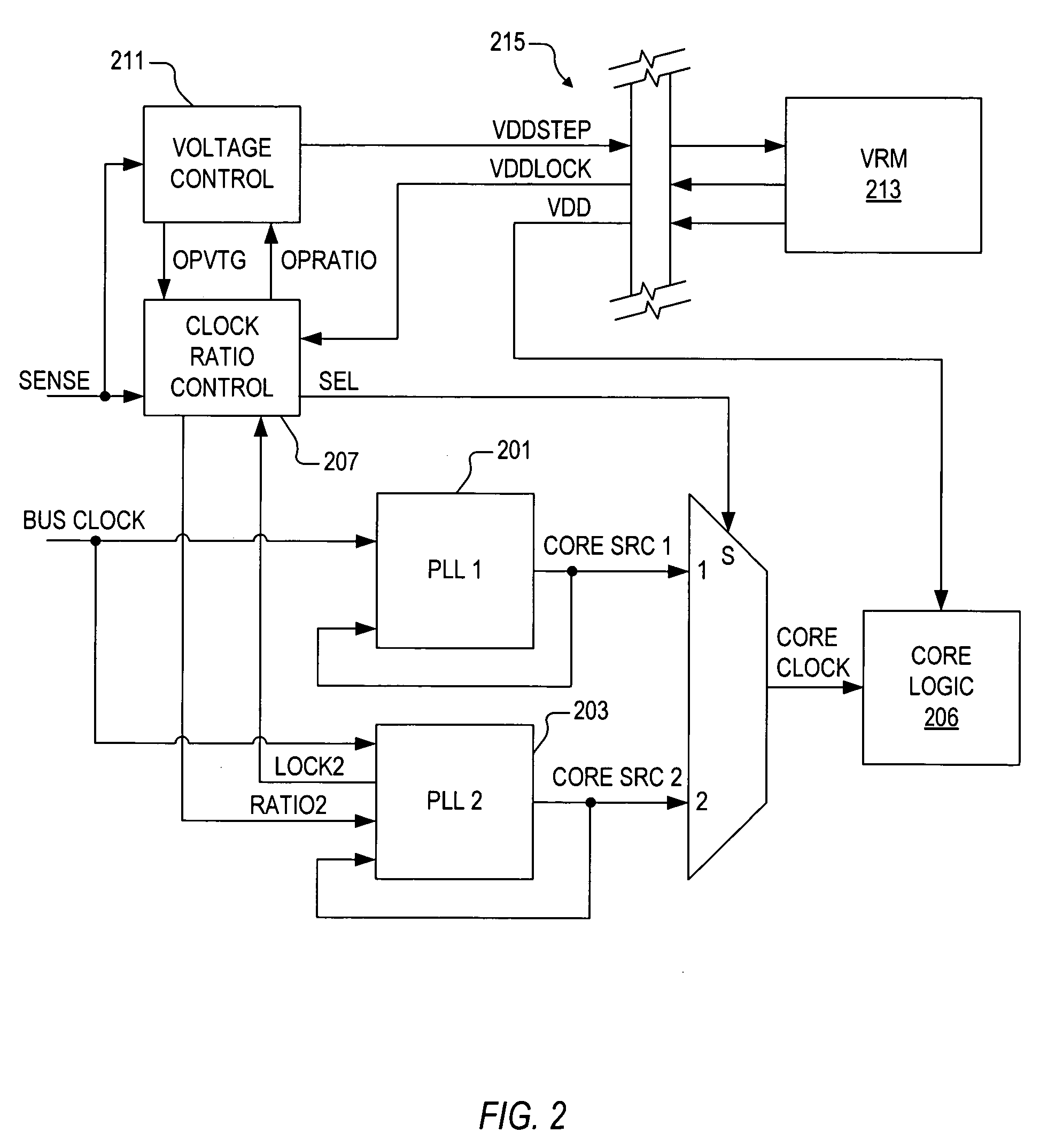

Frequency-voltage mechanism for microprocessor power management

ActiveUS20050138444A1Low working voltageIncrease operating voltageEnergy efficient ICTVolume/mass flow measurementEngineeringPower management

A frequency-voltage mechanism for power management including first and second PLLs, select logic, control logic, and voltage control logic. The first PLL generates a first source clock signal at a first frequency based on a bus clock signal. The second PLL generates a second source clock signal at a second frequency based on a first frequency control signal and the bus clock signal. The select logic selects between the first and second source clock signals to provide a core clock signal based on a select signal. The clock control logic detects power conditions via at least one power sense signal, provides the first frequency control signal according to power conditions, and provides the select signal. The voltage control logic adjusts the operating voltage commensurate with frequency of the core clock signal. Power consumption is dynamically adjusted without undue delay while providing significant power efficiency benefits.

Owner:VIA TECH INC

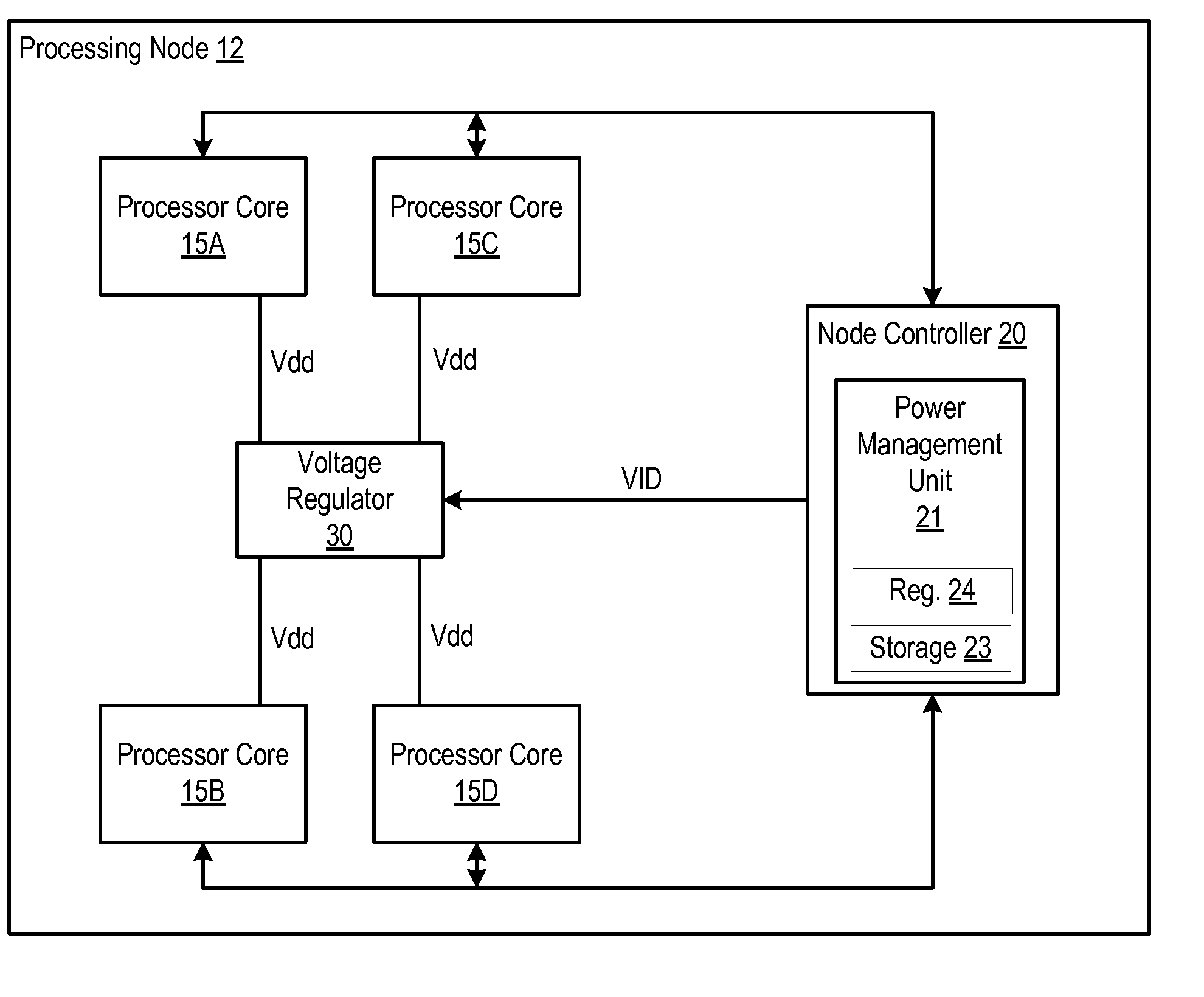

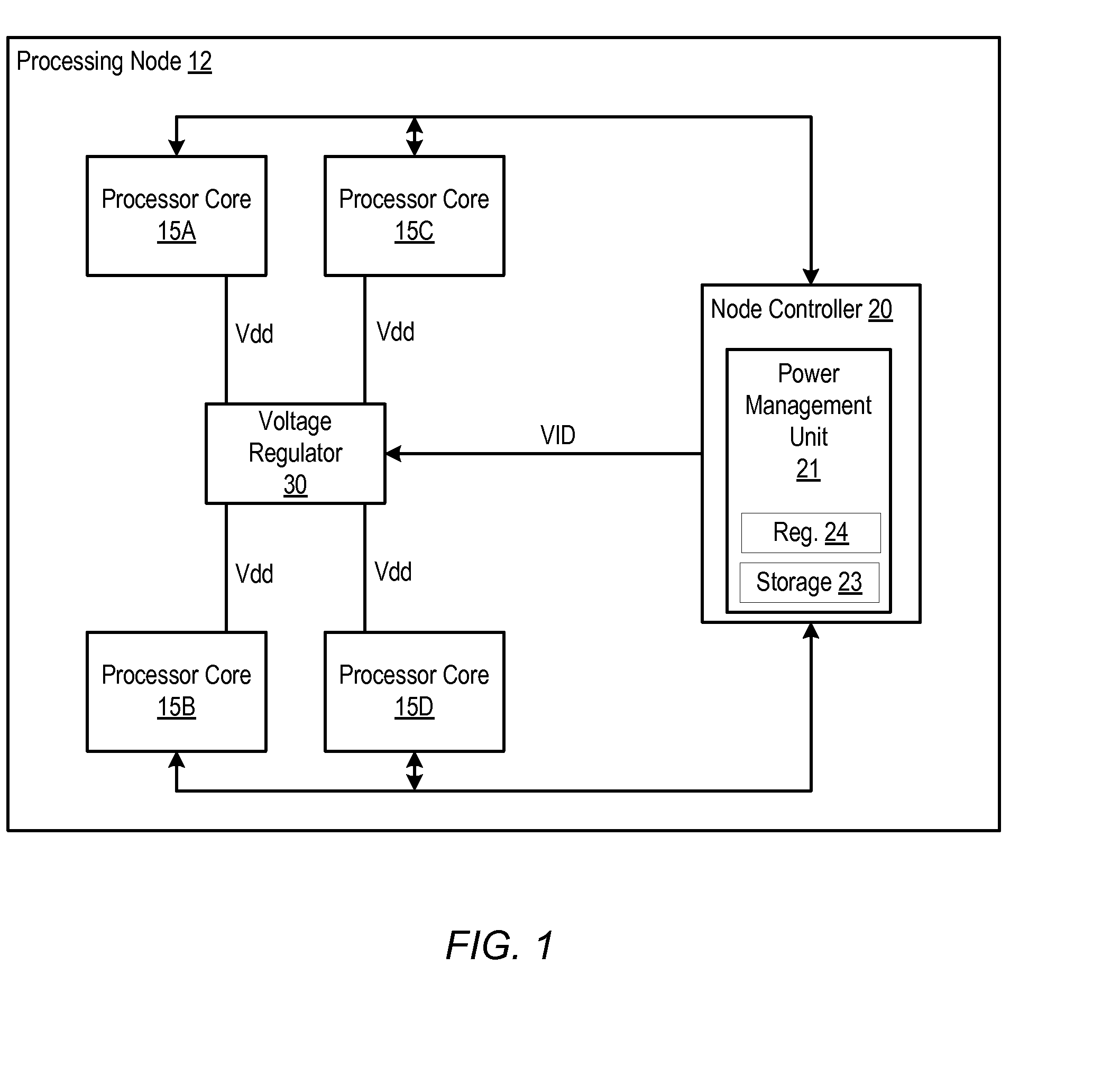

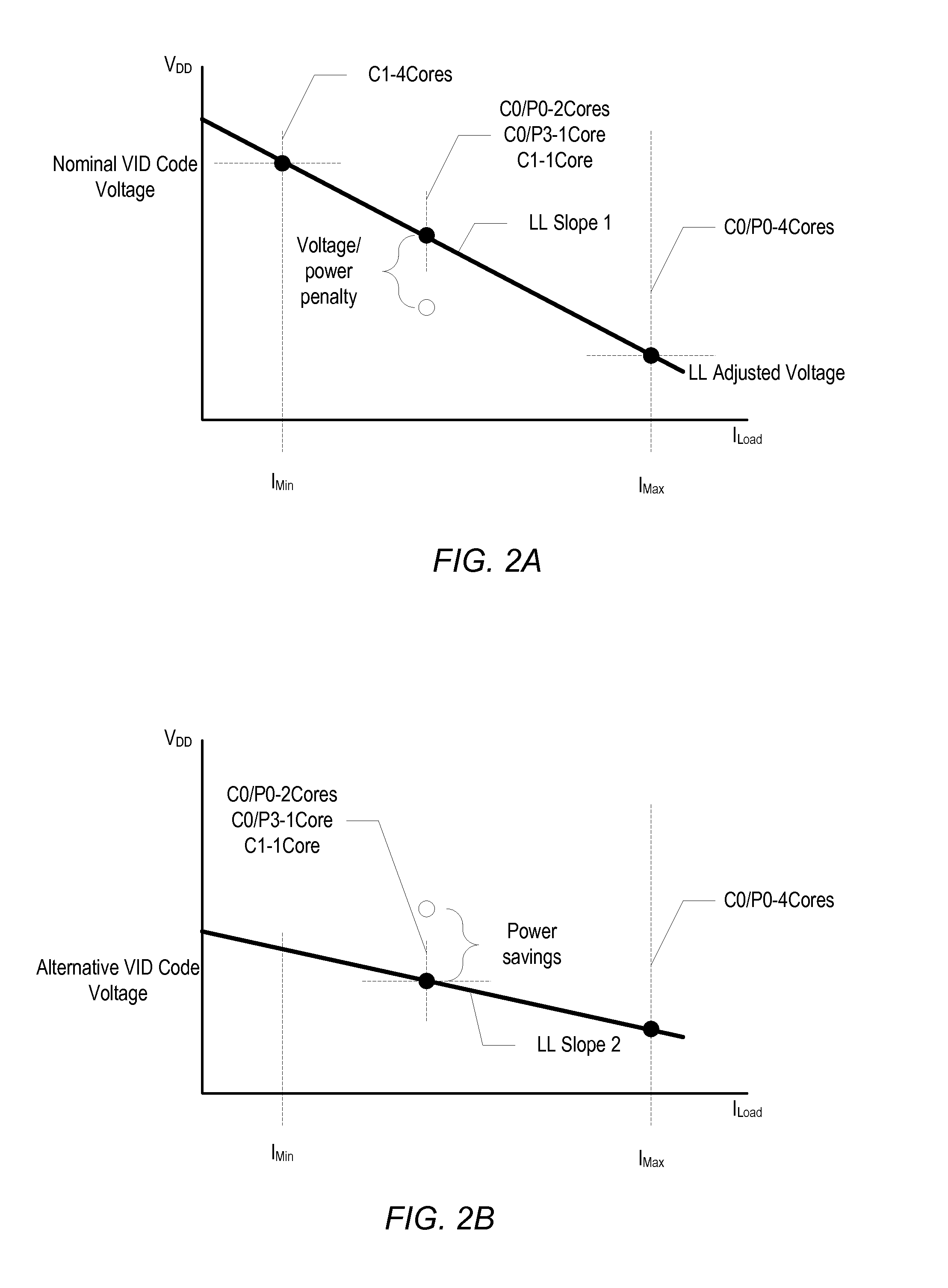

Mechanism for voltage regulator load line compensation using multiple voltage settings per operating state

ActiveUS20120054515A1Save powerReducing voltage outputEnergy efficient ICTVolume/mass flow measurementVoltage regulationPower Management Unit

A system includes one or more processor cores, and a voltage regulator that provides an operating voltage to the one or more processor cores in response to receiving a voltage identifier signal that is indicative of the operating voltage. The system also includes a power management unit that may provide a first voltage identifier signal corresponding to a first operating voltage in response to determining that the processor cores are operating in a first operating state in which the one or more processor cores may draw up to a maximum load current. The power management unit may also provide a second voltage identifier signal corresponding to a second operating voltage, which is less than the first operating voltage, in response to determining that the processor cores are operating in a second operating state in which the processor cores are incapable of an increase in load current above a predetermined amount.

Owner:ADVANCED MICRO DEVICES INC

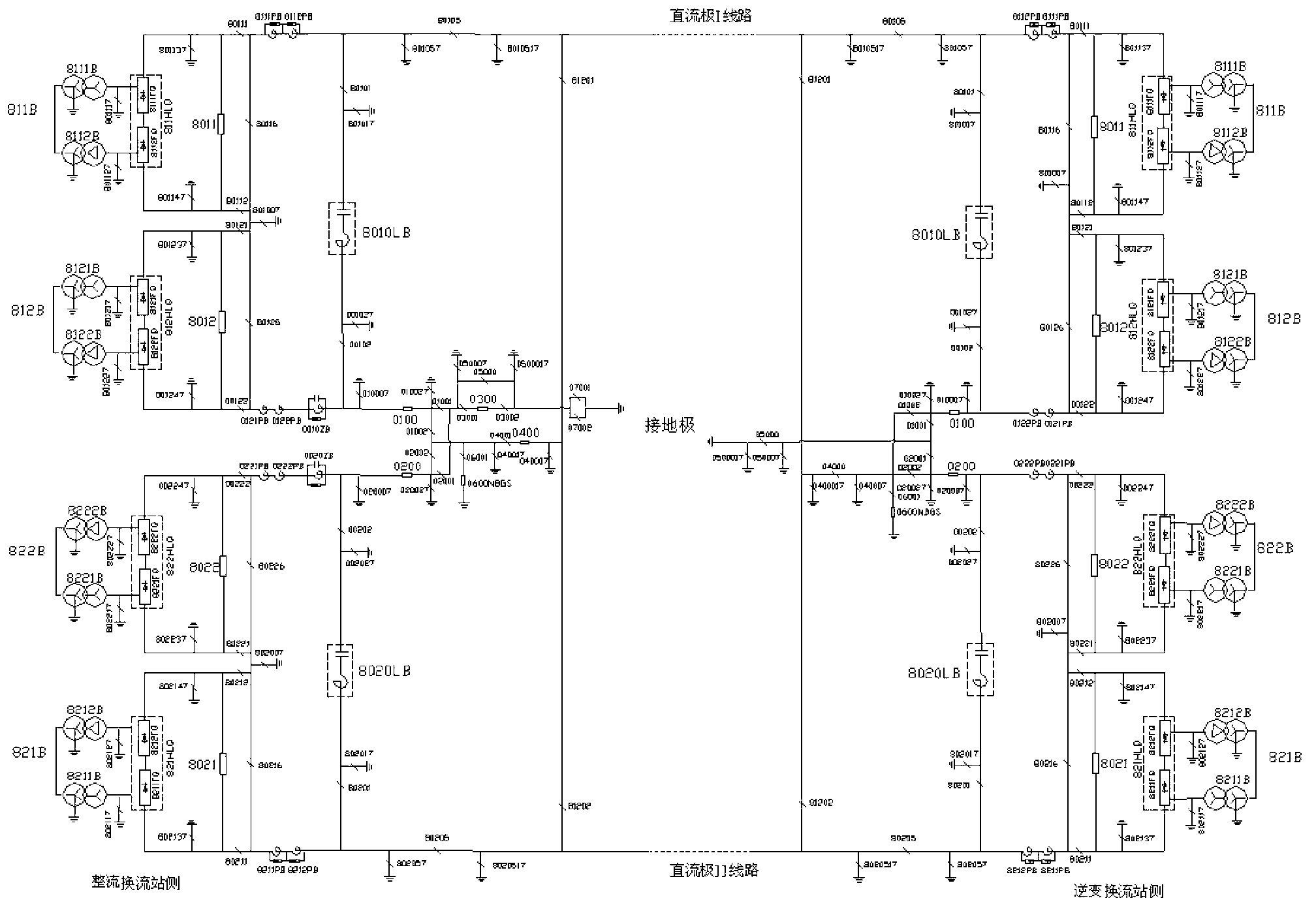

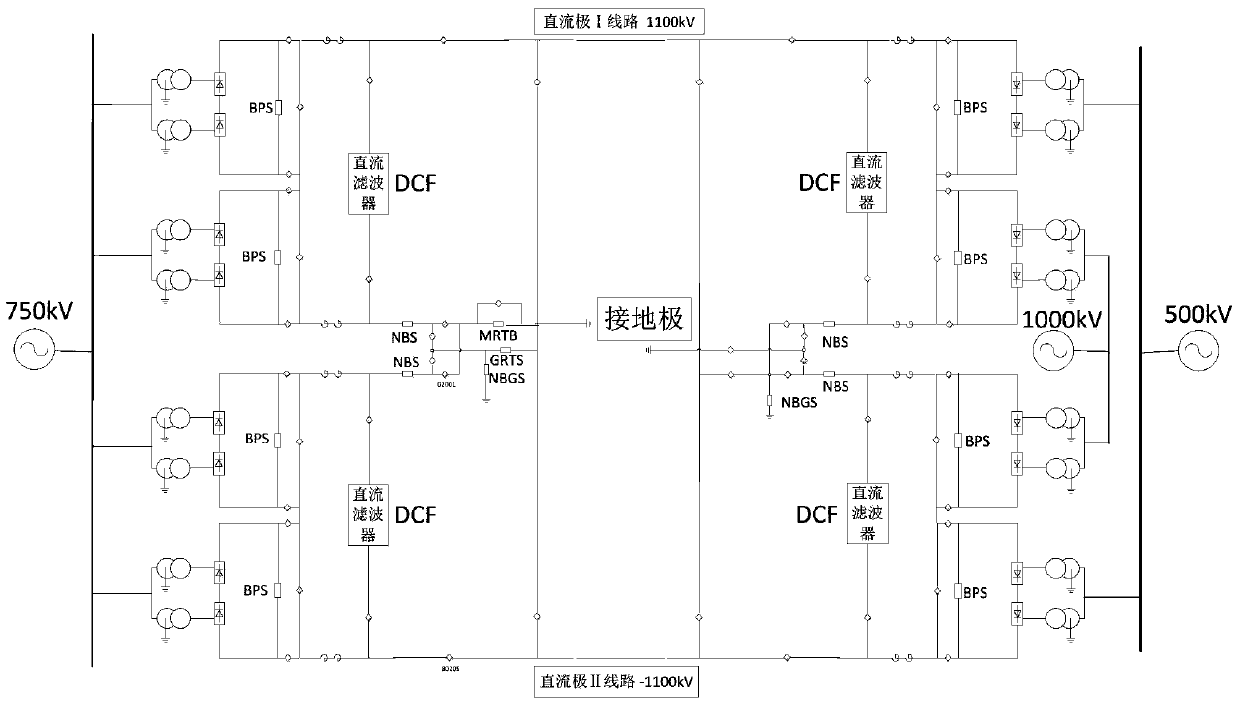

Debugging method for +/- 800 kV ultra-high voltage direct-current transmission project system

ActiveCN103296673AComprehensive scope of commissioningIncrease operating voltageDc network circuit arrangementsElectrical testingEmbedded systemTransmission line

The invention relates to a debugging method for a + / - 800 kV ultra-high voltage direct-current transmission project system. The system comprises convertor stations at two ends and a direct-current transmission line. The debugging method for the + / - 800 kV ultra-high voltage direct-current transmission project system comprises the following steps that (I) the + / - 800 kV ultra-high voltage direct-current transmission project system is subjected to calculation and analysis; (II) a debugging scheme for the + / - 800 kV ultra-high voltage direct-current transmission project system is formed; (III) a debugging plan for the + / - 800 kV ultra-high voltage direct-current transmission project system is made; (IV) the + / - 800 kV ultra-high voltage direct-current transmission project system is subjected to a field debugging test; (V) the + / - 800 kV ultra-high voltage direct-current transmission project system is subjected to a pilot run; (VI) the + / - 800 kV ultra-high voltage direct-current transmission project system is subjected to a debugging summary. According to the debugging method for the + / - 800 kV ultra-high voltage direct-current transmission project system, a single current converter and a monopolar and bipolar system debugging test are combined for the first time, therefore, the efficiency of a system debugging test is improved, the system debugging speed is increased, good conditions are created for finishing system debugging in advance, and experience and reference are provided for the debugging of a direct-current transmission project system in future.

Owner:STATE GRID CORP OF CHINA +1

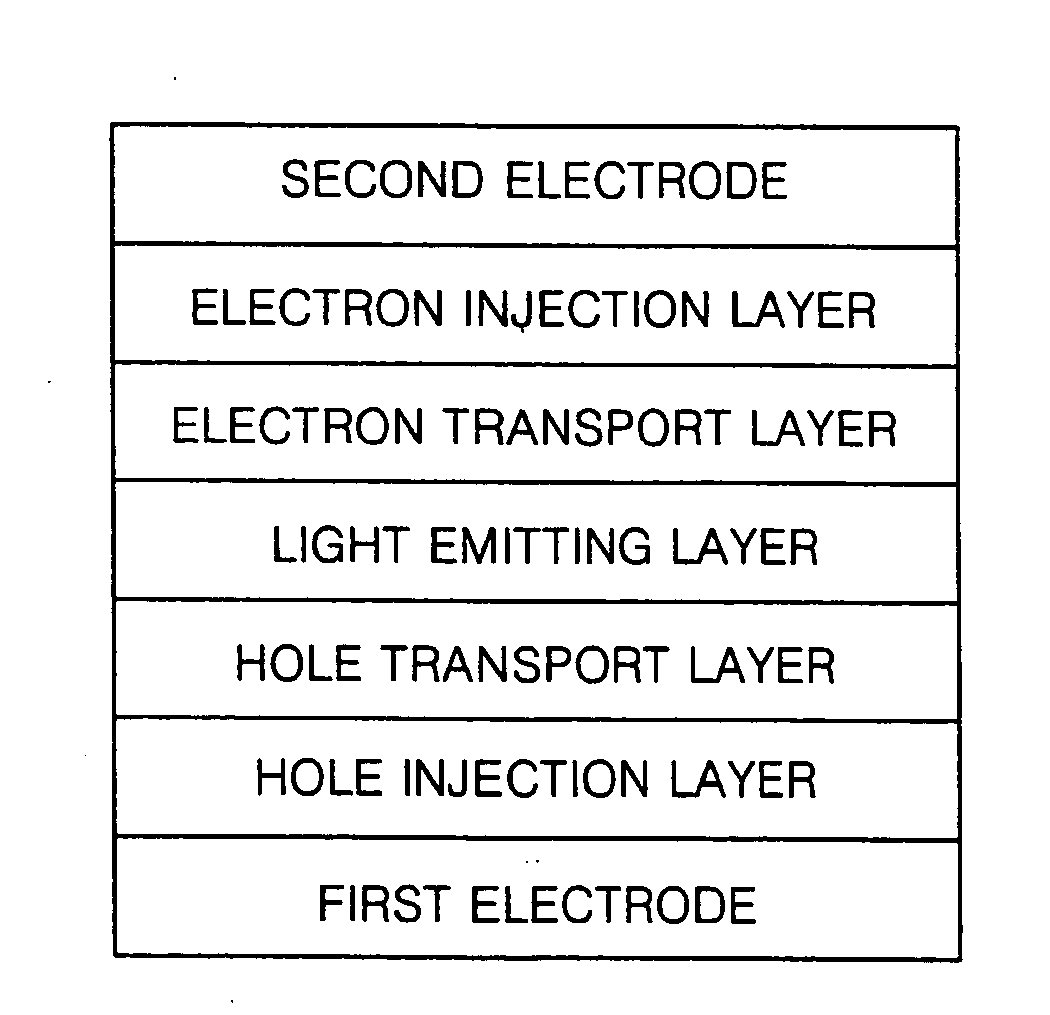

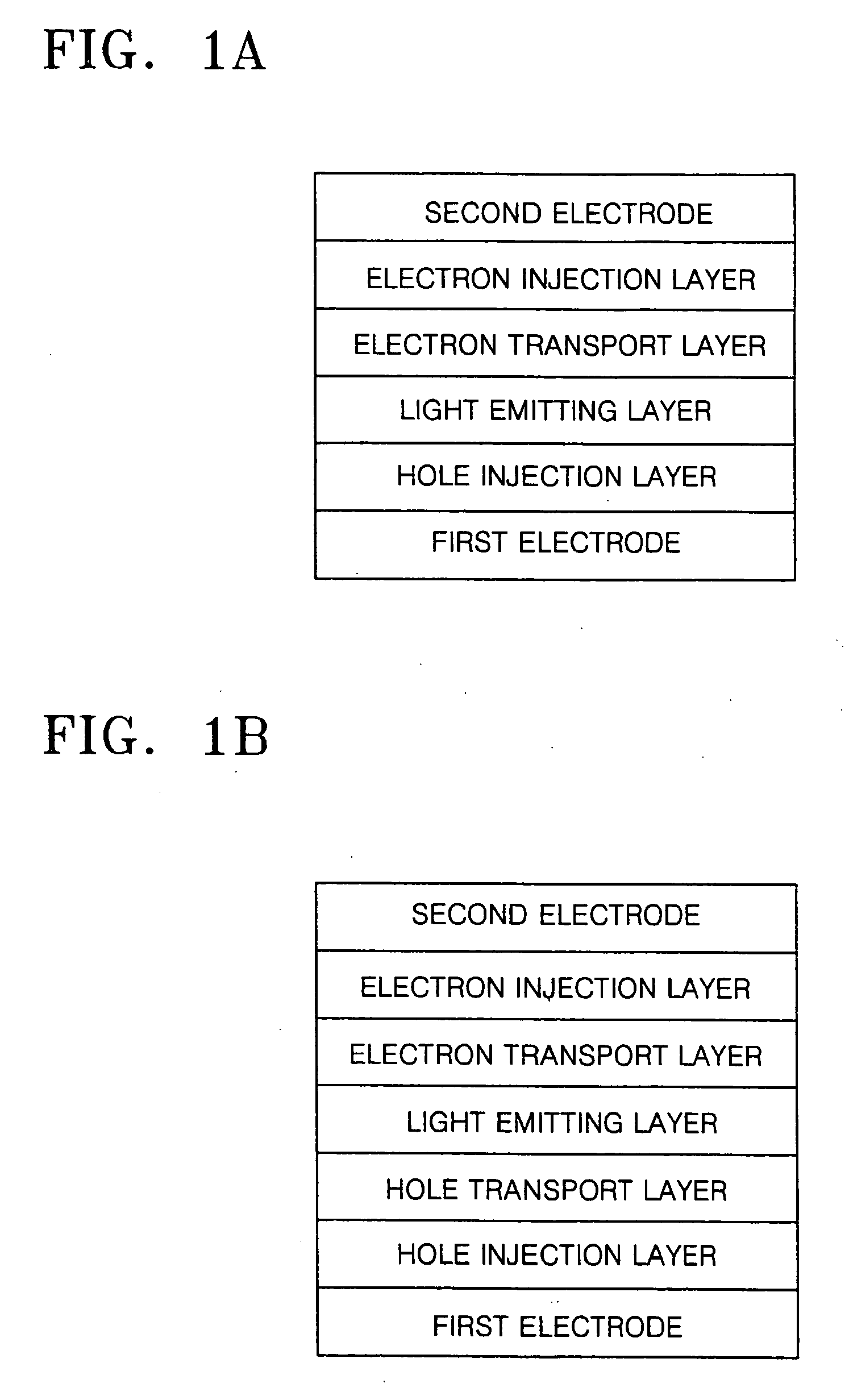

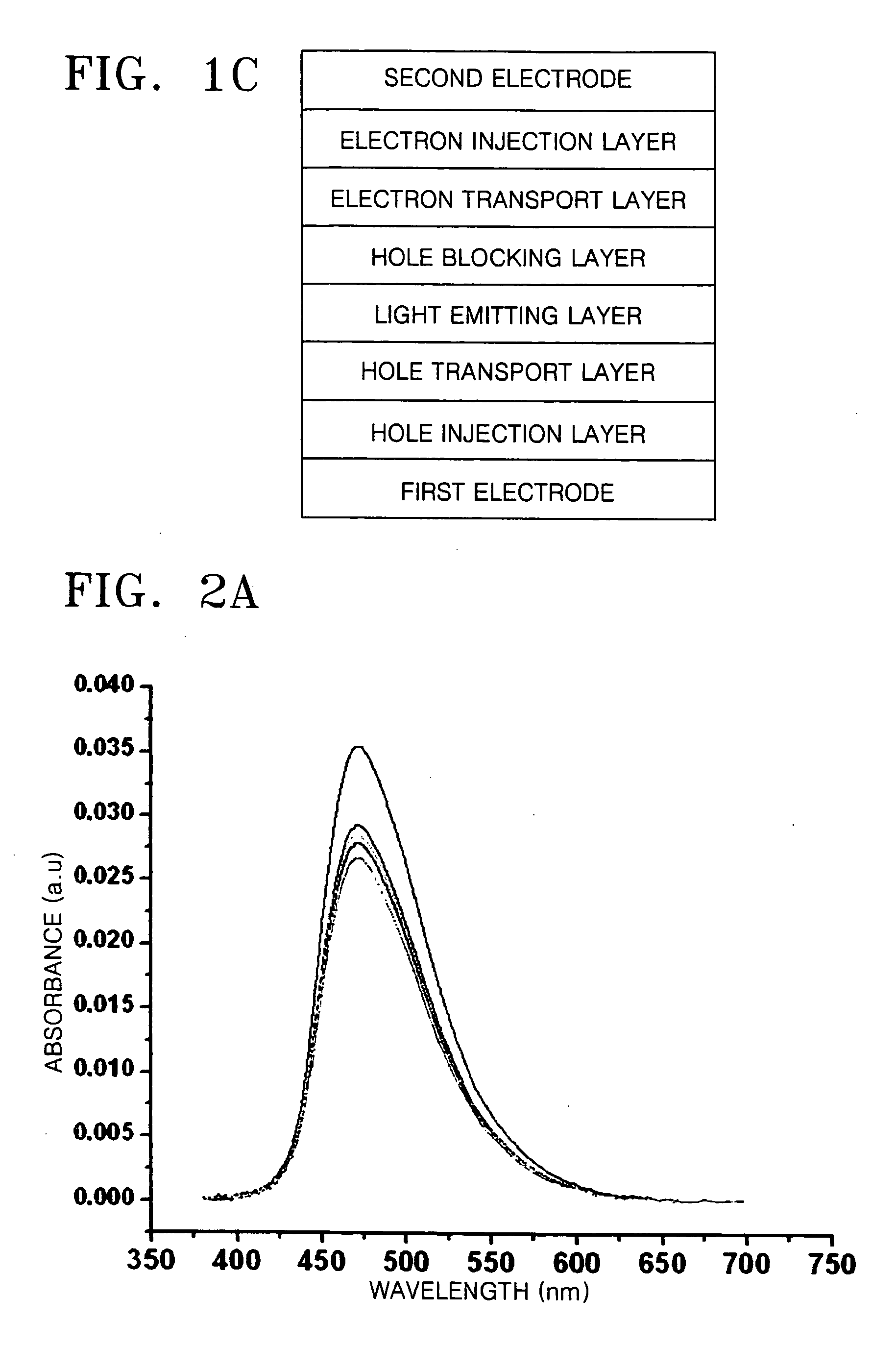

Organic light emitting compound and organic light emitting device comprising the same

ActiveUS20070176541A1Improve thermal stabilityIncrease operating voltageOrganic chemistryDischarge tube luminescnet screensArylHalogen

A compound represented by Formula 1 and an organic light emitting device including the same:where Ar is a substituted or unsubstituted C6-C26 aryl group; X is O, S,R1 and R2 are hydrogen, a halogen, a C1-C12 alkyl group, a C6-C26 aryl group, or a substituted group thereof; R3, R4, R5, R6, R7 and R8 are each independently hydrogen or a substituted or unsubstituted C1-C12 alkyl group; R9 through R22 are each independently hydrogen, a C1-C30 alkyl group, a C1-C30 alkoxy group, a C6-C30 aryl group, a C6-C30 arylalkyl group, a C6-C30 aryloxy group, a C5-C30 heteroaryl group, a C5-C30 heteroarylalkyl group, a C5-C30 heteroaryloxy group, a C5-C20 cycloalkyl group, a C5-C30 heterocycloalkyl group, or a substituted group thereof. An organic light emitting device using the compound has low operating voltage, high color purity, and high efficiency.

Owner:SAMSUNG DISPLAY CO LTD

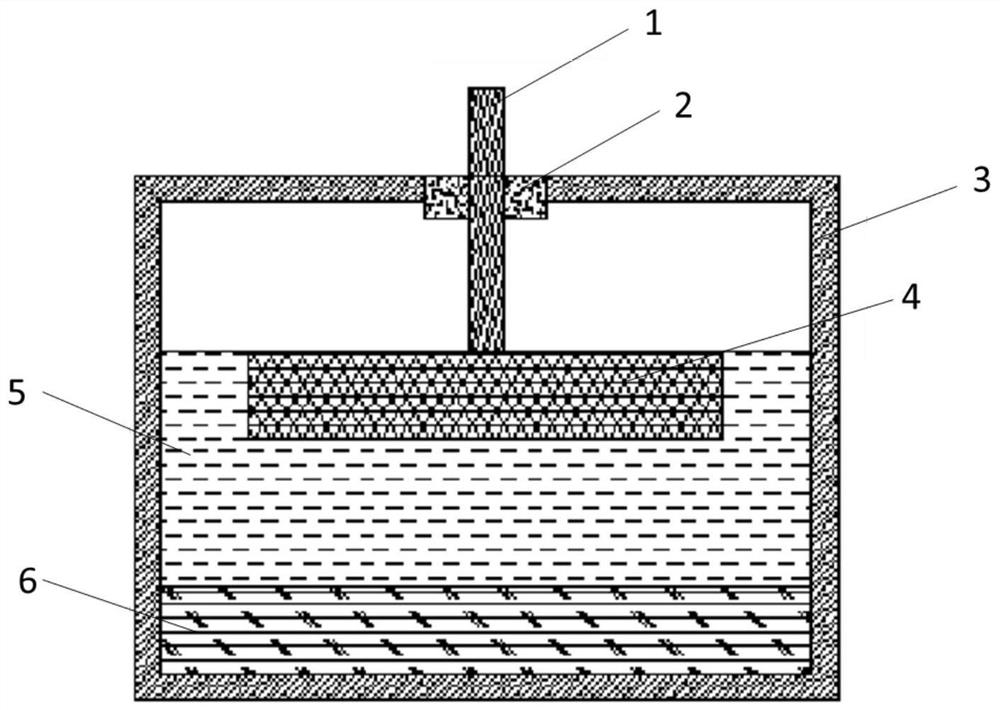

Carbon fibre cloth for gaseous diffusion layer of fuel cell

InactiveCN101330147AHigh flooding resistanceIncrease operating voltageCell electrodesFibre chemical featuresGaseous diffusionFuel cells

Owner:程显军

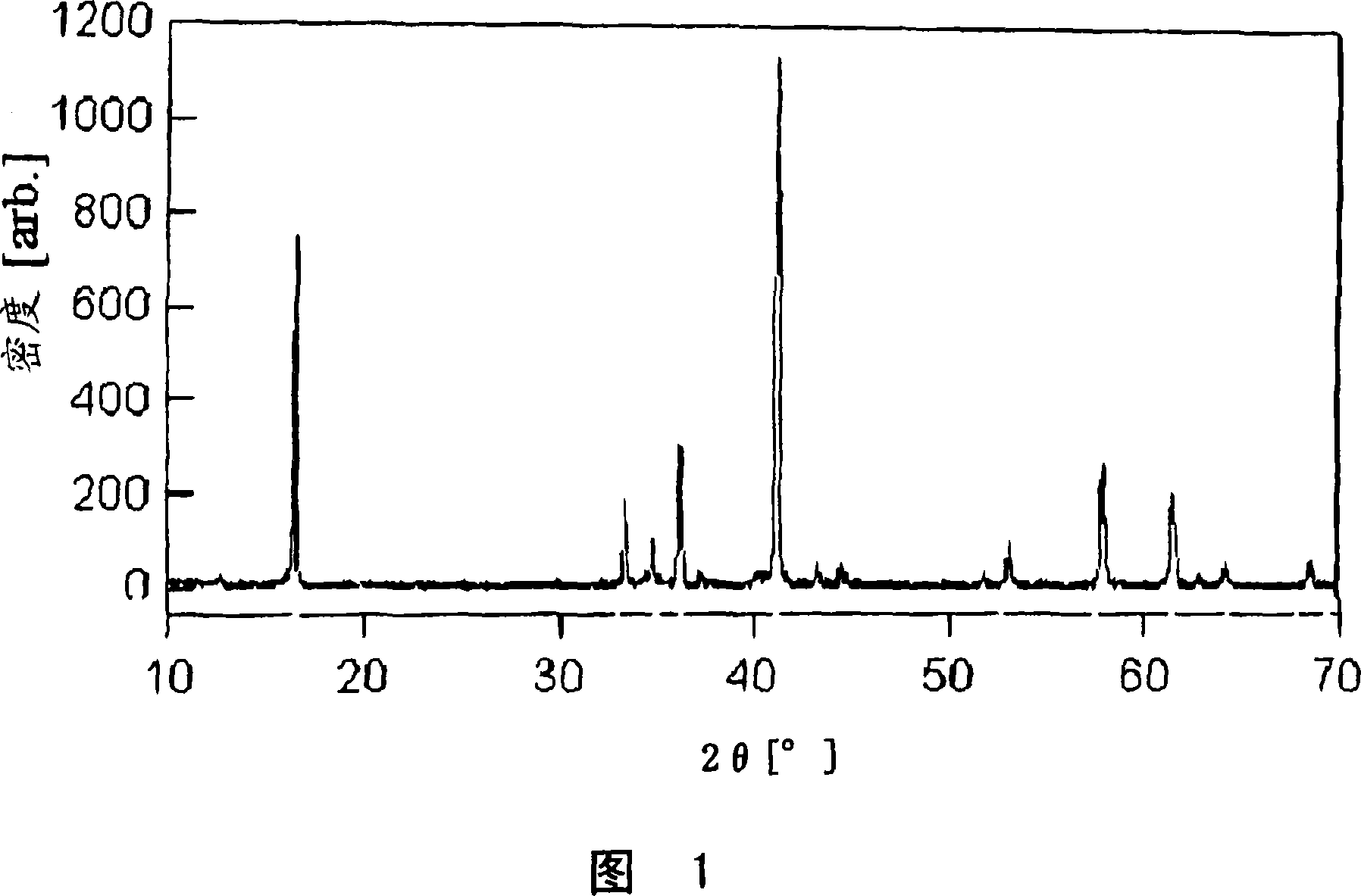

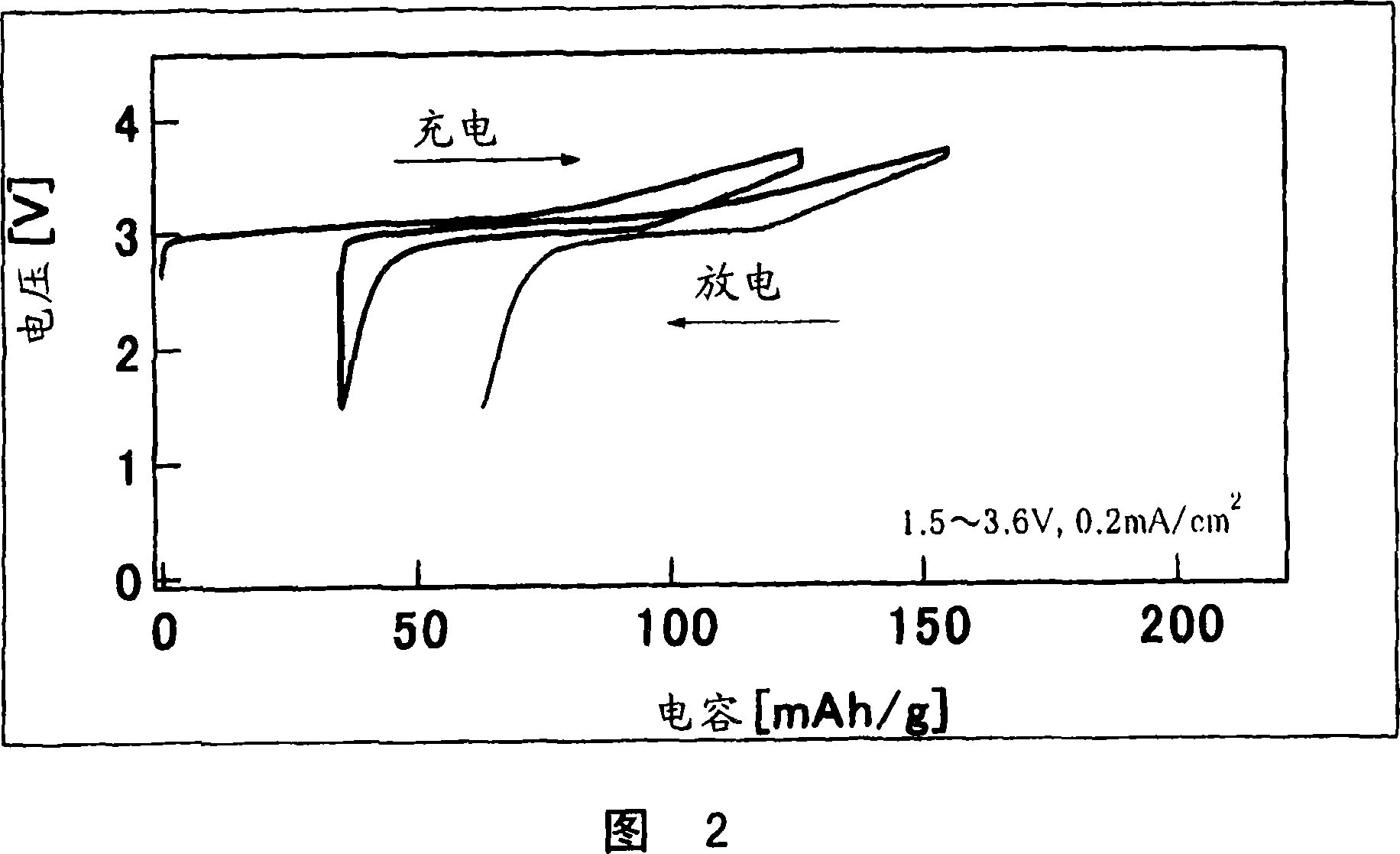

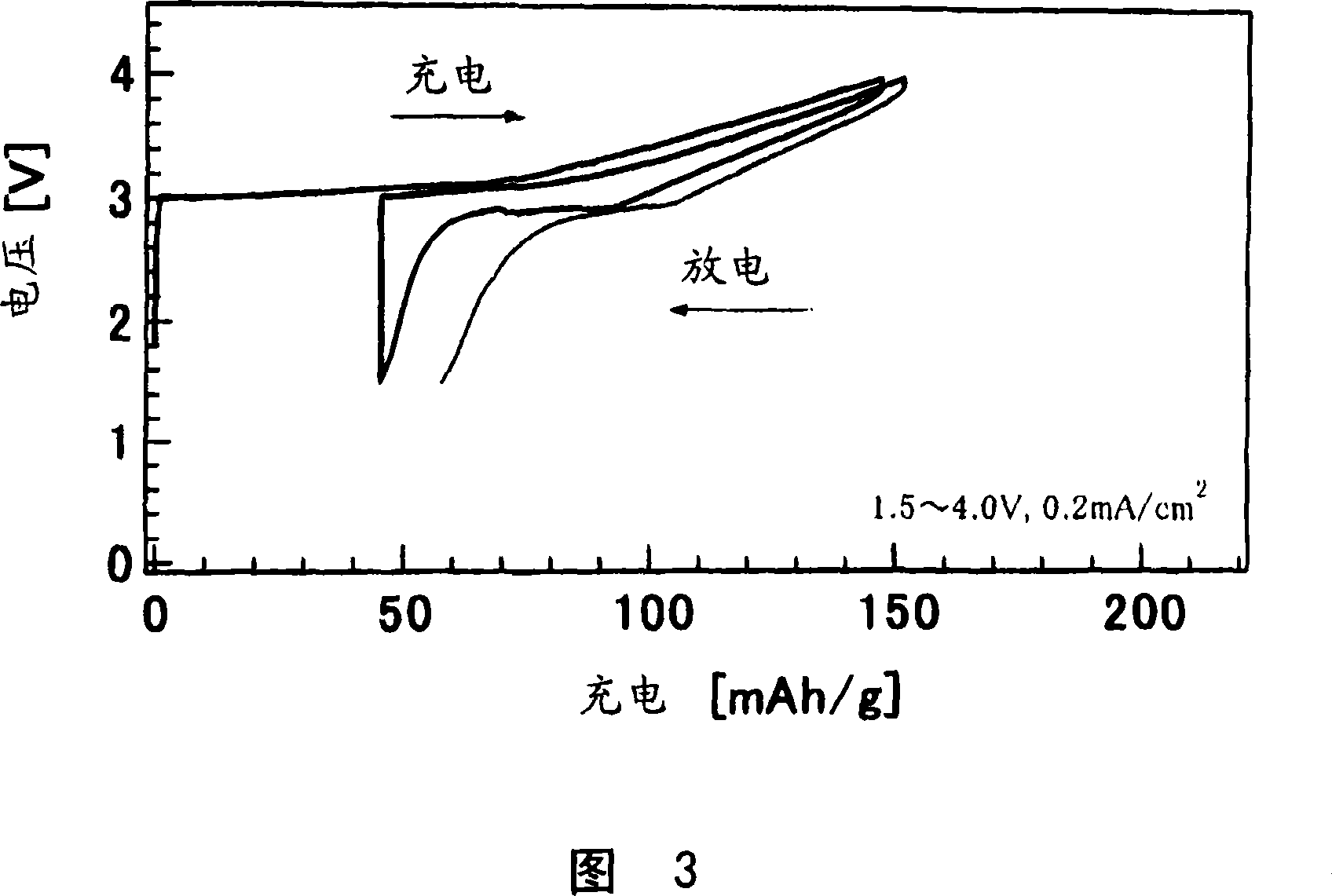

Positive electrode active material for nonaqueous electrolyte secondary battery

ActiveCN101065867AIncrease operating voltageImprove performanceNon-aqueous electrolyte accumulatorsActive material electrodesPhysical chemistryElectrolyte

Disclosed is a positive electrode active material for nonaqueous electrolyte secondary batteries which contains a complex oxide mainly containing sodium, nickel and a tetravalent metal while having a hexagonal structure. This positive electrode active material enables to obtain a nonaqueous electrolyte secondary battery with high operating voltage. The complex oxide is preferably expressed as Na[Na(1 / 3-2x / 3)Ni(x-y)M(2 / 3-x / 3-y)A2y]O2 (wherein M represents one or more tetravalent metals, A represents one or more trivalent metals, 0 < x = 0.5, 0 = y < 1 / 6, AND X > y).

Owner:SUMITOMO CHEM CO LTD +1

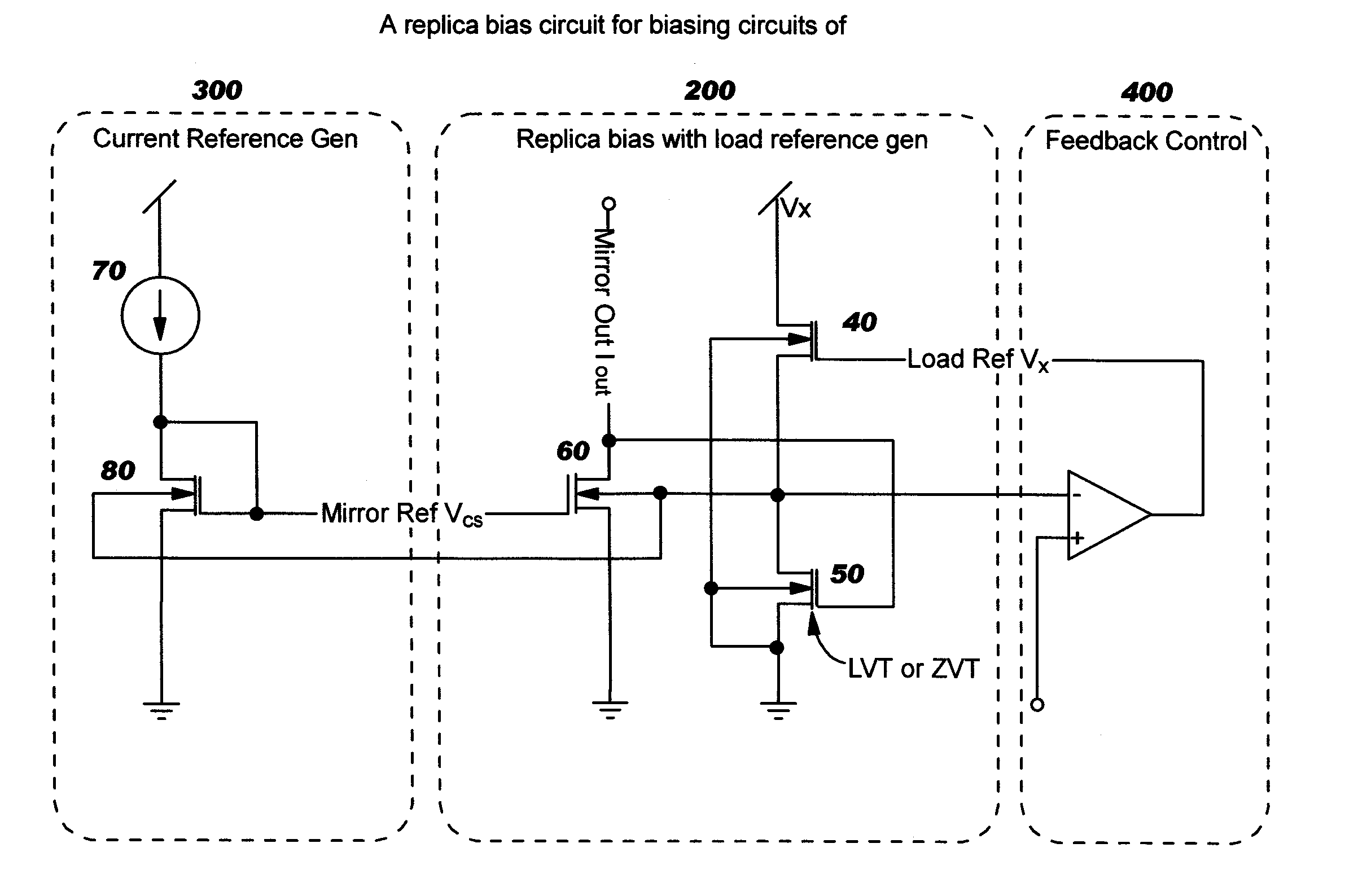

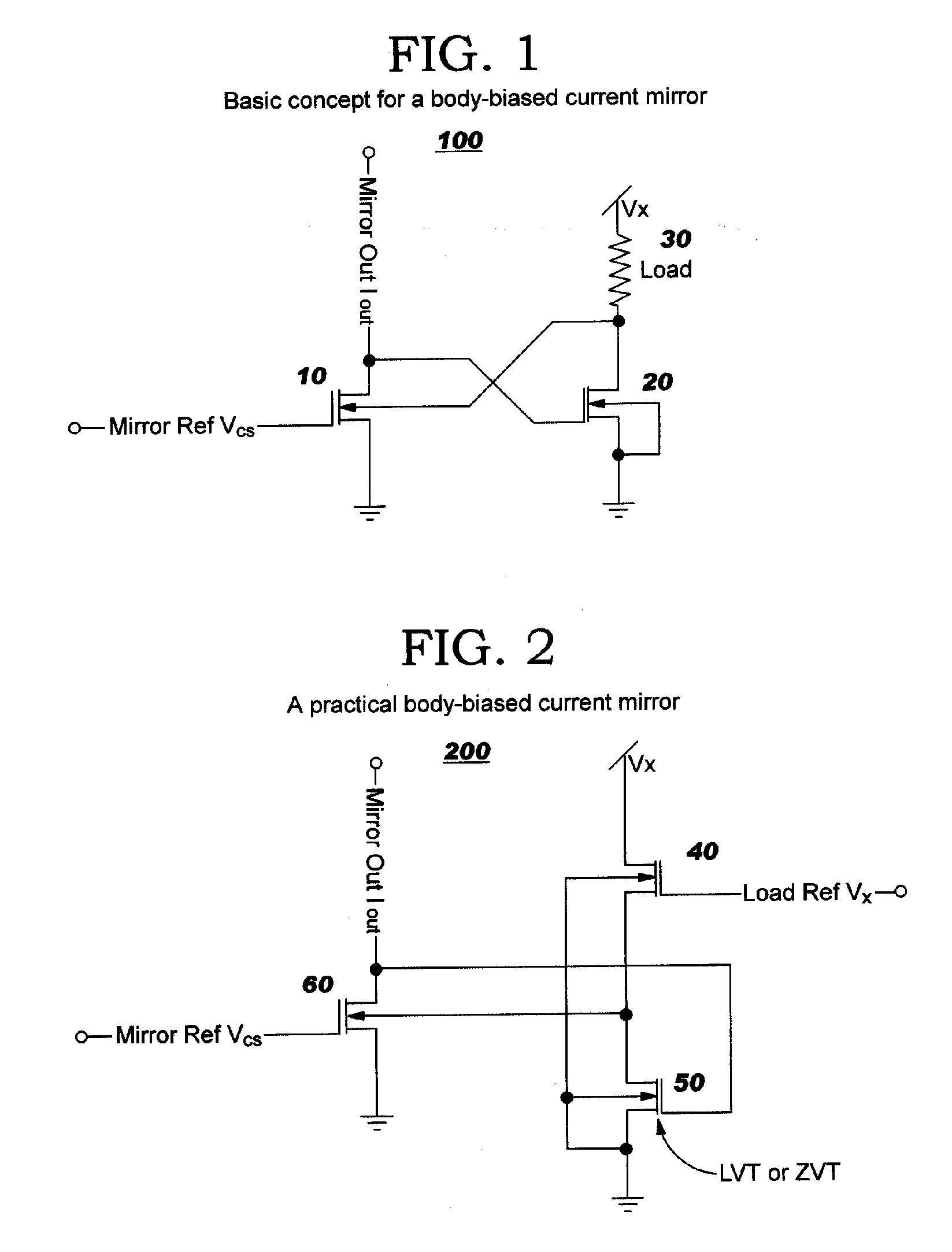

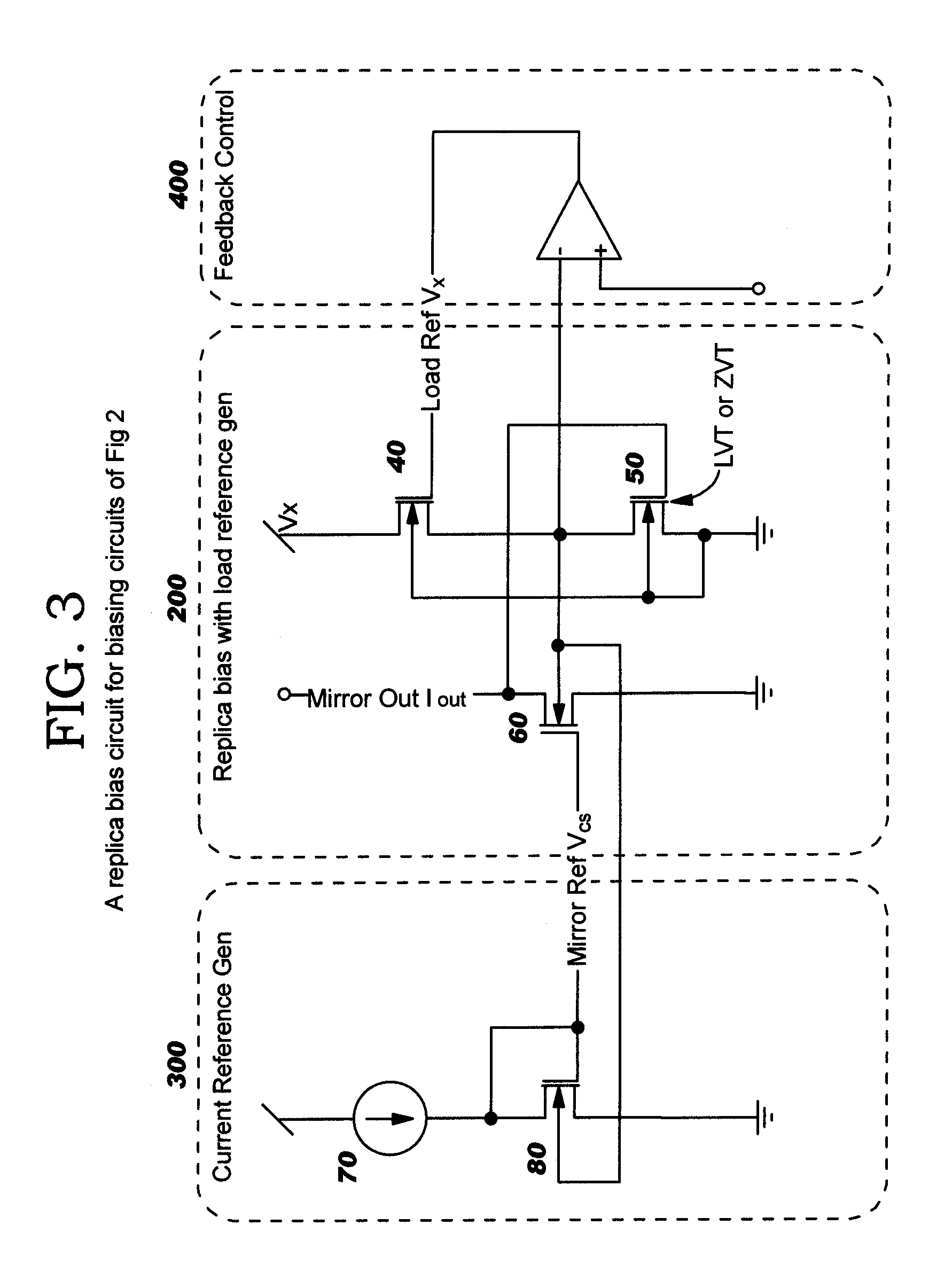

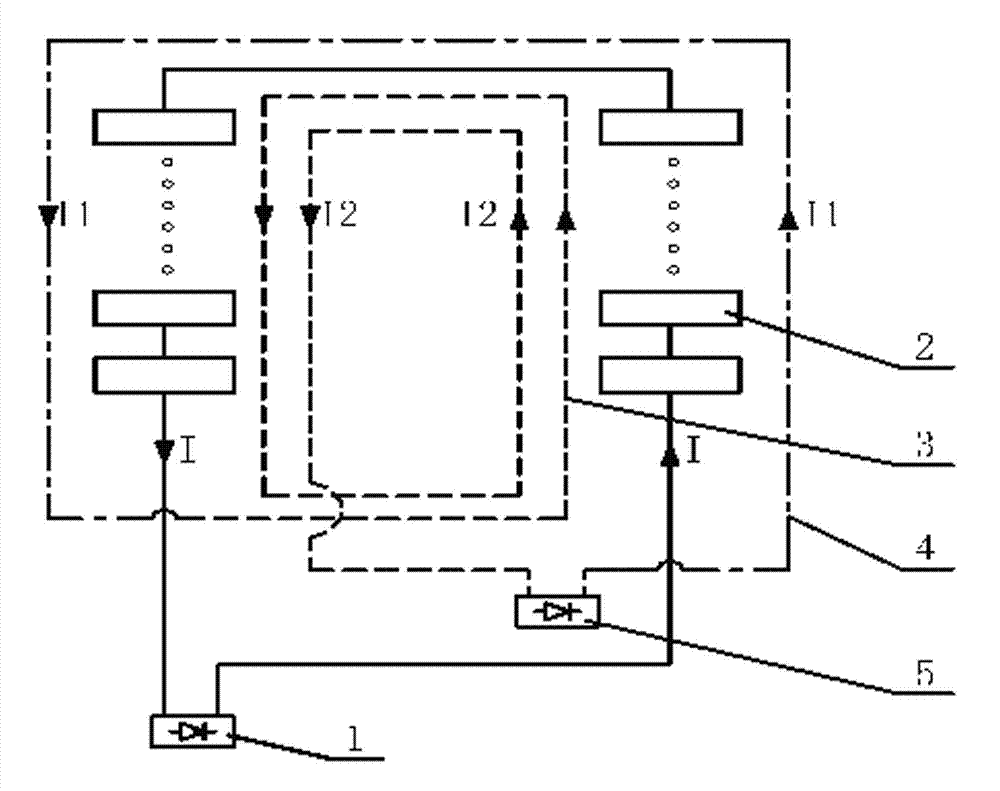

Body-biased enhanced precision current mirror

InactiveUS20060192611A1Consumes circuit areaStable reference current to output current ratioElectric pulse generator detailsElectric variable regulationEngineeringReference circuit

A body-biased enhanced current mirror reference circuit is disclosed wherein the body bias voltage of a current mirror device is varied to adjust its threshold voltage. Both the drain and body potentials of a replica mirror transistor are controlled to selected values. The drain is set to an expected DC voltage output of an NFET current mirror device. The body potential is set to a maximum desired value to prevent forward biasing of the body-to-diffusion junction(s) of one or more current mirror devices, which is accomplished by a feedback control circuit. A low-frequency, low-precision op amp drives the gate of a replica load device so that the body of the replica NFET current mirror device is set to a maximum bias voltage. The maximum bias voltage is also used to bias the body of a diode connected NMOS reference transistor, so that the current in the NFET current mirror device will be approximately equal to the current in the diode-connected NMOS reference. An auxiliary NFET current mirror device may be added to the body-biased enhanced current mirror circuit with the body connected to ground as in the unmodified current mirror to negate a non-monotonicity of the current output.

Owner:IBM CORP

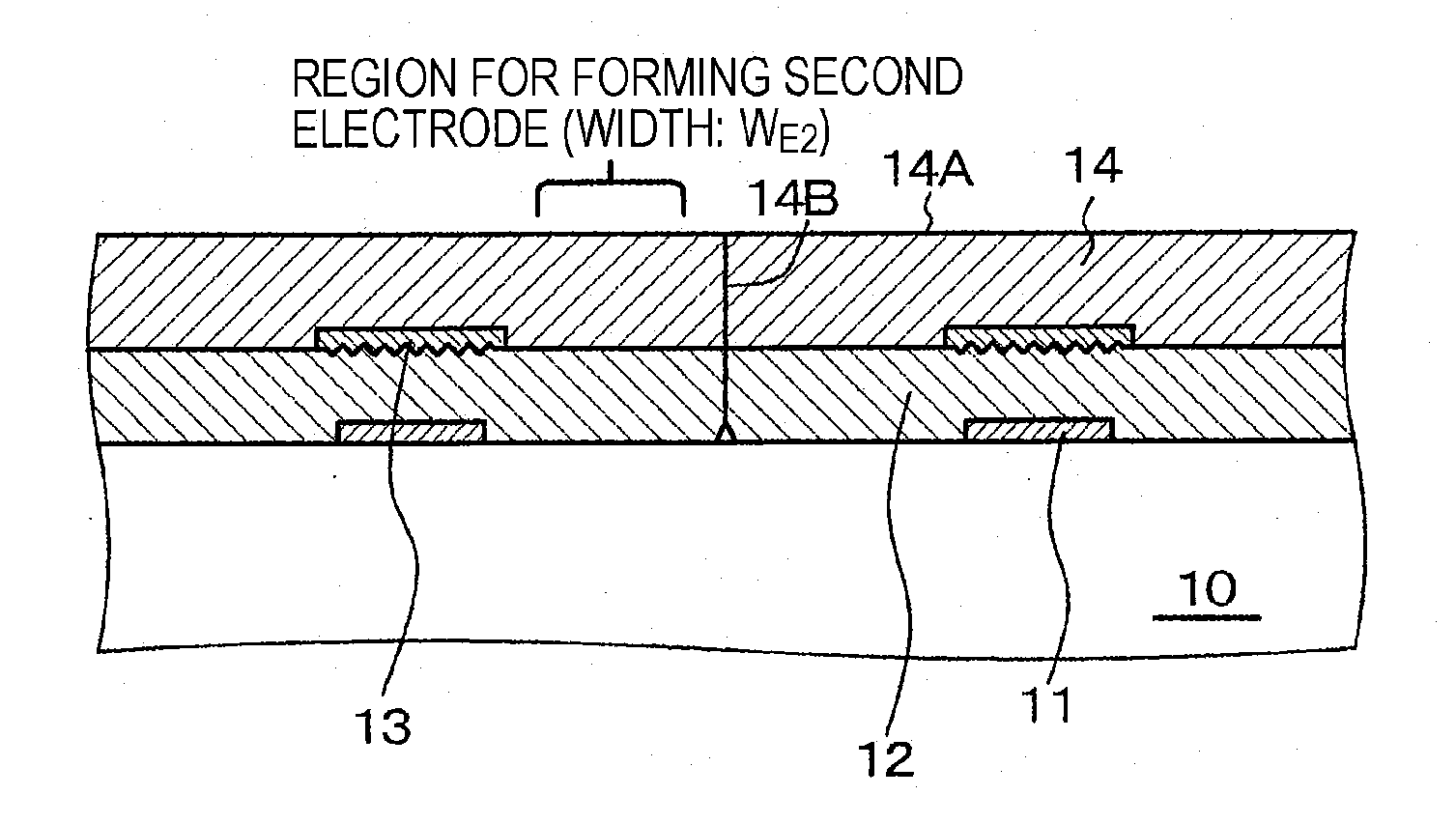

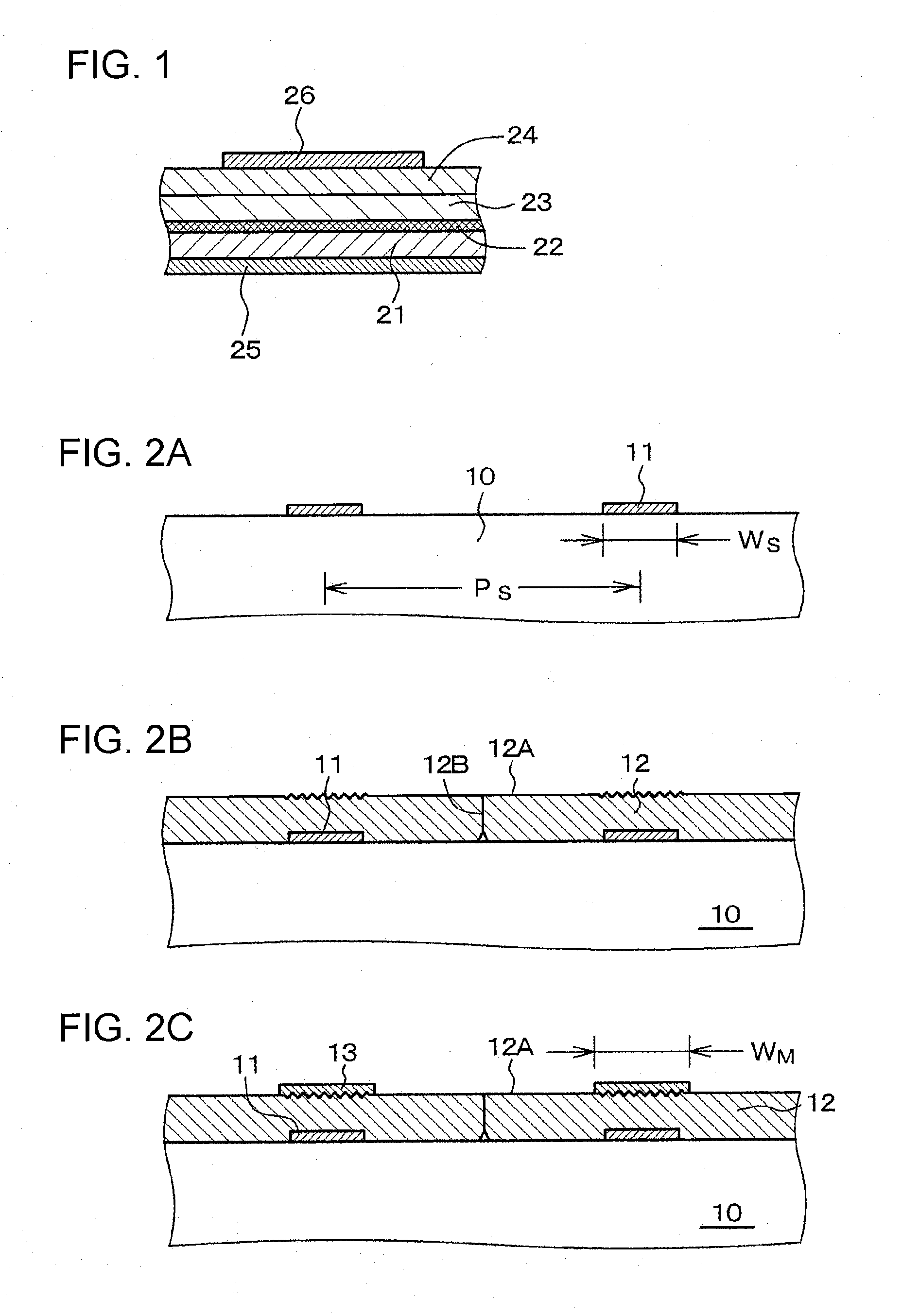

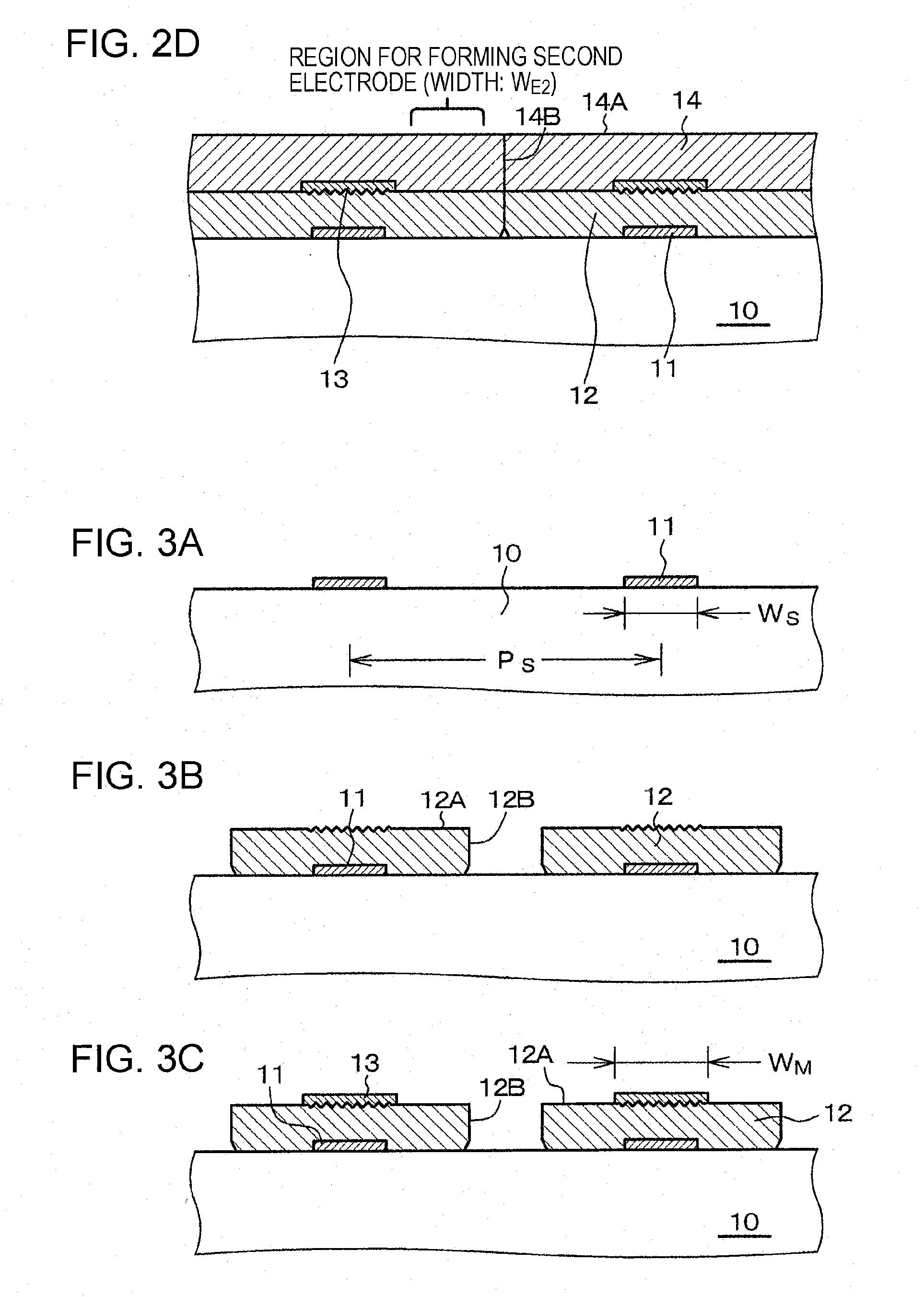

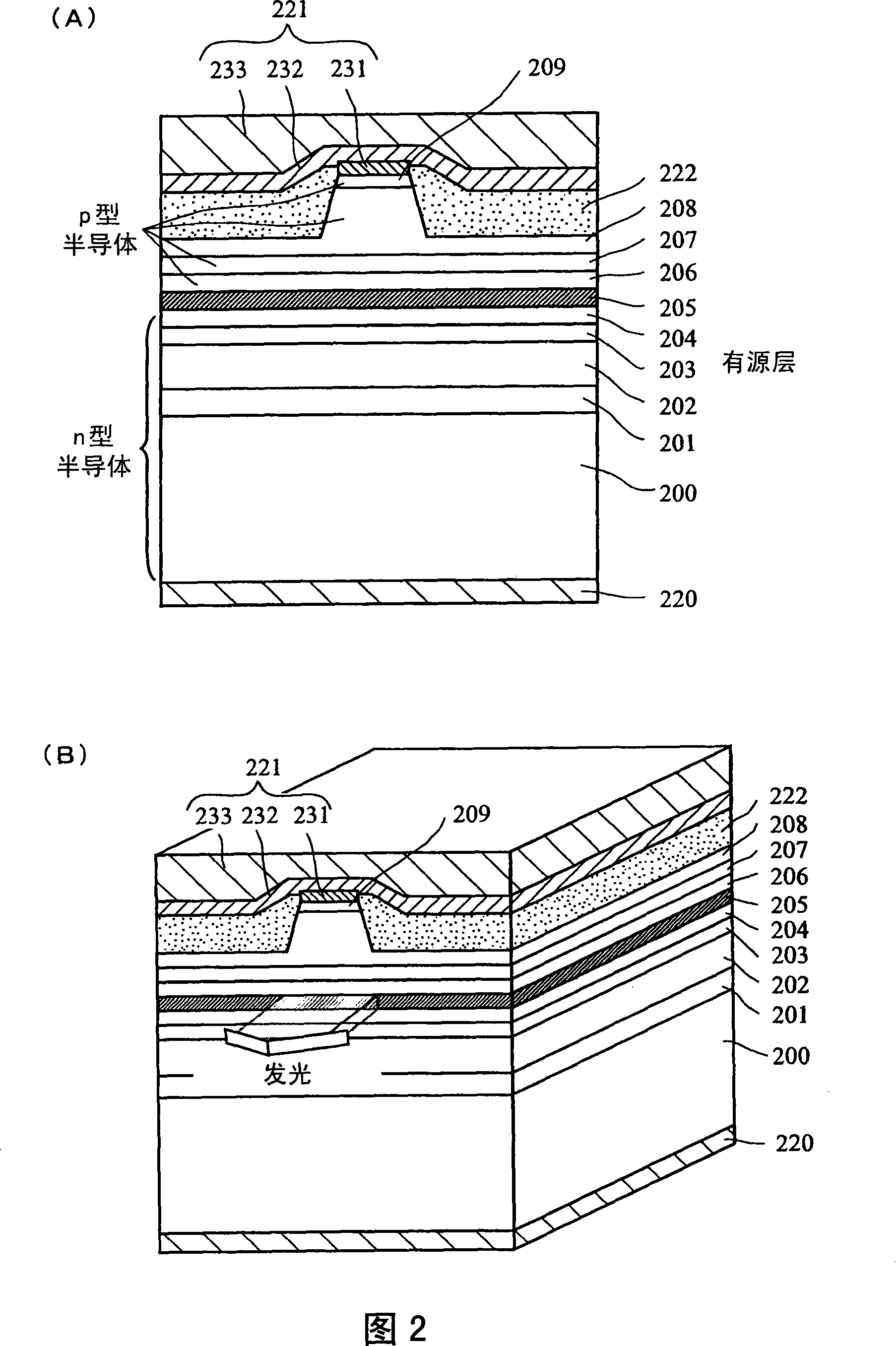

Gan-Based Light-Emitting Element and Method for Producing Same

InactiveUS20080048195A1Reduce crystal defect densityAvoid it happening againSemiconductor/solid-state device manufacturingSemiconductor devicesGalliumContact layer

A GaN-based semiconductor light-emitting element capable of suppressing the occurrence of piezoelectric spontaneous polarization in the thickness direction of an active layer and reducing the driving voltage of a light-emitting diode is provided. The GaN-based semiconductor light-emitting element has a structure with a first GaN-based compound semiconductor layer 21 having the top face parallel to the a-plane and having a first conductivity type, an active layer 22 having the top face parallel to the a-plane, a second GaN-based compound semiconductor layer 23 having the top face parallel to the a-plane and having a second conductivity type, and a contact layer 24 composed of a GaN-based compound semiconductor and having the top face parallel to the a-plane, stacked in that order. The GaN-based semiconductor light-emitting element further includes a first electrode 25 disposed on the first GaN-based compound semiconductor layer 21 and a second electrode 26 disposed on the contact layer 24.

Owner:SONY CORP

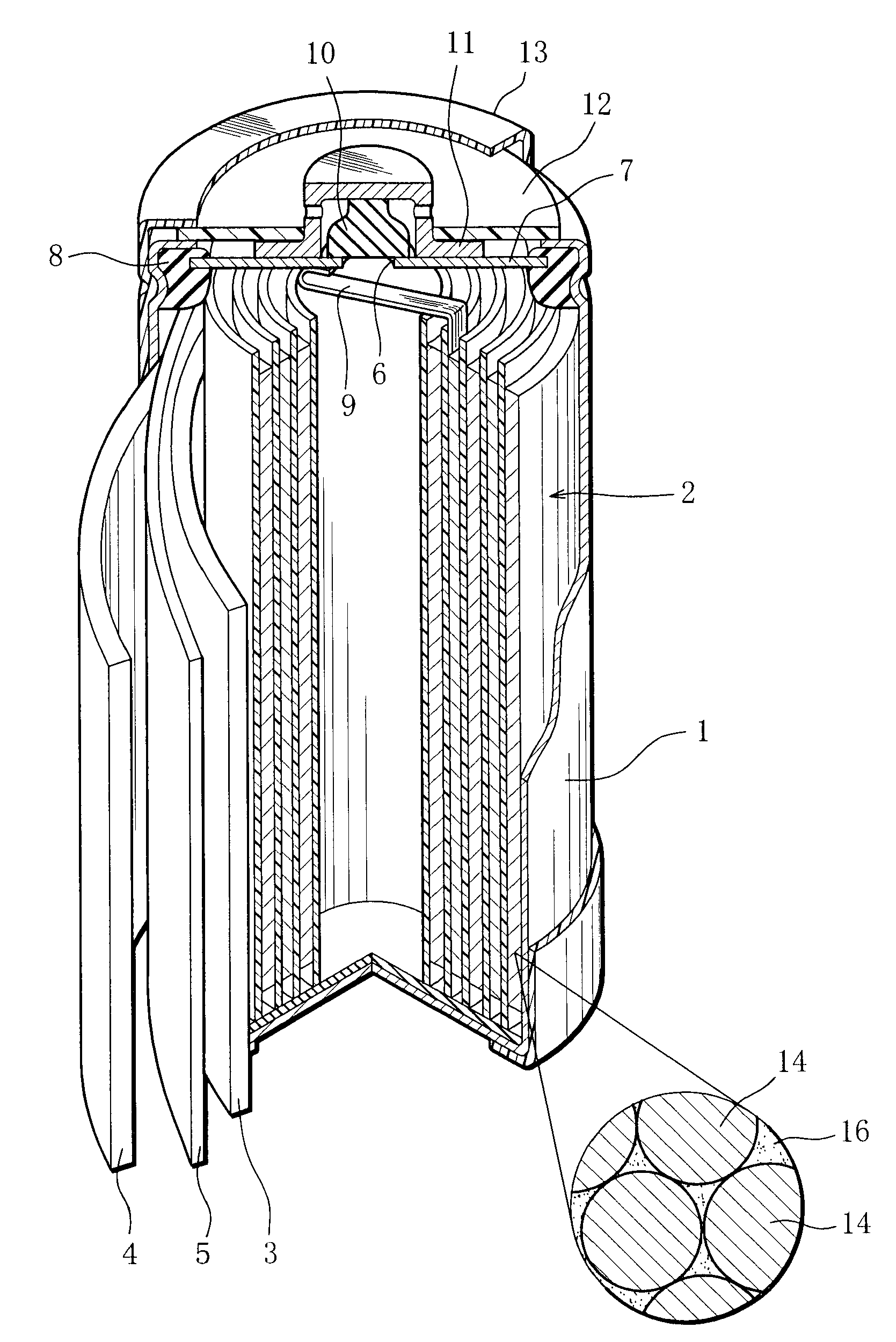

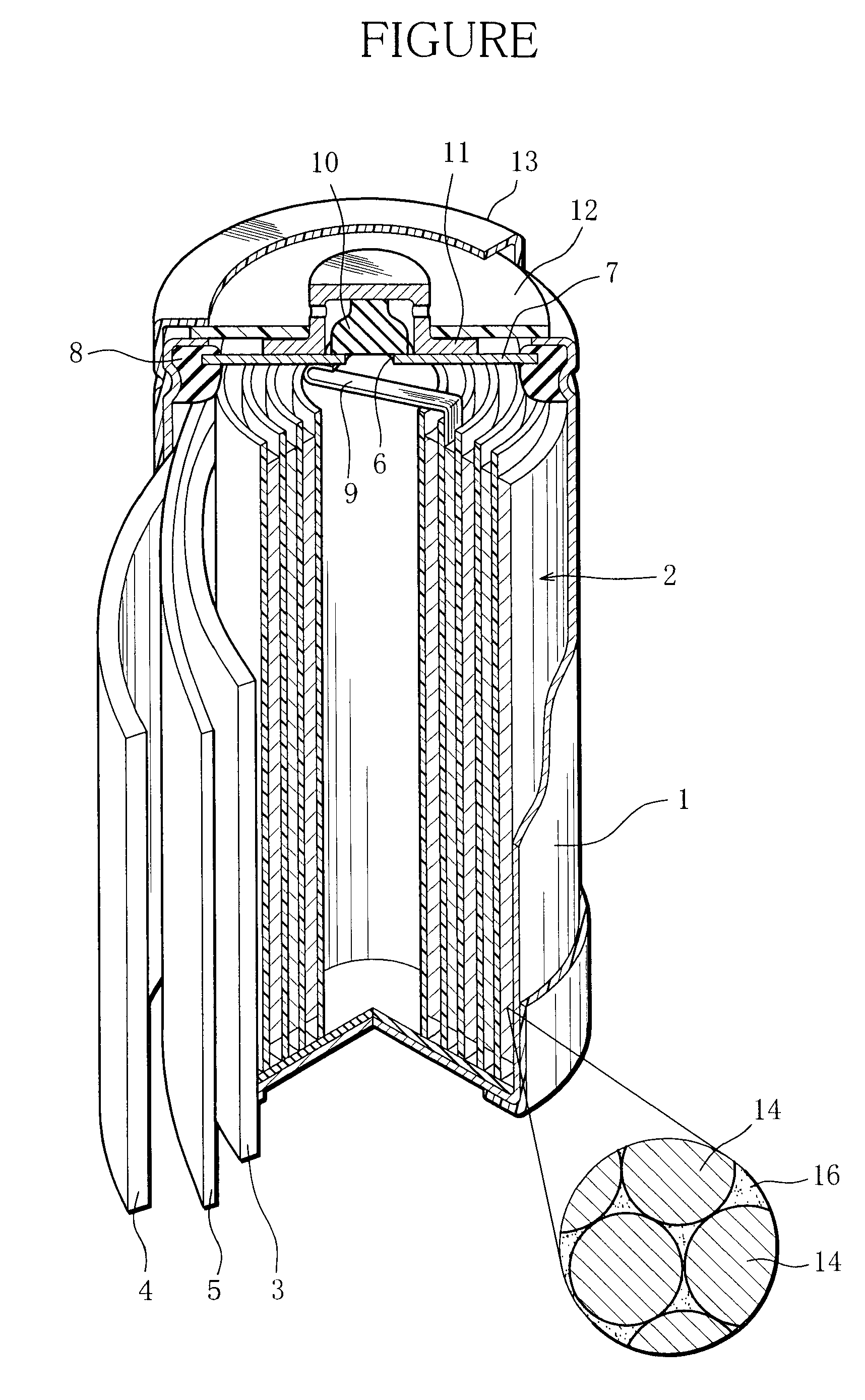

Alkaline storage cell

InactiveUS20090155688A1Improve corrosion resistancePromote oxidationNon-aqueous electrolyte accumulator electrodesRare earthStorage cell

The negative electrode of an alkaline storage cell contains a rare earth-Mg—Ni hydrogen storage alloy. The rare earth-Mg—Ni hydrogen storage alloy has a composition expressed by a general formula: (AαLn1-α)1-βMgβNiγ-δ-εAlδTε wherein A represents one or more elements selected from the group consisting of Pr, Nd, Sm and Gd and including at least Sm, Ln represents at least one element selected from the group consisting of La, Ce, and the like, T represents at least one element selected from the group consisting of V, Nb, and the like, and subscripts α, β, γ, δ and ε represent numerical values which respectively satisfy 0.4≦α, 0.05<β<0.15, 3.0≦γ≦4.2, 0.15≦δ≦0.30 and 0≦ε≦0.20.

Owner:SANYO ELECTRIC CO LTD

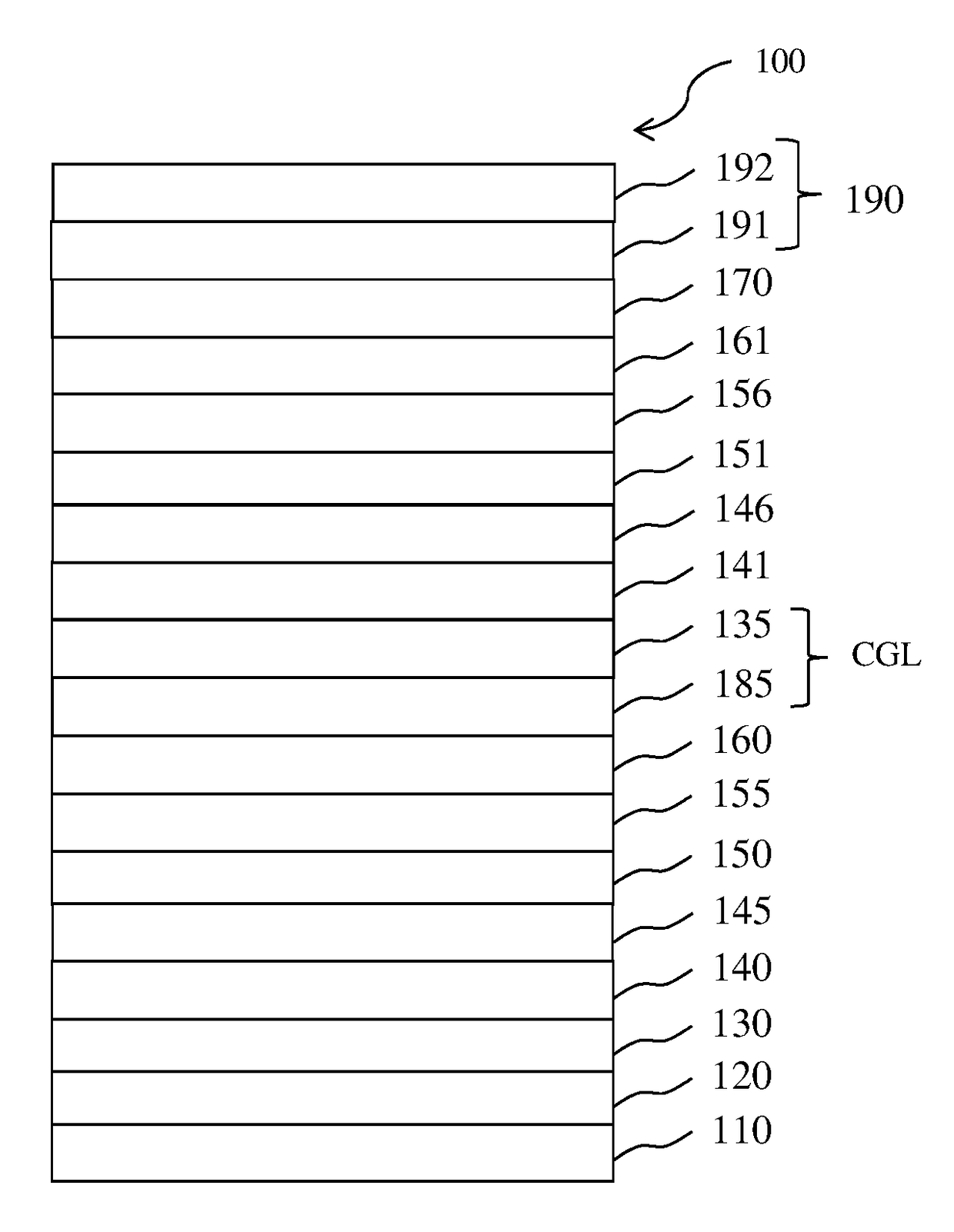

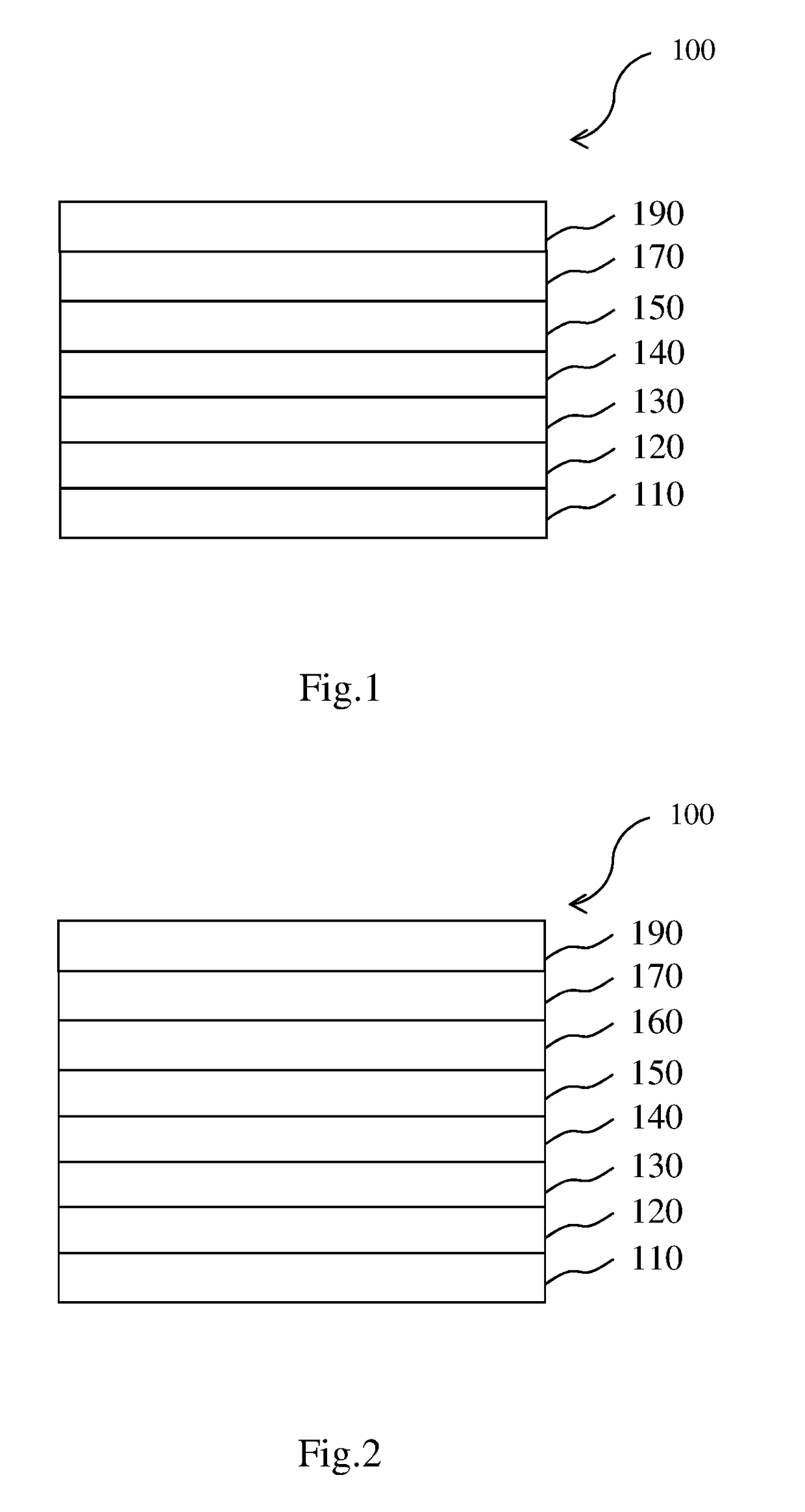

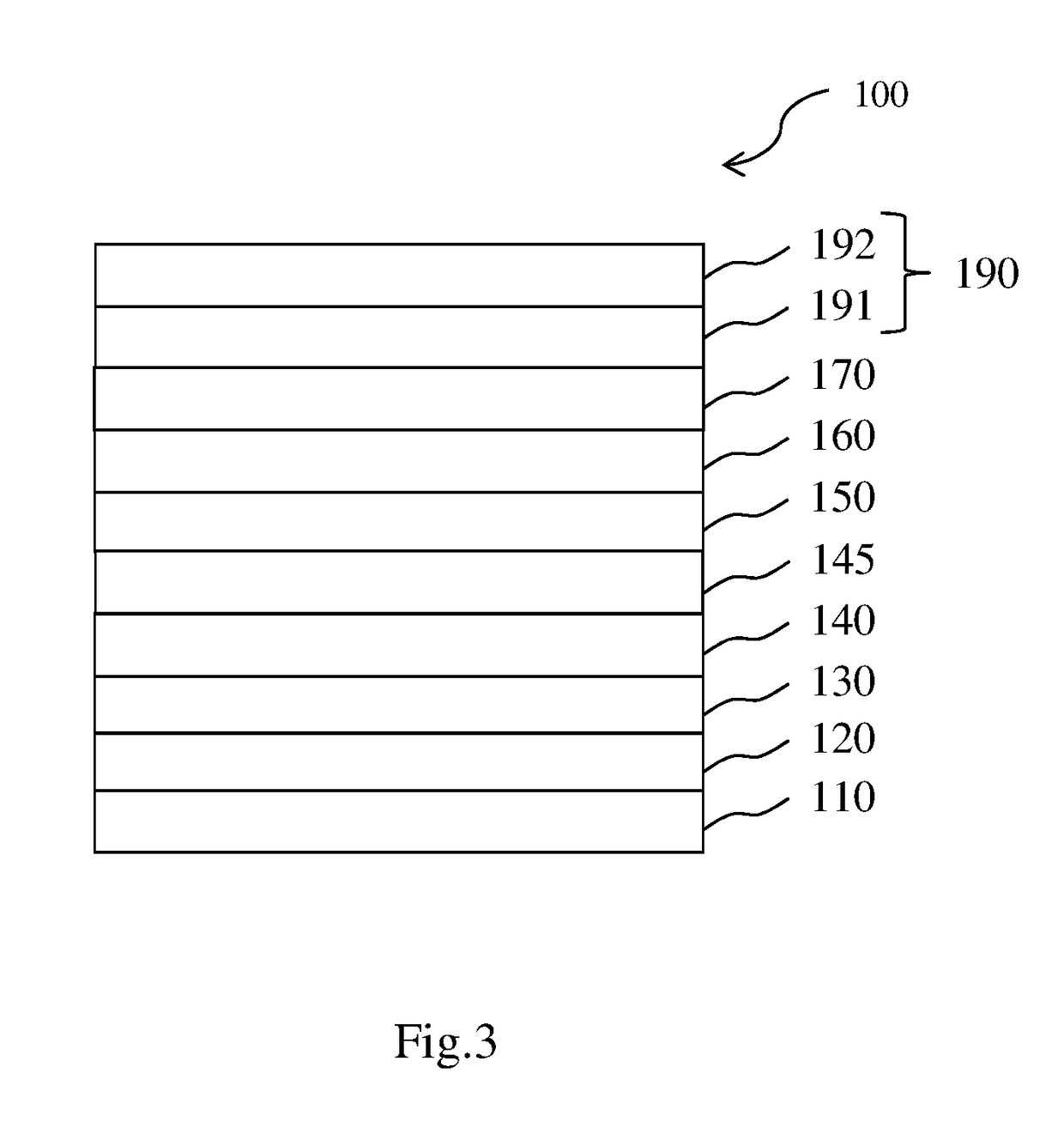

Organic Light Emitting Diode Comprising an Organic Semiconductor Layer

ActiveUS20170346023A1Increase operating voltageReduce compoundingSolid-state devicesSemiconductor/solid-state device manufacturingDopantOrganic semiconductor

The present invention relates to organic light-emitting diodes that include an anode electrode, a transparent cathode electrode, at least one emission layer and at least one organic semiconductor layer, wherein the at least one emission layer and the at least one organic semiconductor layer is arranged between the anode electrode and the transparent cathode electrode and the organic semiconductor layer includes a first zero-valent metal dopant and a first matrix compound wherein the first matrix comprising at least two phenanthrolinyl groups as well as to a method for manufacturing the same.

Owner:NOVALED GMBH

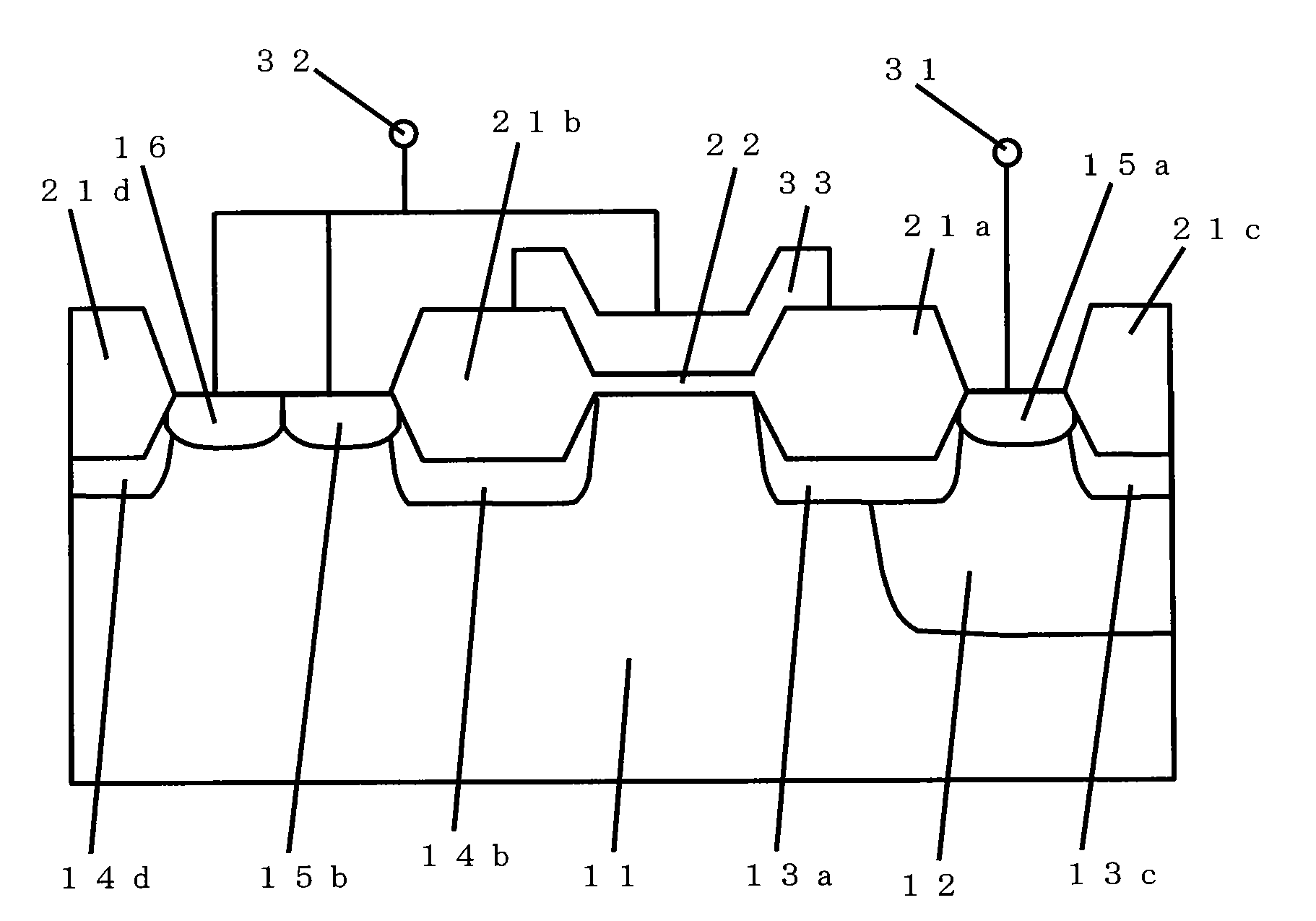

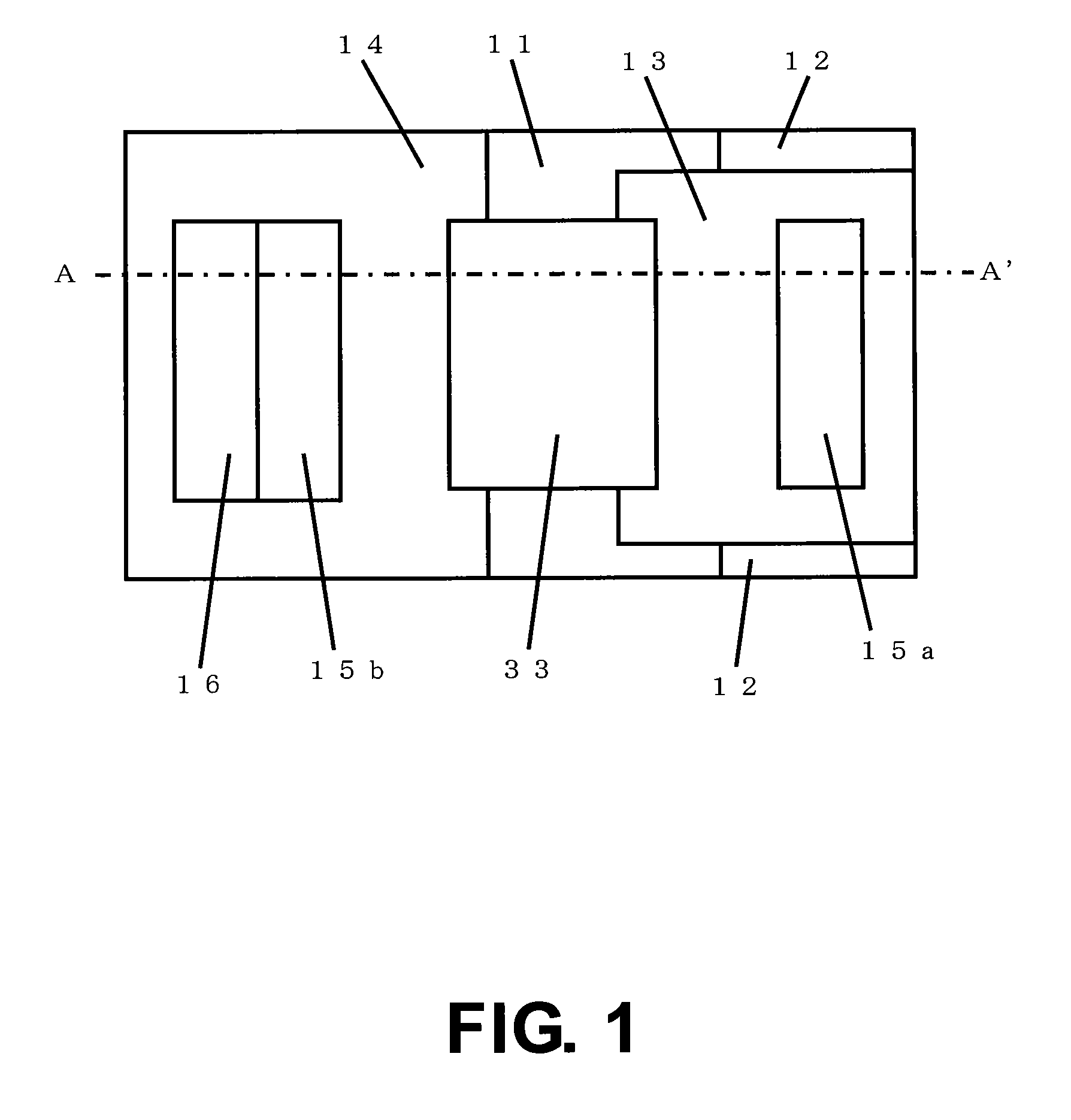

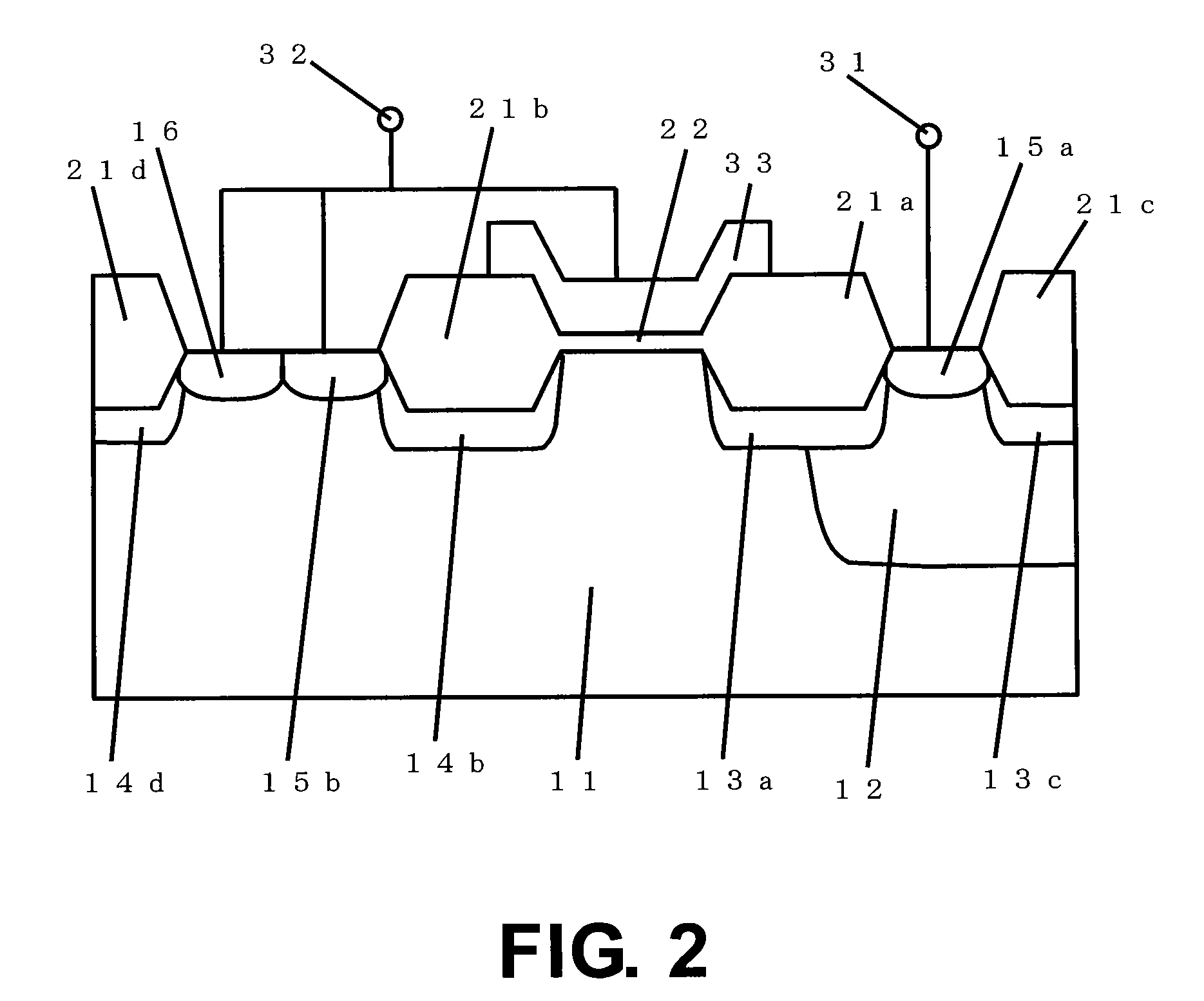

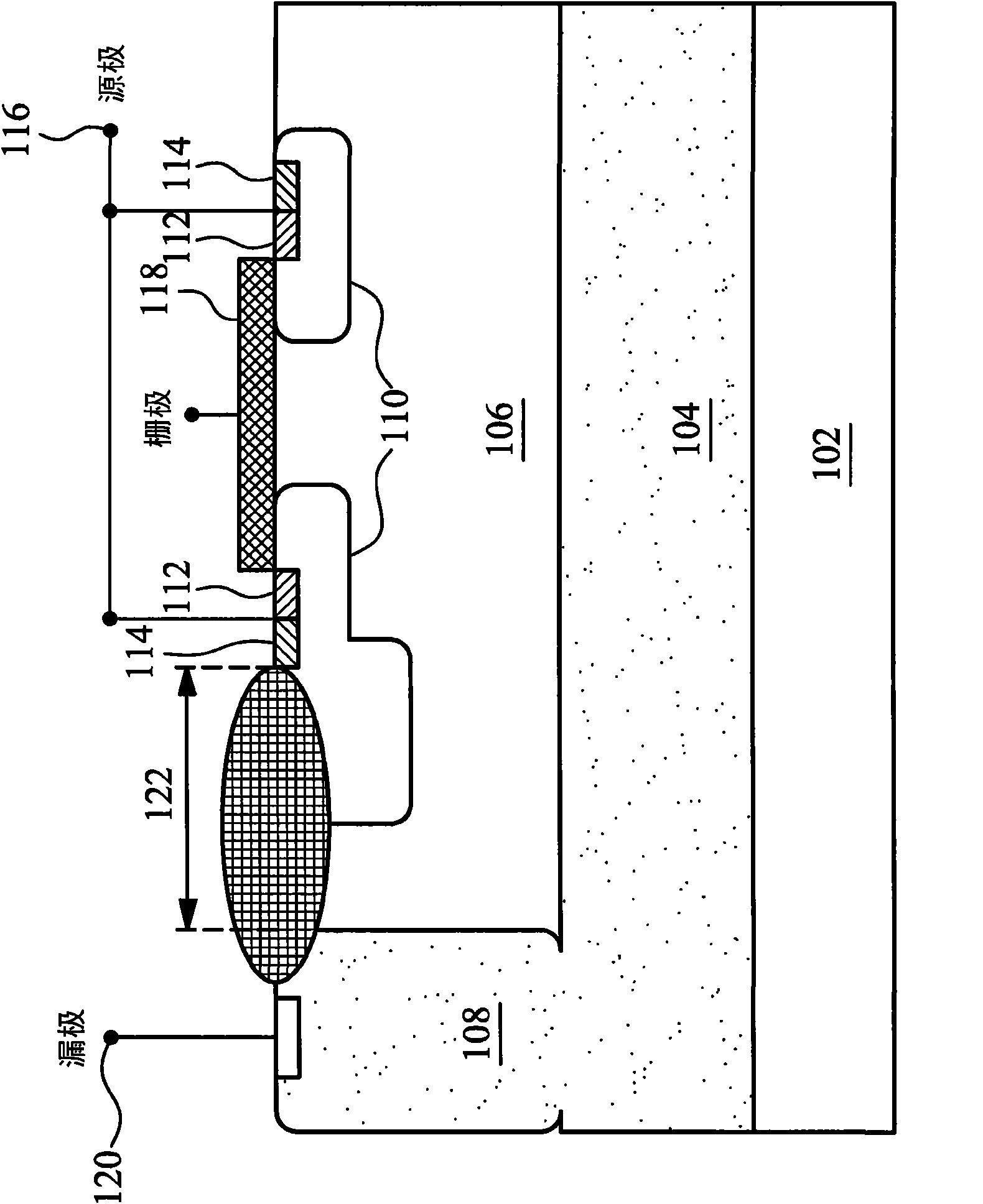

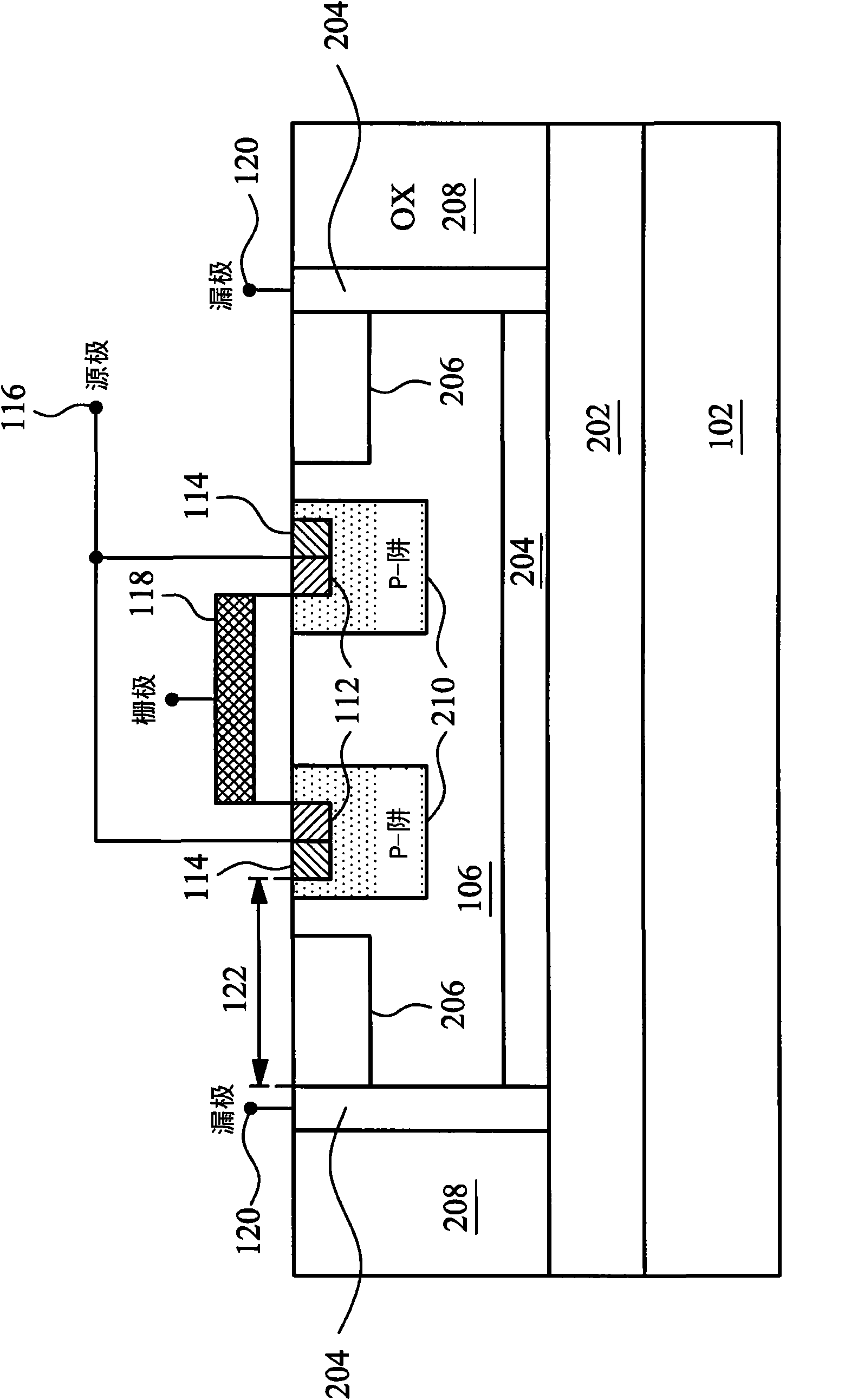

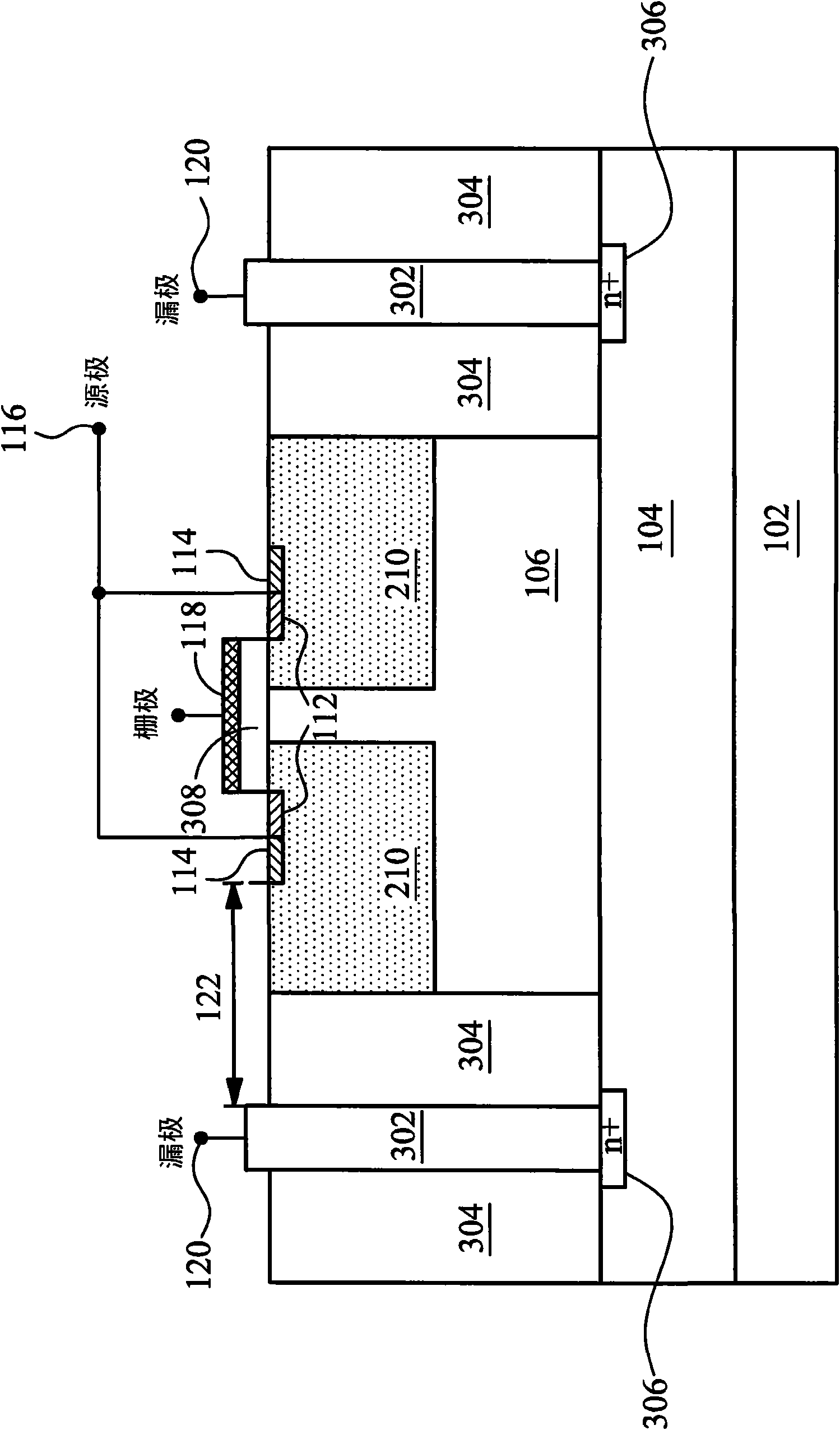

Semiconductor device

ActiveUS20100038706A1Well representedIncrease operating voltageTransistorSemiconductor/solid-state device detailsHigh concentrationStable state

Provided is an ESD protection element, in which: LOCOS oxide films are formed at both ends of a gate electrode, and a conductivity type of a diffusion layer formed below one of the LOCOS oxide films which is not located on a drain side is set to a p-type, to thereby limit an amount of a current flowing in a portion below a source-side n-type high concentration diffusion layer, the current being generated due to surface breakdown of a drain. With this structure, even in a case of protecting a high withstanding voltage element, it is possible to easily satisfy a function required for the ESD protection element, the function of being constantly in an off-state during a steady state, while operating, upon application of a surge or noise to a semiconductor device, so as not to reach a breakage of an internal element, discharging a generated large current, and then returning to the off-state again.

Owner:ABLIC INC

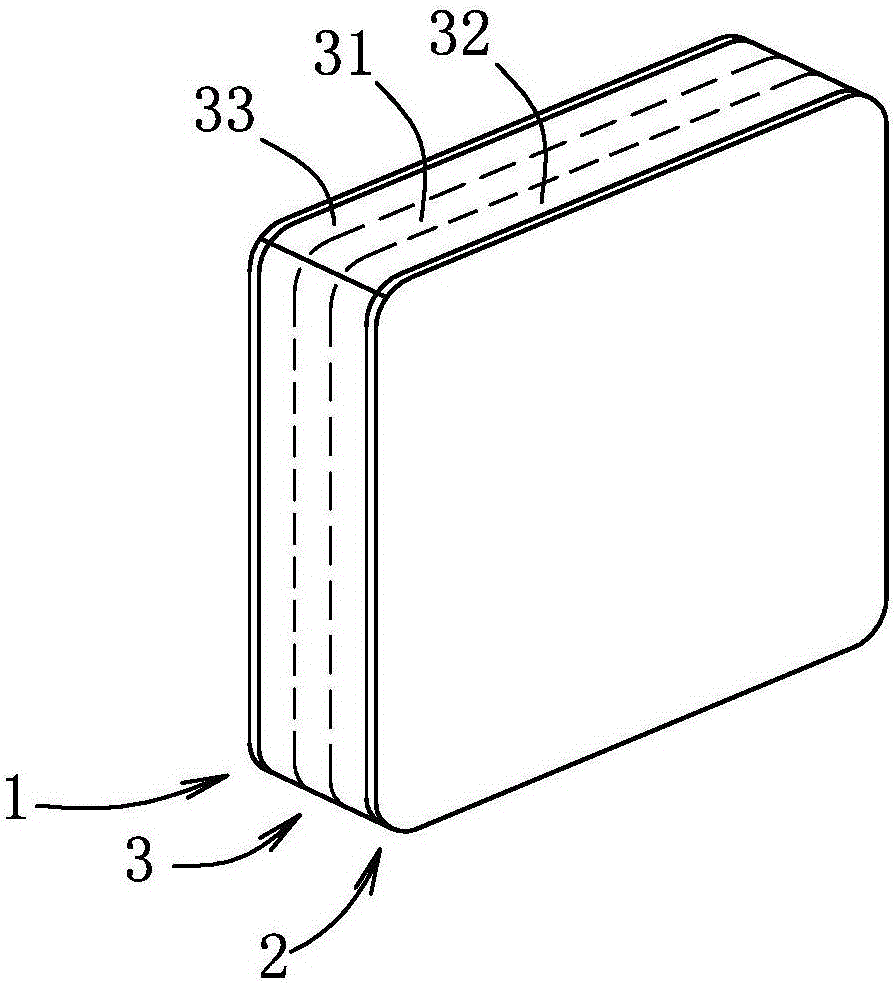

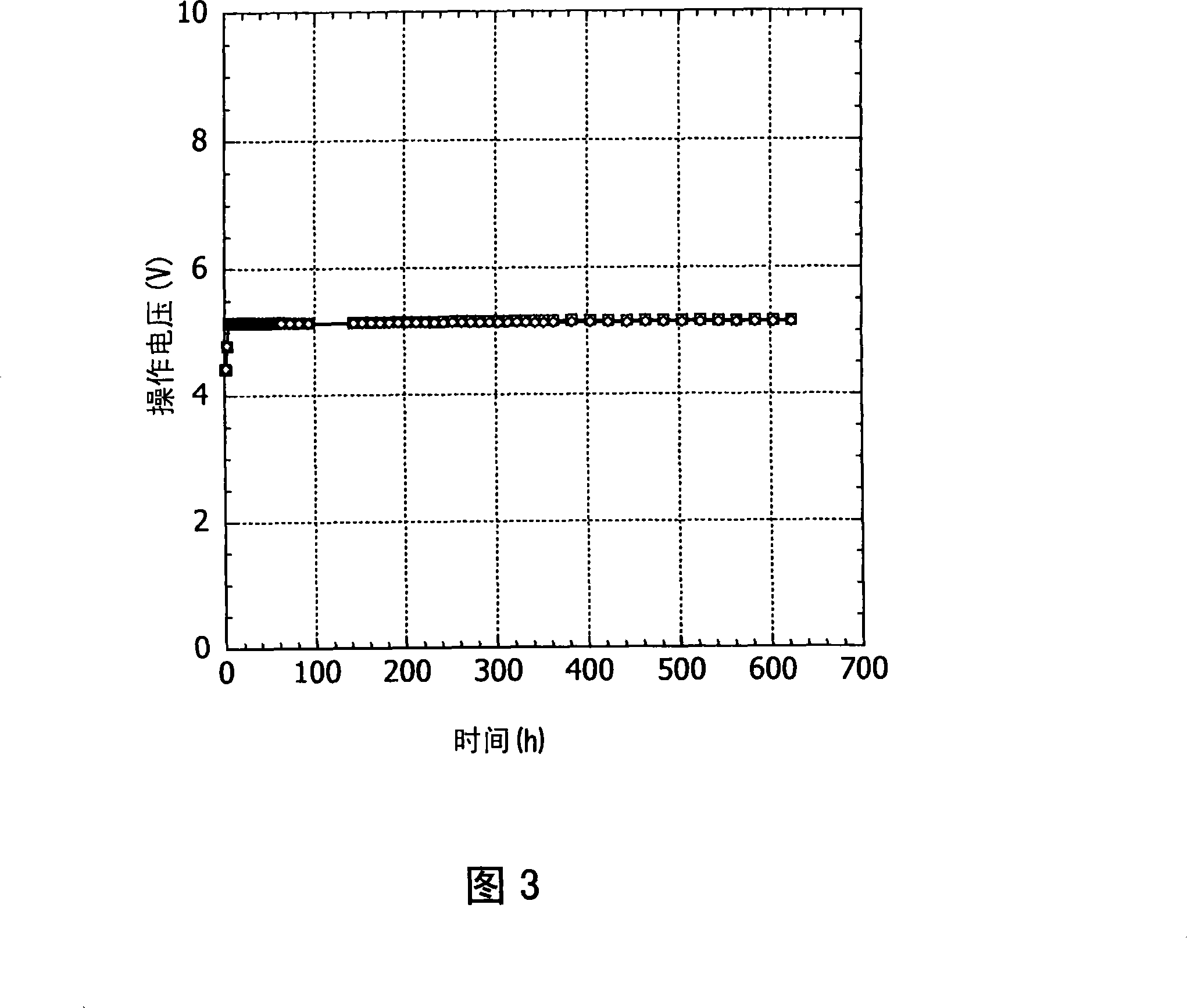

Overcurrent protection device

InactiveCN106548839AHigh operating temperatureIncrease operating voltageCurrent responsive resistorsPositive temperature coefficient thermistorsParticulatesPolyolefin

The invention provides an overcurrent protection device, which comprises a first electrode, a second electrode and a multi-layer structure, wherein the multi-layer structure comprises a first PTC polymer material layer and a second PTC polymer material layer. The first PTC polymer material layer comprises a first polymer matrix material and a particulate conductive filler dispersed into the first polymer matrix material; and the first polymer matrix material is prepared from a first polymeric composition. The second PTC polymer material layer comprises a second polymer matrix material and a particulate conductive filler dispersed into the second polymer matrix material; and the second polymer matrix material is prepared from a second polymeric composition. One of the first polymeric composition and the second polymeric composition contains polyvinylidene fluoride and polyolefin and the other one contains polyolefin or polyvinylidene fluoride. Due to the multi-layer structure design, the operating temperature and voltage ranges of the overcurrent protection device are wider.

Owner:FUZETEC TECHNOLOGY CO LTD

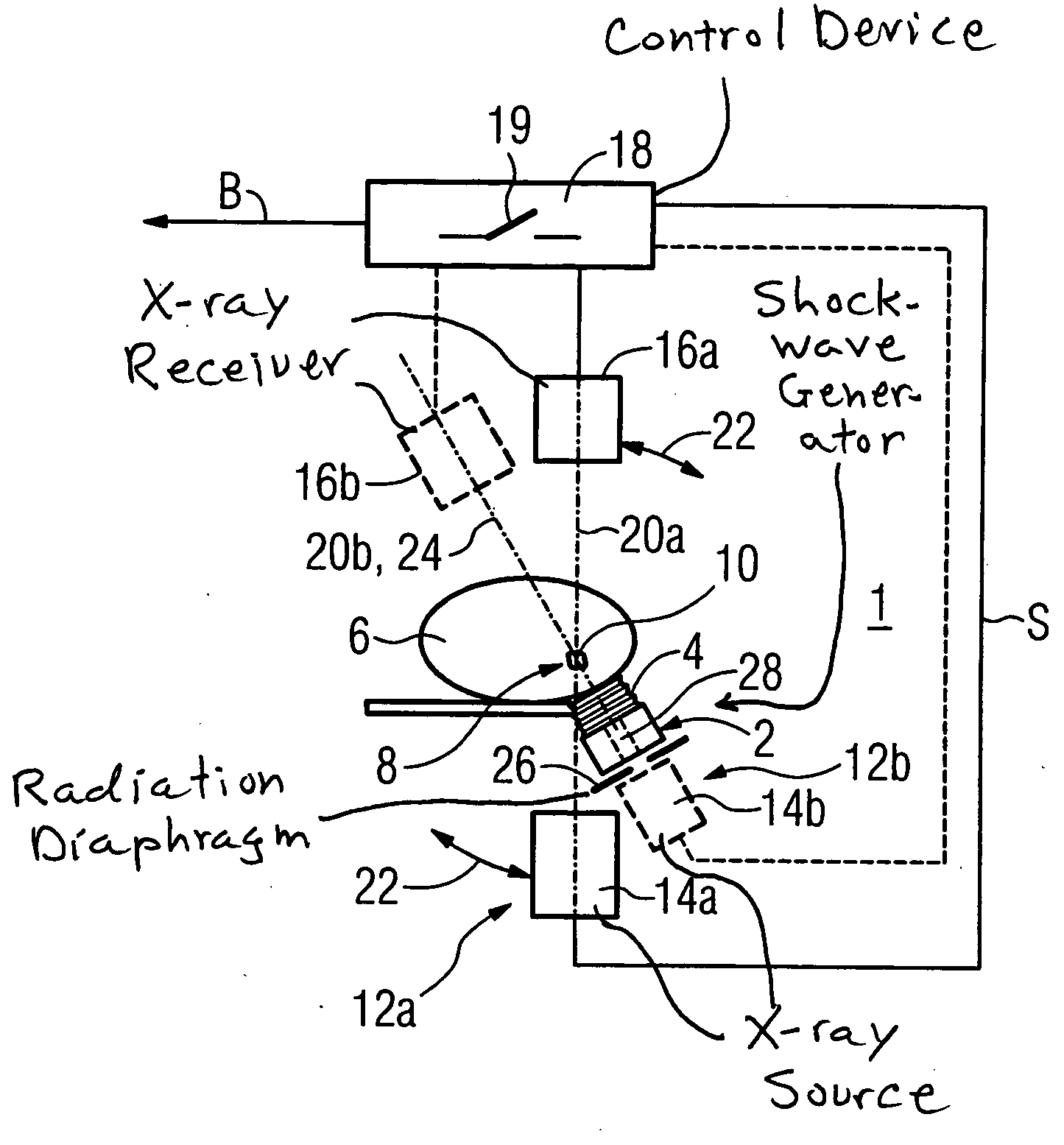

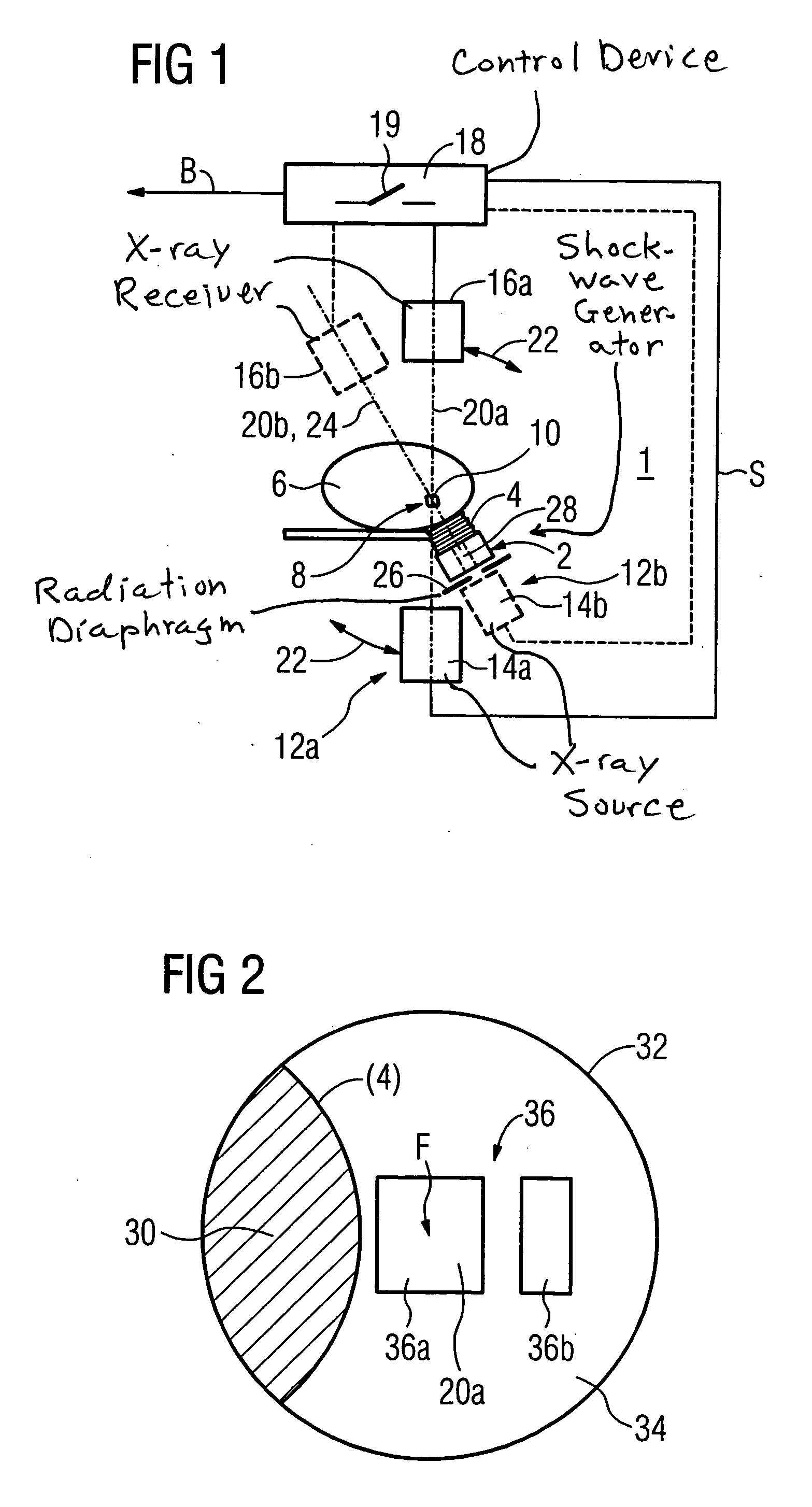

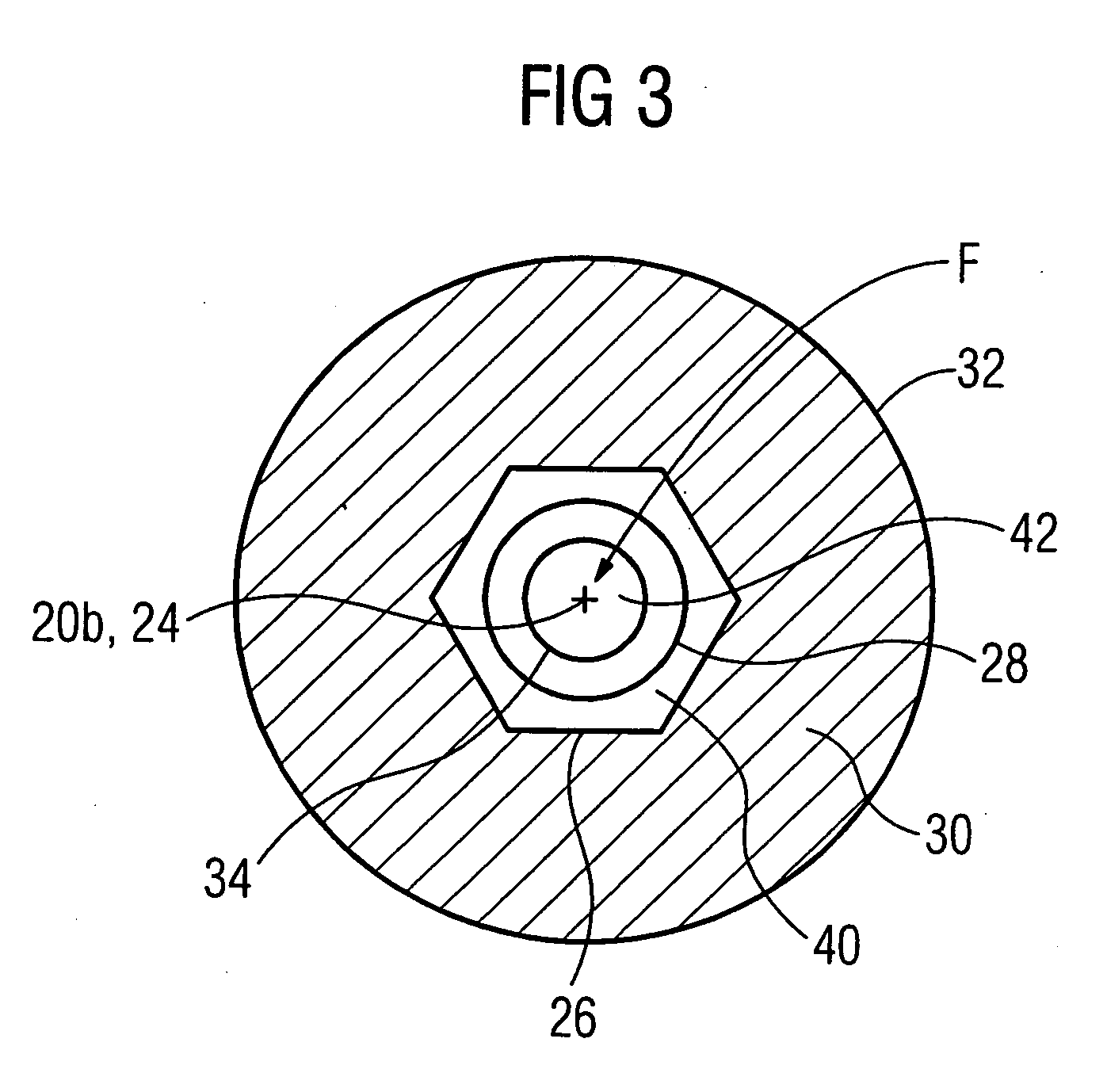

Method and apparatus for controlling the radiation dose in the generation of x-ray images for lithotripsy

InactiveUS20050004455A1Reduce brightnessIncrease dose rateSurgeryChiropractic devicesSoft x rayImage evaluation

In a method and an apparatus to generate an x-ray image from the focus region of a lithotripter using x-rays that pass through the focus region and device parts of the lithotripter, to control the dose of the x-rays, only an image region of the image field exposed by the x-rays, that lies outside of an area shadowed by these device parts, is evaluated.

Owner:SIEMENS AG

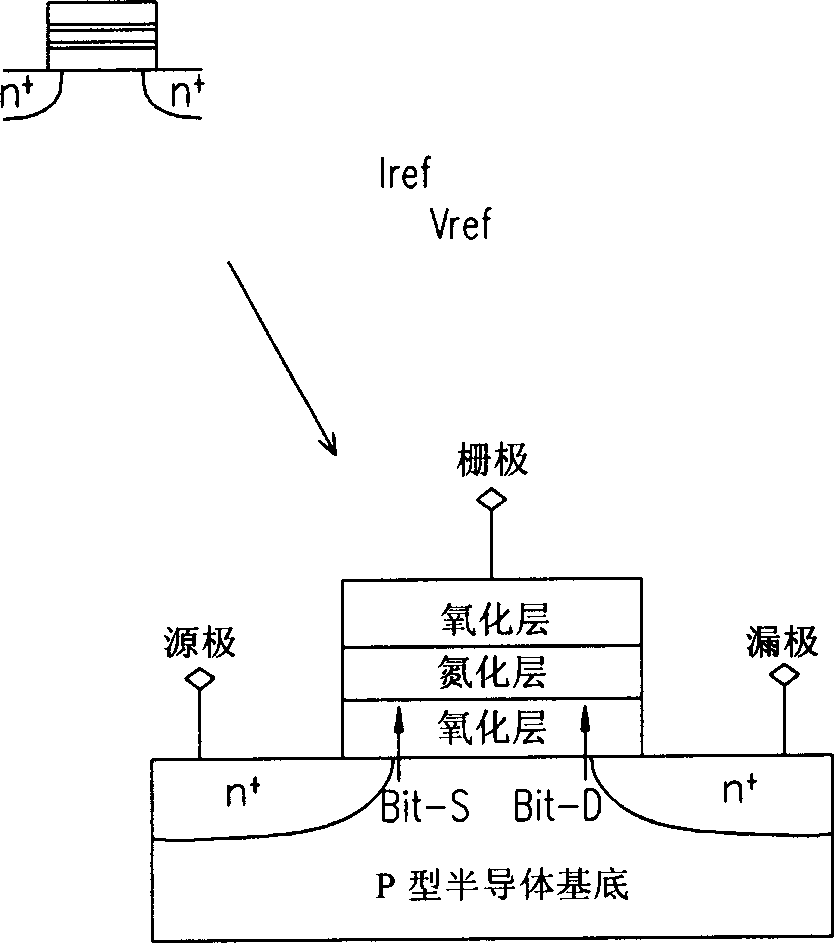

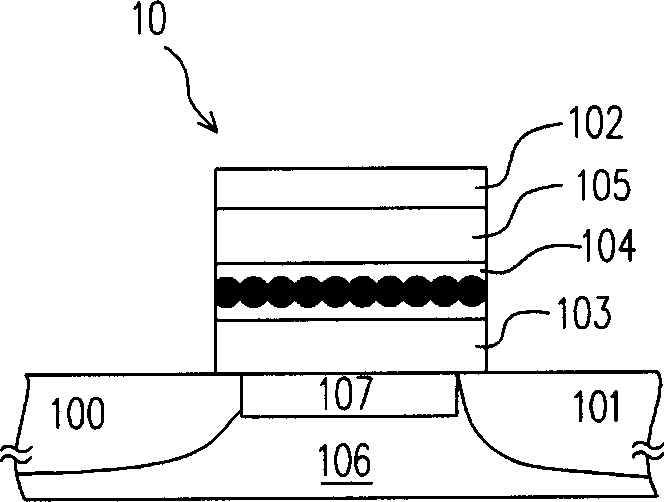

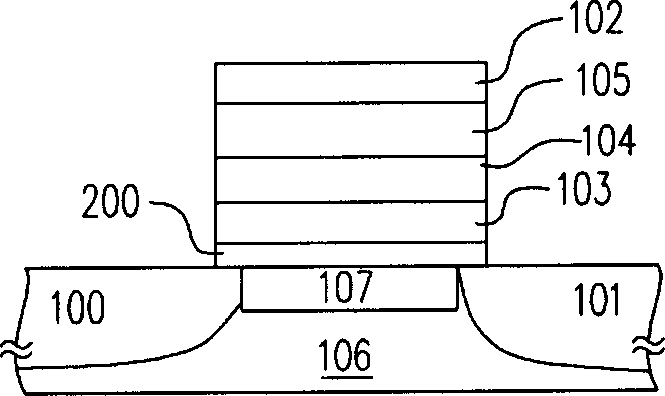

Electronic circuit, system, nonvolatile memory and operating method thereof

InactiveCN1655360AWork around limitationsOptimal accuracyTransistorSolid-state devicesReference currentNitride

One embodiment of the present-invention provides a system having a nonvolatile memory comprising a p type semiconductor substrate, an oxide layer over the p type semiconductor substrate, a nitride layer over the oxide layer, an additional oxide layer over the nitride layer, a gate over the additional oxide layer, two N+ junctions in the p type semiconductor layer, a source and drain respectively formed in the two N+ junctions, a first bit and a second bit in the nonvolatile memory, and accordingly at least two states of operation (i.e., erase and program) therefor. That is, one bit in the nonvolatile memory can either be in an erase state or program state. For erasing a bit, electrons are injected at the gate of the nonvolatile memory. For programming a bit, electric holes are injected or electrons are reduced for that bit. The present invention also provides a method for sensing and reading at least one bit in a nonvolatile memory comprising applying a bias voltage to the memory, detecting a threshold voltage or read current, comparing the threshold voltage with a reference voltage or comparing the read current with a reference current, and identifying the at least one bit as erased or programmed.

Owner:MACRONIX INT CO LTD

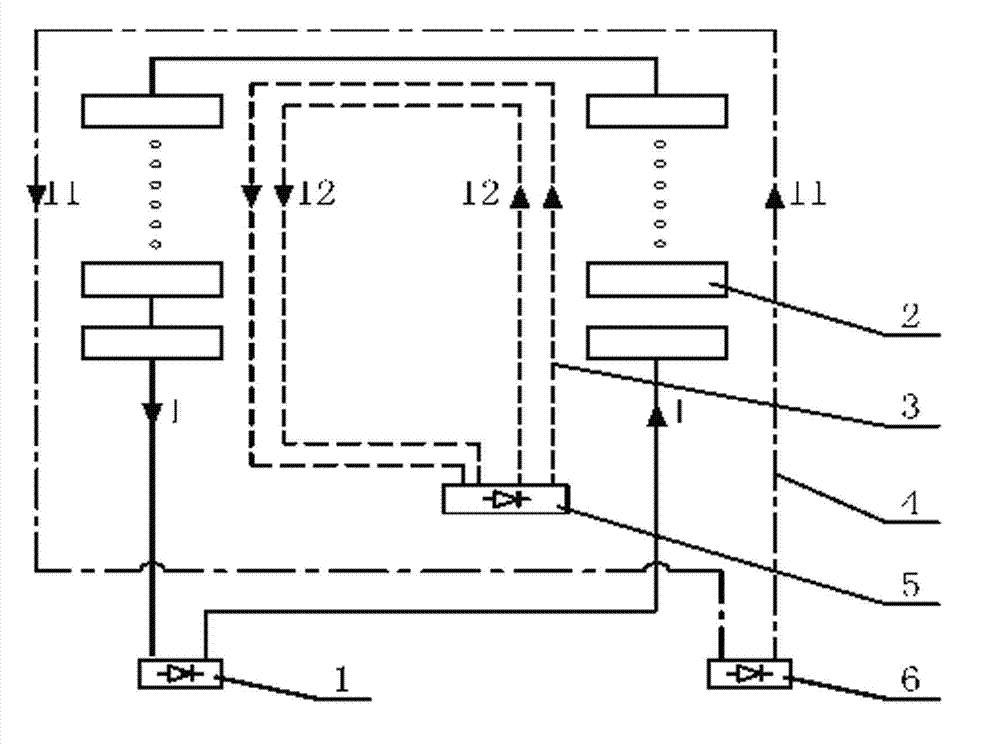

Aluminum electrolysis tank external-compensation power supply rectification set aluminum bus arrangement method and system thereof

ActiveCN103114307AReduce in quantityIncrease working voltageProcess engineeringManufacturing engineering

The invention relates to an aluminum bus arrangement method and a system thereof, and especially relates to an aluminum electrolysis tank external-compensation power supply rectification set aluminum bus arrangement method for the arrangement of the external compensation current direct-current bus of the working current and working voltage parameter selection, the flue end and the aluminum outlet end of an electrolytic aluminum auxiliary power supply rectification system, and a system thereof. An aluminum outlet end rectification system is eliminated, one end of an aluminum outlet end compensation bus is connected with a flue end compensation rectification system, the other end of the aluminum outlet end compensation bus is connected with a flue end compensation bus, and the other end of the flue end compensation bus is connected with the flue end compensation rectification system. The adoption of a current superposing principle in the invention reduces the current of the power supply rectification system and properly improves the direct-current running voltage of the power supply rectification system in order to improve the running efficiency of the rectification system when the electrolytic technology external compensation current is satisfied.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

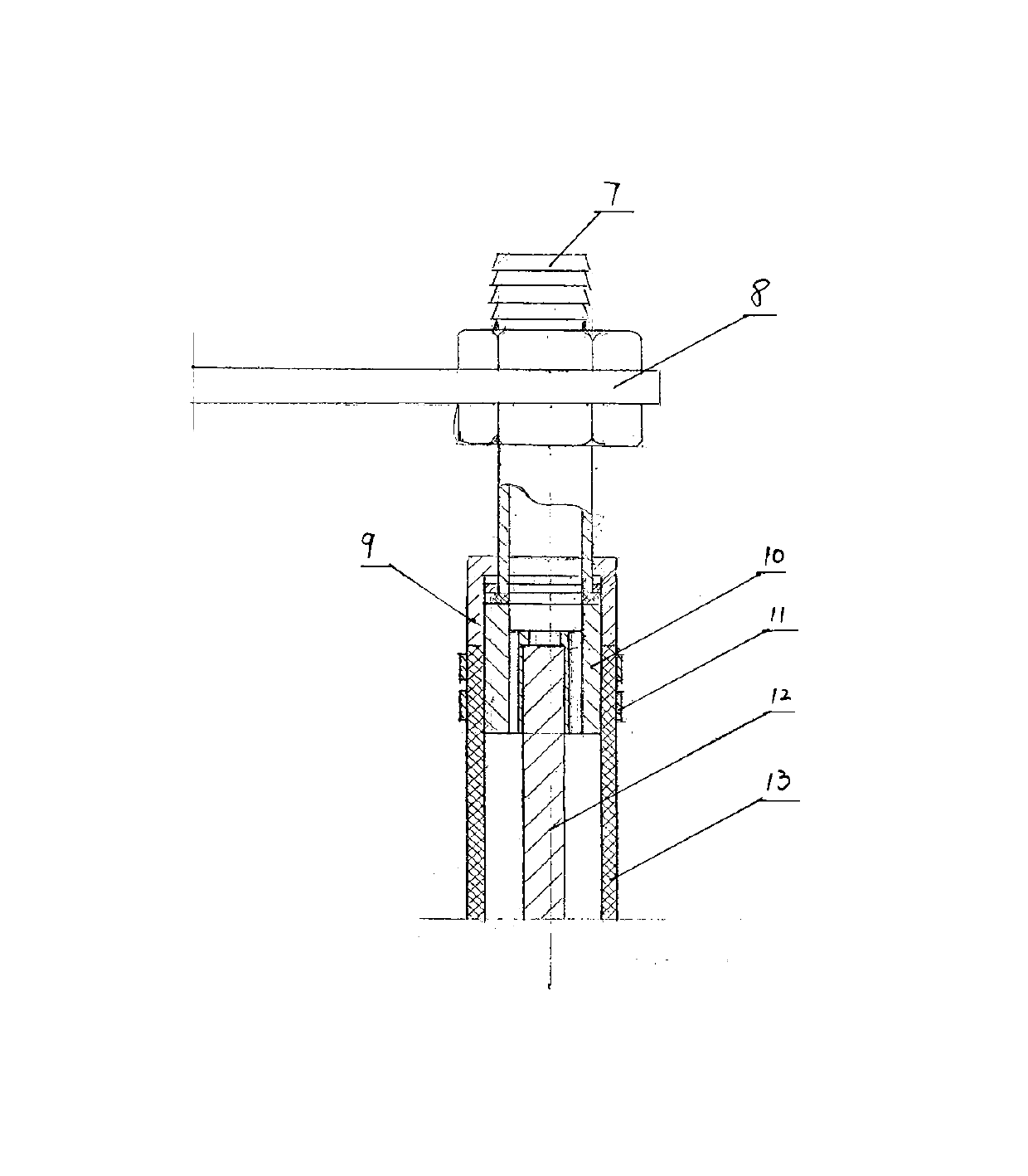

Manufacturing method of air-cooled hydrogenerator VPI (Vacuum Pressure Impregnating) stator coil bar

The invention relates to a manufacturing method of an air-cooled unit capacity hydrogenerator VPI (Vacuum Pressure Impregnating) stator coil bar. An inner shielding layer on the surface of a wire canreduce an internal local discharge probability of the wire. After the coil bar is bound with a VPI main insulation layer, a straight-line segment is bound in a half-lapping mode with a layer of low-resistance anti-corona material, then VPI of epoxy anhydride resin is carried out, after impregnation is ended, the end part is respectively bound in a half-lapping mode with medium resistance, medium-high resistance and high resistance segments, and the surface of an anti-corona segment of the end part is bound with two layers of additional insulation layers; after an anti-corona layer is processedwell, the coil bar is assembled into a hot-pressing die, pressurization is carried out, and the coil bar is placed into a baking oven to carry out heating, curing and forming; and after the main insulation layer is cured and formed, a protection layer is brushed with a high-resistance anti-corona paint and a surface coating varnish so as to obtain the finished product VPI stator coil bar. The air-cooled unit capacity hydrogenerator VPI stator coil bar has the main technical performance indexes that: (1) a breakdown voltage of the finished product coil bar is greater than or equal to 5.5UN; and (2) an electrical aging resistance experiment of the coil bar shows that the service life under a voltage of 3.0UN is greater than 40H, and the service life under a voltage of 2.0UN is greater than1,100h.

Owner:HARBIN ELECTRIC MASCH CO LTD

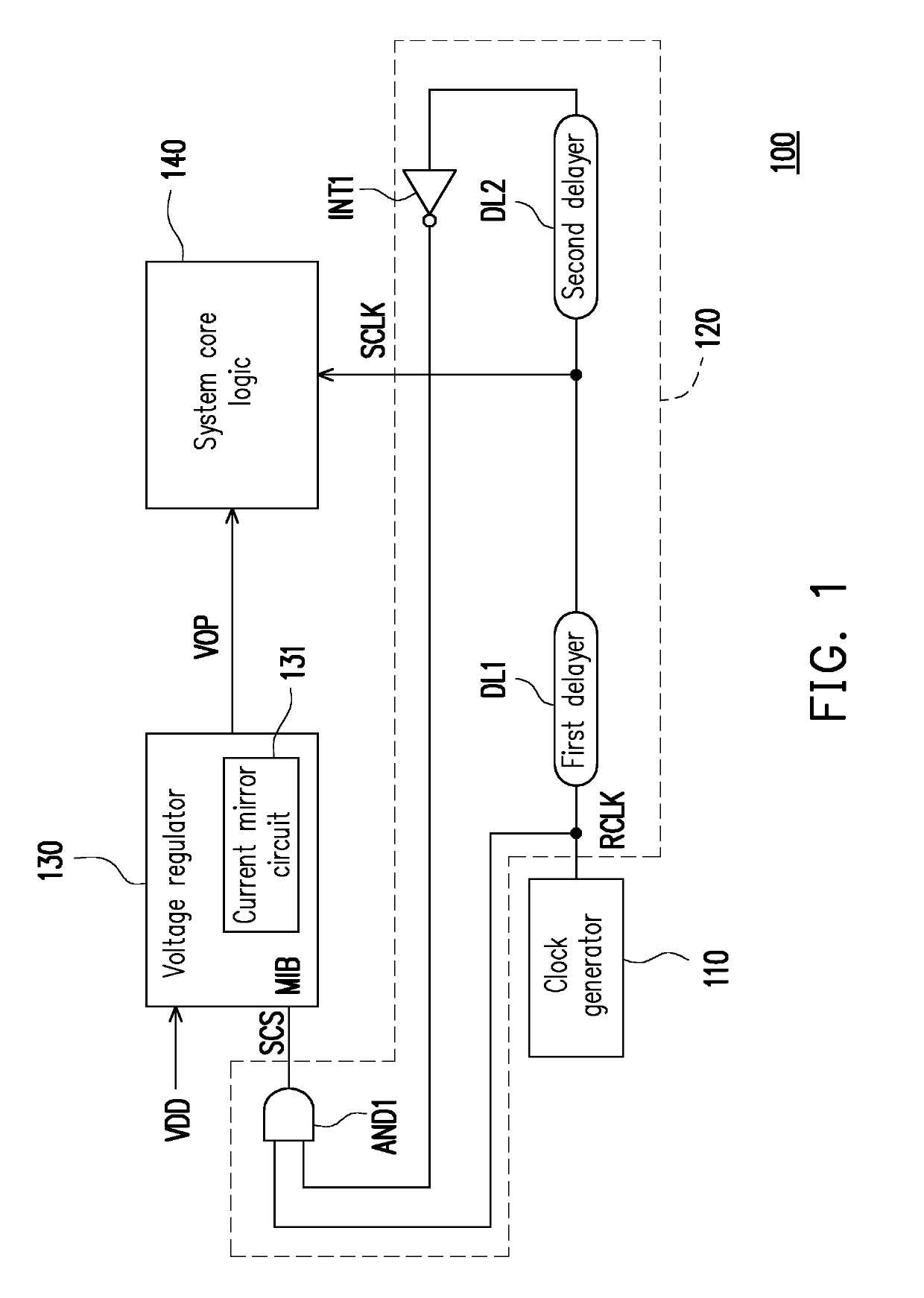

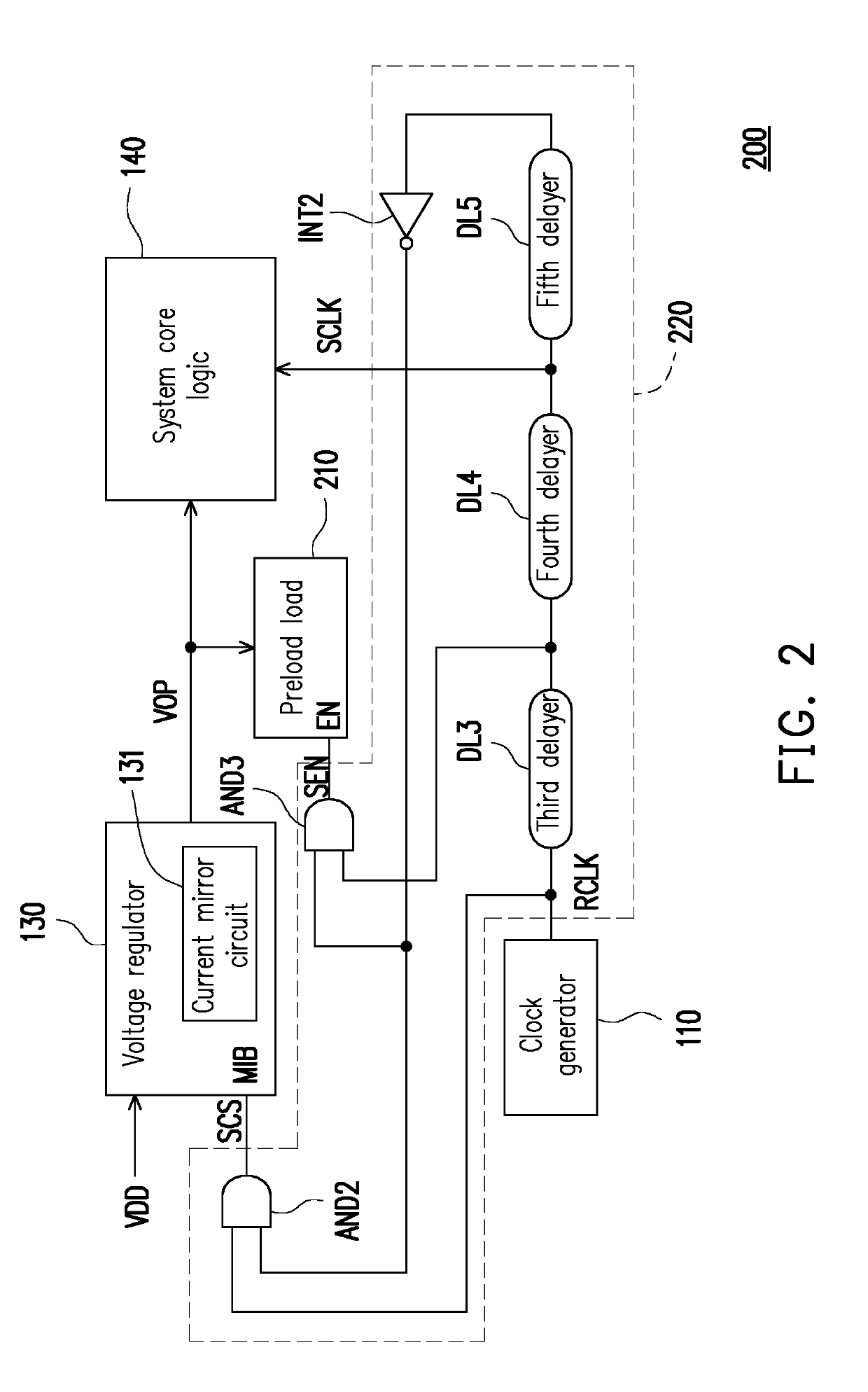

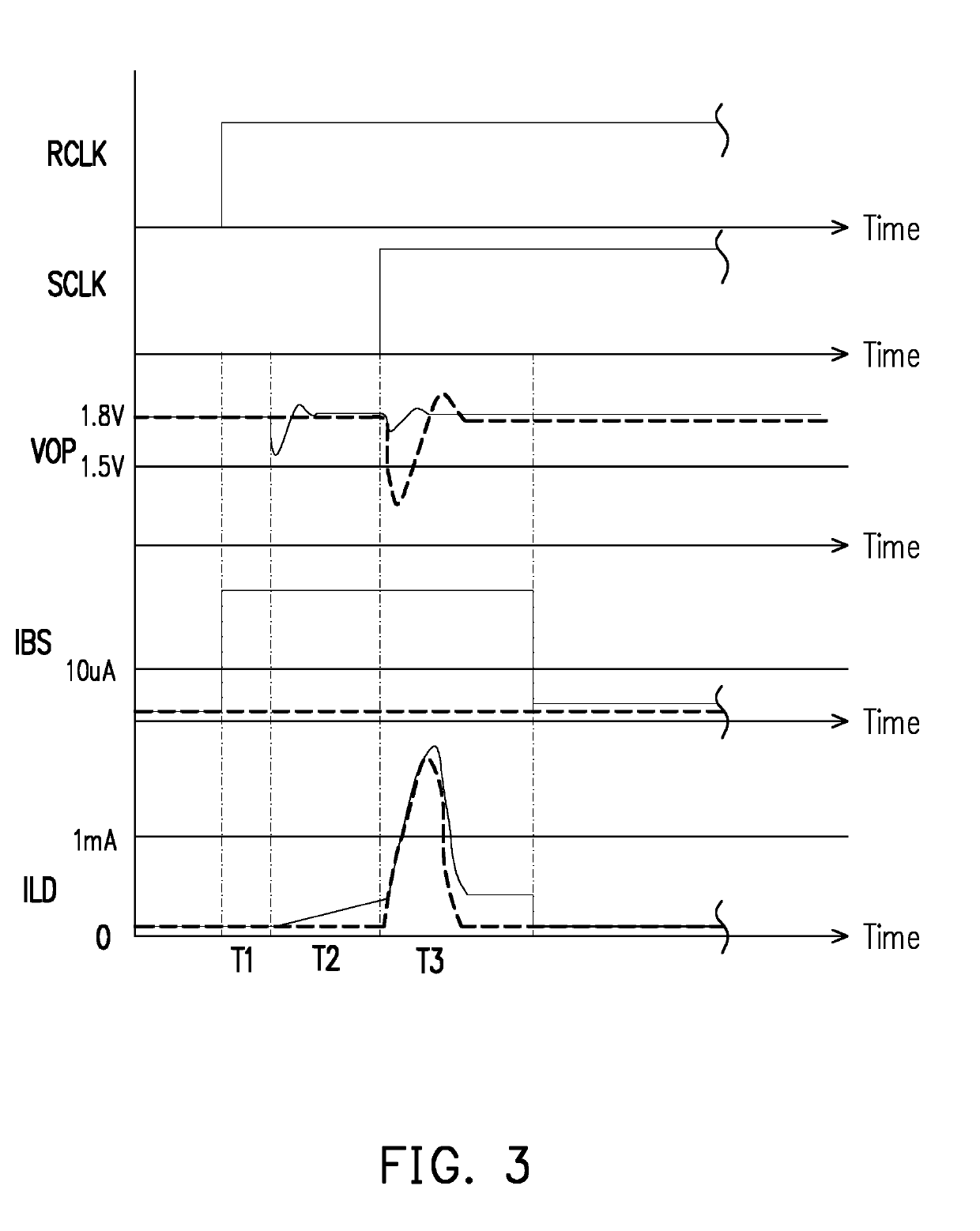

System on chip

ActiveUS20190138043A1Meet the requirementsIncrease operating voltageLogic circuits characterised by logic functionPulse manipulationVoltage regulationClock generator

A system on chip (SOC) is provided. The SOC includes a system core logic, a voltage regulator, a clock generator and a system balance circuit. The voltage regulator provides an operating voltage to the system core logic and receives a current setting signal to set the voltage regulator to a low current mode or a high current mode. The clock generator provides a reference clock signal. The system balance circuit receives the reference clock signal to provide the current setting signal to the voltage regulator and provides the system clock signal to the system core logic, wherein the current setting signal is used to set the voltage regulator to the high current mode before the system clock signal is enabled, and set the voltage regulator to the low current mode after the system clock signal is enabled.

Owner:NUVOTON

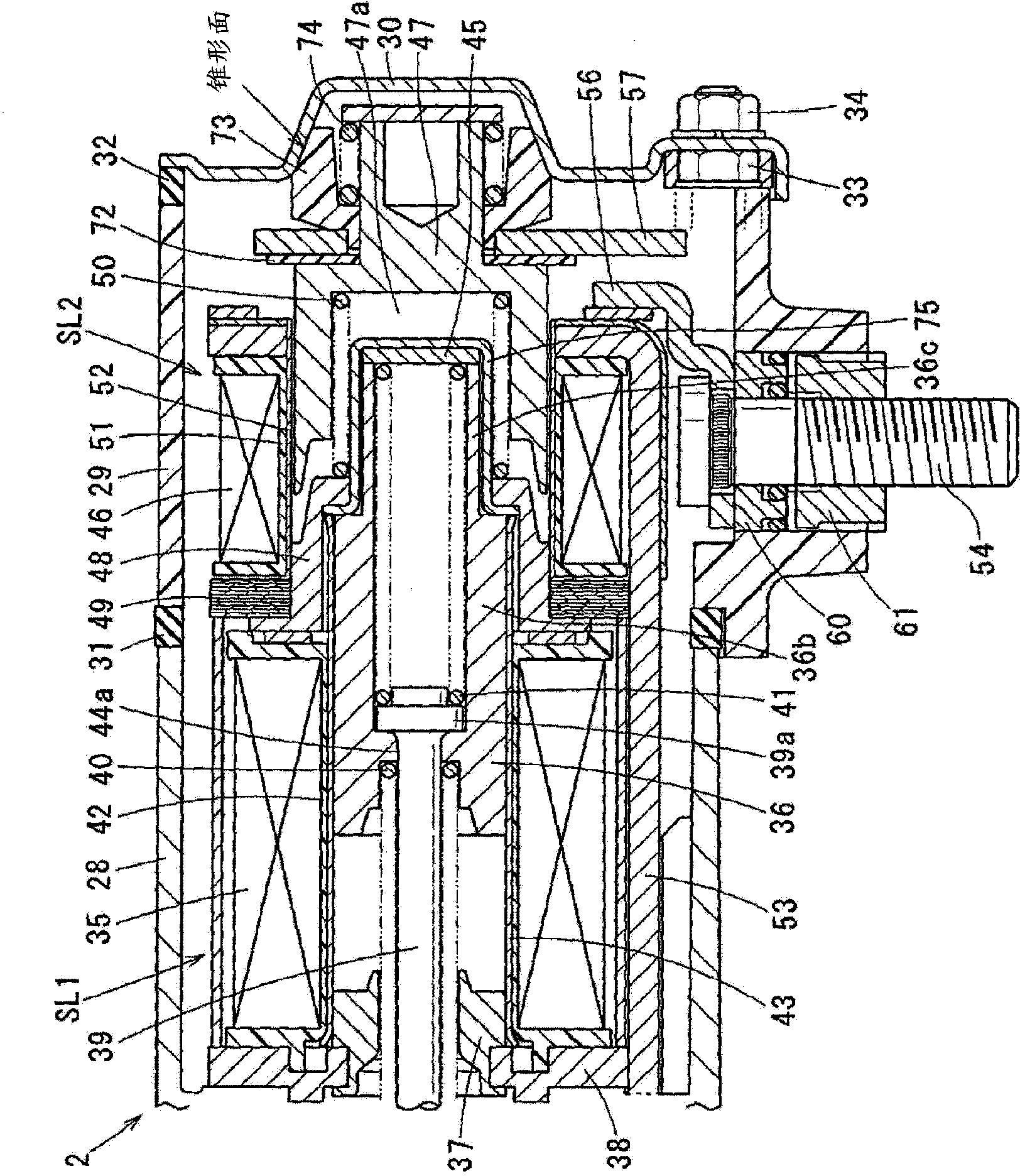

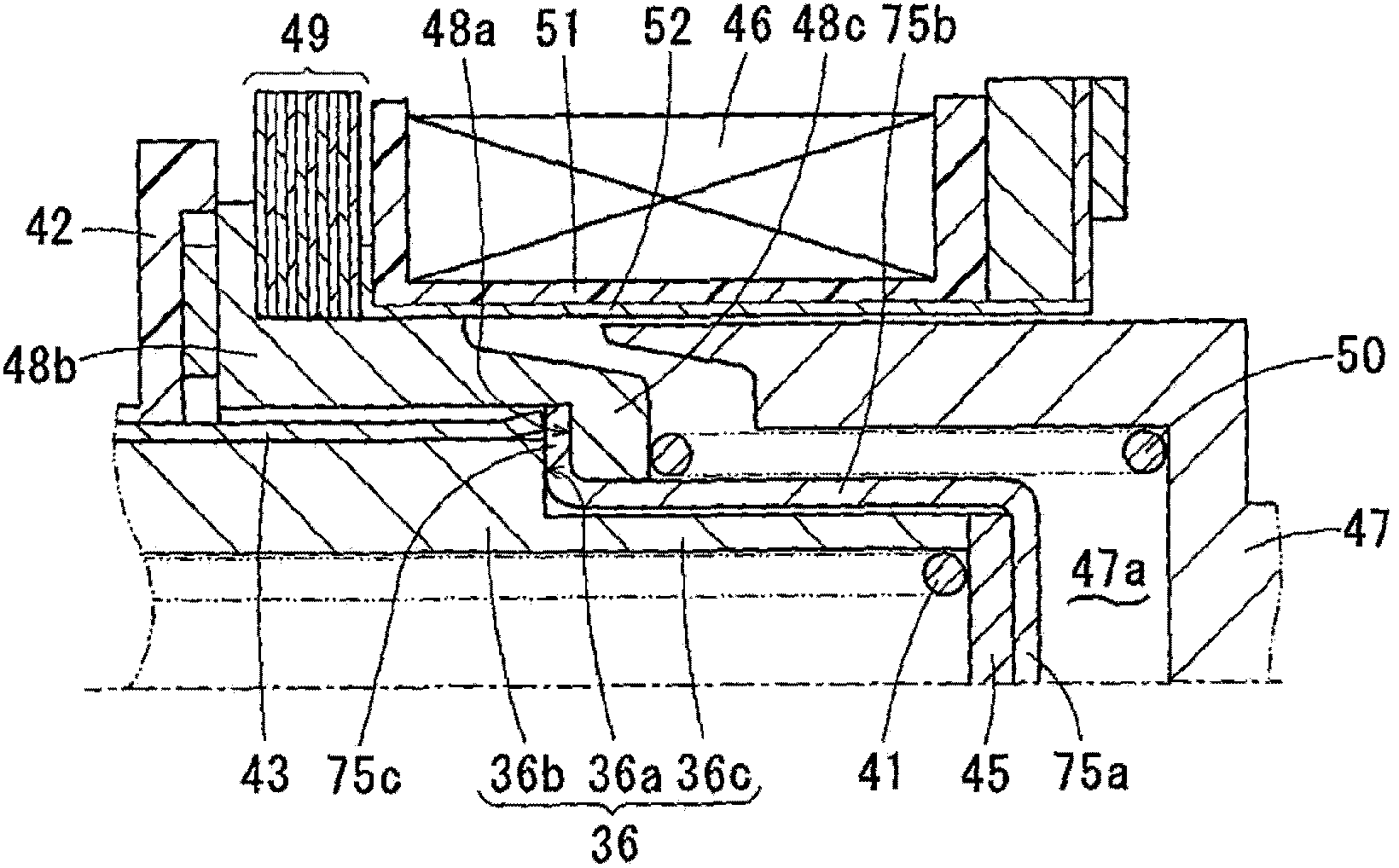

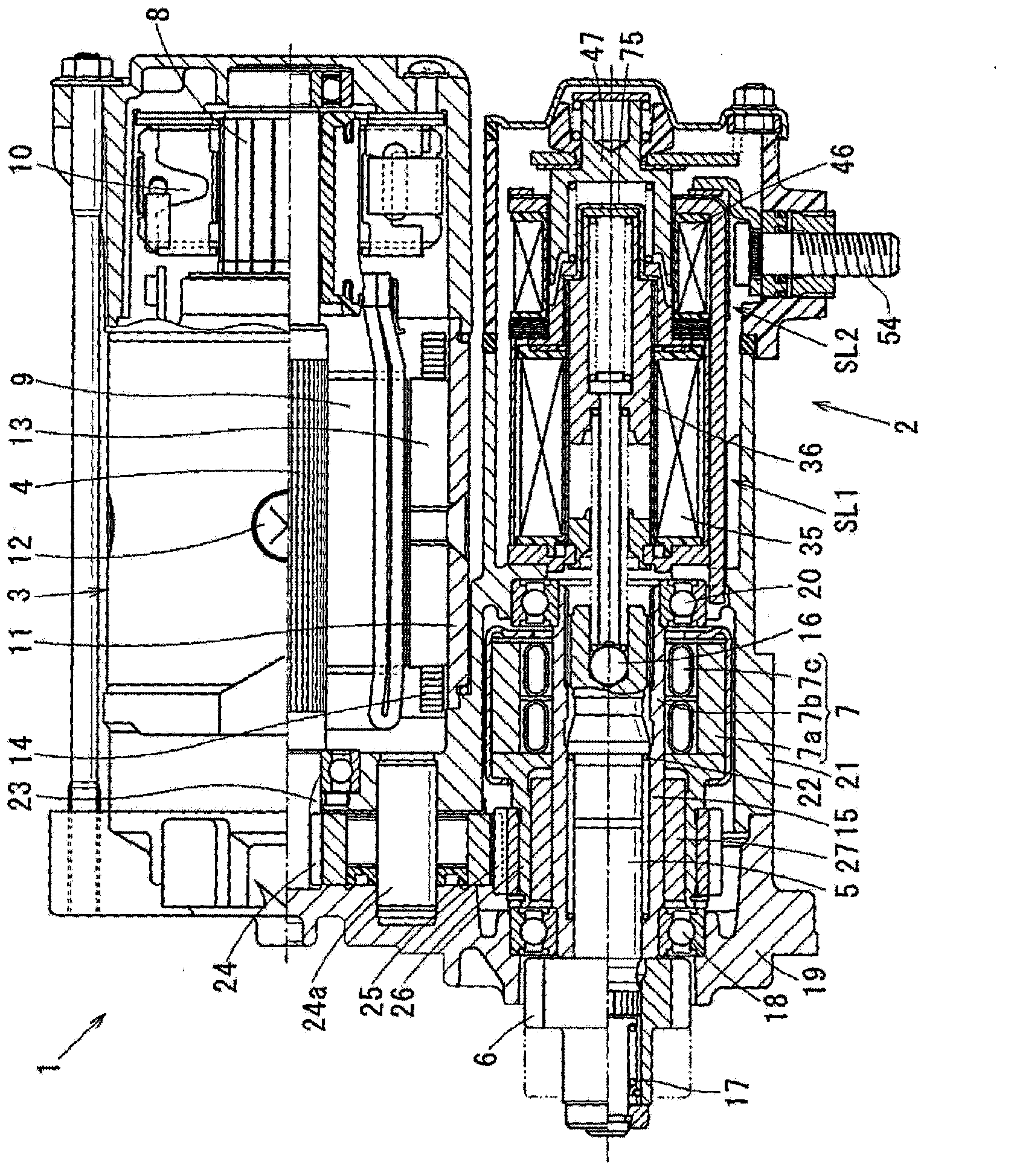

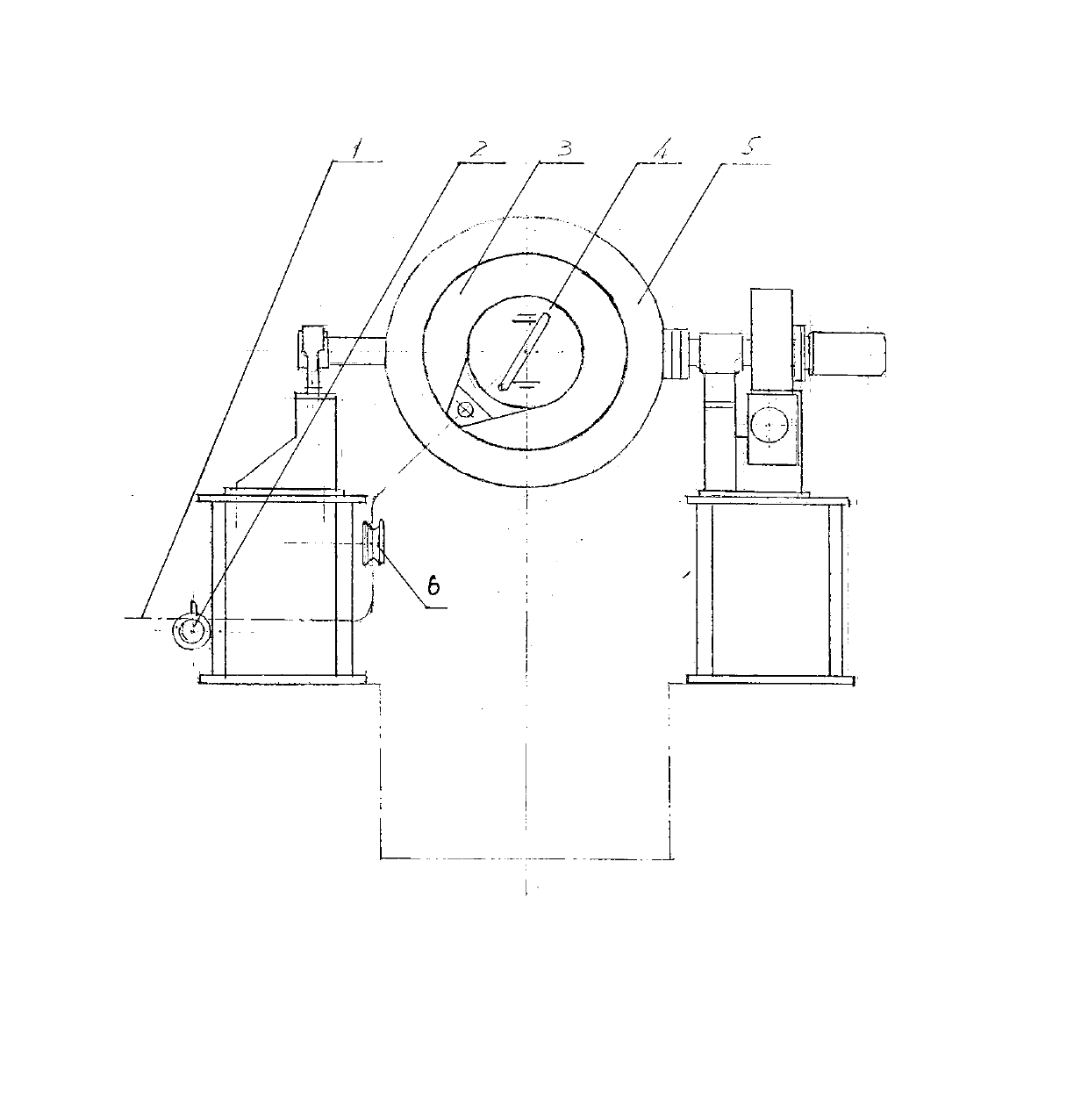

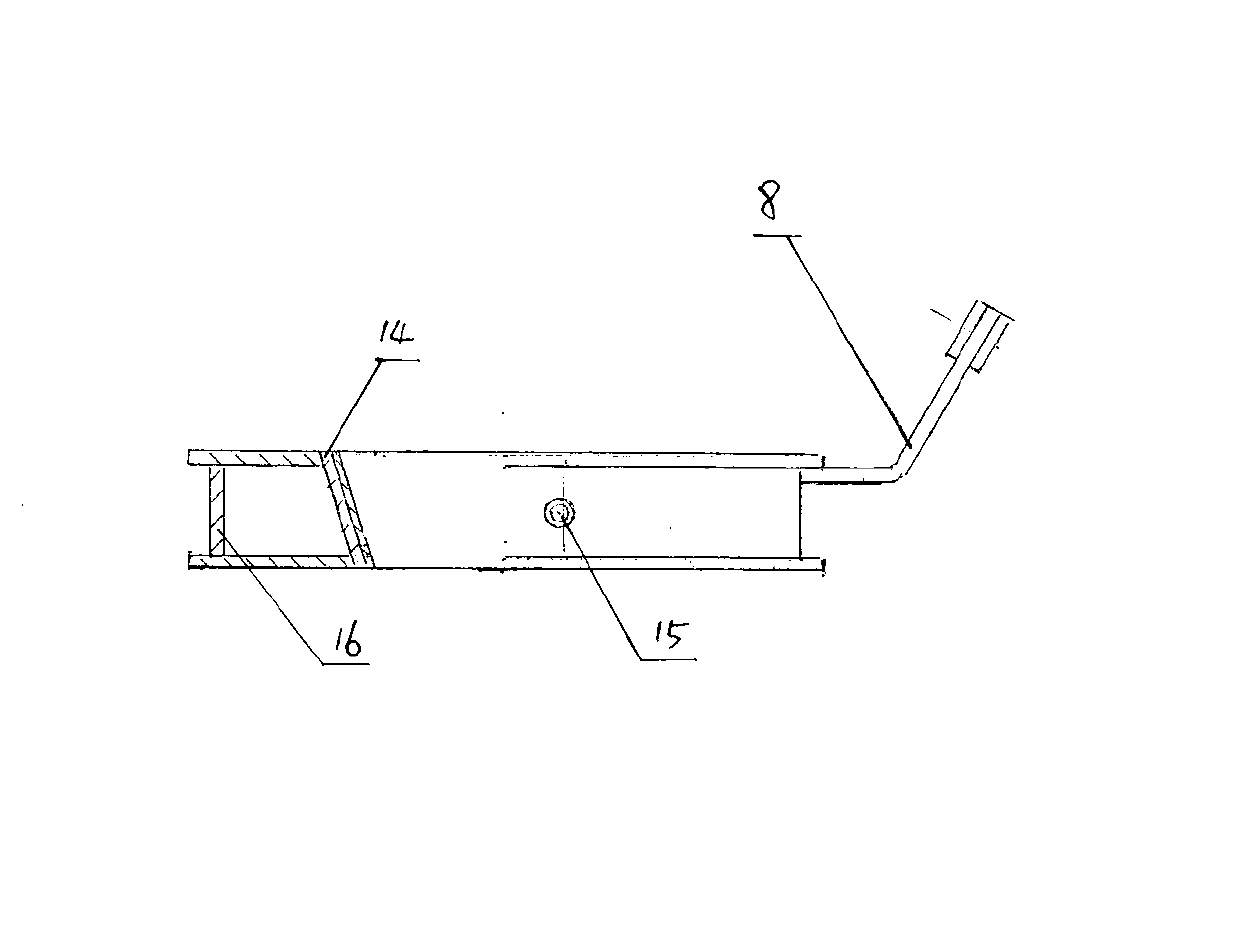

Electromagnetic solenoid device for a starter

ActiveCN103511154AIncrease operating voltageStop the leakPower operated startersElectric motor startersEngineeringNon magnetic

An electromagnetic solenoid device (2) for a starter motor includes a first solenoid (SL1) and a second solenoid (SL2). The first solenoid (SL1) includes a first coil (35) which is energized to form a first electromagnet, and a first plunger (36) is attracted by the first electromagnet to move in an inner periphery of the first coil (35) axially. The second solenoid (SL2) includes a second coil (46) which is energized to form a second electromagnet and a second plunger (47) which is attracted by the said second electromagnet to move in an inner periphery of the second coil (46) axially. The first solenoid (SL1) and the second solenoid (SL2) are held in a common switch frame. One movement direction of the first solenoid (SL1) which moves due to the attraction of the first electromagnet and a moving direction of the second solenoid (SL2) which moves due to the attraction of the second electromagnet are set to the same direction. A non-magnetic partition wall portion (75) is located between the first solenoid (SL1) and the second solenoid (SL2) .

Owner:DENSO CORP

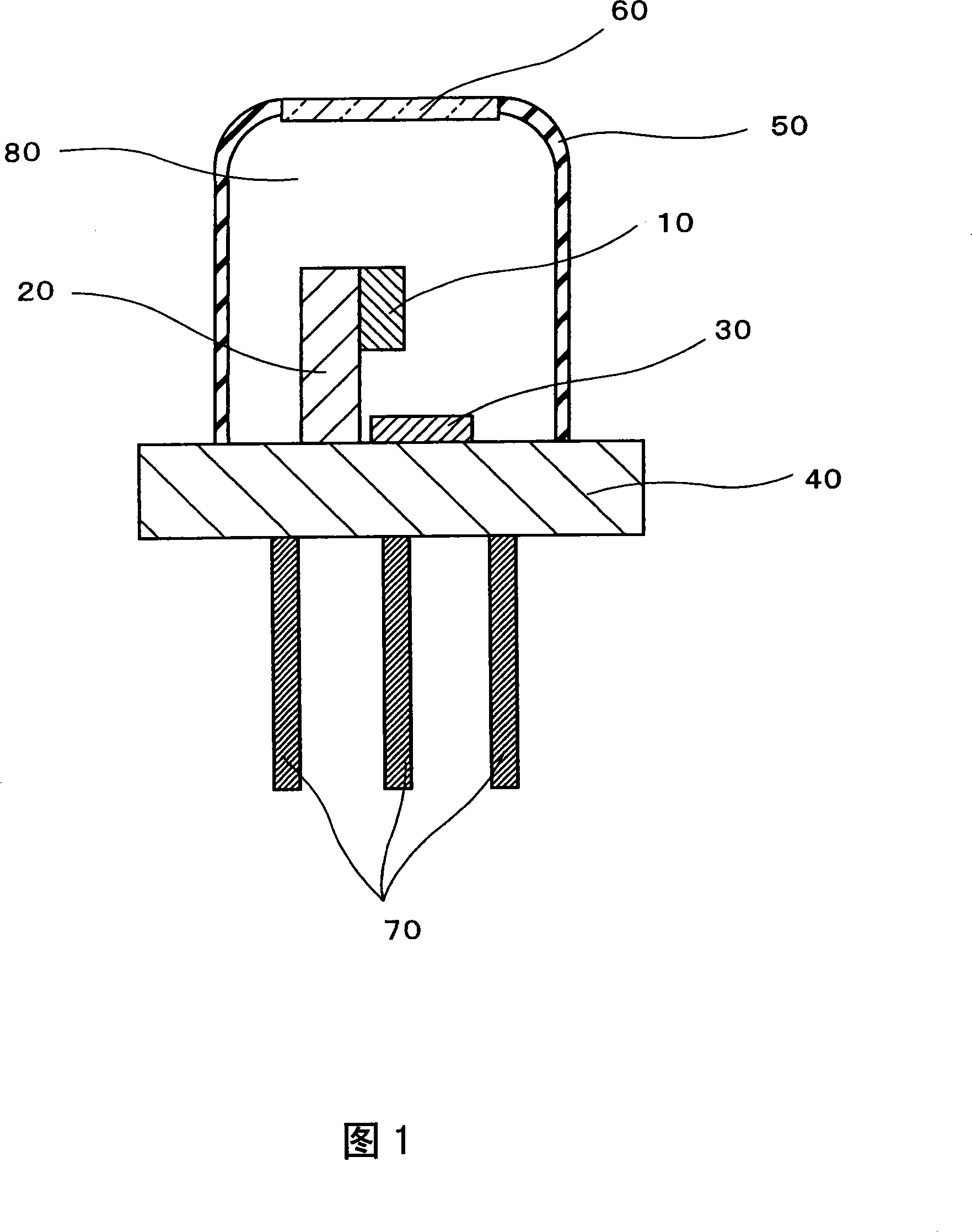

Semiconductor light emitting device and method for fabricating same

ActiveCN101222117AIncrease operating voltageInhibited DiffusionOptical wave guidanceLaser detailsHydrogen atomHydrogen

A nitride semiconductor device includes a stem. A heat sink is provided on the stem. At least one nitride semiconductor light-emitting element is connected to the heat sink. A light-detecting element for detecting light from the semiconductor light-emitting element is provided on the stem. A cap for encapsulating therein the heat sink, the semiconductor light-emitting element, and the light-detecting element in a sealed manner is connected to the stem. The space in the cap has an encapsulated atmosphere. The encapsulated atmosphere contains a component for inhibiting diffusion of hydrogen atoms contained in the semiconductor light-emitting element. The present invention suppresses defect due to an increase in operation voltage to increase a ratio of good goods thereby improving the fabrication yield of the semiconductor light-emitting device.

Owner:SHARP FUKUYAMA LASER CO LTD

Electricity-saving method for ore furnace

The invention relates to an ore furnace electricity-saving method comprising the following steps: a. performing optimum setting to parameters of various types of furnace, the setting also comprising adjusting of the melting chamber diameter, controlling of electrode gaps, therefore, obtaining a practical and scientific configuration of network voltage and the equipment itself; b. improving current work utilization ratio by using a voltage work method and the technical requirement, increasing the ratio of voltage and current, maintaining the ratio of voltage and current at 1:280, reducing the generation of impedance and inductive reactance of ore furnace, and obtaining a power factor over 0.9; c. improving transmission capacity of the short net, namely, increasing the control voltage and reducing the current.By using the method, production energy-consumption can be reduced effectively, the power factor can be improved and the quality of products can also be improved.

Owner:孙孟君

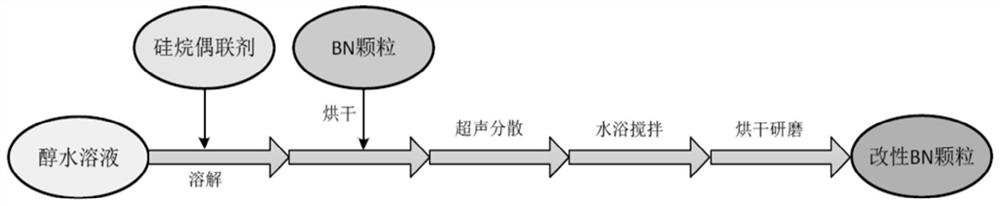

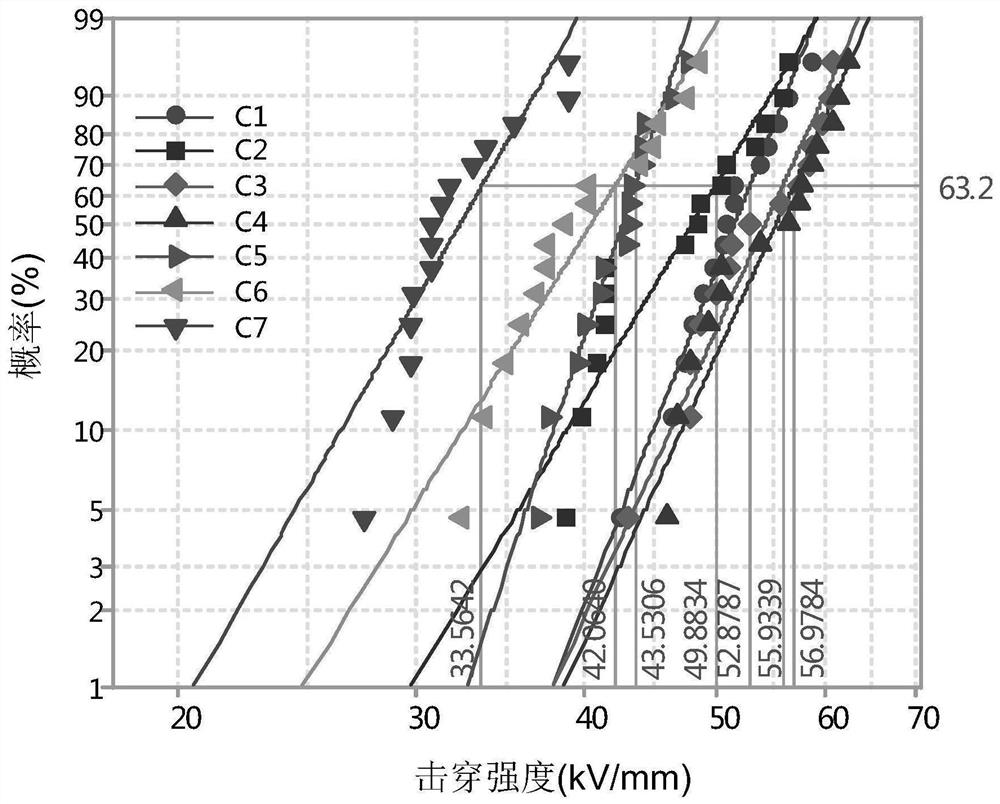

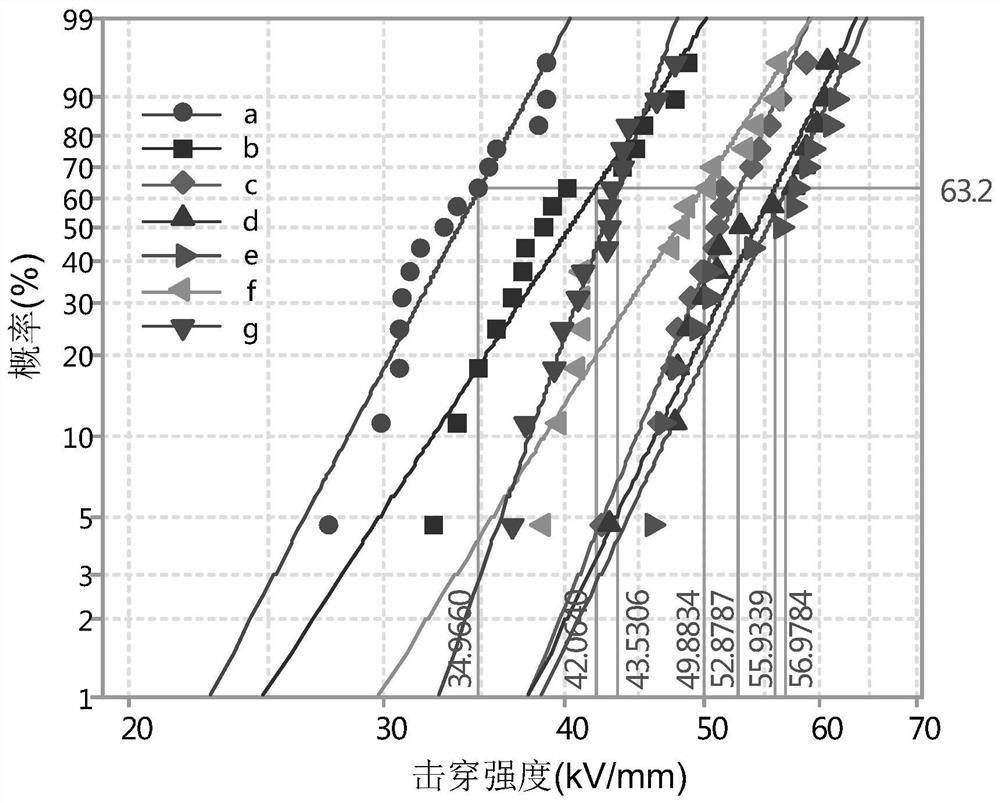

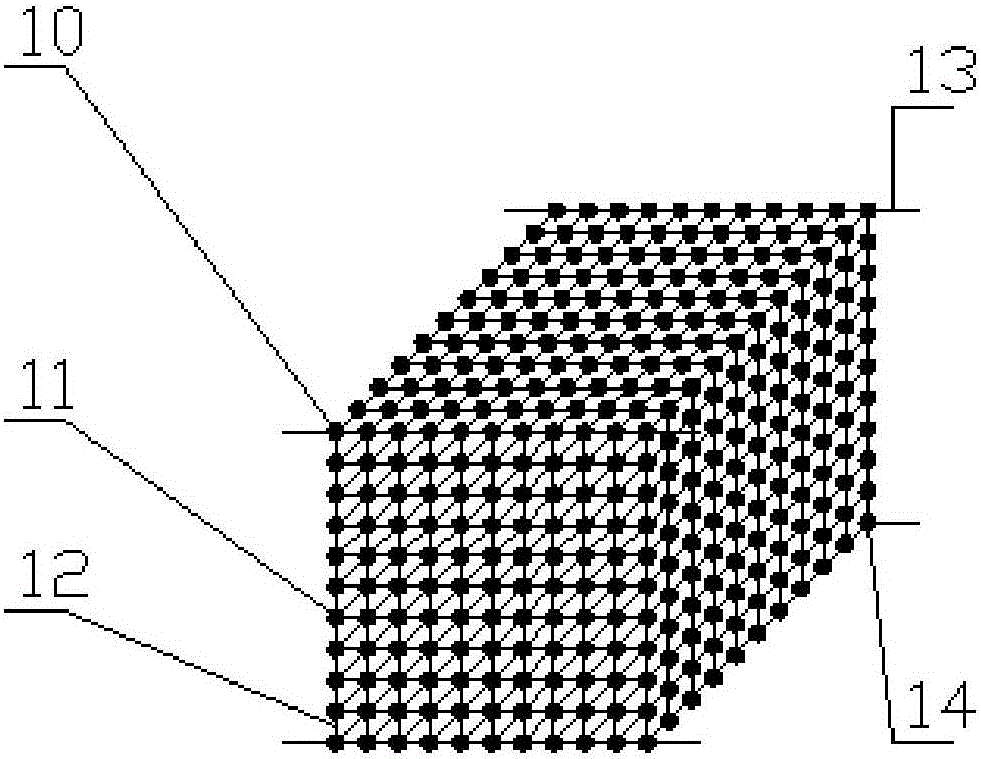

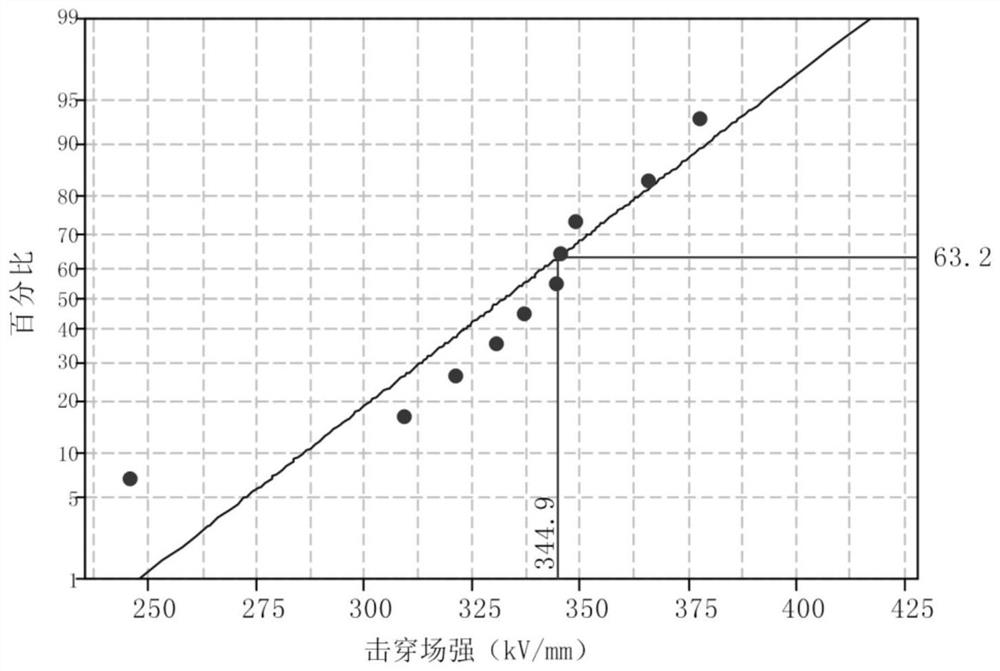

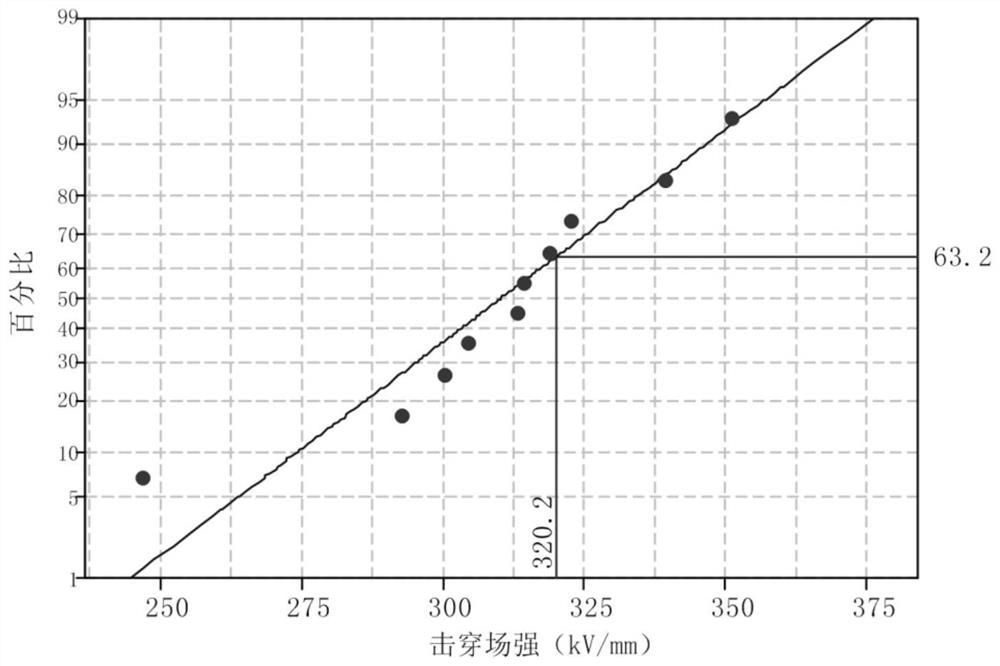

Crosslinked polyethylene composite material as well as preparation method and application thereof

PendingCN113402799AImprove high voltage AC breakdown resistanceIncrease operating voltagePlastic/resin/waxes insulatorsLow-density polyethyleneBoron nitride

The invention discloses a crosslinked polyethylene composite material as well as a preparation method and application thereof, and belongs to the technical field of high-voltage alternating-current cable insulation. The crosslinked polyethylene composite material is prepared from the following components in parts by mass: 100 parts of low-density polyethylene, 1.8 to 2 parts of a cross-linking agent, 0.3 to 0.5 part of an assistant cross-linking agent, 0.2 to 0.3 part of an antioxidant, 2 to 4 parts of nano vinyl polyhedral oligomeric silsesquioxane and 30 to 40 parts of boron nitride, wherein the boron nitride is composed of boron nitride with a micron-scale particle size and boron nitride with a nano-scale particle size, and the mass ratio of the boron nitride with the micron-scale particle size to the boron nitride with the nano-scale particle size is (2-6): 1. According to the crosslinked polyethylene composite material disclosed by the invention, the nano vinyl polyhedral oligomeric silsesquioxane and the boron nitride are taken as additives, so that the insulation and high-voltage alternating current breakdown resistance of the crosslinked polyethylene composite material can be effectively improved.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

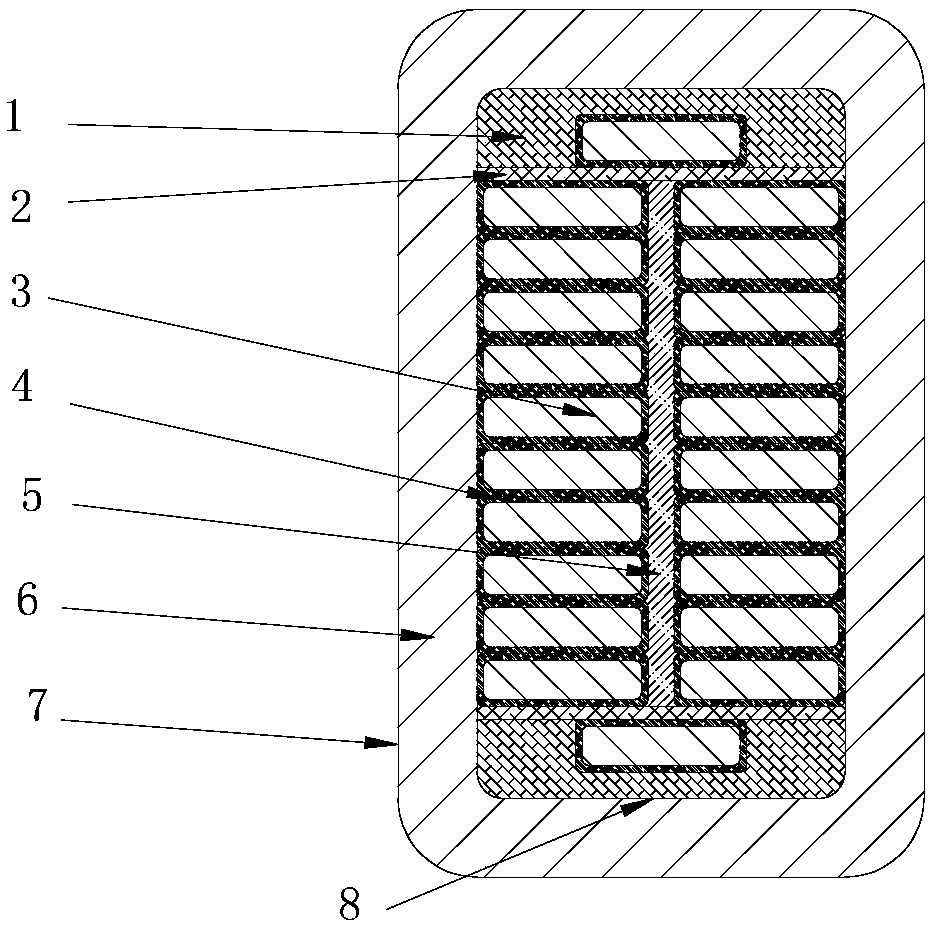

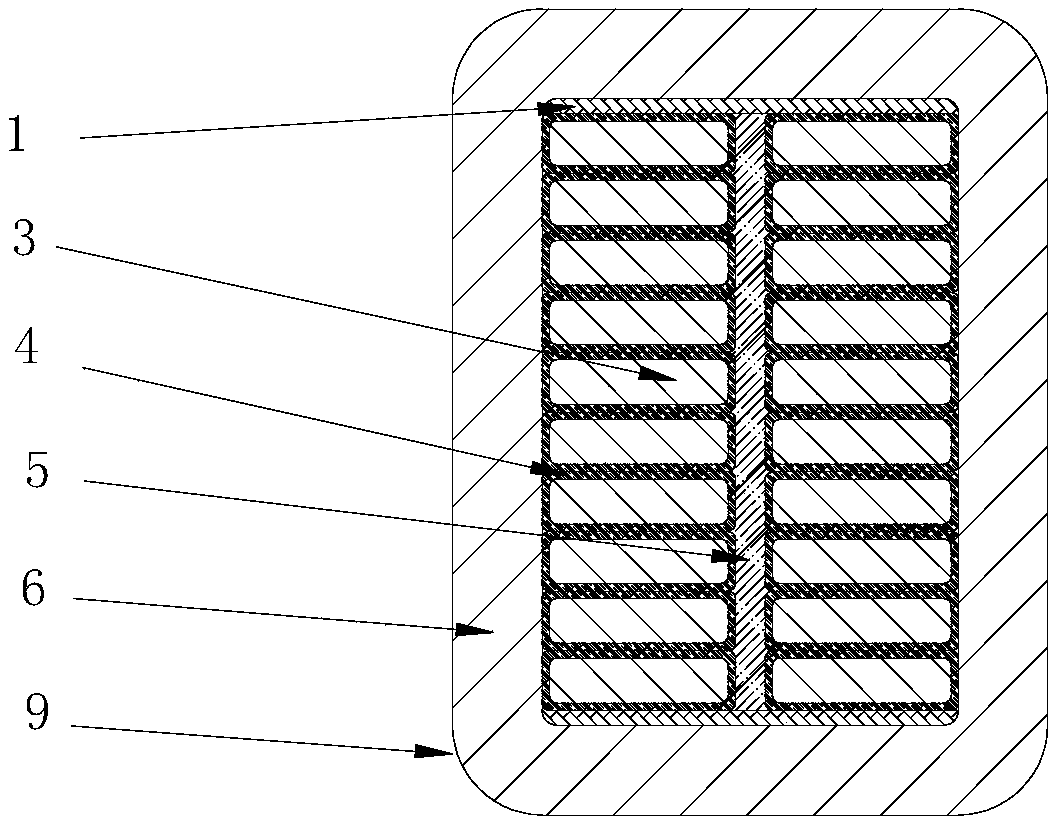

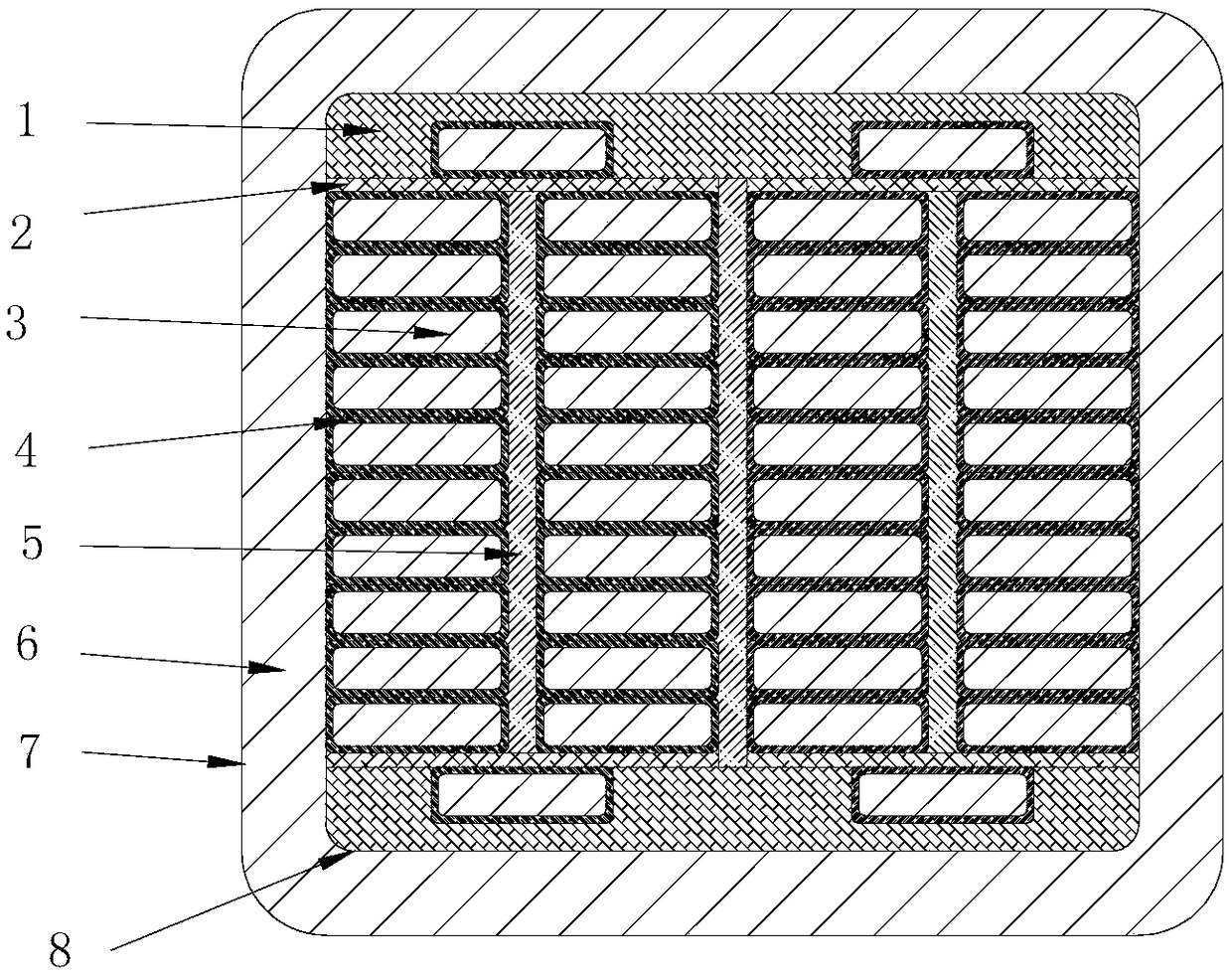

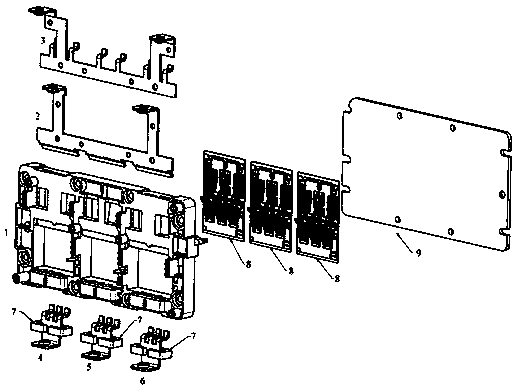

High-performance and high-compactness power module

PendingCN109347340AImprove compactnessAchieve compactnessSemiconductor/solid-state device detailsConversion constructional detailsElectricityStray inductance

The invention relates to the field of power semiconductor and power module application, in particular to a high-performance and high-compactness power module. The power module comprises a plastic shell on which a copper bar is formed by injection molding; a current sensor, an insulation substrate and a heat dissipation bottom plate are fixed in the shell; the bottom of the copper bar is combined with a front copper-clad layer of the insulation substrate in an ultrasonic bonding or welding connection mode; and a back copper-clad layer of the insulation substrate is combined with the heat dissipation bottom plate in a welding mode. According to the high-performance and high-compactness power module, the compactness of system application is achieved by integrating the plastic shell with the current sensor; a heat dissipation structure with fin pins is adopted to increase an operation current of the module, thereby improving the electric performance of the module; the compactness and miniaturization design of the power module is realized by adopting internal three-dimensional and laminated busbar arrangement; and meanwhile, the stray inductance of a busbar is reduced through a laminated busbar structure, so that an operation voltage of the power module is increased, and the electric performance of the module is improved.

Owner:BINZHOU UNIV

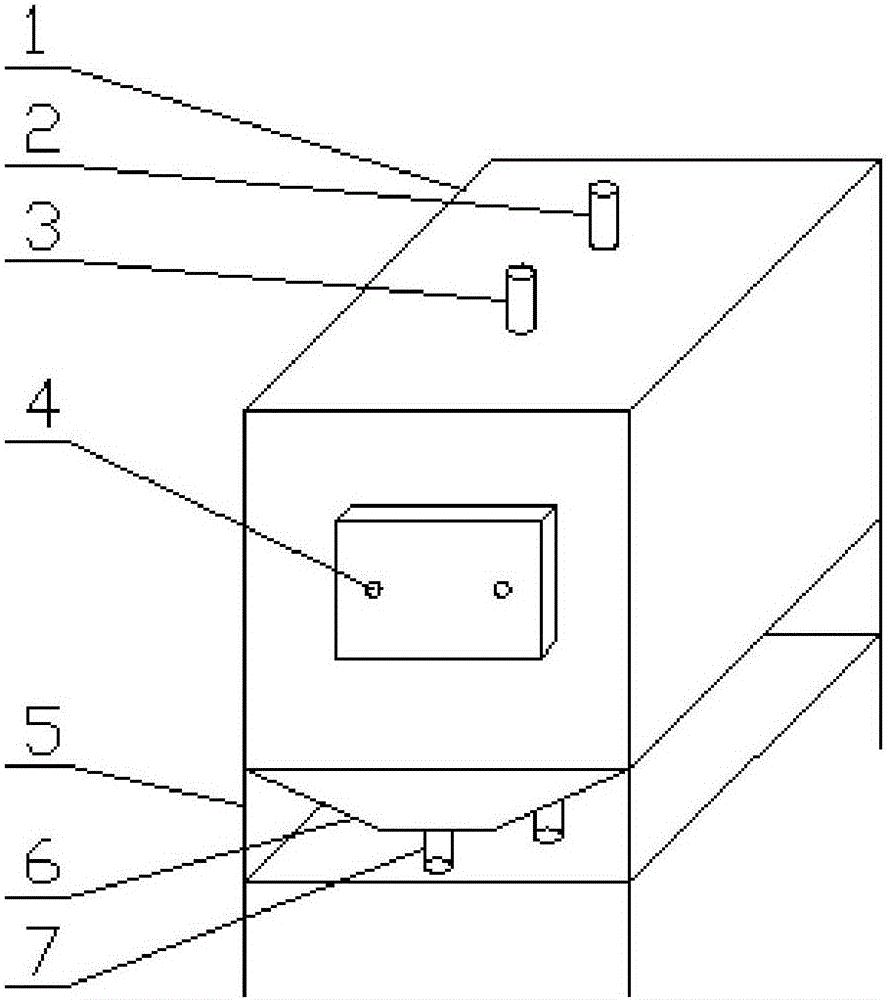

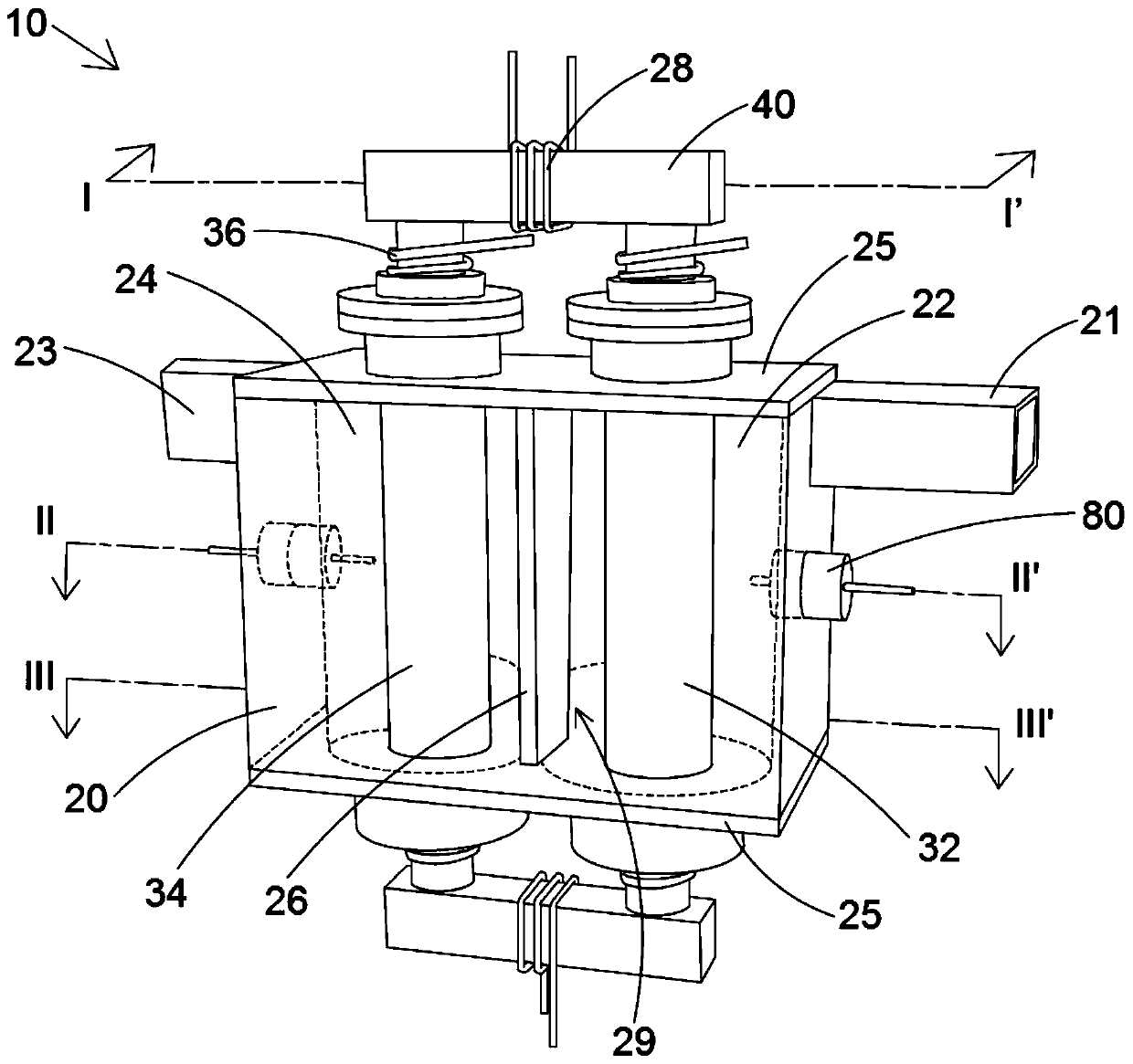

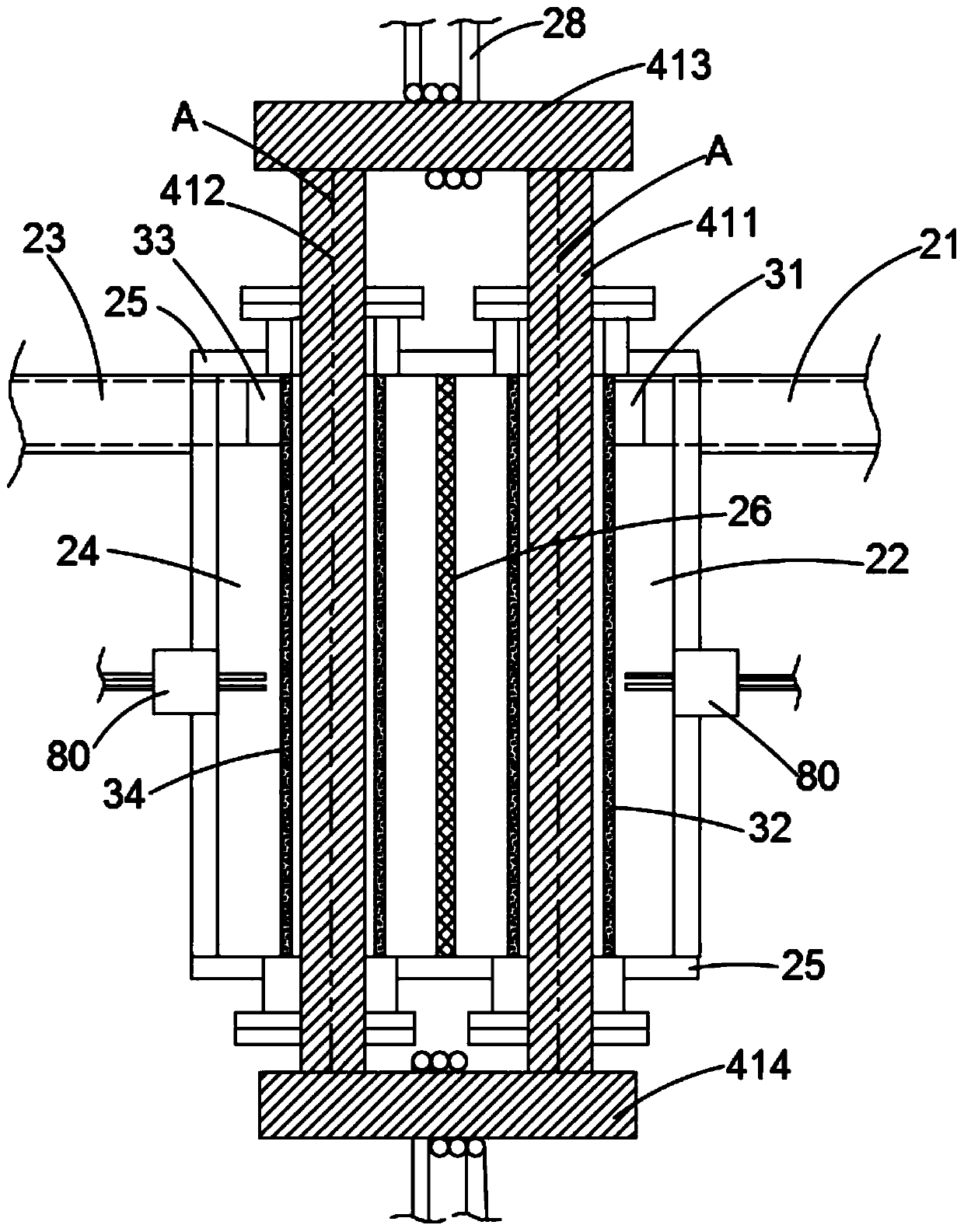

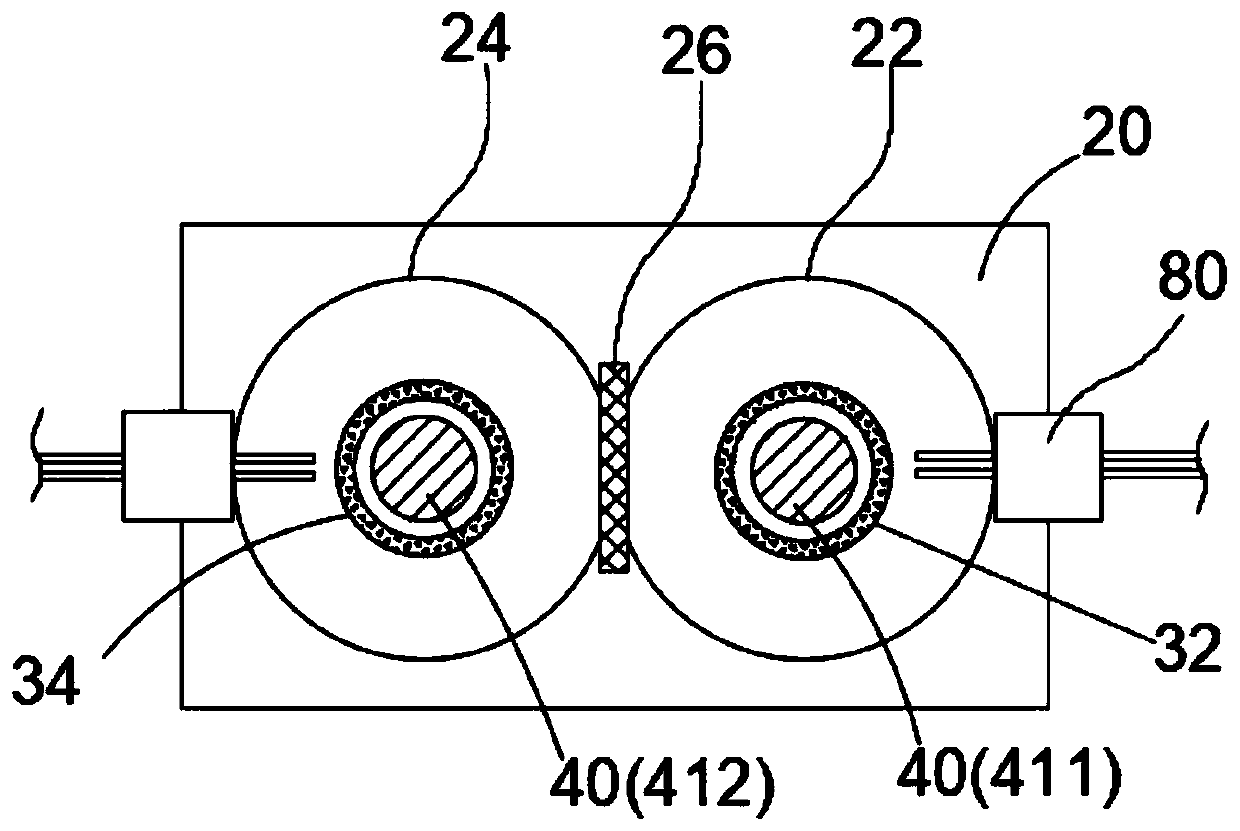

Multi-stage serial connection spherical particle active electrode reaction device

ActiveCN106044958AGood insulationIncrease operating voltageWater/sewage treatment by oxidationEngineeringOxide coating

The invention provides a multi-stage serial connection spherical particle active electrode reaction device, which comprises an insulated reaction device case, wherein the top of the reaction device case is provided with an exhaust pipe and a water outlet pipe; the bottom of the reaction device case is provided with a mud collecting hopper; the bottom of the mud collecting hopper is provided with a water inlet pipe and a mud discharging pipe; a set of multi-stage serial connection spherical particle active electrode reaction system is fixed inside the reaction device through a positioning pin, and comprises spherical particle active electrodes in A row, B lines and C layers; the spherical particle active electrode carriers are spherical titanium metal spheres; a composite noble metal oxide coating is coated at the outer layer; three hole passages which pass through sphere cores and are mutually vertical are formed in the middle; a positioning insulation plastic rod respectively passes through each hole passage; A*B*C particle electrodes are fixed into A rows, B lines and C layers with equal distances, wherein the first spherical particle active electrodes are connected with a positive electrode of an external direct current power supply; the (A*B*C)-th spherical particle active electrode is connected with a negative electrode of the external direct current power supply; the current is enabled to flow through all spherical particle active electrodes.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

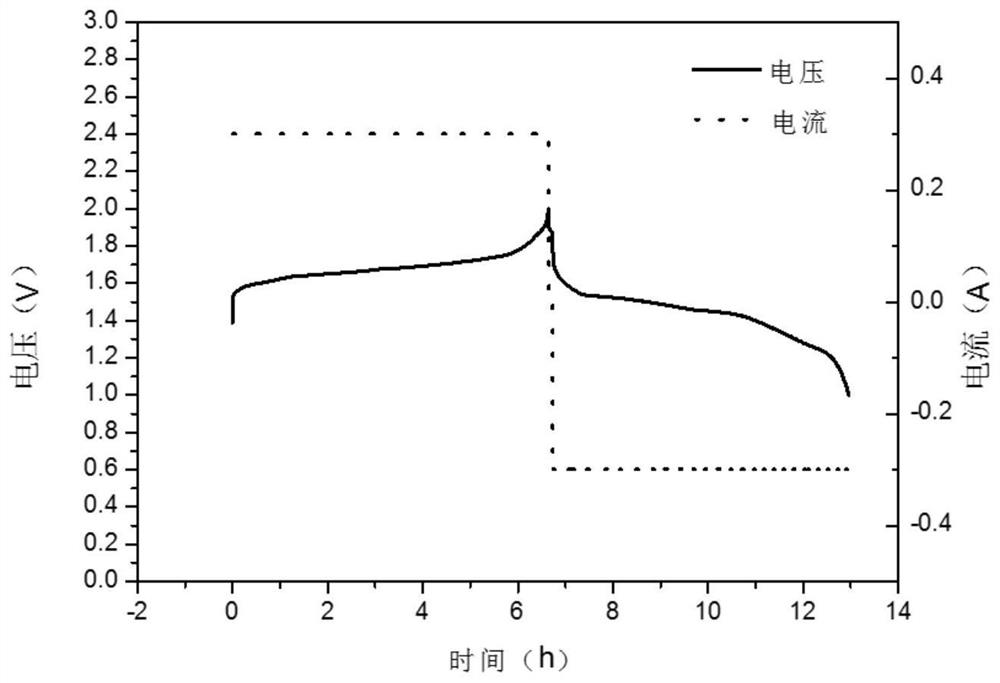

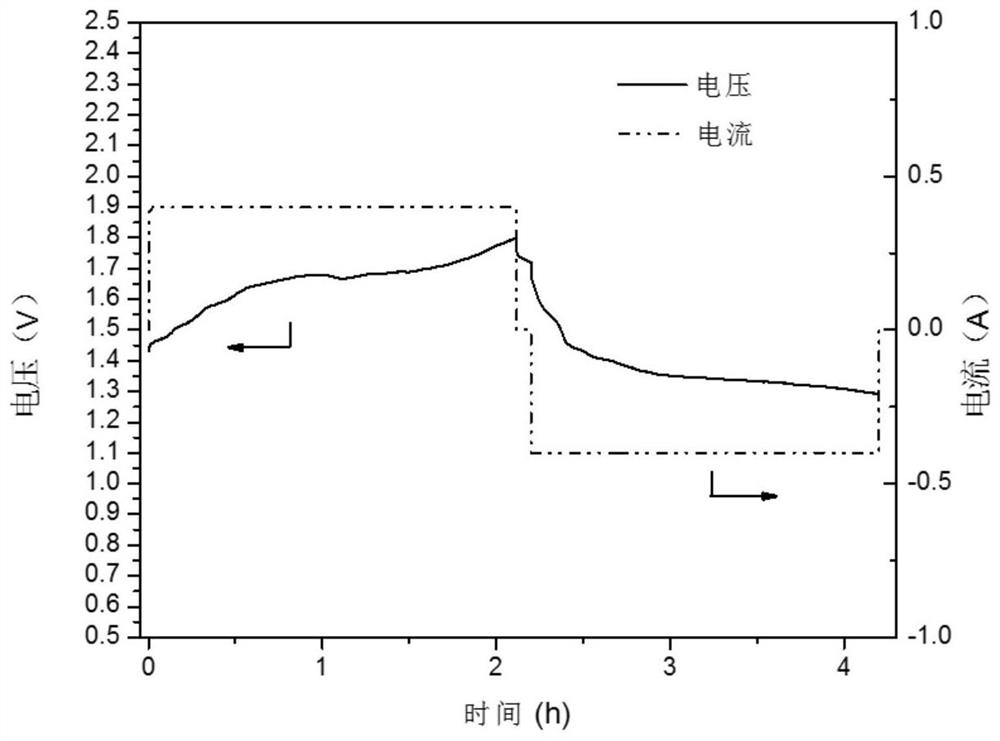

A positive electrode material for liquid and semi-liquid metal batteries

ActiveCN107482209BLow working voltageIncrease operating temperatureFinal product manufactureCell electrodesChemical physicsElectrical battery

The invention belongs to electrode materials for energy storage batteries, in particular to a positive electrode material for liquid and semi-liquid metal batteries. The positive electrode material is formed of metal Te or Te and one or more simple substances in Sn, Sb, Pb, and Bi. Te alloy. The present invention creatively uses metal Te and alloys of Te and Sn, Sb, Pb, Bi as the positive electrode material, the high electronegativity of the metal Te can provide higher voltage, the melting point is low (449°C), the preparation of the Te alloy is simple, and the cost is low. And it has good electrochemical performance with the existing negative electrode materials. When it is applied to the positive electrode materials of liquid / semi-liquid metal batteries, it can effectively solve the problems of low working voltage of liquid / semi-liquid metal batteries and high operating temperature of batteries. Improve battery operating voltage, increase energy density, reduce operating temperature, and reduce battery cost, so it is especially suitable for liquid and semi-liquid metal batteries.

Owner:HUAZHONG UNIV OF SCI & TECH

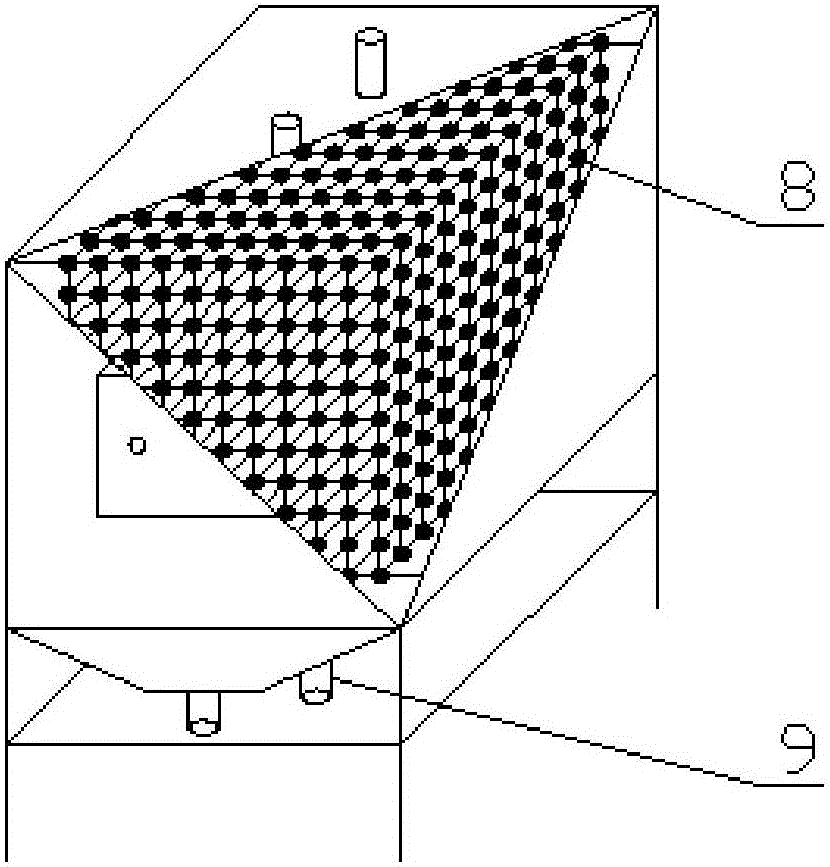

Remote plasma generating device

InactiveCN110718437AExtend your lifeReduce arc phenomenonElectric discharge tubesRemote plasmaParticle physics

A remote plasma generating device at least comprises a reaction cavity and a magnetic core. The reaction cavity is provided with a first cavity body and a second cavity body communicated with each other and is used for introducing gas and accommodating plasma, and a dielectric assembly is arranged between the first cavity body and the second cavity body. The magnetic core penetrates through the first cavity body and the second cavity body. Gas spirally moves in the first cavity body and the second cavity body along the axis of the magnetic core. The magnetic core part in the first cavity and the magnetic core part in the second cavity generate a first axial magnetic field and a second axial magnetic field, so that a first induced angular electric field and a second induced angular electricfield are generated in the first cavity body and in the second cavity body along the axis of the magnetic core. The service life of the reaction cavity can be prolonged by reducing the impact of high-temperature gas particles on the cavity and a ceramic tube.

Owner:FINESSE TECH CO LTD

Two-phase flow integrated quartz resistance furnace

ActiveCN102530964BReduce lossSmall sectionSilicaElectrical resistance and conductanceGraphite electrode

The invention discloses a two-phase flow integrated quartz resistance furnace, which comprises a round metal cylinder body which is arranged on a rotating shaft and can rotate 180 degrees, an graphite electrode is longitudinally arranged in the round metal cylinder body, the two ends of the graphite electrode are connected with composite electrodes arranged at the two ends of the round metal cylinder body through graphite electrode sleeves, the composite electrodes are connected with a low voltage side of a furnace front transformer through cables, the peripheries of the composite electrodes are provided with furnace cover cooling water drums, the periphery of the graphite electrode is provided with water cooled jackets, the composite electrodes and the outer rings of the water cooled jackets are fixed, the cables are water cooled cables, the water cooled cables comprise copper core wires, rubber steam hoses are coated outside the copper core wires, cooling water channels are arrangedbetween the copper core wires and the rubber steam hoses, transition joints are arranged between the water cooled cables and the composite electrodes, and two-phase flow conduits of the transition joints are connected with the water cooled jackets. The two-phase flow integrated quartz resistance furnace reduces areas of the cables by more than 20 times, greatly reduces contact resistance between the electrodes at the two ends, reduces turning weight of a furnace body, greatly reduces operating accidents of equipment, and increases operating efficiency.

Owner:连云港富泰新材料科技有限公司

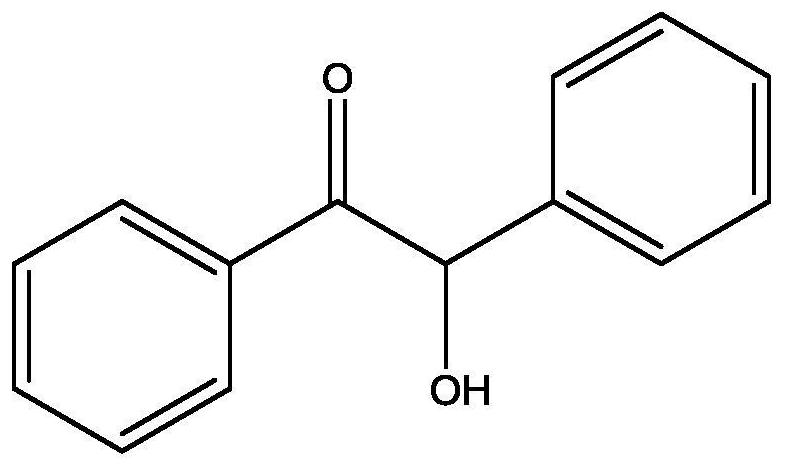

Method for Improving DC Breakdown Field Strength of Capacitor Dielectric Film Based on Benzoin

InactiveCN109659135BHigh breakdown field strengthIncrease operating voltageFixed capacitor dielectricDielectricFilm base

The invention discloses a method for improving the DC breakdown field strength of a capacitor dielectric film based on benzoin. The method comprises the following steps of: 1, fully mixing a dried polypropylene particles and benzoin were in an internal mixer at a mass ratio of 99.5:0.5 to obtain a polypropylene composite material, and, setting a control group, namely a polypropylene material without addition of benzoin ; 2, employing a flat vulcanizing machine to press the polypropylene composite material to a test sample with a side of 90*90mm and a thickness of 80 [Mu]m; 3, performing vacuum drying of the test sample for 24 hours to allow the test sample to fully exclude impurities; 4, employing a plate electrode to perform DC breakdown test for the test sample; and 5, employing the polypropylene material of the control group to repeat the steps 2-4. The experiment shows that the method can effectively improve the breakdown field strength of polypropylene film.

Owner:TIANJIN UNIV

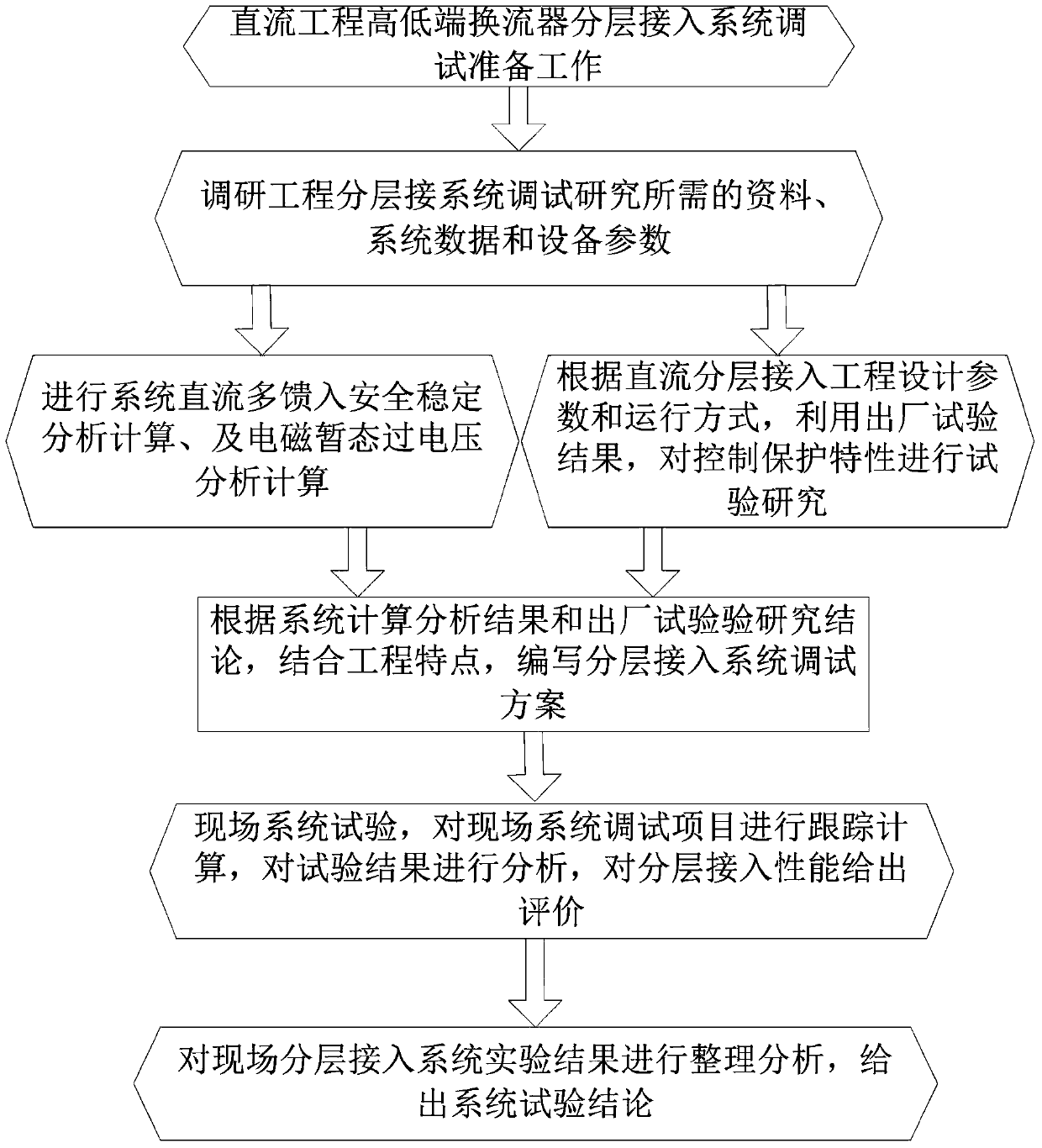

A system debugging method for hierarchical access mode of ±1100kv UHVDC transmission project

ActiveCN106611958BComprehensive scope of commissioningIncrease operating voltageElectric power transfer ac networkEngineeringHigh pressure

The invention relates to a system for layered access of 500kV / 1,000kV AC power grid to converters at a high end and a lower end of + / -1,100kV extra-high voltage DC power transmission engineering and a debugging method of the system. The system comprises converters at two ends and a DC power transmission line. The debugging method for a + / -1,100kV extra-high voltage DC power transmission engineering system comprises the steps of (a) performing calculation and analysis by a + / -1,100kV extra-high voltage DC power transmission engineering multi-feed system; and (b) compiling the debugging method for a layered access system of the + / -1,100kV extra-high voltage DC power transmission engineering. The system is characterized by comprising the following two aspects: (1) 1,100kV voltage is the highest DC voltage class at present, and with regard to a test scheme of the layered access AC system of the converters at the high end and the lower end, the impact on equipment during the test process is needed to be reduced according to performance of the DC multi-feed system and the equipment; and (2) the converters at the high end and the lower end initially employ layered access of the 500kV / 1,000kV AC power grid, and the part of test scheme is also initially compiled.

Owner:CHINA ELECTRIC POWER RES INST +1

Semiconductor device and manufacturing method thereof

ActiveCN101834204AReduce areaIncrease operating voltageSemiconductor/solid-state device manufacturingSemiconductor devicesInsulation layerEngineering

The present invention discloses a semiconductor device providing a high breakdown voltage and a low turn-on resistance. The device includes: a substrate; a buried n+ layer disposed in the substrate; an n-epi layer disposed over the buried n+ layer; a p-well disposed in the n-epi layer; a source n+ region disposed in the p-well and connected to a source contact on one side; a first insulation layer disposed on top of the p-well and the n-epi layer; a gate disposed on top of the first insulation layer; and a metal electrode extending from the buried n+ layer to a drain contact, wherein the metal electrode is insulated from the n-epi layer and the p-well using by a second insulation layer. The semiconductor device is capable of reducing element area due to dielectric separation (e.g. oxide), improving operation voltage (e.g. an voltage more than 700V in one embodiment), and providing a great breakdown voltage due to dielectric isolation (e.g. oxide) which is stronger than silicon.

Owner:TAIWAN SEMICON MFG CO LTD

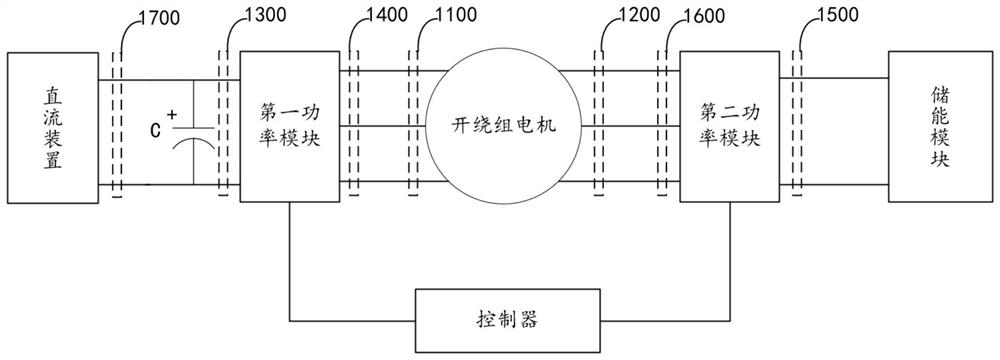

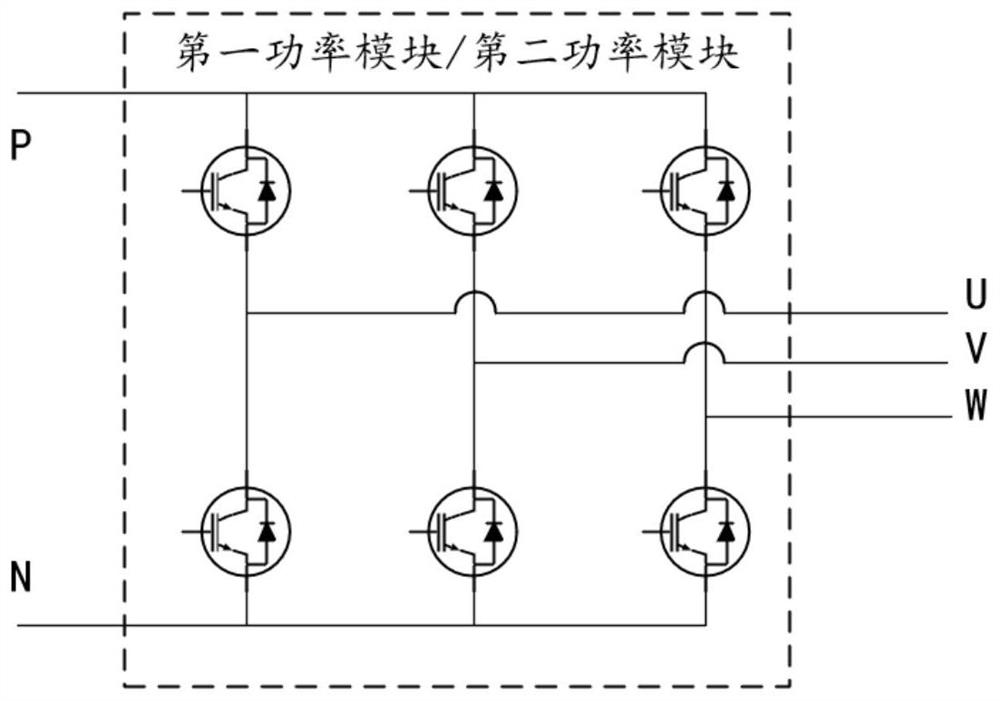

Driving control circuit, driving control method, circuit board and air conditioner

PendingCN114696667AIncrease operating voltageImprove operational efficiencyAC motor controlSpace heating and ventilation safety systemsElectric machineControl signal

The embodiment of the invention discloses a drive control circuit, a drive control method, a circuit board and an air conditioner, and the drive control circuit is connected with a first power module and a second power module at the two ends of an open winding motor, and the second power module is connected with an energy storage module. The controller sends control signals to the first power module and the second power module according to the electric quantity of the energy storage module to change the working state of the driving control circuit, so that electric energy can flow bidirectionally when the motor runs, the energy storage module can supply power to the open winding motor under the condition of sufficient energy, the running voltage of the motor is improved, and the service life of the motor is prolonged. The operation efficiency of the motor is improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com